Page 1

Page 2

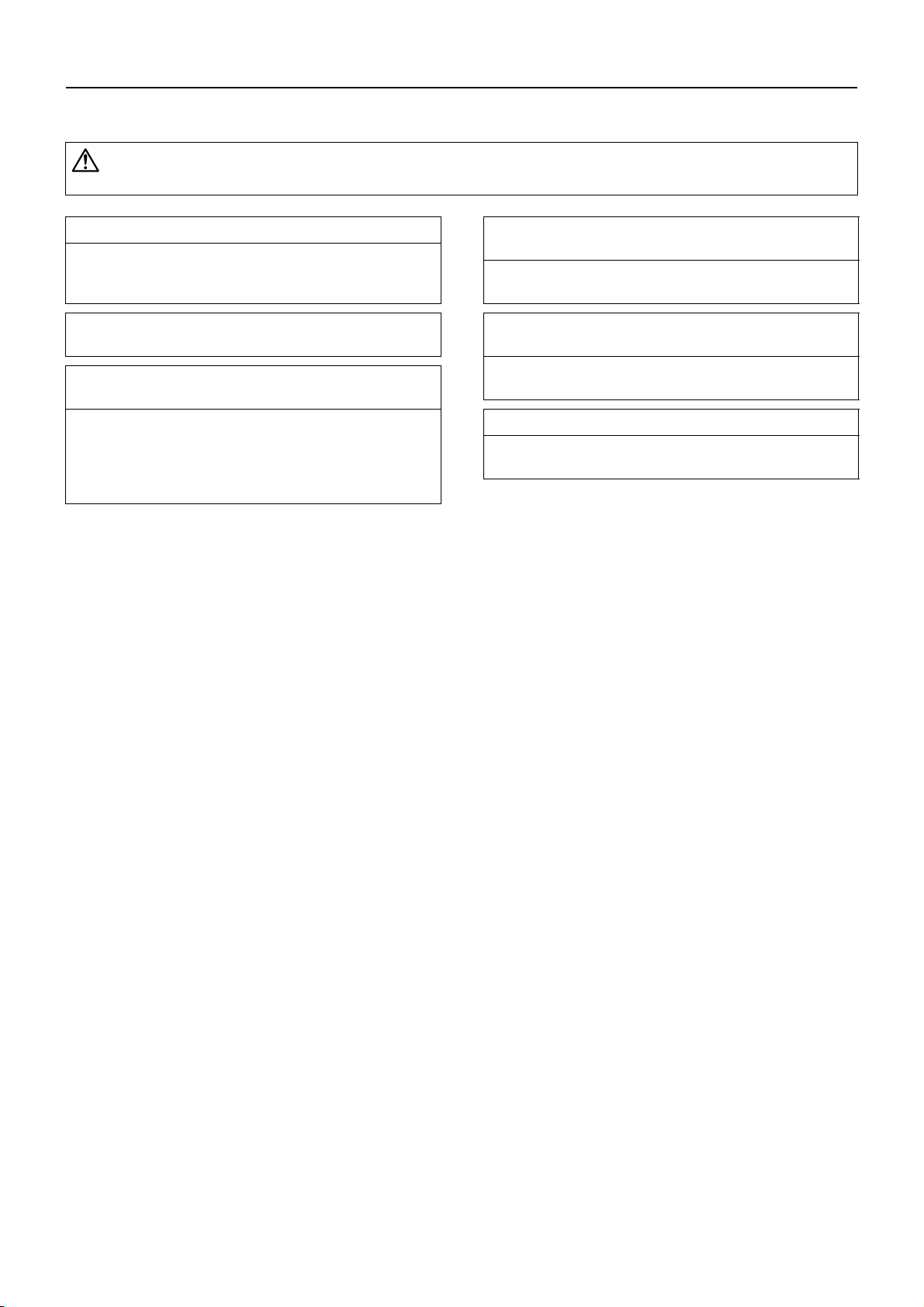

Safety Precautions

Before installing the unit, thoroughly read the following safety precautions.

Observe these safety precautions for your safety.

WARNING

This symbol is intended to alert the user to the presence of important instructions that must be followed to avoid

the risk of serious injury or death.

CAUTION

This symbol is intended to alert the user to the presence of important instructions that must be followed to avoid

the risk of serious injury or damage to the unit.

After reading this manual, give it to the user to retain for future reference.

Keep this manual for easy reference. When the unit is moved or repaired, give this manual to those who provide these

services.

When the user changes, make sure that the new user receives this manual.

WARNING

Ask your dealer or a qualified technician to install the

unit.

Improper installation by the user may result in water leakage, electric shock, smoke, and/or fire.

Properly install the unit on a surface that can withstand the weight of the unit.

Unit installed on an unstable surface may fall and cause injury.

Only use specified cables. Securely connect each cable so that the terminals do not carry the weight of the

cable.

Improperly connected or fixed cables may produce heat

and start a fire.

Take appropriate safety measures against strong

winds and earthquakes to prevent the unit from falling.

If the unit is not installed properly, the unit may fall and

cause serious injury to the person or damage to the unit.

Do not make any modifications or alterations to the

unit. Consult your dealer for repair.

Improper repair may result in water leakage, electric shock,

smoke, and/or fire.

In the event of a refrigerant leak, thoroughly ventilate

the room.

If refrigerant gas leaks and comes in contact with an open

flame, poisonous gases will be produced.

Properly install the unit according to the instructions

in the installation manual.

Improper installation may result in water leakage, electric

shock, smoke, and/or fire.

Have all electrical work performed by an authorized

electrician according to the local regulations and instructions in this manual, and a dedicated circuit must

be used.

Insufficient capacity of the power supply circuit or improper

installation may result in malfunctions of the unit, electric

shock, smoke, and/or fire.

Do not touch the heat exchanger fins.

The fins are sharp and dangerous.

HWE07190 GB

ii

Page 3

WARNING

Securely attach the terminal block cover (panel) to the

unit.

If the terminal block cover (panel) is not installed properly,

dust and/or water may infiltrate and pose a risk of electric

shock, smoke, and/or fire.

Only use the type of refrigerant that is indicated on the

unit when installing or reinstalling the unit.

Infiltration of any other type of refrigerant or air into the unit

may adversely affect the refrigerant cycle and may cause

the pipes to burst or explode.

When installing the unit in a small room, exercise caution and take measures against leaked refrigerant

reaching the limiting concentration.

Consult your dealer with any questions regarding limiting

concentrations and for precautionary measures before installing the unit. Leaked refrigerant gas exceeding the limiting concentration causes oxygen deficiency.

Consult your dealer or a specialist when moving or reinstalling the unit.

Improper installation may result in water leakage, electric

shock, and/or fire.

After completing the service work, check for a gas

leak.

If leaked refrigerant is exposed to a heat source, such as a

fan heater, stove, or electric grill, poisonous gases may be

produced.

Do not try to defeat the safety features of the unit.

Forced operation of the pressure switch or the temperature

switch by defeating the safety features of these devices, or

the use of accessories other than the ones that are recommended by MITSUBISHI may result in smoke, fire, and/or

explosion.

Only use accessories recommended by MITSUBISHI.

Ask a qualified technician to install the unit. Improper installation by the user may result in water leakage, electric

shock, smoke, and/or fire.

Control box houses high-voltage parts.

When opening or closing the front panel of the control box,

do not let it come into contact with any of the internal components. Before inspecting the inside of the control box,

turn off the power, keep the unit off for at least 10 minutes,

and confirm that the voltage between FT-P and FT-N on

INV Board has dropped to DC20V or less. (It takes about

10 minutes to discharge electricity after the power supply is

turned off.)

HWE07190 GB

ii

Page 4

Precautions for handling units for use with R410A

CAUTION

Do not use the existing refrigerant piping.

A large amount of chlorine that may be contained in the re-

sidual refrigerant and refrigerating machine oil in the existing piping may cause the refrigerating machine oil in the

new unit to deteriorate.

R410A is a high-pressure refrigerant and can cause the

existing pipes to burst.

Use refrigerant pipes made of phosphorus deoxidized

copper. Keep the inner and outer surfaces of the pipes

clean and free of such contaminants as sulfur, oxides,

dust, dirt, shaving particles, oil, and water.

These types of contaminants inside the refrigerant pipes

may cause the refrigerant oil to deteriorate.

Store the pipes to be installed indoors, and keep both

ends of the pipes sealed until immediately before brazing. (Keep elbows and other joints wrapped in plastic.)

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerating machine oil to deteriorate or

cause the unit to malfunction.

Use a small amount of ester oil, ether oil, or alkylbenzene to coat flares and flanges.

Infiltration of a large amount of mineral oil may cause the refrigerating machine oil to deteriorate.

Charge liquid refrigerant (as opposed to gaseous refrigerant) into the system.

If gaseous refrigerant is charged into the system, the composition of the refrigerant in the cylinder will change and

may result in performance loss.

Use a vacuum pump with a reverse-flow check valve.

If a vacuum pump that is not equipped with a reverse-flow

check valve is used, the vacuum pump oil may flow into the

refrigerant cycle and cause the refrigerating machine oil to

deteriorate.

Prepare tools for exclusive use with R410A. Do not use

the following tools if they have been used with the conventional refrigerant (gauge manifold, charging hose,

gas leak detector, reverse-flow check valve, refrigerant

charge base, vacuum gauge, and refrigerant recovery

equipment.).

If the refrigerant or the refrigerating machine oil left on

these tools are mixed in with R410A, it may cause the refrigerating machine oil to deteriorate.

Infiltration of water may cause the refrigerating machine

oil to deteriorate.

Gas leak detectors for conventional refrigerants will not

detect an R410A leak because R410A is free of chlorine.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of the refrigerant will change, and the unit may experience power loss.

Exercise special care when handling the tools for use

with R410A.

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerating machine oil to deteriorate.

Only use refrigerant R410A.

The use of other types of refrigerant that contain chlorine

(i.e. R22) may cause the refrigerating machine oil to deteriorate.

HWE07190 GB

iiiiii

Page 5

Before installing the unit

WARNING

Do not install the unit where a gas leak may occur.

If gaseous refrigerant leaks and piles up around the unit, it

may be ignited.

Do not use the unit to keep food items, animals, plants,

artifacts, or for other special purposes.

The unit is not designed to preserve food products.

Do not use the unit in an unusual environment.

Do not install the unit where a large amount of oil or steam

is present or where acidic or alkaline solutions or chemical

sprays are used frequently. Doing so may lead to a remarkable drop in performance, electric shock, malfunctions, smoke, and/or fire.

The presence of organic solvents or corrosive gas (i.e.

ammonia, sulfur compounds, and acid) may cause gas

leakage or water leakage.

When installing the unit in a hospital, take appropriate

measures to reduce noise interference.

High-frequency medical equipment may interfere with the

normal operation of the air conditioner or vice versa.

Do not install the unit on or over things that cannot get

wet.

When the humidity level exceeds 80% or if the drainage

system is clogged, the indoor unit may drip water. Drain water is also discharged from the outdoor unit. Install a centralized drainage system if necessary.

HWE07190 GB

iv

Page 6

Before installing the unit (moving and reinstalling the unit) and performing

electrical work

CAUTION

Properly ground the unit.

Do not connect the grounding wire to a gas pipe, water pipe,

lightning rod, or grounding wire from a telephone pole. Improper grounding may result in electric shock, smoke, fire,

and/or malfunction due to noise interference.

Do not put tension on the power supply wires.

If tension is put on the wires, they may break and result in

excessive heat, smoke, and/or fire.

Install an earth leakage breaker to avoid the risk of

electric shock.

Failure to install an earth leakage breaker may result in

electric shock, smoke, and/or fire.

Use the kind of power supply wires that are specified

in the installation manual.

