Mitsubishi PLFY-P32VBM-E.UK, PLFY-P32VBM-E1.UK, PLFY-P32VBM-ER2.UK, PLFY-P40VBM-E.UK, PLFY-P40VBM-E1.UK Parts Catalog

...Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

PARTS CATALOG

Indoor unit

[Model names] [Service Ref.]

PLFY-P32VBM-E

PLFY-P40VBM-E

PLFY-P50VBM-E

PLFY-P63VBM-E

PLFY-P80VBM-E

PLFY-P100VBM-E

PLFY-P125VBM-E

PLFY-P32VBM-E.UK

PLFY-P32VBM-E

1.UK

PLFY-P32VBM-ER2.UK

PLFY-P40VBM-E.UK

PLFY-P40VBM-E

1.UK

PLFY-P40VBM-ER2.UK

PLFY-P50VBM-E.UK

PLFY-P50VBM-E

1.UK

PLFY-P50VBM-ER2.UK

PLFY-P63VBM-E.UK

PLFY-P63VBM-E

1.UK

PLFY-P63VBM-ER2.UK

PLFY-P80VBM-E.UK

PLFY-P80VBM-E

1.UK

PLFY-P80VBM-ER2.UK

PLFY-P100VBM-E.UK

PLFY-P100VBM-ER2.UK

PLFY-P125VBM-E.UK

PLFY-P125VBM-ER2.UK

February 2009

No. OCB413

REVISED EDITION-B

Revision:

• PLFY-P32/40/50/63/80/100/125

VBM-ER2.UK are added in

REVISED EDITION-B.

• Some descriptions have been

modified.

• Please void OCB413 REVISED

EDITION-A.

Note:

• RoHS compliant products have

<G> mark on the spec name

plate.

Model name

indication

INDOOR UNIT

CONTENTS

1. RoHS PARTS LIST

2. OPTIONAL PARTS

............................................

...........................................

SERVICE MANUAL (OCH413)

