Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TM

A

I

R

S

T

A

N

D

A

R

D

2

4

0

•

M

A

N

U

F

A

C

T

U

R

E

R

C

E

R

T

I

F

I

E

D

T

O

A

R

I

A

S

C

O

M

P

L

Y

I

N

G

W

I

T

H

•

C

E

R

T

I

F

I

C

A

T

I

O

N

S

E

C

T

I

O

N

S

O

F

E

Q

U

I

P

M

E

N

T

A

I

R

-

C

O

N

D

I

T

I

O

N

I

N

G

U

N

I

T

A

R

Y

L

I

S

T

E

D

CUS

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

TECHNICAL & SERVICE MANUAL

No. OC276

REVISED EDITION-A

Series PKH

[Models]

PKH18FL

PKH24FL

PKH30FL

PKH36FL

Wall Mounted

Indoor unit

Revision:

●The wrong descriptions in REFRIGERANT

SYSTEM DIAGRAM have been modified.

(Page 18.)

●The wrong descriptions in WIRING DIAGRAM

have been modified.

(Page 19.)

●Restrictor valve and capillary tube have been

added to "Specifications" of heat exchanger.

(Page 48.)

●Please void OC276.

CONTENTS

1. FEATURES ·······························································2

2. PART NAMES AND FUNCTIONS····························3

3. SPECIFICATIONS·····················································4

4. DATA·········································································5

5. OUTLINES AND DIMENSIONS······························16

6. REFRIGERANT SYSTEM DIAGRAM ····················18

7. WIRING DIAGRAM·················································19

8. OPERATION FLOW-CHART··································20

9. MICROPROCESSOR CONTROL···························24

10. TROUBLESHOOTING············································41

11. DISASSEMBLY PROCEDURE ·······························45

12. PARTS LIST····························································48

Remote controller

Page 2

1

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

FEATURES

Indoor unit

Remote controller

Models Cooling capacity / Heating capacity SEER

PKH18FL 18,000 / 18,600 [25,100] Btu/h 11.1

PKH24FL 24,000 / 25,000 [31,500] Btu/h 10.2

PKH30FL 30,000 / 33,000 [40,500] Btu/h 10.6

PKH36FL 34,200 / 38,000 [45,500] Btu/h 10.5

1. COMPACT DESIGN

The PKH series models have been downsized and now require such minimal wall space that they can even be installed

above windows.

2. LCD WIRELESS REMOTE CONTROLLER

The new wireless remote controller has a larger easy-to-read temperature display, and executes ON/OFF commands

and temperature settings with a press of the button.

3. AUTO FLAP SHUTTER

With a simple flick of the OFF switch the air outlet can be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle 1” securing a comfortable air flow.

4. INSTALLATION : FAST AND EASILY ADAPTABLE

(1) Multi-directional piping

Multi directional drain and refrigerant piping radically improves flexibility in selecting installation layouts.

PKH18/24/30/36FL models boast refrigerant piping in 4 directions and drain piping in 2 directions.

(2) Back plate installation guide

The back plate installation guide gives clear instructions on installation positions. The enlarged back plate secures the

unit firmly to the wall, while the support piece which lifts the unit makes left side piping work much easier.

(3) Easily removable filter and convenient wireless remote controller

The presence of thumb screws on the filters means that the filters can be quickly and smoothly removed.

5. HIGH RELIABILITY AND EASY SERVICING

In addition to the self-diagnostic function, units are also equipped with a 3-minute time delay mechanism (cooling), an auto

restart function, an emergency operation function, a test run switch, etc., to assure high reliability and easy servicing.

6. NITROGEN GAS IS CHARGED TO INDOOR UNIT

Indoor unit and refrigerant pipes are charged with nitrogen gas (N2) instead of R22 before shipment from the factory.

2

Page 3

PART NAMES AND FUNCTIONS2

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

VANE CONTROL button

Used to change the air flow direction.

CLOCK button

RESET button

SET button

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

LOUVER button

This switch the horizontal fan motion ON

and OFF.

(Not available for this model.)

MODE SELECT button

Used to switch the operation mode between

cooling, drying, fan.

CHECK-TEST RUN button

Only press this button to perform an inspection check or test operation.

Do not use it for normal operation.

FAN SPEED SELECT button

Used to change the fan speed.

TIMER display

Displays when in timer operation or when

setting timer.

button

SET TEMPERATURE button sets any desired

room temperature.

CLOCK display

Displays the current time.

“ ” “ ” display

Displays the order of timer operation.

“ ” “ ” display

Displays whether timer is on or off.

Buttons used to set the “hour and minute” of

the current time and timer settings.

h and min buttons

88°F display

SET TEMP. display indicates desired temperature set.

display

FAN SPEED display indicates which fan

speed has been selected.

display

The vertical direction of air flow is indicated.

display

Blinks when model is selected.

display

Lights up while transmission to the indoor

unit is mode using switches.

display

CHECK&TEST RUN display indicates that

the unit is being checked or test-run.

OPERATION MODE display

OPERATION MODE display

Operation mode display indicates which operation mode is in effect.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch

is set, the air conditioner will be automatically stopped at the preset time.

AUTO START (ON timer): when this switch

is set, the air conditioner will be automatically started at the preset time.

MODEL SELECT

CHECK

TEST RUN

●Wireless remote controller

● When cover is open.

3

Page 4

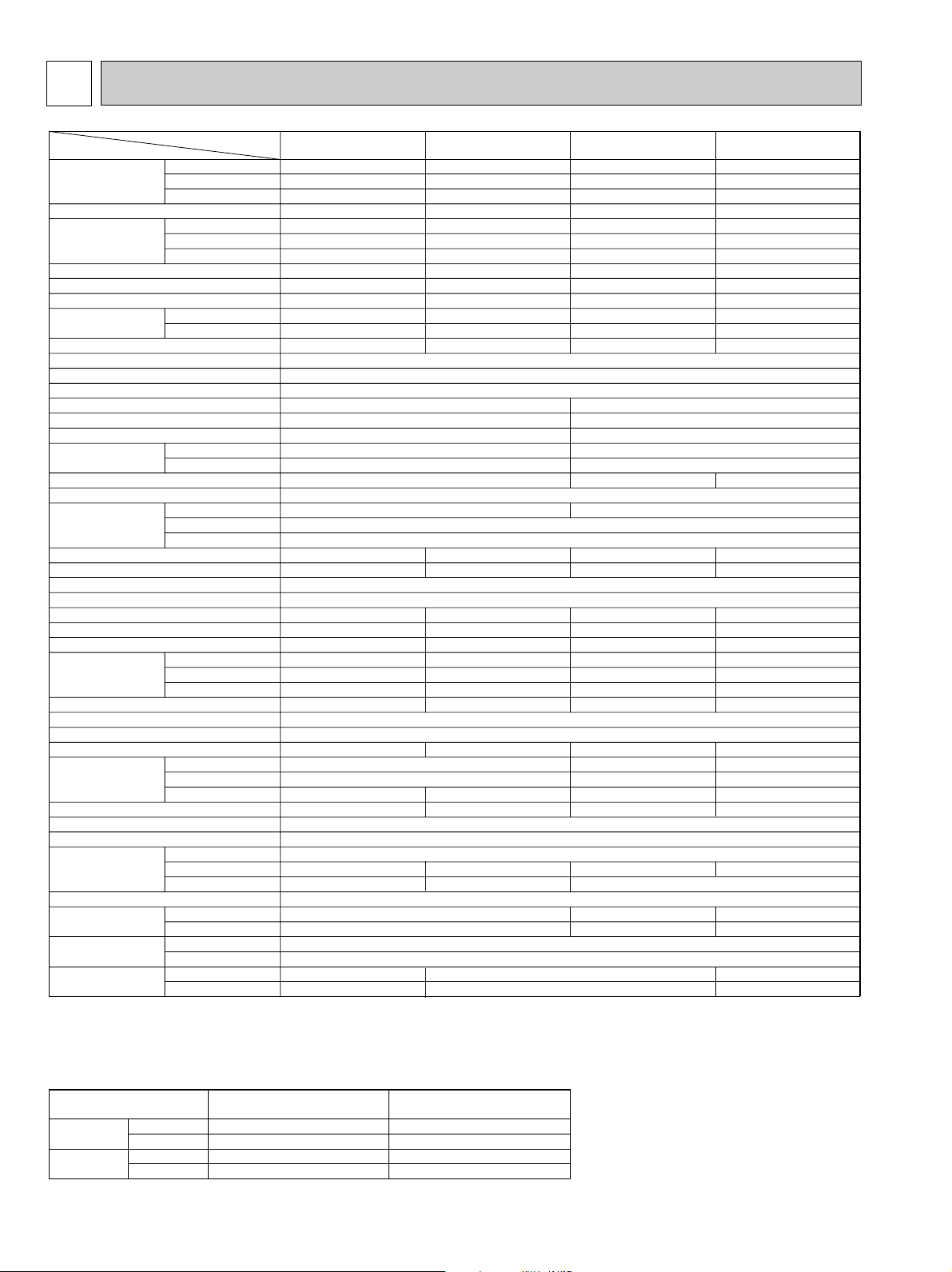

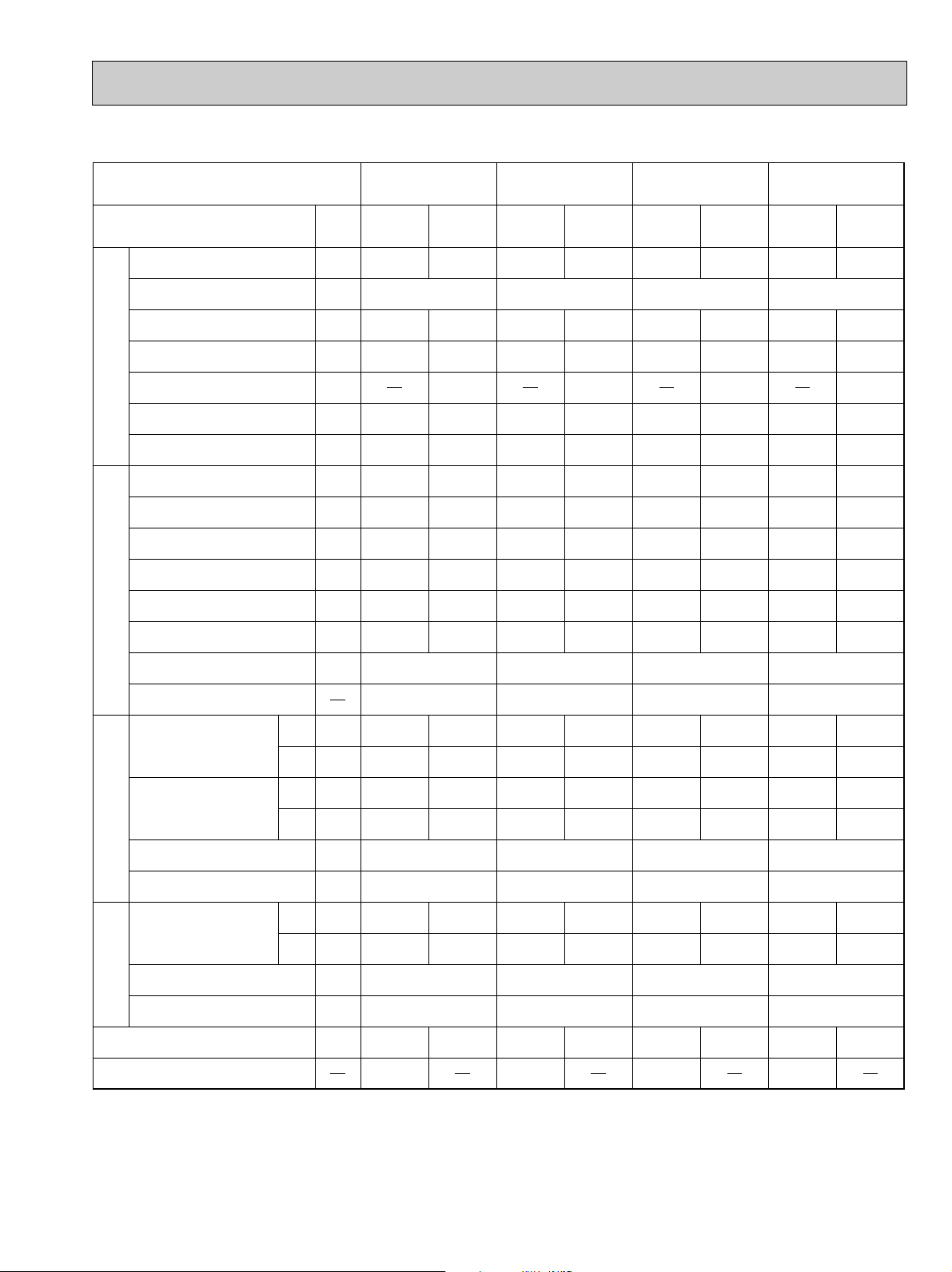

3 SPECIFICATIONS

FK1:48 -41

Capacity

Moisture removal

Power

Consumption

EER

SEER

HSPF

COP

INDOOR UNIT MODELS

External finish

Power supply

Max.fuse size (time delay)

Min.ampacity

Fan motor

Booster heater

Airflow Hi-Lo

Sound level Hi-Lo

Unit drain pipe O.D.

Dimensions

Weight

OUTDOOR UNIT MODELS

External finish

Power supply

Max.fuse size (time delay)

Min.ampacity

Fan motor

Compressor

Crankcase heater

Refrigerant control

Defrost method

Sound level

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT

REFRIGERANT PIPING

Pipe size

Connection

method

Between the indoor

& outdoor units

Cooling *1

Heating *1

Heating *2

Cooling *1

Heating *1

Heating *2

*1

*1

*2

Dry

Wet

W

D

H

Model (type)

W

D

H

Name

Charge

Oil <Model>

Liquid

Gas

Indoors

Outdoors

Height difference

Piping length

Btu/h

Btu/h

Btu/h

Pints/h

kW

kW

kW

V,phase,Hz

A

A

F.L.A.

