Mitsubishi PLFY-P20VLMD-A, PLFY-P25VLMD-A, PLFY-P32VLMD-A, PLFY-P40VLMD-A, PLFY-P50VLMD-A Service Manual

...Page 1

TECHNICAL & SERVICE MANUAL

Air-Conditioners For Building Application

<Indoor unit>

PLFY-P20VLMD-A,PLFY-P63VLMD-A

PLFY-P25VLMD-A,PLFY-P80VLMD-A

PLFY-P32VLMD-A,PLFY-P100VLMD-A

PLFY-P40VLMD-A,PLFY-P125VLMD-A

PLFY-P50VLMD-A

2001

Models

INDOOR UNIT

Ceiling Cassettes

Series PLFY

CONTENTS

SAFETY PRECAUTIONS·························1

1. FEATURES············································3

2. PART NAMES AND FUNCTIONS ········4

3. SPECIFICATION ···································6

4. OUTLINES AND DIMENSIONS············8

5.WIRING DIAGRAM ·····························10

6.

REFRIGERANT SYSTEM DIAGRAM

····11

7.TROUBLE SHOOTING ························12

8. DISASSEMBLY PROCEDURE···········17

For use with the R407C & R22

Page 2

SAFETY PRECAUTIONS

- Inadequate connection and fastening may generate heat and

cause a fire.

• Prepare for ty phoons and othe r str ong wi nds an d earthquak es

and install the unit at the specified place.

- Improper in stal lati on may cause th e unit to to pple and re sult in

injury.

• Always use an air c leaner, humidi fie r, electric hea ter, and other

accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper

installati on by th e user may re sult in water leakag e, el ectric shoc k,

or fire.

• Never repair the uni t. If the air con dit ion er must be rep air ed,

consult the dealer.

- If the unit is repaired improperly, water leakage , electric shoc k, or

fire may result.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the

room.

- If the refrigerant gas comes into contact with a flame, poisonous

gases will be released.

• Install the ai r cond itio ner ac cor ding to th is In stalla tion Man ual.

- If the unit is installed improperly, water leakage , electric shoc k, or

fire may result.

• Have all electr ic w ork don e b y a lic ensed ele ctrici an accor din g

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations”and the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequa te or elec tric work is per-

formed improperly, electric shock and fire may result.

• Securely install the cover of control box and the panel.

- If the cov er and pan el are not ins tal led pro perly,dust or w ate r may

enter the outdoor unit and fire or electric shock may result.

• When installi ng an d mo ving the air co ndit ione r to anot her si te,

do not charge the it with a refrigerant differen t fr om the refr igerant (R407C or R22) specified on the unit.

- If a different refriger ant or air is mixed wit h the original refriger ant,

the refrigerant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures

must be take n to pr event th e re fr ig er ant co ncen tr at ion from

exceeding the safety limit even if the refrigerant should leak.

- Consult the de aler rega rdin g the ap prop ria te me asures to pre-

vent the safety limit from being exceeded. Should the refrigerant

leak and cause th e safety li mit to be exceed ed , haza rds du e to

lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the

dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage, elec-

tric shock, or fire may result.

• After completing installation work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove,

oven, or other heat source, it may generate noxious gases.

• Do not re cons tr uc t or chan g e th e se ttin gs of the prote ct ion

devices.

- If the pressure switch, thermal switch, or other protection device

is shorted an d op erat ed f orci bly, or parts ot her th an th ose sp ecif ied

by Mitsubishi Electric are used, fire or explosion may result.

1. Befor e instal lati on and elec tric work

s Before installing the unit, make sure you read all the

“Safety precautions”.

s The “Safety precautions” provide very important

points regarding safety. Make sure you follow them.

s This equipment may not be applicable to EN61000-3-

2: 1995 and EN61000-3-3: 1995.

s This equipment may cause the adverse effect on the

same supply system.

s Please report to or take consent by the supply au-

thority before connection to the system.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger

of injury or death to the user.

Caution:

Describes pr ecau tion s that shou ld be obse rved to pre vent dama ge

to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates tha t caution should be taken wit h rot ating parts. (This

symbol is displayed on the main unit label.) <Color: Yellow>

: Beware of electric shock (This sym bol is dis played on the main

unit label.) <Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an aut horized tec hnicia n to instal l the air conditioner.

- Improper installatio n b y the use r ma y result in w ater lea kage , elec -

tric shock, or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate str eng th may cause the uni t to fall down, res ult ing in

injuries.

• Use the specified cables for wiring. Make the connections securely so th at th e ou tsid e f or ce of th e ca ble is no t ap plie d to the

terminals.

1

Page 3

2. Precautions for devices that use

R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large amount of chlorine which may cause the refrigerator

oil of the new unit to deteriorate.

• Use refriger ant pi ping made of C122 0 (CU- DHP) phosph orus

deoxidized copper as specified in the *JIS H3300 “Copper and

copper alloy seam le ss pipe s and tube s” . In additi on, be sure

that the inner and outer surfaces of the pipes are clean and

free of hazardous sulphur, oxides, dust/dirt, shaving particles,

oils, moisture, or any other contaminant.

- Contaminan ts on th e in si de of the re fr ig er an t pi pi ng may caus e

the refrigerant residual oil to deteriorate.

*JIS:Japanese Industrial Standard

• Store th e pipi ng to be us ed du ring inst alla tion indo or s and keep

both ends of the piping sealed until just before brazing. (Store

elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

• Use ester oil, ether oil or alk ylb enzene (small amo unt ) as the

refrigerator oil to coat flares and flange connections.

- The refrigerat or oi l wi ll de gr ade if it is mi x ed wi th a larg e am ount of

mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of

the refrigera nt in the cyli nder will chan ge and pe rfor manc e may

drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrig-

erant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve..

- The vacuum pump oil may flow back into the refrigerant cycl e and

cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow

check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the

R407C, the refrigerant may deteriorated.

- If water is mixed in the R407C, the ref rige rator oil may deteriorate.

- Since R407C do es no t cont ain any ch lor in e, ga s leak dete ctor s

for conventional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylind er ma y caus e the re friger ant to de terior ate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refr igerant cyc le, the ref rige rant

may deteriorate.

