Mitsubishi PKA-RP2.5FAL, PCA-RP2GA, PCA-RP3GA, PCA-RP4GA, PCA-RP5GA Service Technical Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SERVICE TECHNICAL GUIDE

<Indoor unit>

[Model names] [Service Ref.]

PLA-RP·AA PLA-RP·AA

PLA-RP·AA1

PLA-RP·AA.UK

PLA-RP·AA1.UK

PKA-RP·GAL PKA-RP·GAL

PKA-RP·FAL PKA-RP·FAL

PCA-RP·GA PCA-RP·GA

PEA-RP·EA PEA-RP·EA.TH-A

PEAD-RP·EA PEAD-RP·EA.UK

PEAD-RP·EA1.UK

PEAD-RP·GA PEAD-RP·GA.UK

<Outdoor unit>

[Model names] [Service Ref.]

No. OCT04

REVISED EDITION-A

R410A

Revision:

• PKA-RP•GAL, PKA-RP•FAL,

PCA-RP•GA, PEAD-RP•GA,

PUHZ-RP•VHA1 and

PUHZ-RP•VHA1-A are added in

REVISED EDITION-A.

• Please void OCT04.

PUHZ-RP·VHA PUHZ-RP·VHA

PUHZ-RP·VHA1

PUHZ-RP·VHA-A

PUHZ-RP·VHA1-A

CONTENTS

1. PAIRING TABLE OF THE INDOOR AND OUTDOOR UNIT·····2

2. SPECIFICATIONS FOR ELECTRICAL WORK ·························3

3. WIRING DIAGRAM·····································································6

4. REFRIGERANT SYSTEM DIAGRAM ······································15

5. HOW TO CHECK THE PARTS ················································24

6. MICROPROCESSOR CONTROL·············································33

7. INDOOR UNIT CONTROL························································39

8. OUTDOOR UNIT CONTROL····················································47

9. DIP SWITCH FUNCTION ·························································63

10. FUNCTION SETTING ·······························································76

11. TEST RUN • REPLACEMENT OPERATION

& EMERGENCY OPERATION···················································86

12. SELF-DIAGNOSIS····································································92

13. TEST POINT DIAGRAM·························································118

14. TROUBLESHOOTING····························································127

15. SYSTEM CONTROL·······························································131

1

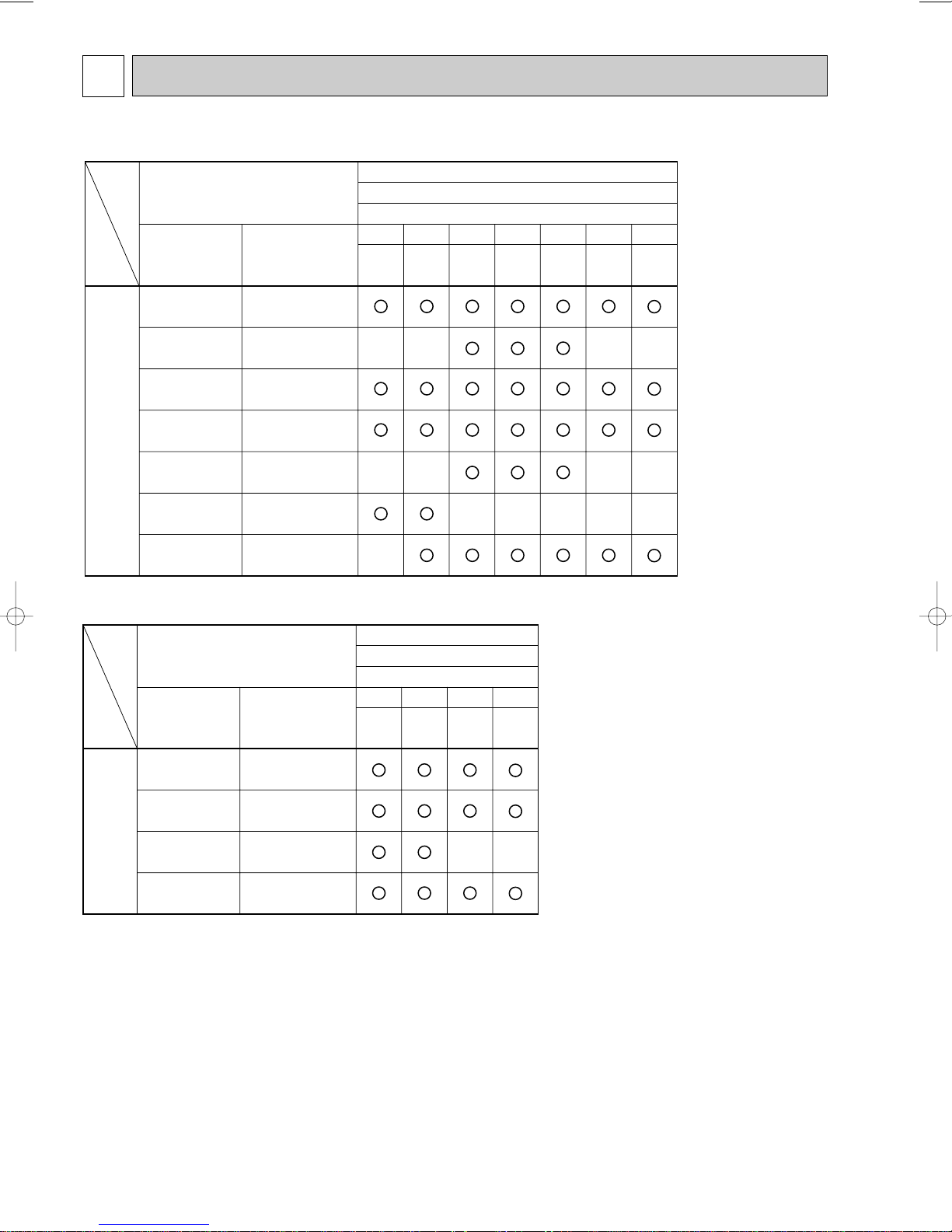

Heat pump type

Outdoor unit

PUHZ-RP

PEAD-RP·EA.UK

PEAD-RP·EA1.UK

PLA-RP·AA.UK

PLA-RP·AA1.UK

PEAD-RP·GA.UK

PLA-RP·AA

PLA-RP·AA1

—

—

OC293

REVISED EDITION-B

OC297

REVISED EDITION-C

PKA-RP·GAL

OC301

REVISED EDITION-A

PKA-RP·FAL

OC305

PCA-RP·GA

OC311

Indoor unit

Service

Manual No.

Service Ref.

45

Heat pump

without

electric heater

VHA VHA

VHA

1

VHA

VHA

1

VHA

VHA

1

6

3

2 2.5

VHA VHA VHA

1.6

——

—

—

—

—

—

————

———

Heat pump type

Outdoor unit

PUHZ-RP

PEA-RP·

EA.TH-A

PLA-RP·AA

PLA-RP·AA1

OC293

REVISED EDITION-B

OC299

REVISED EDITION-A

PKA-RP·FAL

PCA-RP·GA OC311

OC301

REVISED EDITION-A

Indoor unit

Service

Manual No.

Service Ref.

45

Heat pump

without

electric heater

VHA-A

VHA-A

VHA1-A

VHA-A

VHA1-A

—

VHA-A

VHA1-A

—

6

3

PAIRING TABLE OF THE INDOOR AND OUTDOOR UNITS

2

2

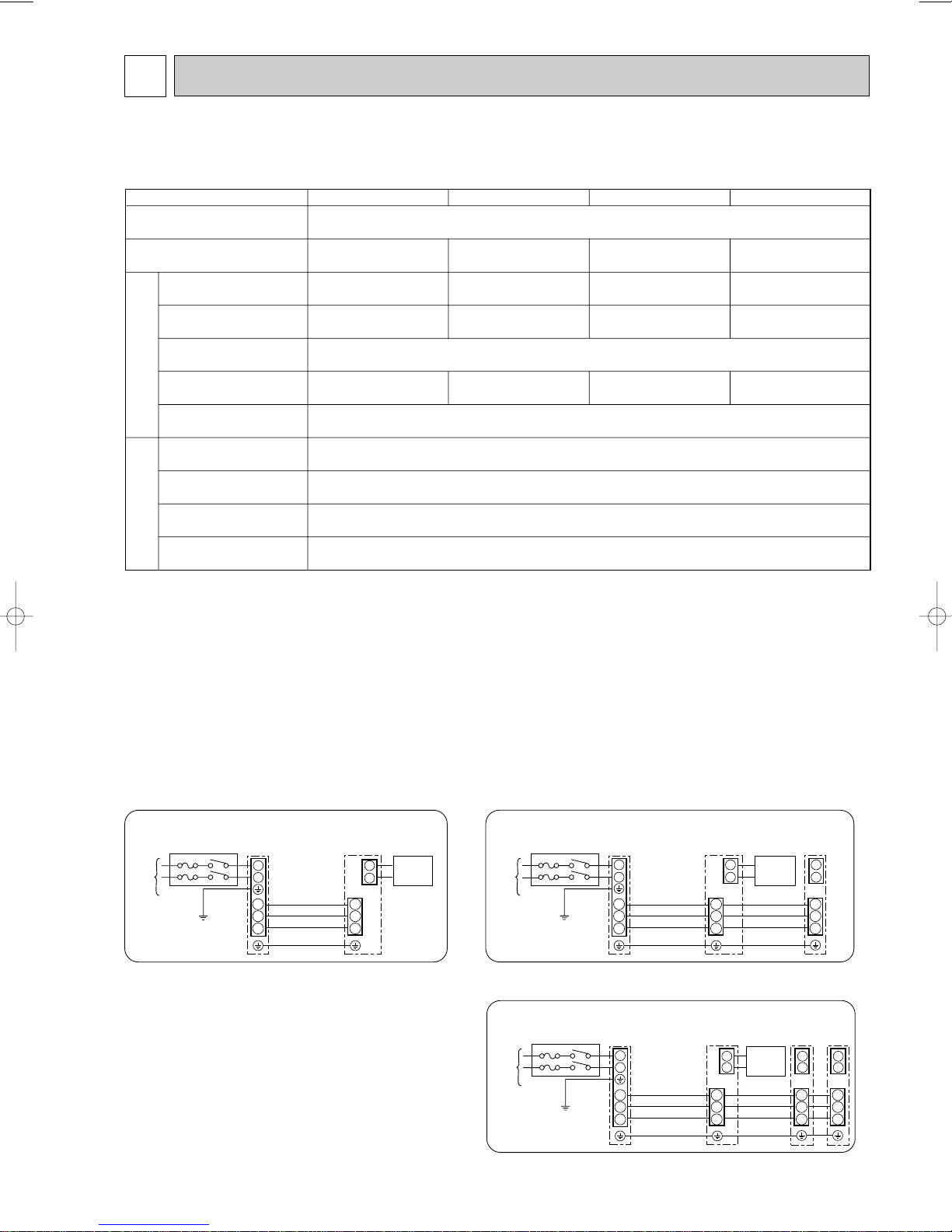

Outdoor unit p

ower supply

*1

*2

*3

*4

*4

*4

*4

Outdoor unit power supply earth

Indoor unit - Outdoor unit

Indoor unit - Outdoor unit earth

Remote controller - Indoor unit

Outdoor unit L-N

Indoor unit-Outdoor unit S1-S2

Indoor unit-Outdoor unit S2-S3

Remote controller - Indoor unit

16A

2 o Min. 1.5

1 o Min. 1.5

1 o Min. 2.5

25A

2 o Min. 2.5

1 o Min. 2.5

1 o Min. 2.5

32A

2 o Min. 4

1 o Min. 4

1 o Min. 2.5

40A

2 o Min. 6

1 o Min. 6

1 o Min. 2.5

Indoor unit model

~ / N (Single) 50Hz,

220-230-240V

2 o 0.69 (Non-polar)

AC 220-230-240V

AC220-230-240V

DC24V

DC14V

Outdoor unit power supply

Outdoor unit input capacity

Main switch (Breaker)

Wiring

Wire No. o size (mm

2

)

Circuit

rating

RP1.6, 2V RP2.5, 3V RP4, 5V RP6V

3 o 2.5 (polar)

1

2

S1

S2

S3

S1

S2

S3

Indoor/outdoor

unit connection

cable

Indoor

unit

Unit

power

supply

Outdoor

unit

Remote

controller

L

N

Grounding

L

N

1

2

1

2

S1

Indoor

unit

S2

S3

S1

S2

S3

S1

S2

S3

Unit

power

supply

Indoor/outdoor

unit connection

cable

Indoor

unit

Outdoor

unit

Remote

controller

Grounding

1

2

1

2

1

2

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

Indoor/outdoor

connection cable

Indoor

unit

Unit

power

supply

Indoor

unit

Indoor

unit

Outdoor

unit

Remote

controller

L

N

Grounding

SPECIFICATIONS FOR ELECTRICAL WORK

2-1. Field electrical wiring(power wiring specifications)

PUHZ-RP•VHA

PUHZ-RP•VHA-A

*1 Abreaker with at least 3mm contact separation in each poles shall be provided.

Use non-fuse breaker (NF) or earth leakage breaker (NV).

*2 Max. 50m Total Max, including all indoor/ indoor connection is 80m.

*3 10m wire is attached in the remote controller accessory.

*4 The figures are NOT always against the ground.

S3 terminal has DC24V against S2 terminal. However, between S3 and S1, these terminals are NOT electrically insulated

by the transformer or other device.

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Power supply cords and indoor/ Outdoor unit connecting cords shall not be lighter than polychloroprene

sheathed flexible cord. (design 254 IEC 57)

3. Install an earth longer and thicker than other cables.

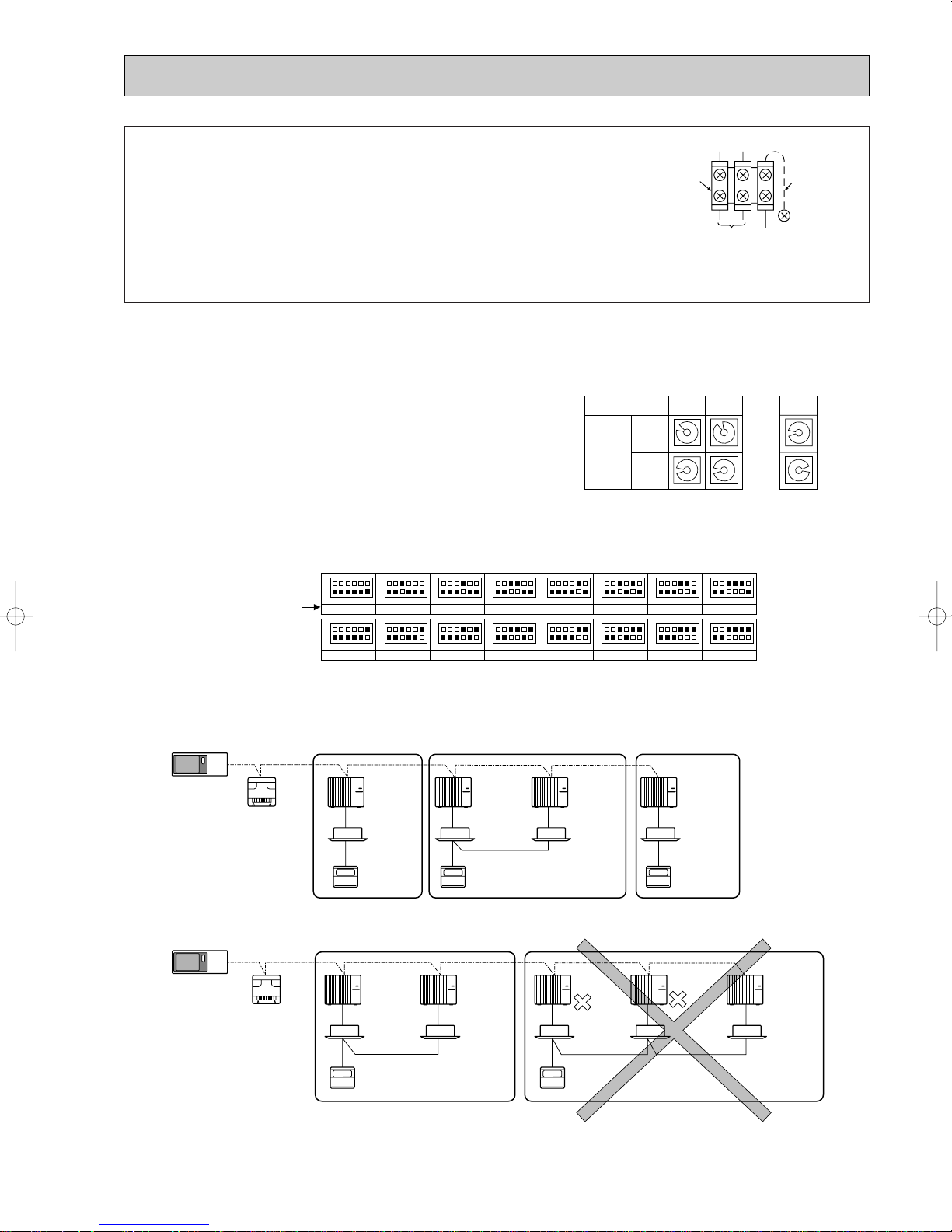

1:1 system Synchronized twin and triple system Electrical wiring

• Synchronized twin

• Synchronized triple

3

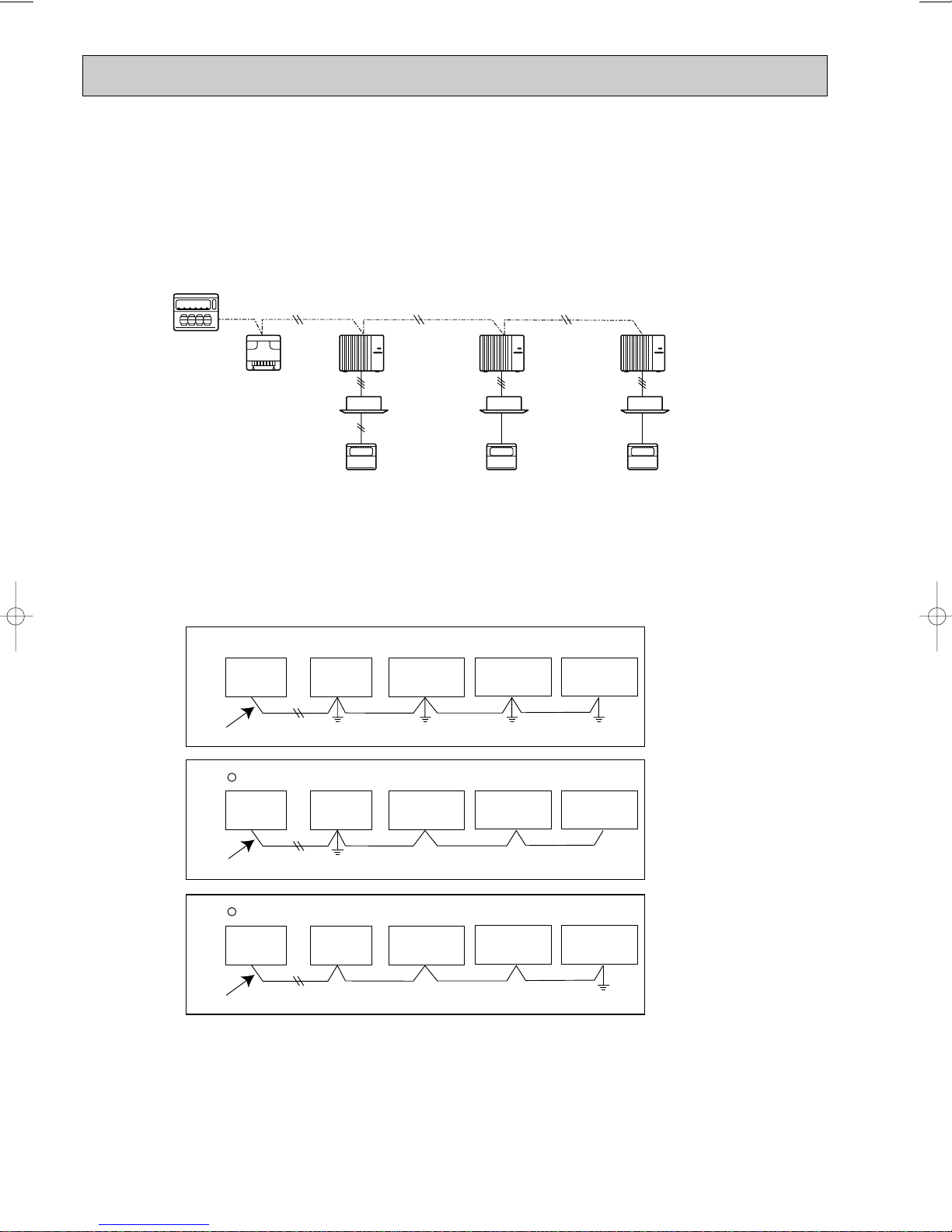

2-2. M-NET wiring method

Group

remote

controller

Refrigerant

address 00

M-NET

address 01

A-control

remote

controller

A-control

remote

controller

A-control

remote

controller

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 00

M-NET

address 03

Power

supply

unit for

transmission

wire

Central

remote

controller

M-NET transmission wire

✕ Bad example (Multi spot grounding of shield wire)

Good example 1 (Single spot grounding of shield wire)

Power

supply

appliance

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Good example 2 (Single spot grounding of shield wire)

(Points to notice)

(1) Outside the unit, transmission wires should stay away from electric wires in order to prevent electromagnetic noise from

making an influence on the signal communication. Place them at intervals of more than 5cm. Do not put them in the same

conduit tube.

