Mitsubishi Electric PEAD-RP100, PEAD-RP140JAA, PEAD-RP125, PEAD-RP71JAA, MPEAD-RP100JAA Installation Manual

...

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

Air-Conditioners

PEAD-RP71, 100, 125, 140JAA

English

FOR INSTALLER

2

3

[Fig. 3-1]

4

[Fig. 4-1]

C

D

C

E

D

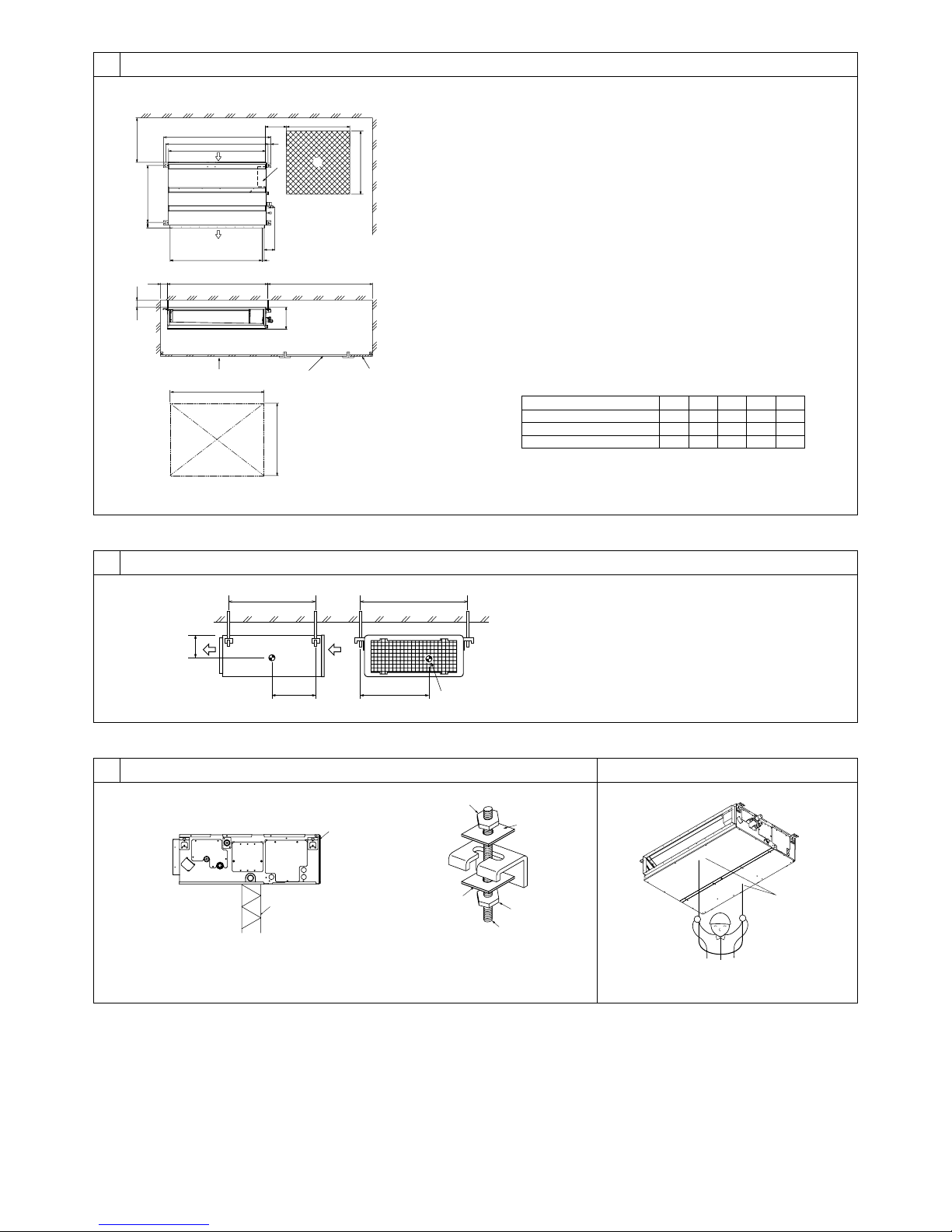

A Unit body

B Lifting machine

5

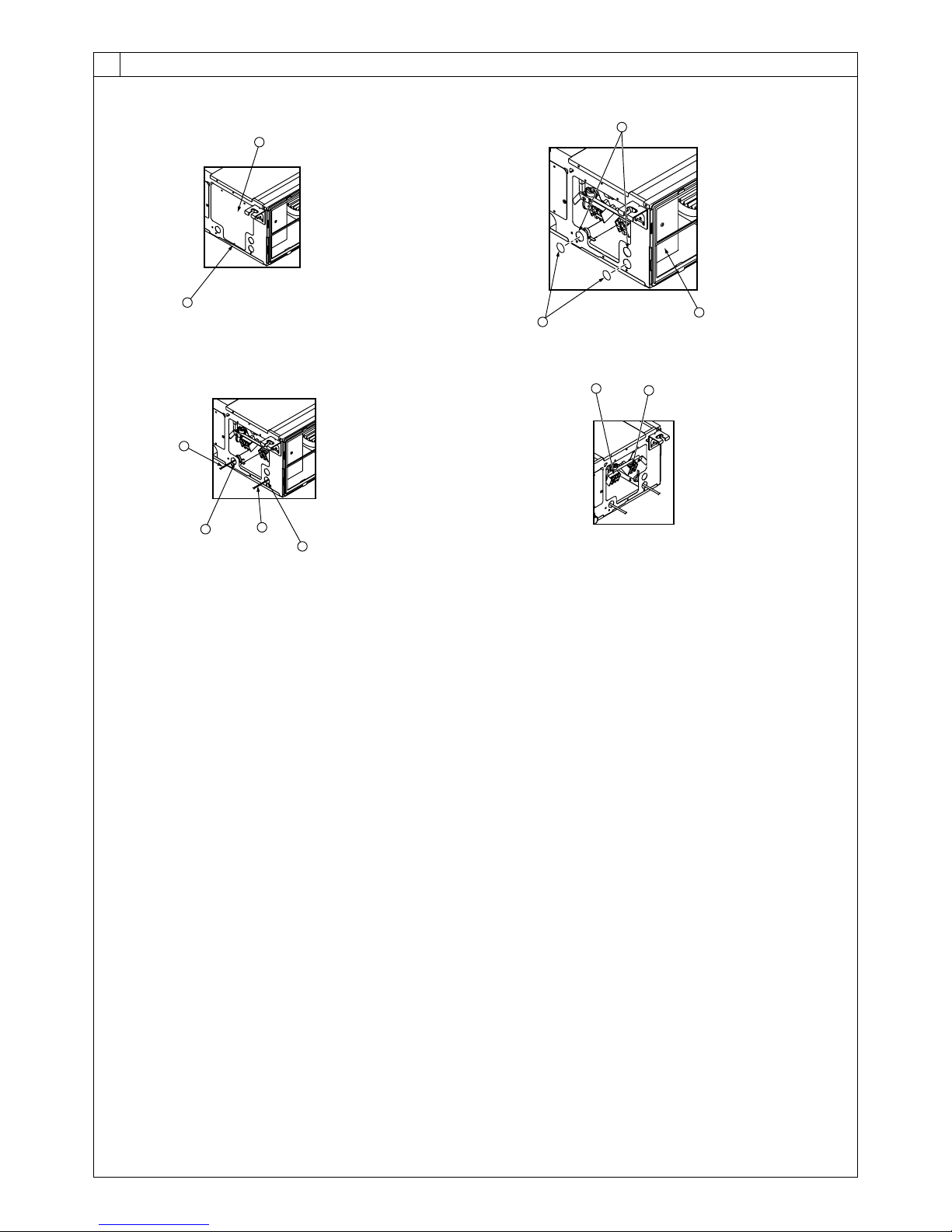

[Fig. 5-1] [Fig. 5-2] [Fig. 5-3]

A Center of gravity

A Indoor unit’s bottom surface

5.25.1

A Access door

B Electrical parts box

C Air inlet

D Air outlet

E Ceiling surface

F Service space (viewed from the side)

G Service space (viewed from the direction of arrow)

1 600 mm or more

2 100 mm or more

3 10 mm or more

4 300 mm or more

YX

LW

A

Z

C Nuts (field supply)

D Washers (accessory)

E M10 hanging bolt (field supply)