2

Page 4

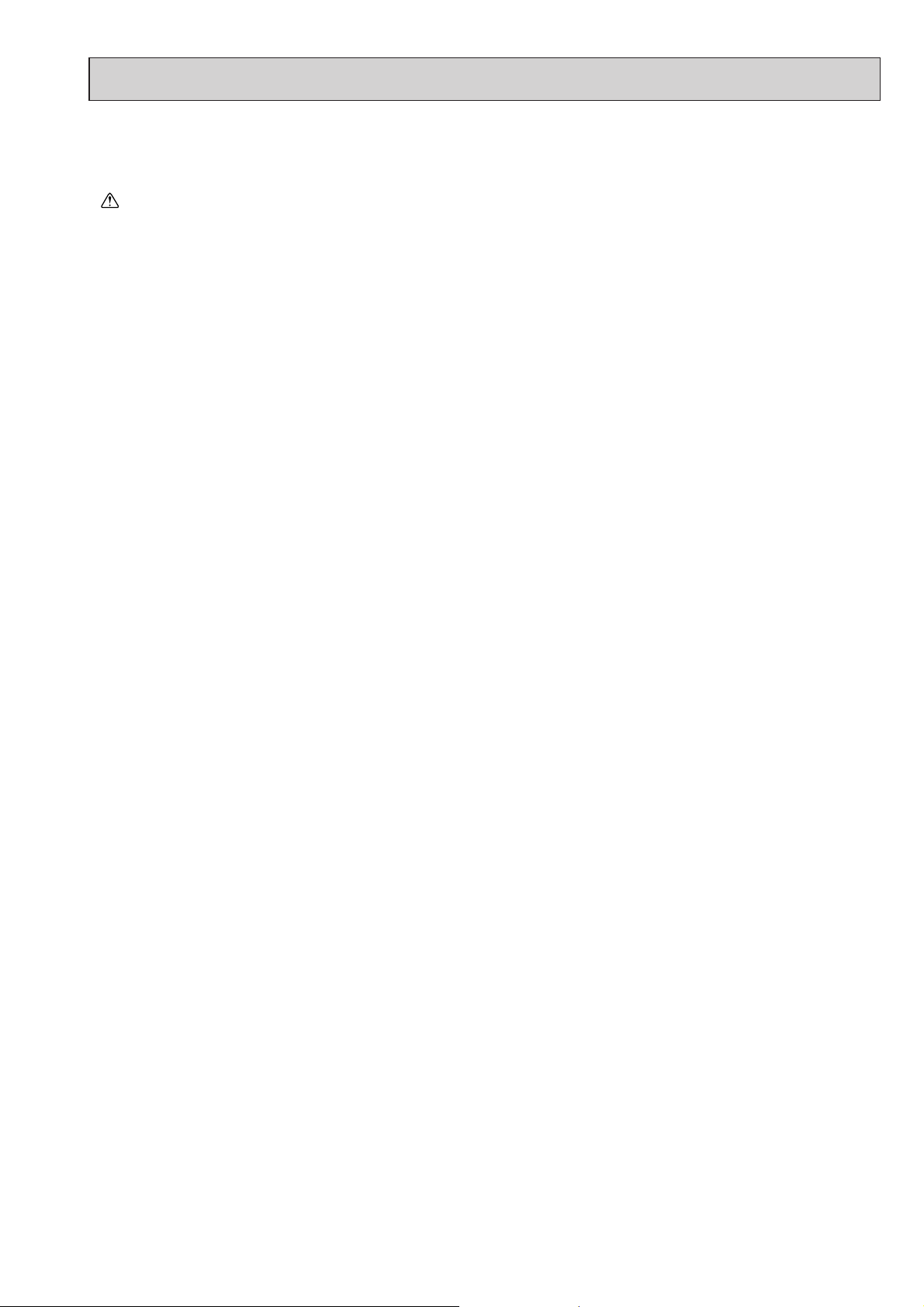

PLFY-P20VLMD-A

PLFY-P25VLMD-A

PLFY-P32VLMD-A

PLFY-P40VLMD-A

PLFY-P50VLMD-A

PLFY-P63VLMD-A

PLFY-P80VLMD-A

PLFY-P100VLMD-A

PLFY-P125VLMD-A

2.2/ 2.5

2.8/ 3.2

3.6/ 4.0

4.5/ 5.0

5.6/ 6.3

7.1/ 8.0

9.0/ 10.0

11.2/ 12.5

14.0/ 16.0

FEATURES

1

Indoor unit

Ceiling Cassettes

Series PLFY

Models

Cooling capacity/Heating capacity

kW

3

Page 5

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

1

2

3

4 56879

0

C

A

B

1 [Room temperature adjustment] Button

2 [Timer/continuous] Button

3 [Selecting operation] Button

4 [Time selection] Button

[Time-setting] Button

5 [Louver] Button

6 [Fan speed adjustment] Button

7 [Up/down airflow direction] Button

8 [Ventilation] Button

9 [Checking/built-in] Button

0 [Test run] Button

A [Filter] Button

B [ON/OFF] Button

C Position of built-in room temperature

•Never expose the remote controller to direct sunlight. Doing so can result in the erroneous measurement of room temperature.

•Never place any obstacle around the lower right-hand section of the remote controller.Doing so can

result in the erroneous measurement of room temperature.

