Page 1

AIR-COOLED SPLIT-TYPE DUCTED AIR CONDITIONERS

DATA BOOK

Series :

PEH

HEAT PUMP : Model PEH-7, 8, 10MYB

Page 2

Page 3

- 1 -

CONTENTS

SAFETY PRECAUTIONS----------------------------------------------2

LINE UP --------------------------------------------------------------------4

MODEL-DESIGNATION BREAKDOWN----------------------------5

SPECIFICATIONS -------------------------------------------------------6

ELECTRICAL DATA------------------------------------------------------7

SELECTION PROCEDURE-------------------------------------------8

CAPACITY TABLES----------------------------------------------------10

OPERATION RANGE--------------------------------------------------19

FAN PERFORMANCE-------------------------------------------------20

SOUND DATA------------------------------------------------------------21

OUTLINE DIMENSIONS----------------------------------------------22

CENTER OF GRAVITY (Outdoor unit)----------------------------24

WIRING DIAGRAMS---------------------------------------------------25

REFRIGERANT SCHEMATICS-------------------------------------28

SAFETY & CONTROL DEVICES ----------------------------------29

OPTION-------------------------------------------------------------------30

INSTALLATION----------------------------------------------------------31

TEST RUN----------------------------------------------------------------45

STANDARD OPERATION DATA ------------------------------------48

SERVICE DATA ---------------------------------------------------------49

INSTRUCTIONS FOR USE------------------------------------------75

SPECIFICATION GUIDELINES-------------------------------------79

Specifications subject to change without notice.

Page 4

SAFETY PRECAUTIONS

- 2 -

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the “Safety

precautions”.

s The “Safety precautions” provide very important points re-

garding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. <Color: yellow>

Warning:

Carefully read the labels affixed to the unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• Install the unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for strong winds and earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in injury.

• Always use an filter and other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• Do not touch the heat exchanger fins and metal edges.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed im-

properly, electric shock and fire may result.

• Securely install the terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter

the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge the it with a refrigerant different from the refrigerant (R22) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit

even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

and operated forcibly , or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Following standards may be applicable if local regulation are not available.

• Pay a special attention to the place, such as a basement, etc. where refrigeration gas can stay, since refrigeration is heavier than the air.

• The appliance is not intended for use by young children or infirm persons without supervision.

• Young children should be supervised to ensure that they do not play

with the appliance.

• Never operate in open phase condition.

Control box may be broken.

1.2. Before Installation

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfur ic smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner

to operate erroneously, or fail to operate. On the other hand, the air conditioner may affect such equipment by creating noise that disturbs medical

treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perf orm collective drainage work

together with the outdoor unit, as required.

1.3. Before Installation (moved) - electrical

work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• The reverse phase of L lines (L

1, L2, L3) can be detected (Error cord: 4103),

but the reverse phase of L lines and N line can be not be detected.

- Some electric parts should be damaged when power is supplied under the

miss wiring.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg.

- Some products use PP bands for packaging. Do not use any PP bands for a

means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspend it at the specified positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

Page 5

- 3 -

• Remote controller is not allowed to install for the place where direct

sunshine strikes.

1.4. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in severe damage to internal parts. K eep the po wer switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be

hot and may be cold, depending on the condition of the refrigerant flowing

through the refrigerant piping, compressor, and other refrigerant cycle parts.

Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards remo ved.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

• Do not operate the air conditioner without the air filter set place.

- Dust may accumulate, and cause a failure.

• At emergency (if you smell something b urning), stop operation and turn

the power source switch off.

- Continuing the operation without eliminating the emergency state may cause

a machine trouble, fire, or electric shock.

• Remote controller should be pushed with finger.

- It occasionally causes the electric shock and the breakdown.

Page 6

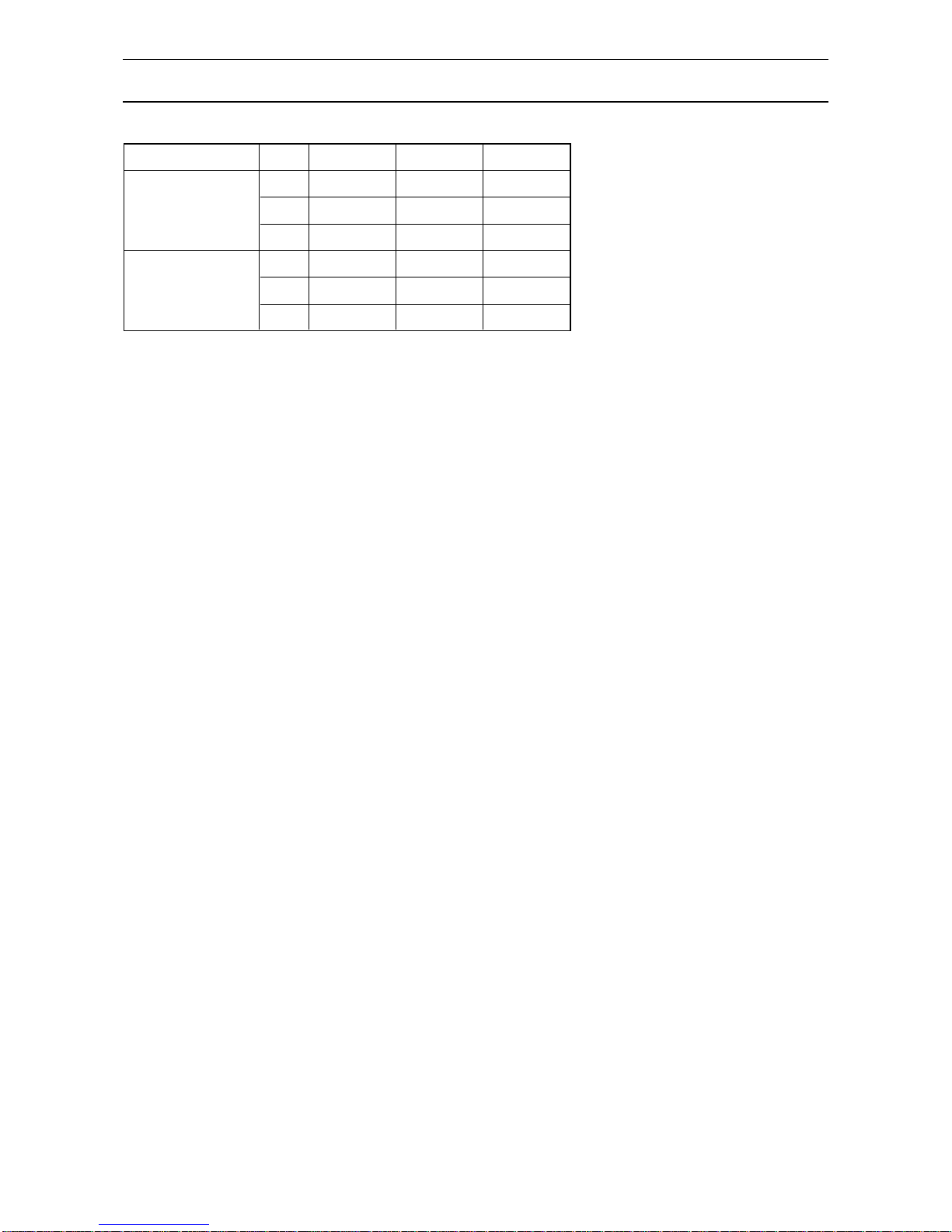

- 4 -

LINE UP

kcal/h

(gross)

Cooling capacity

Btu/h

kW

kcal/h

Heating capacity

Btu/h

kW

PEH-7MYB

16,200

64,200

18.8

17,300

68,600

20.1

PEH-8MYB

19,000

75,100

22.0

19,000

75,100

22.0

PEH-10MYB

24,800

98,300

28.8

24,800

98,300

28.8

Cooling: Indoor:27°CDB, 19°CWB; Outdoor: 35°CDB

Heating: Indoor:20°CDB; Outdoor: 7°CDB, 6°CWB

Cooling and Heating capacities are based 5m pipe length

Page 7

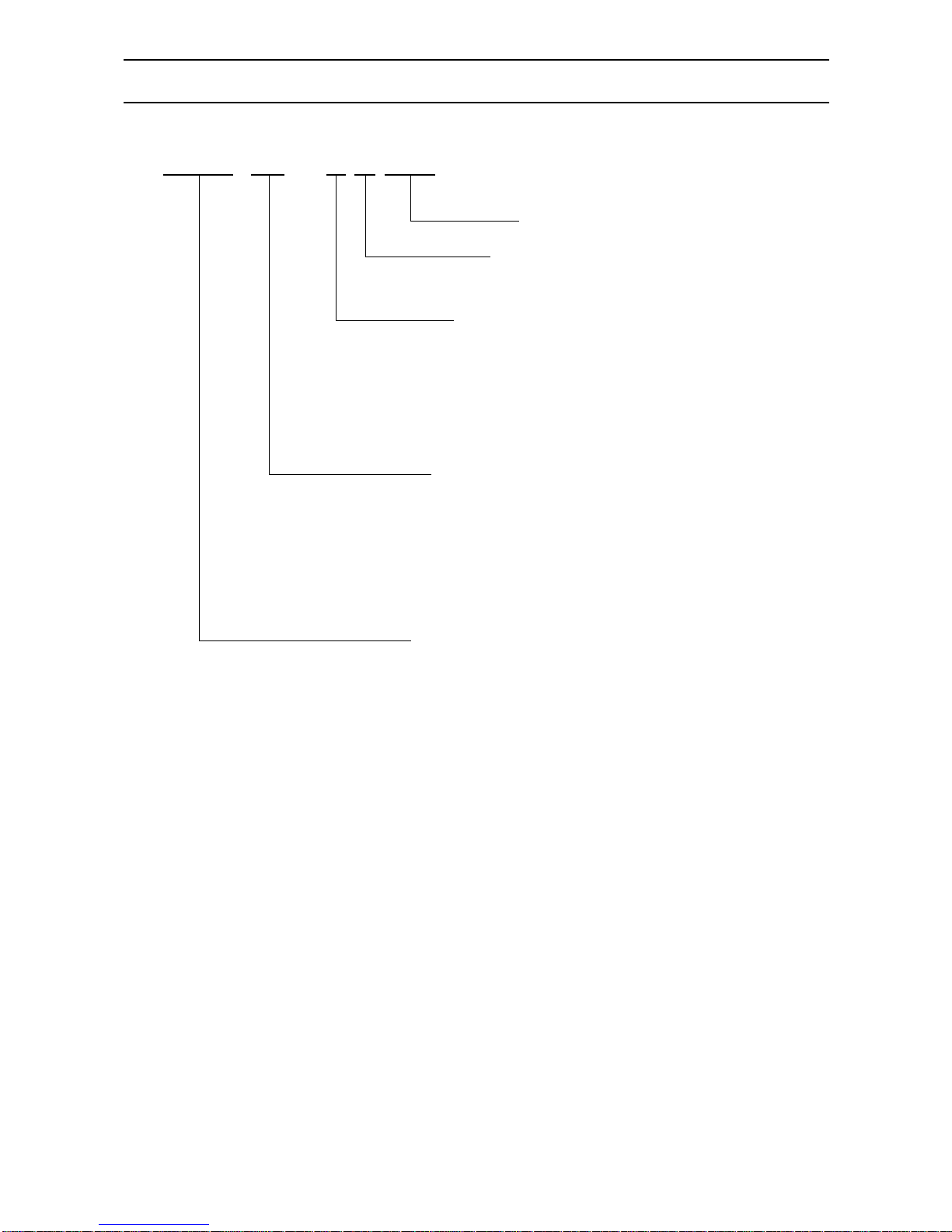

- 5 -

MODEL-DESIGNATION BREAKDOWN

PEH-10MYB -EU

Design Sequence

Electrical Supply

Compressor Horsepower

Series Number

7 = 7 HP

8 = 7.5 HP

10= 10 HP

PEH = Indoor unit

PUH = Outdoor unit

Y = 3 phase 380~415V 50Hz 4 wires

(

In case of PEH-7, 8 Indoor unit

Y = 1 phase 220~240V 50Hz 2 wires

)

Service reference

Page 8

- 6 -

SPECIFICATIONS

kW

BTU/h

kcal/h

%

kg

Capillary tube

Acrylic resin coating

Munsell 5Y 8/1

mm

mm

mm

kg

Cross fin coil

Centrifugal (plastic) - Direct drive

Three phase induction motor

Single phase induction motor

kw

CMM

CFM

L/S

mmAq

Pa

dB(A)

mm

mm

mm

kg

Cross fin coil

Propeller-direct drive

Three phase induction motor

kw

kw

CMM

CFM

L/S

dB(A)

~ 220~240V 50Hz

3N~ 380~415V 50Hz

~ 220~240V 50Hz

3N~ 380~415V 50Hz

3N~ 380~415V 50Hz

3N~ 380~415V 50Hz

18.8

64,200

16,200

kW

BTU/h

kcal/h

18.1

61,800

15,600

0-100

9.96.65.7

2 X 0.09 2 X 0.15

Note 1. Cooling and heating capacitiies are based on the following conditions.

Cooling : Indoor:27°CDB, 19°CWB ; Outdoor:35°CDB.

Heating : Indoor:20°CDB, ; Outdoor:7°CDB, 6°CWB.

Cooling and heating capacities are based 5m pipe length.

2. Refergirant charge volumes are factory charged (at 5m piping length).

Refrigerant is enclosed with the outdoor unit.

3. The measuring point of the sound pressure level is 1m from the unit front surface.

4. (❈1) value is shown with air outlet guide model.

5. Specification subject to change without notice.

R-22

mm

Hermetic line start

PEH-7MYB PEH-8MYB

PEH-10MYB

PEH-7MYB-EU PEH-8MYB-EU

PEH-10MYB-EU

PEH-7MYB PEH-8MYB

PEH-10MYB

PEH-7MYB-EU PEH-8MYB-EU

PEH-10MYB-EU

22.0

75,100

19,000

21.1

72,000

18,200

28.8

98,300

24,800

27.7

94,500

23,900

kW

BTU/h

kcal/h

20.1

68,600

17,300

22.0

75,100

19,000

28.8

98,300

24,800

kW

BTU/h

kcal/h

16.2

55,300

14,000

18.7

63,800

16,100

24.8

84,600

21,400

Galvanized steel

428

1,380

650

67 70

1,580

84

48/60

1,695/2,119

800/1,000

56/70

90

1,978/2,472

933/1,167

3,179

1,500

0.21

0.4

1.0

5.0 5.5

7.5

PUH-7MYF PUH-8MYF PUH-10MYF

PUH-7MYF-EUS PUH-8MYF-EUS PUH-10MYF-EUS

1,480

1,180

550 (❈1 ; +92 <airoutlet guide>)

188 (❈1 ; +5 <airoutlet guide>)

221 (❈1 ; +5 <airoutlet guide>)

167

5,898

2,783

59/59

59/60

190

6,711

3,167

High pressure switch, freeze & frost protection, fuse.

Internal thermostat (comp. & indoor fan & outdoor fan )

Over current relay (comp. & indoor fan)

15

150

55

125

12.5

56

25.4

59

Model name

Service reference

Power supply

Total cooling capacity

(Gross)

Total cooling capacity

(Net)

Total heating capacity

(Net)

Capacity step

Refrigerant

Refrigerant charge

Refrigerant control

Indoor Unit

Model name

Service

reference

External finish

Dimension Height

Width

Depth

Net weight

Compressor

Indoor coil

Indoor fan

Indoor fan motor

Motor output

Indoor fan air flow (Lo/Hi)

External static

pressure

Sound pressure level

Model name

Service

reference

External finish

Color

Dimension Height

Width

Depth

Net weight

Outdoor coil

Outdoor fan

Outdoor fan motor

Motor output

Motor output

Outdoor fan air flow

Sound pressure level (cool/heat)

Protection devices

Drain connection

Sensible cooling capacity

(Gross)

