Page 1

Air-Conditioners For Building Application

INDOOR UNIT

PLFY-NLMD

FOR INSTALLER

据付工事者へ

INSTALLATION MANU AL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit. How to install an

optionally available panel is also described in the panel installation manual.

How to install outdoor units and items about the multi-unit system are described in the outdoor unit installation manual.

∗ Remote controller (PAR-F25M or PAR-F26M) is available as an optional remote controller.

ENGLISH

日本語

据付説明書

据付の前に正しく安全にお使いいただくためこの取扱説明書を必ずお読みください。室外側ユニットの据付方法およびマルチシ

ステム関連の項目は、室外側ユニットの据付説明書に記載されております。また、別売部品のパネルの据付はパネルの据付説明

書に記載されております。

∗ リモコン(PAR-F25M又は、PAR-F26M)は別売品です。

Page 2

Contents

1. Safety precautions ...................................................................... 3

1.1. Before installation and electric work................................3

1.2. Before getting installed.................................................... 3

1.3. Before getting installed (moved) - electrical work .......... 4

1.4. Before starting the test run.............................................. 4

2. Indoor unit accessories ............................................................... 5

3. Selecting an installation site ........................................................ 5

3.1. Securing installation and service space ..........................5

3.2. Split flow duct end connection - fresh air intake ............. 5

3.3. Combining indoor units with outdoor units ..................... 6

4. Fixing hanging bolts .................................................................... 6

4.1. Fixing hanging bolts ........................................................6

4.2. Ceiling hole and hanging bolt positions...........................6

5. Installing the unit ......................................................................... 7

ENGLISH

5.1. Hanging the unit body .....................................................7

5.2. Confirming the unit’s position and fixing hanging bolts .. 8

6. Refrigerant pipe and drain pipe specifications ............................8

6.1. Refrigerant pipe and drain pipe specifications ............... 8

6.2. Refrigerant pipe , drain pipe and filling port ................... 8

6.3. Request for refrigerant piping connection ...................... 9

7. Connecting refrigerant pipes and drain pipes ............................ 10

7.1. Refrigerant piping work .................................................10

7.2. Drain piping work .......................................................... 10

7.3. Confirming drain discharge ........................................... 11

8. Electrical wiring ......................................................................... 11

8.1. Power supply wiring ......................................................12

8.2. Connecting remote controller, indoor and outdoor

transmission cables ...................................................... 12

8.3. Connecting electrical connections................................. 13

8.4. Setting addresses ......................................................... 14

8.5. Sensing room temperature with the built-in sensor in a

remote controller ...........................................................14

9. Test run ..................................................................................... 15

2

Page 3

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the

“Safety precautions”.

s The “Safety precautions” provide very important

points regarding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger

of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage

to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This

symbol is displayed on the main unit label.) <Color: Yellow>

: Indicates that the main switch must be turned off before servic-

ing. (This symbol is displayed on the main unit label.) <Color:

Blue>

: Beware of electric shock. (This symbol is displayed on the main

unit label.) <Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• The unit must be securely installed on a structure that can sus-

tain its weight. If the unit is mounted on an unstable structure, it

may fall down causing injuries.

• Use only specified cables for wiring. The connections must be

made securely without pulling on the terminals. Improper con-

nections or installation may generate heat or cause a fire.

• The unit should be installed according to the instructions in or-

der to minimize the risk of damage from earthquakes, typhoons

or strong winds. An improperly installed unit may fall down and

cause damage or injuries.

• When installing an optional air cleaner or humidifier, be sure to

use only products specified by Mitsubishi.

All accessories must be installed by an authorized technician.

The user must not try to install accessories. Improperly installed

accessories can cause water leakage, electric shock or fire.

• Do not turn on the power until installation has been completed.

Failure to do so may cause an electric shock or fire.

• The unit should not be installed by the user. Ask the dealer or

an authorized technician to install the unit. If the unit is installed

improperly, water leakage, electric shock or fire may result.

• Use only accessories authorized by Mitsubishi Electric and ask

the dealer or an authorized technician to install them. If acces-

sories are installed improperly, water leakage, electric shock or

fire may result.

• The Installation Manual details the suggested installation

method. Any structural alteration necessary for installation must

comply with local building code requirements.

• The user should never attempt to repair the unit or transfer it to

another site. If the unit is repaired improperly, water leakage,

electric shock or fire may result. If the air conditioner must be

repaired or moved, consult the dealer.

• All electric work must be performed by a licensed technician,

according to local regulations and the instructions given in this

manual.

The units should be powered by dedicated power lines. Power

lines with insufficient capacity or improper electrical work may

result in electric shock or fire.

• The terminal bed cover of the outdoor unit must be firmly attached to prevent entry of dust and moisture. Improper mounting of the cover can cause electric shock or fire.

• Use only the specified refrigerant (R-22) to charge the refrigerant circuit. Do not mix it with any other refrigerant and do not

allow air to remain in the circuit. Air enclosed in the circuit can

cause pressure peaks resulting in a rupture and other hazards.

