Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

May 2005

No. OCS01

TECHNICAL DATA BOOK

<Indoor unit>

[Model names]

<Outdoor unit>

[Model names]

PLA-RP·AA

PEAD-RP·EA

PEAD-RP·GA

PEA-RP·EA

PEH-RP·MYA

PKA-RP·GAL

PKA-RP·FAL

PCA-RP·GA

PCA-RP·HA

PSA-RP·GA

PUHZ-RP35/50/60/71/100/125/140VHA

R410A

INVERTER

PUHZ-RP100/125/140/200/250YHA

CONTENTS

1. REFERENCE SERVICE MANUAL·············································2

2. SPECIFICATIONS ······································································3

3. OUTLINES AND DIMENSIONS················································26

4. WIRING DIAGRAM···································································52

5. REFRIGERANT SYSTEM DIAGRAM ······································66

6. PERFORMANCE CURVES······················································69

7. CORRECTION FACTORS························································73

8. APPLICABLE EXTENSION PIPE FOR EACH MODEL··········74

9. AIR FLOW DATA······································································82

10. NOISE CRITERION CURVES ················································100

11. OPTIONAL PARTS···································································116

kW Model

Page 2

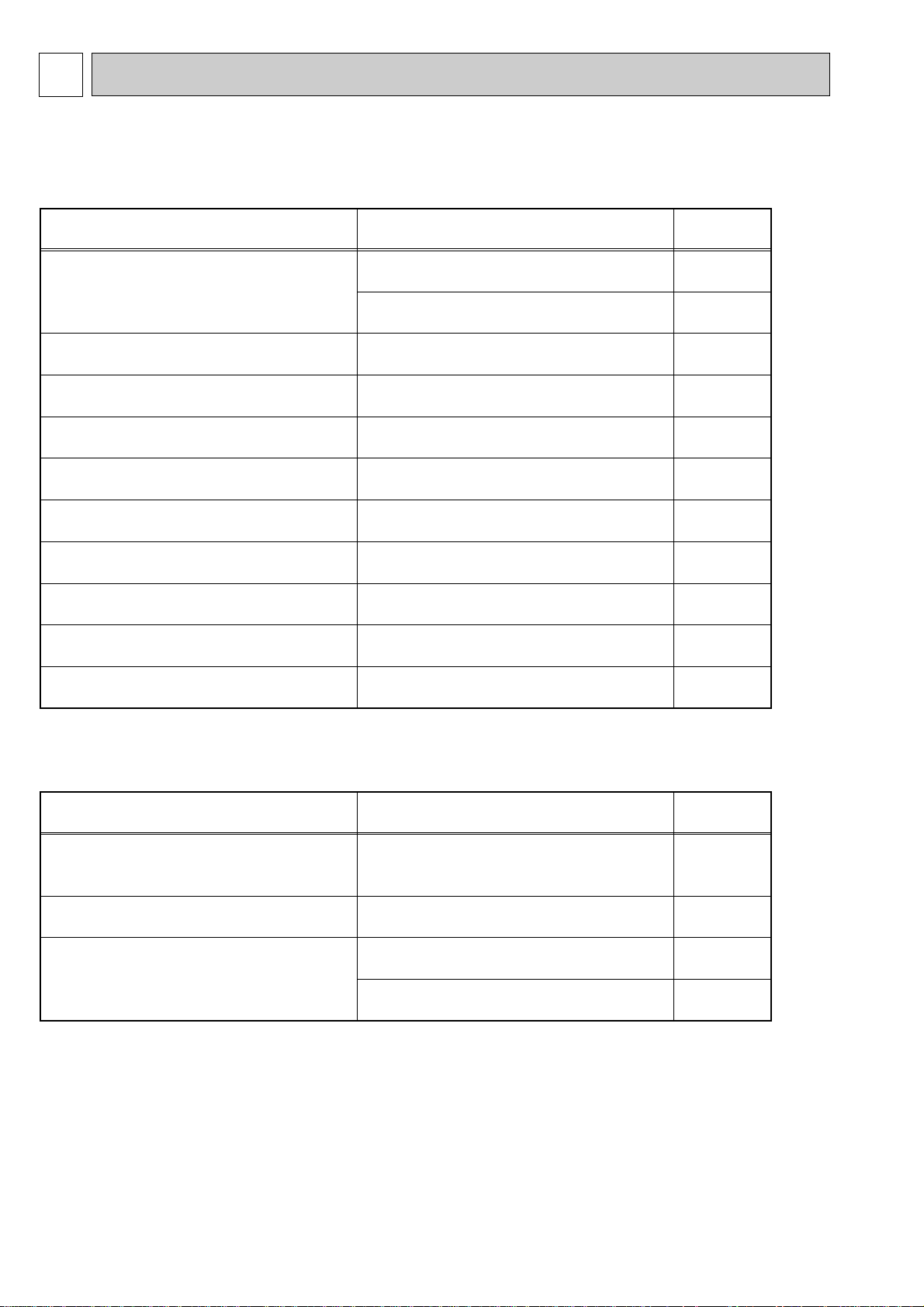

For information on service, please refer to the service manual as follows.

Model name Service Ref. Service

Manual No.

PLA-RP35/50/60/71AA PLA-RP35/50/60/71AA.UK OC335

PLA-RP100/125/140AA

PLA-RP100/125/140AA.UK

PLA-RP35/50/60/71AA OC327

PLA-RP100/125/140AA.UK

PCA-RP50/60/71GA PCA-RP50/60/71GA OC328

PCA-RP100/125/140GA

PCA-RP100/125/140GA

PCA-RP71/125HA PCA-RP71/125HA OC329

PKA-RP35/50GAL PKA-RP35/50GAL OC330

PKA-RP60/71/100FAL PKA-RP60/71/100FAL OC331

PSA-RP71/100/125/140GA PSA-RP71/100/125/140GA OC332

PEA-RP71/100/125/140EA PEA-RP71/100/125/140EA.TH-A OC326

PEAD-RP35/50/60/71EA PEAD-RP35/50/60/71EA.UK -

PEAD-RP100/125/140EA

PEAD-RP100/125/140EA.UK

PEAD-RP60/71/100GA PEAD-RP60/71/100GA.UK PEH-RP200/250MYA PEH-RP200/250MYA -

1-2. OUTDOOR UNIT

Model name Service Ref. Service

Manual No.

