Mitsubishi PEFY-P40VMH-E, PEFY-P50VMH-E, PEFY-P63VMH-E, PEFY-P71VMH-E, PEFY-P80VMH-E SERVICE MANUAL

...Page 1

TECHNICAL & SERVICE MANUAL

Air-Conditioners For Building Application

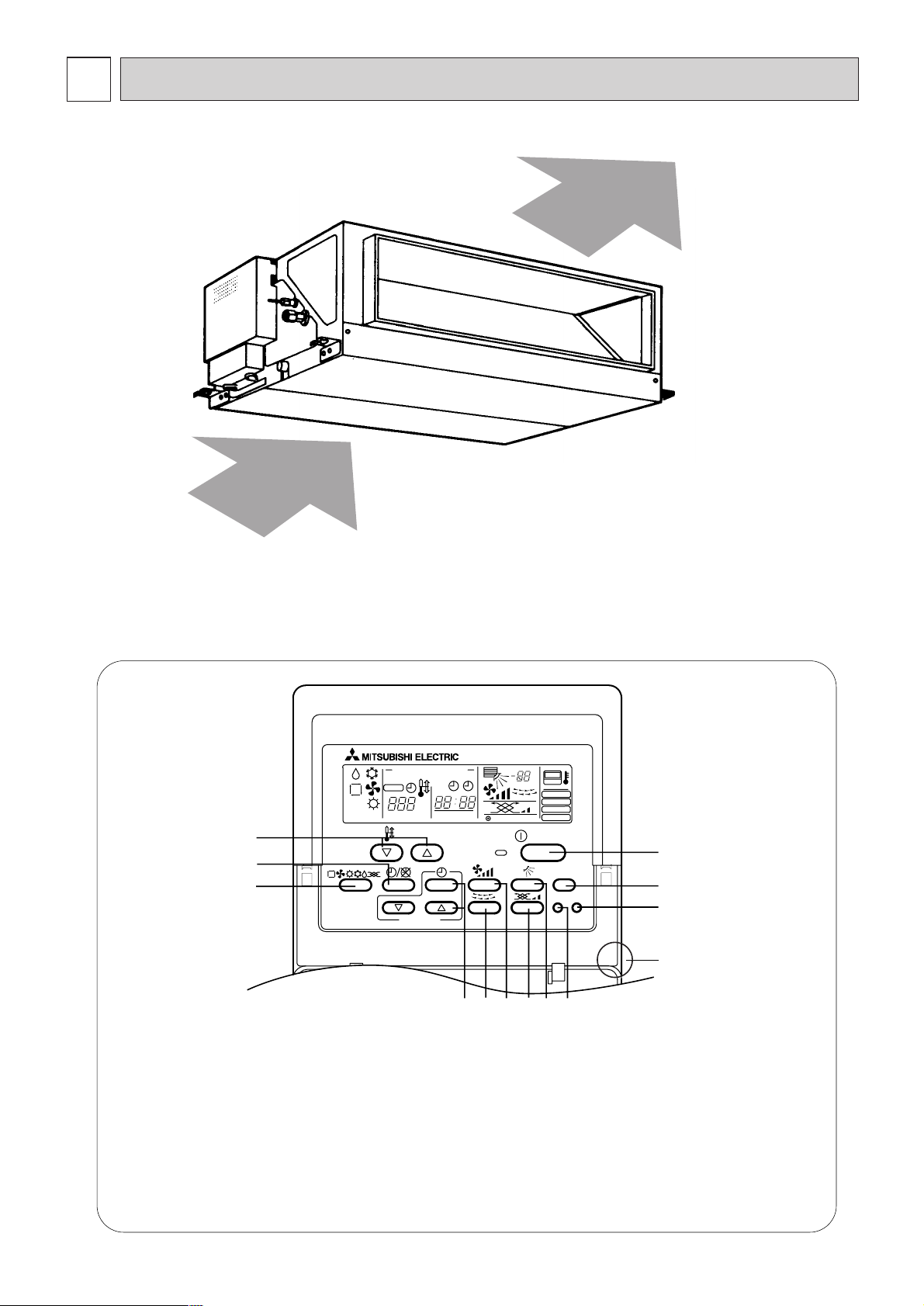

<Indoor unit>

2004

Models

Ceiling Concealed

Series PEFY

PEFY-P40VMH-E,PEFY-P50VMH-E

PEFY-P63VMH-E,PEFY-P71VMH-E

PEFY-P80VMH-E,PEFY-P100VMH-E

PEFY-P125VMH-E,PEFY-P140VMH-E

PEFY-P200VMH-E,PEFY-P250VMH-E

INDOOR UNIT

CONTENTS

SAFETY PRECAUTIONS ·························1

1. FEATURES ···········································3

2. PART NAMES AND FUNCTIONS········4

3. SPECIFICATION ···································6

4. OUTLINES AND DIMENSIONS············9

5. WIRING DIAGRAM ·····························11

6.

REFRIGERANT SYSTEM DIAGRAM

13····

7. TROUBLE SHOOTING ·······················14

8. DISASSEMBLY PROCEDURE···········

17

For use with the R410A & R407C & R22

Page 2

1

SAFETY PRECAUTIONS

and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in

injury.

• Always use an air cleaner, humidifier, electric heater, and other

accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shock,

or fire.

• Never repair the unit. If the air conditioner must be repaired,

consult the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or

fire may result.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the

room.

- If the refrigerant gas comes into contact with a flame, poisonous

gases will be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or

fire may result.

• Have all electric work done by a licensed electrician according

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations”and the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is per-

formed improperly, electric shock and fire may result.

• Securely install the cover of control box and the panel.

- If the cover and panel are not installed properly,dust or water may

enter the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site,

do not charge the it with a refrigerant different from the refrigerant specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures

must be taken to prevent the refrigerant concentration from

exceeding the safety limit even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to pre-

vent the safety limit from being exceeded. Should the refrigerant

leak and cause the safety limit to be exceeded, hazards due to

lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the

dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage, elec-

tric shock, or fire may result.

• After completing installation work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove,

oven, or other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection

devices.

- If the pressure switch, thermal switch, or other protection device

is shorted and operated forcibly, or parts other than those specified

by Mitsubishi Electric are used, fire or explosion may result.

1. Before installation and electric work

s Before installing the unit, make sure you read all the

“Safety precautions”.

s The “Safety precautions” provide very important

points regarding safety. Make sure you follow them.

s This equipment may cause the adverse effect on the

same supply system.

s Please report to or take consent by the supply au-

thority before connection to the system.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger

of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage

to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that impor tant instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This

symbol is displayed on the main unit label.) <Color: Yellow>

: Beware of electric shock (This symbol is displayed on the main

unit label.) <Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, elec-

tric shock, or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in

injuries.

• Use the specified cables for wiring. Make the connections securely so that the outside force of the cable is not applied to the

terminals.

- Inadequate connection and fastening may generate heat and cause

a fire.

• Prepare for typhoons and other strong winds and earthquakes

• Keep the electric parts away from water (washing water etc.).

- It might result in electric shock, catching fire or smoke.

• To dispose of this product, consult your dealer.

• Do not use a leak detection additive.

Page 3

2

2. Precautions for devices that use

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large amount of chlorine which may cause the refrigerator

oil of the new unit to deteriorate.

• Use refrigerant piping made of C1220 (Cu-DHP) phosphorus

deoxidized copper as specified in the *JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. In addition, be sure

that the inner and outer surfaces of the pipes are clean and

free of hazardous sulphur, oxides, dust/dirt, shaving particles,

oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause

the refrigerant residual oil to deteriorate.

*JIS: Japanese Industrial Standard

• Store the piping to be used during installation indoors and keep

both ends of the piping sealed until just before brazing. (Store

elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of

the refrigerant in the cylinder will change and performance may

drop.

• Do not use a refrig

- If another refrigerant (R22, etc.) is used, the chlorine in the refrig-

erant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve..

- The vacuum pump oil may flow back into the refrigerant cycle and

cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow

check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant

may deteriorate.

R410A or R407C refrigerant

erant other than R410A or R407C.

R410A or R407C, the refrigerant may deteriorated.

- If

deteriorate.

water is mixed in the R410A or R407C, the refrigerator oil may

- Since R410A or R407C does not contain any chlorine, gas leak

detectors for conventional refrigerants will not react to it.

