Page 1

Air-Conditioners For Building Application

OUTDOOR UNIT

PUHY-P-YJM-A (-BS)

For use with R410A

PUHY-EP-YJM-A (-BS)

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ ΕΓΚΑΤΑΣΤΑΣΗΣ

Για ασφάλεια και σωστή χρήση, παρακαλείστε διαβάσετε προσεχτικά αυτό το εγχειρίδιο εγκατάστασης πριν αρχίσετε την εγκατάσταση της μονάδας

κλιματισμού.

GBPO HG SV CZ TR RU GR P NL I E F DSLRO BG HR SW

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по установке до

выполнения установки кондиционера.

MONTAJ ELKİTABI

Emniyetli ve doğru biçimde nasıl kullanılacağını öğrenmek için lütfen klima cihazını monte etmeden önce bu elkitabını dikkatle okuyunuz.

安装手册

为了安全和正确地使用本空调器,请在安装前仔细阅读本安装手册。

PŘÍRUČKA K INSTALACI

V zájmu bezpečného a správného používání si před instalací klimatizační jednotky důkladně pročtěte tuto příručku k instalaci.

NÁVOD NA INŠTALÁCIU

Pre bezpečné a správne použitie si pred inštalovaním klimatizačnej jednotky, prosím, starostlivo prečítajte tento návod na inštaláciu.

TELEPÍTÉSI KÉZIKÖNYV

A biztonságos és helyes használathoz, kérjük, olvassa el alaposan ezt a telepítési kézikönyvet, mielőtt telepítené a légkondicionáló egységet.

PODRĘCZNIK INSTALACJI

W celu bezpiecznego i poprawnego korzystania należy przed zainstalowaniem klimatyzatora dokładnie zapoznać się z niniejszym podręcznikiem

instalacji.

PRIROČNIK ZA NAMESTITEV

Za varno in pravilno uporabo pred namestitvijo klimatske naprave skrbno preberite priročnik za namestitev.

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan luftkonditioneringsenheten installeras, för säker och korrekt användning.

PRIRUČNIK ZA UGRADNJU

Radi sigurne i ispravne uporabe, temeljito pročitajte ovaj priručnik prije ugradnje klimatizacijskog uređaja.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасна и правилна употреба, моля, прочетете внимателно това ръководство преди монтажа на климатизатора.

MANUAL CU INSTRUCŢIUNI DE INSTALARE

Pentru o utilizare corectă şi sigură, vă rugăm să citiţi cu atenţie acest manual înainte de a instala unitatea de aer condiţionat.

Page 2

6

15

*

15

*

450

*

300

*

<A>

A

100

*

450

*

50

*

50

*

<A>

A

A

B

<B>

500

H

h

h

H

240

45

A

D

C

50

<C>

1000

30

450

*

300

*

C

BB

C

A

100

450

*

100

*

BB

C

C

A

450

*

100*

CC

B

A

A

A

B

450 450

15

*

C

AAA

450 450

900

300

*

300

*

BB

C

C

A

1000

*

900 300

*

B

B

C

A

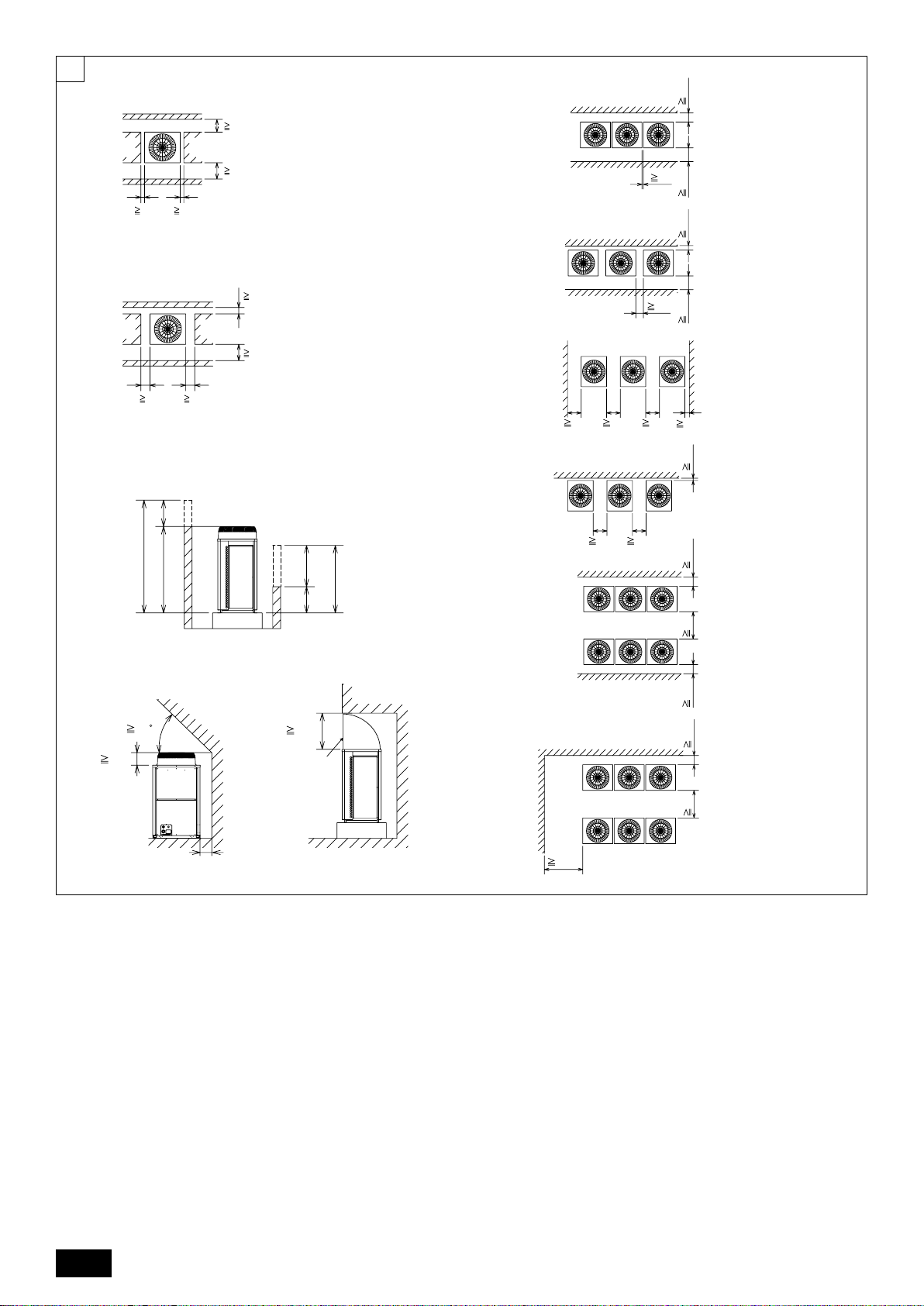

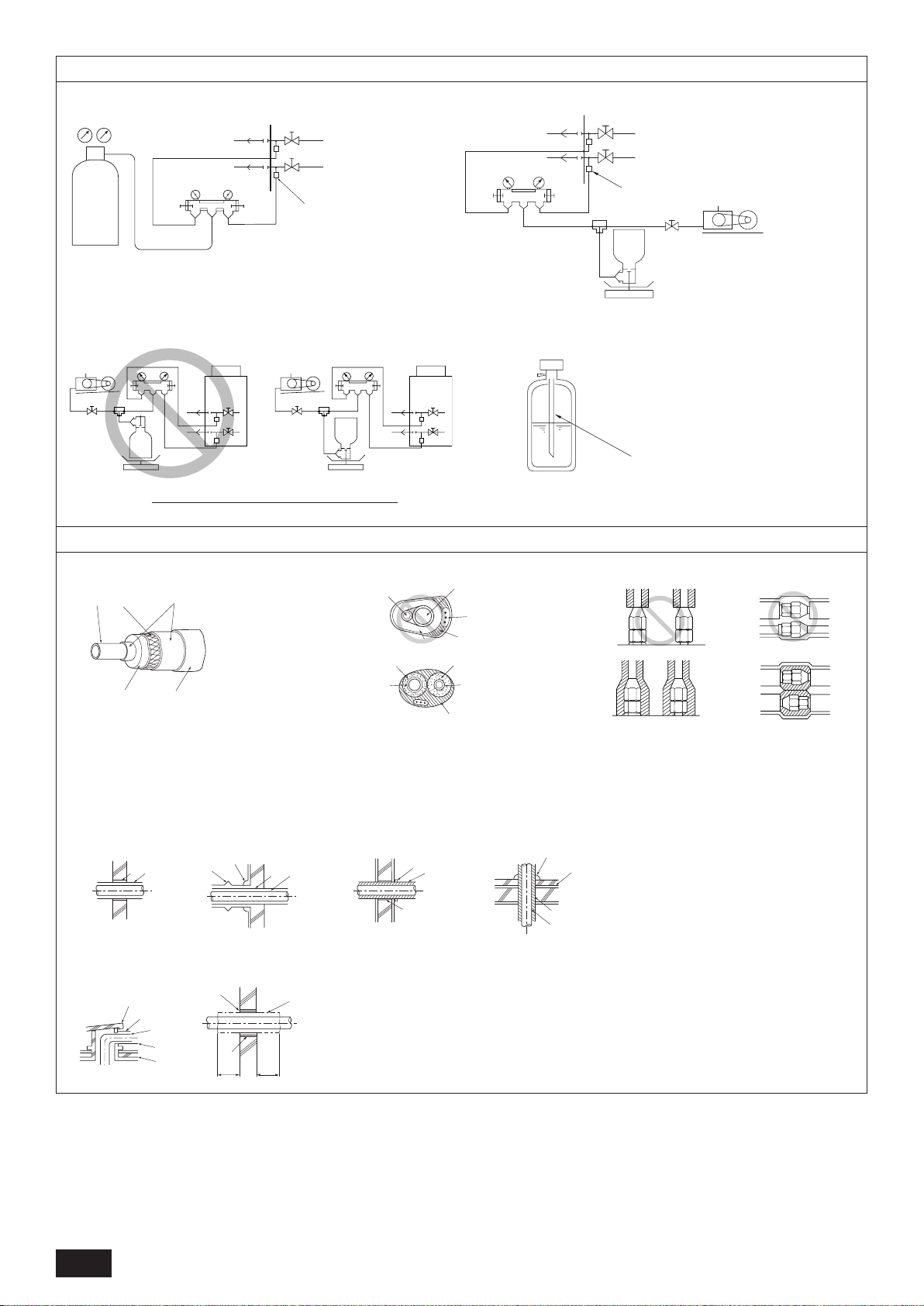

[Fig. 6.0.1]

(1)

(2)

(3)

[Fig. 6.0.2]

<A> : Top view

<B> : Side view

<C> : When there is little space up to an obstruction

A : Front

B : Unit height

C : Back

D : Air outlet guide (Procured at the site)

(4)

(mm)

A : Front

B : Must be open

C : Wall height (H)

(mm)

2

Page 3

8m

8m

40

7

30mm

A

C

8m

8m

40

8m

40

8m

30mm

A

D

B

CD

D

C

A

A

CD

B

[Fig. 7.0.1]

1 P200 ~ P300

EP200

3 P450

EP300

2 P350 ~ P400

EP250

[Fig. 8.1.1]

8

<A> Without detachable leg

<B> With detachable leg

A : M10 anchor bolt procured at the site.