PUHZ-RP35/50/60/71VHA PUHZ-RP35/50/60/71VHA OC334

PUHZ-RP100/125/140VHA

PUHZ-RP100/125/140VHA

PUHZ-RP100/125/140YHA

PUHZ-RP100/125/140YHA

PUHZ-RP100/125/140VHA PUHZ-RP71/100/125/140VHA-A OC337

PUHZ-RP200/250YHA PUHZ-RP200/250YHA OC338

PUHZ-RP200/250YHA-A OC339

1-1. INDOOR UNIT

1

REFERENCE SERVICE MANUAL

2

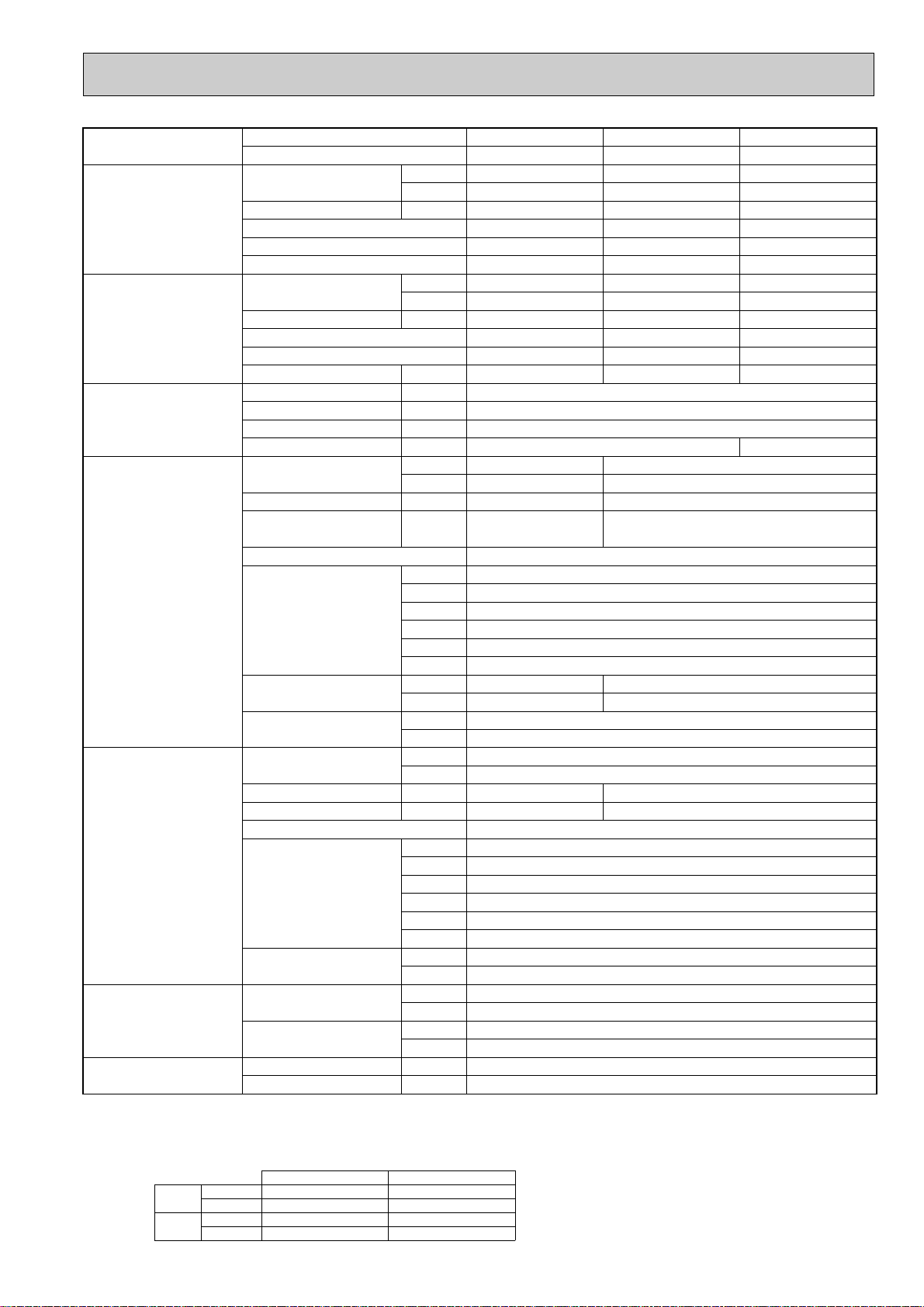

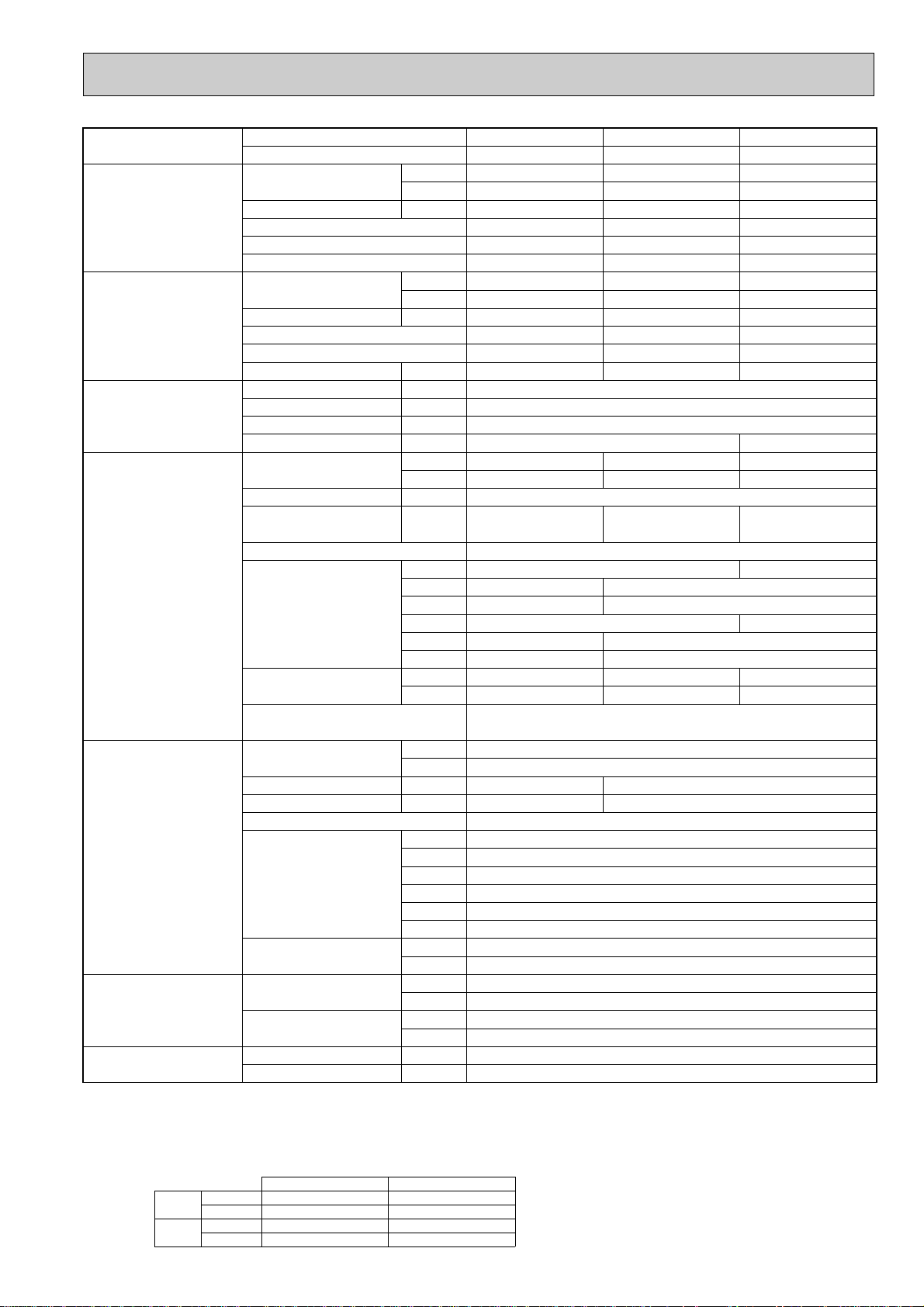

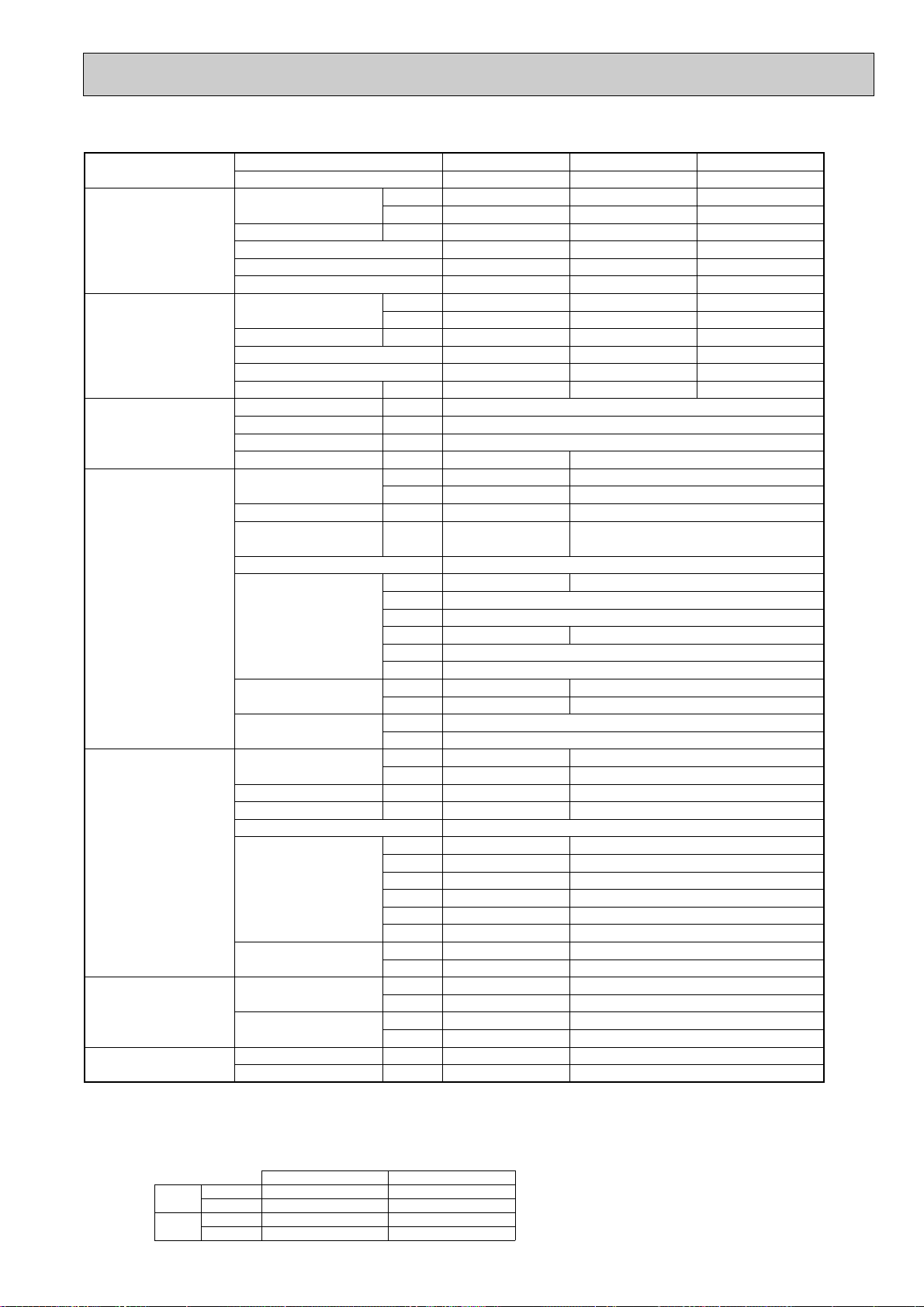

Page 3

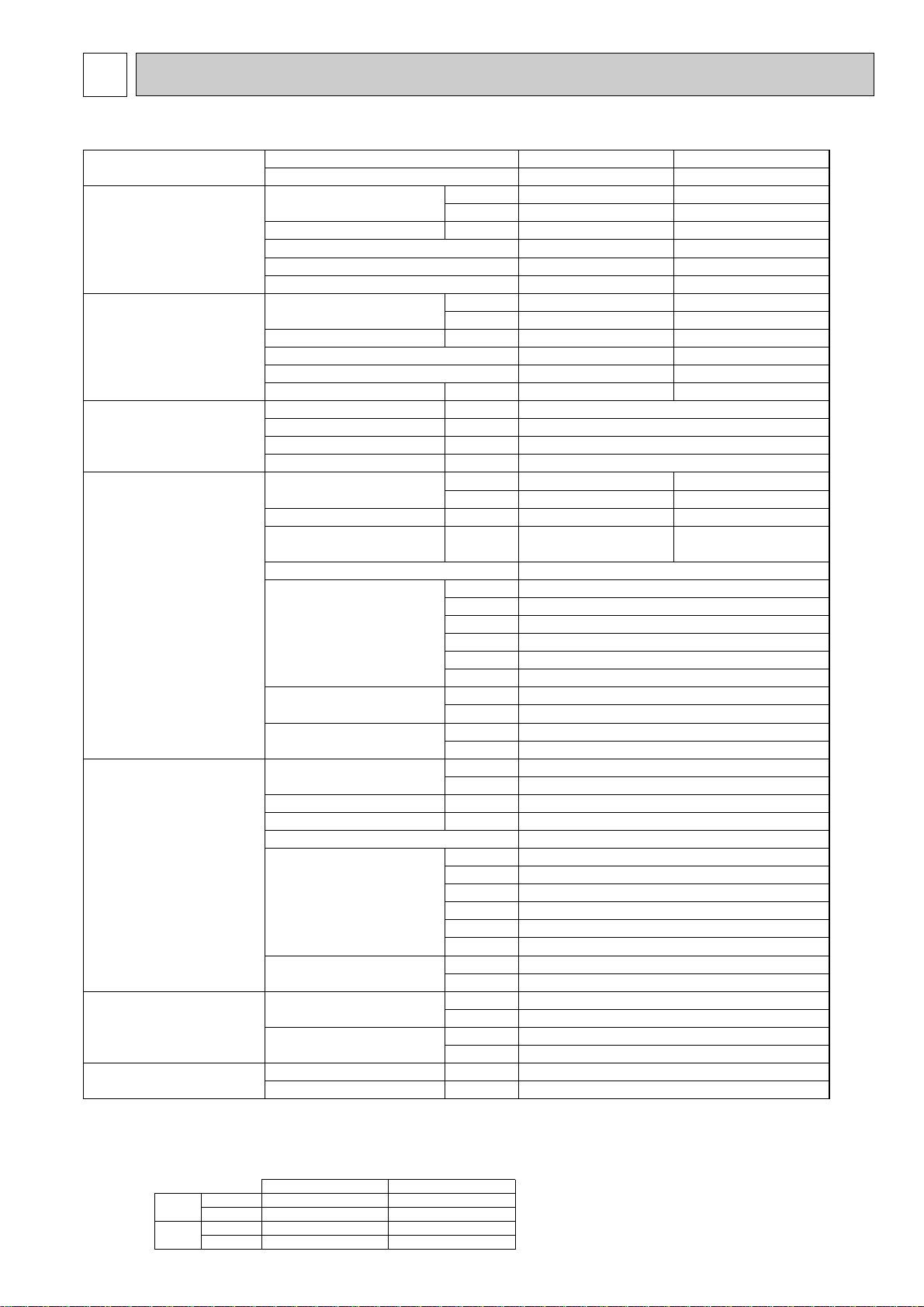

2

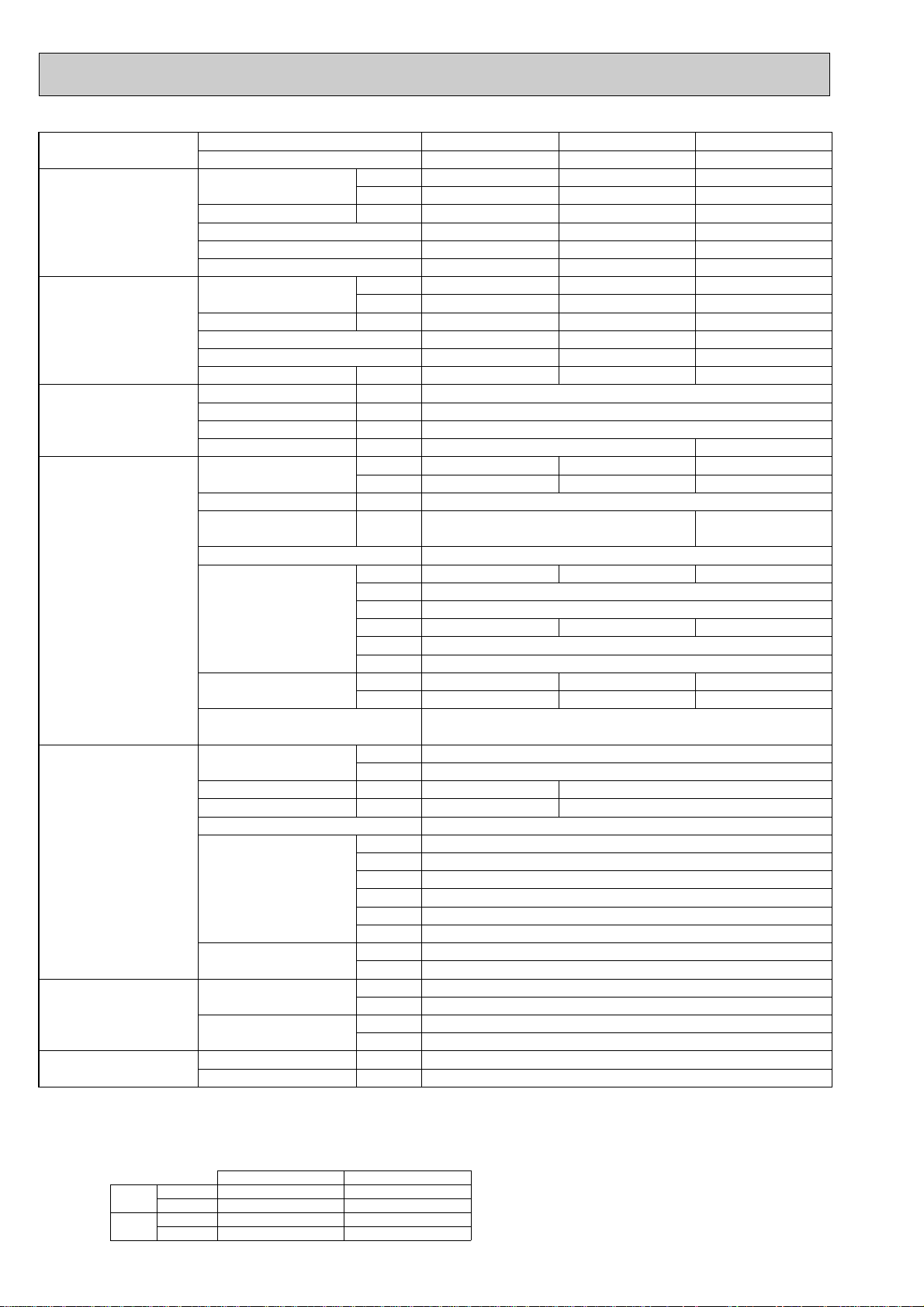

Model name Indoor unit PLA-RP35AA PLA-RP50AA

Outdoor unit PUHZ-RP35VHA PUHZ-RP50VHA

Cooling Capacity Btu/h 12,300 17,100

kW 3.6(1.6-4.5) 5.0(2.3-5.6)

Total input kW 1.07 1.55

EER 3.36 3.23

Energy label class A A

SHF 0.89 0.86

Heating Capacity Btu/h 14,000 20,500

kW 4.1(1.6-5.2) 6.0(2.5-7.3)

Total input kW 1.12 1.62

COP 3.66 3.70

Energy label class A A

Booster heater kW - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 16

Indoor unit Air flow CMM 11-12-13-14 14-15-16-18

(Low-Medium2-Medium1-High)

CFM 390-425-460-495 495-530-565-635

External pressure Pa 0 0

Sound level dB(A) 27-28-29-31 28-29-31-33

(Low-Medium2-Medium1-High)

External finish (Panel) White Munsell 0.70Y 8.59/0.97

Dimension W : mm 840 (950)

Unit (Panel) D : mm 840 (950)

H : mm 258 (30)

W : inch 33-1/16 (37-3/8)

D : inch 33-1/16 (37-3/8)

H : inch 10-3/16 (1-3/16)

Weight kg 24 (5)

Unit (Panel) lbs 53 (11)

Unit drain pipe I.D. mm 32

inch 1-1/4

Outdoor unit Air flow CMM 35

CFM 1,240

Sound level at cooling dB(A) 44

Sound level at heating dB(A) 46

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 800

D : mm 330+23

H : mm 600

W : inch 31-1/2

D : inch 13 + 7/8

H : inch 23-5/8

Weight kg 45

lbs 99

Refrigerant pipe size Gas side O.D. mm 12.7

inch 1/2

Liquid side O.D. mm 6.35

inch 1/4

Refrigerant pipe length Height difference m Max. 30

Length m Max. 50

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46˚C

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

Heating

Upper limit

D.B. 28˚C

D.B. 21˚C, W.B. 15˚C

Lower limit

D.B. 17˚C

D.B. -11˚C, W.B. -12˚C

4. Above data based on indicated voltage

w If optional Air protect guide installed. D.B.-15:

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz

Outdoor unit

3. Guaranteed voltage

198~264V, 50Hz

SPECIFICATIONS

2-1. CEILING CASSETTE TYPE

3

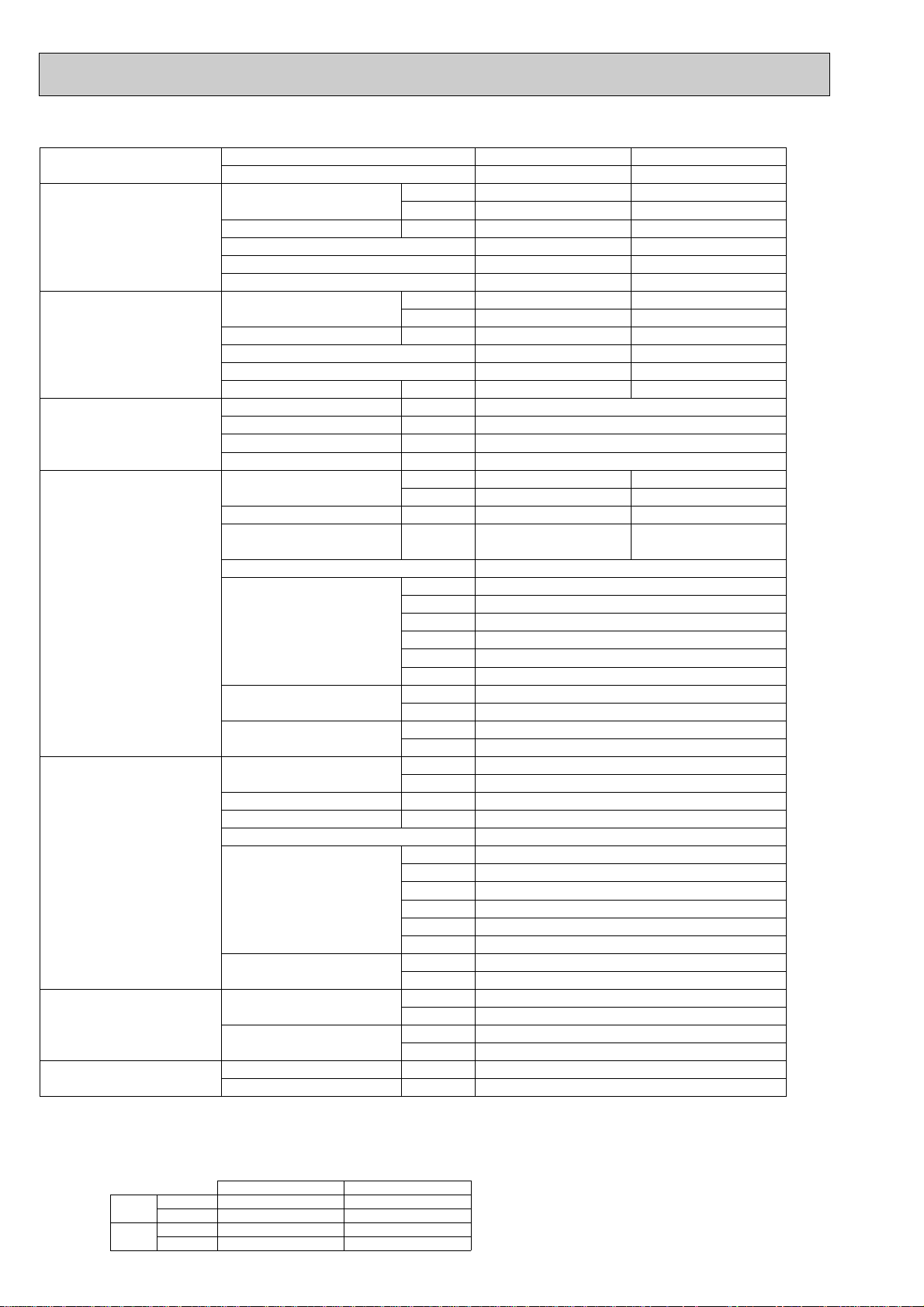

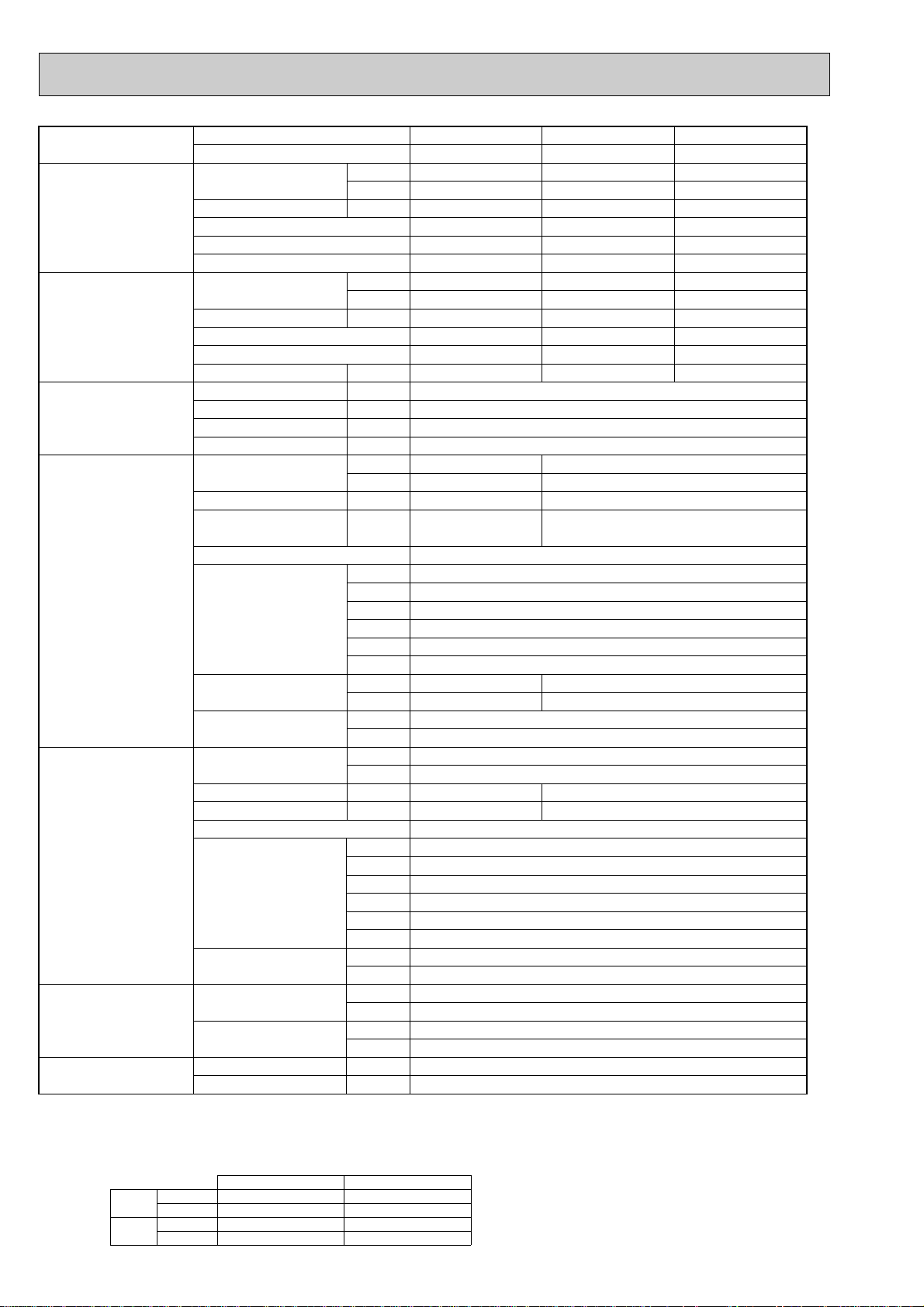

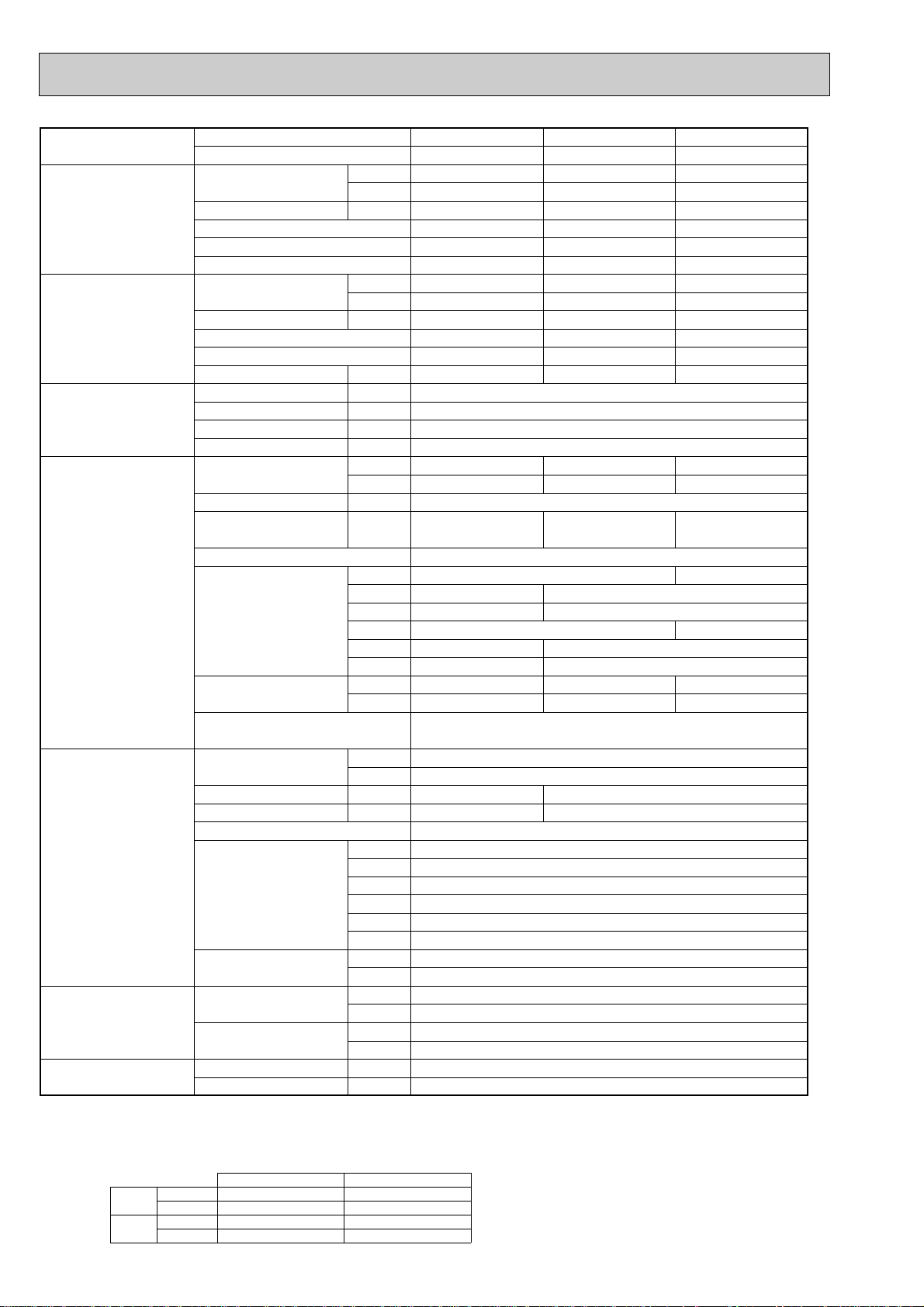

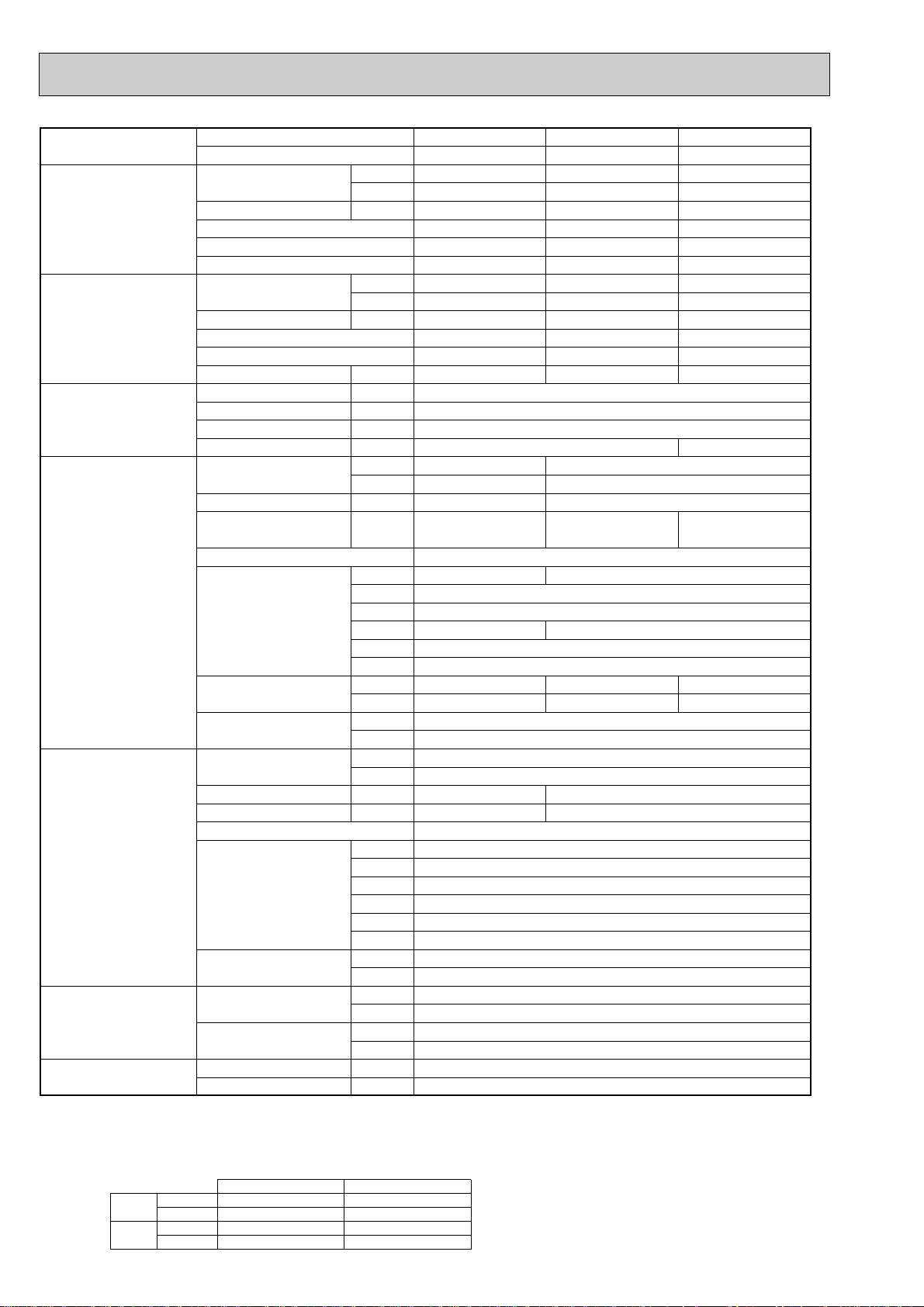

Page 4

Model name Indoor unit PLA-RP60AA PLA-RP71AA

Outdoor unit PUHZ-RP60VHA PUHZ-RP71VHA

Cooling Capacity Btu/h 20,500 24,200

kW 6.0(2.7-6.7) 7.1(3.3-8.1)

Total input kW 1.65 1.97

EER 3.64 3.60

Energy label class A A

SHF 0.78 0.74

Heating Capacity Btu/h 23,900 27,300

kW 7.0(2.8-8.2) 8.0(3.5-10.2)

Total input kW 1.85 2.34

COP 3.78 3.42

Energy label class A B

Booster heater kW - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 25

Indoor unit Air flow CMM 14-15-16-18 15-16-18-20

(Low-Medium2-Medium1-High) CFM 495-530-565-635 530-565-635-705

External pressure Pa 0 0

Sound level dB(A) 28-29-31-33 28-30-32-34

(Low-Medium2-Medium1-High)

External finish (Panel) White Munsell 0.70Y 8.59/0.97

Dimension W : mm 840 (950)

Unit (Panel) D : mm 840 (950)

H : mm 258 (30)

W : inch 33-1/16 (37-3/8)

D : inch 33-1/16 (37-3/8)

H : inch 10-3/16 (1-3/16)

Weight kg 24 (5)

Unit (Panel) lbs 53 (11)

Unit drain pipe I.D. mm 32

inch 1-1/4

Outdoor unit Air flow CMM 55

CFM 1,940

Sound level at cooling dB(A) 47

Sound level at heating dB(A) 48

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 943

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 37-1/8

Weight kg 75

lbs 165

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 50

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

4

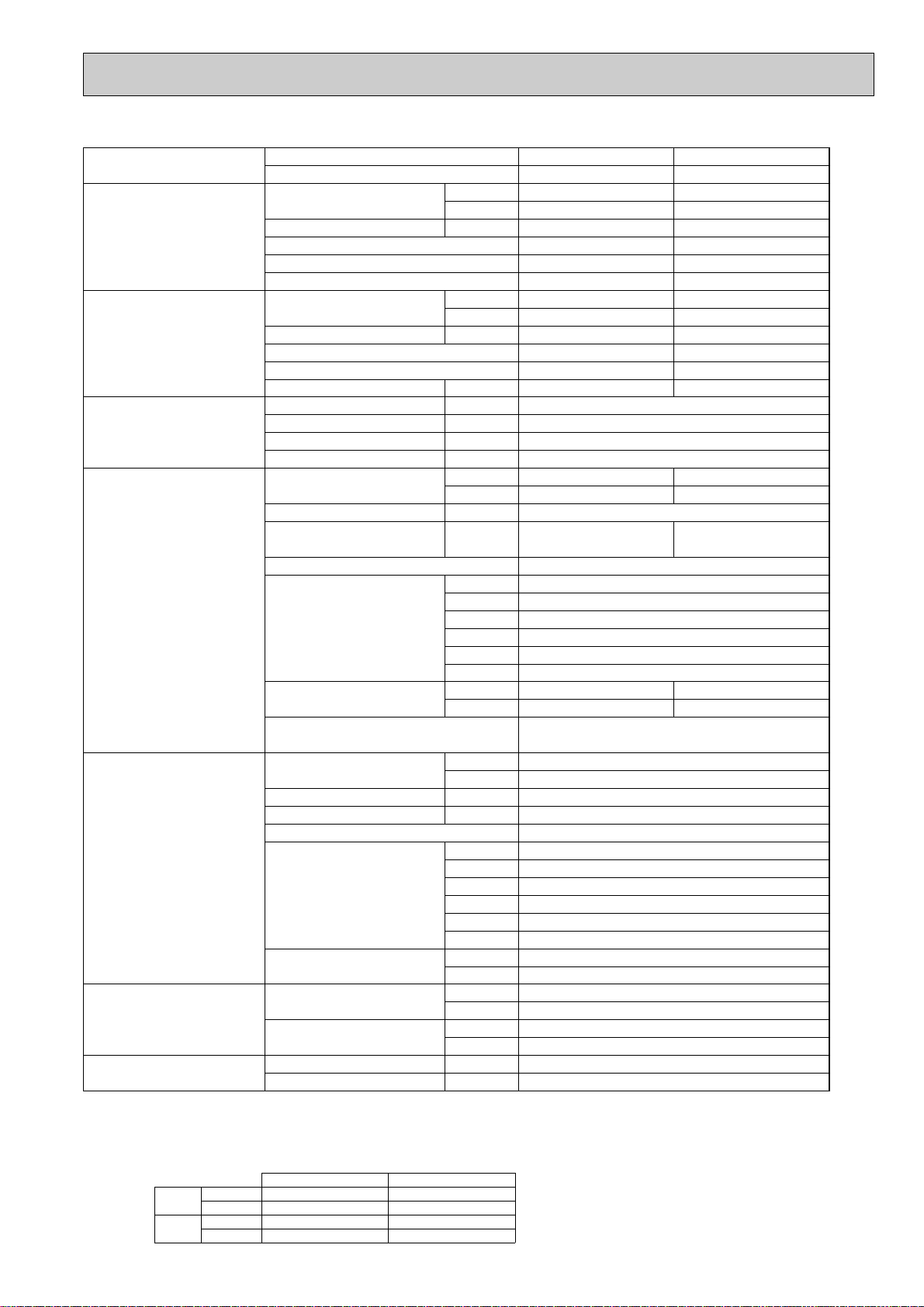

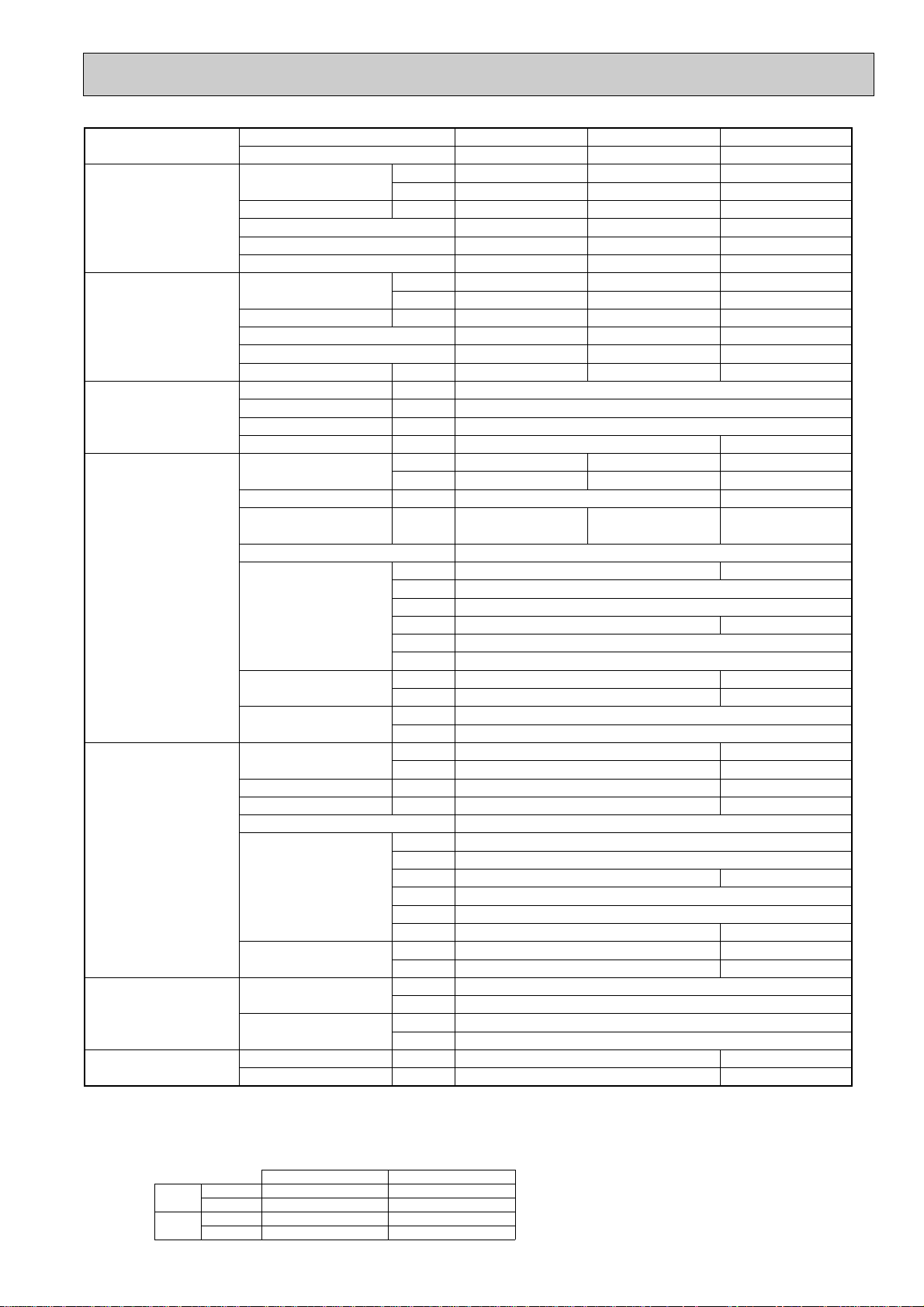

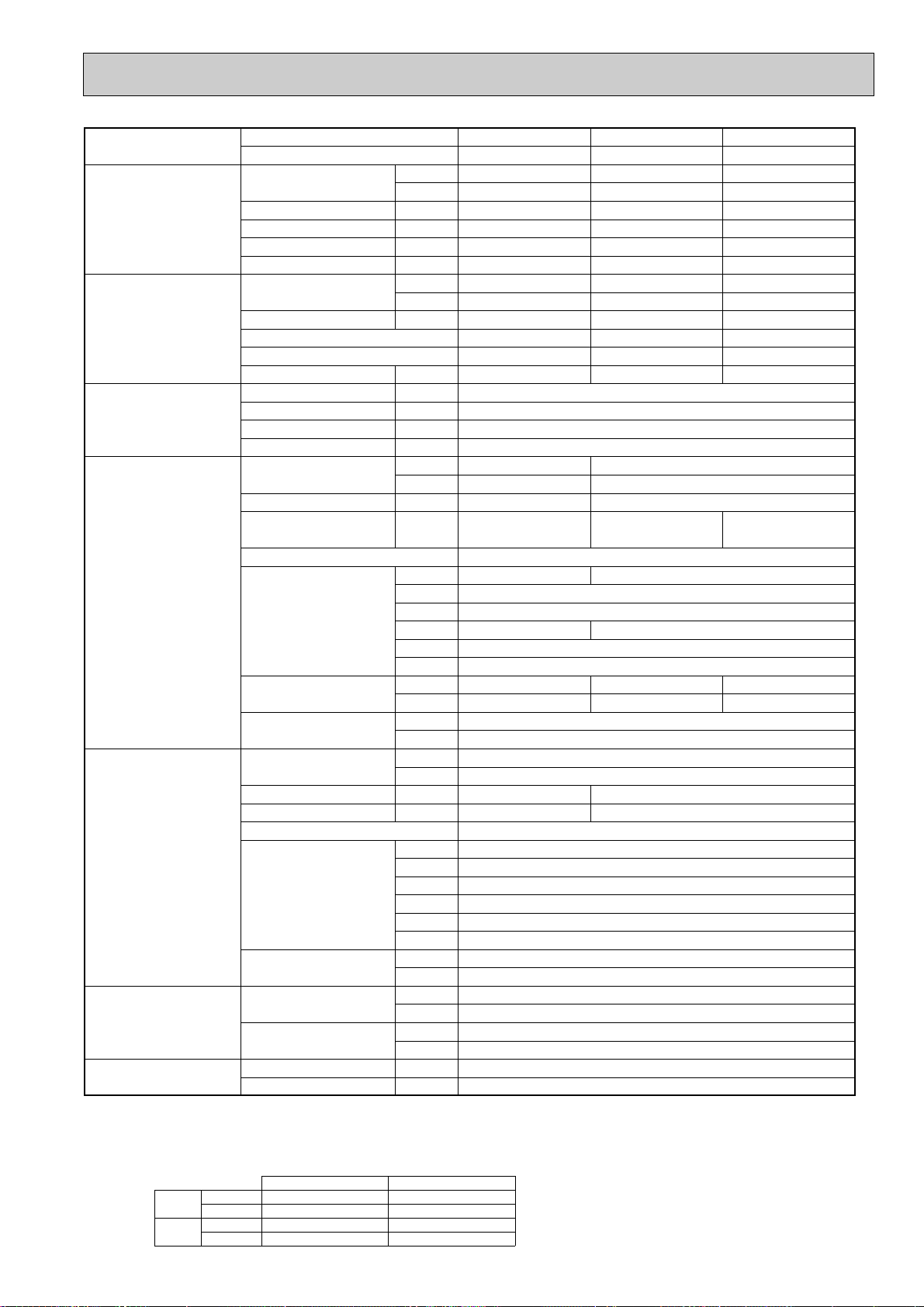

Page 5

Model name Indoor unit PLA-RP100AA PLA-RP125AA PLA-RP140AA

Outdoor unit PUHZ-RP100VHA PUHZ-RP125VHA PUHZ-RP140VHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 3.03 3.89 4.99

EER 3.30 3.21 2.81

Energy label class A A C

SHF 0.77 0.74 0.70

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.39 4.27 4.91

COP 3.30 3.28 3.26

Energy label class C C C

Booster heater kW - - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 32 40

Indoor unit Air flow CMM 20-23-26-28 22-25-28-30

(Low-Medium2-Medium1-High) CFM 705-810-920-990 775-880-990-1,060

External pressure Pa 0 0

Sound level dB(A) 33-36-39-41 37-40-43-45

(Low-Medium2-Medium1-High)

External finish (Panel) White Munsell 0.70Y 8.59/0.97

Dimension W : mm 840 (950)

Unit (Panel) D : mm 840 (950)

H : mm 298 (30)

W : inch 33-1/16 (37-3/8)

D : inch 33-1/16 (37-3/8)

H : inch 11-3/4 (1-3/16)

Weight kg 30 (5) 32 (5)

Unit (Panel) lbs 66 (11) 71 (11)

