Sep.1998

6.0 Introduction to Intelligent

Power Modules (IPM)

Mitsubishi Intelligent Power Modules (IPMs) are advanced hybrid

power devices that combine high

speed, low loss IGBTs with optimized gate drive and protection circuitry. Highly effective over-current

and short-circuit protection is realized through the use of advanced

current sense IGBT chips that allow continuous monitoring of power

device current. System reliability is

further enhanced by the IPM’s integrated over temperature and under

voltage lock out protection. Compact, automatically assembled Intelligent Power Modules are designed to reduce system size, cost,

and time to market. Mitsubishi

Electric introduced the first full line

of Intelligent Power Modules in November, 1991. Continuous improvements in power chip, packaging, and control circuit technology

have lead to the IPM lineup shown

in Table 6.1.

6.0.1 Third Generation Intelli-

gent Power Modules

Mitsubishi third generation intelligent power module family shown in

Table 6.1 represents the industries

most complete line of IPMs. Since

their original introduction in 1993

the series has been expanded to

include 36 types with ratings ranging from 10A 600V to 800A 1200V.

The power semiconductors used in

these modules are based on the

field proven H-Series IGBT and diode processes. In Table 6.1 the

third generation family has been divided into two groups, the “Low

Profile Series” and “High Power

Series” based on the packaging

technology that is used. The third

generation IPM has been optimized

for minimum switching losses in order to meet industry demands for

acoustically noiseless inverters

with carrier frequencies up to

20kHz. The built in gate drive and

protection has been carefully designed to minimize the components

required for the user supplied interface circuit.

6.0.2 V-Series High Power IPMs

The V-Series IPM was developed

in order to address newly emerging

industry requirements for higher reliability, lower cost and reduced

EMI. By utilizing the low inductance

packaging technology developed

for the U-Series IGBT module (described in Section 4.1.5) combined

with an advanced super soft freewheel diode and optimized gate

drive and protection circuits the VSeries IPM family achieves improved performance at reduced

cost. The detailed descriptions of

IPM operation and interface requirements presented in Sections

6.1 through 6.8 apply to V-Series

as well as third generation IPMs.

The only exception being that VSeries IPMs have a unified short

circuit protection function that takes

the place of the separate short circuit and over current functions described in Sections 6.4.4 and 6.4.5.