(2) Terminal block (TB7) for transmission wires should never be connected to 220~240V power supply. If it is connected,

electronic parts on M-NET p.c. board may be burn out.

(3) Use 2-core x 1.25mm2shield wire (CVVS, CPEVS) for the transmission wire. Transmission signals may not be sent or

received normally if different types of transmission wires are put together in the same multi-conductor cable. Never do this

because this may cause a malfunction.

It would be ok if M-NET wire (non-polar, 2-cores) is arranged in addition to the wiring for A-control.

(4) Ground only one of any appliances through M-NET transmission wire (shield wire). Communication error may occur due to

the influence of electromagnetic noise.

“Ed” error will appear on the LED display of outdoor unit.

“0403” error will appear on the central-control remote controller.

If there are more than two grounding spots on the shield wire, noise may enter into the shield wire because the ground wire

To avoid communication errors caused by noise, make sure to observe the single spot grounding method described in the

and shield wire form one circuit and the electric potential difference occurs due to the impedance difference among grounding spots. In case of single spot grounding, noise does not enter into the shield wire because the ground wire and shield

wire do not form one circuit.

installation manual.

4

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

12

~

50

M-NET Address No.

<Setting example>

Switng

setting

SW11

ones

digit

SW12

tens

digit

OFF

ON

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

0

Refuigrant

address

OFF

ON

8

OFF

ON

1

OFF

ON

9

OFF

ON

10

OFF

ON

11

OFF

ON

12

OFF

ON

13

OFF

ON

14

OFF

ON

15

OFF

ON

2

OFF

ON

3

OFF

ON

4

OFF

ON

5

OFF

ON

6

OFF

ON

7

System

controller

A-control

remote

controller

Group A Group B Group C

A-control

remote

controller

TB5

A-control

remote

controller

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 00

M-NET

address 04

Power

supply

unit for

transmission

wire

A-control

remote

controller

A-control

remote

controller

TB5

Group A Group B

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 01

M-NET

address 02

Refrigerant

address 00

M-NET

address 04

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 02

M-NET

address 05

System

controller

Power

supply

unit for

transmission

wire

● M-NET wiring

(1) Use 2-core x 1.25mm

(Excluding the case connecting to system controller.)

(2) Connect the wire to the M-NET terminal block.Connect one core of the

transmission wire (non-polar) to Aterminal and the other to B. Peel the

shield wire, twist the shield part to a string and connect it to S terminal.

(3) In the system which several outdoor units are being connected, the terminal

(A, B, S) on M-NET terminal block should be individually wired to the other

2

shield wire for electric wires.

M-NET

terminal

block

ABS

Transmission

wire

Shield

part

Ground

wire

outdoor unit’s terminal, i.e. Ato A, B to B and S to S.In this case, choose one of those outdoor units and drive a screw

to fix an ground wire on the plate as shown on the right figure.

2-2-1. M-NET address setting

In A-control models, M-NET address and refrigerant address should be set only for the outdoor unit. Similar to Free Combo

system, there is no need to set the address of outdoor unit and remote controller. To construct a central control system, the

setting of M-NET address should be conducted only upon the outdoor unit. The setting range should be 1 to 50 (the same as

that of the indoor unit in Free Combo system), and the address number should be consecutively set in a same group.

Address number can be set by using rotary switches

(SW11 for ones digit and SW12 for tens digit), which

is located on the M-NET board of outdoor unit.

(Factory setting: all addresses are set to “0”.)

2-2-2. Refrigerant address setting

In case of multiple grouping system (multiple refrigerant circuits in one group), indoor units should be connected by remote

controller wiring (TB5) and the refrigerant address needs to be set. Leave the refrigerant addresses to “00” if the group setting is not conducted. Set the refrigerant address by using DIP SW1-3 to -6 on the outdoor controller board. [Factory setting:

all switches are OFF. (All refrigerant addresses are “00”.)]

2-2-3. Regulations in address settings

In case of multiple grouping system, M-NET and refrigerant address settings should be done as explained in the above section. Set the lowest number in the group for the outdoor unit whose refrigerant address is “00” as its M-NET address.

w Refrigerant addresses can be overlapped if they are in the different group.

w In group B, M-NET address of the outdoor unit whose refrigerant address is “00” is not set to the minimum in the group. As

“3” is right for this situation, the setting is wrong. Taking group A as a good sample, set the minimum M-NET address in

the group for the outdoor unit whose refrigerant address is “00”.

5

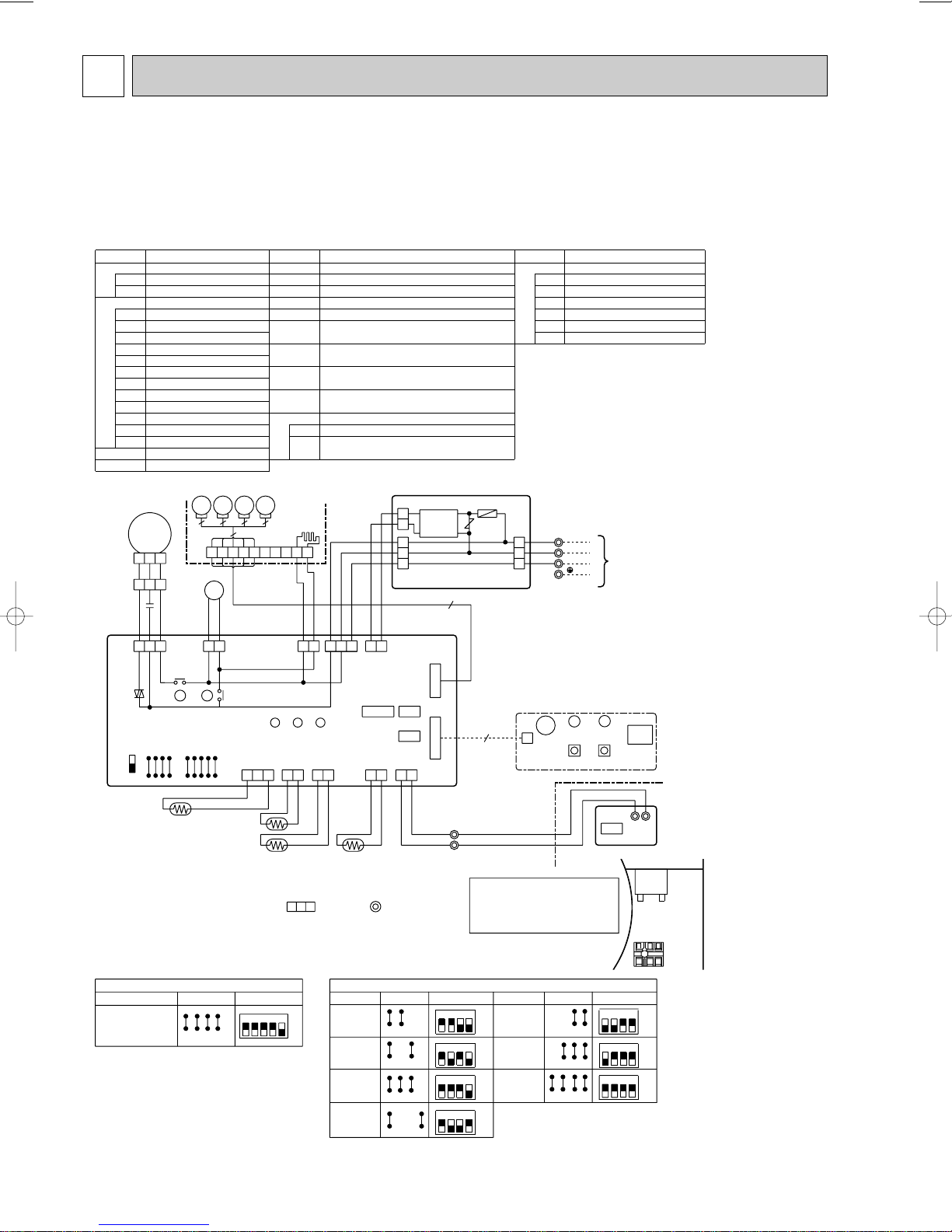

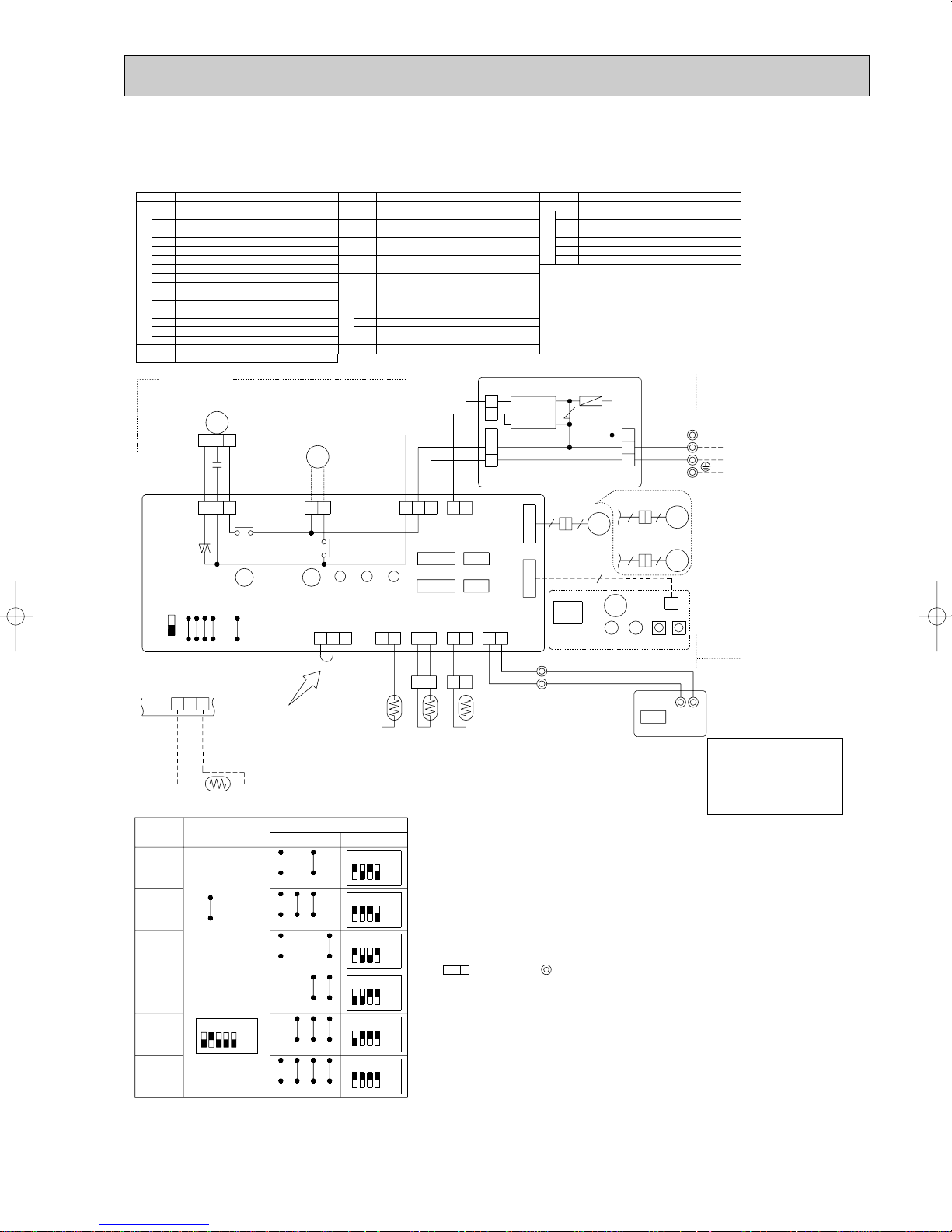

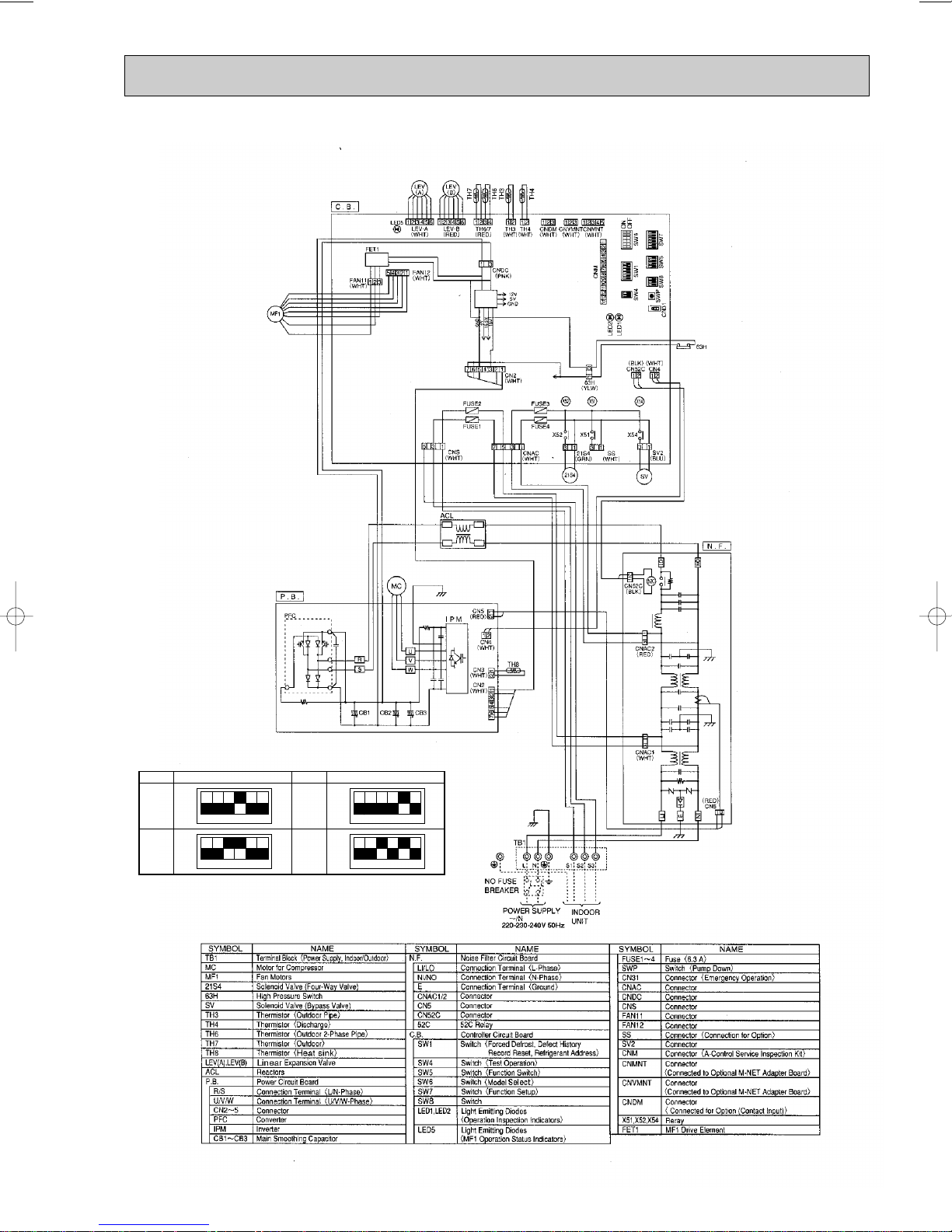

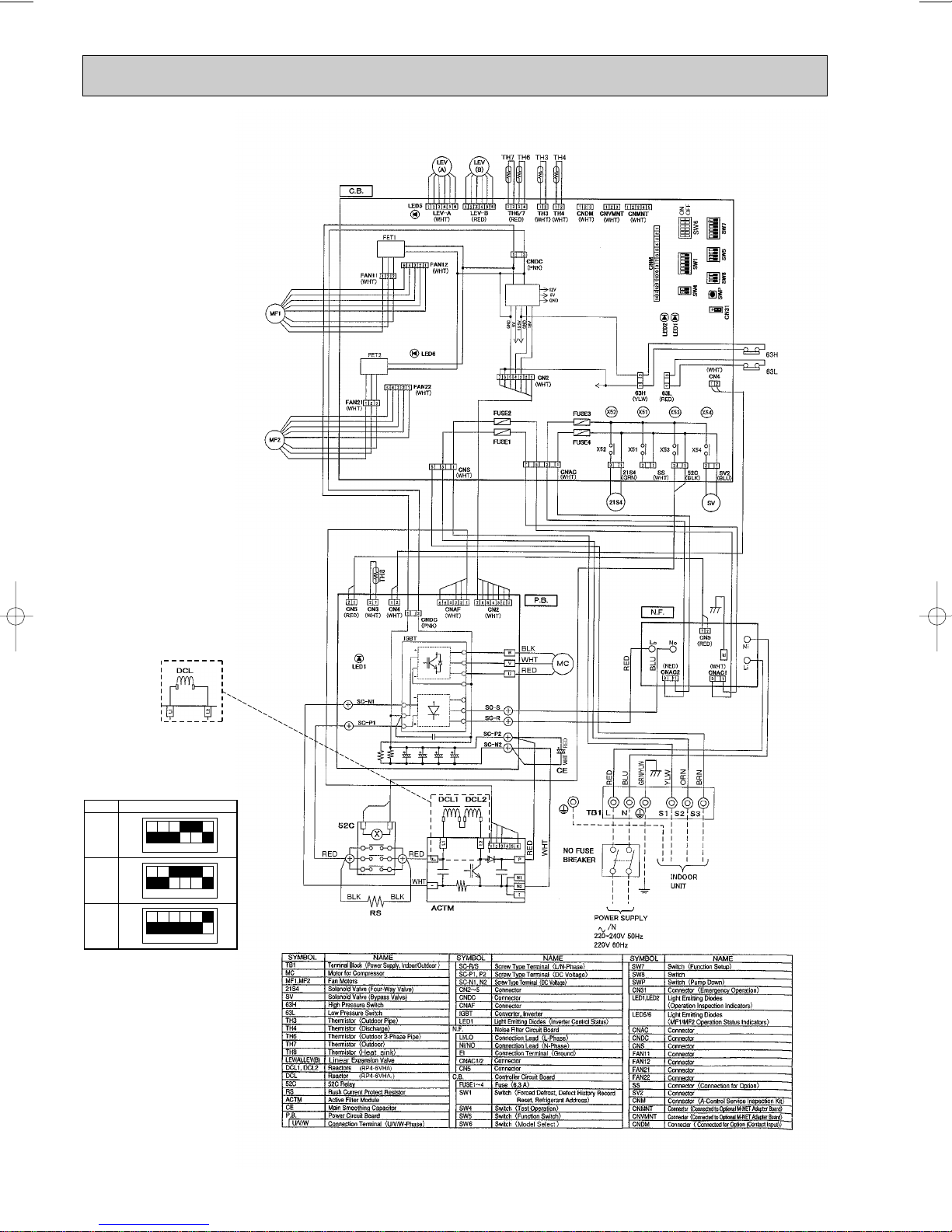

3 WIRING DIAGRAM

[Servicing]

Fasten terminal of the terminal board "TB4" equips lock system.

To remove the fastened terminal, pull it while pressing the protruding portion (locking lever) of

the terminal. The fastened terminal protruding portion should face upward.

NOTES:

1.Since the outdoor side electric wiring may change be sure to

check the outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities, make

wiring matching terminal numbers (S1,S2,S3).

3.Symbols used in wiring diagram above are, :Connector, :Terminal (block).

Please set the voltage using

the remote controller.

For the setting method, please

refer to the indoor unit Installation

Manual.

