Mitsubishi PKFY-08NAMU-A, PKFY-12NGMU-A, PLFY-20NAMU-A, PKFY-20NFMU-A, PLFY-12NAMU-A Technical & Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

L

I

S

T

E

D

CUS

CITY MULTI Indoor Unit

TECHNICAL & SERVICE MANUAL

No. OC291

CITY MULTI Series

[Models]

PKFY-08NAMU-A

PKFY-12NGMU-A

PKFY-20NFMU-A

PKFY-32NFMU-A

CITY MULTI Series

[Models]

PLFY-12NAMU-A

PLFY-20NAMU-A

PLFY-24NAMU-A

PLFY-32NAMU-A

PLFY-40NAMU-A

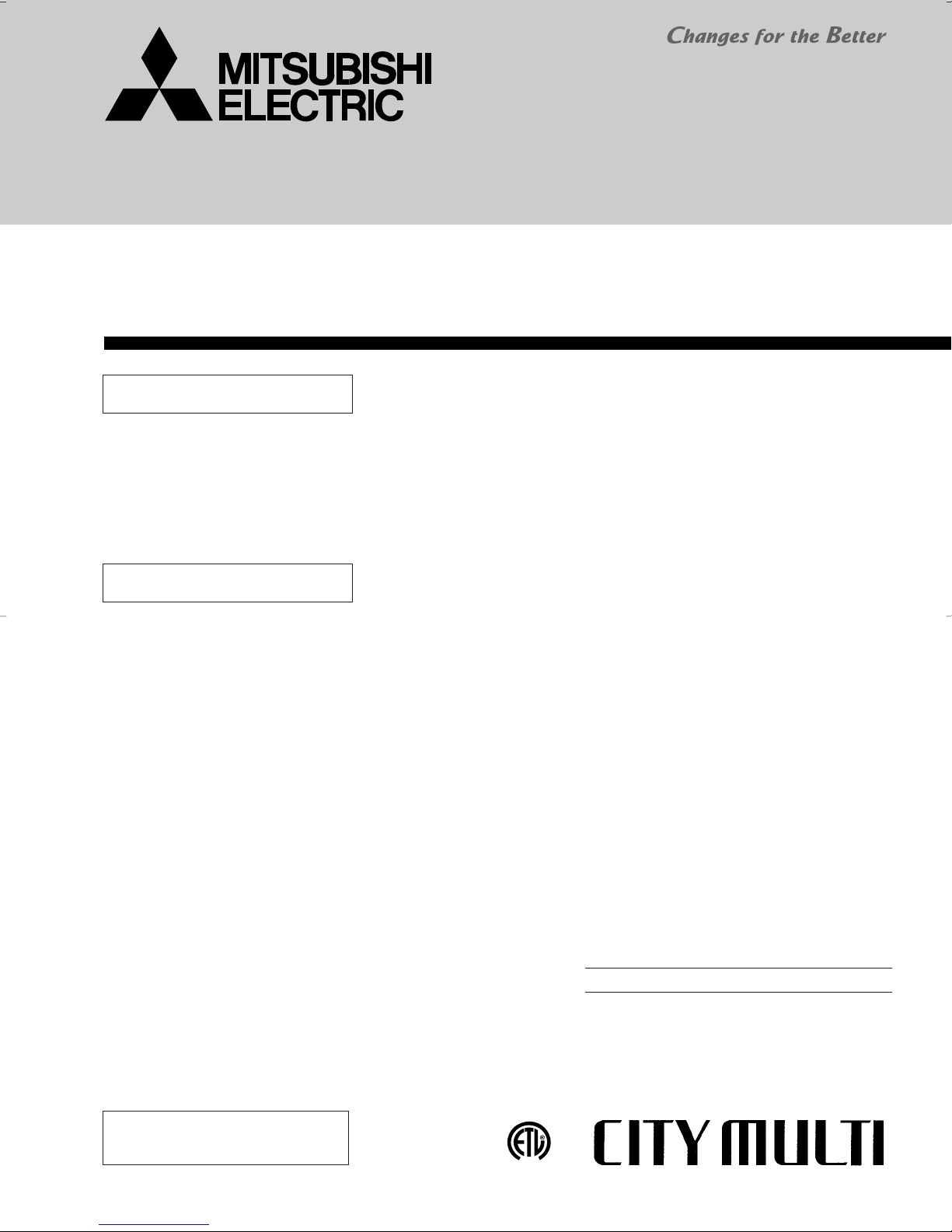

Wall Mounted Type

Ceiling Cassettes Type

• Connected outdoor unit is

PURY-80TMU or PURY-100TMU.

CONTENTS

1. PKFY-•MU-A Type ····················OC292-1

2. PLFY-•NAMU-A Type ···············OC290-1

PKFY-08NAMU-A

PKFY-12NGMU-A

PKFY-20NFMU-A

PKFY-32NFMU-A

CONTENTS

1. DIFFERENCES····························································································OC292- 3

2. FEATURES ··································································································OC292- 4

3. PART NAMES AND FUNCTIONS·······························································OC292- 7

4. SPECIFICATIONS ·······················································································OC292-10

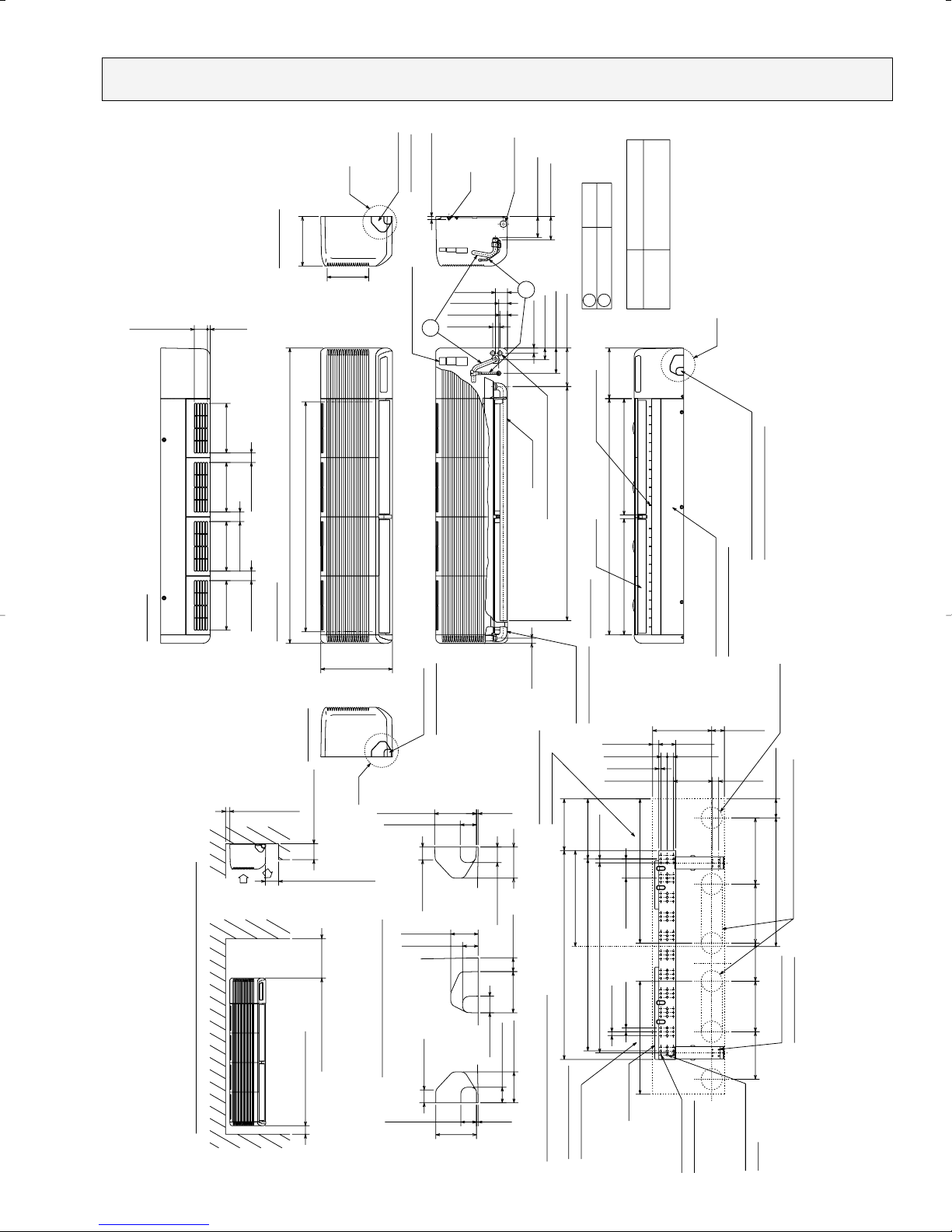

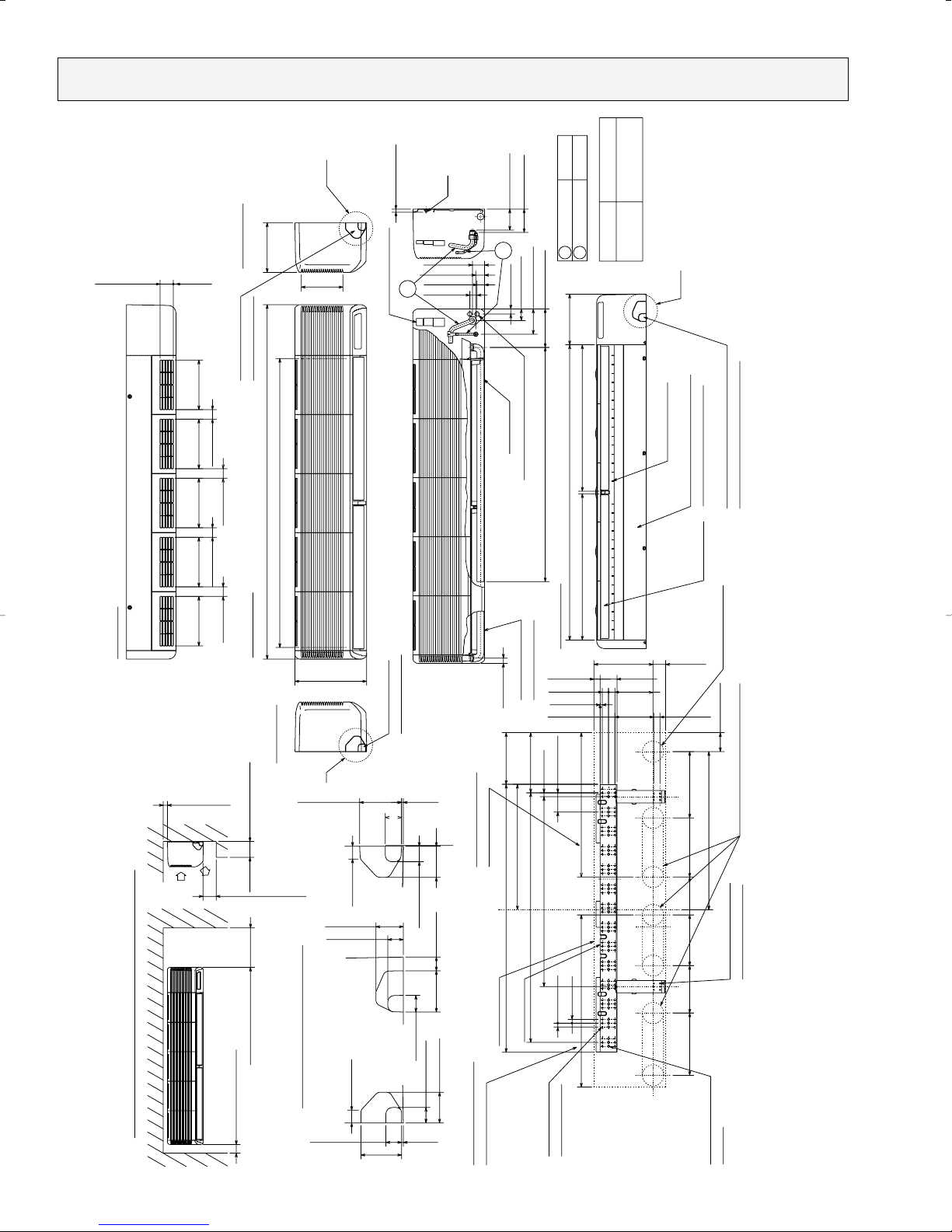

5. OUTLINES AND DIMENSIONS···································································OC292-17

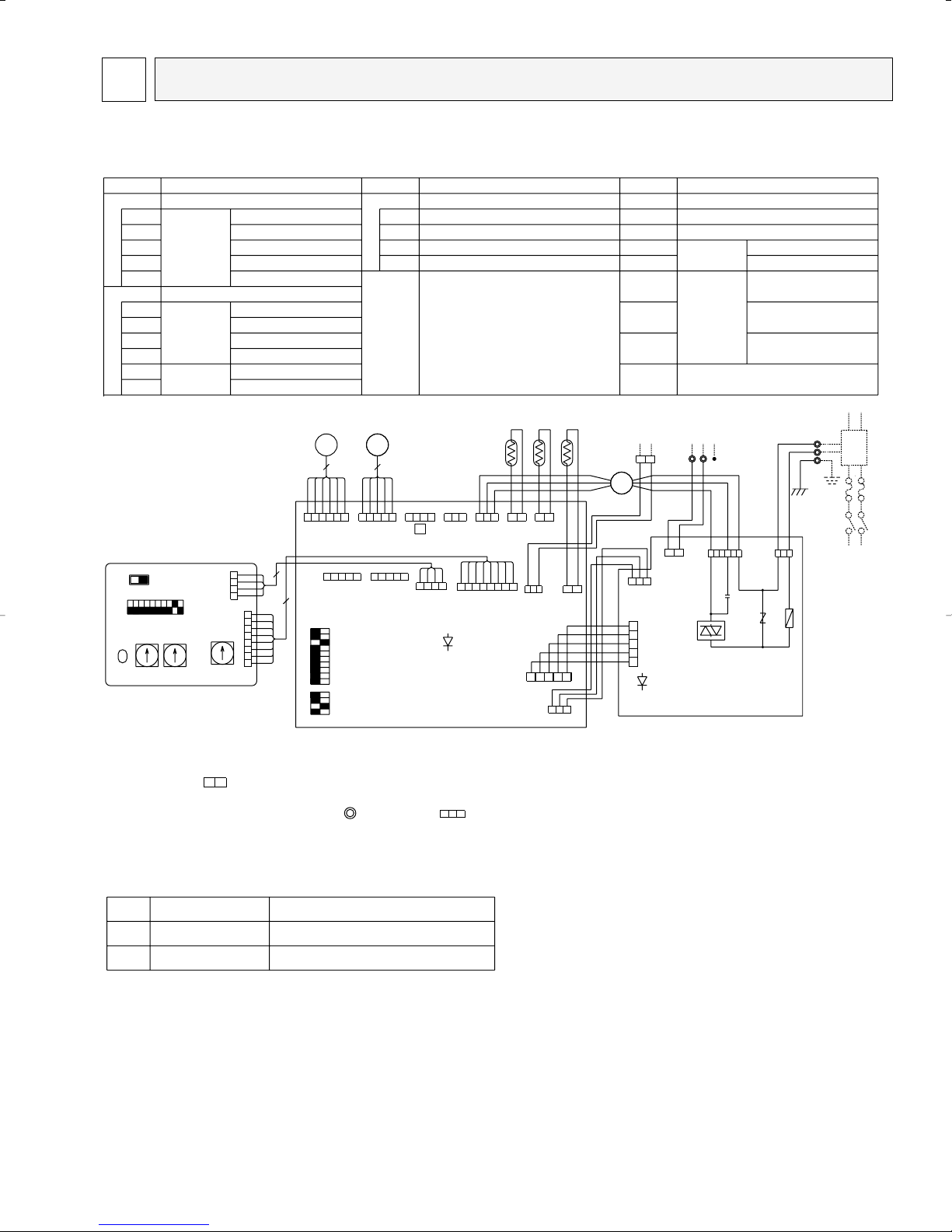

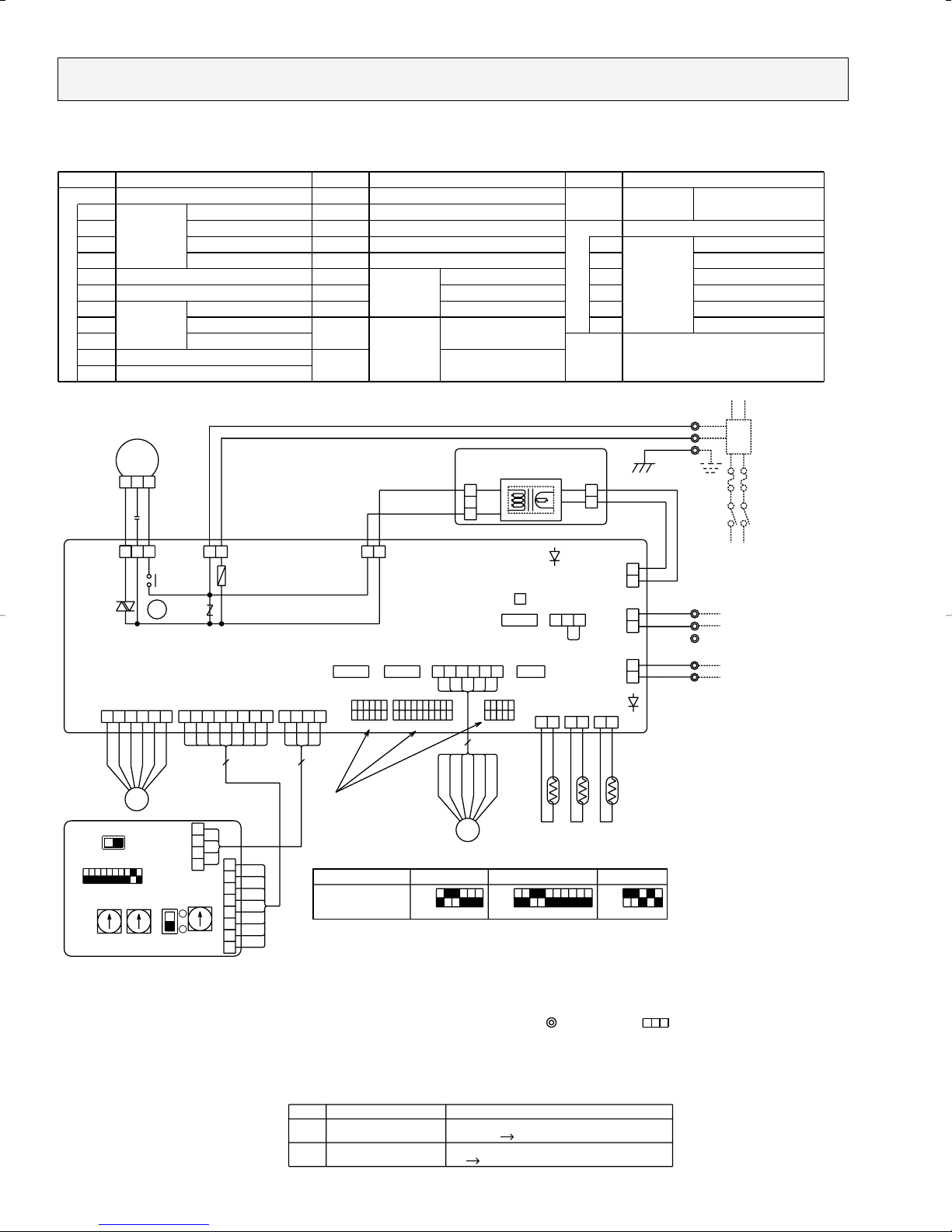

6. WIRING DIAGRAM······················································································OC292-21

7.

