Page 1

,_ MITSUBISHI

ELECTRIC

$LIII

Air-Co "

PKA-A.GA

PKA-A.GAL

e

iNSTALLATiON MANUAL

For safe and correct use, read this manual and the outdoor unit installation manual thoroughly before installing

the air-conditioner unit.

MANUAL DE INSTALACION

Para un uso correcto y seguro, lea detalladamente este manual y el manual de instalaci6n de la unidad exterior

antes de instalar la unidad de aire acondicionado.

Page 2

Contents

1. Safety precautions ................................................................................... 2 5. Drainage piping work ............................................................................... 6

2. Installation location .................................................................................. 3 6. Electrical work .......................................................................................... 7

3. Installing the indoor unit ........................................................................... 3 7. Test run .................................................................................................. 12

4. Installing the refrigerant piping ................................................................. 5 8. Easy maintenance function (Option) ...................................................... 15

1. Safety precautions

Before installing the unit, make sure you read all the "Safety precau-

tions".

Please report to your supply authority or obtain their consent before

connecting this equipment to the power suppmysystem.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Z_ Caution:

Describes precautions that must be observed to prevent damage to the unit.

Warning:

,, Ask a dealer or an authorized technician to install the unit.

,, For installation work, follow the instructions in the Installation Manual and use

tools and pipe components specifically made for use with refrigerant specified

in the outdoor unit installation manual

, The unit must be installed according to the instructions in order to minimize

the risk of damage from earthquakes, typhoons, or strong winds. An incor-

rectly installed unit may fall down and cause damage or injuries.

,, The unit must be securely installed on a structure that can sustain its weight.

,, if the air conditioner is installed in a small room, measures must be taken to

prevent the refrigerant concentration in the room from exceeding the safety

limit in the event of refrigerant leakage. Should the refrigerant leak and cause

the concentration limit to be exceeded, hazards due to lack of oxygen in the

room may result.

1.1. Before installation (Environment)

Caution:

,, Do not use the unit in an unusuam environment, if the air conditioner is in-

stalmedin areas exposed to steam, vomatimeoim(incmuding machine oim),or sulfuric

gas, areas exposed to high salt content such as the seaside, the performance

can be significantmy reduced and the internam parts can be damaged.

,, Do not install the unit where combustible gases may leak, be produced, flow,

or accumulate. If combustible gas accumulates around the unit, fire or explo-

sion may resumt.

,, Do not keep food, plants, caged pets, artwork, or precision instruments in the

direct airflow of the indoor unit or too close to the unit as these items can be

damaged by temperature changes or dripping water.

1.2. Before installation or relocation

Caution:

,, Be extremely carefum when transporting the units.Two or mote persons are

needed to handle the unit as it weighs 20 kg, 44 Ibe or more. Do not grasp the

packaging bands. Wear protective gloves as you can injure your hands on

the fins or other parts.

,, Be sure to safely dispose of the packaging materials. Packaging materiame,

such as naimsand other metam or wooden parts may cause stabs or other

injuries.

1.3. Before electric work

Caution:

,, Be sure to install circuit breakers, if not installed, electric shock may result.

,, For the power lines, use standard cables of sufficient capacity. Otherwise, a

short circuit, overheating, or fire may result.

,, When installing the power lines, do not apply tension to the cables.

After installation work has been completed, explain the "Safety precautions;' use, and

maintenance of the unit to the customer according to the information in the Operation

Manual and perform the test run to ensure normal operation. Both the Installation

Manual and Operation Manual must be given to the user for keeping. These manuals

must be passed on to subsequent users.

(_: Indicates which must be

Warning:

Carefully read the labels affixed to the main unit.

o Ventilate the room if refrigerant leaks during operation, if refrigerant comes

into contact with a flame, poisonous gases will be released.

, All electric work must be performed by a qualified technician according to

local regulations and the instructions given in this manual.

, Use only specified cables for wiring.

, The terminal block cover panel of the unit must be firmly attached.

o Use only accessories authorized by Mitsubishi Electric and ask a dealer or

an authorized technician to instammthem.

, The user shoumd never attempt to repair the unit or transfer it to another moca-

tion.

o After installation has been completed, check for refrigerant leaks, if refriger-

ant leaks into the room and comes into contact with the flame of a heater or

portabme cooking range, poisonous gases will be released.

o When the room humidity exceeds 80% or when the drainpipe is cmogged, wa-

ter may drip from the indoor unit. Do not install the indoor unit where such

dripping can cause damage.

, When installing the unit in a hospital or communications office, be prepared

for noise and electronic interference. Inverters, home appliances, high-fre-

quency medical equipment, and radio communications equipment can cause

the air conditioner to malfunction or breakdown.The air conditioner may also

affect medical equipment, disturbing medical care, and communications equip-

ment, harming the screen display quality.

o Thermal insulation of the refrigerant pipe is necessary to prevent condensa-

tion. if the refrigerant pipe isnot properly insulated, condensation will be formed.

o Place thermal insulation on the pipes to prevent condensation, if the drain-

pipe is installed incorrectly, water leakage and damage to the ceiling, floor,

furniture, or other possessions may result.

, Do not clean the air conditioner unit with water. Electric shock may result.

, Tighten all flare nuts to specification using a torque wrench. If tightened too

much, the flare nut can break after an extended period.

o Be sure to ground the unit. if the unit is not properly grounded, electric shock

may result.

, Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and

molded case circuit breaker) with the specified capacity. If the circuit breaker

capacity is larger than the specified capacity, breakdown or fire may result.

a

part grounded.

1.4. Before starting the test run

/_ Caution:

,, Turn on the main power switch more than 12 hours before starting operation.

Starting operation just after turning on the power switch can severely dam-

age the internal parts.

, Before starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

2

o Do not operate the air conditioner without the air filter set in place, if the air

filter is not installed, dust may accumulate and breakdown may result.

, Do not touch any switch with wet hands. Electric shock may result.

, Do not touch the refrigerant pipes with bare hands during operation.

, After stopping operation, be sure to wait at least five minutes before turning off

the main power switch. Otherwise, water meakage or breakdown may resumt.

Page 3

2. Installation location

®T

©

®

Fig. 2-1

3. Installing the indoor unit

2.1. Outline dimensions (indoor unit) (Fig. 2-1)

Select a proper position allowing the following clearances for installation and mainte-

nance. (mm)

Models W B H (_) _ _F_ _G_ (_

A12, A18 39 9-1/4 13-3/8 Min.l-13/16 Max.5 Max.7-3/32Min.l-31/32Min.5-29/32

Mount the indoor unit on a ceiling strong enough to withstand the weight of the

unit.

990 235 340 Mn 30 Max 130 Mn 180 Mn 50 Mn 160

_ Ceiling

© Wall

@ Furnishing, etc

Warning:

(inch)

2.2. Outline dimensions (Outdoor unit)

Refer to the outdoor unit installation manual.

@

®

®

®

®

®

®

®

3.1. Check the indoor unit accessories (Fig. 3-1)

The indoor unit should be supplied with the following accessories.

PARTNUMBER

d_

®

®

®

®

®

®

®

®

®

(_) - ® are stored in a cut-out section of the packing material (styrofoam).

ACCESSORY

Mount board

Tapping screw 4 × 35

Pipe cover

Band

Felt tape

Wireless remote controller

Remocon holder

Alkali batteries (size AAA)

Mount piece (Package)

Wired remote controller

Drain adaptor

QUANTITY

1

12

1

5

3

1

1

2

1

1

1

LOCATIONOFSETTING

Fixatthe backofthe unit

Set inside the unit

for PKA-A,GAL

for PKA-A,GA

Fig. 3-1

(inch)

3.2. installing the wall mounting fixture (Fig. 3-2)

3.2.1. Setting the wall mounting fixture and piping positions

Using the wall mounting fixture, determine the unit's installation position

and the locations of the piping holes to be drilled.

z_ Warning:

Before drilling a hole in the wall, you must consult the building contractor.

Supporting piece

_ Mount board

© Main body

@ Slot (6-11 x 20,

©

8P-7/16 x 25/32 inch)

Unit center

CF}Bolt hole (14-o14 ram,

14P-9/16 inch)

_) Tapping hole (49-o5 ram,

49P-3/16 inch)

CH}Bottom left pipe slot

(o90 mm, 3-9/18 inch)

Bottom left pipe slot knockout hole

(_) Bottom right pipe slot (o90 ram, 3-9/16 inch)

Bottom right pipe slot knockout hole

_L_Liquid pipe flare connection position

@ Gas pipe flare connection position

(_) Level setting standard

_) Insert scale.

Hole centre

(_) Align the scale with the line.

®®

Fig. 3-2

3.2.2. Drilling the piping hole (Fig. 3-3)

Use a core drill to make a hole of 90-100 ram, 3-9/16 to 4 inch diameter in the

wail in the piping direction, at the position shown in the diagram to the left.

The hole should incline so that the outside opening is lower than the inside

opening.

Sleeve

_ Hole

©

@

®

© (Indoors)

@ Wall

_} (Outdoors)

I_ Insert a sleeve (with a 90 ram, 3-9/16 inch diameter and purchased locally)

through the hole.

Note:

The purpose of the hole's inclination is to promote drain flow.

Fig. 3-3

3

Page 4

3. Installing the indoor unit

Fig. 3-4

©

Fig. 3-5

@ Min. 140 ram,

5-1/2 inch

_) Min. 300 ram,

11-13/16 inch

© Min. 55 mm,

2-3/16 inch

@ Mount board

3.2.3. Installing the wall mounting fixture

II_ Since the indoor unit weighs near 30 kg, 66 Ibs selection of the mounting

location requires thorough consideration. If the wall does not seem to be

strong enough, reinforce it with boards or beams before installation.

II_ The mounting fixture must be secured at both ends and at the centre, if

possible. Never fix it at a single spot or in any nonsymetrical way.

(If possible, secure the fixture at all the positions marked with a bold arrow.)

(Fig. 3-4)

z_ Warning:

If possible, secure the fixture at all positions indicated with a bold arrow.

z_ Caution:

o The unit body must be mounted horizontally.

o Fasten at the holes marked with A as shown by the arrows.

_) Fasten athread to the hole.

_ The levelcan be easily obtained by hanging a weight fromthestring andaligningthe string

with the mark.

3.3. When embedding pipes into the wall (Fig. 3-5)

• The pipes are on the bottom left.

• When the cooling pipe, drain pipes internal/external connection lines etc are to be

embedded into the wall in advance, the extruding pipes etc, may have to be bent

and have their length modified to suit the unit.

• Use marking on the mount board as a reference when adjusting the length of the

embedded cooling pipe.

• During construction, give the length of the extruding pipes etc some leeway.

(_)Mount board

(_)Reference marking forflare connection

C-C)Through hole

(_)On-site piping

3.4. Preparing the indoor unit

Rear, right and lower piping (Fig. 3-6)

1. Bind the cooling pipe and drain pipe together.

• Bind the pipes together with vinyl tape at three or more points. This will facilitate

passing the pipes through the wall.

Fig. 3-6

®

®

2. Remove the corner box and knock out the knockout holes as necessary.

• Remove the corner box by pushing in a downward direction (_), while at the same

time, pressing in the upper side part of the corner box (_.

(_)Corner box

(_)Under cover

Left and left rear piping (Fig. 3-7)

1. Remove the under cover.

• Remove the under cover by sliding it towards the rear of the unit @, while at the

same time, pressing the two points marked by arrow heads (_.

2. Remove the corner box and knock out the knockout holes as necessary.

®

Fig. 3-7

_ _....

_o_)

3.5. Mounting the indoor unit

1. Affix the mounting plate to the wall.

2. Hang the indoor unit on the two hooks positioned on the upper part of the mount-

ing plate.

Rear, right and lower piping (Fig. 3-8)

3. Affix the indoor unit.

4. After connecting the pipes, put the corner box back to where it was (follow the

removal steps backwards).

(_)Square hole

(_)Hooks

Fig. 3-8

®

/

(inch)

Fig. 3-9

Left and left rear piping (Fig. 3-9)

3. Cut out a mounting piece from the packaging material.

4. Pull the indoor unit up towards yourself as shown in the figure below and slide the

mounting piece in to the mounting plate using the mounting piece setting marks

as reference.

5. After connecting the pipes and wiring, put the under cover back to where it was,

and remove the mounting piece and affix the indoor unit as shown in the left

figure.