A(kW

)

CFM

CFM

dB

in.

in.

in.

in.

lb

V,phase,Hz

A

A

F.L.A.

R.L.A.

L.R.A.

A(W

)

dB

in.

in.

in.

lb

L

in.

in.

ft

ft

PKH18FL

Model

18,000

18,600[24,100/25,100

]

10,700[16,200/17,200

]

5.3

1.79

1.56[3.16/3.46

]

1.34[2.94/3.24

]

10.1

11.1

7.2

3.5

2.3

PKH18FL

57

PUH18EK

20

16

0.75

RH247NAB

12

37

0.11/0.12[23/28

]

53

33-1/2

131

5 lbs 8 oz

0.52 <MS-56>

130

130

PKH24FL

24,000

25,000[30,500/31,500

]

14,700[20,200/21,200

]

7.0

2.36

2.37[3.97/4.27

]

1.92[3.52/3.82

]

10.2

10.2

6.8

3.1

2.2

PKH24FL

Munsell 3.4Y 7.7/0.8

208/230,1,60

57

PUH24EK

1

Munsell 5Y 7/1

208/230,1,60

20

16

0.65+0.65

NH33NBD

11.5

54

0.16/0.17[33/39

]

Capillary tube

Reverse cycle

55

49-9/16

202

With indoor unit

Indoor unit-remote controller:DC12V. Indoor unit-outdoor unit:DC12V

R22

9 lbs 15 oz

1.2 <MS32N-1>

Not supplied(optional parts)

Flared

Flared

9-1/4

13-3/8

PKH30FL

30,000

33,000[39,100/40,500

]

19,000[25,100/26,500

]

9.1

3.12

3.02[4.82/5.22

]

2.48[4.28/4.68

]

9.6

10.6

7.1

3.2

2.2

PKH30FL

FK

1:49-44

66

PUH30EK

1

30

20

0.75+0.75

NH41NAD

14.0

73

0.16/0.17[33/39

]

55

38-3/16

13-9/16

49-9/16

245

10 lbs 2 oz

1.3 <MS32N-1>

1/2

3/4

PKH36FL

34,200

38,000[44,100/45,500

]

19,600[25,700/27,100

]

10.5

3.44

3.54[5.34/5.74

]

2.65[4.45/4.85

]

9.9

10.5

6.9

3.1

2.2

PKH36FL

FK

1:50-46

66

PUH36EK

1

30

22

0.75+0.75

NH47NAD

17.5

87

0.16/0.17[33/39

]

55

38-3/16

13-9/16

49-9/16

246

10 lbs 9 oz

1/2

3/4

164

164

Item

34-1/4

11-5/8

3/8

5/8

164

164

55-1/8 66-5/32

NOTES : *1.Rating conditions (cooling)-indoor : 80˚FDB,67˚FWB outdoor : 95˚FDB,75˚FWB.

(heating)-indoor : 70˚FDB,60˚FWB outdoor : 47˚FDB,43˚FWB.

*2.Rating conditions (heating)-indoor : 70˚FDB,60˚FWB outdoor : 17˚FDB,15˚FWB.

*3.Heating capacity and power consumption in [ ] includes heater operation at 208/230V.

Operating range

Indoor intake air temperature

95˚FDB,71˚FWB

67˚FDB,57˚FWB

80˚FDB,67˚FWB

70˚FDB,60˚FWB

Outdoor intake air temperature

115˚FDB

0˚FDB *

75˚FDB,65˚FWB

17˚FDB,15˚FWB

Cooling

Heating

Maximum

Minimum

Maximum

Minimum

1-1/16 (or 7/8)

15

12 13

0.5

0.6

7.6/8.4[1.6/1.9

]

710-530

640-480

8.7/9.6[1.8/2.2

]

990-780

890-700

*

In case of the wind baffle is installed.

(In case of the wind baffle is not installed, the minimum temperature will be 23˚FDB.)

MODELS : PKH18FL, PKH24FL, PKH30FL, PKH36FL

4

Page 5

4

Models

Models Outdoor intake air DB temperature(˚F

)

PKH18FL

71

67

63

62.5

60

59

71

67

63

62.5

60

59

71

67

63

62.5

60

59

71

67

63

62.5

60

59

TC

21.0

19.5

18.2

18.1

17.2

16.8

27.9

26.1

24.3

24.1

23.0

22.5

34.9

32.6

30.4

30.2

28.8

28.2

39.8

37.1

34.7

34.4

32.8

32.2

SHC

14.4

16.0

17.4

15.5

15.1

14.5

16.1

18.5

20.5

18.0

17.6

17.0

21.5

24.5

26.9

23.8

23.2

22.4

23.0

26.3

29.3

25.8

25.1

24.3

TPC

1.56

1.52

1.49

1.49

1.47

1.46

2.05

2.01

1.97

1.96

1.94

1.93

2.72

2.66

2.60

2.59

2.57

2.56

3.00

2.93

2.87

2.86

2.82

2.81

TC

20.2

18.8

17.5

17.4

16.6

16.2

26.9

25.1

23.4

23.2

22.1

21.7

33.7

31.4

29.2

29.0

27.6

27.0

38.4

35.7

33.3

33.1

31.5

30.8

SHC

13.9

15.4

16.7

14.9

14.5

14.0

15.5

17.8

19.7

17.4

16.9

16.4

20.8

23.6

25.8

22.9

22.2

21.5

22.1

25.3

28.1

24.8

24.1

23.2

TPC

1.69

1.65

1.61

1.61

1.58

1.57

2.23

2.18

2.12

2.12

2.09

2.07

2.95

2.88

2.81

2.80

2.77

2.76

3.25

3.17

3.10

3.09

3.04

3.03

TC

19.4

18.0

16.8

16.6

15.8

15.5

25.8

24.0

22.4

22.2

21.1

20.7

32.3

30.0

27.9

27.7

26.3

25.7

36.8

34.2

31.9

31.6

30.1

29.5

SHC

13.3

14.8

16.0

14.3

13.8

13.4

14.9

17.0

18.9

16.6

16.2

15.6

19.9

22.5

24.6

21.9

21.2

20.4

21.2

24.3

26.9

23.7

23.0

22.3

TPC

1.84

1.79

1.74

1.74

1.70

1.69

2.43

2.36

2.30

2.29

2.25

2.24

3.21

3.12

3.04

3.03

2.99

2.98

3.54

3.44

3.35

3.34

3.28

3.26

TC

18.5

17.1

15.9

15.8

15.0

14.6

24.6

22.9

21.3

21.1

20.1

19.7

30.8

28.6

26.6

26.3

24.9

24.4

35.1

32.6

30.3

30.0

28.5

27.9

SHC

12.7

14.0

15.2

13.6

13.1

12.6

14.2

16.3

18.0

15.8

15.4

14.9

19.0

21.5

23.5

20.7

20.1

19.4

20.2

23.1

25.6

22.5

21.8

21.0

TPC

1.99

1.93

1.88

1.87

1.84

1.83

2.63

2.55

2.47

2.47

2.41

2.39

3.48

3.37

3.27

3.26

3.21

3.19

3.83

3.71

3.61

3.59

3.52

3.50

TC

17.6

16.3

15.1

15.0

14.2

13.9

23.4

21.7

20.1

19.9

18.9

18.5

29.3

27.1

25.1

24.9

23.5

22.9

33.4

30.9

28.7

28.4

26.9

26.4

SHC

12.1

13.4

14.4

12.9

12.4

12.0

13.5

15.4

17.0

14.9

14.5

14.0

18.1

20.3

22.2

19.6

18.9

18.2

19.3

21.9

24.2

21.3

20.6

19.9

TPC

2.15

2.07

2.01

2.00

1.96

1.94

2.84

2.73

2.65

2.64

2.58

2.56

3.75

3.61

3.50

3.49

3.43

3.41

4.13

3.98

3.86

3.85

3.76

3.73

IWB

(˚F)

DB 75°F (50%RH)

DB 72°F (50%RH)

DB 70°F (50%RH)

DB 75°F (50%RH)

DB 72°F (50%RH)

DB 70°F (50%RH)

DB 75°F (50%RH)

DB 72°F (50%RH)

DB 70°F (50%RH)

DB 75°F (50%RH)

DB 72°F (50%RH)

DB 70°F (50%RH)

75 85 95 105 115

710

0.16

Airflow

(

CFM

)

