Mitsubishi Electric PUHY-P200YKB-A1, PUHY-P250YKB-A1, PUHY-P300YKB-A1, PUHY-P350YKB-A1, PUHY-P400YKB-A1 INSTALLATION MANUAL

...Page 1

Air-Conditioners For Building Application Inverter Y-Series

OUTDOOR UNIT

<ORIGINAL>

PUHY-P-YKB-A1 (-BS)

For use with R410A

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ ΕΓΚΑΤΑΣΤΑΣΗΣ

Για ασφάλεια και σωστή χρήση, παρακαλείστε διαβάσετε προσεχτικά αυτό το εγχειρίδιο εγκατάστασης πριν αρχίσετε την εγκατάσταση της μονάδας κλιματισμού.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по установке до выполнения установки кондиционера.

GBDFEINLPGRRUTR

MONTAJ ELKİTABI

Emniyetli ve doğru biçimde nasıl kullanılacağını öğrenmek için lütfen klima cihazını monte etmeden önce bu elkitabını dikkatle okuyunuz.

安装手册

为了安全和正确地使用本空调器,请在安装前仔细阅读本安装手册。

PŘÍRUČKA K INSTALACI

V zájmu bezpečného a správného používání si před instalací klimatizační jednotky důkladně pročtěte tuto příručku k instalaci.

NÁVOD NA INŠTALÁCIU

Pre bezpečné a správne použitie si pred inštalovaním klimatizačnej jednotky, prosím, starostlivo prečítajte tento návod na inštaláciu.

TELEPÍTÉSI KÉZIKÖNYV

A biztonságos és helyes használathoz, kérjük, olvassa el alaposan ezt a telepítési kézikönyvet, mielőtt telepítené a légkondicionáló egységet.

PODRĘCZNIK INSTALACJI

W celu bezpiecznego i poprawnego korzystania należy przed zainstalowaniem klimatyzatora dokładnie zapoznać się z niniejszym podręcznikiem instalacji.

PRIROČNIK ZA NAMESTITEV

Za varno in pravilno uporabo pred namestitvijo klimatske naprave skrbno preberite priročnik za namestitev.

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan luftkonditioneringsenheten installeras, för säker och korrekt användning.

PRIRUČNIK ZA UGRADNJU

Radi sigurne i ispravne uporabe, temeljito pročitajte ovaj priručnik prije ugradnje klimatizacijskog uređaja.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасна и правилна употреба, моля, прочетете внимателно това ръководство преди монтажа на климатизатора.

中

CZSVHGPOSLSWHRBGRODK

MANUAL CU INSTRUCŢIUNI DE INSTALARE

Pentru o utilizare corectă şi sigură, vă rugăm să citiţi cu atenţie acest manual înainte de a instala unitatea de aer condiţionat.

INSTALLATIONSMANUAL

Læs venligst denne installationsmanual grundigt, før De installerer airconditionanlægget, af hensyn til sikker og korrekt anvendelse.

Page 2

Page 3

CONTENTS

1. Safety precautions ················································································ 2

1-1. General precautions...............................................................................................................2

1-2. Precautions for transporting the unit ......................................................................................3

1-3. Precautions for unit installation ..............................................................................................4

1-4. Precautions for piping work....................................................................................................4

1-5. Precautions for electrical wiring .............................................................................................5

1-6. Precautions for relocating or repairing the unit ......................................................................5

1-7. Additional precautions ............................................................................................................6

2. About the product ················································································· 8

3. Combination of outdoor units ································································· 8

4. Specifications ······················································································· 9

5. Package contents ·················································································10

6. Transporting the unit ············································································ 11

7. Installation location ··············································································12

7-1. Single unit installation ..........................................................................................................12

7-2. Multiple unit installation ........................................................................................................13

8. Foundation work ··················································································15

9. Refrigerant piping work ········································································17

9-1. Restrictions ..........................................................................................................................17

9-2. Pipe selection.......................................................................................................................19

9-3. Twinning kit selection ...........................................................................................................20

9-4. Pipe connection example .....................................................................................................20

9-5. Piping connections and valve operations ............................................................................23

9-6. Air-tightness test .................................................................................................................. 26

9-7. Thermal insulation for pipes .................................................................................................27

9-8. Evacuation of the system .....................................................................................................29

9-9. Additional refrigerant charge ................................................................................................30

GB

10. Electrical work ···················································································34

10-1. Before electrical work.........................................................................................................34

10-2. Power cables and device capacity .....................................................................................34

10-3. Control cable specifications ...............................................................................................37

10-4. System configuration ......................................................................................................... 37

10-5. Wiring connections in the control box ................................................................................40

10-6. Address setting .................................................................................................................. 43

11. Test run ·····························································································44

11-1. Before a test run .................................................................................................................44

11-2. Function setting ..................................................................................................................45

11-3. Operation characteristics in relation to the refrigerant charge ...........................................45

11-4. Operation check .................................................................................................................46

12. Inspection and maintenance ································································47

13. Rating plate information ······································································48

KD79S703H01

GB-1

Page 4

1. Safety precautions

►Read and observe the safety precautions below and the instructions provided on the

labels affixed to the unit.

►Retain this manual for future reference. Make sure that this manual is passed on to the

end users.

►All refrigerant piping work, electrical work, air-tightness test, and brazing work must be

performed by qualified personnel.

►Incorrect use may result in serious injury.

: indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

: indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

: addresses practices not related to personal injury, such as product

and/or property damage.

1-1. General precautions

Do not use any refrigerant other than the type indicated in the manuals for the unit and on

the nameplate.

- Doing so will cause the unit or pipes to burst, or result in an explosion or fire during use, during

repairs, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for malfunctions or

accidents resulting from the use of the wrong type of refrigerant.

Do not use the unit in an unusual environment.

- If the unit is used in areas exposed to large amounts of oil, steam, organic solvents, or corrosive

gases (such as ammonia, sulfuric compounds, or acids), or areas where acidic/alkaline solutions

or special chemical sprays are used frequently, it may significantly reduce the performance and

corrode the internal parts, resulting in refrigerant leakage, water leakage, injury, electric shock,

malfunction, smoke, or fire.

Do not change the settings of the safety or protection devices.

- Forcing the unit to operate by disabling the safety devices, such as the pressure switch or the

thermal switch, may result in bursting, fire, or explosion.

- Operating the unit with a safety device whose settings have been changed may result in

bursting, fire, or explosion.

- Using safety devices other than those specified by Mitsubishi Electric may result in bursting, fire,

or explosion.

Do not alter or modify the unit.

- Doing so will result in refrigerant leakage, water leakage, serious injury, electric shock, or fire.

Do not wet the electrical parts.

- Doing so may result in current leakage, electric shock, malfunction, or fire.

Do not touch the electrical parts, switches, or buttons with wet fingers.

- Doing so may result in electric shock, malfunction, or fire.

KD79S703H01

GB-2

Page 5

Do not touch the refrigerant pipes and refrigerant line components with bare hands during

and immediately after operation.

- The refrigerant in the pipes will be very hot or very cold, resulting in frostbite or burns.

Do not touch the electrical parts with bare hands during and immediately after operation.

- Doing so may result in burns.

Ventilate the room while servicing the unit.

- If the refrigerant leaks, oxygen deficiency may result. If the leaked refrigerant comes in contact

with a heat source, toxic gas will be generated.

If you notice any abnormality (e.g., a burning smell), stop the operation, turn off the power

switch, and consult your dealer.

- Continuing the operation may result in electric shock, malfunction, or fire.

Properly install all required covers and panels on the terminal box and the control box.

- If dust or water enters the unit, this may result in electric shock or fire.

Periodically check the unit base for damage.

- If the damage is left uncorrected, the unit will fall and cause serious injury.

Consult your dealer for the proper disposal of the unit.

- The refrigerant oil and the refrigerant in the unit will pose a risk of environmental pollution, fire,

or explosion.

GB

Children should be supervised to ensure that they do not play with the appliance.

Do not operate the unit with the panels and guards removed.

- Rotating, hot, or high-voltage parts may cause injury, electric shock, or fire.

Do not touch fans, heat exchanger fins, or the sharp edges of components with bare

hands.

- Doing so may result in injury.

Wear protective gloves when working on the unit.

- Failure to do so may result in injury.

1-2. Precautions for transporting the unit

When lifting the unit, pass the slings through the four designated sling holes.

- Improper lifting will cause the unit to topple or fall, resulting in serious injury.

Do not lift the unit with the PP bands that are used on some products.

- Doing so may result in injury.

Observe the restrictions on the maximum weight that a person can lift, which is specified

in local regulations.

- Failure to do so may result in injury.

KD79S703H01

GB-3

Page 6

1-3. Precautions for unit installation

Do not install the unit where combustible gas may leak.

- If combustible gas accumulates around the unit, fire or explosion may result.

Do not allow children to play with the packing materials.

- Suffocation or serious injury may result.

Cut up the packing materials before disposal.

All installation work must be performed by qualified personnel in accordance with this

manual.

- Improper installation may result in refrigerant leakage, water leakage, serious injury, electric

shock, or fire.

If the air conditioner is installed in a small room, take measures to prevent the refrigerant

concentration from exceeding the safety limit in the event of refrigerant leakage.

- Consult your dealer regarding the appropriate measures to prevent the allowable concentration

from being exceeded. If the refrigerant leaks and the allowable concentration is exceeded,

hazards due to a lack of oxygen in the room will result.

Install the unit in accordance with the instructions to minimize the risk of damage from

earthquakes and strong winds.

- Improper installation will cause the unit to topple, resulting in serious injury.

The unit must be securely installed on a structure that can sustain its weight.

- Failure to do so will cause the unit to fall, resulting in serious injury.

Seal all openings around pipes and wires to keep out small animals, rainwater, or snow.

- Failure to do so may result in current leakage, electric shock, or damage to the unit.

1-4. Precautions for piping work

Before heating the brazed sections, remove the gas and oil that are trapped in the pipes.

- Failure to do so may generate fire, resulting in serious injury.

Do not purge the air using refrigerant. Use a vacuum pump to evacuate the system.

- Residual gas in the refrigerant lines will cause bursting of the pipes or an explosion.

Do not use oxygen, flammable gas, or a refrigerant containing chlorine for air-tightness

testing.

- Doing so may result in an explosion. Chlorine will deteriorate the refrigerant oil.

When installing or relocating the unit, do not allow air or any substance other than the

specified refrigerant to enter the refrigerant lines.

- Any substance other than the specified refrigerant may cause abnormally high pressure in the

refrigerant lines, resulting in bursting of the pipes or an explosion.

After the installation has been completed, check for refrigerant leaks.

- If the refrigerant leaks, oxygen starvation may result. If the leaked refrigerant comes in contact

with a heat source, toxic gas will be generated.

KD79S703H01

GB-4

Page 7

1-5. Precautions for electrical wiring

Include some slack in the power cables.

- Failure to do so may break or overheat the cables, resulting in smoke or fire.

Connections must be made securely and without tension on the terminals.

- Improperly connected cables may break, overheat, or cause smoke or fire.

Tighten all terminal screws to the specified torque.

- Loose screws and contact failure may result in smoke or fire.

Electrical work must be performed by qualified personnel in accordance with local

regulations and the instructions provided in this manual. Only use the specified cables and

dedicated circuits.

- Inadequate power source capacity or improper electrical work will result in electric shock,

malfunction, or fire.

Install an inverter circuit breaker on the power supply of each unit.

- Failure to do so may result in electric shock or fire.

Only use properly rated breakers (an earth leakage breaker, local switch <a switch + fuse

that meets local electrical codes>, or overcurrent breaker).

- Failure to do so may result in electric shock, malfunction, smoke, or fire.

Only use standard power cables of sufficient capacity.

- Failure to do so may result in current leakage, overheating, smoke, or fire.

Proper grounding must be provided by qualified personnel.

- Improper grounding may result in electric shock, fire, explosion, or malfunction due to electrical

noise. Do not connect the ground wire to gas or water pipes, lightning rods, or telephone ground

wires.

GB

After the wiring work has been completed, measure the insulation resistance, and make

sure that it reads at least 1 MΩ.

- Failure to do so may result in electric leakage, malfunction, or fire.

1-6. Precautions for relocating or repairing the unit

Only qualified personnel must relocate or repair the unit. Do not attempt to disassemble or

alter the unit.

- Failure to do so will result in refrigerant leakage, water leakage, serious injury, electric shock, or

fire.

Do not service the unit in the rain.

- Doing so may result in electric leakage, electric shock, wire shorting, malfunction, smoke, or fire.

KD79S703H01

GB-5

Page 8

1-7. Additional precautions

Do not turn off the power immediately after stopping operation.

- Wait for at least five minutes after the unit has stopped before turning off the power. Failure to do

so may result in drain water leakage or the mechanical failure of sensitive parts.

The unit must be periodically inspected by a dealer or qualified personnel.

- If dust or dirt accumulates inside the unit, the drain pipes may become clogged, and water

leakage from the pipes may wet the surroundings and generate odours.

Turn on the power at least 12 hours before starting operation. Keep the power turned on

throughout the operating season.

- Insufficient energizing will result in malfunction.

Do not use the air conditioner for special purposes (e.g. keeping food, animals, plants,

precision devices, or art objects in a room).

- Such items could be damaged or deteriorated.

Collect the refrigerant and properly dispose of it in accordance with local regulations.

Do not install the unit on or over items that are subject to water damage.

- When the room humidity exceeds 80% or if the drain pipe is clogged, condensation may collect

and drip from the indoor unit onto the ceiling or floor.

Drain piping must be installed by a dealer or qualified personnel to ensure proper

drainage.

- Improper drain piping may cause water leakage, resulting in damage to furniture and other

surroundings.

Take appropriate measures against electrical noise interference when installing the unit in

hospitals or radio communication facilities.

- Inverter, high-frequency medical, or wireless communication equipment as well as power

generators may cause the air conditioning system to malfunction. The air conditioning system

may also adversely affect the operation of these types of equipment by creating electrical noise.

Insulate pipes to prevent condensation.

- Condensation may collect and drip from the unit onto the ceiling or floor.

Keep the service valves closed until refrigerant charging is completed.

- Failure to do so will damage the unit.

Place a wet towel on the service valves before brazing the pipes to keep the temperature of

the valves from rising above 120ºC (248ºF).

- Failure to do so may result in equipment damage.

Keep the flame out of contact with the cables and metal sheet when brazing the pipes.

- Failure to do so may result in burnout or malfunction.

Use the following tools specifically designed for use with the specified refrigerant: Gauge

manifold, charge hose, gas leak detector, check valve, refrigerant charge base, vacuum

gauge, and refrigerant recovery equipment.

- Gas leak detectors for conventional refrigerants will not react to a refrigerant that does not

contain chlorine.

- If the specified refrigerant is mixed with water, refrigerant oil, or another refrigerant, the

refrigerant oil will deteriorate and the compressor will malfunction.

KD79S703H01

GB-6

Page 9

Use a vacuum pump with a check valve.

- If the vacuum pump oil flows back into the refrigerant lines, the refrigerant oil may deteriorate

and the compressor may malfunction.

Keep tools clean.

- If dust, dirt, or water accumulates on the charging hose or the flare processing tool, the

refrigerant will deteriorate and the compressor will malfunction.

Use refrigerant piping made of phosphorus deoxidized copper (copper and copper alloy

seamless pipes) that meets local requirements. Pipe joints should also meet local

requirements. Keep the inner and outer surfaces of the pipes clean and free of sulphur,

oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminants.

- Contaminants on the inside of the refrigerant piping will cause the refrigerant oil to deteriorate

and cause the compressor to malfunction.

Store pipes indoors, and keep both ends of the pipes sealed until just before making a

flare connection or brazing. (Store elbows and other joints in plastic bags.)

- If dust, dirt, or water enters the refrigerant lines, the refrigerant oil will deteriorate and the

compressor will malfunction.

Braze the pipes with a nitrogen purge to avoid oxidation.

- Oxidized flux inside the refrigerant pipes will cause the refrigerant oil to deteriorate and cause

the compressor to malfunction.

GB

Do not use existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing piping contain a large amount of chlorine,

which will cause the refrigerant oil in the new unit to deteriorate and cause the compressor to

malfunction.

Charge refrigerant in a liquid state.

- Charging refrigerant in the gaseous state will change the composition of the refrigerant and lead

to a performance drop.

Do not use a charging cylinder when charging refrigerant.

- The use of a charging cylinder may change the composition of the refrigerant and lead to a

performance drop.

If a large electric current flows due to a malfunction or faulty wiring, earth-leakage breakers

on the unit side and on the upstream side of the power supply system could both operate.

Depending on the importance of the system, separate the power supply system or take

protective coordination of breakers.

This appliance is intended to be used by expert or trained users in shops, in light industry

and on farms, or for commercial use by lay persons.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

KD79S703H01

GB-7

Page 10

2. About the product

・The outdoor unit described in this manual is air-conditioning equipment that is designed only for human comfort.

・The numeric values in the unit model name (e.g., PUHY-P***-YKB-A1) indicate the capacity index of the unit.

・This unit uses R410A refrigerant.

