Page 1

Air-Conditioners For Building Application

gepr

fte

Sicherheit

HEAT SOURCE UNIT

PQRY-P-YMF-B

FOR INSTALLER

FÜR INSTALLATEURE

gepr

üfte

Sicherheit

ДЛЯ УСТАНОВИТЕЛЯ

VOOR DE INSTALLATEUR

POUR L’INSTALLATEUR

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

∗ Remote controller (PAR-F25MA) is available as an optional remote controller.

For use with the R407C

Perform refrigerant piping work more carefully than in the past so that dust, dirt, water, or other

foreign matter does not enter the refrigerant cycle.

INSTALLATIONSHANDB UCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

∗ Fernbedienung (PAR-F25MA) ist als Zubehör wahlweise erhältlich.

Bei Verwendung von R407C

die Verlegung der Kältemittelrohrleitung sorgfältiger als bisher durchführen, damit Staub,

Schmutz, Wasser oder andere Fremdstoffe nicht in den Kältemittelkreislauf gelangen.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

∗ Пульт дистанционного управления (PAR-F25MA) поставляется дополнительно

Для использования с моделью R407C

Выполняйте прокладку труб хладагента, проявляя большее внимание, чем прежде, чтобы

в цикл хладагента не проникла пыль, грязь, вода или другие посторонние вещества.

ENGLISH

DEUTSCH

РУССКИЙ

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

∗ De afstandsbedieningseenheid (PAR-F25MA) is verkrijgbaar als een optioneel toe te voegen afstandsbediening.

Bij gebruik van R407C

Voer werkzaamheden aan de koelstofpijpen nog zorgvuldiger dan vroeger uit om te voorkomen dat stof, vuil, water of andere vreemde stoffen in de koelcyclus terecht komen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation

correcte.

∗ La télécommande (PAR-F25MA) est disponible en option.

A utiliser avec le R407C

Effectuez l’installation des tuyaux à réfrigérant avec plus de soin qu’auparavant pour empêcher

l’eau, la poussière, les impuretés ou tout autre contaminant d’entrer dans le cycle du réfrigérant.

NEDERLANDS

FRANÇAIS

Page 2

ENGLISH

2

Page 3

Contents

1. Safety precautions ...................................................................... 4

1.1. Before installation and electric work ............................... 4

1.2. Precautions for devices that use R407C refrigerant....... 4

1.3. Before getting installed ................................................... 5

1.4. Before getting installed (moved) - electrical work........... 5

1.5. Before starting the test run ............................................. 5

2. Combination with indoor units..................................................... 6

3. Confirmation of parts attached ................................................... 6

4. Selection of installation site ........................................................ 7

5. Lifting method and weight of product.......................................... 7

6. Installation of unit and service space.......................................... 8

6.1. Installation ...................................................................... 8

6.2. Service space ................................................................. 8

6.3. Noise level ...................................................................... 8

7. Refrigerant piping installation ..................................................... 9

7.1. Caution ........................................................................... 9

7.2. Refrigerant piping system............................................. 10

7.3. Caution for piping connection/valve operation .............. 12

7.4. Airtight test, evacuation, and refrigerant charging ........ 14

7.5. Thermal insulation of refrigerant piping ........................ 16

7.6. Pressure vessel law (DruckbehV).................................17

8. Water pipe installation...............................................................18

8.1. Precautions during installation...................................... 18

8.2. Insulation installation .................................................... 18

8.3. Water processing and water quality control.................. 18

8.4. Pump interlock.............................................................. 18

9. Electrical work........................................................................... 19

9.1. Caution ......................................................................... 19

9.2. Control box and connecting position of wiring .............. 20

9.3. Wiring transmission cables........................................... 21

9.4. Wiring of main power supply and equipment

capacity ........................................................................ 26

10.Test run.................................................................................... 27

10.1. Checking before getting test run ................................. 27

10.2. Test run method .......................................................... 27

10.3. How to cope with test run trouble................................ 28

10.4. Coping with remote controller trouble ......................... 30

10.5. The following phenomena do not represent trouble

(emergency) ................................................................ 31

ENGLISH

3

Page 4

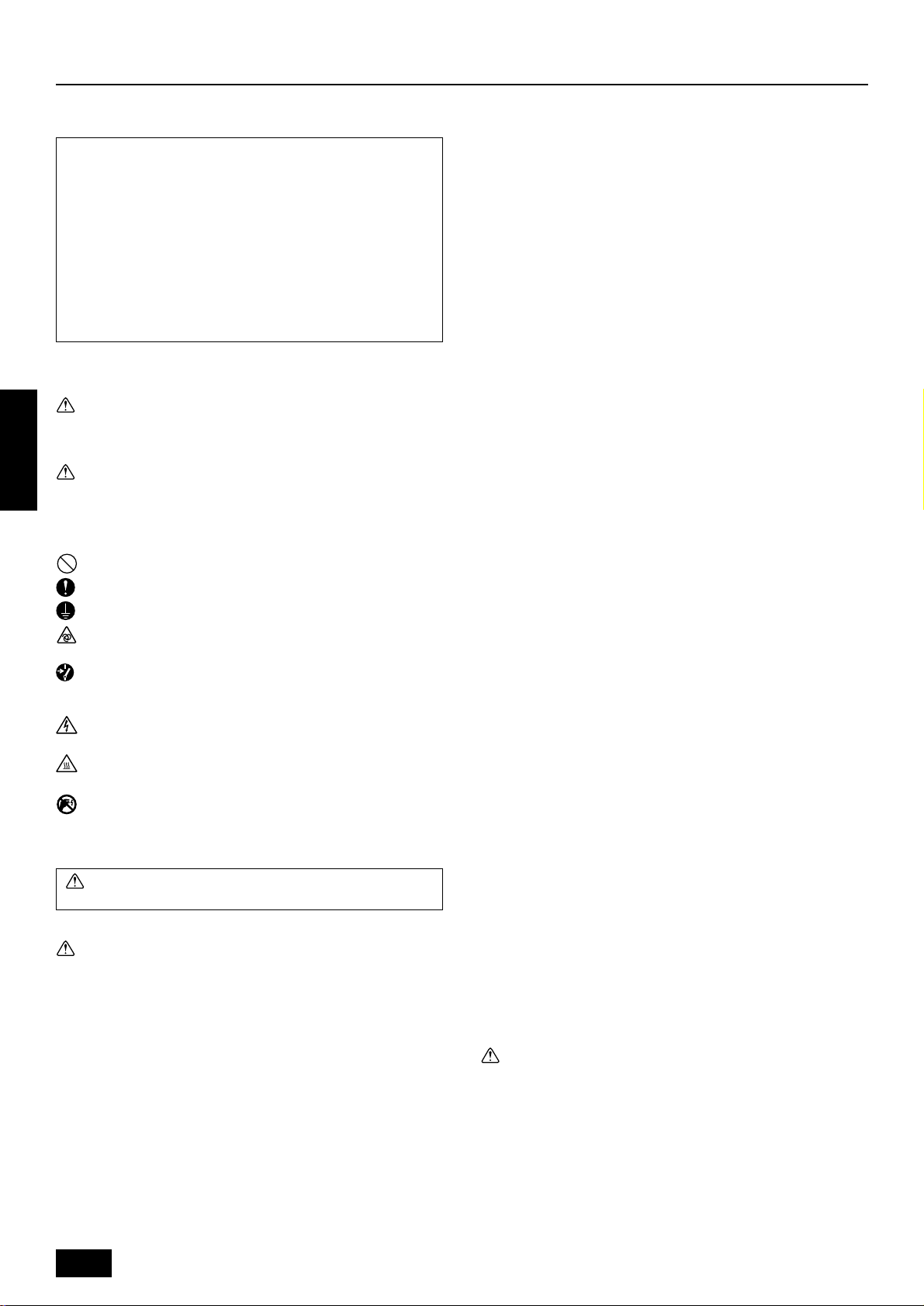

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the

“Safety precautions”.

s The “Safety precautions” provide very important points

regarding safety. Make sure you follow them.

s This equipment may not be applicable to EN61000-3-

2: 1995 and EN61000-3-3: 1995.

s This equipment may cause the adverse effect on the

same supply system.

s Please report to or take consent b y the supply author-

ity before connection to the system.

Symbols used in the text

ENGLISH

Warning:

Describes precautions that should be observed to prevent danger

of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage

to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This

symbol is displayed on the main unit label.) <Color: Yellow>

: Indicates that the main switch must be turned off before servic-

ing. (This symbol is displayed on the main unit label.) <Color:

Blue>

: Beware of electric shock (This symbol is displayed on the main

unit label.) <Color: Yellow>

: Beware of hot surface (This symbol is displayed on the main unit

label.) <Color: Yellow>

: Please pay attention to electric shock fully because this is

ELV

not Safety Extra Low-Voltage (SELV) circuit.

And at servicing, please shut down the power supply for both

of Indoor Unit and Heat Source Unit.

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user ma y result in water leakage, elec-

tric shock, or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in

injuries.

• Use the specified cables for wiring. Make the connections securely so that the outside force of the cable is not applied to the

terminals.

- Inadequate connection and fastening may generate heat and cause

a fire.

• Prepare for rain and other moisture and earthquakes and install

the unit at the specified place.

- Improper installation may cause the unit to topple and result in in-

jury.

• Always use an air cleaner, humidifier, electric heater, and other

accessories specified by Mitsubishi Electric.

4

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shoc k,

or fire.

• Never repair the unit. If the air conditioner must be repaired,

consult the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or

fire may result.

• If refrigerant gas leaks during installation work, ventilate the

room.

- If the refrigerant gas comes into contact with a flame, poisonous

gases will be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or

fire may result.

• Have all electric work done by a licensed electrician according

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations”and the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is per-

formed improperly, electric shock and fire may result.

• Securely install the cover of control box and the panel.

- If the cov er and panel are not installed properly, dust or water may

enter the heat source unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site,

do not charge the it with a refrigerant different from the refrigerant (R407C) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must

be taken to prevent the refrigerant concentration from exceeding the safety limit even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent

the safety limit from being exceeded. Should the refrigerant leak

and cause the safety limit to be exceeded, hazards due to lack of

oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the

dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric

shock, or fire may result.

• After completing installation work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove,

oven, or other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is

shorted and operated forcibly, or parts other than those specified

by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against

leakage according to local regulation or standards. Following

standards may be applicable if local regulation are not availab le.

• Pay a special attention to the place, such as a basement, etc.

where refrigeration gas can stay, since refrigeration is heavier

than the air.

1.2. Precautions for devices that use

R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping con-

tains a large amount of chlorine which may cause the refrigerator

oil of the new unit to deteriorate.

• Use refrigerant piping made of **C1220 phosphorus deoxidized

copper as specified in the *JIS H3300 “Copper and copper allo y

seamless pipes and tubes”. In addition, be sure that the inner

and outer surfaces of the pipes are clean and free of hazardous

sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or

any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the

refrigerant residual oil to deteriorate.

Page 5

• Store the piping to be used during installation indoors and keep

both ends of the piping sealed until just before brazing. (Store

elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refriger-

ant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and

cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow

check valve, refrigerant char ge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the

R407C, the refrigerant may deteriorated.

- If water is mixed in the R407C, the refrigerator oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors for

conventional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant

may deteriorate.

* Japanese industrial standard.

** Comparable to CU-DHP (CUPROCLIMA), Cu-bl (AFNOR),

C12200 (ASTN), SF-Cu (DIN)

• Install the power cable so that tension is not applied to the cable.

- T ension ma y cause the cable to break and generate heat and cause

a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity

and rating.

- Cables that are too small may leak, generate heat, and cause a

fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper

wire may result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause per-

sonal injury or property damage.

• Install the drain piping according to this Installation Manual to

ensure proper drainage. Wrap thermal insulation around the

pipes to prevent condensation.

- Improper drain piping may cause water leakage and damage to

furniture and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than

20 kg.

- Some products use PP bands for packaging. Do not use any PP

bands for a means of transportation. It is dangerous.

- When transporting the heat source unit, etc., by the hanger bolts,

support it at four points. If it is supported at three points or less, it

will become unstable when set down and may fall.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts,

may cause stabs or other injuries.

- Tear apart and throw away plastic pac kaging bags so that children

will not play with them. If children pla y with a plastic bag which w as

not torn apart, they face the risk of suffocation.

ENGLISH

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion

may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the per-

formance of the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station,

or similar place, provide sufficient protection against noise.

- The inverter equipment, pr ivate power generator, high-frequency

medical equipment, or radio communication equipment may cause

the air conditioner to operate erroneously , or f ail to operate. On the

other hand, the air conditioner may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is

clogged, condensation may drip from the indoor unit. Perform collective drainage work together with the heat source unit, as required.

1.4. Before getting installed (moved) -

electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning

rods, or telephone ground lines. Improper grounding may result in

electric shock.

• The reverse phase of L lines (L1, L2, L3) can be detected (Error

cord: 4103), but the reverse phase of L lines and N line can not

be detected.

- The some electric parts should be damaged when power is sup-

plied under the miss wiring.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power

switch can result in severe damage to internal parts. K eep the power

switch turned on during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after

operation.

- During and immediately after operation, the refrigerant pipes are

may be hot and may be cold, depending on the condition of the

refrigerant flowing through the refrigerant piping, compressor, and

other refrigerant cycle parts. Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards

removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always w ait at least five minutes before turning off the power. Oth-

erwise, water leakage and trouble may occur.

