Page 1

TECHNICAL & SERVICE MANUAL

SPLIT-TYPE, AIR CONDITIONERS

CONTENTS

1. FEATURES ···········································2

2. PART NAMES AND FUNCTIONS········3

3. SPECIFICATIONS·································5

4. DATA·····················································7

5. OUTLINES AND DIMENSIONS··········10

6. WIRING DIAGRAM·····························12

7.

REFRIGERANT SYSTEM DIAGRAM

······13

8. OPERATION FLOW-CHART··············14

9. MICROPROCESSOR CONTROL·······17

10. TROUBLESHOOTING ························25

11. 4-WAY AIR FLOW SYSTEM ···············27

12. DISASSEMBLY PROCEDURE···········28

13. PARTS LIST········································31

14. OPTIONAL PARTS·····························35

Indoor unit

[Model names]

PL-1.6KJB

PL-2KJB

PL-2.5KJB

[Service Ref.]

PL-1.6KJB.UK

PL-2KJB.UK

PL-2.5KJB.UK

No. OC146

1997

This manual does not cover the

following outdoor units. When

serving them, please refer to the

service manual No.OC149 and

this manual in a set.

<Service Ref.>

PU-1.6VLJA

2.UK

PU-2VJA

2.UK

PU-2NJA

1.UK

PU-2.5VJA

2.UK

PU-2.5NJA

1.UK

INDOOR UNIT

Ceiling Cassettes

Series PL

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

REMOTE CONTROLLER

The Slim Line.

From Mitsubishi Electric.

Page 2

2

1

FEATURES

Indoor unit

Ceiling Cassettes

Series PL

Remote controller

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

1.PURSUING COMPACTNESS

(1)Panel size and body volume reduced to 64% of previous models

The width and depth of the panel have been reduced by 19cm respectively,resulting in a compact model which fits

smaller environments (like shops) perfectly.

(2)Multi-application panels flexibly adapt to installation conditions.

Space panel and Wide panel may be installed on ceilings with shallow depth using the exiting opening .

2."SMUDGE-FREE", PRECISELY TARGETED AIRFLOW SYSTEM

The new control system regulates airflow to prevent smudging. A projection inside the air passage distributes air evenly

over the top and bottom of the vane. Two projections on the air outlet work to prevent cooled air from rising to the

celling, and also to stop outside air being dragged into the cooled air stream.

3.AIRFLOW ADJUSTABLE TO ANY INDOOR ENVIRONMENT

Airflow can be adjusted according to celling height and the number of air outlets. "Wide Zoming Flow" creates an

optimum airflow for any indoor environment.

4.A FURTHER REFINEMENT OF COMFORT WITH NOISE SUPPRESION

The celling 4-way airflow cassette has a special "silent-design". The "2-Tap"system allows a choice between silent and

standard modes according to the height of the cellig. For ordinary residenced which have a low celling, selection of the

silent mode will result in remarkable noise reductions.

5.ECONOMICAL AND EASY MAINTENANCE

(1)Push-open grill

Filter clogging is widely recognized as a cause of reduced perfomance, but up until now it has been troublesome to

clean filters. With the "push-open grill" the fillter can be smoothly opened out at the push of a button, enabling speedy

cleaning.

(2)An unprecedented level of vane-cleaning

The unique airflow system prevents the intake of indoor air. Dewing therefore does not occur, and the vane is flockless.

The resulting level of dirt on the vane due to tobacco smoke, dust, etc. is very light,and can be wiped off easily with a

neutral detergent.

(3)Long-life filter

This new celling 4-way airflow cassette employs a long life fillter which requires no maintenance for up to 2,500 hours of

operation in general office environments. It adds uo to an ideal blend of comfort and low maintenance.

Service Ref.

Cooling capacity (50/60Hz)

W

3,800/ –

5,600/5,400

6,500/7,000

13,000/ –

19,100/18,400

22,200/23,900

Btu/h

PL-1.6KJB.UK

PL-2KJB.UK

PL-2.5KJB.UK

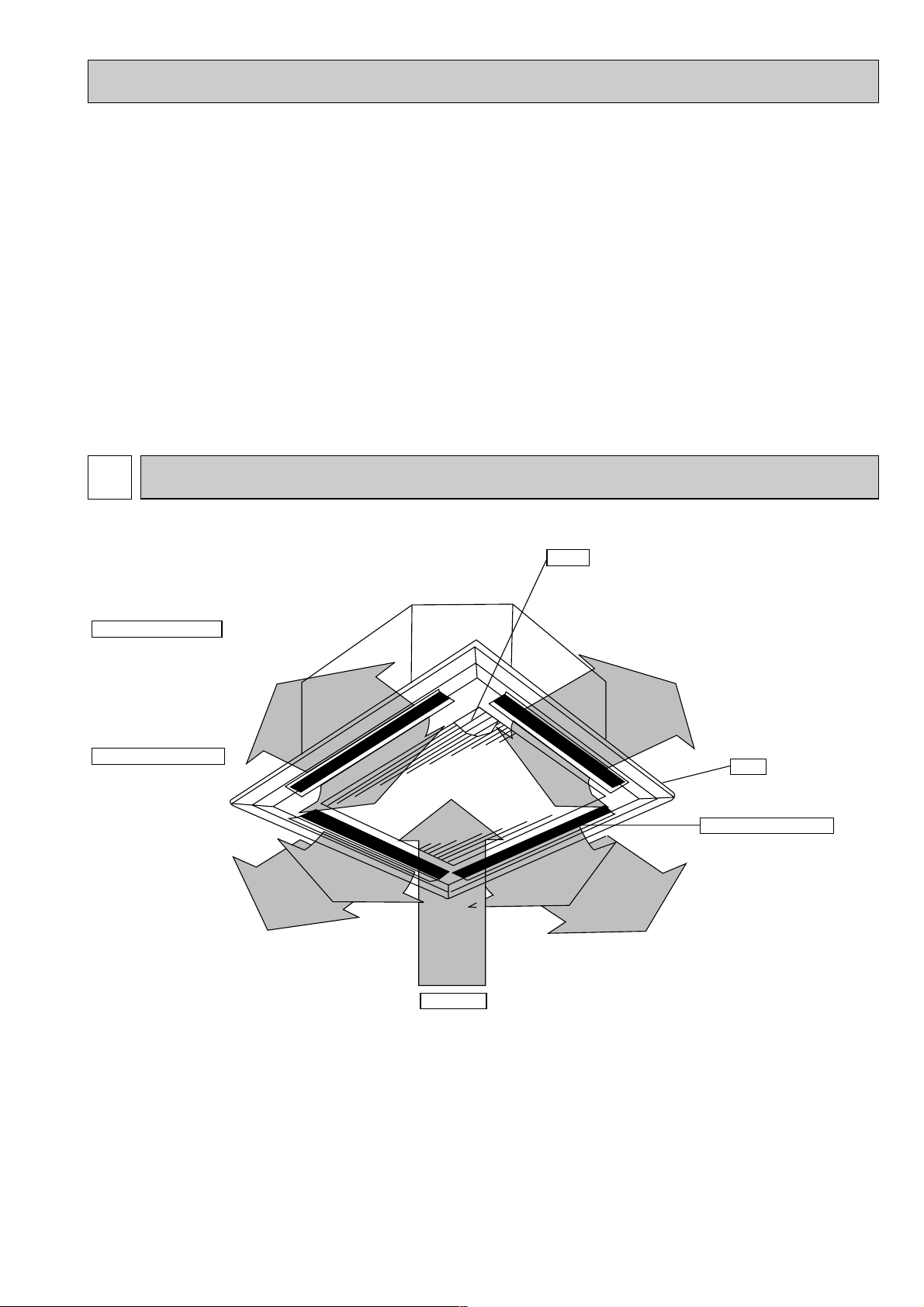

Page 3

3

PART NAMES AND FUNCTIONS2

6.COMPACT DIMENSIONS MEAN EASY INSTALLATION

(1)Carefree suspension work with lightweight unit

The new unit weighs in at 20kg and is easy to handle and install. What's more, suspension work is facillitated by

compact dimensions ensuring a snug fit.

(2)Smooth installation with "one-direction"bolts

Suspension bolts can be fixes consistently from one direction easing suspension work.

(3)Trouble-free fitting work with slender refrigerant piping

Refrigerant piping has been reduced in size, and pipe-curving work at the installation site can now be completed quickly

and economically. In addition, refrigerant and drain piping are set at different corners, which means that flare connections

and drain piping heat insulation work can be smoothly and reliably implemented.

(4)Easy-access terminal and control panels for efficient wiring

When performing wiring work, progress can be checked on the power source terminal and control panels simply by

removing the electrical parts cover. Address setting can also be done easily from beneath at a convenient angle.

(5)"One-push"to provisionally position front panel

Panel weight has been redused from 7kg to 3.7kg. The previous 3-step process for provisionally positioning the panel

has been streamlined, and now a simple "one-push" action at the diagonal corners fixed it into place, resulting in major

time-saving.

● Indoor Unit

PL-1.6KJB.UK

PL-2KJB.UK

PL-2.5KJB.UK

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Grill

Filters

Remove dust and pollutants

from inhaled air

Horizontal Air Outlet

Sets airflow horizontal automatically

during cooling or dehumidifying.

Downward Air Outlet

Sets airflow downward

automatically during

heating.

Air Intake

Inhales air from room.

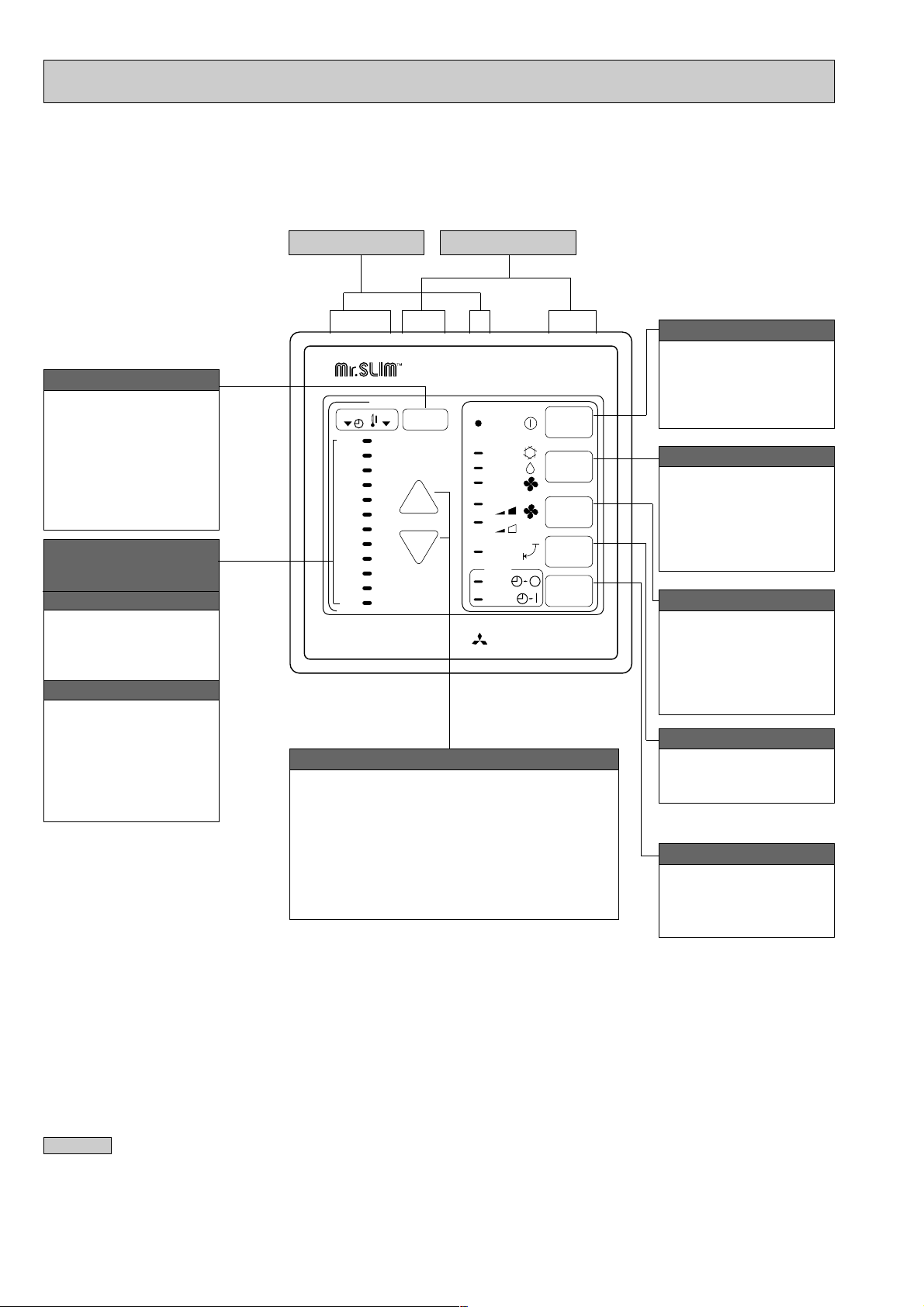

Page 4

4

Attention

● Pressing the UP and DOWN buttons together for more than two seconds will initiate the “test run” or “self-diagnostic” mode.

Avoid pressing these buttons simultaneously during normal operation. Press the ON/OFF button to cancel test run or selfdiagnostic mode.

●All green lamps turn off when air conditioner is OFF.