TO OUTDOOR UNIT

C

TB4

H2

5

GRILLE

MV

MVMVMV

5

5

5

5

PLA-RP4AA

PLA-RP4AA1

TRANSMISSION

WIRES DC12V

MODELS

Manufacture

Service board

MODELS

Manufacture

Service board

SW1

BLK

BLK

BLK

BLK

BLK

BLK

BLU

BLU

TH5

12

PIPE

CN29

(BLK)

REMOCON

CN22

(BLU)

WIRELESS

CN90

(WHT)

SW1

SW2

SWE

VANE

CN6V

(WHT)

POWER

CN03

(RED)

POWER

CN2D

(WHT)

LIQUID

CN21

(WHT)

INTAKE

CN20

(RED)

D.SENSOR

CN31

(WHT)

D.HEATER

CNC (RED)

D.U.M

CNP

(BLU)

FAN

(WHT)

BRN

ORN

YLW

CONTROLLER BOARD

CN02 (WHT)

OUTDOOR UNIT

CN01 (BLU)

CN2S(WHT)

BLK

WHT

YLW

ORN

BRN

YLW

YLW

YLW

YLW

BLK

RED

WHT

CNB

W.B

LED1

LED2

BZ

RU

SW1 SW2

X4

X4

J15

J22J21 J24J23

J22J21 J24J23

J22J21 J24J23

J22J21 J24J23

OFF

ON

OFF

ON

4321

OFF

ON

4321

OFF

ON

4321

OFF

ON

4321

4321

J21J22J23J24

PLA-RP3AA

PLA-RP3AA1

R.B

9

X1

X1

5

31

CN32

CN2LCN41

123

12315

TH1

2

TB5

1

12

TB6

CN2

TH2

DS

3

2

1

DC14V

1

2

3

12

J11

J12

J13

J14

2

121

LED1LED2LED3

ZNR

DP

3

FC

531

1

1

2

ON

OFF

J21

J22

J23

J24

C

MF

I.B

321

P.B

F1

TB4

S1

S2

S3

PLA-RP1.6,2,2.5AA

PLA-RP3,4,5,6AA

PLA-RP3,4,5,6AA

1

1

J11J12J13J142J15

345

ON

OFF

SW2

PLA-RP5AA1

PLA-RP6AA

PLA-RP6AA1

MODELS

Manufacture

Service board

J22J21 J24J23

OFF

ON

OFF

ON

4321

4321

J21J22J23J24

PLA-RP5AA

PLA-RP1.6AA

PLA-RP2AA

PLA-RP2.5AA

10

5

984

7

6321

123

CONNECTOR (PROGRAM TIMER)

TRANSMISSION LINE)

TERMINAL BLOCK (REMOTE CONTROLLER

REMOTE CONTROLLER BOARD

(0:/15kΩ, 25:/5.4kΩ DETECT)

COND./EVA. TEMPERATURE THERMISTOR

(0:/15kΩ, 25:/5.4kΩ DETECT)

PIPE TEMPERATURE THERMISTOR/LIQUID

(0:/15kΩ, 25:/5.4kΩ DETECT)

ROOM TEMPERATURE THERMISTOR

TRANSMISSION LINE)

TERMINAL BLOCK (REMOTE CONTROLLER

TERMINAL BLOCK (INDOOR/OUTDOOR CONNECTING LINE)

CN2

TB6

R.B

TH5

TH2

TH1

TB5

TB4

DEW PREVENTION HEATERH2

W.B

SYMBOL NAME

WIRELESS REMOTE CONTROLLER BOARD

RECEIVING UNIT

BUZZER

LED (HOT ADJUST)

SWITCH (HEATING ON/OFF)

LED (RUN INDICATOR)

BZ

LED1

RU

LED2

SW1

SW2

SWITCH (COOLING ON/OFF)

SYMBOL

SYMBOL

NAME

NAME

I.B

INDOOR POWER BOARD

FUSE (4A)

VARISTOR

INDOOR CONTROLLER BOARD

CN2L

CN32

CN41

SW1

SW2

SWE

X1

X4

FC

CONNECTOR (LOSSNAY)

CONNECTOR (REMOTE SWITCH)

CONNECTOR (HA TERMINAL-A)

JUMPER WIRE (MODEL SELECTION)

JUMPER WIRE (CAPACITY CORD)

SWITCH (EMERGENCY OPERATION)

RELAY (DRAIN PUMP)

RELAY (FAN MOTOR)

FAN PHASE CONTROL

C

CAPACITOR (FAN MOTOR)

MF

FAN MOTOR

DP

DS DRAIN SENSOR

P.B

ZNR

F1

DRAIN PUMP

LED1

LED2

POWER SUPPLY (I.B)

POWER SUPPLY (I.B)

MV

VANE MOTOR

LED3

TRANSMISSION (INDOOR-OUTDOOR)

[LEGEND]

PLA-RP1.6AA PLA-RP2AA PLA-RP2.5AA

PLA-RP1.6AA.UK PLA-RP2AA.UK PLA-RP2.5AA.UK

PLA-RP3AA PLA-RP4AA PLA-RP5AA PLA-RP6AA

PLA-RP3AA1 PLA-RP4AA1 PLA-RP5AA1 PLA-RP6AA1

PLA-RP3AA.UK PLA-RP4AA.UK PLA-RP5AA.UK PLA-RP6AA.UK

PLA-RP3AA1.UK PLA-RP4AA1.UK PLA-RP5AA1.UK PLA-RP6AA1.UK

6

PKA-RP1.6GAL PKA-RP2GAL

3.While pointing the remote controller toward the unit's

receiver, press the h button.

· The check code will be indicated by the number of times

that the buzzer sounds from the receiver section and the

number of blinks of the operation lamp.

4.While pointing the remote controller toward the unit's

receiver, press the ON/OFF button.

· Self-check mode is canceled.

▲

▼

An explanation of the wireless remote controller self checking operations,check codes,buzzer sounds and LED signals are given

below. For check codes and symptom see the table below please.

Triple beep

No sound

Sounds other than

above

Double beepo1

Single beepo2

Single beepo8

Single beepo6

Single beepo2

Single beepo1

Buzzer sound

No trouble generated in the past.

Check code

P1

P2

Abnormality of room temperature thermistor(TH1).

Symptom

Abnormality of pipe temperature thermistor/Liquid(TH2).

P6

P8

E6~EF

F1~F9

---FFFF

Abnormality of signal transmission between indoor unit and outdoor unit

("EE" indicates abnormality of combination).

Freezing /overheating protection is working.

Abnormality of pipe temperature.

No corresponding unit.

P9

Abnormality of pipe temperature thermistor/ Cond./Eva.(TH5).

Abnormality in outdoor unit. Refer to outdoor unit wiring diagram.

U0~UL

Operation lamp

1SEC.FLASHo1

1SEC.FLASHo2

1SEC.FLASHo6

1SEC.FLASHo8

1SEC.FLASHo2

(0.4+0.4)SEC.FLASHo1

OFF

OFF

DIFFERENT FROM ABOVE

1.Press the CHECK button twice continuously.

· CHECK begins to light and refrigerant address display

"00" begins to blink.

· Start this operation from the status of remote controller

display turned off.

2.Press the TEMP , buttons.

· Set the refrigerant address of the indoor unit that is to

be self-diagnosed.

· Set the refrigerant address of outdoor unit by outdoor unit

dip switch "SW1".

(Refer to installation manual of outdoor unit for the detail.)

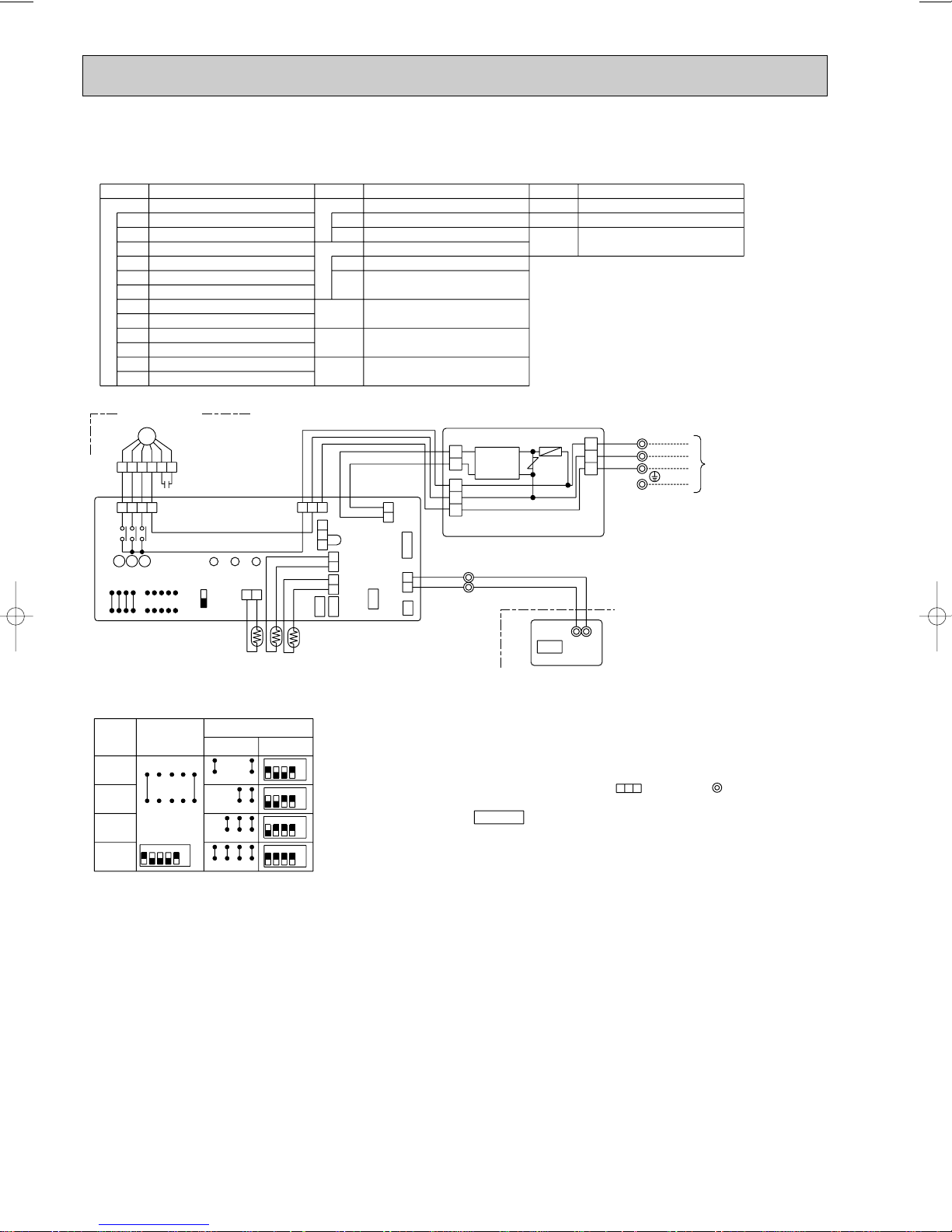

6

MV

VANE

CN6V

(WHT)

TO OUTDOOR UNIT

9

[Self-diagnosis]

TERMINAL BLOCK(INDOOR/OUTDOOR

Manufacture Service board

J24J23J22J21

OFF

1ON432

MODELS

2GAL

SW2

J24J23J22J21

Manufacture

OFF

1ON432

Service board

MODELS

1.6GAL

SW1

Manufacture Service board

J15J14J13J12J11

OFF

ON

54321

BUZZERBZ

RU RECEIVING UNIT

WIRELESS REMOTE CONTROLLER BOARDW.B

REMOTE CONTROLLER BOARD(OPTION)R.B

CN2

TB6

CONNECTOR(PROGRAM TIMER)

TRANSMISSION LINE)

TERMINAL BLOCK(REMOTE CONTROLLER

Please set the voltage using the

remote controller.

For the setting method,please refer to

the indoor unit Installation Manual.

9

TRANSMISSION(INDOOR-OUTDOOR)LED3

VANE MOTORMV

POWER SUPPLY(R.B)

POWER SUPPLY(I.B)

LED2

LED1

NOTES:

:Connector, :Terminal (block).

2.Indoor and outdoor connecting wires are made with polarities,make wiring matching terminal numbers(S1,S2,S3).

4.Symbols used in wiring diagram above are,

3.Make sure that the main power supply of the booster heater is independent.

1.Since the outdoor side electric wiring may change be sure to check the outdoor unit electric wiring for servicing.

SWITCH(COOLING ON/OFF)SW2

SW1

LED2

LED1 LED(RUN INDICATOR)

SWITCH(HEATING ON/OFF)

LED(HOT ADJUST)

COND./EVA.TEMP.THERMISTOR

(0°C/15k",25°C/5.4k" DETECT)

NAME

TRANSMISSION LINE)(OPTION)

TERMINAL BLOCK(REMOTE CONTROLLER

TB5

F1

ZNR

P.B

PIPE TEMP.THERMISTOR/LIQUID

TH5

TH2

TH1 ROOM TEMP.THERMISTOR

(0°C/15k",25°C/5.4k" DETECT)

(0°C/15k",25°C/5.4k" DETECT)

CONNECTING LINE)

TB4

FAN MOTORMF

CAPACITOR(FAN MOTOR)C

FAN PHASE CONTROL

RELAY(FAN MOTOR)

SWITCH(EMERGENCY OPERATION)

JUMPER WIRE(CAPACITY CORD)

JUMPER WIRE(MODEL SELECTION)

CONNECTOR(HA TERMINAL-A)

CONNECTOR(REMOTE SWITCH)

CONNECTOR(LOSSNAY)

FC

X4

SWE

SW2

SW1

CN41

CN32

CN2L

INDOOR CONTROLLER BOARD

VARISTOR

FUSE(4A)

INDOOR POWER BOARD

I.B

NAME SYMBOL

NAME SYMBOLSYMBOL

ZNR

R.B

F1

OUTDOOR

CN01(BLU)

P.B

3

2

1

CONT.BOARD

CN02(WHT)

CN2S(WHT)

DC14V

CN2

TB6

21

1

TB5

2

FAN

(WHT)

LED3 LED2 LED1

INDOOR UNIT

12 12

J14

J13

J12

J11

OFF

ON

SWE SW1SW2

21

D.SENSOR

CN31

(WHT)

INTAKE

CN20

(RED)

LIQUID

CN21

(WHT)

REMOCON

CN22

(BLU)

POWER

CN2D(WHT)

POWER

CN03

(RED)

123

1

2

3

2

1

1

I.B

TH1

5

MF

C

35

FC

13 21

321

CN41

CN2L

X4

J15

X4

TH2 TH5

PIPE

CN29

(BLK)

2

1

WIRELESS

CN90

(WHT)

RED

YLW

CN25

CN32

BRN

ORN

BRN

ORN

YLW

WHT

BLK

WHT

BLK

TRANSMISSION WIRES DC12V

TB4

S1

S2

S3

RECEIVER

RU

CNB

LED2

BZ

LED1 SW1SW2

W.B

J21

J22

J23

J24

21

HEATER

CN24

(YLW)

]

7

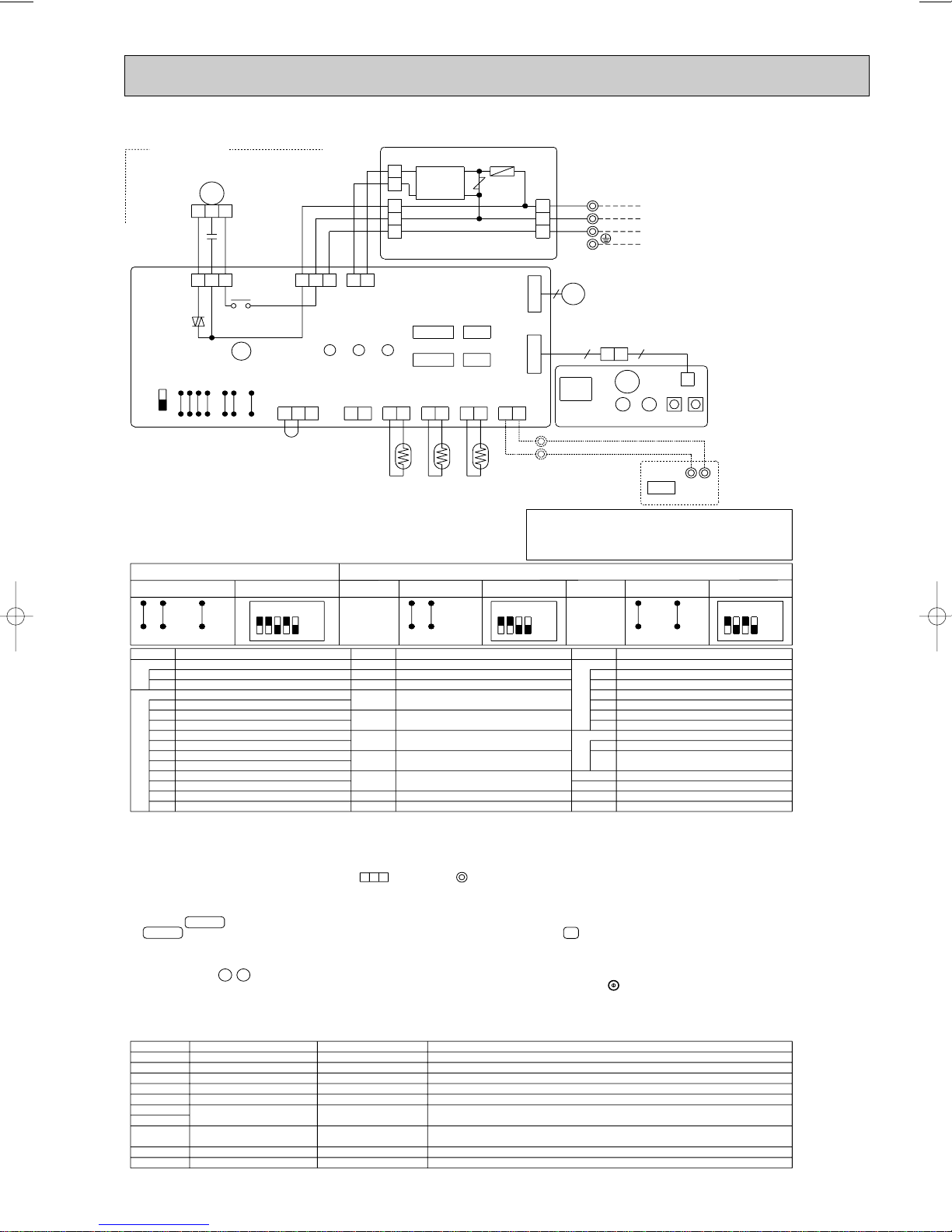

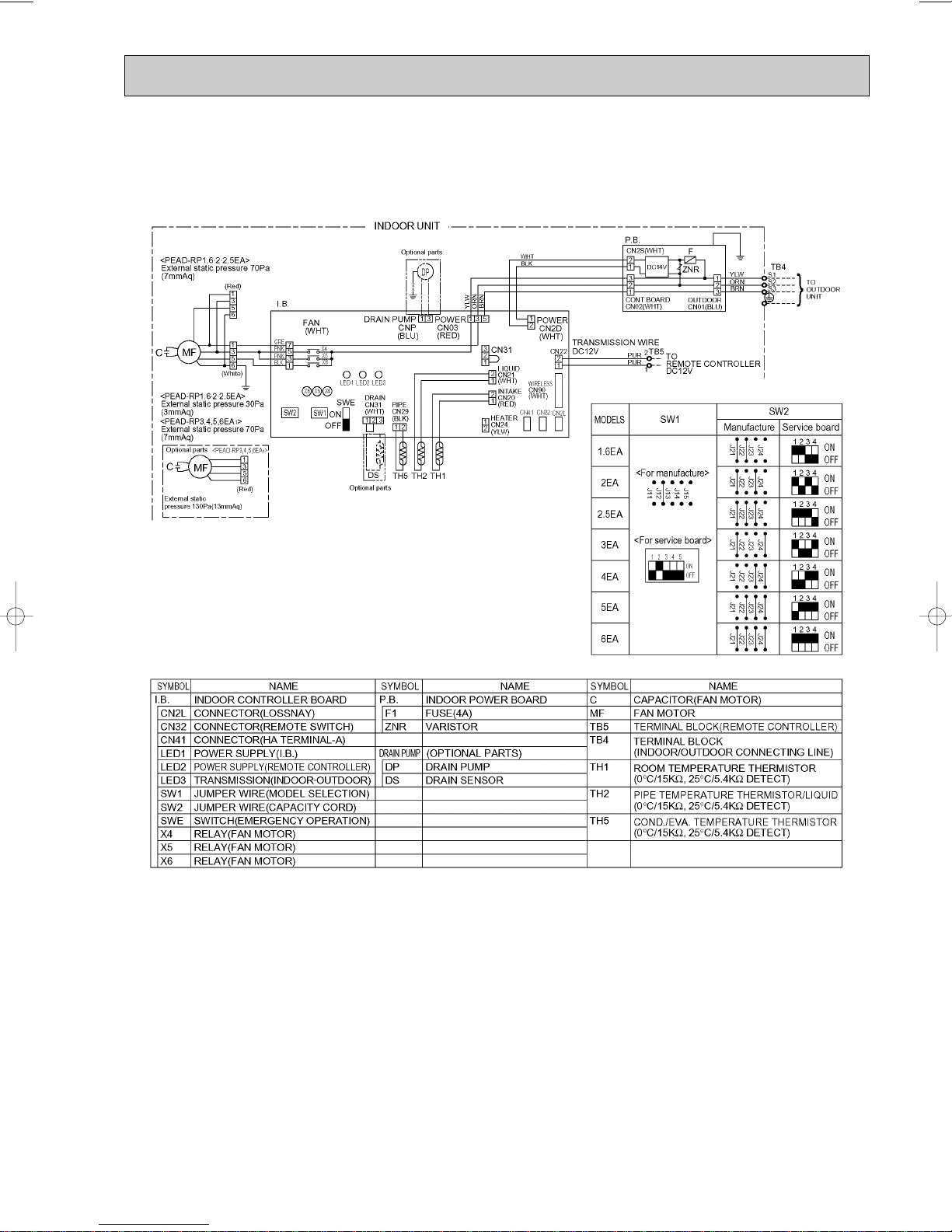

PKA-RP2.5FAL PKA-RP3FAL PKA-RP4FAL

INDOOR POWER BOARD

P.B

F1

FUSE(4A)

ZNR

VARISTOR

INDOOR CONTROLLER BOARD

I.B

CN2L

CONNECTOR(LOSSNAY)

CN32

CONNECTOR(REMOTE SWITCH)

CN41

CONNECTOR(HA TERMINAL-A)

SW1

JUMPER WIRE(MODEL SELECTION)

SW2

JUMPER WIRE(CAPACITY CODE)

SWE

SWITCH(EMERGENCY OPERATION)

X4

RELAY(FAN MOTOR)

FC

FAN PHASE CONTROL

LED1

POWER SUPPLY(I.B)

LED2

POWER SUPPLY(R.B)

LED3

TRANSMISSION(INDOOR-OUTDOOR)

INDOOR UNIT

MF

321

C

I.B

FAN

(WHT)

ON

OFF

Manufacture

Service board

1

FC

SWE SW1SW2

SW1

54321

ON

OFF

WHT

RED

35

J21

J15J14J13J12J11

BLK

J22

J23

J24

MODELS

2.5FAL

3FAL

4FAL

X4

X4

J11

POWER

J13

J12

CN03

(RED)

J14

J15

Manufacture

BRN

YLW

ORN

5

13 21

LED3LED2LED1

SW2

Service board

1ON432

J24J23J22J21

1ON432

J24J23J22J21

1ON432

J24J23J22J21

MF FAN MOTOR

TB4

TB5

TH1 ROOM TEMPERATURE THERMISTOR

TH2

TH5

POWER

CN2D (WHT)

CAPACITOR(FAN MOTOR)C

VANE MOTORMV

TERMINAL BLOCK(INDOOR/OUTDOOR

CONNECTING LINE)

TERMINAL BLOCK(REMOTE CONTROLLER

TRANSMISSION LINE)(OPTION)

(0°C/15kΩ, 25°C/5.4kΩ DETECT)

PIPE TEMPERATURE THERMISTOR/LIQUID

(0°C/15kΩ, 25°C/5.4kΩ DETECT)

CONDENSER / EVAPORATOR TEMPERATURE

THERMISTOR (0°C/15kΩ, 25°C/5.4kΩ DETECT)

CN2S(WHT)

2

DC14V

1

3

2

1

CONT.BOARD

CN02 (WHT)

WHT

BLK

CN41 CN2L

CN25 CN32

LIQUID

INTAKE

HEATER

CN20

CN24

(YLW)

OFF

OFF

OFF

21

CN21

(RED)

(WHT)

12 12

TH1

NOTES:

1.Since the outdoor side electric wiring may change be sure to check the outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities, make wiring matching terminal numbers(S1, S2, S3).