The use of wrong kind of power supply wires may result in

current leak, electric shock, and/or fire.

Use breakers and fuses (current breaker, remote

switch <switch + Type-B fuse>, moulded case circuit

breaker) with the proper current capacity.

The use of wrong capacity fuses, steel wires, or copper

wires may result in malfunctions, smoke, and/or fire.

Periodically check the installation base for damage.

If the unit is left on a damaged platform, it may fall and

cause injury.

Properly install the drain pipes according to the instructions in the installation manual. Keep them insulated to avoid dew condensation.

Improper plumbing work may result in water leakage and

damage to the furnishings.

Exercise caution when transporting products.

Products weighing more than 20 kg should not be carried

alone.

Do not carry the product by the PP bands that are used on

some products.

Do not touch the heat exchanger fins. They are sharp and

dangerous.

When lifting the unit with a crane, secure all four corners

to prevent the unit from falling.

Properly dispose of the packing materials.

Nails and wood pieces in the package may pose a risk of

injury.

Plastic bags may pose a risk of choking hazard to chil-

dren. Tear plastic bags into pieces before disposing of

them.

Do not spray water on the air conditioner or immerse

the air conditioner in water.

Otherwise, electric shock and/or fire may result.

When handling units, always wear protective gloves to

protect your hands from metal parts and high-temperature parts.

HWE07190 GB

vv

Page 7

Before the test run

CAUTION

Turn on the unit at least 12 hours before the test run.

Keep the unit turned on throughout the season. If the unit is

turned off in the middle of a season, it may result in malfunctions.

To avoid the risk of electric shock or malfunction of the

unit, do not operate switches with wet hands.

Do not touch the refrigerant pipes with bare hands during and immediately after operation.

During or immediately after operation, certain parts of the

unit such as pipes and compressor may be either very cold

or hot, depending on the state of the refrigerant in the unit

at the time. To reduce the risk of frost bites and burns, do

not touch these parts with bare hands.

Do not operate the unit without panels and safety

guards.

Rotating, high-temperature, or high-voltage parts on the unit

pose a risk of burns and/or electric shock.

Do not turn off the power immediately after stopping

the operation.

Keep the unit on for at least five minutes before turning off

the power to prevent water leakage or malfunction.

Do not operate the unit without the air filter.

Dust particles may build up in the system and cause malfunctions.

HWE07190 GB

vi

Page 8

CONTENTS

I

II

III

IV

V

VI

VII

VIII

IX

X

Read Before Servicing

[1] Read Before Servicing.............................................................................................................. 3

[2] Necessary Tools and Materials ................................................................................................ 4

[3] Piping Materials ........................................................................................................................ 5

[4] Storage of Piping ...................................................................................................................... 7

[5] Pipe Processing........................................................................................................................ 7

[6] Brazing...................................................................................................................................... 8

[7] Air Tightness Test..................................................................................................................... 9

[8] Vacuum Drying (Evacuation) ..................................................................................................10

[9] Refrigerant Charging .............................................................................................................. 11

[10] Remedies to be taken in case of a Refrigerant Leak............................................................ 11

[11] Characteristics of the Conventional and the New Refrigerants ............................................ 12

[12] Notes on Refrigerating Machine Oil ...................................................................................... 13

Restrictions

[1] System configuration .............................................................................................................. 17

[2] Types and Maximum allowable Length of Cables .................................................................. 18

[3] Switch Settings and Address Settings .................................................................................... 20

[4] An Example of a System to which an MA Remote Controller is connected ........................... 24

[5] Restrictions on Pipe Length.................................................................................................... 32

Outdoor Unit Components

[1] Outdoor Unit Components and Refrigerant Circuit ................................................................. 35

[2] Control Box of the Outdoor Unit.............................................................................................. 37

[3] Outdoor Unit Circuit Board...................................................................................................... 38

Indoor Unit Components

[1] External Dimensions............................................................................................................... 45

[2] Indoor Unit Components and Internal Structure ..................................................................... 47

[3] Control Box of the Indoor Unit ................................................................................................ 51

[4] Indoor Unit Circuit Board ........................................................................................................ 52

[5] Separating the top and bottom of the unit............................................................................... 53

Electrical Wiring Diagram

[1] Electrical Wiring Diagram of the Outdoor Unit ........................................................................ 59

[2] Electrical Wiring Diagram of the Indoor Unit........................................................................... 60

Refrigerant Circuit

[1] Refrigerant Circuit Diagram .................................................................................................... 65

[2] Principal Parts and Functions ................................................................................................. 67

Control

[1] Functions and Factory Settings of the Dipswitches ................................................................ 73

[2] Controlling the Outdoor Unit ................................................................................................... 78

[3] Controlling the Indoor Unit ...................................................................................................... 89

[4] Operation Flow Chart.............................................................................................................. 93

Test Run Mode

[1] Items to be checked before a Test Run .................................................................................. 99

[2] Test Run Method .................................................................................................................. 100

[3] Operating Characteristic and Refrigerant Amount................................................................ 101

[4] Adjusting the Refrigerant Amount......................................................................................... 101

[5] Refrigerant Amount Adjust Mode.......................................................................................... 103

[6] The following symptoms are normal. .................................................................................... 105

[7] Standard Operation Data (Reference Data) ......................................................................... 106

Troubleshooting

[1] Error Code Lists.................................................................................................................... 109

[2] Responding to Error Display on the Remote Controller........................................................ 112

[3] Investigation of Transmission Wave Shape/Noise ............................................................... 160

[4] Troubleshooting Principal Parts............................................................................................ 163

[5] Refrigerant Leak ................................................................................................................... 182

[6] Compressor Replacement Instructions................................................................................. 183

[7] Troubleshooting Using the Outdoor Unit LED Error Display................................................. 185

[8] Maintenance/Inspection Schedule........................................................................................ 186

LED Monitor Display on the Outdoor Unit Board

[1] How to Read the LED on the Service Monitor ...................................................................... 191

HWE07190 GB

Page 9

HWE07190 GB

Page 10

I

Read Before Servicing

[1] Read Before Servicing ....................................................................................................... 3

[2] Necessary Tools and Materials.......................................................................................... 4

[3] Piping Materials .................................................................................................................5

[4] Storage of Piping ............................................................................................................... 7

[5] Pipe Processing................................................................................................................. 7

[6] Brazing............................................................................................................................... 8

[7] Air Tightness Test.............................................................................................................. 9

[8] Vacuum Drying (Evacuation) ........................................................................................... 10

[9] Refrigerant Charging........................................................................................................ 11

[10] Remedies to be taken in case of a Refrigerant Leak .......................................................11

[11] Characteristics of the Conventional and the New Refrigerants .......................................12

[12] Notes on Refrigerating Machine Oil ................................................................................. 13

HWE07190 GB

- 1 -

Page 11

- 2 -

Page 12

[ I Read Before Servicing ]

IRead Be fore Servicing

[1] Read Before Servicing

1. Check the type of refrigerant used in the system to be serviced.

Refrigerant Type

New refrigerant series split-type air-conditioners for computer rooms R410A

2. Check the symptoms exhibited by the unit to be serviced.

Refer to this service handbook for symptoms relating to the refrigerant cycle.

3. Thoroughly read the safety precautions at the beginning of this manual.

4. Preparing necessary tools: Prepare a set of tools to be used exclusively with each type of refrigerant.

Refer to "Necessary Tools and Materials" for information on the use of tools.(page 4)

5. Verification of the connecting pipes: Verify the type of refrigerant used for the unit to be moved or replaced.

Use refrigerant pipes made of phosphorus deoxidized copper. Keep the inner and outer surfaces of the pipes clean and free

of such contaminants as sulfur, oxides, dust, dirt, shaving particles, oil, and water.

These types of contaminants inside the refrigerant pipes may cause the refrigerant oil to deteriorate.

6. If there is a leak of gaseous refrigerant and the remaining refrigerant is exposed to an open flame, a poisonous gas

hydrofluoric acid may form. Keep workplace well ventilated.

CAUTION

Install new pipes immediately after removing old ones to keep moisture out of the refrigerant circuit.

The use of refrigerant that contains chloride, such as R22, will cause the refrigerating machine oil to deteriorate.

HWE07190 GB

- 3 -

Page 13

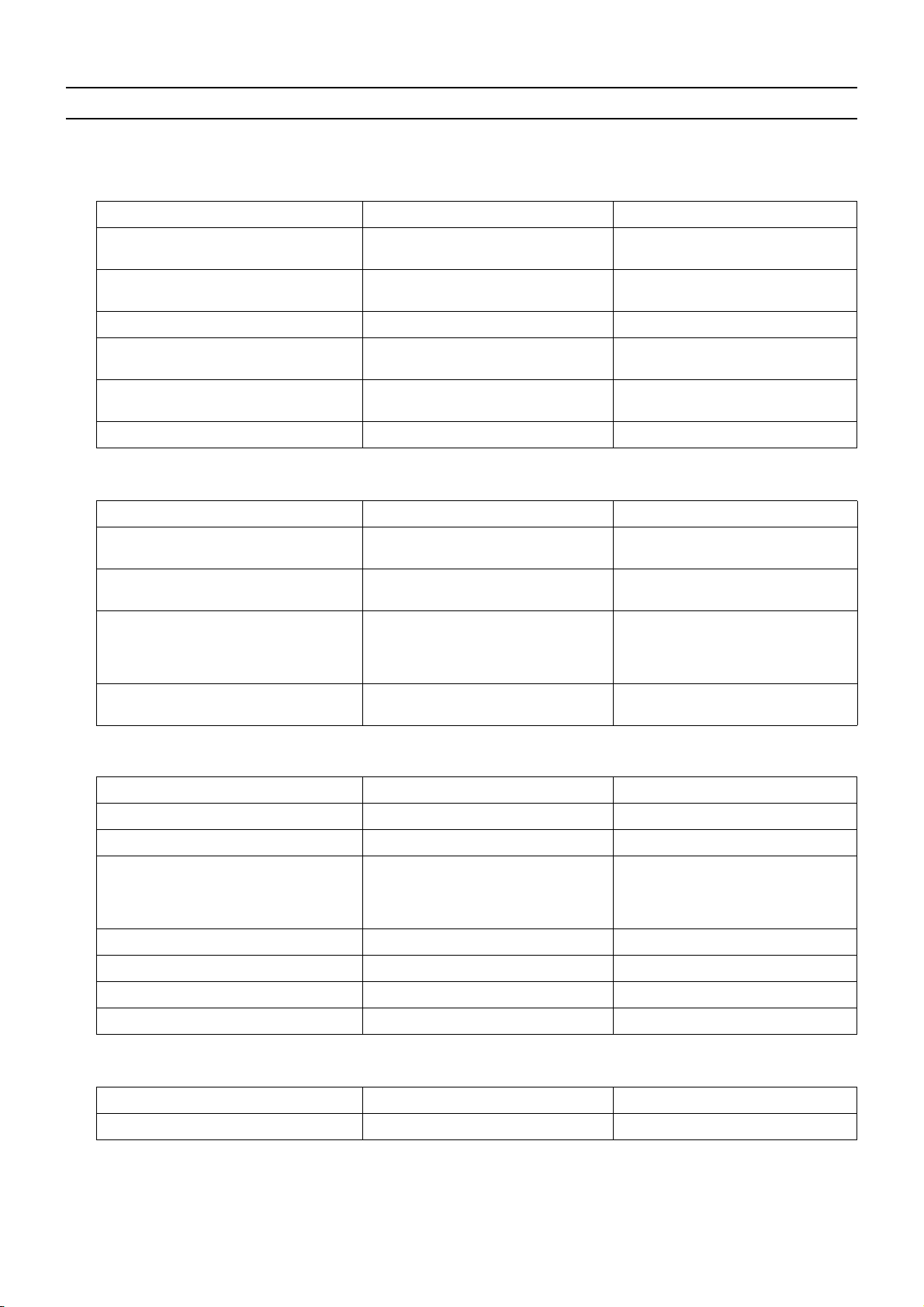

[ I Read Before Servicing ]

[2] Necessary Tools and Materials

Prepare the following tools and materials necessary for installing and servicing the unit.