B.F

PKH24FL

710

0.16

PKH30FL

990

0.15

PKH36FL

990

0.14

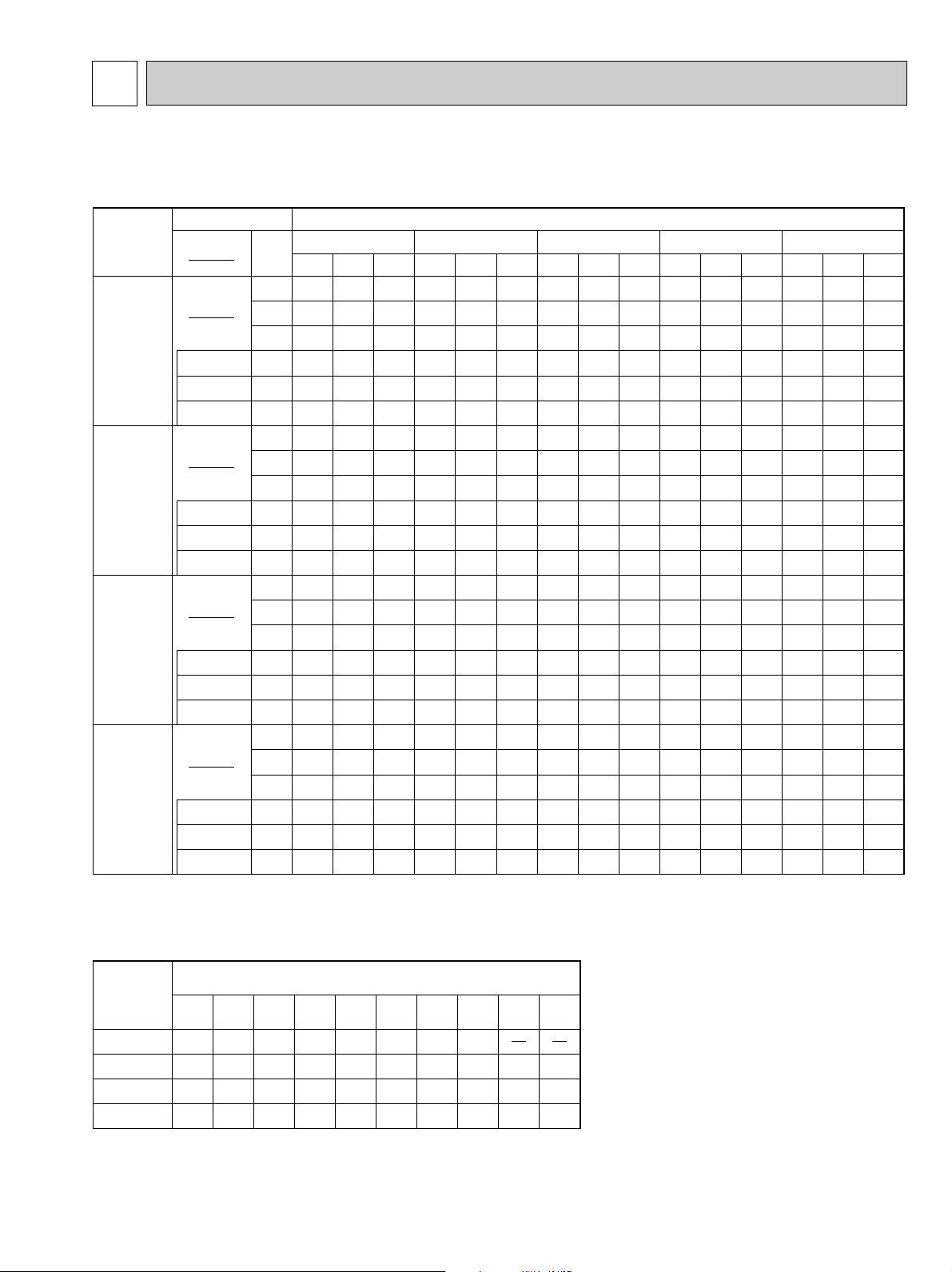

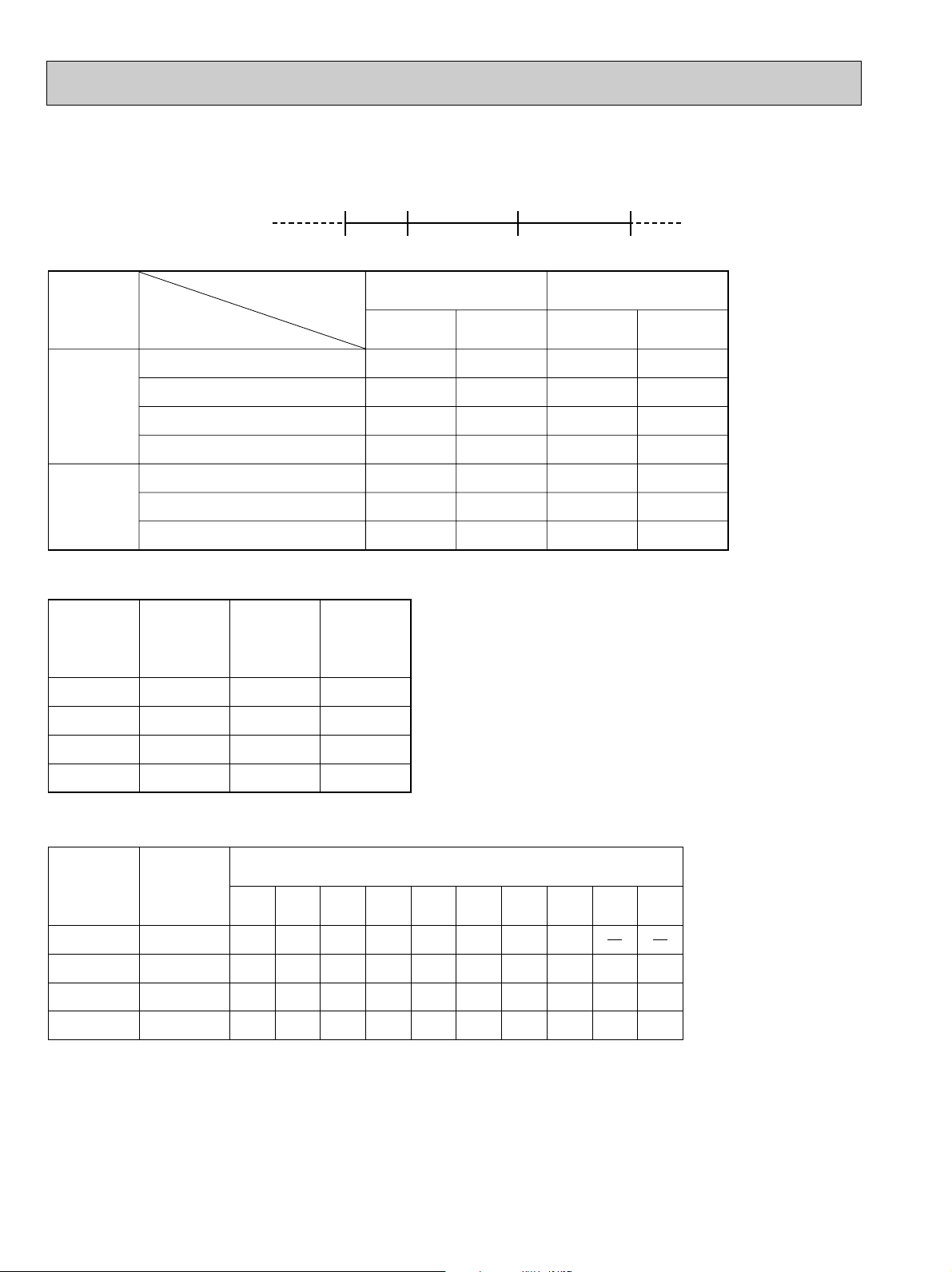

Notes 1. B.F. : Bypass Factor, IWB : Intake air wet-bulb temperature

TC : Total Capacity (x10

3

Btu/h), SHC : Sensible Heat Capacity (x10

3

Btu/h)

TPC : Total Power Consumption (kW)

2. SHC is based on 80˚FDB of indoor intake air temperature.

3. Cooling capacity correction factors and Refrigerant piping length (one way) range.

MODEL

Refrigerant piping length (one way)

1.0

1.0

1.0

1.0

25ft

0.992

0.981

0.981

0.981

40ft

0.983

0.968

0.968

0.968

55ft

0.978

0.952

0.952

0.952

70ft

0.966

0.940

0.940

0.940

85ft

0.959

0.925

0.925

0.925

100ft

0.950

0.913

0.913

0.913

115ft

0.945

0.900

0.900

0.900

130ft

0.886

0.886

0.886

150ft

0.874

0.874

0.874

164ft

PKH18FL

PKH24FL

PKH30FL

PKH36FL

DATA

MODELS : PKH18FL, PKH24FL, PKH30FL, PKH36FL

1. PERFORMANCE DATA

1) COOLING CAPACITY

5

Page 6

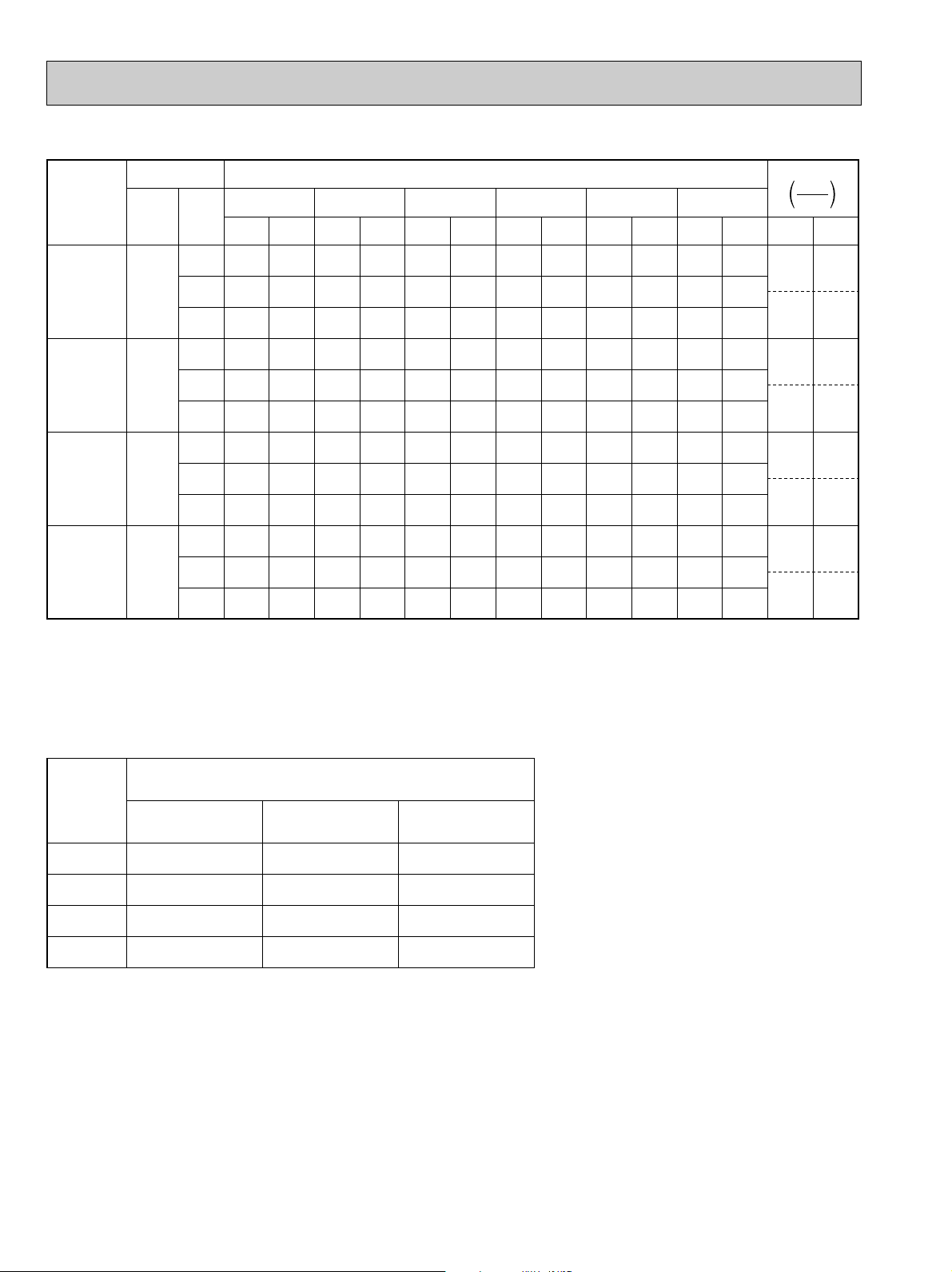

2) HEATING CAPACITY

Models Outdoor intake air WB temperature(˚F

Models

Airflow

(CFM)

IWB

(˚F)

75

15 25 35 45 55 65

CA

PC

CA

PC

CA

PC

CA

PC

CA

PC

12.1

1.20

14.1

1.34

16.3

1.49

18.7

1.65

21.4

1.83

)

CA

23.7

Auxiliary heater

PC

1.99

CA

5.5

208V

230V

PC

1.6

PKH18FL

PKH24FL

PKH30FL

PKH36FL

Notes 1. IDB : Intake air dry-bulb temperature

CA : Capacity (x10

2. When booster heater is "on", total capacity and total power consumption should be added the figures described in

booster heater column.

•Booster heater ON : When the set temperature is higher than the room temperature by more than 5.4 deg.

•Booster heater OFF : When the set temperature is higher than the room temperature by less than 3.6 deg.

3. Heating capacity correction factors.

710

710

990

990

70

12.4

1.16

14.4

1.29

65

12.7

1.11

14.7

1.24

75

16.3

1.82

18.9

2.03

70

16.6

1.76

19.4

1.96

65

17.0

1.69

19.8

1.89

75

21.5

2.32

25.0

2.59

70

21.9

2.24

25.5

2.50

65

22.5

2.15

26.1

2.40

75

24.7

2.71

28.7

3.04

70

25.3

2.62

29.4

2.93

65

25.9

2.53

30.1

2.82

3

Btu/h), PC : Power Consumption (kW)

16.7

17.0

21.9

22.4

22.9

28.9

29.6

30.2

33.3

34.1

34.8

1.44

1.38

2.27

2.19

2.10

2.89

2.78

2.68

3.39

3.26

3.14

19.1

19.5

25.2

25.7

26.2

33.2

33.9

34.6

38.2

39.0

39.9

1.59

1.53

2.51

2.42

2.32

3.20

3.08

2.96

3.75

3.61

3.47

21.8

22.2

28.8

29.3

29.9

38.0

38.6

39.4

43.7

44.5

45.4

1.76

1.69

2.77

2.67

2.56

3.53

3.40

3.26

4.14

3.98

3.83

24.1

24.5

32.8

33.3

33.9

43.2

43.7

44.6

49.6

50.4

51.3

1.91

1.83

3.01

2.90

2.78

3.86

3.72

3.56

4.49

4.28

4.14

6.5

5.5

6.5

6.1

7.5

6.1

7.5

1.9

1.6

1.9

1.8

2.2

1.8

2.2

Models

PKH18FL

PKH24FL

PKH30FL

PKH36FL

Refrigerant piping length (one way)

