Page 1

TECHNICAL & SERVICE MANUAL

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

CONTENTS

1. FEATURES ···········································2

2. PART NAMES AND FUNCTIONS········4

3. SPECIFICATION···································6

4. OUTLINES AND DIMENSIONS············8

5. WIRING DIAGRAM·····························12

6.

REFRIGERANT SYSTEM DIAGRAM

···13

7. TROUBLE SHOOTING·······················14

8. DISASSEMBLY PROCEDURE···········19

9. PARTS LIST········································23

<Indoor unit>

PCFY-40VGM

PCFY-63VGM

PCFY-100VGM

PCFY-125VGM

No. OC122

REVISED EDITION-A

1997

Models

INDOOR UNIT

Ceiling Suspended

Series PCFY

Revision

• Parts List has been partially modified.

• Please destroy OC122.

Page 2

2

1

FEATURES

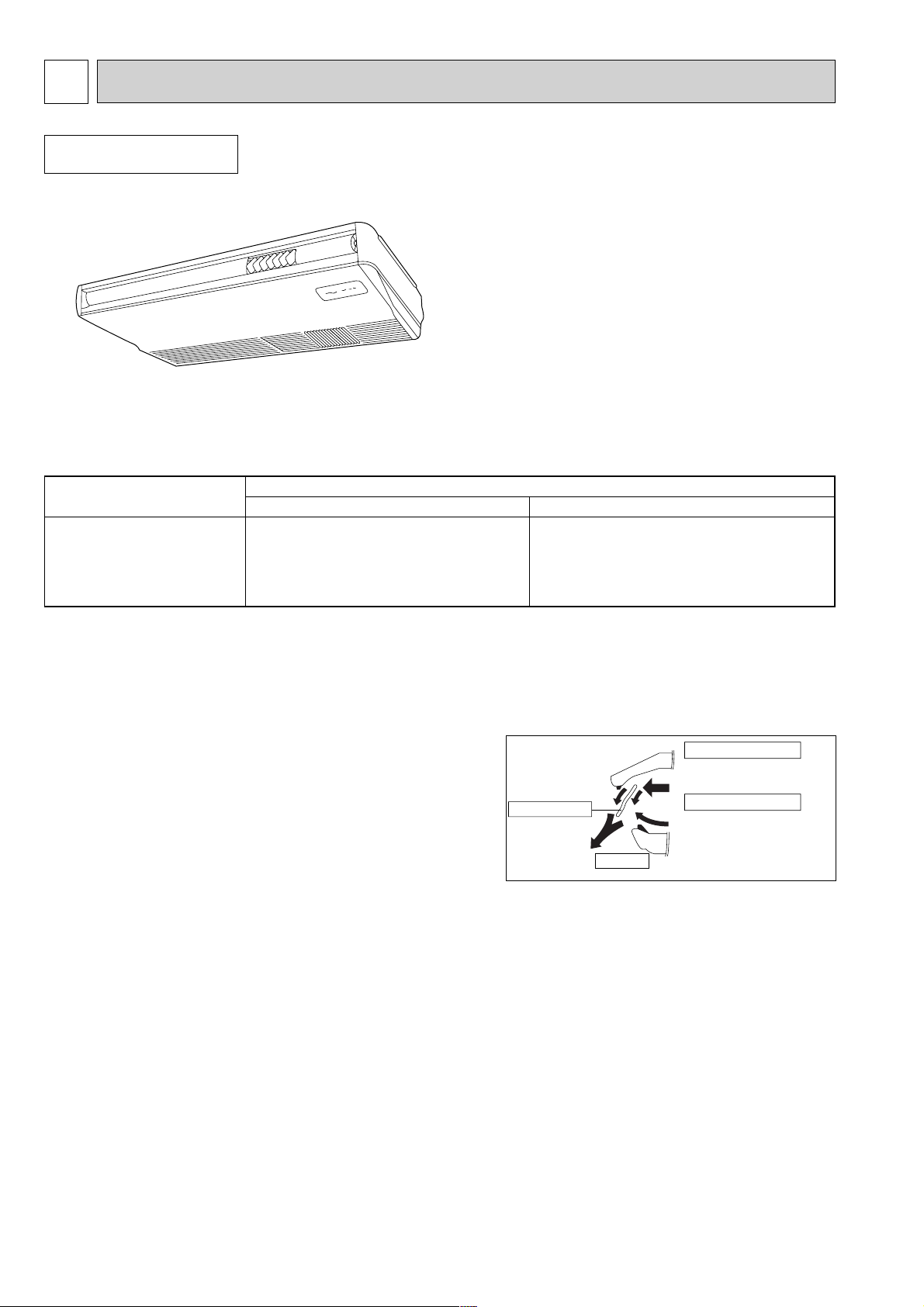

1. AIR OUTLET

New PCFY series models have 1 air outlet (auto vane switching of horizontal air flow / down flow by switched by auto vane)

instead of 2 (horizontal, and down frows).

2. EASY TO CLEAN ; FLOCKLESS VANE

With our original air current control mechanism, a flockless vane is

newly adapted.

The flockless vane prevents the condensation on the vane.

By changing the vane to the flockless type, the unit can be cleaned

much easier with mild household detergent.

3. NEW MATERIALS FOR BETTER OIL RESISTANCE

We have changed the materials of grill, filer, fan and fan casing from ABS to P.P. (polypropylene) for better oil resistance. As

a result, oil crazing is cut in half.

Indoor unit

Ceiling Suspended

Series PCFY

B

A

Unifies the air speed

with the vane.

+

=

Sending the air to the upper

area of the vane

Prevents the air comes from

outside the unit

Flockless vane

Protruding portion A

Protruding portion B

Air outlet

Cooling capacity / Heating capacity

Models

W Kcal/h

PCFY-40VGM 4,700/5,200 4,000/4,500

PCFY-63VGM 7,300/8,300 6,300/7,100

PCFY-100VGM 11,600/13,000 10,000/11,200

PCFY-125VGM 14,500/16,300 12,500/14,000

Page 3

3

1 Removed the knockout work by separating the piping space

from the air outlet for efficiency of the piping work.

❈ Knockout work is needed for the top part. When optional

drain-up machine is installed, the refrigerant pipe exits out

from the top.

2 Improved the flexibility by making it possible for drainage

pipe to exit not only from the right side back but also from

the left side back.

❈ Please move the rubber plug for the unit to the right joint

when drainage pipe exits from the left side.

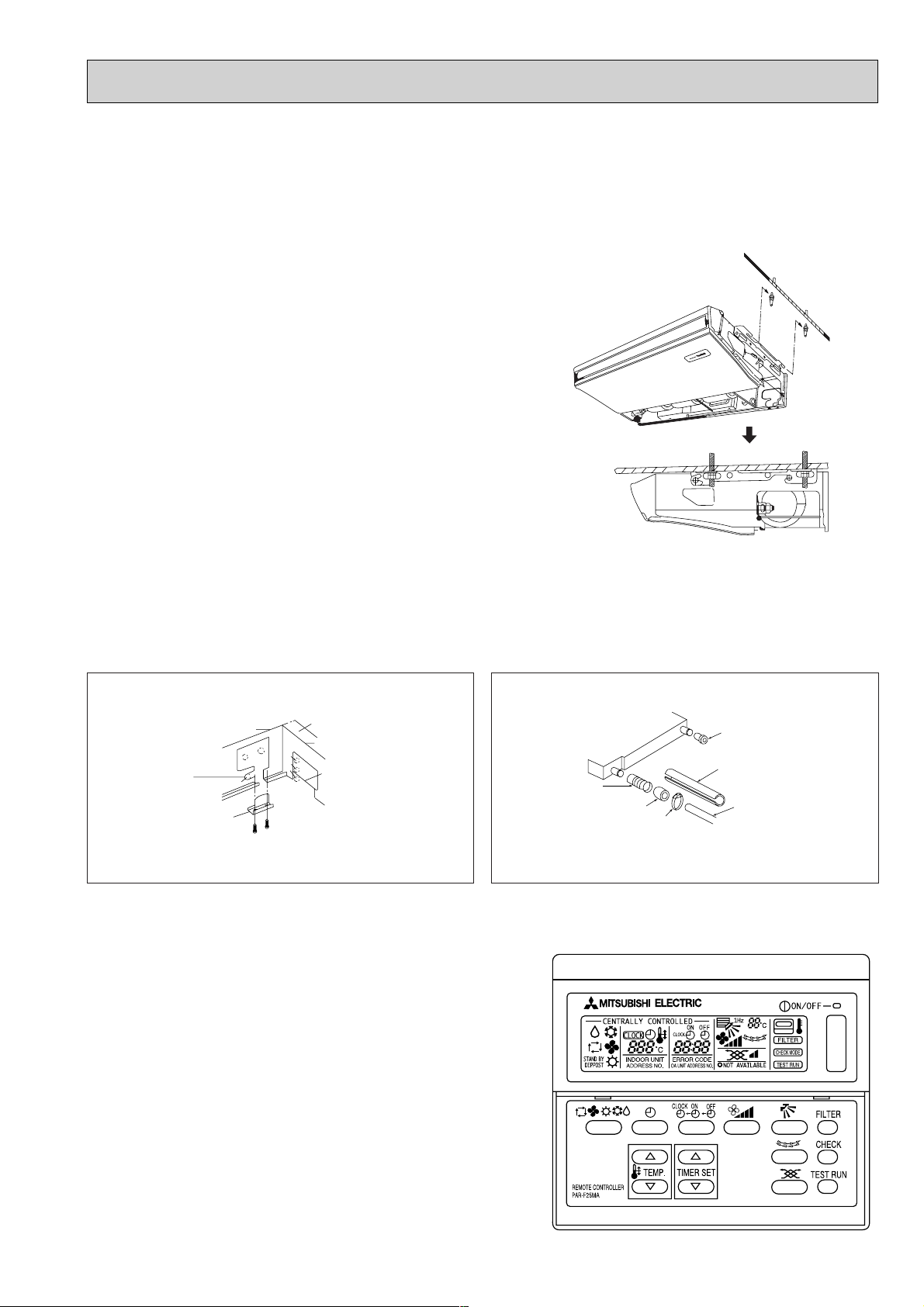

4. SIMPLIFIED INSTALLATION WORK (DIRECT SUSPENDING METHOD)

Simplified the installation work by changing the suspending method to the direct suspending method (suspending the unit

directly from the suspension fixture).

In this way, the unit can be attached to the suspension fixture without removing the installation parts off (Only the side cover

is removed). This method is much simpler than the ¨One-time installation method¨.

5. IMPROVING EFFICIENCY OF PIPING WORK

U-cut

Back panel

L

D

G

Open

Open

L

G

D

Side panel

L : Liquid pipe

G: Gas pipe

D: Drain pipe

6.ADVANCED MICROPROCESSOR [PAR-F25MA]

(1)Easy to use microprocessor

1)Ultra-thin remote controller

The streamlinde,square controller is designed to blend well with

any interior.Also,the sophisticated microproceeor allows you to

easily carry out a wide range of operations.