Page 4

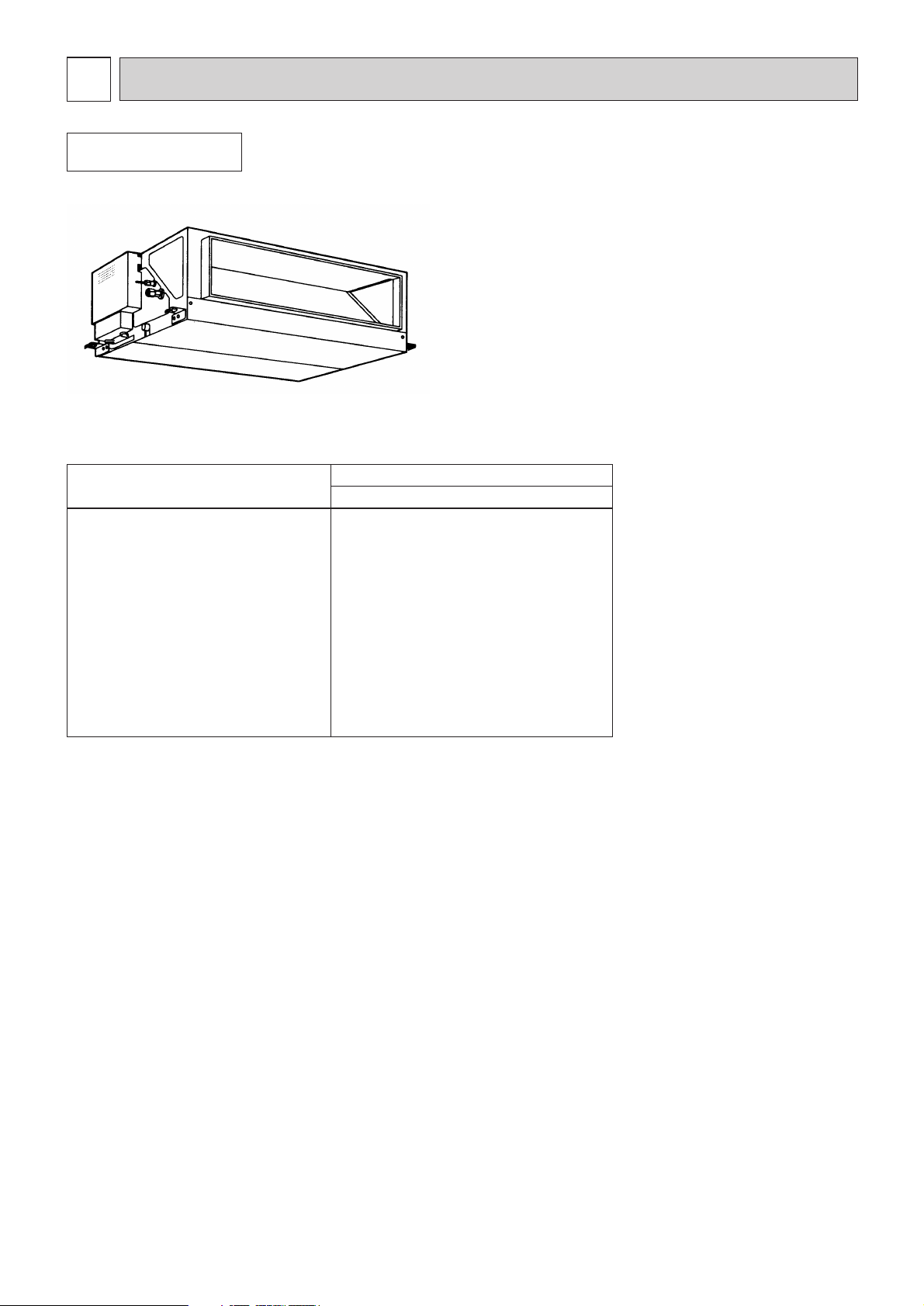

3

PEFY-P40VMH-E

PEFY-P50VMH-E

PEFY-P63VMH-E

PEFY-P71VMH-E

PEFY-P80VMH-E

PEFY-P100VMH-E

PEFY-P125VMH-E

PEFY-P140VMH-E

PEFY-P200VMH-E

PEFY-P250VMH-E

4.5 / 5.0

5.6 / 6.3

7.1 / 8.0

8.0 / 9.0

9.0 / 10.0

11.2 / 12.5

14.0 / 16.0

16.0 / 18.0

22.4 / 25.0

28.0 / 31.5

FEATURES

1

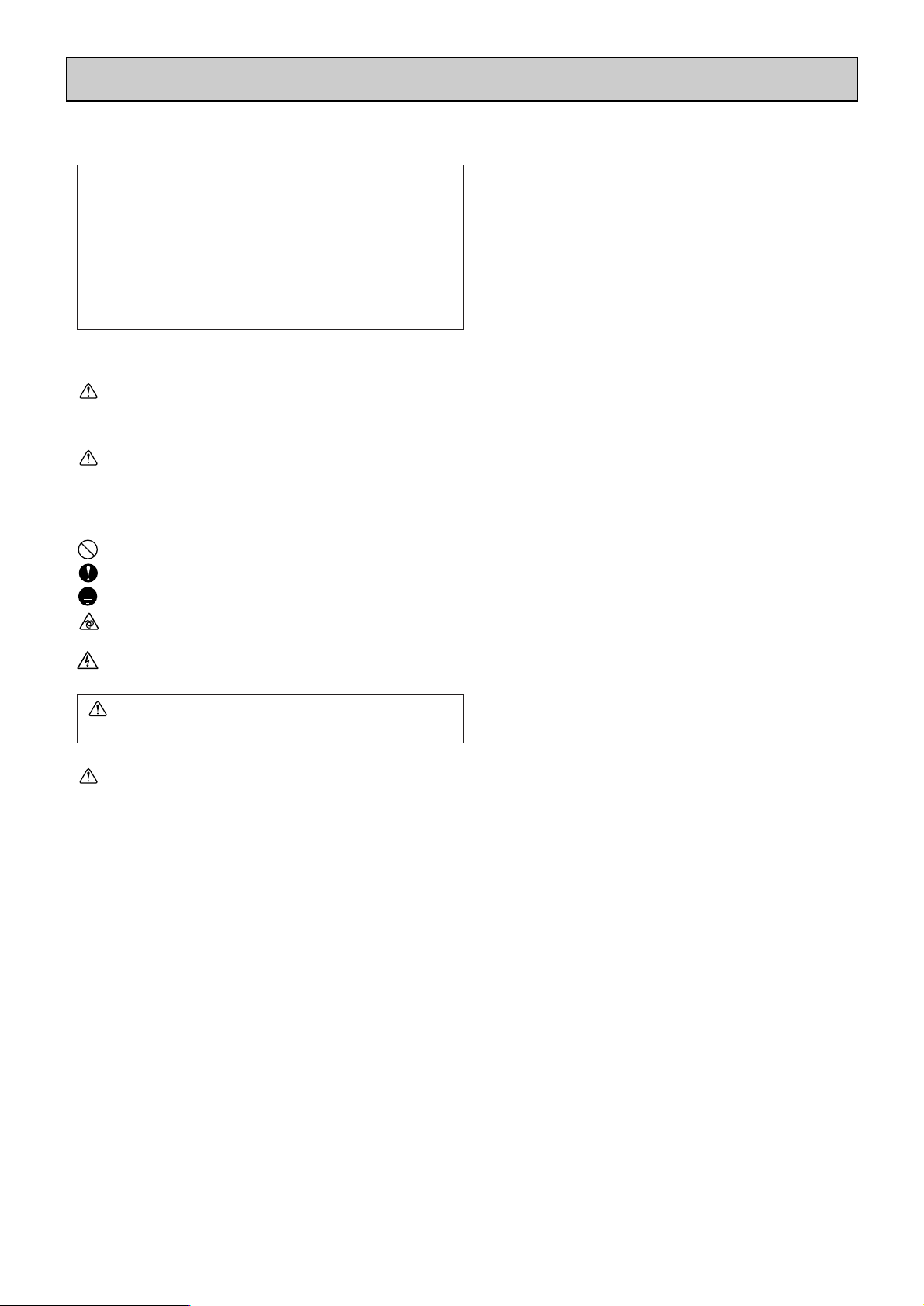

Indoor unit

Ceiling Concealed

Series PEFY

Models

Cooling capacity/Heating capacity

kW

Page 5

4

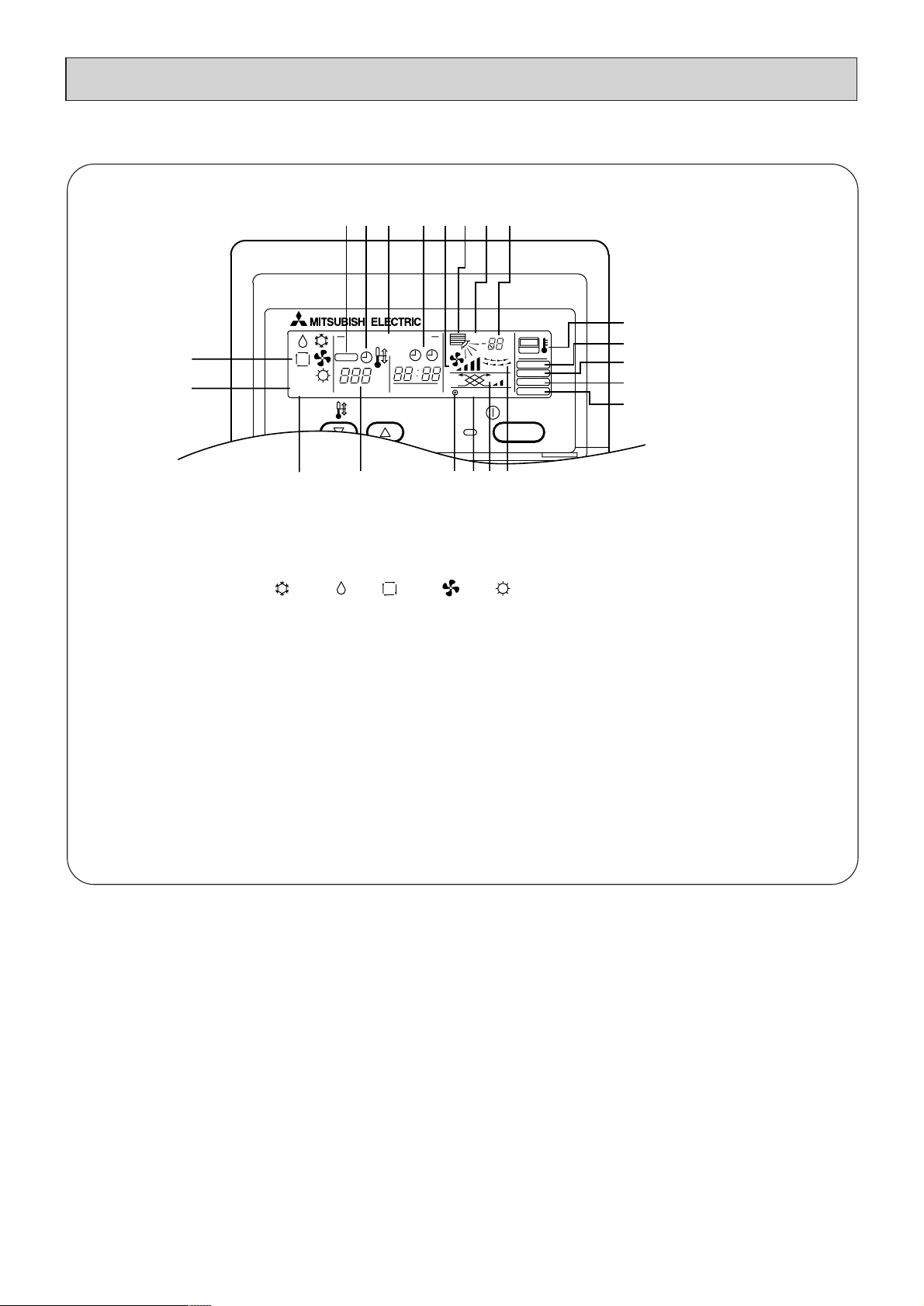

PART NAMES AND FUNCTIONS

2

● Indoor (Main) Unit

● Remote controller

[Operation buttons]

[PAR-20MAA]

● Once the controls are set, the same operation mode can

be repeated by simply pressing the ON/OFF button.