5

Page 6

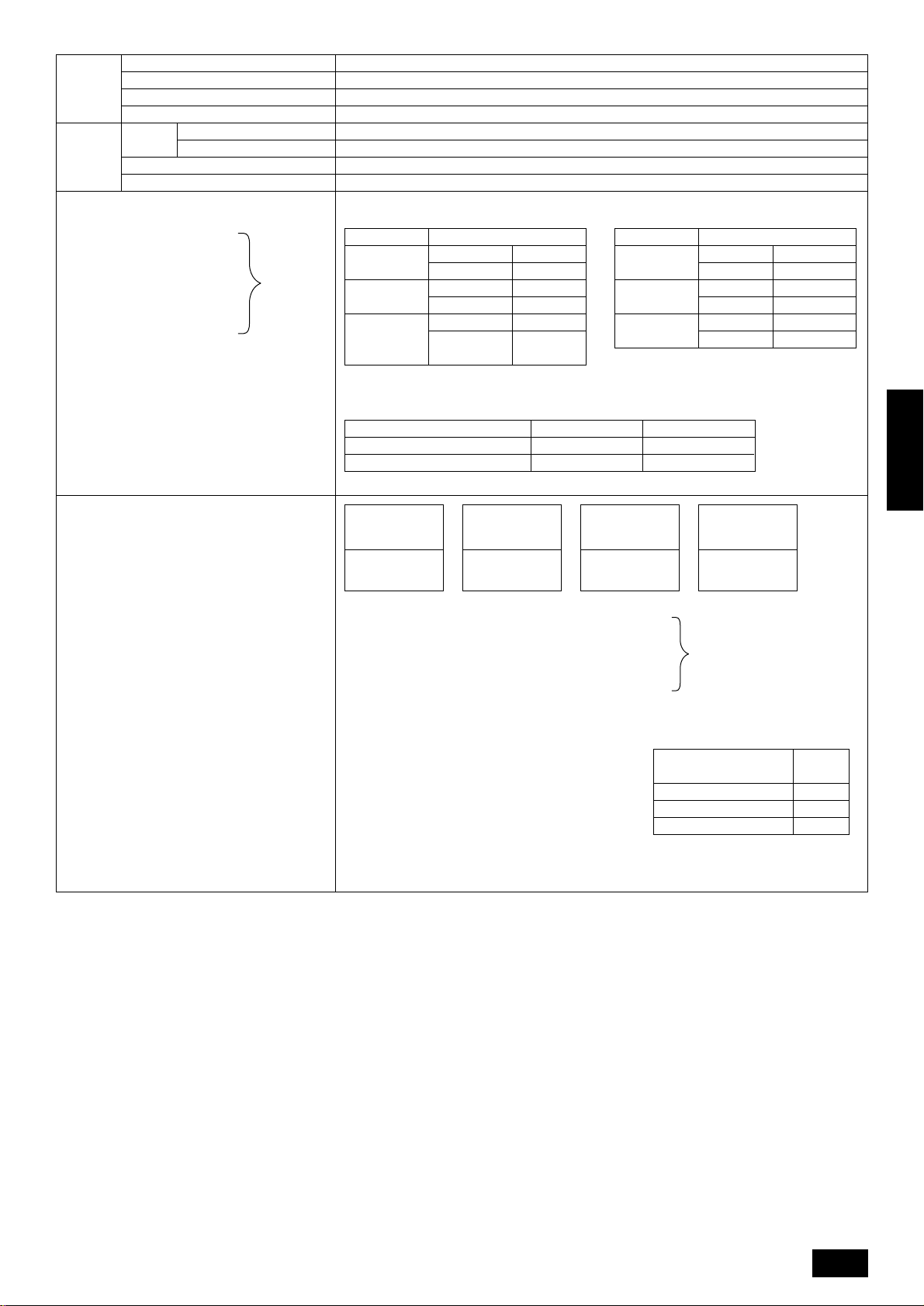

2. Combination with indoor units

The indoor units connectable to this unit are shown below.

Heat source

unit model

name

PQRY-P200

PQRY-P250

ENGLISH

Note:

1. The total capacity of connected indoor unit models represents the total sum of the figures expressed in the indoor model name.

2. Figure in ( ) is to be employed for the actual length of refrigerant piping of 90 m or more for PQRY-P200, P250.

3. With the combination in which the total capacity of connected indoor unit models exceeds the capacity of heat source unit, the capacity

of each indoor unit lowers from the rated capacity at simultaneous operation. Therefore, combine indoor units within the capacity of heat

source unit if the circumstance allows.

Total capacity of

connected indoor

unit models

100 to 302

(100 to 260)

125 to 378

(125 to 325)

Quantity of

connectable

indoor unit

2 to 15

2 to 16

Model name of

connectable

BC controller

CMB-P104V-E

CMB-P105V-E

CMB-P106V-E

CMB-P108V-E

CMB-P1010V-E

CMB-P1013V-E

CMB-P1016V-E

Model name of connectable indoor unit

PMFY-P25 · 32 · 40 · 63 VBM

PDFY-P20 · 25 · 32 · 40 · 50 · 63 · 71 · 80 · 100 · 125 VM

PLFY- P32 · 40 · 50 · 63 · 80 · 100 · 125 VKM

PLFY- P20 · 25 · 32 · 40 · 50 · 63 · 80 · 100 · 125 VLMD

PEFY-P20 · 25 · 32 VML

PEFY-P40 · 50 · 63 · 71 · 80 · 100 · 125 · 140 VMH

PCFY-P40 · 63 · 100 · 125 VGM

PFFY- P20 · 25 · 32 · 40 · 50 · 63 VLEM

PFFY- P20 · 25 · 32 · 40 · 50 · 63 VLRM

PKFY-P20 · 25 VAM

PKFY-P32 · 40 · 50 VGM

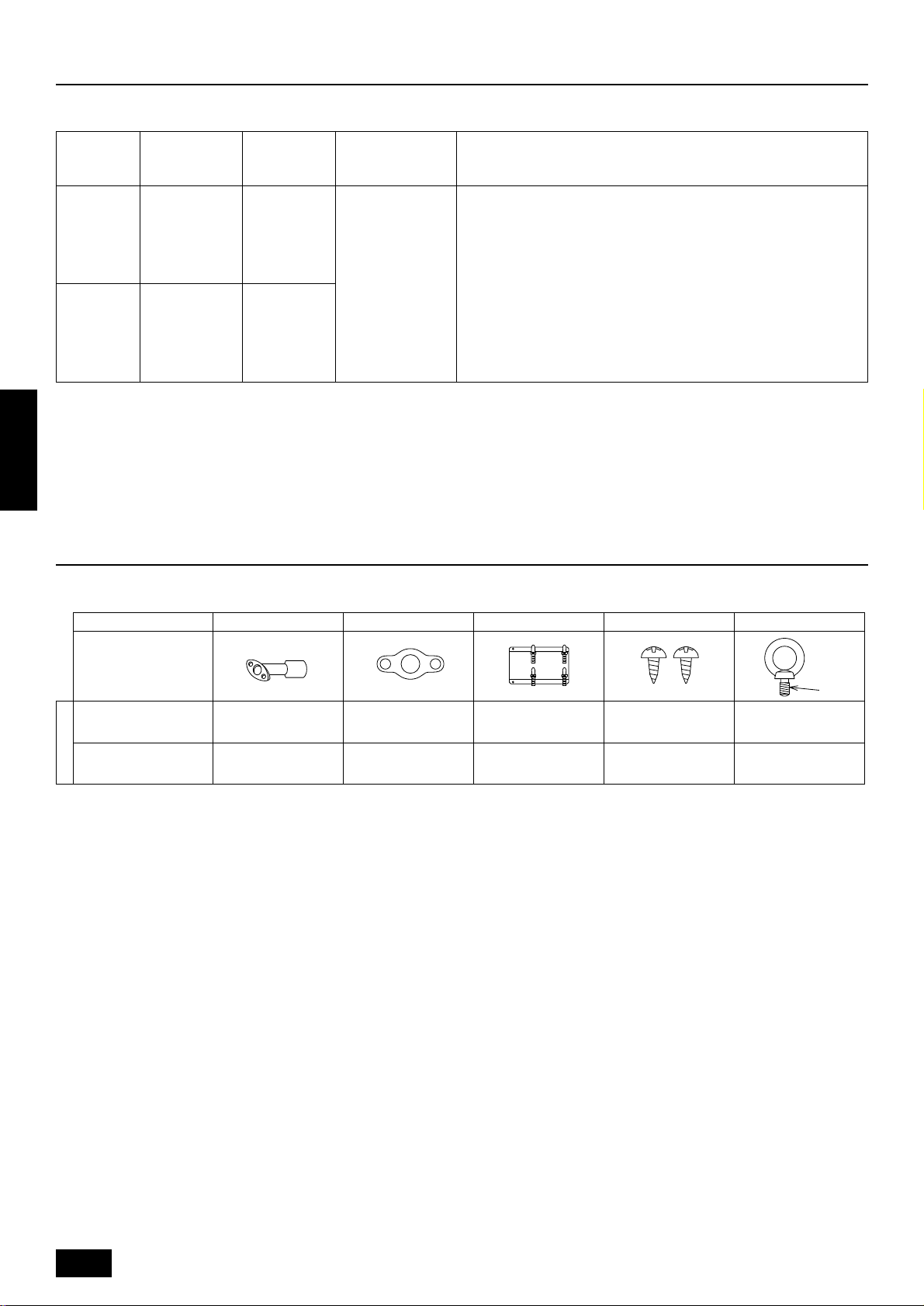

3. Confirmation of parts attached

This heat source unit is attached with the parts below. Please check the quantity for each item.

Name 1 Connecting pipe 2 Packing 3

Shape

inside ø23 outside ø35

PQRY-P200 1 1 1 2 4

PQRY-P250 1 1 1 2 4

Model name

Wiring mounting board

4 Tapping screw M4 5 Hanger bolts

*1 Connecting pipe is fixed with the unit.

M12

6

Page 7

4. Selection of installation site

Select space for installing heat source unit, which will meet the following

conditions:

• no direct thermal radiation from other heat sources

• no possibility of annoying neighbors by noise from unit

• with strength which bears weight of unit

• note that drain flows out of unit when heating

• with space and service work shown 6.2. Service space

Because of the possibility of fire, do not install unit to the space where

generation, inflow, stagnation, and leak of combustible gas is expected.

• Avoid unit installation in a place where acidic solution and spra y (sulfur)

are often used.

• Do not use unit in any special environment where oil, steam and

sulfuric gas exist.

• No exposure to rain or other moisture. (the heat source unit should

only be used indoors)

• The declining gradient of the exhaust pipe should be higher than

1/100.

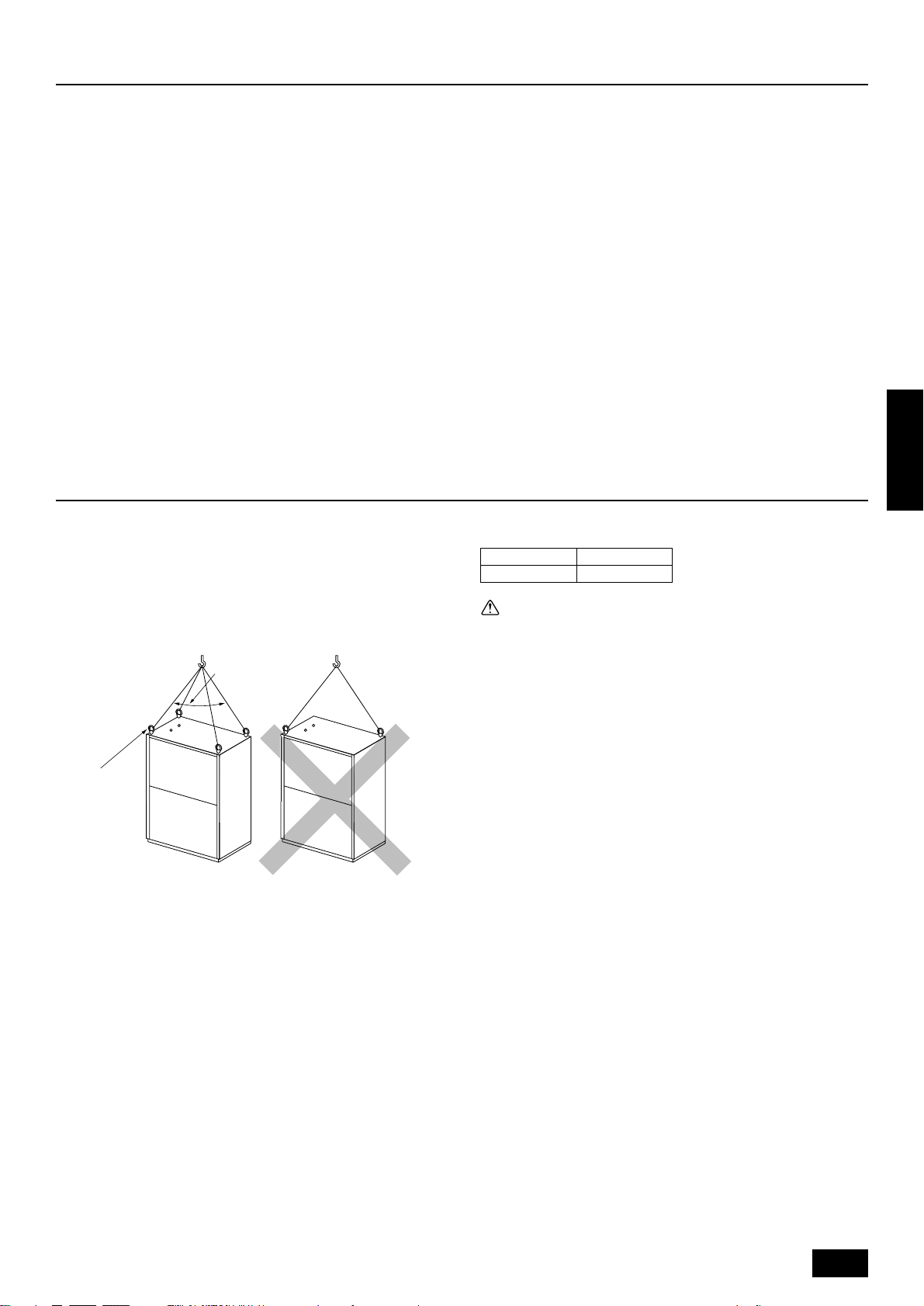

5. Lifting method and weight of product

• When transporting the product by the hanger bolts, make sure to use

accessory hanger bolts firmly screwed into the designated holes on

the unit’s top surface.

• Always lift the unit with ropes attached at four points so that impact is

not applied to the unit.

• Attach the ropes to the unit at an angle of 60° or less.

• Use two ropes at least 3 m long.

B

A

Dangerous!

A Hanger bolts accessory firmly attached all the way in. (at four points)

B 60° or less

ENGLISH

Weight of product:

PQRY-P200 PQRY-P250

270 kg 280 kg

Caution:

Be very careful to carry product.

- Do not have only one person to carry product if it is more than 20 kg.

