Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

<indoor unit> Service ref.

Models

PEAD-RP3EA

PEAD-RP4EA

PEAD-RP5EA

PEAD-RP6EA

TM

1. SAFETY PRECAUTION ···························· 2

2. PART NAMES AND FUNCTIONS ············· 4

3. SPECIFICATION ······································· 7

4. DATA ························································ 9

5. REFRIGERANT SYSTEM DIAGRAM ······ 19

6. OUTLINES & DIMENSIONS ···················· 20

7. WIRING DIAGRAM ·································· 21

8. TROUBLE SHOOTING ···························· 22

9. DISASSEMBLY INSTRUCTIONS ············ 32

10

. PARTS LIST ············································· 34

11

. OPTIONAL PARTS ·································· 38

CONTENTS

INDOOR UNIT

REMOTE CONTROLLER

ON/OFF

TEMP.

Series PEAD

R410A

2003

• Refer to the OCT04 as for control

relation.This manual does not cover

outdoor units.

When serving them, please refer to

the service manual No.OC294 and

this manual as a set.

Page 2

2

SAFETY PRECAUTION

1

<Cautions for units utilizing refrigerant R410A>

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

In case of using the existing pipes for R22, be careful with

the followings.

· For RP4, 5 and 6, be sure to perform replacement opera tion before test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes. For the detail, please refer to the

outdoor unit service manual No. OC294.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

If no reverse flow check valve is used, vacuum pump oil

may flow back into refrigerant cycle and that can cause

deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools (for R410A)

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur which is hazardous for use,

oxides, dirt, shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

Check that cylinder for R410A on the market is syphon type.

Charging should be performed with the cylinder of syphon type stood vertically. (Refrigerant is charged from liquid phase.)

Page 3

3

Gravimeter

Unit

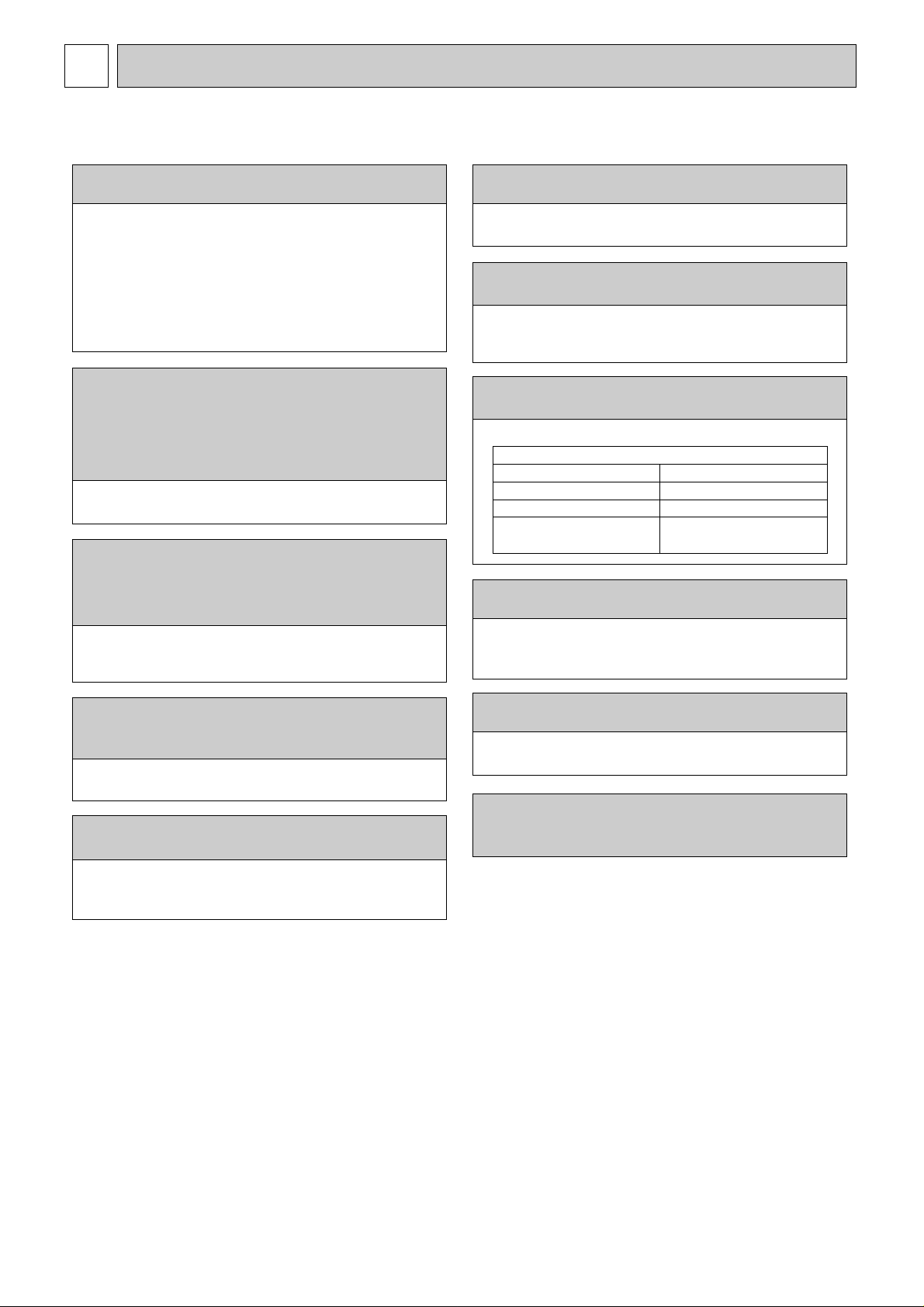

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1

Gauge manifold ·Only for R410A

·Use the existing fitting

specifications

. (UNF1/2)

·Use high-tension side pressure of 5.3MPa·G or over.

2

Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3

Electronic scale

4

Gas leak detector ·Use the detector for R134a, R407C or R410A.

5

Adaptor for reverse flow check ·Attach on vacuum pump.

6

Refrigerant charge base

7

Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

Cylinder with syphon

8

Refrigerant recovery equipment

Page 4

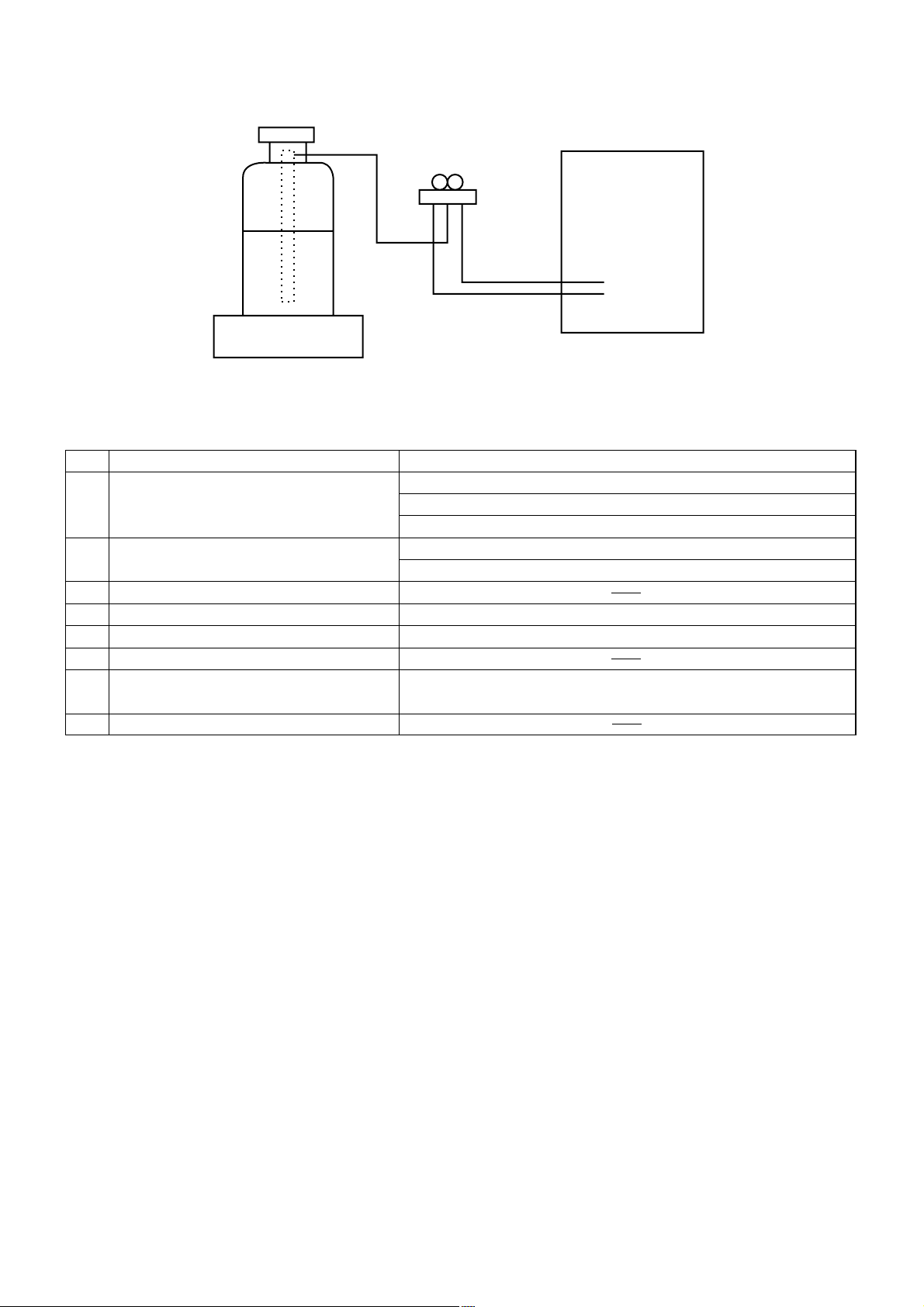

4

PART NAMES AND FUNCTIONS

2

•

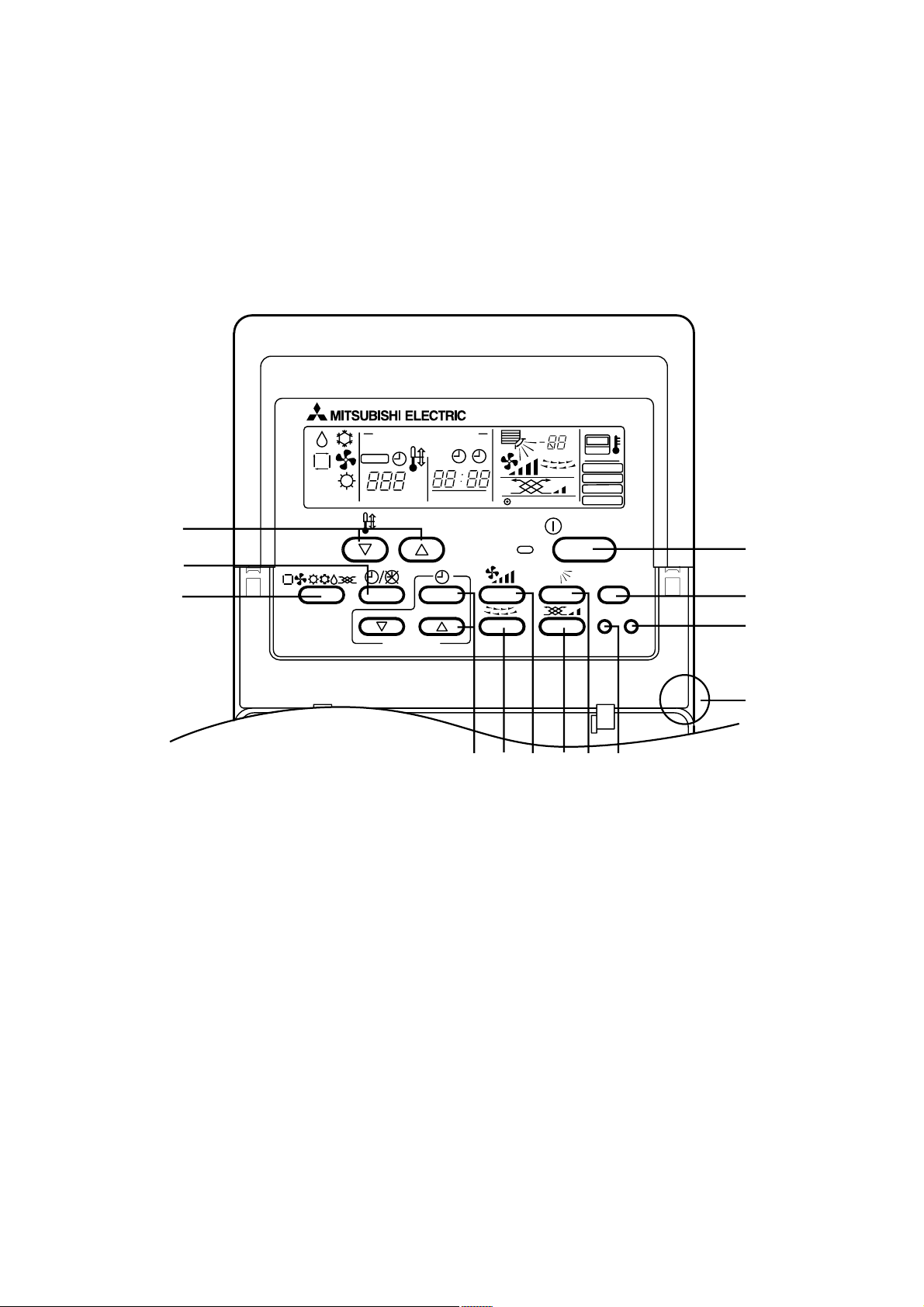

Indoor Unit

Air intake (sucks

the air inside the

room into the

unit)

Air outlet

A

Page 5

5

• Remote controller

• Operation buttons

• Once the operation of the unit is set, subsequent operations can

be performed only by pressing the ON/OFF button repeatedly.

1

[Room temperature adjustment] Button

2

[Timer/continuous] Button

3

[Selecting operation] Button

4

[Time selection] Button

[Time-setting] Button

5

[Louver] Button (This button does not operate in this model)

6

[Fan speed adjustment] Button

7

[Up/down airflow direction] Button (This button does not operate in this model)

8

[Ventilation] Button

9

[Checking/built-in] Button

0

[Test run] Button

A

[Filter] Button (This button does not operate in this model)

B

[ON/OFF] Button

C

Position of built-in room temperature

• Never expose the remote controller to direct sunlight. Doing so can result in the erroneous measurement of room temperature.

• Never place any obstacle around the lower right-hand section of the remote controller. Doing so can result in the erroneous

measurement of room temperature.