Less than 100ft

1.00

1.00

1.00

1.00

100~130ft

0.995

0.995

0.995

0.995

130~164ft

0.990

0.990

0.990

0.990

6

Page 7

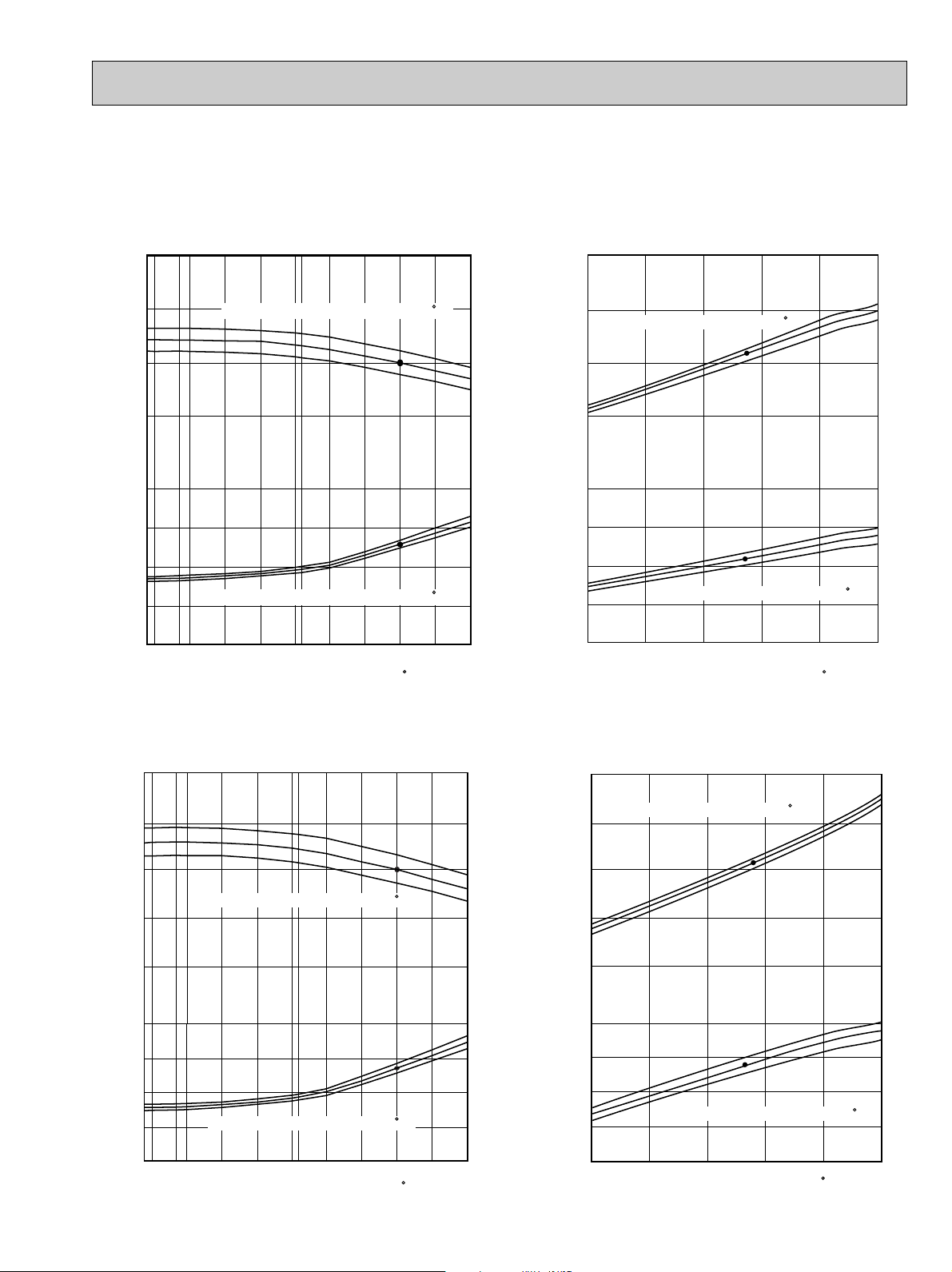

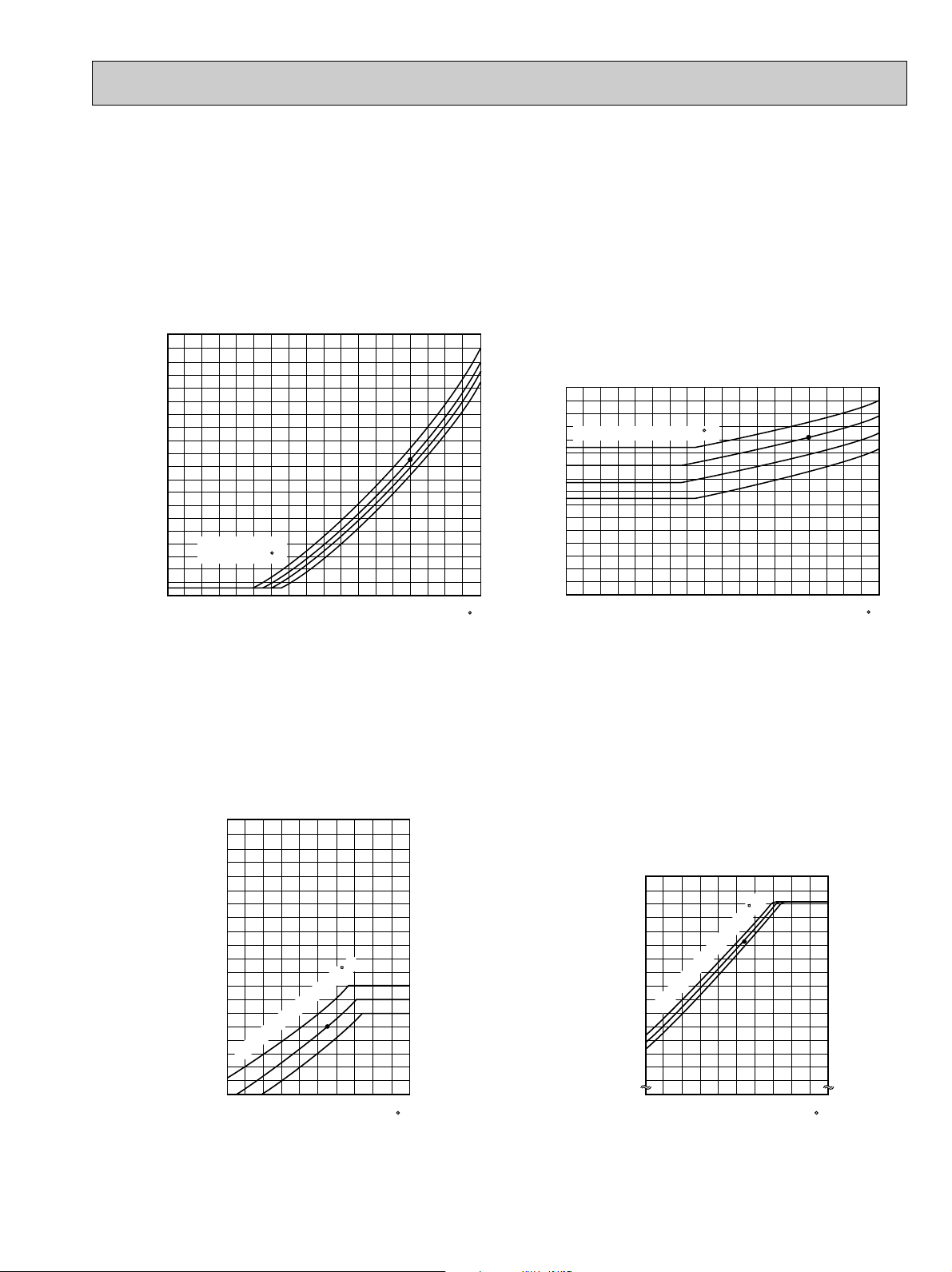

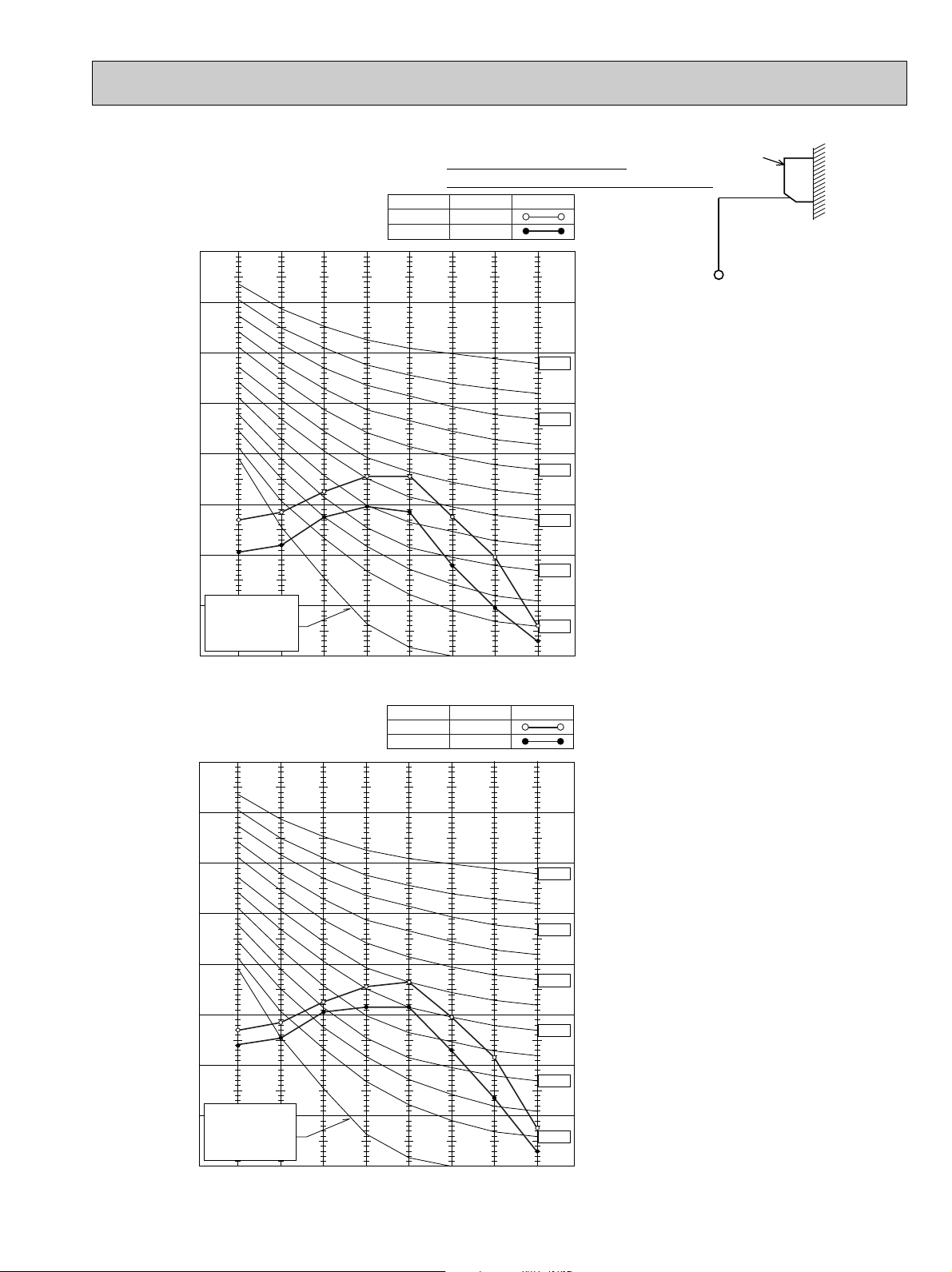

2. PERFORMANCE CURVE

Does not include booster heater (1.9kW)

Total power consumption (kW) Total capacity (x10

3

Btu/h)

30

24

18

12

2.5

2.0

1.5

1.0

15 25 35 45 55 65

Total power consumption (kW) Total capacity (x10

3

Btu/h)

Outdoor intake air DB temperature ( F) Outdoor intake air WB temperature ( F)

Indoor intake air DB temperature ( F)

Indoor intake air DB temperature ( F)

65

65

70

70

75

75

30

24

18

12

2.5

2.0

1.5

1.0

63

67

71

63

67

71

SHF=0.82

023 32 35

45 55

65

(67)

75 85 95 105 115

Indoor intake air WB temperature ( F)

Indoor intake air WB temperature ( F)

NOTES : Apoint on the curve shows the reference point.

<PKH18FL>

COOLING CAPACITY HEATING CAPACITY

<PKH24FL>

Btu/h)

3

3.0

2.5

2.0

1.5

Total power consumption (kW) Total capacity (x10

COOLING CAPACITY HEATING CAPACITY

36

30

24

Indoor intake air WB temperature ( F)

18

12

023 32 35

Indoor intake air WB temperature ( F)

45 55

Outdoor intake air DB temperature ( F)

(67)

65

75 85 95 105 115

SHF=0.71

35

71

67

63

71

67

63

Indoor intake air DB temperature ( F)

Btu/h)

3

30

24

18

12

3.0

2.5

2.0

1.5

Total power consumption (kW) Total capacity (x10

15 25 35 45 55 65

Does not include booster heater (1.9kW)

Indoor intake air DB temperature ( F)

Outdoor intake air WB temperature ( F)

