Mitsubishi PLFY-P08NCMU-ER4, PLFY-P12NCMU-ER4, PLFY-P15NCMU-ER4 User Manual

PLFY-1PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

CEILING-RECESSED CASSETTE (FOUR-WAY AIRFLOW)

PLFY-P-NCMU-ER4, -NBMU-E2

1. SPECIFICATIONS ....................................................................................................................................................PLFY-3

PLFY-P08NCMU-ER4, PLFY-P12NCMU-ER4, PLFY-P15NCMU-ER4.................................................................. PLFY-3

PLFY-P08NBMU-E2, PLFY-P12NBMU-E2, PLFY-P15NBMU-E2, PLFY-P18NBMU-E2 ....................................... PLFY-4

PLFY-P24NBMU-E2, PLFY-P30NBMU-E2, PLFY-P36NBMU-E2 .......................................................................... PLFY-5

2. EXTERNAL DIMENSIONS ....................................................................................................................................... PLFY-6

3. CENTER OF GRAVITY ............................................................................................................................................ PLFY-8

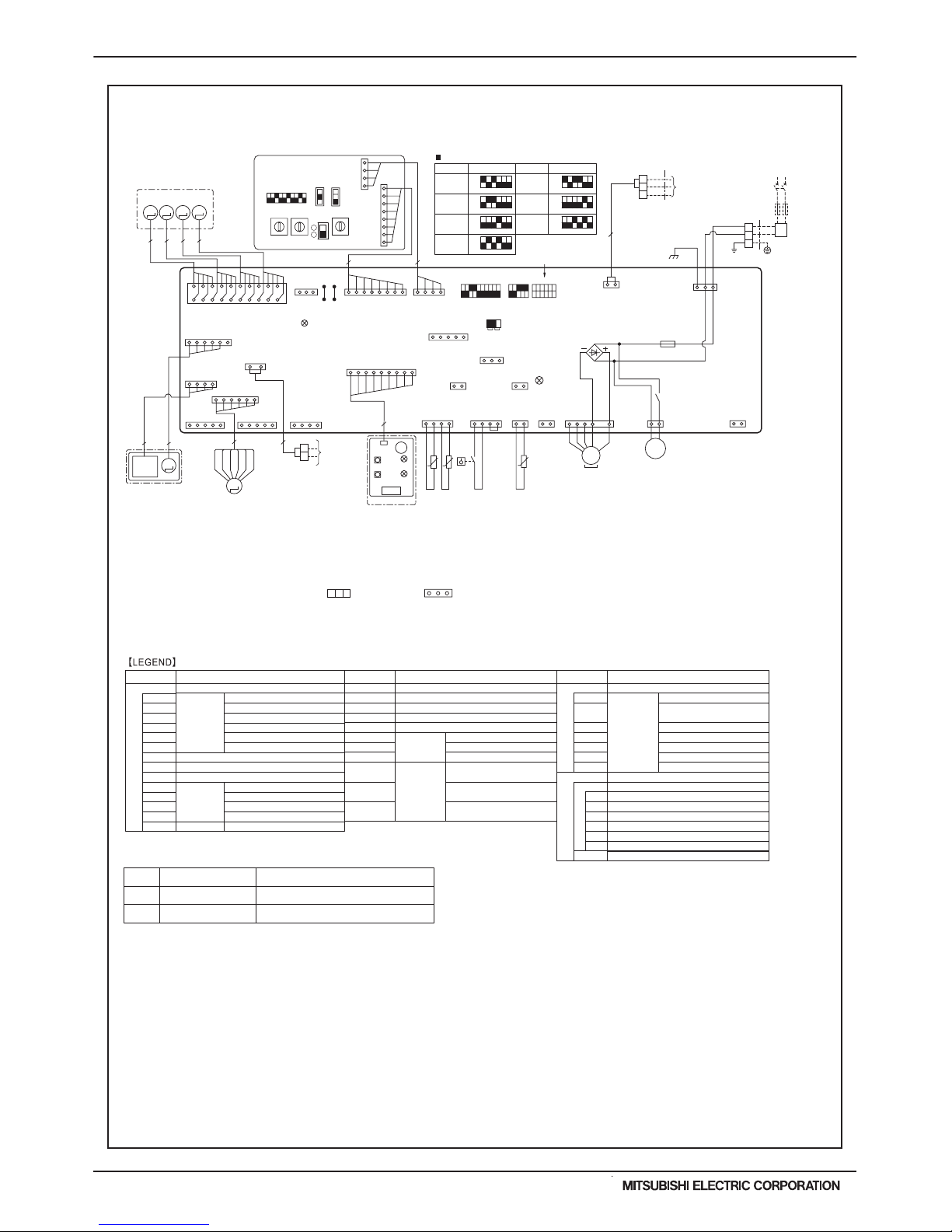

4. ELECTRICAL WIRING DIAGRAMS ......................................................................................................................... PLFY-9

5. SOUND PRESSURE LEVELS ............................................................................................................................... PLFY-11

5-1. Sound Pressure Levels ................................................................................................................................. PLFY-11

5-2. NC Curves..................................................................................................................................................... PLFY-11

6. TEMPERATURE/AIRFLOW DISTRIBUTIONS ......................................................................................................PLFY-12

6-1. Temperature Distributions ............................................................................................................................. PLFY-12

6-2. Airow Distributions ....................................................................................................................................... PLFY-15

6-3. Branch Duct Capacities................................................................................................................................. PLFY-18

7. VENTILATION AIR INTAKE AMOUNT AND STATIC PRESSURE ......................................................................... PLFY-25

7-1. PLFY-P08, 12, 15NCMU-ER4 ....................................................................................................................... PLFY-25

7-2. PLFY-P08, 12, 15, 18, 24, 30, 36NBMU-E2 .................................................................................................. PLFY-25

8. OPTIONAL PARTS .................................................................................................................................................PLFY-27

8-1. Air Outlet Shutter Plate PAC-SH51SP-E for PLFY-P-NBMU-E2 ................................................................... PLFY-28

8-2. High Efciency Filter Element PAC-SH59KF-E (MERV 10) for PLFY-P-NBMU-E2 ...................................... PLFY-29

8-3. Multi-function Casement PAC-SH53TM-E for PLFY-P-NBMU-E2 ................................................................PLFY-29

8-4. i-see Sensor Corner Panel PAC-SA1ME-E for PLFY-P-NBMU-E2 ............................................................... PLFY-30

8-5. Wireless Signal Receiver PAR-SA9FA-E for PLFY-P-NBMU-E2 .................................................................. PLFY-30

8-6. Flange for fresh air intake PAC-SH65OF-E for PLFY-P-NBMU-E2...............................................................PLFY-31

8-7. External Heater Adapter CN24RELAY-KIT-CM3 ........................................................................................... PLFY-32

PLFY-2

PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

CEILING-RECESSED CASSETTE (FOUR-WAY AIRFLOW)