Outdoor unit

indoor

outdoor

PEH-7~10MYB

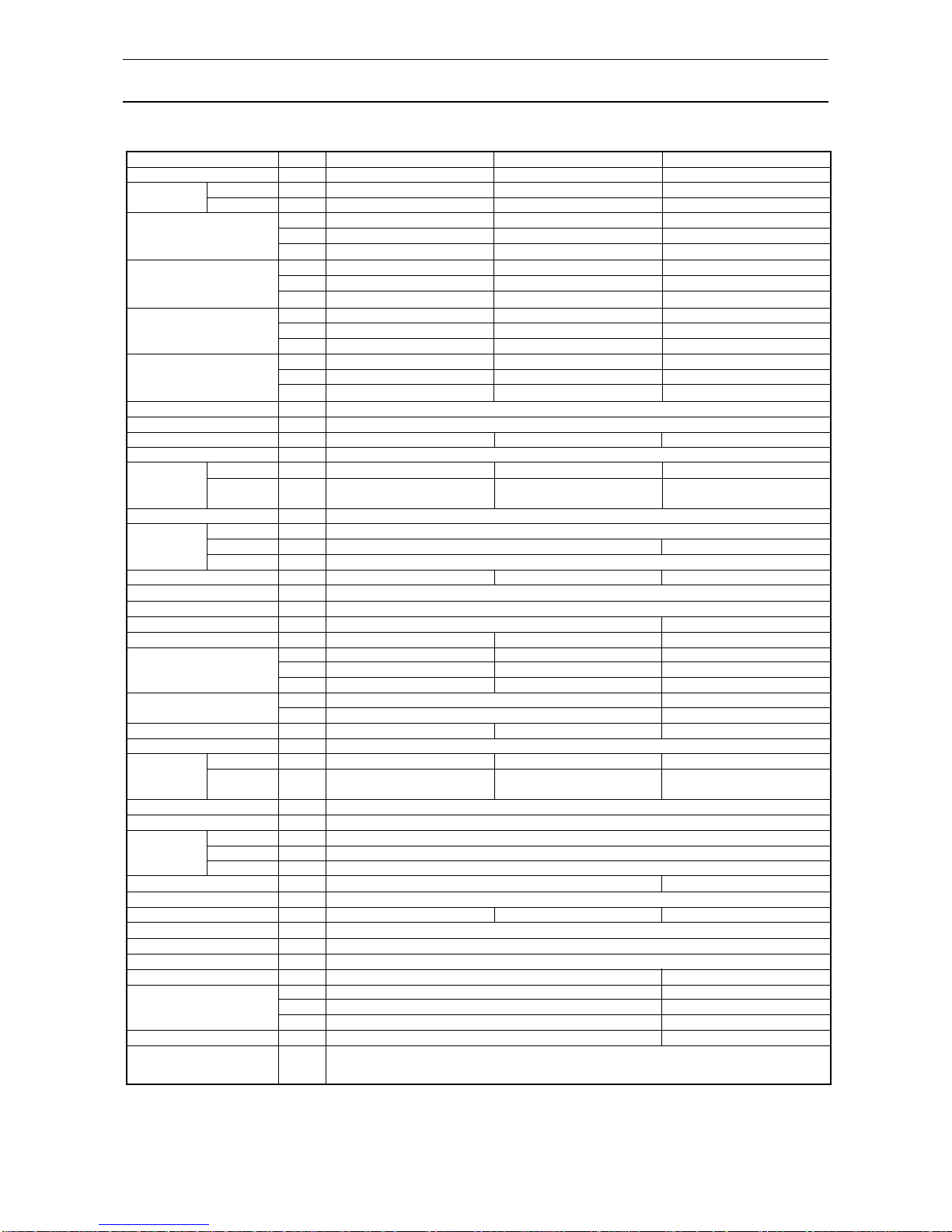

Page 9

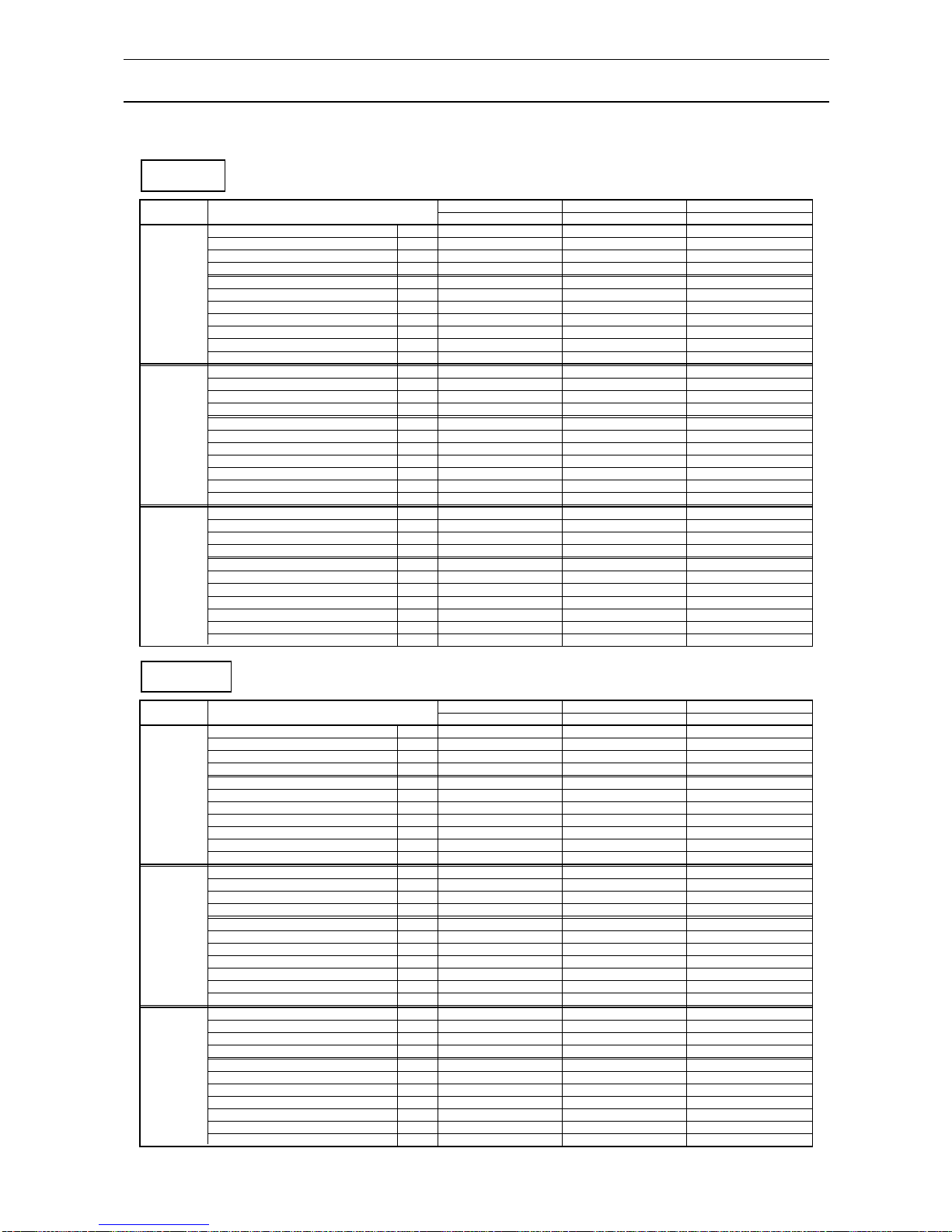

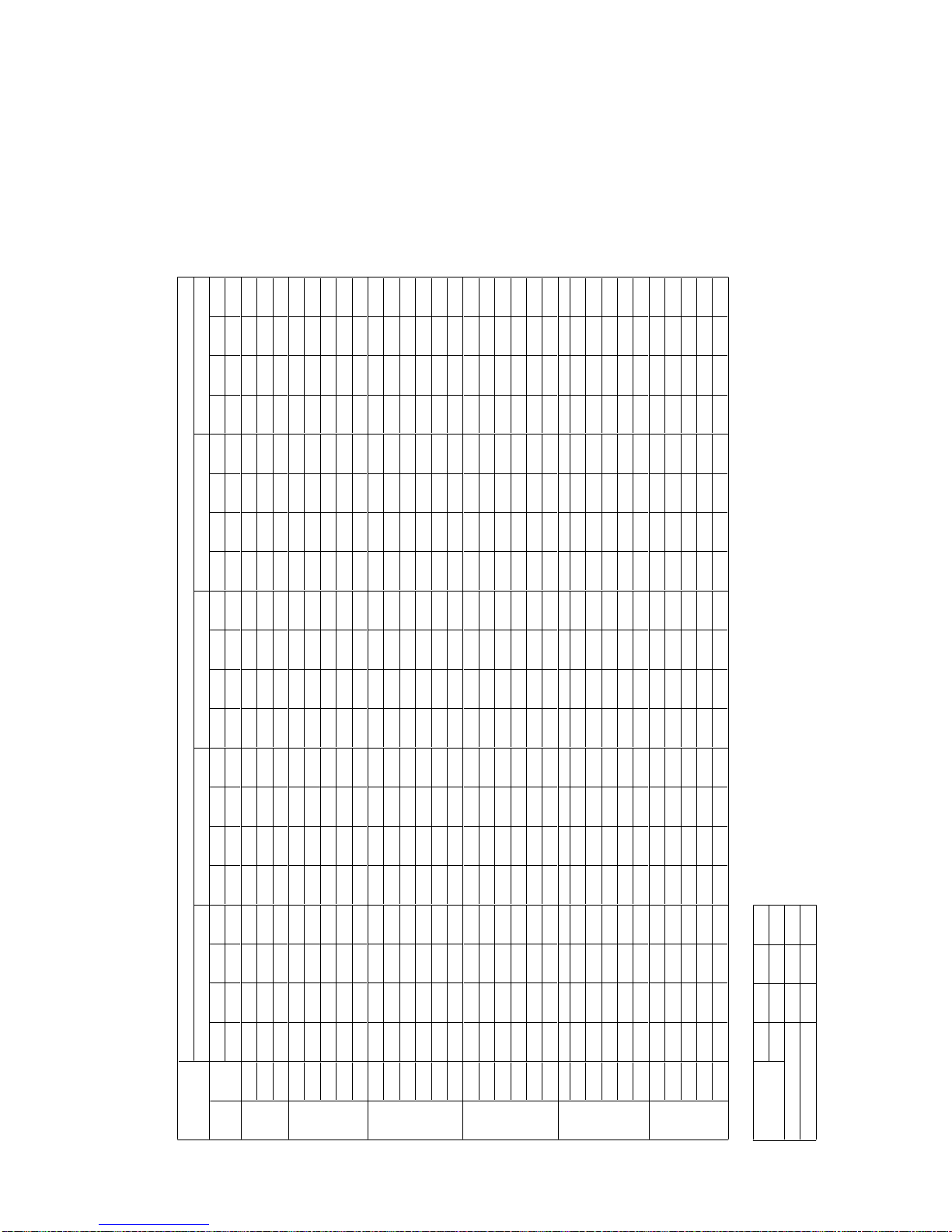

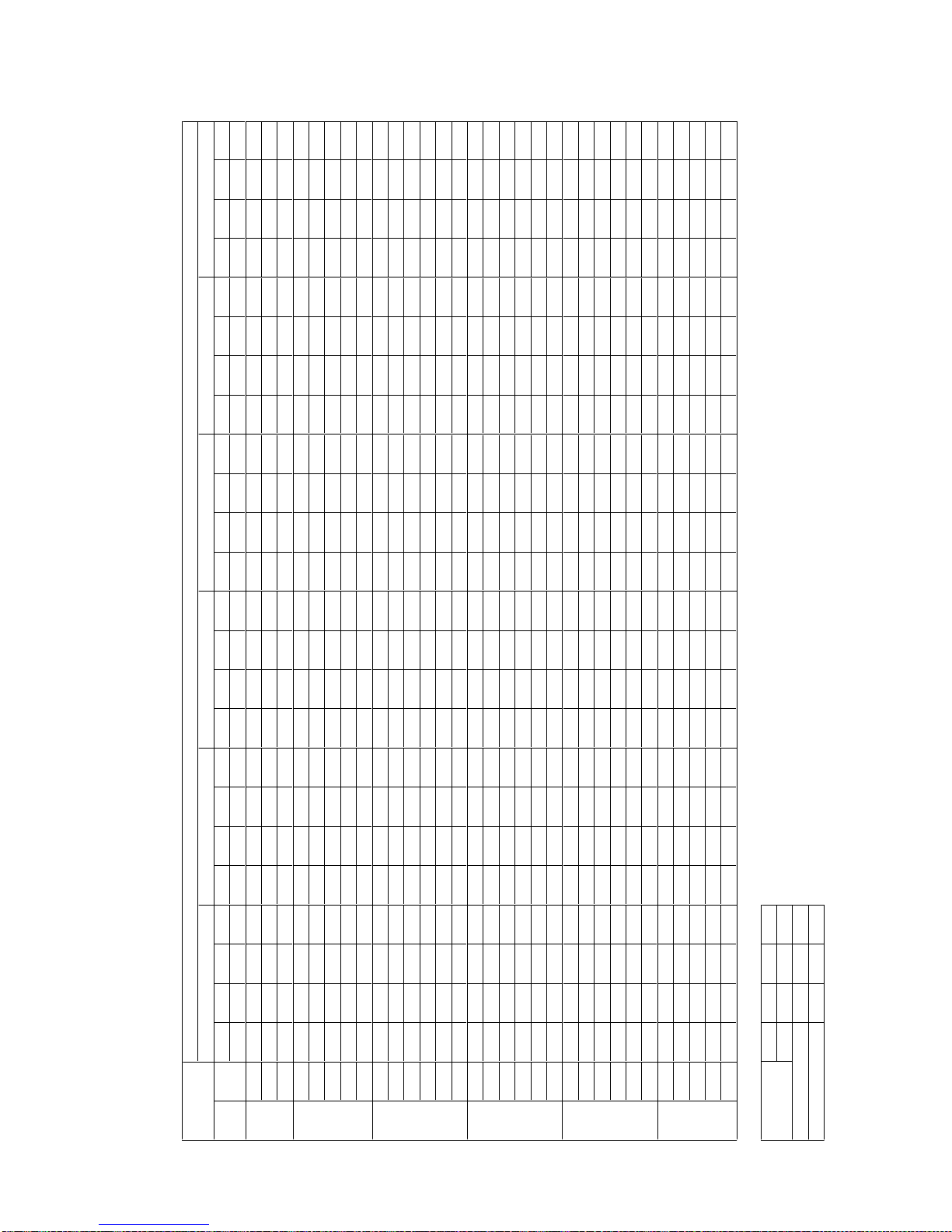

- 7 -

Heating

Cooling

TOTAL INPUT

TOTAL RUN CURRENT

POWER FACTOR

START CURRENT

COMPRESSOR INPUT

RUN CURRENT

INDOOR side External static pressure

O/D FAN INPUT

RUN CURRENT

I/D FAN INPUT

RUN CURRENT

TOTAL INPUT

TOTAL RUN CURRENT

POWER FACTOR

START CURRENT

COMPRESSOR INPUT

RUN CURRENT

INDOOR side External static pressure

O/D FAN INPUT

RUN CURRENT

I/D FAN INPUT

RUN CURRENT

TOTAL INPUT

TOTAL RUN CURRENT

POWER FACTOR

START CURRENT

COMPRESSOR INPUT

RUN CURRENT

INDOOR side External static pressure

O/D FAN INPUT

RUN CURRENT

I/D FAN INPUT

RUN CURRENT

PEH-7,8

240V

PEH-10

PUH-7~10

415V

PEH-7,8

230V

PEH-10

PUH-7~10

400V

PEH-7,8

220V

PEH-10

PUH-~10

380V

VOLT ITEM

kW

A

%

A

kW

A

Pa

kW

A

kW

A

kW

A

%

A

kW

A

Pa

kW

A

kW

A

kW

A

%

A

kW

A

Pa

kW

A

kW

A

7.2

15.0

-

69.0

6.31

11.5

125

0.19

0.46

0.7

3.0

7.2

15.2

-

69.0

6.31

11.6

125

0.19

0.46

0.7

3.1

7.2

15.4

-

69.0

6.31

11.7

125

0.19

0.47

0.7

3.2

8.6

18.0

-

71.0

7.51

13.5

125

0.19

0.45

0.89

4.0

8.6

18.0

-

71.0

7.51

13.5

125

0.19

0.45

0.89

4.0

8.6

18.2

-

71.0

7.51

13.6

125

0.19

0.46

0.89

4.1

10.9

19.5

78%

77.0

9.55

16.9

150

0.25

0.75

1.12

1.8

10.9

19.6

80%

77.0

9.55

17.0

150

0.25

0.75

1.12

1.8

10.9

19.8

84%

77.0

9.55

17.1

150

0.25

0.75

1.12

1.9

PEH-7MYB

PUH-7MYF

PEH-8MYB

PUH-8MYF

PEH-10MYB

PUH-10MYF

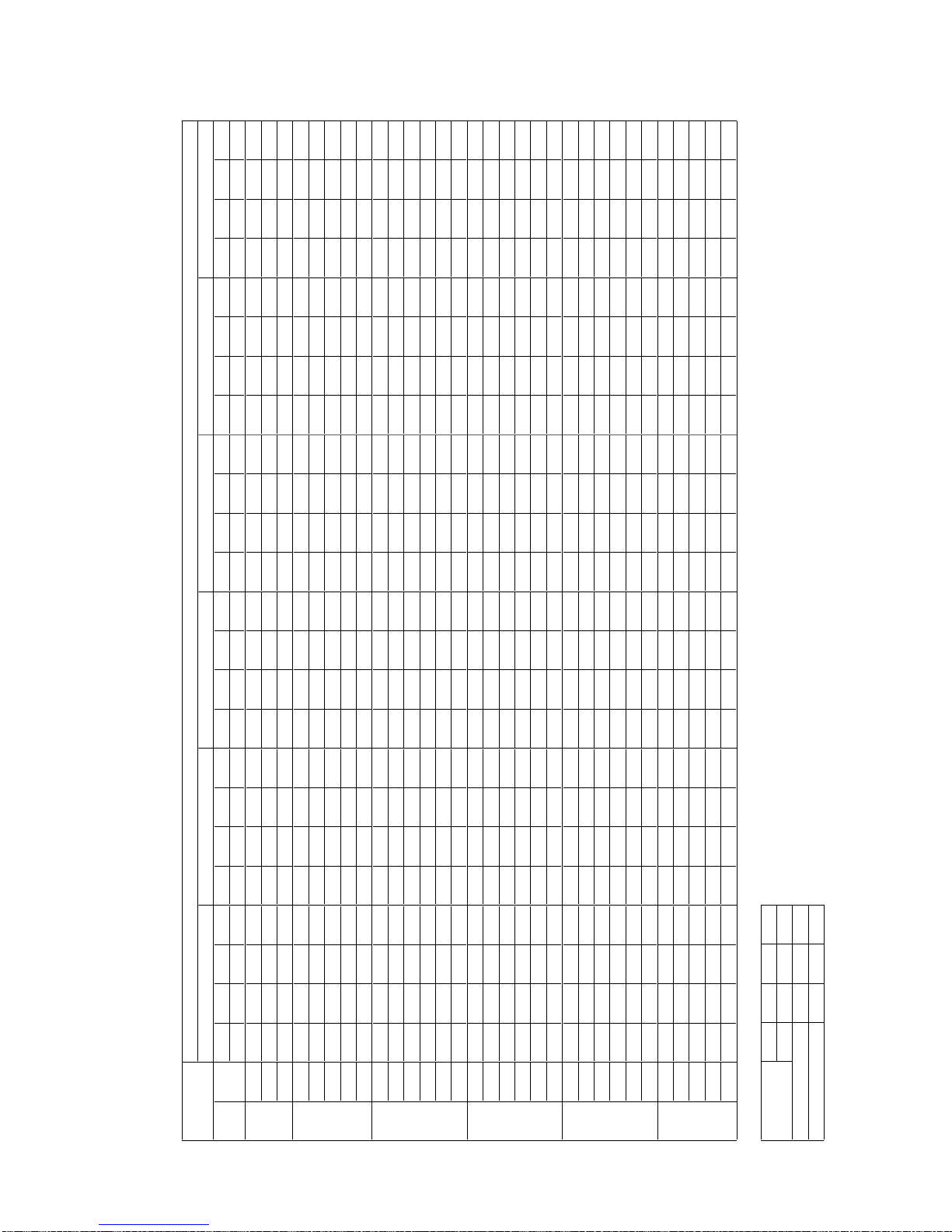

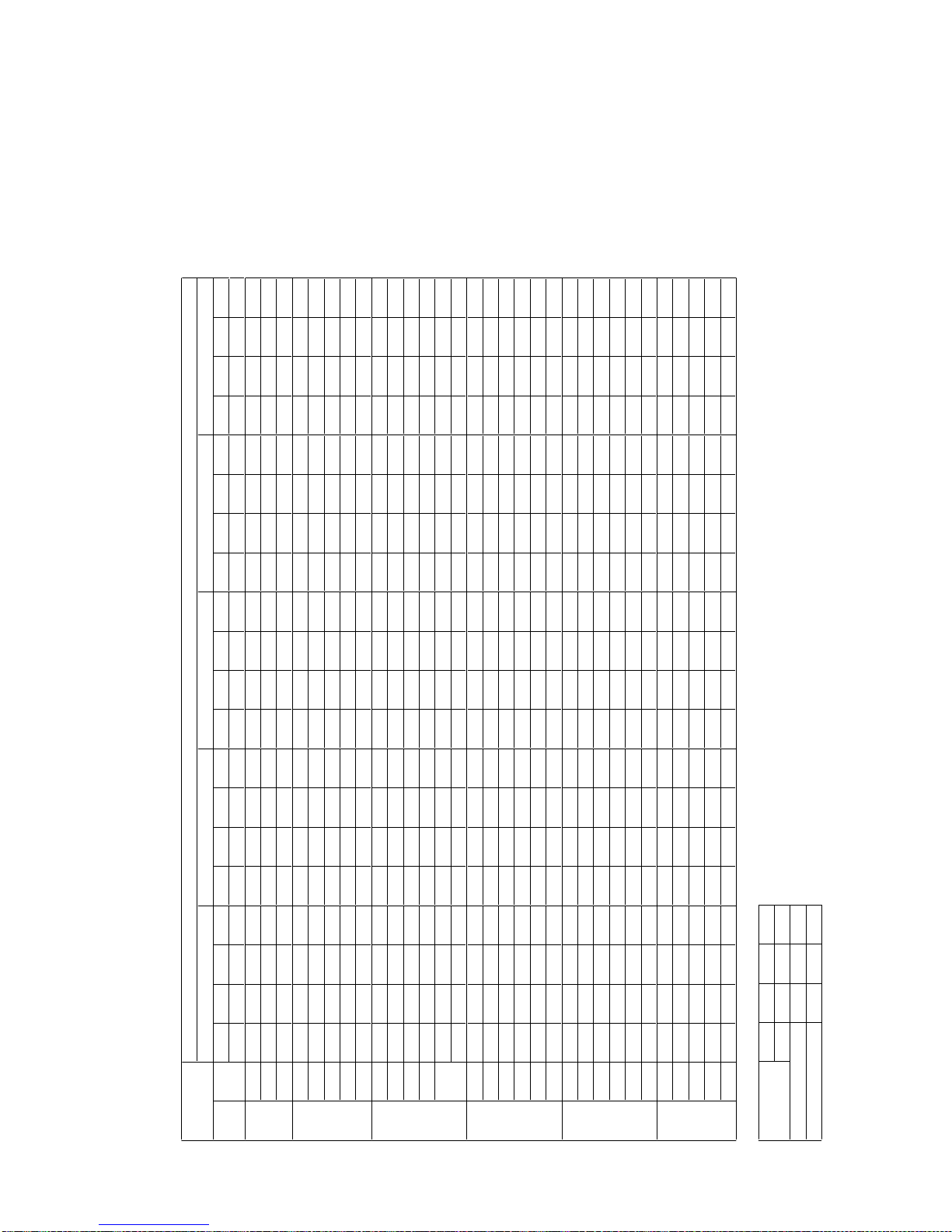

TOTAL INPUT

TOTAL RUN CURRENT

POWER FACTOR

START CURRENT

COMPRESSOR INPUT

RUN CURRENT

INDOOR side External static pressure

O/D FAN INPUT

RUN CURRENT

I/D FAN INPUT

RUN CURRENT

TOTAL INPUT

TOTAL RUN CURRENT

POWER FACTOR

START CURRENT

COMPRESSOR INPUT

RUN CURRENT

INDOOR side External static pressure

O/D FAN INPUT

RUN CURRENT

I/D FAN INPUT

RUN CURRENT

TOTAL INPUT

TOTAL RUN CURRENT

POWER FACTOR

START CURRENT

COMPRESSOR INPUT

RUN CURRENT

INDOOR side External static pressure

O/D FAN INPUT

RUN CURRENT

I/D FAN INPUT

RUN CURRENT

PEH-7,8

240V

PEH-10

PUH-7~10

415V

PEH-7,8

230V

PEH-10

PUH-7~10

400V

PEH-7,8

220V

PEH-10

PUH-7~10

380V

VOLT ITEM

kW

A

%

A

kW

A

Pa

kW

A

kW

A

kW

A

%

A

kW

A

Pa

kW

A

kW

A

kW

A

%

A

kW

A

Pa

kW

A

kW

A

6.8

14.3

-

69.0

5.91

10.8

125

0.19

0.46

0.7

3.0

6.8

14.4

-

69.0

5.91

10.8

125

0.19

0.46

0.7

3.1

6.8

14.5

-

69.0

5.91

10.8

125

0.19

0.47

0.7

3.2

7.1

15.9

-

71.0

6.01

11.4

125

0.19

0.45

0.89

4.0

7.1

15.9

-

71.0

6.01

11.4

125

0.19

0.45

0.89

4.0

7.1

16.0

-

71.0

6.01

11.4

125

0.19

0.46

0.89

4.1

8.8

16.8

72%

77.0

7.45

14.3

150

0.25

0.7

1.12

1.8

8.8

16.8

74%

77.0

7.45

14.3

150

0.25

0.7

1.12

1.8

8.8

16.9

78%

77.0

7.45

14.3

150

0.25

0.7

1.12

1.9

PEH-7MYB

PUH-7MYF

PEH-8MYB

PUH-8MYF

PEH-10MYB

PUH-10MYF

PEH-7,8,10MYB

ELECTRICAL DATA

Page 10

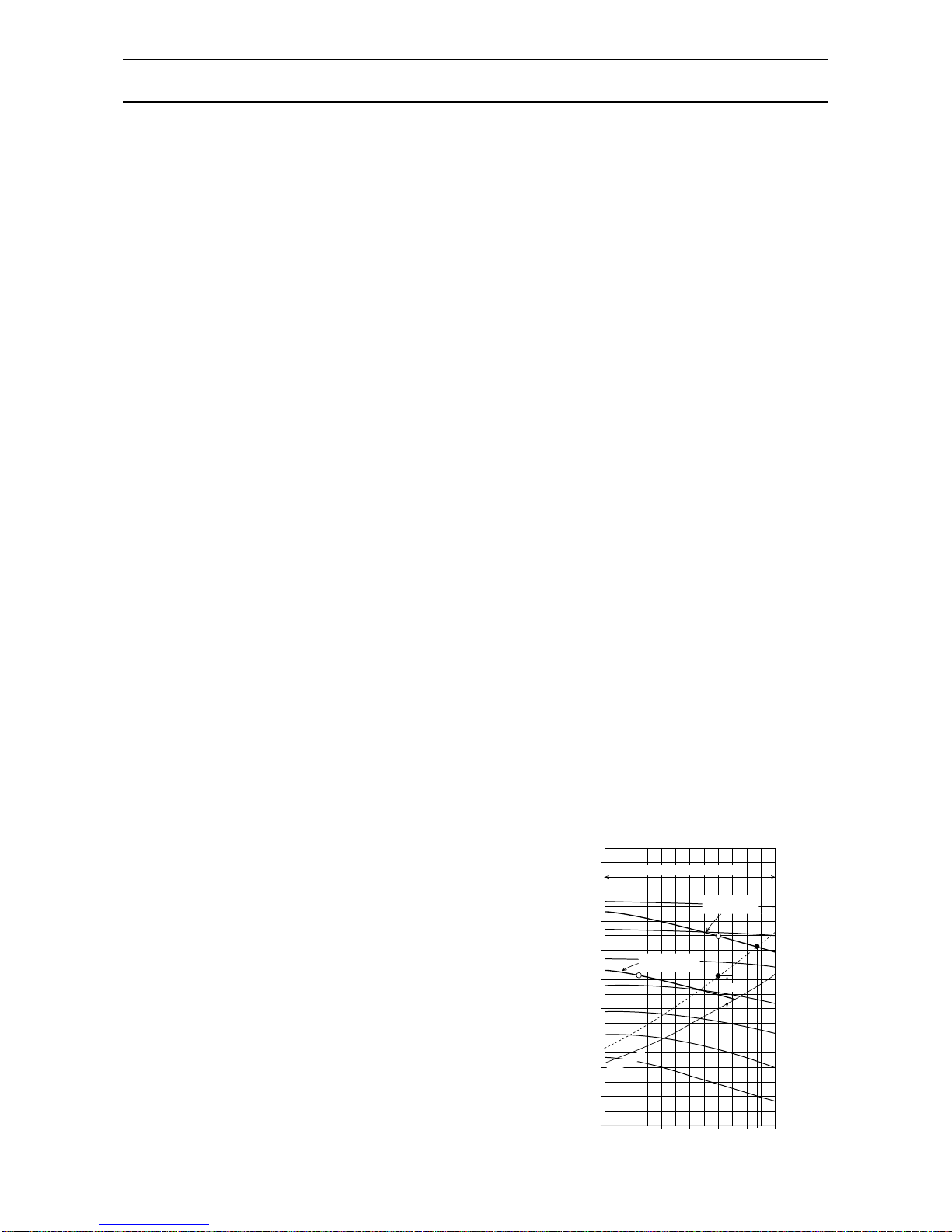

- 8 -

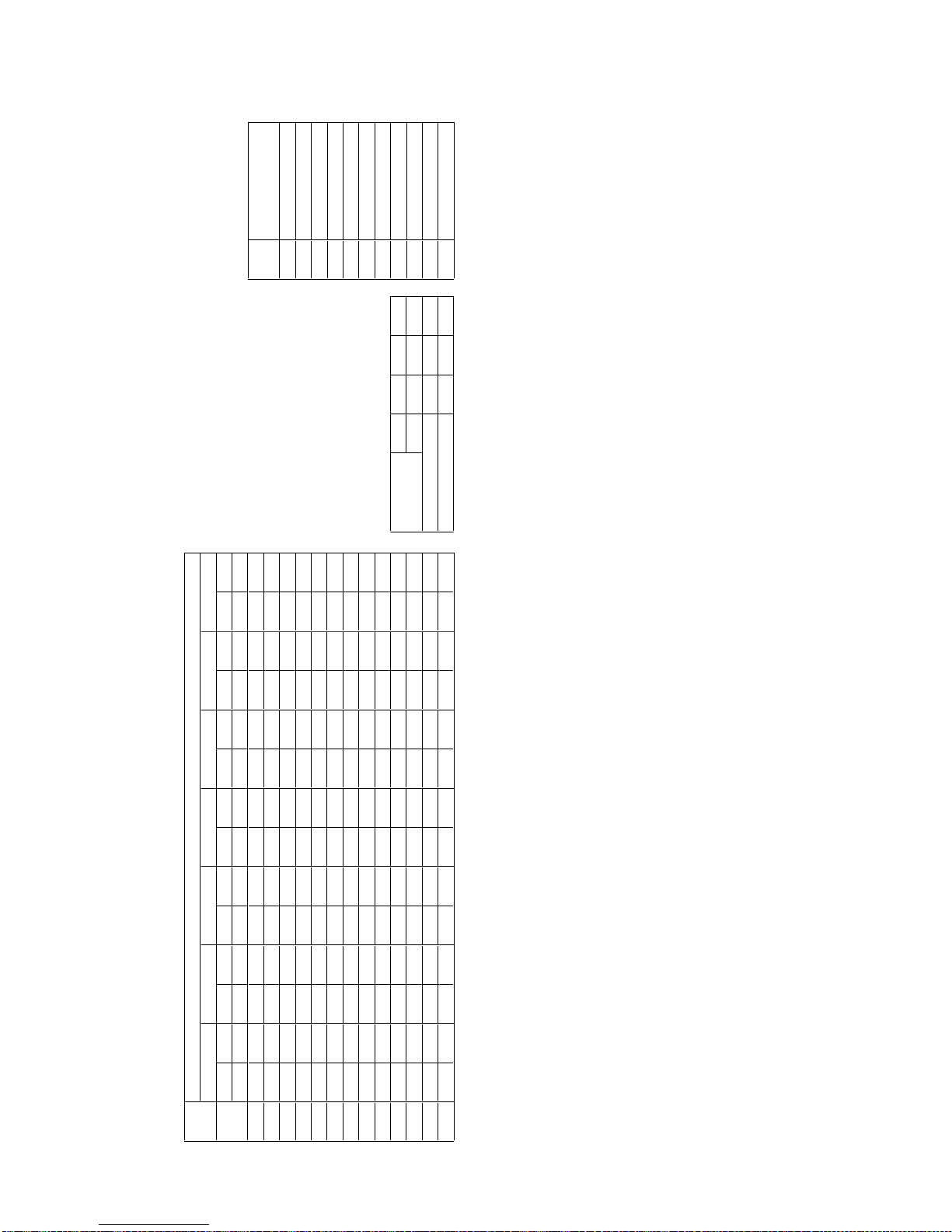

SELECTION PROCEDURE

1. Model Selection (With actual examples)

First step, to select the approximate model:

Based on the cooling load and the cooling capacity listed in the capacity table, select the applicable model.

Notes:

*1. The correct WB is required since it has a serious effect on the capacity.

*2. The cooling capacity decreases as the outdoor temperature increases. Therefore, the estimated highest

temperature during an air conditioning time frame is the "designed outdoor temperature". However, it is

recommended that the abnormal outdoor temperature which may occur once or twice a year be excluded from

the calculation to avoid selection of an excessively large capacity model.

*3. The wind pressure loss of an air duct should be calculated correctly. If a value having an excessive allowance is

used, an excessively large model will be selected. Moreover, an excessively high air flow will be induced during

actual operation causing the generation of high operating sounds and carry-over of condensed water.

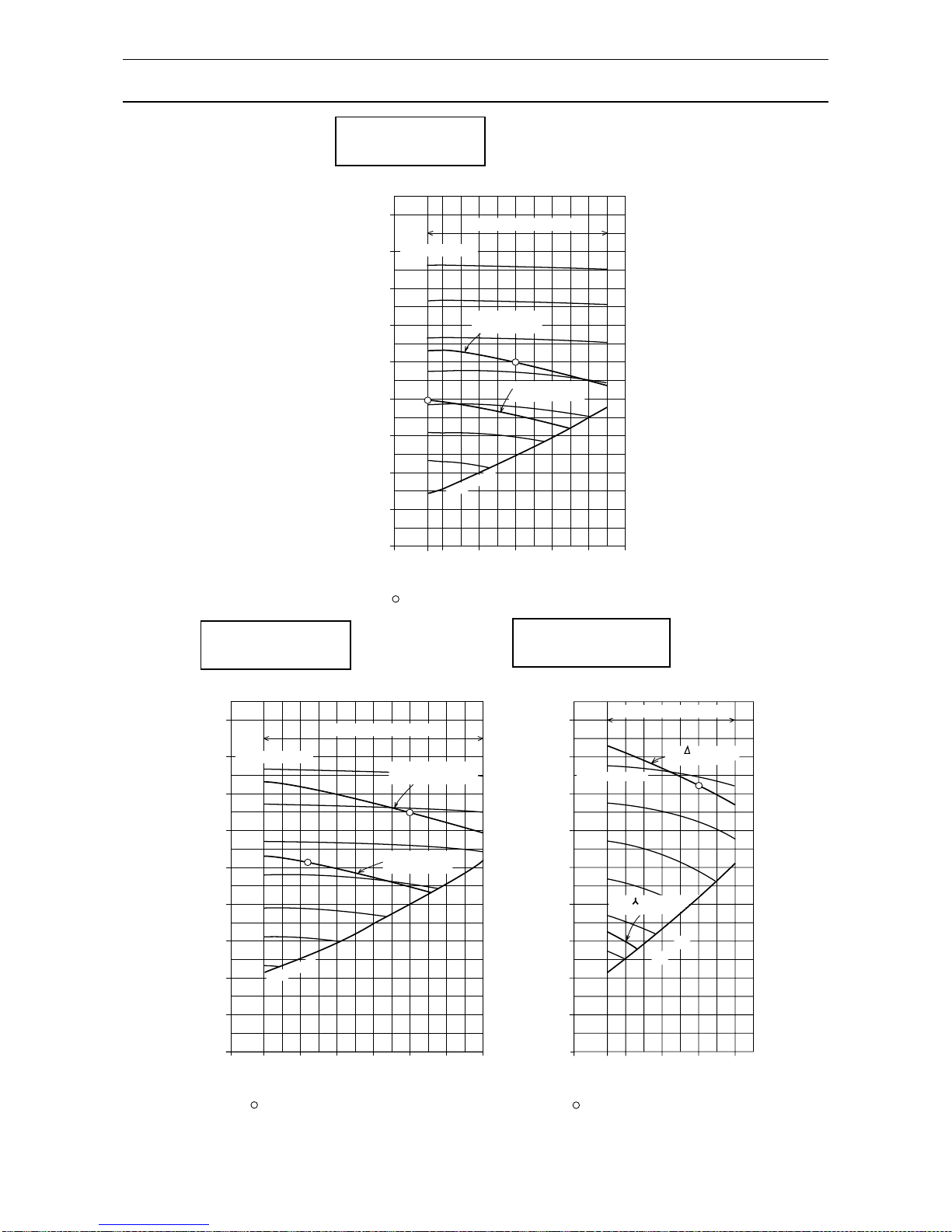

(Step-1) Confirmation of operation range

Confirm that the conditions given above for the model to be selected are within the operation

range listed on Page 19.

(Step-2) Calculation of actual air flow, external static pressure, and fan motor input

Based on the designed air flow and external static pressure, obtain the actual air flow, actual

external static pressure, and fan motor power input from the fan performance table for the model

selected. For an explanation of how to use the fan performance table, see the following

examples.

Example: PEH-8MYB, 50Hz

