Page 1

Outdoor Unit: 14-TON PUHY-P168TSHMU-A

(Consists of One PUHY-P96THMU-A, One PUHY-P72THMU-A, and One CMY-Y100VBK2 Twinning Kit)

Job Name: Location:

Drawing Reference: Schedule No.

System No.: Date:

OUTDOOR VRFZ HEAT PUMP SYSTEM FEATURES

• 3-phase, 208/230V systems

• Modular variable refrigerant ow zoning (VRFZ) systems;

smaller capacity units can be piped together to form a single,

large-capacity two-pipe system

• Compact size for each outdoor module; can be transported

through standard-sized doorways for installation

• Required Twinning Kit allows for easy eld piping connection

• Selectable fan static, 0.12 or 0.24"WG external static

pressure; factory set to 0"WG

• Maximum Total Refrigerant Piping Length: 3,280'; Maximum

Refrigerant Line Length: 541'; Maximum Control Wiring

Length: 1,650'

• Connects to CITY MULTI indoor units; controlled via

CITY MULTI Controls Network (CMCN)

• External finish: Pre-coated Galvanized-steel Sheets

• Operating Temperature Range

Cooling (Outdoor): 23° ~ 109°F (-5° ~ +43°C) DB

Heating (Outdoor): -4° ~ +60°F (-20° ~ +16°C) WB

Specications System Module 1 Module 2

Unit Type PUHY-P168TSHMU-A PUHY-P96THMU-A PUHY-P72THMU-A

Nominal Cooling Capacity Btu/h 168,000 96,000 72,000

Nominal Heating Capacity Btu/h 188,000 108,000 80,000

External Dimensions (H x W x D) In. / mm Refer to Module Data

Net Weight Lbs. / kg 882 / 400 441 / 200 441 / 200

Electrical Power Requirements Voltage, Phase, Hertz Refer to Module Data** 208/230V, 3-phase, 60Hz

Cooling Power Input kW 14.11

Heating Power Input kW 14.73

Cooling Current (208/230V) A 43.5 / 39.3

Heating Current (208/230V) A 45.4 / 41.0

Minimum Circuit Ampacity

(MCA)**

Maximum Overcurrent

Protection (MOCP)**

Piping Diameter

From Twinning Kit to Indoor Units

(Brazed) (In. / mm)

From Modules to Twinning Kit

(Brazed) (In. / mm)

Indoor Unit

Sound Pressure Levels dB(A) 61.0 58.0 58.0

Fan

Type x Quantity Propeller Fan x 1 Propeller Fan x 1

Airow Rate CFM 7,050 7,050

Direct-drive Inverter Motor Output kW 0.92 0.92

Compressor Operating Range 8% to 100% Refer to System Data

Compressor Type x Quantity

Compressor Motor Output kW 6.8 5.1

Compressor Crankcase Heater kW 0.051 0.051

Refrigerant

Lubricant MEL32

High-pressure Protection Device

Compressor / Fan Protection Device Overheat Protection / Thermal Switch Overheat Protection / Thermal Switch

Inverter Protection Device Overheat / Overcurrent Protection Overheat / Overcurrent Protection

Blue Fin Anti-corrosion Protection: Cellulose- and polyurethane-resin coating treatment applied to condenser coil that protects it from air contaminants;

≥1μm thick; Salt Spray Test Method - no unusual rust development to 480 hours.

** Each individual module requires a separate electrical connection. Reference electrical data for each individual module.

A Refer to Module Data** 35 / 32** 23 / 21**

A Refer to Module Data** 40 / 40** 30 / 30**

Liquid (High Pressure) 5/8 / 15.88

Gas (Low Pressure) 1-1/8 / 28.58

Liquid (High Pressure)

