Mitsubishi PLFY-P12NBMU-E, PLFY-P15NBMU-E, PLFY-P24NBMU-E, PLFY-P30NBMU-E, PLFY-P36NBMU-E Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

R410A / R22

Indoor unit

[Model names] [Service Ref.]

PLFY-P12NBMU-E

PLFY-P15NBMU-E

PLFY-P18NBMU-E

PLFY-P24NBMU-E

PLFY-P30NBMU-E

PLFY-P36NBMU-E

PLFY-P12NBMU-E PLFY-P12NBMU-ER1

PLFY-P12NBMU-ER2

PLFY-P15NBMU-E PLFY-P15NBMU-ER1

PLFY-P15NBMU-ER2

PLFY-P18NBMU-E PLFY-P18NBMU-ER1

PLFY-P18NBMU-ER2

PLFY-P24NBMU-E PLFY-P24NBMU-ER1

PLFY-P24NBMU-ER2

PLFY-P30NBMU-E PLFY-P30NBMU-ER1

PLFY-P30NBMU-ER2

PLFY-P36NBMU-E PLFY-P36NBMU-ER1

PLFY-P36NBMU-ER2

April 2012

No. OCH421

REVISED EDITION-B

Revision:

• PLFY-P12/15/18/24/30/36

NBMU-ER2 have been

added in REVISED

EDITION-B.

• Some descriptions have

been modified.

• Please void OCH421

REVISED EDNTION-A.

Note:

•

This manual does not

cover outdoor units.

When servicing them,

please refer to the outdoor

unit’s service manual.

• RoHS compliant products

have <G> mark on the

spec name plate.

Model name

indication

INDOOR UNIT

CONTENTS

1. TECHNICAL CHANGES

2. FEATURES

3. PART NAMES AND FUNCTIONS

4. SPECIFICATIONS

5. 4-WAY AIR FLOW SYSTEM

6. OUTLINES AND DIMENSIONS

7. WIRING DIAGRAM

REFRIGERANT SYSTEM DIAGRAM

8.

9. MICROPROCESSOR CONTROL

10. TROUBLESHOOTING

11. DISASSEMBLY PROCEDURE

.............................................

.........................

...................................

.................

...............................

.........................

PARTS CATALOG (OCB421)

..........

............

......

.........

.............

2

3

4

6

10

13

14

16

17

24

33

Use the specifi ed refrigerant only

OCH421B

Never use any refrigerant other than that specifi ed.

Doing so may cause a burst, an explosion, or fi re when the unit is being used, serviced, or disposed of.

Correct refrigerant is specifi ed in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

1

PLFY-P12NBMU-ER1 PLFY-P12NBMU-ER2

PLFY-P15NBMU-ER1 PLFY-P15NBMU-ER2

PLFY-P18NBMU-ER1 PLFY-P18NBMU-ER2

PKFY-P24NBMU-ER1 PLFY-P24NBMU-ER2

PKFY-P30NBMU-ER1 PLFY-P30NBMU-ER2

PKFY-P36NBMU-ER1 PLFY-P36NBMU-ER2

INDOOR CONTROLLER BOARD (I.B.) has been changed (S/W version up).

PLFY-P12NBMU-E PLFY-P12NBMU-ER1

PLFY-P15NBMU-E PLFY-P15NBMU-ER1

PLFY-P18NBMU-E PLFY-P18NBMU-ER1

PKFY-P24NBMU-E PLFY-P24NBMU-ER1

PKFY-P30NBMU-E PLFY-P30NBMU-ER1

PKFY-P36NBMU-E PLFY-P36NBMU-ER1

INDOOR CONTROLLER BOARD (I.B.) has been changed.

TECHNICAL CHANGES

2

2

OCH421B

FEATURES

Models

Cooling capacity / Heating capacity

PLFY-P12NBMU-E 12,000 / 13,500 Btu/h

PLFY-P15NBMU-E 15,000 / 17,000 Btu/h

PLFY-P18NBMU-E 18,000 / 20,000 Btu/h

PLFY-P24NBMU-E 24,000 / 27,000 Btu/h

PLFY-P30NBMU-E 30,000 / 34,000 Btu/h

PLFY-P36NBMU-E 36,000 / 40,000 Btu/h

Indoor Unit

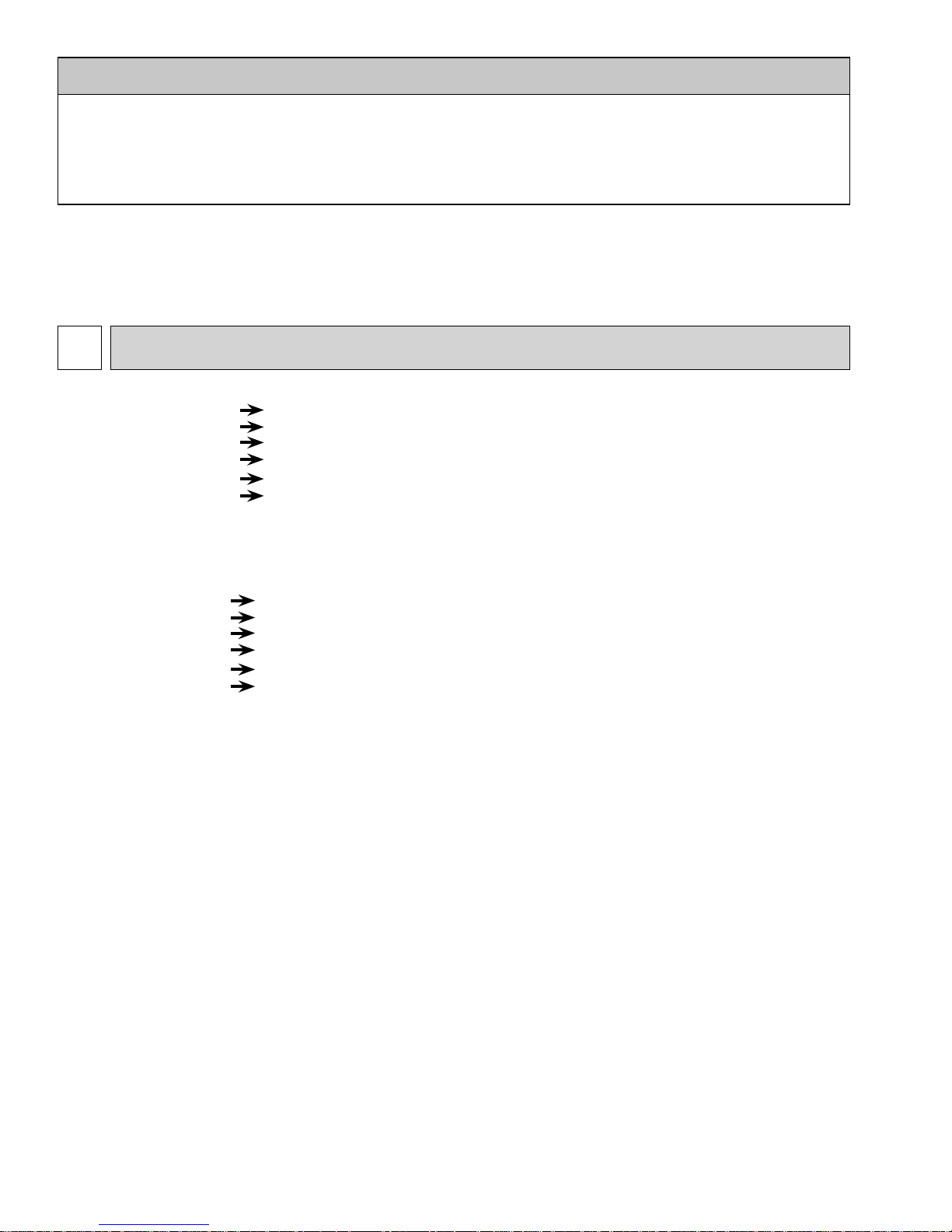

1. WIDE AIRFLOW

The new wide shape vane capable of wide angle air supply provides comfort even at the corners of a room regardless

of cooling and heating operation. A reduction in the air speed by 20% compared to the conventional product eliminates

uncomfortable draft sensation for friendly air conditioning.

2. WAVE AIRFLOW SYSTEM (HEATING MODE)

The wave airflow system has 4 vanes where each vane runs independently. Repeating of horizontal and down blows with a

time lag allows the conditioned warm air to be distributed even to room corners thus preventing uneven room temperature

distribution.