- PP bands are used to pack some products. Do not use them as a

mean for transportation because they are dangerous.

- Tear plastic packaging bag and scrap it so that children cannot play

with it. Otherwise plastic packaging bag ma y suffocate children to death.

- When transporting the heat source unit, etc., by the hanger bolts, support it at four points. If it is supported at three points or less, it will

become unstable when set down and may fall.

7

Page 8

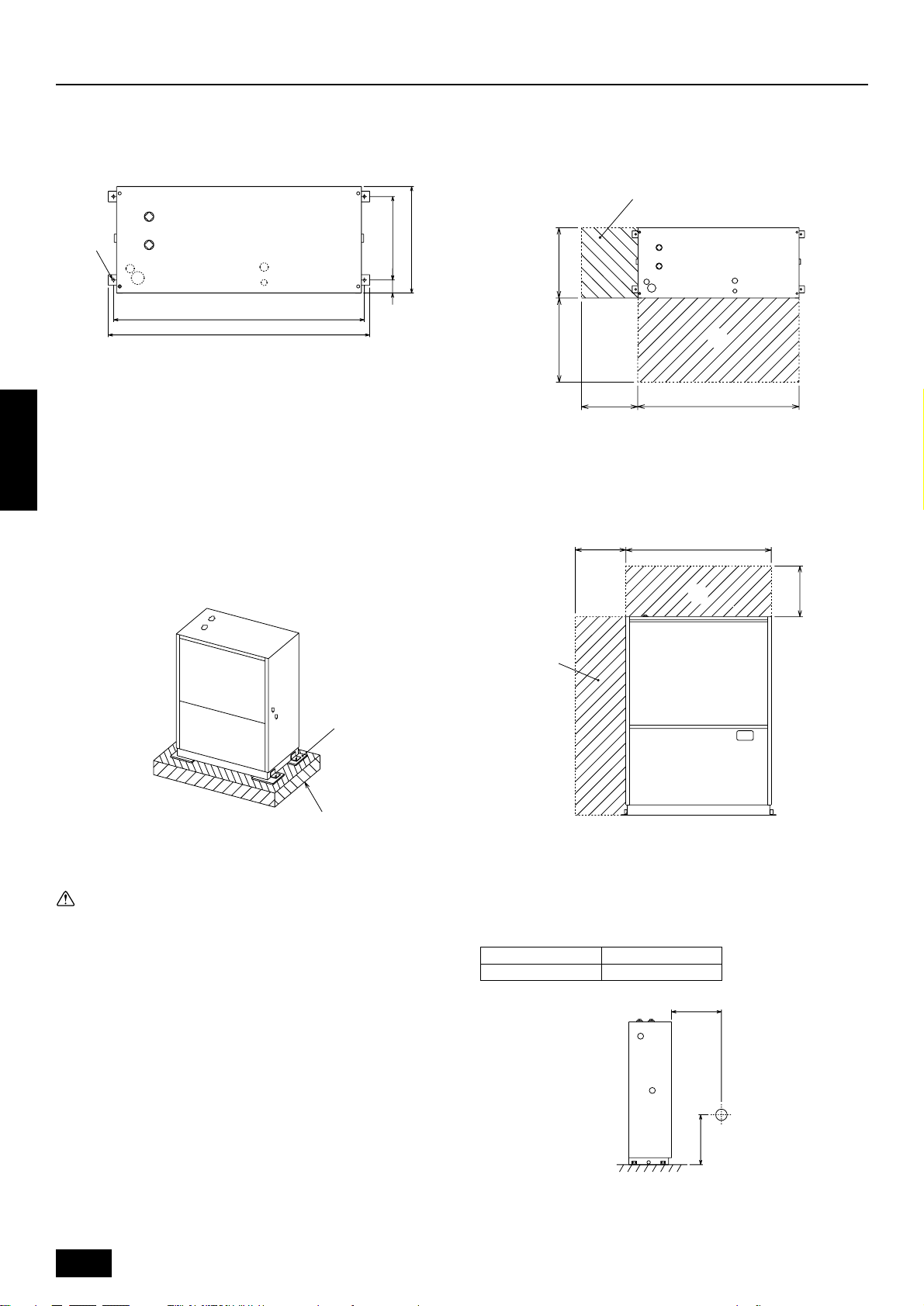

6. Installation of unit and service space

6.1. Installation

• Using the anchoring holes shown below, firmly bolt the unit to the

base.

B

A Heat source unit

ENGLISH

B 4-ø14 (Anchoring hole)

C (Top view)

Bases and anti-vibration

• Be sure to install unit in a place strong enough to withstand its weight.

If the base is unstable, reinforce with a concrete base.

• The unit must be anchored on a level surface. Use a level to check

after installation.

• Anti-vibration pads must be placed under the base of the unit.

• If the unit is installed near a room where noise is a problem, using an

anti-vibration stand on the base of the unit is recommended.

A

1177

1227

C

392

61

500

6.2. Service space

• Please allow for the following service spaces after installation.

(All servicing can be performed from the front of the unit)

A

D

1150

E

B

C

1150

400

500

600

400

A Piping space (for left piping)

B Heat source unit

C Service space (front side)

D (Top view)

E Piping space (f or top piping)

400

D

E

D Anti-vibration pad

E Concrete base

Warning:

• Be sure to install unit in a place strong enough to withstand its

weight.

Any lack of strength may cause unit to fall down, resulting in a

personal injury.

• Have installation work in order to protect against earthquake.

Any installation deficiency may cause unit to fall down, resulting in a personal injury.

F

G

H

F Piping space (for left piping)

G Heat source unit

H (Front view)

6.3. Noise level

PQRY-P200 PQRY-P250

53 dB(A) 54 dB(A)

1m

A

B

1m

A Front

B Measuring point

Measuring location: a room free from echoes and reverberations

8

Page 9

7. Refrigerant piping installation

City Multi WR2 Series is constituted by an end branching system in which the refrigerant piping from heat source unit is branched at BC controller and

connected to each indoor unit.

The connection method adapted is flange connection for low pressure pipe and flare connection for high pressure pipe between heat source unit and

BC controller, and flare connection between BC controller and indoor unit. Brazing connection is employed for joint pipe set and branch pipe set.

Warning:

Always use extreme care to prevent the refrigerant gas (R407C) from leaking while using fire or flame. If the refrigerant gas comes in contact

with the flame from any source, such as a gas sto ve, it breaks down and generates a poisonous gas which can cause gas poisoning. Never

weld in an unventilated room. Al wa ys conduct an inspection f or gas leakage after installation of the refrigerant piping has been completed.

7.1. Caution

1 Use the following materials for refrigeration piping.

• Material: Use refrigerant piping made of **C1220 phosphorus deoxidized copper as specified in the *JIS H3300 “Copper and copper alloy

seamless pipes and tubes”. In addition, be sure that the inner and outer surfaces of the pipes are clean and free of hazardous sulphur, oxides,

dust/dirt, shaving particles, oils, moisture, or any other contaminant.

• Size: Refer to Pages 10 to 11.

2 Commercially available piping often contains dust and other materials. Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the piping during installation.

4 Reduce the number of bending portions as much as possible, and make bending radius as big as possible.

5 Always observe the restrictions on the refrigerant piping (such as rated length, the difference between high/low pressures, and piping diameter).

Failure to do so can result in equipment failure or a decline in heating/cooling performance.

6 The City Multi Series WR2 will stop due an abnormality due to excessive or insufficient coolant. At such a time, always properly charge the unit.

When servicing, always check the notes concerning pipe length and amount of additional refrigerant at both locations, the refrigerant volume

calculation table on the back of the service panel and the additional refrigerant section on the labels for the combined number of indoor units. (Refer

to Pages 10 to 11.)

7 Use liquid refrigerant to fill the system.

8 Never use refrigerant to perform an air purge. Always evacuate using a vacuum pump.

9 Always insulate the piping properly . Insufficient insulation will result in a decline in heating/cooling perf ormance, water drops from condensation and

other such problems. (Refer to Pages 15 to

0 When connecting the refrigerant piping, make sure the ball valve of the heat source unit is completely closed (the factory setting) and do not operate

it until the refrigerant piping for the heat source and indoor units has been connected, a refrigerant leakage test has been performed and the

evacuation process has been completed.

A Always use a non-oxidizing brazing material for brazing the parts. If a non-oxidizing brazing material is not used, it could cause clogging or damage

to the compressor unit. (Details of the piping connections and valve operation can be found on Pages 12 to 13.)

16

.)

ENGLISH

Warning :

When installing and moving the unit, do not charge it with refrigerant other than the refrigerant (R407C) specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to malfunction and result in severe damage.

Caution:

• Use refrigerant piping made of **C1220 phosphorus deoxidized copper as specified in the *JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces of the pipes are c lean and free of hazardous sulphur , o xides, dust/

dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refrigerant residual oil to deteriorate.

• Use liquid refrigerant for sealing.

- Sealing with gas refrigerant will change the composition of the refrigerant in the cylinder and reduce the unit’s performance.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil in the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate and the compressor may fail.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

* Japanese industrial standard.

