Page 1

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

PS21562-P

TRANSFER-MOLD TYPE

INSULATED TYPE

PS21562-P

INTEGRATED POWER FUNCTIONS

600V/5A low-loss 5th generation inverter bridge for three

phase DC-to-AC power conversion

INTEGRATED DRIVE, PROTECTION AND SYSTEM CONTROL FUNCTIONS

• For upper-leg IGBTS :Drive circuit, High voltage isolated high-speed level shifting, Control supply under-voltage (UV) protection.

• For lower-leg IGBT

S : Drive circuit, Control supply under-voltage protection (UV), Short circuit protection (SC).

• Fault signaling : Corresponding to an SC fault (Lower-leg IGBT) or a UV fault (Lower-side supply).

• Input interface : 3, 5V line CMOS/TTL compatible. (High Active)

• UL Approved : Yellow Card No. E80276

APPLICATION

AC100V~200V inverter drive for small power motor control.

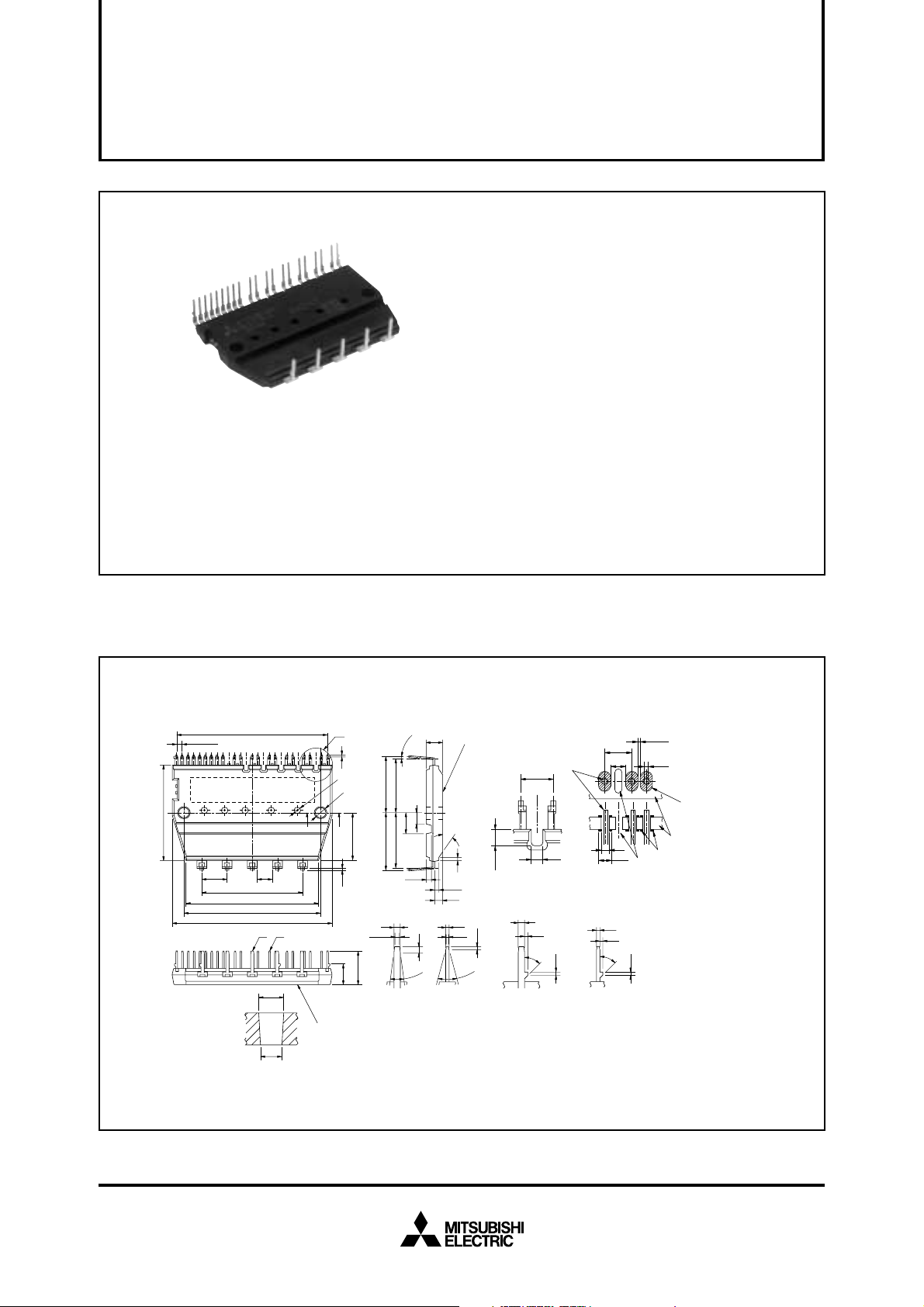

Fig. 1 PACKAGE OUTLINES

Dimensions in mm

TERMINAL CODE

(0.5)