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

1

2

B

3

456 879

A

0

C

Page 6

6

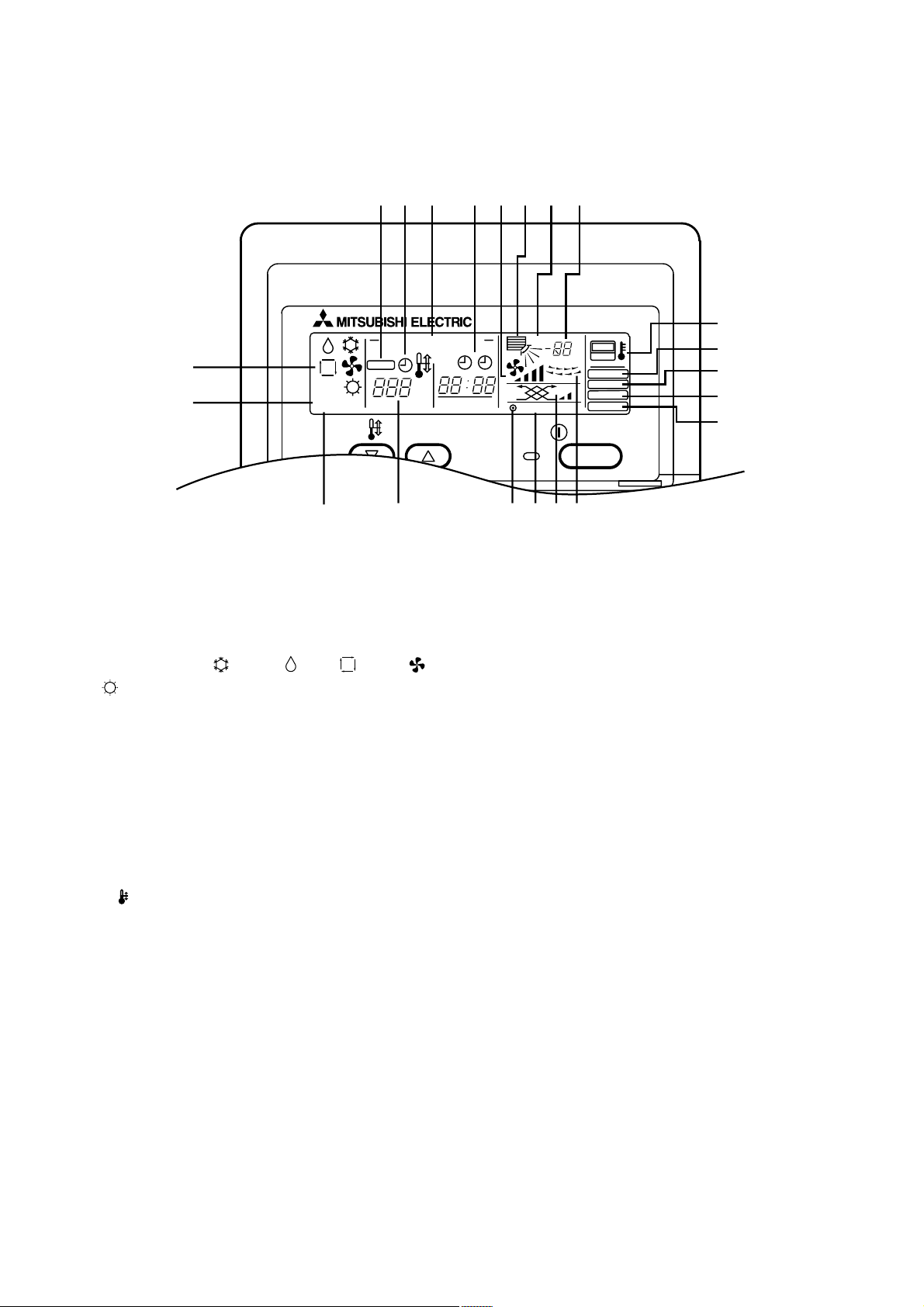

• Display

A Current time/Timer

B Centralized control

C Timer ON

D Abnormality occurs

E Operation mode: COOL, DRY, AUTO, FAN,

HEAT

F Preparing for Heating mode

G Defrost mode

H Set temperature

I Power ON

J Louver

K Not available function

L Ventilation

M Function setting mode

N Test run mode

O Error check mode

P Filter sign

Q Set effective for 1 hr.

R Sensor position

S Room temperature

T Airflow

U Fan speed

Caution

• Power ON display lights up when unit is in standby mode.

• When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not a mal-

function.

• When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

•“NOT AVAILABLE”is displayed when the Airflow direction button or Louver button are pressed.This indicates that this room

unit is not equipped with the fan direction adjustment function and the louver function.

• When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

ABCD

SQTU

R

E

F

STAND BY

DEFROST

CENTRALLY CONTROLLED

CHECK

˚C

ON OFF

CLOCK

ERROR CODE

TEMP.

G

HIKLJ

1Hr.

NOT AVAILABLE

ON/OFF

˚C

FILTER

CHECK MODE

TEST RUN

FUNCTION

P

O

N

M

Page 7

7

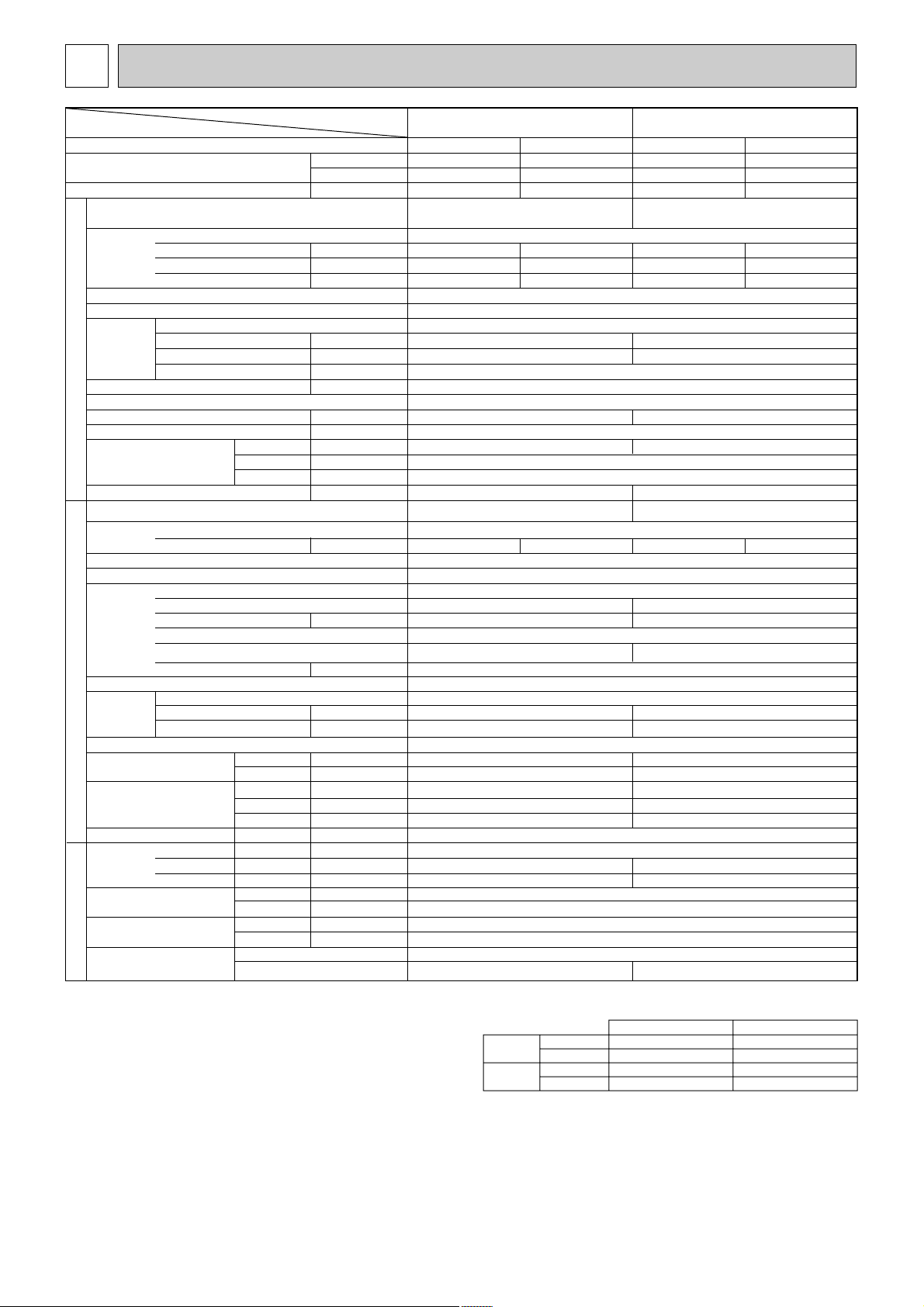

SPECIFICATION

3

Item

Function

Capacity

Total input kW

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Booster heater kW

Operation control & Thermostat

Noise level (Lo-Hi) dB

Unit drain pipe O.D mm (in.)

Dimensions

Weight

Service Ref

Power supply

External finish

Refrigerant control

Compressor

Input kW

Running current A

Starting current A

Fan (drive) × No.

Fan motor output kW

Airflow (Lo-Hi)

External static pressure Pa (mmAq)

W mm (in.)

D mm (in.)

H mm (in.)

.

Running current

Model

Motor output kW

Starter type

Protection devices

Heat exchanger

Fan

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Crankcase heater W

Fan (drive) × No.

Fan motor output kW

Airflow

Cooling dB

Heating dB

W mm (in.)

D mm (in.)

H mm (in.)

Charge kg (lbs)

Oil (Model) L

Liquid mm (in.)

Gas mm (in.)

Indoor side

Outdoor side

Height difference

Piping length

m3/min (CFM)

Service Ref.

Btu/h

W

3

m

/min (CFM)

kg (lbs)

A

kg (lbs)

PEAD-RP3EA PEAD-RP4EA

Cooling Heating Cooling Heating

24,200 27,300 34,100 38,200

7,100 (3,300-8,100)

2.15 2.34 3.08 3.48

0.35 0.35 0.57 0.57

1.55 1.55 2.53 2.53

2.0 2.0 3.2 3.2

20-25 <706-883> 27-34 <953-1,200>

1,175 (46-1/8) 1,415 (55-11/16)

PUHZ-RP3VHA PUHZ-RP4VHA

8.04 9.74 12.33 13.94

TNB220FMBH ANV33FDAMT

HP switch, Discharge thermo. HP switch, Discharge thermo. LP switch.

Propeller (direct)

330+30 (13+1-3/16) 330+30 (13+1-3/16)

8,000

(3,500-10,200)

PEAD-RP3EA PEAD-RP4EA

Single phase,50Hz,220-230-240V

Galvanized sheets

Centrifugal (direct)

0.15 0.27

Built in remote controller

37-41 41-46

325 (12-13/16)

44 (97) 62 (136)

Single phase,50Hz,220-230-240V

Munsell 3Y 7.8/1.1

Linear Expansion Valve

1.6 1.9

× 1 Propeller (direct) × 2

0.060 0.060+0.060

55 (1,940) 100 (3,530)

Reverse cycle

47 49

48 51

950 (37-3/8) 950 (37-3/8)

943(37-1/8) 1,350(53-1/8)

75 (165) 121 (267)

3.5 (7.7) 5.5 (12.1)

0.87 (NE022) 1.4 (MEL 56)

Max.50m Max.75m

10,000

Plate fin coil

70 (130)

–

32 (1-1/4)

740 (29-1/8)

Hermetic

Line start

–

Plate fin coil

R410A

9.52 (3/8)

15.88 (5/8)

Flared

Flared

Max.30m

(5,000-11,400)

× 2

11,200

(5,600-14,000)

Notes 1. Rating Conditions (ISO 13253 T1)

Cooling: Indoor: D.B.27°C (80°F), W.B.19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B.24°C (75°F)

Heating: Indoor: D.B.20°C (68°F)

Outdoor: D.B.7°C (45°F), W.B.6°C (43°F)

Refrigerant piping length (one way): 5m (16ft)

3. Above data based on indicated voltage

Indoor Unit: Single phase 230V 50Hz

Outdoor Unit: Single phase 230V 50Hz

2. Guaranteed operating range

Cooling

Heating

Upper limit D.B.35°C, W .B.22.5°C D.B.46°C

Lower limi D.B.19°C, W.B .15°C D.B.-5°C

Upper limit D.B.28°C D.B.21°C, W.B.15°C

Lower limi D.B.17°C D.B.-11°C , W.B.-12°C

Indoor Outdoor

Page 8

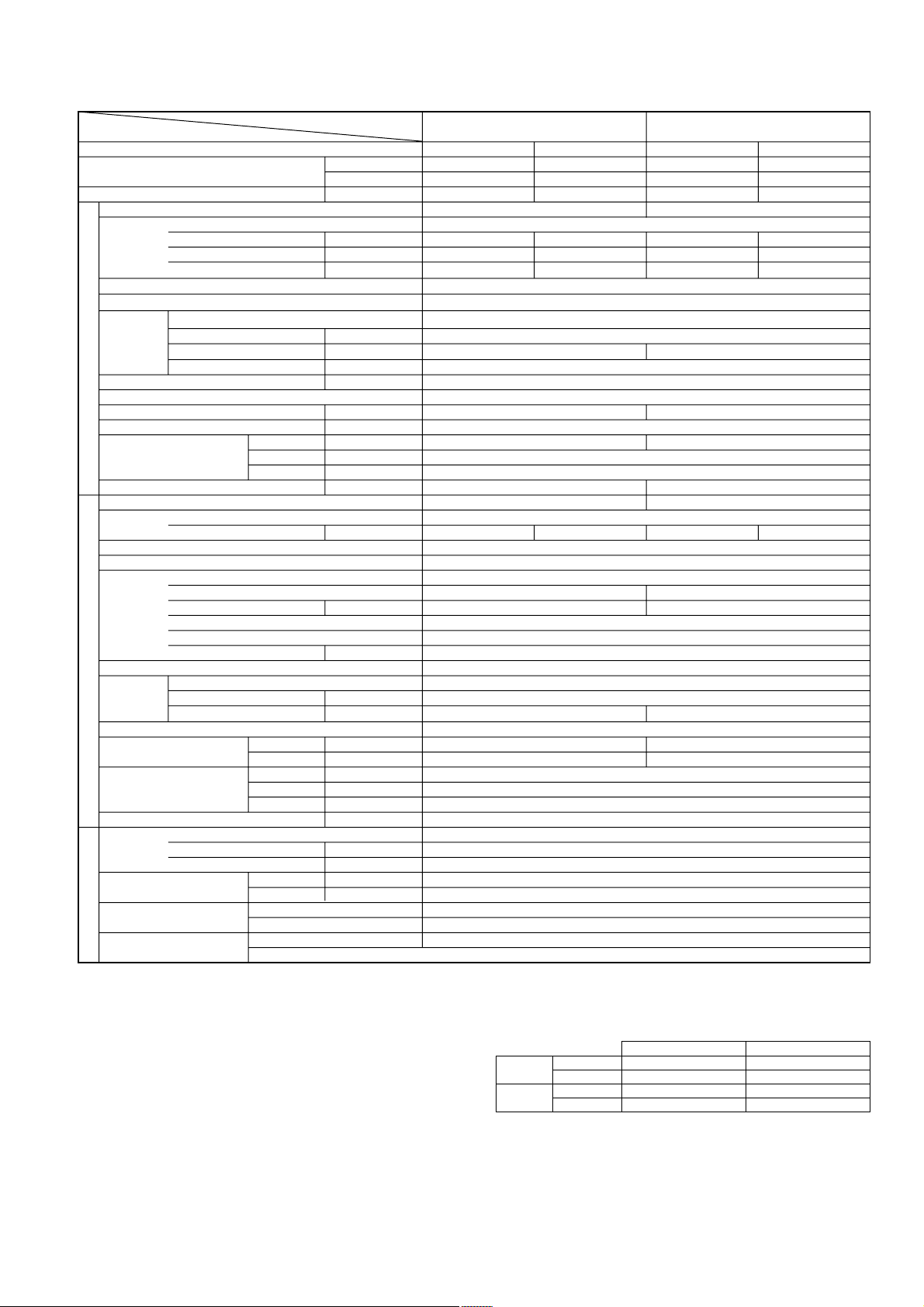

8

Item

Service Ref.

