Mitsubishi Electric PEFY-P20VMR-E-L, PEFY-P20VMR-E-R, PEFY-P25VMR-E-L, PEFY-P25VMR-E-R, PEFY-P32VMR-E-L Service Manual

...Page 1

Air-Conditioners For Building Application

TECHNICAL & SERVICE MANUAL

Models

PEFY-P20VMR-E-L/R

PEFY-P25VMR-E-L/R

PEFY-P32VMR-E-L/R

For use with R410A

2006

Page 2

i

[ SAFETY PRECAUTIONS ]

I SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

1. Read before installation and performing electrical work

Symbol explanations

: Indicates an action that must be avoided.

: Indicates important instructions.

: Indicates a parts that requires grounding.

: Indicates that caution must be taken with rotating parts. (This symbol is on the main unit label.) <Color: Yellow>

: Indicates that the parts that are marked with this symbol pose a risk of electric shock. (This symbol is on the main unit label.)

<Color: Yellow>

WARNING

Thoroughly read the following safety precautions prior to installation.

Observe these safety precautions for your safety.

This equipment may have adverse effects on the equipment on the same power supply system.

Contact the local power authority before connecting to the system.

WARNING

This symbol indicates that failure to follow the instructions exactly as stated poses the risk of serious injury or

death.

CAUTION

This symbol indicates that failure to follow the instructions exactly as stated poses the risk of serious injury or

damage to the unit.

WARNING

Carefully read the labels affixed to the main unit.

Ask your dealer or a qualified technician to install the unit.

Improper installation by the user may result in water

leakage, electric shock, or fire.

Properly install the unit on a surface that can withstand its

weight.

Unit installed on an unstable surface may fall and cause

injury.

Only use specified cables. Securely connect each cable so

that the terminals do not carry the weight of the cable.

Improperly connected cables may produce heat and start a

fire.

Take appropriate safety measures against wind gusts and

earthquakes to prevent the unit from toppling over.

Improper installation may cause the unit to topple over and

cause injury or damage to the unit.

Only use accessories (i.e., air cleaners, humidifiers, electric

heaters) recommended by Mitsubishi Electric.

Do not make any modifications or alterations to the unit.

Consult your dealer for repair.

Improper repair may result in water leakage, electric shock,

or fire.

Do not touch the heat exchanger fins with bare hands.

The fins are sharp and pose a risk of cuts.

In the event of a refrigerant leak, thoroughly ventilate the

room.

If gaseous refrigerant leaks out and comes in contact with

an open flame, toxic gases will be generated.

Properly install the unit according to the instructions in the

Installation Manual.

Improper installation may result in water leakage, electric

shock, or fire.

Have all electrical work performed by an authorized

electrician according to the local regulations and the

instructions in this manual. Use a dedicated circuit.

Insufficient power supply capacity or improper installation

of the unit may result in malfunctions of the unit, electric

shock, or fire.

Page 3

[ SAFETY PRECAUTIONS ]

ii

WARNING

2. Precautions for handling units for use with R410A

CAUTION

Keep electrical parts away from water.

Wet electrical parts pose a risk of electric shock, smoke, or

fire.

Securely attach the control box cover.

If the cover is not installed properly, dust or water may

infiltrate and pose a risk of electric shock, smoke, or fire.

Only use the type of refrigerant that is indicated on the unit

when installing or relocating the unit.

Infiltration of any other types of refrigerant or air into the unit

may adversely affect the refrigerant cycle and may cause

the pipes to burst or explode.

When installing the unit in a small space, take approp riate

precautions to prevent leaked refrigerant from reaching the

limiting concentration.

Leaked refrigerant gas will displace oxygen and may cause

oxygen starvation. Consult your dealer before installing the

unit.

Consult your dealer or a qualified technician when moving

or reinstalling the unit.

Improper installation may result in water leakage, electric

shock, or fire.

After completing the service work, check for a refrigerant

leak.

If leaked refrigerant is exposed to a heat source, such as a

fan heater, stove, or electric grill, toxic gases will be

generated.

Do not try to defeat the safety features of the unit.

Forced operation of the pressure switch or the temperature

switch by defeating the safety features for these devices, or

the use of accessories other than the ones that are

recommended by Mitsubishi Electric may result in smoke,

fire, or explosion.

Consult your dealer for proper disposal method.

Do not use a leak detection additive.

Do not use the existing refrigerant piping.

A large amount of chlorine that may be contained in the

residual refrigerant and refrigerator oil in the existing piping

may cause the refrigerator oil in the new unit to deteriorate.

Use refrigerant piping materials made of phosphorus

deoxidized copper. Keep the inner and outer surfaces of

the pipes clean and free of such contaminants as sulfur,

oxides, dust, dirt, shaving particles, oil, and moisture.