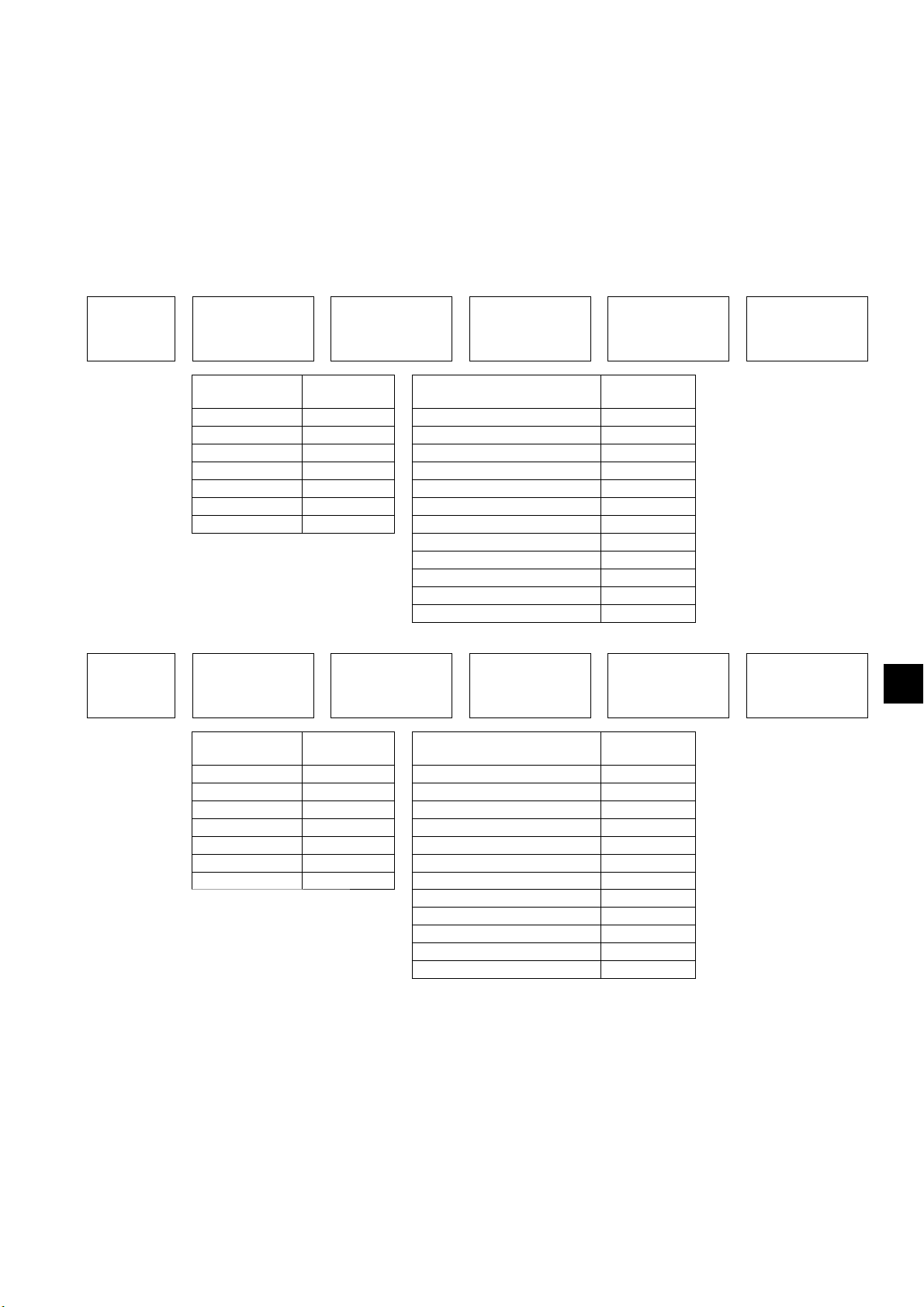

3. Combination of outdoor units

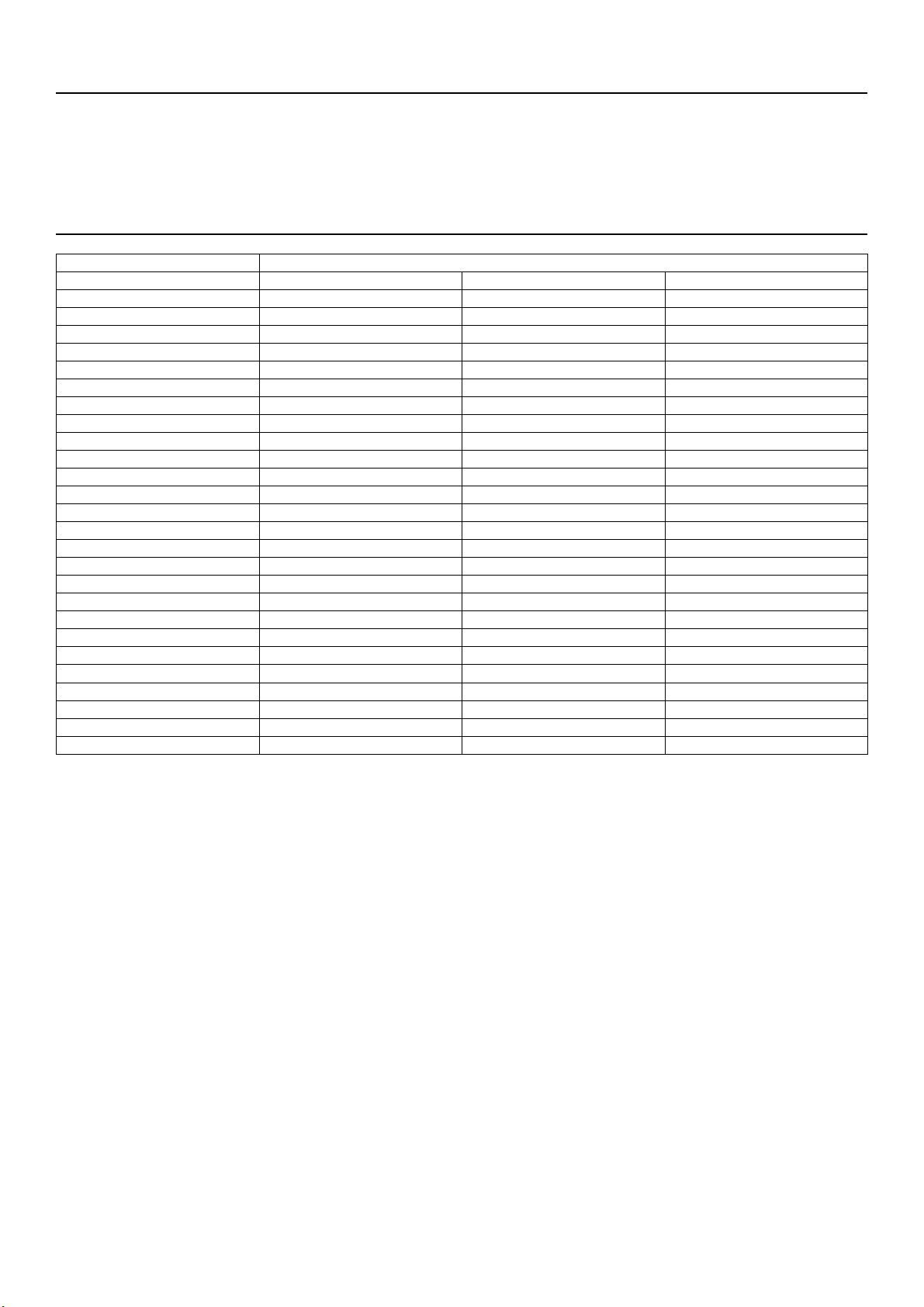

Outdoor unit model Combination of outdoor units

PUHY-P200YKB-A1(-BS) - - PUHY-P250YKB-A1(-BS) - - PUHY-P300YKB-A1(-BS) - - PUHY-P350YKB-A1(-BS) - - PUHY-P400YKB-A1(-BS) - - PUHY-P450YKB-A1(-BS) - - PUHY-P500YKB-A1(-BS) - - PUHY-P400YSKB-A1(-BS) PUHY-P200YKB-A1(-BS) PUHY-P200YKB-A1(-BS) PUHY-P450YSKB-A1(-BS) PUHY-P250YKB-A1(-BS) PUHY-P200YKB-A1(-BS) PUHY-P500YSKB-A1(-BS) PUHY-P250YKB-A1(-BS) PUHY-P250YKB-A1(-BS) PUHY-P550YSKB-A1(-BS) PUHY-P300YKB-A1(-BS) PUHY-P250YKB-A1(-BS) PUHY-P600YSKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P250YKB-A1(-BS) PUHY-P650YSKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P300YKB-A1(-BS) PUHY-P700YSKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P750YSKB-A1(-BS) PUHY-P400YKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P800YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P850YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P400YKB-A1(-BS) PUHY-P900YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P950YSKB-A1(-BS) PUHY-P400YKB-A1(-BS) PUHY-P300YKB-A1(-BS) PUHY-P250YKB-A1(-BS)

PUHY-P1000YSKB-A1(-BS) PUHY-P400YKB-A1(-BS) PUHY-P300YKB-A1(-BS) PUHY-P300YKB-A1(-BS)

PUHY-P1050YSKB-A1(-BS) PUHY-P400YKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P300YKB-A1(-BS)

PUHY-P1100YSKB-A1(-BS) PUHY-P400YKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P350YKB-A1(-BS)

PUHY-P1150YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P350YKB-A1(-BS) PUHY-P350YKB-A1(-BS)

PUHY-P1200YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P400YKB-A1(-BS) PUHY-P350YKB-A1(-BS)

PUHY-P1250YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P350YKB-A1(-BS)

PUHY-P1300YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P400YKB-A1(-BS)

PUHY-P1350YSKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P450YKB-A1(-BS) PUHY-P450YKB-A1(-BS)

* "Twinning Kit" is required to connect combination units on site.

KD79S703H01

GB-8

Page 11

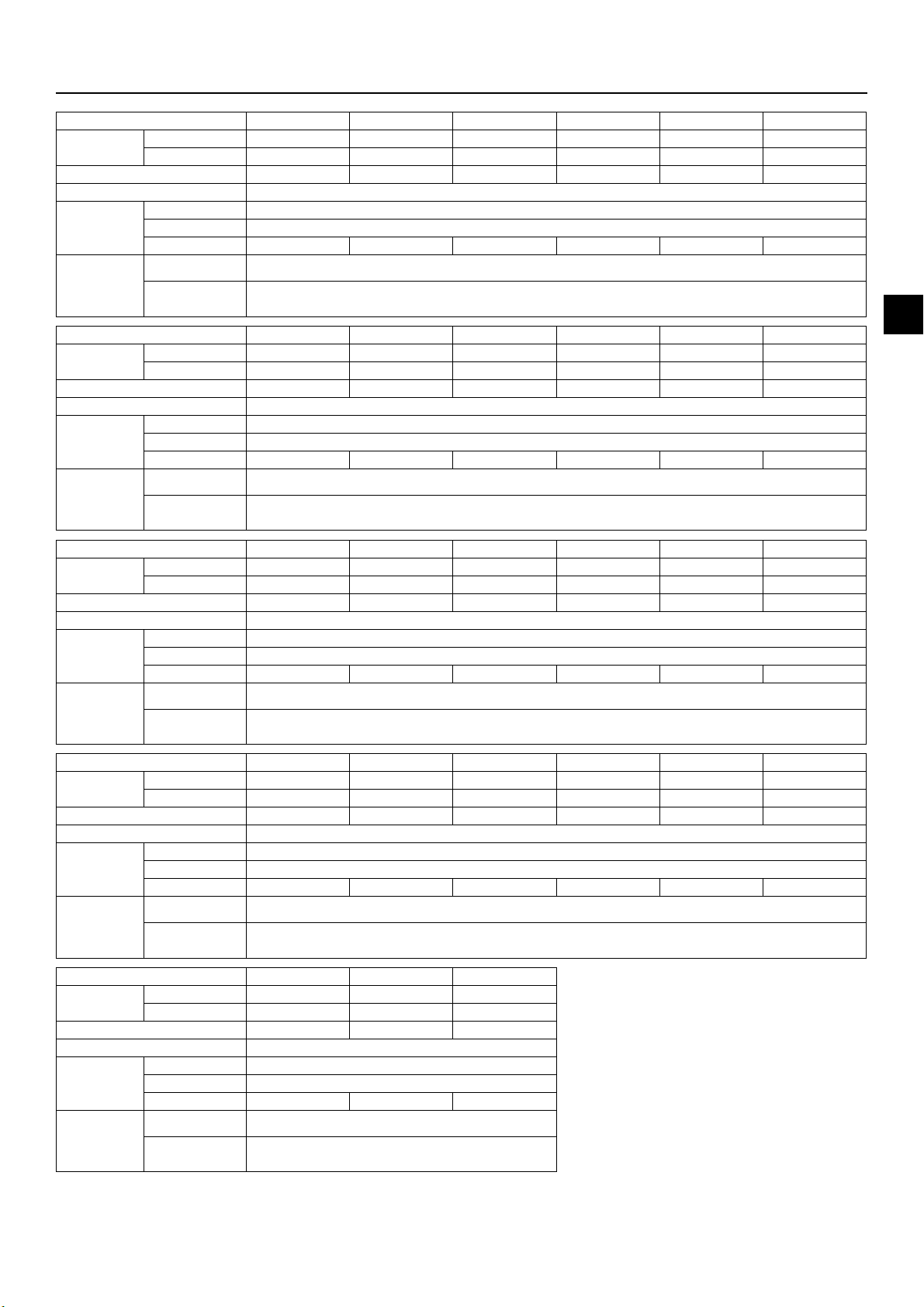

4. Specifications

Model

Power input

Cooling 5.19 6.88 8.56 11.69 13.55 14.79

Heating 5.81 7.34 9.07 11.13 12.50 15.55

PUHY-P200YKB-A1 PUHY-P250YKB-A1 PUHY-P300YKB-A1 PUHY-P350YKB-A1 PUHY-P400YKB-A1 PUHY-P450YKB-A1

Sound level (50/60 Hz) 57.0 dB <A> 59.0 dB <A> 61.0 dB <A> 61.0 dB <A> 63.0 dB <A> 66.0 dB <A>

External static pressure 0 Pa*

Total capacity 50% to 130%*

Indoor unit

Model 15 to 250

2

1

Quantity 1 to 17 1 to 21 1 to 26 1 to 30 1 to 34 1 to 39

Operation

temperature

Model

Power input

Standard type Cooling mode: 10°CDB to 52°CDB

Fresh air intake

type

Cooling mode: 21°CDB to 43°CDB

PUHY-P500YKB-A1 PUHY-P400YSKB-A1 PUHY-P450YSKB-A1 PUHY-P500YSKB-A1 PUHY-P550YSKB-A1 PUHY-P600YSKB-A1

Cooling 18.39 11.00 12.59 14.54 16.66 19.43

Heating 18.52 12.24 13.72 15.46 17.29 19.36

Sound level (50/60 Hz) 66.0 dB <A> 60.0 dB <A> 61.5 dB <A> 62.0 dB <A> 63.5 dB <A> 63.5 dB <A>

External static pressure 0 Pa*

Total capacity 50% to 130%*

Indoor unit

Model 15 to 250

2

1

Quantity 1 to 43 1 to 34 1 to 39 1 to 43 2 to 47 2 to 50

Operation

temperature

Model

Power input

Standard type Cooling mode: 10°CDB to 52°CDB

Fresh air intake

type

Cooling mode: 21°CDB to 43°CDB

PUHY-P650YSKB-A1 PUHY-P700YSKB-A1 PUHY-P750YSKB-A1 PUHY-P800YSKB-A1 PUHY-P850YSKB-A1 PUHY-P900YSKB-A1

Cooling 20.97 24.69 26.56 27.86 30.18 31.46

Heating 21.00 22.97 24.93 27.62 29.90 33.00

Sound level (50/60 Hz) 64.0 dB <A> 64.0 dB <A> 65.5 dB <A> 67.5 dB <A> 68.0 dB <A> 69.0 dB <A>

External static pressure 0 Pa*

Total capacity 50% to 130%*

Indoor unit

Model 15 to 250

2

1

Quantity 2 to 50 2 to 50 2 to 50 2 to 50 2 to 50 2 to 50

Operation

temperature

Standard type Cooling mode: 10°CDB to 52°CDB

Fresh air intake

type

Cooling mode: 21°CDB to 43°CDB

GB

Model

Power input

Cooling 30.25 32.10 35.01 38.62 40.24 44.10

Heating 30.40 32.70 34.25 36.60 39.29 40.76

PUHY-P950YSKB-A1 PUHY-P1000YSKB-A1 PUHY-P1050YSKB-A1 PUHY-P1100YSKB-A1 PUHY-P1150YSKB-A1 PUHY-P1200YSKB-A1

Sound level (50/60 Hz) 66.5 dB <A> 66.5 dB <A> 66.5 dB <A> 66.5 dB <A> 68.5 dB <A> 69.0 dB <A>

External static pressure 0 Pa*

Total capacity 50% to 130%*

Indoor unit

Model 15 to 250

2

1

Quantity 2 to 50 2 to 50 2 to 50 2 to 50 2 to 50 2 to 50

Operation

temperature

Model

Power input

Standard type Cooling mode: 10°CDB to 52°CDB

Fresh air intake

type

Cooling mode: 21°CDB to 43°CDB

PUHY-P1250YSKB-A1 PUHY-P1300YSKB-A1 PUHY-P1350YSKB-A1

Cooling 43.80 47.80 47.40

Heating 44.08 46.04 49.12

Sound level (50/60 Hz) 70.0 dB <A> 70.0 dB <A> 71.0 dB <A>

External static pressure 0 Pa*

Total capacity 50% to 130%*

Indoor unit

Model 15 to 250

2

1

Quantity 2 to 50 2 to 50 2 to 50

Operation

temperature

Standard type Cooling mode: 10°CDB to 52°CDB

Fresh air intake

type

Cooling mode: 21°CDB to 43°CDB

*1 The maximum total capacity of indoor units operating simultaneously is 130%.

*2 To enable the high static pressure setting, set the dipswitch on the main board as follows.

SW6-4: ON

SW6-5: OFF (60 Pa) or ON (30 Pa)

KD79S703H01

GB-9

Page 12

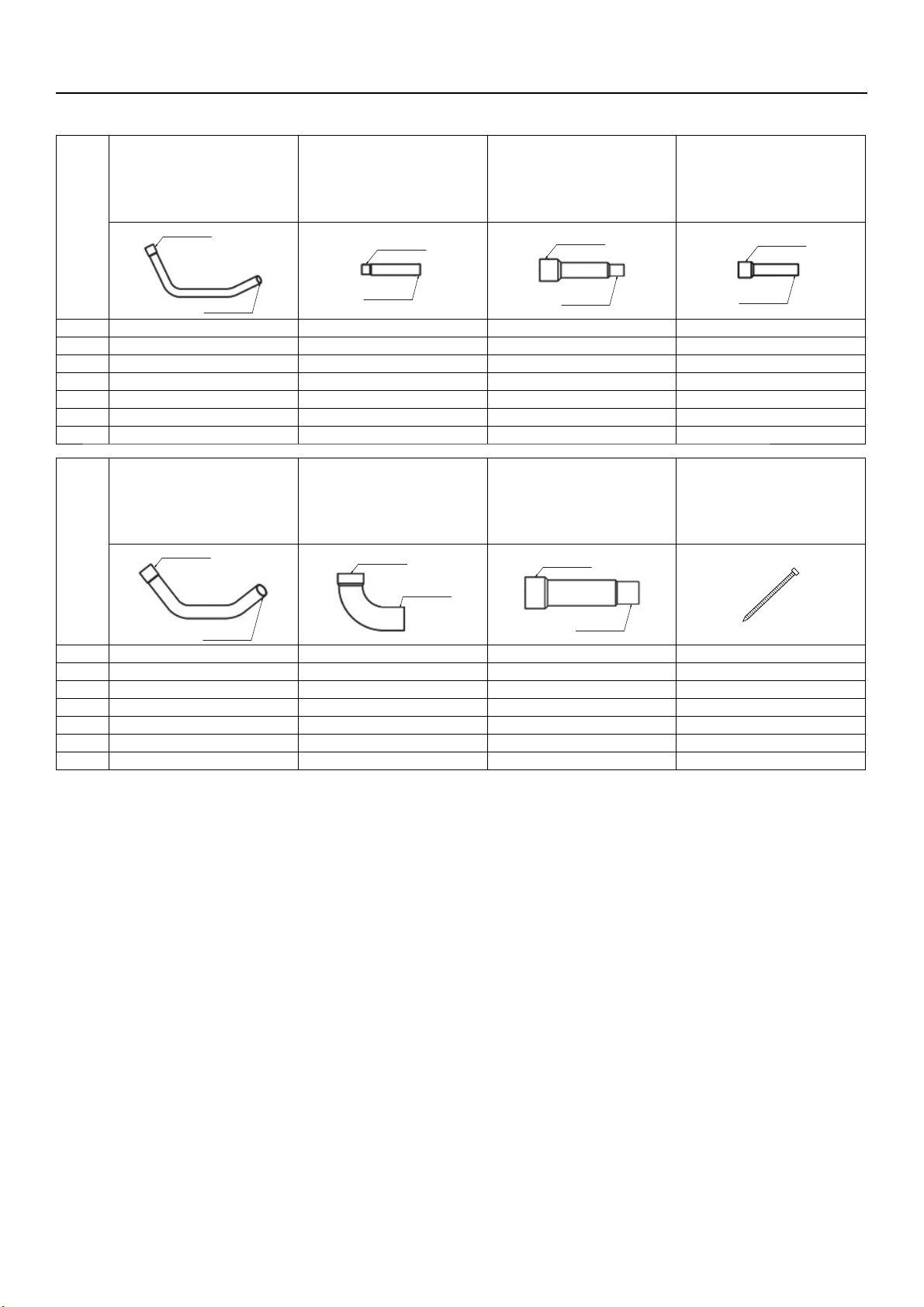

5. Package contents

The table below lists all the parts and their quantities included in the package.

