Page 1

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

TEMP.

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT-TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

2003

No. OC289

Series PCA

Ceiling Suspended

Indoor unit

[Model names] [Service Ref.]

PCA-P3HA PCA-P3HA

PCA-P5HA PCA-P5HA

INDOOR UNIT

R407C

• Refer to the OCT03

REVISED EDITION-E as

regarding control relation.

• This manual does not cover

outdoor units.When serving

them, please refer to the

service manual No.OC261

REVISED EDITION-B and

this manual in a set.

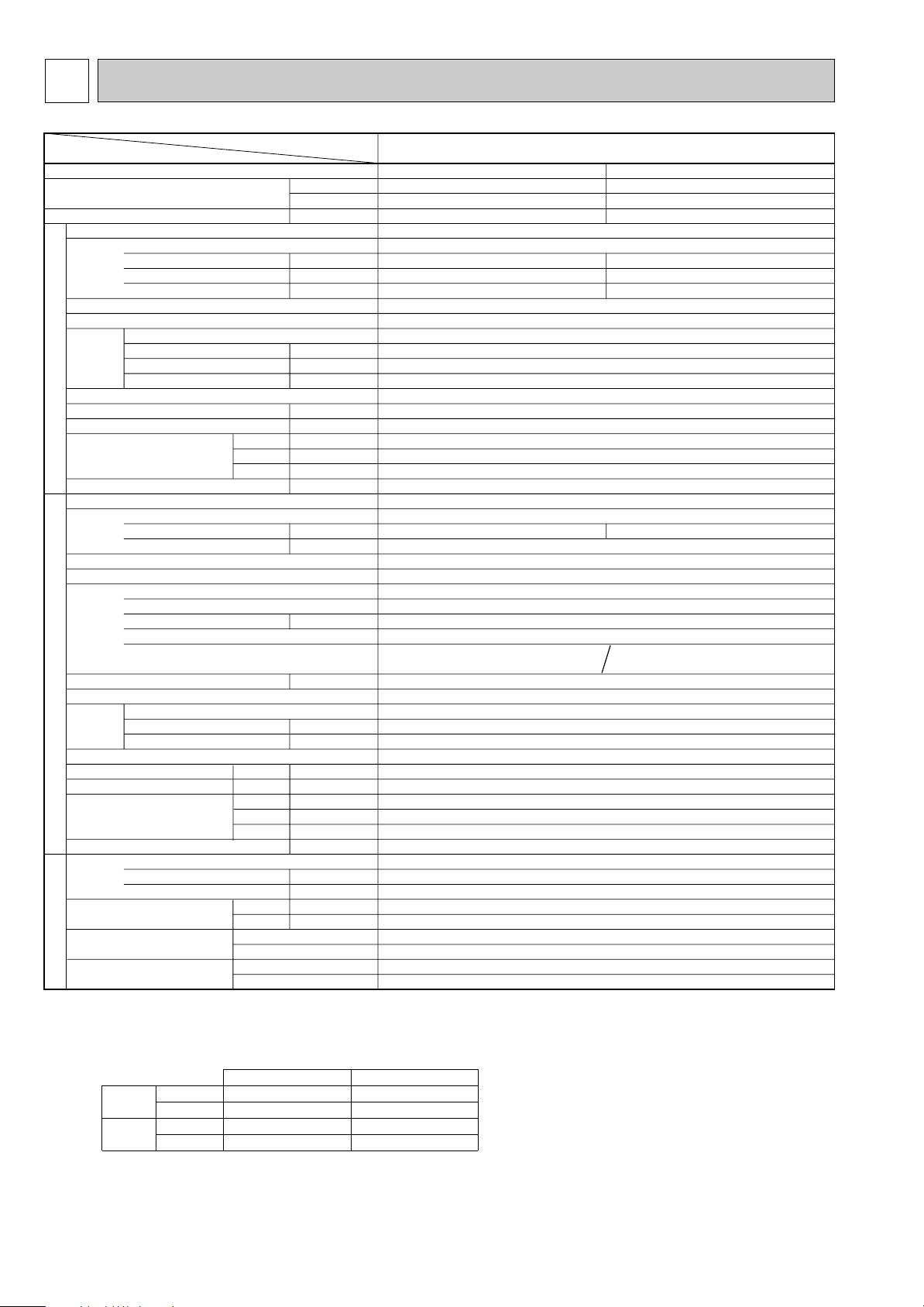

CONTENTS

1. SAFETY PRECAUTION···································2

2. PART NAMES AND FUNCTIONS····················4

3. SPECIFICATIONS············································6

4. DATA·······························································10

5. OUTLINES AND DIMENSIONS·····················21

6.

WIRING DIAGRAM

7.

REFRIGERANT SYSTEM DIAGRAM

8. TROUBLESHOOTING ···································25

9. DISASSEMBLY PROCEDURE······················26

10. PARTS LIST···················································30

11. OPTIONAL PARTS·········································33

············································23

··················24

REMOTE CONTROLLER

Page 2

1

SAFETY PRECAUTION

Cautions for using with the outdoor unit which adopts R407C refrigerant.

