Mitsubishi PLA-RP_AA(1), PLA-RP_AA(1).UK, PEA-RP_EA, PEAD-RP_EA, PEAD-RP_EA.UK TECHNICAL MANUAL

...Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

No. OCT04

SERVICE TECHNICAL GUIDE

<Indoor unit>

[Model names] [Service Ref]

PLA-RP·AA PLA-RP·AA

PLA-RP·AA

R410A

1

PLA-RP·AA.UK

PLA-RP·AA

PEA-RP·EA PEA-RP·EA.TH-A

PEAD-RP·EA PEAD-RP·EA.UK

PEAD-RP·EA

<Outdoor unit>

[Model names] [Service Ref]

PUHZ-RP·VHA PUHZ-RP·VHA

1.UK

1.UK

PUHZ-RP·VHA-A

CONTENTS

1. PAIRING TABLE OF THE INDOOR AND OUTDOOR UNIT·····2

2. SPECIFICATIONS FOR ELECTRICAL WORK ·························3

3. WIRING DIAGRAM·····································································6

4. REFRIGERANT SYSTEM DIAGRAM ······································11

5. HOW TO CHECK THE PARTS ················································18

6. MICROPROCESSOR CONTROL·············································24

7. INDOOR UNIT CONTROL························································30

8. OUTDOOR UNIT CONTROL····················································38

9. DIP SWITCH FUNCTION ·························································54

10. FUNCTION SETTING ·······························································67

11. TEST RUN • REPLACEMENT OPERATION

& EMERGENCY OPERATION···················································77

12. SELF-DIAGNOSIS····································································83

13. TEST POINT DIAGRAM·························································109

14. TROUBLESHOOTING····························································117

15. SYSTEM CONTROL·······························································121

Page 2

1

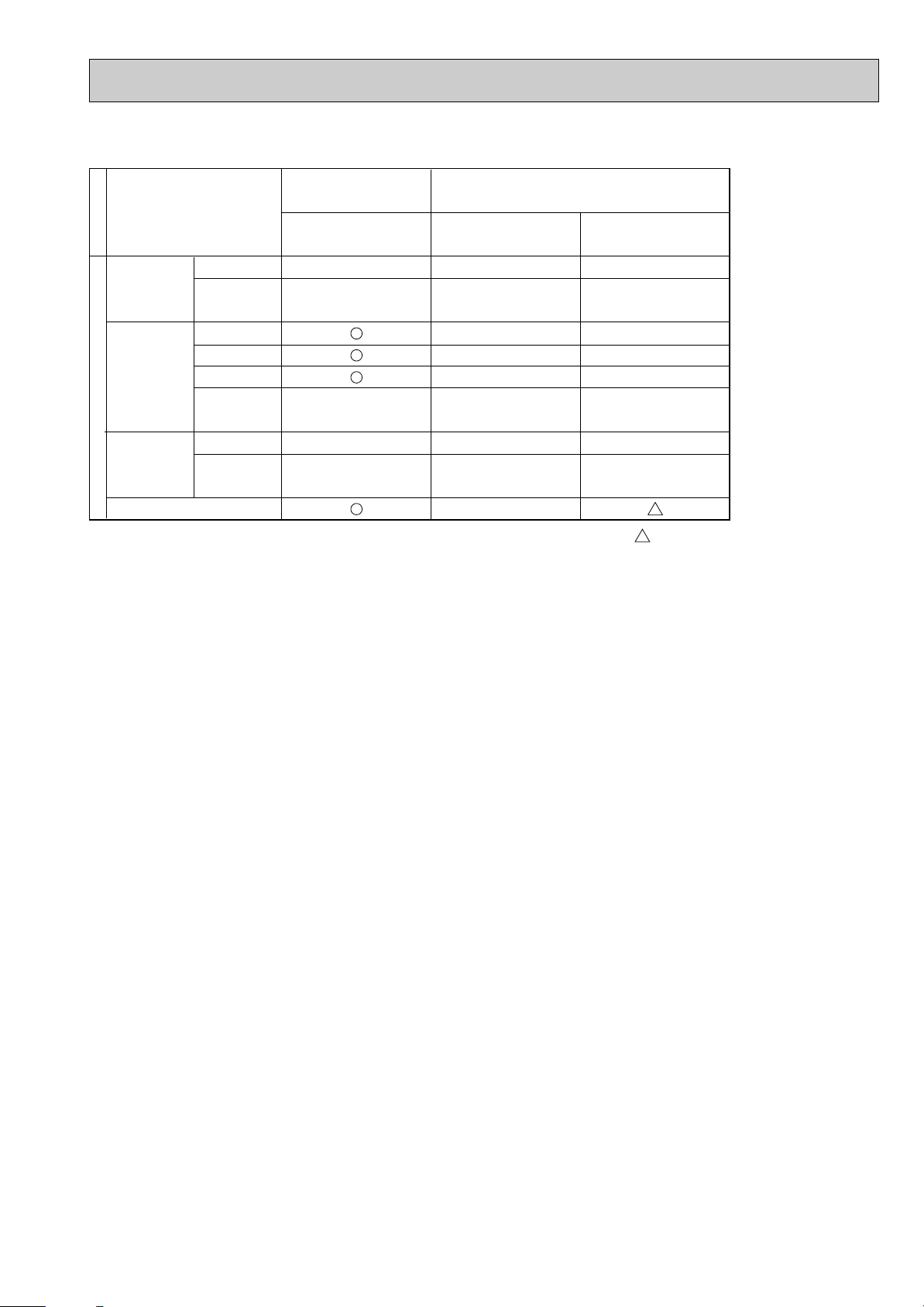

PLA-RP·AA

PLA-RP·AA

1

PLA-RP·AA.UK

PLA-RP·AA

1.UK

PEAD-RP·EA.UK

PEAD-RP·EA

1

.UK

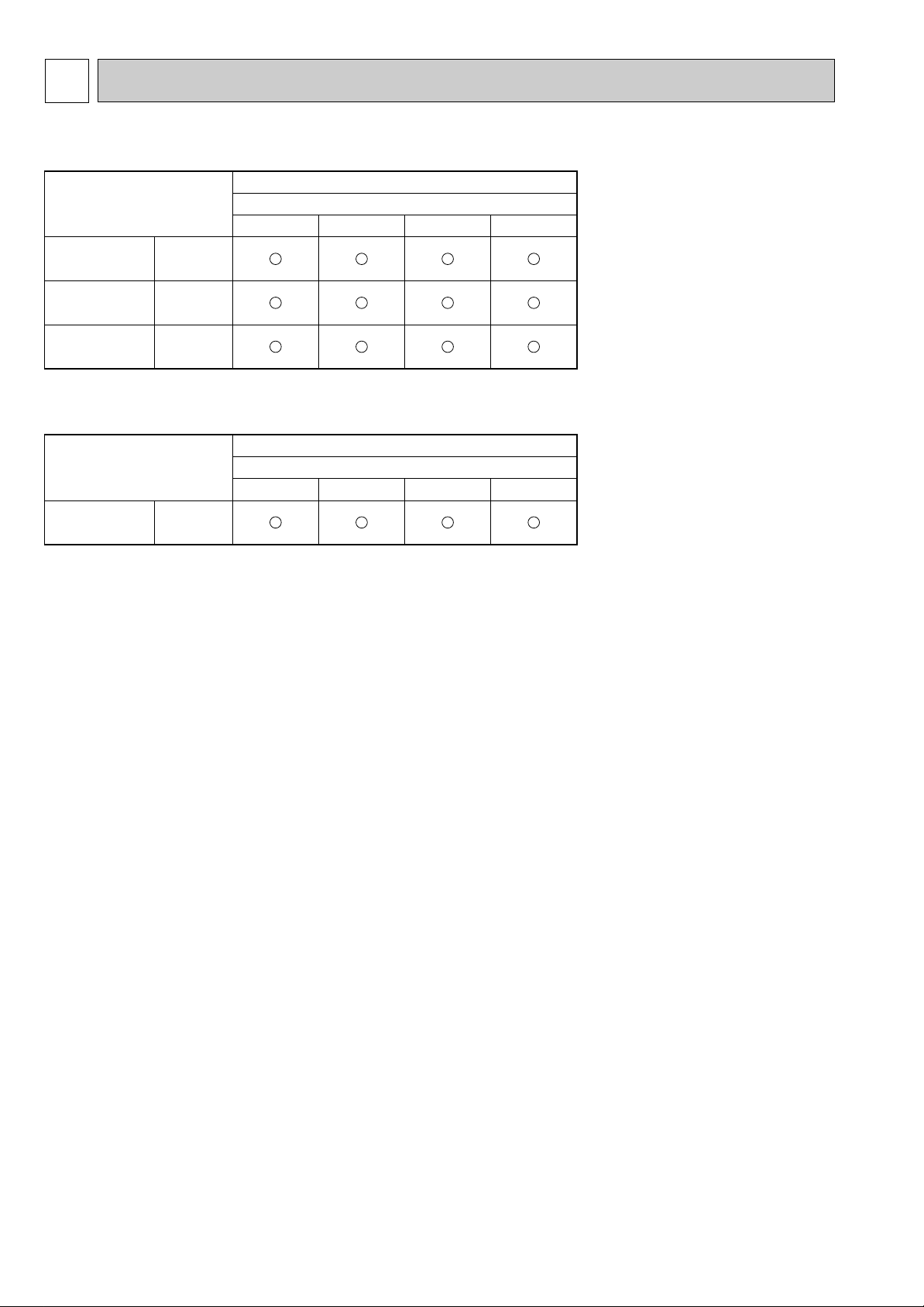

OC293

REVISED EDITION-A

OC297

REVISED EDITION-A

—

RP3VHA RP4VHA RP5VHA RP6VHA

Indoor unit

Outdoor unit [PUHZ]

OC294

PEA–RP·EA.TH-A

OC299

REVISED EDITION-A

RP3VHA-A RP4VHA-A RP5VHA-A RP6VHA-A

Indoor unit

Outdoor unit [PUHZ]

OC300 REVISED EDITION-A

PAIRING TABLE OF THE INDOOR AND OUTDOOR UNITS

2

Page 3

2

Outdoor unit

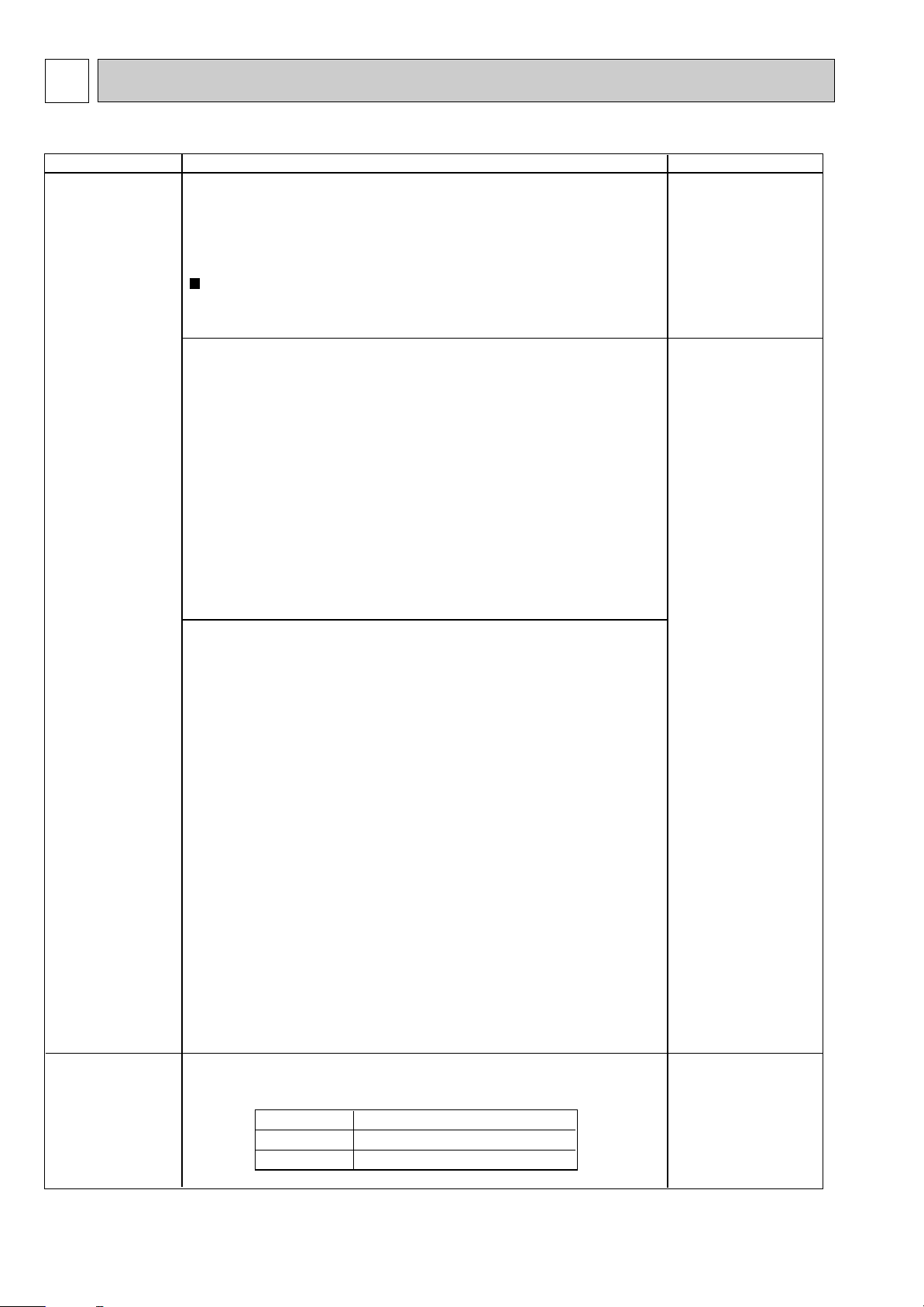

Power supply

Phase

Frequency & Voltage

Indoor unit(A)

Outdoor unit(A)

Wire No.

—

25/25

3

—

32/32

3

—

32/32

3

—

40/40

3

Models (Outdoor unit)

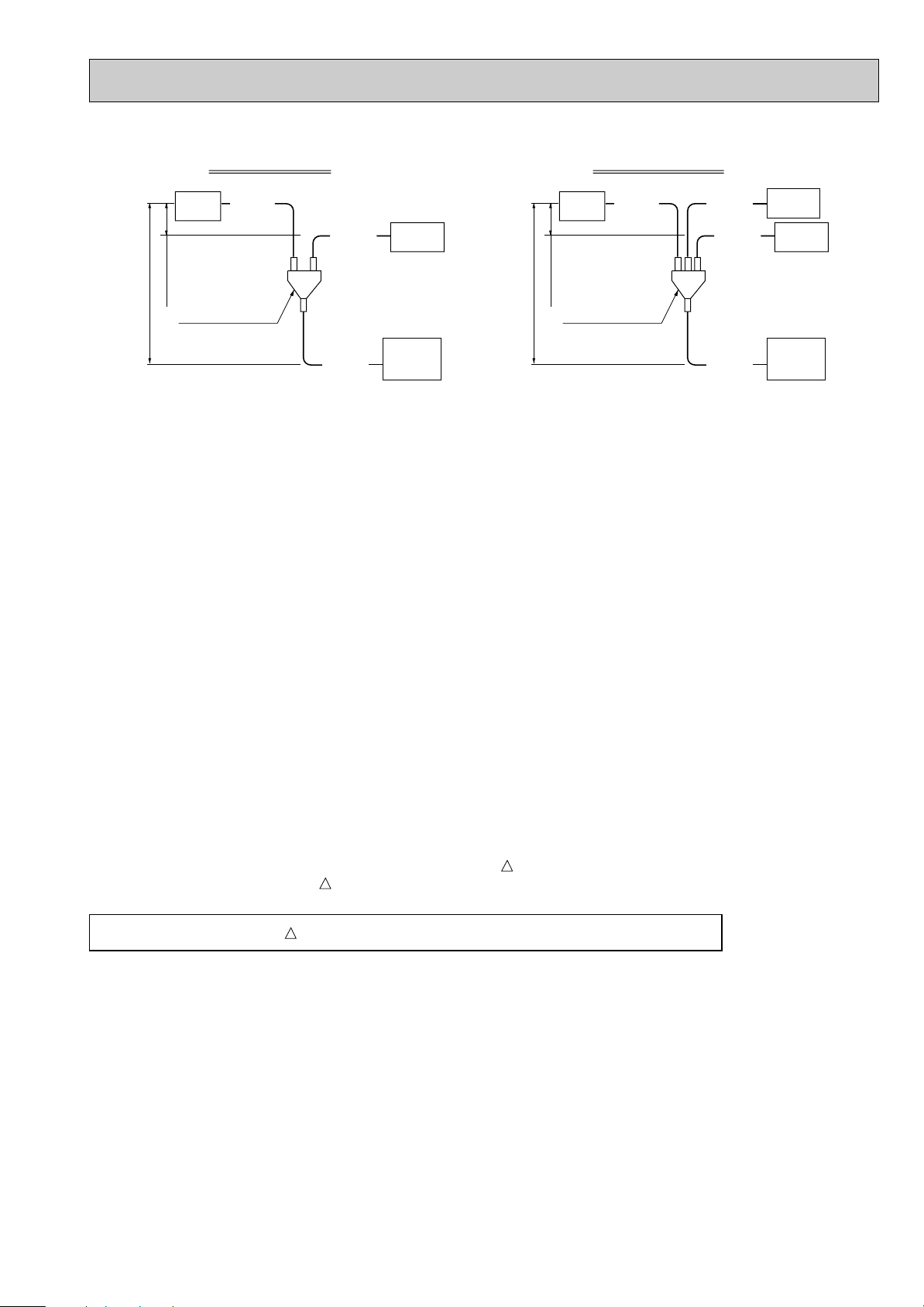

~ / N (Single)

50Hz, 220-230-240V

Outdoor unit

Power supply

Input capacity

Main switch/Fuse

Indoor unit/Outdoor unit connecting

Wire No. o size (e)

Remote controller-indoor unit connecting

Wire No. o size (e)

Indoor unit power supply

~ / N (Single), 50Hz, 220-230-240V

Control circuit rating

Wiring

3 o 2.5 cable (Polar)

Cable 2C o 0.69

This wire is accessory of remote controller (Wire length: 10m, Non-polar)

