Mitsubishi Electric CMB-WP-V-GA1, CMB-WP-V-GB1, PEFY-WP-VMA-E, PLFY-WP-VBM-E, PFFY-WP-VLRMM-E Data Book

...Page 1

CMB-WP-V-GA1

CMB-WP-V-GB1

PEFY-WP-VMS1-E

PEFY-WP-VMA-E

PLFY-WP-VBM-E

PFFY-WP-VLRMM-E

MODEL

YLM 3rd edition

Page 2

HYBRID CITY MULTI

Databook

MEE15K052

1. INDOOR UNITS

Ceiling concealed (Slim type) ............................................................................................................ 1 - 3

PEFY-WP-VMS1-E

Ceiling concealed (Middle static pressure type) ................................................................................ 1 - 19

PEFY-WP-VMA-E

Ceiling cassette (4-way flow type) ..................................................................................................... 1 - 37

PLFY-WP-VBM-E

Floor standing (Concealed type)........................................................................................................ 1 - 49

PFFY-WP-VLRMM-E

HBC controller ................................................................................................................................... 1 - 61

CMB-WP-V-GA1, CMB-WP-V-GB1 (for YLM series only)

ELECTRICAL CHARACTERISTICS.................................................................................................. 1 - 77

CAPACITY TABLES .......................................................................................................................... 1 - 79

2. OUTDOOR/HEAT SOURCE UNITS

YLM R2 SERIES................................................................................................................................ 2 - 3

YLM WR2 SERIES ............................................................................................................................ 2 - 37

3. SYSTEM DESIGN

SYSTEM DESIGN YLM R2 SERIES ................................................................................................. 3 - 3

SYSTEM DESIGN YLM WR2 SERIES.............................................................................................. 3 - 17

INSTALLATION INFORMATION ....................................................................................................... 3 - 31

CAUTION FOR REFRIGERANT LEAKAGE ..................................................................................... 3 - 37

Page 3

MEE15K052

Page 4

1 - 1

HYBRID CITY MULTI

MEE15K052

1. INDOOR UNITS

Ceiling concealed (Slim type) ................................................................................................................. 1 - 3

PEFY-WP-VMS1-E

Ceiling concealed (Middle static pressure type) ..................................................................................... 1 - 19

PEFY-WP-VMA-E

Ceiling cassette (4-way flow type) .......................................................................................................... 1 - 37

PLFY-WP-VBM-E

Floor standing (Concealed type)............................................................................................................. 1 - 49

PFFY-WP-VLRMM-E

HBC controller......................................................................................................................................... 1 - 61

CMB-WP-V-GA1, CMB-WP-V-GB1 (for YLM series only)

ELECTRICAL CHARACTERISTICS....................................................................................................... 1 - 77

CAPACITY TABLES ............................................................................................................................... 1 - 79

Page 5

1 - 2

MEE15K052

Page 6

1 - 3

Ceiling concealed (Slim type)

PEFY-WP-VMS1-E

MEE15K052

I.Ceiling concealed (Slim type)

1. SPECIFICATIONS........................................................................................................................................... 1 - 4

2. EXTERNAL DIMENSIONS .............................................................................................................................. 1 - 6

3. CENTER OF GRAVITY ................................................................................................................................... 1 - 8

4. ELECTRICAL WIRING DIAGRAMS................................................................................................................ 1 - 9

5. SOUND LEVELS ............................................................................................................................................. 1 - 10

5-1. Sound levels ............................................................................................................................................ 1 - 10

5-2. NC curves ................................................................................................................................................ 1 - 11

6. FAN CHARACTERISTICS CURVES............................................................................................................... 1 - 13

7. OPTIONAL PARTS.......................................................................................................................................... 1 - 17

7-1. Optional parts line up for the Indoor unit.................................................................................................. 1 - 17

7-2. Control box replace kit ............................................................................................................................. 1 - 18

Page 7

1 - 4

PEFY

MEE15K052

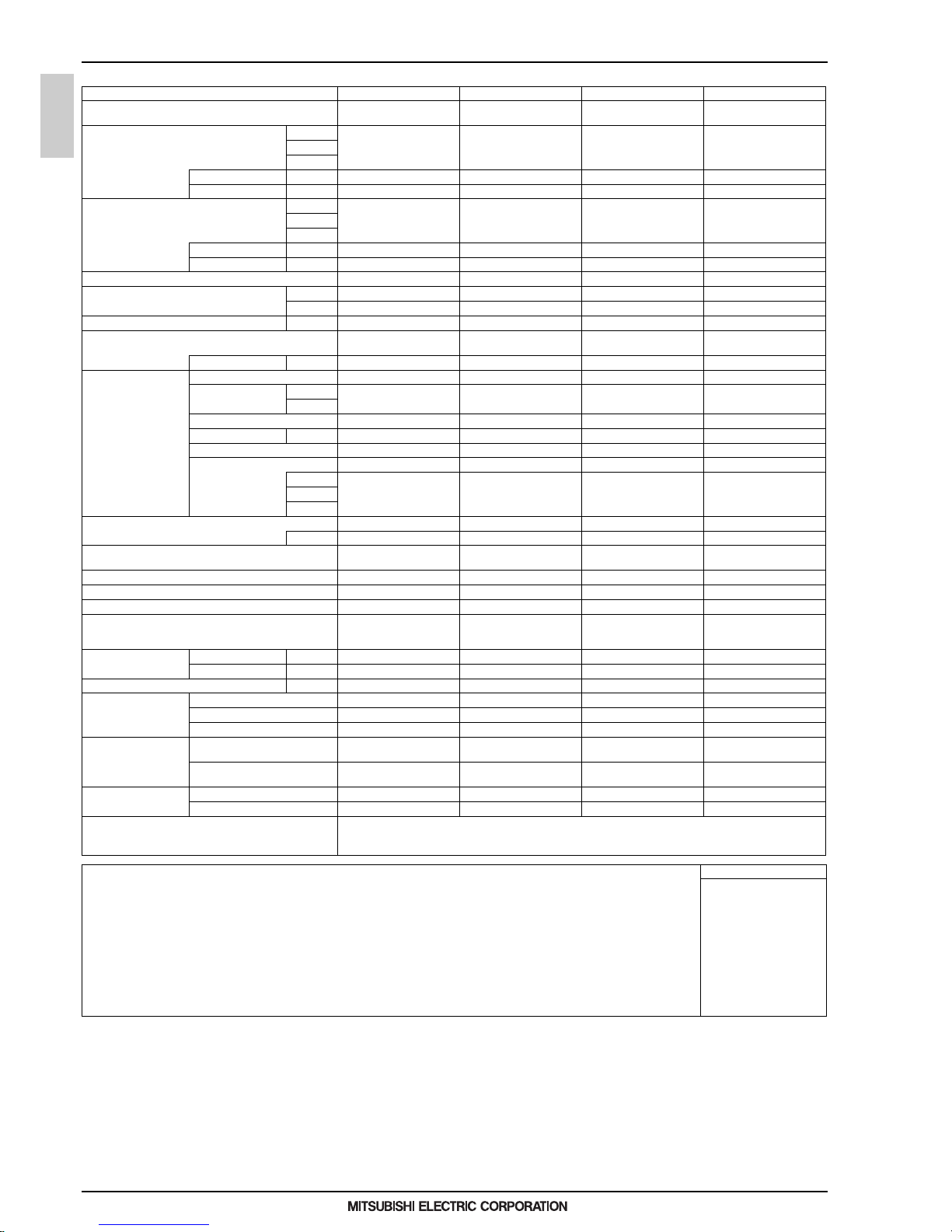

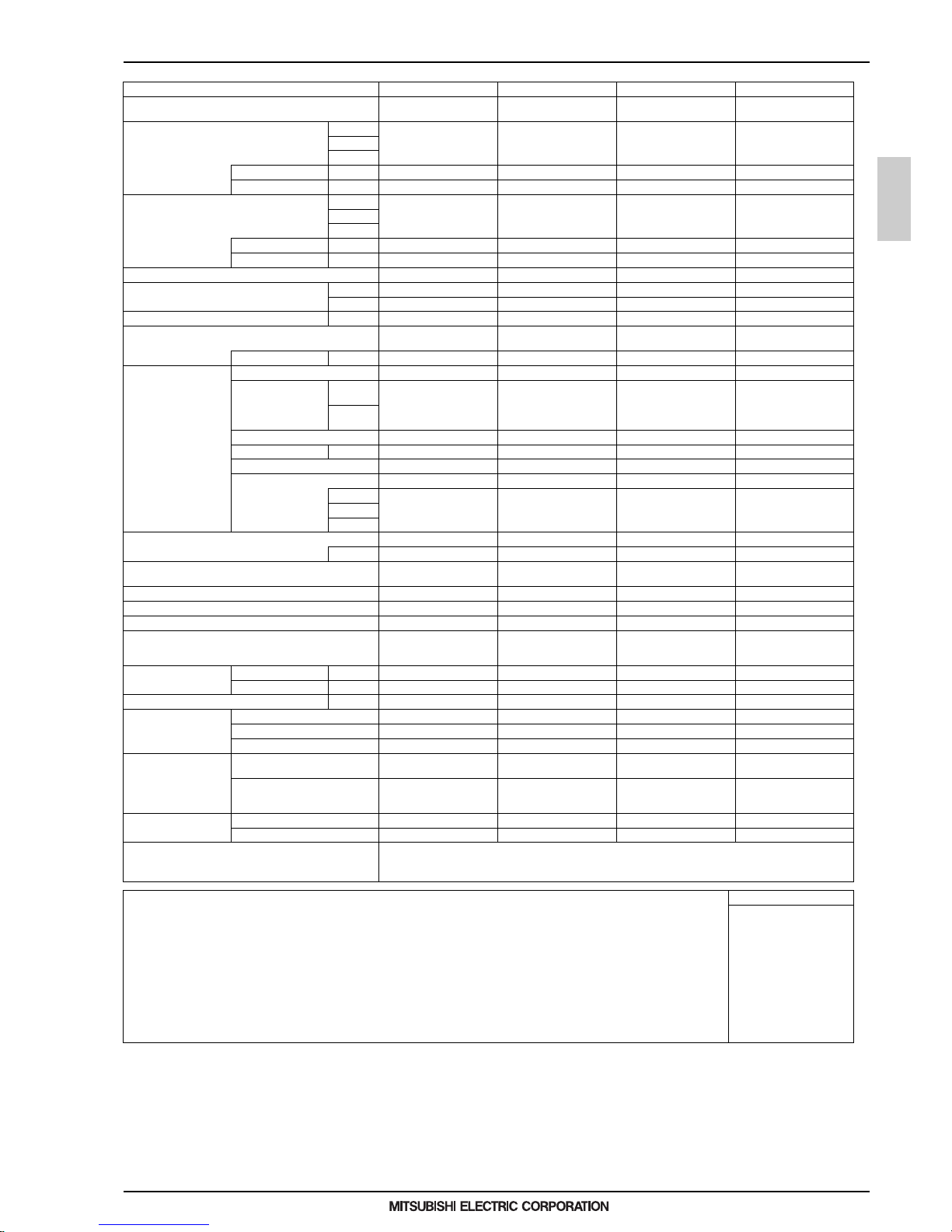

1. SPECIFICATIONS

I.Ceiling concealed (Slim type)1. SPECIFICATIONS

Model PEFY-WP15VMS1-E PEFY-WP20VMS1-E PEFY-WP25VMS1-E PEFY-WP32VMS1-E

Power source

1-phase 220-230-240 V 50/60 Hz1-phase 220-230-240 V 50/60 Hz1-phase 220-230-240 V 50/60 Hz1-phase 220-230-240 V 50/60

Hz

Cooling capacity *1 kW 1.7 2.2 2.8 3.6

(Nominal) *1 kcal/h 1,500 1,900 2,400 3,100

*1 BTU/h 5,800 7,500 9,600 12,300

*2 Power input kW 0.050 0.051 0.060 0.071

*2 Current input A 0.44 0.49 0.51 0.61

Heating capacity *3 kW 1.9 2.5 3.2 4.0

(Nominal) *3 kcal/h 1,600 2,200 2,800 3,400

*3 BTU/h 6,500 8,500 10,900 13,600

*2 Power input kW 0.030 0.031 0.040 0.051

*2 Current input A 0.33 0.38 0.40 0.50

External finish Galvanized steel plate Galvanized steel plate Galvanized steel plate Galvanized steel plate

External dimension H x W x D mm 200 x 790 x 700 200 x 790 x 700 200 x 790 x 700 200 x 990 x 700

in. 7-7/8 x 31-1/8 x 27-9/16 7-7/8 x 31-1/8 x 27-9/16 7-7/8 x 31-1/8 x 27-9/16 7-7/8 x 39 x 27-9/16

Net weight kg (lbs) 19 (42) 20 (45) 20 (45) 25 (56)

Heat exchanger

Cross fin (Aluminum fin and

copper tube)

Cross fin (Aluminum fin and

copper tube)

Cross fin (Aluminum fin and

copper tube)

Cross fin (Aluminum fin and

copper tube)

Water Volume L 0.7 0.9 0. 9 1.0

FAN Type x Quantity Sirocco fan x 2 Sirocco fan x 2 Sirocco fan x 2 Sirocco fan x 3

*4 External static press. Pa <5> - 15 - <35> - <50> <5> - 15 - <35> - <50> <5> - 15 - <35> - <50> <5> - 15 - <35> - <50>

mmH

2

O <0.5> - 1.5 - <3.6> - <5.1> <0.5> - 1.5 - <3.6> - <5.1> <0.5> - 1.5 - <3.6> - <5.1> <0.5> - 1.5 - <3.6> - <5.1>

Motor Type DC motor DC motor DC motor DC motor

Motor output kW 0.096 0.096 0.096 0.096

Driving mechanism Direct-driven by motor Direct-driven by motor Direct-driven by motor Direct-driven by motor

Air flow rate (Low-Mid-High) (Low-Mid-Hig h) (Low-Mid-High) (Low-Mid-High)

m

3

/min 5.0 - 6.0 - 7.0 5.5 - 6.5 - 8.0 5.5 - 7.0 - 9.0 8.0 - 9.0 - 11.0

L/s 83 - 100 - 117 92 - 108 - 133 92 - 117 - 150 133 - 150 - 183

cfm 177 - 212 - 247 194 - 230 - 282 194 - 247 - 318 282 - 318 - 388

Sound pressure level (measured in anechoic room) (Low-Mid-High) (Low-Mid-High) (Low- Mid-High) (Low-Mid-High)

*2 dB <A> 22-24-28 23-25-29 23-26-30 28-30-33

Insulation material

EPS, Polyethylene foam, Ure-

thane foam

EPS, Polyethylene foam, Ure-

thane foam

EPS, Polyethylene foam, Ure-

thane foam

EPS, Polyethylene foam, Ure-

thane foam

Air filter PP honeycomb fabric. PP honeycomb fabric. PP honeycomb fabric. PP honeycomb fabric.

Protection device Fuse Fuse Fuse Fuse

Refrigerant control device - - - -

Connectable outdoor unit/HBC controller

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

Water piping diameter Inlet in. Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw

*5 *6 Outlet in. Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw

Field drain pipe size mm (in.) O.D.32 (1-1/4) O.D.32 (1-1/4) O.D.32 (1-1/4) O.D.32 (1-1/4)

Drawing External KD94T794X01 KD94T794X01 KD94T794X01 KD94T794X01

Wiring KD94T793X01 KD94T793X01 KD94T793X01 KD94T793X01

Refrigerant cycle - - - -

Standard attachment Document

Installation Manual, Instruc-

tion Book

Installation Manual, Instruc-

tion Book

Installation Manual, Instruc-

tion Book

Installation Manual, Instruc-

tion Book

Accessory

Insulation pipe for water pipe,

Washer, Drain hose, Tie band

Insulation pipe for water pipe,

Washer, Drain hose, Tie b and

Insulation pipe for water pipe,

Washer, Drain hose, Tie ban d

Insulation pipe for water pipe,

Washer, Drain hose, Tie band

Optional parts Control box replace kit PAC-KE70HS-E PAC-KE70HS-E PAC-KE70HS-E PAC-KE70HS-E

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

Notes: Unit converter

1.Nominal cooling conditions

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B. (95°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.The values are measured at the factory setting of external static pressure.

3.Nominal heating conditions

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

4.The factory setting of external static pressure is shown without < >.

Refer to "Fan characteristics curves", according to the external static pressure, in DATA BOOK for the usable

range of air flow rate.

