Mitsubishi PK12FK, PK12FK1, PK18FK, PK18FK1, PK18FK2 Instruction Manual

...

PK12FK, PK12FK1

PK18FK, PK18FK1, PK18FK2

PK24FK, PK24FK1, PK24FK2

PK30FK, PK30FK1, PK30FK2

PK36FK, PK36FK1, PK36FK2

CONTENTS

1. TECHNICAL CHANGE ················································································OC196A- 2

2. FEATURES···································································································OC196A- 3

3. PART NAMES AND FUNCTIONS·······························································OC196A- 6

4. SPECIFICATIONS ························································································OC196A-10

5. DATA ············································································································OC196A-11

6. OUTLINES AND DIMENSIONS···································································OC196A-19

7. REFRIGERANT SYSTEM DIAGRAM··························································OC196A-23

8. WIRING DIAGRAM······················································································OC196A- 24

9. OPERATION FLOW-CHART·······································································OC196A-28

10. MICROPROCESSOR CONTROL································································OC196A- 31

11. TROUBLESHOOTING ·················································································OC196A-44

12. SYSTEM CONTROL····················································································OC196A-51

13. DISASSEMBLY PROCEDURE ····································································OC196A- 56

14. PARTS LIST·································································································OC196A-59

15. OPTIONAL PARTS ······················································································OC196A-68

OC196A-1

1

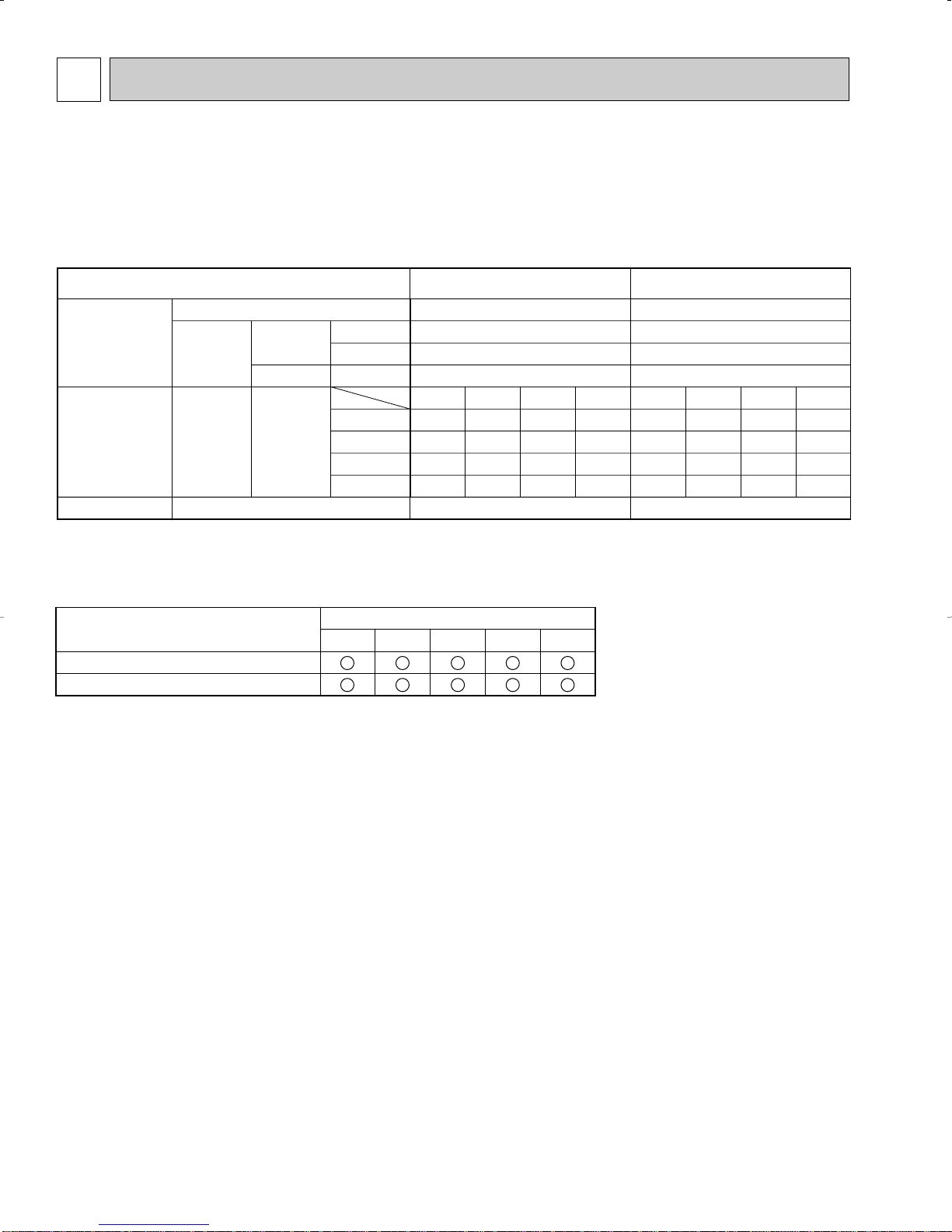

Change points

Optional parts

Program timer

FK

Switch for temperature unit

Switch for louvers

—

PAC–SK65PT

Canceled

Canceled

Addition of "Mode selector"

PAC–SC32PTA

FK1

SW17

SW18

SW7

No.9

No.0

No.1

No.2

No.3

No.4

18

OFF

ON

OFF

OFF

24

OFF

ON

OFF

OFF

30

ON

ON

OFF

OFF

36

ON

ON

OFF

OFF

18

OFF

ON

OFF

OFF

24

ON

ON

OFF

OFF

30

OFF

ON

ON

OFF

36

ON

ON

ON

OFF

Dip SW

Dip SW

Appearances

Remote

controller

Indoor controller

(18,24,30,36 only)

4-3/4 o 2-3/4 o 5/8 5-1/8 o 4-3/4 o 3/4

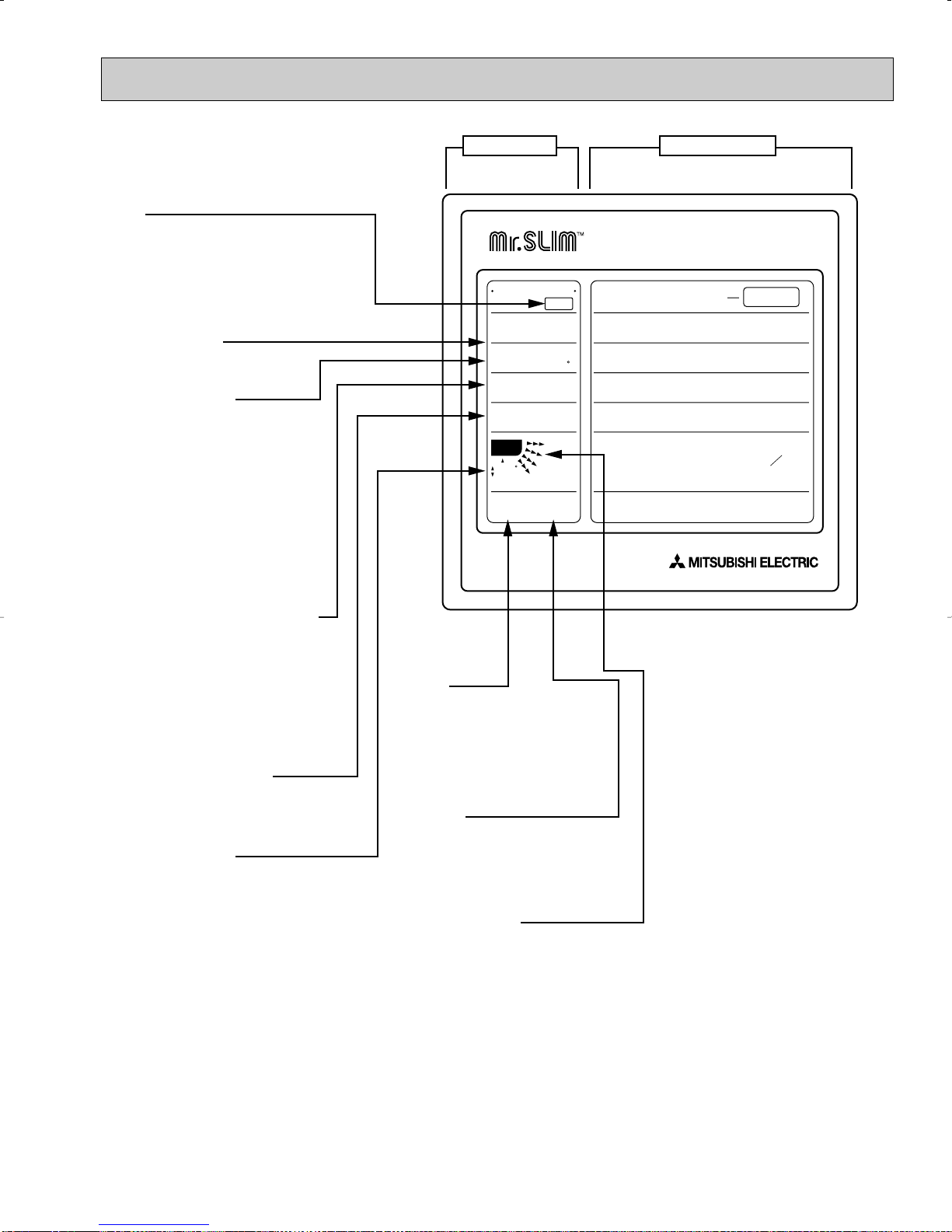

REMOTE CONTROLLER

REMOCON COVER

12 18 24 30 36

PART NAME

Model

TECHNICAL CHANGE

PK12FK ➔ PK12FK

1

PK18FK ➔ PK18FK1

PK24FK ➔ PK24FK1

PK30FK ➔ PK30FK1

PK36FK ➔ PK36FK1

Differences with PK12/18/24/30/36FK which is a basic service manual OC121.

Change of the service parts.

Refer to the parts list on the page OC196A-59 to 67 for the details.

PK18FK1 ➔ PK18FK2

PK24FK1 ➔ PK24FK2

PK30FK1 ➔ PK30FK2

PK36FK1 ➔ PK36FK2

● DRAIN PAN shape has changed.

● NOSE shape has changed.

● UNDER PLATE shape has changed.

OC196A-2

2

FILTER

CHECK MODE

TEST RUN

TIMER OFF TIMER

CHECK SET TEMP.

CLOCK AUTO AUTO

START STOP

SWING

FAN

SPEED

AUTO

RETURN

MITSUBISHI ELECTRIC

ON

DRY

COOL

FAN

CHECK

SET TEMP

TIMER OFF

AUTO STOP

AUTO START

F

HR

F

LOW HIGH

AUTO RETURN

CHECK TEST RUN

POWER

ON/OFF

MODE SELECT

SET

TEMPERATURE

FAN COOL/DRY

COOLERWARMER

TIMER MODE HOURS

FAN SPEED LOW/HIOGH

AIR

DISCHARGE

UP/DOWN

SWING

STOP

CHECK TEST RUN

•CENTRALLY CONTROLLED•

FEATURES

Indoor unit

(PK12/18/24/30/36FK) PK12/18/24/30/36FK1

()

PK18/24/30/36FK2

Remote controller

Models Cooling capacity SEER

PK12FK, PK12FK1 12,500 Btu/h 11.5

PK18FK, PK18FK1, PK18FK2 18,500 Btu/h 11.3

PK24FK, PK24FK1, PK24FK2 24,000 Btu/h 10.6

PK30FK, PK30FK1, PK30FK2 30,000 Btu/h 10.7

PK36FK, PK36FK1, PK36FK2 34,200 Btu/h 10.2

1. COMPACT DESIGN

The PK series models have been downsized and now require such minimal wall space that they can even be installed

above windows. For the PK12, 11-13/16in of wall space between the ceiling and the window allows “above window”

installation. (13-3/8in for the PK24/30/36)

2. AUTO FLAP SHUTTER

With a simple flick of the OFF switch the air outlet will be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle 1” securing a comfortable air flow.