7

65

70

75

75

70

65

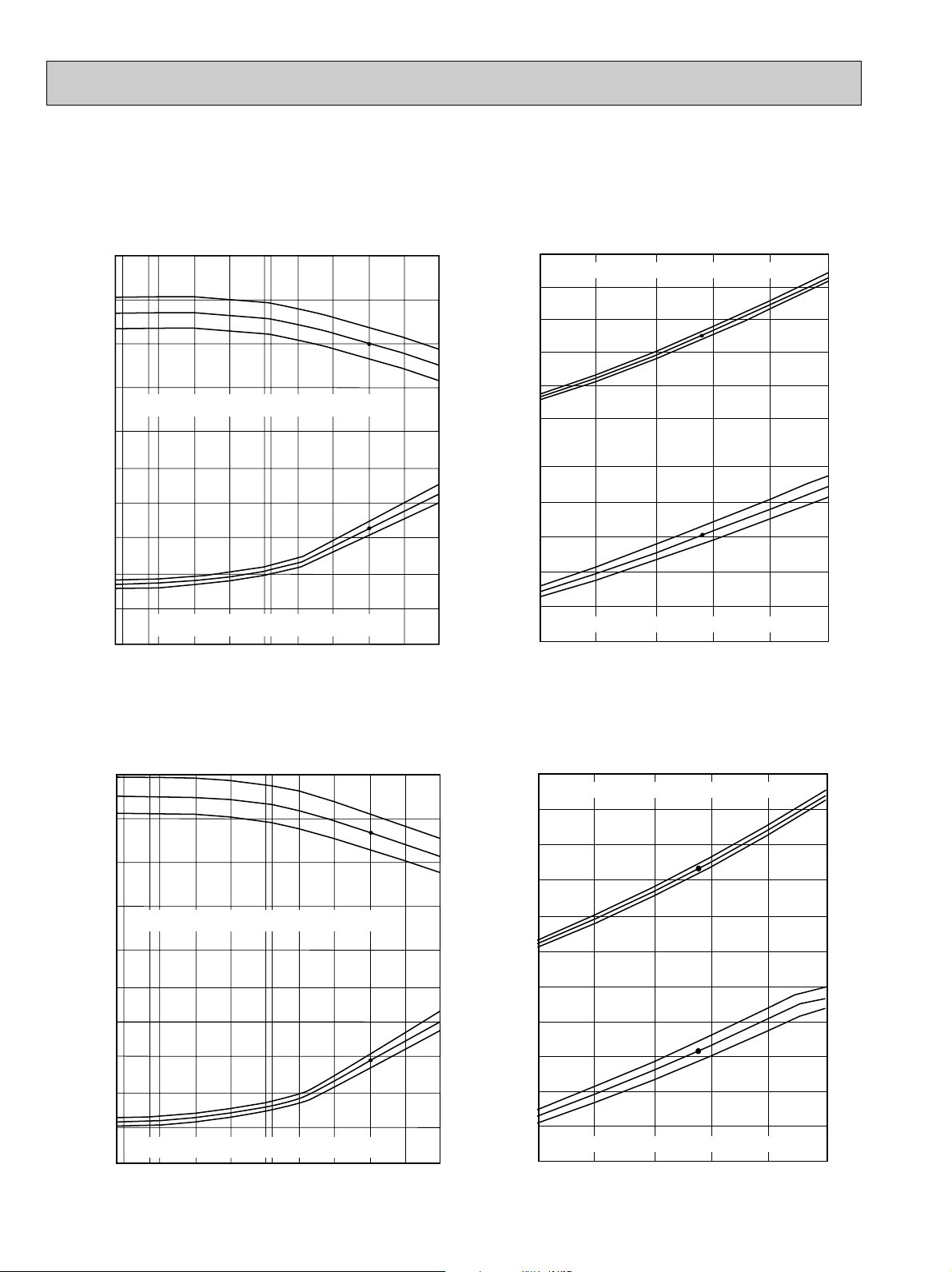

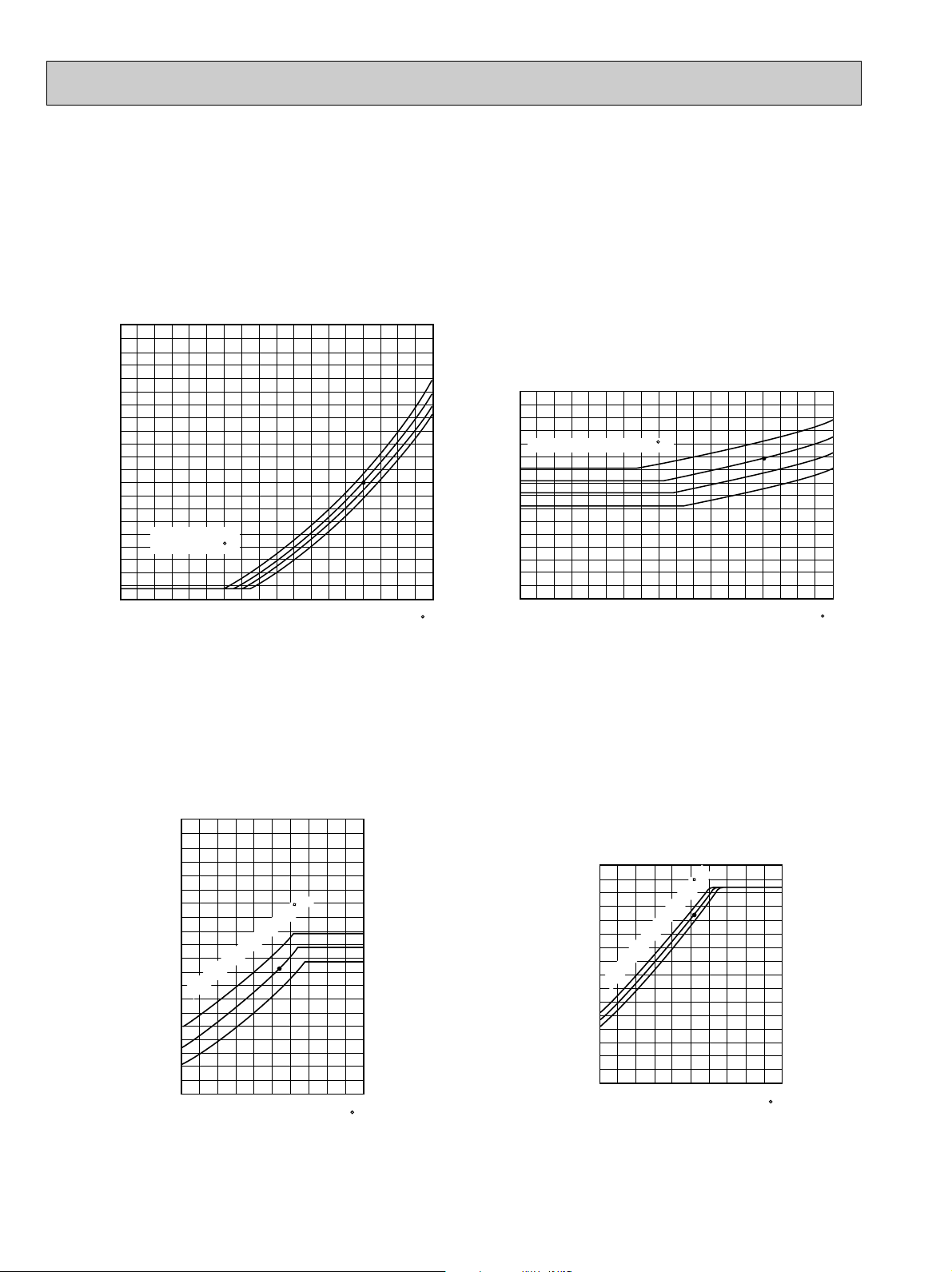

Page 8

NOTES : Apoint on the curve shows the reference point.

71

67

63

71

67

63

42

36

30

24

4.0

3.5

3.0

2.5

2.0

SHF=0.75

Total capacity(x10 Btu/h)

3

Total power consumption(kW)

Outdoor intake air DB temperature(°F)

0 23 32 35 45 55 65 (67) 75 85 95 105 115

indoor intake air WB temperature(°F)

indoor intake air WB temperature(°F)

48

42

36

30

24

18

4.0

3.5

3.0

2.5

2.0

1.5

15 25 35 45 55 65

Outdoor intake air WB temperature(°F)

indoor intake air DB temperature(°F)

indoor intake air DB temperature(°F)

Does not include booster heater(2.2kW)

65

70

75

75

70

65

Total capacity(x10 Btu/h)

3

Total power consumption(kW)

42

36

30

24

4.5

4.0

3.5

3.0

2.5

Total capacity(x10 Btu/h)

3

indoor intake air WB temperature(°F)

SHF=0.71

Total power consumption(kW)

Outdoor intake air DB temperature(°F)

indoor intake air WB temperature(°F)

0 23 32 35 45 55 65 (67) 75 85 95 105 115

71

67

63

71

67

63

54

48

32

36

30

24

4.5

4.0

3.5

3.0

2.5

2.0

15 25 35 45 55 65

Outdoor intake air WB temperature(°F)

indoor intake air DB temperature(°F)

indoor intake air DB temperature(°F)

Does not include booster heater(2.2kW)

65

70

75

75

70

65

Total capacity(x10 Btu/h)

3

Total power consumption(kW)

<PKH30FL>

COOLING CAPACITY HEATING CAPACITY

<PKH36FL>

COOLING CAPACITY HEATING CAPACITY

8

Page 9

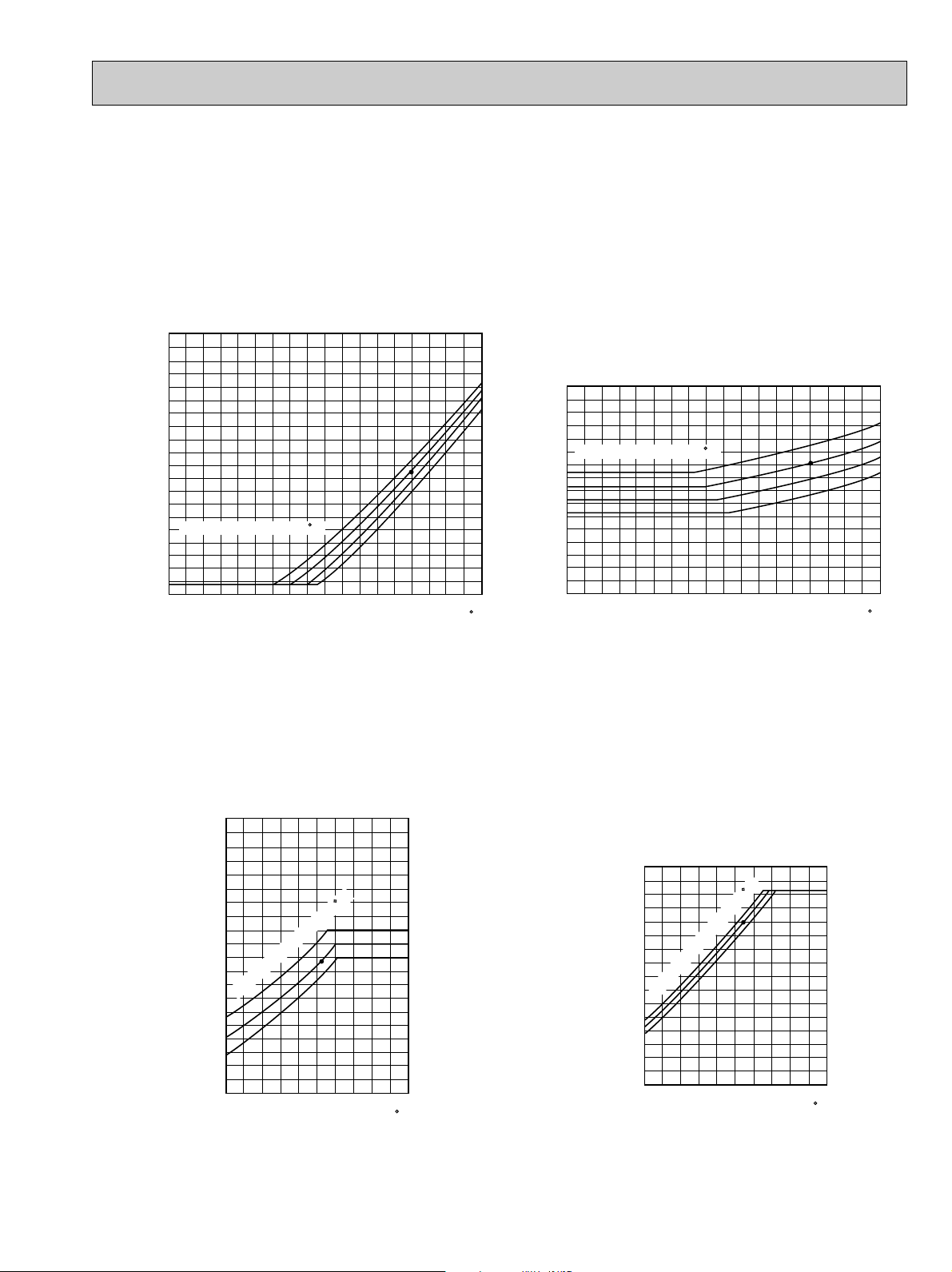

3. CONDENSING PRESSURE AND SUCTION PRESSURE

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

Indoor DB

temperature( F)

86

80

75

70

100

90

80

70

60

50

40

30

20

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Data is based on the condition under indoor humidity 50%.

Air flow should be set at HI.

A point on the curve shows the reference point.

<PKH18FL>

COOLING MODE

Data is based on the condition under outdoor humidity 75%.

A point on the curve shows the reference point.

HEATING MODE

9

Page 10

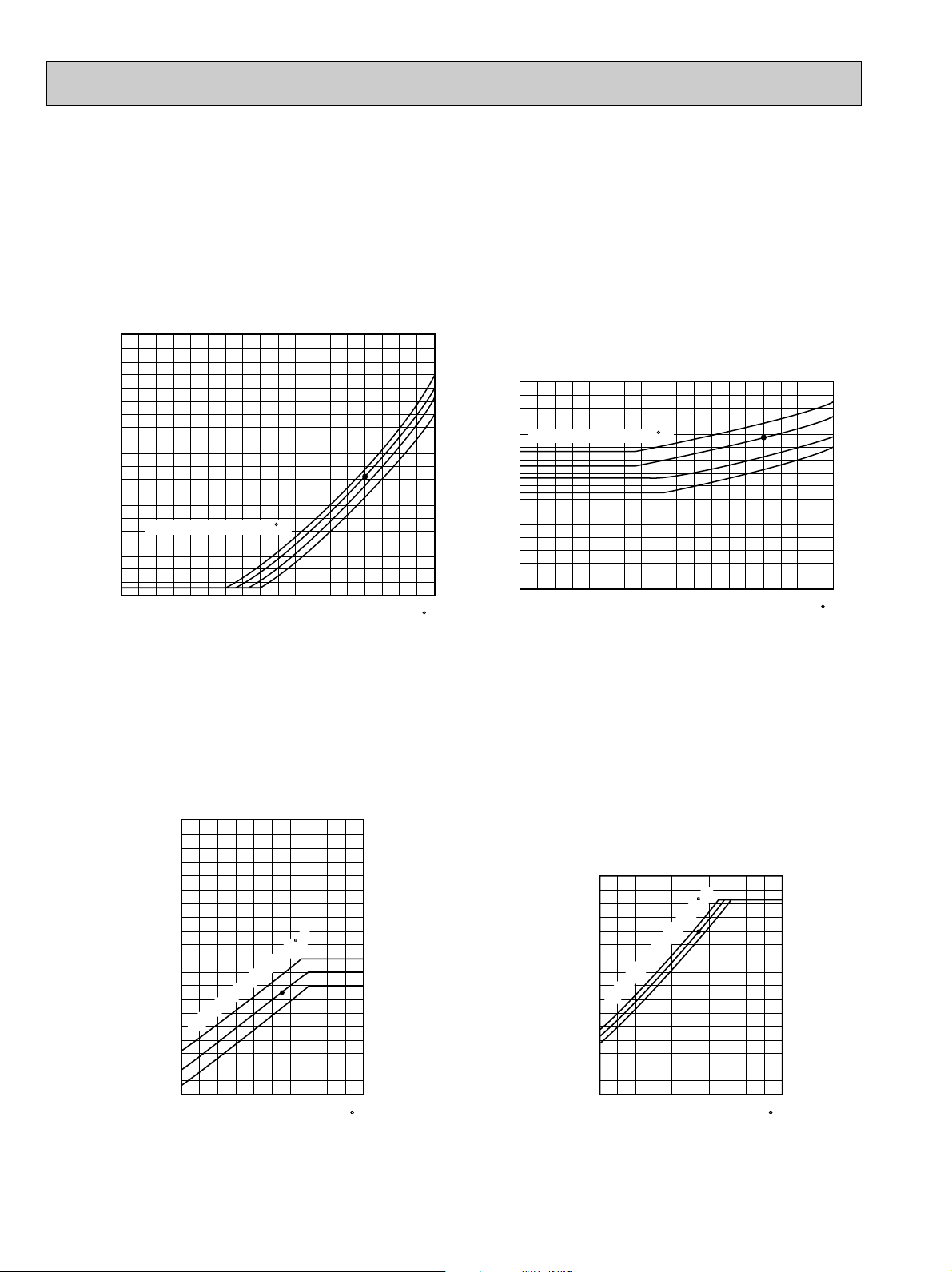

Data is based on the condition under indoor humidity 50%.

360

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

Indoor DB

temperature( F)

86

80

75

70

100

90

80

70

60

50

40

30

20

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Air flow should be set at HI.

A point on the curve shows the reference point.

<PKH24FL>

COOLING MODE

Data is based on the condition under outdoor humidity 75%.

A point on the curve shows the reference point.

HEATING MODE

10

Page 11

Data is based on the condition under indoor humidity 50%.

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

110

100

90

80

70

60

50

40

30

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

Indoor DB temperature( F)

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

140

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Air flow should be set at HI.

A point on the curve shows the reference point.

<PKH30FL>

COOLING MODE

Data is based on the condition under outdoor humidity 75%.

