Mitsubishi PQRY-P96TLMU-A, PQRY-P144TLMU-A, PQRY-P168TLMU-A, PQRY-P120TLMU-A, PQRY-P144TSLMU-A User Manual

...

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-1

© 2017 Mitsubishi Electric US, Inc.

WR2-SERIES WATER-SOURCE UNITS

WATER-SOURCE UNITS

1. SPECIFICATIONS .....................................................................................................................................................WR2-3

1-1. PQRY-P72~336T(S)LMU-A Specications ..................................................................................................WR2-3

1-2. PQRY-P72~336Y(S)LMU-A Specications ................................................................................................WR2-15

1-3. Efciency Ratings ......................................................................................................................................WR2-27

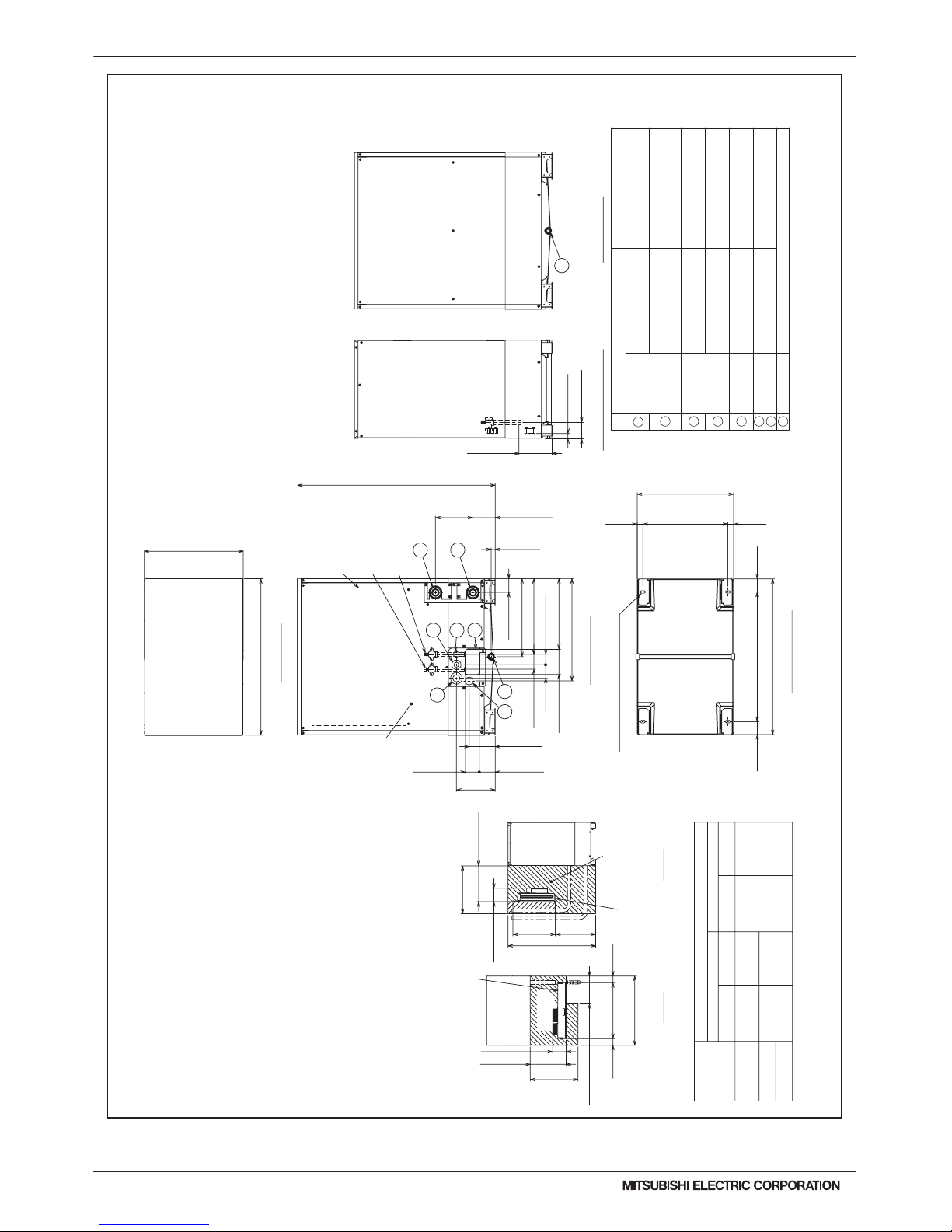

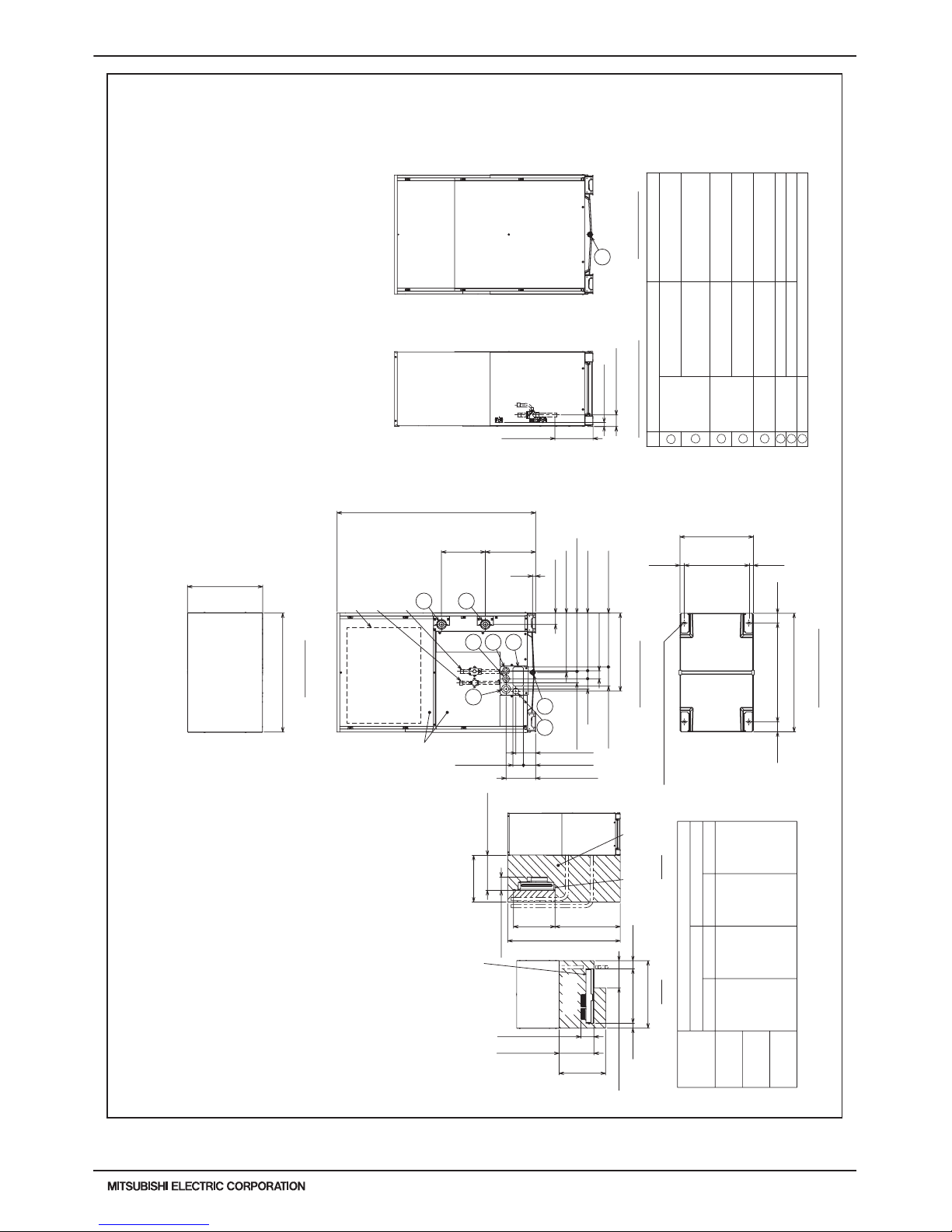

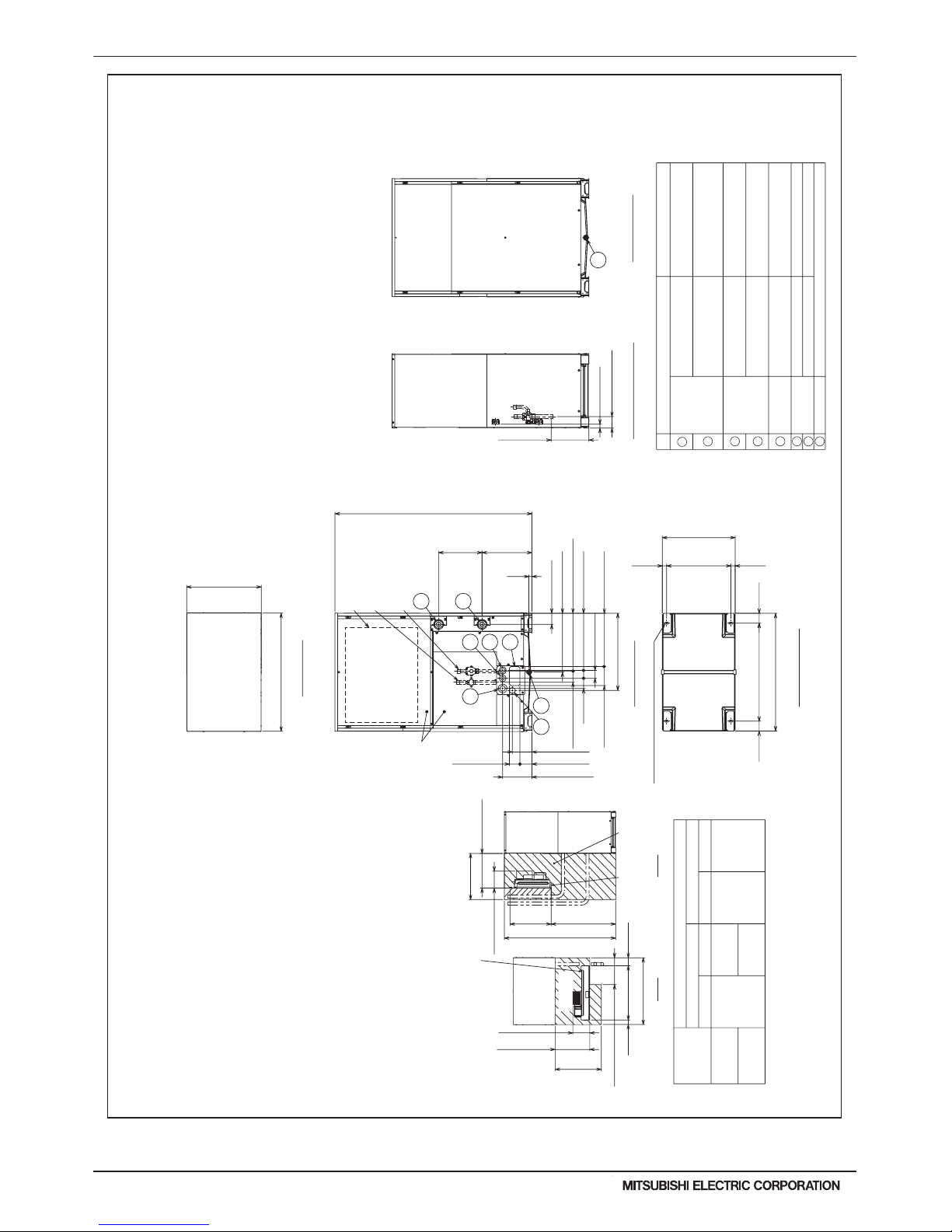

2. EXTERNAL DIMENSIONS ......................................................................................................................................WR2-28

PQRY-P72, 96, 120TLMU-A .............................................................................................................................WR2-28

PQRY-P144, 168, 192TLMU-A .........................................................................................................................WR2-29

PQRY-P216, 240TLMU-A .................................................................................................................................WR2-30

PQRY-P144, 168, 192, 216, 240TSLMU-A .......................................................................................................WR2-31

PQRY-P288, 312, 336TSLMU-A .......................................................................................................................WR2-32

PQRY-P72, 96, 120YLMU-A .............................................................................................................................WR2-33

PQRY-P144, 168, 192YLMU-A .........................................................................................................................WR2-34

PQRY-P216, 240YLMU-A .................................................................................................................................WR2-35

PQRY-P144, 168, 192, 216, 240YSLMU-A.......................................................................................................WR2-36

PQRY-P288, 312, 336YSLMU-A .......................................................................................................................WR2-37

3. CENTER OF GRAVITY ...........................................................................................................................................WR2-38

4. ELECTRICAL WIRING DIAGRAMS ........................................................................................................................WR2-39

5. REFRIGERANT CIRCUIT DIAGRAMS ...................................................................................................................WR2-43

6. SOUND PRESSURE LEVELS ................................................................................................................................WR2-46

7. OPERATION TEMPERATURE RANGE ..................................................................................................................WR2-50

7-1. Connection with standard CITY MULTI indoor units .................................................................................. WR2-50

7-2. Connection with PWFY-P36NMU-E-BU (Booster unit) .............................................................................. WR2-51

7-3. Connection with PWFY-P36/72NMU-E2-AU (HEX unit) ............................................................................ WR2-51

8. CAPACITY TABLES ................................................................................................................................................WR2-52

8-1. Correction by Temperature in Fahrenheit ..................................................................................................WR2-52

8-2. Correction by Temperature in Celsius .......................................................................................................WR2-68

8-3. Water temperature correction factors (Geothermal) ..................................................................................WR2-84

8-4. Water volume correction factors (Geothermal) ..........................................................................................WR2-86

8-5. Indoor temperature correction factors (Geothermal) .................................................................................WR2-91

8-6. Glycol correction factors ............................................................................................................................WR2-94

8-7. Glycol freeze protection % ........................................................................................................................WR2-98

8-8. Correction by Total Indoor .........................................................................................................................WR2-99

8-9. Correction by Refrigerant Piping Length .................................................................................................WR2-105

9. OPTIONAL PARTS ................................................................................................................................................WR2-109

9-1. Branch Joint .............................................................................................................................................WR2-109

9-2. Headers ................................................................................................................................................... WR2-110

9-3. Water-source Unit Twinning Kit ............................................................................................................... WR2-111

9-4. Joint Adapter Kit ......................................................................................................................................WR2-112

WR2-2

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

10. ELECTRICAL WORK ..........................................................................................................................................WR2-113

10-1. General Cautions ................................................................................................................................... WR2-113

10-2. Power Supply for Indoor Unit and Outdoor Unit .................................................................................... WR2-114

10-3. Power Cable Specications ................................................................................................................... WR2-118

10-4. Power Supply Examples ........................................................................................................................ WR2-119

11. M-NET CONTROL ...............................................................................................................................................WR2-121

11-1. Transmission Cable Length Limitation ...................................................................................................WR2-121

11-2. Transmission Cable Specications ........................................................................................................WR2-122

11-3. System Conguration Restrictions .........................................................................................................WR2-123

11-4. Address Setting ......................................................................................................................................WR2-126

12. PIPING DESIGN .................................................................................................................................................WR2-139

12-1. R410A Piping Material ...........................................................................................................................WR2-139

12-2. Piping Design ........................................................................................................................................WR2-139

12-3. Refrigerant Charging Calculation ..........................................................................................................WR2-143

13. INSTALLATION ...................................................................................................................................................WR2-145

13-1. PQRY-P-T(S)LMU/Y(S)LMU’s Installation .............................................................................................WR2-145

13-2. Installation Space ..................................................................................................................................WR2-145

13-3. Piping Direction .....................................................................................................................................WR2-146

14. INSTALLATION INFORMATION .........................................................................................................................WR2-147

14-1. General Precautions ..............................................................................................................................WR2-147

14-2. Precautions for Indoor unit ....................................................................................................................WR2-148

14-3. Precautions for Outdoor unit/Heat source unit ......................................................................................WR2-149

14-4. Precautions for Control-related items ....................................................................................................WR2-150

15. CAUTION FOR REFRIGERANT LEAKAGE .......................................................................................................WR2-151

15-1. Refrigerant property ...............................................................................................................................WR2-151

15-2. Conrm the Critical concentration and take countermeasure................................................................WR2-151

WR2-

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-3

© 2017 Mitsubishi Electric US, Inc.