The unified protection was made

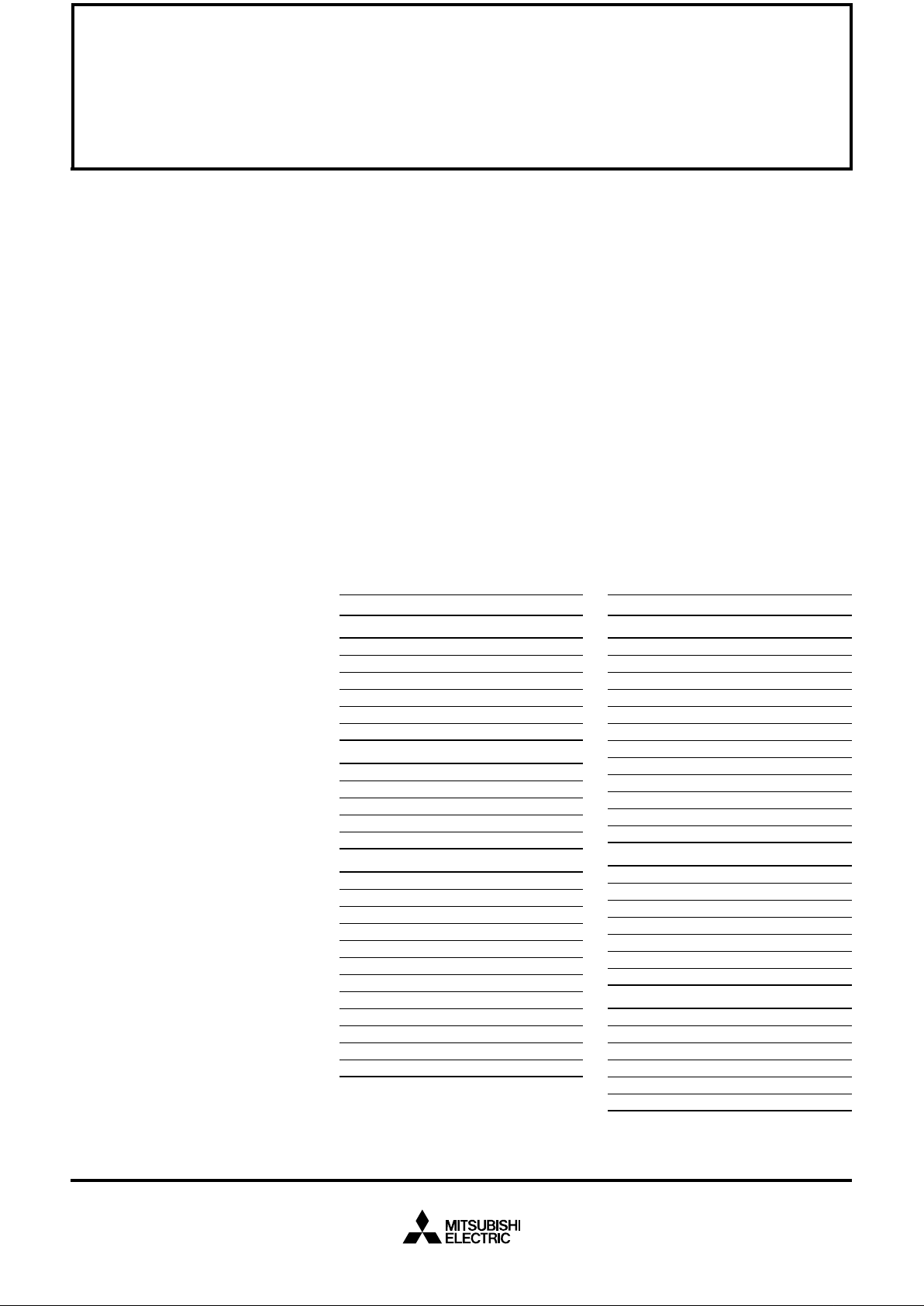

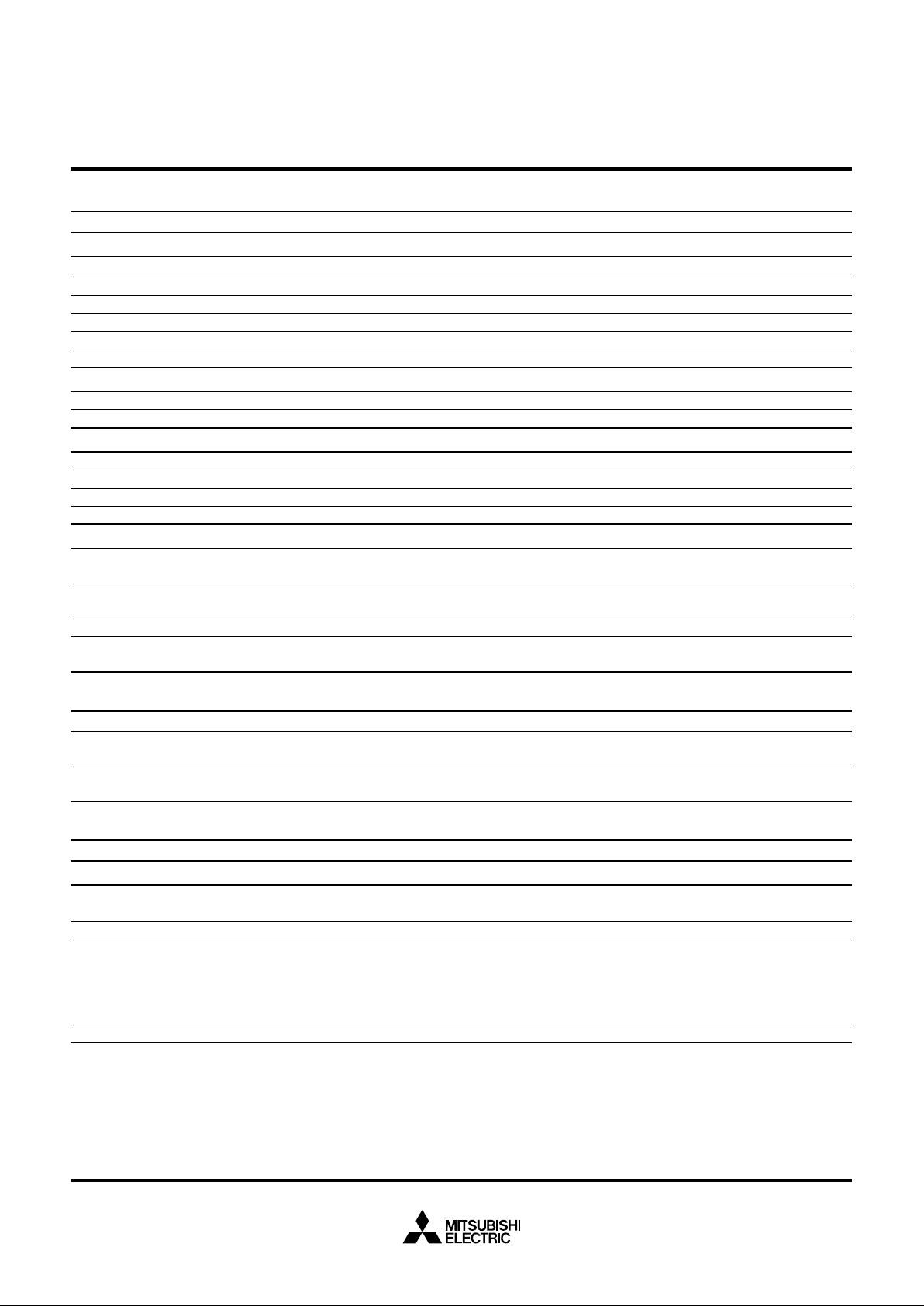

Third Generation Low Profile Series - 600V

PM10CSJ060 10 Six IGBTs

PM15CSJ060 15 Six IGBTs

PM20CSJ060 20 Six IGBTs

PM30CSJ060 30 Six IGBTs

PM50RSK060 50 Six IGBTs + Brake ckt.

PM75RSK060 75 Six IGBTs + Brake ckt.

Third Generation Low Profile Series - 1200V

PM10CZF120 10 Six IGBTs

PM10RSH120 10 Six IGBTs + Brake ckt.

PM15CZF120 15 Six IGBTs

PM15RSH120 15 Six IGBTs + Brake ckt.

PM25RSK120 25 Six IGBTs + Brake ckt.

Third Generation High Power Series - 600V

PM75RSA060 75 Six IGBTs + Brake ckt.

PM100CSA060 100 Six IGBTs

PM100RSA060 100 Six IGBTs + Brake ckt.

PM150CSA060 150 Six IGBTs

PM150RSA060 150 Six IGBTs + Brake ckt.

PM200CSA060 200 Six IGBTs

PM200RSA060 200 Six IGBTs + Brake ckt.

PM200DSA060 200 Two IGBTs: Half Bridge

PM300DSA060 300 Two IGBTs: Half Bridge

PM400DAS060 400 Two IGBTs: Half Bridge

PM600DSA060 600 Two IGBTs: Half Bridge

PM800HSA060 800 One IGBT

Third Generation High Power Series - 1200V

PM25RSB120 25 Six IGBTs + Brake ckt.

PM50RSA120 50 Six IGBTs + Brake ckt.

PM75CSA120 75 Six IGBTs

PM75DSA120 75 Two IGBTs: Half Bridge

PM100CSA120 100 Six IGBTs

PM100DSA120 100 Two IGBTs: Half Bridge

PM150DSA120 150 Two IGBTs: Half Bridge

PM200DSA120 200 Two IGBTs: Half Bridge

PM300DSA120 300 Two IGBTs: Half Bridge

PM400HSA120 400 Two IGBTs: Half Bridge

PM600HSA120 600 One IGBT

PM800HSA120 800 One IGBT

V-Series High Power - 600V

PM75RVA060 75 Six IGBTs + Brake ckt.

PM100CVA060 100 Six IGBTs

PM150CVA060 150 Six IGBTs

PM200CVA060 200 Six IGBTs

PM300CVA060 300 Six IGBTs

PM400DVA060 400 Two IGBTs: Half Bridge

PM600DVA060 600 Two IGBTs: Half Bridge

V-Series High Power - 1200V

PM50RVA120 50 Six IGBTs + Brake ckt.

PM75CVA120 75 Six IGBTs

PM100CVA120 100 Six IGBTs

PM150CVA120 150 Six IGBTs

PM200DVA120 200 Two IGBTs: Half Bridge

PM300DVA120 300 Two IGBTs: Half Bridge

Type Number Amps Power Circuit Type Number Amps Power Circuit

Table 6.1 Mitsubishi Intelligent Power Modules

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

possible by an advanced RTC

(Real Time Control) current clamping circuit that eliminates the need

for the over current protection function. In V-Series IPMs a unified

short circuit protection with a delay

to avoid unwanted operation replaces the over current and short

circuit modes of the third generation devices.

6.1 Structure of Intelligent

Power Modules

Mitsubishi Intelligent Power Modules utilize many of the same field

proven module packaging technologies used in Mitsubishi IGBT

modules. Cost effective implementation of the built in gate drive and

protection circuits over a wide

range of current ratings was

achieved using two different packaging techniques. Low power devices use a multilayer epoxy isolation system while medium and high

