Page 1

TECHNICAL & SERVICE MANUAL

Model nameModel name

PEFY-P72NMHSU-E

PEFY-P96NMHSU-E

2011

AIR CONDITIONERS

Page 2

Page 3

ii

HWE10170 GB

Safety Precautions

Read before installation and performing electrical work

Symbol explanations

Thoroughly read the following safety precautions prior to installation.

Observe these safety precautions for your safety.

This equipment may have adverse effects on the equipment on the same power supply system.

Contact the local power authority before connecting to the system.

WARNING

This symbol indicates that failure to follow the instructions exactly as stated poses the risk of serious injury or death.

CAUTION

This symbol indicates that failure to follow the instructions exactly as stated poses the risk of serious injury or dam-

age to the unit.

Indicates an action that must be avoided.

Indicates important instructions.

Indicates a parts that requires grounding.

Indicates that caution must be taken with rotating parts. (This symbol is on the main unit label.) <Color: Yellow>

Indicates that the parts that are marked with this symbol pose a risk of electric shock. (This symbol is on the main

unit label.) <Color: Yellow>

WARNING

Carefully read the labels affixed to the main unit.

WARNING

Ask your dealer or a qualified technician to install the unit.

Improper installation by the user may result in water leakage, electric shock, or fire.

Properly install the unit on a surface that can withstand its

weight.

Unit installed on an unstable surface may fall and cause injury.

Only use specified cables. Securely connect each cable so

that the terminals do not carry the weight of the cable.

Improperly connected cables may produce heat and start a

fire.

Take appropriate safety measures against wind gusts and

earthquakes to prevent the unit from toppling over.

Improper installation may cause the unit to topple over and

cause injury or damage to the unit.

Only use accessories (i.e., air cleaners, humidifiers, electric

heaters) recommended by Mitsubishi Electric.

Do not make any modifications or alterations to the unit.

Consult your dealer for repair.

Improper repair may result in water leakage, electric shock,

or fire.

Do not touch the heat exchanger fins with bare hands.

The fins are sharp and pose a risk of cuts.

In the event of a refrigerant leak, thoroughly ventilate the

room.

If gaseous refrigerant leaks out and comes in contact with

an open flame, toxic gases will be generated.

Properly install the unit according to the instructions in the

Installation Manual.

Improper installation may result in water leakage, electric

shock, or fire.

Have all electrical work performed by an authorized electrician according to the local regulations and the instructions

in this manual. Use a dedicated circuit.

Insufficient power supply capacity or improper installation

of the unit may result in malfunctions of the unit, electric

shock, or fire.

Page 4

ii

HWE10170 GB

Precautions for handling units for use with R410A

WARNING

Keep electrical parts away from water.

Wet electrical parts pose a risk of electric shock, smoke, or

fire.

Securely attach the control box cover.

If the cover is not installed properly, dust or water may infiltrate and pose a risk of electric shock, smoke, or fire.

Only use the type of refrigerant that is indicated on the unit

when installing or relocating the unit.

Infiltration of any other types of refrigerant or air into the unit

may adversely affect the refrigerant cycle and may cause

the pipes to burst or explode.

When installing the unit in a small space, take appropriate

precautions to prevent leaked refrigerant from reaching the

limiting concentration.

Leaked refrigerant gas will displace oxygen and may cause

oxygen starvation. Consult your dealer before installing the

unit.

Consult your dealer or a qualified technician when moving

or reinstalling the unit.

Improper installation may result in water leakage, electric

shock, or fire.

After completing the service work, check for a refrigerant

leak.

If leaked refrigerant is exposed to a heat source, such as a

fan heater, stove, or electric grill, toxic gases will be generated.

Do not try to defeat the safety features of the unit.

Forced operation of the pressure switch or the temperature

switch by defeating the safety features for these devices, or

the use of accessories other than the ones that are recommended by Mitsubishi Electric may result in smoke, fire, or

explosion.

Consult your dealer for proper disposal method.

Do not use a leak detection additive.

CAUTION

Do not use the existing refrigerant piping.

A large amount of chlorine that may be contained in the residual refrigerant and refrigerator oil in the existing piping

may cause the refrigerator oil in the new unit to deteriorate.

Use refrigerant piping materials made of phosphorus deoxidized copper. Keep the inner and outer surfaces of the

pipes clean and free of such contaminants as sulfur, oxides,

dust, dirt, shaving particles, oil, and moisture.

Contaminants in the refrigerant piping may cause the refrigerator oil to deteriorate.

Store the piping materials indoors, and keep both ends of

the pipes sealed until immediately before brazing. (Keep elbows and other joints wrapped in plastic.)

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerator oil to deteriorate or cause the

compressor to malfunction.

Use a small amount of ester oil, ether oil, or alkyl benzene

to coat flares and flanges.

Infiltration of a large amount of mineral oil may cause the refrigerator oil to deteriorate.

Charge the system with refrigerant in the liquid phase.

If gaseous refrigerant is drawn out of the cylinder first, the

composition of the remaining refrigerant in the cylinder will

change and become unsuitable for use.

Only use R410A.

The use of other types of refrigerant that contain chloride

may cause the refrigerator oil to deteriorate.

Use a vacuum pump with a check valve.

If a vacuum pump that is not equipped with a check valve is

used, the vacuum pump oil may flow into the refrigerant cycle and cause the refrigerator oil to deteriorate.

Prepare tools for exclusive use with R 410A. Do not use the

following tools if they have been used with the conventional

refrigerant: gauge manifold, charging hose, gas leak detector, check valve, refrigerant charge base, vacuum gauge,

and refrigerant recovery equipment.

If the refrigerant or the refrigerator oil that may be left on these

tools are mixed in with R410A, it may cause the refrigerator oil

in the new system to deteriorate.

Infiltration of water may cause the refrigerator oil to deteriorate.

Leak detectors for conventional refrigerants will not detect an

R410A leak because R410A is free of chlorine.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of the refrigerant

in the cylinder will change and become unsuitable for use.

Exercise special care when handling tools for use with R410A.

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerator oil to deteriorate.

Page 5

CONTENTS

HWE10170 GB

[1] Components and Functions...................................................................................................... 1

[2] Specifications............................................................................................................................ 3

[3] Sound pressure levels .............................................................................................................. 5

[4] Fan performance and corrected air flow ................................................................................... 8

[5] Outlines and Dimensions........................................................................................................ 10

[6] Wiring Diagram ....................................................................................................................... 11

[7] Refrigerant system diagram.................................................................................................... 12

[8] Troubleshooting ...................................................................................................................... 13

[9] Disassembly Procedure.......................................................................................................... 60

[10] Optional parts ....................................................................................................................... 67

Page 6

HWE10170 GB

Page 7

1- 1 -

HWE10170 GB

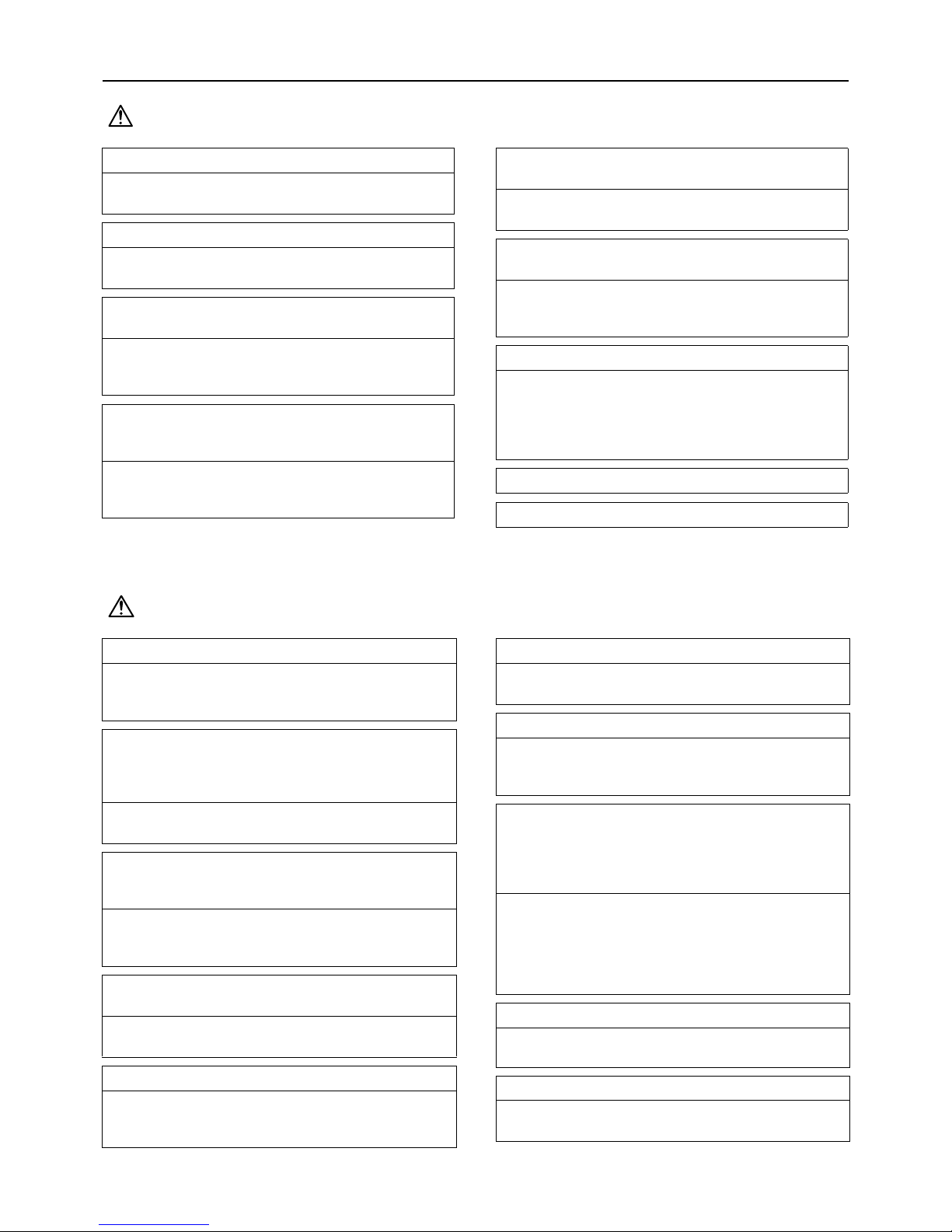

XI Indoor Unit

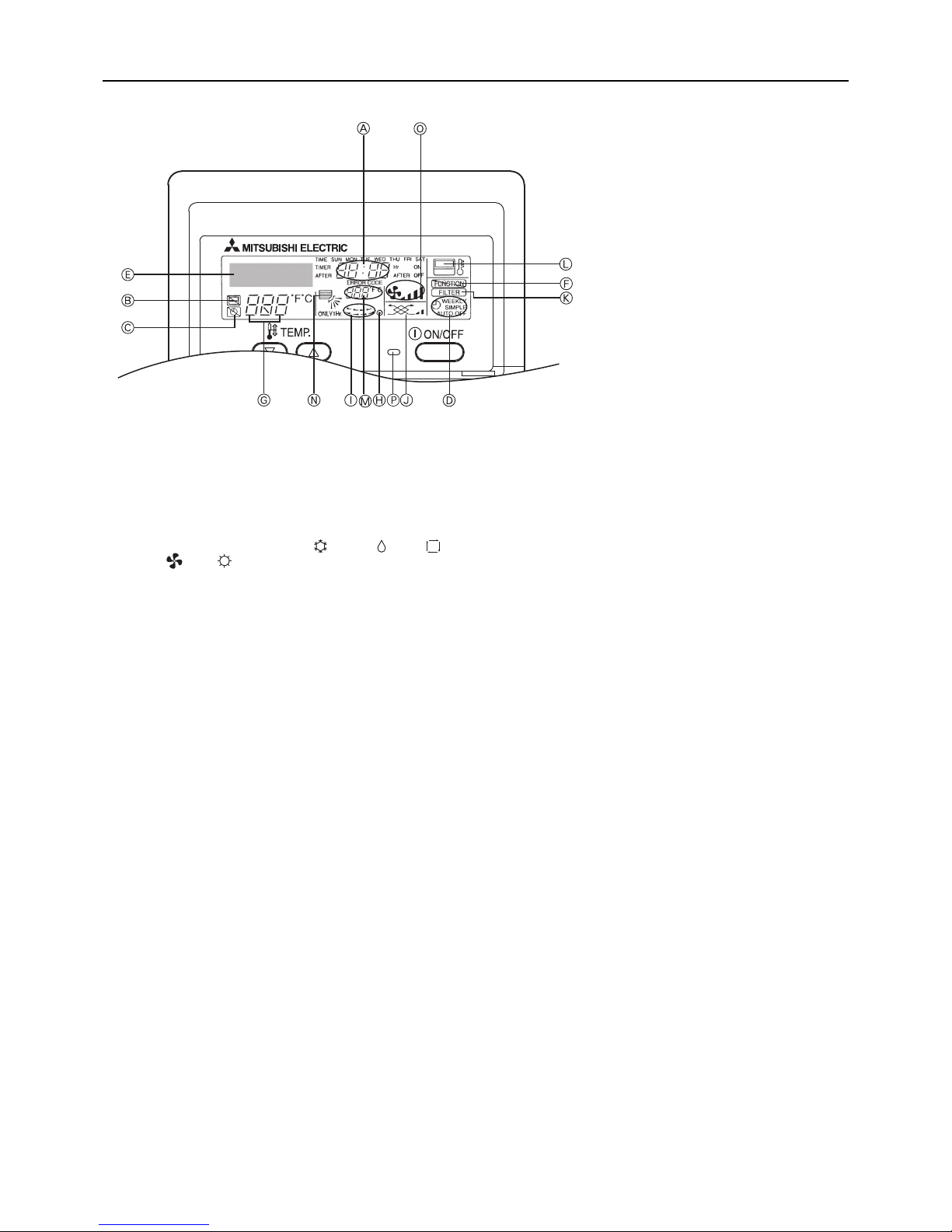

[1] Components and Functions

1. Indoor Unit

2. Remote Controller

[PAR-21MAA]

Once the operation mode is selected, the unit will remain in the selected mode until changed.

(1) Remote Controller Buttons

Keep the remote controller out of direct sunlight to ensure accurate measurement of room temperature.

The thermistor at the lower right-hand section of the remote controller must be free from obstructions to ensure accurate mea-

surement of room temperature.