Air inlet

Air outlet

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

1

2

3

4 56879

0

C

A

B

1 [Room temperature adjustment] Button

2 [Timer/continuous] Button

3 [Selecting operation] Button

4 [Time selection] Button

[Time-setting] Button

5 [Louver] Button

6 [Fan speed adjustment] Button

7 [Up/down airflow direction] Button

8 [Ventilation] Button

9 [Checking/built-in] Button

0 [Test run] Button

A [Filter] Button

B [ON/OFF] Button

C Position of built-in room temperature

•Never expose the remote controller to direct sunlight. Doing so can result in the erroneous measurement of room temperature.

•Never place any obstacle around the lower right-hand section of the remote controller. Doing so can

result in the erroneous measurement of room temperature.

Page 6

5

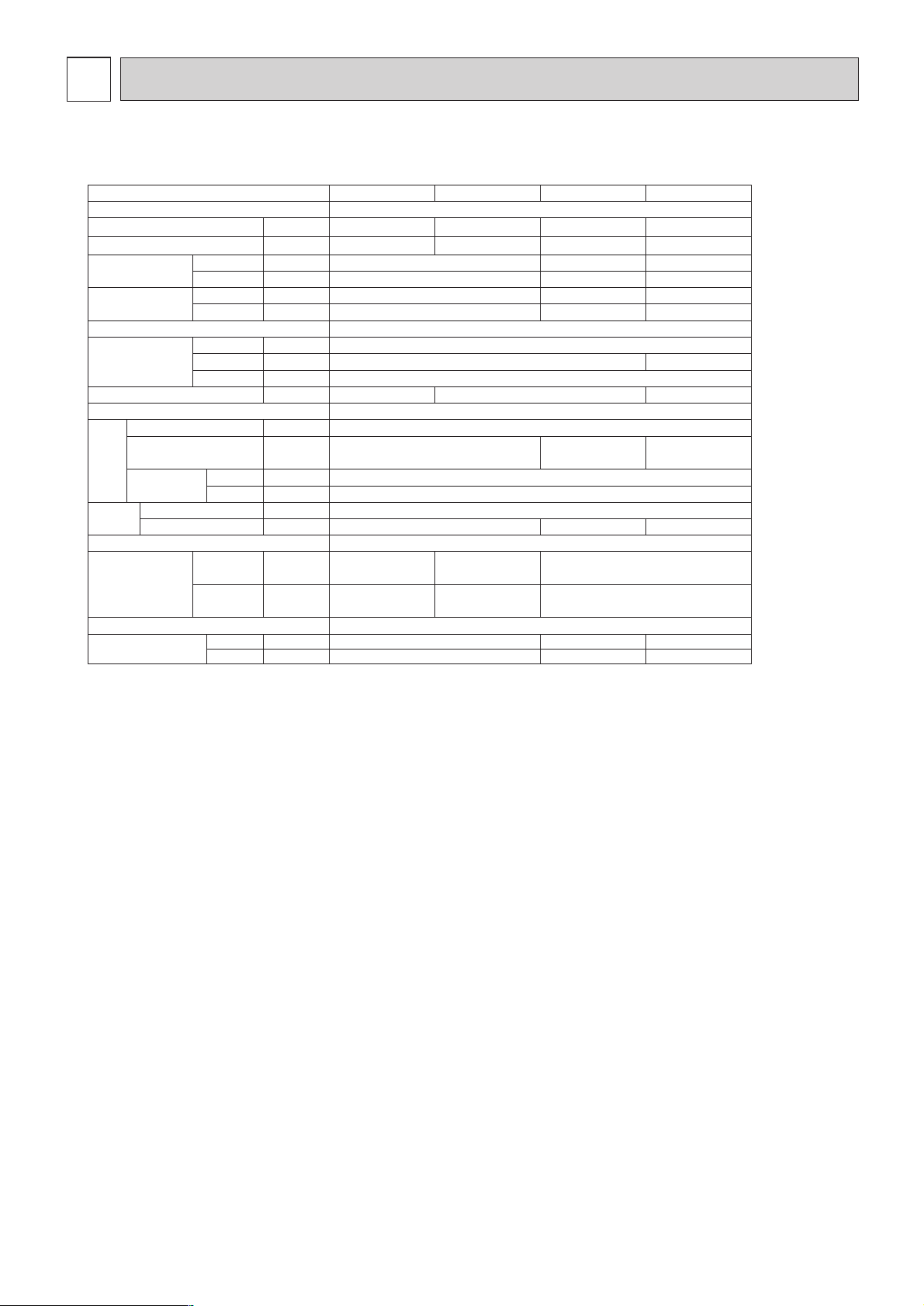

[Display]

Current time/Timer

Centralized control

Timer ON

Abnormality occurs

Operation mode: COOL, DRY, AUTO, FAN, HEAT

Preparing for Heating mode

Defrost mode

Set temperature

Power ON

Louver

Not available function

Ventilation

Function setting mode

Test run mode

Error check mode

Filter sign

Set effective for 1 hr.

Sensor position

Room temperature

Airflow

Fan speed

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

ABCD

SQTU

CENTRALLY CONTROLLED

STAND BY

DEFROST

G

CHECK

TEMP.

HIKLJ

E

F

˚C

ON OFF

CLOCK

ERROR CODE

1Hr.