· Do not use the existing refrigerant piping.

-The old refrigerant and refrigerant oil in the existing piping contains a large amount of chlorine which may cause the refrigerant oil of the new unit to deteriorate.

· Do not use copper pipes which are broken, deformed or discolour .

In addition, be sure that the inner surfaces of the pipes are clean, free of hazardous sulphur and oxides, or have no dust /

dirt, shaving particles, oils, moisture or any other contamination.

-If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the refrigerant oil will

result.

· Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

· Use ester oil, ether oil or alkyl benzene (small amount) as the refrigerant oil to coat flares and flange connections.

-The refrigerant oil will degrade if it is mixed with a large amount of mineral oil.

Use liquid refrigerant to fill the system.

-If gas refrigerant is used to fill the system, the composition of the refrigerant in the cylinder will change and performance

may drop.

· Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerant oil to deteriorate.

· Use a vacuum pump with a reverse flow check valve.

-The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerant oil to deteriorate.

· Do not use the following tools that are used with conventional refrigerant.

(Gauge manifold , charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge,

refrigerant recovery equipment)

-If the conventional refrigerant and refrigerant oil are mixed in the R407C, the refrigerant may deteriorated.

-If water is mixed in the R407C, the refrigerant oil may deteriorate.

-Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerant will not react to it.

· Do not use a charging cylinder.

-Using a charging cylinder may cause the refrigerant to deteriorate.

· Be especially careful when managing the tools.

-if dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

· Do not use the drier which is sold in the field.

-The drier for R407C refrigerant is per-attached to outdoor unit refrigerant circuit.

-Some drier in the field are not in conformity with R407C refrigerant .

2

Page 3

Gravimeter

Unit

[1] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

[2] Notice on repair service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[3] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