Example 1. (To operate with values near to the designed air flow and external static pressure.)

Condition : Designed air flow 70CMM

Designed external static pressure 60Pa

Calculation : The designed point is A. Therefore, duct

resistance line passing A is dotted line.

Therefore, actual point is B for Hi speed

operation line

Actual air flow = 77CMM

Actual external static pressure = 70Pa

Note: Duct resustance line is secondary curve.

Second step, to select the model:

To select the model, the following conditions must be known:

(1) Total cooling load or sensible cooling load

(2) Indoor conditioned temperature (WB*1, DB)

(3) Designed outdoor temperature (DB)*2

(4) Designed air flow

(5) Designed external static pressure (= Wind pressure loss of air duct)*3

450

400

350

300

250

200

150

100

50

(Pa)

Fan speed

(rpm)

50

83355917

(CMM)

(L/S)

60

1,000651,083701,167751,250801,333

Recommended Range

In

te

rn

a

l S

P

0

Total static pressure

Air flow

800

900

1000

1100

1200

1300

1400

Fan Performance Curve 50Hz

77

1,283

60Pa

A

B

For Low speed

operation line

For Hi speed

operation line

Page 11

At 26˚CDB, 19˚CWB of Indoor,

Q = 21.0, SHC = 16.2, T/I = 9.2

Therefore, when air flow is 77(CMM)

Q = 21.0 ✕ (1+(1.025 - 1.0) ✕ 7/10*) 21.4(kW)

SHC = 16.2 ✕ (1+(1.044 - 1.0) ✕ 7/10*) 16.7(kW)

T/I = 9.2 ✕ (1+(1.009-1.0))✕ 7/10*) 9.3(kW) Note * : 7/10 = (77-70)/(80-70)

- 9 -

(Step-3) Calculation of net capacity

Based on the indoor conditioned temperature (WB,DB), designed outdoor temperature (DB), and the

actual air flow obtained in Step-2, obtain the gross capacity from the gross capacity tables (pages 10,

11, 13, 14, 16, 17). Then, calculate the net capacity from the formula below by using the fan motor

input obtained in Step-2.

Net capacity (kW) = Gross capacity (kW) - Fan motor input (kW)

Example: PEH-8MYB

Condition: Cooling

Indoor conditioned temp. : 26˚CDB, 19˚CWB

Designed outdoor temp. : 40˚CDB

Actual air flow : 77CMM

Fan motor input : 0.89kW (See P.7)

Calculation :

The sections of the gross capacity table applicable

for the above conditions are shown right.

Therfore, the net capacity is,

Net total cooling capacity = 21.4 (kw) - 0.89(kW)

= 20.51 (kW)

Net sensible cooling capacity = 16.7 (kW) - 0.89 (kW)

= 15.81 (kW)

• Refrigerant cycle energy efficienty

(1) COP =

(2) EER =

• System energy efficienty

(1) COP =

(2) EER =

Notes:

1. COP : Coefficient of performance

2. EER : Energy efficiency ratio

3. Temperature condition of COP, EER (ARI Standard Ratings)

Indoor entering air temp. : 80˚FDB (=27˚CDB), 66˚FWB(=19˚CWB)

Outdoor entering air temp. : 95˚FDB (=35˚CDB)

4. Total input = Compressor input + Indoor fan motor input + Outdoor fan motor input (page 7).

Gross total cooling capacity (kW)

Compressor input (kW)

Gross total cooling capacity (kW)

Total input (kW)

Net cooling capacity (kW)

Compressor input (kW)

Net cooling capacity (kW)

Total input (kW)

PEH-8MYB

AIR VOLUME

CMM 60 70 80

L/S 1,000 1,167 1,330

COOLING

CAPACITY 0.976 1.0 1.025

TOTAL INPUT 0.991 1.0 1.009

21.0 16.2 0.77 9.2

OUTDOOR DB˚C

INDOOR INDOOR

40.0

Q kW

SHC kW

SHF T/I kW

DB˚C

WB˚C

26 19

Factor for Various Air Flow

1kW = 3412Btu/h

2. Efficiency Calculation

Page 12

Outdoor DB°C

-5.0 0.0 5.0 10. 0 15.0 20.0

Indoor Indoor Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I

DB°CWB°CkWkW kWkWkW kWkWkW kWkWkW kWkWkW kWkWkW kW

15

19. 7 1 3.4 0 .6 8 5.3 19.6 13. 4 0 .68 5 .3 19.6 14. 1 0 .72 5 .3 19.2 13. 0 0 .68 5 .3 18. 8 1 3.0 0 .69 5 .4 18.3 12. 6 0 .69 5 .7

20 16 20. 3 1 2.2 0 .6 0 5 .4 20.2 12. 1 0 .6 0 5 .3 20.1 12. 9 0 .6 4 5 .3 19.7 11. 8 0 .6 0 5 .4 19. 4 1 1.6 0 .60 5 .5 18.9 11. 5 0 .61 5 .8

17 20. 9 1 0.9 0 .52 5 .4 20.8 10. 8 0 .52 5 .4 20.7 11. 6 0 .56 5 .4 20.3 10. 6 0 .52 5 .5 19.9 1 0. 4 0 .52 5 .5 19.5 10. 1 0 .52 5 .8

15 19. 7 1 5.6 0 .79 5 .3 19.6 15. 5 0 .79 5 .3 19.6 16. 4 0 .84 5 .3 19.2 15. 3 0 .80 5 .3 18.8 1 5. 0 0 .80 5 .4 18.3 14. 7 0 .80 5 .7

16 20. 3 1 4.4 0 .71 5 .4 20.2 14. 3 0 .71 5 .3 20.1 15. 3 0 .76 5 .3 19.7 14. 2 0 .72 5 .4 19.4 1 3. 9 0 .72 5 .5 18.9 13. 6 0 .72 5 .8

22 17 20. 9 1 3.1 0 .6 3 5 .4 20.8 13. 1 0 .6 3 5 .4 20.7 13. 9 0 .6 7 5 .4 20.3 12. 8 0 .6 3 5 .5 19. 9 1 2.8 0 .64 5 .5 19.5 12. 5 0 .64 5 .8

18 21. 4 1 2.0 0 .56 5 .4 21.3 11. 9 0 .56 5 .4 21.2 12. 7 0 .60 5 .4 20.9 11. 7 0 .56 5 .5 20.5 1 1. 5 0 .56 5 .6 20.0 11. 4 0 .57 5 .9

19 22. 2 1 0.9 0 .49 5 .5 22.1 10. 8 0 .49 5 .5 22.0 11. 7 0 .53 5 .5 21.6 10. 6 0 .49 5 .6 21.2 1 0. 4 0 .49 5 .7 20.8 10. 2 0 .49 6 .0

16 20. 3 1 6. 6 0 .82 5 .4 20.2 16. 6 0 .82 5 .3 20.1 17. 3 0 .86 5 .3 19.7 16. 4 0 .83 5 .4 19. 4 1 6. 3 0 .84 5 .5 18.9 16. 1 0 .85 5 .8

17 20. 9 1 5. 2 0 .73 5 .4 20.8 15. 2 0 .73 5 .4 20.7 16. 1 0 .78 5 .4 20.3 15. 0 0 .74 5 .5 19. 9 1 4. 9 0 .75 5 .5 19.5 14. 8 0 .76 5 .8

24

18

21. 4 1 3.9 0 .6 5 5 .4 21.3 13. 9 0 .6 5 5 .4 21.2 14. 7 0 .6 9 5 .4 20.9 13. 8 0 .6 6 5 .5 20. 5 1 3.5 0 .66 5 .6 20.0 13. 4 0 .67 5 .9