PLFY-P-NCMU-E

PLFY-P-NBMU-E

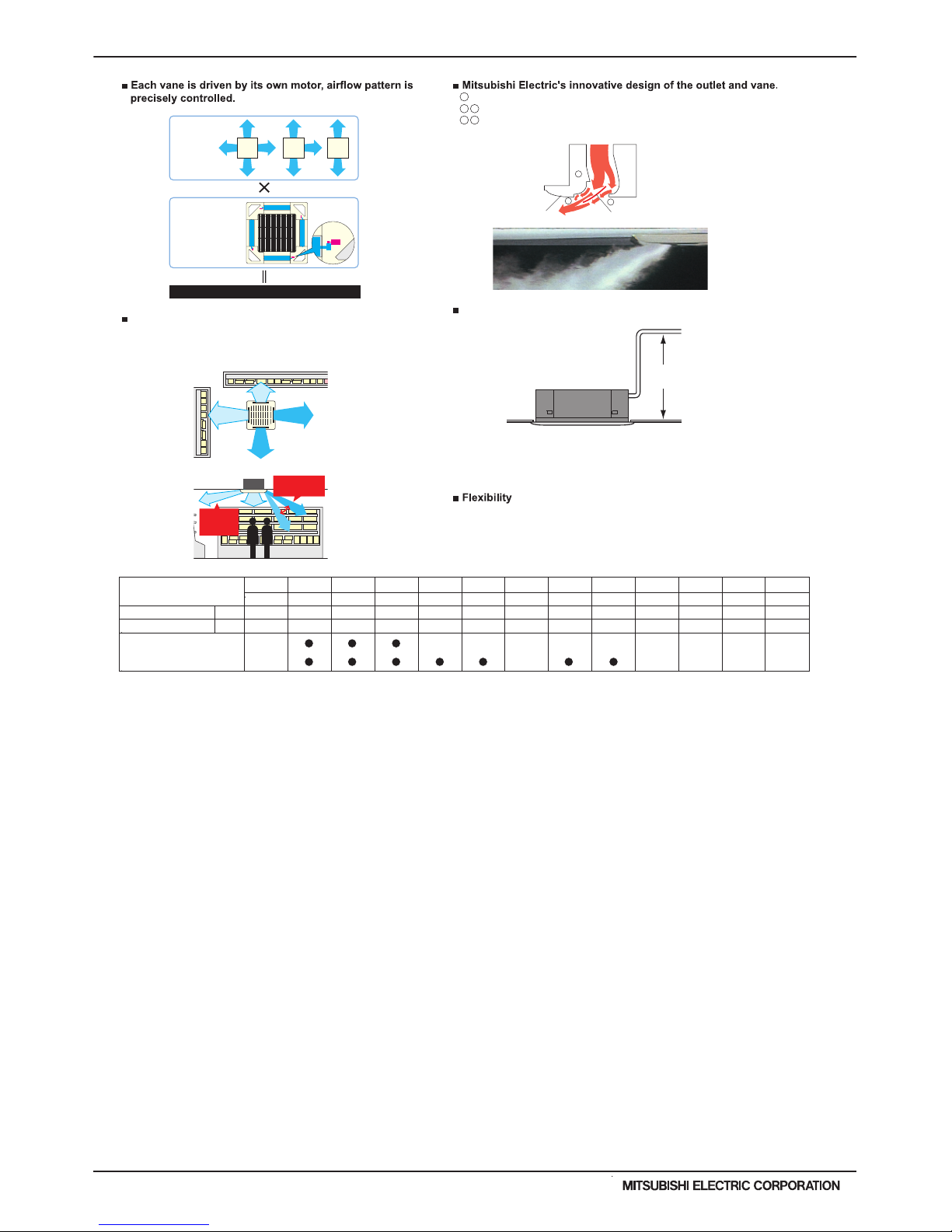

Various airflow pattern to meet your needs, strong airflow power, suitable for ceiling of max.13 -9" height

4-, 3-, or

2-way

outlet

selection

Fixed airflow

direction per

vane

Motor

for the

vane

72 airflow patterns

850mm

(33-

7

/16 in.)

Fixed

Fixed

Fixed

Fixed

Refrigerated

showcase not

affected by air

conditioning

Top or bottom

airflow setting via

remote controller

1

2

3

Outside Inside

Grille Vane

Example (Convenient chain store)

Airflow doesn't disturb the cooled air in show-case

helps energy saving.

1 Uniformly distribute the air onto the louver.

2 3 Avoid airflow rising up.

2 3 Avoid dust attachment.

Allowing long piping and versatility.

The PLFY not only brings outside air into your space, but the PLFY-P-NBMU-E2

can also branch over to air-condition an adjacent room.

Drain water lifted to 33-7/16” (PLFY-P-NBMU-E2) or 19-11/16” (PLFY-P-NCMU-E2)

Precise airflow pattern on PLFY-P-NBMU-E2

(on PLFY-P-NBMU-E2)

PLFY-P-NBMU-E2

PLFY-P-NBMU-E

PLFY-P-NCMU-E

PLFY-P-NBMU-E2

PLFY-P-NCMU-ER4

3.2HP 8.0HP4.0HP 5.0HP

P08 P12 P15 P18 P30 P36 P48P06 P24 P27 P54 P72

10.0HP

P96

0.8HP 1.0HP 1.3HP 1.6HP 2.0HP 2.5HP 2.8HP 5.6HP

Cassette ceiling

48,000

6,700

Nominal cooling cap.*1

Nominal heating cap.*2

6,000 8,000 12,000 15,000 18,000 24,000 27,000 30,000 36,000 54,000 72,000 96,000

60,000 80,000 108,00027,000 30,000 34,000 40,000 54,0009,000 13,500 17,000 20,000

Btu/h

Btu/h

* Nominal conditions *1, *2 are referred to in the Specification sheet.

PLFY-3PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

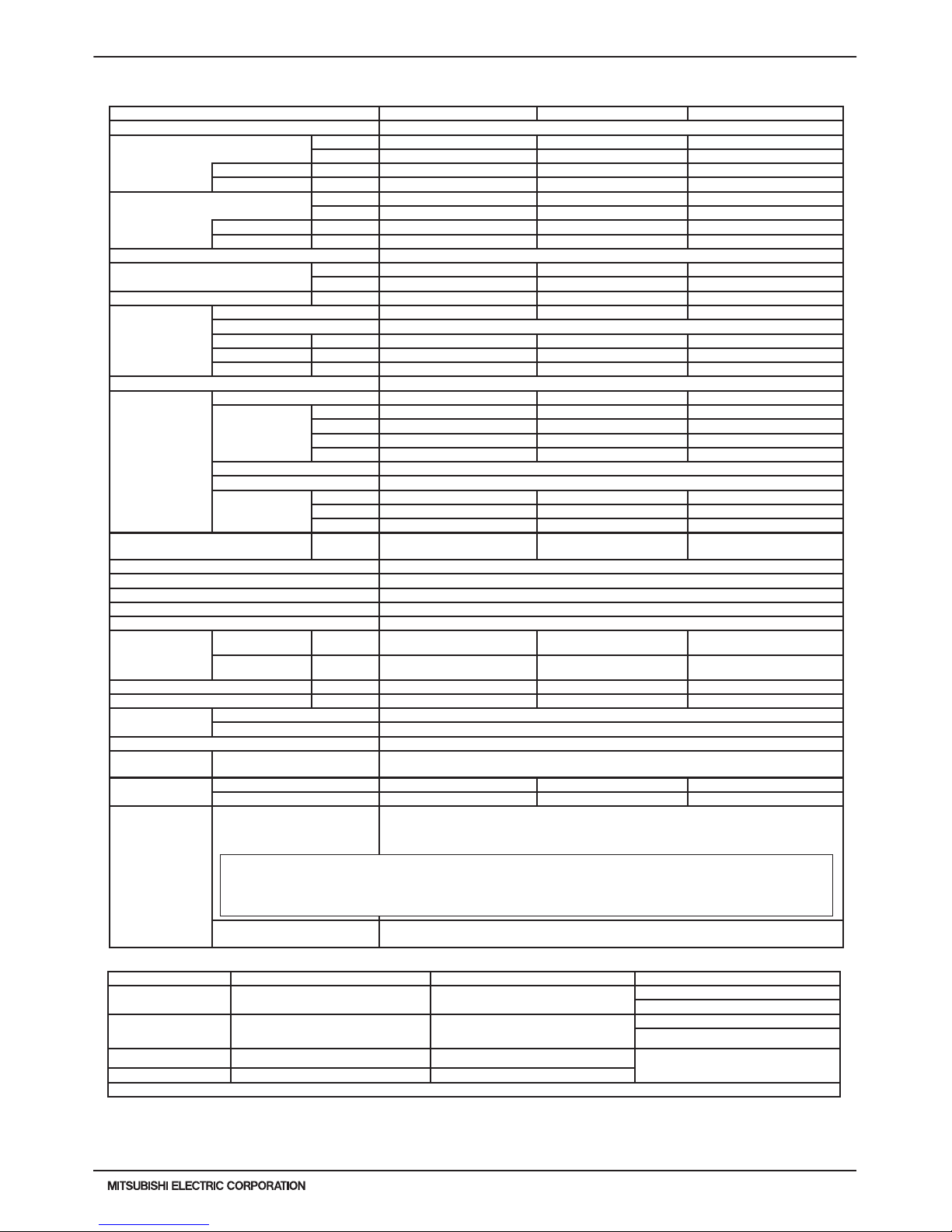

Model PLFY-P08NCMU-ER4 PLFY-P12NCMU-ER4 PLFY-P15NCMU-ER4

Power source 1-phase 208-230 V 60Hz

Cooling capacity *1

(Nominal)

Btu/h 8,000 12,000 15,000

kW 2.3 3.5 4.4

Power input kW 0.05 0.06 0.06

Current input A 0.23 0.28 0.28

Heating capacity *2

(Nominal)

Btu/h 9,000 13,500 17,000

kW 2.6 4.0 5.0

Power input kW 0.05 0.06 0.06

Current input A 0.23 0.28 0.28

External nish Galvanized Steel Sheet

External dimension H x W x D

in. 8-3/16 x 22-7/16 x 22-7/16 8-3/16 x 22-7/16 x 22-7/16 8-3/16 x 22-7/16 x 22-7/16

mm 208 x 570 x 570 208 x 570 x 570 208 x 570 x 570

Net weight lbs (kg) 34 (15.5) 37 (17) 37 (17)

Decoration

panel

Model SLP-15AAUW SLP-15AAUW SLP-15AAUW

External nish Munsell No. 6.4Y 8.9/0.4

Dimension in. 25/32 x 25-19/32 x 25-19/32 25/32 x 25-19/32 x 25-19/32 25/32 x 25-19/32 x 25-19/32

H x W x D mm 20 x 650 x 650 20 x 650 x 650 20 x 650 x 650

Net Weight lbs (kg) 7(3) 7(3) 7(3)

Heat exchanger Cross n

Fan

Type x Quantity Turbo fan x 1 Turbo fan x 1 Turbo fan x 1

External

static pressure

in.WG 0.000 (208V) 0.000 (208V) 0.000 (208V)

Pa 0 0 0

in.WG 0.000 (230V) 0.000 (230V) 0.000 (230V)

Pa 0 0 0

Motor type 1-phase induction motor

Driving mechanism Direct-driven

Airow rate

(Low-Mid-High)

CFM 280-320-350 320-350-390 320-350-390

m3 / min 8.0-9.0-10.0 9.0-10.0-11.0 9.0-10.0-11.0

L / s 133-150-167 150-167-183 150-167-183

Sound pressure level (Low-Mid-High)

(measured in anechoic room)

dB <A> 29-32-38 (208-230V) 30-34-39 (208-230V) 31-35-40(208-230V)

Insulation material Polyethylene foam

Air lter Polypropylene honeycomb fabric

Protection device Fuse

Refrigerant control device LEV

Connectable outdoor unit R410A,R22 CITY MULTI

Diameter of

refrigerant pipe

(O.D.)