3

Page 4

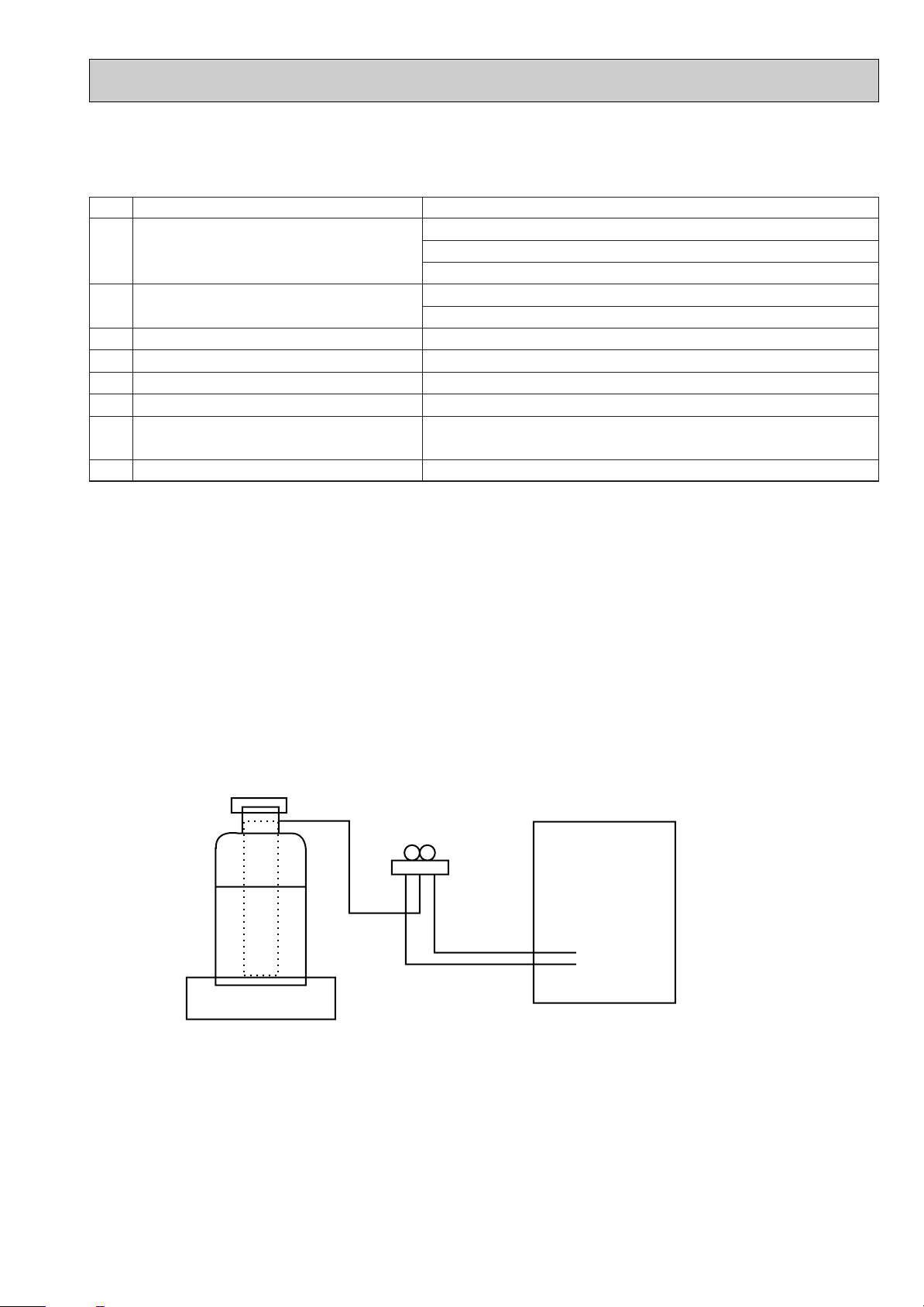

2

Air outlet

Air intake

Oil filter (Air intake)

w It prevents oil from

getting into the unit.

Left/right guide vanes

Change the direction of airflow

from the horizontal blower.

Up/down guide vanes

Change the direction of airflow from the

vartical blower.

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

Press this button to switch the cooler,

electronic dry (dehumidify), automatic

and heater modes.

OPERATION SWITCH button

This sets the room temperature. The

temperature setting can be performed

in 1: units

Setting range

Cooler 19: to 30:

Heater 17: to 28:

TEMP. ADJUSTMENT button

This switches between continuous

operation and the timer operation.

TIMER button

This switches between the operation

and stop modes each time it is pressed.

The lamp on this button lights during

operation.

ON/OFF button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

CHECK-TEST RUN button

This switch the horizontal fan motion

ON and OFF.

(Not available for this model.)

LOUVER button

This sets the ventilation fan speed.

VENTILATION button

This adjusts the vertical angle of the

ventilation.

AIR DIRECTION button

This resets the filter service indication

display

FILTER button

This sets the current time, start time

and stop time.

TIME SETTING button

This sets the ventilation fan speed.

