Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

July 2006

No. OC308

REVISED EDITION-A

Series PCFY

<Indoor unit>

[Model name] [Service Ref.]

PCFY-P40VGM-E

PCFY-P63VGM-E

PCFY-P100VGM-E

PCFY-P125VGM-E

INDOOR UNIT

Ceiling Suspended

PCFY-P40VGM-E

PCFY-P63VGM-E

PCFY-P100VGM-E

PCFY-P125VGM-E

R410A

CONTENTS

1. SAFETY PRECAUTION ······················2

2. PART NAMES AND FUNCTIONS ·······6

3. SPECIFICATIONS ·······························8

4. OUTLINES AND DIMENSIONS·········11

5. WIRING DIAGRAM····························15

6.

REFRIGERANT SYSTEM DIAGRAM

7. TROUBLE SHOOTING······················17

8. DISASSEMBLY PROCEDURE··········24

9. PARTS LIST·······································28

10. RoHS PARTS LIST ···························35

11. OPTIONAL PARTS ··························42

R407C

Revision:

•

RoHS PARTS LIST

• Some descriptions have

been modified.

• Please void OC308.

Note:

• This manual describes only

service data of the indoor

units.

• RoHS compliant products

have <G> mark on the spec

name plate.

• For servicing of RoHS compliant products, refer to the

RoHS Parts List.

R22

is added.

··16

Page 2

1

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping

contains a large amount of chlorine which may cause the

lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.)

inside the piping and joints, deterioration of the lubricant

will result.

Use ESTR , ETHER or HAB as the lubricant to

coat flares and flange connection parts.

If large amount of mineral oil enter, that can cause

deterioration of refrigerant oil etc.

Use liquid refrigerant to seal the system.

If gas refrigerant is used to seal the system, the composition

of the refrigerant in the cylinder will change and performance

may drop.

Do not use a refrigerant other than R407C.

If another refrigerant (R22, etc.) is used, the chlorine in the

refrigerant may cause the lubricant deterioration.

Use a vacuum pump with a reverse flow check valve.

The vacuum pump oil may flow back into the refrigerant

cycle and cause the lubricant deterioration.

Store the piping to be used during installation

indoors with keep both ends sealed until just

before brazing.

(Store elbows and other joints in a plastic bag.)

If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may result.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Gravimeter

Unit

SAFETY PRECAUTION

CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R407C

[1] Cautions for service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[2] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

2

Page 3

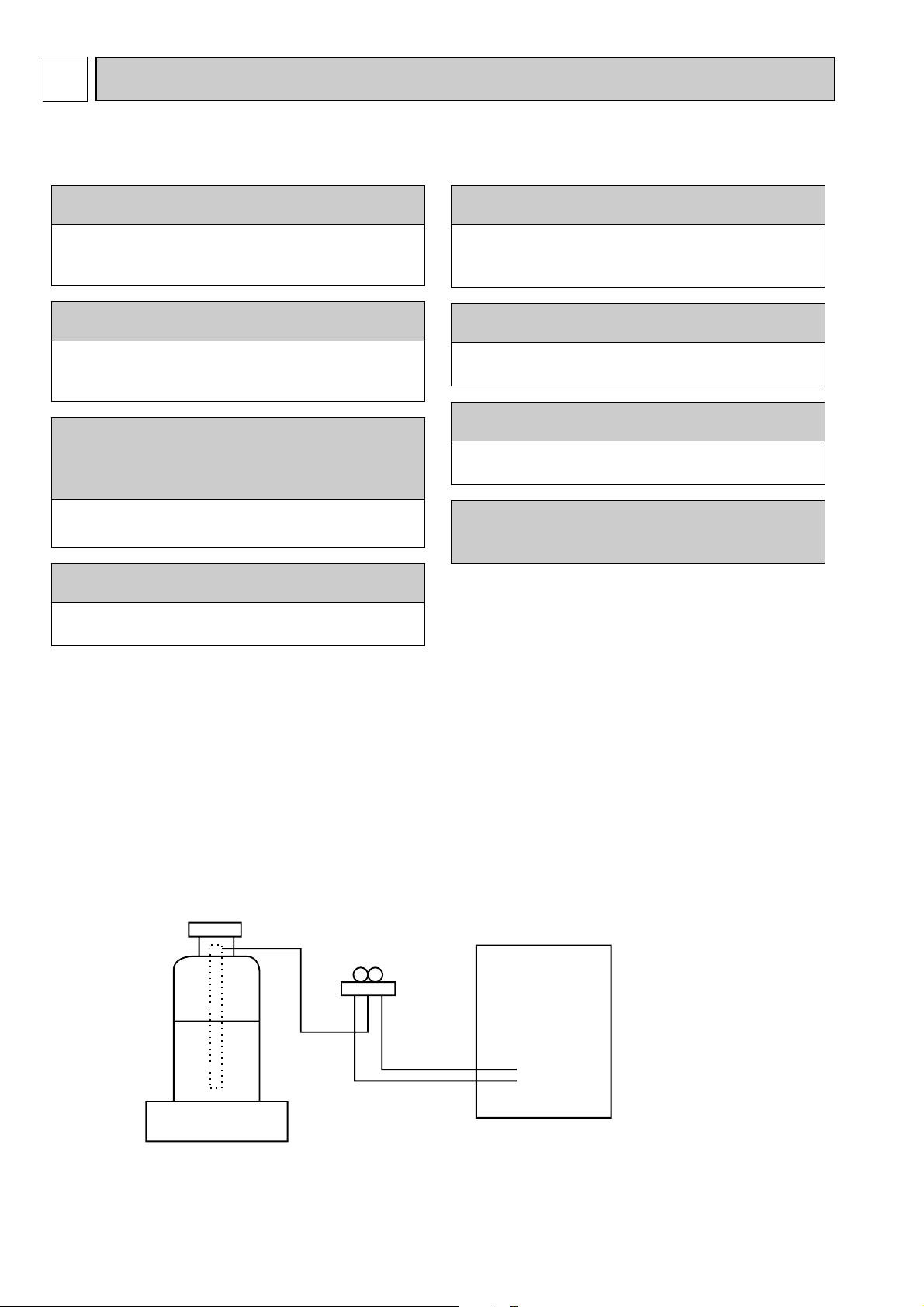

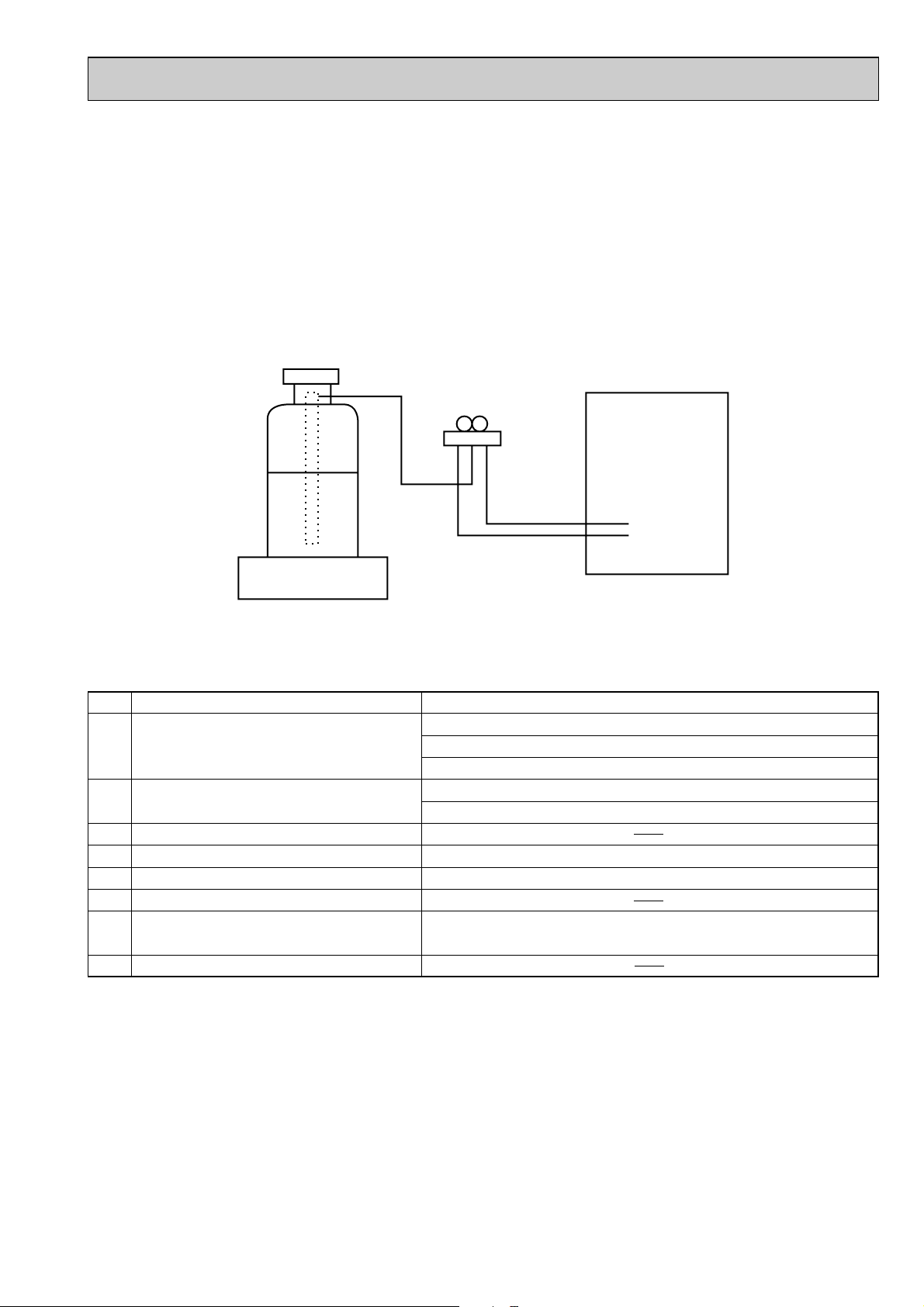

[3] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a or R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

3

Page 4

Cautions for units utilizing refrigerant R410A

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil etc.

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping

contains a large amount of chlorine which may cause the

lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.)

inside the piping and joints, deterioration of the lubricant

will result.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

4

Page 5

[1] Cautions for service

Gravimeter

Unit

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

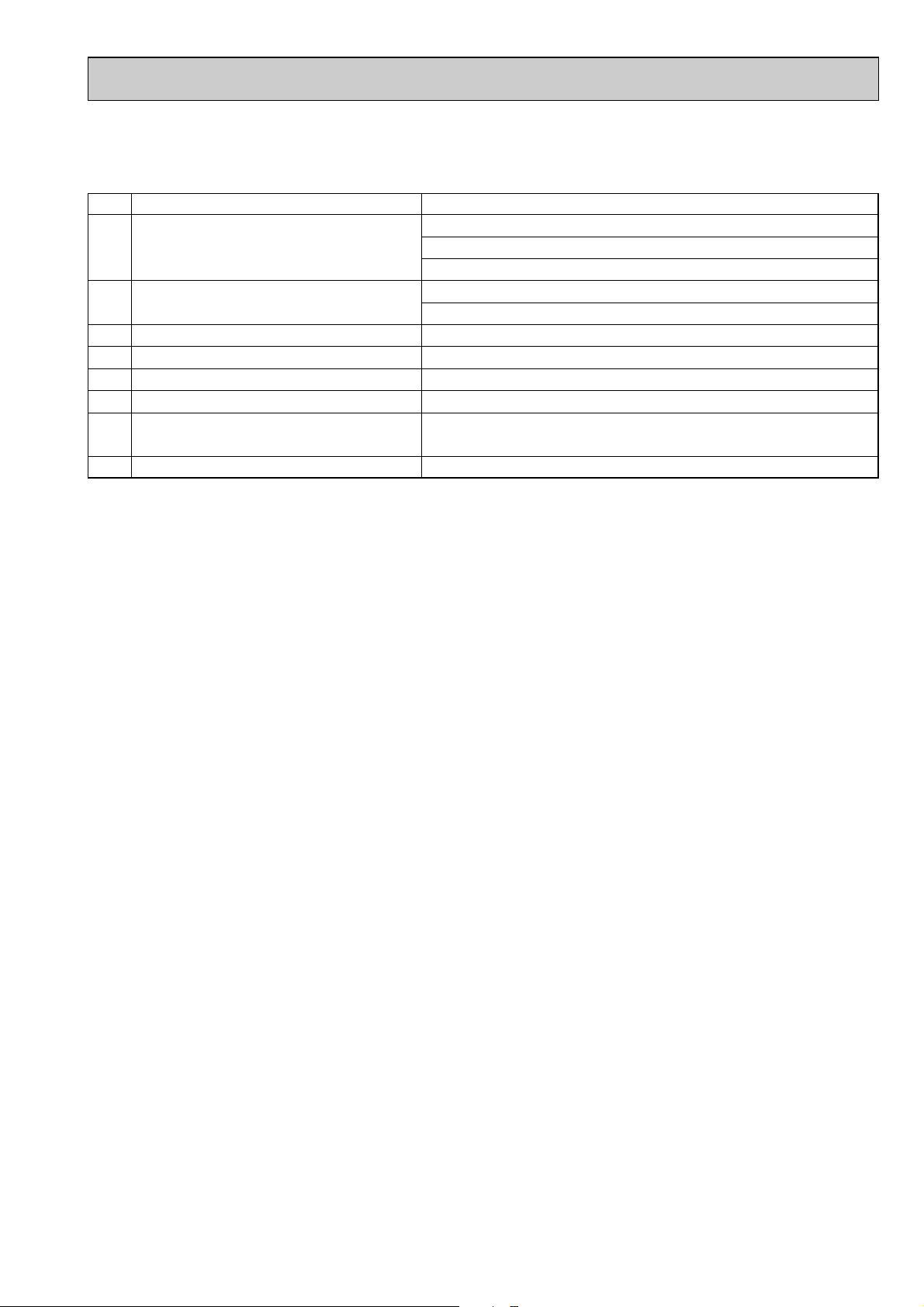

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

8 Refrigerant recovery equipment

specifications

Cylinder with syphon

. (UNF1/2)