Indoor unit-Outdoor unit: S1-S2 AC220V-230V-240V

S2-S3 DC24V

Remote controller-Indoor unit: DC14V

RP3V RP4V RP5V RP6V

1

2

S1

S2

S3

S1

S2

S3

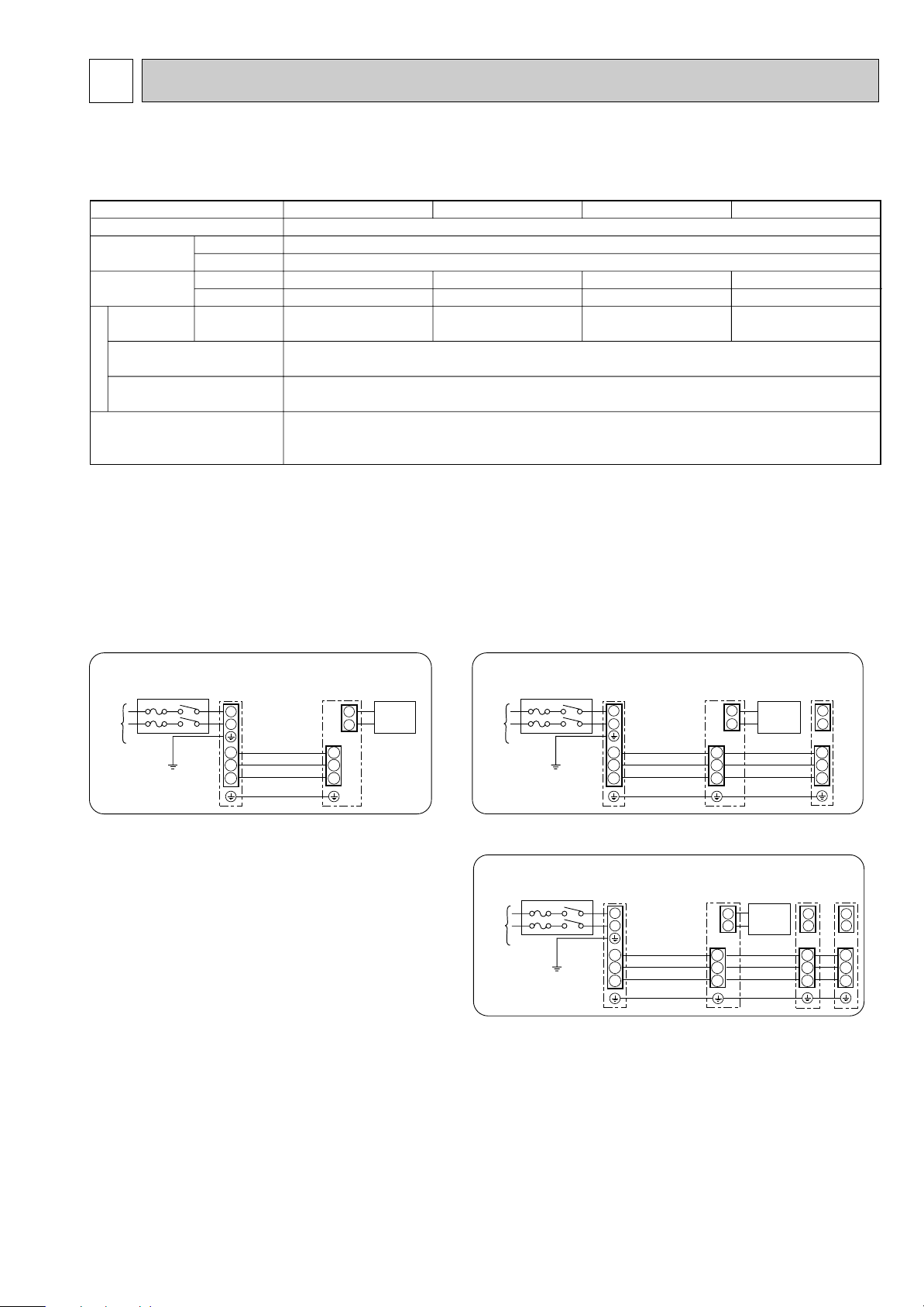

Indoor/outdoor

unit connection

cable

Indoor

unit

Unit

power

supply

Outdoor

unit

Remote

controller

L

N

Grounding

L

N

1

2

1

2

S1

Indoor

unit

S2

S3

S1

S2

S3

S1

S2

S3

Unit

power

supply

Indoor/outdoor

unit connection

cable

Indoor

unit

Outdoor

unit

Remote

controller

Grounding

1

2

1

2

1

2

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

Indoor/outdoor

connection cable

Indoor

unit

Unit

power

supply

Indoor

unit

Indoor

unit

Outdoor

unit

Remote

controller

L

N

Grounding

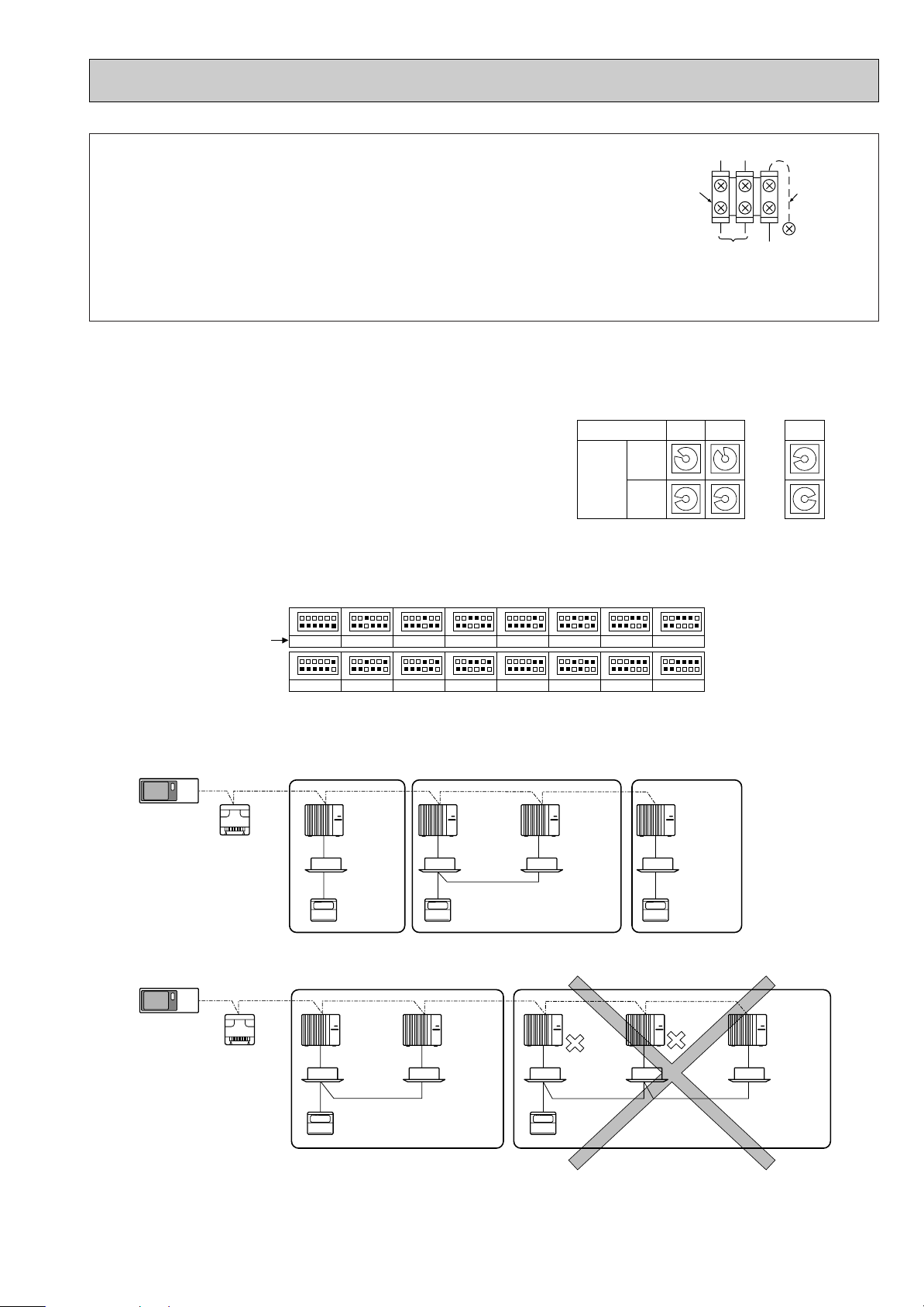

SPECIFICATIONS FOR ELECTRICAL WORK

2-1. Field electrical wiring(power wiring specifications)

PUHZ-RP•VHA

PUHZ-RP•VHA-A

Check items

1. Wiring size must comply with the applicable local and national code.

2. Be careful about choosing the installation location for the earth leakage breaker and how it is installed as the initial electric

current may cause it to malfunction.

3. Power supply cords and indoor unit / Outdoor unit connecting cords shall not be lighter than polychloroprene sheathed flexible cord. (design 254 IEC 57)

1:1 system Synchronized twin and triple system Electrical wiring

• Synchronized twin

• Synchronized triple

3

Page 4

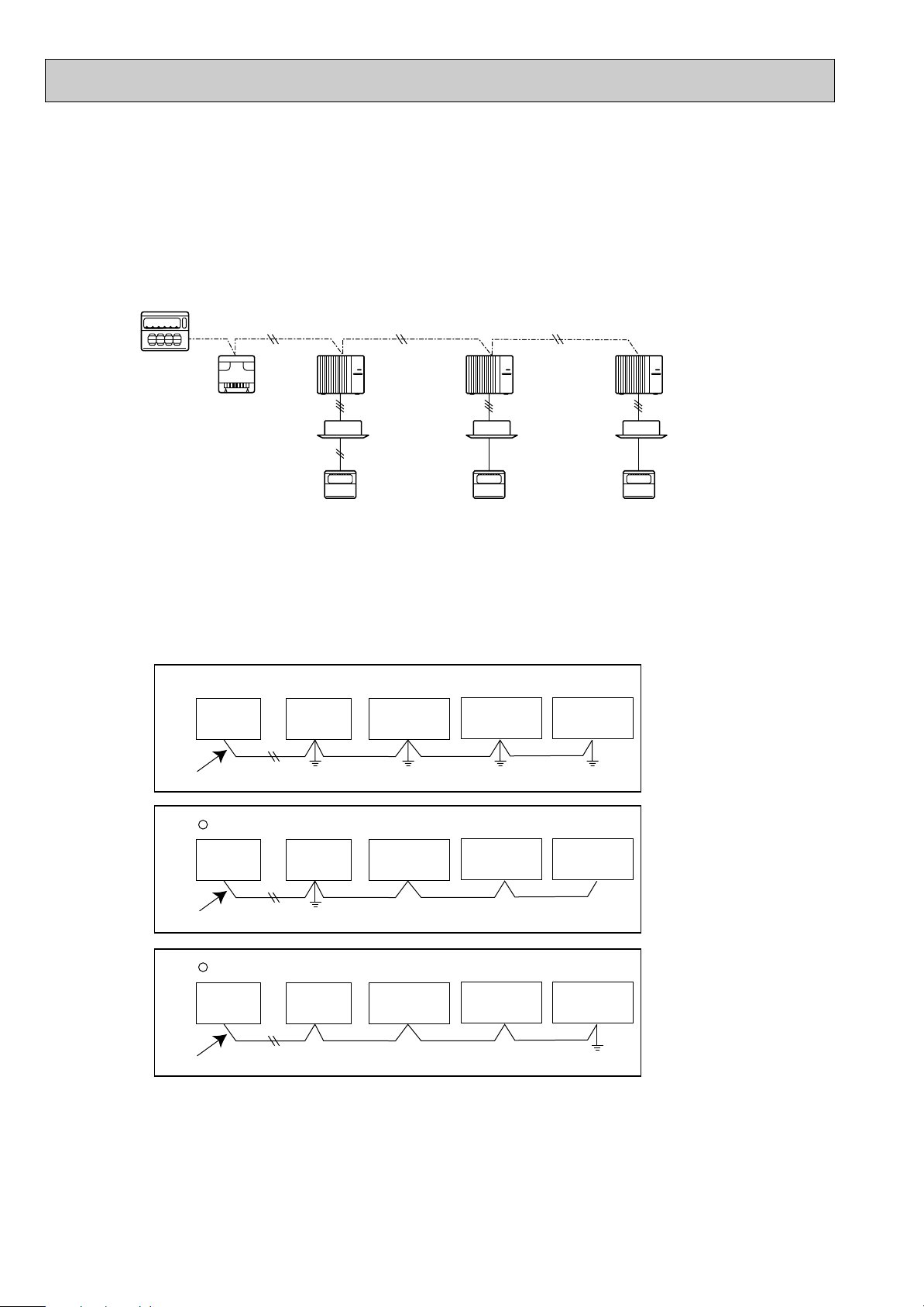

2-2. M-NET wiring method

Group

remote

controller

Refrigerant

address 00

M-NET

address 01

A-control

remote

controller

A-control

remote

controller

A-control

remote

controller

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 00

M-NET

address 03

Power

supply

unit for

transmission

wire

Central

remote

controller

M-NET transmission wire

✕ Bad example (Multi spot grounding of shield wire)

Good example 1 (Single spot grounding of shield wire)

Power

supply

appliance

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Good example 2 (Single spot grounding of shield wire)

(Points to notice)

(1) Outside the unit, transmission wires should stay away from electric wires in order to prevent electromagnetic noise from

making an influence on the signal communication. Place them at intervals of more than 5cm. Do not put them in the same

conduit tube.

(2) Terminal block (TB7) for transmission wires should never be connected to 220~240V power supply. If it is connected,

electronic parts on M-NET p.c. board may be burn out.

(3) Use 2-core x 1.25mm2shield wire (CVVS, CPEVS) for the transmission wire. Transmission signals may not be sent or

received normally if different types of transmission wires are put together in the same multi-conductor cable. Never do this

because this may cause a malfunction.

It would be ok if M-NET wire (non-polar, 2-cores) is arranged in addition to the wiring for A-control.

(4) Ground only one of any appliances through M-NET transmission wire (shield wire). Communication error may occur due to

the influence of electromagnetic noise.

“Ed” error will appear on the LED display of outdoor unit.

“0403” error will appear on the central-control remote controller.

If there are more than two grounding spots on the shield wire, noise may enter into the shield wire because the ground wire

and shield wire form one circuit and the electric potential difference occurs due to the impedance difference among grounding spots. In case of single spot grounding, noise does not enter into the shield wire because the ground wire and shield

wire do not form one circuit.

To avoid communication errors caused by noise, make sure to observe the single spot grounding method described in the

installation manual.

4

Page 5

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

12

~

50

M-NET Address No.

<Setting example>

Switng

setting

SW11

ones

digit

SW12

tens

digit

OFF

ON

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

0

Refuigrant

address

OFF

ON

8

OFF

ON

1

OFF

ON

9

OFF

ON

10

OFF

ON

11

OFF

ON

12

OFF

ON

13

OFF

ON

14

OFF

ON

15

OFF

ON

2

OFF

ON

3

OFF

ON

4

OFF

ON

5

OFF

ON

6

OFF

ON

7

System

controller

A-control

remote

controller

Group A Group B Group C

A-control

remote

controller

TB5

A-control

remote

controller

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 00

M-NET

address 04

Power

supply

unit for

transmission

wire

A-control

remote

controller

A-control

remote

controller

TB5

Group A Group B

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 01

M-NET

address 02

Refrigerant

address 00

M-NET

address 04

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 02

M-NET

address 05

System

controller

Power

supply

unit for

transmission

wire

● M-NET wiring

(1) Use 2-core x 1.25mm

2

shield wire for electric wires.

(Excluding the case connecting to system controller.)

(2) Connect the wire to the M-NET terminal block.Connect one core of the

transmission wire (non-polar) to Aterminal and the other to B. Peel the

shield wire, twist the shield part to a string and connect it to S terminal.

(3) In the system which several outdoor units are being connected, the terminal

(A, B, S) on M-NET terminal block should be individually wired to the other

M-NET

terminal

block

ABS

Transmission

wire

Ground

wire

Shield

part

outdoor unit’s terminal, i.e. Ato A, B to B and S to S.In this case, choose one of those outdoor units and drive a screw

to fix an ground wire on the plate as shown on the right figure.

2-2-1. M-NET address setting

In A-control models, M-NET address and refrigerant address should be set only for the outdoor unit. Similar to Free Combo

system, there is no need to set the address of outdoor unit and remote controller. To construct a central control system, the

setting of M-NET address should be conducted only upon the outdoor unit. The setting range should be 1 to 50 (the same as

that of the indoor unit in Free Combo system), and the address number should be consecutively set in a same group.

Address number can be set by using rotary switches

(SW11 for ones digit and SW12 for tens digit), which

is located on the M-NET p.c. board of outdoor unit.

(Factory setting: all addresses are set to “0”.)

2-2-2. Refrigerant address setting

In case of multiple grouping system (multiple refrigerant circuits in one group), indoor units should be connected by remote

controller wiring (TB5) and the refrigerant address needs to be set. Leave the refrigerant addresses to “00” if the group setting is not conducted. Set the refrigerant address by using DIP SW1-3 to -6 on the outdoor controller board. [Factory setting:

all switches are OFF. (All refrigerant addresses are “00”.)]

2-2-3. Regulations in address settings

In case of multiple grouping system, M-NET and refrigerant address settings should be done as explained in the above section. Set the lowest number in the group for the outdoor unit whose refrigerant address is “00” as its M-NET address.

w Refrigerant addresses can be overlapped if they are in the different group.

w In group B, M-NET address of the outdoor unit whose refrigerant address is “00” is not set to the minimum in the group. As

“3” is right for this situation, the setting is wrong. Taking group A as a good sample, set the minimum M-NET address in

the group for the outdoor unit whose refrigerant address is “00”.

5

Page 6

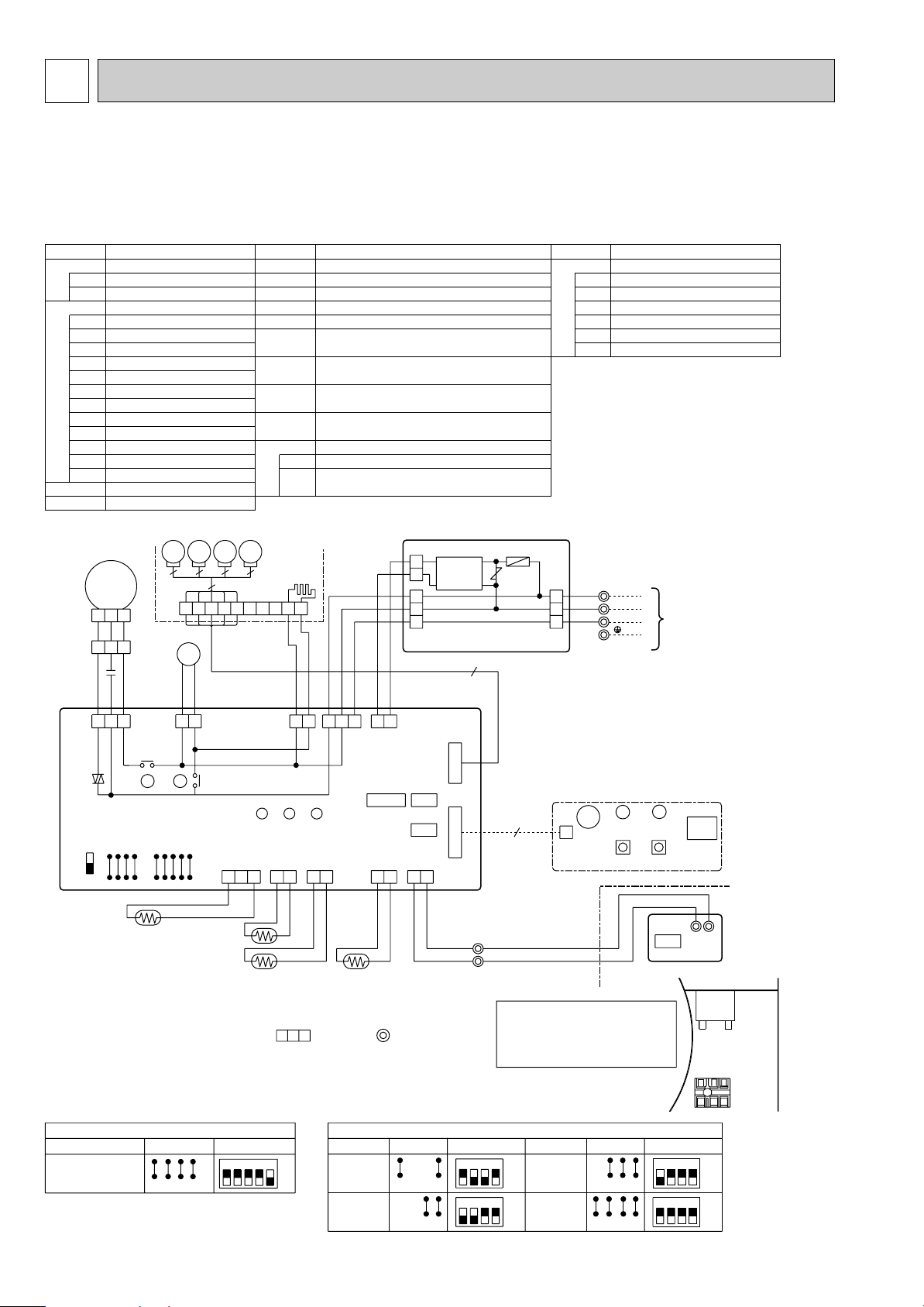

3 WIRING DIAGRAM

[Servicing]

Fasten terminal of the terminal board "TB4" equips lock system.

To remove the fastened terminal, pull it while pressing the protruding portion (locking lever) of

the terminal. The fastened terminal protruding portion should face upward.

NOTES:

1.Since the outdoor side electric wiring may change be sure to

check the outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities, make

wiring matching terminal numbers (S1,S2,S3).

3.Symbols used in wiring diagram above are, :Connector, :Terminal (block).

Please set the voltage using

the remote controller.

For the setting method, please

refer to the indoor unit Installation

Manual.