2)Attractive liquid crystal display(LCD)

The unit´s operation mode,set temperature,room

temperature,timer setting,fan speed,louver oper-ation,and air flow

direction are displayed on the remote controller´s easy-to-read

Liquid Crystal Dis-play(LCD).

3)Convenient 24-hour ON-OFF timer

The timer switches Mr.SLIM on and off automati-cally at the time

you set. Once the timer is set,the remaining time is shown on the

LCD.

Rubber plug

Insulation cover

(attached)

Drain pipe

(purchased locally)

Joint coupliy

(attached)

Drain pan

Insulation

cover

Band

(attached)

Page 4

4

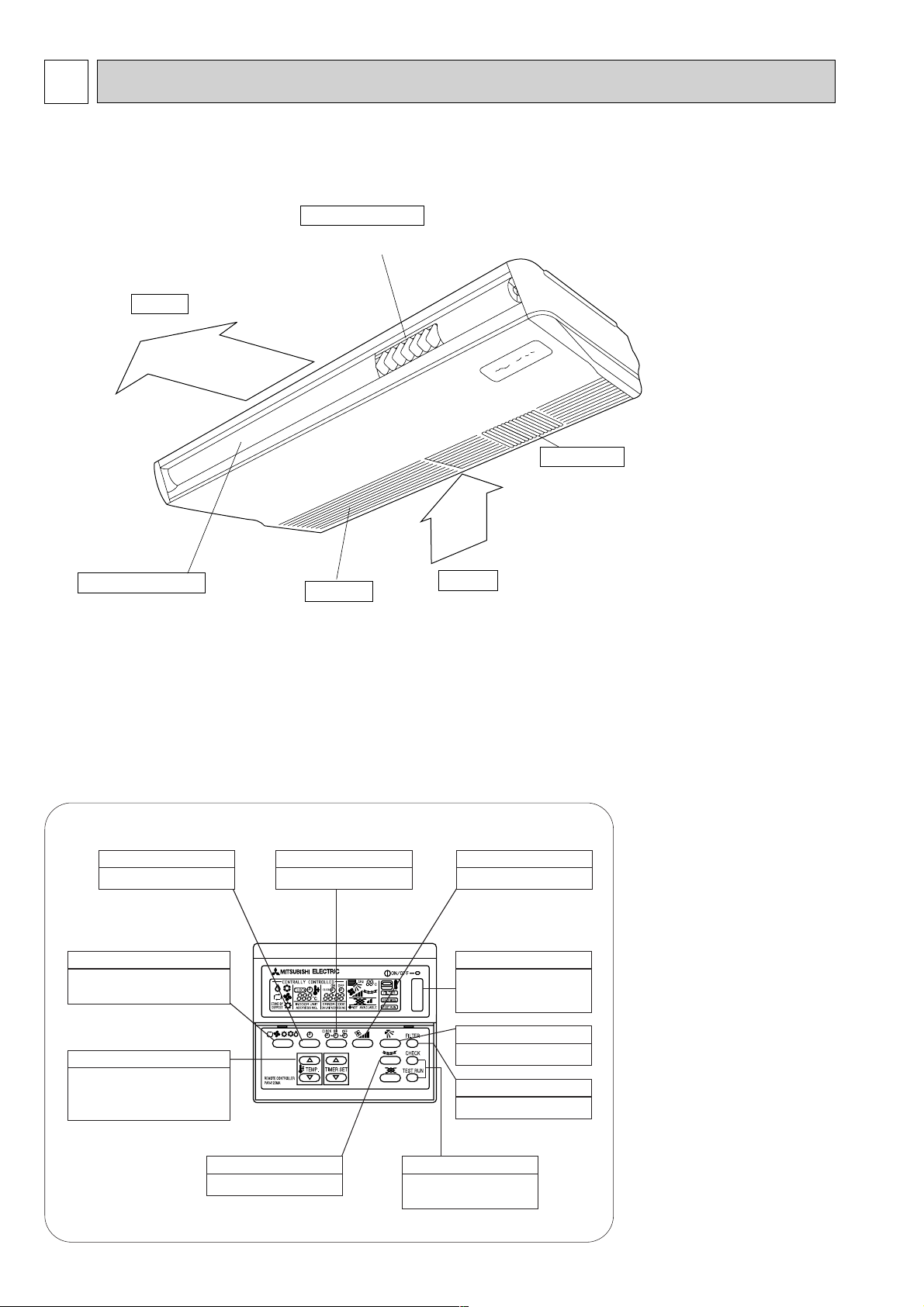

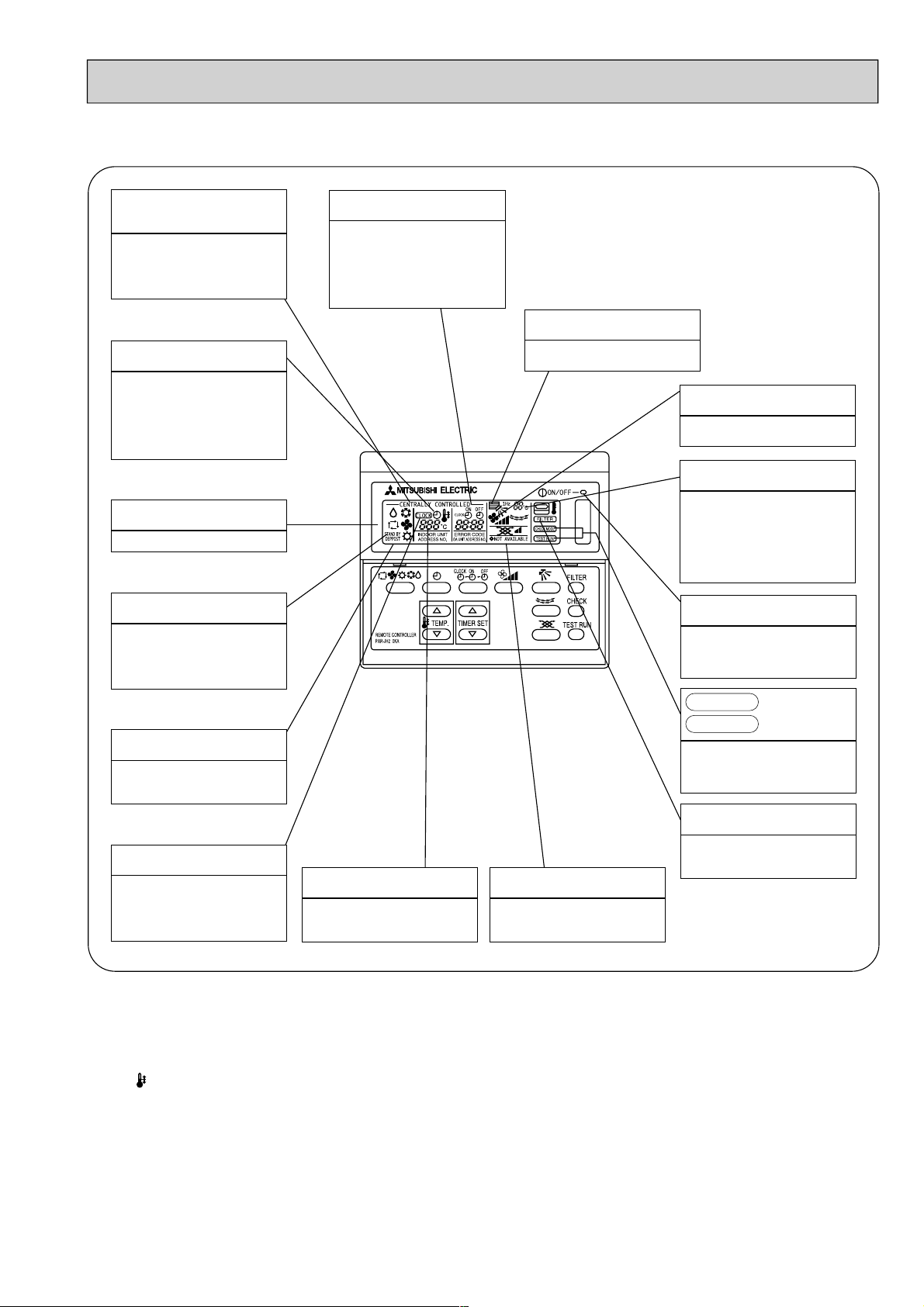

PART NAMES AND FUNCTION

2

● Indoor (Main) Unit

Air outlet

Intake grille

Air intake

Left/right guide vanes

Change the direction of airflow

from the horizontal blower.

Long-life fillter

Removes dust and foreigh matter from air coming in

through the grille (Recommended cleaning interval :

Approx, every 2,500 operating hours)

Up/down guide vanes

Change the direction of airflow from the

vartical blower.

● Remote controller

● Operation buttons

[PAR-F25MA]

● Once the controls are set, the same operation mode can

be repeated by simply pressing the ON/OFF button.

This switches between continuous

operation and the timer operation.

TIMER button

This sets the ventilation fan speed.

AIR SPEED button

Press this button to switch the cooler

electronic dry (dehumidify) automatic and

heater modes.

OPERATION SWITCH button

This sets the room temparature The

temparature setting can be performed in 1°C

units

Setting range

Cooler 19°C to 30°C

TEMP ADJUSTMENT button

This sets of switches the current time.

start time and stop time.

TIME SETTING button

(This button does not operate in this

model)

This switches the horizontal fan

motion ON and OFF.

LOUVER button

This swiches between the operation

and stop modes each time it is

pressed. The lamp on this button

lights during operation.

ON/OFF button

This adjusts the vertical angle of the

ventilation.

AIR DIRECTION button

Only press this button to perform an

inspection check or test operation Do

not use it for nomal operation.

CHECK-TEST RUN button

This resets the filter service indication

display.

FILTER button

Page 5

5

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not a

malfunction.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped

with the fan direction adjustment function and the louver function.

●When power is turned ON for the first time, it is normal that “HO” is displayed on room temperature indecation (For

max.2minutes). Please wait until this “HO” indication disappear then start the operation.

4

CENTRALLY

CONTROLLED display

This indicates when the unit is

controlled by optional features such

as central control type remote

controller.

TIMER display

This indicates when the continous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

This indicates when the standby

mode is set from the time the sleep

operation starts until the heating air

is discharged.

DEFROST display

This indicates when the defrost

operation is performed.

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

CLOCK display

The current time , start time and stop

time can be displayed in tensecond

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

● Display

In this display example on the

bottom left, a condition where all

display lamps light is shown for

explanation purposes although this

differs from actual operation.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when amalfunction occurs.

POWER display

This lamp lights when electricity is

supplied to the unit.