REFRIGERANT SYSTEM DIAGRAM

8. MICROPROCESSOR CONTROL ·······························································OC292- 25

9. TROUBLESHOOTING ·················································································OC292-33

10. DISASSEMBLY PROCEDURE ···································································OC292- 42

11. PARTS LIST·································································································OC292-51

····························································OC292-24

OC292-1

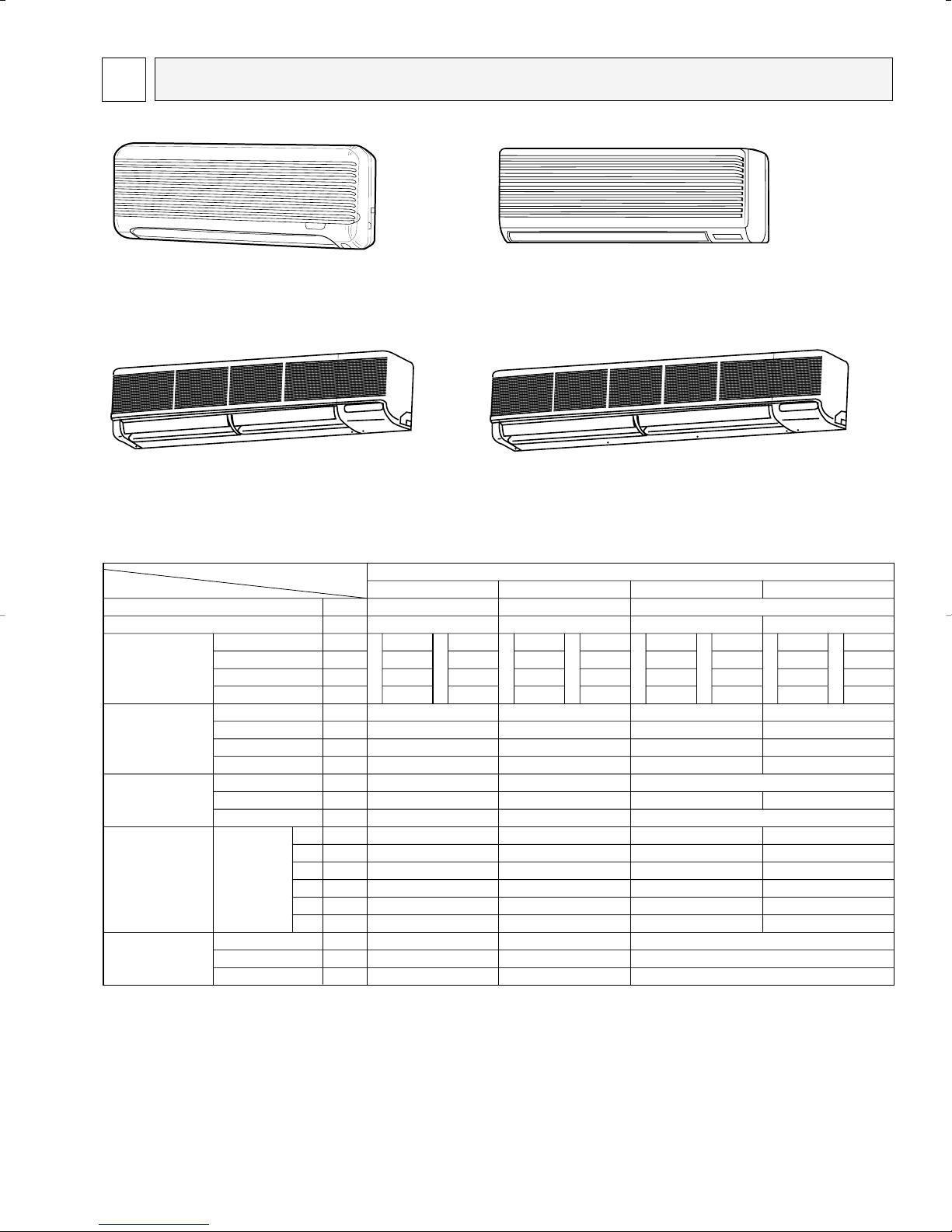

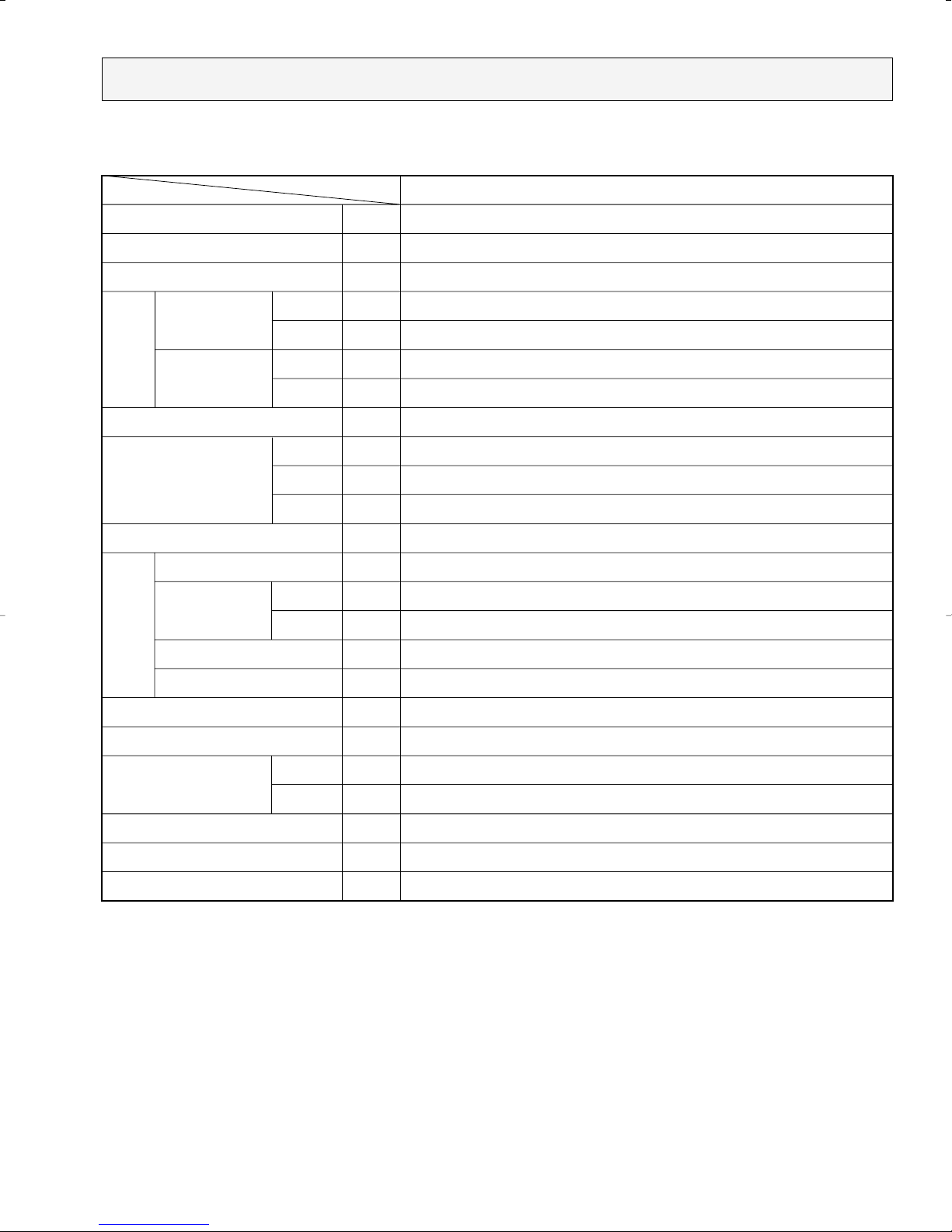

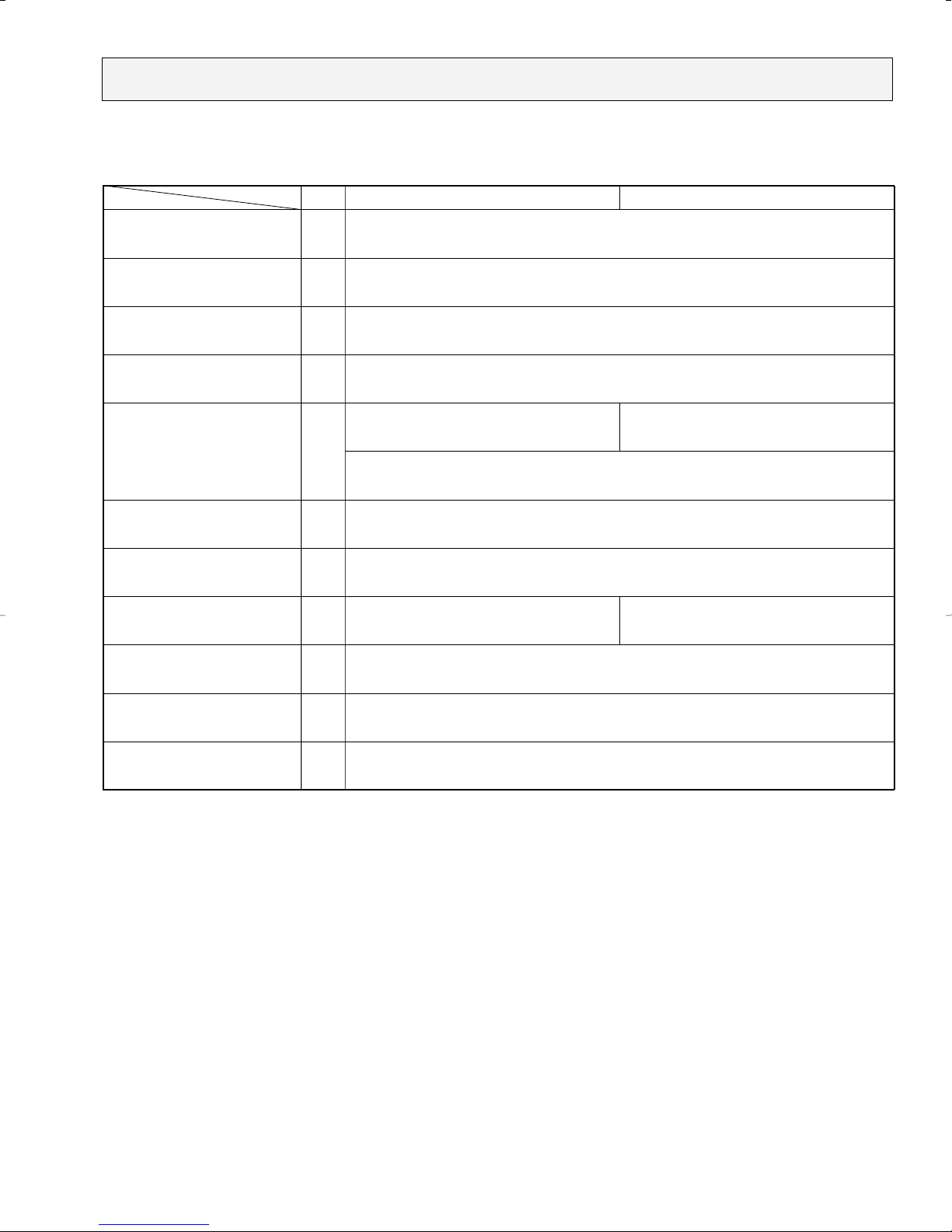

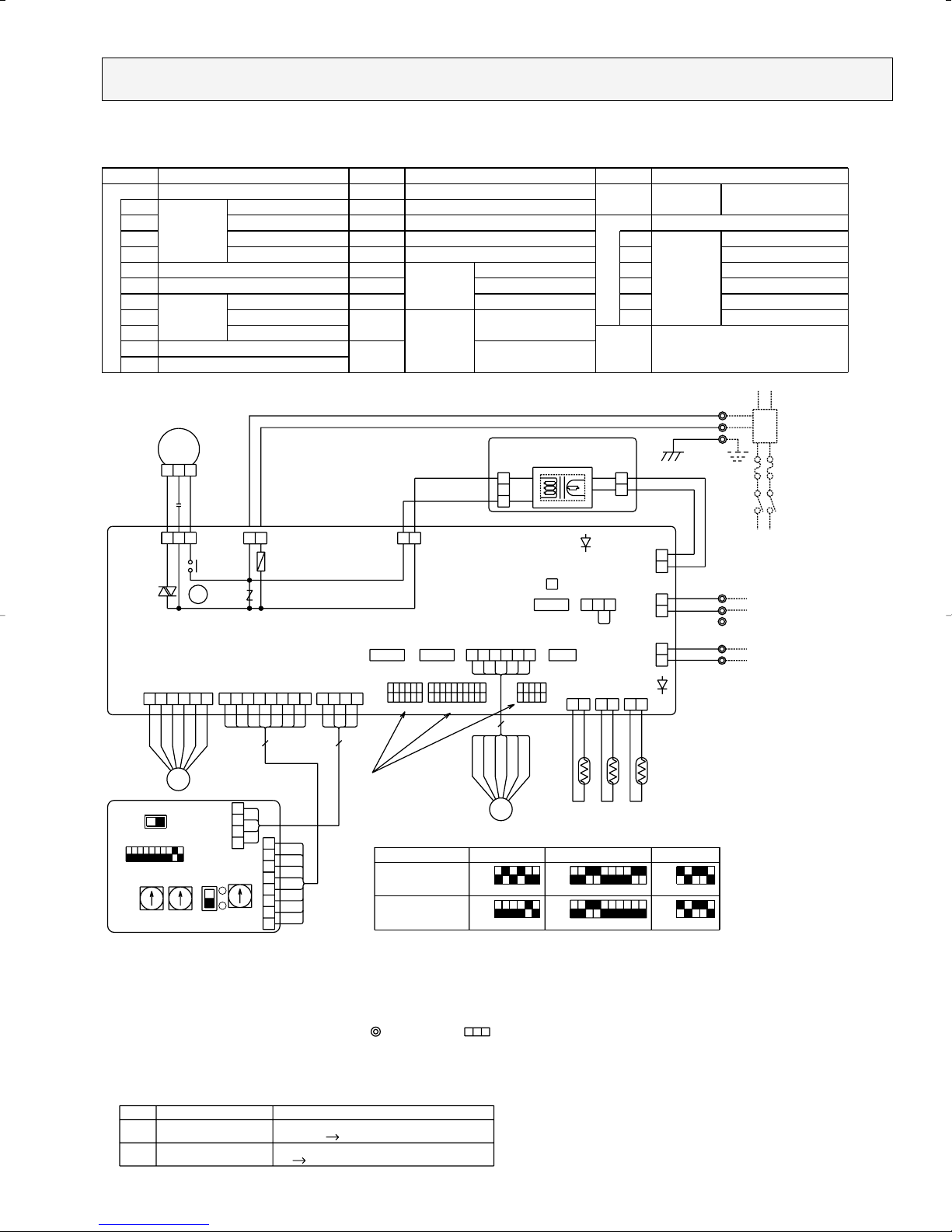

DIFFERENCES1

Lineflow fan ✕ 2

13-3/8

9-1/4

5/8"

3/8"

O.D. 13/16"

Item

Model

Fan

Fan speed

Air flow

Noise level

Out dimension

Controller board

Pipe dimension

—

—

CFM

CFM

CFM

CFM

dB

dB

dB

dB

in.

in.

in.

—

—

—

—

—

—

in.

in.

in.