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

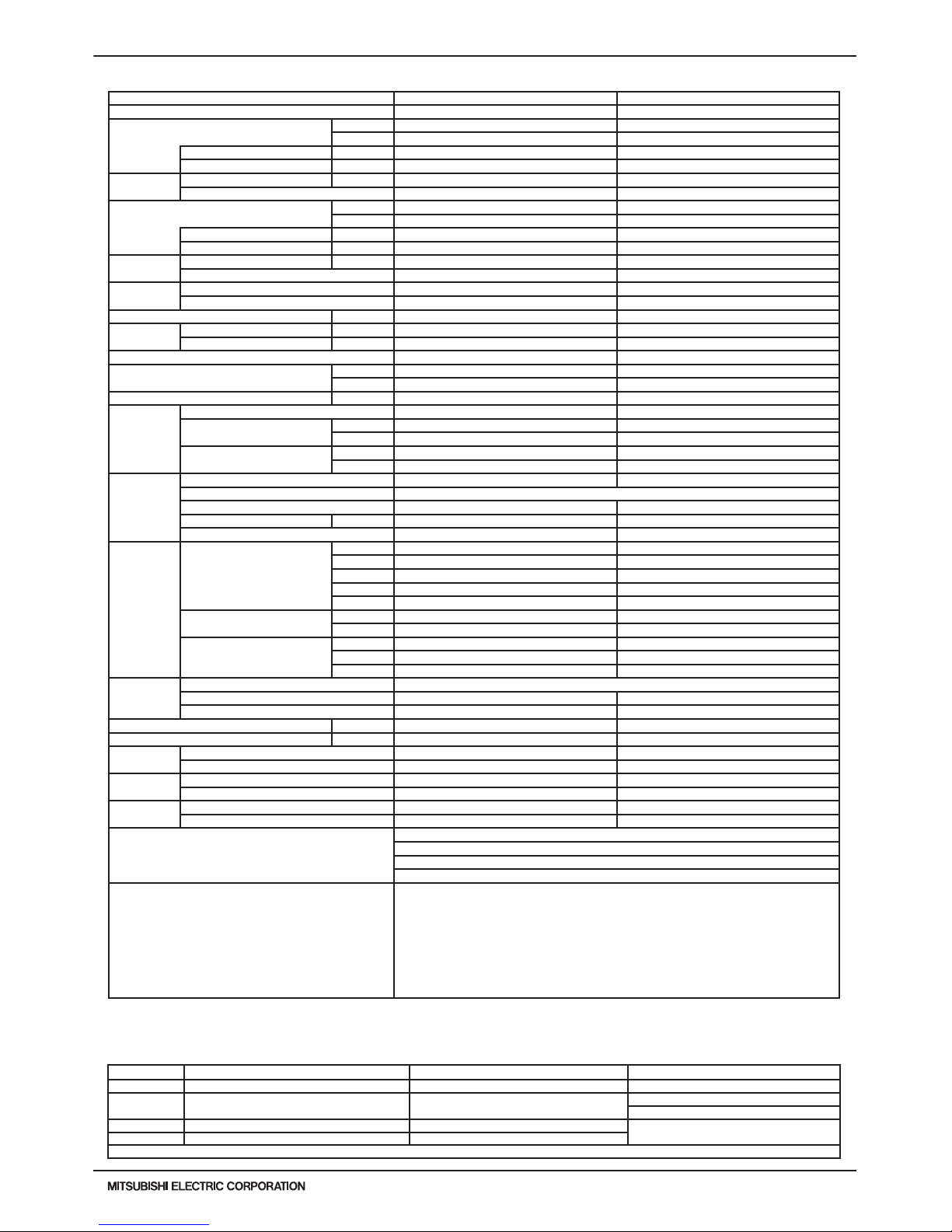

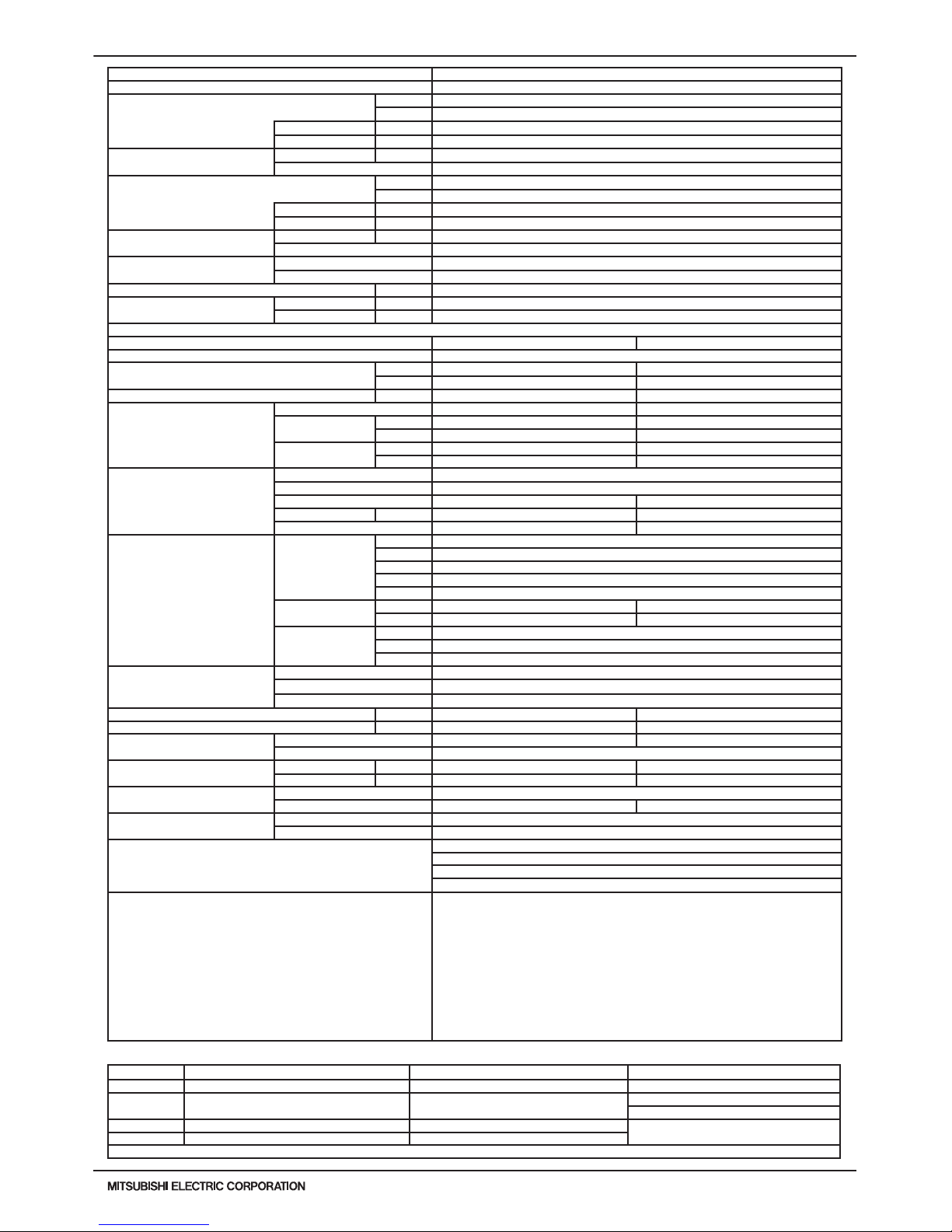

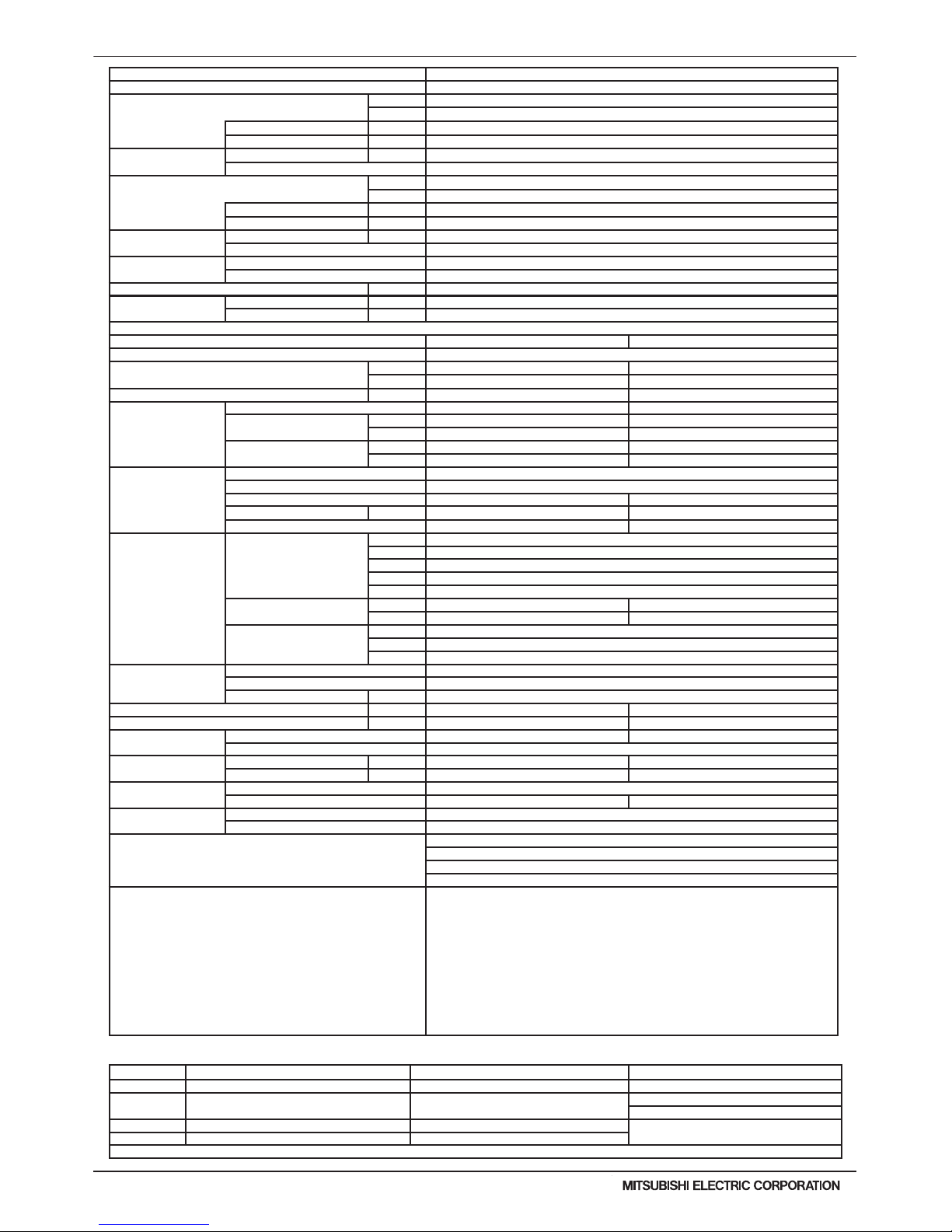

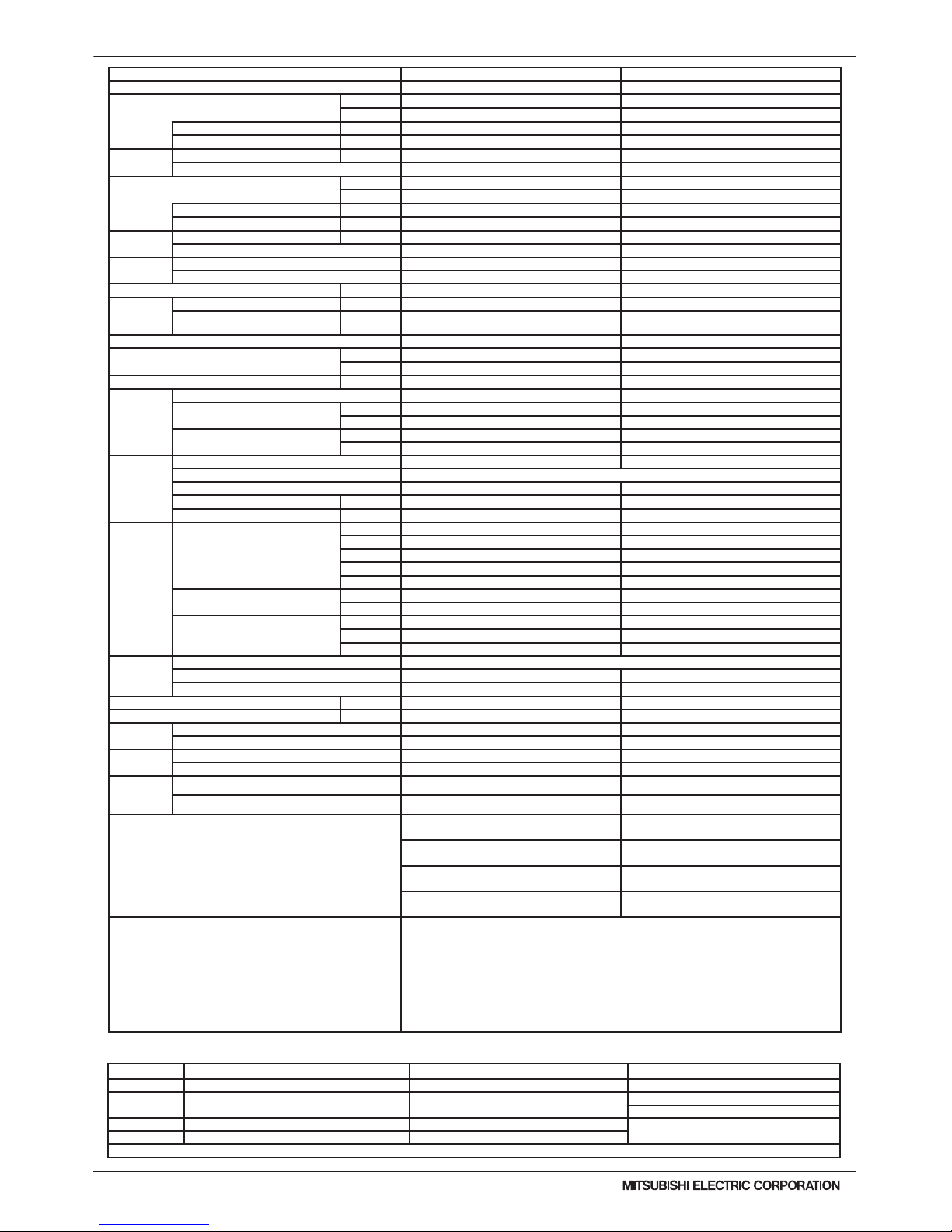

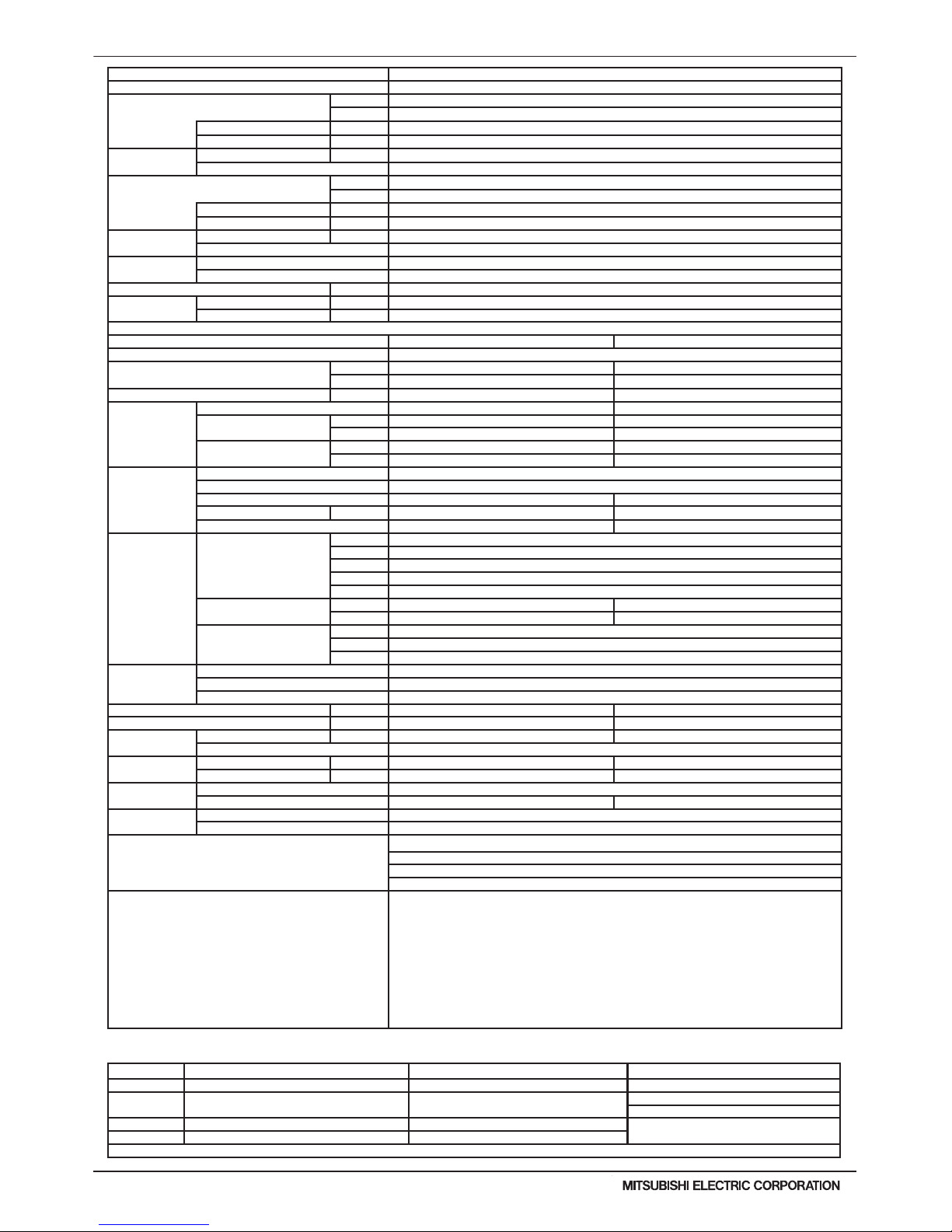

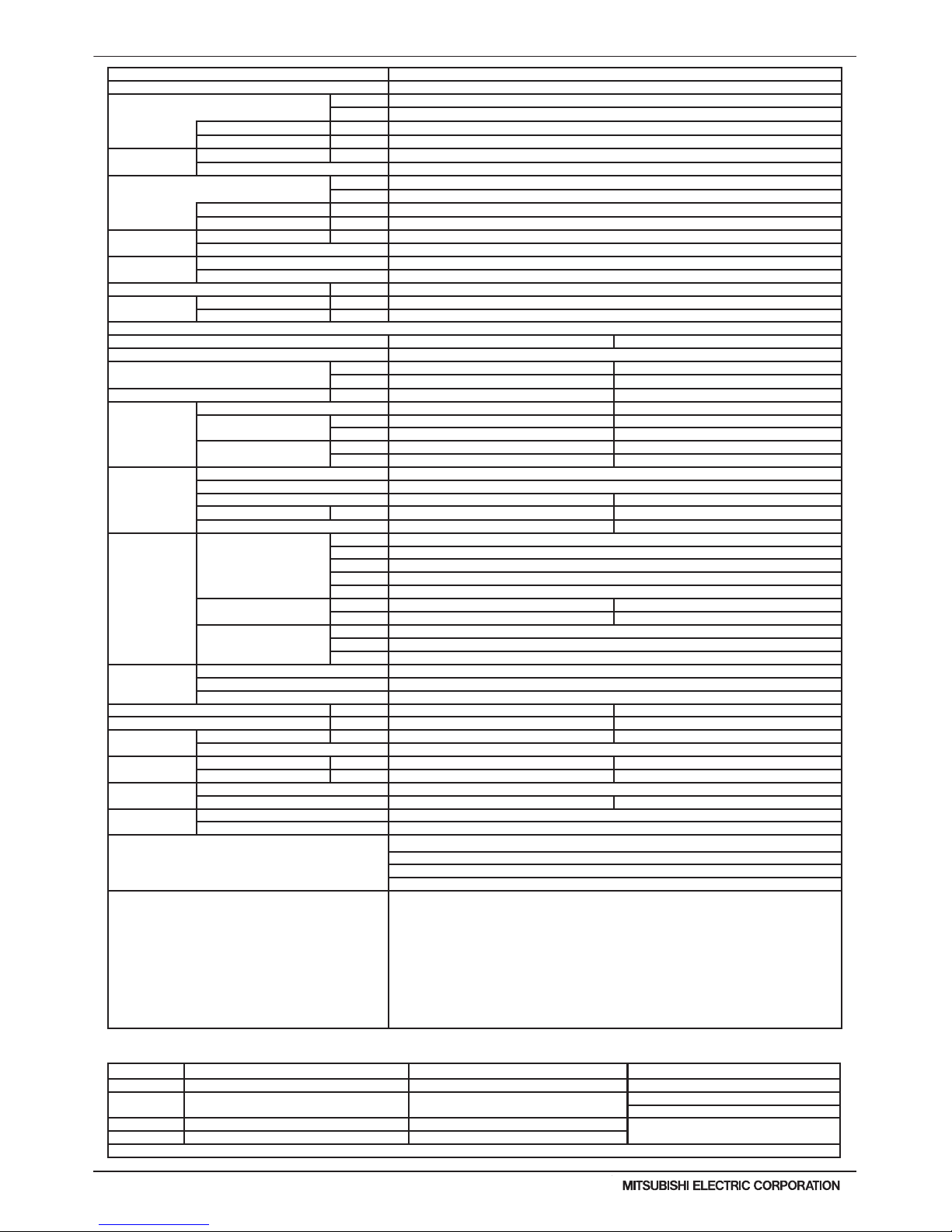

1. SPECIFICATIONS

1-1. PQRY-P72~336T(S)LMU-A Specications

Model PQRY-P72TLMU-A PQRY-P96TLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 72,000 96,000

kW 21.1 28.1

Power input kW 3.23 4.65

Current input A 9.9-9.0 14.3-12.9

Temp. range of

cooling

Indoor W.B. 59~75° F (15~24° C) 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 80,000 108,000

kW 23.4 31.7

Power input kW 3.63 5.05

Current input A 11.1-10.1 15.5-14.0

Temp. range of

heating

Indoor D.B. 59~81° F (15~27° C) 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Indoor unit

connectable

Total capacity 50~150% of heat source unit capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~18 P06~P96/1~24

Sound pressure level (measured in anechoic room) dB <A> 46 48

Refrigerant

piping diameter

High pressure in.(mm) 5/8 (15.88) Brazed 3/4 (19.05) Brazed

Low pressure in.(mm) 3/4 (19.05) Brazed 7/8 (22.2) Brazed

External nish Galvanized steel sheets Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 380 (172) 380 (172)

Heat

exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 4.3 6.0

Lubricant MEL32 MEL32

Circulating

water *3

Water ow rate

G/h 1,522 1,522

G/min(gpm) 25.4 25.4

m3 / h 5.76 5.76

L/min 96 96

cfm 3.4 3.4

Pressure drop

psi 3.48 3.48

kPa 24 24

Operating volume range

G/h 793 ~ 1,902 793 ~ 1,902

G/min(gpm) 13.2 ~ 31.7 13.2 ~ 31.7

m3 / h 3.0 ~ 7.2 3.0 ~ 7.2

Protection

devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Minimum Circuit Ampacity(MCA) A 13 / 12 19 / 17

Maximum Overcurrent Protection(MOP) A 20 / 20 30 / 25

Refrigerant

Type x original charge R410A x (11 lbs + 1 oz) (5.0 kg) R410A x (11 lbs + 1 oz) (5.0 kg)

Control Indoor LEV and BC controller Indoor LEV and BC controller

Drawing

External KJ94T127 KJ94T127

Wiring KE94C966 KE94C966

Standard

attachment

Document Installation Manual Installation Manual

Accessory Details refer to External Drw Details refer to External Drw

Optional parts

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-R160-J1

BC controller: CMB-P104, 105, 106, 108, 1010, 1013, 1016NU-G1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other

items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed and

wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be turned

on and glycol must be used in the water loop to prevent freezing down to 5° F.