Operation image of "Wave Airflow"

3. AUTOMATIC AIR SPEED ADJUSTMENT MODE

The automatic air speed adjustment mode is provided in addition to the 4 air speed stages of "High/Medium 1/Medium 2/

Low." Air speed can be changed freely in accordance with a difference between the set temperature and the room temperature. The automatic air speed adjustment mode presents quick cooling of a room with the high mode, such as at the starting up of cooling operation, for example. After the room temperature is stabilized, the low mode will be applied by automatic

switching to keep your comfort.

Medium 2

Medium 1

HighLow

Automatic air

speed adjustment

4. i-see Sensor (OPTIONAL CORNER PANEL)

The i see sensor is a radiation temperature sensor originated from Mitsubishi’s new technology. In order to create a really

comfortable space in shops and offices, it is essential to control the temperature near the floor where occupants/visitors

gather. The i see sensor measures the infrared rays generated from the surrounding wall and floor surface at an angle of

360° and the infrared ray energy is computed to convert it into the value of temperature. In addition, the floor temperature

at distant spots (radiation temperature) is also measured to supply the optimum airflow to realize comfort which was never

experienced in the past.

3

3

OCH421B

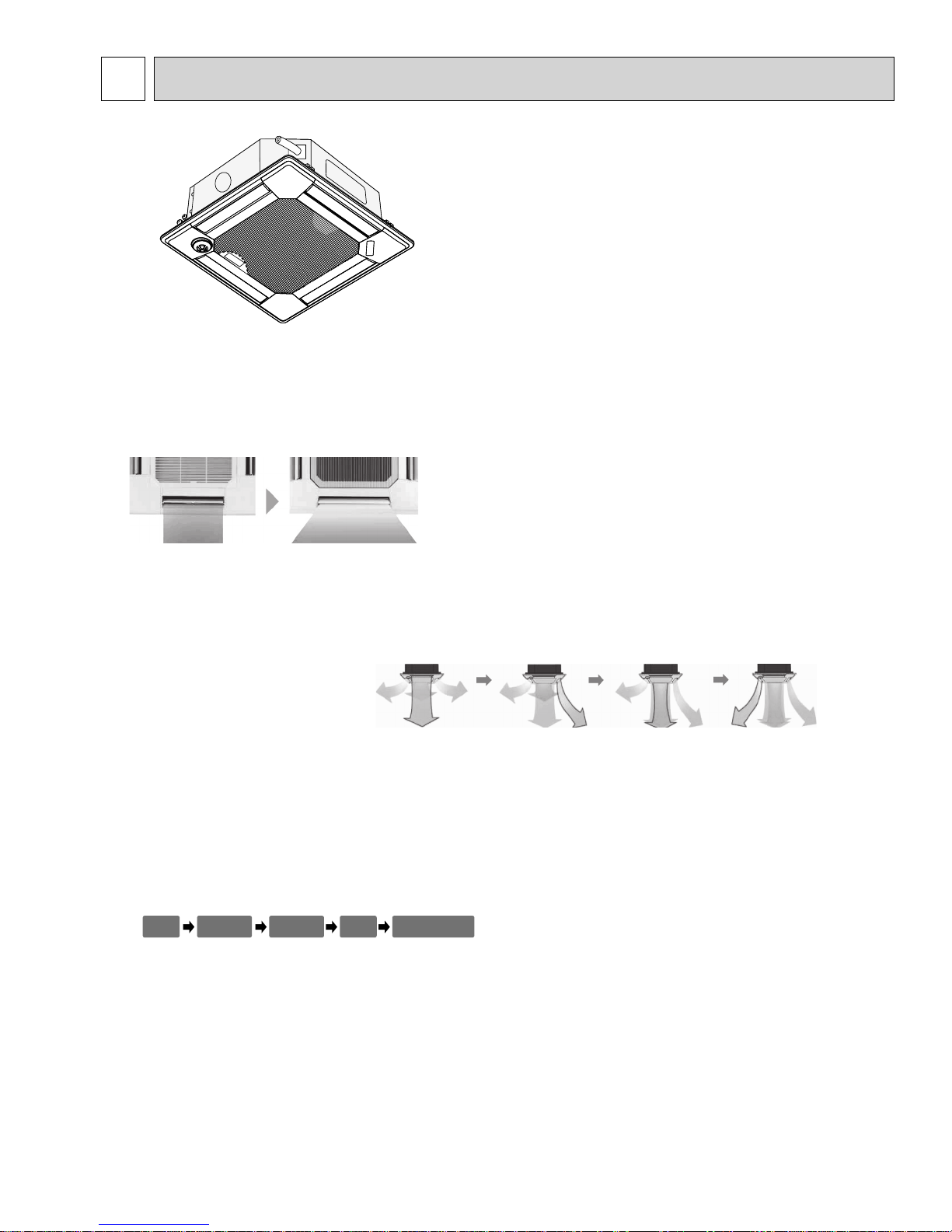

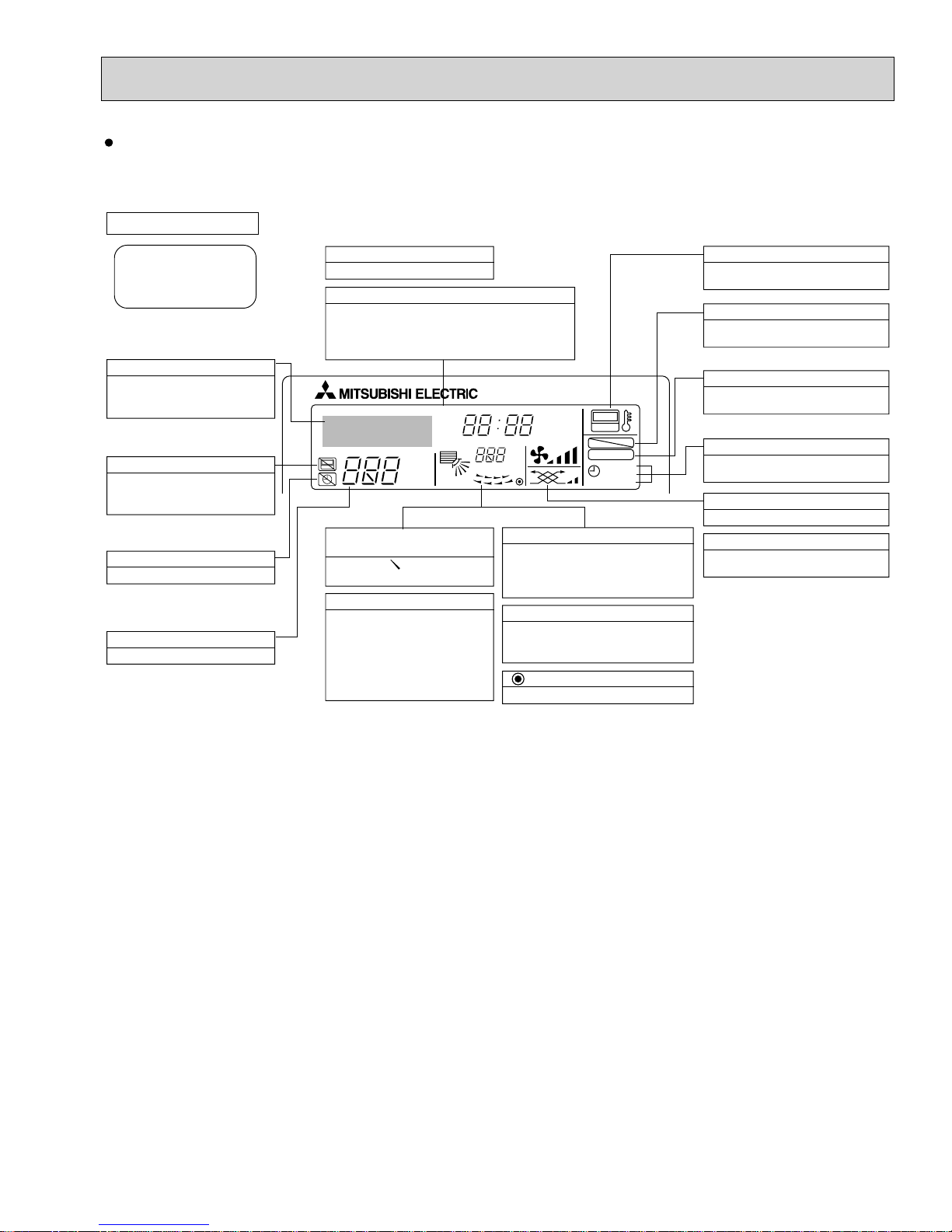

PART NAMES AND FUNCTIONS

Indoor unit

Air outlet

Liquid pipe

Gas pipe

i-see sensor

(option)

Vane

Wired remote controller

Drain pipe

Filter

Air intake

(Intake grille)

Note:

The phrase "Wired remote controller" in this manual refers only to the PAR-21MAA.

