Page 1

Outdoor Unit: 20-TON PUHY-P240YSKMU-A (-BS)

(Consists of Two PUHY-P120YKMU-A (-BS) and One CMY-Y100CBK3 Twinning Kit)

Job Name:

Schedule Reference: Date:

OUTDOOR VRF HEAT PUMP SYSTEM FEATURES

• INVERTER-driven compressor

• Air-source, heat pump system

• Long line lengths - for details see Engineering Manual

• Connects to CITY MULTI indoor units

• Controlled via CITY MULTI Controls Network

UNIT OPTION

□ Standard Model….…...…….......…………….PUHY-P240YSKMU-A

□ Sea Coast (BS) Model…….....………….PUHY-P240YSKMU-A-BS

OPTIONAL PARTS

□ Twinning Kit (required)..............................................… CMY-Y100CBK3

□ Joint Kit.............................…for details see Pipe Accesories Submittal

□ Header Kit.........................…for details see Pipe Accesories Submittal

□ Low Ambient Kit ..... .. ..... ...…..for details see Low Ambient Kit Submittal

□ Snow/Hail Guards K it... ...…for details see Snow/Hail Guards Kit Submittal

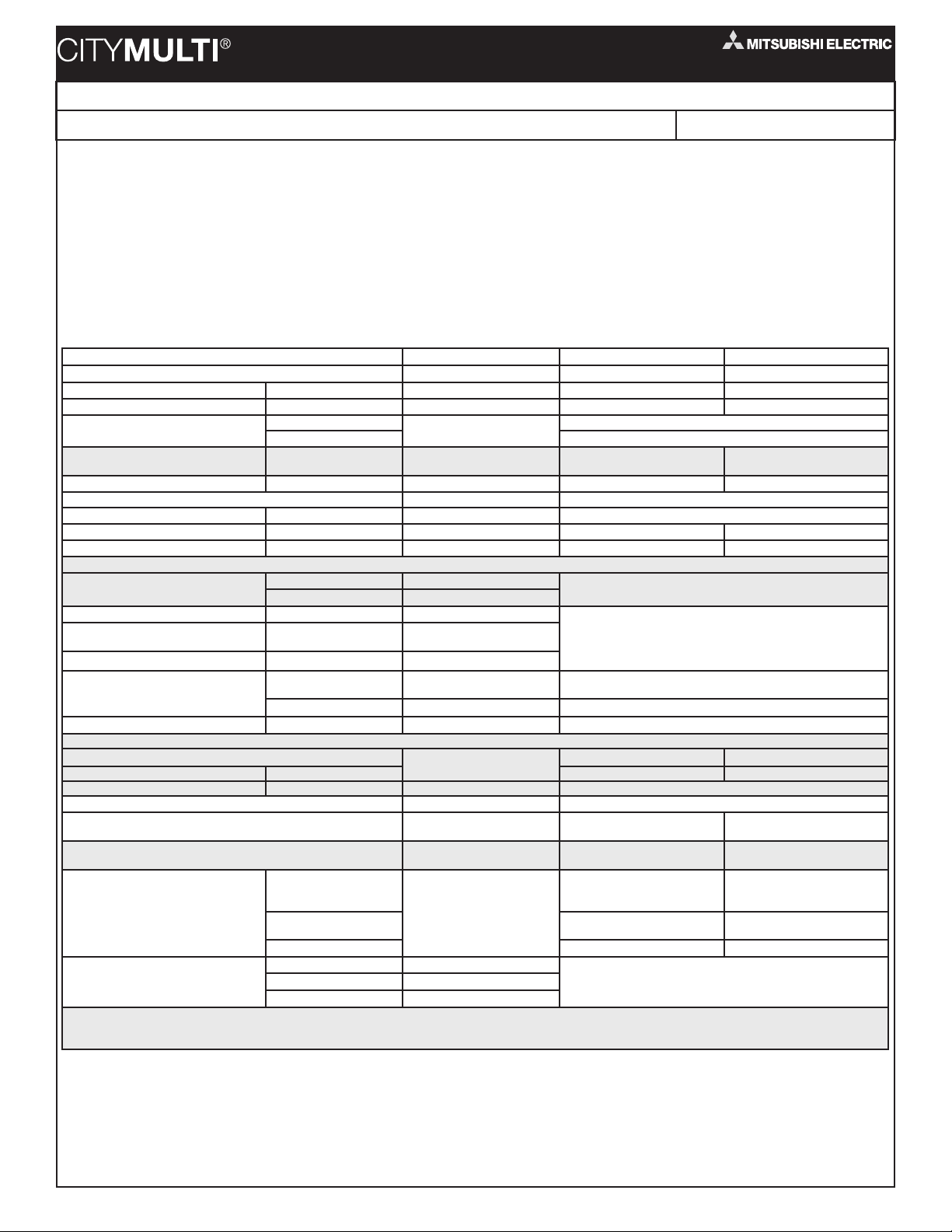

Specications System Module 1 Module 2

Unit Type PUHY-P240YSKMU-A (-BS) PUHY-P120YKMU-A (-BS) PUHY-P120YKMU-A (-BS)

Nominal Cooling Capacity (460V) Btu/h 240,000 120,000 120,000

Nominal Heating Capacity (460V) Btu/h 270,000 135,000 135,000

Operating Temperature Range *1

External Dimensions (H x W x D)

Net Weight Lbs. / kg 1,452 (658) 726 (329) 726 (329)

External Finish

Electrical Power Requirements Voltage, Phase, Hertz Refer to Module Data** 460V, 3-Phase, 60Hz

Minimum Circuit Ampacity (MCA) A Refer to Module Data** 20 20

Maximum Fuse Size A Refer to Module Data** 25 25

Piping Diameter

From Twinning Kit to First Joint or

Header (Brazed) (In. / mm)

Max. Total Refrigerant Line Length Ft. 3,280

Max. Refrigerant Line Length

(Between ODU & IDU)

Max. Control Wiring Length Ft. 1,650

Indoor Unit

Sound Pressure Level dB(A) 63 Refer to System Data

Fan

Type x Quantity