2

5

Page 2

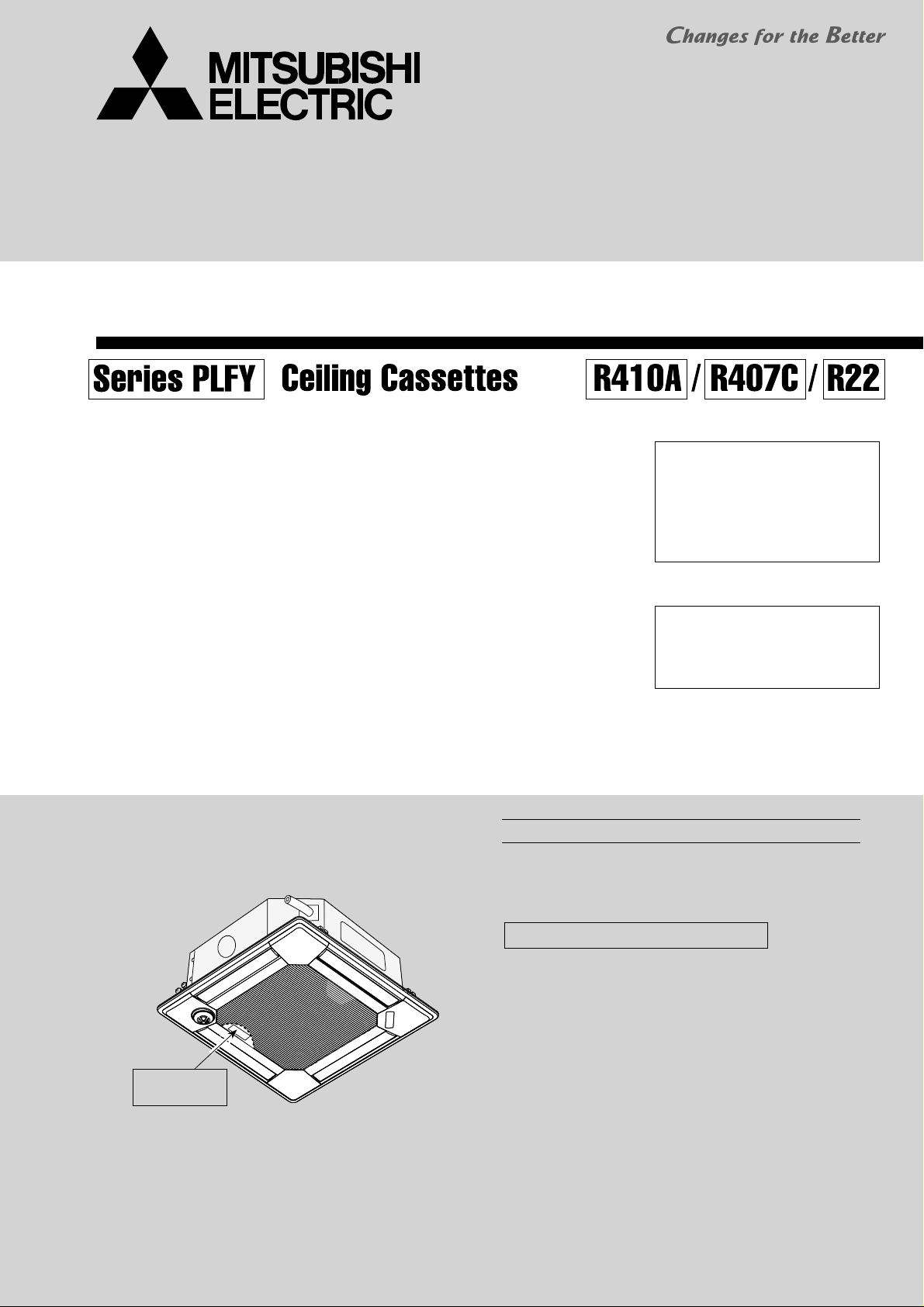

1

RoHS PARTS LIST

PANEL PARTS

PLP-6BA

PLP-6BAJ

14

1

3

15

16

14

2

9

2

4

10

2

2

5

6

7

11

4

13

12

8

Part numbers that are circled are not shown in the illustration.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Parts No. Parts Name

RoHS

G

S70 E20 003

G

S70 E20 002

G

S70 E30 638

G

S70 E40 638

G

S70 E20 638

G

S70 E20 317

G

S70 E50 658

G

S70 E20 500

G

S70 E20 691

G

S70 E30 691

G

S70 E00 223

G

S70 E00 063

G

S70 E00 040

G

S70 E01 040

G

S70 E60 714

G

S70 0B0 213

G

S70 0B6 310

G

S70 0B0 512

G

S70 E20 305

G

S70 E20 673

AIR OUTLET GRILLE

VANE ASSY

CORNER PANEL (L

CORNER PANEL (L

CORNER PANEL

WIRELESS ADAPTER

RECEIVER

L. L. FILTER-A

GRILLE ASSY

GRILLE ASSY

STEPPING MOTOR

VANE BUSH-A

GEAR(Vane

GEAR(S/M

REMOTE CONTROLLER

MOTOR BOX

CONTROLLER BOARD

LIMIT SWITCH

CABLE ASSY

SCREW ASSY

)

)

)

)

Specification

Q'ty/unit

PLP-6

BA BAJ

11

44

1

1

33

1W.B

1RU

11

1

1

44 MV

88

44

44

1

2

1

1

1

11

Remarks

(

Drawing No.

for Auto Grille

for W.B.

Accessory

)