SET TEMPERATURE display

This displays the selected setting

temperature.

FAN SPEED display

This displays the air direction.

ROOM TEMPERATURE display

The temperature of the suction air is

displayed during operation. The

display range is 8° to 39°C. The

display flashes 8°C when the actual

temperature is less than 8° and

flashes 39°C when the actual

temperature is greater than 39°C.

display

This display lights in the check mode

or when a test operation is

performed.

CHECK MODE

TEST RUN

FILTER display

This lamp lights when the filter need

to be cleaned.

AIR DIRECTION display

The selected fan speed is displayed.

Page 6

6

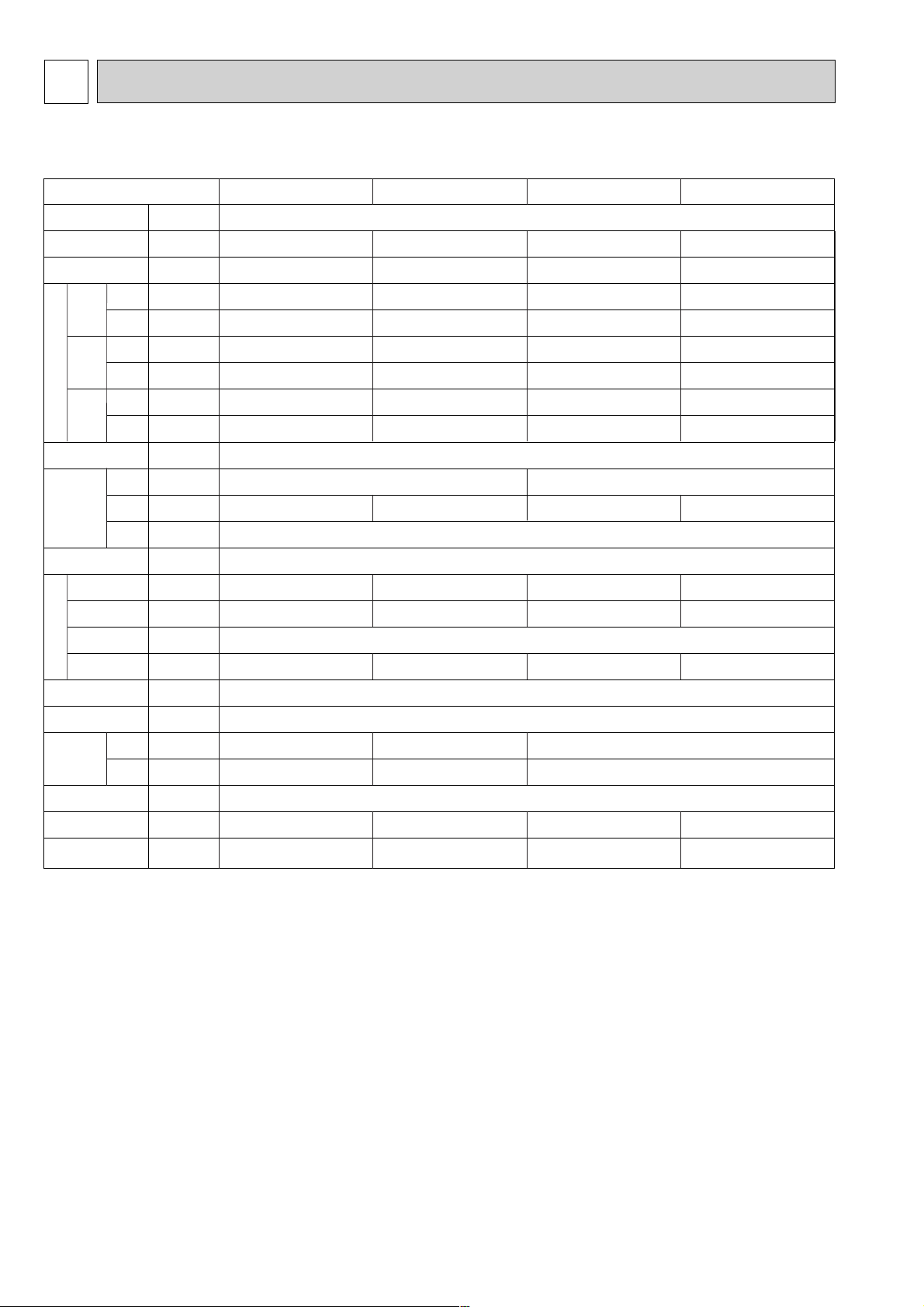

SPECIFICATIONS

3

3-1. Specification

PCFY-40VGM PCFY-63VGM PCFY-100VGM PCFY-125VGM

kW 4.7 7.3 11.6 14.5

kW 5.2 8.3 13.0 14.5

kw 0.10 0.13 0.16 0.24

kW 0.10 0.13 0.16 0.24

A 0.43 0.55 0.70 1.06

A 0.43 0.55 0.70 1.06

%92 93 92 92

%92 93 92 92

– Unit : Munsell<0.70Y 8.59/0.97>

mm 210 270

mm 1000 1310 1310 1620

mm 680

- crosfin

- Sirocco fan

✕

2 Sirocco fan ✕ 3 Sirocco fan ✕ 3 Sirocco fan ✕ 4

k/min 12-11-10-8 18-16-14-12 25-23-20-18 35-32-28-26

Pa 0

kW 0.054 0.07 0.09 0.15

Polyethylene sheet

PP honey comb

[mm 12.7<1/2”> 15.88<5/8”> 19.05<3/4”>

[mm 6.35<1/4”> 9.52<3/8”> 9.52<3/8”>

[mm PVC pipe VP-25 connectable

dB(A) 38-36-33-29 39-37-34-32 43-41-38-36 44-42-39-37

kg 27 34 37 43

V•Hz Single phase 220V-240V 50 HZ

Note 1. Rating conditions(JIS B 8616)

Cooling: Indoor: 27°C DB. 19.5°C WB

outdoor: 35°C DB. 24°C WB

Heating: Indoor: 21°C

outdoor: 7°C DB. 6°C WB

Note 2. Air flow and the noise level are indicated as High-Middium 1-Middium 2-Low.

Item

Power

Cooling capacity

Heating capacity

Cooling

Heating

Cooling

Heating

Cooling

Heating

Exteior

(munsell symbol)

Height

Width

Depth

Heat exchanger

Insulator

Air filter

Gas

side

Pipe

dimensions

Drain pipe size

Noise level

Product weight

Liquid

side

F

a

n

Fan motor

Output

Fan ✕ No

Air flow #3

External

static pressure

Outdimensions

Electric charocteristic

Power

supply

Startin

g

current

Power

factor

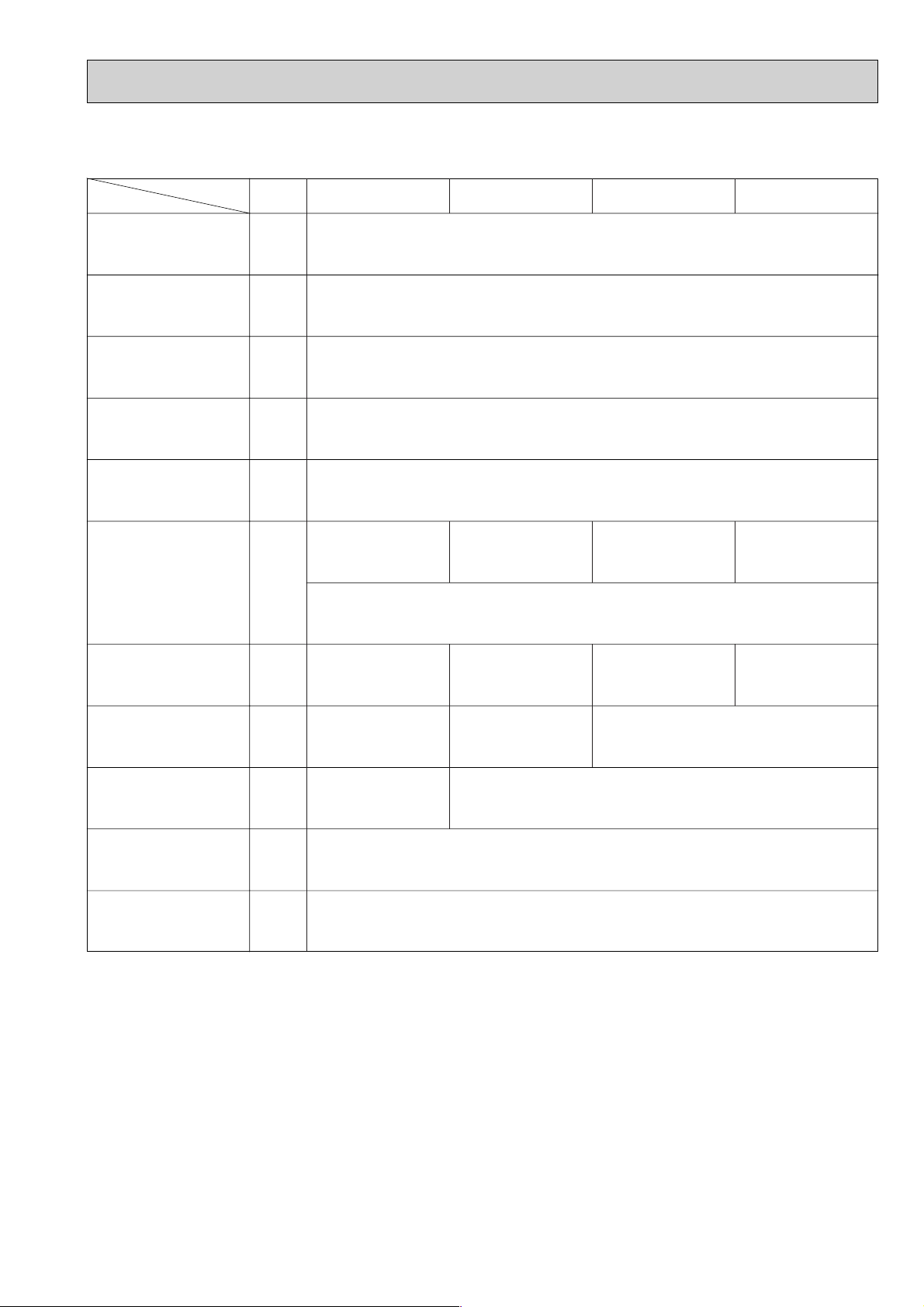

Page 7

7

3-2. Electrical parts specifications

Model

Parts

name

Symbol PCFY-40VGM PCFY-63VGM PCFY-100VGM PCFY-125VGM

Tranrsformer T (Primary) 50/60Hz 220-240V (Secondary) (18.4V 1.7A)

Room temperature

thermistor TH21

Resistance: 0:/15k',10:/9.6k',20:/6.3k',25:/5.4k',30:/4.3k',40:/3.0k

'