Gas (Low Pressure) 7/8 / 22.2 3/4 / 19.05

Total Capacity 50 to 130% of ODUs

Model / Quantity P06 ~ P96 / 1 to 36

Refer to Module Data

Refer to Module Data

Refer to Module Data

Refer to Module Data

Refer to Module Data

PUHY-P96THMU-A

PUHY-P72THMU-A

OPTIONAL PARTS

□ Twinning Kit*.…………………………………...…….CMY-Y100VBK2

□ T-Branch Joint (≤ 72,000 Btu/h)………………..........CMY-Y102S-G2

□ T-Branch Joint (≤ 144,000 Btu/h)……………….…....CMY-Y102L-G2

□ T-Branch Joint (≤ 234,000 Btu/h)………………..........CMY-Y202-G2

□ Header (4-Branch; ≤ 72,000 Btu/h)........………………CMY-Y104-G

□ Header (8-Branch; ≤ 144,000 Btu/h)......………………CMY-Y108-G

□ Header (10-Branch; ≤ 234,000 Btu/h)....……………….CMY-Y1010-G

* Twinning Kit is necessary to combine the refrigerant ows of the

modules and is included in the outdoor unit set.

65 x 36-1/4 x 29-15/16 /

1,650 x 920 x 760

Refer to System Data

Refer to System Data

Refer to System Data

3/8 / 9.52 3/8 / 9.52

Refer to System Data

Inverter-driven Scroll Hermetic x 1 Inverter-driven Scroll Hermetic x 1

R410A

601 psi / 4.15 MPa 601 psi / 4.15 MPa

65 x 36-1/4 x 29-15/16 /

1,650 x 920 x 760

Page 2

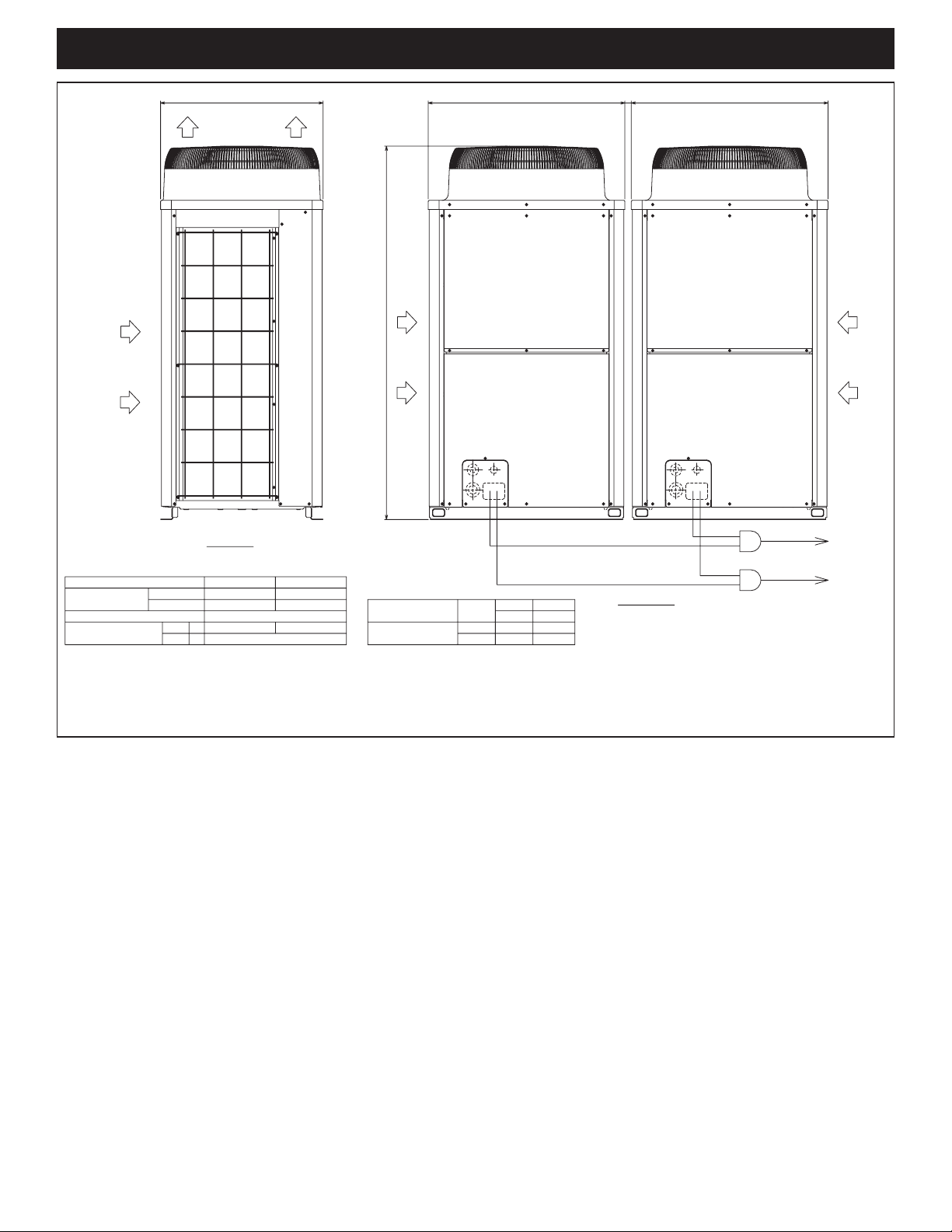

Outdoor Unit: PUHY-P168TSHMU-A – DIMENSIONS

920 (36-1/4)760 (29-15/16)

30 (1-3/16)

920 (36-1/4)

Intake

air

Outdoor unit 2Outdoor unit 1Discharge air

Intake

air

Left view

Front view

Note 1. Connect the pipes as shown in the figure above. Refer to the table above for the pipe size.

2. Twinning pipes should not be tilted more than 15 degrees from the horizontal plane.

Be sure to see the Installation Manual for details of Twinning pipe installation.

3. The pipe section before the Twinning pipe (sections "a" and "b" in the figure) must have at least 500mm (19-11 /16) of straight section

(*including the straight pipe that is supplied with the Twinning pipe).

4. Only use the Twinning pipes manufactured by Mitsubishi (optional parts).

Twinning pipe ~ Outdoor unit

Unit model