Contaminants in the refrigerant piping may cause the

refrigerator oil to deteriorate.

Store the piping materials indoors, and keep both ends of

the pipes sealed until immediately before brazing. (Keep

elbows and other joints wrapped in plastic.)

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerator oil to deteriorate or cause the

compressor to malfunction.

Use a small amount of ester oil, ether oil, or alkyl benzene

to coat flares and flanges.

Infiltration of a large amount of mineral oil may cause the

refrigerator oil to deteriorate.

Charge the system with refrigerant in the liquid phase.

If gaseous refrigerant is drawn out of the cylinder first, the

composition of the remaining refrigerant in the cylinder will

change and become unsuitable for use.

Only use R410A.

The use of other types of refrigerant that contain chloride

may cause the refrigerator oil to deteriorate.

Use a vacuum pump with a check valve.

If a vacuum pump that is not equipped with a check valve is

used, the vacuum pump oil may flow into the refrigerant

cycle and cause the refrigerator oil to deteriorate.

Prepare tools for exclusive use with R 410A. Do not use the

following tools if they have been used with the conventional

refrigerant: gauge manifold, charging hose, gas leak

detector, check valve, refrigerant charge base, vacuum

gauge, and refrigerant recovery equipment.

If the refrigerant or the refrigerator oil that may be left on

these tools are mixed in with R410A, it may cause the

refrigerator oil in the new system to deteriorate.

Infiltration of water may cause the refrigerator oil to

deteriorate.

Leak detectors for conventional refrigerants will not detect

an R410A leak because R410A is free of chlorine.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of the

refrigerant in the cylinder will change and become

unsuitable for use.

Exercise special care when handling tools for use with

R410A.

Infiltration of dust, dirt, or water into the refrigerant system

may cause the refrigerator oil to deteriorate.

Page 4

CONTENTS

[1] FEATURES

Features......................................................................................................................................... 1

[2] COMPONENTS AND FUNCTIONS

Components and functions......................................... ... .... ... ... ... .... ... ... ... ... .... ... ... ......................... 2

[3] SPECIFICATIONS

3-1. Specifications ...................................................................................................................... 4

3-2. Electrical component specifications..... ... .... ... ... ... .... ... ... ... .... ... ... ... ... ................................... 5

[4] OUTLINES AND DIMENSIONS

PEFY-P20· 25· 32VMR-E-L/R .......................................................................................................6

[5] WIRING DIAGRAM

PEFY-P20· 25· 32VMR-E-L/R .......................................................................................................7

[6] REFRIGERANT SYSTEM DIAGRAM

Refrigerant system diagram........................................................................................................... 9

[7] TROUBLESHOOTING

7-1. Check methods.................................................................................................................. 10

7-2. Address switch setting.......................................................................................................12

7-3. Dipswitch setting (Factory setting).... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... ................................. 13

7-4. Functions of the LED on the indoor unit service board...................................................... 13

[8] DISASSEMBLY PROCEDURE

8-1. Control box....... ... ... ... .... ... ... ... .... ... .......................................... ... ... ... .... ... .......................... 14

8-2. Fan and fan motor.............................................................................................................15

8-3. Drainpan............................................................................................................................ 16

8-4. LEV, thermistor (Liquid/gas pipe) ...................................................................................... 17

8-5. Heat exchanger............................................. ... ... .... ... ... .......................................... ... ....... 18

8-6. Control box internal layout............................. ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ....................19

8-7. Thermistor position............................................................................................................ 19

Page 5

- 1 -

[ I FEATURES ]

I FEATURES

[1] FEATURES

Model

Cooling capacity/Heating capacity

kW

PEFY-P20VMR-E-L/R

PEFY-P25VMR-E-L/R

PEFY-P32VMR-E-L/R

2.2/2.5

2.8/3.2

3.6/4.0

Page 6

- 2 -

[ II COMPONENTS AND FUNCTIONS ]