Wiring

Diagram

Symbol

UK1

U.B

LS1

Recommended

Q'ty

2

Page 3

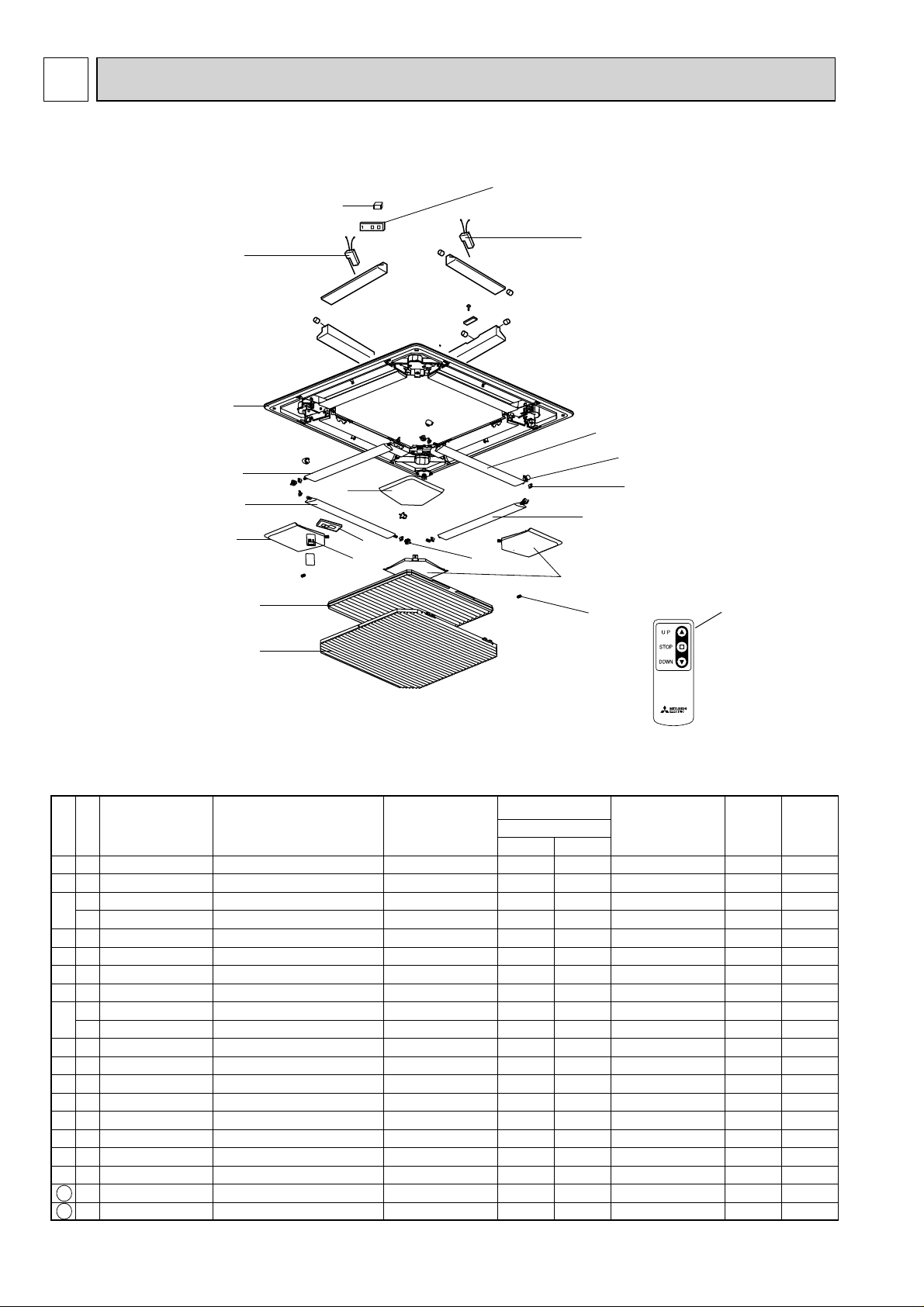

STRUCTIONAL AND FUNCTIONAL PARTS

PLFY-P32VBM-E.UK

PLFY-P40VBM-E.UK

1

2

PLFY-P50VBM-E.UK

PLFY-P63VBM-E.UK

3

PLFY-P80VBM-E.UK

PLFY-P100VBM-E.UK

4

PLFY-P125VBM-E.UK

PLFY-P32VBM-E

PLFY-P40VBM-E

1.UK

1.UK

PLFY-P50VBM-E1.UK

PLFY-P63VBM-E1.UK

PLFY-P80VBM-E1.UK

5

6

PLFY-P32VBM-ER2.UK

PLFY-P40VBM-ER2.UK

7

PLFY-P50VBM-ER2.UK

PLFY-P63VBM-ER2.UK

PLFY-P80VBM-ER2.UK

PLFY-P100VBM-ER2.UK

8

PLFY-P125VBM-ER2.UK

14

13

2

6

10

No.