WR2-4

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

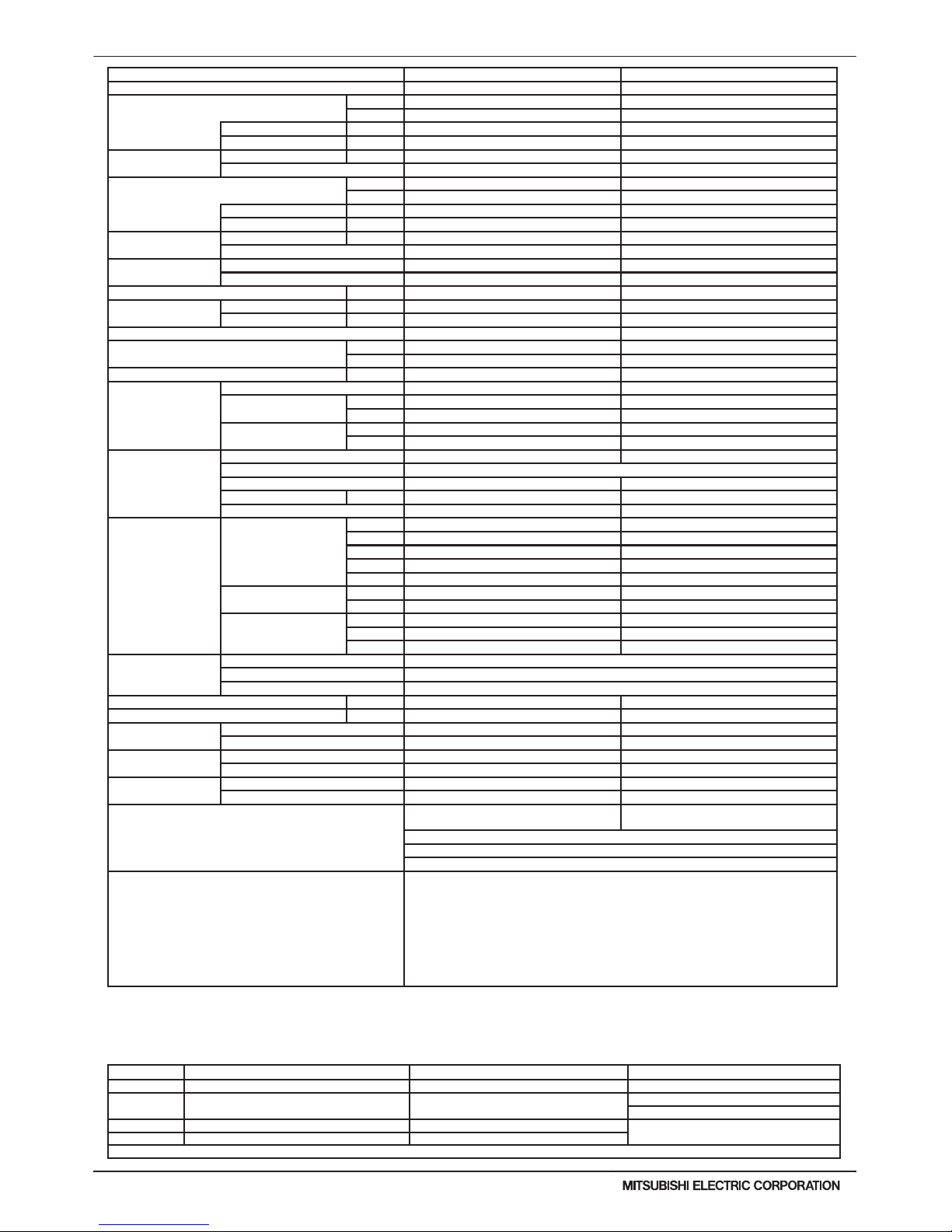

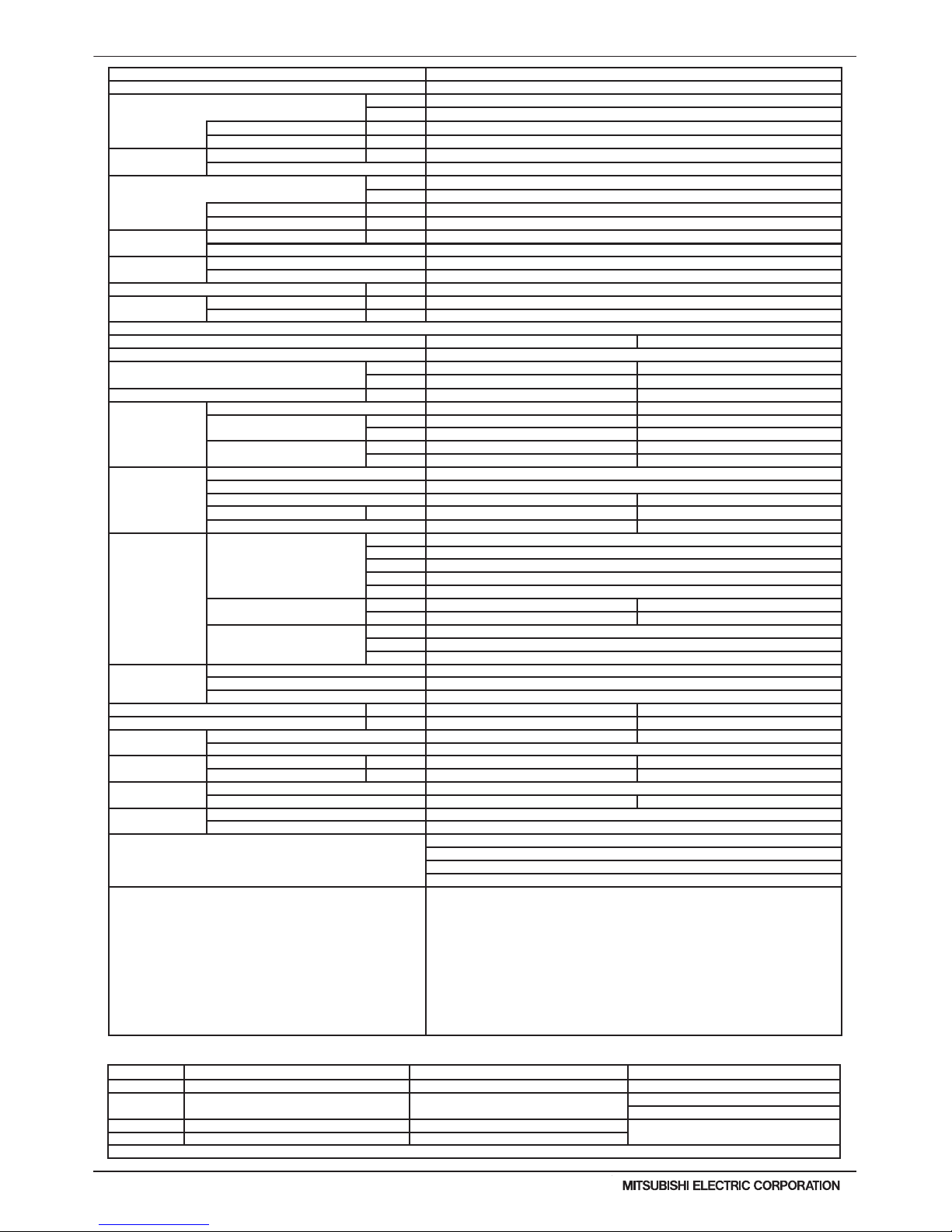

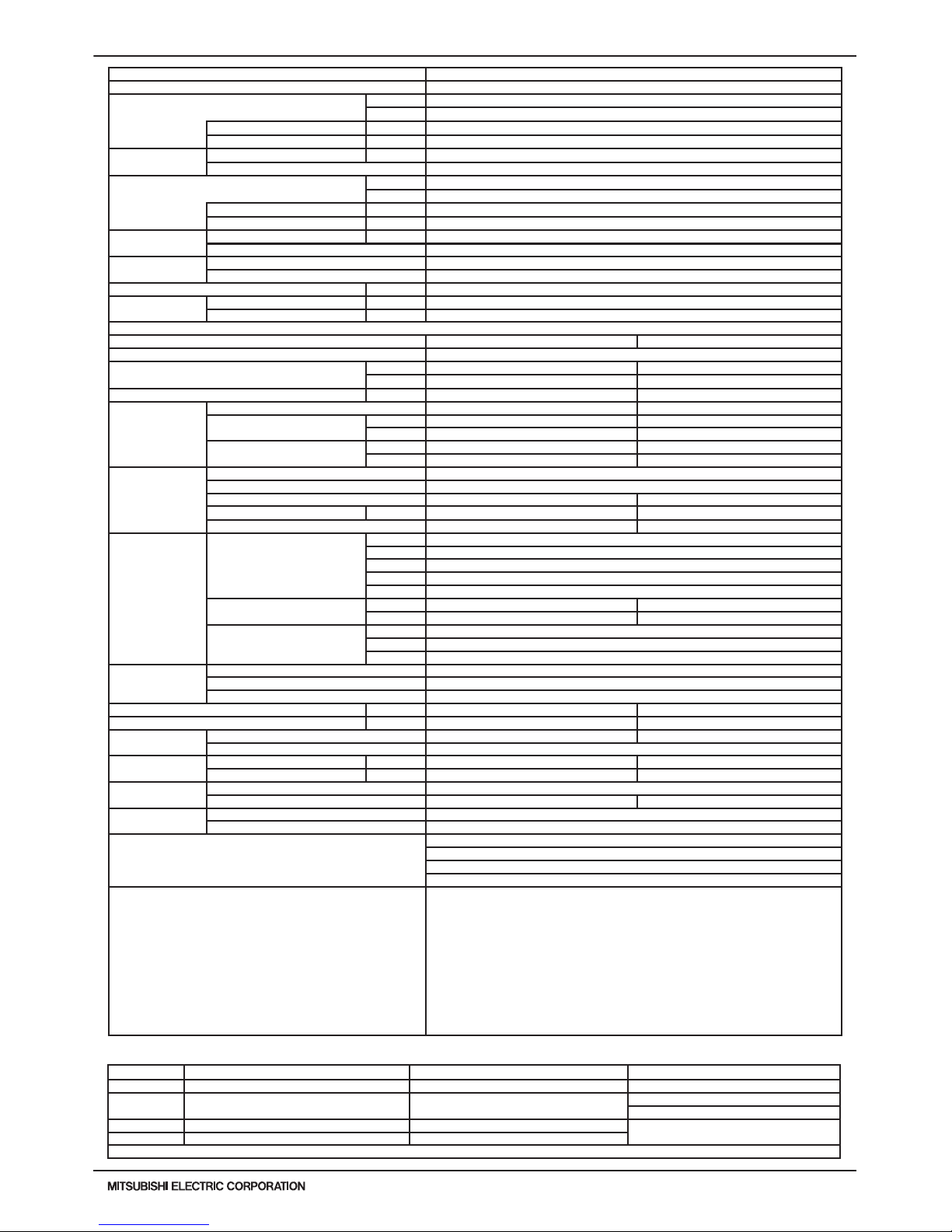

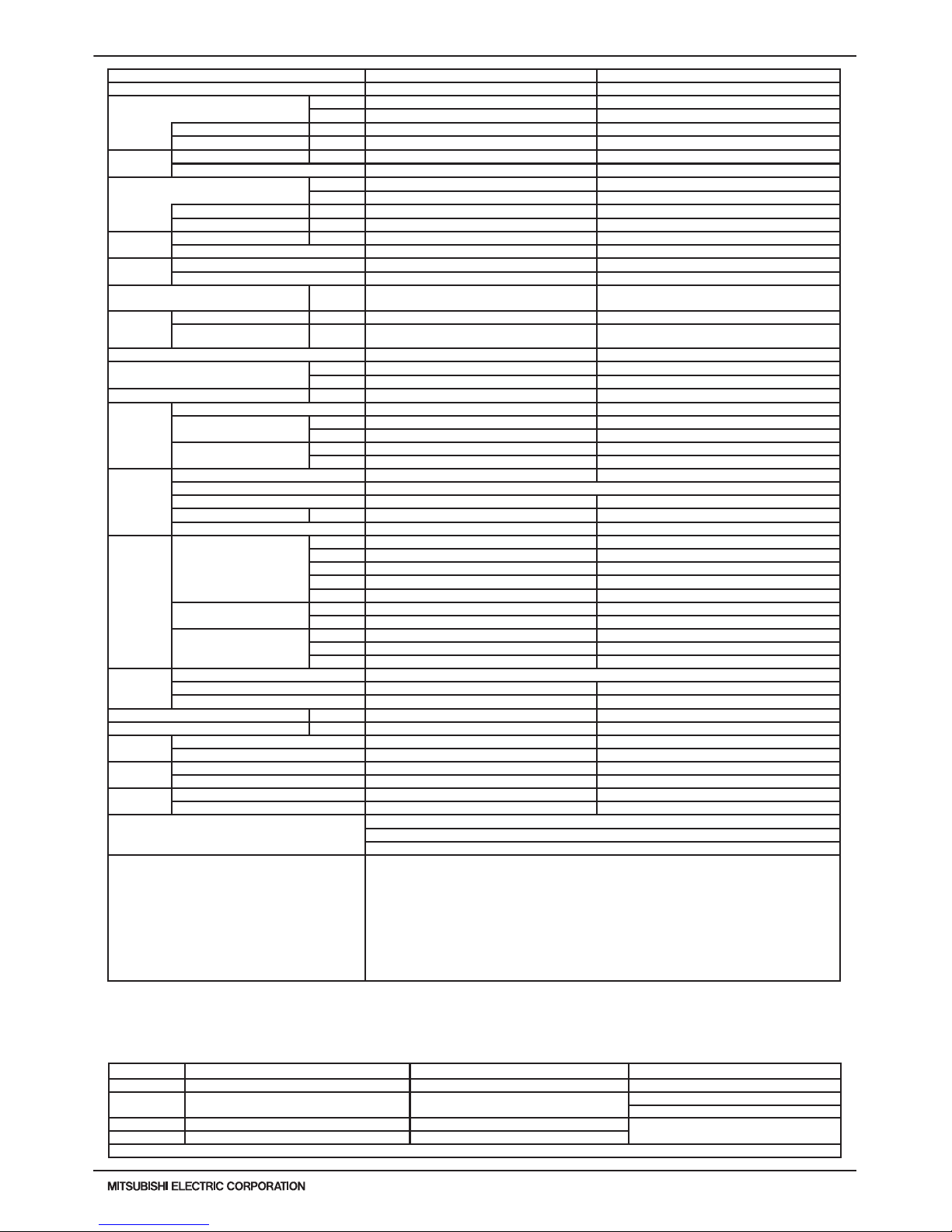

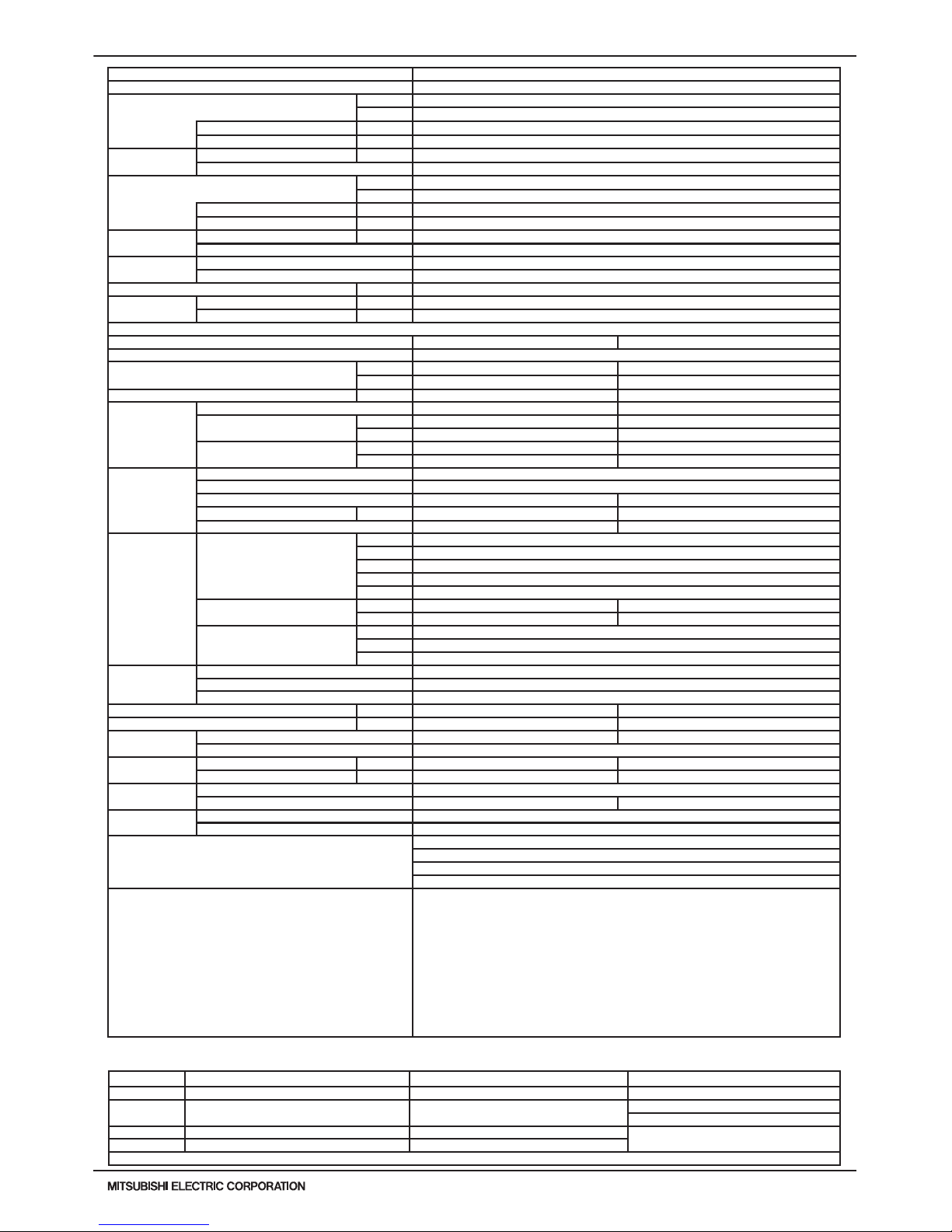

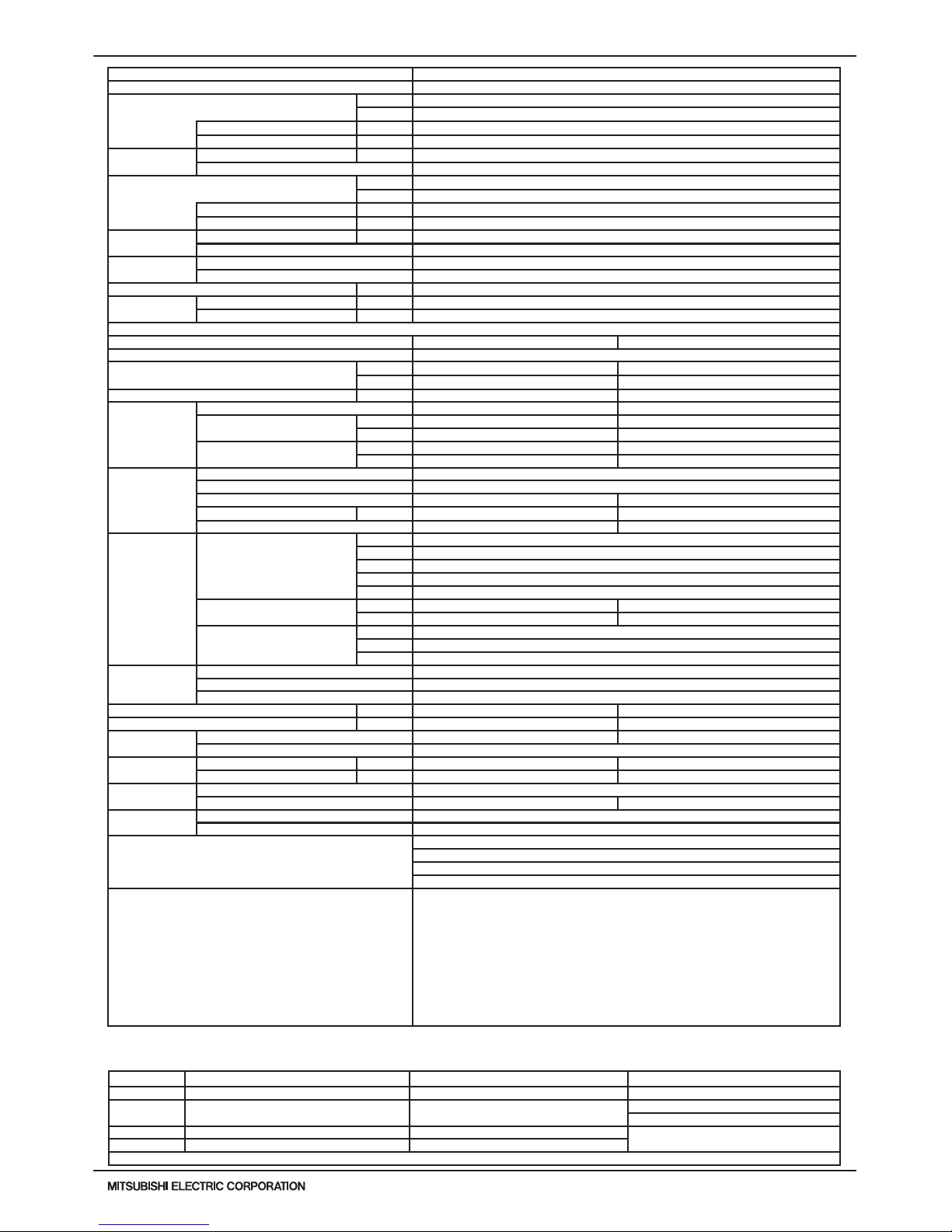

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P120TLMU-A PQRY-P144TLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 120,000 144,000

kW 35.2 42.2

Power input kW 7.24 8.78

Current input A 22.3 / 20.1 27.0 / 24.4

Temp. range of

cooling

Indoor W.B. 59~75° F (15~24° C) 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 135,000 160,000

kW 39.6 46.9

Power input kW 6.83 8.11

Current input A 21.0 / 19.0 25.0 / 22.6

Temp. range of

heating

Indoor D.B. 59~81° F (15~27° C) 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~30 P06~P96/1~36

Sound pressure level (measured in anechoic room) dB <A> 54 54

Refrigerant piping

diameter

High pressure in.(mm) 3/4 (19.05) Brazed 7/8 (22.2) Brazed

Low pressure in.(mm) 7/8 (22.2) Brazed 1-1/8 (28.58) Brazed

External nish Galvanized steel sheets Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 380 (172) 380 (172)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 7.7 9.5

Lubricant MEL32

Circulating water *3

Water ow rate

G/h 1,522 1,902

G/min(gpm) 25.4 31.7

m3 / h 5.76 7.2

L/min 96 120

cfm 3.4 4.2

Pressure drop

psi 3.48 6.38

kPa 24 44

Operating volume range

range

G/h 793 ~ 1,902 1,189 ~ 3,054

G/min(gpm) 13.2 ~ 31.7 19.8 ~ 50.9

m3 / h 3.0 ~ 7.2 4.5 ~ 11.6

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 29 / 26 35 / 32

Maximum Overcurrent Protection(MOP) A 50 / 45 60 / 50

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller Indoor LEV and BC controller

Drawing

External KJ94T127 KJ94T127

Wiring KE94C966 KE94C966

Standard attachment

Document Installation Manual Installation Manual

Accessory Details refer to External Drw Details refer to External Drw

Optional parts

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2,

CMY-R160-J1

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2,

CMY-Y202S-G2, CMY-R160-J1

BC controller: CMB-P104, 105, 106, 108, 1010, 1013, 1016NU-G1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed and

wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-5

© 2017 Mitsubishi Electric US, Inc.