6. Put the corner box back to where it was.

(_)Mounting piece

(_)Ceiling

© Rib

4

Page 5

4. Installing the refrigerant piping

®

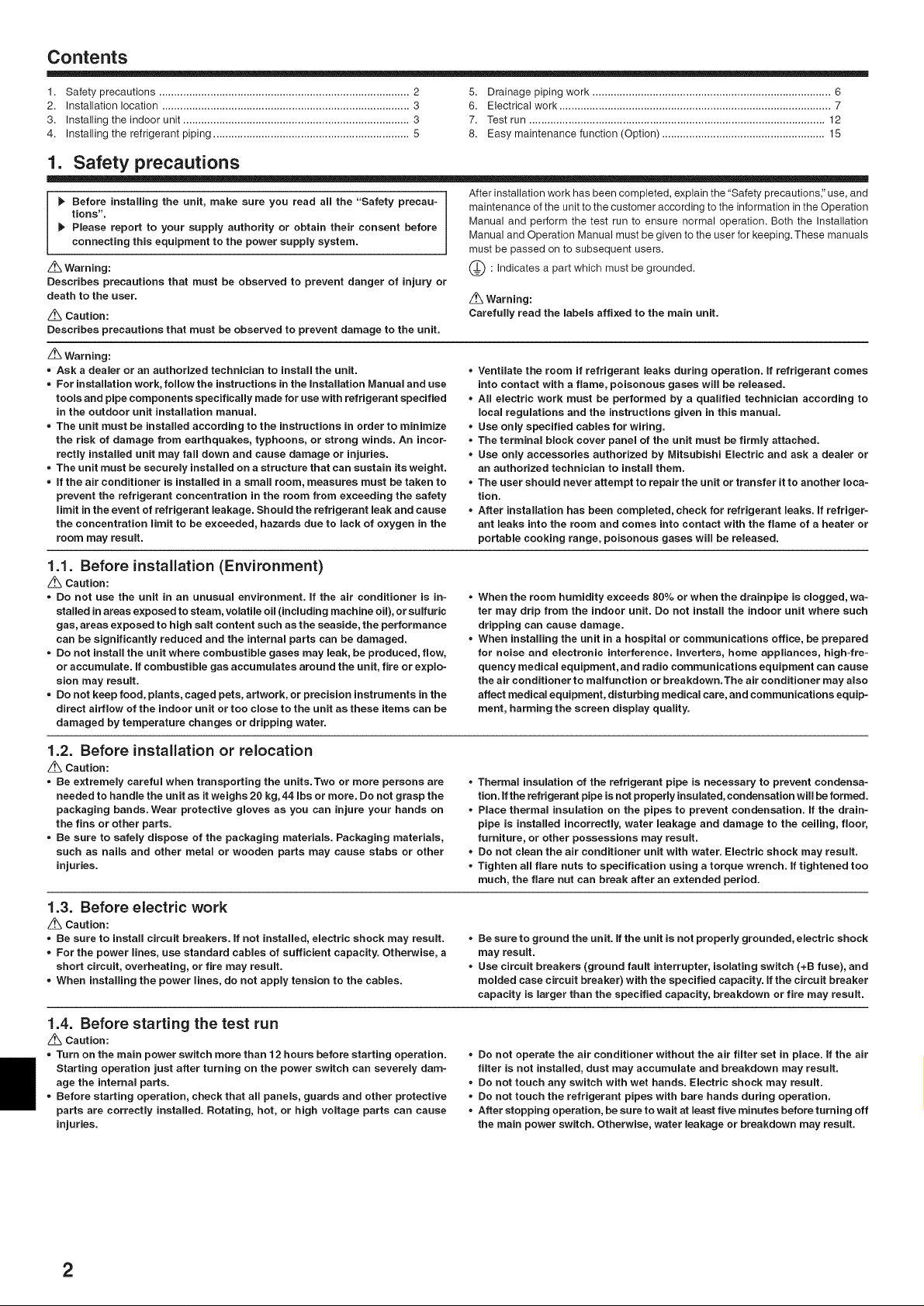

@ Flare cutting dimensions

45o_+2°

Copper pipe O.D. Flare dimensions

(mm, inch) sA dimensions (mm, inch)

06.35, 1/4" 8.7 - 9.1,11/32-23/64

09.52, 3/8" 12.8- 13.2, 1/2-33/64

o12.7, 1/2" 16.2 - 16.6, 41/64-21/32

el 5.88, 5/8" 19.3 - 19.7, 49/64-25/32

®

Fig. 44

(inch)

4.1. Precautions

4.1.1. For devices that use R410A refrigerant

. Use ester oil, ether oil, a(kyibenzene oil (small amount) as the refrigeration oil

applied to the flared sections.

. Use Cl 220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specified in the tab(e to the be(ow. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric com-

pounds, oxidants, debris, or dust.

Z_ Warning:

When installing or moving the air conditioner, use only the specified refriger-

ant (R410A) to charge the refrigerant lines. Do not mix it with any other refriger-

ant and do not a((ow air to remain in the (ines. Air enclosed in the (ines can

cause pressure peaks resulting in a rupture and other hazards.

Liquid pipe e6.35mm, 1/4 inch thickness 0.8 mm, 1/32 inch

I A12, A18

Gas pipe e12.7mm, 1/2 inch thickness 0.8 mm, 1/32 inch

Do not use pipes thinner than those specified above.

4.2. Connecting pipes (Fig. 4-1)

= When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C, 212 °F or

more, thickness of 12 ram, 1/2 inch or more).

= The indoor parts of the drain pipe should be wrapped with polyethylene foam insu-

lation materials (specific gravity of 0.03, thickness of 9 ram, 23/64 inch or more).

= Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

flare nut.

= Use two wrenches to tighten piping connections.

= Use refrigerant piping insulation provided to insulate indoor unit connections. Insu-

late carefully.

(_) Flare nut tightening torque

Copper pipe O.D.

(mm, inch)

06.35, 1/4"

e9.52, 3/8"

o12.7, 1/2"

o15.88, 5/8"

© Apply refrigerating machine oil over the entire flare seat surface.

@ Use correct flare nuts meeting the pipe size of the outdoor unit.

Flare nut O.D. Tightening torque

(mm, inch) (N.m, ft4bs!

17, 43/64 14 - 18, 10-13

22, 7/8 34 - 42, 25-30

26, 1-3/64 49 - 61, 35-44

29, 1-9/64 68 - 82, 49-59

Avaimabmepipe size

A12, A18

Liquid side

Gas side

O : Factory flare nut attachment to the heat-exchanger.

06.35

o12.7

5

Page 6

4. Installing the refrigerant piping

_'_ #............................................................................................................................................................................1_ (inch)

..................................................................................................;;

U_ ........ _ '_)

@2......@

Fig. 4=2

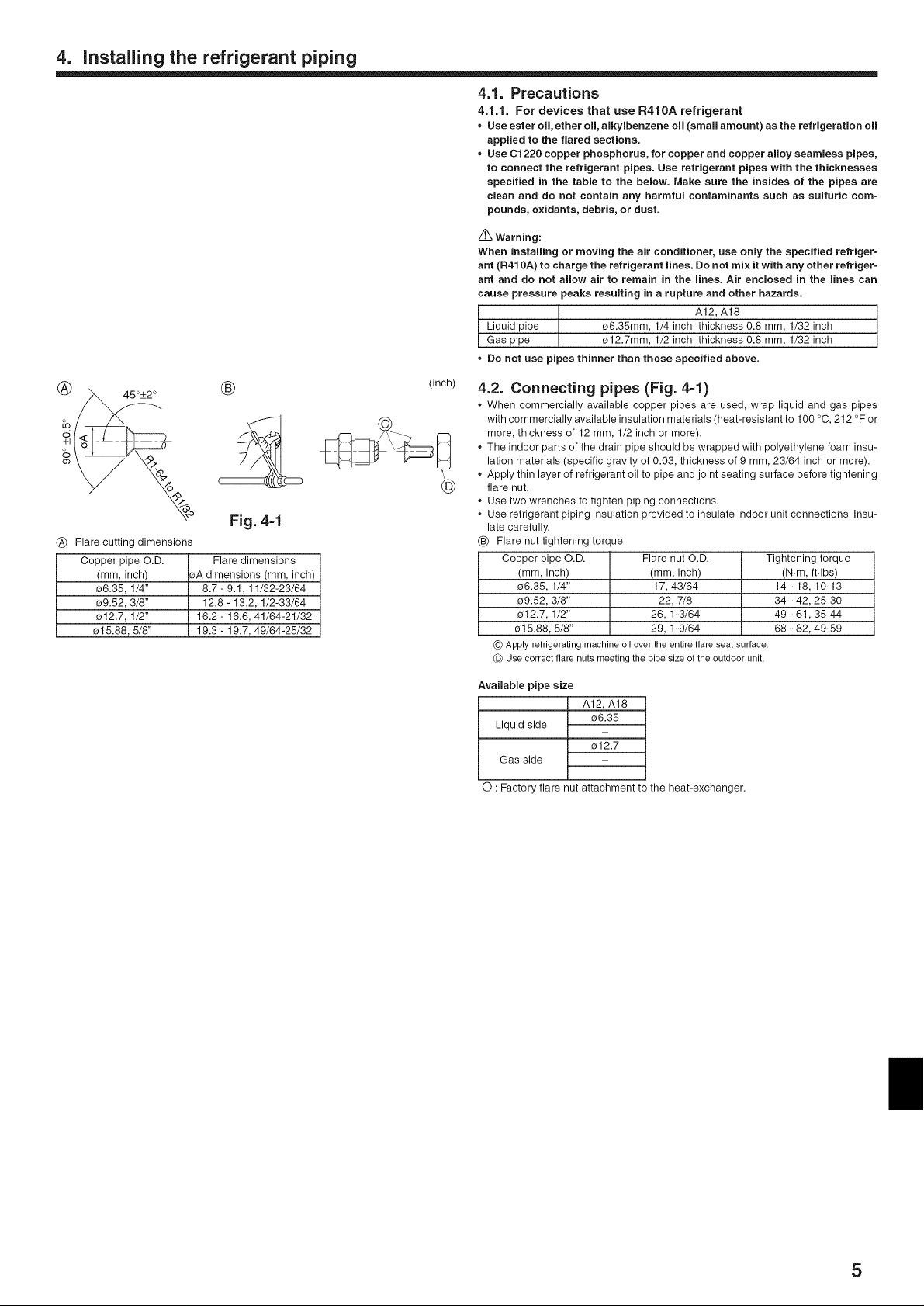

4.3. Positioning refrigerant and drain piping

(_) Position of refrigerant and drain piping (Fig. 4-2)

• The drain pipe can be cut midway to meet the on-site conditions.

(_)(Totallength offlexible hose) @ Drain hose

(_)Liquid pipe _E}Left-side piping

© Gas pipe _} Right-side piping

® Determine the position o1 the knockout holes on the unit body. (Fig. 4-8)

II_ Cut the knockout holes using a saw blade or an adequate knife.

Take care not to damage other parts of the unit.

® ® ® Remove the corner box and drill a knockout hole. If a hole is made without remov-

ing the box, the drain hose could be damaged.

(_) Left-side piping _D}Remote controller cable through hole

(_) Lower piping (E} Corner box

_C)Right-side piping

Fig. 4=3

\

Fig. 4=4

4.4. Refrigerant piping (Fig. 4=4)

1. Remove the flare nut and cap of the indoor unit.

2. Make a flare for the liquid pipe and gas pipe and apply refrigerating machine oil

(available from your local supplier) to the flare sheet surface.

3. Quickly connect the on site cooling pipes to the unit.

4. Wrap the pipe cover ® that is attached to the gas pipe and make sure that the

connection join is not visible.

5. Wrap the pipe cover of the unit's liquid pipe and make sure that it covers the

insulation material of the on site liquid pipe.

6. Use the bands that are provided _') to tighten both ends (15-20mm, 19/32 to

25/32 inch) o1each pipe cover ®.

(_)Cooling pipe and insulation (availablefrom local supplier)

(_)Unit'sgas pipe _} Bands (_0

_c)Unit'sliquid pipe (_F_On site gas pipe

(_)Pipecover _ _) On site liquid pipe

5. Drainage piping work

@ ®

\

©

Fig. 5=1

@

®

@

,',._:3_#ia ,;J,

@bx:_.... .....................,

Fig. 5=2

6

4.5. For twin combination

Refer to the outdoor unit unstallation manual.

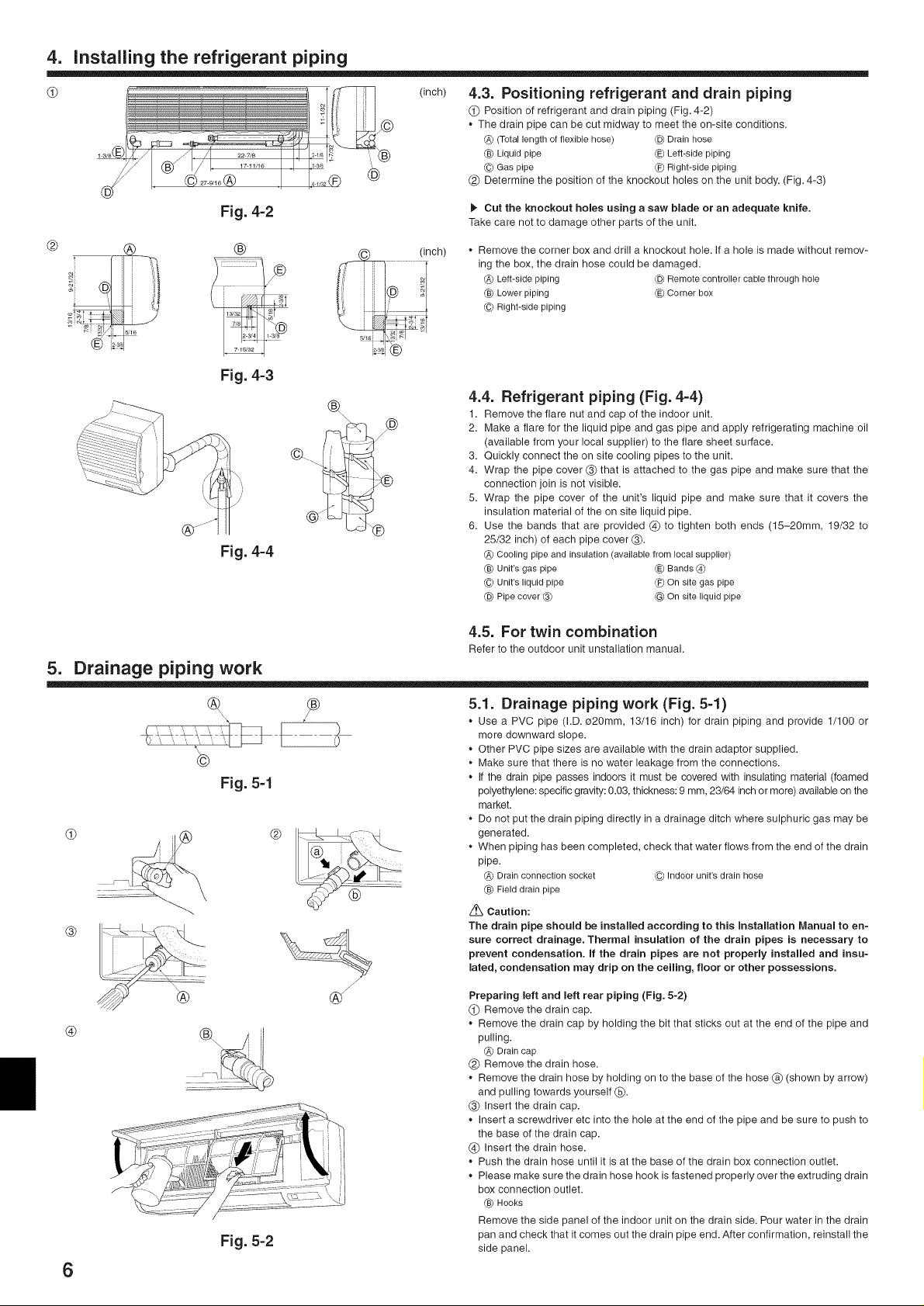

5.1. Drainage piping work (Fig. 5-1)

• Use a PVC pipe (I.D. o20mm, 13/16 inch) for drain piping and provide 1/100 or

more downward slope.

• Other PVC pipe sizes are available with the drain adaptor supplied.

• Make sure that there is no water leakage from the connections.

• If the drain pipe passes indoors it must be covered with insulating material (foamed

polyethylene: specific gravity: 0.03, thickness: 9 mm, 23/64 inch or more) available on the

market.