B : Corner is not seated.

C : Fixingbracketforhole-inanchorbolt(3locationstoxwithscrews).

D : Detachable leg

[Fig. 8.1.2]

A : Screws

3

Page 4

9

B

E

A

A

2

A

1

A

B C D

e

a b c d

C

C

CCC

unit 2

A

unit 1

E

A

A

2

A

1

A

unit 2

A

unit 1

B

a

b

c d e

C

D

CC

CC

B

A

B C D

e

a b c d

C

C

CCC

A

B

A

a

b

c d e

C

D

CC

CC

A

B

B C D

e

a b c d

C

C

CCC

E

A3

A4

A2

unit 3

AAA

unit 2unit 1

E

A1

A

E

A

3

A

4

A

2

A

unit 3

AAA

unit 2unit 1

E

A

1

B

a

b

c d e

C

D

CC

CC

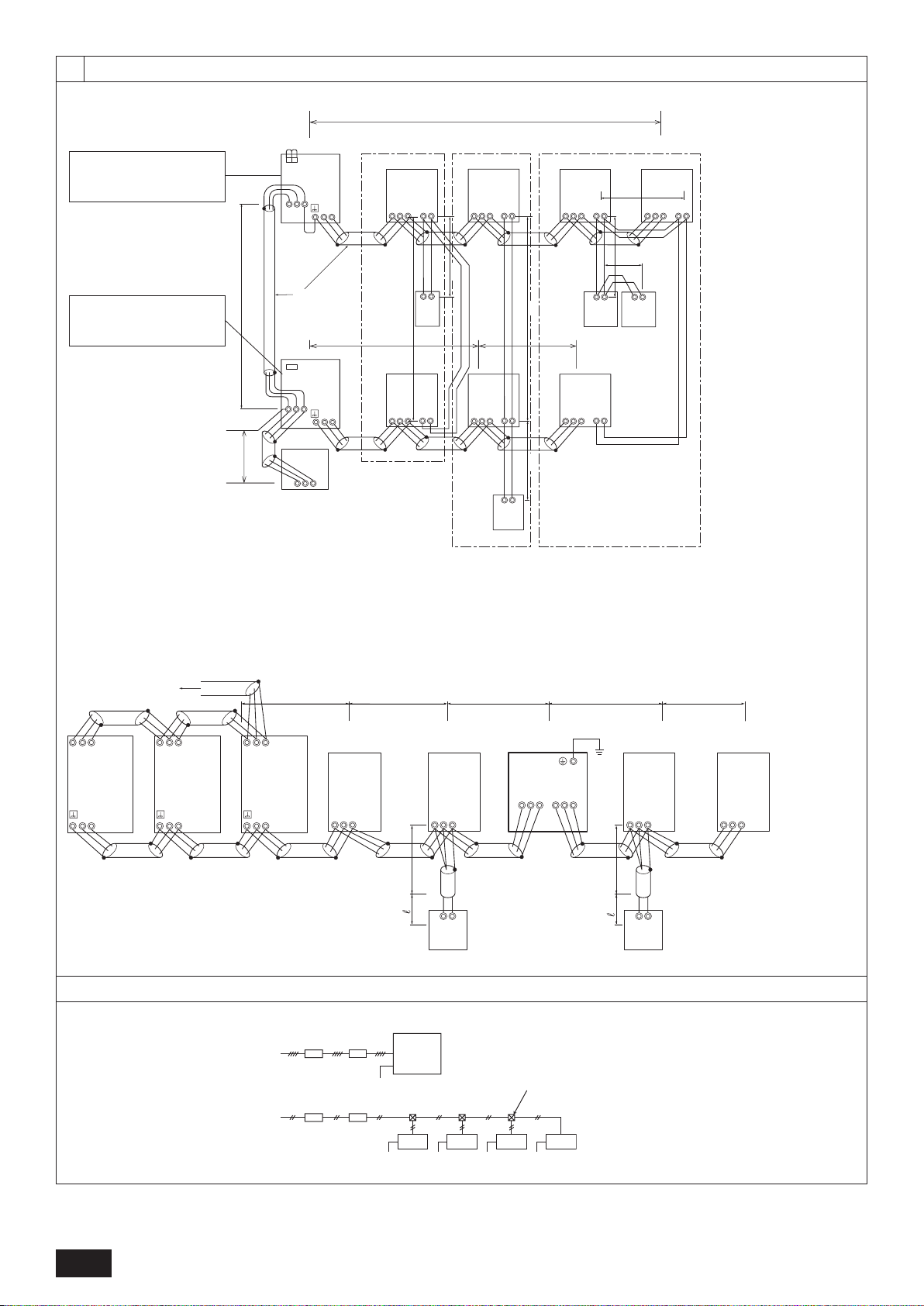

[Fig. 9.2.1]

[P200 ~ P450]

[EP200, EP250, EP300]

[P500 ~ P900]

[EP400 ~ EP600]

9.2

[P950 ~ P1250]

[EP650 ~ EP900]

A : Outdoor unit

B : First branch

C : Indoor unit

D : Cap

E : Outdoor twinning kit

4

Page 5

9

<

<

<

A (mm)

Outdoor model

P200 YJM-A - - - ø9.52 ø19.05 - - - - - - - P250 YJM-A - - - *1 ø9.52 ø22.2 - - - - - - - P300 YJM-A - - - *2 ø9.52 ø22.2 - - - - - - - P350 YJM-A - - - ø12.7 ø28.58 - - - - - - - P400 YJM-A - - - ø12.7 ø28.58 - - - - - - - P450 YJM-A - - - ø15.88 ø28.58 - - - - - - - -

YSJM-A P250 P250 - ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø22.2 - - - -

P500

YSJM-A1 P300 P200 - ø15.88 ø28.58 ø12.7 ø22.2 ø9.52 ø19.05 - - - -

P550 YSJM-A P300 P250 - ø15.88 ø28.58 ø12.7 ø22.2 ø9.52 ø22.2 - - - -

YSJM-A P350 P250 - ø15.88 ø28.58 ø12.7 ø28.58 ø9.52 ø22.2 - - - -

P600

YSJM-A1 P300 P300 - ø15.88 ø28.58 ø12.7 ø22.2 ø12.7 ø22.2 - - - -

P650 YSJM-A P350 P300 - ø15.88 ø28.58 ø12.7 ø28.58 ø12.7 ø22.2 - - - -

YSJM-A P350 P350 - ø19.05 ø34.93 ø12.7 ø28.58 ø12.7 ø28.58 - - - -

P700

YSJM-A1 P400 P300 - ø19.05 ø34.93 ø15.88 ø28.58 ø12.7 ø22.2 - - - -

P750 YSJM-A P400 P350 - ø19.05 ø34.93 ø15.88 ø28.58 ø12.7 ø28.58 - - - -

YSJM-A P450 P350 - ø19.05 ø34.93 ø15.88 ø28.58 ø12.7 ø28.58 - - - -

P800

YSJM-A1 P400 P400 - ø19.05 ø34.93 ø15.88 ø28.58 ø15.88 ø28.58 - - - P850 YSJM-A P450 P400 - ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 - - - P900 YSJM-A P450 P450 - ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 - - - P950 YSJM-A P400 P300 P250 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø22.2 ø9.52 ø22.2 ø19.05 ø34.93

P1000 YSJM-A P400 P300 P300 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø22.2 ø12.7 ø22.2 ø19.05 ø34.93

P1050 YSJM-A P400 P350 P300 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø28.58 ø12.7 ø22.2 ø19.05 ø34.93

P1100 YSJM-A P400 P350 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø28.58 ø12.7 ø28.58 ø19.05 ø34.93

P1150 YSJM-A P450 P350 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø28.58 ø12.7 ø28.58 ø19.05 ø34.93

P1200 YSJM-A P450 P400 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 ø12.7 ø28.58 ø19.05 ø34.93

P1250 YSJM-A P450 P450 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 ø12.7 ø28.58 ø19.05 ø34.93

EP200 YJM-A - - - ø9.52 ø19.05 - - - - - EP250 YJM-A - - - *1 ø9.52 ø22.2 - - - - - - - EP300 YJM-A - - - *2 ø9.52 ø22.2 - - - - - - - EP400 YSJM-A EP200 EP200 - ø12.7 ø28.58 ø9.52 ø19.05 ø9.52 ø19.05 - - - EP450 YSJM-A EP250 EP200 - ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø19.05 - - - -

YSJM-A EP300 EP200 - ø15.88 ø28.58 ø12.7 ø22.2 ø9.52 ø19.05 - - - -

EP500

YSJM-A1 EP250 EP250 - ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø22.2 - - - -

EP550 YSJM-A EP300 EP250 - ø15.88 ø28.58 ø12.7 ø22.2 ø9.52 ø22.2 - - - EP600 YSJM-A EP300 EP300 - ø15.88 ø28.58 ø12.7 ø22.2 ø12.7 ø22.2 - - - EP650 YSJM-A EP250 EP200 EP200 ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø19.05 ø9.52 ø19.05 ø19.05 ø34.93

YSJM-A EP300 EP200 EP200 ø19.05 ø34.93 ø12.7 ø22.2 ø9.52 ø19.05 ø9.52 ø19.05 ø19.05 ø34.93

EP700

YSJM-A1 EP250 EP250 EP200 ø19.05 ø34.93 ø9.52 ø22.2 ø9.52 ø22.2 ø9.52 ø19.05 ø19.05 ø34.93

YSJM-A EP300 EP250 EP200 ø19.05 ø34.93 ø12.7 ø22.2 ø9.52 ø22.2 ø9.52 ø19.05 ø19.05 ø34.93

EP750

YSJM-A1 EP250 EP250 EP250 ø19.05 ø34.93 ø9.52 ø22.2 ø9.52 ø22.2 ø9.52 ø22.2 ø19.05 ø34.93

YSJM-A EP300 EP300 EP200 ø19.05 ø34.93 ø12.7 ø22.2 ø12.7 ø22.2 ø9.52 ø19.05 ø19.05 ø34.93

EP800

YSJM-A1 EP300 EP250 EP250 ø19.05 ø34.93 ø12.7 ø22.2 ø9.52 ø22.2 ø9.52 ø22.2 ø19.05 ø34.93

EP850 YSJM-A EP300 EP300 EP250 ø19.05 ø41.28 ø12.7 ø22.2 ø12.7 ø22.2 ø9.52 ø22.2 ø19.05 ø34.93

EP900 YSJM-A EP300 EP300 EP300 ø19.05 ø41.28 ø12.7 ø22.2 ø12.7 ø22.2 ø12.7 ø22.2 ø19.05 ø34.93

*1 ø12.7 for over 90m

*2 ø12.7 for over 40m

*3 The pipe sizes listed in columns A1 to A3 in this table correspond to the

sizes for the models listed in the unit 1, 2, and 3 columns. When the order

of the models for unit 1, 2, and 3 change, make sure to use the appropriate

pipe size.

