Page 1

PM75B4LA060

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

FEATURE

a) Adopting new 5th generation IGBT (CSTBT

performance is improved by 1µm fine rule process.

For example, typical V

b) Over-temperature protection by detecting Tj of the CSTBT

chips and error output is possible from all each conservation upper and lower arm of IPM.

c) New small package

Reduce the package size by 10%, thickness by 22% from

S-DASH series.

•2φ 75A, 600V Current-sense IGBT type inverter

• Monolithic gate drive & protection logic

• Detection, protection & status indication circuits for, shortcircuit, over-temperature & under-voltage (P-Fo available

from upper arm devices)

• UL Recognized Yellow Card No.E80276(N)

ce(sat)=1.55V @Tj=125°C

File No.E80271

TM

) chip, which

TM

APPLICATION

Photo voltaic power conditioner

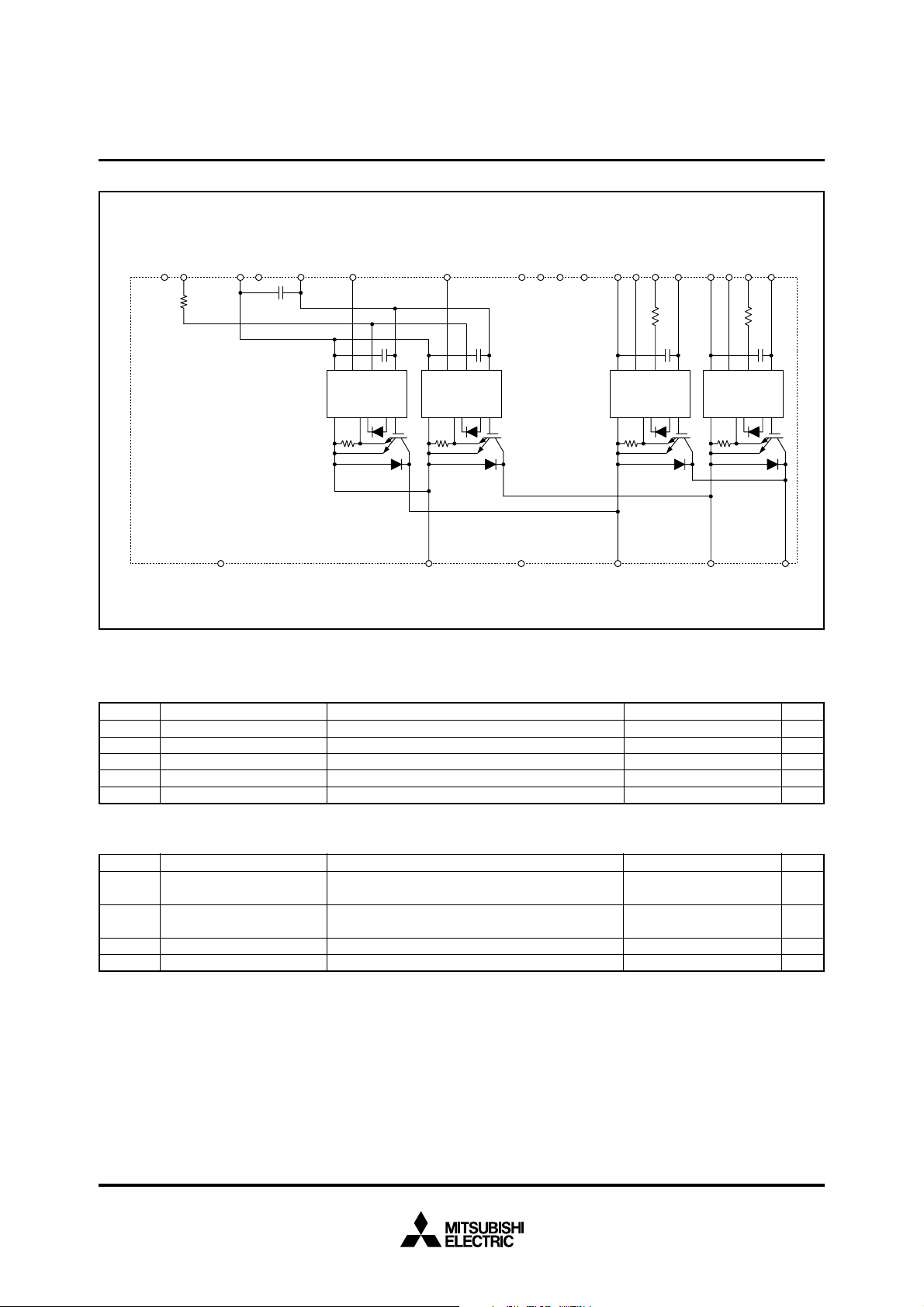

PACKAGE OUTLINES Dimensions in mm

L A B E L

12011

106

1616

16 15.25

6-23-23-23-2

UVW

12 22

19-■0.5

2-φ5.5

MOUNTING HOLES

5511.75

32

13.5

13

31

2-φ2.5

Ter minal code

1. VUPC

2. UFO

3. UP

4. VUP1

5. VVPC

6. VFO

7. VP

16

+

–

8. VVP1

9. NC

10. NC

11. NC

12. NC

13. VNC

14. VN1

3

1

0.5

15. NC

16. UN

17. VN

18. NC

19. Fo

12

17.5 17.5

14.5

6-M5 NUTS

7

(SCREWING DEPTH)

12

7

(19.75)

