Mitsubishi PCA-RP71HAQ, PCA-RP71HAQ-ER, PCA-RP125HAQ Service Manual

SERVICE MANUAL

No. OCH492

REVISED EDITION-A

INDOOR UNIT

REMOTE CONTROLLER

(Option)

[Service Ref.]

PCA-RP71HAQ

PCA-RP71HAQ-ER

PCA-RP125HAQ

CONTENTS

1. REFERENCE MANUAL

...................................

2

2. SAFETY PRECAUTION

...................................

3

3. PARTS NAMES AND FUNCTIONS

.................

6

4. SPECIFICATIONS

...........................................

10

5. NOISE CRITERION CURVES

........................

11

6. OUTLINES AND DIMENSIONS

......................

12

7. WIRING DIAGRAM

.............................................

14

8. REFRIGERANT SYSTEM DIAGRAM

.............

15

9. TROUBLESHOOTING

....................................

16

10. SPECIAL FUNCTION

.....................................

27

11. DISASSEMBLY PROCEDURE

.......................

32

ON/OFF

TEMP.

July 2014

Model name

indication

Indoor unit

[Model Name]

PCA-RP71HAQ

PCA-RP125HAQ

PARTS CATALOG (OCB492)

Notes:

• This manual describes service

data of the indoor units only.

• RoHS compliant products have

<G> mark on the spec name

plate.

• Please void OCH492.

Revision:

•

Added

PCA-RP71HAQR-ER in

REVISED EDITION-A.

• Some descriptions have been

modified.

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT-TYPE, AIR CONDITIONERS

2

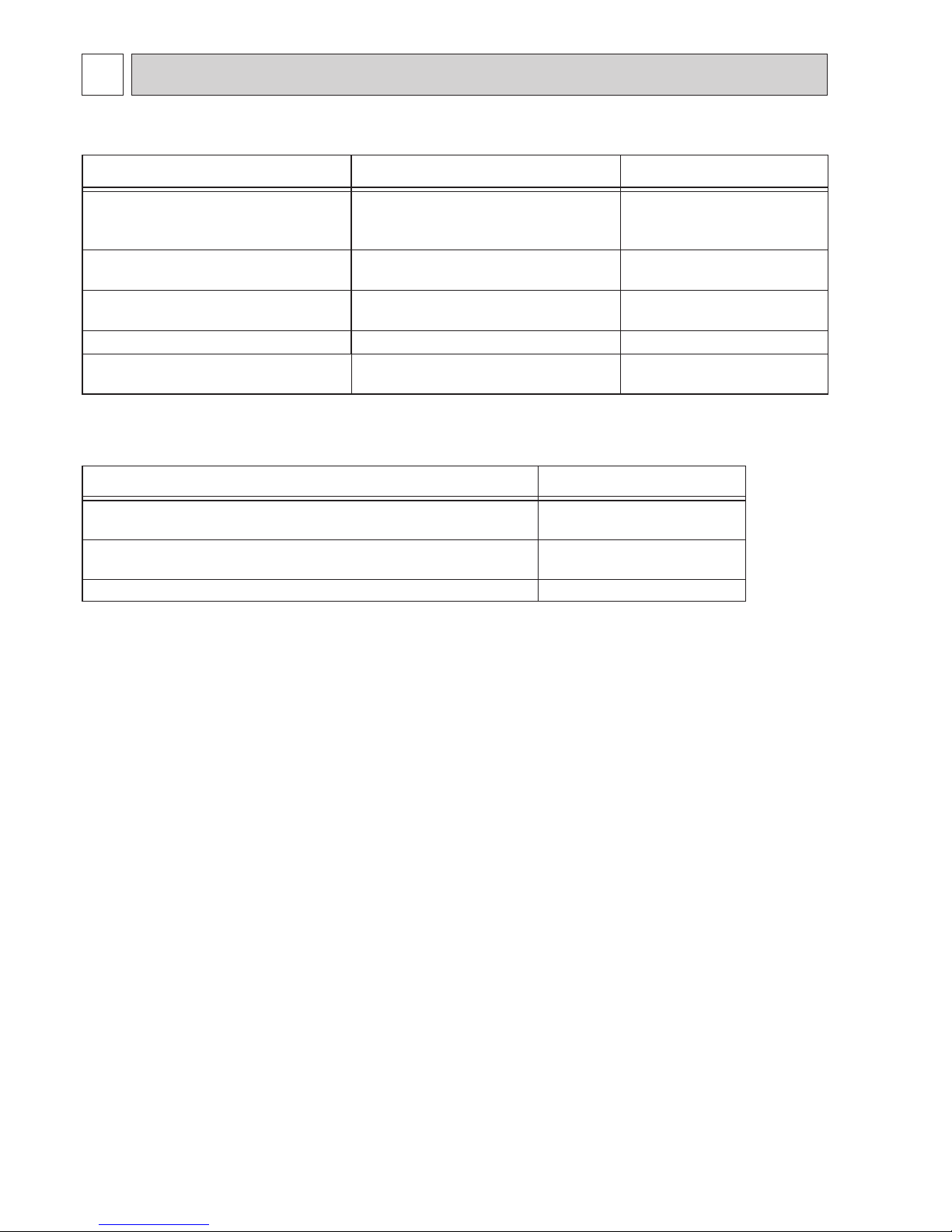

1-1. OUTDOOR UNIT’S SERVICE MANUAL

1-2. TECHNICAL DATA BOOK

1

REFERENCE MANUAL

Model Name Service Ref. Service Manual No.

PUHZ-RP71VHA4

PUHZ-RP125/140VKA

PUHZ-RP125/140/250YKA

PUHZ-RP71VHA4

PUHZ-RP125/140VKA

PUHZ-RP125/140/250YKA

OCH451

OCB451

PU(H)-P71VHAR3

PU(H)-P71/125/140YHAR3

PU(H)-P71VHAR3.UK

PU(H)-P71/125/140YHAR3.UK

OC379

PUHZ-P125/140VHA3R2

PUHZ-P125/140YHAR1

PUHZ-P125/140VHA3R2.UK

PUHZ-P125/140YHAR1.UK

OCH415/OCB415

PUHZ-P250YHA3R2 PUHZ-P250YHA3R2 OCH424/OCB424

PUHZ-ZRP71VHA PUHZ-ZRP71VHAR1(-ER)

OCH527

OCB527

Series (Outdoor unit) Manual No.