Unit drain pipe I.D. mm 32

inch 1-1/4

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 121

lbs 267

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

5

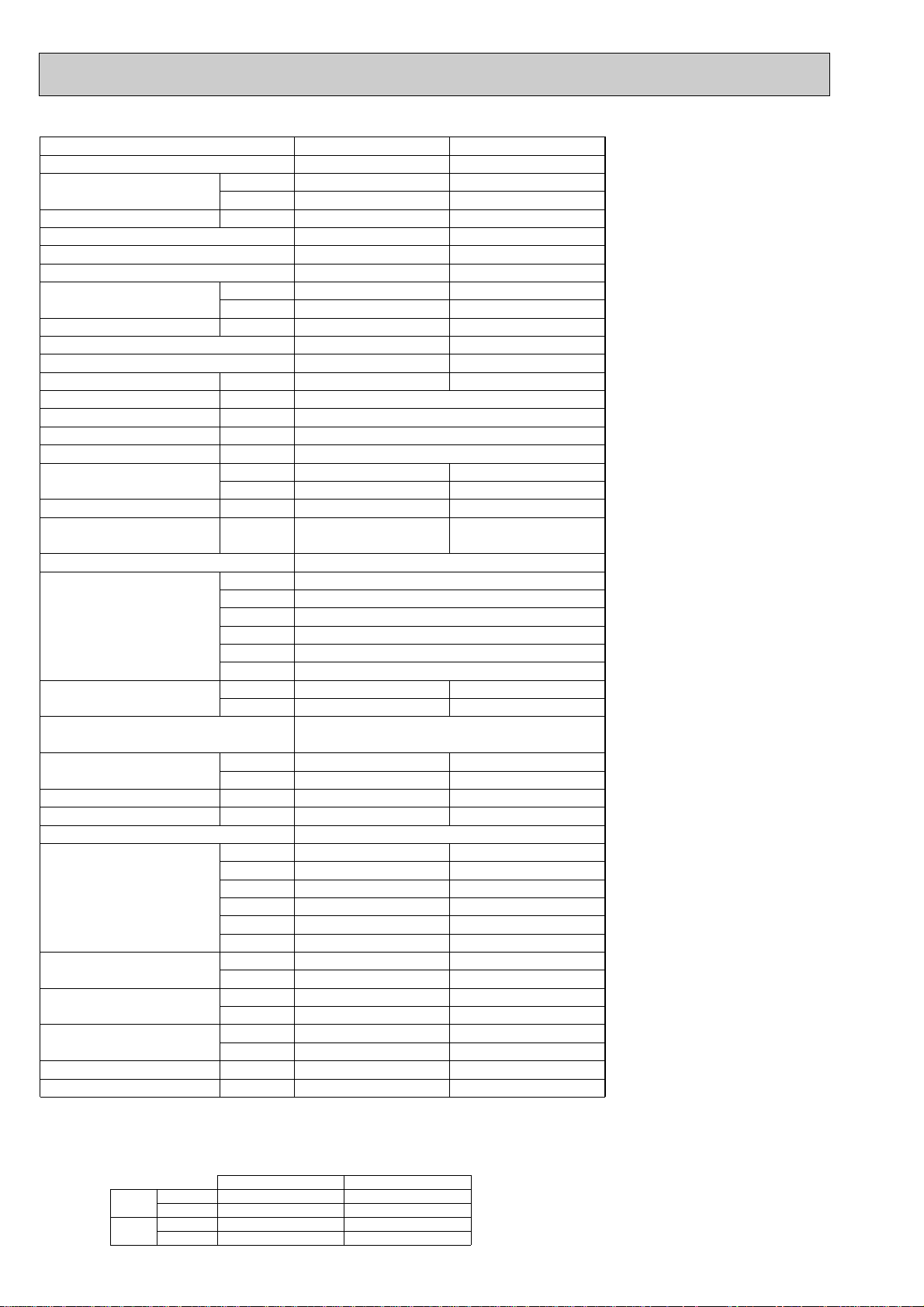

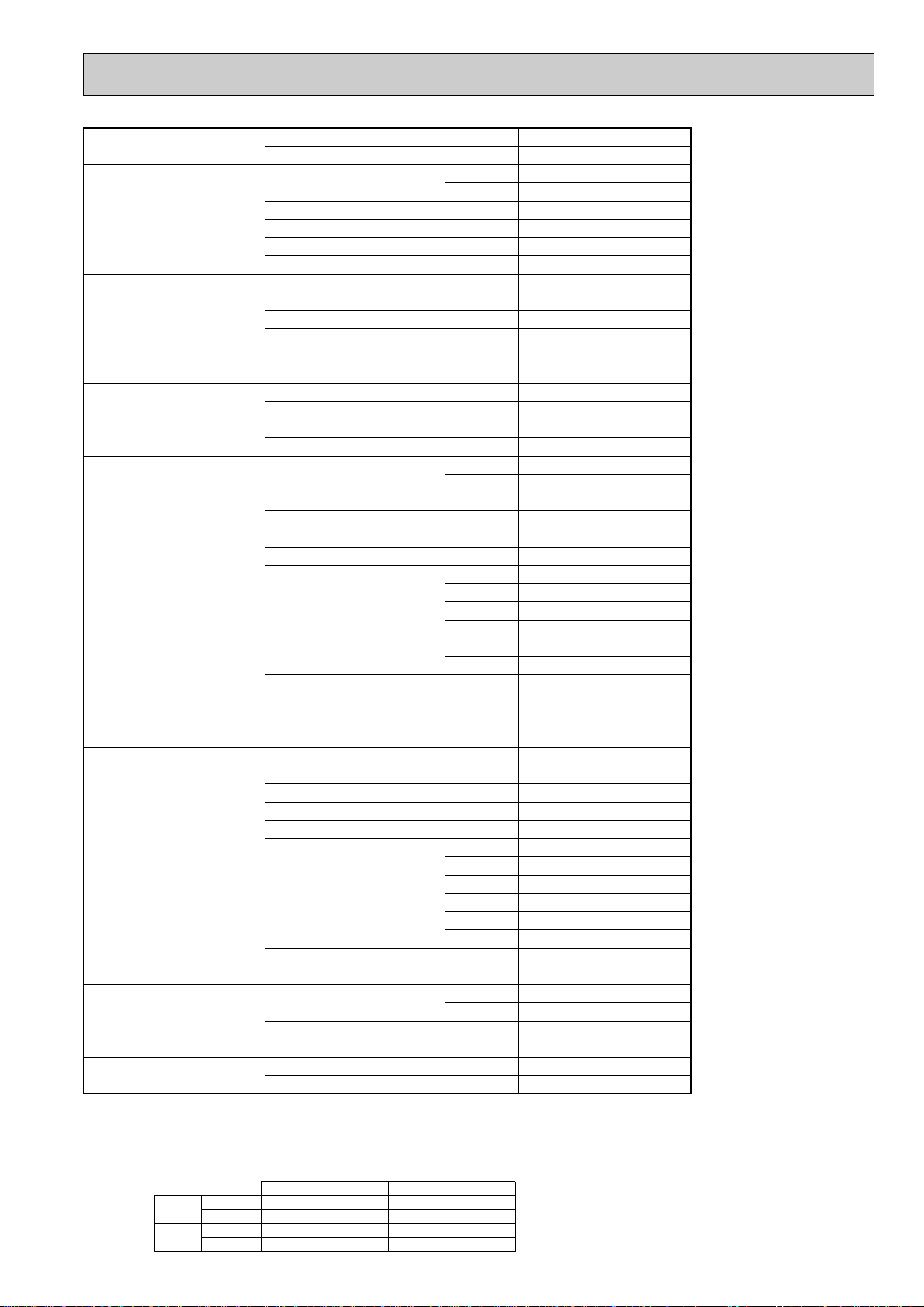

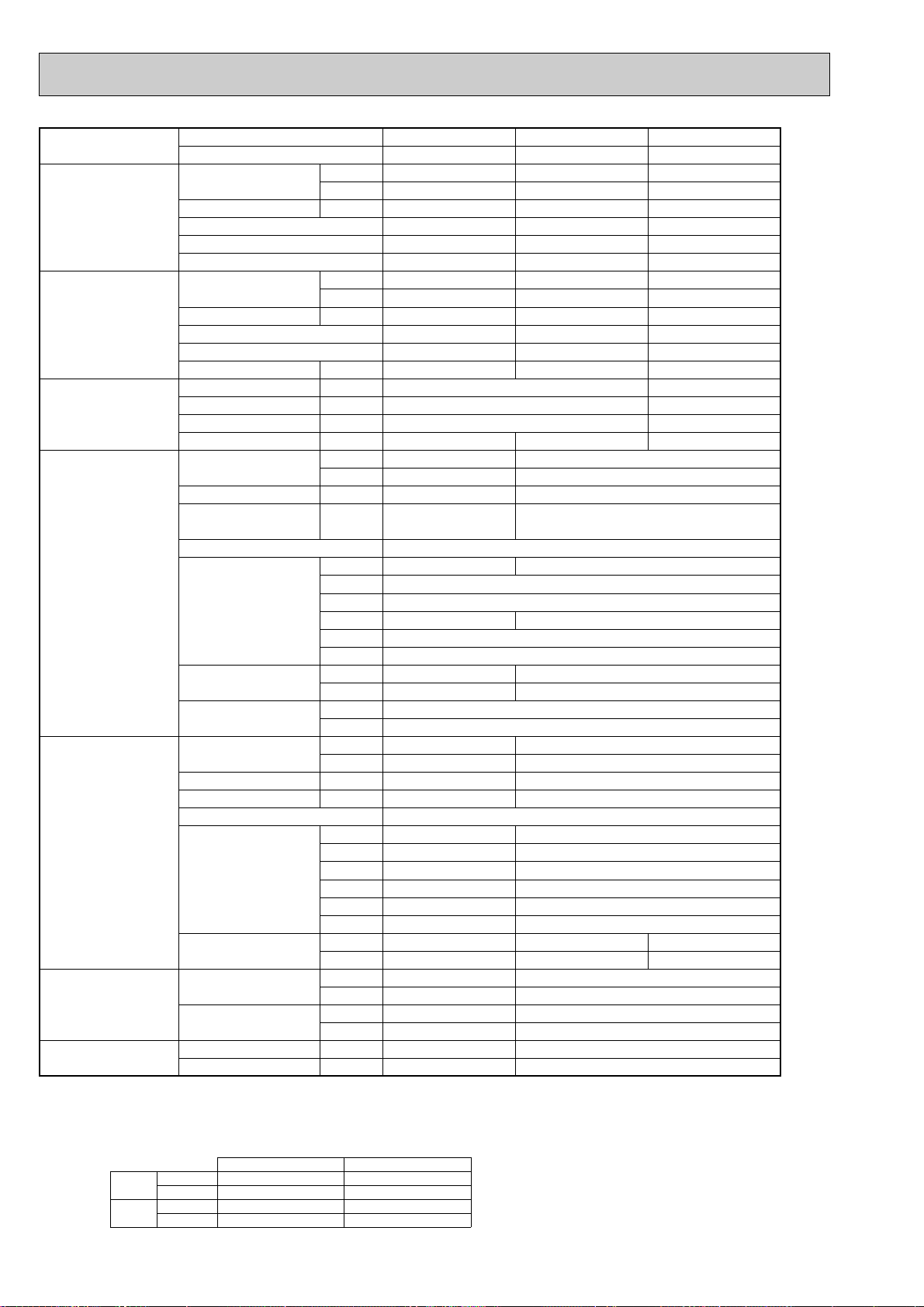

Page 6

Model name Indoor unit PLA-RP100AA PLA-RP125AA PLA-RP140AA

Outdoor unit PUHZ-RP100YHA PUHZ-RP125YHA PUHZ-RP140YHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 3.03 3.89 4.99

EER 3.30 3.21 2.81

Energy label class A A C

SHF 0.77 0.74 0.70

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.39 4.27 4.91

COP 3.30 3.28 3.26

Energy label class C C C

Booster heater kW - - -

Power supply Phase [ 3

Cycle Hz 50

Voltage V 400

Breaker size A 16

Indoor unit Air flow CMM 20-23-26-28 22-25-28-30

(Low-Medium2-Medium1-High) CFM 705-810-920-990 775-880-990-1,060

External pressure Pa 0 0

Sound level dB(A) 33-36-39-41 37-40-43-45

(Low-Medium2-Medium1-High)

External finish (Panel) White Munsell 0.70Y 8.59/0.97

Dimension W : mm 840 (950)

Unit (Panel) D : mm 840 (950)

H : mm 298 (30)

W : inch 33-1/16 (37-3/8)

D : inch 33-1/16 (37-3/8)

H : inch 11-3/4 (1-3/16)

Weight kg 30 (5) 32 (5)

Unit (Panel) lbs 66 (11) 71 (11)

Unit drain pipe I.D. mm 32

inch 1-1/4

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 135

lbs 298

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -20˚C, W.B. -20˚C

3. Guaranteed voltage

Indoor unit 198~264V, 50Hz

Outdoor unit

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

342~457V, 50Hz

3 phase 400V 50Hz

6

Page 7

2-2. CEILING-CONCEALED TYPE

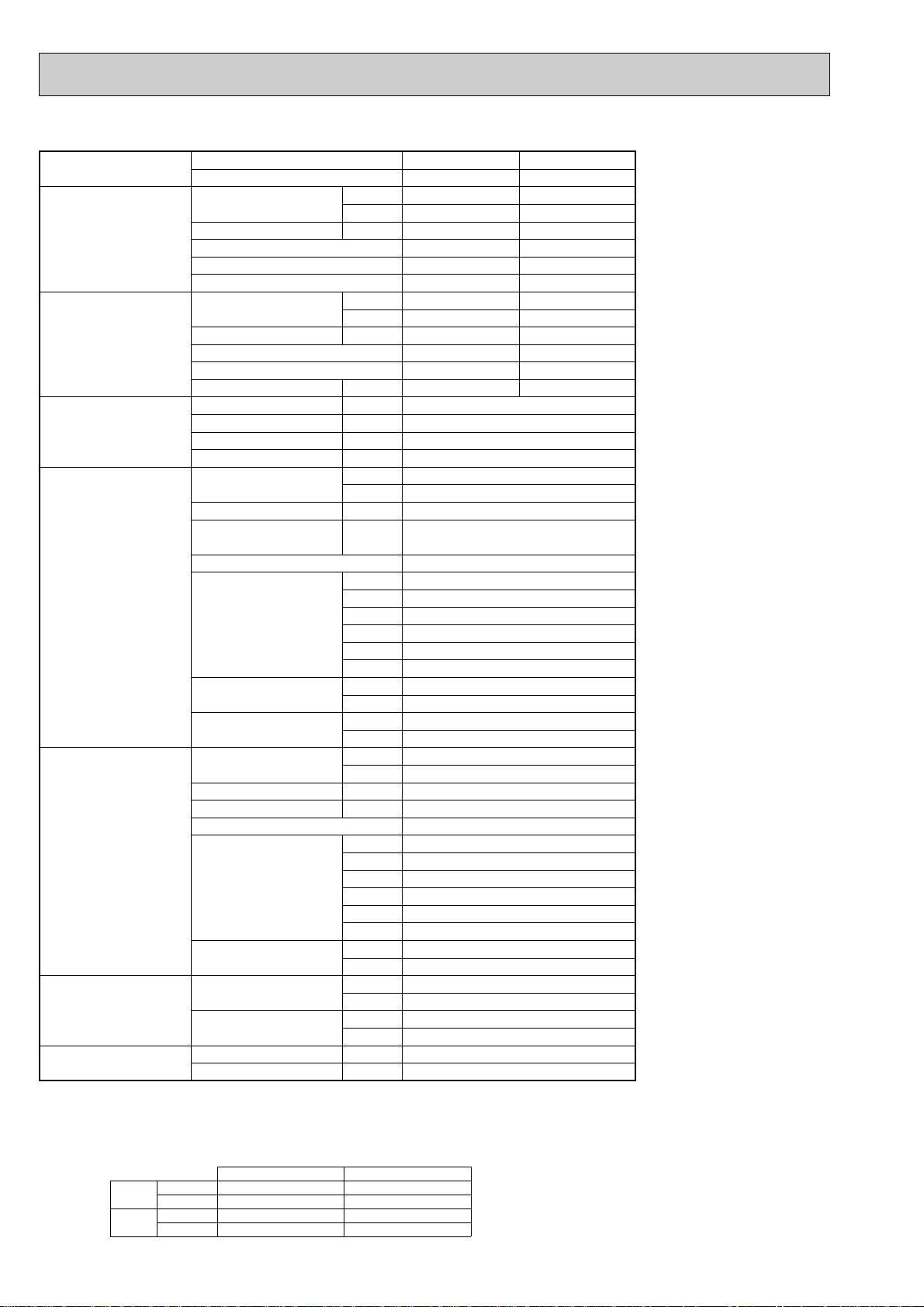

Model name Indoor unit PEAD-RP35EA PEAD-RP50EA

Outdoor unit PUHZ-RP35VHA PUHZ-RP50VHA

Cooling Capacity Btu/h 12,300 16,700

kW 3.6(1.6-4.5) 4.9(2.3-5.6)

Total input kW 1.12 1.52

EER 3.21 3.22

Energy label class A A

SHF 0.88 0.82

Heating Capacity Btu/h 14,000 20,500

kW 4.1(1.6-5.2) 6.0(2.5-7.3)

Total input kW 1.26 1.65

COP 3.25 3.64

Energy label class C A

Booster heater kW - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 16

Indoor unit Air flow CMM 11-14 13.5-17

(Low-High) CFM 388-494 476-600

External pressure Pa 30(70)

Sound level dB(A) 34-38 36-40

(Low-High) (70Pa : 36-43) (70Pa : 38-44)

External finish Galvanized sheets

Dimension W : mm 935

D : mm 700

H : mm 295

W : inch 36-13/16

D : inch 27-5/8

H : inch 11-5/8

Weight kg 33 35

lbs 73 77

Unit drain pipe R1(External thread)

Outdoor unit Air flow CMM 35

CFM 1,240

Sound level at cooling dB(A) 44

Sound level at heating dB(A) 46

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 800

D : mm 330+23

H : mm 600

W : inch 31-1/2

D : inch 13 + 7/8

H : inch 23-5/8

Weight kg 45

lbs 99

Refrigerant pipe size Gas side O.D. mm 12.7

inch 1/2

Liquid side O.D. mm 6.35

inch 1/4

Refrigerant pipe length Height difference m Max. 30

Length m Max. 50

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

7

Page 8

Indoor unit PEAD-RP60EA PEAD-RP71EA

Outdoor unit PUHZ-RP60VHA PUHZ-RP71VHA

Capacity Btu/h 20,500 24,200

kW 6.0(2.7-6.7) 7.1(3.3-8.1)

Total input kW 1.86 2.15

EER 3.23 3.30

Energy label class A A

SHF 0.79 0.83

Capacity Btu/h 23,900 27,300

kW 7.0(2.8-8.2) 8.0(3.5-10.2)

Total input kW 1.90 2.34

COP 3.68 3.42

Energy label class A B

Booster heater kW - Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 25

Air flow CMM 17-21 20-25

(Low-High) CFM 600-741 706-883

External pressure Pa 30(70) 70(130)

Sound level dB(A) 37-41 37-41

(Low-High) (70Pa : 39-46) (130Pa : 40-45)

External finish Galvanized sheets

Dimension W : mm 1175

D : mm 700

H : mm 295

W : inch 46-1/8

D : inch 27-5/8

H : inch 11-5/8

Weight kg 42 44

lbs 92 97

Unit drain pipe R1(External thread)

Air flow CMM 55 55

CFM 1,940 1,940

Sound level at cooling dB(A) 47 47

Sound level at heating dB(A) 48 48

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950 950

D : mm 330+30 330+30

H : mm 943 943

W : inch 37-3/8 37-3/8

D : inch 13 + 1-3/16 13 + 1-3/16

H : inch 37-1/8 37-1/8

Weight kg 75 75

lbs 165 165

Gas side O.D. mm 15.88 15.88

inch 5/8 5/8

Liquid side O.D. mm 9.52 9.52

inch 3/8 3/8

Height difference m Max. 30 Max. 30

Length m Max. 50 Max. 50

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

8

Single phase 230V 50Hz

Page 9

Model name Indoor unit PEAD-RP100EA PEAD-RP125EA PEAD-RP140EA

Outdoor unit PUHZ-RP100VHA PUHZ-RP125VHA PUHZ-RP140VHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 3.08 3.69 4.91

EER 3.25 3.39 2.85

Energy label class A A C

SHF 0.83 0.82 0.82

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.48 4.11 4.76

COP 3.22 3.41 3.36

Energy label class C B C

Booster heater kW - - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 32 40

Indoor unit Air flow CMM 27-34 33.5-42 36.5-46

(Low-High) CFM 953-1200 1183-1483 1288-1624

External pressure Pa 70(130)

Sound level dB(A) 41-46 44-50 46-51

(Low-High) (130Pa : 42-48) (130Pa : 46-52) (130Pa : 47-53)

External finish Galvanized sheets

Dimension W : mm 1415 1715

D : mm 700 740

H : mm 295 325

W : inch 55-11/16 67-1/2

D : inch 27-5/8 29-1/8

H : inch 11-5/8 12-13/16

Weight kg 62 65 70

lbs 136 143 154

Unit drain pipe R1(External thread)