19 22. 2 1 2. 9 0 .58 5 .5 22.1 12. 8 0 .58 5 .5 22.0 13. 6 0 .62 5 .5 21.6 12. 5 0 .58 5 .6 21. 2 1 2. 5 0 .59 5 .7 20.8 12. 3 0 .59 6 .0

20 22. 9 1 1. 7 0 .51 5 .6 22.8 11. 6 0 .51 5 .6 22.7 12. 5 0 .55 5 .5 22.4 11. 4 0 .51 5 .7 22. 0 1 1. 2 0 .51 5 .8 21.5 11. 2 0 .52 6 .0

21 23. 5 1 0. 3 0 .44 5 .7 23.4 10. 3 0 .44 5 .7 23.3 11. 2 0 .48 5 .7 23.0 10. 1 0 .44 5 .8 22. 7 1 0. 0 0 .44 5 .9 22.2 9.8 0 .44 6 .1

18 21. 4 1 6. 1 0 .75 5 .4 21.3 16. 0 0 .75 5 .4 21.2 16. 8 0 .79 5 .4 20.9 15. 9 0 .76 5 .5 20. 5 1 5. 8 0 .77 5 .6 20.0 15. 6 0 .78 5 .9

19 22. 2 1 5. 1 0 .68 5 .5 22.1 15. 0 0 .68 5 .5 22.0 15. 6 0 .71 5 .5 21.6 14. 7 0 .68 5 .6 21. 2 1 4. 7 0 .69 5 .7 20.8 14. 5 0 .70 6 .0

26

20

22. 9 1 3.8 0 .6 0 5 .6 22.8 13. 7 0 .6 0 5 .6 22.7 14. 6 0 .6 4 5 .5 22.4 13. 6 0 .6 1 5 .7 22. 0 1 3.4 0 .61 5 .8 21.5 13. 3 0 .62 6 .0

21 23. 5 1 2. 7 0 .54 5 .7 23.4 12. 6 0 .54 5 .7 23.3 13. 3 0 .57 5 .7 23.0 12. 4 0 .54 5 .8 22. 7 1 2. 5 0 .55 5 .9 22.2 12. 2 0 .55 6 .1

22 24. 1 1 1. 3 0 .47 5 .8 24.0 11. 3 0 .47 5 .8 23.9 12. 2 0 .51 5 .8 23.6 11. 3 0 .48 5 .9 23. 3 1 1. 2 0 .48 6 .0 22.8 11. 0 0 .48 6 .2

23 24. 6 1 0. 1 0 .41 6 .0 24.5 10. 1 0 .41 5 .9 24.4 10. 8 0 .44 5 .9 24. 2 9 .9 0.41 6.0 24. 0 10.1 0.42 6.1 2 3.5 9 .9 0.42 6.3

19 22. 2 1 7. 3 0 .78 5 .5 22.1 17. 2 0 .78 5 .5 22.0 18. 0 0 .82 5 .5 21.6 16. 9 0 .78 5 .6 21. 2 1 6. 6 0 .78 5 .7 20.8 16. 6 0 .80 6 .0

28

20

22. 9 1 6.1 0 .7 0 5 .6 22.8 16. 0 0 .7 0 5 .6 22.7 16. 8 0 .7 4 5 .5 22.4 15. 7 0 .7 0 5 .7 22. 0 1 5.6 0 .71 5 .8 21.5 15. 5 0 .72 6 .0

21 23. 5 1 4. 6 0 .62 5 .7 23.4 14. 5 0 .62 5 .7 23.3 15. 4 0 .66 5 .7 23.0 14. 5 0 .63 5 .8 22. 7 1 4. 3 0 .63 5 .9 22.2 14. 2 0 .64 6 .1

22 24. 1 1 3. 5 0 .56 5 .8 24.0 13. 4 0 .56 5 .8 23.9 14. 3 0 .60 5 .8 23.6 13. 4 0 .57 5 .9 23. 3 1 3. 3 0 .57 6 .0 22.8 13. 0 0 .57 6 .2

23 24. 6 1 2. 3 0 .50 6 .0 24.5 12. 3 0 .50 5 .9 24.4 13. 2 0 .54 5 .9 24.2 12. 1 0 .50 6 .0 24. 0 1 2. 0 0 .50 6 .1 23.5 12. 0 0 .51 6 .3

24 25. 2 1 1. 1 0 .44 6 .1 25.1 11. 0 0 .44 6 .0 25.0 12. 0 0 .48 6 .0 24.8 10. 9 0 .44 6 .1 24. 6 1 0. 8 0 .44 6 .2 24.2 10. 6 0 .44 6 .4

20 22. 9 1 7. 9 0 .78 5 .6 22.8 17. 8 0 .78 5 .6 22.7 18. 7 0 .82 5 .5 22.4 17. 7 0 .79 5 .7 22. 0 1 7. 6 0 .80 5 .8 21.5 17. 4 0 .81 6 .0

21 23. 5 1 6. 9 0 .72 5 .7 23.4 16. 9 0 .72 5 .7 23.3 17. 5 0 .75 5 .7 23.0 16. 5 0 .72 5 .8 22. 7 1 6. 5 0 .73 5 .9 22.2 16. 4 0 .74 6 .1

Air volume

CMM

L/S

50

833

60

1,000

70

1,167

30 22 24. 1 1 5. 6 0 .65 5 .8 24.0 15. 6 0 .65 5 .8 23.9 16. 5 0 .69 5 .8 23.6 15. 3 0 .65 5 .9 23. 3 1 5. 2 0 .65 6 .0 22.8 15. 1 0 .66 6 .2

capacity

23 24. 6 1 4. 5 0 .59 6 .0 24.5 14. 5 0 .59 5 .9 24.4 15. 2 0 .62 5 .9 24.2 14. 3 0 .59 6 .0 24. 0 1 4. 1 0 .59 6 .1 23.5 14. 1 0 .60 6 .3

input

24 25. 2 1 3. 1 0 .52 6 .1 25.1 13. 1 0 .52 6 .0 25.0 14. 0 0 .56 6 .0 24.8 12. 9 0 .52 6 .1 24. 6 1 2. 8 0 .52 6 .2 24.2 12. 8 0 .53 6 .4

Cooling Capacity (Standard Air Flow) ; PEH-7MYB-EU

Factor for various air flow(Cooling)

0.975

0.989

1.0

1.0

1.024

1.009

- 10 -

CAPACITY TABLES

Page 13

- 11 -

Outdoor DB°C

25.0 30.0 35.0 40. 0 46.0

Indoor Indoor QSHCSHFT/IQSHCSHFT/IQSHCSHFT/IQSHCSHFT/IQSHCSHFT/I

DB°CWB°CkWkW kWkWkW kWkWkW kWkWkW kWkWkW kW

15

17.9 12. 5 0 .7 0 6 .0 17.2 12. 0 0 .7 0 6 .4 16.5 11 .7 0.71 6.8 15.5 11. 3 0 .7 3 7 .4 14.2 10. 5 0 .74 8 .1

20 16 18.4 11. 2 0 .61 6 .0 17.7 11. 0 0 .62 6 .5 16 .9 10. 5 0 .62 6 .9 16.0 10. 1 0 .63 7 .5 14. 9 9 .5 0.64 8. 1

17 19.0 10. 1 0 .53 6 .1 18. 2 9 .7 0.53 6.6 1 7.5 9 .4 0.54 7.0 16. 6 9 .0 0.54 7.6 15. 5 8 .4 0.54 8. 2

15 17.9 14. 5 0 .81 6 .0 17.2 14. 1 0 .82 6 .4 16.5 13. 9 0 .84 6 .8 15.5 13. 5 0 .87 7 .4 14.2 12. 6 0 .89 8 .1

16 18.4 13. 4 0 .73 6 .0 17.7 13. 1 0 .74 6 .5 16.9 12. 7 0 .75 6 .9 16.0 12. 3 0 .77 7 .5 14.9 11. 7 0 .79 8 .1

22 17 19.0 12. 3 0 .65 6 .1 18.2 12. 0 0 .66 6 .6 17 .5 11. 7 0 .67 7 .0 16.6 11. 3 0 .68 7 .6 15.5 10. 7 0 .69 8 .2

18 19.6 11. 1 0 .57 6 .2 18.8 10. 9 0 .58 6 .6 18.0 10. 5 0 .58 7 .1 17.2 10. 1 0 .59 7 .6 16. 2 9.7 0.60 8. 3

19 20. 3 9 .9 0.49 6.3 19. 6 9 .6 0.49 6.7 1 8.8 9 .4 0 .50 7 .2 18. 0 9 .2 0.51 7.7 16. 9 8.8 0.52 8. 4

16 18.4 15. 8 0 .86 6 .0 17.7 15. 6 0 .88 6 .5 16.9 15 .1 0.89 6.9 16.0 14. 7 0 .92 7 .5 14.9 14. 0 0 .94 8 .1

17 19.0 14. 6 0 .77 6 .1 18.2 14. 2 0 .78 6 .6 17.5 14 .0 0.80 7.0 16.6 13. 6 0 .82 7 .6 15.5 13. 0 0 .84 8 .2

24

18

19.6 13. 3 0 .6 8 6 .2 18.8 13. 0 0 .6 9 6 .6 18.0 12 .6 0.70 7.1 17.2 12. 4 0 .7 2 7 .6 16.2 11. 8 0 .73 8 .3

19 20.3 12. 2 0 .60 6 .3 19.6 11. 9 0 .61 6 .7 18.8 11 .7 0.62 7.2 18.0 11. 3 0 .63 7 .7 16.9 11. 0 0 .65 8 .4

20 21.1 10. 9 0 .52 6 .3 20.3 10. 8 0 .53 6 .8 19.6 10 .6 0.54 7.3 18.7 10. 3 0 .55 7 .8 17. 7 9 .9 0.56 8.4

21 21. 7 9 .6 0.44 6.4 21. 0 9 .5 0.45 6. 9 2 0.3 9 .3 0.46 7.4 19. 5 9 .0 0.46 7.9 18. 4 8 .7 0.47 8.5

18 19.6 15. 4 0 .79 6 .2 18.8 15. 0 0 .80 6 .6 18.0 14 .8 0.82 7.1 17.2 14. 4 0 .84 7 .6 16.2 13. 9 0 .86 8 .3

19 20.3 14. 2 0 .70 6 .3 19.6 14. 1 0 .72 6 .7 18.8 13 .7 0.73 7.2 18.0 13. 5 0 .75 7 .7 16.9 13. 0 0 .77 8 .4

26

20

21.1 13. 1 0 .6 2 6 .3 20.3 12. 8 0 .6 3 6 .8 19.6 12 .7 0.65 7.3 18.7 12. 3 0 .6 6 7 .8 17.7 12. 0 0 .68 8 .4

21 21.7 11. 9 0 .55 6 .4 21.0 11. 8 0 .56 6 .9 20.3 11 .6 0.57 7.4 19.5 11. 3 0 .58 7 .9 18.4 10. 9 0 .59 8 .5

22 22.4 10. 7 0 .48 6 .5 21.7 10. 6 0 .49 6 .9 21.1 10 .5 0.50 7.4 2 0.2 10. 1 0 .50 8 .0 19. 2 9 .8 0.51 8.6

23 23. 0 9 .4 0.41 6.6 22. 4 9 .4 0.42 7. 0 2 1.8 9 .4 0.43 7 .5 21.0 9.0 0 .4 3 8 .1 19. 9 8 .4 0.42 8.7

19 20.3 16. 6 0 .82 6 .3 19.6 16. 4 0 .84 6 .7 16. 218.8 0.86 18.0 15. 8 0 .8 8 7 .7 16.9 15. 4 0 .9 1 8 .4

28

20

21.1 15. 6 0 .7 4 6 .3 20.3 15. 2 0 .7 5 6 .8 19.6 15 .1 0.77 7.3 18.7 14. 8 0 .7 9 7 .8 17.7 14. 3 0 .81 8 .4

21 21.7 14. 1 0 .65 6 .4 21.0 14. 1 0 .67 6 .9 20.3 13 .8 0.68 7.4 19.5 13. 4 0 .69 7 .9 18.4 13. 1 0 .71 8 .5

22 22.4 13. 0 0 .58 6 .5 21.7 12. 8 0 .59 6 .9 21.1 12 .8 0.61 7.4 2 0.2 12. 5 0 .62 8 .0 19.2 12. 1 0 .63 8 .6

23 23.0 11. 7 0 .51 6 .6 22.4 11. 7 0 .52 7 .0 21.8 11 .6 0.53 7.5 2 1.0 11. 5 0 .55 8 .1 19.9 11. 2 0 .56 8 .7

24 23.7 10. 4 0 .44 6 .6 23.1 10. 4 0 .45 7 .1 22.6 10 .4 0.46 7.5 2 1.7 10. 2 0 .47 8 .1 20.7 10. 1 0 .49 8 .9

20 21.1 17. 3 0 .82 6 .3 20.3 17. 1 0 .84 6 .8 19.6 16 .8 0.86 7.3 18.7 16. 6 0 .89 7 .8 17.7 16. 4 0 .93 8 .4

21 21.7 16. 3 0 .75 6 .4 21.0 16. 0 0 .76 6 .9 20.3 15 .8 0.78 7.4 19.5 15. 8 0 .81 7 .9 18.4 15. 3 0 .83 8 .5

30 22 22.4 15. 0 0 .67 6 .5 21.7 15. 0 0 .69 6 .9 21.1 14 .7 0.70 7.4 2 0.2 14. 6 0 .72 8 .0 19.2 14. 2 0 .74 8 .6

23 23.0 14. 0 0 .61 6 .6 22.4 13. 9 0 .62 7 .0 21.8 13 .7 0.63 7.5 2 1.0 13. 6 0 .65 8 .1 19.9 13. 2 0 .66 8 .7

24 23.7 12. 8 0 .54 6 .6 23.1 12. 7 0 .55 7 .1 22.6 12 .6 0.56 7.5 2 1.7 12. 6 0 .58 8 .1 20.7 12. 2 0 .59 8 .9

7.2

Cooling Capacity (Standard Air Flow) ; PEH-7MYB-EU

Air volume

CMM

L/S

50

833

60

1,000

70

1,167

capacity

input

Factor for various air flow(Cooling)

0.975

0.989

1.0

1.0

1.024

1.009

Page 14

- 12 -

-15. 0 -10. 0 -5.0 0 .0 5.0 10.0 15. 0

Indoor QT/IQT/IQT/IQT/IQT/IQT/IQT/I

outdoor Heating capacit

y

DB°CkWkWkWkWkWkWkWkWkWkWkWkWkWkW

reduction ratio

15 13.3 4.1 14. 7 4 .6 16. 6 5 .2 18. 5 5 .7 20.7 6.3 22. 9 6 .8 25. 7 7.1

16 13.1 4.2 14. 5 4 .7 16. 4 5 .2 18. 3 5 .8 20.5 6.3 22. 7 6 .9 25. 5 7.2

17 12.9 4.3 14. 4 4 .8 16. 2 5 .3 18. 1 5 .9 20.3 6.4 22. 5 7 .0 25. 3 7.3

18 12.8 4.4 14. 2 4 .8 16. 0 5 .4 17. 9 6 .0 20.1 6.5 22. 3 7 .1 25. 1 7.4

19 12.6 4.4 14. 0 4 .9 15. 9 5 .5 17. 7 6 .0 19. 9 6 .6 22. 1 7.2 24. 9 7 .5

20 12.5 4.5 13. 9 5 .0 15. 7 5 .5 17. 5 6 .1 19. 7 6 .7 21. 9 7.3 24. 7 7 .6

21 12.3 4.6 13. 7 5 .0 15. 5 5 .6 17. 3 6 .2 19. 5 6 .8 21. 8 7.4 24. 5 7 .8

22 12.2 4.7 13. 5 5 .1 15. 3 5 .7 17. 1 6 .3 19. 4 6 .9 21. 7 7.5 24. 3 7 .9

23 12.1 4.8 13. 3 5 .2 15. 1 5 .8 16. 9 6 .4 19. 2 7 .0 21. 5 7.6 24. 1 8 .0

24 12.0 4.9 13. 1 5 .3 14. 9 5 .9 16. 7 6 .5 19. 1 7 .1 21. 4 7.8 23. 9 8 .2

25 11.9 5.0 12. 9 5 .4 14. 7 6 .0 16. 5 6 .6 18. 9 7 .2 21. 3 7.9 23. 7 8 .3

26 11.7 5.1 12. 7 5 .5 14. 5 6 .1 16. 3 6 .7 18. 7 7 .4 21. 2 8.0 23. 5 8 .4

27 11.6 5.2 12. 5 5 .5 14. 3 6 .2 16. 1 6 .8 18. 6 7 .5 21. 1 8.1 23. 3 8 .6

Reduction ratio by frosting

1.0

0.98

0.88

0.85

0.86

0.89

0.92

0.92

0.92

0.92

0.92

642

0

-2-4-6

-8

-10

-12

-15

Heating Capacity (Standard Air Flow) ; PEH-7MYB-EU

Outdoor WB°C

WB°C

Air volume

CMM

L/S

50

833

60

1,000

70

1,167

capacity

input

Factor for various air flow(Cooling)

0.980

1.028

1.0

1.0

1.011

0.980

Page 15

- 13 -

-5.0 0.0 5.0 10. 0 15.0 20.0

Indoor Indoor Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I

kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW

15

23. 1 1 5.9 0 .6 9 6 .4 23.0 15. 9 0 .6 9 6 .3 22.9 15. 6 0 .6 8 6 .3 22.4 15. 5 0 .6 9 6 .4 22. 0 1 5.2 0 .69 6 .4 21.5 15. 0 0 .70 6 .8

20 16 23.8 1 4. 5 0 .61 6 .4 23.7 14. 4 0 .61 6 .4 23.5 14. 4 0 .61 6 .4 23.1 14. 1 0 .61 6 .4 22. 7 1 4. 0 0 .62 6 .5 22.1 13. 7 0 .62 6 .9

17 24. 4 1 2.9 0 .53 6 .4 24.3 12. 9 0 .53 6 .4 24.2 12. 8 0 .53 6 .4 23.8 12. 8 0 .54 6 .5 23.3 1 2. 6 0 .54 6 .6 22.8 12. 5 0 .55 7 .0

15 23. 1 1 8.5 0 .80 6 .4 23.0 18. 4 0 .80 6 .3 22.9 18. 3 0 .80 6 .3 22.4 18. 2 0 .81 6 .4 22.0 1 7. 8 0 .81 6 .4 21.5 17. 6 0 .82 6 .8

16 23. 8 1 7.1 0 .72 6 .4 23.7 17. 0 0 .72 6 .4 23.5 17. 2 0 .73 6 .4 23.1 16. 6 0 .72 6 .4 22.7 1 6. 3 0 .72 6 .5 22.1 16. 1 0 .73 6 .9

22 17 24.4 1 5. 6 0 .64 6 .4 24.3 15. 8 0 .65 6 .4 24.2 15. 7 0 .65 6 .4 23.8 15. 2 0 .64 6 .5 23. 3 1 4. 7 0 .63 6 .6 22.8 14. 8 0 .65 7 .0

18 25. 1 1 4.5 0 .58 6 .5 25.0 14. 5 0 .58 6 .5 24.9 14. 4 0 .58 6 .4 24.4 14. 2 0 .58 6 .6 24.0 1 3. 7 0 .57 6 .7 23.4 13. 6 0 .58 7 .0

19 26. 0 1 3.2 0 .51 6 .6 25.9 13. 2 0 .51 6 .5 25.7 13. 1 0 .51 6 .5 25.3 12. 9 0 .51 6 .7 24.9 1 2. 7 0 .51 6 .8 24.3 12. 4 0 .51 7 .1

16 23.8 20. 2 0 .85 6 .4 23.7 20. 1 0 .85 6 .4 23.5 19. 8 0 .84 6 .4 23.1 19. 6 0 .85 6 .4 22. 7 1 9. 3 0 .85 6 .5 22.1 19. 0 0 .86 6 .9

17 24. 4 1 8. 6 0 .76 6 .4 24.3 18. 5 0 .76 6 .4 24.2 18. 4 0 .76 6 .4 23.8 18. 3 0 .77 6 .5 23. 3 1 8. 0 0 .77 6 .6 22.8 17. 8 0 .78 7 .0

24

18

25. 1 1 6.8 0 .6 7 6 .5 25.0 17. 0 0 .6 8 6 .5 24.9 16. 9 0 .6 8 6 .4 24.4 16. 8 0 .6 9 6 .6 24. 0 1 6.5 0 .69 6 .7 23.4 16. 4 0 .70 7 .0

19 26. 0 1 5. 6 0 .60 6 .6 25.9 15. 5 0 .60 6 .5 25.7 15. 4 0 .60 6 .5 25.3 15. 4 0 .61 6 .7 24. 9 1 5. 4 0 .62 6 .8 24.3 15. 1 0 .62 7 .1