** Comparable to CU-DHP (CUPROCLIMA), Cu-bl (AFNOR), C12200 (ASTN), SF-Cu (DIN)

9

Page 10

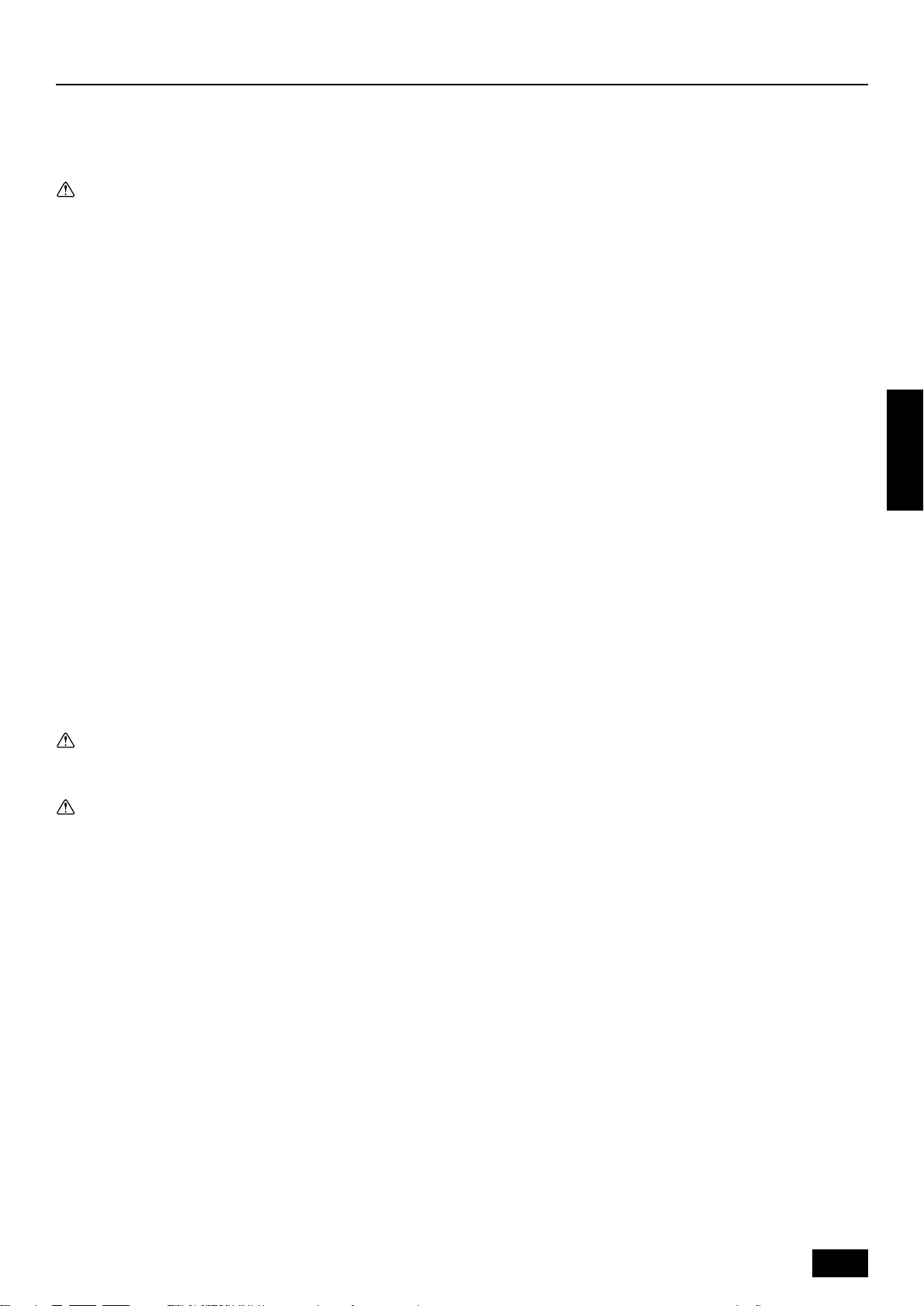

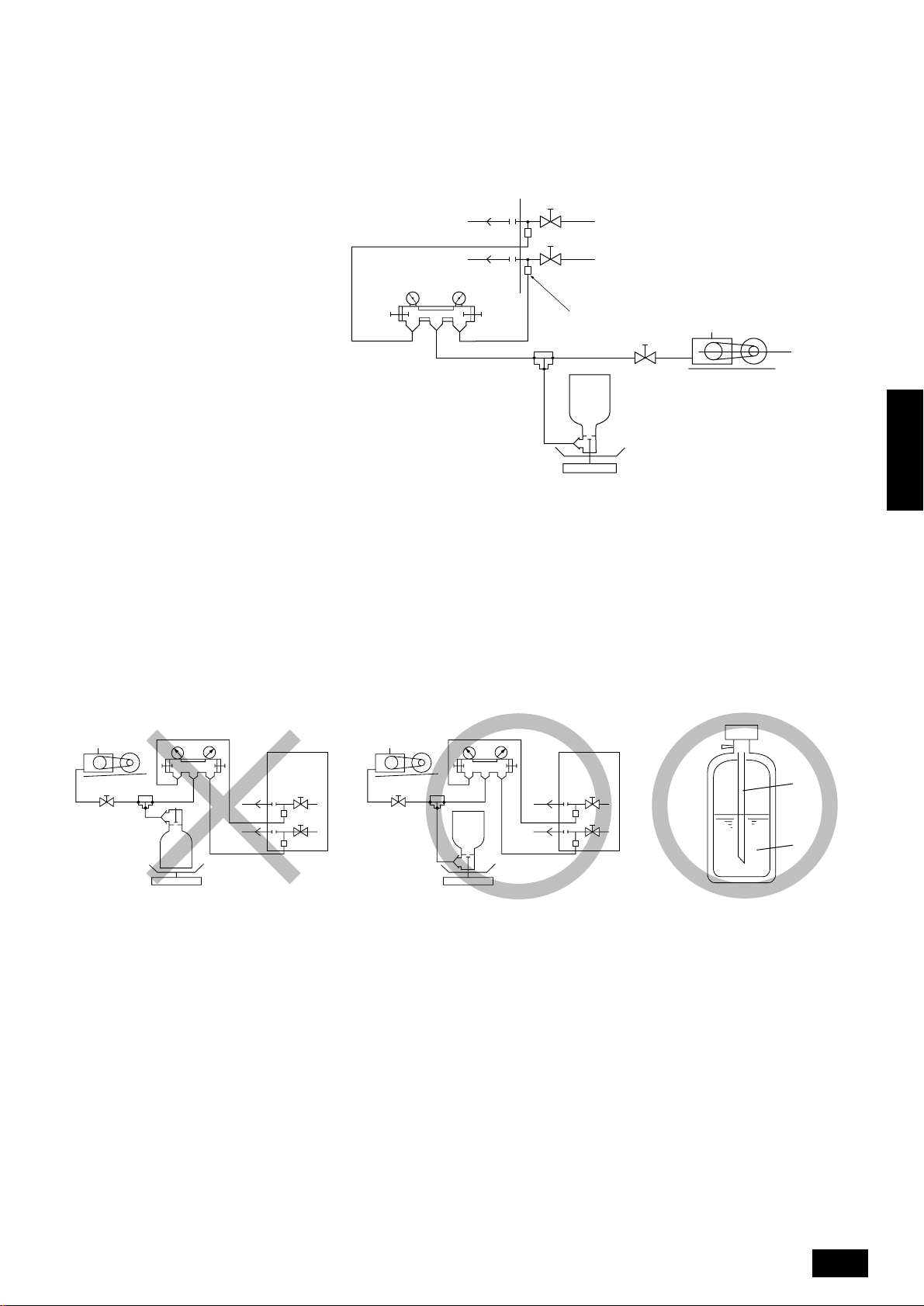

7.2. Refrigerant piping system

• Connection Example (Connection of 5 indoor units)

ENGLISH

BC

D

A

E

A

H

F

G

K

H

J

*1

b

B

L

c

d e

a

I

H H

M

H

N

A Heat source unit

B H=50 meters or less (Higher heat source unit than indoor unit)

C H’=40 meters or less (Lower heat source unit than indoor unit)

D h1=15 meters or less (10 meters or less for type 125 unit)

E h2=15 meters or less

F 70(60) meters or less

G BC controller

H Indoor unit

I Joint pipe CMY-R160-G (For V-E type of BC controller)

J (Models over 81)

K 30 meters or less

L Branch pipe CMY-Y102S-F

M Max. 3 sets for 1 connection

Total capacity less than 80

(But cooling/heating mode is same)

N *1 For selection of piping B. see (3).

10

Page 11

Total Piping Length

Permissible

Length

Farthest Piping Length (A+e)

Heat source-BC Controller Piping Length (A)

Indoor-BC Controller Piping Length (e)

Permissible

High/Low

Difference

Indoor-

Heat source

High/Low Difference in Indoor/BC controller Section (h1)

High/Low Difference in Indoor/Indoor Section

Higher Heat source High/Low Diff erence (H)

Lower Heat source High/Low Diff erence (H’)

■ Select Each Section of Refrigerant Piping

(1) Between Heat Source Unit

and BC Controller (A).

(2) Between BC Controller and

Indoor Units (a, b, c, d, e).

(3) Connection of Plural Indoor

Each

Section of

Piping

Units With One Connection

(B)

Select the size from the table to the right.

■ Additional Refrigerant Charge

At the time of shipping, the heat source unit

PQRY-P200 is charged with 7.5 kilograms of refrigerant and the PQRY-P250 is charged with 8.5

kilograms. As this charge does not include the

amount needed for extended piping, additional

charging for each refrigerant line will be required

on site. In order that future servicing may be properly provided, always keep a record of the size

and length of each refrigerant line and the amount

of additional charge by writing it in the space provided on the heat source unit.

■ Calculation of Additional Refrigerant

Charge

• Calculate the amount of additional charge

based on the length of the piping extension

and the size of the refrigerant line.

• Use the table to the right as guide to calculating the amount of additional charging and

charge the system according.

• If the calculation results of the calculation result in a fraction of less than 0.1 kg, round up

to the next 0.1 kg. For e xample, if the result of

the calculation was 10.62 kilograms, round the

result up to 10.7 kilograms.

A+B+a+b+c+d+e is 220 meters or less

A+e is 100 meters or less (90 meters or less if capacity of indoor unit exceeds 130%)

70 meters or less (60 meters or less if capacity of indoor unit exceeds 130%)

30 meters or less

50 meters or less

40 meters or less

15 meters or less

15 meters or less

(h2)

(1) Diameter of refr igerant piping between

heat source unit and BC controller

Model Piping Diameter (mm)

PQRY-P200

PQRY-P250

Connection of

heat source unit/

BC controller

High press. pipe

Low press. pipe

High press. pipe

Low press. pipe

High press. pipe

Low press. pipe

ø19.05

ø25.4

ø19.05

ø28.58

ø19.05 (Flare)

ø25.4 (Flange)

ø28.58 (Flange)

(2) Diameter of refrigerant piping between BC

controller and indoor unit.

Model number Piping Diameter (mm)

20 · 25 · 32 · 40

50 · 63 · 80

100 · 125

Liquid Line ø6.35

Gas Line ø12.7

Liquid Line ø9.52

Gas Line ø15.88

Liquid Line ø9.52

Gas Line ø19.05

(3) Selection of refrigerant piping (Piping size of B section in the above figure)

Select the size according to the total capacity of indoor units to be installed downstream.

Total capacity of indoor units Liquid line (mm) Gas line (mm)

Less than 80 ø9.52 ø15.88

81 to 160 ø12.7 ø19.05

Additional

refrigerant charge

(kg)

Liquid pipe size

Total length of

ø19.05 × 0.16

=+++ α

(m) × 0.16 (kg/m)

Liquid pipe size

Total length of

ø9.52 × 0.06

(m) × 0.06 (kg/m)

Liquid pipe size

Total length of

ø6.35 × 0.024

(m) × 0.024 (kg/m)

<Example>

Indoor 1 : 40 A : ø19.05 40 m a : ø6.35 10 m

2 : 100 B : ø 9.52 10 m b : ø9.52 5 m

3:40 c:ø6.35 10 m

4:32 d:ø6.35 10 m

At the conditions

below:

5:63 e:ø9.52 10 m

The total length of each liquid line is as follows

ø19.05 : A = 40 m

ø9.52 : B + b + e = 10 + 5 + 10 = 25 m

ø6.35 : a + c + d = 10 + 10 + 10 = 30 m

Therefore,

<Calculation example>

Additional

refrigerant charge = 40 × 0.16 + 25 × 0.06 + 30

× 0.024 + 2 = 10.7 kg

Value of α

Total capacity of

connecting indoor units

to Model 80 1.0 kg

Models 81 to 160 1.5 kg

Models 161 to 325 2.0 kg

ENGLISH

α

11

Page 12

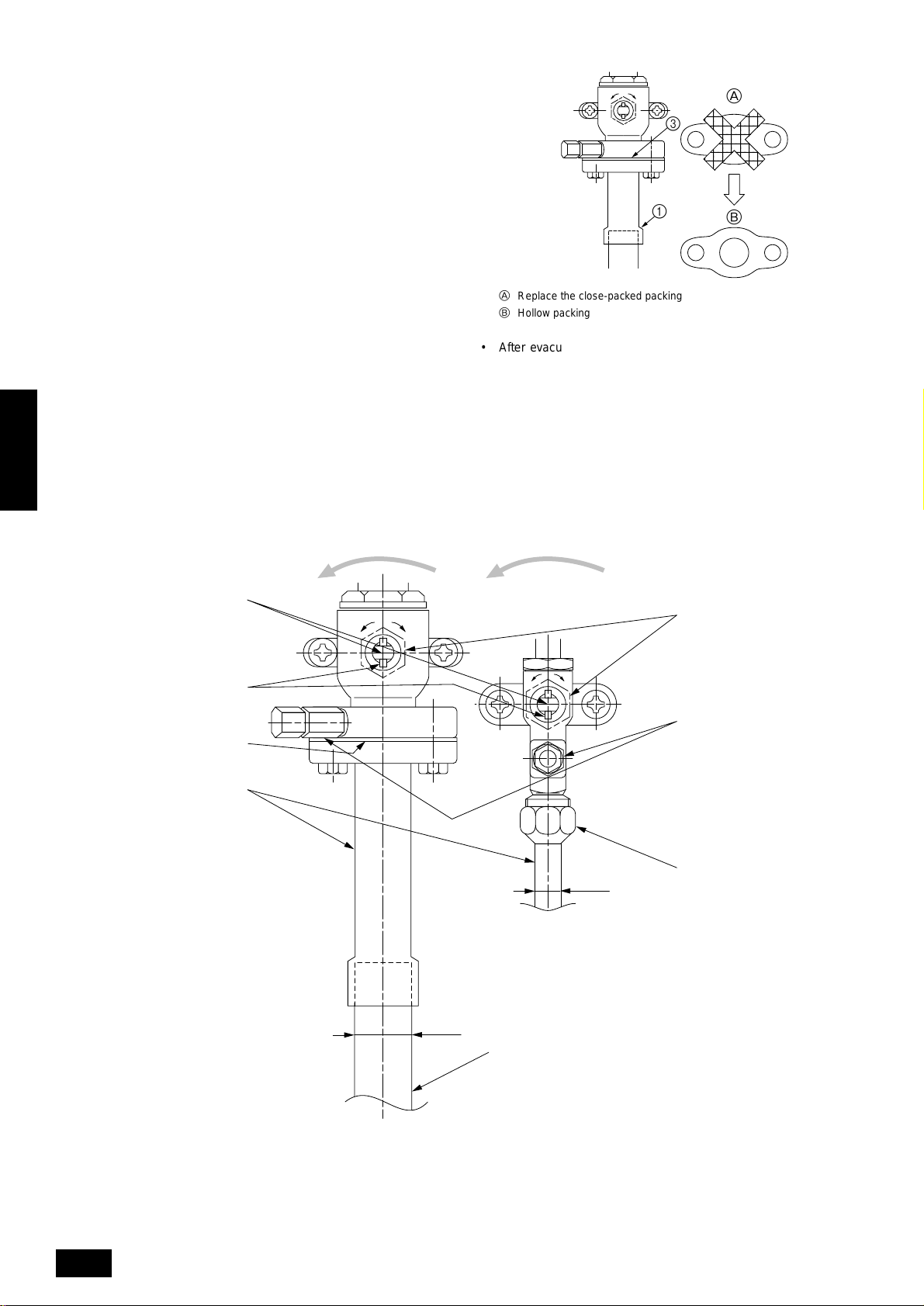

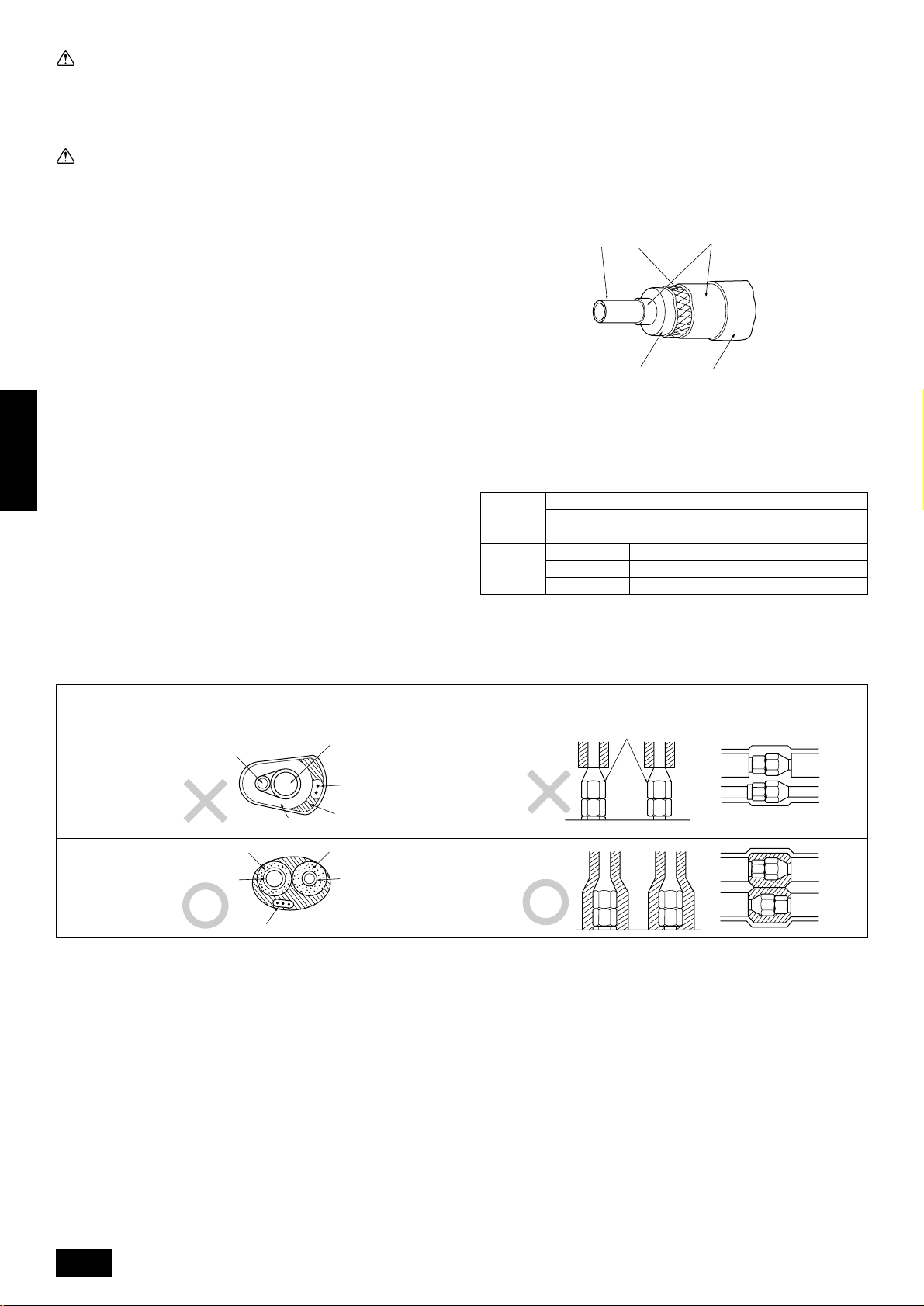

7.3. Caution for piping connection/valve

operation

• Conduct piping connection and valve operation accurately b y follo w-

ing the figure below.