①②③④

Connecting pipe

(Liquid side)

ID ø9.52 mm (ø3/8 in)

OD ø9.52 mm (ø3/8 in)

ID ø9.52

Connecting pipe

(Liquid side)

ID ø9.52 mm (ø3/8 in)

OD ø12.7 mm (ø1/2 in)

ID ø9.52

Connecting pipe

(Liquid side)

ID ø15.88 mm (ø5/8 in)

OD ø9.52 mm (ø3/8 in)

ID ø15.88

Connecting pipe

(Liquid side)

ID ø15.88 mm (ø5/8 in)

OD ø12.7 mm (ø1/2 in)

ID ø15.88

OD ø9.52

OD ø12.7

OD ø9.52

OD ø12.7

P200 1 - - P250 1 1 - P300 - - 1 1

P350 - - - 1

P400 - - - 1

P450 - - - P500 - - - -

⑤⑥⑦⑧

Connecting pipe

(Liquid side)

ID ø15.88 mm (ø5/8 in)

OD ø15.88 mm (ø5/8 in)

ID ø15.88

OD ø15.88

Connecting elbow

(Gas side)

ID ø28.58 mm (ø1-1/8 in)

OD ø28.58 mm (ø1-1/8 in)

ID ø28.58

OD ø28.58

Connecting pipe

(Gas side)

ID ø28.58 mm (ø1-1/8 in)

OD ø22.2 mm (ø7/8 in)

ID ø28.58

OD ø22.2

Tie band

P200 - 1 1 2

P250 - 1 1 2

P300 1 1 1 2

P350 1 1 - 2

P400 1 1 - 2

P450 1 1 - 2

P500 1 1 - 2

KD79S703H01

GB-10

Page 13

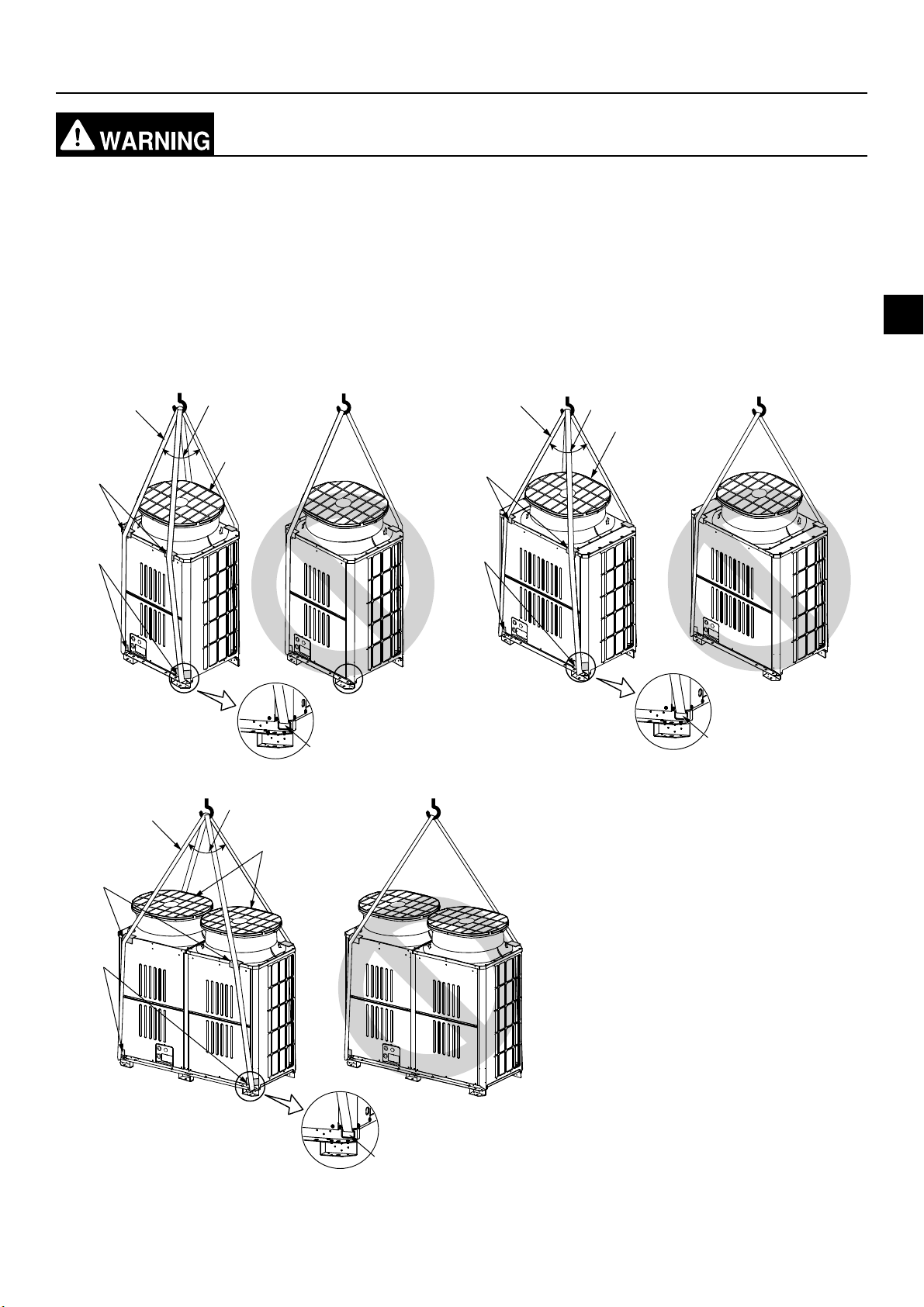

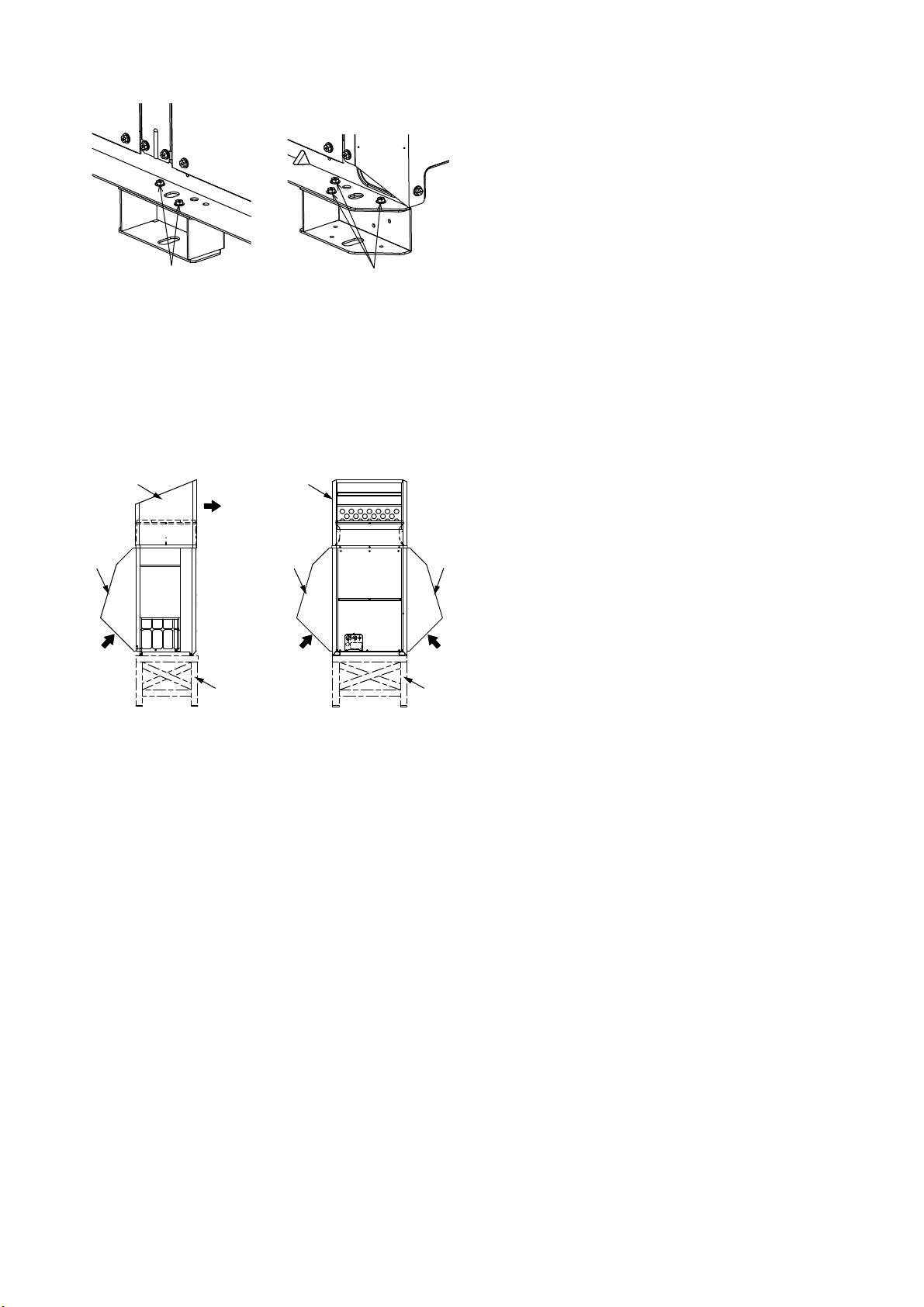

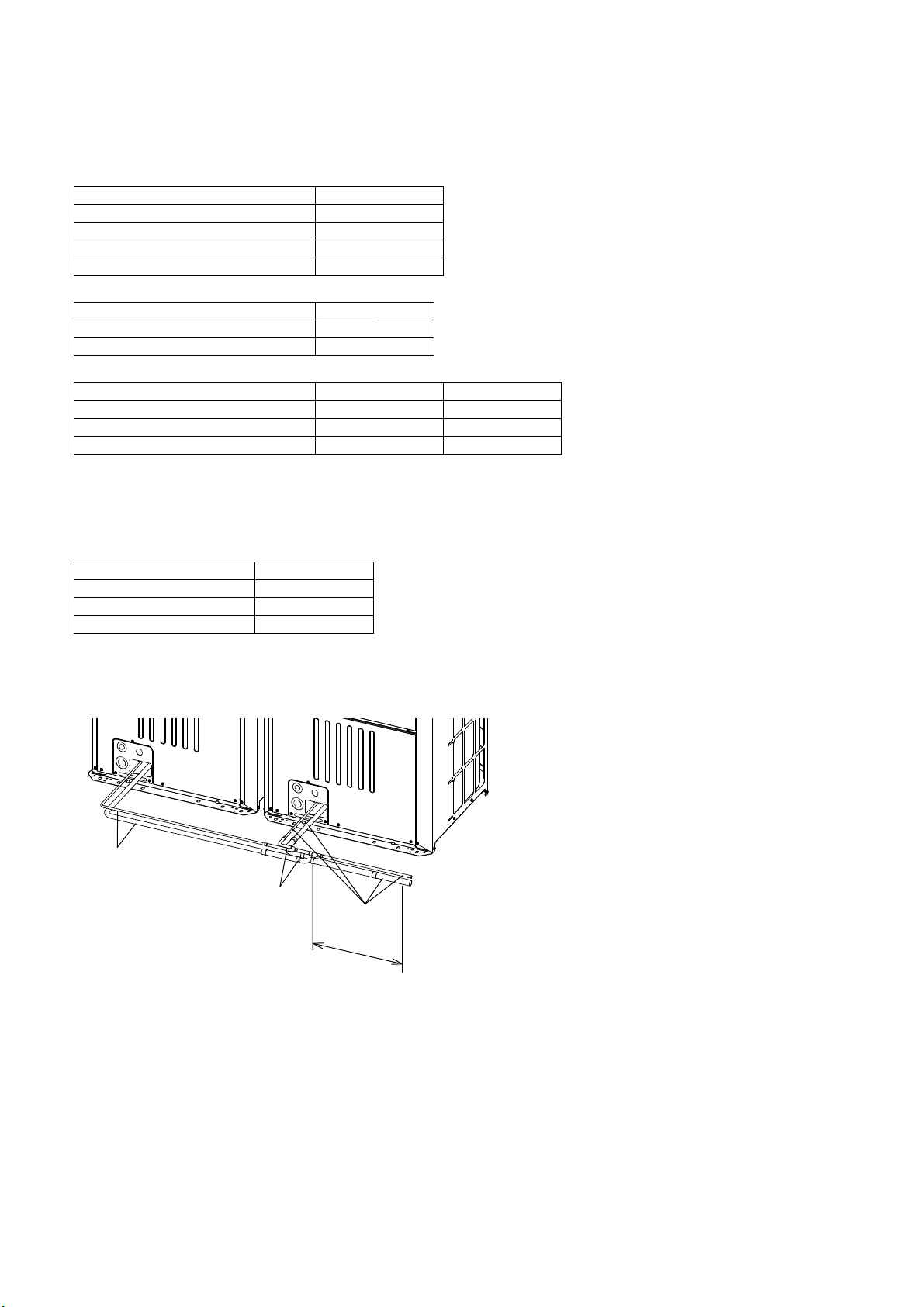

6. Transporting the unit

When lifting the unit, pass the slings through the four designated sling holes.

- Improper lifting will cause the unit to topple or fall, resulting in serious injury.

・Always use two slings to lift up the unit. Each sling must be at least 8 m (26 ft) long and must be able to support the

weight of the unit.

・Put protective pads between slings and the unit where the slings touch the unit at the base to protect the unit from

being scratched.

・Put 50 mm (2 in) or thicker protective pads between slings and the unit where the slings touch the unit at the top of

the unit to protect the unit from being scratched and to avoid contact with the slings and the fan guard.

・Make sure that the angles between slings at the top are less than 40 degrees.

P200 to P250 P300 to P400

Ⓐ

≤ 40°

Ⓐ

≤ 40°

Ⓔ

GB

Ⓑ

Ⓒ

P450 to P500

Ⓐ

Ⓑ

Ⓔ

≤ 40°

Ⓑ

Ⓒ

Ⓓ

Ⓐ Slings (Min. 8 m (26 ft) x 2)

Ⓑ Protective pads (Minimum thickness: 50 mm

Ⓔ

(2 in))

(two each in the front and back)

Ⓒ Protective pads

(two each in the front and back)

Ⓓ Sling holes

(two each in the front and back)

Ⓔ Fan guard

Ⓓ

Ⓒ

KD79S703H01

Ⓓ

GB-11

Page 14

7. Installation location

Do not install the unit where combustible gas may leak.

- If combustible gas accumulates around the unit, fire or explosion may result.

・Provide sufficient space around the unit for effective operation, efficient air movement, and ease of access for

maintenance.

・Note that refrigerant gas is heavier than air and will therefore tend to collect in low spots such as basements.

・When an indoor unit that draws in outside air exits near the outdoor unit, be careful not to affect the normal

operation of the indoor unit.

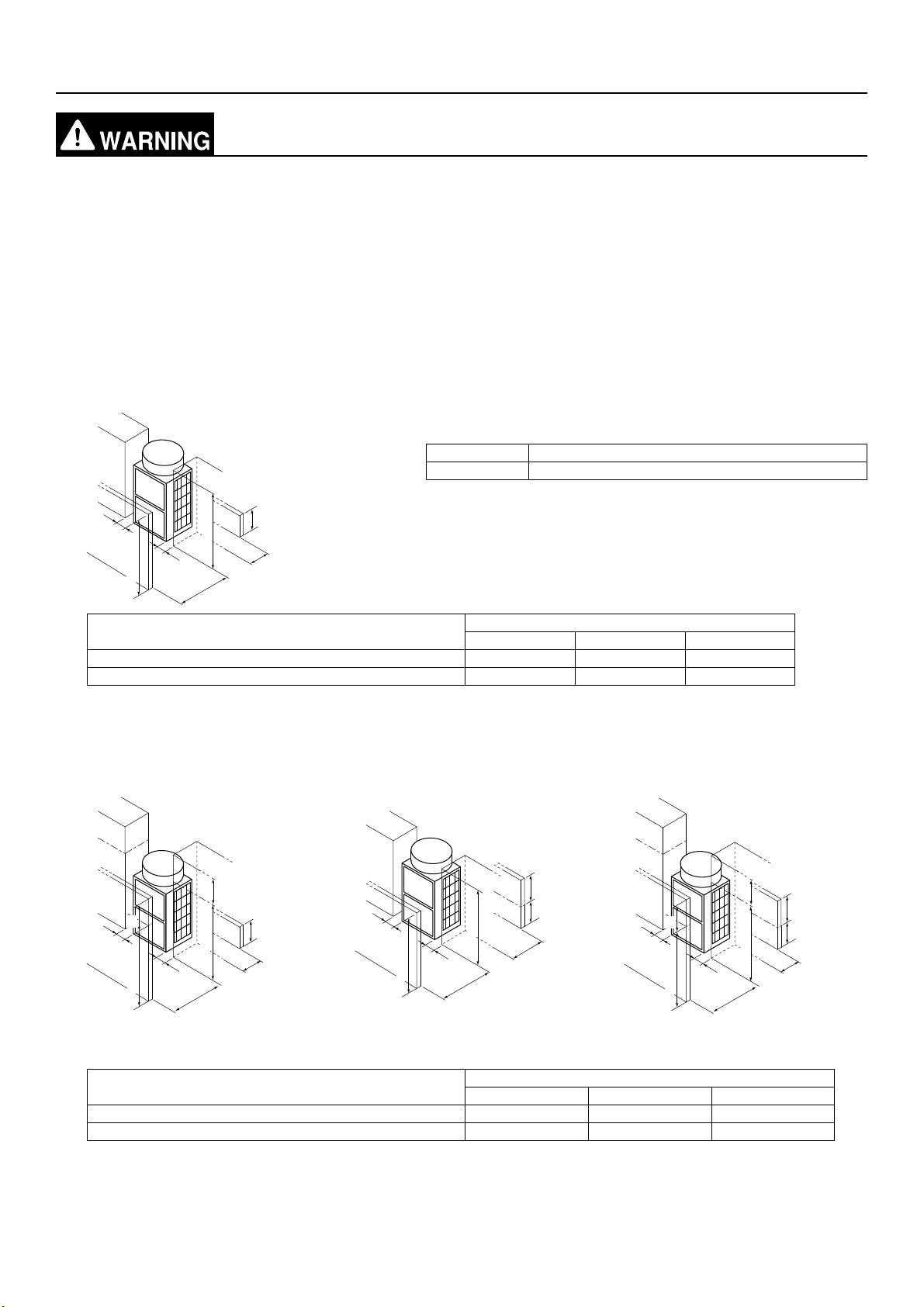

7-1. Single unit installation

(1) When all walls are within their height limits*.

* Height limit

Front/Right/Left Same height or lower than the overall height of the unit

Rear 500 mm (19-11/16 in) or lower from the unit bottom

[mm (in)]

L3

≤ Unit height

L3

≤ Unit height

When the distance behind the unit (L2) needs to be small 450 (17-3/4) 100 (3-15/16) 50 (2)

When the distance to the right or left (L3) needs to be small 450 (17-3/4) 300 (11-13/16) 15 (5/8)

L1

≤ 500 (19-11/16)

L2

Required minimum distance [mm (in)]

L1 (Front) L2 (Rear) L3 (Right/Left)

(2) When one or more walls exceed their height limits*.

When the wall(s) at the front and/

or the right/left exceed(s) their

When the wall at the rear exceeds

its height limit

When all walls exceed their height

limits

height limits

h3

h1

L3

Unit height

L3

Unit height

L1

≤ 500

(19-11/16)

L2

L3

≤ Unit height

L3

≤ Unit height

L1

h2

500

(19-11/16)

L2

h1

L3

Unit height

h3

h2

500

(19-11/16)

Unit height

L3

L1

L2

Add the dimension that exceeds the height limit (shown as "h1" through "h3" in the figures) to L1, L2, and L3 as

shown in the table below.

Required minimum distance [mm (in)]

L1 (Front) L2 (Rear) L3 (Right/Left)

When the distance behind the unit (L2) needs to be small 450 (17-3/4) + h1 100 (3-15/16) + h2 50 (2) + h3

When the distance to the right or left (L3) needs to be small 450 (17-3/4) + h1 300 (11-13/16) + h2 15 (5/8) + h3

KD79S703H01

GB-12

Page 15

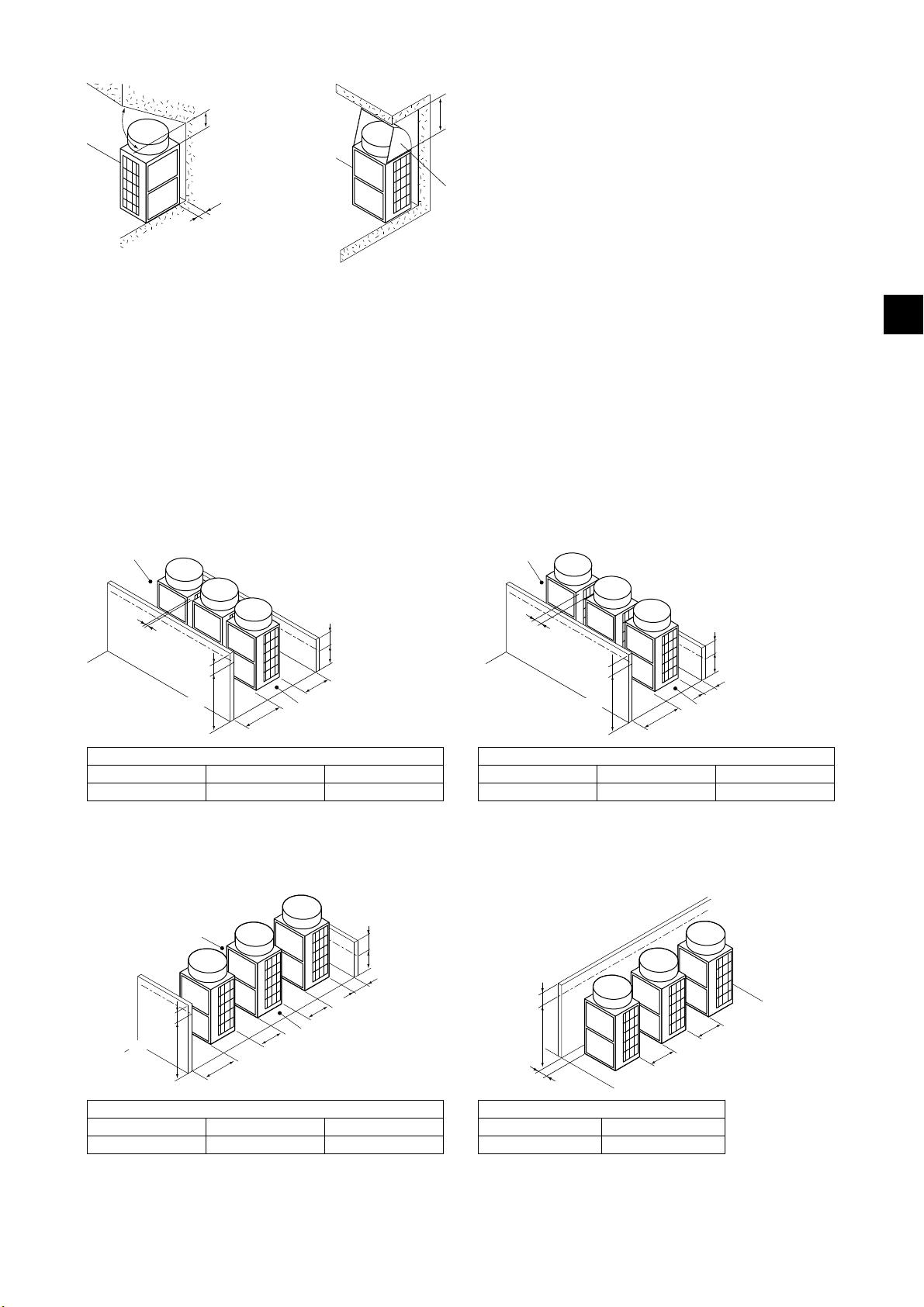

(3) When there are overhead obstacles

≥ 45°

≥ 240 (9-1/2)

≥ 50 (2)

≥ 1000 (39-3/8)

Air outlet guide

(not supplied)

7-2. Multiple unit installation

・When installing multiple units, make sure to take into consideration factors such as providing enough space for

people to pass through, ample space between blocks of units, and sufficient space for airflow. (The areas marked

with Ⓐ in the figures below must be left open.)