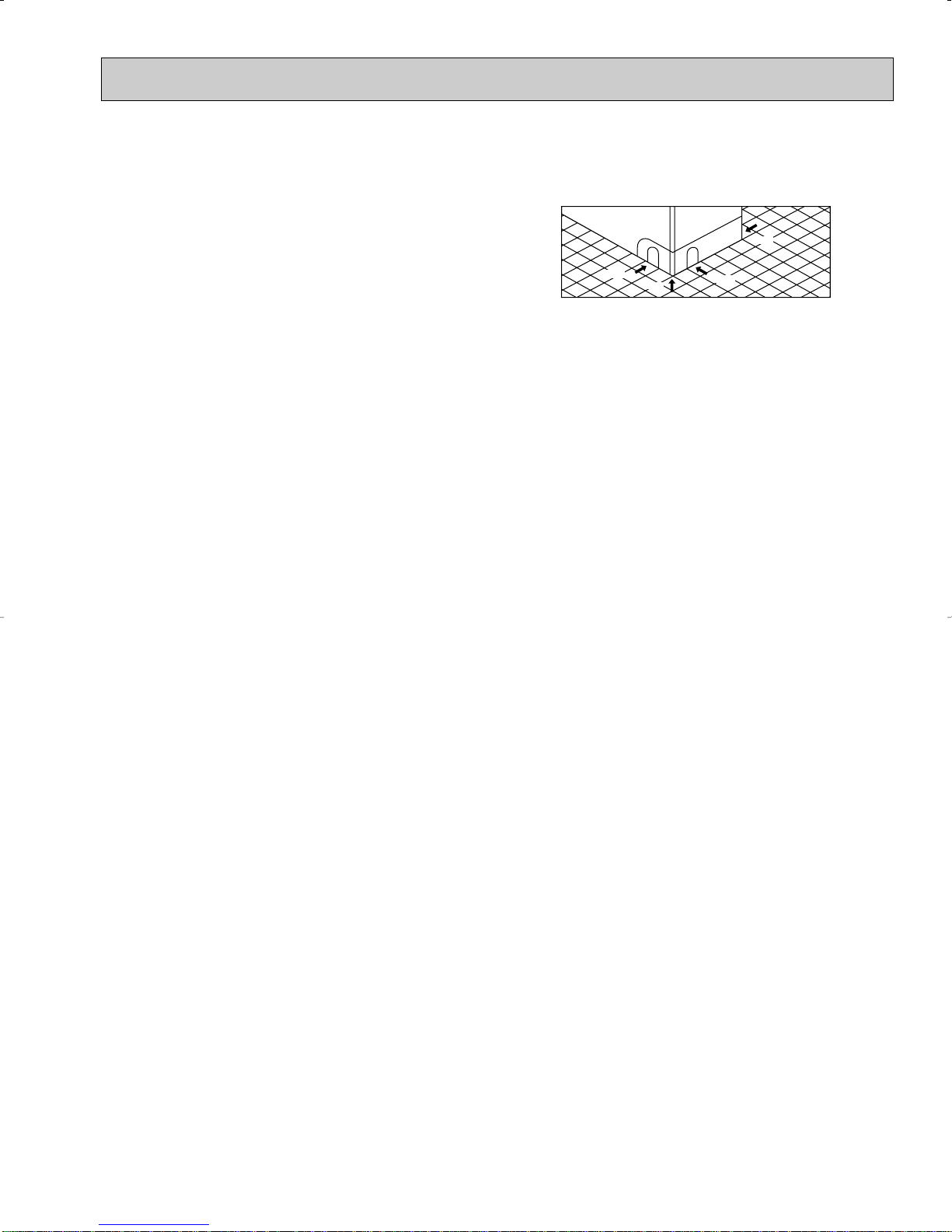

3. INSTALLATION : FAST AND ENDLESSLY ADAPTABLE

(1) Multi-directional piping

Multi directional drain and refrigerant piping radically improves flexibility in selecting installation layouts.

PK12 drain piping can be installed in 5 directions, while PK18/24/30/36 models boast refrigerant piping in 4 directions

and drain piping 2 directions.

(2) Back plate installation guide

The back plate installation guide gives clear instructions on installation positions. The enlarged back plate secures the

unit firmly to the wall, while the support piece which lifts the unit makes left side piping work much easier.

(3) Easily removable filter

The presence of thumbscrews on the filters means that the filters can be quickly and smoothly removed.

OC196A-3

4. ADVANCED MICROPROCESSOR

TIMER OFF TIMER

CHECK SET TEMP.

DRY COOL

FAN

CLOCK AUTO AUTO

START STOP

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

CHECK

TEST RUN

AIR SWEEP

SET TEMP. TIMER SET

F

FAN

SPEED

SWING

AUTO

RETURN

REMOTE CONTROLLER

MITSUBISHI ELECTRIC

ON

DRY

COOL

FAN

CHECK

SET TEMP

TIMER OFF

AUTO STOP

AUTO START

F

HR

F

LOW HIGH

AUTO RETURN

CHECK TEST RUN

POWER

ON/OFF

MODE SELECT

SET

TEMPERATURE

FAN COOL/DRY

COOLERWARMER

TIMER MODE HOURS

FAN SPEED LOW/HIGH

AIR

DISCHARGE

UP/DOWN

SWING

STOP

CHECK TEST RUN

•CENTRALLY CONTROLLED•

[Remote controller]

(1) Easy to Use Microprocessor

1) Ultra-Thin Remote Controller

The streamlined, wide controller is designed to

blend with any kind of interior and the adoption of

a sophisticated microprocessor allows you to

carry out a wide range of operations easily.

2) Attractive Liquid Crystal Display (LCD)

Units operation mode, set temperature, room tem-

perature, timer setting, fan speed,

and air flow direction are displayed on the

remote controller with the easily understood visual

Liquid Crystal Display (LCD).

3) Convenient 24-Hour ON-OFF Timer

The timer allows Mr.SLIM to be switched on or

(PK12/18/24/30/36FK)

PK12/18/24/30/36FK

()

PK18/24/30/36FK2

off automatically at the time is shown on the LCD.

4) Self-Diagnostic Feature Indicates Instantly

In the rare case when a problem occurs, the unit stops operating and the set temperature indicator changes to the

self-diagnostic indicator, indicating the location of the fault.

If the check switch is pressed twice, the unit stops operating and the check mode is initiated. The cause of the most

recent problem stored in the memory is displayed on the LCD. This is extremely useful for maintenance purposes.

5) Useful Memory Feature for Storing Instructions

The previous set value is memorised so that constant temperature control can be obtained. This is convenient when,

for example, a power failure occurs.

(2) Non-polar Two-Wire Remote Controller Cables

The non-polar, two-wire type remote controller cable is slim, installation is simple and trouble-free. Remote controller

wire can be extended up to 550 yards.

1

5. REDI-CHARGED REFRIGERANT SYSTEM

PRE-CHARGE REFRIGERANT REQUIRED FOR LINE LENGTH OF 100ft AT

SHIPMENT. PREVENTING TROUBLES DUE TO SHORTAGE OF REFRIGERANT.

The unique refrigerant circuit and a large accumulator always controls the refrigerant to its optimum condition regardless of

the length of 164ft maximum (PK12/18 130ft maximum). The additional refrigerant charging work at the field which often

caused uncertain problems heretofore is completely eliminated. This unique system serves to improve the quality of work

and reliability, and also helps

to speed up the installation work.

OC196A-4

6. HIGH RELIABILITY AND EASY SERVICING

Rear

Right

Base

Front

In addition to the self-diagnostic function, units are also equipped with a 3-minute time delay mechanism (cooling), an auto

restart function, an emergency operation function, a test run switch, etc., to assure high reliability and easy servicing.

7. FOUR-WAY PIPING ACCESS MAKES

INSTALLATION LAYOUT EASY

Piping on the outdoor unit may be connected from either of

four directions: front, rear, side or beneath the base.

This easy-access design makes it possible to install a

number of units in a compact arrangement at a single site.

The outdoor unit allows for unheard-of flexibility in

determining a piping layout, thus greatly simplifying

installation.

8. FRONT-ACCESS FACILITATES

MAINTENANCE

The outdoor unit has been designed with a front access

service panel that allows easy access to all maintenance

point, regardless of the installation layout. What’s more, this

front panel may be removed by loosening only two screws.

It all adds up to greatly simplified maintenance work.

9. NITROGEN GAS IS CHARGED TO

INDOOR UNIT

Indoor unit and refrigerant pipes are charged with nitrogen

gas (N2) instead of R-22 before shipment from the

factory.

OC196A-5

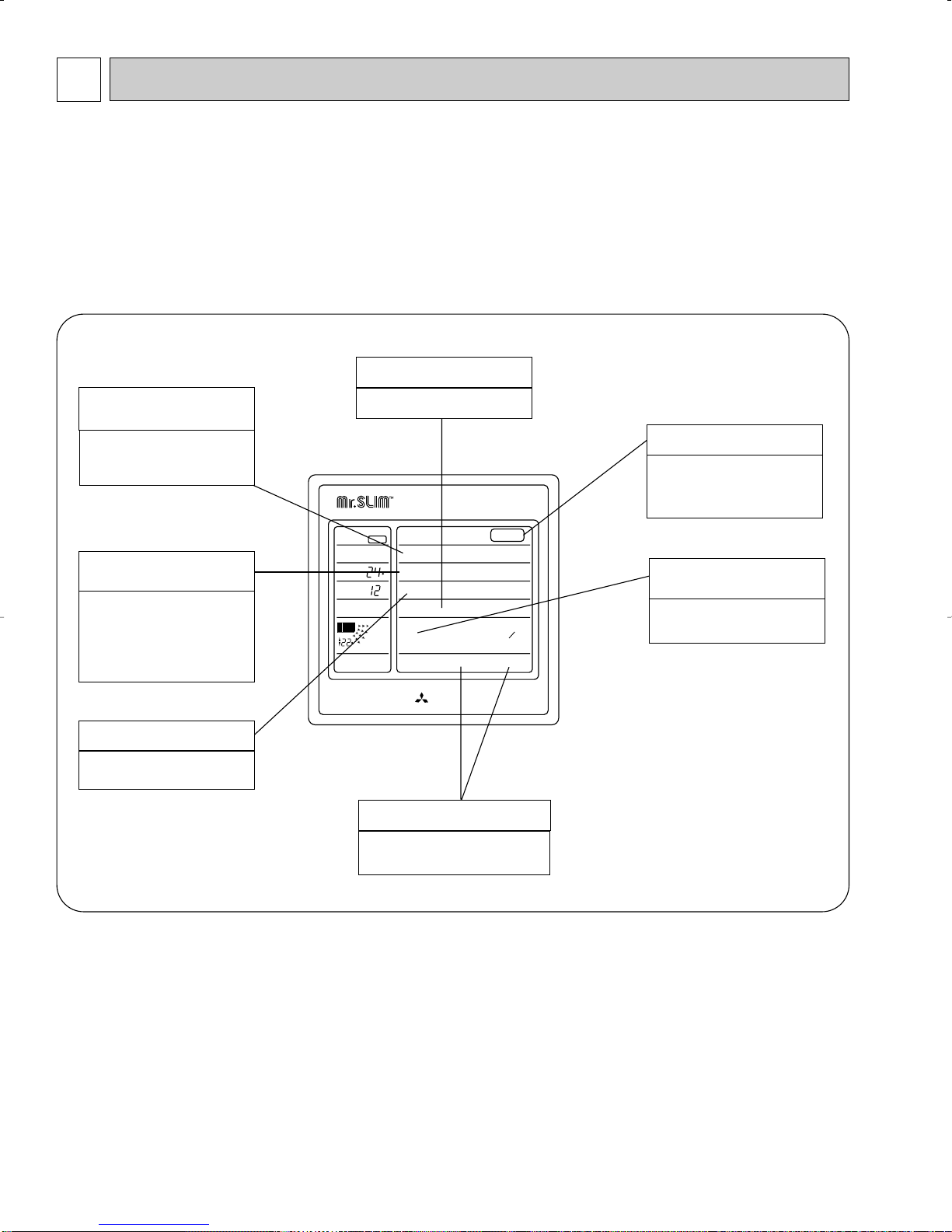

3 PART NAMES AND FUNCTIONS

MITSUBISHI ELECTRIC

ON

DRY

COOL

FAN

CHECK

SET TEMP

TIMER OFF

AUTO STOP

AUTO START

F

HR

F

LOW HIGH

AUTO RETURN

CHECK TEST RUN

POWER

ON/OFF

MODE SELECT

SET

TEMPERATURE

FAN COOL/DRY

COOLERWARMER

TIMER MODE HOURS

FAN SPEED LOW/HIGH

AIR

DISCHARGE

UP/DOWN

SWING

STOP

CHECK TEST RUN

•CENTRALLY CONTROLLED•

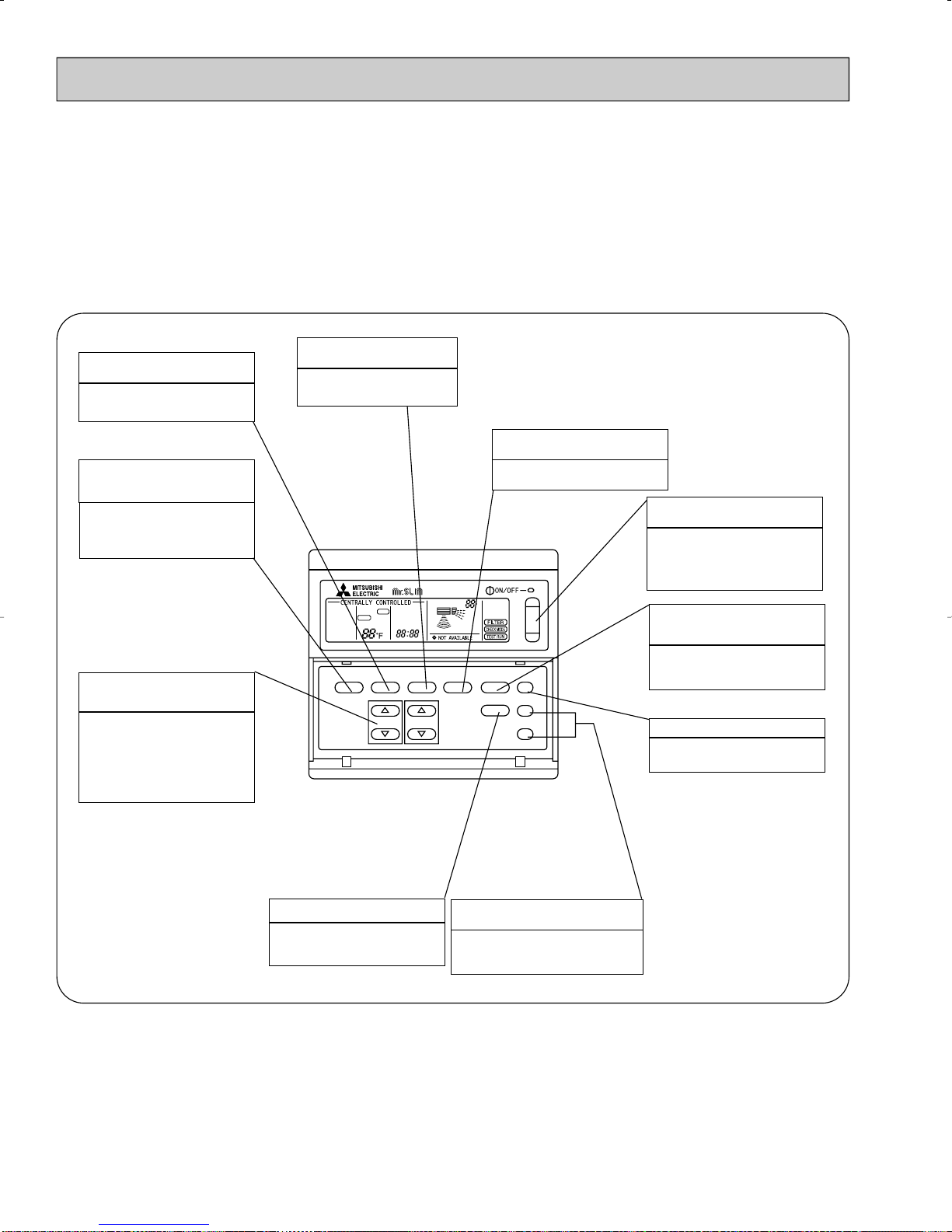

Remote controller (PK12/18/24/30/36FK)

Settings remain in effect until changed.