NP

10.75

3.25

19.75

1591319

B

32.75 23 23 23

Jun. 2005

Page 2

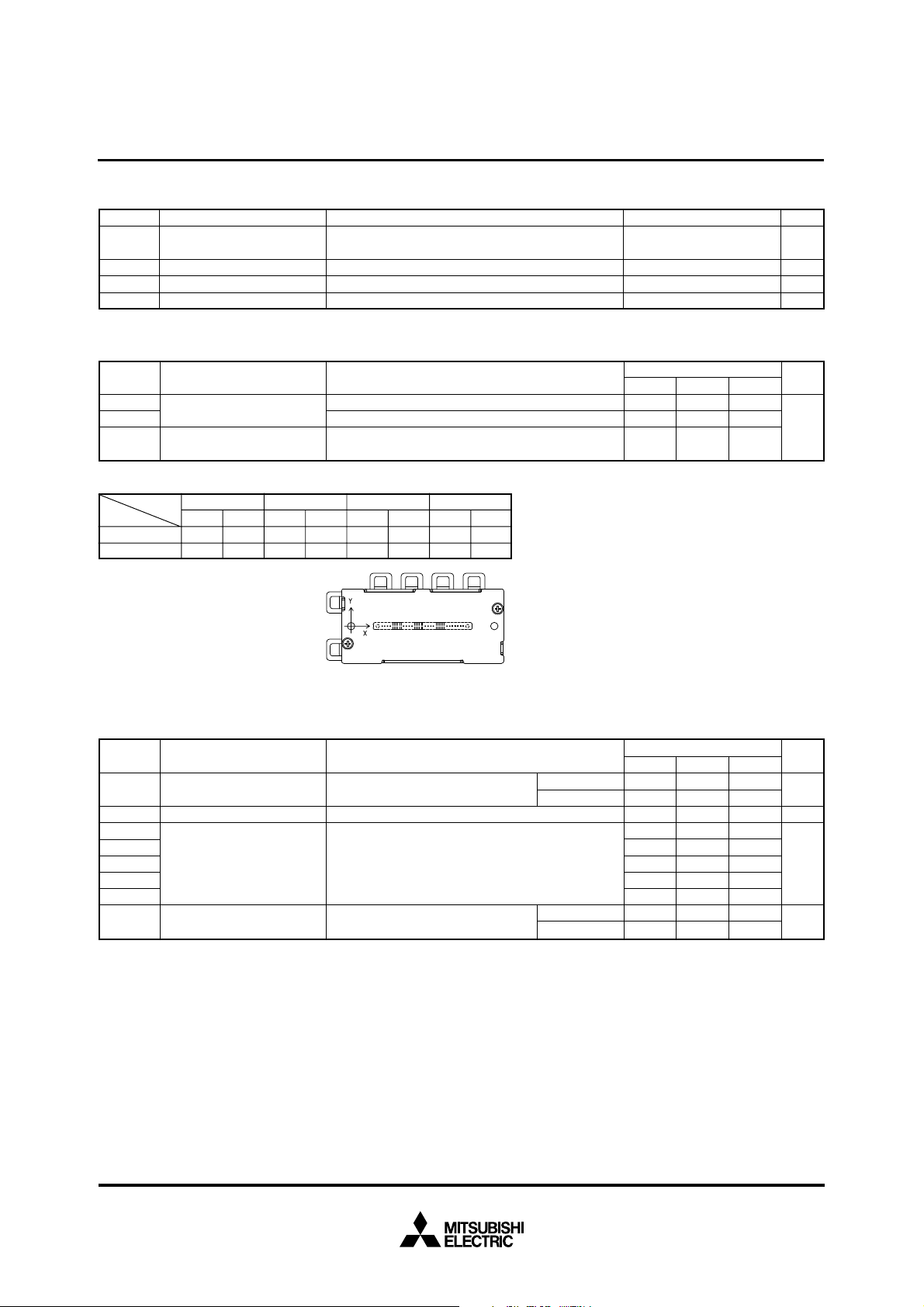

INTERNAL FUNCTIONS BLOCK DIAGRAM

NCV

FONC V

NC

N1

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

UP V

VP V

UNVNV

VPC

NCNCNCNC

VF

VP1

V

O

UPC

UF

UP1

O

1.5k

GND IN Fo Vcc

GND SC OUTOT

GND IN Fo Vcc

GND SC OUTOT

N

GND IN Fo Vcc

GND SC OUTOT

W

1.5k 1.5k

VB

GND IN Fo Vcc

GND SC OUTOT

UP

MAXIMUM RATINGS (Tj = 25°C, unless otherwise noted)

INVERTER PART

Symbol Parameter Condition Unit

VCES

±IC

±ICP

PC

Tj

Collector-Emitter Voltage

Collector Current

Collector Current (Peak)

Collector Dissipation

Junction Temperature

V

D = 15V, VCIN = 15V

T

C = 25°C

T

C = 25°C

T

C = 25°C

Ratings

600

75

150

390

–20 ~ +150

V

A

A

W

°C

CONTROL PART

VD

VCIN

VFO

IFO

Supply Voltage

Input Voltage

Fault Output Supply Voltage

Fault Output Current

Applied between : VUP1-VUPC

VVP1-VVPC, VN1-VNC

Applied between : UP-VUPC, VP-VVPC

UN • VN-VNC

Applied between : UFO-VUPC, VFO-VVPC, FO-VNC

Sink current at UFO, VFO, FO terminals

RatingsCondition UnitSymbol Parameter

20

20

20

20

V

V

V

mA

Jun. 2005

Page 3

TOTAL SYSTEM

Symbol

V

CC(PROT)

V

CC(surge)

Tstg

Viso

Supply Voltage Protected by

SC

Supply Voltage (Surge)

Storage Temperature

Isolation Voltage

Parameter

V

D = 13.5 ~ 16.5V, Inverter Part,

j = +125°C Start

T