PUHZ-RP • HA4

PUHZ-RP • KA

OCS16

PUHZ-P • VHA3

PUHZ-P • YHAR3

OCS17

PUHZ-ZRP • VKA OCS24

OCH492A

33

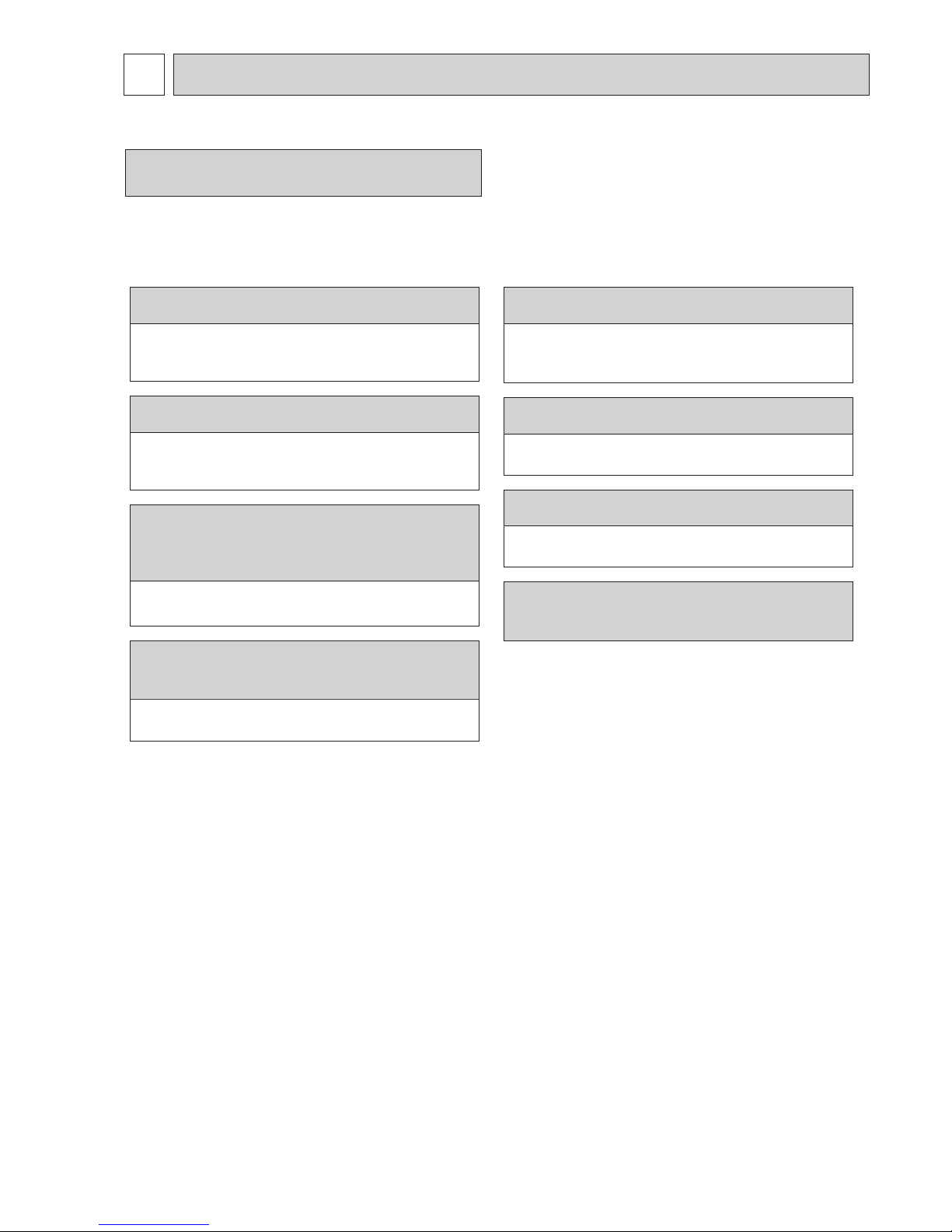

SAFETY PRECAUTION

2

Cautions for units utilising refrigerant R407C

2-2. CAUTIONS RELATED TO NEW REFRIGERANT

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping

contains a large amount of chlorine which may cause the

lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.)

inside the piping and joints, deterioration of the lubricant

will result.

If large amount of mineral oil enter, that can cause

deterioration of refrigerant oil, etc.

Use liquid refrigerant to charge the system.

If gas refrigerant is used to seal the system, the composition

of the refrigerant in the cylinder will change and performance

may drop.

Do not use a refrigerant other than R407C.

If another refrigerant (R22, etc.) is used, the chlorine in the

refrigerant may cause the lubricant deterioration.

Use a vacuum pump with a reverse flow check valve.

The vacuum pump oil may flow back into the refrigerant

cycle and cause the lubricant deterioration.

If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may result.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Store the piping to be used indoors during

installation, and keep both ends of the piping

sealed until just before brazing. (Leave elbow

joints, etc. in their packaging.)

The refrigerant oil applied to flare and flange

connections must be ester oil, ether oil or

alkylbenzene oil in a small amount.

2-1. ALWAYS OBSERVE FOR SAFETY

Before obtaining access to terminal, all supply

circuits must be disconnected.