• If the air conditioner is installed in a small room, measures must

be taken to prevent the refrigerant concentration in the room

from exceeding the safety limit in the event of refrigerant leakage.

Consult the dealer regarding the appropriate measures to prevent the allowable concentration from being exceeded. Should

the refrigerant leak and cause the concentration limit to be exceeded, hazards due to lack of oxygen in the room could result.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a flame, poisonous gases

will be released.

1.2. Before getting installed

Caution:

• Do not install the equipment where combustible gas may leak

and accumulate resulting in fire.

• Do not keep food, plants, caged pets, artwork or precision instruments in the indoor unit’s direct airflow or too close to the

unit, as these items can be damaged by temperature changes

or dripping water.

• When the room humidity exceeds 80% or when the drain pipe is

clogged, water may drip from the indoor unit. Do not install the

indoor unit where such dripping could cause damage.

The outdoor unit produces condensation during the heating operation. Make sure to provide drainage around the outdoor unit

if such condensation is likely to cause damage.

• This air conditioner should not be installed in areas exposed to

thick steam, volatile oil (including machine oil) or sulphuric

smoke, as this could significantly reduce its performance and

damage the internal parts.

• When installing the unit in a hospital, communication station,

etc., provide sufficient protection against noise.

The air-conditioner may operate erroneously or fail to operate

because it is affected by inverter equipment, private power generator, high-frequency medical equipment or radio-used communications equipment. Conversely, it may affect such equipment, creating noise to disturb medical treatment or image

broadcasting.

ENGLISH

3

Page 4

1.3. Before getting installed (moved) electrical work

Caution:

• When installing the power lines, do not apply tension to the ca-

bles, as this could loosen the connections, generate heat and

cause a fire.

• Use only a fuse of specified capacity. A fuse of larger capacity

or a steel or copper wire could cause a general unit failure or

fire.

• Make sure to install an earth leakage breaker as this device helps

reduce the risk of electric shocks. Installation of an earth leakage breaker is mandatory in some areas.

• For the power lines, use standard cables of sufficient current

capacity. Otherwise, current leakage, overheating or fire may

occur.

• Be very careful about product transportation.

Only one person should not carry the product if it is more than

20 kg.

Some products use PP bands for packaging. Do not use any PP

band for a means of transportation.

Do not touch the heat exchanger fins with your bear hands. Doing

so may cut your hands.

Tear off and discard plastic packaging bags so that children will

not play any of them. If children play a plastic bag which was

not torn off, it may cause a risk of suffocation .

• The base and attachments of the outdoor unit should be periodically checked for looseness, cracks or other damage. If such

defects are left uncorrected, the unit may fall and cause personal injury or property damage.

• Be sure to safely dispose of the packaging materials. Packaging materials, such as catches and other metal or wooden parts,

may cause stabs or other injuries.

Earth connection

Caution:

Make sure to install a grounding line. Do not connect the ground-

ENGLISH

ing line to gas or water pipes, lightning conductors or telephone

grounding lines. Improper grounding may cause an electric shock.

Drain piping

Caution:

• Install drain piping according to this Installation Manual to ensure proper drainage. Place thermal insulation on the pipes to

prevent condensation. Improper drain piping may cause water

leakage and damage to furniture or other possessions.

• Thermal insulation of the drain pipes is necessary to prevent

dew condensation. If the drain pipes are not properly insulated,

condensation will result and drip on the ceiling, floor or other

possessions.

Other

Caution:

• Do not wash the air conditioner units. Washing them may cause

an electric shock.

1.4. Before starting the test run

Caution:

• After completing installation work, make sure that refrigerant

gas is not leaked.

If refrigerant gas is leaked and exposed to fan heater, stove,

oven and so on, it may generate noxious gases.

• Before starting operation, check that all panels, guards and other

protective parts are correctly installed. Rotating, hot or high voltage parts can cause injuries.

• Do not touch the refrigerant pipes with bare hands during operation. The refrigerant pipes are sometimes hot and sometimes

cold depending on the condition of the flowing refrigerant. Your

hands may suffer burns or frostbite if you touch the pipes.

• Turn on the main power switch more than twelve hours before

starting operation. Starting operation just after turning the main

power switch on can result in severe damage to internal parts.

Keep the main power switch turned on during the operation season.

• Keep the outlets and inlets free of obstacles. Otherwise, the performance may be reduced or operation may stop.

• Do not touch any switch with wet fingers, as this can cause an

electric shock.

• Do not operate the air conditioner without the air filter set in

place. Dust may accumulate, and cause a failure.

• After stopping operation, be sure to wait for five minutes before

turning off the main power switch. Otherwise, water leakage or

unit failure may occur.

4

Page 5

2. Indoor unit accessories

The unit is provided with the following accessories:

Part No.