・In the same way as with the single unit installation, add the dimension that exceeds the height limit (shown as "h1"

through "h3" in the figures) to L1, L2, and L3 as shown in the tables below.

・If there are walls in the front and rear of the block of units, up to six units (three units for units P450 through P500)

can be installed consecutively side by side, and a space of 1000 mm (39-3/8 in) or more must be left between each

block of six units.

(1) Side-by-side installation

When the distances between the units (L4) need to

be small

Ⓐ

When the distance behind the block of units (L2) needs

to be small

Ⓐ

GB

L4

h1

Unit height

L1

h2

500 (19-11/16)

L2

Ⓐ

Required minimum distance [mm (in)]

L1 (Front) L2 (Rear) L4 (Between)

450 (17-3/4) + h1 300 (11-13/16) + h2 30 (1-3/16)

(2) Face-to-face installation

When there are walls in the front and rear of the

block of units

Ⓐ

L4

Ⓐ

Unit height

h1

L4

L1

h2

500 (19-11/16)

L2

L4

h2

L2

Ⓐ

500 (19-11/16)

h1

Unit height

L1

Required minimum distance [mm (in)]

L1 (Front) L2 (Rear) L4 (Between)

450 (17-3/4) + h1 100 (3-15/16) + h2 100 (3-15/16)

When there is a wall on either the right or left side of the

block of units

h3

Unit height

L4

L3

L4

Required minimum distance [mm (in)]

L1 (Front) L2 (Rear) L4 (Between)

450 (17-3/4) + h1 100 (3-15/16) + h2 450 (17-3/4)

KD79S703H01

Required minimum distance [mm (in)]

L3 (Right/Left) L4 (Between)

15 (5/8) + h3 450 (17-3/4)

GB-13

Page 16

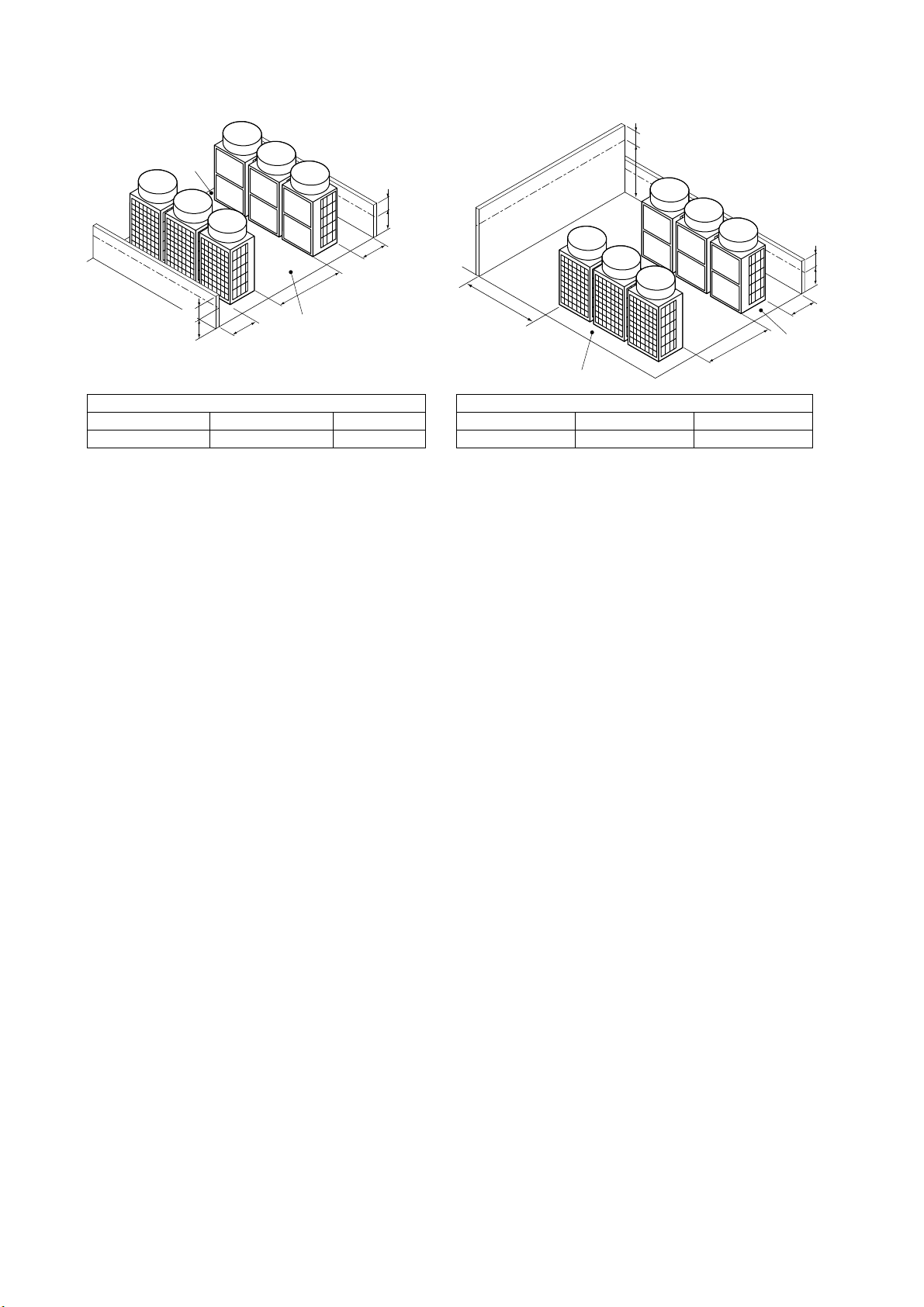

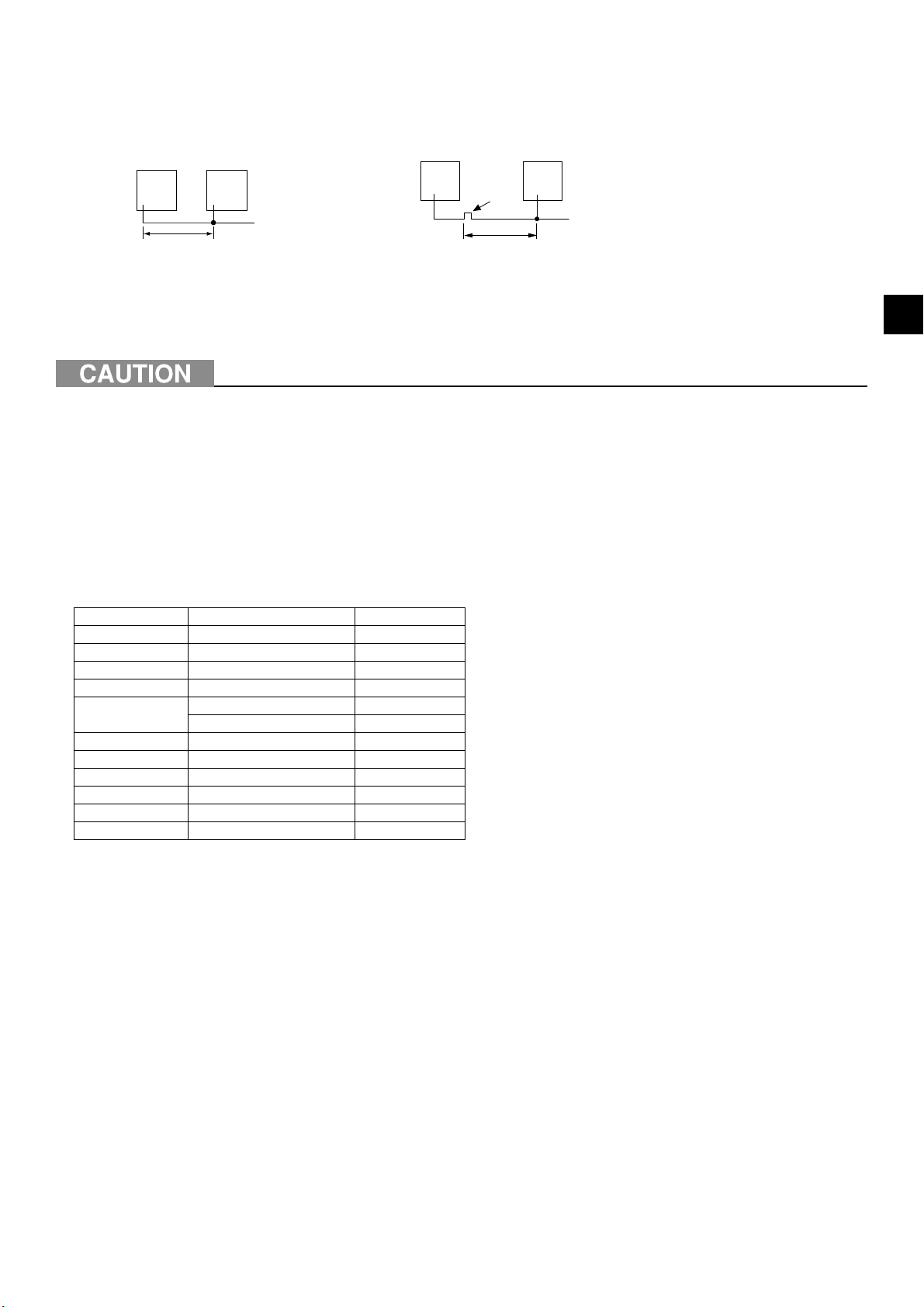

(3) Combination of face-to-face and side-by-side installations

When there are walls in the front and rear of the

When there are two walls in an L-shape

block of units

Ⓐ

h2

500

(19-11/16)

h3

Unit height

L2

L4

500 (19-11/16)

h2’

L2’

Ⓐ

Required minimum distance [mm (in)]

L2 (Right) L2' (Left) L4 (Between)

300 (11-13/16) + h2 300 (11-13/16) + h2' 900 (35-7/16)

Ⓐ Leave open in two directions.

L3

L4

Ⓐ

Required minimum distance [mm (in)]

L2 (Right) L3 (Right/Left) L4 (Between)

300 (11-13/16) + h2 1000 (39-3/8) + h3 900 (35-7/16)

h2

500

(19-11/16)

L2

Ⓐ

KD79S703H01

GB-14

Page 17

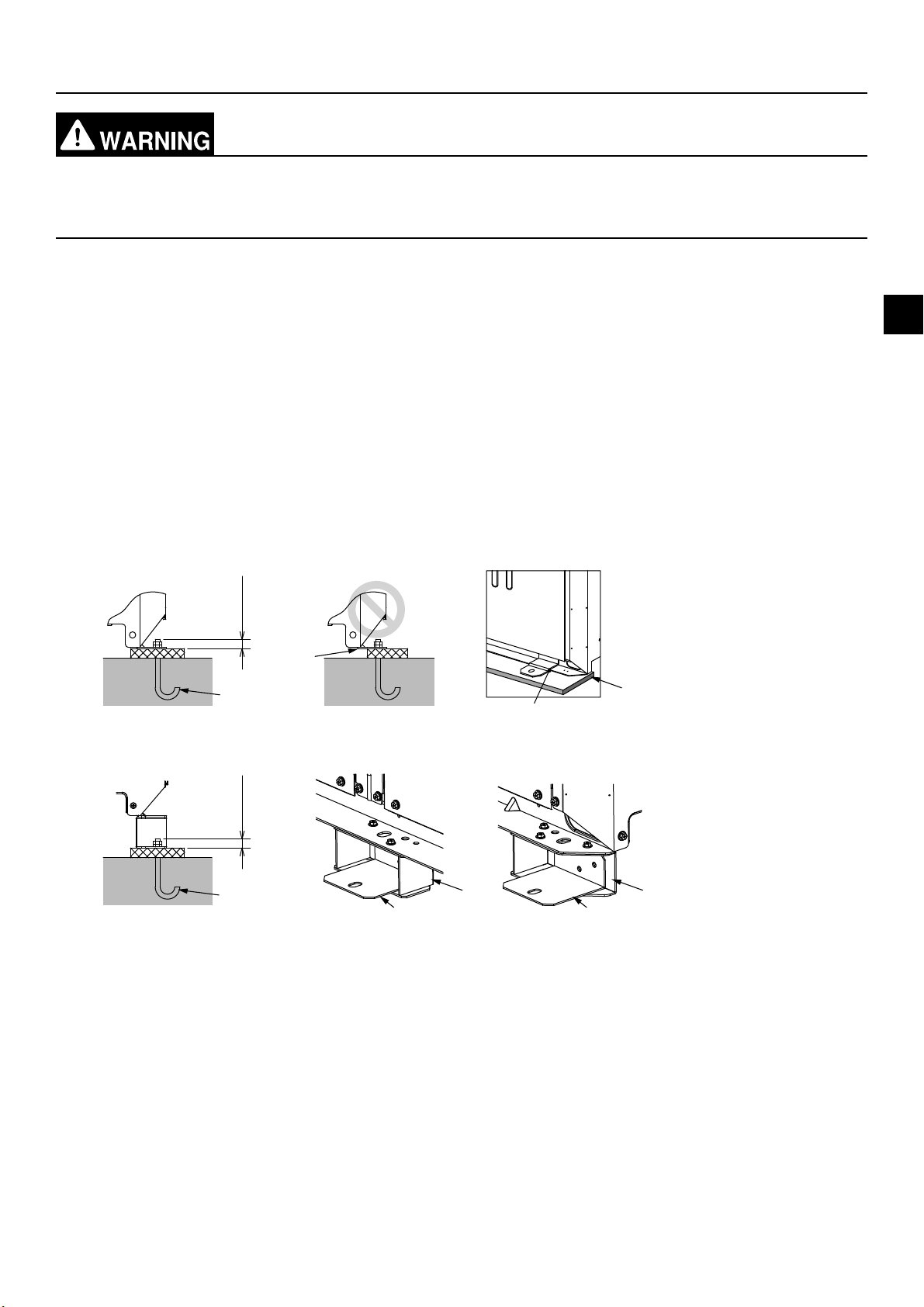

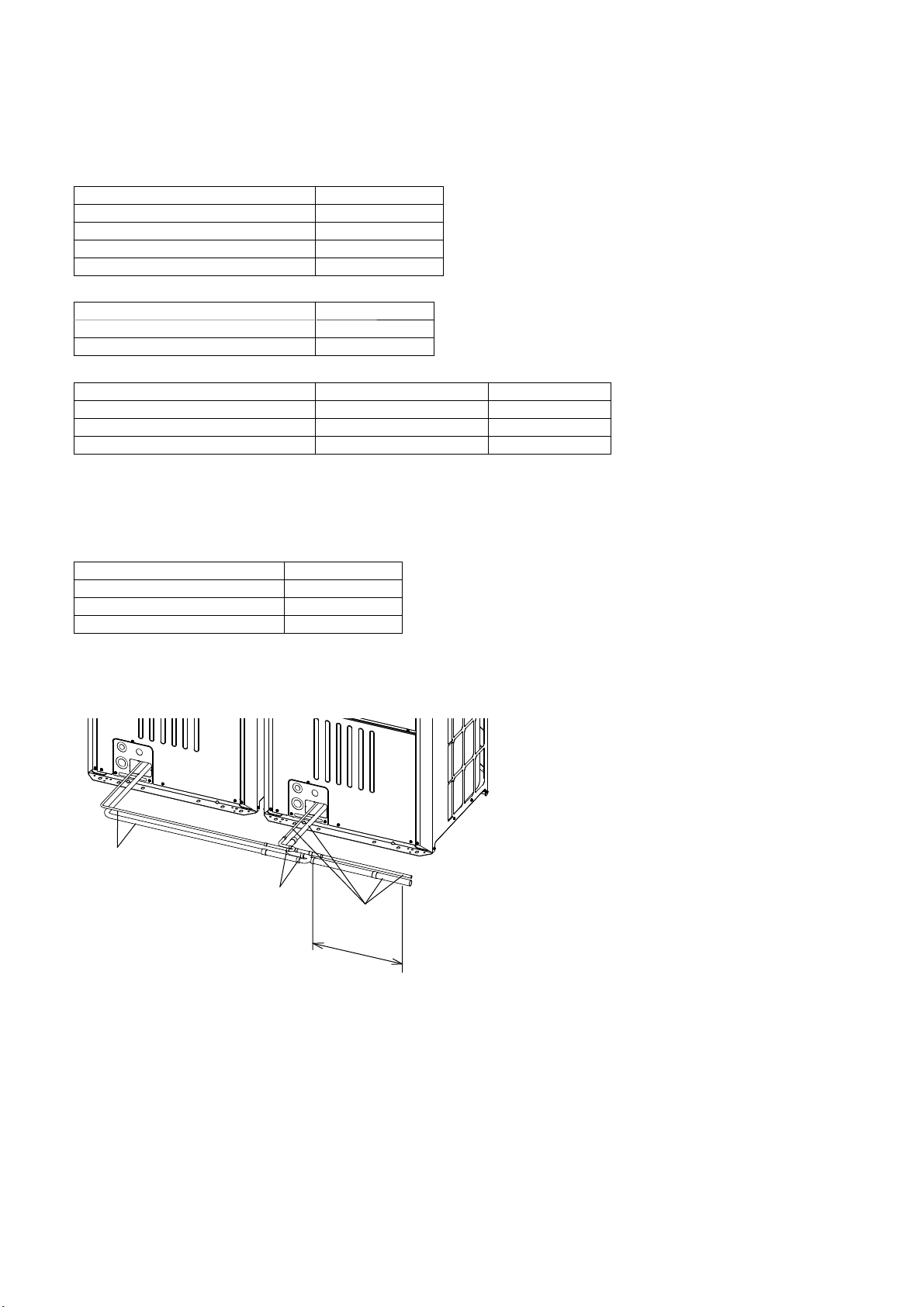

8. Foundation work

Install the unit in accordance with the instructions to minimize the risk of damage from

earthquakes and strong winds.

- Improper installation will cause the unit to topple, resulting in serious injury.

The unit must be securely installed on a structure that can sustain its weight.

- Failure to do so will cause the unit to fall, resulting in serious injury.

・When performing the foundation work, make sure that the floor surface has sufficient strength and carefully route

pipes and wires in consideration of the water drainage that will be required when the unit is operated.

・If considering routing the pipes and wires across the bottom of the unit, make sure that the base is at least 100 mm

(3-15/16 in) high so that the through-holes will not be blocked.

・Provide a strong base of concrete or angle iron. If a stainless steel base is used, insulate the area between the

base and the outdoor unit by putting a rubber cushion or by applying an electrically insulated coating to prevent the

base from rusting.

・Install the unit on a level surface.

・With some types of installation, unit vibration and sound will be transmitted to the floors and walls. In such locations,

take measures to prevent vibration (such as using anti-vibration rubber pads).

[mm (in)]

(1) Without a detachable leg

≤ 30 (1-3/16)≤ 30 (1-3/16)

Ⓑ

Ⓐ

Ⓒ

Ⓓ

(2) With a detachable leg

GB

Ⓐ

ⒸⒸ

Ⓐ M10 anchor bolt (not supplied)

Ⓑ (Incorrect installation) The corner section is not securely received.