●Avoid operation of buttons with fingernails or other sharp objects. Sharp objects may scratch operating panel.

● Controller

Settings remain in effect' until changed. The air

conditioner can be operated by simply pressing

ON/OFF button once settings have been made.

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

This button is used to

change between display of

room temperature and

display of remaining time

on the timer during “AUTO

STOP” operation.

Green lamps light in

selected display mode.

TIMER/TEMP. button

Pressing button starts

operation. Pressing again

stops operation.

Green lamp remains lit

during operation.

ON/OFF button

This button is used to

change between cooling,

DRYING and ventilation

operation modes. One of

three green lamps lights to

indicate mode in effect.

MODE SELECT button

This button is used to

change between low and

high fan speeds. One of

two green lamps lights to

indicate which fan speed is

in effect.

FAN SPEED button

Used to select timed

starting or stopping. Green

lamp lights to indicate timer

mode selected.

TIMER MODE button

This button is used to

switch swing louver

ON/OFF.

LOUVER button

●Temperature control (While green “TEMP” lamp

is lighting.)

Use UP and DOWN buttons to set desired

temperature between 18 and 29 °C.

●Timed operation (While green “TIMER“ lamp is

lighting.)

Use UP and DOWN buttons to set timed

operation between one and twelve hours.

UP and DOWN buttons

Lamps indicate time remaining

until timer stops operation.

Green lamps display the

remaining number of hours.

Lamps display temperature

settings actual room

temperatures.

●Temperature settings :

Green lamps light.

●Temperature in room :

Green lamps flash.

(Example display readings are

for explanations only, so actual

display readings will differ.)

Lamps display remaining

time on the timer or room

temperature.

Remaining timer time display

Room temperature display

Display panel

Operating panel

Page 5

5

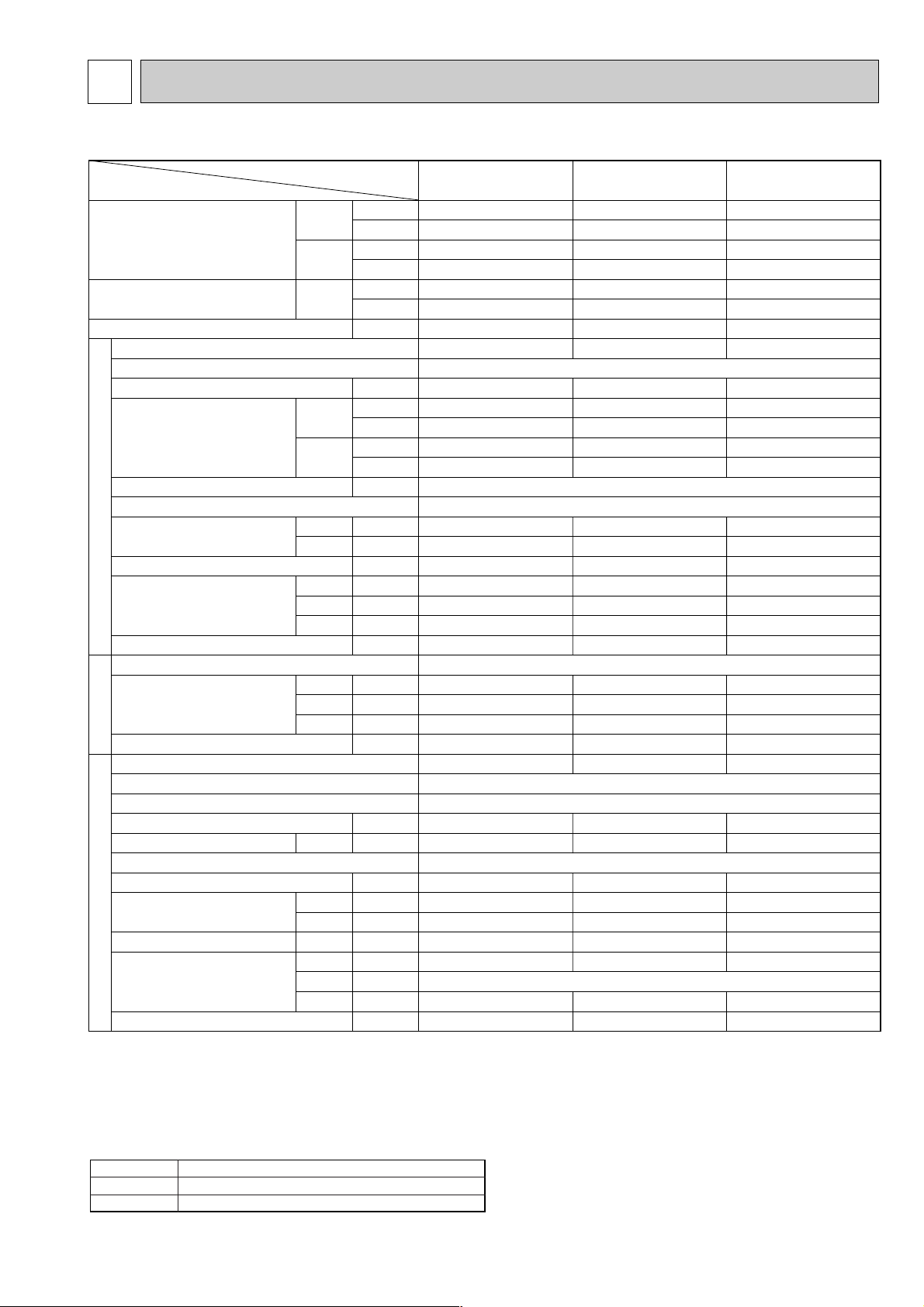

SPECIFICATIONS5

Service Ref.

External finish

Fan motor output

Airflow Lo-Hi

External static pressure

Operation control & Thermostat

Noise level Low-High

Cond. drain connection OD

Dimensions

Weight

External finish

Dimensions

Weight

Service Ref.

External finish

Refrigerant (R-22) control

Crankcase Heater w4

Compressor output

Protection devices

Fan motor output

Airflow

Noise level

Dimensions

Weight

W

Btu/h

W

Btu/h

W

Btu/h

kW

kW

CMM

CFM

CMM

CFM

mmAq,Pa

dB(A)

dB(A)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

W

kW

kW

CMM(CFM)

CMM(CFM)

dB(A)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

50Hz

60Hz

60Hz

50Hz

60Hz

50Hz

60Hz

W

D

H

W

D

H

50/60Hz

50Hz

60Hz

50/60Hz

W

D

H

3,800

13,000

–

–

–

–

1.54/–

PL-1.6KJB.UK

0.03

13-15

460-530

13-15

460-530

31-35

31-35

32 (1-1/4)

660 (26)

660 (26)

253 (10)

19 (42)

760 (30)

760 (30)

30 (1-1/8)

3.7 (8)

PU-1.6VLJA

2.UK

–

1.2/-

0.065

45(1588)

45(1588)

49/–

870(34-1/4)

650(25-5/8)

45(99)

5,600

19,100

5,400

18,400

4,500

15,400

2.57/2.59

PL-2KJB.UK

Galvanized sheets with gray heat insulation

0.03

13-16

460-565

13-16

460-565

0 (Direct blow)

Remote control & Built-in

32-37

32-37

32 (1-1/4)

660 (26)

660 (26)

253 (10)

19 (42)

Munsell 0.70Y 8.59/0.97

760 (30)

760 (30)

30 (1-1/8)

3.7 (8)

PU-2VJA2.UK, 2NJA1.UK

Munsell 5Y7/1

Capillary tube

32/–

2.0/1.5

0.065

45(1588)

45(1588)

49/50

870(34-1/4)

295+24(11-5/8+1)

650(25-5/8)

60(132)

6,500

22,200

7,000

23,900

5,950

20,300

2.59/3.05

PL-2.5KJB.UK

0.03

14-17

495-600

14-17

495-600

35-39.5

35-39.5

32 (1-1/4)

660 (26)

660 (26)

253 (10)

20 (44)

760 (30)

760 (30)

30 (1-1/8)

3.7 (8)

PU-2.5VJA2.UK, 2.5NJA1.UK

32/–

2.0/1.7

0.085

50(1765)

50(1765)

52/53

870(34-1/4)

850(33-7/16)

71(157)

Inner thermostat, HP switch, LP switch

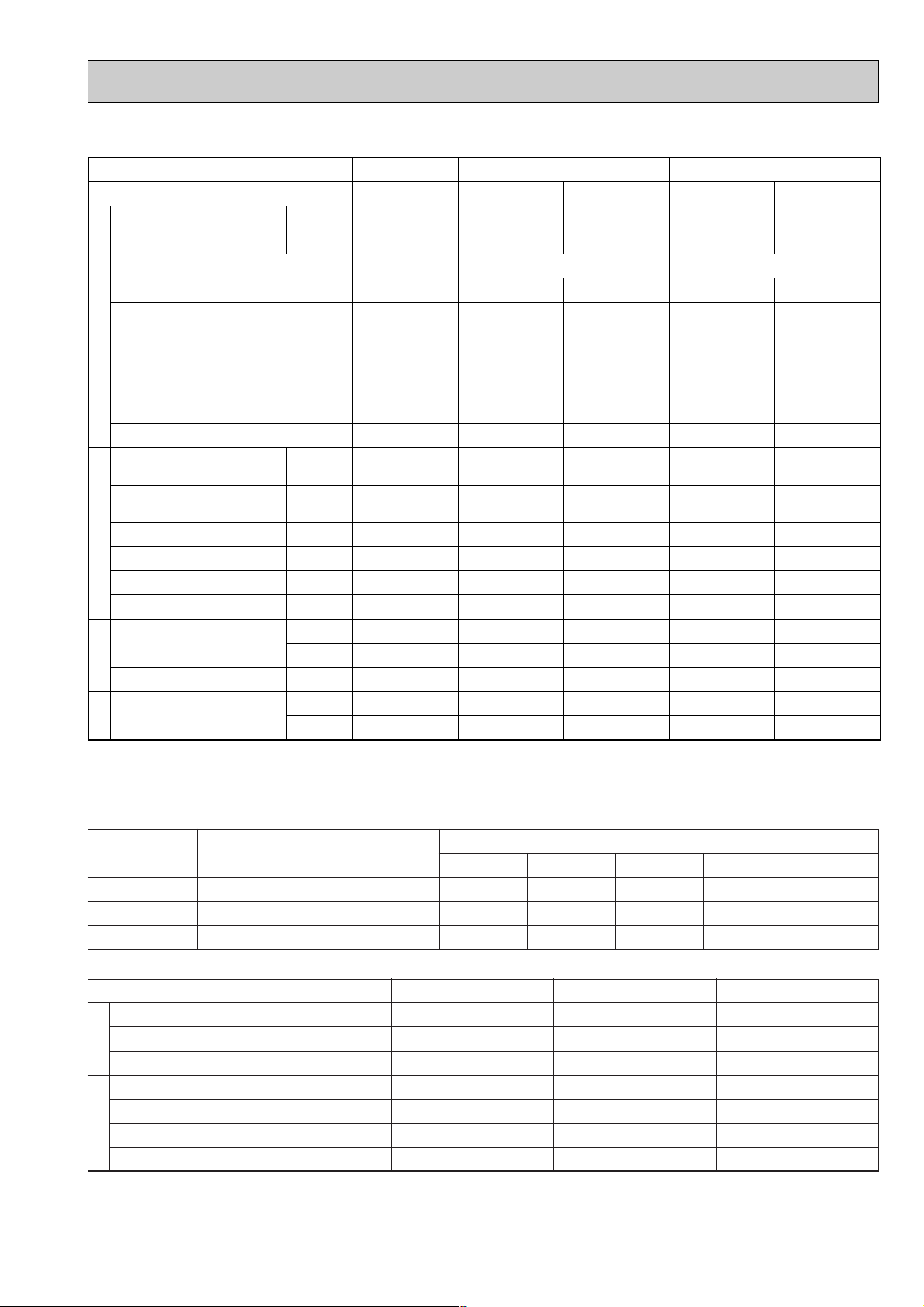

Cooling capacity w1

Cooling capacity w2

Total input (50/60Hz) w3

Item

Service Ref.

PL-1.6KJB.UK PL-2KJB.UK PL-2.5KJB.UK

Indoor unitIndoor grillOutdoor unit

Notes :

w1 Rating conditions (JIS B8616) w2 Rating conditions (SSA 385, 386)

Indoor : 27°C (80°F) DB, 19°C (66°F)WB Indoor : 29°C (84°F) DB, 19°C (66°F)WB

Outdoor : 35°C (95°F) DB, 24°C (75°F)WB Outdoor : 46°C (115°F) DB, 24°C (75°F)WB

Refrigerant piping length (one way) : 5m (16ft) Refrigerant piping length (one way) : 5m (16ft)

w3 Total input based on indicated voltage w4 Capacity of crankcase heater (W) based on 220 volts.

Service Ref. PL-1.6KJB.UK / PL-2KJB.UK / PL-2.5KJB.UK

50Hz 1ph 220V/1ph 220V

60Hz 1ph 220V/1ph 220V

1. STANDARD SPECIFICATIONS

(Indoor / Outdoor)

Rating conditions (JIS B 8616)

Page 6

6

2. POWER SUPPLY & MODEL NAMES

Notes : 1. Power supply key N

...

1ph, 220V,60Hz

V(L)

...