If you need any information for the other remote controller, please refer to either the installation manual or initial setting manual which are included in

remote controller's box.

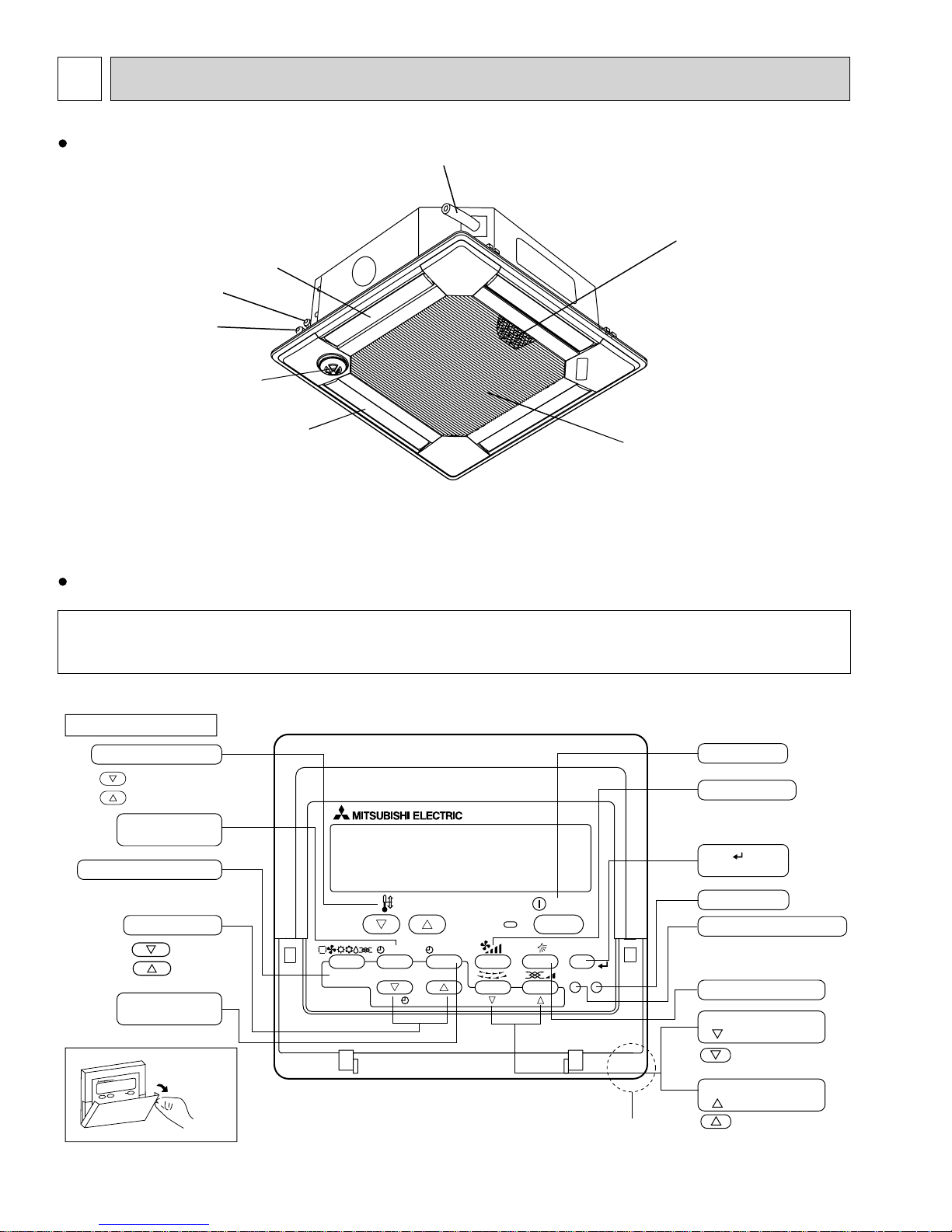

Operation Section

Temperature setting buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

cover

TEMP.

MENU

MONITOR/SET

BACK DAY

PAR-21MAA

CLOCK

ON/OFF

ON/OFF

FILTER

CHECK

OPERATION

Built-in temperature sensor

CLEAR

TEST

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

T o return operation

number

Ventilation button

( Operation button)

To go to next operation

number

4

Wired remote controller

OCH421B

Display Section

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

Identifies the current operation

Shows the operating mode, etc.

*Multilanguage display is available.

“Centrally Controlled” indicator

Indicates that operation from the

remote controller has been prohibited by a master controller.

“Timer is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, the time to be

switched off is shown.

TIME SUN MON TUE WED THU FRI SAT

TIMER

AFTER

ERROR CODE

°F°C

Hr

AFTER

°F°C

ONLY1Hr.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

Low or downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off in one hour,

at which time the airflow direction

also changes.

Room Temperature display

Shows the room temperature. The room

temperature display range is 46–102F.

The display blinks if the temperature

is less than 46

Louver display

Indicates the action of the swing louver.

Does not appear if the louver is not

running.

(Power On indicator)

Indicates that the power is on.