Air conditioner can be operated by simply pushing ON/OFF button once settings have been

made.

Remote controller operation buttons

FAN SPEED button

OPERATION MODE

button

Press this button to switch the cooling,electronic dry (Dehumidify), fan

modes.

SET TEMPERATURE

button

This sets the room temperature.

The temperature setting can be performed in 2˚F units.

Setting range :

Cooling 65˚F to 87˚F

TIMER ON/OFF button

This switches between continuous

operation and the timer operation.

This sets the ventilation fan speed.

ON/OFF button

This switches between the operation and stop modes each time it is

press. The lamp on this button

lights during operation.

AIR DISCHARGE

button

This adjusts the vertical angle of the

ventilation.

CHECK-TEST RUN button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

OC196A-6

CENTRALLY CONTROLLED

ON

ON/OFF

DRY

MODE SELECT

COOL/DRY

FAN

SET

TENPERATURE

WARMER

TIMER

FAN SPEED

LOW/HIGH

UP/DOWN

AIR

DISCHARGE

MODE

CHECK TEST RUN

HOURS

COOLER

FAN COOL

CHECK

SET TEMP

81

88

12

F

AUTO RETURN

HR

F

TIMER OFF

CHECK TEST RUN

AUTO STOP

AUTO START

LOW HIGH

POWER

Display panel Operating panel

SWING

STOP

ON

Displayed during operation (ON).

FAN, COOL/DRY

Operation mode is displayed.

SET TEMP./CHECK

SET TEMP :

The desired temperature setting

is displayed.

CHECK :

When unit malfunctioning occurs,

this display is activated. At this

time, "Unit address" and "checkcode" are alternately displayed,

indicating the malfunctioning unit

and the cause.

TIMER OFF, AUTO STOP, AUTO

START (TIMER MODE)

TIMER OFF (continuous operation), AUTO STOP, AUTO START

mode are displayed. In AUTO

STOP/AUTO START mode, the

set time is also displayed. Time

setting is in 1 hour units for up to

24 hours.

Fan speed (LOW, HIGH)

The fan speed (Low/High) is displayed.

Room Temperature

During operation, the room temperature is displayed (not displayed when

not operating). The room temperature's display range is 47˚F - 97˚F.

When this range is exceeded, "▼

47˚F" or "▲ 97˚F" is displayed.

CHECK

Displayed when "self-diagnostic"

functioning occurs, and simultaneously the check code is displayed in the "set temp."

TEST RUN

Displayed when test run operation mode is functioning. (Turned

automatically off after 2 hours of

operation).

Louver ON/OFF

operation

❈ NOTE

1 "CENTRALLY CONTROLLED"

is displayed for two seconds

after POWER button is turned

to on. This is not defective.

2 All LCD are off during power

OFF.

3 When a button on the operat-

ing panel is pressed, a beep

sound is heard.

4 Do not operate the buttons with

something sharp-pointed, or

the operating panel will be

damaged.

OC196A-7

TIMER OFF TIMER

CHECK SET TEMP.

DRY COOL

FAN

CLOCK AUTO AUTO

START STOP

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

CHECK

TEST RUN

AIR SWEEP

SET TEMP. TIMER SET

F

FAN

SPEED

SWING

AUTO

RETURN

REMOTE CONTROLLER

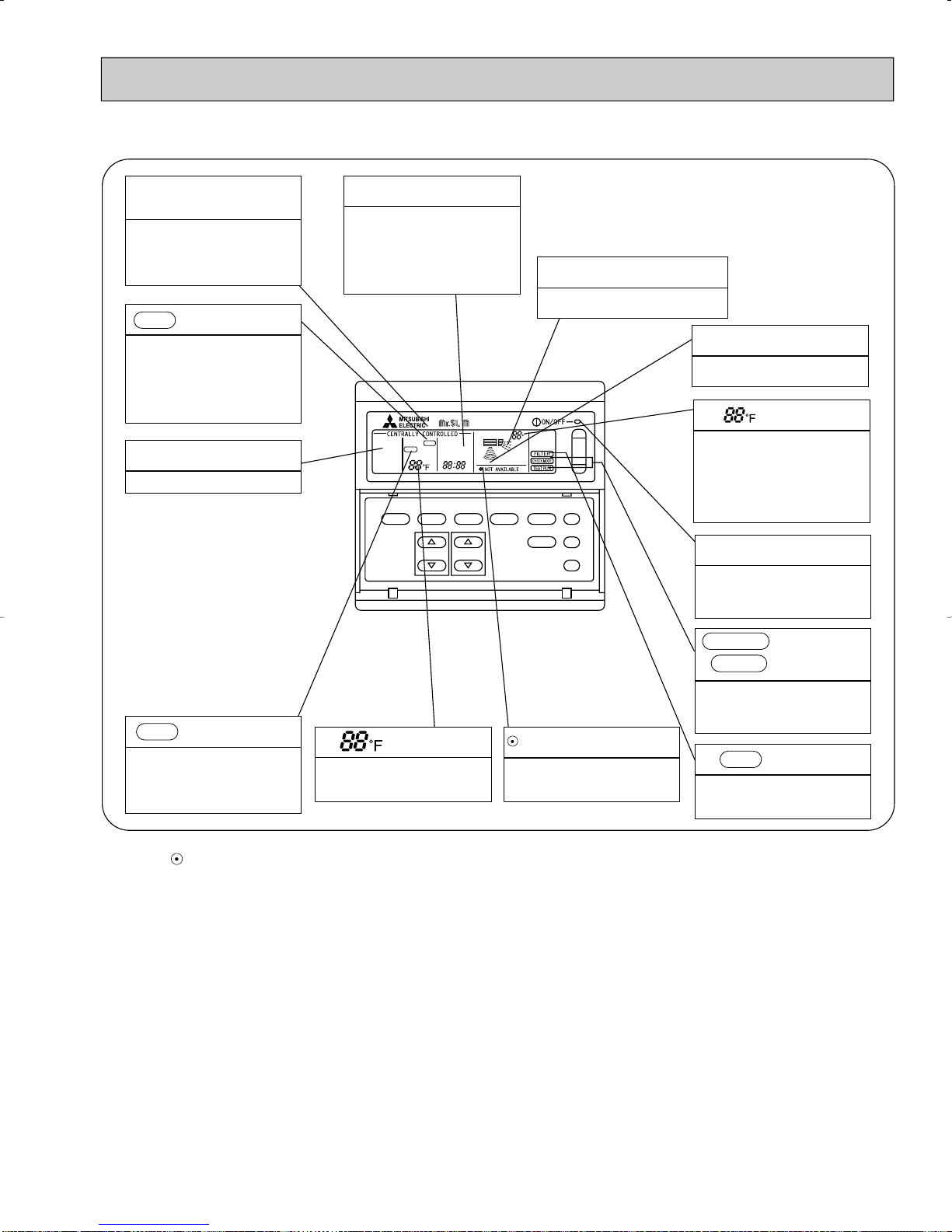

Remote controller (PK12/18/24/30/36FK1, PK18/24/30/36FK2)

Settings remain in effect unit changed.

Air conditioner can be operated by simply pushing ON/OFF button once setting have been

mode.

Remote controller operation buttons

TIMER ON/OFF button

This switches between continuous

operation and the timer operation.

OPERATION MODE

button

Press this button to switch the cooling,electronic dry (Dehumidify), fan

modes.

SET TEMPERATURE

button

This sets the room temperature.

The temperature setting can be performed in 2˚F units.

Setting range :

Cooling 65˚F to 87˚F

CLOCK/TIMER button

This sets or switches the current

time,start time and stop time.

FAN SPEED button

This sets the ventilation fan speed.

ON/OFF button

This switches between the operation and stop modes each time it is

press. The lamp on this button

lights during operation.

AIR DISCHARGE

button

This adjusts the vertical angle of the

ventilation.

FILTER button

This resets the filter service indication display.

AIR SWEEP button

This switches the horizontal fan

motion ON and OFF.

(This button is not available)

CHECK-TEST RUN button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

OC196A-8

Remote controller display

CENTRALLY

CONTROLLED display

This indicates when the unit is controlled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

TIMER OFF TIMER

DRY COOL

FAN

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

REMOTE CONTROLLER

CLOCK AUTO AUTO

CHECK SET TEMP.

START STOP

SET TEMP. TIMER SET

FAN

SPEED

SWING

AUTO

RETURN

In this display example on the bottom left, a condition where all display lamps light is shown for

explanation purposes although this differs from

actual operation.

AIR DISCHARGE display

This displays the air direction.

FAN SPEED display

The selected fan speed is displayed.

display

F

AIR SWEEP

CHECK

TEST RUN

The temperature of the return air is

displayed during operation. The display range is 47° to 97°F. The display flashes 47°F when the actual

temperature is less than 47° and

flashes 97°F when the actual temperature is greater than 97°F.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

display

This displays the selected setting

temperature.

display

This lamp lights when electricity is

supplied to the unit.

CHECK MODE

TEST RUN

This display lights in the check mode

or when a test operation is performed.

FILTER

This lamp lights when the filter needs

to be cleaned.

display

display

Caution

● Only the display lights when the unit is stopped and power supplied to the unit.

● When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not a malfunction.

●When the central control remote control unit, which is sold separately, is used the ON-OFF button,OPERA TION MODE button and SET

TEMP button do not operate.

● “NOTAVAILABLE” is displayed when the AIR SWEEP button are pressed.

(AIR SWEEP function is not provided for PK series.)

OC196A-9

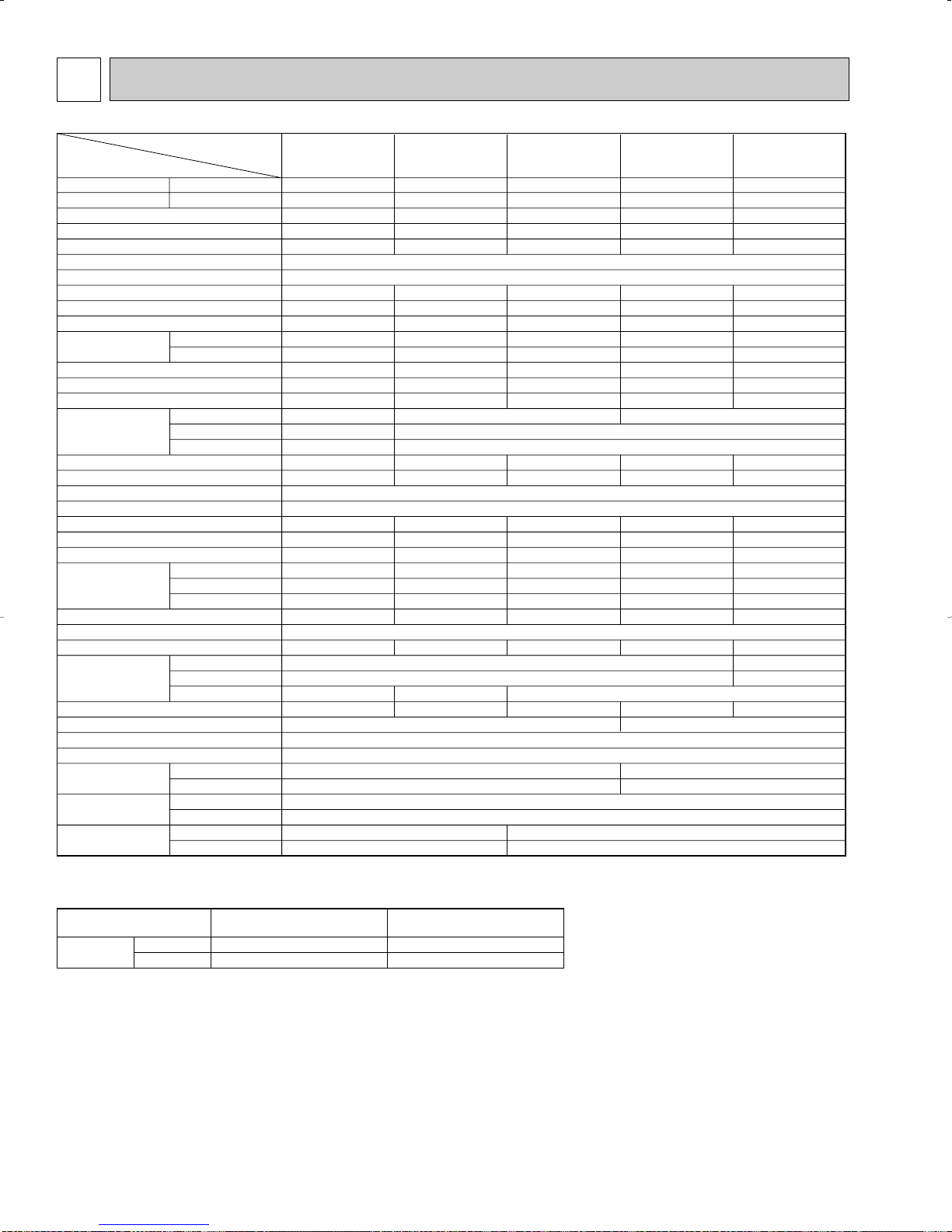

4 SPECIFICATIONS

Capacity

Power consumption

EER

SEER

INDOOR UNIT MODEL

External finish

Power supply

Max. fuse size (time delay)

Min ampacity

Fan motor

Airflow Hi-Lo

Moisture removal

Sound level Hi-Lo

Cond. drain connection OD

Dimensions

Weight

OUTDOOR UNIT MODEL

External finish

Power supply

Max. fuse size (time delay)

Min. ampacity

Fan motor

Compressor

Crankcase heater

Refrigerant control

Sound level

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

Pipe size

Connection method

Between the indoor

& outdoor units

❈ 1

❈ 1

❈ 1

Dry

Wet

W

D

H

Model

W

D

H

Liquid

Gas

Indoors

Outdoors

Height

Piping length

Btu/h

kW

V, Phase, Hz

A

A

F.L.A.