B, C, D (mm)

Total capacity of indoor units Liquid pipe

~ 140 ø9.52 ø15.88

141 ~ 200 ø9.52 ø19.05

201 ~ 300 ø9.52 ø22.2

301 ~ 400 ø12.7 ø28.58

401 ~ 650 ø15.88 ø28.58

651 ~ 800 ø19.05 ø34.93

801 ~ ø19.05 ø41.28

a, b, c, d, e (mm)

Model number

20,25,32,40,50 ø6.35 ø12.7

63,71,80,100,125,140 ø9.52 ø15.88

200 ø9.52 ø19.05

250 ø9.52 ø22.2

Downstream unit model total Joint

The 1st branch of P450 ~ P650

The 1st branch of P700, P750, P800

Unit combination A A1 *3 A2 *3 A3 *3 A4

unit 1 unit 2 unit 3

Liquid pipe

~ 200 CMY-Y102S-G2

201 ~ 400 CMY-Y102L-G2

401 ~ 650

651 ~

Liquid pipe Gas pipe Liquid pipe Gas pipe Liquid pipe Gas pipe Liquid pipe

Gas pipe

Gas pipe

CMY-Y202-G2

CMY-Y302-G2

9.2

4-Branching header

(Downstream unit

model total

Gas pipe

8-Branching header

200)

CMY-Y104-G CMY-Y108-G CMY-Y1010-G

Outdoor model

P500 ~ P650

EP400 ~ EP600

P700 ~ P900 CMY-Y200VBK2

P950 ~ P1250

EP650 ~ EP900

(Downstream unit

model total

400)

Liquid pipe Gas pipe

- -

10-Branching header

(Downstream unit

model total

Outdoor twinning kit

CMY-Y100VBK2

CMY-Y300VBK2

650)

5

Page 6

9

A

C

F

B

C

F

F

C

2m

F

D

E

C

15

±

F

G

H

H

J

J

H

I

6

I

c

8

[Fig. 9.2.2]

9.2

<A> Make sure the pipes from the twinning pipe to the outdoor unit are

sloped downwards (towards the twinning pipes).

<C> Slope of twinning pipes

<D> Pipe connection example [EP650]

<B> When the piping on the outdoor unit side (from the twinning pipe)

exceeds 2 m, ensure a trap (gas pipe only) within 2 m.

A : Downward slope

B : Upward slope

C : Indoor unit

D : Trap (gas pipe only)

E : Within 2 m

F : Twinning pipe

Slope of the

G :

H : Pipes on site

I : Twinning kit

J : Straight run of pipe that is 500 mm or more

6

: ODø12.7×IDø9.52 (Included with outdoor unit)

8

: ODø19.05×IDø15.88 (Included with outdoor unit)

c

: ODø34.93×IDø28.58 (Included with outdoor unit)

(6, 8, c: Refer to item 10.2)

twinning

pipe is at an angle within ±15° to the gro

und

6

Page 7

10

AB

P450

EP300

<B>

<A>

F

G

E

A

D

E

D

G

F

A

O

S

C

B

D

<B>

<A>

P200~P400

EP200,EP250

90ab

<C>

A

B

123

<C>

fed

<C>

754

<C>

90ab<C>

457<C>

A

B

[Fig. 10.2.1] [Fig. 10.2.3]

[Fig. 10.2.2]

<A> Front pipe routing

10.2

<A> Refrigerant service valve

(liquid side/brazed type)

<B> Refrigerant service valve

(gas side/brazed type)

A : Shaft

B : Shaft

C : Stopper pin

D : Service port

E : Cap

F : Pinched connecting pipe severing portion

G : Pinched connecting pipe brazing portion

<B> Bottom pipe routing

A : Exampleofclosurematerials(eldsupply)

B : Fill the gap at the site

No.

C Shape

No.

C Shape

P200 1 1

P250 1 1 1

P300 1 1 1 1

P350 1 1 1 1

P400 1 1 1 1

P450 1 1

EP200 1 1 1

EP250 1 1 1 1 1 1 1 1

EP300 1 1 1 1 1

<A> Front pipe routing <B> Bottom pipe routing

<C> Included with outdoor unit

AGaspipe(eldsupplyrequired) BLiquidpipe(eldsupplyrequired)

C Shape

*4: EP650YSJM-A : Use the included connecting pipe 6 , 8, and c to connect to the twinning kit.

*5: EP700YSJM-A1 : Use the included connecting pipe 6 to connect to the twinning kit.

*6: EP750YSJM-A1 : Use the included connecting pipe 6 to connect to the twinning kit.

(*4 ~ *6 : Refer to item 9.2.)

1 3 5 7 9 a c e

IDø19.05

ODø19.05

<Gas side>

2 4 6 8 0 b d f

IDø25.4

ODø25.4

<Gas side>

1 2 3 4 5 6 7 8 9 0 a b c d e f

IDø28.58

<Gas side>

ODø9.52

IDø12.7

<Liquid side>

ODø28.58

ODø9.52

IDø15.88

<Liquid side>

ODø12.7

IDø9.52

<Liquid side>

ODø12.7

IDø15.88

<Liquid side>

ODø19.05

IDø15.88

<Liquid side>

ODø19.05

IDø25.4

<Gas side>

ODø22.2

IDø25.4

<Gas side>

ODø22.2

IDø28.58

<Gas side>

ODø28.58

IDø25.4

<Gas side>

ODø34.93

IDø28.58

<Gas side>

IDø9.52

ODø9.52

<Liquid side>

IDø12.7

ODø12.7

<Liquid side>

IDø15.88

ODø15.88

<Liquid side>

7

Page 8

10.3

A

D

C

C

B

B

E

F

G

H

I

J

A

LOW

HI

LOW

HI

B

A

K

J

L

H

M

C

D

EN

N

O

F

G

I

C

A

B

D

E

B

A

D

C

E

E

E

D

A

B

A B

A B

D

C

D

F

G

B

E

I

B

F

H

D

B

G

I

A

J

1m1m

[Fig. 10.3.1]

[Fig. 10.3.3]

A : Nitrogen gas

B : To indoor unit

C : System analyzer

D : Low knob

E : Hi knob

F : Valve

G : Liquid pipe

H : Gas pipe

I : Outdoor unit

J : Service port

B In case of the R410A cylinder having no syphon pipe.

[Fig. 10.3.2]

10.4

A : System analyzer

B : Low knob

C : Hi knob

D : Valve

E : Liquid pipe

F : Gas pipe

G : Service port

H : Three-way joint

I : Valve

J : Valve

K : R410A cylinder

L : Scale

M : Vacuum pump

N : To indoor unit

O : Outdoor unit

A : Syphon pipe

[Fig. 10.4.1]

A : Steel wire B : Piping

C : Asphaltic oily mastic or asphalt

D : Heat insulation material A

E : Outer covering B

[Fig. 10.4.4]

<A> Inner wall (concealed)

<E> Roof pipe shaft

<F> Penetrating portion on re

limit and boundary wall

<B> Outer wall

A : Liquid pipe B : Gas pipe

C : Electric wire D : Finishing tape

E : Insulator

<C> Outer wall (exposed)

A : Sleeve B : Heat insulating material

C : Lagging D : Caulking material

E : Band F : Waterproong layer

G : Sleeve with edge H : Lagging material

I : Mortar or other incombustible caulking

J : Incombustible heat insulation material

<D> Floor (waterproong)

[Fig. 10.4.3][Fig. 10.4.2]

8

Page 9

C

L1 L2 L3 N

Terminal block for indoor –

outdoor transmission line

(TB3)

Terminal block for

centralized control

(TB7)

Power supply terminal block

(TB1)

Control box

A

B

11

A B C

E

D

M1M2

M1M2

S

TB7

TB3

IC

(51)

M1 M2 S

TB5

RC

(01)

IC

M1 M2 S

TB5

(02)

IC

M1 M2 S

TB5

(04)

IC

M1 M2 S

TB5

(03)

IC

M1 M2 S

TB5

(05)

IC

M1 M2 S

TB5

(07)

IC

M1 M2 S

TB5

(06)

L

2

L

1

(101)

RC

(105)

RC

(103)

RC

(155)

OC

M1M2

M1M2

S

TB7

TB3

CN40

(52)

OC

3

ABS

System

controller

L

3

L

6

L

4

L

5

2

4

1

AB AB AB

AB

CN40

A

B

C

D

A

B

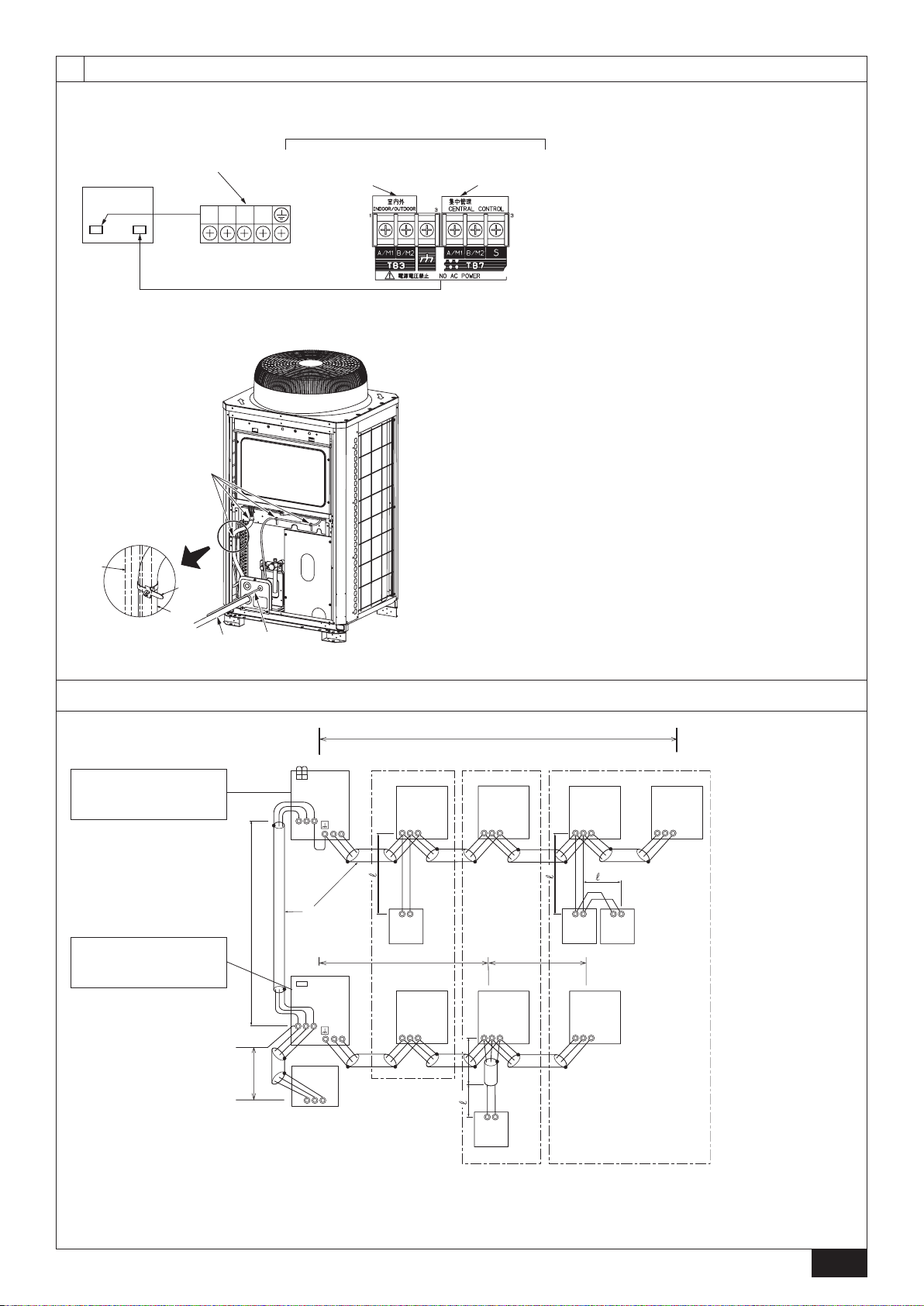

[Fig. 11.2.1]

[Fig. 11.2.2]

A : Cable strap

B : Power source line

C : Transmission line

D : Pillar

11.2

A : Power source

B : Transmission line

C : Earth screw

[Fig. 11.3.1]

<A> Change the jumper connector

from CN41 to CN40 *1

<B> SW2-1:ON *2

( ) Address

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

*1: When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply

connector (CN41) from ONE outdoor unit in the system and connect it to CN40.