B

C

D

A

F

G

3

4

E

A

50~150 450

450

57

643

777

30

98

23

C

B

A

D

B

E

250

1

2

B

A

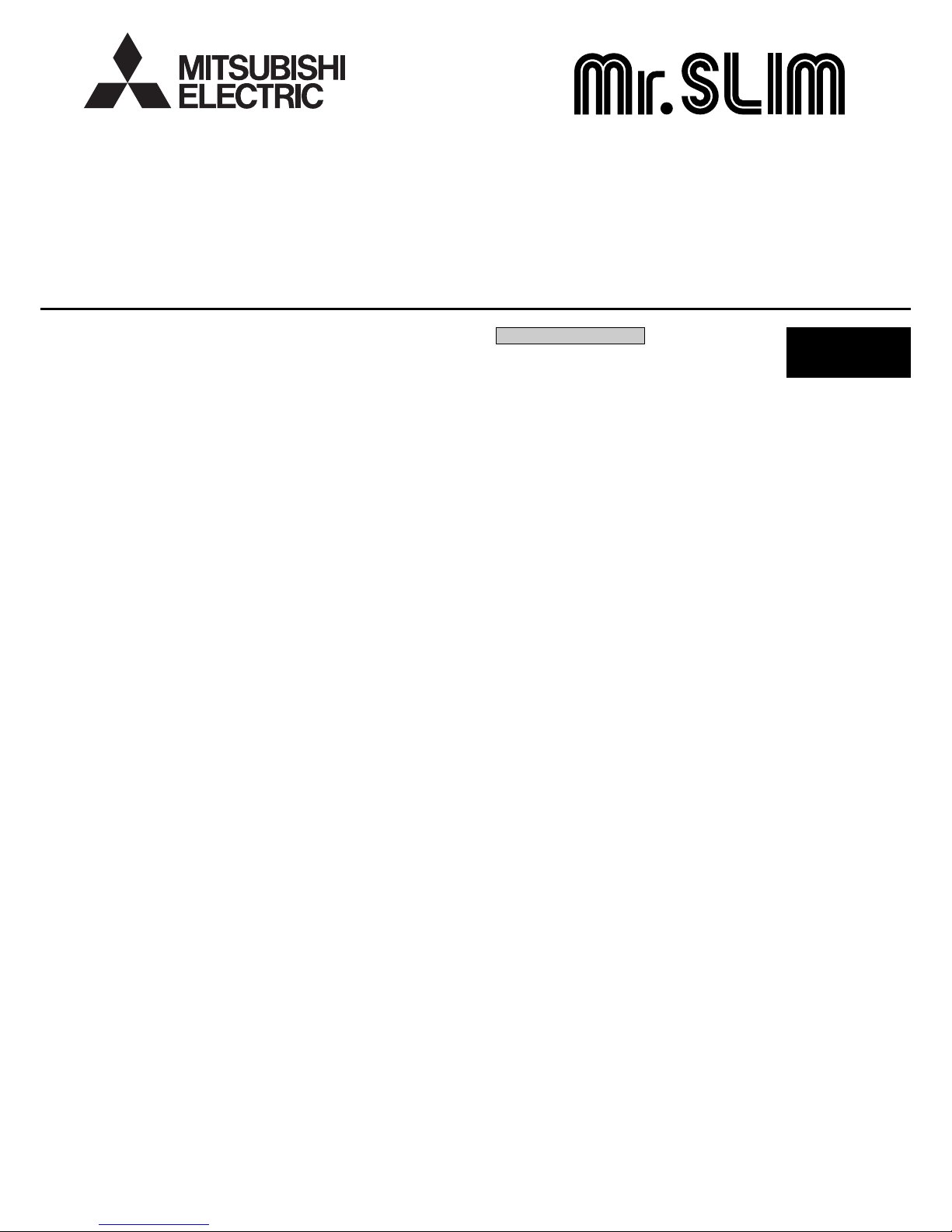

Model

PEAD-RP71

PEAD-RP100, 125

PEAD-RP140

A

1100

1400

1600

B

1154

1454

1654

C

1200

1500

1700

D

1060

1360

1560

E

1200

1500

1700

(mm)