Tools for use with R410A (Adaptability of tools that are for use with R22 or R407C)

1. To be used exclusively with R410A (not to be used if used with R22 or R407C)

Tools/Materials Use Notes

Gauge Manifold Evacuation and refrigerant charging Higher than 5.09MPa[738psi] on the

high-pressure side

Charging Hose Evacuation and refrigerant charging The hose diameter is larger than the

conventional model.

Refrigerant Recovery Cylinder Refrigerant recovery

Refrigerant Cylinder Refrigerant charging The refrigerant type is indicated. The

cylinder is pink.

Charging Port on the Refrigerant Cylinder Refrigerant charging The charge port diameter is larger

than that of the current port.

Flare Nut Connection of the unit with the pipes Use Type-2 Flare nuts.

2. Tools and materials that may be used with R410A with some restrictions

Tools/Materials Use Notes

Gas Leak Detector Gas leak detection The ones for use with HFC refrigerant

may be used.

Vacuum Pump Vacuum drying May be used if a check valve adapter

is attached.

Flare Tool Flare processing Flare processing dimensions for the

piping in the system using the new refrigerant differ from those of R22. Refer to next page.

Refrigerant Recovery Equipment Refrigerant recovery May be used if compatible with

R410A.

3. Tools and materials that are used with R22 or R407C that may also be used with R410A

Tools/Materials Use Notes

Vacuum Pump with a Check Valve Vacuum drying

Bender Bending pipes

Torque Wrench Tightening flare nuts Only the flare processing dimensions

for pipes that have a diameter of

ø12.70 (1/2") and ø15.88 (5/8") have

been changed.

Pipe Cutter Cutting pipes

Welder and Nitrogen Cylinder Welding pipes

Refrigerant Charging Meter Refrigerant charging

Vacuum Gauge Vacuum level check

4. Tools and materials that must not be used with R410A

Tools/Materials Use Notes

Charging Cylinder Refrigerant charging Prohibited to use

Tools for R410A must be handled with special care to keep moisture and dust from infiltrating the cycle.

HWE07190 GB

- 4 -

Page 14

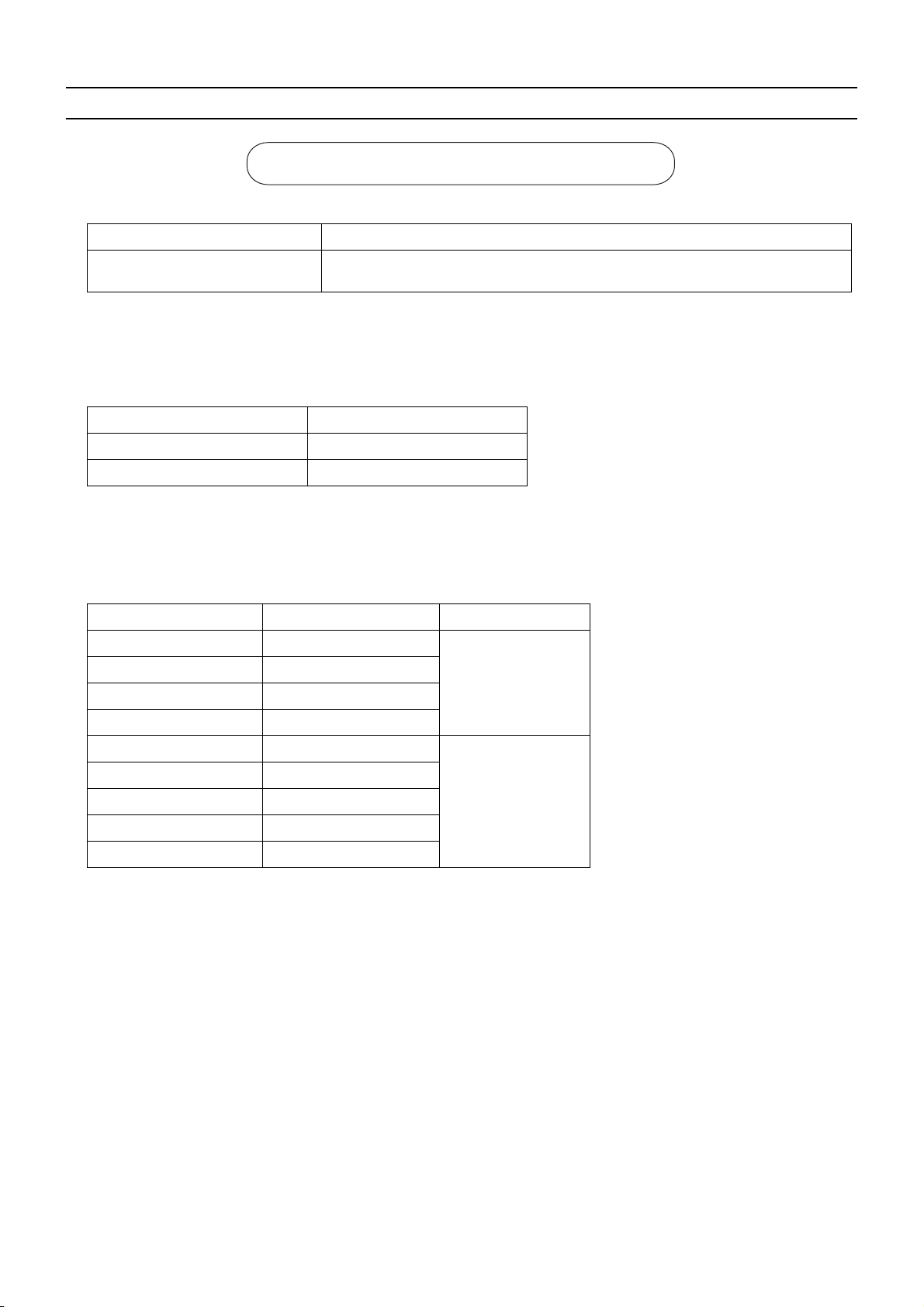

[ I Read Before Servicing ]

[3] Piping Materials

Do not use the existing piping!

1. Copper pipe materials

O-material (Annealed) Soft copper pipes (annealed copper pipes). They can easily be bent with hands.

1/2H-material (Drawn) Hard copper pipes (straight pipes). They are stronger than the O-material (Annealed)

at the same radial thickness.

The distinction between O-materials (Annealed) and 1/2H-materials (Drawn) is made based on the strength of the pipes them-

selves.

O-materials (Annealed) can easily be bent with hands.

1/2H-materials (Drawn) are considerably stronger than O-material (Annealed) at the same thickness.

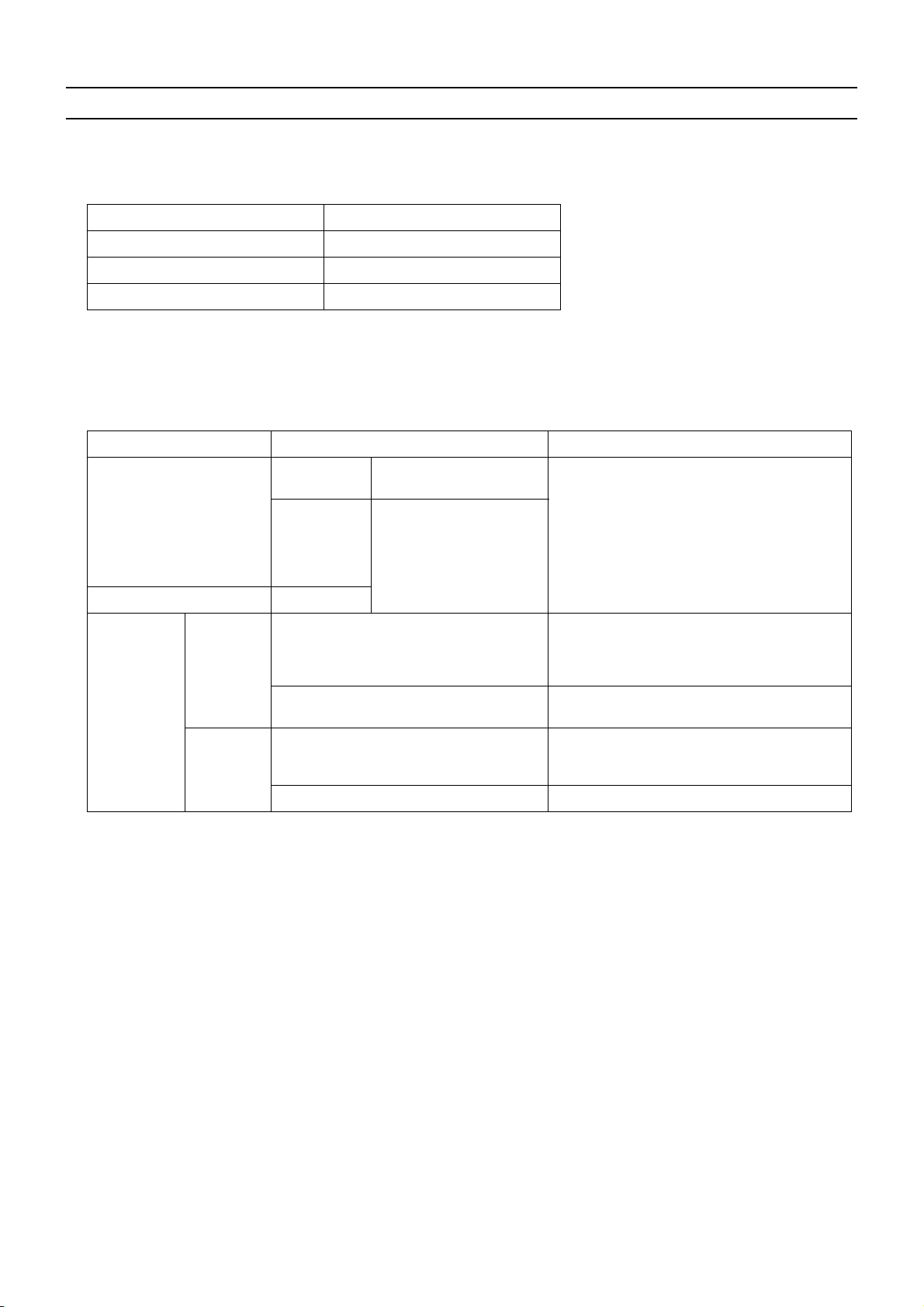

2. Types of copper pipes

Maximum working pressure Refrigerant type

3.45 MPa [500psi] R22, R407C etc.

4.30 MPa [624psi] R410A etc.

3. Piping materials/Radial thickness

Use refrigerant pipes made of phosphorus deoxidized copper.

The operation pressure of the units that use R410A is higher than that of the units that use R22.

Use pipes that have at least the radial thickness specified in the chart below.

(Pipes with a radial thickness of 0.7 mm or less may not be used.)

Pipe size (mm[in]) Radial thickness (mm) Type

ø6.35 [1/4"] 0.8t

ø9.52 [3/8"] 0.8t

ø12.7 [1/2"] 0.8t

ø15.88 [5/8"] 1.0t

ø19.05 [3/4"] 1.0t

ø22.2 [7/8"] 1.0t

ø25.4 [1"] 1.0t

ø28.58 [1-1/8"] 1.0t

ø31.75 [1-1/4"] 1.1t

The pipes in the system that uses the refrigerant currently on the market are made with O-material (Annealed), even if the

pipe diameter is less than ø19.05 (3/4"). For a system that uses R410A, use pipes that are made with 1/2H-material (Drawn)

unless the pipe diameter is at least ø19.05 (3/4") and the radial thickness is at least 1.2t.