(R0.75)

PATTERN

Note1)

1 VUFS

2 (UPG)

3 VUFB

4 VP1

5 (COM)

6 UP

7 VVFS

8 (VPG)

9 VVFB

10 VP1

11 (COM)

12 VP

PCB

13 VWFS

14 (WPG)

15 VWFB

16 VP1

17 (COM)

18 WP

19 (UNG)

20 VNO Note2)

21 UN

22 VN

23 WN

24 FO

25 CFO

26 CIN

27 VNC

28 VN1

29 (WNG)

30 (VNG)

31 P

32 U

33 V

34 W

35 N

1.778 × 26 (=46.228)

±0.15

1.778

161718 131415 10 9 87 6 54 32 1

(4.62)

7.62 × 4 (=30.48)

(41)

±0.15

42

49

C D

(φ3.8)

φ3.3

B-B

12192021222324

11

26 252728

29

Type name , Lot No.

30

30.5

35 34 33 32 31

±0.3

7.62

Note 1: In order to get enough creepage distance between the terminals, please take some countermeasure such as a slit on PCB.

2:The 20

th

terminal VNO is treated as a NC in DIP-IPM ver.2, it should be connected with the terminal N outside in PS21562-P.

A

0.5

(φ2 DEPTH 2)

φ3.3

BB

0.5

6.5

HEAT SINK SIDE

°)

5

(0~3

(17.6)

(3.5)

(6.5)

15.25

17.4 17.4

(17.6)

(1.5)

1

(0.75)

(1)

10.5

(15°)

DETAIL C DETAIL D TERMINAL 32, 35 TERMINAL 1,28

HEAT SINK SIDE

35°

1.2

1.25

2.5

0.5

(0.4)

(30°)

(0.5)

1.75

3.556

1

0.5

(45

°)

TERMINAL

1.2

DETAIL A

(0.5)

All outer lead terminals are with Pb-free solder plating.

3.556

(2.056)

(1)

(1.5)

SLIT

(ex. PCB LAYOUT)

0.5

0.5

(45

°)

(0.5)

(0.278)