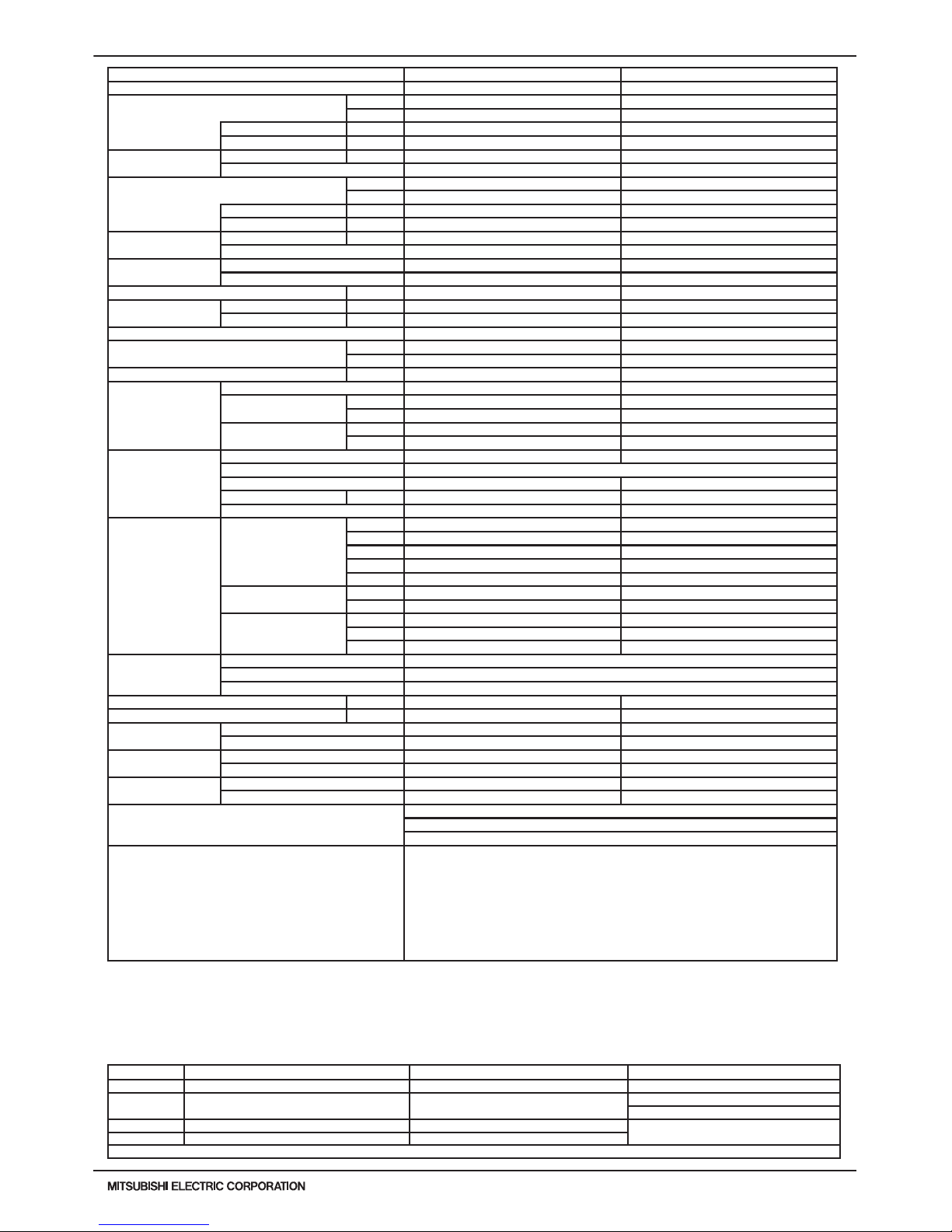

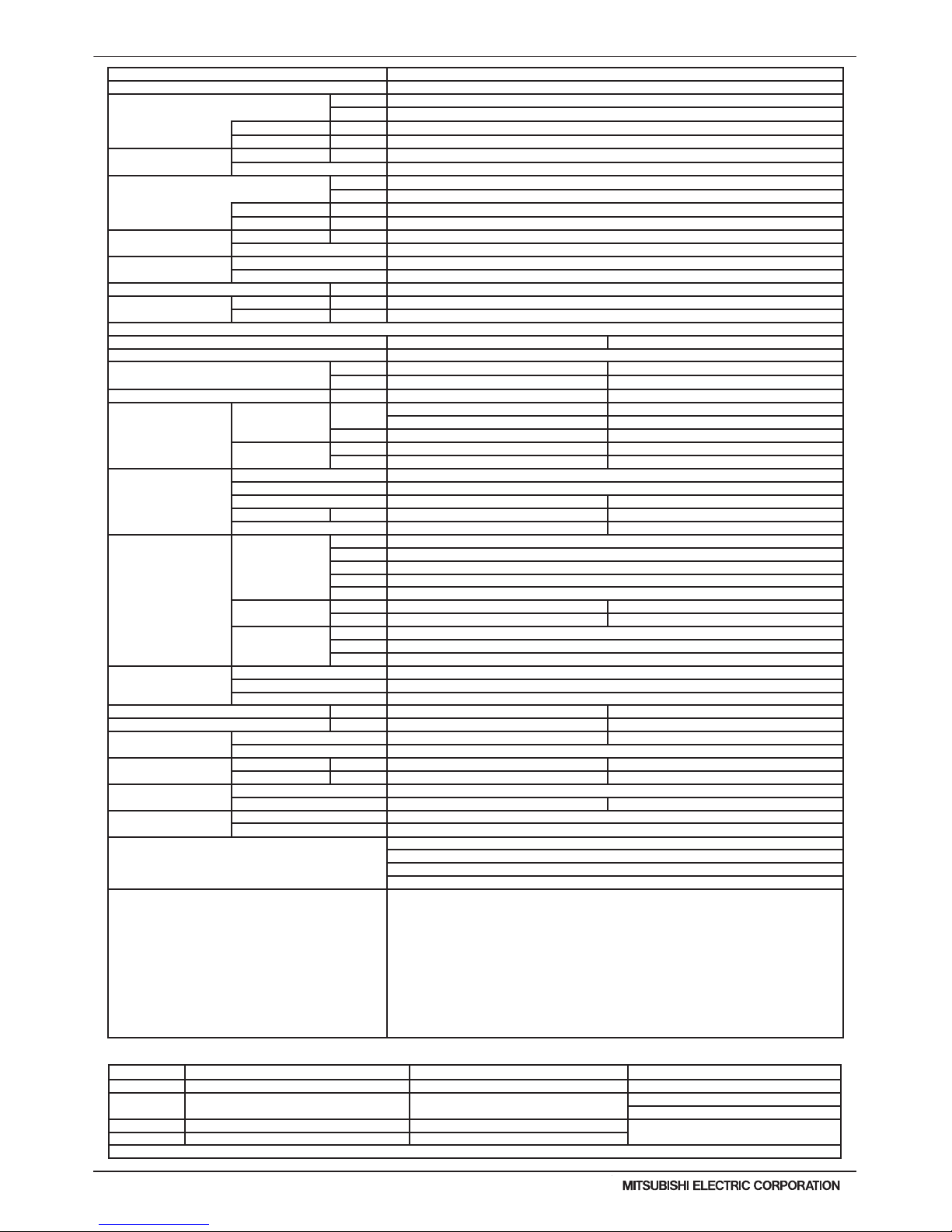

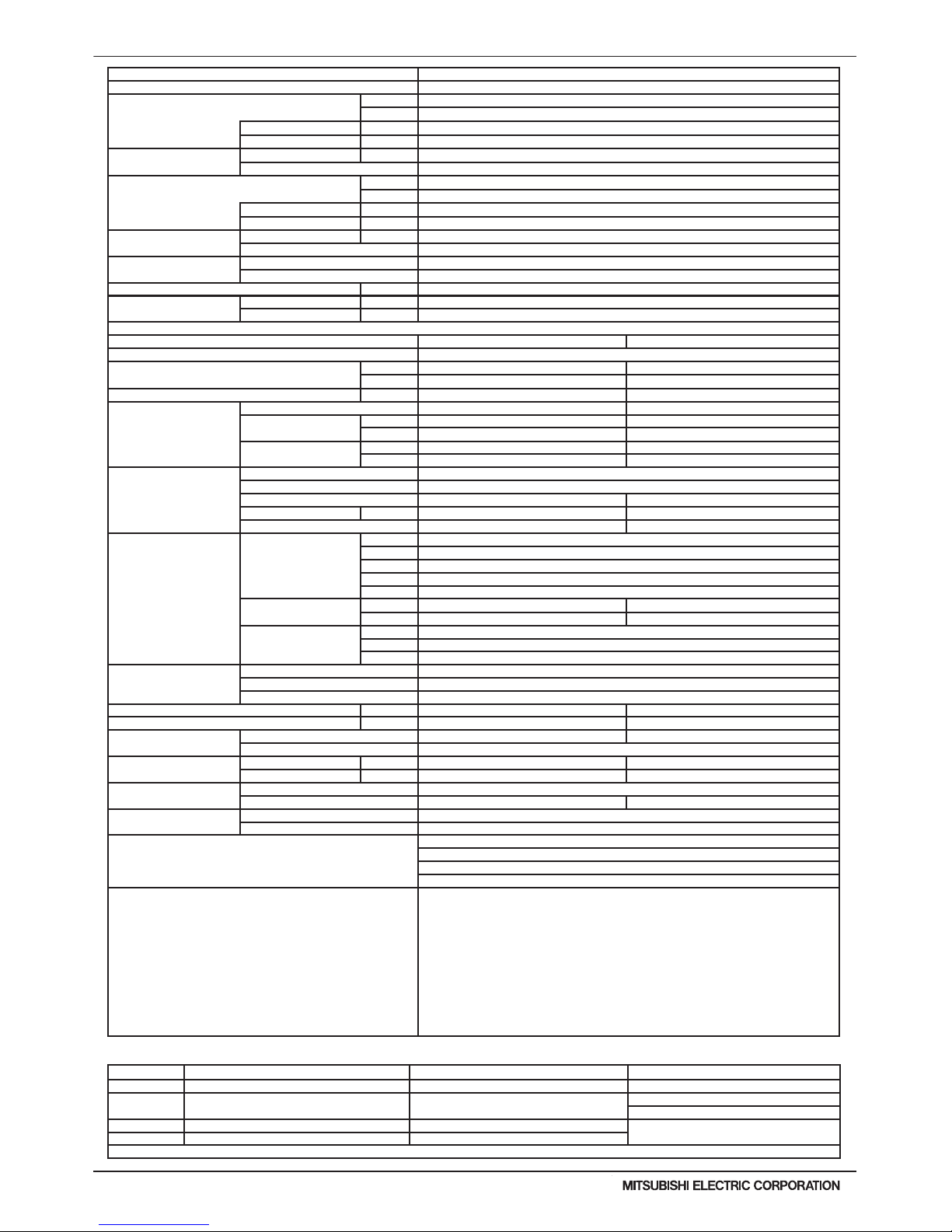

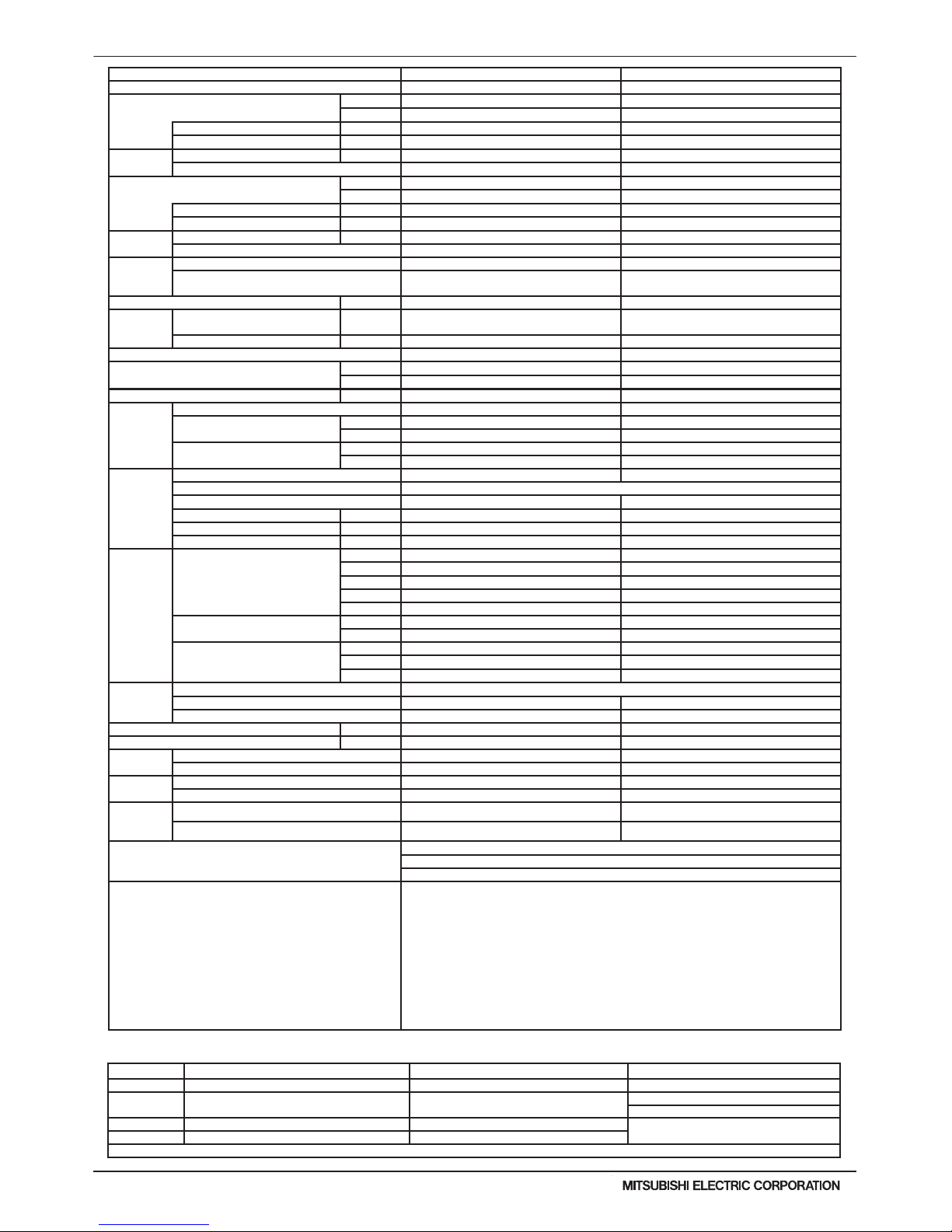

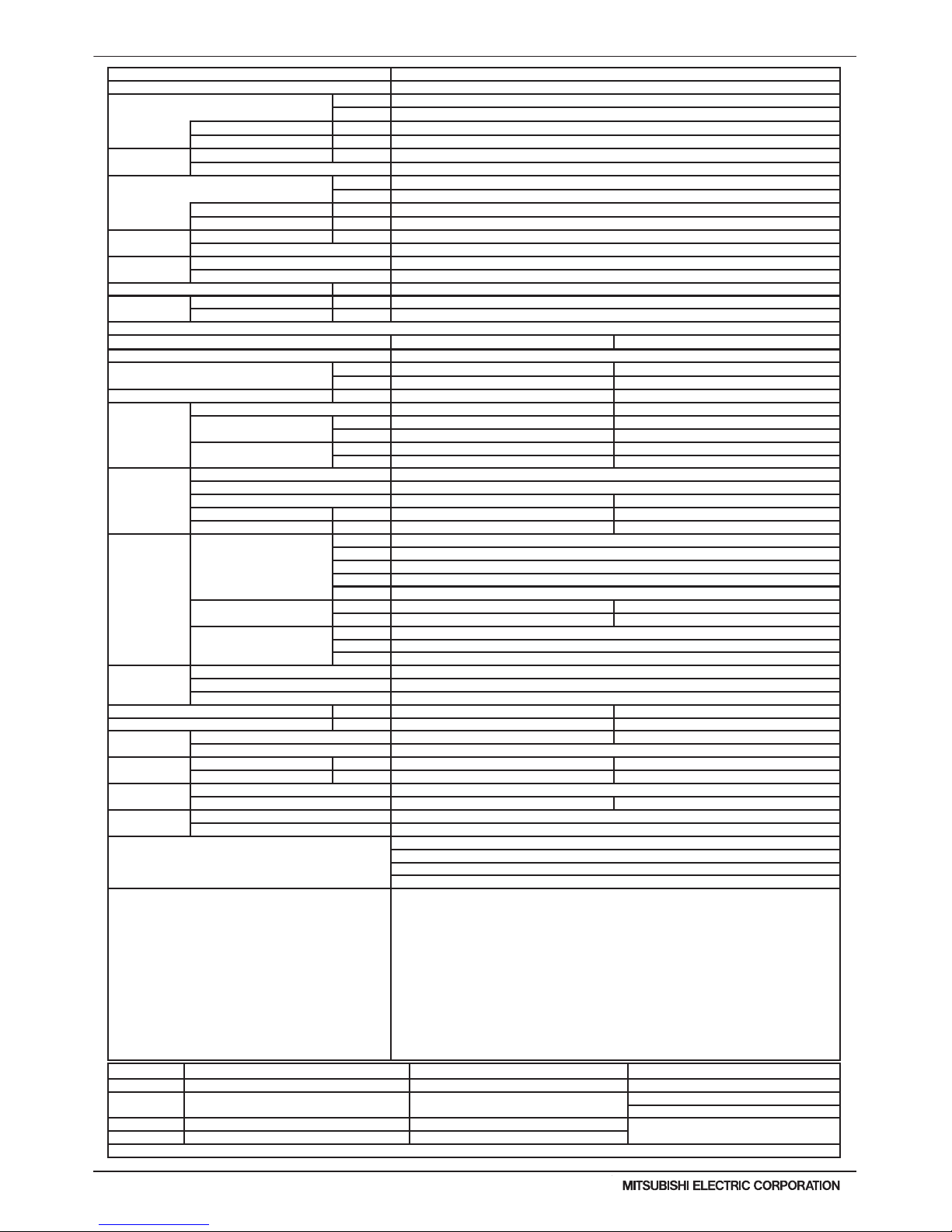

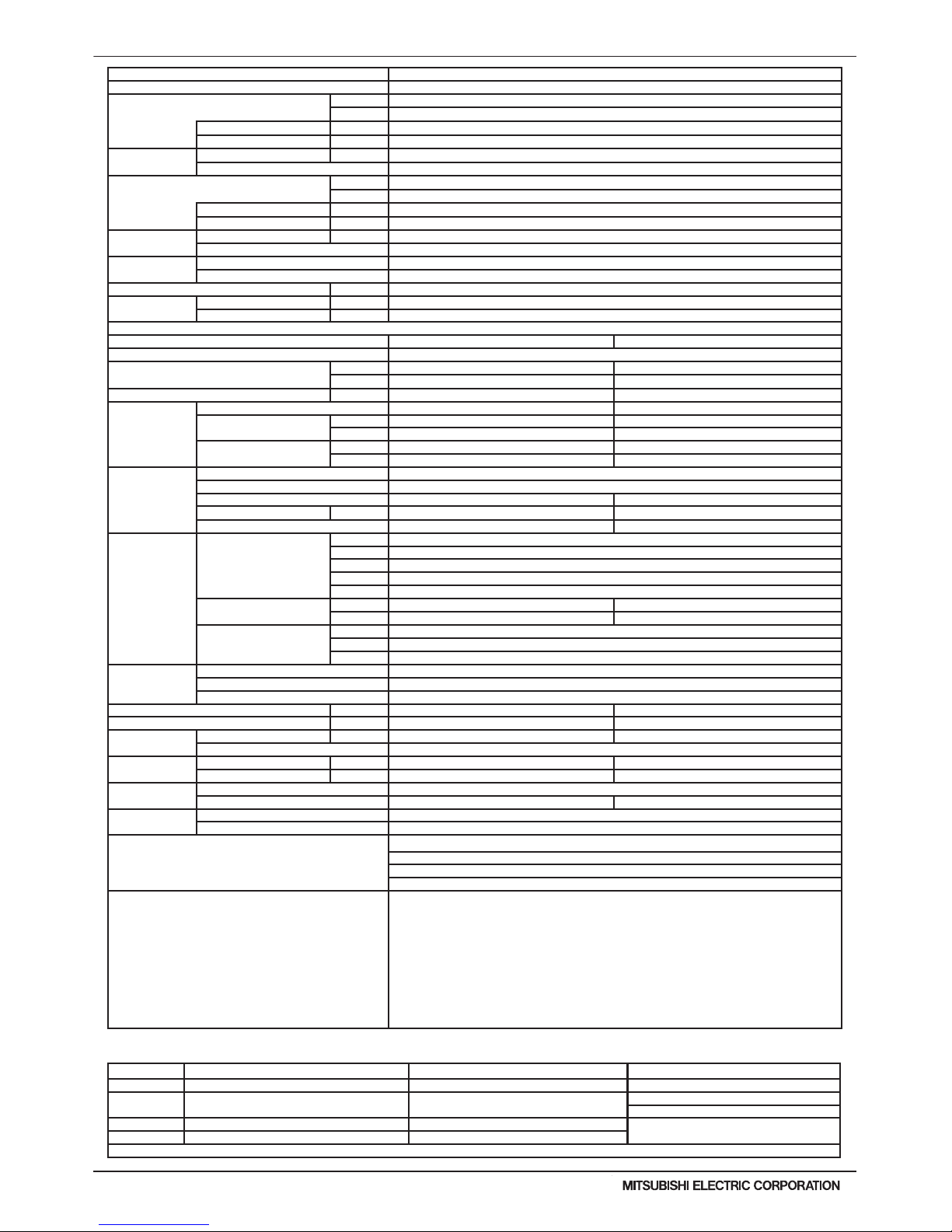

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P168TLMU-A PQRY-P192TLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 168,000 192,000