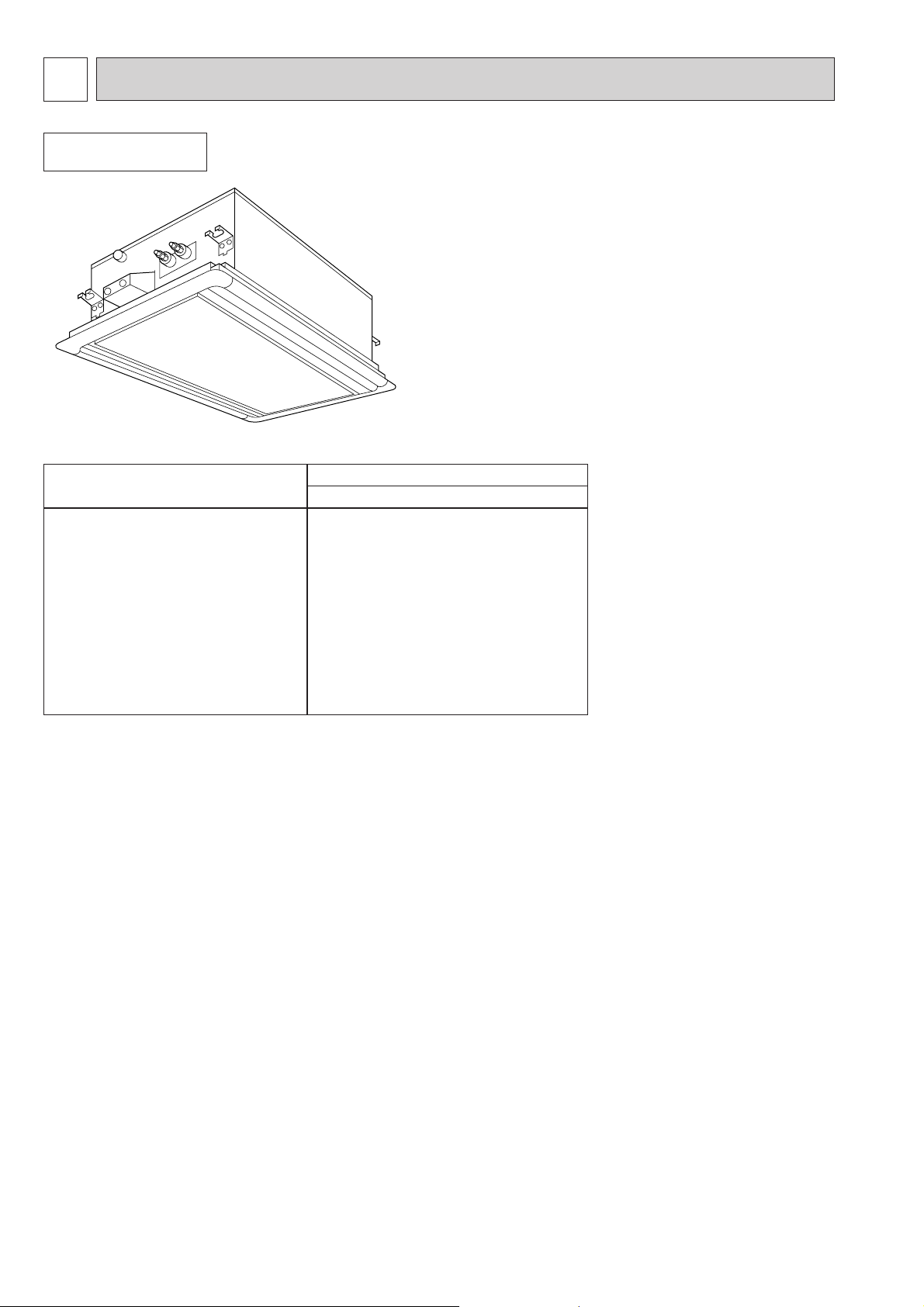

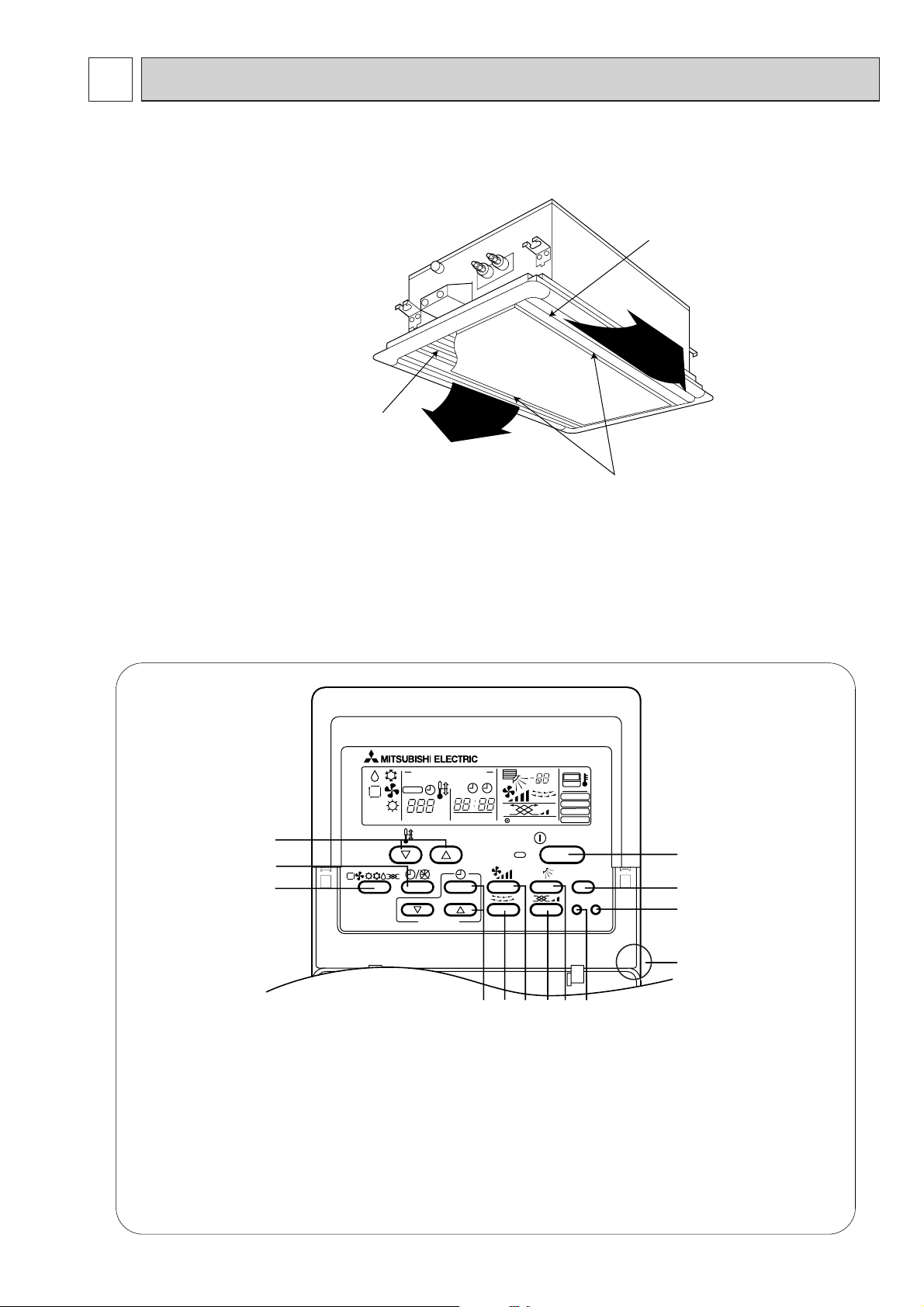

PART NAMES AND FUNCTIONS

2

● Indoor (Main) Unit

● Remote controller

● Operation buttons

[PAR-20MAA]

●Once the controls are set, the same operation mode can

be repeated by simply pressing the ON/OFF button.

Air inlet

Sucks the ambient air in.

Long-life filter

Removes the sucked-in dust and dir t.

Since the long-life filter is used as an air

filter, it should be cleaned at the beginning of air-cooling and heating seasons.

(During seasons with large amounts of

dust and dirt, more frequent cleaning are

recommended.)

Autovane

Disperses the airflow up and down and

adjusts the angle of the airflow.

4

Page 6

● Display

(A) Current time/Timer

(B) Centralized control

(C) Timer ON

(D) Abnormality occurs

(E) Operation mode: COOL, DRY, AUTO, FAN, HEAT

(F) Preparing for Heating mode

(G) Defrost mode

(H) Set temperature

(I) Power ON

(J) Louver

(K) Not available function

(L) Ventilation

(M) Function setting mode

(N) Test run mode

(O) Error check mode

(P) Filter sign

(Q) Set effective for 1 hr.

(R) Sensor position

(S) Room temperature

(T) Airflow

(U) Fan speed

5

ABCD

SQTU

E

F

STAND BY

DEFROST

G

CENTRALLY CONTROLLED

CHECK

˚C

ON OFF

CLOCK

ERROR CODE

TEMP.

HIKLJ

1Hr.

NOT AVAILABLE

˚C

ON/OFF

FILTER

CHECK MODE

TEST RUN

FUNCTION

R

P

O

N

M

Page 7

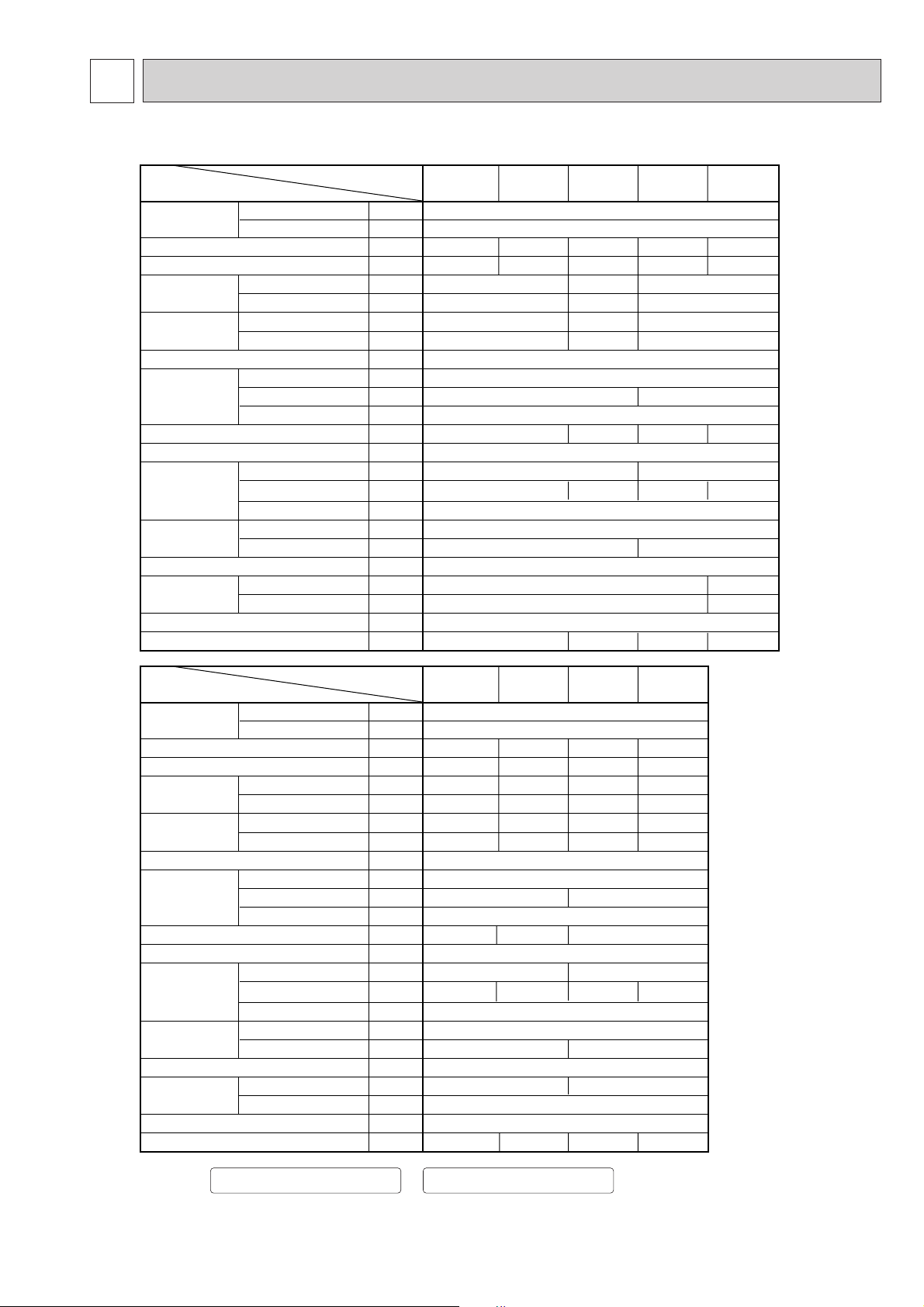

3

SPECIFICATION

3-1. Specification

Note: 1.Cooling / Heating capacity indicates the maximum value at operation under the following condition.