OCH492A

4

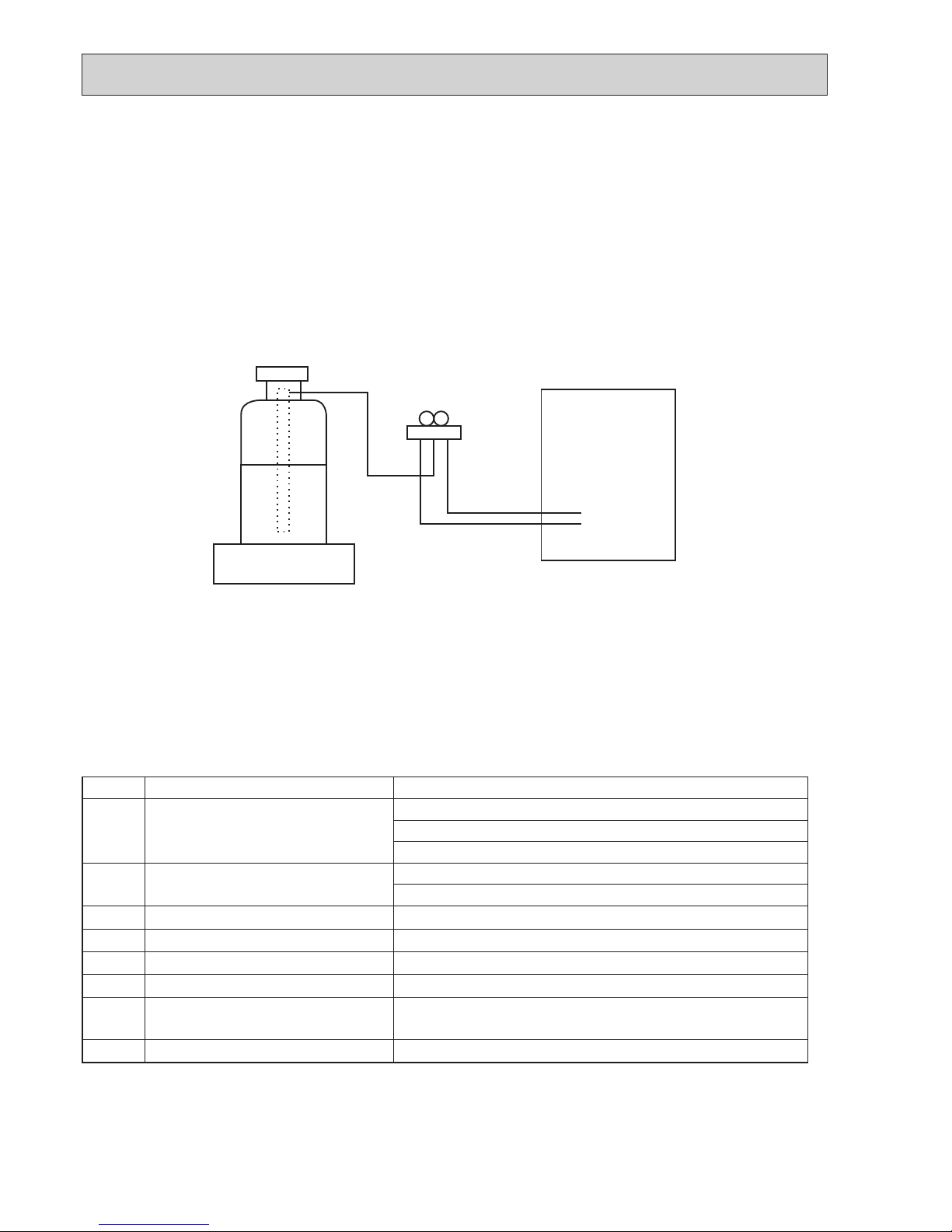

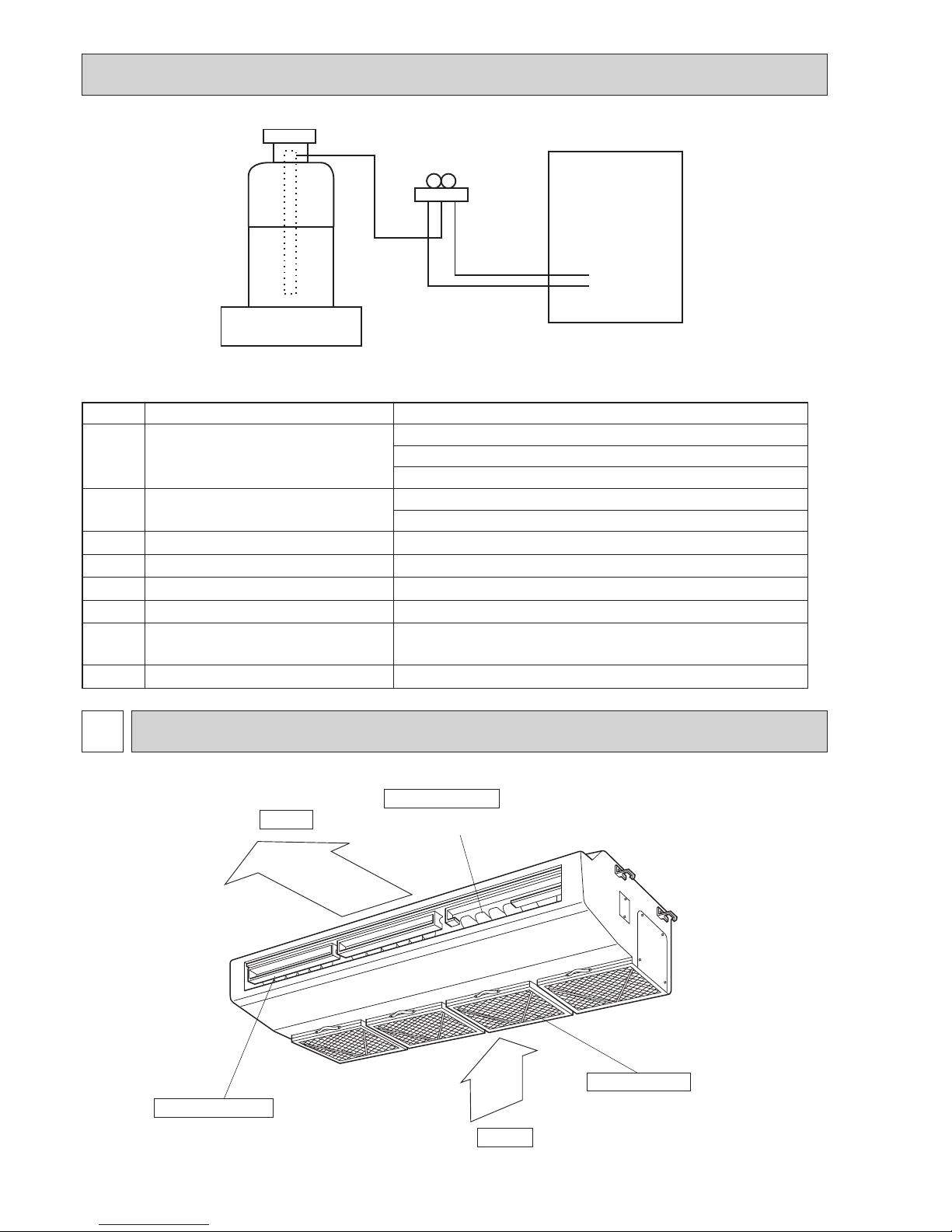

[3] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

[2] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

· R407C cylinder available on the market has a syphon pipe.

· Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

· After recovering the all refrigerant in the unit, proceed to working.

· Do not release the refrigerant in the air.

· After completing the repair service, recharge the cycle with the specified amount of liquid refrigerant.