P96

P72

Liquid

Gas

c or ed or f

bGas

Liquid

Outdoor unit 2

ø9.52 (3/8)

ø9.52 (3/8)ø19.05 (3/4)

ø22.2 (7/8)

1650 (64-31/32)

Intake

air

To indoor unit

c

d

b

a

f

e

Gas Twinning pipe <optional parts>

Liquid Twinning pipe <optional parts>

To indoor unit

Twinning pipe connection size

PUHY-P144TSHMU-A(-BS)

PUHY-P72THMU-A(-BS)

PUHY-P72THMU-A(-BS)

Package unit name

Component unit name

Outdoor Twinning Kit (optional parts)

Indoor unit ~ Twinning pipe

Outdoor unit 1

ø28.58 (1-1/8)

ø15.88 (5/8)

PUHY- P72THMU-A(-BS)

PUHY- P96THMU-A(-BS)

PUHY- P168TSHMU-A(-BS)

CMY- Y100VBK2

a

Unit : mm(in)

ø12.7 (1/2)

Page 3

Twinning Kit: CMY-Y100VBK2

Inches (mm)

ID ø 3/4

(19.05)

ID ø 1/2

(12.7)

OD ø 5/8

(15.88)

OD ø 7/8

(22.2)

OD ø 7/8

(22.2)

OD ø 1/2

(12.7)

ID ø 1-1/8

(28.58)

ID ø 3/8

(9.52)

2-1/2 (62)

2-1/2 (62)

1-15/16 (49)

OD ø 1/2

(12.7)

ID ø 1/2

(12.7)

OD ø 1/2

(12.7)

ID ø 1/2 (12.7)

OD ø 5/8

(15.88)

ID ø 5/8

(15.88)

7-1/4 (183)

9-1/2 (241)

3-5/16 (83)

3-7/8 (98)

ID ø 7/8 (22.2)

ID ø 7/8 (22.2)

ID ø 1-1/8 (28.58)

OD ø 1-1/8 (28.58)

OD ø 1 (25.4)

OD ø 1 (25.4)

6-5/16 (160)

23-3/16 (588)

13-1/2 (342)

19-15/16 (505)

1-15/16 (49)

<Reducer Pipe (Accessory)>

For instructions on piping the units together using the twinning kit,

see the Installation Manual.

Page 4

Certificate Number FM33568

Certificate Number EC97J1227

Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired ISO

9001 certification under Series 9000 of the International Standard Organization (ISO)

based on a review of quality warranties for the production of refrigeration and air

conditioning equipment.

ISO Authorization System

The ISO 9000 series is a plant authorization system relating to quality warranties as

stipulated by the ISO. ISO 9001 certifies quality warranties based on the "design,

development, production, installation and auxiliary services" for products built at

an authorized plant.

Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired environmental

management system standard ISO 14001 certification.

The ISO 14000 series is a set of standards applying to environmental protection set by the

International Standard Organization (ISO).

Modules 1 and 2: PUHY-P96THMU-A and PUHY-P72THMU-A – DIMENSIONS

Refrigerant service

valve <gas>

Refrigerant service

valve <liquid>

Accessories

Connecting pipe

Gas · Elbow (IDø25.4 [1] X ODø25.4 [1])·············P72, P96 1 pc.

· Pipe (IDø25.4 [1] X ODø19.05 [3/4])········P72 1 pc.

· Pipe (IDø25.4 [1] X ODø22.2 [7/8])··········P96 1 pc.

Liquid ·

Pipe (IDø9.52 [3/8] X ODø9.52 [3/8])·······P72, P96 1 pc.

Front access hole

Bottom access hole

Front access hole

Front access hole

Specifications

Usage

NO.

Front access hole

102 X 72 Knockout hole

150 X 92 Knockout hole

Bottom access hole

ø62.7 or ø34.5 Knockout hole

For pipes

For wires

ø43.7 or ø22.2 Knockout hole

ø52 Knockout hole

For transmission cables

ø34 Knockout hole

(29-15/16)

(2-3/16) (1) (1)(2-3/16)

(2-5/32)

(5-7/32) (3-15/32)

(9-29/32)

(8-1/16)

(4-1/32)

(3-7/8)

(3-9/16)

(2-27/32)

(55-17/32)

(64-31/32)

(9-15/32)

(36-1/4)

(29-15/16)

760

5555

A

B

72

Control box

132

6

4

3

1

25

Intake

air

90

204

102251

240

Intake

air

Service

panel

1410

1650

760

920

88

25

54

Intake

air

Discharge air

98

(7/8)

(1-11/32)

(2-1/16)

(1-3/4)

(1-3/8)

(2-15/32)

(3-5/8)(5-29/32)

(2-27/32)(4-1/32)

Front view

Left side view

To p view

(Mounting pitch)

(Mounting pitch)

Refrigerant service

valve <gas>

Refrigerant service

valve <liquid>

(28-17/32)

(5-23/32)

(3-5/8)

(3-13/32)

(3-9/32)

(5-29/32)

(7-11/32)

(8-23/32)

(9-29/32)

(5-3/16)

(5-23/32)

(3-5/32)

(29-15/16)

(3-5/32)

(23/32)

(28-13/32 ~ 28-5/8)

(29-15/16)

(23/32)

2 X 2-14(9/16) X 20(13/16) Oval hole

221 150

145

83

(760)

80

760

80

18

724(721

~ 727)

18

92

86

131

251

186

5

2

145

Bottom view

Note 1. Refer to the Engineering or Installation manual for information regarding

necessary clearance around the unit, and installation site requirements.

2. When brazing the pipes, protect the refrigerant service valve by wrapping

it with a wet cloth to keep its temperature under 120°C (248°F).

1

2

4

3

5

6

(ø12.7 Brazed)*2

ø9.52 Brazed

ø9.52 Brazed

PUHY-P96THMU

(-BS)

PUHY-P72THMU

(-BS)

ø22.2 Brazed

B

A

ø19.05 Brazed

Gas

Liquid

Gas

Liquid

Connection specifications for

the refrigerant service valve

Position dimensions

for the refrigerant

service valve

Model

Connecting pipe specifications

*1 Use the connecting pipes (for bottom and front pipes) that are supplied.

*2 Total length 90m (295')

*1

(1/2)

(3/8)

(3/8)

142

(5-19/32)

172

(6-25/32)

(3/4)

(7/8)

170

(6-23/32)

>

=

Unit : mm(in)

C SD - PUHY-P168TSHMU-A - 1 - 200809 © MITSUBISHI ELECTRIC / HVAC 2008

HVAC Advanced Products Division

Mitsubishi Electric & Electronics USA, Inc.

3400 Lawrenceville Suwanee Rd.

Suwanee, GA 30024

Tele: 678-376-2900 • Fax: 800-889-9904

Toll Free: 800-433-4822 (#4)

www.mehvac.com

Specications are subject to change without notice.

Loading...

Loading...