1 Insulated pipe (small) 1

2 Insulating cover 1

3 Tie band (large) 6

4 Drain hose 1

5 Washer 8

Accessories Qty Place to Set

On the body frame

casing

3. Selecting an installation site

• Select a location so that air can be blown into all corners of the room.

• Avoid locations exposed to outside air.

• Select a location free of obstructions to the airflow in and out of the

unit.

• Avoid locations exposed to steam or oil vapour.

• Avoid locations where combustible gas may leak, settle or be gener-

ated.

• Avoid installation near machines emitting high-frequency waves (highfrequency welders, etc.)

• Avoid locations where the airflow is directed at a fire alarm sensor.

(Hot air could trigger the alarm during the heating operation.)

• Avoid places where acidic solutions are frequently handled.

• Avoid places where sulphur-based or other sprays are frequently used.

Warning:

Install the indoor unit on a ceiling strong enough to sustain its

weight.

If the ceiling lacks strength, it may cause the unit to fall down, resulting in an injury.

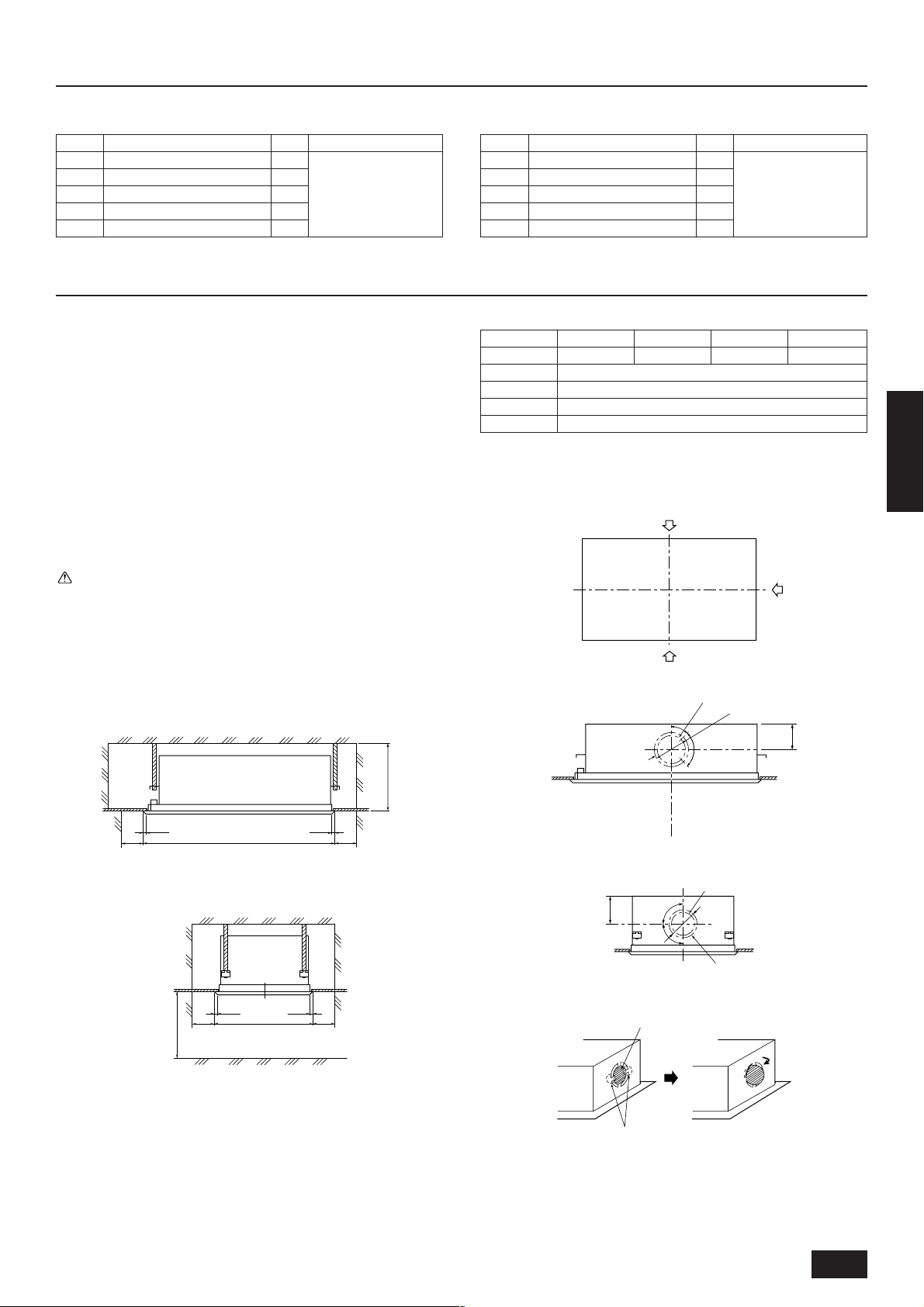

3.1. Securing installation and service

space

Part No.

