Page 1

TECHNICAL & SERVICE MANUAL

CONTENTS

1.

TYPES OF CONNECTED OUTDOOR UNITS

···2

2. SAFETY FOR USE·······························3

3. SAFETY PRECAUTIONS·····················5

4. PART NAMES AND FUNCTIONS········7

5. SPECIFICATIONS·································9

6. DATA ···················································11

7. OUTLINES AND DIMENSIONS··········18

8. WIRING DIAGRAM ·····························20

9.

REFRIGERANT SYSTEM DIAGRAM

······21

10. TROUBLESHOOTING·······················22

11. FUNCTION SETTING·························35

12. SYSTEM CONTROL··························39

13. SERVICE DATA(PARTS NAME)·······47

14. OPTIONAL PARTS····························49

No. HWE07020

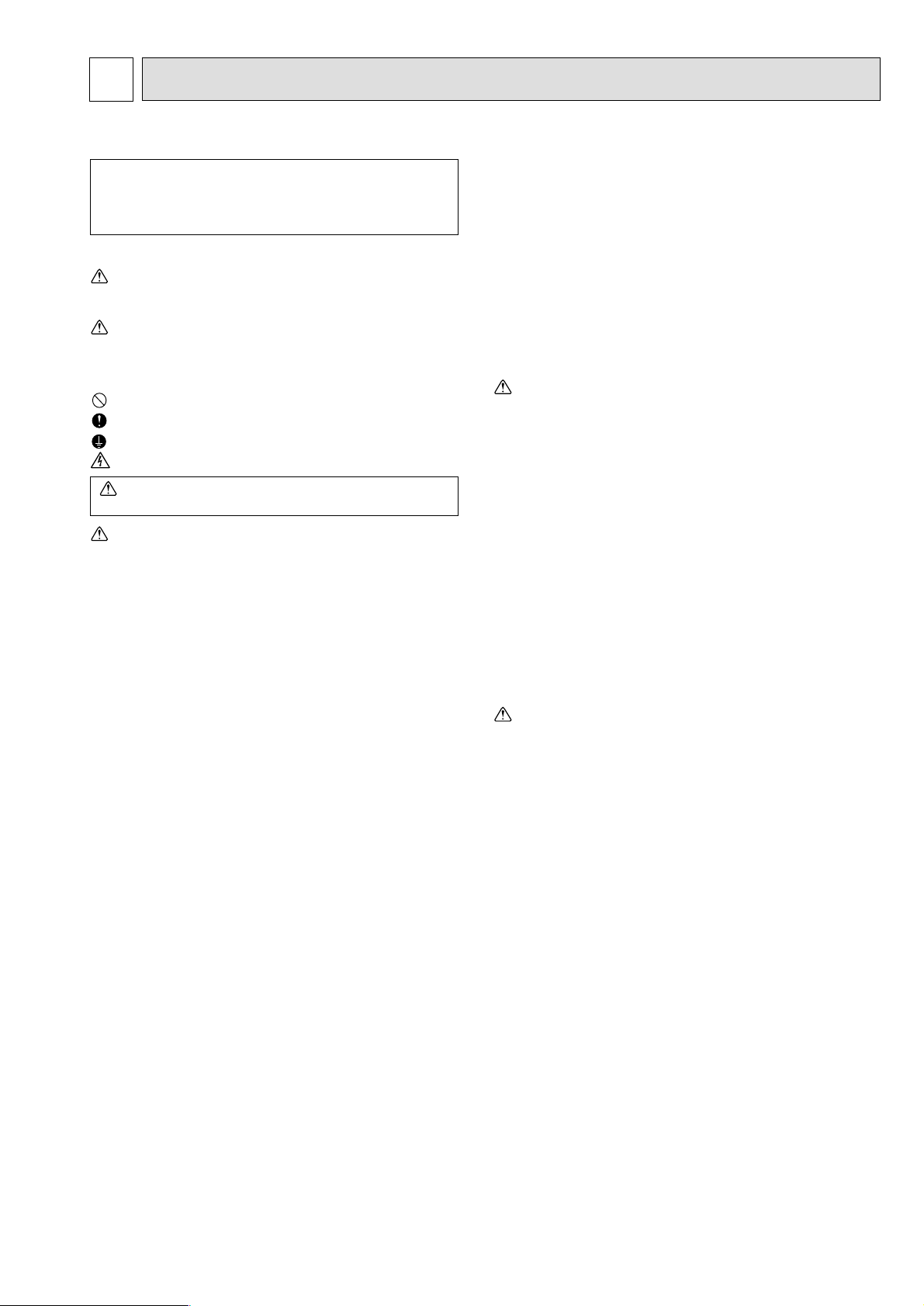

Indoor unit

Ceiling Concealed

Series PEH

Remote controller

ON/OFF

TEMP.

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

[Model name]