1ph, 220, 230, 240V, 50Hz

2. Primary power supplies for all indoor units are single-phase.

3. ELECTRICAL SPECIFICATIONS

(1). Rating conditions -JIS B 8616

Indoor : 27°C (80°F) DB, 19°C (66°F) WB

Outdoor : 35°C (95°F) DB, 24°C (75°F) WB

Series PL Indoor Unit (Single Phase)

220, 230, 240V

380/220, 400/230, 415/240V

220V

220V

1ph.

3ph.

1ph.

3ph.

50Hz

60Hz

Power supply

Service Ref. (Indoor unit)

PL-1.6KJB.UK

PU-1.6VLJA

2.UK

–

–

–

PL-2KJB.UK

PU-2VJA

2.UK

–

PU-2NJA

1.UK

–

Model name (Outdoor unit)

PL-2.5KJB.UK

PU-2.5VJA

2.UK

–

PU-2.5NJA

1.UK

–

PL-1.6KJB.UK

0.59

0.12

0.80

PU-1.6

A

kW

A

PL-2KJB.UK

0.60

0.13

0.80

PU-2

V : 220V 50Hz V : 230V 50Hz

PL-2.5KJB.UK

0.60

0.13

0.80

PU-2.5

PL-1.6KJB.UK

0.62

0.13

0.80

PU-1.6

PL-2KJB.UK

0.63

0.14

0.80

PU-2

PL-2.5KJB.UK

0.63

0.14

0.80

PU-2.5

Power supply (1 Phase)

Service Ref.

Current

Input

Starting current

Outdoor unit

PL-1.6KJB.UK

0.64

0.14

0.80

PU-1.6

A

kW

A

PL-2KJB.UK

0.65

0.15

0.80

PU-2

V : 240V 50Hz N : 220V 60Hz

PL-2.5KJB.UK

0.65

0.15

0.80

PU-2.5

PL-2KJB.UK

0.65

0.14

0.80

PU-2

PL-2.5KJB.UK

0.66

0.14

0.80

PU-2.5

Power supply (1 Phase)

Service Ref.

Current

Input

Starting current

Outdoor unit

Page 7

7

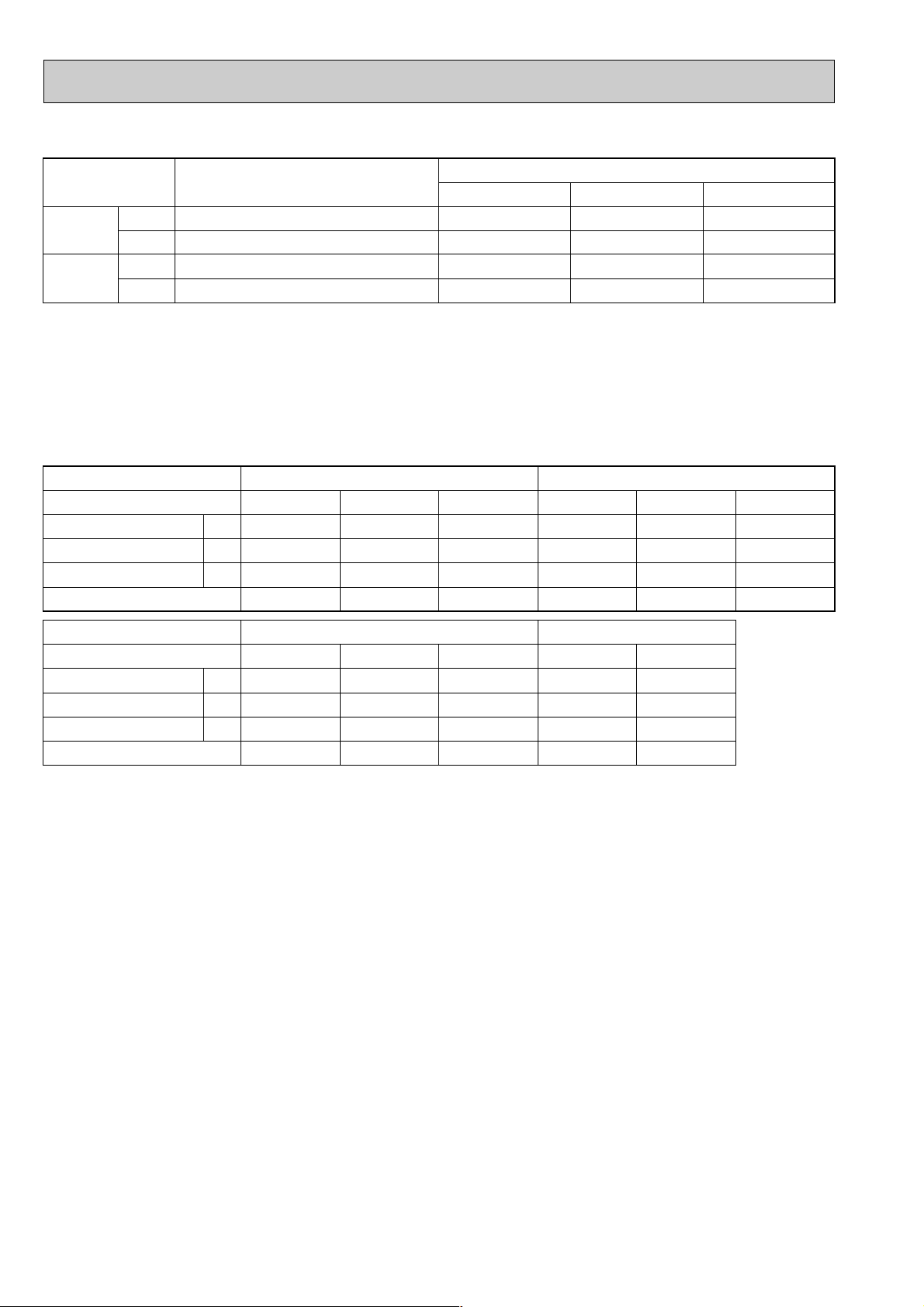

DATA4

1. PERFORMANCE DATA

Cooling capacity 50Hz

PL-2.5KJB.UKPL-2KJB.UK

17

0.14

0.72

Evaporator airflow (CMM)

Bypass factors

S.H.F. at rating conditions

16

0.20

0.74

15

0.21

0.67

Service Ref.

Temperature

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

PL-1.6KJB.UK

0.81

0.82

0.83

0.83

0.84

0.86

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

3.7

4.0

4.1

4.2

4.2

4.5

0.84

0.85

0.86

0.86

0.87

0.89

5.5

5.9

6.0

6.1

6..2

6.6

0.84

0.85

0.86

0.86

0.87

0.89

6.4

6.8

7.0

7.1

7.2

7.7

0.84

0.85

0.86

0.86

0.87

0.89

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

3.4

3.7

3.8

3.8

3.9

4.2

0.96

0.99

1.00

1.00

1.01

1.04

5.1

5.4

5.6

5.7

5.8

6.2

0.96

0.99

1.00

1.00

1.01

1.04

5.9

6.3

6.5

6.6

6.7

7.2

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

3.3

3.5

3.6

3.7

3.7

4.0

1.04

1.06

1.08

1.08

1.09

1.12

4.8

5.2

5.3

5.4

5.5

5.9

1.04

1.06

1.08

1.08

1.09

1.12

5.6

6.0

6.2

6.3

6.4

6.8

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

3.1

3.3

3.4

3.5

3.6

3.8

1.11

1.14

1.15

1.16

1.17

1.21

4.6

4.9

5.1

5.1

5.2

5.6

1.11

1.14

1.15

1.16

1.17

1.21

5.3

5.7

5.9

6.0

6.1

6.5

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

2.9

3.1

3.2

3.3

3.3

3.6

1.19

1.22

1.24

1.25

1.26

1.31

4.3

4.6

4.7

4.8

4.9

5.3

1.19

1.22

1.24

1.25

1.26

1.31

4.9

5.3

5.5

5.6

5.7

6.1

1.19

1.22

1.24

1.25

1.26

1.31

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

3.6

3.8

4.0

4.0

4.1

4.3

0.90

0.92

0.93

0.93

0.94

0.96

5.3

5.6

5.8

5.9

6.0

6.4

0.90

0.92

0.93

0.93

0.94

0.96

6.1

6.6

6.8

6.9

7.0

7.4

0.90

0.92

0.93

0.93

0.94

0.96

21$C

(69.8$F)

25$C

(77$F)

30$C

(86$F)

32.2$C

(90$F)

35$C

(95$F)

40$C

(104$F)

40.6$C

(105$F)

45$C

(113$F)

46$C

(115$F)

50$C

(69.8$F)

52$C

(125.5$F)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

3.8

4.1

4.2

4.2

4.3

4.6

3.5

3.8

3.9

3.9

4.0

4.3

3.3

3.5

3.6

3.7

3.8

4.0

3.1

3.4

3.5

3.5

3.6

3.8

3.0

3.2

3.3

3.3

3.4

3.7

5.6

6.0

6.2

6.2

6.4

6.7

6.5

6.9

7.2

7.3

7.4

7.8

5.2

5.5

5.7

5.8

5.9

6.3

6.0

6.4

6.6

6.7

6.9

7.3

4.9

5.2

5.4

5.4

5.5

5.9

5.6

6.0

6.2

6.3

6.4

6.9

4.6

4.9

5.1

5.2

5.3

5.7

5.4

5.7

5.9

6.0

6.1

6.6

4.4

4.7

4.9

4.9

5.0

5.4

5.1

5.4

5.6

5.7

5.8

6.3

0.81

0.82

0.83

0.83

0.84

0.86

0.81

0.82

0.83

0.83

0.84

0.86

0.93

0.95

0.96

0.97

0.97

0.99

0.93

0.95

0.96

0.97

0.97

0.99

0.93

0.95

0.96

0.97

0.97

0.99

1.03

1.06

1.07

1.08

1.08

1.11

1.03

1.06

1.07

1.08

1.08

1.11

1.10

1.12

1.14

1.15

1.16

1.20

1.10

1.12

1.14

1.15

1.16

1.20

1.16

1.19

1.21

1.22

1.23

1.28

1.16

1.19

1.21

1.22

1.23

1.28

Indoor WBOutdoor DB

T.C. C.F.

(T.I.)

C.F.

(T.I.)

T. C.C.F.

(T.I.)

T. C.

Notes : 1. T.C. : Total capacity (kW) ... (kcal/h) = (kW) o 860, (Btu/h) = 4 o (kW) o 860

C.F. (T.I.) : Correction factors of Total input (Indoor unit input + Outdoor unit input)

2. (°F) = 32 + 9 / 5 (°C)

3. Guaranteed operation range (cooling) :

Lower limit ... Indoor : 21°C (70°F) DB, 15.5°C (60°F) WB, Outdoor : 21°C (70°F) DB.

Upper limit ... Indoor : 35°C (95°F) DB, 22.5°C (72.5°F) WB, Outdoor : 52°C (125.5°F) DB.

wVL ... Outdoor : 46°C (115°F) DB.

Cooling capacity correction factors 50Hz

PL-1.6KJB.UK

PL-2KJB.UK

PL-2.5KJB.UK

Service Ref.

Refrigerant piping length (one way)

5m (16ft)

1.0

1.0

1.0

10m (33ft)

0.992

0.985

0.983

15m (49ft)

0.987

0.975

0.972

20m (66ft)

0.982

0.964

0.961

25m (82ft)

–

0.954

0.951

30m (98ft)

–

0.944

0.940

35m (115ft)

–

–

–

40m (131ft)

–

–

–

Page 8

8

Cooling capacity 60Hz

Notes : 1. T.C. : Total capacity (kW)

...

(kcal/h) = (kW) o 860, (Btu/h) = 4 o (kW) o 860

C.F. (T.I.) : Correction factors of Total input (Indoor unit input + Outdoor unit input)

2. (°F) = 32 + 9 / 5 (°C)

3. Guaranteed operation range (cooling) :

Lower limit ... Indoor : 21°C (70°F) DB, 15.5°C (60°F) WB, Outdoor : 21°C (70°F) DB.

Upper limit ... Indoor : 35°C (95°F) DB, 22.5°C (72.5°F) WB, Outdoor : 52°C (125.5°F) DB.

PL-2.5KJB.UK

17

0.20

0.75

Evaporator airflow (CMM)

Bypass factors

S.H.F. at rating conditions

16

0.21

0.68

Service Ref.