Liquid pipe

thermistor TH22

Resistance: 0:/15k',10:/9.6k',20:/6.3k',25:/5.4k',30:/4.3k',40:/3.0k

'

Gas pipe

Thermistor TH23

Resistance: 0:/15k',10:/9.6k',20:/6.3k',25:/5.4k',30:/4.3k',40:/3.0k

'

Fuse FUSE 250V 6.3A

Fan motor MF1,2

Inner-thermostat

Fan motor capacitor C1 3uF x 440V 4uF x 440V 4uF x 440V 6uF x 440V

Vane motor MV

Linear expansion valve LEV

Power supply

terminal block TB2 (L,N,;) 330V 30A

Transmission

terminal block TB5 (M1,M2,S) 330V 30A

(Indoor controller board)

(with Inner-thermostat)

OFF 130:±5:

MP35EA

DC12V

MP35EA

DC12V

MP42EA

DC12V

DC12V Stepping motor

drive

{ 3.2 (0~2000pulse)

EDM-402ME

DC12V Stepping motor drive

{ 5.2 (0~2000pulse)

EDM-804ME

4-Pole OUTPUT 54W

D09B4P54MS

4-Pole Output 90W

D10B4P90MS

4-Pole Output 150W

D10B4P150MS

4-Pole Output 70W

D09B4P70MS

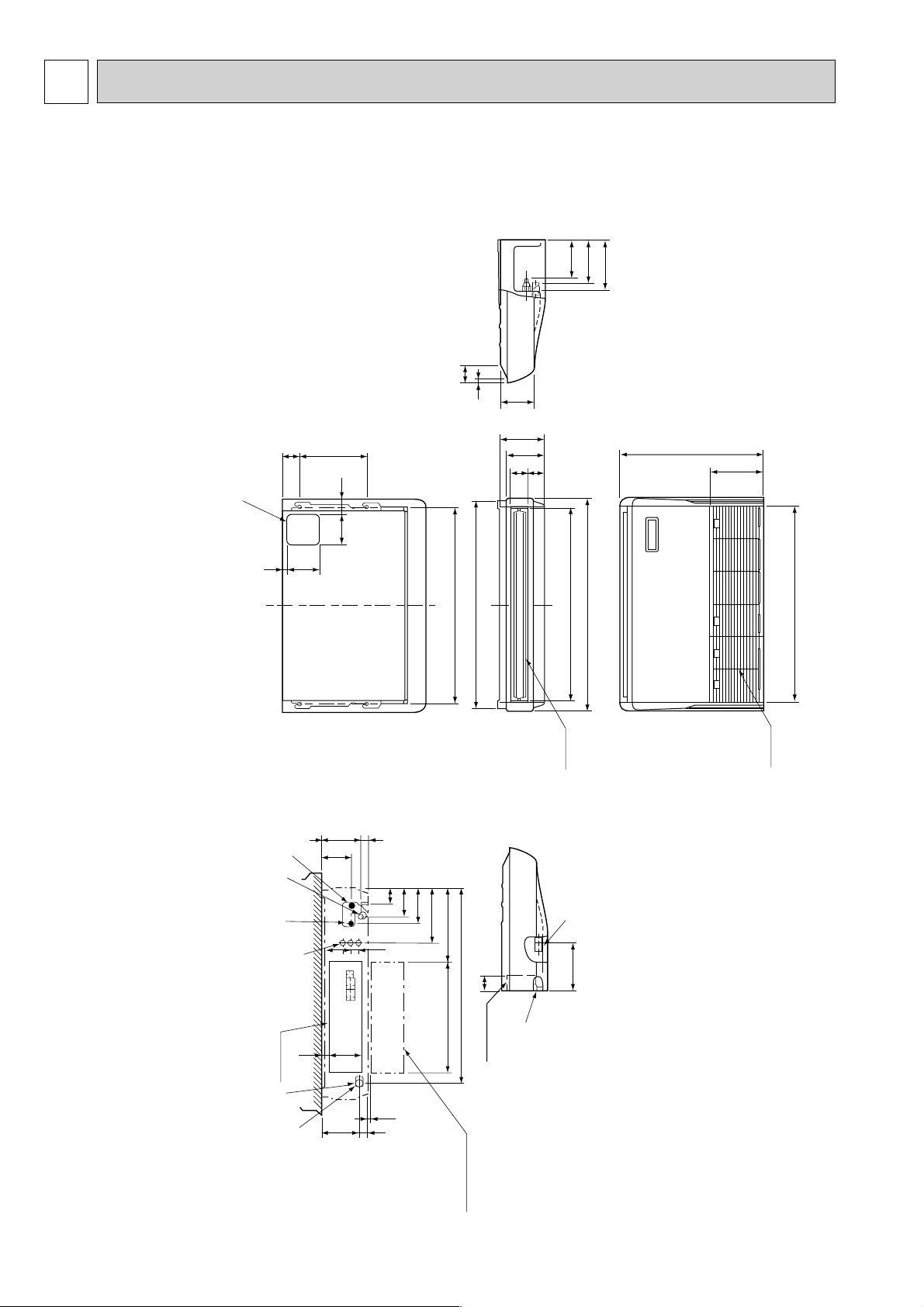

Page 8

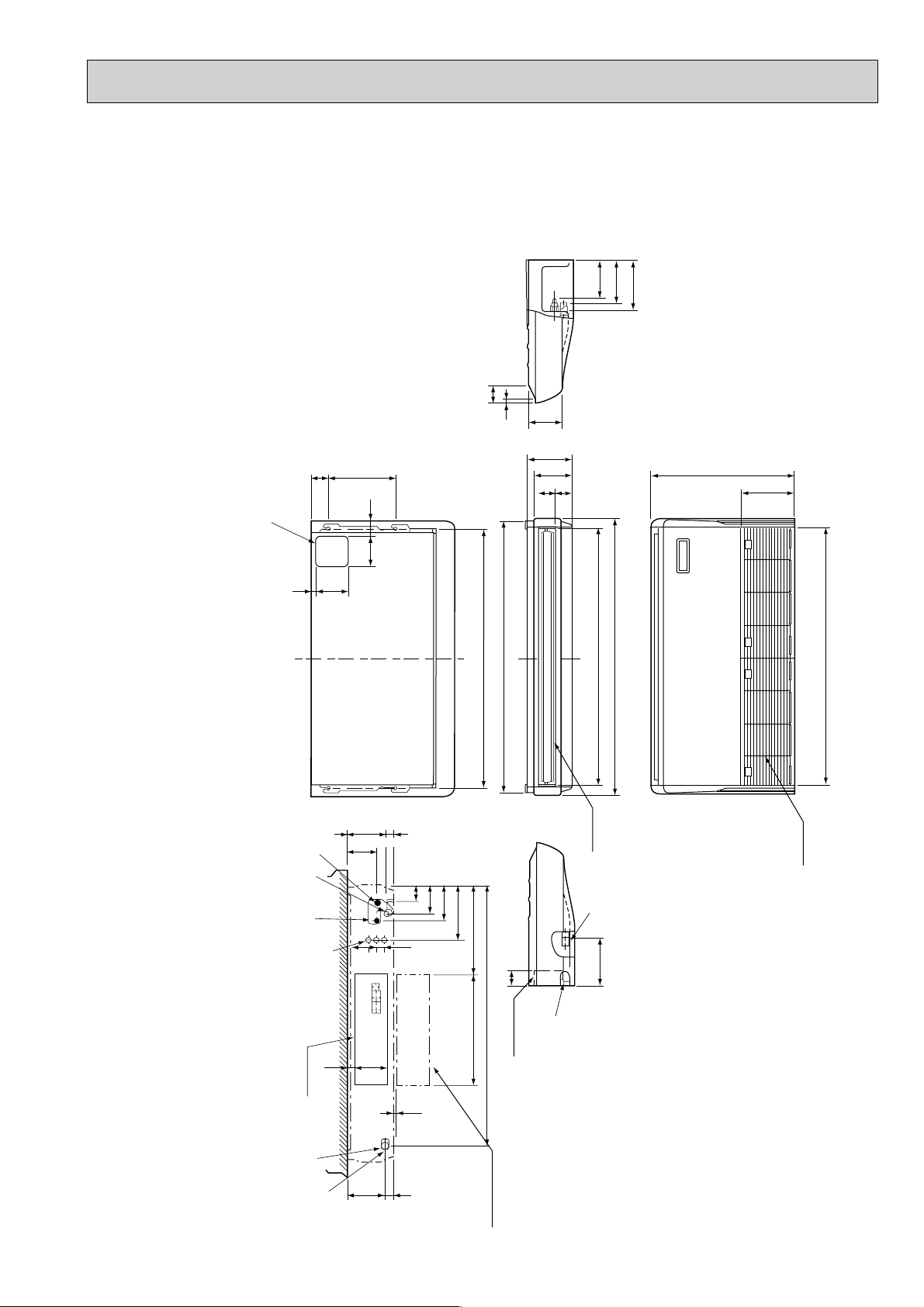

8

OUTLINES AND DIMENSIONS4

INDOOR UNIT

PCFY-40VGM

180

210

157

15

85

182 (3/8F) liquid

201 (5/8F) gas

241 (Drainage)

Air intake

918

254

680

Electrical box

226

70

525

928

352

263

171

138

86

46 175 1

131

38

3879

161

32

179

42

6-7

Celling

Electrical box

[FRONT VIEW]

When electrical

box is pulled

down

3

2

8

5

1

4

6

2

1

17

150

140

70

320

80

933 (suspension bolt pitch)

983

1000

Air outlet

81

904

76

Gap to ceiling

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wining arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