PEH-5GAK

PEH-6GAK

July 2007

Page 2

2

1

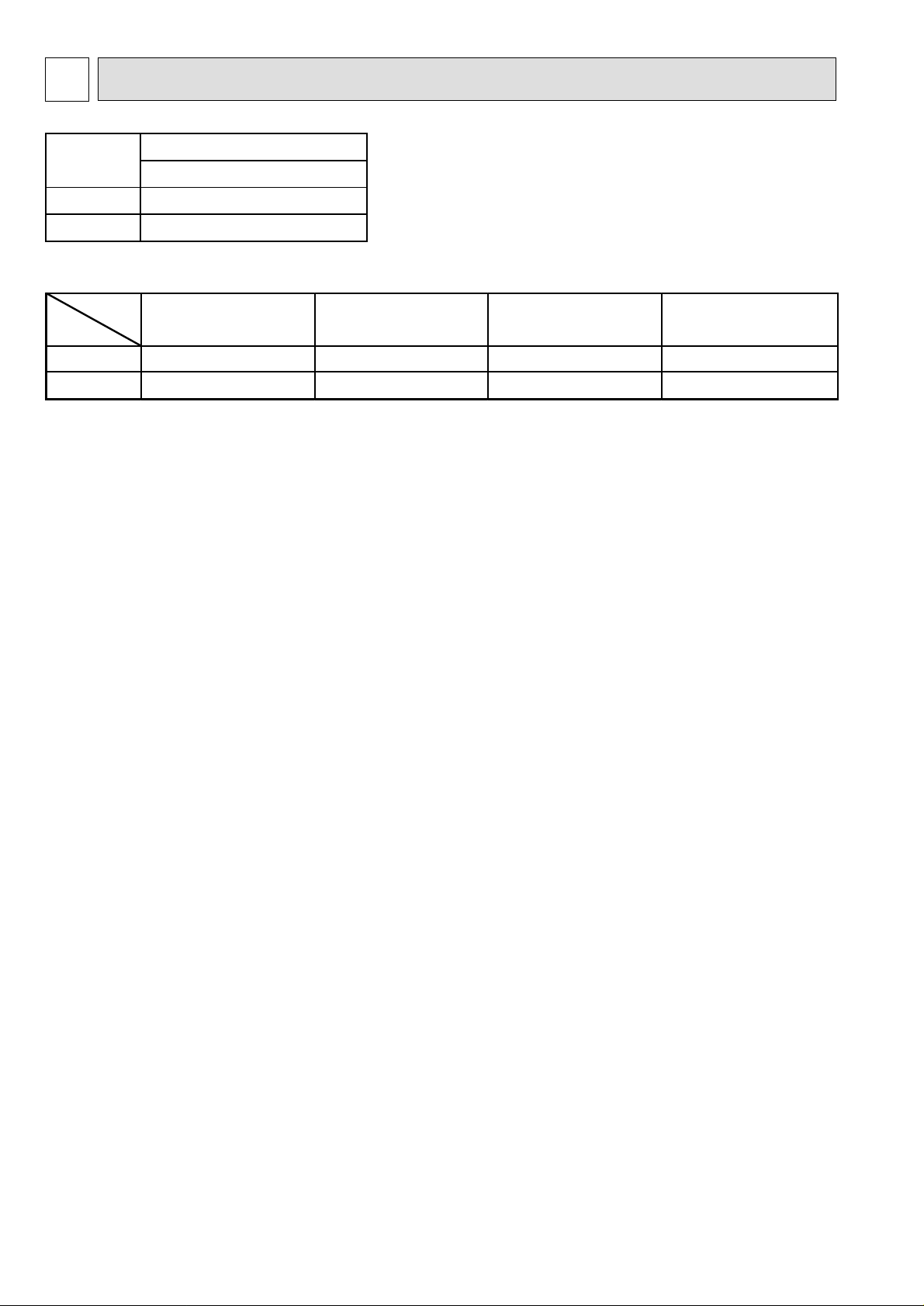

TYPES OF CONNECTED OUTDOOR UNITS

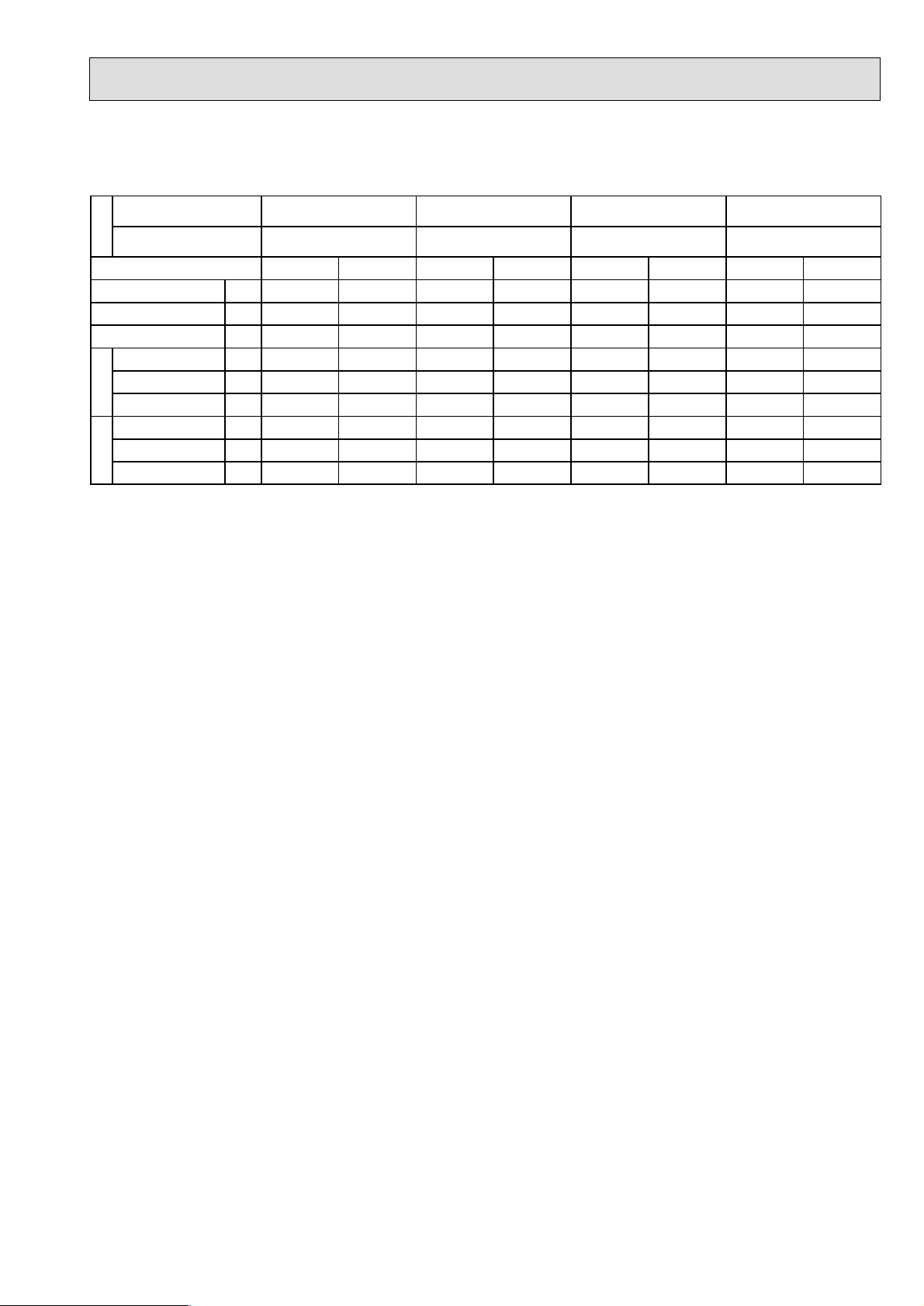

Outdoor Unit List

Indoor unit

PEH-5GAK PUH-5YKSA

PEH-6GAK PUH-6YKSA

Outdoor unit

Model name

Specification

Standard Model High static pressure motor Steel fan

Model name

PEH-5GAK

PEH-6GAK

PEH-5GAK.TH

PEH-6GAK.TH

PEH-5GAK.TH-SP

PEH-6GAK.TH-SP

PEH-5GAK.TH-MF

PEH-6GAK.TH-MF

High static pressure motor/

steel fan

PEH-5GAK.TH-SPMF

PEH-6GAK.TH-SPMF

Page 3

3

2

Before conducting installation work, please read this ''SAFETY FOR USE'' carefully

for

correct installation.

Since the caution items shown here contain important description relative to safety, please

observe them without fail.

After reading, please keep it with you together the Instruction Manual, and read it again at the

movement of the unit.

The unit should not be installed by the user.

If the unit is installed improperly, explosion, water

leakage, electric shock or fire may be result.

Consult your dealer or specialist subcontractor for

repair and movement.

For installation, conduct the work correctly by

following the Installation Manual.

Improper installation may cause a fire, electrical shock

or water leakage.

Install the unit on a spot sufficiently durable against

the unit weight.

Insufficient durability can cause an injury by the falling

down of unit.

All electric work must be performed by licensed

technician, according to local regulations and the

instructions given in this manual.

The units should be powered by dedicated power lines.

Power lines with insufficient capacity or improper

electrical work may result in electric shock or fire.

Use only the specified cables for wiring. The

connections must be made secured without

tension the terminals.

Improper connection or fastening can cause a fire or

electrical shock.

The unit should be installed according to the

instructions in order to minimize the risk of damage

from earthquakes, typhoons or strong winds.

Improper installation work can cause an injury by the

falling down of the unit.

The outdoor unit must be installed on stable, level

surface, in a place where there is no accumulation

of snow , leaves or rubbish.

The outdoor unit should be installed in a location

where air and noise emitted by the unit will not

disturb the neighbors. The indoor unit should be

securely installed.

When installing or relocating the unit, make sure that

no substance other than the specified refrigerant

enters the refrigerant circuit.

Any presence of foreign substance such as air can

cause abnormal pressure rise or explosion.

If the unit is loosely mounted, it may fall, and cause injury.

Never repair the unit, remodel or transfer it to

another site by yourself.

If they are performed improperly, water leakage, electric

shock or fire may result. If you need to have the unit

repaired or moved, consult your dealer.

Use only the specified refrigerant (R-22) to charge

the refrigerant circuit.

Do not mix it with any other refrigerant and do not

allow air to remain in the circuit.

Air enclosed in the circuit can cause high pressure resulting

in a rupture and other hazards.

Ventilate the room if refrigerant leaks during

Installation.

The refrigerant heated generates poisonous gas by

decomposition which can cause poisoning.

After completing installation work, make sure that

refrigerant gas has not leaked.

If refrigerant gas has leaked and exposed to fan heater,

stove, oven and so on, it may generate noxious gases.

Take a proper measure to suppress the critical

concentration of refrigerant if leaked when

installing the unit in a small room.

The limit density is made not to be exceeded even if the

refrigerant leaks by any chance.

You are necessary to ventilation measures to prevent

the accident. If the refrigerant leaks, hypoxia accident

may caused.

For the countermeasure to be taken, consult your

dealer.

The terminal block cover of unit must be firmly

attached to prevent entry of dust and moisture.

Improper mounting of the cover cause electric shock or

fire.

Use only optional parts authorised by Mitsubishi

Electric.

If the accessories are installed improperly, water

leakage, electric shock or fire may result.

Ask your dealer or an authorised company to install

them.

Erroneous handling gives a high possibility to induce serious results such as

death or heavy injury.

Erroneous handling may induce serious injury depending on the situation.

Warning

Warning

Caution

SAFETY FOR USE

Page 4

4

Caution

Never install on the place where a combustible gas

might leak.

The gas may ignite or explode when the gas leaks and

collects in surrounding of the unit.

When the unit is installed at telecommunication

centers or hospitals, take a proper provision

against noise.

The erroneous operation of air conditioner may be

induced by inverter equipment, independent power

device, medical equipment or communication

equipment.

While the erroneous operation of medical equipment or

communication equipment may caused by the air

conditioner.

For special use as for foods, animals/plants,

precision equipment or art objects, the applicability

should be confirmed beforehand.

As the use for the applications other than that

designed originally may result in the deterioration of the

quality. Consult your dealer in this regard.

Do not use the unit under a special atmosphere.

Installing the unit at the following places may cause a

trouble, a place where much machine oil, salt sonnet,

humidity or dust, spa district, a place full of sulfur gas,

volatile gas, or corrosive gas, a place near high

frequency processing machine.

Thermal insulation of the drain pipes is necessary

prevent dew condensation.

If the drain pipes are not properly insulated,

condensation will result and drip on ceiling, floor or other

possessions.

The drain piping must process by surely,and insulate

the drain piping not to be dewy.

When the room humidity exceeds 80% or when the

drain pipe is clogged, water may drip from the indoor

unit. The outdoor unit produces condensation during the

heating operation.

Make sure to provide drainage around the outdoor unit if

such condensation is likely to cause damage.

Install drain piping according to this Installation

Manual to ensure proper drainage.

Place thermal insulation on the pipes to prevent

condensation.

Improper drain piping may cause water leakage and

damage to furniture or other possessions.

The unit must be properly earth connected.

Do not connect the earth wire to gas pipe, city water

pipe, lightning rod or telephone earth wire.

Improper earth connection may cause electrical shock.

When installing at a watery place, provide an

electric leak breaker.

Failure to mount the electric leak breaker may cause

electrical shock.

Use breaker or fuse with proper capacity.

Make sure that there is a main power switch.

Using a wire or a copper wire instead of proper capacity

of fuse can cause fire or trouble.

Other appliances connected to the same line could cause

an overload.

For the power lines, use standard cables of

sufficient current capacity.

Otherwise, current leakage, overheating or fire may

occur.

When installing the power lines, do not apply

tension to the cables.

The tighten or loosen the connections may cause generate

heat and cause fire.

Remote controller is not pushed with the thing

sharpening ahead.

It occasionally causes the electric shock and the

breakdown.

Arrange the configuration of wiring not to bring up

the panel and terminal cover, and fasten the panel

and terminal cover securely.

The poor mounting of the panel or terminal cover may

cause the heat generation of the terminal connection,

a fire or electrical shock.

Do not wash the unit with water.

If washed with water, electrical shock may be caused.

Do not handle the switch with wet hands.

Otherwise electrical shock can be resulted.

Be very careful on handling the unit.

When carrying in outdoor unit, be sure to support it at

four points.

Carrying in and lifting with 3-point support may make

outdoor unit unstable, resulting in a fall of it.

The unit should not be carried by only one person if it is

more than 20kg.

Some units use PP bands for packing.

Do not use any PP band for delivery purpose.

Do not touch the heat exchanger fins with your bear

hands.

Doing so may cut your hands.

Be sure to safely dispose the packaging materials.

Packaging materials, such as catches and other metal

or wooden parts, may cause stabs or other injuries.

Tear off and discard plastic packing bags so that

children will not play any of them.

If children play with a plastic bag which was not torn off,

it may cause a risk of suffocation.

Do not leave the mounting base being damaged.

The damaged base may cause the falling down of

the unit which may give injury.

Turn on the main power switch more than 6 hours

before starting operation.

Do not turn the main power switch OFF during seasons

of heavy use, doing so can result in failure.

Do not touch the compressor or refrigerant piping

without wearing glove on your hands.

Touching directly such part can cause a burn or

frostbite as it becomes high or low temperature

according to the refrigerant state.

Do not touch the metal edges inside the unit

without wearing glove on your hands.

Touching directly it may injure your hands.

Do not remove the panel or the fan guard from

the outdoor unit when it is running.

You could be injured if you touch rotating, hot or highvoltage parts.

Do not operate the air conditioner without the air

filter set place.

Dust may accumulate, and cause a failure.

At emergency (if you smell something burning), stop

operation and turn the power source switch off.

Continuing the operation without eliminating the

emergency state may cause a machine trouble, fire, or

electrical shock.

After stopping operation, be sure to wait for five

minutes before turning off the main power switch.

Otherwise, water leakage or unit failure may occur.

Remote controller is not installed for the place

where direct sunshine strikes.

Page 5

5

3

SAFETY PRECAUTIONS

3.1. Before installation and electric work

s Before installing the unit, make sure y ou read all the “Safety

precautions”.

s The “Safety precautions” provide very important points re-

garding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. <Color: yellow>

Warning:

Carefully read the labels affixed to the unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• Install the unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for strong winds and earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in injury.

• Always use an filter and other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improper ly, water leakage, electric shock, or fire may

result.

• Do not touch the heat exchanger fins and metal edges.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improper ly, water leakage, electric shock, or fire may

result.

• Have all electric work done by a licensed electrician according to “Elec-

tric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed im-

properly, electric shock and fire may result.

• Securely install the terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter

the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge the it with a refrigerant different from the refrigerant (R22) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit

even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prev ent the saf ety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refr igerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

and operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Following standards may be applicable if local regulation are not available.

• Pay a special attention to the place, such as a basement, etc. where refrigeration gas can stay, since refrigeration is heavier than the air.

• The appliance is not intended for use by young children or infirm persons without supervision.

• Young children should be supervised to ensure that they do not play

with the appliance.

• Never operate in open phase condition.

Control box may be broken.

3.2. Before Installation

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfur ic smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, pr ivate power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner

to operate erroneously, or fail to operate. On the other hand, the air conditioner may affect such equipment by creating noise that disturbs medical

treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged,

condensation may drip from the indoor unit. P erform collective drainage work

together with the outdoor unit, as required.

3.3. Before Installation (moved) - electrical

work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• The reverse phase of L lines (L

1, L2, L3) can be detected (Error cord: 4103),

but the reverse phase of L lines and N line can be not be detected.

- Some electr ic par ts should be damaged when power is supplied under the

miss wiring.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg.

- Some products use PP bands for packaging. Do not use any PP bands for a

means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspend it at the specified positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

Page 6

6

• Remote controller is not allowed to install for the place where direct

sunshine strikes.

3.4. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be

hot and may be cold, depending on the condition of the refrigerant flowing

through the refrigerant piping, compressor, and other refrigerant cycle parts.

Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

• Do not operate the air conditioner without the air filter set place.

- Dust may accumulate, and cause a failure.

• At emergency (if you smell something burning), stop operation and turn

the power source switch off.

- Continuing the operation without eliminating the emergency state may cause

a machine trouble, fire, or electric shock.

• Remote controller should be pushed with finger.

- It occasionally causes the electric shock and the breakdown.

Page 7

7

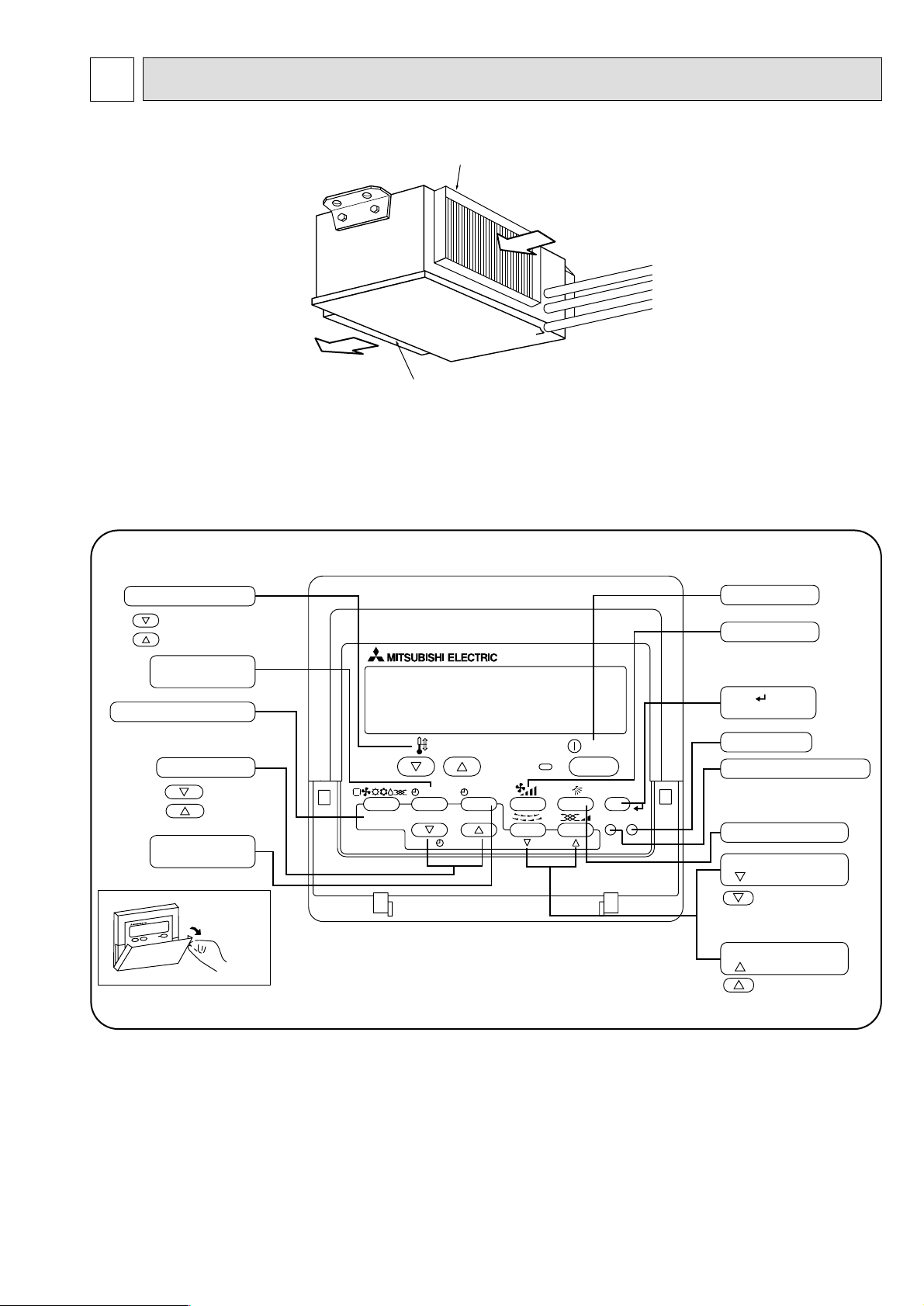

PART NAMES AND FUNCTIONS

4

● Indoor (Main) Unit

Air intake duct flange

Air outlet duct flange

Air outlet

Air intake

(sucks the air inside the room into the unit)

● Remote controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

(

Operation button)

To preceding operation

number.

Ventilation button

(

Operation button)

To next operation number.

Page 8

8

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

● Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

● If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if he feature is not

present at the parent unit.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indica-

tion (For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappear then start the operation.

Page 9

9

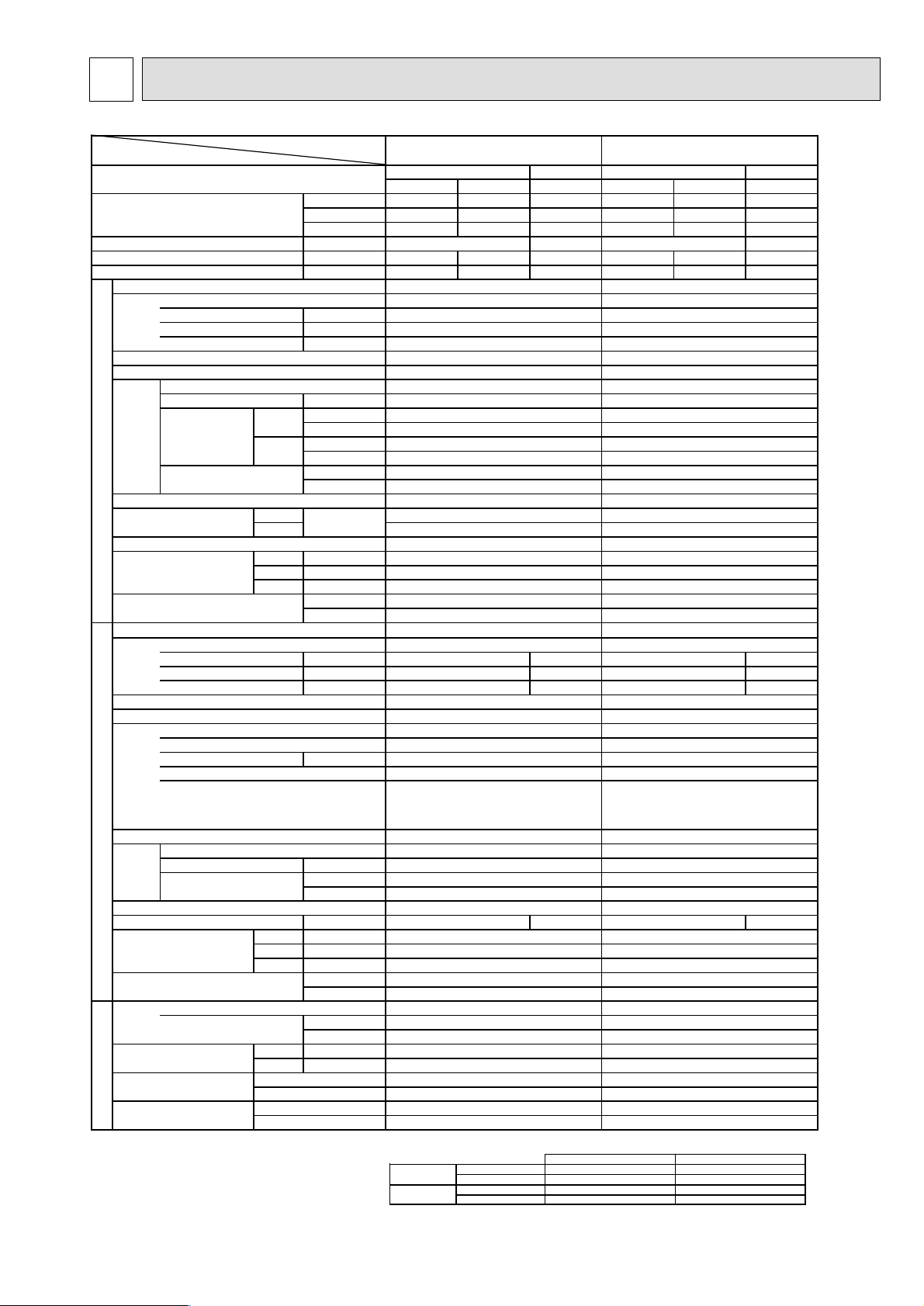

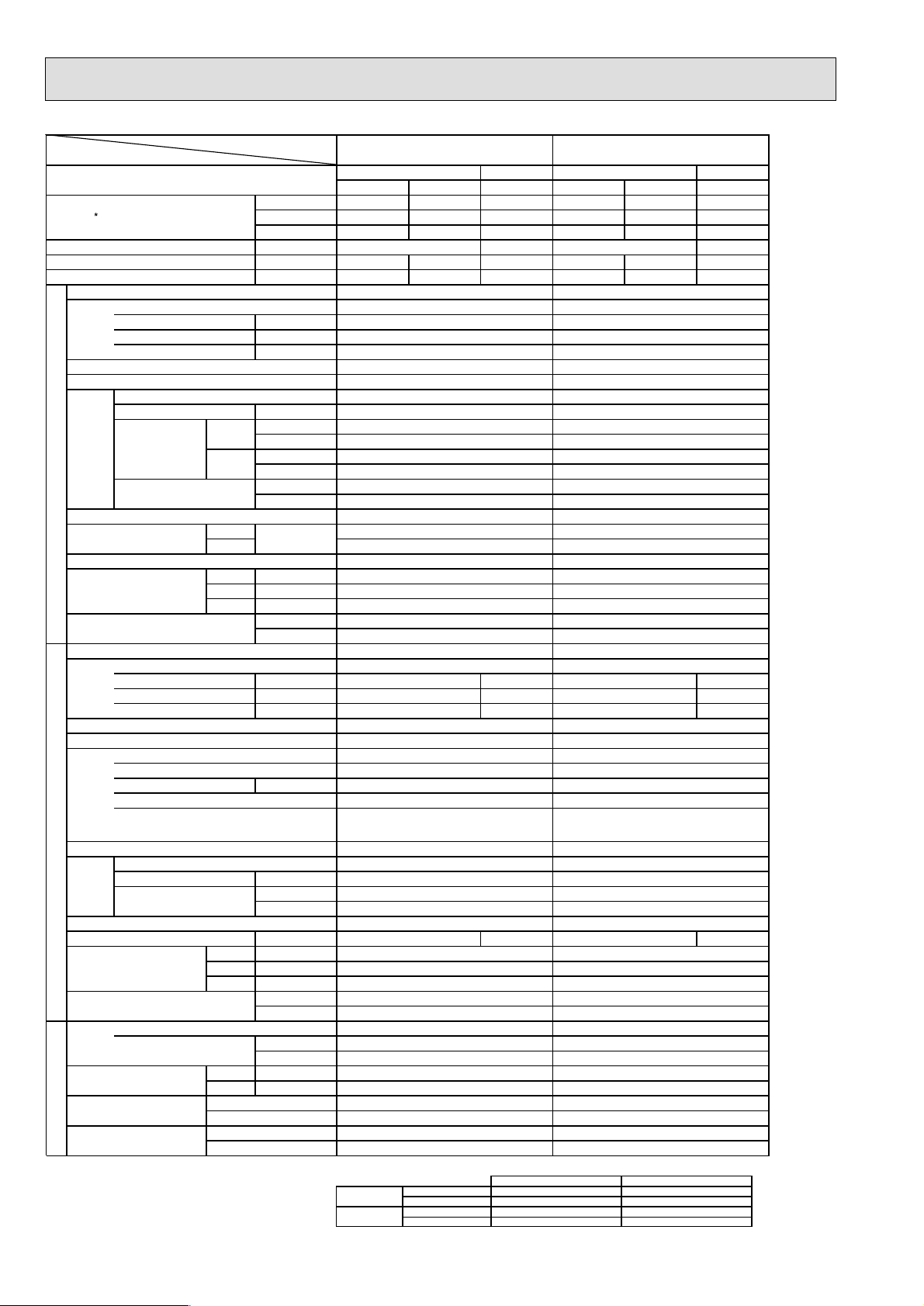

5 SPECIFICATIONS

Item

Function

Model name

Gross Net Net Gross Net Net

PEH-5GAK

Cooling Cooling

Btu/h 44,000 41,000 46,000 54,000 51,000 62,000

Capacity *1

kW 12.9 12.0 13.5 15.8 14.9 18.2

kcal/h 11,000 10,300 11,600 13,500 12,800 15,600

Total input

EER

COP

Model name

Power supply(phase,cycle,voltage)

Input

Running current

Starting current

External finish

Heat exchanger

×

Fan(drive)

No.