power devices use ceramic isolation. These packaging technologies

are described in more detail in Sections 6.1.1 and 6.1.2. IPM are

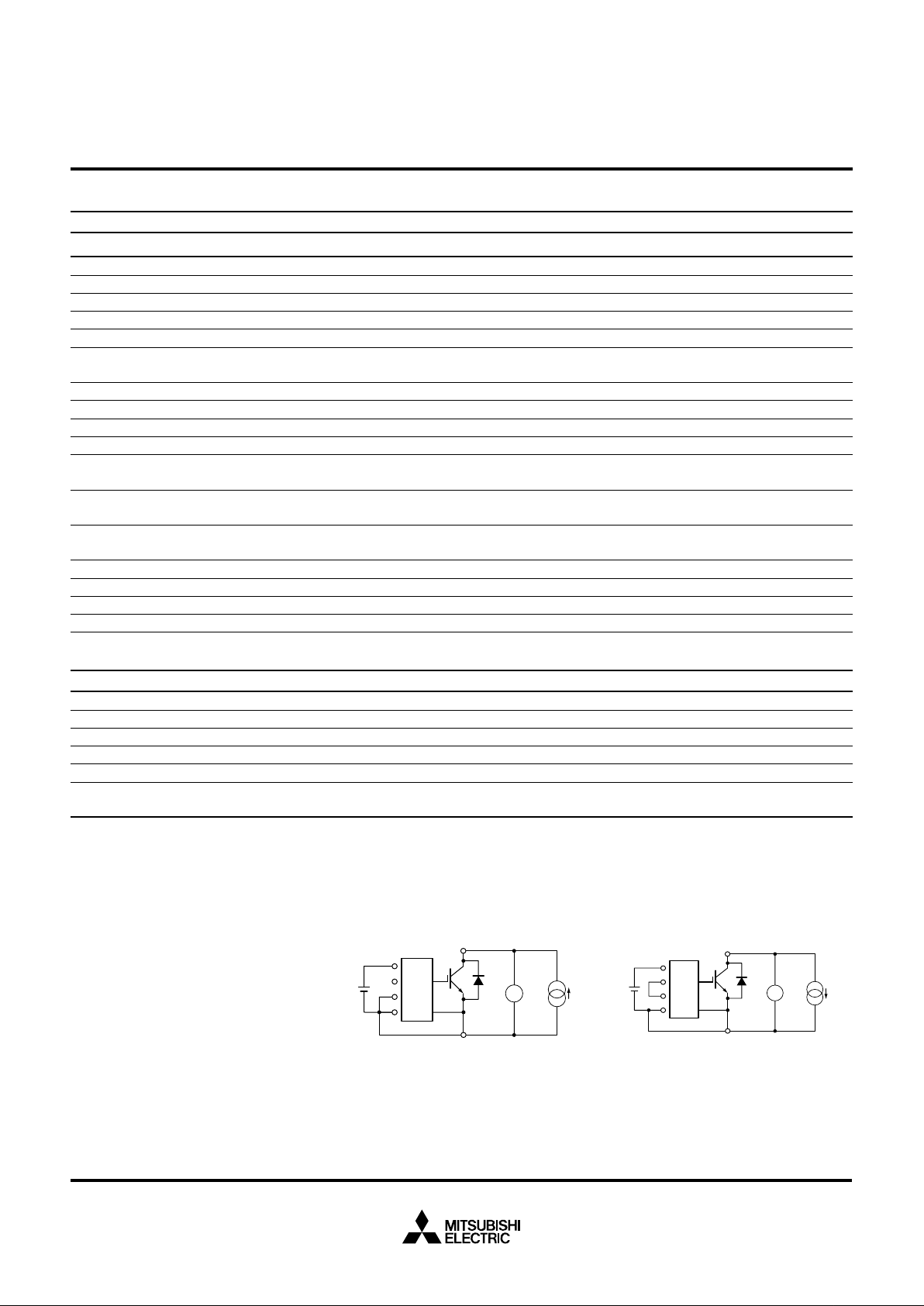

available in four power circuit configurations, single (H), dual (D), six

pack (C), and seven pack (R).

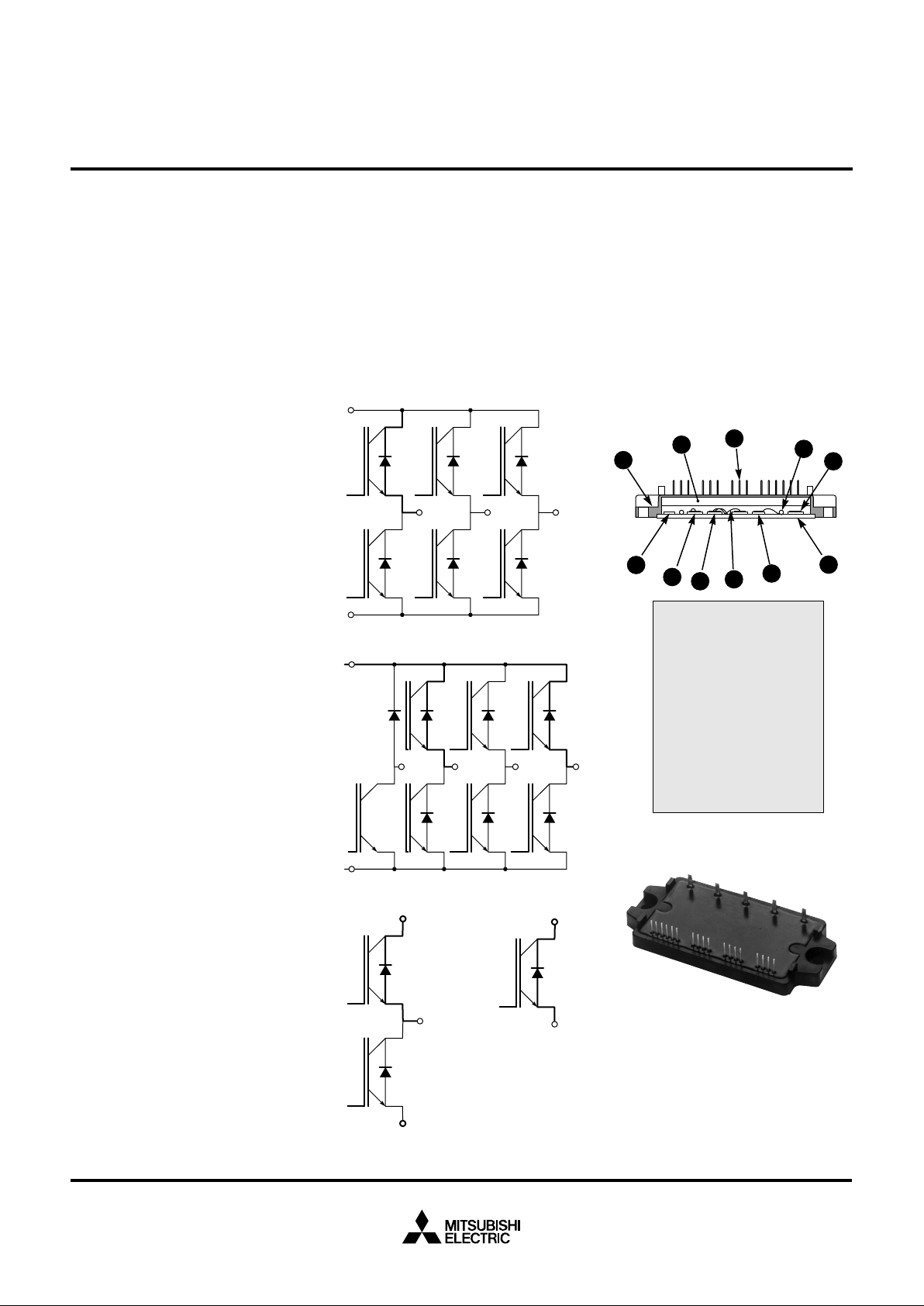

Table 6.1 indicates the power circuit of each IPM and Figure 6.1

shows the power circuit configurations.

6.1.1 Multilayer Epoxy Construc-

tion

Low power IPM (10-50A, 600V and

10-15A, 1200V) use a multilayer

epoxy based isolation system. In

this system, alternate layers of copper and epoxy are used to create a

shielded printed circuit directly on

the aluminum base plate. Power

chips and gate control circuit components are soldered directly to the

substrate eliminating the need for a

separate printed circuit board and

ceramic isolation materials. Modules constructed using this technique are easily identified by their

extremely low profile packages.

This package design is ideally

suited for consumer and industrial

applications where low cost and

compact size are important.

Figure 6.2 shows a cross section

of this type of IPM package. Figure

6.3 is a PM20CSJ060 20A, 600V

IPM.

P

UVW

C2E1

C1

E2

E

C

N

TYPE C

TYPE D

TYPE H

P

N

U

TYPE R

V WB

Figure 6.2 Multi-Layer Epoxy

Construction

Figure 6.1 Power Circuit

Configuration

Figure 6.3 PM20CSJ060

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Case

Epoxy Resin

Input Signal Terminal

SMT Resistor

Gate Control IC

SMT Capacitor

IGBT Chip

Free-wheel Diode Chip

Bond Wire

Copper Block

Baseplate with Epoxy

Based Isolation

11

10

9

8

6

7

1

2

3

4

5

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

6.1.2 Ceramic Isolation Con-

struction

Higher power IPMs are constructed

using ceramic isolation material. A

direct bond copper process in

which copper patterns are bonded

directly to the ceramic substrate

without the use of solder is used in

these modules. This substrate provides the improved thermal characteristics and greater current carrying capabilities that are needed in

these higher power devices. Gate

drive and control circuits are contained on a separate PCB mounted

directly above the power devices.