• The gas side connecting pipe is being assembled for shipment.

(See the figure at the right.)

1 For brazing to the connecting pipe with flange, remove the con-

necting pipe with flange from the ball valve, and braze it at the

outside of the unit.

2 During the time when removing the connecting pipe with flange,

remove the seal attached on the back side of this sheet and paste

it onto the flange surface of the ball valve to prevent the entry of

dust into the valve.

3 The refrigerant circuit is closed with a round, close-packed pack-

ing at the shipment to prevent gas leak between flanges. As no

operation can be done under this state, be sure replace the packing with the hollow packing attached at the piping connection.

4 At the mounting of the hollow packing, wipe off dust attached on

ENGLISH

the flange sheet surface and the packing. Coat refrigerating machine oil (Ester oil, ether oil or alkylbenzene [small amount]) onto

both surfaces of the packing.

A

3

1

A Replace the close-packed packing

B Hollow packing

• After evacuation and refrigerant charge, ensure that the handle is

fully open. If operating with the valve closed, abnormal pressure will

be imparted to the high- or low-pressure side of the refrigerant circuit, giving damage to the compressor, four-w ay valve, etc.

• Determine the amount of additional refrigerant charge by using the

formula, and charge refrigerant additionally through the service port

after completing piping connection work.

• After completing work, tighten the service port and cap securely not

to generate gas leak.

B

A

B

C

D

[Ball valve (low press side)] [Ball valve (high press side)]

EE

O

S

S

O

I

F

G

H

12

J

K

(This figure shows the valve in the fully open state.)

Page 13

A Valve stem

[Fully closed at the factory , when connecting the piping, when evacuating,

and when charging additional refrigerant. Open fully after the operations

above are completed.]

B Stopper pin [Prevents the valve stem from turning 90° or more.]

C Packing (Accessory)

[Manufacturer: Nichiasu corporation]

[T ype: T/#1991-NF]

D Connecting pipe (Accessory)

[Use packing and securely install this pipe to the valve flange so that gas

leakage will not occur. (Tightening torque: 250 kg-cm (25 N·m)) Coat both

surfaces of the packing with refrigerator oil (Ester oil, ether oil or

alkylbenzene [small amount]).]

E Open (Operate slowly)

F Cap, copper packing

[Remove the cap and operate the valv e stem. Alwa ys reinstall the cap after

operation is completed. (Valve stem cap tightening torque: 250 kg-cm (25

N·m) or more)]

G Service port

[Use this port to evacuate the refrigerant piping and add an additional charge

at the site.

Open and close the port using a double-ended wrench.

Always reinstall the cap after operation is completed. (Service port cap

tightening torque: 140 kg-cm (14 N·m) or more)]

H Flare nut

[Tightening torque: 1200 kg-cm (120 N·m)

Loosen and tighten this nut using a double-ended wrench.

Coat the flare contact surface with refrigerator oil (Ester oil, ether oil or

alkylbenzene [small amount]).]

I ø19.05

J ø25.4 (PQRY-P200)

ø28.58 (PQRY-P250)

K Field piping

[Braze to the connecting pipe. (When brazing, use unoxidized brazing.)]

Caution:

• Always remove the connecting pipe from the ball v alve and braze

it outside the unit.

- Brazing the connecting pipe while it is installed will heat the ball

valve and cause trouble or gas leakage. The piping, etc. inside the

unit may also be burned.

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

ENGLISH

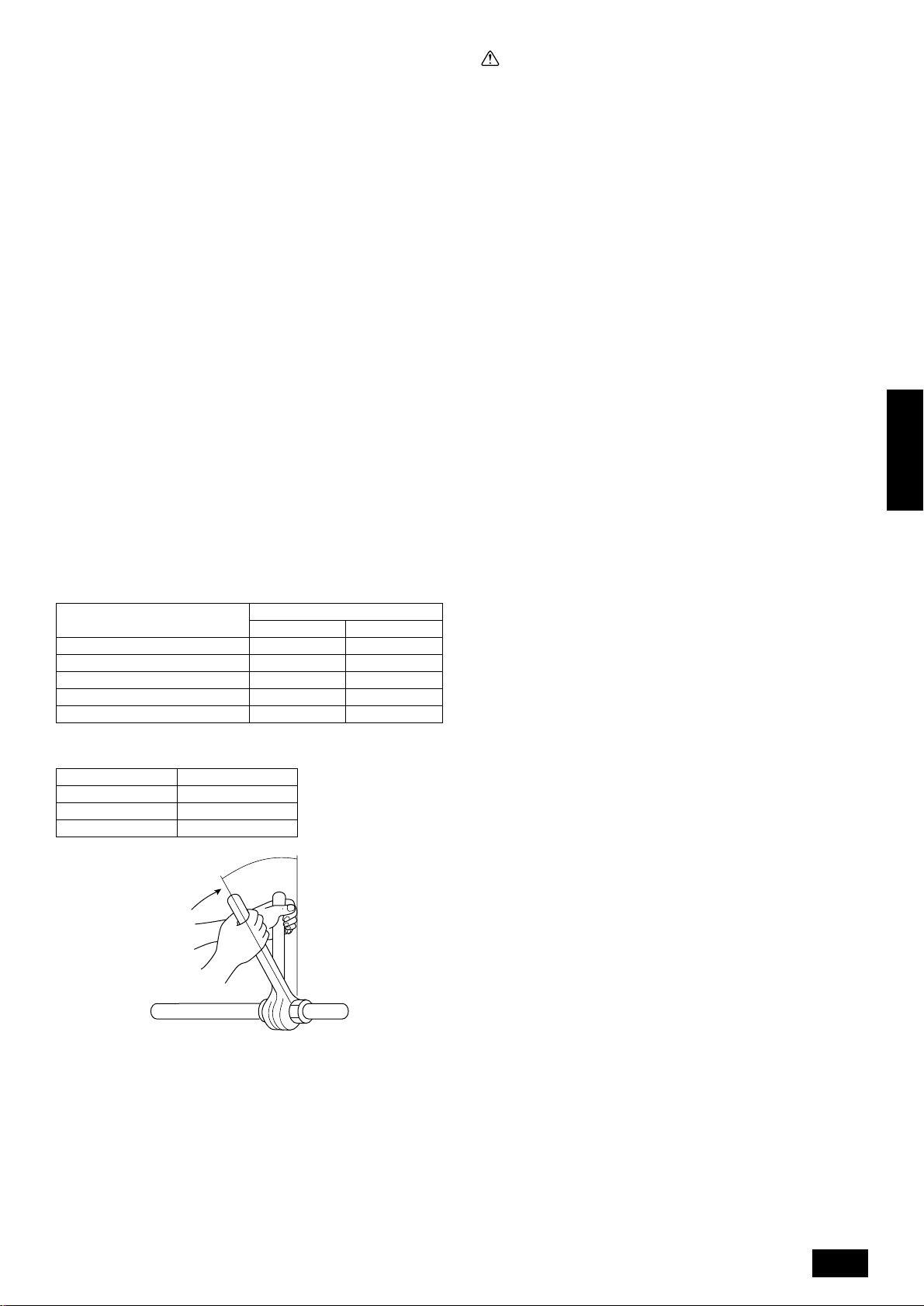

Appropriate tightening torque by torque wrench

Copper pipe external dia. Tightening torque

(mm) (kg-cm) (N·m)

ø6.35 140 to 180 14 to 18

ø9.52 350 to 420 35 to 42

ø12.7 500 to 575 50 to 57.5

ø15.88 750 to 800 75 to 80

ø19.05 1000 to 1400 100 to 140

Tightening angle standard

Pipe diameter (mm) Tightening angle (°)

ø6.35, ø9.52 60 to 90

ø12.7, ø15.88 30 to 60

ø19.05 20 to 35

Note:

If a torque wrench is not available, use the following method as a

standard.

When you tighten the flare nut with a wrench, y ou will reach a point

where the tightening torque will abrupt increase. Turn the flare nut

beyond this point by the angle shown in the table above.

13

Page 14

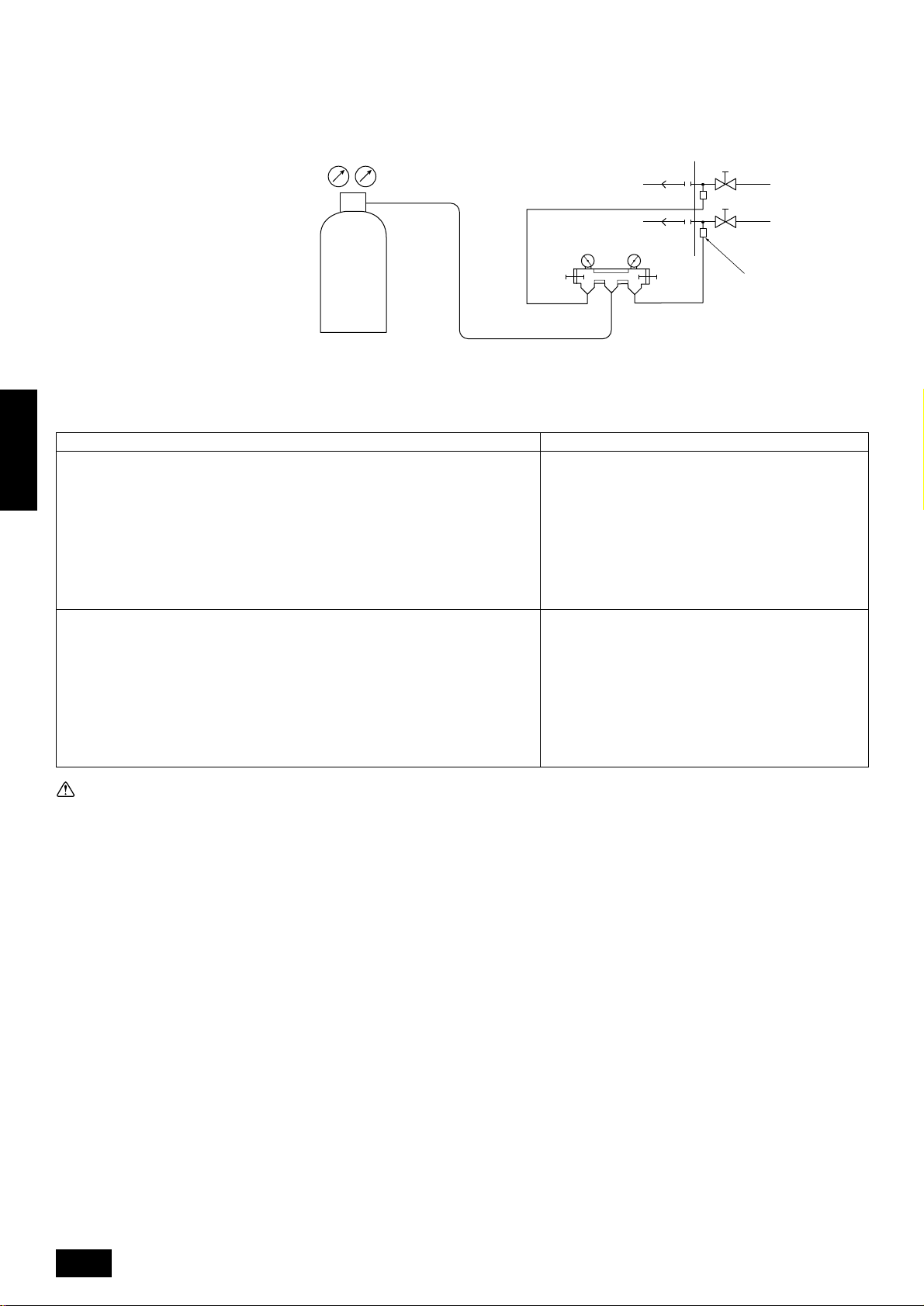

7.4. Airtight test, evacuation, and refrigerant charging

1 Airtight test

Perform with the stop valv e of the heat source unit closed, and pressurize the connection piping and the indoor unit from the service port provided

on the stop valve of the heat source unit. (Always pressurize from both the liquid pipe and the gas pipe service ports.)

A Nitrogen gas

B To indoor unit

C System analyzer

D Lo Knob

E Hi Knob

F Stop valve

G Liquid pipe

H Gas pipe

I Heat source unit

J Service port

The method of conducting the airtight test is basically the same as for older models. Howe ver, since the restrictions have a large affect on deterioration

of the refrigerator oil, always observe them. Also, with nonazeotropic refrigerant (R407C, etc.), gas leakage causes the composition to change and

affects performance. Therefore, since the entire amount must be replaced if gas leakage occurs, perform the airtightness test cautiously.

ENGLISH

Airtight test procedure

1.Nitrogen gas pressurization

(1) After pressurizing to the design pressure (2.94 MPa) using nitrogen gas, let stand

for about one day. If the pressure does not drop, airtightness is good.

However, if the pressure drops, since the leaking point is unknown, the following

bubble test may also be performed.

(2) After the pressurization described above, spray the flare connection parts, brazed

parts, flanges, and other parts that may leak with a bubbling agent (Kyuboflex,

etc.) and visually check for bubbles.

(3) After the airtight test, wipe off the bubbling agent.