5

Page 6

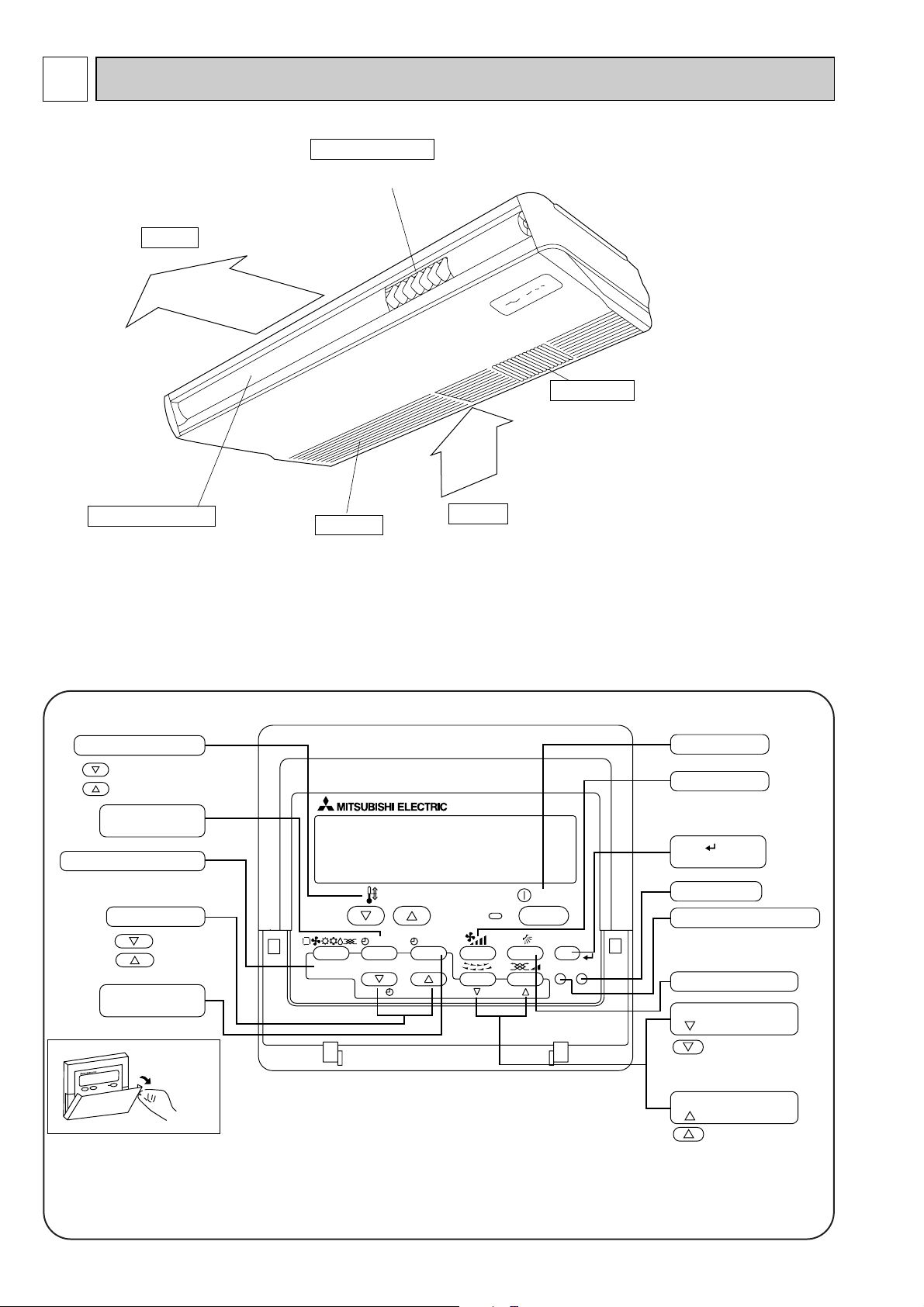

2

Air outlet

Intake grille

Air intake

Left/right guide vanes

Change the direction of airflow

from the horizontal blower.

Long-life fillter

Removes dust and foreigh matter from air coming in

through the grille (Recommended cleaning interval :

Approx, every 2,500 operating hours)

Up/down guide vanes

Change the direction of airflow from the

vartical blower.

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To preceding operation

number.

Ventilation button

(

Operation button)

To next operation number.

PART NAMES AND FUNCTIONS

● Indoor Unit

● Wired remote controller

On the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

6

Page 7

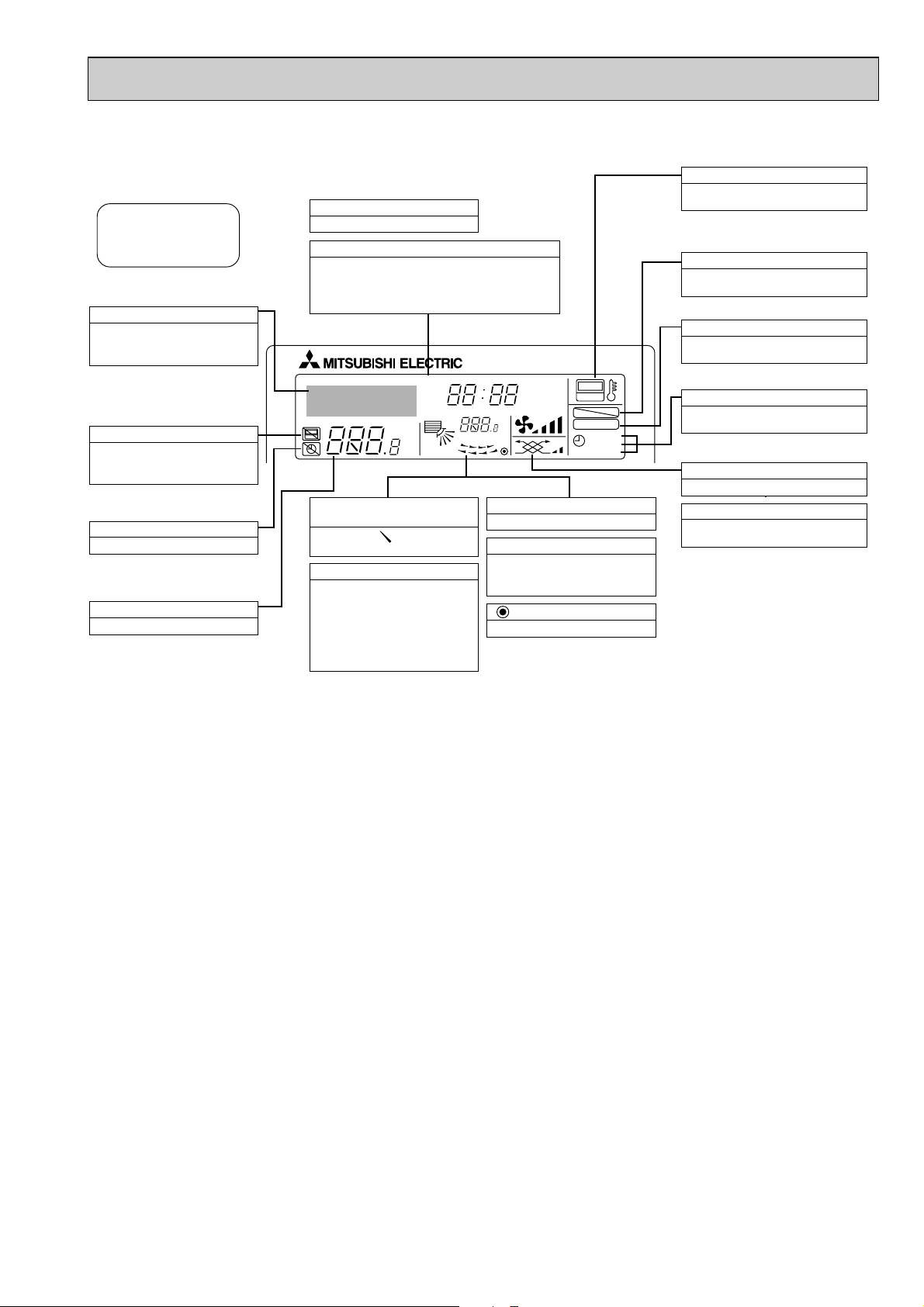

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

● Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

● If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if he feature is not

present at the parent unit.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication (For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappear then start the operation.