PEAD-RP5EA PEAD-RP6EA

Function Cooling Heating Cooling Heating

Capacity

Btu/h 42,700 47,800 47,800 54,600

W

12,500 (6,000-14,000) 14,000 (6,000-16,000) 14,000 (6,200-15,300) 16,000 (6,200-18,000)

Total input kW 3.69 4.11 4.91 4.76

Service Ref.

PEAD-RP5EA PEAD-RP6EA

Power supply Single phase, 50Hz,220-230-240V

Input kW 0.59 0.59 0.61 0.61

Running current A 2.62 2.69

2.62 2.69

Starting current A 3.4 3.4 3.5 3.5

External finish Galvanized sheets

Heat exchanger Plate fin coil

Fan

Fan (drive) × No. Centrifugal (direct) × 2

Fan motor output kW 0.40

Airflow (Lo-Hi)

3

m

/min (CFM)

33.5-42 <1,183-1,483> 36.5-46 <1,288-1,624>

External static pressure Pa (mmAq) 70 (130)

Booster heater kW

–

Operation control & Thermostat Built in remote controller

Noise level (Lo-Hi) dB 44-50 46-51

Unit drain pipe O.D mm (in.) 32 (1-1/4)

W mm (in.) 1,415 (55-11/16) 1,715 (67-1/2)

Dimensions

D mm (in.) 740 (29-1/8)

H mm (in.) 325 (12-13/16)

Weight

kg (lbs) 65 (143) 70 (154)

Service Ref. PUHZ-RP5VHA PUHZ-RP6VHA

Power supply Single phase, 50Hz,220-230-240V

Running current A 15.80 17.50 20.73 20.37

External finish Munsell 3Y 7.8/1.1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Model ANV33FDAMT ANV33FDAMT

Motor output kW 2.4 2.9

Starter type Line start

Protection de

vices

Crankcase heater

W

LP switch, HP switch, Discharge thermo

–

Heat exchanger Plate fin coil

Fan

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan (drive) × No. Propeller (direct) × 2

Fan motor output kW 0.060+0.060

Airflow

m3/min (CFM)

100 (3,530) 100 (3,530)

Defrost method Reverse cycle

Noise level

Cooling dB 50 50

Heating dB 52 52

Dimensions

W mm (in.) 950 (37-3/8)

D mm (in.) 330+30 (13+1-3/16)

H mm (in.) 1,350 (53-1/8)

Weight kg (lbs) 121 (267)

Refrigerant R410A

Charge kg (lbs) 5.5 (12.1)

Oil (Model) L 1.4 (MEL56)

Pipe size O.D

Liquid mm (in.) 9.52 (3/8)

Gas mm (in.) 15.88 (5/8)

Connection method

Indoor side Flared

Outdoor side Flared

Between the indoor &

outdoor unit

Height difference Max.30m

Piping length Max.75m

Notes 1. Rating Conditions (ISO 13253 T1)

Cooling: Indoor: D.B.27°C (80°F), W.B.19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B.24°C (75°F)

Heating: Indoor: D.B.20°C (68°F)

Outdoor: D.B.7°C (45°F), W.B.6°C (43°F)

Refrigerant piping length (one way): 5m (16ft)

3. Above data based on indicated voltage

Indoor Unit: Single phase 230V 50Hz

Outdoor Unit: Single phase 230V 50Hz

2. Guaranteed operating range

Cooling

Heating

Upper limit D.B.35°C, W .B.22.5°C D.B.46°C

Lower limi D.B.19°C, W.B .15°C D.B.-5°C

Upper limit D.B.28°C D.B.21°C, W.B.15°C

Lower limi D.B.17°C D.B.-11°C , W.B.-12°C

Indoor Outdoor

Page 9

9

4

DA T A

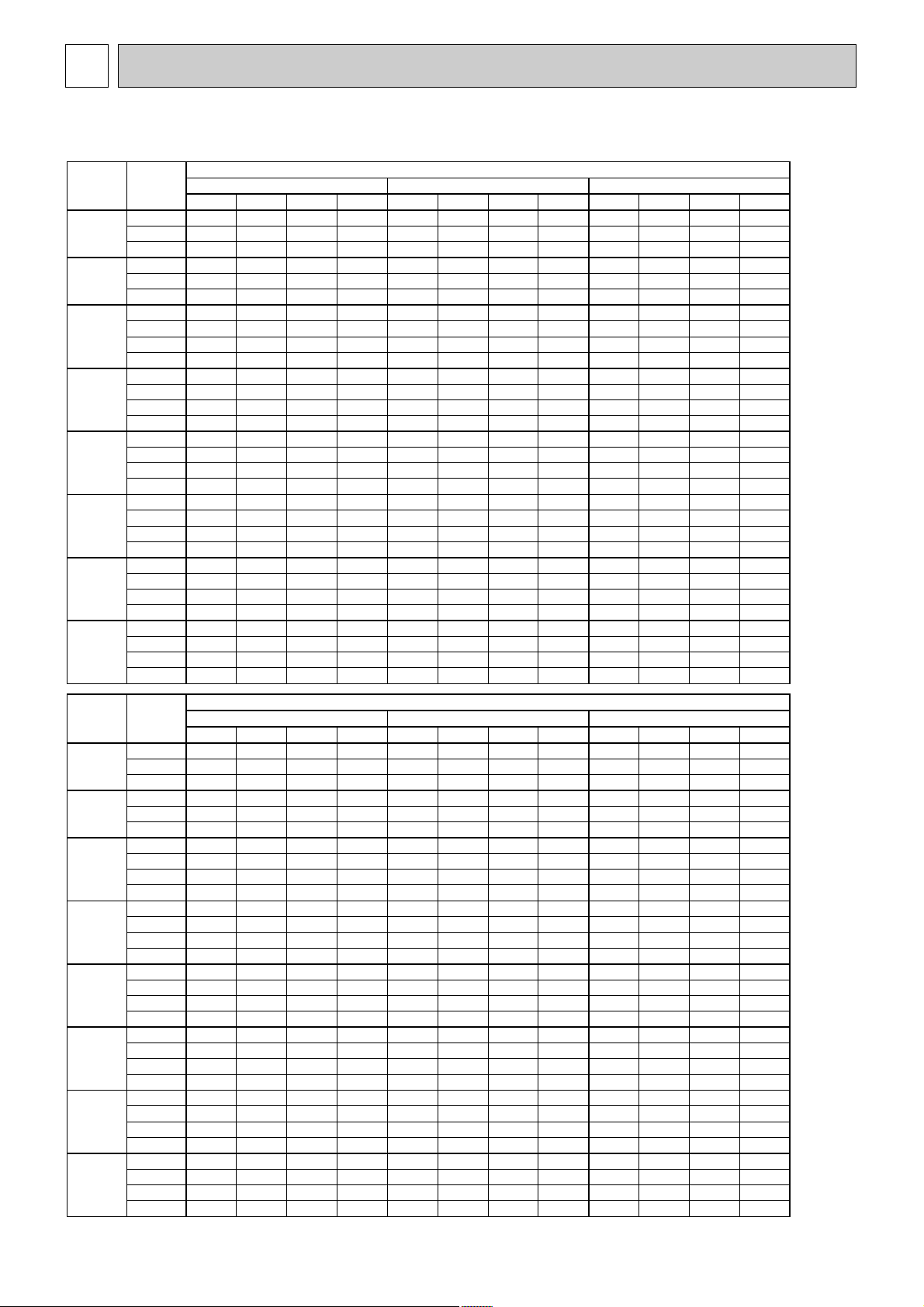

20 30

CA SHC(W) SHF P.C. CA

SHC(W)

SHF P.C. CA SHC(W) SHF P.C.

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

35 40 45

CA

SHC(W)

SHF P.C. CA SHC(W) SHF P.C. CA

SHC(W)

SHF P.C.

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

7,029 5,061 0.72 1.72 6,816 4,908 0.72 1.81 6,603 4,754 0.72 1.92

7,526 4,365 0.58 1.76 7,313 4,242 0.58 1.84 7,065 4,098 0.58 1.98

8,094 3,642 0.45 1.80 7,917 3,563 0.45 1.89 7,704 3,467 0.45 2.02

7,029 5,693 0.81 1.72 6,816 5,521 0.81 1.81 6,603 5,348 0.81 1.92

7,526 5,042 0.67 1.76 7,313 4,900 0.67 1.84 7,065 4,734 0.67 1.98

8,094 4,371 0.54 1.80 7,917 4,275 0.54 1.89 7,704 4,160 0.54 2.02

7,029 6,326 0.90 1.72 6,816 6,134 0.90 1.81 6,603 5,943 0.90 1.92

7,526 5,720 0.76 1.76 7,313 5,558 0.76 1.84 7,065 5,369 0.76 1.98

8,094 5,099 0.63 1.80 7,917 4,988 0.63 1.89 7,704 4,854 0.63 2.02

8,627 4,227 0.49 1.84 8,449 4,140 0.49 1.95 8,236 4,036 0.49 2.08

7,029 6,959 0.99 1.72 6,816 6,748 0.99 1.81 6,603 6,537 0.99 1.92

7,526 6,397 0.85 1.76 7,313 6,216 0.85 1.84 7,065 6,005 0.85 1.98

8,094 5,828 0.72 1.80 7,917 5,700 0.72 1.89 7,704 5,547 0.72 2.02

8,627 5,004 0.58 1.84 8,449 4,900 0.58 1.95 8,236 4,777 0.58 2.08

7,029 7,029 1.00 1.72 6,816 6,816 1.00 1.81 6,603 6,603 1.00 1.92

7,526 7,074 0.94 1.76 7,313 6,874 0.94 1.84 7,065 6,641 0.94 1.98

8,094 6,556 0.81 1.80 7,917 6,413 0.81 1.89 7,704 6,240 0.81 2.02

8,627 5,780 0.67 1.84 8,449 5,661 0.67 1.95 8,236 5,518 0.67 2.08

7,029 7,029 1.00 1.72 6,816 6,816 1.00 1.81 6,603 6,603 1.00 1.92

7,526 7,526 1.00 1.76 7,313 7,313 1.00 1.84 7,065 7,065 1.00 1.98

8,094 7,285 0.90 1.80 7,917 7,125 0.90 1.89 7,704 6,934 0.90 2.02

8,627 6,557 0.76 1.84 8,449 6,421 0.76 1.95 8,236 6,259 0.76 2.08

7,029 7,029 1.00 1.72 6,816 6,816 1.00 1.81 6,603 6,603 1.00 1.92

7,526 7,526 1.00 1.76 7,313 7,313 1.00 1.84 7,065 7,065 1.00 1.98

8,094 8,013 0.99 1.80 7,917 7,838 0.99 1.89 7,704 7,627 0.99 2.02

8,627 7,333 0.85 1.84 8,449 7,182 0.85 1.95 8,236 7,001 0.85 2.08

7,029 7,029 1.00 1.72 6,816 6,816 1.00 1.81 6,603 6,603 1.00 1.92

7,526 7,526 1.00 1.76 7,313 7,313 1.00 1.84 7,065 7,065 1.00 1.98

8,094 8,094 1.00 1.80 7,917 7,917 1.00 1.89 7,704 7,704 1.00 2.02

8,627 8,109 0.94 1.84 8,449 7,942 0.94 1.95 8,236 7,742 0.94 2.08

6,319 4,550 0.72 2.06 6,035 4,345 0.72 2.22 5,751 4,141 0.72 2.40

6,816 3,953 0.58 2.12 6,603 3,830 0.58 2.28 6,177 3,583 0.58 2.46

7,384 3,323 0.45 2.17 7,100 3,195 0.45 2.32 6,674 3,003 0.45 2.50

6,319 5,118 0.81 2.06 6,035 4,888 0.81 2.22 5,751 4,658 0.81 2.40

6,816 4,567 0.67 2.12 6,603 4,424 0.67 2.28 6,177 4,139 0.67 2.46

7,384 3,987 0.54 2.17 7,100 3,834 0.54 2.32 6,674 3,604 0.54 2.50

6,319 5,687 0.90 2.06 6,035 5,432 0.90 2.22 5,751 5,176 0.90 2.40

6,816 5,180 0.76 2.12 6,603 5,018 0.76 2.28 6,177 4,695 0.76 2.46

7,384 4,652 0.63 2.17 7,100 4,473 0.63 2.32 6,674 4,205 0.63 2.50

7,952 3,896 0.49 2.22 7,668 3,757 0.49 2.39 7,242 3,549 0.49 2.53

6,319 6,256 0.99 2.06 6,035 5,975 0.99 2.22 5,751 5,693 0.99 2.40

6,816 5,794 0.85 2.12 6,603 5,613 0.85 2.28 6,177 5,250 0.85 2.46

7,384 5,316 0.72 2.17 7,100 5,112 0.72 2.32 6,674 4,805 0.72 2.50

7,952 4,612 0.58 2.22 7,668 4,447 0.58 2.39 7,242 4,200 0.58 2.53

6,319 6,319 1.00 2.06 6,035 6,035 1.00 2.22 5,751 5,751 1.00 2.40

6,816 6,407 0.94 2.12 6,603 6,207 0.94 2.28 6,177 5,806 0.94 2.46

7,384 5,981 0.81 2.17 7,100 5,751 0.81 2.32 6,674 5,406 0.81 2.50

7,952 5,328 0.67 2.22 7,668 5,138 0.67 2.39 7,242 4,852 0.67 2.53

6,319 6,319 1.00 2.06 6,035 6,035 1.00 2.22 5,751 5,751 1.00 2.40

6,816 6,816 1.00 2.12 6,603 6,603 1.00 2.28 6,177 6,177 1.00 2.46

7,384 6,646 0.90 2.17 7,100 6,390 0.90 2.32 6,674 6,007 0.90 2.50

7,952 6,044 0.76 2.22 7,668 5,828 0.76 2.39 7,242 5,504 0.76 2.53

6,319 6,319 1.00 2.06 6,035 6,035 1.00 2.22 5,751 5,751 1.00 2.40

6,816 6,816 1.00 2.12 6,603 6,603 1.00 2.28 6,177 6,177 1.00 2.46

7,384 7,310 0.99 2.17 7,100 7,029 0.99 2.32 6,674 6,607 0.99 2.50

7,952 6,759 0.85 2.22 7,668 6,518 0.85 2.39 7,242 6,156 0.85 2.53

6,319 6,319 1.00 2.06 6,035 6,035 1.00 2.22 5,751 5,751 1.00 2.40

6,816 6,816 1.00 2.12 6,603 6,603 1.00 2.28 6,177 6,177 1.00 2.46

7,384 7,384 1.00 2.17 7,100 7,100 1.00 2.32 6,674 6,674 1.00 2.50

7,952 7,475 0.94 2.22 7,668 7,208 0.94 2.39 7,242 6,807 0.94 2.53

Indoor

Intake air

D.B. (°C)