TO OUTDOOR UNIT

C

TB4

H2

5

GRILLE

MV

MV

MV

MV

5

5

5

5

TRANSMISSION

WIRES DC12V

MODELS

Manufacture

Service board

MODELS

Manufacture

Service board

SW1

BLK

BLK

BLK

BLK

BLK

BLK

BLU

BLU

TH5

12

PIPE

CN29

(BLK)

REMOCON

CN22

(BLU)

WIRELESS

CN90

(WHT)

SW1

SW2

SWE

VANE

CN6V

(WHT)

POWER

CN03

(RED)

POWER

CN2D

(WHT)

LIQUID

CN21

(WHT)

INTAKE

CN20

(RED)

D.SENSOR

CN31

(WHT)

D.HEATER

CNC (RED)

D.U.M

CNP

(BLU)

FAN

(WHT)

BRN

ORN

YLW

CONTROLLER BOARD

CN02 (WHT)

OUTDOOR UNIT

CN01 (BLU)

CN2S(WHT)

BLK

WHT

YLW

ORN

BRN

YLW

YLW

YLW

YLW

BLK

RED

WHT

CNB

W.B

LED1

LED2

BZ

RU

SW1 SW2

X4

X4

J15

J22J21 J24J23

OFF

ON

OFF

ON

4321

4321

J21J22J23J24

PLA-RP3AA

PLA-RP3AA

1

PLA-RP4AA

PLA-RP4AA

1

PLA-RP5AA

1

PLA-RP6AA

PLA-RP6AA

1

R.B

9

X1

X1

5

31

CN32

CN2LCN41

123

12315

TH1

2

TB5

1

12

TB6

CN2

TH2

DS

3

2

1

DC14V

1

2

3

12

J11

J12

J13

J14

2

121

LED1LED2LED3

ZNR

DP

3

FC

531

1

1

2

ON

OFF

J21

J22

J23

J24

C

MF

I.B

321

P.B

F1

TB4

S1

S2

S3

PLA-RP3,4,5,6AA

PLA-RP3,4,5,6AA

1

1

J11J12J13J142J15

345

ON

OFF

SW2

MODELS

Manufacture

Service board

J22J21 J24J23

OFF

ON

OFF

ON

4321

4321

J21J22J23J24

PLA-RP5AA

10

5

9

8

4

7

6321

123

CONNECTOR (PROGRAM TIMER)

TRANSMISSION LINE)

TERMINAL BLOCK (REMOTE CONTROLLER

REMOTE CONTROLLER BOARD

(0:/15kΩ, 25:/5.4kΩ DETECT)

COND./EVA. TEMPERATURE THERMISTOR

(0:/15kΩ, 25:/5.4kΩ DETECT)

PIPE TEMPERATURE THERMISTOR/LIQUID

(0:/15kΩ, 25:/5.4kΩ DETECT)

ROOM TEMPERATURE THERMISTOR

TRANSMISSION LINE)

TERMINAL BLOCK (REMOTE CONTROLLER

TERMINAL BLOCK (INDOOR/OUTDOOR CONNECTING LINE)

CN2

TB6

R.B

TH5

TH2

TH1

TB5

TB4

DEW PREVENTION HEATERH2

W.B

SYMBOL NAME

WIRELESS REMOTE CONTROLLER BOARD

RECEIVING UNIT

BUZZER

LED (HOT ADJUST)

SWITCH (HEATING ON/OFF)

LED (RUN INDICATOR)

BZ

LED1

RU

LED2

SW1

SW2

SWITCH (COOLING ON/OFF)

SYMBOL

SYMBOL

NAME

NAME

I.B

INDOOR POWER BOARD

FUSE (4A)

VARISTOR

INDOOR CONTROLLER BOARD

CN2L

CN32

CN41

SW1

SW2

SWE

X1

X4

FC

CONNECTOR (LOSSNAY)

CONNECTOR (REMOTE SWITCH)

CONNECTOR (HA TERMINAL-A)

JUMPER WIRE (MODEL SELECTION)

JUMPER WIRE (CAPACITY CORD)

SWITCH (EMERGENCY OPERATION)

RELAY (DRAIN PUMP)

RELAY (FAN MOTOR)

FAN PHASE CONTROL

C

CAPACITOR (FAN MOTOR)

MF

FAN MOTOR

DP

DS DRAIN SENSOR

P.B

ZNR

F1

DRAIN-UP MACHINE

LED1

LED2

POWER SUPPLY (I.B)

POWER SUPPLY (I.B)

MV

VANE MOTOR

LED3

TRANSMISSION (INDOOR-OUTDOOR)

[LEGEND]

PLA-RP3AA PLA-RP4AA PLA-RP5AA PLA-RP6AA

PLA-RP3AA1 PLA-RP4AA1 PLA-RP5AA1 PLA-RP6AA1

PLA-RP3AA.UK PLA-RP4AA.UK PLA-RP5AA.UK PLA-RP6AA.UK

PLA-RP3AA1.UK PLA-RP4AA1.UK PLA-RP5AA1.UK PLA-RP6AA1.UK

6

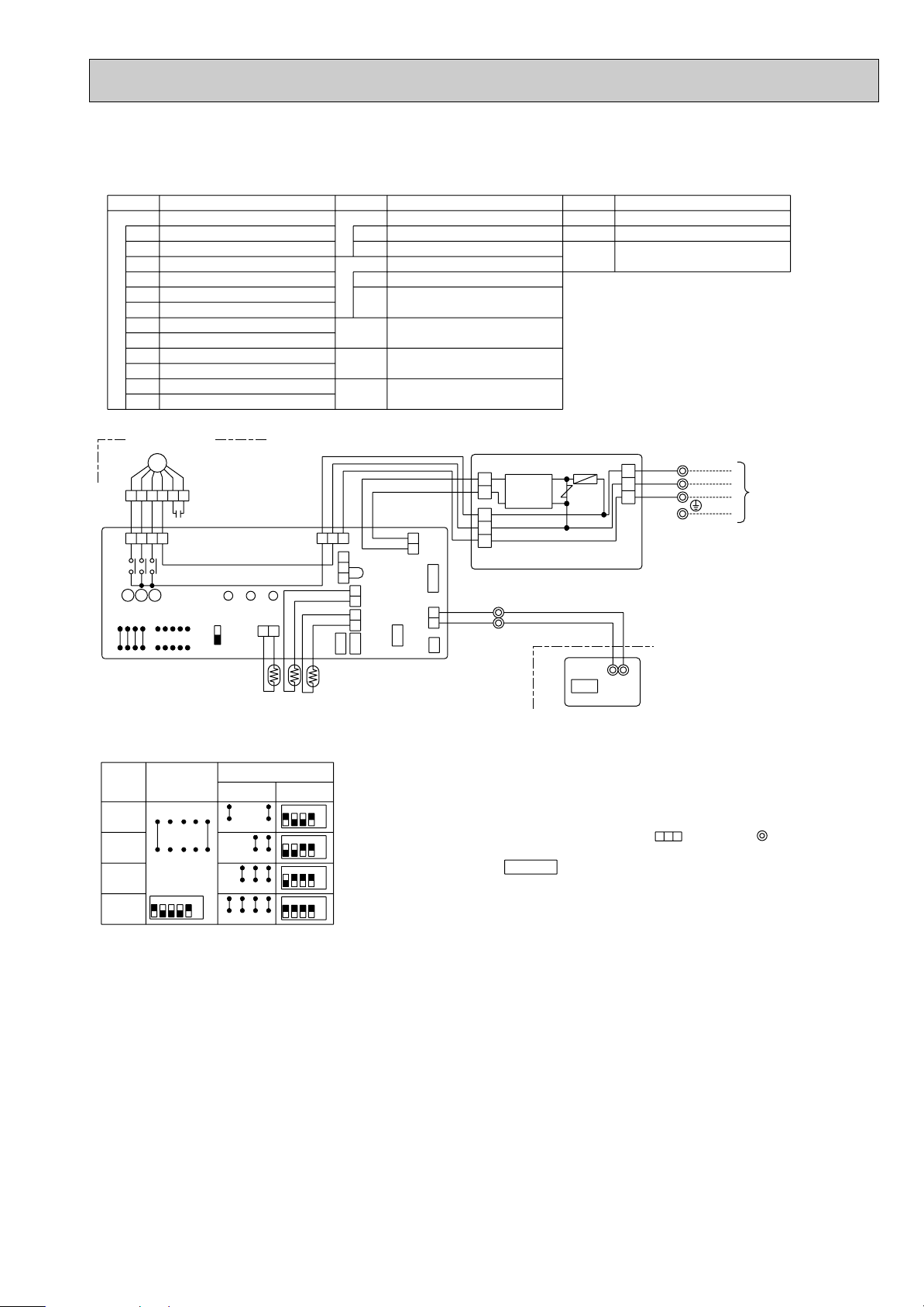

Page 7

PEA-RP3EA.TH-A PEA-RP5EA.TH-A

TO OUTDOOR UNIT

12

TB6

R.B

562341

PIPE TEMPERATURE THERMISTOR/LIQUID

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

COND./EVA. TEMPERATURE THERMISTOR

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

ROOM TEMPERATURE THERMISTOR

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

TH5

TH2

TH1

CN24

NAME

SYMBOL

NAME

SYMBOL SYMBOL

NAME

CN2

R.B

CONNECTOR(PROGRAM TIMER)

REMOTE CONTROLLER BOARD

TERMINAL BLOCK(REMOTE

CONTROLLER TRANSMISSON LINE)

TB6

RELAY(FAN MOTOR)

X6

X5

X4

SWE

SW2

SW1

JUMPER WIRE(MODEL SELECTION)

JUMPER WIRE(CAPACITY CORD)

SWITCH(EMERGENCY OPERATION)

RELAY(FAN MOTOR)

RELAY(FAN MOTOR)

LED3

LED2

POWER SUPPLY(R.B)

TRANSMISSOION(INDOOR • OUTDOOR)

I.B

CN2L

CN41

CN32

LED1

INDOOR CONTROLLER BOARD

CONNECTOR(LOSSNAY)

CONNECTOR(HA TERMINAL-A)

CONNECTOR(REMOTE SWITCH))

POWER SUPPLY(I.B)

FUSE(4A)

INDOOR POWER BOARD

VARISTOR

P.B

F1

ZNR

CAPACITOR(FAN MOTOR)

FAN MOTOR

MF

TB4

TERMINAL BLOCK

(INDOOR/OUTDOOR CONNECTING LINE)

C

J21J22J23J24

J21J22J23J24

J21J22J23J24

J24J23J22

1

BLU

2

3

2

1

CN31

2

1

2

1

1

2

1

2

J24

J23

J22

P.B

ZNR

X4X5

X6 X5

X6

1357

RED

C

ORN

MF

1.Since the outdoor side electric wiring may change be sure to check the

outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities,make wiring

matching terminal numbers(S1,S2,S3).

3.Symbols used in wiring diagram above are, :Connector, :Terminal (block).

FAN

(WHT)

1.When pressing the CHECK switch twice on the remote controller,the unit

changes to the self-diagnosis mode and will display the check code by

LED(light Emitting Diode)

Refer to the right table for the check codes and abnormarities.

LED3 LED2 LED1

INDOOR UNIT

TRANSMISSION WIRE

DC12V

OFF

ON

4321

Manufacture

<For manufacture>

SW1

[Self diagnosis]

[NOTES]

J21

OFF

ON

SWE

SW2

WIRELESS

INTAKE

CN20

(RED)

LIQUID

CN21

(WHT)

REMOCON

CN22

(BLU)

CN90

(WHT)

POWER

CN2D

(WHT)

POWER

CN03

(RED)

S3

S2

S1

F1

OUTDOOR

CN01(BLU)

3

2

1

CONT.BOARD

CN02(WHT)

CN2S(WHT)

DC14V

1

2

3

2

1

TH1

CN2

TB5

I.B

TH2

513

CN41

CN2L

CN32

X4

BLK

BLU

BRN

WHT

YLW

ORN

BRN

WHT

BLK

YLW

ORN

BRN

SW1

J11

J12

J13

J14

J15

TB4

TH5

1

2

PIPE

CN29

(BLK)

BLU

SW2

MODELS

J14J13J12J11 J15

Service board

OFF

ON

4321

OFF

ON

4321

J21

OFF

ON

4321

3EA

4EA

5EA

6EA

123 5

ON

OFF

4

<For service board>

PEA-RP4EA.TH-A PEA-RP6EA.TH-A

7

Page 8

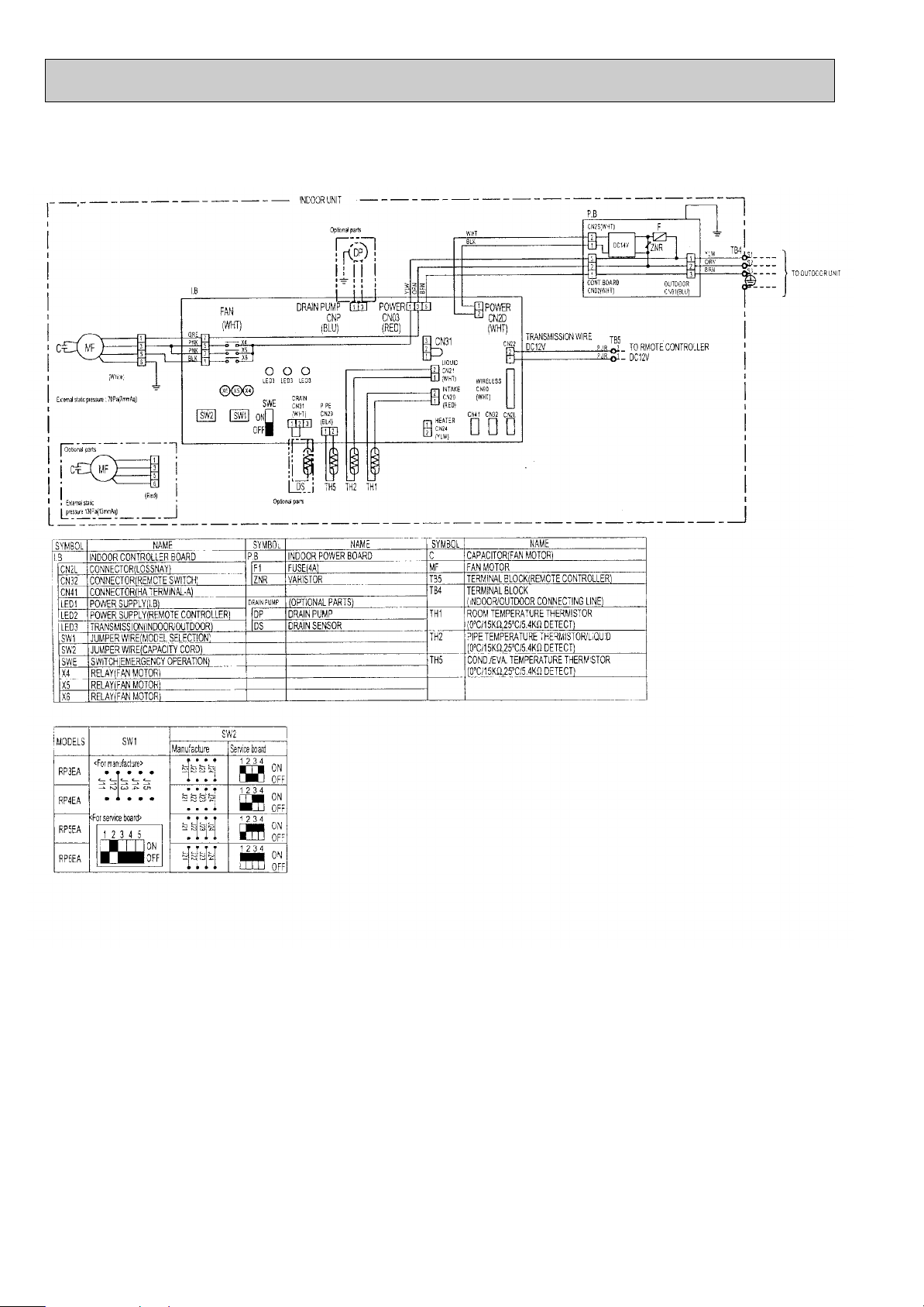

PEAD-RP3EA.UK PEAD-RP4EA.UK PEAD-RP5EA.UK PEAD-RP6EA.UK

PEAD-RP3EA1.UK PEAD-RP4EA1.UK PEAD-RP5EA1.UK PEAD-RP6EA1.UK

8

Page 9

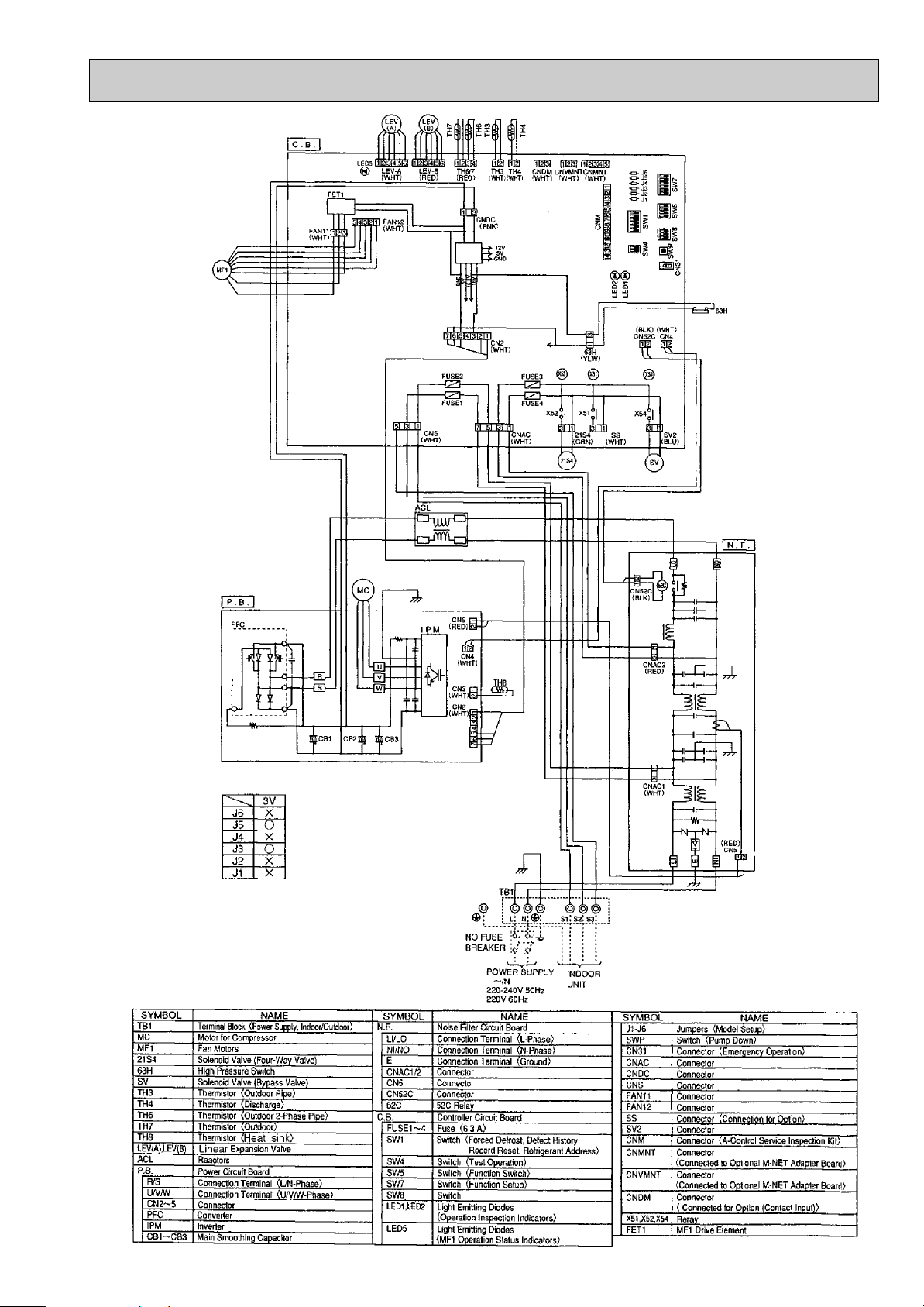

PUHZ-RP3VHA

PUHZ-RP3VHA-A

9

Page 10

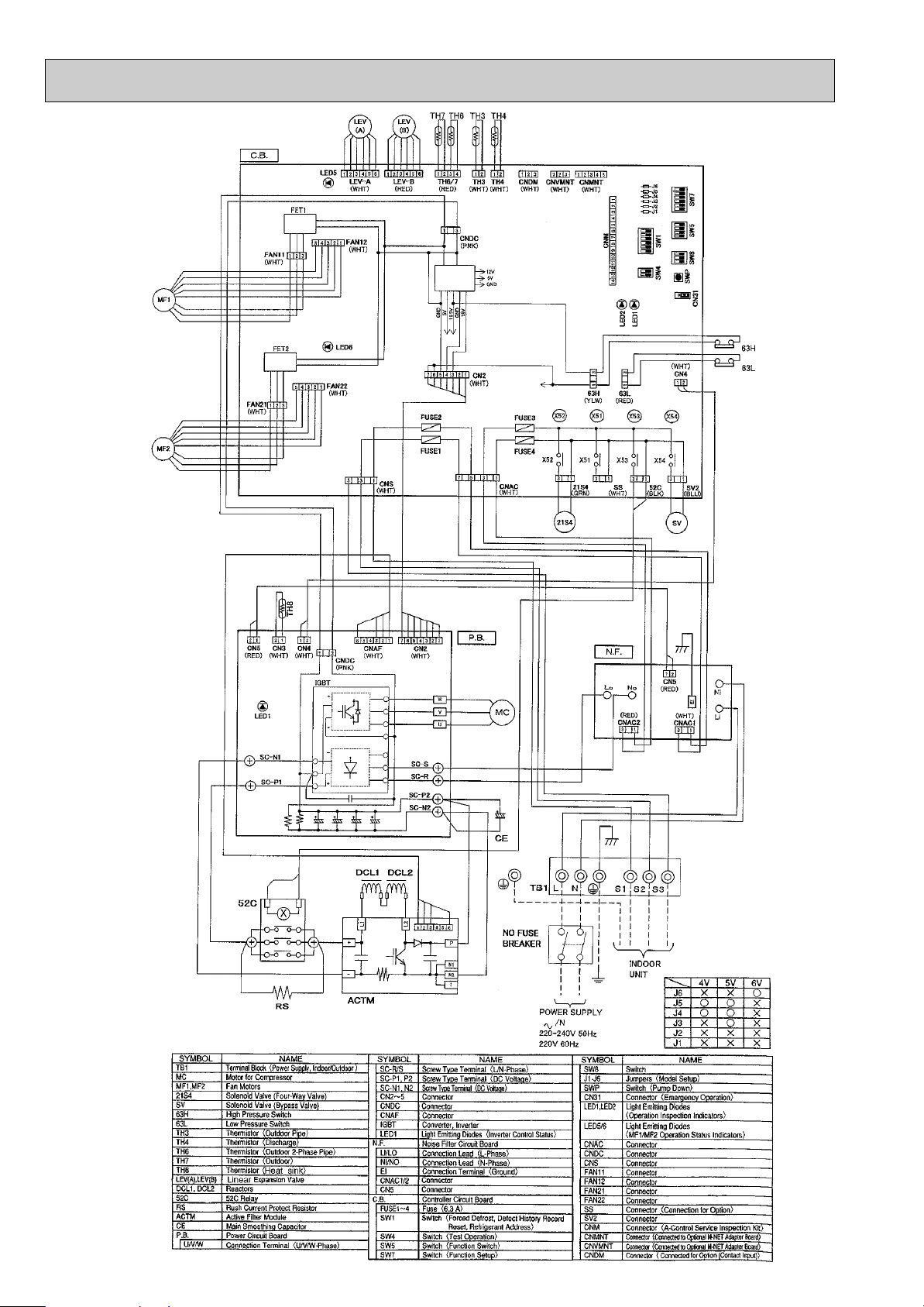

PUHZ-RP4VHA

PUHZ-RP5VHA

PUHZ-RP6VHA

PUHZ-RP4VHA-A

PUHZ-RP5VHA-A

PUHZ-RP6VHA-A

10

Page 11

4

Measurement item

COOL: 2.3 ~ 3.0 HEAT: 2.0 ~ 3.2

0.55 ~ 1.0

50 ~ 100

-2 ~ +18

COOL: 27: HEAT: 20:

COOL: 8 ~ 20

HEAT: 30 ~ 50

COOL: 35 HEAT: 7

COOL: 40 ~ 50 HEAT: 0 ~ 5

Measurement method, remarks

Connect the pressure gauge to the high-pressure check valve.