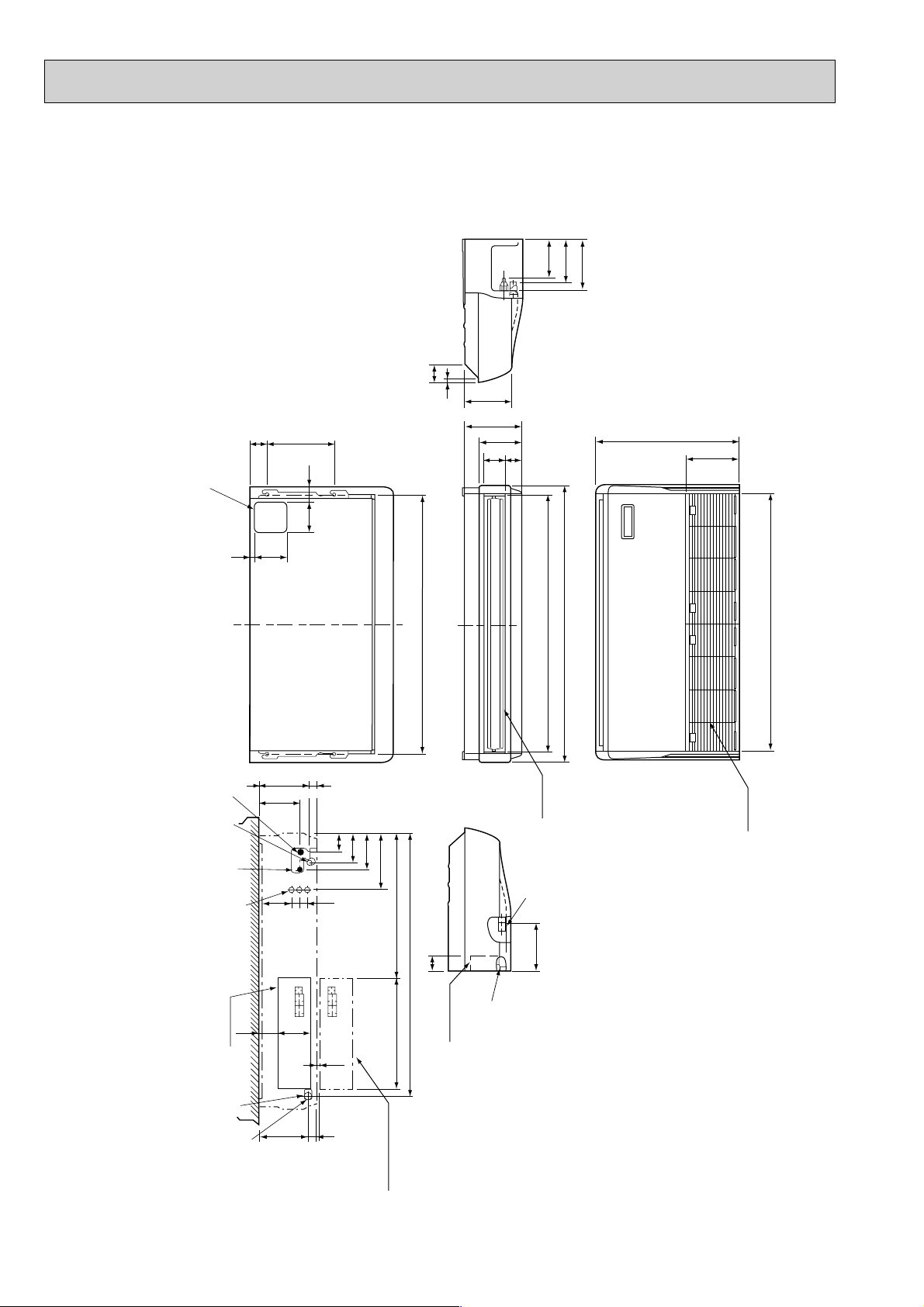

Page 9

9

PCFY-63VGM

1240 (suspension bolt pitch)

140

150

320 80

17

70

6

1290

1214

210

180

81 76

1310

Air outlet

1228

680

254

Air intake

85

182

201

241

15

157

(3/8F liquid)

(5/8F gas)

(Drainage)

3

2

8

5

1

4

Electnical box

When electrical

box is pulled

down

[ FRONT VIEW ]

Celling

32

179

161

38

3879

42

6~7

525

1235

416

263

171

138

86

131

175 1

46

1

2

Electrical box

70

226

Gap to ceiling

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wining arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

Page 10

10

1228

680

254

Air intake

1214

270

207

81 96

1310

Air outlet

1240 (suspension bolt pitch)

140

150

320 80

17

70

6

87

182

198

245

16

217

(3/8F liquid)

(5/8F gas)

(Drainage)

3

2

8

5

1

4

Electnical box

When electrical

box is pulled

down

[ FRONT VIEW ]

Celling

93

160

38

38 140

42 239

6~7

525

1235

687

263

171

138

86

192

236

1

45

1

2

Electrical box

70

229

Gap to ceiling

PCFY-100VGM

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wining arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

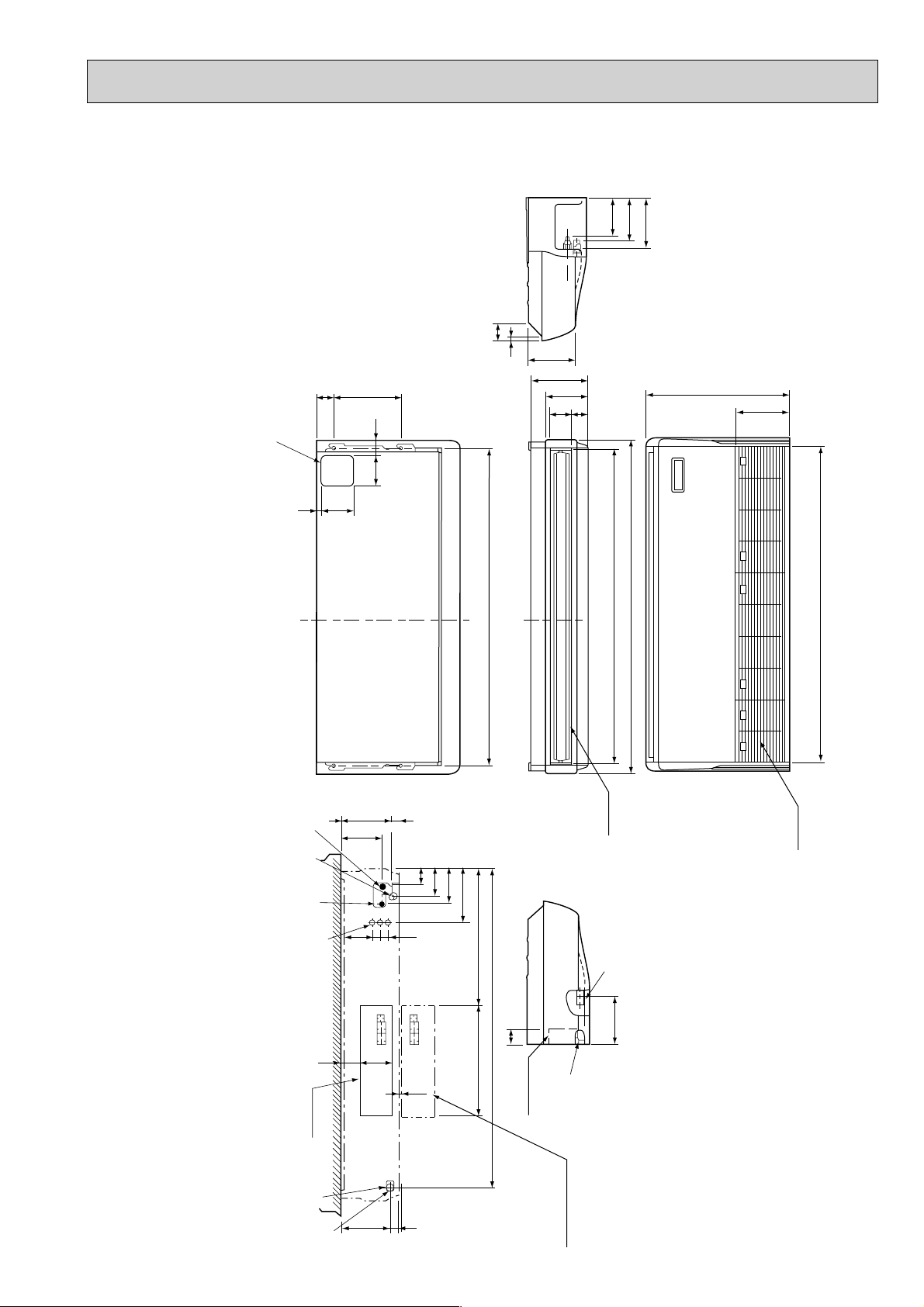

Page 11

11

PCFY-125VGM

1 Drainage pipe connection (26mm I.D.) 5 Refrigerant-pipe connection (liquid pipe side/flared connection)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper drain pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wining arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

refrigerant pipe will be only upper drain pipe arrangement.

6

(3/8F liquid)

(3/4F gas)

(Drainage)

182

198

245

87

16

320 80

70

140

150

18

217

270

207

680

81 96

254

Gap to ceiling

1

4

1

5

8

Celling

[ FRONT VIEW ]

93

Electrical box

236

192

38 140

160

1535

1620

1524

1547(suspension bolt pitch)

45

86

138

171

687

263

38

Air outlet

Air intake

2

229

1

6~7

525

1545

70

Electrical box

2

3

When electrical

box is pulled

42 239

down

Page 12

12

5

WIRING DIAGRAM

MODELS : PCFY-40~125VGM WIRING DIAGRAM

SYMBOL

NAME

I.B

SYMBOL

T TRANSFORMER

DRAIN SENSOR

DRAIN WATER LIFTING-UP MACH.

FAN MOTOR (WITH INNER THERMO.)

FAN MOTOR CAPACITOR

VANE MOTOR

POWER SUPPLY TERMINAL BLOCK

TRANSMISSION TERMINAL BLOCK

LINEAR EXPANSION VALVE

CIRCUIT BOARD

MODE SELECTOR

DS

DP

MF

C1

MV

TB2

TB5

LEV

A,B

SW1(A,B)

SW5(A,B)

SW11(A,B)

SW12(A,B)

SW14(A,B)

SWA(A,B)

SWC(A,B)

INDOOR CONTROLLER BOARD

REMOTE SWITCH CONNECTOR

CENTRALLY CONTROL CONNECTOR

REMOTE INDICATION CONNECTOR

DRAIN-UP MACHINE CONNECTOR

CAPACITY CORD SWITCH

FUNCTION SELECTOR

UNIT SELECTOR

DRAIN UP MECH. RELAY

FAN MOTOR RELAY

CN32

CN51

CN52

CNP

SW2

SW3

SW4

X1

X4

F.C

ZNR

FUSE

VARISTOR

FUSE(6.3A)

FAN PHASE CONTROL

TH21

TH22

TH23

ROOM TEMPERATURE THERMISTOR

(0:/15k',25:/5.4k')

LIQUID PIPE THERMISTOR

(0:/15k',25:/5.4k')

GAS PIPE THERMISTOR

(0:/15k',25:/5.4k')

VOLTAGE SELECTOR

1ST DIGIT ADDRESS SETTING

2ND DIGIT ADDRESS SETTING

CONNCTION NO.

CEILING HEIGHT SELECTOR

OPTION SELECTOR

NAME

SYMBOL

NAME

NOTE

1.At servicing for outdoor unit,always follow the wiring diagram of outdoor unit.

2.Symbol(S) of TB5 is the shield wire connection.

3.Symbols used in wiring diagram above are, :Terminal block, :Connector.

4.The setting of the SW2 dip switches differs in the capacity.

For the detail,see the table below.

5.Please set the switch SW5 according to the power supply voltage.

Set SW5 to 240V side when the power supply is 230 and 240 volts.

When the power supply is 220 volts,set SW5 to 220V side.