II COMPONENTS AND FUNCTIONS

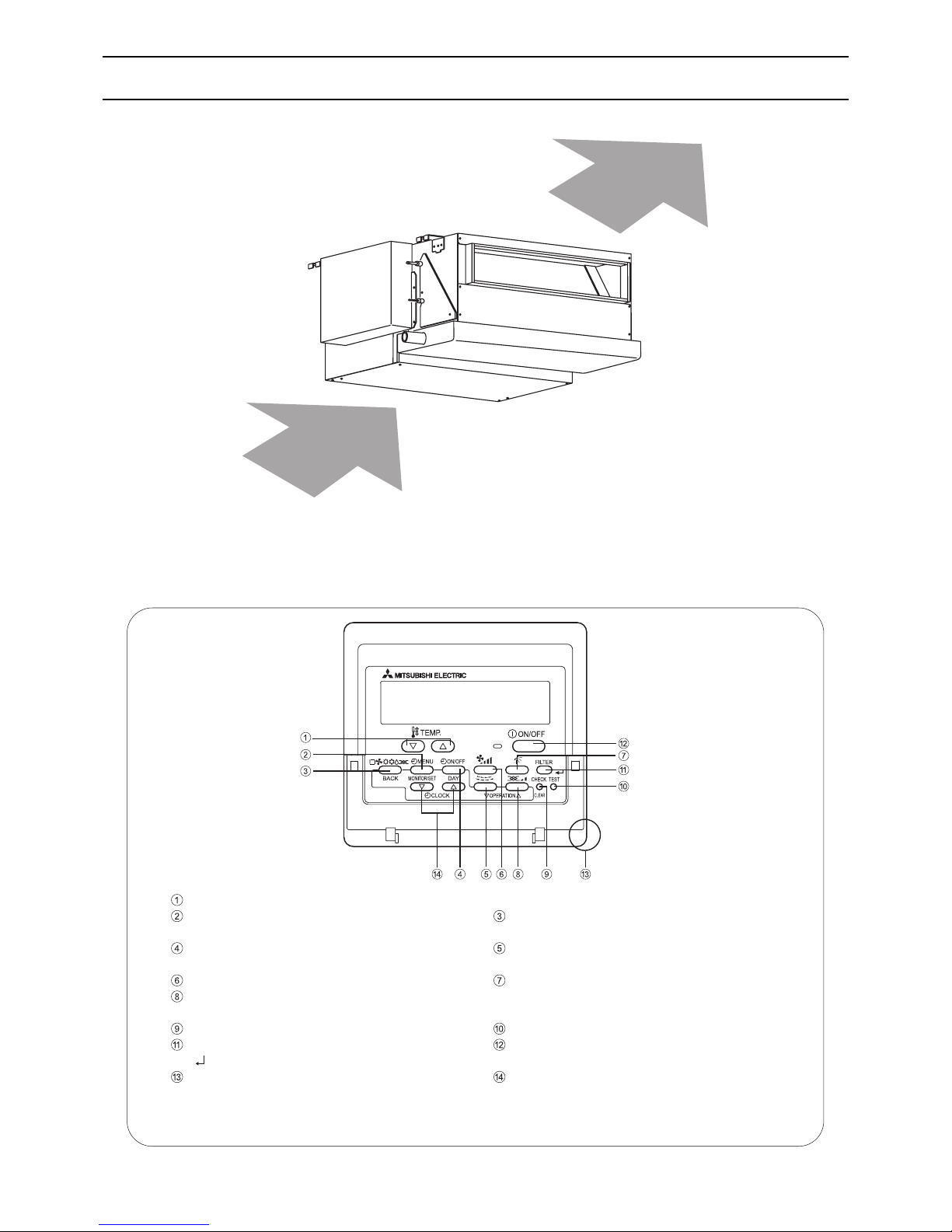

[2] COMPONENTS AND FUNCTIONS

Indoor (Main) Unit

Remote controller

[PAR-21MAA]

Once the operation mode is selected, the unit will remain in the selected mode until

changed.

[Remote Controller Button]

Air

Air

Keep the remote controller out of direct sunlight to ensure accurate measurement of room temperature.

The sensor at the lower right-hand section of the remote controller must be free from obstructions to

ensure accurate measurement of room temperature.

[Set Temperature] Button

[Timer Menu] Button [Mode] Button

[Monitor/Set] Button [Back] Button

[Timer On/Off] Button [Louver] Button

[Set Day] Button [Operation] Button

[Fan Speed] Button [Vane Control] Button

[Ventilation] Button

[Operation] Button

[Check/Clear] Button [Test Run] Button

[Filter] Button [ON/OFF] Button

[ ] Button

Position of built-in room temperature thermistor

[Set Time] Button

Page 7

- 3 -

[ II COMPONENTS AND FUNCTIONS ]