The PCB is a multilayer construction with special shield layers for

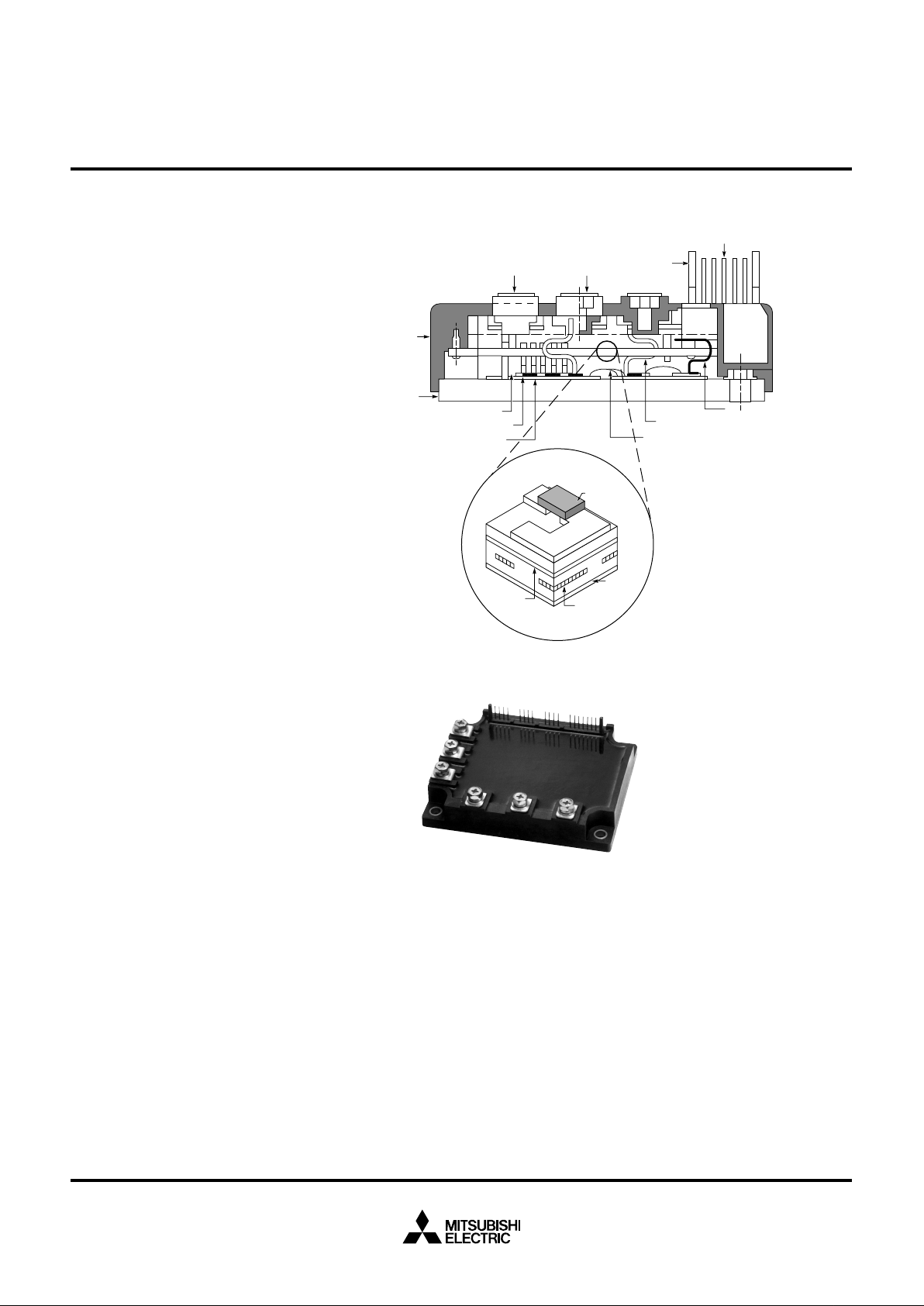

EMI noise immunity. Figure 6.4

shows the structure of a ceramic

isolated Intelligent Power Module.

Figure 6.5 is a PM75RSA060 75 A,

600V IPM.

Figure 6.4 Ceramic Isolation Construction

Figure 6.5 PM75RSA060

SILICON CHIP

DBC PLATE

BASE

PLATE

SILICON GEL

CASE

MAIN

TERMINAL

EPOXY

RESIN

GUIDE

PIN

INPUT SIGNAL

TERMINAL

INTERCONNECT

TERMINAL

ELECTRODE

ALUMINUM WIRE

SHIELD

LAYER

RESISTOR

CONTROL BOARD

PCB

SHIELD

LAYER

SIGNAL

TRACE

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

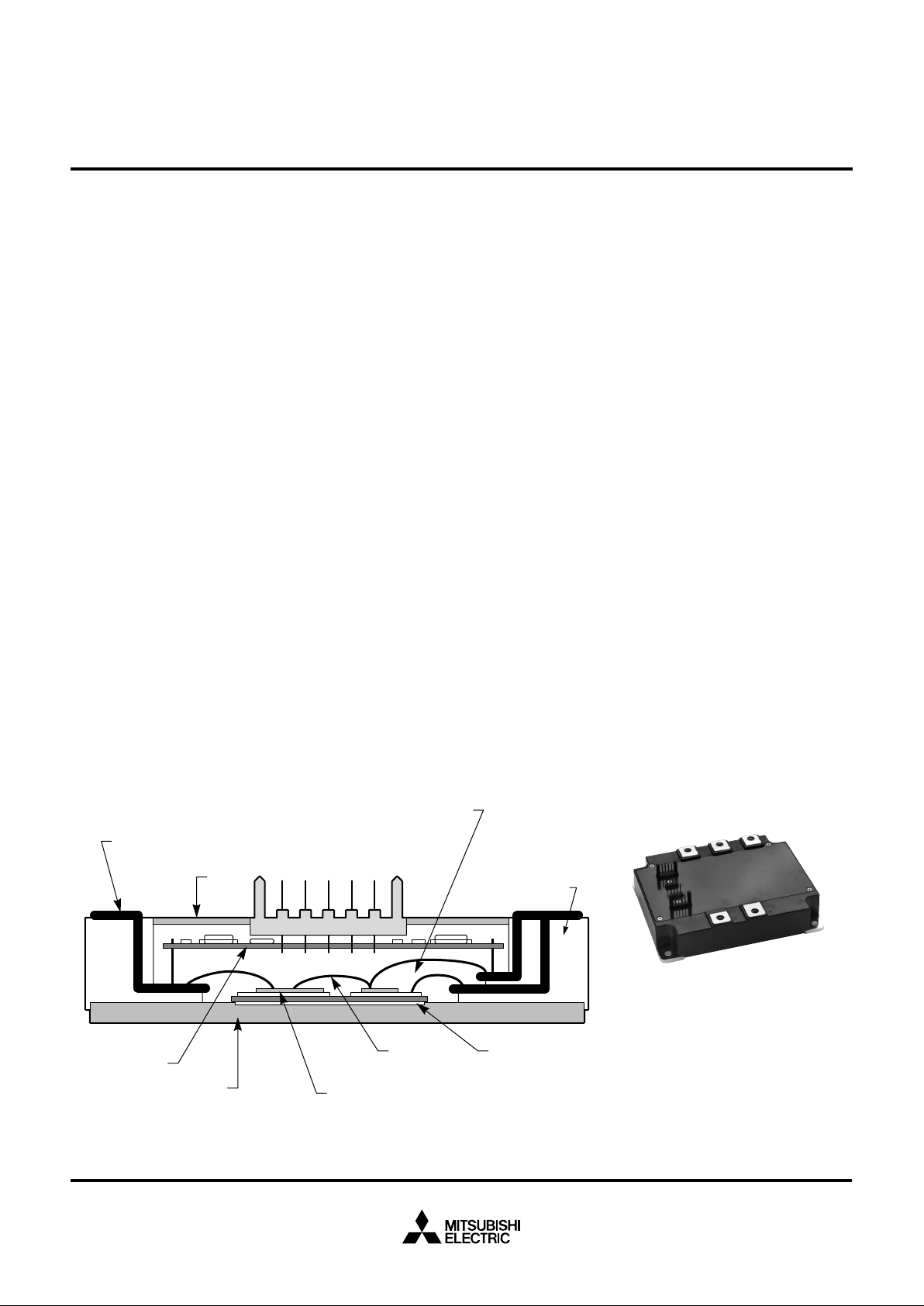

6.1.3 V-Series IPM Construction

V-Series IPMs are similar to the ceramic isolated types described

in Section 6.1.2 except that an insert molded case similar to the

U-Series IGBT is used. Like the

U-Series IGBT described in Section 4.1.5, the V-Series IPM

has lower internal inductance and

improved power cycle durability.