Liquid (R410A) in. (mm) 1/4 (6.35) Flare 1/4 (6.35) Flare 1/4 (6.35) Flare

Gas (R410A) in. (mm) 1/2 (12.7) Flare 1/2 (12.7) Flare 1/2 (12.7) Flare

Field drain pipe size in. (mm) O.D. 1-1/4(32) O.D. 1-1/4(32) O.D. 1-1/4(32)

Drain Lift Mechanism in. (mm) 19-11/16 (500) 19-11/16 (500) 19-11/16 (500)

Drawing

External RG01N654

Wiring RG79V389

Refrigerant cycle -

Standard attachment

Document

Accessory

Installation Manual,Installation Book

Drain hose<1-1/4in.(32mm)>

Optional parts

External heater adapter CN24RELAY-KIT-CM3 CN24RELAY-KIT-CM3 CN24RELAY-KIT-CM3

Decoration panel SLP-15AAUW SLP-15AAUW SLP-15AAUW

Remark

*PLFY-P-NCMU-E should used together with SLP-15AAUW.

Installation

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

Ventilation Air: Providing sufcient ventilation air is an important part of every building design.

ASHRAE standard 62 provides the minimum ventilation air requirements. Also check local

codes.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B. / 67degF W.B.

(26.7degC D.B. / 19.4degC W.B.)

70degF D.B. (21.1degC D.B.)

kcal/h = kW x 860

BTU/h = kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B. / 43degF W.B.

(8.3degC D.B. / 6.1degC W.B.)

cfm = m3/min x 35.31

lbs = kg / 0.4536

Pipe length: 25 ft. (7.6 m) 25 ft. (7.6 m)

*Above specication data is subject to

rounding variation.

Level difference: 0 ft. (0 m) 0 ft. (0 m)

*Due to continuing improvement, above specication may be subject to change without notice.

PLFY-P08NCMU-ER4, PLFY-P12NCMU-ER4, PLFY-P15NCMU-ER4

PLFY-4

PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

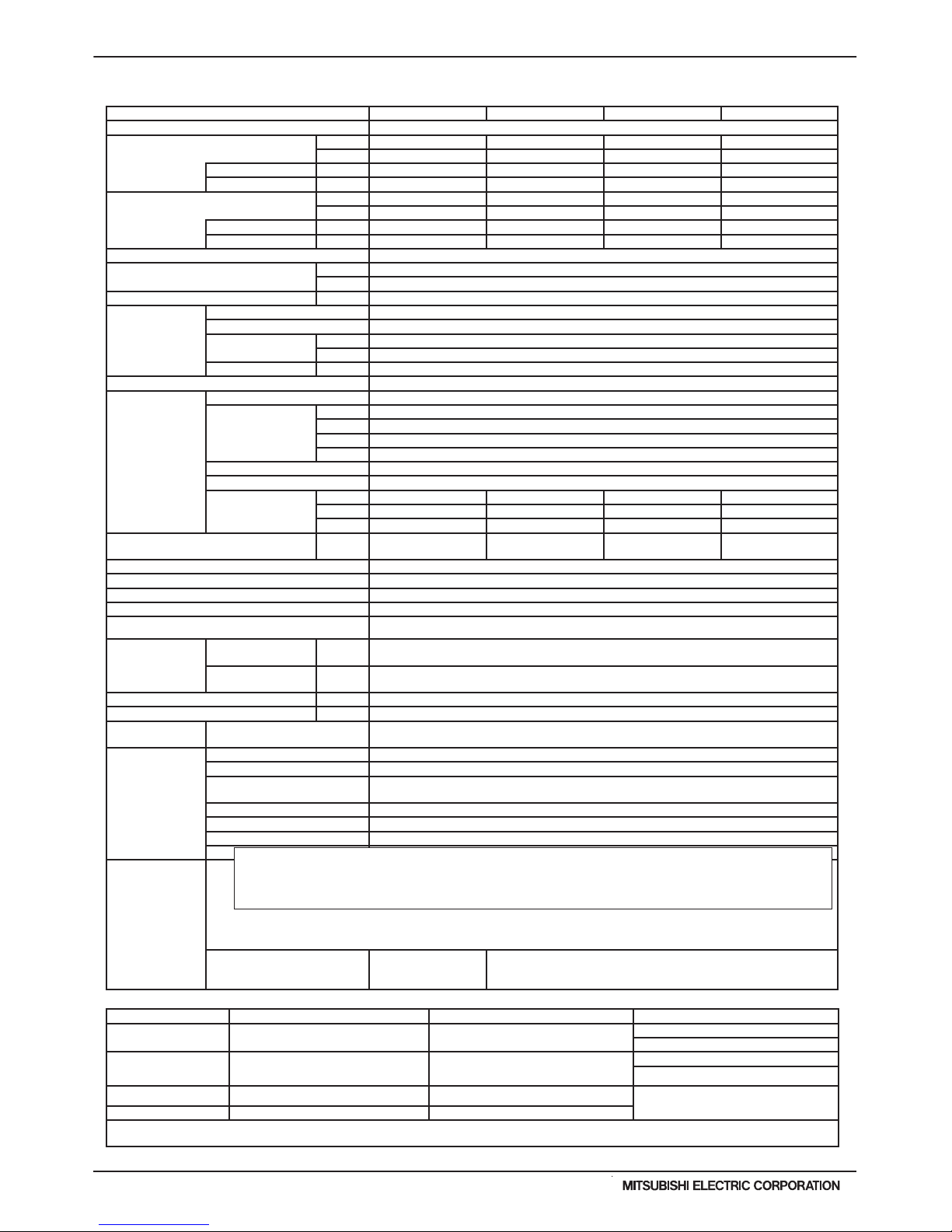

Model PLFY-P08NBMU-E2 *3 PLFY-P12NBMU-E2 PLFY-P15NBMU-E2 PLFY-P18NBMU-E2

Power source 1-phase 208-230 V 60Hz

Cooling capacity *1

(Nominal)

Btu/h 8,000 12,000 15,000 18,000

kW 2.4 3.5 4.4 5.3

Power input kW 0.03 0.03 0.03 0.04

Current input A 0.31 0.31 0.31 0.33

Heating capacity *2

(Nominal)

Btu/h 9,000 13,500 17,000 20,000

kW 2.7 4.0 5.0 5.9

Power input kW 0.02 0.02 0.02 0.03

Current input A 0.24 0.24 0.24 0.26

External nish Galvanized steel sheet

External dimension H x W x D

in. 10-3/16 x 33-3/32 x 33-3/32

mm 258 x 840 x 840

Net weight lbs (kg) 51 (23)

Decoration

panel

Model PLP-40BAU

External nish Munsell No. (6.4Y 8.9/0.4)

Dimension

H x W x D

in. 1-3/8 x 37-13/32 x 37-13/32

mm 35 x 950 x 950

Net Weight lbs (kg) 13 (6)

Heat exchanger Cross n

FAN

Type x Quantity Turbo fan x 1

External static

pressure

in.WG 0.000 (208V)

Pa 0

in.WG 0.000 (230V)

Pa 0

Motor type DC motor

Driving mechanism Direct-driven

Airow rate (LowMid2-Mid1-High)

CFM 494 - 530 - 547 - 565 494 - 530 - 547 - 565 494 - 530 - 547 - 565 494 - 530 - 565 - 636

m3 / min 14.0 - 15.0 - 15.5 - 16.0 14.0 - 15.0 - 15.5 - 16.0 14.0 - 15.0 - 15.5 - 16.0 14.0 - 15.0 - 16.0 - 18.0

L / s 233 - 250 - 259 - 267 233 - 250 - 259 - 267 233 - 250 - 259 - 267 233 - 250 - 267 - 300

Sound pressure level (Low-Mid2-Mid1-High)

(measured in anechoic room)

dB <A>

27 - 29 - 30 - 31(208-

230V)

27 - 29 - 30 - 31(208-

230V)

28 - 29 - 30 - 31(208-

230V)

28 - 29 - 30- 32(208-

230V)

Insulation material PS

Air lter PP honeycomb (long life lter, anti-bacterial type)

Protection device Fuse

Refrigerant control device LEV

Connectable outdoor unit R410A CITY MULTI

Diameter of

refrigerant pipe

(O.D.)