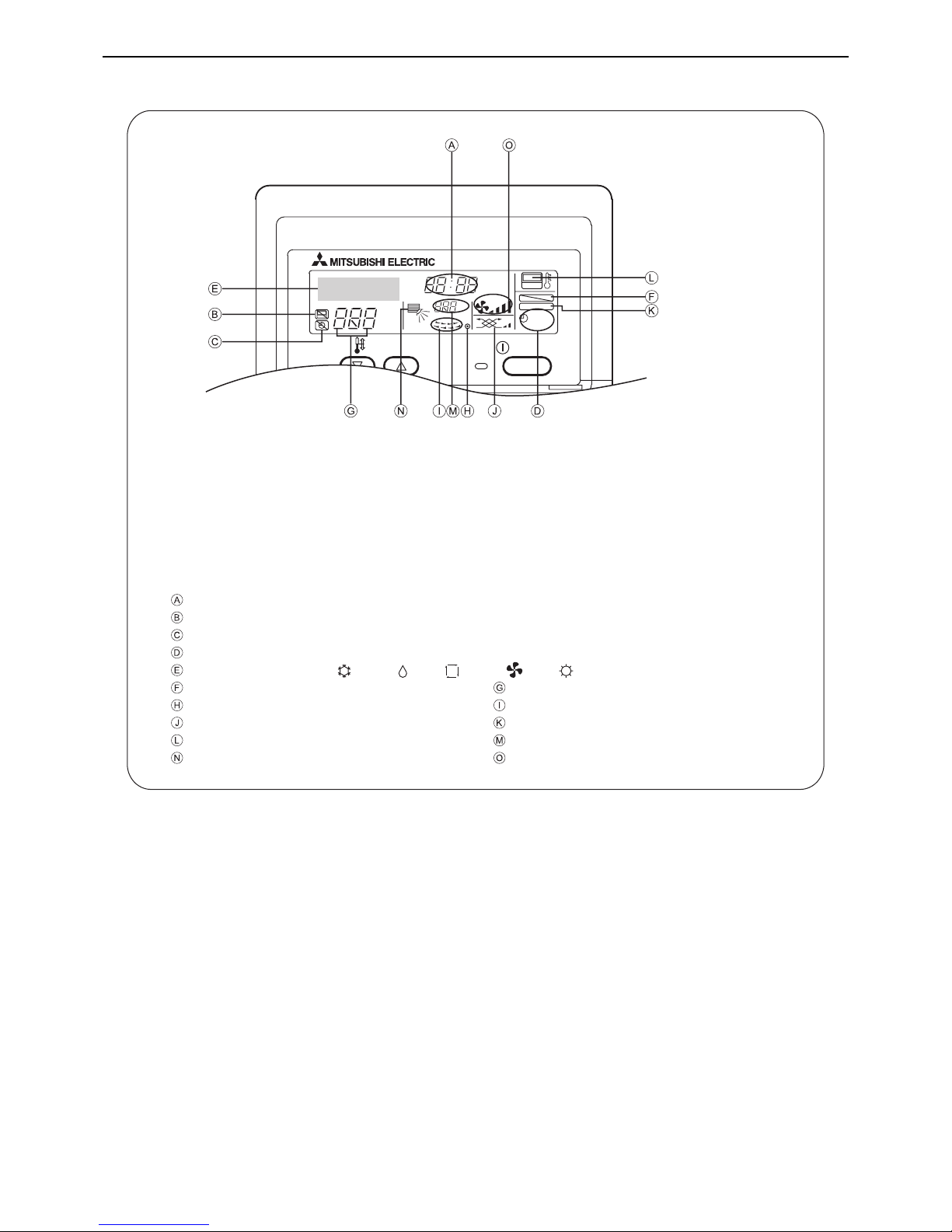

[Remote Controller Display]

ON/OFF

ERROR CODE

TIME

ON

OFFHrAFTER

SUN MON TUE WED THU FRI SAT

TIMER

AFTER

ONLY 1Hr.

°C°F

WEEKLY

SIMPLE

AUTO OFF

FILTER

FUNCTION

°C

°F

TEMP.

Current time/Timer time

Centralized control indicator

Timer OFF indicator

Timer mode

Operation mode display: COOL, DRY, AUTO, FAN, HEAT

Function Lock indicator Preset temperature

Power indicator Louver swing

Ventilation Filter sign

Thermistor position Room temperature

Vane setting Fan speed

Page 8

- 4 -

[ III SPECIFICATIONS ]

III SPECIFICATIONS

[3] SPECIFICATIONS

3-1. Specifications

Model PEFY-P20VMR-E-L/R PEFY-P25VMR-E-L/R PEFY-P32VMR-E-L/R

Cooling capacity *1 kW 2.2 2.8 3.6

Heating capacity *1 kW 2.5 3.2 4.0

Power supply voltage/frequency Single-phase 220/230/24 0 V 50Hz 220/230 V 60Hz

Power consumption

Cooling kW 0.06/0.06 0.07/0.08

Heating kW 0.06/0.06 0.07/0.08

Current consumption

Cooling A 0.29/0.29 0.34/0.38

Heating A 0.29/0.29 0.34/0.38

Settable temperature

range on the remote

controller

Cooling °C (°F) 19 to 30 (67 to 86)

Heating °C (°F) 17 to 28 (63 to 83)