7

Page 8

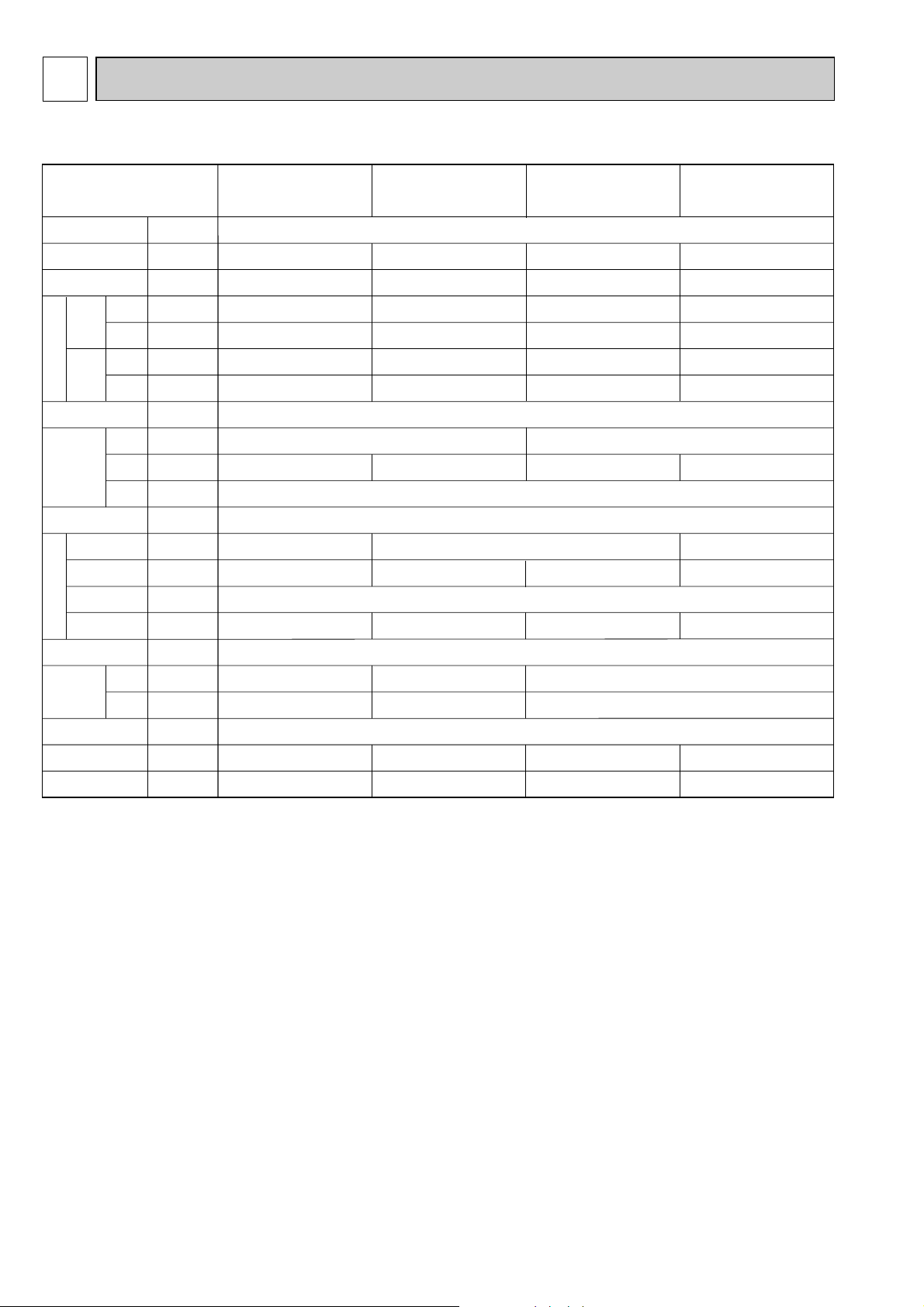

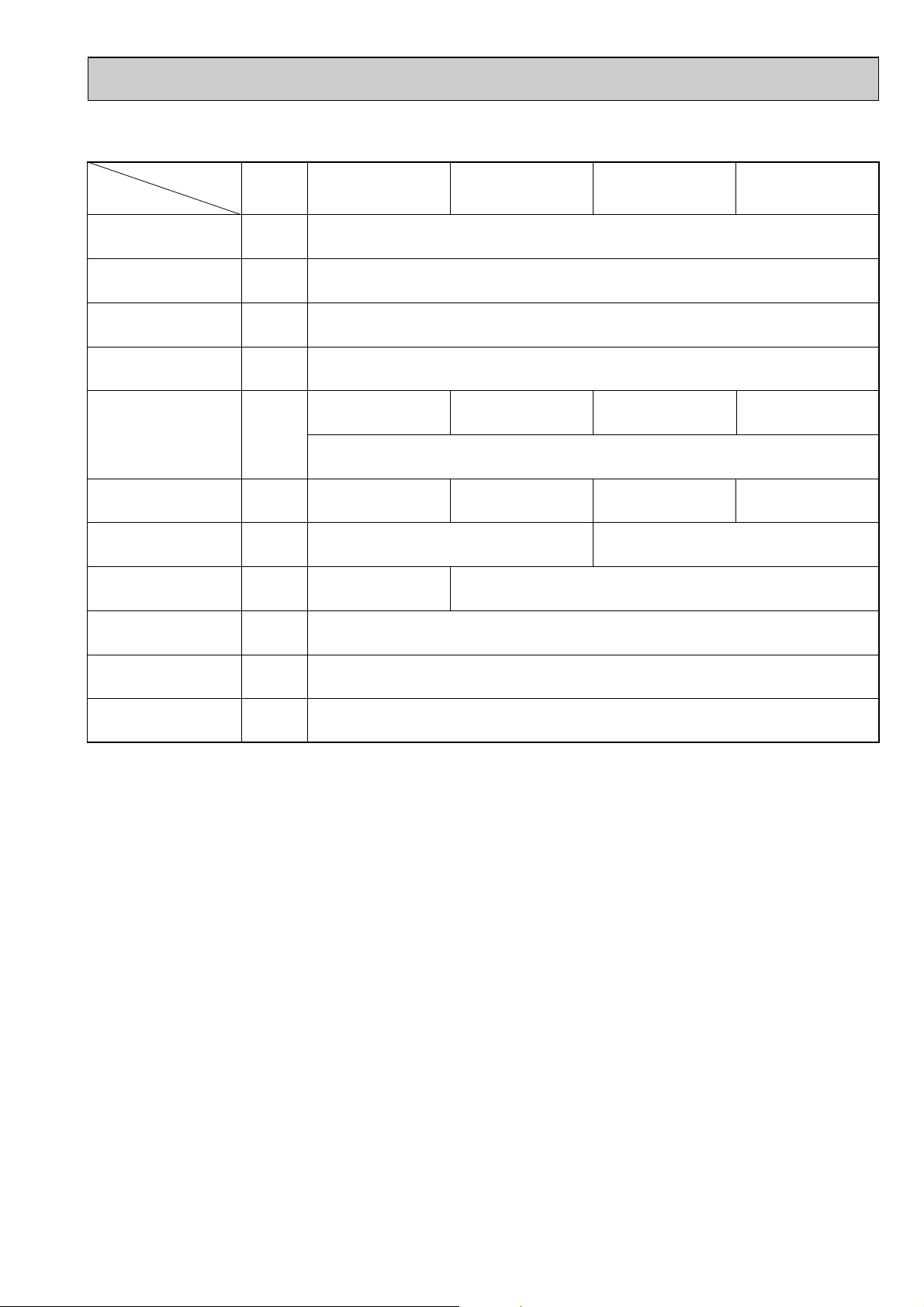

3

Item

V

·Hz

kW

kW

kW

kW

A

A

—

mm

mm

mm

—

—

k/min

Pa

kW

—

[mm(in.)

[mm(in.)

[mm

dB

kg

Cooling capacity

Power

Heat exchanger

Air filter

Fan ✕ No

Air flow W

Pipe

dimensions

Unit drain pipe size

Noise level W

Product weight

Exterior

(munsell symbol)

Fan motor

output

External

static pressure

Liquid

side

Gas

side

Heating capacity

F

a

n

Dimensions

Height

Width

Depth

Electric characteristic

Input

Cooling

Heating

Cooling

Heating

Current

PCFY-P40VGM-E PCFY-P63VGM-E PCFY-P100VGM-E PCFY-P125VGM-E

Single phase 220-230-240V 50Hz / 220V 60Hz

4.5

5.0

0.10

0.10

0.46

0.46

7.1

8.0

0.13

0.13

0.60

0.60

11.2

12.5

0.16

0.16

0.73

0.73

14.0

16.0

0.24

0.24

1.10

1.10

1310

18 -16 -14 -12

0.07

15.88(5/8")

9.52(3/8")

39 -37 -34 -32

34

Unit : Munsell<0.70Y 8.59/0.97>

680

Cross fin (Aluminum plate fine and copper tube)

Sirocco fan ✕ 3

0

PP honey comb

I.D.26 (PVC pipe VP-20 connectable)

15.88(5/8") / 19.05(3/4")

9.52(3/8")

210 270

1310

25 -23 -20 -18

0.09

43 -41 -38 -36

37

1620

Sirocco fan ✕ 4

35 -32 -28 -26

0.15

44 -42 -39 -37

43

1000

Sirocco fan ✕ 2

12 -11 -10 -8

0.054

12.7(1/2")

6.35(1/4")

38 -36 -33 -29

27

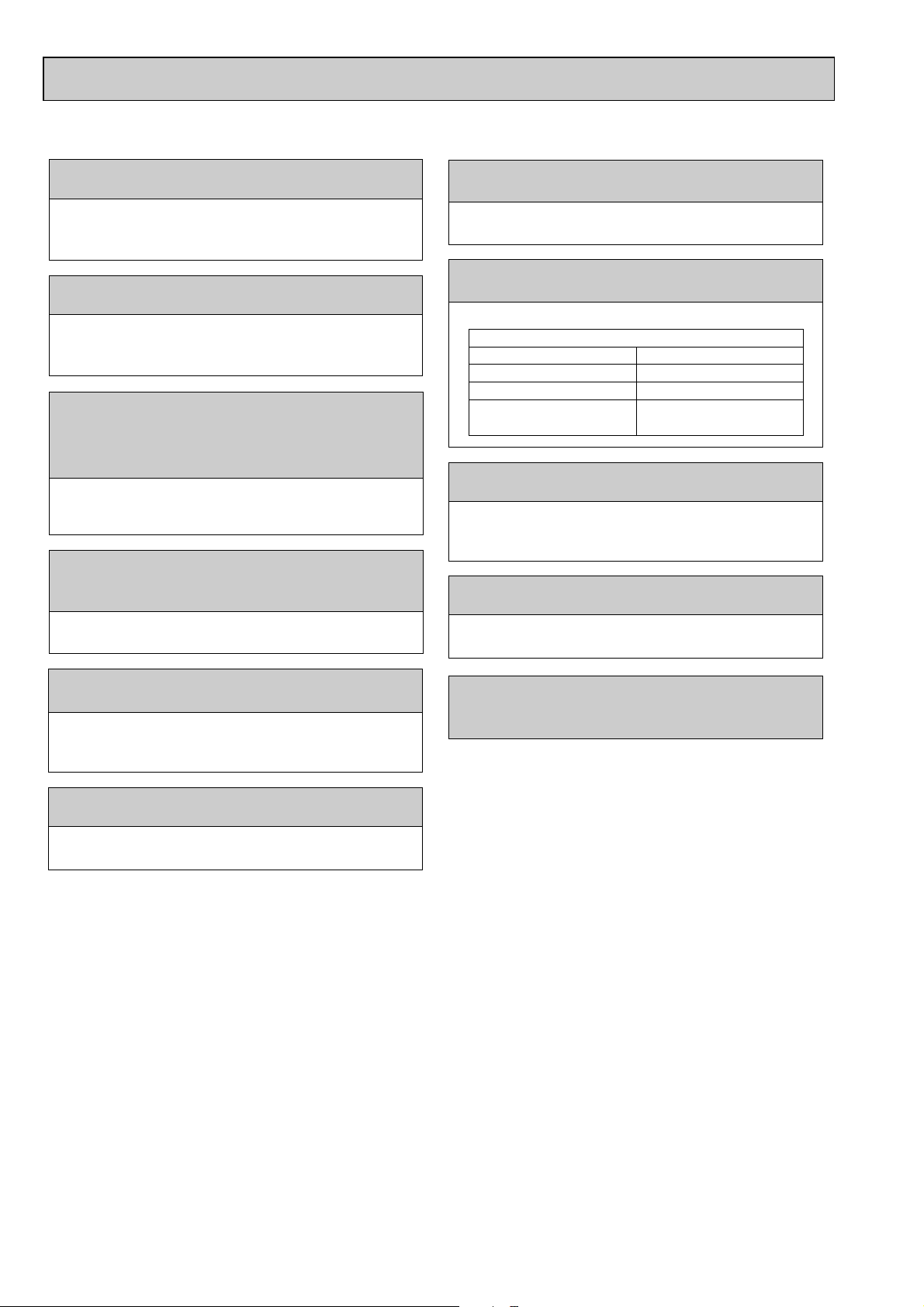

SPECIFICATIONS

3-1. SPECIFICATIONS

Note 1. Rating conditions(JIS B 8615-1)

W Air flow and the noise level are indicated as High – Middium1 – Middium2 – Low.

Cooling : Indoor : D.B. 27°C W.B. 19°C

Heating : Indoor : D.B. 20°C

outdoor : D.B. 35°C

outdoor : D.B. 7°C W.B. 6°C

8

Page 9

3-2. ELECTRICAL PARTS SPECIFICATIONS

Parts name

Model

Symbol

TH21

TH22

TH23

FUSE

MF

C1

MV

LEV

TB2

TB5

TB15

Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.4k", 30:/4.3k", 40:/3.0k"

Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.4k", 30:/4.3k", 40:/3.0k"

Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.4k", 30:/4.3k", 40:/3.0k"

250V 6.3A

OFF 130: I5:

(L, N, ;) 330V 30A

(M1, M2, S) 250V 20A

(1, 2) 250V 10A

3µF ✕ 440V

Inner-thermostat

4µF ✕ 440V 4µF ✕ 440V 6µF ✕ 440VFan motor capacitor

Vane motor

Linear expansion valve

PCFY-P40VGM-E PCFY-P63VGM-E PCFY-P100VGM-E PCFY-P125VGM-E

Room temperature

thermistor

Liquid pipe temperature

thermistor

Gas pipe temperature

thermistor

Fuse

(Indoor controller board)

Fan motor

(with inner-thermostat)

Power supply

terminal block

Transmission

terminal block

MA remote controller

terminal block

DC12V Stepping

motor drive

[3.2 (0~2000pulse)

4-Pole Output 54W

D09B4P54MS

MP35EA

DC12V

MP42EA

DC12V

4-Pole Output 70W

D09C4P70MS

4-Pole Output 90W

D10B4P90MS

4-Pole Output 150W

D10B4P150MS

DC12V Stepping motor drive

[3.2 (0~2000pulse)