MF

51 3

BLK

RED

WHT

C1

I.B

FAN1

51 3

(WHT)

X4

F.C

X4 X1

(GRN)

VANE

CN6V

6

RED

WHT

YEL

ORN

BRN

MV

BLU

WHT

RED

CNT

(WHT)

13

(RED)

ADDRESS

8

DP

CNP

(BLU)

(OPTION)

1

3

(RED)

ADDRESS

RED

BLU

AC220-240V

31

(RED)

CND

T

AC18.4V

BLU

BLU

31

CN3T

(RED)

(WHT)

(WHT)

REMOTO

LEV

SWITCH

CN32

CN60

123456

135151

(BLK)

SW4

YEL

432

WHT

0N

0FF

(WHT)

GAS

LIQUID

CN29 CN21

12 2 1

13 2 1

TH23

SW3SW2

1

6

BLU

RED

ORN

BRN

56123456 1234

LEV

TH22

LED5LED2LED1LED3LED4

(RED)

DRAIN

CN50

(RED)

INTAKE

CN20

TH21

CN2M

1

(BLU)

2

M-NET

12345

12

RED

BLU

FUSE

(WHT)

REMOTE

INDICATION

CN52

0N

0FF

12341234567856 1234

1

6.3A

250V

ZNR

(WHT)

CENTRALLY

CONTROL

CN51

1234567891023456

X1

CN42CN81

See fig:*1

4

TO NEXT INDOOR UNIT

TB2

L

N

GRN/YEL

BLU

BLU

MODELS

PCFY-100,125VGM

(GRN)

VANE

CN6V

56 1234

RED

ORN

BRN

56 1234

PULL BOX

FUSE(15A)

BREAKER(15A)

POWER SUPPLY

~/N 220-240VÅ@50Hz

TB5

S(SHIELD)

{

M2

TO OUTDOOR UNIT

BC CONTROLLER

M1

REMOTE CONTROLLER

DC24-30V

6

BLU

WHT

YEL

MV

(RED)

DRAIN

54

GRY

CN50

3

1

2

BLK

DS(OPTION)

Models SW2

PCFY-40VGM

PCFY-100VGM

A.B

OFF

3RD

DIGIT

SW5

220V 240V

SW1

ON

12345678910

SW12 SW11

00

2ND

DIGIT

ON

OFF

ON

OFF

1ST

DIGIT

654321

SW2Models

123456

SWA

ADDRESS

3

2

1

SWC

CONNECTION

NO.

Models

PCFY-63VGM

Models

PCFY-125VGM

4

(RED)

3

CN43

2

1

(RED)

ADDRESS

CN82

SW14

0

OFF

OFF

8

7

6

5

4

3

2

1

SW2

ON

SW2

ON

123456

654321

Page 13

13

6

REFRIGERANT SYSTEM DIAGRAM

Strainer (#50mesh)

Strainer (#100mesh)

Strainer (#100mesh)

Heat exchanger

Room temperature thermistor TH21

Gas pipe thermistor TH23

Liquid pipe thermistor TH22

Linear expansion valve

Gas pipe

Flare connection

Gas pipe

PCFY-40VGM

{12.7<1/2F>

PCFY-63VGM

{15.88<5/8F>

PCFY-100,125VGM

{19.05<3/4F>

Liquid pipe

{6.35<1/4F> {9.52<3/8F> {9.52<3/8F>

Capacity

Item

Page 14

14

7

TROUBLE SHOOTING

7-1. How to check the parts PCFY-VGM

Room temperature thermistor

(TH21)

Liquid pipe thermistor (TH22)

Gas pipe thermistor (TH23)

Parts name

Check points

Trans

Fan motor

Linear expansion

valve

Drain-up mechanism

(Optional)

Drain sensor

(Optional)

Vane motor

Disconnect the connector, then measure the resistance using a tester.

(Sorrounding temperature 10°C~30°C)

Disconnect the connector and measure the resistance using a tester.

Measure the resistance between the terminals using a tester.

Disconnect the connector then measure the resistance valve using a tester.

Refer to the next page for a detail.

Measure the resistance between the terminals using a tester.(Surrounding temperature

20;~30;)

Measure the resistance between the terminals using a tester.(Surrounding temperature

20;~30;)

Measure the resistance between the terminals using a tester.

(Refer to the thermistor)

(Refer to the thermistor)

Normal

4.3k'~9.6k'

Abnormal

Open or short

Normal

92'

Abnormal

Open or short

CNT(1)-(3)

Normal

App.45'

CN3T(1)-(3)

App.1'

Abnormal

Open or short

Motor terminal

or

Relay connector

Normal

PCFY-VGM

40 63 100 125

Abnormal

Red-Black

70.6' 45.0' 43.7' 20.4'

Open or short

White-Black

69.6' 44.8' 53.3'

Connector

Normal

PCFY-40VGM PCFY-63VGM

Abnormal

Brown-Yellow

186~214' 140~160'

Open or short

Brown-Blue

Brown-Orange

Brown-Pink

Connector PCFY-100,125VGM Abnormal

Red-Blue

140~160'

Open or short

Red-Yellow

Red-Pink

Red-Orange

20.7'

(1)-(3)

Normal

82'

(4)-(5)

4.3k'~9.6k'

Abnormal

Open or short

Normal

(1)-(5)

White-Red

150' ±10%

Abnormal

Open or short

(2)-(6)

Yellow-

Blown

(3)-(5)

Orange-Red

(4)-(6)

Blue-Brown

CNT T CN3T

Red Blue

1

2

3

White

Blue

1

2

3

Relay connector

1

Red

1

White

2

2

3

Black

3

Protector

LEV

White

Yellow

Orange

Blue

Red

Brown

CN60

1

2

3

4

5

6

Gray

Gray

1

2

4

Orange

5

Red

2

Pink

Connector

Pin No.

2

Pink

4

Orange

5

Red

Connector

Pin No.

3

Yellow

3

1

2

3

4

5

61

BlueYellow Brown

Blue

1

Page 15

15

<Thermistor Characteristic graph>

Room temperature thermistor(TH21)

Liquid pipe thermistor(TH22)

Gas pipe thermistor(TH23)

Drain sensor(THD)

Thermistor R

0=15k' ±3%

Fixed number of B=3480k' ±2%

Rt=15exp { 3480( ) }

0: 15k'

10: 9.6k'

20: 6.3k'

25: 5.2k'

30: 4.3k'

40: 3.0k'

Thermistor at

lower temperature

Linear expansion valve

① Operation summary of the linear expansion valve.

• Linear expansion valve open/close through stepping motor after receiving the pulse signal from the indoor controller board.

• Valve opening can be changed in proportion to the number of pulse signal.

<Connection between the indoor controller board and the linear expasion valve>

4

[4

3

62

5

[3

2

[2

1

[1

[4

[3

[2

[1

Controller board

Drive circuit

Relay connector

Connector(CN60)

DC12V

Brown

Red

Blue

Orange

Yellow

White

5

1

3

4

6

M

4

6

2

3

5

1

Blue

Brown

Yellow

Orange

Red

White

Linear expansion valve

1

273+t

1

273

Note : Since the number of the connector at the controller board side and the relay connector are different, follow the color of

the lead wire.

< Thermistor at lower temperature >

50

40

30

Resistance (K")

20

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

Page 16

16

Output

(Phase)

number

Output

{1

1

ON

{2

ON

{3

OFF

{4

OFF

2

OFF

ON

ON

OFF

3

OFF

OFF

ON

ON

4

ON

OFF

OFF

ON

Closing a valve : 1 → 2 → 3 → 4 → 1

Opening a valve : 4 → 3 → 2 → 1 → 4

The output pulse shift as above order.

❈ 1. When linear expasion valve operation stops, all output phase

become OFF.

2. At phase interruption or when phase does not shift in order,

motor does not rotate smoothly and motor will lock and vibrate.

❈ When the switch is turned on, 2200 pulse opening valve signal

will be send till it goes to

A point in order to define the valve

position.

When the valve move smoothly, there is no noise or vibration

occur from the linear expansion valve : however, when the pulse

number moves from

E to A or when the valve is locked, more

noise can be hear than normal situation.

❈ Noise can be detected by placing the ear against the screw

driver handle while putting the screw driver to the linear

expansion valve.

<Output pulse signal and the valve operation>

➁

Linear expansion valve operation

➂

Trouble shooting

D

A

E

B

C

Open

extra tightning (80~100pulse)

Pulse number

2000 pulse

Open the valve

all the way

Close

Symptom

Check points

Operation circuit

failure of the micro

processor

Disconnect the connector on the controller board, then

connect LED for checking.

Pulse signal will be sending out for 10 seconds as soon as

the main switch is rurned on. If there is LRD with lights on or

lights off, it means the operation circuit is abnormal.

Countermeasures

Exchange the indoor

controller board at drive

circuit failure.

Lock at the linear

expansion valve

mechanism area.

Valve doesn’t close

completely(thermisto

r leaking)

Wrong connection of

the connector or

contact failure.

To check the linear expansion valve of the indoor unit,

operate the indoor unit in fan mode and operate other indoor

units in cooling mode then check the pipe temperature <liquid

pipe temperature> of the indoor unit by

monitorring the outdoor multi controller

board operation. During fan operation,

linear expansion valve is closed completely

and if there are some leaking, detecting

temperature of the thermistor will go lower.

If the detected temperature is much lower

than the temperature indicated in the

remote contoroller, it means the valve is not closed all the

way. It is not necessary to exchange the linear expasion

valve, if the leakage is small or does not make any trouble.

Liquid pipe

thermistor

Linear

expansion

valve

Morter will idle and make ticking noise when motor is

operated while the linear expansion valve is locked. This

ticking noise is the sign of the abnormality.

Check the color of lead wire and missing terminal of the

connector.

Check the color of lead wire and missing terminal of the

connector.

Exchange the linear

expansion valve.

Exchange the linear

expasion valve.

If large amount of

thermistor is leaked,

exchande the linear

expasion valve.

Disconnect the connecttor

at the controller board,

then check the continuity.

Measure the resistance between the each coil(red-white, redorange, brown-yellow, brown-blue) using atester. It is normal

if the resistance is in the range of 150 '±10%.

Short or breakage of

the motor coil of the

linear expansion

valve.