Liquid (R410A) in. (mm) 1/4 (6.35) Flare

Gas (R410A)

in. (mm) 1/2 (12.7) Flare

Field drain pipe size in. (mm) O.D. 1-1/4(32)

Drain lift mechanism in. (mm) 33-7/16 (850)

Standard

attachment

Document

Accessory

Installation Manual, Instruction Book

Optional parts

External heater adapter CN24RELAY-KIT-CM3

Air outlet shutter plate PAC-SH51SP-E

High efciency lter element

(MERV 10)

PAC-SH59KF-E

Multi-function casement PAC-SH53TM-E

i-see sensor corner panel PAC-SA1ME-E

Flange for fresh air intake PAC-SH65OF-E

Wireless signal receiver PAR-SA9FA-E

Remark

Installation

Details on foundation work, duct work, insulation work, electrical wiring,

power source switch, and other items shall be referred to the Installation

Manual.

Ventilation Air: Providing sufcient ventilation air is an important part of every building design.

ASHRAE standard 62 provides the minimum ventilation air requirements. Also check local

codes.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B. / 67degF W.B.

(26.7degC D.B. / 19.4degC W.B.)

70degF D.B. (21.1degC D.B.)

kcal/h = kW x 860

BTU/h = kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B. / 43degF W.B.

(8.3degC D.B. / 6.1degC W.B.)

cfm = m3/min x 35.31

lbs = kg / 0.4536

Pipe length: 25 ft. (7.6 m) 25 ft. (7.6 m)

*Above specication data is subject to

rounding variation.

Level difference: 0 ft. (0 m) 0 ft. (0 m)

*Due to continuing improvement, above specication may be subject to change without notice.

*3 PLFY-P08NBMU-E2 is not compatible with PUMY-P**NHMU/NKMU outdoor units.

PLFY-P08NBMU-E2, PLFY-P12NBMU-E2, PLFY-P15NBMU-E2, PLFY-P18NBMU-E2

PLFY-5PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

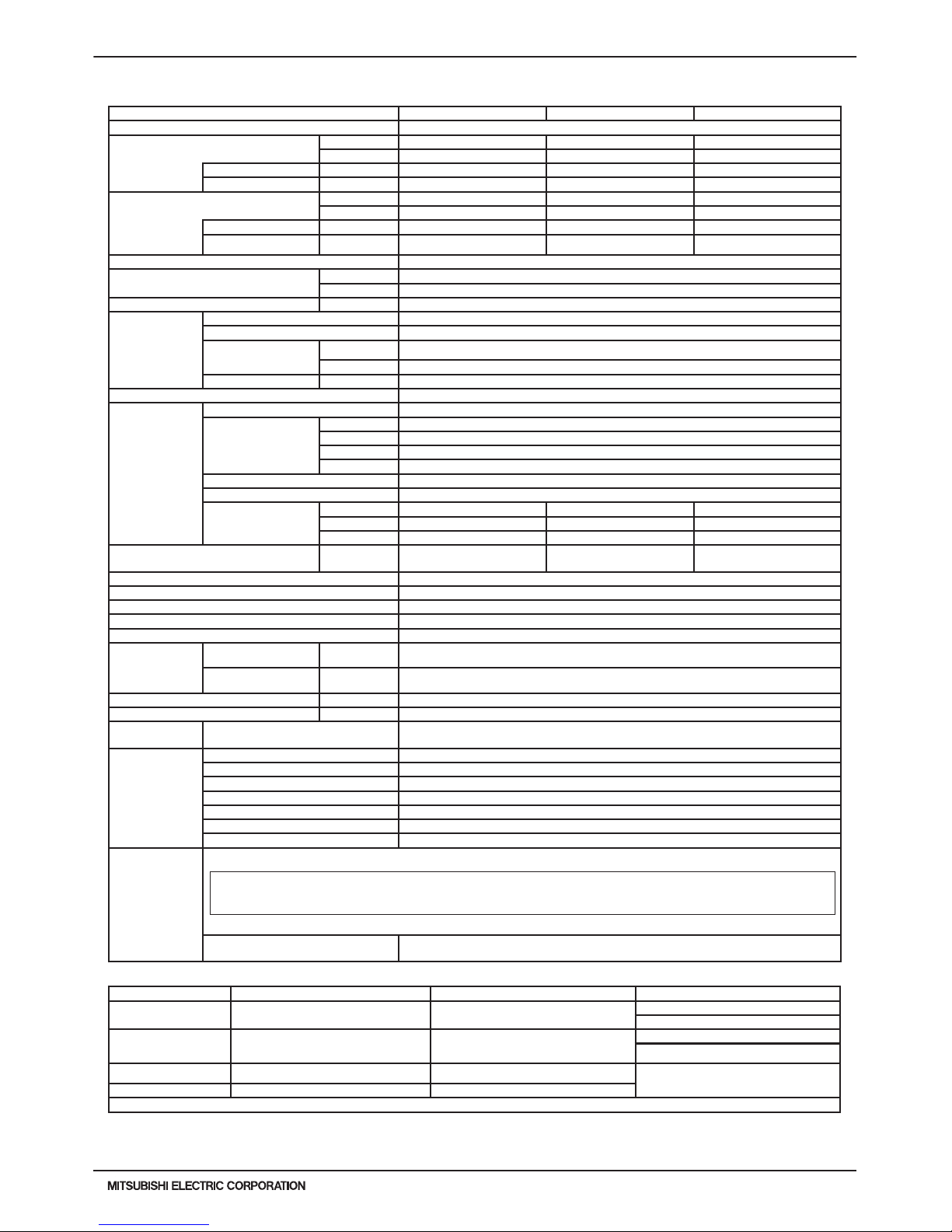

Model PLFY-P24NBMU-E2 PLFY-P30NBMU-E2 PLFY-P36NBMU-E2

Power source 1-phase 208-230 V 60Hz

Cooling capacity *1

(Nominal)

Btu/h 24,000 30,000 36,000

kW 7.0 8.8 10.5

Power input kW 0.05 0.05 0.09

Current input A 0.47 0.50 0.87

Heating capacity *2

(Nominal)

Btu/h 27,000 34,000 40,000

kW 7.9 10.0 11.7

Power input kW 0.04 0.04 0.08

Current input A 0.40 0.43 0.80

External nish Galvanized steel sheet

External dimension H x W x D

in. 11-3/4 x 33-3/32 x 33-3/32

mm 298 x 840 x 840

Net weight lbs (kg) 60 (27)

Decoration

panel

Model PLP-40BAU

External nish Munsell No. (6.4Y 8.9/0.4)

Dimension

H x W x D

in. 1-3/8 x 37-13/32 x 37-13/32

mm 35 x 950 x 950

Net Weight lbs (kg) 13 (6)

Heat exchanger Cross n

Fan

Type x Quantity Turbo fan x 1

External

static pressure

in.WG 0.000 (208V)

Pa 0

in.WG 0.000 (230V)

Pa 0

Motor type DC motor

Driving mechanism Direct-driven

Airow rate

(Low-Mid2-Mid1-High)

CFM 565 - 636 - 706 - 777 565 - 636 - 742 - 812 777 - 883 - 989 - 1,059

m3 / min 16.0 - 18.0 - 20.0 - 22.0 16.0 - 18.0 - 21.0 - 23.0 22.0 - 25.0 - 28.0 - 30.0

L / s 267 - 300 - 333 - 367 267 - 300 - 350 - 384 367 - 417 - 467 - 500

Sound pressure level (Low-Mid2-Mid1-High)

(measured in anechoic room)

dB <A> 28 - 31 - 34 - 37(208-230V) 28 - 32 - 35 - 37(208-230V) 35 - 38 - 41 - 43(208-230V)

Insulation material PS

Air lter PP honeycomb (long life lter, anti-bacterial type)

Protection device Fuse

Refrigerant control device LEV

Connectable outdoor unit R410A CITY MULTI

Diameter of

refrigerant pipe

(O.D.)

Liquid (R410A) in. (mm) 3/8 (9.52) Flare

Gas (R410A) in. (mm) 5/8 (15.88) Flare

Field drain pipe size in. (mm) O.D. 1-1/4(32)

Drain lift mechanism in. (mm) 33-7/16 (850)

Standard

attachment

Document

Accessory

Installation Manual, Instruction Book

Optional parts

External heater adapter CN24RELAY-KIT-CM3

Air outlet shutter plate PAC-SH51SP-E

High efciency lter element (MERV 10) PAC-SH59KF-E

Multi-function casement PAC-SH53TM-E

i-see sensor corner panel PAC-SA1ME-E

Flange for fresh air intake PAC-SH65OF-E

Wireless signal receiver PAR-SA9FA-E

Remark

Installation

Details on foundation work, duct work, insulation work, electrical wiring, power source switch,

and other items shall be referred to the Installation Manual.

Ventilation Air: Providing sufcient ventilation air is an important part of every building design.

ASHRAE standard 62 provides the minimum ventilation air requirements. Also check local codes.

1. SPECIFICATIONS

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B. / 67degF W.B.

(26.7degC D.B. / 19.4degC W.B.)

70degF D.B. (21.1degC D.B.)

kcal/h = kW x 860

BTU/h = kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B. / 43degF W.B.

(8.3degC D.B. / 6.1degC W.B.)

cfm = m3/min x 35.31

lbs = kg / 0.4536

Pipe length: 25 ft. (7.6 m) 25 ft. (7.6 m)

*Above specication data is subject to

rounding variation.