CFM

CFM

Pints/h

dB

in.

in.

in.

in.

Ib.

V, Phase, Hz

A

A

F.L.A

R.L.A

L.R.A

A(W)

dB

in.

in.

in.

Ib.

in.

in.

ft

fr

PK12FK

PK12FK

1

Model

12,500

1.21

10.3

11.5

PK12FK,PK12FK

1

15

1

0.7

490-350

440-320

3.8

45-38

1

49-7/32

7-7/8

11-13/16

37

PU12EK

1

15

11

0.65

RH167NAB

8.9

29

0.11/0.12 (23/28)

50

25-9/16

105

130

130

PK18FK

PK18FK

1

PK18FK2

18,500

1.75

10.6

11.3

PK18FK, PK18FK1, PK18FK2

15

1

0.7

710-530

640-480

5.3

48-41

1

53

PU18EK

1

20

16

0.75

RH247NAB

12.0

37

0.11/0.12 (23/28)

53

33-1/2

154

3/8

5/8

55-1/8

34-1/4

11-5/8

PK24FK

PK24FK

1

PK24FK2

24,000

2.34

10.3

10.6

PK24FK, PK24FK1, PK24FK2

Munsell 3.4Y7.7/0.8

115, 1, 60

15

1

0.7

710-530

640-480

7.2

48-41

1

9-1/4

13-3/8

53

PU24EK

1

Munsell 5Y7/1

208/230, 1, 60

20

16

0.65+0.65

NH33NBD

11.5

54

0.16/0.17 (33/39)

Capillary tube

55

207

With indoor unit

Indoor unit - remote controller : DC12V, Indoor unit - outdoor unit : DC12V

Not supplied (optional parts)

Flared

Flared

PK30FK

PK30FK

1

PK30FK2

30,000

3.06

9.8

10.7

PK30FK, PK30FK1, PK30FK2

15

2

1.0

990-780

890-700

9.6

49-44

1

62

PU30EK

1

30

20

0.65+0.65

NH41NAD

14.0

73

0.16/0.17 (33/39)

55

49-9/16

208

164

164

1/2

3/4

PK36FK

PK36FK

1

PK36FK2

34,200

3.47

9.9

10.2

PK36FK, PK36FK1, PK36FK2

15

2

1.0

990-780

890-700

10.5

49-44

1

62

PU36EK

1

30

22

0.75+0.75

NH47NAD

17.5

87

0.16/0.17 (33/39)

55

38-3/16

13-9/16

220

66-5/32

Item

NOTES : ❈ 1.Rating conditions —indoor : D.B. 80˚F, W.B. 67˚F outdoor : D.B. 95˚F, W.B. 75˚F.

Operating range

Indoor intake air temperature

D.B. 95˚F, W.B. 71˚F

D.B. 67˚F, W.B. 57˚F

Outdoor intake air temperature

D.B. 115˚F

D.B. 0˚F *

Cooling

Maximum

Minimum

*

In case of the wind baffle is installed.

(In case of the wind baffle is not installed, the minimum temperature will be D.B. 23˚F.)

MODELS : PK12/18/24/30/36FK, PK12/18/24/30/36FK1, PK18/24/30/36FK2

OC196A-10

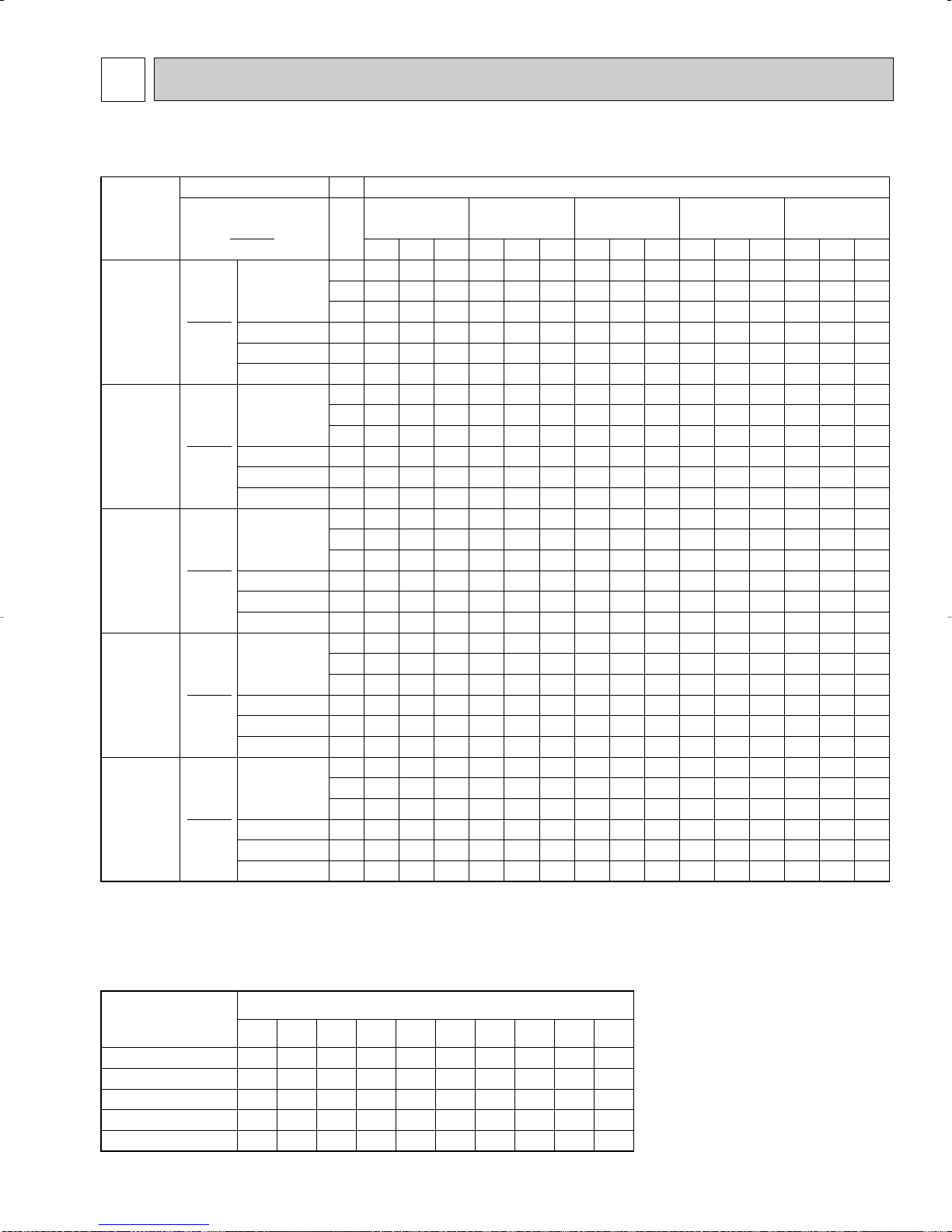

5

Notes 1. B.F. : Bypass Factor, IWB : Intake air wet-bulb temperature

TC : Total Capacity (x10

3

Btu/h), SHC : Sensible Heat Capacity (x10

3

Btu/h)

TPC : Total Power Consumption (kW)

2. Cooling capacity correction factors and Refrigerant piping length (one way) range.

MODEL

Refrigerant piping length (one way)

PK12FK, PK12FK

1

PK18FK, PK18FK1, PK18FK2

PK24FK, PK24FK1, PK24FK2

PK30FK, PK30FK1, PK30FK2

PK36FK, PK36FK1, PK36FK2

1.0

1.0

1.0

1.0

1.0

25ft

0.992

0.992

0.981

0.981

0.981

40ft

0.983

0.983

0.968

0.968

0.968

55ft

0.978

0.978

0.952

0.952

0.952

70ft

0.966

0.966

0.940

0.940

0.940

85ft

0.959

0.959

0.925

0.925

0.925

100ft

0.950

0.950

0.913

0.913

0.913

115ft

0.945

0.945

0.900

0.900

0.900

130ft

—

—

0.886

0.886

0.886

150ft

—

—

0.874

0.874

0.874

164ft

TC

14.5

13.6

12.7

12.6

12.0

11.8

21.5

20.1

18.8

18.6

17.8

17.4

27.9

26.1

24.3

24.1

23.0

22.6

34.9

32.6

30.4

30.2

28.8

28.3

39.8

37.1

34.7

34.4

32.8

32.2

IWB

(˚F)

71

67

63

62.5

60

59

71

67

63

62.5

60

59

71

67

63

62.5

60

59

71

67

63

62.5

60

59

71

67

63

62.5

60

59

Indoor air

Airflow

(CFM)

B.F

Models

PK12FK

PK12FK

1

PK18FK

PK18FK

1

PK18FK2

PK24FK

PK24FK

1

PK24FK2

PK30FK

PK30FK

1

PK30FK2

PK36FK

PK36FK

1

PK36FK2

490

0.18

710

0.14

710

0.14

990

0.15

990

0.15

D.B. 80˚F

D.B.75˚F(50%RH)

D.B.72˚F(50%RH)

D.B.70˚F(50%RH)

D.B. 80˚F

D.B.75˚F(50%RH)

D.B.72˚F(50%RH)

D.B.70˚F(50%RH)

D.B. 80˚F

D.B.75˚F(50%RH)

D.B.72˚F(50%RH)

D.B.70˚F(50%RH)

D.B. 80˚F

D.B.75˚F(50%RH)

D.B.72˚F(50%RH)

D.B.70˚F(50%RH)

D.B. 80˚F

D.B.75˚F(50%RH)

D.B.72˚F(50%RH)

D.B.70˚F(50%RH)

75

SHC

9.8

11.0

12.0

10.7

10.4

10.1

14.8

16.5

17.9

16.0

15.6

15.0

16.4

18.8

20.7

18.3

17.8

17.3

21.5

24.5

26.9

23.8

23.2

22.5

23.0

26.3

29.3

25.8

25.1

24.3

TPC

1.05

1.03

1.01

1.01

0.99

0.99

1.52

1.49

1.46

1.45

1.43

1.43

2.04

1.99

1.95

1.94

1.92

1.91

2.66

2.61

2.55

2.54

2.51

2.49

3.02

2.96

2.89

2.88

2.84

2.83

TC

14.0

13.1

12.2

12.1

11.5

11.3

20.8

19.3

18.0

17.9

17.1

16.7

26.9

25.1

23.4

23.2

22.1

21.7

33.7

31.4

29.2

29.0

27.7

27.1

38.4

35.7

33.3

33.1

31.5

30.9

85

SHC

9.5

10.6

11.5

10.3

10.0

9.7

14.3

15.8

17.2

15.4

15.0

14.4

15.8

18.1

20.0

17.6

17.1

16.6

20.8

23.6

25.8

22.9

22.3

21.5

22.1

25.3

28.1

24.8

24.1

23.3

TPC

1.14

1.12

1.09

1.09

1.07

1.06

1.65

1.61

1.57

1.57

1.55

1.54

2.21

2.16

2.11

2.10

2.07

2.05

2.89

2.82

2.75

2.75

2.70

2.69

3.28

3.20

3.12

3.11

3.07

3.05

TC

13.5

12.5

11.6

11.5

11.0

10.8

19.9

18.5

17.2

17.1

16.3

16.0

25.8

24.0

22.4

22.2

21.1

20.7

32.3

30.0

27.9

27.7

26.4

25.9

36.8

34.2

31.9

31.6

30.1

29.5

Outdoor intake air DB temperature(˚F

)