ON

OFF

FUNCTION

FILTER

WEEKLY

SIMPLE

AUTO OFF

F

or 102F or more.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

To be displayed on when it is time to

clean the filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

5

4

OCH421B

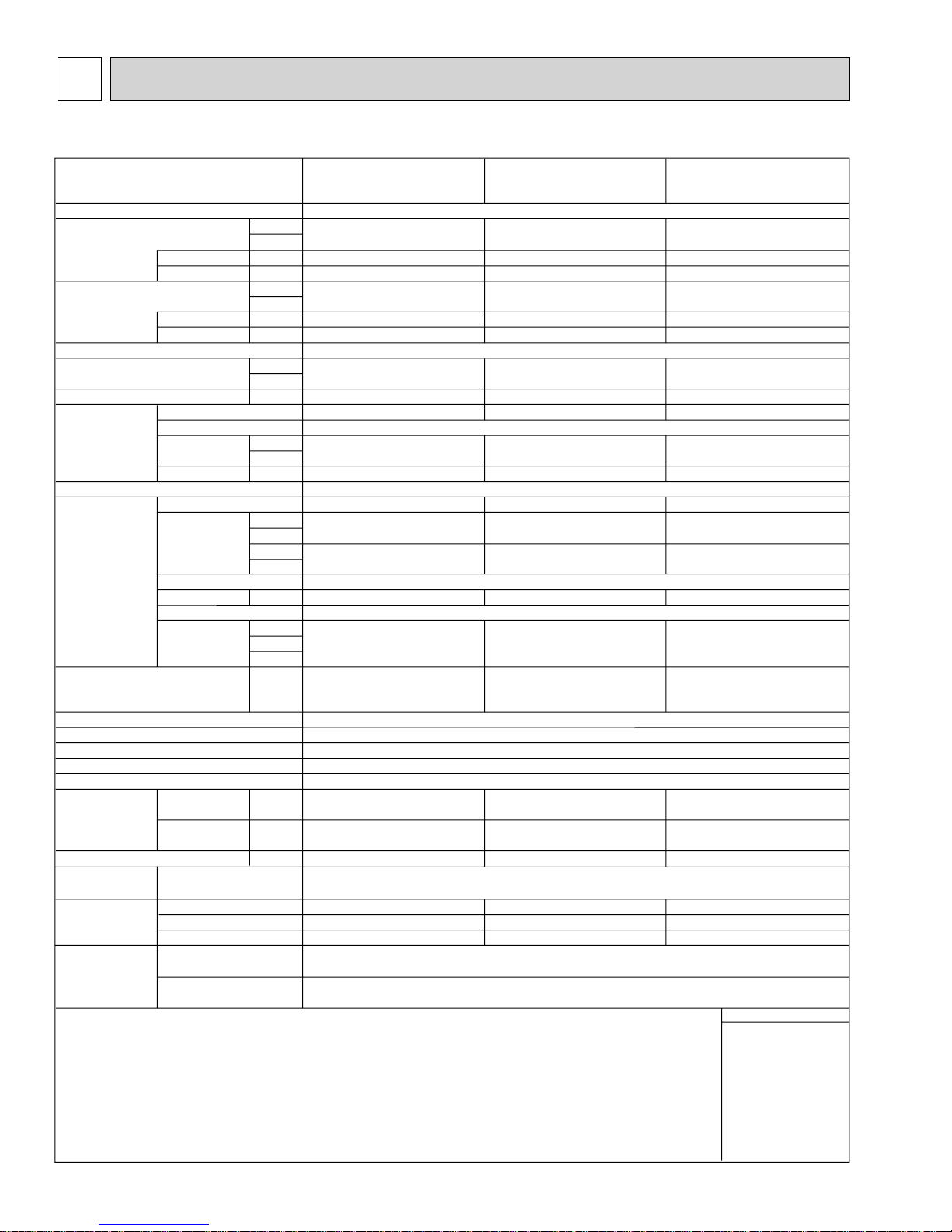

SPECIFICATIONS

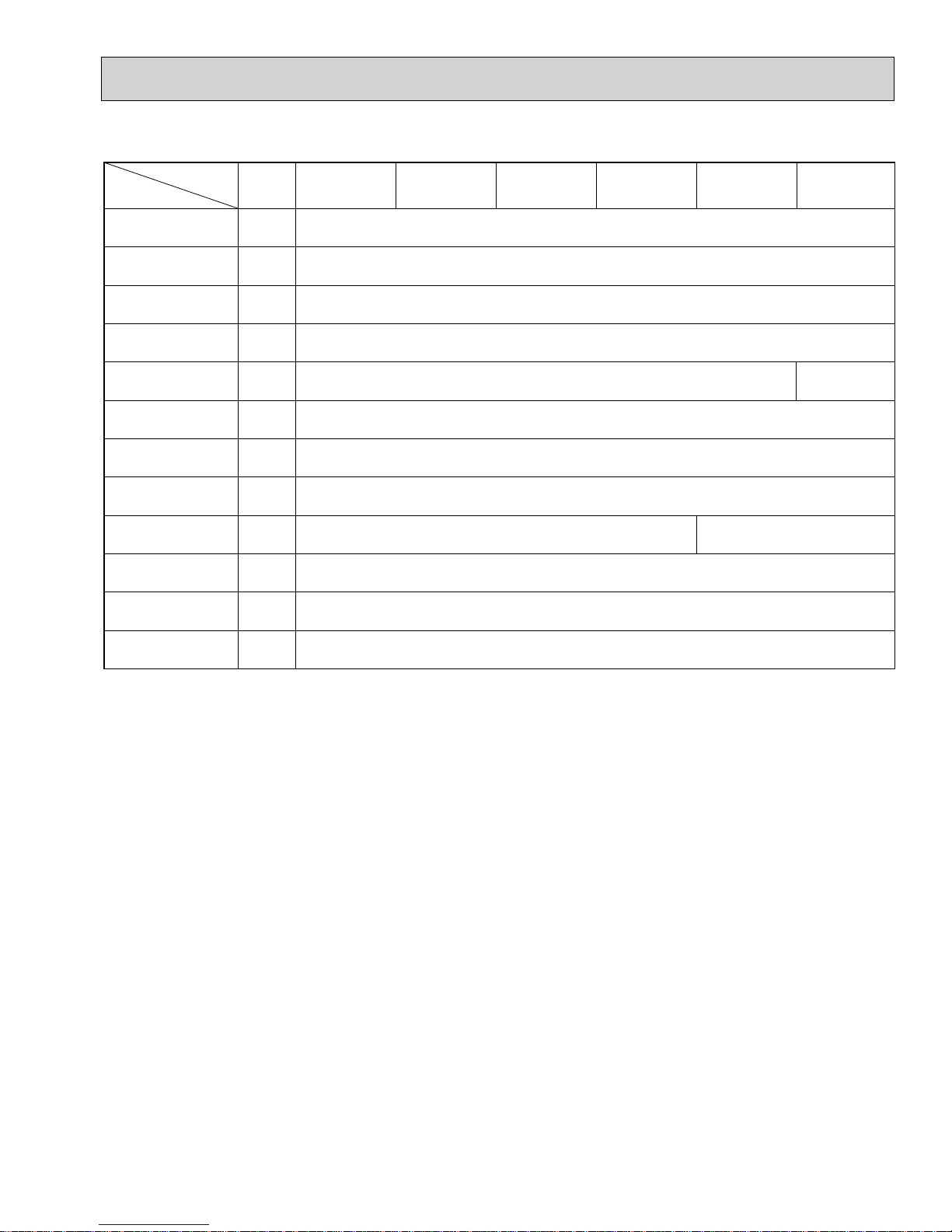

4-1. SPECIFICATIONS

Model

Power source

Cooling capacity

(Nominal)

Heating capacity

(Nominal )

External finish

External dimension H

Net weight

Decoration panel

Heat exchanger

FAN

Noise level (Low-Mid2-Mid1-High)

(measured in anechoic room)

Insulation material

Air filter

Protection device

Refrigerant control device

Connectable outdoor unit

Diameter of

refrigerant pipe

(O.D.)

Field drain pipe size

Standard

attachment

Optional parts

Remark

Power input

Current input

Power input

Current input

×

W × D

Model

External finish

Dimension

H

×

W × D

Net weight

Type x Quantity

External

static press.

Motor type

Motor output

Driving mechanism

Airflow rate

(Low-Mid2-

Mid1-High)

Liquid

Gas

Document

Accessory

Air outlet shutter plate

High efficiency filterelement

Multi-function casement

*1

*1

*2

*2

(R410A)

(R22)

(R410A)

(R22)

BTU/h

kW

kW

A

Btu/h

kcal/h

kW

A

in.

mm

Ibs (kg)

in.

mm

Ibs (kg)

in.WG

Pa

in.WG

Pa

kW

cfm

m3/min

L / s

dB <A>

dB <A>

dB <A>

in. (mm)

in. (mm)

in. (mm)

PLFY-P12NBMU-E

PLFY-P12NBMU-ER1

PLFY-P12NBMU-ER2

12,000

3.5

0.03

0.22

13,500

4.0

0.02

0.14

10-3/16 × 33-3/32 × 33-3/32 10-3/16 × 33-3/32 × 33-3/32 10-3/16 × 33-3/32 × 33-3/32

258

×

840 × 840

49 (22) 49 (22) 51 (23)

PLP-40BAU PLP-40BAU PLP-40BAU

1-3/8 × 37-13/32 × 37-13/32

×

950 × 950

35

13 (6) 13 (6) 13 (6)

0.000 (208V) 0.000 (208V) 0.000 (208V)

0

0.000 (230V)

0

0.050

388 - 424 - 459 - 494

11.0 - 12.0 - 13.0 - 14.0

183 - 200 - 217 - 233

27 - 28 - 29 - 31 (208-230V)

—

—

PP honeycomb (long life filter, anti-bacterial type)

1/4 (6.35) Flare

1/4 (6.35) Flare

1/2 (12.7) Flare

1/2 (12.7) Flare

O.D. 1-1/4 (32) O.D. 1-1/4 (32) O.D. 1-1/4 (32)

PAC-SH51SP-E

PAC-SH59KF-E

PAC-SH53TM-E

PLFY-P15NBMU-E

PLFY-P15NBMU-ER1

PLFY-P15NBMU-ER2

1-phase 208-230V 60Hz

15,000

4.4

0.04

0.29

17,000

5.0

0.03

0.22

Galvanized steel sheet

258× 840 × 840 258× 840 × 840

MUNSELL (6.4Y 8.9/0.4)

1-3/8 × 37-13/32 × 37-13/32

35× 950 × 950

Cross fin

Turbo fan

0.000 (230V)

424 - 459 - 494 - 565

12.0 - 13.0 - 14.0 - 16.0

200 - 217 - 233 - 267

27 - 28 - 30 - 31 (208-230V)

R410A, R22 CITY MULTI

1/4 (6.35) Flare

1/4 (6.35) Flare

1/2 (12.7) Flare

1/2 (12.7) Flare

Installation Manual, Instruction Book

PAC-SH51SP-E

PAC-SH59KF-E

PAC-SH53TM-E

0

0

DC motor

0.050

Direct-drive

—

—

PS

Fuse

LEV

×

1Turbo fan × 1 Turbo fan × 1

PLFY-P18NBMU-E

PLFY-P18NBMU-ER1

PLFY-P18NBMU-ER2

18,000

5.3

0.05

0.36

20,000

5.9

0.04

0.29

1-3/8 × 37-13/32 × 37-13/32

35× 950 × 950

0

0.000 (230V)

0

0.050

494 - 530 - 565 - 636

14.0 - 15.0 - 16.0 - 18.0

233 - 250 - 267 - 300

28 - 29 - 30- 32 (208-230V)

—

—

1/4 (6.35) Flare

3/8 (9.52) Flare

1/2 (12.7) Flare

5/8 (15.88) Flare

PAC-SH51SP-E

PAC-SH59KF-E

PAC-SH53TM-E

Installation

*1 Nominal cooling conditions Note: *2 Nominal heating conditions

Indoor : 80degF D.B. / 67degF W.B.