1

2 G S70 0B2 130 LEG 1A 22222222222222222

3 G S70 0B1 130 LEG 1B 11111111111111111

4

5

6 G S70 0B1 105 MOTOR MOUNT 33333333333333333

7

8

9

10

11

12 G S70 0B2 202 THERMISTOR 11111111111111111

13

14 G S70 0B1 687 BASE 11111111111111111

Parts No. Parts Name

RoHS

G S70 0B3 688 DRUM 2 ASSY 11111 1111111111

G S70 0B4 688 DRUM 2 ASSY 1 1

G S70 0B1 659 INNER COVER ASSY - S 11111 1111111111

G S70 0B2 659 INNER COVER ASSY - L 1 1

G S70 0B1 762 FAN MOTOR 11111 MF

G S70 0B2 762 FAN MOTOR 1 1 MF

G S70 0B3 762 FAN MOTOR 1 1 1 1111111 MF

G S70 0B1 114 TURBO FAN 11111

G S70 0B2 114 TURBO FAN 1 1

G S70 0B3 114 TURBO FAN 1 1 1 1111111

G S70 08K 097 SPL WASHER/NUT M8 111111 1

G S70 10B 097 SPL WASHER/NUT M6 1 1 1 1111111

G S70 0B1 401

G S70 0B2 401

G S70 0C1 480 HEAT EXCHANGER 1 1 1

G S70 0C2 480 HEAT EXCHANGER 1 1 1

G S70 0C3 480 HEAT EXCHANGER 1 1

G S70 0C4 480 HEAT EXCHANGER 1 1 1

G S70 0C5 480 HEAT EXCHANGER 1 1 1

G S70 0C6 480 HEAT EXCHANGER 1

G S70 0C7 480 HEAT EXCHANGER 1

G S70 0C8 480 HEAT EXCHANGER 1

G S70 E17 097 FLARE NUT 3/8" 1 1 1 1 1 1

G S70 E15 097 FLARE NUT 5/8" 1 1 1 1 1

G S70 E16 097 FLARE NUT 3/4" 1 1

G S70 0B1 688 DRUM 1 ASSY 11111 1111111111

G S70 0B2 688 DRUM 1 ASSY 1 1

LINER EXPANSION VALVE

LINER EXPANSION VALVE

Specifi -

PLFY-P·VBM-E.UK

cation

32 40 50 63 80

1111 1111 1111 LEV

PLFY-P·VBM-E1.UK

100

32 40 50 63 80 32 40 50 63 80

125

1 1 1 1 1 LEV

9

Q'ty/unit

PLFY-P·VBM-E2.UK

100

125

Remarks

(Drawing

No.)