Connect the pressure gauge to the low-pressure check valve.

Measured with piping surface thermometer.

Measured with piping surface thermometer.

Can be displayed on remote controller.

Measured with piping surface thermometer.

Measured with piping surface thermometer.

High pressure (MPa)

Low pressure (MPa)

Discharge pipe temperature (:)

Suction pipe temperature (:)

Indoor intake temperature (:)

Indoor outlet temperature (:)

Outdoor intake temperature (:)

Outdoor outlet temperature (:)

Pressure/temperature near JIS

standard operating conditions

A

B

C

D

E

F

G

H

Notes : The operation statuses vary depending on the compressor's operating frequency because units are inverter-type.

Outdoor

heat exchanger

Stop valve

(with service port)

Power

receiver

Linear

expansion

valve B Linear

expansion

valve A

4-way valve

Compressor

Ball valve

Indoor heat

exchanger

A

B

C

D

Overload operation

Standard operation

Permissible operation range

Normal operation range

0 0.2 0.4 0.6 0.8 1 1.2

Suction pressure (MPa)

Discharge pressure (MPa)

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

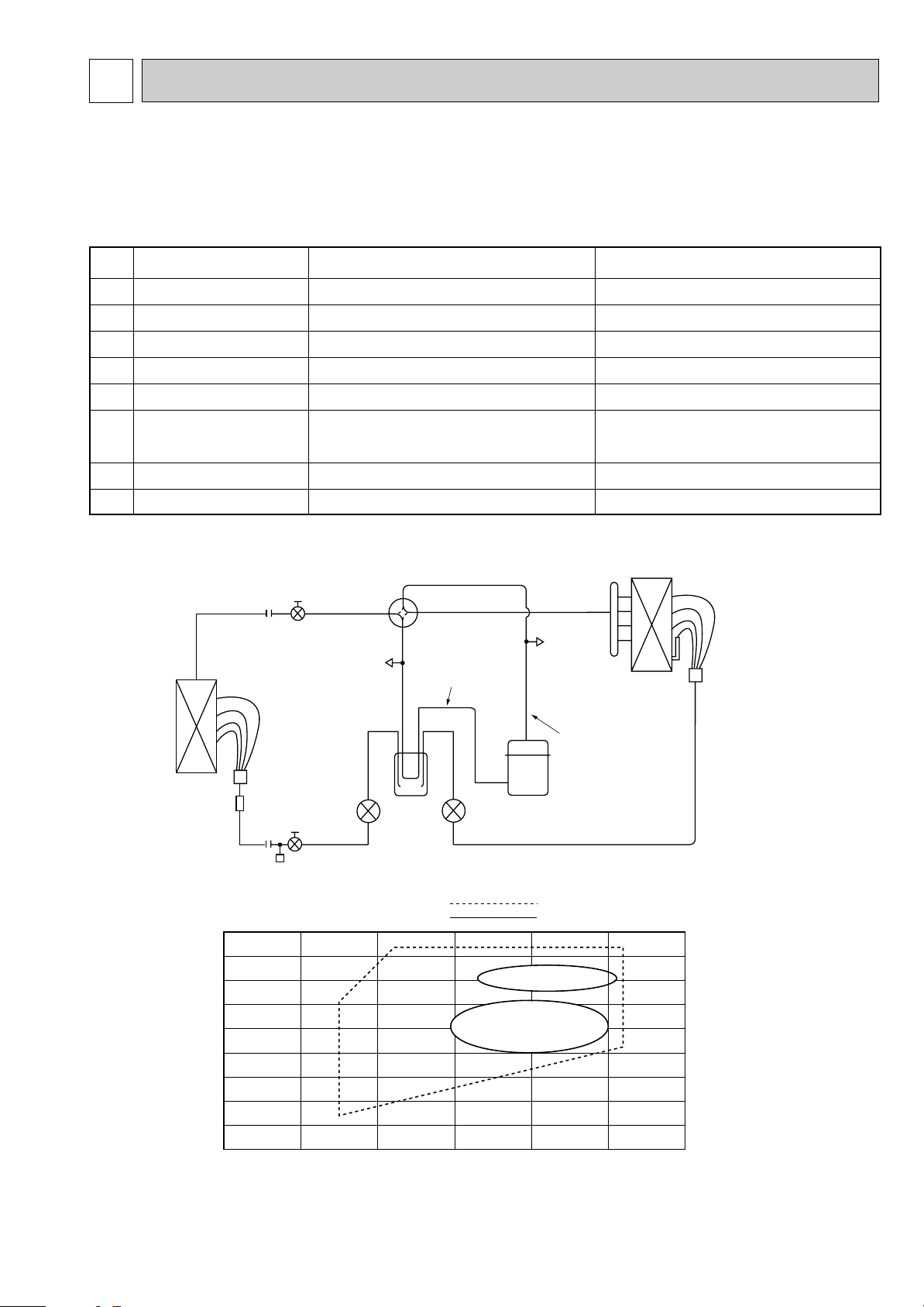

REFRIGERANT SYSTEM DIAGRAM

4-1. Checking operation statuses PUHZ-RP • HA

4-1-1. Measurement points and items

•The table and diagrams below show the measurement item for each measurement point, and the pressure and temperature

near the ISO T1 standard operating conditions.

•Measure the temperature and pressure of each part by following the descriptions in the table.

•Measurement time: Be sure to wait until the refrigerant circuit has stabilized (30 minutes to 1 hour) before taking

measurements.

4-1-2. Operation pressure ranges

11

Page 12

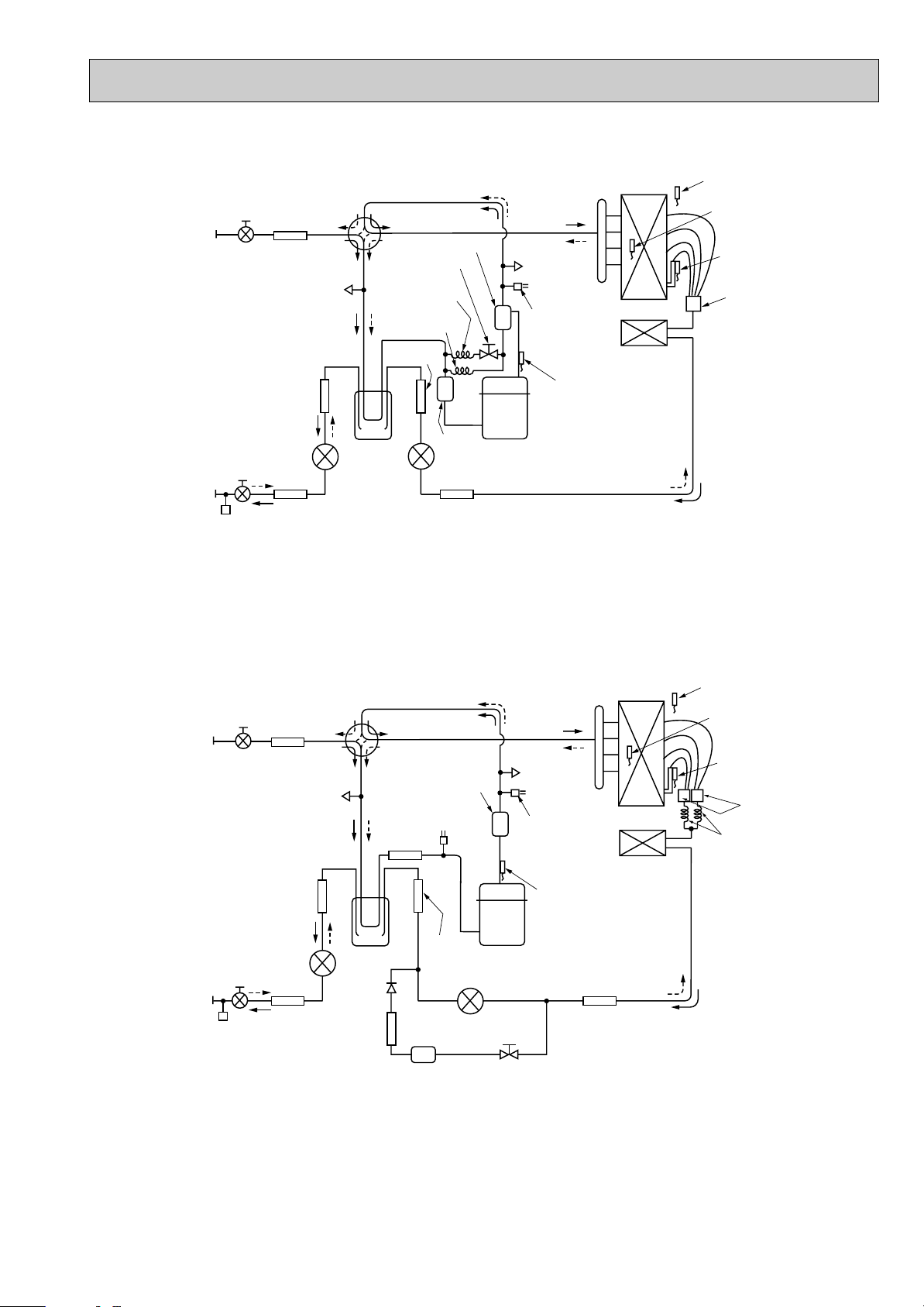

4-2. Refrigerant System Diagram

Pipe temperature

thermistor/liquid

(TH2)

Distributor

with strainer

#50

Condenser/evaporator

temperature thermistor

(TH5)

Room temperature

thermistor (TH1)

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#50

Strainer

#50

Heat exchanger

Refrigerant GAS pipe connection

(Flare)

Refrigerant LIQUID pipe connection

(Flare)

PLA-RP3AA PLA-RP4AA PLA-RP5AA PLA-RP6AA

PLA-RP3AA1 PLA-RP4AA1 PLA-RP5AA1 PLA-RP6AA1

PLA-RP3AA.UK PLA-RP4AA.UK PLA-RP5AA.UK PLA-RP6AA.UK

PLA-RP3AA1.UK PLA-RP4AA1.UK PLA-RP5AA1.UK PLA-RP6AA1.UK

PEA-RP3EA.TH-A PEA-RP4EA.TH-A PEA-RP5EA.TH-A PEA-RP6EA.TH-A

PEAD-RP3EA.UK PEAD-RP4EA.UK PEAD-RP5EA.UK PEAD-RP6EA.UK

PEAD-RP3EA1.UK PEAD-RP4EA1.UK PEAD-RP5EA1.UK PEAD-RP6EA1.UK

12

Page 13

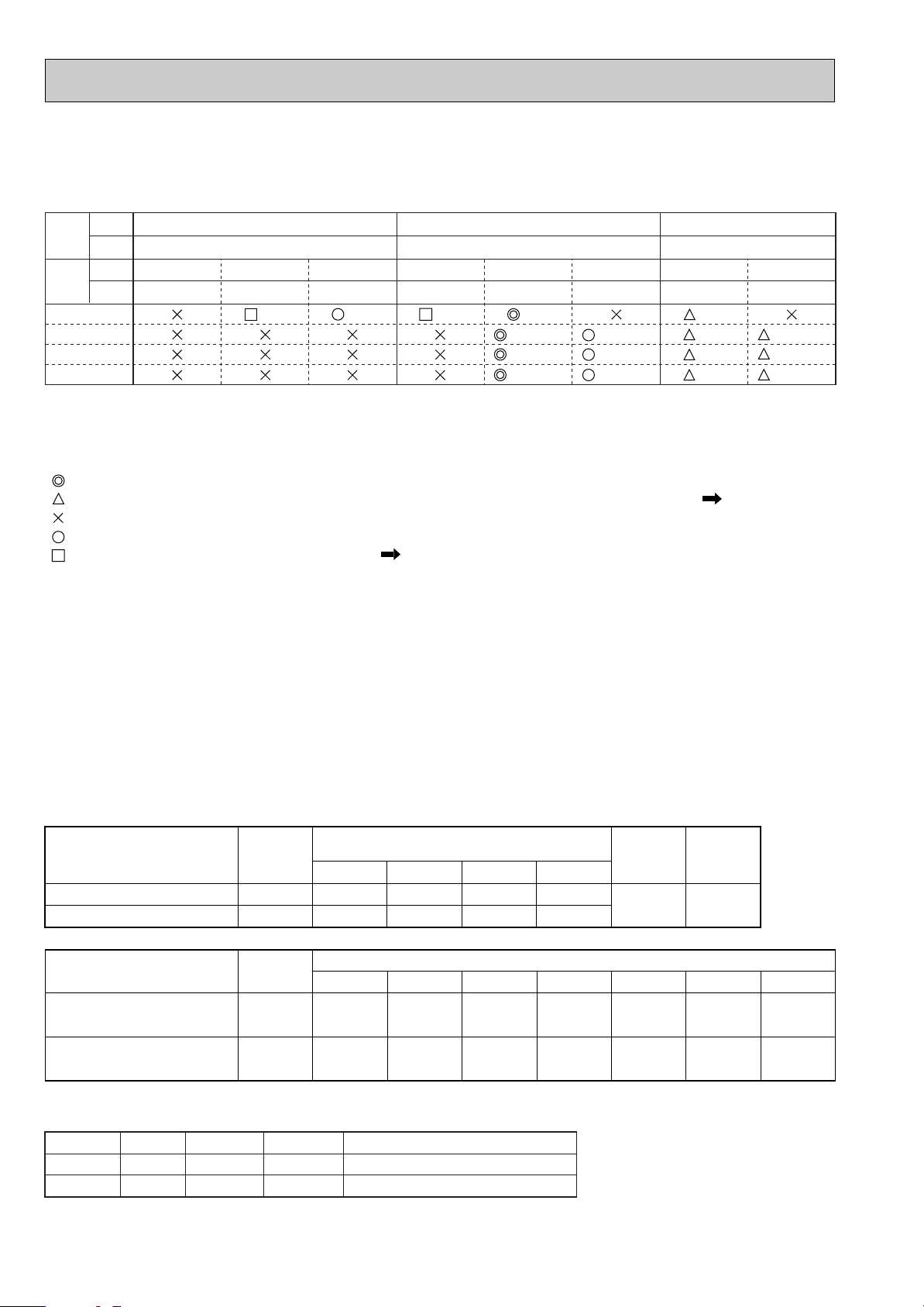

Distributor

Thermistor TH7

(Outdoor)

Heat exchanger

Refrigerant GAS pipe

connection(5/8F)

Refrigerant LIQUID pipe

connection(3/8F)

Stop valve

(with service port)

Strainer

#100

Power

receiver

Linear expansion valve B

Linear expansion valve A

Strainer

#100

Strainer

#100

Strainer

#100

Thermistor TH6

(Outdoor 2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Service port

(Low pressure)

Service port

(High pressure)

High pressure

switch 63H

Bypass valve

Replace filter

Thermistor TH4

(Discharge)

Compressor

Strainer

#50

4-way valve

Capillary tube

(O.D.4.0OI.D.3.0OL200)O2pcs

Strainer

#100

Strainer

#100

Low pressure

switch 63L

Muffler

Ball valve

Restrictor

valve

PUHZ-RP3VHA

Distributor

Thermistor TH7

(Outdoor)

Heat exchanger

Refrigerant GAS pipe

connection(5/8F)

Refrigerant LIQUID pipe

connection(3/8F)

Stop valve

(with service port)

Strainer

#100

Power

receiver

Linear

expansion

valve B

Linear expansion valve A

Strainer

#100

Strainer

#100

Strainer

#100

Thermistor TH6

(Outdoor 2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Service port

(Low pressure)

Service port

(High pressure)

High pressure

switch 63H

Bypass valve

Oil separator

Thermistor TH4

(Discharge)

Muffler

Strainer

#50

4-way valve

Compressor

Ball valve

Capillary tube

O.D.4.0OI.D.2.4OL500

Capillary tube

O.D.2.5OI.D.0.6OL1000

PUHZ-RP3VHA-A

PUHZ-RP4VHA PUHZ-RP5VHA PUHZ-RP6VHA

PUHZ-RP4VHA-A PUHZ-RP5VHA-A PUHZ-RP6VHA-A

13

Page 14

4-3. Applicable extension pipe for each model

<Table 4>

Additional refrigerant charging amount for liquid pipe which is one size larger than

standard diameter

[12.7

[12.7

RP3

RP4 — RP6

Liquid pipe dia

Chargeless

30m

50m

100 g addition per 1 m when pipe length exceeds 20 m

100 g addition per 1 m when pipe length exceeds 20 m

20m

20m

Max. pipe length

Additional refrigerant charging amount

15

30m or

above

31 — 40m

0.6Kg

0.6kg

10m or below

41 — 50m

1.2Kg

1.2kg

51 — 60m

—

1.8kg

61 — 75m

—

2.4kg

<Table 2> Additional refrigerant charging amount for pipe of standard diameter

<Table 3>

Outdoor unit

Permitted

pipe length

Additional refrigerant charging amount for pipe

length exceeding 30 m (kg)

PUHZ-RP3

PUHZ-RP4 — RP6

Outdoor unit

PUHZ-RP3

PUHZ-RP4 — RP6

Number of

bends

Height

difference

50m or below

75m or below

Permitted

pipe length

50m or below

75m or below

3.1

5.1

11 — 20m 21 — 30m

3.3

5.3

3.5

5.5

31 — 40m

4.1

0.6

6.1

0.6

4.7

1.2

6.7

1.2

—

—

7.3

1.8

—

—

7.9

2.4

41 — 50m 51 — 60m 61 — 75m

Additional refrigerant charging amount for recharging (above) and pipe length exceeding 30m (below) (kg)

Liquid

pipe

(mm)

Gas

pipe

(mm)

[6.35

[9.52 [12.7

[9.52

OD

Thick-

ness

OD

Thick-

ness

RP3

RP4

RP5

RP6

t0.8

t0.8

[12.7

t0.8

[15.88

t1.0

[12.7

t0.8

[15.88

t1.0

[19.05

t1.0

[15.88

t1.0

[19.05

t1.0

t0.8

t0.8

: Normal piping

: It can be used, however, additional refrigerant charge is required when the pipe length exceeds 20m. Refer to table 4.

: It cannot be used.

: It can be used.

: It can be used, however, the capacity is lowered. Refer to (C) Capacity correction.

<Table 1> Pipe length for 1:1 system

*1: Set DIP SW8-1 on outdoor unit controller board to ON.

*2: The maximum length is 50 m in case of using existing pipes.

*3: The height difference between indoor and outdoor unit should be kept within 30 m for all models.

[Marks in the table above]

10m 30m 30m

50m

50m

50m

10m

50m

(*1)

75m

(*2)

50m

75m

(*2)

75m

(*2)

50m

(*1)

50m

(*1)

50m

(*1)

50m

(*1)

50m

(*1)

4-3-1. 1:1 system

(a) Pipe length

(b) Adjusting the amount of refrigerant

• Additional refrigerant charge is not necessary for the pipe length up to 30 m. When the pipe length exceeds 30 m or service

(refrigerant replacement) is performed, charge proper amount of refrigerant for each pipe length referring to table below.

Use refrigerant R410A. Use charge hose exclusive for R410A.

• When charging additional refrigerant, charge the refrigerant from low-pressure side of the port valve using a safety charger.

• Make sure that air purge for this unit at refrigerant replacement is performed from both high-pressure check valve and ser-

vice port. (If air purge is performed only from one of them, air in not purged enough.)

• When replacing refrigerant, charge the refrigerant from service port. When charged refrigerant is less than specified amount,

charge the refrigerant again from low pressure side of the port valve using a safety charger.

• Tighten the service port cap (nut) of stop valve firmly. The tightening torque is 12 to 16 N·m. (For the prevention of slow-leak)

• Check additional refrigerant charging amount referring to table 4 when liquid pipe is one size larger than standard diameter,

and table 2 when the pipe is standard diameter.