1

2

3

4

5

6

High

Medium 1

Medium 2

Low

High

Medium 1

Medium 2

Low

Height

Width

Depth

SW2

Gas side

Liquid side

Drain(unit side)

08NAMU-A

Lineflow fan ✕ 1

4 speeds type

36

35

33

32

11-5/8

32-3/32

6-7/32

OFF

OFF

ON

OFF

—

—

1/2"

1/4"

O.D. 5/8"

12NGMU-A

Lineflow fan ✕ 1

4 speeds type

42

40

36

32

13-3/8

39

9-1/4

OFF

ON

ON

OFF

OFF

OFF

1/2"

1/4"

O.D. 13/16"

20NFMU-A

2 speeds type

45

—

—

39

55-1/8

OFF

ON

OFF

ON

OFF

OFF

32NFMU-A

2 speeds type

49

—

—

46

66-1/8

OFF

OFF

OFF

OFF

ON

OFF

PKFY-

210

200

180

170

190

180

170

160

D

R

Y

W

E

T

410

370

340

280

370

330

300

250

D

R

Y

W

E

T

640

—

—

490

570

—

—

440

D

R

Y

W

E

T

990

—

—

780

890

—

—

700

D

R

Y

W

E

T

PKFY-08NAMU-A

Indoor Unit

PKFY-20NFMU-A

Indoor Unit

Differences among the models of PKFY series.

PKFY-12NGMU-A

Indoor Unit

PKFY-32NFMU-A

Indoor Unit

OC292-3

2

FEATURES

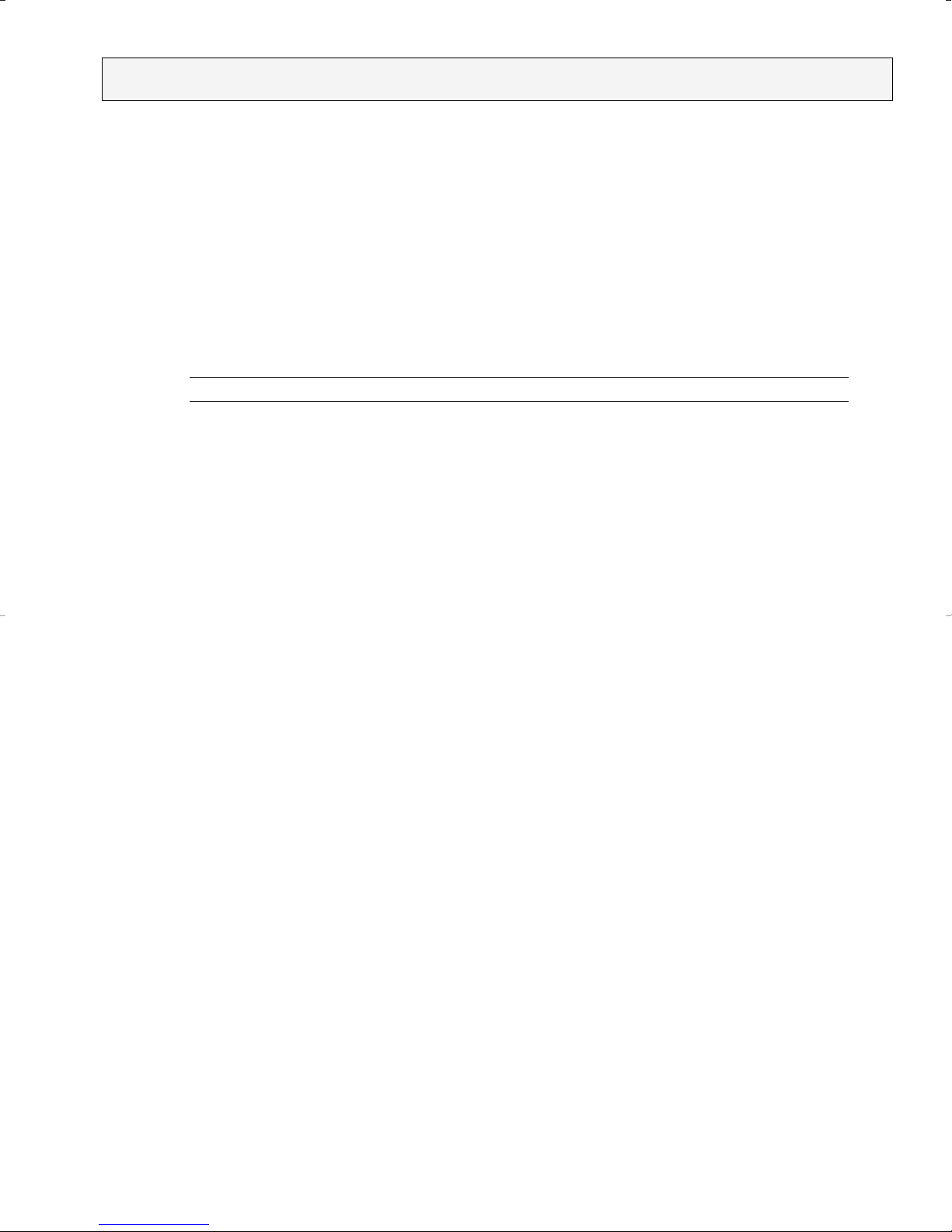

PKFY-08NAMU-A

Indoor Unit

Microprocessor

Remote controller

Model Cooling capacity / Heating capacity

PKFY-08NAMU-A 8,000/9,000 Btu/h

2-1. New Compact Design

• Compact 11-5/8 inch (29.5cm) high body fits snugly in even limited spaces.

• Light weight 19lbs (8.5kg) unit easy to transport and install.

2-2. Auto-flap shutter Enhances good Looks

With a simple flick of the OFF switch the air outlet can be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle” securing a comfortable air flow.

2-3. Front power supply box for easier wiring even after installation

The front power supply box allows electrical wiring work to be done after the indoor unit has been installed. For easier

installation, all the screws required for securing the indoor unit to the wall are accessible from the front of the unit.

2-4. 4-way piping provides more flexibility in selecting installation sites

All piping including drainage can be connected from the rear, right, base, and left of the unit, providing much greater

flexibility out piping and selecting installation site.

OC292-4

PKFY-12NGMU-A

Indoor Unit

Microprocessor

Remote controller

Model Cooling capacity / Heating capacity

PKFY-12NGMU-A 12,000 / 12,500 Btu/h

2-1. New Compact Design

Units have now been downsized to require minimal wall space.

A20% reduction in width 38-31/32 inch (990mm) compared to previous models means that installation is possible in very narrow spaces.

2-2. Auto-flap shutter Enhances Good Looks

With a simple flick of the OFF switch the air outlet can be closed off with a with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle” securing a comfortable air flow.

2-3. The Intake Grille Filter Can be Completely Removed Allowing Easy Cleaning

(Can be washed in water)

• Front grille

opens out

2-4. Quiet Operation

•Airflow passage configuration that assures quiet operation

1 The unit incorporates a randompitch cycling fan.

By changing fan intervals, quiet operation is achieved

without reduction in airflow. Optimal design of the

airflow passage gives a shortened fan diameter

and allows a highly compact installation.

2 Thanks to a highly practical casing configuration,

airflow generated by the fan is distributed uniformly.

3 Due to careful positioning of the vertical vane axis,

air is blown evenly from the outlet. This prevents mixing

with secondary air and also suppresses condensation.

2-5. 4-way Piping Provides more Flexibility in Selecting Installation Sites

OC292-5

PKFY-20NFMU-A

PKFY-32NFMU-A

Indoor Unit

Microprocessor

Remote controller

Models Cooling capacity / Heating capacity

PKFY-20NFMU-A 20,000 / 22,500 Btu/h

PKFY-32NFMU-A 32,000 / 35,500 Btu/h

2-1. COMPACT DESIGN

The PKFY series models have been downsized and now require such minimal wall space that they can even be

installed above windows. For the PKFY series models, 14-9/16 inch (37 cm) of wall space between the ceiling and the

window allows “above window” installation.

2-2. A FURTHER REFINEMENT OF COMFORT WITH NISE SUPPRESSION

Remarkably tow-noise operation has been achieved through the development of a “near -silent” fan and the design

which minimises air flow resistance.

2-3. AUTO FLAP SHUTTER

With a simple flick of the OFF switch the air outlet can be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle” securing a comfortable air flow.

2-4. INSTALLATION : FAST AND ENDLESSLY ADAPTABLE

(1) Multi-directional piping

Multi directional drain and refrigerant piping radically improves flexibility in selecting installation layouts.

PKFY- • NFMU-A models boast refrigerant piping in 4 directions and drain piping 2 directions.

(2) Back plate installation guide

The back plate installation guide gives clear instructions on installation positions. The enlarged back plate secures the

unit firmly to the wall, while the support piece which lifts the unit makes left side piping work much easier.

(3) Easily removable filter

The presence of thumbscrews on the filters means that the filters can be quickly and smoothly removed.

OC292-6

3

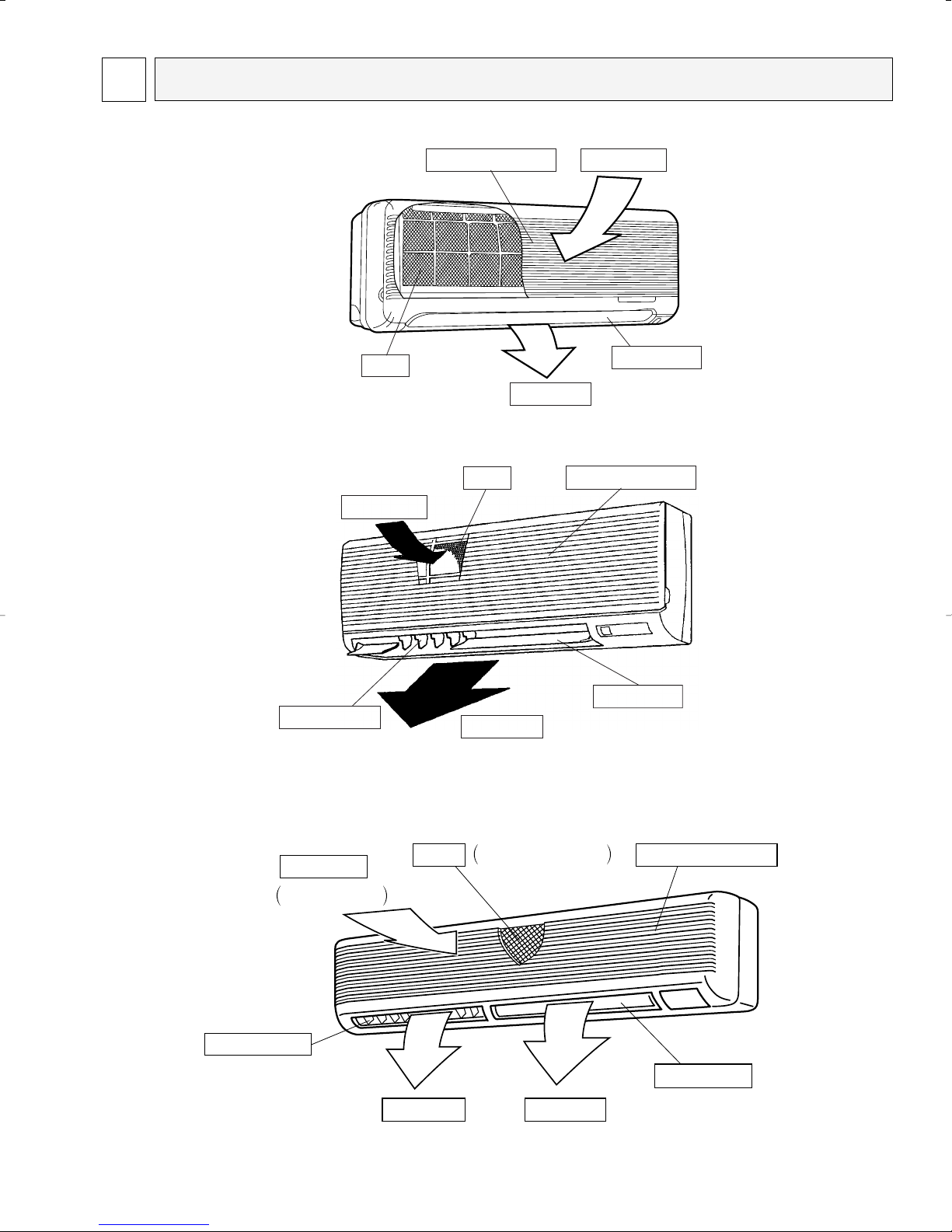

Air intake

Room air is

suctioned in here.

Removes dust and dirt

from the intake air.

Filter Air intake grilles

Air outletAir outlet

Auto vane

Air flow can be changed to

horizontally by moving the

Guide vane to the left or right.

Guide vane

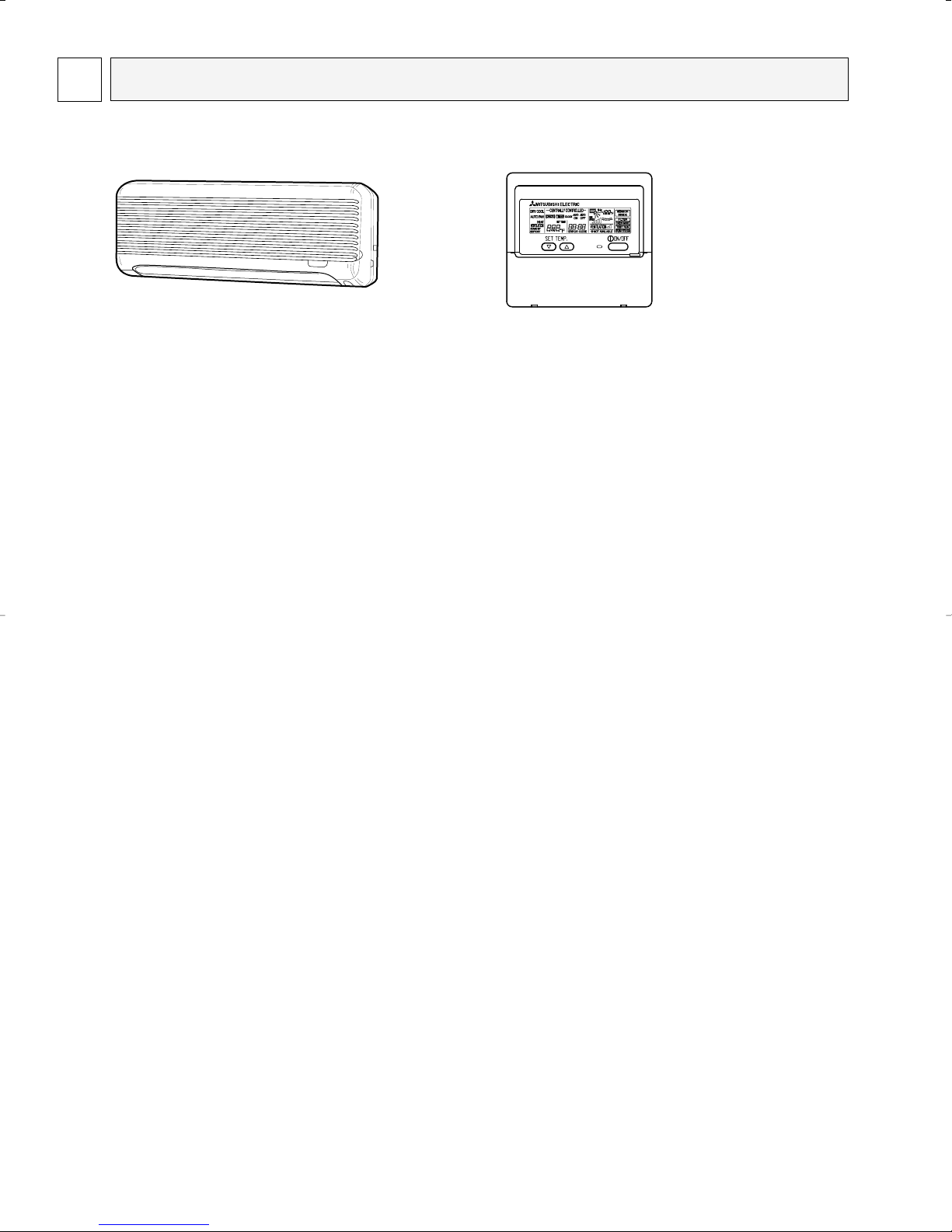

PART NAMES AND FUNCTIONS

● Indoor Unit

[PKFY-08NAMU-A]

[PKFY-12NGMU-A]

Filter

Air intake

Air intake grille Air intake

Auto vane

Air outlet

Filter

Air intake grille

[PKFY-20NFMU-A]

[PKFY-32NFMU-A]