(1) In case of rear inlet

1 [Set Temperature] Button 7 [Vane Control] Button

2 [Timer Menu] Button 8 [Ventilation] Button

[Monitor/Set] Button [Operation] Button

3 [Mode] Button 9 [Check/Clear] Button

[Back] Button 10 [Test Run] Button

4 [Timer On/Off] Button 11 [Filter] Button

[Set Day] Button [ ] Button

5 [Louver] Button 12 [ON/OFF] Button

[Operation] Button 13 Position of built-in room thermistor

6 [Fan Speed] Button 14 [Set Time] Button

Air inlet

Air outlet

Page 8

2- 2 -

HWE10170 GB

(2) Remote Controller Display

A Current time/Timer time I Louver swing

B Centralized control indicator J Ventilation

C Timer OFF indicator K Filter sign

D Timer mode indicator L Sensor position

E Operation mode display: COOL, DRY, AUTO,

FAN, HEAT

M Room temperature

F Function mode indicator N Vane setting

G Preset temperature O Fan speed

H Power indicator P Operation lamp

Page 9

3- 3 -

HWE10170 GB

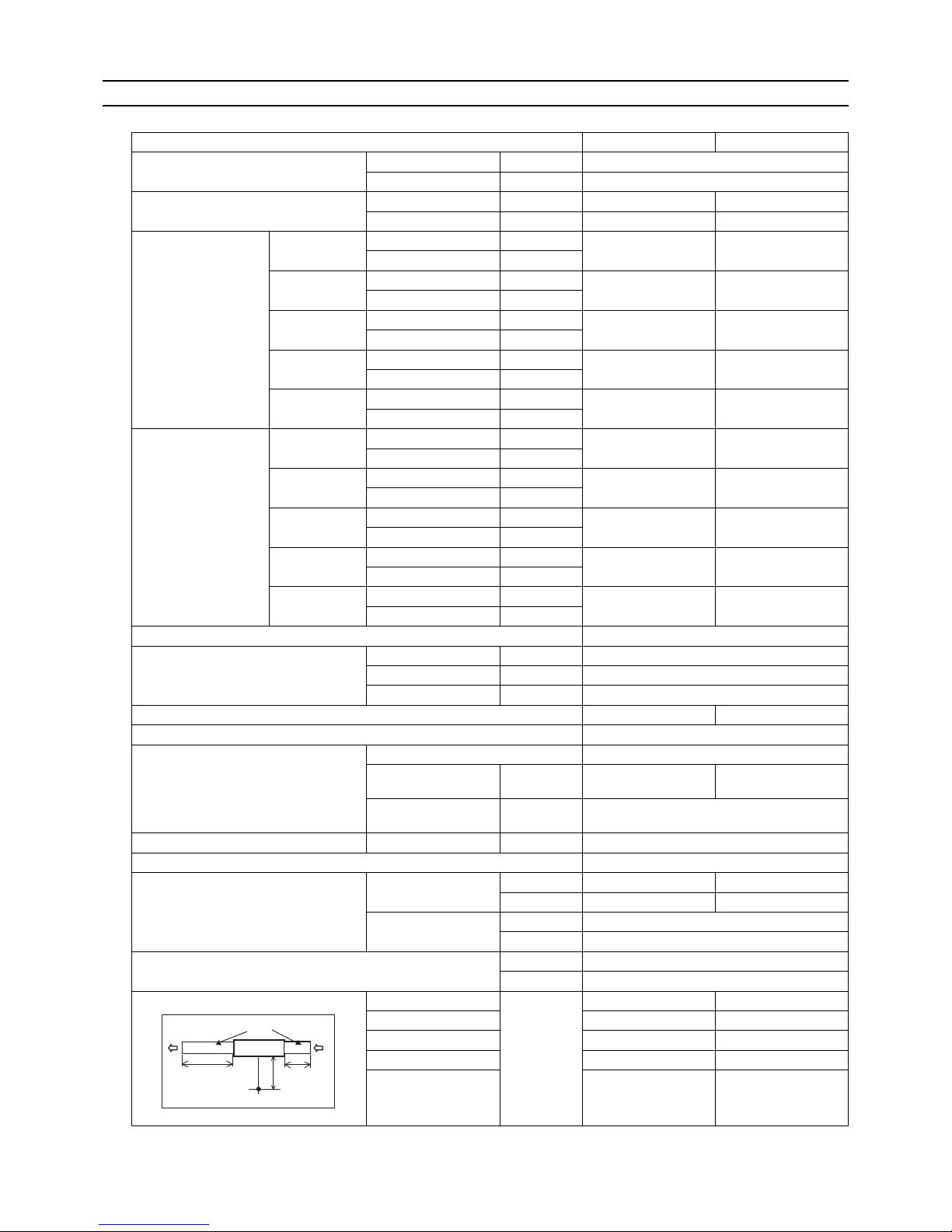

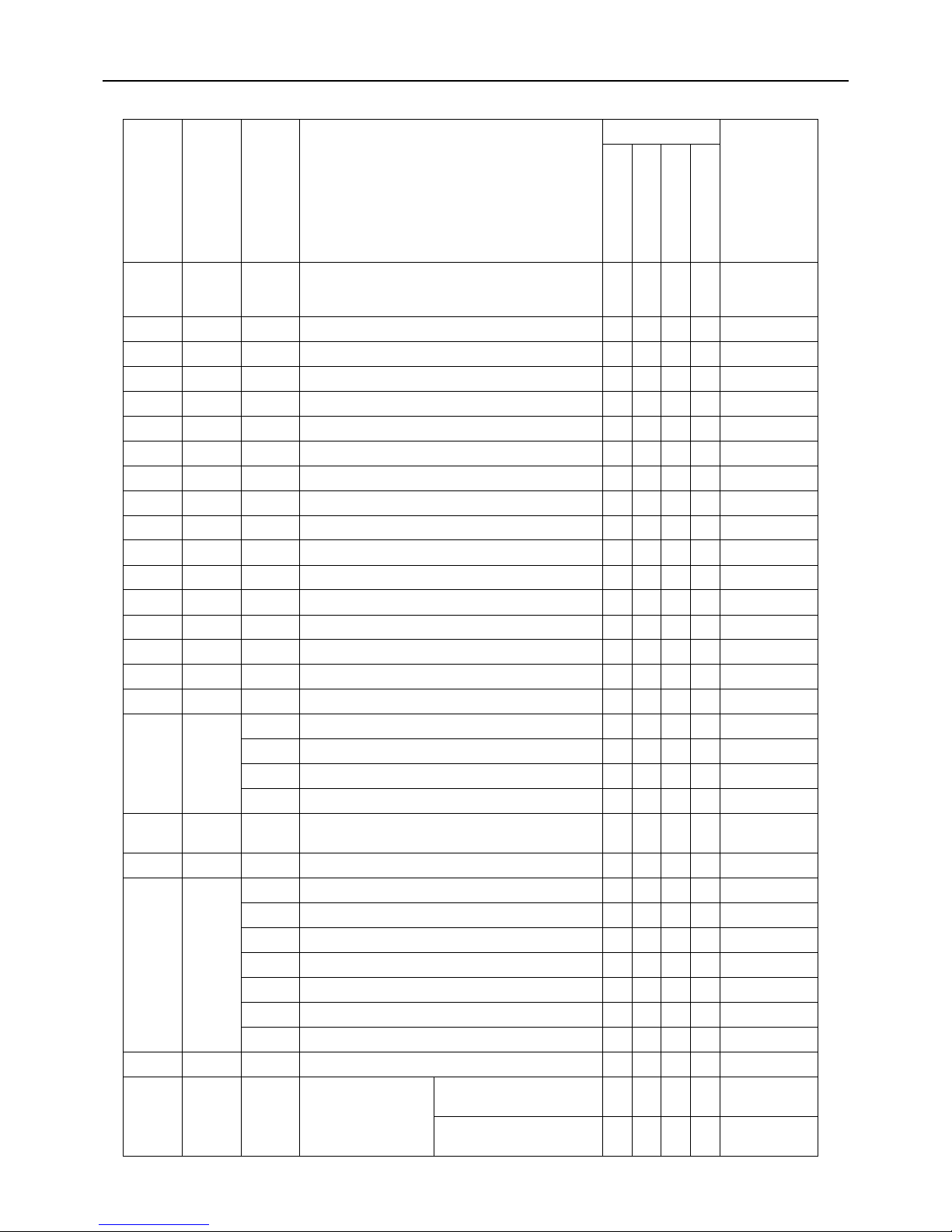

[2] Specifications

1. Specifications

*1 <Cooling> Indoor temperature: 80°FD.B./67°FW.B. (26.7°CD.B./19.4°CW.B.) Outdoor temperature: 95°FD.B.(35°CD.B.)

<Heating> Indoor temperature: 70°FD.B.(21.1°CD.B.) Outdoor temperature: 47°FD.B./43°FW.B. (8.3°CD.B./6.1°CW.B.)

*2 Measured at a power supply voltage of 230 V

Model PEFY-P72NMHSU-E PEFY-P96NMHSU-E

Power supply

Voltage V 1-phase 208-230

Frequency Hz 50/60

Capacity*1 Cooling kW[BTU/h] 21.1 (72,000) 28.1 (96,000)

Heating kW[BTU/h] 23.4 (80,000) 31.7 (108,000)

Power consumption

50Pa

[0.20in.WG]

Cooling kW

0.43 0.59

Heating kW

100Pa

[0.40in.WG]

Cooling kW

0.52 0.70

Heating kW

150Pa

[0.60in.WG]

Cooling kW

0.63 0.82

Heating kW

200Pa

[0.80in.WG]

Cooling kW

0.75 0.95

Heating kW

250Pa

[1.00in.WG]

Cooling kW

0.89 0.97

Heating kW

Current consumption

*2

50Pa

[0.20in.WG]

Cooling A

2.31 3.08

Heating A

100Pa

[0.40in.WG]

Cooling A

2.79 3.75

Heating A

150Pa

[0.60in.WG]

Cooling A

3.32 4.43

Heating A

200Pa

[0.80in.WG]

Cooling A

3.95 5.10

Heating A

250Pa

[1.00in.WG]

Cooling A

4.81 5.29

Heating A

External finish Galvanized

Dimensions Height mm[in.] 470 (18-9/16)

Width mm[in.] 1250 (49-1/4)

Depth mm[in.] 1120 (44-1/8)

Net weight 97 100

Heat exchanger Cross fin (Alminium fin and copper tube)

Fan Type Sirocco fan x 2

Airflow rate (H-M-L)

m

3

/min

[cfm]

72-61-50

2542-2154-1766

84-71-58

2966-2507-2048

External static

pressure

Pa

[in.WG]

(50)/(100)/150/(200)/(250)

(0.20)/(0.40)/0.60/(0.80)/(1.00)

Motor Output kW 0.87

Air filter Option

Refriferant pipe dimensions Gas

(Brazed connection)

mm ø19.05 ø22.2

[in.] ø3/4 ø7/8

Liquid

(Brazed connection)

mm ø9.52

[in.] ø3/8

Drain pipe dimensions mm O.D.32

[in.] 1-1/4

Operating noise (H-M-L) 50Pa [0.20in.WG] dB(A) 39-35-32 42-38-35

100Pa [0.40in.WG] 41-37-34 44-40-37

150Pa [0.60in.WG] 43-39-36 46-42-39

200Pa [0.80in.WG] 45-41-38 48-44-41

250Pa [1.00in.WG] 47-43-40 50-46-43

*

Measured in anechoic room.

2m

1m

Aux. duct

1.5m

Measurement location 2

Page 10

4- 4 -

HWE10170 GB

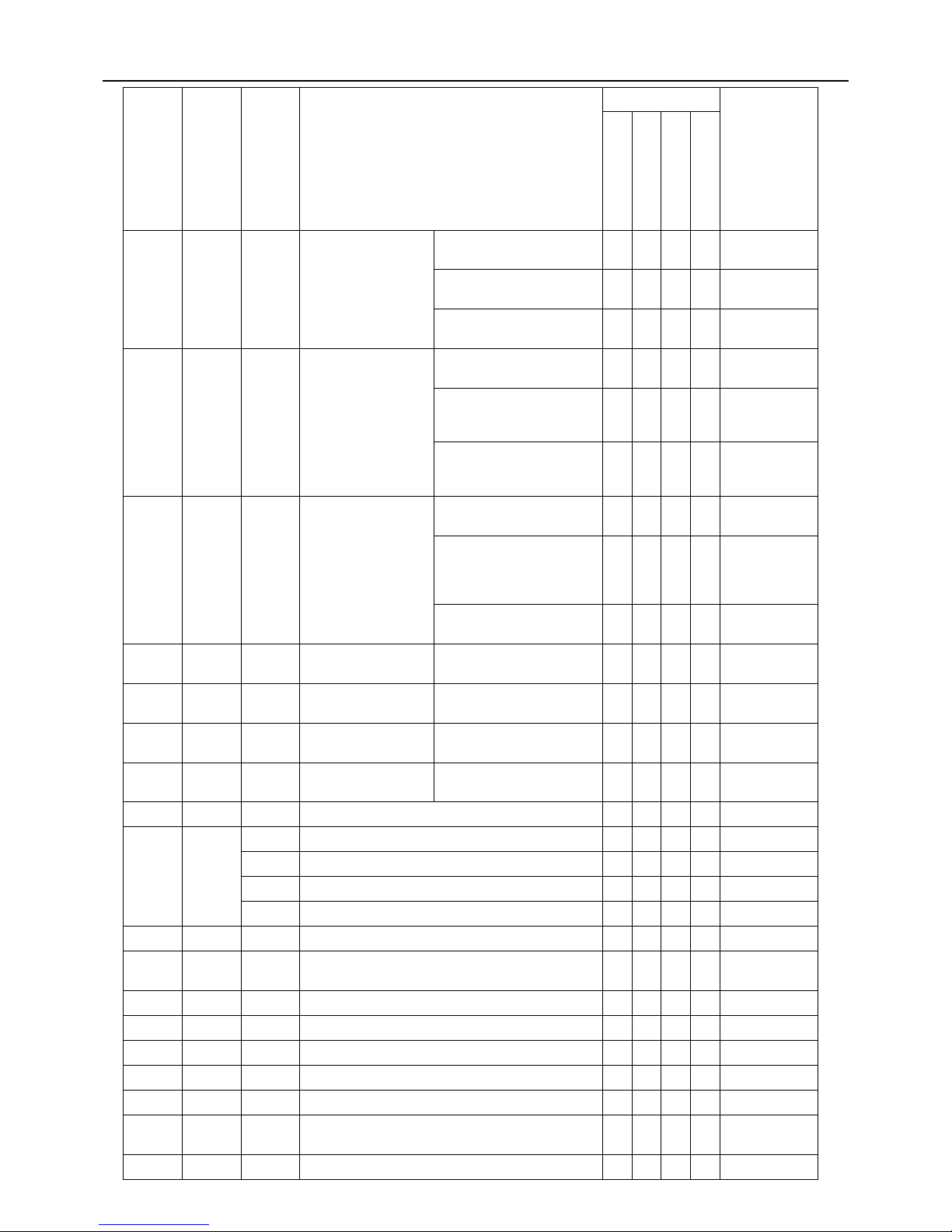

2. Electrical component specifications

Component Symbol

Room temperature

thermistor

TH21 Resistance 32°F (0°C)/15k, 50°F (10°C)/9.6k, 68°F (20°C)/6.3k,

77°F (25°C)/5.4k, 86°F (30°C)/4.3k, 104°F (40°C)/3.0k

Liquid pipe thermistor TH22 Resistance 32°F (0°C)/15k, 50°F (10°C)/9.6k, 68°F (20°C)/6.3k,