Sep. 2005

Page 2

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

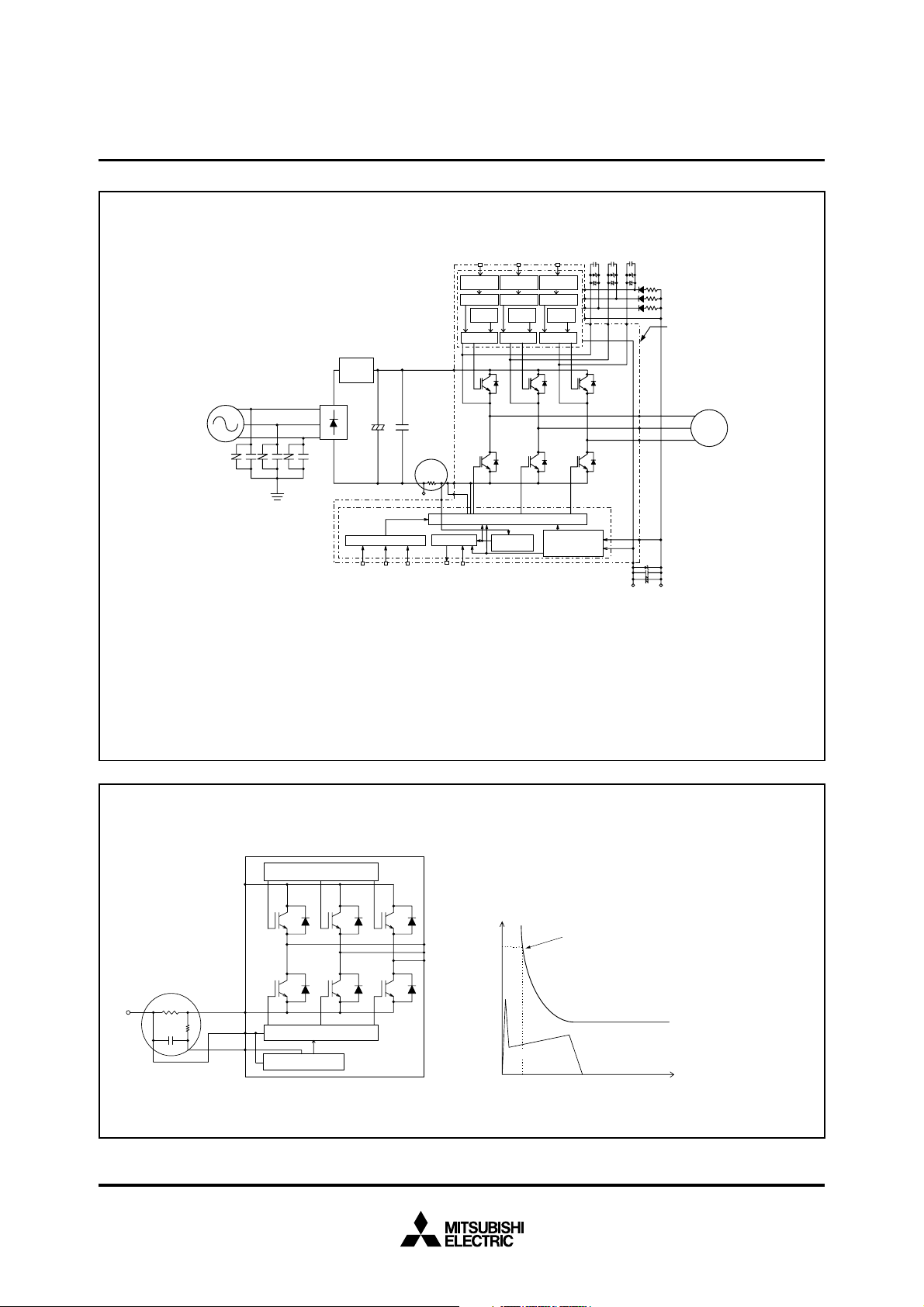

Fig. 2 INTERNAL FUNCTIONS BLOCK DIAGRAM (TYPICAL APPLICATION EXAMPLE)

CBW+

CBW–

CBV+

CBU–

CBV–

C1 : Tight tolerance, temp-compensated electrolytic type

(Note : The capacitance value depends on the PWM control

scheme used in the applied system).

C2 : 0.22~2µF R-category ceramic capacitor for noise filtering.

Inrush current

limiter circuit

High-side input (PWM)

(3, 5V line) (Note 1,2)

Input signal

conditioning

Level shifter

Protection

circuit (UV)

Drive circuit

P

Input signal

Input signal

conditioning

conditioning

Level shifter Level shifter

Drive circuit Drive circuit

Protection

circuit (UV)

Protection

circuit (UV)

CBU+

PS21562-P

TRANSFER-MOLD TYPE

INSULATED TYPE

C2

(Note 8)

C1

(Note 6)

DIP-IPM

AC line input

(Note 4)

C

Z

Z : ZNR (Surge absorber)

C : AC filter (Ceramic capacitor 2.2~6.5nF)

(Note : Additionally, an appropriate line-to line

surge absorber circuit may become necessary

depending on the application environment).

Note1: Input logic is high-active. There is a 2.5kΩ (min) pull-down resistor built-in each input circuit. When using an external CR filter, please make it satisfy the

input threshold voltage.

2: By virtue of integrating an application specific type HVIC inside the module, direct coupling to MCU terminals without any opto-coupler or transformer

isolation is possible. (see also Fig. 8)

3: This output is open drain type. The signal line should be pulled up to the positive side of the 5V power supply with approximately 10kΩ resistance.

(see also Fig. 8)

4: The wiring between the power DC link capacitor and the P, N1 terminals should be as short as possible to protect the DIP-IPM against catastrophic high

surge voltages. For extra precaution, a small film type snubber capacitor (0.1~0.22µF, high voltage type) is recommended to be mounted close to

these P-N1 DC power input pins.

5: Fo output pulse width should be decided by putting external capacitor between CFO and V

6: High voltage (600V or more) and fast recovery type (less than 100ns) diodes should be used in the bootstrap circuit.

7: The terminal V

8: To prevent ICs from surge destruction, it is recommended to insert a Zener diode (24V, 1W) nearby each pair of supply terminals.

NO should be connected to the terminal N outside of DIP-IPM.