Cooling :Indoor 27¡CDB/19¡CWB Heating :Indoor 20¡C

:Outdoor 35¡CDB :Outdoor 7¡CDB/6¡CWB

2.The figure in

< >

indicates panel´s

.

6

Item

Power source

Cooling capacity

Heating capacity

Power consumption

Current

External finish (Munsel No.)

Dimension

Net weight

Heat exchanger

Fan

Motor

Air filter

Refrigerant

pipe dimension

Drain pipe dimension

Noise level

(Low-Middle2-Middle1-High)

Model

Voltage

Frequency

Cooling

Heating

Cooling

Heating

Height

Width

Depth

Type

Airflow rate

(Low-Middle2-Middle1-High)

External static pressure

Type

Output

Gas(Flare)

Liquid(Flare)

~V

Hz

kW

kW

kW

kW

A

A

mm

mm

mm

kg

m3/min

Pa

kW

mm

mm

dB(A)

PLFY-P20

VLMD-A

2.2

2.5

PLFY-P25

VLMD-A

2.8

3.2

0.09

0.08

0.43

0.38

Unit: Galvanized steel plate Panel: 0.70Y8.59/0.97

768<1,060>

24<7>

Cross fin( Alminium plate fin and copper tube)

Sirocco fanX1

6.0-6.5-7.3-8.0

Single phase induction motor

0.033 0.075

Synthetic fiber unwoven cloth filter( long life)

PLFY-P32

VLMD-A

220-240

50

3.6

4.0

0.10

0.09

0.48

0.43

338<8>

606<670>

25<7>

6.5-7.0-7.8-8.5

ø12.7

ø6.35

VP-25

PLFY-P40

VLMD-A

4.5

5.0

1,008<1,300>

33.5<8> 35<8>

Sirocco fanX2

9.0-10.5-11.5-12.5 10.0-11.0-12.0-13.0

0

29-32-34-36 32-34-36-3829-31-34-3628-30-33-35

PLFY-P50

0.16

0.15

0.77

0.71

VLMD-A

5.6

6.3

ø15.88

ø9.52

Note:1

Note:1

Note:2

Note:2

Note:2

Note:2

Item

Power source

Cooling capacity

Heating capacity

Power consumption

Current

External finish (Munsel No.)

Dimension

Net weight

Heat exchanger

Fan

Motor

Refrigerant

pipe dimension

Drain pipe dimension

Noise level

(Low-Middle2-Middle1-High)

External static pressure

Air filter

(Low-Middle2-Middle1-High)

Voltage

Frequency

Cooling

Heating

Cooling

Heating

Height

Width

Depth

Type

Airflow rate

Type

Output

Gas(Flare)

Liquid(Flare)

Model

PLFY-P63

VLMD-A

~V

Hz

kW

kW

kW

kW

A

A

mm

mm

mm

kg

m3/min

Pa

kW

mm

mm

dB(A)

7.1

8.0

0.22

0.21

1.05

1.00

Unit: Galvanized steel plate Panel: 0.70Y8.59/0.97

1,358<1,650>

39<10> 41<10>

Cross fin( Alminium plate fin and copper tube)

Sirocco fanX2

13.0-14.0-16.0-18.0 15.0-17.0-19.0-21.0

Synthetic fiber unwoven cloth filter( long life)

ø15.88 ø19.05

32-34-37-39 36-38-41-43 37-39-41-43 40-42-44-46

PLFY-P80

VLMD-A

10.0

0.23

0.22

1.10

1.05

Single phase induction motor

0.078

220-240

9.0

338<8>

606<670>

ø9.52

VP-25

PLFY-P100

VLMD-A

50

11.2

12.5

0.25

0.24

1.20

1.15

1,708<2,000>

56<11.5>

Sirocco fanX4

21.0-23.0-26.0-29.0

0

0.078

PLFY-P125

VLMD-A

14.0

16.0

0.28

0.27

1.35

1.33

24.0-27.0-30.0-33.0

X2

Note:1

Note:1

Note:2

Note:2

Note:2

Note:2

Page 8

5.0µF

X440V

4.0µF

X440V

6.0µF

X440V

5.0µFX440V

LEV

C1 2.5µFX440V

MF1,2

PLFY-P20 PLFY-P25 PLFY-P32 PLFY-P40 PLFY-P50 PLFY-P63 PLFY-P80 PLFY-P100 PLFY-P125

VLMD-A VLMD-A VLMD-A VLMD-A VLMD-A VLMD-A VLMD-A VLMD-A VLMD-A

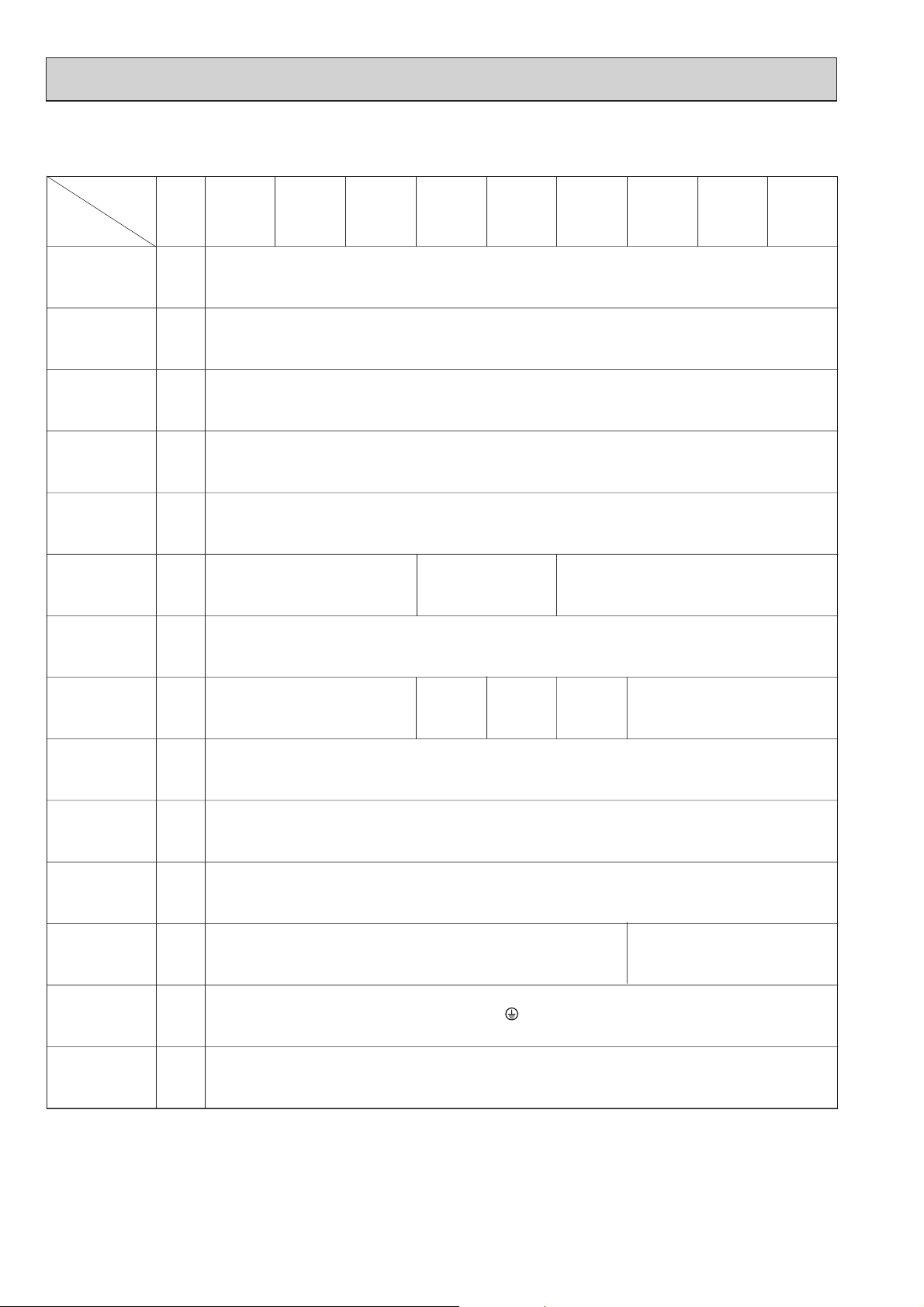

3-2. Electrical par ts specifications

Model

Parts

name

Tranrsformer T (Primary) 50/60Hz 220-240V (Secondry) (18.4V 1.7A)