6 Tie band (small) 2

7 Insulated pipe (large) 1

8 Piping manual 1

9 Tape 1

10

Model name 20 · 25 · 32 40 · 50 63 · 80 100 · 125

A 1060 1300 1650 2000

B More than 1000

C More than 500

D Lap: 20

E 360

Accessories Qty Place to Set

Connector for drain pump test

1

On the body frame

casing

3.2. Split flow duct end connection - fresh

air intake

A

D

A

B

45°

ø224

ENGLISH

E

D

C

B

• Select a blowout direction suited for room shape, installation site and

so on.

• Piping, wiring and maintenance are all done on the bottom and the

side. So, secure the space given above for such work. Also, taking

into consideration serviceability and safety in hanging, secure as large

space as possible.

A

D

C

670

D

C

D

C

181

E

F

D

90˚

90˚

90°

C

ø172

G

145

5

Page 6

• Knockouts are provided at each position as shown in the figure. Use

them for your purposes when installing the unit.

A Split flow duct end connection

B Split flow duct end connection (ø200 knockout on both sides)

C Fresh air intake (ø150 knockout)

D Fresh air intake

E To be cut

F 4-ø2.9 mounting hole

G 4-ø2.9 mounting hole

4. Fixing hanging bolts

Notes:

• Affixed on the back surface of each split flow duct end connection is insulating material. Use a cutter knife to cut the insulating material along the end connection.

• To adjust the fresh air intake capacity, cut the two places as

shown in the figure at right, and rotate the intake.

3.3. Combining indoor units with outdoor

units

For combining indoor units with outdoor units, refer to the outdoor unit

installation manual.

4.1. Fixing hanging bolts

(Use M10 hanging bolts. The bolts should be procured locally.)

ENGLISH

(Give site of suspension strong structure.)

Hanging structure

• Ceiling: The ceiling structure varies from building to one another. For

detailed information, consult your construction company.

1 Reinforcing the ceiling with additional members (edge beam, etc.)

must be required to keep the ceiling at level and to prevent the ceiling

from vibrations.

2 Cut and remove the ceiling members.

3 Reinforce the ceiling members, and add other members for fixing the

ceiling boards.

For wooden construction

• Use the tie beam (for one story building) or second-floor beam (for

two story building) as strength members.

• To hang the air-conditioner, use a hard square timber of more than

6 cm if the distance between beams is less than 90 cm and a hard

square timber of more than 9 cm if the distance between beams is

less than 180 cm.

E

E

A

B

A Ceiling board

B Edge beam

C Tie beam

D Square timber for hanging the air conditioner

E Pitch

C

D

For reinforced concrete construction

• As shown in the figure below, fix the hanging bolts, or use square

timbers to fix the hanging bolts.

H

F

G

F Insert: 100 to 150 kg (1 piece) (field supply)

G M10 hanging bolt (field supply)

H Reinforcement

Product Weight (kg)

Model name 20 · 25 32 40 50 63

Body frame 24 25 33.5 35 39 41 56

Panel 7 7 8 8 10 10 11.5

80 100 · 125

4.2. Ceiling hole and hanging bolt posi-

tions

• Use the gage supplied with the panel to fix hanging bolts so that the

unit body and ceiling hole are positioned in place as shown in the

figure below. For how to use the gage, refer to the instruction manual

supplied with the panel.

Notes:

• The gage may expand or shrink with changes in the temperature and humidity. First be sure to check the product dimensions, and then use the gage.

• The ceiling hole is adjustable as shown in the figure below. Align

the centers of both ceiling hole and unit body so that the unit

body is not biased to the ceiling hole and that the gaps between

the ceiling hole edges and the unit body’s external dimensions

come to be identical.

6

Page 7

• Use M10 hanging bolts (for all bolts). (field supply)

A

• Each hanging bolt must extrude Cmm from the ceiling. It is possible

to slide the unit body 15 mm max. within part of the heights of the

unit body and decorative panel in order to make fine installation adjustments to the finished ceiling surface. Sliding the unit body and

incorporating a high-performance filter requires the dimensions given

in the figure below. To this, attach nuts which will fix a hanging bracket

as shown in the figure.

A

B

A

C

B

F

B

50±10

D

G

A

C

A Nut

B Washer (supplied with the unit body)

C Hanging bolt ø10 (M10 screw)

D Ceiling hole dimensions

E Hanging bolt pitch

F Hanging bolt

G Finished ceiling surface

H Hanging bracket

Model name 20 · 25 · 32 40 · 50 63 · 80 100 · 125

A 1020 1260 1610 1960

B 816 1056 1406 1756

• α indicates a range of 0 to 15 mm.

Installation

example

Dimension C 338

Dimension D 143 143+α

For not sliding unit body For sliding unit body

338+α

(353 Max.)

ENGLISH

H

D 630

E 550 4040

E B 102102

D A

5. Installing the unit

5.1. Hanging the unit body

s Bring the indoor unit to an installation site as it is packed.

s To hang the indoor unit, use a lifting machine to lift and pass

through the hanging bolts.

s Install the indoor unit before ceiling work.

s When lifting with a lifting machine, in order to protect against

damage, reverse the unit body as is packed with the packing

cap and lift it.