Fan motor output

Fan

INDOOR UNIT

Airflow

External static pressure

Operation control & Thermostat

Cond. Drain connection O.D.

Dimensions

Weight

Model name

Power supply(phase,cycle,voltage)

Input

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Heat exchanger

×

No.

Fan

Fan(drive)

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

REFRIGERANT PIPING OUTDOOR UNIT

kW 5.03 5.45

kcal/h.W 2.16 2.02 2.30 2.41 2.28 2.86

W/W 2.53 2.36 2.68 2.82 2.66 3.33

kW

A

A

kW

Hi

Lo

CMM

L/s

CMM

L/s

Pa

mmAq

Hi

Lo

dB(A)Noise level

Hmm

Wmm

Dmm

kg

lbs

kW 4.16 4.58

A 6.81 7.50

A5374

kW

kW

3

m

/min

L/s

dB(A) 55 56

Hmm

Wmm

Dmm

kg

lbs

kg

lbs

Liquid mm

Gas mm

Indoor side

Outdoor side

Height difference

Piping length

5.08

PEH-5GAK PEH-6GAK

~ 50Hz 220-240V ~ 50Hz 220-240V

0.87

4.0

6.1

Galvanized steel

Cross fin coil

Centrifugal (direct)

×

0.46

50

833

40

667

100

10

Remote control & built in

46

42

R1

400

1180

634

56

123

PUH-5YKSA

3PH 4W 50Hz 380-415V

4.21

6.89

53

Munsell 3Y 7.8/1.1

Capillary tube

Hermetic

ZR61KC-TFD

3.5

Line start

Thermal relay, Thermal switch

HP switch, Anti-phase protector

Cross fin coil

Propeller(direct)

0.085

×

2

×

2

95

1,583

Reverse cycle

55

1258

970

345+24

117

257

R-22

5.4

11.9

9.52

19.05

Flared

Flared

Max. 50m

Max. 50m

*1 Rating condition 2. Guaranteed operating range

Cooling·····Indoor unit D.B. 27˚C, W.B. 19˚C

Outdoor unit D.B. 35˚C

Heating·····Indoor unit D.B. 20˚C

Outdoor unit D.B. 7˚C, W.B. 6˚C

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

Refrigerant piping length (one way): 5m 3. Above data based on indicated voltage

Indoor unit: 1 phase 240V 50Hz Outdoor unit: 3 phase 415V 50Hz

PEH-6GAK

Heating Heating

5.60

0.87

4.0

6.1

Galvanized steel

Cross fin coil

1

Centrifugal (direct) ×1

0.46

55

917

44

733

100

10

Remote control & built in

49

45

R1

400

1180

634

59

130

PUH-6YKSA

3PH 4W 50Hz 380-415V

4.73

7.74

74

Munsell 3Y 7.8/1.1

Capillary tube

Hermetic

ZR68KC-TFD

4.0

Line start

Thermal relay, Thermal switch

HP switch, Anti-phase protector

Cross fin coil

×

Propeller(direct)

0.10

2

×

2

100

1,666

Reverse cycle

56

1258

970

345+24

117

257

R-22

5.0

11.0

9.52

19.05

Flared

Flared

Max. 50m

Max. 50m

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 21˚C, W.B. 15.5˚C

D.B. 27˚C

D.B. 20˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 21˚C, W.B. 15.5˚C

D.B. -8.5˚C, W.B. -9.5˚C

Page 10

10

Item

Function

Model name

<With a high static pressure motor>

Gross Net Net Gross Net Net

PEH-5GAK

Cooling Cooling

Btu/h 44,000 41,000 46,000 54,000 51,000 62,000

Capacity 1

kW 12.9 12.0 13.5 15.8 14.9 18.2

kcal/h 11,000 10,300 11,600 13,500 12,800 15,600

Total input

EER

COP

kW 5.03 5.45

kcal/h.W 2.16 2.02 2.30 2.41 2.28 2.86

W/W 2.53 2.36 2.68 2.82 2.66 3.33

Model name

Power supply(phase,cycle,voltage)

Input

Running current

Starting current

kW

A

A

External finish

Heat exchanger

Fan(drive)×No.

Fan motor output

Fan

INDOOR UNIT

Airflow

External static pressure

Hi

Lo

kW

CMM

L/s

CMM

L/s

Pa

mmAq

Operation control & Thermostat

Noise level

Hi

Lo

dB(A)

Cond. Drain connection O.D.

Hmm

Dimensions

Wmm

Dmm

Weight

kg

lbs

Model name

Power supply(phase,cycle,voltage)

Input

Running current

Starting current

kW 4.16 4.58

A 6.81 7.50

A5374

External finish

Refrigerant control

Compressor

Model

Motor output

kW

Starter type

Protection devices

Heat exchanger

Fan(drive)×No.

Fan

Fan motor output

Airflow

kW

3

m

/min

L/s

Defrost method

Noise level

dB(A) 55 56

Hmm

Dimensions

Wmm

Dmm

Weight

kg

lbs

Refrigerant

Charge

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING OUTDOOR UNIT

outdoor unit

*1 Rating condition 2. Guaranteed operating range

Cooling·····Indoor unit D.B. 27˚C, W.B. 19˚C

Heating·····Indoor unit D.B. 20˚C

Refrigerant piping length (one way): 5m

Outdoor unit D.B. 35˚C

Outdoor unit D.B. 7˚C, W.B. 6˚C

Liquid mm

Gas mm

Indoor side

Outdoor side

Height difference

Piping length

kg

lbs

3. Above data based on indicated voltage

Indoor unit: 1 phase 240V 50Hz Outdoor unit: 3 phase 415V 50Hz

5.08 5.60

PEH-5GAK PEH-6GAK

~ 50Hz 220-240V ~ 50Hz 220-240V

0.87 0.87

4.0 4.0

7.8 7.8

Galvanized steel Galvanized steel

Cross fin coil Cross fin coil

Centrifugal (direct) ×1 Centrifugal (direct) ×1

0.54 0.54

50 55

833 917

40 44

667 733

150 150

15 15

Remote control & built in Remote control & built in

48 51

45 48

R1 R1

400 400

1180 1180

634 634

56 59

123 130

PUH-5YKSA PUH-6YKSA

3PH 4W 50Hz 380-415V 3PH 4W 50Hz 380-415V

4.21 4.73

6.89 7.74

53

Munsell 3Y 7.8/1.1 Munsell 3Y 7.8/1.1

Capillary tube Capillary tube

Hermetic Hermetic

ZR61KC-TFD ZR68KC-TFD

3.5 4.0

Line start Line start

Thermal relay, Thermal switch

HP switch, Anti-phase protector

Cross fin coil Cross fin coil

Propeller(direct)×2 Propeller(direct)×2

0.085×20.10×2

95 100

1,583 1,666

Reverse cycle Reverse cycle

55 56

1258 1258

970 970

345+24 345+24

117 117

257 257

R-22 R-22

5.4 5.0

11.9 11.0

9.52 9.52

19.05 19.05

Flared Flared

Flared Flared

Max. 50m Max. 50m

Max. 50m Max. 50m

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

<With a high static pressure motor>

PEH-6GAK

Heating Heating

74

Thermal relay, Thermal switch

HP switch, Anti-phase protector

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 21˚C, W.B. 15.5˚C

D.B. 27˚C

D.B. 20˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 21˚C, W.B. 15.5˚C

D.B. -8.5˚C, W.B. -9.5˚C

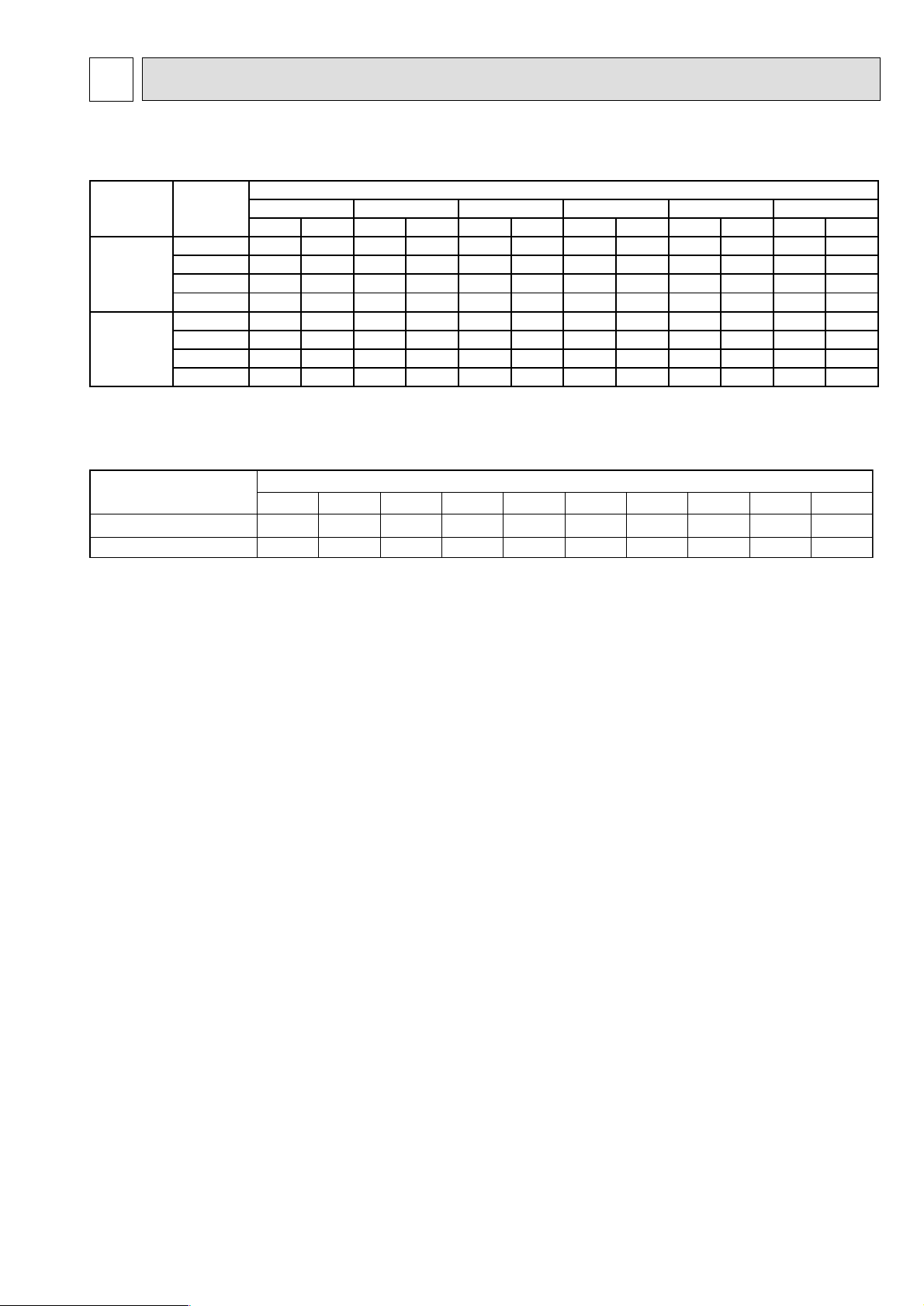

Page 11

11

DATA

6

6-1. PERFORMANCE DATA

1) COOLING CAPACITY

Note:C A : Capacity (W)