AIR SPEED button

PART NAMES AND FUNCTIONS

● Indoor (Main) Unit

● Remote controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

4

Page 5

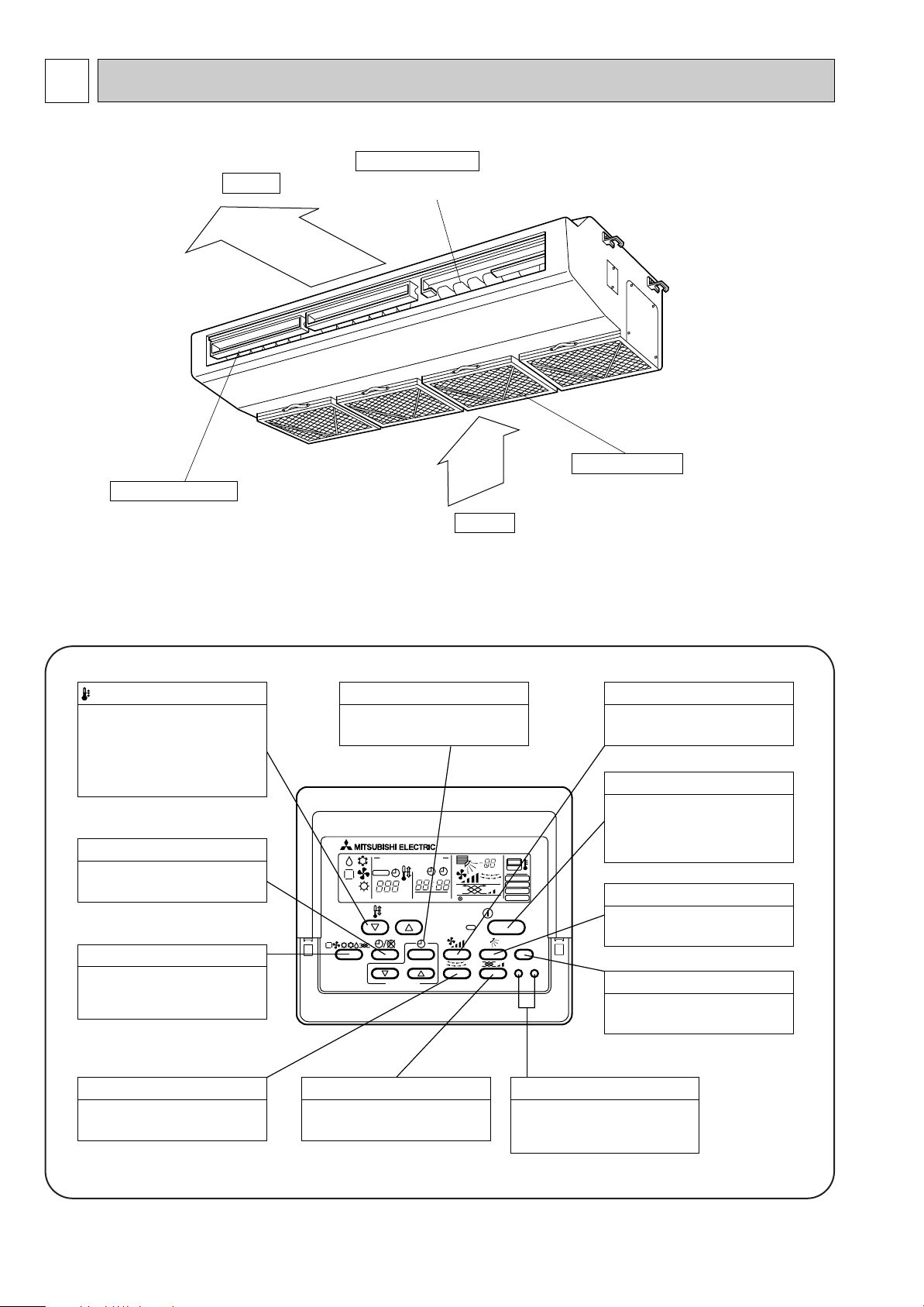

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

● Display

CENTRALLY

CONTROLLED display

This indicates when the unit is controlled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

This indicates when the standby

mode is set from the time the sleep

operation starts until the heating air

is discharged.

DEFROST display

This indicates when the defrost operation is performed.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

AIR DIRECTION display

This displays the air direction.

FAN SPEED display

The selected fan speed is displayed.

ROOM TEMPERATURE display

The temperature of the suction air is

displayed during operation. The display range is 8° to 39°C. The display

flashes 8°C when the actual temperature is less than 8° and flashes

39°C when the actual temperature is

greater than 39°C.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

CHECK MODE

TEST RUN

This display lights in the check mode

or when a test operation is performed.

display

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

SET TEMPERATURE display

This displays the selected setting

temperature.

FILTER

This lamp lights when the filter need

to be cleaned.

POWER display

This lamp lights when electricity is

supplied to the unit.