TH21 Resistance 0˚C/15kW,10˚C/9.6kW˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

TH22 Resistance 0˚C/15kW,10˚C/9.6kW,20˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

Gas pipe

thermistor

FUSE 250V 6.3A

MV

DP

Drain sensor DS

TB2 (L,N, ) 330V 30A

TB5

(1,2),(M1,M2,S) 300V 10A

TB15

Fuse

(Indoor con-

troller board)

Power supply

terminal bed

Transmission

terminal bed

OFF 130˚C±5˚C

ON 90˚C±20˚C

MULB49Z

2.5/2W 4.99/5.99R.P.M

PJV-0720

INPUT 8/7.5W 24R/Hr

Heater resistance 82W

/25˚C

Thermistor resistance 0˚C/15kW,10˚C/9.6kW,20˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

Room

temperature

thermistor

Fan motor

(with Inner-

thermostat)

DC12V Stepping motor drive

port dimension 5.2W(0~2000pulse)

EDM-804MD

4-pole OUTPUT 33W

D094P35MW

4-pole Output 78W

D104P95MW

4-pole Output 75W

D104P85MW

Symbol

DC12V Stepping motor drive port

dimension 3.2W (0~2000pulse)

EDM-402MD

TH23 Resistance 0˚C/15kW,10˚C/9.6kW,20˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

Innerthermostat

(Fan motor)

Liquid pipe

thermistor

Fan motor

capacitor

Drain-up

mechanism

Linear

expansion valve

Vane motor

(with limit

switch)

7

Page 9

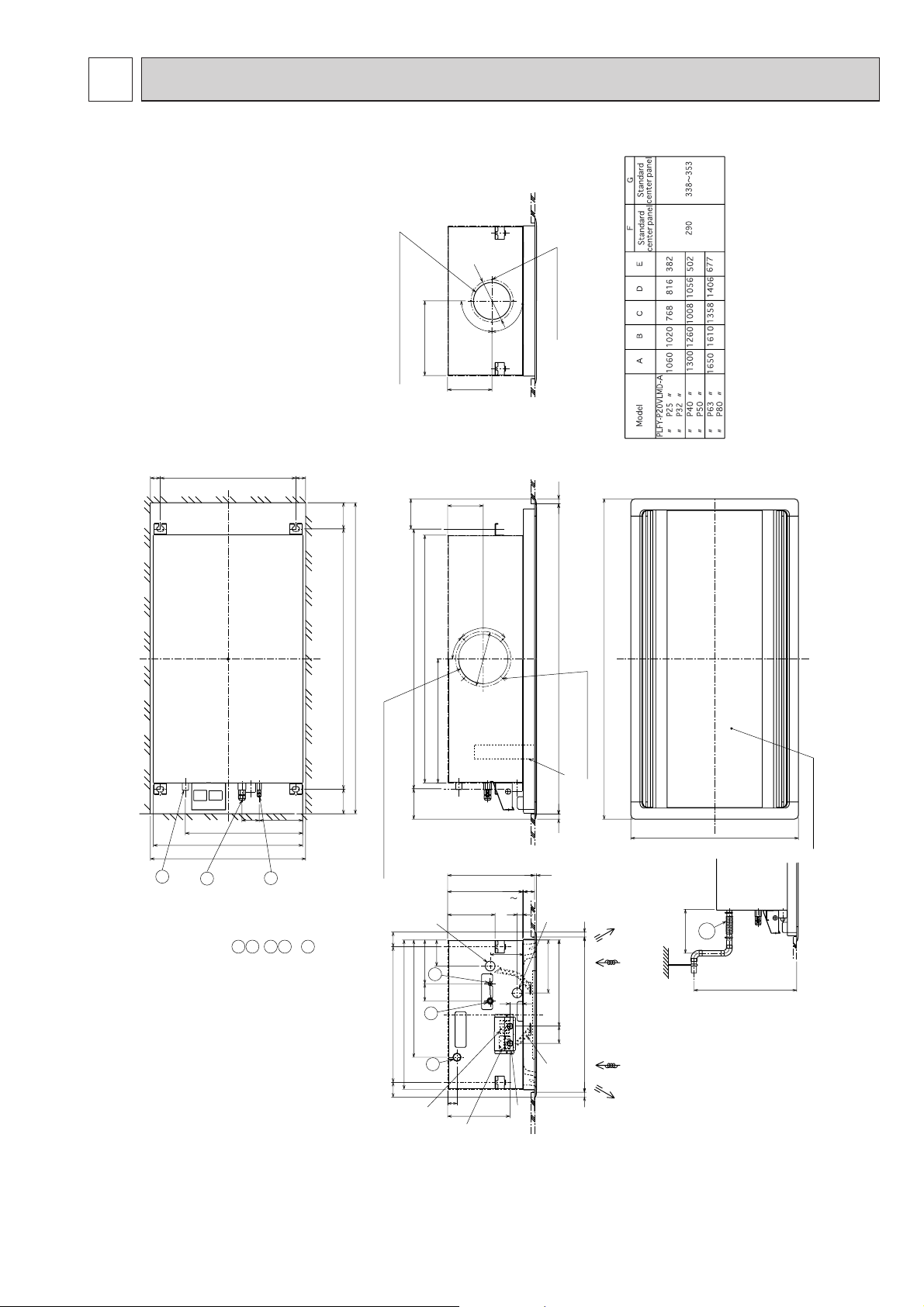

4

OUTLINES AND DIMENSIONS

Indoor Unit PLFY-P20·25·32·40·50·63·80VLMD-A

Unit :

mm

8

45˚

90˚

ø

224

90˚

ø

172

Branch duct ø200 knock out hole (both side)

45 3 18

8

(Ceiling opening)

(Lifting bolt pitch)

4-ø2.9Mounting hole

4-ø2.9Mounting hole

(Ceiling opening)

(Lifting bolt pitch)

<flare>

Model Gas pipe :LP ø 12.7 ··············

20·25·32·40

Liquid pipe :HP ø 6.35 ··············

Model Gas pipe :LP ø15.88 ··············

50·63·80

Liquid pipe :HP ø 9.52 ··············

Drain hose VP-25<flexible joint> (accessory) ········

Note:1.Use M10 screw for the lifing bolt (field supply).