B

C

D

A Drain pipe side

B Unit body

C Packing cap

D Lifting machine

7

Page 8

5.2. Confirming the unit’s position and

38

35070

476

20 20630

60 60

C

550

606

70 178

192

338-3538

2903-1845

135

52

B

D

A

E

fixing hanging bolts

s Use the gage supplied with the panel to confirm that the unit

body and hanging bolts are positioned in place. If they are not

positioned in place, it may result in dew drops due to wind leak.

Be sure to check the positional relationship.

s Use a level to check that the surface indicated by A is at level.

Ensure that the hanging bolt nuts are tightened to fix the hanging bolts.

s To ensure that drain is discharged, be sure to hang the unit at

level using a level.

Caution:

Be sure to install the unit body at level.

ENGLISH

6. Refrigerant pipe and drain pipe specifications

A

B Indoor unit’s bottom surface

(Surface to which a decorative panel is attached)

B

To avoid dew drops, provide sufficient antisweating and insulating work

to the refrigerant and drain pipes.

When using commercially available refrigerant pipes, be sure to wind

commercially available insulating material (with a heat-resisting temperature of more than 100°C and thickness given below) onto both liquid and

gas pipes.

Be also sure to wind commercially available insulating material (with a

form polyethylene’s specific gravity of 0.03 and thickness given below)

onto all pipes which pass through rooms.

1 Select the thickness of insulating material by pipe size.

Pipe size Insulating material’s thickness

6.4 mm to 25.4 mm More than 10 mm

28.6 mm to 38.1 mm More than 15 mm

2 If the unit is used on the highest story of a building and under condi-

tions of high temperature and humidity, it is necessary to use pipe

size and insulating material’s thickness more than those given in the

table above.

3 If there are customer’s specifications, simply follow them.

6.1. Refrigerant pipe and drain pipe

specifications

Model

Item

Refrigerant pipe

(Flare connection)

Drain pipe VP-25

Liquid pipe ø6.35 ø9.52

Gas pipe ø12.7 ø15.88 ø19.05

20·25·32·40 50·63·80 100 · 125

6.2. Refrigerant pipe , drain pipe and filling port

A Refrigerant pipe (liquid pipe): HP

B Drain pipe

C Hanging bolt pitch

D Refrigerant pipe (gas pipe): LP

E Filling port

8

Page 9

6.3. Request for refrigerant piping connection

C

B

A

DE

F

G

*2

20

20

20

20

C

B

A

*3

*4

Description of parts to be used

No.

1

2

3

Work procedures

Mount the provided pipe insulation (1) on the liquid pipe

of the refrigerant piping, and

then mount the flare insulation (2) on the gas pipe.

Fixing of insulated pipe

Fixing of flare insulation

Detail of work

“INNER” and “OUTER” are marked on

the inside of the flare insulation. Mount

the portion marked “INNER” near the

unit body and the portion marked

“OUTER” on the field piping side.

• Fasten the insulated pipe with the in-

sulation tape.

• Firmly secure the insulation with the

provided tie band (4) at the position

indicated on the drawing.

• Fasten the flare insulation with the pro-

vided tape (3).

• Fasten with the provided tie band (4)

at the position indicated on the drawing.

Item to be observed

• Using the flare insulation of a different model

may result in condensation forming. Check

the model name on the insulation and be sure

to use the correct one.

• To prevent a gap from forming near the unit’s

side plate, be sure that the flare insulation

firmly contacts the unit’s side plate before

mounting.

• Incorrectly mounting the “INNER” and

“OUTER” sides of the insulation may result

in condensation forming.

Seal the slit securely so that there are no openings. Be sure to mount the insulation so that

the slit is on the top.

Seal the slit securely so that there are no openings. Be sure to mount the insulation so that

the slit is on the top.

Reference drawing

Fig-1

Fig-2 (Note *2)

Fig-2

Fig-3 (Note *3)

Fig-3 (Note *4)

ENGLISH

A

C

D

L

A “0-0 gas” mark

B “INNER” mark

C “OUTER” mark

D Flare insulation (2)

E Refrigerant piping (gas)

F Refrigerant piping (liquid)

G Field refrigerant piping

H Pipe insulation (1)

I Insulation material

J Flare

K Pull in this direction.

L Insulation material

M Flare

N There must be no gap.

O Move to the original position.

B

G

O

K

Fig-1

*1

N

M

E

F

H

Fig-2 (figure showing the flare insulation)

JI

A Field refrigerant piping E INNER

B There must be no gap. F Unit body

C Unit body plate G Provided flare insulation (2)

D OUTER

Fig-3

A Tape (3) C Provided tie band (4)

B Fasten with tape.

Notes:

*1 Insert the flare nut into the field refrigerant piping. Pull the

insulation material back at the area where it will be flared,

then return it to its original position after performing the

flare work.