9

Page 10

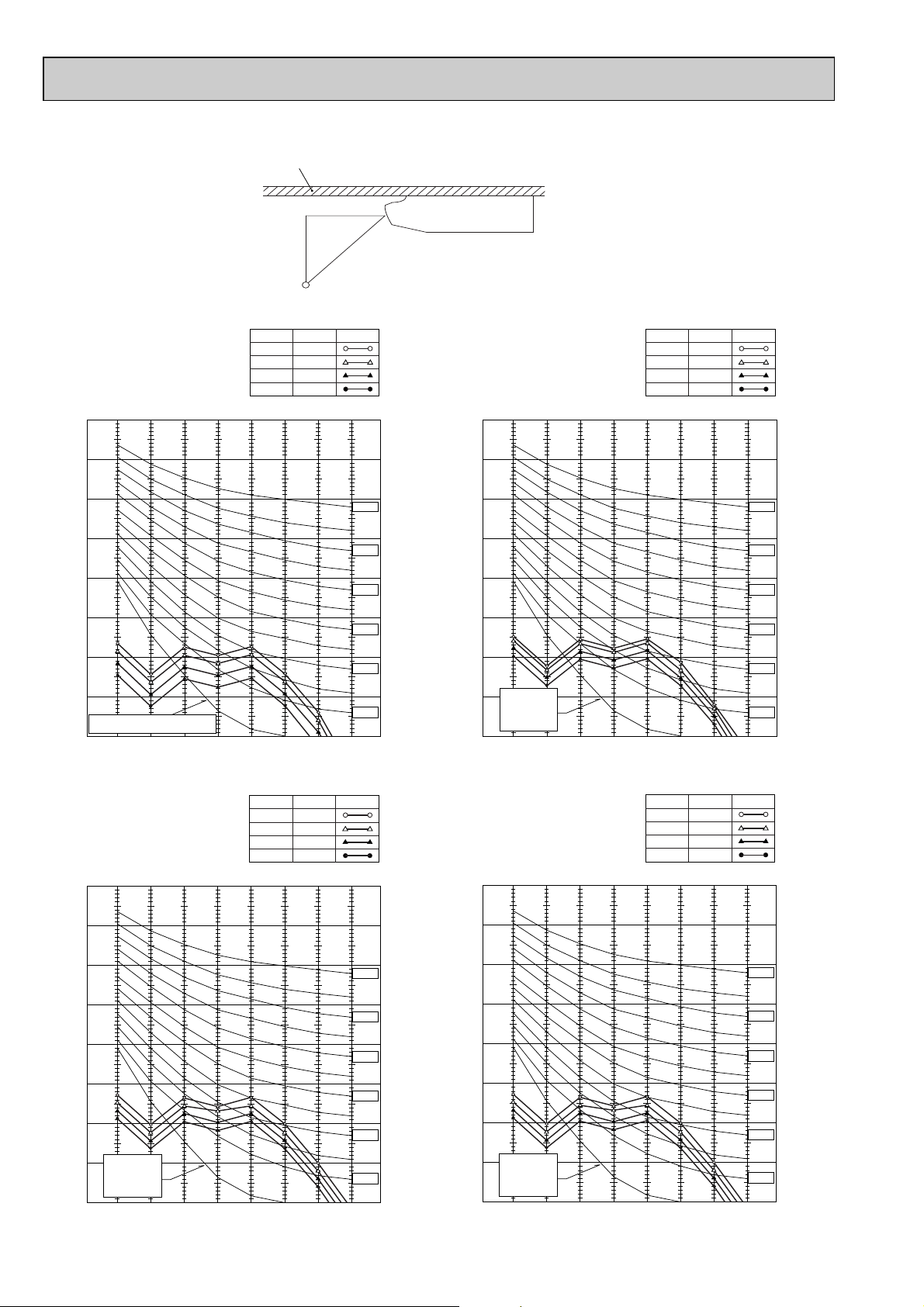

3-3. NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE THRESHOLD OF HEARING

FOR CONTINUOUS NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

PCFY-P40VGM-E

Hi

NOTCH

Mi1

Mi2

Lo

35

SPL(dB)

33

30

27

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

PCFY-P63VGM-E

Hi

NOTCH

Mi1

Mi2

Lo

37

SPL(dB)

36

34

32

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

PCFY-P100VGM-E

Hi

NOTCH

Mi1

Mi2

Lo

39

SPL(dB)

37

35

33

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

PCFY-P125VGM-E

Hi

NOTCH

Mi1

Mi2

Lo

39

SPL(dB)

37

35

33

LINE

UNIT

About 1.4m

MICROPHONE

CEILING

1m

1m

10

Page 11

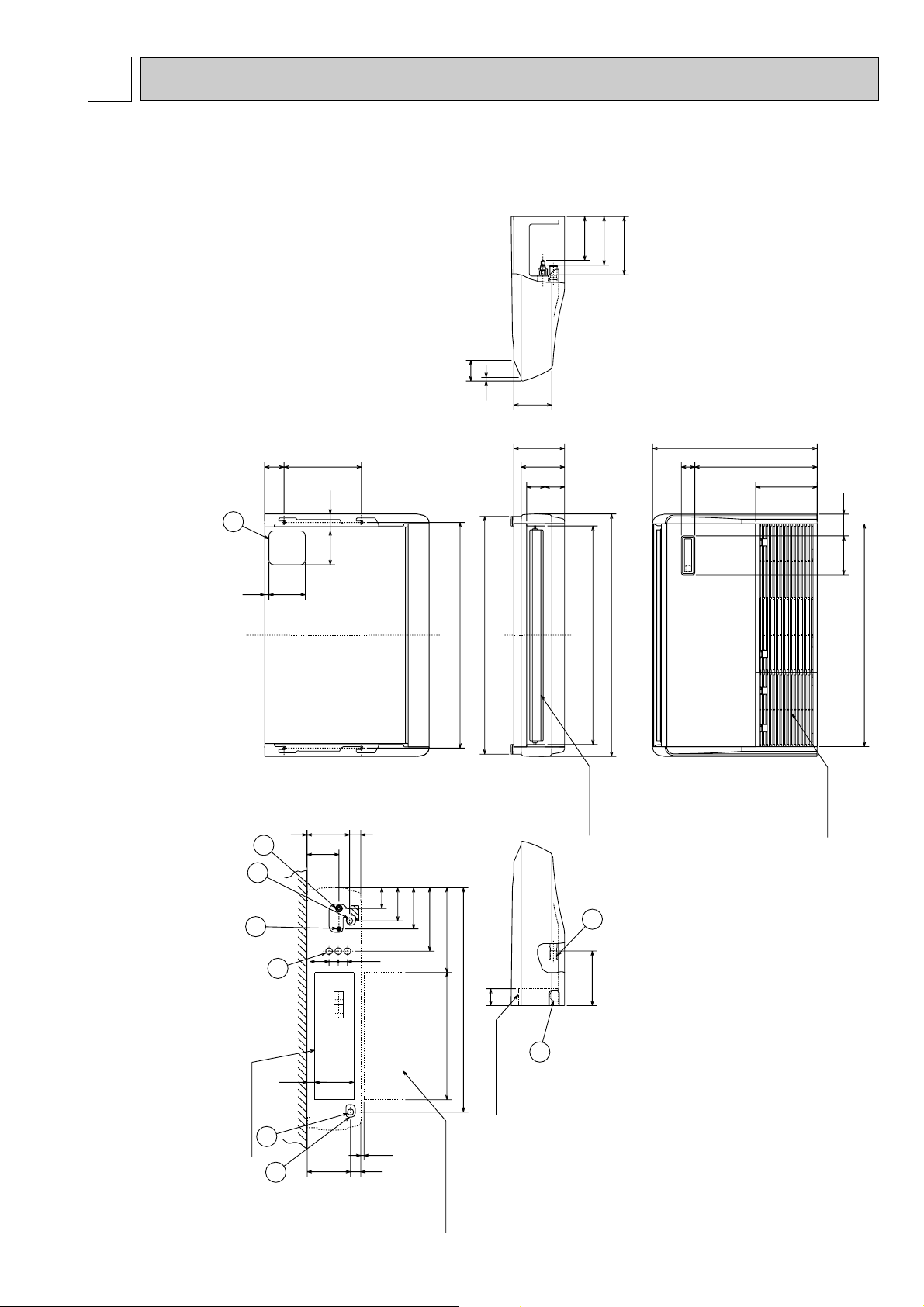

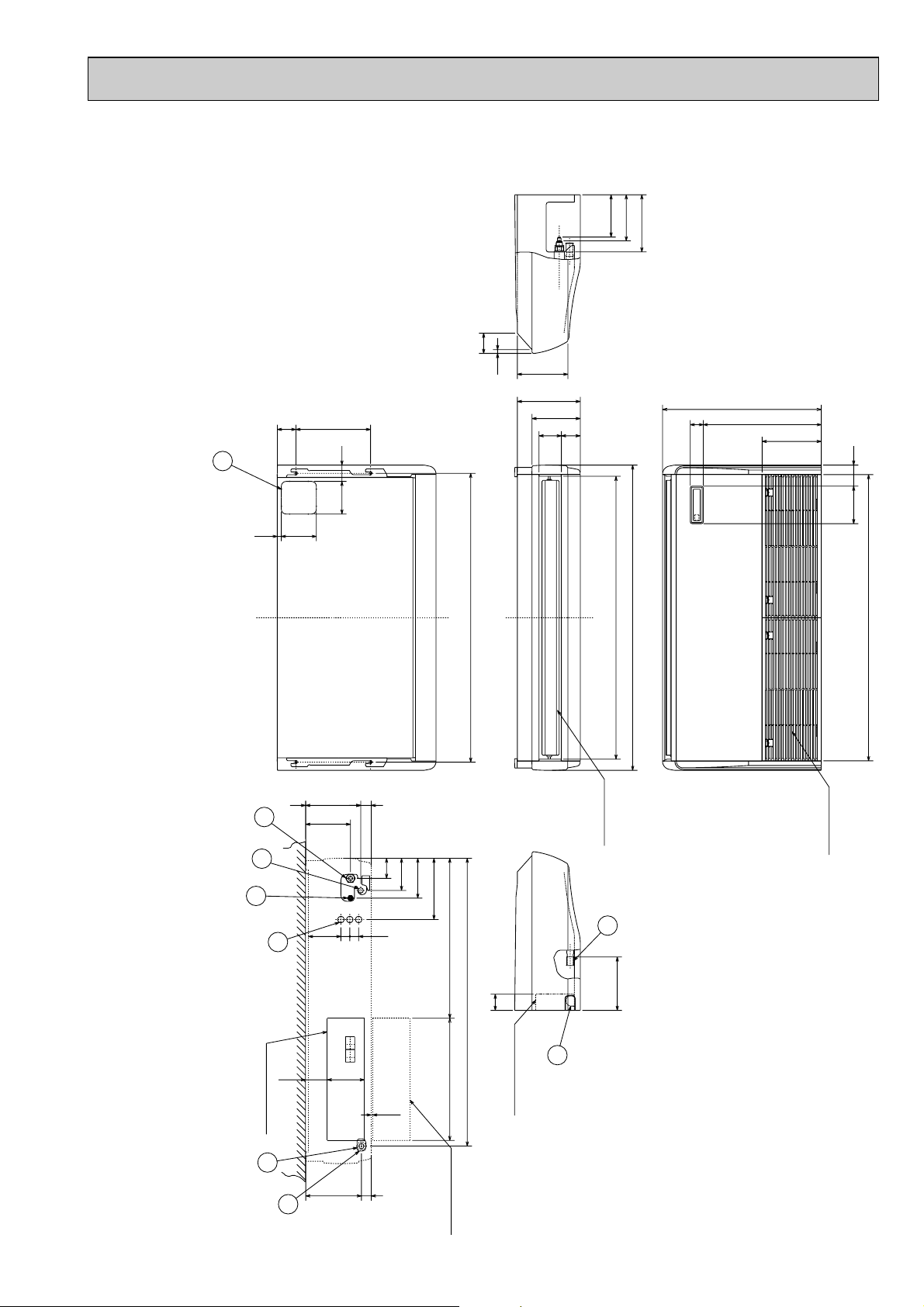

OUTLINES AND DIMENSIONS4

2

1

Air intake

When electrical box

is pulled down

Electrical box

Air outlet

7

8

5

4

3

2

6

Electrical box

(Drainage)

(1/2F)gas

(1/4F)liquid

( FRONT VIEW )

Ceiling

56506

161 90

904

933 (Suspension bolt pitch)

157

70

15

85

81

210

226

241

201

182

180

76

680

254

150 18

70140

320 80

918

1000

983

6 ~ 7

928

525

42 179

161 32

46

175

131

1

352

171

138

86

263

38

38

79

INDOOR UNIT

PCFY-P40VGM-E

refrigerant pipe will be only upper drain pipe arrangement.