Guide vane

Air outlet

OC292-7

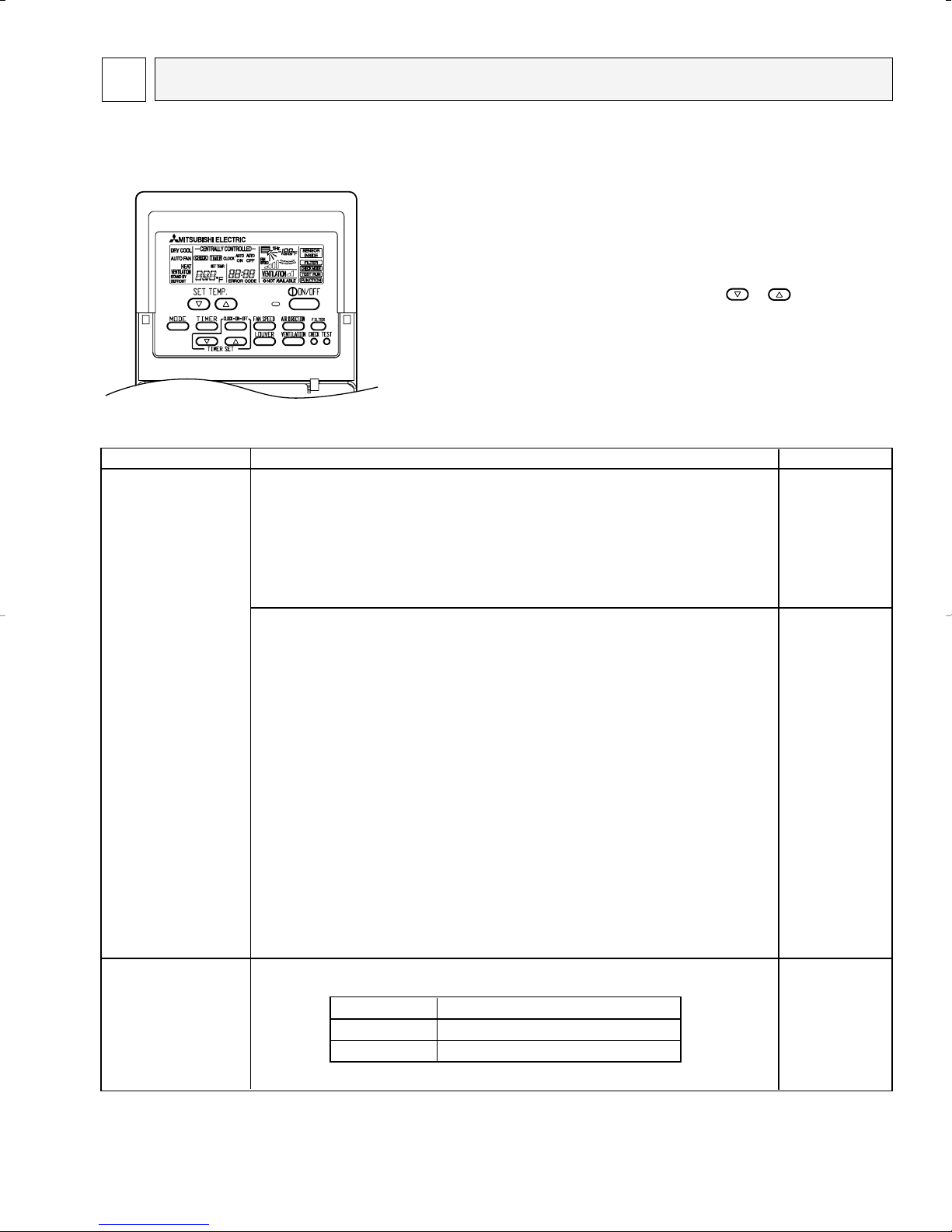

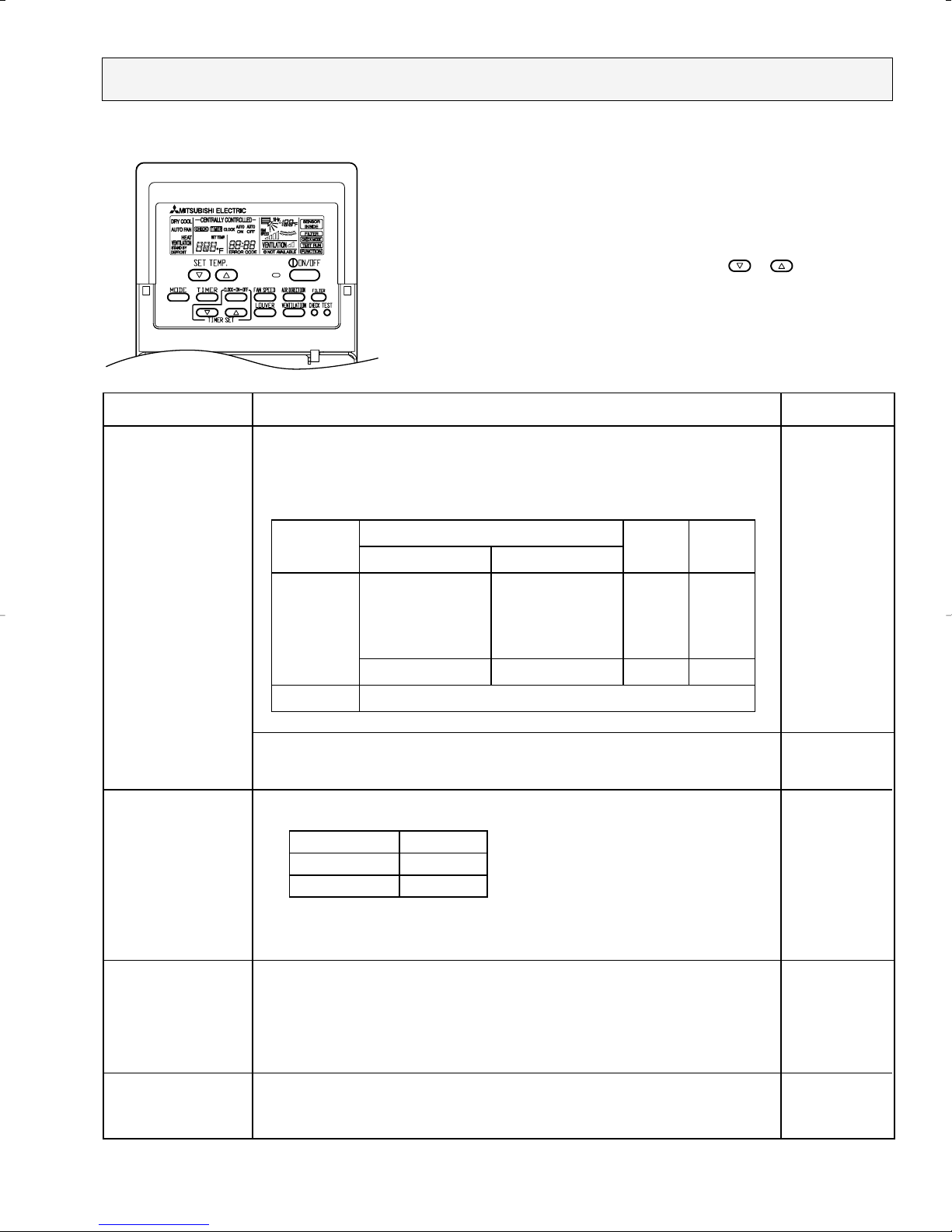

Auto vane

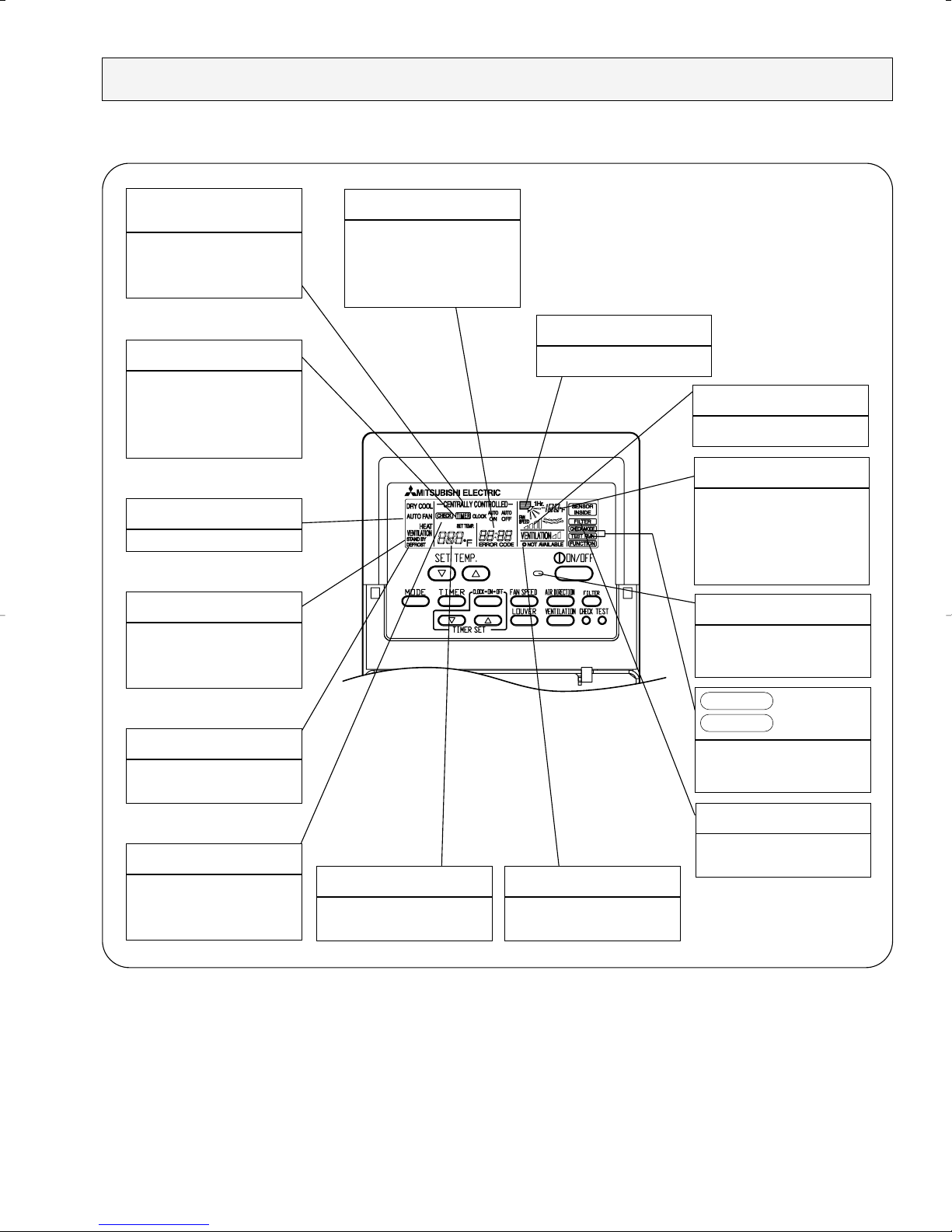

Press this button to switch the cooler,

electronic dry (dehumidify), automatic

and heater modes.

OPERATION SWITCH button

This sets the room temperature. The

temperature setting can be performed

in 2_F units

Setting range

Cooler 67_F to 87_F

Heater 63_F to 83_F

TEMP . ADJUSTMENT button

This switches between continuous

operation and the timer operation.

TIMER button

This switches between the operation

and stop modes each time it is pressed.

The lamp on this button lights during

operation.

ON/OFF button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

CHECK-TEST RUN button

This switch the horizontal fan motion

ON and OFF.

(Not available for this model.)

LOUVER button

This adjusts the vertical angle of the

ventilation.

AIR DIRECTION button

This resets the filter service indication

display

FILTER button

This sets the current time, start time

and stop time.

TIME SETTING button

This sets the ventilation fan speed.

AIR SPEED button

● Remote controller

● Once the operation of the unit is set, subsequent operations can only be performed by pressing the ON/OFF button

repeatedly.

● Operation buttons

OC292-8

● Display

CENTRALLY

CONTROLLED display

This indicates when the unit is controlled by optional features such as

central control type remote

controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

The [STANDBY] symbol is only displayed from the time the heating

operation starts unit the heated air

begins to blow.

DEFROST display

This indicates when the defrost

operation is performed.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

AIR DIRECTION display

This displays the air direction.

AIR SPEED display

The selected fan speed is displayed.

ROOM TEMPERATURE display

The temperature of the return air

is displayed during operation. The

display range is 46_F to 102_F. The

display flashes 46_F when the actual

temperature is less than 46_F and

flashes 102_F when the actual

temperature is greater than 102_F.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

This display lights in the check

mode or when a test operation is

performed.

CHECK MODE

TEST RUN

display

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button is pressed. This indicates that this room unit is not equipped with

the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

SET TEMPERATURE display

This displays the selected set

temperature.

FILTER display

This lamp lights when the filter need

to be cleaned.

POWER display

This lamp lights when electricity is

supplied to the unit.

OC292-9

4

Power Supply

Starting Current

Fan ✕ No.

Air flow w 2

External static pressure

Fan motor output

Item

Power

Cooling capacity

Heating capacity

Exterior <munsell symbol>

Out dimensions

Heat exchanger

Fan

Insulator

Air filter

Pipe dimensions

Unit drain pipe size

Noise level w 2

Product weight

Unit

[,V,Hz

Btu/h

Btu/h

kW

kW

A

A

—

in.

in.

in.

—

—

CFM

CFM

Pa

kW

—

—

in.

in.

in.

dB

lbs

Cooling

Heating

Cooling

Heating

Height

Width

Depth

DRY

WET

Gas side

Liquid side

PKFY-08NAMU-A

8,000

9,000

0.03

0.03

0.15

0.15

Plastic munsell : <2.60Y 8.66/0.69>

11-5/8

32-3/32

6-7/32

Cross fin

Lineflow fan ✕ 1

170-180-200-210

160-170-180-190

0

0.008

Polyethylene sheet

PP honey comb

1/2"

1/4"

PVC pipe with O.D. 5/8"

32-33-35-36

19

Electric

characteristic

Single phase, 208/230V, 60Hz

SPECIFICATIONS

4-1. Specifications

PKFY-08NAMU-A

Note 1. Rating conditions

Cooling :Indoor D.B. 80˚F W.B. 67˚F

Outdoor D.B. 95˚F W.B. 75˚F

Heating : Indoor D.B. 70˚F

ww

2. Air flow and the noise level are indicated as Low - Medium2 - Medium1 - High.

Outdoor D.B. 47˚F W.B. 43˚F

• Connected outdoor unit is PURY-80TMU or PURY-100TMU.

OC292-10

Input

Current

Fan ✕ No.

Air flow w 2

External static pressure

Fan motor output

Item

Power

Cooling capacity

Heating capacity

Exterior <munsell symbol>

Out dimensions

Heat exchanger

Fan

Insulator

Air filter

Pipe dimensions

Unit drain pipe size

Noise level w 2

Product weight

Unit

[,V,Hz

Btu/h

Btu/h

kW

kW

A

A

—

in.

in.

in.

—

—

CFM

CFM

Pa

kW

—

—

in.

in.

in.

dB

lbs

Cooling

Heating

Cooling

Heating

Height

Width

Depth

DRY

WET

Gas side

Liquid side

PKFY-12NGMU-A

Single phase, 208/230V, 60Hz

12,000

12,500

0.07

0.07

0.34

0.34

Plastic , white : <0.70Y 8.59/0.97>

13-3/8

39

9-1/4

Cross fin (Aluminum plate fin and copper tube)

Lineflow fan ✕ 1

280-340-370-410

250-300-330-370

0

0.03

Polyethylene sheet

PP honey comb

1/2"

1/4"

PVC pipe with O.D. 13/16"

32-36-40-42

35

Electric

characteristic

PKFY-12NGMU-A

Note 1. Rating conditions

W 2. Air flow and the noise level are indicated as Low - Medium2 - Medium1 - High.

Cooling : Indoor : D.B. 80_F W.B. 67_F

Heating : Indoor : D.B. 70_F

outdoor : D.B. 95_F W.B. 75_F

outdoor : D.B. 47_F W.B. 43_F

• Connected outdoor unit is PURY-80TMU or PURY-100TMU.

OC292-11

PKFY-20NFMU-A

Input

Current

Type ✕ No.

Air flow

Low - High

External static pressure

Fan motor output

Item

Power source

Cooling capacity

Heating capacity

Exterior <munsell symbol>

Dimensions

Heat exchanger

Fan

Insulator

Air filter

Pipe dimensions

Unit drain pipe dimension

Noise level Low - High

Product weight

Unit

[,V,Hz

Btu/h

Btu/h

kW

kW

A

A

—

in.

in.

in.

—

—

CFM

CFM

Pa

kW

—

—

in.

in.

in.

dB

lbs

Cooling

Heating

Cooling

Heating

Height

Width

Depth

DRY

WET

Gas side

Liquid side

PKFY-20NFMU-A

20,000

22,500

0.09

0.09

0.44

0.44

55-1/8

490 - 640

440 - 570

0.045

39 - 45

53

PKFY-32NFMU-A

32,000

35,500

0.12

0.12

0.58

0.58

66-1/8

780 - 990

700 - 890

0.070

46 - 49

62

Electric

characteristic

Single phase, 208V-220V, 60Hz

Plastic , white : <3.4Y 7.7/0.8>

13-3/8

9-1/4

Cross fin(Aluminum plate fin and copper tube)

Lineflow fan ✕ 2

0

Polyethylene sheet

PP Honeycomb fabric

5/8"

3/8"

PVC pipe with O.D. 13/16"

PKFY-30NFMU-A

Note 1. Rating conditions

Cooling : Indoor : D.B. 80_F W.B. 67_F

Heating : Indoor : D.B. 70_F

outdoor : D.B. 95_F W.B. 75_F

outdoor : D.B. 47_F W.B. 43_F

• Connected outdoor unit is PURY-80TMU or PURY-100TMU.