The figures in the radial thickness column are based on the Japanese standards and provided only as a reference. Use pipes

that meet the local standards.

O-material (Annealed)

1/2H-material,

H-material (Drawn)

HWE07190 GB

- 5 -

Page 15

[ I Read Before Servicing ]

4. Thickness and refrigerant type indicated on the piping materials

Ask the pipe manufacturer for the symbols indicated on the piping material for new refrigerant.

5. Flare processing (O-material (Annealed) and OL-material only)

The flare processing dimensions for the pipes that are used in the R410A system are larger than those in the R22 system.

Flare processing dimensions (mm[in])

A dimension (mm)

Pipe size (mm[in])

R410A R22, R407C

ø6.35 [1/4"] 9.1 9.0

ø9.52 [3/8"] 13.2 13.0

ø12.7 [1/2"] 16.6 16.2

Dimension A

ø15.88 [5/8"] 19.7 19.4

ø19.05 [3/4"] 24.0 23.3

If a clutch-type flare tool is used to flare the pipes in the system using R410A, the length of the pipes must be between 1.0

and 1.5 mm. For margin adjustment, a copper pipe gauge is necessary.

6. Flare nut

The flare nut type has been changed to increase the strength. The size of some of the flare nuts have also been changed.

Flare nut dimensions (mm[in])

B dimension (mm)

Pipe size (mm[in])

R410A R22, R407C

ø6.35 [1/4"] 17.0 17.0

ø9.52 [3/8"] 22.0 22.0

ø12.7 [1/2"] 26.0 24.0

Dimension B

ø15.88 [5/8"] 29.0 27.0

ø19.05 [3/4"] 36.0 36.0

The figures in the radial thickness column are based on the Japanese standards and provided only as a reference. Use pipes

that meet the local standards.

HWE07190 GB

- 6 -

Page 16

[ I Read Before Servicing ]

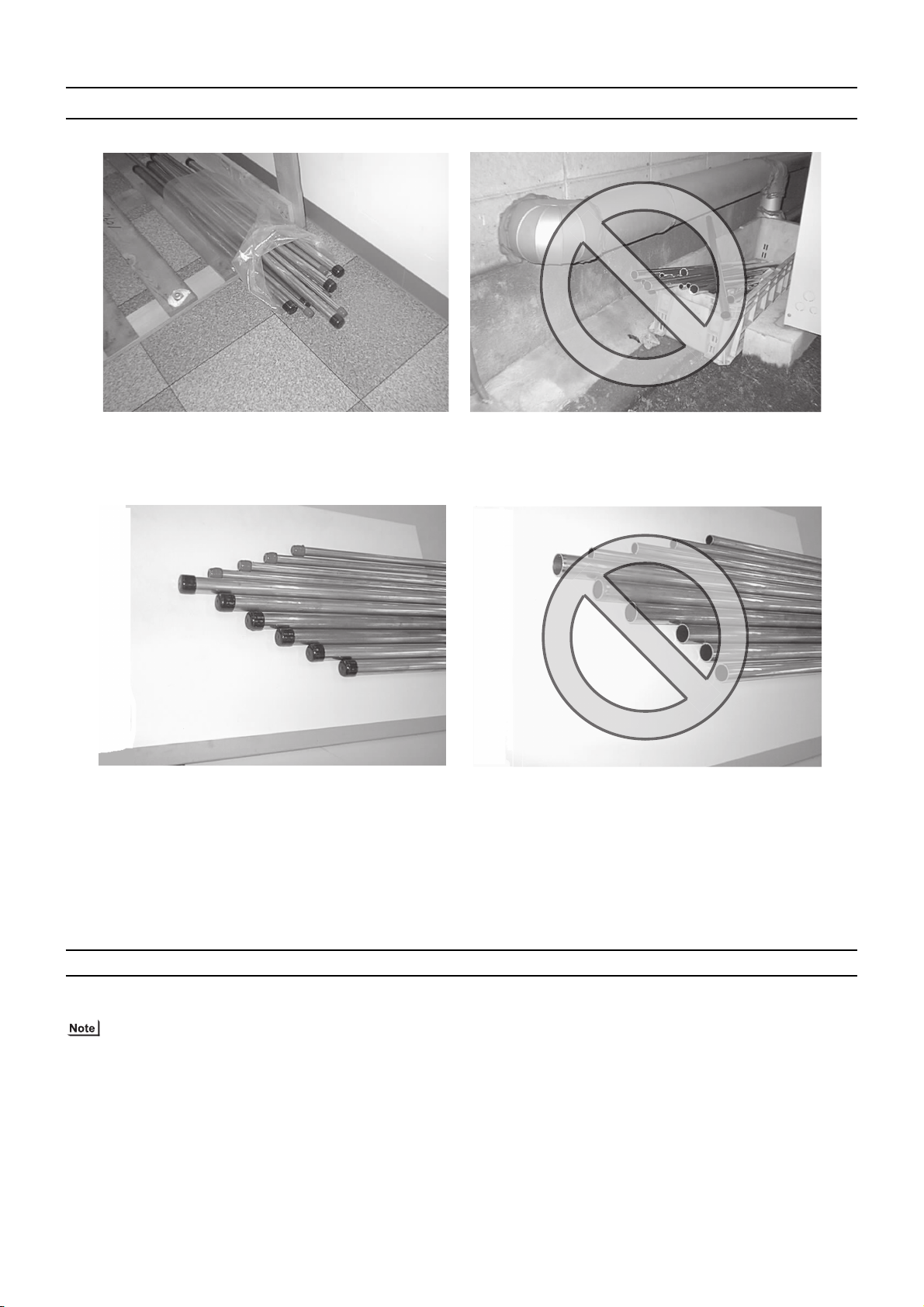

[4] Storage of Piping

1. Storage location

Store the pipes to be used indoors. (Warehouse at site or owner's warehouse)

If they are left outdoors, dust, dirt, or moisture may infiltrate and contaminate the pipe.

2. Sealing the pipe ends

Both ends of the pipes should be sealed until just before brazing.

Keep elbow pipes and T-joints in plastic bags.

The new refrigerator oil is 10 times as hygroscopic as the conventional refrigerating machine oil (such as Suniso) and, if not

handled with care, could easily introduce moisture into the system. Keep moisture out of the pipes, for it will cause the oil to

deteriorate and cause a compressor failure.

[5] Pipe Processing

Use a small amount of ester oil, ether oil, or alkylbenzene to coat flares and flanges.

Use a minimum amount of oil.

Use only ester oil, ether oil, and alkylbenzene.

HWE07190 GB

- 7 -

Page 17

[ I Read Before Servicing ]

[6] Brazing

No changes have been made in the brazing procedures. Perform brazing with special care to keep foreign objects (such as oxide

scale, water, and dust) out of the refrigerant system.

Example: Inside the brazed connection

Use of oxidized solder for brazing Use of non-oxidized solder for brazing

1. Items to be strictly observed

Do not conduct refrigerant piping work outdoors if raining.

Use non-oxidized solder.

Use a brazing material (BCuP-3) that requires no flux when brazing between copper pipes or between a copper pipe and

copper coupling.

If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends.

2. Reasons

The new refrigerating machine oil is 10 times as hygroscopic as the conventional oil and is more likely to cause unit failure if

water infiltrates into the system.

Flux generally contains chloride. Residual flux in the refrigerant circuit will cause sludge to form.

3. Notes

Do not use commercially available antioxidants because they may cause the pipes to corrode or refrigerating machine oil to

deteriorate.

HWE07190 GB

- 8 -

Page 18

[ I Read Before Servicing ]

[7] Air Tightness Test

No changes have been made in the detection method. Note that a refrigerant leak detector for R22 will not detect an R410A leak.

Halide torch R22 leakage detector

1. Items to be strictly observed

Pressurize the equipment with nitrogen up to the design pressure (4.15MPa[601psi]), and then judge the equipment's air tight-

ness, taking temperature variations into account.

When using refrigerant instead of a leak detector to find the location of a leak, use R410A.

Refrigerant R410A must be charged in its liquid state (vs. gaseous state).

2. Reasons

Oxygen, if used for an air tightness test, poses a risk of explosion. (Only use nitrogen to check air tightness.)

Refrigerant R410A must be charged in its liquid state. If gaseous refrigerant in the cylinder is drawn out first, the composition

of the remaining refrigerant in the cylinder will change and become unsuitable for use.

3. Notes

Procure a leak detector that is specifically designed to detect an HFC leak. A leak detector for R22 will not detect an

HFC(R410A) leak.

HWE07190 GB

- 9 -

Page 19

[ I Read Before Servicing ]

[8] Vacuum Drying (Evacuation)

(Photo1) 15010H (Photo2) 14010

Recommended vacuum gauge:

ROBINAIR 14010 Thermistor Vacuum Gauge

1. Vacuum pump with a reverse-flow check valve (Photo1)

To prevent the vacuum pump oil from flowing into the refrigerant circuit during power OFF or power failure, use a vacuum

pump with a reverse-flow check valve.

A reverse-flow check valve may also be added to the vacuum pump currently in use.

2. Standard of vacuum degree (Photo 2)

Use a vacuum pump that attains 0.5Torr(65Pa) or lower degree of vacuum after 5 minutes of operation, and connect it directly

to the vacuum gauge. Use a pump well-maintained with an appropriate lubricant. A poorly maintained vacuum pump may not

be able to attain the desired degree of vacuum.

3. Required precision of vacuum gauge

Use a vacuum gauge that registers a vacuum degree of 5Torr(650Pa) and measures at intervals of 1Torr(130Pa). (A recommended vacuum gauge is shown in Photo2.)

Do not use a commonly used gauge manifold because it cannot register a vacuum degree of 5Torr(650Pa).

4. Evacuation time

After the degree of vacuum has reached 5Torr(650Pa), evacuate for an additional 1 hour. (A thorough vacuum drying re-

moves moisture in the pipes.)

Verify that the vacuum degree has not risen by more than 1Torr(130Pa) 1hour after evacuation. A rise by less than

1Torr(130Pa) is acceptable.

If the vacuum is lost by more than 1Torr(130Pa), conduct evacuation, following the instructions in section 6. Special vacuum

drying.

5. Procedures for stopping vacuum pump

To prevent the reverse flow of vacuum pump oil, open the relief valve on the vacuum pump side, or draw in air by loosening

the charge hose, and then stop the operation.

The same procedures should be followed when stopping a vacuum pump with a reverse-flow check valve.

6. Special vacuum drying

When 5Torr(650Pa) or lower degree of vacuum cannot be attained after 3 hours of evacuation, it is likely that water has pen-

etrated the system or that there is a leak.

If water infiltrates the system, break the vacuum with nitrogen. Pressurize the system with nitrogen gas to

0.5kgf/cm

2

G(0.05MPa) and evacuate again. Repeat this cycle of pressurizing and evacuation either until the degree of vac-

uum below 5Torr(650Pa) is attained or until the pressure stops rising.

Only use nitrogen gas for vacuum breaking. (The use of oxygen may result in an explosion.)