Applied between : P-N, Surge value

60Hz, Sinusoidal, Charged part to Base, AC 1 min.

THERMAL RESISTANCES

Symbol

Rth(j-c)Q

Rth(j-c)F

Rth(c-f)

Junction to case Thermal

Resistances

Contact Thermal Resistance

(Note-1) Tc (under the chip) measurement point is below.

arm

axis

X

Y

IGBT

30.4

–8.3

Parameter

UP

FWDi

30.4

–0.8

Inverter IGBT part (per 1/4 module) (Note-1)

Inverter FWDi part (per 1/4 module) (Note-1)

Case to fin, (per 1 module)

Thermal grease applied (Note-1)

VP UN VN

IGBT

FWDi

IGBT

39.7

61.7

61.7

6.3

–0.8

–8.3

FWDi

39.7

–1.2

Condition

Condition

(unit : mm)

IGBT

52.4

6.3

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

Ratings

400

500

–40 ~ +125

2500

Limits

Min.

—

—

—

FWDi

52.4

–1.2

Typ. Max.

—

—

—

0.32

0.53

0.038

Unit

V

V

°C

V

rms

Unit

°C/W

Bottom view

ELECTRICAL CHARACTERISTICS (Tj = 25°C, unless otherwise noted)

INVERTER PART

= 15V

Condition

(Fig. 5)

Symbol

CE(sat)

V

VEC

ton

trr

tc(on)

toff

tc(off)

ICES

Parameter

Collector-Emitter

Saturation Voltage

FWDi Forward Voltage

Switching Time

Collector-Emitter

Cutoff Current

D = 15V, IC = 75A

V

V

CIN = 0V (Fig. 1)

–I

C = 75A, VD = 15V, VCIN = 15V (Fig. 2)

D = 15V, VCIN = 0V↔15V

V

V

CC = 300V, IC = 75A

T

j = 125°C

Inductive Load (Fig. 3,4)

VCE = V

CES

, V

CIN

T

j = 25°C

T

j = 125°C

j = 25°C

T

T

j = 125°C

Limits

Min. Typ. Max.