Fan

Type × Quantity Sirocco fan × 1

External static pressure

5

Single-phase induction motor

Motor output kW 0.018 0.023

Driving mechanism Direct-driven

Airflow rate

(Low-Mid-High)

m

3

/min 4.8-5.8-7.9 4.8-5.8-9.3

External finish Galvanized

External dimensions

H × W × D

Rear inlet model

mm 292 × 640 × 580

In. 11-1/2 × 25-1/4 × 22-7/8

Bottom inlet model

mm 300 × 640 × 570

In. 11-7/8 × 25-1/4 × 22-1/2

Net weight kg 18

Wire

Min. wire size mm (in.) 1.6 (1/8)

Breaker amperage A 16

Refrigerant pipe

diameter

Liquid R410A mm (in.) ø6.35 (ø1/4) Brazed connection

Gas R410A mm (in.) ø12.7(ø1/2) Brazed connection

Drain pipe diameter mm (in.) Drain hose O.D. 26 (1-1/32)

Operating noise *2

(Low-Mid-High)

(measured in

anechoic room)

220V dB<A> 20-25-30 20-25-33

230V dB<A> 21-26-32 21-26-35

240V dB<A> 22-27-30 22-27-33

Insulation material Polyethylene foam, Urethane foam

Air filter PP Honeycomb fabric (washable)

Refrigerant control device LEV

Connectable outdoor unit R410A CITY MULTI

Protection devices Fuse

Heat exchanger Cross fin (Aluminium fin and copper tube)

Note:*1 Maximum capacity of the unit under the following conditions

<Cooling> Indoor temperature: 27°CDB/19°CWB (81°FDB/66°FWB Outdoor temperature: 35°CDB (95°FDB)

<Heating> Indoor temperature: 20°CDB (68°FDB) Outdoor temperature: 7°CDB/6°CWB (45°FDB/43°FWB)

Pipe length: 7.5m (24-9/16ft) Height difference: 0m (0ft)

*2 Noise levels of the unit with a rear air inlet. (Noise levels are higher for the unit with a bottom air inlet.)

Page 9

- 5 -

[ III SPECIFICATIONS ]

3-2. Electrical component specifications

Model

Component

Symbol PEFY-P20VMR-E-L/R PEFY-P25VMR-E-L/R PEFY-P32VMR-E-L/R

Transformer T (Primary) 50/60Hz 220-240V (Secondry) (23.5V 0.9A)

Room temperature

thermistor

TH21 Resistance 0°C/15kΩ, 10°C/9.6kΩ, 20°C/6.3kΩ, 25°C/5.4kΩ, 30°C/4.3kΩ, 40°C/3.0kΩ

Liquid pipe

thermistor

TH22 Resistance 0°C/15kΩ, 10°C/9.6kΩ, 20°C/6.3kΩ, 25°C/5.4kΩ, 30°C/4.3kΩ, 40°C/3.0kΩ

Gas pipe thermistor TH23 Resistance 0°C/15kΩ, 10°C/9.6kΩ, 20°C/6.3kΩ, 25°C/5.4k Ω, 30°C/4.3kΩ, 40°C/3.0kΩ

Fuse

(Control board)

F1 250V 6.3A

Fan motor

(with Innerthermostat)

MF 4-pole, Output 18W 4-pole, Output 23W

Inner-thermostat

(Fan motor)

OFF 135°C±5°C ON 86°C±15°C

Fan motor capacitor C1 1.5µF × 440V

Linear expansion

valve

LEV

12VDC Stepping motor drive port diameter ø3.2

(0~1800 pulses <on R410-compatible outdoor units>,

0~2000 pulses <on other types of outdoor units>)

Power supply

terminal block

TB2 (L, N, ) 330V 30A

Transmission

terminal block

TB5 TB15 (1, 2), (M1, M2, S) 300V 10A

Page 10

- 6 -

[ IV OUTLINES AND DIMENSIONS ]

IV OUTLINES AND DIMENSIONS

[4] OUTLINES AND DIMENSIONS

PEFY-P20· 25· 32VMR-E-L/R

2×10-φ3

2×2-

φ3

(In case of bottom inlet)

(In case of rear inlet)

(Suspension bolt pitch)

439

584

80

530

480

105

50×9=450

23

630

50

113

20mm min.

20mm min.

25

5

00

5

0

-

1

5

0

45

0

45

050

- 150

3

00

100

622

250

outlet (Note 1)

(In case of rear inlet)

(In case of bottom inlet)

(Suspension bolt pitch)

Suspension bolt

50 or below

50

15

292

570

300

148

580

62

25

100

30

28

25

275

15

Hard vinyl chloride drainpipe

Drain hose (accessory)

Drain pan

Insulation material

(150)

To be bonded with adhesive

To be gap-free

Hose band

Insulation material

for drain pan

Urethane foam

Right side

Left side

<Pipe size>

Refrigerant pipe (gas,brazed connection) φ12.7 ·········

Refrigerant pipe (liquid,brazed connection) φ6.35 ·········

Drain pipe connection diameter VP20 (dia. 26mm) ·········

Control box

Air outlet

Bottom air inlet

Rear

air inlet

Rear

air inlet

Bottom plate

Terminal block (Power supply)

Terminal block (M-Net Transmission)

Ceiling surface

Access door

1

Suspension bolt hole

Air filter

3

2

(A)

(B)

Note 1. Use M10 suspension bolts. (not supplied)

2. Keep the distance between the bottom end of the suspension bolt on the heat exchanger side and the top panel of the indoor unit to no more than

50 mm to allow easy removal of the panel and access to the indoor unit heat exchanger for maintenance.