P.C. : Power consumption (kW)

Cooling capacity correction factors

Indoor

Model name

PEH-5GAK

PEH-6GAK

Intake

air W.B.˚C CA P.C. CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

16 13,014 4.07 12,658 4.25 12,193 4.57 11,699 4.90 11,176 5.23 10,624 5.56

18 13,857 4.15 13,492 4.33 13,000 4.68 12,485 5.02 11,945 5.36 11,381 5.71

20 14,708 4.23 14,363 4.42 13,850 4.78 13,315 5.14 12,759 5.51 12,180 5.88

22 15,569 4.31 15,270 4.51 14,741 4.88 14,191 5.26 13,618 5.66 13,023 6.07

16 15,940 4.49 15,503 4.68 14,934 5.04 14,329 5.40 13,688 5.77 13,013 6.13

18 16,972 4.58 16,525 4.78 15,923 5.15 15,291 5.53 14,630 5.91 13,939 6.29

20 18,015 4.67 17,591 4.87 16,963 5.27 16,309 5.67 15,627 6.07 14,918 6.48

22 19,069 4.75 18,703 4.97 18,055 5.38 17,381 5.80 16,679 6.24 15,950 6.70

Model name

PEH-5GAK

PEH-6GAK

20 25 30 35 40

5m

1.00

1.00

10m

0.981

0.975

15m

0.968

0.955

Outdoor intake air D.B.˚C

Refrigerant piping length (one way)

20m

0.952

0.935

25m

0.940

0.918

30m

0.925

0.99

35m

0.913

0.884

40m

0.900

0.869

45m

0.886

0.855

45

50m

0.874

0.840

Page 12

12

Heating

1.4

1.2

1.0

0.8

0.6

1.4

1.2

1.0

0.8

0.6

0.4

-12-10 -5 0 5 10 15

OUTDOOR W.B.(°C)

INDOOR D.B. (°C)

INDOOR D.B. (°C)

15

20

25

25

20

15

TOTAL INPUT (RATIO) CAPACITY (RATIO)

Cooling

1.4

1.2

1.0

0.8

0.6

1.4

1.2

1.0

0.8

0.6

0.4

-5 5 15 253546

OUTDOOR D.B.(°C)

TOTAL INPUT (RATIO) CAPACITY (RATIO)

INDOOR W.B.(°C)

INDOOR W.B.(°C)

22

20

18

16

22

20

18

16

6-2. PERFORMANCE CURVE

2) HEATING CAPACITY

Note:C A : Capacity (W)

P.C. : Power consumption (kW)

Heating capacity correction factors

Model name

Intake

air D.B.

˚C

-10 -5 0 5 10 15

CA P.C. CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

15 9,245 3.43 10,596 3.79 12,077 4.18 13,686 4.58 15,421 5.01 17,280 5.47

Indoor

PEH-5GAK

20 8,852 3.70 10,180 4.09 11,621 4.50 13,176 4.94 14,842 5.40 16,617 5.89

25 8,507 3.93 9,766 4.36 11,160 4.81 12,688 5.29 14,349 5.79 16,141 6.31

15 12,464 3.72 14,284 4.11 16,281 4.53 18,451 4.97 20,790 5.43 23,297 5.92

PEH-6GAK

20 11,934 4.01 13,724 4.43 15,667 4.88 17,763 5.35 20,009 5.85 22,403 6.38

25 11,469 4.25 13,166 4.72 15,045 5.21 17,105 5.73 19,344 6.27 21,761 6.84

Service Ref.

PEH-5GAK

PEH-6GAK

5m

1.00

1.00

10m

1.00

1.00

15m

1.00

1.00

Outdoor intake air W.B.

Refrigerant piping length (one way)

20m

1.00

1.00

25m

1.00

1.00

30m

1.00

1.00

35m

0.998

0.998

˚C

40m

0.995

0.995

45m

0.993

0.993

50m

0.990

0.990

Page 13

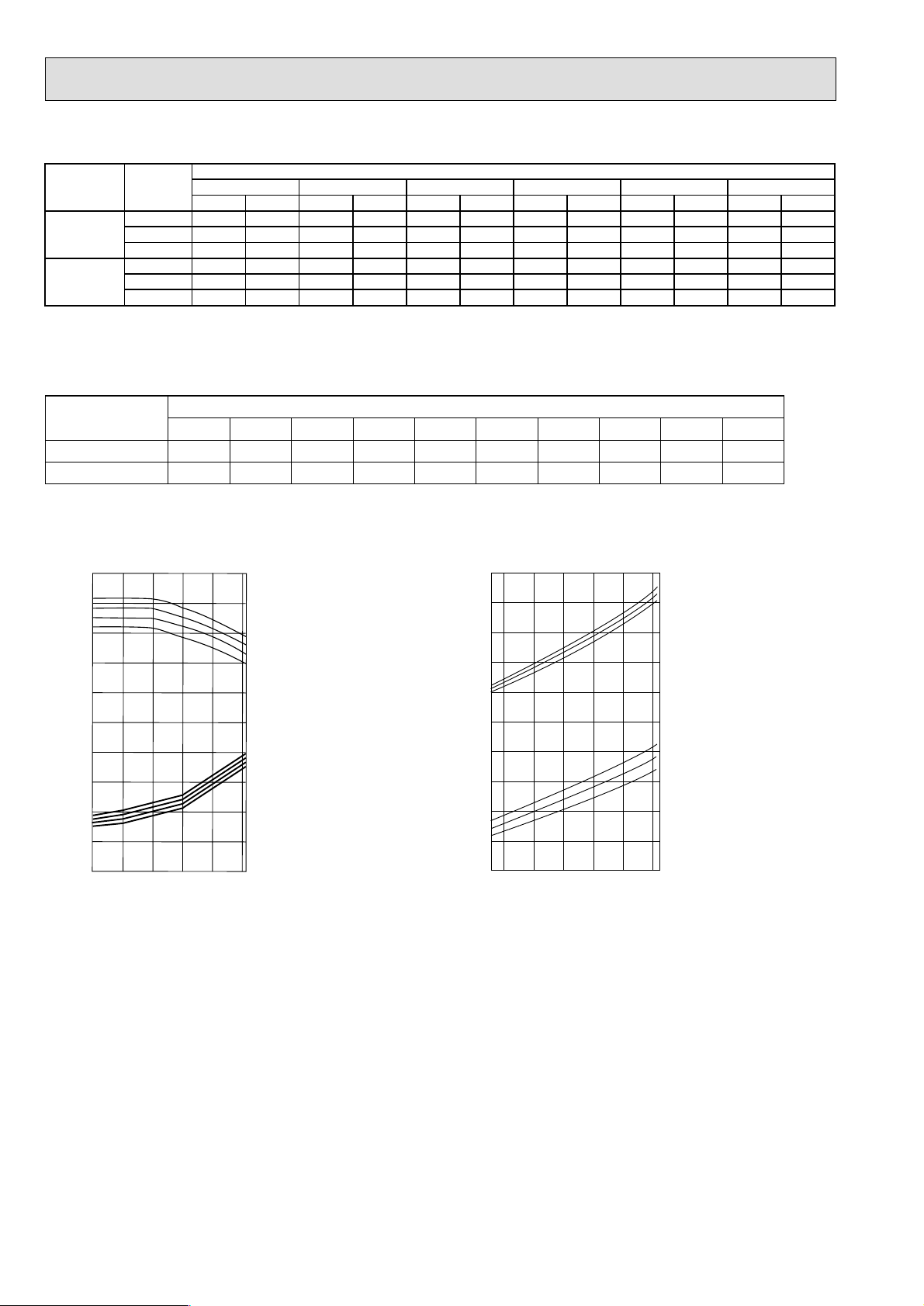

13

6-3. FAN PERFORMANCE AND CORRECTED AIR FLOW

(1) PEH-5GAK

(2) PEH-6GAK

300

250

200

Hi

150

100

External static pressure (Pa)

50

0

35.0 40.0 45.0 50.0 55.0

1.1

1.0

Capacity/ input factor

0.9

35 40 45 50 55

300

Lo

Air flow

Cooling

(CMM)

Capacity

input

1.1

Heating

Capacity

input

1.0

Capacity/ input factor

0.9

Air flow

(CMM)

35 40 45 50 55

Air flow rate

(CMM)

250

200

150

100

External static pressure (Pa)

50

0

Lo

40.0 45.0 50.0 55.0 60.0

Hi

Air flow

Cooling

1.1

1.0

Capacity/ input factor

0.9

40 45 50 55 60

Air flow

(CMM)

Capacity

input

(CMM)

Heating

1.1

1.0

Capacity/ input factor

0.9

40 45 50 55 60

Air flow

Capacity

input

(CMM)

Page 14

14

(3) PEH-5GAK (With a high static pressure motor)

(4) PEH-6GAK (With a high static pressure motor)

300

250

200

150

100

External static pressure (Pa)

50

0

35.0 40.0 45.0 50.0 55.0

Lo

Air flow

Hi

Cooling

1.1

1.0

Capacity/ input factor

0.9

35 40 45 50 55

Air flow

(CMM)

Capacity

input

(CMM)

Heating

1.1

1.0

Capacity/ input factor

0.9

35 40 45 50 55

Air flow rate

Capacity

input

(CMM)

300

250

200

150

100

External static pressure (Pa)

50

0

40.0 45.0 50.0 55.0 60.0

Lo

Air flow

1.1

1.0

Capacity/ input factor

0.9

40 45 50 55 60

Hi

Cooling

Air flow

(CMM)

Capacity

input

(CMM)

Heating

1.1

1.0

Capacity/ input factor

0.9

40 45 50 55 60

Air flow

Capacity

input

(CMM)