20 26. 8 1 4. 2 0 .53 6 .7 26.7 14. 2 0 .53 6 .6 26.6 13. 8 0 .52 6 .6 26.2 13. 9 0 .53 6 .7 25. 7 1 3. 9 0 .54 6 .9 25.2 13. 6 0 .54 7 .2

21 27. 5 1 2. 7 0 .46 6 .8 27.4 12. 3 0 .45 6 .8 27.3 12. 0 0 .44 6 .7 26.9 12. 4 0 .46 6 .9 26. 5 1 2. 5 0 .47 7 .0 26.0 11. 9 0 .46 7 .3

18 25. 1 1 9. 6 0 .78 6 .5 25.0 19. 2 0 .77 6 .5 24.9 18. 6 0 .75 6 .4 24.4 18. 8 0 .77 6 .6 24. 0 1 8. 9 0 .79 6 .7 23.4 18. 7 0 .80 7 .0

19 26. 0 1 8. 4 0 .71 6 .6 25.9 18. 1 0 .70 6 .5 25.7 17. 8 0 .69 6 .5 25.3 17. 7 0 .70 6 .7 24. 9 1 7. 7 0 .71 6 .8 24.3 17. 5 0 .72 7 .1

26

20

26. 8 1 6.9 0 .6 3 6 .7 26.7 16. 8 0 .6 3 6 .6 26.6 16. 8 0 .6 3 6 .6 26.2 16. 5 0 .6 3 6 .7 25. 7 1 6.2 0 .63 6 .9 25.2 16. 1 0 .64 7 .2

21 27. 5 1 5. 7 0 .57 6 .8 27.4 15. 6 0 .57 6 .8 27.3 15. 3 0 .56 6 .7 26.9 15. 1 0 .56 6 .9 26. 5 1 4. 8 0 .56 7 .0 26.0 14. 8 0 .57 7 .3

22 28. 2 1 4. 1 0 .50 7 .0 28.1 14. 0 0 .50 6 .9 27.9 13. 7 0 .49 6 .9 27.6 13. 5 0 .49 7 .0 27. 3 1 3. 4 0 .49 7 .1 26.7 13. 4 0 .50 7 .4

23 28. 8 1 2. 7 0 .44 7 .1 28.7 12. 3 0 .43 7 .1 28.6 12. 0 0 .42 7 .0 28.3 11. 9 0 .42 7 .1 28. 1 1 1. 8 0 .42 7 .3 27.5 11. 8 0 .43 7 .5

19 26.0 20. 8 0 .80 6 .6 25.9 20. 7 0 .80 6 .5 25.7 20. 6 0 .80 6 .5 25.3 20. 5 0 .81 6 .7 24. 9 20. 1 0 .81 6 .8 24.3 19. 9 0 .82 7 .1

28

20

26. 8 1 9.6 0 .7 3 6 .7 26.7 19. 5 0 .7 3 6 .6 26.6 19. 7 0 .7 4 6 .6 26.2 19. 4 0 .7 4 6 .7 25. 7 1 9.0 0 .74 6 .9 25.2 18. 9 0 .75 7 .2

21 27. 5 1 8. 2 0 .66 6 .8 27.4 18. 4 0 .67 6 .8 27.3 18. 3 0 .67 6 .7 26.9 18. 0 0 .67 6 .9 26. 5 1 7. 8 0 .67 7 .0 26.0 17. 7 0 .68 7 .3

22 28. 2 1 6. 9 0 .60 7 .0 28.1 16. 8 0 .60 6 .9 27.9 16. 8 0 .60 6 .9 27.6 16. 6 0 .60 7 .0 27. 3 1 6. 4 0 .60 7 .1 26.7 16. 3 0 .61 7 .4

23 28. 8 1 5. 3 0 .53 7 .1 28.7 15. 2 0 .53 7 .1 28.6 15. 2 0 .53 7 .0 28.3 15. 0 0 .53 7 .1 28. 1 1 4. 9 0 .53 7 .3 27.5 14. 9 0 .54 7 .5

24 29. 5 1 3. 9 0 .47 7 .3 29.4 13. 8 0 .47 7 .2 29.3 13. 5 0 .46 7 .1 29.0 13. 4 0 .46 7 .3 28. 8 1 3. 3 0 .46 7 .4 28.3 13. 3 0 .47 7 .6

20 26.8 22. 0 0 .82 6 .7 26.7 22. 2 0 .83 6 .6 26.6 22. 1 0 .83 6 .6 26.2 22. 0 0 .84 6 .7 25. 7 21. 6 0 .84 6 .9 25.2 21. 7 0 .86 7 .2

21 27.5 20. 6 0 .75 6 .8 27.4 20. 8 0 .76 6 .8 27.3 20. 7 0 .76 6 .7 26.9 20. 4 0 .76 6 .9 26. 5 20. 4 0 .77 7 .0 26.0 20. 2 0 .78 7 .3

30 22 28. 2 1 9. 1 0 .68 7 .0 28.1 19. 1 0 .68 6 .9 27.9 19. 0 0 .68 6 .9 27.6 19. 1 0 .69 7 .0 27. 3 1 8. 8 0 .69 7 .1 26.7 18. 7 0 .70 7 .4

23 28. 8 1 7. 9 0 .62 7 .1 28.7 17. 8 0 .62 7 .1 28.6 17. 7 0 .62 7 .0 28.3 17. 6 0 .62 7 .1 28. 1 1 7. 4 0 .62 7 .3 27.5 17. 3 0 .63 7 .5

24 29. 5 1 6. 2 0 .55 7 .3 29.4 16. 2 0 .55 7 .2 29.3 16. 1 0 .55 7 .1 29.0 16. 0 0 .55 7 .3 28. 8 1 5. 9 0 .55 7 .4 28.3 15. 8 0 .56 7 .6

DB°CWB°C

Cooling Capacity (Standard Air Flow) ; PEH-8MYB-EU

Outdoor DB°C

Air volume

CMM

L/S

60

1,000

70

1,167

80

1,333

capacity

input

Factor for various air flow(Cooling)

0.976

0.991

1.0

1.0

1.025

1.009

Page 16

- 14 -

25.0 30.0 35.0 40. 0 46. 0

Indoor Indoor Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I Q SHC SHF T/I

kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW

15

20.9 14. 8 0 .7 1 7 .1 20.1 14. 5 0 .7 2 7 .6 19.4 14 .1 0.73 8.2 18.1 13. 4 0 .7 4 8 .8 16.6 12. 5 0 .75 9 .6

20 16 21.6 13. 6 0 .6 3 7 .2 20.7 13. 0 0 .6 3 7 .7 19 .8 12. 5 0 .63 8 .2 18.7 12. 2 0 .65 8 .9 17.4 11. 5 0.66 9 .7

17 22.2 12. 2 0 .5 5 7 .3 21.3 11. 7 0 .5 5 7 .8 20.5 11. 0 0 .5 4 8 .3 19.4 10. 7 0 .5 5 9 .0 18.2 10. 3 0 .57 9 .8

15 20.9 17. 3 0 .8 3 7 .1 20.1 17. 1 0 .8 5 7 .6 19.4 16. 8 0 .8 7 8 .2 18.1 15. 9 0 .8 8 8 .8 16.6 14. 8 0 .89 9 .6

16 21.6 16. 2 0 .7 5 7 .2 20.7 15. 7 0 .7 6 7 .7 19.8 15. 2 0 .7 7 8 .2 18.7 14. 6 0 .7 8 8 .9 17.4 13. 7 0 .79 9 .7

22 17 22.2 14. 7 0 .6 6 7 .3 21.3 14. 3 0 .6 7 7 .8 20 .5 13. 7 0 .67 8 .3 19.4 13. 2 0 .68 9 .0 18.2 12. 7 0.70 9 .8

18 22.9 13. 5 0 .5 9 7 .4 22.0 13. 0 0 .5 9 7 .9 21.1 12. 7 0 .6 0 8 .4 20.1 12. 3 0 .6 1 9 .1 18.9 11. 7 0 .62 9 .9

19 23.8 12. 1 0 .5 1 7 .5 22.9 11. 9 0 .5 2 8 .0 22.0 11. 4 0 .5 2 8 .6 21.0 11. 1 0 .5 3 9 .2 19.8 10. 7 0 .54 1 0.0

16 21.6 18. 8 0 .87 7 .2 20.7 18. 4 0 .89 7 .7 19.8 17 .8 0.90 8.2 18.7 17. 2 0 .9 2 8 .9 17.4 16. 3 0 .9 4 9 .7

17 22.2 17. 6 0 .79 7 .3 21.3 17. 1 0 .80 7 .8 20.5 16 .6 0.81 8.3 19.4 16. 1 0 .8 3 9 .0 18.2 15. 2 0 .8 4 9 .8

24

18

22.9 16. 0 0 .7 0 7 .4 22.0 15. 6 0 .7 1 7 .9 21.1 15 .2 0.72 8. 4 2 0.1 14. 9 0 .74 9 .1 18.9 14. 2 0 .75 9 .9

19 23.8 14. 7 0 .62 7 .5 22.9 14. 4 0 .63 8 .0 22.0 14 .1 0.64 8.6 2 1.0 13. 7 0 .6 5 9 .2 19.8 13. 1 0 .6 6 1 0.0

20 24.6 13. 3 0 .54 7 .6 23.8 13. 1 0 .55 8 .2 22.9 12 .6 0.55 8.8 2 1.9 12. 3 0 .5 6 9 .4 20.7 11. 8 0 .5 7 1 0.1

21 25.4 11. 7 0 .46 7 .6 24.6 11. 3 0 .46 8 .2 23.8 11 .2 0.47 8.8 2 2.8 10. 7 0 .4 7 9 .4 21.6 10. 3 0 .4 8 1 0.2

18 22.9 18. 3 0 .80 7 .4 22.0 18. 0 0 .82 7 .9 21.1 17 .5 0.83 8.4 2 0.1 17. 1 0 .8 5 9 .1 18.9 16. 3 0 .8 6 9 .9

19 23.8 17. 3 0 .73 7 .5 22.9 16. 9 0 .74 8 .0 22.0 16 .5 0.75 8.6 2 1.0 16. 2 0 .7 7 9 .2 19.8 15. 4 0 .7 8 1 0.0

26

20

24.6 16. 0 0 .6 5 7 .6 23.8 15. 7 0 .6 6 8 .2 22.9 15 .3 0.67 8. 8 2 1.9 15. 1 0 .69 9 .4 20.7 14. 5 0 .70 1 0. 1

21 25.4 14. 7 0 .58 7 .6 24.6 14. 3 0 .58 8 .2 23.8 14 .0 0.59 8.8 2 2.8 13. 7 0 .6 0 9 .4 21.6 13. 2 0 .6 1 1 0.2

22 26.2 13. 1 0 .50 7 .7 25.4 13. 0 0 .51 8 .3 24.6 12 .6 0.51 8.8 2 3.7 12. 3 0 .5 2 9 .5 22.4 11. 7 0 .5 2 1 0.3

23 27.0 11. 6 0 .43 7 .8 26.2 11. 3 0 .43 8 .4 25.5 11 .0 0.43 8.9 2 4.5 10. 5 0 .4 3 9 .6 23.3 10. 0 0 .4 3 1 0.4

19 23.8 19. 7 0 .83 7 .5 22.9 19. 2 0 .84 8 .0 18.722.0 0.85 21.0 18. 5 0 .88 9 .2 19.8 18. 0 0 .91 1 0. 0

28

20

24.6 18. 7 0 .7 6 7 .6 23.8 18. 3 0 .7 7 8 .2 22.9 17 .8 0.78 8. 8 2 1.9 17. 5 0 .80 9 .4 20.7 17. 2 0 .83 1 0. 1

21 25.4 17. 3 0 .68 7 .6 24.6 17. 0 0 .69 8 .2 23.8 16 .6 0.70 8.8 2 2.8 16. 6 0 .7 3 9 .4 21.6 16. 2 0 .7 5 1 0.2

22 26.2 16. 0 0 .61 7 .7 25.4 15. 8 0 .62 8 .3 24.6 15 .5 0.63 8.8 2 3.7 15. 1 0 .6 4 9 .5 22.4 14. 8 0 .6 6 1 0.3

23 27.0 14. 6 0 .54 7 .8 26.2 14. 4 0 .55 8 .4 25.5 14 .0 0.55 8.9 2 4.5 13. 7 0 .5 6 9 .6 23.3 13. 3 0 .5 7 1 0.4

24 27.7 13. 0 0 .47 7 .9 27.1 13. 0 0 .48 8 .4 26.4 12 .7 0.48 8.9 2 5.4 12. 2 0 .4 8 9 .7 24.2 11. 6 0 .4 8 1 0.6

20 24.6 21. 4 0 .87 7 .6 23. 8 2 1. 1 0 .89 8 .2 22.9 20 .6 0.90 8.8 2 1.9 20. 1 0 .92 9 .4 20.7 19. 2 0 .93 1 0.1

21 25.4 20. 1 0 .79 7 .6 24.6 19. 7 0 .80 8 .2 23.8 19 .5 0.82 8.8 2 2.8 18. 9 0 .8 3 9 .4 21.6 18. 3 0 .8 5 1 0.2

30 22 26.2 18. 3 0 .70 7 .7 25.4 18. 3 0 .72 8 .3 24.6 18 .0 0.73 8.8 2 3.7 17. 7 0 .7 5 9 .5 22.4 17. 3 0 .7 7 1 0.3

23 27.0 17. 2 0 .64 7 .8 26.2 17. 1 0 .65 8 .4 25.5 17 .1 0.67 8.9 2 4.5 16. 9 0 .6 9 9 .6 23.3 16. 6 0 .7 1 1 0.4

24 27.7 15. 8 0 .57 7 .9 27.1 16. 0 0 .59 8 .4 26.4 16 .1 0.61 8.9 2 5.4 16. 0 0 .6 3 9 .7 24.2 15. 7 0 .6 5 1 0.6

8.6

DB°CWB°C

Cooling Capacity (Standard Air Flow) ; PEH-8MYB-EU

Outdoor DB°C

Air volume

CMM

L/S

60

1,000

70

1,167

80

1,333

capacity

input

Factor for various air flow(Cooling)

0.976

0.991

1.0

1.0

1.025

1.009

Page 17

- 15 -

-15. 0 -10. 0 -5.0 0 .0 5.0 10.0 15. 0

Indoor QT/IQT/IQT/IQT/IQT/IQT/IQT/I

outdoor Heating capacity

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

reduction ratio

15 14.5 4.3 16. 1 4 .8 18. 2 5 .4 20. 2 6 .0 22.7 6.5 25. 1 7 .1 28. 2 7.4

16 14.3 4.4 15. 9 4 .9 18. 0 5 .5 20. 0 6 .0 22.4 6.6 24. 9 7 .2 27. 9 7.5

17 14.2 4.5 15. 7 5 .0 17. 8 5 .5 19. 8 6 .1 22.2 6.7 24. 6 7 .3 27. 7 7.6

18 14.0 4.5 15. 5 5 .0 17. 6 5 .6 19. 6 6 .2 22.0 6.8 24. 4 7 .4 27. 5 7.7

19 13.8 4.6 15. 4 5 .1 17. 4 5 .7 19. 4 6 .3 21.8 6.9 24. 2 7 .5 27. 3 7.8

20 13.6 4.7 15. 2 5 .2 17. 2 5 .8 19. 1 6 .4 21.5 7.0 24. 0 7 .6 27. 1 7.9

21 13.5 4.8 15. 0 5 .3 16. 9 5 .9 18. 9 6 .5 21.4 7.1 23. 8 7 .7 26. 8 8.1

22 13.4 4.9 14. 7 5 .3 16. 7 6 .0 18. 7 6 .6 21.2 7.2 23. 7 7 .8 26. 6 8.2

23 13.2 5.0 14. 5 5 .4 16. 5 6 .1 18. 5 6 .7 21.0 7.3 23. 6 8 .0 26. 4 8.4

24 13.1 5.1 14. 3 5 .5 16. 3 6 .1 18. 3 6 .8 20.9 7.4 23. 5 8 .1 26. 2 8.5

25 13.0 5.2 14. 1 5 .6 16. 1 6 .2 18. 0 6 .9 20.7 7.6 23. 3 8 .2 26. 0 8.6

26 12.8 5.4 13. 9 5 .7 15. 8 6 .3 17. 8 7 .0 20.5 7.7 23. 2 8 .4 25. 7 8.8

27 12.7 5.5 13. 6 5 .8 15. 6 6 .4 17. 6 7 .1 20.3 7.8 23. 1 8 .5 25. 5 8.9

Reduction ratio by frosting

Heating Capacity (Standard Air Flow) ; PEH-8MYB-EU

WB°C

Outdoor WB°C

DB°C

1.0

0.98

0.88

0.85

0.86

0.89

0.92

0.92

0.92

0.92

0.92

642

0

-2-4-6

-8

-10

-12

-15

Air volume

CMM

L/S

60

1,000

70

1,167

80

1,333

capacity

input

Factor for various air flow(Cooling)

0.989

1.010

1.0

1.0

1.011

0.987

Page 18

- 16 -

-5.0 0.0 5.0 10. 0 15.0 20.0

Indoor Indoor QSHCSHFT/I QSHCSHFT/I QSHCSHFT/I QSHCSHFT/I QSHCSHFT/I QSHCSHFT/I

kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW

15

30.2 20. 9 0 .6 9 8 .1 30.1 20. 8 0 .6 9 8 .0 30.0 20. 7 0 .6 9 8 .0 29.4 20. 6 0 .7 0 8 .1 28. 8 20. 2 0 .7 0 8 .2 28.1 19. 9 0 .71 8 .6

20 16 31.1 1 9. 0 0 .61 8 .1 31.0 18. 9 0 .61 8 .1 30.8 18. 8 0 .61 8 .1 30.2 18. 7 0 .62 8 .2 29. 7 1 8. 7 0 .63 8 .3 28.9 18. 2 0 .63 8 .7

17 32. 0 1 7.3 0 .54 8 .2 31.8 17. 2 0 .54 8 .2 31.7 17. 1 0 .54 8 .1 31.1 16. 8 0 .54 8 .3 30.5 1 6. 8 0 .55 8 .4 29.8 16. 7 0 .56 8 .8

15 30.2 23. 9 0 .79 8 .1 30.1 23. 8 0 .79 8 .0 30.0 23. 7 0 .79 8 .0 29.4 23. 5 0 .80 8 .1 28.8 23.0 0 .80 8 .2 28.1 22. 7 0 .81 8 .6

16 31.1 22. 1 0 .71 8 .1 31.0 22. 3 0 .72 8 .1 30.8 22. 2 0 .72 8 .1 30.2 21. 8 0 .72 8 .2 29.7 21.7 0 .73 8 .3 28.9 21. 4 0 .74 8 .7

22 17 32.0 20. 5 0 .64 8 .2 31.8 20. 4 0 .64 8 .2 31.7 20. 6 0 .65 8 .1 31.1 20. 2 0 .65 8 .3 30. 5 1 9. 8 0 .65 8 .4 29.8 19. 7 0 .66 8 .8

18 32. 8 1 8.7 0 .57 8 .2 32.7 19. 0 0 .58 8 .2 32.5 18. 9 0 .58 8 .2 32.0 18. 5 0 .58 8 .4 31.4 1 8. 2 0 .58 8 .5 30.7 18. 1 0 .59 9 .0

19 34. 0 1 7.3 0 .51 8 .4 33.8 17. 3 0 .51 8 .3 33.7 17. 2 0 .51 8 .3 33.1 16. 9 0 .51 8 .5 32.5 1 6. 6 0 .51 8 .6 31.8 16. 2 0 .51 9 .1

16 31.1 25. 5 0 .82 8 .1 31.0 25. 4 0 .82 8 .1 30.8 25. 6 0 .83 8 .1 30.2 25. 1 0 .83 8 .2 29. 7 24. 9 0 .84 8 .3 28.9 24. 6 0 .85 8 .7

17 32.0 23. 7 0 .74 8 .2 31.8 23. 9 0 .75 8 .2 31.7 23. 8 0 .75 8 .1 31.1 23. 3 0 .75 8 .3 30. 5 23. 2 0 .76 8 .4 29.8 23. 0 0 .77 8 .8

24

18

32.8 22. 0 0 .6 7 8 .2 32.7 21. 9 0 .6 7 8 .2 32.5 21. 8 0 .6 7 8 .2 32.0 21. 4 0 .6 7 8 .4 31. 4 21. 3 0 .6 8 8 .5 30.7 20. 9 0 .68 9 .0

19 34.0 20. 4 0 .60 8 .4 33.8 20. 3 0 .60 8 .3 33.7 20. 2 0 .60 8 .3 33.1 19. 9 0 .60 8 .5 32. 5 1 9. 9 0 .61 8 .6 31.8 19. 4 0 .61 9 .1