Input signal conditioning

Low-side input (PWM)

(3, 5V line) (Note 1, 2)

Fig. 3

N1

V

NC

Fo logic

FOCFO

Fault output (5V line)

(Note 3, 5)

(Note 7)

N

V

NO

CIN

Drive circuit

Protection

circuit

NC terminals. (Example : CFO=22nF → tFO=1.8ms (Typ.))

L-side IGBT

Control supply

Under-Voltage

protection

H-side IGBT

V

S

U

V

W

S

NC

(15V line)

AC line output

(Note 8)

V

D

Fig. 3 EXTERNAL PART OF THE DIP-IPM PROTECTION CIRCUIT

M

DIP-IPM

P

H-side IGBT

External protection circuit

Shunt Resistor

N1

(Note 1)

R

C

C

Note1: In the recommended external protection circuit, please select the RC time constant in the range 1.5~2.0µs.

2: To prevent erroneous protection operation, the wiring of A, B, C should be as short as possible.

L-side IGBT

A

N

NC

V

CIN

B

(Note 2)

Drive circuit

S

S

Drive circuit

Protection circuit

Short Circuit Protective Function (SC) :

SC protection is achieved by sensing the L-side DC-Bus current (through the external

shunt resistor) after allowing a suitable filtering time (defined by the RC circuit).

When the sensed shunt voltage exceeds the SC trip-level, all the L-side IGBTs are turned

OFF and a fault signal (Fo) is output. Since the SC fault may be repetitive, it is

recommended to stop the system when the Fo signal is received and check the fault.

U

V

W

IC (A)

0

Collector current

waveform

2

SC Protection

Trip Level

w

(µs)