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

Unit : mm

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

11

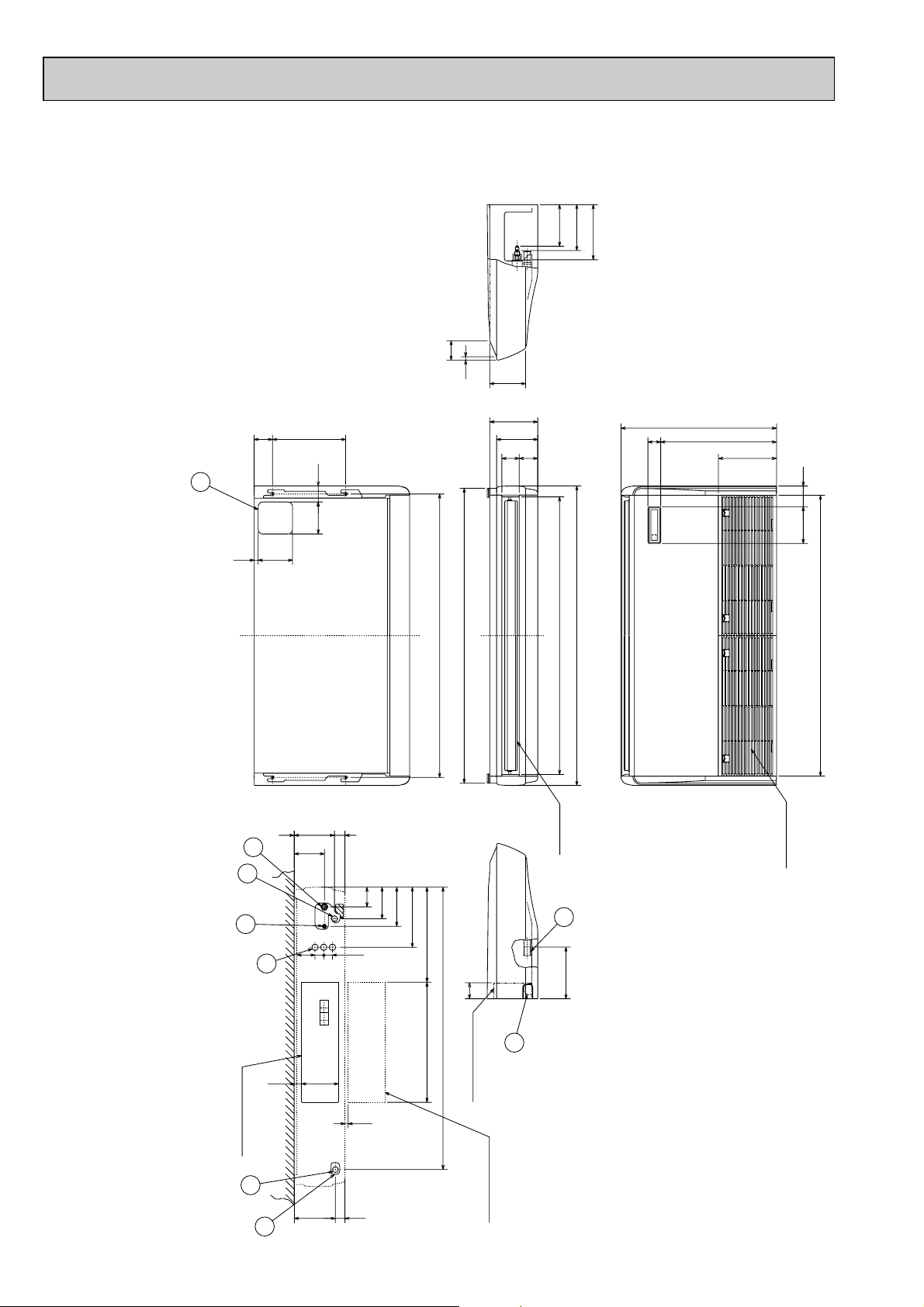

Page 12

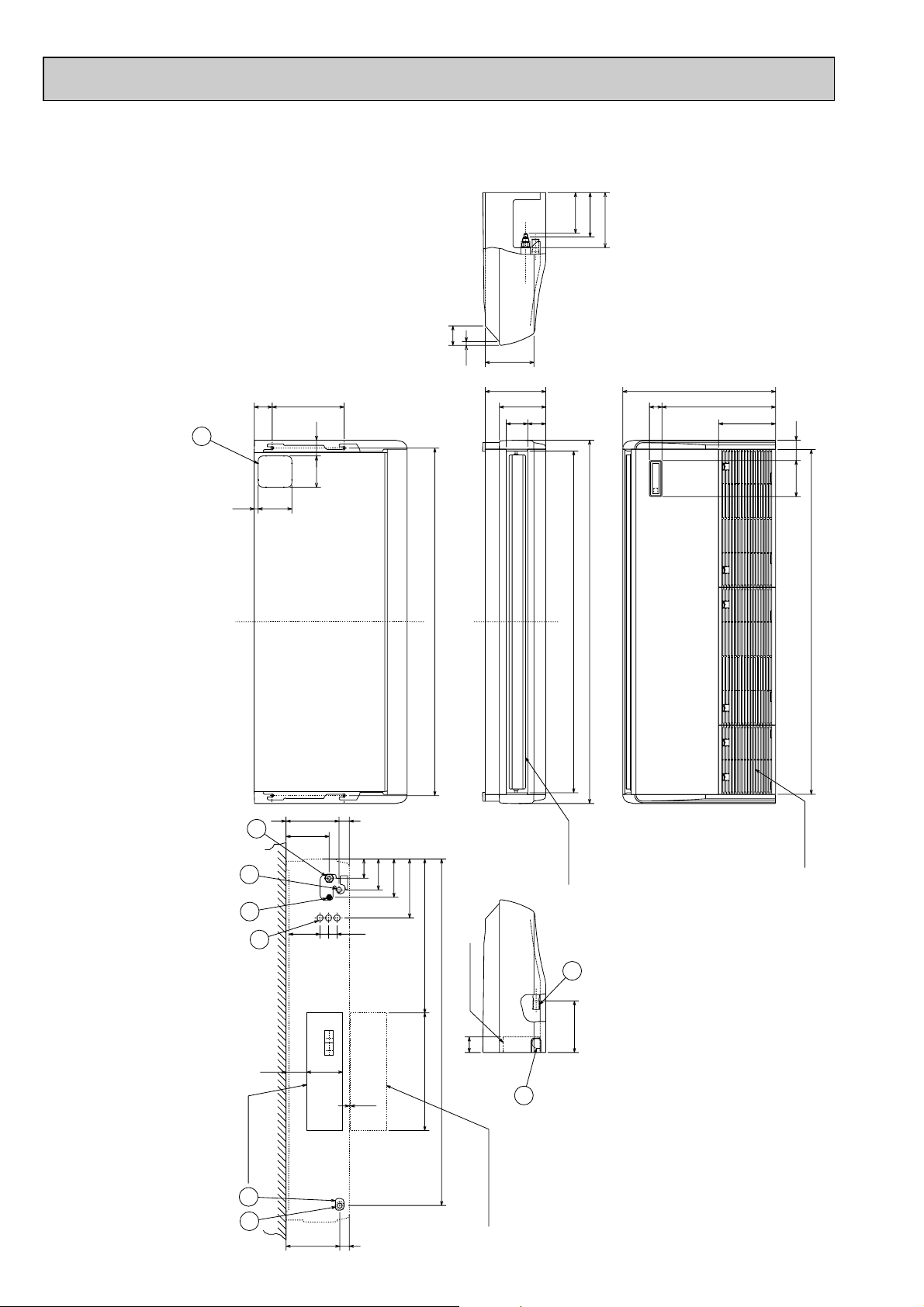

(Drainage)

(5/8F)gas

(3/8F)liquid

Air intake

Air outlet

Electrical box

When electrical box

is pulled down

Ceiling

( FRONT VIEW )

Electrical box

6

4

1

5

8

2

3

7

2

506 56

90161

1240 (Suspension bolt pitch)

157

1228

1310

1214

1290

15

85

81

210

226

241

201

182

180

76

680

254

150 18

70140

320 80

70

6 ~ 7

1235

416525

42 179

161 32

46

175

131

1

171

138

86

263

38

38

79

PCFY-P63VGM-E

Unit : mm

refrigerant pipe will be only upper drain pipe arrangement.

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

12

Page 13

(3/8F)liquid

(5/8F or 3/4F)gas

(Drainage)

Air intake

Air outlet

1240 (Suspension bolt pitch)

Electrical box

When electrical box

is pulled down

( FRONT VIEW )

Ceiling

Electrical box

6

2

7

4

1

5

8

2

3

506

56

90161

229

217

70

70140

18150

80320

1214

1310

81 96

207

270

680

254

1228

182

198

245

16

87

38

38

140

525

6 ~ 7

160 93

42

239

1235

687

263

171

138

86

45

192

236 1

PCFY-P100VGM-E

Unit : mm

refrigerant pipe will be only upper drain pipe arrangement.

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

13

Page 14

Air intake

Air outlet

Electrical box

When electrical box

is pulled down

( FRONT VIEW )

Ceiling

Electrical box

(Drainage)

(5/8F or 3/4F)gas

(3/8F)liquid

6

2

2

7

4

1

5

8

3

506

56

90161

229

217

1545

1547 (Suspension bolt pitch)

1524

1620

1535

198

87

270

81 96

207

182

245

16

680

254

80

150 18

140 70

320

70

525 687

263

171

138

86

38

38

140

6 ~ 7

160 93

42

239

45

192

236

1

PCFY-P125VGM-E

Unit : mm

refrigerant pipe will be only upper drain pipe arrangement.

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

14

Page 15

5

(GRN)

(BLU)

5

RED

ORN

YLW

WHT

BLU

CN6V

VANE

(GRN)

MV

MODEL

PCFY-P125VGM

P.B

INDOOR POWER BOARD

DS(OPTION)

(WHT)

DRAIN

CN31

Power supply for MA-Remote controller

on ➔ lamp is lit

Main power supply(Indoor unit:220-240V)

power on ➔ lamp is lit

LED on indoor board for service

Power supply for

MA-Remote controller

Function

Main power supply

Meaning

LED2

LED1

Mark

(OPTION)

NameNameName SymbolSymbolSymbol

SW3

21

OFF

ON

345678910

1098756

ON

OFF

1234

Option selector

Ceiling heigh selector

SWC

SWA

Linear expansion valve

LEV

Varistor

ZNR

Model selection

Capacity code

Mode selection

Remote indication

Centrally control

Remote switch

Legend

I.B

Indoor controller board

Connector

CN32

CN51

CN52

Switch

SW2

SW3

SW4

CNP

PCFY-P100VGM

ON

OFF

123456

[w1]

ON

OFF

123456

PCFY-P125VGM

PCFY-P63VGM

654321

OFF

ON

654321

OFF

ON

PCFY-P40VGM

Models

SW2

Voltage selection

Address setting 2nd digit

Connection No.

Address setting 1st digit

Mode selection

Address

Power supply

Vane motor

Circuit board

Switch

Terminal

block

SW5

A.B

SW1

SW11

SW12

SW14

TB2

MV

Capacitor(fan motor)

C1

FUSE (6.3A)

Pipe temperature,detection/Gas

Pipe temperature,detection/liguid

Room temperature,detection

Fan phase control

Thermistor

(0˚C/15k",25˚C/5.4k")

(0˚C/15k",25˚C/5.4k")

(0˚C/15k",25˚C/5.4k")

F.C

FUSE

TH21

TH22

TH23

Aux.Relay

Fan motor

X4

X1

Drain-up machine

Fan motor(with inner thermo)

MF

Drain-up machine

6

BRN

RED

ORN

YLW

WHT

BLU

MV

CN6V

VANE

(GRN)

MODEL

PCFY-P100VGM

LED2

5432

TH22

1

4

1 1234567891023456

6

6

8

LEV

TH21 TH23

0N

SW4

0N

SW3SW2

0FF

0FF

P.B

TRANS

CN2S

DC13.1V

(RED)

AC220~240V

CNSK

X1

X4

CNDK

CN2D

WHT

ORN

ORN

1

CN41

4

CNP

X1

13

51

51

X4

LED1

FAN

F.C

CND

FUSE

250V

6.3A

HA

ZNR

CN51

CN31

I.B

C1

CN3A

DRAIN

{

TB15

1

2

{

MV

CN6V

VANE

(GRN)

ADDRESS

(RED)

CN81

ADDRESS

(RED)

CN42

See fig:w1

REMOTE

INDICATION

CN52

CENTRALLY

CONTROL

(WHT)

(WHT)

LEV

CN60

(WHT)

CN32

REMOTE

SWITCH

(RED)

CN20

INTAKE

CN21

LIQUID

(WHT)

CN29

GAS

(BLK)

CN2M

M-NET

(BLU)

(BLU)

BLU

BLU

(WHT)

(WHT)

(WHT)

BLK

(WHT)

(RED)

(RED)

(WHT)

RED

WHT

BLK

WHT

BLK

WHT

WHT

YLW

YLW

ORN

ORN

BLU

BLU

RED

RED

BRN

BRN

CONTROLLER

DC8.7-13V

TO MA-REMOTE

M1

M2

S(SHIELD)

DC24-30V

BC CONTROLLER

BLU

RED

REMOTE CONTROLLER

TO OUTDOOR UNIT

~/N 220V 60Hz

BREAKER

(15A)

FUSE(15A)

~/N 220-240V 50Hz

TO NEXT INDOOR UNIT

PULL BOX

N

L

TB5

TB2

GRN/YLW

BLU

RED

Drain sensor (OPTION)

Drain-up machine (OPTION)

DS

DP

TB5

Transmission

TB15

MA-remote controller

DS

I.B

Note

1. At servicing for outdoor unit,always follow the wiring diagram of outdoor unit.

2. In case of using MA-Remote controller,please connect to TB15.

(Remote controller wire is non-polar.)

3. In case of using M-NET,please connect to TB5.(Transmission line is non-polar.)

4. Symbol[S] of TB5 is the shield wire connection.

5. Symbols used in wiring diagram above are, :terminal block, :connector.

6. The setting of the SW2 dip switches differs in the capacity.

For the detail,refer to the fig: w 1.