Exposing copper piping may result in condensation form-

ing. Be extremely careful when performing this operation.

*2 There must be no gap.

*3, *4 There must be no gap. Slit should be on the top.

9

Page 10

7. Connecting refrigerant pipes and drain pipes

7.1. Refrigerant piping work

This piping work must be done in accordance with the installation manual

for the outdoor unit.

• For constraints on pipe length and allowable difference of elevation,

refer to the outdoor unit manual.

• The method of pipe connection is flare connection.

H

I

Cautions on refrigerant piping

ss

s Be sure to use non-oxidative brazing for brazing to ensure that

ss

no foreign matter or moisture enter into the pipe.

ss

s Be sure to apply refrigerating machine oil over the flare connec-

ss

tion seating surface and tighten the connection using a double

spanner.

ss

s Provide a metal brace to support the refrigerant pipe so that no

ss

ENGLISH

load is imparted to the indoor unit end pipe. This metal brace

should be provided 50 cm away from the indoor unit’s flare connection.

Warning:

Do not mix anything other than the specified refrigerant (R-22) into

the refrigerating cycle. Mixing air may cause the refrigerating cycle

to get abnormally high temperature, resulting in a burst.

7.2. Drain piping work

C

A B

A

1

A: 25 cm

B: 1.5 – 2 m

A Downward pitch of more than 1/100

B Insulating material

C Metal brace

E

F

2

B

DDD

G

J

C

D

K I

C: 30 cm

G Drain hose (Accessory)

ss

s Be sure to use the supplied drain hose (Accessory).

ss

H Less than 300 mm

I Hard vinyl chloride 90° elbow (field supply)

J Hard vinyl chloride (VP-25) (field supply)

K Tie band (small) (Accessory)

ss

s Connect each connection with vinyl chloride adhesive. But never

ss

use any adhesive over the indoor unit discharge port. Otherwise the drain-up mechanism cannot be serviced later. Also,

the end connection may be eroded by resin and so cracked.

1. Ensure that the drain piping is downward (pitch of more than 1/100)

to the outdoor (discharge) side. Do not provide any trap or irregularity on the way. (1)

2. Ensure that any cross-wise drain piping is less than 20 m (excluding

the difference of elevation). If the drain piping is long, provide metal

braces to prevent it from waving. Never provide any air vent pipe.

Otherwise drain may be ejected.

3. Use a hard vinyl chloride pipe VP-25 (with an external diameter of 32

mm) for drain piping.

4. Ensure that collected pipes are 10 cm lower than the unit body’s

drain port as shown in 2.

5. Do not provide any odor trap at the drain discharge port.

6. Put the end of the drain piping in a position where no odor is generated.

7. Do not put the end of the drain piping in any drain where ionic gases

are generated.

8. The intake of the drain piping can be made 30 cm higher than the

drain discharge port. If there are some obstacles under the ceiling,

use elbows to make it at least height according to the site. (3)

3

D Indoor unit

E Take as large as possible. About 10 cm

F Collected pipes

10

Note:

If the rise portion is long, there will be a lot of returned water in an

operation stop, generating slime or odor during off-season. Ensure that the rise portion is at a minimum.

Caution:

Pipe the drain piping to ensure that it discharges drain, and insulate it to prevent dew condensation. A failure to the piping work

may cause water leakage and so wet your property.

Page 11

7.3. Confirming drain discharge

ss

s Make sure that the drain-up mechanism operates normally for

ss

discharge and that there is no water leakage from the connections.

• Be sure to confirm the above in a period of heating operation.

• Be sure to confirm the above before ceiling work is done in the case

of a new construction.

1. Plug the drain pump test connector (accessory) into the connector

on the same side as the control box. For more details, see the information on the control box cover.

2. Remove the polyethylene plug on the same side as the indoor unit

piping.

3. Fill water into the feed water pump using a feed water tank. In filling,

be sure to put the end of the pump or tank in a drain pan. (If the

insertion is incomplete, water may flow over the machine.)

4. Turn on the main power. The drain pump is forced to operate without

any remote controller operation. Make sure using a transparent hose

that drain is discharged.

5. After confirmation, turn off the main power, remove the connector,

and insert the polyethylene plug into its original position.

B

A Insert the pump’s end 2 to 4 cm.

B Remove the polyethylene plug.

C About 1000 ml

D Water

E Filling port

A

E

C

D

8. Electrical wiring

Precautions on electrical wiring

Warning:

Electrical work should be done by qualified electrical engineers in

accordance with “Engineering Standards For Electrical Installation”

and supplied installation manuals. Special circuits should also be

used. If the power circuit lacks capacity or has an installation failure, it may cause a risk of electric shock or fire.

1. Be sure to take power from the special branch circuit.

2. Be sure to install an earth leakage breaker to the power.

3. Install the unit to prevent that any of the control circuit cables (remote

controller, transmission cables) is brought in direct contact with the

power cable outside the unit.