*2: If a system controller is used, set SW2-1 on all of the outdoor units to ON.

11.3

9

Page 10

A B C

E

D

M1 M2

M1 M2

M1M2

S

TB7

TB3

IC

(51)

M1 M2 12S

TB5TB15

12

TB15

12

TB15

12

TB15

12

TB 15

12

TB15

MA

(01)

IC

M1 M2 S

TB5

(02)

IC

M1 M2 S

TB5

(04)

IC

M1 M2 S

TB5

(03)

IC

M1 M2 S

TB5

(05)

IC

M1 M2 S

TB5

(07)

IC

M1 M2 S

TB5

(06)

L

2

L

1

MAMAMA

OC

M1M2

S

TB7

TB3

(52)

OC

m

1

m

1

m

1

m

4

m

3

S

System

controller

L

3

L

6

L

4

ABABAB

AB

AB

m

2

m

2

m

2

CN40

CN40

RC

IC

M1M2 S

TB5

IC

M1M2 S

TB5

RP

Ground

AB

ABAB

S

TB2

ABS

TB3

L

4

1

1

M1M2

TB3

M1M2

TB3

M1M2

M1M2 S

TB3

TB7

M1M2 S

TB7

M1M2 S

TB7

OC

(51)

L

7

RC

IC

M1M2 S

TB5

IC

M1M2 S

TB5

L

6

L

5

L

3

L

2

L

1

OS1

(52)

OS2

(53)

To another

refrigerant system

BA

C

3N~380–415V

L

1

, L2, L

3,

N

BA

~220–240V

L, N

Earth

Earth EarthEEarth Earth

E

D

E E

11

[Fig. 11.3.2]

<A> Change the jumper connector

from CN41 to CN40 *1

<B> SW2-1:ON *2

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

A : Group 1

B : Group 3

C : Group 5

D : Shielded wire

E : Sub remote

controller

( ) Address

11.3

*1: When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply

connector (CN41) from ONE outdoor unit in the system and connect it to CN40.

*2: If a system controller is used, set SW2-1 on all of the outdoor units to ON.

[Fig. 11.3.3]

( ) Address

11.4

[Fig. 11.4.1]

A : Switch (Breakers for

wi ri ng and c urre nt

leakage)

B : Breakers for current

C : Outdoor unit

D : Pull box

E : Indoor unit

leakage

10

Page 11

Contents

1. Safety precautions ......................................................................................11

1.1. Before installation and electric work ...........................................11

1.2. Precautions for devices that use R410A refrigerant .................. 12

1.3. Before installation ...................................................................... 12

1.4. Before installation (relocation) - electrical work ......................... 12

1.5. Before starting the test run ........................................................ 12

2. About the product ....................................................................................... 12

3. Combination of outdoor units ..................................................................... 13

4. Specications ............................................................................................. 13

5. Conrmation of parts attached ................................................................... 14

6. Space required around unit ........................................................................ 14

7. Lifting method ............................................................................................ 14

8. Installation of unit ....................................................................................... 15

8.1. Installation ................................................................................. 15

9. Refrigerant piping installation ..................................................................... 15

9.1. Caution ...................................................................................... 15

9.2. Refrigerant piping system ........................................................ 16

1. Safety precautions

1.1. Before installation and electric work

u Before installing the unit, make sure you read all the

“Safety precautions”.

u The “Safety precautions” provide very important points

regarding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main unit

label.) <Color: yellow>

Warning:

Carefully read the labels afxed to the main unit.

HIGH VOLTAGE WARNING:

Con• trol box houses high-voltage parts.

When opening or closing the front panel of the control box, do not let it •

come into contact with any of the internal components.

Before inspecting the inside of the control box, turn off the power, •

keep the unit off for at least 10 minutes, and conrm that the voltage

between FT-P and FT-N on INV Board has dropped to DC20V or less.

(It takes about 10 minutes to discharge electricity after the power

supply is turned off.)

Warning:

Ask the dealer or an authorized technician to install the air conditioner.•

- Improper installation by the user may result in water leakage, electric

shock, or re.

This appliance is not intended for use by persons (including children)•

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

Install the unit at a place that can withstand its weight.•

- Failure to do so may cause the unit to fall down, resulting in injuries and

damage to the unit.

Use the specied cables for wiring. Make the connections securely so •

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a re.

Prepare for strong winds and earthquakes and install the unit at the •

specied place.

- Improper installation may cause the unit to topple and result in injury and

damage to the unit.

Always use lters and other accessories specied by Mitsubishi •

Electric.

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shock, or re.

10. Additional refrigerant charge ...................................................................... 16

10.1. Calculation of additional refrigerant charge ............................... 16

10.2. Precautions concerning piping connection and

valve operation .......................................................................... 17

10.3. Airtight test, evacuation, and refrigerant charging ..................... 18

10.4. Thermal insulation of refrigerant piping ..................................... 18

11. Wiring

12. Test run ...................................................................................................... 22

13. Information on rating plate ......................................................................... 22

(For details, refer to the installation manual of each unit and controller.)

11.1. Caution ...................................................................................... 19

11.2. Control box and connecting position of wiring ........................... 19

11.3. Wiring transmission cables ....................................................... 19

11.4. Wiring of main power supply and equipment capacity .............. 21

12.1. The following phenomena do not represent faults. ................... 22

Never repair the unit. If the air conditioner must be repaired, consult •

the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or re may

result.

If the supply cord is damaged, it must be replaced by the manufacturer, •

its service agent or similarly qualied persons in order to avoid a

hazard.

Do not touch the heat exchanger ns.•

- Improper handling may result in injury.

If refrigerant gas leaks during installation work, ventilate the room.•

- If the refrigerant gas comes into contact with a ame, poisonous gases will

be released.

Install the air conditioner according to this Installation Manual.•

- If the unit is installed improperly, water leakage, electric shock, or re may

result.

Have all electric work done by a licensed electrician according to•

Facility Engineering Standard” and “Interior Wire Regulations” and the

instructions given in this manual and always use a dedicated power

supply.

- If the power source capacity is inadequate or electric work is performed

improperly, electric shock and re may result.

Securely install the outdoor unit terminal cover (panel).•

- If the terminal cover (panel) is not installed properly, dust or water may

enter the outdoor unit and re or electric shock may result.

When installing and moving the air conditioner to another site, do not •

charge it with a refrigerant different from the refrigerant specied on

the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the

refrigerant cycle may malfunction and the unit may be damaged.

If the air conditioner is installed in a small room, measures must be •

taken to prevent the refrigerant concentration from exceeding the

safety limit if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the

safety limit from being exceeded. Should the refrigerant leak and cause

the safety limit to be exceeded, hazards due to lack of oxygen in the room

could result.

When moving and reinstalling the air conditioner, consult the dealer or •

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock,

or re may result.

After completing installation work, make sure that refrigerant gas is not •

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

Do not reconstruct or change the settings of the protection devices.•

- If the pressure switch, thermal switch, or other protection device is shorted

or operated forcibly, or parts other than those specied by Mitsubishi

Electric are used, re or explosion may result.

To dispose of this product, consult your dealer.•

The installer and system specialist shall secure safety against leakage •

according to local regulation or standards.

- The size of the wire and capacities of the switch for the main power supply

are applicable if local regulations are not available.

Pay special attention to the place of installation, such as a basement, •

etc. where refrigeration gas can accumulate, since refrigeration is

heavier than the air.

For outdoor units that allow fresh air intake to the indoor unit, the •

installation site must be carefully chosen because outdoor air can

directly blow into the room when the thermostat is turned off.

- Direct exposure to outdoor air may have harmful effects on people or food.

Children should be supervised to ensure that they do not play with the •

appliance.

........ 19

“Electric

GB

11

Page 12

1.2. Precautions for devices that use

R410A refrigerant

Caution:

Do not use existing refrigerant piping.•

- The old refrigerant and refrigerant oil in the existing piping contains a large

amount of chlorine which may cause the refrigerant oil of the new unit to

deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to burst.

Use refrigerant piping made of phosphorus deoxidized copper and •

copper alloy seamless pipes and tubes. In addition, be sure that the

inner and outer surfaces of the pipes are clean and free of hazardous

sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other

contaminant.

- Contaminants on the inside of the refrigerant piping may cause the

refrigerant residual oil to deteriorate.

Store the piping to be used during installation indoors and keep both •

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

GB

compressor failure may result.

Apply a small amount of ester oil, ether oil, or alkyl benzene to ares. •

(for indoor unit)

- Inltration of a large amount of mineral oil may cause the refrigerant oil to

deteriorate.

Use liquid refrigerant to ll the system.•

- If gas refrigerant is used to ll the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

Do not use a refrigerant other than R410A.•

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the

refrigerant may cause the refrigerant oil to deteriorate.

Use a vacuum pump with a reverse ow check valve.•

- The vacuum pump oil may ow back into the refrigerant cycle and cause

the refrigerant oil to deteriorate.

Do not use the following tools that are used with conventional •

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse ow check

valve, refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R410A,

the refrigerant may deteriorated.

- If water is mixed in the R410A, the refrigerant oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for

conventional refrigerants will not react to it.

Do not use a charging cylinder.•

- Using a charging cylinder may cause the refrigerant to deteriorate.

Be especially careful when managing the tools.•

- If dust, dirt, or water gets into the refrigerant cycle, the refrigerant may

deteriorate.

1.3. Before installation

Caution:

Do not install the unit where combustible gas may leak.•

- If the gas leaks and accumulates around the unit, an explosion may result.

Do not use the air conditioner where food, pets, plants, precision •

instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

Do not use the air conditioner in special environments.•

- Oil, steam, sulfuric smoke, etc. can signicantly reduce the performance of

the air conditioner or damage its parts.

When installing the unit in a hospital, communication station, or similar •

place, provide sufcient protection against noise.

- Inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air

conditioner to operate erroneously, or fail to operate. On the other hand,

the air conditioner may affect such equipment by creating noise that

disturbs medical treatment or image broadcasting.

Do not install the unit on a structure that may cause leakage.•

- When the room humidity exceeds 80% or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage

work together with the outdoor unit, as required.

1.4.

Before installation (relocation) electrical work

Caution:

Ground the unit.•

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

Never connect in reverse phases. •

Never connect the Power Line L1, L2, and L3 to Terminal N.