—

—

—

0.3

—

—

—

—

—

—

1.7

1.55

2.2

0.7

0.1

0.2

0.9

0.2

—

—

—

—

3.3

1.4

0.2

0.4

1.8

0.4

10

Unit

V

V

µs

1

mA

Jun. 2005

Page 4

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

CONTROL PART

—

—

1.2

1.7

150

—

135

—

11.5

—

—

—

1.0

Limits

15

1.5

2.0

—

0.2

145

125

12.0

12.5

—

10

1.8

1.8

2.3

—

—

—

—

—

—

25

12

15

Unit

mA

V

A

µs

°C

V

mA

ms

Max.

6

12.5

0.01

Symbol

ID

V

th(ON)

Vth(OFF)

SC

t

off(SC)

OT

OT

r

UV

UV

r

IFO(H)

IFO(L)

tFO

Circuit Current

Input ON Threshold Voltage

Input OFF Threshold Voltage

Short Circuit Trip Level

Short Circuit Current Delay

Time

Over Temperature Protection

Supply Circuit Under-Voltage

Protection

Fault Output Current

Minimum Fault Output Pulse

Width

Parameter

Condition

VD = 15V, VCIN = 15V

Applied between : U

P-VUPC, VP-VVPC

VN1-VNC

V*P1-V*PC

UN • VN-VNC

j ≤ 125°C, VD = 15V (Fig. 3,6)

–20 ≤ T

V

D = 15V (Fig. 3,6)

V

D = 15V

Detect T

j of IGBT chip

j ≤ 125°C

–20 ≤ T

D = 15V, VFO = 15V (Note-2)

V

D = 15V (Note-2)

V

Trip level

Reset level

Trip level

Reset level

Min. Typ.

(Note-2) Fault output is given only when the internal SC, OT & UV protections schemes of either upper or lower arm device operate to

protect it.

MECHANICAL RATINGS AND CHARACTERISTICS

Symbol

—

—

—

Parameter

Mounting torque

Mounting torque

Weight

Main terminal screw : M5

Mounting part screw : M5

Condition

—

Min.

2.5

2.5

—

RECOMMENDED CONDITIONS FOR USE

Symbol Parameter

VCC

VD

VCIN(ON)

VCIN(OFF)

fPWM

tdead

Supply Voltage

Control Supply Voltage

Input ON Voltage

Input OFF Voltage

PWM Input Frequency

Arm Shoot-through

Blocking Time

Applied across P-N terminals

Applied between : V

Applied between : U

Using Application Circuit of Fig. 8

For IPM’s each input signals (Fig. 7)

Condition

UP1-VUPC, VVP1-VVPC

VN1-VNC (Note-3)

P-VUPC, VP-VVPC

UN • VN-VNC

(Note-3) With ripple satisfying the following conditions : dv/dt swing ≤ ±5V/µs, Variation ≤ 2V peak to peak

Recommended value

Limits

Typ.

3.0

3.0

380

≤ 400

15 ± 1.5

≤ 0.8

≥ 9.0

≤ 20

≥ 2.0

Max.

3.5

3.5

—

Unit

N • m

N • m

g

Unit

V

V

V

kHz

µs

Jun. 2005

Page 5

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

PRECAUTIONS FOR TESTING

1. Before appling any control supply voltage (V

sponding supply voltage and each input signal should be kept off state.

After this, the specified ON and OFF level setting for each input signal should be done.

2. When performing “SC” tests, the turn-off surge voltage spike at the corresponding protection operation should not be allowed to rise above V

CES rating of the device.

(These test should not be done by using a curve tracer or its equivalent.)