Ⓒ Fixing bracket for post-installed anchor bolts (not supplied) (To be fixed with three screws)

Ⓓ Anti-vibration rubber pad

(The pad needs to be large enough to cover the entire width of each unit leg.)

Ⓔ Detachable leg

ⒺⒺ

・Make sure that the corner section is securely received. If not, the unit legs could bend.

・The length of the projecting part of the anchor bolt should be 30 mm (1-3/16 in) or less.

・This unit is not designed to be anchored with post-installed anchor bolts unless fixing brackets are installed at

the bottom four locations (six locations for units P450 through P500).

KD79S703H01

GB-15

Page 18

・To remove the detachable legs on site, unscrew the screws shown in the figure below. If the unit leg coating is

damaged when the detachable leg is removed, repair the coating on site.

Ⓐ Screws

Ⓐ

Ⓐ

・In abnormally harsh environments such as cold and/or windy areas, sufficient countermeasures to guard against

excessive wind and snow should be taken to ensure the unit’s correct operation. When the unit is expected to

operate in cooling mode in conditions under 10°C (50°F), in snowy areas, in environments subject to strong

winds or rain, install snow hoods of the following specifications (not supplied) as shown in the figure below.

Material: Galvanized steel plate 1.2T

Painting: Overall painting with polyester powder

Color: Munsell 3.0Y 7.8/1.1 (same as the unit color)

Size: Refer to the Data Book.

ⒸⒸ

Ⓐ

Ⓒ

ⒷⒷ

ⒹⒹ

Ⓒ

Ⓐ Outlet

Ⓑ Inlet

Ⓒ Snow hood

Ⓓ Raised base

Ⓒ

Ⓑ

・Install the unit so that the wind will not blow directly against the inlet and outlet.

・If necessary, install the unit on a raised base of the following specifications (not supplied) to prevent damage

from snow.

Material: Angle iron (Build a structure that snow and wind can pass through.)

Height: Expected maximum snowfall plus 200 mm (7-7/8 in)

Width: Within the unit width (If the raised base is too wide, snow will accumulate on the raised base.)

・When the unit is used in a cold region and the heating operation is continuously performed for a long time when

the outside air temperature is below freezing, install a heater on the raised base or take other appropriate

measures to prevent water from freezing on the raised base.

KD79S703H01

GB-16

Page 19

9. Refrigerant piping work

Do not use any refrigerant other than the type indicated in the manuals for the unit and on

the nameplate.

- Doing so will cause the unit or pipes to burst, or result in an explosion or fire during use, during

repairs, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for malfunctions or

accidents resulting from the use of the wrong type of refrigerant.

After the installation has been completed, check for refrigerant leaks.

- If the refrigerant leaks, oxygen starvation may result. If the leaked refrigerant comes in contact

with a heat source, toxic gas will be generated.

Use the following tools specifically designed for use with the specified refrigerant: Gauge

manifold, charge hose, gas leak detector, check valve, refrigerant charge base, vacuum

gauge, and refrigerant recovery equipment.

- Gas leak detectors for conventional refrigerants will not react to a refrigerant that does not

contain chlorine.

- If the specified refrigerant is mixed with water, refrigerant oil, or another refrigerant, the

refrigerant oil will deteriorate and the compressor will malfunction.

GB

Do not use existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing piping contain a large amount of chlorine,

which will cause the refrigerant oil in the new unit to deteriorate and cause the compressor to

malfunction.

9-1. Restrictions

・Existing refrigerant piping must not be used because the design pressure for systems using R410A is higher than

that for systems using other types of refrigerants.

・Do not install outdoor unit piping when it is raining.

・Do not use special detergents for washing piping.

・Always observe the restrictions on refrigerant piping (such as pipe size, pipe length, and vertical separation

distance) to prevent equipment failure or a decline in heating/cooling performance.

・Do not install solenoid valves to prevent oil backflow and compressor start-up failure.

・Do not install a sight glass because it may show improper refrigerant flow. If a sight glass is installed, inexperienced

technicians that use the glass may overcharge the refrigerant.

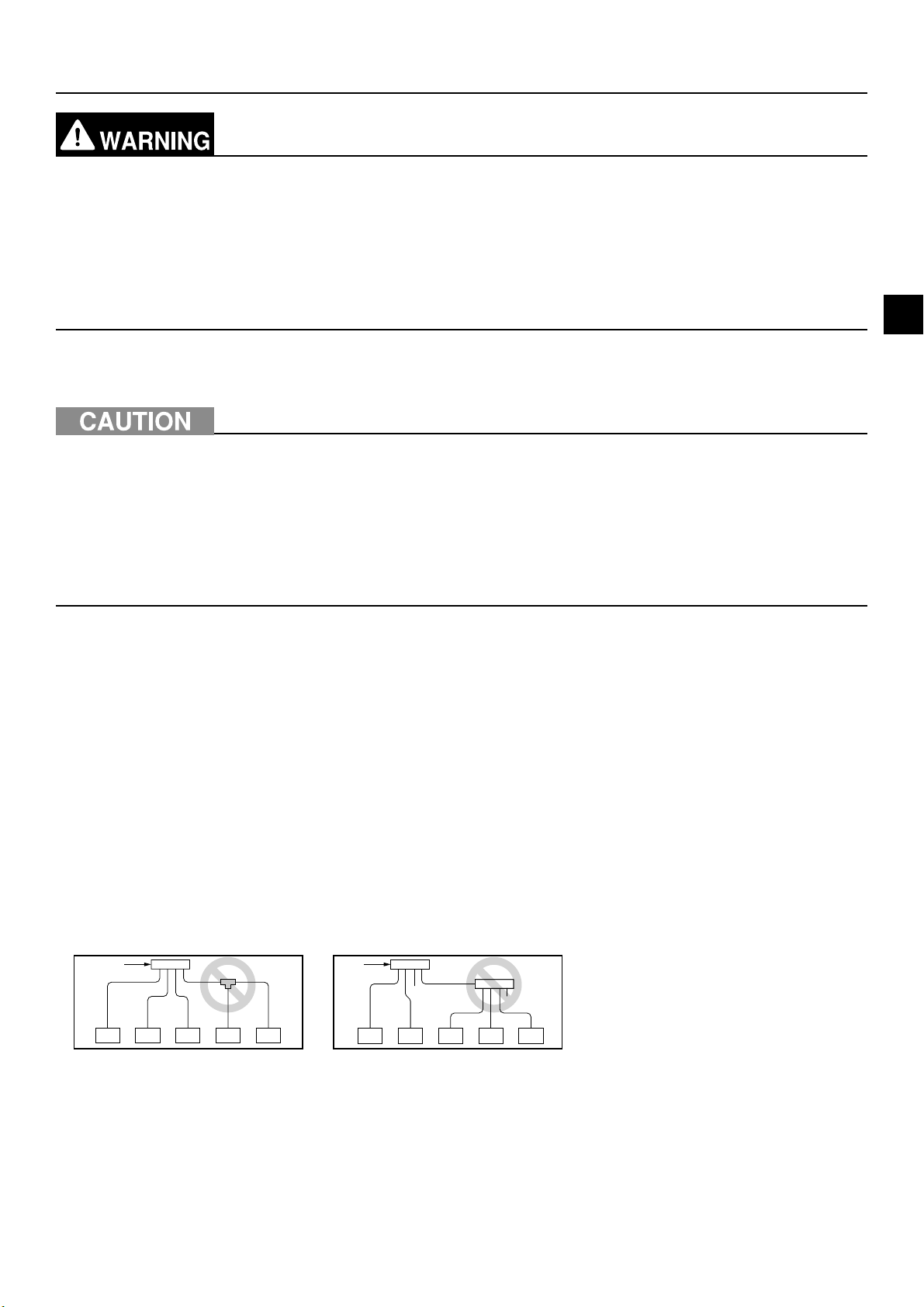

・Branching cannot be made after header branching.

ⒶⒶ

Ⓑ

ⒸⒸⒸ ⒸⒸ Ⓒ ⒸⒸⒸⒸ

Ⓑ

Ⓐ From outdoor unit

Ⓑ Cap

Ⓒ Indoor unit

KD79S703H01

GB-17

Page 20

・The pipe from multiple outdoor units must be installed so that oil will not accumulate in the pipe under certain

conditions. Refer to the figures below for details.

* Small dots in the figures indicate branching points.

Ⓐ To indoor units

(1) The pipe from the outdoor units must be inclined downward to the indoor unit side. In the figure on the right,

because the pipe is inclined upward, the oil in the pipe accumulates when Unit 1 is in operation and Unit 3 is

stopped.

Unit 1 Unit 3Unit 2Unit 1

Ⓐ

Unit 2

Unit 3

Ⓐ

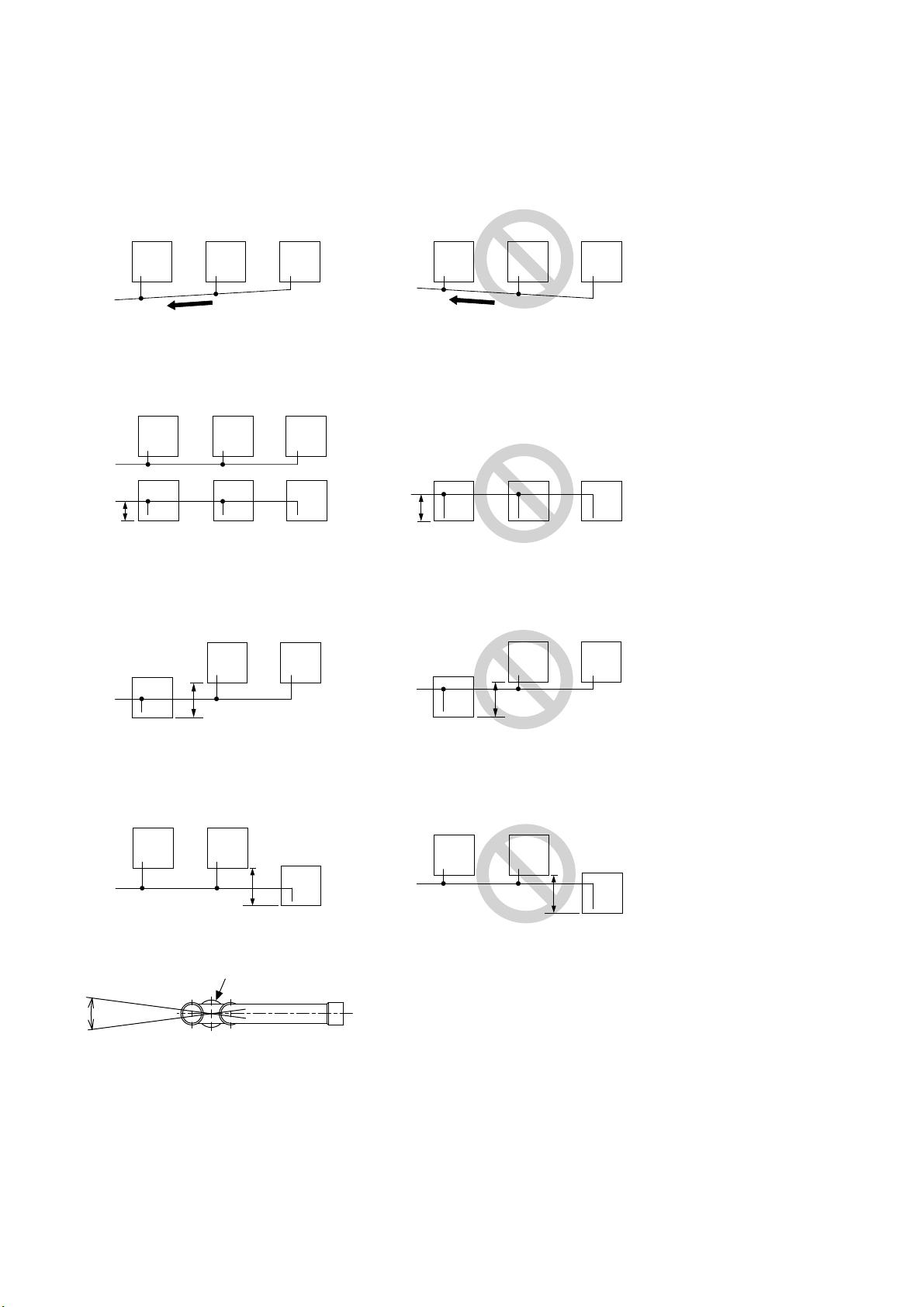

(2) The distance between the unit bottom and the pipe (H) must be 0.2 m (7-7/8 in) or below. In the figure on the

right, because the distance is more than 0.2 m (7-7/8 in), the oil accumulates in Units 1 and 2 when Unit 3 is in

operation and Units 1 and 2 are stopped.

Unit 1

Ⓐ

Unit 1

Ⓐ

H

H ≤ 0.2 m (7-7/8 in)

Unit 2

Unit 2

Unit 3

Unit 3

Ⓐ

H

H > 0.2 m (7-7/8 in)

Unit 2Unit 1

Unit 3

(3) The vertical separation between units (H) must be 0.1 m (3-15/16 in) or below. In the figure on the right,

because the distance is more than 0.1 m (3-15/16 in), the oil accumulates in Unit 1 when Unit 3 is in operation

and Unit 1 is stopped.

Unit 2

Unit 1

Ⓐ

H

H ≤ 0.1 m (3-15/16 in)

Unit 3

Unit 1

Ⓐ

H

Unit 3Unit 2

H > 0.1 m (3-15/16 in)

(4) The vertical separation between units (H) must be 0.1 m (3-15/16 in) or below. In the figure on the right,

because the distance is more than 0.1 m (3-15/16 in), the oil accumulates in Unit 3 when Unit 1 is in operation

and Unit 3 is stopped.

Unit 1

Ⓐ

Unit 2

H

H ≤ 0.1 m (3-15/16 in)

Unit 3

Unit 1

Ⓐ

Unit 2

Unit 3

H

H > 0.1 m (3-15/16 in)

・Make sure that the inclination tolerance of the Twinning Kit is ±15˚ to the ground to avoid unit damage.

Ⓐ

±15°

Ⓐ Twinning Kit

KD79S703H01

GB-18

Page 21

・If the length of the pipe between the branching point and the outdoor unit exceeds 2 m (6 ft), provide a trap within 2

m (6 ft) from the branching point.

The trap must be at least 200 mm (7-7/8 in) in height. (gas pipe only) If there is no trap, oil can accumulate inside

the pipe, causing a shortage of oil and may damage the compressor.

* Small dots in the figures indicate branching points.

Ⓑ

2 m (6 ft)

Ⓐ To indoor units

Ⓑ Trap (gas pipe only)

Ⓒ Gas pipe

Ⓐ

Ⓒ

≤ 2 m (6 ft)

Ⓐ

9-2. Pipe selection

Use refrigerant piping made of phosphorus deoxidized copper (copper and copper alloy

seamless pipes) that meets local requirements. Pipe joints should also meet local

requirements. Keep the inner and outer surfaces of the pipes clean and free of sulphur,

oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminants.

- Contaminants on the inside of the refrigerant piping will cause the refrigerant oil to deteriorate

and cause the compressor to malfunction.

GB

Use refrigerant pipes for use with R410A refrigerant system. Piping for systems for use with other types of refrigerants

may not be able to be used.

Use refrigerant pipes with the thicknesses specified in the table below.

Size [mm (in)] Radial thickness [mm (mil)] Type

ø6.35 (ø1/4) 0.8 (32) Type-O

ø9.52 (ø3/8) 0.8 (32) Type-O

ø12.7 (ø1/2) 0.8 (32) Type-O

ø15.88 (ø5/8) 1.0 (40) Type-O

ø19.05 (ø3/4)

ø22.2 (ø7/8) 1.0 (40) Type-1/2H or H

ø25.4 (ø1) 1.0 (40) Type-1/2H or H

ø28.58 (ø1-1/8) 1.0 (40) Type-1/2H or H

ø31.75 (ø1-1/4) 1.1 (44) Type-1/2H or H

ø34.93 (ø1-3/8) 1.2 (48) Type-1/2H or H

ø41.28 (ø1-5/8) 1.4 (56) Type-1/2H or H

1.2 (48) Type-O

1.0 (40) Type-1/2H or H

KD79S703H01

GB-19

Page 22

9-3. Twinning kit selection

9-3-1. Indoor unit twinning kit

Select a proper indoor unit twinning kit (sold separately) based on the total capacity of the downstream indoor units,

using the table below as a reference.

Line branching

Total capacity of downstream indoor units Kit model

200 or below CMY-Y102SS-G2

201 to 400 CMY-Y102LS-G2

401 to 650 CMY-Y202S-G2

651 or above CMY-Y302S-G2

Line branching for the 1st branching point

Outdoor unit model Kit model

P450 to P650 CMY-Y202S-G2

P700 to P1350 CMY-Y302S-G2

Header branching

Total capacity of downstream indoor units Number of branches Kit model

200 or below 4 CMY-Y104-G

400 or below 8 CMY-Y108-G

650 or below 10 CMY-Y1010-G

* Use an adapter, if necessary, to connect a refrigerant pipe to a twinning pipe of a different diameter.

9-3-2. Outdoor unit twinning kit

Select a proper outdoor unit twinning kit (sold separately) based on the total capacity of the outdoor units, using the

table below as a reference.

Total capacity of outdoor units Kit model

P400 to P650 CMY-Y100VBK3

P700 to P900 CMY-Y200VBK2

P950 to P1350 CMY-Y300VBK3

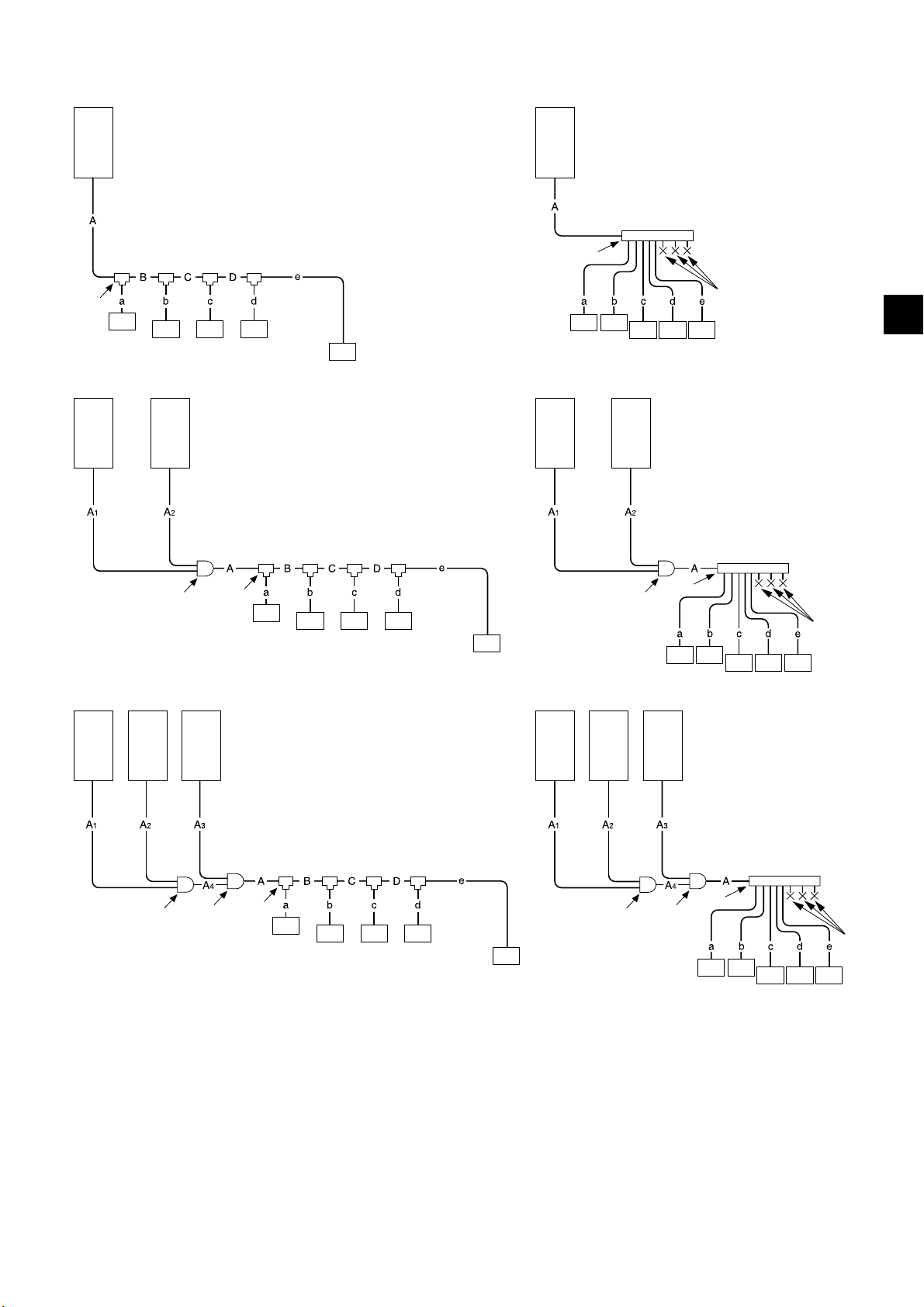

9-4. Pipe connection example

・Example of pipe connection between outdoor units

Ⓐ

Ⓑ

Ⓐ

Ⓒ

Ⓐ On-site piping

Ⓑ Twinning Kit

Ⓒ The pipe section before the twinning pipe must

have at least 500 mm (19-11/16 in) of straight

section.