4. Ensure that there is no slack on all wire connections.

5. Some cables (power, remote controller, transmission cables) above

the ceiling may be bitten by mouses. Use as many metal pipes as

possible to insert the cables into them for protection.

ENGLISH

6. Never connect the power cable to leads for the transmission cables.

Otherwise the cables would be broken.

7. Be sure to connect control cables to the indoor unit, remote controller, and the outdoor unit.

8. Put the unit to the ground on the outdoor unit side.

9. Select control cables from the conditions given in page 12.

Caution:

Be sure to put the unit to the ground on the outdoor unit side. Do

not connect the earth cable to any gas pipe, water pipe, lightening

rod, or telephone earth cable. Incomplete grounding may cause a

risk of electric shock.

11

Page 12

EF

C

20 ~ 80

Types of control cables

1. Wiring transmission cables

• Types of transmission cables

Design wiring in accordance with the following table <Table 1>.

• Cable diameter

More than 1.25 mm

<Table 1>

System configuration For a single-refrigerant system For a multi-refrigerant system

Transmission cable length Less than 120 m More than 120 m Regardless of length

Facility example

(for noise judgment)

Types of transmission

cables

ENGLISH

2. Remote controller cables

Types of cables

Cable diameter More than 0.5 to 0.75 mm

Length

2

Building, clinic, hospital or communica-

tions station without noise supposedly

Residence or independent

store without noise

VCTF, VCTFK, CVV, CVS,

VVR, VVF, VCT or shielding

wire CVVS or CPEVS

Network remote controller

Non-shielding wire for up to 10 m; the same specifications as “1.” Wiring transmission cables for

more than 10 m

2

Add any portion in excess of 10 m to within

the longest allowable transmission cable length

200 m (Shielding portion is more than 1.25 mm2)

generated from inverter equipment, private power generator, high-frequency

medical equipment, radio-used communications equipment and so on

Shielding wire CVVS or CPEVS

GH

All facilities

C

100 · 125

8.1. Power supply wiring

Power cable size (diameter) if optional heater is not attached: more

than 1.6 mm

AB

DE

CCCCCCC

E Switch 15 A

F Overcurrent protection 15 A

G Switch 30 A

H Overcurrent protection 20 A

Caution:

Do not use anything other than the correct capacity breaker and

fuse. Using fuse, wire or copper wire with too large capacity may

cause a risk of malfunction or fire.

A Switch 15 A

B Overcurrent protection 15 A

C Indoor unit

D Total operating current be less than 15 A

E Pull box

[Selecting non-fuse breaker (NF) or earth leakage breaker (NV)]

To select NF or NV instead of a combination of Class B fuse with switch,

use the following:

• In the case of Class B fuse rated 15 A or 20 A,

NF model name (MITSUBISHI): NF30-CS (15 A) (20 A)

NV model name (MITSUBISHI): NV30-CA (15 A) (20 A)

Use an earth leakage breaker with a sensitivity of less than 30 mA 0.1 s.

8.2. Connecting remote controller, indoor

and outdoor transmission cables

(Remote controller is optionally available.)

• Connect indoor unit TB5 and outdoor unit TB3. (Non-polarized 2-

wire)

The “S” on indoor unit TB5 is a shielding wire connection. For speci-

fications about the connecting cables, refer to the outdoor unit instal-

lation manual.

• Install a remote controller following the manual supplied with the re-

mote controller.

12

Page 13

[For using a network remote controller]

Connect the “M1” and “M2” on indoor unit TB5 to a network remote controller. (Non-polarized 2-wire) Connect the remote controller’s transmission cable within 10 m using a 0.75 mm2 core cable. If the distance is

more than 10 m, use a 1.25 mm2 junction cable.

8.3. Connecting electrical connections

(Be sure to prevent terminal screws from loosening.)

1. Remove 2 screws which secures the terminal bed box cover using a

screwdriver. (1)

AD

TB5

SM1M2

TB5

SM1M2

C

E

TB3

SM2M1

B

A Terminal bed for indoor transmission cable

B Terminal bed for outdoor transmission cable

C Indoor unit

D After indoor unit

E Field supply

F Network remote controller

• DC24 to 30 V between M1 and M2

Longest wiring length (L1+L2+L4 or L1+L3 or L2+L3+L4): less than 200 m

Length between indoor unit and remote controller (R): within 10 m

Notes:

*1 Put the transmission cable earth via the outdoor unit’s earth

terminal to the ground.

*2 If the remote controller cable exceeds 10 m, use a 1.25 mm2 di-

ameter cable over the exceeded portion, and add that exceeded

portion to within 200 m.

PARF25M/F26M

F

A

B

C

1

A Side frame

B Cover

C Cover securing screw (2 places)

2. As shown at 2, wire the power supply, transmission cable and re-

mote controller. There is no need to remove the terminal bed box.