NOT AVAILABLE

˚C

FILTER

CHECK MODE

TEST RUN

FUNCTION

ON/OFF

R

P

O

N

M

Page 7

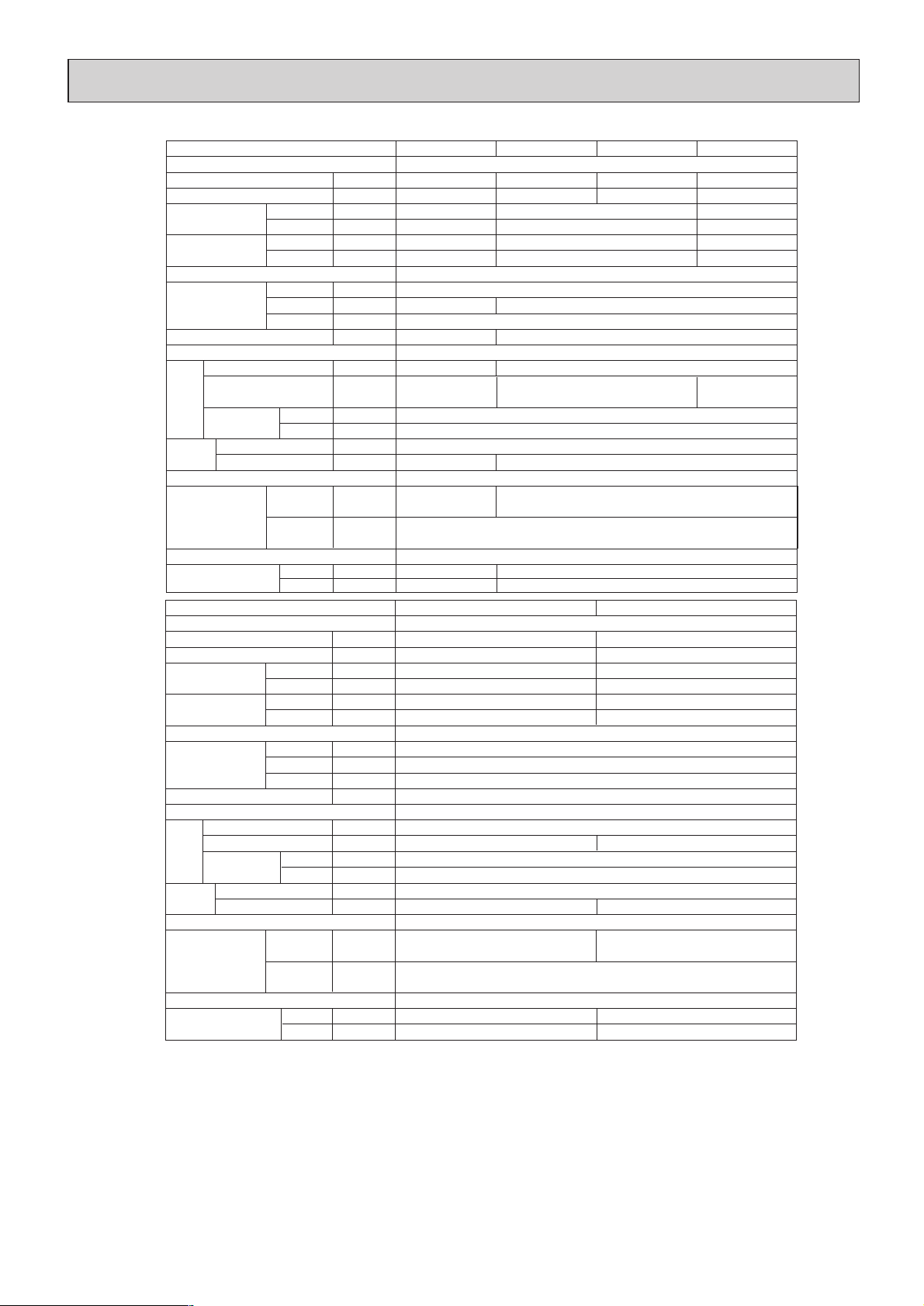

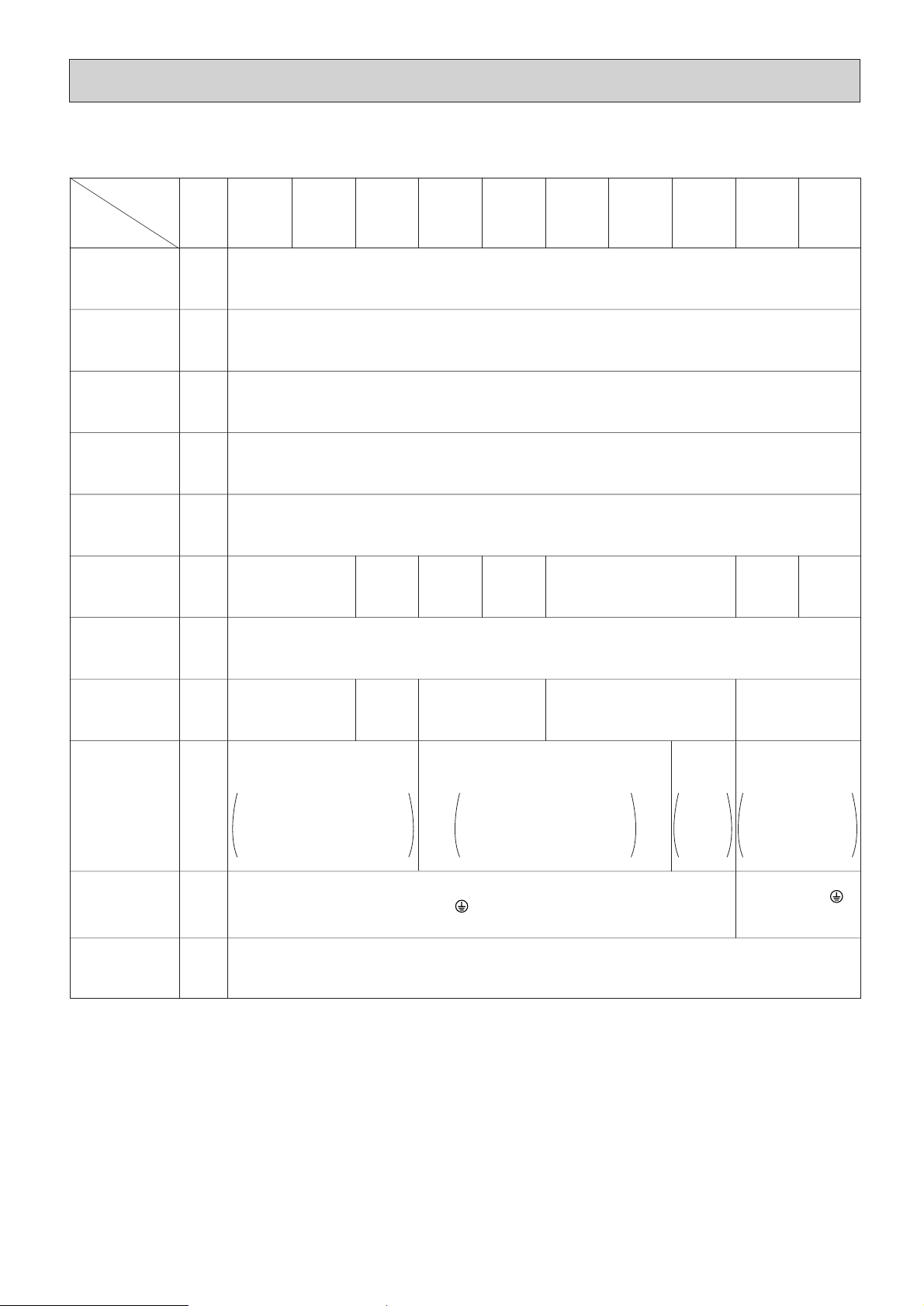

3

SPECIFICATION

3-1. Specification

Power source

Model

kWCooling capacity ❇1

kW

kWCooling

Heating

Cooling

Heating

kW

A

A

mm

mm

mm

kg

m

3

/min

Pa

Pa

50/100/200

100/150/200

220V

230, 240V

kW

mm

mm

dB(A)

dB(A)

27-34

31-37

32-38

36-41

32-39

35-41

Heating capacity ❇1

Power consumption

(50/60Hz)

Current

External finish

Dimension

Height

Width

Depth

Net weight

Heat exchanger

Fan

Type

Airflow rate

(Lo-Hi)

External static

pressure ❇2

Motor

Output ❇3

Type

Air filter (option)

Refrigerant

pipe dimension

Gas

(Flare)

Liquid

(Flare)

Drain pipe dimension

Noise level (Lo-Hi)

220V

230, 240V

~

750 1000

44

Cross fin (Aluminum plate fin and copper tube)

Sirocco fan

✕

Single phase induction motor

Synthethic fiber unwoven cloth filter(long life)

10.0-14.0

220-240V 50Hz /60Hz

PEFY-P40VMH-E PEFY-P50VMH-E

5.64.5

6.35.0

Galvanizing

380

900

1

12.7

6.35

32 (1-1/4 inch)

0.08

0.19/0.23

0.19/0.23

0.88/1.06

0.88/1.06

0.24/0.30

0.24/0.30

1.12/1.38

1.12/1.38

0.26/0.33

0.26/0.33

1.20/1.51

1.20/1.51

45 50

ø

ø

9.52

ø

PEFY-P63VMH-E

7.1

8.0

ø

15.88

ø

12.7(R410A)

ø

15.88

(R22,R407C)

ø

6.35(R410A)

ø

9.52

(R22,R407C)

13.5-19.0

0.12 0.14

PEFY-P71VMH-E

8.0

9.0

15.5-22.0

Note: ❇1 Cooling/Heating capacity indicates the maximum value at operation under the following condition.

Cooling : Indoor 27˚CDB/19˚CWB,Outdoor 35˚CDB (WR2: water 30˚C)

Heating : Indoor 20˚CDB,Outdoor 7˚CDB/6˚CWB (WR2: water 20˚C)

❇

2 The external static pressure is set to 100Pa (at 220V) /150Pa (at 230, 240V) at factory shipment.

❇

3 The value are that at 240V.

6

Page 8

7

Power source

kWCooling capacity ❇1

kW

kWCooling

Heating

Cooling

Heating

kW

A

A

mm

mm

mm

kg

m

3

/min

Pa

Pa

50/100/200

100/150/200

220V

230, 240V

kW

mm

mm

dB(A)

dB(A)

35-41

38-43

34-42

38-44

Heating capacity ❇1

Power consumption

(50/60Hz)

Current

External finish

Dimension

Height

Width

Depth

Net weight

Heat exchanger

Fan

Type

Airflow rate

(Lo-Hi)

External static

pressure ❇2

Motor

Output ❇3

Type

Air filter (option)

Refrigerant

pipe dimension

Gas

(Flare)

Liquid

(Flare)

Drain pipe dimension

Noise level (Lo-Hi)

220V

230, 240V

~

1000 1200

50

Cross fin (Aluminum plate fin and copper tube)

Sirocco fan

✕

Single phase induction motor

Synthethic fiber unwoven cloth filter(long life)

18.0-25.0

220-240V 50Hz /60Hz

PEFY-P80VMH-E

PEFY-P100VMH-E

11.29.0

12.510.0

Galvanizing

380

900

1 Sirocco fan✕2

15.88

32 (1-1/4 inch)

0.18

0.48/0.58

0.48/0.58

2.34/2.66

2.34/2.66

0.48/0.59

0.48/0.59

2.35/2.70

2.35/2.70

0.32/0.40

0.32/0.40

1.47/1.83

1.47/1.83

70

ø

9.52

ø

PEFY-P125VMH-E

14.0

16.0

26.5-38.0

0.26

PEFY-P140VMH-E

16.0

18.0

28.0-40.0

PEFY-P200VMH-E

~

380-415V 50Hz / 60Hz

PEFY-P250VMH-E

22.4 28.0

25.0 31.5

Power source

kWCooling capacity ❇1

kW

kWCooling

Heating

Cooling

Heating

kW

A

A

mm

mm

mm

kg

m

3

/min

Pa

Pa

kW

mm

mm

dB(A)

dB(A)

Heating capacity ❇1

Power consumption

(50/60Hz)

Current

External finish

Dimension

Height

Width

Depth

380V

400, 415V

380V

400, 415V

Net weight

Heat exchanger

Fan

Type

Airflow rate

External static

pressure

❇

4

Motor

Output ❇5

Type

Air filter (option)

Refrigerant

pipe dimension

Gas

(Brazing)

Liquid

(Brazing)

Drain pipe dimension

Noise level

Galvanizing

470

1250

1120

100

Cross fin (Aluminum plate fin and copper tube)

Sirocco fan✕2

phase induction motor

Synthethic fiber unwoven cloth filter(long life)

32 (1-1/4 inch)

58.0 72.0

110/220

130/260

0.76 1.08

52(130Pa)/54(260Pa)

50(110Pa)/52(220Pa)

44(130Pa)/47(260Pa)

42(110Pa)/45(220Pa)

0.99/1.14

0.99/1.14

1.62/1.86

1.62/1.86

1.23/1.41

1.23/1.41

2.0/2.3

2.0/2.3

Note: ❇1 Cooling/Heating capacity indicates the maximum value at operation under the following condition.