2.Pressurization using refrigerant gas and nitrogen gas

(1) After sealing with liquid R407C from a cylinder and pressurizing to a gas pressure

of approximately 0.2 MPa, pressurize to the design pressure (2.94 MPa) using

nitrogen gas.

However , do not pressurize at one time. Stop during pressurization and check that

the pressure does not drop.

(2) Check for gas leaks b y checking the flare connection parts, brazed parts, flanges,

and other parts which may leak using an R407C compatible electric leak detector.

(3) This test may be used together the with bubble type gas leak test.

A

C

D

• If a flammable gas or air (oxygen) is used as the pres-

• Do not use a refrigerant other than that indicated on the

• Sealing with gas from a cylinder will cause the composi-

• Use a pressure gauge, charge box, and other parts es-

• An electric leak detector for R22 cannot detect leaks.

• Do not use a haloid torch. (Leaks cannot be detected.)

B

C

LO

HI

E

surization gas, it may catch fire or explode.

unit.

tion of the refrigerant in the cylinder to change.

pecially for R407C.

F

G

H

I

J

Restriction

Caution:

Do not use a refrigerant other than R407C.

- If a refrigerant (R22, etc,) other than R407C is used, the chlorine in the refrigerant will cause the refrigerator oil to deteriorate.

14

Page 15

2 Evacuation

As shown in the figure below , ev acuate with the ball valve of the heat source unit closed and e vacuate both the connection piping and the indoor unit

from the service port provided on the ball valve of the heat source unit using a vacuum pump. (Always evacuate from the service port of both the

liquid pipe and the gas pipe.) After the vacuum reaches 5 Torr, continue evacuation for at least one hour or more. Then, stop the vacuum pump and

let stand for one day and check if the vacuum does not rise. (If the vacuum increases by 1 Torr, since water may be mixed in, pressurize up to

0.05 MPa using dry nitrogen gas and evacuate again.) Finally, seal with liquid refrigerant from the liquid pipe. Moreover , during operation, adjust the

refrigerant amount from the gas pipe so that the refrigerant is always an appropriate amount.

* Never perform air purging using refrigerant.

D

A System analyzer

B Lo Knob

C Hi Knob

D Ball valve

E Liquid pipe

F Gas pipe

G Service port

H Three-way joint

I Valve

J Valve

K R407C cylinder

L Scale

Use a graviometer. (One that can measure down to 0.1 kg.)

M Vacuum pump

Use a vacuum pump with a reverse flow check valve.

(Recommended vacuum gauge: ROBINAIR 14010 Thermistor Vacuum Gauge)

Also use a vacuum pump that reaches 0.5 Torr or greater after operating for five minutes.

B

A

LO HI

C

H

G

K

E

F

J

I

M

L

ENGLISH

Note:

• Always add an appropriate amount of refrigerant. (For the refrigerant additional char ge, see pa ges 11.) Also always seal the system with

liquid refrigerant. Too much or too little refrigerant will cause trouble.

• Use a gauge manifold, charging hose, and other parts for the refrigerant indicated on the unit.

3 Refrigerant Charging

Since the refrigerant used with the unit is nonazerotropic, it must be charged in the liquid state. Consequently , when charging the unit with refrigerant

from a cylinder, if the cylinder does not hav e a syphon pipe, charge the liquid refrigerant by turning the cylinder upside-down as shown belo w . If the

cylinder has a syphon valve like that shown in the figure at the right, the liquid refrigerant can be charged with the cylinder standing upright.

Therefore, give careful attention to the cylinder specifications . If the unit should be charged with gas refrigerant, replace all the refrigerant with new

refrigerant. Do not use the refrigerant remaining in the cylinder.

B

A

C

A R407C cylinder

B Syphon pipe

C Liquid refrigerant

A

[When cylinder does not have a syphon pipe] [When cylinder has a syphon pipe

(Refrigerant can be charged with the

cylinder standing upright.)]

15

Page 16

Warning:

When installing or moving the unit, do not charge it with refrigerant

other than the refrigerant (R407C) specified on the unit.

- Mixing of different refrigerant, air, etc. may cause the refrigerant cycle

to malfunction and result in severe damage.

Caution:

• Use a vacuum pump with a reverse flow check valve.

- If the vacuum pump does not have a reverse flow check valve, the

vacuum pump oil may flow back into the refrigerant cycle and cause

deterioration of the refrigerator oil and other trouble.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Do not use the tools shown below used with conventional refrigerant.

(Gauge manifold, charge hose, gas leak detector, check valve,

refrigerant charge base, refrigerant recovery equipment)

- Mixing of conventional refrigerant and refrigerator oil may cause

the refrigerator oil to deteriorate.

- Mixing of water will cause the refrigerator oil to deteriorate.

- R407C refrigerant does not contain any chlorine. Therefore, gas

ENGLISH

leak detectors for conventional refrigerants will not react to it.

• Manage the tools more carefully than normal.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerator oil

will deteriorate.

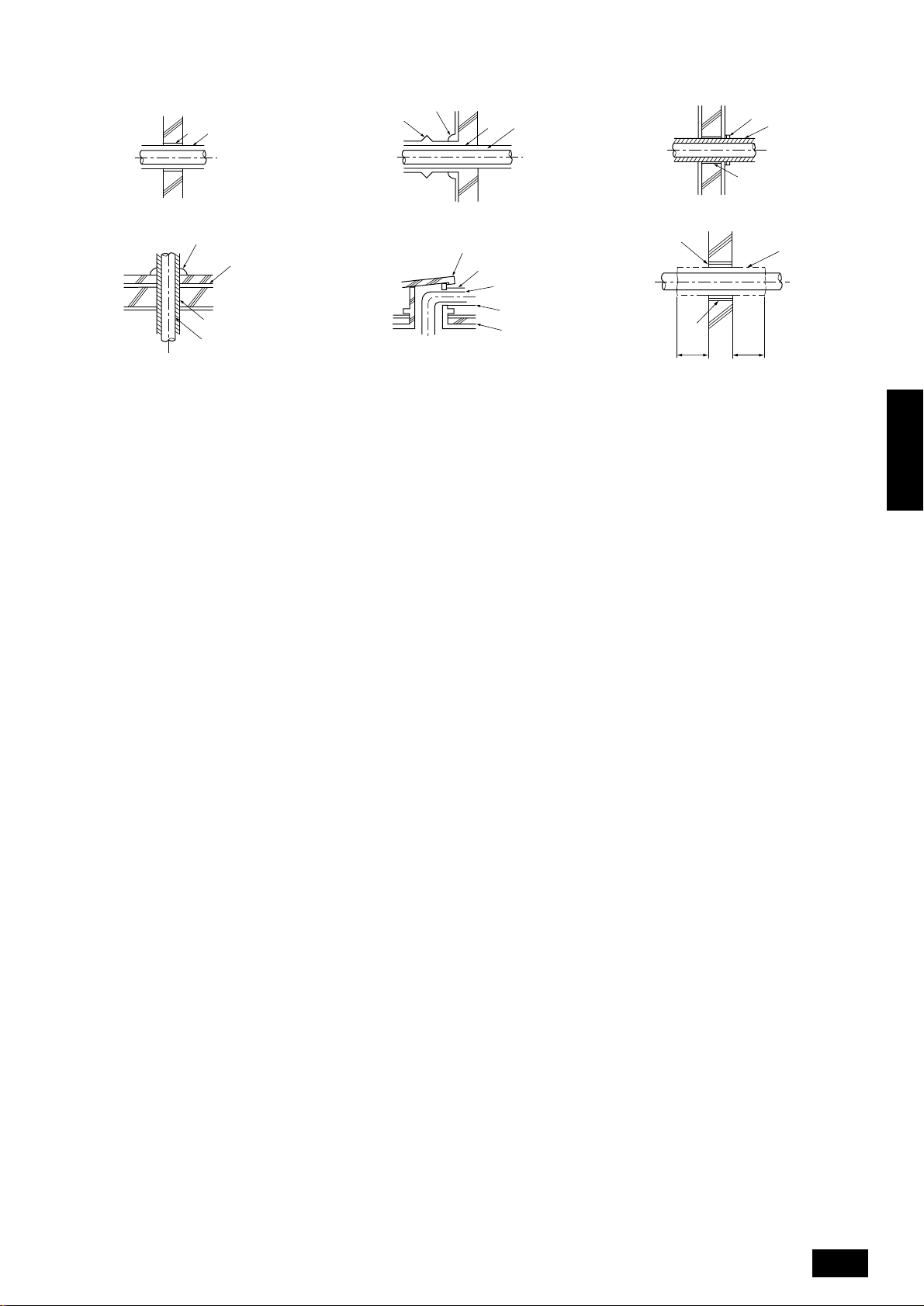

7.5. Thermal insulation of refrigerant piping

Be sure to give insulation work to refrigerant piping by covering liquid

pipe and gas pipe separately with enough thickness heat-resistant

polyethylene, so that no gap is observed in the joint between indoor unit

and insulating material, and insulating materials themselves. When insulation work is insufficient, there is a possibility of condensation drip,

etc. Pay special attention to insulation work to ceiling plenum.

B

A

D

A Steel wire

B Piping

C Asphaltic oily mastic or asphalt

D Heat insulation material A

E Outer covering B

C

E

Bad example

Good example

insulation

material A

covering B

Note:

When using polyethylene cover as co vering material, asphalt r oofing shall not be required.

• Do not insulate gas or low pressure pipe and liquid or high

pressure pipe together.

A Liquid pipe

E

B

B Gas pipe

C Electric wire

D Finishing tape

C

E Insulating material

D

A Liquid pipe

E

B Gas pipe

A

D Finishing tape

E Insulating material

A

E

B

D

Heat

Outer

Glass fiber + Steel wire

Adhesive + Heat - resistant polyethylene foam +

Adhesive tape

Indoor Vinyl tape

Floor exposed

Outdoor

• Be sure to fully insulate connecting portion.

Water-proof hemp cloth + Bronze asphalt

Water-proof hemp cloth + Zinc plate + Oily paint

A

A These parts are not insulated.

Note:

No heat insulation must be provided for electric wires.

16

Page 17

Penetrations

Inner wall (concealed) Outer wall Outer wall (exposed)

Floor (fireproofing) Roof pipe shaft Penetrating portion on fire limit and boundary wall

A Sleeve

B Heat insulating material

C Lagging

D Caulking material

E Band

F Waterproofing layer

G Sleeve with edge

A B

D

G

B

F

C

D

E

A B

B

I

G

I

J

D

B

H

F

H Lagging material

I Mortar or other incombustible caulking

J Incombustible heat insulation material

When filling a gap with mortar, cover the penetration part with steel plate

so that the insulation material will not be caved in. For this part, use

incombustible materials for both insulation and covering. (Vin yl cov ering

should not be used.)

A

1m1m

ENGLISH

7.6. Pressure vessel law (DruckbehV)

Pressure Vessel to Annex II for §12

(1) Type approval of the accumulator for ZU466/1 from competent TÜO according to §9 (1) of the Pressure Vessel Law (DruckbehV) is implemented.

(2) Expert’s inspection of accumulator group II based on §9 (2) is implemented according to §32 of the Pressure Vessel Law (DruckbehV).

(3) After installation of refrigerant gas of the air conditioner, the expert’s inspection is implemented according to VBG20 §30.