77°F (25°C)/5.4k, 86°F (30°C)/4.3k, 104°F (40°C)/3.0k

Gas pipe thermistor TH23 Resistance 32°F (0°C)/15k, 50°F (10°C)/9.6k, 68°F (20°C)/6.3k,

77°F (25°C)/5.4k, 86°F (30°C)/4.3k, 104°F (40°C)/3.0k

Fuse (INV board) F01 250V 15A

Fuse (NF board) F001 250V 10A

Fuse (NF board) F100 250V 3.15A

Fan motor MF 8-pole, Output 870W ERC8801AB

Linear expansion valve

LEV1

LEV2

12VDC Stepping motor drive port diameter ø3.2 (0~2000 pulse)

Power supply terminal

block

TB2

(L, N, ) 450V 30A

Page 11

5- 5 -

HWE10170 GB

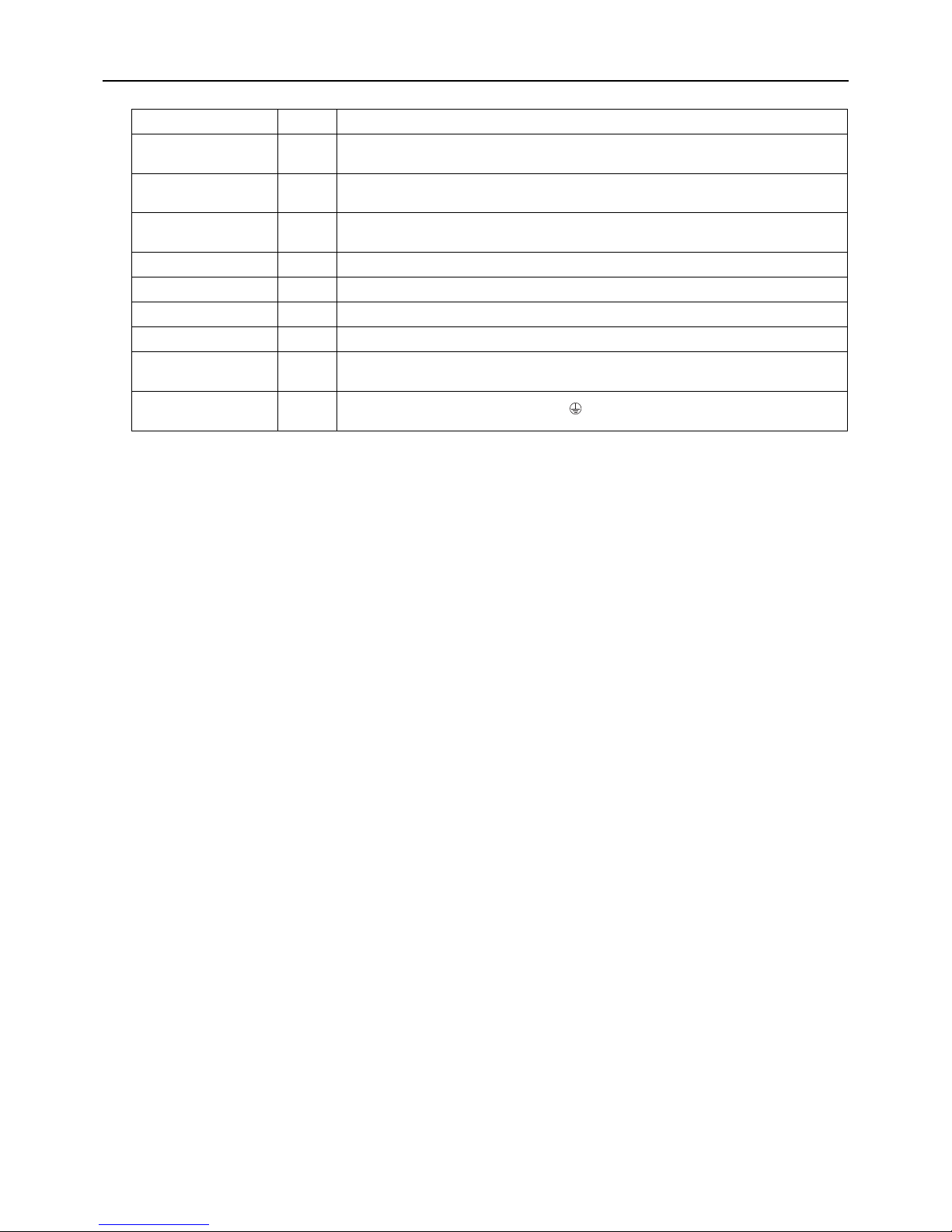

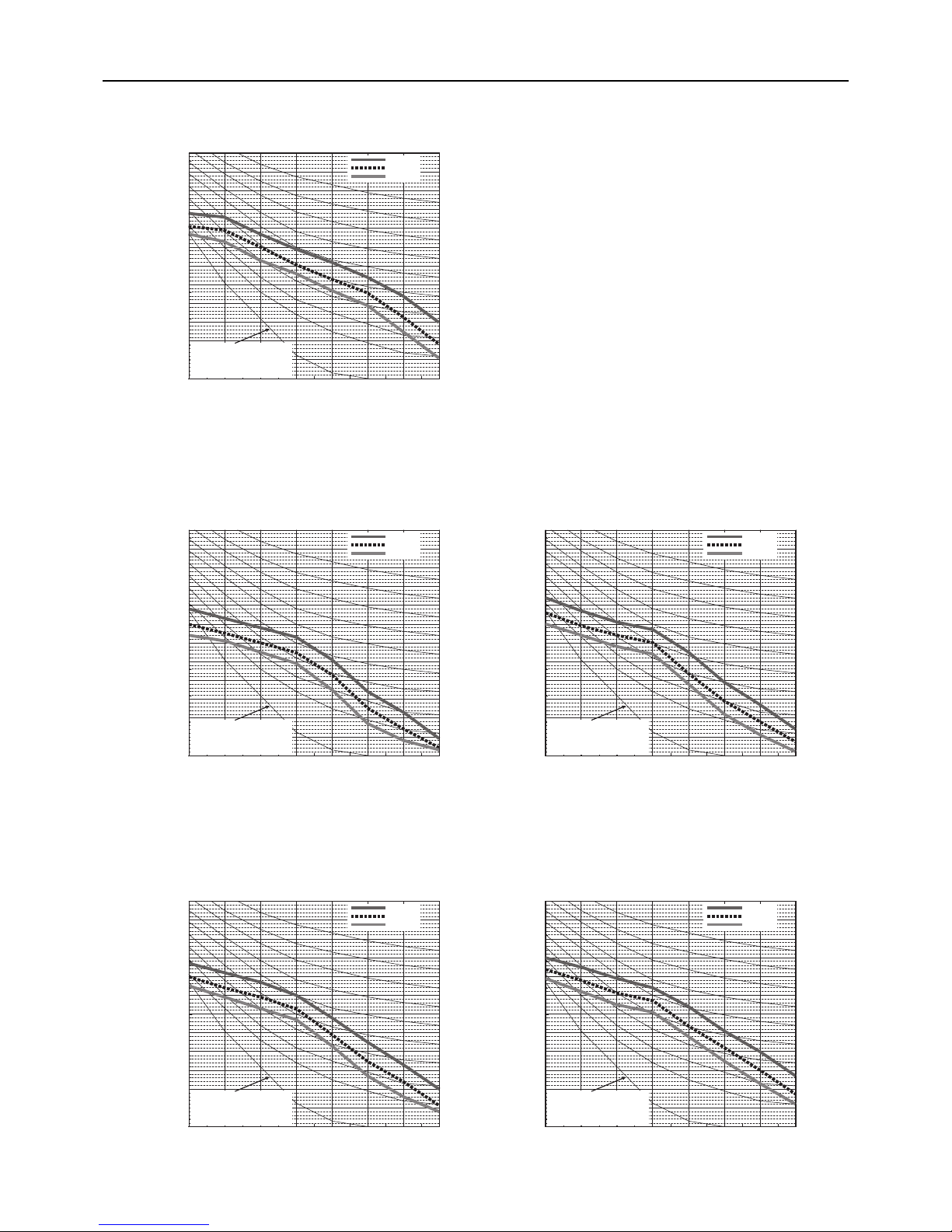

[3] Sound pressure levels

1. Sound pressure level

Ceiling concealed

2. NC curves

PEFY-P72NMHSU-E

Measurement point

Inlet

Outlet

1.5m

2m

1m

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:50Pa, 0.20[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:100Pa, 0.40[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:150Pa, 0.60[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:200Pa, 0.80[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

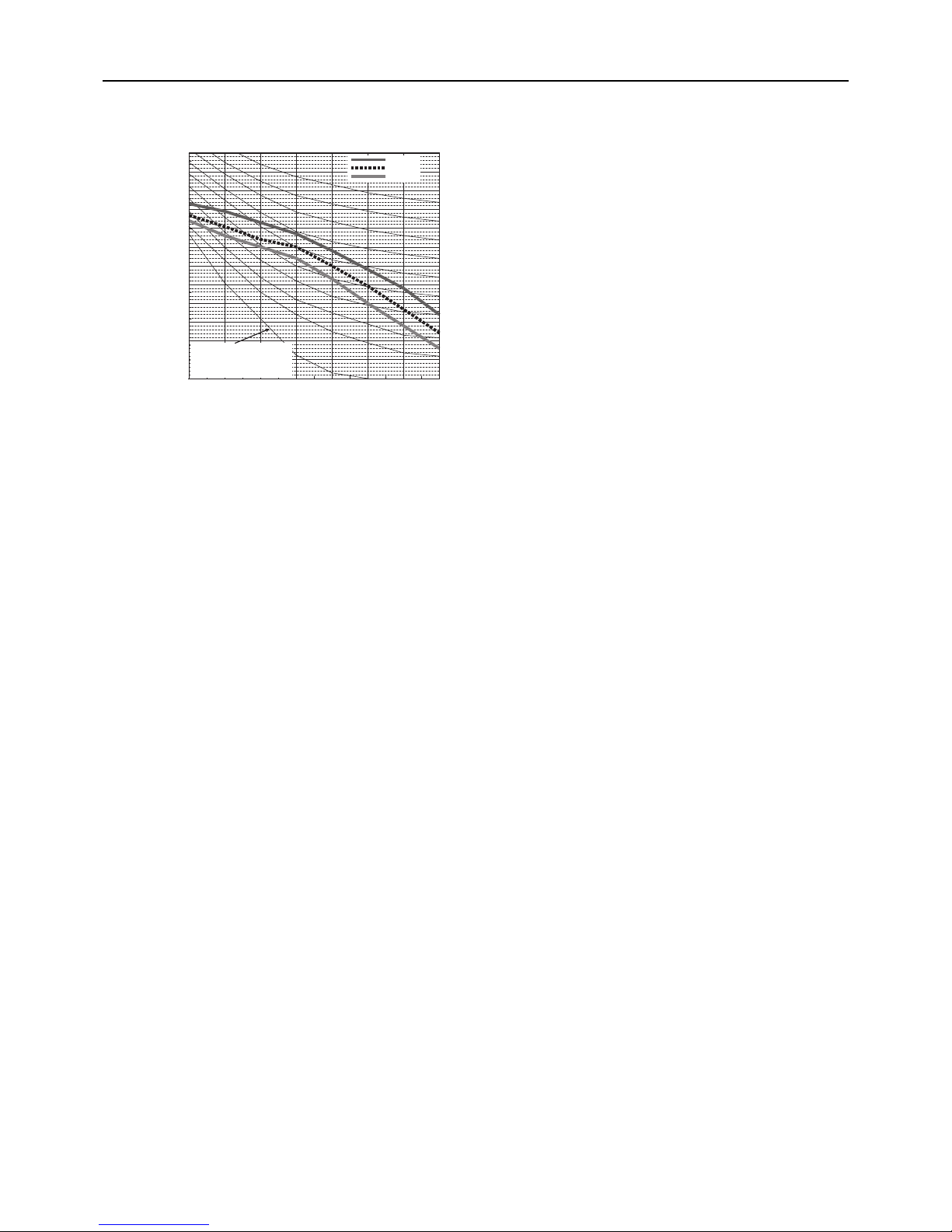

Page 12

6- 6 -

HWE10170 GB

PEFY-P96NMHSU-E

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:250Pa, 1.00[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:50Pa, 0.20[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:100Pa, 0.40[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:150Pa, 0.60[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:200Pa, 0.80[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

Page 13

7- 7 -

HWE10170 GB

Approximate minimum

audible limit on

continuous noise

High

Middle

Low

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

65.0

70.0

63 125 250 500 1k 2k 4k 8k

NC-60

NC-50

Octave band pressure level (dB) 0dB=20μPa

NC-40

NC-30

NC-20

Octave band center frequencies (Hz)

External Static Pressure:250Pa, 1.00[in.WG]