HWE07190 GB

- 10 -

Page 20

[ I Read Before Servicing ]

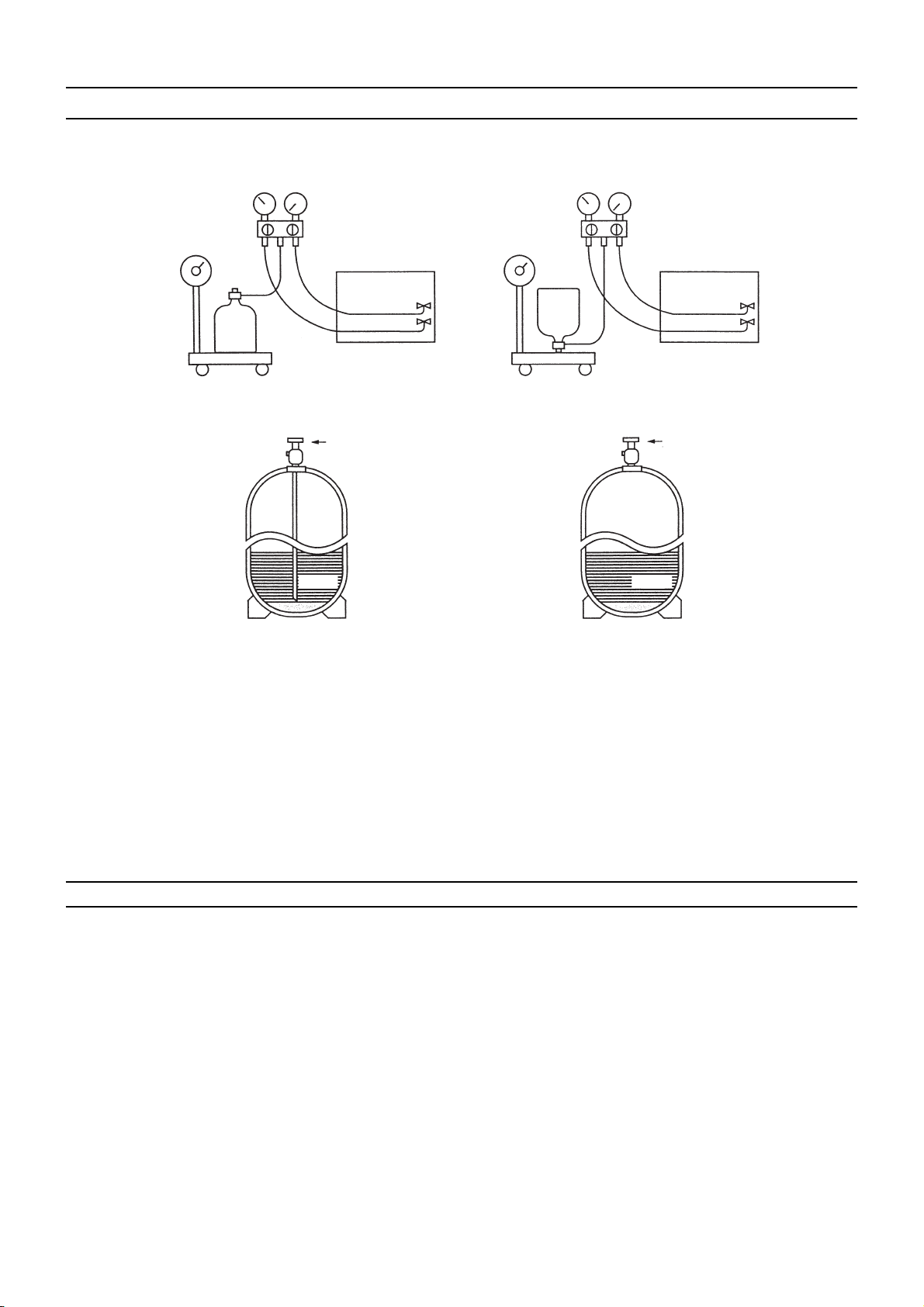

[9] Refrigerant Charging

Cylinder with a siphon

Cylinder without a siphon

Cylin-

Cylin-

der

der

Cylinder color R410A is pink. Refrigerant charging in the liquid state

Valve Valve

liquid

liquid

1. Reasons

R410A is a pseudo-azeotropic HFC blend (boiling point R32=-52°C[-62°F], R125=-49°C[-52°F]) and can almost be handled

the same way as a single refrigerant, such as R22. To be safe, however, draw out the refrigerant from the cylinder in the liquid

phase. If the refrigerant in the gaseous phase is drawn out, the composition of the remaining refrigerant will change and become unsuitable for use.

2. Notes

When using a cylinder with a siphon, refrigerant is charged in the liquid state without the need for turning it upside down. Check

the type of the cylinder on the label before use.

[10] Remedies to be taken in case of a Refrigerant Leak

If the refrigerant leaks out, it may be replenished. The entire refrigerant does not need to be replaced. (Charge refrigerant in the

liquid state.)

Refer to "IX [5] Refrigerant Leak".(page 182)

HWE07190 GB

- 11 -

Page 21

[ I Read Before Servicing ]

[11] Characteristics of the Conventional and the New Refrigerants

1. Chemical property

As with R22, the new refrigerant (R410A) is low in toxicity and chemically stable nonflammable refrigerant.

However, because the specific gravity of vapor refrigerant is greater than that of air, leaked refrigerant in a closed room will

accumulate at the bottom of the room and may cause hypoxia.

If exposed to an open flame, refrigerant will generate poisonous gases. Do not perform installation or service work in a confined area.

New Refrigerant (HFC type) Conventional Refriger-

ant (HCFC type)

R410A R407C R22

R32/R125 R32/R125/R134a R22

Composition (wt%) (50/50) (23/25/52) (100)

Type of Refrigerant Pseudo-azeotropic

Refrigerant

Non-azeotropic

Refrigerant

Single Refrigerant

Chloride Not included Not included Included

Safety Class A1/A1 A1/A1 A1

Molecular Weight 72.6 86.2 86.5

Boiling Point (°C/°F) -51.4/-60.5 -43.6/-46.4 -40.8/-41.4

Steam Pressure

1.557/226 0.9177/133 0.94/136

(25°C,MPa/77°F,psi) (gauge)

Saturated Steam Density

(25°C,kg/m

3

/77°F,psi)

64.0 42.5 44.4

Flammability Nonflammable Nonflammable Nonflammable

Ozone Depletion Coefficient (ODP)

Global Warming Coefficient (GWP)

Refrigerant Charging Method Refrigerant charging i n

Replenishment of Refrigerant after a Refrigerant

*1

*2

0 0 0.055

1730 1530 1700

the liquid state

Refrigerant charging in

the liquid state

Refrigerant charging in

the gaseous state

Available Available Available

Leak

*1 When CFC11 is used as a reference

*2 When CO

is used as a reference

2

2. Refrigerant composition

R410A is a pseudo-azeotropic HFC blend and can almost be handled the same way as a single refrigerant, such as R22. To

be safe, however, draw out the refrigerant from the cylinder in the liquid phase. If the refrigerant in the gaseous phase is drawn

out, the composition of the remaining refrigerant will change and become unsuitable for use.

If the refrigerant leaks out, it may be replenished. The entire refrigerant does not need to be replaced.

3. Pressure characteristics

The pressure in the system using R410A is 1.6 times as great as that in the system using R22.

Pressure (gauge)

Temperature (°C/°F)

R410A R407C R22

MPa/psi MPa/psi MPa/psi

-20/-4 0.30/44 0.18/26 0.14/20

0/32 0.70/102 0.47/68 0.40/58

20/68 1.34/194 0.94/136 0.81/117

40/104 2.31/335 1.44/209 1.44/209

60/140 3.73/541 2.44/354 2.33/338

65/149 4.17/605 2.75/399 2.60/377

HWE07190 GB

- 12 -

Page 22

[ I Read Before Servicing ]

[12] Notes on Refrigerating Machine Oil

1. Refrigerating machine oil in the HFC refrigerant system

HFC type refrigerants use a refrigerating machine oil different from that used in the R22 system.

Note that the ester oil used in the system has properties that are different from commercially available ester oil.

Refrigerant Refrigerating machine oil

R22 Mineral oil

R407C Ester oil

R410A Ester oil

2. Effects of contaminants

*1

Refrigerating machine oil used in the HFC system must be handled with special care to keep contaminants out.

The table below shows the effect of contaminants in the refrigerating machine oil on the refrigeration cycle.

3. The effects of contaminants in the refrigerating machine oil on the refrigeration cycle.

Cause Symptoms Effects on the refrigerant cycle

Water infiltration Frozen expansion valve

and capillary tubes

Clogged expansion valve and capillary tubes

Poor cooling performance

Compressor overheat

Motor insulation failure

Burnt motor

Coppering of the orbiting scroll

Lock

Burn-in on the orbiting scroll

Hydrolysis

Sludge formation and adhesion

Acid generation

Oxidization

Oil degradation

Air infiltration Oxidization

Adhesion to expansion valve and capillary

tubes

Clogged expansion valve, capillary tubes, and

drier

Poor cooling performance

Infiltration of

contaminants

Dust, dirt

Infiltration of contaminants into the compressor

Compressor overheat

Burn-in on the orbiting scroll

Sludge formation and adhesion Clogged expansion valve and capillary tubes

Mineral oil

etc.

Poor cooling performance

Compressor overheat

Oil degradation Burn-in on the orbiting scroll

*1. Contaminants is defined as moisture, air, processing oil, dust/dirt, wrong types of refrigerant, and refrigerating machine oil.

HWE07190 GB

- 13 -

Page 23

- 14 -

Page 24

II

Restrictions

[1] System configuration ....................................................................................................... 17

[2] Types and Maximum allowable Length of Cables ...........................................................18

[3] Switch Settings and Address Settings ............................................................................. 20

[4] An Example of a System to which an MA Remote Controller is connected..................... 24

[5] Restrictions on Pipe Length ............................................................................................. 32

HWE07190 GB

- 15 -

Page 25

- 16 -

Page 26

[ II Restrictions ]

IIRestrictions

[1] System configuration

Indoor unit model Outdoor unit model

PFD-P250VM-E PUHY-P250YHM-A

PFD-P500VM-E PUHY-P250YHM-A x 2 *1

*1 When two outdoor units are connected to one indoor unit, two refrigerant circuits must be connected.

Only one refrigerant circuit can be connected to the indoor unit at factory shipment. To connect two refrigerant circuits, perform some work on the unit.

1. Restrictions when the PFD-type indoor units are connected (related to the system)

(1) The PFD-type indoor units cannot be connected to the ME remote controller.

(2) The address settings must be made on this system.

(3) The following functions cannot be selected on the PFD-type indoor units.

1) Switching between automatic power recovery Enabled/Disabled (Fixed to "Enabled" in the PFD-type indoor units)

2) Switching between power source start/stop (Fixed to "Disabled" in the PFD-type indoor units)

(4) The PFD-type indoor units and other types of indoor units cannot be grouped.

(5) The following functions are limited when the system controller (such as G-50A) is connected.

1) To perform group operation in the system with two refrigerant circuits (combination of two outdoor units and one indoor unit:

P500 model only), the addresses of the controller boards No.1 and No.2 on a indoor unit must be set within a group.

2) The local operation cannot be prohibited with the main remote controller.

3) When the switches of the PFD-type indoor units are set as follows, the unit ON/OFF operation cannot be made with the main

remote controller.

When the Normal/Local switching switch is set to "Local"

When the DipSW1-10 on the controller circuit board is set to "ON"

HWE07190 GB

- 17 -

Page 27

[ II Restrictions ]

[2] Types and Maximum allowable Length of Cables

1. Wiring work

(1) Notes

1) Have all electrical work performed by an authorized electrician according to the local regulations and instructions in this manual.

2) Install external transmission cables at least 5cm [1-31/32"] away from the power supply cable to avoid noise interference.

(Do not put the control cable and power supply cable in the same conduit tube.)

3) Provide grounding for the outdoor unit as required.

4) Run the cable from the electric box of the indoor or outdoor unit in such way that the box is accessible for servicing.