95

SHC

9.1

10.1

10.9

9.8

9.5

9.2

13.7

15.2

16.4

14.7

14.3

13.8

15.1

17.3

19.1

16.8

16.4

15.8

19.9

22.5

24.6

21.9

21.3

20.6

21.2

24.3

26.9

23.7

23.0

22.3

TPC

1.24

1.21

1.18

1.17

1.15

1.15

1.80

1.75

1.70

1.70

1.67

1.66

2.40

2.34

2.28

2.27

2.23

2.22

3.14

3.06

2.98

2.97

2.92

2.90

3.57

3.47

3.38

3.37

3.31

3.29

TC

12.8

11.9

11.1

11.0

10.4

10.2

19.0

17.6

16.4

16.2

15.5

15.1

24.6

22.9

21.3

21.1

20.0

19.6

30.8

28.6

26.6

26.3

25.1

24.6

35.1

32.6

30.3

30.0

28.6

28.0

105

SHC

8.7

9.6

10.5

9.3

9.0

8.7

13.0

14.4

15.6

13.9

13.6

13.1

14.4

16.5

18.2

16.0

15.5

15.0

19.0

21.5

23.5

20.7

20.2

19.5

20.2

23.1

25.6

22.5

21.9

21.1

TPC

1.35

1.31

1.27

1.26

1.24

1.23

1.95

1.89

1.83

1.83

1.79

1.78

2.61

2.53

2.45

2.44

2.40

2.38

3.41

3.30

3.21

3.20

3.14

3.11

3.87

3.74

3.64

3.63

3.56

3.53

TC

12.2

11.3

10.5

10.4

9.9

9.7

18.1

16.7

15.5

15.4

14.6

14.3

23.4

21.7

20.1

19.9

18.9

18.5

29.3

27.1

25.1

24.9

23.7

23.2

33.4

30.9

28.7

28.4

27.0

26.4

115

SHC

8.3

9.2

9.9

8.8

8.6

8.3

12.4

13.7

14.8

13.2

12.8

12.4

13.7

15.6

17.2

15.1

14.7

14.1

18.1

20.3

22.2

19.6

19.1

18.4

19.3

21.9

24.2

21.3

20.7

19.9

TPC

1.45

1.40

1.36

1.35

1.32

1.31

2.10

2.03

1.96

1.96

1.92

1.90

2.81

2.71

2.62

2.62

2.56

2.54

3.68

3.54

3.43

3.42

3.35

3.32

4.17

4.02

3.89

3.88

3.80

3.77

DATA

1. PERFORMANCE DATA

1) COOLING CAPACITY

2) COOLING CAPACITY CORRECTIONS

OC196A-11

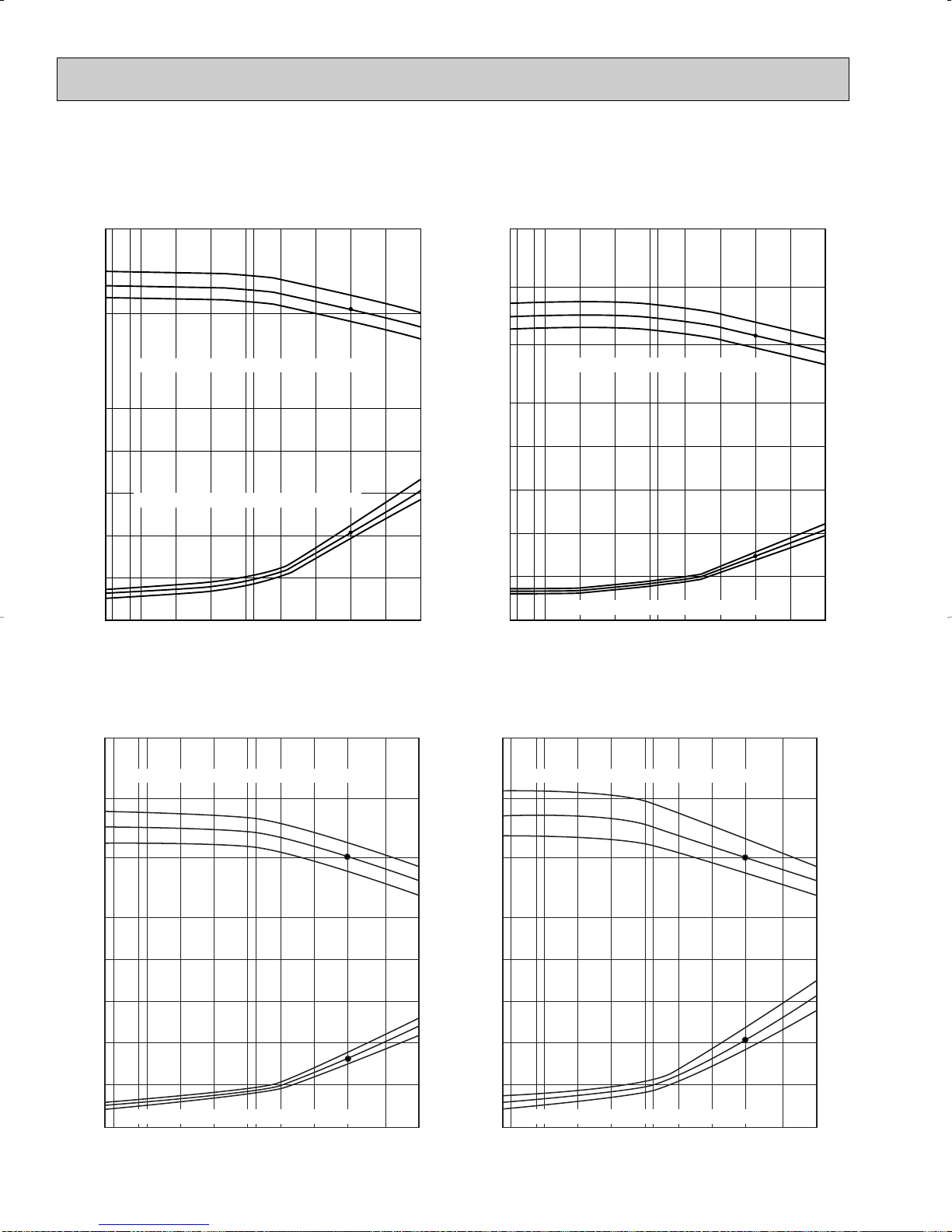

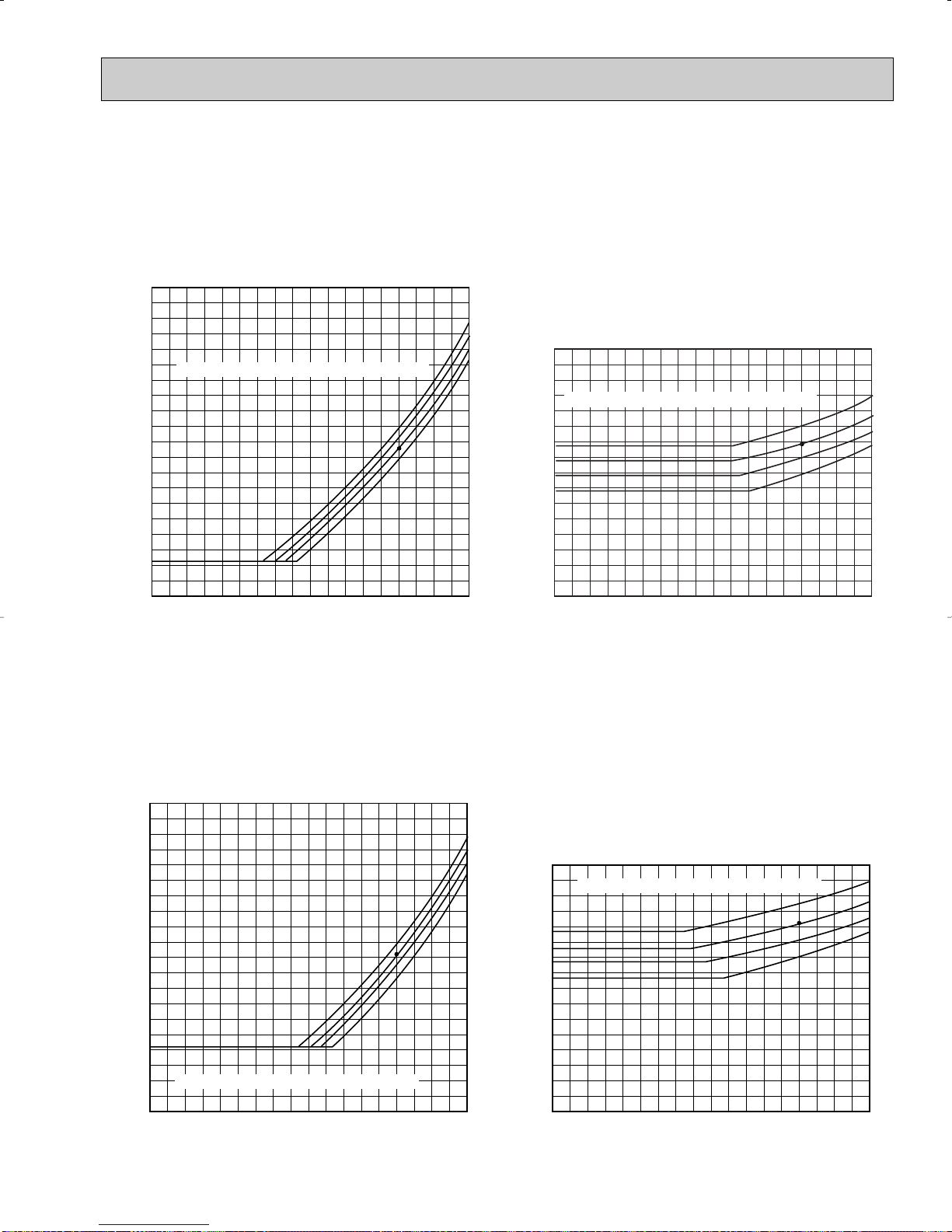

2. PERFORMANCE CURVE

18

71

67

63

71

67

63

12

6

1.6

1.4

1.2

1.0

0.8

023 3235

45 55

65(67) 75

85 95 105 115

Total capacity (✕10

3

Btu/h)Total power consumption (kW)

Outdoor intake air D.B. temperature (°F)

indoor intake air W.B. temperature (°F)

indoor intake air W.B. temperature (°F)

SHF=0.81

30

71

67

63

71

67

63

18

24

12

3.0

2.5

2.0

1.5

1.0

023 3235

45 55

65(67)

75 85 95 105 115

Total capacity (✕10

3

Btu/h)Total power consumption (kW)

Outdoor intake air D.B. temperature (°F)

indoor intake air W.B. temperature (°F)

indoor intake air W.B. temperature (°F)

SHF=0.82

Total capacity (✕10

3

Btu/h)Total power consumption (kW)

Outdoor intake air D.B. temperature (°F)

023 3235

45

65 (67)

75 85 95 105 11555

1.5

2.0

2.5

3.0

3.5

18

36

24

30

71

67

63

71

67

63

023 3235

45

65 (67)

75 85 95 105 11555

2.0

2.5

3.0

3.5

4.0

24

42

30

36

71

67

63

71

67

63

indoor intake air W.B. temperature (°F)

indoor intake air W.B. temperature (°F)

Total capacity (✕10

3

Btu/h)Total power consumption (kW)

Outdoor intake air D.B. temperature (°F)

indoor intake air W.B. temperature (°F)

indoor intake air W.B. temperature (°F)

SHF=0.72 SHF=0.72

NOTE : Apoint on the curve shows the reference point.

PK12FK

PK12FK1

COOLING CAPACITY COOLING CAPACITY

PK18FK

PK18FK1

PK18FK2

PK24FK

COOLING CAPACITY COOLING CAPACITY

PK24FK1

PK24FK2

PK30FK

PK30FK1

PK30FK2

OC196A-12

Outdoor ambient temperature (°F)

indoor intake air W.B. temperature (°F)

[psi. G]

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

86

80

75

70

PK12FK

PK12FK

1

<Cooling mode>

Condensing pressure

30 40 50 60 70 80 90 100 110

D.B.(°F)

Outdoor ambient temperature (°F)

indoor intake air W.B. temperature (°F)

[psi. G]

100

90

80

70

60

50

40

30

86

80

75

70

PK12FK

PK12FK

1

Suction pressure

30 40 50 60 70 80 90 100 110

D.B.(°F)

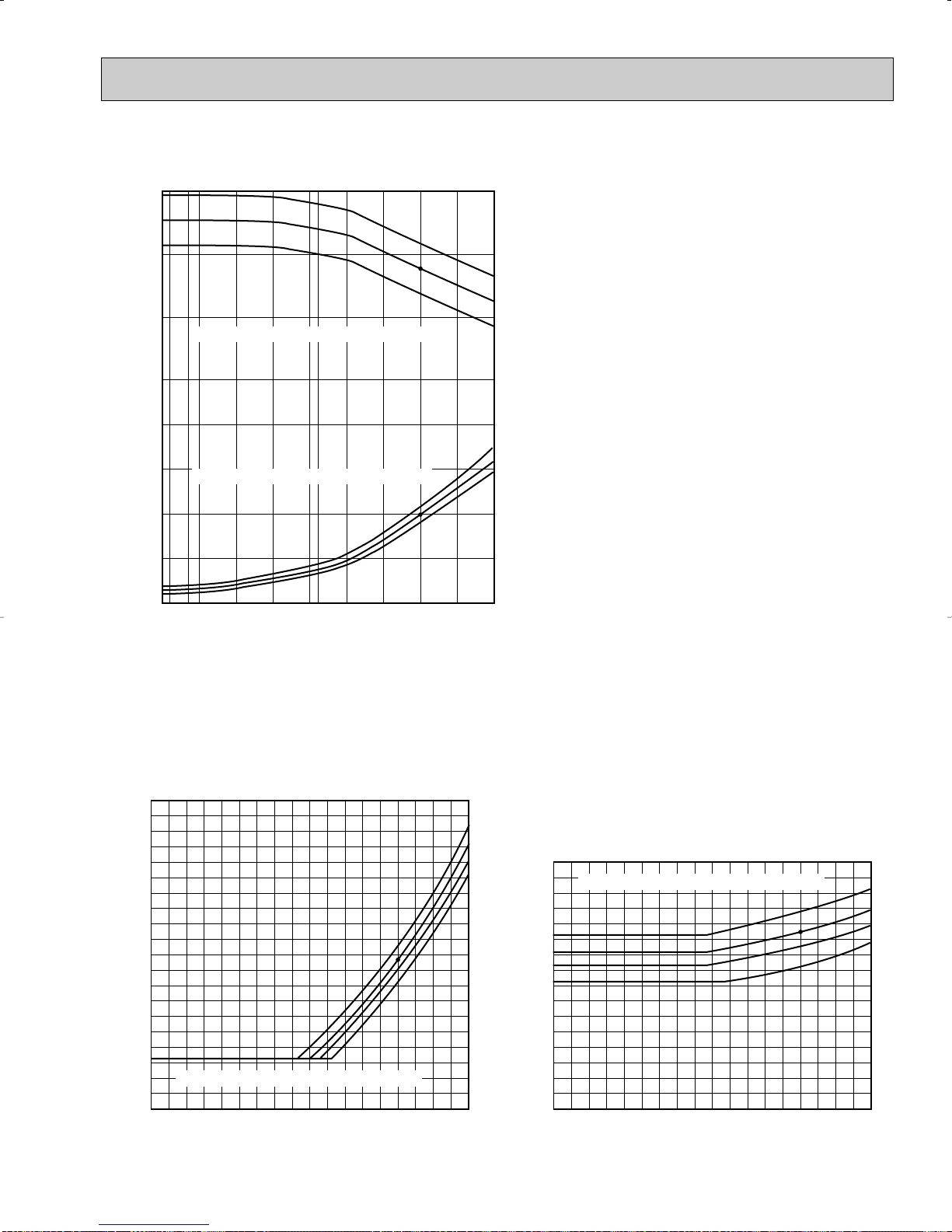

42

71

67

63

71

67

63

30

36

24

4.5

4.0

3.5

3.0

2.5

023 3235

45 55

65(67) 75

85 95 105 115

Total capacity (✕10

3

Btu/h)Total power consumption (kW)

Outdoor intake air D.B. temperature (°F)

indoor intake air W.B. temperature (°F)

indoor intake air W.B. temperature (°F)

SHF=0.71

PK36FK

PK36FK1

PK36FK2

COOLING CAPACITY

Data is based on the condition of indoor humidity 50%.