5.Be sure to install a valve on the water outlet.

6.Install a strainer (40 mesh or more) on the pip e next to the valve to remove the foreign matters.

7.Please group units that operate on 1 branch.

kcal/h =kW x 860

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

Page 8

1 - 5

PEFY

MEE15K052

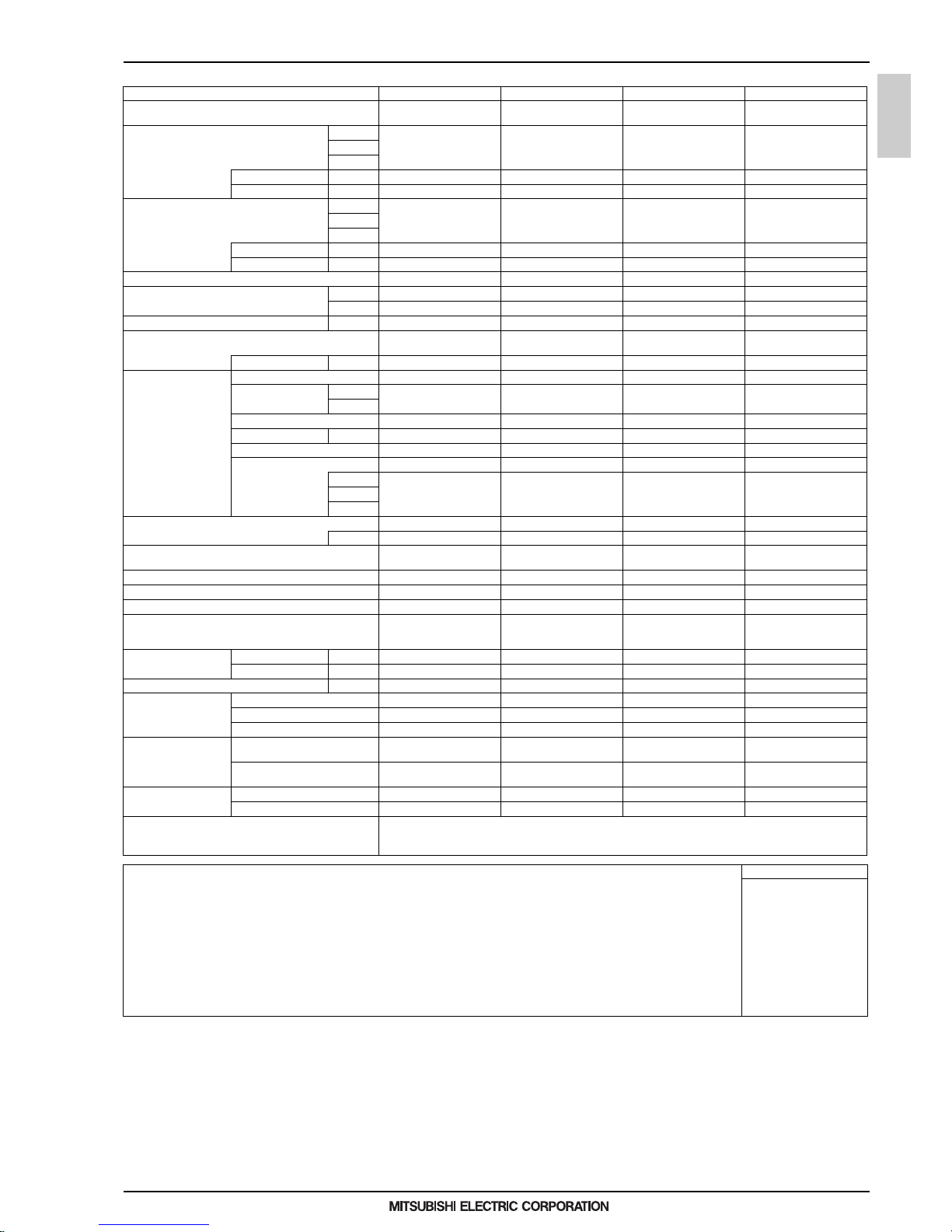

1. SPECIFICATIONS

Model PEFY-WP40VMS1-E PEFY-WP50VMS1-E

Power source

1-phase 220-230-240 V 50/60 Hz1-phase 220-230-240 V 50/ 60

Hz

Cooling capacity *1 kW 4.5 5.6

(Nominal) *1 kcal/h 3,900 4,800

*1 BTU/h 15,400 19,100

*2 Power input kW 0.090 0.090

*2 Current input A 0.73 0.77

Heating capacity * 3 kW 5.0 6.3

(Nominal) *3 kcal/h 4,300 5,400

*3 BTU/h 17,100 21,500

*2 Power input kW 0.070 0.070

*2 Current input A 0.62 0.66

External finish Galvanized steel plate Galvanized steel plate

External dimension H x W x D mm 200 x 990 x 700 200 x 1,190 x 700

in. 7-7/8 x 39 x 27-9/16 7-7 /8 x 46-7/8 x 27-9/16

Net weight kg (lbs) 25 (56) 27 (60)

Heat exchanger

Cross fin (Aluminum fin and

copper tube)

Cross fin (Aluminum fin and

copper tube)

Water Volume L 1.0 1.7

FAN Type x Quantity Sirocco fan x 3 Sirocco fan x 4

*4 External static press. Pa <5> - 15 - <35> - <50> <5> - 15 - <35> - <50>

mmH

2

O <0.5> - 1.5 - <3.6> - <5.1> <0.5> - 1.5 - <3.6> - <5.1>

Motor Type DC motor DC motor

Motor output kW 0.096 0.096

Driving mechanism Direct-driven by motor Direct-driven by motor

Air flow rate (Low-Mid-High) (Low-Mi d-High)

m

3

/min 9.5 - 11.0 - 13.0 12.0 - 14.0 - 16.5

L/s 158 - 183 - 217 200 - 233 - 275

cfm 335 - 388 - 459 424 - 494 - 583

Sound pressure level (measured in anechoic room) (Low-Mid-High) (Low-Mid-High)

*2 dB <A> 30-32-35 30-33-36

Insulation material

EPS, Polyethylene foam, Ure-

thane foam

EPS, Polyethylene foam, Ure-

thane foam

Air filter PP honeycomb fabric. PP honeycomb fabric.

Protection device Fuse Fuse

Refrigerant control device - -

Connectable outdoor unit/HBC controlle r

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

Water piping diameter Inlet in. Rc 3/4 screw Rc 3/4 screw

*5 *6 Outlet in. Rc 3/4 screw Rc 3/4 screw

Field drain pipe size mm (in.) O.D.32 (1-1/4) O.D.32 (1-1/4)

Drawing External K D94T794X01 KD94T794X01

Wiring KD94T793X01 KD94T793X01

Refrigerant cycle - -

Standard attachment Document

Installation Manual, Instruc-

tion Book

Installation Manual, Instruc-

tion Book

Accessory

Insulation pipe for water pipe,

Washer, Drain hose, Tie band

Insulation pipe for water pipe,

Washer, Drain hose, Tie band

Optional parts Control box replace kit PAC-KE70HS-E PAC-KE70HS-E

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, ab ove specifications may be subject to change without notice.

Notes: Unit converter

1.Nominal cooling conditions

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B. (95°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.The values are measured at the factory setting of external static pressure.

3.Nominal heating conditions

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

4.The factory setting of external static pressure is shown without < >.

Refer to "Fan characteristics curves", according to the external static pressure, in DATA BOOK for the usable

range of air flow rate.

5.Be sure to install a valve on the water outlet.

6.Install a strainer (40 mesh or more) on the pipe next to the valve to remove the foreign matters.

7.Please group units that operate on 1 branch.

kcal/h =kW x 860

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

Page 9

1 - 6

PEFY

MEE15K052

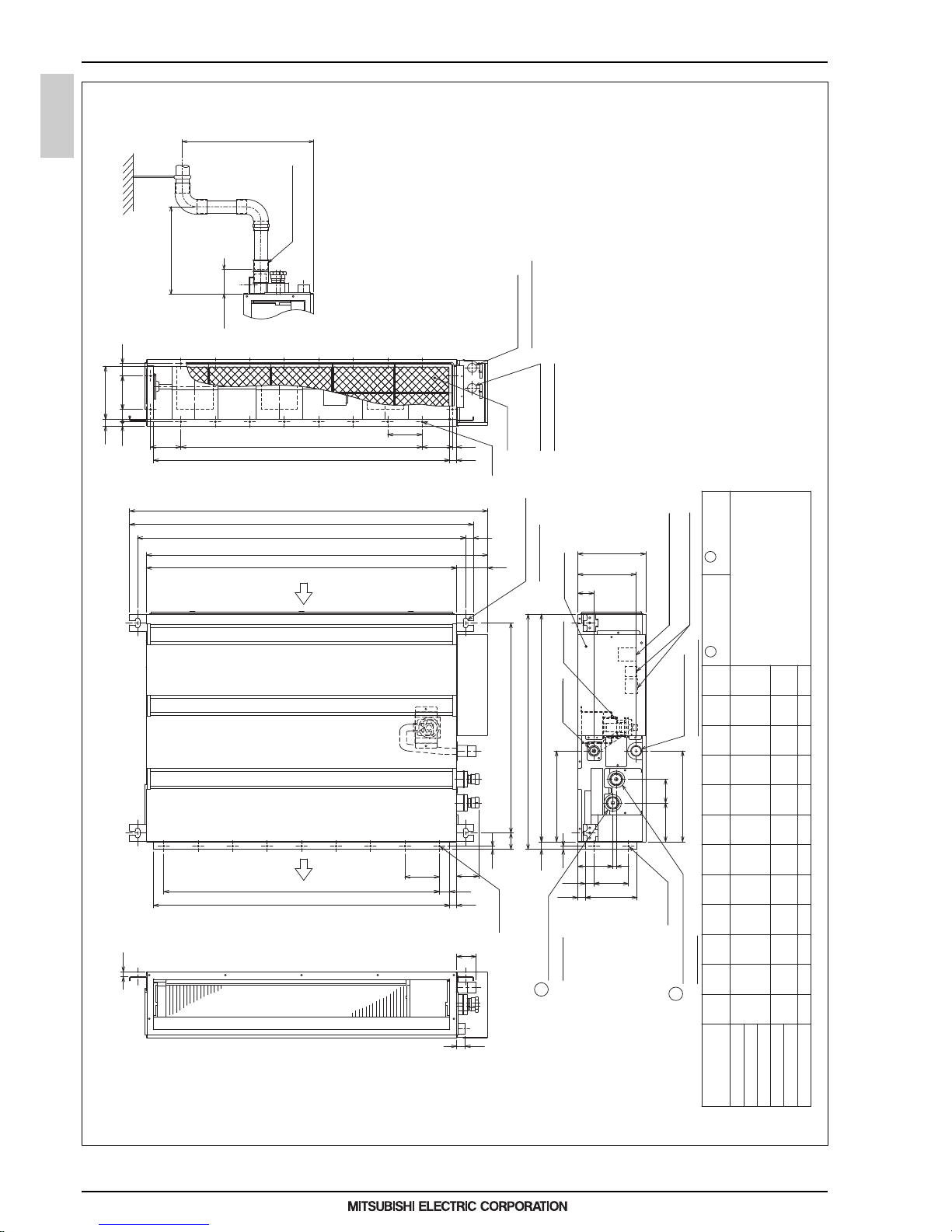

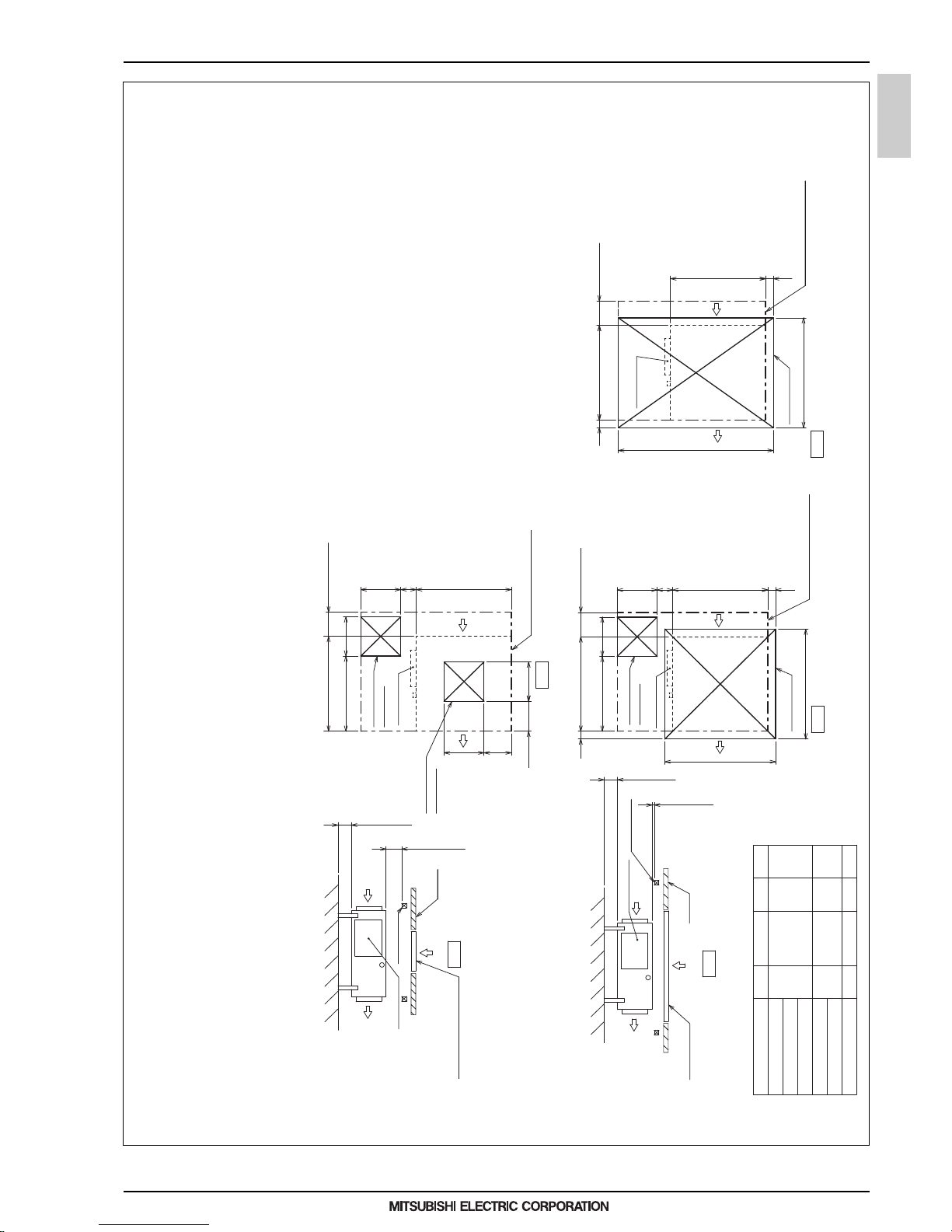

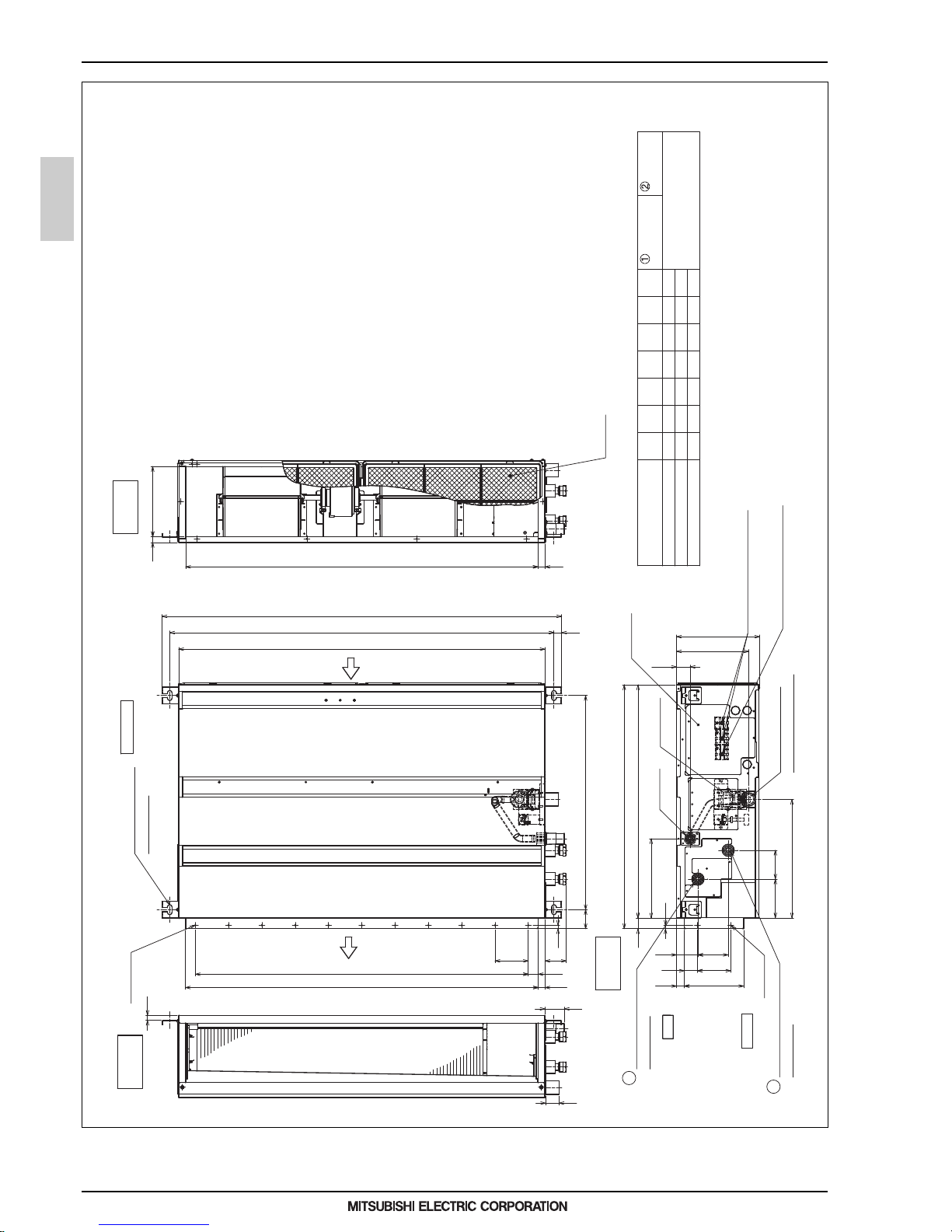

2. EXTERNAL DIMENSIONS

2. EXTERNAL DIMENSIONS

(Actual length)