Level difference: 0 ft. (0 m) 0 ft. (0 m)

*Due to continuing improvement, above specication may be subject to change without notice.

PLFY-P24NBMU-E2, PLFY-P30NBMU-E2, PLFY-P36NBMU-E2

PLFY-6

PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

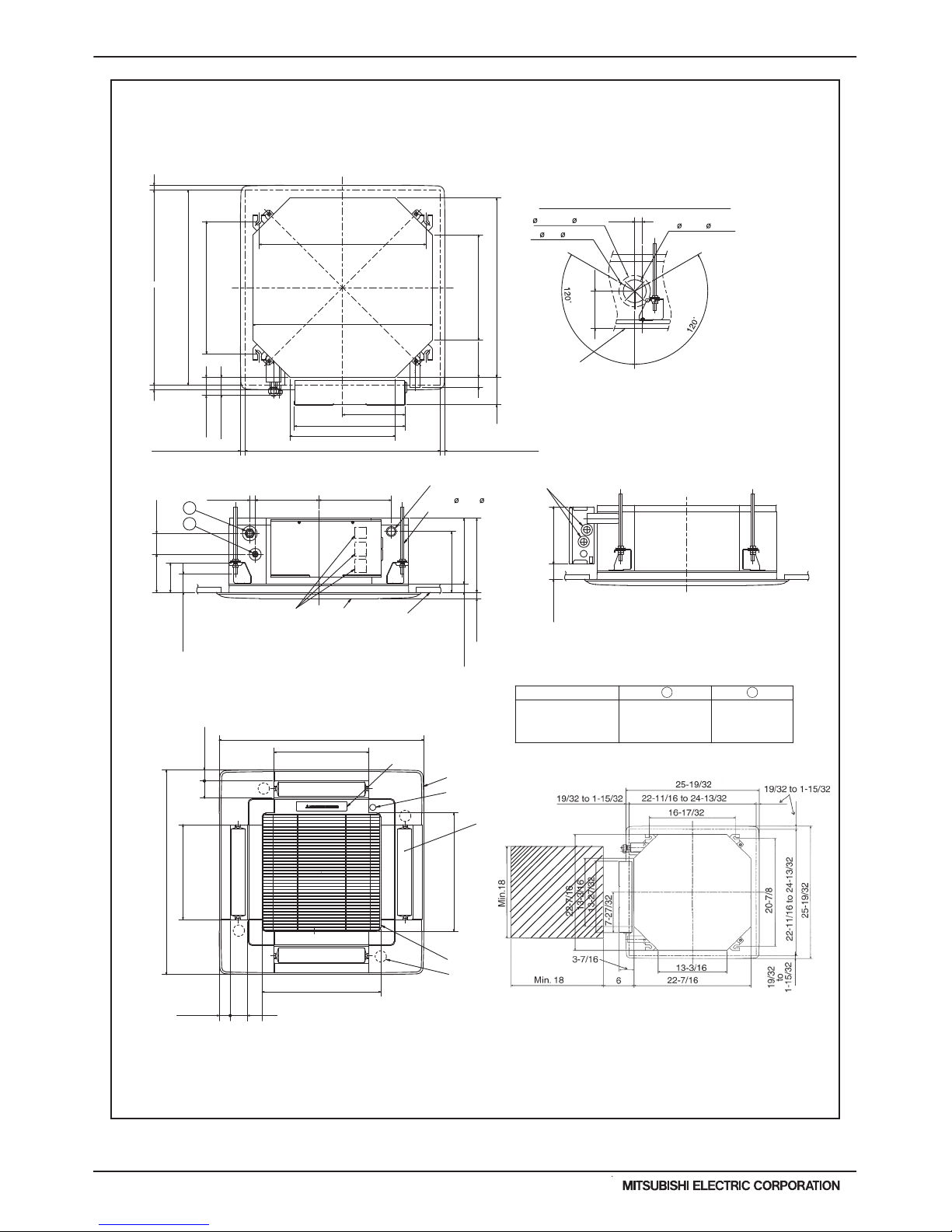

PLFY-P08,12,15 NCMU-ER4

PLFY-P15NCMU-ER4

PLFY-P12NCMU-ER4

PLFY-P08NCMU-ER4

Brand label

(1/2 (12.7) dia.)

1/2

flared connection

Refrigerant pipe

flared connection

1/4

Refrigerant pipe

(1/4 (6.35) dia.)

V/M

V/M

V/M

V/M

1

Detail drawing of fresh air intake

Ceiling surface

Cut out hole

2-7/8( 73.4)

Burring hole

3- 1/8( 2.8)

3-15/16( 100)

4-21/32(118)

1(25)

Unit : in.(mm)

19/32~1-15/32(15~37) 19/32~1-15/32(15~37)

22-11/16~24-13/32(576~620)

22-7/16(570)

20-7/8(530)

1

2

2

Grille

Fresh air intake

Drain pipe

VP-25 connection

(O.D. 1-1/4( 32))

Vane motor

Drain hole

Models

Air intake grille

2-5/32(55)

1-3/8(35)

1-3/8(35)

2-5/32(55)

Auto vane

Grille

Air intake hole

Air intake hole

Air outlet hole

Air outlet hole

11-27/32(301)

11-27/32(301)

14-27/32(377)

14-27/32(377)

25-19/32(650)

Suspension bolt M10 or W3/8

Suspension bolt lower edge

9-1/16(230)

7-5/32(182)1-7/8(48)

Wiring entry

Terminal block

Ceiling surface

9-1/4(235)

8-3/16(208)

7-19/32(193)

25/32(20)

3-21/32(93)

1-1/2~2-9/32(38~58)

2-19/32(66)

4-3/4(121)

7-15/16(202)

2-7/32(56)

2-1/14(57)

3-7/16(87)

1-7/32(31)

Ceiling hole

Suspension bolt pitch

19/32~1-15/32(15~37)

19/32~1-15/32(15~37)

22-11/16~24-13/32(576~620)

16-17/32(420)

22-7/16(570)

13-3/16(335)

7-27/32(199)

13-27/32(352)

13-3/16(335)

Suspension bolt pitch

Ceiling hole

25-19/32(650)

Ref. : PLFY-NCMU-E_EXD_USDB_P08-15

Unit : in.(mm)

1-1/16

+3/16

0

(

+5

)

0

2. EXTERNAL DIMENSIONS

Service Access Required

PLFY-7PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

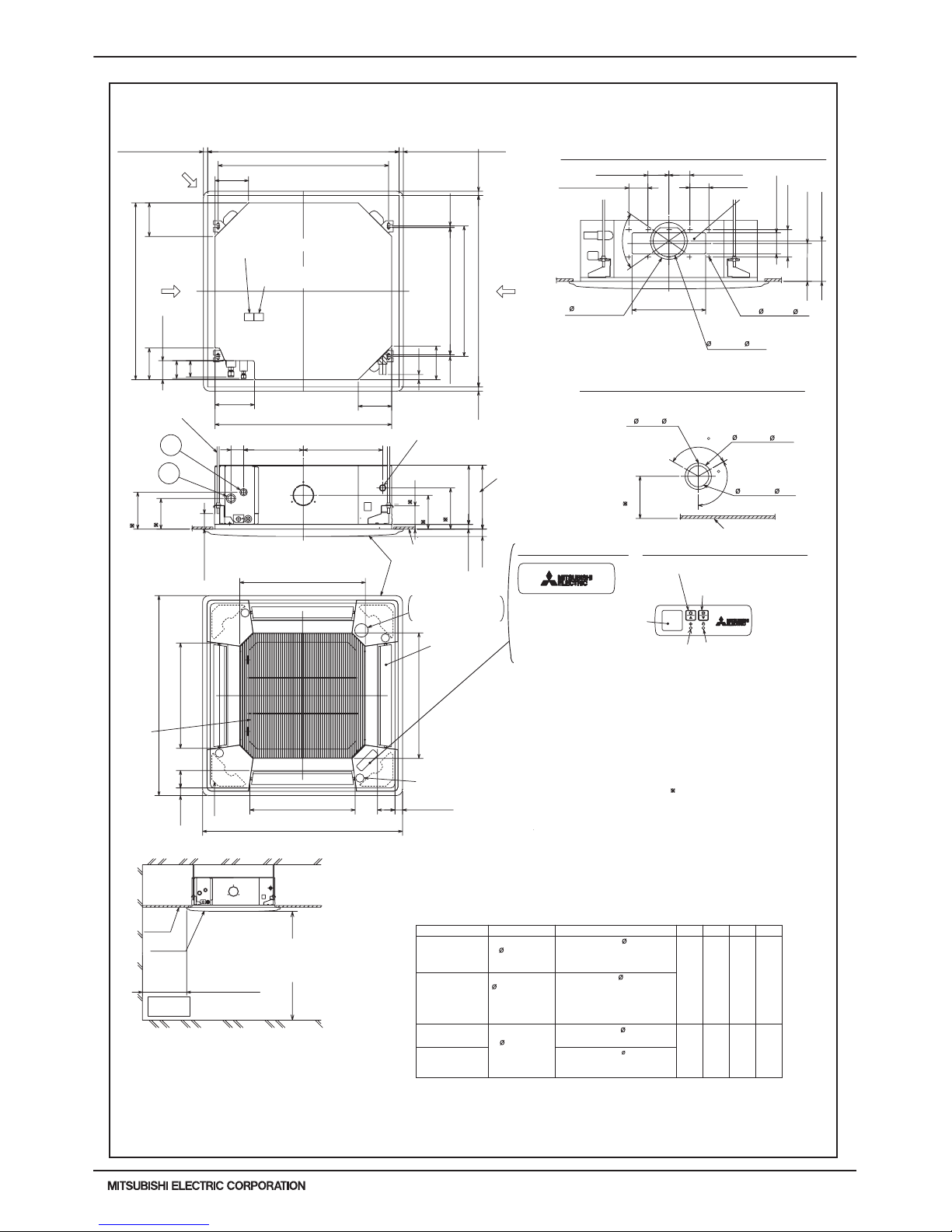

PLFY-P08, 12, 15, 18, 24, 30, 36 NBMU-E2

Unit : in. (mm)

14-27/3211-3/16

2-3/8

+5

0

+35

-5

(187.5)

(160)

(160)

(7.5)

(950)

(500)

Keep 25/64(10) to 19/32(15)

between unit ceiling

and ceiling slab.