- If the unit is miss wired, when power is supplied, some electrical parts will

be damaged.

Install the power cable so that tension is not applied to the cable.•

- Tension may cause the cable to break and generate heat and cause a re.

Install a leak circuit breaker, as required.•

- If a leak circuit breaker is not installed, electric shock may result.

Use power line cables of sufcient current carrying capacity and rating.•

- Cables that are too small may leak, generate heat, and cause a re.

Use only a circuit breaker and fuse of the specied capacity.•

- A fuse or circuit breaker of a larger capacity, or the use of a substitute

simple steel or copper wire may result in a general unit failure or re.

Do not wash the air conditioner units.•

- Washing them may cause an electric shock.

Be careful that the installation base is not damaged by long use.•

- If the damage is left uncorrected, the unit may fall and cause personal

injury or property damage.

Install the drain piping according to this Installation Manual to ensure •

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage causing damage to

furniture and other possessions.

Be very careful about transporting the product.•

- One person should not carry the product. Its weight is in excess of 20kg.

- Some products use PP bands for packaging. Do not use any PP bands as

a means of transportation. It is dangerous.

- Do not touch the heat exchanger ns. Doing so may cut your ngers.

- When transporting the outdoor unit, support it at the specied positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

Safely dispose of the packing materials.•

- Packing materials, such as nails and other metal or wooden parts, may

cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which has not been torn

apart, they face the risk of suffocation.

1.5. Before starting the test run

Caution:

Turn on the power at least 12 hours before starting operation.•

- Starting operation immediately after turning on the main power switch can

result in irreversible damage to internal parts. Keep the power switch turned

on during the operational season. Make sure of the phase order of power

supply and voltage between each phase.

Do not touch the switches with wet ngers.•

- Touching a switch with wet ngers can result in an electric shock.

Do not touch the refrigerant pipes during and immediately after •

operation.

- During and immediately after operation, the refrigerant pipes may be hot

or cold, depending on the condition of the refrigerant owing through the

refrigerant piping, compressor, and other refrigerant cycle parts. Your hands

may suffer burns or frostbite if you touch the refrigerant pipes.

Do not operate the air conditioner with the panels and guards removed.•

- Rotating, hot, or high-voltage parts can cause injuries.

Do not turn off the power immediately after stopping operation.•

- Always wait at least 5 minutes before turning off the power. Otherwise,

drainage water leakage or mechanical failure of sensitive parts may occur.

Do not touch the surface of the compressor during servicing.•

- If unit is connected to a supply and not running, the crank case heater

located at the base of the compressor may still be operating.

2. About the product

This unit uses R410A-type refrigerant.•

Piping for systems using R410A may be different from that for systems using •

conventional refrigerant because the design pressure in systems using

R410A is higher. Refer to the Data Book for more information.

Some of the tools and equipment used for installation with systems that use •

other types of refrigerant cannot be used with the systems using R410A.

Refer to the Data Book for more information.

12

Do not use the existing piping, as it contains chlorine, which is found in •

conventional refrigerating machine oil and refrigerant. This chlorine will

deteriorate the refrigerant machine oil in the new equipment. The existing

piping must not be used as the design pressure in systems using R410A

is higher than that in the systems using other types of refrigerant and the

existing pipes may burst.

Caution:

Do not vent R410A into the atmosphere.•

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol •

with a Global Warming Potential (GWP) = 1975.

Page 13

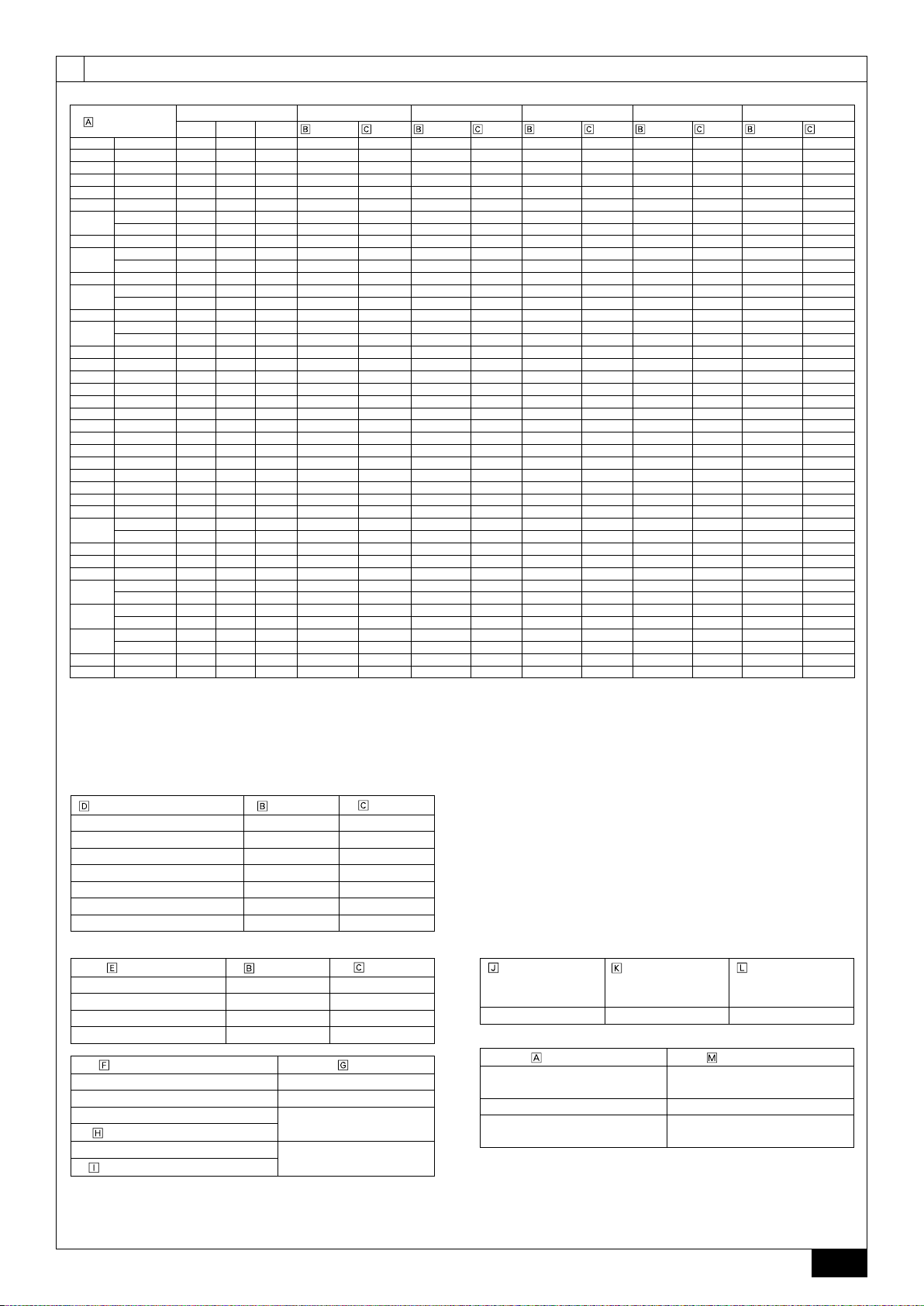

3. Combination of outdoor units

Component units of PUHY-P500 to P1250 are listed below.

Outdoor unit model Component unit model

PUHY-P200YJM-A(-BS) - - PUHY-P250YJM-A(-BS) - - PUHY-P300YJM-A(-BS) - - PUHY-P350YJM-A(-BS) - - PUHY-P400YJM-A(-BS) - - PUHY-P450YJM-A(-BS) - - PUHY-P500YSJM-A(-BS) PUHY-P250YJM-A(-BS) PUHY-P250YJM-A(-BS) PUHY-P500YSJM-A1(-BS) PUHY-P300YJM-A(-BS) PUHY-P200YJM-A(-BS) PUHY-P550YSJM-A(-BS) PUHY-P300YJM-A(-BS) PUHY-P250YJM-A(-BS) PUHY-P600YSJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P250YJM-A(-BS) PUHY-P600YSJM-A1(-BS) PUHY-P300YJM-A(-BS) PUHY-P300YJM-A(-BS) PUHY-P650YSJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P300YJM-A(-BS) PUHY-P700YSJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P700YSJM-A1(-BS) PUHY-P400YJM-A(-BS) PUHY-P300YJM-A(-BS) PUHY-P750YSJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P800YSJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P800YSJM-A1(-BS) PUHY-P400YJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P850YSJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P900YSJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P950YSJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P300YJM-A(-BS) PUHY-P250YJM-A(-BS)

PUHY-P1000YSJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P300YJM-A(-BS) PUHY-P300YJM-A(-BS)

PUHY-P1050YSJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P300YJM-A(-BS)

PUHY-P1100YSJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P350YJM-A(-BS)

PUHY-P1150YSJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P350YJM-A(-BS) PUHY-P350YJM-A(-BS)

PUHY-P1200YSJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P400YJM-A(-BS) PUHY-P350YJM-A(-BS)

PUHY-P1250YSJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P450YJM-A(-BS) PUHY-P350YJM-A(-BS)

Component units of PUHY-EP400 to EP900 are listed below.

Outdoor unit model Component unit model

PUHY-EP200YJM-A(-BS) - - PUHY-EP250YJM-A(-BS) - - PUHY-EP300YJM-A(-BS) - - PUHY-EP400YSJM-A(-BS) PUHY-EP200YJM-A(-BS) PUHY-EP200YJM-A(-BS) PUHY-EP450YSJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP200YJM-A(-BS) PUHY-EP500YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP200YJM-A(-BS) PUHY-EP500YSJM-A1(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP550YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP600YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP650YSJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP200YJM-A(-BS) PUHY-EP200YJM-A(-BS)

PUHY-EP700YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP200YJM-A(-BS) PUHY-EP200YJM-A(-BS)

PUHY-EP700YSJM-A1(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP200YJM-A(-BS)

PUHY-EP750YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP200YJM-A(-BS)

PUHY-EP750YSJM-A1(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP250YJM-A(-BS)

PUHY-EP800YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP200YJM-A(-BS)

PUHY-EP800YSJM-A1(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP250YJM-A(-BS) PUHY-EP250YJM-A(-BS)

PUHY-EP850YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP250YJM-A(-BS)

PUHY-EP900YSJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP300YJM-A(-BS) PUHY-EP300YJM-A(-BS)

GB

4. Specications

Model

Noise level (50/60Hz)

External static pressure 0 Pa *2

Indoor units

Operation

temperature

Model

Noise level (50/60Hz)

External static pressure 0 Pa *2

Indoor units

Operation

temperature

Model

Noise level (50/60Hz)