<accessory>

Drain hose (I.D.ø32)

Less than 300mm

65

0

-10

Less than 550mm

Unit : mm

PEFY-WP15, 20, 25, 32, 40, 50VMS1-E

64

70116

10

102

Note1. Use M10 screw for the suspension bolt (field supply).

2. Keep the service space for the maintenance at the bottom.

3. This chart indicates for PEFY-WP32, 40VMS1-E models, which has 3 fans.

PEFY-WP15, 20, 25VMS1-E models have 2 fans.

PEFY-WP50VMS1-E models have 4 fans.

4. In case an inlet duct is used, remove the air filter (supply with

the unit), then install the filter (field supply) at suction side.

Water pipe(To HBC unit)

Rc3/4 screw

Rc3/4 screw

Water pipe(From HBC unit)

Air

outlet

Air

inlet

(O.D.

ø

32)

Drain pipe

Drain pump

Terminal bed(Transmission)

Drain pipe(O.D.

ø

32)

(Spontaneous draining)

1

2

Terminal bed(Power source)

Suspension bolt hole

4-14×30 Slot

Air filter

Control box

2

×

E-

ø

2.9

2

×

2-

ø

2.9

K-

ø

2.9

Knockout hole

ø

27

Knockout hole

ø

27

(Power source wiring)

(Transmission wiring)

PEFY-WP50VMS1-E

PEFY-WP40VMS1-E

PEFY-WP32VMS1-E

PEFY-WP25VMS1-E

PEFY-WP20VMS1-E

119 0

990

790

1239

1039

839

M

24

20

16

900

700

500

9

7

5

1060

860

660

LJHK

700 752 798 660 7 600

Rc3/4 screw

(To HBC unit)

(From HBC unit)

119 8

998

A

Model

PEFY-WP15VMS1-E

115 2

952

B

110 0

900

C

1060

860

D

11

9

E

1000

800

FG

57

15

700

150(Duct)

200

23

677

23

90

20

C

D (Duct)

A

M

L

49

625(Suspension bolt pitch)

23

B (Suspension bolt pitch)

270

48

270

170

10

100

100

×

(E-1)=F

30

25

100

25

20

100

100

×

H=J

12

88

37

100 37

88

12

157.5

20

G

10

Water pipe

1

Watetr pipe

2

To

HBC Unit

From

HBC Unit

Page 10

1 - 7

PEFY

MEE15K052

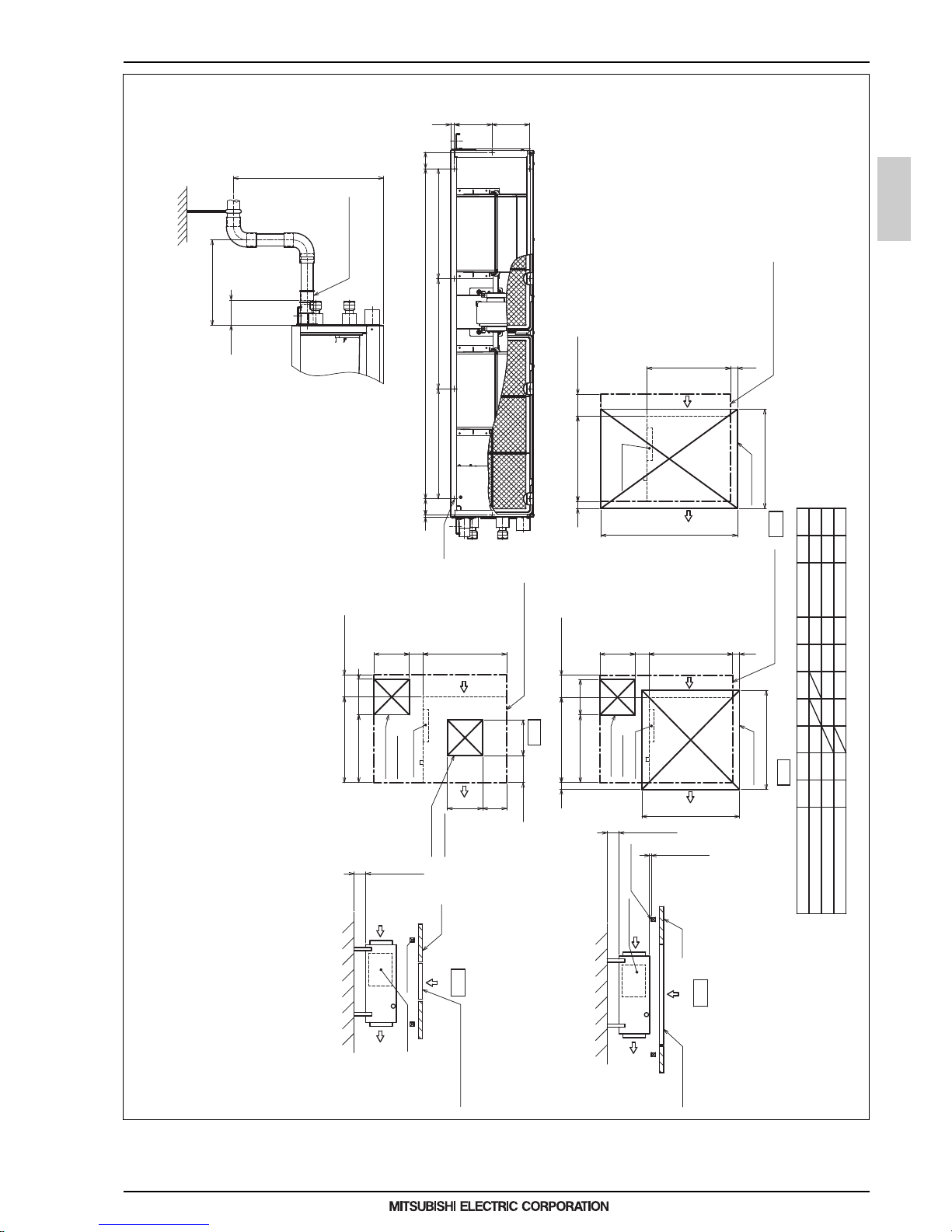

2. EXTERNAL DIMENSIONS

Unit : mm

PEFY-WP15, 20, 25, 32, 40, 50VMS1-E

Min.300mm

Access door 1

(450×450)

Access door 3

Electric box

Intake air

Access door 1

(450×450)

Ceiling beam

Access door 2 (450×450)

Electric box

Supply air

Supply air Intake air

Maintenance access space

Maintenance access space

Maintenance access space

Electric box

Access door 4

(Viewed from the direction

of the arrow B)

Access door 3

Electric box

Bottom of

indoor unit

(Viewed from the direction of the arrow B)

B

Ceiling beam

Ceiling

(Viewed from the direction of the arrow A)

Access door 2

(450×450)

Ceiling

A

Bottom of indoor unit

100~200

100~200

Electric box

Min.10mm

450

450

450

50~150

P

700

700

Min.300mm

N

50

50

R

777

777

50

Q

50

475

N

450

Min.20mm

Min.300mm

N

450

475

700

450

Min.300mm

Min.10mm

Fig.3

Fig.4

Fig.5

Fig.2

Fig.1

Bottom of

indoor unit

[Maintenance access space]

Secure enough access space to allow for the maintenance, inspection, and replacement of the motor, fan, drain pump, heat exchanger,

and electric box in one of the following ways.

Select an installation site for the indoor unit so that its maintenance access space will not be obstructed by beams or other objects.

(1) When a space of 300mm or more is available below the unit between the unit and the ceiling. (Fig.1)

·

Create access door 1 and 2 (450x450mm each) as shown in Fig.2.

(Access door 2 is not required if enough space is available below the unit for a maintenance worker to work in.)

(2) When a space of less than 300mm is available below the unit between the unit and the ceiling.

(At least 20mm of space should be left below the unit as shown in Fig.3.)

·

Create access door 1 diagonally below the electric box and access door 3 below the unit as shown in Fig.4.

or

PEFY-WP15VMS1-E

PEFY-WP20VMS1-E

PEFY-WP25VMS1-E

PEFY-WP32VMS1-E

PEFY-WP40VMS1-E

PEFY-WP50VMS1-E

700

N

Model

110 0

900

150~250

250~350

P

50~150

800

Q

1200

1000

R

1700

1500

1300

·

Create access door 4 below the electric box and the unit as shown in Fig.5.

Page 11

1 - 8

PEFY

MEE15K052

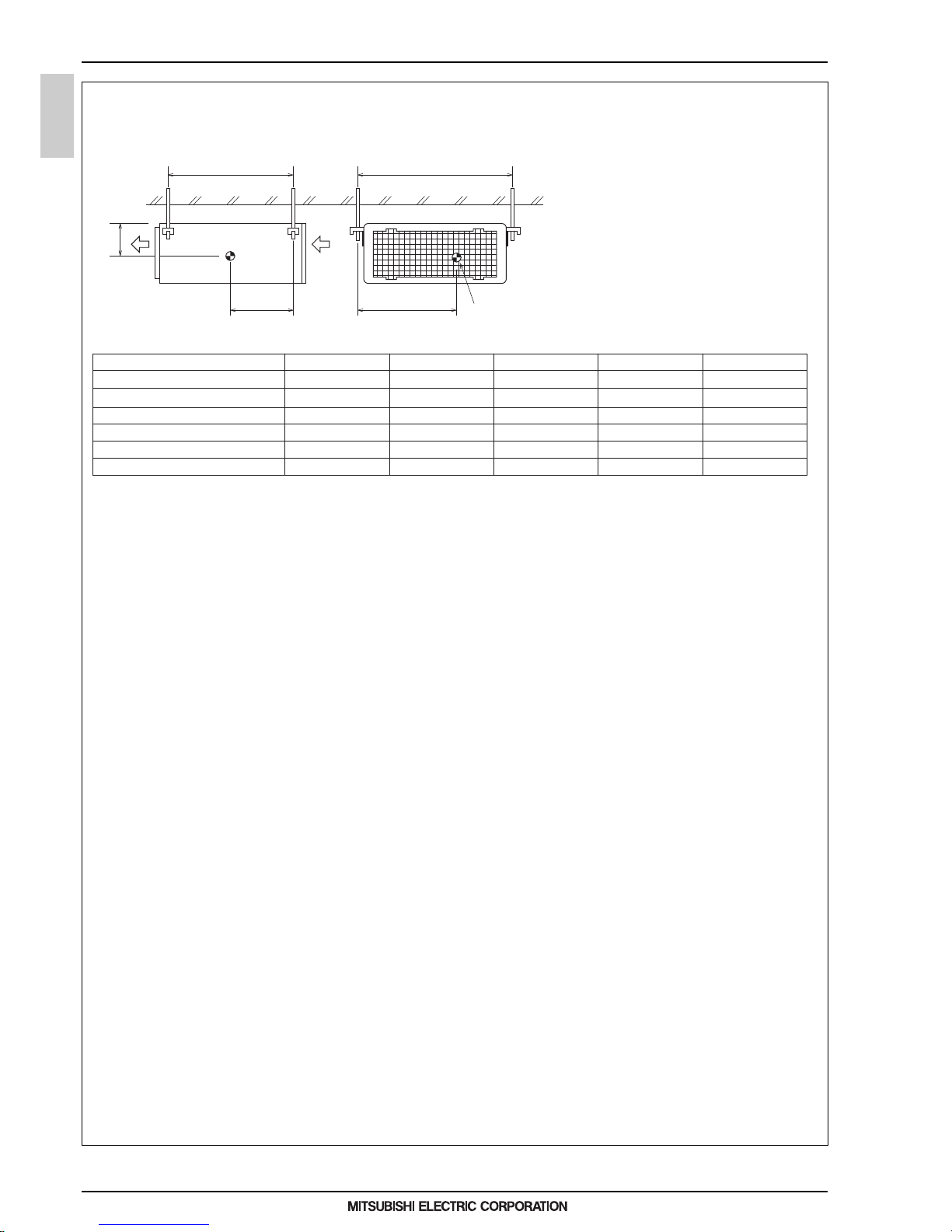

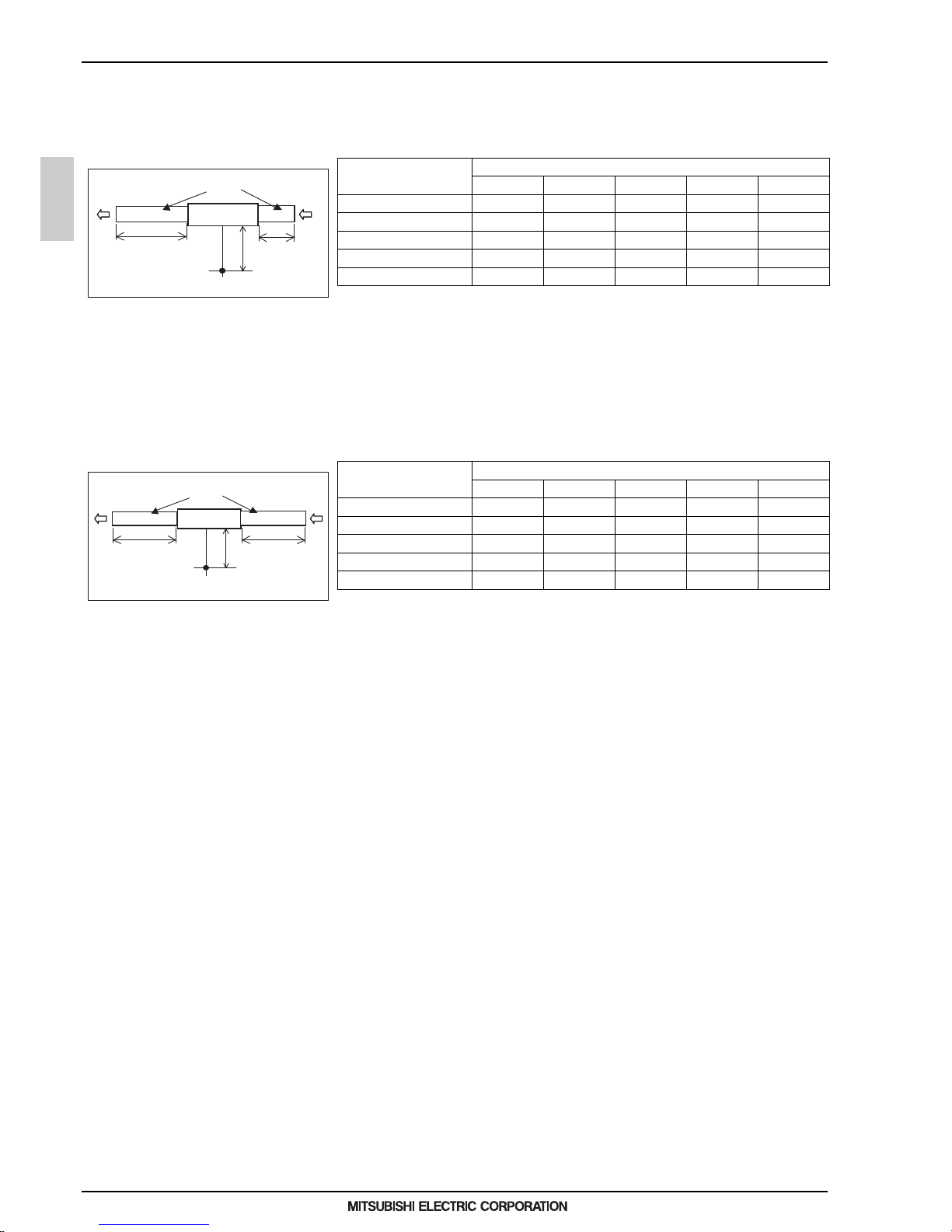

3. CENTER OF GRAVITY

3. CENTER OF GRAVITY

Model name

PEFY-WP15VMS1-E

PEFY-WP50VMS1-E

PEFY-WP40VMS1-E

PEFY-WP32VMS1-E

PEFY-WP25VMS1-E

PEFY-WP20VMS1-E

W

625 [24-5/8]