Grille

Indoor unit

Ceiling

Floor

Min.94-1/2(2400)

from floor

Min.19-11/16(500)

Entire

periphery

(36)

(83)

(36)

(83)

(500)

(950)

(597)

(597)

( 158)

( 175)

(350)

(130)

(100)

(90)

(100)

(90)

(100)

(77)

3-1/32

(85)

3-11/32

(298)

11-3/4

11-1/16

(281)

(74)(80)(258)(241)

2-29/32

3-5/32

10-3/16

PLFY-P36NBMU-E2

PLFY-P24NBMU-E2

PLFY-P30NBMU-E2

(35)

(17 )

+3/16

0

(190)

(156)

(50~70)

(140)

(170)

(377)

(284)

(60)

(24)

(840)

(160)

(20~45)

to 1-25/32

(620)

(605 )

-3/16

+1-3/8

(90)

(150)

(160)

(7.5)

(20~45)

1-25/32

Corner pocket

In case of wireless remote controller

In case of standard grille

9-1/2

Drain hole

Drain pump clean hole

and Drain emergency

drainage hole

For MA-Remote controller

terminal block

Emergency operation switch<Cooling>

Emergency operation

switch<Heating>

Ceiling

Cut out hole

Burring hole pitch

3- 1/8(3- 2.8)

Burring hole

Detail drawing of fresh air intake hole

Burring hole

14- 1/8(14- 2.8)

Cut out hole

Burring hole pitch

Cut out hole

Detail connecting of branch duct(Both aspects)

Refrigerant pipe 15.88

Flared connection 5/8

(compatible)

DCBA

Refrigerant pipe 12.7

Flared connection 1/2

(compatible)

Refrigerant pipe

...

15.88

Flared connection

...

5/8

Refrigerant pipe

...

12.7

Flared connection

...

1/2

Refrigerant pipe

...

6.35

Flared connection

...

1/4

Refrigerant pipe

6.35

Flared connection

1/4

(compatible)

PLFY-P18NBMU-E2

Refrigerant pipe

...

9.52

Flared connection

...

3/8

Models

PLFY-P08NBMU-E2

PLFY-P12NBMU-E2

PLFY-P15NBMU-E2

Suspension bolt

lower edge

Vane motor

Air intake

grille

Air outlet hole

Air outlet hole

Auto vane

(Air outlet)

Air intake hole

Air intake hole

Grille

Ceiling

)(

Connected the attached

flexible pipe or socket.

I.D.1(26)

Integrated lift pump outlet

PVC pipe O.D.1(26)

Suspension bolt

M10 or W3/8

Branch duct hole

Fresh air

intake hole

Branch

duct hole

Ceiling hole

Suspension bolt pitch

Suspension bolt pitch

Ceiling hole

(5/16)(5/16)

23-13/16

24-13/32

DEFROST/STAND BY lamp

Receiver

Operation lamp

6-5/16

6-16/5

1

2

3-15/16

5-1/8

13-25/32

3-17/32

3-15/16

3-15/16

3-17/32

70

*6-9/16(167)

*6-3/32(155)

5-29/32( 150)

6-7/8

19-11/16

19-11/16

23-1/2

M

M

M

M

3-17/64

1-27/64

37-3/8

3-17/64

1-27/64

37-3/8

23-1/2

1-31/32 to 2-3/4

5-1/2

6-11/16

1-3/8

11/16

4-1/8(105)

6-9/64

7-15/32

A

B

6-5/16

33-1/16(840)

5-29/32

3-17/32

C

D

33-1/16

7-3/8

25/32~1-25/32(20~45)

33-27/32 to 35-13/16(860~910) 25/32 to 1-25/32(20~45)

31-7/8(810)

25/32 to

33-27/32 to 35-13/16(860~910)25/32

15/16

6-5/16

Indoor unit/Outdoor unit

connecting terminal block

4-29/32( 125)

3-15/16( 100)

6-7/32

120

120

12

Note:

1. As for drain pipe, please use VP-25 O.D. 1-1/4(32) PVC TUBE.

Drain pump is included.

Max. lifting height is 33-7/16 (850mm) from the ceiling.

2. As for suspension bolt, please use M10 or W3/8. (Procured at local site)

3. Electrical box may be removed for the service purpose.

Make sure to slack the electrical wire little bit for control/power wires connection.

4. The height of the indoor unit is able to be adjusted with the grille attached.

5. For the installation of the optional high efficiency filter or optional multi-functional

casement.

1 Add 5-5/16"(135mm) to the dimensions marked on the figure.

2 The optional high efficiency filter becomes optional multi-functional casement

and concomitant use.

6. When installing the branch ducts, be sure to insulate adequately.

Otherwise condensation and dripping may occur.

(It becomes the cause of dew drops/water dew.)

As for necessary installation / service space, please refer to the left figure.

Accessory∙∙∙Drain socket(I.D.1-1/4(32) )

Flare nut 3/8 (For P18)

Flare nut 5/8 (For P18)

Flare nut 3/4 (For P36)

2. EXTERNAL DIMENSIONS

PLFY-8

PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

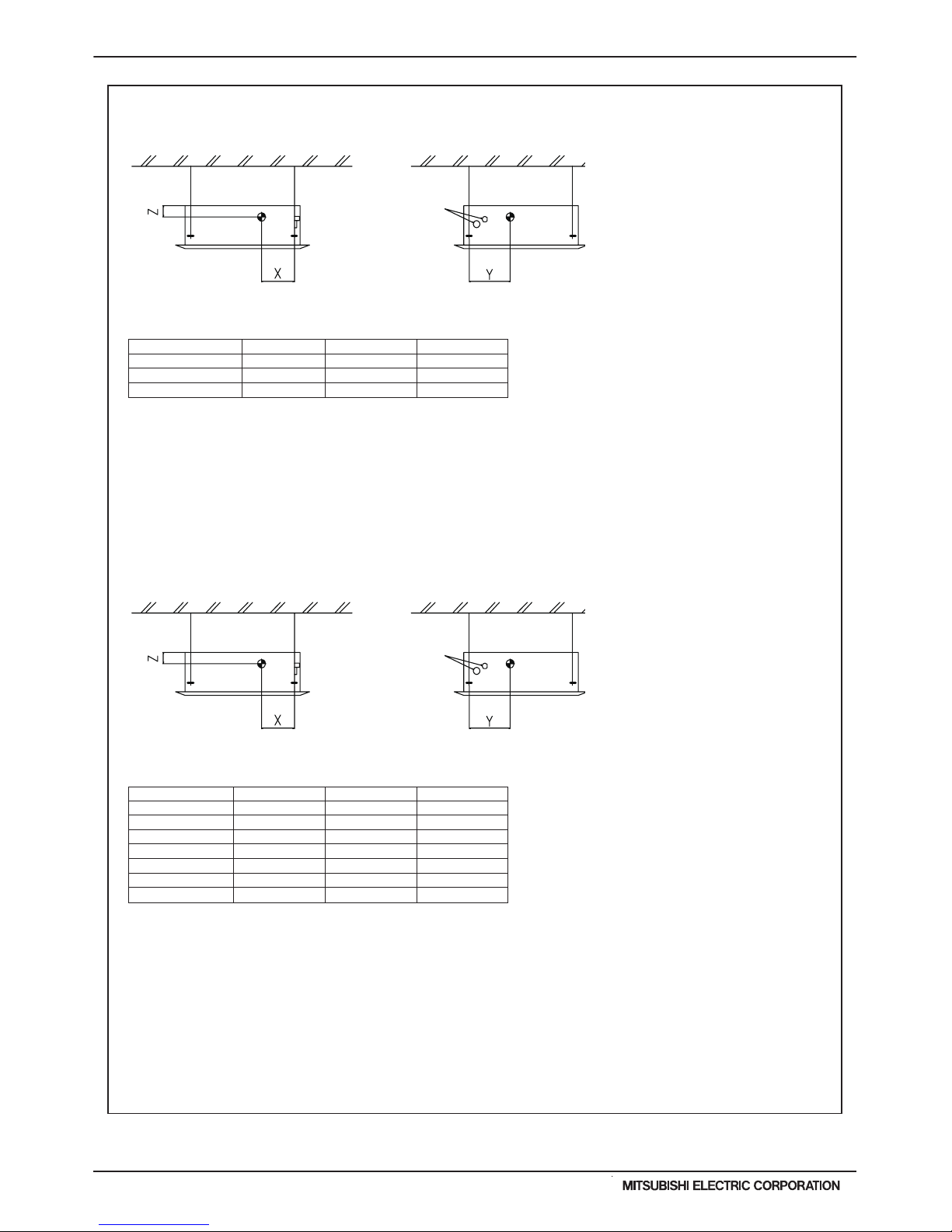

3. CENTER OF GRAVITY

PLFY-P08, 12, 15NCMU-E

PLFY-P08, 12, 15, 18, 24, 30, 36NBMU-E2

150 [5-29/32] 260 [10-1/4] 105 [4-5/32]