External static pressure 0 Pa *2

Indoor units

Operation

temperature

Total capacity

Model

Quantity 1~17 1~21 1~26 1~30 1~34 1~39 1~43 1~43 1~47 1~50 1~50 1~50 1~50

Standard type

Fresh air

intake type

Total capacity

Model

Quantity 1~50 1~50 1~50 1~50 1~50 1~50 1~50 2~50 2~50 2~50 2~50 2~50 2~50

Standard type

Fresh air

intake type

Total capacity

Model

Quantity 1~17 1~21 1~26 1~34 1~39 1~43 1~43 1~47 1~50

Standard type

Fresh air

intake type

PUHY-P200YJM-A PUHY-P250YJM-A PUHY-P300YJM-A PUHY-P350YJM-A PUHY-P400YJM-A PUHY-P450YJM-A

56dB<A> 58dB<A> 59dB<A> 60dB<A> 61dB<A> 62dB<A> 61dB<A> 61dB<A>

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

PUHY-P700YSJM-A1 PUHY-P750YSJM-A PUHY-P800YSJM-A PUHY-P800YSJM-A1 PUHY-P850YSJM-A PUHY-P900YSJM-A PUHY-P950YSJM-A PUHY-P1000YSJM-A PUHY-P1050YSJM-A PUHY-P1100YSJM-A PUHY-P1150YSJM-A PUHY-P1200YSJM-A PUHY-P1250YSJM-A

63dB<A>

PUHY-EP200YJM-A PUHY-EP250YJM-A PUHY-EP300YJM-A

63.5dB<A>

57dB<A> 60dB<A> 61dB<A> 60dB<A> 62dB<A> 62.5dB<A> 63dB<A> 63.5dB<A> 64dB<A>

64dB<A> 64dB<A>

64.5dB<A>

65dB<A>

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

PUHY-EP400YSJM-A PUHY-EP450YSJM-A PUHY-EP500YSJM-A

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

PUHY-P500YSJM-A

50~130% *1

15~250

64.5dB<A> 64.5dB<A>

50~130% *1

15~250

50~130% *1

15~250

PUHY-P500YSJM-A1 PUHY-P550YSJM-A PUHY-P600YSJM-A PUHY-P600YSJM-A1 PUHY-P650YSJM-A PUHY-P700YSJM-A

61.5dB<A>

65dB<A> 65dB<A>

62dB<A> 62dB<A>

PUHY-EP500YSJM-A1

62.5dB<A>

65.5dB<A>

PUHY-EP550YSJM-A PUHY-EP600YSJM-A

66dB<A> 66dB<A>

63dB<A>

13

Page 14

Model

Noise level (50/60Hz)

External static pressure 0 Pa *2

Indoor units

Operation

temperature

Total capacity

Model

Quantity 1~50 1~50 1~50 1~50 1~50 1~50 1~50 1~50 1~50

Standard type

Fresh air

intake type

PUHY-EP650YSJM-A PUHY-EP700YSJM-A

63dB<A> 63.5dB<A> 64dB<A> 64.5dB<A> 65dB<A> 65dB<A> 65dB<A> 65.5dB<A> 66dB<A>

PUHY-EP700YSJM-A1

PUHY-EP750YSJM-A

PUHY-EP750YSJM-A1

50~130% *1

15~250

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

PUHY-EP800YSJM-A

PUHY-EP800YSJM-A1

PUHY-EP850YSJM-A PUHY-EP900YSJM-A

*1: The total indoor capacity of units run simultaneously is 130% or less.

*2: To enable high static pressure with (E)P200, (E)P250, (E)P300, P350, P400, and P450, set the DipSW on the main panel as follows.

SW3-9: ON, SW3-10 60Pa compatible: OFF, 30Pa compatible: ON

5. Conrmation of parts attached

This unit includes the following parts. Please check.•

For usage methods, refer to item 10.2.•

GB

1 Connecting elbow

ø

19.05, ODø19.05

ID

<Gas side>

Model P200 1pc. - - - - - - -

P250 - 1pc. - - - - - P300 - 1pc. - 1pc. - - - P350 - 1pc. - - - - 1pc. P400 - 1pc. - - - - 1pc. P450 - - 1pc. - - - - EP200 - 1pc. - - - - - EP250 - 1pc. - - 1pc. 1pc. 1pc. 1pc.

EP300 - - 1pc. - 1pc. - 1pc. -

2 Connecting elbow

ø

25.4, ODø25.4

ID

<Gas side>

3 Connecting elbow

ø

28.58, ODø28.58

ID

<Gas side>

4 Connecting pipe

ø

12.7, ODø9.52

ID

<Liquid side>

5 Connecting pipe

ø

15.88, ODø9.52

ID

<Liquid side>

6 Connecting pipe

ø

9.52, ODø12.7

ID

<Liquid side>

7 Connecting pipe

ø

15.88, ODø12.7

ID

<Liquid side>

8 Connecting pipe

ø

15.88, ODø19.05

ID

<Liquid side>

9 Connecting pipe

ø

25.4, ODø19.05

ID

<Gas side>

0 Connecting pipe

ø

25.4, ODø22.2

ID

<Gas side>

a Connecting pipe

ø

28.58, ODø22.2

ID

<Gas side>

b Connecting pipe

ø

25.4, ODø28.58

ID

<Gas side>

c Connecting pipe

ø

28.58, ODø34.93

ID

<Gas side>

d Connecting pipe

ø

9.52, ODø9.52

ID

<Liquid side>

e Connecting pipe

ø

12.7, ODø12.7

ID

<Liquid side>

f Connecting pipe

ø

15.88, ODø15.88

ID

<Liquid side>

Model P200 - - - - - 1pc. - -

P250 - 1pc. - - - 1pc. - P300 - 1pc. - - - - 1pc. P350 - - - 1pc. - - - 1pc.

P400 - - - 1pc. - - - 1pc.

P450 - - - - - - - 1pc.

EP200 1pc. - - - - 1pc. - EP250 - 1pc. - - 1pc. - - 1pc.

EP300 - - 1pc. - - - - 1pc.

6. Space required around unit

1 In case of single installation

Secure enough space around the unit as shown in the gure on page 2.•

[Fig. 6.0.1] (P.2)

<A> Top view <B> Side view

<C> When there is little space up to an obstruction

Front

A

Back

C

Unit height

B

Air outlet guide (Procured at the site)

D

(1) If the distance is 300 mm or more between the rear side and the wall

(2) If the distance is 100 mm or more between the rear side and the wall

(3) If the wall height (H) of the front, rear or side exceeds the wall height

restriction

When the height of the walls on the front, back or on the sides <H> exceeds •

the wall height limit as dened here, add the height that exceeds the height

limit <h> to the gures that are marked with an asterisk.

If the unit cannot be kept clear of the wall, please change the direction of the •

air outlet of the unit to blow against the wall to avoid air short cycle.

7. Lifting method

<Wall height limit> Front: Up to the unit height

Back: Up to 500 mm from the unit bottom

Side: Up to the unit height

(4) If there are obstacles at the upper part of the unit

2 In case of collective installation

[Fig. 6.0.2] (P.2)

Front

A

Wall height (H)

C

Must be open

B

When multiple units are installed adjacent to each other, secure enough •

space to allow for air circulation and walkway between groups of units as

shown in the gures on page 2.

At least two sides must be left open.•

As with the single installation, add the height that exceeds the height limit •

<h> to the gures that are marked with an asterisk.

If there is a wall at both the front and the rear of the unit. Install up to six •

units (three units: P450, EP300) consecutively in the side direction and

provide a space of 1000 mm or more as inlet space/passage space for each

six units (three units: P450, EP300).

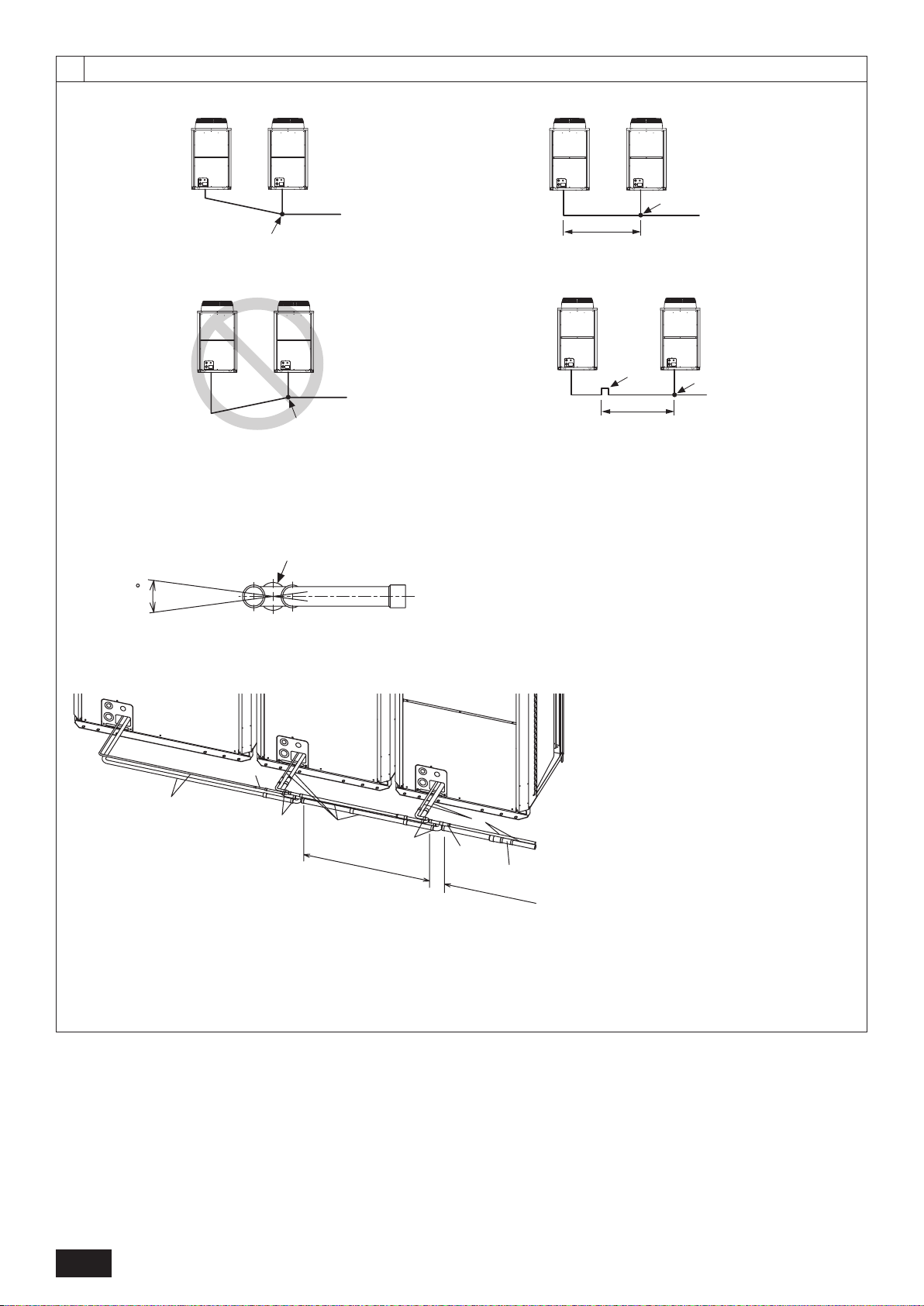

[Fig. 7.0.1] (P.3)

Use suspension ropes that will withstand the weight of the unit.•

When moving the unit, use a • 4-point suspension, and avoid giving impacts

to the unit (Do not use 2-point suspension).

Place protective pads on the unit where it comes in contact with the ropes to •

protect the unit from being scratched.

Set the angle of roping at 40° or less.•

Use 2 ropes that are each longer than 8 meters.•

Place protective padding at the corners of the product to protect the product •

from scratches or dents that might be caused by the rope.