3.Symbols used in wiring diagram above are, :Connector, :Terminal (block).

[Self-diagnosis]

An explanation of the wireless remote controller self checking operations, check codes, buzzer sounds and LED signals are given

below. For check codes and symptom see the table below please.

1.Press the CHECK button twice continuously.

• CHECK begins to light and refrigerant address display

"00" begins to blink.

• Start this operation from the status of remote controller

display turned off.

2.Press the TEMP ▼ , ▲ buttons.

• Set the refrigerant address of the indoor unit that is to

be self-diagnosed.

• Set the refrigerant address of outdoor unit by outdoor unit

dip switch "SW1".

(Refer to installation manual of outdoor unit for the detail.)

Check code

U0~UL

F1~F9

E6~EF

Operation lamp

1SEC.FLASH ✕ 1

P1

1SEC.FLASH ✕ 2

P2

P4 1SEC.FLASH ✕ 4 Abnormality of drain sensor(DS).

P5 1SEC.FLASH ✕ 5 Malfunction of drain-up machine.

1SEC.FLASH ✕ 6

P6

1SEC.FLASH ✕ 8

P8

1SEC.FLASH ✕ 2

P9

(0.4+0.4)SEC.FLASH ✕ 1

DIFFERENT FROM ABOVE

OFF

---OFF

FFFF

Buzzer sound

Single beep ✕ 1

Single beep ✕ 2

Single beep ✕ 4

Single beep ✕ 5

Single beep ✕ 6

Single beep ✕ 8

Single beep ✕ 2

Double beep ✕ 1

Sounds other than

above

No sound

Triple beep

Abnormality of room temperature thermistor(TH1).

Abnormality of pipe temperature thermistor/Liquid(TH2).

Freezing /overheating protection is working.

Abnormality of pipe temperature.

Abnormality of pipe temperature thermistor/ Condenser/Evaporator(TH5).

Abnormality in outdoor unit. Refer to outdoor unit wiring diagram.

Abnormality of signal transmission between indoor unit and outdoor unit

("EE" indicates abnormality of combination).

No trouble generated in the past.

No corresponding unit.

NAME SYMBOLNAME SYMBOLSYMBOL

ZNR

OUTDOOR

CN01 (BLU)

VANE

CN6V

(WHT)

WIRELESS

CN90

(WHT)

REMOCON

PIPE

CN22

CN29

(BLU)

(BLK)

21

F1

21

W.B

R.B

P.B

YLW

1

ORN

2

BRN

3

MV

6

2

1

TH2 TH5

3.While pointing the remote controller toward the unit's

receiver, press the h button.

• The check code will be indicated by the number of times

that the buzzer sounds from the receiver section and the

number of blinks of the operation lamp.

4.While pointing the remote controller toward the unit's

receiver, press the ON/OFF button.

• Self-check mode is canceled.

TB5

WIRELESS REMOTE CONTROLLER BOARD

RU RECEIVING UNIT

BUZZERBZ

LED1 LED(RUN INDICATOR)

LED2

LED(HOT ADJUST)

SW1

SWITCH(HEATING ON/OFF)

SWITCH(COOLING ON/OFF)SW2

REMOTE CONTROLLER BOARD(OPTION)

CN2

CONNECTOR(SCHEDULE TIMER)

TERMINAL BLOCK(REMOTE CONTROLLER

TB6

TRANSMISSION LINE)

TB4

S1

S2

TO OUTDOOR UNIT

S3

9

W.B

RECEI

-VER

RU

CNB

BZ

LED2

LED1 SW1SW2

TRANSMISSION WIRES DC12V

Please set the voltage

using the remote controller.

For the setting method,

please refer to the indoor

unit Installation Manual.

Symptom

NAME

TB6

R.B

12

CN2

8

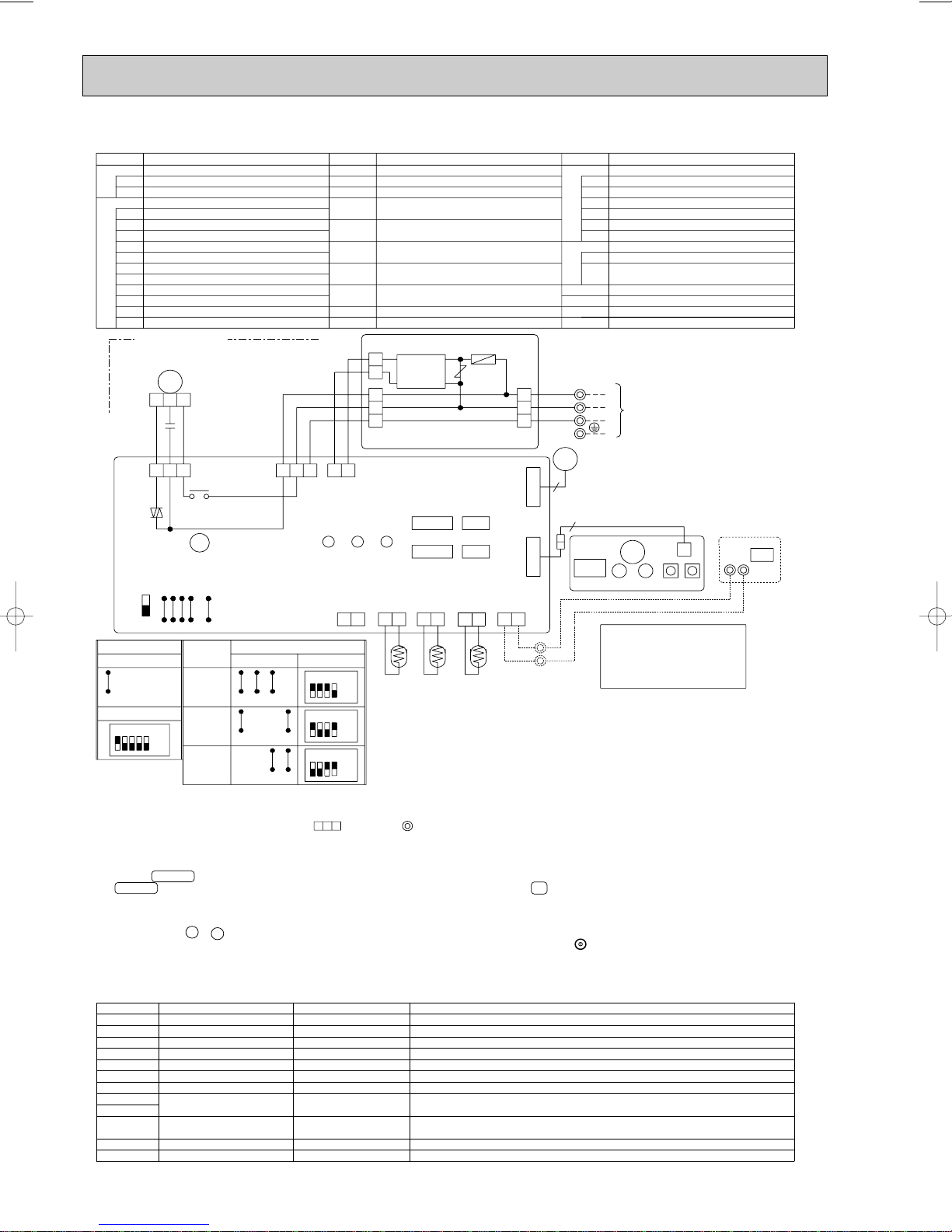

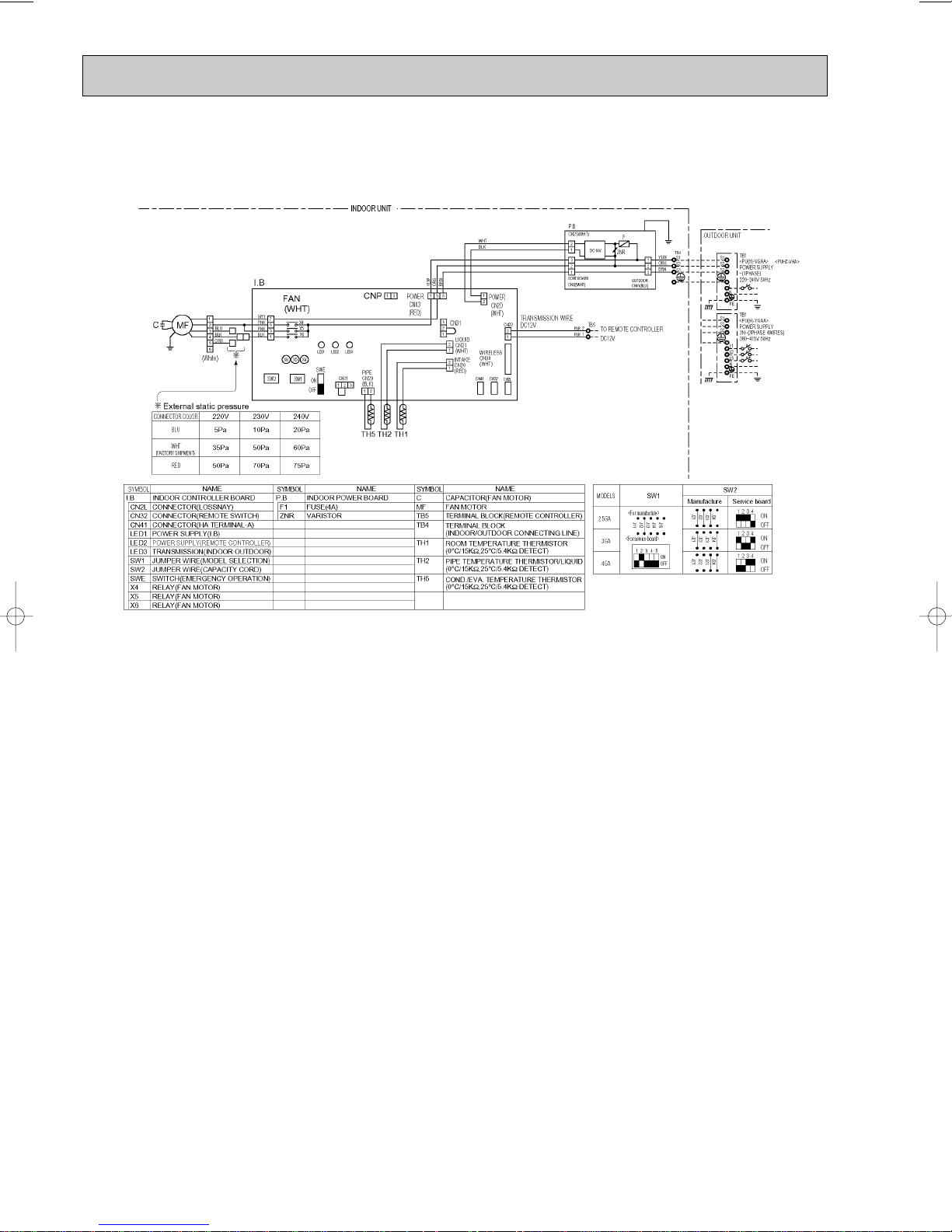

PCA-RP2GA PCA-RP2.5GA PCA-RP3GA

Service board

234

ON

1

OFF

234ON1

OFF

234ON1

OFF

234ON1

OFF

234ON1

OFF

OFF

ON

4321

Manufacture

<For service board>

<For manufacture>

OFF

ON

54321

J21

J21

J21

J21

J21

J21

J22

J22

J22

J22

J22

J22J23

J23

J23

J23

J23

J23

J24

J24

J24

J24

J24

J24

J15J14J13J12J11

MODELS

SW1

SW2

2GA

2.5GA

3GA

4GA

5GA

6GA

[Self-diagnosis]

1.For details on how to operate self-diagnosis with the wireless

remote control,refer to the technical manuals etc.

[Emergency operation procedure]

1.When the wired remote control or the indoor unit microcomputer has failed,but all other

components work properly, if you set the switch(SWE) on the indoor control panel ON,the indoor

unit will begin Emergency Operation.

When Emergency Operation is activated, the indoor unit operates as follows:

(1)Indoor fan is running at high speed.

(2)Drain-up machine(optional) is working.

NOTES:

2.Indoor and outdoor connecting wires are made with polarities,make

wiring matching terminal numbers(S1,S2,S3).

4.Symbols used in wiring diagram above are,

3.Make sure that the main power supply of the booster heater is

independent.

1.Since the outdoor side electric wiring may change be sure to

check the outdoor unit electric wiring for servicing.

:Connector, : Terminal (block).

[Servicing]

CN31 DRAIN SENSOR

When installing drain-up

machine(Optional part).

WWhen installing optional

drain-up machine,disconnect

the CN31 jumper connector

and replace it with the

drain sensor(DS).

Fasten terminal of the terminal board "TB4" equips lock system.

To remove the fastened terminal,pull it while pressing the protruding

portion(locking lever)of the terminal.The fastened terminal protruding

portion should face upward.

TRANSMISSION(INDOOR-OUTDOOR)LED3

VANE MOTORMV

POWER SUPPLY(R.B)

POWER SUPPLY(I.B)

LED2

LED1

SWITCH(COOLING ON/OFF)SW2

SW1

LED2

RU

BZ

W.B

LED(RUN INDICATOR)

SWITCH(HEATING ON/OFF)

LED(HOT ADJUST)

BUZZER

RECEIVING UNIT

WIRELESS REMOTE CONTROLLER BOARD(OPTION)

TERMINAL BLOCK(REMOTE CONTROLLER

TRANSMISSION LINE)

CONNECTOR(SCHEDULE TIMER)

REMOTE CONTROLLER BOARD

TB6

CN2

COND./EVA.TEMP.THERMISTOR

(0:/15k",25:/5.4k" DETECT)

NAME

R.B

DRAIN-UP MACHINE(OPTION)

TRANSMISSION LINE)

TERMINAL BLOCK(REMOTE CONTROLLER

TB5

F1

ZNR

P.B

PIPE TEMP.THERMISTOR/LIQUID

TH5

TH2

TH1 ROOM TEMP.THERMISTOR

(0:/15k",25:/5.4k" DETECT)

(0:/15k",25:/5.4k" DETECT)

TERMINAL BLOCK(INDOOR/OUTDOOR CONNECTING LINE)

TB4

DRAIN SENSOR(OPTION)DS

DP

FAN MOTORMF

CAPACITOR(FAN MOTOR)C

FAN PHASE CONTROL

RELAY(FAN MOTOR)

RELAY(DRAIN PUMP)

SWITCH(EMERGENCY OPERATION)

JUMPER WIRE(CAPACITY CORD)

JUMPER WIRE(MODEL SELECTION)

CONNECTOR(HA TERMINAL-A)

CONNECTOR(REMOTE SWITCH)

CONNECTOR(LOSSNAY)

FC

X4

X1

SWE

SW2

SW1

CN41

CN32

CN2L

INDOOR CONTROLLER BOARD

VARISTOR

FUSE(4A)

INDOOR POWER BOARD

NAME SYMBOLNAME SYMBOLSYMBOL

TB2 TERMINAL BLOCK(HEATER)

LED1

312

DS

(WHT)

12

TH1 TH2 TH5

BLK

BLK21BLU

BLK

BLK

BLU

R.B

CN2

TB6

21

1

TB5

2

TRANSMISSION WIRES DC12V

Please set the voltage using

the remote controller.

For the setting method,

please refer to the indoor

unit Installation Manual.

I.B

D.SENSOR

CN31

(WHT)

INTAKE

CN20

(RED)

LIQUID

CN21

(WHT)

REMOCON

CN22

(BLU)

PIPE

CN29

(BLK)

12 12 2132121

SWE SW1SW2

OFF

ON

J14

J13

J12

J11

J15

J21

J22

J23

J24

FAN

(WHT)

FC

POWER

CN03

(RED)

D.U.M

CNP

(BLU)

X1

X4

X1X4

LED3LED2 LED1

VANE

CN6V

(WHT)

POWER

CN2D(WHT)

WIRELESS

CN90

(WHT)

CN41 CN2L

CN25 CN32

513 21

BRN

ORN

YLW

WHT

BLK

(OPTION)

1DP3

ZNR

F1

OUTDOOR

CN01(BLU)

P.B

3

2

1

CONT.BOARD

CN02(WHT)

CN2S(WHT)

DC14V

1

2

3

2

1

YLW

BRN

ORN

TO

OUTDOOR

UNIT

TB4

S1

S2

S3

}

RECEIVER

RU

CNB

LED2

BZ

LED1 SW1SW2

W.B

P4~P6 TYPE

6

MV

6

MV

55

P2,P3 TYPE

9

6MV6

INDOOR UNIT

123

1

I.B

MF

C

35

RED

BLK

WHT

PCA-RP4GA PCA-RP5GA PCA-RP6GA

9

PEA-RP3EA.TH-A PEA-RP5EA.TH-A

TO OUTDOOR UNIT

12

TB6

R.B

562341

PIPE TEMPERATURE THERMISTOR/LIQUID

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

COND./EVA. TEMPERATURE THERMISTOR

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

ROOM TEMPERATURE THERMISTOR

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

TH5

TH2

TH1

CN24

NAME

SYMBOL

NAME

SYMBOL SYMBOL

NAME

CN2

R.B

CONNECTOR(PROGRAM TIMER)

REMOTE CONTROLLER BOARD

TERMINAL BLOCK(REMOTE

CONTROLLER TRANSMISSON LINE)

TB6

RELAY(FAN MOTOR)

X6

X5

X4

SWE

SW2

SW1

JUMPER WIRE(MODEL SELECTION)

JUMPER WIRE(CAPACITY CORD)

SWITCH(EMERGENCY OPERATION)

RELAY(FAN MOTOR)

RELAY(FAN MOTOR)

LED3

LED2

POWER SUPPLY(R.B)

TRANSMISSOION(INDOOR • OUTDOOR)

I.B

CN2L

CN41

CN32

LED1

INDOOR CONTROLLER BOARD

CONNECTOR(LOSSNAY)

CONNECTOR(HA TERMINAL-A)

CONNECTOR(REMOTE SWITCH))

POWER SUPPLY(I.B)

FUSE(4A)

INDOOR POWER BOARD

VARISTOR

P.B

F1

ZNR

CAPACITOR(FAN MOTOR)

FAN MOTOR

MF

TB4

TERMINAL BLOCK

(INDOOR/OUTDOOR CONNECTING LINE)

C

J21J22J23J24

J21J22J23J24

J21J22J23J24

J24J23J22

1

BLU

2

3

2

1

CN31

2

1

2

1

1

2

1

2

J24

J23

J22

P.B

ZNR

X4X5

X6 X5

X6

1357

RED

C

ORN

MF

1.Since the outdoor side electric wiring may change be sure to check the

outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities,make wiring

matching terminal numbers(S1,S2,S3).

3.Symbols used in wiring diagram above are, :Connector, :Terminal (block).

FAN

(WHT)

1.When pressing the CHECK switch twice on the remote controller,the unit

changes to the self-diagnosis mode and will display the check code by

LED(light Emitting Diode)

Refer to the right table for the check codes and abnormarities.