Cooling : Indoor 27˚CDB/19˚CWB,Outdoor 35˚CDB (WR2: water 30˚C)

Heating : Indoor 20˚CDB,Outdoor 7˚CDB/6˚CWB (WR2: water 20˚C)

❇

2 The external static pressure is set to 100Pa (at 220V) /150Pa (at 230, 240V) at factory shipment.

❇

3 The value are that at 240V.

❇

4 The external static pressure is set to 110Pa (at 380V) /130Pa (at 400, 415V) at factory shipment.

❇

5 The value are that at 415V.

3N

Model

Model

ø

15.88 (R410A)

ø

19.05 (R22,R407C)

ø

9.52 (R410A)

ø

12.7 (R22,R407C)

ø

22.2 (R410A)

ø

28.58 (R22,R407C)

ø

19.05 (R410A)

ø

25.4 (R22,R407C)

Page 9

8

LEV

C1

MF1,2

P

EFY-

P40VMH-E

3-2. Electrical parts specifications

Model

Parts

name

Tranrsformer T (Primary) 50/60Hz 220-240V (Secondry) (23.5V 0.9A)

TH21 Resistance 0˚C/15kΩ,10˚C/9.6kΩ,20˚C/6.3kΩ,25˚C/5.4kΩ,30˚C/4.3kΩ,40˚C/3.0kΩ

TH22 Resistance 0˚C/15kΩ,10˚C/9.6kΩ,20˚C/6.3kΩ,25˚C/5.4kΩ,30˚C/4.3kΩ,40˚C/3.0kΩ

Gas pipe

thermistor

FUSE 250V 6.3A

TB2 (L,N, ) 330V 30A

TB5

TB15

(1,2),(M1,M2,S) 300V 10A

Fuse

(Indoor con-

troller board)

Power supply

terminal bed

Transmission

terminal bed

P

EFY-

P50VMH-E

P

EFY-

P63VMH-E

P

EFY-

P71VMH-E

P

EFY-

P80VMH-E

P

EFY-

P100VMH-E

P

EFY-

P125VMH-E

P

EFY-

P140VMH-E

P

EFY-

P200VMH-E

P

EFY-

P250VMH-E

OFF 135˚C±5˚C

ON 95˚C±20˚C

Room

temperature

thermistor

Fan motor

(with Inner-

thermostat)

4-pole OUTPUT

130W

NC-45VMH

4-pole

Output

180W

NC-71VMH

Symbol

(L1,L2,L3,N, )

660V 40A

TH23 Resistance 0˚C/15kΩ,10˚C/9.6kΩ,20˚C/6.3kΩ,25˚C/5.4kΩ,30˚C/4.3kΩ,40˚C/3.0kΩ

Innerthermostat

(F

an motor)

Liquid pipe

thermistor

Fan motor

capacitor

Linear

expansion valve

4-pole

Output

220W

NC-80VMH

4-pole

Output

230W

NC-90VMH

4-pole

Output

550W

NS-200VMH

4-pole

Output

800W

NS-250VMH

4-pole OUTPUT 400W

NS-112VMH

3.0µF✕440V

4.0µF

✕440V

5.0µF✕440V

-

7.0µF✕440V

DC12V Stepping motor drive

port dimension ø 3.2

0~1800pulse

<at R410A outdoor unit>

0~2000pulse

<at the other outdoor unit>

0~1800pulse

<at R410A outdoor unit>

0~2000pulse

<at the other outdoor unit>

0~1800pulse

<at R410A outdoor unit>

0~2000pulse

<at the other outdoor unit>

0~1800pulse

<at R410A

outdoor unit>

0~2000pulse

<at the other

outdoor unit>

DC12V Stepping motor drive

port dimension ø 5.2

DC12V Stepping motor drive

port dimension ø 5.2

DC12V Stepping

motor drive port

dimension ø 6.4

Page 10

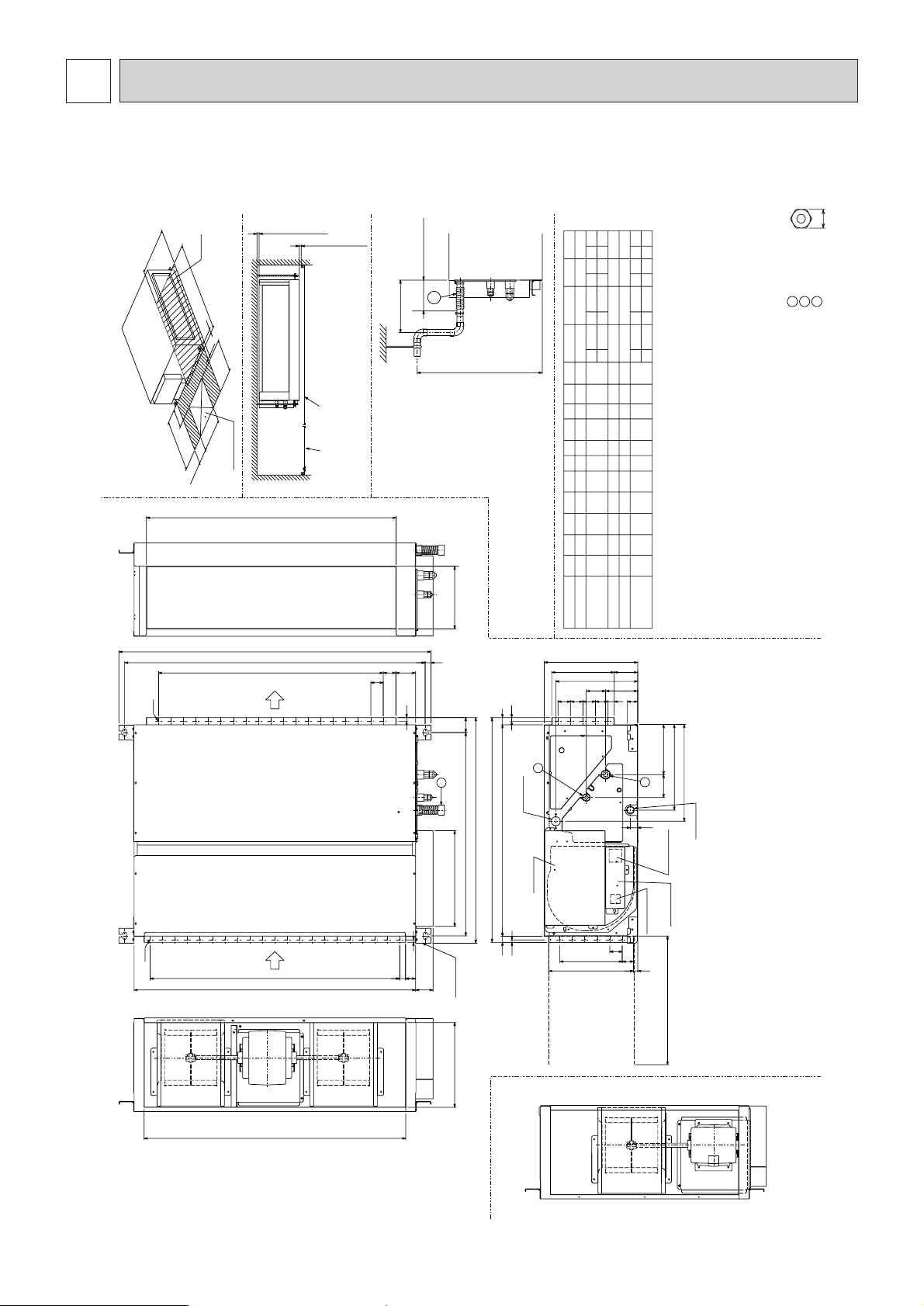

9

4

OUTLINES AND DIMENSIONS

Unit : mm

PEFY-P40· 50· 63· 71· 80· 100· 125· 140VMH-E

Terminal bed

(Transmission)

Terminal bed

(Power source)

150~200

700

50

50

L

Access door

625

Note 2

Reguired space for service and maintenance

450

100~200

450

Make the access door at the appointed position

properly for service maintenance.

Access door

Ceiling surface

Higher than 20mm

Higher than 20mm

Drain hole

(option)

Control box

2

1

30

Drain hole

Terminal box

340

D

814 (Lifting bolt pitch)

B (Lifting bolt pitch)

A

904

Lifting bolt

383

60

23

15

80

3

50

10

F

G-ø3

J-ø3

50

50x(J-1)=K

250

E

24

50x(G-1)=H

50

50x5= 250

45

10

340

17

900

847

15

29

380

50505050

250

25

328

94

41

130 77

387

343

20092

C

41

70

Model:40-80(Note 3)

Air outlet

Air inlet

Keep duct-work length 850mm or more.

Note1.Use M10 screw for the lifting bolt (field supply).

2.Keep the service space for the maintenance from the bottom when the heat exchanger is cleaned.

3.This chart indicates for PEFY-P100·125·140 models, which has 2 fans.

PEFY-P40·50·63·71·80 models have 1 fan.

4.Make sure to install the air filter(field supply) on the air intake side.

In case field supplied air filter is used, attach it where the filter service is easily done.

5.On Model :50, 100, 125, 140, you would use flare nut packed with the Indoor Unit,

when connnecting the Outdoor Unit for R407C, R22.

6.In order to increase the strength of the flare nut, the size of some of them has been increased.

Refrigerant piping flare connection(gas M copper tube):HP··············

Refrigerant piping flare connection(liquid N copper tube):LP············

Drain hose 32mm(1-1/4inch) <flexible joint 200mm> (accessory)·····

123

P

✻1

✻2

ø12.7

ø15.88

✻1

✻2

ø15.88

ø19.05

✻1

✻2

ø6.35

ø9.52

✻1

✻2

ø9.52

ø9.52

✻1

✻2

22

22

✻1

✻2

22

22

✻1

✻2

29

29

✻1

✻2

36

36

Model A

800

800

800

1050

1250

B

754

754

754

1004

1204

C

680

680

680

930

1130

D

600

600

600

850

1050

E

550

550

550

800

1000

H

500

500

500

800

1000

F

5050502525

G

1111111721

J

1010101519

K

450

450

450

700

900

L

780

780

780

1030

1230

M

ø12.7

ø15.88

ø15.88

N

ø6.35

ø9.52

ø9.52

P(Liquid)

17

22

22

P(Gas)

27

29

29

P40VMH-E

P50VMH-E

P63VMH-E

P71·80VMH-E

P100·125

·140VMH-E

✻1:R410A outdoor unit

✻2:The other outdoor unit

Lower than 550mm

Lower than 300mm

170mm

±5mm

(Actual length)

3

When installing the drain water lifting-up mech(option).

Page 11

10

PEFY-P200· 250VMH-E

Unit : mm

2

1

3

Note1.Use M10 screw for the lifting bolt (field supply).

2.Keep the service space for the maintenance from the bottom

when the heat exchanger is cleaned.

3.Make sure to install the air filter(field supply)

on the air intake side.

In case field supplied air filter is used, attach it where

the filter service is easily done.

Terminal bed

(Power source)

Terminal bed

(Transmission)

Lifting bolt

24

10

50x6=300

50x7=350

327

30

21-ø3

22-ø3

1250

50x21=1050

25102

50x20=1000

50

15

100

420

35

20

1120

10

1067

15

29

470

340105

44164

20

41

489

422

95 249

23

1326

(Lifting bolt pitch)

1372

1100

420

1124

1034(Lifting bolt pitch) 60 340

1100

Drain hole

Control box

Drain hole

(option)

Keep duct-work length 850mm or more.