D

G

Power Source

NL

Transmission

M1 M2 S

ENGLISH

[Constraints on transmission cable]

*1

G

H

III

L1

II

G Outdoor unit

H Earth

I Indoor unit

J Remote controller

K Non-polarized 2-wire

L2

K

L3

I

F

E

H

2

*2

JJ

J

L4

l

K

12

J

JF

<Viewed from bottom of the terminal bed box>

D Terminal bed for transmission cable

E Transmission cable

(To terminal bed for remote controller, indoor unit and BC controller)

F To single-phase power supply

G Terminal bed for power supply

H To terminal bed for outdoor transmission cable

(Use shielding earth cable

I Non-polarity

J Network remote controller

K DC24 to 30 V

on outdoor unit side.)

• Fix power source wiring to terminal bed box by using buffer bushing

for tensile force. (PG screw connection or the like.) Connect trans-

mission wiring to transmission terminal bed through the knockout

hole of terminal bed box using ordinary bushing.

13

Page 14

3. After wiring is complete, make sure again that there is no slack on

the connections, and attach the cover onto the terminal bed box in

the reverse order of removal.

Caution:

Wire the power supply so that no tension is imparted. Otherwise

disconnection, heating or fire may result.

• How to set addresses

Example: If Address is “3”, remain SW12 (for 1 to 9) at “0”, and match

SW11(for over 10) with “3”.

• The rotary switches are all set to “0” when shipped from the factory.

These switches can be used to set unit addresses at will.

• The determination of indoor unit addresses varies with the system at

site. Set them referring to technical data.

8.4. Setting addresses

(Be sure to operate with the main power turned OFF.)

ENGLISH

<Address board>

W254613G03

FP-AD-S

3

2

1

MADE IN JAPAN

@\ •

ON

1

JP1

Iv

V

W

SWCSWA

SW1

( • ‡/Ao • L)

0

240V 220V

SW14

SW5

yA

N0

“ß

N0

10

SW12

0

10

'¨Ah X

CN828161

SW11

0

˚

1

˚

CN62

JP2

JP3

JP4

8.5. Sensing room temperature with the

built-in sensor in a remote controller

If you want to sense room temperature with the built-in sensor in a remote controller, set SW1-1 on the control board to “ON”. The setting of

SW1-7 and SW1-8 as necessary also makes it possible to adjust the air

flow at a time when the heating thermometer is OFF.

14

Page 15

9. Test run

^]/ ~|

” @Ah XNo

G [No

A fi @Ah XNo

˚C

XC O

– @\˝Ł„æ

˚C

tB ^[

ª”‹†•

^C}[/A–

^] •

_[o[

^]• C •”•†

lbg [N R

PAR-F26M

W ˙

A – ^C}[

_ Ł•x

ZT[

tB ^[

_

^ ]

R

{

» Jn I„

hC[

' fi

@@@g[

g[ ı

P

Ł L ł

• C›ª

‹

A

D

B

C

E

2

5

9

4

3

6

ss

s Read the operation manual, too.

ss

• After installing, piping and wiring indoor and outdoor units, make sure

again that there is no refrigerant leakage, no slack on the power and

transmission cables, or no polarity incorrectness.

• Make sure using a DC 500 V megger that the resistance between

the power terminal bed and ground is more than 1.0 MΩ. If less than

1.0 MΩ, do not operate the unit.

Warning:

Never measure the insulation resistance of the terminal bed for

transmission cables.

Operational procedure

1 Turn ON power at least 12 hours before operation

2 Press [TEST RUN] button twice → displaying “TEST RUN” on the

screen

3 Press [Selecting operation] button → Check that wind is blowing out

4 Press [Selecting operation] button to change over to cooling (or heat-

ing) → Check that cool (or warm) air is blowing out

5 Press [Fan speed adjustment] button → Check that the wind speed

is changed

6 Press [Up/down airflow selection] button to change wind direction →

Check that the wind direction is adjustable for horizontal or downward blowing

7 → Check that the outdoor unit fan is operating

8 Check that interlocking devices such as ventilator are operating if

any

9 Press [ON/OFF] button to clear test run → Test run stops

A Lighting in operation

B Displaying inspection code

C Displaying remaining test run time

D Displaying indoor unit’s liquid pipe temperature

E Displaying test run

Notes:

• If the remote controller shows an inspection code or does not

operate normally, refer to the outdoor unit installation manual.

• The 2-hour-set timer is activated to automatically stop test run

after two hours.

• The remote controller displays the remaining test run time on

the time display section during test run.

• The remote controller displays the temperature of the indoor

unit’s liquid pipe on the temperature display section during test

run.

• Depending on the model, the remote controller displays “This

function is not available” when pressing the [Up/down airflow

selection] button. This is not a malfunction.

ENGLISH

15

Page 16

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

WT02174X02

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

HEAD OFFICE MITSUBISHI DENKI BLDG MARUNOUCHI TOKYO 100 TELEX J24532 CABLE MELCO TOKYO

Printed in Japan

Loading...

Loading...