Figure 6.6 is a cross section drawing showing the construction of the

V-Series IPM. The insert molded

case makes the V-Series IPM is

easier to manufacture and lower in

cost. Figure 6.7 shows a

PM150CV A120 which is a 150A

1200V V-Series IPM.

6.1.4 Advantages of Intelligent

Power Module

IPM (Intelligent Power Module)

products were designed and developed to provide advantages to

Customers by reducing design, development, and manufacturing

costs as well as providing improvement in system performance and

reliability over conventional IGBTs.

Design and development effort is

simplified and successful drive coordination is assured by the integration of the drive and protection

circuitry directly into the IPM. Reduced time to market is only one of

the additional benefits of using an

IPM. Others include increased system reliability through automated

IPM assembly and test and reduction in the number of components

that must be purchased, stored,

and assembled. Often the system

size can be reduced through

smaller heatsink requirements as a

result of lower on-state and switching losses. All IPMs use the same

standardized gate control interface

with logic level control circuits allowing extension of the product line

without additional drive circuit design. Finally, the ability of the IPM

to self protect in fault situations reduce the chance of device destruction during development testing as

well as in field stress situations.

6.2 IPM Ratings and Characteristics

IPM datasheets are divided into

three sections:

• Maximum Ratings

• Characteristics (electrical,

thermal, mechanical)

• Recommended Operating

Conditions

The limits given as maximum rating

must not be exceeded under any

circumstances, otherwise destruction of the IPM may result.

Key parameters needed for system

design are indicated as electrical,

thermal, and mechanical characteristics.

The given recommended operating

conditions and application circuits

should be considered as a preferable design guideline fitting most

applications.

POWER TERMINALS

SILICONE GEL

COVER

INSERT MOLD CASE

DBC AIN CERAMIC

SUBSTRATE

SILICON CHIPS

BASE PLATE

PRINTED CIRCUIT

BOARD

ALUMINUM

BOND WIRES

SIGNAL TERMINALS

Figure 6.6 V-Series IPM Construction Figure 6.7 PM150CVA120

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

6.2.1 Maximum Ratings

Symbol Parameter Definition

Inverter Part

V

CC

Supply Voltage Maximum DC bus voltage applied between P-N

V

CES

Collector-Emitter Voltage Maximum off-state collector-emitter voltage at applied control input off signal

±I

C

Collector-Current Maximum DC collector and FWDi current @ Tj ≤ 150°C

±I

CP

Collector-Current (peak) Maximum peak collector and FWDi current @ Tj ≤ 150°C

P

C

Collector Dissipation Maximum power dissipation per IGBT switch at Tj = 25°C

T

j

Junction Temperature Range of IGBT junction temperature during operation

Brake Part

V

R(DC)

FWDi Reverse Voltage Maximum reverse voltage of FWDi

I

F

FWDi Forward Current Maximum FWDi DC current at Tj ≤ 150°C

Control Part

V

D

Supply Voltage Maximum control supply voltage

V

CIN

Input Voltage Maximum voltage between input (I) and ground (C) pins

V

FO

Fault Output Supply Voltage Maximum voltage between fault output (FO) and ground (C) pins

I

FO

Fault Output Current Maximum sink current of fault output (FO) pin

Total System

V

CC(prot)

Supply Voltage Protected Maximum DC bus voltage applied between P-N with guaranteed OC and SC protection

by OC & SC

T

C

Module Case Operating Range of allowable case temperature at specified reference point during operation

Temperature

T

stg

Storage Temperature Range of allowable ambient temperature without voltage or current

V

iso

Isolation Voltage Maximum isolation voltage (AC 60Hz 1 min.) between baseplate and module terminals

(all main and signal terminals externally shorted together)

6.2.2 Thermal Resistance

Symbol Parameter Definition

R

th(j-c)

Junction to Case Maximum value of thermal resistance between junction and case per switch

Thermal Resistance

R

th(c-f)

Contact Thermal Maximum value of thermal resistance between case and fin (heatsink) per IGBT/FWDi pair

Resistance with thermal grease applied according to mounting recommendations

6.2.3 Electrical Characteristics

Symbol Parameter Definition

Inverter and Brake Part

VCE(sat) Collector-Emitter IGBT on-state voltage at rated collector current under specified conditions

Saturation Voltage

V

EC

FWDi Forward Voltage FWDi forward voltage at rated current under specified conditions

t

on

Turn-On Time

t

rr

FWDi Recovery Time Inductive load switching times under rated conditions

t

c(on)

Turn-On Crossover Time (See Figure 6.10)

t

off

Turn-Off Time

t

c(off)

Turn-Off Crossover Time

I

CES

Collector-Emitter Cutoff Collector-Emitter current in off-state at VCE = V

CES

under specified conditions

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

The following test circuits are used

to evaluate the IPM characteristics.

1. VCE(sat) and V

EC

To ensure specified junction

temperature, Tj, measurements

of VCE(sat) and VEC must be

performed as low duty factor

pulsed tests. (See Figures 6.8

and 6.9)

6.2.3 Electrical Characteristics (continued)

Symbol Parameter Definition

Control Part

V

D

Supply Voltage Range of allowable control supply voltage in switching operation

I

D

Circuit Current Control supply current in stand-by mode

V

CIN(on)

Input ON-Voltage A voltage applied between input (I) and ground (C) pins less than this value will turn on the IPM

V

CIN(off)

Input OFF-Voltage A voltage applied between input (I) and ground (C) pins higher than this value will turn off the IPM

f

PWM

PWM Input Frequency Range of PWM frequency for VVVF inverter operations

t

dead

Arm Shoot Through Time delay required between high and low side input off/on signals to prevent an

Blocking Time arm shoot through

OC Over-Current Trip Level Collector that will activate the over-current protection

SC Short-Circuit Trip Level Collector current that will activate the short-circuit protection

t

off(OC)

Over-Current Delay Time Time delay after collector current exceeds OC trip level until OC protection is activated

OT Over-Temperature Trip Level Baseplate temperature that will activate the over-temperature protection

OT

r

Over-Temperature Temperature that the baseplate must fall below to reset an over-temperature fault

Reset Level

UV Control Supply Control supply voltage below this value will activate the undervoltage protection

Undervoltage Trip Level

UV

r

Control Supply Control supply voltage that must exceed to reset an undervoltage fault

Undervoltage Reset Level

I

FO(H)

Fault Output Inactive Current Fault output sink current when no fault has occurred

I

FO(L)

Fault Output Active Current Fault Output sink current when a fault has occurred

t

FO

Fault Output Pulsed Width Duration of the generated fault output pulse

V

SXR

SXR Terminal Output Voltage Regulated power supply voltage on SXR terminal for driving the external optocoupler

6.2.4 Recommended Operation Conditions

Symbol Parameter Definition

V

CC

Main Supply Voltage Recommended DC bus voltage range

V

D

Control Supply Voltage Recommended control supply voltage range

V

CIN(on)

Input ON-Voltage Recommended input voltage range to turn on the IPM

V

CIN(off)

Input OFF-Voltage Recommended input voltage range to turn off the IPM

f

PWM

PWM Input Frequency Recommended range of PWM carrier frequency using the recommended application circuit

t

DEAD

Arm Shoot Through Recommended time delay between high and low side off/on signals to the optocouplers

Blocking Time using the recommended application circuit

VX1

SXR

CX1

VXC

E1(E2)