14

Page 15

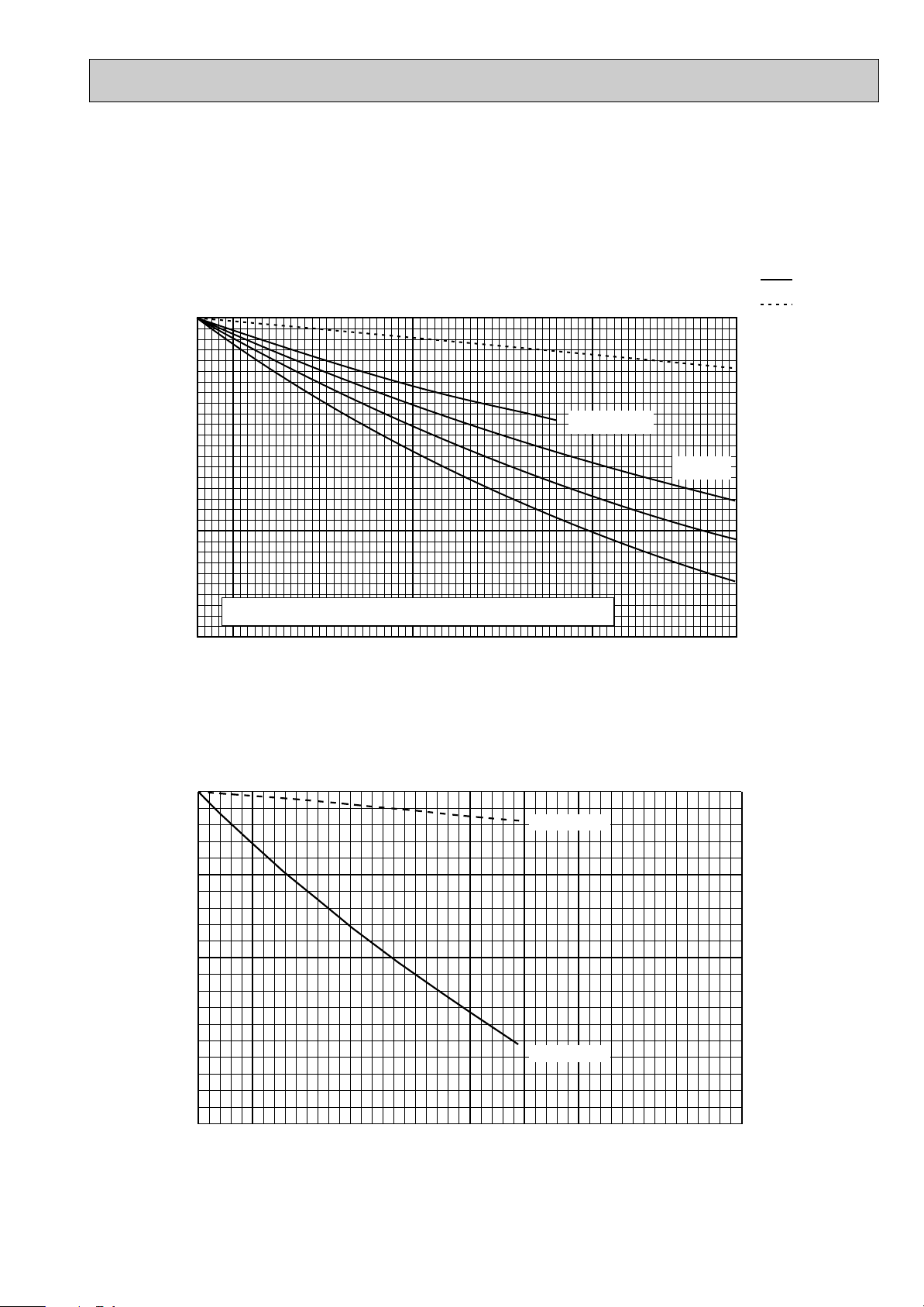

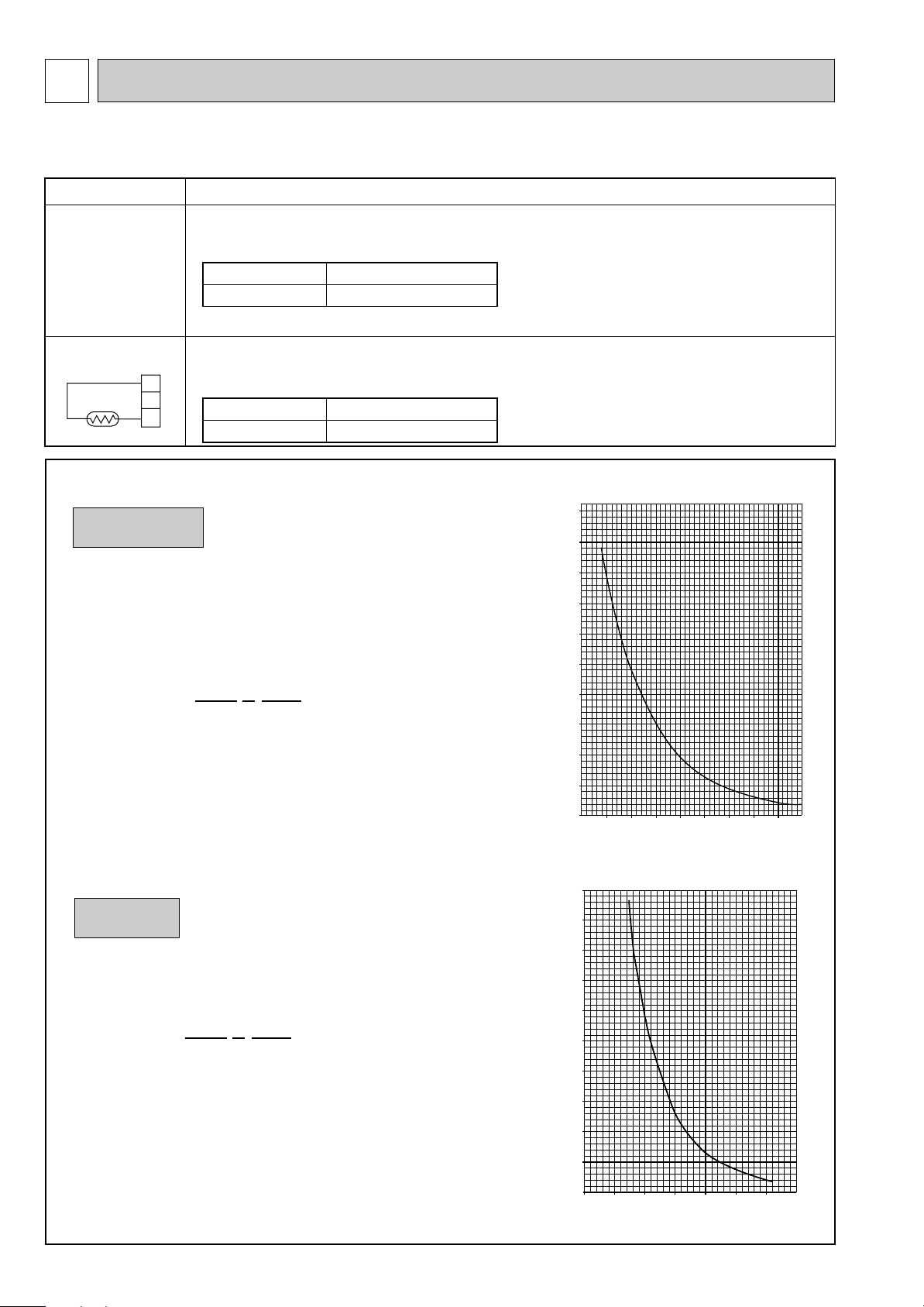

100

95

90

85

80

75

70

5 101520253035404550556065707580

Note: The permitted pipe length is up to 55m for RP3 model.

RP3 model

RP4 model

Heating RP3, 4, 5

and 6 models

(Up to 55m for

RP3 model)

RP5 model

RP6 model

Cooling

Capacity ratio [%]

Corrected pipe length

(c) Capacity correction

5 10152025303540455055

80

Capacity ratio [%]

Corrected pipe length

85

90

95

100

Heating RP3

Cooling RP3

Cooling

Heating

Cooling and heating capacity is lowered according to pipe length. Capacity can be obtained by referring to the capacity

curves below. When the diameter of gas pipe is one size smaller than standard diameter, cooling capacity is lowered comparing to the standard diameter. The lowered capacity can be obtained by referring to capacity curves for gas pipe which is

one size smaller than standard size.

Corrected pipe length (m) = actual pipe length (m) + number of bends x 0.3 (m)

11

Capacity curves for PUHZ-RP • HA model <Standard size>

22

Capacity curve for PUHZ-RP3 model

<When gas pipe is one size smaller than standard size>

33

When gas pipe is one size larger than standard size for PUHZ-RP4, 5 and 6.

1 Capacity can be obtained by referring to capacity curves of standard size.

15

Page 16

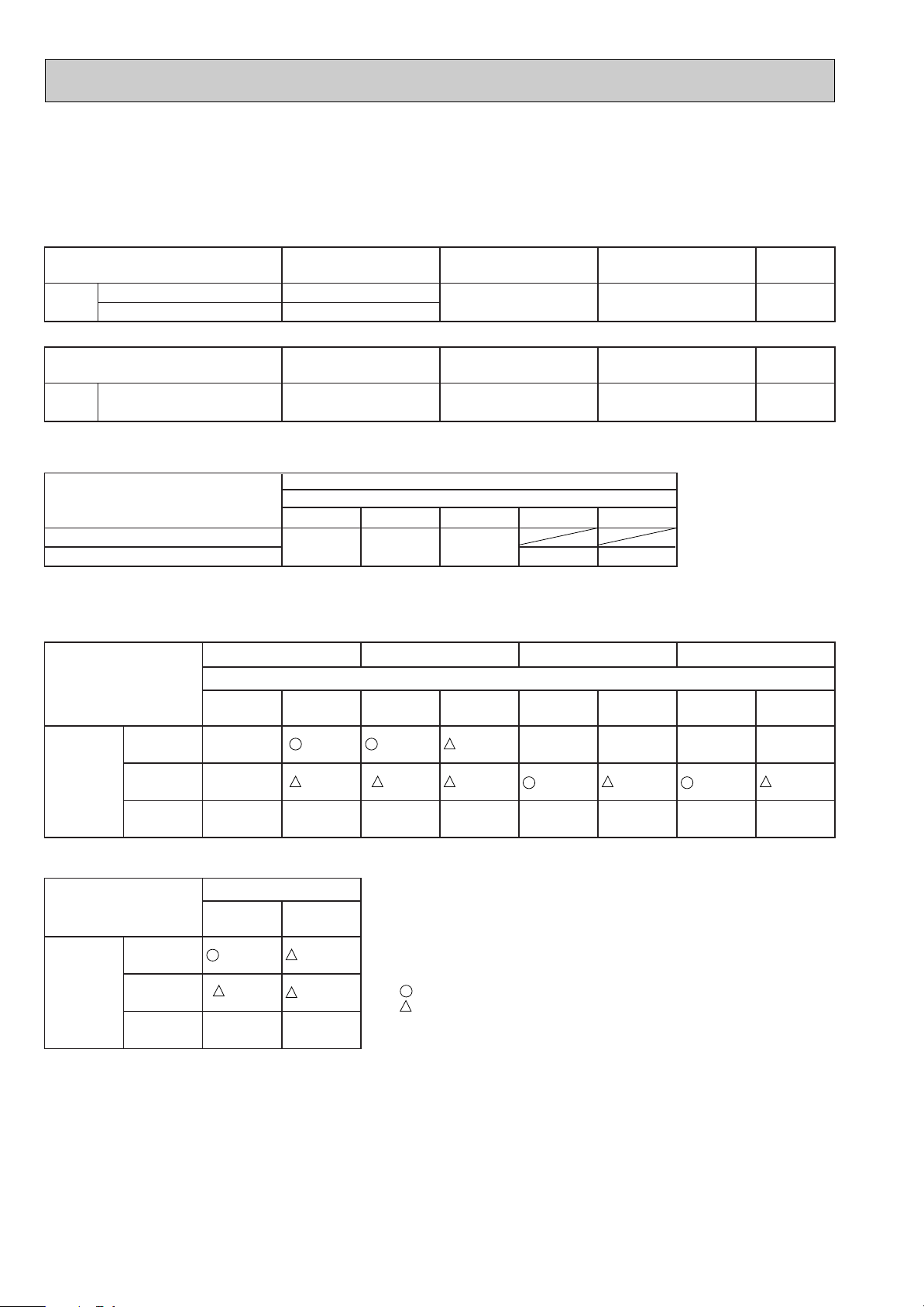

4-3-2. Synchronized twin and triple

(a) Pipe length

Please note that refrigerant piping length, bend number and height difference of indoor units are specified for each unit

combination.

Note: Be sure to use our Multi-distributor for distributing pipe to use existing piping.

<Table 5>

Synchronized twin

Outdoor

unit

<Table 6>

Outdoor

unit

Note 1: If total piping length exceeds charge-less piping length of 30 m, charge additional refrigerant according to the table 7.

PUHZ-RP3VHA

PUHZ-RP4~6VHA

Synchronized twin

PUHZ-RP6VHA 30 m or less70 m or less

Permitted total piping

length A + B + C

50 m or less

75 m or less

Permitted total piping

length A + B + C + D

Chargeless piping

length A + B + C

30 m or less

Charge-less piping

length A + B + C + D

Indoor unit’s height

difference [B and C]

8 m or less

Indoor unit’s height difference

[B and C] [C and D] [B and D]

8 m or less

Bend number

w 2

15 at most

Bend number

w 2

15 at most

<Table 7>

A + B + C (+D)

Outdoor unit

30 m or less

PUHZ-RP3VHA

PUHZ-RP4~6VHA

Note 2: Bends number (w 2) should be within 8 for each combination, A + B, A +C and A + D, and 15 in all.

Note 3: Height difference between indoor and outdoor unit is referred to no matter which unit is located higher or lower.

<Table 8> Pipe length for twin of RP 3 - 6 (Piping length: A + B + C)

RP3 Twin (RP1.6✕2)

Liquid [6.35

Gas [12.7

Branch pipe

diameter

[B and C]

<Table 9> Pipe length for triple of RP6 (Piping length: A + B + C + D)

Branch pipe

diameter

[B,C and D]

Liquid [6.35

Gas [12.7

Liquid [9.52

Gas [15.88

Liquid [12.7

Gas [19.05

Liquid [6.35

Gas [12.7

Liquid [9.52

Gas [15.88

Liquid [12.7

Gas [19.05

✕

✕

✕

Main pipe diameter [A]

Liquid [9.52

Gas [15.88

75 m(✽2)

50 m

✕

Not required

Liquid [9.52

Gas [15.88

50 m

50 m

Liquid [12.7

Gas [19.05

50 m(✽1)

50 m(✽1)

Additional refrigerant to be charged (kg)

31 - 40 m 41 - 50 m 51 - 60 m 61 - 75 m

0.6

RP4 Twin (RP2✕2) RP5 T win (RP2.5✕2) RP6 Twin (RP3✕2)

Liquid [9.52

Gas [15.88

75 m(✽2)

50 m

✕

✕

✕

✽1 ··· Set DIP SW8-1 on outdoor unit control circuit board to ON.

✽2 ··· When using existing piping, pipe length should be 50 m at most.

✽3 ··· Height difference between indoor and outdoor unit should be

kept within 30 m in every case.

[Marks in table]

··· Normal piping

··· It can be used with some changes of piping length and the

amount of refrigerant to be charged.

✕ ··· It cannot be used.

1.2

Main pipe diameter [A]

Liquid [12.7

Gas [19.05

50 m(✽1)

50 m(✽1)

✕

1.8 2.4

Liquid [9.52

Gas [15.88

✕

75 m(✽2)

✕

Liquid [12.7

Gas [19.05

✕

50 m(✽1)

✕

w Charge additional

refrigerant from

the check valve

connected to the

pipe of low-pressure

side in indoor unit.

Liquid [9.52

Gas [15.88

✕

75 m(✽2)

✕

Liquid [12.7

Gas [19.05

50 m(✽1)

✕

✕

16

Page 17

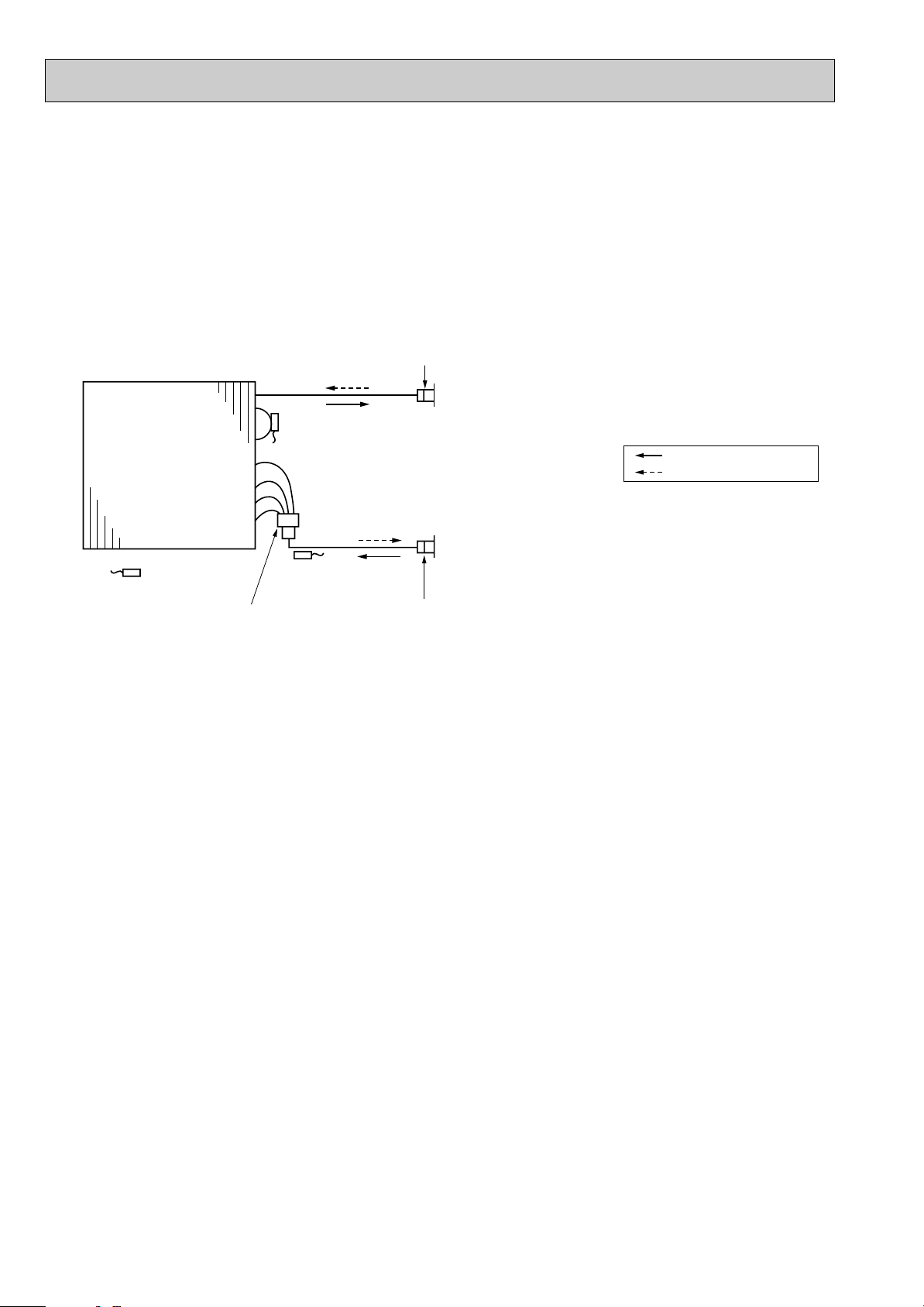

Synchronized twin

Synchronized triple

Indoor

unit

Optional

distributing pipe

1 m or less

Multi-distributor

30 m or less

Branch

pipe B

Branch

pipe C

Main

pipe A

Indoor

unit

Outdoor

unit

Indoor

unit

Optional

distributing pipe

1 m or less

Multi-distributor

30 m or less

Branch

pipe B

Branch

pipe C

Branch

pipe D

Main

pipe A

Indoor

unit

Indoor

unit

Outdoor

unit

1. Keep Stop valve in outdoor unit fully closed (as it is shipped), and after completing refrigerant piping connection, conduct air

purge from service port of stop valve at outdoor unit.

2. After air purging, make the valve rod of stop valve at outdoor unit fully open.

Now refrigerating cycle is complete between indoor and outdoor unit.

Handle stop valve following the indication on outdoor unit.

Caution:

• Be sure to apply refrigerating oil to flare sheet face. Never apply it to screws. (As it causes flare nut loosening.)

• Use double spanner for piping connection.

• Be sure to check gas leak by using leak detector or soapy water.

• Use attached parts for refrigerant piping to provide correct insulation to the connection of indoor unit side in accordance with

attached explanation sheet.

• Be sure to provide anoxidized brazing.

(b) Adjusting the amount of refrigerant oil

(i) In case of RP 3 twin

Check the additional refrigerant oil to be charged referring to table 2 when using pipe of size referred in table 8.

(ii) In case of RP4 - 6 twin or RP6 triple

When using liquid pipe one size larger than standard diameter for main pipe A, calculate the amount of additional

refrigerant oil referring to 2 below.

1 When using piping of standard diameter or gas pipe one size larger than standard diameter for main pipe A.

Check the additional refrigerant oil to be charged referring to table 2 like 1:1 system.

2 When using liquid pipe one size larger than standard diameter for main pipe A.

[In case of RP4-6 using liquid pipe of [12.7]

• When total length of extension pipe (main pipe and branch pipe) is less than 20 m.

No adjustment is required for refrigerant oil. (Chargeless)

• When total length of extension pipe (main pipe and branch pipe) is more than 20 m.

Calculate the amount of additional refrigerant oil, referred to as W (g) in the following, using the equation below and add

proper amount of refrigerant oil. If W is less than or equal to 0, no additional charge is required. (Chargeless)

[Additional refrigerant oil] W (g) = {100(g) ✕ L1} + {60(g) ✕ L2} + {30(g) ✕ L3} - 2000(g)

Note: Put “0” in L1-3 if it is not used. L1: Liquid pipe length of [12.7 (m)

L2: Liquid pipe length of [9.52 (m)

L3: Liquid pipe length of [6.35 (m)

(c) Capacity correction

Apply pipe length between indoor and outdoor unit which is the longest of all for the calculation of capacity lowering according

to each pipe length.