Temperature

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

PL-2KJB.UK

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

5.3

5.6

5.8

5.9

6.0

6.4

0.84

0.85

0.86

0.86

0.87

0.89

6.9

7.3

7.6

7.7

7.8

8.3

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

4.9

5.2

5.4

5.5

5.6

5.9

0.96

0.99

1.00

1.00

1.01

1.04

6.3

6.8

7.0

7.1

7.2

7.7

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

4.7

5.0

5.1

5.2

5.3

5.7

1.04

1.06

1.08

1.08

1.09

1.12

6.0

6.4

6.7

6.8

6.9

7.4

4.4

4.7

4.9

4.9

5.0

5.4

1.11

1.14

1.15

1.16

1.17

1.21

5.7

6.1

6.3

6.4

6.5

7.0

4.1

4.4

4.6

4.6

4.7

5.1

1.19

1.22

1.24

1.25

1.26

1.31

5.3

5.7

5.9

6.0

6.1

6.6

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

5.1

5.4

5.6

5.7

5.8

6.2

0.90

0.92

0.93

0.93

0.94

0.96

6.6

7.1

7.3

7.4

7.5

8.0

21$C

(69.8$F)

25$C

(77$F)

30$C

(86$F)

32.2$C

(90$F)

35$C

(95$F)

40$C

(104$F)

40.6$C

(105$F)

45$C

(113$F)

46$C

(115$F)

50$C

(122$F)

52$C

(125.5$F)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

16$C (60.8$F

)

18$C (64.4$F

)

19$C (66.2$F

)

19.4$C (67$F

)

20$C (68$F

)

22$C (71.6$F

)

5.4

5.8

6.0

6.0

6.1

6.5

5.0

5.3

5.5

5.6

5.7

6.1

4.7

5.0

5.2

5.2

5.3

5.7

4.4

4.8

4.9

5.0

5.1

5.5

4.2

4.5

4.7

4.7

4.8

5.2

0.81

0.82

0.83

0.83

0.84

0.86

0.93

0.95

0.96

0.97

0.97

0.99

1.03

1.06

1.07

1.08

1.08

1.11

1.10

1.12

1.14

1.15

1.16

1.20

1.16

1.19

1.21

1.22

1.23

1.28

0.84

0.85

0.86

0.86

0.87

0.89

0.96

0.99

1.00

1.00

1.01

1.04

1.04

1.06

1.08

1.08

1.09

1.12

1.11

1.14

1.15

1.16

1.17

1.21

1.19

1.22

1.24

1.25

1.26

1.31

0.90

0.92

0.93

0.93

0.94

0.96

0.81

0.82

0.83

0.83

0.84

0.86

0.93

0.95

0.96

0.97

0.97

0.99

1.03

1.06

1.07

1.08

1.08

1.11

1.10

1.12

1.14

1.15

1.16

1.20

1.16

1.19

1.21

1.22

1.23

1.28

7.0

7.5

7.7

7.8

7.9

8.4

6.5

6.9

7.2

7.3

7.4

7.9

6.1

6.5

6.7

6.8

6.9

7.4

5.8

6.2

6.4

6.5

6.6

7.1

5.5

5.9

6.1

6.2

6.3

6.7

Indoor WBOutdoor DB

C.F.

(T.I.)

T. C.C.F.

(T.I.)

T. C.

Cooling capacity correction factors 60Hz

PL-2KJB.UK

PL-2.5KJB.UK

Service Ref.

Refrigerant piping length (one way)

5m (16ft)

1.0

1.0

10m (33ft)

0.985

0.978

15m (49ft)

0.975

0.963

20m (66ft)

0.964

0.948

25m (82ft)

0.954

0.934

30m (98ft)

0.944

0.921

35m (115ft)

–

–

40m (131ft)

–

–

Page 9

9

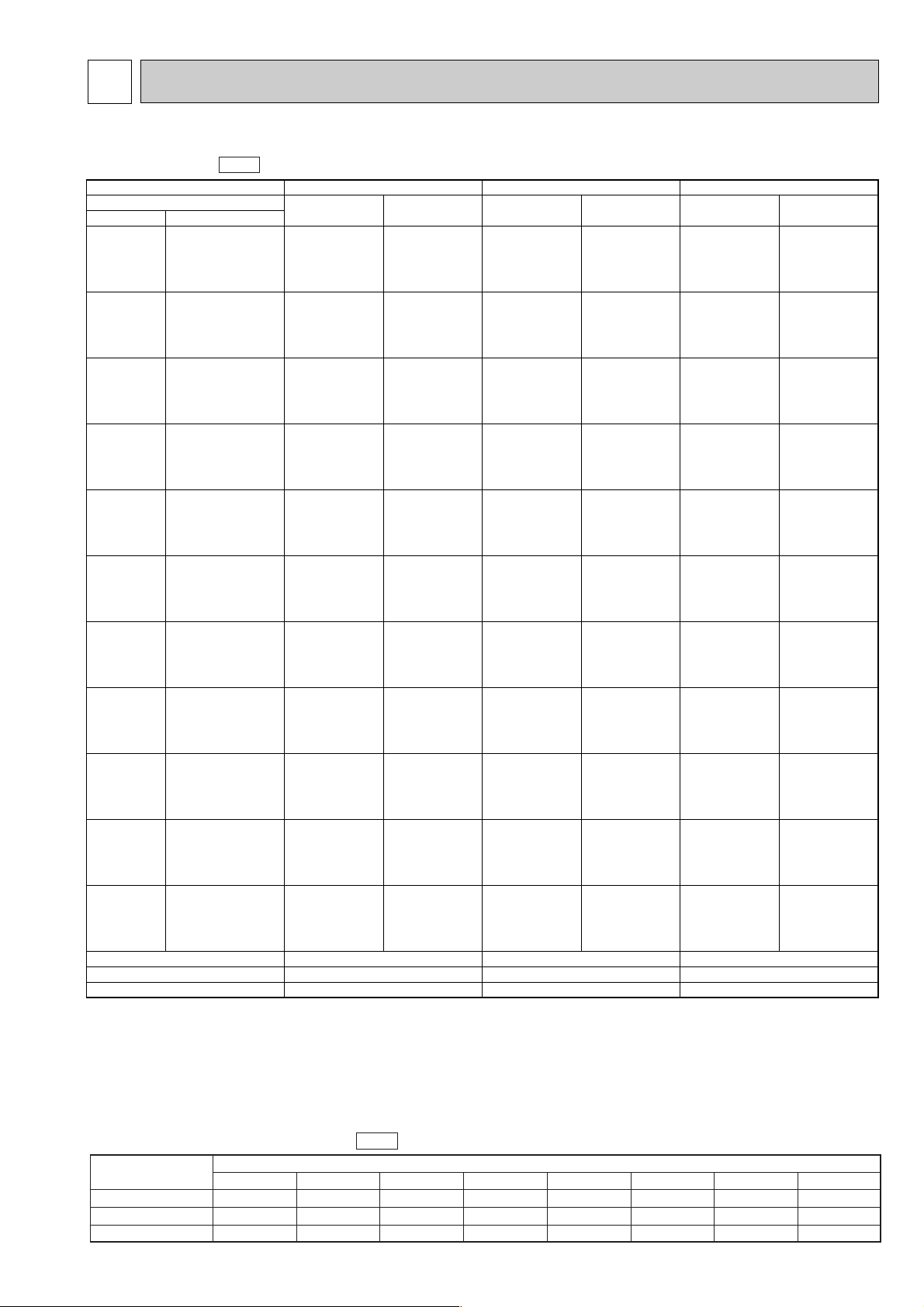

2. STANDARD OPERATION DATA

w The air coverage range is the value up to the position where the air speed is 0.25 m/sec. when air is blown out horizontally

from the unit at the Hi notch position.

The coverage range should be used only as a general guideline since it varies according to the size of the room and furniture

inside the room.

3. ADDITIONAL REFRIGERANT CHARGE (R-22

......

Kg(lbs))

4. OUTLET AIR SPEED AND COVERAGE RANGE

Capacity

Input

Indoor unit Service Ref.

phase, Hz

Volts

Amperes

Outdoor unit Service Ref.

phase, Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

W

kW

$C

$C

$C

m

DB$C

WB$C

DB$C

DB$C

WB$C

PL-1.6KJB.UK

cooling

3,800

1.54

PL-1.6KJB.UK

1, 50

220

0.59

PU-1.6VLJA2.UK

1, 50

220

6.7

62.3

37.4

6.3

5

27

19

17.1

35

24

cooling

5,600

2.57

1, 50

220

0.60

PU-2VJA2.UK

1, 50

220

11.3

75.9

48.9

13.1

5

27

19

15.5

35

24

PL-2KJB.UKService Ref.

Electrical circuit TotalRefrigerant circuit

Indoor side

Outdoor

side

MODE

PL-2.5KJB.UK

PL-2KJB.UK PL-2.5KJB.UK

cooling

5,400

2.59

1, 60

220

0.65

PU-2NJA1.UK

1, 60

220

11.4

63.6

46.0

5.8

5

27

19

14.6

35

24

cooling

6,500

2.59

1, 50

220

0.60

PU-2.5VJA2.UK

1, 50

220

11.4

74.3

46.4

10.3

5

27

19

13.1

35

24

cooling

7,000

3.05

1, 60

220

0.66

PU-2.5NJA1.UK

1, 60

220

13.4

83.4

47.6

7.2

5

27

19

13.0

35

24

1.94

(19.8)

0.52

(5.3)

1.95

(19.9)

0.45

(4.6)

1.95

(19.9)

0.48

(4.9)

1.92

(19.6)

0.48

(4.9)

2.03

(20.7)

0.47

(4.8)

Mpa·G

(kgf/FG)

Mpa·G

(kgf/FG)

Service Ref.

PL-1.6KJB.UK

PL-2KJB.UK

PL-2.5KJB.UK

Outdoor unit precharged (kg)

(up to 20m)

V

...

1.3

V

...

1.78, N

...

1.9

V

...

2.4, N

...

2.4

Refrigerant piping length (one way)

20m(66ft)

0

0

0

25m(82ft)

–

0.06(0.13)

0.06(0.13)

30m(98ft)

–

0.12(0.26)

0.12(0.26)

35m(115ft)

–

–

–

40m(131ft)

–

–

–

Air flow

Air speed

Coverage range

Air flow

Air speed

Coverage range

Total width of discharge outlets

CMM

m/sec.

m

CMM

m/sec.

m

mm

PL-1.6KJB.UK

15.0

5.2

5.7

16.0

5.6

6.0

0

PL-2KJB.UK

16.0

5.6

6.0

17.0

5.9

6.4

0

PL-2.5KJB.UK

17.0

5.9

6.4

18.0

6.3

6.8

0

Standard

High ceiling

The unit of pressure has been changed to Mpa based on the international SI system.

The conversion factor is : 1(Mpa·G)=10.2(kgf/F·G)

Page 10

10

5

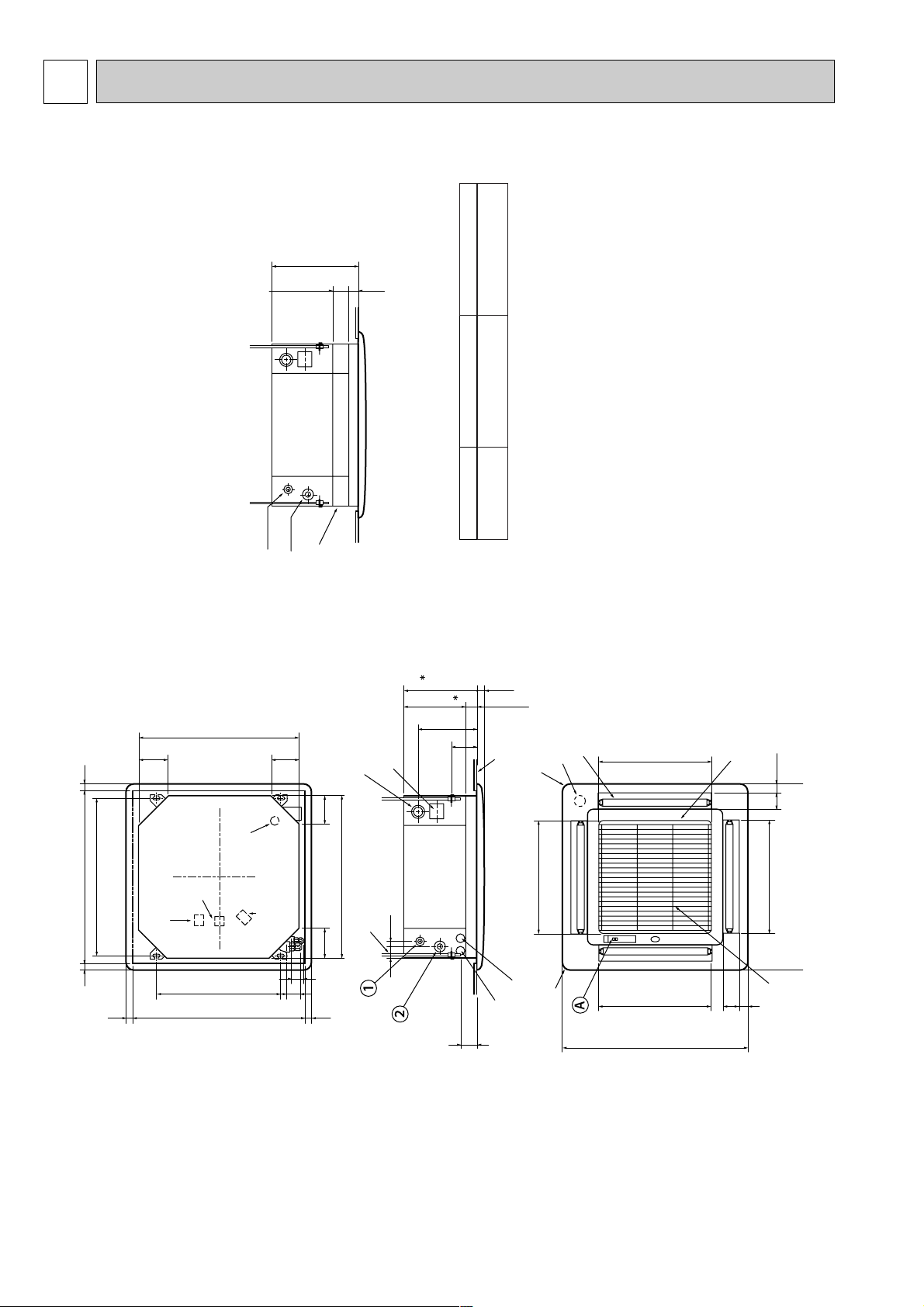

OUTLINES AND DIMENSIONS

Unit : mm

Ceiling hole

Suspension bolt pitch

Suspension bolt M10 or

Air intake hole

Air outlet hole

Air intake grill

690~710 25~3525~35

640

660

466

460

66 35

760

117 117

117

435

13545

117

Ceiling hole

Suspension bolt pitch

Suspension bolt lower edge

Air outlet hole

Air outlet hole

690~710

25~35

25~35

65~80

760

460

466

6635

115

243

253

29330

54

+3

- 2

507

660

54

53

Terminal block for control

Terminal block for

remote controller

Terminal block for

power supply

Drain hole

Drain hole

VP-25 connection

W3/8

Feeding hole

(Drain pump)

Leave space of 10~15mm between the

top surface of the unit and the ceiling slab.