5) Do not connect power supply wiring to the terminal block for transmission line. Doing so will damage the electronic components on the terminal block.

6) Use 2-core shielded cables as transmission cables.

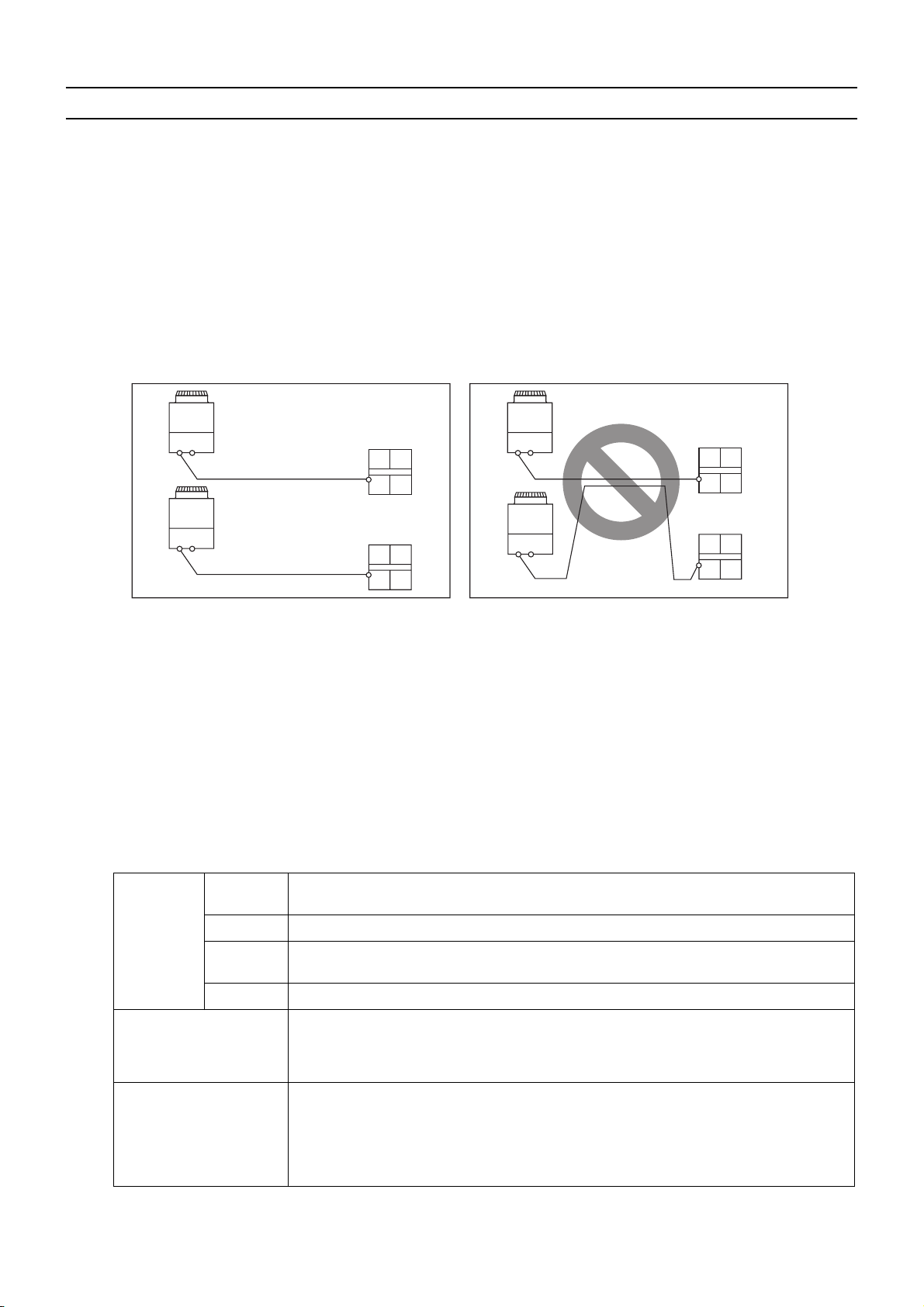

Use a separate 2-core control cable for each refrigerant system. Do not use a single multiple-core cable to connect indoor

units that belong to different refrigerant systems. The use of a multiple-core cable may result in signal transmission errors and

malfunctions.

TB7

TB7

Outdoor unit

Indoor unit

multiple-core cable

Indoor unit

TB3

TB3

Outdoor unit

TB7

TB7

2-core shielded cable

Outdoor unit

2-core shielded cable

Indoor unit

Indoor unit

TB3

TB3

TB3:Terminal block for transmission line connection

TB7:Terminal block for transmission line for centralized control

(2) Control wiring

Different types of control wiring are used for different systems.

Refer to section "[4] An Example of a System to which an MA Remote Controller is connected" before performing wiring work.

Types and maximum allowable length of cables

Control lines are categorized into 2 types: transmission line and remote controller line.

Use the appropriate type of cables and observe the maximum allowable length specified for a given system. If a given system

has a long transmission line or if a noise source is located near the unit, place the unit away from the noise source to reduce

noise interference.

1) M-NET transmission line

Facility

type

All facility types

Type Shielded cable CVVS, CPEVS, MVVS

Cable type

Number of

cores

Cable size Larger than 1.25mm

2-core cable

2

[AWG16]

Maximum transmission

line distance between the

outdoor unit and the far-

200m [656ft] max.

thest indoor unit

Maximum transmission

line distance for centralized control and Indoor/

outdoor transmission line

(Maximum line distance

500m [1640ft] max.

*The maximum overall line length from the power supply unit on the transmission lines for

centralized control to each outdoor unit or to the system controller is 200m [656ft] max.

via outdoor unit)

HWE07190 GB

- 18 -

Page 28

[ II Restrictions ]

2) Remote controller wiring

Type CVV

Number of

Cable type

cores

Cable size

Maximum overall line

length

MA remote controller

2-core cable

0.3 to 1.25mm

2 *1

[AWG22 to 16]

200m [656ft] max.

*1 The use of cables that are smaller than 0.75mm

2

[AWG18] is recommended for easy handling.

HWE07190 GB

- 19 -

Page 29

[ II Restrictions ]

[3] Switch Settings and Address Settings

1. Switch setting

Refer to section "[4] An Example of a System to which an MA Remote Controller is connected" before performing wiring work.

Set the switches while the power is turned off.

If the switch settings are changed while the unit is being powered, those changes will not take effect, and the unit will not

function properly.

2. Address settings

(1) Address settings table

The need for address settings and the range of address setting depend on the configuration of the system. Refer to section

"II [4] An Example of a System to which an MA Remote Controller is connected"

Unit or controller Symbols Address setting

range

Setting method Ad-

dress

setting

Indoor

unit

Main/sub

unit

MA remote

controller

IC 01 to 50

*1

MA No address settings required. (The main/sub switch must be configured if two

remote controllers are connected to the system or if the indoor units are con-

In case of 10HP system, assign an odd number starting with

"01". In case of 20HP system with two refrigerant circuits, assign a sequential odd number starting with "01" to the upper

indoor controller, and assign "the address of the upper indoor

controller + 1" to the lower indoor controller.

nected to different outdoor units.)

Outdoor unit OC 51 to 100

*1

Assign an address of the indoor units in the same refrigerant system and 50.

*1. If a given address overlaps any of the addresses that are assigned to indoor or outdoor units in other refrigerant systems,

use a different, unused address within the setting range.

(2) Power supply switch connector connection on the outdoor unit

(Factory setting: The male power supply switch connector is connected to CN41.)

System configuration

Connection to the

system controller

Power supply unit for

transmission lines

Group operation of

units in a system with

Power supply switch connector connection

multiple outdoor units

System with one

outdoor unit

System with multiple outdoor units

Not connected _ Not grouped

With connection to

the indoor-outdoor

transmission line

With connection to

the centralized control system

_ _ _ Leave CN41 as it is

(Factory setting)

Grouped Disconnect the male con-

Not required Grouped/not grouped

nector from the female

power supply switch connector (CN41) and connect it to the female power

Not required

(Powered from the

outdoor unit)

Grouped/not grouped

supply switch connector

(CN40) on only one of the

outdoor units.

*Connect the S (shielded)

terminal on the terminal

block (TB7) on the outdoor unit whose CN41

was replaced with CN40

to the ground terminal

( ) on the electric box.

Required Grouped/not grouped Leave CN41 as it is

(Factory setting)

00

Main

00

HWE07190 GB

- 20 -

Page 30

[ II Restrictions ]

(3) Settings of MA remote controller Main/Sub switching switch (When MA remote controller is used: factory setting

"Main")

Main/sub settings are available on the MA remote controller. When two remote controllers are connected, set either of them

to "Sub".

(4) Selecting the position of temperature detection for the indoor unit (Factory setting: SWC "Standard")

To use a suction temperature sensor, set SWC to "Option". (The suction temperature sensor is supplied as standard specification.)

(5) Connection of two refrigerant circuits

When two refrigerant circuits are connected on site, make the switch settings on the controller circuit board following the instructions described in the installation manual for the indoor unit.

(6) Cooling-only setting for the indoor unit (Factory setting: SW3-1 on the indoor unit to "OFF.")

When using indoor unit as a cooling-only unit, set SW3-1 on the indoor unit to ON.

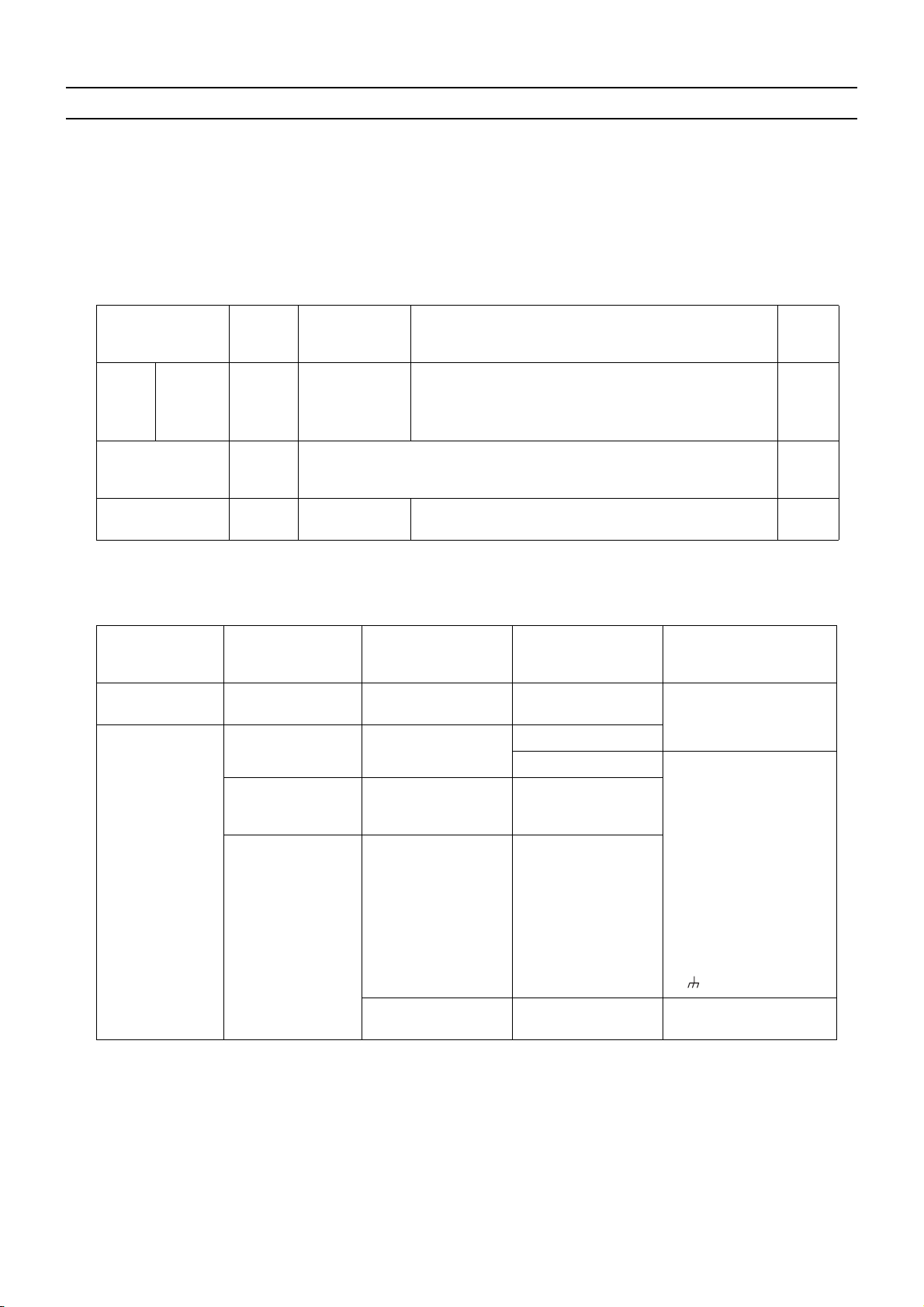

(7) Various types of control using input-output signal connector on the outdoor unit (various connection options)

Type Usage Function

Input Prohibiting cooling/heating operation (thermo OFF) by an external

DEMAND (level) CN3D

input to the outdoor unit.