7. Please set the switch SW5 according to the power supply voltage.

Set SW5 to 240V side when the power supply is 230 and 240 volts.

When the power supply is 220 volts,set SW5 to 220V side.

8. Fasten terminal of the terminal board "TB5" equips lock system.

To remove the fasten terminal,pull it while pressing the protruding portion (locking level)

of the terminal. Connection of the fasten terminal,protruding portion shouid face upward.

432165

432165

A.B

0

SWA

SWC

SW5

220V 240V

2ND

DIGIT

CN82

ADDRESS

(RED)

ON

OFF

12345678910

SW1

SW12 SW11

3RD

DIGIT

00

1ST

DIGIT

CONNECTION

NO.

SW14

0

ADDRESS

(RED)

CN43

3

1

2

4

3

2

1

8

7

6

5

4

3

2

1

432165

432165

12

1221

432165

21

12

432165 87654321 4321

321

MF

315

315

654321

2

1

13

2

1

3

DP

13

1

2

31

1

2

3

1

2

432165

123

WIRING DIAGRAM

PCFY-P40VGM-E PCFY-P63VGM-E PCFY-P100VGM-E PCFY-P125VGM-E

15

Page 16

6

Strainer (#50mesh)

Strainer (#100mesh)

Strainer (#100mesh)

Heat exchanger

Room temperature thermistor TH21

Gas pipe temperature

thermistor TH23

Liquid pipe temperature

thermistor TH22

Linear expansion valve

Gas pipe

Liquid pipe

Flare connection

REFRIGERANT SYSTEM DIAGRAM

PCFY-P40VGM-E

PCFY-P63VGM-E

PCFY-P100VGM-E

PCFY-P125VGM-E

Item

Gas pipe

Liquid pipe

Capacity

PCFY-P40VGM-E

{12.7(1/2”)

PCFY-P63VGM-E

{15.88(5/8”)

PCFY-P100VGM-E

PCFY-P125VGM-E

{15.88(5/8”) or

{19.05(3/4”)

{6.35(1/4”) {9.52(3/8”) {9.52(3/8”)

16

Page 17

7

Parts name Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

Disconnect the connector then measure the resistance valve using a tester.

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:~30:)

Measure the resistance after 3 minutes have passed since the power supply was intercepted.

(Surrounding temperature 0:~60:)

Linear expansion

valve

Drain-up machine

(Optional)

Drain sensor

(Optional)

Refer to the next page for the details.

Room temperature

thermistor (TH21)

Liquid pipe temperature

thermistor (TH22)

Gas pipe temperature

thermistor (TH23)

1

3

Gray

Gray

1

2

3

Normal

4.3k"~9.6k"

Abnormal

Open or short

Abnormal

Open or short

Normal

0.6k"~6.0k"

Abnormal

Open or short

Normal

150k" i10%

(1)-(5)

White-Red

(2)-(6)

Yellow-Brown

(3)-(5)

Orange-Red

(4)-(6)

Blue-Brown

Normal Abnormal

92" Open or short

Orange

Red

White

Blue

Brown

Yellow

3

6

1

5

4

2

M

Measure the resistance between the terminals using a tester.Fan motor

1

1

3

3

5

5

Red

White

Black

Connector

Protector

P40VGM-E

70.6"

69.6"

P63VGM-E

45.0"

44.8"

P100VGM-E

43.7"

53.3"

P125VGM-E

20.4"

20.7"

Abnormal

Open or short

Red-Black

White-Black

Motor terminal

or

Connector

Normal

PCFY-

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:~30:)

Vane motor

Normal

PCFY-P40VGM-E PCFY-P63VGM-E

Connector

Abnormal

186~214" 140~160" Open or short

Brown — Yellow

Brown — Blue

Red — Orange

Red — Pink

Normal

PCFY-P100VGM-E, PCFY-P125VGM-E

Connector

Abnormal

140~160" Open or short

Red — Blue

Red —Yellow

Red — Pink

Red — Orange

Refer to the next

page for the details.

BlueYellow Brown

Orange

Red

Pink

2

3

Yellow

3

4

5

Orange

Red

Pink

2

4

5

61

Blue

1

Connector

Pin No.

Connector

Pin No.

M

M

TROUBLE SHOOTING

7-1. How to check the parts

PCFY-P40VGM-E PCFY-P63VGM-E PCFY-P100VGM-E PCFY-P125VGM-E

17

Page 18

<Thermistor Characteristic graph>

4

[4

3

62

5

[3

2

[2

1

[1

[4

[3

[2

[1

Controller board

Drive circuit

Relay connector

Connector(CN60)

DC12V

Brown

Red

Blue

Orange

Yellow

White

5

1

3

4

6

M

4

6

2

3

5

1

Blue

Brown

Yellow

Orange

Red

White

Linear expansion valve

Thermistor at

lower temperature

Room temperature thermistor(TH21)

Liquid pipe temperature thermistor(TH22)

Gas pipe temperature thermistor(TH23)

Thermistor R0=15k' ±3%

Fixed number of B=3480K ± 2%

Rt=15exp { 3480( ) }

1

273+t

1

273

0: 15k'

10: 9.6k'

20: 6.3k'

25: 5.4k'

30: 4.3k'

40: 3.0k'

< Thermistor at lower temperature >

50

40

30

Resistance (K")

20

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

Linear expansion valve

11

Operation summary of the linear expansion valve.

• Linear expansion valve open/close through stepping motor after receiving the pulse signal from the indoor controller board.

• Valve opening can be changed in proportion to the number of pulse signal.

<Connection between the indoor controller board and the linear expansion valve>

Note : Since the number of the connector at the controller board side and the relay connector are different, follow the color of

the lead wire.

18

Page 19

<Output pulse signal and the valve operation>

D

A

E

B

C

Open

Extra tightning (80~100pulse)

Pulse number

2000 pulse

Open the valve

all the way

Close

6

5

4

3

2

1

LED1T

Thermistor

(Liquid pipe)

Linear

expansion

valve

Output

Output

(Phase)

number

{1

{2

{3

{4

Linear expansion valve operation

22

1

ON

ON

OFF

OFF

2

OFF

ON

ON

OFF

3

OFF

OFF

ON

ON

4

ON

OFF

OFF

ON

Closing a valve : 1 → 2 → 3 → 4 → 1

Opening a valve : 4 → 3 → 2 → 1 → 4

The output pulse shift as above order.

❈ 1. When linear expansion valve operation stops, all output phase

become OFF.

2. At phase interruption or when phase does not shift in order,

motor does not rotate smoothly and motor will lock and vibrate.

❈ When the switch is turned on, 2200 pulse closing valve signal

will be send till it goes to

A point in order to define the valve

position.

When the valve move smoothly, there is no noise or vibration

occur from the linear expansion valve : however, when the pulse

number moves from E to A or when the valve is locked, more

noise can be hear than normal situation.

❈ Noise can be detected by placing the ear against the screw dri-

ver handle while putting the screw driver to the linear expansion

valve.

Trouble shooting

33

Symptom

Operation circuit failure of the micro

processor.

Linear expansion

valve mechanism is

locked.

Short or breakage of

the motor coil of the

linear expansion

valve.

Valve doesn't close

completely (thermistor leaking).

Wrong connection of

the connector or

contact failure.

Disconnect the connector on the controller board, then connect LED for checking.

Pulse signal will be sent out for 10 seconds as soon as the

main switch is turn on. If there is LED with lights on or lights

off, it means the operation circuit is abnormal.

Motor will idle and make ticking noise when motor is operated

while the linear expansion valve is locked. This ticking sound

is the sign of the abnormality.

Measure the resistance between the each coil (red-white,

red-orange, brown-yellow, brown-blue) using a tester. It is

normal if the resistance is in the range of 150"I10%

To check the linear expansion valve, operate the indoor unit

in fan mode and at the same time operate other indoor units

in cooling mode, then check the pipe temperature <liquid

controller, it means the valve is not closed all the way. It is

not necessary to exchange the linear expansion valve, if the

leakage is small and not making any trouble.

Check the color of lead wire and missing terminal of the connector.

Check points

pipe temperature> of the indoor unit by the

outdoor multi controller board operation

monitor. During fan operation, linear

expansion valve is closed completely and if

there are some leaking, detecting temperature of the thermistor will go lower. If the

detected temperature is much lower than

the temperature indicated in the remote

19

Countermeasures

Exchange the indoor controller board at drive circuit

failure.

Exchange the linear

expansion vale.

Exchange the linear

expansion valve.

If large amount of thermistor is leaked, exchange the

linear expansion valve.

Disconnect the connector

at the controller board,

then check the continuity.

Page 20

7-2. FUNCTION OF DIP SWITCH

PCFY-P40VGM-E PCFY-P63VGM-E PCFY-P100VGM-E PCFY-P125VGM-E

Operation by switch

Switch Pole

Function Remarks

ON OFF

SW1

Mode

Selection

10

Room temperature Thermistor

1

position

Filter clogging detection Provided Not provided

2

Filter cleaning sign 2500hr 100hr

3

Air intake Effective Not effective

4

Remote indication switching Thermostat ON signal indication Fan output indication

5

Humidifier control

6

Air flow set in case of Fix to LOW w3 Fix to EXTRA lOW w3

7

heat thermostat OFF

8

Auto reset function Effective Not effective

9

Built-in remote controller

Always operated while the heating mode

Depends on setting remote controller

Power resource ON/OFF Effective Not effective

Indoor unit

w1

Operated depends on the condition

w2

w3 Depends on SW1-7

NOTE:

w1 At Heating mode, fan

w2 At Heater mode, operating

w3 SW1-7=OFF, SW1-8=ON

Indoor controller board

Set while the unit is off.

Set for each capacity.

SW2

Capacity

code

1~6

setting

Capacity SW2 Capacity SW2 Capacity SW2

PCFYP40VGM-E

PCFYP125VGM-E

ON

OFF

ON

OFF

123456

123456

PCFYP63VGM-E

ON

OFF

123456

PCFYP100VGM-E

ON

OFF

123456

Address board

<At delivery>

ON

OFF

12345678910

operating.

heat thermostat ON.

→Setting air flow.

SW1-7=ON, SW1-8=ON

→Indoor fan stop.

<At delivery>

SW3

Function

Selection

10

SW4

Unit

1~4

Selection

Heat pump/Cool only Cooling only Heat pump

1

Louver Available Not available

2

Vane Available Not available

3

Vane swing function Available Not available

4

Vane horizontal angle Second setting First setting

5

Vane cooling limit angle setting

6

Indoor linear expansion

7

valve opening

Heater 4degrees up Not effective Effective

8

Target Superheat setting

9

w4 Horizontal angle Down B,C

Effective Not effective

w5 9degrees 6degrees

Target Subcool setting 15degrees 10degrees

ON

OFF

12345

Indoor controller board

Set while the unit is off.

<At delivery>

ON

OFF

12345678910

NOTE:

w4 At cooling mode, each

angle can be used only 1

hour.

w5 SW3-9 setting

P40 = ON

P63,P100,P125 = OFF

Indoor controller board

Set while the unit is off.

<At delivery>

ON

OFF

12345

20

Page 21

Operation by switchSwitch Remarks

220V 240V

220V 240V

SWA

Set the

ceiling

height

SWC

Option

SW11

1st digit

address

setting

SW12

2nd digit

address

setting

(High)

1~3

(Standard)

(Low)

2

Rotary switch

Option

(Standard)

SW12

0

1

9

2

8

3

7

4

6

5

10 1

3

2

1

SW11

0

9

8

7

6

5

❈ Ceiling height can be changed depends on

Address board

SW A setting.

<At delivery>

3

2

1

Address board

When the optional high performance filter elements (filter casement) is attached to the unit,

be sure to set switch to the option side in

order to prevent the airflow reducing.

<At delivery>

Option

Address board

Address can be set while the

unit is stopped.

1

Address setting should be done when M-NET

2

remote controller is being used.

3

4

<At delivery>

SW12

SW11

0

9

8

7

6

0

1

5

1

9

2

8

3

7

4

6

5

2

3

4

SW14

Connection

No. setting

SW5

Voltage

selection

Rotary switch

2

SW14

0

F

E

D

C

B

A

8

9

Address board

1

2

3

4

5

6

7

This is the switch to be used when the indoor

unit is operated with R2 series outdoor unit

as a set.

<At delivery>

SW14

0

1

2

F

3

E

4

D

5

C

6

B

7

A

8

9

Address board

If the unit is used at the 230V or 240V area,

set the switch to 240V side.

If the unit is used at the 220V, set the switch

to 220V side.