kW 49.2 56.3

Power input kW 12.05 15.05

Current input A 37.1 / 33.6 46.4 / 41.9

Temp. range of

cooling

Indoor W.B. 59~75° F (15~24° C) 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 188,000 215,000

kW 55.1 63

Power input kW 9.86 11.9

Current input A 30.4 / 27.5 36.7 / 33.1

Temp. range of

heating

Indoor D.B. 59~81° F (15~27° C) 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~42 P06~P96/1~48

Sound pressure level (measured in anechoic room) dB <A> 56 58

Refrigerant piping

diameter

High pressure in.(mm) 7/8 (22.2) Brazed 7/8 (22.2) Brazed

Low pressure in.(mm) 1-1/8 (28.58) Brazed 1-1/8 (28.58) Brazed

External nish Galvanized steel sheets Galvanized steel sheets

External dimension HxWxD

in. 57-1/8 x 34-11/16 x 21-11/16 57-1/8 x 34-11/16 x 21-11/16

mm 1,450 x 880 x 550 1,450 x 880 x 550

Net weight lbs(kg) 479 (217) 479 (217)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 11.0 12.4

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,902 1,902

G/min(gpm) 31.7 31.7

m3 / h 7.2 7.2

L/min 120 120

cfm 4.2 4.2

Pressure drop

psi 6.38 6.38

kPa 44 44

Operating volume range

range

G/h 1,189 ~ 3,054 1,189 ~ 3,054

G/min(gpm) 19.8 ~ 50.9 19.8 ~ 50.9

m3 / h 4.5 ~ 11.6 4.5 ~ 11.6

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 44 / 39 54 / 49

Maximum Overcurrent Protection(MOP) A 70 / 70 90 / 80

Refrigerant

Type x original charge R410A x 13 lbs + 4 oz (6.0 kg) R410A x 13 lbs + 4 oz (6.0 kg)