17

Page 18

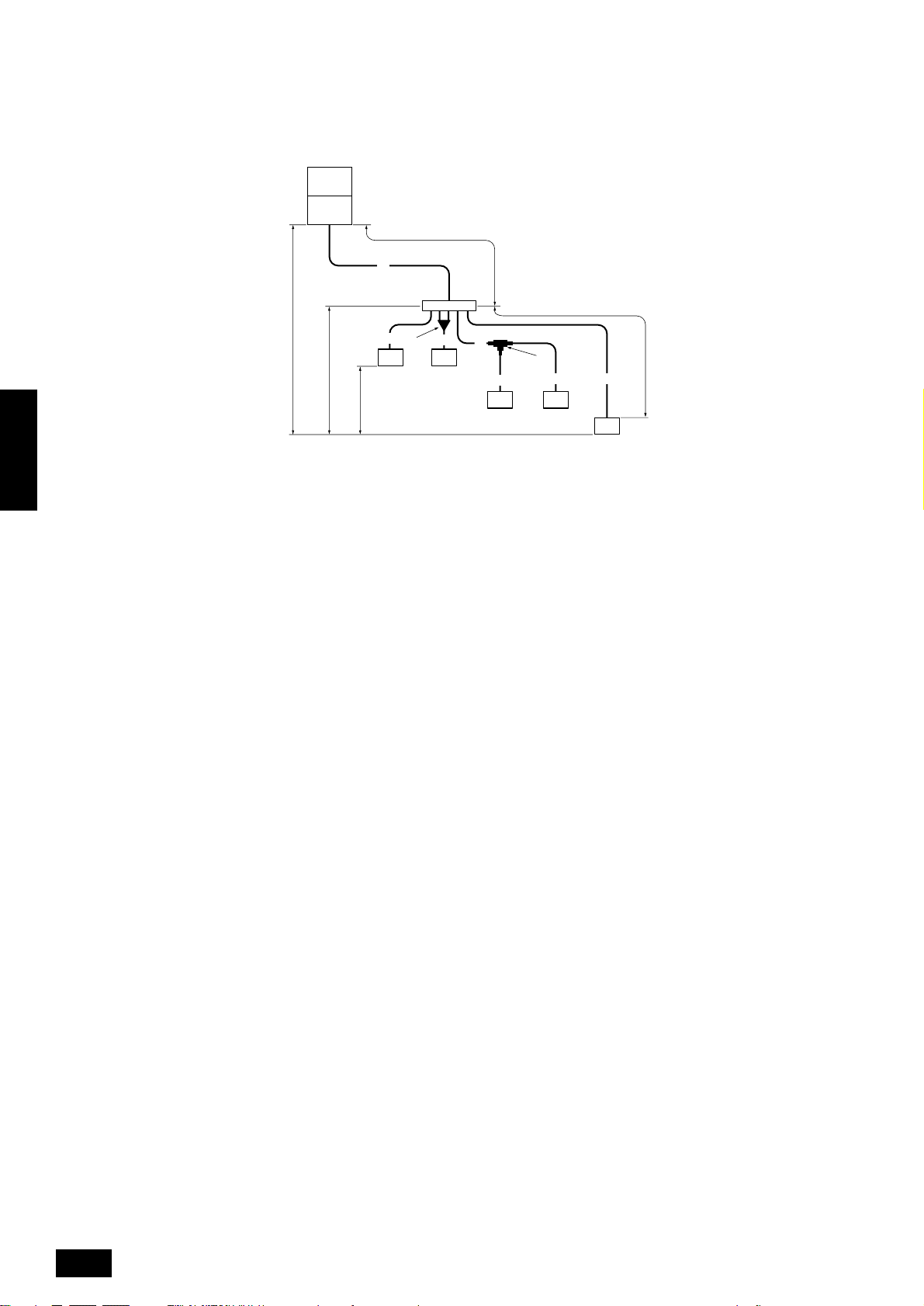

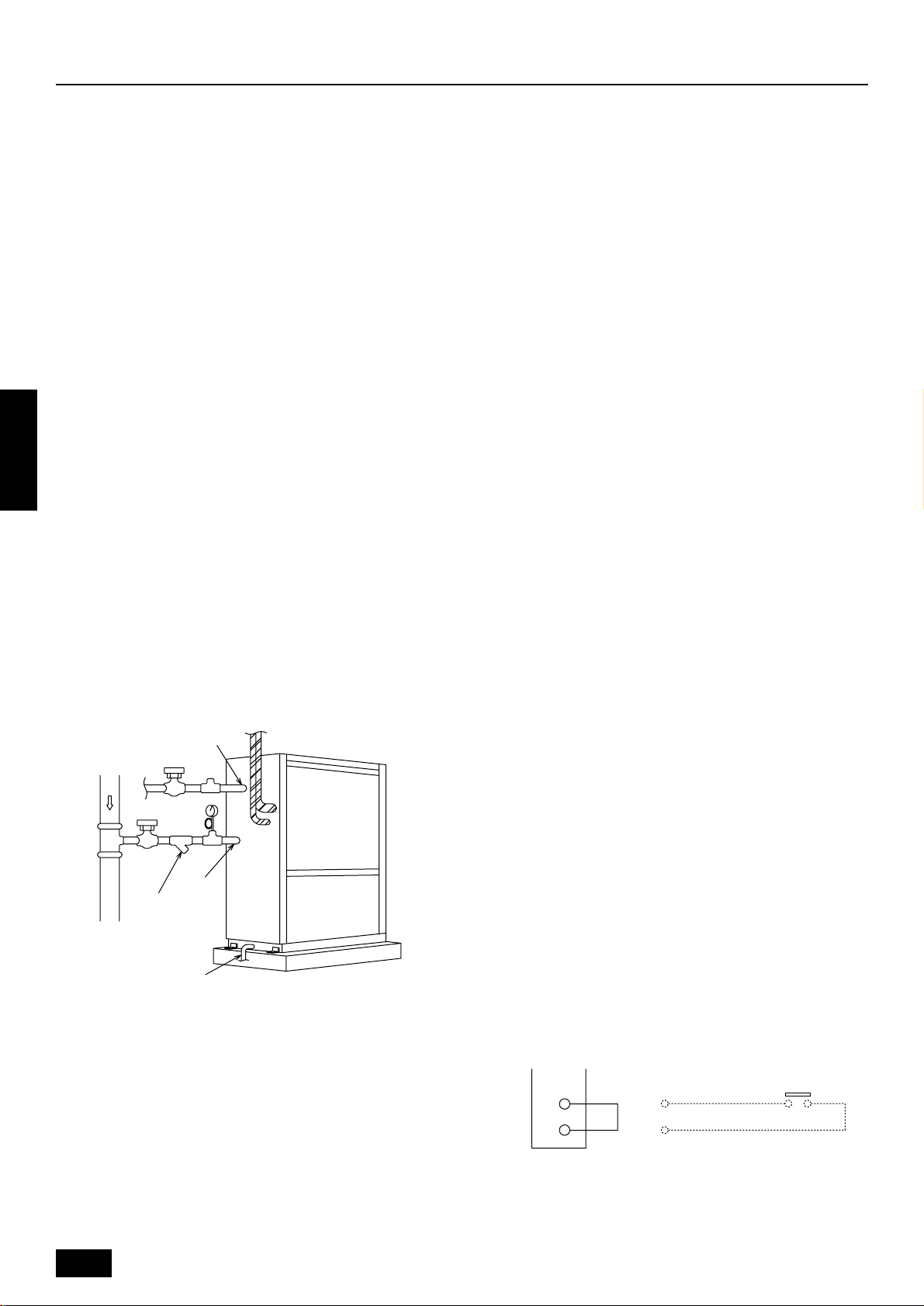

8. Water pipe installation

• City Multi WR2 Series pipes are similar to other air-conditioning pipes,

however, please observe the following precautions during installation.

8.1. Precautions during installation

• Use the reverse-return method to insure proper pipe resistance to

each unit.

• T o insure easy maintenance, inspection, and replacement of the unit,

use a proper joint, valve, etc. on the water intake and outlet port. In

addition, be sure to install a strainer on the water intake pipe. (In

order to maintain the heat source unit, a strainer on the circulating

water inlet is necessary.)

* An example of the heat source unit installation is shown in the dia-

gram below.

• Install a suitable air vent on the water pipe. After sending water through

the pipe, be sure to vent the excess air.

• Compressed water may form in the low-temperature sections of heat

ENGLISH

source unit. Use a drainage pipe connected to the drain v alve at the

base of the unit to drain the water.

• There is a water vent plug in the center of the heat exchanger water

inlet head at the middle of the unit. Use this for maintenance, etc.

In addition, do not allow any of the unit’s electrical parts (such as the

solenoid valve coil or compressor power supply) to become wet.

• Install a back flow-prev ention valve on the pump and a fle xible joint to

prevent excess vibration.

• Use a sleeve to protect the pipes where they go through a wall.

• Use metal fittings to secure the pipes, and install them so that they

have maximum protection against breakage and bending.

• Do not confuse the water intake and outlet valves.

• This unit doesn’t have any heater to prevent freezing within tubes.

When the water flow is stopped on low ambient, take out the water

from tubes.

Example of heat source unit installation (using left piping)

E

D

A

B

C

G

F

8.2. Insulation installation

With City Multi WR2 Series piping, as long as the temperature range of

the circulating water is kept to average temperatures year-round (30°C

in the summer, 20°C in the winter), there is no need to insulate or otherwise protect indoor piping from exposure. You should use insulation in

the following situations:

• Any outdoor piping.

• Indoor piping in cold-weather regions where frozen pipes are a prob-

lem.

• When air coming from the outside causes condensation to form on

piping.

• Any drainage piping.

8.3. Water processing and water quality

control

To preserve water quality, use the closed type of cooling tower for WR2.

When the circulating water quality is poor, the water heat e xchanger can

develop scales, leading to a reduction in heat-e xchange power and possible corrosion of the heat exchanger. Please pay careful attention to

water processing and water quality control when installing the water circulation system.

• Removal of foreign objects or impurities within the pipes.

During installation, be careful that foreign objects, such as welding

fragments, sealant particles, or rust, do not enter the pipes.

• Water Quality Processing

1 Depending on the quality of the cold-temperature water used in

the air-conditioner, the copper piping of the heat exchanger may

become corroded. We recommend regular w ater quality processing.

Cold water circulation systems using open heat storage tanks

are particularly prone to corrosion.

2 For detailed water quality control methods and water quality cal-

culations, please refer to each regulation of the region.

(Ex. pH8.5 ~ 9.5 reference to CIBSE GUIDE)

3 Please consult with a water quality control specialist about water

quality control methods and water quality calculations before using anti-corrosive solutions for water quality management.

4 When replacing a previously installed air conditioning device (even

when only the heat exchanger is being replaced), first conduct a

water quality analysis and check for possible corrosion.

Corrosion can occur in cold-water systems even if there has been

no prior signs of corrosion.

If the water quality level has dropped, please adjust w ater quality

sufficiently before replacing the unit.

8.4. Pump interlock

A Water circulation pipe

B Close valv e

C Close valv e

D Water outlet

E Refrigerant piping

F Y-type strainer

G Water inlet

H Drain pipe

18

H

The heat source unit may become damaged if it is operated with no

water circulating through the pipes.

Be sure to interlock unit operation and the water-circuit pump. Use the

terminal blocks for interlocking (TB8-3, 4) that can be found on the unit.

In the case of a pump interlock circuit signal connection to the TB8-3, 4,

remove the short-circuit wire. Also, to prevent mistaken error detection,

resulting from a poor connection, in the pressure valve 63PW, use a low

maintained current of 5mA or less.

TB8

3

4

A

63PW

B

A Short-circuit wire (Connected before delivery from manufacturer)

B Pump interlock circuit connection

Page 19

9. Electrical w ork

9.1. Caution

1 Follow ordinance of your governmental organization for technical standard related to electrical equipment, wiring regulations and guidance of each

electric power company.

Warning:

Be sure to have authorized electric engineers do electric work using special circuits in accordance with regulations and this installation

manual. If power supply circuit has a lack of capacity or electric work deficiency, if may cause an electric shock or fire.

2 Wiring for control (hereinafter referred to as transmission line) shall be (5 cm or more) apart from power source wiring so that it is not influenced by

electric noise from power source wiring. (Do not insert transmission line and power source wire in the same conduit.)

3 Be sure to provide designated grounding work to heat source unit.

Caution:

Be sure to put heat source unit to earth. Do not connect earth line to any gas pipe, water pipe, lightning rod or telephone earth line. If earth

is incomplete, it may cause an electric shock.

4 Give some allowance to wiring for electrical part box of indoor and heat source units, because the box is sometimes removed at the time of service

work.

5 Never connect the main power source to terminal block of transmission line. If connected, electrical parts will be burnt out.

6 Use 2-core shield cable for transmission line. If transmission lines of different systems are wired with the same multiplecore cable , the resultant poor

transmitting and receiving will cause erroneous operations.

7 Only the transmission line specified should be connected to the terminal block for heat source unit transmission.

(Transmission line to be connected with indoor unit : Terminal block TB3 for transmission line, Other : Terminal block TB7 for centralized control)

Erroneous connection does not allow the system to operate.

8 In case to connect with the upper class controller or to conduct group operation in different refrigerant systems, the control line for transmission is

required between the heat source units each other.

Connect this control line between the terminal blocks for centralized control. (2-wire line with no polarity)

When conducting group operation in different refrigerant systems without connecting to the upper class controller, replace the insertion of the short

circuit connector from CN41 of one heat source unit to CN40.

9 Group is set by operating the remote controller.

ENGLISH

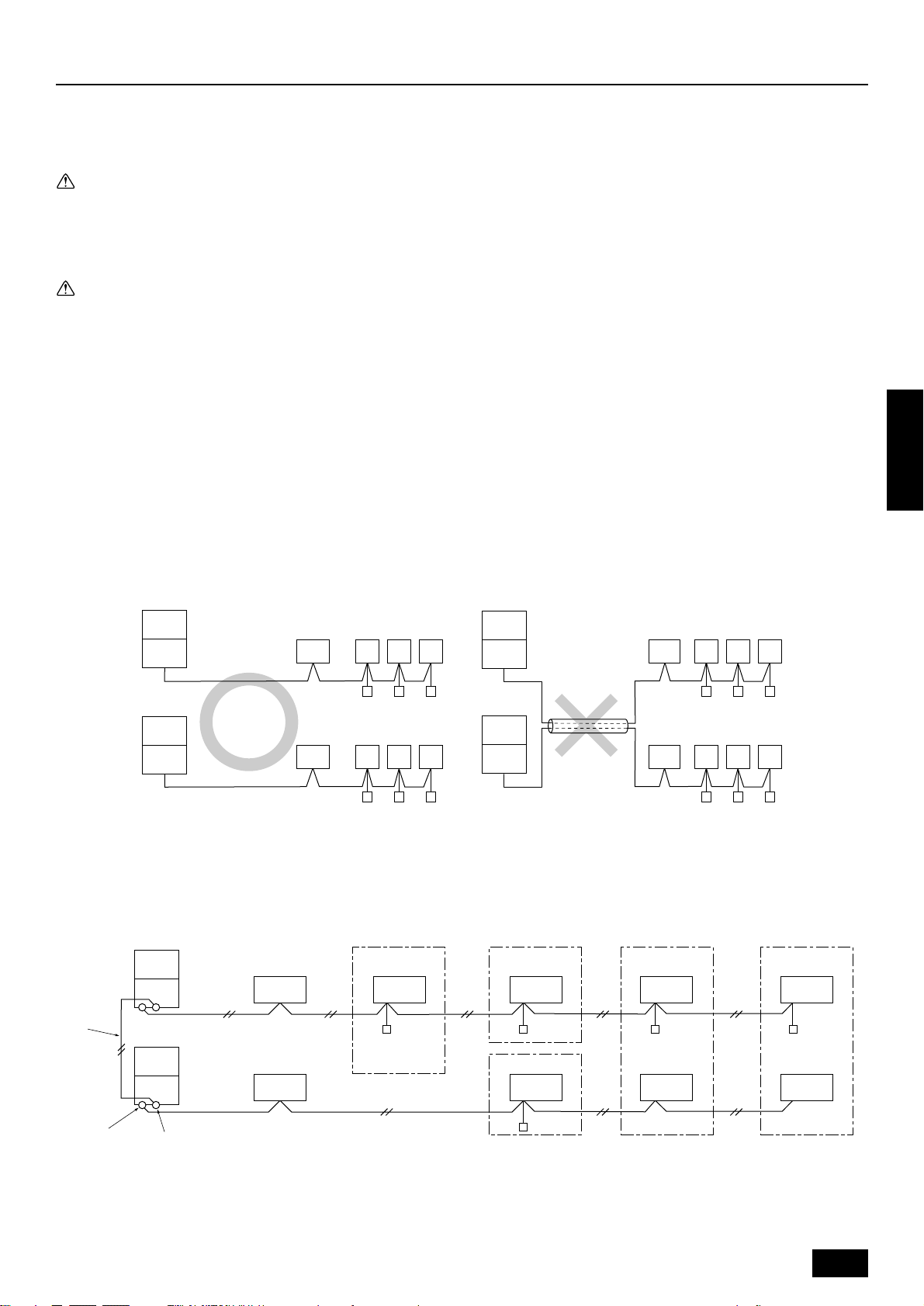

A

B

F

A Heat source unit

B Transmission line (2-core shielding cable)

C BC controller

D Indoor unit

E Remote controller

F Transmission line (2-core shielding cable)

B

GH HHH

A

C

D

DC

E

G

H

G Heat source unit

H Multiple-core cable

I BC controller

J Indoor unit

K Remote controller

JI

K

H

C

E

A Transmission line for centralized control (required for the group operation

in different refrigerant system)

B Heat source unit (No. 1)

C Transmission line

D Heat source unit (No. 2)

F

H

E Terminal block for transmission line TB3

F Terminal block for centralized control TB7

G BC controller

H Indoor unit

HG

19

Page 20

9.2. Control box and connecting position

A

of wiring

1 Heat source unit

1. The service panel can be taken off by removing the three screws

along the top, leaning the panel forward, and lifting upwards. (see

diagram below)

A

3. Connect the indoor unit transmission line to transmission terminal

block (TB3), or connect the wiring between heat source units or the

wiring with the central control system to the central control terminal

block (TB7).