Indoor

Intake air

W.B. (°C)

Outdoor intake air D.B. (°C)

Indoor

Intake air

D.B. (°C)

Indoor

Intake air

W.B. (°C)

Outdoor intake air D.B. (°C)

1. PERFORMANCE DATA

1) COOLING CAPACITY

PEAD-RP3EA/PUHZ-RP3VHA

20

22

24

26

28

30

32

34

20

22

24

26

28

30

32

34

Notes CA: Capacity (W) SHC: Sensible heat capacity (W)

P.C.: Power consumption (kW) SHF: Sensible heat factor

(230V)

Page 10

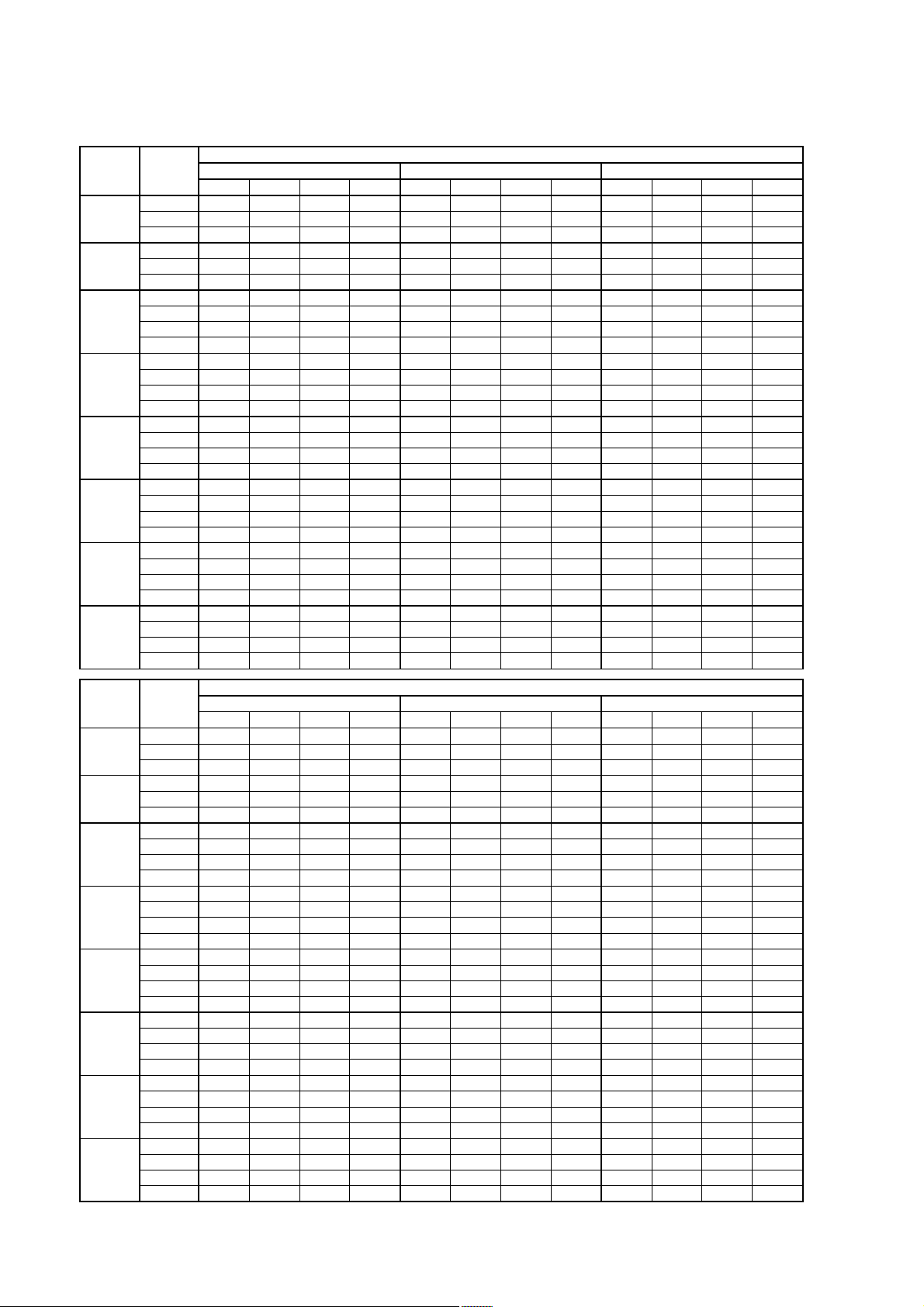

10

PEAD-RP4EA/PUHZ-RP4VHA

Indoor

Intake air

D.B. (°C)

20

22

24

26

28

30

32

34

Indoor

Intake air

D.B. (°C)

20

22

24

26

28

30

32

34

Indoor

Intake air

W.B. (°C)

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

Indoor

Intake air

W.B. (°C)

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA SHC(W) SHF P.C. CA SHC(W) SHF P.C. CA SHC(W) SHF P.C.

9,900 7,128 0.72 2.46 9,600 6,912 0.72 2.60 9,300 6,696 0.72 2.75

10,600 6,254 0.59 2.51 10,300 6,077 0.59 2.65 9,950 5,871 0.59 2.84

11,400 5,130 0.45 2.59 11,150 5,018 0.45 2.71 10,850 4,883 0.45 2.90

9,900 8,019 0.81 2.46 9,600 7,776 0.81 2.60 9,300 7,533 0.81 2.75

10,600 7,208 0.68 2.51 10,300 7,004 0.68 2.65 9,950 6,766 0.68 2.84

11,400 6,156 0.54 2.59 11,150 6,021 0.54 2.71 10,850 5,859 0.54 2.90

9,900 8,910 0.90 2.46 9,600 8,640 0.90 2.60 9,300 8,370 0.90 2.75

10,600 8,056 0.76 2.51 10,300 7,828 0.76 2.65 9,950 7,562 0.76 2.84

11,400 7,182 0.63 2.59 11,150 7,025 0.63 2.71 10,850 6,836 0.63 2.90

12,150 6,075 0.50 2.65 11,900 5,950 0.50 2.81 11,600 5,800 0.50 2.99

9,900 9,702 0.98 2.46 9,600 9,408 0.98 2.60 9,300 9,114 0.98 2.75

10,600 9,010 0.85 2.51 10,300 8,755 0.85 2.65 9,950 8,458 0.85 2.84

11,400 8,208 0.72 2.59 11,150 8,028 0.72 2.71 10,850 7,812 0.72 2.90

12,150 7,169 0.59 2.65 11,900 7,021 0.59 2.81 11,600 6,844 0.59 2.99

9,900 9,900 1.00 2.46 9,600 9,600 1.00 2.60 9,300 9,300 1.00 2.75

10,600 9,964 0.94 2.51 10,300 9,682 0.94 2.65 9,950 9,353 0.94 2.84

11,400 9,234 0.81 2.59 11,150 9,032 0.81 2.71 10,850 8,789 0.81 2.90

12,150 8,262 0.68 2.65 11,900 8,092 0.68 2.81 11,600 7,888 0.68 2.99

9,900 9,900 1.00 2.46 9,600 9,600 1.00 2.60 9,300 9,300 1.00 2.75

10,600 10,600 1.00 2.51 10,300 10,300 1.00 2.65 9,950 9,950 1.00 2.84

11,400 10,260 0.90 2.59 11,150 10,035 0.90 2.71 10,850 9,765 0.90 2.90

12,150 9,234 0.76 2.65 11,900 9,044 0.76 2.81 11,600 8,816 0.76 2.99

9,900 9,900 1.00 2.46 9,600 9,600 1.00 2.60 9,300 9,300 1.00 2.75

10,600 10,600 1.00 2.51 10,300 10,300 1.00 2.65 9,950 9,950 1.00 2.84

11,400 11,172 0.98 2.59 11,150 10,927 0.98 2.71 10,850 10,633 0.98 2.90

12,150 10,328 0.85 2.65 11,900 10,115 0.85 2.81 11,600 9,860 0.85 2.99

9,900 9,900 1.00 2.46 9,600 9,600 1.00 2.60 9,300 9,300 1.00 2.75

10,600 10,600 1.00 2.51 10,300 10,300 1.00 2.65 9,950 9,950 1.00 2.84

11,400 11,400 1.00 2.59 11,150 11,150 1.00 2.71 10,850 10,850 1.00 2.90

12,150 11,421 0.94 2.65 11,900 11,186 0.94 2.81 11,600 10,904 0.94 2.99

CA SHC(W) SHF P.C. CA SHC(W) SHF P.C. CA

8,900 6,408 0.72 2.96 8,500 6,120 0.72 3.17 8,100 5,832 0.72 3.44

9,600 5,664 0.59 3.03 9,300 5,487 0.59 3.26 8,700 5,133 0.59 3.51

10,400 4,680 0.45 3.11 10,000 4,500 0.45 3.32 9,400 4,230 0.45 3.57

8,900 7,209 0.81 2.96 8,500 6,885 0.81 3.17 8,100 6,561 0.81 3.44

9,600 6,528 0.68 3.03 9,300 6,324 0.68 3.26 8,700 5,916 0.68 3.51

10,400 5,616 0.54 3.11 10,000 5,400 0.54 3.32 9,400 5,076 0.54 3.57

8,900 8,010 0.90 2.96 8,500 7,650 0.90 3.17 8,100 7,290 0.90 3.44

9,600 7,296 0.76 3.03 9,300 7,068 0.76 3.26 8,700 6,612 0.76 3.51

10,400 6,552 0.63 3.11 10,000 6,300 0.63 3.32 9,400 5,922 0.63 3.57

11,200 5,600 0.50 3.17 10,800 5,400 0.50 3.42 10,200 5,100 0.50 3.64

8,900 8,722 0.98 2.96 8,500 8,330 0.98 3.17 8,100 7,938 0.98 3.44

9,600 8,160 0.85 3.03 9,300 7,905 0.85 3.26 8,700 7,395 0.85 3.51

10,400 7,488 0.72 3.11 10,000 7,200 0.72 3.32 9,400 6,768 0.72 3.57

11,200 6,608 0.59 3.17 10,800 6,372 0.59 3.42 10,200 6,018 0.59 3.64

8,900 8,900 1.00 2.96 8,500 8,500 1.00 3.17 8,100 8,100 1.00 3.44

9,600 9,024 0.94 3.03 9,300 8,742 0.94 3.26 8,700 8,178 0.94 3.51

10,400 8,424 0.81 3.11 10,000 8,100 0.81 3.32 9,400 7,614 0.81 3.57

11,200 7,616 0.68 3.17 10,800 7,344 0.68 3.42 10,200 6,936 0.68 3.64

8,900 8,900 1.00 2.96 8,500 8,500 1.00 3.17 8,100 8,100 1.00 3.44

9,600 9,600 1.00 3.03 9,300 9,300 1.00 3.26 8,700 8,700 1.00 3.51

10,400 9,360 0.90 3.11 10,000 9,000 0.90 3.32 9,400 8,460 0.90 3.57

11,200 8,512 0.76 3.17 10,800 8,208 0.76 3.42 10,200 7,752 0.76 3.64

8,900 8,900 1.00 2.96 8,500 8,500 1.00 3.17 8,100 8,100 1.00 3.44

9,600 9,600 1.00 3.03 9,300 9,300 1.00 3.26 8,700 8,700 1.00 3.51

10,400 10,192 0.98 3.11 10,000 9,800 0.98 3.32 9,400 9,212 0.98 3.57

11,200 9,520 0.85 3.17 10,800 9,180 0.85 3.42 10,200 8,670 0.85 3.64

8,900 8,900 1.00 2.96 8,500 8,500 1.00 3.17 8,100 8,100 1.00 3.44

9,600 9,600 1.00 3.03 9,300 9,300 1.00 3.26 8,700 8,700 1.00 3.51

10,400 10,400 1.00 3.11 10,000 10,000 1.00 3.32 9,400 9,400 1.00 3.57

11,200 10,528 0.94 3.17 10,800 10,152 0.94 3.42 10,200 9,588 0.94 3.64

Outdoor intake air D.B. (°C)

20 25 30

Outdoor intake air D.B. (°C)

35 40 45

SHC(W)

Notes CA: Capacity (W) SHC: Sensible heat capacity (W)

P.C.: Power consumption (kW) SHF: Sensible heat factor

(230V)

SHF P.C.