Ceiling surface

4-Auto vanes

Intake grill opening/closing side

Vane motor

Decorative panel

Control wire entry

Refrigerant piping side

electric wire entry side

Power line entry

41 25

Liquid pipe

Gas pipe

Optional high-efficiency hilter

NOTE1. For electrical parts box may be removed during servicing. When

connecting the power line and the control wire, provide enough length to

the electric wires.

NOTE2. When installing the optional high-efficiency filter, the dimension

between the transom and ceiling shall be more than 440mm. Also,when

installing the optional casement, the dimension between the transom

and ceiling shall be more than 440m. (The optional highefficiency filter

can also be installed.)

1

2

Refrigerant pipe Ø9.52

Flared connection 3/8F

Refrigerant pipe Ø15.88

Flared connection 5/8F

1.6/2/2.5KJ

1.INDOOR UNIT

PL-1.6KJB.UK / PL-2KJB.UK / PL-2.5KJB.UK

Page 11

11

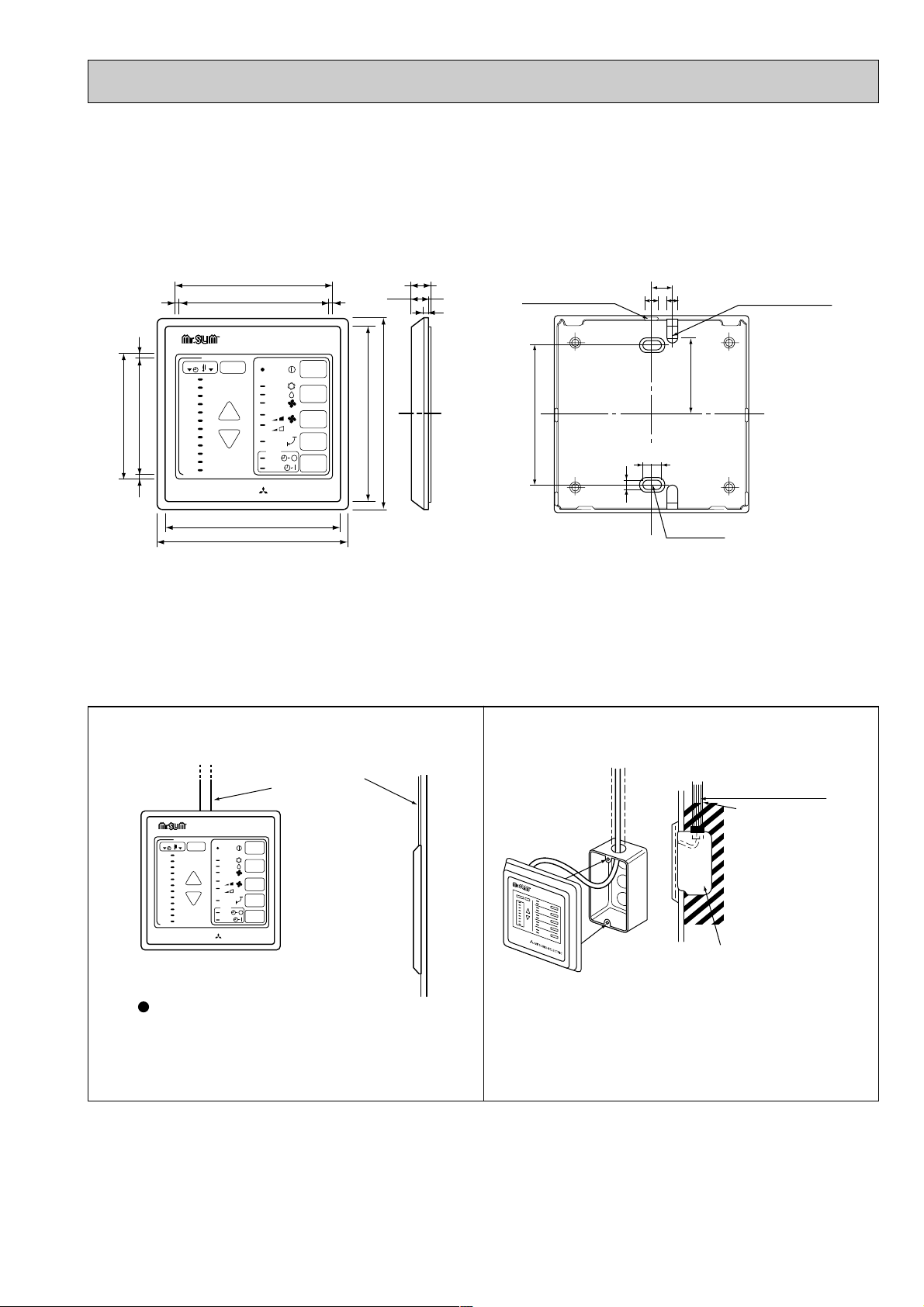

2. REMOTE CONTROLLER

Remote controller cable installation

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

75

69

108(4-1/4)

117(4-5/8)

108(4-1/4)

96.5

12(15/32)

90.5

11.6

3.6

33

117(4-5/8)

33

Rear side wiring

arrangememt opening

Upper side wiring

arrangement

opening

Fixing hole

83.5(3-9/32)

12(15/32)

86

4.6

46

9.2

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

Exposed remote controller

cable

Cable connection is only from the top.

(right, left and bottom not possible)

Remote controller cable

Conduit tube

(local arrangement)

Switch box

(local arrangement)

Set screw (match with switch box),

local arrangement.

●For exposed remote controller cable installation

Note : The cable for the remote controller is 10m (32ft) and 12-core with connectors O.D. ø 5.8.

●For recessed remote controller cable installation

Unit : mm (inch)

Page 12

12

6

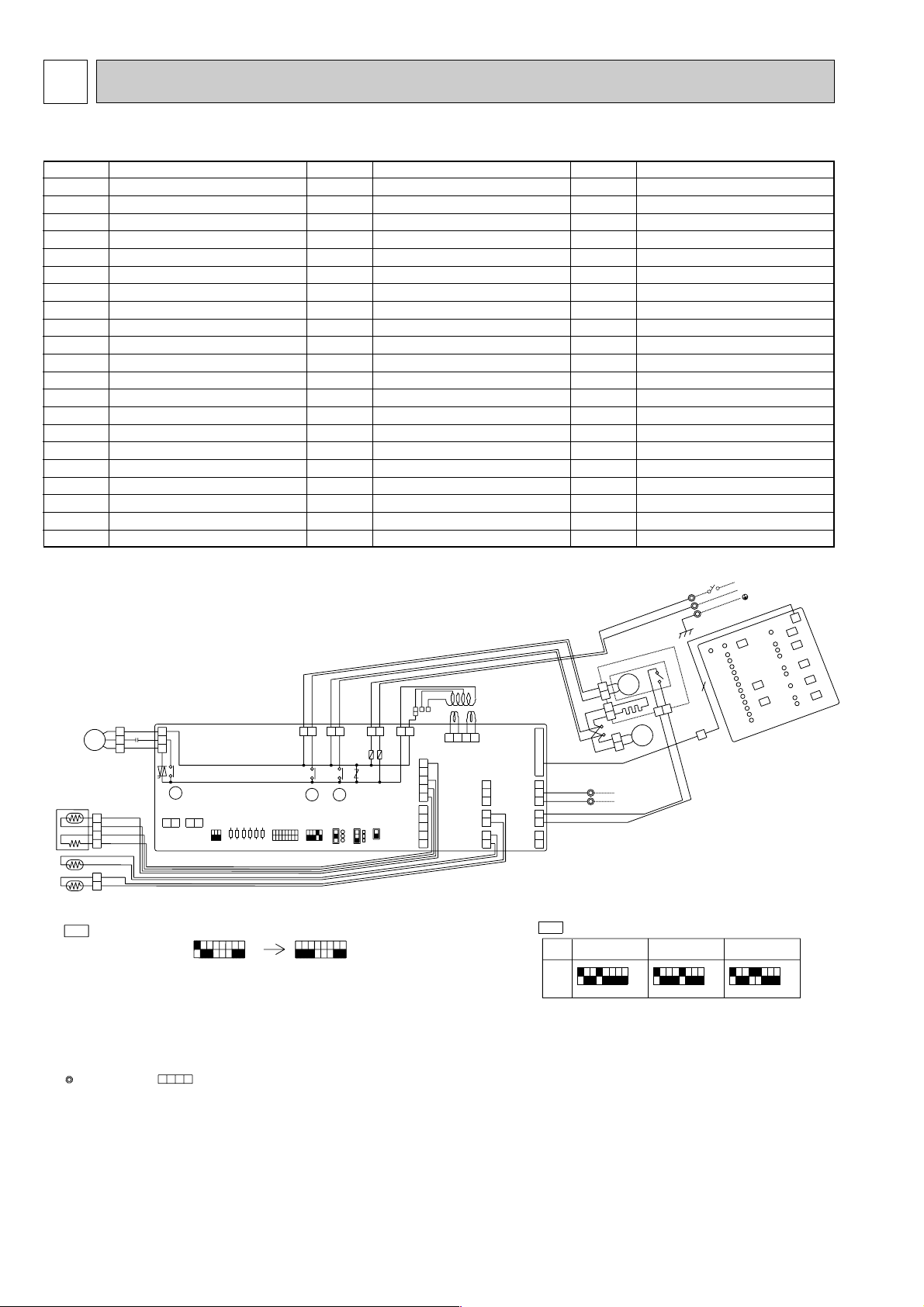

WIRING DIAGRAM

SYMBOL NAME

I.B

MF

MV

LS

RT1

RT2

DS

DP

T

C1

TB2

TB4

CND<I.B>

FAN1<I.B>

CNV<I.B>

CNP<I.B>

CN30<I.B>

CN120<I.B>

CN23<I.B>

CN20<I.B>

CN21<I.B>

INDOOR CONTROLLER BOARD

INDOOR FAN MOTOR

VANE MOTOR

LIMIT SWITCH

ROOM TEMPERATURE THERMISTOR (0°C/15k1, 25°C/5.4k1)

INDOOR COIL THERMISTOR (0°C/15k1, 25°C/5.4k1)

DRAIN SENSOR

DRAIN PUMP

TRANSFORMER

INDOOR FAN CAPACITOR

POWER SUPPLY TERMINAL BLOCK

INDOOR/OUTDOOR CONNECTING WIRE TERMINAL BLOCK

POWER SUPPLY CONNECTOR

FAN MOTOR CONNECTOR

VANE MOTOR CONNECTOR

DRAIN PUMP CONNECTOR

INDOOR/OUTDOOR CONNECTING WIRE CONNECTOR

REMOTE CONTROLLER TRANSMISSION WIRE CONNECTOR

VANE POSITION CONNECTOR

INTAKE CONNECTOR

PIPE CONNECTOR

PL-1.6KJB.UK / PL-2KJB.UK / PL-2.5KJB.UK

SYMBOL

NAME

CN50<I.B>

CN51<I.B>

CN2A<I.B>

CN2B<I.B>

CN28<I.B>

CN2<I.B>

SW1<I.B>

SW2<I.B>

SW3<I.B>

SWA<I.B>

SWB<I.B>

SWC<I.B>

X1<I.B>

X3<I.B>

X4<I.B>

F1<I.B>

F2<I.B>

ZNR<I.B>

H

R.B

CNR120<R.B>

DRAIN SENSOR CONNECTOR

MULTIPLE CONNECTOR

TRANSMISSION WIRES No.1 CONNECTOR

TRANSMISSION WIRES No.2 CONNECTOR

TIME SHORTENING CONNECTOR

TIMER ADAPTOR CONNECTOR

FUNCTION SWITCH

UNIT SWITCH

EMERGENCY OPERATION SWITCH

HIGH CEILING, NOISE SAVING SWITCH

NUMBER OF AIR OUTLETS SWITCH

OPTION SWITCH

DRAIN PUMP/D.HEATER RELAY

VANE MOTOR RELAY

FAN MOTOR RALAY

FUSE (6.3A)

FUSE (6.3A)

VARISTOR

DEW PREVENTION HEATER

REMOTE CONTROLLER BOARD

CONNECTOR (REMOTE CONTROLLER TRANSMISSION WIRE)

SYMBOL NAME

SW1<R.B>

SW2<R.B>

SW3<R.B>

SW4<R.B>

SW5<R.B>

SW6<R.B>

SW7<R.B>

SW8<R.B>

LD1<R.B>

LD3<R.B>

LD4<R.B>

LD5<R.B>

LD6<R.B>

LD7<R.B>

LD8<R.B>

LD9<R.B>

LD10<R.B>

LD11<R.B>

LD12<R.B>

LD13~24<R.B>

ON/OFF SWITCH

MODE SWITCH

FAN SPEED HIGH/LOW SWITCH

VANE ON/OFF SWITCH

DISPLAY SWITCH

SET TEMPERATURE/TIMER UP SWITCH

SET TEMPERATURE/TIMER DOWN SWITCH

TIMER MODE SWITCH

RUN INDICATOR LED

COOLING INDICATORLED

FAN MODE INDICATOR LED

FAN HIGH INDICATOR LED

VANE ON INDICATOR LED

INDICATOR MODE TEMPERATURE LED

INDICATOR MODE TIMER LED

DRY INDICATOR LED

FAN LOW INDICATOR LED

OFF TIMER INDICATOR LED

ON TIMER INDICATOR LED

TEMPERATURE TIMER REMAINING TIME INDICATOR LED

(5)Em

ergency cooling should be lim

ited to 10 hours m

axim

am

. (the indoor unit heat exchanger m

ay freeze.)