Gravimeter

Unit

[1] Cautions for service

· After recovering the all refrigerant in the unit, proceed to working.

· Do not release refrigerant in the air.

· After completing the repair service, recharge the cycle with the specified amount of liquid refrigerant.

No. Tool name Specifications

1

Gauge manifold · Only for R407C

· Use the existing fitting SPECIFICATIONS. (UNF7/16)

· Use high-tension side pressure of 3.43MPa·G or over.

2

Charge hose · Only for R407C

· Use pressure performance of 5.10MPa·G or over.

3

Electronic scale

—

4

Gas leak detector

· Use the detector for R134a or R407C.

5

Adaptor for reverse flow check

· Attach on vacuum pump.

6

Refrigerant charge base

—

7

Refrigerant cylinder · For R407C · Top of cylinder (Brown)

· Cylinder with syphon

8

Refrigerant recovery equipment

—

OCH492A

5

Cautions for units utilising refrigerant R410A

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Store the piping to be used during installation

indoors, and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

In case of using the existing pipes for R22, be careful with

the followings.

· For RP71VHA3 and RP125 be sure to perform

replacement operation before test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22, etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil, etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil, etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil, etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil, etc.

The refrigerant oil applied to flare and flange

connections must be ester oil, ether oil or

alkylbenzene oil in a small amount.

Make sure that the inside and outside of refrigerant piping is clean and it has no contaminants

such as sulfur, oxides, dirt, shaving particles, etc,

which are hazards to refrigerant cycle.

In addition, use pipes with specified thickness.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the

unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the

spec labels provided with our products.

We will not be held responsible for mechanical failure,

system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

Use the specified refrigerant only.

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

OCH492A

6

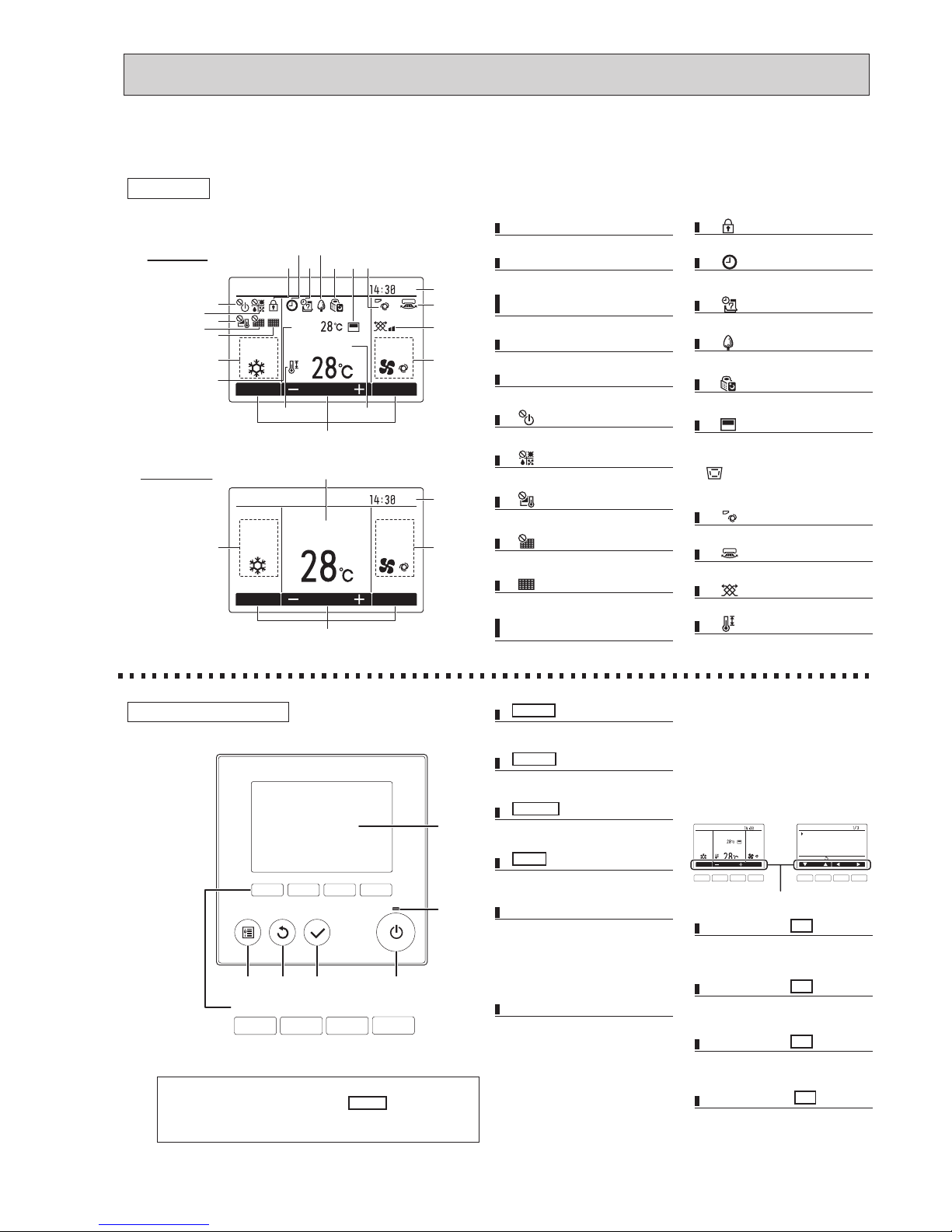

3

PARTS NAMES AND FUNCTIONS

3-1. Indoor (Main) Unit

Air outlet

Air intake

Oil filter (Air intake)

It prevents oil from

getting into the unit.

Left/right guide vanes

Change the direction of airflow

from the horizontal blower.

Up/down guide vanes

Change the direction of airflow from the

vartical blower.

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

Gravimeter

Unit

No. Tool name Specifications

1

Gauge manifold · Only for R410A

· Use the existing fitting

specifications

. (UNF1/2)

· Use high-tension side pressure of 5.3MPa·G or over.

2

Charge hose · Only for R410A

· Use pressure performance of 5.09MPa·G or over.

3

Electronic scale

—

4

Gas leak detector

· Use the detector for R134a, R407C or R410A.

5

Adaptor for reverse flow check

· Attach on vacuum pump.