KD79S703H01

GB-20

Page 23

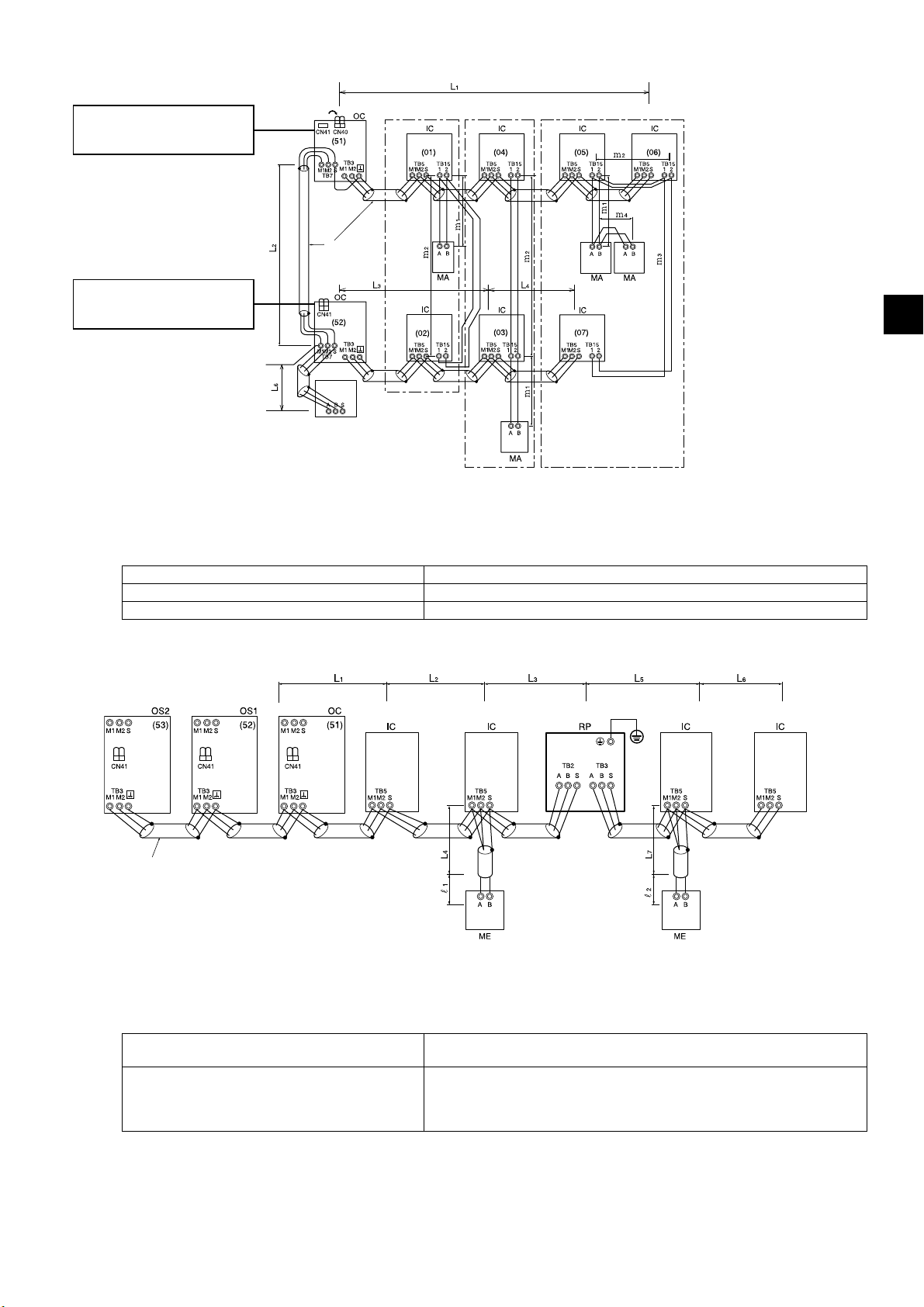

・Example of pipe connection between outdoor units and indoor units

P200 to P500YKB-A1

Unit 1

Unit 1

Ⓐ

Ⓑ

Ⓒ

Ⓒ Ⓒ Ⓒ

Ⓒ

Ⓐ

Ⓑ

Ⓒ Ⓒ

P400 to P650YSKB-A1

Unit 1 Unit 2

Ⓐ Ⓐ Ⓐ Ⓐ

Ⓔ

Ⓑ

Ⓒ

ⒸⒸⒸ

Ⓒ

Unit 1 Unit 2

Ⓕ

Ⓒ Ⓒ Ⓒ

Ⓔ

Ⓑ

ⒸⒸ

Ⓓ

GB

Ⓓ

ⒸⒸⒻⒸ

P950 to P1350YSKB-A1

Unit 1 Unit 2 Unit 3

Ⓐ Ⓐ Ⓐ Ⓐ Ⓐ Ⓐ

Ⓔ

Ⓔ

Ⓑ

Ⓒ

Ⓒ Ⓒ Ⓒ

Unit 1 Unit 2 Unit 3

Ⓔ

Ⓒ

Ⓐ Outdoor unit

Ⓑ 1st branching

Ⓒ Indoor unit

Ⓓ Cap

Ⓔ Outdoor unit twinning kit

Ⓕ Header branching

* The total length of A

1, A2, A3, and A4 is less than 10 m (32 ft).

Ⓔ

Ⓑ

ⒸⒸ

Ⓕ

Ⓓ

ⒸⒸⒸ

KD79S703H01

GB-21

Page 24

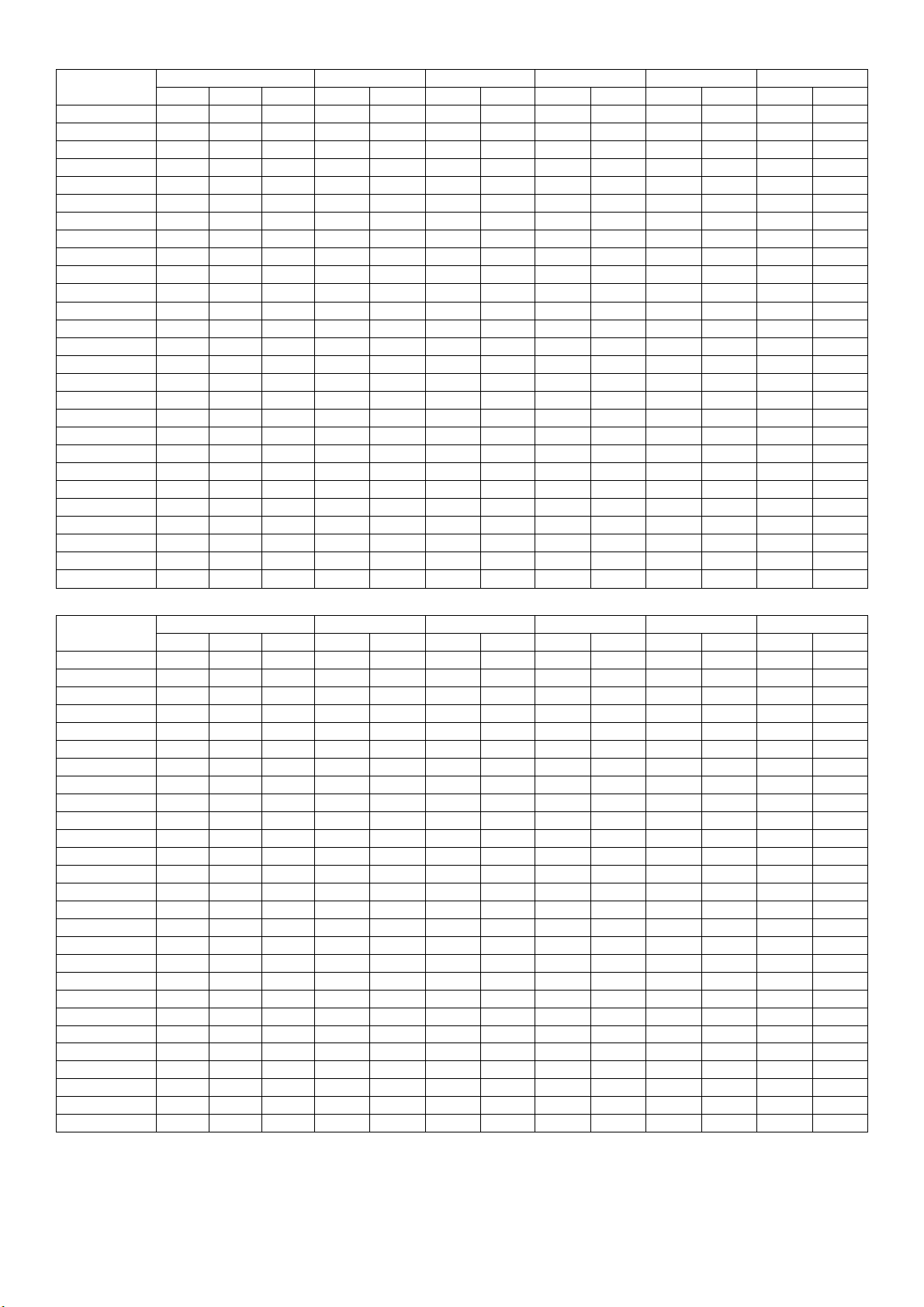

Pipes A, A1, A2, A3, A4 [mm]

Unit model

Combination unit Pipe A Pipe A1*

3

Unit 1 Unit 2 Unit 3 Liquid Gas Liquid Gas Liquid Gas Liquid Gas Liquid Gas

Pipe A2*

3

Pipe A3*

3

Pipe A4

P200YKB-A1 - - - ø9.52 ø22.2 - - - - - - - -

1

P250YKB-A1 - - - ø9.52*

P300YKB-A1 - - - ø9.52*

ø22.2 - - - - - - - -

2

ø22.2 - - - - - - - P350YKB-A1 - - - ø12.7 ø28.58 - - - - - - - P400YKB-A1 - - - ø12.7 ø28.58 - - - - - - - P450YKB-A1 - - - ø15.88 ø28.58 - - - - - - - P500YKB-A1 - - - ø15.88 ø28.58 - - - - - - - P400YSKB-A1 P200 P200 - ø12.7 ø28.58 ø9.52 ø22.2 ø9.52 ø22.2 - - - P450YSKB-A1 P250 P200 - ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø22.2 - - - P500YSKB-A1 P250 P250 - ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø22.2 - - - P550YSKB-A1

P300 P250 - ø15.88 ø28.58 ø12.7 ø22.2 ø9.52 ø22.2 - - - P600YSKB-A1 P350 P250 - ø15.88 ø28.58 ø12.7 ø28.58 ø9.52 ø22.2 - - - P650YSKB-A1 P350 P300 - ø15.88 ø28.58 ø15.88 ø28.58 ø9.52 ø22.2 - - - P700YSKB-A1 P350 P350 - ø19.05 ø34.93 ø15.88 ø28.58 ø15.88 ø28.58 - - - P750YSKB-A1 P400 P350 - ø19.05 ø34.93 ø15.88 ø28.58 ø15.88 ø28.58 - - - P800YSKB-A1 P450 P350 - ø19.05 ø34.93 ø15.88 ø28.58 ø15.88 ø28.58 - - - P850YSKB-A1 P450 P400 - ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 - - - P900YSKB-A1 P450 P450 - ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 - - - P950YSKB-A1 P400 P300 P250 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø22.2 ø12.7 ø22.2 ø19.05 ø34.93

P1000YSKB-A1 P400 P300 P300 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø22.2 ø12.7 ø22.2 ø19.05 ø34.93

P1050YSKB-A1 P400 P350 P300 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø28.58 ø12.7 ø22.2 ø19.05 ø34.93

P1100YSKB-A1 P400 P350 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø12.7 ø28.58 ø12.7 ø28.58 ø19.05 ø34.93

P1150YSKB-A1 P450 P350 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 ø15.88 ø28.58 ø19.05 ø34.93

P1200YSKB-A1 P450 P400 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 ø15.88 ø28.58 ø19.05 ø34.93

P1250YSKB-A1 P450 P450 P350 ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 ø15.88 ø28.58 ø19.05 ø34.93

P1300YSKB-A1 P450 P450 P400 ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 ø15.88 ø28.58 ø19.05 ø34.93

P1350YSKB-A1

P450 P450 P450 ø19.05 ø41.28 ø15.88 ø28.58 ø15.88 ø28.58 ø15.88 ø28.58 ø19.05 ø34.93

Pipes A, A1, A2, A3, A4 [in]

Unit model

Combination unit Pipe A Pipe A

3

1*

Unit 1 Unit 2 Unit 3 Liquid Gas Liquid Gas Liquid Gas Liquid Gas Liquid Gas

Pipe A2*

3

Pipe A3*

3

Pipe A4

P200YKB-A1 - - - ø3/8 ø7/8 - - - - - - - -

1

P250YKB-A1 - - - ø3/8*

P300YKB-A1 - - - ø3/8*

ø7/8 - - - - - - - -

2

ø7/8 - - - - - - - P350YKB-A1 - - - ø1/2 ø1-1/8 - - - - - - - P400YKB-A1 - - - ø1/2 ø1-1/8 - - - - - - - P450YKB-A1 - - - ø5/8 ø1-1/8 - - - - - - - P500YKB-A1 - - - ø5/8 ø1-1/8 - - - - - - - P400YSKB-A1 P200 P200 - ø1/2 ø1-1/8 ø3/8 ø7/8 ø3/8 ø7/8 - - - P450YSKB-A1 P250 P200 - ø5/8 ø1-1/8 ø3/8 ø7/8 ø3/8 ø7/8 - - - P500YSKB-A1 P250 P250 - ø5/8 ø1-1/8 ø3/8 ø7/8 ø3/8 ø7/8 - - - P550YSKB-A1 P300 P250 - ø5/8 ø1-1/8 ø1/2 ø7/8 ø3/8 ø7/8 - - - P600YSKB-A1 P350 P250 - ø5/8 ø1-1/8 ø1/2 ø1-1/8 ø3/8 ø7/8 - - - P650YSKB-A1 P350 P300 - ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø3/8 ø7/8 - - - P700YSKB-A1 P350 P350 - ø3/4 ø1-3/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 - - - P750YSKB-A1 P400 P350 - ø3/4 ø1-3/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 - - - P800YSKB-A1 P450 P350 - ø3/4 ø1-3/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 - - - P850YSKB-A1 P450 P400 - ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 - - - P900YSKB-A1 P450 P450 - ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 - - - P950YSKB-A1 P400 P300 P250 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø1/2 ø7/8 ø1/2 ø7/8 ø3/4 ø1-3/8

P1000YSKB-A1 P400 P300 P300 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø1/2 ø7/8 ø1/2 ø7/8 ø3/4 ø1-3/8

P1050YSKB-A1 P400 P350 P300 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø1/2 ø1-1/8 ø1/2 ø7/8 ø3/4 ø1-3/8

P1100YSKB-A1 P400 P350 P350 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø1/2 ø1-1/8 ø1/2 ø1-1/8 ø3/4 ø1-3/8

P1150YSKB-A1 P450 P350 P350 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø3/4 ø1-3/8

P1200YSKB-A1 P450 P400 P350 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø3/4 ø1-3/8

P1250YSKB-A1 P450 P450 P350 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø3/4 ø1-3/8

P1300YSKB-A1 P450 P450 P400 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø3/4 ø1-3/8

P1350YSKB-A1 P450 P450 P450 ø3/4 ø1-5/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø5/8 ø1-1/8 ø3/4 ø1-3/8

*1 Use the ø12.7 (ø1/2) pipe if the piping length from the outdoor unit to the farthest indoor unit is 90 m (295 ft) or longer.

*2 Use the ø12.7 (ø1/2) pipe if the piping length from the outdoor unit to the farthest indoor unit is 40 m (131 ft) or longer.

*3 If the combination units 1, 2, and 3 are in a different order as listed in the table, make sure to use the pipes of appropriate size for the situation.

*4 If the pipe length after the first branching point exceeds 40 m (131 ft) (≤ 90 m (295 ft)), use the one size larger liquid pipe for all pipes from indoor

units to the first branch.

*5 When the vertical separation between the indoor units is 15 m (49 ft) (≤ 30 m (98 ft)), use the one size larger liquid pipe for all pipes from the

lower indoor units to the first branch.

KD79S703H01

GB-22

Page 25

Pipes B,C,D [mm (in)]

Total capacity of indoor units

140 or below ø9.52 (ø3/8) ø15.88 (ø5/8)

141 to 200 ø9.52 (ø3/8) ø19.05 (ø3/4)

201 to 300 ø9.52 (ø3/8) ø22.2 (ø7/8)

301 to 400 ø12.7 (ø1/2) ø28.58 (ø1-1/8)

401 to 650 ø15.88 (ø5/8) ø28.58 (ø1-1/8)

651 to 800 ø19.05 (ø3/4) ø34.93 (ø1-3/8)

801 or above ø19.05 (ø3/4) ø41.28 (ø1-5/8)

Pipes a,b,c,d,e [mm (in)]

Capacity index of indoor unit

20, 25, 32, 40, 50 ø6.35 (ø1/4) ø12.7 (ø1/2)

63, 71, 80, 100, 125, 140 ø9.52 (ø3/8) ø15.88 (ø5/8)

200 ø9.52 (ø3/8) ø19.05 (ø3/4)

250 ø9.52 (ø3/8) ø22.2 (ø7/8)

Liquid Gas

Pipe

Pipe

Liquid Gas

9-5. Piping connections and valve operations

Before heating the brazed sections, remove the gas and oil that are trapped in the pipes.

- Failure to do so may generate fire, resulting in serious injury.

GB

Ventilate the room while servicing the unit.

- If the refrigerant leaks, oxygen deficiency may result. If the leaked refrigerant comes in contact

with a heat source, toxic gas will be generated.

Store pipes indoors, and keep both ends of the pipes sealed until just before making a

flare connection or brazing. (Store elbows and other joints in plastic bags.)

- If dust, dirt, or water enters the refrigerant lines, the refrigerant oil will deteriorate and the

compressor will malfunction.

Keep the service valves closed until refrigerant charging is completed.

- Failure to do so will damage the unit.

Place a wet towel on the service valves before brazing the pipes to keep the temperature of

the valves from rising above 120ºC (248ºF).

- Failure to do so may result in equipment damage.

Keep the flame out of contact with the cables and metal sheet when brazing the pipes.

- Failure to do so may result in burnout or malfunction.

Braze the pipes with a nitrogen purge to avoid oxidation.

- Oxidized flux inside the refrigerant pipes will cause the refrigerant oil to deteriorate and cause

the compressor to malfunction.