• Do not put the drain piping directly in a drainage ditch where sulphuric gas may be

®

/

generated.

• When piping has been completed, check that water flows from the end of the drain

pipe.

(_)Drain connectionsocket © Indoor unit's drain hose

(_)Field drain pipe

Caution:

The drain pipe should be installed according to this Installation Manual to en-

sure correct drainage. Thermal insulation of the drain pipes is necessary to

prevent condensation. If the drain pipes are not properly installed and insu-

lated, condensation may drip on the ceiling, floor or other possessions.

Preparing left and left rear piping (Fig. 5-2)

(_) Remove the drain cap.

• Remove the drain cap by holding the bit that sticks out at the end of the pipe and

pulling.

(_)Drain cap

® Remove the drain hose.

• Remove the drain hose by holding on to the base of the hose (_ (shown by arrow)

and pulling towards yourself (_).

® Insert the drain cap.

• Insert a screwdriver etc into the hole at the end of the pipe and be sure to push to

the base of the drain cap.

_) Insert the drain hose.

• Push the drain hose until it is at the base of the drain box connection outlet.

• Please make sure the drain hose hook is fastened properly over the extruding drain

box connection outlet.

(_)Hooks

Remove the side panel of the indoor unit on the drain side. Pour water in the drain

pan and check that it comes out the drain pipe end. After confirmation, reinstall the

side panel.

Page 7

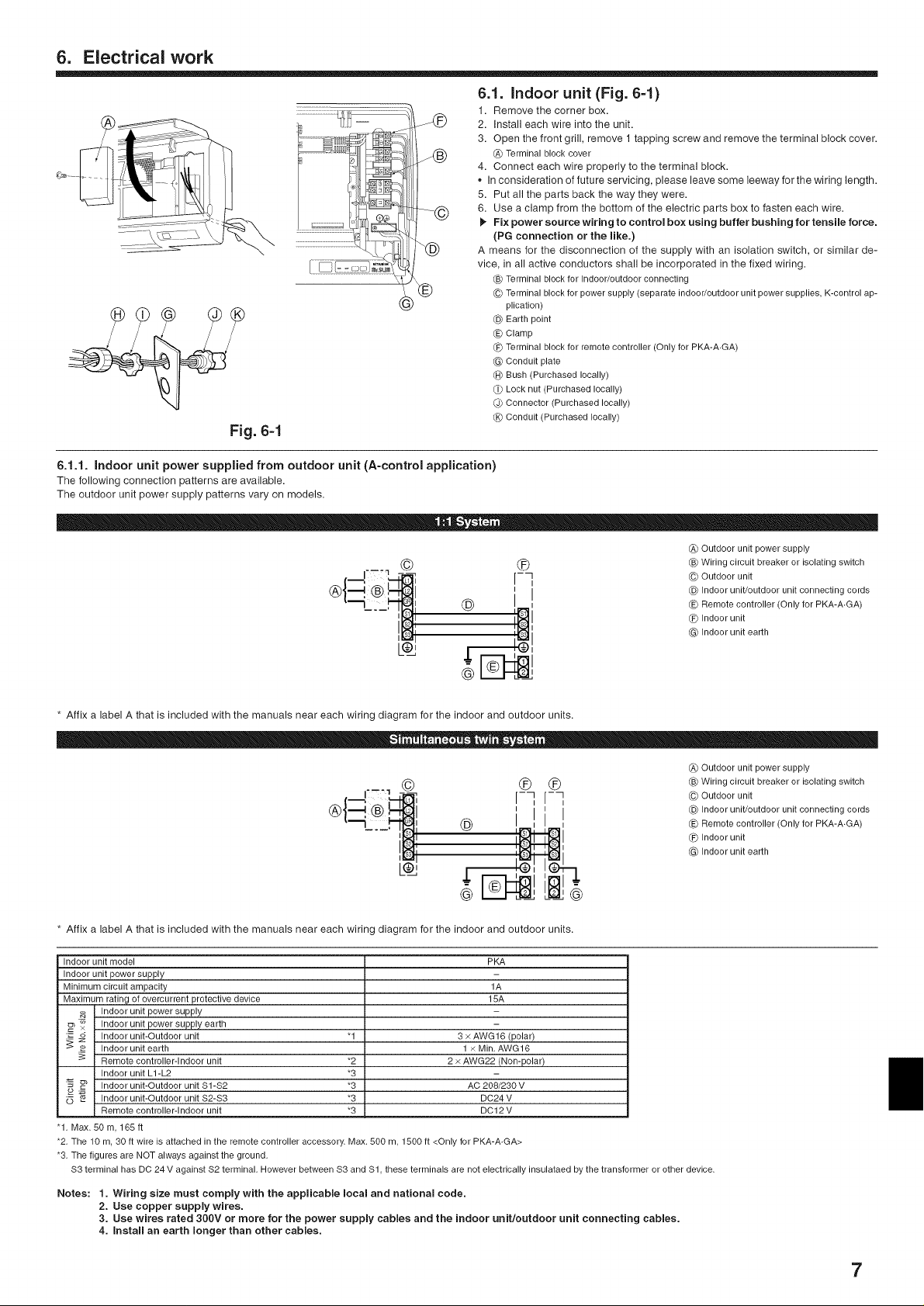

6. Electrical work

\

®

Fig. 6-1

6.1.1. indoor unit power supplied from outdoor unit (A-control application)

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

6.1. Indoor unit (Fig. 6-1)

1. Remove the corner box.

2. install each wire into the unit.

3. Open the front grill, remove 1 tapping screw and remove the terminal block cover.

@ Terminal block cover

4. Connect each wire properly to the terminal block.

o In consideration of future servicing, please leave some leeway for the wiring length.

5. Put all the parts back the way they were.

6. Use a clamp from the bottom of the electric parts box to fasten each wire.

I_ Fix power source wiring to control box using buffer bushing for tensile force.

(PG connection or the like.)

A means for the disconnection of the supply with an isolation switch, or similar de-

vice, in all active conductors shall be incorporated in the fixed wiring.

_p Terminal block for Indoor/outdoor connecting

© Terminal block for power supply (separate indoor/outdoor unit power supplies, K-control ap-

plication)

@ Earth point

Clamp

CF_Terminal block for remote controller (Only for PKA-A.GA)

_) Conduit plate

CH_Bush (Purchased locally)

Ci_Lock nut (Purchased locally)

_3_Connector (Purchased locally)

(K_Conduit (Purchased locally)

(_ (_ _ Wiring circuit breaker or isolating switch

®

(_ IIi _ Remote controller (Only for PKA-A.GA)

LCJ _/-_/

@

[-ql © Outdoor unit

i I _D)Indoor unit/outdoor unit connecting cords

i_! CF)Indoor unit

_! _) Indoor unit earth

* Affix a label A that is included with the manuals near each wiring diagram for the indoor and outdoor units.

(_ (_ (_ _ Wiring circuit breaker or isolating switch

®

@ I , I I ®Remotecontroller(Only for PKA-A.GA)

[-ql [-ql © Outdoor unit

i I i @ Indoor unit/outdoor unit connecting cords

H! CF_Indoor unit

L¢i _O_, I _) Indoor unit earth

* Affix a label A that is included with the manuals near each wiring diagram for the indoor and outdoor units.

Indoor unit model

Indoor unit power supply

Minimum circuit ampacity

Maximum rating of overcurrent protective device

Indoor unit power supply

u_ _ Indoor unit power supply earth

•__o

•- z Indoor unit-Outdoor unit 41

_ Indoor unit earth

_: Remote controller-Indoor unit 42

Indoor unit L1-L2 43

,_, ._ Indoor unit-Outdoor unit $1-$2 43

"_ Indoor unit-Outdoor unit $2-S3 43

Remote controller-Indoor unit 43

"1. Max. 50 m, 168ft

*2. The 10 m, 30 ft wire is attached in the remote controller accessory. Max. 800 m, 1800 ft <Only for PKA-A.GA>

*3. The figures are NOT always against the ground.

$3 terminal has DC 24 V against $2 terminal. However between $3 and $1, these terminals are not electrically insulataed by the transformer or other device.

Notes:

1. Wiring size must comply with the applicable local and national code.

2. Use copper supply wires.

3. Use wires rated 300V or more for the power supply cables and the indoor unit/outdoor unit connecting cables.

4. Install an earth longer than other cables.

PKA

1A

15A

3 x AWGf6 (polar)

t x Min. AWG16

2 x AWG22 (Non-polar)

AC 208/230 V

DC24 V

DCf2V

@ Outdoor unit power supply

@ Outdoor unit power supply

7

Page 8

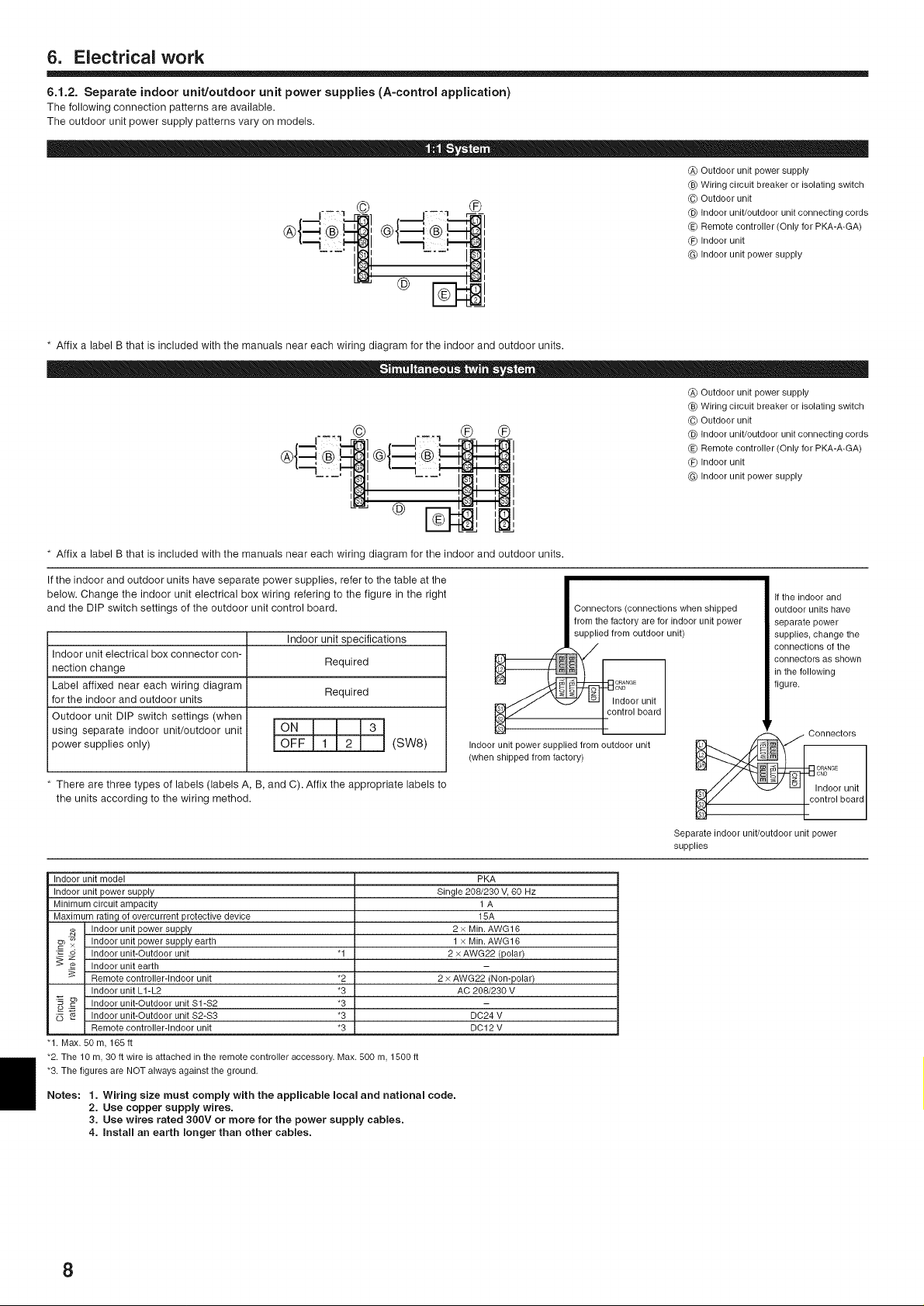

6. Electrical work

6.1.2. Separate indoor unit/outdoor unit power suppJies (A-controJ appJication)

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

© ®

®

@

* Affix a label B that is included with the manuals near each wiring diagram for the indoor and outdoor units.

©

._._ ® ®

(_) Outdoor unit power supply

© Wiring circuit breaker or isolating switch

© Outdoor unit

© Indoor unit/outdoor unit connecting cords

© Remote controller (Only for PKA-A.GA)

(_ Indoor unit

(G'_Indoor unit power supply

(_) Outdoor unit power supply

© Wiring circuit breaker or isolating switch

© Outdoor unit

© Indoor unit/outdoor unit connecting cords

© Remote controller (Only for PKA-A.GA)

(_ Indoor unit

(G'_Indoor unit power supply

@ I

I '

* Affix a label B that is included with the manuals near each wiring diagram for the indoor and outdoor units.

If the indoor and outdoor units have separate power supplies, refer to the table at the

below. Change the indoor unit electrical box wiring refering to the figure in the right

and the DIP switch settings of the outdoor unit control board.

Indoor unit specifications

Indoor unit electrical box connector con-

nection change Required

Label affixed near each wiring diagram Required

for the indoor and outdoor units

Outdoor unit DIP switch settings (when

using separate indoor unit/outdoor unit L£3__

power supplies only) _ (SW8)

Ao, _

Indoor unit power supplied from outdoor unit

(when shipped from factory)

There are three types of labels (labels A, B, and C). Affix the appropriate labels to

the units according to the wiring method.

Indoor unit model

Indoor unit power supply

Minimum circuit ampacity

Maximum rating of overcurrent protective device

,_ Indoor unit power supply

Indoor unit power supply earth

×

;_ Indoor unit-Outdoor unit "1

'_ Indoor unit earth

_: Remote controller-Indoor unit *2

Indoor unit L1-L2 *3

R ._ Indoor unit-Outdoor unit $1-$2 *3

_- _ Indoor unit-Outdoor unit $2-$3 *3

Remote controller-Indoor unit *3

41. Max. 80m, 165ft

42. The 10 m, 30 ft wire is attached in the remote controller accessory. Max. 800 m, 1800 ft

43. The figures are NOT always against the ground.

Notes:

1. Wiring size must comply with the applicable local and national code.

PKA

Single 208/230 V, 60 Hz

1A

18A

2x Min. AWG16

1 x Min. AWG16

2 x AWG22 (polar)

2 x AWG22 (Non-polar)

AC 208/230 V

DC24 V

DC12 V

2. Use copper supply wires.

3. Use wires rated 300V or more for the power supply cables.

4. mnstaNman earth monger than other cabmes.