C1(C2)

V

D

V

I

C

VX1

SXR

CX1

VXC

E1(E2)

C1(C2)

V

D

V

I

C

Figure 6.8 VCE(sat) Test

Figure 6.9 VEC Test

6.2.5 Test Circuits and Conditions

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

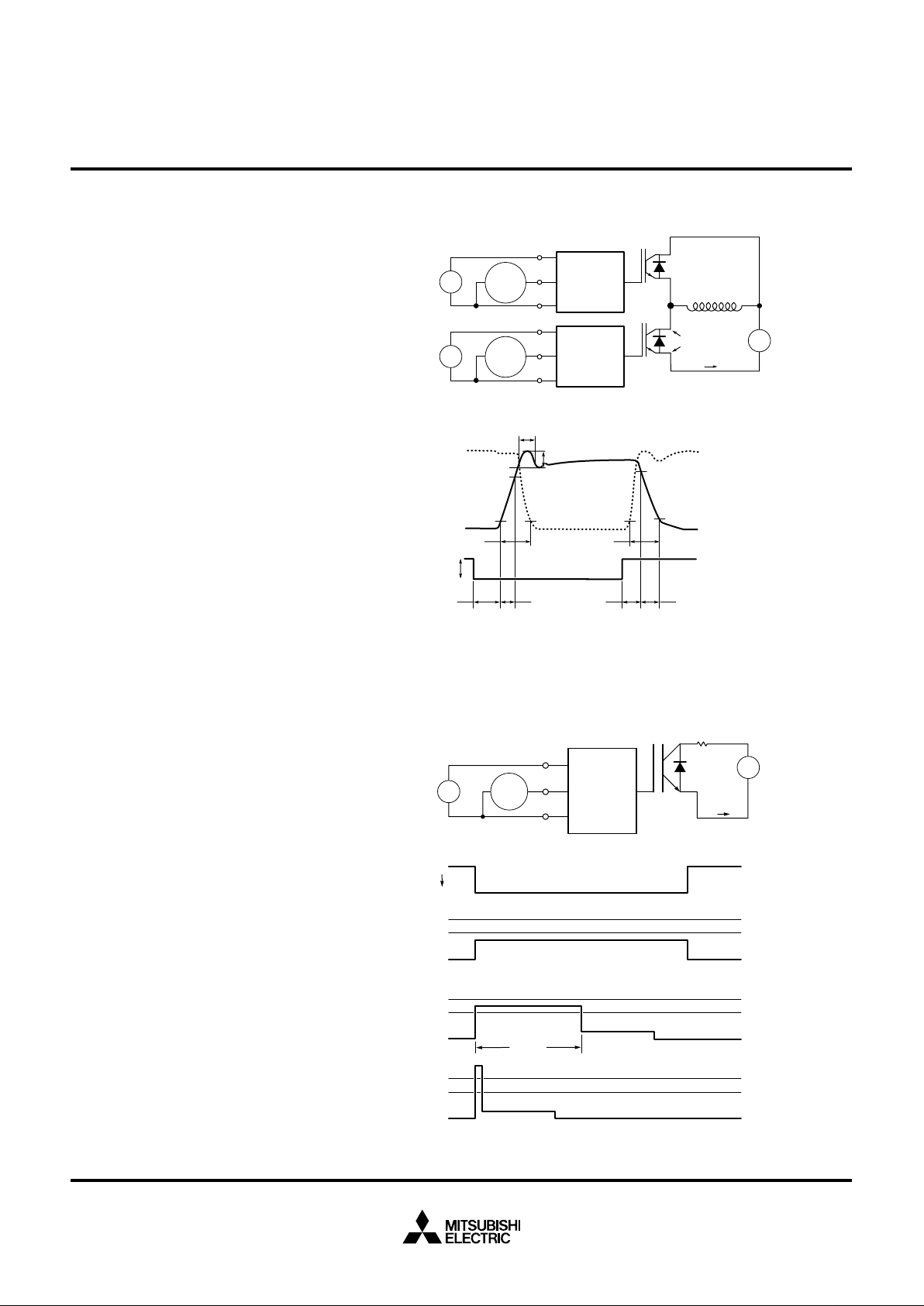

2. Half-Bridge Test Circuit and

Switching Time Definitions.

Figure 6.10 shows the stan-

dard half-bridge test circuit and

switching waveforms. Switching times and FWDi recovery

characteristics are defined as

shown in this figure.

3. Overcurrent and

Short-Circuit Test

I

trip

levels and timing specifications in short circuit and

overcurrent are defined as

shown in Figure 6.11. By using

a fixed load resistance the supply voltage, VCC, is gradually

increased until OC and SC trip

levels are reached.

Precautions:

A. Before applying any main bus

voltage, VCC, the input terminals should be pulled up by resistors to their corresponding

control supply (or SXR) pin,

each input signal should be

kept in OFF state, and the control supply should be provided.

After this, the specified ON and

OFF level for each input signal

should be applied. The control

supply should also be applied

to the non-operating arm of the

module under test and inputs

of these arms should be kept

to their OFF state.

B. When performing OC and SC

tests the applied voltage, VCC,

must be less than V

CC(prot)

and the turn-off surge voltage

spike must not be allowed to

rise above the V

CES

rating of

the device. (These tests must

not be attempted using a

curve tracer.)

+

I

C

INTEGRATED

GATE

CONTROL

CIRCUIT

INTEGRATED

GATE

CONTROL

CIRCUIT

+

+

t

d (on)

I

CIN

(t

on

=

t

d (on

)

+ tr)

t

r

t

d (off)

(t

off

= t

d (off)

+

tf)

t

f

t

c (off)

t

c (on)

10%

90%

10%

90%

I

C

t

rr

I

rr

V

CE

I

C

V

CE

OFF

SIGNAL

ON

PULSE

V

CC

V

D

V

D

Figure 6.10 Half-Bridge Test Circuit and Switching Time Definitions

ON

PULSE

SC

OC

INPUT

SIGNAL

NORMAL

OPERATION

OVER

CURRENT

SHORT

CIRCUIT

V

C

ON

PULSE

R*

R IS SIZED TO CAUSE

SC AND OC CONDITIONS

*

V

CC

+

t

off

(OC)

I

C

INTEGRATED

GATE

CONTROL

CIRCUIT

SC

OC

SC

OC

I

C

I

C

I

C

Figure 6.11 Over-Current and Short-Circuit Test Circuit

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

6.3 Area of Safe Operation for

Intelligent Power Modules

The IPMs built-in gate drive and

protection circuits protect it from

many of the operating modes that

would violate the Safe Operation

Area (SOA) of non-intelligent IGBT

modules. A conventional SOA definition that characterizes all possible combinations of voltage, current, and time that would cause

power device failure is not required. In order to define the SOA

for IPMs, the power device capability and control circuit operation

must both be considered. The resulting easy to use short circuit and

switching SOA definitions for Intelligent Power Modules are summarized

in this section.