Page 11

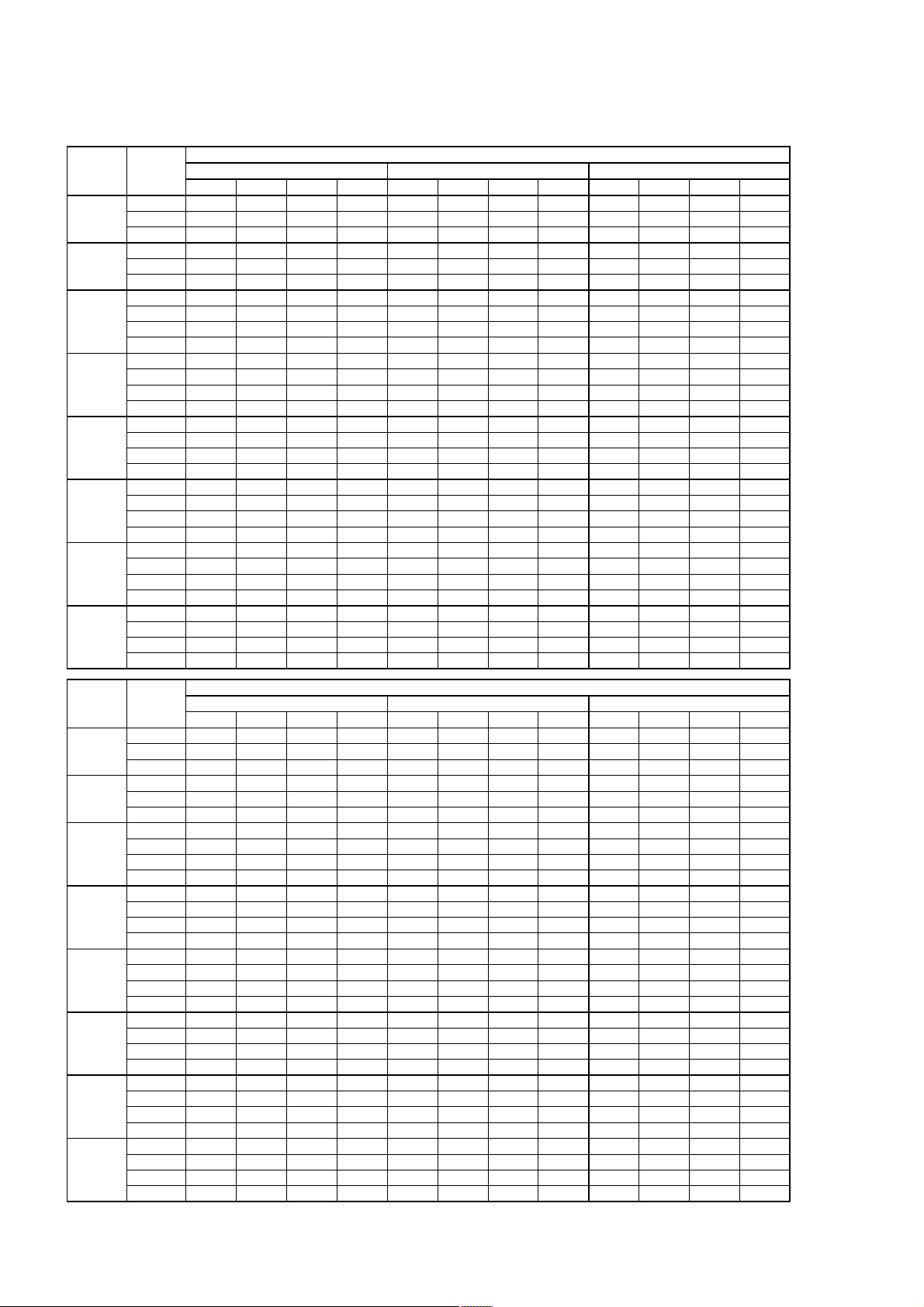

11

PEAD-RP5EA/PUHZ-RP5VHA

Indoor

Intake air

D.B. (°C)

20

22

24

26

28

30

32

34

Indoor

Intake air

W.B. (°C)

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA SHC(W) SHF P.C. CA SHC(W) SHF P.C. CA

12,375 8,910 0.72 2.95 12,000 8,640 0.72 3.12 11,625 8,370 0.72 3.30

13,250 7,685 0.58 3.01 12,875 7,468 0.58 3.18 12,438 7,214 0.58 3.40

14,250 6,413 0.45 3.10 13,938 6,272 0.45 3.24 13,563 6,103 0.45 3.47

12,375 10,024 0.81 2.95 12,000 9,720 0.81 3.12 11,625 9,416 0.81 3.30

13,250 8,878 0.67 3.01 12,875 8,626 0.67 3.18 12,438 8,333 0.67 3.40

14,250 7,695 0.54 3.10 13,938 7,527 0.54 3.24 13,563 7,324 0.54 3.47

12,375 11,138 0.90 2.95 12,000 10,800 0.90 3.12 11,625 10,463 0.90 3.30

13,250 10,070 0.76 3.01 12,875 9,785 0.76 3.18 12,438 9,453 0.76 3.40

14,250 8,978 0.63 3.10 13,938 8,781 0.63 3.24 13,563 8,545 0.63 3.47

15,188 7,442 0.49 3.18 14,875 7,289 0.49 3.36 14,500 7,105 0.49 3.58

12,375 12,251 0.99 2.95 12,000 11,880 0.99 3.12 11,625 11,509 0.99 3.30

13,250 11,263 0.85 3.01 12,875 10,944 0.85 3.18 12,438 10,572 0.85 3.40

14,250 10,260 0.72 3.10 13,938 10,035 0.72 3.24 13,563 9,765 0.72 3.47

15,188 8,809 0.58 3.18 14,875 8,628 0.58 3.36 14,500 8,410 0.58 3.58

12,375 12,375 1.00 2.95 12,000 12,000 1.00 3.12 11,625 11,625 1.00 3.30

13,250 12,455 0.94 3.01 12,875 12,103 0.94 3.18 12,438 11,692 0.94 3.40

14,250 11,543 0.81 3.10 13,938 11,290 0.81 3.24 13,563 10,986 0.81 3.47

15,188 10,176 0.67 3.18 14,875 9,966 0.67 3.36 14,500 9,715 0.67 3.58

12,375 12,375 1.00 2.95 12,000 12,000 1.00 3.12 11,625 11,625 1.00 3.30

13,250 13,250 1.00 3.01 12,875 12,875 1.00 3.18 12,438 12,438 1.00 3.40

14,250 12,825 0.90 3.10 13,938 12,544 0.90 3.24 13,563 12,207 0.90 3.47

15,188 11,543 0.76 3.18 14,875 11,305 0.76 3.36 14,500 11,020 0.76 3.58

12,375 12,375 1.00 2.95 12,000 12,000 1.00 3.12 11,625 11,625 1.00 3.30

13,250 13,250 1.00 3.01 12,875 12,875 1.00 3.18 12,438 12,438 1.00 3.40

14,250 14,108 0.99 3.10 13,938 13,799 0.99 3.24 13,563 13,427 0.99 3.47

15,188 12,910 0.85 3.18 14,875 12,644 0.85 3.36 14,500 12,325 0.85 3.58

12,375 12,375 1.00 2.95 12,000 12,000 1.00 3.12 11,625 11,625 1.00 3.30

13,250 13,250 1.00 3.01 12,875 12,875 1.00 3.18 12,438 12,438 1.00 3.40

14,250 14,250 1.00 3.10 13,938 13,938 1.00 3.24 13,563 13,563 1.00 3.47

15,188 14,277 0.94 3.18 14,875 13,983 0.94 3.36 14,500 13,630 0.94 3.58

Outdoor intake air D.B. (°C)

20 25 30

SHC(W)

(230V)

SHF P.C.

Indoor

Intake air

D.B. (°C)

20

22

24

26

28

30

32

34

Indoor

Intake air

W.B. (°C)

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

Outdoor intake air D.B. (°C)

35 40 45

CA SHC(W) SHF P.C. CA SHC(W) SHF P.C. CA

11,125 8,010 0.72 3.54 10,625 7,650 0.72 3.80 10,125 7,290 0.72 4.12

12,000 6,960 0.58 3.63 11,625 6,743 0.58 3.91 10,875 6,308 0.58 4.20

13,000 5,850 0.45 3.73 12,500 5,625 0.45 3.98 11,750 5,288 0.45 4.28

11,125 9,011 0.81 3.54 10,625 8,606 0.81 3.80 10,125 8,201 0.81 4.12

12,000 8,040 0.67 3.63 11,625 7,789 0.67 3.91 10,875 7,286 0.67 4.20

13,000 7,020 0.54 3.73 12,500 6,750 0.54 3.98 11,750 6,345 0.54 4.28

11,125 10,013 0.90 3.54 10,625 9,563 0.90 3.80 10,125 9,113 0.90 4.12

12,000 9,120 0.76 3.63 11,625 8,835 0.76 3.91 10,875 8,265 0.76 4.20

13,000 8,190 0.63 3.73 12,500 7,875 0.63 3.98 11,750 7,403 0.63 4.28

14,000 6,860 0.49 3.80 13,500 6,615 0.49 4.10 12,750 6,248 0.49 4.35

11,125 11,014 0.99 3.54 10,625 10,519 0.99 3.80 10,125 10,024 0.99 4.12

12,000 10,200 0.85 3.63 11,625 9,881 0.85 3.91 10,875 9,244 0.85 4.20

13,000 9,360 0.72 3.73 12,500 9,000 0.72 3.98 11,750 8,460 0.72 4.28

14,000 8,120 0.58 3.80 13,500 7,830 0.58 4.10 12,750 7,395 0.58 4.35

11,125 11,125 1.00 3.54 10,625 10,625 1.00 3.80 10,125 10,125 1.00 4.12

12,000 11,280 0.94 3.63 11,625 10,928 0.94 3.91 10,875 10,223 0.94 4.20

13,000 10,530 0.81 3.73 12,500 10,125 0.81 3.98 11,750 9,518 0.81 4.28

14,000 9,380 0.67 3.80 13,500 9,045 0.67 4.10 12,750 8,543 0.67 4.35

11,125 11,125 1.00 3.54 10,625 10,625 1.00 3.80 10,125 10,125 1.00 4.12

12,000 12,000 1.00 3.63 11,625 11,625 1.00 3.91 10,875 10,875 1.00 4.20

13,000 11,700 0.90 3.73 12,500 11,250 0.90 3.98 11,750 10,575 0.90 4.28

14,000 10,640 0.76 3.80 13,500 10,260 0.76 4.10 12,750 9,690 0.76 4.35

11,125 11,125 1.00 3.54 10,625 10,625 1.00 3.80 10,125 10,125 1.00 4.12

12,000 12,000 1.00 3.63 11,625 11,625 1.00 3.91 10,875 10,875 1.00 4.20

13,000 12,870 0.99 3.73 12,500 12,375 0.99 3.98 11,750 11,633 0.99 4.28

14,000 11,900 0.85 3.80 13,500 11,475 0.85 4.10 12,750 10,838 0.85 4.35

11,125 11,125 1.00 3.54 10,625 10,625 1.00 3.80 10,125 10,125 1.00 4.12

12,000 12,000 1.00 3.63 11,625 11,625 1.00 3.91 10,875 10,875 1.00 4.20

13,000 13,000 1.00 3.73 12,500 12,500 1.00 3.98 11,750 11,750 1.00 4.28

14,000 13,160 0.94 3.80 13,500 12,690 0.94 4.10 12,750 11,985 0.94 4.35

Notes CA: Capacity (W) SHC: Sensible heat capacity (W)

P.C.: Power consumption (kW) SHF: Sensible heat factor

SHC(W)

SHF P.C.

Page 12

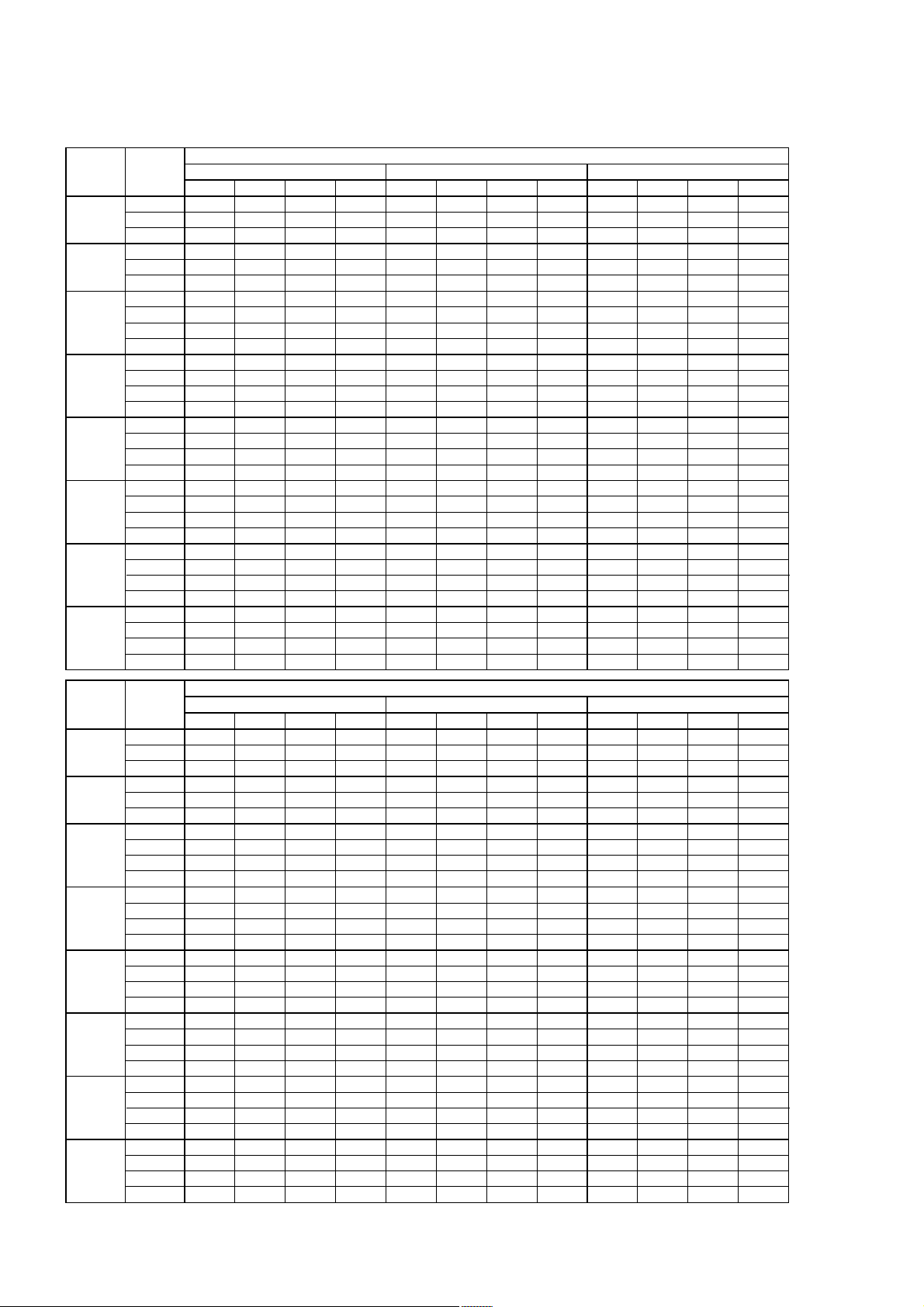

12

PEAD-RP6EA/PUHZ-RP6VHA

Indoor

Intake air

D.B. (°C)