When using shielded wiring, connect shield ground of the heat source

unit transmission line to the earth screw (

ground of the line between heat source units and the central control

system transmission line to the shield (S) terminal of the central control terminal block (TB7) shield (S) terminal. In addition, in the case

of heat source units whose power supply connector CN41 has been

replaced by CN40, the shield terminal (S) of central control terminal

block (TB7) should also be connected to the ground ( ).

4. When attaching an interlock to the water circuit pump, use the pump

interlock terminal block (TB8-3, 4). At this time, be sure to remove

the short-circuit wire attached to the terminal block.

) and connect shield

ENGLISH

A Service panel

2. Remove the screw on each side (right and left) of the control box

cover, then pull the cover down to remove it. (The illustration below

shows the control box with the cover removed.)

C

LD1

E

D

F

M2M1

S

G

4321

TB8

H

NL3L2L1

TB1

TB3

M1 M2

TB7

I

A

B

A Control box

2 Wiring Procedure

When wiring at the site of installation, separate the power source lines

and transmission lines, and proceed with installation holding them in

proper bundles.

Also use the wiring mounting board and cable straps to hold the wires in

place. When installing pump interlock wiring on-site, use the same path

as the power source lines.

A

D

C

C

B

D

B

A Inverter board (INV board)

B Control board (MAIN board)

C Relay board

D Ten position

E One position

F Address switch

G Signal IN/OUT (1, 2 : UNIT ON/OFF, 3, 4 : PUMP INTERLOCK)

H Power source

I Transmission line

20

B

A Wiring mounting board

B Cable straps

C ø39 Knockout hole (Hole for the power supply)

D ø28 Knockout hole (Hole for the control wiring)

D

C

Page 21

9.3. Wiring transmission cables

1 Types of control cables

1. Wiring transmission cables

• Types of transmission cables

Shielding wire CVVS or CPEVS

• Cable diameter

More than 1.25 mm

• Maximum wiring length within 200 m

2. Remote control cables

2

Kind of remote control

cable

Cable diameter

Remarks

2 Wiring examples

Typical wiring examples are shown on pages 22 to 25.

• Controller name, symbol and allowable number of controllers.

Name Symbol Allowable number of controllers

Heat Source Unit Controller

BC Controller BC One controller for one OC

Indoor Unit Controller IC

Remote Controller RC Maximum of two per group

2-core cable (unshielded)

0.5 to 0.75 mm

When 10 m is exceeded, use cable with

the same specifications as (1) Transmission line wiring.

OC

Two to sixteen controllers for one OC

2

ENGLISH

21

Page 22

A. Example of a single-heat source-unit system (Shielding wires and address setting are necessary.)

Example of wiring control cables Wiring Method and Address Setting

1. Standard operation

L

OC

(51)

TB3 TB7

M1 M2

M1 M2 S

• One remote controller for each indoor

unit

• Inside ( ): Address

ENGLISH

There is no need for setting the 100 po-

1

BC

(52)

M1 M2 S

L

2

TB5

M2

M1

S

4

L

1

r

TB6

(101)

RC

(01)

L

3

IC

2

r

M1

TB6

(102)

TB5

M2

RC

IC

(02)

S

sition on the remote controller.

2. Operation Using Two Remote controllers

OC

(51)

TB3 TB7

M1 M2

M1 M2 S

BC

(52)

M1 M2 S

TB6

(101)

RC

IC

(01)

TB5

M2

M1

S

TB6

(151)

RC

TB6

(102)

IC

(02)

TB5

M2

M1

S

TB6

(152)

RC

RC

AB AB

• Using two remote controllers for each indoor unit.

3. Group operation

OC

(51)

TB3 TB7

M1 M2

M1 M2 S

• Two to five indoor units

operated together by one

remote controller

BC

(52)

M1 M2 S

M1

TB6

(101)

TB5

M2

RC

IC

(01)

S

A Main Remote Controller

B Sub Remote Controller

A

M1

A Main

B Sub

TB5

M2

B

IC

(02)

S

a. Use feed wiring to connect terminals M1 and M2 on

transmission cable block (TB3) for the heat source

unit (OC) to terminals M1 and M2 on the transmission

cable block (TB5) of each indoor unit (IC). Use nonpolarized two wire.

To ground the shielded wire, use cross-over wiring

from the ground terminal on the heat source unit

and terminal S on the indoor unit (TB5).

b. Connect terminals A and B on the transmission cable

block (TB4) for each indoor unit with the terminal bloc k

(TB6) for the remote controller (RC).

c. Set the address setting switch as shown below.

* To set the heat source unit address to 100, the heat

source address setting switch must be set to 50.

Unit

Indoor Unit

Heat Source

Unit

BC controller

Remote

controller

Range

01 to 50

51 to 100

51 to 100

101 to 150

Setting Method

—

Use the most recent address

of all the indoor units plus 50.

Heat source unit

address plus 1.

Indoor unit address plus

100.

a. Same as above .

b. Same as above.

c. Set address switch as shown below .

* To set the heat source unit address to 100, the heat

source address setting switch must be set to 50.

Unit

Indoor Unit

Heat Source

Unit

BC

controller

Main Remote

Controller

Sub Remote

Controller

Range

01 to 50

51 to 100

51 to 100

101 to 150

151 to 200

Setting Method

—

Use the most recent

address of all the indoor

units plus 50.

Heat source unit

address plus 1.

Indoor unit address plus

100.

Indoor unit address plus

150.

a. Same as above.

b. Connect terminals M1 and M2 on transmission cable

terminal block (TB5) of the IC main unit with the most

recent address within the same indoor unit (IC) group

to terminal block (TB6) on the remote controller.

c. Set the address setting switch as shown below.

* To set the heat source unit address to 100, the heat

source address setting switch must be set to 50.

Unit

Range

Setting Method

Use the most recent ad-

IC (Main)

01 to 50

dress within the same group

of indoor units.

Use an address, other than

that of the IC (Main) from

IC (Sub)

01 to 50

among the units within the

same group of indoor units.

This must be in sequence

with the IC (Main).

Heat Source

Unit

BC controller

Main Remote

Controller

Sub Remote

Controller

51 to 100

51 to 100

101 to 150

151 to 200

Use the most recent address of all the indoor units

plus 50.

Heat source unit address plus 1.

Set at an IC (Main) address

within the same group plus

100.

Set at an IC (Main) address

within the same group plus

150.

d. Use the indoor unit (IC) within the group with the most

functions as the IC (Main) unit.

Combinations of 1 through 3 above are possible.

22

Page 23

Permissible Lengths Prohibited items

Longest transmission cable length

(1.25 mm2)

L1 + L2 + L3, L3 + L4,

4 + L1 + L2

L

Remote controller cable length

1 If 0.5 to 0.75 mm

200 m

=

2

r1 , r2 = 10 m

2 If the length exceeds 10 meters,

the exceeding section should be

1.25 mm2 and that section should

be a value within the total extension length of the transmission cable and maximum transmission

cable length. (L

4)

Same as above

Same as above

OC

(51)

TB3 TB7

M1 M2

M1 M2 S

TB3 TB7

M1 M2

(51)

OC

M1 M2 S

BC

(52)

M1 M2 S

TB6

(101)

RC

(52)

M1 M2 S

IC

(01)

TB5

M2

M1

S

IC

(02)

TB5

M2

M1

S

• Use the indoor unit

(IC) address plus 150

as the sub remote

controller address. In

ENGLISH

this case, it is 152.

• Three or more remote

controllers (RC)

cannot be connected

TB6

(151)

RC

TB6

(102)

RC

TB6

(103)

RC

TB6

(104)

RC

to one indoor unit.

ABAB

A Main

B Sub

BC

A B

IC

(01)

TB5

M2

M1

S

IC

(02)

TB5

M2

M1

S

TB6

(102)

RC

• The remote controller address is the

indoor unit main

address plus 100. In

this case, it is 101.

A Main

B Sub

23

Page 24

B. Example of a group operation system with multiple heat source units (Shielding wires and address setting are necessary.)

L

L

1

L

2

3

L

4

L

5

ENGLISH

Examples of Transmission Cable Wiring

OC

CN40

(51)

TB3

M1 M2

M1 M2 S

TB7

11

L

D

TB3

M1 M2

(52)

OC

M1 M2 S

TB7

A Group 1

B Group 3

C Group 5

D Shielded Wire

E Sub Remote Controller

A B C

TB5

M1 M2 S

TB6

(101)

RC

TB5

M1 M2 S

(01)

(02)

IC

L

8

IC

BC

(53)

M1 M2 S

1

r

L

6

M1 M2 S

BC

(54)

L

7

IC

(04)

TB5

M1 M2 S

L

9

IC

(03)

TB5

M1 M2 S

10

L

4

r

TB6

(103)

RC

IC

(05)

TB5

M1 M2 S

2

r

TB6

(105)

RC

TB5

M1 M2 S

(07)

IC

r3

E

TB6

(155)

RC

TB5

M1 M2 S

IC

(06)

( ) Address

a. Always use shielded wire when making connections between the heat source unit (OC) and the indoor unit (IC), as well for all OC-OC, and

IC-IC wiring intervals.

b. Use feed wiring to connect terminals M1 and M2 and the ground terminal on the transmission cable terminal block (TB3) of each heat source

unit (OC) to terminals M1, M2 and terminal S on the transmission cable block of the indoor unit (IC).

c. Connect ter minals M1 and M2 on the transmission cable terminal block of the indoor unit (IC) that has the most recent address within the

same group to the terminal block (TB6) on the remote controller (RC).

d. Connect together terminals M1, M2 and terminal S on the terminal block for central control (TB7) for the heat source unit (OC).

e. On one heat source unit only, change the jumper connector on the control panel from CN41 to CN40.

f. If the jumper connector was changed to CN40 in step e, connect terminal S on the central control terminal block (TB7) of the heat source unit

(OC) to the ground screw in the electrical component box.

g. Set the address setting switch as follows.

* To set the heat source unit address to 100, the heat source address setting switch must be set to 50.

Unit Range Setting Method

IC (Main) 01 to 50 Use the most recent address within the same group of indoor units.

IC (Sub) 01 to 50

Use an address, other than that of the IC (Main) from among the units within the same group of

indoor units. This must be in sequence with the IC (Main).

Heat Source Unit 51 to 100 Use the most recent address of all the indoor units plus 50.

Wiring Method and Address Settings

BC controller 51 to 100 Heat source unit address plus 1. Make sure that each heat source unit and BC controller is set

to a different withiin the specified range.

Main Remote Controller 101 to 150 Set at an IC (Main) address within the same group plus 100.

Sub Remote Controller 151 to 200 Set at an IC (Main) address within the same group plus 150.

h. The group setting operations among the multiple indoor units is done by the remote controller (RC) after the electrical power has been

turned on.

24

Page 25

• Max length via heat source units : L1+L2+L3+L4+L5+L6+L7+L8+L9+L11,

L1+L2+L3+L4+L5+L6+L7+L8+L10+L11 = 500 meters (1.25 mm2)

• Max transmission cable length : L

• Remote controller cable length : r

1+L2+L3+L4+L5, L6+L7+L8+L9, L6+L7+L8+L10, L9+L10

1, r2, r3, r4

10 meters (0.5 to 0.75 mm2)

=

If the length exceeds 10 meters, use a 1.25 mm2 shielded wire. The length of this section (L8) should

Permissible Lengths

be included in the calculation of the maximum length and overall length.

200 meters (1.25 mm2)

=

Prohibited items

TB3

M1 M2

D

TB3

M1 M2

OC

CN40

(51)

OC

(52)

M1 M2 S

TB7

M1 M2 S

TB7

BC

(53)

M1 M2 S

BC

(54)

M1 M2 S

A B C

TB5

M1 M2 S

TB6

(101)

RC

TB5

M1 M2 S

(01)

(02)

IC

IC

TB5

M1 M2 S

TB5

M1 M2 S

IC

(04)

IC

(03)

TB5

M1 M2 S

TB6

(105)

RC

TB5

M1 M2 S

(05)

(07)

IC

TB6

(155)

E

IC

IC

(06)

TB5

M1 M2 S

ENGLISH

RC

TB6

(103)

RC

A Group 1

B Group 3

C Group 5

D Shielded wire

E Sub Remote Controller

• The terminal S on the terminal block (TB7) for the central control panel should be connected to the ground terminal of the electric

components box for one heat source unit only.

• Never connect together the terminal blocks (TB5) for transmission wires for indoor units (IC) that have been connected to different heat

source units (OC).

• Set all addresses to ensure that they are not overlapped.

25

Page 26

9.4. Wiring of main power supply and equipment capacity

Warning:

• Be sure to use specified wires to connect so that no external force is imparted to terminal connections. If connections are not fixed firmly,

it may cause heating or fire.

• Be sure to use the appropriate type of overcurrent protection switch. Note that generated overcurrent may inc lude some amount of direct current.

Caution:

• The reverse phase of L lines (L1, L2, L3) can be detected (Error cord: 4103), b ut the reverse phase of L lines and N line can not be detected.

The some electric parts should be damaged when power is supplied under the miss wiring.

• Some installation site may require attachment of an earth leakage breaker. If no earth leakage breaker is installed, it may cause an electric shock.