LED3 LED2 LED1

INDOOR UNIT

TRANSMISSION WIRE

DC12V

OFF

ON

4321

Manufacture

<For manufacture>

SW1

[Self diagnosis]

[NOTES]

J21

OFF

ON

SWE

SW2

WIRELESS

INTAKE

CN20

(RED)

LIQUID

CN21

(WHT)

REMOCON

CN22

(BLU)

CN90

(WHT)

POWER

CN2D

(WHT)

POWER

CN03

(RED)

S3

S2

S1

F1

OUTDOOR

CN01(BLU)

3

2

1

CONT.BOARD

CN02(WHT)

CN2S(WHT)

DC14V

1

2

3

2

1

TH1

CN2

TB5

I.B

TH2

513

CN41

CN2L

CN32

X4

BLK

BLU

BRN

WHT

YLW

ORN

BRN

WHT

BLK

YLW

ORN

BRN

SW1

J11

J12

J13

J14

J15

TB4

TH5

1

2

PIPE

CN29

(BLK)

BLU

SW2

MODELS

J14J13J12J11 J15

Service board

OFF

ON

4321

OFF

ON

4321

J21

OFF

ON

4321

3EA

4EA

5EA

6EA

123 5

ON

OFF

4

<For service board>

PEA-RP4EA.TH-A PEA-RP6EA.TH-A

10

PEAD-RP1.6EA.UK PEAD-RP2EA.UK PEAD-RP2.5EA.UK

PEAD-RP3EA.UK PEAD-RP4EA.UK PEAD-RP5EA.UK PEAD-RP6EA.UK

PEAD-RP3EA1.UK PEAD-RP4EA1.UK PEAD-RP5EA1.UK PEAD-RP6EA1.UK

11

PEAD-RP2.5GA

PEAD-RP3GA

PEAD-RP4GA

12

PUHZ-RP1.6VHA

MODELS

SW6

W1 MODEL SELECT

1.6V

2V

MODELS

SW6

2.5V

3V

1

ON

OFF

23456

1

ON

OFF

23456

1

ON

OFF

23456

1

ON

OFF

23456

PUHZ-RP2VHA

PUHZ-RP2.5VHA

PUHZ-RP3VHA

PUHZ-RP3VHA-A

W1

W2 Only PUHZ-RP2.5, 3VHA.

W2

13

PUHZ-RP4VHA

MODELS

SW6

W1 MODEL SELECT

4V

5V

6V

1

ON

OFF

23456

1

ON

OFF

23456

1

ON

OFF

23456

PUHZ-RP5VHA

PUHZ-RP6VHA

PUHZ-RP4VHA1

PUHZ-RP5VHA1

PUHZ-RP6VHA1

PUHZ-RP4VHA-A

PUHZ-RP5VHA-A

PUHZ-RP6VHA-A

PUHZ-RP4VHA1-A

PUHZ-RP5VHA1-A

PUHZ-RP6VHA1-A

W1

Only PUHZ-RP4VHA1

PUHZ-RP5VHA1

PUHZ-RP6VHA1

14

4

Measurement item

COOL: 2.3 ~ 3.0 HEAT: 2.0 ~ 3.2

0.55 ~ 1.0

50 ~ 100

-2 ~ +18

COOL: 27: HEAT: 20:

COOL: 8 ~ 20

HEAT: 30 ~ 50

COOL: 35 HEAT: 7

COOL: 40 ~ 50 HEAT: 0 ~ 5

Measurement method, remarks

Connect the pressure gauge to the high-pressure check valve.

Connect the pressure gauge to the low-pressure check valve.

Measured with piping surface thermometer.

Measured with piping surface thermometer.

Can be displayed on remote controller.

Measured with piping surface thermometer.

Measured with piping surface thermometer.

High pressure (MPa)

Low pressure (MPa)

Discharge pipe temperature (:)

Suction pipe temperature (:)

Indoor intake temperature (:)

Indoor outlet temperature (:)

Outdoor intake temperature (:)

Outdoor outlet temperature (:)

Pressure/temperature near JIS

standard operating conditions

A

B

C

D

E

F

G

H

Notes : The operation statuses vary depending on the compressor's operating frequency because units are inverter-type.

Outdoor

heat exchanger

Stop valve

(with service port)

Power

receiver

Linear

expansion

valve B Linear

expansion

valve A

4-way valve

Compressor

Ball valve

Indoor heat

exchanger

A

B

C

D

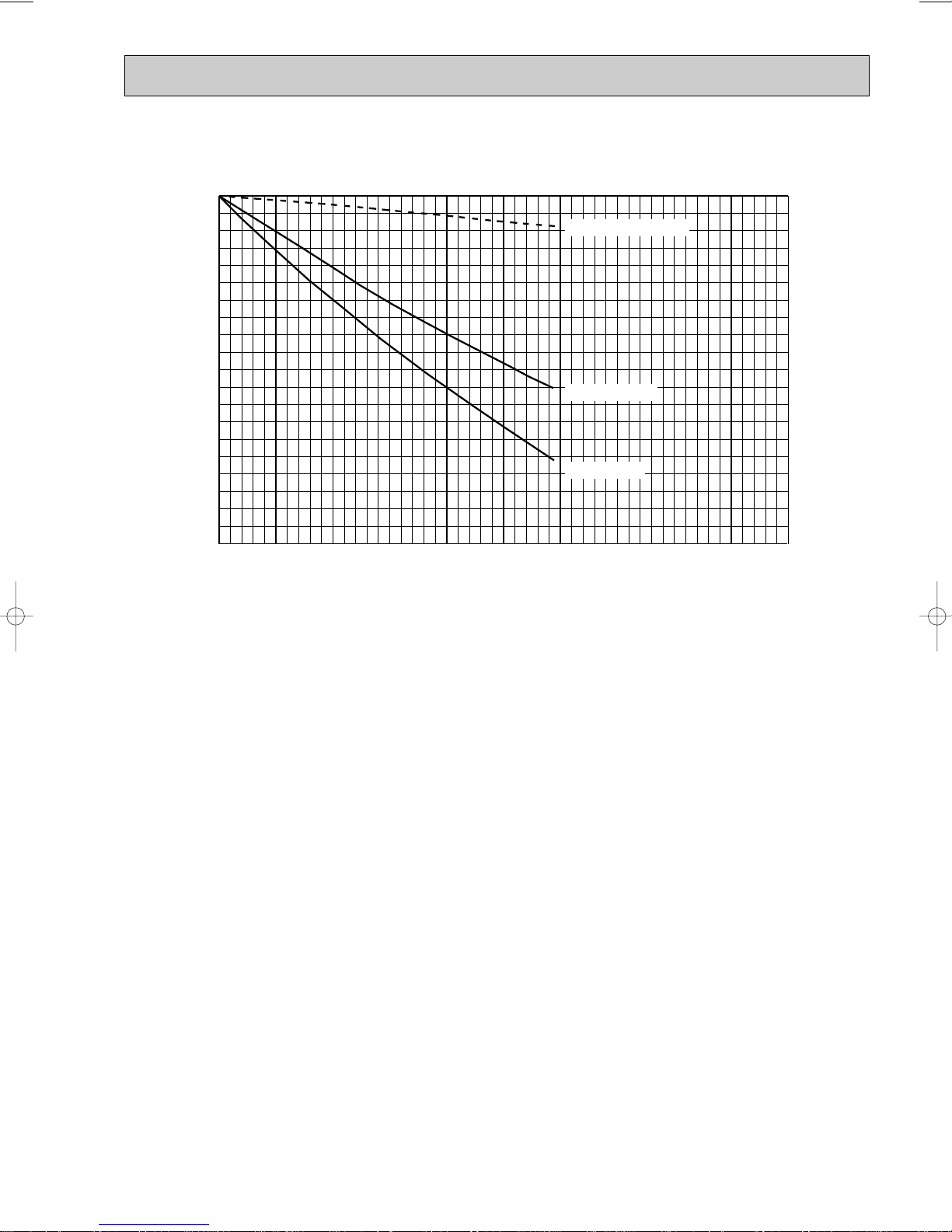

Overload operation

Standard operation

Permissible operation range

Normal operation range

0 0.2 0.4 0.6 0.8 1 1.2

Suction pressure (MPa)

Discharge pressure (MPa)

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

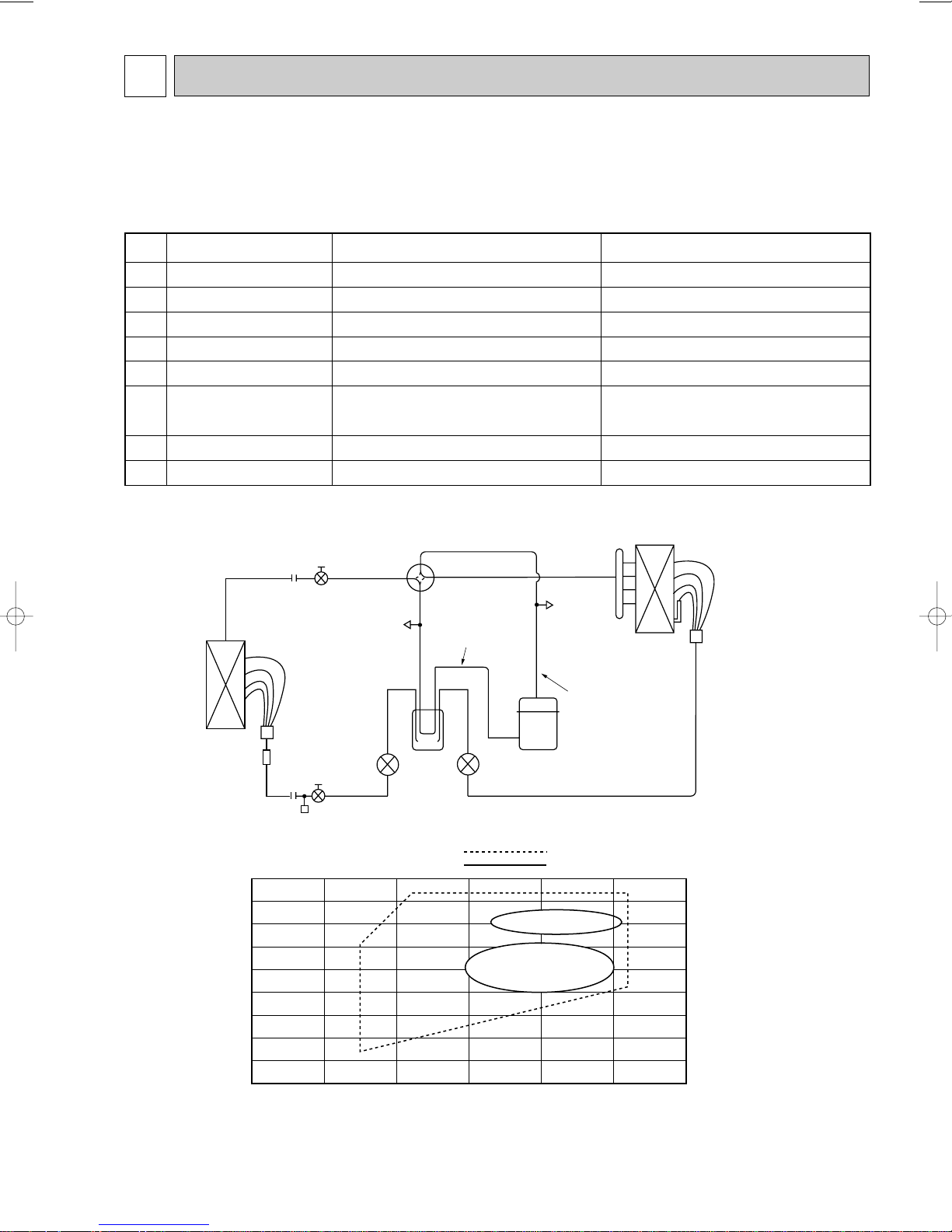

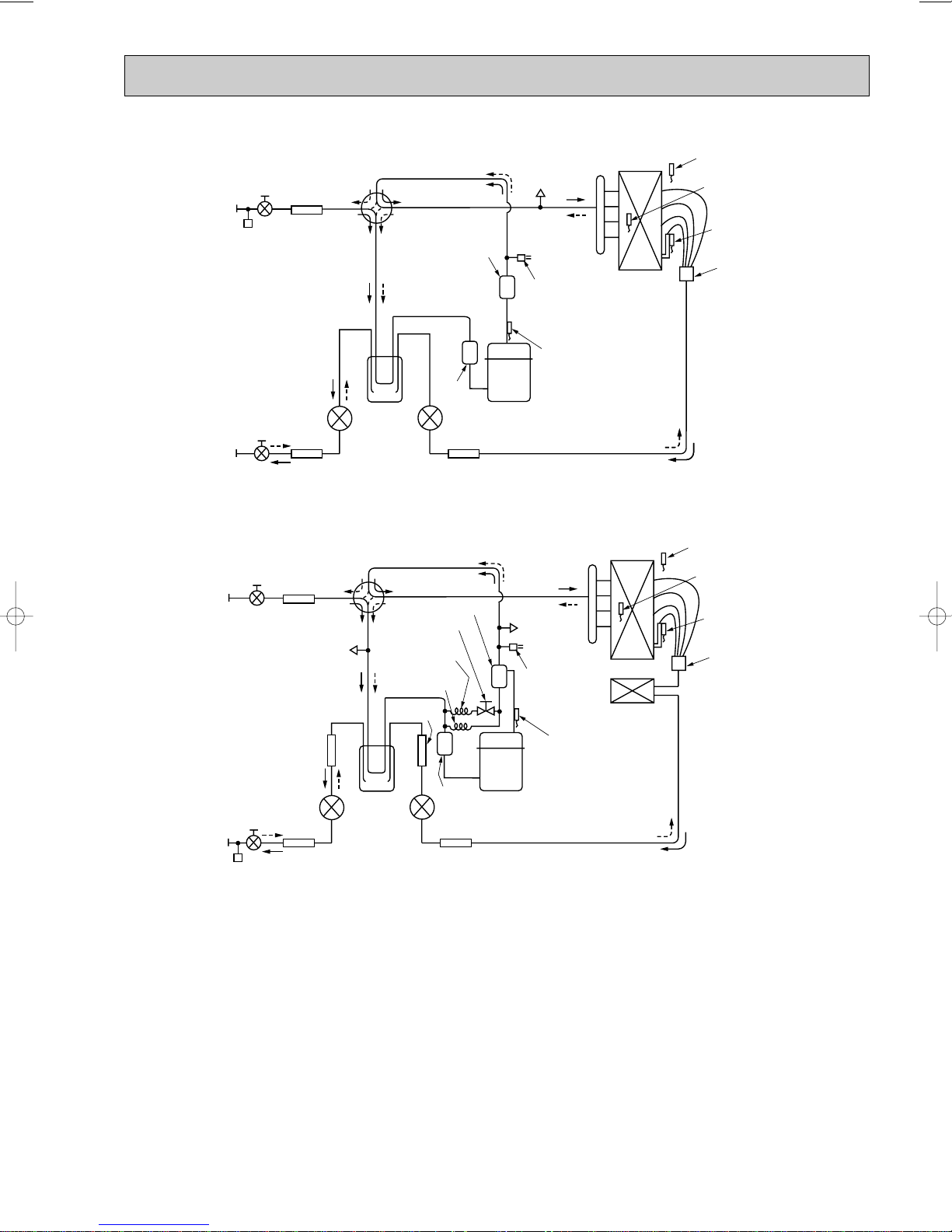

REFRIGERANT SYSTEM DIAGRAM

4-1. Checking operation statuses PUHZ-RP • HA

4-1-1. Measurement points and items

•The table and diagrams below show the measurement item for each measurement point, and the pressure and temperature

near the ISO T1 standard operating conditions.

•Measure the temperature and pressure of each part by following the descriptions in the table.

•Measurement time: Be sure to wait until the refrigerant circuit has stabilized (30 minutes to 1 hour) before taking

measurements.

4-1-2. Operation pressure ranges

15

4-2. Refrigerant System Diagram

Pipe temperature

thermistor/liquid

(TH2)

Distributor

with strainer

#50

Condenser/evaporator

temperature thermistor

(TH5)

Room temperature

thermistor (TH1)

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#50

Strainer

#50

Heat exchanger

Refrigerant GAS pipe connection

(Flare)

Refrigerant LIQUID pipe connection

(Flare)

PLA-RP1.6AA PLA-RP2AA PLA-RP2.5AA

PLA-RP1.6AA.UK PLA-RP2AA.UK PLA-RP2.5AA.UK

PLA-RP3AA PLA-RP4AA PLA-RP5AA PLA-RP6AA

PLA-RP3AA.UK PLA-RP4AA.UK PLA-RP5AA.UK PLA-RP6AA.UK

PLA-RP3AA

1 PLA-RP4AA1 PLA-RP5AA1 PLA-RP6AA1

PLA-RP3AA1.UK PLA-RP4AA1.UK PLA-RP5AA1.UK PLA-RP6AA1.UK

PKA-RP1.6GAL PKA-RP2GAL

PKA-RP2.5FAL PKA-RP3FAL PKA-RP4FAL

PCA-RP2GA PCA-RP2.5GA

PCA-RP3GA PCA-RP4GA PCA-RP5GA PCA-RP6GA

PEA-RP3EA.TH-A PEA-RP4EA.TH-A PEA-RP5EA.TH-A PEA-RP6EA.TH-A

PEAD-RP1.6EA.UK PEAD-RP2EA.UK PEAD-RP2.5EA.UK

PEAD-RP3EA.UK PEAD-RP4EA.UK PEAD-RP5EA.UK PEAD-RP6EA.UK

PEAD-RP3EA

1.UK PEAD-RP4EA1.UK PEAD-RP5EA1.UK PEAD-RP6EA1.UK

PEAD-RP2.5GA.UK PEAD-RP3GA.UK PEAD-RP4GA.UK

16

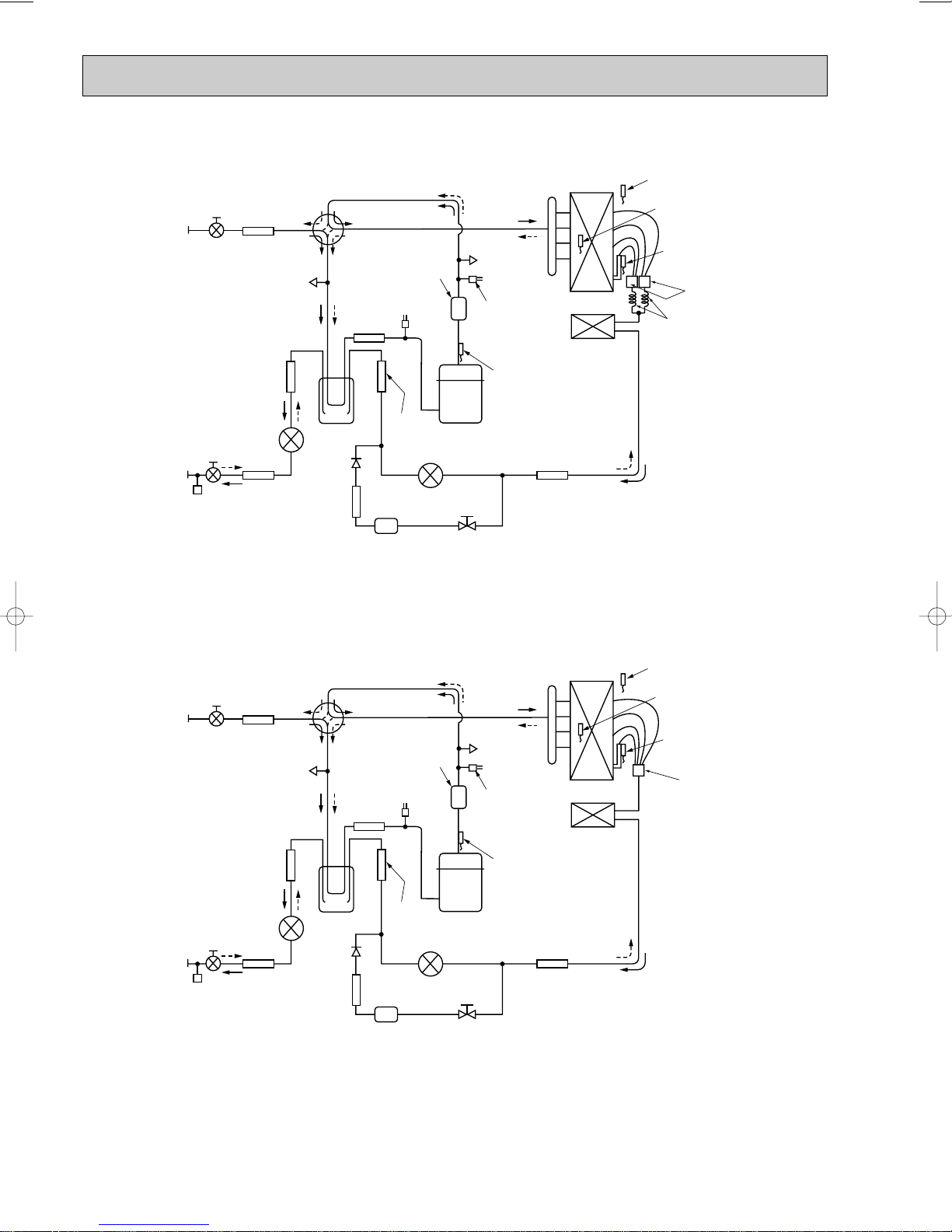

Distributor

Thermistor TH7

(Outdoor)

Heat exchanger

Refrigerant GAS pipe

connection(5/8F)

Refrigerant LIQUID pipe

connection(3/8F)

Stop valve

(with service port)

Strainer

#100

Power

receiver

Linear

expansion

valve B

Linear expansion valve A

Strainer

#100

Strainer

#100

Strainer

#100

Thermistor TH6

(Outdoor 2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Service port

(Low pressure)

Service port

(High pressure)