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 121

lbs 267

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

9

Page 10

Model name Indoor unit PEAD-RP100EA PEAD-RP125EA PEAD-RP140EA

Outdoor unit PUHZ-RP100YHA PUHZ-RP125YHA PUHZ-RP140YHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 3.08 3.69 4.91

EER 3.25 3.39 2.85

Energy label class A A C

SHF 0.83 0.82 0.82

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.48 4.11 4.76

COP 3.22 3.41 3.36

Energy label class C B C

Booster heater kW - - -

Power supply Phase [ 3

Cycle Hz 50

Voltage V 400

Breaker size A 16

Indoor unit Air flow CMM 27-34 33.5-42 36.5-46

(Low-High) CFM 953-1200 1183-1483 1288-1624

External pressure Pa 70(130)

Sound level dB(A) 41-46 44-50 46-51

(Low-High) (130Pa : 42-48) (130Pa : 46-52) (130Pa : 47-53)

External finish Galvanized sheets

Dimension W : mm 1415 1715

D : mm 700 740

H : mm 295 325

W : inch 55-11/16 67-1/2

D : inch 27-5/8 29-1/8

H : inch 11-5/8 12-13/16

Weight kg 62 65 70

lbs 136 143 154

Unit drain pipe R1(External thread)

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 135

lbs 298

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -20˚C, W.B. -20˚C

3. Guaranteed voltage

Indoor unit 198~264V, 50Hz

Outdoor unit

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

342~457V, 50Hz

3 phase 400V 50Hz

10

Page 11

,

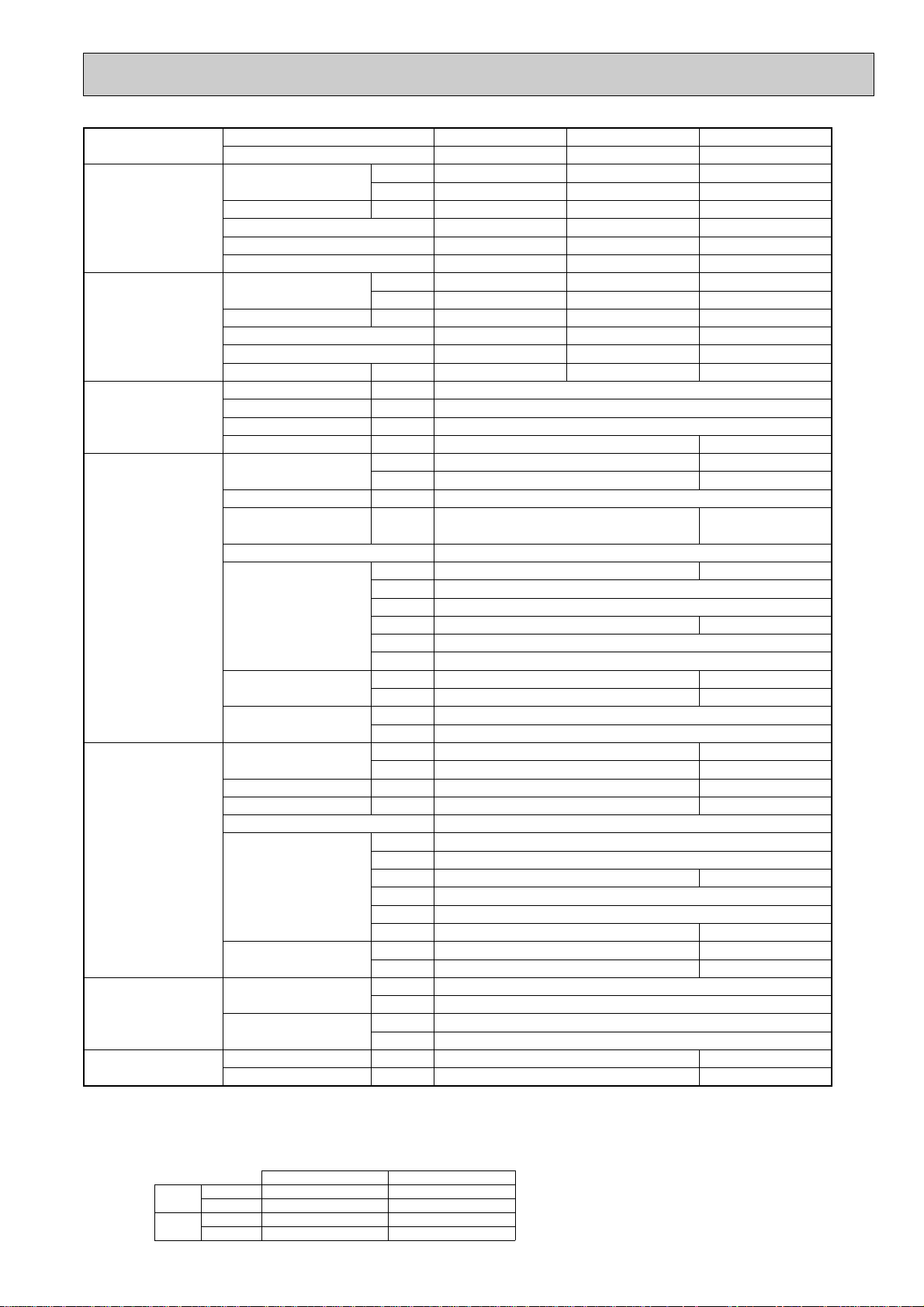

Model name Indoor unit PEAD-RP60GA PEAD-RP71GA PEAD-RP100GA

Outdoor unit PUHZ-RP60VHA PUHZ-RP71VHA PUHZ-RP100VHA

Cooling Capacity Btu/h 20,500 24,200 34,100

kW 6.0(2.7-6.7) 7.1(3.3-8.1) 10.0(4.9-11.4)

Total input kW 1.68 2.15 3.08

EER 3.57 3.30 3.25

Energy label class A A A

SHF 0.88 0.83 0.83

Heating Capacity Btu/h 23,900 27,300 38,200

kW 7.0(2.8-8.2) 8.0(3.5-10.2) 11.2(4.5-14.0)

Total input kW 1.77 2.34 3.48

COP 3.95 3.42 3.22

Energy label class A B C

Booster heater kW - - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 25 32

Indoor unit Air flow CMM 16.5-21 20-25 26.5-33

(Low-High) CFM 582-741 706-883 935-1165

External pressure Pa 10/50/70 10/50/70

Sound level dB(A) 33-37/35-40/36-42 35-38/37-41/37-43 40-43/42-45/42-46

(Low-High) (10/50/70Pa) (10/50/70Pa) (10/50/70Pa)

External finish Galvanized sheets

Dimension W : mm 1171 1411

D : mm 740

H : mm 275

W : inch 46-1/8 55-9/16

D : inch 29-1/8

H : inch 10-13/16

Weight kg 42 50

lbs 93 111

Unit drain pipe O.D. mm 32

inch 1-1/4

Outdoor unit Air flow CMM 55 100

CFM 1,940 3,530

Sound level at cooling dB(A) 47 49

Sound level at heating dB(A) 48 51

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 943 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 37-1/8 53-1/8

Weight kg 75 121

lbs 165 267

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30 Max. 30

Length m Max. 50 Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w1

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C w2

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w1. If optional Air protect guide installed. D.B.-15:

w2. For RP100 D.B. -20:

Single phase 230V 50Hz

W.B. -20:

11

Page 12

g

Model name Indoor unit PEAD-RP100GA

Outdoor unit PUHZ-RP100YHA

Cooling Capacity Btu/h 34,100

kW 10.0(4.9-11.4)

Total input kW 3.08

EER 3.25

Energy label class A

SHF 0.83

Heating Capacity Btu/h 38,200

kW 11.2(4.5-14.0)

Total input kW 3.48

COP 3.22

Energy label class C

Booster heater kW -

Power supply Phase [ 3

Cycle Hz 50

Voltage V 400

Breaker size A 16

Indoor unit Air flow CMM 26.5-33

(Low-High) CFM 935-1165

External pressure Pa 10/50/70

Sound level dB(A) 40-43/42-45/42-46

(Low-High) (10/50/70Pa)

External finish Galvanized sheets

Dimension W : mm 1411

D : mm 740

H : mm 275

W : inch 55-9/16

D : inch 29-1/8

H : inch 10-13/16

Weight kg 50

lbs 111

Unit drain pipe O.D. mm 32

inch 1-1/4

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49

Sound level at heating dB(A) 51

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 943

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 135

lbs 298

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect

12

Single phase 230V 50Hz

uide installed. D.B.-15:

Page 13

g

Model name Indoor unit PEA-RP71EA

Outdoor unit PUHZ-RP71VHA

Cooling Capacity Btu/h 24,200

kW 7.1(3.3-8.1)

Total input kW 2.48

EER 2.86

SRI 3.87

SHF 0.82

Heating Capacity Btu/h 27,300

kW 8.0(3.5-10.2)

Total input kW 2.47

COP 3.24

SRI 4.13

Booster heater kW -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 25

Indoor unit Air flow CMM 22-27

(Low-High) CFM 780-955

External pressure Pa 125

Sound level dB(A) 52-55

(Low-High)

External finish Galvanized sheets

Dimension W : mm 785

D : mm 690

H : mm 428

W : inch 31

D : inch 27-1/16

H : inch 16-7/8

Weight kg 46

lbs 101

Unit drain pipe R1(External thread)

Outdoor unit Air flow CMM 55

CFM 1,940

Sound level at cooling dB(A) 47

Sound level at heating dB(A) 48

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 943

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 37-1/8

Weight kg 75

lbs 165

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 50

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect

13

Single phase 230V 50Hz

uide installed. D.B.-15:

Page 14

Model name Indoor unit PEA-RP100EA PEA-RP125EA PEA-RP140EA

Outdoor unit PUHZ-RP100VHA PUHZ-RP125VHA PUHZ-RP140VHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 3.25 4.42 5.03

EER 3.08 2.83 2.78

SRI 4.60 3.77 3.60

SHF 0.82 0.81 0.89

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.2 4.30 4.73

COP 3.50 3.26 3.38

SRI 5.00 4.20 4.60

Booster heater kW - - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 32 40

Indoor unit Air flow CMM 27-34 34-42 48-60

(Low-High) CFM 955-1200 1200-1480 1695-2120

External pressure Pa 125

Sound level dB(A) 54-58 51-55

(Low-High)

External finish Galvanized sheets

Dimension W : mm 1055 1255 1415

D : mm 690

H : mm 428

W : inch 41-1/2 49-7/16 55-3/4

D : inch 27-1/16

H : inch 16-7/8

Weight kg 58 72 73

lbs 128 159 161

Unit drain pipe R1(External thread)

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 121

lbs 267

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

14

Page 15

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46:

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5: w

Heating

Upper limit

D.B. 28˚C

D.B. 21:, W.B. 15:

Lower limit

D.B. 17˚C

D.B. -20:, W.B. -20:

4. Above data based on indicated voltage

w If optional Air protect guide installed. D.B.-15:

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz

Outdoor unit

3. Guaranteed voltage

198~264V, 50Hz

Model name Indoor unit PEH-RP200MYA PEH-RP250MYA

Outdoor unit PUHZ-RP200YHA PUHZ-RP250YHA

Cooling Capacity Btu/h 64,800 75,000

kW 19.0(10.0-22.4) 22.0(12.5-28.0)

Total input kW 7.28 8.43

EER 2.61 2.61

Energy label class D D

SHF 0.75 0.82

Heating Capacity Btu/h 76,400 92,100

kW 22.4(10.0-25.0) 27.0(15.7-31.5)

Total input kW 6.98 8.41

COP 3.21 3.21

Energy label class C C

Booster heater kW - -

Power supply Phase [ 3

Cycle Hz 50

Voltage V 400

Breaker size A 32

Indoor unit Air flow CMM 60 80

CFM 2120 2825

External pressure Pa 50/150

Sound level dB(A) 49 53

(50Pa) (50Pa)

External finish Galvanizing

Dimension W : mm 1380 1580

D : mm 650

H : mm 428

W : inch 54-5/16 62-3/16

D : inch 25-9/16

H : inch 16-7/8

Weight kg 70 80

lbs 154 176

Unit drain pipe RC1

Outdoor unit Air flow CMM 150

CFM 5,300

Sound level at cooling dB(A) 55 58

Sound level at heating dB(A) 56 58

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 900

D : mm 750

H : mm 1798

W : inch 35-7/16

D : inch 29-17/32

H : inch 70-25/32

Weight kg 198

lbs 436

Refrigerant pipe size Gas side O.D. mm 25.4 28.58

inch 1 1-1/8

Liquid side O.D. mm 9.52 12.7

inch 3/8 1/2

Refrigerant pipe length Height difference m Max. 40

Length m Max. 120

15

Page 16

2-3. WALL-MOUNTED TYPE

Model name Indoor unit PKA-RP35GAL PKA-RP50GAL

Outdoor unit PUHZ-RP35VHA PUHZ-RP50VHA

Cooling Capacity Btu/h 12,300 15,700

kW 3.6(1.6-4.5) 4.6(2.3-5.4)

Total input kW 1.03 1.63

EER 3.50 2.82

Energy label class A C

SHF 0.84 0.74

Heating Capacity Btu/h 14,000 15,400

kW 4.1(1.6-5.2) 4.5(2.5-6.2)

Total input kW 1.27 1.40

COP 3.23 3.21

Energy label class C C

Booster heater kW - -

Power supply Phase

Cycle Hz 50

Voltage V 230

Breaker size A 16

Indoor unit Air flow CMM 9-10-11-12

(Low-Medium2-Medium1-High) CFM 320-355-390-425

External pressure Pa 0

Sound level dB(A) 36-38-41-43

(Low-Medium2-Medium1-High)

External finish White Munsell 0.70Y 8.59/0.97

Dimension W : mm 990

Weight kg 16

Unit drain pipe O.D. mm 20

Outdoor unit Air flow CMM 35

Sound level at cooling dB(A) 44

Sound level at heating dB(A) 46

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 800

Weight kg 45

Refrigerant pipe size Gas side O.D. mm 12.7

Liquid side O.D. mm 6.35

Refrigerant pipe length Height difference m Max. 30

Length m Max. 50

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

[ 1

D : mm 235

H : mm 340

W : inch 39

D : inch 9-1/4

H : inch 13-3/8

lbs 35

inch 13/16

CFM 1,240

D : mm 330+23

H : mm 600

W : inch 31-1/2

D : inch 13 + 7/8

H : inch 23-5/8

lbs 99

inch 1/2

inch 1/4

3. Guaranteed voltage

198~264V, 50Hz

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

16

Page 17

Model name Indoor unit PKA-RP60FAL PKA-RP71FAL PKA-RP100FAL

Outdoor unit PUHZ-RP60VHA PUHZ-RP71VHA PUHZ-RP100VHA

Cooling Capacity Btu/h 20,500 24,200 34,100

kW 6.0(2.7-6.7) 7.1(3.3-8.1) 10.0(4.9-11.4)

Total input kW 1.55 1.98 2.93

EER 3.87 3.59 3.41

Energy label class A A A

SHF 0.83 0.77 0.77

Heating Capacity Btu/h 23,900 27,300 38,200

kW 7.0(2.8-8.2) 8.0(3.5-10.2) 11.2(4.5-14.0)

Total input kW 2.01 2.40 3.25

COP 3.48 3.33 3.45

Energy label class B C B

Booster heater kW - - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 25 32

Indoor unit Air flow CMM 15-20 22-28

(Low-High) CFM 530-705 780-990

External pressure Pa 0

Sound level dB(A) 39-45 41-46

(Low-High)

External finish Munsell 3.4Y 7.7/0.8

Dimension W : mm 1400 1680

D : mm 235

H : mm 340

W : inch 55-1/8 66-1/8

D : inch 9-1/4

H : inch 13-3/8

Weight kg 24 28

lbs 53 62

Unit drain pipe O.D. mm 20

inch 13/16

Outdoor unit Air flow CMM 55 100

CFM 1,940 3,530

Sound level at cooling dB(A) 47 49

Sound level at heating dB(A) 48 51

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 943 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 37-1/8 53-1/8

Weight kg 75 121

lbs 165 267

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30 Max. 30

Length m Max. 50 Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w1

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C w2

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w1. If optional Air protect guide installed. D.B.-15:

w2. For RP100 D.B. -20:, W.B. -20:

Single phase 230V 50Hz

17

Page 18

Model name Indoor unit PKA-RP100FAL

Outdoor unit PUHZ-RP100YHA

Cooling Capacity Btu/h 34,100

kW 10.0(4.9-11.4)

Total input kW 2.93

EER 3.41

Energy label class A

SHF 0.77

Heating Capacity Btu/h 38,200

kW 11.2(4.5-14.0)

Total input kW 3.25

COP 3.45

Energy label class B

Booster heater kW -

Power supply Phase 3

Cycle Hz

[

50

Voltage V 400

Breaker size A 16

Indoor unit Air flow CMM 22-28

(Low-High) CFM 780-990

External pressure Pa 0

Sound level dB(A) 41-46

(Low-High)

External finish Munsell 3.4Y 7.7/0.8

Dimension W : mm 1680

D : mm 235

H : mm 340

W : inch 66-1/8

D : inch 9-1/4

H : inch 13-3/8

Weight kg 28

lbs 62

Unit drain pipe O.D. mm 20

inch 13/16

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49

Sound level at heating dB(A) 51

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 135

lbs 298

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

w If optional Air protect guide installed. D.B.-15:

18

Indoor unit Single phase 230V 50Hz

Outdoor unit

Single phase 230V 50Hz

Page 19

2-4. CEILING-SUSPENDED TYPE

Model name Indoor unit PCA-RP50GA PCA-RP60GA PCA-RP71GA

Outdoor unit PUHZ-RP50VHA PUHZ-RP60VHA PUHZ-RP71VHA

Cooling Capacity Btu/h 16,000 20,500 24,200

kW 4.7(2.3-5.4) 6.0(2.7-6.7) 7.1(3.3-8.1)

Total input kW 1.67 1.63 2.14

EER 2.81 3.68 3.32

Energy label class C A A

SHF 0.76 0.81 0.74

Heating Capacity Btu/h 18,800 23,900 27,300

kW 5.5(2.5-6.6) 7.0(2.8-8.2) 8.0(3.5-10.2)

Total input kW 1.71 2.03 2.43

COP 3.22 3.45 3.29

Energy label class C B C

Booster heater kW - - -

Power supply Phase

Cycle Hz 50

Voltage V 230

Breaker size A 16 25

Indoor unit Air flow CMM 10-11-12-13 14-15-16-18

(Low-Medium2-Medium1-High) CFM 355-390-425-460 495-530-565-635

External pressure Pa 0 0

Sound level dB(A) 37-38-40-42 37-39-41-43

(Low-Medium2-Medium1-High)

External finish White Munsell 0.70Y 8.59/0.97

Dimension W : mm 1000 1310

Weight kg 27 34

Unit drain pipe I.D. mm 26

Outdoor unit Air flow CMM 35 55

Sound level at cooling dB(A) 44 47

Sound level at heating dB(A) 46 48

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 800 950

Weight kg 45 75

Refrigerant pipe size Gas side O.D. mm 12.7 15.88

Liquid side O.D. mm 6.35 9.52

Refrigerant pipe length Height difference m Max. 30 Max. 30

Length m Max. 50 Max. 50

[ 1

D : mm 680

H : mm 210

W : inch 39-3/8 51-9/16

D : inch 26-3/4

H : inch 8-1/4

lbs 60 75

inch 1

CFM 1,240 1,940

D : mm 330+23 330+30

H : mm 600 943

W : inch 31-1/2 37-3/8

D : inch 13 + 7/8 13 + 1-3/16

H : inch 23-5/8 37-1/8

lbs 99 165

inch 1/2 5/8

inch 1/4 3/8

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

19

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

Page 20

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46:

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5: w

Heating

Upper limit

D.B. 28˚C

D.B. 21:, W.B. 15:

Lower limit

D.B. 17˚C

D.B. -20:, W.B. -20:

4. Above data based on indicated voltage

w If optional Air protect guide installed. D.B.-15:

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz

Outdoor unit

3. Guaranteed voltage

198~264V, 50Hz

Model name Indoor unit PCA-RP100GA PCA-RP125GA PCA-RP140GA

Outdoor unit PUHZ-RP100VHA PUHZ-RP125VHA PUHZ-RP140VHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 2.92 3.89 4.96

EER 3.42 3.21 2.82

Energy label class A A C

SHF 0.75 0.77 0.74

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.26 4.34 4.60

COP 3.44 3.23 3.48

Energy label class B C B

Booster heater kW - - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 32 40

Indoor unit Air flow CMM 20-21-23-25 27-30-32-34

(Low-Medium2-Medium1-High) CFM 705-840-810-885 955-1060-1130-1200

External pressure Pa 0 0

Sound level dB(A) 40-41-43-45 41-43-45-46 42-44-46-48

(Low-Medium2-Medium1-High)

External finish White Munsell 0.70Y 8.59/0.97

Dimension W : mm 1310 1620

D : mm 680

H : mm 270

W : inch 51-9/16 63-3/4

D : inch 26-3/4

H : inch 10-5/8

Weight kg 37 43 45

lbs 82 95 99

Unit drain pipe I.D. mm 26

inch 1

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 121

lbs 267

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

20

Page 21

Model name Indoor unit PCA-RP100GA PCA-RP125GA PCA-RP140GA

Outdoor unit PUHZ-RP100YHA PUHZ-RP125YHA PUHZ-RP140YHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 2.92 3.89 4.96

EER 3.42 3.21 2.82

Energy label class A A C

SHF 0.75 0.77 0.74

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.26 4.34 4.60

COP 3.44 3.23 3.48

Energy label class B C B

Booster heater kW - - -

Power supply Phase [ 3

Cycle Hz 50

Voltage V 400

Breaker size A 16

Indoor unit Air flow CMM 20-21-23-25 27-30-32-34

(Low-Medium2-Medium1-High) CFM 705-840-810-885 955-1060-1130-1200

External pressure Pa 0 0

Sound level dB(A) 40-41-43-45 41-43-45-46 42-44-46-48

(Low-Medium2-Medium1-High)

External finish White Munsell 0.70Y 8.59/0.97

Dimension W : mm 1310 1620

D : mm 680

H : mm 270

W : inch 51-9/16 63-3/4

D : inch 26-3/4

H : inch 10-5/8

Weight kg 37 43 45

lbs 82 95 99

Unit drain pipe I.D. mm 26

inch 1

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 135

lbs 298

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

21

Page 22

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Upper limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 46˚C

Lower limit

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w1

Heating

Upper limit

D.B. 28˚C

D.B. 21˚C, W.B. 15˚C

Lower limit

D.B. 17˚C

D.B. -11˚C, W.B. -12˚C w2

4. Above data based on indicated voltage

w1. If optional Air protect guide installed. D.B.-15:

w2. For RP125 D.B. -20:, W.B. -20:

Indoor unit Single phase 230V 50Hz

Single phase 230V 50Hz

Outdoor unit

3. Guaranteed voltage

198~264V, 50Hz

Model name Indoor unit PCA-RP71HA PCA-RP125HA PCA-RP125HA

Outdoor unit PUHZ-RP71VHA PUHZ-RP125VHA PUHZ-RP125YHA

Cooling Capacity Btu/h 24,200 42,700 42,700

kW 7.1(3.3-8.1) 12.5(5.5-14.0) 12.5(5.5-14.0)

Total input kW 2.21 4.15 4.15

EER 3.21 3.01 3.01

Energy label class A B B

SHF 0.74 0.77 0.77

Heating Capacity Btu/h 27,300 47,800 47,800

kW 8.0(3.5-10.2) 14.0(5.0-16.0) 14.0(5.0-16.0)

Total input kW 2.49 4.25 4.25

COP 3.21 3.29 3.29

Energy label class C C C

Booster heater kW - - -

Power supply Phase [ 13

Cycle Hz 50 50

Voltage V 230 400

Breaker size A 322525 16

Indoor unit Air flow CMM 17-19 30-38

(Low-High) CFM 600-670 1060-1350

External pressure Pa 0 0

Sound level dB(A) 34-38 44-50

(Low-High)

External finish Stainless steel

Dimension W : mm 1136 1520

D : mm 650

H : mm 280

W : inch 44-3/4 59-7/8

D : inch 25-5/8

H : inch 11

Weight kg 41 56

lbs 90 124

Unit drain pipe I.D. mm 26

inch 1

Outdoor unit Air flow CMM 55 100

CFM 1,940 3,530

Sound level at cooling dB(A) 47 50

Sound level at heating dB(A) 48 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950 950

D : mm 330+30 330+30

H : mm 943 1350

W : inch 37-3/8 37-3/8

D : inch 13 + 1-3/16 13 + 1-3/16

H : inch 37-1/8 53-1/8

Weight kg 75 121 135

lbs 165 267 298

Refrigerant pipe size Gas side O.D. mm 15.88 15.88

inch 5/8 5/8

Liquid side O.D. mm 9.52 9.52

inch 3/8 3/8

Refrigerant pipe length Height difference m Max. 30 Max. 30

Length m Max. 50 Max. 75

22

Page 23

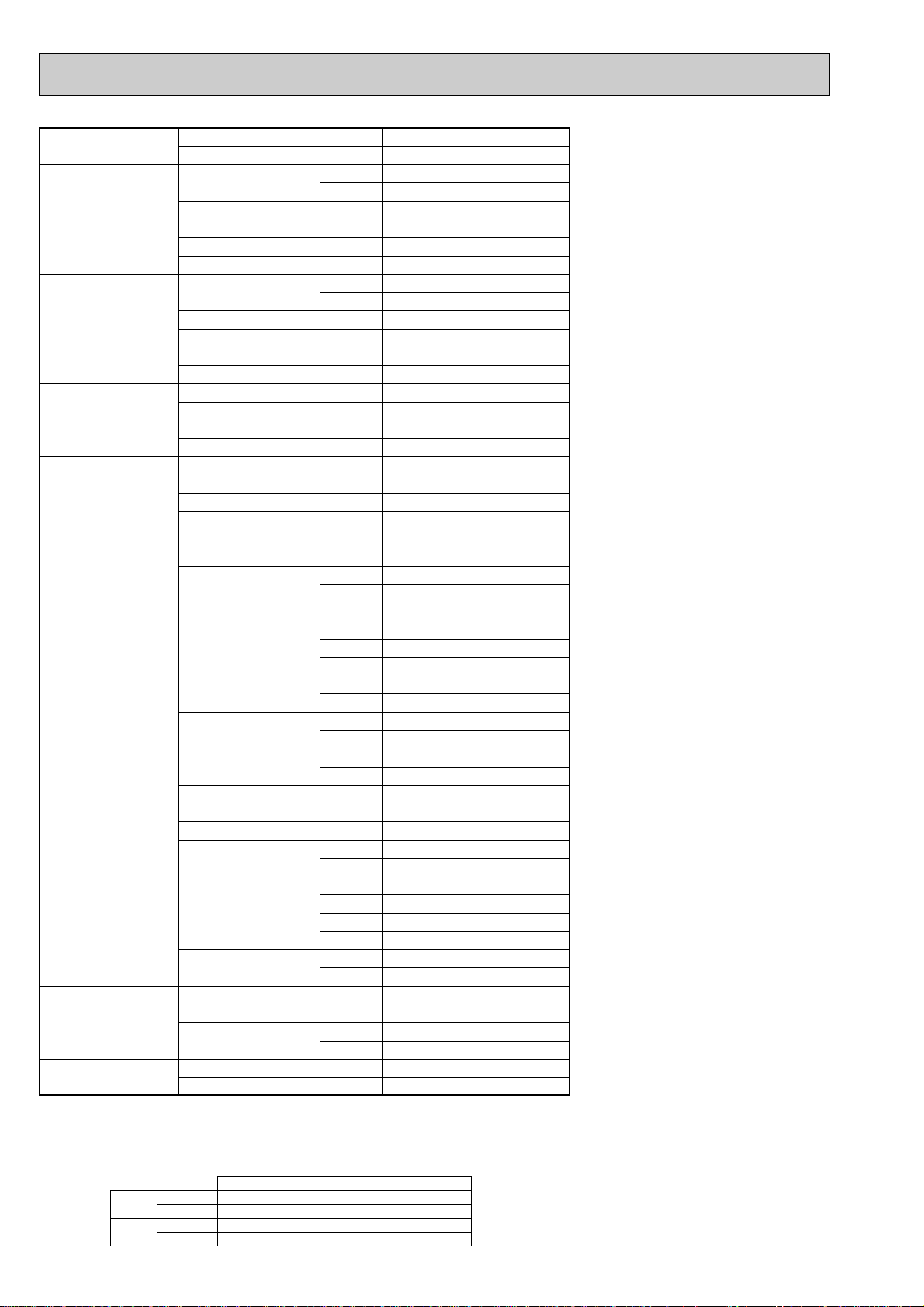

2-5. FLOOR STANDING TYPE

Model name Indoor unit PSA-RP71GA

Outdoor unit PUHZ-RP71VHA

Cooling Capacity Btu/h 24,200

kW 7.1(3.3-8.1)

Total input kW 2.20

EER 3.23

Energy label class A

SHF 0.73

Heating Capacity Btu/h 27,300

kW 8.0(3.5-10.2)

Total input kW 2.49

COP 3.21

Energy label class C

Booster heater kW -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 25

Indoor unit Air flow CMM 15-18

(Low-High) CFM 530-635

External pressure Pa 0

Sound level dB(A) 40-45

(Low-High)

External finish White Munsell 0.70Y 8.59/0.97

Dimension W : mm 600

D : mm 270

H : mm 1900

W : inch 23-5/8

D : inch 10-5/8

H : inch 74-13/16

Weight kg 43

lbs 98

Unit drain pipeO.D. mm 20

inch 13/16

Outdoor unit Air flow CMM 55

CFM 1,940

Sound level at cooling dB(A) 47

Sound level at heating dB(A) 48

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 943

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 37-1/8

Weight kg 75

lbs 165

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 50

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5˚C w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

23

Page 24

Model name Indoor unit PSA-RP100GA PSA-RP125GA PSA-RP140GA

Outdoor unit PUHZ-RP100VHA PUHZ-RP125VHA PUHZ-RP140VHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 2.99 4.15 4.98

EER 3.34 3.01 2.81

Energy label class A B C

SHF 0.81 0.75 0.73

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.28 4.36 4.98

COP 3.41 3.21 3.21

Energy label class B C C

Booster heater kW - - -

Power supply Phase [ 1

Cycle Hz 50

Voltage V 230

Breaker size A 32 40

Indoor unit Air flow CMM 24-31 26-33 27-35

(Low-High) CFM 850-1060 920-1165 955-1240

External pressure Pa 0

Sound level dB(A) 44-49 46-51 47-52

(Low-High)

External finish White Munsell 0.70Y 8.59/0.97

Dimension W : mm 600

D : mm 350

H : mm 1900

W : inch 23-5/8

D : inch 13-3/4

H : inch 74-13/16

Weight kg 51 53

lbs 112 117

Unit drain pipeO.D. mm 20

inch 13/16

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 121

lbs 267

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

24

Page 25

Model name Indoor unit PSA-RP100GA PSA-RP125GA PSA-RP140GA

Outdoor unit PUHZ-RP100YHA PUHZ-RP125YHA PUHZ-RP140YHA

Cooling Capacity Btu/h 34,100 42,700 47,800

kW 10.0(4.9-11.4) 12.5(5.5-14.0) 14.0(5.5-15.3)

Total input kW 2.99 4.15 4.98

EER 3.34 3.01 2.81

Energy label class A B C

SHF 0.81 0.75 0.73

Heating Capacity Btu/h 38,200 47,800 54,600

kW 11.2(4.5-14.0) 14.0(5.0-16.0) 16.0(5.0-18.0)

Total input kW 3.28 4.36 4.98

COP 3.41 3.21 3.21

Energy label class B C C

Booster heater kW - - -

Power supply Phase [ 3

Cycle Hz 50

Voltage V 400

Breaker size A 16

Indoor unit Air flow CMM 24-31 26-33 27-35

(Low-High) CFM 850-1060 920-1165 955-1240

External pressure Pa 0

Sound level dB(A) 44-49 46-51 47-52

(Low-High)

External finish White Munsell 0.70Y 8.59/0.97

Dimension W : mm 600

D : mm 350

H : mm 1900

W : inch 23-5/8

D : inch 13-3/4

H : inch 74-13/16

Weight kg 51 51 53

lbs 112 112 117

Unit drain pipe O.D. mm 20

inch 13/16

Outdoor unit Air flow CMM 100

CFM 3,530

Sound level at cooling dB(A) 49 50

Sound level at heating dB(A) 51 52

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm 950

D : mm 330+30

H : mm 1350

W : inch 37-3/8

D : inch 13 + 1-3/16

H : inch 53-1/8

Weight kg 135

lbs 298

Refrigerant pipe size Gas side O.D. mm 15.88

inch 5/8

Liquid side O.D. mm 9.52

inch 3/8

Refrigerant pipe length Height difference m Max. 30

Length m Max. 75

NOTE: 1. Rating conditions (ISO T1)

Cooling Indoor : D.B. 27: (80˚F) W.B. 19: (66˚F) Outdoor : D.B. 35: (95˚F) W.B. 24: (75˚F)

Heating Indoor: D.B. 20: (68˚F) Outdoor : D.B. 7: (45˚F) W.B. 6: (43˚F)

Refrigerant piping length (one way) : 5m (16ft.)

2. Guaranteed operating range

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C D.B. -5: w

D.B. 28˚C

D.B. 17˚C

Indoor Outdoor

D.B. 46:

D.B. 21:, W.B. 15:

D.B. -20:, W.B. -20:

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor unit Single phase 230V 50Hz

Outdoor unit

w If optional Air protect guide installed. D.B.-15:

Single phase 230V 50Hz

25

Page 26

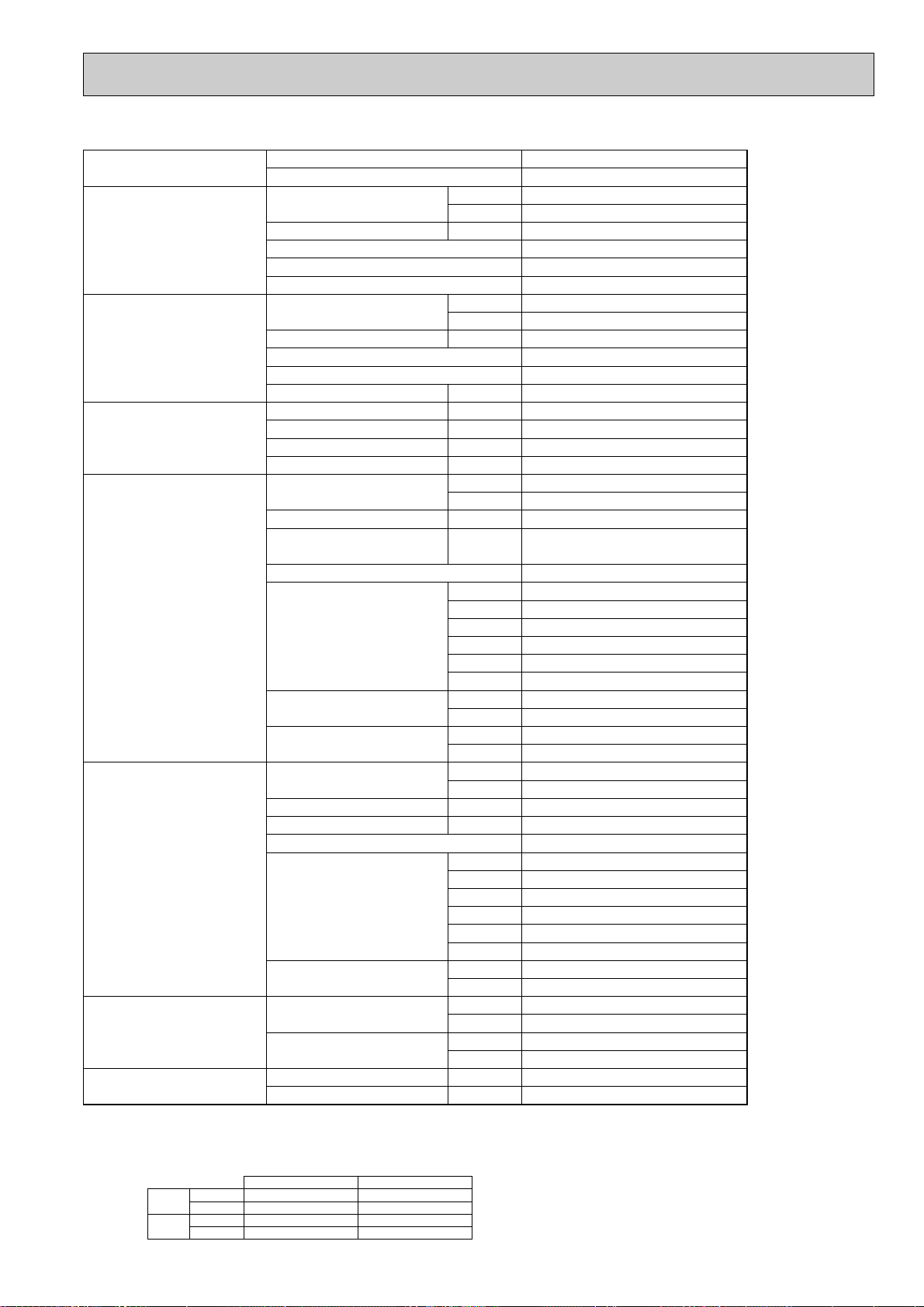

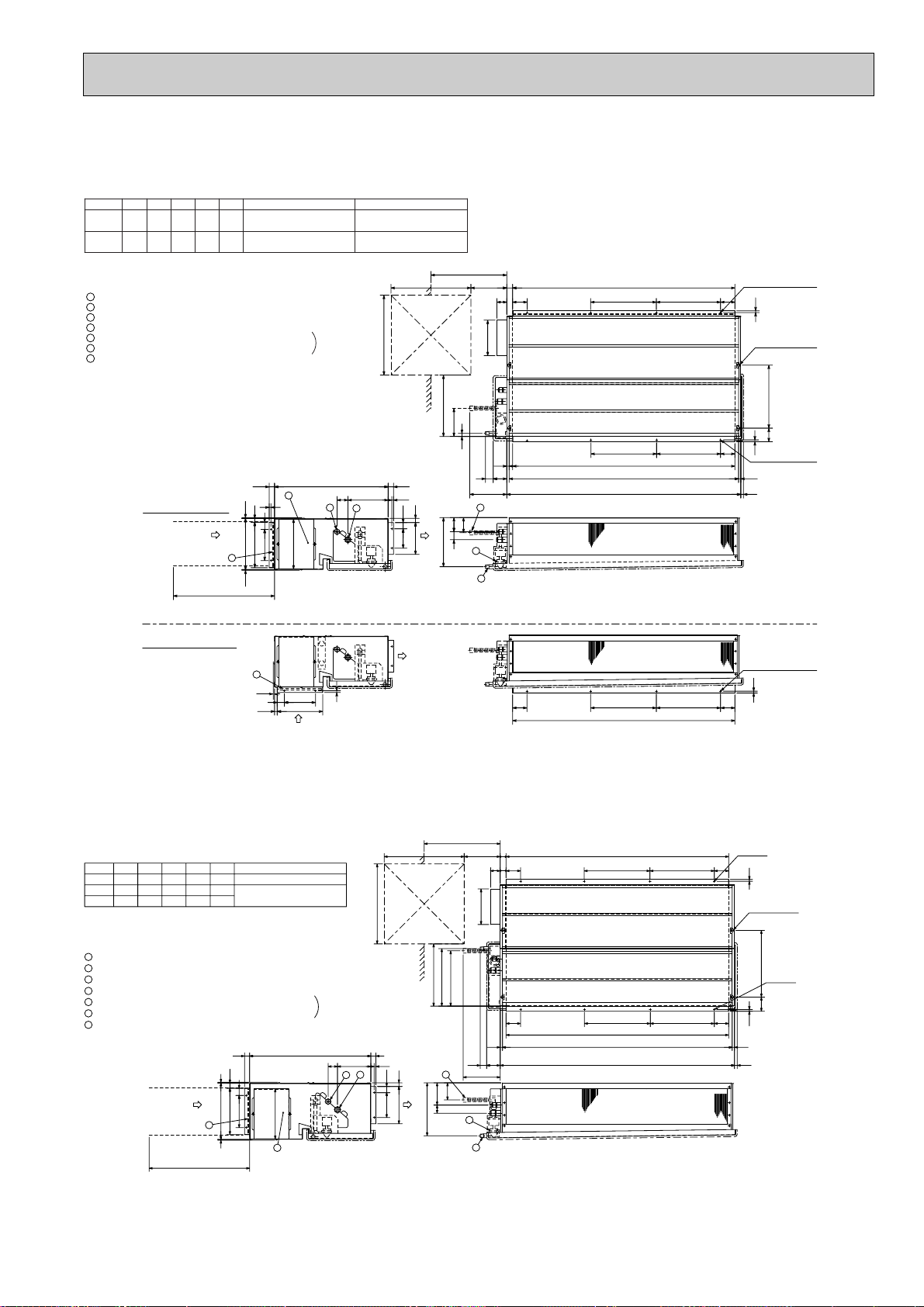

3

PLA-RP60,71AA

PLA-RP35,50AA

Models

PLA-RP100,125,140AA

241

281

A

258

298

B

80

84

C

Receiver

Operation lamp

DEFROST/STAND BY lamp

Emergency operation switch (cooling)