(26.7degC D.B. / 19.4degC W.B.)

Outdoor : 95degF D.B. 47degF D.B. / 43degF W.B.

Pipe length : 25 ft. (7.6 m) 25 ft. (7.6 m)

Level difference : 0 ft. (0 m) 0 ft. (0 m)

*Due to continuing improvement, above specification may be subject to change without notice.

(35degC D.B.) (8.3degC D.B. / 6.1degC W.B.)

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items

shall be referred to the Installation Manual.

70degF D.B.

(21.1degC D.B.)

Unit converter

kcal/h = kW × 860

BTU/h = kW × 3,412

3

cfm = m

/min × 35.31

lbs = kg/0.4536

*Above specification

data is subject to

rounding variation.

6

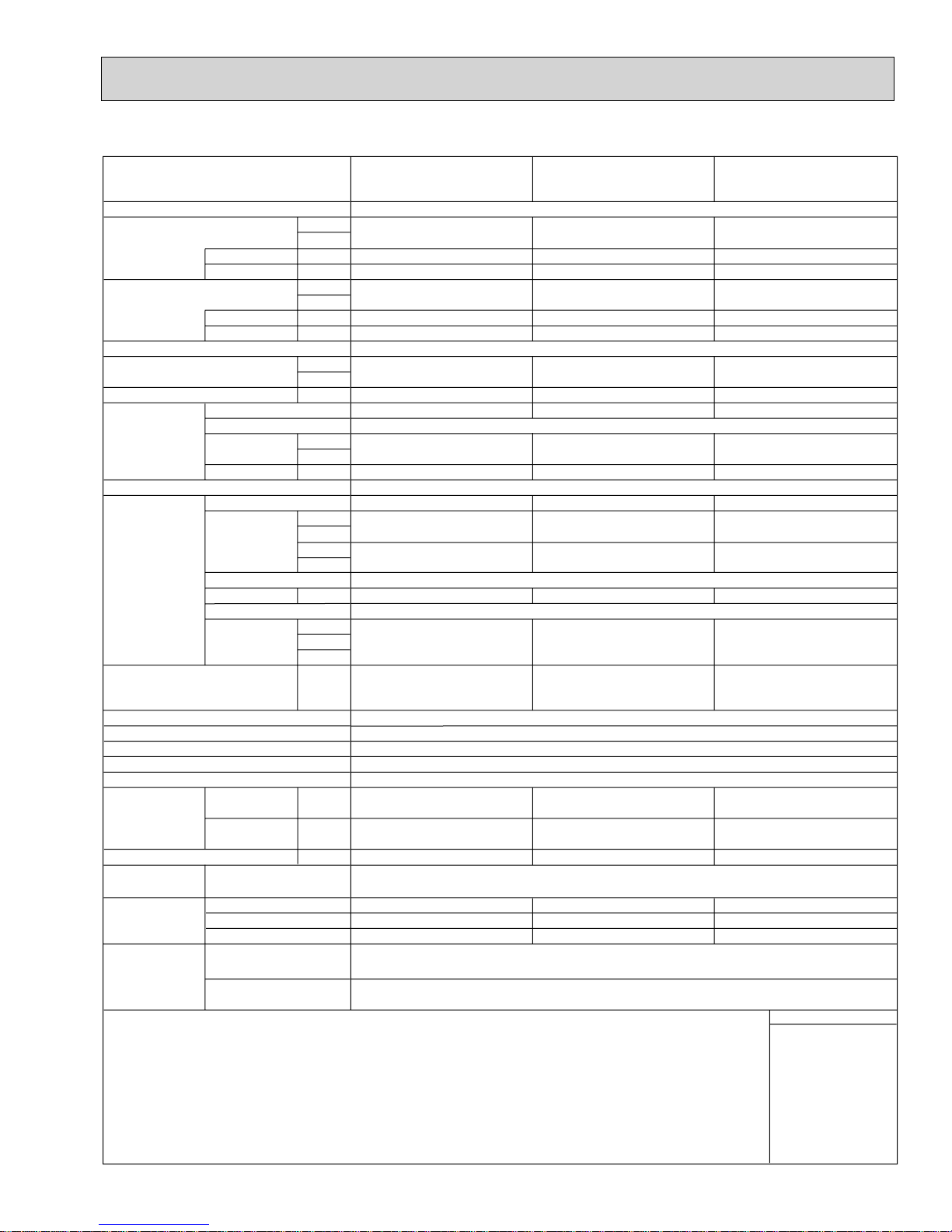

Model

OCH421B

Power source

Cooling capacity

(Nominal)

Heating capacity

(Nominal )

External finish

External dimension H × W × D

Net weight

Decoration panel

Heat exchanger

FAN

Noise level (Low-Mid2-Mid1-High)

(measured in anechoic room)

Insulation material

Air filter

Protection device

Refrigerant control device

Connectable outdoor unit

Diameter of

refrigerant pipe

(O.D.)

Field drain pipe size

Standard

attachment

Optional parts

Remark

Power input

Current input

Power input

Current input

Model

External finish

Dimension

H × W × D

Net weight

Type × Quantity

External

static press.

Motor type

Motor output

Driving mechanism

Airflow rate

(Low-Mid2-

Mid1-High)

Liquid

Gas

Document

Accessory

(R410A)

(R410A)

Air outlet shutter plate

High efficiency filterelement

Multi-function casement

(R22)

(R22)

*1

*1

*2

*2

BTU/h

kW

kW

A

Btu/h

kcal/h

kW

A

in.

mm

Ibs (kg)

in.

mm

Ibs (kg)

in.WG

Pa

in.WG

Pa

kW

cfm

3

m

/min

L/s

dB <A>

dB <A>

dB <A>

in. (mm)

in. (mm)

in. (mm)

PLFY-P24NBMU-E

PLFY-P24NBMU-ER1

PLFY-P24NBMU-ER2

24,000

7.0

0.06

0.43

27,000

7.9

0.05

0.36

10-3/16× 33-3/32 × 33-3/32

258 × 840 × 840

51 (23)

PLP-40BAU

1-3/8× 37-13/32 × 37-13/32

35 × 950 × 950

13 (6)

0.000 (208V)

0

0.000 (230V)

0

0.050

530 - 565 - 636 - 706

15.0 - 16.0 - 18.0 -20.0

250 - 267 - 300 - 333

28 - 30 - 32 - 34 (208-230V)

—

—

3/8 (9.52) Flare

3/8 (9.52) Flare

5/8 (15.88) Flare

5/8 (15.88) Flare

O.D. 1-1/4 (32)

PAC-SH51SP-E

PAC-SH59KF-E

PAC-SH53TM-E

PLFY-P30NBMU-E

PLFY-P30NBMU-ER1

PLFY-P30NBMU-ER2

1-phase 208-230V 60Hz

30,000

8.8

0.07

0.51

34,000

10.0

0.06

0.43

Galvanized steel sheet

10-3/16× 33-3/32 × 33-3/32

258 × 840 × 840

51 (23)

PLP-40BAU

MUNSELL (6.4Y 8.9/0.4)

1-3/8× 37-13/32 × 37-13/32

35 × 950 × 950

13 (6)

Cross fin

0.000 (208V)

0

0.000 (230V)