KD79S703H01

GB-23

Page 26

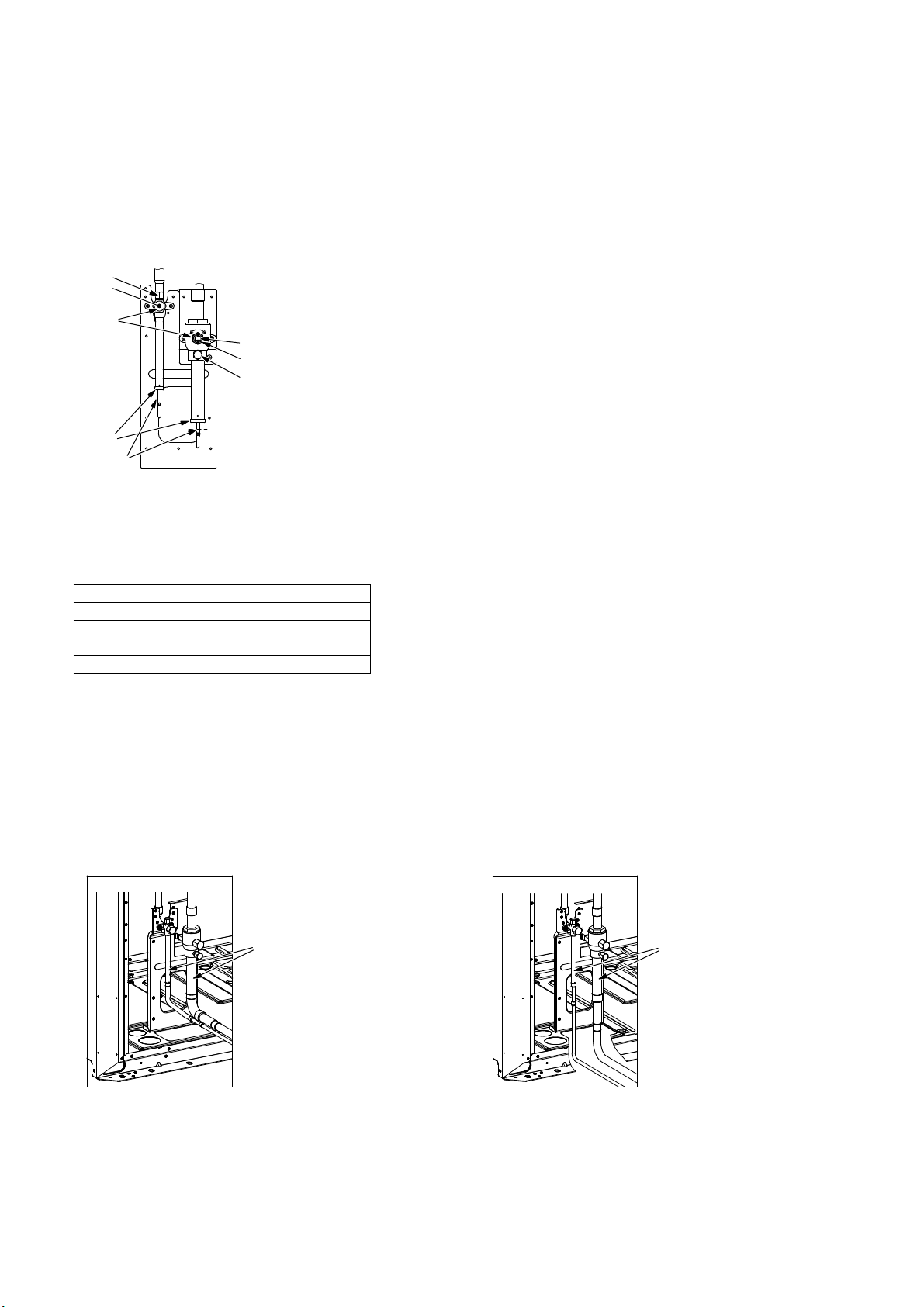

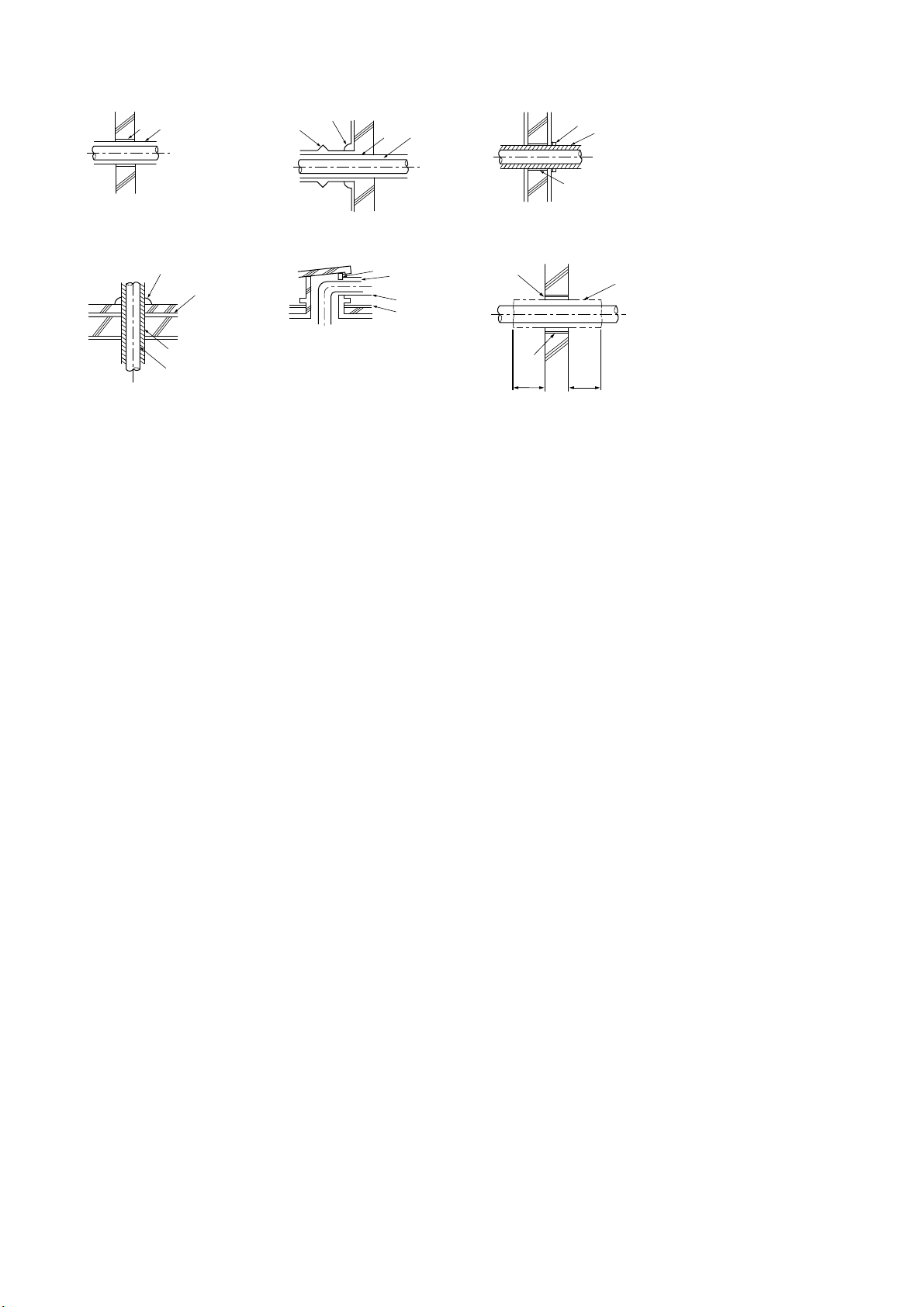

9-5-1. Removing the pinched connecting pipes

The unit is shipped with the pinched connecting pipes attached to the liquid- and gas-side service valves to prevent

gas leakage.

Take the following steps ① through ③ to remove the pinched connecting pipes before connecting refrigerant pipes to

the outdoor unit.

① Check that the service valves are fully closed (turned clockwise all the way).

② Remove the gas in the pinched connecting pipes, and drain out all the refrigerant oil. (See Ⓔ below.)

③ Remove the pinched connecting pipes. (See Ⓕ below.)

<A> Refrigerant service valve (liquid/brazed)

Ⓒ

Ⓐ

Ⓓ

Ⓕ

Ⓔ

<A> <B>

O

S

Ⓐ

Ⓑ

Ⓒ

<B> Refrigerant service valve (gas/brazed)

Ⓐ Valve shaft

The unit is shipped with the valve closed. Keep the valve closed while connecting pipes or

evacuating the system. Open the valve upon completion of this work.

Turn the shaft counterclockwise as far as it will go (90˚) to open the valve, and clockwise to close

it.

Ⓑ Stopper pin

Prevents the shaft from turning 90˚ or more.

Ⓒ Service port

Through the service ports, you can charge refrigerant, remove the gas in the pinched connecting

pipes, or evacuate the system.

Ⓓ Cap

Remove the cap before turning the shaft. Put the cap back on upon completion of all work.

Ⓔ Severed section of the pinched connecting pipe

Ⓕ Brazed section of the pinched connecting pipe

9-5-2. Connecting pipes

・The refrigerant pipe from the outdoor unit is branched at the pipe end, and each branch is then connected to an

indoor unit.

Connecting method

Indoor unit Brazed or flared

Outdoor unit

Branched section Brazed

・Refer to section 5 "Package contents" for details about the supplied connecting pipes.

・When connecting pipes, make sure the service valves are completely closed.

・Commercially available pipes often contain dust or debris. Always blow them clean with a dry inert gas.

・Take care to prevent dust, water or other contaminants from entering the pipes during installation.

・Reduce the number of bending portions as much as possible, and make the bending radius as big as possible.

・Do not use any commercially available anti-oxidizing agents since they may cause pipe corrosion and degrading of

the refrigerant oil. Please contact Mitsubishi Electric for more details.

・Make sure that the pipes are not in contact with each other, unit panels, or base plates.

(1) When routing the pipes through the front of the unit (2) When routing the pipes through the bottom of the unit

Gas pipe Brazed

Liquid pipe Brazed

<A> <B>

Ⓐ

<A> <B>

Ⓐ

<A> Liquid side

<B> Gas side

Ⓐ Refrigerant service valve piping

KD79S703H01

GB-24

Page 27

・Connecting the on-site piping and the service valve piping

When routing the pipes through the front of the unit

Liquid side Gas side

P200

P250

P300

P350

P400

P450

P500

Use the supplied connecting pipe ①.

*1

*2

Use the supplied connecting pipes ① and ②.

*3

Use the supplied connecting pipes ⑤ and ③.

*4*6

Use the supplied connecting pipes ⑤ and ④.

*5

*6

Use the supplied connecting pipe ⑤.

When routing the pipes through the bottom of the unit

Liquid side Gas side

P200

P250

P300

P350

P400

P450

P500

Expand the end of the on-site piping. (ID ø9.52 mm (ø3/8 in))

*1

*2

Use the supplied connecting pipe ②.

*3

Use the supplied connecting pipe ③.

*4*6

Use the supplied connecting pipe ④.

*5

*6

Expand the end of the on-site piping. (ID ø15.88 mm (ø5/8 in))

Use the supplied connecting elbow ⑥ and connecting

pipe ⑦.

Use the supplied connecting elbow ⑥.

GB

Use the supplied connecting pipe ⑦.

Expand the end of the on-site piping. (ID ø28.58

mm (ø1-1/8 in))

<Reference> Size of refrigerant pipes

On-site piping [mm (in)] Service valve piping [mm (in)]

Liquid Gas Liquid Gas

P200 ø9.52 (ø3/8)

P250

P300

P350 ø12.7 (ø1/2)

P400

P450 ø15.88 (ø5/8)

P500 ø15.88 (ø5/8)

*1 When the piping length from the outdoor unit to the farthest indoor unit is less than 90 m (295 ft)

*2 When the piping length from the outdoor unit to the farthest indoor unit is 90 m (295 ft) or more

*3 When the piping length from the outdoor unit to the farthest indoor unit is less than 40 m (131 ft)

*4 When the piping length from the outdoor unit to the farthest indoor unit is 40 m (131 ft) or more

*5 When the unit is used alone

*6 When the unit is used in combination with other outdoor units

*1 ø9.52 (ø3/8)

*2 ø12.7 (ø1/2)

*3 ø9.52 (ø3/8)

*4*6 ø12.7 (ø1/2)

*5 ø12.7 (ø1/2)

*6 ø15.88 (ø5/8)

ø22.2 (ø7/8)

ø28.58 (ø1-1/8)

ø9.52 (ø3/8)

ø28.58 (ø1-1/8)

ø15.88 (ø5/8)

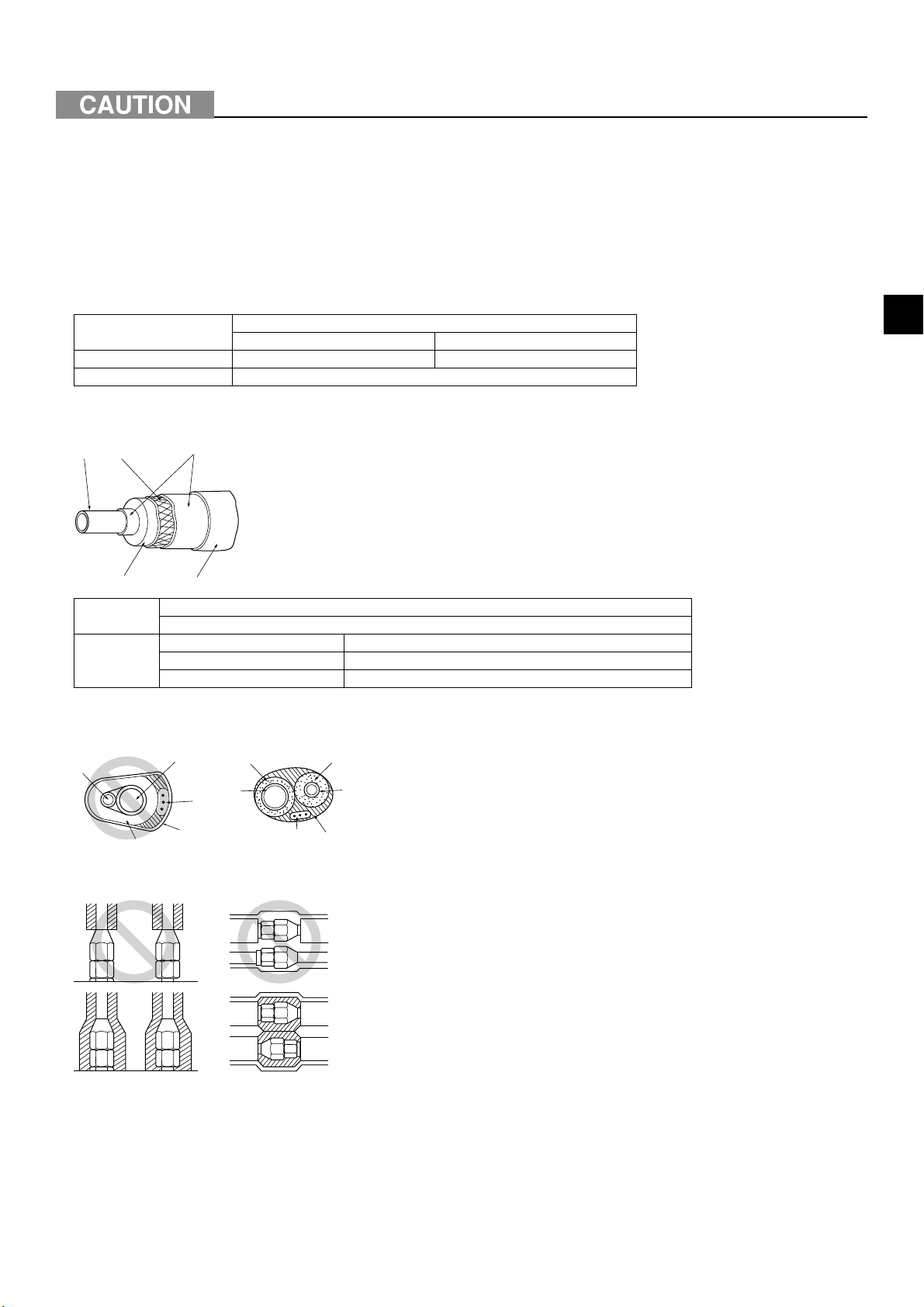

・When expanding the on-site piping, satisfy the minimum insertion depth requirement as follows.

Pipe size [mm (in)] Minimum insertion depth [mm (in)]

ø5 (ø1/4) or more, less than ø8 (ø3/8) 6 (1/4)

ø8 (ø3/8) or more, less than ø12 (ø1/2) 7 (5/16)

ø12 (ø1/2) or more, less than ø16 (ø11/16) 8 (3/8)

ø16 (ø11/16) or more, less than ø25 (ø1) 10 (7/16)

ø25 (ø1) or more, less than ø35 (ø1-7/16) 12 (1/2)

ø35 (ø1-7/16) or more, less than ø45 (ø1-13/16) 14 (9/16)

KD79S703H01

GB-25

Page 28

9-5-3. Sealing the openings around the pipes

Seal all openings around pipes and wires to keep out small animals, rainwater, or snow.

- Failure to do so may result in current leakage, electric shock, or damage to the unit.

Ⓐ Example of closure materials (not supplied)

Ⓑ Fill the openings

ⒶⒷ

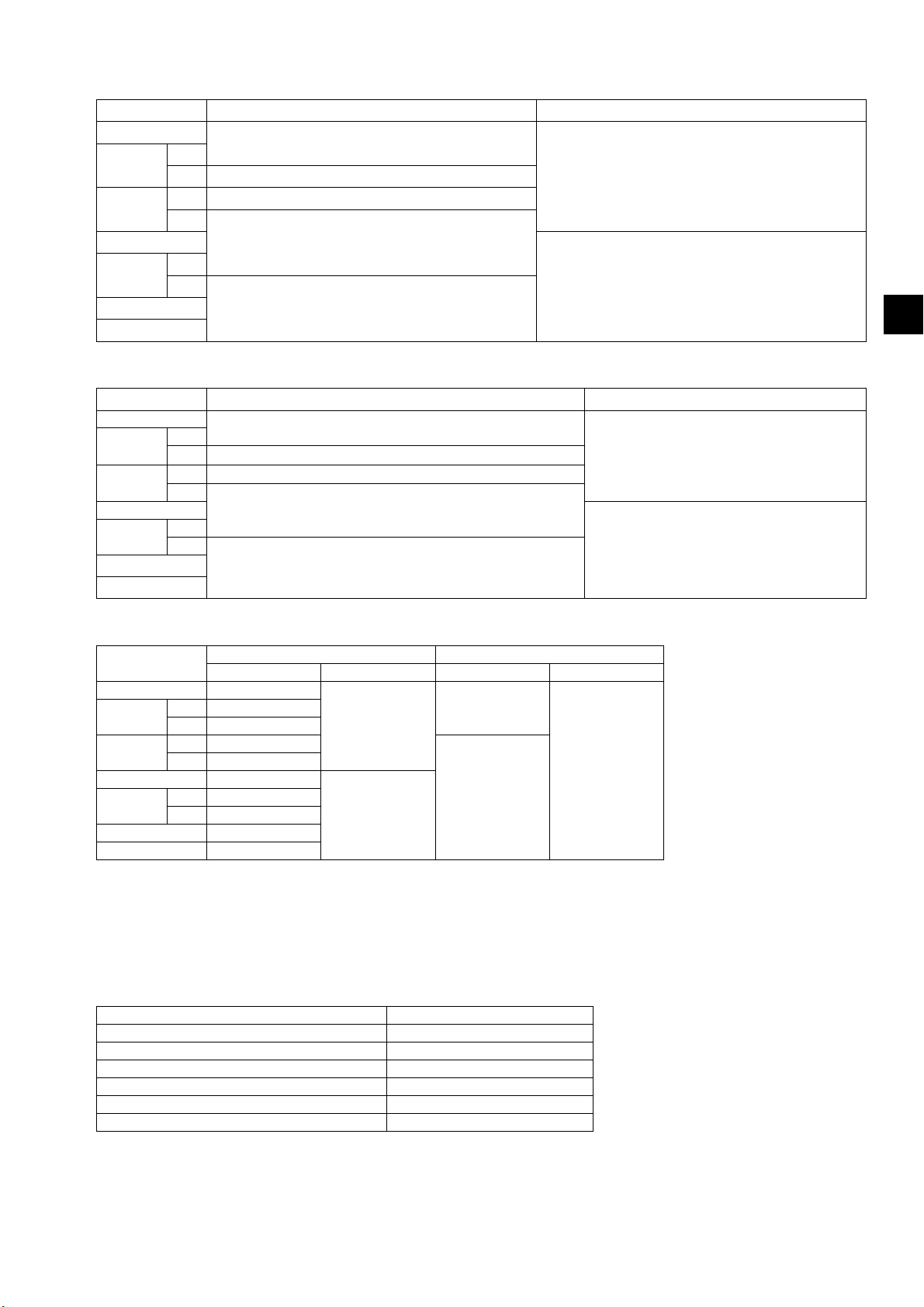

9-6. Air-tightness test

Do not use oxygen, flammable gas, or a refrigerant containing chlorine for air-tightness

testing.

- Doing so may result in an explosion. Chlorine will deteriorate the refrigerant oil.

After refrigerant pipe installation is completed, check the system for leaks by conducting an air-tightness test. If there

is a leak, the composition of the refrigerant will change and the performance will drop.

<Air-tightness test procedures>

① Make sure the service valves are closed.

② Add pressure to the refrigerant pipes through the service ports of the liquid and gas pipes.

* Pressurize to the design pressure (4.15 MPa) using nitrogen gas.