14

Caution:

Be very careful when carrying/moving the product.

- When installing the outdoor unit, suspend the unit at the specied location of

the unit base. Stabilize as necessary so that it does not move to the side and

support it at 4 points. If the unit is installed or suspended with 3-point support,

the unit may become unstable and fall.

Page 15

8. Installation of unit

8.1. Installation

[Fig. 8.1.1] (P.3)

<A> Without detachable leg <B> With detachable leg

M10 anchor bolt procured at the site.

A

Fixing bracket for the hole-in anchor bolt (3 locations to x with screws).

C

Detachable leg

D

Fix unit tightly with bolts so that unit will not fall down due to earthquakes or •

strong winds.

Use concrete or an angle bracket as the foundation of unit.•

Vibration may be transmitted to the installation section and noise and •

vibration may be generated from the oor and walls, depending on the

installation conditions. Therefore, provide ample vibrationproong (cushion

pads, cushion frame, etc.).

Build the foundation in such way that the corner of the installation leg is •

securely supported as shown in the gure. (Fig. 8.1.1)

When using a rubber isolating cushion, please ensure it is large enough to

cover the entire width of each of the unit's legs. If the corners are not rmly

seated, the installation feet may be bent.

The projecting length of the anchor bolt should be less than 30 mm.•

Hole-in anchor bolts are not compatible with this product. However, if xing •

brackets are mounted on the 4 locations (6 locations: P450, EP300) of the

unit attachment part, hole-in anchor bolts can be used.

Corner is not seated.

B

9. Refrigerant piping installation

The pipe is connected via a terminal-branch type connection in which refrigerant

piping from the outdoor unit is branched at the terminal and is connected to each

of the indoor units.

The method of pipe connection is as follows: are connection for the indoor

units, gas pipes and liquid pipes for outdoor units, brazed connection. Note that

the branched sections are brazed.

Warning:

Always use extreme care to prevent the refrigerant gas from leaking while

using re or ame. If the refrigerant gas comes in to contact with a ame

from any source, such as a gas stove, it breaks down and generates

a poisonous gas which can cause gas poisoning. Never weld in an

unventilated room. Always conduct an inspection for gas leakage after

installation of the refrigerant piping has been completed.

Caution:

Do not vent R410A into the atmosphere.•

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol •

with a Global Warming Potential (GWP) = 1975.

9.1. Caution

This unit uses refrigerant R410A. Follow the local regulations on materials and

pipe thickness when selecting pipes. (Refer to the table on the right.)

1 Use the following materials for refrigeration piping.

Material: Use copper alloy seamless pipes made of phosphorus •

deoxidized copper. Ensure the inner and outer surfaces of the pipes are

clean and free from hazardous sulfur, oxide, dusts, shaving particles, oils,

and moisture (contamination).

Size: Refer to item 9.2. for detailed information on refrigerant piping •

system.

[Fig. 8.1.2] (P.3)

Screws

A

The detachable leg can be removed at the site.•

Detaching the detachable leg•

Loosen the three screws to detach the detachable leg (Two (three: P450,

EP300) each in the front and back).

If the base leg nish is damaged when detaching, be sure to repair at the

site.

Warning:

Be sure to install unit in a place strong enough to withstand its weight.•

Any lack of strength may cause unit to fall down, resulting in a

personal injury.

Have installation work in order to protect against strong winds and •

earthquakes.

Any installation deciency may cause unit to fall down, resulting in a

personal injury.

When building the foundation, give full attention to the oor strength, drain water

disposal <during operation, drain water ows out of the unit>, and piping and

wiring routes.

Precautions when routing the pipes and wires below the unit (Without

detachable leg)

When routing the pipes and wires below the unit, be sure that the foundation and

base work do not block the base through-holes. Also make sure the foundation

is at least 100 mm high so that the piping can pass under the unit.

2 Commercially available piping often contains dust and other materials.

Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the

piping during installation.

4 Reduce the number of bending portions as much as possible, and make

bending radii as big as possible.

5 For indoor and outdoor branching, be sure to use the following twinning pipe

sets (sold separately).

Copper pipe size and radial thickness for R410A CITY MULTI.

Size (mm) Size (inch) Radial thickness (mm) Pipe type

ø6.35 ø1/4" 0.8 Type-O

ø9.52 ø3/8" 0.8 Type-O

ø12.7 ø1/2" 0.8 Type-O

ø15.88 ø5/8" 1.0 Type-O

ø19.05 ø3/4" 1.2 Type-O

ø19.05 ø3/4" 1.0 Type-1/2H or H

ø22.2 ø7/8" 1.0 Type-1/2H or H

ø25.4 ø1" 1.0 Type-1/2H or H

ø28.58 ø1-1/8" 1.0 Type-1/2H or H

ø31.75 ø1-1/4" 1.1 Type-1/2H or H

ø34.93 ø1-3/8" 1.2 Type-1/2H or H

ø41.28 ø1-5/8" 1.4 Type-1/2H or H

* For pipe sized ø19.05 (3/4") for R410A air conditioner, choice of pipe type is

up to you.

GB

Lower stream unit

model

Less than 200 in total

CMY-Y102S-G2 CMY-Y102L-G2 CMY-Y202-G2 CMY-Y302-G2 CMY-Y104-G CMY-Y108-G CMY-Y1010-G

Total outdoor model

P500 ~ P650

EP400 ~ EP600

CMY-Y100VBK2 CMY-Y200VBK2 CMY-Y300VBK2

Lower stream unit model

More than 201 and less

than 400 in total

Outdoor twinning kit model

Total outdoor model

P700 ~ P900

Line branch Header branch

Lower stream unit model

More than 401 and less

Indoor twinning pipe set model

than 650 in total

Total outdoor model

P950 ~ P1250

EP650 ~ EP900

Lower stream unit model

More than 651 in total

4 branching 8 branching 10 branching

15

Page 16

6 Use a tting if a specied refrigerant pipe has a different diameter from that

of a branching pipe.

7 Always observe the restrictions on the refrigerant piping (such as rated

length, height difference, and piping diameter) to prevent equipment failure

or a decline in heating/cooling performance.

8 Branching cannot be made after header branching (corresponding parts are

marked with

in the diagram below).

To the outdoor unit

To the outdoor unit

CAP

GB

9 Either a lack or an excess of refrigerant causes the unit to make an

emergency stop. Charge the system with an appropriate amount of

refrigerant. When servicing, always check the notes concerning pipe

length and amount of additional refrigerant at both locations, the refrigerant

volume calculation table on the back of the service panel and the additional

refrigerant section on the labels for the combined number of indoor units

(Refer to item 9.2. for detailed information on refrigerant piping system).

0 Be sure to charge the system using liquid refrigerant.

a Never use refrigerant to perform an air purge. Always evacuate using a

vacuum pump.

Always insulate the piping properly. Insufcient insulation will result in a decline

b

in heating/cooling performance, water drops from condensation and other such

problems (Refer to item 10.4 for thermal insulation of refrigerant piping).

c When connecting the refrigerant piping, make sure the valve of the outdoor

unit is completely closed (the factory setting) and do not operate it until the

refrigerant piping for the outdoor and indoor units has been connected, a

refrigerant leakage test has been performed and the evacuation process has

been completed.

d Braze only with non-oxide brazing material for piping. Failure to do so

may damage the compressor. Be sure to perform the non-oxidation

brazing with a nitrogen purge.

Do not use any commercially available anti-oxidizing agent since it may

cause pipe corrosion and degrading of the refrigerant oil.

Please contact Mitsubishi Electric for more details.

(Refer to item 10.2. for details of the piping connection and valve operation)

e Never perform outdoor unit piping connection work when it is raining.

Warning:

When installing and moving the unit, do not charge the system with any

other refrigerant other than the refrigerant specied on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to

malfunction and may result in severe damage.

Caution:

Use a vacuum pump with a reverse ow check valve.•

- If the vacuum pump does not have a reverse ow check valve, the vacuum

pump oil may ow back into the refrigerant cycle and cause deterioration of

the refrigerant oil.

Do not use the tools shown below used with conventional refrigerant. •

(Gauge manifold, charge hose, gas leak detector, check valve, refrigerant

charge base, vacuum gauge, refrigerant recovery equipment)

- Mixing of conventional refrigerant and refrigerant oil may cause the

refrigerant oil to deteriorate.

10. Additional refrigerant charge

- Mixing of water will cause the refrigerant oil to deteriorate.

- R410A refrigerant does not contain any chlorine. Therefore, gas leak

detectors for conventional refrigerants will not react to it.

Manage the tools used for R410A more carefully than normal.•

If dust, dirt, or water gets in the refrigerant cycle, the

-

refrigerant

oil will deteriorate.

Never use existing refrigerant piping.•

- The large amount of chlorine in conventional refrigerant and refrigerant oil

in the existing piping will cause the new refrigerant to deteriorate.

Store the piping to be used during installation indoors and keep both •

ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate

and the compressor may fail.

Do not use a charging cylinder.•

- Using a charging cylinder may cause the refrigerant to deteriorate.

Do not use special detergents for washing piping.•

9.2. Refrigerant piping system

Connection example

[Fig. 9.2.1] (P.4)

Outdoor model Liquid pipe

Gas pipe Total capacity of indoor units

Model number Downstream unit model total

Joint The 1st branch of P450 ~ P650

The 1st branch of P700, P750, P800

4-Branching header (Downstream unit model total 200)

8-Branching header (Downstream unit model total

10-Branching header (Downstream unit model total 650)

Outdoor twinning kit

Outdoor unit

A

Indoor unit

C

Outdoor twinning kit

E

*1 ø12.7 for over 90 m

*2 ø12.7 for over 40 m

*3 The pipe sizes listed in columns A1 to A3 in this table correspond to the sizes

for the models listed in the unit 1, 2, and 3 columns. When the order of the

models for unit 1, 2, and 3 change, make sure to use the appropriate pipe size.

B

D

Precautions for outdoor unit combinations

Refer to [Fig. 9.2.2] for the positioning of twinning pipes.

[Fig. 9.2.2] (P.6)

<A> Make sure the pipes from the twinning pipe to the outdoor unit are sloped

downwards (towards the twinning pipes).

When the piping on the outdoor unit side (from the twinning pipe) exceeds 2 m,

<B>

ensure a trap (gas pipe only) within 2 m. Make sure the height of the trap is

200 mm or more.

If there is no trap, oil can accumulate inside the pipe, causing a shortage of

oil and may damage the compressor.

<C> Slope of twinning pipes

Make sure the slope of the twinning pipes are at an angle within ±15° to the

ground.

If the slope exceeds the specied angle, the unit may be damaged.

<D> Pipe connection example

Downward slope

A

Indoor unit

C

Within 2 m

E

Slope of the twinning pipes are at an angle within ±15° to the ground

G

Pipes on site

H

Straight run of pipe that is 500 mm or more

J

ODø12.7 × IDø9.52 (included with outdoor unit)

6

ODø19.05 × IDø15.88 (included with outdoor unit)

8

ODø34.93 × IDø28.58 (included with outdoor unit)

c

(6, 8, c: Refer to item 10.2.)

Upward slope

B

Trap (gas pipe only)

D

Twinning pipe

F

Twinning kit

I

Caution:

Do not install traps other than the ones between outdoor units described on •

a separate sheet to prevent oil backow and compressor start-up failure.