625 [24-5/8]

625 [24-5/8]

625 [24-5/8]

625 [24-5/8]

L

752 [29-5/8]

752 [29-5/8]

952 [37-1/2]

952 [37-1/2]

1152 [45-3/8]

X

263 [10-3/8]

263 [10-3/8]

280 [11-1/32]

280 [11-1/32]

285 [11-1/4]

Y

338 [13-5/16]

338 [13-5/16]

422 [16-5/8]

422 [16-5/8]

511 [20-1/8]

Z

105 [4-5/32]

625 [24-5/8] 752 [29-5/8] 263 [10-3/8] 338 [13-5/16] 105 [4-5/32]

105 [4-5/32]

104 [4-1/8]

104 [4-1/8]

104 [4-1/8]

A: Center of gravity

YX

L

W

A

Z

PEFY-WP15, 20, 25, 32, 40, 50VMS1-E

(mm)[in]

Page 12

1 - 9

PEFY

MEE15K052

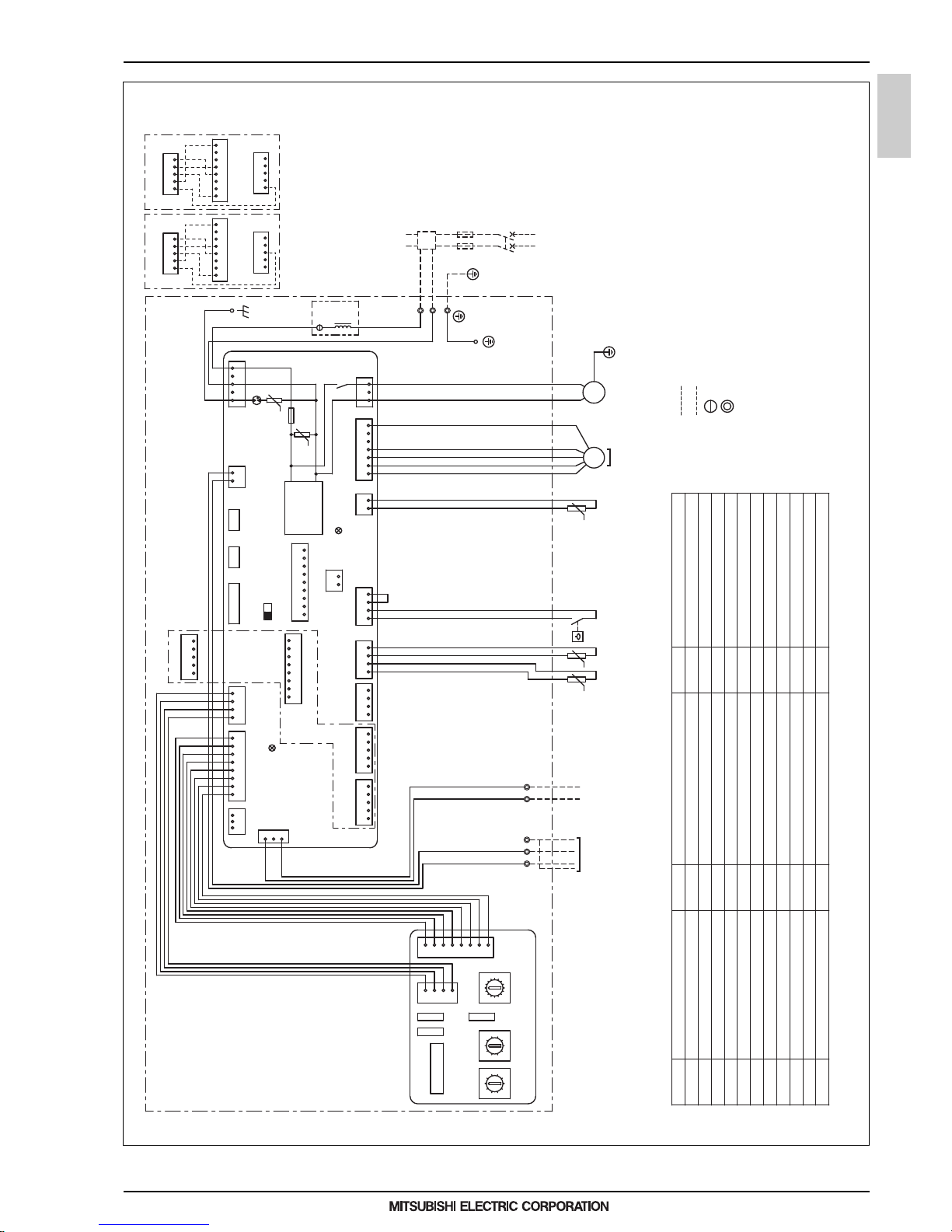

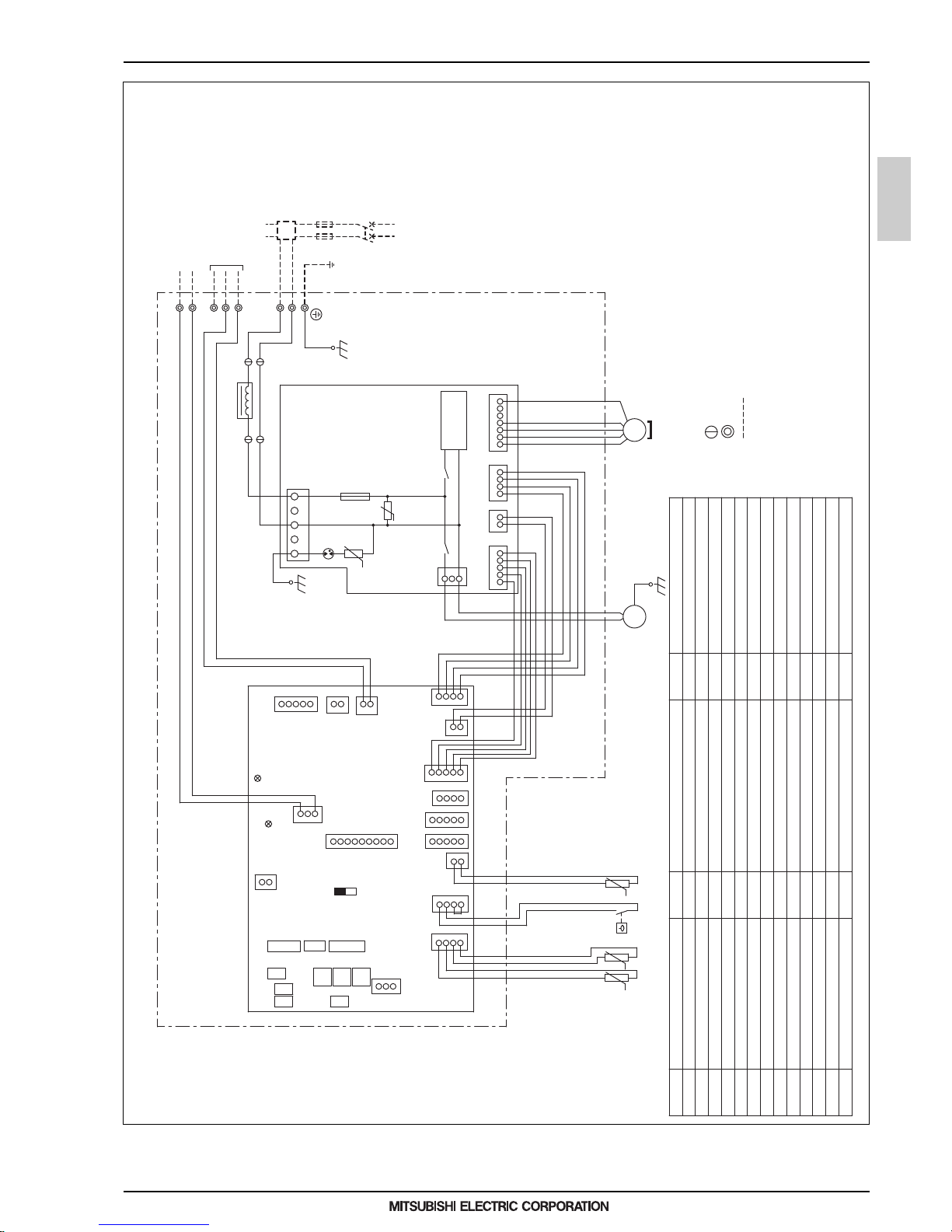

4. ELECTRICAL WIRING DIAGRAMS

4. ELECTRICAL WIRING DIAGRAMS

NOTE: Symbols used in wiring diagram above are,

(HEAVY DOTTED LINE):FIELD WIRING

(THIN DOTTED LINE) :OPTIONAL PARTS

: CONNECTOR

: TERMINAL

Connector (IT terminal)

CN100

Switch (for mode selection)

SW3(I.B.)

Switch (for model selection)

Connector (emergency operation)

Switch (for mode selection)

Switch (10ths digit address set)

Switch (connection No.set)

Switch (for static pressure selection)

Switch (for model selection)

Switch (for static pressure selection)

Switch (for capacity code)

Thermistor (piping temp.detection/water out)

Thermistor (piping temp.detection/water in)

SWB(A.B.)

AC reactor (Power factor improvement)

L1

SWA(A.B.)

SWC(A.B.)

Drainpump

Connector (Wireless)

X1

Aux. relay

Arrester

DSA

Varistor

ZNR01, 02

Fuse AC250V 6.3A

FUSE

Fan motor

SWE(I.B.)

Float switch

FS

Connector (Remote indication)

Connector (Centrally control)

CN90

Connector (Remote switch)

Connector (Damper)

CN32

CN52

CN51

CN41

Transmission terminal block

TB15

TH21

Thermistor (inlet air temp.detection)

TH23

TH22

NAME SYMBOL SYMBOL

I.B.

A.B.

Indoor controller board

Address board

Switch (1s digit address set)

SW2(I.B.)

SW11(A.B.)

SW12(A.B.)

SW14(A.B.)

SW1(A.B.)

SW4(I.B.)

TB2

TB5

Transmission terminal block

Power source terminal block

SYMBOL EXPLANATION

NAME

CN27

Connector (HA terminal-A)

SYMBOL NAME

*A

In connecting optional IT terminal,

use either CN51 or CN52 which is

not connected.

Be careful for connector colors.

*A

L1: only PEFY-WP50VMS1-E

INSIDE SECTION OF CONTROL BOX

TO MA REMOTE

CONTROLLER

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

SW14

(Connection No.)

SWBSWA

SWC

SW12

(10ths digit)

SW11

(1s digit)

SW1

A. B.

I. B.

31

12345

54185418

12345

8145

34512

MS

3~

8765432

1

432

1

1~

M

4231 1324

12 14567

3

1

135

12

132481324567

13

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

IT terminal

(PAC-IT51AD-E)

IT terminal

(PAC-IT52AD-E)

CN52

(Green)

CN100

CN51

CN100

CN100

IT terminal

CN82

CN43

L1

t° t°

U

LED1

LED2

DC310~340V

Rectify circuit

ZNR01

POWER SUPPLY

~220, 230, 240V

50, 60Hz

TO NEXT INDOOR UNIT

FUSE (16A)

PULL BOX

BREAKER (16A)

FUSE

X1

ZNR02

DSA

U

t°

(Green)

(Blue)

(Red)

(Red)

(Red)

(Red)

(Blue)

(Blue)

(Black)

TB5

N

L

TB15

12

S(SHIELD)

M2

TB2

M1

FSTH22 TH23

TH21

CN3A

CNMF

CNP

CND

CN2M

SW2SW4SW3

CN90

CN42CN81CN32

CN27

CN20

CN4FCN44CN41CN52 CN51

SWE

ON

OFF

PEFY-WP15, 20, 25, 32, 40, 50VMS1-E

Page 13

1 - 10

PEFY

MEE15K052

5. SOUND LEVELS

5. SOUND LEVELS

5-1. Sound levels

PEFY-WP-VMS1-E Sound level at anechoic room : Low-Mid-High

Sound level dB ( A )

5Pa 15Pa 35Pa 50Pa

PEFY-WP15VMS1-E 220-240V 22 - 24 - 26 22 - 24 - 28 23 - 26 - 29 23 - 27 - 30

PEFY-WP20VMS1-E 220-240V 22 - 25 - 28 23 - 25 - 29 24 - 27 - 30 25 - 28 - 32

PEFY-WP25VMS1-E 220-240V 22 - 25 - 29 23 - 26 - 30 24 - 28 - 31 25 - 29 - 33

PEFY-WP32VMS1-E 220-240V 26 - 28 - 30 28 - 30 - 33 30 - 32- 35 31 - 33 - 36

PEFY-WP40VMS1-E 220-240V 29 - 31 - 34 30 - 32 - 35 31 - 34 - 37 32 - 34 - 38

PEFY-WP50VMS1-E 220-240V 29 - 32 - 35 30 - 33 - 36 31 - 35 - 39 32 - 36 - 40

* Measured in anechoic room.