Air flow should be set at HI.

A point on the curve shows the reference point.

OC196A-13

Data is based on the condition of indoor humidity 50%.

PK18FK

PK18FK

1

PK18FK2

<Cooling mode>

PK18FK

PK18FK

1

PK18FK2

86

80

75

70

86

80

75

70

Outdoor ambient temperature

30 40 50 60 70 80 90 100 110

360

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

[psi.G]

100

90

80

70

60

50

40

30

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

D.B.(°F)

D.B.(°F)

[psi.G]

Indoor D.B. temperature (°F)

Indoor D.B. temperature (°F)

Condensing pressure

Suction pressure

PK24FK

PK24FK

1

PK24FK2

<Cooling mode>

PK24FK

PK24FK

1

PK24FK2

Outdoor ambient temperature

Outdoor ambient temperature

D.B.(°F)

D.B.(°F)

86

80

75

70

86

80

75

70

30 40 50 60 70 80 90 100 110

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

[psi.G]

100

90

80

70

60

50

40

30

20

30 40 50 60 70 80 90 100 110

[psi.G]

Indoor D.B. temperature (°F)

Indoor D.B. temperature (°F)

Condensing pressure

Suction pressure

Air flow should be set at HI.

A point on the curve shows the reference point.

OC196A-14

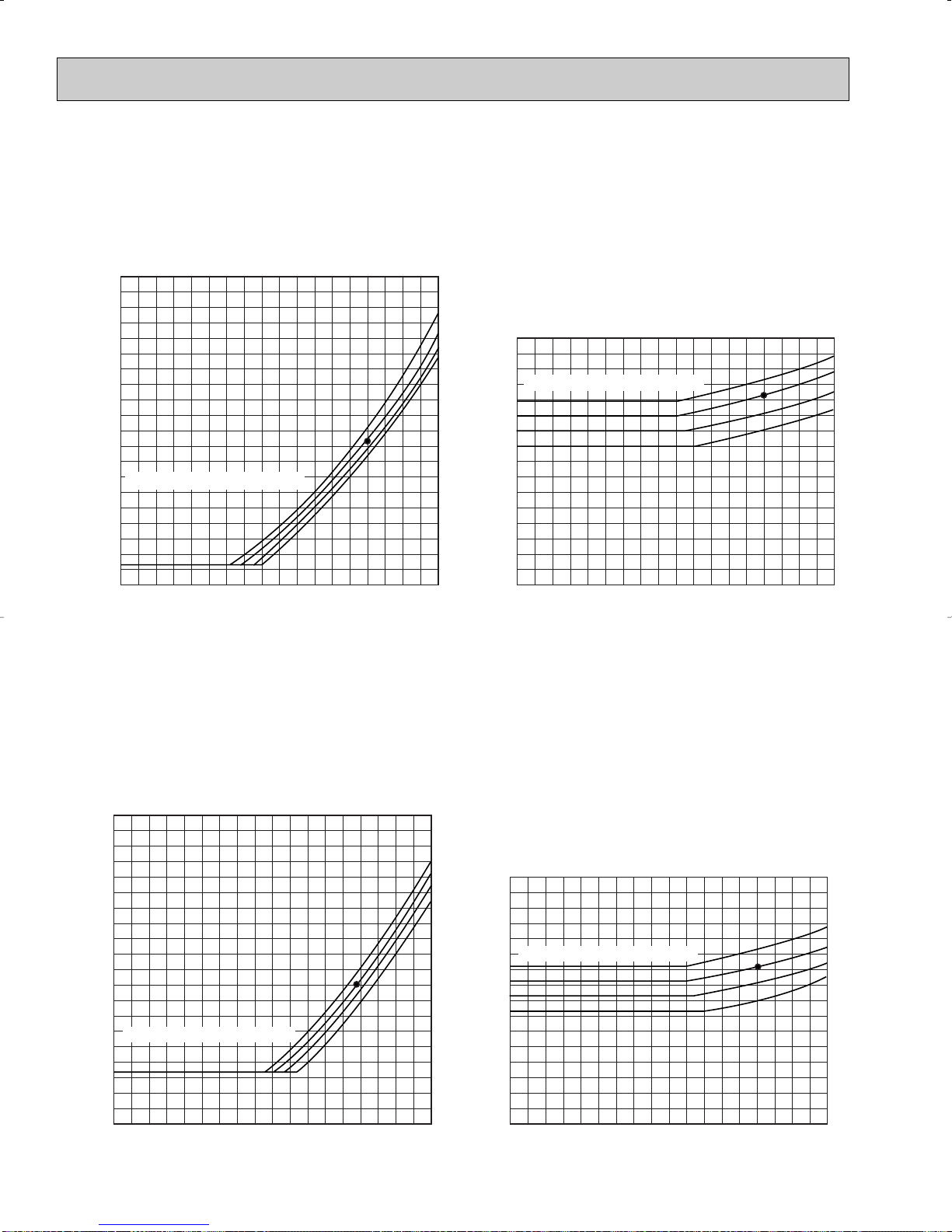

Data is based on the condition of indoor humidity 50%.

Outdoor ambient temperature (°F)

indoor intake air W.B. temperature (°F)

[psi. G]

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

140

86

80

75

70

PK30FK

PK30FK

1

PK30FK2

<Cooling mode>

Condensing pressure

30 40 50 60 70 80 90 100 110

D.B.(°F)

Outdoor ambient temperature (°F)

PK30FK

PK30FK

1

PK30FK2

Suction pressure

D.B.(°F)

86

80

75

70

100

90

80

70

60

50

40

30

30 40 50 60 70 80 90 100 110

[psi.G]

indoor intake air W.B. temperature (°F)

Outdoor ambient temperature (°F)

indoor intake air W.B. temperature (°F)

[psi. G]

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

140

86

80

75

70

PK36FK

PK36FK

1

PK36FK2

<Cooling mode>

Condensing pressure

30 40 50 60 70 80 90 100 110

D.B.(°F)

Outdoor ambient temperature (°F)

indoor intake air W.B. temperature (°F)

[psi. G]

90

80

70

60

50

40

30

20

86

80

75

70

PK36FK

PK36FK

1

PK36FK2

Suction pressure

30 40 50 60 70 80 90 100 110

D.B.(°F)

Air flow should be set at HI.

A point on the curve shows the reference point.

OC196A-15

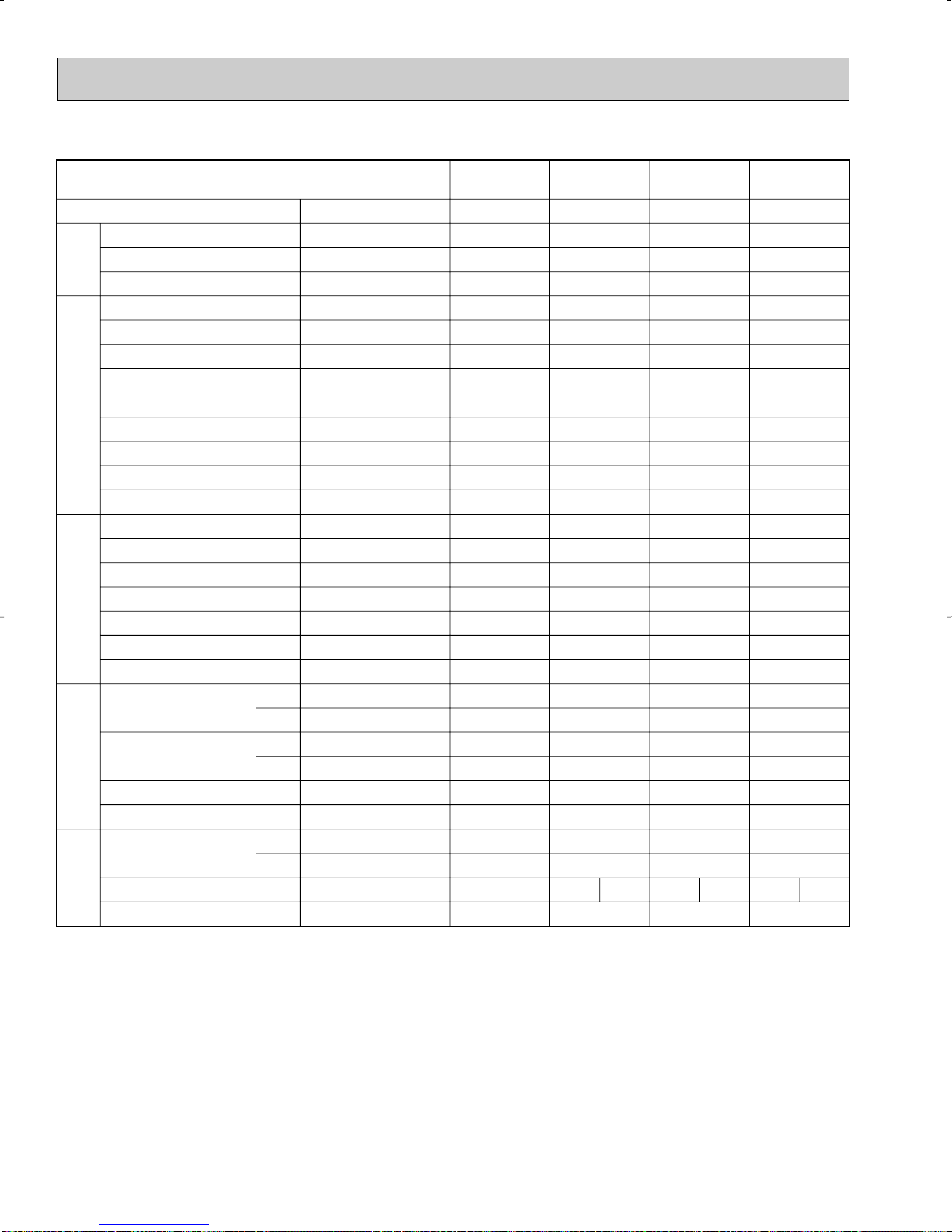

3. STANDARD OPERATION DATA

750 750 750 750 760 760

Capacity

SHF

Input

INDOOR UNIT MODEL

Power supply (V, phase, Hz)

Input

Fan current

OUTDOOR UNIT MODEL

Power supply (V, phase, Hz)

Input

Comp. current

Fan current

Condensing pressure

Suction pressure

Discharge temp.

Condensing temp.

Suction temp.

Ref. pipe length

Refrigerant charge

Intake air temperature

Discharge air temperature

Fan speed (High)

Airflow (High)

Intake air temperature

Fan speed upper / lower

Airflow

Unit

Btu / t

—

kW

kW

A

kW

A

A

psi-G

psi-G

˚F

˚F

˚F

ft

—

˚F

˚F

˚F

˚F

rpm

CFM

˚F

˚F

rpm

CFM

Cooling

12,500

0.81

1.21

PK12FK, PK12FK

1

115, 1, 60

0.07

0.7

PU12EK

1

208/230, 1, 60

1.14

8.9

0.65

247

87

155

116

52

25

4 lbs 14oz

80

67

61

59

1,420

490

95

75

790

1,590

Cooling

18,500

0.82

1.75

PK18FK, PK18FK1, PK18FK2

115, 1, 60

0.09

0.7

PU18EK

1

208/230, 1, 60

1.66

12.0

0.75

255

82

171

118

51

25

5 lbs 8 oz

80

67

61

59

1,300

710

95

75

790

1,590

Cooling

24,000

0.72

2.34

PK24FK, PK24FK1, PK24FK2

115, 1, 60

0.09

0.7

PU24EK

1

208/230, 1, 60

2.25

11.5

0.65+0.65

240

74

155

114

44

25

9 lbs 15 oz

80

67

58

56

1,300

710

95

75

3,170

Cooling

30,000

0.75

3.06

PK30FK, PK30FK1, PK30FK2

115, 1, 60

0.12

1.0

PU30EK

1

208/230, 1, 60

2.94

14.0

0.65+0.65

247

77

163

116

46

25

10 lbs 2 oz

80

67

59

58

1,380

990

95

75

3,170

Cooling

34,200

0.71

3.47

PK36FK, PK36FK1, PK36FK2

115, 1, 60

0.12

1.0

PU36EK

1

208/230, 1, 60

3.35

17.5

0.75+0.75

247

73

163

116

43

25

10 lbs 9 oz

80

67

58

56

1,380

990

95

75

3,350

PK12FK

PK12FK

1

PK18FK

PK18FK

1

PK18FK2

PK24FK

PK24FK

1

PK24FK2

PK30FK

PK30FK

1

PK30FK2

PK36FK

PK36FK

1

PK36FK2

D.B.

W.B.

D.B.

W.B.

D.B.

W.B.