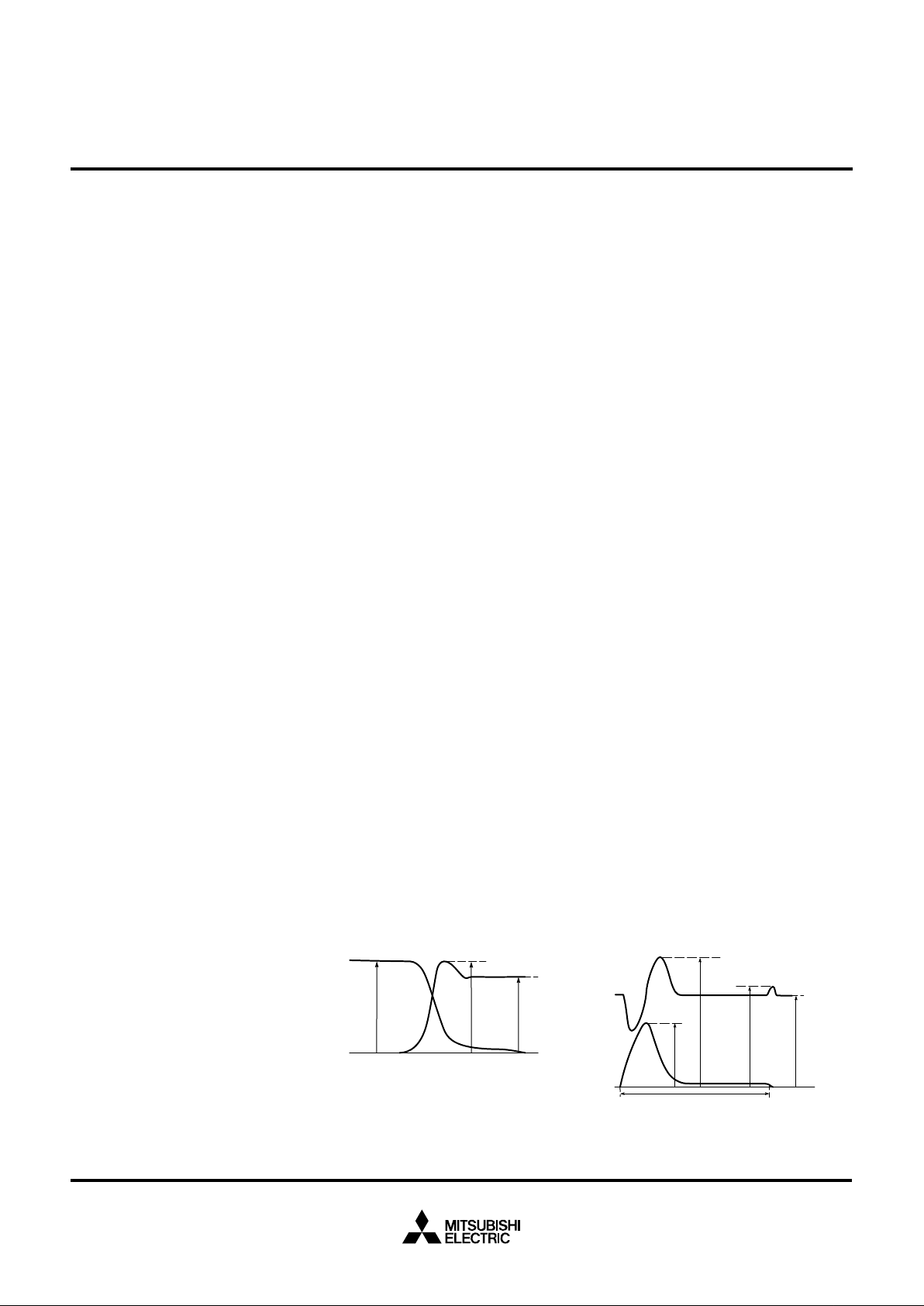

6.3.1 Switching SOA

Switching or turn-off SOA is normally defined in terms of the maximum allowable simultaneous voltage and current during repetitive

turn-off switching operations. In the

case of the IPM the built-in gate

drive eliminates many of the dangerous combinations of voltage

and current that are caused by improper gate drive. In addition, the

maximum operating current is limited by the over current protection

circuit. Given these constraints the

switching SOA can be defined using the waveform shown in Figure

6.12. This waveform shows that the

IPM will operate safely as long as

the DC bus voltage is below the

data sheet V

CC(prot)

specification,

the turn-off transient voltage across

C-E terminals of each IPM switch is

maintained below the V

CES

specification, Tj is less than 125°C, and

the control power supply voltage is

between 13.5V and 16.5V. In this

waveform IOC is the maximum current that the IPM will allow without

causing an Over Current (OC) fault

to occur. In other words, it is just

below the OC trip level. This waveform defines the worst case for

hard turn-off operations because

the IPM will initiate a controlled

slow shutdown for currents higher

than the OC

trip level.

6.3.2 Short Circuit SOA

The waveform in Figure 6.13 depicts typical short circuit operation.

The standard test condition uses a

minimum impedance short circuit

which causes the maximum short

circuit current to flow in the device.

In this test, the short circuit current

(ISC) is limited only by the device

characteristics. The IPM is guaranteed to survive non-repetitive short

circuit and over current conditions

as long as the initial DC bus voltage is less than the V

CC(prot)

specification, all transient voltages

across C-E terminals of each IPM

switch are maintained less than the

V

CES

specification, Tj is less than

125°C, and the control supply voltage is between 13.5V and 16.5V.

The waveform shown depicts the

controlled slow shutdown that is

used by the IPM in order to help

minimize transient voltages.

Note:

The condition VCE ≤ V

CES

has to

be carefully checked for each IPM

switch. For easing the design another rating is given on the data

sheets, V

CC(surge)

, i.e., the maximum allowable switching surge

voltage applied between the P and

N terminals.

6.3.3 Active Region SOA

Like most IGBTs, the IGBTs used in

the IPM are not suitable for linear

or active region operation. Normally device capabilities in this

mode of operation are described in

terms of FBSOA (Forward Biased

Safe Operating Area). The IPM’s

internal gate drive forces the IGBT

to operate with a gate voltage of either zero for the off state or the

control supply voltage (VD) for the

on state. The IPMs under-voltage

lock out prevents any possibility of

active or linear operation by automatically turning the power device

off if VD drops to a level

that could cause desaturation of

the IGBT.

Figure 6.13 Short-Circuit

Operation

Figure 6.12 Turn-Off Waveform

I

OC

≤V

CES

≤V

CC(PROT)

t

off(OC)

≤V

CES

≤V

CES

≤V

CC(PROT)

I

SC

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

6.4. IPM Self Protection

6.4.1 Self Protection Features

IPM (Intelligent Power Modules)

have sophisticated built-in protection circuits that prevent the power

devices from being damaged

should the system malfunction or

be over stressed. Our design and

applications engineers have developed fault detection and shut down

schemes that allow maximum utilization of power device capability

without compromising reliability.