A

(WIRELESS PANEL)

Emergency operation switch (heating)

Branch duct hole

(Cut out hole)

{175

{150

14 - {2.8

Burring hole

350

90

70

_

100 100 90

100

130

155

167

Suspension bolt pitch

Ceiling hole

Branch

duct hole

Suspension bolt pitch

Ceiling hole

840

197 159

159

605

159192

98

89

C

840

860 - 91020 - 45 20 - 45

20 - 4520 - 45

Fresh air intake

Branch duct hole

860 - 910

810

159

16

Terminal block

Drain pipe

VP-25connection

(O.D.{32)

Ceiling surface

Power line entry

Suspension bolt lower edge

Suspension bolt M10

or W3/8

Control wire entry

Feeding hole

(Drain pump)

37428660

17

+5

0

30

190

170

140

50 - 70

105

A

B

1

2

High efficiency filter

& Fresh air intake casement (option)

17

+5

0

135

Air outlet hole

Vane motor

Auto vane

Drain hole

Grille

Air outlet hole

Air intake hole

411

Air intake hole

Air intake grille

577

77 51

M

M

M

A

M

950

51 77

950

577

411

RP35, 50

Use the current nuts meeting the pipe size of the outdoor unit.

Available pipe size

Factory flare nut attachment to the heat-exchanger.

1 LIQUID SIDE

2 GAS SIDE

RP60 RP71

[6.35 [6.35 — —

[9.52 [9.52 [9.52 [9.52

[12.7 — — —

[15.88 [15.88 [15.88 [15.88

———[19.05

RP100, 125, 140

Detail drawing of fresh air intake

3 - {2.8

Burring hole

{125

Burring hole pitch

{100

(Cut out hole)

Ceiling surface

120

_

120_

158

OUTLINES AND DIMENSIONS

INDOOR UNIT

PLA-RP35AA PLA-RP50AA PLA-RP60AA PLA-RP71AA

PLA-RP100AA PLA-RP125AA PLA-RP140AA

Unit : mm

26

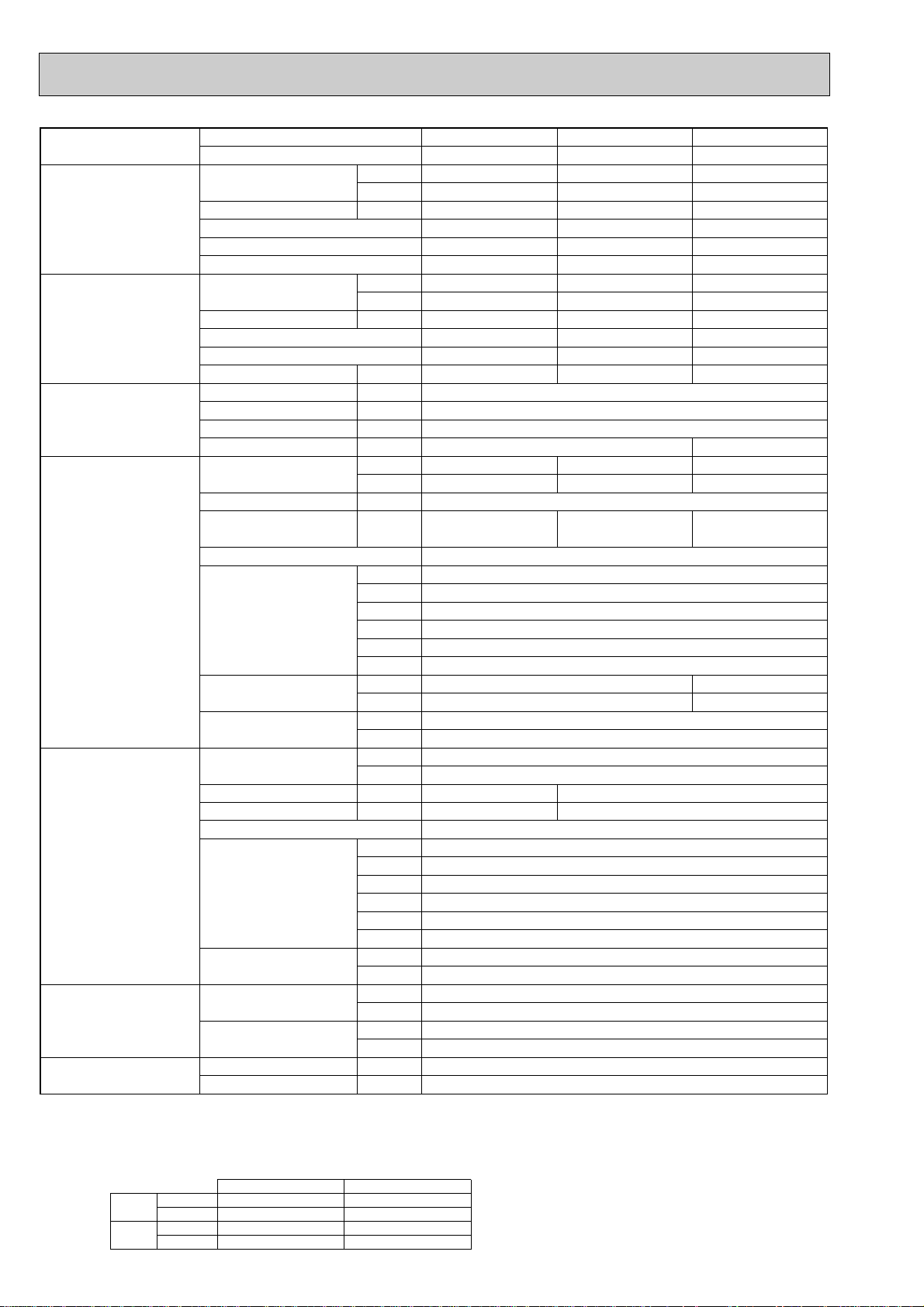

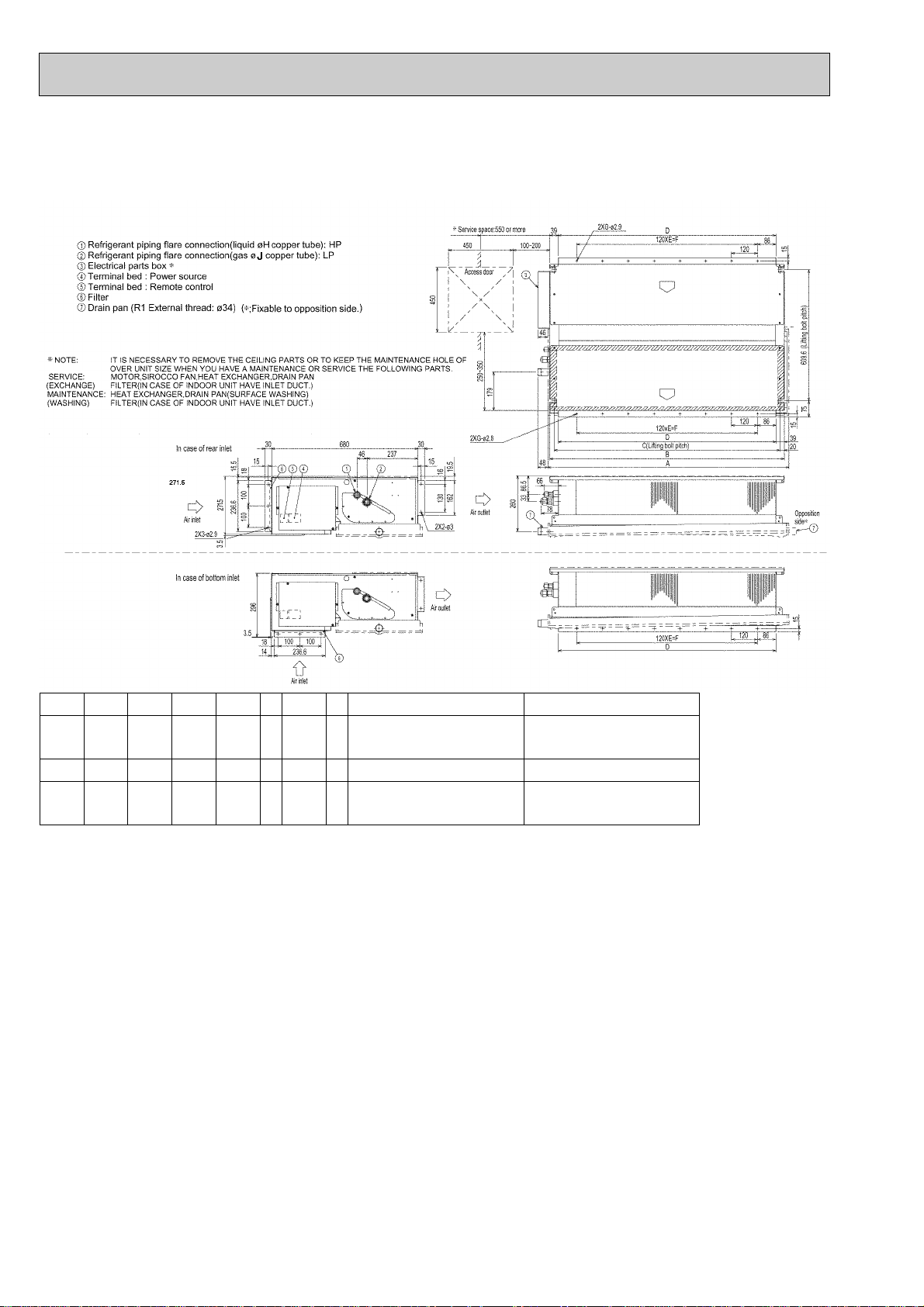

Page 27

PEAD-RP35EA

2

1

3

4

5

6

7

Refrigerant piping flare connection (liquid [ F copper tube):HP

Refrigerant piping flare connection (gas [G copper tube):LP

Drain R1(External thread)

Electrical parts box

Drain Pump (Option)

Drain Pipe (Option) ... Flexible joint VP-25(I.D.

[

32)

Filter

R407C Outdoor unit : 9.52

F

R410A Outdoor unit : 6.35 w

R407C Outdoor unit : 9.52 w

Outdoor unit (SUZ) : 6.35

EDCBA

804830

-

305772

Model

RP60

R407C Outdoor unit : 15.88

G

R410A Outdoor unit : 12.7 w

15.88

104410702902801012

RP35,50

w Setting at shipment

2

1

3

4

Air inlet

Air outlet

Access door

55

50~150

81

197

Service space:500 or more

Keep duct-work length 850mm or more.

Be sure to apply the air filter

near the air inlet grille.

5

6

75

44

18

365~465

B 81

10

56 355

7

159

243

Air outlet

Air inlet

7

Lifting bolt hole

(14×22)

10- [3 (RP35,50)

12-

[

3 (RP60)

In case of rear inlet

In case of bottom inlet

10- [3 (RP35,50)

12-

[

3 (RP60)

D

30

C

10

81BC

A

450

450

10- [3 (RP35,50)

12-

[

3 (RP60)

176

40

288

256

3.5

3.5

10

109

179

10

35

24

30640

30

21

277

80

45

282

13

13E

A

61 227

29

85

40

176

10

15

3.5

256

BC 81

10

81

A

Set

R407C outdoor unit : 19.05158416104704601552RP140

15.8810441070290

F

R410A Outdoor unit : 15.88 w

EDCBA

12841310370360

2801012

1252

Model

RP100,125

RP71

w

Setting at shipment

7

44

243

308

323

75

6

5

13

Refrigerant piping flare connection (liquid [9.52 copper tube):HP

Refrigerant piping flare connection (gas [F copper tube):LP

Drain R1 (External thread)

Electrical parts box

Drain Pump (Option)

Drain Pipe (Option) ... Flexible joint VP25(I.D.[32)

Filter

Service space:500 or more

81

365~465

197

81

50~150

55

29

Access door

Air outlet

Air inlet

4

3

1

2

7

6

5

4

3

2

1

113

307

122

12-[3

(14x22)

Lifting bolt hole

45

Set

210

12-[3

450

450

140

282

680

3.5

3.5

30

319

261

181

40

30

A

C B

81

10

375

10

80

C B 81

A

E 13

30D

20

35

30

1053 169

Keep duct-work length 850mm or more.

Be sure to apply the air filter

near the air inlet grille.