6

Refrigerant charge base

—

7

Refrigerant cylinder · Only for R410A · Top of cylinder (Pink)

· Cylinder with syphon

8

Refrigerant recovery equipment

—

OCH492A

7

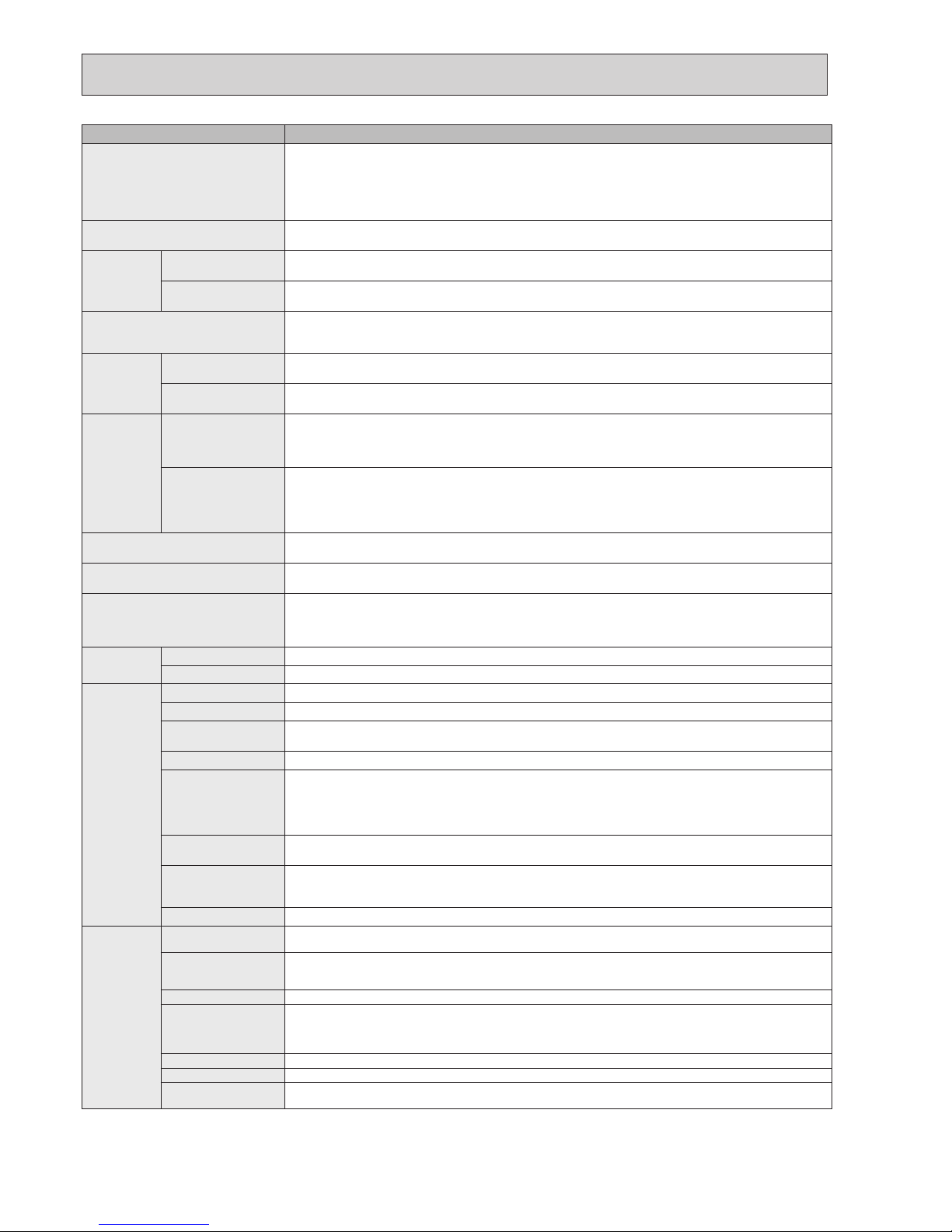

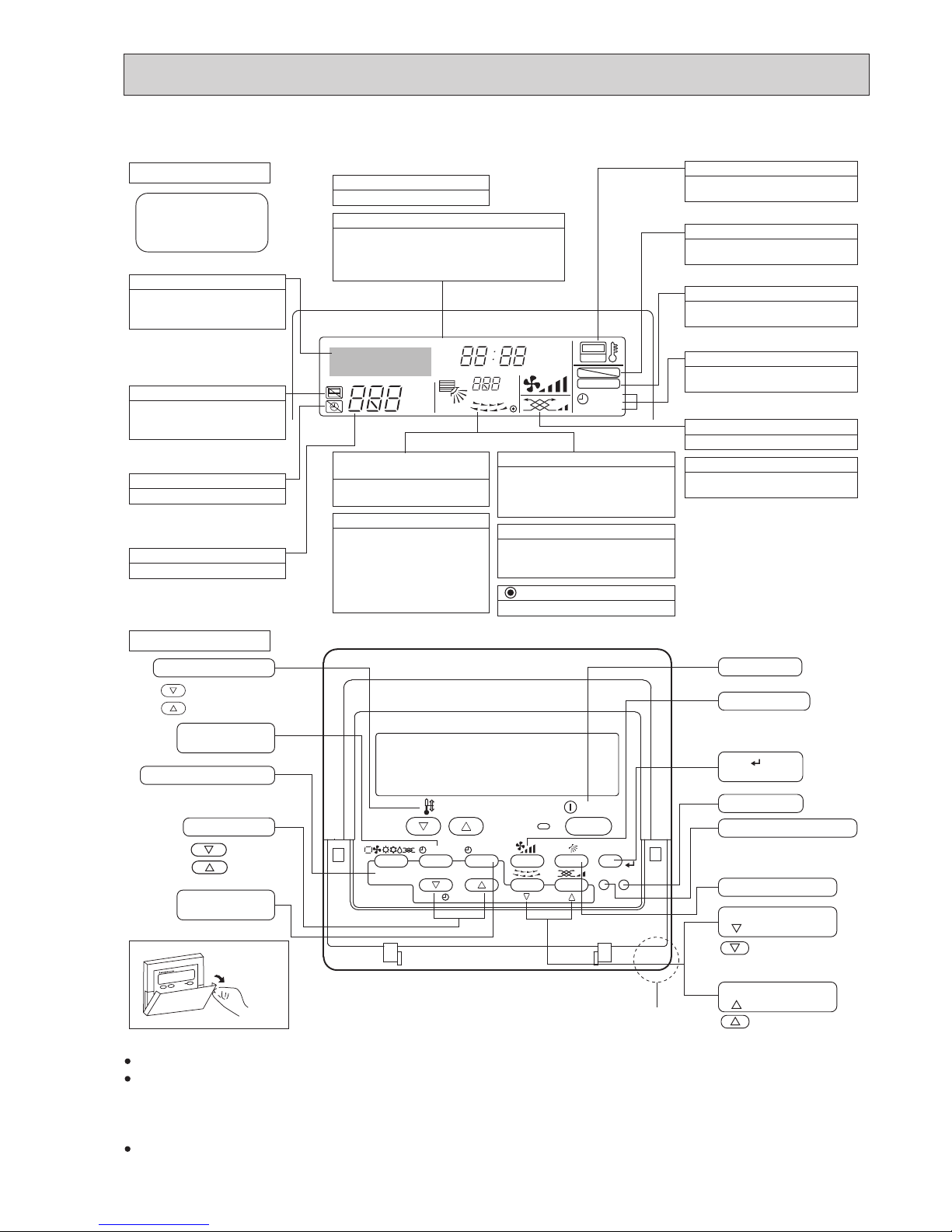

3-2. WIRED REMOTE CONTROLLER (OPTION) <PAR-30MAA><PAR-31MAA>

The functions which can be used are restricted according to each model.

The main display can be displayed in two different modes: "Full" and "Basic."

The initial setting is "Full."

Fri

Mode Temp. Fan

Room

Cool Auto

Set temp.

Fri

Cool

Mode Temp. Fan

AutoSet temp.

1

2

3

4

5

20

19

4

3

181716

15

14

13

12

6

8

10

1

11

7

9

21

5

2

Fan speed setting appears here.

4 Fan speed

Appears while the units are operated in the

energy-save mode.

Appears while the outdoor units are operated in

the silent mode.

Preset temperature appears here.

Appears when the ON/OFF operation is centrally

controlled.

Current time appears here.

Appears when the buttons are locked.

Indoor unit operation mode appears here.

Appears when the operation mode is centrally

controlled.

15

16

2 Preset temperature

6

12

1 Operation mode

7

Indicates the vane setting.

18

Indicates the louver setting.

Indicates the ventilation setting.

Appears when the On/Off timer or Night setback

function is enabled.

19

20

13

Appears

when filter needs maintenance .

Appears when the filter reset function is centrally

controlled.

Appears when the preset temperature is centrally

controlled.

10

9

8

Appears when the Weekly timer is enabled.

14

Appears when the preset temperature range is

restricted.

21

Functions of the corresponding buttons appear

here.

5 Button function guide

Appears when the built-in thermistor on the

remote controller is activated to monitor the

room temperature.

appears when the thermistor on the

indoor unit is activated to monitor the room

temperature.

17

3 Clock

(See the Installation Manual.)