Connectors (connections when shipped

from the factory are for indoor unit power

supplied from outdoor unit)

Separate indoor unit/outdoor unit power

supplies

If the indoor and

outdoor units have

separate power

supplies, change the

connections of the

connectors as shown

in the following

figure.

Connectors

8

Page 9

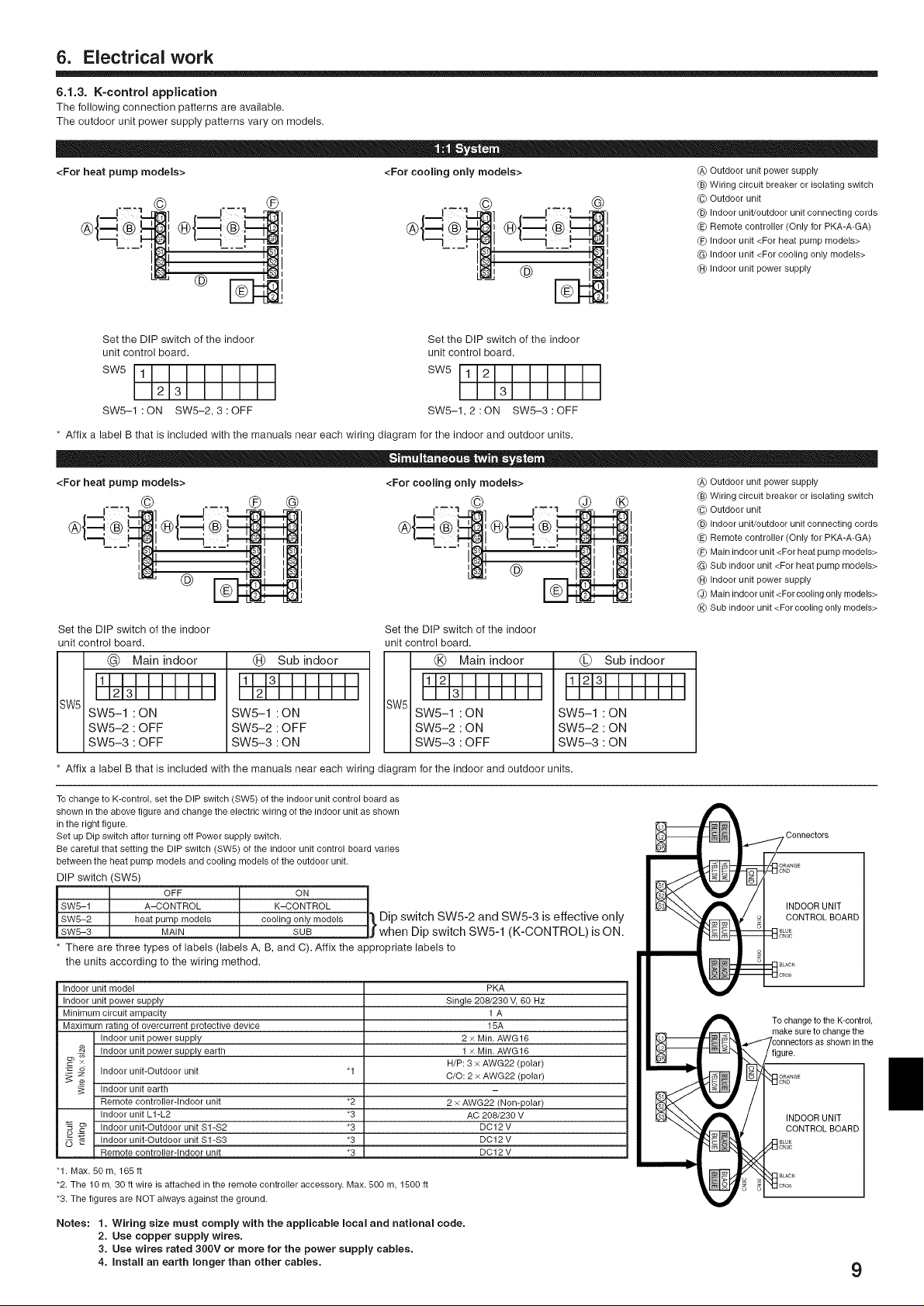

6. Electrical work

6.1.3. K-control application

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

<For cooming onmymodems><For heat pump modems>

© ® © @

® ®

@

Set the DIP switch of the indoor

unit control board.

SW5 1 2 3

SW5-1 :ON SW5-2, 3 : OFF

@

Set the DIP switch of the indoor

unit control board.

SW5 1 2 3

SW5-1,2 :ON SW5-3 : OFF

(_) Outdoor unit power supply

(_) Wiring circuit breaker or isolating switch

C-C}Outdoor unit

(_) Indoor unit/outdoor unit connecting cords

Remote controller (Only for PKA-A.GA)

(_ Indoor unit <For heat pump models>

(G'_Indoor unit <For cooling only models>

(_ Indoor unit power supply

* Affix a label B that is included with the manuals near each wiring diagram for the indoor and outdoor units.

<For heat pump models> <For cooling only models> _) Outdoor unit power supply

© @ @ © @ @

.

@

Set the DIP switch of the indoor

unit control board.

© Main indoor (_) Sub indoor

@

Set the DIP switch of the indoor

unit control board.

(_ Main indoor (_ Sub indoor

(_) Wiring circuit breaker or isolating switch

C-C}Outdoor unit

(_) Indoor unit/outdoor unit connecting cords

_E_Remote controller (Only for PKA-A.GA)

(_ Main indoor unit <For heat pump models>

(G'_Sub indoor unit <For heat pump models>

(_ Indoor unit power supply

(_) Main indoor unit <For cooling only models>

Sub indoor unit <For cooling only models>

123 1123 I

SW5

SW5-1 : ON SW5-1 : ON

SW5-2 : OFF SW5-2 :OFF

SW5-3 : OFF SW5-3 :ON

1 23 1 23 I

SW5

SW5-1 : ON SW5-1 : ON

SW5-2 : ON SW5-2 : ON

SW5-3 : OFF SW5-3 : ON

* Affix a label B that is included with the manuals near each wiring diagram for the indoor and outdoor units.

To change to K-control, set the DIP switch (SW5) of the indoor unit control board as

shown in the above figure and change the electric wiring of the indoor unit as shown

in the right figure.

Set up Dip switch after turning off Power supply switch.

Be careful that setting the DIP switch (SW5) of the indoor unit control board varies

between the heat pump models and cooling models of the outdoor unit.

DIP switch (SW5)

SW5-1 A_CONTROL K-CONTROL

SW5-2 heat pump models cooling only models _ Dip switch SW5-2 and SW5-3 is effective only

OFF ON

sw5-3 MAIN SUB _Jwhen Dip switch SW5-1 (K-CONTROL) is ON.

* There are three types of labels (labels A, B, and C). Affix the appropriate labels to

the units according to the wiring method.

Indoor unit model PKA

Indoor unit power supply Single 208/230 V, 60 Hz

Minimum circuit ampacity 1 A

Maximum rating of overcurrent protective device 15A

Indoor unit power supply 2 x Min. AWG16

-_ Indoor unit power supply earth 1 x Min. AWG16

× H/P: 3 x AWG22 (polar)

Indoor unit-Outdoor unit "1

_;_ C/O: 2 x AWG22 (polar)

Indoor unit earth

Remote controller-Indoor unit *2 2 x AWG22 (Non-polar)

Indoor unit L1-L2 *3 AC 208/230 V

# _ Indoor unit-Outdoor unit $1-$2 *3 DC12 V

E "_ Indoor unit-Outdoor unit $1 -$3 *3 D012 V

_5

Remote controller-Indoor unit *3 DC12 V

41. Max. 50 m, 185 ft

42. The 10 m, 30 ft wire is attached in the remote controller accessory. Max. 500 m, 1500 ft

43. The figures are NOT always against the ground.

Notes:

1. Wiring size must comply with the applicable local and national code.

2. Use copper supply wires.

3. Use wires rated 300V or more for the power supply cables.

4. mnstamman earth monger than other cabmes.

Connectors

INDOOR UNIT

CONTROL BOARD

To change to the K-control,

make sure to change the

INDOOR UNIT

CONTROL BOARD

9

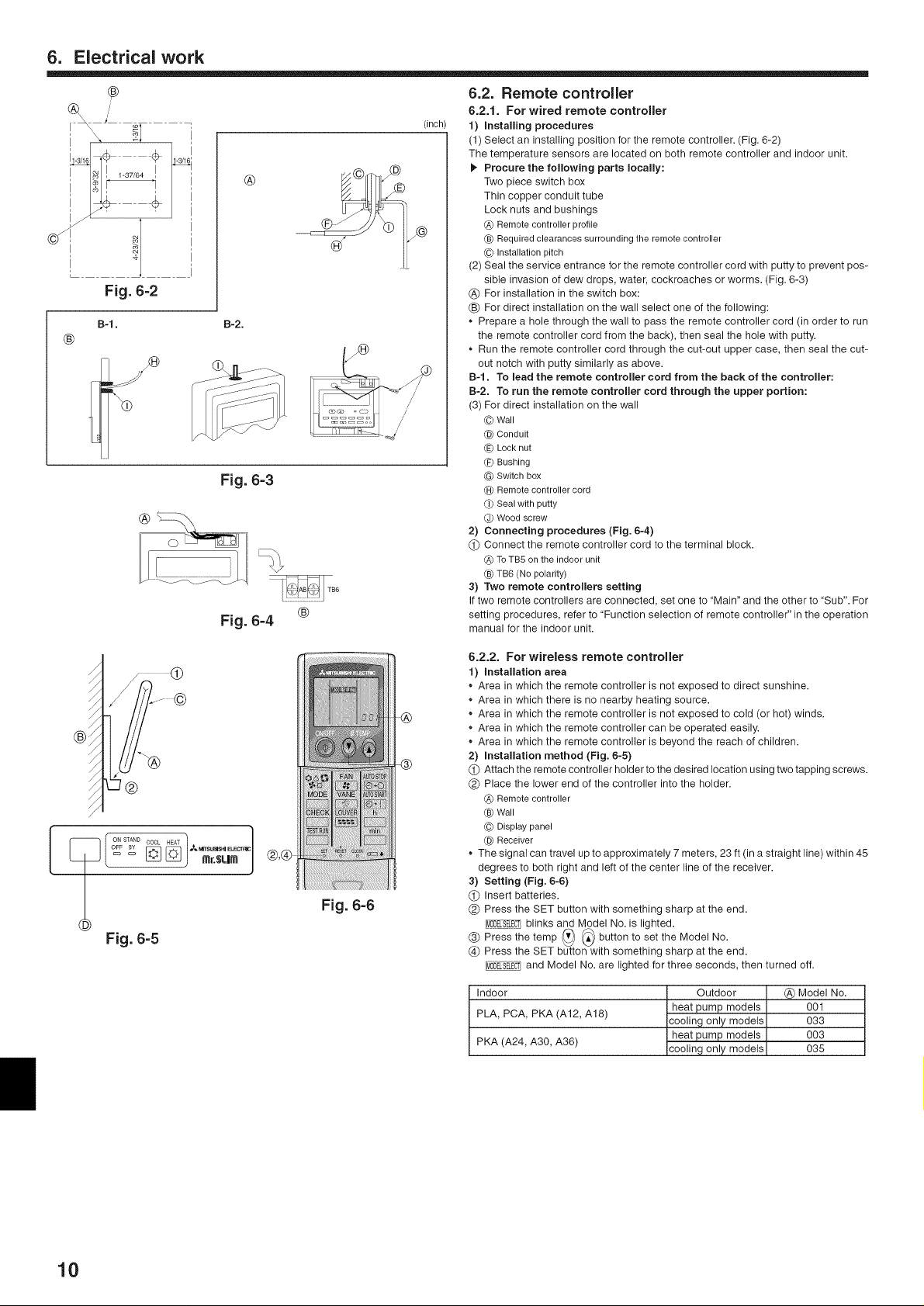

Page 10

6. Electrical work

®

®

®

Fig. 6=2

B-I.

6.2. Remote controller

6.2.1. For wired remote controJJer

(inch) 1) installing procedures

(1) Select an installing position for the remote controller. (Fig. 6-2)

The temperature sensors are located on both remote controller and indoor unit.

®

B-2.

®

Fig. 6=3

TB6

Fig. 6=4

®

I_ Procure the following parts locally:

Two piece switch box

Thin copper conduit tube

Lock nuts and bushings

(_)Remotecontroller profile

(_)Required clearancessurrounding the remote controller

_-C_Installationpitch

(2) Seal the service entrance for the remote controller cord with putty to prevent pos-

sible invasion of dew drops, water, cockroaches or worms. (Fig. 6-3)

® For installation in the switch box:

® For direct installation on the wall select one of the following:

Prepare a hole through the wall to pass the remote controller cord (in order to run

the remote controller cord from the back), then seal the hole with putty.

Run the remote controller cord through the cut-out upper case, then seal the cut-

out notch with putty similarly as above.

B-1. To meadthe remote controller cord from the back of the controller:

B-2. To run the remote controller cord through the upper portion:

(3) For direct installation on the wall

_c)Wall

(_)Conduit

Lock nut

(_ Bushing

(G'_Switch box

(_ Remote controller cord

Sealwith putty

(J_Woodscrew

2) Connecting procedures (Fig. 6-4)

(_) Connect the remote controller cord to the terminal block.

(_)ToTB5 on the indoor unit

(_)TB6 (No polarity)

3) Two remote controllers setting

If two remote controllers are connected, set one to "Main" and the other to "Sub". For

setting procedures, refer to "Function selection of remote controller" in the operation

manual for the indoor unit.

[

/

/

ON STAND COOL HEAT

Fig. 6=5

Fig. 6=6

6.2.2. For wireless remote controJJer

1) mnstammationarea

• Area in which the remote controller is not exposed to direct sunshine.

• Area in which there is no nearby heating source.

• Area in which the remote controller is not exposed to cold (or hot) winds.