Page 15

15

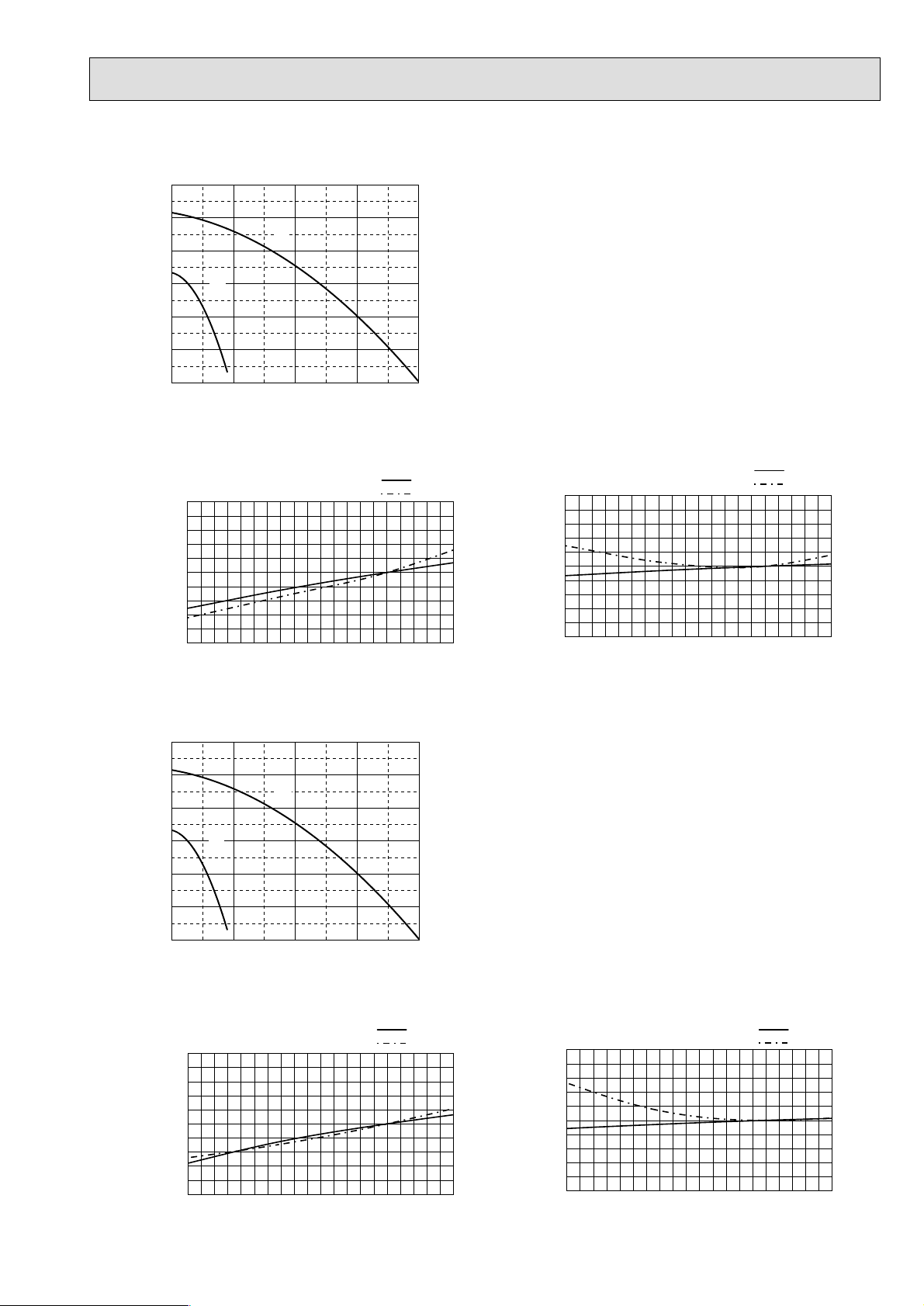

6-4. ELECTRICAL DATA

Indoor unit········240V 50Hz 1phase

Outdoor unit ·····415V 50Hz 3phase

Indoor unit

Outdoor unit

PEH-5GAK

PUH-5YKSA

PEH-6GAK

PUH-6YKSA

PEH-5GAK

<With a high static pressure motor>

PUH-5YKSA PUH-6YKSA

<With a high static pressure motor>

PEH-6GAK

Mode

Capacity (GROSS)

Capacity (NET)

Total input

Input kW 0.87 0.87 0.87 0.87 0.87 0.87 0.87 0.87

Current A 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0

Starting current A 6.1 6.1 6.1 6.1 7.8 7.8 7.8 7.8

Indoor unit

Input kW 4.21 4.16 4.73 4.58 4.21 4.16 4.73 4.58

Current A 6.89 6.81 7.74 7.50 6.89 6.81 7.74 7.50

Starting current A 53 53 74 74 53 53 74 74

Outdoor unit

kW 12.9 - 15.8 - 12.9 - 15.8 kW 12.0 13.5 14.9 18.2 12.0 13.5 14.9 18.2

kW 5.08 5.03 5.60 5.45 5.08 5.03 5.60 5.45

Cool Heat Cool Heat Cool Heat Cool Heat

Page 16

16

6-5. STANDARD OPERATION DATA

The unit of pressure has been changed to MPa based on SI (International System of Units) in accordance with I.S.O.

(International Organization for Standardization).

The conversion factor is : 1(MPa) =10.2 (OOf/FF)

Mode

Capacity (GROSS)

Capacity (NET)

Total

Input

Indoor unit

Phase, Hz

Volts

Amperes

Outdoor unit

Phase, Hz

Electrical circuit

Volts

Amperes

Discharge

Pressure

Suction

Pressure

Discharge temp.

Suction temp.

Refrigerant circuit

Ref. pipe length

Indoor intake

air temp.

Outdoor intake

air temp.

Model name

D.B.

W.B.

D.B.

W.B.

SHF

BF

PEH-6GAKPEH-5GAK

Cooling Heating Cooling Heating Cooling Heating Cooling Heating

kW 12.9 - 15.8 - 12.9 - 15.8 kW 12.0 13.5 14.9 18.2 12.0 13.5 14.9 18.2

kW 5.08 5.03 5.60 5.45 5.08 5.03 5.60 5.45

PEH-5GAK

1, 50

V

A 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0

V

A 6.89 6.81 7.74 7.50 6.89 6.81 7.74 7.50

MPa 1.91 2.02 1.95 1.92 1.91 2.02 1.95 1.92

2

kgf/cm

MPa 0.43 0.33 0.43 0.34 0.43 0.33 0.43 0.34

2

kgf/cm

˚C

˚C

m 5555 5 5 5 5

˚C

˚C

˚C

˚C

240

PUH-5YKSA PUH-6YKSA

3, 50 3, 50

415

19.5 20.6 19.9 19.6 19.5 20.6 19.9 19.6

4.4 3.4 4.4 3.5 4.4 3.4 4.4 3.5

76 84 77 79 76 84 77 79

4 -2 4 -3 4 -2 4 -3

27 20 27 20 27 20 27 20

19 15 19 15 19 15 19 15

35 7 35 7 35 7 35 7

24 6 24 6 24 6 24 6

0.82 - 0.82 - 0.82 - 0.82 -

0.27 - 0.19 - 0.27 - 0.19 -

PEH-6GAK

1, 50

240

415

PEH-5GAK PEH-6GAK

<With a high static pressure motor> <With a high static pressure motor>

PEH-5GAK PEH-6GAK

<With a high static pressure motor> <With a high static pressure motor>

1, 50 1, 50

240 240

PUH-5YKSA PUH-6YKSA

3, 50 3, 50

415 415

Page 17

17

PEH-5,6: Upper High/Lower Low

SPL

dB(A) 63Hz 125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

46 50 49 46 44 42 38 28 22

42 44 44 41 40 38 34 23 15

49 54 53 51 47 43 34 29 25

45 51 51 47 44 40 31 25 21

48 52 51 48 46 44 40 30 24

45 47 47 44 43 41 37 26 18

51 55 54 51 49 47 43 33 27

48 50 50 47 46 44 40 29 21

1) Sound Levels

PEH-5GAK

PEH-6GAK

PEH-5GAK

(High static pressure motor)

PEH-6GAK

(High static pressure motor)

6-6. SOUND DATA

Model

Position measurement

Indoor unit

2m

Outlet

OCTAVE BAND FREQ.Hz

1m

Inlet

1.5m

Measurement point

Page 18

18

OUTLINES AND DIMENSIONS

7

7-1. INDOOR UNITS

PEH-5GAK, PEH-6GAK

Unit : mm

Return air

duct flange

34124

51

10

130

3 Holes

882

6X130(=780)51

20-

199

20

1080

200

131

3.1 Holes

14-

12 Holes

4-

For hanging bolt M10

[Field supply]

10

55

130

3X130(=390)

Top view

55

Supply air

duct flange

1180

1120

11 250 95

1064

Front view

361 500 179

42

2pcs.

62

1pc.

20

462

Control box

Remote

Rubber bush

controller wiring

40

70 1295575

Outdoor unit

Rubber bush

connection wiring

Rubber bush

A

Power supply

wiring

<

40 1040 40

54

10

634

530

50

10

Return air

sensor

400

376

2510010025

262 73

35

130

144

22330

Supply air

A

130

145

35

56539

Drain R1

89

Refrigerant pipe

Left side view

9.52 (3/8 flare)

Accessory

Pipe cover

(For dew condensation prevention of

local piping and unit connection.)

Remote controller

19.05 (3/4 flare)

Refrigerant pipe

Return air

Page 19

19

Unit : mm

7-2. REMOTE CONTROLLER

130

120

19

Page 20

20

WIRING DIAGRAM

8

PEH-5GAK, PEH-6GAK

ROOM TEMP

LIQUID PIPE TEMP

OVER CURRENT RELAY (INDOOR FAN MOTOR)

THERMISTOR

MAGNETIC CONTACTOR (INDOOR FAN MOTOR)

TERMINAL BLOCK

52F

51F

TH1

TB2,4,5

TH2

MF1 FAN MOTOR (INDOOR)

SYMBOL NAME

INDOOR UNIT

CONNECTOR (LOSSNAY)

CONNECTOR (REMOTE SWITCH)

CONNECTOR (HA TERMINAL-A)

CONNECTOR (CENTRALLY CONTROL)

AUXILIARY RELAY (INDOOR FAN MOTOR<HIGH SPEED>)

AUXILIARY RELAY (INDOOR FAN MOTOR<LOW SPEED>)

CAPACITOR

C

X1Lo

FUSE (T6.3AL250V)

FERRITE CORE

SURGE KILLER

FUSE

FB

CR

X2Hi

INDOOR

VARISTOR

AUXILIARY RELAY

SWITCH (MODEL SELECTION)

SWITCH (SYSTEM SELECTION)

ZNR

X4-6

SW5

SW1

CONTROLLER

BOARD

LED (POWER SUPPLY <REMOTE CONTROLLER>)

SWITCH (EMERGENCY OPERATION)

CONNECTOR (EMERGENCY OPERATION)

LED (POWER SUPPLY)

CN2L

SWE

LED1

LED2

SW6

CN31 CONNECTOR (DRAIN SENSOR)

CONNECTOR (WIRELESS REMOTE CONTROLLER)

CN32

CN41

CN51

CN90

NAME

ARRESTER

VARISTOR

DSA,DSR

ZNR5~7

SYMBOL

SNB BOARD 1

REMOTE CONTROLLER

TERMINAL BLOCK

TB6

1. The dotted lines show field wiring.

Note:

polarities,make sure matching wiring and terminal.

If a trouble occurs with either the remote controller or the

2. Color of earth wire is yellow and green twisting.

3. Specification subject to change without notice.

4. Indoor and outdoor connecting wires are made with

BOARD

REMOTE CONTROLLER

indoor microcom-puter and no other trouble exists, emergency

5. Emergency operation

LCD

TB6

SWE :ON / Indoor fan is running high speed.

operation for cooling or heating can be performed by changing

the setting of connector (SWE) and switch (SW6) on the indoor

controller board.