LED1S

6

5

4

3

2

1

Page 17

17

3-2. FUNCTION OF DIPSWITCH

PCFY-VGM

1

2

3

4

5

6

7

8

9

10

1~6

1

2

3

4

5

6

7

8

9

10

1~4

Thermistor<Intake temperature

detection>position

ON OFF

Filter crogging detection ProvidedNot provided

Filter life 2,500hr 100hr

Air intake Effective Not effective

Remote indication switching Thermostat ON signal indication Fan output indication

Humidifier control

Always operated while the heat is ON

Operated depends on the condition

Air flow st Low Extra low

Heat thermostat OFF Setting air flow Reset to SW1-7

Auto reset function Effective Not effective

Power ON/OFF Effective Not effective

Heat pump/Cool only Cooling only Heat pump

Louver Available Not available

Vane Available Not available

Vane swing function Available Not available

Vane holizontal angle Second setting First setting

Vane cooling limit angle setting

Horizontal angle Down B,C

Effective Not effective

Heater 4deg. up Not effective Effective

Superheat setting temparature

5deg 2deg

Sybcool setting 15deg 10deg

ON

OFF

ON

OFF

123

1234

ON

OFF

12345678910

ON

OFF

12345678910

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

MODELS SW2 MODELS SW2 MODELS SW2

PCFY-40VGM PCFY-63VGM

PCFY-100VGM

PCFY-125VGM

Address board

<At delivery>

Indoor controller board

Indoor controller board

Indoor controller board

<At delivery>

<At delivery>

SW4

Unit

Selection

SW3

Function

Selection

SW2

Capacity

code

setting

SW1

Mode

Selection

Switch Pole

Function Remarks

Operation by switch

Bult-in remote controller

Indoor unit

Indoor linear expansion

valve opening

(Note1) Fan operation at Heating

mode

(Note2) Heater thermo ON is

operating.

(Note3) SW1-7=OFF, SW1-8=ON

→Setting air flow.

SW1-7=OFF, SW1-8=ON

→Indoor fan stop.

Set while the unit is off.

<At delivery>

Set for each capacity.

Set while the unit is off.

(Note1) At cooling mode, each

angle can be used only 1

hour.

Set while the unit is off.

Page 18

18

Address board

Address board

Address board

Address board

Operation by switchSwitch Remarks

❈ Ceiling height can be changed depends on

SWB setting.

<At delivery>

<At delivery>

<At delivery>

<At delivery>

1~3

SWA

Set the

Ceiling

height

2

SWC

Option

SW11

1st digit

address

setting

SW12

2st digit

address

setting

Rotary switch

SW14

Conne-

ction

No.

Setting

Rotary switch

When attach the optional high performance

filter elementsm (filter casement) to the unit,

be sure to attach it to the option side in order

to prevent the airflow reducing.

Address setting should be done when network

remote controller (OAR-F25M) is being used.

This is the switch to be used when the indoor

unit is operated with R2, R3 series outdoor

unit as a set.

Address can be set while the

unit is stopped.

220V 240V

220V 240V

Address board

<At delivery>

2

SW5

Voltage

selection

If the unit is used at the 230V or 240V area,

set the voltage to 240V.

If the unit is used at the 220V, set the voltage

to 220V.

(High)

(Standard)

(Low)

Option

standard

SW12

0

1

9

2

8

3

7

4

6

5

10

3

2

1

SW11

0

9

8

7

6

5

1

3

2

1

Option

1

2

3

4

SW12

SW11

0

0

1

9

8

7

6

5

1

9

2

8

3

7

4

6

5

2

3

4

SW14

0

1

F

E

D

C

B

A

8

9

2

3

4

5

6

7

SW14

0

1

2

F

3

E

4

D

5

C

6

B

7

A

8

9

Page 19

19

DISASSEMBLY INSTRUCTIONS

8

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

1. Removing the air intake grill

(1) Slide the intake grill holding knobs (at two locations)

backward to open the intake grill.

(2) When the intake grill left open, push the stoppers on the

rear hinges (at two locations) to pull out the intake grill.

2. Removing the electrical box

(1) Remove the air intake grill.

(2) Remove the screw from the beam and remove the beam.

(3) Remove the screws from the electrical cover, and remove

the electrical cover.

(4) Disconnectors including CN6V and CN21.

(5) Remove the screws from the electrical box and pull out

the electrical box.

<Electrical parts in the electrical box>

Terminal block (for power supply)

Terminal block (for in/outdoor connecting wire)

Operation condenser

Indoor control board

Power Trans

Figure 1

Figure 2

Photo 1

slide

intake grill

intake grill

hoiding knobs

shinges

Pull out the intake grill

electrical cover

screw(electrical cover)

screw(electrical box)

Slide to the left

beam

clamp

INDOOR UNIT PCFY-63VGM

Operation

condenser

Power

trans

Indoor

control

board

terminal

block

(in / out conncting)

Addoress board

Terminal

block(power supply)

Page 20

20

Figure 2

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

3. Removing the fan motor

(1) Remove the air intake grill.

(2) Disconnect the fan motor guard.

(3) Unscrew screws for removing the motor guard.

(4) Unscrew screws for removing the fan guard.

(5) Remove the screw for removing the motor support at both

left and right side.

(6) Loosen the set screws at the fan motor side of the

connecting joint.

(7) Slide the fan motor to the left side and pull it out.

4. Removing the sirocco fan

(1) Remove the air intake grill.

(2) Remove 1 beam.

(3) Unscrew screws for removing the motor guard.

(4) Unscrew screws for removing the fan guard.

(5) Remove the lower casing while pressing the stoppers at

upper side of the casing.

(6) Loosen the set screws at the connecting joint.

(7) Remove the sirocco fan and shaft together by sliding the

shaft to the left.

(Note)

Make sure that the upper side casing is snaped to the fan

plate securely with catch.

5. Removing the side panel

(1) Remove the air intake grill.

(2) Remove the screw from the side panel, and remove the

side panel by sliding the panel to the front.

screw

side panel

sliding the panel

to the front

Photo 2

Photo 3

Screws

Motor

Motor guard

Motor support

Connecting joint

Motor guard

Fan guard

Connecting

joint

Sirocco fan

Bearing

CasingMotor

Page 21

21

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

7. Removing the pipe thermistor

(1) Remove the air intake grill.

(2) Remove the right side panel.

(3) Remove the relay connector of the pipe thermistor.

(4) Remove the screw, and remove the check panel.

(5) Extract the pipe thermistor from the holder.

<Caution for the installation>

There is a possibility for the short circuit when connector gets

wet by water through the thermistor lead wire.

Therefore, lead wire of the pipe thermistor should be traped

as shown in the picture.

(5)Gas pipe thermistor is inserted to the holder of the gas

pipe (heater)

8. Removing the under panel

(1) Remove the air intake grill.

(2) Remove the beam.

(3) Remove the side panel (right and left).

(4) Unscrew the screws of the under panel, then remove the

lower panel.

❈ Weight of the lower panel : app. 2kg.

6. Removing the vane motor

(1) Remove the air intake.

(2) Remove the left side panel.

(3) Remove the relay connector of vane motor.

(4) Remove the electrical box.

(5) Remove the screws of vane motor, then remove vane

motor.

(Note)

Connect the lead wires and connectors properly and place

them in the proper position so that the wires are not pinched

by other parts.

Photo 5

Photo 6

Photo 4

Photo 7

Screw

Screw

Screw

Hold Pipe thermistor Trap

Check

panel

Relay connector of

the vane motor

Vane motor

Under panel

Relay connector of

the pipe thermistor

Left side

panel

Check panel

Liquid pipe thermistor

Gas pipe (Header)

Gas pipe thermistor

Page 22

22

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

9. Removing the drain pan

(1) Remove the air intake grill.

(2) Remove the beam.

(3) Remove the side panel (right and left).

(4) Remove the under panel. Remove the screws of the right

and left side drain pan.

(5) Remove the insiation in center of the drain pan, and after

removing the screw, remove the drain pan.

(Note)

Please aware that there might be drain left in the drain pan

when you remove the drain pan.

10. Removing the guide vane

(1) Remove the intake grill.

(2) Remove the beam.

(3) Remove the side panel (right and left).

(4) Remove the under panel.

(5) Remove the drain pan.

(6) Remove the screw from the guide vane, then remove the

guide vane.

11. Removing the Auto vane

(1) Remove the intake grill.

(2) Remove the left side panel.

(3) Remove the left side box.

(4) Remove the under panel.

(5) Remove the screw from the auto vane.

(6) Slide the auto vane to the right side and pull the auto vane

out.

Photo 8

Screw

Screw

Screw

Guide vane

Auto vane

Drain pan

Screw

Drain pan

Screw

(Insulation)

Photo 9

Photo 10

Page 23

23

No.

Parts No. Parts Name Specifications

63

VGM

100

VGM

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

Q'ty / set Price

1

2

3

4

5

6

7

8

9

10

11

12

CONTROLLER BOARD

FUSE

TRANSFORMER

ADDRESS BOARD

CONTROL BOX

CAPACITOR

RUN CAPACITOR

RUN CAPACITOR

TERMINAL BLOCK

TERMINAL BLOCK

ADDRESS CABLE

BOX COVER

REMOTE CONTROLLER

REMOTE CONTROLLER

CABLE

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

40

VGM

1

1

1

1

1

1

1

1

1

1

1

1

(BG00N015G12)

(BG02A804G12)

(BG02A804G13)

(BG02A804G14)

I.B

F1,2

T

A.B

C

C

C

TB2

TB4

R.B

250V 6.3A

3 440V

3P(L,N,;)

3P(1,2,3)

10m

Remarks

(Drawing No.)

125

VGM

1

1

1

1

1

1

1

1

1

1

1

1

T7W B06 310

T7W 520 239

T7W B06 260

T7W B01 294

—

R01 30L 255

T7W 39J 255

T7W 43J 255

T7W A14 716

T7W A02 716

R01 05A 304

—

—

—

T7W B00 713

T7W A00 305

10

8

9

4

11

12

1

ELECTRICAL PARTS

PCFY-40VGM

PCFY-63VGM

PCFY-100VGM

PCFY-125VGM

PARTS LIST

9

Page 24

24

STRUCTURAL PART

PCFY-40VGM

23

5

17

7

8

1

962632024

25

18

14

11

10

27

161241513192

22

Page 25

25

No.

Parts No. Parts Name Specifications

1

R01 17J 661

2

R01 17J 662

3

R01 17J 669

4

R01 17J 676

5

R01 17J 500

6

R01 18J 500

7

R01 17J 691

8

R01 18J 691

9

R01 17J 054

10

R01 17J 651

11

R01 17J 085

12

R01 18J 086

13

R01 29J 223

14

R01 17J 067

15

R01 17J 068

16

R01 17J 002

17

R01 17J 061

18

R01 17J 808

19

R01 17J 809

20

R01 17J 070

21

R01 17J 523

22

T7W B06 665

23

R01 57N 666

24

R01 17J 668

25

26

27

—

—

—

RIGHT SIDE PANEL

LEFT SIDE PANEL

UNDER PANEL

REAR PANEL

L.L FILTER

L.L FILTER

GRILLE ASSY

GRILLE ASSY

GRILLE CATCH

FRONT PANEL

G.V ASSY-6L

G.V ASSY-6F

VANE MOTOR

RIGHT SIDE BOX

LEFT SIDE BOX

AUTO VANE

GRILLE HINGE

RIGHT LEG

LEFT LEG

W.BOARD CASE

JOINT SOCKET

S.PLATE-R

S.PLATE-L

SERVICE PANEL

BEAM(GA)

REAR SUPPORT

VANE SUPPORT

Q'ty / set Price

PCFY-40

VGM

Remarks

(Drawing No.)