(4)Therm

ostat will not function.

1.Since the indoor fan m

otor(M

F) is connected w

ith 220V pow

er, using 230, 240V pow

er w

ill require a setting change of the

dip sw

itch(SW

1<I.B>) on the indoor controller board show

ing fig:1.

2.Since the indoor transform

er(T) is connected w

ith 220V pow

er, if 230, 240V pow

er is used. C

hange the w

iring connection

show

ing fig:3.

(3)During em

ergency operation indoor fan runs at high speed but auto-vane does not work.

[Em

ergency operation procedure]

(1)Set the dip switch(SW

3<I.B>) on the indoor controller board to 1 , 2 on and 3 off for cooling

(2)Turn on the outdoor unit side circuit breaker, then the indoor unit side circuit breaker.

(3) Do not attem

pt em

ergency operation when drain pump fails(drain overflows).

(4) Emergency operation will be a continuous operation mode due to power ON/OFF.

(ON/OFF with the remote controller is not possible.)

[Check items]

(1) Compressor and fan.

(2) Check the trouble position using self diagnostic function.

If the result of self diagnosis indicates protective device such as freeze

protection is functioning emergency operation is not possible unless the cause

is rem

ove.

If remote controller or microcomputer fails but there is no other trouble,em

ergency

operation is possible by setting dip switch(SW3<I.B>) on the indoor controller board.

[Emergency operation]

N

O

TES:

:C

onnector

:Term

inal block

3.Since the outdoor side electric w

iring m

ay change be sure to check the outdoor unit electric w

iring for servicing.

4.Sym

bols used in w

iring diagram

are the follow

ing.

Indoor fan m

otor(M

F) for 230, 240V

8

7

6

5

4

1

2

3

O

FF

8

7

6

5

4

1

2

3

O

FF

SW

1

O

N

O

N

SW

1

fig:1

8765

4

1

23

ON

OFF

8765

4

1

23

ON

OFF

78

4

56

fig:2

1.6KJ

2.5KJ

2KJ

OFF

ON

32

1

MODELS

SW1

1

2

31 3 1

3

2

1

2

1

3

4

1

5

4

3

2

1

3

5

10

DP

6

1

7

2

MV

MF

1

5

4

3

2

2

1

2

1

1

12

3

1

2

2

1

2

1

1234

3

1

31

3131

5

SW

8

SW

4

SW

3

SW

2

SW

1

SW

7

SW

6

LD11

LD12

LD6

LD10

LD5

LD1

LD4

LD9

LD3

SW

5

LD24

LD23

LD22

LD21

LD20

LD19

LD18

LD17

LD16

LD15

LD14

LD13

LD7

LD8

TO OUTDOOR UNIT

CONNECTING WIRES

DC 12V

CNR120

B

R

N

B

RN

LS

TWIN1

CN2A

TWIN2

CN2B

JR05

JR06

JR03

JR04

JR02

JR01

CN2

TIMER

F1

SWC

STD

OP

TO REMOCON

CN120

X1

X3

SW3

321

X4

X3

1

2

3

SWA

SW1

8765432143215

SW2

OFF

ON

2

SWB

4

3

CN51

MULTIPLE

RT2

DS

RT1

DRAIN

CN50

INTAKE

CN20

PIPE

CN21

CN30

OUTDOOR

CN23

VANE

CN28

LINETEST

R.B.

12

ORN

YLW

1

2

TB4

BLK

WHT

GRILL

H2

B

LU

B

LU

B

R

N

B

RN

BRN

BRN

CN4T

TRANS

10.6V AC

14.5V AC

BRN

RED

T

YLW

ORN

YLW

RED

WHT

BLU

RED

GRN/YLW

POWER SUPPLY

~(1PHASE)

220-240V 50Hz

220V 60Hz

N

L

TB2

YLW

YLW

C1

RED

F2

ZNR

X1

X4

TRANS

POWER

D.U.M.VANEFAN

CNT

CND

CNPCNVFA N1

Page 13

13

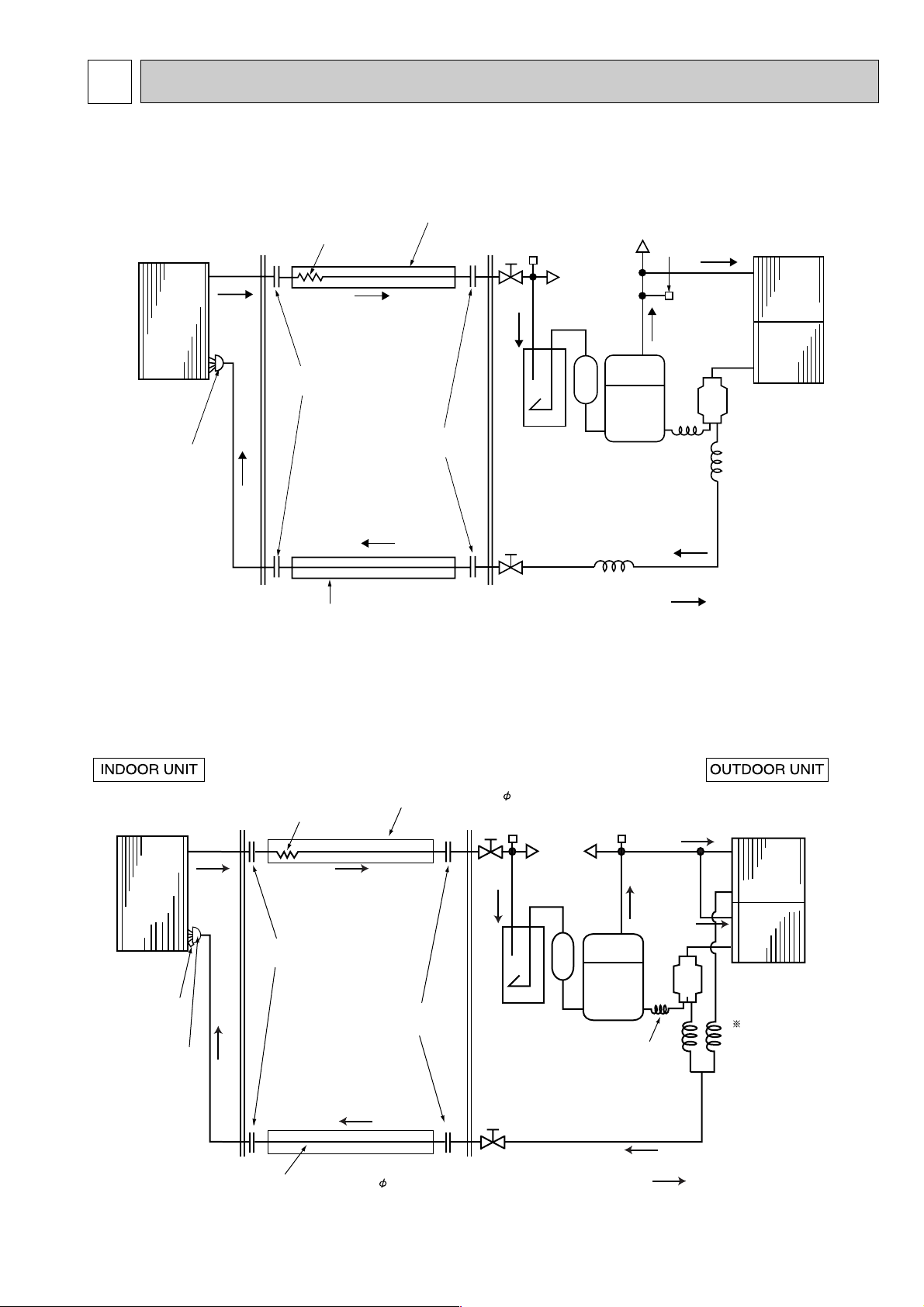

REFRIGERANT SYSTEM DIAGRAM7

INDOOR UNIT

PL-1.6KJB.UK

PL-2KJB.UK

Indoor heat

exchanger

OUTDOOR UNIT

PU-1.6

PU-2

Outdoor heat

exchanger

Distributor

Flexible tube

Flared

connection

Flared

connection

Ball valve

(with service port)

Refrigerant pipe {9.52(3/8)

(With insulator) option

Refrigerant pipe {15.88(5/8)

(With insulator) option

Accumulator

Compressor

Capillary tube

wCapillary tube size

: flow of refrigerant

PU-1.6(O.D.3.2

o

I.D.1.8-R900)

PU-2 (O.D.3.2

o

I.D.2.0-R430)

Strainer

Check

plug

High pressure

switch

Low pressure

switch

Charge

plug

Ball

valve

PL-1.6KJB.UK, PL-2KJB.UK/PU-1.6VLJA2.UK,PU-2VJA2.UK,PU-2NJA1.UK

PL-2.5KJB.UK/PU-2.5VJA

2

.UK,PU-2.5NJA1.UK

Indoor heat

exchanger

Indoor coil

thermistor

RT2

Distributor

with strainer

Outdoor heat

exchanger

Ball valve

(with service port)

Flared

connection

Flexible tube

Compressor

flow of refrigerant

wCapillary tube size

Capillary

tube

Capillary tube for

injection

Flared

connection

Low pressure

switch

High pressure

switch

Refrigerant pipe

15.88 (5/8)

(With insulator) option

Refrigerant pipe

9.52 (3/8)

Strainer

Ball

valve

Check

plug

Charge

plug

Accumulator

PU-2.5 (O.D.3.2oI.D.1.6-R760)o2pcs

PL-2.5KJB.UK PU-2.5

Page 14

14

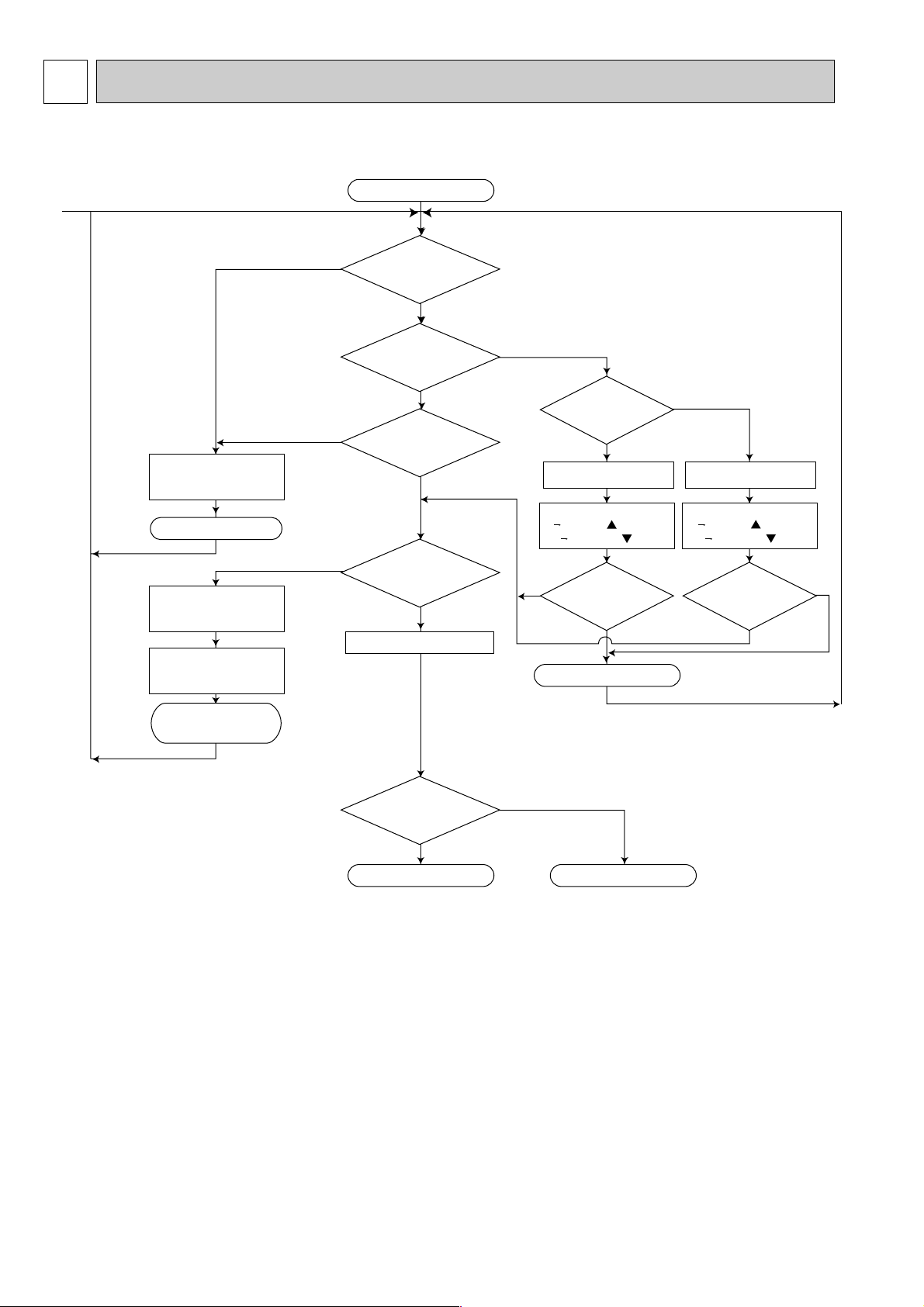

8

OPERATION FLOW-CHART

Models : PL-KJB.UK

1. Main operation

1

Start

POWER SUPPLY

Live

ON/OFF

button ON

TIMER MODE

button ON

During

operation

AUTO STOP lamp ON AUTO START lamp ON

Auto start timer

1 12Hr up/ press

12 1Hr down/ press

Abnormal

operation mode

MODE SELECT

button

EMERGENCY

ALL STOP

STOP

STOP

Self-diagnostic function

Indicate & Memory

Protection device

Self hold

Protection device

Self hold reset

COOL OPERATION

DRY OPERATION

POWER lamp ON

NO

NO

NO

NO

NO

NO

NO

DRY

COOL

YES

YES

YES YES

YES

YES

YES

<Note 1>

<Note 3>

<Note 2>

<Note 5>

<Note 4>

Auto stop timer

1 12Hr up/ press

12 1Hr down/ press

Set time Elapsed time=0

Set time Elapsed time=0

Note 1. Refer to page 21~22 for timer mode details.