Do not install solenoid valves to prevent oil backow and compressor •

start-up failure.

Do not install a sight glass because it may show improper refrigerant ow.•

If a sight glass is installed, inexperienced technicians that use the

glass may overcharge the refrigerant.

400)

First branch

Cap

At the time of shipping, the outdoor unit is charged with refrigerant.

This charge does not include the amount needed for extended piping and

additional charging of each refrigerant line will be required on site. In order that

future servicing may be properly provided, always keep a record of the size and

length of each refrigerant line and the amount of additional charge by writing it in

the space provided on the outdoor unit.

10.1. Calculation of additional refrigerant

charge

Calculate the amount of additional charge based on the length of the piping •

extension and the size of the refrigerant line.

Use the table to the right as a guide to calculating the amount of additional •

charging and charge the system accordingly.

16

If the calculation results in a fraction of less than 0.1 kg, round up to the next •

0.1 kg. For example, if the result of the calculation was 12.38 kg, round the

result up to 12.4 kg.

<Additional Charge>

Additional

refrigerant charge

Liquid pipe size

Total length of

=

ø19.05 × 0.29

(kg) (m) × 0.29 (kg/m) (m) × 0.2 (kg/m) (m) × 0.12 (kg/m)

Liquid pipe size

Total length of

+

ø9.52 × 0.06

(m) × 0.06 (kg/m) (m) × 0.024 (kg/m)

Liquid pipe size

Total length of

+

ø15.88 × 0.2

Liquid pipe size

Total length of

+

ø6.35 × 0.024

Liquid pipe size

Total length of

+

ø12.7 × 0.12

+

α

Page 17

<Example>

Indoor 1: 125 A: ø12.7 40 m a: ø9.52 10 m

2: 100 B: ø9.52 10 m b: ø9.52 5 m

3: 40 C: ø9.52 15 m c: ø6.35 10 m

4: 32 D: ø9.52 10 m d: ø6.35 10 m

At the

conditions

below:

5: 63 e: ø9.52 10 m

The total length of each liquid line is as follows:

ø12.7: A = 40 = 40 m

ø9.52: B + C + D + a + b + e = 10 + 15 + 10 + 10 + 5 + 10 = 60 m

ø6.35: c + d = 10 + 10 = 20 m

Therefore,

<Calculation example>

Additional refrigerant charge

= 40 × 0.12 + 60 × 0.06 + 20 × 0.024 + 3.5 = 12.4 kg

Value of α

Total capacity of connecting indoor units

Models ~ 80 2.0 k

Models 81 ~ 160 2.5 k

Models 161 ~ 330 3.0 k

Models 331 ~ 390 3.5 k

Models 391 ~ 480 4.5 k

Models 481 ~ 630 5.0 k

Models 631 ~ 710 6.0 k

Models 711 ~ 800 8.0 k

Models 801 ~ 890 9.0 k

Models 891 ~ 1070 10.0 k

Models 1071 ~ 1250 12.0 k

Models 1251 ~ 14.0 k

α

g

g

g

g

g

g

g

g

g

g

g

g

10.2. Precautions concerning piping

connection and valve operation

Conduct piping connection and valve operation accurately and carefully.•

Removing the pinched connecting pipe•

When shipped, a pinched connecting pipe is attached to the on-site liquid

and gas valves to prevent gas leakage.

Take the following steps 1 through 4 to remove the pinched connecting

pipe before connecting refrigerant pipes to the outdoor unit.

1 Check that the refrigerant service valve is fully closed (turned clockwise

all the way).

2 Connect a charging hose to the service port on the liquid/gas refrigerant

service valve, and extract the gas in the pipe section between the

refrigerant service valve and the pinched connecting pipe.

3 After vacuuming gas from the pinched connecting pipe, sever the

pinched connecting pipe at the location shown in [Fig.10.2.1] and drain

the refrigerant.

4 After completing 2 and 3 heat the brazed section to remove the

pinched connecting pipe.

[Fig. 10.2.1] (P.7)

<A> Refrigerant service valve (liquid side/brazed type)

<B> Refrigerant service valve (gas side/brazed type)

Shaft

A

Fully closed at the factory, when connecting the piping, and when

vacuuming. Open fully after these operations are completed.

<When opening>

• Turn the shaft counterclockwise with a hexagonal wrench.

• Turn around the shaft until it stops.

<When closing>

• Turn the shaft clockwise with a hexagonal wrench.

• Turn around the shaft until it stops.

Shaft

B

Fully closed at the factory, when connecting the piping, and when

vacuuming. Open fully after these operations are completed.

<When opening>

• Turn the shaft counterclockwise.

• Turn around the shaft until it stops.

<When closing>

• Turn the shaft clockwise.

• Turn around the shaft until it stops.

Stopper pin

C

Prevents the shaft from turning 90° or more.

Service port

D

Available for gas venting of the pinched connecting pipe, or vacuuming in the

refrigerant pipes on the site.

Cap

E

Remove the cap before operating the shaft. Be sure to return it to the original

position after completing the operation.

Pinched connecting pipe severing portion

F

Pinched connecting pipe brazing portion

G

Warning:

The sections between the refrigerant service valves and the pinched •

connecting pipes are lled with gas and refrigerant oil. Extract the gas

and refrigerant oil in the above-mentioned pipe section before heating

the brazed section to remove the refrigerant service valve pinched

connecting pipe.

- If the brazed section is heated without rst extracting the gas and

refrigerant oil, the pipe may burst or the pinched connecting pipe may blow

off and ignite the refrigerant oil, causing serious injury.

Caution:

Place a wet towel on the refrigerant service valve before heating the brazed •

section to keep the temperature of the valve from exceeding 120 ˚C.

Direct the ame away from the wiring and metal sheets inside the unit •

to prevent heat damage.

Caution:

Do not vent R410A into the atmosphere.•

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto •

Protocol, with a Global Warming Potential (GWP) = 1975.

Refrigerant pipe connection•

This product includes connecting pipes for front piping and bottom postpiping. (Refer to [Fig.10.2.2])

Check the liquid/gas piping dimensions before connecting the refrigerant pipe.

Refer to item 9.2 Refrigerant piping system for piping dimensions.

Make sure that the refrigerant pipe is not touching other refrigerants pipes,

unit panels, or base plates.

Be sure to use non-oxidative brazing when connecting pipes.

Be careful not to burn the wiring and plate when brazing.

<Refrigerant piping connection examples>

[Fig.10.2.2] (P.7)

<A> Front pipe routing <B> Bottom pipe routing

<C> Included with outdoor unit

Gas pipe (eld supply required)

A

Shape

C

Liquid pipe (eld supply required)

B

Front pipe routing•

P200,P250,EP200

P300

P300*2 *3

Liquid

EP250, EP300

side

EP250*1, EP300*2 *3

P350, P400

P400*3, P450

P200

EP200

P250, EP250, P300

Gas

EP300

side

P350, P400

P450

Use the included connecting pipe d to connect.

Use the included connecting pipe 4 and e to connect.

Use the included connecting pipe e to connect.

Use the included connecting pipe 5 and f to connect.

Use the included connecting pipe 7 and f to connect.

Use the included connecting pipe f to connect.

Use the included elbow 1 to connect.

Use the included elbow 2 and connecting pipe 9 to connect.

Use the included elbow 2 and connecting pipe 0 to connect.

Use the included elbow 3 and connecting pipe a to connect.

Use the included elbow 2 and connecting pipe b to connect.

Use the included elbow 3 to connect.

Bottom pipe routing•

P200, P250, EP200

P300

P300

Liquid

side

EP250, EP300

EP250*1, EP300*2 *3,

P350, P400

P400*3, P450

P200

EP200

P250, EP250, P300

Gas

side

EP300

P350, P400

P450

*2 *3

Expand the liquid side on-site piping (ID ø9.52)

and connect to the refrigerant service valve piping.

Use the included connecting pipe 4 to connect.

Expand the liquid side on-site piping (ID ø12.7)

and connect to the refrigerant service valve piping.

Use the included connecting pipe 5 to connect.

Use the included connecting pipe 7 to connect.

Expand the liquid side on-site piping (ID ø15.88)

and connect to the refrigerant service valve piping.

Expand the gas side on-site piping (ID ø19.05)

and connect to the refrigerant service valve piping.

Use the included connecting pipe 9 to connect.

Use the included connecting pipe 0 to connect.

Use the included connecting pipe a to connect.

Use the included connecting pipe b to connect.

Expand the gas side on-site piping (ID ø28.58)

and connect to the refrigerant service valve piping.

*1 Over 90m

*2 Over 40m

*3 In the case the unit is used in combination with other outdoor units.

*4 EP650YSJM-A : Use the included connecting pipe 6 , 8, and c to connect to the

twinning kit.

*5 EP700YSJM-A1 : Use the included connecting pipe 6 to connect to the twinning kit.

*6 EP750YSJM-A1 : Use the included connecting pipe 6 to connect to the twinning kit.

(*4~*6: Refer to item 9.2.)

Satisfy the minimum insertion depth in the table below when expanding on-site piping

Pipe diameter (mm) Minimum insertion depth (mm)

5 or more less than 8 6

8 or more less than 12 7

12 or more less than 16 8

16 or more less than 25 10

25 or more less than 35 12

35 or more less than 45 14

After evacuation and refrigerant charging, ensure that the handle is fully •

open. If operating with the valve closed, abnormal pressure will be imparted

to the high- or low-pressure side of the refrigerant circuit, giving damage to

the compressor, four-way valve, etc.

17

GB

Page 18

Determine the amount of additional refrigerant charge by using the formula, •

and charge refrigerant additionally through the service port after completing

piping connection work.

After completing work, tighten the service port and cap securely so as not to •

generate any gas leakage. (Refer to the table on the below for appropriate

tightening torque.)

Appropriate tightening torque:

Outer diameter

of copper pipe

(mm)

Cap

(N·m)

Shaft

(N·m)

Size of

hexagonal

wrench (mm)

ø9.52 15 6 4

ø12.7 20 9 4

ø15.88 25 15 6

ø19.05 25 30 8

ø25.4 25 30 8

ø28.58 25 - - 16

Caution:

Keep the valve closed until refrigerant charging to the pipes to be •

added on site has been completed. Opening the valve before charging

the refrigerant may cause damage to the unit.

GB

Do not use a leak detection additive.•

[Fig. 10.2.3] (P.7)

A Example of closure materials (eld supply)

B Fill the gap at the site

Make sure to seal-off the space around areas where the wires and refrigerant

pipes enter the unit to ensure that small animals, rainwater, or snow cannot

enter the unit through such openings and cause damage to the unit.

Caution:

Make sure to seal-off the openings for the pipe and wire retrieval.

Small animals, rainwater, or snow entering through the openings may •

cause damage to the device.

Service port

(N·m)

12

10.3. Airtight test, evacuation, and

refrigerant charging

1 Airtight test

Perform with the valve of the outdoor unit closed, and pressurize the

connection piping and the indoor unit from the service port provided on the

valve of the outdoor unit. (Always pressurize from both the liquid pipe and

the gas pipe service ports.)

[Fig. 10.3.1] (P.8)

Nitrogen gas

A

Low knob

D

Liquid pipe

G

Service port

J