Control supply under-voltage, overtemperature, over-current, and

short-circuit protection are all provided by the IPM's internal gate

control circuits. A fault output signal

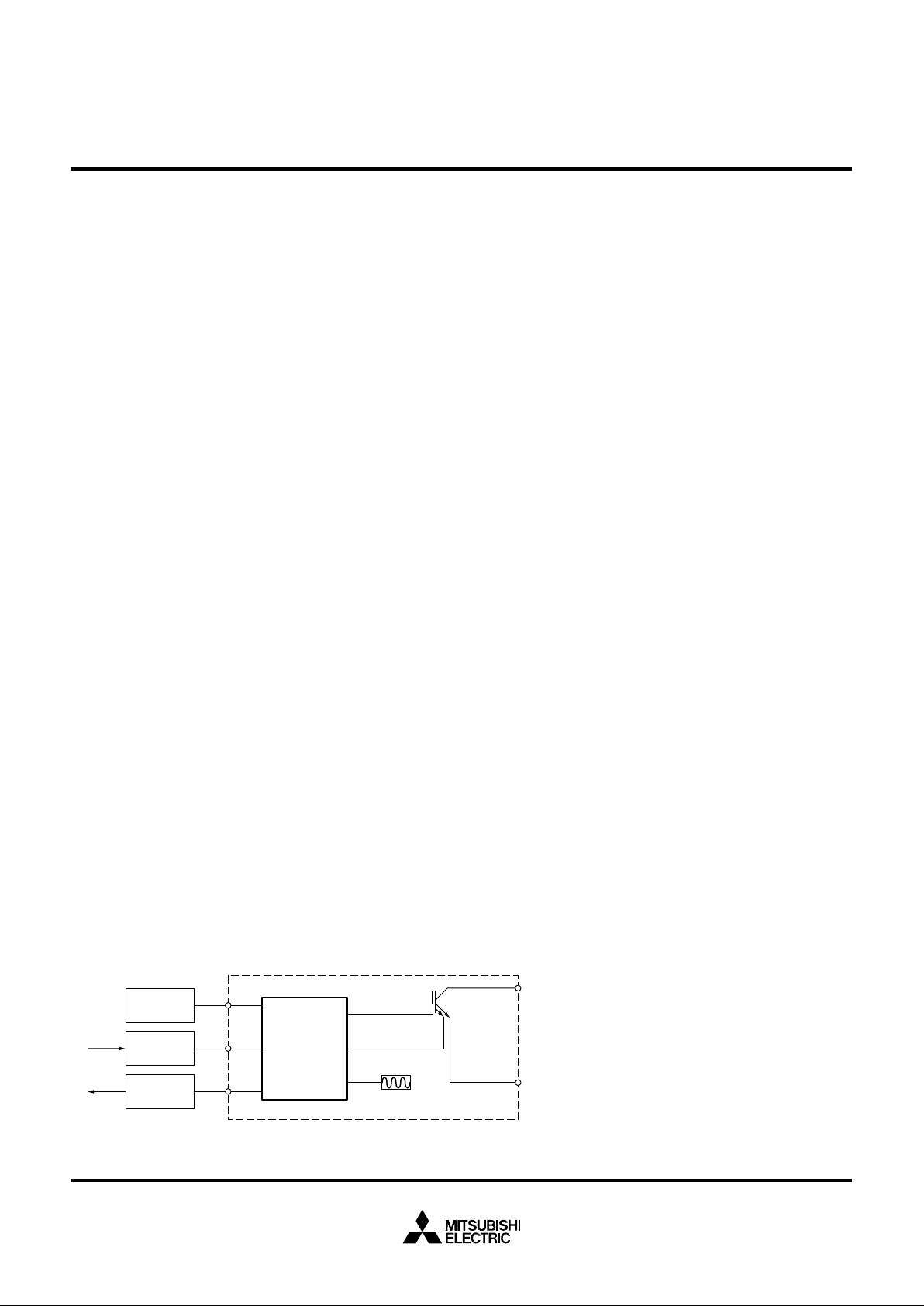

is provided to alert the system controller if any of the protection circuits are activated. Figure 6.14 is a

block diagram showing the IPMs

internally integrated functions. This

diagram also shows the isolated interface circuits and control power

supply that must be provided by

the user. The internal gate control

circuit requires only a simple +15V

DC supply. Specially designed gate

drive circuits eliminate the need for

a negative supply to off bias the

IGBT. The IPM control input is designed to interface with

optocoupled transistors with a minimum of external components. The

operation and timing of each protection feature is described in Sections 6.4.2 through 6.4.5.

6.4.2 Control Supply

Under-Voltage Lock-Out

The Intelligent Power Module's internal control circuits operate from

an isolated 15V DC supply. If, for

any reason, the voltage of this supply drops below the specified under-voltage trip level (UVt), the

power devices will be turned off

and a fault signal will be generated.

Small glitches less than the specified t

dUV

in length will not affect the

operation of the control circuitry

and will be ignored by the undervoltage protection circuit. In order

for normal operation to resume, the

supply voltage must exceed the under-voltage reset level (UVr). Operation of the under-voltage protection circuit will also occur during

power up and power down of the

control supply. This operation is

normal and the system controller's

program should take the fault output delay (tfo) into account. Figure

6.15 is a timing diagram showing

the operation of the under-voltage

lock-out protection circuit. In this

diagram an active low input signal

is applied to the input pin of the

IPM by the system controller. The

effects of control supply power up,

power down and failure on the

power device gate drive and fault

output are shown.

Caution:

1. Application of the main bus

voltage at a rate greater than

20V/µs before the control

power supply is on and stabilized may cause destruction of

the power devices.

2. Voltage ripple on the control

power supply with dv/dt in excess of 5V/µs may cause a

false trip of the UV lock-out.

6.4.3 Over-Temperature

Protection

The Intelligent Power Module has a

temperature sensor mounted on

the isolating base plate near the

IGBT chips. If the temperature of

the base plate exceeds the overtemperature trip level (OT) the

IPMs internal control circuit will

protect the power devices by disabling the gate drive and ignoring

the control input signal until the

over temperature condition has

subsided. In six and seven pack

modules all three low side devices

will be turned off and a low side

fault signal will be generated. High

side switches are unaffected and

can still be turned on and off by the

system controller. Similarly, in dual

type modules only the low side device is disabled. The fault output

will remain as long as the overtemperature condition exists. When

the temperature falls below the

over-temperature reset level (OTr),

and the control input is high (offstate) the power device will be enabled and normal operation will resume at the next low (on) input signal. Figure 6.16 is a timing diagram

showing the operation of the over-

GATE

CONTROL

CIRCUIT

GATE DRIVE

OVER TEMP

UV LOCK-OUT

OVER CURRENT

SHORT CIRCUIT

ISOLATED

POWER

SUPPLY

ISOLATING

INTERFACE

CIRCUIT

ISOLATING

INTERFACE

CIRCUIT

CURRENT

SENSE

IGBT

TEMPERATURE

SENSOR

SENSE

CURRENT

INTELLIGENT POWER MODULE

INPUT

SIGNAL

FAULT

OUTPUT

COLLECTOR

EMITTER

Figure 6.14 IPM Functional Diagram

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Sep.1998

temperature protection circuit.

The over temperature function provides effective protection against

overloads and cooling system failures in most applications. However,

it does not guarantee that the maximum junction temperature rating of

the IGBT chip will never be exceeded. In cases of abnormally

high losses such as failure of the

system controller to properly regulate current or excessively high

switching frequency it is possible

for IGBT chip to exceed T

j(max)

before the base plate reaches the OT

trip level.

Caution:

Tripping of the over-temperature

protection is an indication of stressful operation. Repetitive tripping

should be avoided.

6.4.4 Over-Current Protection

The IPM uses current sense IGBT

chips to continuously monitor

power device current. If the current

though the Intelligent Power Module exceeds the specified

overcurrent trip level (OC) for a period longer than t

off(OC)

the IPMs

internal control circuit will protect

the power device by disabling the

gate drive and generating a fault

output signal. The timing of the

over-current protection is shown in

Figure 6.17. The t

off(OC)

delay is

implemented in order to avoid tripping of the OC protection on short

pulses of current above the OC

level that are not dangerous for the

power device. When an over-cur-

rent is detected a controlled shutdown is initiated and a fault output

is generated. The controlled shutdown lowers the turn-off di/dt which

helps to control transient voltages

that can occur during

shut down from high fault currents.

Most Intelligent Modules use the

two step shutdown depicted in Figure 6.17. In the two step shutdown,

the gate voltage is reduced to an

intermediate voltage causing the

current through the device to drop

slowly to a low level. Then, about

5µs later, the gate voltage is reduced to zero completing the shut

down. Some of the large six and

seven pack IPMs use an active

ramp of gate voltage to achieve the

desired reduction in turn off di/dt

under high fault currents. The oscillographs in Figure 6.18 illustrate

Figure 6.15 Operation of Under-Voltage Lockout

INPUT

SIGNAL

BASE PLATE

TEMPERATURE

(Tb)

FAULT OUTPUT

CURRENT

(I

FO

)

INTERNAL

GATE

VOLTAGE

V

GE

OT

OT

r

Figure 6.16 Operation of Over-Temperature

INPUT

SIGNAL

CONTROL

SUPPLY

VOLTAGE

FAULT

OUTPUT

CURRENT

(I

FO

)

INTERNAL

GATE

VOLTAGE

V

GE

CONTROL SUPPLY ON SHORT

GLITCH

IGNORED

POWER SUPPLY

FAULT AND

RECOVERY

CONTROL SUPPLY OFF

UV

r

UV

t

t

FO

t

dUV

t

FO

t

dUV

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING INTELLIGENT POWER MODULES

Loading...

Loading...