Airow Rate CFM 11,300 11,300

External Static Pressure In. WG (Pa) Refer to Module Data Selectable; 0, 0.12 or 0.24”WG; factory set to 0”W.G.

Compressor Operating Range 8% to 100% Refer to System Data

Compressor Type x Quantity Refer to Module Data

Refrigerant Refer to Module Data

Protection Devices

AHRI Ratings

(Ducted/Non-Ducted)

Blue Fin Anti-corrosion Protection: Cellulose- and polyurethane-resin coating treatment applied to condenser coil that protects it from air contaminants

Standard: ≥1μm thick; Salt Spray Test Method - no unusual rust development to 480 hours.

Sea Coast (BS): ≥1μm thick; Salt Spray Test Method - no unusual rust development to 960 hours.

Cooling (Outdoor) *2

Heating (Outdoor) -4~60° F (-20~15.5° C) WB

In.

mm

Liquid (High Pressure) 5/8 (15.88) Brazed

Gas (Low Pressure) 1-1/8 (28.58) Brazed

Ft. 541

Total Capacity

Model / Quantity P06~P96/2~50 Refer to System Data

High Pressure

Inverter Circuit

(Comp. / Fan)

Fan Motor Thermal switch Thermal switch

EER 12.1 / 12.0

COP 3.55 / 3.53

Refer to Module Data

Refer to Module Data

Refer to Module Data Pre-coated galvanized steel sheet

50~130% of outdoor unit

capacity

Refer to Module Data

Refer to Module Data

64-31/32 x 68-29/32 x 29-5/32

1,650 x 1,750 x 740

Propeller fan x 2 Propeller fan x 2

Inverter-driven Scroll

Hermetic x 1

R410A x 26 lbs + 1 oz

High pressure sensor, High

pressure switch at 4.15 MPa

Over-current protection Over-current protection

23~115° F (-5~46° C) DB

Refer to System Data

Refer to System Data

Refer to System Data

(11.8 kg)

(601 psi)

Refer to System DataIEER 18.6 / 18.1

64-31/32 x 68-29/32 x 29-5/32

1,650 x 1,750 x 740

Inverter-driven Scroll

Hermetic x 1

R410A x 26 lbs + 1 oz

(11.8 kg)

High pressure sensor, High

pressure switch at 4.15 MPa

(601 psi)

NOTES:

*1. Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details about your region.