OC292-12

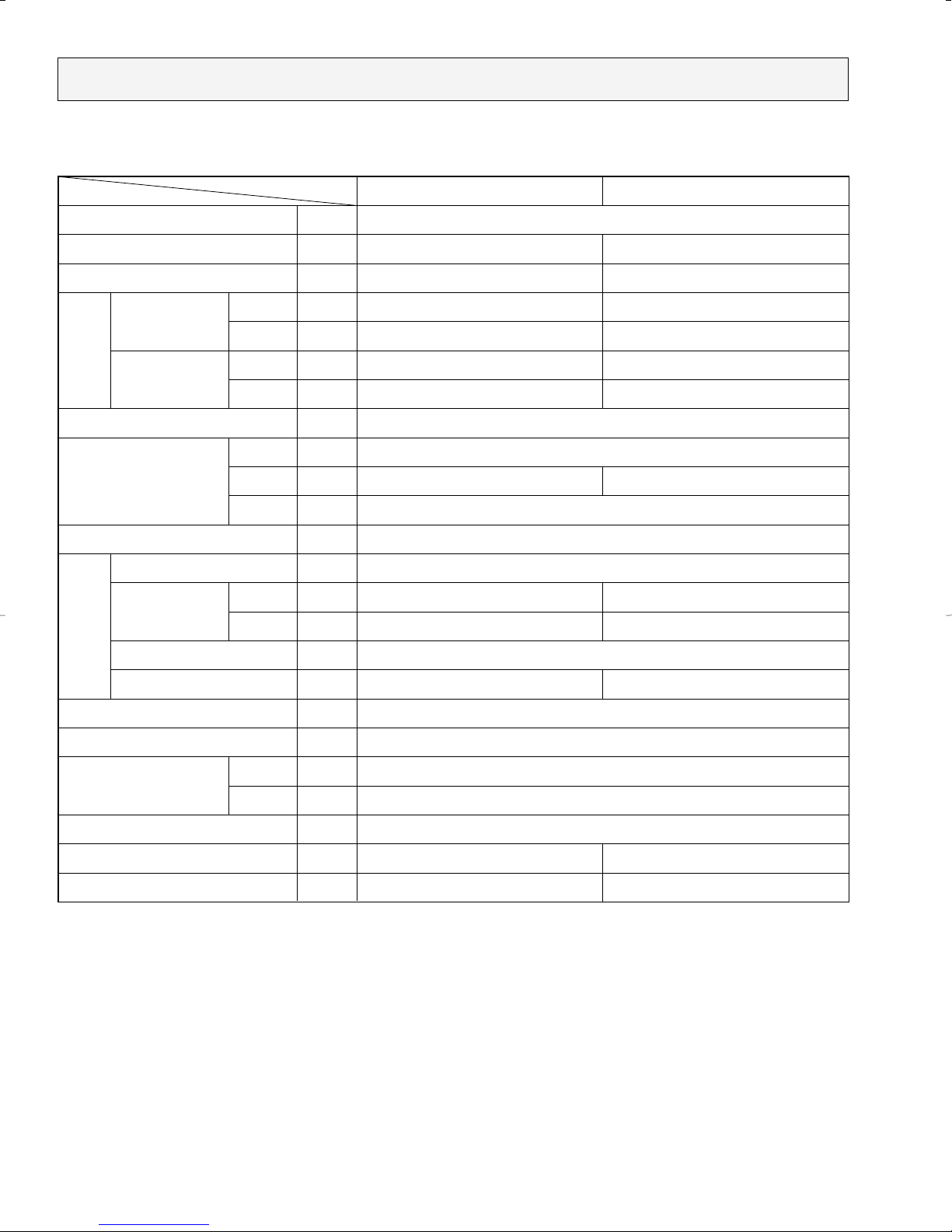

4-2. Electrical parts specifications

Parts name

Model

Symbol

TH21

TH22

TH23

FUSE

MF

C

MV

LEV

TB2

TB5

Resistance 30˚F/15.8k", 50˚F/9.6k", 70˚F/6.0k", 80˚F/4.8k", 90˚F/3.9k", 100˚F/3.2k"

Resistance 30˚F/15.8k", 50˚F/9.6k", 70˚F/6.0k", 80˚F/4.8k", 90˚F/3.9k", 100˚F/3.2k"

Resistance 30˚F/15.8k", 50˚F/9.6k", 70˚F/6.0k", 80˚F/4.8k", 90˚F/3.9k", 100˚F/3.2k"

250V 6A

4-Pole Output 8W / PS4N8

1.2µF ✕ 440V

MSFBC20A03 DC12V

(L1, L2,GR) 250V 20A

(M1, M2) 250V 10A

Liquid pipe thermistor

Gas pipe thermistor

Fan motor capacitor

Linear expansion valve

PKFY-08NAMU-A

Room temperature

thermistor

Fuse

(Indoor power board)

Fan motor

(with thermal fuse)

Vane motor

(with limit switch)

Power supply terminal

block

Transmission terminal

block

DC12V Stepping motor drive

Port [3.2 (0~2000pulse) EDM-402ME

PKFY-08NAMU-A

OC292-13

PKFY-12NGMU-A

Room temperature thermistor

Liquid pipe temperature thermistor

Gas pipe temperature thermistor

Fuse

(Indoor controller board)

Fan motor

(with inner-thermostat)

Fan motor capacitor

Vane motor

Linear expansion valve

Power supply terminal block

Transmission terminal block

MA remote controller terminal block

Symbol

TH21

TH22

TH23

FUSE

MF

C

MV

LEV

TB2

TB5

TB15

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

250V 6A

PM4N30-KA 208V/230V 60Hz

4 pole Output 30W

OPEN 257±9°F

2.0µF 440V

MP 35 EA DC12V

DC12V Stepping motor drive

Port dimension [3.2 (0 ~ 2000pulse)

(L1, L2, GR) 330V 30A

(M1, M2, S) 250V 20A

(1,2) 250V 10A

Model

Parts name

Inner-thermostat

PKFY-12NGMU-A

OC292-14

Room temperature thermistor

Liquid pipe temperature thermistor

Gas pipe temperature thermistor

Fuse

(Indoor controller board)

Fan motor

(with inner-thermostat)

Fan motor capacitor

Vane motor

Linear expansion valve

Power supply terminal block

Transmission terminal block

MA remote controller

terminal block

Symbol

TH21

TH22

TH23

FUSE

MF

C

MV

LEV

TB2

TB5

TB15

PKFY-20NFMU-A

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

250V 6A

OPEN 266±9°F

2.5= 440V

MP 35 EA DC12V

(L1, L2, GR) 330V 30A

(M1, M2, S) 250V 20A

(1,2) 250V 10A

Model

Parts name

PKFY-32NFMU-A

Inner-thermostat

DC12V Stepping motor drive

Port dimension [5.2 (0 ~ 2,000pulse)

DC12V Stepping motor drive

Port dimension [3.2 (0 ~ 2,000pulse)

D10B4P70MS

208-230V 60Hz

4pole Output 70w

D094P45MS

208-230V 60Hz

4pole Output 45w

PKFY-20NFMU-A

PKFY-30NFMU-A

OC292-15

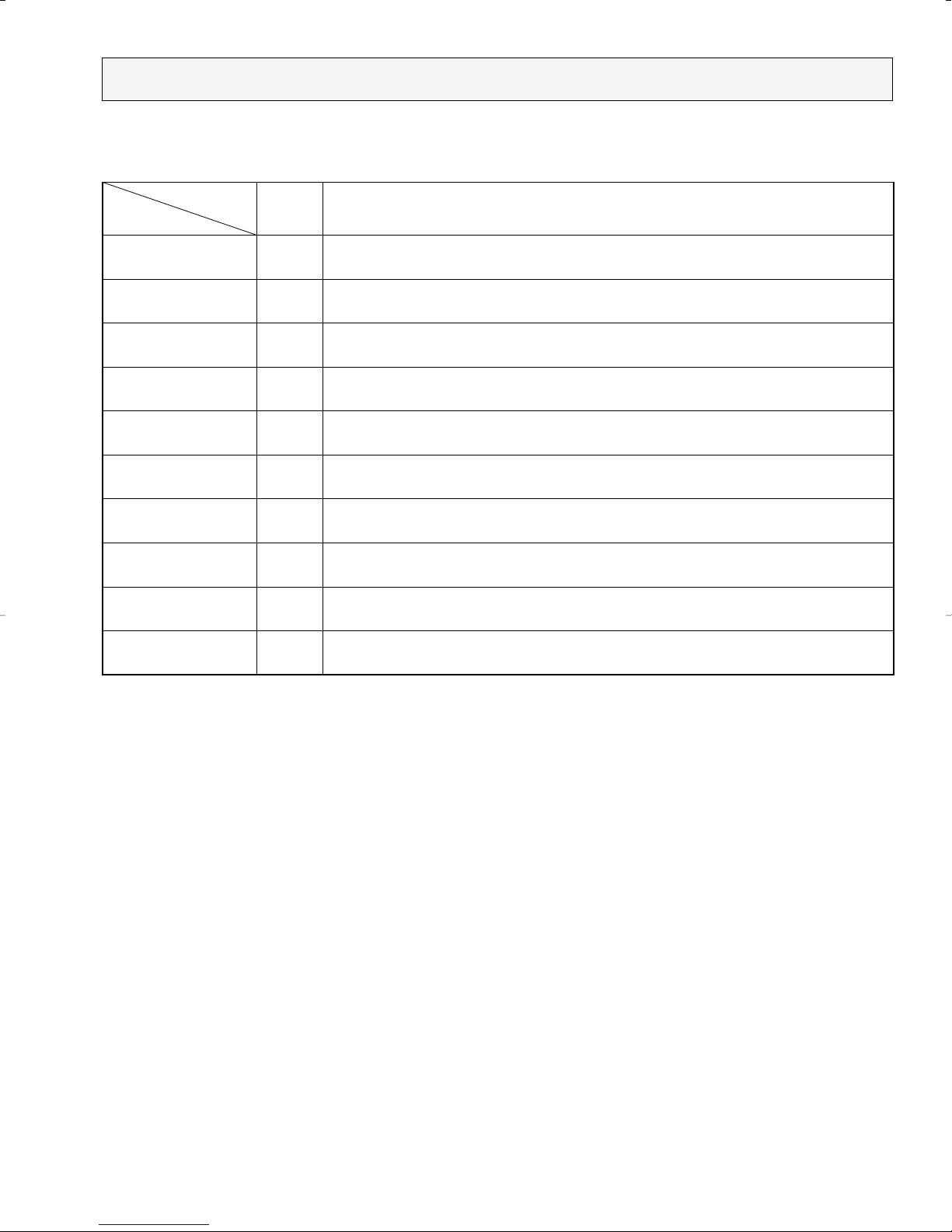

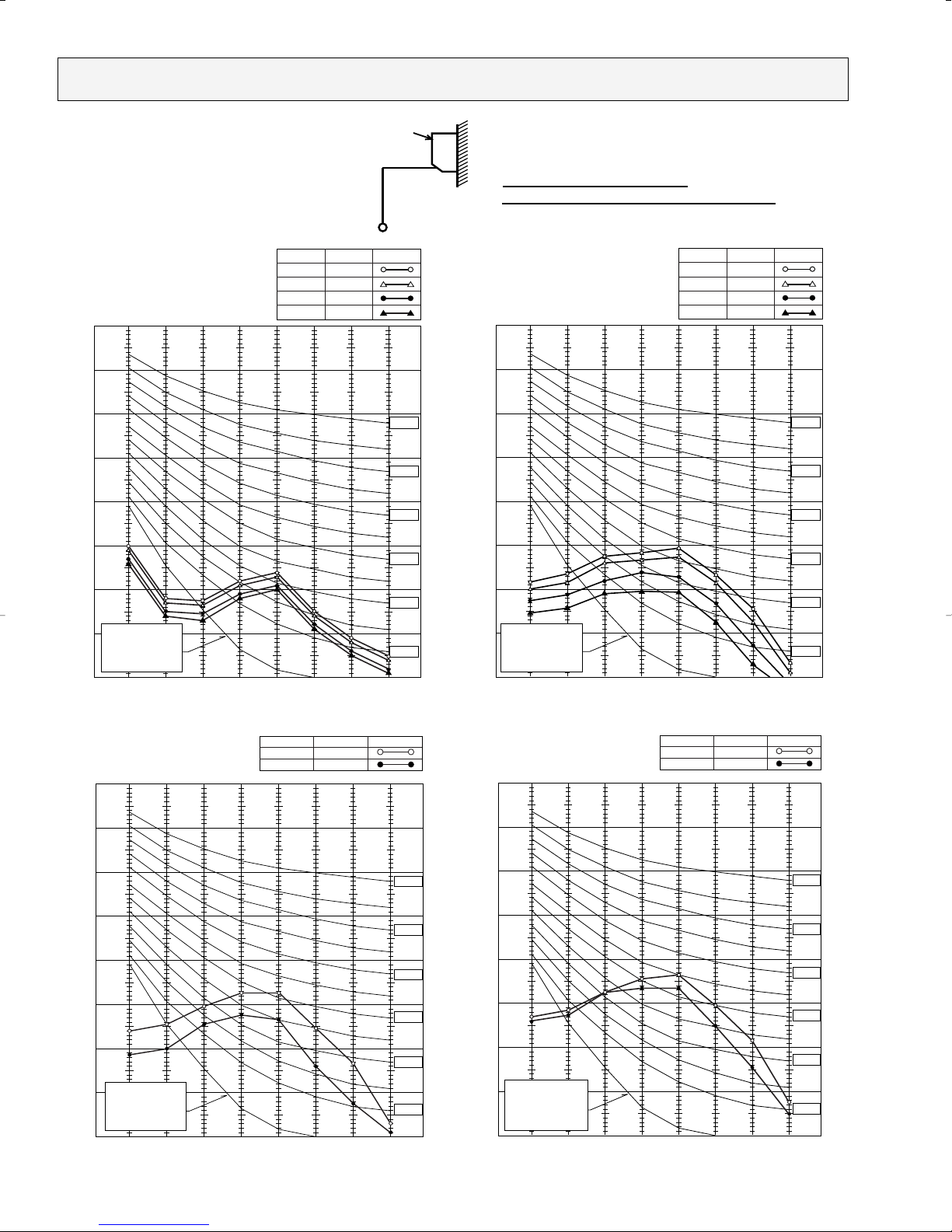

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

PKFY-08NAMU-A

Hi

Med1

Med2

Lo

NOTCH

36

35

33

32

SPL(dB)

LINE

4-3. Noise criterion curves

Ambient temperature 80˚F

Test conditions are based on JIS Z8731

Wall

Unit

3.3ft

3.3ft

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

PKFY-12NGMU-A

Hi

Med1

Med2

Lo

NOTCH

42

40

36

32

SPL(dB)

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

Hi

NOTCH

Lo

49

SPL(dB)46LINE

PKFY-32NFMU-A

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

Hi

NOTCH

Lo

45

SPL(dB)39LINE

PKFY-20NFMU-A

OC292-16

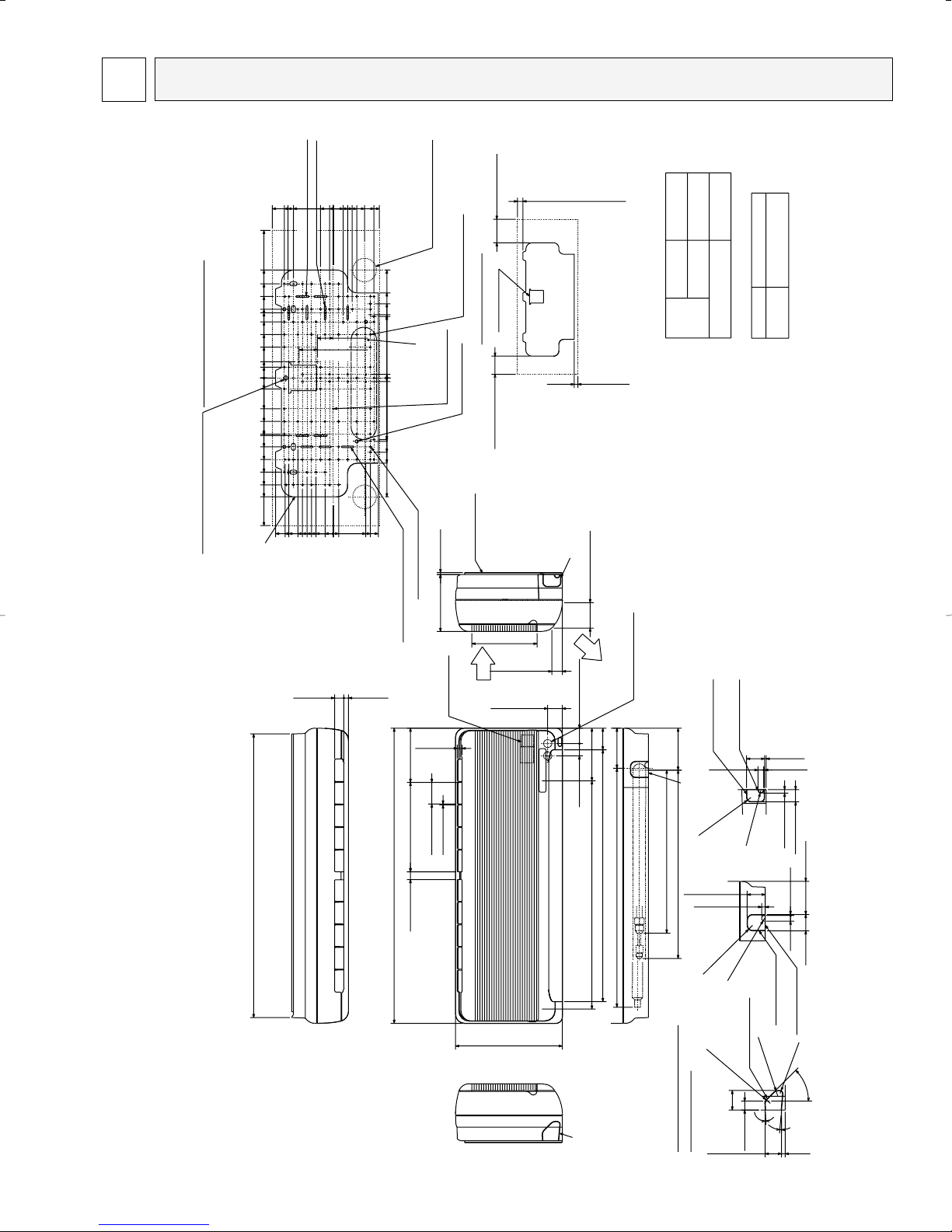

5

1-11/ 32(34)

1-11/16(42.5)

1-5/8(40.5)

Unit:inch (mm)

Installation space

Details of installation plate

9-3/4(247.5)

3/32(2.5)

2-3/8(60)

5-29/32(150)

20-25/32(520)

17-23/32(450)

0

3-27/32(97.5)

7-3/32(180)

0

6-1/4(159)

0

1-3/32(27.5)

4-29/32(125)

0

2-3/32(53)

0

1-3/4(45)

26-31/32(660)

Liquid pipe

Gas pipe

(Drain pipe total 29-29/32(760))

4-11/32(110)

4-9/16(116)

11-23/32(298)

9-1/4(235)

8-1/16(205)

6-7/8(175)

0

6-11/16(170)

2-9/16(65)

1-9/16(40)

0

5-1/32(128)

4-7/8(124)

3-17/32(90)

0

6-1/4(159)

6-5/8(168)

4-7/16(113)

3-7/16(87)

5-5/16(135)

4-11/32(110)

1-3/8(35)013/32(10)

0

12-29/32 (328)

4-1/32(102.5)

0

19/32(15)

0

4-13/16(122.5)

5-1/4(133)

2-27/32(72.5)

3-11/32(85)

1-7/8(47.5)

2-3/8(60)

7/8(22.5)

0

16-1/32(407.5)

12-29/32(328)

11-5/8(295)

10-1/4(260)

8-27/32(225)

7-15/32(190)

6-3/32(155)

4-23/32(120)

3-11/32(85)

0

1-3/16(30)

16-1/32(407.5)

11-23/32(298)

10-1/4(260)

8-27/32(225)

7-15/32(190)

6-3/32(155)

4-23/32(120)

3-11/32(85)

0

1-3/16(30)

13/32(10)

13/32(10)

1-31/32(50)

1-23/32(44)

0

6-7/8(175)

9-1/4(235)

6-11/16(170)

8-1/16(205)

3/16(5)

❊1

2-3/8 (60)

5-3/4 (146)

1-15/32(37.4)

2-25/32(70.3)

Air outlet

Air outlet

Air intake

Air intake

Air intake

7-3/32(180)

Air outlet

Air intake

24-13/16(630)

1/2(13)

1/2(13) 1(25.5)

27-3/8(695)

11-5/8(295)

27/32(21.5)

32-3/32(815)

3-15/16(100) or more

5-1/8(130) or more

W1 5-1/8(130) or more

25/32(20) or more

30-13/16(783)

6-7/32(158)

[2-9/16~[2-3/4

([65~[70)

Through hole

3.Sleeves are available on the market.