High pressure

switch 63H

Bypass valve

Oil separator

Thermistor TH4

(Discharge)

Muffler

Strainer

#50

4-way valve

Compressor

Ball valve

Capillary tube

O.D.4.0OI.D.2.4OL500

Capillary tube

O.D.2.5OI.D.0.6OL1000

PUHZ-RP1.6VHA

Thermistor TH7

(Outdoor)

Heat exchanger

Refrigerant GAS pipe

connection(1/2F)

Refrigerant LIQUID pipe

connection(1/4F)

Stop valve

Strainer

#100

Power

receiver

Linear

expansion valve B

Thermistor TH6

(Outdoor 2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Service port

High pressure

switch 63H

Thermistor TH4

(Discharge)

Compressor

Strainer

#50

Solenoid valve

(Four-way valve)

Muffler

Distributor

Linear expansion valve A

Strainer

#100

Muffler

Stop valve

(with service port)

PUHZ-RP2VHA

PUHZ-RP2.5VHA

PUHZ-RP3VHA

PUHZ-RP3VHA-A

17

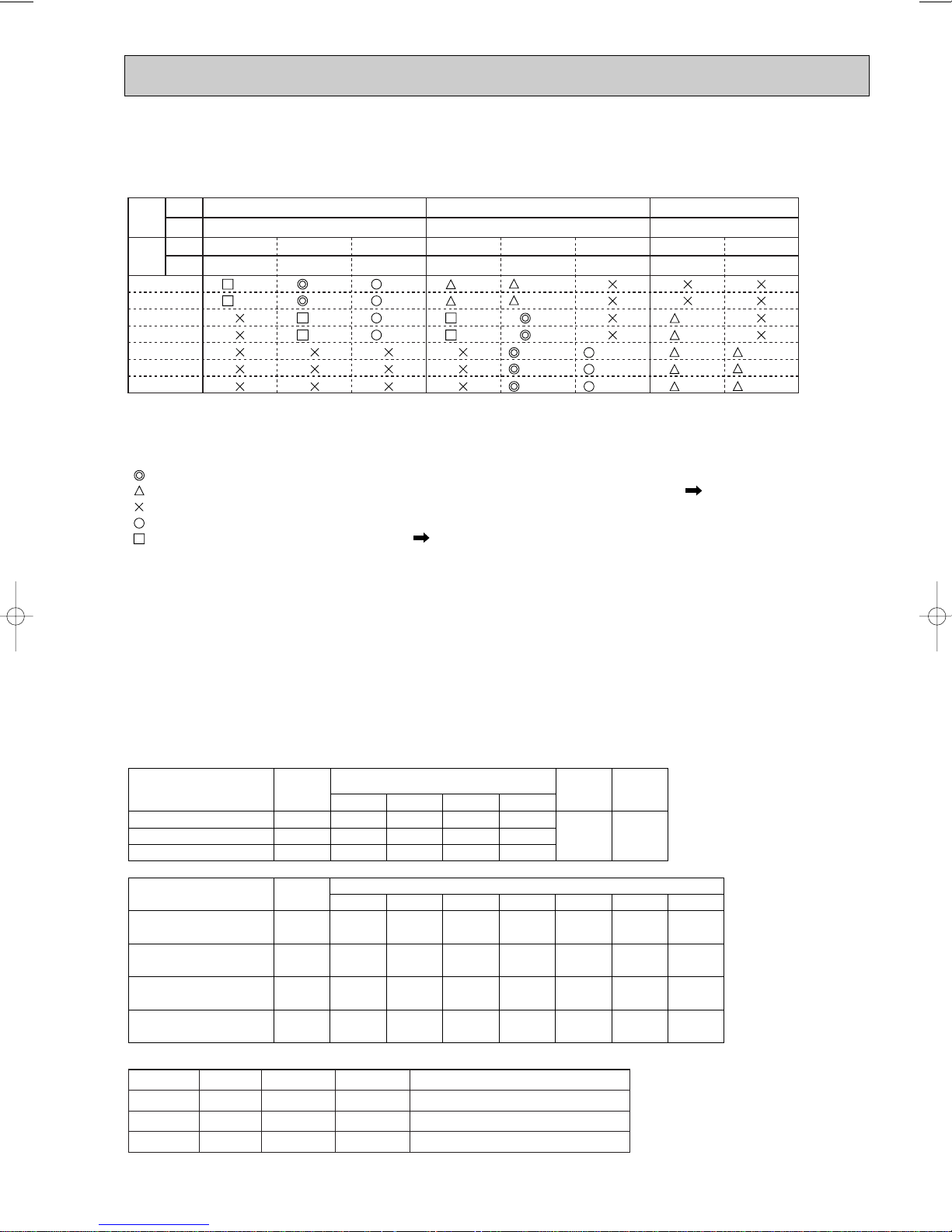

PUHZ-RP4VHA PUHZ-RP4VHA-A

Distributor

Thermistor TH7

(Outdoor)

Heat exchanger

Refrigerant GAS pipe

connection(5/8F)

Refrigerant LIQUID pipe

connection(3/8F)

Stop valve

(with service port)

Strainer

#100

Power

receiver

Linear

expansion valve B

Linear expansion valve A

Strainer

#100

Strainer

#100

Strainer

#100

Thermistor TH6

(Outdoor 2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Service port

(Low pressure)

Service port

(High pressure)

High pressure

switch 63H

Replace filter

Thermistor TH4

(Discharge)

Compressor

Strainer

#50

Solenoid valve

(Four-way valve)

Capillary tube

(O.D.4.0OI.D.3.0OL200)O2pcs

Strainer

#100

Strainer

#100

Low pressure

switch 63L

Muffler

Ball valve

Restrictor

valve

Solenoid valve

(Bypass valve)

Distributor

Thermistor TH7

(Outdoor)

Heat exchanger

Refrigerant GAS pipe

connection(5/8F)

Refrigerant LIQUID pipe

connection(3/8F)

Stop valve

(with service port)

Strainer

#100

Power

receiver

Linear

expansion valve B

Linear expansion valve A

Strainer

#100

Strainer

#100

Strainer

#100

Thermistor TH6

(Outdoor 2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Service port

(Low pressure)

Service port

(High pressure)

High pressure

switch 63H

Replace filter

Thermistor TH4

(Discharge)

Compressor

Strainer

#50

Solenoid valve

(Four-way valve)

Strainer

#100

Strainer

#100

Low pressure

switch 63L

Muffler

Ball valve

Restrictor

valve

Solenoid valve

(Bypass valve)

PUHZ-RP5VHA PUHZ-RP5VHA-A

PUHZ-RP6VHA PUHZ-RP6VHA-A

PUHZ-RP4VHA1 PUHZ-RP4VHA1-A

PUHZ-RP5VHA

PUHZ-RP6VHA

1 PUHZ-RP5VHA1-A

1 PUHZ-RP6VHA1-A

18

4-3. Applicable extension pipe for each model

15

30m or

above

31 — 40m

0.2kg

0.6Kg

0.6kg

10m or below

41 — 50m

0.4kg

1.2Kg

1.2kg

51 — 60m

—

—

1.8kg

61 — 75m

—

—

2.4kg

<Table 2> Additional refrigerant charging amount for pipe of standard diameter

<Table 3>

Outdoor unit

Permitted

pipe length

Additional refrigerant charging amount for pipe

length exceeding 30 m (kg)

PUHZ-RP1.6, 2V

PUHZ-RP2.5, 3V

PUHZ-RP4-6V, RP4-6V

1

Outdoor unit

PUHZ-RP1.6, 2V

PUHZ-RP2.5, 3V

PUHZ-RP4-6V

PUHZ-RP4-6V

1

Number of

bends

Height

difference

50m or less

50m or less

75m or less

Permitted

pipe length

50m or less

50m or less

75m or less

75m or less

2.1

3.1

5.1

4.6

11 — 20m 21 — 30m

2.3

3.3

5.3

4.8

2.5

3.5

5.5

5.0

31 — 40m

2.7

0.2

4.1

0.6

6.1

0.6

5.6

0.6

2.9

0.4

4.7

1.2

6.7

1.2

6.2

1.2

—

—

—

—

7.3

1.8

6.8

1.8

—

—

—

—

7.9

2.4

7.4

2.4

41 — 50m 51 — 60m 61 — 75m

Additional refrigerant charging amount for recharging (above) and pipe length exceeding 30m (below) (kg)

Liquid

pipe

(mm)

Gas

pipe

(mm)

[6.35

[9.52 [12.7

[9.52

OD

Thick-

ness

OD

Thick-

ness

RP1.6

RP2

RP2.5

RP3

RP4

RP5

RP6

t0.8

[12.7

t0.8

[15.88

t1.0

[12.7

t0.8

[15.88

t1.0

[19.05

t1.0

[15.88

t1.0

[19.05

t1.0

t0.8

t0.8

: Normal piping

: It can be used, however, additional refrigerant charge is required when the pipe length exceeds 20m. Refer to <table 4>.

: It cannot be used.

: It can be used.

: It can be used, however, the capacity is lowered. Refer to (c) Capacity correction.

<Table 1> Pipe length for 1:1 system

*1: Set DIP SW8-1 on outdoor unit controller board to ON.

*2: The maximum length is 50 m in case of using existing pipes.

*3: The height difference between indoor and outdoor unit should be kept within 30 m for all models.

[Marks in the table above]

50m

t0.8

30m 30m

10m 30m 30m

50m

30m

50m

50m

10m

50m

(*1)

75m

(*2)

50m

10m 30m 30m10m 50m

75m

(*2)

75m

(*2)

50m

(*1)

30m

(*1)

50m

(*1)

50m

(*1)

50m

(*1)

50m

(*1)

50m10m 30m 30m 30m

(*1)

<Table 4>

Additional refrigerant charging amount for liquid pipe which is one size larger than standard diameter

[9.52

[12.7

[12.7

RP1.6, 2

RP2.5, 3

RP4-6

Liquid pipe dia

Chargeless

30m

30m

50m

60 g addition per 1 m when pipe length exceeds 20 m

100 g addition per 1 m when pipe length exceeds 20 m

100 g addition per 1 m when pipe length exceeds 20 m

20m

20m

20m

Max. pipe length

Additional refrigerant charging amount

4-3-1. 1:1 system

(a) Pipe length

(b) Adjusting the amount of refrigerant

• Additional refrigerant charge is not necessary for the pipe length up to 30 m. When the pipe length exceeds 30 m or service

(refrigerant replacement) is performed, charge proper amount of refrigerant for each pipe length referring to table below.

Use refrigerant R410A. Use charge hose exclusive for R410A.

• When charging additional refrigerant, charge the refrigerant from low-pressure side of the port valve using a safety charger.

• Make sure that air purge for this unit at refrigerant replacement is performed from both high-pressure check valve and ser-

vice port. (If air purge is performed only from one of them, air in not purged enough.)

• When replacing refrigerant, charge the refrigerant from service port. When charged refrigerant is less than specified amount,

charge the refrigerant again from low pressure side of the port valve using a safety charger.

• Tighten the service port cap (nut) of stop valve firmly. The tightening torque is 12 to 16 N·m. (For the prevention of slow-leak)

• Check additional refrigerant charging amount referring to table 4 when liquid pipe is one size larger than standard diameter,

and table 2 when the pipe is standard diameter.

19

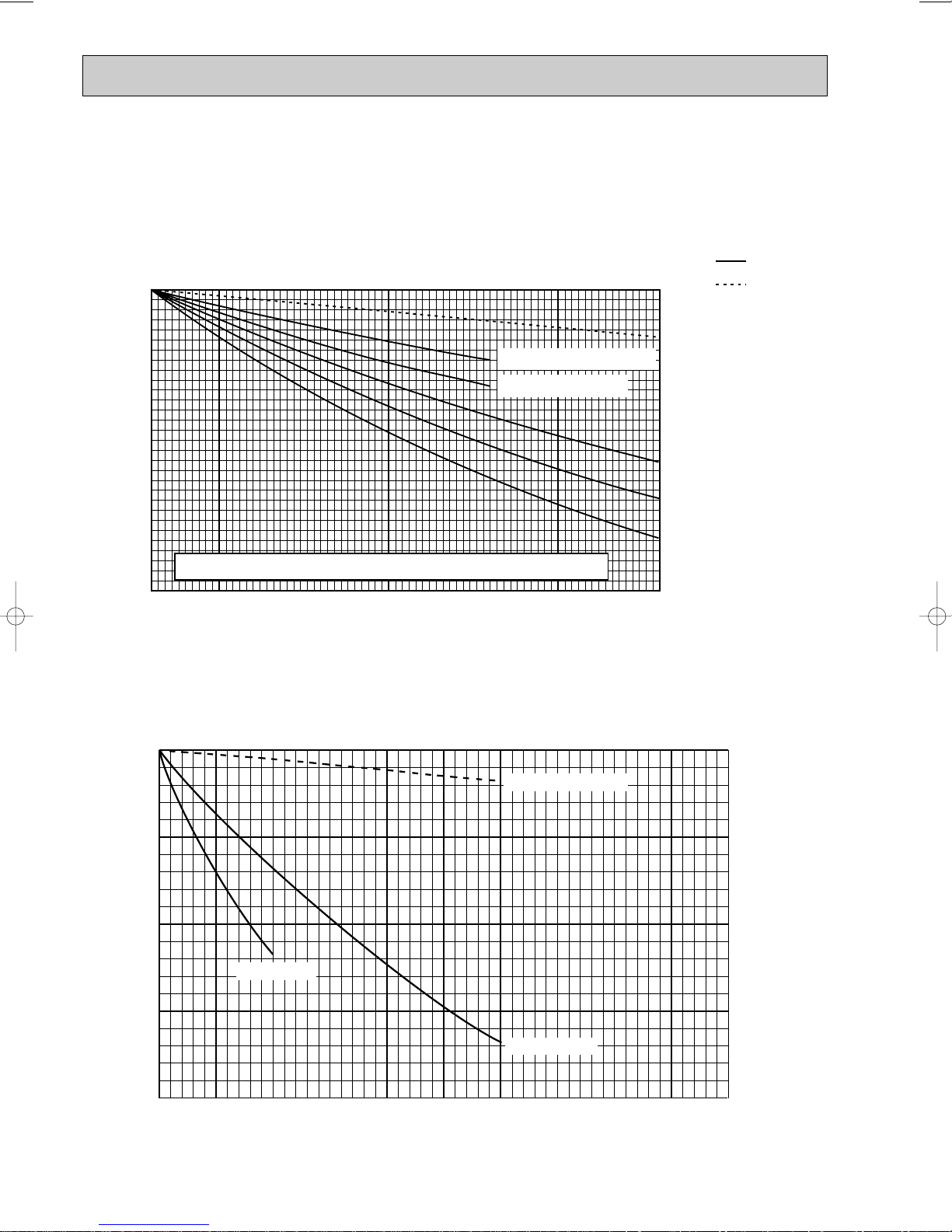

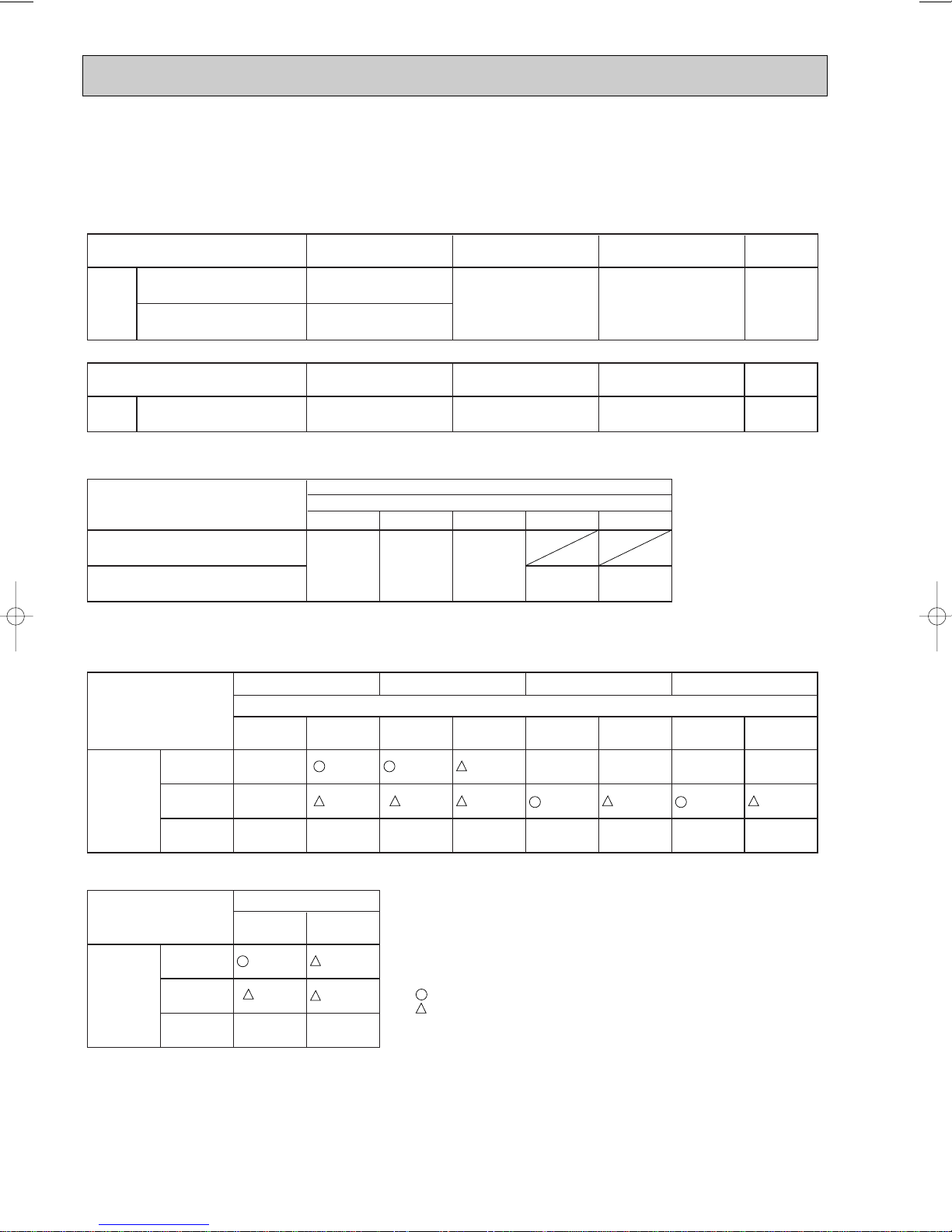

(c) Capacity correction

Cooling

Heating

Cooling and heating capacity is lowered according to pipe length. Capacity can be obtained by referring to the capacity

curves below. When the diameter of gas pipe is one size smaller than standard diameter, cooling capacity is lowered comparing to the standard diameter. The lowered capacity can be obtained by referring to capacity curves for gas pipe which is

one size smaller than standard size.

Corrected pipe length (m) = actual pipe length (m) + number of bends x 0.3 (m)

11

Capacity curves for PUHZ-RP • HA model <Standard size>

100

95

Cooling RP1.6, 2.5 models

90

Cooling RP3 model

85

80

Capacity ratio [%]

75

Note: The permitted pipe length is up to 55m for RP1.6, 2, 2.5, 3 model.

70

5 101520253035404550556065707580

Corrected pipe length

22

Capacity curve for PUHZ-RP1.6, 2 models

<When gas pipe is one size smaller than standard size>

100

Heating RP1.6, RP2

Heating RP1.6, 2, 2.5,

3, 4, 5 and 6 models

(Up to 55m for RP1.6,

2, 2.5, 3 model)

Cooling RP2, 4 models

(Up to 55m for RP2

model)

Cooling RP5 model

Cooling RP6 model

95

90

Cooling RP2

Capacity ratio [%]

85

80

5 10152025303540455055

Cooling RP1.6

Corrected pipe length

20

33

Capacity curve for PUHZ-RP2.5, 3 models

<When gas pipe is one size smaller than standard size>

100

95

90

Capacity ratio [%]

85

80

5 10152025303540455055

Corrected pipe length

Heating RP2.5, RP3

Cooling RP2.5

Cooling RP3

44

When gas pipe is one size larger than standard size for PUHZ-RP4, 5 and 6.

1 Capacity can be obtained by referring to capacity curves of standard size.

21

4-3-2. Synchronized twin and triple

(a) Pipe length

Please note that refrigerant piping length, bend number and height difference of indoor units are specified for each unit

combination.

Note: Be sure to use our Multi-distributor for distributing pipe to use existing piping.

<Table 5>

Synchronized twin

Outdoor

unit

<Table 6>

Outdoor

unit

Note 1: If total piping length exceeds charge-less piping length of 30 m, charge additional refrigerant according to the table 7.

PUHZ-RP3VHA

PUHZ-RP3VHA-A

PUHZ-RP4-6VHA

PUHZ-RP4-6VHA-A

Synchronized twin

PUHZ-RP6VHA

PUHZ-RP6VHA-A

Permitted total piping

length A + B + C

50 m or less

75 m or less

Permitted total piping

length A + B + C + D

Chargeless piping

length A + B + C

30 m or less

Charge-less piping

length A + B + C + D

30 m or less70 m or less

Indoor unit’s height

difference [B and C]

8 m or less

Indoor unit’s height difference

[B and C] [C and D] [B and D]

8 m or less

Bend number

w 2

15 at most

Bend number

w 2

15 at most

<Table 7>

Outdoor unit

30 m or less

PUHZ-RP3VHA

PUHZ-RP3VHA-A

PUHZ-RP4-6VHA

PUHZ-RP4-6VHA-A

Note 2: Bends number (w 2) should be within 8 for each combination, A + B, A +C and A + D, and 15 in all.