• Area in which the remote controller can be operated easily.

• Area in which the remote controller is beyond the reach of children.

2) installation method (Fig. 6-5)

_'_ Attach the remote controller holder to the desired location using two tapping screws.

® Place the lower end of the controller into the holder.

(_)Remotecontroller

(_)Wall

_C)Display panel

(_)Receiver

• The signal can travel up to approximately 7 meters, 23 ft (in a straight line) within 45

degrees to both right and left of the center line of the receiver.

3) Setting (Fig. 6-6)

(_) Insert batteries.

® Press the SET button with something sharp at the end.

blinks and Model No. is lighted.

® Press the temp _v_ 0'_ button to set the Model No.

® Press the SET button with something sharp at the end.

Indoor Outdoor ® Model No.

PLA, PCA, PKA (A12, A18) heat pump models 001

PKA (A24, A30, A36) i heat pump models 003

and Model No. are lighted for three seconds, then turned off.

icooling only models 033

3ooling only models 035

10

Page 11

6. Electrical work

© ©

\

u u _ _

/

_ _ LU _ __

C!:-I .]--

Fig. 6=7

-@

L_I_ II_ I

<_ Mode number

(I[) Setting number

_ Refrigerant address

@) Unit number

I

,q,q'7-I12_-

uu LI_ i __

4) Assigning a remote controller to each unit (Fig. 6-7)

Each unit can be operated only by the assigned remote controller.

Make sure each pair of an indoor unit PC board and a remote controller is assigned

to the same pair No.

5) Wireless remote controller pair number setting operation

Press the SET button with something sharp at the end.

Start this operation from the status of remote controller display turned off.

blinks and Model No. is lighted.

Press the _ button twice continuously.

Pair No. "0" blinks.

Press the temp _ _'_,_button to set the pair number you want to set.

®

_') Press the SET button with something sharp at the end.

Set pair number is lighted for three seconds then turned off.

@ Pair No. of wireless remote controller Indoor PC board

0 Factory setting

1 Cut J41

2 Cut J42

3-9 Cut J41, J42

6.3. Function settings

6.3.1 Function setting on the unit (Selecting the unit functions)

1) For wired remote controller (Fig. 6-8)

Changing the power voltage setting

= Be sure to change the power voltage setting depending on the voltage used.

Go to the function setting mode.

Switch OFF the remote controller.

Press the @ and (_) buttons simultaneously and hold them for at least 2

seconds. FUNCTION will start to flash.

Use the © button to set the refrigerant address (]][) to 00.

® Press @ and [--] will start to flash in the unit number (_) display.

(_ Use the © button to set the unit number (IV) to 00.

(_) Press the (_ MODE button to designate the refrigerant address/unit number. [--]

will flash in the mode number ( I ) display momentarily.

® Press the (_ buttons to set the mode number ( t ) to 04.

(_ Press the (_) button and the current set setting number ( _ ) will flash.

Use the (_ button to switch the setting number in response to the power supply

voltage to be used.

Power supply voltage

® Press the MODE button (_) and mode and the setting number ( I ) and ( _ ) will

change to being on constantly and the contents of the setting can be confirmed.

_) Press the FILTER @ and TEST RUN _) buttons simultaneously for at least two

seconds. The function selection screen will disappear momentarily and the air

conditioner OFF display will appear.

230V : setting number = 1

208V : setting number- 2

,@ ®

Fig. 6=9

\ _1_/-

4,-,,1

2) For wireless remote controller (Fig. 6-9)

Changing the power voltage setting

o Be sure to change the power voltage setting depending on the voltage used.

Go to the function select mode

Press the _ button (_ twice

(Start this operation from the status of remote controller display turned off.)

is lighted and_"00" blinks.

Press the temp f,,v_ button @ once to set "50". Direct the wireless remote controller

®

\ _I_Z

\4 I /

Ji,-,,1

ll

toward the receiver of the indoor unit and press the _ button (_).

Setting the unit number

Press the temp (\v)) ((A_button © and (_ to set the unit number"00". Direct the wireless

remote controller toward the receiver of the indoor unit and press the _ button (_).

® Selecting a mode

Enter 04 to change the power voltage setting using the _vj_ © and _ @ buttons.

Direct the wireless remote controller toward the receiver of the indoor unit and press

the _ button @.

Current setting number: 1 = 1 beep (one second)

(_ Selecting the setting number

Use the

Direct the wireless remote controller toward the sensor of the indoor unit and press

i

the _ button @.

(_ To select multiple functions continuously

Repeat steps ® and @ to change multiple function settings continuously.

(_ Complete function selection

Direct the wireless remote controller toward the sensor of the indoor unit and press

the _$_ button ®.

Note:

Whenever changes are made to the function settings after installation or main-

tenance, be sure to record the changes with a mark in the "Setting" column of

the Function table.

_J

© and _ @ buttons to change the power voltage setting to 01 (240 V).

continuously.

h

min

2 = 2 beeps (one second each)

3 = 3 beeps (one second each)

6.3.2 Function setting on the remote controller

Referto the indoor unit operation manual.

11

Page 12

6. Electrical work

Function table

Select unit number 00

Mode

Power failure automatic recovery

Indoor temperature detecting

LOSSNAY connectivity

Power voltage

Auto mode (only for PUHZ)

Select unit numbers 01 to 03 or all units (AL [wired remote controller]/07 [wireless remote controller])

Mode Settings

Filter sign 100Hr

Fan speed

No. of air outlets

Installed options (high-performance filter)

Up/down vane setting

Energy saving air flow

(Heating mode)

"1 When the power supply returns, the air conditioner will start 3 minutes later.

Settings Mode no.

Not available 01

Available "1

Indoor unit operating average

Set by indoor unit's remote controller 02

Remote controller's internal sensor

Not Supported

Supported (indoor unit is not equipped with outdoor-air intake) 03

Supported (indoor unit is equipped with outdoor-air intake)

230 V 04

208 V

Energy saving cycle automatically enabled 05

Energy saving cycle automatically disabled

2500Hr

No filter sign indicator

Standard (PLA)/Silent (PCA)

High ceiling _ (PLA)/Standard (PCA)

High ceiling (_) (PLA)/High ceiling (PCA)

4 directions

3 directions

2 directions

Not supported

Supported

No vanes

Equipped with vanes (vanes angle setup _'})

Equipped with vanes (vanes angle setup @})

Disabled

Enabled

Mode no.

O7

O8

O9

10

11

12

Setting no. Initial setting

1

2 O

1 O

2

3

1 O

2

3

1 O

2

1 O

2

Setting no. Initial setting

1 O

2

3

1

2

3

1

2

3

1

2

1

2

3

1

2

setting

setting

7. Test run

7.1. Before test run

I_ After completing installation and thewiring and piping of the indoor and outdoor _ Do not carry out this test on the control wiring (low voltage circuit) termi-

units, check for refrigerant leakage, looseness in the power supply or control hale.

wiring, wrong polarity, and no disconnection of one phase in the supply. Z_ Warning:

I_ Use a 500-volt megohmmeter to check that the resistance between the power Do not use the air conditioner if the insulation resistance is less than 1.0 M_.

supply terminals and ground is at least 1.0 M_. Insulation resistance

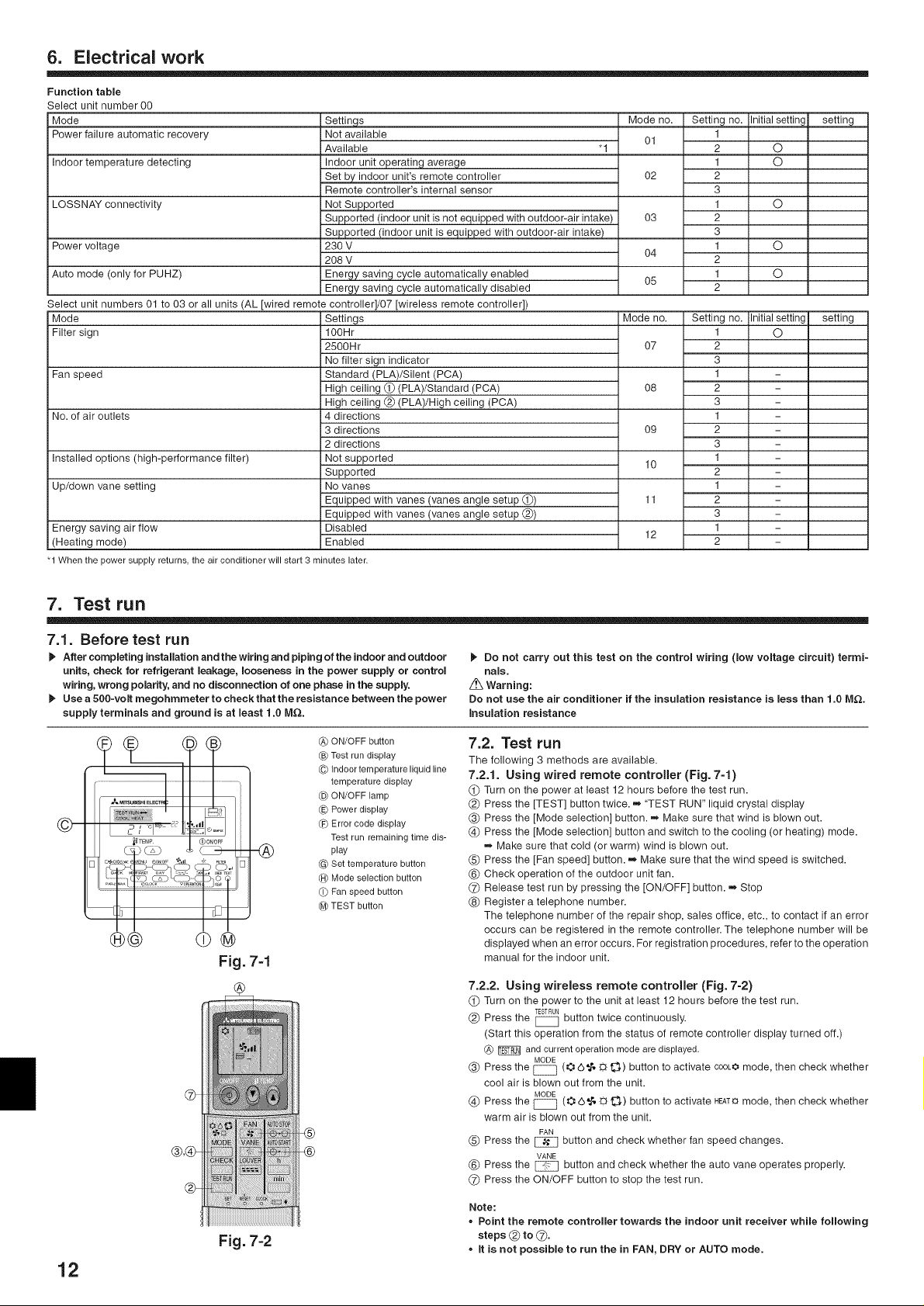

@ ON/OFF button

_p Test run display

© Indoor temperature liquid line

temperature display

@ ON/OFF lamp

Power display

CF_Error code display

Test run remaining time dis-

play

Set temperature button

CH)Mode selection button

Ci_Fan speed button

@ TEST button

®@ (D @

Fig. 74

7.2. Test run

The following 3 methods are available.

7.2.1. Using wired remote controller (Fig. 7-1)

(_) Turn on the power at least 12 hours before the test run.

@_ Press the [TEST] button twice. =, "TEST RUN" liquid crystal display

(_) Press the [Mode selection] button. = Make sure that wind is blown out.

@ Press the [Mode selection] button and switch to the cooling (or heating) mode.

=, Make sure that cold (or warm) wind is blown out.

(_ Press the [Fan speed] button. = Make sure that the wind speed is switched.

(_ Check operation of the outdoor unit fan.

_'} Release test run by pressing the [ON/OFF] button. _, Stop

(_ Register a telephone number.

The telephone number of the repair shop, sales office, etc., to contact if an error

occurs can be registered in the remote controller. The telephone number will be

displayed when an error occurs. For registration procedures, refer to the operation

manual for the indoor unit.

7.2.2. Using wireless remote controller (Fig. 7-2)

_} Turn on the power to the unit at least 12 hours before the test run.

@Press the _ button twice continuously.

(Start this operation from the status of remote controller display turned off.)

(_)_ and current operation mode are displayed.

(_) Press the [L_ (O O"_, D I;3) button to activate COOLOmode, then check whether

cool air is blown out from the unit.

_} Press the _ (O O'_ _ t_3.) button to activate HEATamode, then check whether

Fig. 7-2

warm air is blown out from the unit.

(_) Press the _ button and check whether fan speed changes.

(_ Press the _ button and check whether the auto vane operates properly.

(_ Press the ON/OFF button to stop the test run.

Note:

o Point the remote controller towards the indoor unit receiver while following

steps (_) to (_).

, It is not possible to run the in FAN, DRY or AUTO mode.