Air outlet

Air inlet

Lower than 550mm

Lower than 300mm

3

When installing the drain water lifting-up mech(option).

Refrigerant piping flare connection(gas M copper tube):HP··············

Refrigerant piping flare connection(liquid N copper tube):LP············

Drain hose 32mm(1-1/4inch) <flexible joint 200mm> (accessory)·····

123

Make the access door at the appointed position

properly for service maintenance.

Access door

Ceiling surface

Higher than 20mm

Higher than 20mm

150~200

700

50

50

1359

Access door

625

Note 2

Reguired space for service and maintenance

450

100~200

450

170mm±5mm

(Actual Length)

Model A B

P200VMH-E

ø19.05

ø25.4

ø22.2

ø28.58

ø9.52

ø12.7

ø9.52

ø12.7

P250VMH-E

✻1✻2✻1

✻2

✻1✻2✻1

✻2

✻1:R410A outdoor unit

✻2:The other outdoor unit

Page 12

11

5

WIRING DIAGRAM

PEFY-P40·50·63·71·80·100·125·140VMH-E

Switch(for voltage selection)

attachment to alter the external static pressure on the fan

PE

*NOTE 1,2

*NOTE 1

*NOTE 1

*A connector is

attached to the

drain lift up

mechanism,

which is an

optional part.

TO OUTDOOR UNIT

TO MA REMOTE CONTROLLER

BC CONTROLLER

REMOTE CONTROLLER

BREAKER(16A)

FUSE(16A)

PULL BOX

TO NEXT INDOOR UNIT

TO DUCT

POWER SUPPLY

~

220,230,240V

50,60Hz

Switch(for model selection)

Switch(for mode selection)

Switch (connection No.set)

Switch (2nd digit address set)

Switch(for capacity code)

Switch(for mode selection)

*B Capacitor

MODELS 40/50 3.0µF

MODEL 63 4.0µF

MODELS 71/80 5.0µF

MODELS 100/125/140 7.0µF

Thermistor (piping temp.detection/gas)

Thermistor (piping temp.detection/liquid)

Aux.relay

*insert

SW5(A.B)

NOTE;1.The part of the broken line indicates the circuit

for optional parts.

2.*A in the chart is the connector for a drain pump

test run operation.

(The Drain Pump operates continuously if the

connector is inserted and the power is supplied.)

After the test run, make sure to remove the

*A connector.

3.The wirings to TB2,TB5 (shown in dotted line) are

field work.

4.Mark indicates terminal bed, connector, board

insertion connector or fastening connector of control

board.

inside < > is the optional parts.

NAME

SYMBOL EXPLANATION

Power source terminal bed

Transmission terminal bed TB5

Transmission terminal bedTB15

TB2

SW4(I.B)

SW1(A.B)

SW14(A.B)

SW12(A.B)

SW11(A.B)

SW3(I.B)

SW2(I.B)

Switch (1st digit address set)

Transformer

Address board

Indoor controller board

Electronic linear expan. valve

*B Capacitor (for MF)

Fan motor

LEV

T

A.B

I.B

C

MF

SYMBOL

<DS>

<DP>

SYMBOL

NAME

TH22

TH23

Thermistor (inlet temp.detection)

TH21

X04

~

X06

<F2>

F1 Fuse AC250V 6.3A F

Fuse AC250V 5A F

S.B Surge absorber board

Drain sensor

Drain Pump

Color/External Static Pressure

Red/200Pa (at 220,230,240V)

Blue/50Pa (at 220V),100Pa(at 230,240V)

White/100Pa (at 220V),150Pa(at 230,240V)

C

TB2

1

2

3

4

5

6

7

8

0

8

7

6

5

4

3

2

1

0

9

9

A

B

C

D

E

F

1

9

0

2

3

4

6

5

7

8

TB5(TRANSMISSION TERMINAL BED)

TB15(TRANSMISSION TERMINAL BED)

56

SW5

T

ZNR

CN82

CN62

(Blue)

SW4

CN42

4

321

4321

7

8

TH23

2

1

CN29

8

7

1

2

3

4

5

6

A.B

CN3T

3

1

M1

M2

SW1

SW2

SW3

TH22TH21

DS

MF

LEV

N

L

6

2

5

17

8

8

9

4

CN31

Drain sensor

31

3

3

11

3

2

2

2

4

4

3

3

1

1

13

3

1

11

1

6

5

4

321

CN81

CN20

CN21

CN31 CN60

CNT

CND

CNP

FAN3

X01

X05X06 X04

CN2M

I.B

1

2

1

2

CN3A

1

3

*B

(Red)

3

98198

63

1

9

(White)

56

44

8

8

9

9

5

313

1

DP

1

2

*A

S.B

DSA1

CN1

1

3

ZNR1

SW14

(Connection No.)

SW11

(1st digit)

SW12

(2nd digit)

AC250V

5A F

AC250V

6.3A F

F1

F2

2

11

2

INSIDE SECTION OF CONTROL BOX

S(SHIELD)

PE

Page 13

12

PEFY-P200· 250VMH-E

TO OUTDOOR UNIT

BC CONTROLLER

TO MA REMOTE CONTROLLER

TB15(TRANSMISSION TERMINAL BED)

2

1

3

1

I.B

CN3A

X05X06 X04

INSIDE SECTION OF CONTROL BOX

AC250V

REMOTE CONTROLLER

TB5(TRANSMISSION TERMINAL BED)

M2

M1

S(SHIELD)

2

1

CN2M

FAN3

CNP

X01

CND

ZNR

F1

CNT

6.3A F

CN3T

CN60CN31CN21CN20

3

1

CN1

S.B

DSA1

ZNR1

7

5

3

1

52F

CR

3

31

1

1

3

1

T

3

1

2

3

4

5

6

POWER SUPPLY

BREAKER

TB2

L1

52F

51F

F2

AC250V

2

1

2

1

1

2

*A

to the drain lift up

*A connector is attached

3N~

380/400/415V 50/60Hz

PENL3

L2

( 5A )

5A F

*NOTE 1,2

mechanism,

which is an optional part.

LEV adapter board

654321

(Blue)

89

4

5

6

9

8

1

2

3

(White)

654321

123456

123456 654321

TO DUCT

PE

Colour/External Static Pressure

Blue/110Pa(at 380V),130Pa(at 400,415V)

White/220Pa(at 380V),260Pa(at 400,415V)

connector to alter the external static pressure on the fan

95

8

49F

6

MF

1234

DP

*NOTE 1

is installed. Therefore, do not change factory set value of Over

current relays.

LEV2

LEV1

CAUTION;1.To protect Fan motor from abnormal current, Over current relays<51F>

After the test run, make sure to remove the *A connector.

(The Drain Pump operates continuously if the connector is inserted

and the power is supplied.)

2. *A in the chart is the connector for a drain pump test run operation.

connector or fastening connector of control board.

3.The wirings to TB2,TB5 shown in dotted line are field work.

4.Mark indicates terminal bed, connector, board insertion

NOTE;1.The part of the broken line indicates the circuit for optional parts.

SW2

SW3

SW4

123

CN42

4

123

CN81

4

5

CN29

7

6

8

1

2

CN31

Drain sensor

12

11

22

31

56

1234

A.B

CN62

CN82

8

SW5

SW1

65432

7

1

0

9

1

0

9

2

1

0

F

E

3

2

7

8

3

2

7

8

4

3

5

B

D

C

1

4

5

6

(1st digit)

SW11

4

5

6

SW12

(2nd digit)

6

7

8

9

A

SW14

(Connection No.)

NOTE 1

DS

*

TH23

NAME

TH22

TH21

Thermistor (inlet temp.detection)

Over current relay (fan motor)

51F

SYMBOL

TH21

Switch (2nd digit address set)

Thermistor (piping temp.detection/gas)

Thermistor (piping temp.detection/liquid)

Switch (1st digit address set)

SW12(A.B)

SW11(A.B)

TH23

TH22

Switch(for model selection)

Switch(for voltage selection)

Switch(for mode selection)

Switch (connection No.set)

Switch(for capacity code)

Switch(for mode selection)

SW4(I.B)

SW1(A.B)

SW14(A.B)

SW5(A.B)

SW3(I.B)

SW2(I.B)

inside < > is the optional parts.

Inner thermostat

Aux.relay

X06

~

X04

49F

NAME

Transmission terminal bed

Fan motor

MF

SYMBOL

SYMBOL EXPLANATION

Address board

Indoor controller board

Power source terminal bed

Transmission terminal bed

TB2

A.B

I.B

TB5

Fuse AC250V 6.3A F

TB15

F1

Transformer

Electronic linear expan. valve

Fuse AC250V 5A F

Drain Pump

T

<F2>

<DP>

Contactor (fan motor)

Surge absorber board

Drain sensor

52F

S.B

LEV1,LEV2

<DS>

Page 14

13

REFRIGERANT SYSTEM DIAGRAM

6

Gas pipe

PEFY-P40VMH-E PEFY-P50VMH-E

Liquid pipe

Capacity

Item

ø 12.7 <1/2F> (R410A)

ø 12.7 <1/2F>

ø 6.35 <1/4F>

ø 15.88 <5/8F>

ø 9.52 <3/8F>

ø 15.88 <5/8F> (R22,R407C)

ø 6.35 <1/4F> (R410A)

ø 9.52 <3/8F> (R22,R407C)

PEFY-P63,71,80VMH-E

Gas pipe

PEFY-P100,125,140VMH-E PEFY-P200VMH-E

Liquid pipe

Capacity

Item

ø 19.05 <3/4> (R410A)

ø 9.52 <3/8F>

ø 25.4 <1> (R22,R407C)

ø 15.88 <5/8F> (R410A)

ø 19.05 <3/4F> (

R22,R407C

)

ø 9.52 <3/8> (R410A)

ø 12.7 <1/2> (R22,R407C)

ø 22.2 <7/8> (R410A)

ø 28.58 <1-1/8>

(R22,R407C

)

ø 9.52 <3/8> (R410A)

ø 12.7 <1/2> (

R22,R407C

)

PEFY-P250VMH-E

Gas pipe thermistor TH23

Liquid pipe thermistor TH22

Heat exchanger

Linear expansion valve

Strainer (#100mesh)

Room temperature thermistor TH21

Strainer (#100mesh)

Gas pipe

Flared joints(Type 40~140)

Brazed joints(Type 200·250)

Page 15

14

7

TROUBLE SHOOTING

7-1. How to check the parts

Room temperature

thermistor

(TH21)

Liquid pipe thermistor

(TH22)

Gas pipe thermistor

(TH23)

Trans

Fan motor

Fan motor

Linear expansion

valve

Disconnect the connector, then measure the resistance using a tester.