3. Provide a 450 mm x 450 mm access door in the ceiling as shown below to allow access to the heat exchanger for cleaning and maintenance.

4. The figures in this drawing show the left-piping specifications. Upside-down mirror images of these figures would show the right-piping specificat ions.

5. Regular cleaning of the drain pan will prevent water overflow.

6. Either the bottom or rear inlet can be used.

7. Leave adequate space between the ceiling and unit when the bottom inlet is used.

(A) Space required for service and maintenance

(Note 2)

(B) Provide an access door as shown in the figure for maint enance.

Page 11

- 7 -

[ V WIRING DIAGRAM ]

V WIRING DIAGRAM

[5] WIRING DIAGRAM

PEFY-P20· 25· 32VMR-E-L/R

PE

S (SHIELD)

INSIDE THE CONTROL BOX

F1

AC250V

6.3A F

( )

SW7

CN3A

3

1

2

1

2

SW12

(10's digit)

SW11

(1's digit)

SW14

(Connection No.)

ZNR1

3

1

CN1

DSA1

S. B

5

4

(White)

2

1

I. B

CN2M

X04X06 X05

X01

CN70

CNP

CND

CNT

CN60

CN31

CN21CN20

CN81

123

4

5

6

1

1

1

1

1

31

12

3

2

2

2

3

31

3

3

4

7

6

71

56

CN52

12345

CN51

12345

CN40

1234

L

N

LEV

MF

TH21 TH22

SW3

SW2

SW1

SWA SWC SW5

M2

M1

1

3

CN3T

A. B

6

5

4

3

2

1

7

8

CN29

1

2

TH23

8

7

1234

123

4

CN42

SW4

(Blue)

CN62

CN82

ZNR

T

65

5

12

3

4

56

7

12

3

4

56

7

12

3

4

56

7

TB15 (TRANSMISSION TERMINAL BLOCK)

TB5 (TRANSMISSION TERMINAL

BLOCK)

8

7

5

6

4

3

2

0

9

1

F

E

D

C

B

A

9

9

0

1

2

3

4

5

6

7

8

0

8

7

6

5

4

3

2

1

TB2

]

C

1.5μF

TO MA REMOTE CONTROLLER

POWER SUPPLY

(A)

- 220,230,240V

50,60Hz

TO DUCT

TO NEXT INDOOR UNIT

PULL BOX

FUSE(16A)

BREAKER(16A)

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

PE

Page 12

- 8 -

[ V WIRING DIAGRAM ]

[5] WIRING DIAGRAM

(A)

The fan motor connector is ready for connection to a 220V/230V power supply at factory shipment. Use blue connector adapter

(supplied) to connect to a 240V power supply.

Coler/Power supply voltage

White/220V. 230V

Blue/240V

NOTE: 1. Wiring to TB2, TB5, and TB15 indicated by the dash-double-dotted lines is on-site work.

2. terminal block, connector.

SYMBOL EXPLANATION

SYMBOL NAME SYMBOL NAME

MF Fan motor TH21 Thermistor (inlet temp.)

C Capacity (for MF) 1.5µF TH22 Thermistor (liquid pipe temp.)

I.B Indoor control board TH23 Thermistor (gas pipe temp.)

A.B Address board SW11 (A.B) Switch (For setting the 1’s digit in the address)

TB2 Power supply terminal block SW12 (A.B) Switch (For setting the 10’s digit in the address)

TB5 Transmission terminal block SW14 (A.B) Switch (connection No. setting)

TB15 Transmission terminal block SW1 (A.B) Switch (function setting)

F1 Fuse 250V AC 6.3A F SW2 (A.B) Switch (capacity code setting)

T Transformer SW3 (A.B) Switch (function setting)

LEV Electronic linear expan. valve SW4 (A.B) Switch (model setting)

S.B Surge absorber board SW5 (A.B) Switch (voltage setting)

X04~X06 Aux. relay SW7 (A.B) Switch (function setting)

Page 13

- 9 -

[ VI REFRIGERANT SYSTEM DIAGRAM ]