Control Indoor LEV and BC controller Indoor LEV and BC controller

Drawing

External KJ94T128 KJ94T128

Wiring KE94C968 KE94C968

Standard attachment

Document Installation Manual Installation Manual

Accessory Details refer to External Drw Details refer to External Drw

Optional parts

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed and

wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

WR2-6

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

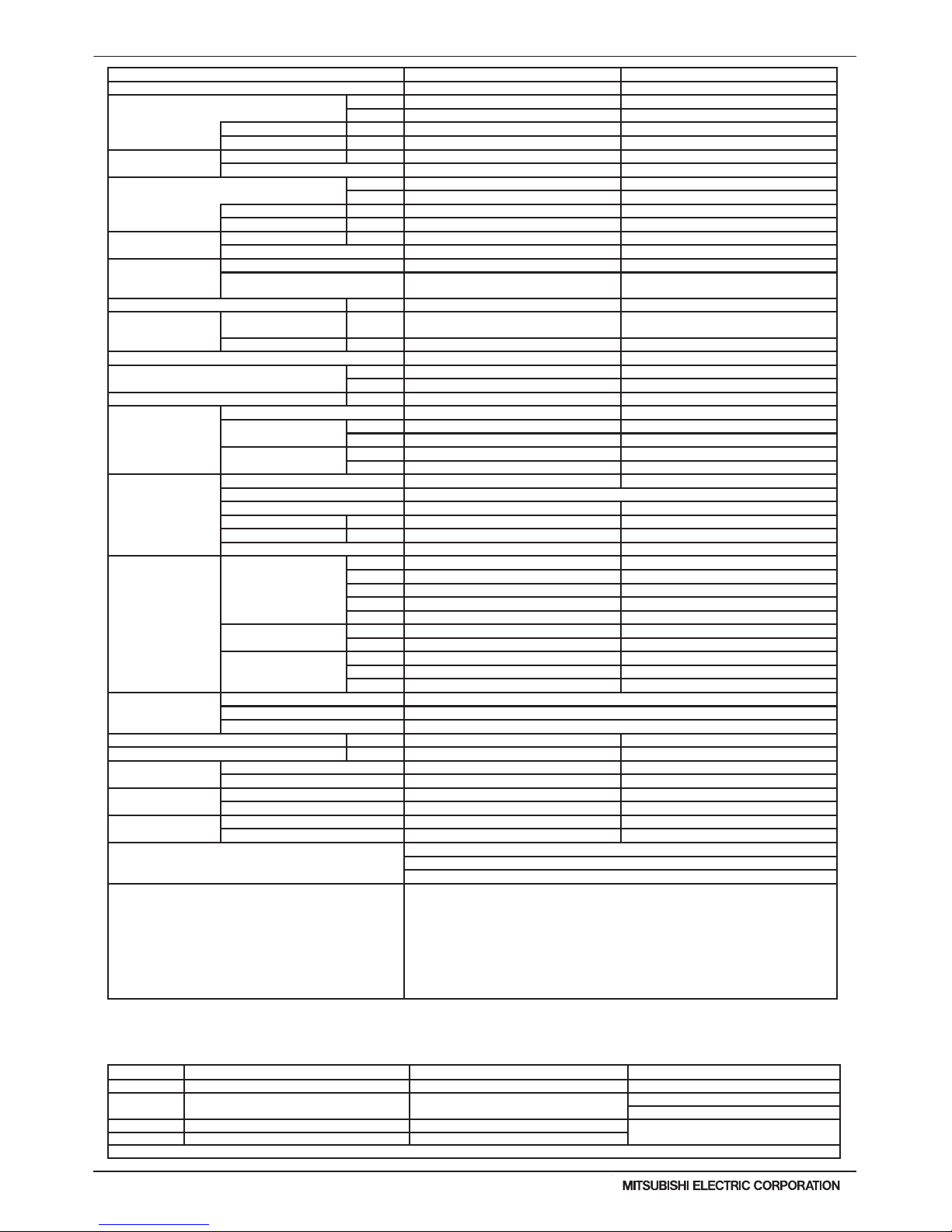

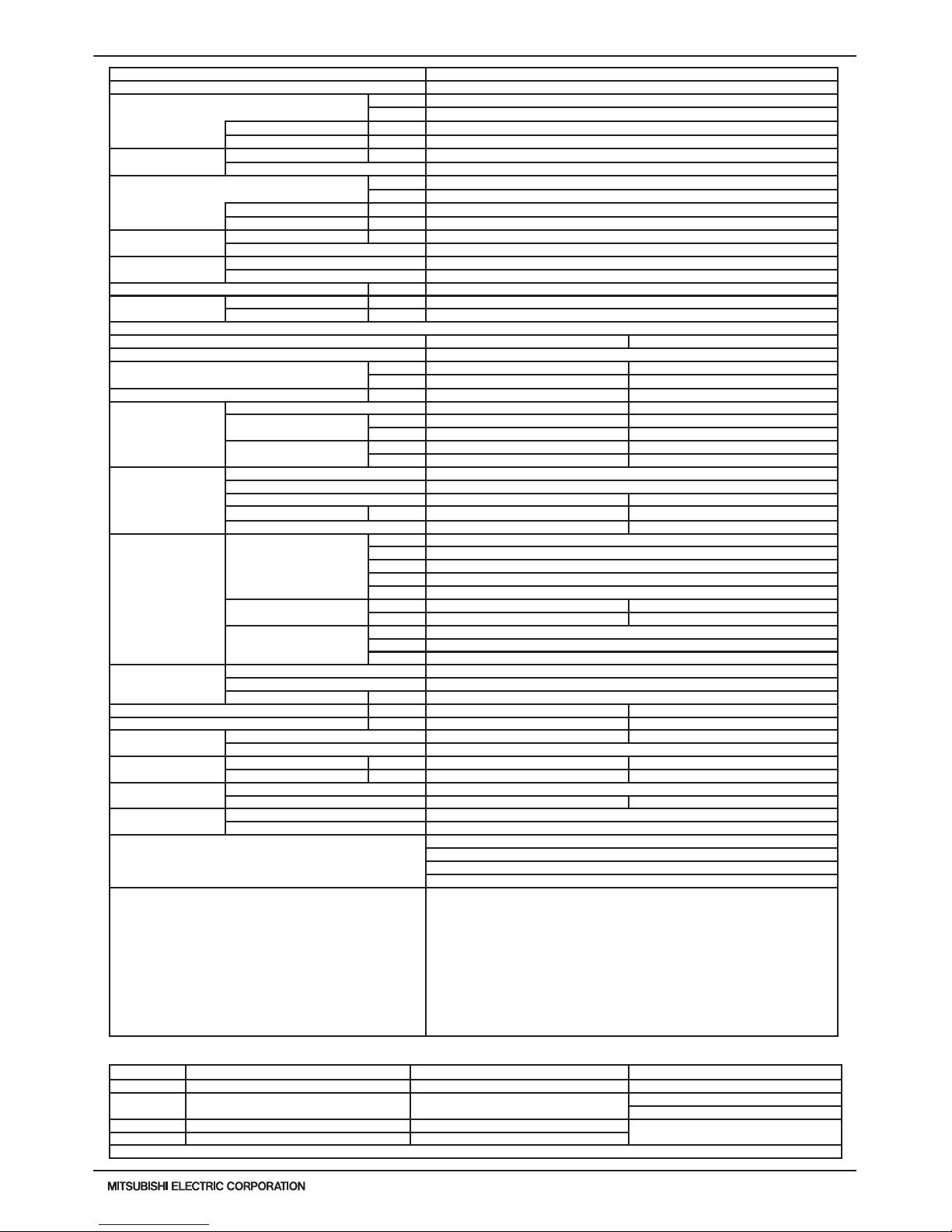

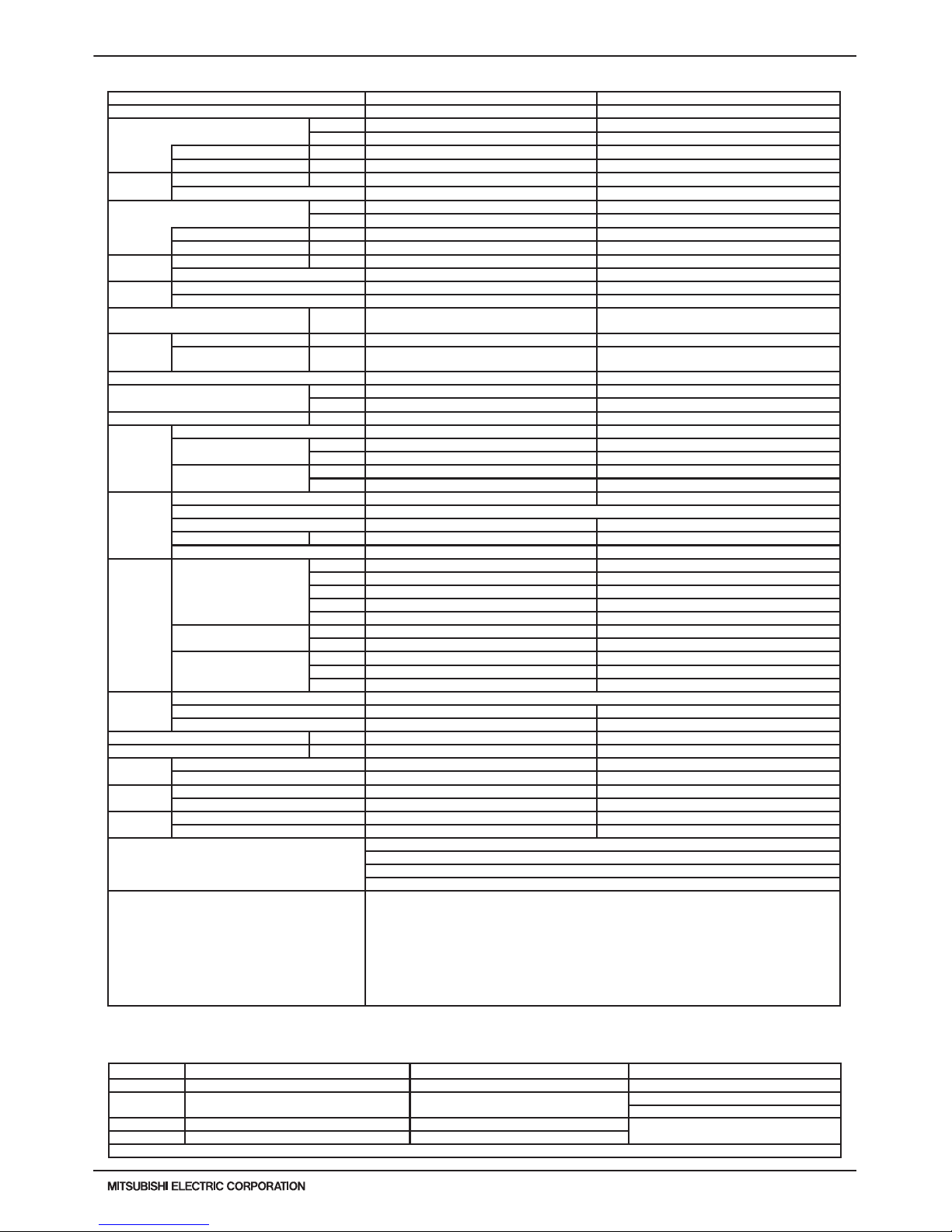

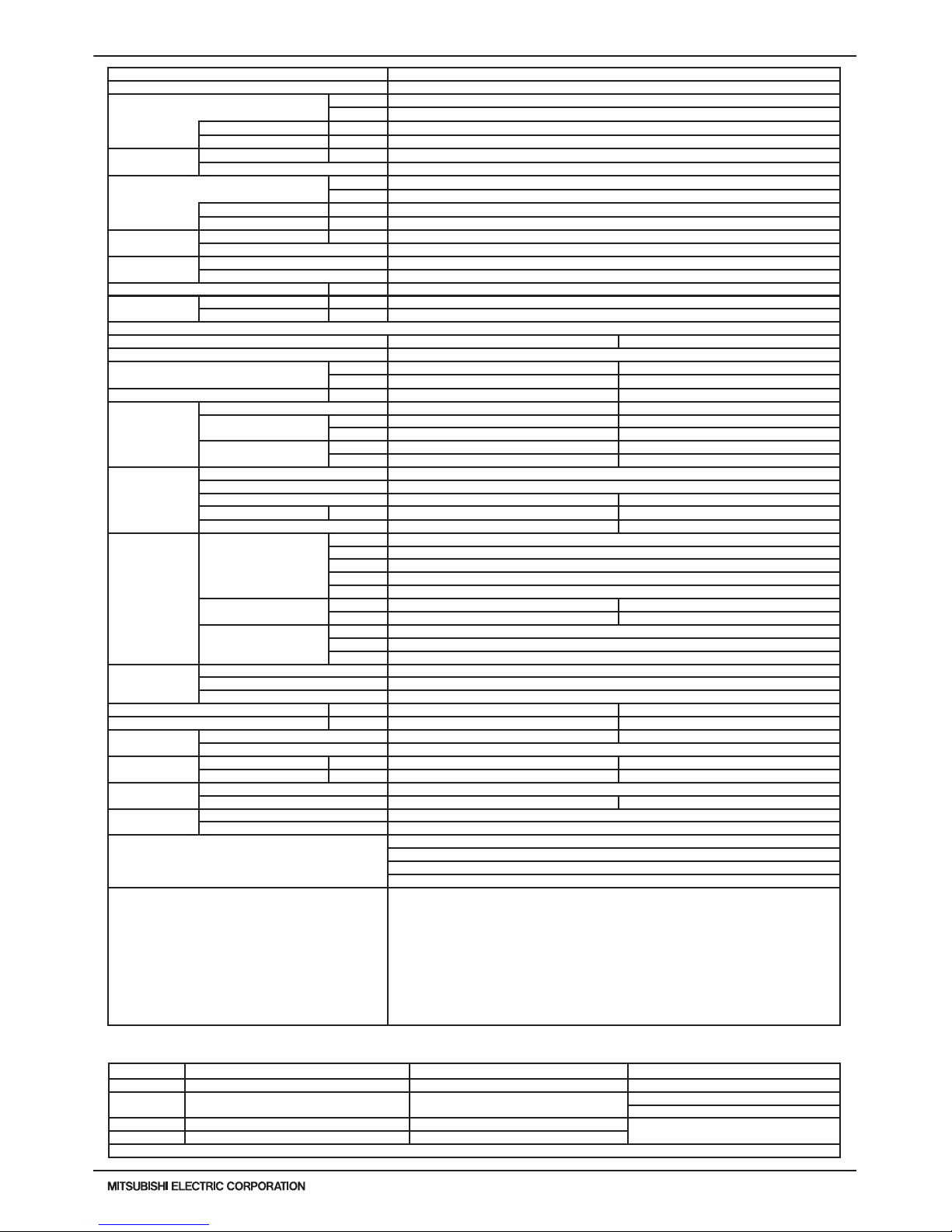

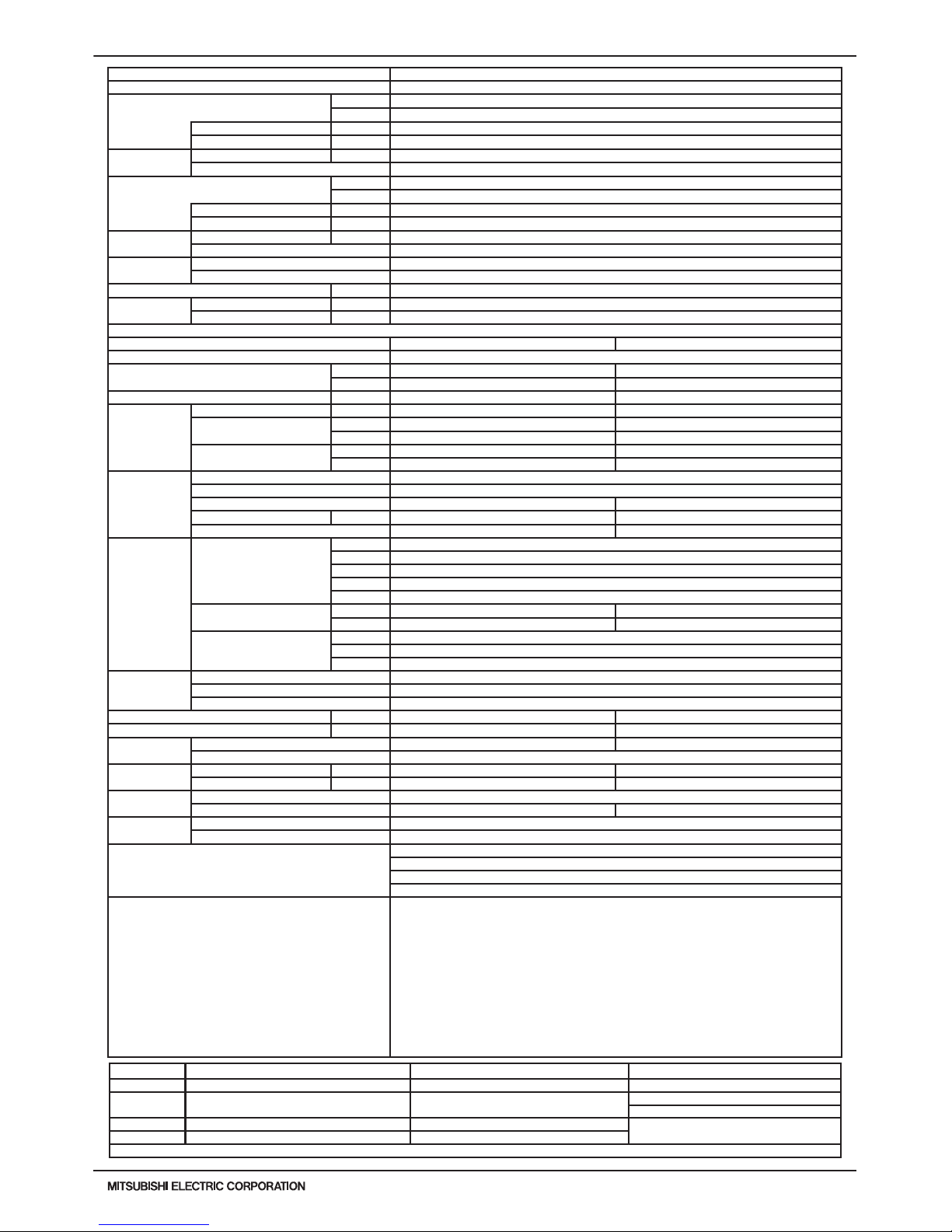

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P216TLMU-A PQRY-P240TLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 216,000 240,000

kW 63.3 70.3

Power input kW 19.23 21.14

Current input A 59.3 / 53.6 65.1 / 58.9

Temp. range of

cooling

Indoor W.B. 59~75° F (15~24° C) 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 243,000 270,000

kW 71.2 79.1

Power input kW 13.04 15.12

Current input A 40.2 / 36.3 46.6 / 42.1

Temp. range of

heating

Indoor D.B. 59~81° F (15~27° C) 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity 50~150% of heat source unit capacity

Model / Quantity

P06~P96/2~50

(Connectable branch pipe number is max. 48.)

P06~P96/2~50

(Connectable branch pipe number is max. 48.)

Sound pressure level (measured in anechoic room) dB <A> 58 58

Refrigerant piping

diameter

High pressure in.(mm)

7/8 (22.2) Brazed (1-1/8 (28.58)

Brazed for the part that exceeds 65 m)

7/8 (22.2) Brazed (1-1/8 (28.58)

Brazed for the part that exceeds 65 m)

Low pressure in.(mm) 1-1/8 (28.58) Brazed 1-3/8 (34.93) Brazed

External nish Galvanized steel sheets Galvanized steel sheets

External dimension HxWxD

in. 57-1/8 x 34-11/16 x 21-11/16 57-1/8 x 34-11/16 x 21-11/16

mm 1,450 x 880 x 550 1,450 x 880 x 550

Net weight lbs(kg) 556 (252) 556 (252)

Heat exchanger

Type Plate Plate

Water volume in plate

G 2.64 2.64

I 10 10

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 14.5 16.1

Case heater kW 0.045 (240 V) 0.045 (240 V)

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 3,044 3,044

G/min(gpm) 50.7 50.7

m3 / h 11.52 11.52

L/min 192 192

cfm 6.8 6.8

Pressure drop

psi 6.53 6.53

kPa 45 45

Operating volume range

range

G/h 1,585 ~ 3,804 1,585 ~ 3,804

G/min(gpm) 26.4 ~ 63.4 26.4 ~ 63.4

m3 / h 6.0 ~ 14.4 6.0 ~ 14.4

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 69 / 63 79 / 71

Maximum Overcurrent Protection(MOP) A 110 / 110 125 / 125

Refrigerant

Type x original charge R410A x 25 lbs + 13 oz (11.7 kg) R410A x 25 lbs + 13 oz (11.7 kg)

Control Indoor LEV and BC controller Indoor LEV and BC controller

Drawing

External KJ94T172 KJ94T172

Wiring KE94G037 KE94G037

Standard attachment

Document Installation Manual Installation Manual

Accessory Details refer to External Drw Details refer to External Drw

Optional parts

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed and

wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-7

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P144TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 144,000

kW 42.2

Power input kW 7.11

Current input A 21.9 / 19.8

Temp. range of cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 160,000

kW 46.9

Power input kW 7.45

Current input A 22.9 / 20.7

Temp. range of heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~36

Sound pressure level (measured in anechoic room) dB <A> 49

Refrigerant piping diameter

High pressure in.(mm) 7/8 (22.2) Brazed

Low pressure in.(mm) 1-1/8 (28.58) Brazed

Module Set

Module PQRY-P72TLMU-A PQRY-P72TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in.

43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 380 (172) 380 (172)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 4.3 4.3

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,522 + 1,522

G/min(gpm) 25.4 + 25.4

m3 / h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop

psi 3.48 3.48

kPa 24 24

Operating volume

range

G/h 793 + 793 ~ 1,902 + 1,902

G/min(gpm) 13.2 + 13.2 ~ 31.7 + 31.7

m3 / h 3.0 + 3.0 ~ 7.2 + 7.2

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 13 / 12 13 / 12

Maximum Overcurrent Protection(MOP) A 20 / 20 20 / 20

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller

Pipe between unit and

distributor

High pressure in.(mm) 5/8 (15.88) Brazed 5/8 (15.88) Brazed

Low pressure in.(mm) - 3/4 (19.05) Brazed

Drawing

External KJ94T151

Wiring KE94C966 KE94C966

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q100CBK2

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch,

and other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50

meshes) at the water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the

heat source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld

installed and wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

WR2-8

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

1. SPECIFICATIONS

Model PQRY-P168TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 168,000

kW 49.2

Power input kW 9.33

Current input A 28.7 / 26.0

Temp. range of

cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 188,000

kW 55.1

Power input kW 9.34

Current input A 28.8 / 26.0

Temp. range of

heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit

connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~42

Sound pressure level (measured in anechoic room) dB <A> 50

Refrigerant piping

diameter

High pressure in.(mm) 7/8 (22.2) Brazed

Low pressure in.(mm) 1-1/8 (28.58) Brazed

Module Set

Module PQRY-P96TLMU-A PQRY-P72TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 380 (172) 380 (172)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 6.0 4.3

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,522 + 1,522

G/min(gpm) 25.4 + 25.4

m3 / h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop

psi 3.48 3.48

kPa 24 24

Operating volume range

G/h 793 + 793 ~ 1,902 + 1,902

G/min(gpm) 13.2 + 13.2 ~ 31.7 + 31.7

m3 / h 3.0 + 3.0 ~ 7.2 + 7.2

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 19 / 17 13 / 12

Maximum Overcurrent Protection(MOP) A 30 / 25 20 / 20

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller

Pipe between unit

and distributor

High pressure in.(mm) 3/4 (19.05) Brazed 3/4 (19.05) Brazed

Low pressure in.(mm) - 7/8 (22.2) Brazed

Drawing

External KJ94T151

Wiring KE94C966 KE94C966

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q100CBK2