*2. For details on extended cooling operation range down to -10° F DB , see Low Ambient Kit Submittal.

Specications are subject to change without notice.

© 2014 Mitsubishi Electric US, Inc.

** Each individual module requires a separate electrical connection.

Refer to electrical data for each individual module.

Page 2

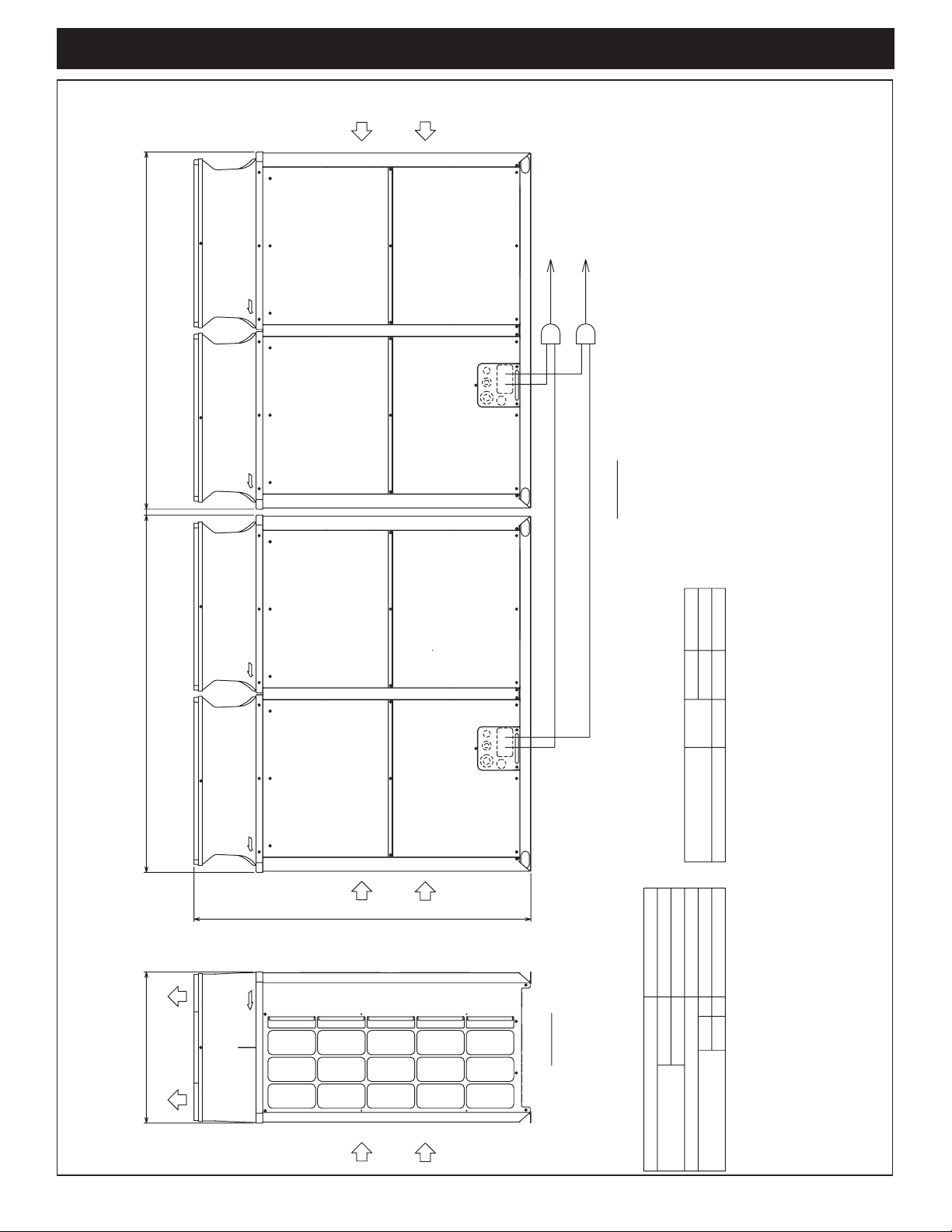

Outdoor Unit: PUHY-P240YSKMU-A (-BS) – DIMENSIONS

PUHY-P240YSKMU-A(-BS)

Outdoor unit 2

Intake

air

To indoor unit

a

b

Liquid Twinning pipe<optional parts>

e

f

c

To indoor unit

Gas Twinning pipe<optional parts>

Front view

d

Unit : mm(in.)

Outdoor unit 1

1750(68-29/32) 30(1-3/16) 1750(68-29/32)

Discharge air

740(29-5/32)

Intake

air

1650(64-31/32)

Gas

d or fc or e

ø28.58(1-1/8)ø12.7(1/2)

Liquid

P120

Unit model

Twinning pipe~Outdoor unit

CMY-Y100CBK3

ø28.58(1-1/8)

ø15.88(5/8)

PUHY-P120YKMU-A(-BS)

PUHY-P120YKMU-A(-BS)

PUHY-P240YSKMU-A(-BS)

b

a

Gas

Liquid

Outdoor unit 2

Left view

Outdoor unit 1

Specications are subject to change without notice.

© 2014 Mitsubishi Electric US, Inc.

Intake

air

Package unit name

Outdoor Twinning Kit(optional parts)

Indoor unit~Twinning pipe

Component unit name

Twinning pipe connection size

Be sure to see the Installation Manual for details of Twinning pipe installation.

Note 1.Connect the pipes as shown in the figure above. Refer to the table above for the pipe size.

2.Twinning pipes should not be tilted more than 15 degrees from the horizontal plane.