4.1

3.1

A

3

6

øB

øA

a

b

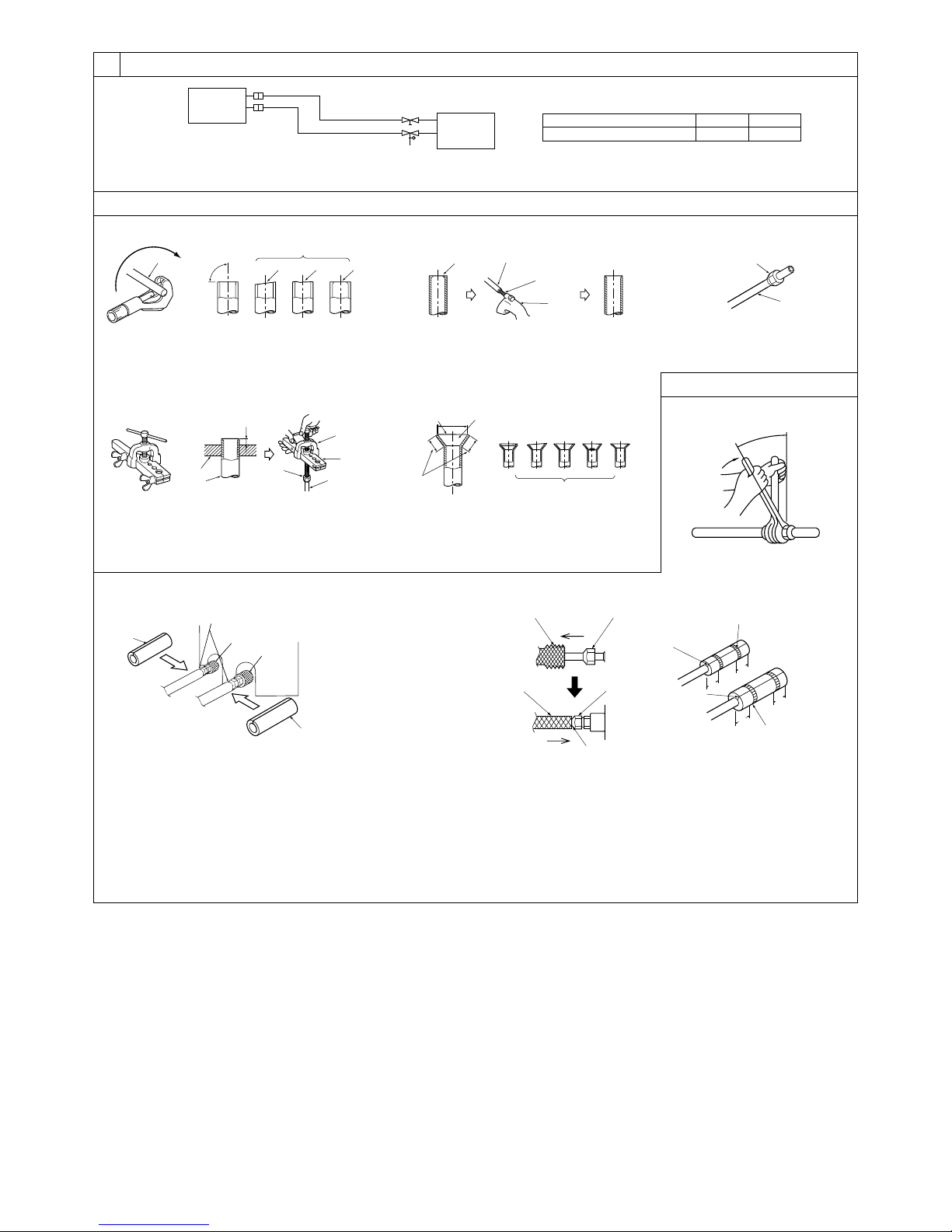

[Fig. 6-1]

a Indoor unit

b Outdoor unit

a

dcbef

90°

d

c

b

a

b

a

a

b

e

b

c

d

c

A

c

b

a

defg h

i

[Fig. 6-9]

A Pipe cover (small) (accessory)

B Caution:

Pull out the thermal insulation on the refrigerant piping at the

site, insert the flare nut to flare the end, and replace the insulation in its original position.

Take care to ensure that condensation does not form on exposed copper piping.

C Liquid end of refrigerant piping

D Gas end of refrigerant piping

E Site refrigerant piping

F Main body

G Pipe cover (large) (accessory)

H Thermal insulation (field supply)

I Pull

J Flare nut

K Return to original position

A

B

C

D

F

G

E

H

H

K

L

J

I

J

O

O

N

N

20

20

20

20

[Fig. 6-3]

[Fig. 6-6]

[Fig. 6-4] [Fig. 6-5]

a Flare nut

b Copper tube

a Burr

b Copper tube/pipe

c Spare reamer

d Pipe cutter

[Fig. 6-7]

[Fig. 6-8]

a Flaring tool

b Die

c Copper tube

d Flare nut

e Yoke

a Smooth all around

b Inside is shining without

any scratches

c Even length all around

d Too much

e Tilted

f Scratch on

flared plane

g Cracked

h Uneven

i Bad examples

L Ensure that there is no gap here

M Plate on main body

N Band (accessory)

O Ensure that there is no gap here. Place join upwards.

6.1

6.2

a Copper tubes

b Good

c No good

d Tilted

e Uneven

f Burred

6.3

Model

PEAD-RP71, 100, 125, 140

A

ø15.88Bø9.52

4

[Fig. 6-10]

[Fig. 6-11]

6

6.5

C

D

G

F

E

B

525

A

A Indoor unit

B Tie band (accessory)

C Band fixing part

D Insertion margin

E Drain socket (accessory)

F Drain pipe (O.D. ø32 PVC TUBE, field supply)

G Insulating material (field supply)

A

B1

C C C

D2

E

A Downward slope 1/100 or more

B Connection dia. R1 external thread

C Indoor un it

D Collective piping

E Maximize this length to approx. 10 cm

5

8

[Fig. 8-1]