FAN

VANE

12

Page 13

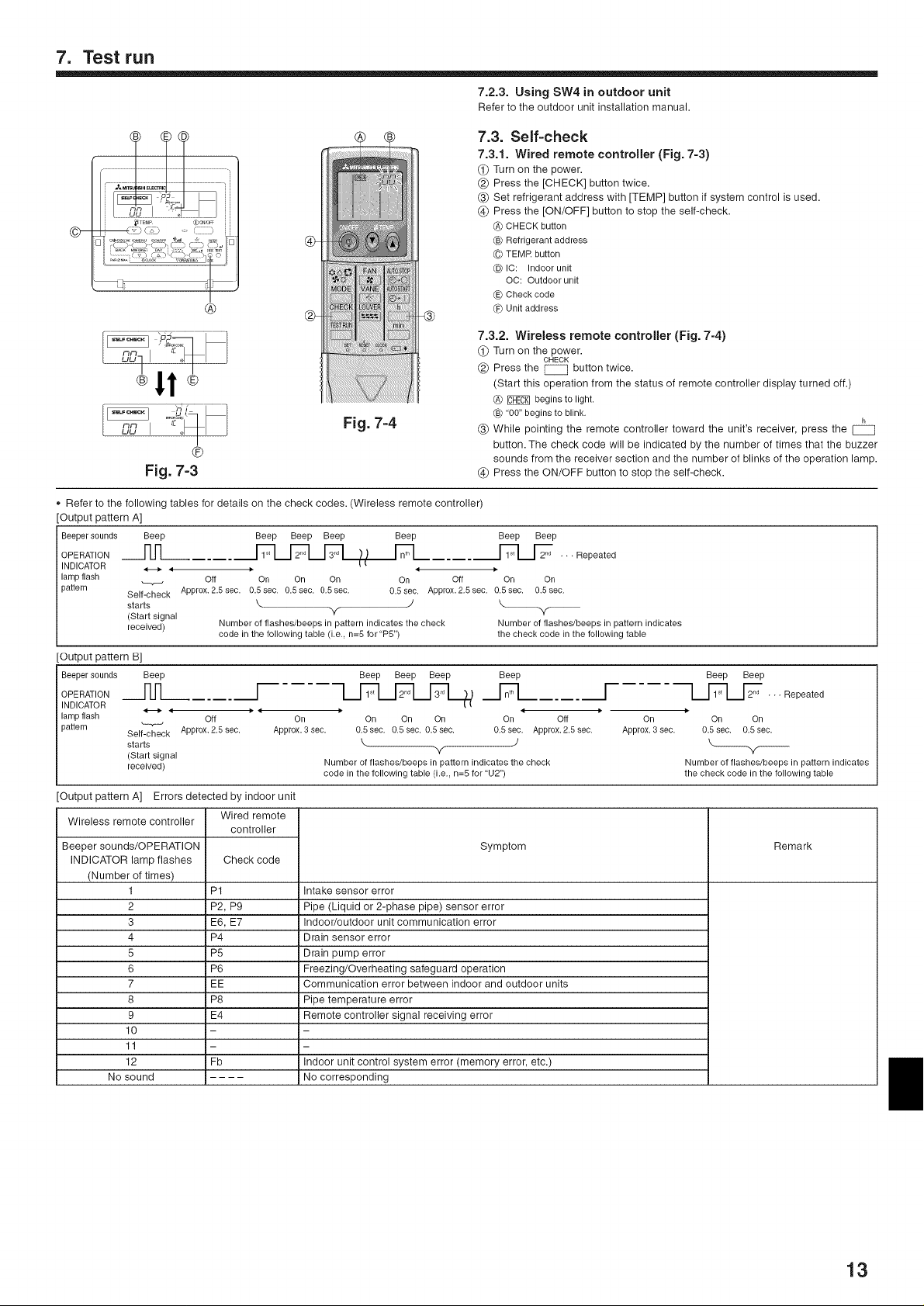

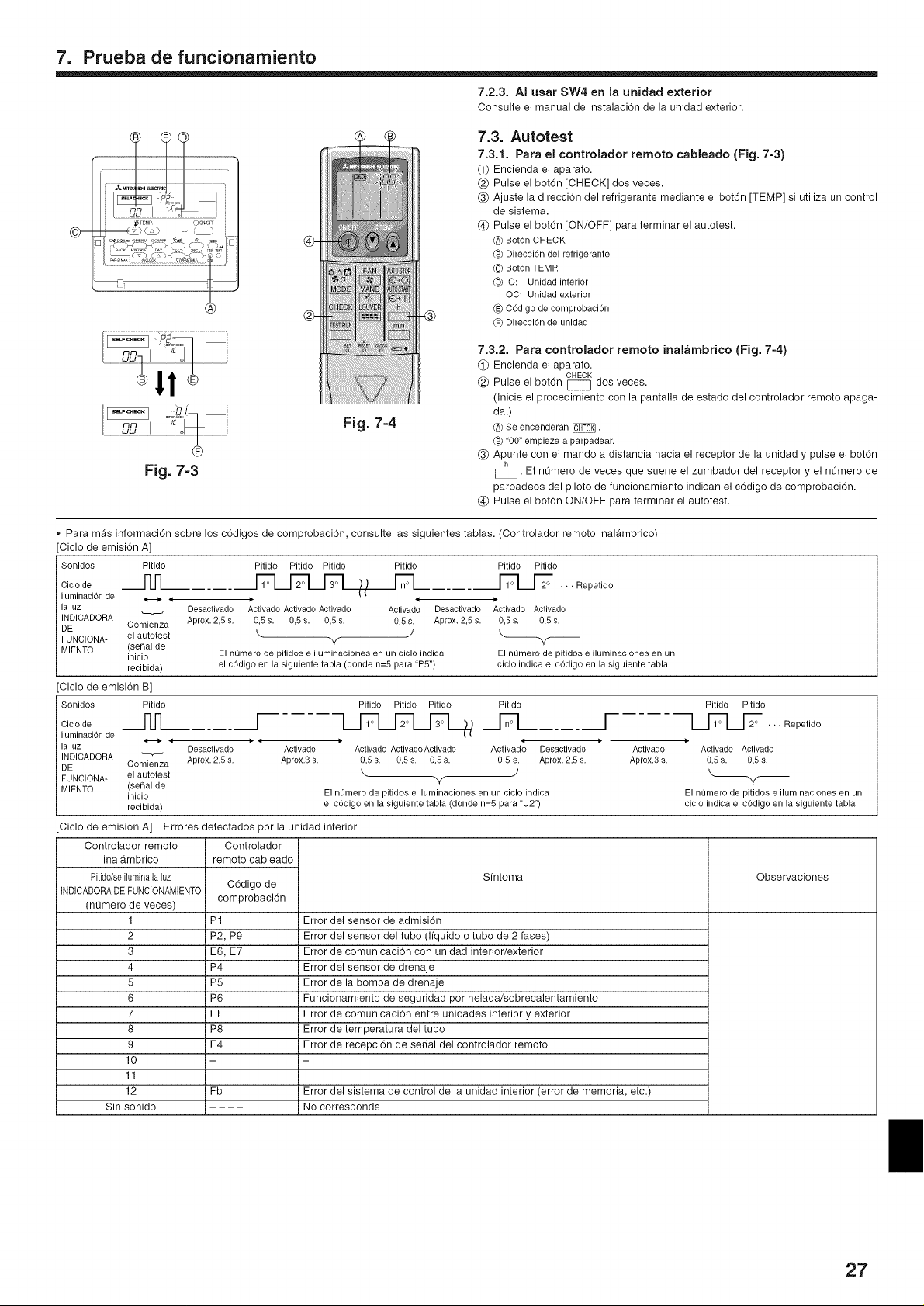

7. Test run

@-

®

® ®

Fig. 7=4

®

Fig. 7-3

o Refer to the following tables for details on the check codes. (Wireless remote controller)

[Output pattern A]

Beeper sounds Beep Beep Beep Beep Beep

OPERATION

INDICATOR

lamp flash

_attern

[Output pattern B]

Beeper sounds Beep

OPERATION j-[j-[ [

INDICATOR

lamp flash Off

_attern

[Output pattern A]

Wireless remote controller

Beeper sounds/OPERATION

INDICATOR lamp flashes

(Number of times)

J-hr[ ..... _ _ ... Repeated

4 < i,

._.._. off on on on on off on on

Self-check Approx. 2.Ssec. 0.Ssec. 0.Ssec. 0.5sec. 0.Ssec. Approx.2.Ssec. 0.Ssec. 0.Ssec.

starts \ J

(Start signal _'f _-----mf--

received) Number of flashes/beeps in pattern indicates the check Number of flashes/beeps in pattern indicates

code in the following table (i.e., n=5 for "PS") the check code in the following table

Beep Beep Beep Beep

_ t

On On On On On Off

Self-check Approx.2.5 sec.

starts

(Start signal

received)

Approx.3sec. 0.5sec. 0.5sec. 0.5sec. 0.5sec. Approx.2.5sec.

\ )

Number of flashes/beeps in pattern indicates the check

code in the following table (i.e. n=B for "U2")

"V-

Errors detected by indoor unit

Wired remote

controller

Check code

1

2

3

4

5

6

7

8

9

P1 Intake sensor error

P2, P9 Pipe (Liquid or 2-phase pipe) sensor error

E6, E7 Indoor/outdoor unit communication error

P4 Drain sensor error

P5 Drain pump error

P6 Freezing/Overheating safeguard operation

EE Communication error between indoor and outdoor units

P8 Pipe temperature error

E4 Remote controller signal receiving error

10

11

12

No sound

Fb

Indoor unit control system error (memory error, etc.)

No corresponding

7.2.3. Using SW4 in outdoor unit

Refer to the outdoor unit installation manual.

7.3. Self=check

7.3.1. Wired remote controller (Fig. 7=3)

(_ Turn on the power.

® Press the [CHECK] button twice.

(_ Set refrigerant address with [TEMP] button if system control is used.

® Press the [ON/OFF] button to stop the self-check.

@ CHECK button

_p Refrigerant address

© TEMRbutton

@ IC: Indoor unit

OC: Outdoor unit

Checkcode

CF_Unitaddress

7.3.2. Wireless remote controller (Fig. 7=4)

L_ Turn on the power.

® Press the _ button twice.

(Start this operation from the status of remote controller display turned off.)

@ _ begins to light.

_p "00" begins to blink.

(_ While pointing the remote controller toward the unit's receiver, press the [_B

button. The check code will be indicated by the number of times that the buzzer

sounds from the receiver section and the number of blinks of the operation lamp.

® Press the ON/OFF button to stop the self-check.

Symptom

Beep Beep

CHECK

[

)

On

Approx.3 sec,

Beep Beep

• .. Repeated

On On

0.5 sec. 0.Ssec.

\

Number of flashes/beeps in pattern indicates

the check code in the following table

Y

Remark

13

Page 14

7. Test run

[Output pattern B]

Wireless remote controller

Beeper sounds/OPERATION

INDICATOR lamp flashes

(Number of times)

"1 If the beeper does not sound again after the initial two beeps to confirm the self-check start signal was received and the OPERATION INDICATOR lamp does not come on,

there are no error records.

*2 If the beeper sounds three times continuously "beep, beep, beep (0.4 4-0.4 4- 0.4 sec.)" after the initial two beeps to confirm the self-check start signal was received, the

specified refrigerant address is incorrect.

o On wireless remote controller

The continuous buzzer sounds from receiving section of indoor unit.

Blink of operation lamp

On wired remote controller

Check code displayed in the LCD.

If the unit cannot be operated properly after the above test run has been performed, refer to the following table to remove the cause.

PLEASE WAIT

PLEASE WAIT -_ Error code

Display messages do not appear even

when operation switch is turned ON

i (operation lamp does not light up).

Errors detected by unit other than indoor unit (outdoor unit, etc.)

Wired remote

controller

Check code

1 E9 Indoor/outdoor unit communication error (Transmitting error) (Outdoor unit)

2 UP Compressor overcurrent interruption

3 U3, U4 Open/short of outdoor unit thermistors

4 UF Compressor overcurrent interruption (When compressor locked)

5 iU2 Abnormal high discharging temperature/49C worked/insufficient refrigerant

6 iU1, Ud Abnormal high pressure (63H worked)/Overheating safeguard operation

7 iU5 Abnormal temperature of heat sink

8 iU8 Outdoor unit fan safeguard stop of the outdoor controller board.

9 iU6 Compressor overcurrent interruption/Abnormal of power module

10 i U7 Abnormality of super heat due to low discharge temperature

11 i U9, UH Abnormality such as overvoltage or voltage shortage and abnormal synchronous

12 ,- -

13 ,- -

14 Others Other errors (Refer to the technical manual for the outdoor unit.)

Wired remote controller

signal to main circuit/Current sensor error

Symptom

For about 2

minutes following

power-on

After about 2

minutes has

expired following

power-on

LED 1,2 (PCB in outdoor unit)

After LED 1,2 are lighted, LED 2 is turned off,

i then only LED 1 is lighted. (Correct operation)

Only LED 1 is lighted. -_ LED 1,2 blink.

i Only LED 1 is lighted. -_ LED 1 blinks twice,

i LED 2 blinks once.

Symptom

For details, check the LED display

Cause

For about 2 minutes following power-on, operation of the

remote controller is not possible due to system start-up. (Cor-

rect operation)

Connector for the outdoor unit's protection device is not con-

nected.

Reverse or open phase wiring for the outdoor unit's power

terminal block (L1, L2, GR)

Incorrect wiring between indoor and outdoor units (incorrect

polarity of Sl, S2, $3)

Remote controller wire short

Remark

On the wireless remote controller with condition above, followin

No signals from the remote controller are accepted.

OPE lamp is blinking.

The buzzer makes a short pipng sound.

Note:

Operation is not possible for about 30 seconds after cancellation of function selection. (Correct operation)

For description of each LED (LED 1,2, 3) provided on the indoor controller, refer to the following table.

LED 1 (power for microcomputer) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED 2 (power for remote controller) Indicates whether power is supplied to the remote controller. This LED lights only in the case of the

LED 3 (communication between indoor and outdoor units only A-control) Indicates state of communication between the indoor and outdoor units. Make sure that this LED is

phenomena takes place.

indoor unit which is connected to the outdoor unit refrigerant address "0".

always blinking.