③ If the pressure holds for one day and does not decrease, the pipes have passed the test and there are no leaks.

If the pressure decreases, there is a leak. Look for the source of the leak by spraying a bubbling agent (e.g.,

Gupoflex) on the flared or brazed sections.

④ Wipe off the bubbling agent.

Ⓕ

Ⓑ

Ⓑ

Ⓒ

LO

Ⓐ

ⒹⒺ

HI

Ⓘ

Ⓙ

Ⓐ Nitrogen gas

Ⓑ To indoor unit

Ⓖ

Ⓒ Gauge manifold

Ⓓ Low pressure knob

Ⓗ

Ⓔ High pressure knob

Ⓕ Service valve

Ⓖ Liquid piping

Ⓗ Gas piping

Ⓘ Outdoor unit

Ⓙ Service port

KD79S703H01

GB-26

Page 29

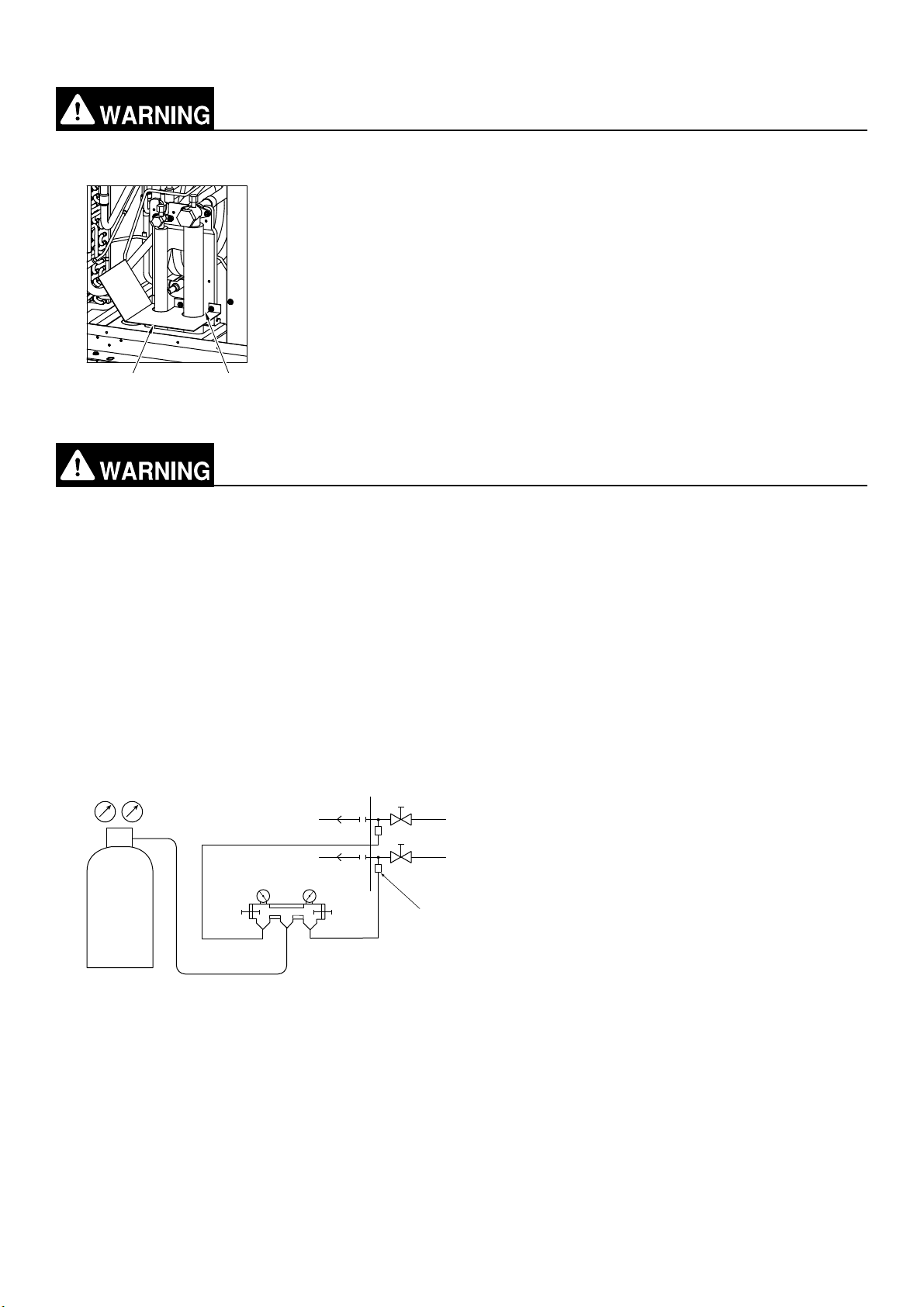

9-7. Thermal insulation for pipes

Insulate pipes to prevent condensation.

- Condensation may collect and drip from the unit onto the ceiling or floor.

Insulate the liquid and gas pipes separately with polyethylene foam insulation materials. Inadequate insulation may

cause condensation to drip. Pipes in the ceiling are especially vulnerable to condensation and require adequate

insulation.

9-7-1. Insulation material

・Check that the insulation materials meet the standards in the table below.

Pipe size [mm (in)]

ø6.35 (ø1/4)–ø25.4 (ø1) ø28.58 (ø1-1/8)–ø41.28 (ø1–5/8)

Thickness [mm (in)] Min. 10 (7/16) Min. 15 (5/8)

Heat resistance Min. 120°C (248°F)

* The insulation thickness may need to be increased in high-temperature/humidity conditions.

* Even when specifications are defined by your client, the standards in the table should be met.

Ⓑ

Ⓐ

Ⓓ

Insulation

material A

Outer

covering B

* If a polyethylene cover is used as an outer covering, asphalt roofing is not necessary.

Ⓒ

Ⓔ

Glass fiber + Steel wire

Adhesive + Heat-resistant polyethylene foam + Adhesive tape

Indoor Vinyl tape

Under the floor and exposed Waterproof hemp cloth + Bronze asphalt

Outdoor Waterproof hemp cloth + Zinc plate + Oily paint

Ⓐ Steel wire

Ⓑ Pipe

Ⓒ Oily mastic asphalt or asphalt

Ⓓ Insulation material A

Ⓔ Outer covering B

・Do not insulate the electric wires.

Ⓐ

Ⓑ

Ⓒ

Ⓔ

Ⓓ

Ⓔ

Ⓑ

Ⓔ

Ⓒ

Ⓓ

Ⓐ Liquid pipe

Ⓑ Gas pipe

Ⓐ

Ⓒ Electric wire

Ⓓ Finishing tape

Ⓔ Insulation material

GB

・Make sure that the pipe connections all the way from the indoor unit are properly insulated.

KD79S703H01

GB-27

Page 30

9-7-2. Insulation for the section of the pipe that goes through a wall

(1) Inner wall (concealed) (2) Outer wall (3) Outer wall (exposed)

ⒶⒷ

Ⓓ

Ⓒ

Ⓐ

Ⓑ

(4) Floor (waterproof) (5) Rooftop pipe shaft (6) Protecting the penetrating parts in a fire limit zone

or through a parting wall

Ⓓ

Ⓕ

Ⓓ

Ⓑ

Ⓒ

Ⓕ

Ⓗ

Ⓔ

Ⓑ

Ⓗ

Ⓘ

[mm (in)]

Ⓖ

Ⓑ

Ⓐ

1000

(39-3/8)

1000

(39-3/8)

Ⓐ Sleeve

Ⓑ Insulation material

Ⓒ Lagging

Ⓓ Caulking material

Ⓔ Band

Ⓕ Waterproof layer

Ⓖ Sleeve with a flange

Ⓗ Caulk with a nonflammable material such as mortar.

Ⓘ Nonflammable insulation material

・When caulking the gaps with mortar, cover the section of the pipe that goes through the wall with a metal sheet to

prevent the insulation material from sagging. For this section, use nonflammable insulation and covering materials.

(Vinyl tape should not be used.)

KD79S703H01

GB-28

Page 31

9-8. Evacuation of the system

Do not purge the air using refrigerant. Use a vacuum pump to evacuate the system.

- Residual gas in the refrigerant lines will cause bursting of the pipes or an explosion.

Use a vacuum pump with a check valve.

- If the vacuum pump oil flows back into the refrigerant lines, the refrigerant oil may deteriorate

and the compressor may malfunction.

<Evacuation procedures>

① Evacuate the system from both service ports, using a vacuum pump with the service valves closed.

② After the vacuum reaches 650 Pa, continue evacuation for at least one hour.

③ Stop the vacuum pump and leave it for an hour.

④ Verify that the vacuum has not increased by more than 130 Pa.

⑤ If the vacuum has increased by more than 130 Pa, water infiltration is suspected. Pressurize the system with dry

nitrogen gas up to 0.05 MPa. Repeat ① though ⑤ until the vacuum is increased by 130 Pa or below. If the

results persist, then perform the "Triple Evacuation" below.

<Triple Evacuation>

① Evacuate the system to 533 Pa from both service ports, using a vacuum pump.

② Pressurize the system with dry nitrogen gas up to 0 Pa from the discharge service port.

③ Evacuate the system to 200 Pa from the suction service port, using a vacuum pump.

④ Pressurize the system with dry nitrogen gas up to 0 Pa from the discharge service port.

⑤ Evacuate the system from both service ports, using a vacuum pump.

⑥ After the vacuum reaches 66.7 Pa, stop the vacuum pump and leave it for an hour. A vacuum of 66.7 Pa must

be maintained for at least one hour.

⑦ Verify that the vacuum has not increased for at least 30 minutes.

Ⓓ

Ⓝ

Ⓝ

Ⓐ

LO

ⒷⒸ

HI

Ⓞ

Ⓖ

Ⓗ

Ⓚ

Ⓔ

Ⓕ

Ⓘ

Ⓜ

Ⓙ

Ⓛ

Ⓐ Gauge manifold

Ⓑ Low pressure knob

Ⓒ High pressure knob

Ⓓ Service valve

Ⓔ Liquid piping

Ⓕ Gas piping

Ⓖ Service port

Ⓗ Three-way joint

Ⓘ Valve (vacuum pump)

Ⓙ Valve (for charging refrigerant)

Ⓚ Refrigerant tank

Ⓛ Scale

Ⓜ Vacuum pump

Ⓝ To indoor unit

Ⓞ Outdoor unit

・Use a scale that can measure down to 0.1 kg (0.1 oz).

・Recommended vacuum gauge: ROBINAIR 14830A Thermistor Vacuum Gauge or Micron Gauge

・Do not use a gauge manifold to measure the vacuum pressure.

・Use a vacuum pump capable of attaining a vacuum of 65 Pa (abs) within five minutes of operation.

GB

KD79S703H01

GB-29

Page 32

9-9. Additional refrigerant charge

Charge refrigerant in a liquid state.

- Charging refrigerant in the gaseous state will change the composition of the refrigerant and lead

to a performance drop.

Do not use a charging cylinder when charging refrigerant.

- The use of a charging cylinder may change the composition of the refrigerant and lead to a

performance drop.

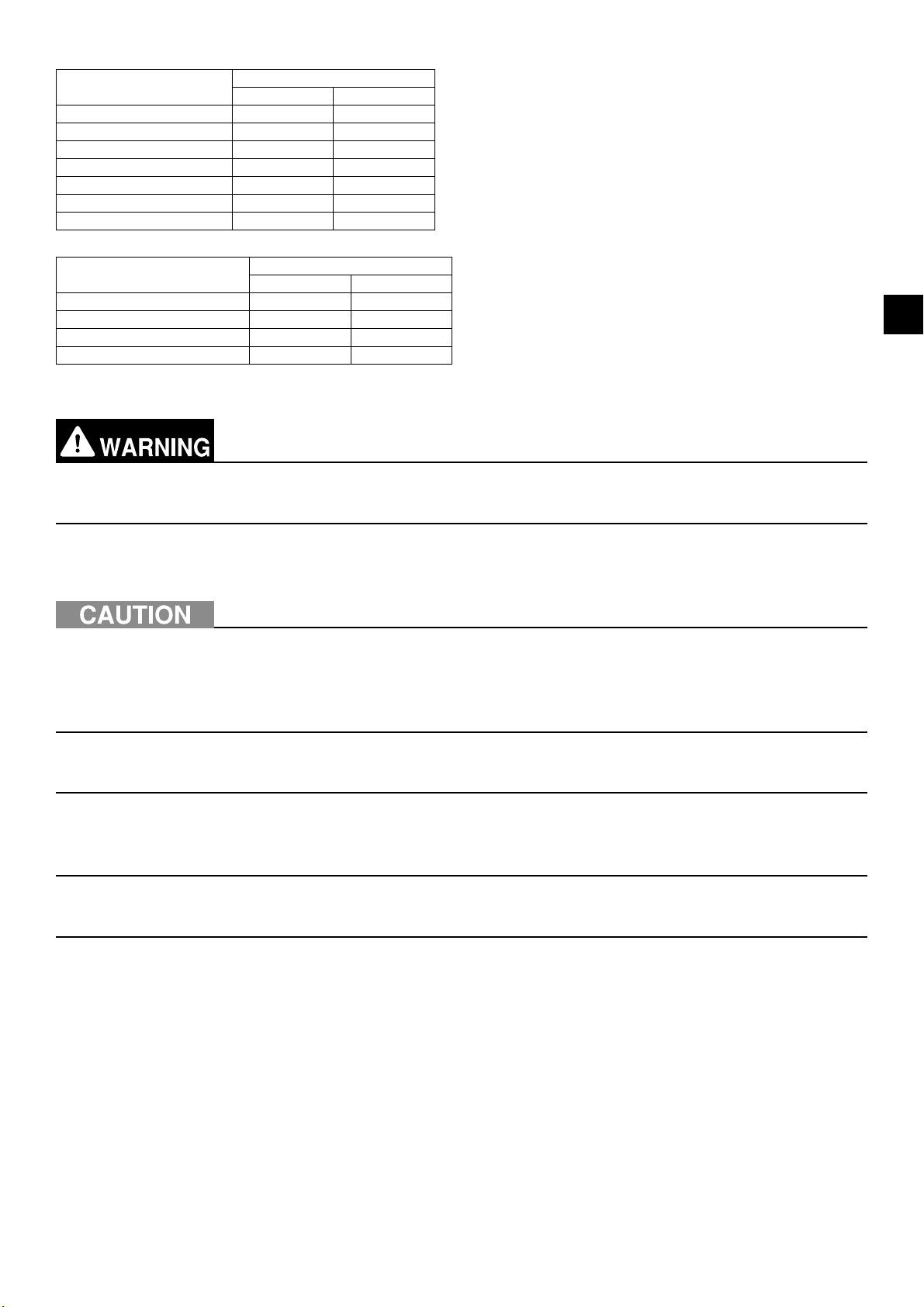

The amount of refrigerant that is shown in the table below is factory-charged in the outdoor units. The amount

necessary for extended piping is not included and needs to be added on site.

Unit model Factory-charged amount [kg (oz)] Unit model Factory-charged amount [kg (oz)]

P200 6.5 (230) P400 11.5 (406)

P250 8.0 (283) P450 11.8 (417)

P300 11.5 (406) P500 11.8 (417)

P350 11.5 (406)

The amount of refrigerant that is shown in the table below is the maximum amount to be added on site.

Unit model Maximum amount to be added [kg (oz)] Unit model Maximum amount to be added [kg (oz)]

P200YKB-A1 22.3 (786) P400YSKB-A1 45.0 (1589)

P250YKB-A1 29.7 (1048) P450YSKB-A1 45.9 (1621)

P300YKB-A1 32.7 (1152) P500YSKB-A1 47.0 (1659)

P350YKB-A1 33.6 (1184) P550YSKB-A1 51.3 (1811)

P400YKB-A1 37.2 (1311) P600YSKB-A1 53.9 (1900)

P450YKB-A1 45.0 (1589) P650YSKB-A1 56.5 (1992)

P500YKB-A1 45.9 (1621) P700YSKB-A1 68.9 (2430)

P750YSKB-A1 68.9 (2430)

P800YSKB-A1 71.4 (2519)

P850YSKB-A1 73.2 (2583)

P900YSKB-A1 75.7 (2671)

P950YSKB-A1 96.9 (3421)

P1000YSKB-A1 99.9 (3527)

P1050YSKB-A1 102.9 (3634)

P1100YSKB-A1 106.0 (3740)

P1150YSKB-A1 109.0 (3847)

P1200YSKB-A1 112.0 (3954)

P1250YSKB-A1 112.0 (3954)

P1300YSKB-A1 112.0 (3954)

P1350YSKB-A1 112.0 (3954)

Both refrigerant overcharge and undercharge will cause problems. Charge the system with the proper amount of

refrigerant.

Record the added refrigerant amount on the label attached to the control box panel for future servicing.

KD79S703H01

GB-30

Page 33

9-9-1. Calculation of the amount of additional refrigerant

・The amount of refrigerant to be added depends on the size and the total length of the liquid piping.

・Calculate the amount of refrigerant to be charged according to the formula below.

・Round up the calculation result to the nearest 0.1 kg (0.1 oz).

(1) Units "m" and "kg"

<Formula>

・When the piping length from the outdoor unit to the farthest indoor unit is 30.5 m (100 ft) or shorter

Amount of

additional

charge (kg)

ø19.05 total length

=

× 0.29 (kg/m)

ø15.88 total length

+

× 0.2 (kg/m)

ø12.7 total length

+

× 0.12 (kg/m)

ø9.52 total length

+

× 0.06 (kg/m)

+

ø6.35 total length

× 0.024 (kg/m)

+

Outdoor unit

model

P200 0 80 or below 2.0

P250 0 81 to 160 2.5

P300 0 161 to 330 3.0

P350 0 331 to 390 3.5

P400 0 391 to 480 4.5

P450 0 481 to 630 5.0

P500 0 631 to 710 6.0

Amount (kg)

Total capacity of connected

indoor units

+

711 to 800 8.0

801 to 890 9.0

891 to 1070 10.0

1071 to 1250 12.0

1251 or above 14.0

Amount (kg)

・When the piping length from the outdoor unit to the farthest indoor unit is longer than 30.5 m (100 ft)

Amount of

additional

charge (kg)

ø19.05 total length

=

× 0.26 (kg/m)

Outdoor unit

model

P200 0 80 or below 2.0

P250 0 81 to 160 2.5

+

P300 0 161 to 330 3.0

P350 0 331 to 390 3.5

P400 0 391 to 480 4.5

P450 0 481 to 630 5.0

P500 0 631 to 710 6.0

ø15.88 total length

+

× 0.18 (kg/m)

Amount (kg)

ø12.7 total length

+

× 0.11 (kg/m)

Total capacity of connected

indoor units

+

711 to 800 8.0

801 to 890 9.0

891 to 1070 10.0

1071 to 1250 12.0

1251 or above 14.0

ø9.52 total length

+

× 0.054 (kg/m)

Amount (kg)

ø6.35 total length

+

× 0.021 (kg/m)

GB

<Example>

Outdoor unit model: P300

Total capacity of connected indoor units: 361

* Refer to the pipe connection examples in section 9-4 for the pipes marked with the letters below.

A: ø12.7; 40 m

B: ø9.52; 10 m

C: ø9.52; 15 m

D: ø9.52; 10 m

a: ø9.52; 10 m

b: ø9.52; 5 m

c: ø6.35; 10 m

d: ø6.35; 10 m

e: ø9.52; 10 m

KD79S703H01

GB-31

Page 34

The total length of each liquid piping is as follows:

ø12.7 total length: 40 (A)

ø9.52 total length: 10 (B) + 15 (C) + 10 (D) + 10 (a) + 5 (b) + 10 (e) = 60

ø6.35 total length: 10 (c) + 10 (d) = 20

Therefore, when the piping length from the outdoor unit to the farthest indoor unit is longer than 30.5 m (100 ft),

Amount of additional charge=(40 × 0.11) + (60 × 0.054) + (20 × 0.021) + 0 + 3.5

= 11.6 kg (Fractions are rounded up.)

(2) Units "ft" and "oz"

<Formula>

・When the piping length from the outdoor unit to the farthest indoor unit is 30.5 m (100 ft) or shorter

Amount of

additional

charge (oz)

ø3/4 total length

=

× 3.1 (oz/ft)

ø5/8 total length

+

× 2.15 (oz/ft)

ø1/2 total length

+

× 1.29 (oz/ft)

ø3/8 total length

+

× 0.65 (oz/ft)

ø1/4 total length

+

× 0.26 (oz/ft)

+

Outdoor unit

model

P200 0 80 or below 71

P250 0 81 to 160 89

P300 0 161 to 330 106

P350 0 331 to 390 124

P400 0 391 to 480 160