Item

Model

TotalRefrigerant circuitIndoor sideOutdoor side Electrical circuit

OC196A-16

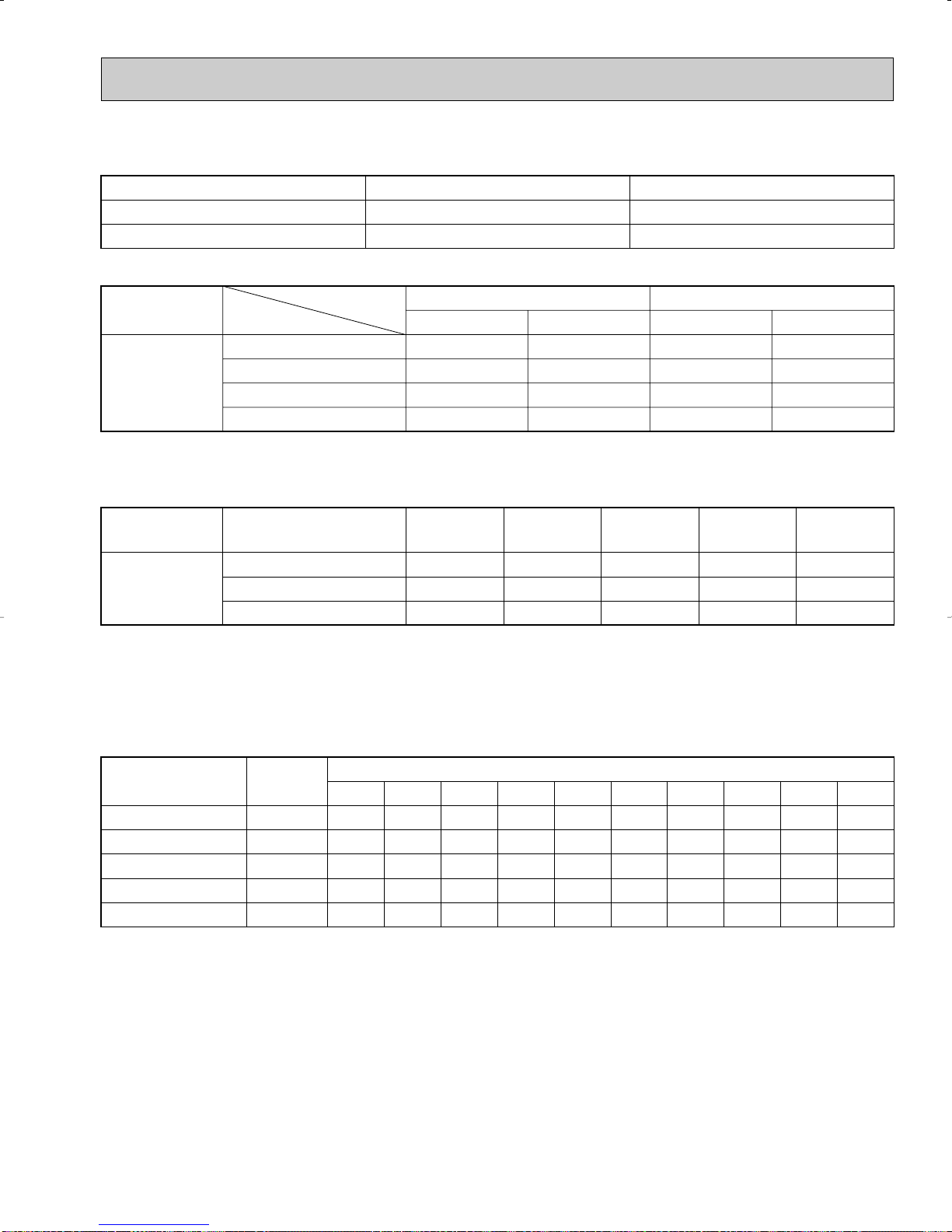

4. OPERATING RANGE

Indoor unit

Outdoor unit

Rating

115V 1 phase 60Hz

208/230V 1 phase 60Hz

Allowable voltage

Min. 103V — Max. 127V

Min. 198V — Max. 253V

Function

Cooling

D.B.(˚F)

80

95

67

80

Condition

Standard temperature

Maximum temperature

Minimum temperature

Maximum humidity

Indoor

Intake air temperature

Outdoor

W.B.(˚F)

67

71

57

75

D.B.(˚F)

95

115

*0

80

* With wind baffle D.B. 23˚F if no wind baffle.

W.B.(˚F)

75

75

—

75

Airflow

Air speed

Coverage range

(CFM)

(ft / sec.)

(ft)

Standard

height

(8.2ft)

490

14.1

32

710

16.1

41

710

16.1

41

990

17.7

50

990

17.7

50

PK12FK

PK12FK

1

PK18FK

PK18FK

1

PK18FK2

PK24FK

PK24FK

1

PK24FK2

PK30FK

PK30FK

1

PK30FK2

PK36FK

PK36FK

1

PK36FK2

Model

PK12FK, PK12FK1

PK18FK, PK18FK1, PK18FK2

PK24FK, PK24FK1, PK24FK2

PK30FK, PK30FK1, PK30FK2

PK36FK, PK36FK1, PK36FK2

4 lbs 14 oz

5 lbs 8 oz

9 lbs 15 oz

10 lbs 2 oz

10 lbs 9 oz

25ft

0

0

0

0

0

40ft

0

0

0

0

0

55ft

0

0

0

0

0

70ft

0

0

0

0

0

85ft

0

0

0

0

0

Refrigerant piping length (over way)

100ft

0

0

0

0

0

115ft

2

2

2

5

5

130ft

4

4

4

10

10

150ft

—

—

7

16

16

164ft

—

—

9

20

20

Outdoor unit

precharged

(up to 100ft)

1) POWER SUPPLY

2) OPERATION

5. OUTLET AIR SPEED AND COVERAGE RANGE

● The air coverage range is the value up to the position where the air speed is 0.8ft/sec. when air is blown out

horizontally from the unit at the High fan setting.

The coverage range should be used only as a general guideline since it varies according to the size of the

room and furniture installed inside the room.

6. ADDITIONAL REFRIGERANT CHARGE (R22 (oz))

OC196A-17

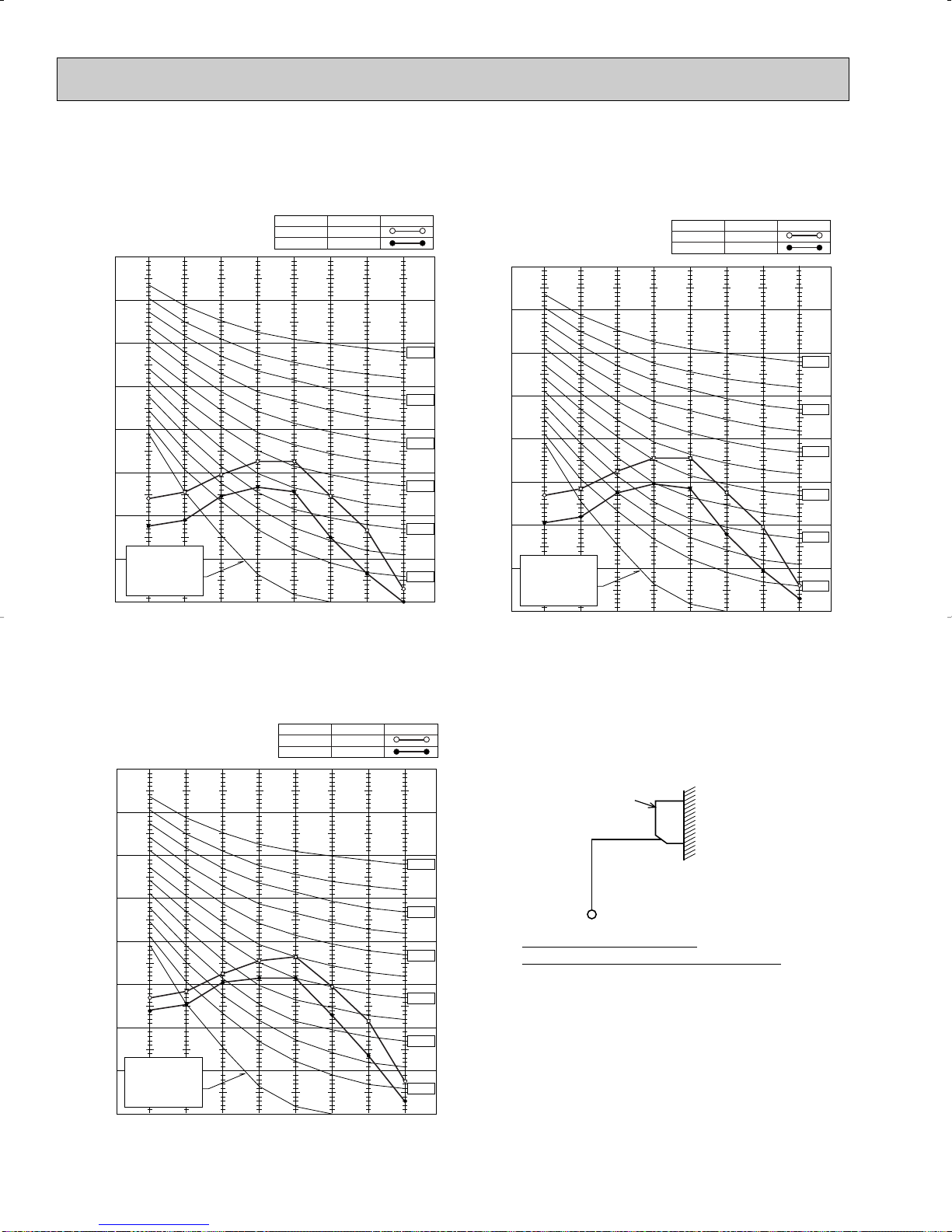

6. NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

Hi

NOTCH

Lo

49

SPL(dB)44LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

Hi

NOTCH

Lo

48

SPL(dB)41LINE

Wall

Unit

3.3ft

3.3ft

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Hi

NOTCH

Lo

45

SPL(dB)38LINE

PK12FK

PK12FK1

PK18/24FK

PK18/24FK1

PK18/24FK2

PK30/36FK

PK30/36FK1

PK30/36FK2

Ambient temperature 80˚F

Test conditions are based on JIS Z8731

OC196A-18

6

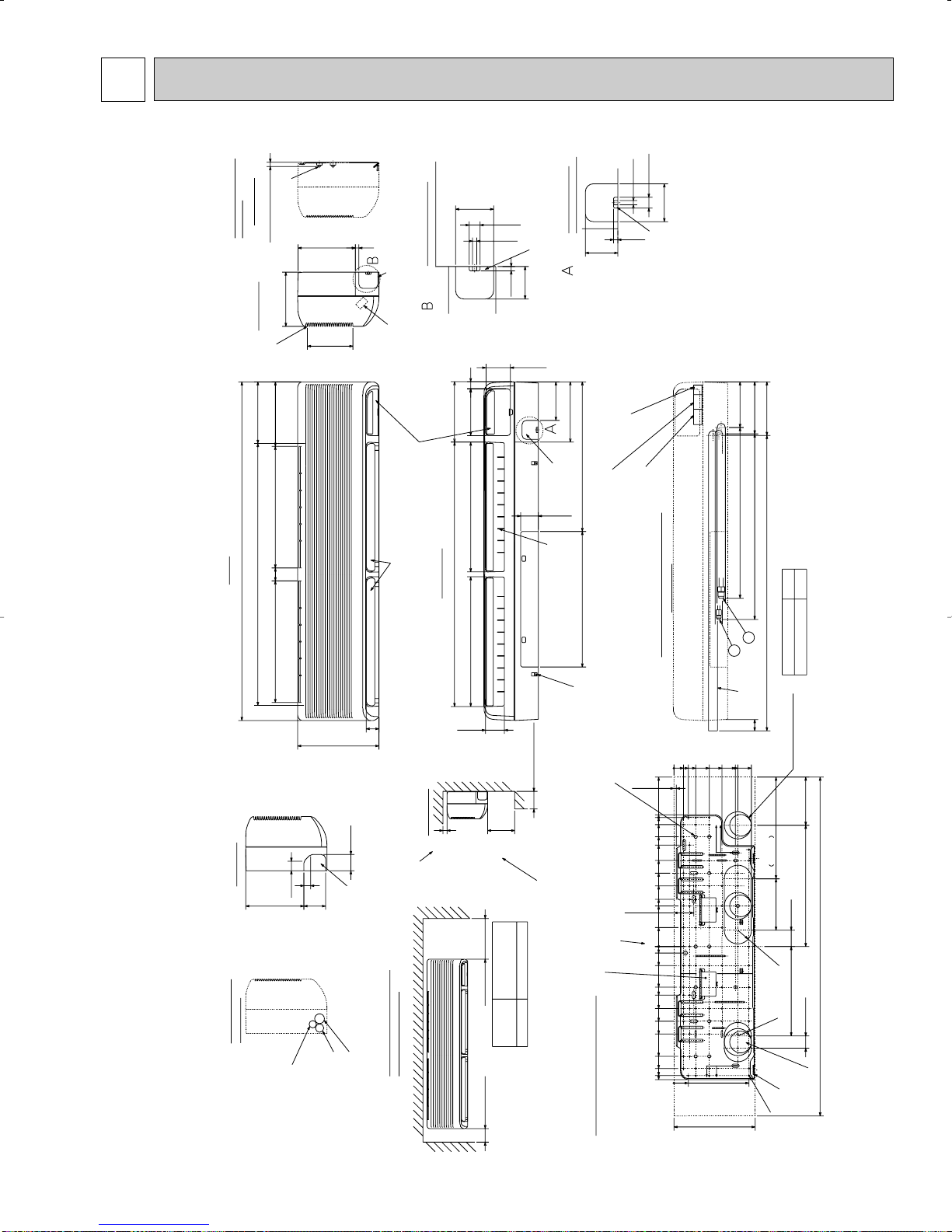

0

10-29/32

0

2-3/32

(2:1)

11-13/16

(Hight of unit)

7-1/8

or more

6 or more

17-19/32

49-7/32 (Width of unit)

Gas pipe

Liquid pipe

2

1

2

1

Terminal block for

control

knock out hole

for piping

16-louvers

(manual)

Lower side

Air outletAir outlet

(2:1)

Terminal block

Right side

service panel for power supply connection

Front

Air intake

Air intake

Knock out hole for left-rear piping

11-1/4

9-9/32

8-15/16

6-31/32

5-1/8

3-5/32

2-3/32

0

1-3/8

2-unit hangers

Liquid pipe

for installation plate

hole

1-3/16

or more

2O5-{1/8

hole for

tapping

screw

68-{3/16

hole for

tapping

screw

5/8F

3/8F

Sleeve

13-{9/16 hole

Air intake

2-3/8

Knock out hole

for piping

knock out hole

for piping

W2

end of through hole.