VI REFRIGERANT SYSTEM DIAGRAM

[6] REFRIGERANT SYSTEM DIAGRAM

Capacity PEFY-P20, 25, 32VMR-E-L/R

Gas pipe ø12.7<1/2>

Liquid pipe ø6.35<1/4>

Gas pipe thermistor TH23

Gas pipe

Brazed connections

Strainer (#100 mesh)

Linear expansion valve

Room temperature thermistor TH21

Heat exchanger

Liquid pipe thermistor

TH22

Page 14

- 10 -

[ VII TROUBLESHOOTING ]

VII TROUBLESHOOTING

[7] TROUBLESHOOTING

7-1. Check methods

1. Component and Check points

(1) Thermistor

• Room temperature thermistor (TH21)

• Liquid pipe thermistor (TH22)

• Gas pipe thermistor (TH23)

Disconnect the connector, and measure the resistance with a tester.

(Ambient temperature 10°C-30°C)

(Refer to the thermistor characteristic graph below.)

(2) Transformer

Disconnect the connector, and measure the resistance with a tester.

(3) Fan motor PEFY-P20· 25· 32

Measure the resistance between the terminals with a tester. (at 20°C)

Normal Abnormal

4.3kΩ-9.6kΩ Open or short

Normal Abnormal

CNT(1)-(3) Approx.15Ω

Open or short

CN3T(1)-(3) Approx. 4Ω

Motor terminal

or

Relay connector

Normal

Abnormal

P20· 25 P32

White-Black 192Ω 164Ω

Open or short

White-Brown 214Ω 185Ω

White-Yellow 236Ω 227Ω

White-Blue 272Ω 257Ω

White-Red 376Ω 355Ω

Yellow/Green

RedOrange

Blue

Yellow

Brown

Black

White

220~240V

50/60Hz

Page 15

- 11 -

[ VII TROUBLESHOOTING ]

(4) Linear expansion valve

Disconnect the connector, and measure the resistance with a tester.

<Thermistor characteristic graph>

Room temperature thermistor (TH21)

Liquid pipe thermistor (TH22)

Gas pipe thermistor (TH23)

Thermistor R

0

=15kΩ ±3%

Multiplier of B=3480kΩ ±2%

0°C 15kΩ

10°C 9.6kΩ

20°C 6.3kΩ

25°C 5.2kΩ

30°C 4.3kΩ

40°C 3.0kΩ

Normal Abnormal

(1)-(5)

White-Red

(2)-(6)

Yellow-Brown

(3)-(5)

Orange-Red

(4)-(6)

Blue-Brown

Open or short

150Ω ±10%

White

Yellow

Orange

Blue

Red

Brown

Resistance (kΩ)

Temperature (°C)

Rt=15exp {3480(

-

)}

1

273+t1273

Page 16

- 12 -

[ VII TROUBLESHOOTING ]

7-2. Address switch setting

1) When using an ME remote controller, set the address with the rotary switches (SW11, SW12).

* Address setting is not required when the unit remote controller is used.

2) Address settings vary in different systems.

Refer to the section on address setting in the outdoor unit installation manual.

3) Address is set with a combination of SW12 (10's digit) and SW11 (1's digit).

To set the address to "3," set SW12 to "0" and SW11 to "3."

To set the address to "25," set SW12 to "2" and SW11 to "5."

Make sure that power to the unit is turned off.

12345678910

123 54

Indoor unit control board

ON

OFF

ON

OFF

<Factory setting (All models)>

<Factory setting (All models)>

Refer to the next page for setting dipswitches SW2 and

SW3.

On-site address setting is required for the indoor units to run.

Page 17

- 13 -

[ VII TROUBLESHOOTING ]

7-3. Dipswitch setting (Factory setting)

7-4. Functions of the LED on the indoor unit service board

Symbol Printing: Silk printing Normal LED display

LED1 Main power supply When a voltage of 220-240 is applied to the indoor unit board → Lit

LED2 Transmission power supply When the MA remote controller is powered → Lit

PEFY-P32VMR-E-R

PEFY-P25VMR-E-R

PEFY-P20VMR-E-R

PEFY-P32VMR-E-L

PEFY-P25VMR-E-L

PEFY-P20VMR-E-L

G01

G02

G03

SW1 SW2 SW3

SW7SW4

SWC

SWA

SW5

12345678910

12345678910

220 V

240 V

220 V

240 V

220 V

240 V

1

111

2

1

11

1

3

1

1

1112

222

4

2

22

2

5

2

2

22

333

6

3

33

3

7

3

3

333

4544

8

4

454

4

9

544

55

10

5

5

55

66

6

6

66

77788899910

1010

3

3

3

2

2

2

1

1

1

Group No. Models

Option

Standard

Option

Standard

Option

Standard

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

Page 18

- 14 -

[ VIII DISASSEMBLY PROCEDURE ]

VIII DISASSEMBLY PROCEDURE

[8] DISASSEMBLY PROCEDURE

8-1. Control box

1. Removing the control box cover

Remove the two fixing screws on the control box, and remove the

cover. (Fig. 1)

* The following services can be performed with the cover

removed. (Fig. 2)

Functions of the switches on the control board.