Aux.duct

1m

1.5m

Measurement location

2m

Page 14

1 - 11

PEFY

MEE15K052

5. SOUND LEVELS

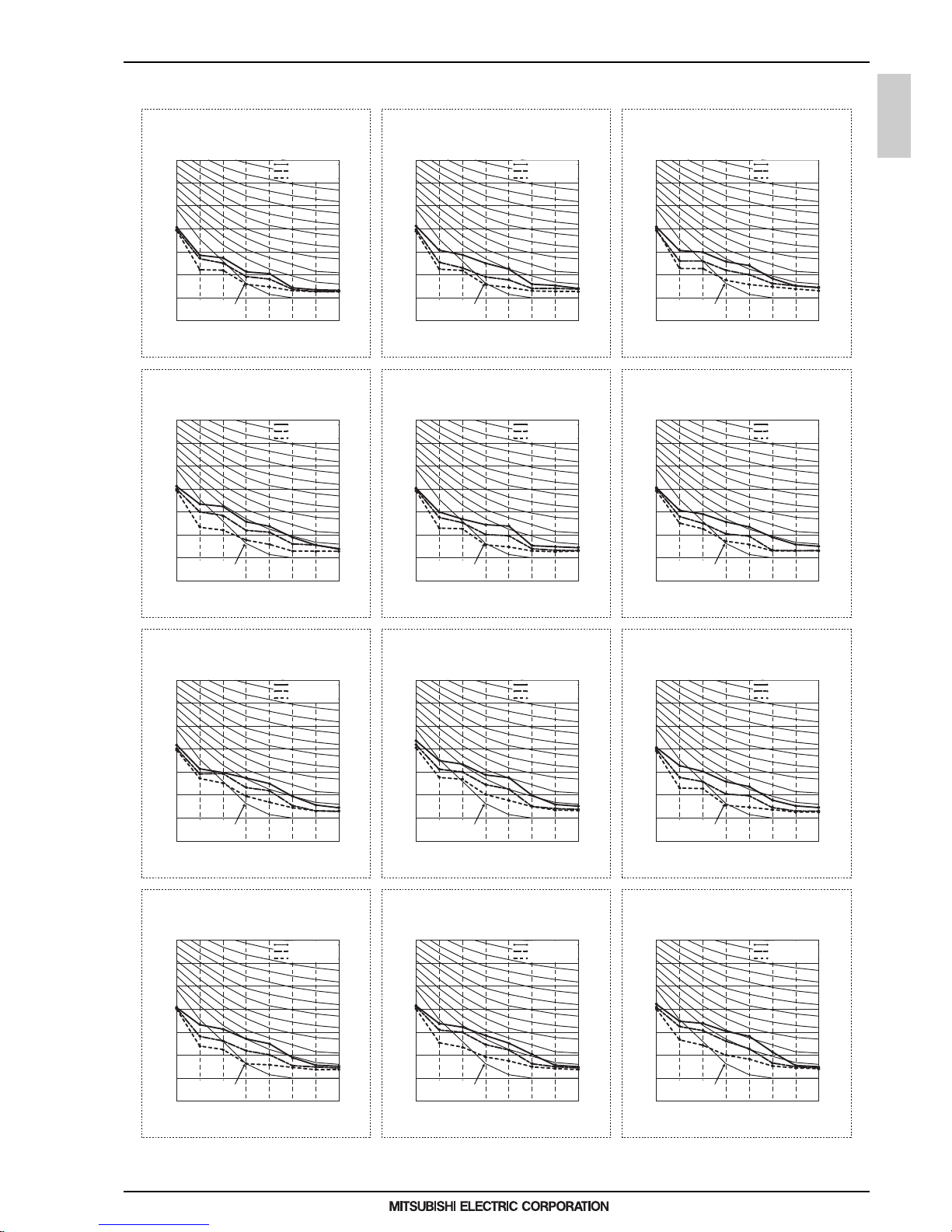

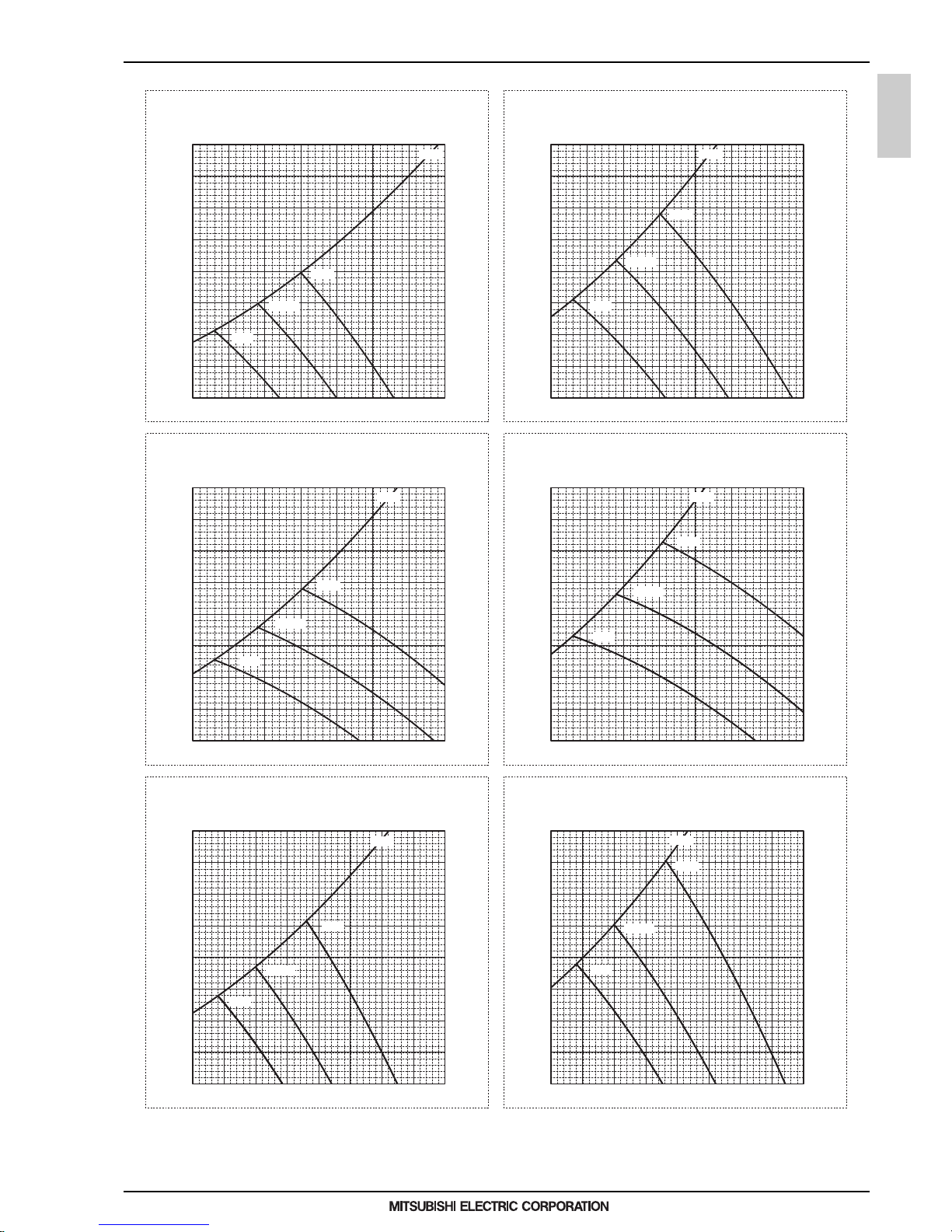

5-2. NC curves

PEFY-WP15VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP15VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP15VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP15VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP20VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP20VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP20VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP20VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP25VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP25VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP25VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP25VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Page 15

1 - 12

PEFY

MEE15K052

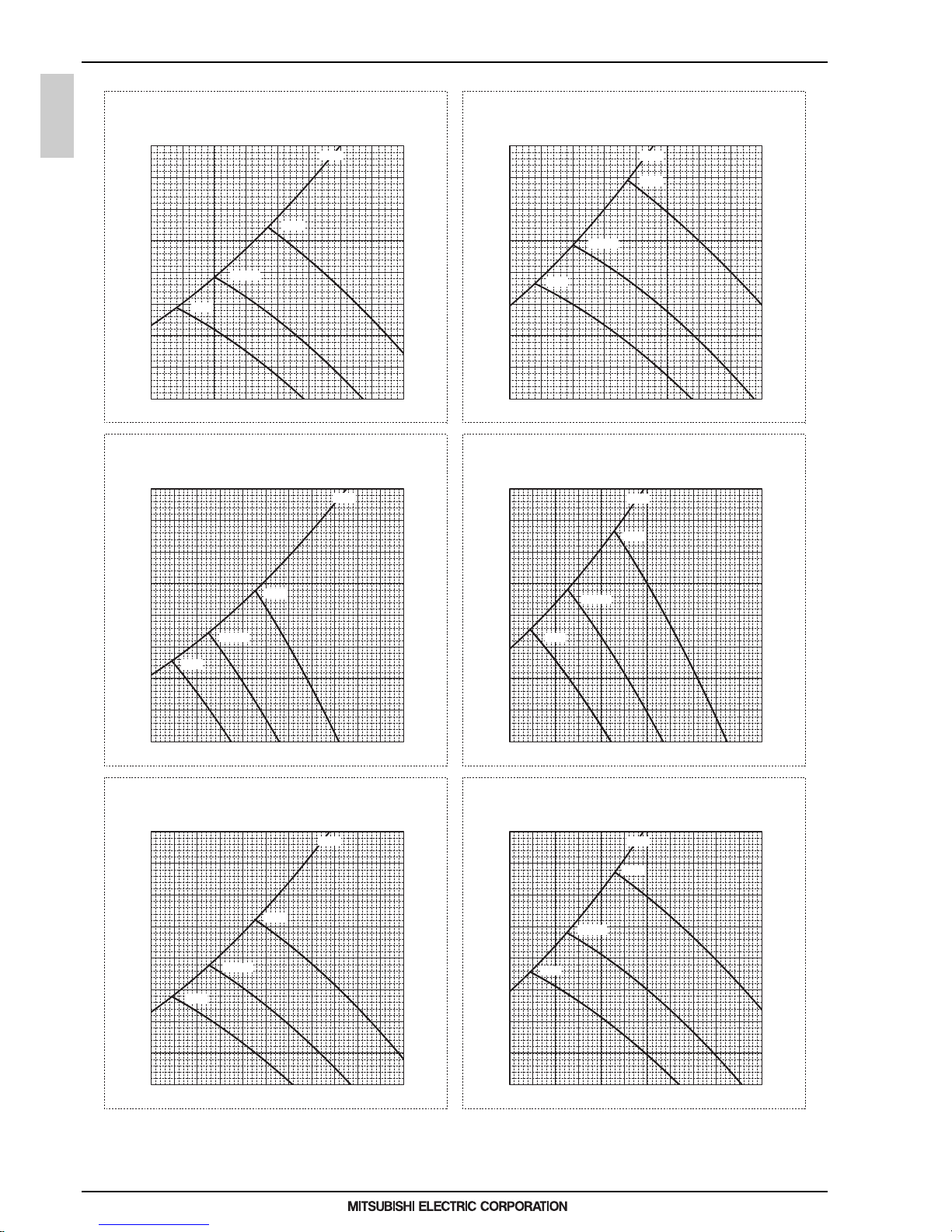

5. SOUND LEVELS

PEFY-WP32VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP32VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP32VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP32VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP40VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP40VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP40VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP40VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP50VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP50VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP50VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP50VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

NC20

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

NC20

Approximate minimum

audible limit on

continuous noise

70

60

50

40

30

20

63 125 250 500 1000 2000 4000 8000

10

0

NC60

NC50

NC40

NC30

Approximate minimum

audible limit on

continuous noise

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

High speed

Low speed

Middle speed

Page 16

1 - 13

PEFY

MEE15K052

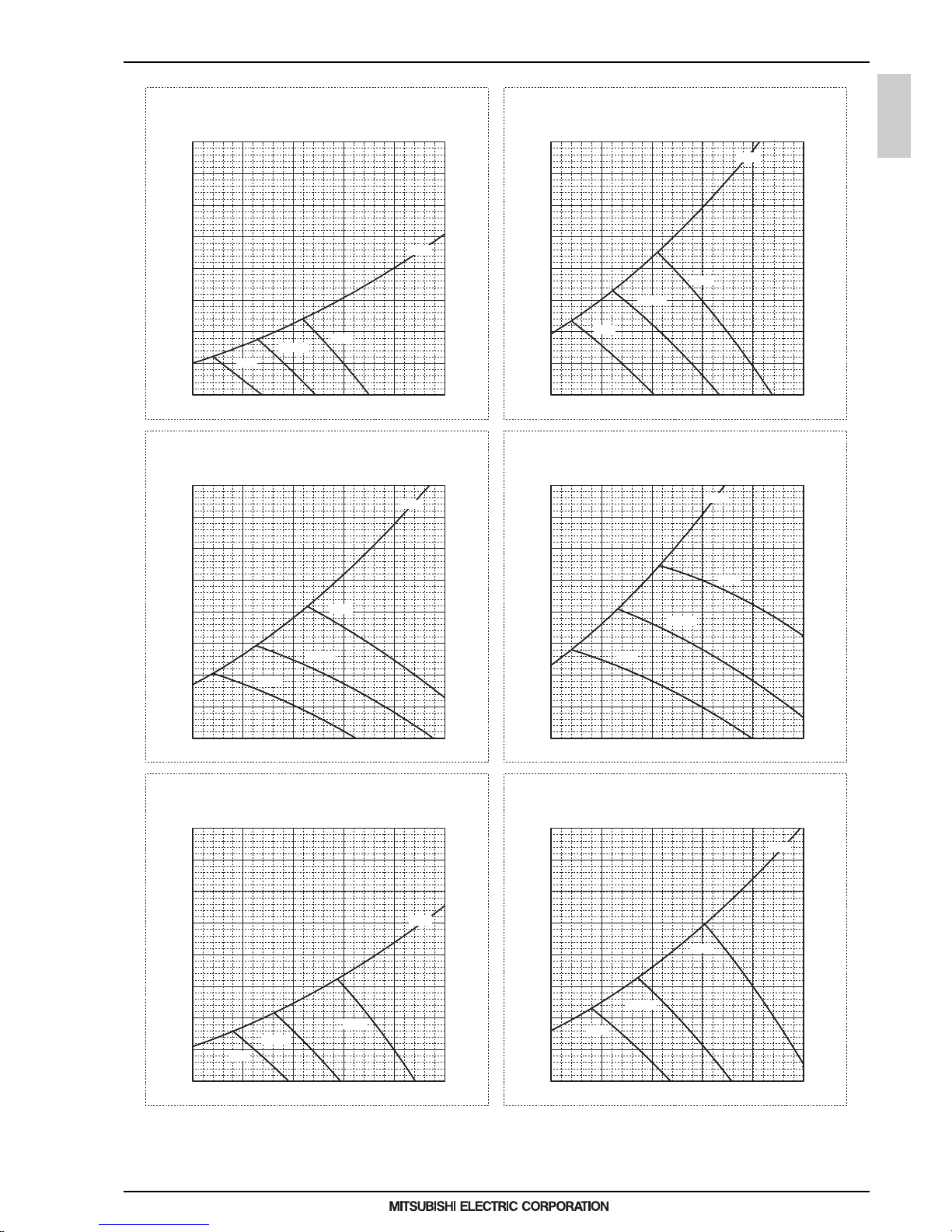

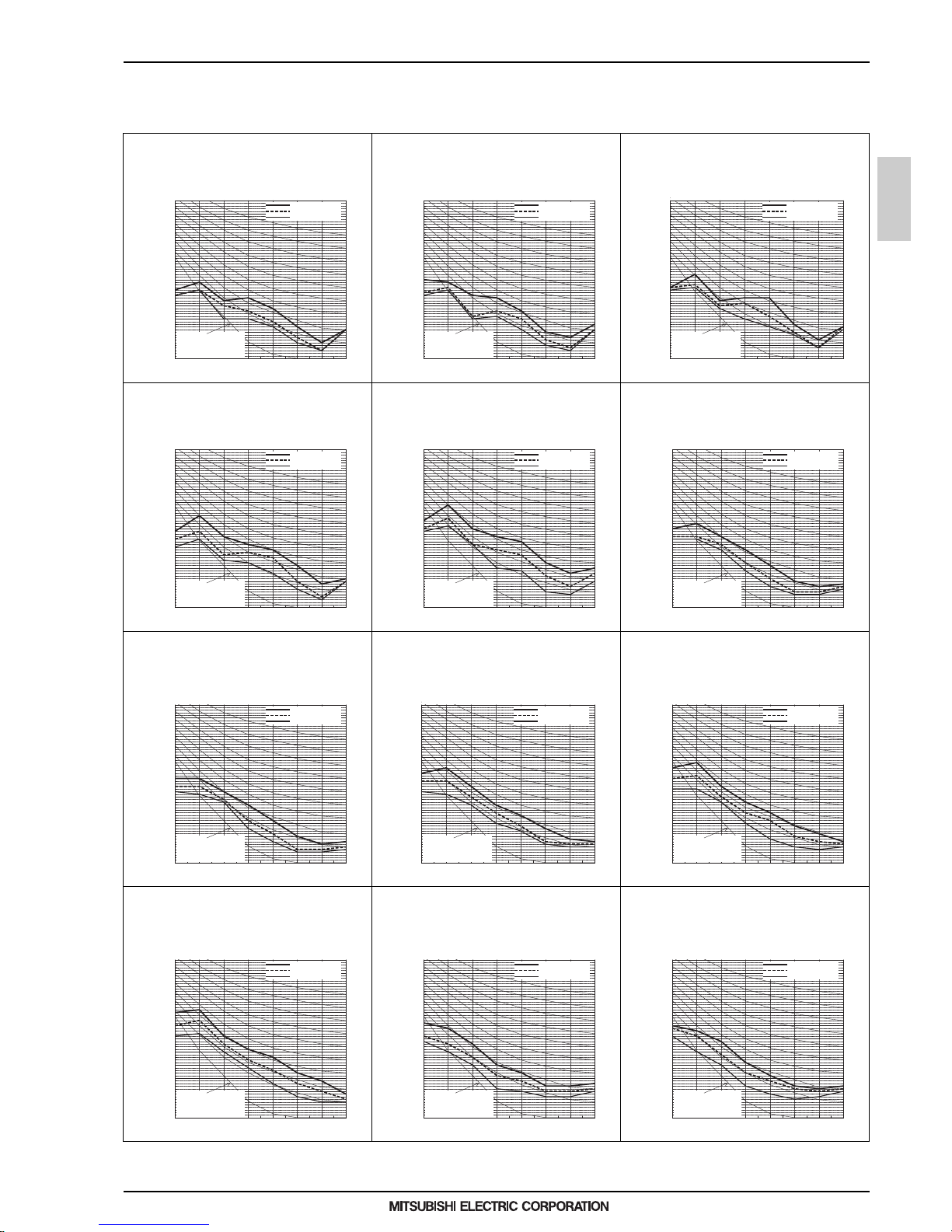

6. FAN CHARACTERISTICS CURVES

6. FAN CHARACTERISTICS CURVES

PEFY-WP15VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP15VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP15VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP15VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP20VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP20VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