t

Sep. 2005

Page 3

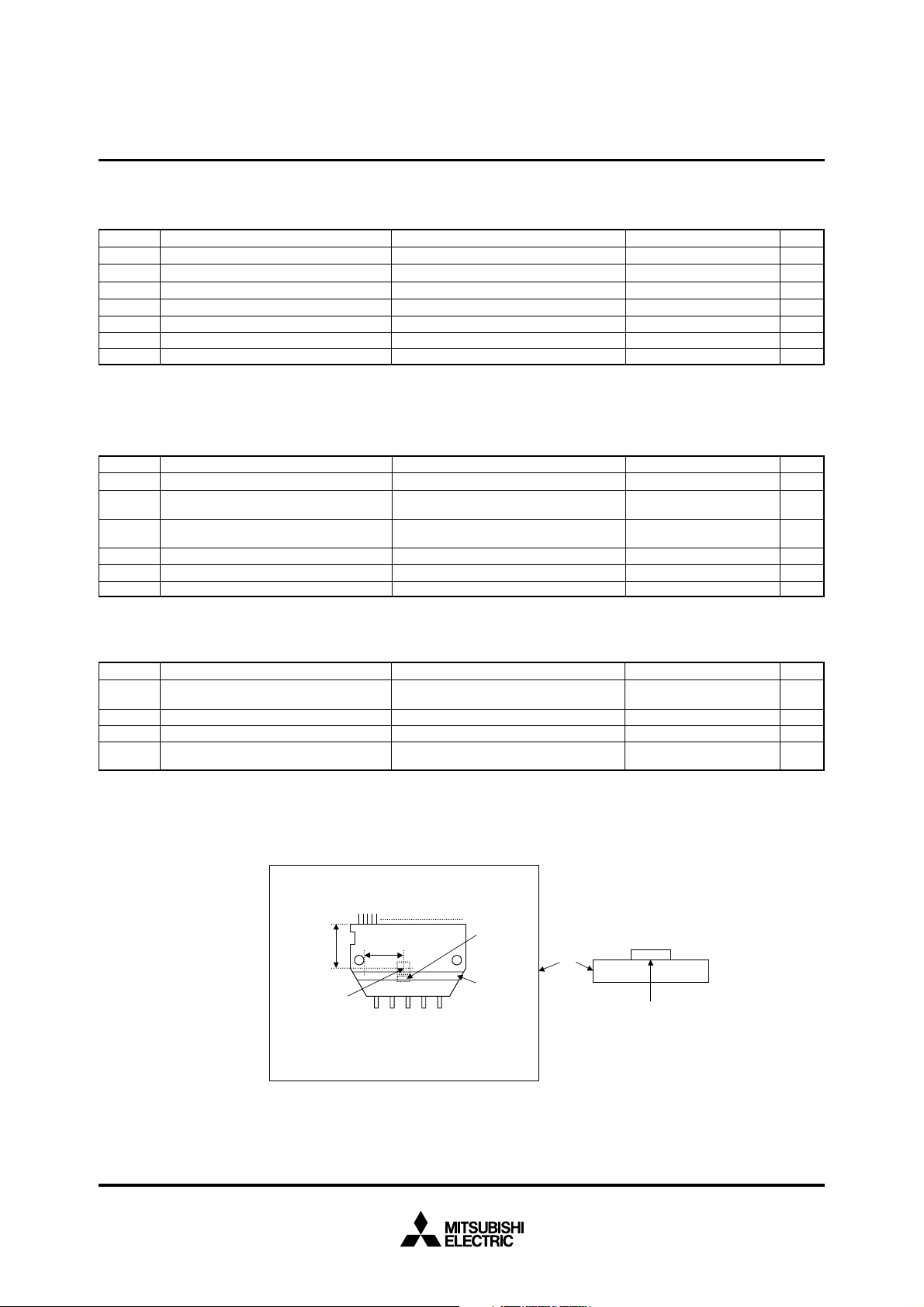

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

PS21562-P

TRANSFER-MOLD TYPE

INSULATED TYPE

MAXIMUM RATINGS (Tj = 25°C, unless otherwise noted)

INVERTER PART

ConditionSymbol Parameter Ratings Unit

CC

V

VCC(surge)

VCES

±IC

±ICP

PC

Tj

Supply voltage

Supply voltage (surge)

Collector-emitter voltage

Each IGBT collector current

Each IGBT collector current (peak)

Collector dissipation

Junction temperature

Applied between P-N

Applied between P-N

T

f = 25°C

f = 25°C, less than 1ms

T

f = 25°C, per 1 chip

T

(Note 1)

450

500

600

5

10

16.7

–20~+125

Note 1 : The maximum junction temperature rating of the power chips integrated within the DIP-IPM is 150°C (@ Tf ≤ 100°C) however, to en-

sure safe operation of the DIP-IPM, the average junction temperature should be limited to Tj(ave) ≤ 125°C (@ Tf ≤ 100°C).

CONTROL (PROTECTION) PART

ConditionSymbol Parameter Ratings Unit

VD

VDB

VIN

VFO

IFO

VSC

Control supply voltage

Control supply voltage

Input voltage

Fault output supply voltage

Fault output current

Current sensing input voltage

Applied between V

Applied between VUFB-VUFS, VVFB-VVFS,

Applied between UP, VP, WP, UN, VN,

Applied between FO-VNC

Sink current at FO terminal

Applied between CIN-V

P1-VNC, VN1-VNC

VWFB-VWFS

WN-VNC

NC

–0.5~V

–0.5~V

–0.5~V

20

20

D+0.5

D+0.5

1

D+0.5

V

V

V

A

A

W

°C

V

V

V

V

mA

V

TOTAL SYSTEM

Symbol Ratings Unit

V

CC(PROT)

Tf

Tstg

Viso

Self protection supply voltage limit

(short circuit protection capability)

Module case operation temperature

Storage temperature

Isolation voltage

Parameter

D = 13.5~16.5V, Inverter part

V

Tj = 125°C, non-repetitive, less than 2 µs

60Hz, Sinusoidal, 1 minute,

All connected pins to heat-sink plate

Note 2 : Tf measurement point

Al Board Specification :

Dimensions : 100✕100✕10mm, Finishing : 12s, Warp : –50~100µm

Control Terminals

18mm

IGBT Chip

Temperature

measurement point

(inside the AI board)

Silicon-grease should be applied evenly with a thickness of 100~200µm

16mm

PUVWN

Power Terminals

Condition

FWDi Chip

Groove

Al Board

(Note 2)

IGBT/FWDi Chip

Temperature measurement

point (inside the AI board)

400

–20~+100

–40~+125

2500

V

°C

°C

rms

V

Sep. 2005

Page 4

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

PS21562-P

TRANSFER-MOLD TYPE

INSULATED TYPE

THERMAL RESISTANCE

Parameter

Rth(j-f)Q

Rth(j-f)F

Note 3: Grease with good thermal conductivity should be applied evenly with about +100µm~+200µm on the contacting surface of DIP-IPM

Junction to case thermal

resistance (Note 3)

and heat-sink.

Inverter IGBT part (per 1/6 module)

Inverter FWD part (per 1/6 module)

ConditionSymbol

Min.