20

22

24

26

28

30

32

34

Indoor

Intake air

W.B. (°C)

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

13,860 9,702 0.70 3.93 13,440 9,408 0.70 4.15 13,020 9,114 0.70 4.40

14,840 8,459 0.57 4.00 14,420 8,219 0.57 4.22 13,930 7,940 0.57 4.52

15,960 6,863 0.43 4.12 14,610 6,282 0.43 4.32 15,190 6,532 0.43 4.61

13,860 11,088 0.80 3.93 13,440 10,752 0.80 4.15 13,020 10,416 0.80 4.40

14,840 9,794 0.66 4.00 14,420 9,517 0.66 4.22 13,930 9,194 0.66 4.52

15,960 8,299 0.52 4.12 14,610 7,597 0.52 4.32 15,190 7,899 0.52 4.61

13,860 12,335 0.89 3.93 13,440 11,962 0.89 4.15 13,020 11,588 0.89 4.40

14,840 11,130 0.75 4.00 14,420 10,815 0.75 4.22 13,930 10,448 0.75 4.52

15,960 9,736 0.61 4.12 14,610 8,912 0.61 4.32 15,190 9,266 0.61 4.61

17,010 7,995 0.47 4.22 16,660 7,830 0.47 4.47 16,240 7,633 0.47 4.76

13,860 13,583 0.98 3.93 13,440 13,171 0.98 4.15 13,020 12,760 0.98 4.40

14,840 12,466 0.84 4.00 14,420 12,113 0.84 4.22 13,930 11,701 0.84 4.52

15,960 11,172 0.70 4.12 14,610 10,227 0.70 4.32 15,190 10,633 0.70 4.61

17,010 9,696 0.57 4.22 16,660 9,496 0.57 4.47 16,240 9,257 0.57 4.76

13,860 13,860 1.00 3.93 13,440 13,440 1.00 4.15 13,020 13,020 1.00 4.40

14,840 13,950 0.94 4.00 14,420 13,555 0.94 4.22 13,930 13,094 0.94 4.52

15,960 12,768 0.80 4.12 14,610 11,688 0.80 4.32 15,190 12,152 0.80 4.61

17,010 11,227 0.66 4.22 16,660 10,996 0.66 4.47 16,240 10,718 0.66 4.76

13,860 13,860 1.00 3.93 13,440 13,440 1.00 4.15 13,020 13,020 1.00 4.40

14,840 14,840 1.00 4.00 14,420 14,420 1.00 4.22 13,930 13,930 1.00 4.52

15,960 14,204 0.89 4.12 14,610 13,003 0.89 4.32 15,190 13,519 0.89 4.61

17,010 12,758 0.75 4.22 16,660 12,495 0.75 4.47 16,240 12,180 0.75 4.76

13,860 13,860 1.00 3.93 13,440 13,440 1.00 4.15 13,020 13,020 1.00 4.40

14,840 14,840 1.00 4.00 14,420 14,420 1.00 4.22 13,930 13,930 1.00 4.52

15,960 15,641 0.98 4.12 14,610 14,318 0.98 4.32 15,190 14,886 0.98 4.61

17,010 14,288 0.84 4.22 16,660 13,994 0.84 4.47 16,240 13,642 0.84 4.76

13,860 13,860 1.00 3.93 13,440 13,440 1.00 4.15 13,020 13,020 1.00 4.40

14,840 14,840 1.00 4.00 14,420 14,420 1.00 4.22 13,930 13,930 1.00 4.52

15,960 15,960 1.00 4.12 14,610 14,610 1.00 4.32 15,190 15,190 1.00 4.61

17,010 15,989 0.94 4.22 16,660 15,660 0.94 4.47 16,240 15,266 0.94 4.76

Outdoor intake air D.B. (°C)

20 25 30

SHC(W)

SHF P.C. CA SHC(W) SHF P.C. CA SHC(W) SHF P.C.

(230V)

Indoor

Intake air

D.B. (°C)

20

22

24

26

28

30

32

34

Indoor

Intake air

W.B. (°C)

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

Outdoor intake air D.B. (°C)

35 40 45

CA SHC(W) SHF P.C. CA SHC(W) SHF P.C. CA SHC(W) SHF P.C.

12,460 8,722 0.70 4.71 11,900 8,330 0.70 5.06 11,340 7,938 0.70 5.47

13,440 7,661 0.57 4.84 13,020 7,421 0.57 5.21 12,180 6,943 0.57 5.60

14,560 6,261 0.43 4.96 14,000 6,020 0.43 5.30 13,160 5,659 0.43 5.70

12,460 9,968 0.80 4.71 11,900 9,520 0.80 5.06 11,340 9,072 0.80 5.47

13,440 8,870 0.66 4.84 13,020 8,593 0.66 5.21 12,180 8,039 0.66 5.60

14,560 7,571 0.52 4.96 14,000 7,280 0.52 5.30 13,160 6,843 0.52 5.70

12,460 11,089 0.89 4.71 11,900 10,591 0.89 5.06 11,340 10,093 0.89 5.47

13,440 10,080 0.75 4.84 13,020 9,765 0.75 5.21 12,180 9,135 0.75 5.60

14,560 8,882 0.61 4.96 14,000 8,540 0.61 5.30 13,160 8,028 0.61 5.70

15,680 7,370 0.47 5.06 15,120 7,106 0.47 5.45 14,280 6,712 0.47 5.80

12,460 12,211 0.98 4.71 11,900 11,662 0.98 5.06 11,340 11,113 0.98 5.47

13,440 11,290 0.84 4.84 13,020 10,937 0.84 5.21 12,180 10,231 0.84 5.60

14,560 10,192 0.70 4.96 14,000 9,800 0.70 5.30 13,160 9,212 0.70 5.70

15,680 8,938 0.57 5.06 15,120 8,618 0.57 5.45 14,280 8,140 0.57 5.80

12,460 12,460 1.00 4.71 11,900 11,900 1.00 5.06 11,340 11,340 1.00 5.47

13,440 12,634 0.94 4.84 13,020 12,239 0.94 5.21 12,180 11,449 0.94 5.60

14,560 11,648 0.80 4.96 14,000 11,200 0.80 5.30 13,160 10,528 0.80 5.70

15,680 10,349 0.66 5.06 15,120 9,979 0.66 5.45 14,280 9,425 0.66 5.80

12,460 12,460 1.00 4.71 11,900 11,900 1.00 5.06 11,340 11,340 1.00 5.47

13,440 13,440 1.00 4.84 13,020 13,020 1.00 5.21 12,180 12,180 1.00 5.60

14,560 12,958 0.89 4.96 14,000 12,460 0.89 5.30 13,160 11,712 0.89 5.70

15,680 11,760 0.75 5.06 15,120 11,340 0.75 5.45 14,280 10,710 0.75 5.80

12,460 12,460 1.00 4.71 11,900 11,900 1.00 5.06 11,340 11,340 1.00 5.47

13,440 13,440 1.00 4.84 13,020 13,020 1.00 5.21 12,180 12,180 1.00 5.60

14,560 14,269 0.98 4.96 14,000 13,720 0.98 5.30 13,160 12,897 0.98 5.70

15,680 13,171 0.84 5.06 15,120 12,701 0.84 5.45 14,280 11,995 0.84 5.80

12,460 12,460 1.00 4.71 11,900 11,900 1.00 5.06 11,340 11,340 1.00 5.47

13,440 13,440 1.00 4.84 13,020 13,020 1.00 5.21 12,180 12,180 1.00 5.60

14,560 14,560 1.00 4.96 14,000 14,000 1.00 5.30 13,160 13,160 1.00 5.70

15,680 14,739 0.94 5.06 15,120 14,213 0.94 5.45 14,280 13,423 0.94 5.80

Notes CA: Capacity (W) SHC: Sensible heat capacity (W)

P.C.: Power consumption (kW) SHF: Sensible heat factor

Page 13

13

Cooling capacity correction factors

Service Ref.

PEAD-RP3EA

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m 55m 60m 65m 70m 75m 80m

1.00

0.989

0.978

0.967

0.956

Refrigerant piping length (one way)

0.947

0.938

0.930

0.913

0.905

PEAD-RP4EA

PEAD-RP5EA

PEAD-RP6EA

1.4

1.2

1.0

0.8

1.2

1.0

0.8

0.6

TOTAL INPUT (RATIO) CAPACITY (RATIO)

0.4

1.00

1.00

1.00

0.985

0.971

0.982

0.963

0.976

0.953

10

20 30 46400-5

OUTDOOR D.B.(°C)

0.958

0.947

0.932

0.943

0.931

0.930

0.914

0.912

0.893

INDOOR W.B.(°C)

22

20

18

16

INDOOR W.B.(°C)

22

20

18

16

0.919

0.900

0.876

0.908

0.885

0.858

0.898

0.871

0.842

0.887

0.858

0.828

0.876

0.845

0.813

0.865

0.834

0.800

0.855

0.823

0.788

0.847

0.812

0.776

0.838

0.802

0.764

0.829

0.792

0.753

Page 14

14

2) HEATING CAPACITY

PUHZ-RP3VHA, PUHZ-RP4VHA, PUHZ-RP5VHA, PUHZ-RP6VHA

Indoor

Service Ref.

PEAD-RP3EA

PEAD-RP4EA

PEAD-RP5EA

PEAD-RP6EA

Note CA: Capacity (W)

P.C.: Power consumption (kW)

intake are

D.B. (˚C)

15

20

25

15

20

25

15

20

25

15

20

25

-10 -5 0 5 10 15

CA

P.C. CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

5,080

4,880

4,720

7,112

6,832

6,608

8,890

8,540

8,260

10,160

9,760

9,440

1.38

1.50

1.59

2.05

2.23

2.37

2.43

2.63

2.79

2.81

3.04

3.24

5,520

5,280

5,120

7,728

7,392

7,168

9,660

9,240

8,960

11,040

10,560

10,240

1.52

1.64

1.78

2.26

2.43

2.65

2.68

2.88

3.13

3.09

3.34

3.62

Outdoor intake air W.B. (:)

6,160

5,840

5,600

8,624

8,176

7,840

10,780

10,220

9,800

12,320

11,680

11,200

Heating capacity correction factors

Service Ref.

PEAD-RP3EA

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m 55m 60m 65m 70m 75m 80m

1.00

0.997

0.994

0.991

0.988

Refrigerant piping length (one way)

0.985

0.982

0.979

1.76

1.90

2.06

2.61

2.82

3.06

3.08

3.33

3.62

3.57

3.86

4.19

0.976

8,080

7,800

7,360

11,312

10,920

10,304

14,140

13,650

12,880

16,160

15,600

14,720

0.973

2.11

2.27

2.41

3.13

3.38

3.58

3.70

3.98

4.24

4.29

4.61

4.91

9,120

8,800

8,480

12,768

12,320

11,872

15,960

15,400

14,840

18,240

17,600

16,960

2.34

2.53

2.70

3.48

3.76

4.02

4.11

4.44

4.75

4.76

5.14

5.50

10,160

9,800

9,440

14,224

13,720

13,216

17,780

17,150

16,520

20,320

19,600

18,880

(230V)

2.53

2.71

2.91

3.76

4.03

4.33

4.44

4.76

5.12

5.14

5.53

5.92

PEAD-RP4EA

PEAD-RP5EA

PEAD-RP6EA

1.00

1.00

1.00

0.997

0.997

0.997

0.994

0.994

0.994

0.991

0.991

0.991

0.988

0.988

0.988

0.985

0.985

0.985

0.982

0.982

0.982

0.979

0.979

0.979

0.976

0.976

0.976

0.973

0.973

0.973

0.970

0.970

0.970

0.967

0.967

0.967

0.964

0.964

0.964

0.961

0.961

0.961

0.958

0.958

0.958

0.955

0.955

0.955

Page 15

15

1.4

1.2

1.0

15

20

25

25

20

15

0.8

0.6

0.4

1.4

1.2

1.0

0.8

0.6

0.4

-12 -10 -5 0 5 10 15

INDOOR

D.B.(°C)

INDOOR

D.B.(°C)

OUTDOOR W.B.(°C)

CAPACITY (RATIO)TOTAL INPUT (RATIO)

Correcting the capacity line influenced by frosting

Not correcting the capacity line influenced by frosting

In some cases, heating operation

cannot be conducted with the maximum

frequency in the area below the slanting line.

In some cases, heating operation

cannot be conducted with the maximum

frequency in the area above the slanting line.

Heating

Page 16

16

PEAD-RP4EA

2 .FAN PERFORMANCE AND CORRECTED AIR FLOW

PEAD-RP3EA

Fan performance <130pa>

Recommended range

200

180

160

140

120

100

80

=

60

40

(1Pa 0.1mmAg)

20

Extemal static pressure (Pa)

12 16 20 24 28 32

Air flow

Corrected Air Flow

Cooling

1.1

1.0

0.9

Correction factor

0.8

12 16 20 24 28 32

Hi

Lo

(CMM)

Capacity

Input

Air flow (CMM)

Fan performance <70pa>

Recommended range

180

160

140

120

100

80

=

60

40

(1Pa 0.1mmAg)

20

Extemal static pressure (Pa)

12 16 20 24 28 32

Air flow

Heating

1.3

1.2

1.1

1.0

Correction factor

0.9

0.8

12 16 20 24 28 32

Lo

Hi

(CMM)

Air flow (CMM)

Fan performance <130pa>

Recommended range

200

180

160

140

120

100

80

=

60

40

(1Pa 0.1mmAg)

20

Extemal static pressure (Pa)

Lo

26 28 30 32 34 36 38 40

Air flow

Corrected Air Flow

Cooling

1.1

1.0

0.9

Correction factor

0.8

24 26 28 30 32 34 36 38 40

Hi

(CMM)

Air flow (CMM)

Capacity

Input

Fan performance <70pa>

Recommended range

220

200

180

160

140

120

100

80

=

60

40

(1Pa 0.1mmAg)

20

Extemal static pressure (Pa)

24 26 28 30 32 34 36 38

Air flow

Heating

1.2

1.1

1.0

0.9

Correction factor

0.8

24 26 28 30 32 34 36 38 40

Hi

Lo

(CMM)

Air flow (CMM)

Page 17

17

PEAD-RP5EA

PEAD-RP6EA

Fan performance <130pa>

Recommended range

220

200

180

160

140

120

100

80

=

60

(1Pa 0.1mmAg)

40

20

Extemal static pressure (Pa)

Lo

Hi

Fan performance <70pa>

Recommended range

220

200

180

160

140

120

100

80

=

60

(1Pa 0.1mmAg)

40

20

Extemal static pressure (Pa)

Hi

Lo

32 34 36 38 40 42 44 46 48

Air flow

(CMM)

Corrected Air Flow

Cooling

1.1

1.0

0.9

Correction factor

0.8

32 34 36 38 40 42 44 46 48

Air flow (CMM)

Fan performance <130pa>

Recommended range

220

200

180

160

140

120

100

=

80

60

(1Pa 0.1mmAg)

40

20

Extemal static pressure (Pa)

Lo

38 40 42 44 46 48 50

36

Air flow

Hi

52

(CMM)

Corrected Air Flow Capacity

Cooling

1.1

Capacity

Input

Input

32 34 36 38 40 42 44 46

Air flow

(CMM)

Heating

1.2

1.1

1.0

0.9

Correction factor

0.8

32 34 36 38 40 42 44 46 48

Fan performance <70pa>

Recommended range

200

180

160

140

120

=

100

80

(1Pa 0.1mmAg)

60

40

Extemal static pressure (Pa)

20

Lo

38 40 42 44 46 48

36

Air flow

(CMM)

Heating

1.2

1.1

Air flow (CMM)

Hi

50

1.0

0.9

Correction factor

0.8

36 38 40 42 44 46

Air flow (CMM)

48 50

52

1.0

0.9

Correction factor

0.8

36 38 40 42 44 46

Air flow (CMM)

48

50 52

Page 18

18

3. STANDARD OPERATION DATA

TotalElectrical circuitRefrigerant circuitIndoor side

Outdoor

side

Service Ref.