(Sorrounding temperature 10°C~30°C)

Disconnect the connector and measure the resistance using a tester.

Measure the resistance between the terminals using a tester. (at 20˚C)

Measure the resistance between the terminals using

a tester.

Disconnect the connector then measure the resistance valve using a tester.

Drain Pump

(Drain water lift up kit)

Drain sensor

(Drain water lift up kit)

Disconnect the connector then measure the resistance

valve using a tester.

(Sorrounding temperature 20°C~30°C)

(Refer to the thermistor characteristic graph)

Normal

4.3kΩ~9.6kΩ

Abnormal

Open or short

CNT(1)-(3)

Normal

App.15Ω

CN3T(1)-(3) App.4Ω

Abnormal

Open or short

Motor terminal

or

Relay connector

Normal

P40· 50 P63

Abnormal

Gray-Orange

68.8

Ω

Open or short

Gray-Black

Gray-Brown

Gray-Blue

53.73

Ω

59.92

Ω

74.17

Ω

47

Ω

37.29

Ω

39.81

Ω

49.8

Ω

P71

32.9

Ω

27.56

Ω

30.64

Ω

38.31

Ω

P80

33.3

Ω

27.1

Ω

28.56

Ω

36.82

Ω

P100·125·140

14.05

Ω

9.11

Ω

9.87

Ω

12.89

Ω

Motor terminal

or

Relay connector

Normal Abnormal

Red-White 5Ω

Open or short

White-Black

Red-Black

Brown-Gray

5Ω

5Ω

6.08Ω

Gray-Yellow

Brown-Yellow

6.08Ω

6.08Ω

Nor

mal

(1)-(5)

White-Red

150Ω ±10%

Abnor

mal

Open or short

(2)-(6)

Yellow-

Brown

(3)-(5)

Orange-Red

(4)-(6)

Blue-Brown

Parts name Check points

PEFY-P40~140

PEFY-P200· 250

Measure the resistance between the terminals using a tester. (at 20˚C)

Normal

399Ω

Abnormal

Open or short

(Refer to the thermistor characteristic graph)

<Ther

mistor characteristic graph>

Room temperature thermistor(TH21)

Liquid pipe ther

mistor(TH22)

Gas pipe temperature thermistor(TH23)

Drain sensor(DS)

Thermistor R

0=15kΩ

± 3%

Fixed number of B=3480kΩ±2%

Rt=15exp { 3480( ) }

0˚C 15kΩ

10˚C 9.6kΩ

20˚C 6.3kΩ

25˚C 5.2kΩ

30˚C 4.3kΩ

40˚C 3.0kΩ

1

273+t

1

273

0˚C/6.0kΩ, 10˚C/3.9kΩ

20˚C/2.6kΩ, 25˚C/2.2kΩ

30˚C/1.8kΩ, 40˚C/1.3kΩ

1

3

CN3T

3

CNT

1

3T

Protector

LEV

CN60

White

Yellow

Orange

Blue

Red

Brown

Relay connector

Gray

1

2

Blue

3

Black

4

Orange

5

Blown

6

7

Red

8

Red

9

Relay connector

Brown

4

Red

1

Orange

Protector

1

2

3

4

5

6

8

Orange

9

White

2

Gray

5

Black

3

Yellow

6

Red

Red

1

3

50

40

30

20

Resistance (KΩ)

10

0

-20 -10

0 1020304050

Temperature (˚C)

Page 16

15

7-2. Setting of address switch

Make sure that power source is turning off.

1)In case using network remote controller, address is set by rotary switches.(SW11,SW12)

* It is not necessary setting address in case of using unit remote controller.

2) Indoor unit address setting rule is different b

y each field work.

Refer to install manual of outdoor unit , operate the address setting.

3)Setting the address is combination of SW11(1st digit address setting) and SW12(2nd digit address setting).

Address " 3 " setting is composed SW11 " 3 " and SW12 " 0 " .

Address " 25 " setting is composed SW11 " 5 " and SW12 " 2 " .

Indoor unit do not run without address setting in field.

CN62

SW1

SW7

ON

ON

ON

W254665G06

JP2

SW14

FP-AD-R

CN82

681 1

240V 220V

1

1

01

12

ASSY

2

34567891021

345678 9

G23

1

1

O

F

F

2

3

3

ABCDE F

10

JP1

SW5SWCSWA

1

3

2

SW12 SW11

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

ON

OFF

12 543

SW4

< At delivery (All models)>

SW4

SW2 SW3

Indoor unit control board

< At delivery (All models)>

SW1

ON

OFF

123456789

10

Refer to the next page for SW2,SW3 setting.

Page 17

16

7-3. Setting of Dip-switch (at delivery)

7-4. Attention for test run

12345678910 12345678910 123123456

SW1 SW2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SW3 SW4

5

ON

OFF

220V

240V

SW5

123

SW4

5

123

SW4

5

123

SW4

5

123

SW4

5

123

SW4

5

123

SW4

5

123

SW4

5

PEFY-P40VMH-E

12345678910 12345678910123456

ON

OFF

220V

240V

SW5

PEFY-P50VMH-E

SW1 SW2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SW3

SWA1SWC

Standard

Indicate

Models Dip-SW

ON

OFF

220V

240V

SW5

PEFY-P71VMH-E

SW1 SW2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SW3

12345678910 12345678910123456

12345678910 12345678910123456

ON

OFF

220V

240V

SW5

PEFY-P63VMH-E

SW1 SW2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SW3

ON

OFF

220V

240V

SW5

PEFY-P100VMH-E

SW1 SW2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SW3

12345678910 12345678910123456

ON

OFF

220V

240V

SW5

PEFY-P125VMH-E

SW1 SW2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SW3

12345678910 12345678910123456

ON

OFF

220V

240V

SW5

PEFY-P140VMH-E

SW1

ON

OFF

SW2

ON

OFF

ON

OFF

SW3

ON

OFF

12345678910 12345678910123456

ON

OFF

220V

240V

SW5

PEFY-P200VMH-E

SW1

ON

OFF

SW2

ON

OFF

ON

OFF

SW3

ON

OFF

SW4

5

12345678910 12345678910 123

SW4

5

4

4

4

4

4

4

4

4

4

4

123

123456

ON

OFF

220V

240V

SW5

PEFY-P250VMH-E

SW1

ON

OFF

SW2

ON

OFF

ON

OFF

SW3

ON

OFF

12345678910 12345678910123456

12345678910 12345678910123456

ON

OFF

220V

240V

SW5

PEFY-P80VMH-E

SW1 SW2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SW3

Equipment which is attached drain water lift up kit can be tested

pump out test when power supplied.(connect the connector(A))

< Drain-up machine >

After test run,remove the connector (A)(Fig .1)

7-4. Function the

7-5. Function the unit of the indoor

LED service board

Symbol Silk display LED operation under normal state

LED1 Main power source At applying main power source (indoor unit 200V)

LED2 Transmission power source

Test run Connector (red)(A)

After pump out test, remove the connector

and put in the dummy connector.

At receiving M-NET transmission power source

Lighting

Lighting

Page 18

17

8

DISASSEMBLY PROCEDURE

OPERATING PROCEDURE PHOTOS

Models 40~140

1.Removing the control box cover

(1) Remove the fixing screws (two) of the control box (A), and

remove the cover. (Fig. 1)

*At this stage, the following servicing is possible.

1 Operation and check of the switches (listed below) which

are on the control board.

• Dip switch SW2 ···········Capacity code setting

• Dip switch SW3 ···········Function change

• Dip switch SW4 ···········Model code setting

2 Connection check of the lead wires (listed below) which are

connected to the controller board.

• Power supply lead wire.

• Network remote contoller transmission lead wire.

• Fan motor lead wire.

• LEV lead wire

• Intake air sensor lead wire

• Liquid piping sensor lead wire

• Gas piping sensor lead wire

• Power supply transformer lead wire

Address board lead wire

(• Drain pump lead wire)

(• Drain sensor lead wire)

3 Control board exchange

4 Condenser exchange

5 Power supply transformer e

xchange

6 Arrest exchange

7 Intake air sensor exchange

( ):Optional parts

2.Removing the terminal bed cover

(1) Remove the fixing screws (two) of the terminal bed cover

(B), and remove the cover. (Fig. 2)

*At this stage, the following servicing is possible

.(Fig. 3)

1 Operation and check of the switches (listed below) which

are on the adress board.

• Rotar

y switches SW11, 12 ··· Address setting

• Rotary switch SW14 ········· Branch port setting

• Dip switch SW1 ············· Function change (main)

2 Address board exchange

3 Power supply terminal bed exchange

4 Transmission terminal bed exchange

8-1. CONTROL BOX

Be careful on removing heavy parts.

Fig.1

Fig.2

Fig.3

(A)

(B)

Page 19

18

OPERATING PROCEDURE PHOTOS

Be careful on removing heavy parts.

Fig.4

Fig.5

Models 200· 250

1.Removing the control box cover

(1) Remove the fixing screws (four) of the control box cover (C),

and remove the cover. (Fig. 4)

*At this stage, the following servicing is possible.(Fig. 5)

1 Operation and check of the switches (listed below) which

are on the control board.

• Dip switch SW2 ···········Capacity code setting

• Dip switch SW3 ···········Function change

• Dip switch SW4 ···········Model code setting

2

Connection check of the lead wires (listed below) which are

connected to the controller board.

• Power supply lead wire.

• Network remote contoller transmission lead wire.

• Fan motor lead wire.