Note 2. The unit starts operation by pressing the ON / OFF switch when unit is OFF.

During operation, the unit stops operation by pressing the ON / OFF switch.

In addition, operation can be turned ON / OFF with the contralized remote controller or the remote switch.

Note 3. The factors which cause "abnormal operation mode" are as follows.

●Outdoor unit abnormal operation.

●Fault of room temperature thermistor (RT1).

●Fault of indoor coil thermistor (RT2).

●Indoor coil frost protection mode.

●Drain water overflow prevention mode.

Refer to page 25 for abnormal operation mode details.

Note 4. The indoor fan runs on the low speed for 1 minute to eliminate remaining heat.

Note 5. The compressor will not start for 3 minutes after the stop.

Page 15

15

2. COOL operation

Note 6. The thermostat is continuously ON during the test run.

Note 7. Refer to page 18~19 for coil frost protection.

Note 8. Range A : Indoor coil temperature is more than 5 degrees above room temperature.

Range B : Indoor coil temperature is within 5 degrees either way of room temperature.

Range C : Indoor coil temperature is more than 5 degrees below room temperature.

COOL operation

<Note 6>

Compressor

thermostat ON

NO

Allowance release

YES

YES

YES

NO

<Note 7>

<Note 8>

NO

NO

3-minute

time delay

NO

6-minute

time delay

NO

Compressor start

3 minutes elapse

YES

Coil frost

protection

NO

Range C

YES

Compressor

start 10 minutes

elapse

YES

Allowance release

Coil frost

prevention

NO

Compressor

start 16 minutes

elapse

YES

Indoor coil

temperature

1C or below

NO

YES

YES

NO

YES

Indoor coil

temperature 10:

or more

YES

3-minute time delay

Coil frost

prevention release

Coil frost

prevention set

Allowance

NO

6-minute time delay

Allowance set

NO

NO

NO

YES

Continue

1 minute

YES

Fan speed LOW

Fan speed LOW

5 minutes elapse

YES

Outdoor unit abnor-

mality check mode

Coil frost

protection

check mode

Compressor ON Compressor OFF

1

Page 16

16

1

DRY operation

Compressor ON

Compressor OFF

10 minutes completed

Compressor ON

3 min.elapse

Compressor

thermostat ON

Compressor

thermostat ON

Compressor ON

time completed

Fan stop

Compressor OFF

Compressor ON

time set

Compressor ON

Fan speed LOW

Compressor OFF

10-minute timer start

Room temperature

18 C or below

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

<Note 6>

<Note 9>

<Note 6>

<Note 10>

<Note 11>

<Note 11>

3-minute

time delay

NO

3. DRY operation

Note 9. When the room temperature is 18°C or below, the compressor can not turn ON. When the room temperature rises to

18°C or above, the compressor will start operation after a 3-minute time delay.

Note 10. Refer to page 20 for the compressor operation time.

Note 11. In DRY operation, the indoor fan runs on the low speed during the compressor ON and stops during the compressor

OFF.

Page 17

17

MICROPROCESSOR CONTROL9

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

● OFF-ON switching.

● COOL/DRY-FAN selector switching.

● HIGH-LOW fan speed switching.

● Swing louvers SWING-FIXED switching.

● TIMER mode selector switching.

● Thermostat setting.

● Timer setting.

● Self diagnostic troubleshooting.

● Test run switching.

● Room temperature thermistor.

● Indoor coil thermistor.

● Drain sensor.

● Compressor protection device working

● Compressor motor and outdoor fan motor :

ON - OFF

● Fan : ON - OFF.

● Fan speed : HIGH - LOW

● Swing louvers : ON-OFF.

● Drain water lift-up mechanism : ON-OFF

● Emergency stop.

OUTPUT to indoor unit

INPUT from indoor unit

INPUT to remote controller

● Transmits and receives signal.

REMOTE CONTROLLER

OUTPUT to remote controller

INDOOR CONTROLLER BOARD

● Receives orders from remote controller and temperature data from

indoor unit.

● Processes orders and data.

● Transmits the power of indication LED to remote controller

● Controls indoor and outdoor operation.

● Self diagnostic function.

w System control operation.<Optional>

w Emergency operation.

12VDC

12VDC

Polar, twelve (12) - core cable

Maximum length 50m (164ft)

Non - polar, two (2) - core cable

12

Outdoor unit

● Indication LED lights.

Indoor unit

PL-KJB.UK

OUTPUT to outdoor unit

INPUT from outdoor unit

OUTDOOR UNIT

● Receives order from indoor

controller.

● Emergency stop.

1.OUTLINE OF MICROPROCESSOR CONTROL

Page 18

18

2. INDOOR UNIT CONTROL

2-1COOL operation

(1) Compressor control

1 3-minute time delay

To prevent overload, the compressor will not start within 3 minutes after stop.

2 The compressor runs when the room temperature is higher than the set temperature.

The compressor stops when the room temperature is equal to or lower than the set temperature.

3 The compressor stops in check mode or during protective functions.

4 Coil frost prevention

To prevent indoor coil frost, the compressor will stop when the indoor coil thermistor (RT2) reads 1°C or below after the

compressor has been continuously operated for 16 minutes or more. The coil frost prevention is released under any of the

following conditions.

● The indoor coil thermistor rises to 10°C or above.

● The room temperature becomes equal to or lower than the set temperature.

● COOL mode is stopped or changed to another mode.

NOTE : By cutting the jumper wire JRO2 on the indoor controller board, the temperature to start coil frost prevention

changes from 1°C to -3°C.

<How to operate>

1 Press POWER ON/OFF button.

2 Press MODE SELECT button to set operation mode to COOL.

3 Check lamp is ON and set desired temperature with UP

or DOWN button.

NOTES : 1. When lamp is ON, press TIMER/TEMP button

to change the display to temperature mode.

2. Set temperature changes by 1°C in the range 18 ~ 29°C

each time UP or DOWN button is pressed.

3. The lighting lamp shows the set temperature, and the

flashing lamp shows the room temperature.

When the room temperature is equal to the set

temperature, the lamp keeps lighting, 0.5 seconds

brightly and 0.5 seconds faintly.

TIMER

<COOL operation time chart>

w1 Even if the room temperature rise above the set temperature during this period, the compressor will not start until this

period has ended.

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

Operation starts by

POWER button

ON.

ON

Thermostat

OFF

TEMP

Room temperature

becomes equal to

set temperature.

Room temperature

rises above set

temperature.

Operation stops by

POWER button

OFF.

ON

LOW or HIGHLOW or HIGH

Indoor fan

Louver

OFF

ON

OFF

Depends on remote controller setting

ON

Drain pump

OFF

ON

Compressor

OFF

MIN. 3 minutes w1

3 minutes

Page 19

19

5 Coil frost protection

When indoor coil temperatuer becomes -15°C or below,coil frost protection will proceed as follows.

<Start condition>

After the compressor has been continuously operated for 3 minutes or more,and the indoor coil temperature has been 15°C or below for 3 minutes,the coil frost protection will start.

<Coil frost protection>

Compressor stops for 6 minutes,and then restarts.

lf the start condition is satisfied again during the first 10 minutes of compressor operation,both the indoor and outdoor

units stop, and the remote controller displays this occurrence.

<Termination conditions>

Coil frost protection is released when the start condition is not satisfied again during the allowance, or when the COOL

mode stops or changes to another mode.

(2) Indoor fan control

Indoor fan speed LOW/HIGH depends on the remote controller setting.

However, if an outdoor unit abnormality is detected, the indoor fan speed will be LOW, regardless of the remote controller

setting.

(3) Louver control

Louver operation (SWING LOUVER ON / OFF) depends on the remote controller setting.

(4) Detecting abnormalities in the outdoor unit

After the compressor has been continuously operated for 3 minutes, if the difference between the indoor coil temperature

and the room temperature is out of RANGE C for 1 minute, the indoor fan speed will turn to LOW. Five minutes later, if the

difference is still out of RANGE C,the outdoor unit is functioning abnormally. Thus, the compressor will stops and the

remote controller will display this occurrence.

RANGE A : Indoor coil temperature is more than 5 degrees above room temperature.

RANGE B : Indoor coil temperature is within 5 degrees either way of room temperature.

RANGE C : Indoor coil temperature is more than 5 degrees below room tempetature.

(5) Dew prevention heater

To prevent dew from accumulating on the grill, dew prevention heater is continuously ON in COOL or DRY operation.

It is independant of the thermostat ON/OFF

(6) Drain pump control

The drain pump works in COOL or DRY operation. When COOL or DRY operation stops or changes to another mode, the

drain pump continues to operate for 3 more minutes. Even if the check mode starts during COOL or DRY operation, the

drain pump continues to operate for 3 more minutes.

<Drain sensor>

When both the drain pump and the unit are operating, the drain sensor detects the temperature. This temperature tells

whether the drain water level is above or under the drain sensor. If the drain water levels rises above the drain sensor due

to a drain pump malfunction, the unit will enter the check mode. The operation will stop and only the drain pump will

continue to operate for 3 more minutes. When either of the following conditions are satisfied, the drain sensor is deemed

under water.

● Though the drain sensor has been heated by the drain sensor heater for more than 40 seconds, its temperature rise is

less than 20 degrees.

● The drain sensor temperature is below 63°C.

2-2 DRY operation

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

<How to operate>

1 Press POWER ON/OFF button.

2 Press MODE SELECT button to set operation mode to DRY.

3 Check lamp is ON and set desired temperature with UP

or DOWN button.

NOTES : 1. When lamp is ON, press DISPLAY SELECT

button to change the display to temperature mode.

2. Set temperature changes by 1°C in the range 18 ~ 29°C

each time UP or DOWN button is pressed.

3. The lighting lamp shows the set temperature, and the

flashing lamp shows the room temperature.

When the room temperature is equal to the set

temperature, the lamp keeps lighting, 0.5 seconds

brightly and 0.5 seconds faintly.

TIMER

TEMP

Page 20

20

<DRY operation time chart>

MIN. 3 minutes w2

ON

Thermostat

Indoor fan

Louver

Drain pump

Compressor

ON

ON

LOW speedLOW speed

ON

OFF

OFF

ON

OFF

3 minutes

OFF

OFF

Operation starts by

POWER button

ON.

Operation stops by

POWER button

OFF.

Room temperature

becomes equal to

set temperature.

Room temperature

rises above set

temperature.

Depends on remote controller setting

w2 Even if the room temperature rises above the set temperature during this period, the compressor will not start

until this period has ended.

(1) Compressor control

13-minute time delay

To prevent overload, the compressor will not start within 3 minutes after stop.

2The compressor runs when the room temperature is higher than the set temperature.

The compressor stops when the room temperature is equal to or lower than the set temperature.

3The compressor stops in check mode or during protective functions.

4The compressor will not start when the room temperature is below 18°C.

The compressor starts intermittent operation when the power is turned ON with room temperature above 18°C. The

compressor ON/OFF time depends on the thermostat ON/OFF and the room temperatures as follows.

After 3-minute compressor operation,

● If the room temperature thermistor reads above 28°C with thermostat ON, the compressor will operate for 6 more

minutes and then stop for 3 minutes.

● If the room temperature thermistor reads 26°C~28°C with thermostat ON, the compressor will operate for 4 more

minutes and then stop for 3 minutes.

● If the room themperature thermistor reads 24°C~26°C with thermostat ON, the compressor will operate for 2 more

minutes and then stop for 3 minutes.

● If the room temperature thermistor reads below 24°C with thermostat ON, the compressor will stop for 3 minutes.

● If the thermostat is OFF regardless of room temperature, the compressor will stop for 10 minutes.

5Coil frost protection

Coil frost protection in DRY operation is the same as in COOL operation.

6Coil frost prevention

Coil frost prevention does not operate in DRY operation.

(2) Indoor fan control

The indoor fan runs on LOW speed during compressor operation. The fan speed cannot be changed with the remote

controller.

Also, the indoor fan does not run during compressor OFF.