20 35. 1 1 8. 6 0 .53 8 .5 35.0 18. 5 0 .53 8 .4 34.8 18. 5 0 .53 8 .4 34.3 18. 2 0 .53 8 .6 33. 7 1 8. 2 0 .54 8 .7 33.0 17. 8 0 .54 9 .2

21 36. 0 1 6. 6 0 .46 8 .7 35.9 16. 5 0 .46 8 .6 35.7 16. 4 0 .46 8 .6 35.2 16. 2 0 .46 8 .7 34. 7 1 6. 3 0 .47 8 .9 34.0 16. 0 0 .47 9 .3

18 32.8 25. 0 0 .76 8 .2 32.7 24. 8 0 .76 8 .2 32.5 24. 7 0 .76 8 .2 32.0 24. 3 0 .76 8 .4 31. 4 24. 2 0 .77 8 .5 30.7 23. 9 0 .78 9 .0

19 34.0 23. 4 0 .69 8 .4 33.8 23. 3 0 .69 8 .3 33.7 23. 3 0 .69 8 .3 33.1 22. 9 0 .69 8 .5 32. 5 22. 5 0 .69 8 .6 31.8 22. 3 0 .70 9 .1

26

20

35.1 21. 8 0 .6 2 8 .5 35.0 21. 7 0 .6 2 8 .4 34.8 21. 6 0 .6 2 8 .4 34.3 21. 2 0 .6 2 8 .6 33. 7 20. 9 0 .6 2 8 .7 33.0 20. 8 0 .63 9 .2

21 36.0 20. 2 0 .56 8 .7 35.9 20. 1 0 .56 8 .6 35.7 20. 0 0 .56 8 .6 35.2 19. 7 0 .56 8 .7 34. 7 1 9. 4 0 .56 8 .9 34.0 19. 4 0 .57 9 .3

22 36. 9 1 8. 4 0 .50 8 .8 36.7 18. 4 0 .50 8 .8 36.6 18. 3 0 .50 8 .7 36.1 18. 1 0 .50 8 .9 35. 7 1 7. 9 0 .50 9 .1 35.0 17. 5 0 .50 9 .4

23 37. 7 1 6. 6 0 .44 9 .0 37.6 16. 5 0 .44 9 .0 37.4 16. 5 0 .44 8 .9 37.1 16. 3 0 .44 9 .1 36. 7 1 6. 2 0 .44 9 .2 36.0 15. 8 0 .44 9 .6

19 34.0 26. 8 0 .79 8 .4 33.8 26. 7 0 .79 8 .3 33.7 26. 6 0 .79 8 .3 33.1 26. 2 0 .79 8 .5 32. 5 26. 0 0 .80 8 .6 31.8 25. 8 0 .81 9 .1

28

20

35.1 24. 9 0 .7 1 8 .5 35.0 25. 2 0 .7 2 8 .4 34.8 25. 1 0 .7 2 8 .4 34.3 24. 7 0 .7 2 8 .6 33. 7 24. 3 0 .7 2 8 .7 33.0 24. 1 0 .73 9 .2

21 36.0 23. 0 0 .64 8 .7 35.9 22. 9 0 .64 8 .6 35.7 23. 2 0 .65 8 .6 35.2 22. 9 0 .65 8 .7 34. 7 22. 6 0 .65 8 .9 34.0 22. 4 0 .66 9 .3

22 36.9 21. 4 0 .58 8 .8 36.7 21. 7 0 .59 8 .8 36.6 21. 6 0 .59 8 .7 36.1 21. 3 0 .59 8 .9 35. 7 21. 1 0 .59 9 .1 35.0 21. 0 0 .60 9 .4

23 37.7 20. 0 0 .53 9 .0 37.6 19. 9 0 .53 9 .0 37.4 19. 8 0 .53 8 .9 37.1 19. 7 0 .53 9 .1 36. 7 1 9. 5 0 .53 9 .2 36.0 19. 1 0 .53 9 .6

24 38. 6 1 8. 1 0 .47 9 .2 38.4 18. 1 0 .47 9 .1 38.3 18. 0 0 .47 9 .1 38.0 17. 9 0 .47 9 .2 37. 7 1 7. 7 0 .47 9 .4 37.0 17. 4 0 .47 9 .7

20 35.1 27. 8 0 .79 8 .5 35.0 27. 6 0 .79 8 .4 34.8 27. 5 0 .79 8 .4 34.3 27. 1 0 .79 8 .6 33. 7 27. 0 0 .80 8 .7 33.0 26. 7 0 .81 9 .2

21 36.0 26. 3 0 .73 8 .7 35.9 26. 2 0 .73 8 .6 35.7 26. 1 0 .73 8 .6 35.2 25. 7 0 .73 8 .7 34. 7 25. 7 0 .74 8 .9 34.0 25. 5 0 .75 9 .3

30 22 36.9 24. 7 0 .67 8 .8 36.7 24. 6 0 .67 8 .8 36.6 24. 5 0 .67 8 .7 36.1 24. 2 0 .67 8 .9 35. 7 24. 3 0 .68 9 .1 35.0 23. 8 0 .68 9 .4

23 37.7 23. 0 0 .61 9 .0 37.6 22. 9 0 .61 9 .0 37.4 22. 8 0 .61 8 .9 37.1 22. 6 0 .61 9 .1 36. 7 22. 8 0 .62 9 .2 36.0 22. 3 0 .62 9 .6

24 38.6 21. 2 0 .55 9 .2 38.4 21. 1 0 .55 9 .1 38.3 21. 1 0 .55 9 .1 38.0 20. 9 0 .55 9 .2 37. 7 21. 1 0 .56 9 .4 37.0 20. 7 0 .56 9 .7

Cooling Capacity (Standard Air Flow) ; PEH-10MYB-EU

DB°C

WB°C

Outdoor DB°C

Air volume

CMM

L/S

80

1,333

90

1,500

100

1,666

capacity

input

Factor for various air flow(Cooling)

0.977

0.991

1.0

1.0

1.035

1.005

Page 19

- 17 -

25.0 30.0 35.0 40. 0 46.0

Indoor Indoor Q SHC SHF T/ I Q SHC SHF T/ I Q SHC SHF T/ I Q SHC SHF T/ I Q SHC SHF T/ I

kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW

15

27.4 19. 4 0 .7 1 9 .1 26.4 19. 0 0 .7 2 9 .7 25.3 18 .2 0.72 10.4 23.7 17. 5 0 .74 11.2 21.7 16. 3 0 .75 1 2.2

20 16 28.2 18. 1 0 .6 4 9 .2 27.1 17. 3 0 .6 4 9 .8 25 .9 16. 6 0.64 1 0.5 2 4.5 15. 9 0 .65 11.4 22.8 15. 0 0 .6 6 1 2.3

17 29.1 16. 3 0 .5 6 9 .3 27.9 15. 6 0 .5 6 9 .9 26.8 15. 0 0 .56 1 0.6 2 5.4 14. 5 0 .57 11.5 23.8 13. 5 0 .5 7 1 2.4

15 27.4 22. 4 0 .8 2 9 .1 26. 4 2 2. 1 0 .84 9 .7 25.3 21.5 0.85 10.4 23.7 20. 6 0 .87 11.2 21.7 19. 4 0.89 1 2.2

16 28.2 21. 2 0 .7 5 9 .2 27. 1 2 0. 6 0 .76 9 .8 25.9 20.0 0.77 10.5 24.5 19. 1 0 .78 11.4 22.8 18. 2 0.80 1 2.3

22 17 29.1 19. 5 0 .6 7 9 .3 27.9 19. 0 0 .6 8 9 .9 26 .8 18. 2 0.68 1 0.6 2 5.4 17. 8 0 .70 11.5 23.8 16. 9 0 .7 1 1 2.4

18 30.0 17. 7 0 .5 9 9 .4 28.8 17. 3 0 .60 10. 0 2 7. 6 16. 9 0 .6 1 1 0.7 2 6.4 16. 3 0 .62 11.6 24.8 15. 6 0 .63 1 2. 6

19 31.1 16. 2 0 .5 2 9 .5 30.0 15. 6 0 .52 10. 2 2 8. 8 15. 3 0 .5 3 1 0.9 2 7.5 14. 9 0 .54 11.7 25.9 14. 0 0 .54 1 2. 7

16 28.2 24. 3 0 .86 9 .2 27. 1 2 3. 8 0 .88 9 .8 25.9 23 .1 0.89 10.5 24.5 22. 5 0 .92 11.4 22. 8 2 1. 4 0 .94 1 2. 3

17 29.1 22. 7 0 .78 9 .3 27. 9 2 2. 1 0 .79 9 .9 26.8 21 .4 0.80 10.6 25.4 20. 8 0 .82 11.5 23. 8 2 0. 2 0 .85 1 2. 4

24

18

30.0 20. 7 0 .6 9 9 .4 28. 8 2 0.2 0 .70 10. 0 2 7. 6 1 9.6 0 .7 1 1 0.7 2 6.4 19. 2 0 .73 11.6 24.8 18. 6 0 .75 1 2.6

19 31.1 19. 0 0 .61 9 .5 30.0 18. 6 0 .62 10. 2 2 8.8 1 8.1 0 .6 3 1 0.9 2 7.5 17. 9 0 .65 11.7 25.9 17. 1 0 .66 1 2.7

20 32.3 17. 4 0 .54 9 .6 31.1 16. 8 0 .54 10. 4 3 0.0 1 6.5 0 .5 5 1 1.1 2 8.7 16. 0 0 .56 11.9 27.1 15. 4 0 .57 1 2.8

21 33.3 15. 3 0 .46 9 .7 32.2 15. 1 0 .47 10. 5 3 1.1 1 4.6 0 .4 7 1 1.2 2 9.8 14. 3 0 .48 12.0 28.2 13. 5 0 .48 1 2.9

18 30.0 23. 7 0 .79 9 .4 28. 8 2 3. 3 0 .81 10. 0 2 7.6 2 2. 7 0 .82 1 0. 7 2 6.4 22. 4 0 .85 11.6 24. 8 2 1. 5 0 .87 1 2. 6

19 31.1 22. 1 0 .71 9 .5 30. 0 2 1. 6 0 .72 10. 2 2 8.8 2 1. 3 0 .74 1 0. 9 2 7.5 20. 9 0 .76 11.7 25. 9 2 0. 2 0 .78 1 2. 7

26

20

32.3 20. 6 0 .6 4 9 .6 31.1 19. 9 0 .64 10. 4 3 0. 0 1 9.5 0 .6 5 1 1.1 2 8.7 19. 2 0 .67 11.9 27.1 18. 7 0 .69 1 2. 8

21 33.3 19. 0 0 .57 9 .7 32.2 18. 7 0 .58 10. 5 3 1.1 1 8.0 0 .5 8 1 1.2 2 9.8 17. 9 0 .60 12.0 28.2 17. 5 0 .62 1 2.9

22 34.3 17. 5 0 .51 9 .8 33.3 17. 0 0 .51 10. 5 3 2.3 1 6.8 0 .5 2 1 1.2 3 1.0 16. 4 0 .53 12.1 29.4 15. 9 0 .54 1 3.1

23 35.3 15. 5 0 .44 9 .9 34.3 15. 5 0 .45 10. 6 3 3.4 1 5.0 0 .4 5 1 1.3 3 2.1 14. 8 0 .46 12.2 30.5 14. 3 0 .47 1 3.3

19 31.1 25. 5 0 .82 9 .5 30. 0 2 5. 2 0 .84 10. 2 24.828.8 0.86 27.5 24. 5 0 .89 11.7 25. 9 2 3.6 0 .9 1 1 2.7

28

20

32.3 23. 9 0 .7 4 9 .6 31. 1 2 3.6 0 .76 10. 4 3 0. 0 2 3.4 0 .7 8 1 1.1 2 8.7 22. 9 0 .80 11.9 27. 1 2 2. 5 0 .83 1 2. 8

21 33.3 22. 3 0 .67 9 .7 32. 2 2 1. 9 0 .68 10. 5 3 1.1 2 1. 8 0 .70 1 1. 2 2 9.8 21. 5 0 .72 12.0 28. 2 2 0. 9 0 .74 1 2. 9

22 34.3 20. 6 0 .60 9 .8 33. 3 2 0. 6 0 .62 10. 5 3 2.3 2 0. 3 0 .63 1 1. 2 3 1.0 19. 8 0 .64 12.1 29.4 19. 4 0 .66 1 3.1

23 35.3 19. 1 0 .54 9 .9 34.3 18. 9 0 .55 10. 6 3 3.4 1 8.7 0 .5 6 1 1.3 3 2.1 18. 3 0 .57 12.2 30.5 17. 7 0 .58 1 3.3

24 36.3 17. 1 0 .47 10.0 35.4 17. 0 0 .48 10. 7 3 4. 6 16. 9 0 .49 1 1.4 3 3.3 16.3 0 .49 12.3 31.7 15. 8 0 .50 1 3. 4

20 32.3 26. 4 0 .82 9 .6 31. 1 2 5. 8 0 .83 10. 4 3 0.0 2 5. 5 0 .85 1 1. 1 2 8.7 25. 5 0 .89 11.9 27. 1 2 4. 9 0 .92 1 2. 8

21 33.3 24. 9 0 .75 9 .7 32. 2 2 4. 8 0 .77 10. 5 3 1.1 2 4. 3 0 .78 1 1. 2 2 9.8 24. 1 0 .81 12.0 28. 2 2 3. 7 0 .84 1 2. 9

30 22 34.3 23. 6 0 .69 9 .8 33. 3 2 3. 3 0 .70 10. 5 3 2.3 2 3. 2 0 .72 1 1. 2 3 1.0 22. 9 0 .74 12.1 29. 4 2 2. 3 0 .76 1 3. 1

23 35.3 22. 2 0 .63 9 .9 34. 3 2 2. 0 0 .64 10. 6 3 3.4 2 1. 7 0 .65 1 1. 3 3 2.1 21. 5 0 .67 12.2 30. 5 2 1. 1 0 .69 1 3. 3

24 36.3 20. 7 0 .57 10.0 35. 4 2 0.5 0 .58 10. 7 3 4.6 20.4 0.59 11.4 33.3 20. 0 0 .60 12.3 31.7 19. 3 0 .6 1 1 3.4

10.9

Cooling Capacity (Standard Air Flow) ; PEH-10MYB-EU

DB°C

WB°C

Outdoor DB°C

Air volume

CMM

L/S

80

1,333

90

1,500

100

1,666

capacity

input

Factor for various air flow(Cooling)

0.977

0.991

1.0

1.0

1.035

1.005

Page 20

- 18 -

-15. 0 -10. 0 -5.0 0 .0 5.0 10.0 15. 0

Indoor QT/IQT/IQT/IQT/IQT/IQT/IQT/I

outdoor

Heating capacity

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

reduction ratio

15 19.0 5.4 21. 0 6 .0 23. 8 6 .7 26. 5 7 .4 29.7 8.1 32. 8 8 .8 36. 9 9.3

16 18.8 5.5 20. 8 6 .1 23. 5 6 .8 26. 2 7 .5 29.4 8.2 32. 5 8 .9 36. 6 9.4

17 18.5 5.6 20. 6 6 .2 23. 2 6 .9 25. 9 7 .6 29.1 8.3 32. 3 9 .1 36. 3 9.5

18 18.3 5.6 20. 3 6 .3 23. 0 7 .0 25. 6 7 .7 28.8 8.5 32. 0 9 .2 36. 0 9.6

19 18.1 5.7 20. 1 6 .4 22. 7 7 .1 25. 3 7 .8 28.5 8.6 31. 7 9 .3 35. 7 9.8

20 17.9 5.8 19. 9 6 .4 22. 5 7 .2 25. 0 7 .9 28.2 8.7 31. 4 9 .4 35. 4 9.9

21 17.7 6.0 19. 6 6 .5 22. 2 7 .3 24. 8 8 .1 28.0 8.8 31. 2 9 .6 35.1 10. 1

22 17.5 6.1 19. 3 6 .7 21. 9 7 .4 24. 5 8 .2 27.8 9.0 31. 0 9 .8 34.8 10. 2

23 17.3 6.2 19. 0 6 .8 21. 6 7 .5 24. 2 8 .3 27.5 9.1 30. 9 9 .9 34.6 10. 4

24 17.2 6.4 18. 7 6 .9 21. 3 7 .6 23. 9 8 .4 27.3 9.3 30.7 10.1 34.3 10. 6

25 17.0 6.5 18. 4 7 .0 21. 0 7 .8 23. 6 8 .6 27.1 9.4 30.5 10.2 34.0 10. 8

26 16.8 6.7 18. 1 7 .1 20. 7 7 .9 23. 3 8 .7 26.8 9.5 30.4 10.4 33.7 10. 9

27 16.6 6.8 17. 9 7 .2 20. 4 8 .0 23. 0 8 .8 26.6 9.7 30.2 10.5 33.4 11. 1

Reduction ratio by frosting

Heating Capacity (Standard Air Flow) ; PEH-10MYB-EU

DB°C

Outdoor WB°C

WB°C

1.0

0.98

0.88

0.85

0.86

0.89

0.92

0.92

0.92

0.92

0.92

642

0

-2-4-6

-8

-10

-12

-15

Air volume

CMM

L/S

80

1,333

90

1,500

100

1,666

capacity

input

Factor for various air flow(Cooling)