20

20 630 20

1

111

222

3

3

2

3

Fresh air intake ø150 knock out hole

476

606

550

300mm or less

600mmMAX

Terminal bed(Transmission)

Terminal bed(Power source)

178 70

630

4040

102102

20

B

B

670

D

122

122 D

C

F

G

606

60

60

550

Water filling port

A

17870

476

135

106

38

Standard center panel

145

192

52

235

Drain hole

70 350

222

35

181

303

90˚

Control box

Terminal box

E

Air filter

3

Page 10

Indoor Unit PLFY-P100·125VLMD-A

Unit : mm

9

45˚

90˚

ø

224

Branch duct ø200 knock out hole (both side)

(Ceiling opening)

(Lifting bolt pitch)

4-ø2.9Mounting hole

4-

ø2.9Mounting hole

550

290

338 353

70

4040

670

122122

Control box

2000

1756

1708

856

145

2020

1960

102 1021756

1960

178

476

606

630

45 3 18

8

(Ceiling opening)

(Lifting bolt pitch)

20 630 20

1

2

3

Terminal bed(Transmission)

Terminal bed(Power source)

606

60

60

550

Water filling port

17870

476

135

106

38

192

52

235

Drain hole

70 350

222

35

Terminal box

Air filter

90˚

ø

172

Fresh air intake ø150 knock out hole

181

303

90˚

300mm or less

600mmMAX

3

<flare>

Gas pipe :LP ø19.05 ··············

Liquid pipe:HP ø 9.52 ··············

Drain hose VP-25<flexible joint> (accessory) ·······

Note:1.Use M10 screw for the lifing bolt (field supply).

11223

3

Standard center panel

Page 11

5

WIRING DIAGRAM

10

POWER SUPPLY

TO NEXT INDOOR UNIT

PULL BOX

FUSE(16A)

BREAKER(16A)

TO OUTDOOR UNIT

TO MA REMOTE CONTROLLER

BC CONTROLLER

REMOTE CONTROLLER

For test of pump out

(After confirm drain pump out,take this connector off.)

PLFY-P100 · 125VLMD

CN2M

ZNR

CND

X1

X3

X4

FAN1

FAN2

FAN CON

CNV

CNPCNT

CN23

CN31

CN21CN20CN81

C

T

LEV

MV

DP

MF

DS

TH22

SW3

SW2

CN3T

SW14

(Connection No.)

SW12

(2nd digit)

CN29

TH23

SWASWC

CN42

SW4

TH21

SW11

(1st digit)

(Red)

(Black)(White)

ZNR1

CN1

DSA1

CN82

(White)

(White)

(Red)

(White)

(Green)

LS

(White)

MF1

C1

MF2

C2

CN3A

TB2

TB5(TRANSMISSION TERMINAL BED)

TB15(TRANSMISSION TERMINAL BED)

INSIDE SECTION OF CONTROL BOX

INSIDE SECTION OF

TERMINAL BED BOX

MODELS 20/25/32 2.5µF

MODELS 40/80 5.0µF

MODEL 50 4.0µF

MODEL 63 6.0µF

MODELS 100/125 5.0µF X 2

*Capacitor

NOTE;1.TB2,TB5 shown in dotted line are

field work.

2.Mark indicates terminal bed,

connector, board insertion

connector or fastening connector

of control board.

DP

Drain pump

MF,MF1,MF2

C,C1,C2

I.B

A.B

F

T

LEV

Fan motor

*Capacitor(for MF,MF1

.

MF2)

Electronic linear expan. valve

Indoor controller board

Address board

Transformer

TB2

TB5 Transmission terminal bed

Power source terminal bed

Fuse AC250V 6.3AF

TB15 Transmission terminal bed

Surge absorber boardS.B

Limit switch (MV built in)LS

Motor for vane (with limit switch)MV

Drain sensor

DS

Thermistor (inlet temp.detection)

TH21

Thermistor (piping temp.detection/liquid)

Thermistor (piping temp.detection/gas)

Switch (2nd digit address set)

Switch (connection No.set)

Switch (1st digit address set)

TH22

TH23

SW11(A.B)

SW12(A.B)

SW14(A.B)

X1,X3,X4

Aux.relay

Switch(for mode selection)

Switch(for capacity code)

Switch(for mode selection)

Switch(for model selection)

Switch(for voltage selection)

SW2(I.B)

SW3(I.B)

SW1(A.B)

SW4(I.B)

SW5(A.B)

Switch(optional parts)

SWA(A.B)

Switch(optional parts)

SWC(A.B)

Page 12

REFRIGERANT SYSTEM DIAGRAM6

Gas pipe

PLFY-P20,25,32,40VLMD-A

ø12.7<1/2F>

PLFY-P50,63,80VLMD-A

ø15.88<5/8F>

PLFY-P100,125VLMD-A

ø19.05<3/4F>

Liquid pipe

ø6.35<1/4F> ø9.52<3/8F> ø9.52<3/8F>

Capacity

Item

11

Gas pipe thermistor TH23

Gas pipe

Liquid pipe thermistor TH22

Flare connection

Heat exchanger

Linear expansion valve

Strainer (#100mesh)

Room temparature thermistor TH21

Strainer (#100mesh)

Page 13

7

TROUBLE SHOOTING

7-1. How to check the parts

Room temparature

thermistor

(TH21)

Liquid pipe thermistor

(TH22)

Gas pipe thermistor

(TH23)

Trans

Vane motor

Fan motor

Linear expansion

valve

Drain-up

mechanism

Drain sensor

Disconnect the connector, then measure the resistance using a tester.

(Sorrounding temperature 10¡C~30¡C)

Disconnect the connector and measure the resistance using a tester.

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20˚C~30˚C)

Measure the resistance between the terminals using a tester.

Disconnect the connector then measure the resistance valve using a tester.

Refer to the next page for a detail.

Measure the resistance between the terminals using a tester.(Surrounding temperature :20˚C~30˚C)

Measure the resistance between the terminals using a tester.

(Refer to the thermistor)

(Refer to the thermistor)

Normal

4.3kW~9.6kW

Abnormal

Open or short

Normal

App.18kW

Abnormal

Open or short

Normal

0.43kW

Abnormal

Open or short

CNT(1)-(3)

Normal

App.45W

CN3T(1)-(3) App.1W

Abnormal

Open or short

Motor terminal

or

Relay connector

Normal

25,25,32 40,50 63,80,100,125

Abnormal

Red-Black 109.6W 43.1W 40.5W

Open or short

White-Black 141.6W 53.6W 48.8W

(1)-(3)

Normal

82W

(4)-(5) 4.3kW~9.6kW

Abnormal

Open or short

Normal

(1)-(5)

White-Red

150W ±10%

Abnormal

Open or short

(2)-(6)

Yellow-

Blown

(3)-(5)

Orange-Red

(4)-(6)

Blue-Brown

Parts name Check points

12

CNT T CN3T

Red Blue

1

2

3

White

Blue

1

2

3

Relay connector

1

LEV

Red

White

2

3

Black

Protector

White

Yellow

Orange

Blue

Red

Brown

Blue

Blue

1

2

1

2

3

CN60

1

2

3

4

5

6

1

2

3

4

5

Page 14

<Thermistor Characteristic graph>

Room temparature thermistor(TH21)

Liquid pipe thermistor(TH22)

Gas pipe temparature thermistor(TH23)

Drain sensor(DS)

Thermistor R0=15kW ± 3%

Fixed number of B=3480kW ± 2%

Rt=15exp { 3480( ) }

0˚C 15kW

10˚C 9.6kW

20˚C 6.3kW

25˚C 5.2kW

30˚C 4.3kW

40˚C 3.0kW

Thermistor for

lower temperature

Linear expansion valve

1 Operation summary of the linear expansion valve.

• Linear expansion valve open/close through stepping motor after receiving the pulse signal from the indoor controller board.

• Valve position can be changed in proportion to the number of pulse signal.

<Connection between the indoor controller board and the linear expasion valve>

1

273+t

1

273

13

< Thermistor for lower temperature >

50

40

30

Resistance (KW)

20

10

0

-20 -10 0 10 20 30 40 50

Temperature (˚C)

Linear expansion valve

4

M

6

2

5

White

1

Red

3

Orange

Blue

Brown

Yellow

ø4

ø3

ø2

ø1

Brown

Red

Blue

Orange

Yellow

White

Connector(CN60)

Controller board

DC12V

6

5

4

3

2

1

Drive circuit

ø4

ø3

ø2

ø1

Page 15

Output

(Phase)

Output

ø1

1

ON

ø2 ON

ø3 OFF

ø4 OFF

2

OFF

ON

ON

OFF

3

OFF

OFF

ON

ON

4

ON

OFF

OFF

ON

<Output pulse signal and the valve operation>

➁

Linear expansion valve operation

➂

Trouble shooting

Symptom

Check points

Operation circuit failure of the micro

processor.