display

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not a

malfunction.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped

with the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

5

Page 6

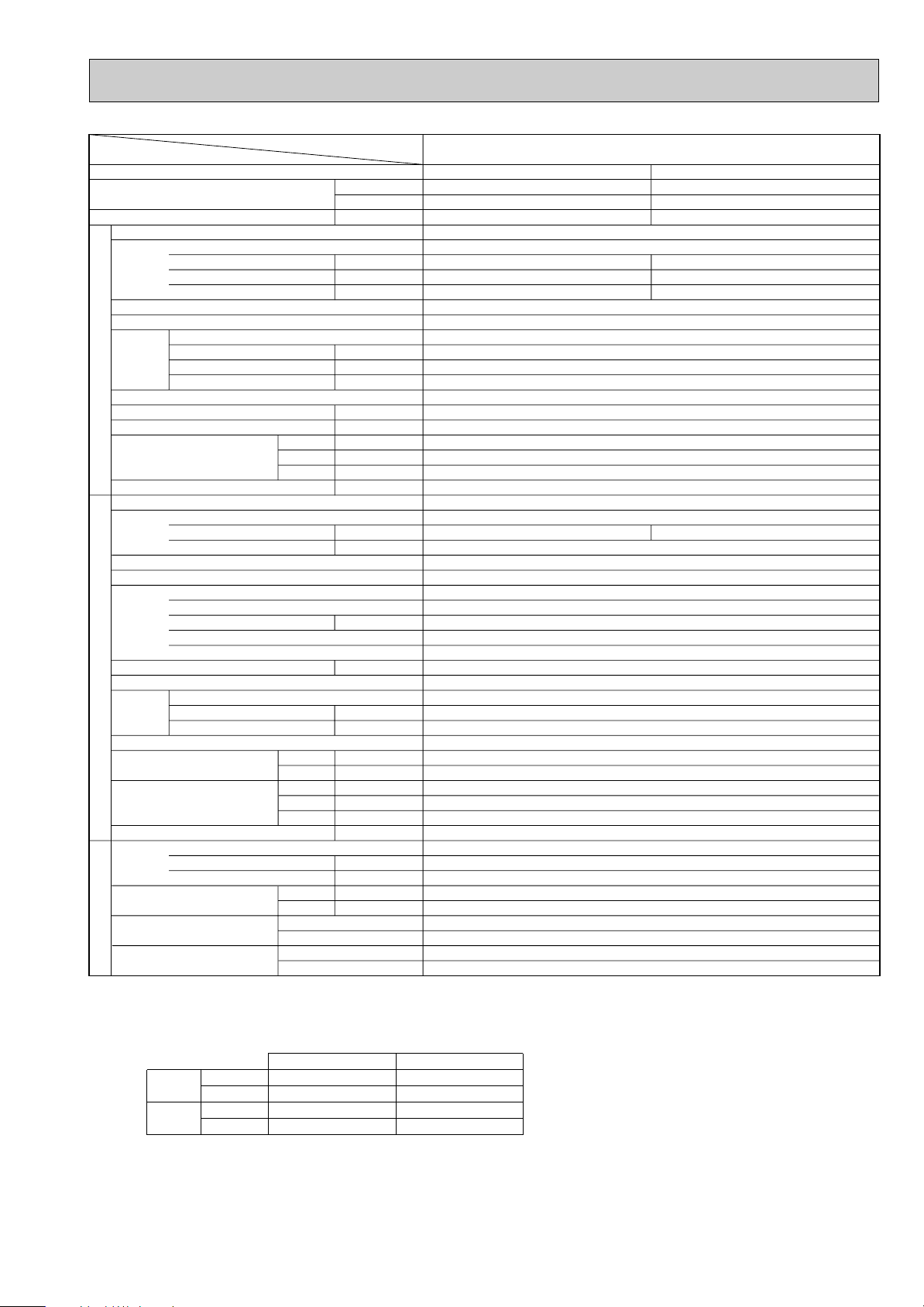

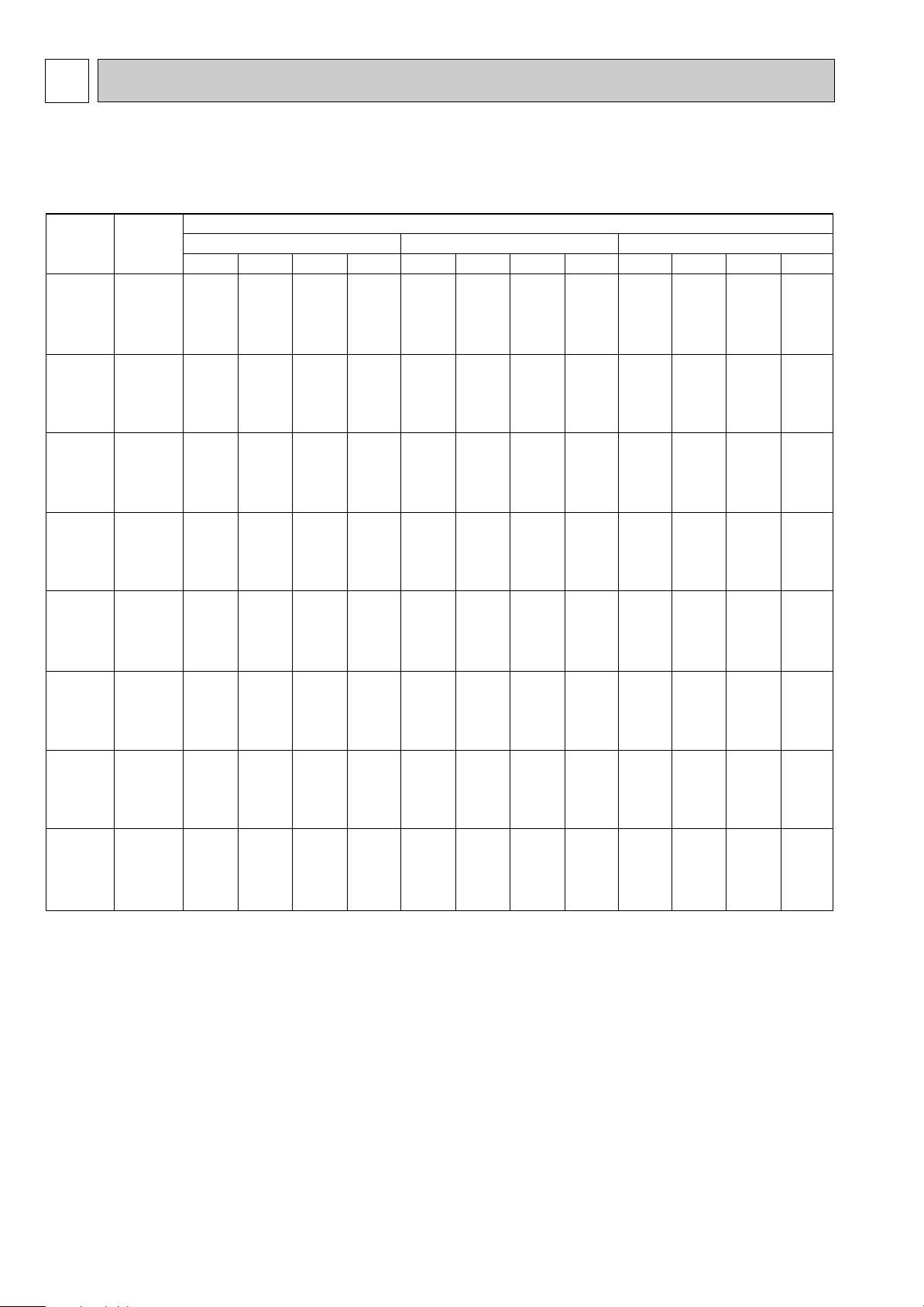

3

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Capacity

Total input

Service Ref.