[2-9/16

([65)

Sleeve

Wiring entrance holes

Terminal block

Detailed figure dwg (ABC)

(Knock out hole)

R5/16(R8)

R19/32(R15)

R19/32(R15)

R19/32(R15)

R5/16(R8)

R15/32(R12)

R5/16(R8)

Knock out hole of

right piping

Knock out hole of

remocon wiring

(Direction)

Knock of hole

Knock out hole for

remocon wiring

3/16x1-3/8(4.5x35) 4 holes

installaion plate

Knock out holt for

under piping

13/32(10)

1-31/32(50)

5/8(16)

3/32(2.5)

1-25/32 (45)

3-19/32 (91.5)

Installat plate palance point hole

Supporting piece

3/16x1-9/16 (4.5x40) 4 holes

3/16x1-15/32 (4.5x37) 4 holes

12-[1/8([2.8)holes

4-[11/32([9)holes

8-[5/32([4.3) holes

87-[3/16([5.1)holes

Piping hole[2-9/16([65)

2-1/8(54)

Knock out hole for

left piping

45

-

31/32(24.4)

3

-

5

-

1-25/32(45)13/32(10)

13/32(10)

1-11/32(34)

5/8 (16)

3/32(2.5)

1-31/32 (50)

5/32(4)

Air intake

Air outlet

(Direction)

Installation plate

2-1/8(54) of more

leftpiping

left-rear piping

Notes 1.Use M10 or W3/8 screw for installation plate.

2.Extension piping side.

[5/8([16) I.D

1/2F

1/4F

Drain pipe

Liquid pipe

Gas pipe

Refrigerart

piping

C

C

B

A

B

A

OUTLINES AND DIMENSIONS

PKFY-08NAMU-A

Unit : inch(mm)

OC292-17

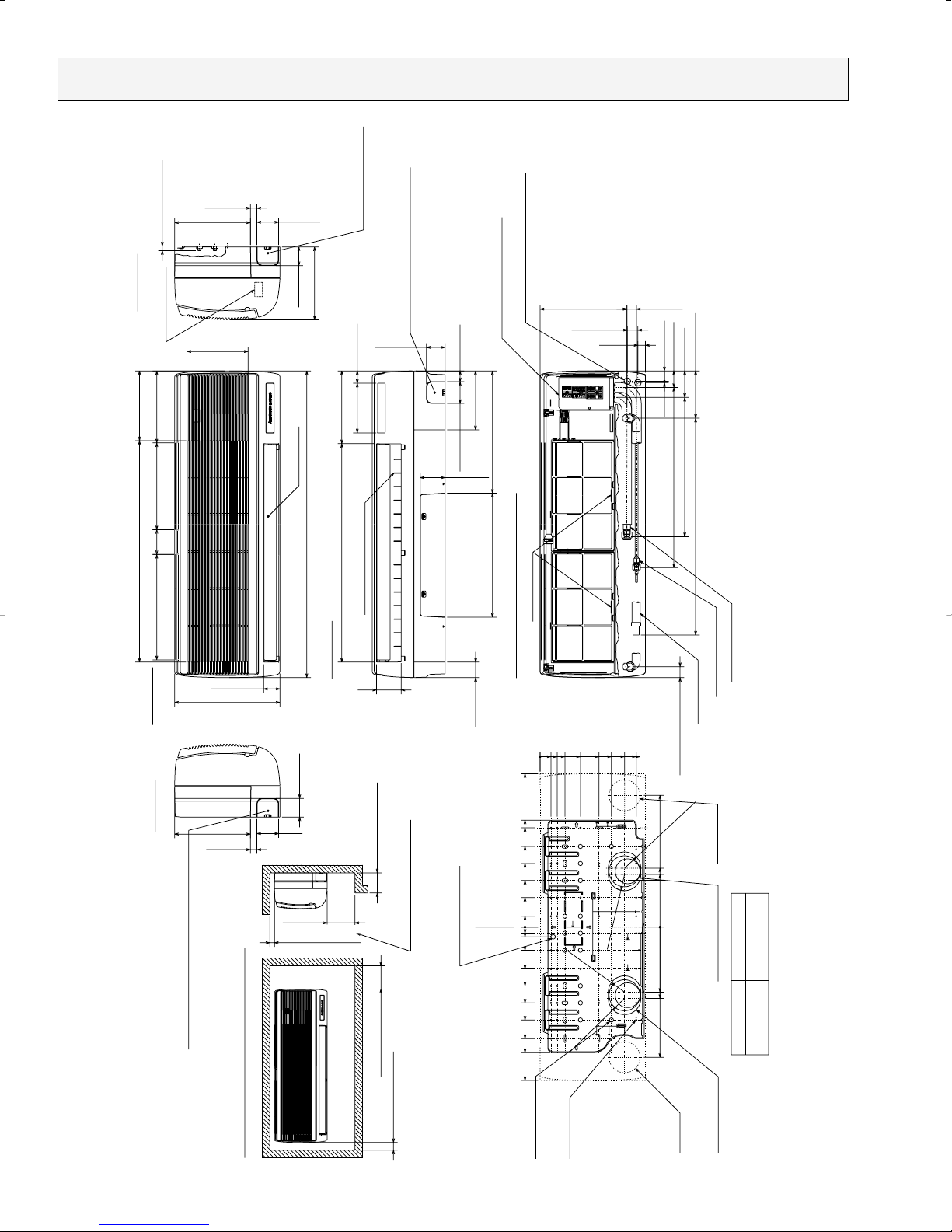

Drain hose

Wiring entrance holes

3/16(5)

1(25)

1-11/32(34)

1-5/16(33)

Air intake

Air intake

Service space required around indoor unit

Details of installation plate

Front view (top open the grille)

Lower side

Right side

Left side

Front view

22-7/8(581)

17-11/16(449)

Installation plate

balance point hole

Knock out hole for right piping

Refrigerant pipe.Drain pipe.

Wiring hole

Gas pipe 1/2F

Liquid pipe 1/4F

49-[3/16([5)holes

for tapping screw

Knock out hole for

right-rear piping

Right-rear

piping hole

(Necessary clearance for

Unit installation)

Address board

Filter grip

13/16(21)

13/16(21)

R2-1/16(R52.5)

R2-1/16(R52.5)

R2-1/16(R52.5)

R2-1/16(R52.5)

Unit center

Knock out hole for under piping

Refrigerant piping.Drain pipe.

Wiring hole

Service panel

(Power supply access)

Right side

w1 Sleeves are available on the market.

w2 This size shows the lower end of through hole.

[2-15/16~[3-5/32

([75~[80)

[2-15/16([75)

Through holeSleeve W1

14-[9/16([14)holes

for bolts

Left-rear

piping hole

Knock out hole for

left-rear piping

(Flexible hose total length 31-1/2(800))

(Right side piping installation)

(Left side piping

installation)

12—Louvers (manual)

Auto vane

Air intake

Knock out hole for left piping

Refrigerant pipe.Drain pipe.Wiring hole.

1-3/8(35)

Less than 5-1/8(130)

1-31/32(50) or more

5-29/32(150) or more

7-3/32(180) or more

1-13/16(30) or more

27-9/16(700) 6-1/32(153)

3-3/8(86)

2-1/8(54)

1-7/32(31) 11-1/32(280)

3-1/8(80)

2-3/8(60)

2-3/4(70)

9-21/32(245)

1-31/32(50)

15-9/16(395)15-3/4(400)

7-15/32(190)

2-3/8(60)

2-3/4(70) 1-3/8(35)

3-1/8(79)

6-5/16(160) 1-9/16(40)

27-3/4(705) Air outlet 9-1/4(235)

Less than 19/32(15)

7-25/32(198)

2-3/4(70)

9-21/32(245)

2-3/8(60)

9-1/4(235)

2-3/32(53)

13-3/8(340)

28-5/32(715) Air intake 8-27/32(225)

13-3/8(340)

3-5/32(80)

11-1/32(280) 9-3/16(233)

39(990)

16-23/32(425)

16-17/32(420)

6-11/16(170)

7-15/32(190)

8-9/32(210)

9-1/16(230)

0

12-11/16(322)w1

0

1-3/8(35)

2-5/32(55)

3-5/32(80)

5-1/8(130)

7-15/32(190)

9-1/16(230)

10-23/32(272)

12-7/32(310)

0

1-3/8(35)

3-3/4(95)

5-29/32(150)

8-1/16(205)

10-1/4(260)

12-19/32(320)

13-19/32(345)

19-1/2(495)

25/32(20)

2-15/16(75)

5-5/16(135)

7-15/32(190)

9-21/32(245)

11-13/16(300)

14-3/16(360)

15-15/16(405)

19-1/2(495)

1-1/4(32)

0

PKFY-12NGMU-A

Unit : inch(mm)

OC292-18

15/16(24)

1-5/16(34)

1-7/16(36)

1

Wiring entrance holes

Terminal blockTerminal block

Details of installation plate

Knock out hole

for right piping

Right side

Front view

Top side

1-31/32(50) or more

9-27/32(250) or more

9-27/32(250) or more

1-3/16(30) or more

Less than 9-27/32(250)

Service space required around indoor unit

3-19/32(91)

8-27/32(225)

7-1/4(184)

1-3/16(30)

9-7/16(240)

7-3/32(180)

11-1/32(280) 12-3/8(314)

23/32(18)

23/32(18)

13/32✕3-19/32=(35-13/16) (10✕91=(910)) 11-7/32(285)

1-3/16(30)

1-3/16(30)

3/4(19)

35-7/16(900)

3-17/32(90)

24-1/32(610)

11-1/32(280)

2-3/8(60)

9-21/32(245)

17-29/32(455)

1-5/32(29)

13/32(10)

38-31/32(990)

3-1/8(80)

12-1/4(6) holes

for tapping screws

32-[15/32([12) holes

for bolts

Wall fixture

Rear piping hole

66-[1/4([6) holes

for tapping screws

Unit center

Bolt

Less than 19/32(15)

Drain hose

4-3/8(111)

Drain hose for

left-hand side piping

4-7/32(107)

7-7/32(183)

2-5/32(55)

4-23/32(120)

1-21/32(42)

2-9/32(58)

Drain hose

1-25/32(45)

1-25/32(45)

1-25/32(45)

Knock out hole for wiring

AB C

1-3/16(30)

1-3/16(30)

1-17/32(39)

B

A

2-29/32(74)

C

3-27/32(98)

1-15/32(37)

2-29/32(74)

1-15/32(37)

2-9/16(65)

5/32(4)

1-17/32(39)

1-9/16(39)

3-15/16(100)

1-1/4(32)

1-15/32(37)

3-15/16(100)

5/32(4)

21-23/32(552) Air outlet

44-3/32(1120)

13-3/8(340)

7-3/4(197)

1/2(13)

2-15/32(62.5)

9-1/4(235) 9-1/4(235)

55-1/8(1400)

9-7/16(240)

42-29/32(1090) Air intake

9-1/4(235)

21-23/32(552) Air outlet

9-1/4(235)

9-1/4(235)

Sleeve

2

31/32(25)

43-11/16(1110) Drain hose

Knock out hole

for left piping

Drainage range on

left hand side

Knock out hole for under-piping

Refrigerant pipe /Drain pipe

Drainage range on

right-hand side

[3-17/32

([90)

w1 Sleeves are available

on the market.

w1

Through hole

Left side

Lower side

Louvers(Manual)Auto vanes

Range for left rear piping hole

Under panel(Removable at

left-hand side piping)

[3-17/32~[3-15/16

([90~[100)

1

2

5/8F

3/8FLiquid pipe

Gas pipe

Air

outlet

Air

intake

PKFY-20NFMU-A

Unit : inch(mm)

OC292-19

Front view

15/16(24)

1-5/16(34)

1-7/16(36)

Wiring entrance holes

Terminal block

1-31/32(50) or more

9-27/32(250) or more

Less than 5-29/32(150)

9-27/32(250) or more

1-3/16(30) or more

Less than 9/16(15)

1

2

Gas pipe

Liquid pipe 3/8F

5/8F

Sleeve

[3-17/32~[3-15/16

([90~[100)

Through hole

[3-17/32

([90)

w1

w1 Sleeves are available

on the market.

Unit out line

Wall fixture

Rear piping hole

11-5/8(295) 8-27/32(225)

1-3/16(30) 7-1/4(184)

9-7/16(240) 7-3/32(180) 11-1/32(280) 12-3/8(314)

23/32(18)

23/32(18)

3-5/32(80)

1/2✕3-19/32=(46-9/16) (13✕91=(1183))

3-19/32(91)

50(1270)

13/32(10)

1-3/16(30)

1-3/16(30)

3/4(19)

35-7/16(900)

23-7/16(595)

29-17/32(750)

2-3/8(60)

9-21/32(245)

11-7/32(285)

3-9/16(90)

1-5/32(29)

11-1/32(280)

84-[1/4([6) holes

for tapping screws

41-[15/32([12) holes

for bolts

12-[1/4([6) holes

for tapping screws

Unit center

Bolt

Range for left rear piping hole

Drainage range on

left hand side

Drainage range on

right-hand side

1

2

A

ACB

3-15/16(100)

5/32(4) 1-17/32(39)

2-29/32(74)

1-15/32(37)

2-9/16(65)

1-15/32(37)

1-17/32(39)

1-1/4(32)

3-27/32(98)

5/32(4)

2-29/32(74)

1-15/32(37)

1-17/32(39)

3-15/16(100)

1-3/16(30)

1-3/16(30)

Drain hose for

left-hand side piping

1-21/32(42)

2-9/32(58)

27-5/16(694) Air outlet

9-7/16(240)

1-25/32(45)

13-3/8(340)

1/2(13)

1-25/32(45)

2-15/32(62.5)

9-1/4(235)

1-25/32(45)

9-1/4(235)

Service space required around indoor unit

55-1/8(1400)

9-1/4(235)

53-15/16(1370) Air intake

9-1/4(235)

7-7/32(183)

2-5/32(55)

Under panel(Removable at

left-hand side piping)

4-23/32(120)

27-5/16(694) Air outlet

9-1/4(235)

C

Drain hose

66-1/8(1680)

4-3/8(111)

4-1/32(102)

43-11/16(1110) Drain hose

31/32(25)

7-3/4(197)

9-1/4(235)

Knock out hole

for left piping

Knock out hole for under-piping

Refrigerant pipe /Drain pipe

Right side

Left side

Top side

1-25/32(45)

Lower side

Louvers(Manual)

B

Knock out hole for wiring

Auto vanes

Knock out hole

for right piping

Air

outlet

Air

intake

PKFY-32NFMU-A

Unit : inch(mm)

OC292-20

WIRING DIAGRAM6

21

LEV

56

YLW

ORN

BLU

PNK

RED

BRN

RED

BLU

ORN

YLW

5VDC SUPPLY

(WHT)

ADDRESS SETTING 2ND DIGIT

CIRCUIT BOARD (ADDRESS)A.B

SW1

SW5

SW11

SW12

SW14

VOLTAGE SELECTION

CONNECTION No.