0.989

1.025

1.0

1.0

1.008

0.984

Page 21

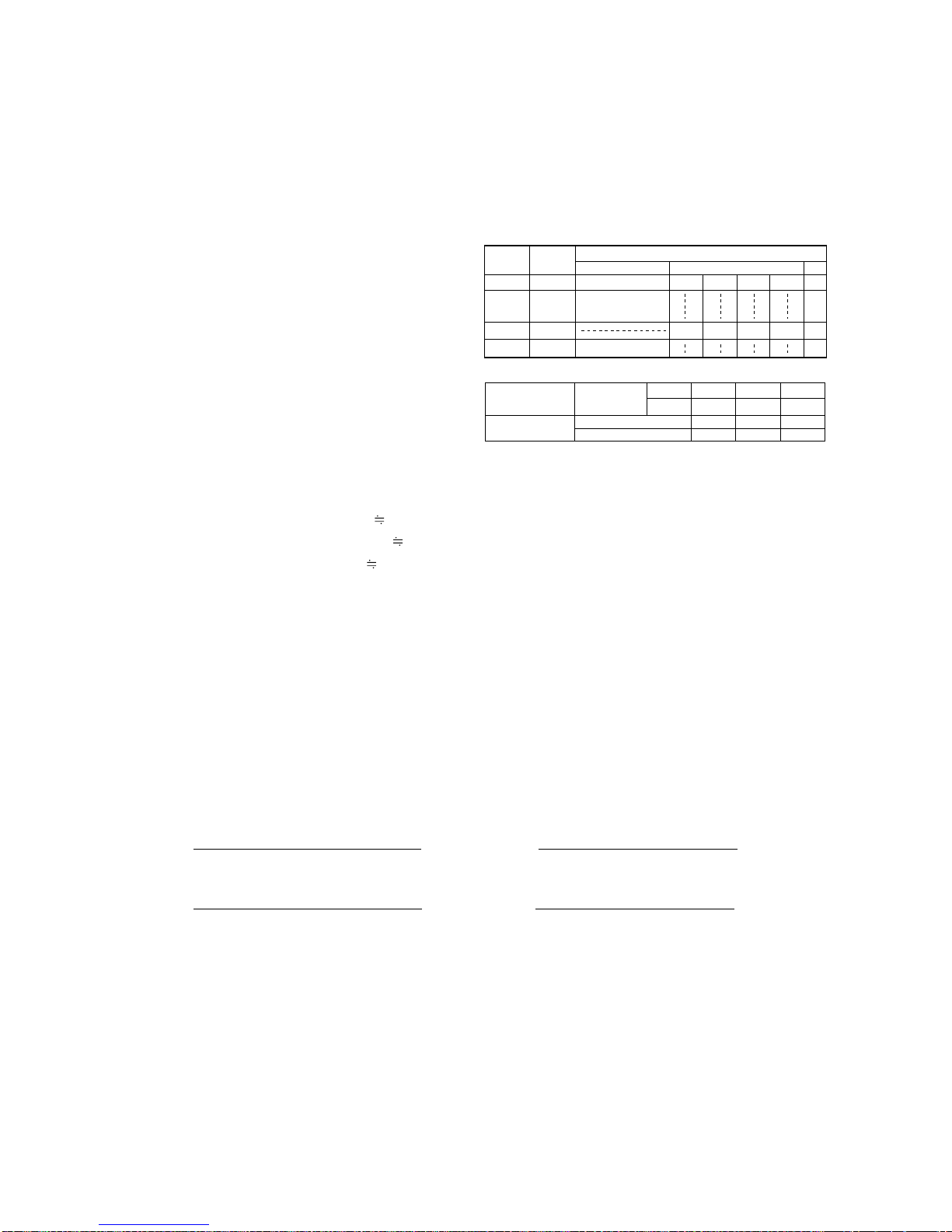

- 19 -

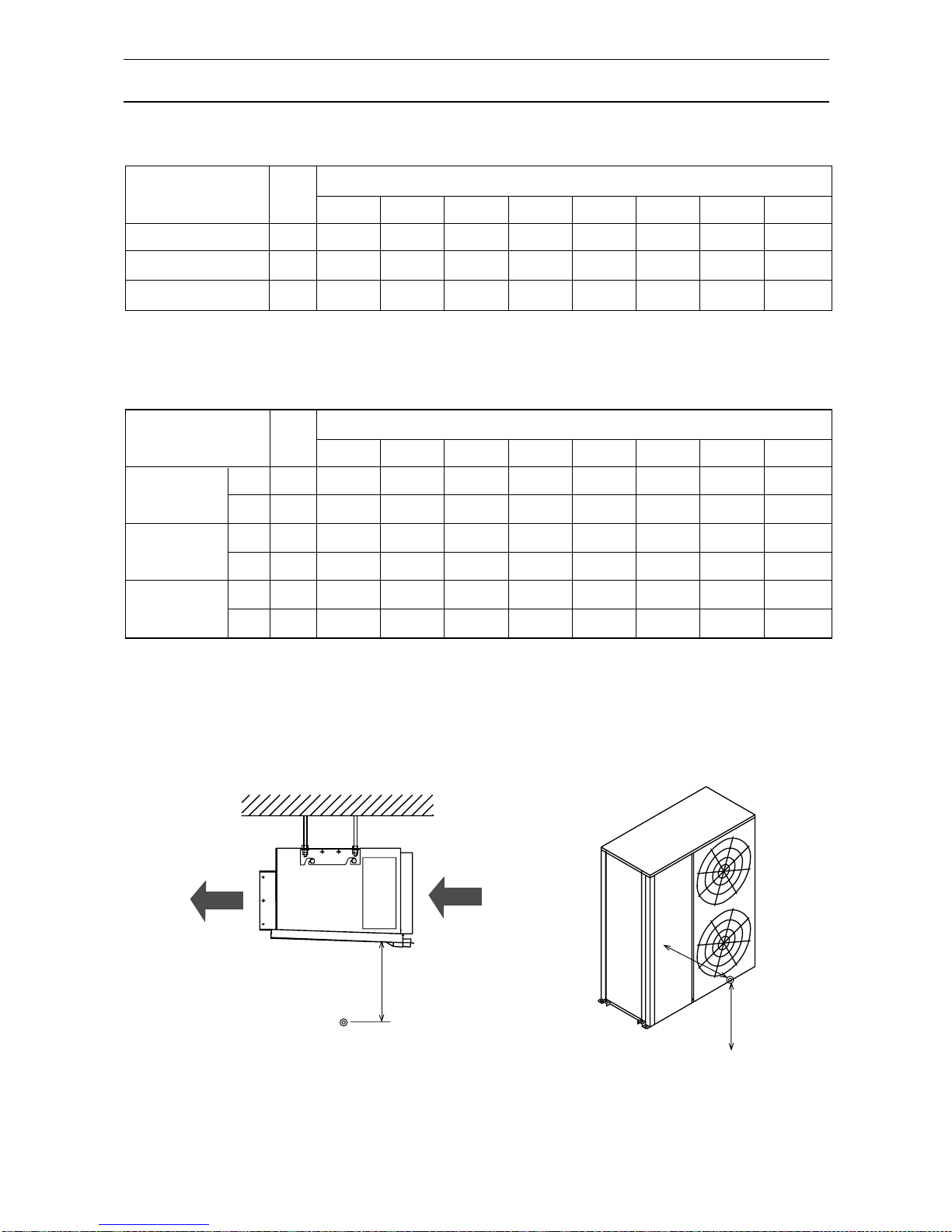

OPERATION RANGE

The range of working temperatures is as below.

Make sure which unit you are using and confirm the range of application.

Note:

As an applicable humidity outside standard for both indoors and outdoors, we

recommend use within a range of 35-80% relative humidity.

However, it is a condition that there is no be dewy in surfaces of electric parts.

Caution:

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

10 15 20

25

30

20

30

40

50

24

46

-5

-10

1510 302520

Indoor temp.(˚CWB)

Outdoor temp.(

˚CDB

)

Indoor temp.(˚CDB)

Outdoor temp.(

˚CWB

)

0

- 5

10

5

15

27

Cooling

Heating

10

0

Range for

continuous operation

1510 302520 27

-10

Range for

continuous operation

-15

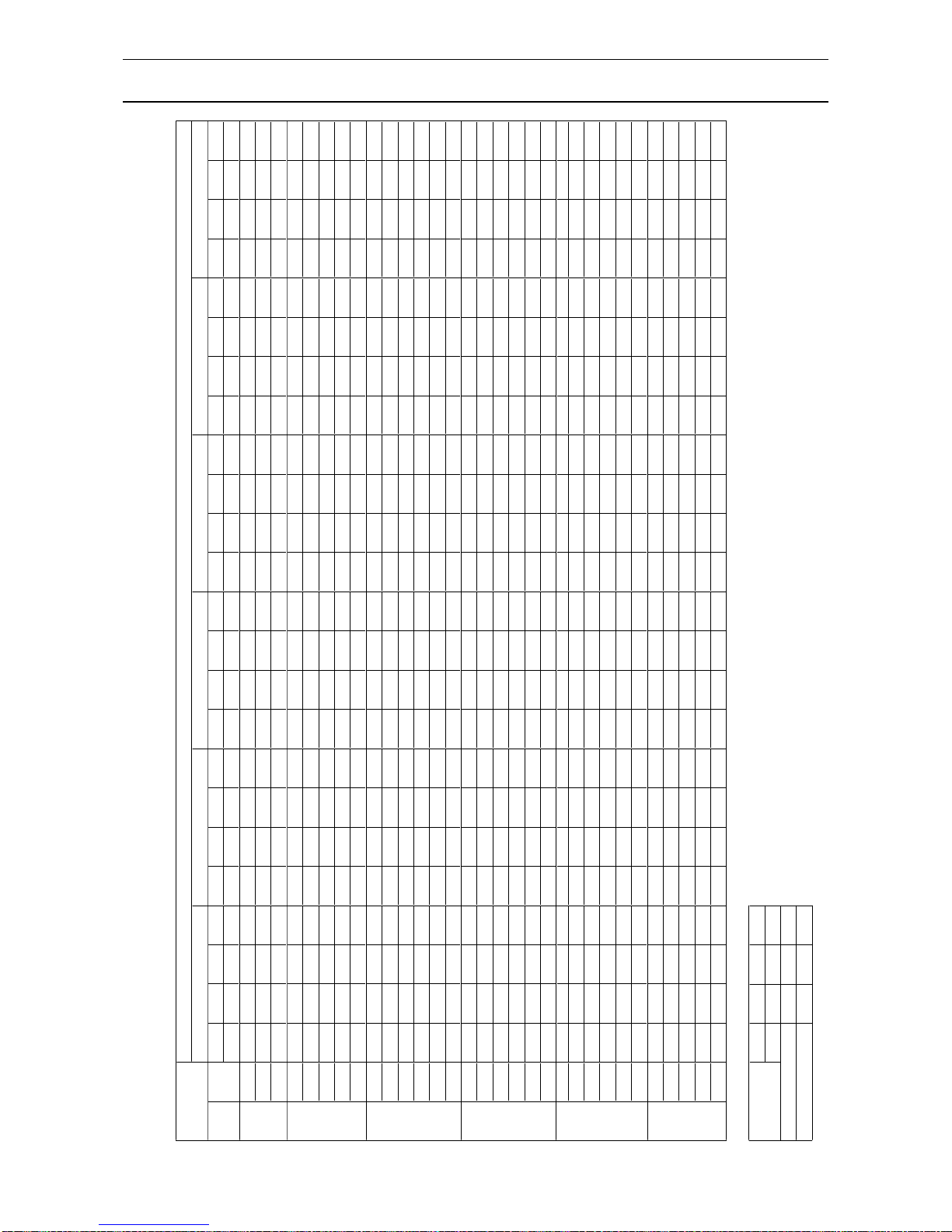

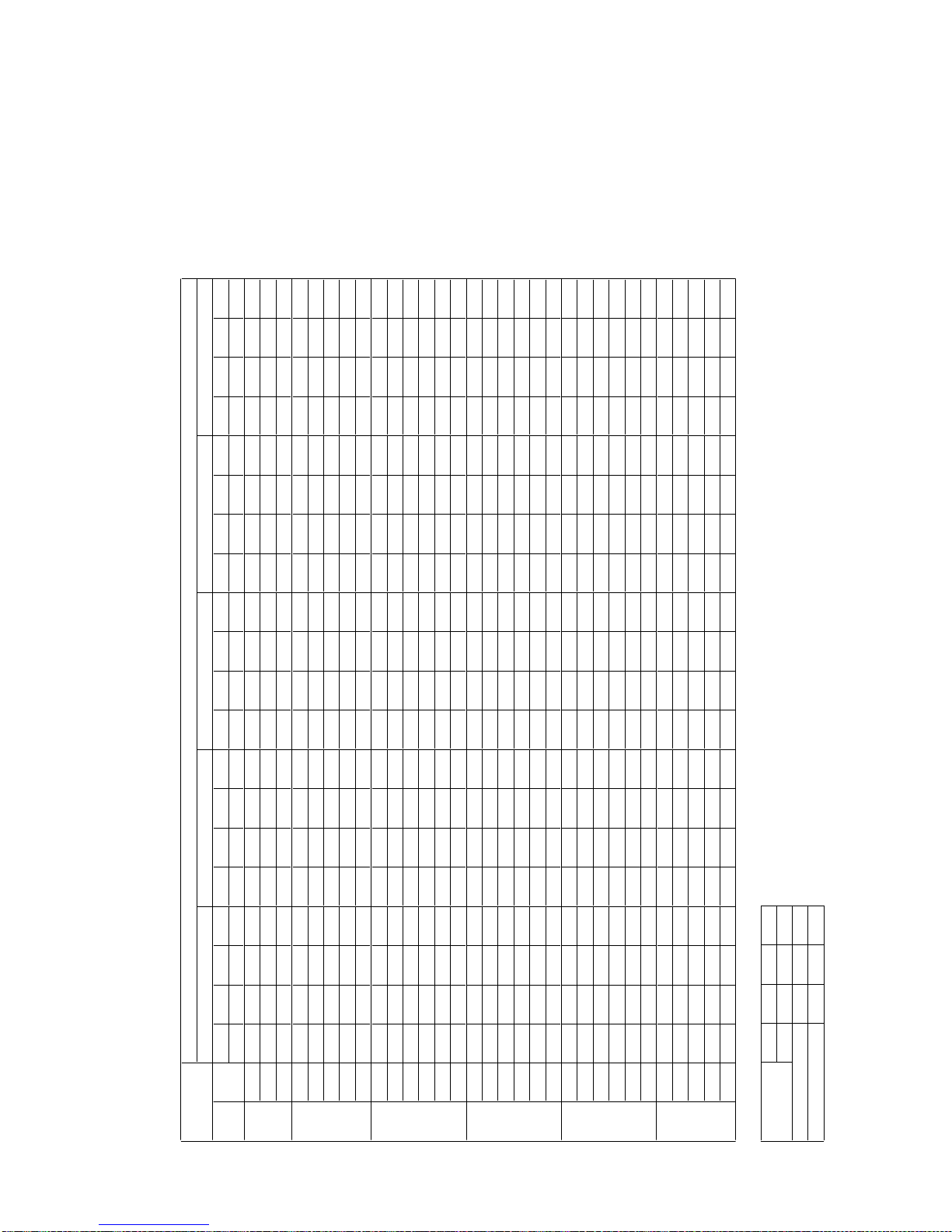

Page 22

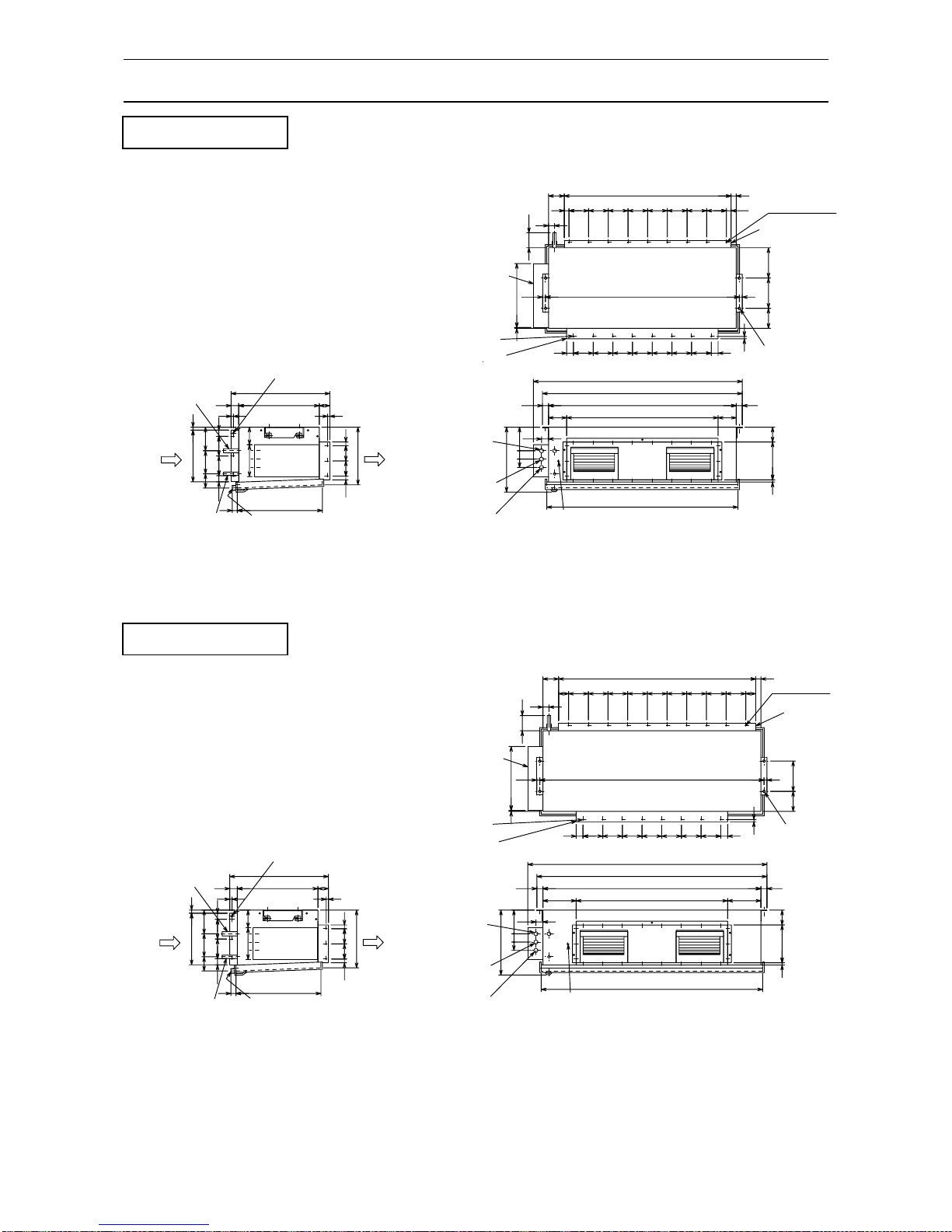

- 20 -

FAN PERFORMANCE

PEH-8MYB

PEH-10MYB

450

400

350

300

250

200

150

100

50

(Pa)

(Pa)

50

83355917601,000651,083

70

1,167751,250

80

1,333

Recommended Range

Internal SP

0

Total static pressure

Air flow

factory pre setting ESP = 125Pa

800

900

1000

1100

1200

1300

1400

Fan Performance Curve

50Hz

50

833

48

800

55

917601,000651,083701,167751,250

Recommended Range

Internal SP

450

400

350

300

250

200

150

100

50

0

For Hi speed

operation line

(Pa)

Total static pressure

Air flow

factory pre setting ESP = 125Pa

800

900

1000

1100

1200

1300

1400

For Low speed

operation line

Fan Performance Curve

50Hz

Fan Performance Curve

50Hz

65

1,083701,167

80

1,333901,500

100

1,667

(CMM)

(L/S)

(CMM)

(L/S)

(CMM)

(L/S)

0

Total static pressure

Air flow

factory pre setting ESP = 150Pa

900

1000

1100

1200

1300

1400

Internal SP

Recommended Range

For Hi speed

operation line

For Low speed

operation line

For connection

operation line

For connection

operation line

450

400

350

300

250

200

150

100

50

Fan speed (rpm)

Fan speed (rpm)

Fan speed (rpm)

PEH-7MYB

Page 23

- 21 -

SOUND DATA

Indoor units

Sound Levels

OCTAVE BAND FREQ. Hz

MODEL

SPL

63Hz 125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

63Hz 125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

56

59

63

62

61

62.5

55

58.5

54

59.5

51

53

43.5

48

38

43.5

32.5

36

Outdoor units

Indoor unit Outdoor unit

Position mesurement

Sound Levels

Inlet

PEH PUH

PEH-8MYB

PEH-10MYB

dB(A)

SPL

dB(A)