Power supply

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Lo-Hi)

External static pressure

Operation control & Thermostat

Noise level(Lo-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

PCA-P3HA

Cooling

25,600

7,500

3.36

0.09

0.43

0.86

14.83 / 4.96

Heating

31,400

9,200

3.41

0.09

0.43

0.86

14.85/ 5.04

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

PCA-P3HA

Single phase, 50Hz, 220-230-240V

Stainless steel

Plate fin coil

Sirocco (direct) x 2

0.04

17-19 <600-670>

0 (direct blow)

Remote controller & built-in

34-38

26(1)

1,136(44-3/4)

650(25-5/8)

280(11)

41(90)

PUH-P3VGAA

1.UK / PUH-P3YGAA1.UK

Single phase, 50Hz, 220-230-240V / 3 phase, 50Hz, 380-400-415V (4wires)

93 / 47

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE52VNJMT / NE52YDKMT

2.5

Line start

38

Plate fin coil

Propeller (direct) x 1

0.070

50(1,770)

Reverse cycle

49

51

900(35-7/16)

330+20(13+3/4)

855(33-5/8)

79(174)

R407C

3.3(7.3)

1.3 (Ester) MEL56

9.52(3/8)

15.88(5/8)

Flared

Flared

Max. 50m

Max. 50m

Inner thermostat,

HP switch, Discharge thermo.

Anti-phase protector, Thermal relay,

HP switch, Discharge thermo.

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

3. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit Single phase 230V 50Hz / 3 phase 400V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