17

Page 18

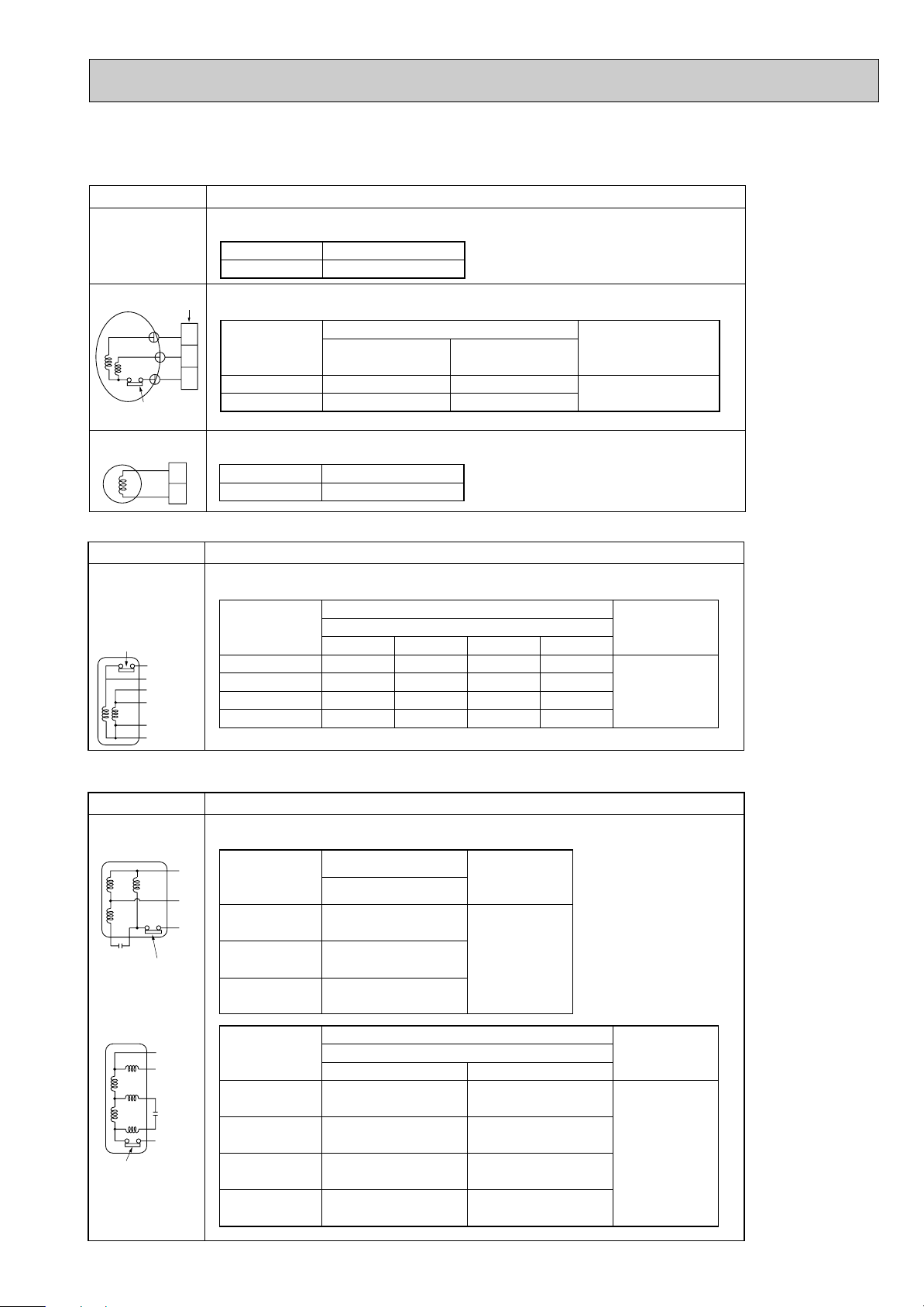

5

Parts name Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

Drain sensor

(Refer to below for a detail.)

(Refer to below for a detail.)

Room temperature

thermistor (TH1)

Pipe temperature

thermistor (TH2)

Condenser/evaporator

temperature thermistor

(TH5)

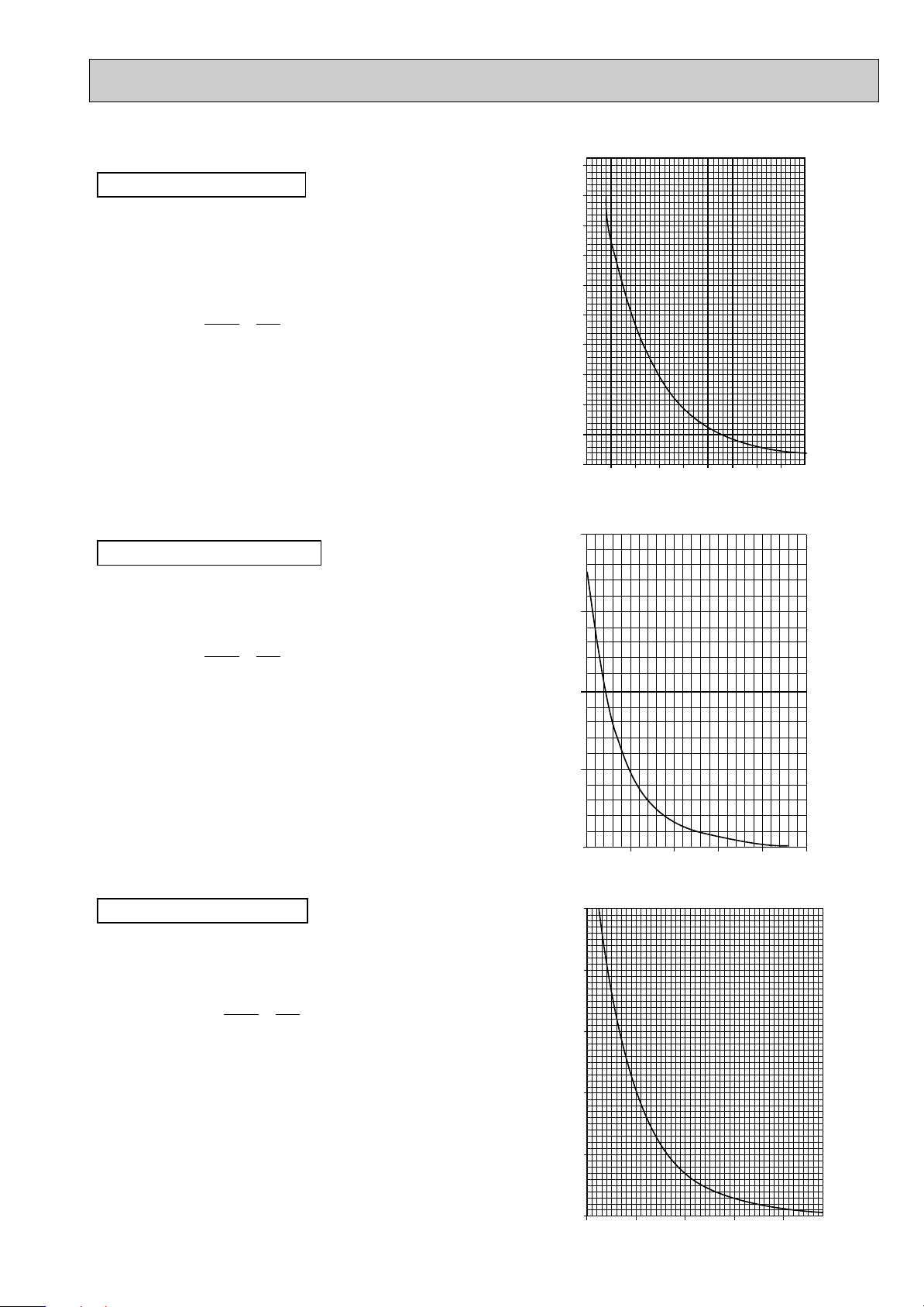

1

2

3

Normal

4.3k"~9.6k"

Abnormal

Open or short

Abnormal

Open or short

Normal

0.6k"~6.0k"

Measure the resistance between the terminals using a tester.

Measure the resistance after 3 minutes have passed since the power supply was intercepted.

(Surrounding temperature 0:~60:)

-200 20406080

< Thermistor for drain sensor >

Temperature (:)

0

1

2

3

4

5

6

7

8

9

10

Resistance (K")

HOW TO CHECK THE PARTS

5-1. INDOOR UNIT

• Common parts

<Thermistor Characteristic graph>

Thermistor for

lower temperature

Room temperature thermistor(TH1)

Pipe temperature thermistor(TH2)

Condenser/evaporator temperature

thermistor(TH5)

Thermistor R0=15kΩ ±3%

Fixed number of B=3480kΩ ±2%

Rt=15exp { 3480( ) }

1

273+t

0: 15kΩ

10: 9.6kΩ

20: 6.3kΩ

25: 5.2kΩ

30: 4.3kΩ

40: 3.0kΩ

Drain sensor

1

273

< Thermistor for lower temperature >

50

40

30

20

Resistance (K")

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

Thermistor R0=6.0kΩ ±5%

Fixed number of B=3390kΩ ±2%

Rt=6exp { 3390( ) }

0: 6.0kΩ

10: 3.9kΩ

20: 2.6kΩ

25: 2.2kΩ

30: 1.8kΩ

40: 1.3kΩ

1

273+t

1

273

18

Page 19

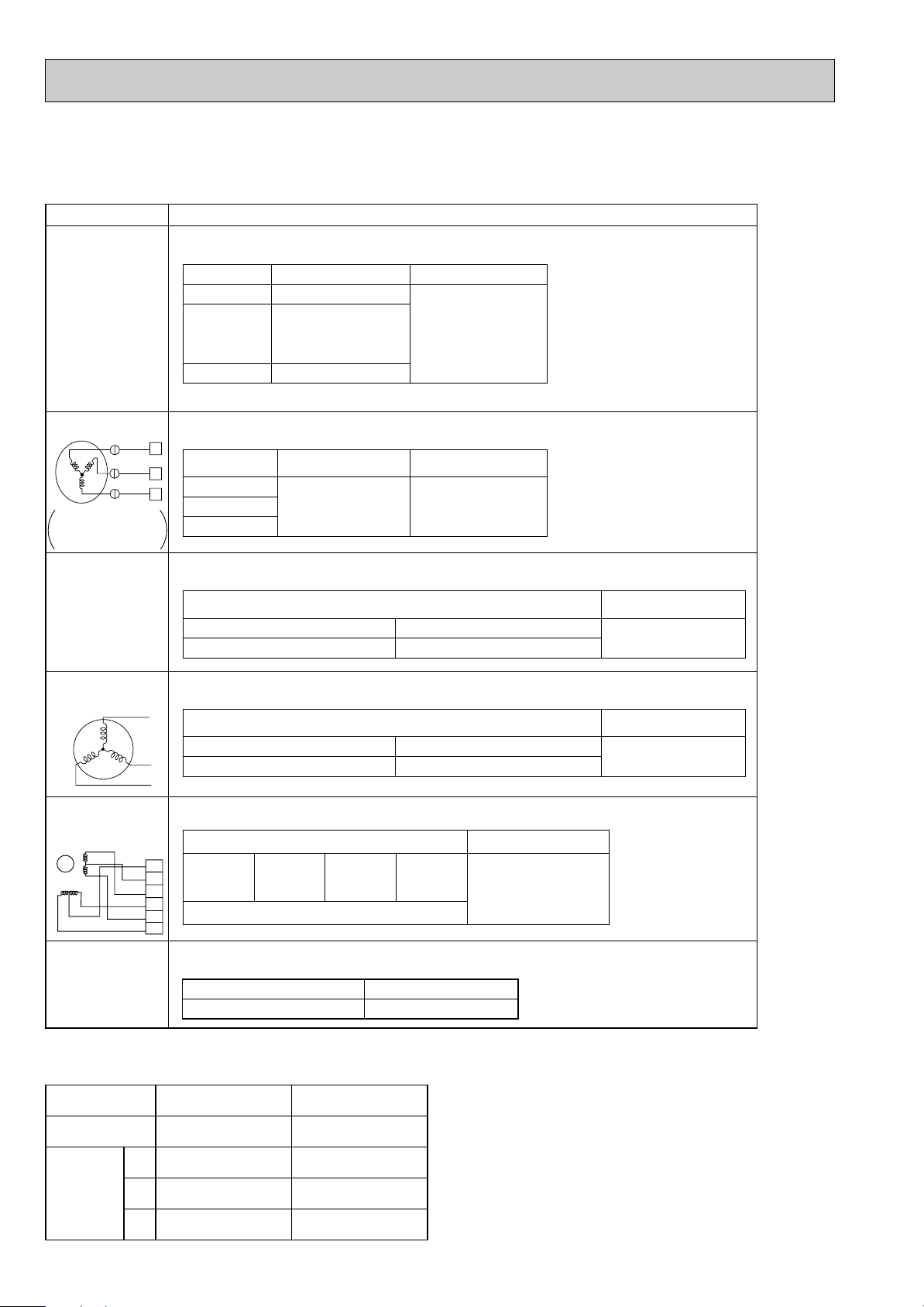

Parts name Check points

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor (MF)

Brown

White

Blue

Red

Orange

Black

Protector

(PEA-RP3,4,5EA)

OPEN :135:

CLOSE:86i15:

(PEA-RP6EA)

OPEN :150:

CLOSE:96i15:

Abnormal

Open or short

White-Black

Black-Blue

Blue-Brown

Brown-Red

Motor terminal

or

Relay connector

Normal

PEA-

RP3EA.TH-A RP4EA.TH-A RP5EA.TH-A RP6EA.TH-A

28.6"

12.5"

4.3"

23.6"

20.6"

8.1"

3.2"

16.0"

15.3"

5.1"

2.7"

14.5"

10.2"

5.2"

3.1"

12.1"

Parts name Check points

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor (MF)

PEAD-RP4,5,6EA

(1)

.UK

PEAD-RP3EA(1).UK

White

Blue

Red

Gray

Black

Protector

OPEN :135:

CLOSE:86i15:

Blue

WhiteRed

Gray

Black

Protector

OPEN :150:

CLOSE:96i15:

Abnormal

Open or short

Gray-Black

(White or Red open)

Blue-Black

Black-Red

(White or Red open)

Gray-Red

(White or Red open)

Motor terminal

or

Relay connector

Normal

PEAD-

RP4EA

(1).UK

RP5EA

(1)

.UK RP6EA

(1)

.UK

24.76"

4.78"

18.99"

36.63"

10.27"

2.11"

20.75"

25.44"

Abnormal

Open or short

Gray-Black

(White or Red open)

Black-Blue

(White or Red open)

Blue-Red

(White or Red open)

Motor terminal

or

Relay connector

Normal

PEAD-RP3EA

(1).UK

43.5"

14.74"

57.5"

PLA-RP3AA PLA-RP4AA PLA-RP5AA PLA-RP6AA

PLA-RP3AA

1 PLA-RP4AA1 PLA-RP5AA1 PLA-RP6AA1

PLA-RP3AA.UK PLA-RP4AA.UK PLA-RP5AA.UK PLA-RP6AA.UK

PLA-RP3AA

Parts name Check points

Vane motor

Fan motor

Relay connector

1

2

3

Protector

OPEN :130:

CLOSE:80i20:

Drain pump

Red

Red

1.UK PLA-RP4AA1.UK PLA-RP5AA1.UK PLA-RP6AA1.UK

Measure the resistance between the terminals using a tester.

(Surrounding temperature20:)

Normal Abnormal

15k" Open or short

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Red

White

Black

1

2

3

Motor terminal

or

Relay connector

Red-Black

White-Black

PLA-RP3AA PLA-RP4,5,6AA

87.2"

104.1"

Normal

28.7"

41.6"

Abnormal

Open or short

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

1

2

Normal Abnormal

290" Open or short

PEA-RP3EA.TH-A PEA-RP4EA.TH-A PEA-RP5EA.TH-A PEA-RP6EA.TH-A

PEAD-RP3EA.UK PEAD-RP4EA.UK PEAD-RP5EA.UK PEAD-RP6EA.UK

PEAD-RP3EA1.UK PEAD-RP4EA1.UK PEAD-RP5EA1.UK PEAD-RP6EA1.UK

19

Page 20

U-V

U-W

W-V

Unit

Compressor model

Winding

Resistance

( " )

ANV33FDAMT

(at 20°C)

0.266

0.266

0.266

TNB220FMBH

0.865 ~ 0.895

0.865 ~ 0.895

0.865 ~ 0.895

PUHZ-RP4,5,6VHA

PUHZ-RP3VHA

5-2. OUTDOOR UNIT

4

6

2

3

1

2

3

4

5

6

5

1

M

Blue

Brown

Yellow

Orange

Red

White

Parts name

Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

Disconnect the connector then measure the resistance using a tester.

(

Winding temperature 20

:)

Thermistor (TH3)

<Outdoor pipe>

Thermistor (TH4)

<Discharge>

Thermistor (TH6)

<Outdoor 2-phase pipe>

Thermistor (TH7)

<Outdoor>

Thermistor (TH8)

<Heat sink>

Normal

160k"~410k"

4.3k"~9.6k"

39k"~105k"

TH4

TH3

TH6

TH7

TH8

Abnormal

Open or short

Normal

(1) - (6)

Red - White

(1) - (4)

Red - Orange

(2) - (5)

Brown - Yellow

(2) - (3)

Brown - Blue

Abnormal

46±4"

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20

:

)

Solenoid valve coil

<Four-way valve>

(21S4)

Pin number of relay

connector is different

from that motor

connector

Motor for compressor

(MC)

Linear expansion valve

( LEV(A),LEV(B) )

Normal

Abnormal

Open or short

PUHZ-RP3VHA PUHZ-RP4, 5, 6VHA

Open or short

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20

:

)

Normal

1197±10"

Abnormal

Open or short

Solenoid valve coil

<Bypass valve>

(SV)

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor(MF1,MF2)

Normal

15.1±0.5"

2350±170" 1370±100"

PUHZ-RP3VHA PUHZ-RP4, 5, 6VHA

0.865"~0.895" 0.266"

Measure the resistance between the terminals using a tester.

(Winding temperature 20

:

)

Normal

Abnormal

Open or short

Relay connector

Abnormal

Open or short

Red — Black

Black — White

White — Red

Red

W

V

U

W

V

U

White

Black

PUHZ-RP3VHA PUHZ-RP4VHA PUHZ-RP5VHA PUHZ-RP6VHA

PUHZ-RP3VHA-A PUHZ-RP4VHA-A PUHZ-RP5VHA-A PUHZ-RP6VHA-A

5-3. COMPRESSOR TECHNICAL DATA

20

Page 21

HOW TO CHECK THE COMPONENTS

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

Temperature (:)

Resistance (K")

200

150

100

50

0

25 50 75 100 125

Temperature (:)

Resistance (K")

500

400

300

200

100

0

25

50 75 100 120

Temperature (:)

Resistance (K")

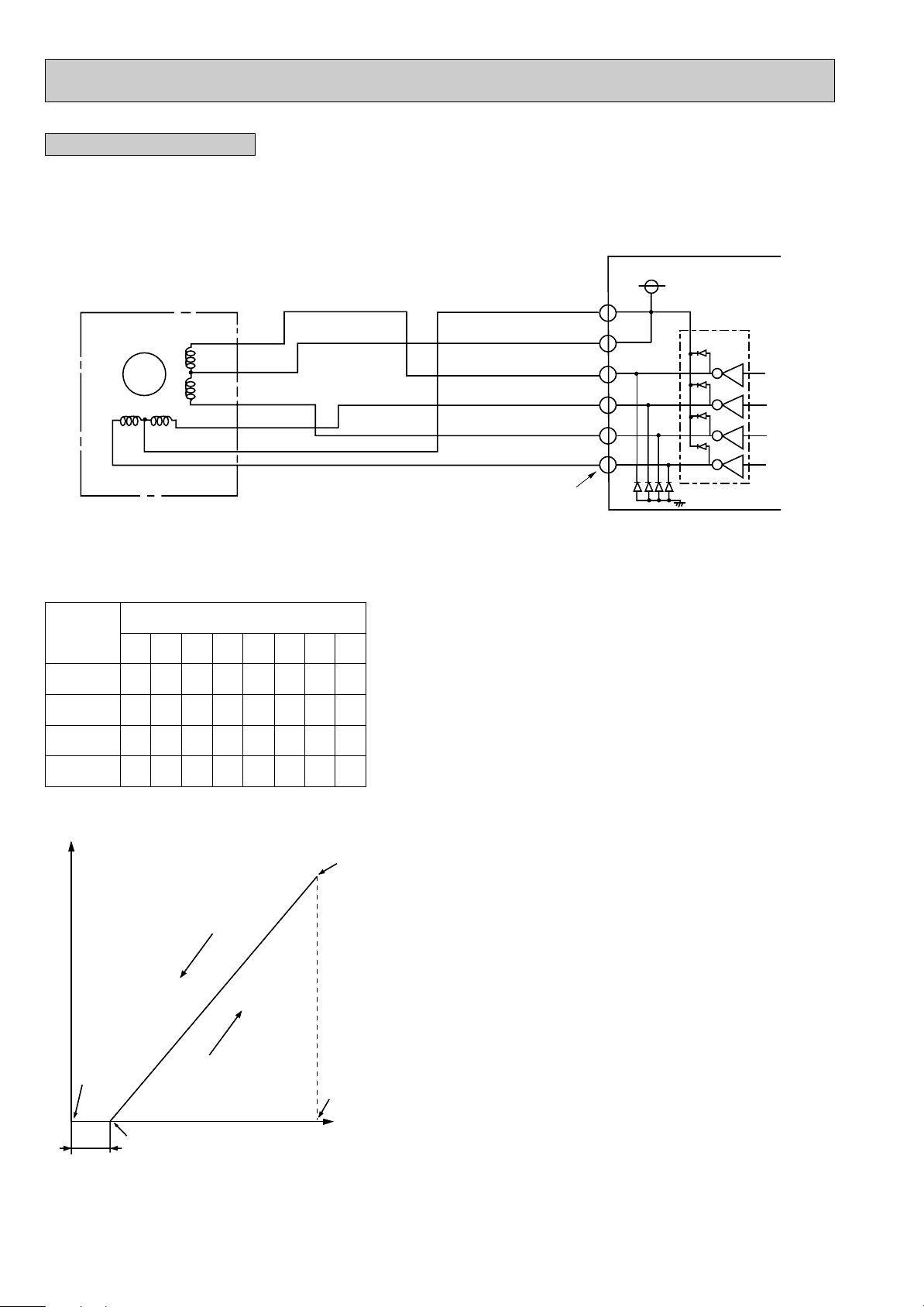

<Thermistor feature chart>

Low temperature thermistors

• Thermistor <Outdoor pipe> (TH3)