*It can be used as the DEMAND control device for each refriger-

ant system.

Performs a low level noise operation of the outdoor unit by an external input to the outdoor unit.

Low-noise mode

*3*4

(level)

to be

used

*1

*2

Option

Adapter for

external input

(PACSC36NA-E)

Terminal

* It can be used as the silent operation device for each refrigerant

system.

Forces the outdoor unit to perform a fan operation by receiving signals from the snow sensor.

Out-

How to extract signals from the outdoor unit

put

*It can be used as an operation status display device.

*5

*It can be used for an interlock operation with external devices.

Snow sensor signal

input (level)

Operation status of

the compressor

Error status

CN3S

CN51 Adapter for

external output

(PACSC37SA-E)

*1. For detailed drawing, refer to "Example of wiring connection".

*2. For details, refer to 1) through 2) shown below.

*3. Low-noise mode is valid when Dip SW4-4 on the outdoor unit is set to OFF. When DIP SW4-4 is set to ON, 4 levels of

on-DEMAND are possible, using different configurations of low-noise mode input and DEMAND input settings.

*4. By setting Dip SW5-5, the Low-noise mode can be switched between the Capacity priority mode and the Low-noise pri-

ority mode.

When SW5-5 is set to ON: The Low-noise mode always remains effective.

When SW5-5 is set to OFF: The Low-noise mode is cancelled when certain outside temperature or pressure criteria are

met, and the unit goes into normal operation (capacity priority mode).

Low-noise mode is effective Capacity priority mode becomes effective

Cooling Heating Cooling Heating

TH7 < 30°C [86°F]

and

63HS1 < 32kg/cm

2

TH7 > 3°C [37°F]

and

63LS > 4.6kg/cm

TH7 > 35°C [95°F]

2

or

63HS1 > 35kg/cm

2

TH7 < 0°C [32°F]

or

63LS < 3.9kg/cm

2

*5. When multiple outdoor units exist in one refrigerant circuit system, settings on every outdoor unit (signal input) are re-

quired.

HWE07190 GB

- 21 -

Page 31

[ II Restrictions ]

CAUTION

1) Wiring should be covered by insulation tube with supplementary insulation.

2) Use relays or switches with IEC or equivalent standard.

3) The electric strength between accessible parts and control circuit should have 2750V or more.

Example of wiring connection

CN51

Distant control

board

ecruosrewoppmaL

1

L

L

2

L1 : Outdoor unit error display lamp

L2 : Compressor operation lamp (compressor running state)

X, Y : Relay (coil =<0.9W : DC12V)

1. Optional part : PAC-SC37SA-E or field supply.

CN3D

Relay circuit

Preparations

in the field

X : Low-noise mode

Y : Compressor ON/OFF

X,Y : Relay

2. Optional part : PAC-SC36NA-E or field supply.

Relay circuit Adapter

X

Y

Y

X

Preparations

in the field

Adapter

X

Y

Maximum cable

length is 10m

Contact rating voltage >= DC15V

Contact rating current >= 0.1A

Minimum appicable load =< 1mA at DC

2

1

2

3

Maximum cable

length is 10m

Outdoor unit

control board

CN3D

1

5

4

3

Outdoor unit

control board

CN51

CN3S

Relay circuit

X

Preparations

in the field

X : Relay

Snow sensor : The outdoor fan runs when X is closed

2. Optional part : PAC-SC36NA-E or field supply.

Relay circuit

X

Preparations

in the field

X : Low-noise mode

X : Relay

2. Optional part : PAC-SC36NA-E or field supply.

Low-noise mode : The noise level is reduced by controlling the maximum

Adapter

Maximum cable

length is 10m

Contact rating voltage >= DC15V

Contact rating current >= 0.1A

Minimum applicable load =< 1mA at DC

in stop mode or thermostat mode.

Adapter

Maximum cable

length is 10m

Contact rating voltage >= DC15V

Contact rating current >= 0.1A

Minimum applicable load =< 1mA at DC

fan frequency and maximum compressor frequency.

1

2

3

1

2

3

Outdoor unit

2

control board

CN3S

Outdoor unit

2

control board

CN3D

1) SW4-4: OFF (Compressor ON/OFF, Low-noise mode)

CN3D 1-3P Compressor ON/OFF

Open Compressor ON

Short-circuit Compressor OFF

CN3D 1-2P Low-noise mode

*1

Open OFF

Short-circuit ON

*1. This function and the 4-level on-DEMAND function can be used together. Input the order to CN3D 1-2P on the outdoor

unit whose SW4-4 is set to OFF.

HWE07190 GB

- 22 -

Page 32

[ II Restrictions ]

2) When SW4-4 on one outdoor unit in one refrigerant circuit system is set to ON (4 levels of on-DEMAND)

CN3D 1-2P

CN3D 1-3P Open Short-circuit

Open 100% (No DEMAND) 75%

Short-circuit 0% (Compressor OFF) 50%

*2. Input the order to CN3D on the outdoor unit whose SW4-4 is set to ON.

Note the following steps to be taken when using the STEP DEMAND

(Example) When switching from 100% to 50%

Demand control

steps

If the step listed as the wrong example above is taken, thermo may go off.

The percentage of the demand listed in the table above is an approximate value based on the

compressor volume and does not necessarily correspond with the capacity.

When this function is enabled, the night mode cannot be enabled.

(Wrong)

(Correct)

100%

100%

0%

75%

50%

50%

*2

HWE07190 GB

- 23 -

Page 33

[ II Restrictions ]

[4] An Example of a System to which an MA Remote Controller is connected

1. System with one refrigerant

(1) Sample control wiring

Leave the male

connector on

CN41 as it is.

TB7

M1M2

51

S

OC

TB3

M1M2

L1

IC

01

TB5-1

A1B1S

TB15

1

AB

MA

2

*Two indoor controllers (controller circuit boards)

are equipped in the indoor unit (P500).

02

TB5-2

A2 B2

S

(2) Notes

1) Leave the male connector on the female power supply

switch connector (CN41) on the outdoor unit as it is.

2) It is not necessary to provide grounding to S terminal on

the terminal block for transmission line for centralized

control (TB7).

3) Although two indoor controllers (controller circuit boards)

are equipped inside the indoor unit, the board on No.2

side (lower side) is not used. Do not connect wiring to the

lower controller circuit board.

(3) Maximum allowable length

1) Indoor/outdoor transmission line

2

Maximum distance (1.25mm

[AWG16] or larger)

L1 200m [656ft]

- 24 -

GBHWE07190

Page 34

[ II Restrictions ]

(4) Wiring method

1) Indoor/outdoor transmission line

Connect M1, M2 terminals of the indoor/outdoor trans-

mission line terminal block (TB3) on the outdoor unit

(OC) and A1, B1 terminals of the indoor/outdoor terminal

block (TB5-1) on the indoor unit (IC). (Non-polarized 2core cable)

Only use shielded cables.

(5) Address setting method

Procedures Unit or controller

1 Indoor

Main unit IC 01 to 50 Assign a sequential odd number

unit

Sub unit IC 01 to 50 Assign sequential numbers start-

2 Outdoor unit OC 51 to 100 Add 50 to the address assigned

3MA

remote

controller

Main

remote

controller

Sub

MA No settings

MA Sub

remote

controller

Address

setting range

required.

remote

controller

Shielded cable connection

Connect the earth terminal of the OC and S terminal of

the IC terminal block (TB5-1).

2) Switch setting

Address setting is required as follows.

Setting method Notes

starting with "01" to the upper indoor controller.

ing with the address of the main

unit in the same group. (Main

unit address +1)

to the indoor unit connected to

the system with one outdoor unit.

- Main

Settings to be made with the sub/

main switch

Factory

setting

00

00

HWE07190 GB

25- 25 -

Page 35

[ II Restrictions ]

2. System with two refrigerant circuits

(1) Sample control wiring

CN40

CN41

Replace

TB7

M1M2

51

S

OC

TB3

M1M2

L1

IC

01

TB5-1

A1 B1

S

*Two indoor controllers (controller circuit boards)

are equipped in the indoor unit (P500).

TB15

TB5-2

A2 B2

Not connect

L2

1

AB

MA

2

02

S

L31

Connect

Leave the male

connector on

CN41 as it is.

TB7

M1M2

52

S

OC

TB3

M1M2

(2) Notes

1) Assign the sequential number to the indoor units.

2) Do not connect the terminal blocks (TB5) on the indoor

unitsthat are connected to different outdoor units with

each other.

3) Replacement of male power supply switch connector(CN41) must be performed only on one of the outdoor

units.

4) Provide grounding to S terminal on the terminal block fortransmission line for centralized control (TB7) on only

one ofthe outdoor units.

5) When the power supply unit is connected to the transmission line for centralized control, leave the male connector on the female power supply switch connector

(CN41) as it is. (Factory setting)

(3) Maximum allowable length

1) Indoor/outdoor transmission line

2

Maximum distance (1.25mm

[AWG16] or larger)

L1, L2 200m [656ft]

2) Transmission line for centralized control

Maximum line distance via outdoor unit.

(1.25mm2[AWG16] or larger)

L1+L31+L2 500m [1640ft]

- 26 -

GBHWE07190

Page 36

[ II Restrictions ]

(4) Wiring method

1) Indoor/outdoor transmission line

Connect M1, M2 terminals of the indoor/outdoor trans-

mission line terminal block (TB3) on the outdoor unit

(OC) and A1, B1 terminals of the indoor/outdoor terminal

block (TB5-1) on the indoor unit (IC). (Non-polarized 2core cable)

Only use shielded cables.

Shielded cable connection

Connect the earth terminal of the OC and S terminal of

the IC terminal block (TB5-1).

2) Transmission line for centralized control

Daisy-chain terminals M1 and M2 on the terminal block

for transmission line for centralized control (TB7) on

each outdoor unit (OC). Disconnect the male connector

(5) Address setting method

Procedures Unit or controller

1 Indoor

Main unit IC 01 to 50 Assign a sequential odd number

unit

Sub unit IC 01 to 50 Assign sequential numbers start-

Address

setting range

on the controller board from the female power supply

switch connector (CN41), and connect it to the female

power supply switch connector (CN40) on only one of the

outdoor units.