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50 meshes)

at the water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the

heat source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed

and wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-9

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P192TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 192,000

kW 56.3

Power input kW 11.3

Current input A 34.8 / 31.5

Temp. range of cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 215,000

kW 63

Power input kW 11.02

Current input A 33.9 / 30.7

Temp. range of heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~48

Sound pressure level (measured in anechoic room) dB <A> 51

Refrigerant piping diameter

High pressure in.(mm) 7/8 (22.2) Brazed

Low pressure in.(mm) 1-1/8 (28.58) Brazed

Module Set

Module PQRY-P96TLMU-A PQRY-P96TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 380 (172) 380 (172)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 6.0 6.0

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,522 + 1,522

G/min(gpm) 25.4 + 25.4

m3 / h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop

psi 3.48 3.48

kPa 24 24

Operating volume range

G/h 793 + 793 ~ 1,902 + 1,902

G/min(gpm) 13.2 + 13.2 ~ 31.7 + 31.7

m3 / h 3.0 + 3.0 ~ 7.2 + 7.2

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 19 / 17 19 / 17

Maximum Overcurrent Protection(MOP) A 30 / 25 30 / 25

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller

Pipe between unit and

distributor

High pressure in.(mm) 3/4 (19.05) Brazed 3/4 (19.05) Brazed

Low pressure in.(mm) - 7/8 (22.2) Brazed

Drawing

External KJ94T151

Wiring KE94C966 KE94C966

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q100CBK2

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50 meshes)

at the water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the

heat source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed

and wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

WR2-10

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P216TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 216,000

kW 63.3

Power input kW 14.03

Current input A 43.2 / 39.1

Temp. range of cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 243,000

kW 71.2

Power input kW 12.88

Current input A 39.7 / 35.9

Temp. range of heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/2~50 (Connectable branch pipe number is max. 48.)

Sound pressure level (measured in anechoic room) dB <A> 55

Refrigerant piping diameter

High pressure in.(mm) 7/8 (22.2) Brazed (1-1/8 (28.58) Brazed for the part that exceeds 65 m)

Low pressure in.(mm) 1-1/8 (28.58) Brazed

Module Set

Module PQRY-P120TLMU-A PQRY-P96TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 380 (172) 380 (172)

Heat exchanger

Water volume in plate

G

Plate Plate

1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 7.7 6.0

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,522 + 1,522

G/min(gpm) 25.4 + 25.4

m3 / h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop

psi 3.48 3.48

kPa 24 24

Operating volume

range

G/h 793 + 793 ~ 1,902 + 1,902

G/min(gpm) 13.2 + 13.2 ~ 31.7 + 31.7

m3 / h 3.0 + 3.0 ~ 7.2 + 7.2

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 29 / 26 19 / 17

Maximum Overcurrent Protection(MOP) A 50 / 45 30 / 25

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller

Pipe between unit and

distributor

High pressure in.(mm) 3/4 (19.05) Brazed 3/4 (19.05) Brazed

Low pressure in.(mm) - 7/8 (22.2) Brazed

Drawing

External KJ94T151

Wiring KE94C966 KE94C966

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q100CBK2

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other

items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB). The

ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50 meshes) at the

water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the heat

source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed and wired

to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be turned on

and glycol must be used in the water loop to prevent freezing down to 5° F.

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-11

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P240TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 240,000

kW 70.3

Power input kW 16.89

Current input A 52.0 / 47.1

Temp. range of cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 270,000

kW 79.1

Power input kW 14.58

Current input A 44.9 / 40.6

Temp. range of heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/2~50 (Connectable branch pipe number is max. 48.)

Sound pressure level (measured in anechoic room) dB <A> 57

Refrigerant piping

diameter

High pressure in.(mm) 7/8 (22.2) Brazed (1-1/8 (28.58) Brazed for the part that exceeds 65 m)

Low pressure in.(mm) 1-3/8 (34.93) Brazed

Module Set

Module PQRY-P120TLMU-A PQRY-P120TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 380 (172) 380 (172)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output

kW 7.7 7.7

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,522 + 1,522

G/min(gpm) 25.4 + 25.4

m3 / h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop

psi 3.48 3.48

kPa 24 24

Operating volume range

G/h 793 + 793 ~ 1,902 + 1,902

G/min(gpm) 13.2 + 13.2 ~ 31.7 + 31.7

m3 / h 3.0 + 3.0 ~ 7.2 + 7.2

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 29 / 26 29 / 26

Maximum Overcurrent Protection(MOP) A 50 / 45 50 / 45

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller

Pipe between unit and

distributor

High pressure in.(mm) 3/4 (19.05) Brazed 3/4 (19.05) Brazed

Low pressure in.(mm) - 7/8 (22.2) Brazed

Drawing

External KJ94T152

Wiring KE94C968 KE94C968

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q100CBK2

joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50 meshes)

at the water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the

heat source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed

and wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

WR2-12

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P288TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 288,000

kW 84.4

Power input kW 20.42

Current input A 62.9 / 56.9

Temp. range of cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 323,000

kW 94.7

Power input kW 17.5

Current input A 53.9 / 48.8

Temp. range of heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/2~50 (Connectable branch pipe number is max. 48.)