14

Page 15

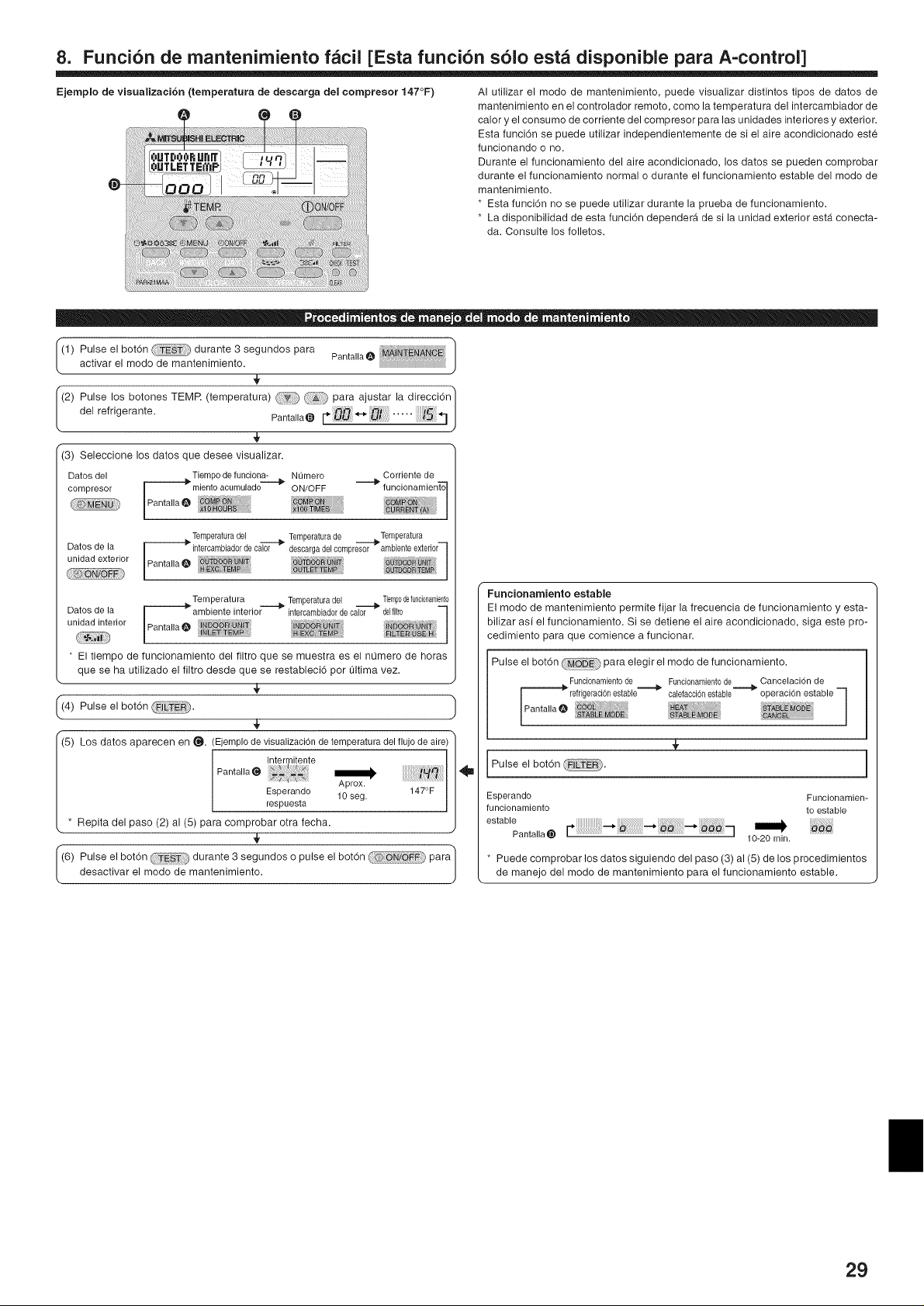

8. Easy maintenance function [This function only for A-control]

Dispmay exampme (Comp discharge temperature 147°F) By using the maintenance mode, you can display many types of maintenance data

1) Press the button for three seconds to jNAi EN N |

activate the maintenance mode.

Display

on the remote controller such as the heat exchanger temperature and compressor

current consumption for the indoor and outdoor units.

This function can be used whether the air conditioner is operating or not.

During air conditioner operation, data can be checked during either normal operation

or maintenance mode stable operation.

* This function cannot be used during the test run.

* The availability of this function depends on the connecting outdoor unit. Refer to the

brochures.

J

4,

(2) Press the TEMP. buttons to set the refrigerant address. ]

Display@ r* ...... 7 j

/

4,

(3) Select the data you want to display.

Compressor Cumulative _ ON/OFF _ Operation

information number current

Outdoor unit [------_temperatuEe _ temperature J

information DisplayO _ :;o DOe'U IT

Indoor unit [-------_ tempe[a!u[e

information mDisplayO

* The filter operation time displayed is the number of hours the filter has been

used since the filter reset was performed.

I(4) Press the button. 1

I Display0 £X f_

Heat exchanger Cornp discharge Outdoor ambient

Indoor room

4,

4,

Stable operation

Using the maintenance mode, the operation frequency can be fixed and the op-

eration can be stabilized. If the air conditioner is stopped, use the following proce-

dure to start this operation.

Press the button to select the operation mode.

Stablecooling Stableheating Stableoperation

operation _ cancellation

STABPE _1 _

Flashing I//

Display e _ /

(5) The data is displayed in O. (Airflowtemperature display example) ]

* Repeat steps (2) to (5) to check another date. J

Wai;ingfor A_PsreCX' 147°F I/

response ' I /

4,

I(6) Press the button for three seconds or press the button to 1deactivate the maintenance mode.

Press the button.

4=

Waiting for stable operation

operatJoo

Display _ 10-20 rain.

* You can check the data using steps (3) to (5) of the maintenance mode opera-

tion procedures while waiting for the stable operation.

Stable

15

Page 16

Contenido

1. Medidas de Seguridad ........................................................................... 16

2. Lugaren que se instalar_. ...................................................................... 17

3. InstalaciOn de la unidad interior ............................................................. 17

4. Instalaci6n de los tubos del refrigerante ................................................ 19

1. Medidas de Seguridad

Antes de instalar la unidad, asegurese de haber leido el capitulo de "Me-

didas de seguridad'.

Jl_Informe al encargado del suministro u obtenga su consentimiento antes

de conectar este equipo al sistema de suministro de alimentaci6n.

z_ Atencion:

Describe las precauciones que deben tenerse en cuenta para evitar el riesgo

de lesiones o muerte del usuario.

Z_ Cuidado:

Describe las precauciones que deben tenerse en cuenta para evitar dahos en

la unidad.

z_ Atenci6n:

, La instalaci6n del aire acondicionado debe correr a cargo del distribuidor o

t_cnico autodzado.

, Para mainstalaci6n, siga masinstrucciones del Manual de instamacion y utimice mas

herramientas y piezae de fontaneria especfficamente dise_adas para utilizar con

el refrigerante especificado en el manual de instalaci6n de la unidad exterior.

, La unidad debe instalarse segt_n las instrucciones para reducir poeibles da-

i_os en cseo de terremoto, hurac&n o vientos fuertes. Si no se instala correc-

tamente, la unidad podda caerse y provocar daSos o mesiones.

, La unidad debe instalarse firmemente sobre una estructura capaz de sopor-

tar su peso.

, Si el equipo de aire acondicionado se instala en una sala pequet_a deberan

tomaree medidas para prevenir que la concentraci6n de refrigerante exceda

los limites de seguridad en caso de fugas. Si se produce una fuga de refrige-

rante que sobrepase mosmimites de concentraci6n, maestancia en masamapuede

ser pemigrosa pot famtade oxigeno.

5. Tuberfa de drenaje ................................................................................. 20

6. Trabajo electrico ..................................................................................... 21

7. Prueba de funcionamiento ..................................................................... 26

8. Funci6n de mantenimiento f_.cil (opcional) ............................................ 29

Despues de terminar la instalaciOn, explique las "Medidas de Seguridad", funciona-

miento y mantenimiento de la unidad al cliente segQn el Manual de instrucciones y

realice una prueba para asegurarse de que funciona correctamente. Entregue una

copia del Manual de instalaci6n y del Manual de instrucciones al usuario. Estos ma-

nuales deben pasar a usuarios posteriores del equipo.

(_: Indica una debe estar conectada a tierra.

z_ Atenci6n:

Lea atentamente las etiquetas adheridas a la unidad principal.

o Si se produce una fuga de refrigerante durante el funcionamiento, ventile la

sala. Si el refrigerante entra en contacto con una llama, se desprenderan

gases nocJvoe.

o Todas las conexiones el_ctricas deber&n set realizadas pot un t_cnico cuali-

ficado segt_n manormativa mocal y masinstrucciones de este manual.

o Utimice s61o cabmes especificados para el cabmeado.

o Empanemde la cubierta del bmoque de terminales de maunidad debe comocarse

firmemente.

o Utilice s61o accesorios autorizados pot Mitsubishi Electric y pida a su distri-

buidor o a un tecnico autorizado que se los instale.

o El usuario nunca debe intentar reparar la unidad o moverla de sitio.

o Tras haber realizado la instalaci6n, compruebe si hay fugas de refrigerante. Si

en caso de fuga el refrigerante entra en contacto con las llamas de un calen-

tador o de un equipo de cocina port&til, se desprenderan gases nocivos.

pieza que

1.1. Cuestiones previas a la instalaci6n (Ambiente)

z_ Cuidado:

, No utilice maunidad en un ambiente enrareeido. Si instamael aire acondiciona-

do en zireas expuestas amvapor, aceite esenciam (incmuyendo el aceite para

maquinas), o humo suffurico, areas con alto contenido en samcomo pmayas, el

rendimiento puede verse reducido significativamente y maspiezas internas

pueden daiiarse.

, No instame la unidad donde se puedan verter, producir, circular o acumumar

gases inflamabmes. Sise acumula gas inflamabme en zonas pr6ximas amauni-

dad, se podria producir un incendio o una expmosi6n.

, No comoque amimentos, pmantas, animames, obras de arte o instrumentos de pre-

cisi6n en masamida de aire directa de maunidad exterior o demasiado cerca de

ella, ya que moscambios de temperatura o el agua que gotea podrian da_arlos.

1.2. Antes de la instalaci6n o reubicaci6n

/_ Cuidado:

, Tenga mucho cuidado cuando mueva las unidades. Se neeesitan dos o m&s

personas para Hevar la unidad ya que pesa 20 kg, 44 robso mas. No masujete

por mas bandas de embamaje. Utimice guantes protectores ya que se podria

mesionar con las ametas u otras partes.

, Guarde mosembalajes en un lugar seguro. Los materiales de embalaje, eomo

clavos y otras piezas de metal o de madera pueden producir pinchazos y

otras lesiones.

, El tubo de refrigerante debe estar aislado termicamente para evitar la con-

densacion. Si el tubo de refrigerante no se aisla correctamente, se formarzi

condensaci6n.

1.3. Antes de la instalaci6n el_ctrica

/_ Cuidado:

, Asegt_rese de instalar disyuntores. Si no se instalan, se podrian producir

descargas eieetricas.

, Use cables est&ndar de suficiente eapacidad para las lineas electricas. Si no

Io hace asi, se podria producir un cortocircuito, un sobrecalentamiento o un

incendio.

o Cuando la humedad de la habitacion supera el 80%, o cuando el tubo de

drenaje este obstruido, puede gotear agua de la unidad interior. No instale la

unidad interior en lugares donde el goteo pueda causar dahos.

o Si instala la unidad en un hospital o en un centro de comunicaciones, recuer-

de que la unidad produce ruidos e interferencias eleetronicas. Los conmuta-

dotes, aparatos dom_sticos, equipos m_dicos de alta frecuencia y las comu-

nicaciones de radio pueden provocar un real funcionamiento o la averia del

equipo de aire acondicionado. El equipo de aire aeondicionado tambien puede

afectar los equipos m_dicos e interrumpir los cuidados m_dicos, asi como

los equipos de comunicaci6n y da_ar la calidad de la pantalla.

o Sitt_e material aislante termico en las tuberias para evitar la condensaci6n. Si

el tubo de drenaje no se instala correctamente, se puede producir un escape

de agua o daSos en el techo, suelo, muebles u otros objetos.

o No limpie con agua el equipo de aire acondicionado. Puede sufrir una des-

carga el_ctrica.

o Apriete las tuercas de aboeardado a los niveles especificados mediante una

llave dinamom_trica. Si las aprieta demasiado, se pueden romper al cabo de

un tiempo.

o Cuando instale las lineas el_ctricas, los cables no deben tenet corriente.

o Asegurese de instalar una toma de tierra. Si la unidad no est& bien conectada

a la linea de tierra, se puede producir una descarga el_etrica.

o Utilice disyuntores (interruptor de falta de tierra, interrupter aislante (+fusi-

ble B) e interruptores en caja moldeada) con la potencia especificada. Si la

potencia del interruptor es mayor que la especificada, puede ocurrir un in-

cendio o una averia.

1.4. Antes de realizar las pruebas de funcionamiento

,/fk Cuidado:

, Coneete la corriente al menos 12 horas antes de que empieee a funcionar el

equipo. Si se acciona inmediatamente despues de habedo coneetado a la

corriente, pueden producirse da5os graves en las piezas internas.

, Antes de que comience a funcionar el equipo, compruebe que todos los pa-

neles y proteetores estan instalados correctamente. Las piezas giratorias,

calientes o de alto voltaje pueden provocar lesiones.

, No haga funcionar el equipo de aire acondicionado sin el filtro de aire insta-

lado. Si el filtro de aire no esta colocado, se puede acumular el polvo y se

puede averiar el equipo.

16

o No toque ningun interruptor con las manos mojadas. Puede sufrir una des-

carga el_ctrica.

o No toque la tuberia del refrigerante sin guantes mientras durante el funcio-

namiento.

o Una vez deje de funcionar el aparato, espere cinco minutos antes de apagar

el interrupter principal. De Io contrario, se puede producir un goteo de agua

o una averia.