(3) Louver & drain pump controls

Same as in COOL operation.

(4) Detecting abnormalities in the outdoor unit

An abnormality in the outdoor unit can not be detected in DRY operation.

Page 21

21

2-3 FAN operation

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

<How to operate>

1 Press POWER ON/OFF button.

2 Press MODE SELECT button to set operation mode to FAN.

NOTE : Temperature can not be set in FAN operation.

1 Indoor fan control

The indoor fan speed LOW/HIGH depends on the remote controller setting.

2 Louver control

The louver operation ON/OFF depends on the remote controller setting.

3 Drain pump control does not work in FAN operation. As an exception, when COOL mode changes to FAN mode, the drain

pump continues to operate for the first 3 minutes in FAN operation.

<Timer function>

AUTO STOP ·········Air conditioner stops after the set time lapses.

AUTO START ········Air conditioner starts after the set time lapses.

<How to operate

●

AUTO STOP timer>

1 While ● POWER I lamp is lighting, press TIMER MODE button.

■■■

STOP

and lamps turn ON.

2 Set the time for the AUTO STOP timer with the UP or DOWN button.

NOTE : The time setting is in 1 hour units up to 12 hours.

3 With the lapse of time, the timer lamps turn OFF one by one, showing

the remaining time.

4 To cancel the AUTO STOP timer and continue operation, press the

TIMER MODE button.

To cancel the AUTO STOP timer and stop operation, press the

POWER ON/OFF button.

<How to operate AUTO START timer>

1 While ❍ POWER I lamp is OFF, press TIMER MODE button.

■■■

START

I and lamps turn ON.

2 Set the time for the AUTO START timer with the UP or DOWN button.

NOTE : The time setting is in 1 hour units up to 12 hours.

3 With the lapse of time, the timer lamps turn OFF one by one, showing

the remaining time.

4 To cancel the AUTO START timer and keep the unit OFF, press the

TIMER MODE button.

To cancel the AUTO START timer and start operation, press the

POWER ON/OFF button.

TIMER

2-4 TIMER operation

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

LOUVER

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

ON

AUTO

STOP

START

AUTO

AUTO

TIMER

Page 22

22

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

Green

lamps

Remaining time:2 hour

59 minutes to 2 hour

TIMER TEMP

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

1 hour 59 minutes

to 1 hour

TIMER TEMP

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

59 minutes to 0

TIMER TEMP

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

Time counting

is completed.

TIMER TEMP

<Remaining time display>

NOTE : When AUTO STOP timer is active, the remaining time display can be changed to the temperature display by pressing

DISPLAY button.

The green lamps show the remaining time until the time is up. When the time is up, the green lamps are all off.

TIMER TEMP

2-5 Test run

The unit starts the test run by pressing both the UP and DOWN buttons simultaneously for more than two seconds

during lamp ON or the unit OFF.

● The test run automatically stops in 2 hours.

● Set temperature is not displayed during test run.

● To cancel the test run, press the POWER ON/OFF button.

<Initial setting>

The units are set as follows by the factory.

1) Initial operation mode: FAN 3) Swing louver :OFF

2) Fan speed : LOW 4) Set temperature : 28°C

2-6 Emergency operation

When the remote controller or microprocessor malfunctions and

no other trouble exists, emergency operation is available by

setting the dipswitch on the indoor controller board.

[Check items]

1 Make sure the compressor and the fans are running normally.

2 Locate the trouble with the self-doagnostic function. If the self-

doagnostic function indicates that the protection device (such

as coil frost protection)is functioning, the sources must be

removed before attempting emergency operation.

Emergency operation ON/OFF is activated not with the remote

controller but with the circuit breaker.

[Emergency operation procedure]

1 Cooling operation is available by setting the dipswitch SW3 1

and 2 ON and 3 OFF on the indoor controller board.

2 To start emergency operation, turn the outdoor side circuit breaker ON first, and then the indoor side circuit breaker ON.

3 During emergency operation, the indoor fan runs on HIGH speed, the compressor runs continuously, and the louver

stops.

When the drain pump is attached, it works in emergency operation.

4 Thermostat will not function.

5 Do not use emergency cooling operation for more than 10 hours, as the indoor coil may freeze.

w If the self-diagnostic function shows a drain pump malfunction, do not attempt emergency operation, as the drain may

overflow.

INDOOR CONTROLLER BOARD

TIMER

SW3

Page 23

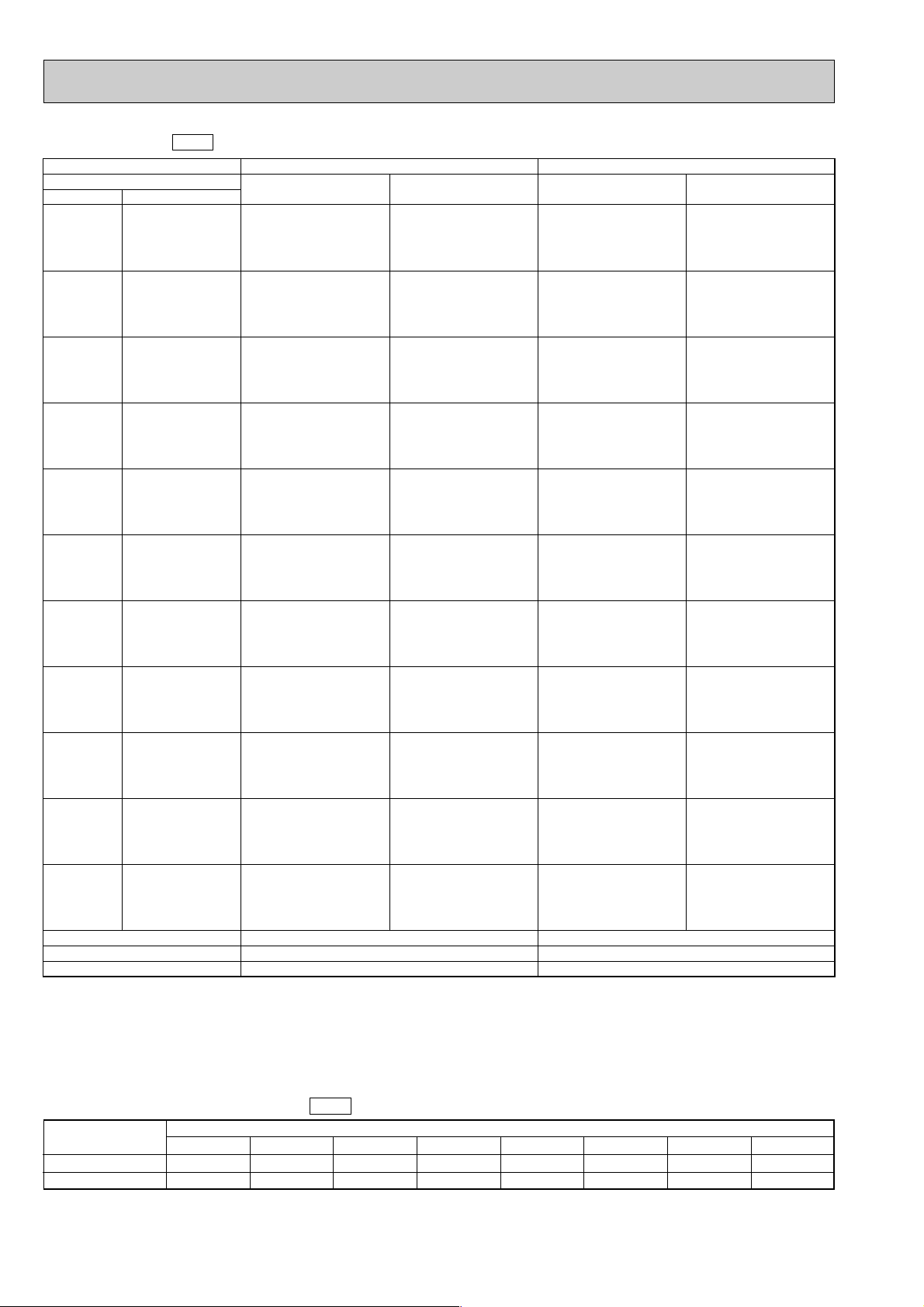

2-8 Function of jumper wire and dipswitch on indoor controller board

1. Jumper wire

1 JR01

...

Jumper wire for the auto vanes.

Cut JR01 for the unit WITHOUT auto vanes.

2 JR02

...

Jumper wire for the temperature to start coil frost prevention

Cutting JR02 changes the temperature from +1°C to -3°C.

3 JR03

...

Jumper wire for set temperature adjustment in HEAT mode.

In HEAT operation, heated air stagnates in the upper part of the room. The indoor unit installed in the upper part of the

room will detect the air temperature higher than the actual temperature in the living space. This difference is about 4

degrees. Therefore, the temperature detected by the room temperature thermistor should be corrected 4 degrees down.

The unit with JR04 attached will make this adjustment.

4 JR04

...

Jumper wire for the indoor fan speed during thermostat OFF in HEAT mode

Cutting JR04 changes the speed from Extra-Low to Low.

5 JR05

...

Jumper wire for detecting abnormalities in the outdoor unit

Cutting JR05 makes this detection unavailable. (Occurrence of abnormality can not be detected. )

6 JR06

...

Jumper wire for auto restart function

Cutting JR06 makes the auto restart function available.

2. Dipswitch

1 SW1 (Function switch)

SW1-1) Switch for power supply

ON : 220V

OFF : 230V, 240V

SW1-2) Switch for single or twin control

ON : Twin control

OFF : Single control

SW1-3) Switch for unit number in twin control (This switch is valid when SW1-2 is ON. )

ON : Unit No. 2

OFF : Unit No. 1

SW1-4~SW1-6 Switch for capacity of each model

SW1-7, SW1-8 Switch for the pair number of wireless remote controller

2-7 Auto Restart function

Unit can be start / stop by turning the breaker ON / OFF.

1) Cutting the JR06 on the indoor board.

Unit can be start / stop using the remote controller. Only in case the unit was operated before a power cut, the unit will

restart automatically after power is back.

2) Short all the CN2 on the indoor board.

Unit can not be start / stop using remote controller.

Unit will restart automatically whether the unit was operated or stopped when the power was cut off.

JR06

Available

Not available

Auto restart

Not effective

Effective

1

2

3

CN2

ORN

BRN

RED

Optional timer adapter

PAC-SA89TA-E

1 2 3 4 5 6 7 8

ON

OFF

PL-1.6KJB.UK PL-2KJB.UK PL-2.5KJB.UK

4 5 6

ON

OFF

4 5 6

ON

OFF

4 5 6

ON

OFF

0

7 8

ON

OFF

1

7 8

ON

OFF

2

7 8

ON

OFF

3

7 8

ON

OFF

23

Page 24

24

1 2 3 4 5

ON

OFF

PL-KJB.UK

3 4 5

ON

OFF

3 SW3 (Emergency operation switch)

1 2 3

Normal operation

ON

OFF

1 2 3

For emergency cooling

ON

OFF

4 SWA (High ceiling, noise saving switch)

High ceiling 2

High ceiling 1

Standard

5 SWB (Air outlet number switch)

(Not used)

3-direction airflow

4-direction airflow

(Standard)

6 SWC (Option switch)

Option

Standard

When mounting the optional high efficiency

filter, set this switch to “option”

SWA

4-direction airflow

3-direction airflow

Standard

2.4

2.7

High ceiling 1

2.7

3.0

High ceiling 2

3.0

3.3

Ceiling height & airflow direction

(Unit : m)

SWB

2 SW2 (Unit switch)

SW2-1) Switch for air conditioner with or without electric heater

ON : Unit with electric heater

OFF: Unit without electric heater

SW2-2) Switch for air conditioner with or without heat pump

ON : Unit with heat pump

OFF: Unit without heat pump

SW2-3, SW2-4) Switch for function code

Page 25

25

TROUBLESHOOTING10

1. SELF-DIAGNOSTIC FUNCTION

! When trouble occurs during operation, the unit stops and enters the self-diagnostic mode, and displays the trouble

location with the timer lamps on the remote controller. All the other lamps are OFF.

@ To activate the self-diagnostic function for service, press the UP and DOWN buttons simultaneously for more than two

seconds during operation with lamp ON.

# The timer lamps show the latest trouble. Trouble data is memorized until the next trouble occurs, even when the breaker

turns OFF. To clear the memory, press the UP and DOWN buttons simultaneously for more than two seconds during the

test run.

$ All buttons except the POWER ON/OFF button are unavailable during the self-diagnostic mode.

% To release the self-diagnostic mode, press the POWER ON/OFF button.

TEMP

Unit

Trouble location

Transmission error

in twin control

Cause

● Wrong wiring between No. 1

and No. 2 units

● Poor connector contact

Measures

● Check dipswitch setting

● Check wiring

Outdoor unit

● Wrong wiring between

indoor/outdoor units

● Outdoor unit abnormality

detection

● Malfunction of outdoor coil

thermistor

● Reversed phase detected

● Check wiring

● Check outdoor unit

● Check outdoor coil thermistor

Unit

No.1

Unit

No.2

Room

temperature

thermistor

(RT1)

● Poor connector contact

● Thermistor malfunction

● Check connector

● Check thermistor

➔ No trouble ➔ replace indoor

controller

board.

Unit

No.1

Unit

No.2

Indoor coil

thermistor

(RT2)

● Poor connector contact

● Thermistor malfunction

● Check connector

● Check thermistor

➔ No trouble ➔ replace indoor