33

12

11 Flare nut

Wiring

Daigram

Symbol

TH22/TH23

Recommended

Q'ty

Page 4

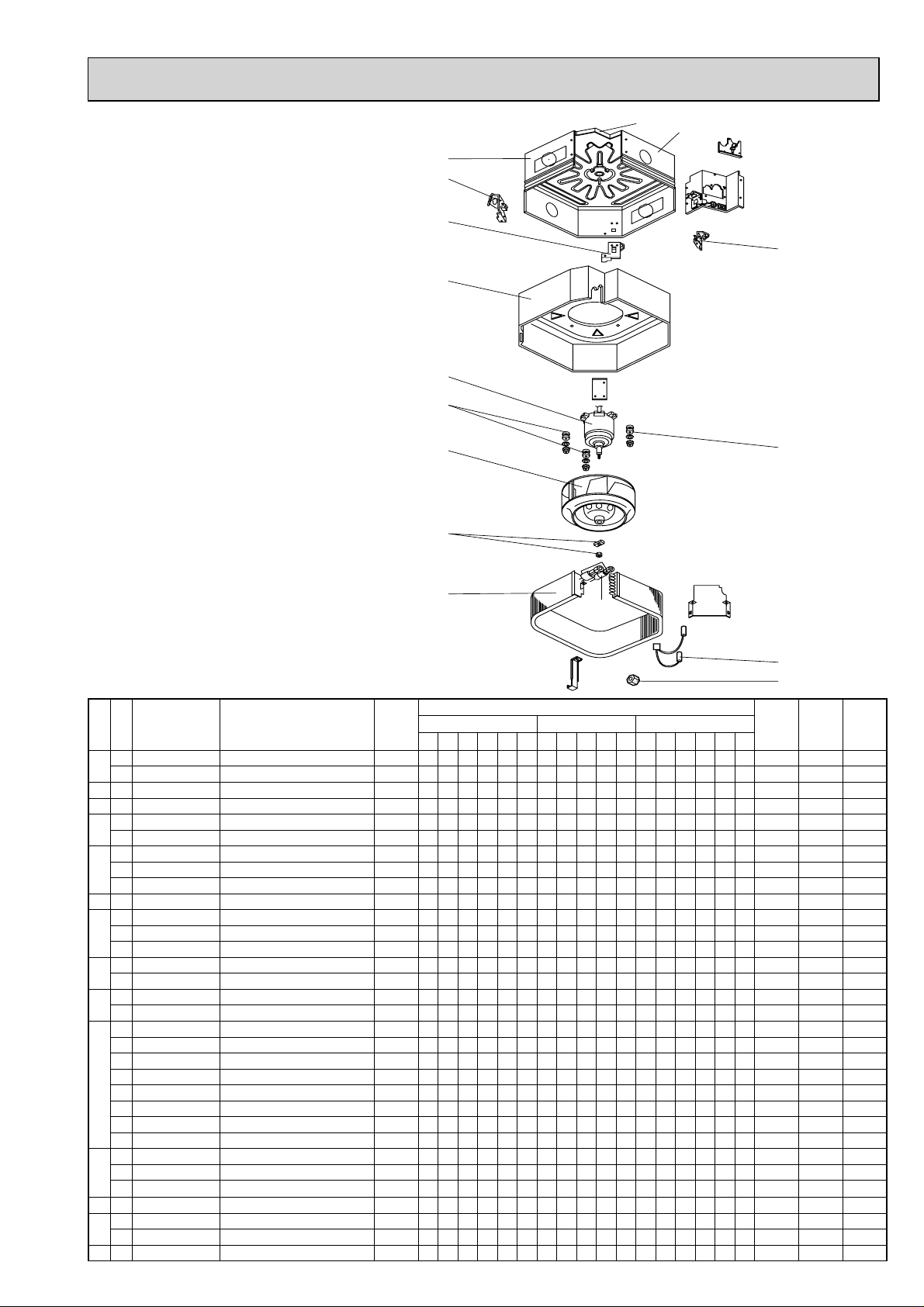

FUNCTIONAL AND ELECTRICAL PARTS

PLFY-P32VBM-E.UK

PLFY-P40VBM-E.UK

PLFY-P50VBM-E.UK

PLFY-P63VBM-E.UK

PLFY-P80VBM-E.UK

PLFY-P100VBM-E.UK

PLFY-P125VBM-E.UK

PLFY-P32VBM-E

PLFY-P40VBM-E

1.UK

1.UK

PLFY-P50VBM-E1.UK

PLFY-P63VBM-E1.UK

PLFY-P80VBM-E1.UK

PLFY-P32VBM-ER2.UK

PLFY-P40VBM-ER2.UK

PLFY-P50VBM-ER2.UK

PLFY-P63VBM-ER2.UK

5

4

PLFY-P80VBM-ER2.UK

PLFY-P100VBM-ER2.UK

12

PLFY-P125VBM-ER2.UK

1

14

2

13

12

11

10

3

2

15

9

16

8

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

Parts No. Parts Name

RoHS

S70 0B2 529

S70 0B6 501

S70 B02 716

S70 0B4 716

S70 512 716

S70 0B5 310

S70 0B4 310

S70 29H 523

S70 0B1 527

S70 0B1 266

S70 0B1 533

S70 0B1 355

S70 0B2 502

S70 A41 524

S70 0B1 663

S70 0B1 313

S70 0B1 202

DRAIN PAN

ELECTRICAL CONTROL BOX

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

INDOOR CONTROLLER BOARD

INDOOR CONTROLLER BOARD

DRAIN SOCKET

DRAIN HOSE ASSY

DRAIN SENSOR (Float Switch)

DRAIN SENSOR HOLDER

DRAIN PUMP

BELLMOUTH

DRAIN PLUG

CORNER COVER

ADDRESS BOARD

ROOM TEMP. THERMISTOR

RS SBA

7

6

Qty/unit

Specification

3P (M1,M2,S) TB4

3P (L, N, )TB2

2P (1,2) TB15

PLFY-P·VBM-E(1).UK

32/40/50/63/80/100/125

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

PLFY-P·VBM-ER2.UK

32/40/50/63/80/100/125

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Remarks

(Drawing

No.)

ACCESSORY

Wiring

Diagram

Symbol

I.B

I.B

FS

DP

A.B

TH21

Recommended

Q'ty

4

Page 5

2

2-1. OPTIONAL PARTS LIST

2-1-1. MULTI FUNCTION CASEMENT

OPTIONAL PARTS

Part No.

2-1-2. AIR OUTLET SHUTTER PLATE

Part No. PAC-SH51SP-E

2-1-3. HIGH EFFICIENCY FILTER (PAC-SH53TM-E is required in using this optional part.)