Power Source: 208, 230V, 50Hz/60Hz

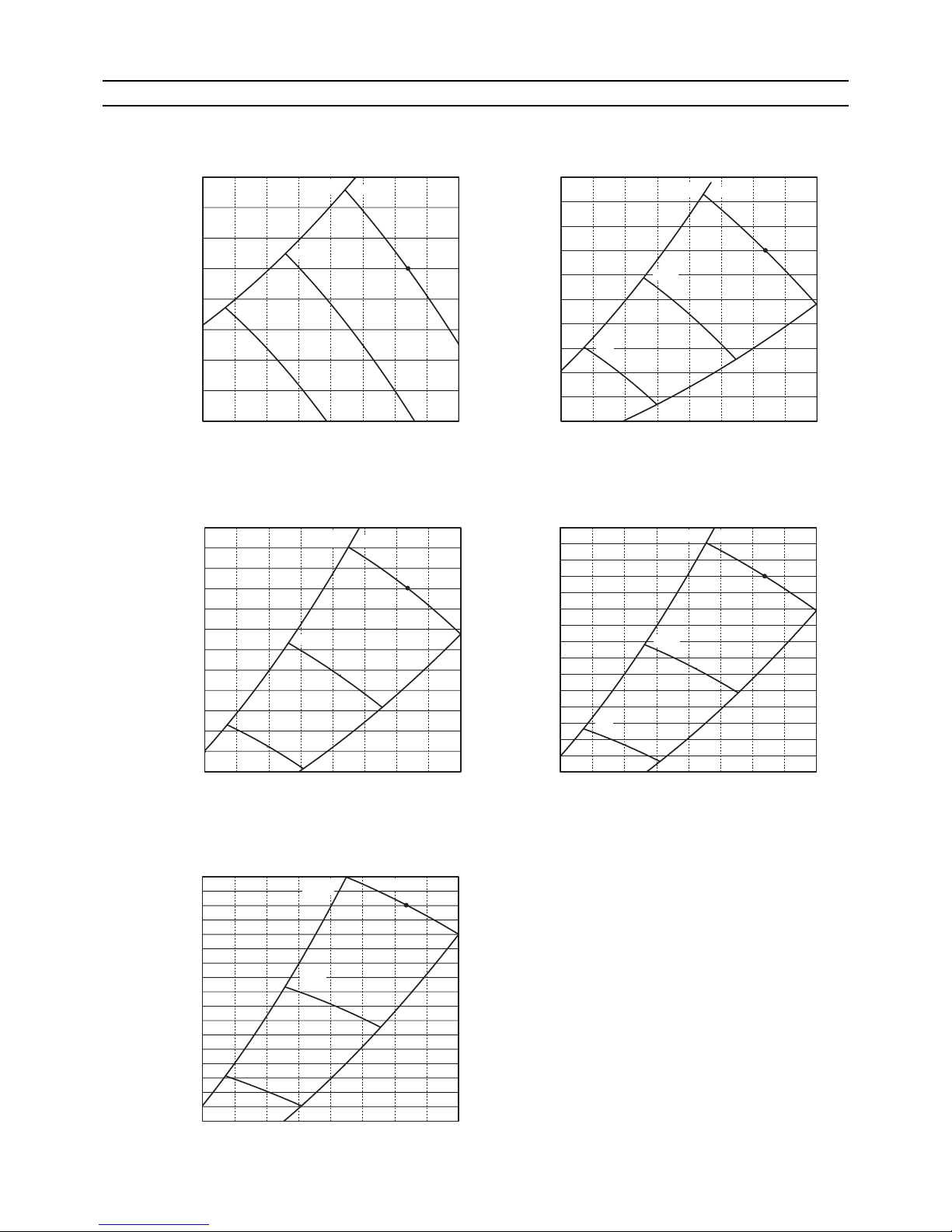

Page 14

8- 8 -

HWE10170 GB

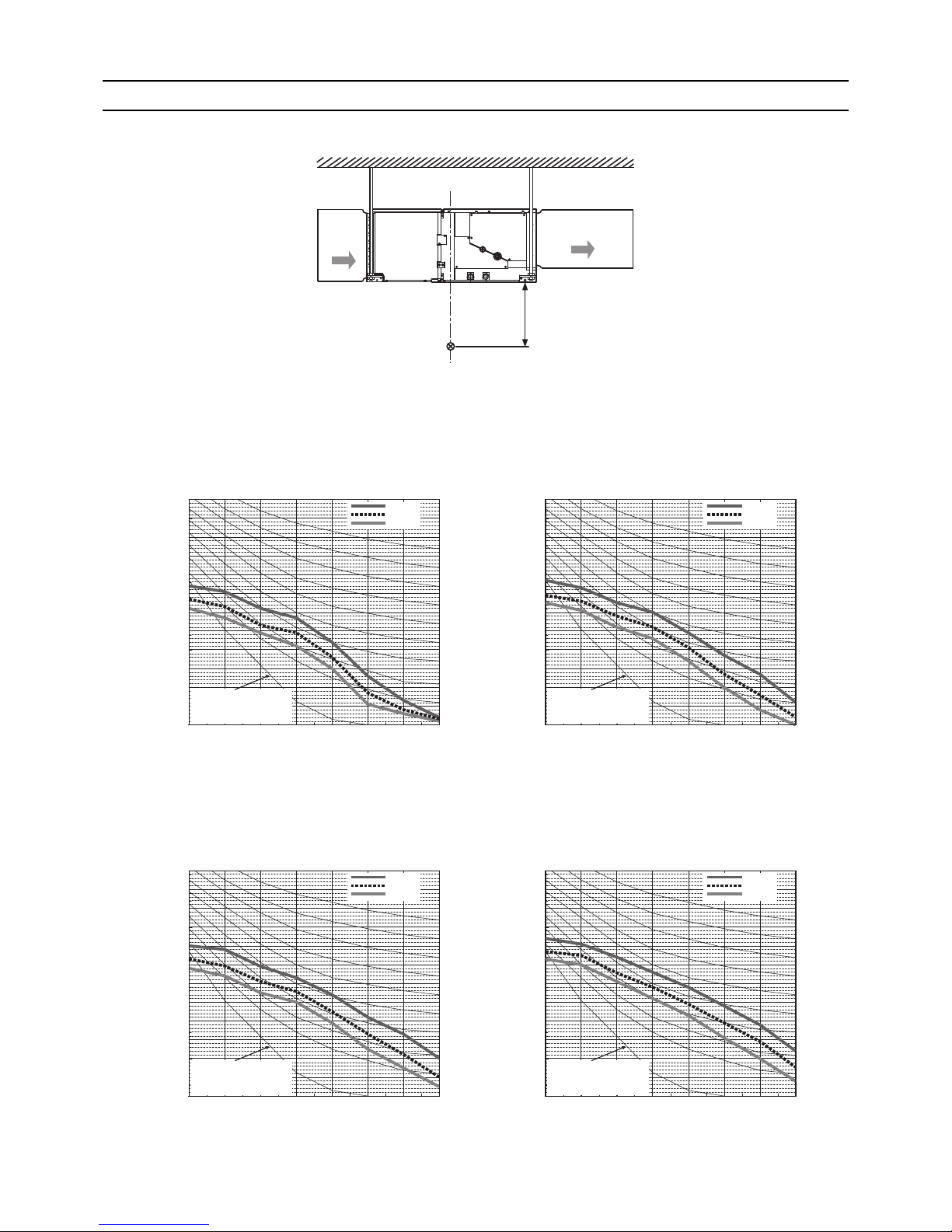

[4] Fan performance and corrected air flow

PEFY-P72NMHSU-E

Static pressure (Pa)

[in.WG]

Airflow rate (m3/min)

[cfm]

External static pressure :50Pa, 0.20[in.WG]

Power source:208, 230V, 50Hz/60Hz

Middle

High

Low

Limit

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[2119]

60

[1942]

55

[1412]

40

[1766]

50

[1589]

45

10

[0.04]

20

[0.08]

30

[0.12]

40

[0.16]

50

[0.20]

60

[0.24]

70

[0.28]

80

[0.32]

0

[0]

Static pressure (Pa)

[in.WG]

Airflow rate (m3/min)

[cfm]

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[2119]

60

[1942]

55

[1412]

40

[1766]

50

[1589]

45

30

[0.12]

40

[0.16]

50

[0.20]

60

[0.24]

70

[0.28]

80

[0.32]

90

[0.36]

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

External static pressure :100Pa, 0.40[in.WG]

Power source:208, 230V, 50Hz/60Hz

Middle

High

Low

Limit

External static pressure :150Pa, 0.60[in.WG]

Power source:208, 230V, 50Hz/60Hz

Middle

High

Low

Limit

Static pressure (Pa)

[in.WG]

Airflow rate (m3/min)

[cfm]

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[2119]

60

[1942]

55

[1412]

40

[1766]

50

[1589]

45

60

[0.24]

70

[0.28]

80

[0.32]

90

[0.36]

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

140

[0.56]

150

[0.60]

160

[0.64]

170

[0.68]

180

[0.72]

External static pressure :200Pa, 0.80[in.WG]

Power source:208, 230V, 50Hz/60Hz

Middle

High

Low

Limit

Static pressure (Pa)

[in.WG]

Airflow rate (m3/min)

[cfm]

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[2119]

60

[1942]

55

[1412]

40

[1766]

50

[1589]

45

80

[0.32]

90

[0.36]

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

140

[0.56]

150

[0.60]

160

[0.64]

170

[0.68]

180

[0.72]

190

[0.76]

200

[0.80]

210

[0.84]

220

[0.88]

230

[0.92]

External static pressure :250Pa, 1.00[in.WG]

Power source:208, 230V, 50Hz/60Hz

Middle

High

Low

Limit

Static pressure (Pa)

[in.WG]

Airflow rate (m3/min)

[cfm]

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[2119]

60

[1942]

55

[1412]

40

[1766]

50

[1589]

45

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

140

[0.56]

150

[0.60]

160

[0.64]

170

[0.68]

180

[0.72]

190

[0.76]

200

[0.80]

210

[0.84]

220

[0.88]

230

[0.92]

240

[0.96]

250

[1.00]

260

[1.04]

270

[1.09]

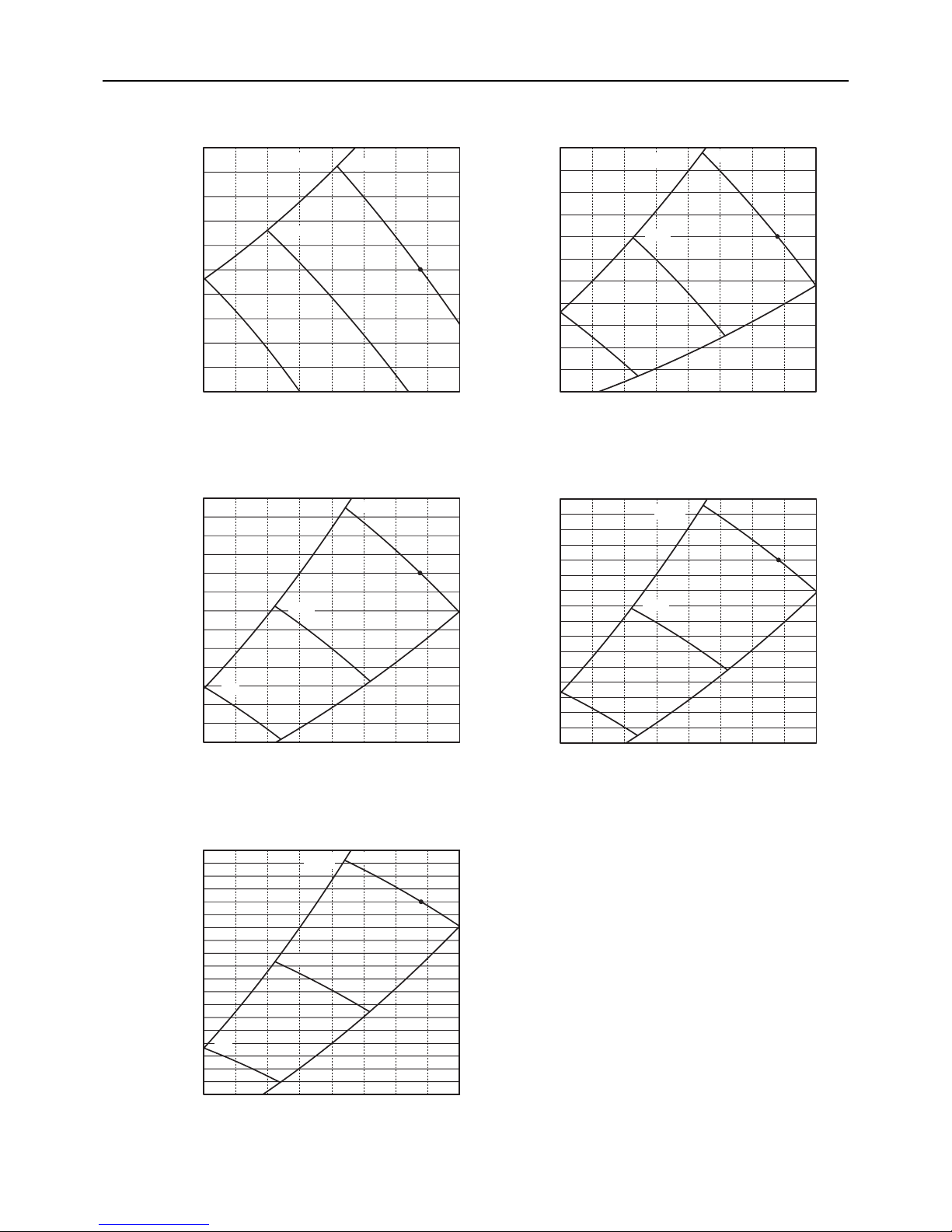

Page 15

9- 9 -

HWE10170 GB

PEFY-P96NMHSU-E

Middle

High

Low

Limit

Static pressure (Pa)

[in.WG]

Airflow rate (m3/min)

[cfm]

External static pressure :50Pa, 0.20[in.WG]

Power source:208, 230V, 50Hz/60Hz

[3178]

90

[3001]

85

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[1766]

50

[2119]

60

[1942]

55

10

[0.04]

20

[0.08]

30

[0.12]

40

[0.16]

50

[0.20]

60

[0.24]

70

[0.28]

80

[0.32]

90

[0.36]

100

[0.40]

0

[0]

Middle

High

Low

Limit

Static pressure (Pa)

[in.WG]

Airflow rate (m3/min)

[cfm]

30

[0.12]

40

[0.16]

50

[0.20]

60

[0.24]

70

[0.28]

80

[0.32]

90

[0.36]

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

140

[0.56]

External static pressure :100Pa, 0.40[in.WG]

Power source:208, 230V, 50Hz/60Hz

[3178]

90

[3001]

85

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[1766]

50

[2119]

60

[1942]

55

External static pressure :150Pa, 0.60[in.WG]

Power source:208, 230V, 50Hz/60Hz

Static pressure (Pa)

[in.WG]

60

[0.24]

70

[0.28]

80

[0.32]

90

[0.36]

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

140

[0.56]

150

[0.60]

160

[0.64]

170

[0.68]

180

[0.72]

190

[0.76]

Middle

High

Low

Limit

Airflow rate (m3/min)

[cfm]

[3178]

90

[3001]

85

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[1766]

50

[2119]

60

[1942]

55

Middle

High

Low

Limit

Airflow rate (m3/min)

[cfm]

External static pressure :200Pa, 0.80[in.WG]

Power source:208, 230V, 50Hz/60Hz

Static pressure (Pa)

[in.WG]

80

[0.32]

90

[0.36]

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

140

[0.56]

150

[0.60]

160

[0.64]

170

[0.68]

180

[0.72]

190

[0.76]

200

[0.80]

210

[0.84]

220

[0.88]

230

[0.92]

240

[0.96]

[3178]

90

[3001]

85

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[1766]

50

[2119]

60

[1942]

55

Middle

High

Low

Limit

Airflow rate (m3/min)

[cfm]

External static pressure :250Pa, 1.00[in.WG]

Power source:208, 230V, 50Hz/60Hz

Static pressure (Pa)

[in.WG]

100

[0.40]

110

[0.44]