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

1

1

1

1

1

1

1

1

4

1

1

1

1

MV

1

1

1

4

1

1

1

1

1

1

1

2

1

1

(BG17H464H08)

(BG02H454H04)

(BG02R321G07)

Page 26

26

STRUCTURAL PART

PCFY-63VGM

PCFY-100VGM

22

18

2

4

8

9 6 3 7 19 25 24 21

1

17

23

10

5

15

26

1214131116

Page 27

27

No.

Parts No. Parts Name Specifications

Q'ty / set Price

PCFY-63

VGM

PCFY-100

VGM

Remarks

(Drawing No.)

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

R01 17J 661

1

R01 35J 661

R01 17J 662

2

R01 35J 662

3

R01 17J 500

R01 29J 676

4

R01 35J 676

R01 29J 651

5

R01 36J 651

6

R01 17J 691

7

R01 29J 669

8

R01 17J 061

9

R01 17J 054

R01 17J 067

10

R01 35J 067

R01 17J 068

11

R01 35J 068

12

R01 17J 085

13

R01 18J 086

14

R01 29J 087

R01 29J 002

15

R01 35J 002

R01 29J 223

16

R01 35J 223

17

R01 17J 808

18

R01 17J 809

19

R01 17J 070

20

R01 17J 523

T7W B06 665

21

T7W B07 665

R01 18J 666

22

R01 35J 666

23

R01 17J 668

24

25

26

—

—

—

—

RIGHT SIDE PANEL

RIGHT SIDE PANEL

LEFT SIDE PANEL

LEFT SIDE PANEL

L.L FILTER

REAR PANEL

REAR PANEL

FRONT PANEL

FRONT PANEL

GRILLE ASSY

UNDER PANEL

GRILLE HINGE

GRILLE CATCH

RIGHT SIDE BOX

RIGHT SIDE BOX

LEFT SIDE BOX

LEFT SIDE BOX

G.V ASSY-6R

G.V ASSY-6L

G.V ASSY-6C

AUTO VANE

AUTO VANE

VANE MOTOR

VANE MOTOR

RIGHT LEG

LEFT LEG

W.BOARD CASE

JOINT SOCKET

S.PLATE-R

S.PLATE-R

S.PLATE-L

S.PLATE-L

SERVICE PANEL

BEAM(GA)

REAR SUPPORT

VANE SUPPORT

VANE SUPPORT

1

1

1

1

2

2

1

1

1

1

2

1

4

4

2

1

4

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MV

MV

1

1

1

1

1

2

1

2

1

2

(BG17H464H08)

1

(BG02H454H04)

(BG02R321G07)

(BG02R805G05)

2

Page 28

28

STRUCTURAL PART

PCFY-125VGM

28

24

26

27

23

25

Page 29

29

No.

Parts No. Parts Name Specifications

1

R01 35J 661

2

R01 35J 662

3

R01 41J 669

4

R01 41J 676

5

R01 17J 500

6

R01 18J 500

7

R01 17J 691

8

R01 18J 691

9

R01 17J 054

10

R01 41J 651

11

R01 41J 085

12

R01 42J 086

13

R01 43J 087

14

R01 35J 223

15

R01 35J 067

16

R01 35J 068

17

R01 41J 002

18

R01 17J 061

19

R01 17J 808

20

R01 17J 809

21

R01 17J 070

22

R01 17J 523

23

T7W B07 665

24

R01 35J 666

25

R01 17J 668

26

27

28

—

—

—

RIGHT SIDE PANEL

LEFT SIDE PANEL

UNDER PANEL

REAR PANEL

L.L FILTER

L.L FILTER

GRILLE ASSY

GRILLE ASSY

GRILLE CATCH

FRONT PANEL

G.V ASSY-5R

G.V ASSY-5L

G.V ASSY-5C

VANE MOTOR

RIGHT SIDE BOX

LEFT SIDE BOX

AUTO VANE

GRILLE HINGE

RIGHT LEG

LEFT LEG

W.BOARD CASE

JOINT SOCKET

S.PLATE-R

S.PLATE-L

SERVICE PANEL

BEAM(GA)

REAR SUPPORT

VANE SUPPORT

Q'ty / set Price

PCFY-125

VGM

Remarks

(Drawing No.)

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

1

1

1

1

2

1

2

1

4

1

1

1

2

1

MV

1

1

1

4

1

1

1

1

1

1

1

3

1

3

(BG17H464H08)

(BG02H454H04)

(BG02R805G05)

Amount

Page 30

30

No.

Parts No.

Parts Name

Specifications

PCFY-40

VGM

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

Q'ty / set

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

FAN MOTOR

MOTOR LEG

PIECE (MOTOR)

CASING

SIROCCO FAN

GAS PIPE THERMISTOR

DRAIN PAN ASSY

ROOM TEMPERATURE THERMISTOR

HEAT EXCHANGER

DRAIN PLUG

FAN GUARD

FAN GUARD

FAN GUARD

LIQUID PIPE THERMISTOR

EXPANSION VALVE

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

MF

TH21

TH23

TH22

LEV

[R&L:2

Q'ty

/

set

]

Remarks

(Drawing No.)

T7W 23J 762

R01 17J 130

R01 43E 126

T7W B06 110

R01 17J 114

R01 17J 202

R01 17J 529

R01 18J 202

R01 57N 480

R01 17J 524

T7W 17J 675

T7W 18J 675

T7W 19J 675

R01 57N 202

R01 P21 401

FAN AND HEATER PARTS

PCFY-40VGM

Part numbers that are circled are not shown in the figure.

9

6

14

4

4

3

5

8

5

13

10

7

12

11

15

Page 31

31

FAN AND HEATER PARTS

PCFY-63VGM

11

13

15

16

3

7

9

19

6

10

8

18

12

17

14

20

No.

Parts No.

1

T7W 30J 762

2

R01 29J 116

3

R01 29J 100

4

R01 705 103

5

R01 29J 130

6

R01 29J 114

7

R01 33J 114

8

T7W B06 110

9

R01 17J 202

10

R01 18J 202

11

R01 61N 480

12

R01 29J 529

13

R01 17J 524

14

R01 29J 145

15

T7W 20J 675

16

T7W 21J 675

17

T7W 18J 675

18

R01 43E 126

19

R01 57N 202

20

R01 P21 401

Parts Name

FAN MOTOR

FAN JOINT

SHAFT(FAN)

SLEEVE BEARING

MOTOR LEG

SIROCCO FAN

SIROCCO FAN

CASING

GAS PIPE THERMISTOR

ROOM TEMPERATURE THERMISTOR

HEAT EXCHANGER

DRAIN PAN ASSY

DRAIN PLUG

BEARING SUPPORT

FAN GUARD

FAN GUARD

FAN GUARD

PIECE(MOTOR)

LIQUID PIPE THERMISTOR

EXPANSION VALVE

Specifications

Q'ty

[R&L:2

/

set

]

Q'ty / set

PCFY-63

VGM

1

1

1

1

1

2

1

3

1

1

1

1

1

1

1

2

1

1

1

1

Remarks

(Drawing No.)

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Price

Amount

MF

TH21

TH23

TH22

LEV

Page 32

32

No.

Parts No.

Parts Name

Specifications

PCFY-100

VGM

Wiring

Diagram

Symbol

Recommended

Q'ty

Unit

Amount

Q'ty / set

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

FAN MOTOR

FAN JOINT

SHAFT

SLEEVE BEARING

MOTOR LEG

SIROCCO FAN

SIROCCO FAN

CASING

GAS PIPE THERMISTOR

ROOM TEMPERATURE THERMISTOR

HEAT EXCHANGER

DRAIN PAN ASSY

DRAIN PLUG

BEARING SUPPORT

FAN GUARD

FAN GUARD

FAN GUARD

PIECE(MOTOR)

LIQUID PIPE THERMISTOR

EXPANSION VALVE

1

1

1

1

1

2

1

3

1

1

1

1

1

1

1

2

1

1

1

1

MF

TH21

TH23

TH22

LEV

[R&L:2

Q'ty

/

set

]

Remarks

(Drawing No.)

T7W 39J 762

R01 29J 116

R01 29J 100

R01 705 103

R01 35J 130

R01 35J 114

R01 39J 114

T7W B07 110

R01 17J 202

R01 18J 202

R01 67N 480

R01 35J 529

R01 17J 524

R01 35J 145

T7W 22J 675

T7W 23J 675

T7W 24J 675

R01 43E 126

R01 57N 202

R01 P25 401

FAN AND HEATER PARTS

PCFY-100VGM

11

18

10

13

15

16

19

3

8

6

9

7

12

17

14

20

Page 33

33

No.

Parts No. Parts Name

Specifications

PCFY-125

VGM

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Unit

Amount

Q'ty / set

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

FAN MOTOR

FAN JOINT

SHAFT

SLEEVE BEARING

MOTOR LEG

SIROCCO FAN

SIROCCO FAN

SIROCCO FAN

CASING

GAS PIPE THERMISTOR

ROOM TEMPERATURE THERMISTOR

HEAT EXCHANGER

DRAIN PAN ASSY

DRAIN PLUG

BEARING SUPPORT

FAN GUARD

FAN GUARD

FAN GUARD

FAN GUARD

PIECE(MOTOR)

LIQUID PIPE THERMISTOR

EXPANSION VALVE

1

1

1

1

1

1

2

1

4

1

1

1

1

1

1

1

2

1

1

1

1

1

MF

TH21

TH23

TH22

LEV

[R&L:2

Q'ty

/

set

]

Remarks

(Drawing No.)

T7W 43J 762

R01 29J 116

R01 29J 100

R01 705 103

R01 41J 130

R01 41J 114

R01 39J 114

R01 35J 114

T7W B07 110

R01 17J 202

R01 18J 202

R01 69N 480

R01 41J 529

R01 17J 524

R01 35J 145

T7W 25J 675

T7W 23J 675

T7W 24J 675

T7W 26J 675

R01 43E 126

R01 57N 202

R01 P25 401

FAN AND HEATER PARTS

PCFY-125VGM

12

10

4·15

18

21

13

14

19

16

6

9

7

8

11

17

20

22

Page 34

HEAD OFFICE MITSUBISHI DENKI BLDG.MARUNOUCHI TOKYO100 TELEX J24532 CABLE MELCO TOKYO

CCopyright 1997 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD.

Issued in Feb. 1998. No. OC0122 Revised edition-A 60

Issued in Mar. 1997. No. OC0122 1700

Printed in Japan

New publication, effective Feb. 1998

Specifications subject to change without notice

Loading...

Loading...