SWITCH MODE SELECTION

ADDRESS SETTING 1ST DIGIT

[LEGEND]

NAME

TH22

TH21

THERMISTOR

CONNECTOR

M.B

SYMBOL

CN32

CN41

CN51

CN52

SWITCHSW2

SW3

LEV LINEAR EXPANSION VALVE

ROOM TEMPERATURE DETECTION

(32°F/15kΩ,77°F/5.4kΩ)

PIPE

TEMPERATURE

DETECTION

/LIQUID (32°F/15kΩ,77°F/5.4kΩ)

F.C FAN PHASE CONTROL

FUSE FUSE (6A/250V)

VARISTORZNR

SYMBOL

NAME

SYMBOL

INDOOR POWER BOARDP.B

CAPACITY CODE

MODE SELECTION

REMOTE INDICATION

CENTRALLY CONTROL

HA TERMINAL-A

REMOTE SWITCH

INDOOR CONTROLLER BOARD

TH23

MF

C CAPACITOR (FAN MOTOR)

PIPE TEMPERATURE DETECTION

/GAS (32°F/15kΩ,77°F/5.4kΩ)

TB2

TB5

FAN MOTOR

MV VANE MOTOR

NAME

TRANSMISSION

POWER SUPPLY

TERMINAL

BLOCK

GR

L1

to the connector .(Remote controller wire is non-polar.)

TB5 S(SHIELD)

TB2

L2

TO NEXT

INDOOR UNIT

PULL

BOX

FUSE

(15A)

~/N 208-230V 60Hz

BREAKER

(15A)

POWER SUPPLY

GRN/YLW

ORN

ORN

Mark

LED1

LED2

Meaning

Main power supply

Function

Power supply for

MA-Remote controller

LED on indoor board for service

Main power supply(Indoor unit:208-230V)

power on ➔ lamp is lit

Power supply for MA-Remote controller

on ➔ lamp is lit

3.In case of using M-NET,please connect to TB5.(Transmission line is non-polar.)

In case of connecting MA-Remote controller,please connect MA remote controller cable in an accessorie2.

CN35P

MICON

BOARD

(BLU)

CN53P

MICON

BOARD

(RED)

(BLU)

(RED)

POWER BOARD

POWER BOARD

CN53M

CN35M

CN43

ADDRESS

(RED)

(RED)

ADDRESS

CN82

SW5

208V

230V

3RD

DIGIT

2ND

DIGIT

1ST

DIGIT

CONNECTION

NO.

(WHT)

CENTRALLY

CONTROL

(GRN)

REMOTE

INDICATION

(RED)

ADDRESS

(RED)

ADDRESS

(BLU)

CN20

INTAKE

(RED)

(BLU)

(GRN)

(RED)

BLU

RED

BLK

RED

WHT

BLU

BLU

M-NET REMOTE CONTROLLER

TO OUTDOOR UNIT

BC CONTROLLER

CONTROLLER

TO MA-REMOTE

LIQUID

(BLK)

GAS

(GRN)

SWITCH

(WHT)

(WHT)

(WHT)

WHT

BLK

BRN

BRN

RED

YLW

ORN

ORN

YLW

5.

4.

1.

Notes:

Symbols used in wiring diagram above are, :terminal block, :connecter, ●:direct wire connection.

At servicing for outdoor unit,always follow the wiring diagram of outdoor unit.

Please set the switch SW5 according to the power supply voltage.

Set SW5 to 230V side when the power supply is 230 volts.

When the power supply is 208 volts,set SW5 to 208V side.

CN5V

(BLU)

CN41

HA

REMOTE

CN32

CN34

CN29

LEV

CN60

CN3A

CN81

CN42

CN52

CN51

12345678910

SW3

0FF

0N

1234

SW2

LED2

M.B

CN21

CN2M

M-NET

FAN

CND

C

FUSE

250V

6A

8

4

ON

OFF

12345678910

SW1

SW12 SW11

SW14

A.B

00

0

LED1

TH22

TH23

TH21

MF

M1

M2

DC24-30V

DC8.7-13V

{

P.B

ZNR

F.C

MV

{

2

532

2

2

1

654321

12345

4321

123 123 1 2 21

32145

32145

4123

612345 78

31

12

13245

123

1

2

3

4

5

6

7

8

1

2

3

4

5

4

2

3

1

321

12

146

13

PKFY-08NAMU-A

OC292-21

0

5VDC SUPPLY

REMOTE

SWITCH

ADDRESS SETTING 2ND DIGIT

13

SW3

109876

ON

OFF

12345

SW2

ON

OFF

123456

SW4

ON

OFF

12345

PKFY-12NGMU-A

Model

0

SW12 SW11

00

CONNECTION

NO.

1ST

DIGIT

2ND

DIGIT

3RD

DIGIT

ON

OFF

SWC

10987654321

CN82(RED)

ADDRESS

SW14

CN43(RED)

ADDRESS

SW5

230V

SW1

208V

A.B

X4

BRN

RED

ORN

YLW

PNK

BLU

MV

8

ADDRESS

CN81(RED)

CN6V(GRN)

VANE

C

BLK

WHT

RED

I.B

(WHT)

FAN

F.C

X4

CND

(RED)

ZNR

6A

250V

FUSE

LEV

TH22 TH23TH21

See fig:w1

<fig:w1>

4

ADDRESS

CN42(RED)

BLK

WHT

5

CN52(GRN)

REMOTE

INDICATION

1

SW2

0FF

0N

65432110987654321

12345

6

BRN

RED

BLU

ORN

YLW

WHT

5

1

SW3

(RED)

CNDK

CENTRALLY

CONTROL

CN51(WHT)

LEV

CN60(WHT)

4

HA

CN41(WHT)

1

CN32(WHT)

3

1

SW4

0FF

0N

CN21

LIQUID

(WHT)

INTAKE

CN20

(RED)

CN29

GAS

(BLK)

LED2

ORN

ORN

BLU

BLU

WHT

BLK

M-NET

(BLU)

CN3A

(BLU)

CN2M

(WHT)

CN2D

LED1

CN31(WHT)

DRAIN

P.B

CNSK

AC208-230V

(RED)

TRANS

(WHT)

DC13.1V

CN2S

GRN/YLW

RED

BLU

TB2

L1

L2

GR

TB5

M2

M1

TB15

2

1

TO NEXT INDOOR UNIT

PULL BOX

BREAKER

(15A)

FUSE(15A)

~/N 208-230V 60Hz

POWER SUPPLY

TO OUTDOOR UNIT

BC CONTROLLER

DC24-30V

REMOTE CONTROLLER

{

S(SHIELD)

DC8.7-13V

{

TO MA-REMOTE

CONTROLLER

SYMBOL

I.B

CN32

CN41

CN51

CN52

F.C

FUSE

SW2

SW3

SW4

X4

ZNR VARISTOR

AUX. RELAY (FAN MOTOR)

MODEL SELECTION

MODE SELECTION

CAPACITY CODESWITCH

FUSE (6A/250V)

FAN PHASE CONTROL

REMOTE INDICATION

CENTRALLY CONTROL

HA TERMINAL-A

CONNECTOR

REMOTE SWITCH

INDOOR CONTROLLER BOARD

NAME

SYMBOL

NAME

SW1

SW5

SW11

SW12

SW14

SWC

OPTION SELECTOR

CONNECTION No.

ADDRESS SETTING 1ST DIGIT

VOLTAGE SELECTION

MODE SELECTIONSWITCH

CIRCUIT BOARD (ADDRESS)

A.B

TH23

SYMBOL

NAME

Mark

LED1

LED2

Power supply for

MA-Remote controller

Main power supply

Meaning

LED on indoor board for service

Function

Main power supply(Indoor unit:208-230V)

power on lamp is lit

Power supply for MA-Remote controller

on lamp is lit

321

THERMISTOR

(32°F/15kΩ,77°F/5.4kΩ)

PIPE TEMPERATURE DETECTION/GAS

INDOOR POWER BOARD

P.B

MA-REMOTE CONTROLLER

TB15

121221

4

3

2

1

8

7

6

5

4

3

2

1

2

1

3

2

1

13

2

1

3

1

1

2

123456

513

MF

123412345678561234

MV

MF

C

VANE MOTOR

TERMINAL

BLOCK

TB5

TB2

FAN MOTOR(WITH INNER THERMOSTAT)

POWER SUPPLY

TRANSMISSION

LEV

LINEAR EXPANSION VALVE

CAPACITOR (FAN MOTOR)

(32°F/15kΩ,77°F/5.4kΩ)

PIPE TEMPERATURE DETECTION/LIQUID

(32°F/15kΩ,77°F/5.4kΩ)

ROOM TEMPERATURE DETECTION

TH22

TH21

THERMISTOR

1. At servicing for outdoor unit,always follow the wiring diagram of outdoor unit.

2. In case of using MA-Remote controller, please connect to TB15.

(Remote controller wire is non-polar.)

3. In case of using M-NET, please connect to TB5.

(Transmisson line is non-polar.)

4. Symbol[S] of TB5 is the shield wire connection.

5. Symbols used in wiring diagram above are, :terminal block, :connecter.

6.

The setting of the SW2/SW3/SW4 dip switches differs in the capacity for the detail, refer to the fig:w1.

7. Please set the switch SW5 according to the power supply voltage.

Set SW5 to 230V side when the power supply is 230 volts.

When the power supply is 208 volts, set SW5 to 208V side.

Notes:

[LEGEND]

2

1

PKFY-12NGMU-A

OC292-22

0

5VDC SUPPLY

REMOTE

SWITCH

ADDRESS SETTING 2ND DIGIT

13

SW3SW2 SW4

4

54321

OFF

ON

ON

OFF

123 5

654321

OFF

ON

ON

123456

54321

OFF

ON

678910

54321

OFF

ON

678910

OFF

Models

PKFY-20NFMU-A

PKFY-32NFMU-A

0

SW12 SW11

00

CONNECTION

NO.

1ST

DIGIT

2ND

DIGIT

3RD

DIGIT

ON

OFF

SWC

10987654321

CN82(RED)

ADDRESS

SW14

CN43(RED)

ADDRESS

SW5

230V

SW1

208V

A.B

X4

BRN

RED

ORN

YLW

PNK

BLU

MV

8

ADDRESS

CN81(RED)

CN6V(GRN)

VANE

C

BLK

WHT

RED

I.B

(WHT)

FAN

F.C

X4

CND

(RED)

ZNR

6A

250V

FUSE

LEV

TH22 TH23TH21

See fig:w1

<fig:w1>

4

ADDRESS

CN42(RED)

BLK

WHT

5

CN52(GRN)

REMOTE

INDICATION

1

SW2

0FF

0N

65432110987654321

12345

6

BRN

RED

BLU

ORN

YLW

WHT

5

1

SW3

(RED)

CNDK

CENTRALLY

CONTROL

CN51(WHT)

LEV

CN60(WHT)

4

HA

CN41(WHT)

1

CN32(WHT)

3

1

SW4

0FF

0N

CN21

LIQUID

(WHT)

INTAKE

CN20

(RED)

CN29

GAS

(BLK)

LED2

ORN

ORN

BLU

BLU

WHT

BLK

M-NET

(BLU)

CN3A

(BLU)

CN2M

(WHT)

CN2D

LED1

CN31(WHT)

DRAIN

P.B

CNSK

AC208-230V

(RED)

TRANS

(WHT)

DC13.1V

CN2S

GRN/YLW

RED

BLU

TB2

L1

L2

GR

TB5

M2

M1

TB15

2

1

TO NEXT INDOOR UNIT

PULL BOX

BREAKER

(15A)

FUSE(15A)

~/N 208-230V 60Hz

POWER SUPPLY

TO OUTDOOR UNIT

BC CONTROLLER

DC24-30V

REMOTE CONTROLLER

{

S(SHIELD)

DC8.7-13V

{

TO MA-REMOTE

CONTROLLER

SYMBOL

I.B

CN32

CN41

CN51

CN52

F.C

FUSE

SW2

SW3

SW4

X4

ZNR VARISTOR

AUX. RELAY (FAN MOTOR)

MODEL SELECTION

MODE SELECTION

CAPACITY CODESWITCH

FUSE (6A/250V)

FAN PHASE CONTROL

REMOTE INDICATION

CENTRALLY CONTROL

HA TERMINAL-A

CONNECTOR

REMOTE SWITCH

INDOOR CONTROLLER BOARD

NAME

SYMBOL

NAME

SW1

SW5

SW11

SW12

SW14

SWC

OPTION SELECTOR

CONNECTION No.

ADDRESS SETTING 1ST DIGIT

VOLTAGE SELECTION

MODE SELECTIONSWITCH

CIRCUIT BOARD (ADDRESS)

A.B

TH23

SYMBOL

NAME

Mark

LED1

LED2

Power supply for

MA-Remote controller

Main power supply

Meaning

LED on indoor board for service

Function

Main power supply(Indoor unit:208-230V)

power on lamp is lit

Power supply for MA-Remote controller

on lamp is lit

321

THERMISTOR

(32°F/15kΩ,77°F/5.4kΩ)

PIPE TEMPERATURE DETECTION/GAS

INDOOR POWER BOARD

P.B

MA-REMOTE CONTROLLER

TB15

121221

4

3

2

1

8

7

6

5

4

3

2

1

2

1

3

2

1

13

2

1

3

1

1

2

123456

513

MF

123412345678561234

MV

MF

C

VANE MOTOR

TERMINAL

BLOCK

TB5

TB2

FAN MOTOR(WITH INNER THERMOSTAT)

POWER SUPPLY

TRANSMISSION

LEV

LINEAR EXPANSION VALVE

CAPACITOR (FAN MOTOR)

(32°F/15kΩ,77°F/5.4kΩ)

PIPE TEMPERATURE DETECTION/LIQUID

(32°F/15kΩ,77°F/5.4kΩ)

ROOM TEMPERATURE DETECTION

TH22

TH21

THERMISTOR

1. At servicing for outdoor unit,always follow the wiring diagram of outdoor unit.

2. In case of using MA-Remote controller, please connect to TB15.

(Remote controller wire is non-polar.)

3. In case of using M-NET, please connect to TB5.

(Transmisson line is non-polar.)

4. Symbol[S] of TB5 is the shield wire connection.

5. Symbols used in wiring diagram above are, :terminal block, :connecter.

6. The setting of the SW2 / SW3 / SW4 dip switches differs in the capacity for the detail,refer to the fig:w1.

7. Please set the switch SW5 according to the power supply voltage.

Set SW5 to 230V side when the power supply is 230 volts.

When the power supply is 208 volts,set SW5 to 208V side.

Notes:

[LEGEND]