Only use shielded cables.

Shielded cable connection

To ground the shielded cable, daisy-chain the S-terminals on the terminal block (TB7) on each of the outdoor

units. Connect the S (shielded) terminal on the terminal

block (TB7) on the outdoor unit whose male connector

on CN41 was disconnected and connected to CN40 to

the earth terminal( ) on the electric box.

3) Switch setting

Address setting is required as follows.

Setting method Notes

Factory

setting

starting with "01" to the upper indoor controller.

ing with the address of the main

unit in the same group. (Main

unit address +1)

00

2 Outdoor unit OC 51 to 100 Add 50 to the address assigned

to the indoor unit connected to

the system with one outdoor unit.

3MA

remote

controller

Main

remote

controller

Sub

remote

controller

MA No settings

required.

MA Sub

remote

controller

-Main

Settings to be made with the sub/

main switch

00

HWE07190 GB

27- 27 -

Page 37

[ II Restrictions ]

3. System in which two MA remote controllers are connected to one indoor unit

(1) Sample control wiring

Leave the male

connector on

CN41 as it is.

TB7

M1M2

S

OC

51

TB3

M1M2

m1

L1

IC

01

TB5-1

A1B1

S

TB15

1

2

AB

MA(Main)

AB

MA(Sub)

*Two indoor controllers (controller circuit boards)

are equipped in the indoor unit (P500).

m2

A1 B2

MA

02

TB5-2

A2 B2

S

(2) Notes

1) Leave the male connector on the female power supply

switch connector (CN41) on the outdoor unit as it is.

2) It is not necessary to provide grounding to S terminal on

the terminal block for transmission line for centralized

control (TB7).

3) Although two indoor controllers (controller circuit boards)

are equipped inside the indoor unit, the board on No.2

side (lower side) is not used. Do not connect wiring to the

lower controller circuit board.

4) No more than two MA remote controllers (including both

main and sub controllers) can be connected to a group of

indoor units. If three or more MA remote controllers are

connected, remove the wire for the MA remote controller

from the terminal block (TB15).

(3) Maximum allowable length

1) Indoor/outdoor transmission line

Same as [4] 1.

2) MA remote controller wiring

Maximum overall line length (0.3 to 1.25mm

16])

m1+m2 200m [656ft]

2

[AWG 22 to

- 28 -

GBHWE07190

Page 38

[ II Restrictions ]

(4) Wiring method

1) Indoor/outdoor transmission line

Same as [4] 1.

2) MA remote controller wiring

When 2 remote controllers are connected to the system

When two remote controllers are connected to the system, connect terminals 1 and 2 of the terminal block

(TB15) on the indoor unit (IC) to the terminal block on the

MA remote controllers (option).

(5) Address setting method

Procedures Unit or controller

1 Indoor

Main unit IC 01 to 50 Assign a sequential odd number

unit

Sub unit IC 01 to 50 Assign sequential numbers start-

2 Outdoor unit OC 51 to 100 Add 50 to the address assigned

3MA

remote

controller

Main

remote

controller

MA No settings re-

Address

setting range

quired.

Set the Main/Sub switch on the connected MA remote

controllers (option) to SUB.(See the installation manual

for the MA remote controller for the setting method.)

3) Switch setting

Address setting is required as follows.

Setting method Notes

starting with "01" to the upper indoor controller.

ing with the address of the main

unit in the same group. (Main

unit address +1)

to the indoor unit connected to

the system with one outdoor unit.

-Main

Factory

setting

00

00

Sub

remote

controller

MA Sub

remote

controller

Settings to be made with the sub/

main switch

HWE07190 GB

29- 29 -

Page 39

[ II Restrictions ]

4. System in which two indoor units are grouped with the MA remote controller

(1) Sample control wiring

Leave the male

connector on

CN41 as it is.

TB7

M1M2

L1

OC

51

TB3

M1M2

S

m1 m2

IC

01

TB5-1

A1 B1

S

TB15

1

2

AB

MA(Main) MA(Sub)

Leave the male

connector on

CN41 as it is.

02

TB5-2

A2 B2

S

TB7

M1M2

m3

L1

TB5-1

A1

TB15

1

AB

IC

03

*Two indoor controllers (controller circuit boards)

are equipped in the indoor unit (P500).

B1

S

2

OC

53

TB3

M1M2

S

04

TB5-2

A2 B2

S

(2) Notes

1) Leave the male connector on the female power supply

switch connector (CN41) on the outdoor unit as it is.

2) It is not necessary to provide grounding to S terminal on

the terminal block for transmission line for centralized

control (TB7).

3) Although two indoor controllers (controller circuit boards)

are equipped inside the indoor unit, the board on No.2

side (lower side) is not used. Do not connect wiring to the

lower controller circuit board.

4) No more than two MA remote controllers (including both

main and sub controllers) can be connected to a group of

indoor units. If three or more MA remote controllers are

connected, remove the wire for the MA remote controller

from the terminal block (TB15).

(3) Maximum allowable length

1) Indoor/outdoor transmission line

Same as [4] 1.

2) MA remote controller wiring

Maximum overall line length ( 0.3 to 1.25mm

16])

m1+m2+m3 200m [656ft]

2

[AWG22 to

- 30 -

GBHWE07190

Page 40

[ II Restrictions ]

(4) Wiring method

1) Indoor/outdoor transmission line

Same as [4] 1.

2) MA remote controller wiring

Group operation of indoor units

To perform a group operation of indoor units (IC), daisychain terminals 1 and 2 on the terminal block (TB15) on

all indoor units (IC). (Non-polarized 2-core cable)

(5) Address setting method

Procedures Unit or controller

1 Indoor

Main unit IC 01 to 50 Assign a sequential odd number

unit

Sub unit IC 01 to 50 Assign sequential numbers start-

2 Outdoor unit OC 51 to 100 Add 50 to the address assigned

3MA

remote

controller

Main

remote

controller

Sub

MA No settings

MA Sub

remote

controller

Address

setting range

required.

remote

controller

Set the Main/Sub switch on one of the MA remote con-

trollers to SUB.

3) Switch setting

Address setting is required as follows.

Setting method Notes

Factory

setting

starting with "01" to the upper indoor controller.

ing with the address of the main

unit in the same group. (Main

unit address +1)

to the indoor unit connected to

the system with one outdoor unit.

-Main

Settings to be made with the sub

/ main switch

00

00

HWE07190 GB

31- 31 -

Page 41

[ II Restrictions ]

[5] Restrictions on Pipe Length

1. Sample connection

(1) System with one refrigerant circuit

Outdoor unit

H

(2) System with two refrigerant circuits

A

L

Indoor

Allowable length Total pipe length (L) from the outdoor

Allowable height

difference

2. Refrigerant pipe size

Outdoor unit

A

H

L

unit to thefarthest indoor unit

Height difference between the indoor

and the outdoor units (H)

L

Indoor

Actual length 165m [541ft] or less

50m [164ft] or less (40m [131ft] or less when the outdoor

unit is lower, 15m [49ft] when the outdoor temperature is

10°C [50°F] or lower)

Outdoor unit model Liquid pipe (mm)[inch] Gas pipe (mm)[inch]

P250 model ø9.52 [3/8"] *1 ø22.2 [7/8"]

*1 Use the pipe whose size is ø12.7 [1/2"] when the pipe length is 90m [295ft] or more.

HWE07190 GB

- 32 -

Page 42

III

Outdoor Unit Components

[1] Outdoor Unit Components and Refrigerant Circuit .......................................................... 35

[2] Control Box of the Outdoor Unit....................................................................................... 37

[3] Outdoor Unit Circuit Board............................................................................................... 38

HWE07190 GB

- 33 -

Page 43

- 34 -

Page 44

[ III Outdoor Unit Components ]

III Outdoor Unit Components

[1] Outdoor Unit Components and Refrigerant Circuit

1. PUHY-P250YHM-A

(1) Front view of a outdoor unit

Fan guard

Fan

Heat exchanger

Front panel

Control

Box

Fin guard

HWE07190 GB

- 35 -

Page 45

[ III Outdoor Unit Components ]

2. PUHY-P250YHM-A

(1) Refrigerant circuit

Check valve

4-way valve(21S4b)

4-way valve(21S4a)

High pressure check joint

Low pressure check joint

Subcool coil

Linear Expansion

Valve(LEV1)

Solenoid valve(SV5b)

Linear Expansion Valve(LEV2a,2b)

Low pressure sensor(63LS)

Liquid side valve

Solenoid valve (SV1a)

Solenoid valve (SV9)

Gas side valve

High pressure sensor(63HS1)

High-pressure switch(63H1)

Accumulator

Compressor cover

Compressor

Oil separator

HWE07190 GB

- 36 -

Page 46

[ III Outdoor Unit Components ]

[2] Control Box of the Outdoor Unit

<HIGH VOLTAGE WARNING>

Control box houses high-voltage parts.

When opening or closing the front panel of the control box, do not let it come into contact with any of

the internal components.

Before inspecting the inside of the control box, turn off the power, keep the unit off for at least 10 minutes,

and confirm that the voltage between FT-P and FT-N on INV Board has dropped to DC20V or less.

(It takes about 10 minutes to discharge electricity after the power supply is turned off.)

Electromagnetic relay(72C)

DC reactor (DCL)

Noise filter

Capacitor(C100)

Terminal block for power supply

L1,L2,L3,N,

(TB1)

Rush current protection resistor

(R1,R5) Note.2

Note.1

Fan board

INV board

Control board

M-NET board

Terminal block for transmission

line (TB3, TB7)

1) Exercise caution not to damage the bottom and the front panel of the control box. Damage to these parts affect the waterproof and dust proof properties of the control box and may result in damage to its internal components.

2) Faston terminals have a locking function. Make sure the cable heads are securely locked in place. Press the tab on the terminals to remove them.

HWE07190 GB

- 37 -

Page 47

[ III Outdoor Unit Components ]

[3] Outdoor Unit Circuit Board

1. Outdoor unit control board

CNAC2

L1

N

CN51

Output 12VDC

Compressor

ON/OFF output

Error output

Actuator

driving output

CNDC

Bus voltage input

P

N

CN2

Serial communication signal input

INV board)

GND (

Output 17VDC

CN801

Pressure switch

connection

CN332

Output 18VDC

GND

Fan board

)

(

CN4

GND

Serial communication signal output

LEV

driving output

LED1

Service LED

SWU1,2

Address switch

SW1-5

switch

Dip

CN72

72C

driving output

LED3

Lit

when powered

LED2

Lit during normal

CPU operation

CNAC

L1

N

LED3

Lit

when powered

F01

Fuse

250V AC/3.15A

External signal input (contact input)

CN102

Power supply input for centralized control system (30VDC)

Indoor/outdoor transmission line input/output (30VDC)

CN41

Power supply for

CN40

centralized control OFF

Power supply for

centralized control ON

Sensor

input

CNVCC2

Output 12VDC

Output 5VDC

CNIT

Output 12VDC

GND

Output 5VDC

Power supply detection input

CNS2

Transmission line input/output

for centralized control system (30VDC)

Power supply ON/OFF signal output

GND

HWE07190 GB

- 38 -

Page 48

[ III Outdoor Unit Components ]

2. M-NET board

Grounding

CN04

Bus voltage input

P

N

CNS2

Transmission line input/output for

CN102

Power supply output for centralized control system

Indoor/outdoor transmission line input/output

Grounding

Grounding

TB3

Indoor/outdoor

transmission block

centralized control system

Ground terminal for

transmission line

CNIT

Input 12VDC

GND

Input 5VDC

Power supply detection output

Power supply ON/OFF

signal input

TB7

Terminal block for

transmission line for

centralized control

LED1

Power supply for

indoor

transmission line

TP1,2