OUTDOOR UNIT INDOOR UNIT

REFRIGERANT PIPING

SPECIFICATIONS

1. Heat pump type Rating Conditions (ISO T1)

6

Page 7

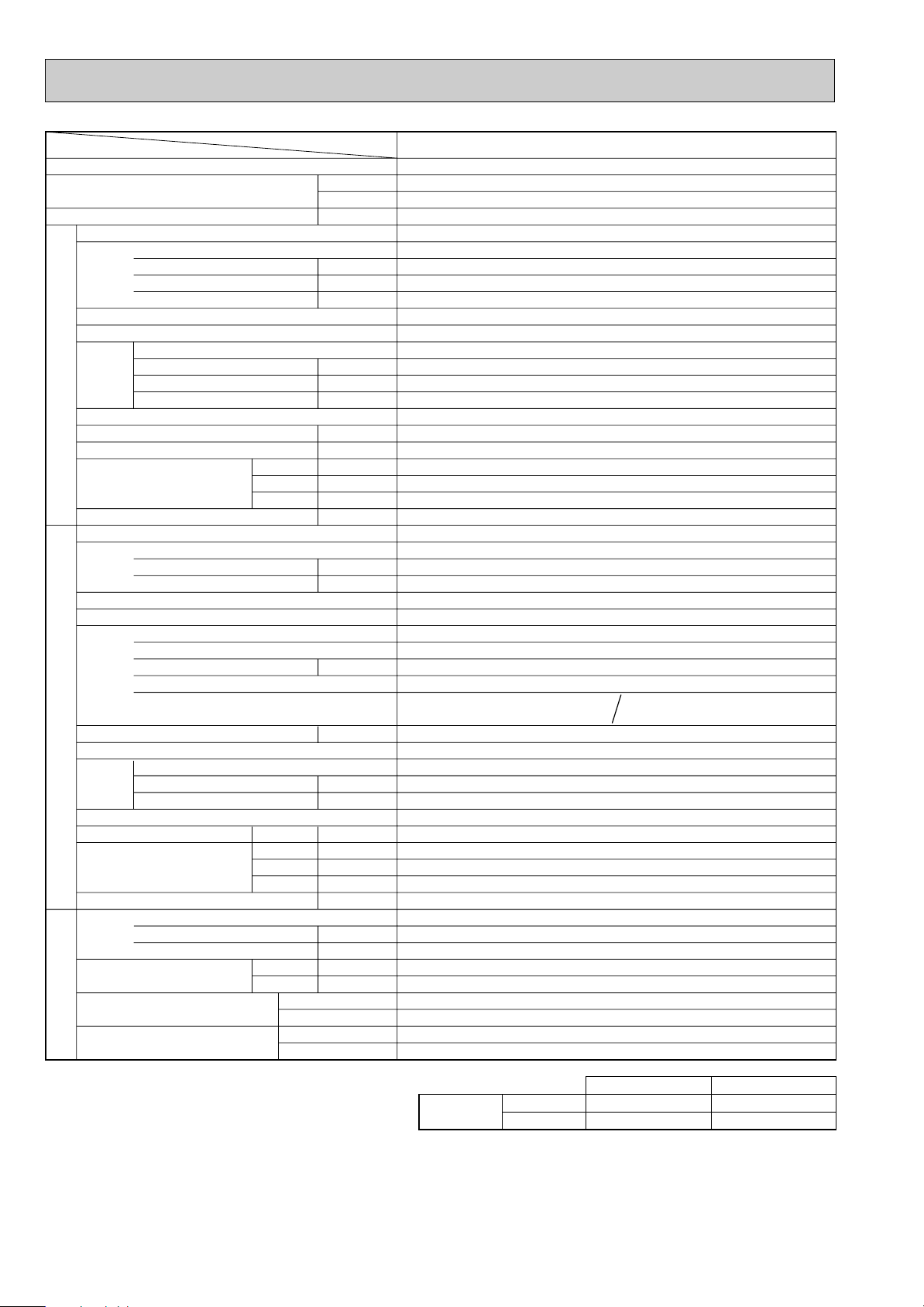

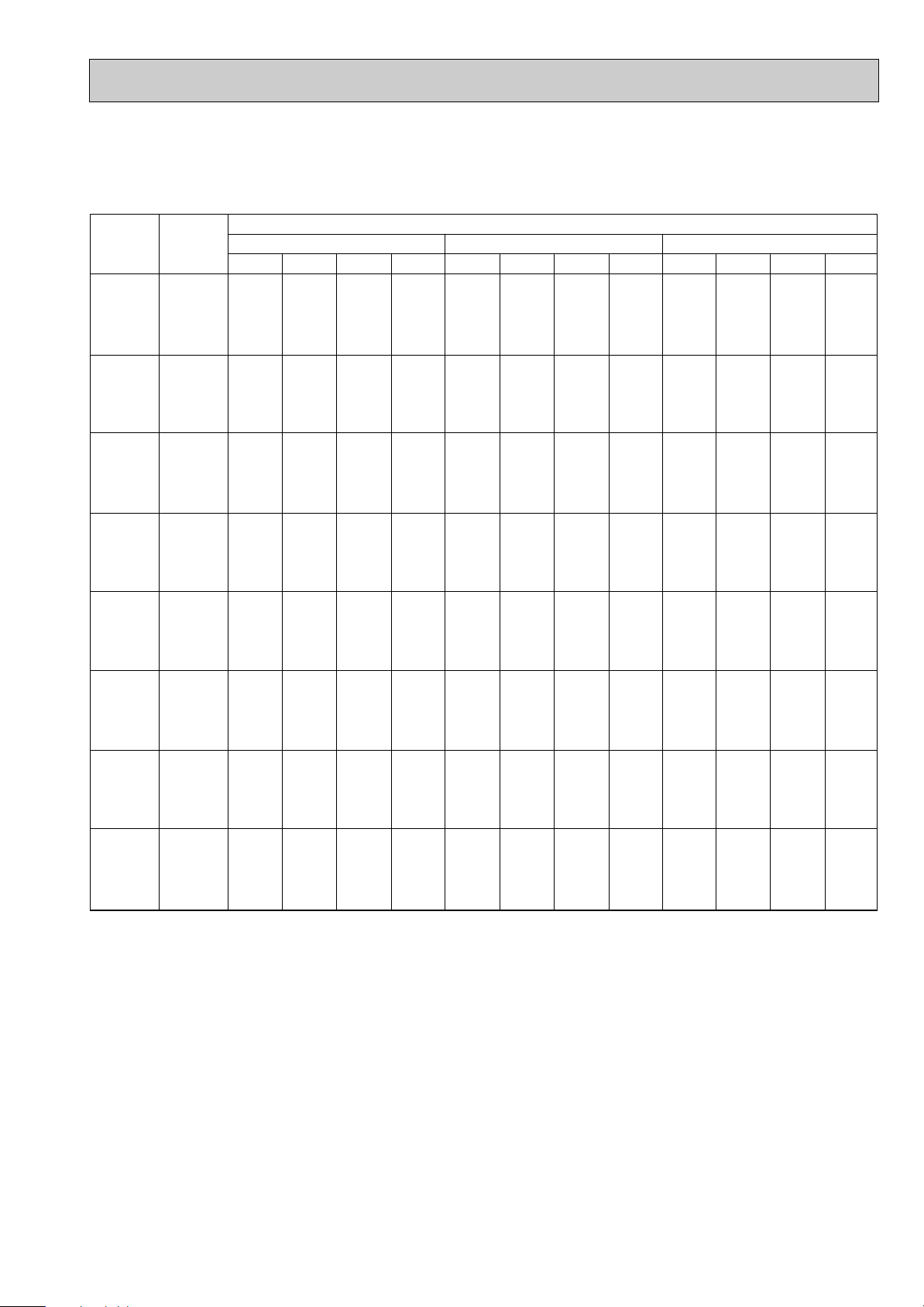

Rating Conditions (ISO T1)

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Capacity

Total input

Service Ref.

Power supply

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Lo-Hi)

External static pressure

Operation control & Thermostat

Noise level(Lo-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

PCA-P5HA

Cooling

44,400

13,000

4.90

0.26

1.19

2.38

6.85

Heating

54,600

16,000

4,98

0.26

1.19

2.38

7.07

W

D

H

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

PCA-P5HA

Single phase, 50Hz, 220-230-240V

Stainless steel

Plate fin coil

Sirocco (direct) x 4

0.08+0.08

30-38 <1,060-1,350>

0 (direct blow)

Remote controller & built-in

44-50

26(1)

1,520(59-7/8)

650(25-5/8)

280(11)

56(124)

PUH-P5YGAA

1.UK

3 phase, 50Hz, 380-400-415V (4wires)

65.5

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

ZR61KCW-TFD

3.5

Line start

Anti-phase protector, Internal thermostat, HP switch,Thermal relay, Discharge thermo