Current room temperature appears here.

11 Room temperature

(See the Installation Manual.)

All icons are displayed for explanation.

5

6

1234

Press to turn ON/OFF the indoor unit.

1 ON/OFF button

This lamp lights up in green while the unit

is in operation. It blinks while the remote

controller is starting up or when there is

an error.

Press to save the setting.

Main display: Press to change the operation

mode.

Main menu: Press to move the cursor down.

Press to return to the previous screen.

Main

display

: Press to decrease temperature.

Main menu: Press to move the cursor up.

Press to bring up the Main menu.

Main

display

: Press to increase temperature.

Main menu: Press to go to the previous page.

Operation settings will appear.

When the backlight is off, pressing any

button turns the backlight on and it

will stay lit for a certain period of time

depending on the screen.

Main

display

: Press to change the fan speed.

Main menu: Press to go to the next page.

6 ON/OFF lamp

2 SELECT button

7 Function button F1

3 RETURN button

8 Function button F2

4 MENU button

9 Function button F3

5 Backlit LCD

10 Function button F4

Fri

Room

Set temp.

Mode Temp. Fan

Cool Auto

Main

Main display:

Cursor Page

Main menu

Vane·Louver·Vent. (Lossnay)

High power

Timer

Weekly timer

OU silent mode

The functions of the function buttons

change depending on the screen. Refer

to the button function guide that appears

at the bottom of the LCD for the functions

they serve on a given screen.

When the system is centrally controlled,

the button function guide that

corresponds to the locked button will not

appear.

Main display Main menu

Function guide

7 8 9 10 107 8 9

• When the backlight is off, pressing any button turns the backlight on and

does not perform its function. (except for the ON/OFF button)

• Most settings (except ON/OFF, mode, fan speed, temperature) can be

made from the Menu screen.