55

62 60 54

53

50

42.5

37

31.5

PEH-7MYB

OCTAVE BAND FREQ. Hz

MODEL

PUH-8MYF

PUH-10MYF

PUH-7MYF

cool

cool

65

66

65

66

64

65

59

59

59

59

59

60

63

64

63

64

62

62

63.5

64

63.5

64

62

60

55

55

54

55

54

59

52

51

52

51

52

54

50

49

50

49

51

50

43

41

44

42

48

45

39

38

40

39

44.5

41

cool

Heat

Heat

Heat

Outlet

1m

1m

1m

Page 24

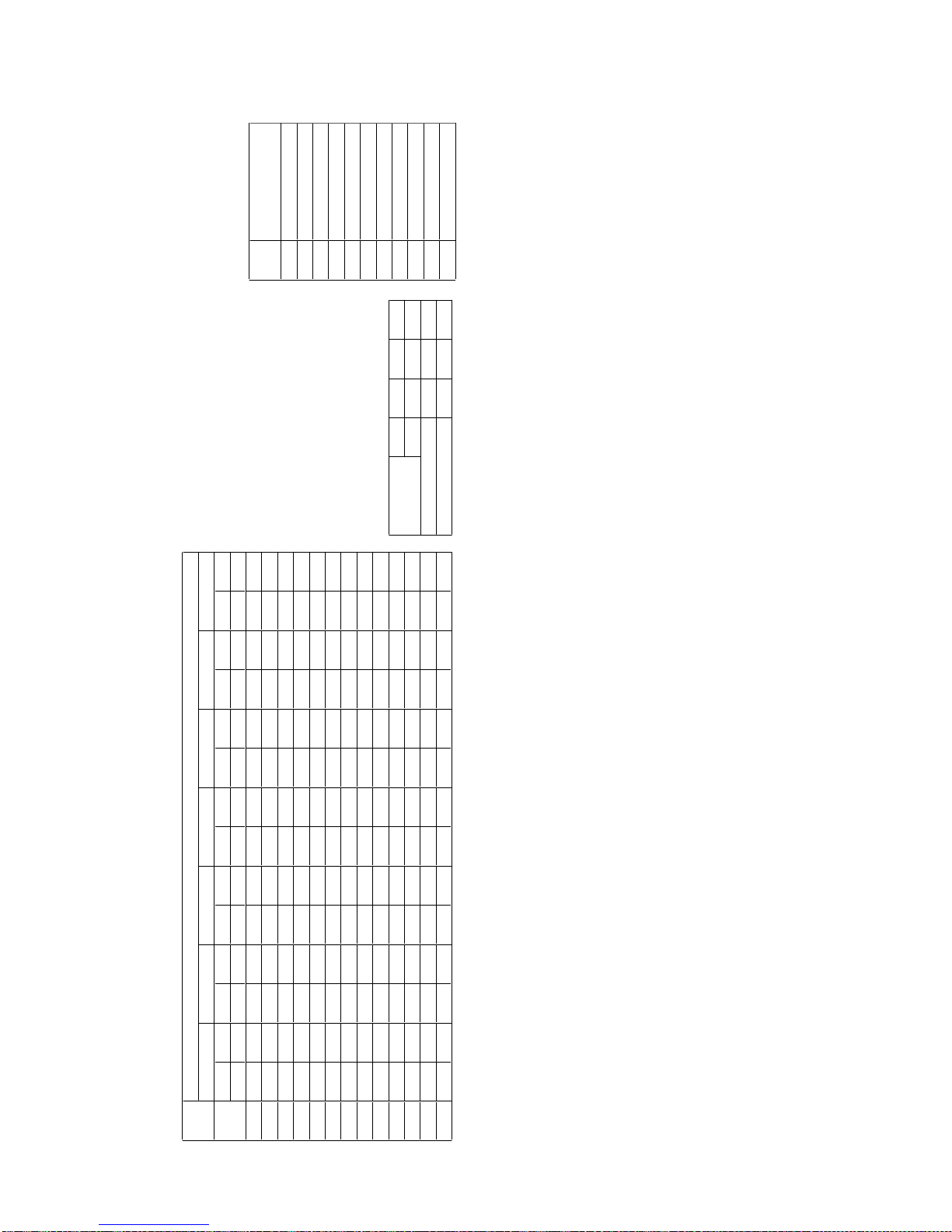

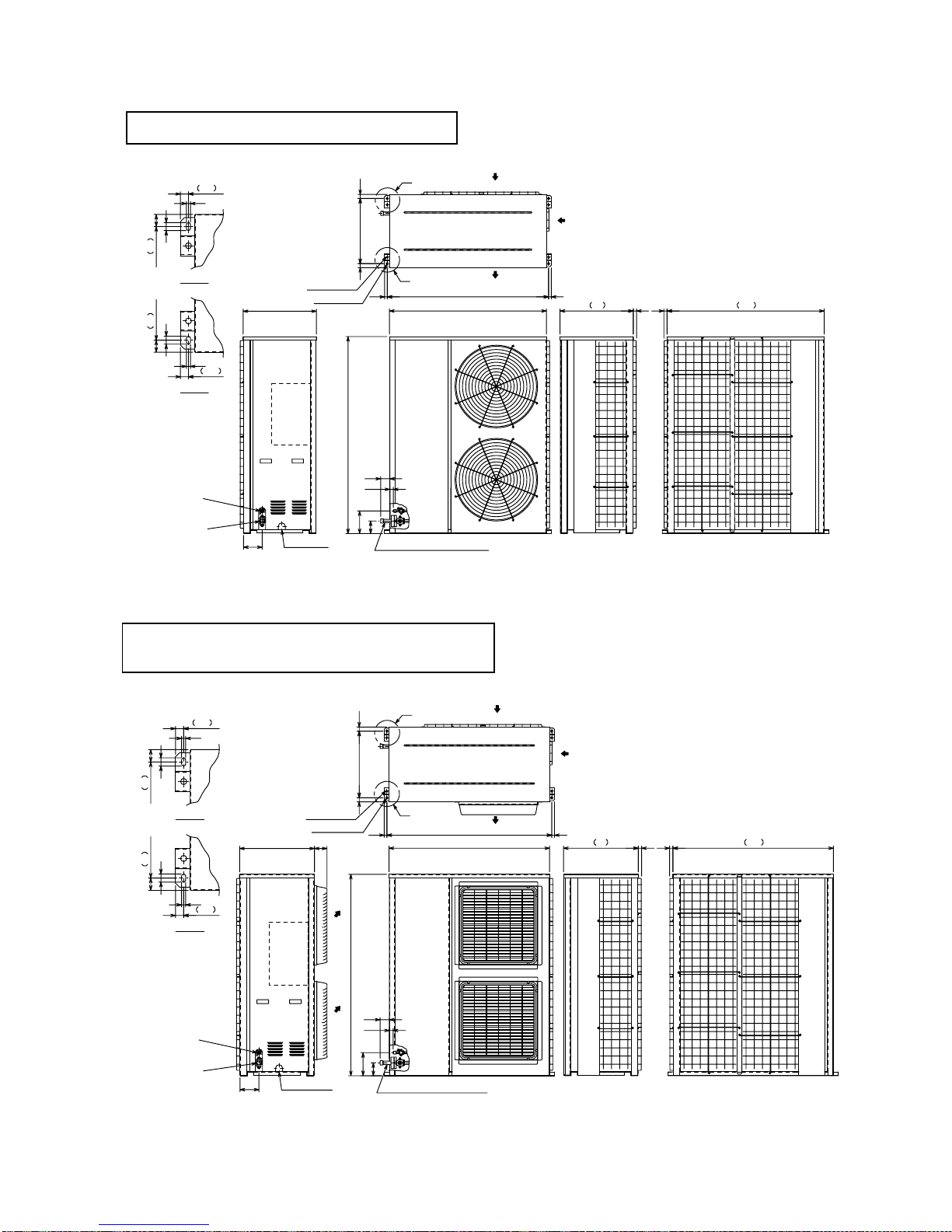

- 22 -

OUTLINE DIMENSIONS

100

40

66130

1440

AIR INLET SENSOR

REFRIGERANT PIPE

ø15.88(5/8 BRAZE)

REFRIGERANT PIPE

ø28.6(1 BRAZE)

CONNECT WIRE

(PEH-PUH)

WIRING HOLE ø27

(AIR INLET SIDE)

AIR OUTLET

CONTROLLER

WIRING HOLE ø27

(AIR INLET SIDE)

AIR INLET

POWER SUPPLY

WIRING HOLE ø27

(AIR INLET SIDE)

DUCT EARTH POINT

(BOTH DUCT SIDE)

26-ø3 HOLES

152

650

428

DRAIN:Rc 1

156

530 70

25

15

10025 100

42

50

130

130

344

20

42

95

33

562

382

AIR INLET

DUCT

FLANGE

341302104

13013013013013013013013066

4-ø12 HOLES

(FOR HUNGING

BOLT M10)

<FIELD SUPPLY>

CONTROL BOX

22-ø3 HOLES

AIR OUTLET DUCT

FLANGE

20

20

1480

15

40

220

4513013013013013013013045

40

1520

1000220

1464

98250

14

15

210 116

4235

46

5555 156

1580

131 200

PEH-10MYB

AIR INLET SENSOR

REFRIGERANT PIPE

ø15.88(5/8 BRAZE)

REFRIGERANT PIPE

ø25.4(1 BRAZE)

CONNECT WIRE

(PEH-PUH)

WIRING HOLE ø27

(AIR INLET SIDE)

AIR OUTLET

CONTROLLER

WIRING HOLE ø27

(AIR INLET SIDE)

AIR INLET

POWER SUPPLY

WIRING HOLE ø27

(AIR INLET SIDE)

DUCT EARTH POINT

(BOTH DUCT SIDE)

152

650

428

DRAIN:Rc 1

156

530 70

25

15

10025 100

42

50

130

130

344

20

42

95

33

562

382

AIR INLET DUCT

FLANGE

24-ø3.1 HOLES

341102104

31130130130130130130130130

31

4-ø12 HOLES

(FOR HUNGING

BOLT M10)

<FIELD SUPPLY>

CONTROL BOX

22-ø3.1 HOLES

1240

20

20

1280

15

40

120

4513013013013013013013045

40

1320

1000120

1264

98250

14

15

100

40

210 116

4235

46

5555 156

1380

131 200 199

AIR OUTLET DUCT

FLANGE

PEH-7,8MYB

(unit; mm) *Except: Drain size (unit; inch)

Page 25

- 23 -

2020

4-ø15 HOLES

(HUNGING)

4-10X20 HOLES

WIRING HOLE

CONTROL

BOX

ACCESSORY PIPE (WITH FLANGE)

REFRAIGERANT PIPE

<FIELD SUPPLY>

7,8MYF:ø25.4(1 FLANGE)

10MYF:ø28.6(1-1/8 FLANGE)

REFRAIGERANT PIPE

<FIELD SUPPLY>

ø15.88(5/8 FLARE)

AIR INLET

AIR INLET

AIR OUTLET

DETAIL B

DETAIL A

10

20

20

1212

30

490

1212

10

20

490

30

20

A

B

142

1180550

550

30490(BOLT PITCH)30

20 201212(BOLT PITCH)

170

95

1480

30

66

1180

(FOR MOUNTING

ANCHOR BOLT M8)

<FIELD SUPPLY>

PUH-7,8,10MYF (Standard)

2020

4-ø15 HOLES

(HUNGING)

4-10X20 HOLES

WIRING HOLE

CONTROL

BOX

NOTE.THIS DRAWING IS SHOWN AT UPWARD BLOW

AIR

OUTLET

AIR

OUTLET

ACCESSORY PIPE (WITH FLANGE)

REFRAIGERANT PIPE

<FIELD SUPPLY>

7,8MYF:ø25.4(1 FLANGE)

10MYF:ø28.6(1-1/8 FLANGE)

REFRAIGERANT PIPE

<FIELD SUPPLY>

ø15.88(5/8 FLARE)

AIR INLET

AIR INLET

AIR OUTLET

DETAIL B

DETAIL A

10

20

20

1212

30

490

1212

10

20

490

30

20

A

B

92

142

1180550

550

30490(BOLT PITCH)30

20 201212(BOLT PITCH)

170

95

1480

30

66

1180

(FOR MOUNTING

ANCHOR BOLT M8)

<FIELD SUPPLY>

PUH-7,8,10MYF

(with Air outlet guide <option

✻1

>)

✻1 : Outdoor unit with air outlet guide is special

order in some customers.

Page 26

- 24 -

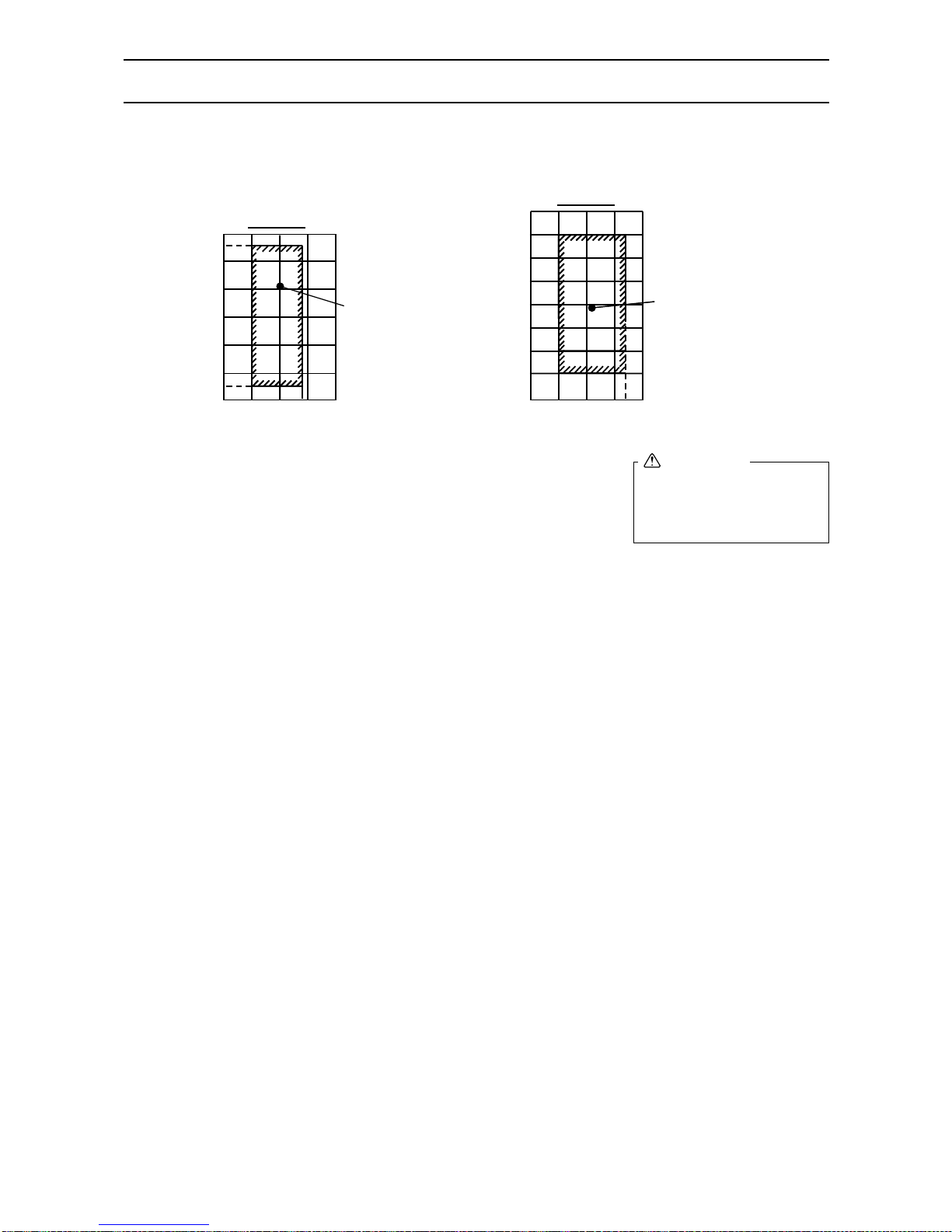

CENTER OF GRAVITY (Outdoor unit)

Item

PUH-7MYF

PUH-10MYF

PUH-8MYF

290

290

280

490

490

480

510

510

500

188

188

221

Model name

XYZ

Center of gravity(mm)

Net weight

(kg)

X

Y

G

Z

G : Center of gravity

(1) Caution for lifting

Page 27

- 25 -

WIRING DIAGRAMS

INLET

DUCT

OUTLET

DUCT

CR

POWER SUPPLY

~PE

220/230/240V

50HZ

CIRCUIT BREAKER

(FIELD SUPPLY)

PEH-7,8MYB-EU :15A

51F

INDOOR

POWER BOARD

INDOOR

CONTROLLER BOARD

REMOTE CONTROLLER

BOARD

TO OUTDOOR UNIT

CONNECTING WIRES

(POLER)

FERRITE COREFB

AUXILIARY RELAYX1-1,X2-1

SYMBOL

MF1

51F

INDOOR UNIT

52F

TB2,4,5

TH6

TH4

TH5

LED2

LED3

LED1

SWE

SW2

SW1

X4-6

ZNR

F1

CR

CONTACTOR (INDOOR FAN MOTOR)

SURGE KILLER

SWITCH(EMERGENCY OPERATION)

SWITCH(CAPACITY CORD)

SWITCH(MODEL SELECTION)

COND./EVA.TEMP ( 0°C/15kΩ.25°C/5.4kΩ)

LED (TRANSMISSION :INDOOR.OUTDOOR)

LED (POWER SUPPLY :REMOTE CONTROLLER)

LED (POWER SUPPLY :INDOOR CONTROLLER BOARD)

AUXILIARY RELAY(INDOOR CONTROLLER BOARD)

VARISTOR

FUSE(4A 250VAC CLASS T)

PIPE TEMP ( 0°C/15kΩ.25°C/5.4kΩ)

THERMISTOR

ROOM TEMP ( 0°C/15kΩ.25°C/5.4kΩ)

TERMINAL BLOCK

OVER CURRENT RELAY (INDOOR FAN MOTOR)

FAN MOTOR (INDOOR)

NAME

CN03,CN2L,2D

CN20-22,29,32

CN41,90,FAN

CONNECTOR(INDOOR CONTROLLER BOARD)

CN01,02,2S CONNECTOR(INDOOR POWER BOARD)

C01 CONNECTOR(FAN MOTOR)

51F

FB

PE

PE

PE

PE

PE

ORANGE

X1-1 X2-1

BLUE

VIOLET

WHITE

52F

X1-1

X2-1

GRAY

4

X2-1

X1-1

MF1

2

1

C01 C01

5

6

C

BROWN

RED

ON

OFF

SWE

ON

OFF

ON

OFF

SW1

SW2

54321

4321

BLUE

RED

S3

S2

S1

TB3

OUTDOOR UNIT

52F

10

S1

PE

1

2

CN20

TH6

2

1

2

1

4

3

2

1

7

8

9

4

5

6

3

3

1

2

1

2

1

2

1

2

1

2

CN

DC

14V

X6X5X4

LED3

LED2

LED1

INDOOR UNIT CONTROL BOX

[PEH-7,8MYB-EU]

REMOTE CONTROLLER

CN2S

DC14V

1

2

TB4

S2

S3

TB5

TB6

TB2

TH5

TH4

CN02

CN01

1

ZNR

132

2

3

F1

LCD

X6X5X4

3

FAN

75 1

3

CN03

15

CN2D

DC14V

21

CN21

CN29

CN41

CN32

CN22

CN2L

CN90

N

L3

L2

L1

OUTDOOR UNIT

TERMINAL BLOCK

NAMESYMBOL

SYMBOL NAME

REMOTE CONTROLLER

TB6 TERMINAL BLOCK

TB3

Note:1. The dotted lines show field wiring.

2. Color of earth wire is yellow and green twisting.

3. Specification subject to change without notice.

4. Indoor and outdoor connecting wires are made with polarities,

make sure matching wiring and terminal.

5. Emergency operation If a trouble occurs with either the remote

controller or the indoor microcomputer and no other trouble exisits,

emergency operation for cooling or heating can be performed by

changing the setting of switch (SWE) on the indoor controller

board.

Caution,

1. To protect fan motor from abnormal current,over current relays is

installed.

Therefore, do not change factory set value of Over current relays.

PEH-7,8MYB

Page 28

- 26 -

OUTLET

DUCT

INLET

DUCT

CR

MF1

C02

C01

Attach the accessory

3

1

2

Remove

This circuit diagram shows connections.

(If the external static pressure is less

than 30 pa, change to connections.)

3

2

1

3

2

1

POWER SUPPLY

50HZ

380/400/415V

3N~PE

(FIELD SUPPLY)

PEH-10MYB-EU :15A

CIRCUIT BREAKER

51F

TO OUTDOOR UNIT

CONNECTING WIRES

(POLER)

REMOTE CONTROLLER

BOARD

INDOOR

CONTROLLER

BOARD

POWER BOARD

INDOOR

51F

FB

PE

PE

PE

PE

PE

PE

4321

ON

OFF

ON

OFF

4

BLACK

WHITE

RED

C02

1

3

2

C01

C01

52F

10

S1

PE

1

2

CN20

TH6

SW2

2

1

2

1

4

3

2

1

ON

OFF

7

8

9

4

5

6

3

3

1

2

1

2

1

2

1

2

1

2

OUTDOOR UNIT

TB3

S1

S2

S3

CN

DC

14V

X6X5X4

LED3

LED2

LED1

INDOOR UNIT CONTROL BOX

[PEH-10MYB-EU]

REMOTE CONTROLLER

SW1

SWE

1

2

3

5

4

CN2S

DC14V

1

2

TB4

S2

S3

TB5

TB6

49F

52F

MF1

TB2

TH5

TH4

CN02

CN01

1

ZNR

132

2

3

F1

LCD

X6X5X4

1235

3

FAN

75 1

3

CN03

15

CN2D

DC14V

21

CN21

CN29

CN41

CN32

CN22

CN2L

CN90

N

L3

L2

L1

FB FERRITE CORE

TERMINAL BLOCKTB6

NAMESYMBOL

TERMINAL BLOCKTB3

CONNECTOR(FAN MOTOR)C01,02

CONNECTOR(INDOOR POWER BOARD)

CN01,02,2S

CN41,90,FAN

CN20-22,29,32

COND./EVA.TEMP ( 0°C/15kΩ.25°C/5.4kΩ)

PIPE TEMP ( 0°C/15kΩ.25°C/5.4kΩ)

ROOM TEMP ( 0°C/15kΩ.25°C/5.4kΩ)

OUTDOOR UNIT

SYMBOL NAME

52F CONTACTOR (INDOOR FAN MOTOR)

SURGE KILLERCR

SWITCH(EMERGENCY OPERATION)

SWITCH(CAPACITY CORD)

SW1 SWITCH(MODEL SELECTION)

TH5

LED (TRANSMISSION :INDOOR.OUTDOOR)LED3

LED (POWER SUPPLY :REMOTE CONTROLLER)

LED2

LED (POWER SUPPLY :INDOOR CONTROLLER BOARD)

LED1

SWE

SW2

X4-6

AUXILIARY RELAY(INDOOR CONTROLLER BOARD)

VARISTORZNR

FUSE(4A 250VAC CLASS T )F1

REMOTE CONTROLLER

INDOOR UNIT

CONNECTOR(INDOOR CONTROLLER BOARD)

THERMISTOR

TERMINAL BLOCK

INTERNAL THERMOSTAT (INDOOR FAN MOTOR)

OVER CURRENT RELAY (INDOOR FAN MOTOR)

FAN MOTOR (INDOOR)

CN03,CN2L,2D

TH4

TH6

TB2,4,5

49F

51F

MF1

NAMESYMBOL

Note: 1. The dotted lines show field wiring.

2. Color of earth wire is yellow and green twisting.

3. Specification subject to change without notice.

4. Indoor and outdoor connecting wires are made with polarities,make

sure matching wiring and terminal.

5. Emergency operation

If a trouble occurs with either the remote controller or the indoor

microcom- puter and no other trouble exisits, emergency operation