8.1

7

7.1

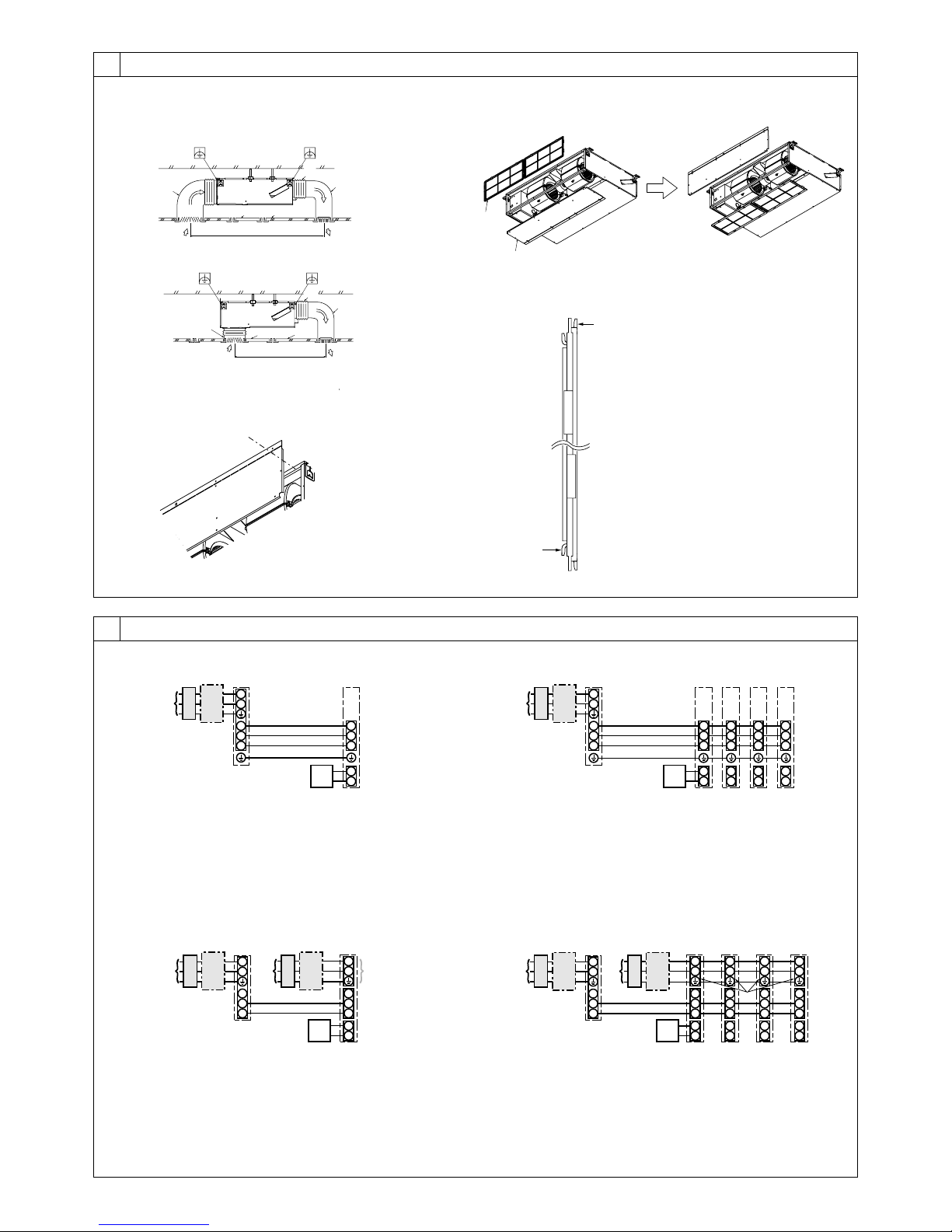

A Outdoor unit power supply

B Earth leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Indoor unit/outdoor unit connecting cords

F Remote controller (option)

G Indoor unit

S1

S2

L

N

1

2

S1

S2

S3

S3

AB C

D

E

F

G

A Outdoor unit power supply

B Earth leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Indoor unit/outdoor unit connecting cords

F Remote controller (option)

G Indoor unit

S1

S2

L

N

1

2

S1

S2

S3

1

2

S1

S2

S3

S3

1

2

S1

S2

S3

1

2

S1

S2

S3

ABC

D

E

F

GGGG

A Outdoor unit power supply

B Earth leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Indoor unit/outdoor unit connecting cords

F Remote controller (option)

G Indoor unit

H Option

J Indoor unit power supply

S1

S2

L

N

1

2

L

N

S1

S2

S3

S3

A

CB

D

JEB

C

F

G

H

A Outdoor unit power supply

B Earth leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Indoor unit/outdoor unit connecting cords

F Remote controller (option)

G Indoor unit

H Option

J Indoor unit power supply

S1

S2

L

N

1

2

L

N

S1

S2

S3

1

2

L

N

S1

S2

S3

1

2

L

N

S1

S2

S3

1

2

L

N

S1

S2

S3

S3

ABC

D

E

JBC

F

H

GGGG

[Fig. 8-2]

[Fig. 8-3] [Fig. 8-4]