<At delivery>

21

Page 22

7-3. TEST POINT DIAGRAM

7-3-1. Indoor controller board

PCFY-P40VGM-E

PCFY-P63VGM-E

PCFY-P100VGM-E

PCFY-P125VGM-E

CN2D

Connect to the indoor

power board (CN2S)

12.5-13.7V DC (Pin11(+))

CN2M

Connect to the terminal block (TB5)

(M-NET transmission connecting wire)

24-30V DC (non-polar)

CN3A

Connect to the terminal block (TB15)

(MA-Remote controller connecting wire)

11

Between

to 338.7-13V DC (Pin11(+))

CN29

Pipe temperature

thermistor/Gas (TH23)

CN21

Pipe temperature

thermistor/Liquid (TH22)

LED1

Main power supply

(Indoor unit : 220-240V)

CND

Power supply for

indoor controller board

Between

CNP

Drain-up machine output (DP)

Between

CNDK

Connect to the indoor power

Between

11

11

board (CNSK)

11

to 33220-240V AC

to 33220-240V AC

FUSE

6.3A 250V

to 33220-240V AC

LED2

Power supply for

MA-Remote controller

CN20

Room temperature

thermistor (TH21)

CN32

Connector

(Remote switch)

SW4

Model selection

CN60

Linear expansion valve

output (LEV)

CN31

Drain sensor (DS)

SW3

Mode selection

CN51

Centrally control

SW2

Capacity setting

CN52

Remote indication

FAN

Fan motor output (MF)

CN6V

Vane moter output (MV)

22

Page 23

7-3-2. Indoor power board

PCFY-P40VGM-E

PCFY-P63VGM-E

PCFY-P100VGM-E

PCFY-P125VGM-E

CN2S

Connect to the indoor power board (CN2D)

11

Between

33

to

12.6-13.7V DC (Pin11(+))

CNSK

Connect to the indoor controller board (CNDK)

11

Between

to 33220-240V AC

23

Page 24

8

slide

intake grille

intake grille

holding knobs

hinges

Pull out the intake grille

electrical cover

screws(electrical cover)

screws(electrical box)

Slide to the left

beam

clamp

DISASSEMBLY PROCEDURE

PCFY-P40VGM-E PCFY-P63VGM-E PCFY-P100VGM-E PCFY-P125VGM-E

OPERATING PROCEDURE

1. Removing the air intake grille

(1) Slide the intake grille holding the knobs at backward to

open the intake grille.

(2) When the intake grille left open, push the stoppers on the

rear hinges (at two locations) to pull out the intake grille.

2. Removing the electrical box

(1) Remove the air intake grille.

(2) Remove the screw from the beam and remove the beam.

(3) Remove the screws from the electrical cover, and remove

the electrical cover.

(4) Disconnect the following wires from the indoor control

board.

• Fan motor : FAN

• Vane motor : CN6V

• Linear expansion valve : CN60

• Room temperature thermistor : CN20

• Liquid pipe temperature thermistor : CN21

• Gas pipe temperature thermistor : CN29

PHOTOS & ILLUSTRATIONS

Figure 1

Figure 2

(5) Remove the screws from the electrical box and pull out

the electrical box.

<Electrical parts in the electrical box>

Terminal block (for power supply)

Terminal block (for transmission)

Terminal block (for MA remote controller)

Indoor control board

Address board

Power board

Capacitor

24

Photo 1

Capacitor

Power board

Indoor

control

board

Address board

Terminal block

(transmission)

Terminal block

(power supply)

Terminal block

(MA remote

controller)

Page 25

OPERATING PROCEDURE PHOTOS & ILLUSTRATIONS

screw

side panel

sliding the panel

to the front

3. Removing the fan motor

(1) Remove the air intake grille.

(2) Disconnect the fan motor guard.

(3) Unscrew screws for removing the motor guard.

(4) Unscrew screws for removing the fan guard.

(5) Remove the screw for removing the motor support at

both left and right side.

(6) Loosen the set screws at the fan motor side of the

connecting joint.

(7) Slide the fan motor to the left side and pull it out.

4. Removing the sirocco fan

(1) Remove the air intake grille.

(2) Remove 1 beam.

(3) Unscrew screws for removing the motor guard.

(4) Unscrew screws for removing the fan guard.

(5) Remove the lower casing while pressing the stoppers at

upper side of the casing.

(6) Loosen the set screws at the connecting joint.

(7) Remove the sirocco fan and shaft together by sliding the

shaft to the left.

Photo 2

Photo 3

Screws

Motor support

Motor guard

Motor guard

Motor

Set screw

Connecting joint

Fan guard

(Note)

Make sure that the upper side casing is snapped to the fan

plate securely with catch.

5. Removing the side panel

(1) Remove the air intake grille.

(2) Remove the screw from the side panel, and remove the

side panel by sliding the panel to the front.

Figure 3

Sirocco fan

Connecting

joint

CasingMotor

Bearing

25

Page 26

OPERATING PROCEDURE PHOTOS & ILLUSTRATIONS

6. Removing the vane motor

(1) Remove the air intake.

(2) Remove the left side panel.

(3) Remove the relay connector of vane motor.

(4) Remove the electrical box.

(5) Remove the screws of vane motor, then remove vane

motor.

(Note)

Connect the lead wires and connectors properly and place

them in the proper position so that the wires are not pinched

by other parts.

7. Removing the pipe temperature thermistor

(1) Remove the air intake grille.

(2) Remove the right side panel.

(3) Remove the relay connector of the pipe temperature thermistor.

(4) Remove the screw, and remove the check panel.

(5) Extract the pipe temperature thermistor from the holder.

<Caution for the installation>

There is a possibility for the short circuit when connector gets

wet by water through the thermistor lead wire.

Therefore, lead wire of the pipe temperature thermistor

should be trapped as shown in photo 6.

(6) Gas pipe temperature thermistor is inserted to the holder

of the gas pipe (Header)

Figure 4

Check panel

Liquid pipe thermistor

Photo 4

Relay connector of

the vane motor

Photo 5

Left side

panel

Photo 6

Screw

Check

panel

Screws

Vane motor

Relay connector of

the pipe temperature

thermistor

Gas pipe (Header)

Gas pipe thermistor

8. Removing the under panel

(1) Remove the air intake grille.

(2) Remove the beam.

(3) Remove the side panel (right and left).

(4) Unscrew the screws of the under panel, then remove the

lower panel.

❈ Weight of the lower panel : Approx. 2kg.

26

Hold Pipe temperature thermistor Trap

Photo 7

Screws

Under panel

Page 27

OPERATING PROCEDURE PHOTOS & ILLUSTRATIONS

9. Removing the drain pan

(1) Remove the air intake grille.

(2) Remove the beam.

(3) Remove the side panel (right and left).

(4) Remove the under panel. Remove the screws of the right

and left side drain pan.

(5) Remove the insulation in centre of the drain pan, and

after removing the screw, remove the drain pan.

(Note)

Please aware that there might be drain left in the drain pan

when you remove the drain pan.

10. Removing the guide vane

(1) Remove the intake grille.

(2) Remove the beam.

(3) Remove the side panel (right and left).

(4) Remove the under panel.

(5) Remove the drain pan.

(6) Remove the screw from the guide vane, then remove the

guide vane.

Photo 8

Screw

Photo 9

Drain pan

Screws

(Insulation)

Screw

11. Removing the Auto vane

(1) Remove the intake grille.

(2) Remove the left side panel.

(3) Remove the left side box.

(4) Remove the under panel.

(5) Remove the screw from the auto vane.

(6) Slide the auto vane to the right side and pull the auto

vane out.

Drain pan

Photo 10

Guide vane

Auto vane

Screw

Screw

27

Page 28

9

No.

Parts No. Parts Name Specifications

P63 P100

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

Q'ty/set

PCFY- • VGM-E

Price

1

2

3

4

5

6

7

8

9

10

11

12

P40

Remarks

(Drawing No.)

P125

R01 30L 255

T7W 39J 255

R01 A13 255

T7W 520 239

T7W E34 310

T7W A14 716

T7W E00 716

T7W 515 716

—

T7W B01 294

R01 05A 304

R01 E02 313

—

—

—

—

CAPACITOR

CAPACITOR

CAPACITOR

FUSE

INDOOR CONTROLLER BOARD

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

CONTROL BOX

ADDRESS BOARD

ADDRESS CABLE

POWER BOARD

BOX COVER

BOX COVER

BOX COVER

REMOTE CONTROLLER

3= 440V

4

= 440V

6

= 440V

250V 6.3A

3P(L,N,;)

3P(M1,M2,S)

2P(1,2)

PAR-21MAA

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(BG00N015G31)

(BG02A804G20)

(BG02A804G21)

(BG02A804G22)

C1

C1

C1

I.B

TB2

TB5

TB15

A.B

P.B

ON/OFF

TEMP.

PARTS LIST (non-RoHS compliant)

ELECTRICAL PARTS

PCFY-P40VGM-E

PCFY-P63VGM-E

PCFY-P100VGM-E

PCFY-P125VGM-E

9

10

8

1

2

3

4

5

6

7

11

28

12

Page 29

STRUCTURAL PART

No.

Parts No. Parts Name Specifications

PCFY-

P40VGM-E

Q'ty/set

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

1

1

4

1

1

4

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(BG02H454K01)

(BG17H464H08)

(BG02R321G07)

MV

Remarks

(Drawing No.)

R01 57N 666

R01 A15 500

R01 17J 061

R01 18J 691

R01 17J 691

R01 17J 054

R01 A14 500

—

R01 17J 669

—

T7W E00 070

R01 18J 665

R01 17J 808

R01 17J 668

R01 17J 661

R01 17J 067

R01 17J 085

—

R01 17J 651

R01 17J 002

R01 18J 086

R01 A14 676

R01 17J 068

R01 E03 223

R01 17J 809

R01 17J 662

R01 17J 523

S.PLATE-L

L.L FILTER

GRILLE HINGE

GRILLE ASSY

GRILLE ASSY

GRILLE CATCH

L.L FILTER

REAR SUPPORT

UNDER PANEL

BEAM(GA)

W.BOARD CASE

S.PLATE-R

RIGHT LEG (R)

SERVICE PANEL

RIGHT SIDE PANEL

RIGHT SIDE BOX

G.V ASSY-6R

VANE SUPPORT

FRONT PANEL

AUTO VANE

G.V ASSY-6L

REAR PANEL

LEFT SIDE BOX

VANE MOTOR

LEFT LEG (L)

LEFT SIDE PANEL

JOINT SOCKET

PCFY-P40VGM-E

1

2

3

4

5

20212223242526

19

18

17

16

15

Part number that is circled is not shown in the figure.

6

7

8

9

11

10

12

13

14

29

Page 30

STRUCTURAL PART

No.

Parts No. Parts Name

Specifications

P63

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

Q'ty/set

PCFY- • VGM-E

Price

1

1

1

1

4

4

2

2

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

P100

1

1

1

1

4

4

2

2

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

MV

MV

Remarks

(Drawing No.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

R01 17J 662

R01 35J 662

R01 17J 809

R01 57N 666

R01 35J 666

R01 A15 676

R01 A16 676

R01 17J 061

R01 17J 054

R01 17J 691

R01 A14 500

R01 29J 669

T7W E00 070

—

—

R01 18J 665

R01 E00 665

R01 17J 661

R01 35J 661

R01 17J 808

R01 17J 668

R01 18J 668

R01 17J 067

R01 35J 067

R01 29J 651

R01 36J 651

R01 29J 002

R01 E03 002

—

—

R01 17J 085

R01 37J 085

R01 29J 087

R01 37J 087

R01 18J 086

R01 37J 086

R01 17J 068

R01 E00 068

R01 29J 223

R01 35J 223

R01 17J 523

(BG02H454K01)

(BG17H464H08)

(BG02R321G07)

(BG02R805G05)

LEFT SIDE PANEL

LEFT SIDE PANEL

LEFT LEG

S.PLATE-L

S.PLATE-L

REAR PANEL

REAR PANEL

GRILLE HINGE

GRILLE CATCH

GRILLE ASSY

L.L FILTER

UNDER PANEL

W.BOARD CASE

REAR SUPPORT

BEAM (GA)

S.PLATE-R

S.PLATE-R

RIGHT SIDE PANEL

RIGHT SIDE PANEL

RIGHT LEG

SERVICE PANEL

SERVICE PANEL

RIGHT SIDE BOX

RIGHT SIDE BOX

FRONT PANEL

FRONT PANEL

AUTO VANE

AUTO VANE

VANE SUPPORT

VANE SUPPORT

G.V ASSY-6R

G.V ASSY-6R

G.V ASSY-6C

G.V ASSY-6C

G.V ASSY-6L

G.V ASSY-6L

LEFT SIDE BOX

LEFT SIDE BOX

VANE MOTOR

VANE MOTOR

JOINT SOCKET

PCFY-P63VGM-E

PCFY-P100VGM-E

Part number that is circled is not show in the figure.

1

2

3

4

5

6 7 8 9 10 11 12 13

23

2425

2122

20

19

18

17

16

15

14

30

Page 31

STRUCTURAL PART

No.

Parts No.