0

DC motor

0.050

Direct-drive

565 - 636 - 706 - 777

16.0 - 18.0 - 20.0 - 22.0

267 - 300 - 333 - 367

30 - 32 - 35 - 37 (208-230V)

PP honeycomb (long life filter, anti-bacterial type)

R410A, R22 CITY MULTI

Installation Manual, Instruction Book

—

—

PS

Fuse

LEV

3/8 (9.52) Flare

3/8 (9.52) Flare

5/8 (15.88) Flare

5/8 (15.88) Flare

O.D. 1-1/4 (32)

PAC-SH51SP-E

PAC-SH59KF-E

PAC-SH53TM-E

PLFY-P36NBMU-E

PLFY-P36NBMU-ER1

PLFY-P36NBMU-ER2

36,000

10.5

0.16

1.07

40,000

11.7

0.15

1.00

11-3/4 × 33-3/32 × 33-3/32

298 × 840 × 840

60 (27)

PLP-40BAU

1-3/8× 37-13/32 × 37-13/32

35 × 950 × 950

13 (6)

Turbo fan × 1 Turbo fan × 1 Turbo fan × 1

0.000 (208V)

0

0.000 (230V)

0

0.120

777 - 883 - 989 - 1,059

22.0 - 25.0 - 28.0 - 30.0

367 - 417 - 467 - 500

35 - 38 - 41 - 43 (208-230V)

—

—

3/8 (9.52) Flare

3/8 (9.52) Flare

5/8 (15.88) Flare

3/4 (19.05) Flare

O.D. 1-1/4 (32)

PAC-SH51SP-E

PAC-SH59KF-E

PAC-SH53TM-E

Installation

*1 Nominal cooling conditions Note: *2 Nominal heating conditions

Indoor : 80degF D.B. / 67degF W.B.

(26.7degC D.B. / 19.4degC W.B.)

Outdoor : 95degF D.B. 47degF D.B. / 43degF W.B.

Pipe length : 25 ft. (7.6 m) 25 ft. (7.6 m)

Level difference : 0 ft. (0 m) 0 ft. (0 m)

*Due to continuing improvement, above specification may be subject to change without notice.

(35degC D.B.) (8.3degC D.B. / 6.1degC W.B.)

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items

shall be referred to the Installation Manual.

70degF D.B.

(21.1degC D.B.)

Unit converter

kcal/h = kW × 860

BTU/h = kW × 3,412

3

/min × 35.31

cfm = m

lbs = kg/0.4536

*Above specification

data is subject to

rounding variation.

7

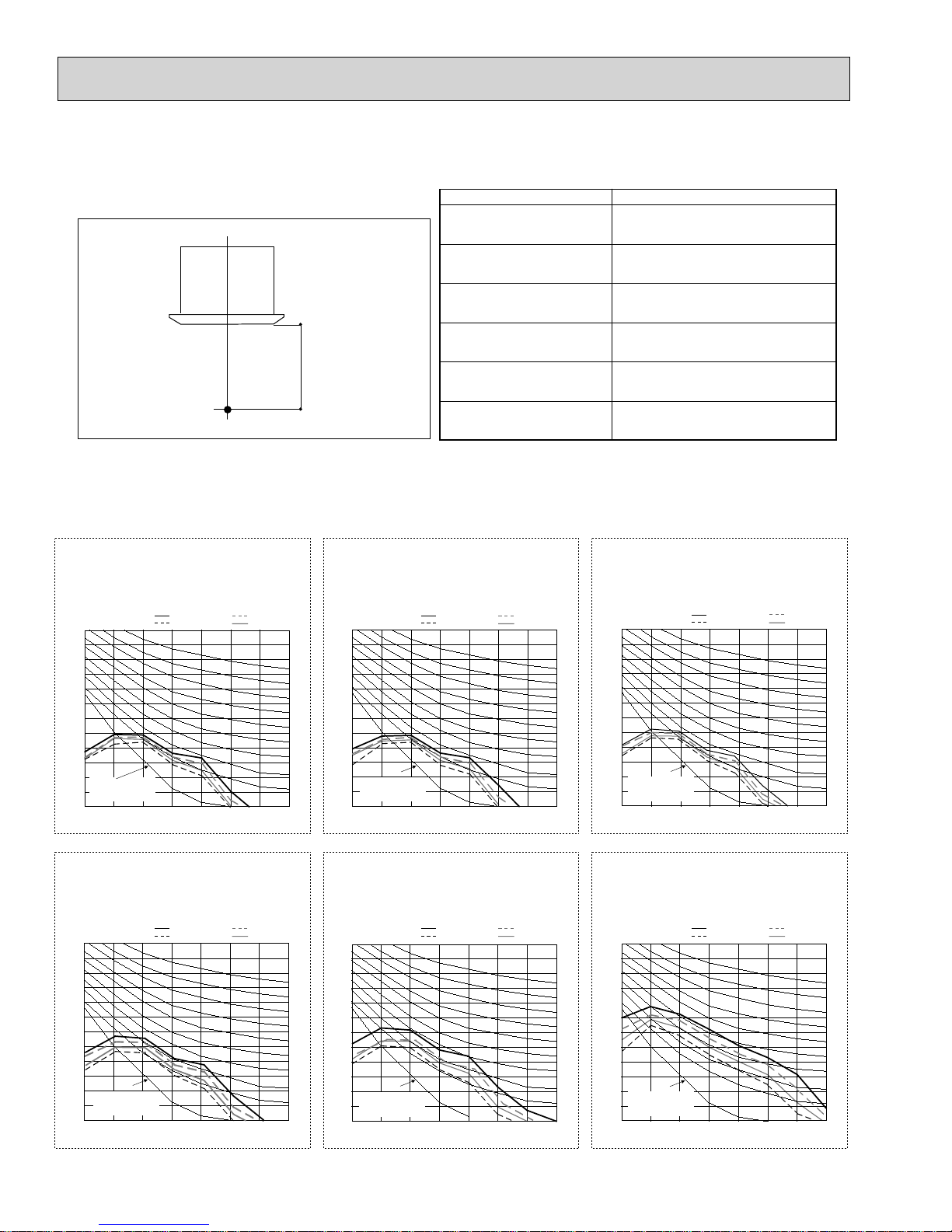

4-2. SOUND LEVEL

OCH421B

PLFY-P-NBMU-E

Measurement location

4-3. NC CURVES

PLFY-P12NBMU-E

PLFY-P12NBMU-ER1

PLFY-P12NBMU-ER2

External static pressure : 0Pa

Power source : 208,230V, 60Hz

70.0

65.0

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

20.0

Approximate minimum

audible limit on

15.0

continuous noise

Octave band pressure level (dB) 0dB=20Pa

10.0

63 125 250 500 1k 2k 4k 8k

Octave band center frequencies (Hz)

High 60Hz

Low 60Hz

Middle1 60Hz

Middle2 60Hz

5 ft (1.5m)

PLFY-P15NBMU-E

PLFY-P15NBMU-ER1

PLFY-P15NBMU-ER2

External static pressure : 0Pa

Power source : 208,230V, 60Hz

70.0

65.0

NC-60

NC-50

NC-40

NC-30

NC-20

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

20.0

Approximate minimum

audible limit on

15.0

continuous noise

Octave band pressure level (dB) 0dB=20Pa

10.0

63 125 250 500 1k 2k 4k 8k

Octave band center frequencies (Hz)

PLFY-P12NBMU-E

PLFY-P12NBMU-ER1

PLFY-P12NBMU-ER2

PLFY-P15NBMU-E

PLFY-P15NBMU-ER1

PLFY-P15NBMU-ER2

PLFY-P18NBMU-E

PLFY-P18NBMU-ER1

PLFY-P18NBMU-ER2

PLFY-P24NBMU-E

PLFY-P24NBMU-ER1

PLFY-P24NBMU-ER2

PLFY-P30NBMU-E

PLFY-P30NBMU-ER1

PLFY-P30NBMU-ER2

PLFY-P36NBMU-E

PLFY-P36NBMU-ER1

PLFY-P36NBMU-ER2

High 60Hz

Low 60Hz

Middle1 60Hz

Middle2 60Hz

Sound level at anechoic room : Low-

Sound level dB (A)