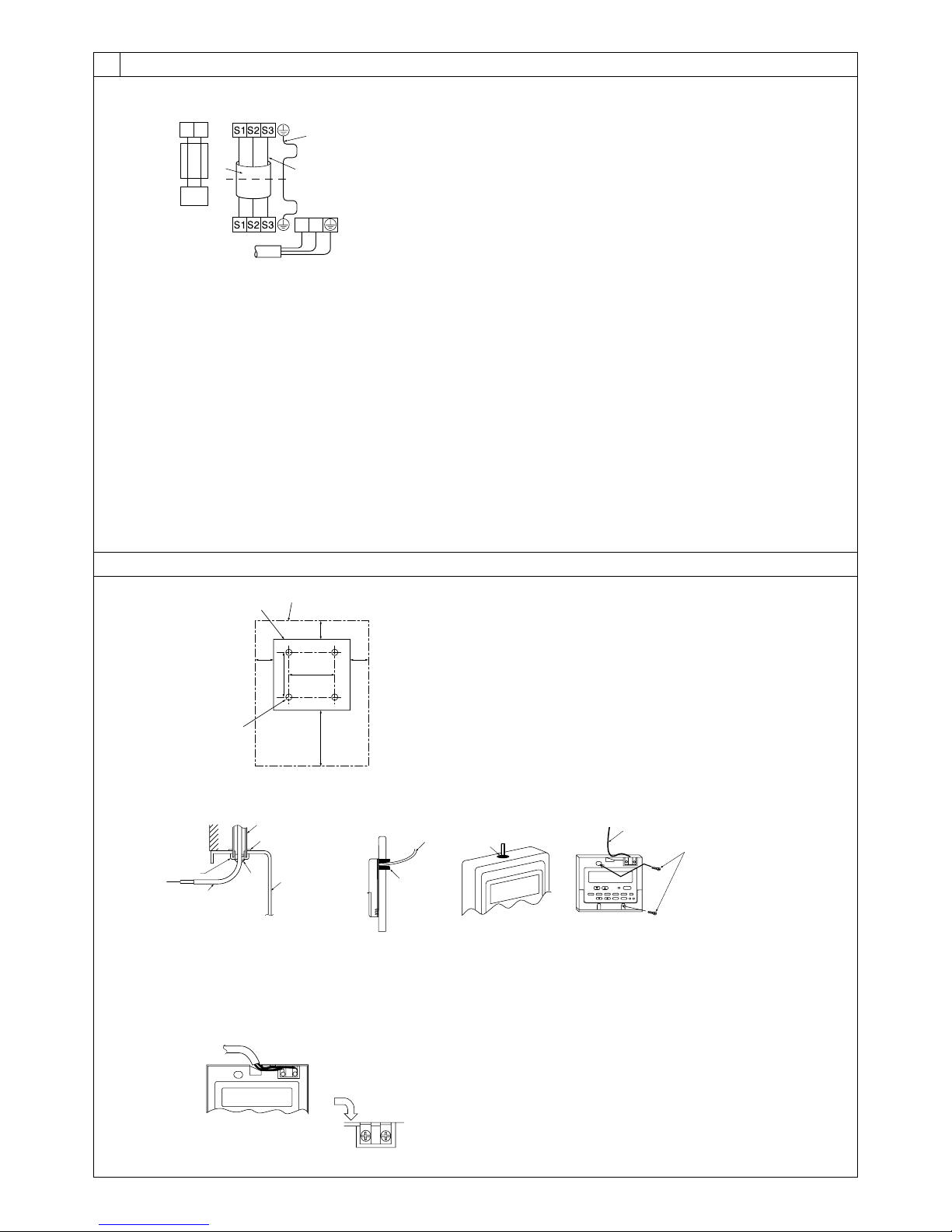

[Fig. 7-1] [Fig. 7-2]

[Fig. 7-3]

[Fig. 7-4]