Heat pump type

SHF

BF

V

kW

A

V

A

MPa

MPa

°C

°C

°C

m

°C

°C

°C

°C

°C

Mode

Phase, Hz

Volts

Input

Amperes

Outdoor unit Service Ref.

Phase, Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

1 , 50

230

PUHZ-RP6VHA

1, 50

230

0.61

2.69

20.73

2.88

0.88

77.0

48.1

10.4

5

27

19

14.9

35

24

0.82

0.14

(29.4)

(9.0)

(27.7)

(7.0)

(kgf/F)

(kgf/F)

0.61

2.69

20.37

2.72

0.69

72.9

—

-0.2

5

20

15

38.6

7

6

—

—

Indoor unit Service Ref.

PEAD-RP6EA

Capacity

Input

W

kW

Cooling

14,000

4.91

1 , 50

230

PUHZ-RP5VHA

1, 50

230

0.59

2.62

15.80

2.69

0.95

69.0

46.0

10.1

5

27

19

15.1

35

24

0.83

0.14

(27.4)

(9.7)

(25.0)

(6.9)

0.59

2.62

17.50

2.45

0.68

65.7

—

-0.7

5

20

15

37.8

7

6

—

—

PEAD-RP5EA

Cooling

12,500

3.69

1 , 50

230

PUHZ-RP4VHA

1, 50

230

0.57

2.53

12.33

2.65

0.92

70.1

45.1

10.0

5

27

19

15.2

35

24

0.83

0.15

(27.0)

(9.4)

(30.8)

(7.7)

0.57

2.53

13.94

3.02

0.75

79.1

—

1.9

5

20

15

37.6

7

6

—

—

PEAD-RP4EA

Cooling

10,000

3.08

0.35

1.55

8.04

2.69

0.95

69.4

45.8

9.8

5

27

19

15.5

35

24

0.83

0.18

(27.4)

(9.7)

(26.2)

(7.0)

0.35

1.55

9.74

2.57

0.69

68.8

—

0.9

5

20

15

37.0

7

6

—

—

PEAD-RP3EA

PEAD-RP6EAPEAD-RP5EAPEAD-RP4EAPEAD-RP3EA

Cooling

7,100

2.15

D.B.

W.B.

D.B.

D.B.

W.B.

The unit of pressure has been changed to Mpa based on international SI system.

The conversion factor is : 1 (Mpa) = 10.2 (kgf/cm

2

)

Heating

8,000

2.34

Heating

11,200

3.48

Heating

14,000

4.11

Heating

16,000

4.76

1 , 50

230

PUHZ-RP3VHA

1, 50

230

Page 19

19

5

REFRIGERANT SYSTEM DIAGRAM

PEAD-RP3, 4, 5, 6EA

Indoor unit

Indoor

heat

exchanger

Thermistor TH5

(Cond./Eva.

temperature)

Strainer

Refrigerant flow in cooling

Refrigerant flow in heating

Refrigerant GAS pipe connection

Thermistor TH1

(Room temperature)

Thermistor TH2

Pipe temperature

(Liquid)

Distributor

with strainer

Refrigerant LIQUID pipe connection

Page 20

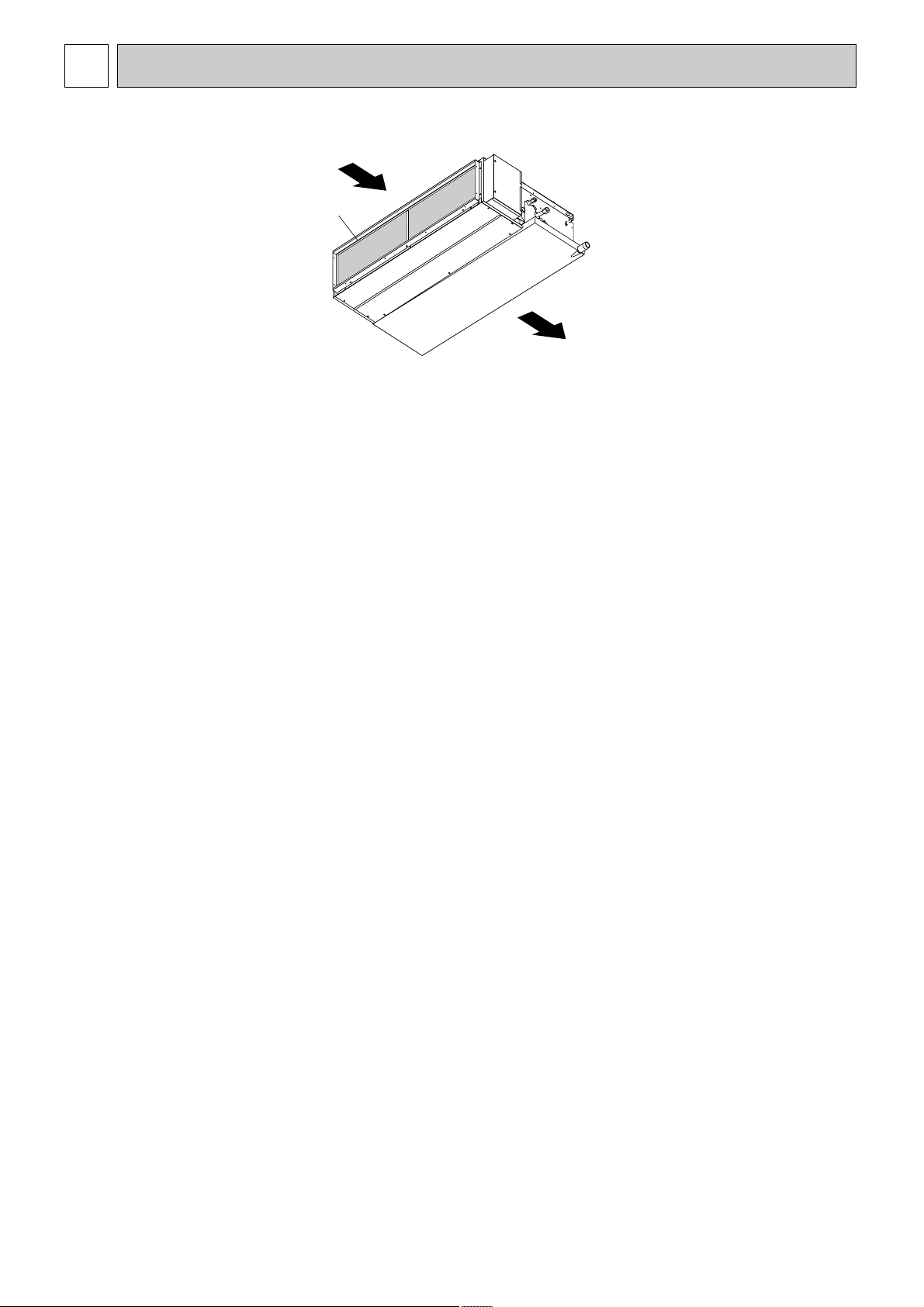

20

2. REMOTE CONTROLLER

6

OUTLINES & DIMENSIONS

1. INDOOR UNIT

PEAD-RP3, 4, 5, 6EA

Model

2801012

RP3

1252

RP4.5

1

Refrigerant piping flare connection (liquid ø9.52 copper tube) : HP

Refrigerant piping flare connection (gas øF copper tube) : LP

2

Drain 25A (male screw)

3

Electrical parts box

4

5

Drain Pump (Option)

6

Drain Pipe (Option) Flexible joint VP25(I.D.ø32)

7

Filter

Air inlet

. . .

30

30

319

261

181 40

7

3 3

EDCBA

12841310370360

F

15.8810441070290

For PUHZ-RP type :15.88

For PU(H)-P type :19.05158416104704601552RP6

680

282

4

Service space:500 or more

450

Access door

450

365-465

Set

30

1053

1

2

35

20

122

210

140

Air outlet

307

45

323

50-150

81

55

197

308

81

13

44

75

243

6

113

5

3

A

C B 81

C B 81

A

E 13

12-ø3

10

Lifting bolt hole

375

80

10

30D

(4X22)

12-ø3

Keep duct-work length 850mm or more.

Be sure to apply the air filter (field supply) near the air inlet grille.

(Front view) (Side view) (Rear view)

120

130

19

83.5

46

Page 21

21

7

WIRING DIAGRAM

MF

C

(White)

External static pressure : 70Pa(7mmAq)

Optional parts

MF

C

External static

pressure 130Pa(13mmAq)

INDOOR UNIT

P.B

Optional parts

DP

I.B

3

CNP

(BLU)

PIPE

CN29

(BLK)

21

1

LED3 LED3 LED3

SWE

ON

OFF

Optional parts

DRAIN PUMP

DRAIN

CN31

(WHT)

12

DS

FAN

(WHT)

GRE

1

3

5

6

(Red)

7

PNK

PNK

BLK

1

3

5

6

5

3

1

SW2

X6 X5 X4

SW1

X4

X5

X6

3

TH1TH2TH5

POWER

CN03

(RED)

YLW

13

ORN

BRN

5

3

2

1

1

2

CN31

LIQUID

2

CN21

1

(WHT)

INTAKE

2

CN20

1

(RED)

HEATER

CN24

(YLW)

WHT

BLK

1

2

WIRELESS

CN90

(WHT)

POWER

CN2D

(WHT)

TRANSMISSION WIRE

CN22

DC12V

2

1

CN32CN41

CN2L

CN2S(WHT)

2

DC14V

1

3

2

1

CONT.BOARD

CN02(WHT)

ZNR

TB5

2

PUR

TO RMOTE CONTROLLER

PUR

1

DC12V

F

OUTDOOR

CN01(BLU)

TB4

YLW

ORN

BRN

S1

S2

S3

TO OUTDOOR UNIT

1

2

3

SYMBOL

I.B

INDOOR CONTROLLER BOARD

CN2L

CONNECTOR(LOSSNAY)

CONNECTOR(REMOTE SWITCH)

CN32

CONNECTOR(HA TERMINAL-A)

CN41

POWER SUPPLY(I.B)

LED1

POWER SUPPLY(REMOTE CONTROLLER)

LED2

TRANSMISSION(INDOOR/OUTDOOR)

LED3

JUMPER WIRE(MODEL SELECTION)

SW1

JUMPER WIRE(CAPACITY CORD)

SW2

SWITCH(EMERGENCY OPERATION)

SWE

RELAY(FAN MOTOR)

X4

RELAY(FAN MOTOR)

X5

RELAY(FAN MOTOR)

X6

NAME

SYMBOL

P.B

INDOOR POWER BOARD

FUSE(4A)

F1

VARISTOR

ZNR

DRAIN PUMP

(OPTIONAL PARTS)

DPDSDRAIN PUMP

DRAIN SENSOR

NAME NAME

SYMBOL

C

CAPACITOR(FAN MOTOR)

FAN MOTOR

MF

TERMINAL BLOCK(REMOTE CONTROLLER)

TB5

TB4

TERMINAL BLOCK

(INDOOR/OUTDOOR CONNECTING LINE)

TH1

ROOM TEMPERATURE THERMISTOR

(0ºC/15KΩ,25ºC/5.4KΩ DETECT)

TH2

PIPE TEMPERATURE THERMISTOR/LIQUID

(0ºC/15KΩ,25ºC/5.4KΩ DETECT)

TH5

COND./EVA. TEMPERATURE THERMISTOR

(0ºC/15KΩ,25ºC/5.4KΩ DETECT)

MODELS

<For manufacture>

RP3EA

J11

RP4EA

<For service board>

RP5EA

RP6EA

J12

SW1

J13

J14

54321

J15

ON

OFF

Manufacture

J21

J22

J23

J24

J21

J22

J23

J24

J21

J22

J23

J24

J21

J22

J23

J24

SW2

Service board

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Page 22

22

8

TROUBLESHOOTING

<Error code display by self-diagnosis and actions to be taken for service (summary)>

Present and past error codes are logged and displayed on the wired remote controller and control board of outdoor unit.

Actions to be taken for service, which depends on whether or not the inferior phenomenon is reoccurring at service, are summarized in the table below. Check the contents below before investigating details.

8-1.TROUBLESHOOTING

Unit conditions at service

Error code

Actions to be taken for service (summary)

The inferior phenomenon is

reoccurring.

Displayed

Not displayed

Judge what is wrong and take a corrective action according to “Self-diagnosis action table” (P.23).

Conduct trouble shooting and ascertain the cause of the

inferior phenomenon according to “Trouble shooting by

inferior phenomena” (P.26).

The inferior phenomenon is

not reoccurring.

Logged

Not logged

1Consider the temporary defects such as the work of

protection devices in the refrigerant circuit including

compressor, poor connection of wiring, noise and etc.

Re-check the symptom, and check the installation en vironment, refrigerant amount, weather when the infe rior phenomenon occurred, matters related to wiring

and etc.

2Reset error code logs and restart the unit after finishing

service.

3There is no abnormality concerning of parts such as

electrical component, controller board, remote controll er and etc.

1Recheck the abnormal symptom.

2Conduct trouble shooting and ascertain the cause of

the inferior phenomenon according to “Trouble shooting

by inferior phenomena” (P.26).

3Continue to operate unit for the time being if the cause

is not ascertained.

4There is no abnormality concerning of parts such as el ectrical component, controller board, remote controller

and etc.