A point on the curve shows the reference point.

HEATING MODE

11

Page 12

Data is based on the condition under indoor humidity 50%.

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

90

80

70

60

50

40

30

20

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

Indoor DB temperature( F)

390

380

370

360

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Air flow should be set at HI.

A point on the curve shows the reference point.

<PKH36FL>

COOLING MODE

Data is based on the condition under outdoor humidity 75%.

A point on the curve shows the reference point.

HEATING MODE

12

Page 13

4. STANDARD OPERATION DATA

Models

Item

Electrical circuitRefrigerant circuitIndoor sideOutdoor side

Voltage

Frequency

Total input

Indoor fan current

Booster heater current

Outdoor fan current

Comp. current

Condensing pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Comp.shell bottom temperature

Ref. pipe length

Refrigerant charge

Fan speed

Airflow (High)

Fan speed upper/lower

Airflow

Unit

V

Hz

kW

A

A

A

A

psi.G

psi.G

˚F

˚F

˚F

˚F

ft

˚F

˚F

˚F

˚F

r.p.m.

CFM

˚F

˚F

r.p.m.

CFM

Btu/h

208/230

1.79

0.5

0.75

7.4/6.9

255

81

182

118

66

171

80

67

61

59

95

75

18,000

0.82

60

Cooling

208/230

1.56

0.5

7.6/8.4

0.75

6.1/5.9

202

61

126

102

34

111

70

60

96

68

47

43

18,600

Heating

PKH18FL

208/230

2.36

0.5

0.65+0.65

9.3/8.7

240

75

158

115

46

141

80

67

58

56

95

75

24,000

0.71

60

Cooling

208/230

2.37

0.5

7.6/8.4

0.65+0.65

9.5/8.7

243

63

149

115

35

126

70

60

105

70

47

43

25,000

Heating

PKH24FL

208/230

3.12

0.6

0.75+0.75

12.6/11.8

245

80

158

115

49

138

80

67

59

58

95

75

30,000

0.75

60

Cooling

208/230

3.02

0.6

8.7/9.6

0.75+0.75

12.2/11.4

236

60

159

113

32

130

70

60

103

70

47

43

33,000

Heating

PKH30FL

208/230

3.44

0.6

0.75+0.75

14.3/13.2

243

74

160

115

45

142

80

67

58

56

95

75

34,200

0.71

60

25

5 lbs 8 oz

1,310

710

1,310

710

1,400

990

1,400

990

790

1,590

750/750

3,170

760/760

3,350

760/760

3,350

25

9 lbs 15 oz

25

10 lbs 2 oz

25

10 lbs 9 oz

Cooling

208/230

3.54

0.6

8.7/9.6

0.75+0.75

14.7/13.7

263

60

170

120

33

148

70

60

109

71

47

43

38,000

Heating

PKH36FL

Intake

air temperature

Discharge

air temperature

Intake

air temperature

Capacity

SHF

DB

WB

DB

WB

DB

WB

13

Page 14

5. OPERATING RANGE

1) POWER SUPPLY

1 Phase 60Hz 208/230V

Guaranteed voltage range

2) OPERATION

Min. Max.

198V 208V 230V 253V

Function

Cooling

Heating

Air intake temperature

Condition

Standard temperature

Maximum temperature

Minimum temperature

Maximum humidity

Standard temperature

Maximum temperature

Minimum temperature

DB(˚F

80

95

67

80

70

80

70

Indoor

)

WB(˚F

6. OUTLET AIR SPEED AND COVERAGE RANGE

Model

PKH18FL

PKH24FL

PKH30FL

Airflow

(

CFM

710

710

990

)

Air speed

(

ft/sec

16.1

16.1

17.7

)

Coverage

range(ft

41

41

50

)

Outdoor

)

67

71

57

75

60

67

60

* With wind baffle D.B. 23°F if no wind baffle.

The air coverage range is the value up to the position

where the air speed is 0.8ft/sec. when air is blown out

horizontally from the unit at the High notch position.

The coverage range should be used only as a general

guideline since it varies according to the size of the

room and furniture installed inside the room.

DB(˚F

95

115

*0

80

47

75

17

)

WB(˚F

75

—

—

75

43

65

15

)

PKH36FL

990

17.7

50

7. ADDITIONAL REFRIGERANT CHARGE (R22(oz))

Refrigerant piping length (one way)

100ft

85ft

70ft

55ft

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Model

PKH18FL

PKH24FL

PKH30FL

PKH36FL

Outdoor unit

precharged

(

up to 100ft

5 lbs 8 oz

9 lbs 15 oz

10 lbs 2 oz

10 lbs 9 oz

)

25ft

0

0

0

0

40ft

0

0

0

0

14

115ft

2

2

5

5

130ft

4

4

10

10

150ft

7

16

16

164ft

9

20

20

Page 15

6. NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Hi

NOTCH

Lo

49

SPL(dB)44LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Hi

NOTCH

Lo

48

SPL(dB)41LINE

Wall

Unit

3.3ft

3.3ft

PKH18FL

PKH24FL

Ambient temperature 80˚F

Test conditions are based on JIS Z8731

PKH30FL

PKH36FL

15

Page 16

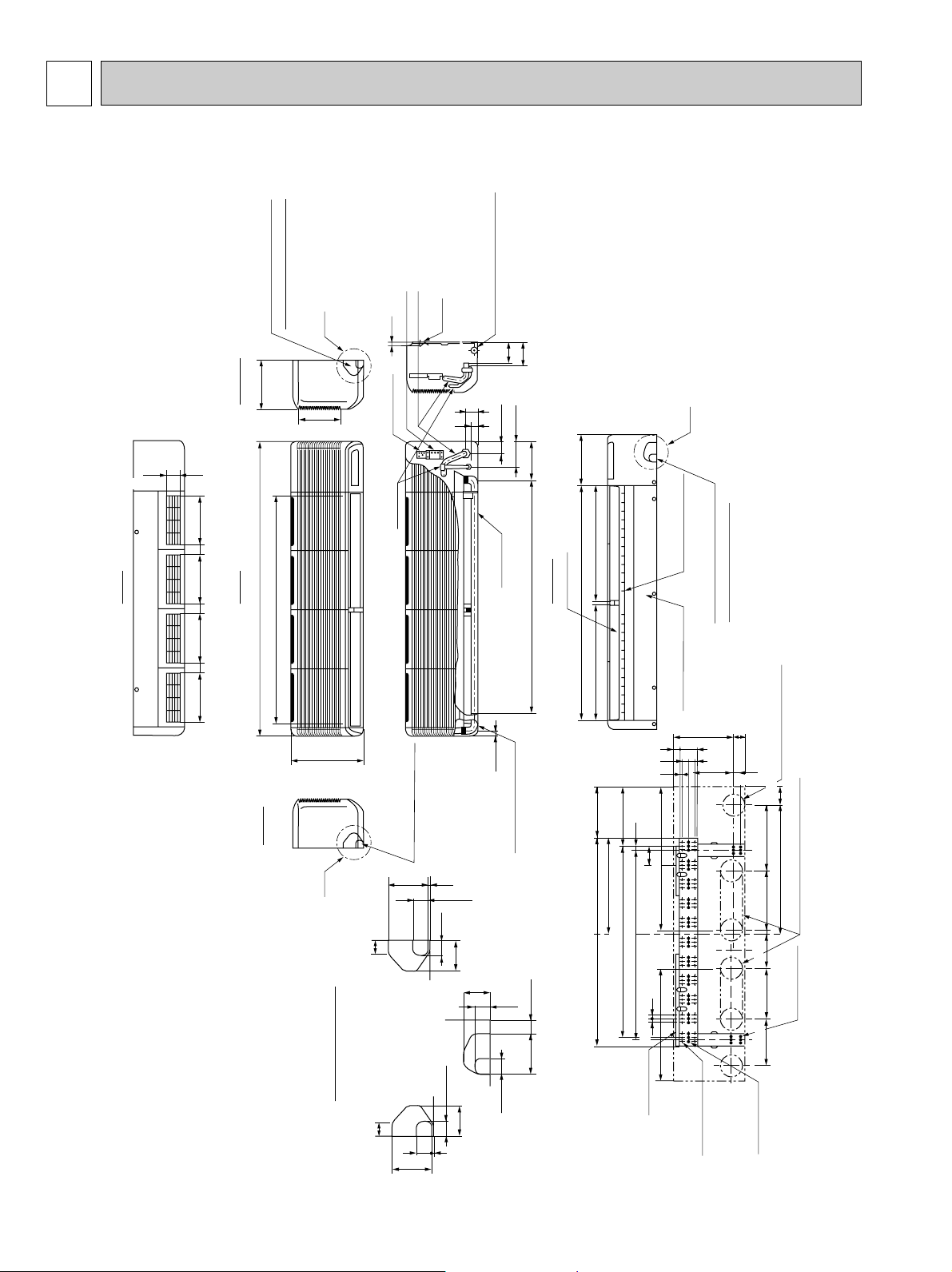

5

9-1/4

1-25/32

9-1/4

1-25/32

9-1/4 9-1/4

1-25/32

1/2

13-3/8

7-3/4

1-21/32

2-9/32

Top

Front

Right side

Left side

55-1/8

42-15/16

Air intake

9-1/4

C

Knock out hole for right piping

Refrigerant pipe. Drain pipe

Knock out hole for

left piping

Drain hose for

left-hand side piping

Drain hose

Lower side

Auto vane

(Gas pipe)

Drain hose O.D.1-1/16(or 7/8)

Bolt

Gas pipe

19/32

Terminal block for power supply

Terminal block for control

(Liquid pipe)

Liquid pipe 3/8F

Gas pipe 5/8F

Liquid pipe

A

1-3/16

1-15/32

1-17/32

3-27/32 2-9/16

2-29/32

5/32

3-15/16

1-17/32

1-3/16

1-15/32

2-29/32

5/32

1-5/32

11-1/32

1-3/16

7-1/4

1-3/16

3-5/32

1-3/18

2-3/8

13/32

1-17/32

1-15/32

2-9/16

3-15/16

A

B

C

Knock out hole for piping

31/32

43-11/16

7-7/32

9-7/16

B

44-3/32

21-23/32

4-23/32

2-5/32

4-7/32

4-3/8

Air outlet

21-23/32

Air outlet

Change vane (manual)

Under panel

Removable at left-hand

side piping

Knock out hole for under-piping

Refrigerant pipe. Drain pipe

Rear piping opening

Range for left rear piping opening

12-{1/4 Hole for

tapping screw

66-{1/4 hole for

tapping screw

Wall fixture

Unit center

32-{15/32

hole for bolt

23/32

3-19/32

35-7/16

38-31/32

17-29/32

11-7/32

9-21/32

3/4

9-7/16 11-1/32 12-3/8

24

Drainage range

on left-hand side

Drainage range

on right-hand side

10x3-19/32=(35-13/16)

7-3/32

2-15/32

8-27/32

3-17/32

23/32

OUTLINES AND DIMENSIONS

Indoor Unit

PKH18FL

PKH24FL

Unit : inch

16

Page 17

PKH30FL

PKH36FL

Unit : inch

3/4F

Through hole

on the market.

3-1/2 3-1/2~ 4

>< 1 Sleeves are available

B

9-1/4

Right side

7-3/4

C

19/32

or less

Drain hose O.D.1-1/16(or 7/8)

Bolt

4-3/8

4-1/32

Gas pipe

Liquid pipe 1/2F

1

2

Sleeve >< 1

2-9/32

2-15/32

1/2

9-1/4

Knock out hole

1-25/32

for right piping

2

1-21/32

2-5/32(Gas pipe)

9-7/16

4-23/32(Liquid pipe)

7-7/32

1

9-1/4

1-25/32

Front

Top

9-1/4

9-1/4

1-25/32

1-25/32

66-5/32

53-15/16 Air Intake

Terminal block for control

Terminal block for power supply

Lower side

55-1/8

Drain hose

43-11/16 (Drain hose)

27-5/16 Air outlet 27-5/16 Air outlet

9-1/4

13-3/8

louvers(manual)

Under panel (Removable at

left-hand piping)

Knock out hole for under-piping

Auto vanes

11-1/32

1-5/32

3-5/32

1-3/16

1-3/16

7-1/4 13/32

1-3/16

Refrigerant pipe .Drain pipe

2-3/8

7-17/32

12- 1/4 hole

for tapping screw

Front

Air

intake

or more

1-3/16

Air

outlet

5-/15/16 or less

Left side

10 or more

Knock out hole for wiring

2 or more 10 or more

C

A

A

1-3/161-3/16

B

3-15/16

1-17/32

3-15/16

Knock out hole

for left piping

5/32

1-17/32

1-15/32

2-29/32

2-9/16

1-15/32

1-17/32

2-29/32

5/32

17

1-15/32

2-9/16

3-27/32

Drain hose for

left-hand side piping

31/32

Unit center

Drainage range on

9-21/32

Drainage range on

11-7/32

right-hand side

23-7/16

13x3-19/32=(7-3/16)

50

Wall fixture

Unit out line

Left hand side

3/4

3-19/32

35-7/16

23/32

23/32

84-{1/4 hole

for tapping

screw

12-3/8

29-17/32

11-1/32

7-3/32

9-7/16

Range for left

rear piping hole

8-27/32

11-5/8

41- 15/32 hole

Rear piping hole

Range for left rear piping hole

for bolt

Page 18

Remote controller

Pipe temperature

thermistor / Liquid

(RT2)

Distributor

Restrictor

valve

Capillary tube

PKH18FL : ({0.126x{0.071x19.7)

PKH24FL : ({0.157x{0.079x19.7) w

Refrigerant pipe

(option)

{3/8"

(with heat insulator)

Refrigerant pipe

(option)

{5/8"

(with heat insulator)

Strainer

Flared connection

Flared connection

w An error in this diagram has been

modified. The size of capillary tube

{0.157x{0.07x19.7, was wrong.