120

[0.48]

130

[0.52]

140

[0.56]

150

[0.60]

160

[0.64]

170

[0.68]

180

[0.72]

190

[0.76]

200

[0.80]

210

[0.84]

220

[0.88]

230

[0.92]

240

[0.96]

250

[1.00]

260

[1.04]

270

[1.09]

280

[1.13]

290

[1.17]

[3178]

90

[3001]

85

[2825]

80

[2648]

75

[2472]

70

[2295]

65

[1766]

50

[2119]

60

[1942]

55

Page 16

10- 10 -

HWE10170 GB

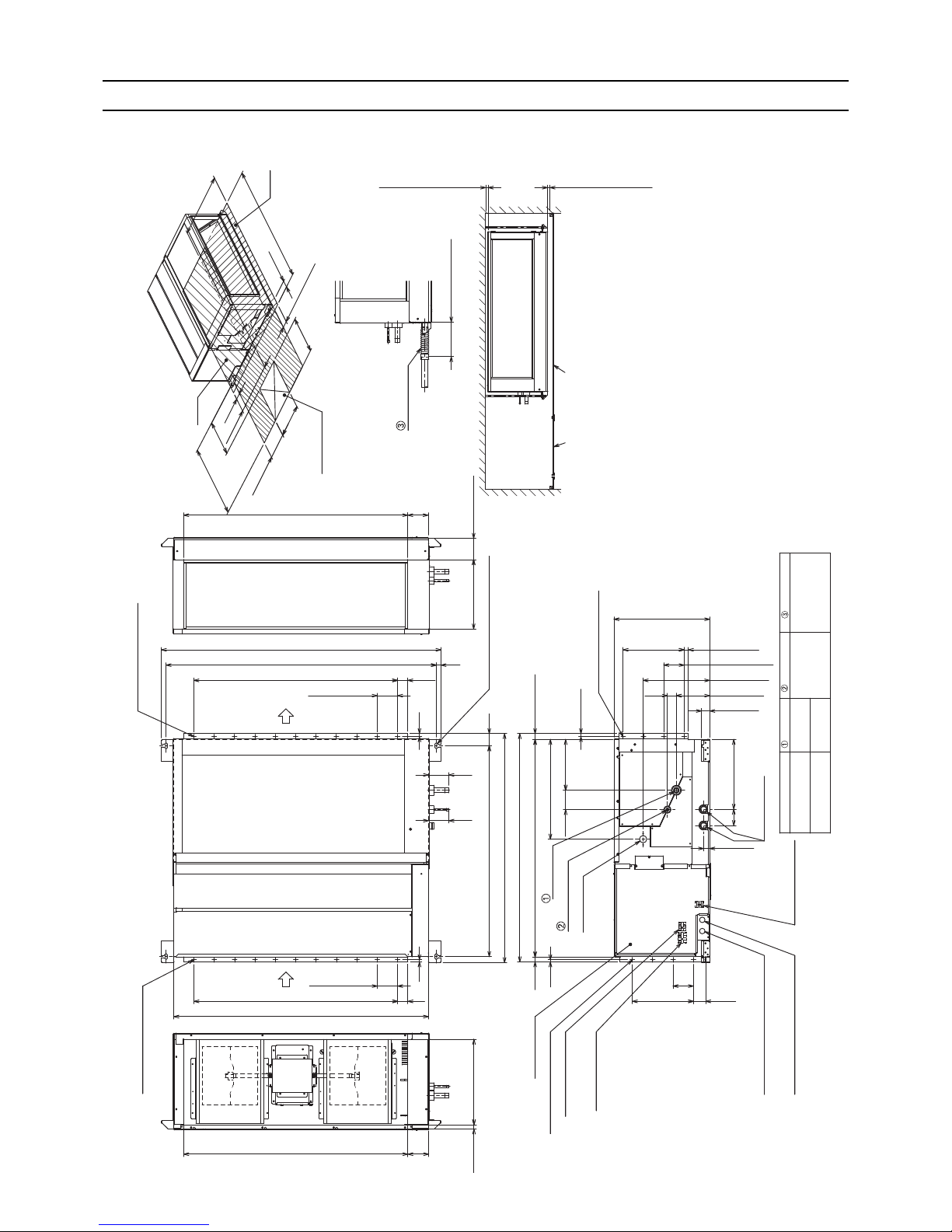

[5] Outlines and Dimensions

Air inlet Air outlet

(DUCT)

(7/16)

(2-3/8)

(3-3/16)

(2-3/8)

(3-15/16x3=11-13/16)

(3-15/16x3=11-13/16)

(1-3/4)

(9-13/16)

(DUCT)

(7/16)

(5/8)

(3-15/16)

(3-15/16)

(15/16)

(3-15/16)

(Actual length)

Drain Piping.

(21-11/16)

(7-7/8~11-13/16)

(17-3/4)

(5-15/16~7-7/8)

(17-3/4)

2X4-ø3(1/8) holes

2X11-ø3(1/8) holes

Drain hole

Drain hole

Control box

(Power source)

Terminal block

(MA remocon)

(Transmission wiring)

(Power souse wiring)

(Normal type)

(Option)

(Transmission)

Suspension bolt hole

Terminal blockKnockout hole ø22.2(7/8)

Knockout hole ø22.2(7/8)

Terminal block

4-14X30(9/16x3/16) Slot

2X4-ø3(1/8) holes

2X11-ø3(1/8) holes

Make the access door

at the appointed position properly

for service maintenance.

Access door Ceiling surface

Access door

Note2

Note3

Required space for service and maintenance.

MODEL

PEFY-P72NMHSU-E

PEFY-P96NMHSU-E

ø

19.05(3/4)

ø

22.2(7/8)

ø

9.52(3/8)

Drain hose 32mm

(1-1/4inch)

<flexible joint>

<accessory>

Note 1.Use M10 screw for the suspension bolt (field supply).

2.Keep the service space for the maintenance from the bottom

when the heat exchanger is cleaned.

3.Keep the service space for the maintenance from the bottom

when the fan motor is changed.

4.Make sure to install the air filter (field supply) on the air intake side.

In case field supplied air filter is used, attach it

where the filter service is easily done.

Unit:mm(in.)

Unit:mm(in.)

249

95(3-4/3)

342(13-1/2)

80

170(6-3/4±1/4)

23

100

470(18-9/16)

20(13/16)

102(4-1/16)

105(4-3/16)

420(16-9/16)

1100(43-5/16)(DUCT)

1250(49-1/4)

1372(54-1/16)

1124(44-5/16)

15

10

100x10=1000(3-15/16x10=39-3/8)

100(3-15/16)

50(2)

60

1326(52-1/4)(Suspension bolt pitch)

1034(40-3/4)(Suspension bolt pitch)

340(13-7/16)

1100(43-5/16)(DUCT)

100

100

29(1-3/16)

41(1-5/8)

1067(42-1/16)

24(1)

1120(44-1/8)

489(19-5/16)

327(12-7/8)

44

164(6-1/2)

30(1-3/16)

15(5/8)

100X3(=300)

100(3-15/16)

20(13/16)

100(3-15/16)

10

100x3=300

60

100x10=1000(3-15/16x10=39-3/8)

50(2)

100(3-15/16)

More than 20(13/16)

More than 20(13/16)

550

50(2)

150~200

50(2)

50(2)

450

800(31-1/2)

450

200~300

1350(53-3/16)

730(28-3/4)

PEFY-P72,96NMHSU-E

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Drain hose

Drain hose

Page 17

11- 11 -

HWE10170 GB

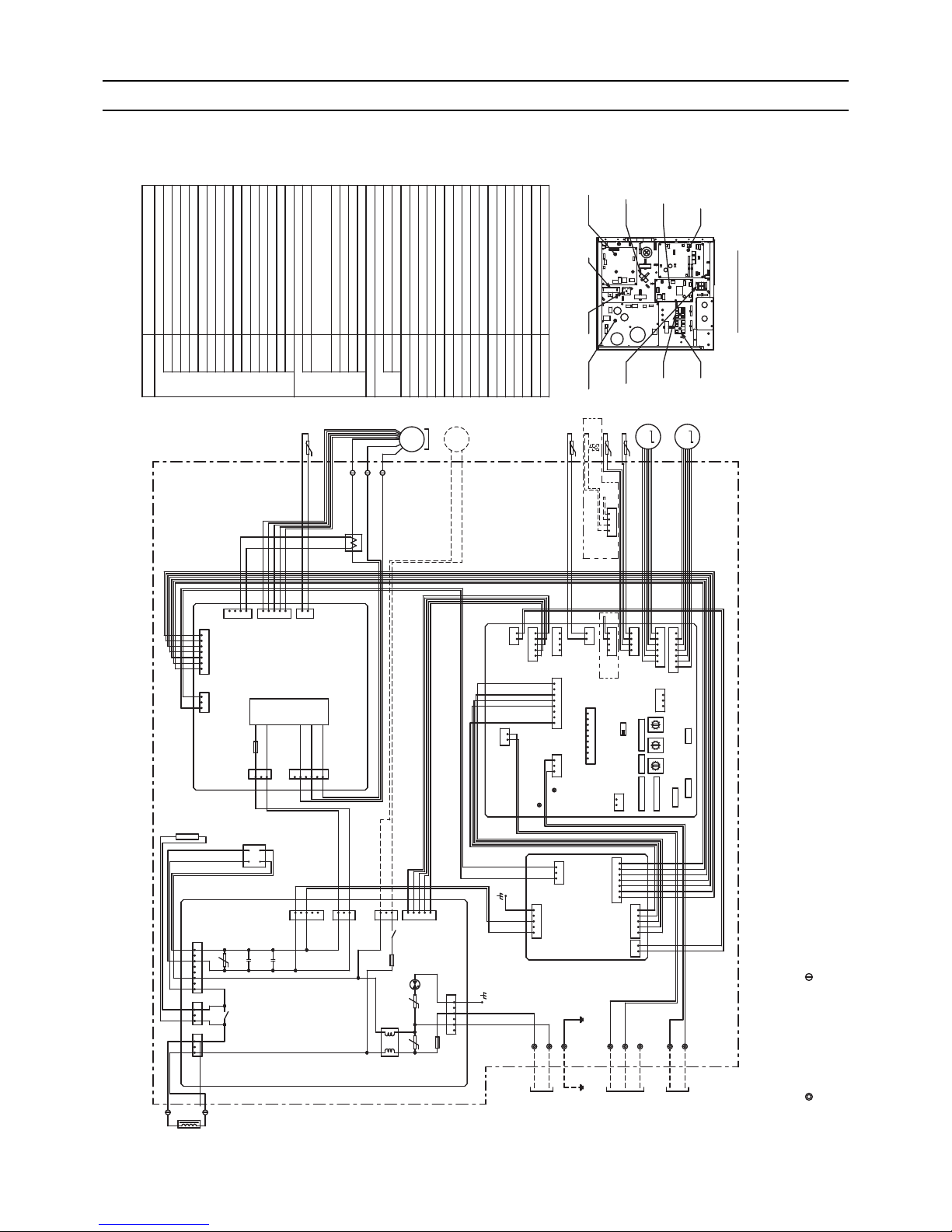

[6] Wiring Diagram

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

642

1

3

1

2

2

2

1

1

25431

21

85431

2131442331

4321

6

6

5

5

5

4

4

3

3

3

2

2

1

1

1

54321

12345

1

2

76543213

3

1

1

1

2

3

4

5

3

3

1

1

1

3

8

7

1

6

6

5

3

43

5

3

2

1

1

3

3

1

1

CN25

F01

IPM

(BLUE)

CNCT2

CNFAN

CNP

X010

X100

CNR1

(RED)

(RED)

CNACL

ZNR

003

C015

C016

ZNR

002

DSA

001

ZNR

001

F001

F100

CNPW1

CNRSC

CNRSP

CNXC1

CNXB1

CNDB

CNPW2

CN18V

(GREEN)

CNTH

(RED)

CNCT1

CNRS2

CN15V

CNVDC

CNDP

CNINV

NF

CNXC2

CN100

CN41

CN90

LED2

LED1

CN3A

(BLUE)

CN2M

(BLUE)

CN7V

CN60

CN44

CN4F CN4F

CN20

(RED)

CN32

SW3

SWC

SW5

SWA

SWE

ONOFF

SW2SW1

SW4

SW11SW12SW14

1s

DIGIT DIGIT

( ) ( ) ( )

10ths

BRANCH

No.

CNXB2

POWER SUPPLY

AC208-230V

60Hz

Note 1

Note 1

ACL

2

2

1

1

INSIDE SECTION OF CONTROL BOX

TO MA REMOTE

CONTROLLER

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

MF

DP

MS

3

~

M

1

~

UVW

R

NF.B.

INV.B.

I.B.

P.B .

TB2

DB01

ACCT

TB5

TB15

LEV1

LEV2

THHS

TH21

TH22FSTH23

L1

3

4

2

1

33112

2

M1M2S(SHIELD)

L2

G

1

2

DB01 RNF.B.

TB2

TB5

TB15

P. B .

I.B.

ACCT

INV.B.

PARTS LOCATION

Inside < > is the optional parts.

NOTE:1.The part of thin dotted line indicates the circuit for optional parts.

2.To perform a drainage test for the drain pump turn on the SWE

on the control board while the indoor unit is being powerd.

*Be sure to turn off the SWE after completing a drainage test or test run.

3.The wirings to TB2,TB5,TB15 shown in dotted line are field work.

4.Mark indicates terminal block, connector.

5.Use copper supply wire.

SYMBOL NAME

SYMBOL EXPLANATION

Aux. relay

X010,X100

Var ist or

Arrester

Intelligent power module

Fuse(AC250V 15A)

DSA001

IPM

F01

Electronic linear expan.valve

LEV1,LEV2

F001

F100

NF

Fuse(AC250V 10A)

Fuse(3.15A)

Noise filter

Switch (for mode selection)

Switch (for capacity code)

Switch (for mode selection)

Switch (for model selection)

Switch (for mode selection)

Switch (1s digit address set)

Switch (10ths digit address set)

Switch (BRANCH No.)

Switch (for static pressure selection)

Switch (for static pressure selection)

TB2

TB5

TB15

CN25

I.B.

NF.B.

INV.B.