3.The pipe section before the Twinning pipe (sections "a" and "b" in the figure) must have at least 500mm(19-11/16) of straight section

(*including the straight pipe that is supplied with the Twinning pipe).

4.Only use the Twinning pipe by Mitsubishi (optional parts).

Page 3

Modules 1 & 2: PUHY-P120YKMU-A (-BS) – DIMENSIONS

PUHY-P120,144YKMU-A(-BS)

Unit : mm(in.)

(1-1/8)

ø28.58

(1/2)

ø12.7

Specifications

140 × 77 Knockout hole

150 × 94 Knockout hole

(5-17/32) (3-1/16)

(1-3/8)

ø62.7 or ø34.5 Knockout hole

(2-15/32)

(5-29/32) (3-23/32)

(7/8)

ø34 Knockout hole

ø65 Knockout hole

ø52 Knockout hole

ø43.7 or ø22.2 Knockout hole

(1-3/4)

(2-9/16)

(2-1/16)

(1-11/32)

Diameter

Note1.Please refer to the engineering manual for information

regarding necessary spacing around the unit and

foundation work. Outdoor unit must be mounted at least

12" off the ground or 12" above the highest average snow

depth, whichever is greater.

2.At brazing of pipes, wrap the refrigerant service valve

with wet cloth and keep the temperature of

refrigerant service valve under 120°C(248°F).

Connecting pipe specifications

740(29-5/32)

49(1-15/16)

60070

(23-5/8)

Gas GasLiquidLiquid

Refrigerant pipe Service valve

ø9.52 Brazed

Model

19.5

(25/32)

831(32-23/32)

Top view

1750(68-29/32)

831(32-23/32)

19.5

(2-25/32)

(25/32)

*2

(1-1/8)

ø28.58 Brazed

*1 *3 *4

*2

(1/2)

(3/8)

(ø12.7 Brazed)

PUHY-P120YKMU

303

Control box

>

=

*1

(1/2)

ø12.7 Brazed

PUHY-P144YKMU

*1 Expand the on-site piping and connect to the refrigerant service valve piping.