PEAD-RP50EA

PEAD-RP60EA

Unit : mm

PEAD-RP71EA

PEAD-RP100EA

PEAD-RP125EA

PEAD-RP140EA

27

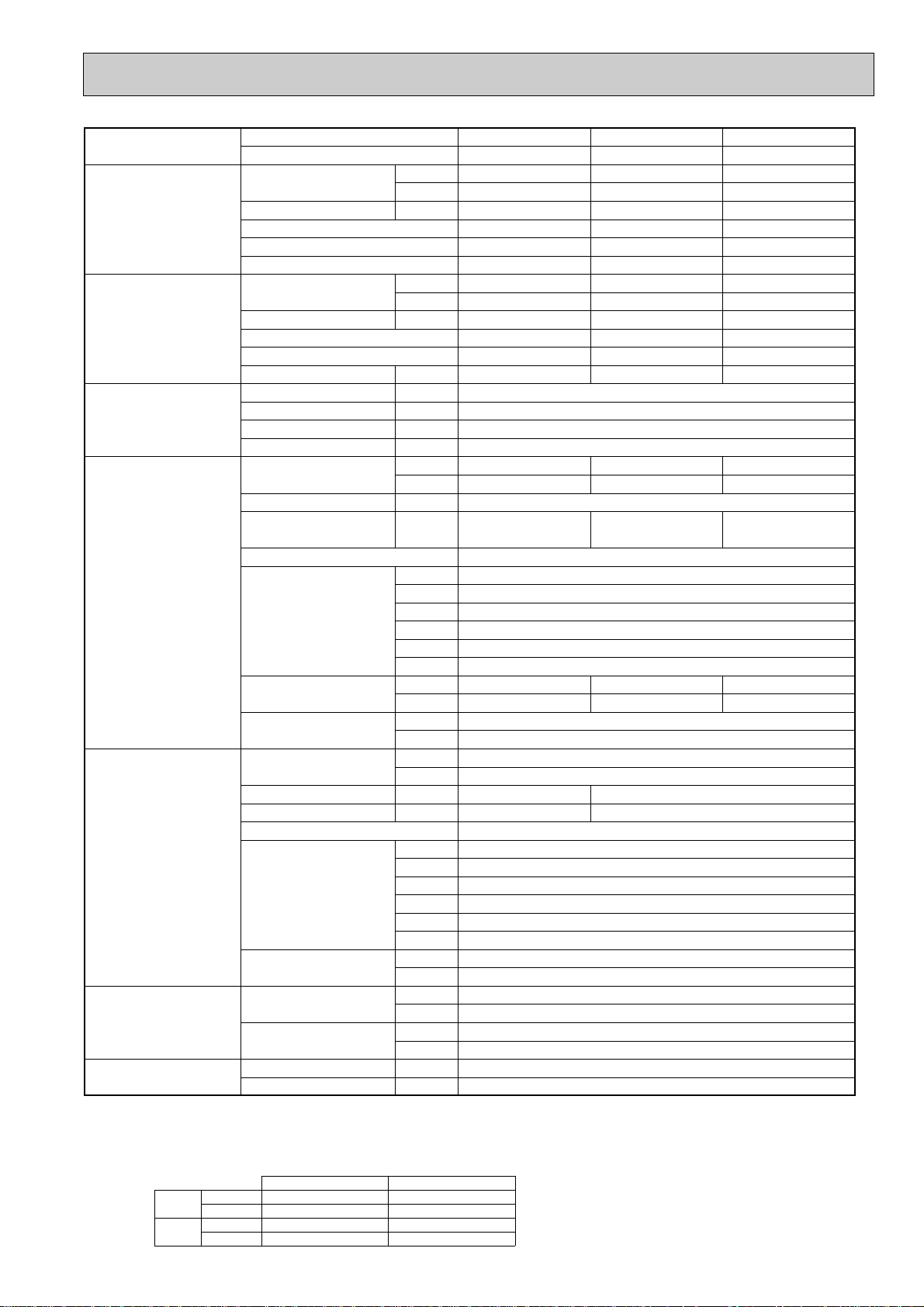

Page 28

PEAD-RP60GA

Model

ABCDE

7

7

9

8

9.52

9.52

15.88

15.88

8

10

FG H J

RP60

RP71

RP100

1125

1125

1365

1090

1090

1330

1050

1050

1290

1012

1012

1252

840

840

1080

Outdoor unit(SUZ) : 6.35

Other outdoor unit : 9.52 w

R410A Outdoor unit : 15.88 w

R407C Outdoor unit : 19.05

w Setting at shipment

PEAD-RP71GA

PEAD-RP100GA

Unit : mm

28

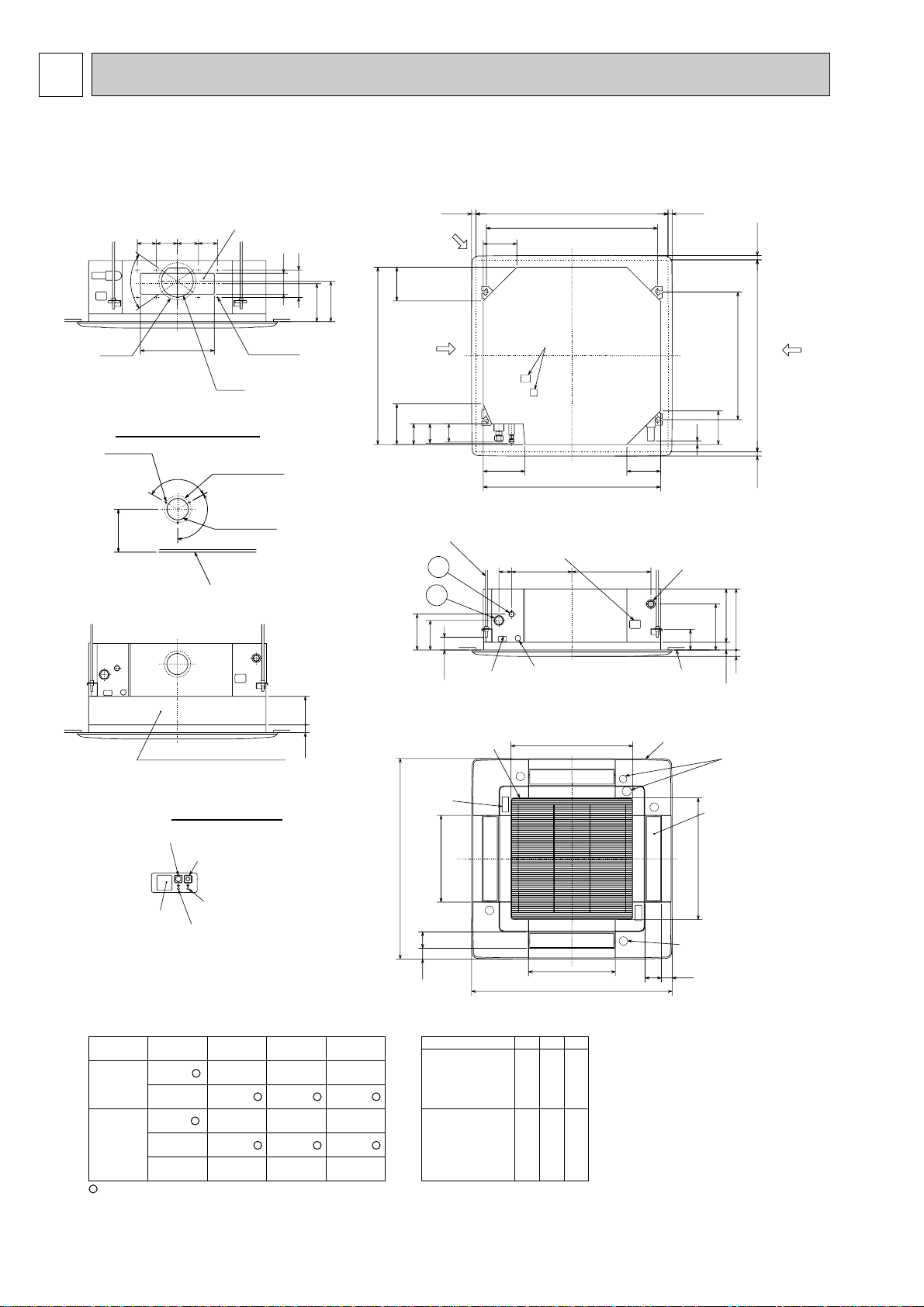

Page 29

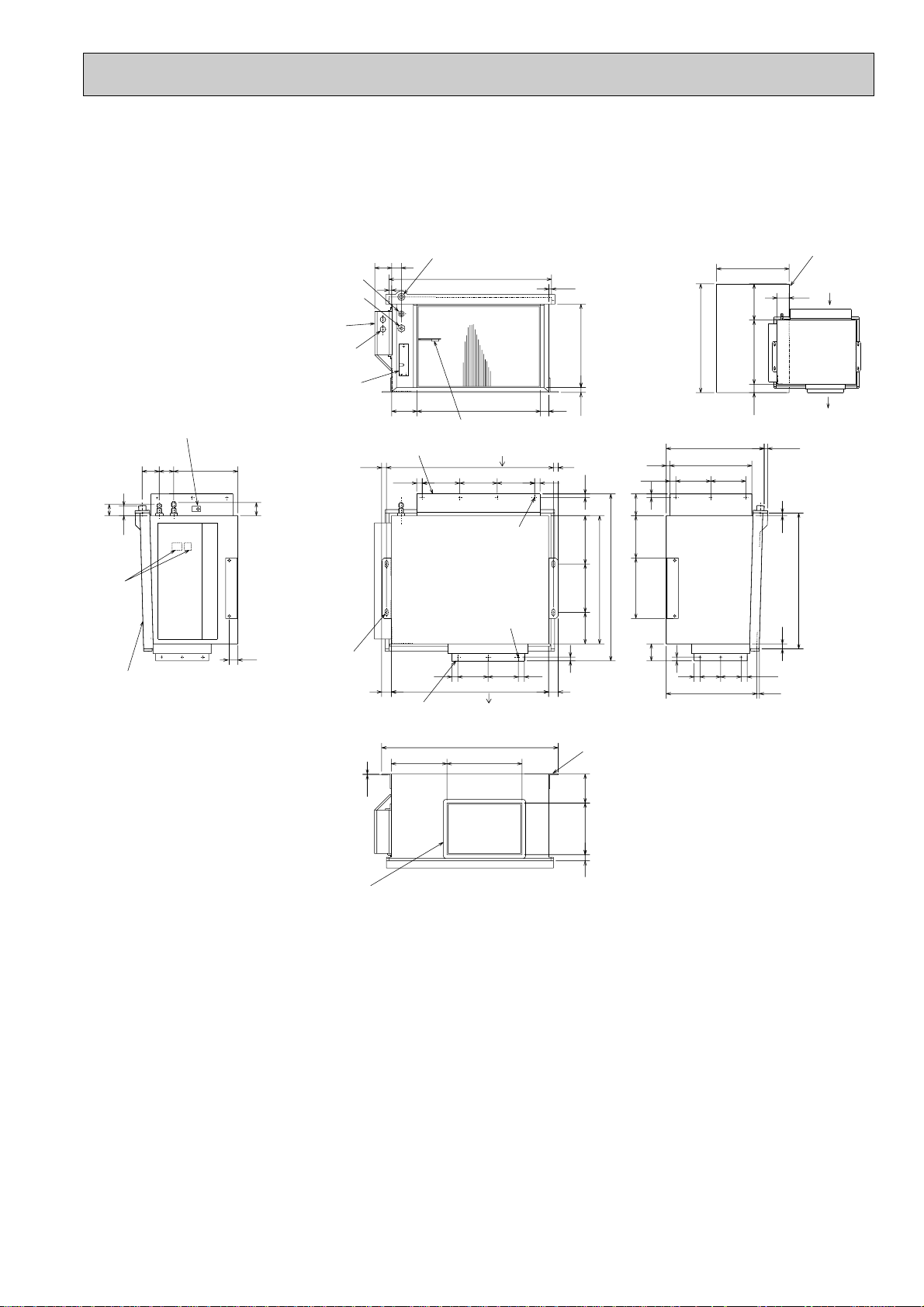

50

55

530

690

(130)

22.5

4070

105 510 35

40 40

650

15

15

730

155 155155

14 220 120

3.2

300242

2656075

35

45

20 345

11

11

672

22.5

20 20690

15

2512512525

100

600

70

(530)

300

900

(10)

25

562

21

(10)381

858525

15

70

11

14514524.5

33920

418

90

200 200

250 175

Terminal

block

4-12 ✕ 30

oblong

Suspension

bolt holes

Air intake

Air outlet

Service space

(opening)

in the ceiling

Heat insulator t10

(Drainage pan)

Room temperature thermistor

Drainage pan connection R1

Wiring entry(2-[22holes)

Refrigerant-pipe flared

connection [15.88(5/8)

Refrigerant-pipe flared

connection [9.52(3/8)

Electrical parts box

Service panel

(Condenser/evaporator

temperature thermistor)

Service panel

(Room temperature thermistor)

Air intake

Air intake duct flange

14-[2.9 holes

For air intake

duct connection

Heat insulator t10

Air outlet duct flange

Air outlet

(Drainage pan)

12-[2.9 holes

For air outlet

duct connection

Mounting plate

PEA-RP71EA

Unit : mm

29

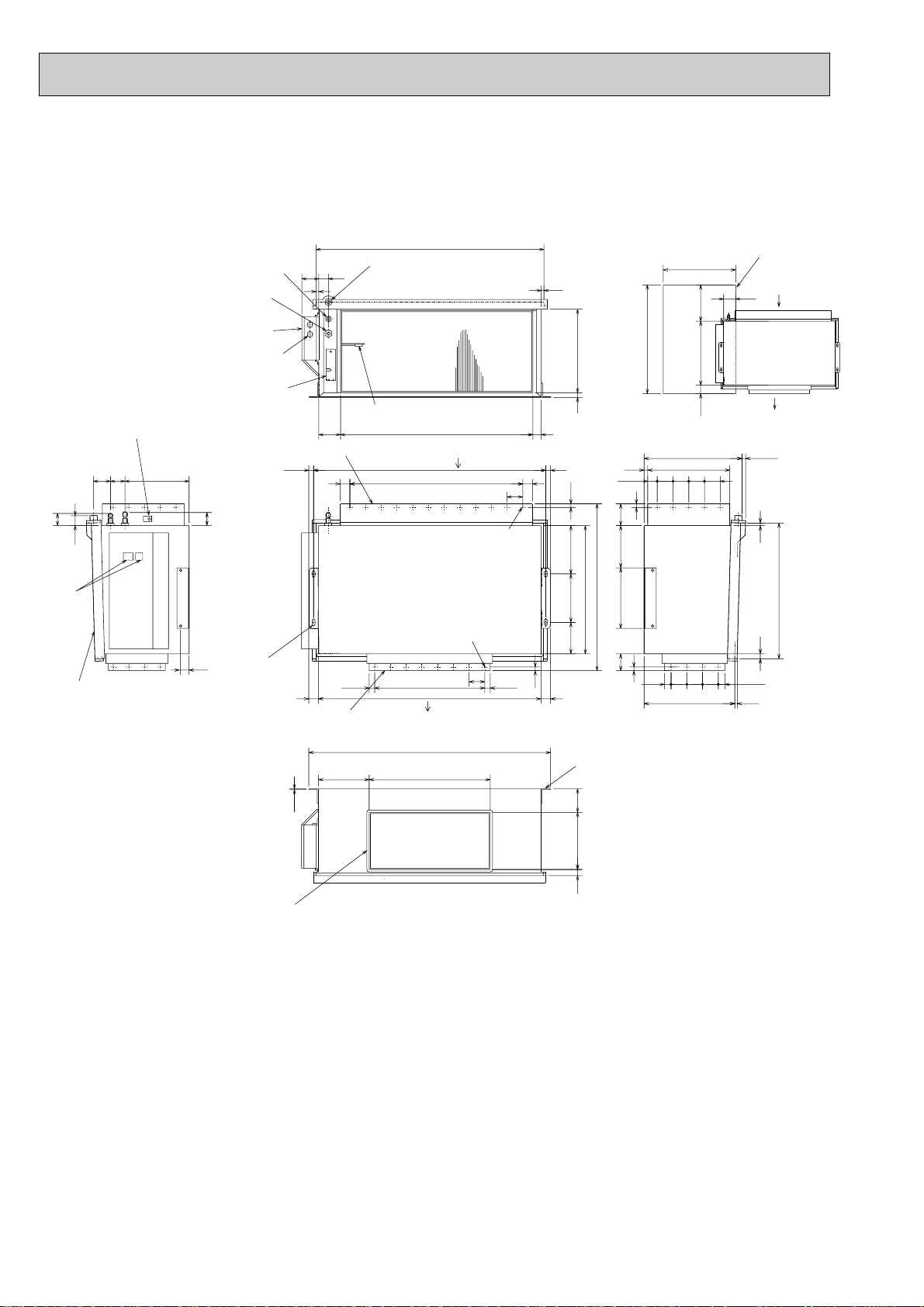

Page 30

PEA-RP100EA

50

60

690

530

27.5

15

3.2

14 250 98

1000

500

20 345

11

65

656527.5

(130)

65

15

65656539.5

(10)

562

21

(10)381

15

70

11

33920

418

90

200 200

250 175

24570

45

15

217

35

79590

942

11

4070

960

65

65✕11=715

40

40

2020

65

65✕7=455 22.522.5

920

4040

70

900

300

(530)

70

600

100

Terminal

block

34-[2.9 holes

For air outlet

duct connection

(Drainage pan)

Air outlet

Air intake

(Drainage pan)

Drainage pan connection R1

Refrigerant-pipe flared

connection [9.52(3/8)

Refrigerant-pipe flared

connection [15.88(5/8)

Electrical parts box

Wiring entry(2-[22holes)

Room temperature thermistor

Air intake

Air intake duct flange

Air outlet

24-[2.9 holes

For air outlet

duct connection

Air outlet duct flange

Heat insulator t10

Heat insulator t10

Service space

(opening)

in the ceiling

Service panel

(Room temperature thermistor)

Service panel

(Condenser/evaporator

temperature thermistor)

4-12 ✕ 30

oblong

Suspension

bolt holes

35

Mounting plate

Unit : mm

30

Page 31

PEA-RP125EA

50

60

690

530

3.2

11 11

1142

20 345

900

14 250 84

(130)

15

27.5 27.5

27.5

15

39.524570

45

381

15

70

33920

90

200 200

250 175

65✕13=845

65✕14=910

65

65

1160

42.5

2020

70 40

117

15

1200

405

70

112040 40

35

995

90

42.5

300

(530)

70

100

600

900

11

(10)

21

562

(10)

65 65 65

65 65 65 27.5

65

Refrigerant-pipe flared

connection [15.88(5/8)

Refrigerant-pipe flared

connection [9.52(3/8)

4-12✕30

oblong

Suspension

bolt holes

Terminal

block

Air outlet

Air intake

Service space(opening)

in the ceiling

Air intake duct flange

(Drainage pan)

(Drainage pan)

40-[2.9 holes

For air outlet

duct connection

36-[2.9 holes

For air outlet

duct connection

Drainage pan connection R1

Electrical parts box

Wiring entry(2-[22holes)

Room temperature thermistor

Air intake

Heat insulator t10

Air outlet duct flange

Air outlet

Heat insulator t10

Service panel

(Condenser/evaporator

temperature thermistor)

Service panel

(Room temperature

thermistor)

35

Mounting plate

Unit : mm

31

Page 32

PEA-RP140EA

60

4040

37.5

381 (10)

(10)405

6565

39.5

339

65 65

25 100100

24570

50

45

70

160 1000

1385

9814 250

3.2

11

562

690

1415

11

1327

100

153

15

70

15

90175250

1305

45

130✕7=91045

15

530

(130)

200 200

70

15

40

65✕16=104037.5

20

(20)

1345

20 345

90

1115

900

600

100

70

(530)

300

Refrigerant-pipe flared

connection [15.88(5/8)

4-12✕30

oblong

Suspension

bolt holes

Terminal

block

Refrigerant-pipe flared connection

[9.52(3/8)

Air intake

Service space(opening)

in the ceiling

Air outlet

130

65

(Drainage pan)

Air outlet duct flange

22-[3.1 holes

For air outlet

duct connection

Air outlet

44-[2.9 holes

For air outlet

duct connection

Air intake duct flange

Air intake

Drainage pan connection R1

(Drainage pan)

Room temperature thermistor

Service panel

(Condenser/evaporator

temperature thermistor)

Wiring entry(2-[22holes)

Electrical parts box

Heat insulator t10

Heat insulator t10

Service panel

(Room

temperature

thermistor)

35

Mounting plate

Unit : mm

32

Page 33

PEH-RP200MYA

Unit : mm

(B)

730

200

530

(A)

199

200

13132

400

20

(B)

1240

1280

1880

(C)

(D)

20

200

(1)

25 75

428500

928

(2)

(3)

(A)

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

REFRIGERANT PIPE [25.4

(1 BRAZE)

20

42

156

344

152

AIR INLET

ACCESSORY PIPE

[

9.52(3/8 BRAZE)

(USE FOR ONLY R410A)

130

95

42

AIR INLET SENSOR

15

130

210 116

33

DRAIN: Rc 1

REFRIGERANT PIPE

(1/2 BRAZE)

104

31

40

100

1102

34

130130130130130130130130

31

24- [3.1 HOLES

AIR INLET DUCT

FLANGE

CONTROL BOX

20

4235

1280

22- [3.1 HOLES

AIR OUTLET DUCT

650

562

7053050

[

12.7

15

100 25

25 100

CONTROLLER

382

AIR OUTLET

WIRING HOLE [27

(AIR INLET SIDE)

CONNECT WIRE (PEH-PUH)

WIRING HOLE [27

(AIR INLET SIDE)

FLANGE

428

POWER SUPPLY

WIRING HOLE [27

(AIR INLET SIDE)

40

46

55 55 156

120

DUCT EARTH POINT

(BOTH DUCT SIDE)

1380

1320

1240

1000

1264

20

15

4513013013013013013013045

120

131 200 199

4- [12 HOLES

(FOR HUNGING

<FIELD SUPPLY>

40

98250

14

BOLT M10)

Note: When connecting duct to the inlet side, remove the air filter attached to the unit body, and mount

an air filter onto the inlet duct side separately.

33

Page 34

PEH-RP250MYA

POWER SUPPLY

WIRING HOLE [27

(AIR INLET SIDE)

CONTROLLER

WIRING HOLE [27

(AIR INLET SIDE)

CONNECT WIRE

(PEH-PUH)

WIRING HOLE [27

(AIR INLET SIDE)

DUCT EARTH POINT

(BOTH DUCT SIDE)

428

1440 40

220

40

1520

1000

220

1464

98

250

14

46

55 55 156

1580

AIR INLET DUCT

FLANGE

26-[3.1 HOLES

34

66

1302

104

130130130130130130130130

66

CONTROL BOX

4-[12 HOLES

22-

[

3.1 HOLES

AIR OUTLET DUCT

FLANGE

20

20

1480

15

45130130130130

130

130

45

(FOR HUNGING

BOLT M10)

<FIELD SUPPLY>

100

40

423

5

131 200 199

130

130

(1) When connecting air inlet

(2) When installing the suspension fixtures prior to installation of the indoor unit without inlet duct

(3) When hanging the indoor unit directly without inlet duct

(A) Service space

(B) Suspension bolt pitch

(C) Air inlet

(D) Air outlet

1440

20

530

13132

200

199

400

730

200

1480

2080

200

20

(A)

(C)

(B)

(B)

(D)

AIR INLET SENSOR

REFRIGERANT PIPE [12.7

(1/2 BRAZE)

REFRIGERANT PIPE

[

28.6 (1-1/8 BRAZE)

AIR INLET

AIR OUTLET

152

650

95

156

344

20

15

7053050

130

130

42

42

DRAIN: Rc 1

33

562

382

25 100

100 25

15

210 116

928

428500

25 75

(1)

(2)

(3)

(A)

Note: When connecting duct to the inlet side, remove the air filter attached to the unit body, and mount

an air filter onto the inlet duct side separately.

Unit : mm

34

Page 35

INDOOR UNIT

BYOFF

ON STAND

HEATCOOL

OFF BY

ON STAND

COOL HEAT

ÅrÇoÇoÅqÅ@ëOñ Å@ÇeÇqÇnÇmÇs ÅrÇoÇoÅqÅ@ëOñÅ@ÇeÇqÇnÇmÇs

r.SLI.SLI

m m

MITSUBISHI ELECTRICMITSUBISHI ELECTRIC

r.S.S

L

I

m m

MITSUBISHI ELECTRICMITSUBISHI ELECTRIC

Knock out hole for right piping

Refrigerant pipe.Drain pipe.

Wiring hole

21

Right side

Less than 15

70

245

60

235

Auto vane

Front view

Air intake

Air intake

Air intake

Air intake

198