D), the input terminals should be pulled up by resistores, etc. to their corre-

P, (U,V)

P, (U,V)

V

(0V)

IN

V

Fo

D (all)

CIN

V V

U,V, (N) U,V, (N)

Ic

V

(15V)

CIN

IN

Fo

VD (all)

Fig. 1 VCE(sat) Test Fig. 2 VEC Test

a) Lower Arm Switching

Signal input

VCIN

(Upper Arm)

(15V)

VCIN

Signal input

(Lower Arm)

b) Upper Arm Switching

VCIN

(15V)

Signal input

(Upper Arm)

Signal input

(Lower Arm)

VCIN

Fo

D (all)

V

Fo

D (all)

V

P

Fo

U,V

N

P

Fo

U,V

N

Vcc

CS

Ic

V

CIN

Vcc

CS

(ton= td(on) + tr) (toff= td(off) + tf)

Ic

10%

90%

trr

Irr

10% 10%

tc(on) tc(off)

trtd(on)

Fig. 3 Switching Time and SC Test Circuit Fig. 4 Switching Time Test Waveform

VCIN

(15V)

P, (U,V)

IN

Fo

U,V, (N)

VD (all)

Fig. 5 ICES Test

VCIN

A

Pulse

VCE

Ic

Fo

Short Circuit Current

Constant Current

toff(SC)

Fig. 6 SC Test Waveform

Ic

td(off)

–Ic

V

CE

90%

10%

tf

SC Trip

IPM’ input signal V

(Upper Arm)

IPM’ input signal V

(Lower Arm)

1.5V: Input on threshold voltage Vth(on) typical value, 2V: Input off threshold voltage Vth(off) typical value

CIN

0V

CIN

0V

1.5V 1.5V

2V

2V

1.5V

2V

tdeadtdeadtdead

Fig. 7 Dead Time Measurement Point Example

t

t

Jun. 2005

Page 6

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

20k

I

F

→

≥0.1µ≥10µ

20k

I

F

→

≥0.1µ≥10µ

I

F

→

I

F

→

20k

≥0.1µ≥10µ

20k

≥0.1µ≥10µ

V

UF

UP

V

V

VF

VP

V

NC

NC

NC

NC

UN

VN

V

UP1

1.5k

O

UPC

VP1

1.5k

O

VPC

N1

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

OUT

OT

SC

GND

OUT

OT

SC

GND

OUT

OT

SC

GND

OUT

OT

SC

GND

P

U

~

AC Output

V

W

N

NC

V

NC

B

1.5k

F

O

NC

Fig. 8 Application Example Circuit

NOTES FOR STABLE AND SAFE OPERATION ;

Design the PCB pattern to minimize wiring length between opto-coupler and IPM’s input terminal, and also to minimize the

•

stray capacity between the input and output wirings of opto-coupler.

Connect low impedance capacitor between the Vcc and GND terminal of each fast switching opto-coupler.

•

Fast switching opto-couplers: tPLH, tPHL ≤ 0.8µs, Use High CMR type.

•

Slow switching opto-coupler: CTR > 100%

•

Use 3 isolated control power supplies (VD). Also, care should be taken to minimize the instantaneous voltage charge of the

•

power supply.

Make inductance of DC bus line as small as possible, and minimize surge voltage using snubber capacitor between P and N

•

terminal.

Jun. 2005

Page 7

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

PERFORMANCE CURVES

OUTPUT CHARACTERISTICS

100

T

j

= 25°C

(A)

C

80

60

40

20

COLLECTOR CURRENT I

0

0

COLLECTOR-EMITTER SATURATION VOLTAGE V

COLLECTOR-EMITTER SATURATION

VOLTAGE (VS. V

2

(V)

CE (sat)

1.5

1

0.5

COLLECTOR-EMITTER

SATURATION VOLTAGE V

0

(TYPICAL)

VD = 17V

10.5 1.5 2

D

) CHARACTERISTICS

(TYPICAL)

IC = 75A

T

T

1312 1514 1716

15V

13V

j

= 25°C

j

= 125°C

18

CE (sat)

(V)

CE (sat)

1.5

0.5

COLLECTOR-EMITTER

SATURATION VOLTAGE V

(V)

10

(µs)

c(off)

, t

c(on)

10

SWITCHING TIME t

10

COLLECTOR-EMITTER SATURATION

VOLTAGE (VS. Ic) CHARACTERISTICS

(TYPICAL)

2

VD = 15V

1

T

j

= 25°C

T

j

0

20 40 60 80 100

0

COLLECTOR CURRENT I

= 125°C

C

(A)