Duct

Air inlet

Access door

Canvas duct

Ceiling surface

Air outlet

Leave distance

enough to prevent short cycle

<A> In case of rear inlet

A

B

G

F

A

A

B

C

D

E

F

G

D

CE

<B> In case of bottom inlet

A

B

G

C

E

A

F

D

A

B

A Filter

B Bottom plate

C

D

C Nail for the bottom inlet

D Nail for the rear inlet

6

8.2

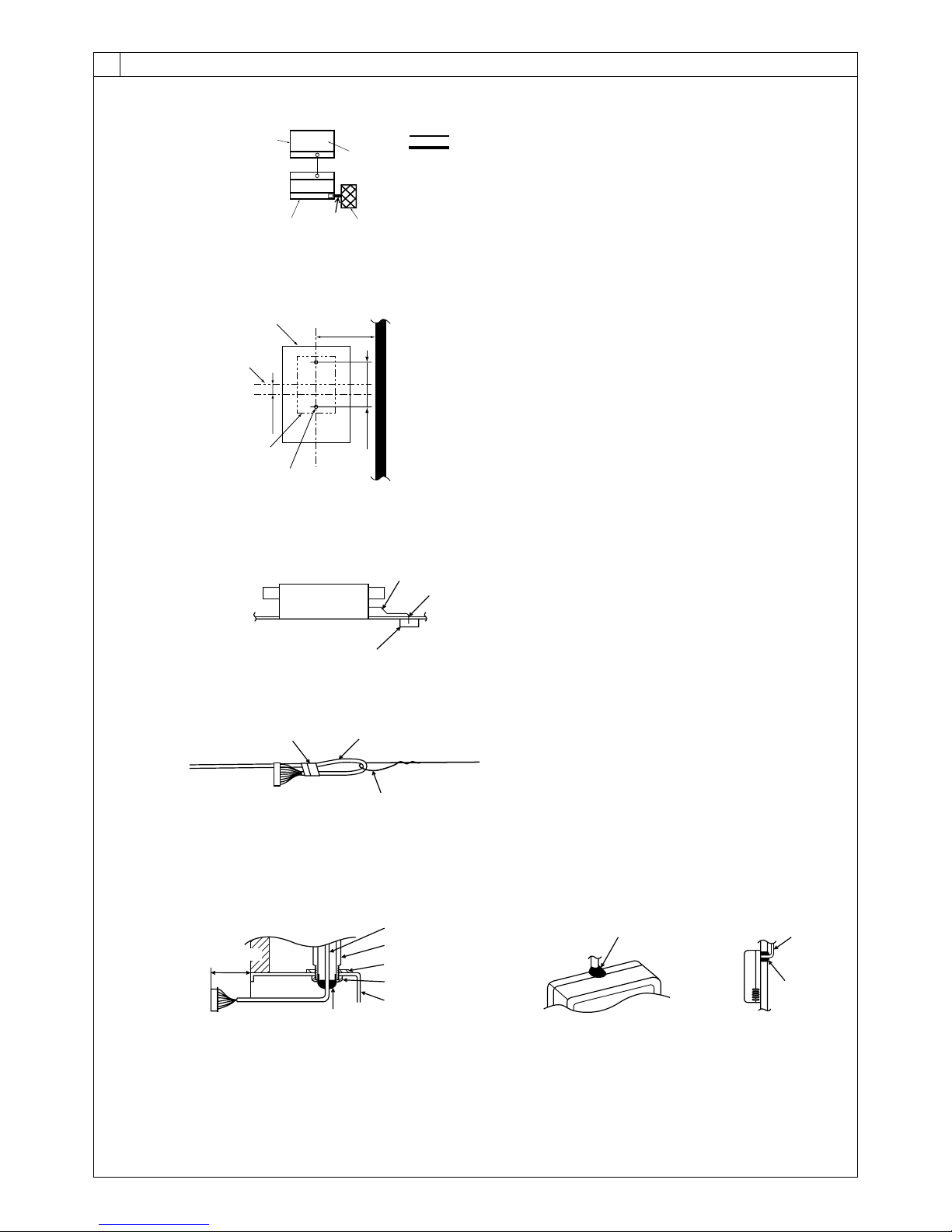

F Use PG bushing to keep the weight of the cable and external force from being applied to

the power supply terminal connector. Use a cable tie to secure the cable.

G Power source wiring

H Use ordinary bushing

I Transmission wiring

J Terminal block for power source and indoor transmission

K Terminal block for remote controller

[Fig. 8-2-3] [Fig. 8-2-4]

C Terminal box

D Knockout hole

E Remove

A Screw holding cover (1pc)

B Cover

[Fig. 8-2-1]

[Fig. 8-2-2]