Limits

Typ. Max.

—

—

—

—

ELECTRICAL CHARACTERISTICS (Tj = 25°C, unless otherwise noted)

INVERTER PART

Symbol

V

CE(sat)

VEC

ton

trr

tc(on)

toff

tc(off)

ICES

Parameter

Collector-emitter saturation

voltage

FWD forward voltage

Switching times

Collector-emitter cut-off

current

Condition

VD = VDB = 15V

VIN = 5V

C = 5A, Tj = 25°C

I

IC = 5A, Tj = 125°C

Tj = 25°C, –IC = 5A, VIN = 0V

CC = 300V, VD = VDB = 15V

V

IC = 5A, Tj = 125°C, VIN = 0

↔

Inductive load (upper-lower arm)

T

CE = VCES

V

j = 25°C

Tj = 125°C

Min. Typ. Max.

0.60

5V

Limits

—

1.60

—

1.70

—

1.50

1.20

—

0.30

—

0.40

—

1.30

—

0.50

—

—

2.10

2.20

2.00

1.80

0.60

2.00

0.80

—

—

6.0

6.5

—

10

Unit

°C/W

°C/W

Unit

V

V

µs

µs

µs

µs

µs

1

mA

CONTROL (PROTECTION) PART

—

—

—

—

4.9

—

1.0

1.0

2.1

0.8

Limits

—

—

—

—

—

—

—

1.5

—

—

—

—

1.8

2.3

1.4

5.00

0.40

7.00

0.55

0.95

0.52

12.0

12.5

12.5

13.0

Symbol

I

D

VFOH

VFOL

VSC(ref)

IIN

UVDBt

UVDBr

UVDt

UVDr

tFO

Vth(on)

Vth(off)

Parameter Condition

Circuit current

Fault output voltage

Short circuit trip level

Input current

Control supply under-voltage

protection

Fault output pulse width

ON threshold voltage

OFF threshold voltage

D = VDB = 15V

V

V

IN = 5V

V

D = VDB = 15V

V

IN = 0V

Total of V

P1-VNC, VN1-VNC

VUFB-VUFS, VVFB-VVFS, VWFB-VWFS

P1-VNC, VN1-VNC

Total of V

VUFB-VUFS, VVFB-VVFS, VWFB-VWFS

VSC = 0V, FO circuit pull-up to 5V with 10kΩ

V

SC = 1V, IFO = 1mA

T

f = –20~100°C, VD = 15V (Note 4)

V

IN = 5V

Trip level

Tj ≤ 125°C

Reset level

Trip level

Reset level

C

FO = 22nF (Note 5)

Applied between U

P, VP, WP-VNC, UN, VN, WN-VNC

Min. Typ. Max.

0.45

10.0

10.5

10.3

10.8

Note 4: Short circuit protection is functioning only for the lower-arms. Please select the external shunt resistance such that the SC trip-level is

less than 2.0 times of the current rating.

5:Fault signal is asserted corresponding to a short circuit or lower side control supply under-voltage failure. The fault output pulse width tFO

depends on the capacitance value of CFO according to the following approximate equation : CFO = 12.2 ✕ 10-6 ✕ tFO [F].

—

2.0

—

2.6

2.1

Unit

mA

V

V

V

mA

V

V

V

V

ms

V

V

Sep. 2005

Page 5

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

MECHANICAL CHARACTERISTICS AND RATINGS

Parameter

Mounting torque

Weight

Heat-sink flatness

Note 6: Measurement point of heat-sink flatness

Mounting screw : M3

Condition

Recommended : 0.78 N·m

(

Note 6

PS21562-P

TRANSFER-MOLD TYPE

INSULATED TYPE

Limits

Min.

0.59

—

)

–50

Typ. Max.

—

20

—

0.98

—

100

Unit

N·m

g

µm

+ –

Measurement location

3mm

Heat-sink side

–

+

Heat-sink side

RECOMMENDED OPERATION CONDITIONS

Parameter

CC

V

VD

VDB

∆VD, ∆V

tdead

fPWM

IO

Supply voltage

Control supply voltage

Control supply voltage

DB

Control supply variation

Arm shoot-through blocking time

PWM input frequency

Allowable r.m.s. current

Applied between P-N

Applied between V

Applied between VUFB-VUFS, VVFB-VVFS, VWFB-VWFS

For each input signal, Tf ≤ 100°C

T

f ≤ 100°C, Tj ≤ 125°C

V

CC = 300V, VD = VDB = 15V,

P.F = 0.8, sinusoidal output

T

f ≤ 100°C, Tj ≤ 125°C (Note 7)

PWIN(on)

200 ≤ V

CC ≤ 350V,

13.5 ≤ V

PWIN(off)

Allowable minimum input

pulse width

13.0 ≤ V

–20°C ≤ T

D ≤ 16.5V,

DB ≤ 18.5V,

f ≤ 100°C,

N-line wiring inductance less than

10nH

V

NC

V

NC variation

Between V

NC-N (including surge)

Note 7: The allowable r.m.s. current value depends on the actual application conditions.