Part No. PAC-SH59KF-E

2-1-4. i-SEE SENSOR CORNER PANEL

Part No. PAC-SA1ME-E

2-1-5. AUTOMATIC FILTER ELEVATION PANEL

Part No. PLP-6BAJ

2-1-6. SPACE PANEL

PAC-SH53TM-E

Part No.

2-1-7. FLANGE FOR FRESH AIR INTAKE

Part No.

2-1-8. WIRELESS SIGNAL RECEIVER (CORNER PANEL)

Part No.

2-1-9. WIRELESS REMOTE CONTROLLER

Part No.

2-1-10. WIRED REMOTE CONTROLLER (MA REMOTE CONTROLLER)

Part No.

2-1-11. WIRED REMOTE CONTROLLER (ME REMOTE CONTROLLER)

PAC-SH48AS-E

PAC-SH65OF-E

PAR-SA9FA-E

PAR-FL32MA

PAR-21MAA

Part No.

2-1-12. DECORATION PANEL

Part No.

PAR-F27MEA

PLP-6BA

5

Page 6

2-2. AUTOMATIC FILTER ELEVATION PANEL

2-2-1. OPERATION (AUTOMATIC FILTER ELEVATION PANEL: PLP-6BAJ)

(1) Normal operation

UP/DOWN

Air intake grille is raised/lowered by

instructions of “UP” and “DOWN”.

Air intake grille does not move under the

UP/DOWN

Machine 1

state of no-load detection or obstacle detection.

Air intake grille stops automatically at the set lowering

distance from the ceiling level.

STOP

It stops in the cases below :

Detection

switch

• When it reaches at the set lowering distance from

the ceiling level.

It automatically stops based on the calculation at

distance from the time taken to lower.

• When it is stored in the panel.

Wire 1a

Air intake grille is judged to be stored in the panel

when storage detection switch is pressed for 3 seconds continuously.

• When receiving instructions of “STOP”, “DOWN” while moving up and “UP” while moving down.

“STOP” button is only for the remote controller for Automatic Filter Elevation Panel.

As for wired remote controller, it takes several seconds to stop due to transmission speed.

• When both wire 1b and wire 2b are no-loaded.

Only the wire b in each UP/DOWN Machine has tension detection switch.

(2) Special operation

Re-storing operation

Case : Catch of grille or malfunction of storage detection switch

Re-storing operation will be done when storage detection switch is not pressed with air intake grille raised

by the set distance. And operation below will be repeated up to 4 times.

10cm down 30cm up ···· 10cm down 30cm up

No-load detection

Case : “UP/DOWN” instruction without grille.

When both wire 1b and wire 2b are no-loaded, grille does not move.

Obstacle detection

Case : Making contact with something while lowering.

When both wire 1b and wire 2b are no-loaded by making contact with something while lowering, it stops and

is raised by 10cm and stops again.

Wire 1b

Wire 2a

Fig.1

UP/DOWN

Machine 2

Wire 2b

[Emergency operation]

• When the wireless remote controller cannot be used (in the case of battery discharge, misplacing of the wireless

remote controller, malfunctioning and so on), the emergency switch on the sensor can be used as an alternative.

* When doing this, particular caution must be taken not to fall.

To lower the air intake grille : Press the button once.

(For emergency heating operation, press this button.)

To raise the air intake grille : Press the button once.

(For emergency cooling operation, press this button.)

• To stop the air intake grille from moving, use the opposite buttons to those used to initiate movement.

(To stop it from lowering, press the “UP” button; To stop it from rising, press the “Down” button.)

• When up/down machine is out of order, fix air intake grille temporarily and indoor can be operated.

+ For details, refer to installation manual for grille.

SW22 (Lowering distance Set Up)

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

1.2 m

- 2.4 m 2.4 m - 2.8 m 2.8 m - 3.2 m 3.2m - 3.6m

ON

OFF

123456789

2.8 m 3.6 m

3.6 m - 4.0 m 4.0 m - 4.4 m 4.4 m - 4.8 m 4.8 m - 5.2 m

ON

OFF

123456789

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

10

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

10

1.6 m (Initial setting)

ON

OFF

123456789

3.2 m 4.0 m

ON

OFF

123456789

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

10

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

10

2.0 m

ON

OFF

123456789

ON

OFF

123456789

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

10

Lowering distance

Rough Indication of

the Ceiling Height

Configuration

10

ON

OFF

123456789

ON

OFF

123456789

2.4 m

10

10

6

Page 7

2-2-2. ELECTRICAL CIRCUIT

(1) Wiring diagram (Panel)