Disconnect the connector on the controller board, then connect LED for checking.

Pulse signal will be sent out for 10 seconds as soon as the

main switch is turn on. If there is LED with lights on or lights

off, it means the operation circuit is abnormal.

Countermeasures

Exchange the indoor controller board at drive circuit

failure.

Linear expansion

valve mechanism is

locked.

Valve doesn

´t close

completely (thermistor leaking).

Wrong connection of

the connector or

contact failure.

To check the linear expansion valve, operate the indoor unit in

fan mode and at the same time operate other indoor units in

cooling mode, then check the pipe temperature <liquid pipe

temperature> of the indoor unit by the outdoor multi controller board operation monitor. During fan operation, linear expansion

valve is closed completely and if there are

some leaking, detecting temperature of the

thermistor will go lower. If the detected

temperature is much lower than the temper-

ature indicated in the remote controller, it

means the valve is not closed all the way. It is not necessary

to exchange the linear expansion valve, if the leakage is small

and not making any trouble.

Motor will idle and make ticking noise when motor is operated

while the linear expansion valve is locked. This ticking sound

is the sign of the abnormality.

Check the color of lead wire and missing terminal of the connector.

Exchange the linear

expansion vale.

Exchange the linear

expansion valve.

If large amount of refrigeration is leaked, exchange

the linear expansion valve.

Disconnect the connector

at the controller board,

then check the continuity.

Measure the resistance between the each coil (red-white,

red-orange, brown-yellow, brown-blue) using a tester. It is

normal if the resistance is in the range of

Short or breakage of

the motor coil of the

linear expansion

valve.

Closing a valve :1 → 2 → 3 → 4 → 1

Opening a valve : 4 → 3 → 2 → 1 → 4

The output pulse shifts in above order.

*1. When linear expansion valve operation stops, all output phase

become OFF.

2. At phase interruption or when phase does not shift in order,

motor does not rotate smoothly and motor will locks and vibrates.

* When the switch is turned on, 2200 pulse closing valve signal will

be send till it goes to A point in order to define the valve position.

When the valve move smoothly, there is no noise or vibration

occurring from the linear expansion valve :however, when the

pulse number moves from E to A or when the valve is locked,

more noise can be heard than normal situation.

* Noise can be detected by placing the ear against the screw dri-

ver handle while putting the screw driver to the linear expansion

valve.

14

Valve position (capacity)

A

Extra tightning (80~100pulse)

Close

E

B

Open

Pulse number

D

C

2000 pulse

Opening a valve

all the way

LED1kW

Thermistor

(TH21)

Linear

expansion

valve

6

5

4

3

2

1

150W

10%.

Page 16

ON

OFF

123456

7-2. FUNCTION OF DIP-SWICH

1

2

3

4

5

6

7

8

9

10

1~6

1

2

3

4

5

6

7

8

1~4

Thermistor<Intake temperature

detection>position

ON OFF

Filter crogging detection Provided Not provided

Filter life 2,500hr 100hr

Air intake Effective Not effective

Remote indication switching Thermostat ON signal indication Fan output indication

Humidifier control

Always operated while the heat is ON

Operated depends on the condition

Air flow st Low Extra low

Heat thermostat OFF Setting air flow Reset to SW1-7

Auto reset function Effective Not effective

Power ON/OFF Effective Not effective

Heat pump/Cool only Cooling only Heat pump

Louver Available Not available

Vane Available Not available

Vane swing function Available Not available

Vane holizontal angle Second setting First setting

Vane cooling limit angle setting

Horizontal angle Down blow

———

Heating 4deg up Not effective Effective

ON

OFF

ON

OFF

1234

1234

ON

OFF

12345678

ON

OFF

12345678910

ON

OFF

123456

ON

OFF

123456

MODELS SW2 MODELS SW2 MODELS SW2

PLFY-

P20VLMD-A

PLFY-

P25VLMD-A

PLFY-

P40VLMD-A

PLFY-

P50VLMD-A

PLFY-

P80VLMD-A

Address board

<At delivery>

Indoor controller board

Indoor controller board

Indoor controller board

<At delivery>

<At delivery>

SW4

Unit

Selection

SW3

Function

Selection

SW2

Capacity

code

setting

SW1

Mode

Selection

Switch Pole

Function

Built-in remote controller

Indoor unit

Set while the unit is off.

<At delivery>

Set for each capacity.

Set while the unit is off.

(Note) At cooling mode, each

angle can be used only 1

hour.

Set while the unit is off.

Operation by switch

Remarks

ON

OFF

123456

PLFY-

P100VLMD-A

PLFY-

P32VLMD-A

PLFY-

P63VLMD-A

ON

OFF

123456

PLFY-

P125VLMD-A

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

Note :The DipSW setting is effective during unit stopping ( remote controller OFF ) for SW1,2,3 and 4 commonly and the

power souce is not required to reset.

15

Page 17

Address board

Address board

Address board

Address board

Operation by switchSwitch Pole Remarks

* As this switch is used by interlocking with

SWC,refer to the item of SWC for detail

<At delivery>

<At delivery>

<At delivery>

<At delivery>

1~3

SWA

Option

2

SWC

Option

SW11

1st digit

address

setting

SW12

2nd degit

address

setting

Rotary switch

SW14

Connect

ion No.

setting

Rotary switch

When attach the optional high performance filter elements (filter casement)

to the unit, be sure to attach it to the

option side in order to prevent the airflow reducing.

Address setting should be done when network

remote controller (PAR-F25MA) is being used.

This is the switch to be used when the indoor

unit is operated with R2 series outdoor unit as

a set.

Address board

<At delivery>

2

SW5

Voltage

Selection

If the unit is used at the 230V or 240V area,

set the voltage to 240V.

If the unit is used at the 220V, set the voltage

to 220V.

Address can be set while the

unit is stopped.

Note:1

Note:1

Note:2

Note:2

Note:2

Note 1:The DipSW setting is effective always after powering ( remote controller ON ) for SWA and SWC.

2:The DipSW setting is effective during unit stopping ( remote controller OFF ) f

or SW11,12,14 and 5.

16

3

2

1

3

2

1

1

2

3

(Option)

(Standard)

(SWA)

SW12

SW11

0

9

8

7

6

10

0

1

9

2

8

3

7

4

6

5

5

1

SW14

0

1

2

F

3

E

4

D

5

C

6

B

7

A

8

9

220V 240V

SWC

1

2

3

4

(Option)

(Standard)

SW12

SW11

0

9

8

7

6

0

1

5

1

9

2

4

2

8

3

3

7

4

6

5

SW14

0

1

2

F

3

E

4

D

5

C

6

B

7

A

8

9

220V 240V

Page 18

8

DISASSEMBLY PROCEDURE

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

1.Removing the service panel (A)

(1) Slide the service panel (A) in the direction of the arrow 1

while lifting it.( depending on the local installation,the slide

direction is reverse )

(2) After sliding, if it is opened in direction 2, the service

panel (A) drops down as shown in fig. 2.

(3) Remove the service panel (A) from the two pins. (Be care-

ful not to allow it to drop).

2.Removing the filter (B)

(1) Move the fixing claws (C) of the filter (B) in the direction of

the arrow 3. (Pull them while lifting them up.)

(2) After removing the fixing claws (C) of the filter (B) from the

filter support plate (D), pull out the filter (B) in the direction

of the arrow 4.

8-1. SERVICE PANEL and FILTER

Be careful on removing heavy parts.

fig.1

fig.2

17

(A)

(B)

(D)

(C)

Page 19

1.Remove the service panel and filter with procedure 8-1.

2.Removing the connector cover (A).

Remove the fixing screws (two) of the connector cover (A),

and remove the cover. (Fig. 1)

* At this stage, the following servicing is possible. (It is even

possible with the filter attached.)

1 Operation and check of the switches (listed below) which

are on the address board (B).