• Thermistor <Outdoor 2-phase pipe> (TH6)

• Thermistor <Outdoor> (TH7)

Thermistor R0 = 15k' ±3%

B constant = 3480k' ±2%

1

R

t =15exp{3480(

0: 15k'

10: 9.6k'

20: 6.3k'

25: 5.2k'

Medium temperature thermistor

• Thermistor <Heat sink> (TH8)

1

273+t – 273

30: 4.3k'

40: 3.0k'

)}

Thermistor R50 = 17k' ±2%

B constant = 4150k' ±3%

1

t =17exp{4150(

R

1

273+t – 323

)}

0: 180k'

25: 50k'

50: 17k'

70: 8k'

90: 4k'

High temperature thermistor

• Thermistor <Discharge> (TH4)

Thermistor R120 = 7.465k' ±2%

B constant = 4057k' ±2%

1

t =7.465exp{4057(

R

20: 250k'

30: 160k'

40: 104k'

50: 70k'

60: 48k'

1

273+t – 393

70: 34k'

80: 24k'

90: 17.5k'

100: 13.0k'

110: 9.8k'

)}

21

Page 22

A

B

C

Open

Extra tightning (about 32 pulse)

Pulse number

500 pulse

Opening a valve

all the way

Close

Valve position (capacity)

LEV

M

1

6

[4

[4

[3

[2

[1

2

1

Red

Brown

Blue

Orange

Yellow

White

3

4

5

6

Connector LEV-A

LEV-B

DC12V

Outdoor controller board

Drive circuit

[3

[2

[1

3

2

5

4

Linear expansion valve

1

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

ON

OFF

[1

Output

(Phase)

Output

[2

[3

[4

234

5678

OFF

OFF

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

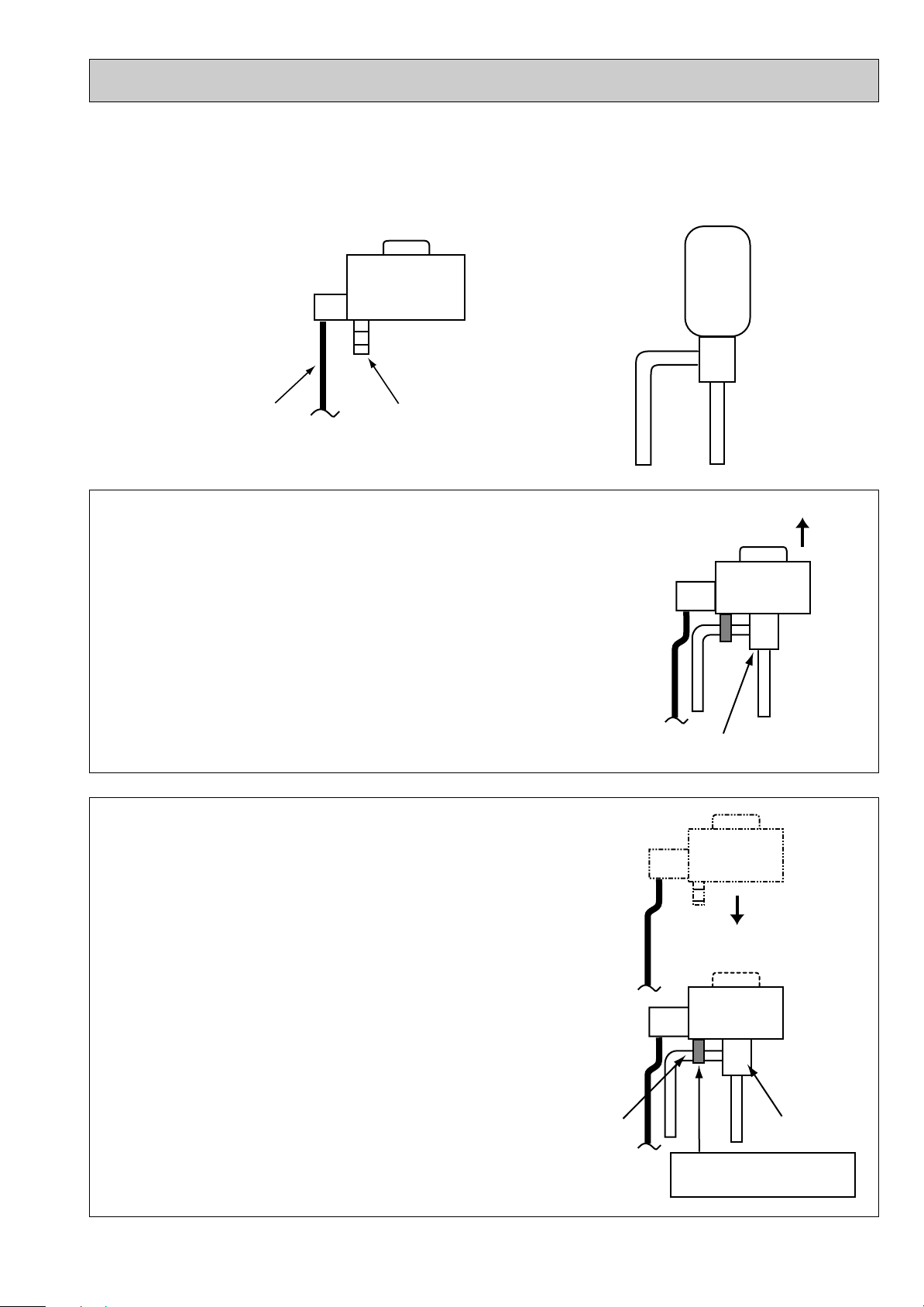

(1) Operation summary of the linear expansion valve.

• Linear expansion valve open/close through stepping motor after receiving the pulse signal from the outdoor controller board.

• Valve position can be changed in proportion to the number of pulse signal.

<Connection between the outdoor controller board and the linear expansion valve>

<Output pulse signal and the valve operation>

(2) Linear expansion valve operation

Opening a valve : 8 → 7 → 6 → 5 → 4 → 3 → 2 → 1 → 8

Closing a valve : 1 → 2 → 3 → 4 → 5 → 6 → 7 → 8 → 1

The output pulse shifts in above order.

❈ 1. When linear expansion valve operation stops, all output phase

become OFF.

❈ When the switch is turned on, 700 pulse closing valve signal will

be sent till it goes to

A point in order to define the valve position.

(The pulse signal is being sent for about 20 seconds.)

When the valve moves smoothly, there is no noise or vibration

occurring from the linear expansion valve : however, when the

pulse number moves from B to A or when the valve is locked,

more noise can be heard than normal situation.

No noise is heard when the pulse number moves from B to A in

case coil is burn out or motor is locked by open-phase.

❈ Noise can be detected by placing the ear against the screw dri-

ver handle while putting the screw driver to the linear expansion

valve.

22

Page 23

(3) How to attach and detach the coil of linear expansion valve

<Composition>

Linear expansion valve is separable into the main body and the coil as shown in the diagram below.

Coil

Lead wire

<How to detach the coil>

Hold the lower part of the main body (shown as A) firmly so that

the main body does not move and detach the coil by pulling it

upward.

Be sure to detach the coil holding main body firmly. Otherwise

pipes can bend due to pressure.

Stopper

Main body

<How to attach the coil>

Hold the lower part of the main body (shown as A) firmly so that

the main body does not move and attach the coil by inserting it

downward into the main body. Then securely attach the coil stopper to pipe B. (At this time, be careful that stress is not added to

lead wire and main body is not wound by lead wire.) If the stopper is not firmly attached to pipe B, coil may be detached from

the main body and that can cause defective operation of linear

expansion valve.

To prevent piping stress, be sure to attach the coil holding the

main body of linear expansion valve firmly. Otherwise pipe may

break.

B

A

A

Be sure to attach the

stopper to pipe B.

23

Page 24

6 MICROPROCESSOR CONTROL

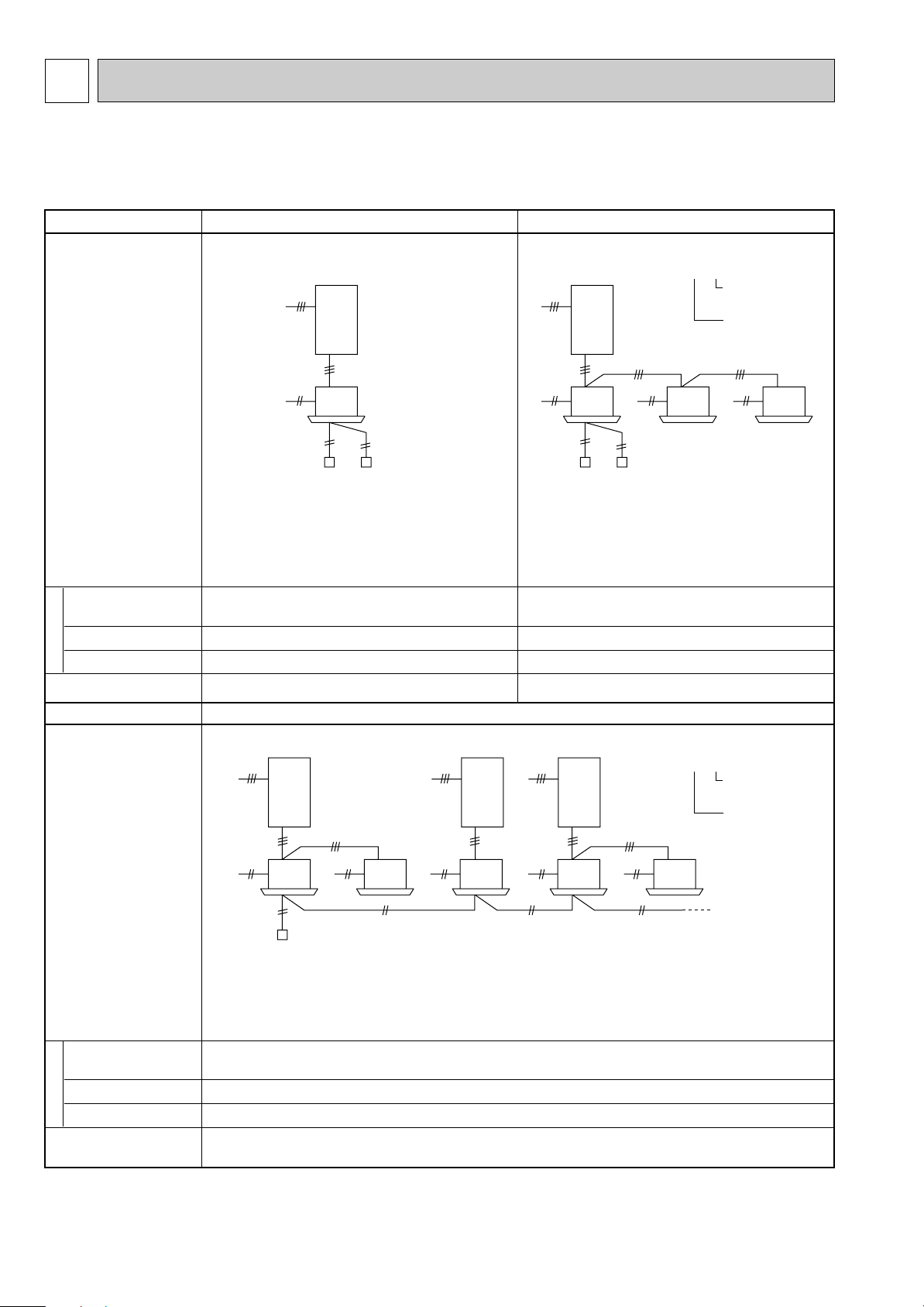

Standard 1:1 Synchronized twin. Triple

1Unit (indoor/outdoor) power supply L/N

2Connecting line between the indoor and

outdoor; S1/S2/S3, Polarized 3-wire

3Remote controller transmission line; Non

polarezed 2-wire

4Auxiliary heater exclusive power supply; L/N

1Unit (indoor/outdoor) power supply L/N

2Connecting line between the indoor and outdoor; S1/S2/S3, Polarized 3-wire

3Remote controller transmission line; Non polarezed 2-wire

4Auxiliary heater exclusive power supply; L/N

1Unit (indoor/outdoor) power supply L/N

2Connecting line between the indoor and

outdoor; S1/S2/S3, Polarized 3-wire

3Remote controller transmission line; Non

polarezed 2-wire

4Auxiliary heater exclusive power supply; L/N

Remote control main/sub setting necessity

(In case of 2 remote controllers)

No setting (initial setting)

Refrigerant address setting; SW1; 3~6

Various setting

Remote controller

Main Sub

Indoor unit

Outdoor unit

Remarks

Group control

1

4

2

3

Main

(00)

Outdoor unit; (00)...Refrigerant address

(SW1; 3~6)

Indoor unit; (00)–w

Indoor unit number

(auto setting)

Refrigerant address

(receiving from the

outdoor unit)

Outdoor unit; (00)...Refrigerant address

(SW1; 3~6)

Indoor unit; (00)–w

Indoor unit number

(auto setting)

Refrigerant address

(receiving from the

outdoor unit)

(00)-1 (00)-2 (00)-3

Sub

1

44

222

4

3

Main

(00)

(00)-1 (00)-2 (01)-1

1

(01)

1

(02)

1

44

222

4

(02)-1 (02)-2

4

2

2

4

3

333

(1) Indoor unit number is set automatically

(2) When the refrigerant address of the unit is "00", Remote controller is supplied.

Remote control main/sub setting necessity

(In case of 2 remote controllers)

No setting

No setting

Remote control main/sub setting necessity

(In case of 2 remote controllers)

No setting (initial setting)

No setting (initial setting)

Various setting

Remote controller

System construction

System construction

Indoor unit

Outdoor unit

Remarks (1) Indoor unit number is set automatically

6-1. System construction

(1) System construction

A-control model which just wires the connecting line between the indoor and outdoor unit and supply the power is applicable to

any models of standard (1:1), twin and triple. (Refer to 2 Start-up system.)

24

Page 25

(2) The transmitting specification for “A” control

Cross section

of cable

Round

2.5

2.5

1.5

2.5

3

3

4

4

(50)

✽2

(45)

✽3

60

✽4

Not

applicable

✽5

Flat

✽1 : Power supply cords of appliances shall not be lighter than design 245 IEC or 227 IEC.

✽2 : In case that cable with stripe of yellow and green is available.

✽3 : In case of regular polarity connection (S1-S2-S3), wire size is 1.5mm

2

.

✽4 : In case of regular polarity connection (S1-S2-S3).

✽5 : In the flat cables are connected as this picture, they can be used up to 80m.

✽6 : Mentioned cable length is just a reference value.

It may be different depending on the condition of installation, Humidity or materials, etc.

Flat

Round

Wire size

(mm

2

)

Number

of wires

Clockwise : S1-S2-S3

w Pay attention to stripe of yellow and green

Clockwise : S1-S2-S3-Open

w Connect S1 and S3 to the opposite angle

Not applicable

(Because center wire has no cover finish)

From left to right : S1-Open-S2-S3

Polarity

L(m)

✽6

(3C Flat cable ✕ 2)

S1 S2 S3

1Wiring regulations

Section Communications from remote controllers

The maximum length of

500m 80m (Including the wiring among indoor units

total wiring

The maximum numbers

for connection

One remote controller can connect and operate

up to 16 indoor units by grouping them.

One group can connect up to two remote controllers.

❋1 Remote controller considers multiplex units as

a single group.

Communications between indoor and outdoor units

in addition to the wiring between indoor and

outdoor units)

1

❋

One outdoor unit can connect up to three

indoor units.

The cables applicable 0.3mm

2

to 1.25mm

2

Use either flat-type cable (3 cores: {1.6mm or

more) or wires in the table below.

❋2 The diameter of the cables depends on

each unit.

Others The wirings as follows are not allowed:

• The wiring that the indoor units of the same

The core wire connected to terminal S2 shall be

placed at the center of flat-type cable.

refrigerant system are connected through TB5.

• The wiring which directly connects the terminals

for remote controllers.

2Transmitting specification

Section Communications from remote controllers

Communications between indoor and outdoor units

Transmitting speed 83.3 bit/sec. (1 bit = 12ms) 83.3 bit/sec. (1 bit = 12ms)

Normal transmission The terminal for remote controller transmits sig-

nals every 7.5 seconds; the indoor unit whose

Outdoor unit transmits signals every 3 seconds;

all the connected indoor units respond them.

refrigerant address is “0” responds them.

Modulation The waveform modulates at 50kHz. There is no modulation.

Detection of abnormal

communication

When transmitting error is detected for three con-

secutive minutes.

When transmitting error is detected for three

consecutive minute.

WIRING SPECIFICATIONS FOR 220~240V 50Hz

(INDOOR-OUTDOOR CONNECTING CABLE)

25

Page 26

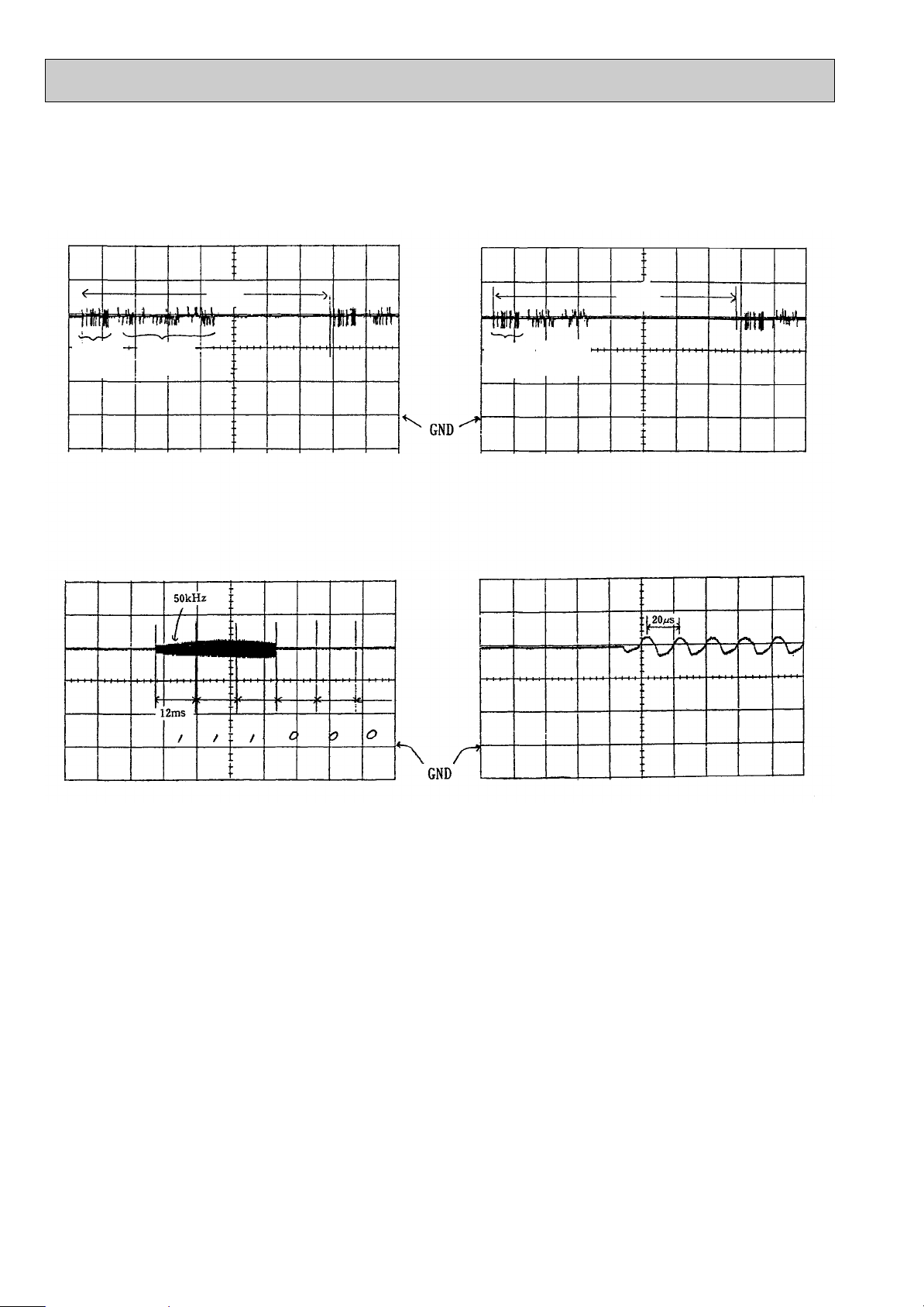

(3) The waveforms of from remote controller communications

The following graphs are the examples for measuring waveforms on the wirings of remote controlled transmission at the

terminal block for remote controller.

a) Ameasuring example in the sequence of startup b) Ameasuring example during normal stop

Transmission

from

remote

controller

Transmission

from

indoor unit

7.5

seconds

Transmission

from

remote

controller

Transmission

from

indoor unit

7.5

seconds

5V/div, 1sec/div: 5V/div, 1sec/div:

c) Expanded waveform 1 (signal 111000....) d) Expanded waveform 2 (50Hz carrier)

5V/div, 10msec/div: 5V/div, 2µsec/div:

• During normal operation, the remote controller interactively exchanges signals with the indoor unit of refrigerant address “0”.