P. B.

TH21

TH22

TH23

THHS

<FS>

Connector

Indoor controller board

Noise filter board

Inverter board

Power supply board

Power source terminal block

Transmission terminal block

Transmission terminal block

Float switch

Thermistor(piping temp.detection/liquid)

Thermistor(piping temp.detection/gas)

Thermistor(heatsink)

Thermistor(inlet air temp.detection)

MF

Fan motor

AC reactor (Power factor improvement)

Resistor

Diode bridge

LED (Power supply)

Current Sensor (AC)

LED (Remote controller supply)

ACL

R

DB01

LED1

ACCT

LED2

Connector (emergency operation)

Connector (Remote switch)

CN32

Connector (HA terminal-A)

CN41

Connector (Wireless)

CN90

SW1

SW2

SW3

SW4

SW5

SW11

SW12

SW14

SWA

SWC

SWE

ZNR01~

ZNR03

Drain pump

<DP>

t°

t°

t°

t°

U

UU

M

M

PEFY-P72,96NMHSU-E

Page 18

12- 12 -

HWE10170 GB

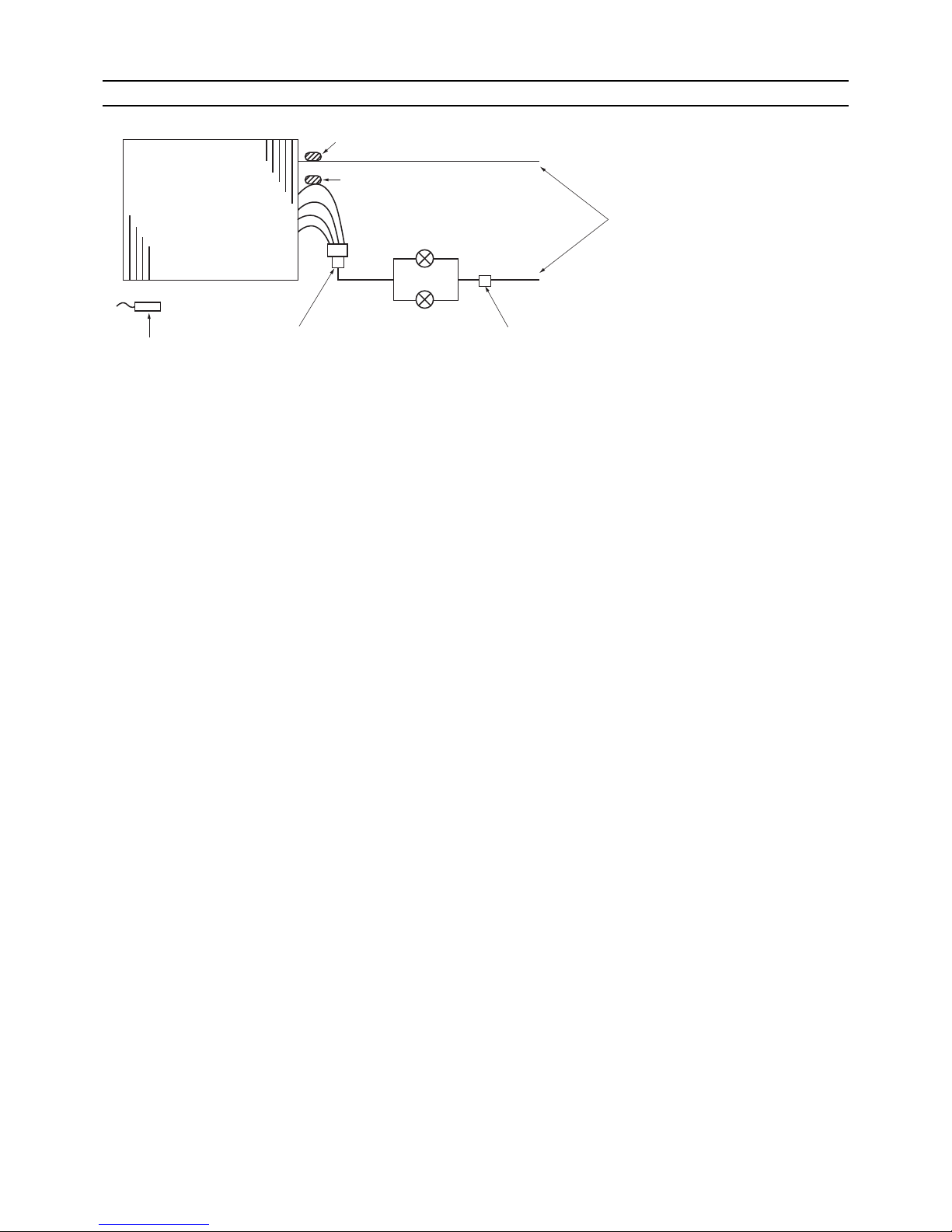

[7] Refrigerant system diagram

(A) Gas pipe thermistor TH23

(B) Gas pipe

(C) Liquid pipe

(D) Brazed connections

(E) Strainer (#100 mesh)

(F) Linear expansion valve

(G) Liquid pipe thermistor TH22

(H) Heat exchanger

(I) Room temperature thermistor TH21

(H)

(I)

(F)

(E)

(E)

(C)

(G)

(A)

(D)

(B)

Page 19

13- 13 -

HWE10170 GB

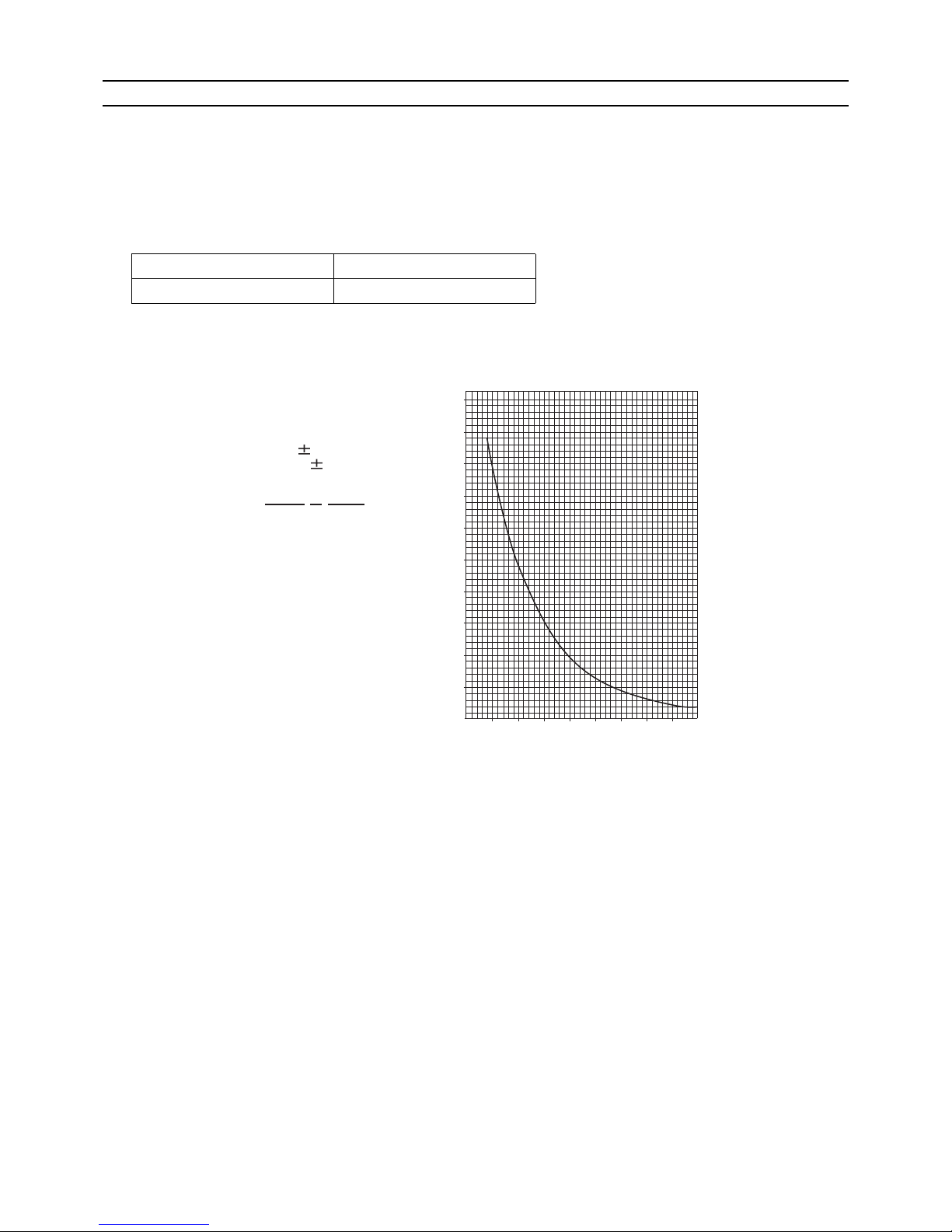

[8] Troubleshooting

1. Check methods

1. Component and check points

(1) Thermistor

Room temperature thermistor (TH21)

Liquid pipe thermistor (TH22)

Gas pipe thermistor (TH23)

Disconnect the connector and measure the resistance between terminals with a tester.

(Ambient temperature 50°F (10°C) - 86°F (30°C))

1) Thermistor characteristic graph

(2) Fan motor

Refer to the page on "DC fan motor (fan motor/INV board)."(page 47)

(3) Linear expansion valve

Refer to the page on "LEV". ([8] 4)(page 51)

Normal Abnormal

4.3kΩ - 9.6kΩ Open or short

(Refer to the thermistor characteristic graph below.)

Low-temperature thermistor

Room temperature thermistor (TH21)

Liquid pipe thermistor (TH22)

Gas pipe thermistor (TH23)

Thermistor R

0

= 15 kΩ 3%

Multiplier of B = 3480 kΩ 2%

32°F (0°C) 15kΩ

50°F (10°C) 9.6kΩ

68°F (20°C) 6.3kΩ

77°F (25°C) 5.2kΩ

86°F (30°C) 4.3kΩ

104°F (40°C) 3.0kΩ

(A) Temperature °F (°C)

(B) Resistance (kΩ)

Rt = 15 exp { 3480( ) }

1

273+t

1

273

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

(A)

(B)

Page 20

14- 14 -

HWE10170 GB

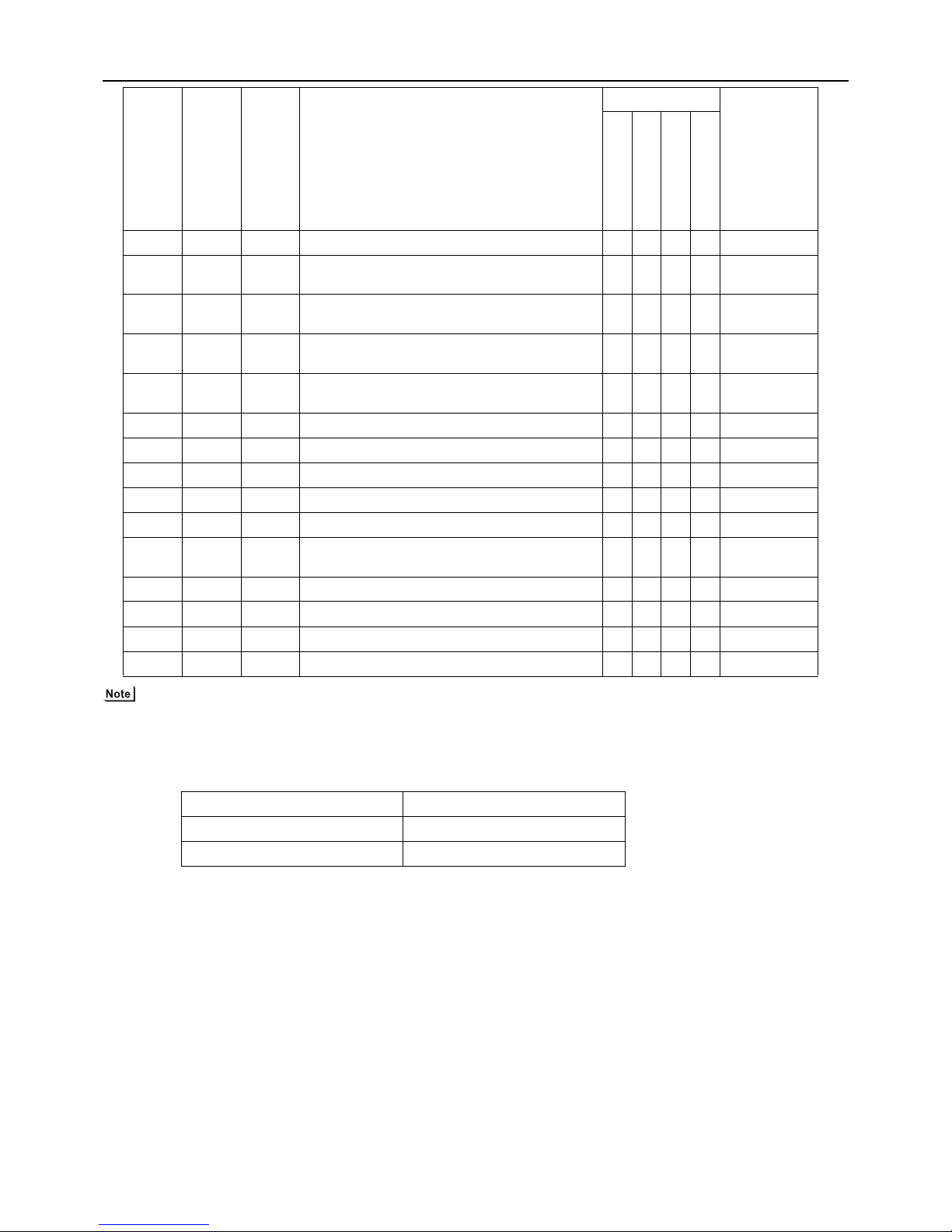

2. Error Code Lists

Error

Code

Prelimi-

nary

error

code

Error

(prelim-

inary)

detail

code

Error code definition

Searched unit

Notes

0403

4300

4305

01

05

(Note)

Serial communication error O O

0900 - - Test run O

1102 1202 - Discharge temperature fault O

1301 - - Low pressure fault O

1302 1402 - High pressure fault O

1500 1600 - Refrigerant overcharge O

- 1605 - Preliminary suction pressure fault O

2500 - - Drain sensor submergence O

2502 - - Drain pump fault O

2503 - - Drain sensor (Thd) fault O O

2600 - - Water leakage O

2601 - - Water supply cutoff O

4102 4152 - Open phase O

4106 - - Transmission power supply fault O

4109 - - Fan operation status detection error O

4115 - - Power supply signal sync error O

4116 - - RPM error/Motor error O O

4220

4225

(Note)

4320

4325

(Note)

[108] Abnormal bus voltage drop O O

[109] Abnormal bus voltage rise O O

[111] Logic error O O

[131] Low bus voltage at startup O

4230

4235

4330

4335

- Heatsink overheat protection O O

4240 4340 - Overload protection O

4250

4255

(Note)

4350

4355

(Note)

[101] IPM error O O

[104] Short-circuited IPM/Ground fault O O

[105] Overcurrent error due to short-circuited motor O O

[106] Instantaneous overcurrent (S/W detection) O O

[107] Overcurrent (effective value) (S/W detection) O O

[121] Position detection error at startup O

[122] Position detection error during operation O

4260 - - Heatsink overheat protection at startup O

5101 1202 -

Temperature sensor

fault

Return air temperature

(TH21)