PKH30FL : ({0.157x{0.079x23.6)

PKH36FL : ({0.157x{0.079x15.7)

Pipe temperature

thermistor / Liquid

(RT2)

Distributor

Restrictor

valve

Capillary tube

Refrigerant pipe

(option)

{1/2"

(with heat insulator)

Refrigerant pipe

(option)

{3/4"

(with heat insulator)

Strainer

Flared connection

Flared connection

COOLING

HEATING

Refrigerant flow

2-9/32

6-3/8

3/4

ON/OFF TEMP

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

WIRELESS REMOTE CONTROLLER

Unit : inch

6

PKH18FL

PKH24FL

PKH30FL

PKH36FL

REFRIGERANT SYSTEM DIAGRAM

18

Page 19

7

GR

L1

L2

POWER SUPPLY

~(1PHASE)

AC208/230V 60Hz

GROUND

3

LED(HOT ADJUST)

LED(RUN INDICATOR)

LED1

LED2

WIRELESS REMOTE CONTROLLER

W.R

FS1,2

THERMAL FUSE

88H

HEATER CONTACTOR

HEATER THERMAL SWITCH

HEATER

26H

H

HEATER

12 312 312 3

36FL

OFF

ON

30FL

OFF

ON

MODELS 24FL

12 3

ON

OFF OFF

ON

SW7

18FL

ON

OFF

LED(DC5V POWER)

X4

RELAY(FAN MOTOR)

LED1

LED2

LED(DC12V POWER)

SW9

SWITCH(MODEL SELECTOR)

F1,F2

VARISTORZNR

SYMBOL NAME

I.B

INDOOR POWER BOARD

INDOOR CONTROLLER BOARD

CN2L

SW1

SW2

SW6

FC

CONNECTOR(LOSSNAY)

SWITCH(FUNCTION SELECTOR)

SWITCH(ADDRESS SELECTOR)

SWITCH(MODEL SELECTOR)

FAN PHASE CONTROL

P.B

CN51

CONNECTOR(CENTRALLY CONTROL)

SW3

SWITCH(EMERGENCY OPERATION)

SW5

SWITCH(MODEL SELECTOR)

SW7

SWITCH(TWIN/TRIPLE SELECTOR)

SW8

SWITCH(OPTION)

BZ

TB2~TB6 TERMINAL BLOCK

ROOM TEMPERATURE THERMISTOR

RT1

RT2

PIPE TEMPERATURE THERMISTOR/LIQUID

W.B

WIRELESS REMOTE CONTROLLER BOARD

BUZZER

SWITCH(HEATER ON/OFF)

SW1

SWITCH(COOLING ON/OFF)SW2

RECEIVING UNIT

RU

NAMESYMBOL

VANE MOTOR

MV

FAN MOTOR

MF

CAPACITOR(FAN MOTOR)

C

12

OFF

ON

1542

231

2341

165432

1432

165432

10987654321

ON

OFF

ON

OFF

ON

OFF

RG79J693H02

321

9

ORN

YLW

1

2

TB4

3

BRN

TB3

OUTDOOR UNIT

1

2

TRANSMISSION WIRES DC12V

3

9

REMOTE

W.R

CONTROLLER

CNB

W.B

LED1

LED2

BZ

RU

SW1 SW2

ON

123456

OFF

OFF

123456

ON

NOTES:

1.Since the indoor fan motor(MF)is connected with 230V power,if 208V power is used,change the dip switch(SW8)on

the indoor controller board as shown in fig:*1.

fig:*1

Indoor fan motor(MF)for 208V.

2.Since the outdoor side electric wiring may change be sure to check the outdoor unit electric wiring for servicing.

3.Indoor and outdoor connecting wires are made with polarities, make wiring matching terminal numbers.

4.Symbols used in wiring diagram above are, :Connector, :Terminal block.

5.Emergency operation

If remote controller or microcomputer fails but there is no other trouble emergency operation is possible by setting

dip switch(SW3<I.B>) on the indoor controller board.

[Check items]

(1) Make sure that no other trouble exist in the outdoor unit.Trouble with the outdoor unit prevents emergency operation.

(2) Make sure that there is no trouble with the indoor fan.

Emergency operation will be continuous run with the power ON/OFF(ON/OFF with the remote controller is not possible).

[Emergency operation procedure]

(1) Set the dip switch(SW3<I.B>)on the indoor controller board to 1 on and 2 off for cooling and 1 • 2 on for heating.

(2) Turn on outdoor unit side circuit breaker,then indoor unit side circuit breaker.

(3) During emergency operation indoor fan runs at high speed but auto-vane does not work.

(4) Thermostat will not function.Cold air blows out for defrosting during heating thus do not operate defrosting for a long time.

(5) Emergency cooling should be limited to 10 hours maximum

(the indoor unit heat exchanger may freeze).

(6) After every emergency operation,set all dip switches(SW3<I.B>) to OFF.

(7) Movement of the vanes does not work in emergency operation,therefore you have to slowly set them manually to the

appropriate position.

SW8

SW8

H

FS1FS2

88H

TB2

26H

BWN

YLW

8

88H

5

6

GRY

7

GRY

RED

BLUBLU

64

35

RED

2

1

12

HEATER

CN24

(YLW)

6

[LEGEND]

2

1

3

2

1

3

2

1

2

1

312 12

12

4

3

2

1

213131

SW3 SW9

SW7

SW6

SW1

SW8

SW5

RT2

RT1

F2

F1

SW2

CN51

CENTRALLY

CONTROL

(WHT)

CN40

REMOCON

POWER

LED1 LED2

CN2L

LOSSNAY

ZNR

OUT

DOOR

CN30

WHT

BLK

CN2D

(WHT)

GRN/YLW

RED

BLU

RED

BLU

P.B

TRANS

(DC13.1V)

CN2S (WHT)

CNSK(RED)

I.B

MF

C

135

FC

MV

X4

X4

WHT

RED

BLK

WHT

BLK

FAN

(WHT)

INTAKE

CN20

(RED)

POWER

CNDK

(WHT)

POWER

CND

(RED)

WIRELESS

CN90

(WHT)

REMOCON

CN22

(BLU)

PIPE

CN21

(WHT)

VANE

CN6V

(WHT)

DRAIN

CN31

(WHT)

243˚F ,10A(18,24FL)/16A(30,36FL)

FUSE(6A/250V)

(32˚F /15kΩ, 77˚F /5.4kΩ DETECT)

(32˚F /15kΩ, 77˚F /5.4kΩ DETECT)

(AC208/230V)

(BLU)

WIRING DIAGRAM

MODELS PKH18FL, PKH24FL, PKH30FL, PKH36FL

19

WIRING DIAGRAM

The drawing has been revised as some errors in

WIRING DIAGRAM have been modified.

The former drawing number is RG79J693H01.

Page 20

8 OPERATION FLOW-CHART

START

Power circuit

breaker

Check SW

ON twice

Operation SW

ON

“OFF” timer

“ON” timer

STOP

Set time

complete

Set time

complete

1

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

w 1

w 2

w 3

w 4

w 5

w 7

w 6

PROTECTION DEVICE

SELF HOLD RELEASE

Remote controller

indicator lamp OFF

Trouble STOP

Remote controller

operation display

Operating mode

(COOL)

Operating mode

(DRY)

Operating mode

(HEAT)

Operating mode

(FAN)

Auto COOL/HEAT

operation

COOL operation

DRY operation

HEAT operation

FAN operation

Trouble

PROTECTION DEVICE

SELF HOLD

Remote controller

trouble display

Indoor side

Outdoor side

Fan STOP

Auxiliary heater OFF

Compressor OFF

Fan STOP

Four-way valve OFF

MAIN OPERATION

w1 In addition, the centralised control and remote control can be operated.

w2 The modes which indicate the sources of trouble are listed below.

● E0-Signal transmitting/receiving error

● P1-Room temperature thermistor malfunction

● P2-Indoor coil thermistor malfunction

● P4-Drain sensor malfunction

● P5-Drain overflow

● P6-Coil frost/overheat protection

● P7-System error

● P8-Outdoor unit trouble

w3 The CHECK switch will show if an error has occurred in the past.

w4 Fan runs on low speed for 1 minute in order to remove overheat air.

w5 The 3-minute (6 minutes …heating mode) time-delay functions after compressor stops.

w6 FAN or AUTO mode is selected by the indoor dip switch setting.

w7 In FAN mode, fan speed and vane operation depend on the remote controller setting. (Compressor is OFF.)

20

Page 21

COOLING OPERATION

COOL operation

Four-way valve/OFF

NO

NO

NO

Vane setting notch

Initial

COOLING

w 8

55 deg downward angle

70 deg downward angle

NO

Downward discharge

Vane horizontal

w 9

YES

Vane initial

setting

Vane

YES

Fan speed

LOW

YES

1 hour

YES

airflow

Compressor

thermostat ON

Allowance

cancel

NO

YES

NO

YES

YES

NO

compressor operation

w 10

w 11

NO

compressor operation

Allowance cancel

NO

compressor operation

temperature is 34˚F

3-minute

time delay

NO

6-minute

time delay

NO

3-minute

YES

Coil frost

protection

NO

Cooling area

YES

10-minute

YES

Coil frost

prevention

NO

16-minute

YES

Indoor pipe

or lower

NO

YES

YES

YES

NO

Coil frost

prevention

Indoor coil

temperature is 50˚F

or higher

YES

Defrosting

protection detection

temperature 30˚F

or lower

YES

6-minute

time delay

Coil frost

prevention release

NO

NO

3-minute

time delay

Allowance

period

NO

6 minute

time delay

Allowance set

YES

NO

1 min continue

FAN speed

LOW 5 min elapse

YES

LOW

FAN speed

NO

Coil frost protection

YES

Outdoor unit

trouble

Compressor ON

1

Compressor OFF

w8 When operation stops or changes to cooling or dry mode, the auto vane turns to a horizontal angle. If operation changes

during auto vane SWING, the auto vane will continue to swing.

w9 When operating TEST RUN, the thermostat will be continuously ON.

w10 After 3 minute compressor operation, if the indoor coil thermistor reads 5°F or below for 3 minutes, the compressor will

stop for 6 minutes.

w11Heating area : Indoor coil temperature is more than 9 degrees above the room temperature.

Cooling area : Indoor coil temperature is more than 9 degrees below the room temperature.

FAN area : Indoor coil temperature is within 9 degrees either way of the room temperature.

21

Page 22

DRY OPERATION

DRY

operation

Four-way valve / OFF

Initial dry

operation

Room temperature is

64°F or lower

During

compressor ON

Compressor &

thermostat ON

Vane initial setting

Vane

setting notch

10-minute compressor

OFF timer start

Compressor OFF

Fan STOP

3-minute

time delay

10-minute

compressor

OFF

Compressor ON

time set

Compressor ON

Fan speed LOW

1

Compressor &

thermostat

ON

3-minute

compressor

operation

Compressor ON

time completes

NO

YES

NO

NO

YES

w14

w14

w13

YES

YES

NO

YES

NO

NO

w9

YES

YES

w9

NO

NO

w12

YES

NO

YES

w8

w8—9 Refer to page OC276-21.

w12 When room temperature is 64°F or below, the compressor cannot operate.

When room temperature rises over 64°F the compressor starts after a 3-minute time delay.

w13 Compressor ON time is decided by room temperature. Refer to page OC276-30.

w14 In dry operation, compressor ON makes the fan speed LOW. Also, when the compressor OFF and the pipe temperature

is 79°F or less, the fan stops, or when the compressor OFF and the pipe temperature is below 43°F the fan speed

changes to LOW mode.

It is not possible to set the fan speed with the remote controller

22

Page 23

HEATING OPERATION

Heat operation

initial

YES

setting

NO

NO

NO

NO

Compressor

NO

trouble

1

operation

YES

>

T

1 To

=

YES

w 15

YES

YES

YES

YES

YES

YES

6 min. restart

2

Hot adjust start

FAN SPEED

Compressor ON

w 16

NO

3 min.restart

prevention

prevention

very low

HEAT mode

NO

HEATING

Vane setting

notch

Vane initial

defrosting

Four-way

valve ON

Hot adjust

in process

Compressor ON

w 9

thermostat ON

Allowance cancel

NO

Indoor piping

5°F or lower

YES

Outdoor unit

FAN SPEED

Very low airflow

Compressor OFF

AUTOMATIC COOLING/HEATING OPERATION

Auto COOL/HEAT

NO

Initial mode

w 17

COOL mode

NO

NO

10-minute

NO

compressor

operation

YES

Allowance cancel

w 11

Heating

area

FAN STOP

w 11

Fan area

20 min.elaspe

YES

Fan area

Heating area

w 11

Fan area

Cooling area

YES

Defrost operation

START

Four-way valve

OFF

NO

NO

NO

w 11

YES

YES

w 10

NO

Heating area

NO

Defrost

30 min. elapse

YES

Outdoor unit

trouble

1

A

Outdoor unit

trouble

YES

Defrost release

NO

Indoor piping

131°F or lower

NO

Auxiliary

heater ON

NO

Indoor piping

140°F or higher

YES

Auxiliary heater

Overheat remote

NO

Indoor Coil. temp.

150°F or higher

Allowance

period

Overload protect

2

B

NO

YES

OFF

START

YES

YES

1

YES

NO

Auxiliary heater

thermostat ON

Auxiliary heater

NO

6-minute restart

prevention

Allowance set

Compressor OFF

ON

YES

YES

FAN SPEED

FAN SPEED

setting notch

Auxiliary heater

thermistor is 140°F

FAN speed

Airflow 10% up

Indoor piping

95°F or higher

NO

HOT adjust

5 min. elapse

YES

Low

FAN SPEED

Low 2 min.

elapse

YES

Hot adjust

release

A

3-minute

OFF

YES

Indoor coil

or higher

YES

Low notch

YES

B

NO

NO

NO

NO

NO

FAN setting

notch

YES

YES

NO

NO

YES

NO

T

1 ] (To + 4)

YES

NO

YES

Cool mode

set

After 15min.