0

5

10

15

20

25

30

35

40

456789

0

5

10

15

20

25

30

35

40

456789

456789

0

10

20

30

40

50

60

70

80

456789

0

10

20

30

40

50

60

70

80

0

5

10

15

20

25

30

35

40

456789

0

5

10

15

20

25

30

35

40

456789

High

Limit

Limit

Low

Middle

High

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Limit

Low

Middle

High

Low

Middle

Page 17

1 - 14

PEFY

MEE15K052

6. FAN CHARACTERISTICS CURVES

PEFY-WP20VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP20VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP25VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP25VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP25VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP25VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

456789

0

10

20

30

40

50

60

70

80

456789

0

10

20

30

40

50

60

70

80

0

5

10

15

20

25

30

35

40

4 5678 910

0

5

10

15

20

25

30

35

40

45678910

45678910

0

10

20

30

40

50

60

70

80

45678910

0

10

20

30

40

50

60

70

80

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

Page 18

1 - 15

PEFY

MEE15K052

6. FAN CHARACTERISTICS CURVES

PEFY-WP32VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP32VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

PEFY-WP40VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP40VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

Suction : Back inlet

PEFY-WP32VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP32VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

678910111213 678910111213

0

5

10

15

20

25

30

35

40

678910111213

0

5

10

15

20

25

30

35

40

678910111213

0

10

20

30

40

50

60

70

80

0

10

20

30

40

50

60

70

80

0

5

10

15

20

25

30

35

40

7 8 9 101112131415

0

5

10

15

20

25

30

35

40

7 8 9 101112131415

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

Page 19

1 - 16

PEFY

MEE15K052

6. FAN CHARACTERISTICS CURVES

PEFY-WP40VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP40VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP50VMS1-E

External static pressure : 15Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP50VMS1-E

External static pressure : 5Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP50VMS1-E

External static pressure : 50Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

PEFY-WP50VMS1-E

External static pressure : 35Pa

Power source : 220,230,240V, 50/60Hz

Suction : Back inlet

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

Airflow rate (m3/min)

Static pressure (Pa)

7 8 9 101112131415

0

10

20

30

40

50

60

70

80

7 8 9 101112131415

0

10

20

30

40

50

60

70

80

0

5

10

15

20

25

30

35

40

9 1011121314151617181920

0

5

10

15

20

25

30

35

40

9 1011121314151617181920

9 1011121314151617181920

0

10

20

30

40

50

60

70

80

9 1011121314151617181920

0

10

20

30

40

50

60

70

80

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

High

Limit

Low

Middle

Page 20

1 - 17

PEFY

MEE15K052

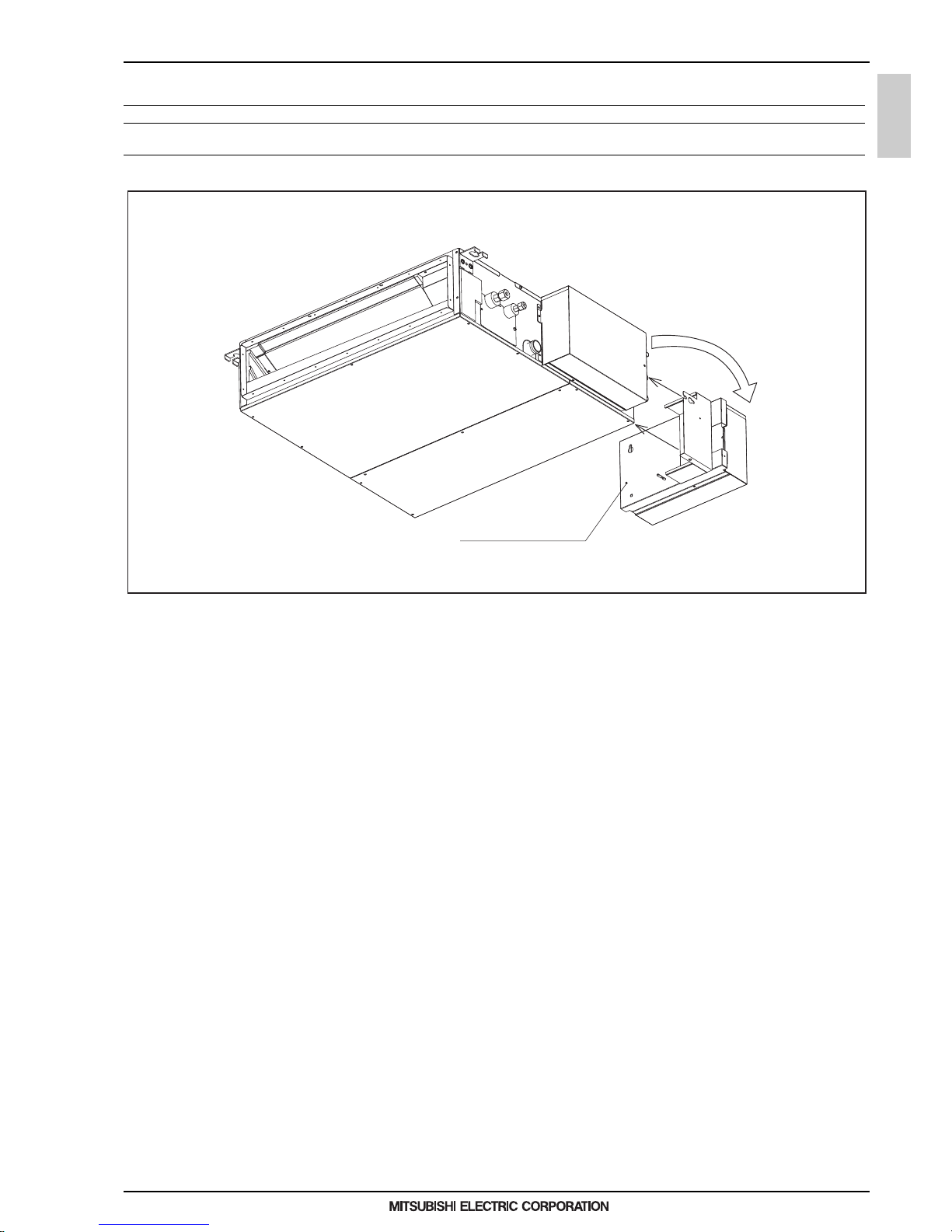

7. OPTIONAL PARTS

7. OPTIONAL PARTS

7-1. Optional parts line up for the Indoor unit

Control box replace kit

PEFY-WP15, 20, 25, 32, 40, 50VMS1-E PAC-KE70HS-E

Control box replace kit

PAC-KE70HS-E

PEFY-WP-VMS1-E

Page 21

1 - 18

PEFY

MEE15K052

7. OPTIONAL PARTS

7-2. Control box replace kit

Shape

PLATE A

Q'ty

Parts

1

PLATE B

1

PLATE C

1

COVER A

1

Shape

COVER B

Q'ty

Parts

1

LEAD WIRE MOTOR

White 7-pin connector White 6-pin connector White 4-pin connector

Ring terminal on both endsRed 2-pin connector

4X10

Blue 3-pin connector

4X10 with a washer 5X10 with a washer

White 4-pin connector

1

LEAD WIRE LEV

1

LEAD WIRE THM A

1

Shape

LEAD WIRE THM B

Q'ty

Parts

1

LEAD WIRE EARTH

1

LEAD WIRE PUMP

1

LEAD WIRE FS

1

Shape

INSULATOR

Q'ty

Parts

3

Connecting terminals

4

BAND

6

CLAMP

4

Shape

SCREW 1

Q'ty

Parts

2

SCREW 2

4

SCREW 3

5

FERRITE CORE

1

When installing the control box replace kit on the air inlet on the unit, LEAD WIRE FS is not used.

12

10

9

5

11

12

13 14 15

17 18 19

16

20

6

7 8

4321

PAC-KE70HS-E

Page 22

1 - 19

Ceiling concealed (Middle static pressure type)

PEFY-WP-VMA-E

MEE15K052

I.Ceiling concealed (Middle static pressure type)

1. SPECIFICATIONS........................................................................................................................................... 1 - 20

2. EXTERNAL DIMENSIONS .............................................................................................................................. 1 - 22

3. CENTER OF GRAVITY ................................................................................................................................... 1 - 24

4. ELECTRICAL WIRING DIAGRAMS................................................................................................................ 1 - 25

5. SOUND LEVELS ............................................................................................................................................. 1 - 26

5-1. Sound levels ............................................................................................................................................ 1 - 26

5-2. NC curves ................................................................................................................................................ 1 - 27

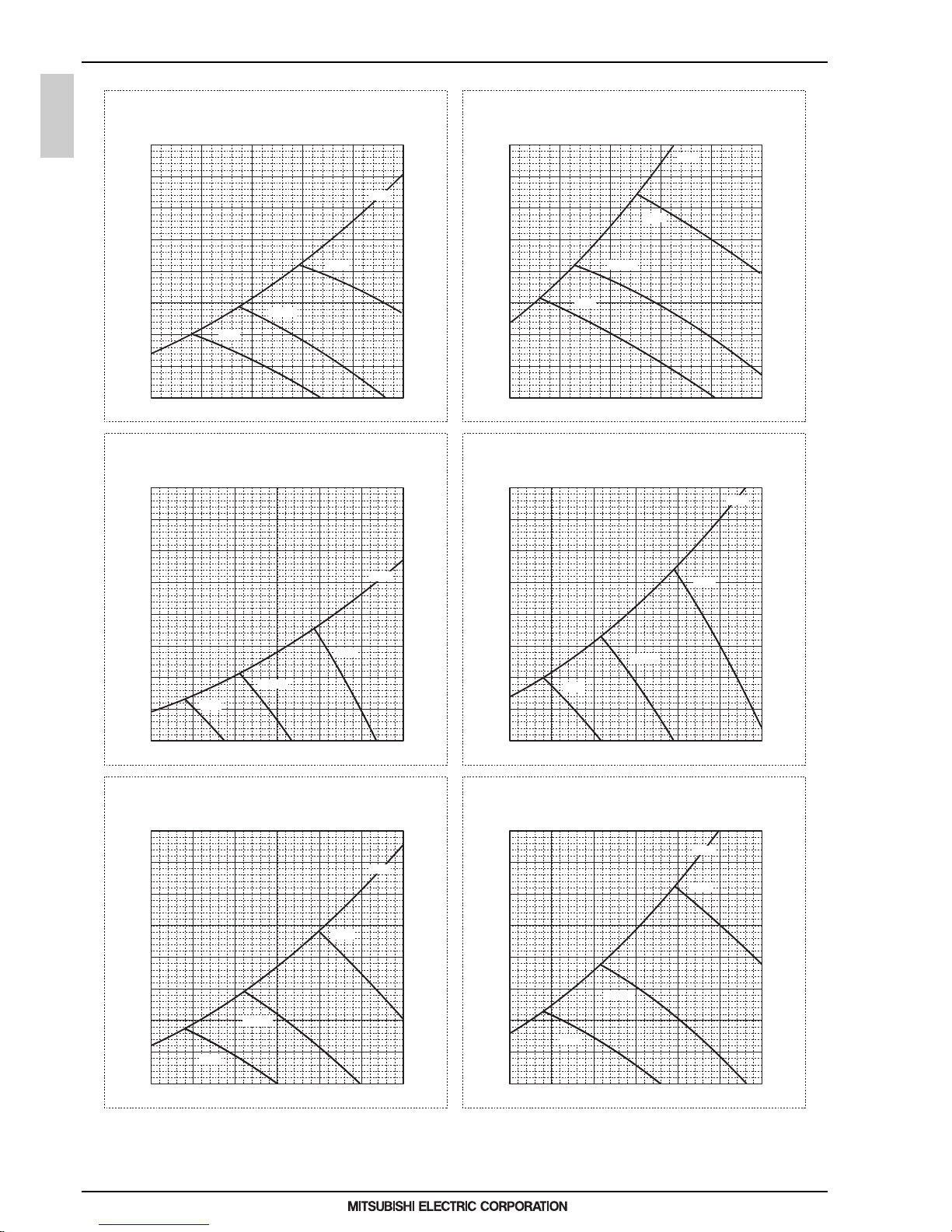

6. FAN CHARACTERISTICS CURVES............................................................................................................... 1 - 31

7. OPTIONAL PARTS.......................................................................................................................................... 1 - 35

7-1. Optional parts line up for the Indoor unit.................................................................................................. 1 - 35

7-2. Filter box .................................................................................................................................................. 1 - 35

Page 23

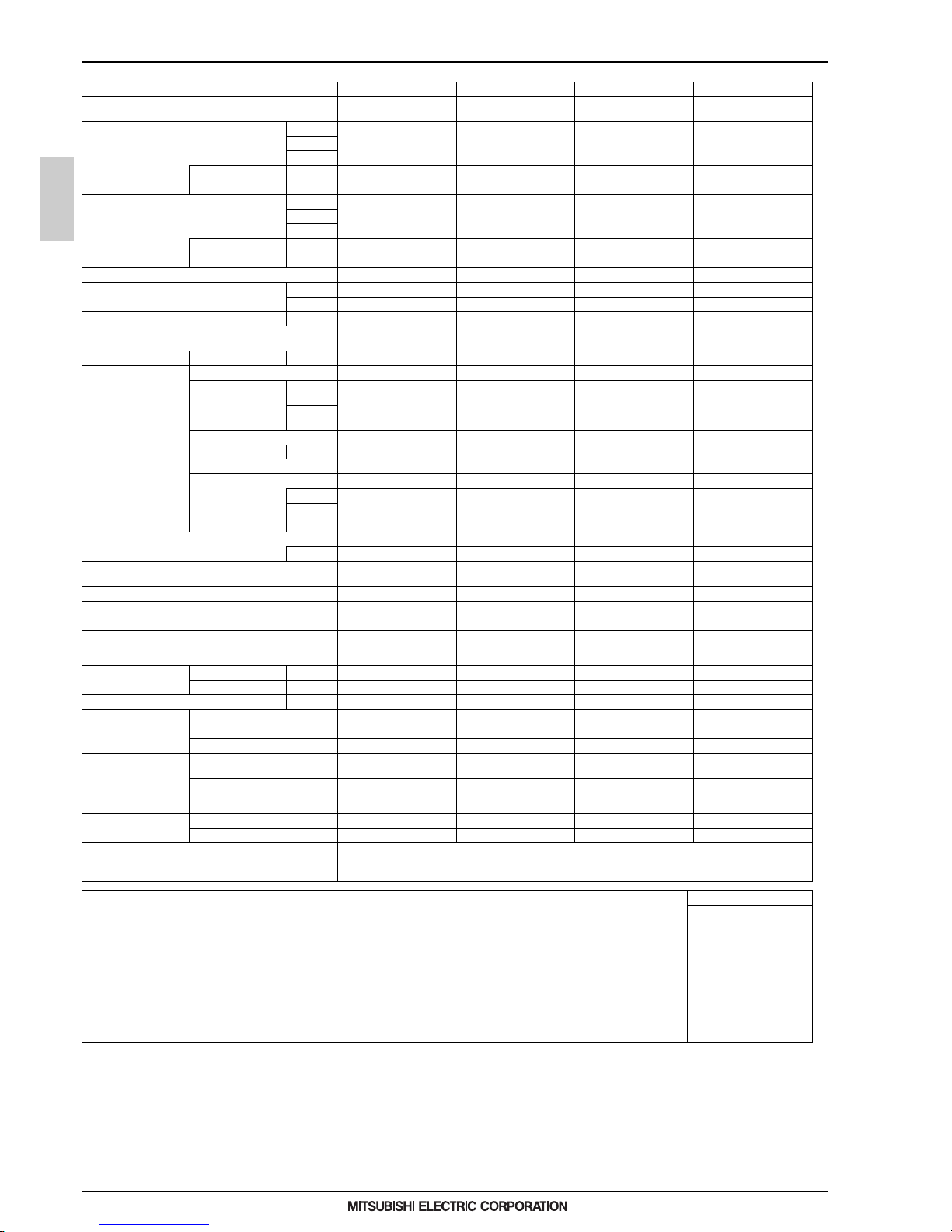

1. SPECIFICATIONS

1 - 20

PEFY-VMA

MEE15K052

I.Ceiling concealed (Middle static pressure type)1. SPECIFICATIONS

Model PEFY-WP20VMA-E PEFY-WP25VMA-E PEFY-WP32VMA-E PEFY-WP40VMA-E

Power source

1-phase 220-230-240 V 50/

60 Hz

1-phase 220-230-240 V 50/

60 Hz

1-phase 220-230-240 V 50/

60 Hz

1-phase 220-230-240 V 50/

60 Hz

Cooling capacity *1 kW 2.2 2.8 3.6 4.5

(Nominal) *1 kcal/h 1,900 2,400 3,100 3,900

*1 BTU/h 7,500 9,600 12,300 15,400

*2 Power input kW 0.07 0.09 0.11 0.14

*2 Current input A 0.55 0.64 0.74 1.15

Heating capacity *3 kW 2.5 3.2 4.0 5.0

(Nominal) *3 kcal/h 2,200 2,800 3,400 4,300

*3 BTU/h 8,500 10,900 13,600 17,100

*2 Power input kW 0.05 0.07 0.09 0.12

*2 Current input A 0.44 0.53 0.63 1.04

External finish Galvanized steel plate Galvanized steel plate Galvanized steel plate Galvanized steel plate