O

OA processing unit inlet

temperature (TH4)

O

Outdoor unit

Indoor unit

LOSSNAY

Remote controller

Page 21

15- 15 -

HWE10170 GB

5102 1217 -

Temperature sensor

fault

Indoor unit pipe temperature (TH22)

O

OA processing unit pipe

temperature (TH2)

O

HIC bypass circuit outlet

temperature (TH2)

O

5103 1205 00

Temperature sensor

fault

Indoor unit gas-side pipe

temperature (TH23)

O

OA processing unit gasside pipe temperature

(TH3)

O

Pipe temperature at

heatexchanger outlet

(TH3)

O

5104 1202 -

Temperature sensor

fault

OA processing unit intake

air temperature (TH1)

O

Outside temperature

(TH24)

O

Detectable

only by the AllFresh type indoor units

Outdoor unit discharge

temperature (TH4)

O

5105 1204 -

Temperature sensor

fault

Accumulator inlet temperature (TH5)

O

5106 1216 -

Temperature sensor

fault

HIC circuit outlet temperature (TH6)

O

5107 1221 -

Temperature sensor

fault

Outside temperature (TH7) O

5110 1214 01

Temperature sensor

fault

Heatsink temperature

(THHS)

OO

5201 - - High-pressure sensor fault (63HS1) O

5301

5305

4300

4305

[115] ACCT sensor fault O

[117] ACCT sensor circuit fault O O

[119] Open-circuited IPM/Loose ACCT connector O O

[120] Faulty ACCT wiring O

5701 - - Loose float switch connector O

6201 - -

Remote controller board fault (nonvolatile memory

error)

O

6202 - - Remote controller board fault (clock IC error) O

6600 - - Address overlap OOOO

6601 - - Polarity setting error O

6602 - - Transmission processor hardware error OOOO

6603 - - Transmission line bus busy error OOOO

6606 - -

Communication error between device and transmission processors

OOOO

6607 - - No ACK error OOOO

Error

Code

Prelimi-

nary

error

code

Error

(prelim-

inary)

detail

code

Error code definition

Searched unit

Notes

Outdoor unit

Indoor unit

LOSSNAY

Remote controller

Page 22

16- 16 -

HWE10170 GB

The last digit in the check error codes in the 4000's and 5000's and two-digit detail codes indicate if the codes apply to

compressor inverter on fan inverter.

Example

Code 4225 (detail code 108): Bus voltage drop in the fan inverter system

Code 4230 : Heatsink overheat protection in the compressor inverter system

There are no preliminary error codes or detail codes for indoor units.

XII

6608 - - No response error OOOO

6831 - -

MA controller signal reception error (No signal reception)

OO

6832 - -

MA remote controller signal transmission error

(Synchronization error)

OO

6833 - -

MA remote controller signal transmission error

(Hardware error)

OO

6834 - -

MA controller signal reception error (Start bit detection error)

OO

7100 - - Total capacity error O

7101 - - Capacity code setting error O O O

7102 - - Wrong number of connected units O

7105 - - Address setting error O

7106 - - Attribute setting error O

7110 - -

Connection information signal transmission/reception error

O

7111 - - Remote controller sensor fault O O

7113 - - Function setting error O

7117 - - Model setting error O

7130 - - Incompatible unit combination O

The last digit Inverter system

0 or 1 Compressor inverter system

5 Fan inverter system

Error

Code

Prelimi-

nary

error

code

Error

(prelim-

inary)

detail

code

Error code definition

Searched unit

Notes

Outdoor unit

Indoor unit

LOSSNAY

Remote controller

Page 23

17- 17 -

HWE10170 GB

1. Error Code

Serial communication error (Indoor unit)

2. Error definition and error detection method

Serial communication cannot be established between the Indoor controller board and the INV board.

3. Cause, check method and remedy

(1) Faulty wiring

Check the following wiring connections.

1) Between Indoor controller board and Power supply board

2) Between Power supply board and INV board

(2) INV board failure or Indoor controller board failure or Power supply board failure

If the error persists after a power reset, replace the INV board, the Indoor controller board, or the Power supply board.

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

Drain sensor submergence (Models with a drain sensor)

2. Error definition and error detection method

1) If an immersion of the drain sensor in the water is detected while the unit is in any mode other than the Cool/Dry mode and

when the drain pump goes from OFF to ON, this condition is considered preliminary water leakage. While this error is being

detected, humidifier output cannot be turned on.(Applicable to the units manufactured in or after October 2006)

2) If the immersion of the sensor in the water is detected four consecutive times at an hour interval, this is considered water leakage, and "2500" appears on the monitor.

3) Detection of water leakage is also performed while the unit is stopped.

4) Preliminary water leakage is cancelled when the following conditions are met:

One hour after the preliminary water leakage was detected, it is not detected that the drain pump goes from OFF to ON.

The operation mode is changed to Cool/Dry.

The liquid pipe temperature minus the inlet temperature is -10°C [-18°F] or less.

3. Cause, check method and remedy

0403

2500

CN100 CNRSC

Indoor controller board Power supply board

CNRSP CNRS2

Power supply board INV board

Cause Check method and remedy

(1) Drain water drainage problem

Clogged drain pump

Clogged drain piping

Backflow of drain water from other units

Check for proper drainage.

(2) Adhesion of water drops to the drain sensor

Trickling of water along the lead wire

Rippling of drain water caused by filter clogging

1) Check for proper lead wire installation.

2) Check for clogged filter.

(3) Failure of the relay circuit for the solenoid valve Replace the relay.

(4) Indoor controller board failure

Drain sensor circuit failure

If the above item checks out OK, replace the indoor controller board.

Page 24

18- 18 -

HWE10170 GB

1. Error Code

Drain sensor submergence (Models with a float switch)

2. Error definition and error detection method

1) If an immersion of the float switch in the water is detected while the unit is in any mode other than the Cool/Dry mode and

when the drain pump goes from OFF to ON, this condition is considered preliminary water leakage. While this error is being

detected, humidifier output cannot be turned on.

2) If the drain pump turns on within one hour after preliminary water leakage is detected and the above-mentioned condition is

detected two consecutive times, water leakage error water leakage is detected, and "2500" appears on the monitor.

3) Detection of water leakage is also performed while the unit is stopped.

4) Preliminary water leakage is cancelled when the following conditions are met:

One hour after the preliminary water leakage was detected, it is not detected that the drain pump goes from OFF to ON.

The operation mode is changed to Cool/Dry.

The liquid pipe temperature minus the inlet temperature is - 10°C [ -18°F] or less.

3. Cause, check method and remedy

<Reference>

2500

Cause Check method and remedy

(1) Drain water drainage problem

Clogged drain pump

Clogged drain piping

Backflow of drain water from other units

Check for proper drainage.

(2) Stuck float switch

Check for slime in the moving parts of the float

switch.

Check for normal operation of the float switch.

(3) Float switch failure Check the resistance with the float switch turned on and

turned off.

6 minutes6 minutes

15

seconds

15

seconds

15

seconds

15

seconds

15

seconds

ON

OFF

ON

OFF

Drain pump operation triggered by a submergence of the liquid level sensor

(except during the Cooing/Dry mode)

Drain pump

output

Float switch

input

Submergence of

the sensor

Submergence of

the sensor

Preliminary water leakage

Submergence of

the sensor

Water leakage

Sensor in the airSensor in the air

Within 1-hour periodWithin 1-hour period

Page 25

19- 19 -

HWE10170 GB

1. Error Code

Drain pump fault (Models with a drain sensor)

2. Error definition and error detection method

1) Make the drain sensor thermistor self-heat. If the temperature rise is small, it is interpreted that the sensor is immersed in

water. This condition is considered to be a preliminary error, and the unit goes into the 3-minute restart delay mode.

2) If another episode of the above condition is detected during the preliminary error, this is considered a drain pump error, and

"2502" appears on the monitor.

3) This error is always detected while the drain pump is in operation.

4) The following criteria are met when the criteria for the forced stoppage of outdoor unit (system stoppage) are met.

∗"Liquid pipe temperature - inlet temperature -10°C [ -18 °F] " has been detected for 30 minutes.

∗The immersion of drain sensor is detected 10 consecutive times.

∗The conditions that are listed under items 1) through 3) above are always met before the criteria for the forced stoppage

of the outdoor unit.

5) The indoor unit that detected the conditions that are listed in item 4) above brings the outdoor unit in the same refrigerant

circuit to an error stop (compressor operation prohibited), and the outdoor unit brings all the indoor units in the same refrigerant

circuit that are in any mode other than Fan or Stop to an error stop. "2502" appears on the monitor of the units that came to

an error stop.

6) Forced stoppage of the outdoor unit

Detection timing: The error is detected whether the unit is in operation or stopped.

7) Ending criteria for the forced stoppage of outdoor unit

Power reset the indoor unit that was identified as the error source and the outdoor unit that is connected to the same refrigerant circuit.

Forced stoppage of the outdoor unit cannot be cancelled by stopping the unit via the remote controller.

(Note) Items 1) - 3) and 4) - 7) are detected independently from each other.

The address and attribute that appear on the remote controller are those of the indoor unit that caused the error.

3. Cause, check method and remedy

2502

Cause Check method and remedy

(1) Drain pump failure Check for proper functioning of the drain pump.

(2) Drain water drainage problem

Clogged drain pump

Clogged drain piping

Check for proper drainage.

(3) Adhesion of water drops to the drain sensor

Trickling of water along the lead wire

Rippling of drain water caused by filter clogging

1) Check for proper lead wire installation.

2) Check for clogged filter.

(4) Indoor controller board failure

Drain pump drive circuit failure

Drain heater output circuit failure

If the above item checks out OK, replace the indoor controller board.

(5) Items (1) through (4) above and an indoor unit elec-

tronic valve closure failure (leaky valve) occurred simultaneously.

Check the solenoid valves on the indoor unit for leaks.

Page 26

20- 20 -

HWE10170 GB

1. Error Code

Drain pump fault (Models with a float switch)

2. Error definition and error detection method

1) The immersion of sensor tip in water is detected by the ON/OFF signal from the float switch.

∗Submergence of the sensor

When it is detected that the float switch has been ON for 15 seconds, it is interpreted that the sensor tip is immersed in

water.

∗Sensor in the air

When it is detected that the float switch has been OFF for 15 seconds, it is interpreted that the sensor tip is not immersed

in water.

2) If it is detected that the float switch has been ON for 3 minutes after the immersion of the sensor tip was detected, this is considered a drain pump failure, and "2502" appears on the monitor.

∗The total time it takes for this error to be detected is 3 minutes and 15 seconds, including the time it takes for the first im-

mersion of the sensor tip to be detected.

3) Detection of drain pump failure is performed while the unit is stopped.

4) The following criteria are met when the criteria for the forced stoppage of outdoor unit (system stoppage) are met.

∗"Liquid pipe temperature - inlet temperature - 10°C [ -18°F] " has been detected for 30 minutes.

∗It is detected by the float switch that the sensor tip has been immersed in water for 15 minutes or more.

∗The conditions that are listed under items 1) through 3) above are always met before the criteria for the forced stoppage

of the outdoor unit.

5) The indoor unit that detected the conditions that are listed in item 4) above brings the outdoor unit in the same refrigerant

circuit to an error stop (compressor operation prohibited), and the outdoor unit brings all the indoor units in the same refrigerant

circuit that are in any mode other than Fan or Stop to an error stop.

6) Forced stoppage of the outdoor unit

Detection timing: The error is detected whether the unit is in operation or stopped.

This error is detected whether the unit is in operation or stopped.

7) Ending criteria for the forced stoppage of outdoor unit

Power reset the indoor unit that was identified as the error source and the outdoor unit that is connected to the same refrigerant circuit.

Forced stoppage of the outdoor unit cannot be cancelled by stopping the unit via the remote controller.

(Note) Items 1) - 3) and 4) - 7) are detected independently from each other.

The address and attribute that appear on the remote controller are those of the indoor unit that caused the error.

3. Cause, check method and remedy

2502

Cause Check method and remedy

(1) Drain pump failure Check for proper functioning of the drain pump

mechanism

(2) Drain water drainage problem

Clogged drain pump

Clogged drain piping

Check for proper drainage.

(3) Stuck float switch

Check for slime in the moving parts of the float switch.

Check for normal operation of the float switch.

(4) Float switch failure Check the resistance with the float switch turned

on and turned off.

(5) Indoor controller board failure

Drain pump drive circuit failure

Float switch input circuit failure

Replace indoor controller board.

(6) Items (1) through (5) above and an indoor unit electronic

valve closure failure (leaky valve) occurred simultaneously.

Check the solenoid valves on the indoor unit for

leaks.

Page 27

21- 21 -

HWE10170 GB

1. Error Code

Drain sensor (Thd) fault

2. Error definition and error detection method

If the open or short circuit of the thermistor has been detected for 30 seconds, this condition is considered to be a preliminary

error, and the unit goes into the 3-minute restart delay mode.

If another episode of the above condition is detected during the preliminary error, this is considered a drain sensor error.(If

the short or open circuit of the thermistor is no longer detected, normal operation will be restored in 3 minutes.)

This error is detected when one of the following conditions are met.

∗During Cool/Dry operation

∗Liquid pipe temperature minus inlet temperature is equal to or smaller than - 10°C [ -18°F] (except during the defrost cycle)

∗When the liquid temperature thermistor or suction temperature thermistor or short or open circuited.

∗Drain pump is in operation.

∗One hour has elapsed since the drain sensor went off.

Short: 90°C [194 °F] or above

Open: - 20°C [-4 °F] or below

3. Cause, check method and remedy

1. Error Code

Indoor unit fan operation error

2. Error definition and error detection method

1) Connector CN28 has remained open-circuited for 100 consecutive secondsduring operation.

3. Cause, check method and remedy

2503

Cause Check method and remedy

(1) Faulty connector (CN31) insertion. 1) Check for connector connection failure.

Reinsert the connector, restart the operation, and check for

proper operation.

(2) Broken or semi-broken thermistor wire 2) Check for a broken thermistor wire.

(3) Thermistor failure 3) Check the resistance of the thermistor.

0°C[32 °F]:6.0k

10°C[50 °F]:3.9k

20°C[68°F]:2.6k

30°C[86°F]:1.8k

40°C[104 °F]:1.3k

(4) Indoor controller board (error detection circuit)

failure

4) Replace the indoor controller board if the problem recurs

when the unit is operated with the No.-1 and No.-2 pins on

the drain sensor connector (CN31) being short-circuited.

If the above item checks out OK, there are no problems with

the drain sensor.

Turn off the power and turn it back on.