2

1

PKFY-20NFMU-A PKFY-32NFMU-A

OC292-23

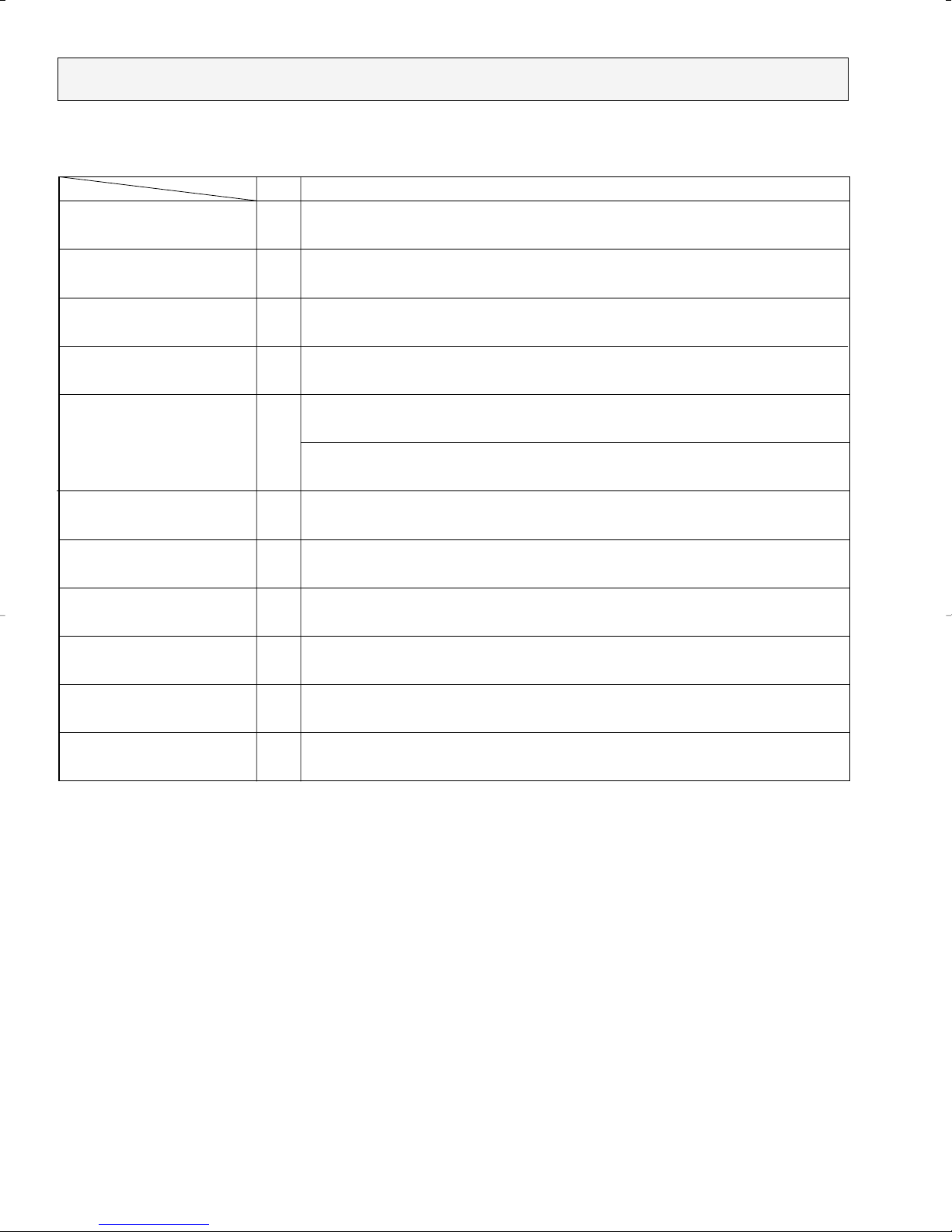

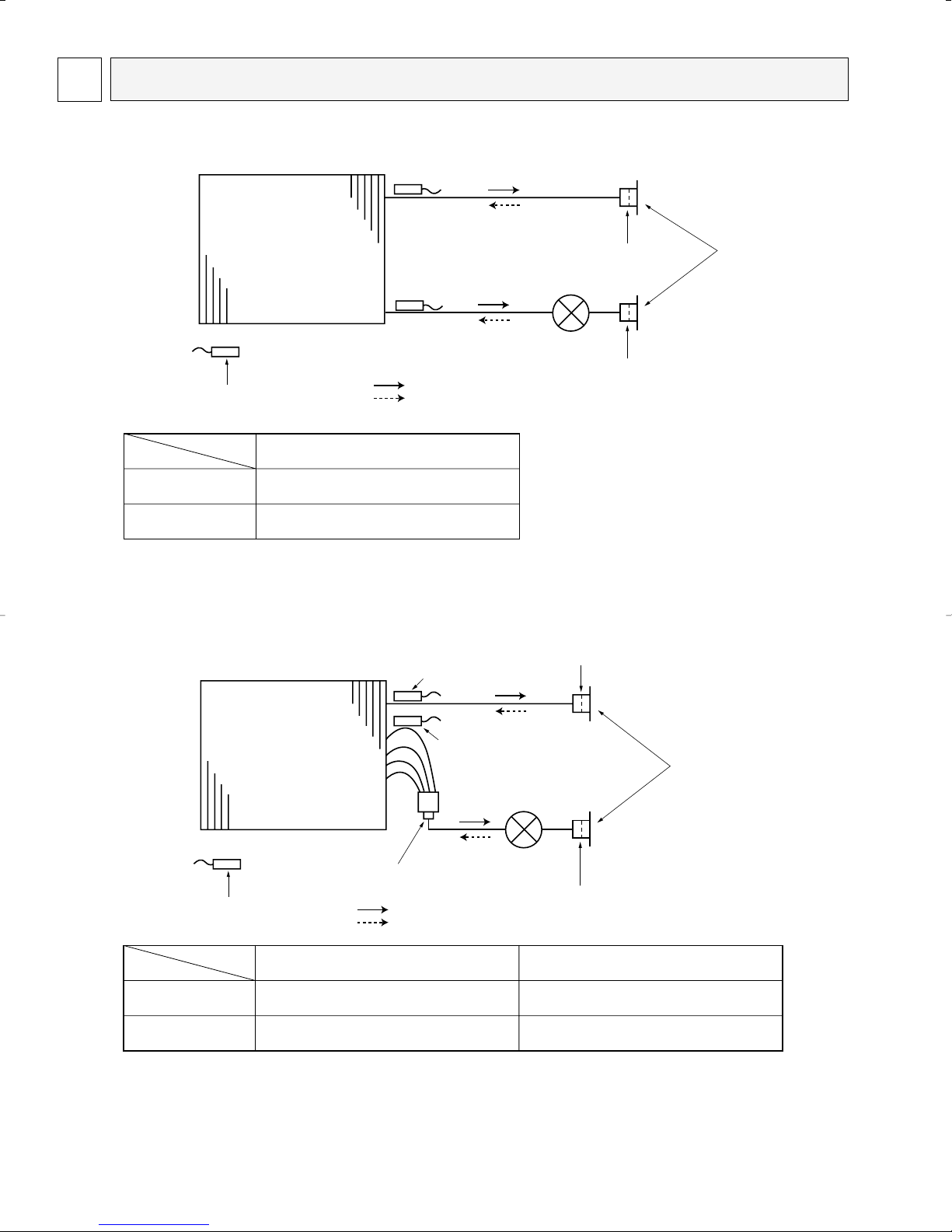

7 REFRIGERANT SYSTEM DIAGRAM

Strainer

(#100mesh)

Strainer

(#50mesh)

Heat exchanger

Room temperature

thermistor TH21

Gas pipe temperature thermistor

TH23

Liquid pipe temperature thermistor

TH22

Gas pipe

Liquid pipe

Flare

Linear expansion

valve

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer (#50mesh)

Strainer (#100mesh)

Strainer (#100mesh)

Heat exchanger

Room temparature

thermistor TH21

Gas pipe thermistor

thermistor TH23

Liquid pipe thermistor TH22

Linear expansion valve

Gas pipe

Liquid pipe

Flare connection

Refrigerant flow in cooling

Refrigerant flow in heating

Gas pipe

Liquid pipe

PKFY-20NFMU-A

PKFY-32NFMU-A

5/8''

3/8''

Item

Service Ref.

PKFY-12NGMU-A

1/2''

1/4''

Gas pipe

Liquid pipe

Item

Service Ref.

PKFY-08NAMU-A

1/2''

1/4''

PKFY-08NAMU-A

PKFY-12NGMU-A

PKFY-20NFMU-A

PKFY-32NFMU-A

OC292-24

MICROPROCESSOR CONTROL8

Control modes

Control details

1-1. Thermoregulating function (Function to prevent restarting for 3 minutes)

• Room temperature ] desired temperature + 2°F

···Thermo ON

• Room temperature [ desired temperature

···Thermo OFF

1-2. Anti-freezing control

Detected condition : When the liquid pipe temp. (TH22) is 36°F or less in 16

minutes from compressors start up, anti-freezing control

starts and the thermo OFF.

Released condition : The timer which prevents reactivating is set for 3 minutes,

and anti- freezing control is cancelled when any one of the

following conditions is satisfied.

1 Liquid pipe temp. (TH22) turn 50°F or above.

2 The condition of the thermo OFF has become complete

by thermoregulating, etc.

3 The operation modes became mode other than COOL.

4 The operation stopped.

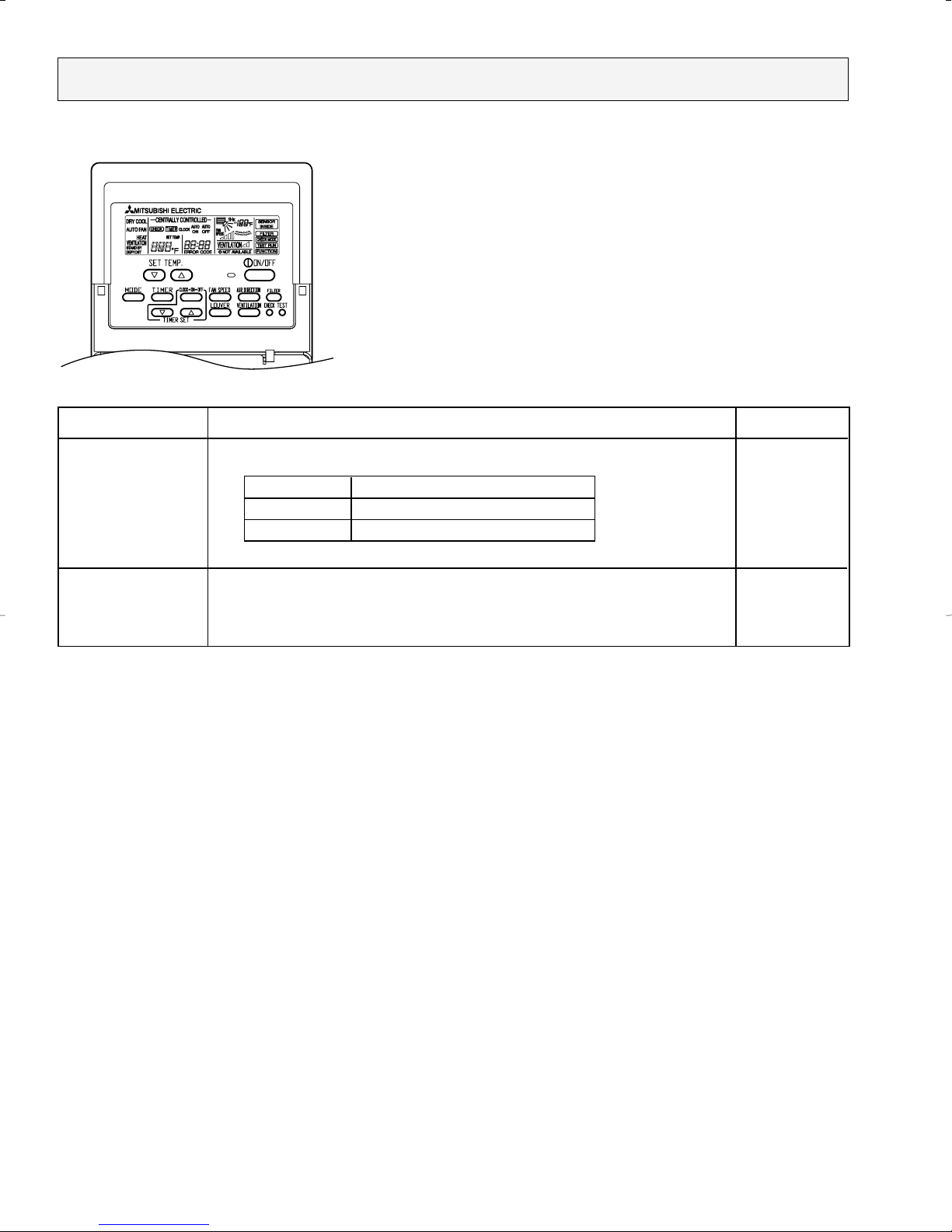

By the remote controller setting (switch of 4 speeds or 2 speeds)

2. Fan

1. Thermoregulating

function

Remarks

Type

Fan speed notch

[Low], [Med2], [Med1], [High]

[Low], [High]

4 speeds type

2 speeds type

To be continued on the next page.

INDOOR UNIT CONTROL

8-1. COOL operation

<How to operate>

1 Press POWER ON/OFF button.

2 Press the operation MODE button to display COOL.

3 Press the SET TEMP. button to set the desired temperature.

NOTE: The set temperature changes 2°F when the or button is

pressed one time Cooling 67 to 87°F.

OC292-25

→→

3

2

1

→

3

2

1

→

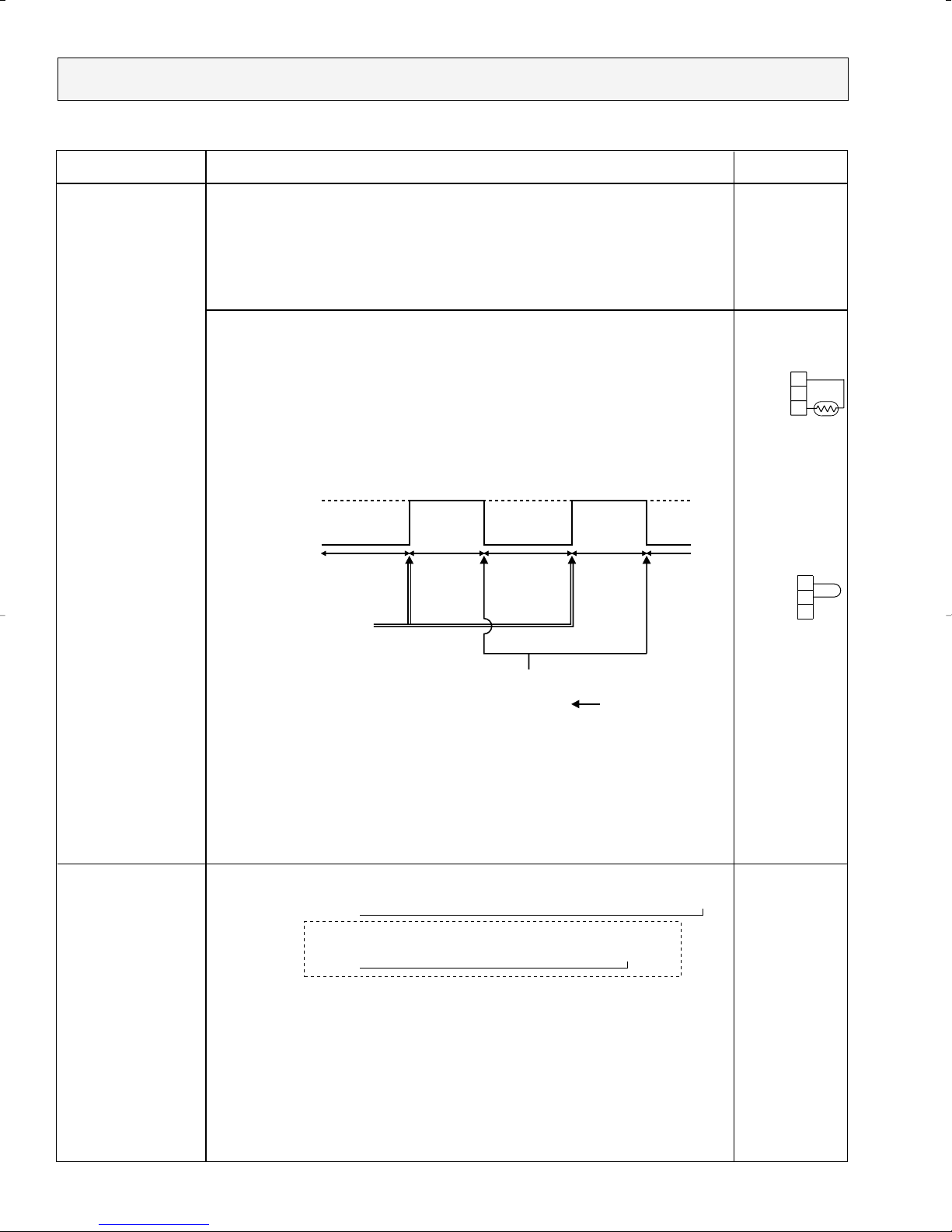

Control modes

Control details

3-1. Drain pump control

•Always drain pump ON during the COOL and DRY mode operation.

(Regardless of the thermo ON/ OFF)

•When the operation mode has changed from the COOL or DRY to the others

(including Stop), OFF the control after the drain pump ON for 3 minutes.

Drain sensor function

• Energize drain sensor at a fixed voltage for a fixed duration. After energizing,

compare the drain sensor’s temperature to the one before energizing, and judge

whether the sensor is in the air or in the water.

Basic control system

• While drain pump is turned on, repeat the following control system and judge

whether the sensor is in the air or in the water.

•Drain sensor temperature rise (∆t)

•Temperature of drain sensor before current is applied (T0)

•Temperature of drain sensor after current is applied (T

1)

[ ∆t = T1 – T0 ]

(1)Initial setting : Start at COOL mode and horizontal vane.

(2)Vane position : Horizontal →Downward A →Downward B →Downward C→Swing

PKFY-08NAMU-A is not equipped with the swing function.

: Horizontal →Downward A →Downward B →Downward C

(3) In case of PKFY-08NAMU-A and PKFY-12NGMU-A :

Restriction of the downward vane setting

When setting the downward vane A, B or C in [Med1], [Med2] or [Low] of the fan

speed notch, the vane changes to horizontal position after 1 hour have passed.

In case of PKFY-20NFMU-A and PKFY-32NFMU-A :

Restriction of the downward vane setting

When setting the downward vane A, B or C in [Low] of the fan speed notch,

the vane changes to horizontal position after 1 hour have passed.

4. Vane

(up/ down vane change)

3. Drain pump

Except for

PKFY-08NAMU-A.

Remarks

W

1

"SET FOR 1 HOUR"

appears on the

wired remote

controller.

Timing of

energizing

drain sensor

ON

OFF

Stand by for

a minute

30 sec.

Detect the

temperature

before

energizing

(T0)

Detect the

temperature

after

energizing

(T1)

Judge whether

the sensor is in

the air or in the

water.

30 sec.Stand by for

a minute

·······Repeat

From the preceding page.

W1 Drain sensor

Indoor control

p.c. board

CN31

W2 If the unit is

without the drain

sensor, install

the jumper

connector.

Indoor control

p.c. board

CN31

When installing

the jumper

connector,

determine to

detect

compulsorily in

the air.

OC292-26

8-2. DRY operation

<How to operate>

1 Press POWER ON/OFF button.

2 Press the operation MODE button to display DRY.

3 Press the SET TEMP. button to set the desired temperature.

NOTE: The set temperature changes 2°F when the or button is

pressed one time. Dry 67 to 87°F.

Control modes

1. Thermoregulating

function

2. Fan

Control details

1-1. Thermoregulating function (Function to prevent restarting for 3 minutes)

Setting the Dry thermo by the thermoregulating signal and the

room temperature (TH1).

Dry thermo ON Room temperature ] desired temperature + 2°F

Dry thermo OFF Room temperature [ desired temperature

Room

temperature

Over 64°F

Less than 64°F

3 min. passed since starting operation

Thermoregulating signal

ON

OFF

Room temperature (T1)

82°F > T1 ] 79°F

79°F > T1 ] 75°F

75°F > T1

Unconditional

Dry thermo OFF

Dry thermo

time (min)

T1 ] 82°F

Dry thermo

ON

93

7

5

33

3

OFF

time (min)

1-2. Frozen prevention control

No control function

Indoor fan operation controlled depends on the compressor conditions.

Dry thermo

ON

OFF

Fan speed notch

[Low]

Stop

Remarks

3

3

10

Note: Remote controller setting is not acceptable.

3. Drain pump

Same control as COOL operation

Except for

PKFY-08NAMU-A.

4. Vane

Same control as COOL operation

(up/ down vane change)

OC292-27

Control modes

Control details

Set by remote controller.

Remarks

1. Fan

2. Vane

(up/ down vane change)

Same as the control performed during the COOL operation, but with no restriction

on the vane's downward blow setting.

Type

Fan speed notches

[Low], [Med2], [Med1], [High]

[Low], [High]

4 speeds type

2 speeds type

8-3. FAN operation

<How to operate>

1 Press POWER ON/OFF button.

2 Press the operation MODE button to display FAN.

OC292-28

Loading...

Loading...