Page 17

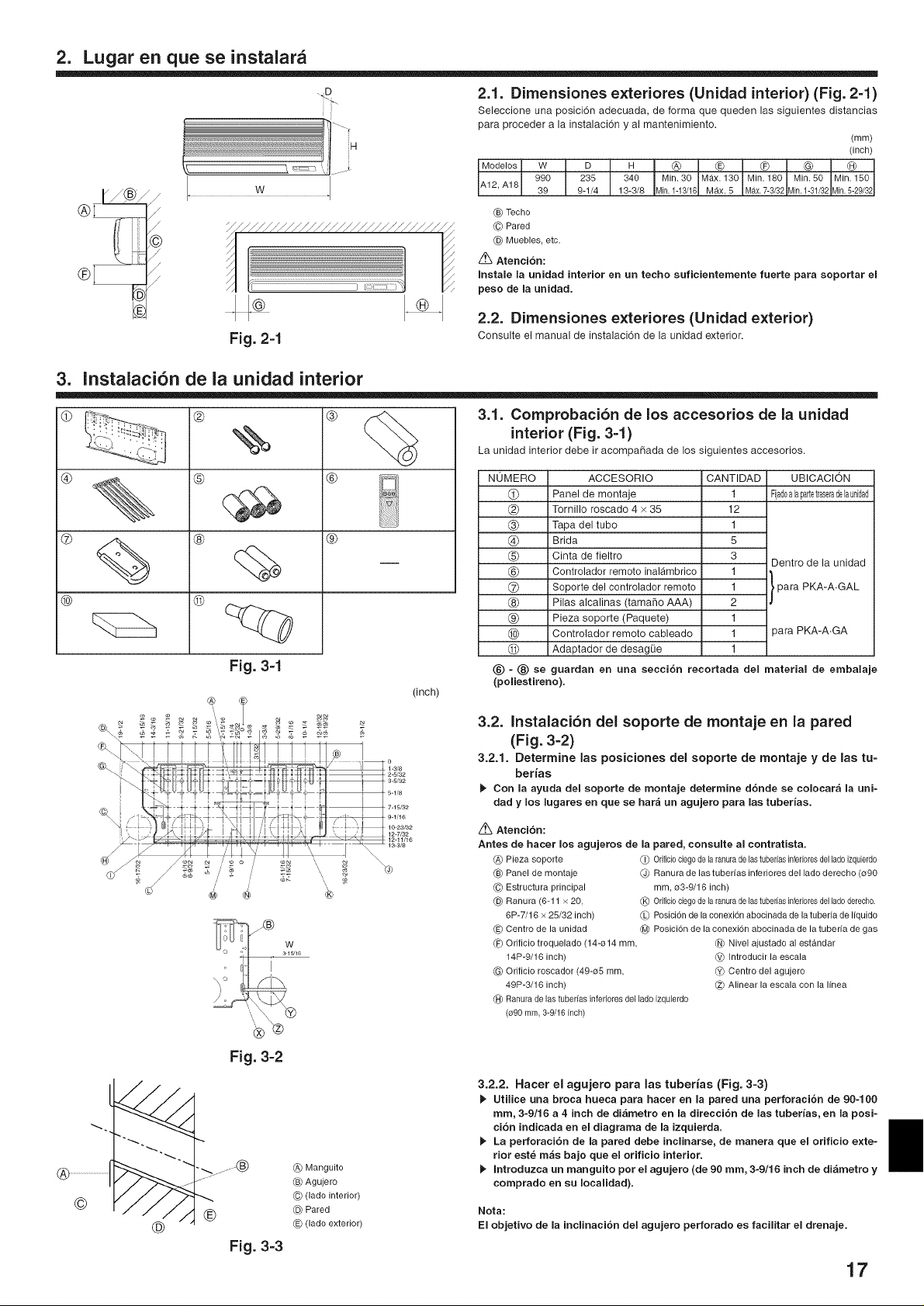

2. Lugar en que se instalara

.@

®7

©

®

Fig. 2-1

3. Instalaci6n de la unidad interior

®

®

®

@

®

®

®

@

Fig. 3-1

(inch)

2.1. Dimensiones exteriores (Unidad interior) (Fig. 2-1)

Seleccisne una pssici6n adecuada, de fsrma que queden las siguientss distancias

para prscsder a la instalaci6n y al mantsnimients.

Modelos W U m (_) _ CF_ (G_

A12, A18 39 9-1/4 13-3/8 Min.l-13/16 Max.5 Max.7-3/32Min.l-31/32Min.5-29/32

Z_ Atenci6n:

Instale la unidad interior snun techo suficisntemente fusrte para soportar el

peso de la unidad.

990 235 340 Mn 30 Max 130 Mn 180 Mn 50 Mn 160

(_)Techo

_C}Pared

(_)Muebles, etc.

(mm)

(inch)

2.2. Dimensiones exteriores (Unidad exterior)

Csnsulte el manual de instalaci6n de la unidad exterior.

3.1. Comprobaci6n de los accesorios de la unidad

interior (Fig. 3-1)

La unidad interior debe ir acsmpa_ada de los siguientss accessrios.

NOMERO

@

®

@

@

@

@

@

@

@

@

@

(_) - _) se uardan en una secci6n recortada

(poliestireno).

ACCESORIO

i Panel de montaje

Tornills rsscado 4 x 35

Tapa del tubs

Brida

Cinta de fieltrs

Controlador remots inal_.mbrico

Soporte del controlador remoto

Pilas alcalinas (tama_s AAA)

i Pieza sopsrte (Paquete)

i Csntrolador remsts cableads

Adaptador de desagL_e

CANTIDAD

1

Fiiad0alapartetraseradelaunidad

12

1

5

3

Dentro de la unidad

1

1

para PKA-A,GAL

2

1

para PKA-A,GA

1

1

del material de embalaje

UBICACION

3.2. Instalaci6n del soporte de montaje en la pared

(Fig. 3-2)

3.2.1. Determine las posiciones del soporte de montaje y de las tu-

berias

I_ Con la ayuda dsl soporte de montajs determine d6nds se colocara la uni-

dad y los lugares en que se har& un agujero para las tuberias.

Z_ Atenci6n:

Antes de hacer los agujeros de la pared, consulte al contratista.

(_) Pieza soporte

(_) Panel de montaje

©

{C)Estructura principal

(_) Ranura (6-11 x 20,

8P-7/18 x 25/32 inch)

Centro de la unidad

(_) Orificio troquelado (14-o14 mm,

14P-9/16 inch)

(G')Orificio roscador (49-05 mm,

49P-3/16 inch)

(_ Ranura de las tuber/as inferiores del lado izquierdo

(o90 ram, 3-9/16 inch)

Ci} Orifbio ciegode la ranurade Bs tuberlas inferioresdel ladoizqubrdo

_3} Ranura de las tuberias inferiores del lado derecho (_90

mm, o3-9/16 inch)

_. Orifbio ciegode la ranuradelastuberias inferioresdelladoderecho.

_ PosiciOn de la conexiOn abocinada de la tuberla de liquido

_) Posicion de la conexion abocinada de la tuberia de gas

(N) Nivel ajustado al estandar

_ Introducir la escala

(_ Centro del agujero

(2pAlinear la escala con la linea

Fig. 3-2

3.2.2. Hacer el agujero para las tuberias (Fig. 3-3)

II_ Utilice una broca hueca para hacer en la pared una perforaci6n de 90-100

ram, 3-9/16 a 4 inch de diametro en la direcci6n de las tuberias, en la posi-

ci6n indicada en el diagrama de la izquierda.

La perforacion de la pared debe inclinarse, de manera que el orificio exte-

@ Manguito

_p Agujero

©

®

@

© (lado interior)

@ Pared

_ (lado exterior)

rior este m_is bajo qus el orificio interior.

I_ Introduzca un manguito pot el agujero (de 90 ram, 3-9/16 inch de diametro y

comprado sn su Iocalidad).

Nota:

El objetivo de la inclinaci6n del agujero perforado es facilitar el drenaje.

Fig. 3-3

17

Page 18

3. Instalacion de la unidad interior

Fig. 3=4

©

Fig. 3=5

@ Min. 140 mm,

5-1/2 inch

_ Min. 300 mm,

11-13/16 inch

© Min. 66 mm,

2-3/16 inch

@ Placa de montaje

3.2.3. Instalaci6n deJ soporte de montaje en la pared

I_ Come maunidad interior pesa casi 30 kg, 66 robstendrzi que tenet en cuenta em

mugarde montaje. Si la pared no parece mosuficientemente fuerte, refuercema

con tablas y vigas antes de instalar la unidad.

I_ El soporte de montaje se fijarzi por ambos extremes y por el centro, si es

posible. No Io fije nunca por un solo punto o de manera asim_trica.

(Si es posible, sujete el soporte pot todos los lados marcados con una fie-

cha gruesa.) (Fig. 3-4)

Z_ Atenci6n:

Si es posible, fije el soporte en todas las posiciones marcadas con una flecha.

Z_, Cuidado:

o La unidad se tiene que montar hodzontalmente.

o Apdete en mosagujeros marcados con A.

_ Introduzcaun hilo en el orificio y atelo.

_ El nivel se puede comprobar facilmente si se cuelga unaplemada de la cuerda y se alinea

esta a la marca.

3.3. Cuando coloque los tubos en la pared (Fig. 3=5)

• Los tubos estan en el lado inferior izquierdo.

• Cuando las Ifneas de conexi6n interna/externa del tubo de refrigerante y de los

tubos de drenaje tienen que empotrarse en la pared con anterioridad, es probable

que haya que doblar los tubos troquelados y tener que modificar su Iongitud para

adaptarlos a la unidad.

• Haga una marca en la placa de montaje para que sirva de referencia cuando vaya

a ajustar la Iongitud del tubo de refrigerante empotrado.

• Durante la construcci6n, deje algLin margen en la Iongitud de los tubos troquelados.

(_)Placade montaje

(_)Marca de referencia de la conexion abocinada

© Orificio pasante

(_)Tuberia local

3.4. Preparacion de la unidad interior

Tuberias trasera, derecha e inferior (Fig. 3-6)

1. Junte el tubo de refrigerants con el tubo de drenaje.

• Junte los tubos con cinta de vinilo en tres puntos o mas. Esto facilitara el paso de

los tubos por la pared.

Fig. 3-6

2. Saque la caja lateral y destape los orificios ciegos si fuera necesario.

• Saque la caja lateral empujandola hacia abajo @ y al mismo tiempo, apriete la

parte superior de la misma (_.

(_)Caja lateral

(_)Tapa inferior

®

Tuberias izquierda y posterior izquierda (Fig. 3-7)

1. Saque la tapa inferior.

Saque la tapa inferior desliz_.ndola hacia la parts posterior de la unidad @ y, al

®

mismo tiempo, apriete las dos posiciones marcadas con flechas m_.s gruesas (_).

2. Saque la caja lateral y destape los orificios ciegos si fuera necesario.

3.5. Montaje de la unidad interior

1. Sujete la placa de montaje a la pared.

2. Cuelgue la unidad inferior en los dos ganchos que estan colocados en la parts

superior de la place de montaje.

Tuberia izquierda y posterior izquierda (Fig. 3-8)

3. Sujste la unidad interior.

4. Despues de conectar los tubes, coloqus la caja lateral sn el sitio en donde sstaba

(siga los pasos de la extracci6n indicados anteriormsnte a la invsrsa).

(_)Orificio cuadrado

(_)Ganchos

18

®

Fig. 3=8

®

/

< (inch)

t_

Fig. 3-9

Tuberia izquierda y posterior izquierda (Fig. 3-9)

3. Corte una pieza soporte del material de embalaje.

4. Tire de la unidad interior hacia usted tal ycomo se muestra en la figura de abajo

y deslice la pieza soporte en la placa de montaje, utilizando la pieza soporte

come marca de referencia.

5. Despues de conectar las tuberfas y los cables, coloque la tapa inferior en el sitio

en donde estaba, saque la pieza soporte y sujete la unidad interior tal y como se

muestra en la figura de la izquierda.

6. Coloque la caja lateral en el sitio en donde estaba.

(_)Piezasoporte

Techo

© Reborde

Page 19

4. Instalaci6n de los tubes del refrigerante

4.1. Precauciones

4.1.1. Para aparatos con refrigerante R410A

, Utilice aceite de _ster, de _ter o alquilobenceno (en pequehas cantidades)

para recubrir las secciones abocardadas.

, Utilice tubes de cobre fosforoso del ripe C1220 y tubes de aleaci6n de cobre

sin costuras para cenectar los tubes del refrigerante. Utilice tuberias para

refrigerante del grosor especificado en la tabla siguiente. Asegurese de que

el interior de las tuberias est_ limpio y que no contienen ningun contaminan-

te nocivo come compuestos sulfuricos, oxidantes, restos o polvo.

Z_ Atenci6n:

Cuando instale o mueva el equipe de aire acondicionado, utilice s61o el refrigeran-

te indicado (R410A) para cargar los tubes de refrigerante. No Io mezcle con otto

tipo de refrigerante y vacie cornpletarnente de aire los tubes. Ei aire que quede en

los tubes puede provocar picos de presi6n que causarian su rotura y otros dahos.

®

45o_+2°

®

o

b

o)

Fig. 4-1

@ Dimensiones del corte abocinado

Tube de cobre O.D. Dimensiones de abocinado

(mm, inch) dimensiones eA (ram, inch)

e6,35, 1/4" 8,7 - 9,1,11/32-23/64

e9,52, 3/8" 12,8- 13,2, 1/2-33/64

e12,7, 1/2" 16,2 - 16,6, 41/64-21/32

el 5,88, 5/8" 19,3 - 19,7, 49/64-25/32

(inch)

Tube de liquido 06,35 mm, 1/4 inch grosor 0,8 mm, 1/32 inch

Tube de gas o12,7 mm, 1/2 inch grosor 0,8 mm, 1/32 inch

No utilice tubes con un grosor rnenor del especificado a continuaci6n.

l A12, A18

4.2. Tubes de conexi6n (Fig. 44)

o Si se utilizan tubes de cobre convencionales, envuelva los tubes de gas y Ifquido

con materiales aislantes (resistente al calor hasta 100 °C, 212°F o mdts, espesor

de 12 mm, 1/2 inch o mas).

Las piezas interiores del tube de drenaje tienen que estar envueltas en materiales

aislantes de espuma de polietileno (gravedad especifica de 0,03 y espesor de

9 mm, 23/64 inch o m_ts).

®

Aplique una capa delgada de aceite refrigerante a la superficie tube y de la junta

de asiento antes de apretar la tuerca de abocardado.

Utilice dos Ilaves de apriete para apretar las conexiones de los tubes.

Utilice el aislante de tuberia de refrigerante suministrado para aislar las conexio-

nes de la unidad interior. Realice los aislamientos con cuidado.

(_) TorsiOn de apriete de la tuerca abocardada

Tube de cobre O.D. Tuerca de abocardado

(mm, inch) O.D. (ram, inch)

e6,35, 1/4" 17, 43/64

e9,52, 3/8" 22, 7/8

e12,7, 1/2" 26, 1-3/64

e15,88, 5/8" 29, 1-9/64

C-C)Aplique aceite refrigerante para m_.quinas en toda la superficie abocinada.

(_) Utilice tuercas abocardadas que coincidan con eltamai_o de la tuberia de la unidad exterior.

Tamahos de tuberia disponibles

A12, A18

Lade del Ifquido

Lade del gas

e6,35

e12,7

TorsiOn de apriete

(N.m, ft.lbs)

14- 18, 10-13

34 - 42, 25-30

49- 61, 35-44

68 - 82, 49-59

O : Accesorio de fabrica para acoplar la tuerca abocardada al intercambiador de

calor.

lg

Page 20

4. InstaIaci6n de los tubes del refrigerante

Q (inch)

©

@

Fig. 4-2

®

®

(inch)

Fig. 4=3

\

Fig. 4-4

4.3. ColocaciOn de los tubes del refrigerante y de drenaje

(_) PosiciOn de los tubes del refrigerante y de drenaje (Fig. 4-2)

• La tuberia de drenaje se puede cortar per la mitad para adaptarse a las condicio-

nes del lugar.

(_)(Longitudtotal de la rnangueraflexible) _D)Manguerade drenaje

(_)Tuberia de liquido _ Tuberiadel lade izquierdo

© Tuberia de gas CF_Tuberiadel lade derecho

® Determine la posiciOn de los agujeros ciegos en la unidad. (Fig. 4-3)

II_ Abra los agujeros ciegos con un serrucho o un cuchillo adecuado.