• Rotary switches SW11, 12 Address setting

• Rotary switch SW14············Branch port setting

• Dip switch SW1 ···················Function change (main)

• Slide switches SWA, C ········Airflow rate change

2 Connection check and local connection of lead wires (list-

ed below) which are connected to the control box (C).

• Power supply lead wire (Connected at the factory)

• Drain pump lead wire (Connected at the factory)

• LEV lead wire (Connected at the factory)

• Panel vane motor lead wire (Connected locally)

• Panel limit switch lead wire (Connected locally)

• Drain pump trial operation connector (Connected locally)

3.Removing the control box (C)

(1) Remove the fixing screws (three) of the filter fixed plate

(D) . (Fig. 2)

(2) Also remove the fixing screws (three) of the control box

cover (F) and remove it. (Fig. 3)

* At this stage, the following servicing is possible.

1 Operation and check of the switches (listed below) which

are on the control board.

• Dip switch SW2········Capacity code setting

• Dip switch SW3········Function change (auxiliar y)

• Dip switch SW4········Model code setting

And the address board exchange.

2 Connection check of the lead wires (listed below) which

are connected to the control box

• Power supply lead wire

• Remote control communication lead wire

• Fan motor lead wire

• LEV lead wire

• Drain pump lead wire

• Drain sensor lead wire

• Intake air sensor lead wire

• Liquid piping sensor lead wire

• Gas piping sensor lead wire

• Power supply transformer lead wire

• Address board lead wire

• Panel vane motor lead wire

• Panel limit switch lead wire

8-2. CONTROL BOX

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig.1

fig.2

fig.3

18

(B)

(A)

(C)

(D)

(D)

(F)

(C)

Vane motor cover

Page 20

3.Removing the control box (C)

(3) If the control box (C) fixing screws (two) are removed, the

control box (C) is left hanging from the main unit by the

falling prevention claws.If the control box (C) is lifted the

claws are released and the control box (C) can be lowered

down.Also, in order to completely lower the control box (C),

it is necessary to remove the following lead wire connectors.

• Power supply lead wire connector (3P : White)

• Drain pump lead wire connector (3P :White)

• LEV lead wire connector (6P : White)

• Panel vane motor lead wire connector (4P :White)

• Panel limit switch lead wire connector (2 :Green)

• Remote control communication lead wire connector (2P : Blue)

• Drain sensor lead wire connector (5P : Red)

• Intake air sensor lead wire connector (2P : Red)

• Liquid piping sensor lead wire connector (2P : White)

• Gas piping sensor lead wire connector (2P : Black)

• Fan motor lead wire connector ····· motor side connector (Black)

(4) Remove the control box earth wire (green/yellow) from the

control box (C), and remove the control box (C).

* At this stage, the following servicing is possible.

1 Control board exchange

2 Condenser exchange

3 Power supply transformer exchange

CONTROL BOX

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig 4

fig.5

Control

box

Control

Board

fig.6

fig.7

19

(C)

Falling prevention claw

Earth wire (green/yellow)

Page 21

1.Remove the service panel and filter with procedure 8-1.

2.Removing the filter fixed plate (A)

Remove the fixing screws (three) of the filter fixed plate(A)

and remove it.(Fig.1)

3.Removing the under-fan-casing (C)

Push the fixing claws of the under-fan-casing(C) and

remove it.

4.Removing the fan motor (D)

Remove the lead wire connectors which are connected to

the fan motor (D), and remove the motor fixtures (E) (two

for each motor.Each motor is screwed down in two.)

Note:There are no falling prevention measures for the fan

motor.In order to prevent the fan motor from falling when it

is removed, the work is to be performed by two people. (It

is dangerous to do this alone.)

5.Removing the sirocco fan (F)

Remove the fan motor shaft fixing screw (one for each fan),

and remove the sirocco fan (F).

8-3. FAN and FAN MOTOR

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig 1

fig.2

fig 3

20

Fixing claws (Four for each casing)

(C)

Fixing screw

(E)

(F)

(D)

(A)

Page 22

1.Remove the service panel and filter with procedure 8-1.

2.Remove the control box cover with the procedure up to 3.

(2) of 8-2.

3.Removing the thermistor

(1) Remove the fixing screw (one) of the thermistor installation

plate (A), and pull down the thermistor with installation

plate.

(2) Remove the thermistor lead wire which is connected to the

control board.

8-4.THERMISTOR (Intake air temperature detection)

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig 1

21

(A)

Page 23

1.Remove the service panel and filter with procedure 8-1.

2.Remove the control box with procedure 8-2.

3.Removing the decorative panel frame (A)

(1) Loosen the panel fixing staired screws (four), and the

panel frame (A) is left hanging in midair.(Fig. 1)

(2) The panel frame (A) is pushed (or pulled) in the length

direction, the staired screws come out of the pear-shaped

holes in the panel frame (A), and the panel fame (A) can

be removed.

4.Removing the drain pan (B)

(1) Remove the screws which are fixing the drain pan fixing

plates (C) (two), and remove the plates.

(2) Remove the drain pan falling prevention parts. (fixing pin

(D), fixing plate (E) and filter fixing plate installation plate

(F).)

(3) Loosen the rubber plug (G) which in is the drain socket of

the drain pan (B), and drain the water which is still in.

(4) Pull down the drain pan (B).

Note:Take it out by moving a little in all four directions.The

drain pan is made from polystyrene.Handle it carefully so

that it is not broken.

5.Removing the partition plate (H).

Note:Take it out by moving a little in all four directions.The

partition plate is made from polystyrene.Handle it carefully

so that it is not broken.

8-5.THERMISTOR (Liquid and gas piping temperature detection)

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig 1

fig.2

fig 3

(A)

22

(C)

(E)

(F)

(B)(D)

(H)

(G)

Page 24

6.Removing the thermistors

Remove the thermistors (K and L) from the thermistor

holders (I and J) which are installed on the steel piping

(liquid piping ····· fine piping, gas piping ····· thick piping).

THERMISTOR (Liquid and gas piping temperature detection)

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig 4

fig 5

fig 6

23

(B)

(H)

(J) (L)

(K)

( I )

Page 25

1.Remove the service panel and filter with procedure 8-1.

2.Remove the controle box with procedure 8-2.

3.Remove the decorative panel frame, drain pan and partition plate with the procedure up to 3.~5. of 8-5.

4.Removing the drain pump(A)

(1) Cut the drain hose fixing binder(C) , which hose is con-

nected to the drain pump (A)

(2) Remove the fixing screws (two) which fix the bracket (E) to

the unit fixtures (D), and remove the drain pump (A) from

the main unit.

8-6. DRAIN PUMP and DRAIN SENSOR

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig 1

24

(D)(A) (E)

(C)

(B)

Page 26

1.Remove the service panel and filter with procedure 8-1.

2.Remove the controle box with procedure 8-2.

3.Remove the decorative panel frame, drain pan and partition plate with the procedure up to 3.~5. of 8-5.

4.Removing the LEV driving motor (B)

Remove the LEV driving motor (B) with a double spanner.

5.Removing the heat exchanger (C)

After removing the liquid piping connection flare (D) and

gas piping connection flare (E), lower the unit and remove

the heat exchanger (C).

(1) Remove the non-piping side frame (F).

(Secured by seven screws.)

(2) Remove the side frames (G and H).

(secured by seven screws each.)

(3) Remove the piping side frame (I) and the piping fixing

plate (J).

(The frame (I) is secured by three screws and the piping

fixing plate (J) by two screws.)

(4) Slide the heat exchanger (C) towards the non-piping side,

and remove it from the ceiling (K) hanging holes.

8-7. LEV and HEAT EXCHANGER

Be careful on removing heavy parts.

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

fig 1

fig 2

fig 3

25

(J)

(B)

(H)( I )(E)

(A)

(F)

(C)

(K)(G)(D)

Page 27

Page 28

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Issued in May. 2001 MEE01K049

Printed in Japan

New publication, effective May. 2001

Specifications subject to change without notice

Loading...

Loading...