External dimension HxWxD mm 250 x 700 x 732 250 x 900 x 732 250 x 900 x 732 250 x 1,100 x 732

in. 9-7/8 x 27-9/16 x 28-7/8 9-7/8 x 35-7/16 x 28-7/8 9-7/8 x 35-7/16 x 28-7/8 9-7/8 x 43-5/16 x 28-7/8

Net weight kg (lbs) 21 (47) 26 (58) 26 (58) 31 (69)

Heat exchanger

Cross fin (Aluminum fin and

copper tube)

Cross fin (Aluminum fin and

copper tube)

Cross fin (Aluminum fin and

copper tube)

Cross fin (Aluminum fin and

copper tube)

Water Volume L 0.7 1.0 1.0 1.8

FAN Type x Quantity Sirocco fan x 1 Sirocco fan x 1 Sirocco fan x 1 Sirocco fan x 2

*4 External static press. Pa

<35> - 50 - <70> - <100> -

<150>

<35> - 50 - <70> - <100> -

<150>

<35> - 50 - <70> - <100> -

<150>

<35> - 50 - <70> - <100> -

<150>

mmH

2

O

<3.6> - 5.1 - <7.1> - <10.2> -

<15.3>

<3.6> - 5.1 - <7.1> - <10.2> -

<15.3>

<3.6> - 5.1 - <7.1> - <10.2> -

<15.3>

<3.6> - 5.1 - <7.1> - <10.2> -

<15.3>

Motor Type DC motor DC motor DC motor DC motor

Motor output kW 0.085 0.085 0.085 0.121

Driving mechanism Direct-driven by motor Direct-driven by motor Direct-driven by motor Direct-driven by motor

Air flow rate (Low-Mid-High) (Low-Mid-High) (Low-Mid-High) (Low-Mid-High)

m

3

/min 7.5 - 9.0 - 10.5 10.0 - 12.0 - 14.0 12.0 - 14.5 - 17.0 14.5 - 18.0 - 21.0

L/s 125 - 150 - 175 167 - 200 - 233 200 - 242 - 283 242 - 300 - 350

cfm 265 - 318 - 371 353 - 4 24 - 494 424 - 512 - 600 512 - 636 - 742

Sound pressure level (measured in anechoic room) (Low-Mid-High) (Low-Mid-High) (Low-Mid-High) (Low-Mid-High)

*2 dB <A> 23-26-29 23-27-30 25-29-32 26-29-34

Insulation material

EPS, Polyethylene foam,

Urethane foam

EPS, Polyethylene foam,

Urethane foam

EPS, Polyethylene foam,

Urethane foam

EPS, Polyethylene foam,

Urethane foam

Air filter PP honeycomb fabric. PP honeycomb fabric. PP honeycomb fabric. PP honeycomb fabric.

Protection device Fuse Fuse Fuse Fuse

Refrigerant control device - - - -

Connectable outdoor unit/HBC controller

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

Diameter of water pipe Inlet in. Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw

*5 *6 Outlet in. Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw Rc 3/4 screw

Field drain pipe size mm (in.) O.D.32 (1-1/4) O.D.32 (1-1/4) O.D.32 (1-1/4) O.D.32 (1-1/4)

Drawing Exter nal KD94L918X 01 KD94L918X01 K D94L918X01 KD94L918X 01

Wiring KD94L919X01 KD94L919X01 KD94L919X01 KD94L919X01

Refrigerant cycle - - - -

Standard attachment Document

Installation Manual, Instruc-

tion Book

Installation Manual, Instruc-

tion Book

Installation Manual, Instruc-

tion Book

Installation Manual, Instruc-

tion Book

Accessory

Insulation pipe for water pipe,

Washer, Drain hose, Tie

band

Insulation pipe for water pipe,

Washer, Drain hose, Tie

band

Insulation pipe for water pipe,

Washer, Drain hose, Tie

band

Insulation pipe for water pipe,

Washer, Drain hose, Tie

band

Optional parts Filter box PAC-KE91TB-E PAC-KE92TB-E PAC-KE92TB-E PAC-KE93TB-E

Remarks * Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

referred to the Installation Manual.

* Due to continuing improvement, above specifications may be subject to change without notice.

Notes: Unit converter

1.Nominal cooling conditions

Indoor: 27°CD.B./19°CW.B. (81°CD.B./66°CW.B.), Outdoor: 35°CD.B. (95°CD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.The values are measured at the factory setting of external static pressure.

3.Nominal heating conditions

Indoor: 20°CD.B. (68°CD.B.), Outdoor: 7°CD.B./6°CW.B. (45°CD.B./43°CW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

4.The factory setting of external static pressure is shown without < >.

Refer to "Fan characteristics curves", according to the external static pressure, in DATA BOOK for the usable

range of air flow rate.

5.Be sure to install a valve on the water outlet.

6.Install a strainer (40 mesh or more) on the pip e next to the valve to remove the foreign matters.

7.Group units that operat e on 1 branch.

kcal/h =kW x 860

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg / 0.4536

*Above specification data is

subject to rounding variation.

Page 24

1 - 21

1. SPECIFICATIONS

PEFY-VMA

MEE15K052

Model PEFY-WP50VMA-E

Power source

1-phase 220-230-240 V 50/

60 Hz

Cooling capacity *1 kW 5.6

(Nominal) *1 kcal/h 4,800

*1 BTU/h 19,100

*2 Power input kW 0.14

*2 Current input A 1.15

Heating capacity *3 kW 6.3

(Nominal) *3 kcal/h 5,400

*3 BTU/h 21,500

*2 Power input kW 0.12

*2 Current input A 1.04

External finish Galvanized steel plate

External dimension HxWxD mm 250 x 1,100 x 732

in. 9-7/8 x 43-5/16 x 28-7/8

Net weight kg (lbs) 31 (69)

Heat exchanger

Cross fin (Aluminum fin and

copper tube)

Water Volume L 1.8

FAN Type x Quantity Sirocco fan x 2

*4 External static press. Pa

<35> - 50 - <70> - <100> -

<150>

mmH

2

O

<3.6> - 5.1 - <7.1> - <10.2> -

<15.3>

Motor Type DC motor

Motor output kW 0.121

Driving mechanism Direct-d riven by motor

Air flow rate (Low-Mid-High)

m

3

/min 14.5 - 18.0 - 21.0

L/s 242 - 300 - 350

cfm 512 - 636 - 742

Sound pressure level (measured in anechoic room) (Low-Mid-High)

*2 dB <A> 26-29-34

Insulation material

EPS, Polyethylene foam,

Urethane foam

Air filter PP honeyco mb fabric.

Protection device Fus e

Refrigerant control device -

Connectable outdoor unit/HBC controlle r

CITY MULTI YLM series/

CMB-WP-V-GA1, CMB-WP-

V-GB1

Diameter of water pipe Inlet in. Rc 3/4 screw

*5 *6 Outlet in. Rc 3/4 screw

Field drain pipe size mm (in.) O.D.32 (1-1/4)

Drawing External KD94L918X01

Wiring KD94L919X01

Refrigerant cycle -

Standard attachment Document

Installation Manual, Instruc-

tion Book

Accessory

Insulation pipe for water pipe,

Washer, Drain hose, Tie

band

Optional parts Filter box PAC-KE93TB-E

Remarks * Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

referred to the Installation Manual.

* Due to continuing improvement, ab ove specifications may be subject to chan ge without notice.

Notes : Unit converter

1.Nominal cooling conditions

Indoor: 27°CD.B./19°CW.B. (81°CD.B./66°CW.B.), Outdoor: 35°CD.B. (95°CD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.The values are measured at the factory setting of external static pressure.

3.Nominal heating conditions

Indoor: 20°CD.B. (68°CD.B.), Outdoor: 7°CD.B./6°CW.B. (45°CD.B./43°CW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

4.The factory setting of external static pressure is shown without < >.

Refer to "Fan characteristics curves", according to the external static pressure, in DATA BOOK for the usable

range of air flow rate.

5.Be sure to install a valve on the water outlet.

6.Install a strainer (40 mesh or more) on the pipe next to the valve to remove the foreign matters.

7.Group units that operate on 1 branch.

kcal/h =kW x 860

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg / 0.4536

*Above specification data is

subject to rounding variation.

Page 25

2. EXTERNAL DIMENSIONS

1 - 22

PEFY-VMA

MEE15K052

2. EXTERNAL DIMENSIONS

Control box

2×2-ø2.9

Air

outlet

Air

inlet

2×E-ø2.9

Water pipe(To HBC unit)

Rc3/4 screw

2

1

Water pipe(From HBC unit)

Rc3/4 screw

Drain pump

Air Filter

Terminal block(Power source)

Terminal block(Transmission)

Drain pipe(O.D.ø32)

(Spontaneous draining)

Drain pipe

(O.D.ø32)

Suspension bolt hole

4-14×30 Slot

Note 1.Use M10 screw for the Suspension bolt (field supply).

2.Keep the service space for the maintenance at the bottom.

3.This chart indicates for PEFY-WP40·50VMA-E models,

which have 2 fans.PEFY-WP20·25·32VMA-E models

have 1 fan.

4.In case of the inlet duct is used,remove the air filter

(supply with the unit),then install the filter

(field supply) at suction side.

Rc3/4 screw

Water pipe

(To HBC unit)

Water pipe

(From HBC unit)

7

Model

A

660800

1200

700 754

900 954 860 9

E

11

D

1060

C

1100

B

1154PEFY-WP40,50VMA-E

PEFY-WP25,32VMA-E

PEFY-WP20VMA-E

1000

1000

F

858800G658

1058

600

Outlet air

side view

Top view

Inlet air

side view

Piping

side view

To p

Bottom

91 64

87117

20

64

40

250

40

D (Duct)

21018

G21

57

10

A

B(Suspension bolt pitch)

C

23

643(Suspension bolt pitch)

178(Duct)

23

10

238

32 700

732

356

100

41

217

100

30

100×(E-1)=F

58

15

Unit: mm

PEFY-WP20, 25, 32, 40, 50VMA-E

Page 26

1 - 23

2. EXTERNAL DIMENSIONS

PEFY-VMA

MEE15K052

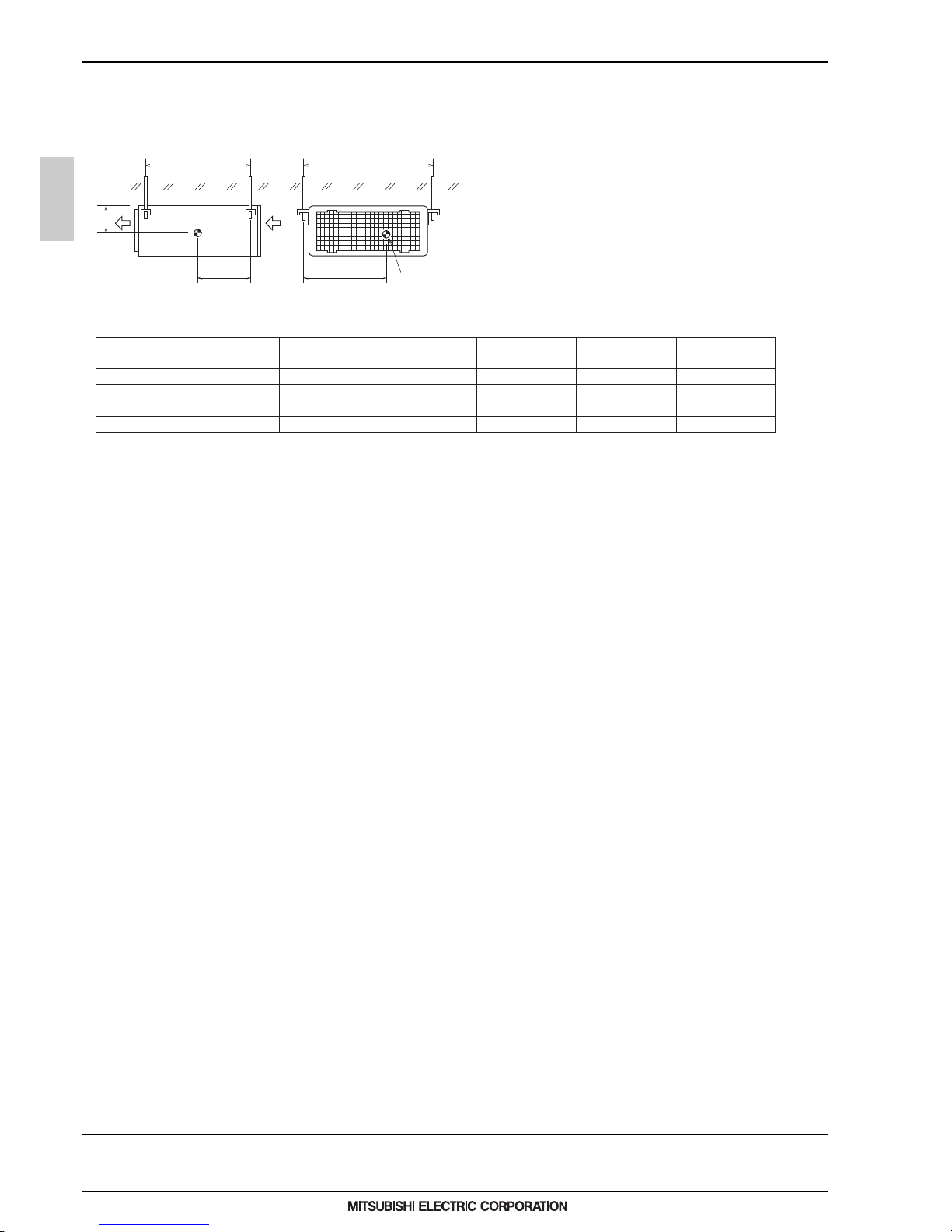

PEFY-WP20, 25, 32, 40, 50VMA-E

Unit: mm

N-ø2.9

(Actual length)

<accessory>

Drain hose (I.D.ø32)

Model H RQS

PEFY-WP20VMA-E 44 50~150 800 1300

K

300

PEFY-WP25,32VMA-E 1000150~250 150054

P

700

900

1100

N

101010

M

780

990

J

150

260

330PEFY-WP40,50VMA-E 1200250~350 1700

L

4

449

Maintenance access space

Maintenance access space

Maintenance access space

Access door 3

Access door 4

Access door 2

(450×450)

Ceiling

Ceiling

A

B

Fig.3

Fig.4

Fig.2

Fig.1

Fig.5

(Viewed from the direction of the arrow A)

(Viewed from the direction of the arrow B)

(Viewed from the direction

of the arrow B)

Intake air

Intake air

Supply air

Supply air

Access door 2(450×450)

Access door 3

Ceiling beam

Ceiling beam

Bottom of indoor unit

Bottom of

indoor unit

Bottom of

indoor unit

100~200

100~200

Access door 1

(450×450)

Access door 1

(450×450)

Electric box

Electric box

Electric box

Electric box

Electric box

[Maintenance access space]

Secure enough access space to allow for the maintenance, inspection, and replacement of the motor, fan, drain pump, heat exchanger,

and electric box in one of the following ways.