*2 Use the pipe joint(field supply) and connect to the refrigerant service valve piping.

*3 Indicates dimensions and connection specifications in the case the unit is

used in combination with other outdoor units.

*4 Furthest piping length (OU from IU) 40m(131ft)

(11-15/16)

Intake

air

1650(64-31/32)

1347(53-1/16)

Service

panel

Fan box

7789

Bottom through hole

Front through hole

Front through hole

Front through hole

Bottom through hole

Bottom through hole

Usage

For pipes

2

1

NO.

2X2-80(3-5/32)X35(1-13/32) Oval hole

For wires

6

5

3

4

(1-3/16)

2X3-14(9/16)X20(13/16) Oval hole

<Sling hole>

(3-5/16)

(3-17/32) (3-1/16)

8494

(5-23/32)

145

1

7

4

140(5-17/32)

58(2-5/16)

Front view

83(3-9/32)

150(5-29/32)

3

75(2-31/32)

541(21-5/16)

562(22-5/32)

590(23-1/4)

561(22-3/32)

516(20-11/32)

(4-25/32)

(5-31/32)

(7-23/32)

Intake

air

Service panel

217

223

Transformer box

172

(8-9/16)

(8-25/32)

(6-25/32)

Front through hole

For transmission cables

7

(740)(29-5/32)

(Mounting pitch)

(26-13/16)

681

(3-23/32)

Refrigerant service

valve <gas>

2

6

5

Refrigerant service

valve <liquid>

121

151

196

(1-3/16)

29.529.5

80

(3-5/32)

(Mounting pitch)

795(31-5/16)

Bottom view

795(31-5/16)

(Mounting pitch)

80

(3-5/32)

<Snow hood attachment hole>

2X7-ø4.6(3/16) Hole

(Make hole at the plastic fan guard

for snow hood attachment)

Discharge air

Specications are subject to change without notice.

© 2014 Mitsubishi Electric US, Inc.

Intake

air

Refrigerant service valve

<liquid>

Refrigerant service valve

<gas>

20

20

54(2-5/32)

57

(2-1/4)

586(23-3/32)

(13/16) (13/16)

57

(2-1/4)

Left side view

Page 4

Twinning Kit: CMY-Y100CBK3

4. Only use the Twinning pipe by Mitsubishi (optional parts) .

Note 1. Reference the attitude angle of the branch pipe below the fig.

CMY-Y100CBK3

For Gas pipe: For Liquid pipe:

19-29/32"

7/8"

part)

Distributer

1-1/8"

Note 2

1-1/8"

13-15/32"

Pipe cover

(Dot-dashed

Local brazing

23-5/32"

ID: Inner Diameter OD: Outer Diameter

15

The angle of the branch pipe for hign pressure is within against the horizontal plane.

2. Use the attached pipe to braze the port-opening of the distributer.

3. Pipe diameter is indicated by inside diameter.

1"

5/8"

Local brazing

6-5/16"

7/8"

1"

5/8"

Note 2

3-9/32"

Distributer

15

7-7/32"

1/2"

9-1/2"

Pipe cover

part)

(Dot-dashed

Distributer

Ref.: CMY_Y100VBK2_EXD_EUDB_SI

in.

<Reducer(Accessory)>

1/2"

1-1/8"

7/8"

5/8"

1-15/16"

2-15/32"

(2 pcs.)

1/2"

3/4"

1/2"

1/2"

3-7/8"

7/8"

1/2"

1-15/16"

(2 pcs.)

2-15/32"

(2 pcs.)

3/8"

Notes:

FORM# PUHY-P240YSKMU-A (-BS) - 201407

Specications are subject to change without notice.

© 2014 Mitsubishi Electric US, Inc.

1340 Satellite Boulevard

Suwanee, GA 30024

Toll Free: 800-433-4822

www.mehvac.com

Loading...

Loading...