Page 23

23

8-2. SELF-DIAGNOSIS ACTION TABLE

Error Code

Meaning of error code and detection method

Case

Judgment and action

P1

Abnormality of room temperature thermistor (TH1)

1 The unit is in three-minute resume pre-

vention mode if short/open of thermistor

is detected. Abnormal if the unit does

not reset normally after three minutes.

(The unit returns to normal operation, if

it has normally reset.)

2 Constantly detected during cooling, dr y-

ing, and heating operation.

Short: 90: or more

Open: -40: or less

1 Defective thermistor character-

istics

2 Contact failure of connector

(Insert failure)

3 Breaking of wire or contact fail-

ure of thermistor wiring

4 Defective indoor control p.c.

board

1–3 Check resistance value of thermistor.

0: ······15.0k"

10: ····9.6k"

20: ····6.3k"

30: ····4.3k"

40: ····3.0k"

If you put force on (draw or bend) the lead wire

with measuring resistance value of thermistor

breaking of wire or contact failure can be

detected.

2 Check contact failure of connector.

Put the power on again and check restart

after inserting connector again.

4 Check room temperature display on remote

controller

Replace indoor control p.c.board if there is

abnormal difference with actual room temperature.

There is no abnormality if none of above

comes within the unit.

Put the power off, and on again to operate.

P2

Abnormality of pipe temperature thermistor/Liquid (TH2)

1 The unit is in three-minute resume pre-

vention mode if short/open of thermistor

is detected. Abnormal if the unit does

not reset normally after three minutes.

(The unit returns to normal operation, if

it has normally reset.)

2 Constantly detected during cooling, dr y-

ing, and heating (except defrosting)

operation.

Short: 90: or more

Open: -40: or less

1 Defective thermistor character-

istics

2 Contact failure of connector

(Insert failure)

3 Breaking of wire or contact fail-

ure of thermistor wiring

4 Defective refrigerant circuit is

causing thermistor temperature

of 90: or more or -40: or

less.

5 Defective indoor control p.c.

board.

1–3 Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2 Check contact failure of connector

Put the power on and check restart after

inserting connector again.

4 Check pipe <liquid> temperature with remote

controller in test run mode. If pipe <liquid>

temperature is exclusively low (in cooling

mode) or high (in heating mode), refrigerant

circuit may have defective.

5 Check pipe <liquid> temperature with remote

controller in test run mode. If there is exclusive difference with actual pipe <liquid> temperature, replace indoor control p.c.board.

There is no abnormality if none of above

comes within the unit.

Put the power off, and on again to operate.

P4

Abnormality of drain sensor (DS)

1 Suspensive abnormality, if short/open of

thermistor is detected for 30 seconds

continuously.

Put off compressor and indoor fan.

2 Shor t/open is detected for 30 seconds

continuously during suspensive abnormality.

(The unit returns to normal operation, if

it has normally reset.)

3 Detect the following condition.

• During cooling and drying operation.

• In case that pipe <liquid> temperature-

room temperature <-10deg

(Except defrosting)

• When pipe <liquid> temperature or

room temperature is short/open temperature.

• During drain pomp operation.

1 Defective thermistor character-

istics

2 Contact failure of connector

(Insert failure)

3 Breaking of wire or contact fail-

ure of drain sensor wiring

4 Defective indoor control p.c.

board.

1–3 Check resistance value of thermistor.

0: ······6.0k"

10: ····3.9k"

20: ····2.6k"

30: ····1.8k"

40: ····1.3k"

2 Check contact failure of connector.

Put the power on again and check restart

after inserting connector again.

4 Replace indoor control p.c. board if drain

pump operates with the line of drain sensor

connector CN31-1 and 2 is short-circuited,

and abnormality reappears.

There is no abnormality if none of above

comes within the unit. Put the power off, and

on again to operate.

P5

Malfunction of drain pump

1 Suspensive abnormality, if thermistor of

drain sensor is let heat itself and temperature rises slightly. Put off compressor and indoor fan.

2 Drain pomp is abnormal if the condition

above is detected during suspensive

abnormality.

3 Constantly detected during drain pomp

operation.

1 Malfunction of drain pump

2 Defective drain

Clogged drain pump

Clogged drain pipe

3 Attached drop of water at the

drain sensor

• Drops of drain trickles from

lead wire.

• Clogged filter is causing

wave of drain.

4 Defective indoor control p.c.

board.

1 Check if drain-up machine works.

2 Check drain function.

3 Check the setting of lead wire of drain sensor

and check clogs of the filter.

4 Replace indoor control p.c. board if drain

pump operates with the line of drain sensor

connector CN31-1 and 2 is short-circuited

and abnormality reappears.

There is no abnormality if none of above

comes within the unit. Put the power off, and

on again to operate.

Note: Refer to the manual of outdoor unit for the details of display such as F,

U, and other E.

Page 24

24

Error Code

Meaning of error code and detection method

Case

Judgment and action

P6

Freezing/overheating protection is

working

1 Freezing protection (Cooling mode)

The unit is in six-minute resume prevention mode if pipe <liquid or condenserevaporator> temperature stays under

-15: for three minutes, three minutes

after the compressor started. Abnormal

if it stays under -15: for three minutes

again within 16 minutes after six-minute

resume prevention mode.

2 Frost abnormality (Only for the combina-

tion with inverter-type outdoor unit)

Suspensive abnormal if unit operates in

frost prevention mode (below) for 9

minutes or more. After that, when frost

prevention mode is released and

compressor restarts its operation, unit is

not detected as abnormal if compressor

keeps operating for 20 minutes continuously and abnormal if compressor stops

operating within 20 minutes and unit

operates in frost prevention mode for

more than 9 minutes again. (Not abnormal if unit stops operating in frost prevention mode within 9 minutes)

<Frost prevention mode>

If pipe <liquid or condenser-evaporator>

temperature is 2: or below when 16

minutes has passed after compressor

starts operating, unit will start operating

in frost prevention mode which stops

compressor operation. After that, when

pipe <liquid or condenser-evaporator>

temperature stays 10: or more for 3

minutes, frost prevention mode will be

released and compressor will restart its

operation.

3 Overheating protection (Heating mode)

The units is in six-minute resume prevention mode if pipe <condenser-evaporator> temperature is detected as over

74: after the compressor started.

Abnormal if the temperature of over

74: is detected again within 10 minutes

after six-minute resume prevention

mode.

P8

1 Slight temperature difference

between indoor room temperature and pipe <liquid or condenser-evaporator> temperature thermistor

• Shortage of refrigerant

• Disconnected holder of pipe

<liquid or condenser-evaporator> thermistor

• Defective refrigerant circuit

2 Converse connection of exten-

sion pipe (on plural units connection)

3 Converse wiring of indoor/out-

door unit connecting wire (on

plural units connection)

4 Defective detection of indoor

room temperature and pipe

<liquid or condenser-evaporator> temperature thermistor

5 Defective stop valve action

(It does not open fully.)

14Check pipe <liquid or condenser-evapora-

tor> temperature with room temperature

display on remote controller and outdoor

control board.

23Check converse connection of extension

pipe or converse wiring of indoor/outdoor

unit connecting wire.

(Cooling or drying mode)

1 Clogged filter (reduced airflow)

2 Shor t cycle of air path

3 Low-load (low temperature)

operation beyond the tolerance

range

4 Defective indoor fan motor

Fan motor is defective.

Control board is defective.

5 Defective outdoor fan control

(middle season, winter season)

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

(Heating mode)

1 Clogged filter (reduced airflow)

2 Short cycle of air path

3 Over-load (high temperature)

operation beyond the tolerance

range

4 Defective indoor fan motor

Fan motor is defective.

Control board is defective.

5 Malfunction of outdoor fan.

(Season when air conditioner

is not used.)

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

8 Bypass circuit of outdoor unit

is defective.

(Cooling or drying mode)

1 Check clogs of the filter.

2 Remove shields.

4 Measure the resistance of fan motor's wind-

ing.

Measure the output voltage of fan's connector (FAN) on control board.

WThe control board should be normal when

a current of AC100V to 240V is detected

while fan motor is connected.

5 Check action of outdoor fan motor.

67Check operating condition of refrigerant cir-

cuit.

(Heating mode)

1 Check clogs of the filter.

2 Remove shields.

4 Measure the resistance of fan motor's wind-

ing.

Measure the output voltage of fan's connector (FAN) on control board.

WThe control board should be normal when

a current of AC100V to 240V is detected

while fan motor is connected.

5Check the operation of fan motor in outdoor

unit.

6~8Check operating condition of refrigerant

circuit.

Abnormality of pipe temperature

(Cooling mode)

Detected as abnormal when the pipe temperature is not in the cooling range 3 minutes later of compressor start and 6 minutes later of the liquid or condenser/evaporator pipe is out of cooling range.

Note 1) It takes at least 9 min. to detect

abnormality.

Note 2) Abnormality P8 is not detected in

drying mode.

Cooling range- = TH – intake temperature

[ 3 deg

TH: Lower temperature between: liquid

pipe temperature and condenser/ evaporator temperature

(Heating mode)

When 10 seconds have passed after the

compressor starts operation and the hot

adjustment mode has finished, the unit is

detected as abnormal when

condenser/evaporator pipe temperature is

not in heating range within 20 minutes.

Note 3) It takes at least 27 minutes to

detect abnormality.

Note 4) It excludes the period of defrosting

(Detection restarts when defrosting mode is over)

Heating operation = 3 deg [ (Condenser/

Evaporator temperature – intake

temperature)

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

A-Control Service Tool SW2 setting

Temperature display of indoor liquid pipe

Indoor 1

Temperature display of indoor liquid pipe

Indoor 2

Temperature display of indoor condenser/

evaporator pipe Indoor 1

Temperature display of indoor condenser/

evaporator pipe Indoor 2

In case of checking pipe temperature

with outdoor control board, be sure to

connect A-control service tool

(PAC-SK52ST).

(

)

Page 25

25

Error Code

Meaning of error code and detection method

Case

Judgment and action

P9

Abnormality of pipe temperature thermistor / Condenser-Evaporator (TH5)

1 The unit is in three-minute resume pro-

tection mode if short/open of thermistor

is detected. Abnormal if the unit does

not get back to normal within three minutes. (The unit returns to normal operation, if it has normally reset.)

2 Constantly detected during cooling, dr y-

ing, and heating operation (except

defrosting)

Short: 90: or more

Open: -40: or less

1 Defective thermistor character-

istics

2 Contact failure of connector

(Insert failure)

3 Breaking of wire or contact fail-

ure of thermistor wiring

4 Temperature of thermistor is

90: or more or -40: or less

caused by defective refrigerant

circuit.

5 Defective indoor control p.c.

board

1–3 Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2 Check contact failure of connector

Put the power on and check restart after

inserting connector again.

4 Operate in test run mode and check pipe

<condenser- evaporator> temperature with

outdoor control p.c.board. If pipe <condenser-evaporator> temperature is exclusively low (in cooling mode) or high (in heating mode), refrigerant circuit may have

defective.

5 Operate in test run mode and check pipe

<condenser- evaporator> temperature with

outdoor control p.c.board. If there is exclusive difference with actual pipe <condenserevaporator> temperature replace indoor control p.c.board

There is no abnormality if none of above

comes within the unit.

Put the power off and on again to operate.

E4

Remote controller signal receiving error

1 Abnormal if indoor control p.c. board can

not receive normally any data from

remote controller or from other indoor

control p.c.board for three minutes.

2 Indoor control p.c.board cannot receive

any signal from remote controller for two

minutes.

1 Check disconnection or looseness of indoor

unit or transmission wire of remote controller.

2 Set one of the remote controllers “main”.

If there is no problem with the action above.

3 Diagnose remote controllers.

a) When “RC OK” is displayed,

Remote controllers have no problem.Put

the power off, and on again to check.If

abnormality generates again, replace

indoor control p.c.board.

b) When “RC NG” is displayed,

Replace remote controller.

c) When “RC E3” is displayed,

d) When “ERC 00-06” is displayed,

➜Noise may be causing abnormality.

✽ If the unit is not normal after replacing

indoor control p.c.board in group control, indoor control p.c.board of address

“0” may be abnormal.

E5

Remote controller transmitting error

1 Abnor mal if indoor control p.c. board

cannot check the blank of transmission

path for three minutes.

2 Abnor mal if indoor control p.c. board

cannot finish transmitting 30 times

consecutively.

12 Put the power off, and on again to check. If

abnormality generates again, replace

indoor control p.c.board.

1 Contact failure at transmission

wire of remote controller

2 All remote controllers are set

as “sub” remote controller. In

this case, E0 is displayed on

remote controller, and E4 is

displayed at outdoor LED.

3 Defective transmitting receiving

circuit of remote controller

4 Defective transmitting receiving

circuit of indoor control p.c.

board

5 Noise has entered into the

transmission wire of remote

controller.

1 Defective transmitting receiving

circuit of indoor control p.c.

board

2 Noise has entered into the

transmittion wire of remote

controller.

E6

(

e6)

1 Contact failure, short circuit or,

mis-wiring (converse wiring) of

indoor/outdoor unit connecting

wire

2 Defective transmitting receiving

circuit of indoor control p.c.

board

3 Defective transmitting receiving

circuit of indoor control p.c.

board

4 Noise has entered into

indoor/outdoor unit connecting

wire.

✽ Check LED display on outdoor control p.c.

board.

Refer to EA-EC item (on outdoor unit section) if LED displays EA-EC.

1 Check disconnection or looseness of indoor/

outdoor unit connecting wire of indoor unit or

outdoor unit.

Check all the units in case of twin triple

indoor unit system.

2-4 Put the power off, and on again to check.

If abnormality generates again, replace

indoor control p.c.board or outdoor control p.c.board.

✽ Other indoor control p.c.board may have

defective in case of twin triple indoor unit

system.

E7

Indoor/outdoor unit communication

error (Transmitting error)

Abnormal if “1” receiving is detected 30

times continuously though indoor control

p.c.board has transmitted “0”.

1 Defective transmitting receiving

circuit of indoor control p.c.

board

2 Noise has entered into power

supply.

3 Noise has entered into outdoor

control wire.

1-3 Put the power off, and on again to check.

If abnormality generates again, replace

indoor control p.c.board.

Indoor/outdoor unit communication

error (Signal receiving error)

1 Abnor mal if indoor control p.c. board

cannot receive any signal normally for

six minutes after putting the power on.

2 Abnor mal if indoor control p.c. board

cannot receive any signal normally for

three minutes.

3 Consider the unit abnor mal under the

following condition:When two or more

indoor units are connected to one outdoor unit, indoor control p.c.board cannot receive a signal for three minutes

from outdoor control p.c.board, a signal

which allows outdoor controller board to

transmit signals.

123456

ON

OFF

123456

ON

OFF

A-Control Service Tool SW2 setting