Note 3: Height difference between indoor and outdoor unit is referred to no matter which unit is located higher or lower.

<Table 8> Pipe length for twin of RP 3 - 6 (Piping length: A + B + C)

RP3 Twin (RP1.6✕2)

Liquid [6.35

Gas [12.7

Branch pipe

diameter

[B and C]

<Table 9> Pipe length for triple of RP6 (Piping length: A + B + C + D)

Branch pipe

diameter

[B,C and D]

Liquid [6.35

Gas [12.7

Liquid [9.52

Gas [15.88

Liquid [12.7

Gas [19.05

Liquid [6.35

Gas [12.7

Liquid [9.52

Gas [15.88

Liquid [12.7

Gas [19.05

Main pipe diameter [A]

Liquid [9.52

Gas [15.88

75 m(✽2)

50 m

✕

✕

✕

✕

Not required

Liquid [9.52

Gas [15.88

50 m

50 m

Liquid [12.7

Gas [19.05

50 m(✽1)

50 m(✽1)

Additional refrigerant to be charged (kg)

31 - 40 m 41 - 50 m 51 - 60 m 61 - 75 m

RP4 Twin (RP2✕2) RP5 Twin (RP2.5✕2) RP6 T win (RP3✕2)

Liquid [9.52

Gas [15.88

75 m(✽2)

✕

✕

A + B + C (+D)

0.6

50 m

✕

✽1 ··· Set DIP SW8-1 on outdoor unit control circuit board to ON.

✽2 ··· When using existing piping, pipe length should be 50 m at most.

✽3 ··· Height difference between indoor and outdoor unit should be

kept within 30 m in every case.

[Marks in table]

··· Normal piping

··· It can be used with some changes of piping length and the

amount of refrigerant to be charged.

✕ ··· It cannot be used.

1.2

1.8 2.4

Main pipe diameter [A]

Liquid [12.7

Gas [19.05

50 m(✽1)

50 m(✽1)

✕

Liquid [9.52

Gas [15.88

✕

75 m(✽2)

✕

Liquid [12.7

Gas [19.05

50 m(✽1)

w Charge additional

refrigerant from

the check valve

connected to the

pipe of low-pressure

side in indoor unit.

Liquid [9.52

Gas [15.88

✕

✕

✕

75 m(✽2)

✕

Liquid [12.7

Gas [19.05

50 m(✽1)

✕

✕

22

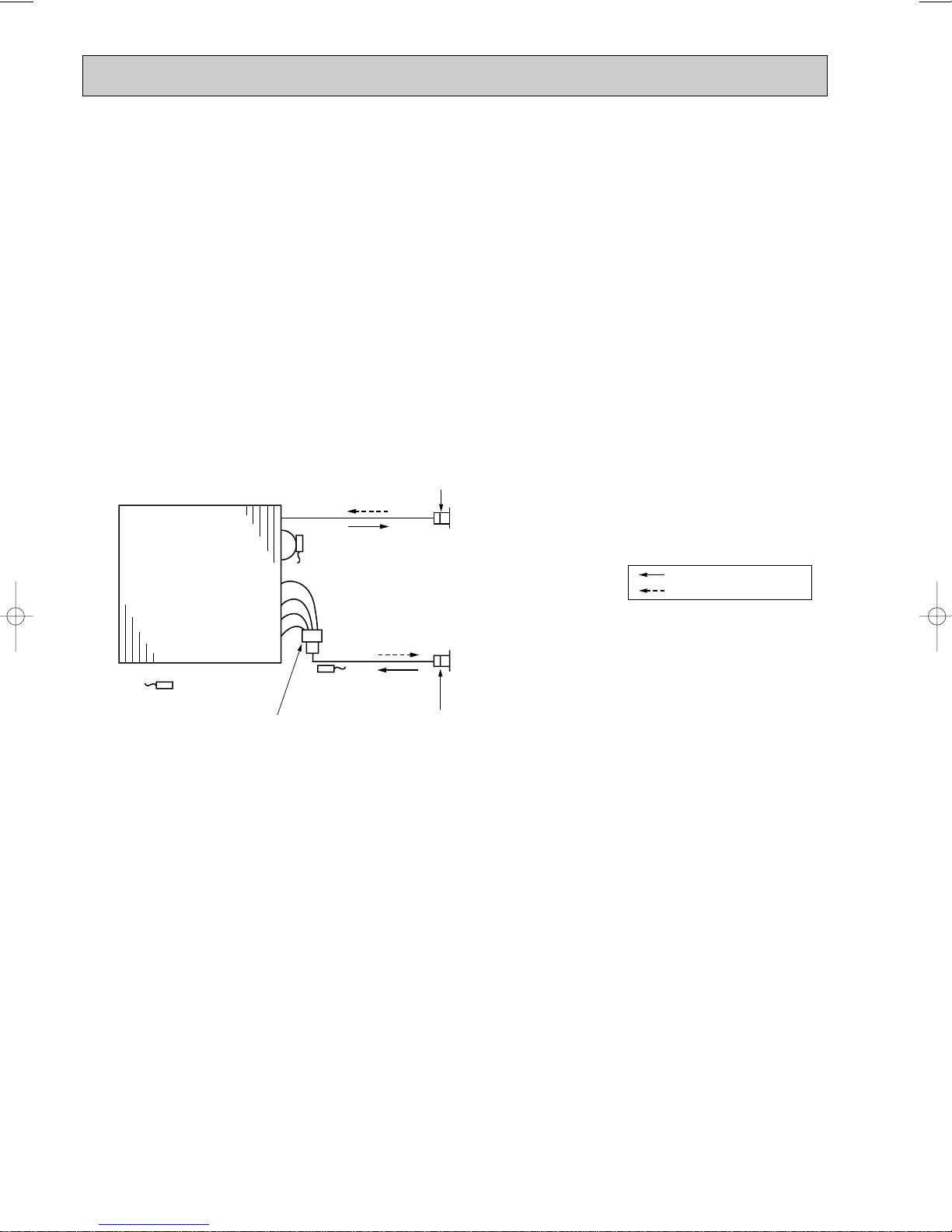

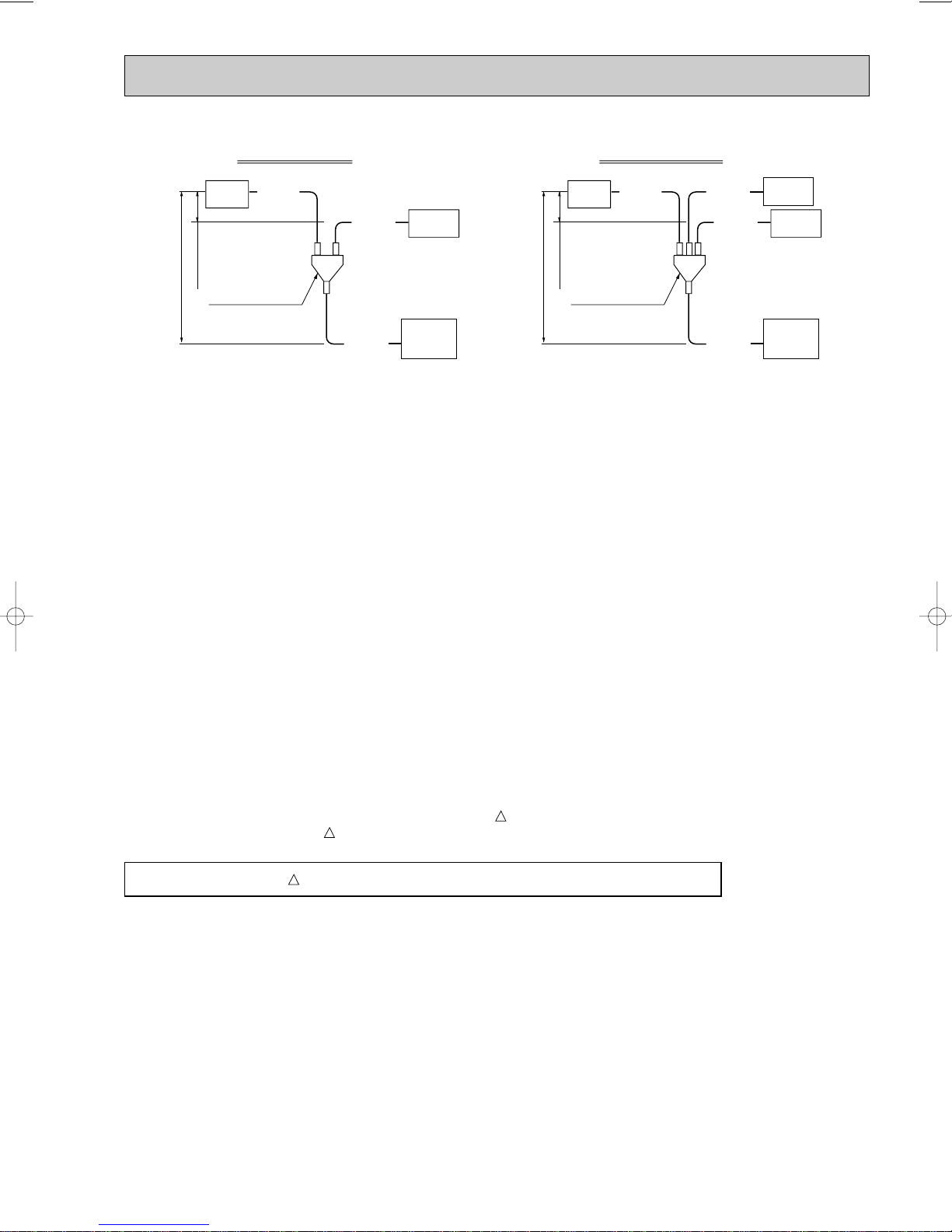

Synchronized twin

Synchronized triple

Indoor

unit

Optional

distributing pipe

1 m or less

Multi-distributor

30 m or less

Branch

pipe B

Branch

pipe C

Main

pipe A

Indoor

unit

Outdoor

unit

Indoor

unit

Optional

distributing pipe

1 m or less

Multi-distributor

30 m or less

Branch

pipe B

Branch

pipe C

Branch

pipe D

Main

pipe A

Indoor

unit

Indoor

unit

Outdoor

unit

1. Keep Stop valve in outdoor unit fully closed (as it is shipped), and after completing refrigerant piping connection, conduct air

purge from service port of stop valve at outdoor unit.

2. After air purging, make the valve rod of stop valve at outdoor unit fully open.

Now refrigerating cycle is complete between indoor and outdoor unit.

Handle stop valve following the indication on outdoor unit.

Caution:

• Be sure to apply refrigerating oil to flare sheet face. Never apply it to screws. (As it causes flare nut loosening.)

• Use double spanner for piping connection.

• Be sure to check gas leak by using leak detector or soapy water.

• Use attached parts for refrigerant piping to provide correct insulation to the connection of indoor unit side in accordance with

attached explanation sheet.

• Be sure to provide anoxidized brazing.

(b) Adjusting the amount of refrigerant

(i) In case of RP 3 twin

Check the additional refrigerant to be charged referring to table 2 when using pipe of size referred in table 8.

(ii) In case of RP4 - 6 twin or RP6 triple

When using liquid pipe one size larger than standard diameter for main pipe A, calculate the amount of additional

refrigerant referring to 2 below.

1 When using piping of standard diameter or gas pipe one size larger than standard diameter for main pipe A.

Check the additional refrigerant to be charged referring to table 2 like 1:1 system.

2 When using liquid pipe one size larger than standard diameter for main pipe A.

[In case of RP4-6 using liquid pipe of [12.7]

• When total length of extension pipe (main pipe and branch pipe) is less than 20 m.

No adjustment is required for refrigerant. (Chargeless)

• When total length of extension pipe (main pipe and branch pipe) is more than 20 m.

Calculate the amount of additional refrigerant, referred to as W (g) in the following, using the equation below and add

proper amount of refrigerant. If W is less than or equal to 0, no additional charge is required. (Chargeless)

[Additional refrigerant] W (g) = {100(g) ✕ L1} + {60(g) ✕ L2} + {30(g) ✕ L3} - 2000(g)

Note: Put “0” in L1-3 if it is not used. L1: Liquid pipe length of [12.7 (m)

(c) Capacity correction

Apply pipe length between indoor and outdoor unit which is the longest of all for the calculation of capacity lowering according

to each pipe length.

L2: Liquid pipe length of [9.52 (m)

L3: Liquid pipe length of [6.35 (m)

23

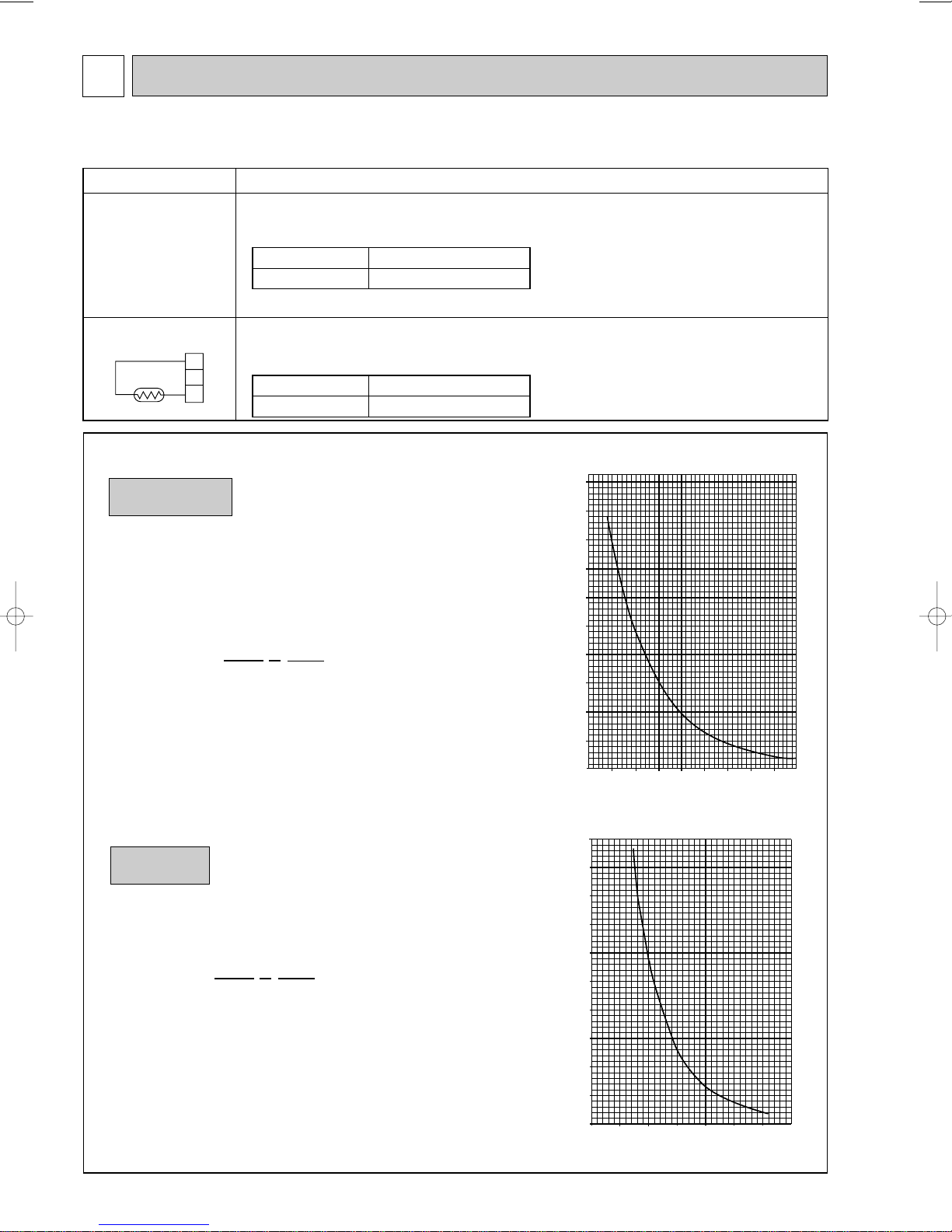

5

Parts name Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

Drain sensor

(Refer to below for a detail.)

(Refer to below for a detail.)

Room temperature

thermistor (TH1)

Pipe temperature

thermistor/ liguid (TH2)

Condenser/evaporator

temperature thermistor

(TH5)

1

2

3

Normal

4.3k"~9.6k"

Abnormal

Open or short

Abnormal

Open or short

Normal

0.6k"~6.0k"

Measure the resistance between the terminals using a tester.

Measure the resistance after 3 minutes have passed since the power supply was intercepted.

(Surrounding temperature 0:~60:)

-200 20406080

< Thermistor for drain sensor >

Temperature (:)

0

1

2

3

4

5

6

7

8

9

10

Resistance (k")

HOW TO CHECK THE PARTS

5-1. INDOOR UNIT

• Common parts

<Thermistor Characteristic graph>

Thermistor for

lower temperature

Thermistor R0=15kΩ ±3%

Fixed number of B=3480K ± 2%

Rt=15exp { 3480( ) }

0: 15kΩ

10: 9.6kΩ

20: 6.3kΩ

25: 5.2kΩ

30: 4.3kΩ

40: 3.0kΩ

Drain sensor

Room temperature thermistor(TH1)

Pipe temperature thermistor(TH2)

Condenser/evaporator temperature

thermistor(TH5)

1

273+t

1

273

< Thermistor for lower temperature >

50

40

30

20

Resistance (k")

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

Thermistor R0=6.0kΩ ±5%

Fixed number of B=3390K ±2%

Rt=6exp { 3390( ) }

1

273+t

0: 6.0kΩ

10: 3.9kΩ

20: 2.6kΩ

25: 2.2kΩ

30: 1.8kΩ

40: 1.3kΩ

60: 0.6kΩ

1

273

24

PLA-RP1.6AA PLA-RP2AA PLA-RP2.5AA

1

1

2

2

3

3

Red

White

Black

Relay connector

Protector

OPEN : 125i5:

CLOSE : 79i 15:

4

5

2

361

Orange

Red

Pink

Yellow Brown Blue

M

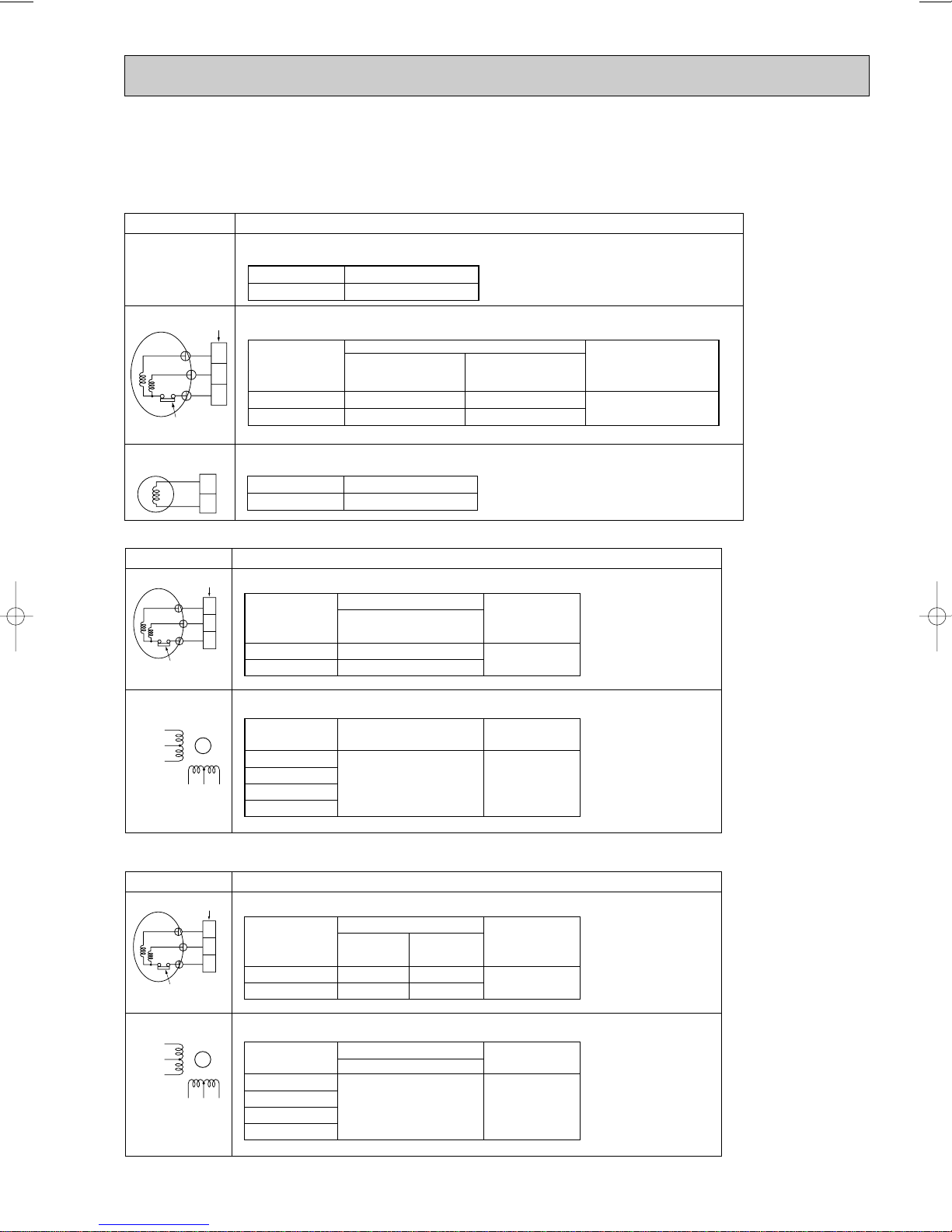

Parts name Check points

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor (MF)