Parts Name

Specifications

PCFY-

P125VGM-E

Q'ty/set

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

1

1

1

1

6

1

6

2

2

1

1

1

3

1

1

1

1

1

1

1

1

2

3

1

1

1

1

1

(BG02H454K01)

(BG17H464H08)

(BG02R805G05)

MV

Remarks

(Drawing No.)

R01 35J 662

R01 35J 666

R01 A17 676

R01 A15 500

R01 17J 061

R01 18J 691

R01 17J 054

R01 17J 691

R01 A14 500

R01 41J 669

T7W E00 070

—

—

R01 35J 661

R01 17J 808

R01 18J 668

R01 35J 067

R01 E00 665

R01 41J 651

R01 E04 002

R01 41J 085

R01 43J 087

—

R01 42J 086

R01 E00 068

R01 35J 223

R01 17J 809

R01 17J 523

LEFT SIDE PANEL

S.PLATE-L

REAR PANEL

L.L FILTER

GRILLE HINGE

GRILLE ASSY

GRILLE CATCH

GRILLE ASSY

L.L FILTER

UNDER PANEL

W.BOARD CASE

REAR SUPPORT

BEAM(GA)

RIGHT SIDE PANEL

RIGHT LEG

SERVICE PANEL

RIGHT SIDE BOX

S.PLATE-R

FRONT PANEL

AUTO VANE

G.V ASSY-5R

G.V ASSY-5C

VANE SUPPORT

G.V ASSY-5L

LEFT SIDE BOX

VANE MOTOR

LEFT LEG

JOINT SOCKET

PCFY-P125VGM-E

1

27

26 25 24

23

22

21

2

3

4

5

6

7

8

Part number that is circled is not shown in the figure.

9

31

10

11

12

13

20

19

18

17

16

15

14

Page 32

No.

Parts No.

Parts Name

Specifications

PCFY-

P40VGM-E

Q'ty/set

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

TH21

MF

TH22

LEV

TH23

D09B4P54MS

2pcs/set

Remarks

(Drawing No.)

R01 17J 130

T7W B06 110

R01 17J 114

T7W 19J 675

R01 E26 202

R01 43E 126

T7W 23J 762

R01 17J 524

T7W 17J 675

R01 A14 529

T7W 18J 675

R01 E27 202

R01 E60 401

R01 17J 202

R01 H47 480

T7W E00 072

MOTOR LEG

CASING

SIROCCO FAN

FAN GUARD

ROOM TEMPERATURE THERMISTOR

PIECE (MOTOR)

FAN MOTOR

DRAIN PLUG

FAN GUARD

DRAIN PAN ASSY

FAN GUARD

LIQUID PIPE TEMPERATURE THERMISTOR

LINEAR EXPANSION VALVE

GAS PIPE TEMPERATURE THERMISTOR

HEAT EXCHANGER

DRAIN HOSE COVER

FAN AND HEATER PARTS

PCFY-P40VGM-E

2

3

15

1

14

4

5

6

7

8

10

9

Part number that is circled is not shown in the figure.

11

13

12

3

2

32

Page 33

FAN AND HEATER PARTS

PCFY-P63VGM-E

PCFY-P100VGM-E

1

20

2

3

4

5

6

7

8

9

Part number that is circled is not shown in the figure.

No.

Parts No.

R01 29J 130

1

R01 35J 130

R01 43E 126

2

T7W 30J 762

3

T7W 39J 762

R01 700 116

4

R01 29J 114

5

R01 35J 114

T7W 20J 675

6

T7W 22J 675

R01 E26 202

7

R01 29J 100

8

T7W 21J 675

9

T7W 23J 675

R01 E00 103

10

R01 29J 145

11

R01 35J 145

R01 17J 524

12

R01 A15 529

13

R01 A16 529

T7W 18J 675

14

T7W 24J 675

T7W B06 110

15

T7W B07 110

R01 33J 114

16

R01 39J 114

R01 E27 202

17

R01 E60 401

18

R01 E61 401

R01 17J 202

19

R01 H49 480

20

R01 H52 480

T7W E00 072

21

Parts Name

MOTOR LEG

MOTOR LEG

PIECE(MOTOR)

FAN MOTOR

FAN MOTOR

FAN JOINT

SIROCCO FAN

SIROCCO FAN

FAN GUARD

FAN GUARD

ROOM TEMPERATURE THERMISTOR

SHAFT

FAN GUARD

FAN GUARD

SLEEVE BEARING

BEARING SUPPORT

BEARING SUPPORT

DRAIN PLUG

DRAIN PAN ASSY

DRAIN PAN ASSY

FAN GUARD

FAN GUARD

CASING

CASING

SIROCCO FAN

SIROCCO FAN

LIQUID PIPE TEMPERATURE THERMISTOR

LINEAR EXPANSION VALVE

LINEAR EXPANSION VALVE

GAS PIPE TEMPERATURE THERMISTOR

HEAT EXCHANGER

HEAT EXCHANGER

DRAIN HOSE COVER

Specifications

D09C4P70MS

D10B4P90MS

10

11

Q'ty/set

PCFY- • VGM-E

P63

P100

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

3

1

1

1

1

1

1

16

15

14

13

12

Remarks

(Drawing No.)

2pcs/set

Wiring

Diagram

Symbol

MF

MF

TH21

TH22

LEV

LEV

TH23

17

Recommended

Q'ty

18

Unit

19

Price

Amount

33

Page 34

No.

Parts No.

Parts Name

Specifications

PCFY-

P125VGM-E

Q'ty/set

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

4

1

1

1

1

1

1

1

TH21

MF

TH22

LEV

TH23

D10B4P150MS

2pcs/set

Remarks

(Drawing No.)

R01 29J 100

R01 41J 130

R01 43E 126

R01 41J 114

R01 E26 202

T7W 26J 675

T7W 25J 675

T7W 43J 762

R01 35J 114

R01 A17 529

R01 700 116

T7W 23J 675

R01 39J 114

R01 17J 524

T7W 24J 675

T7W B07 110

R01 E00 103

R01 35J 145

R01 E27 202

R01 E61 401

R01 17J 202

R01 H53 480

T7W E00 072

SHAFT

MOTOR LEG

PIECE (MOTOR)

SIROCCO FAN

ROOM TEMPERATURE THERMISTOR

FAN GUARD

FAN GUARD

FAN MOTOR

SIROCCO FAN

DRAIN PAN ASSY

FAN JOINT

FAN GUARD

SIROCCO FAN

DRAIN PLUG

FAN GUARD

CASING

SLEEVE BEARING

BEARING SUPPORT

LIQUID PIPE TEMPERATURE THERMISTOR

LINEAR EXPANSION VALVE

GAS PIPE TEMPERATURE THERMISTOR

HEAT EXCHANGER

DRAIN HOSE COVER

FAN AND HEATER PARTS

PCFY-P125VGM-E

2

3

4

5

6

7

8

9

10

11

12

13

Part number that is circled is not shown in the figure.

1

22

21

20

19

17·18

16

15

14

34

Page 35

10

No.

Parts No. Parts Name Specifications

P63

P100

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

Q'ty/set

PCFY- • VGM-E

Price

1

2

3

4

5

6

7

8

9

10

11

12

RoHS

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

P40

Remarks

(Drawing No.)

P125

R01 A15 255

T7W E13 255

R01 A14 255

R01 E06 239

T7W E53 310

T7W E32 716

T7W E35 716

T7W E36 716

—

T7W E01 294

R01 A01 304

R01 E38 313

—

—

—

—

CAPACITOR

CAPACITOR

CAPACITOR

FUSE

INDOOR CONTROLLER BOARD

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

CONTROL BOX

ADDRESS BOARD

ADDRESS CABLE

POWER BOARD

BOX COVER

BOX COVER

BOX COVER

REMOTE CONTROLLER

3= 440V

4

= 440V

6

= 440V

250V 6.3A

3P(L,N,;)

3P(M1,M2,S)

2P(1,2)

PAR-21MAA

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(BG00N015G31)

(BG02A804G20)

(BG02A804G21)

(BG02A804G22)

C1

C1

C1

I.B

TB2

TB5

TB15

A.B

P.B

ON/OFF

TEMP.

RoHS PARTS LIST

ELECTRICAL PARTS

PCFY-P40VGM-E

PCFY-P63VGM-E

PCFY-P100VGM-E

PCFY-P125VGM-E

9

10

8

1

2

3

4

5

6

7

35

11

12

Page 36

STRUCTURAL PART

No.

Parts No. Parts Name Specifications

PCFY-

P40VGM-E

Q'ty/set

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

RoHS

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

1

1

4

1

1

4

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(BG02H454K01)

(BG17H464H08)

(BG02R321G07)

MV

Remarks

(Drawing No.)

R01 E00 666

R01 A30 500

R01 18J 061

R01 20J 691

R01 19J 691

R01 19J 054

R01 A29 500

—

R01 31J 669

—

T7W E03 070

R01 19J 665

R01 18J 808

R01 19J 668

R01 18J 661

R01 18J 067

R01 40J 085

—

R01 37J 651

R01 31J 002

R01 40J 086

R01 A18 676

R01 18J 068

R01 E11 223

R01 18J 809

R01 18J 662

R01 18J 523

S.PLATE-L

L.L FILTER

GRILLE HINGE

GRILLE ASSY

GRILLE ASSY

GRILLE CATCH

L.L FILTER

REAR SUPPORT

UNDER PANEL

BEAM(GA)

W.BOARD CASE

S.PLATE-R

RIGHT LEG (R)

SERVICE PANEL

RIGHT SIDE PANEL

RIGHT SIDE BOX

G.V ASSY-6R

VANE SUPPORT

FRONT PANEL

AUTO VANE

G.V ASSY-6L

REAR PANEL

LEFT SIDE BOX

VANE MOTOR

LEFT LEG (L)

LEFT SIDE PANEL

JOINT SOCKET

PCFY-P40VGM-E

1

2

3

4

5

20212223242526

19

18

17

16

15

Part number that is circled is not shown in the figure.

6

7

8

9

10

11

13

12

14

36

Page 37

STRUCTURAL PART

No.

Parts No. Parts Name

Specifications

P63

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

Q'ty/set

PCFY- • VGM-E

Price

1

1

1

1

4

4

2

2

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

P100

1

1

1

1

4

4

2

2

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

MV

MV

Remarks

(Drawing No.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

RoHS

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

R01 18J 662

R01 36J 662

R01 18J 809

R01 E00 666

R01 E01 666

R01 30J 676

R01 A21 676

R01 18J 061

R01 19J 054

R01 19J 691

R01 A29 500

R01 30J 669

T7W E03 070

—

—

R01 19J 665

R01 E01 665

R01 18J 661

R01 36J 661

R01 18J 808

R01 19J 668

R01 20J 668

R01 18J 067

R01 36J 067

R01 30J 651

R01 38J 651

R01 30J 002

R01 E14 002

—

—

R01 40J 085

R01 38J 085

R01 40J 087

R01 38J 087

R01 40J 086

R01 38J 086

R01 18J 068

R01 E01 068

R01 E10 223

R01 E12 223

R01 18J 523

(BG02H454K01)

(BG17H464H08)

(BG02R321G07)

(BG02R805G05)

LEFT SIDE PANEL

LEFT SIDE PANEL

LEFT LEG

S.PLATE-L

S.PLATE-L

REAR PANEL

REAR PANEL

GRILLE HINGE

GRILLE CATCH

GRILLE ASSY

L.L FILTER

UNDER PANEL

W.BOARD CASE

REAR SUPPORT

BEAM (GA)

S.PLATE-R

S.PLATE-R

RIGHT SIDE PANEL

RIGHT SIDE PANEL

RIGHT LEG

SERVICE PANEL

SERVICE PANEL

RIGHT SIDE BOX

RIGHT SIDE BOX

FRONT PANEL

FRONT PANEL

AUTO VANE

AUTO VANE

VANE SUPPORT

VANE SUPPORT

G.V ASSY-6R

G.V ASSY-6R

G.V ASSY-6C

G.V ASSY-6C

G.V ASSY-6L

G.V ASSY-6L

LEFT SIDE BOX

LEFT SIDE BOX

VANE MOTOR

VANE MOTOR

JOINT SOCKET

PCFY-P63VGM-E

PCFY-P100VGM-E

Part number that is circled is not show in the figure.

1

2

3

4

5

6 7 8 9 10 11 12 13

23

2425

2122

20

19

18

17

16

15

14

37

Page 38

STRUCTURAL PART

No.

Parts No.

Parts Name

Specifications

PCFY-

P125VGM-E

Q'ty/set

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

RoHS

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

1

1

1

1

6

1

6

2

2

1

1

1

3

1

1

1

1

1

1

1

1

2

3

1

1

1

1

1

(BG02H454K01)

(BG17H464H08)

(BG02R805G05)

MV

Remarks

(Drawing No.)

R01 36J 662

R01 E01 666

R01 A19 676

R01 A30 500

R01 18J 061

R01 20J 691

R01 19J 054

R01 19J 691

R01 A29 500

R01 32J 669

T7W E03 070

—

—

R01 36J 661

R01 18J 808