REMOTE CONTROLLER

SW6-1 :ON / Emargency operation of cooling mode.

SW6-1,2 :ON / Emargency operation of heating mode.

6. mark is connector. mark is terminal.

is installed.

Therefore, do not change factory set value of over current

relays.

1. To protect fan motor from abnormal current,over current relays

7. This motor(*1) includes auto reset type internal thermostat.

Caution,

OUTDOOR UNIT

C

5

6

MF1

124

C01

X2Hi

X1Lo

51F52F

RED

REDL1

WHITE

TB2

INDOOR UNIT

L2L3N

(*1)

BLACK

BLUE

GREEN/YELLOW

DSA

DSR

ZNR5~7

SNB BOARD 1

2

INDOOR

DC

13.1V

POWER BOARD

3

X1

X2

Hi Lo

CR

52F

TO OUTDOOR UNIT

CONNECTING WIRES

(POLAR)

TB5

1

2

FB

1 2

LED1

CN2D

1

CNSK CN2S

1

X2

Lo Hi

X1

DC13.1V

1 3

CND

1 3

CNDK

1 3 5 7

FAN

FUSE

ZNR

X5 X4

X6

LED2

X6 X5 X4

51F

CN2L

CN41

12

OFF

ON

INDOOR

CN51 CN32 CN31

SW6

1

2

CN22

CONTROLLER BOARD

123

123

CN30

1

2

1

2

CN20

CN21

CN90

OFF

ON

8764123

5

SW5

OFF

ON

SW1

12345

SWE

OFF

ON

TB4

TH1

TH2

CIRCUIT BREAKER

(FIELD SUPPLY)

PEH-5,6GAK : 15A

PE

220/230/240V

50Hz

POWER SUPPLY

~

PE

Page 21

21

PEH-5GAK / PUH-5YKSA

PEH-6GAK / PUH-6YKSA

Refrigerant flow in cooling

R.V.coil

Heating:ON

Cooling:OFF

Refrigerant flow in heating

9 REFRIGERANT SYSTEM DIAGRAM

Unit : mm

Indoor unit

Indoor

heat

exchanger

Strainer

Thermistor

TH2

Distributor

with strainer

PEH-5,6 (O.D. 4.0 × I.D. 2.4 -L700)

Restrictor

valve

Capillary

tube

Refrigerant pipe

(option)

19.05mm( 3/4¨)

(With heat insulator)

Flexible tube

Flared

connection

Flexible tube

Refrigerant pipe

(option)

9.52 mm( 3/8¨)

(With heat insulator)

Ball Valve

Strainer

Service

port

(check)

Accumulator

Ball Valve

(with service port)

Oil separator

4-way valve

Service

port

Compressor

High pressure

control switch

Capillary tube

Thermal switch

Outdoor unit

Outdoor heat exchanger

Bypass valve

Strainer

Thermistor

RT

Restrictor

valve

Capillary

tube

PUH-5

(O.D. 4.0 × I.D. 2.4

-

L

840) ×

2pcs

PUH-6

(O.D. 4.0 × I.D. 2.4

-

L

1200) ×

2pcs

Page 22

22

10

TROUBLESHOOTING

<Error code display by self-diagnosis and actions to be taken for service (summary)>

Present and past error codes are logged and displayed on the wired remote controller or controller board of outdoor unit.

Actions to be taken for service,which depends on whether or not the the inferior phenomenon is reoccurring at service, are

summarized in the table below. Check the contents below before investigating details.

10-1. TROUBLESHOOTING

Unit conditions at service

Error code

Actions to be taken for service (summary)

The inferior phenomenon is

reoccurring.

Displayed

Not displayed

Judge what is wrong and take a corrective action

according to “SELF-DIAGNOSIS ACTION TABLE” (10-3).

Identify the cause of the inferior phenomenon and take

a corrective action according to “TROUBLESHOOTING

BY INFERIOR PHENOMENA ” (10-4).

The inferior phenomenon is

not reoccurring.

Logged

Not logged

1Consider the temporary defects such as the work of

protection devices in the refrigerant circuit including

compressor, poor connection of wiring, noise and etc.

Re-check the symptom, and check the installation

environment, refrigerant amount, weather when the

inferior phenomenon occurred, and wiring related.

2Reset error code logs and restart the unit after finishing

service.

3There is no abnormality in electrical components,

controller boards, and remote controller.

1Recheck the abnormal symptom.

2Identify the cause of the inferior phenomenon and take

a corrective action according to “TROUBLESHOOTING

BY INFERIOR PHENOMENA ” (10-4).

3Continue to operate unit for the time being if the cause

is not ascertained.

4There is no abnormality in electrical components,

controller boards, remote controller etc.

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

ERROR CODE

ERROR CODE

ERROR CODE

1 Turn on the power.

2 Press the [CHECK] button twice.

3 Set address with [TEMP] button if system control is used.

4 Press the [ON/OFF] button to stop the self-check.

A CHECK button

B Address

C TEMP. button

D IC : Indoor unit

OC: Outdoor unit

E Check code

F Unit No.

G Timer ON/OFF button

A

F

C

BBEED

G

<To delete check code>

1 Display the error code at the self-check result display screen.

2 The address for self-check will blink when the

G ON/OFF

button is pressed twice within three seconds.

– – – – : No trouble generated in the past.

F F F F : No corresponding unit.

10-2. MALFUNCTION-DIAGNOSIS METHOD BY REMOTE CONTROLLER

<In case of trouble during operation>

When a malfunction occurs to air conditioner, both indoor unit and outdoor unit will stop and operation lamp blinks to inform

unusual stop.

■ Wired remote controller

Page 23

23

Wired remote controller

1 Check code

Symptom Remark

P1

P2

P4

P5

PA

P6

P8

E4, E5

–

–

Fb

E0, E3

E1, E2

Intake sensor error

Pipe (TH2) sensor error

Drain sensor error

Drain pump error

Forced compressor stop

Freezing/ Overheating safeguard operation

Pipe temperature error / Outdoor unit error

Remote controller signal receiving error

–

–

Indoor unit control system error (memory error, etc.)

Remote controller transmission error

Remote controller control board error

• On wired remote controller

1Check code displayed in the LCD.

If the unit cannot be operated properly after the above test run has been performed, refer to the following table to remove the cause.

•

Wired remote controller

PLEASE WAIT

Symptom

For about 2

minutes following power-on

•For about 2 minutes following power-on,operation of the remote controller is not possible

due to system start-up. (Correct operation)

Cause

•Connector for the outdoor unit’s protection

PLEASE WAIT → Error code

Display messages do not

appear even when operation

switch is turned ON (operation

lamp does not light up).

After about 2

minutes has

expired following power-on

device is not connected.

•Reverse or open phase wiring for the outdoor

unit’s power terminal block

•Incorrect wiring between indoor and outdoor

units

•Remote controller wire short

On the wireless remote controller with condition above, following phenomena takes place.

• No signals from the remote controller are accepted.

• Operation lamp is blinking.

• The buzzer makes a short piping sound.

Note:

Operation is not possible for about 30 seconds after cancellation of function selection. (Correct operation)

For description of each LED (LED1, 2) provided on the indoor controller, refer to the following table.

LED1 (power for microcomputer) Indicates whether control power is supplied. Make sure that this LED is

always lit.

LED2 (power for wired remote controller)

Indicates whether power is supplied to the wired remote controller.

This LED lights only in the case of the main indoor unit.

Page 24

24

10-3. SELF-DIAGNOSIS ACTION TABLE

Note: Refer to the manual of outdoor unit for the details of display

such as F, U, and other E.

Error Code

Meaning of error code and detection method

Cause

Countermeasure

P1

Abnormality of room temperature

thermistor (TH1)

1 The unit is in three-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after three

minutes. (The unit returns to normal

operation, if it has normally reset.)

2 Constantly detected during cooling,

drying, and heating operation.

Short: 90

: or more

Open: -40

: or less

1 Defective thermistor

characteristics.

2 Contact failure of connector

(CN20) on the indoor controller

board. (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring.

4 Defective indoor controller

board.

1–3 Check resistance value of thermistor.

0

: ······15.0k"

10: ····9.6k"

20: ····6.3k"

30: ····4.3k"

40: ····3.0k"

If you put force on (draw or bend) the lead wire

with measuring resistance value of thermistor

breaking of wire or contact failure can be

detected.

2 Check contact failure of connector

(CN20)

on

the indoor controller board. Refer to 10-7.

Turn the power on again and check restart

after inserting connector again.

4 Check room temperature display on remote

controller.

Replace indoor controller board if there is

abnormal difference with actual room

temperature.

Turn the power off, and on again to operate

after check.

P2

Abnormality of pipe temperature

thermistor/Liquid (TH2)

1 The unit is in three-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after three

minutes. (The unit returns to normal

operation, if it has normally reset.)

2 Constantly detected during cooling,

drying, and heating (except defrosting)

operation.

Short: 90

: or more

Open: -40

: or less

1 Defective thermistor

characteristics.

2 Contact failure of connector

(CN21) on the indoor controller

board. (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring.

4 Defective refrigerant circuit is

causing thermistor temperature

of 90

: or more or -40: or

less.

5 Defective indoor controller board.

1–3 Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2 Check contact failure of connector

(CN21)

on

the indoor controller board. Refer to

10-7

.

Turn

the power on and check restart after

inserting

connector again.

4

Check pipe <liquid> temperature with remote

controller in test run mode. If pipe <liquid>

temperature is exclusively low (in cooling

mode) or high (in heating mode), refrigerant

circuit may have defective.

5 Check pipe <liquid> temperature with remote

controller in test run mode. If there is exclusive

difference with actual pipe <liquid> temperature

,

replace indoor controller board.

Turn the power off, and on again to operate

after check.

P4

Abnormality of drain sensor (DS)

1 Suspensive abnormality, if short/open of

thermistor is detected for 30 seconds

continuously.

Turn off compressor and indoor fan.

2 Short/open is detected for 30 seconds

continuously during suspensive

abnormality.

(The unit returns to normal operation,

if it has normally reset.)

3 Detect the following condition.

• During cooling and drying operation.

• In case that pipe <liquid> temperature

- room temperature <-10deg

(Except defrosting)

• When pipe <liquid> temperature or

room temperature is short/open

temperature.

• During drain pump operation.

1 Defective thermistor

characteristics

2 Contact failure of connector

(CN31) on the indoor controller

board. (Insert failure).

3 Breaking of wire or contact

failure of drain sensor wiring.

4 Defective indoor controller board.

1–3 Check resistance value of thermistor.

0

: ······6.0k"

10: ····3.9k"

20: ····2.6k"

30: ····1.8k"

40: ····1.3k"

2 Check contact failure of connector

(CN31)

on

the indoor controller board. Refer to

10-7

.

Turn the power on again and check restart

after inserting connector again.

4 Replace indoor controller board if drain

pump operates with the line of drain sensor

connector CN31-

1 and 2 is short-circuited,

and abnormality reappears.

Turn the power off, and on again to operate

after check.

P5

Malfunction of drain pump (DP)

1 Suspensive abnormality, if thermistor

of drain sensor is let heat itself and

temperature rises slightly. Turn off

compressor and indoor fan.

2 Drain pump is abnormal if the condition

above is detected during suspensive

abnormality.

3 Constantly detected during drain pump

operation.