Abnormal

Open or short

Red – Black

White – Black

Motor terminal

or

Relay connector

RP1.6 , RP2

120.5"

111.3"

Normal

Open or short

Abnormal

Brown – Yellow

Brown – Blue

Red – Orange

Red – Pink

Connector

Normal

186~214"

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:~30:)

Vane motor (MV)

1

1

2

2

3

3

Red

White

Black

Relay connector

Protector

OPEN : 130i5:

CLOSE : 80i 20:

4

5

2

361

Orange

Red

Pink

Yellow Brown Blue

M

Parts name Check points

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor (MF)

Abnormal

Open or short

Red – Black

White – Black

Motor terminal

or

Relay connector

RP2.5

RP3

99.5"

103.9"

RP4

62.6"

74.0"

Normal

Open or short

Abnormal

Brown –Y ellow

Brown – Blue

Red – Orange

Red – Pink

Connector

Normal

RP2.5, RP3, RP4

186~214"

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:~30:)

Vane motor (MV)

PLA-RP1.6AA.UK PLA-RP2AA.UK PLA-RP2.5AA.UK

PLA-RP3AA PLA-RP4AA PLA-RP5AA PLA-RP6AA

PLA-RP3AA

1 PLA-RP4AA1 PLA-RP5AA1 PLA-RP6AA1

PLA-RP3AA.UK PLA-RP4AA.UK PLA-RP5AA.UK PLA-RP6AA.UK

PLA-RP3AA

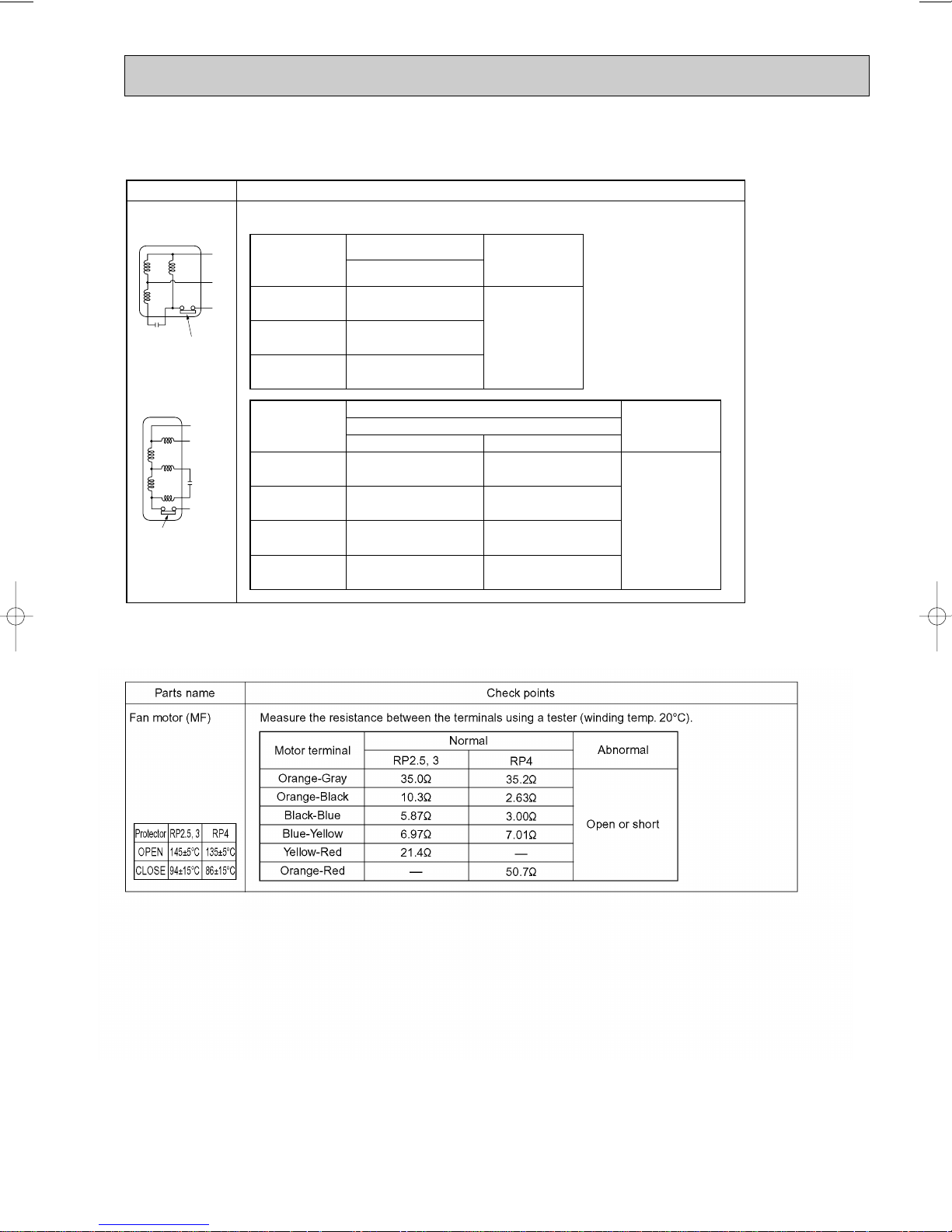

Parts name Check points

Vane motor

Fan motor

Relay connector

1

3

Protector

OPEN :130:

CLOSE:80i20:

Drain pump

Red

Red

1.UK PLA-RP4AA1.UK PLA-RP5AA1.UK PLA-RP6AA1.UK

Measure the resistance between the terminals using a tester.

(Surrounding temperature20:)

Normal Abnormal

15k" Open or short

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Red

1

2

3

Motor terminal

or

Relay connector

Red-Black

White

2

Black

White-Black

PLA-RP1.6, 2, 2.5, 3AA

PLA-RP1.6, 2, 2.5, 3AA.UK

PLA-RP3AA

PLA-RP3AA1.UK

1

87.2"

104.1"

Normal

PLA-RP4, 5, 6AA

PLA-RP4, 5, 6AA.UK

PLA-RP4, 5, 6AA

PLA-RP4, 5, 6AA1.UK

28.7"

41.6"

1

Abnormal

Open or short

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

1

2

Normal Abnormal

290" Open or short

PKA-RP1.6GAL PKA-RP2GAL

PKA-RP2.5FAL PKA-RP3FAL PKA-RP4FAL

25

PCA-RP2GA PCA-RP2.5GA PCA-RP3GA

1

1

2

2

3

3

Red

White

Black

Relay connector

Protector

1

2

Gray

Gray

4

5

2

361

Orange

Red

Pink

Yellow Brown Blue

M

4

2

5

31

Pink

Orange

Red

Yellow Blue

M

OFF:130i 5:

ON :80i 20:

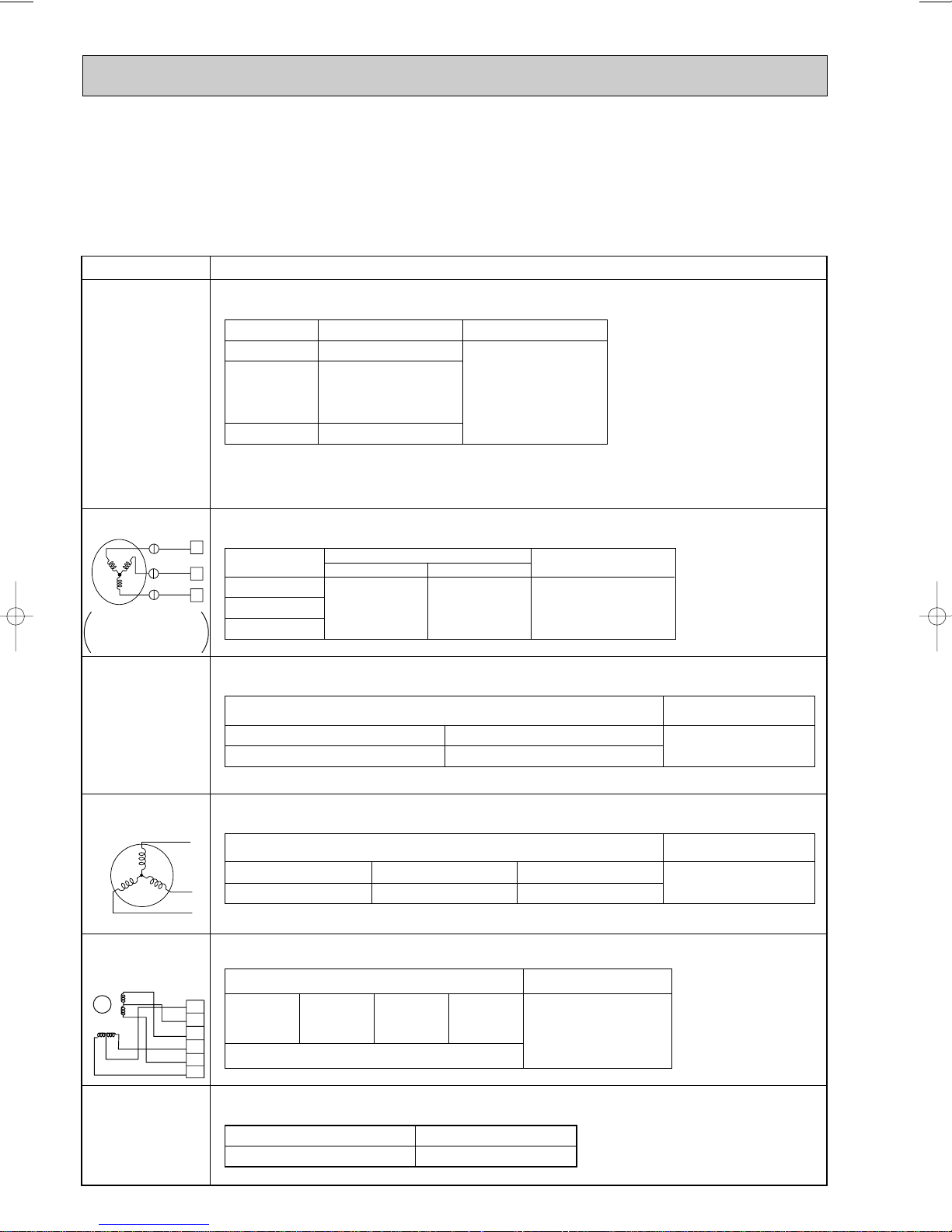

Parts name Check points

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Drain-up

mechanism (Option)

Fan motor

Abnormal

Open or short

Normal

195"

Abnormal

Open or short

Red – Black

White – Black

Motor terminal

or

Relay connector

RP2

70.6"

69.6"

RP2.5, RP3

45.0"

44.8"

RP4

43.7"

55.3"

RP5, RP6

20.4"

20.7"

Normal

Open or short

Abnormal

Brown – Yellow

Brown – Blue

Red – Orange

Red – Pink

Connector

RP2

186~214"

RP2.5, RP3

140~160"

Normal

Open or short

Abnormal

Brown – Yellow

Brown – Blue

Red – Orange

Red – Pink

Connector

RP4, RP5, RP6

140~160"

Normal

Vane motor

Parts name Check points

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor (MF)

Brown

White

Blue

Red

Orange

Black

Protector

(PEA-RP3,4,5EA)

OPEN :135:

CLOSE:86i15:

(PEA-RP6EA)

OPEN :150:

CLOSE:96i15:

Abnormal

Open or short

White – Black

Black – Blue

Blue – Brown

Brown – Red

Motor terminal

or

Relay connector

Normal

PEA-

RP3EA.TH-A RP4EA.TH-A RP5EA.TH-A RP6EA.TH-A

28.6"

12.5"

4.3"

23.6"

20.6"

8.1"

3.2"

16.0"

15.3"

5.1"

2.7"

14.5"

10.2"

5.2"

3.1"

12.1"

PCA-RP4GA PCA-RP5GA PCA-RP6GA

PEA-RP3EA.TH-A PEA-RP4EA.TH-A PEA-RP5EA.TH-A PEA-RP6EA.TH-A

26

PEAD-RP1.6EA.UK PEAD-RP2EA.UK PEAD-RP2.5EA.UK

PEAD-RP3EA.UK PEAD-RP4EA.UK PEAD-RP5EA.UK PEAD-RP6EA.UK

PEAD-RP3EA

Parts name Check points

Fan motor (MF)

PEAD-RP3EA(1).UK

WhiteRed

Protector

OPEN :150:

CLOSE:96i15:

1.UK PEAD-RP4EA1.UK PEAD-RP5EA1.UK PEAD-RP6EA1.UK

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Black

Relay connector

Blue

Gray

(White or Red open)

(White or Red open)

(White or Red open)

Motor terminal

or

Gray – Black

Black – Blue

Blue – Red

PEAD-RP1.6, 2, 2.5EA.UK

Normal

PEAD-RP3EA

43.5"

14.74"

57.5"

Abnormal

(1).UK

Open or short

PEAD-RP4,5,6EA

Protector

OPEN :135:

CLOSE:86i15:

Black

Blue

Red

White

Gray

(1)

.UK

PEAD-RP2.5GA

PEAD-RP3GA

PEAD-RP4GA

Motor terminal

or

Relay connector

Gray-Black

(White or Red open)

Blue – Black

Black – Red

(White or Red open)

Gray – Red

(White or Red open)

RP4EA

24.76"

4.78"

18.99"

36.63"

(1).UK

Normal

PEAD-

RP5EA

(1)

.UK RP6EA

10.27"

2.11"

20.75"

25.44"

(1)

Abnormal

.UK

Open or short

27

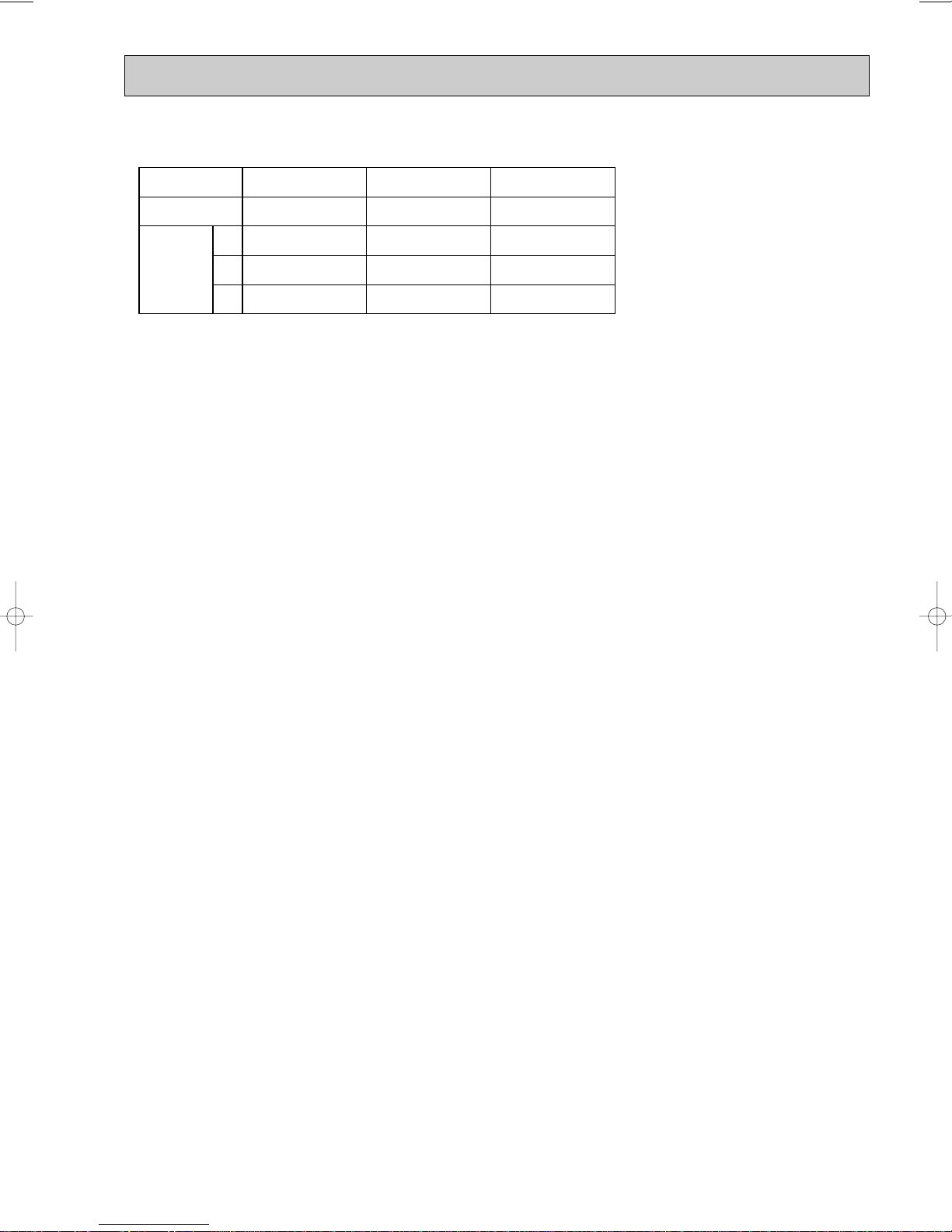

5-2. OUTDOOR UNIT

4

6

2

3

1

2

3

4

5

6

5

1

M

Blue

Brown

Yellow

Orange

Red

White

Parts name

Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

Disconnect the connector then measure the resistance using a tester.

(

Winding temperature 20

:)

Thermistor (TH3)

<Outdoor pipe>

Thermistor (TH4)

<Discharge>

Thermistor (TH6)

<Outdoor 2-phase pipe>

Thermistor (TH7)

<Outdoor>

Thermistor (TH8)

<Heat sink>

Normal

160k"~410k"

4.3k"~9.6k"

39k"~105k"

TH4

TH3

TH6

TH7

TH8

Abnormal

Open or short

Normal

(1) - (6)

Red - White

(1) - (4)

Red - Orange

(2) - (5)

Brown - Yellow

(2) - (3)

Brown - Blue

Abnormal

46±4"

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20

:

)

Solenoid valve coil

<Four-way valve>

(21S4)

Pin number of relay

connector is different

from that motor

connector

Motor for compressor

(MC)

Linear expansion valve

( LEV(A),LEV(B) )

Normal

Abnormal

Open or short

RP1.6-3V RP4-6V

Open or short

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20

:

)

Normal

1197±10"

Abnormal

Open or short

Solenoid valve coil

<Bypass valve>

(SV)

RP2.5-6VHA only

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor(MF1,MF2)

Normal

RP1.6V, 2V

66.5±3.3"

RP2.5-6V

15.1±0.5"

2350±170" 1370±100"

RP1.6V, 2V RP4-6V

0.300"~0.340"

RP2.5V, 3V

0.865"~0.895" 0.266"

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Normal

Abnormal

Open or short

Relay connector

Abnormal

Open or short

Red — Black

Black — White

White — Red

Red

W

V

U

W

V

U

White

Black

PUHZ-RP1.6HA PUHZ-RP2VHA PUHZ-RP2.5VHA PUHZ-RP3VHA

PUHZ-RP4VHA PUHZ-RP5VHA PUHZ-RP6VHA

PUHZ-RP4VHA1 PUHZ-RP5VHA1 PUHZ-RP6VHA1

PUHZ-RP4VHA-A PUHZ-RP5VHA-A PUHZ-RP6VHA-A

PUHZ-RP4VHA1-A PUHZ-RP5VHA1-A PUHZ-RP6VHA1-A

28

5-3. COMPRESSOR TECHNICAL DATA

U-V

U-W

W-V

Unit

Compressor model

Winding

Resistance

( " )

ANV33FDAMT

(at 20°C)

0.266

0.266

0.266

SNB130FLBH

0.300 ~ 0.340

0.300 ~ 0.340

0.300 ~ 0.340

PUHZ-RP4,5,6VHA

PUHZ-RP1.6,2VHA

TNB220FMBH

0.865 ~ 0.895

0.865 ~ 0.895

0.865 ~ 0.895

PUHZ-RP2.5,3VHA

29

HOW TO CHECK THE COMPONENTS

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

Temperature (:)

Resistance (k")

200

150

100

50

0

25 50 75 100 125

Temperature (:)

Resistance (k")

500

400

300

200

100

0

25

50 75 100 120

Temperature (:)

Resistance (k")

<Thermistor feature chart>

Low temperature thermistors

• Thermistor <Outdoor pipe> (TH3)

• Thermistor <Outdoor 2-phase pipe> (TH6)

• Thermistor <Outdoor> (TH7)

Thermistor R0 = 15k' ±3%

B constant = 3480K ± 2%

1

R

t =15exp{3480(

0: 15k'

10: 9.6k'

20: 6.3k'

25: 5.2k'

Medium temperature thermistor

• Thermistor <Heat sink> (TH8)

Thermistor R50 = 17k' ±2%

B constant = 4150K ± 3%

t =17exp{4150(

R

0: 180k'

25: 50k'

50: 17k'

70: 8k'

90: 4k'

1

273+t – 273

30: 4.3k'

40: 3.0k'