Display

Full mode

Basic mode

Controller interface

Function buttons

10987

OCH492A

8

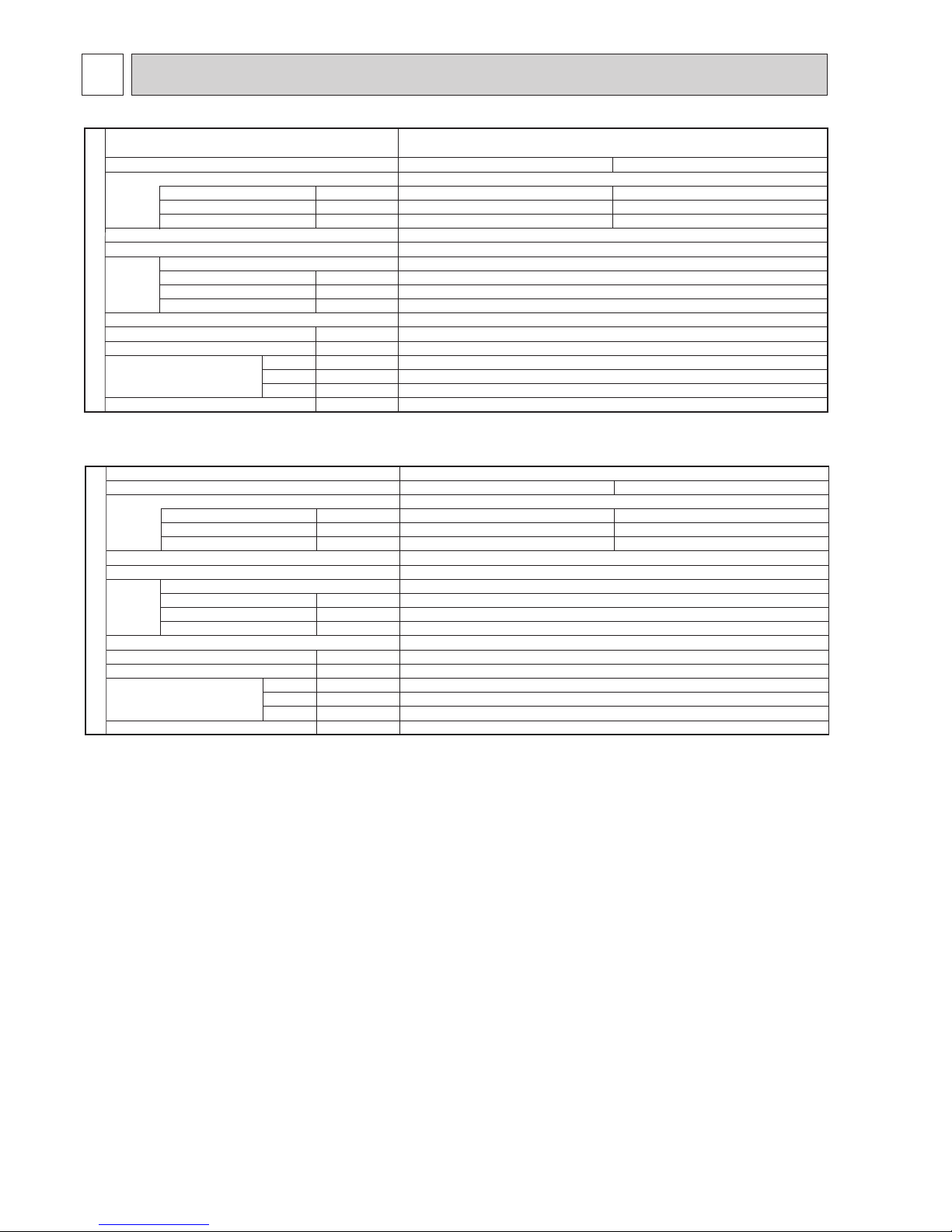

Setting and display items Setting details

Vane · Louver · Vent.

(Lossnay)

Use to set the vane angle.

• Select a desired vane setting from ve different settings.

Use to turn ON / OFF the louver.

• Select a desired setting from "ON" and "OFF."

Use to set the amount of ventilation.

• Select a desired setting from "Off," "Low," and "High."

High power Use to reach the comfortable room temperature quickly.

• Units can be operated in the High-power mode for up to 30 minutes.

Timer On/Off timer* Use to set the operation On/Off times.

• Time can be set in 5-minute increments.

Auto-Off timer Use to set the Auto-Off time.

• Time can be set to a value from 30 to 240 in 10-minute increments.

Weekly timer* Use to set the weekly operation On / Off times.

• Up to eight operation patterns can be set for each day.

(Not valid when the On/Off timer is enabled.)

Restriction Temp. range Use to restrict the preset temperature range.

• Different temperature ranges can be set for different operation modes.

Operation lock Use to lock selected functions.

• The locked functions cannot be operated.

Energy saving Auto return Use to get the units to operate at the preset temperature after performing energy-save operation for a specied

time period.

• Time can be set to a value from 30 and 120 in 10-minute increments.

(This function will not be valid when the preset temperature ranges are restricted.)

Schedule* Set the start/stop times to operate the units in the energy-save mode for each day of the week, and set the

energy-saving rate.

• Up to four energy-save operation patterns can be set for each day.

• Time can be set in 5-minute increments.

• Energy-saving rate can be set to a value from 0% or 50 to 90% in 10% increments.

Night setback* Use to make Night setback settings.

•

Select "Yes" to enable the setting, and "No" to disable the setting. The temperature range and the start/stop times can be set.

Filter information Use to check the lter status.

• The lter sign can be reset.

Error information Use to check error information when an error occurs.

• Check code, error source, refrigerant address, unit model, manufacturing number, contact information (dealer's phone

number) can be displayed.

(The unit model, manufacturing number, and contact information need to be registered in advance to be displayed.)

Maintenance

Auto descending panel

Auto descending panel (Optional parts) Up / Down you can do.

Manual vane angle Use to set the vane angle for each vane to a xed position.

Initial setting Main/Sub When connecting two remote controllers, one of them needs to be designated as a sub controller.

Clock Use to set the current time.

Main display Use to swich between "Full" and "Basic" modes for the Main display.

• The initial setting is "Full."

Contrast Use to adjust screen contrast.

Display details Make the settings for the remote controller related items as necessary.

Clock: The initial settings are "Yes" and "24h" format.

Temperature: Set either Celsius (°C) or Fahrenheit (°F).

Room temp. : Set Show or Hide.

Auto mode: Set the Auto mode display or Only Auto display.

Auto mode Whether or not to use the Auto mode can be selected by using the button.

This setting is valid only when indoor units with the Auto mode function are connected.

Administrator

password

The administrator password is required to make the settings for the following items.

• Timer setting • Energy-save setting • Weekly timer setting

• Restriction setting • Outdoor unit silent mode setting • Night set back

Language selection Use to select the desired language.

Service Test run Select "Test run" from the Service menu to bring up the Test run menu.

• Test run • Drain pump test run

Input maintenance Select "Input maintenance Info." from the Service menu to bring up the Maintenance information screen.

The following settings can be made from the Maintenance Information screen.

• Model name input • Serial No. input • Dealer information input

Function setting Make the settings for the indoor unit functions via the remote controller as necessary.

Check Error history: Display the error history and execute "delete error history".

Refrigerant leak check: Refrigerant leaks can be judged.

Smooth maintenance: The indoor and outdoor maintenance data can be displayed.

Request code: Details of the operation data including each thermistor temperature and error history can be checked.

Self check Error history of each unit can be checked via the remote controller.

Maintenance password Take the following steps to change the maintenance password.

Remote controller check When the remote controller does not work properly, use the remote controller checking function to trouble-

shoot the problem.

*Clock setting is required.

Main menu list

OCH492A

9

Caution:

Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if the feature is not present

at every unit connected.

When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication (For

max. 2 minutes). Please wait until this “PLEASE WAIT” indication disappear then start the operation.

3-3. WIRED REMOTE CONTROLLER (OPTION) <PAR-21MAA>

°F°C

°F°C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Display Section

For the purposes of explanation,

all parts of the display are shown.

During actual operation, only

the relevant items will be lit.

Identifies the current operation

Shows the operating mode, etc.

Multilanguage display is available.

“Centrally Controlled” indicator

Indicates that operation from the

remote controller has been prohibited by a master controller.

“Timer is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, the time to be

switched off is shown.

“Sensor” indication

Displays when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

To be displayed on when it is time to

clean the filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Room Temperature display

Shows the room temperature. The room

temperature display range is 8 to 39°C.