150 [5-29/32] 260 [10-1/4] 105 [4-5/32]

150 [5-29/32] 260 [10-1/4] 105 [4-5/32]

PLFY-P08NCMU-E

PLFY-P12NCMU-E

PLFY-P15NCMU-E

XY Z

(mm)[in]

Model name

280 [11-1/32] 400 [15-3/4] 105 [4-5/32]

280 [11-1/32] 400 [15-3/4]

105 [4-5/32]

280 [11-1/32]

280 [11-1/32]

280 [11-1/32]

280 [11-1/32]

400 [15-3/4]

400 [15-3/4]

400 [15-3/4]

400 [15-3/4]

105 [4-5/32]

125 [4-15/16]

125 [4-15/16]

125 [4-15/16]

PLFY-P12NBMU-E2

280 [11-1/32] 400 [15-3/4] 105 [4-5/32]PLFY-P08NBMU-E2

PLFY-P15NBMU-E2

PLFY-P18NBMU-E2

PLFY-P24NBMU-E2

PLFY-P30NBMU-E2

PLFY-P36NBMU-E2

XY Z

(mm)[in]

Model name

Refrigerant pipe side

Refrigerant pipe

Refrigerant pipe side

Refrigerant pipe

Refrigerant pipe side

Refrigerant pipe

PLFY-P08,12,15NCMU-ER4

Ref.: PLFY_NCMU_COG_USDB_ALL

150 [5-29/32] 260 [10-1/4] 105 [4-5/32]

150 [5-29/32] 260 [10-1/4] 105 [4-5/32]

150 [5-29/32] 260 [10-1/4] 105 [4-5/32]

PLFY-P08NCMU-ER4

PLFY-P12NCMU-ER4

PLFY-P15NCMU-ER4

XY Z

(mm)[in]

Model name

Refrigerant pipe side

Refrigerant pipe

PLFY-9PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

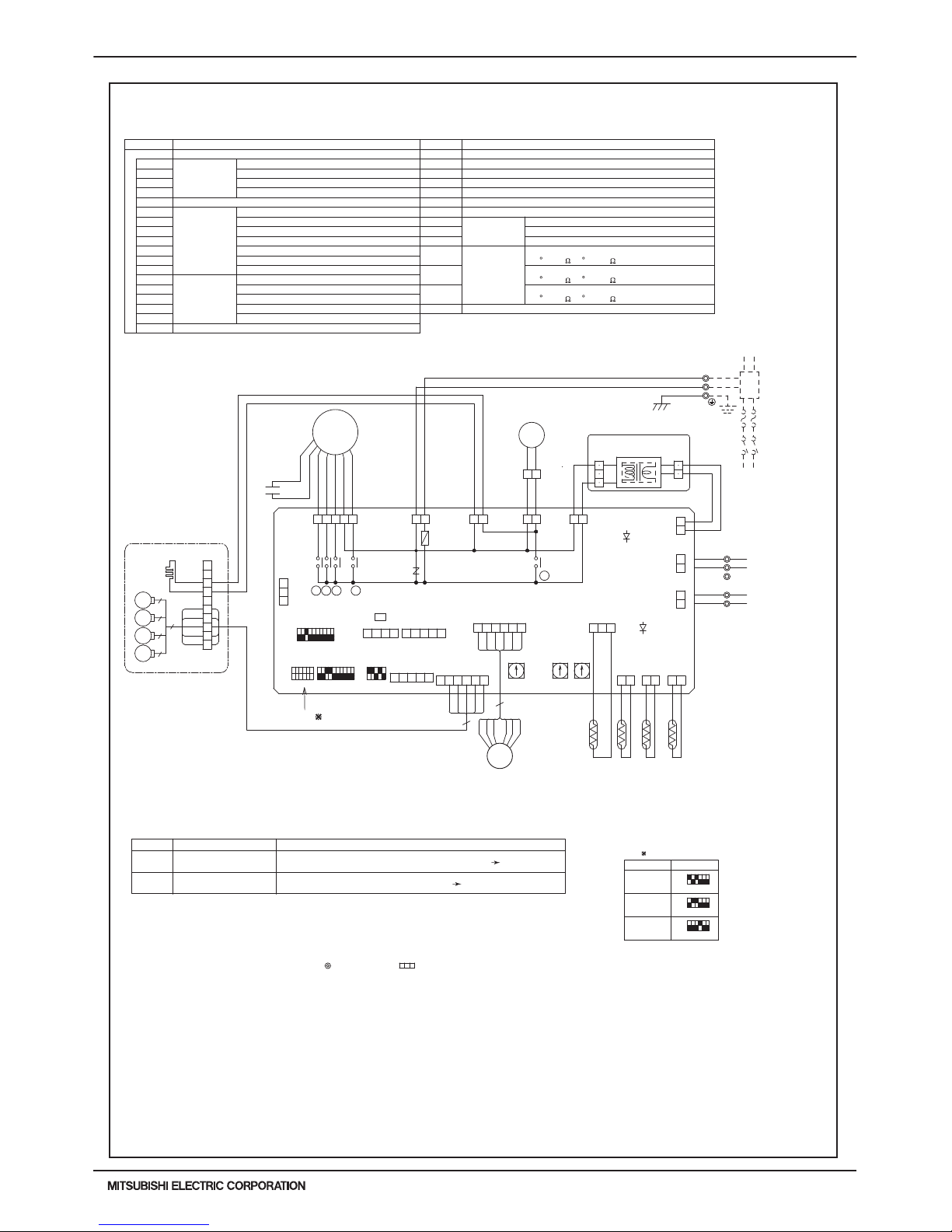

© 2015 Mitsubishi Electric US, Inc.

Ref. : PLFY-NCMU-E_EWD_USDB_P08-15

PLFY-P08,12,15 NCMU-ER4

DP

WHT

(DRAIN)

WHT

FAN

(FAN)

See fig: 1

MODELS

P08

P12

P15

<fig: 1>

ON

OFF

12 34 56

ON

OFF

12 34 56

ON

OFF

12 34 56

SW2

Power supply for MA-Remote controller on Lamp is lit.

Main power supply(Indoor unit:208-230V) power on Lamp is lit.Main power supply

LED2

LED1

Mark Meaning

LED on indoor controller board for service

Function

CN32

(REMOTE SWITCH)

WHT

3 2 1

DC24-30V

CONTROLLER

TO NEXT INDOOR UNIT

PULL BOX

FUSE(15A)

BREAKER

(15A)

60Hz

HA

1234

WHT

CN41

CN51

WHT

(CENTRALLY

CONTROL)

5 4 3 2 1

CN52

(REMOTE

INDICATION)

GRN

12345

REMOTE SWITCHCN32

X7 FAN MOTOR (Me)

X6 FAN MOTOR (Hi)

X5 FAN MOTOR (Lo)

SW1 SWITCH MODE SELECTION

CONNECTION No.SW14

SW12

SW11 ADDRESS SETTING 1ST DIGIT

ADDRESS SETTING 2ND DIGIT

MODEL SELECTION

MODE SELECTION

CAPACITY CODE

SW4

SW3

SW2

(32 F/15k 77 F/5.4k )

(32 F/15k 77 F/5.4k )

DP

DRAIN PUMP

DS

DRAIN SENSOR

H2

DEW PREVENTION HEATER

FAN MOTOR (LL)

DRAIN PUMP/DEW PREVENTION HEATERX1 AUX. RELAY

SYMBOL NAME

VARISTOR

INDOOR POWER BOARD

P.B

ZNR

X4

I.B

CN41

CN51

CN52

FUSE FUSE (6.3A/250V)

REMOTE INDICATION

CENTRALLY CONTROL

HA TERMINAL-A

CONNECTOR

INDOOR CONTROLLER BOARD

[LEGEND]

NAMESYMBOL

PIPE TEMPERATURE DETECTION/GAS

TH23

TRANSMISSION

TERMINAL

BLOCK

POWER SUPPLY

TB5

TB15

TB2

(32 F/15k 77 F/5.4k )

THERMISTOR ROOM TEMPERATURE DETECTION

TH22

TH21

LEV

LINEAR EXPANSION VALVE

MV

MF

VANE MOTOR

FAN MOTOR (WITH THERMAL FUSE)