1 Malfunction of drain pump

2 Defective drain

Clogged drain pump

Clogged drain pipe

3 Attached drop of water at the

drain sensor

• Drops of drain trickles from

lead wire.

• Clogged filter is causing

wave of drain.

4 Defective indoor controller board.

1 Check if drain-up machine works.

2 Check drain function.

3

Check the setting of lead wire of drain senso

r

and check clogs of the filter.

4 Replace indoor controller board if drain

pump operates with the line of drain sensor

connector CN31-1 and 2 is short-circuited

and abnormality reappears.

Refer to 10-7.

Turn the power off, and on again to operate

after check.

Page 25

25

<Heating mode>

When 10 seconds have passed after the

compressor starts operation and the hot

adjustment mode has finished, the unit is

detected as abnormal when

condenser/evaporator pipe temperature is

not in heating range within 20 minutes.

Note 3) It takes at least 27 minutes to

detect abnormality.

Note 4) It excludes the period of defrosting

(Detection restarts when defrosting

mode is over)

Heating range : 5 deg [ (TH2-TH1)

Error Code

Meaning of error code and detection method

Cause

Countermeasure

P6

Freezing/overheating protection is

working

1 Freezing protection (Cooling mode)

The unit is in six-minute resume prevention

mode if pipe temperature stays under

-15: for three minutes, three minutes

after the compressor started. Abnormal

if it stays under -15: for three minutes

again within 16 minutes after six-minute

resume prevention mode.

<Frost prevention mode>

If pipe temperature is 1: or below

when 16 minutes has passed after compressor starts operating, unit will start

operating in frost prevention mode which

stops compressor operation. After that,

when pipe temperature stays 10: or

more for 3 minutes, frost prevention

mode will be released and compressor

will restart its operation.

2 Overheating protection (Heating mode)

The units is in six-minute resume

prevention mode if pipe temperature is

detected as over 70: after the compressor started. Abnormal if the temperature of over 70: is detected again

within 10 minutes after six-minute

resume prevention mode.

P8

1 Slight temperature difference

between indoor room

temperature and pipe temperature thermistor

• Shortage of refrigerant

• Disconnected holder of pipe

thermistor

• Defective refrigerant circuit

2 Converse connection of

extension pipe (on plural units

connection)

3 Converse wiring of indoor/

outdoor unit connecting wire

(on plural units connection)

4 Defective detection of indoor

room temperature and pipe

temperature thermistor

5 Stop valve is not opened

completely.

(Cooling or drying mode)

1 Clogged filter (reduced airflow)

2 Short cycle of air path

3 Low-load (low temperature)

operation beyond the tolerance

range

4 Defective indoor fan motor

• Fan motor is defective.

• Indoor controller board is

defective.

5 Defective outdoor fan control

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

(Heating mode)

1 Clogged filter (reduced airflow)

2 Short cycle of air path

3 Over-load (high temperature)

operation beyond the tolerance

range

4 Defective indoor fan motor

• Fan motor is defective.

• Indoor controller board is

defective.

5 Defective outdoor fan control

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

8 Bypass circuit of outdoor unit

is defective.

(Cooling or drying mode)

1 Check clogs of the filter.

2 Remove shields.

4 Measure the resistance of fan motor's winding.

Measure the output voltage of fan's connector

(Relay for FAN) onthe indoor controller

board.

* The indoor controller board should be

normal when voltage of AC 220~240V is

detected while fan motor is connected.

Refer to 10-7.

5 Check outdoor fan motor.

67 Check operating condition of refrigerant

circuit.

(Heating mode)

1 Check clogs of the filter.

2 Remove shields.

4 Measure the resistance of fan motor's

winding.

Measure the output voltage of fan's connector

(Relay for FAN) onthe indoor controller

board.

* The indoor controller board should be

normal when voltage of AC 220~240V is

detected while fan motor is connected.

Refer to 10-7.

5 Check outdoor fan motor.

6~8Check operating condition of refrigerant

circuit.

Abnormality of pipe temperature

<Cooling mode>

Detected as abnormal when the pipe temperature is not in the cooling range 3 minutes later of compressor start and 6 minutes later of the liquid pipe is out of cooling

range.

Note 1) It takes at least 9 min. to detect.

Note 2) Abnormality P8 is not detected in

drying mode.

Cooling range : -5 deg ] (TH2-TH1)

TH2: Liquid pipe temperature

TH1: Intake temperature

1~4 Check pipe temperature with room

temperature display on remote

controller.

23Check converse connection of extension

pipe or converse wiring of indoor/outdoor

unit connecting wire.

1 Wrong wiring of indoor/outdoor

connecting wire

2 Reversed phase

3 Protection device is working

4 Damaged outdoor coil thermis-

tor

Abnormality in outdoor unit

1 Check the indoor/outdoor connecting wire.

2 Change the connection of electric wiring.

3 Check the protection device.

4 Measure the resistance of the outdoor coil

thermistor. If the resistance is normal,

replace the outdoor controller board.

Page 26

26

Error Code

Meaning of error code and detection method

Cause

Countermeasure

E0

or

E4

Remote controller transmission

error(E0)/signal receiving error(E4)

1 Abnormal if main or sub remote con-

troller can not receive normally any

transmission from indoor unit of refrigerant address “0” for three minutes.

(Error code : E0)

2 Abnormal if sub remote controller could

not receive for any signal for two minutes. (Error code: E0)

1 Abnormal if indoor controller board can

not receive normally any data from

remote controller board or from other

indoor controller board for three minutes.

(Error code: E4)

2 Indoor controller board cannot receive

any signal from remote controller for two

minutes. (Error code: E4)

1 Check disconnection or looseness of indoor

unit or transmission wire of remote controller.

2 Set one of the remote controllers “main”.

If there is no problem with the action above.

3 Check wiring of remote controller.

• Total wiring length: max.500m

(Do not use cable x 3 or more)

• The number of connecting indoor units:

max.16units

• The number of connecting remote con-

troller: max.2units

When it is not the above-mentioned problem of

1~3

4 Diagnose remote controllers.

a) When “RC OK” is displayed,

Remote controllers have no problem.

Put the power off, and on again to check.

If abnormality generates again, replace

indoor controller board.

b) When “RC NG” is displayed,

Replace remote controller.

c) When “RC E3” is displayed,

d) When “ERC 00-06” is displayed,

[ c),d)→Noise may be causing abnormality. ]

* If the unit is not normal after replacing

indoor controller board in group control,

indoor controller board of address “0”

may be abnormal.

E3

or

E5

Remote controller transmission

error(E3)/signal receiving error(E5)

1 Abnormal if remote controller could not

find blank of transmission path for six

seconds and could not transmit.

(Error code: E3)

2 Remote controller receives transmitted

data at the same time, compares the

data, and when detecting it, judges

different data to be abnormal 30

continuous times. (Error code: E3)

1 Abnormal if indoor controller board could

not find blank of transmission path.

(Error code: E5)

2 Indoor controller board receives trans-

mitted data at the same time, compares

the data,and when detecting it, judges

different data to be abnormal 30

continuous times. (Error code: E5)

1 Set a remote controller to main, and the

other to sub.

2

Remote controller is connected with only one

indoor unit.

3 The address changes to a separate setting.

4~6 Diagnose remote controller.

a) When “RC OK”is displayed, remote con-

trollers have no problem.

Put the power off,and on again to check.

When becoming abnormal again, replace

indoor controller board.

b)When “RC NG”is displayed, replace

remote controller.

c)When “RC E3”or “ERC 00-66”is displayed,

noise may be causing abnormality.

1 Contact failure at transmission

wire of remote controller

2 All remote controllers are set

as “sub” remote controller. In

this case, E0 is displayed on

remote controller, and E4 is

displayed at LED (LED1, LED2)

on the outdoor controller circuit

board.

3 Mis-wiring of remote controller.

4 Defective transmitting receiving

circuit of remote controller

5 Defective transmitting receiving

circuit of indoor controller board

of refrigerant address “0”.

6 Noise has entered into the

transmission wire of remote

controller.

1 Two remote controller are set

as “main.”

(In case of 2 remote con-

trollers)

2 Remote controller is connected

with two indoor units or more.

3 Repetition of refrigerant

address.

4 Defective transmitting receiving

circuit of remote controller.

5 Defective transmitting receiving

circuit of indoor controller

board.

6 Noise has entered into trans-

mission wire of remote controller.

Page 27

27

Error Code

Meaning of error code and detection method

Cause

Countermeasure

Fb

Abnormality of indoor controller board

Abnormal if data cannot be normally read

from the nonvolatile memory of the indoor

controller board.

1 Defective indoor controller

board.

1 Replace indoor controller board.

E1

or

E2

Abnormality of remote controller control board

1 Abnormal if data cannot be normally

read from the nonvolatile memory of the

remote controller control board.

(Error code: E1)

2 Abnormal if the clock function of remote

controller cannot be normally operated.

(Error code: E2)

1 Defective remote controller. 1 Replace remote controller.

PA

(2502)

(2500)

Forced compressor stop

(due to water leakage abnormality)

1 When the intake temperature subtracted

with liquid pipe temperature is less than

-10

:, drain sensor is detected whether

it is soaked in the water or not at the interval

of 90 seconds. (Drain pump will start operating

when the drain sensor is detected to be

soaked in the water.)

2 The unit has a water leakage abnormality

when the following conditions, a and b, are

satisfied while the above-mentioned detection

is performed.

a) The drain sensor is detected to be

soaked in the water 10 times in a row.

b) The intake temperature subtracted with

liquid pipe temperature is detected to be

less than -10

: for a total of 30 minutes.

(When the drain sensor is detected to

be NOT soaked in the water, the detection

record of a and b will be cleared.)

3 The drain sensor detection is performed

in operations other than cooling. (When

the unit stops operating, during heating

or fan operation, when the unit stops

because of some abnormality)

*Once the water leakage abnormality is

detected, abnormality state will not be

released until the main power is reset.

1 Drain pump trouble

2 Drain defective

· Drain pump clogging

· Drain pipe clogging

3 Open circuit of drain sensor

side heater

4 Contact failure of drain sensor

connector

5 Dew condensation on drain

sensor

· Drain water descends along

lead wire.

· Drain water waving due to filter

clogging.

6 Extension piping connection

difference at twin, triple,

quadruple system.

7 Mis-wiring of indoor/ outdoor

connecting at twin, triple,

quadruple system.

8 Room temperature thermistor /

liquid pipe temperature thermistor detection is defective.

1Check the drain pump.

2

Please confirm whether water can be drained.

3Confirm the resistance of the drain sensor.

4Check the connector contact failure.

5 Check the drain sensor leadwire mounted.

Check the filter clogging

6Check the piping connection.

7Check the indoor/ outdoor connecting wires.

8Check the room temperature display of

remote controller.

Check the indoor liquid pipe temperature

display of outdoor controller board.

Page 28

28

10-4. TROUBLESHOOTING BY INFERIOR PHENOMENA

• When LED1 on indoor controller board is also off.

1 Power supply of 220~240V AC is not supplied to

indoor unit.

2 Defective indoor controller board.

3 Defective indoor power board.

Phenomena

Cause

Countermeasure

(1)LED2 on indoor controller board

is off.

• When LED1 on indoor controller board is lit.

1 Mis-setting of main/sub for indoor unit

(There is no unit corresponding to main unit.)

1 Reconfirm the setting of main/sub for

indoor unit

Set the main unit.

Set main/sub using SW5-3 on indoor

controller board.

1 Check the voltage of indoor power supply

terminal block (L,N).

• When AC220~240V is not detected.