The display blinks if the temperature

is less than 8°C or 39°C or more.

Louver display

Indicates the action of the swing louver.

Does not appear if the louver is not

running.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Operation Section

Temperature setting buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

cover

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To return operation

number

Ventilation button

( Operation button)

To go to next operation

number

Built-in temperature sensor

Displays if the airflow is set to

low or downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off in 1 hour,

when the airflow direction

also changes.

The functions which can be used are restricted according to each model.

OCH492A

10

SPECIFICATIONS

4

kW

A

A

kW

K/min (CFM)

Pa(mmAq)

dB

mm (in)

mm (in)

mm (in)

mm (in)

kg (lb)

Service Ref.

Mode

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan (drive) × No.

Fan motor output

Airflow (Low-High)

External static pressure

Operation control & Thermostat

Noise level (Low-High)

Unit drain pipe I.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

PCA-RP125HAQ

Cooling

0.26

1.19

2.38

Heating

0.26

1.19

2.38

Single phase, 50Hz, 230V

Stainless steel

Plate fin coil

Sirocco fan (direct) × 4

0.08 + 0.08

30-38 (1,060-1,350)

0 (direct blow)

Remote controller & built-in

44-50

26 (1)

1,520 (59-7/8)

650 (25-5/8)

280 (11)

56 (124)

Cooling

0.09

0.43

0.86

Heating

0.09

0.43

0.86

Single phase, 50Hz, 230V

Stainless steel

Plate fin coil

Sirocco fan (direct) × 2

0.04

17-19 (600-670)

0 (direct blow)

Remote controller & built-in

34-38

26 (1)

1,136 (44-3/4)

650 (25-5/8)

280 (11)

41 (90)

PCA-RP71HAQ

PCA-RP71HAQ-ER

kW

A

A

kW

K/min (CFM)

Pa (mmAq)

dB

mm (in)

mm (in)

mm (in)

mm (in)

kg (lb)

Service Ref.

Mode

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan (drive) × No.

Fan motor output

Airflow (Low-High)

External static pressure

Operation control & Thermostat

Noise level (Low-High)

Unit drain pipe I.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

OCH492A

11

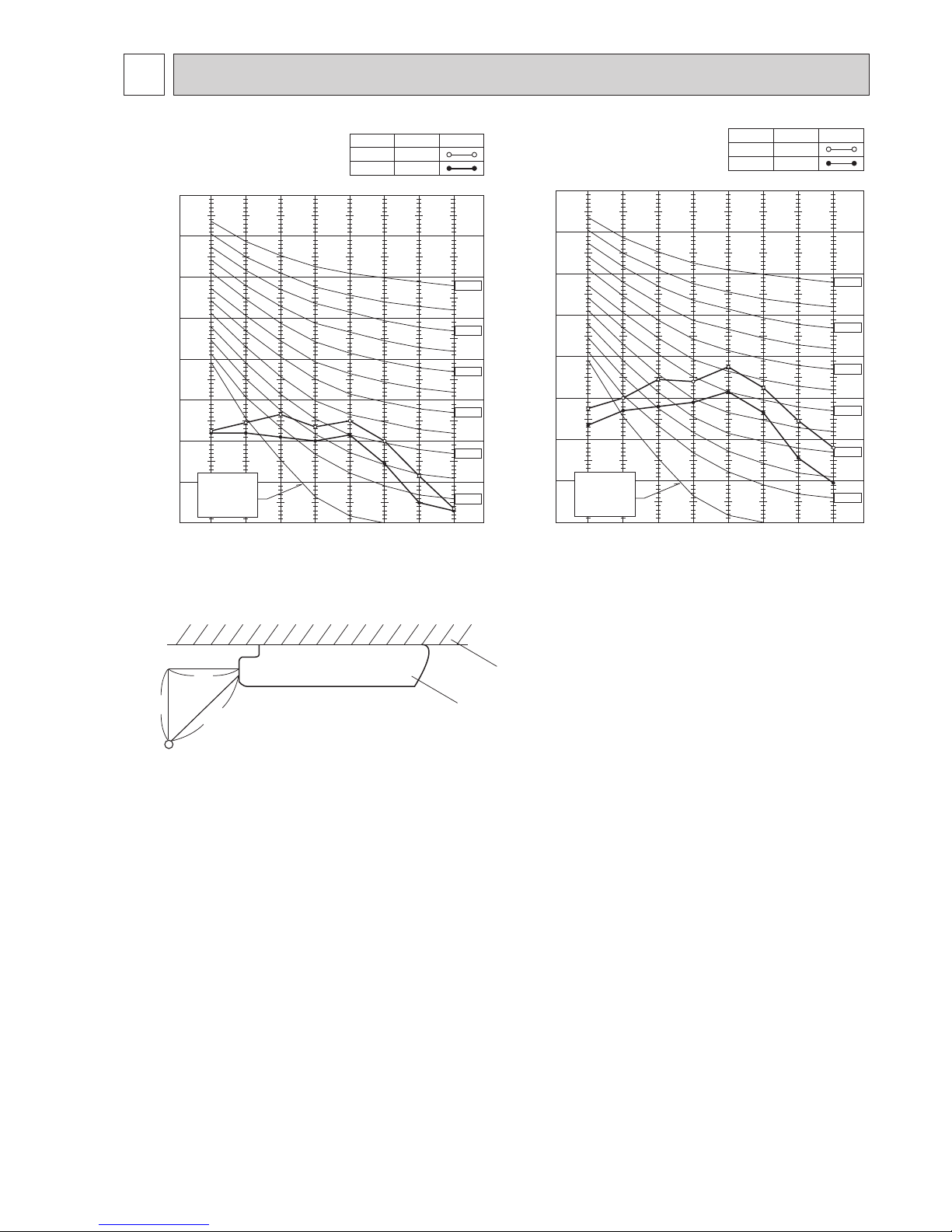

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB ( 0dB = 0.0002 µbar )

BAND CENTER FREQUENCIES, Hz

PCA-RP71HAQ

PCA-RP71HAQ-ER

NOTCH

High

Low

SPL(dB)

38

34

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB ( 0dB = 0.0002 µbar )

BAND CENTER FREQUENCIES, Hz

PCA-RP125HAQ

NOTCH

High

Low

SPL(dB)

50

44

LINE

1m

1m

unit

about 1.4m

MICROPHONE

ceiling

NOISE CRITERION CURVES

5

OCH492A

Loading...

Loading...