CAPACITOR (FAN MOTOR)

C1

PIPE TEMPERATURE DETECTION/LIQUID

MA-REMOTE CONTROLLER

LED2

LED1

31 1 3

CND

(POWER)

YLW

21

YLW

1 3

BLU

(D+U+M)

CNC

(D+HEATER)

RED

ORN

FUSE

ZNR

CNP

X1

RED

ORN

GRILLE

BLU

5

WHT

BLU

RED

ORN

YLW

RED

RED

1

10

7

2

3

6

4

5

8

9

3

5

5

5

5

C1

1 5

BLK

YLW

WHT

BRN

7 9

X6 X5 X4 X7

X4X7X5X6

MF

I.B

CN20

CN31

123

BLU

WHT

ORN

RED

YLW

6

6 5 4 3 2 1

(VANE)

CN6V

GRN

RED

ORN

BLU

6 5 4 3 2 1

(LEV)

CN60

WHT

WHT

YLW

BRN

BLK

2 2 11

(LIQUID)

(INTAKE)

CN21

RED WHT

2 1

(GAS)

CN29

(REMOCON)

WHT

13

RED

P.B

RED

CNDK

(POWER

BORD)

1

2

3

AC208-230V

CNSK(RED)

TB2

L1

L2

GR

RED

BLU

GRN/YLW

~/N 208-230V

POWER SUPPLY

TRANS

DC13.1V

CN2S(WHT)

2

1

2 1

(POWER

BORD)

CN2D

WHT

WHT

BLK

M1

1

2

CONTROLLER

DC8.7-13V

TO MA-REMOTE

CN2M

(M-NET)

123 1

CN3A

BLU

BLU

M2

TB15

S(SHIELD)

M-NET REMOTE

TO OUTDOOR UNIT

BC CONTROLLER

TB5

X1

TH23

TH22

TH21DS

LEV

5

3RD

DIGIT

0

O

0

0N

0FF

SW1

1 2 3 4 5 6 7 8 9 10

SW12

SW11

1ST

DIGIT

0

2ND

DIGIT

SW14

CONNECTION

No.

1 2 3 4 5

0FF

0N

SW4

SW2

654321 10987654321

0FF

0N

SW3

MV

H2

MV

MV

MV

Notes:

2.In case of using MA-Remote controller, please connect to TB15. (Remote controller wire is non-polar.)

3.In case of using M-NET, please connect to TB5. (Transmisson line is non-polar.)

4.Symbol[S] of TB5 is the shield wire connection.

5.Symbols used in wiring diagram above are, :terminal block, :connecter.

7.Use copper supply wire.

6.The setting of the SW2 dip switches differs in the capacity for the detail, refer to the fig:1.

1.At servicing for outdoor unit, always follow the wiring diagram of outdoor unit.

Power supply for

MA-Remote controller

4. ELECTRICAL WIRING DIAGRAMS

PLFY-10

PLFY-P-NCMU-ER4, -NBMU-E2 (November 2015)

© 2015 Mitsubishi Electric US, Inc.

PLFY-P08, 12, 15, 18, 24, 30, 36NBMU-E2

NOTES:

1. At servicing for outdoor unit, always follow the wiring diagram of outdoor unit.

2. In case of using MA-Remote controller, please connect to TB15. (Remote controller wire is non-polar.)

3. In case of using M-NET, please connect to TB5. (Transmission line is non-polar.)

4. Symbol [S] of TB5 is the shield wire connection.

5. Symbols used in wiring diagram above are, : terminal block, : connecter.

6. The setting of the SW2 dip switches differs in the capacity. For the detail, refer to fig <*1>.

CN27

CN32

CN51

CN52

SW2

SW3

SW4

SWE

FUSE

X1

LED1

LED2

MF

MV

DP

FS

TB2

TB5

TB15

TH21

TH22

TH23

LEV

SW1

SW11

SW12

SW14

SWA

SWB

SWC

W.B

RU

BZ

LED1

LED2

SW1

SW2

POWER SUPPLY

TRANSMISSION

MA-REMOTE CONTROLLER

ROOM TEMP. DETECTION

PIPE TEMP. DETECTION / LIQUID

PIPE TEMP. DETECTION / GAS

FAN MOTOR

VANE MOTOR

DRAIN PUMP

DRAIN FLOAT SWITCH

TERMINAL

BLOCK

THERMISTOR

LINEAR EXPANSION VALVE

I. B

Mark

LED1

Main power supply

Power supply for

MA-Remote controller

Main Power supply (Indoor unit:208-230V)

power on → lamp is lit

Power supply for MA-Remote controller

on → lamp is lit

LED2

Meaning Function

INDOOR CONTROLLER BOARD

CONNECTOR

DAMPER

EXTERNAL HEATER

REMOTE SWITCH

CENTRALLY CONTROL

REMOTE INDICATION

CAPACITY CODE

MODE SELECTION

MODEL SELECTION

DRAIN PUMP (TEST MODE)

SWITCH

FUSE (T6.3AL250V)

AUX. RELAY

POWER SUPPLY (I. B)

POWER SUPPLY (I. B)

DRAIN PUMP

SYMBOL

A. B

OPTION PART

ADDRESS BOARD

SWITCH

MODE SELECTION

ADDRESS SETTING 1s DIGIT

ADDRESS SETTING 10ths DIGIT

BRANCH NO.

CEILING HEIGHT SELECTOR

DISCHARGE OUTLET NUMBER

SELECTOR

OPTION SELECTOR

PCB FOR WIRELESS REMOTE CONTROLLER

RECEVING UNIT

BUZZER

LED (OPERATION INDICATION : GREEN)

LED (PREPARATION FOR HEATING : ORANGE)

EMERGENCY OPERATION (HEAT / DOWN)

EMERGENCY OPERATION (COOL / UP)

SYMBOLNAME NAME

LED on indoor board for service

CN24

SYMBOL NAME

MT

I-SEE SENSOR MOTOR

CN105

IT TERMINAL

(32°F/15kΩ, 77°F/5.4kΩ)

(32°F/15kΩ, 77°F/5.4kΩ)

(32°F/15kΩ, 77°F/5.4kΩ)

19

*Be sure to turn off the source power

and then disconnect fan motor connector.

(Failure to do so will cause trouble in Fan motor)

A.B

(RED)

ADDRESS

CN43

ADDRESS

CN81

(RED)

LED2

ADDRESS

CN42

(RED)

(RED)

ADDRESS

CN82

VANE

CNV

(WHT)

SWBSWA

SW1

MV MV MV MV

CN32

(WHT)

SW3 SW4

SWE

SW2

ON

OFF

ON

OFF

ON

OFF

ONOFF

9

6

54

8

5555

4

3

2

1

12345678910

12345612345

GRILLE

2

3

4

See fig: *1

*2

M-NET

CN2M

(BLU)

CND

(BLK)

CNAC

(WHT)

D.U.M

CNP

(BLU)

FAN

CNMF

(WHT)

INTAKE

CN20

(RED)

CN25

(WHT)

FLOAT SW

CN4F

(WHT)

WIRELESS

CN90

(WHT)

LEV

CN60

(WHT)

WHT

YLW

ORN

BLU

RED

BRN

MA REMOCON

CN3A

(BLU)

I-SEE SENSOR

CN4Y

(WHT)

I-SEE SENSOR MOTOR

CN6Y

(RED)

LIQUID/GAS

CN44

(WHT)

CN41

(WHT)

CN51

(WHT)

CN52

(GRN)

CN3G

(BLK)

TH21TH23TH22 FS

CN27

(RED)

LED1

X1

FUSE

TB5

(SHIELD)

TB2

RED

BLU

GRN/YLW

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

24-30V DC

TO NEXT

INDOOR UNIT

PULL BOX

FUSE(16A)

BREAKER

(16A)

POWER SUPPLY

~/N 208-230V 60Hz

I.B

DC311~339V

RECTIFICATION

BZ

LEV

MT

LED2

SW1

CNB

TO MA-REMOTE

CONTROLLER

8.7-13V DC

I-SEE SENSOR CORNER PANEL

(OPTION PART)

(OPTION PART)

I-SEE

SENSOR

TB15

SW2

LED1

RU

W.B

Pair No.

J42 J41

2

2

14

1

2

1

4

1

8

1515

16

M

M

14

16

13

13

12345678910111213141516171819

20

ON

OFF

1 23456

ON

OFF

1 23456

ON

OFF

1 23456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

P12

MODELS MODELS

<*1>

SW2 SW2

P15

P18

P24

P30

P36

ON

OFF

1 23456

P08

t° t°

14

14

21

CN24

(YLW)

21

31

2121

74

1

1313

3~

MF

MS

M

1~

21

135

L1

L2

GR

M1

M2

S

M M M M

1418

CN105

(RED)

15

DP

is the switch position.

t°

12345678910

*2. Use copper supply wires.

*2. Utilisez des fils d’alimentation en cuivre.

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10ths

DIGIT

1s

DIGIT

BRANCH

No.

SWC

SW12 SW11

SW14

2

1

4. ELECTRICAL WIRING DIAGRAMS

Loading...

Loading...