UK1

UK1

LS21

MU1

LS21

MU1

Panel

FUSE

R

E

D

3

W.B

CNB

1

(WHT)

2

BZ

3

4

SW1

5

6

7

SW2

8

RU

9

B

R

L

E

K

D

11325

U.B

GRN/YLW

LS1

2

1

WHT

2

WHT

1

WHT

WHT

BLK

BLK

CN2G

(BLK)

CN2F

(BLK)

1

1

ON

2

2

SW22

123456789

1

CN2E

(RED)

B

O

Y

R

R

L

N

N

W

CN3G

3

(BLK)

2

CN2B

CN2C

(WHT)

(WHT)

1

1

B

10

L

K

2

2

R

E

D

CN3A

B

R

(RED)

L

E

K

D

Indoor unit

9

I.B

CNAC

(WHT)

CN22

(BLU)

CN90

(WHT)

Symbol Name Symbol Name

U.B Auto grille controller board W.B Wireless remote controller board

FUSE Fuse (3.15A)

BZ Buzzer

RU Receiver

SW22 switch (Lowering distance set up) SW1 Emergency switch (heating/down)

UK1 Up/down machine SW2 Emergency switch (cooling/up)

MU1 Motor (Up/down) LS1 Limit switch (storage detection)

LS21 Limit switch (tension detection) R.B Wired remote controller

I.B Indoor controller board

CN3G

(BLK)

TB5

11

22

TB6

R.B

(2) Check point of trouble

<LED display>

Turn OFF : No power supply

Blink : Storage detection switch ON (short)

One blink : Storage detection switch OFF (open)

Two blinks : Tension detection switch OFF (open)

<controller board>

Check item Check point Normal Remarks

Up/down controller

P.C. board supply

voltage

Up/down machine

supply voltage

CN3A

(between 3-5)

AC198~264V

CN2B,CN2C DC10~12V

Check when instructing up/down with LED

blinking once.

<Up/down machine>

Check item Check point Normal Check contents

Storage detection

switch

Tension detection

switch

Motor CN2B,CN2C 5~20 Check if it is not open or short.

Entwining wires Pull wire

CN2E open or short

Check if it is short when pressing push switch.

CN2F,CN2G open or short Check if it is short when wire b is tensioned.

Retension :

about 2kgf

Check if wire is drawn out by pulling with 3kgf.

7

Page 8

2-2-3. Troubleshooting

• Check the following points.

Problem Possible Reason Corrective Action

Air intake grille does not

function with operation of the

wireless remote controller.

Air intake grille cannot be

fixed in place.

Air-conditioner is running. Stop running the air-conditioner and try again.

Power failure

Batteries are not inserted into the wireless remote controller.

After recovering from power failure, try again.

Install or replace the battery.

Or battery power is running low.

There is something on the air intake grille.

Or something is stuck in the air intake grille.

Remove the objects or obstacles from the

air intake grille.

Or, remove the stuck object.

There is something on the air intake grille.

Remove the objects or obstacles from the

air intake grille.

Filter is not properly installed.

Lower the air intake grille again and check

whether the filter is installed in the correct

position.

Air intake grille stops lowering.

(Air intake grille would not

lower any further.)

Noises are made during

up/down operation.

(While air intake grille is

moving up/down.)

Noises are made while putting

the air intake grille into place.

Air intake grille repeats rising

and lowering several times

while being put into place.

Air intake grille leans toward

one side during the up/down

operation.

Air intake grille is not hung with all 4 hooks.

The air intake grille has finished lowering to the auto-stop

position.

This is the noise made when the wire is wound and

unwound.

This is the operational noise for putting the air intake

grille into place.

This is the operation for putting the air intake grille into

place.

The speeds of winding/unwinding wires are slightly

different for each wire.

Lower the air intake grille again and hook

on the air intake grille.

This is normal.

This is normal.

HEAD OFFICE : TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

cCopyright 2007 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Distributed in Feb. 2009 No. OCB413 REVISED EDITION-B PDF 6

Distributed in Oct. 2007 No. OCB413 REVISED EDITION-A PDF 7

Distributed in Mar. 2007 No. OCB413 PDF 7

Made in Japan

New publication, effective Feb. 2009

Specifications subject to change without notice

Loading...

Loading...