8:The input pulse width less than PWIN(on) might make no response.

9:IPM might not work properly or make response for the input signal with OFF pulse width less than PWIN(off).

Please refer to Fig.7.

ConditionSymbol

P1-VNC, VN1-VNC

(Note 9)

fPWM = 5kHz

PWM = 15kHz

f

(Note 8)

Below rated current

Between rated current and

1.7 times of rated current

Between 1.7 times and

2.0 times of rated current

Recommended value

Min. Typ. Max.

0

13.5

13.0

–1

1.5

—

—

—

0.3

0.5

0.5

0.5

–5.0

300

15.0

15.0

—

—

—

—

—

—

—

—

—

—

400

16.5

18.5

1

—

20

3.5

3.2

—

—

—

—

5.0

Unit

V

V

V

V/µs

µs

kHz

Arms

µs

V

Sep. 2005

Page 6

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

Fig. 4 THE DIP-IPM INTERNAL CIRCUIT

V

UFB

V

UFS

V

P1

U

P

V

VFB

V

VFS

V

P1

V

P

V

WFB

V

WFS

V

P1

W

P

HVIC1

V

CC

IN

COM

HVIC2

V

CC

IN

COM

HVIC3

V

CC

IN

COM

HO

HO

HO

PS21562-P

TRANSFER-MOLD TYPE

INSULATED TYPE

DIP-IPM

P

V

B

V

S

V

B

V

S

V

B

V

S

IGBT1

IGBT2

IGBT3

Di1

U

Di2

V

Di3

W

LVIC

U

OUT

V

N1

U

N

V

N

W

N

Fo

V

CC

V

OUT

U

N

V

N

W

OUT

N

W

Fo

V

NO

IGBT4

IGBT5

IGBT6

Di4

Di5

Di6

CIN

V

NC

GND

CFO

N

V

NO

CFO CIN

Sep. 2005

Page 7

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

TRANSFER-MOLD TYPE

Fig. 5 TIMING CHART OF THE DIP-IPM PROTECTIVE FUNCTIONS

[A] Short-Circuit Protection (Lower-arms only with the external shunt resistor and CR filter)

a1. Normal operation : IGBT ON and carrying current.

a2. Short circuit current detection (SC trigger).

a3. IGBT gate hard interruption.

a4. IGBT turns OFF.

O timer operation starts : The pulse width of the FO signal is set by the external capacitor CFO.

a5. F

a6. Input “L” : IGBT OFF.

a7. Input “H” : IGBT ON.

a8. IGBT OFF in spite of input “H”.

PS21562-P

INSULATED TYPE

Lower-arms control

input

Protection circuit state

Internal IGBT gate

SET

a3

a7a6

RESET

a2

Output current Ic

Sense voltage of the

shunt resistor

a1

SC

a4

a8

SC reference voltage

CR circuit time

Error output Fo

a5

constant DELAY

[B] Under-Voltage Protection (Lower-arm, UVD)

b1. Control supply voltage rises : After the voltage level reaches UVDr, the circuits start to operate when next input is applied.

b2. Normal operation : IGBT ON and carrying current.

b3. Under voltage trip (UVDt).

b4. IGBT OFF in spite of control input condition.

b5. FO operation starts.

b6. Under voltage reset (UVDr).

b7. Normal operation : IGBT ON and carrying current.

Control input

Protection circuit state

Control supply voltage V

Output current Ic

Error output Fo

RESET

UV

Dr

D

b1

UV

b2

SET

Dt

b3

b4

RESET

b6

b7

b5

Sep. 2005

Page 8

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

TRANSFER-MOLD TYPE

[C] Under-Voltage Protection (Upper-arm, UVDB)

c1. Control supply voltage rises : After the voltage reaches UVDBr, the circuits start to operate when next input is applied.

c2. Normal operation : IGBT ON and carrying current.

c3. Under voltage trip (UVDBt).

c4. IGBT OFF in spite of control input condition, but there is no FO signal output.

c5. Under voltage reset (UVDBr).

c6. Normal operation : IGBT ON and carrying current.