8

A

B

C

D

E

H

I

F

G

J

K

7

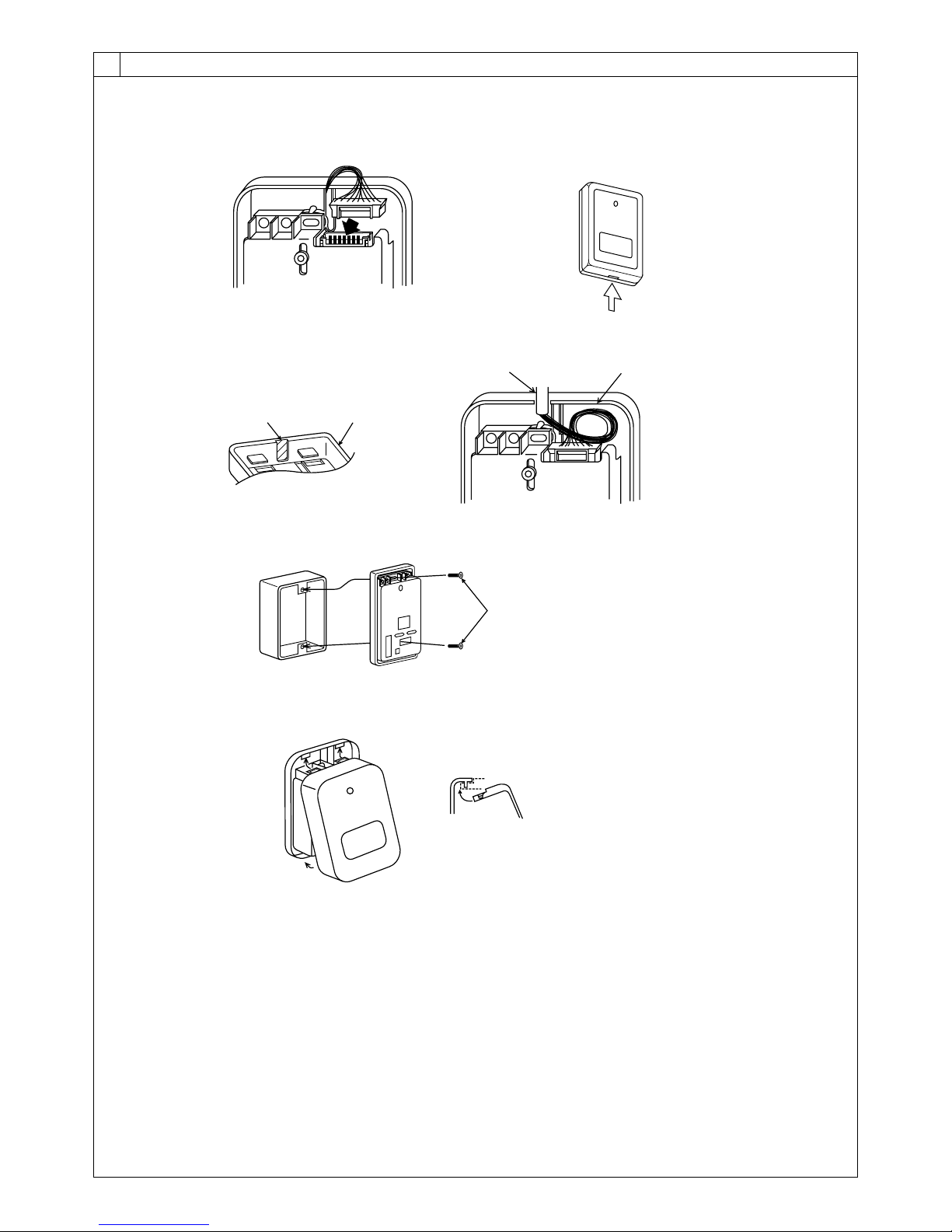

A For installation in the switch box:

B For direct installation on the wall select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run the remote controller cord from

the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cut-out notch with putty similarly as

above.

C Wall

D Conduit

E Lock nut

F Bushing

G Switch box

H Remote controller cord

I Seal with putty

J Wood screw

F

A

H

C

D

E

G

I

I

I

H

B

J

H

B-1. B-2.

[Fig. 8-5]

8

A

AB TB6

B

A To the terminal block on the indoor unit

B TB6 (No polarity)

[Fig. 8-6]

8.2

30

46

30

30120

83.5

A

B

C

A Remote controller profile

B Required clearances surrounding the remote controller

C Installation pitch

[Fig. 8-4]

[Fig. 8-3]

A Indoor terminal block

B Earth wire (green/yellow)

C Indoor/outdoor unit connecting wire 3-

core 1.5 mm2 or more

D Outdoor terminal block

E Power supply cord : 2.0 mm2 or more

1 Connecting cable

Cable 3-core 1.5 mm2, in conformity

with Design 245 IEC 57.

2 Indoor terminal block

3 Outdoor terminal block

A Indoor terminal block

4 Always install an earth wire (1-core 1.5 mm2)

longer than other cables

5 Remote controller cable

Wire No × size (mm2) : Cable 2C × 0.3

This wire accessory of remote controller

(wire length : 10m, non-polar. Max. 500m)

6 Wired remote controller (option)

7 Power supply cord

Cable 3-core 2.0 mm2 or more, in conformity with Design 245 IEC 57.

12

6

5

2

4

3

7

L

N

1

C Indoor/outdoor unit

connecting wire

3-core 1.5 mm2 or

more

D Outdoor terminal block

B Earth wire (green/yellow)

E Power supply cord : 2.0 mm2 or more

8.3

8

A

B

C

D

E

G

H

F

A Signal receiving unit external

B Center of Switch box

C Switch box

D Installation pitch

E 6.5 mm (1/4 inch)

F 70 mm (2 - 3/4 inch)

G 83.5 ± 0.4 mm (3 - 9/32 inch)

H Protrusion (pillar, etc)

[Fig. 8-9]

A

B

C

A Remote controller wire

B Hole (drill a hole on the ceiling to pass the remote controller wire.)

C Signal Receiving Unit

Ceiling cassette type, Ceiling concealed type

[Fig. 8-10]

A

B

C

A Fix tightly with tape.

B Remote controller wire

C Order wire

Indoor unit

[Fig. 8-8]

[Fig. 8-11]

H

J

I

When using the switch box

When installing directly on the wall

A 150 mm (5 - 15/16 inch)

B Remote controller wire

C Wiring pipe

D Locknut

H Seal around here with putty

I Remote controller wire

J Seal around here with putty

E Bushing

F Switch box

G Seal around here with putty

C

D

B

F

E

G

A

Wall

8

8.4

IC

OC(00)

CN90

TB1

TB4

1

D

C

A

B

Standard 1:1

[Fig. 8-7]

A Outdoor unit

B Refrigerant address

C Indoor unit

D Signal receiving unit

Indoor/outdoor wiring

Signal receiving unit wiring

9

8

8.4

[Fig. 8-12]

[Fig. 8-13]

AB

C

D

A Thin-wall portion

B Bottom case

C Remote controller wire

D Conducting wire

[Fig. 8-14]

A

A Screw (M4 x 30)

* When installing the lower case directly on the wall or the ceiling,

use wood screws.

Insert the minus screwdriver toward the

arrow pointed and wrench it to remove the

cover.

A flat screwdriver whose width of blade is

between 4 and 7mm (5/32 - 9/32inch)

must be used.

[Fig. 8-15]

1

1

2

A

1 Hang the cover to the upper hooks (2 places).

2 Mount the cover to the lower case

A Cross-section of upper hooks

Loading...

Loading...