Select an installation site for the indoor unit so that its maintenance access space will not be obstructed by beams or other objects.

(1)When a space of 300mm or more is available below the unit between the unit and the ceiling. (Fig.1)

·Create access door 1 and 2 (450×450mm each) as shown in Fig.2.

(Access door 2 is not required if enough space is available below the unit for a maintenance worker to work in.)

(2)When a space of less than 300mm is available below the unit between the unit and the ceiling.

(At least 20mm of space should be left below the unit as shown in Fig.3.)

·Create access door 1 diagonally below the electric box and access door 3 below the unit as shown in Fig.4.

or

·Create access door 4 below the electric box and the unit as shown in Fig.5.

112 11112

H

JK

6 H

J

J×(L-1)=M

65

0

-10

Less than 300mm

Less than 700mm

700

700

475

Min.10mm

475

Min.10mm

450

450

50

Q

50~150

450

Min.300mm

450

450

450

50

50

Min.300mm50 700

777

777

R

S

P

P

P

Min.300mm

Min.20mm

Page 27

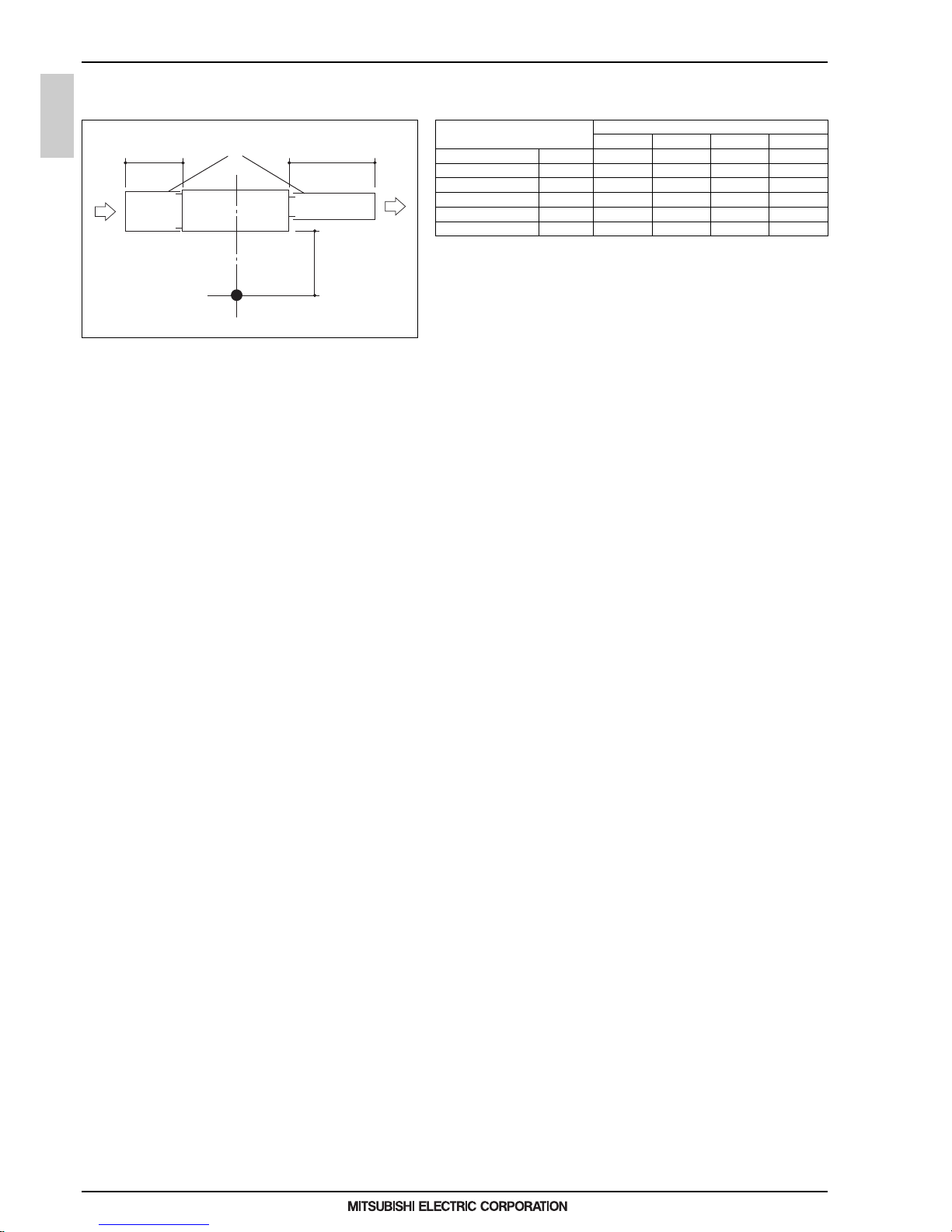

3. CENTER OF GRAVITY

1 - 24

PEFY-VMA

MEE15K052

3. CENTER OF GRAVITY

Model name

PEFY-WP20VMA-E

PEFY-WP25VMA-E

PEFY-WP32VMA-E

PEFY-WP40VMA-E

PEFY-WP50VMA-E

W

643 [25 - 6/16]

643 [25 - 6/16]

643 [25 - 6/16]

643 [25 - 6/16]

L

754 [29 - 11/16]

954 [37 - 9/16]

954 [37 - 9/16]

1154 [45 - 7/16]

X

330 [13]

340 [13 - 7/16]

340 [13 - 7/16]

325 [12 - 13/16]

Y

300 [11 -13/16]

375 [14 -13/16]

375 [14 -13/16]

525 [20 -11/16]

Z

130 [5 -2/16]

130 [5 -2/16]

130 [5 -2/16]

130 [5 -2/16]

643 [25 - 6/16] 1154 [45 - 7/16]

325 [12 - 13/16]

525 [20 -11/16] 130 [5 -2/16]

A : Center of gravity

YX

LW

A

Z

PEFY-WP20, 25, 32, 40, 50VMA-E

(mm)[in]

Page 28

1 - 25

4. ELECTRICAL WIRING DIAGRAMS

PEFY-VMA

MEE15K052

4. ELECTRICAL WIRING DIAGRAMS

INSIDE SECTION OF CONTROL BOX

Drainpump

Fan motor

Thermistor (piping temp.detection/water in)

Thermistor (piping temp.detection/water out)

Switch (for mode selection)

Switch (for capacity code)

Switch (10ths digit address set)

Switch (for static pressure selection)

Switch (for static pressure selection)

Switch (BRANCH No.)

Switch (for mode selection)

Switch (for model selection)

Switch (for mode selection)

Connector (emergency operation)

Transmission terminal block

Fuse AC250V 6.3A

Arrester

Aux. relay

Aux. relay

AC reactor(Power factor improvement)

Varistor

TB15

F01

DSA

X01

X10

ACL

ZNR01,02

TH21

LED1

Thermistor (inlet air temp.detection)

LED(Power supply)

LED(Remote controller supply)

TH23

TH22

LED2

NAMESYMBOLSYMBOL

I.B.

P. B.

Indoor controller board

Power supply board

Switch (1s digit address set)

SW2(I.B.)

SW3(I.B.)

SW11(I.B.)

SW12(I.B.)

SWA(I.B.)

SW14(I.B.)

SWC(I.B.)

SW1(I.B.)

SW4(I.B.)

SW5(I.B.)

SWE(I.B.)

TB2

TB5

Transmission terminal block

Power source terminal block

SYMBOL EXPLANATION

NAME

CN27

CN41

CN51

CN52

CN90

CN2A

CN105

FS

Connector (HA terminal-A)

Connector (Centrally control)

Connector (Remote indication)

Connector (Wireless)

Connector (0-10V Analog input)

Connector (IT terminal)

Float switch

SYMBOL NAME

Connector (Damper)

CN32

Connector (Remote switch)

NOTE:Symbols used in wiring diagram above are,

:Connector

:Terminal

(Heavy dotted line):Field wiring

I.B.

P. B .

TH23

TH21

TH22

t° t°

t°

FS

(Blue)

(Blue)

(Blue)

(Blue)

(Blue)

(Black)

(Green)

(Red)

CN44

(Red)

(Red)

(Red)

CN27

ON

ZNR01

CNP

CND

ZNR02

DSA

OFF

F01

SW5

SWC

SW14

SW12

SW11

SW4

SWA

ACL

SW1

SW2

SW3

CNXC1

X01 X10

CNXA1CNXB1 CNMF

CNXC2

CN2A

CN2M

CNXB2

CNXA2

CN51

CN4F

CN41

CN105

CN90

CN20

SWE

CN52

CN32

CN3A

TB5

LED2

LED1

DC280-340V

Rectifier circuit

U

U

AC220-240V

50,60Hz

N

L

TB15

M2

2

TB2

M1

1

S(SHIELD)

M

MS

3~

1111

1

11

22752

5

33445 6 4

3

22

2

1

3

1

3

2 32

3

1 2

1

1

3

431454

1

2

4

1

2

2

1

1~

TO MA REMOTE

CONTROLLER

TO OUTDOOR UNIT

HBC CONTROLLER

REMOTE CONTROLLER

POWER SUPPLY

PULL BOX

BREAKER (16A)

FUSE (16A)

TO NEXT INDOOR UNIT

PEFY-WP20, 25, 32, 40, 50VMA-E

Page 29

5. SOUND LEVELS

1 - 26

PEFY-VMA

MEE15K052

5. SOUND LEVELS

5-1. Sound levels

5-1-1. Sound levels (Measured condition : With 1m air inlet duct and 2m air outlet duct)

5-1-2. Sound levels (Measured condition : With 2m air inlet duct and 2m air outlet duct)

Sound level at anechoic room : Low-Mid-High

Model Sound level dB(A)

35Pa 50Pa 70Pa 100Pa 150Pa

PEFY-WP20VMA-E 28-30-34 28-30-34 29-32-36 29-33-37 31-35-40

PEFY-WP25VMA-E 28-30-34 28-30-34 29-32-36 29-33-37 32-36-40

PEFY-WP32VMA-E 28-31-35 28-32-35 29-33-37 30-34-38 32-37-41

PEFY-WP40VMA-E 30-33-37 30-34-38 31-36-39 33-37-41 36-41-44

PEFY-WP50VMA-E 30-33-37 30-34-38 31-36-39 33-37-41 36-41-44

*

Measured in anechoic room.

PEFY-WP-VMA-E

2m

1m

Aux. duct

1.5m

Measurement location

Sound level at anechoic room : Low-Mid-High

Model Sound level dB(A)

35Pa 50Pa 70Pa 100Pa 150Pa

PEFY-WP20VMA-E 23-25-28 23-26-29 24-27-30 25-28-32 28-32-36

PEFY-WP25VMA-E 23-26-29 23-27-30 24-28-31 26-29-33 29-33-37

PEFY-WP32VMA-E 24-28-31 25-29-32 26-30-33 27-31-34 29-34-38

PEFY-WP40VMA-E 26-29-33 26-29-34 26-30-35 29-33-37 32-37-41

PEFY-WP50VMA-E 26-29-33 26-29-34 26-30-35 29-33-37 32-37-41

Measurement location

Aux. duct

*

Measured in anechoic room.

PEFY-WP-VMA-E

2m 2m

1.5m

Page 30

1 - 27

5. SOUND LEVELS

PEFY-VMA

MEE15K052

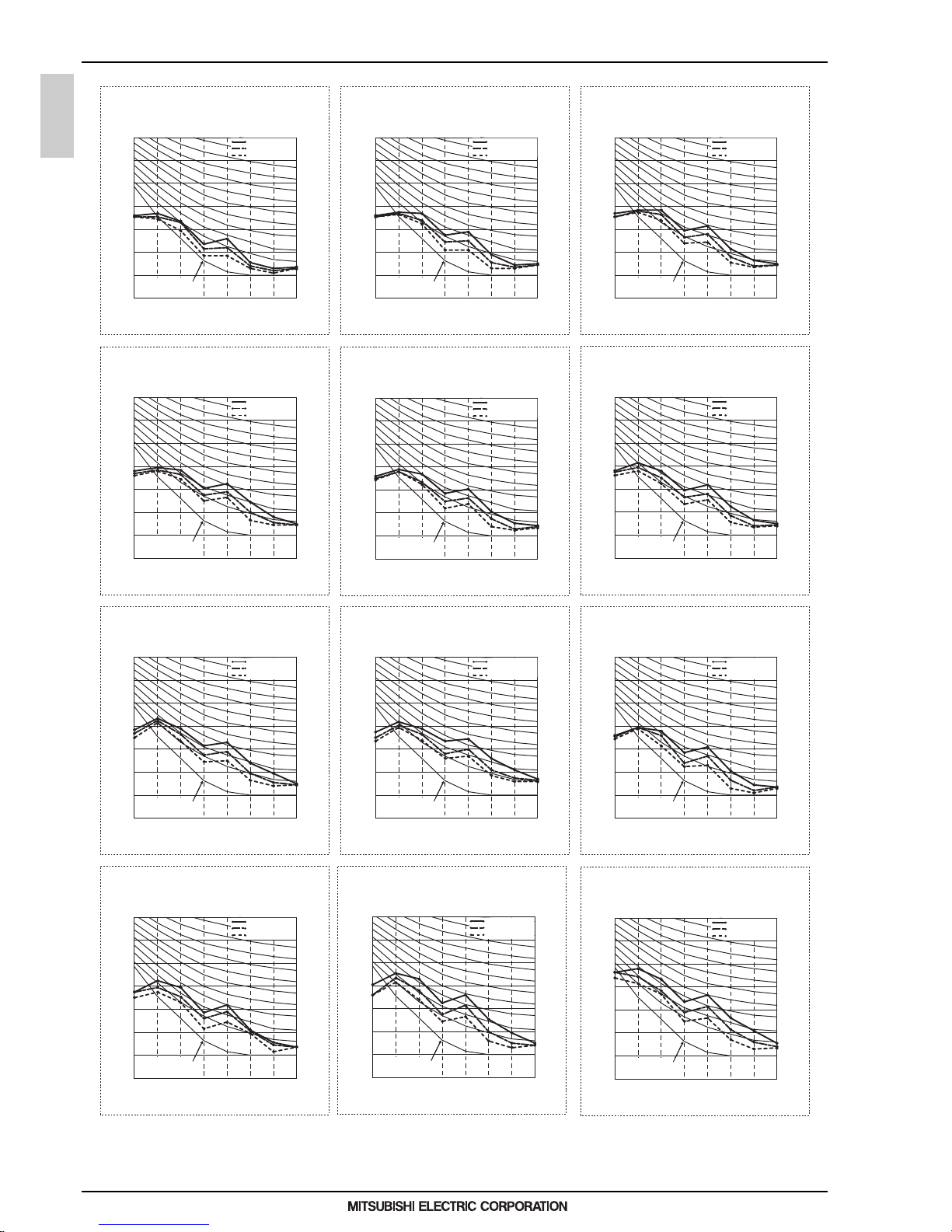

5-2. NC curves

5-2-1. NC curves (Sound level measured condition : With 1m air inlet duct and 2m air outlet duct)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP20VMA-E

External Static Pressure: 35Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP20VMA-E

External Static Pressure: 50Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP20VMA-E

External Static Pressure: 70Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP20VMA-E

External Static Pressure: 100Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP20VMA-E

External Static Pressure: 150Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP25VMA-E

External Static Pressure: 35Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP25VMA-E

External Static Pressure: 50Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP25VMA-E

External Static Pressure: 70Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low

50/60Hz

50/60Hz

PEFY-WP25VMA-E

External Static Pressure: 100Pa

Power Source: 220-240V(50/60Hz)

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

Approximate minimum

audible limit on

continuous noise

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

High

Middle

50/60Hz

Low