Control input

PS21562-P

INSULATED TYPE

Protection circuit state

UVDBr

Control supply voltage V

DB

c1

Output current Ic

High-level (no fault output)

Error output Fo

Fig. 6 RECOMMENDED CPU I/O INTERFACE CIRCUIT

5V line

MCU

UV

DBt

c2 c4

10kΩ

SETRESET

RESET

c5

c3

c6

DIP-IPM

P,VP,WP,UN,VN,WN

U

Fo

VNC(Logic)

Note :The setting of RC coupling at each input (parts shown dotted) depends on the PWM control scheme and the

wiring impedance of the printed circuit board.

The DIP-IPM input section integrates a 2.5kΩ (min) pull-down resistor. Therefore, when using an external

filtering resistor, pay attention to the turn-on threshold voltage.

Fig. 7 WIRING CONNECTION OF SHUNT RESISTOR

DIP-IPM

V

NO

V

NC

N

Wiring inductance should be less than 10nH.

Equivalent to the inductance of a copper pattern

with length=17mm, width=3mm,

and thickness=100µm

Shunt resistor

Please make the GND wiring connection

of shunt resistor to the V

as close as possible.

NC

terminal

Sep. 2005

Page 9

MITSUBISHI SEMICONDUCTOR <Dual-In-Line Package Intelligent Power Module>

Fig. 8 TYPICAL DIP-IPM APPLICATION CIRCUIT EXAMPLE

C1:Tight tolerance temp-compensated electrolytic type

C2,C3: 0.22~2µF R-category ceramic capacitor for noise filtering.

V

UFB

C2

C1

V

CONTROLLER

5V line

UFS

V

P1

C3

C3

C3

C3

U

P

C2

V

VFB

C1

V

VFS

V

P1

V

P

C2

V

WFB

C1

V

WFS

V

P1

W

P

V

N1

COM

COM

COM

V

V

CC

IN

V

CC

IN

V

CC

IN

CC

HVIC1

HVIC2

HVIC3

LVIC

HO

HO

HO

V

B

V

S

V

B

V

S

V

B

V

S

U

OUT

V

OUT

DIP-IPM

PS21562-P

TRANSFER-MOLD TYPE

INSULATED TYPE

P

U

V

W

M

U

N

U

N

N

V

N

W

N

W

F

GND

OUT

N

V

CIN

CFO

NO

CFO

C4(C

A

CIN

FO

)

B

R1

C5

If this wiring is too long, the SC level

fluctuation might be larger and cause

SC malfunction.

o

Too long wiring here might

cause short-circuit.

N

V

NO

C

Shunt

resistor

N1

15V line

V

W

Fo

V

NC

Long GND wiring here might generate

noise to input and cause IGBT

malfunction.

Note 1: To prevent the input signals oscillation, the wiring of each input should be as short as possible. (Less than 2cm)

2:By virtue of integrating an application specific type HVIC inside the module, direct coupling to MCU terminals without any opto-coupler

or transformer isolation is possible.

3:FO output is open drain type. This signal line should be pulled up to the positive side of the 5V power supply with approximately 10kΩ

resistor.

4:FO output pulse width is determined by the external capacitor between CFO and VNC terminals (CFO). (Example : CFO = 22 nF → tFO

= 1.8 ms (typ.))

5:The logic of input signal is high-active. The DIP-IPM input signal section integrates a 2.5kΩ (min) pull-down resistor. Therefore, when

using external filtering resistor, care must be taken to satisfy the turn-on threshold voltage requirement.

6:To prevent malfunction of protection, the wiring of A, B, C should be as short as possible.

7:Please set the C5R1 time constant in the range 1.5~2µs.

8:Each capacitor should be located as nearby the pins of the DIP-IPM as possible.

9:To prevent surge destruction, the wiring between the smoothing capacitor and the P, N1 pins should be as short as possible. Approxi-

mately a 0.1~0.22µF snubber capacitor between the P-N1 pins is recommended.

10

: The terminal VNO should be connected with the terminal N outside.

11

: To prevent ICs from surge destruction, it is recommended to insert a Zener diode (24V, 1W) nearby each pair of supply terminals.

Sep. 2005

Loading...

Loading...