Sound pressure level (measured in anechoic room) dB <A> 57

Refrigerant piping

diameter

High pressure in.(mm) 1-1/8 (28.58) Brazed

Low pressure in.(mm) 1-3/8 (34.93) Brazed

Module Set

Module PQRY-P144TLMU-A PQRY-P144TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in. 57-1/8 x 34-11/16 x 21-11/16 57-1/8 x 34-11/16 x 21-11/16

mm 1,450 x 880 x 550 1,450 x 880 x 550

Net weight lbs(kg) 479 (217) 479 (217)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 9.5 9.5

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,902 + 1,902

G/min(gpm) 31.7 + 31.7

m3 / h 7.20 + 7.20

L/min 120 + 120

cfm 4.2 + 4.2

Pressure drop

psi 6.38 6.38

kPa 44 44

Operating volume range

G/h 1,189 + 1,189 ~ 3,054 + 3,054

G/min(gpm) 19.8 + 19.8 ~ 50.9 + 50.9

m3 / h 4.5 + 4.5 ~ 11.6 + 11.6

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 35 / 32 35 / 32

Maximum Overcurrent Protection(MOP) A 60 / 50 60 / 50

Refrigerant

Type x original charge R410A x 13 lbs + 4 oz (6.0 kg) R410A x 13 lbs + 4 oz (6.0 kg)

Control Indoor LEV and BC controller

Pipe between unit and

distributor

High pressure in.(mm) 7/8 (22.2) Brazed 7/8 (22.2) Brazed

Low pressure in.(mm) - 1-1/8 (28.58) Brazed

Drawing

External KJ94T152

Wiring KE94C968 KE94C968

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q200CBK

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50 meshes)

at the water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the

heat source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed

and wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-13

© 2017 Mitsubishi Electric US, Inc.

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

1. SPECIFICATIONS

Model PQRY-P312TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 312,000

kW 91.4

Power input kW 23.41

Current input A 72.1 / 65.2

Temp. range of

cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 350,000

kW 102.6

Power input kW 19.11

Current input A 58.9 / 53.3

Temp. range of

heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit

connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/2~50 (Connectable branch pipe number is max. 48.)

Sound pressure level (measured in anechoic room) dB <A> 58

Refrigerant piping

diameter

High pressure in.(mm) 1-1/8 (28.58) Brazed

Low pressure in.(mm) 1-3/8 (34.93) Brazed

Module Set

Module PQRY-P168TLMU-A PQRY-P144TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 479 (217) 479 (217)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 11.0 9.5

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,902 + 1,902

G/min(gpm) 31.7 + 31.7

m3 / h 7.20 + 7.20

L/min 120 + 120

cfm 4.2 + 4.2

Pressure drop

psi 6.38 6.38

kPa 44 44

Operating volume range

G/h 1,189 + 1,189 ~ 3,054 + 3,054

G/min(gpm) 19.8 + 19.8 ~ 50.9 + 50.9

m3 / h 4.5 + 4.5 ~ 11.6 + 11.6

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 44 / 39 35 / 32

Maximum Overcurrent Protection(MOP) A 70 / 70 60 / 50

Refrigerant

Type x original charge R410A x 13 lbs + 4 oz (6.0 kg) R410A x 13 lbs + 4 oz (6.0 kg)

Control Indoor LEV and BC controller

Pipe between unit

and distributor

High pressure in.(mm) 7/8 (22.2) Brazed 7/8 (22.2) Brazed

Low pressure in.(mm) - 1-1/8 (28.58) Brazed

Drawing

External KJ94T152

Wiring KE94C968 KE94C968

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q200CBK

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50 meshes)

at the water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the

heat source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed

and wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

WR2-14

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P336TSLMU-A

Power source 3-phase 3-wire 208 / 230 ±10% 60Hz

Cooling capacity (Nominal) *1 (208/230V)

Btu/h 336,000

kW 98.5

Power input kW 26.84

Current input A 82.7 / 74.8

Temp. range of cooling

Indoor W.B. 59~75° F (15~24° C)

Circulating water *3 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (208/230V)

Btu/h 378,000

kW 110.8

Power input kW 20.77

Current input A 64.0 / 57.9

Temp. range of heating

Indoor D.B. 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C)

Indoor unit connectable

Total capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/2~50 (Connectable branch pipe number is max. 48.)

Sound pressure level (measured in anechoic room) dB <A> 59

Refrigerant piping diameter

High pressure in.(mm) 1-1/8 (28.58) Brazed

Low pressure in.(mm) 1-5/8 (41.28) Brazed

Module Set

Module PQRY-P168TLMU-A PQRY-P168TLMU-A

External nish Galvanized steel sheets

External dimension HxWxD

in. 57-1/8 x 34-11/16 x 21-11/16 57-1/8 x 34-11/16 x 21-11/16

mm 1,450 x 880 x 550 1,450 x 880 x 550

Net weight lbs(kg) 479 (217) 479 (217)

Heat exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 11.0 11.0

Lubricant MEL32 MEL32

Circulating water *3

Water ow rate

G/h 1,902 + 1,902

G/min(gpm) 31.7 + 31.7

m3 / h 7.20 + 7.20

L/min 120 + 120

cfm 4.2 + 4.2

Pressure drop

psi 6.38 6.38

kPa 44 44

Operating volume range

G/h 1,189 + 1,189 ~ 3,054 + 3,054

G/min(gpm) 19.8 + 19.8 ~ 50.9 + 50.9

m3 / h 4.5 + 4.5 ~ 11.6 + 11.6

Protection devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection

Compressor Over-heat protection

Minimum Circuit Ampacity(MCA) A 44 / 39 44 / 39

Maximum Overcurrent Protection(MOP) A 70 / 70 70 / 70

Refrigerant

Type x original charge R410A x 13 lbs + 4 oz (6.0 kg) R410A x 13 lbs + 4 oz (6.0 kg)

Control Indoor LEV and BC controller

Pipe between unit and

distributor

High pressure in.(mm) 7/8 (22.2) Brazed 7/8 (22.2) Brazed

Low pressure in.(mm) - 1-1/8 (28.58) Brazed

Drawing

External KJ94T152

Wiring KE94C968 KE94C968

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Heat Source Twinning kit: CMY-Q200CBK

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-Y202S-G2, CMY-Y302S-G2, CMY-R160-J1

Main BC controller: CMB-P108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor. Mount a strainer (more than 50 meshes)

at the water inlet piping of the unit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the

heat source unit.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed

and wired to TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be

turned on and glycol must be used in the water loop to prevent freezing down to 5° F.

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

WR2-15

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

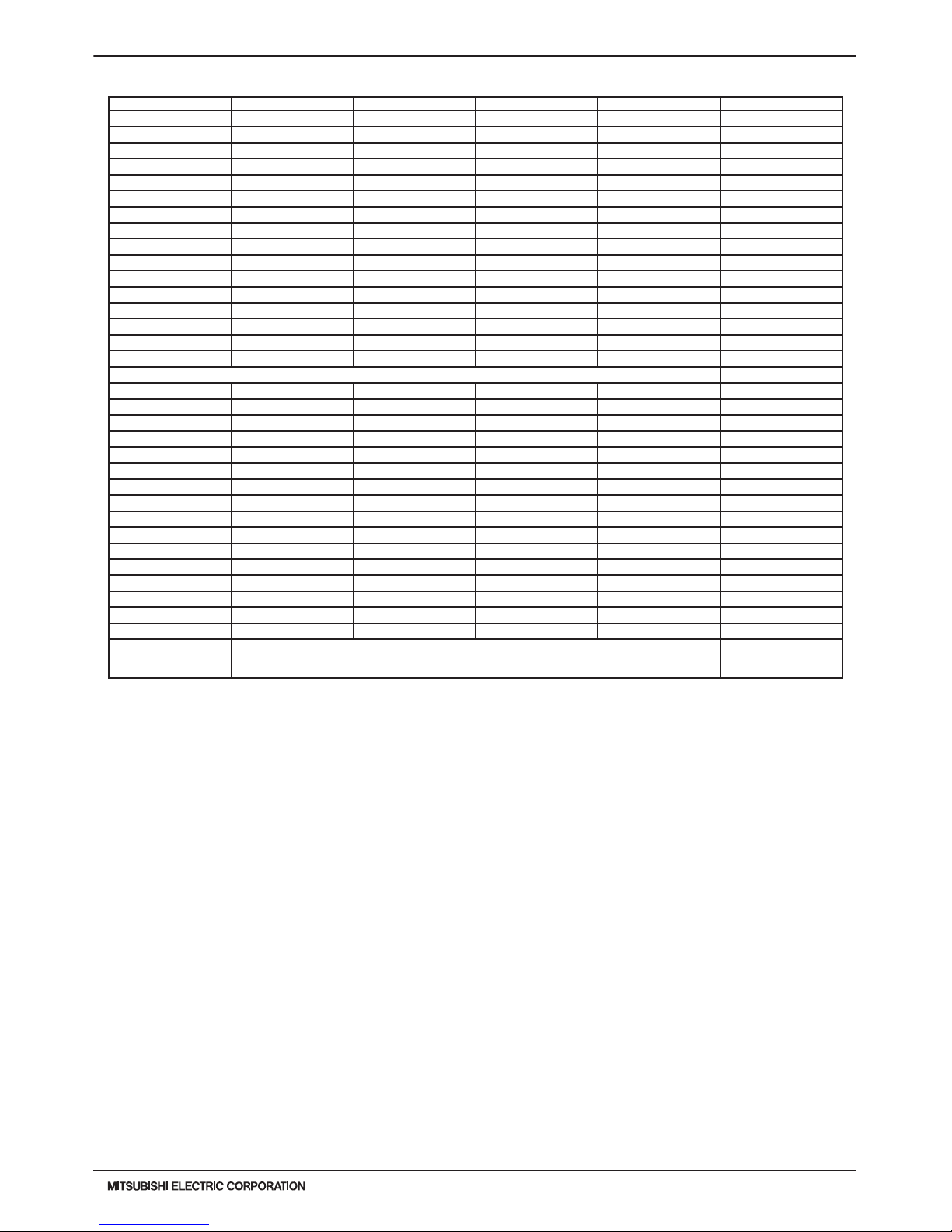

Model PQRY-P72YLMU-A PQRY-P96YLMU-A

Power source 3-phase 3-wire 460 ±10% 60Hz 3-phase 3-wire 460 ±10% 60Hz

Cooling capacity (Nominal) *1 (460V)

Btu/h 72,000 96,000

kW 21.1 28.1

Power input kW 3.23 4.65

Current input A

4.5 6.4

Temp. range

of cooling

Indoor W.B. 59~75° F (15~24° C) 59~75° F (15~24° C)

Circulating water *3

50~113° F (10~45° C) 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (460V)

Btu/h

80,000 108,000

kW 23.4 31.7

Power input kW 3.63 5.05

Current input A 5 7

Temp. range

of heating

Indoor D.B. 59~81° F (15~27° C) 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Indoor unit

connectable

Total capacity 50~150% of heat source unit capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~18 P06~P96/1~24

Sound pressure level (measured in anechoic

room)

dB <A> 46 48

Refrigerant

piping

diameter

High pressure in.(mm) 5/8 (15.88) Brazed 3/4 (19.05) Brazed

Low pressure in.(mm) 3/4 (19.05) Brazed 7/8 (22.2) Brazed

External nish Galvanized steel sheets Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Net weight lbs(kg) 404 (183) 404 (183)

Heat

exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISH ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 4.3 6.0

Lubricant MEL32 MEL32

Circulating

water *3

Water ow rate

G/h 1,522 1,522

G/min(gpm) 25.4 25.4

m3 / h 5.76 5.76

L/min 96 96

cfm 3.4 3.4

Pressure drop

psi 3.48 3.48

kPa 24 24

Operating volume range

G/h 793 ~ 1,902 793 ~ 1,902

G/min(gpm) 13.2 ~ 31.7 13.2 ~ 31.7

m3 / h 3.0 ~ 7.2 3.0 ~ 7.2

Protection

devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Minimum Circuit Ampacity(MCA) A 6 9

Maximum Overcurrent Protection(MOP) A 15 15

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller Indoor LEV and BC controller

Drawing

External KJ94T129 KJ94T129

Wiring KE94C952 KE94C952

Standard

attachment

Document Installation Manual Installation Manual

Accessory Details refer to External Drw Details refer to External Drw

Optional parts

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-R160-J1

BC controller: CMB-P104, 105, 106, 108, 1010, 1013, 1016NU-G1

Main BC controller: CMB-P108, 1010, 1013, 1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller: CMB-P104, 108NU-GB1, CMB-P1016NU-HB1

Remarks

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items

shall be referred to the Installation Manual.

The ambient temperature of the Heat Source Unit needs to be kept below 104°F DB(40° C DB).

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor.

Mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

A eld provided ow switch is required for minimum ow protection on each module, eld installed and wired to

TB8 (terminal 3-4).

*3 If using Circulating water temperatures that are between 23 and 50° F, Dip switch 3-9 must be turned

on and glycol must be used in the water loop to prevent freezing down to 5° F.

1-2. PQRY-P72~336Y(S)LMU-A Specications

WR2-16

PQRY-P-T(S)LMU, Y(S)LMU (April 2017 Ver2)

© 2017 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions (subject to JIS B8615-1) *2 Nominal heating conditions (subject to JIS B8615-1) Unit converter

Indoor: 81degF D.B./ 66degF W.B. (27degC D.B./ 19degC W.B.) 68degF D.B. (20degC D.B.) BTU/h =kW x 3,412

Water Temp.: 86degF (30degC) 68degF (20degC)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 24-9/16ft.(7.5m) 25ft.(7.6m)

* Above specication data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

Model PQRY-P120YLMU-A PQRY-P144YLMU-A

Power source 3-phase 3-wire 460 ±10% 60Hz 3-phase 3-wire 460 ±10% 60Hz

Cooling capacity (Nominal) *1 (460V)

Btu/h 120,000 144,000

kW 35.2 42.2

Power input kW 7.24 8.78

Current input A

10 12.2

Temp. range

of cooling

Indoor W.B. 59~75° F (15~24° C) 59~75° F (15~24° C)

Circulating water *3

50~113° F (10~45° C) 50~113° F (10~45° C)

Heating capacity (Nominal) *2 (460V)

Btu/h

135,000 160,000

kW 39.6 46.9

Power input kW 6.83 8.11

Current input A 9.5 11.3

Temp. range

of heating

Indoor D.B. 59~81° F (15~27° C) 59~81° F (15~27° C)

Circulating water *3 50~113° F (10~45° C) 50~113° F (10~45° C)

Indoor unit

connectable

Total capacity 50~150% of heat source unit capacity 50~150% of heat source unit capacity

Model / Quantity P06~P96/1~30 P06~P96/1~36

Sound pressure level (measured in anechoic room) dB <A> 54 54

Refrigerant

piping

diameter

High pressure in.(mm) 3/4 (19.05) Brazed 7/8 (22.2) Brazed

Low pressure in.(mm) 7/8 (22.2) Brazed 1-1/8 (28.58) Brazed

External nish Galvanized steel sheets Galvanized steel sheets

External dimension HxWxD

in. 43-5/16 x 34-11/16 x 21-11/16 57-1/8 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,450 x 880 x 550

Net weight lbs(kg) 404 (183) 505 (229)

Heat

exchanger

Type Plate Plate

Water volume in plate

G 1.32 1.32

I 5 5

Water pressure Max.

psi 290 290

MPa 2 2

Compressor

Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 7.7 9.5

Lubricant MEL32 MEL32

Circulating

water *3

Water ow rate

G/h 1,522 1,902

G/min(gpm) 25.4 31.7

m3 / h 5.76 7.2

L/min 96 120

cfm 3.4 4.2

Pressure drop

psi 3.48 6.38

kPa 24 44

Operating volume range

G/h 793 ~ 1,902 1,189 ~ 3,054

G/min(gpm) 13.2 ~ 31.7 19.8 ~ 50.9

m3 / h 3.0 ~ 7.2 4.5 ~ 11.6

Protection

devices

High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit(comp) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Minimum Circuit Ampacity(MCA) A 13 16

Maximum Overcurrent Protection(MOP) A 20 25

Refrigerant

Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 13 lbs + 4 oz (6.0 kg)

Control Indoor LEV and BC controller Indoor LEV and BC controller

Drawing

External KJ94T129 KJ94T130

Wiring KE94C952 KE94C952

Standard

attachment

Document Installation Manual Installation Manual

Accessory Details refer to External Drw Details refer to External Drw

Optional parts

Joint :CMY-Y102SS-G2, CMY-Y102LS-G2,

CMY-R160C-J

Joint: CMY-Y102SS-G2, CMY-Y102LS-G2,

CMY-Y202S-G2, CMY-R160-J1

BC controller : CMB-P104, 105, 106, 108, 1010,

1013, 1016NU-G

-

Main BC controller : CMB-P108, 1010, 1013,

1016NU-GA

Main BC controller: CMB-P108, 1010, 1013,

1016NU-GA1, 108, 1010, 1016NU-HA1

Sub BC controller : CMB-P104, 108NU-GB,

CMB-P1016NU-HB

Sub BC controller: CMB-P104, 108NU-GB1,

CMB-P1016NU-HB1

Remarks