27-28-29-31

27-28-30-31

28-29-30-32

28-30-32-34

30-32-35-37

35-38-41-43

PLFY-P18NBMU-E

PLFY-P18NBMU-ER1

PLFY-P18NBMU-ER2

External static pressure : 0Pa

Power source : 208,230V, 60Hz

70.0

65.0

NC-60

NC-50

NC-40

NC-30

NC-20

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

20.0

Approximate minimum

audible limit on

15.0

continuous noise

Octave band pressure level (dB) 0dB=20Pa

10.0

63 125 250 500 1k 2k 4k 8k

Octave band center frequencies (Hz)

High 60Hz

Low 60Hz

Mid2-Mid1-High

Middle1 60Hz

Middle2 60Hz

NC-60

NC-50

NC-40

NC-30

NC-20

PLFY-P24NBMU-E

PLFY-P24NBMU-ER1

PLFY-P24NBMU-ER2

External static pressure : 0Pa

Power source : 208,230V, 60Hz Power source : 208,230V, 60Hz

70.0

65.0

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

20.0

Approximate minimum

audible limit on

15.0

continuous noise

Octave band pressure level (dB) 0dB=20Pa

10.0

63 125 250 500 1k 2k 4k 8k

Octave band center frequencies (Hz)

High 60Hz

Low 60Hz

Middle1 60Hz

Middle2 60Hz

NC-60

NC-50

NC-40

NC-30

NC-20

PLFY-P30NBMU-E

PLFY-P30NBMU-ER1

PLFY-P30NBMU-ER2

External static pressure : 0Pa

Power source : 208,230V, 60Hz

70.0

65.0

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

20.0

Approximate minimum

audible limit on

15.0

continuous noise

Octave band pressure level (dB) 0dB=20Pa

10.0

63 125 250 500 1k 2k 4k 8k

Octave band center frequencies (Hz)

High 60Hz

Low 60Hz

8

Middle1 60Hz

Middle2 60Hz

PLFY-P36NBMU-E

PLFY-P36NBMU-ER1

PLFY-P36NBMU-ER2

External static pressure : 0Pa

70.0

65.0

NC-60

NC-50

NC-40

NC-30

NC-20

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

20.0

Approximate minimum

audible limit on

15.0

continuous noise

Octave band pressure level (dB) 0dB=20Pa

10.0

63 125 250 500 1k 2k 4k 8k

Octave band center frequencies (Hz)

High 60Hz

Low 60Hz

Middle1 60Hz

Middle2 60Hz

NC-60

NC-50

NC-40

NC-30

NC-20

4-4. ELECTRICAL PARTS SPECIFICATIONS

OCH421B

Service Ref.

Parts name

Room temperature

thermistor

Liquid pipe thermistor

Gas pipe thermistor

Fuse

(Indoor controller board)

Fan motor

Vane motor

Drain pump

Drain float swich

Linear expansion valve

Power supply terminal

block

Transmission terminal

block

MA remote controller

terminal block

Symbol

TH21

TH22

TH23

FUSE

MF

MV

DP

FS

LEV

TB2

TB5

TB15

PLFY-P12NBMU-E

PLFY-P12NBMU-ER1

PLFY-P12NBMU-ER2

DC12V Stepping motor drive port dimension :3.2 (0~2000pulse)

PLFY-P15NBMU-E

PLFY-P15NBMU-ER1

PLFY-P15NBMU-ER2

Resistance 30"F/15.8k, 50"F/9.6k, 70"F/6.0k, 80"F/4.8k, 90"F/3.9k, 100"F/3.2k

Resistance 30"F/15.8k, 50"F/9.6k, 70"F/6.0k, 80"F/4.8k, 90"F/3.9k, 100"F/3.2k

Resistance 30"F/15.8k, 50"F/9.6k, 70"F/6.0k, 80"F/4.8k, 90"F/3.9k, 100"F/3.2k

PLFY-P18NBMU-E

PLFY-P18NBMU-ER1

PLFY-P18NBMU-ER2

8-pole OUTPUT 50W

EDM-40YGME

PLFY-P24NBMU-E

PLFY-P24NBMU-ER1

PLFY-P24NBMU-ER2

250V 6.3A

MSBPC20M04

DC12V 300

PLD-12230ME-1

INPUT 12/10.8W 241/Hr

Open/short detection

(L1, L2, GR) 330V 30A

(M1, M2, S) 250V 20A

(1, 2) 250V 10A

/phase

PLFY-P30NBMU-E

PLFY-P30NBMU-ER1

PLFY-P30NBMU-ER2

DC12V Stepping motor drive port

dimension :

PLFY-P36NBMU-E

PLFY-P36NBMU-ER1

PLFY-P36NBMU-ER2

8-pole OUTPUT,

5.2

(0~2000pulse)

EDM-80YGME

120W

9

5

OCH421B

4-WAY AIR FLOW SYSTEM

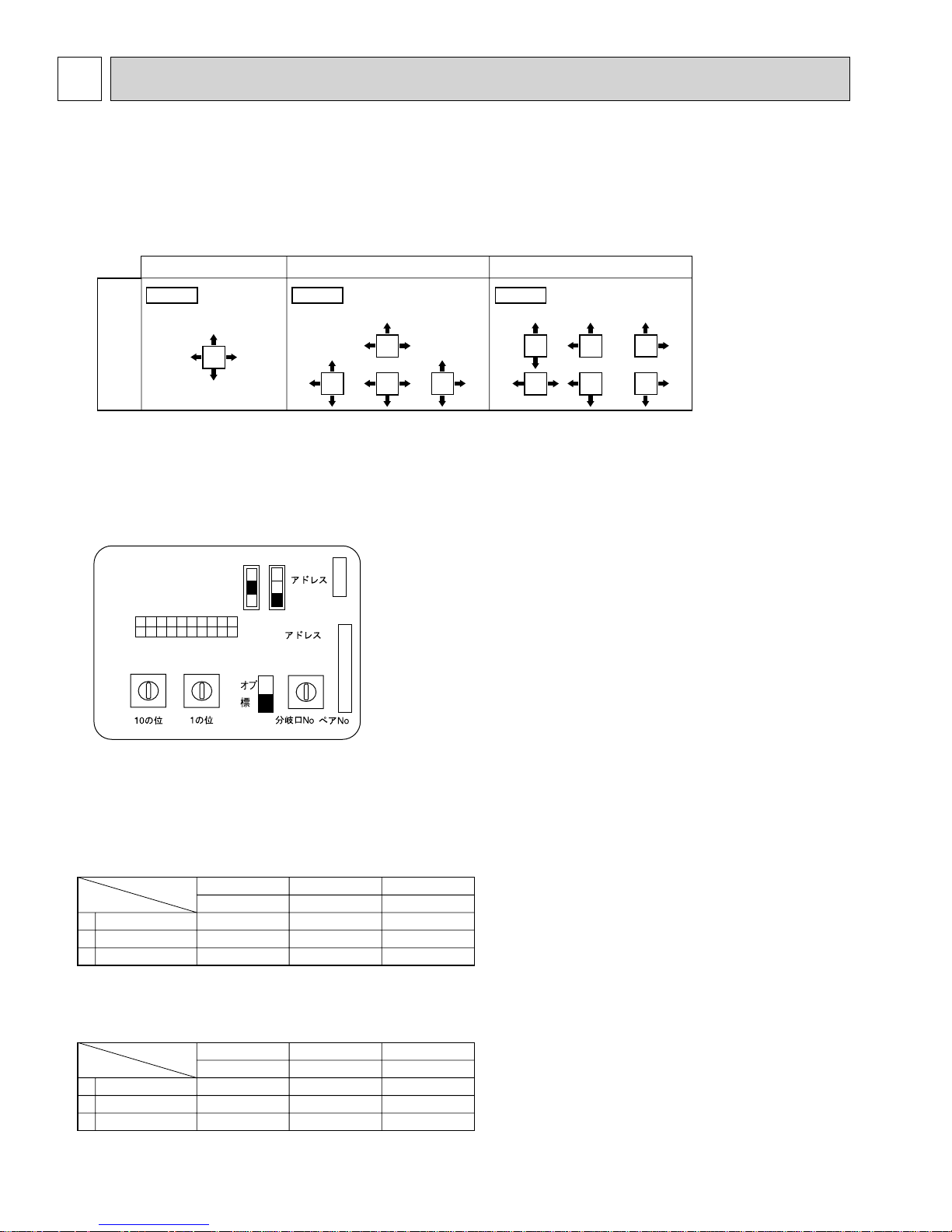

5-1. PLACEMENT OF THE AIR OUTLETS

• For this grille, the blowout direction comes in 11 patterns.