When the remote controller cannot receive signals from the indoor unit of refrigerant address “0” for 3 minutes, it is considered

as abnormal. E0 is displayed on the remote controller as an error.

26

Page 27

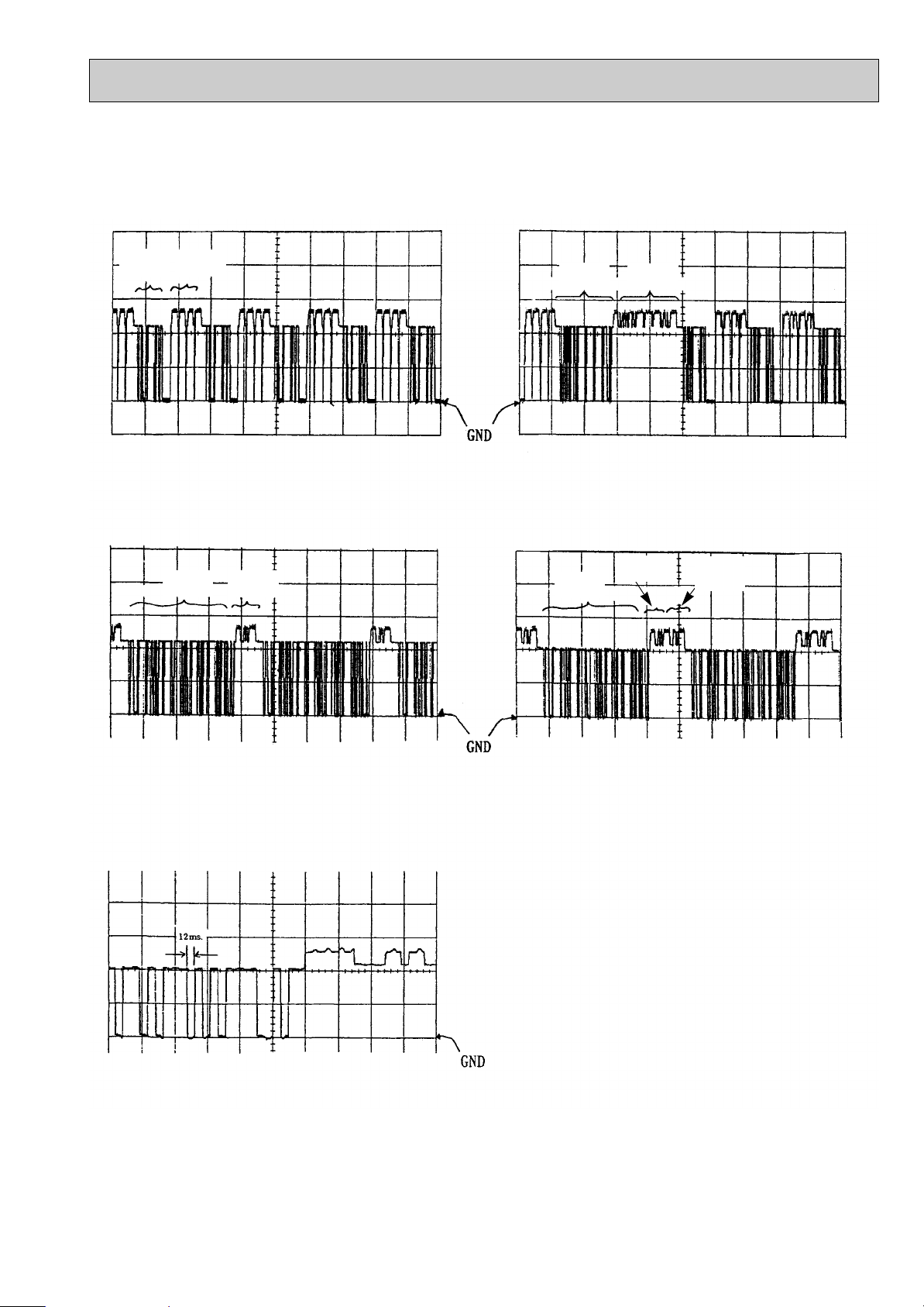

(4) The waveforms of communications between indoor and outdoor units

The following graphs are the examples for measuring waveforms on the wirings of connecting indoor and outdoor units at

between S2 and S3 of the outdoor terminal block TB1.

a) Ameasuring example the sequence of startup: 1 b) A measuring example in the sequence of startup: 2

Transmission

from

indoor unit

Transmission

from

outdoor unit

10V/div, 500msec/div: 10V/div, 500msec/div:

c) Ameasuring example during normal stop

(When one outdoor unit connects one indoor unit)

Transmission

from

indoor unit

Transmission

from

outdoor unit

Transmission

from

indoor unit

Transmission

from

outdoor unit

d) Ameasuring example during normal stop

(When one outdoor unit connects two indoor units)

Transmission

from

indoor unit

Transmission

from

one indoor unit

Transmission

from

another

indoor unit

10V/div, 500msec/div: 10V/div, 500msec/div:

c) Expanded waveform

10V/div, 50msec/div:

• During normal operation, outdoor unit interactively exchanges signals with all the connected indoor units.

• When outdoor unit cannot receive signals for three minutes from an indoor unit due to any trouble like cable disconnection, it

is considered as abnormal and the outdoor unit stops. E8 is displayed on the remote controller. This is to avoid independent

operation of indoor units.

27

Page 28

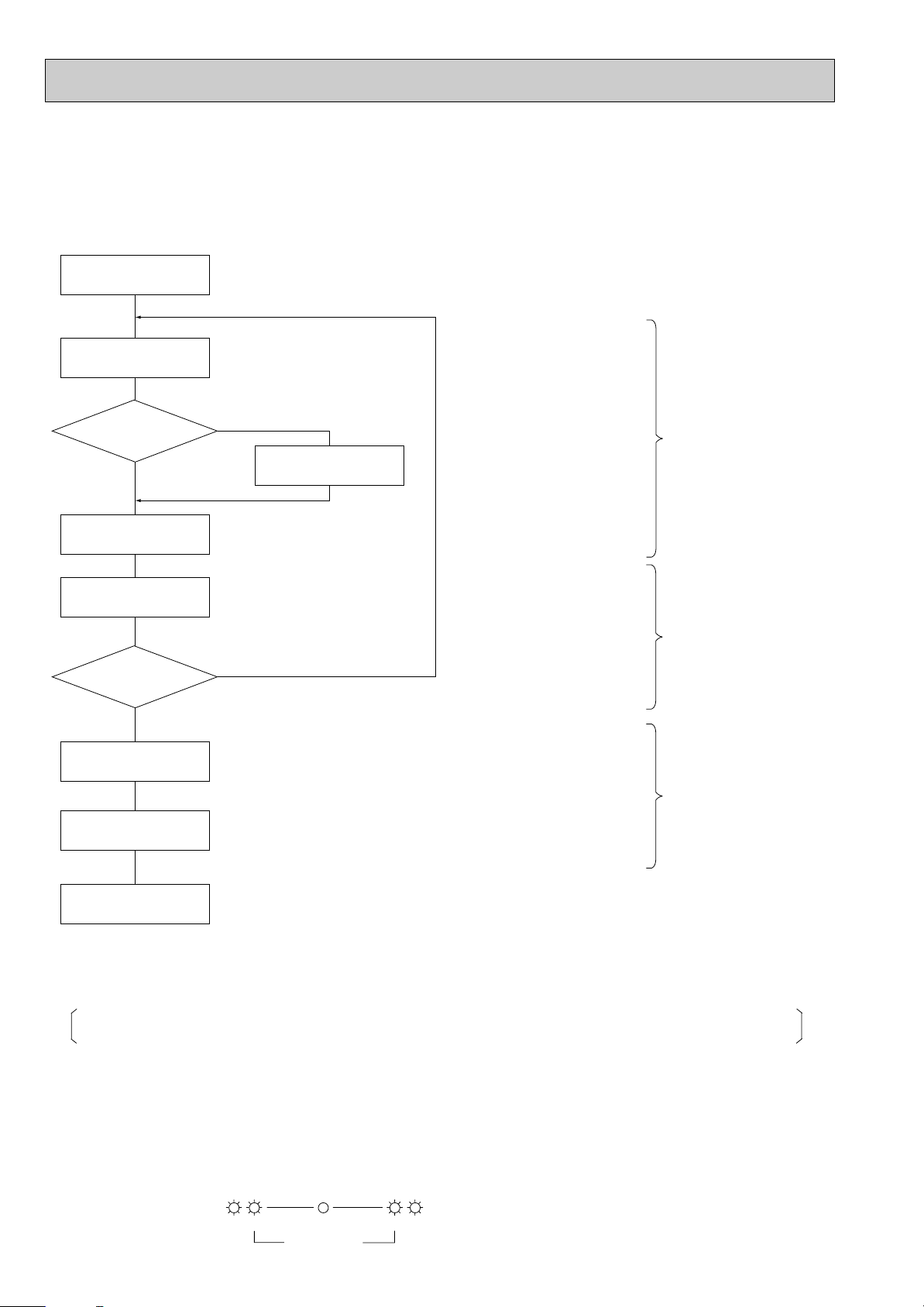

(5) Start-up system

Power ON

YES

NO

1 Refrigerant address

transmitting

Power supply control

to remote controller

3 Set number of the

connected unit

4 Set number of the

indoor unit

6 Collecting the unit

information

7 Collecting the

operation data

Set up finish

2 Refrigerant

address "0"?

YES

NO

5 Duplication

detection

Example

2 blinking 2 blinkingNot lighted

3 seconds

A control unit is applicable to any models of standard (1:1), twin and triple without switch setting according to carrying out the

below process automatically when the power is supplied.

When the power is supplied, following processes of 1 Refrigerant address transmitting, 2 Power supply control to remote

controller, 3 Set number of the connected unit, 4 Set number of the indoor unit, 5 Duplication detection, 6 Collecting the unit

information and 7 Collecting the operation data are carried out as shown on the figure.

Also when detecting the duplicated setting in the step 5, back to the first step and reset it.

; Transmitting the switch setting

contents on the outdoor unit

remote controller

(SW1-3~6)

; Feeding control to remote

controller

Feeding the indoor unit of the

refrigerant address “0”

EA error if 4 minutes have

passed since the power is

supplied.

; If there are 2 or more speci-

fied indoor unit, back to the

first step.

<<Feature>>

A. Start-up time from the second time will be shorter since setting of the number of connected units is memorized once set.

Start-up time can be estimated as following;

•When installing ... 1~2 minutes (Depending the number of connecting units)

•Since the second time .... 20 seconds ~ 1 minute (Depending the number of connecting units)

w When the above processing does not finish, even if 4 minutes have passed, consider the processing an error and

Ea, Eb or Ec will be displayed.

However if power is not supplied to the indoor unit due to miss-wiring or looseness of the connecting lines

between the indoor and outdoor unit, there will be no display on the remote controller. Also when the data can not

be received from the outdoor unit, E6 is displayed on the remote controller after 6 minutes.

B. When replacing the p.c.board, only the unit number which has had it`s p.c.board replaced is reset.

Even if the power supply is reset, the unit number which has not had it`s replaced does not change.

C. Automatic set unit is possible to confirm by blinking the frequency of LED3 in the indoor controller board.

At intervals of approx. 3 seconds, the number of the unit-number blinks.(Example:The unit(unit number:2) blinks twice at

3-second intervals.

; Collecting the vane, louver

information and transmittance

to the remote controller.

; Collecting the preceding oper-

ation setting information and

transmittance to the remote

controller.

EB error if 4 minutes have

passed since the power is

supplied.

EC error if 4 minutes have

passed since the power is

supplied.

28

Page 29

Function/control specifications

Item

Fan

Up/down

auto vane

Left/right

Function / specification

swing louver

Drain pump

Number of fan speed

Drive method

Provided

Swing function

Shutter mechanism

Moter type

Provided

Moter type

4-way ceiling cassette

PLA-RP•AA

4

Pulsation

(AC motor)

Stepping

(12V DC)

—

—

Ceiling concealed

PEA-RP•EA

2

Tap-changing

(AC motor)

—

—

—

—

—

—

—

Note: The parts marked are optional.

PEAD-RP•EA

2

Tap-changing

(AC motor)

—

—

—

—

—

—

29

Page 30

7

Control modes

Control details

1-1. Thermoregulating function (Function to prevent restarting for 3 minutes)

• Room temperature ] desired temperature +1:···Compressor ON

• Room temperature [ desired temperature ···Compressor OFF

Crankcase heater: OFF when compressor operates

ON when compressor stopped

(including when thermo is OFF)

Crankcase heater switches ON when 220-240V AC current is applied between

connectors CH 1 and 2 on the outdoor control board.

1-2. Anti-freezing control

Detected condition : When the liquid pipe temperature (TH2 ) or Condenser/

Evaporator temperature (TH5 ) (w3) is 2: or less (w4) in 16

minutes from compressors start up, anti-freezing control

starts and the compressor will be suspended.

Released condition : The timer which prevents reactivating is set for 3 minutes,

and anti- freezing control is cancelled when any one of the

following conditions is satisfied.

1

Liquid pipe temperature (TH2) and Condenser / Evaporator

temperature (TH5) turn 10: or above.

2 The condition of the compressor stop has become

complete by thermoregulating, etc.

3 The operation modes became mode other than COOL.

4 The operation stopped.

1-3. Frozen protection

Detected condition : 1 When the indoor pipe temperature (TH2 ) or Condenser/

Evaporator temperature (TH5 ) continues -15: for 3 minutes

since 3 minutes has passed after the compressor start, the

compressor stops and then the mode changes to prevent

restarting for 6 minutes. After restarting of 6 minutes, when

the indoor pipe temp. (TH2) or Condenser / Evaporator

temperature (TH5) continues -15 or less for three minutes again

by the time 16 minutes have passed, the frozen protection

operates. (P6)

Detected condition : 2

In case the indoor unit continues to be under the anti-freezing

control for 9 minutes or more, the unit will be in a state of the

suspensive abnormality. Restart the compressor after releasing

the anti-freezing control. The suspensive abnormality will be

cancelled if the compressor keeps operating for 20 minutes.

However, the suspensive abnormality will turn into the

abnormality if the anti-freezing control works again for 9

minutes during that period. On the other hand, the suspensive

abnormality will be cancelled if the anti-freezing control

works for less than 9 minutes

Released condition : When the operation stops by the remote controller operation.

By the remote controller setting (switch of 4 speeds or 2 speeds)

When determining the abnormality of the pipe temp. low speed fan is fixed.

2. Fan

1. Compressor

Remarks

Type

Fan speed notch

[Low] [Mid2] [Mid1] [High]

[Low] [High]

4 speeds type

2 speeds type

Refer to w2.

Refer to w3.

w1 The thermoregulating

function is provided in the

outdoor unit.

The indoor unit transmits

the indoor room

temperature and set

temperature data to

outdoor unit, then the

outdoor unit controls

thermoregulation.

INDOOR UNIT CONTROL

7-1. COOL operation

w2 Compare liquid pipe temperature to Condenser/ Evaporator temperature, and the lower one is applied to anti-freezing control.

• Liquid pipe temperature [ Condenser/ Evaporator temperature····· Liquid pipe

• Liquid pipe temperature > Condenser/ Evaporator temperature····· Condenser/ Evaporator pipe

w3 The function of remote controller can change the temperature to start anti-freezing control.

30

Page 31

→

3

2

1

→

3

2

1

→

Control modes

Control details

3-1. Drain pump control

•Always drain pump ON during the COOL and DRY mode operation.

(Regardless of the compressor ON/ OFF)

•When the operation mode has changed from the COOL or DRY to the others

(including Stop), OFF the control after the drain pump ON for 3 minutes.

Drain sensor function

• Energize drain sensor at a fixed voltage for a fixed duration. After energizing,

compare the drain sensor’s temperature to the one before energizing, and judge

whether the sensor is in the air or in the water.

Basic control system

• While drain pump is turned on, repeat the following control system and judge

whether the sensor is in the air or in the water.

•Drain sensor temperature rise (∆t)

•Temperature of drain sensor before current is applied (T0)

•Temperature of drain sensor after current is applied (T

1)

[ ∆t = T1 – T0 ]

(1)Initial setting : Start at COOL mode and horizontal vane.

(2)Vane position : Horizontal →Downward A →Downward B →Downward C→Swing

(3)Restriction of the downward vane setting

When setting the downward vane A, B and C in [Mid2] or [Low] of the fan speed

notch, the vane changes to horizontal position after 1 hour have passed.

4. Vane

(up/ down vane change)

3. Drain pump

Remarks

✻1 Drain sensor

Indoor control

board

CN31

✻2 If the unit is

without the

drain sensor,

install the

jumper

connector.

Indoor control

board

CN31

When installing

the jumper

connector,

determine to

detect

compulsorily in

the air.

✻1 Whether the

unit has a swing

function is listed

in the function/

control specifications.

✻2 See the

function/control

specifications

for the vane

motor type.

✻3 "1Hr"

appears on the

wired remote

controller.

Timing of

energizing

drain sensor

ON

OFF

Stand by for

a minute

30 sec.

Detect the

temperature

before

energizing

(T0)

Detect the

temperature

after

energizing

(T1)

Judge whether

the sensor is in

the air or in the

water.

30 sec.Stand by for

a minute

·······Repeat

31

Page 32

7-2. DRY operation

Control modes

Control details

1-1. Thermoregulating function (Function to prevent restarting for 3 minutes)

Setting the compressor operation time by the thermoregulating signal

and the room temperature (TH1).

Thermoregulating signal ON Room temperature ] desired temperature +1:

Thermoregulating signal OFF Room temperature [ desired temperature

1-2. Frozen prevention control

No control function

Indoor fan operation controlled depends on the compressor conditions.

3. Drain pump

1. Compressor

Remarks

✻1

The thermoregulating

function is provided in

the outdoor unit.

The indoor unit

transmits the indoor

room temperature and

set temperature data to

outdoor unit, then the

outdoor unit controls

thermoregulation.

Room temp.

Thermoregulating

signal

Operating

time (min)

OFF time

(min)

Less than 18:

Over 18:

ON 9 3

OFF

10

3

Compressor operation stop

1-3. Frozen protection

Same control as COOL operation

2. Fan

Note: Remote controller setting is not acceptable.

Compressor

Fan speed

ON

OFF

[Low]

Stop (

✻1)

✻1 Note that even when

the compressor is OFF, the

unit starts operating in

[LOW] if the start condition

below is met.

Start condition: The piping

temperature (fluid piping or

2-phase piping) has fallen

to 1

: or less.

Release condition: The

piping temperature (fluid

piping or 2-phase piping)

has returned to at least

10

:.

4. Vane

(up/ down vane change)

Same control as COOL operation

Same control as COOL operation

5. Louver

(Left/ right change)

Remote controller setting

✻1 Model which is

installed louver

function.

Control modes

Control details

None (always stopped)

Set by remote controller.

3. Drain pump

1. Compressor

Remarks

2. Fan

Number of fan speeds

Fan speed notches

4

2

[Low], [Mid2], [Mid1], [High]

[Low]

[High]

4. Vane

(up/ down vane change)

3.1 Drain pump control

The drain pump turns ON for the specified amount of time when any of the following

conditions is met:

1 ON for 3 minutes after the operation mode is switched from COOL or DRY to

another operation mode (FAN).

2 ON for 6 minutes after the drain sensor is determined to be submerged using the

liquid level detection method given below.

3 ON for 6 minutes after indoor piping (liquid piping) temperature - indoor intake

temperature [ -10:, AND the drain sensor input is at the short or open level.

(If condition 2 or 3 is still being met after the drain pump has been turned ON for 6

minutes, the drain pump is kept ON for a further 6 minutes.)

3.2 Liquid level detection method

The liquid level is detected by determining whether or not the drain sensor is

submerged, based on the amount the temperature rises after self-heating the

sensor. This process is performed if any of the following conditions is met:

1 Drain pump is ON.

2 Indoor piping (liquid piping) temperature - indoor intake temperature [ -10:

3 Indoor piping (liquid piping) temperature or indoor intake temperature is at the

short or open level temperature.

4 Every hour after the drain pump has been switched from ON to OFF.

Same as the control performed during the COOL operation, but with no restriction

on the vane's downward blow setting.

7-3. FAN operation

32

Page 33

7-4. HEAT operation

Control modes

Control details

1-1. Thermoregulating function (Function to prevent restarting for

3 minutes)

• Room temperature [ desired temperature-1: ···Compressor ON

• Room temperature ] desired temperature ···Compressor OFF