W2 This size shows the lower

W1 Sleeves are available

on the market.

3-1/2~{4{3-1/2

W1

Through

0

15/16

1/2

25

27

(100 for left-hand

side piping)

Pipe position

Left side

Installation bolt

position

2-3/8

Drain hose(Flexible hose;length 47-1/4)

Drain hose

Terminal block & pipe position

1-25/32

13 2-3/8

7-15/32 14-3/4

(7)

14-23/32

Details of installation plate

(Necessary clearance for

Unit installation)

2

43-5/16(Drain hose) 7-7/8

Rear piping hole

Right side

Lower side

Auto vanes

Service space required

around indoor unit

2-tapping screws

Terminal block

for power supply

Terminal block for

remote controller

5/16

25/32

5/16

2-3/4

Knock out hole

for under piping

5/16

25/32

5/16

2-3/4

Knock-out hole for

right-hand side piping

R2-1/16

R2-1/16

0

24-19/32

19-1/8

0

19-11/32

18-3/4

17-23/32

15-15/16

12-23/32

10-7/8

9-1/32

7-1/16

5-29/32

2-3/4

0

18-3/4

17-23/32

15-15/16

12-17/32

10-21/32

8-13/16

6-27/32

5-29/32

0

2-3/4

unit center

8-25/32

1

Air intake

Knock out hole

for right-hand side piping

Knock out hole

for left-hand

side piping

Front

Right side

Left side

Drain hose

Gas pipe

5-5/8

3-5/32

7-1/2

6-3/4

Bolt

8-15/16

3-1/8

5-1/8 or less

6-5/8

19/32 or less

2 or more

1-7/8

2-7/8

11/32

3-19/32

1-27/32

9-9/32

1

1-3/8

8-15/32

2-3/8

17-11/16 17-11/16

2-3/4

6-13/16

2-9/16

21-25/32

8-3/8

7-7/8

38-7/16

18-27/32 18-27/32

8-3/4

19-11/16

11-13/16

49-7/32

OUTLINES AND DIMENSIONS

Indoor Unit

PK12FK

PK12FK1

OC196A-19

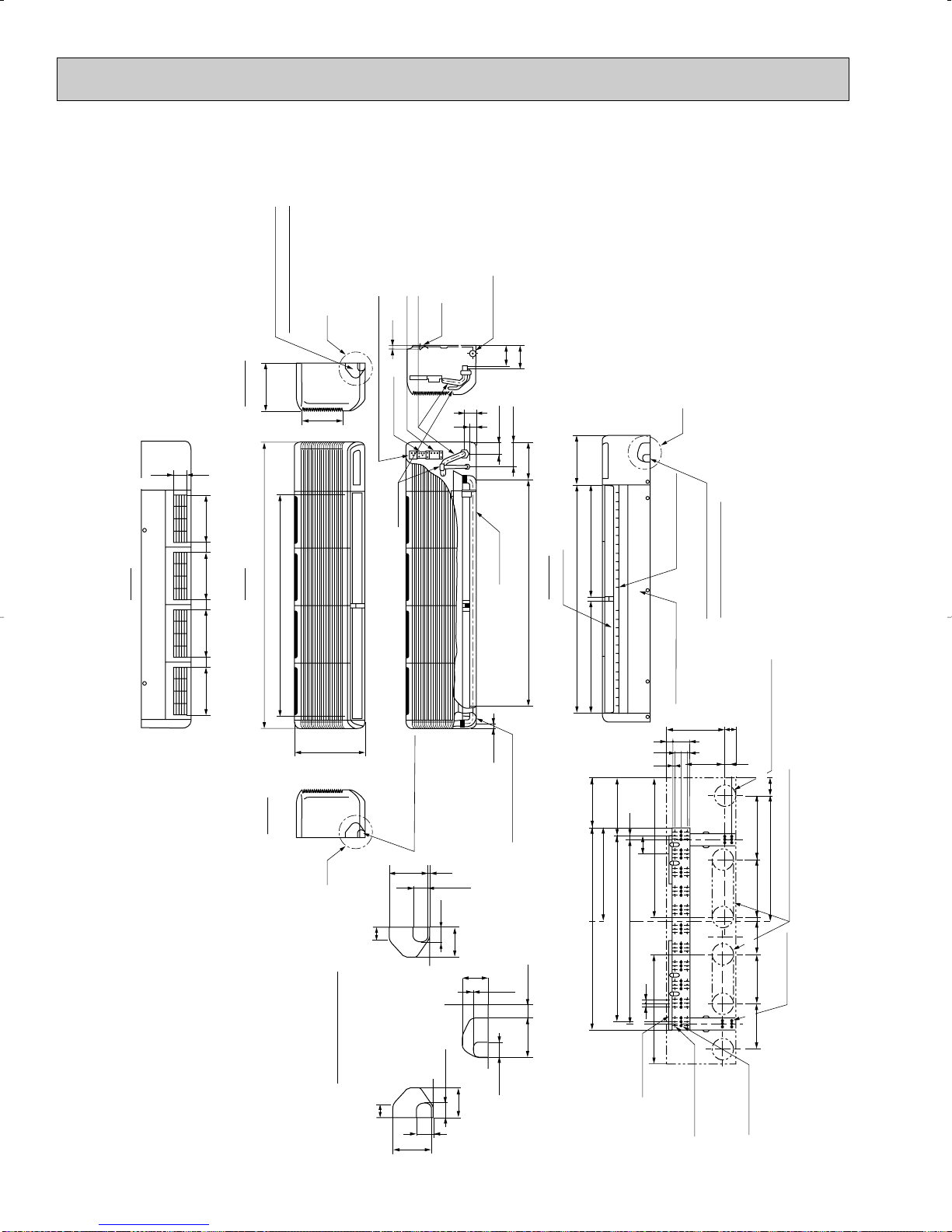

PK18/24FK

9-1/4

1-25/32

9-1/4

1-25/32

9-1/4 9-1/4

1-25/32

1/2

13-3/8

7-3/4

1-21/32

2-9/32

Top

Front

Right side

Left side

55-1/8

42-15/16

Air intake

9-1/4

C

Knock out hole for right piping

Refrigerant pipe. Drain pipe

Knock out hole for

left piping

Drain hose for

left-hand side piping

Drain hose

Lower side

Auto vane

(Gas pipe)

Drain hose

Bolt

Gas pipe

19/32

Terminal block for power supply

Terminal block for control

Terminal block for remote controller

(Liquid pipe)

Liquid pipe

Gas pipe

Liquid pipe

A

1-3/16

1-15/32

1-17/32

3-27/32 2-9/16

2-29/32

5/32

3-15/16

1-17/32

1-3/16

1-15/32

2-29/32

5/32

1-5/32

11-1/32

1-3/16

7-1/4

1-3/16

3-5/32

1-3/18

2-3/8

13/32

1-17/32

1-15/32

2-9/16

3-15/16

A

B

C

Knock out hole for piping

31/32

43-11/16

7-7/32

9-7/16

B

44-3/32

21-23/32

4-23/32

2-5/32

4-1/32

4-3/8

Air outlet

21-23/32

Air outlet

Change vane (manual)

Under panel

Removable at left-hand

side piping

Knock out hole for under-piping

Refrigerant pipe. Drain pipe

Rear piping opening

Range for left rear piping opening

12-{1/4 Hole for

tapping screw

66-{1/4 hole for

tapping screw

Wall fixture

Unit center

32-{15/32

hole for bolt

23/32

3-19/32

35-7/16

38-31/32

17-29/32

11-7/32

9-21/32

3/4

9-7/16 11-1/32 12-3/8

24

Drainage range

on left-hand side

Drainage range

on right-hand side

10x3-19/32=(35-13/16)

7-3/32

2-15/32

8-27/32

3-17/32

23/32

PK18/24FK1

PK18/24FK2

OC196A-20

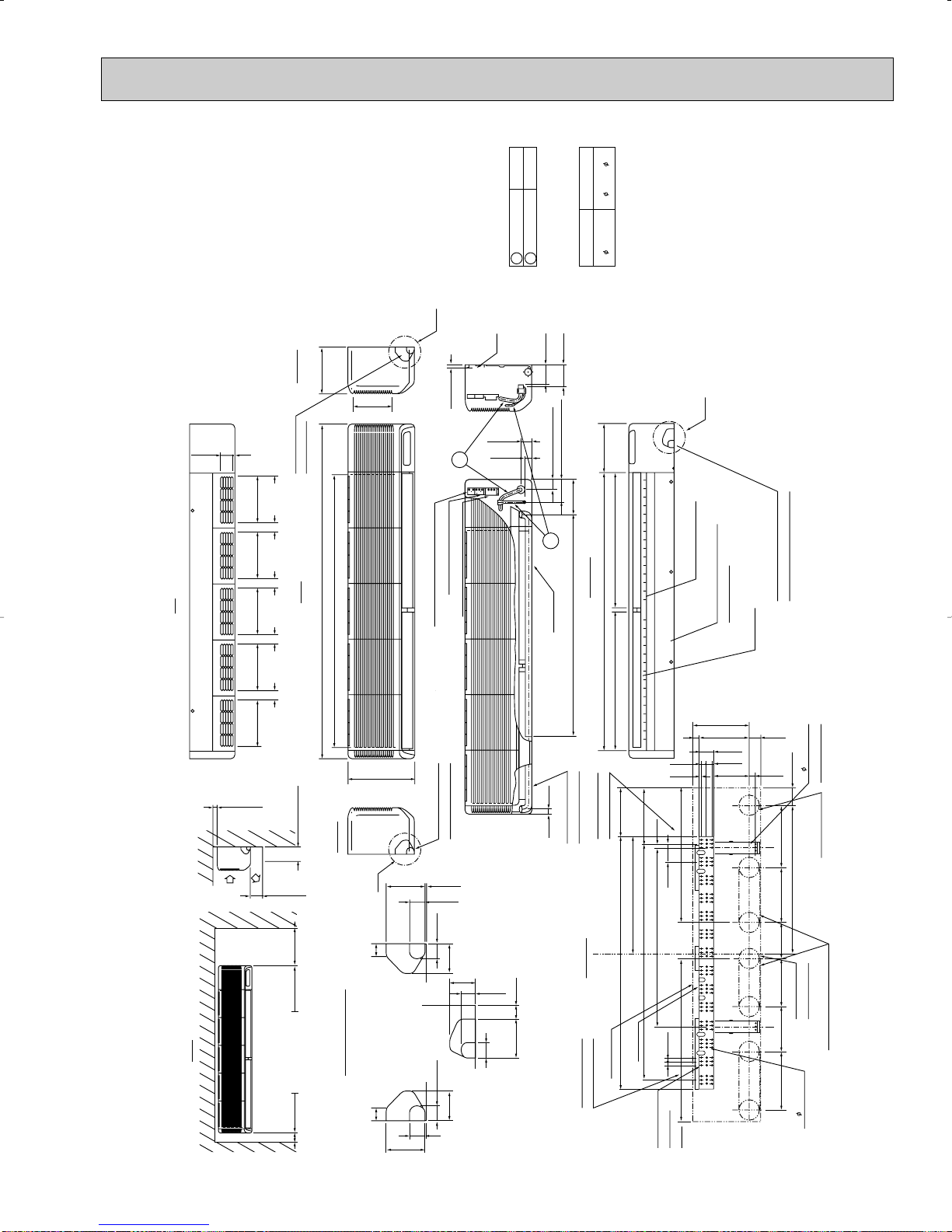

PK30/36FK

66-5/32

9-1/4

53-15/16 Air Intake

Front

Knock out hole

Right side

9-1/4

7-3/4

C

for right piping

B

A

A

B

C

4-1/32

Liquid pipe 1/2F

Gas pipe

Sleeve >< 1

>< 1 Sleeves are available

on the market.

Through hole

3-1/2 3-1/2~ 4

3/4F

Bolt

19/32

or less

Terminal block for remote controller

4-3/8

2-5/32(Gas pipe)

Terminal block for control

Terminal block for power supply

31/32

Drain hose for

left-hand side piping

7-7/32

9-7/16

43-11/16 (Drain hose)

27-5/16 Air outlet 27-5/16 Air outlet

louvers(manual)

Under panel (Removable at

Auto vanes

Knock out hole for under-piping

Refrigerant pipe .Drain pipe

left-hand piping)

55-1/8

Drain hose

1-21/32

2-9/32

4-23/32(Liquid pipe)

Top

Front

Left side

Air

intake

5-/15/16 or less

1-3/16

or more

10 or more

Air

outlet

13-3/8

Knock out hole

for left piping

1-3/161-3/16

1-15/32

1-15/32

2-9/16

1-15/32

1-17/32

1-17/32

3-15/16

3-15/16

5/32

5/32

2-29/32

2-29/32

2-9/163-27/32

1-17/32

Lower side

2

1

Knock out hole for wiring

2 or more 10 or more

9-1/4

1-25/32

9-1/4

1-25/32

9-1/4

1-25/32

9-1/4

1/2

1-25/32

2-15/32

1

2

11-5/8

23/32

Wall fixture

Unit out line

84-{1/4 hole

for tapping

screw

Drainage range on

Left hand side

23/32

35-7/16

23-7/16

50

13x3-19/32=(7-3/16) 11-7/32

9-21/32

Drainage range on

right-hand side

3-19/32

3/4

Range for left rear piping hole

Range for left

rear piping hole

41- 15/32 hole

for bolt

9-7/16 7-3/328-27/32 11-1/32 12-3/8

1-3/16

7-1/4 13/32

1-3/16

1-3/16

3-5/32

1-5/32

11-1/32

2-3/8

29-17/32

7-17/32

12- 1/4 hole

for tapping screwRear piping hole

Unit center

PK30/36FK1

PK30/36FK2

OC196A-21

Loading...

Loading...