• Dip switch SW2......................Capacity code setting

• Dip switch SW3......................Function setting

• Dip switch SW4......................Model setting

Functions of the switches on the address board.

• Rotary switches SW11, 12.....Address setting

• Rotary switch SW14 ..............Connection No. setting

• Dip switch SW1......................Function setting (main)

Lead wires that are connected with the control box below can

be checked.

• Power supply lead wire

• Network remote contoller transmission wire

• Fan motor lead wire

• LEV lead wire

• Intake air thermistor lead wire

• Liquid pipe thermistor lead wire

• Gas pipe thermistor lead wire

• Power supply transformer lead wire

• Address board lead wire

Control board replacement

Address board replacement

Capacitor replacement

Power supply transformer replacement

Arrestor replacement

Intake air thermistor replacement

Power supply terminal block replacement

Transmission terminal block replacement

Exercise caution when removing heavy parts.

Control box

Fig. 1

Fig. 2

Note: Refer to "8-6. Control box internal layout" (P19) for the

positions of switches on the controller board and address

board.

Page 19

- 15 -

[ VIII DISASSEMBLY PROCEDURE ]

8-2. Fan and fan motor

1. Removing the fan casing, sirocco fan, and fan motor

(1) Remove the filter. (Fig. 3)

(2) Open the control box to remove the fan motor cable

connector.

(Unscrew the two fixing screws if it is difficult to remove the

connector.) (Fig. 4)

(3) Squeeze the four tabs on the fan casing to remove it. (Fig. 5)

(4) Remove the set screw on the sirocco fan and the two motor

set screws to remove the sirocco fan and fan motor. (Fig. 6)

Exercise caution when removing heavy parts.

Filter

Fig. 3

Fig. 4

Fan motor cable connector

Fig. 5

Fan casing

Fig. 6

Set screw

Page 20

- 16 -

[ VIII DISASSEMBLY PROCEDURE ]

8-3. Drainpan

1. Removing the drainpan

(1) Remove the one fixing screw on the drainpan. (Fig. 7)

(2) Slide the drainpan in the order as indicated with arrows ,

, and to remove the drainpan. (Fig. 8)

Exercise caution when removing heavy parts.

Fig. 7

Fig. 8

Page 21

- 17 -

[ VIII DISASSEMBLY PROCEDURE ]

8-4. LEV, thermistor (Liquid/gas pipe)

1. Removing the LEV

(1) Remove the drainpan according to the procedure in section

8-3.

(2) Remove the bottom plate by unscrewing the six fixing

screws. (Fig. 9)

(3) Remove the LEV driving motor using two spanners. (Fig. 10)

2. Removing the thermistors

(1) Remove the thermistors from the thermistor holders on the

piping. (Fig. 11)

(Liquid piping: small diameter; Gas piping: large diameter)

Exercise caution when removing heavy parts.

Fig. 9

LEV

Fig. 10

Thermistor

Fig. 11

Page 22

- 18 -

[ VIII DISASSEMBLY PROCEDURE ]

8-5. Heat exchanger

1. Removing the heat exchanger

(1) Remove the drainpan according to the procedure in section

8-3.

(2) Remove the bottom plate according to the procedure in

section 8-4.

(3) Remove the heat exchanger cover by unscrewing the five

fixing screws. (Fig. 12)

(4) Remove the heat exchanger by unscrewing the two fixing

screws. (Fig. 13)

Exercise caution when removing heavy parts.

Heat exchanger

cover

Fig. 12

Fig. 13

Page 23

- 19 -

[ VIII DISASSEMBLY PROCEDURE ]

8-6. Control box internal layout

8-7. Thermistor position

LN

SW2 SW3 SW4

CN31

CN60

CN29

CN21

CN20

CN2M

CN3A

CN3T

CND

CNT

CN70

CN42

CN81

SW14

SW5SWCSWA

SW12 SW11

SW7

MA Remo.Con.

CAUTION

Transmission.

M-NET Remo.Con.

TB5

TB15

12

M1

M2

S

Never connect

Power

supply

Power

supply

EARTH

N

L

Connector

adapter

Secondary

Transformer

Power supply

terminal block

DSA board

Transmission

terminal block

Capacitor (for motor)

Indoor unit control board

PrimaryAddress board

Fan motor connector

Gas thermistor

Liquid thermistor

Page 24

Oct. 2006 HWE06010

Printed in Japan

New publication, effective Oct. 2006

Specifications subject to change without notice

Loading...

Loading...