4109

Cause Check method and remedy

(1) Auxiliary relay (X13) fault The coil or the wiring of the auxiliary relay connected to

CN28 is faulty.

(2) Connector (CN28) is disconnected. Check the connector for proper connection.

(3) Blown fuse Check the fuse on the control circuit board.

(4) Motor error (thermistor error inside the motor) Check the unit fan for proper operation in the test run

mode.

If no problems are found with items 1 through 3 above and

the fan does not operate, replace the motor.

Page 28

22- 22 -

HWE10170 GB

1. Error Code

RPM error/Motor error

2. Error definition and error detection method

LOSSNAY

∗The motor keep running even if the power is OFF.

∗The thermal overload relay is ON. (Only for the three-phase model)

Indoor unit

If detected less than 180rpm or more than 2000rpm, the indoor unit will restart and keep running for 3 minutes.If detected

again, the display will appear.

3. Cause, check method and remedy

1. Error Code

Abnormal bus voltage drop (Indoor unit)

2. Error definition and error detection method

If Vdc 130V or less is detected during Inverter operation. (S/W detection)

3. Cause, check method and remedy

(1) Power supply environment

Check whether the unit makes an instantaneous stop when the detection result is abnormal or a power failure occurs.

Check whether the power voltage is 198V or above across all phases.

(2) Voltage drop detected

Check the voltage at CNVDC (between pins 1 and 3(+)) on the INV board while the inverter is stopped and if it is less than

220V, check the following items.

1) Check the wiring between TB2 and NF board, NF board and ACL, NF board and inrush current resistor, NF board and

DB01, NF board and INV board, NF board and indoor controller board.

2) Check the inrush current resistance.

Measure the interphase resistance of the resistor (R). 22 10%

3) Check ACL for broken wires.

Check that the resistance between pins 1 and 3 (housing side) of the CNACL connector is not infinite ( ).

4) Check the diode bridge (DB01) for problem.

Refer to section 5. "Troubleshooting the diode bridge".(page 50)

5) If no problems were found with items 1) through 4) above, replace the NF board.

(3) Indoor controller board failure

Confirm that DC12V is applied to the connector CNXB2 (between pins 4 and 5(+)) on the Indoor controller board while the

inverter is operating. If not, replace the Indoor controller board.

(4) NF board failure

If the unit stops within 10 seconds after resuming operation and the same error is detected, replace the NF board.

(5) INV board failure

If no problems were found with items (1) through (4) above, replace the INV board.

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

4116

Cause Check method and remedy

(1) Board failure Replace the board.

(2) Motor malfunction Check for the motor and the solenoid switch.

(3) Solenoid switch malfunction

4225

Page 29

23- 23 -

HWE10170 GB

1. Error Code

Abnormal bus voltage rise (Indoor unit)

2. Error definition and error detection method

If Vdc 425V is detected during inverter operation.

3. Cause, check method and remedy

(1) Different voltage connection

Check the power supply voltage on the power supply terminal block (TB2).

(2) INV board failure

If the problem recurs, replace the INV board.

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

Logic error (Indoor unit)

2. Error definition and error detection method

H/W error

If only the H/W error logic circuit operates, and no identifiable error is detected.

3. Cause, Check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

Heatsink overheat protection (Indoor unit)

2. Error definition and error detection method

When the heat sink temperature (THHS) remains at or above 85°C [185°F] is detected.

3. Cause, check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

4225

4225

Cause Check method and remedy

(1) External noise If the problem recurs when the unit is put into opera-

tion, replace the INV board.

(2) INV board failure

4235

Cause Check method and remedy

(1) Air passage blockage Check that the heat sink cooling air passage is not blocked

(2) Fan motor error Check the fan motor for proper operation (sound, vibration, and rotation).

If any problems were found, check the items listed in sections 2 [3] and [4].

->Refer to [8] 3.2[3][4].(page 49)

(3) THHS failure If the problem persists after resuming operation, replace the THHS sensor.

(4) INV board fault If no problems were found with items (1) through (3) and the same error is de-

tected after resuming operation, replace the INV board.

Page 30

24- 24 -

HWE10170 GB

1. Error Code

IPM error (Indoor unit)

2. Error definition and error detection method

IPM error signal is detected.

3. Cause, check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

Instantaneous overcurrent (Indoor unit)

Overcurrent (Indoor unit)

2. Error definition and error detection method

Overcurrent 18 Arms and above is detected by the current sensor.

3. Cause, check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

4255

Cause Check method and remedy

(1) Power supply environment Check the power supply voltage.

Check whether the power voltage is 176V or above across all phases.

(2) Static pressure setting error Check that the static pressure setting and the design static pressure

are correct.

(3) Inverter failure or fan motor error 1) Refer to [8] 3.2.[1].(page 48)

2) Refer to [8] 3.2.[2].(page 48)

3) Refer to [8] 3.2.[3].(page 49)

4) Refer to [8] 3.2.[4].(page 49)

4255

Cause Check method and remedy

(1) Power supply environment Check the power supply voltage.

Check whether the power voltage is 176V or above across all

phases.

(2) Static pressure setting error Check that the static pressure setting and the design static pres-

sure are correct.

(3) Inverter failure or fan motor error 1) Refer to [8] 3.2.[1].(page 48)

2) Refer to [8] 3.2.[2].(page 48)

3) Refer to [8] 3.2.[3].(page 49)

4) Refer to [8] 3.2.[4].(page 49)

Page 31

25- 25 -

HWE10170 GB

1. Error Code

Short-circuited IPM/Ground fault (Indoor unit)

2. Error definition and error detection method

When IPM/IGBT short damage or grounding on the load side is detected just before starting the inverter.

3. Cause, check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

Overcurrent error due to short-circuited motor (Indoor unit)

2. Error definition and error detection method

When a short is detected on the load side just before starting the inverter operation.

3. Cause, Check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

4255

Cause Check method and remedy

(1) Ground fault of the fan motor Refer to [8] 3.2.[4].(page 49)

(2) Inverter failure 1) Refer to [8] 3.2.[1].(page 48)

2) Refer to [8] 3.2.[2].(page 48)

4255

Cause Check method and remedy

(1) Short-circuited fan motor coil or inverter failure 1) Refer to [8] 3.2.[1].(page 48)

2) Refer to [8] 3.2.[2].(page 48)

3) Refer to [8] 3.2.[3].(page 49)

(2) Output wiring Check for a short circuit

Page 32

26- 26 -

HWE10170 GB

1. Error Code

Position detection error at startup (Indoor unit)

2. Error definition and error detection method

Position error is detected by the hall sensor at inverter startup.

3. Cause, Check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

Position detection error during operation (Indoor unit)

2. Error definition and error detection method

Position error is detected by the hall sensor during operation.

3. Cause, Check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

4255

Cause Check method and remedy

(1) Loose connector Check the CNCT1 and CNINV connectors on the

INV board for proper connection.

(2) Inverter failure or fan motor error 1) Refer to [8] 3.2.[2].(page 48)

2) Refer to [8] 3.2.[3].(page 49)

4255

Cause Check method and remedy

(1) Loose connector Check the CNCT1 and CNINV connectors on the

INV board for proper connection.

(2) Inverter failure or fan motor error 1) Refer to [8] 3.2.[2].(page 48)

2) Refer to [8] 3.2.[3].(page 49)

Page 33

27- 27 -

HWE10170 GB

1. Error Code

Return air temperature sensor (TH21) fault (Indoor unit)

Return air temperature sensor (TH4) fault (OA processing unit)

Pipe temperature sensor (TH22) fault (Indoor unit)

Pipe temperature sensor (TH2) fault (OA processing unit)

Gas-side pipe temperature sensor (TH23) fault (Indoor unit)

Gas-side pipe temperature sensor (TH3) fault (OA processing unit)

Intake air temperature sensor (TH1) fault (OA processing unit)

Intake air temperature sensor (TH24) fault (All-fresh (100% outdoor air) type indoor unit)

2. Error definition and error detection method

If a short or an open is detected during thermostat ON, the outdoor unit turns to anti-restart mode for 3 minutes. When the

error is not restored after 3 minutes (if restored, the outdoor unit runs normally), the outdoor unit makes an error stop.

Short: detectable at 90°C [194°F] or higher

Open: detectable at -40°C [-40°F] or lower

Sensor error at gas-side cannot be detected under the following conditions.

∗During heating operation

∗During cooling operation for 3 minutes after the compressor turns on.

3. Cause, check method and remedy

5101

5102

5103

5104

Cause Check method and remedy

(1) Thermistor failure Check the thermistor resistor.

0°C [32°F]: 15 kohm

10°C [50°F]: 9.7 kohm

20°C [68°F] : 6.4 kohm

30°C [86°F] : 4.3 kohm

40°C [104°F] : 3.1 kohm

(2) Connector contact failure

(3) Disconnected wire or partial disconnected

thermistor wire

(4) Unattached thermistor or contact failure

(5) Indoor board (detection circuit) failure Check the connector contact.

When no fault is found, the indoor board is a failure.

Page 34

28- 28 -

HWE10170 GB

1. Error Code

Heatsink temperature sensor (THHS) fault (Indoor unit)

2. Error definition and error detection method

When a short or an open of THHS is detected just before or during the inverter operation.

3. Cause, check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

ACCT sensor circuit fault (Indoor unit)

2. Error definition and error detection method

When abnormal value is detected by the ACCT detection circuit immediately before the inverter starts

3. Cause, check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

5110

Cause Check method and remedy

(1) Loose connector Check the CNTH on the INV board for proper connection.

(2) THHS sensor fault If the problem persists after resuming operation, replace the THHS sensor.

(3) INV board failure If no problems were found with items (1) and (2) above and the problem per-

sists after resuming operation, replace the INV board.

5305

Cause Check method and remedy

(1) INV board failure Refer to [8] 3.2.[1].(page 48)

(2) Fan motor error Refer to [8] 3.2.[4].(page 49)

Page 35

29- 29 -

HWE10170 GB

1. Error Code

Open-circuited IPM/Loose ACCT connector (Indoor unit)

2. Error definition and error detection method

ACCT sensor detected that not enough current is available.

3. Cause, check method and remedy

Refer to section [8] Troubleshooting, item 3. DC fan motor (fan motor/INV board) for error codes related to the inverter.

(page 47)

1. Error Code

Loose float switch connector

2. Error definition and error detection method

Detection of the disconnected float switch (open-phase condition) during operation

3. Cause, check method and remedy

(1) CN4F disconnection or contact failure

Check for disconnection of the connector (CN4F) on the indoor controller board.

5305

Cause Check method and remedy

(1) Disconnected ACCT sensor Check CNCT2 on the INV board for proper connection.

(2) ACCT sensor fault Disconnect the CNCT2 connector, and check the resistance between

the terminals.

Refer to [8] 3.4.(page 50)

(3) Inverter failure or fan motor error 1) Refer to [8] 3.2.[2].(page 48)

2) Refer to [8] 3.2.[4].(page 49)

3) If no problems were found with items 1) and 2) above and the problem persists after resuming operation, replace the INV board and the

ACCT sensor.

4) If the problem persists after taking step 3) above, replace the fan motor.

5701

Page 36

30- 30 -

HWE10170 GB

1. Error Code

Address overlap

2. Error definition and error detection method

An error in which signals from more than one indoor units with the same address are received

The address and attribute that appear on the remote controller indicate the controller that detected the error.

3. Cause, check method and remedy

6600

Cause Check method and remedy

(1) Two or more of the following have the same address:

Outdoor units, indoor units, LOSSNAY units, controllers such as ME remote controllers.

<Example>

6600 "01" appears on the remote controller

Unit #01 detected the error.

Two or more units in the system have 01 as their address.

Find the unit that has the same address as that of the error

source.Once the unit is found, correct the address.

Then, turn off the outdoor units, indoor units, and

LOSSNAY units, keep them all turned off for at least

five minutes, and turn them back on.

When air conditioning units are operating normally despite

the address overlap error

Check the transmission wave shape and noise on the

transmission line.

Refer to the service handbook that came with the outdoor

unit.

(2) Signals are distorted by the noise on the transmission

line.

Page 37

31- 31 -

HWE10170 GB

1. Error Code

Transmission processor hardware error

2. Error definition and error detection method

Although "0" was surely transmitted by the transmission processor, "1" is displayed on the transmission line.

The address/attribute appeared on the display on the remote controller indicates the controller where an error occurred.

3. Cause

1) When the wiring work of or the polarity of either the indoor or outdoor transmission line is performed or is changed while the

power is on, the transmitted data will collide, the wave shape will be changed, and an error will be detected.

2) Grounding fault of the transmission line

3) When grouping the indoor units that are connected to different outdoor units, the male power supply connectors on the multiple

outdoor units are connected to the female power supply switch connector (CN40).

4) When the power supply unit for transmission lines is used in the system connected with MELANS, the male power supply

connector is connected to the female power supply switch connector (CN40) on the outdoor unit.

5) Controller failure of the source of the error

6) When the transmission data is changed due to the noise on the transmission line

7) Voltage is not applied on the transmission line for centralized control (in case of grouped indoor units connected to different

outdoor units or in case of the system connected with MELANS)

4. Check method and remedy

6602

NO

Tightly reconnect the male power

supply connector to the female

power supply switch connector (CN40).

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

Is the transmission line work

performed while the power is on?

Check the power source of the indoor unit.

198 / 264V?

Check the transmission line work is performed

and the shielded wire is treated properly.

Grounding fault or does the shielded

wire contact with the transmission line?

System ?

Faulty power source work

Improper transmission line work

Turn off the power source of outdoor/indoor

units, and turn them on again.

NO

Investigation into the

transmission line noise

Noise exist?

Controller failure of the

source of the error

*For the investigation method, follow

<Investigation method of transmission wave shape/noise>

Investigation into the

cause of the noise

Correct the error.

System with the power supply

unit for transmission lines

Is the male power supply connector

connected to the female power supply

switch connector (CN40) on only one

of the outdoor unit?

Is the male power supply connector

connected to the female power supply

switch connector (CN40) ?

Confirm that the power supply

connector on the outdoor

unit is not plugged into CN40.

Confirm that the power supply

connector on the outdoor

unit is not plugged into CN40.

Disconnect the male

power supply on

CN40 and connect it to CN41

Single-outdoor-unit system

Multiple-outdoor-unit system

Page 38

32- 32 -

HWE10170 GB

1. Error Code

Transmission line bus busy error

2. Error definition and error detection method

Generated error when the command cannot be transmitted for 4-10 minutes in a row due to bus-busy

Generated error when the command cannot be transmitted to the transmission line for 4-10 minutes in a row due to noise

The address/attribute appeared on the display on the remote controller indicates the controller where an error occurred.

3. Cause, check method and remedy

1. Error Code

Communication error between device and transmission processors

2. Error definition and error detection method

Communication error between the main microcomputer on the indoor unit board and the microcomputer for transmission