SWITCHING TIME CHARACTERISTICS

(TYPICAL)

0

7

5

3

2

–1

7

5

3

2

–2

10

t

c(off)

t

c(on)

t

c(off)

VCC = 300V

D

= 15V

V

j

= 25°C

T

j

= 125°C

T

Inductive load

0

23 57

10

1

23 57

10

2

CONTROL SUPPLY VOLTAGE VD (V)

SWITCHING TIME CHARACTERISTICS

1

10

7

5

(µs)

off

3

, t

on

2

0

10

7

5

3

2

SWITCHING TIME t

–1

10

0

10

(TYPICAL)

t

off

t

on

23 57

VCC = 300V

D

V

T

T

Inductive load

t

off

1

10

COLLECTOR CURRENT IC (A) COLLECTOR CURRENT IC (A)

= 15V

j

= 25°C

j

= 125°C

t

on

23 57

10

COLLECTOR CURRENT IC (A)

SWITCHING LOSS CHARACTERISTICS

1

10

VCC = 300V

7

5

V

D

10

3

2

0

7

5

E

3

2

–1

7

5

3

2

–2

0

10

= 15V

T

T

Inductive load

SW(on)

(mJ/Pulse)

SW(off)

, E

SW(on)

10

2

10

SWITCHING LOSS E

(TYPICAL)

j

= 25°C

j

= 125°C

E

SW(off)

23 57

10

E

SW(off)

1

E

SW(on)

23 57

10

2

Jun. 2005

Page 8

MITSUBISHI <INTELLIGENT POWER MODULES>

PM75B4LA060

FLAT-BASE TYPE

INSULATED PACKAGE

FWDi FORWARD VOLTAGE CHARACTERISTICS

2

(A)

10

C

VD = 15V

7

5

3

2

1

10

7

5

3

2

0

10

COLLECTOR REVERSE CURRENT –I

0

EMITTER-COLLECTOR VOLTAGE V

(TYPICAL)

T

j

= 25°C

j

= 125°C

T

0.5 1 1.5 2 2.5

EC

(V)

FWDi REVERSE RECOVERY LOSS CHARACTERISTICS

1

10

VCC = 300V

7

5

V

D

3

T

2

T

Inductive load

0

10

7

5

3

2

–1

7

5

3

2

–2

0

10

= 15V

(mJ/Pulse)

rr

10

10

REVERSE RECOVERY LOSS E

(TYPICAL)

j

= 25°C

j

= 125°C

E

rr

23 57

10

1

23 57

10

2

COLLECTOR REVERSE CURRENT –IC (A)

FWDi REVERSE RECOVERY CHARACTERISTICS

(TYPICAL)

1

10

7

5

(µs)

rr

3

2

I

0

10

7

5

3

2

–1

10

7

5

3

2

REVERSE RECOVERY TIME t

–2

10

0

10

rr

t

rr

23 57

10

1

COLLECTOR CURRENT I

VCC = 300V

D

= 15V

V

T

j

= 25°C

j

= 125°C

T

Inductive load

23 57

C

(A)

10

10

7

5

3

2

10

7

5

3

2

10

7

5

3

2

10

2

2

(A)

rr

1

0

–1

REVERSE RECOVERY CURRENT l

TRANSIENT THERMAL

IMPEDANCE CHARACTERISTICS

(IGBT PART)

0

10

7

5

3

th (j – c)

2

–1

10

7

5

3

2

–2

10

7

5

NORMALIZED TRANSIENT

3

Single Pulse

THERMAL IMPEDANCE Z

2

Per unit base = R

–3

10

10

–5

23 57

–3

–4

23 57

23 57 23 57

10

10

TIME

th(j – c)Q

–2

23 57

10

(s)

= 0.32°C/W

–1

0

10

23 57

10

10

TRANSIENT THERMAL

IMPEDANCE CHARACTERISTICS

(FWDi PART)

0

10

7

5

3

th (j – c)

2

–1

10

7

5

3

2

–2

10

7

5

NORMALIZED TRANSIENT

3

Single Pulse

THERMAL IMPEDANCE Z

2

Per unit base = R

–3

1

10

10

–5

–4

23 57

23 57 23 57

10

10

–3

23 57

th(j – c)F

–2

23 57

10

= 0.53°C/W

–1

0

10

23 57

10

10

1

TIME (s)

Jun. 2005

Loading...

Loading...