• LEV lead wire

• Intake air sensor lead wire

• Liquid piping sensor lead wire

• Gas piping sensor lead wire

• Power supply transformer lead wire

• Address board lead wire

(• Drain pump lead wire)

(• Drain sensor lead wire)

3

Control board exchange

4

Power supply transformer exchange

5

Arrest exchange

6

Intake air sensor exchange

7

Operation and check of the switches (listed below) which

are on the address board

• Rotary switches SW11, 12 ····Address setting

• Rotary switch SW14 ··········Branch port setting

• Dip switch SW1·············· Function change (main)

8

Address board exchange

9

Po

wer supply terminal bed exchange

10

Transmission terminal bed exchange

( ):Optional parts

(C)

Page 20

19

Fig.1

Fig.2

Fig.3

Fig.4

8-2. FAN and FAN MOTOR

OPERATING PROCEDURE PHOTOS

Models 40~140

1.Removing the control box.

(1) Remove the control box cover and terminal bed cover with

procedure 8-1.

(2) Remove the fan motor connectors.

(3) Remove the fixing screws (two) of the control box and slide

the control box to remove.(Fig. 1)

(4) Move the control box to place that is not block operation.

(Fig. 2)

2.Removing the fan motor

Models 40~80

*After motor base (D) and bell mouse (C) attached the fan

case (B) removed,motor (A) can be pull with motor base

and fan along rail.

(1) Remove the fan motor connector (E).

(2) Loosen the fixing screws (F) (three) of the bell mouse (C),

and removed the bell mouse (D) turning screws in direction

arrow (counterclockwise).(Fig. 3)

(3) Remove the fixing screws (four) of the motor base(D).

Notice: It's necessary using the driver over 30cm length to

remove the fixing screws (a) .

(Fixing screws are placed back)

Be careful on removing heavy parts.

Fixing screws

Motor base (D)

Fixing screws (a)

Control box

Control box

(A)

(E)

(B)

(C)

(D)

Fixing screws (F)

Loosen fixing screws (not remove)

Models 40~63

Page 21

20

(A)

(D)

Arrow 1

Motor (A)

OPERATING PROCEDURE PHOTOS

(4) Slide the motor (A) with motor base (D) in direction of allow

1

. (Fig. 5)

Models 100~140

*Motor maintenance procedure is almost 40~80 models

procedure.

Models 100~140 have twin shaft motor

.After removing the

fan and fan case which are in front of motor,remov

e the

motor

.

(1) Remove the bell mouse of the front fan motor with procedure

models 40~140.

(2) Loosen the setting scre

ws of the front fan , removed the fan.

(3) Remove the front fan case.

(4) Operate with procedure models 40~80.

Notice: Fixing screws of the fan case are shown Fig. 7.

Remo

ve the fixing screws (H) ,fan case can be removed.

Fig.5

Fig.6

Fig.7

Be careful on removing heavy parts.

Fan case

Service side

Fan case fixing screws (H)

Page 22

21

Fig.7

Fig.8

Fig.9

Fig.10

OPERATING PROCEDURE PHOTOS

Models 200· 250

1.Removing the control box.

(1) Remove the control box cover1 with procedure 8-1.

(2) Remove the fixing screws (four) of the control cover 2, and

remove the control cover2. (Fig. 7)

(3) Remove the fan motor connectors.

(4) Remove the fixing screws (three) of the control box and

remove the control box (Fig. 8)

(5) Move the control box to place that is not block operation.

(Fig. 9)

2.Removing the fan motor

*After the fan (A) ,the fan case (B) and the bell mouse (C)

remo

ved, motor can be pull with motor base and inner fan

along rail.

(1) Remove the fixing screws (three) of the bell mouse (C), and

remove the bell mouse (C). (Fig. 3)

(2) Loosen the setting screws (G) of the front fan , removed the

fan.(Fig. 10)

Be careful on removing heavy parts.

Control box

cover 2

Control box

Control box

(A)

(E)

(B)

(C)

(D)

Fixing screws (F)

(G)

Page 23

22

OPERATING PROCEDURE PHOTOS

(3) After removing the fixing screws (H)(as shown models

100~140) of the front fan case(B) and remove the fan.

Pull the fan case (B).

(4) Remove the fixing screws (K)(three) of the bell mouse (J)

attached fan case (L), and remove the bell mouse (J).

(Fig.12)

(5) Remove the fixing screws (four) of the motor base(D).

Notice: It's necessary using the driver over 30cm length to

remove the fixing screws (a) .

(Fixing screws are placed back)(Fig. 13)

(6) Slide the motor (M) with motor base (D) in direction of arrow

2

. (Fig. 14)

Notice: It's not necessary removing the fan case (L).

Fig.11

Fig.12

Fig.14

Be careful on removing heavy parts.

Fig.13

Fig.15

(B)

Fixing screws (H)

(J)

Fixing screws (K)

(L)

(D)

Fixing screws

Motor base(D)

Fixing screws (a)

Motor (M)

(M)

(D)

Arrow 2

Page 24

23

8-3.

LEV,THERMISTOR (Liquid/Gas piping temperature detection)

OPERATING PROCEDURE PHOTOS

Models 40~140

1.Removing the LEV.

(1) Remove the control box cover with procedure 8-1.

(2) Remove the fixing screws (four) of the heat exchanger cover

(A), and remove the cover (A).(Fig. 1)

(3) Remove the LEV driving motor with a double spanner.(Fig. 2)

2.Removing the thermistors.

(1) Remove the thermistors from the thermistor holders which

are installed on the piping.(Fig. 2)

(liquid piping : fine piping , gas piping : thick piping)

Models 200· 250

1.Removing the LEV. (These models have 2 LEV)

(1) Remo

ve the fixing screws (three) of the heat exchanger cover

(A), and remove the cover (A).

(2) Remove the fixing screws (four) of the maintenance cover

(B),

and remove the cover (B).(Fig. 3)

(3) Remove the LEV driving motor with a doub

le spanner.(Fig. 4)

2.Removing the thermistors.

(1) Remove the thermistors from the thermistor holders which

are installed on the piping.(Fig. 4)

(liquid piping : fine piping , gas piping : thick piping)

Fig.1

Fig.2

Fig.3

LEV

Thermistor

Fig.4

Be careful on removing heavy parts.

(A)

Fixing screws

LEV

Thermistor

(A)

(B)

Fixing screws

Fixing screws

Page 25

24

8-4. HEAT EXCHANGER

OPERATING PROCEDURE PHOTOS

Models 40~140

1.Removing the heat exchanger.

(1) Remove the heat exchanger cover with procedure 8-3-1.

(2) Remove the bottom plate which is air outlet side.(fixing

screws : ten) (Fig. 1)

(3) Remove the drainpan.(Fig. 2)

Fig.1

Fig.2

Fig.3

Be careful on removing heavy parts.

Bottom plate

Drainpan

Fixing screws

Page 26

25

OPERATING PROCEDURE PHOTOS

(4) Remove the maintenance cover.(fixing screws : two) (Fig. 4)

(5) Remove the heat exchanger.(fixing screws : four) (Fig. 3,5)

*Removerd heat exchanger is as shown Fig .6

Fig.4

Fig.5

Fig.6

Be careful on removing heavy parts.

Fixing screwsMaintenance cover

Fixing screws

Page 27

26

Bottom plate

Drainpan

Fixing screws

OPERATING PROCEDURE PHOTOS

Models 200· 250

1.Removing the heat exchanger.

(1) Remove the refrigerant piping and drain hose from main

unit.(Be care that water is not leaking from drain hose. )

(2) Remove the power supply wire and the transmission line.

(Make sure that power source is turning off. )

(3) Pull down the main unit.

(4) Turn over the main unit upside the bottom plate

(5) Remove the bottom plate which is air outlet side.(fixing

screws : fifteen) (Fig. 7)

(6) Remove the drainpan.(Fig. 8)

Fig.7

Fig.8

Fig.9

Be careful on removing heavy parts.

Page 28

27

OPERATING PROCEDURE PHOTOS

(7) Remove the fixing screws (three) of the heat exchanger

cover, and remove the cover. Remove the fixing screws

(four) of the maintenance cover, and remove the cover. (Fig.

10)

(7) Remove the heat exchanger.

Fixing screws(non-piping side) : two (Fig. 9)

Fixing screws(piping side) : two (Fig. 11)

*Removerd heat exchanger is as shown Fig.12

Fig.10

Fig.11

Fig.12

Be careful on removing heavy parts.

Fixing screws

Fixing screws

(A)

Maintenance cover

Fixing screws

Page 29

28

8-5. CONTROL BOX INSIDE LAYOUT

Models 40~140

Models 200· 250

21

Trans

Condenser

(for motor)

DSA board

Magnet contactor

FAN2

CNP

FAN3

X04X05X06

CN26

CN23

CN24

CN42

CN81

SW4SW3SW2

LN

SWA

Power sourse

terminal bed

CN3T

CNDCNT

STR2012

Indoor unit

contoller board

CN2M

CN3R

CN20

CN25

CN27

CN52

CN60

CN82

SW1

SW12SW14

SW11

SW5

SWC

CN29 CN21

CN51

CN41

CN50

CN62

Transmission terminal bed

Address board

DSA board

Power sourse

terminal bed

FAN2

FAN3

X06 X05 X04

CN42

CN81

Trans

CNP

CNT CND

CN3T

STR2012

Indoor unit

contoller board

CN2M

CN20

CN60

SWA SWC

LEV1

SW12

CN62CN82

SW11

SW1

SW14

SW5

LEV adapter board

Address board

Transmission terminal bed

Page 30

29

8-6. SENSOR POSITION

●PEFY-P40VMH-E ●PEFY-P50· 63VMH-E

●PEFY-P71· 80VMH-E ●PEFY-P100· 125VMH-E

●PEFY-P140VMH-E ●PEFY-P200· 250VMH-E

Liquid sensor

Gas sensor

Liquid sensor

Gas sensor

Gas sensor(100)

Liquid sensor

Gas sensor

Liquid sensor

Gas sensor(125)

Liquid sensor

Liquid sensor(200·250)

Gas sensor

Gas sensor(200)

Gas sensor(250)

Page 31

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Issued in June 2004 MEE04K242

Printed in Japan

New publication, effective June 2004

Specifications subject to change without notice

Loading...

Loading...