Also, by setting the remote controller to the appropriate settings, you can adjust the air flow and speed. Select the settings

from Table1 according to the location in which you want to install the unit.

1) Decide on the pattern of the airflow direction.

4-direction<Table 1> 3-direction 2-direction

Pattern 1 Initial setting Pattern 4 One air outlet

fully closed

Pattern 6 2 air outlet

fully closed

pattern

Blowout direction

Note: For 3 and 2-direction settings, please use the air outlet shutter plate (option).

2) According to the number of air outlets and height of the ceiling to install the unit, be sure to set up the switches

(SWA, SWB) on the address board to the appropriate setting.

• Correspondence of ceiling heights to numbers of air outlets

SWB

SWA

2

3

3

ON

OFF

12345678910

SW12

0

1

9

2

8

3

7

4

6

5

(10ths DIGIT)

SW1

SW11

9

8

7

6

(1s DIGIT)

2

1

0

1

5

SWC

2

3

4

4

CN82

SW14

E

D

C

(BRANCH No.)

F

B

A

CN43

0

1

2

3

6

7

8

9

./

4

5

.

PLFY-P12·P15·P18·P24·P30NBMU-E

PLFY-P12·P15·P18·P24·P30NBMU-ER1

PLFY-P12·P15·P18·P24·P30NBMU-ER2

Silent

2.5m, 8.2ft

2.7m, 8.9ft

3.0m, 9.8ft

Standard

2.7m, 8.9ft

3.0m, 9.8ft

3.3m, 10.8ft

SWB

4 direction

3 direction

2 direction

SWA

PLFY-P36NBMU-E

PLFY-P36NBMU-ER1

PLFY-P36NBMU-ER2

SWA

SWB

4 direction

3 direction

2 direction

Silent

2.7m, 8.9ft

3.0m, 9.8ft

3.3m, 10.8ft

Standard

3.2m, 10.5ft

3.6m, 11.8ft

4.0m, 13.1ft

High ceiling

3.5m, 11.5ft

3.5m, 11.5ft

3.5m, 11.5ft

High ceiling

4.5m, 14.8ft

4.5m, 14.8ft

4.5m, 14.8ft

10

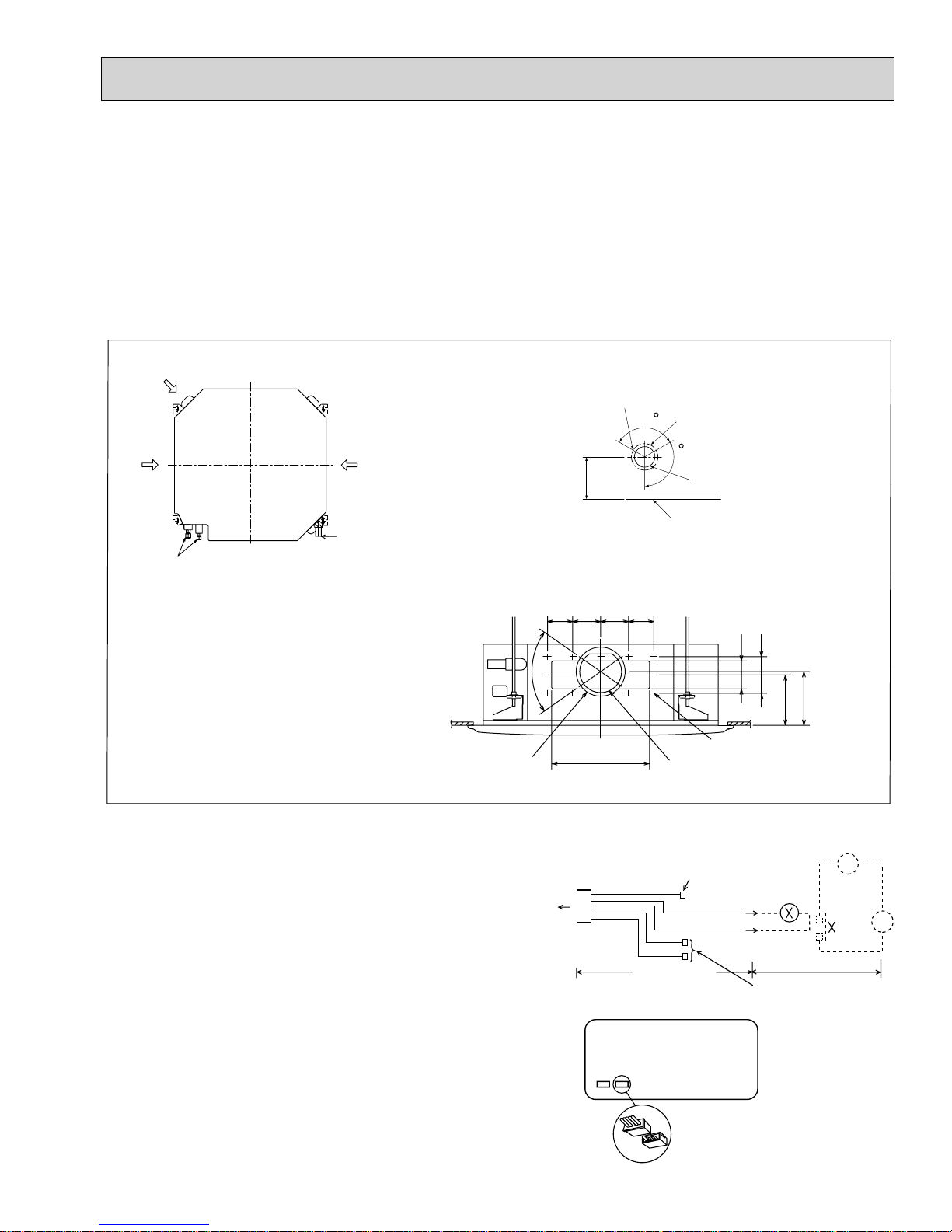

5-2. BRANCH DUCT HOLE AND FRESH AIR INTAKE HOLE

OCH421B

At the time of installation, use the duct holes (cut out) located at the positions shown in following diagram, as and when required.

• A fresh air intake hole for the optional multi function casement can also be made.

Note:

The figures marked with * in the drawing below represent the dimensions of the main unit excluding those of the optional multi

function casement.

When installing the optional multi function casement, add 5-5/16” (135 mm) to the dimensions marked on the figure.

When installing the branch ducts, be sure to insulate adequately.

Otherwise, condensation and dripping may occur.

Unit : inch(mm)

Fresh air intake hole

Refrigerant pipe

Indoor unit

Branch duct hole

Drain pipe

:6-7/8 (:175) burring hole pitch

Branch duct hole diagram

(view from either side)

Fresh air intake hole diagram

3-:1/8 (:2.8) burring hole

120

(*158)

6-7/32

3-17/32

3-15/16

3-15/16

(90)

3-17/32

(90)

70

(90)

(100)

13-25/32 (350)

:4-29/32 (:125) burring hole pitch

120

:3-15/16 (:100) cut out hole

Ceiling

3-15/16 (100)

5-1/8 (130)

*6-3/32 (155)

*6-9/16 (167)

14-:1/8 (:2.8) burring hole

:5-29/32 (:150) cut out hole

5-3. OPERATION IN CONJUNCTION WITH

DUCT FAN (Booster fan)

• Whenever the indoor unit is operating, the duct fan also

operates.

(1) Connect the optional multiple remote controller adapter

(PAC-SA88HA-E) to the connector CN51 on the indoor

controller board.

(2) Drive the relay after connecting the 12V DC relay

between the Yellow and Orange connector lines.

MB: Electromagnetic switch power relay for duct fan.

X: Auxiliary relay (For DC 12V, coil rating: 1.0W or smaller)

CN51

on

indoor

controller

board

Indoor controller board

Multiple remote

controller adapter

PAC-SA88HA-E

11

5

1

Connector (5P)

Indoor unit side

CN51

Be sure to secure insulation

Green

CN51

material by tape, etc.

Red

Brown

Multiple remote

controller adapter

PAC-SA88HA-E

Yellow

Orange

~

MB

Installation at site

Be sure to secure insulation

material by tape, etc.

Distance between indoor

controller board and relay

must be within 10m (33ft).

Loading...

Loading...