T

1 ] (To + 4)

HEAT operation

11

HEAT operation

COOL mode

NO

T

1 [ (To - 4)

After 15min.

1 [ (To-4)

T

COOL operation

w15 ( i ) Until Low airflow is set while in hot adjustment

(ii )While defrosting (FAN STOP)

(iii)When thermostat is OFF

In the case of( i ), (ii) and (iii) above, airflow is horizontal regardless the VANE setting.

w16 When AUTO operation is started, COOLor HEAT mode is selected automatically.

w17 T1 : Room temperature.

To : Set temperature

23

Page 24

9 MICROPROCESSOR CONTROL

ON/OFF TEMP

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

1.OUTLINE OF MICROPROCESSOR CONTROL

INPUT to remote controller

● OFF-ON switching.

● COOL/DRY-AUTO-HEAT selector switching.

● Thermostat setting.

● TIMER mode selector-switching and Timer

setting.

● HIGH-LOW fan speed switching.

● AUTO Vane selector (AIR DISCHARGE)

switching.

● TEST RUN switching.

● CHECK mode switching.

(Self diagnostic trouble shooting)

Indoor

unit

INPUT from indoor unit

Remote controller board

● Processes and transmits

orders.

Indoor controller board

OUTPUT to remote controller

● Indication LCD lights.

● Room temperature thermistor (RT1)

● Pipe temperature thermistor (RT2)

OUTPUT to indoor unit

● Auto vane’s angle setting.

● Booster heater ON-OFF Control.

● Emergency stop.

Independent Control of

Outdoor Unit

● Compressor protection

device working

● Defrosting

START-STOP

● Fan speed control.

● Crankcase heater control

ON-OFF.

● Self diagnostic function

● Receives orders from remote controller and tem-

perature data from indoor unit.

● Processes orders and data.

● Controls indoor and outdoor operation.

● Self diagnostic function.

w System control operation.

w Emergency operation.

w Set by dip switch on indoor controller board.

123

Polar three-wire cable

Outdoor unit

OUTPUT to outdoor unit

12VDC

1

2

3

● Compressor and

outdoor fan : ONOFF

● Operation mode

change :COOLHEAT.

24

Page 25

2. INDOOR UNIT CONTROL

Minimum 3 minutes w1

ON

Thermostat

Indoor fan

Auto vane

Booster heater

Compressor

ON

LOW or HIGH LOW or HIGH

ON

ON

OFF

OFF

ON

OFF

OFF

OFF

OFF

Operation starts by

POWER button

ON.

Operation stops by

POWER button

OFF.

Room temperature

becomes equal to

set temperature.

Room temperature

rises above set

temperature.

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

FAN

˚F

COOL

AM

2-1 COOL operation

<COOL operation time chart>

<How to operate>

1 Press POWER ON/OFF button.

2 Press the MODE button to display COOL.

3 Press the TEMP( or ) button to set the desired temperature.

NOTE:

Set temperature changes 2°F when the TEMP( or )

button is pressed one time.

Cooling 65 to 87°F.

w1 Even if the room temperature rise above the set temperature during this period, the compressor will not start until this peri-

od has ended.

25

Page 26

(1) Compressor control

5 minutes

SET

low

5 minutes

SET

low

OFF

1 3-minute time delay

To prevent overload, the compressor will not start within 3 minutes after stop.

2 The compressor runs when room temperature is higher than set temperature.

The compressor stops when room temperature is equal to or lower than the set temperature.

The compressor maintains the previous state when the room temperature minus the set temperature is 0 degrees or more,

or lower than 2 degrees.

3 The compressor stops in check mode or during protective functions.

4 Coil frost prevention

To prevent indoor coil frost, the compressor will stop when the indoor coil thermistor (RT2) reads 34°F or below after the

compressor has been continuously operated for at least 16 minutes or more. When the indoor coil temperature rises to

50°F or above, the compressor will start in a 3-minute(w2) time delay.

w2 When the indoor coil temperature is 30°F or less, the compressor starts in 6 minutes.

NOTE : By turning OFF the dip switch SW1-3 on indoor controller board, the start temperature of coil frost prevention changes

from 34°F to 36°F.

5 Coil frost protection

When indoor coil temperature becomes 5°F or below,coil frost protection will proceed as follows.

<Start condition>

After the compressor has been continuously operated for 3 minutes or more,and the indoor coil temperature has been 5°F

or below for 3 minutes,the coil frost protection will start.

<Coil frost protection>

Compressor stops for 6 minutes,and then restarts.

lf the start condition is satisfied again during the first 10 minutes of compressor operation,both the indoor and outdoor units

stop,displaying a check code of“P6”on the remote controller.

<Termination conditions>

Coil frost protection is released when the start condition is not satisfied again during the allowance, or when the COOL

mode stops or changes to another mode.

(2) Indoor fan control

Indoor fan speed depends on the remote controller setting.

However, if an outdoor unit abnormality is detected, the indoor fan speed will be low, regardless of the remote controller

setting.

When the outdoor unit abnormality detection is released and the fan speed returns to the set speed, the quiet cycle control

will work.

(a) Normal control

(i ) Fan speed depends on the remote controller setting regardless of the thermostat on/off.

(ii) Fan speed will remain on low if an abnormality in outdoor unit is detected. (5 minutes)

1 Start-up of outdoor unit abnormality detec-

tion.

2 Release of outdoor unit abnormality detec-

tion.

3 Unit stop due to outdoor unit abnormality

with P8 indication.

NOTE 1 : Fan stops immediately if the unit stops or the check mode is started.

26

Page 27

(3) Auto vane control

10°

1

30° downward

2

60° downward

3

70° downward

4

SWING5

Auto vane position is set to 10 degrees airflow at the start-up of COOL operation. It can then be changed by the remote

controller.

(a) Vane position set mode & swing mode.

( i ) Every time AIR DISCHARGE button is pressed, setting will be changed .

(ii) Airflow direction can be changed with AIR DISCHARGE button.

1 Fan speed : LOW

10°

60°

70°

SWING

2 Fan speed : HIGH

10°

30°

60°

70°

SWING

<AUTO RETURN>

When discharge 60° or 70° continues for 1 hour with the fan speed at LOW, the discharge direction turns to the horizontal

discharge automatically.

After that, 60° or 70° is available by setting with the remote controller, and it continues for 1 hour.

If the discharge direction changes from 60° or 70°, the direction returns to the horizontal discharge when 1 hour has

passed since the discharge 60° started.

If the discharge direction changes from 60° (or 70°) to the horizontal discharge, the 1-hour timer to return the horizontal

discharge is cancelled.

<Remote controller display>

Changes by pressing the AIR DISCHARGE button.

27

Page 28

(4) Detecting abnormalities in the outdoor unit

After the compressor has been continuously operated for 3 minutes, if the difference between the indoor coil temperature

and room temperature is out of RANGE C for 1 minute, the indoor fan speed will turn to LOW. Five minutes later, if the difference is still out of RANGE C,the outdoor unit is functioning abnormally. Thus, the compressor stops and check code

“P8” appears on remote controller.

RANGE A: Indoor coil temperature is more than 9 degrees above room temperature.

RANGE B : Indoor coil temperature is within 9 degrees either way of room temperature.

RANGE C : Indoor coil temperature is more than 9 degrees below room temperature.

Indoor coil temperature

minus room temperature

(degree)

+9

-9

RANGE A

0

RANGE B

RANGE C

28

Page 29

Minimum 3 minutes w1

ON

Thermostat

Indoor fan

Auto vane

Booster heater

Compressor

ON

DRY MODE

DRY MODE

ON

ON

OFF

OFF

ON

OFF

OFF

OFF

OFF

Operation starts by

POWER button

ON.

Operation stops by

POWER button

OFF.

Room temperature

becomes equal to

set temperature.

Room temperature

rises above set

temperature.

2-2 DRY operation

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

FAN

˚F

DRY

AM

<DRY operation time chart>

<How to operate>

1 Press POWER ON/OFF button.

2 Press the MODE button to display “DRY”

3 Press the TEMP( or ) button to set the desired temperature.

NOTE: The set temperature changes 2°F when the TEMP( or )

button is pressed one time.

Dry 65 to 87°F

w1 Even if the room temperature rises above the set temperature during this period, the compressor will not start until this

period has ended.

29

Page 30

1) Compressor control

Compressor OFF

43°F or more

Below 43°F

STOP

Pipe temp. Fan

LOW

All LOW

Compressor ON

1 3-minute time delay

To prevent overload, the compressor will not start within 3 minutes after stop.

2 The compressor runs when room temperature is higher than set temperature.

The compressor stops when room temperature is equal to or lower than the set temperature.

The compressor maintains the previous state when the room temperature minus the set temperature is 0°F or more, or

lower than 2°F.

3 The compressor stops in check mode or during protective functions.

4 The compressor will not start when the room temperature is 64°F or below.

The compressor starts intermittent operation when the power is turned ON with room temperature above 64°F. The compressor ON/OFF time depends on the thermostat ON/OFF and the following room temperatures.After 3-minute compressor

operation,

● If the room temperature thermistor reads above 82°F with thermostat ON, the compressor will operate for 6 more minutes

and then stop for 3 minutes.

● If the room temperature thermistor reads 79°F to 82°F with thermostat ON, the compressor will operate for 4 more minutes and then stop for 3 minutes.

● If the room temperature thermistor reads 75°F to 79°F with thermostat ON, the compressor will operate for 2 more minutes and then stop for 3 minutes.

● If the room temperature thermistor reads below 75°F with thermostat ON, the compressor will stop for 3 minutes.

● If the thermostat is OFF regardless of room temperature, the compressor will stop for 10 minutes.

5Coil frost protection

Coil frost protection in DRY operation is the same as in COOL operation.

6Coil frost prevention

Coil frost prevention does not operate in DRY operation.

(2) Indoor fan control

The indoor fan runs on LOW speed during compressor operation. The fan speed cannot be changed with the remote controller. Also, the fan runs on LOW speed when the pipe temperature is 43°F or more, or the compressor is OFF and the

pipe temperature is below 43°F.

(a)During compressor OFF

● When the indoor coil temperature is 43°F or above, the indoor fan will stop.

● When the indoor coil temperature is below 43°F, the indoor fan will run on LOW speed.

(b)During compressor ON

● The indoor fan runs on LOW speed.

<Dry mode>

The fan notch is controlled by the indoor coil temperature every 30 seconds.

Fan control in DRY operation.

(3) Auto vane control

Same as in COOL operation

(4) Detecting abnormalities in the outdoor unit

An abnormality in the outdoor unit can not be detected in DRY operation.

30

Page 31

2-3 HEAT operation

Minimum 3 minutes w2

ON

Thermostat

Indoor fan

Auto vane

Booster heater

Compressor

Power ON lamp

STAND BY lamp

ON

ON

LOW or HIGHLOW or HIGH

ON

OFF

OFF

OFF

Horizontal Horizontal

OFF

ON

OFF

ON

OFF

ON

OFF

LOW

w

1

LOW

w

1

Hot adjustment

From POWER ON until

warm begins to blow

Hot adjustment

Depends on remote

controller setting

Depends on remote

controller setting

w

1 Changeable LOW or HIGH

by indoor dip switch SW1-6 .

OFF during thermostat OFF

hot adjustment

defrosting

Operation starts by

POWER button

ON.

Operation stops by

POWER button

OFF.

Room temperature

becomes equal to

set temperature.

Room temperature

falls below set temperature.

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

FAN

˚F

HEAT

AM

<HEAT operation time chart>

<How to operate>

1 Press POWER ON/OFF button.

2 Press the MODE button to display “HEAT”

3 Press the TEMP( or ) button to set the desired temperature.

NOTE: The set temperature changes 2°F when the TEMP( or ).

button is pressed one time.

Heating 63 to 83°F.

<Display in HEAT operation>

[DEFROST]

The [DEFROST] symbol is only displayed during the defrost operation.

[STANDBY]

The [STANDBY] symbol is only displayed from the time the heating

operation starts until the heated air begins to blow.

w2 Even if the room temperature falls below the set temperature during this period, the compressor will not start until this peri-

od has ended.

31

Page 32

(1) Compressor control

13-minute time delay

To prevent overload, the compressor will not start within 3 minutes after stop.

2The compressor runs when the room temperature is lower than the set temperature.

The compressor stops when the room temperature is equal to or higher than the set temperature.

3The compressor stops in check mode or during protective functions.

4Overheat protection

<Start condition>

When the indoor coil thermistor reads 158°F or above, the overheat protection will start.

<Overheat protection>

The compressor stops for 6 minutes, and then restarts.

If the start condition is satisfied again within 10 minutes of compressor operation, both the indoor and outdoor units stop,

displaying a check code of “P6” on the remote controller.

<Termination conditions>

Overheat protection is terminated when the start condition is not satisfied again during the allowance (10-minute compressor operation), when operation mode changes to other mode, or when thermostat turns OFF.

(2) Indoor fan control

(a) Normal control

( i )The indoor fan runs on LOW speed during the thermostat OFF.

LOW speed can be changed to HIGH speed by setting the dip switch SW1-6.

If the indoor coil temperature becomes more than 5 degrees below the room temperature during the thermostat

OFF, the indoor fan will stop. After, when the indoor coil temperature becomes within 5 degrees of room temperature, the indoor fan will run on LOW speed.

(ii)Hot adjustment

Hot adjustment is a warm-up for HEAT operation

<Start conditions>

The hot adjustment works under any of the following conditions.

● HEAT operation starts.

● Defrosting ends.

● Thermostat turns ON.

[Hot adjustment]

Initially, the indoor fan runs on LOW speed. When 5 minutes have passed or the indoor coil temperature exceeds