38

Plate fin coil

Propeller (direct) x 2

0.070+0.070

95(3,360)

Reverse cycle

55

56

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

112(247)

R407C

4.6(10.1)

1.690 (Ester) 3MAW-POE

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

3. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit 3 phase 400V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

OUTDOOR UNIT INDOOR UNIT

REFRIGERANT PIPING

7

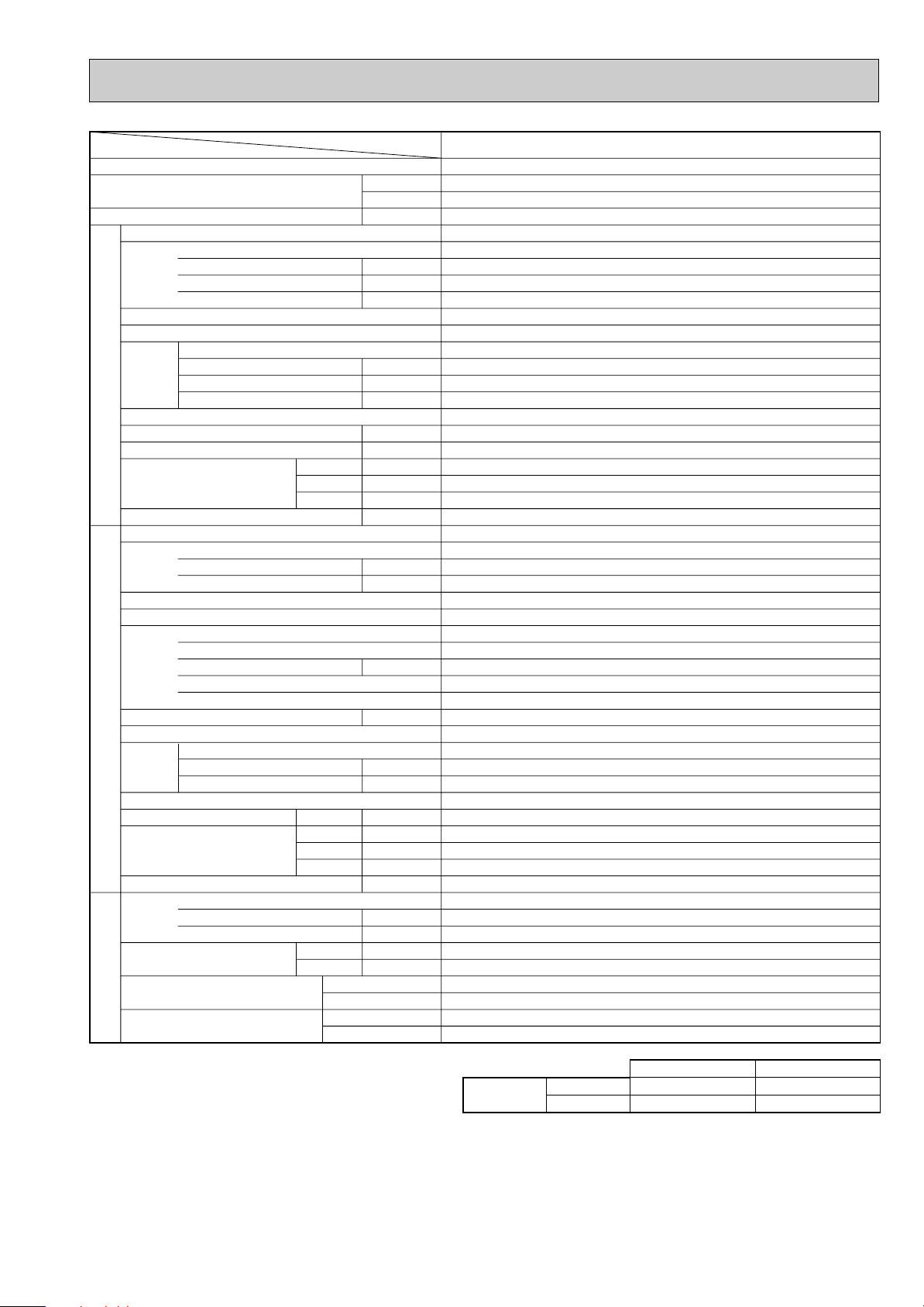

Page 8

OUTDOOR UNIT

REFRIGERANT

PIPING

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Operation control & Thermostat

Noise level(Lo-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Crankcase heater

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Indoor side

Outdoor side

Height difference

Piping length

Liquid

Gas

Cooling

W

D

H

Input

Running current

Starting current

Fan(drive))No.

Fan motor output

Airflow(Lo-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

W

D

H

Item

Service Ref.

PCA-P3HA

Function

Total input

2. Guaranteed operating range

Upper limit

Lower limit

Indoor

D.B. 35:, D.B. 22.5:

D.B. 19:, D.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Cooling

INDOOR UNIT

Cooling

25,600

7,500

3.36

PCA-P3HA

Single phase, 50Hz, 220-230-240V

0.09

0.41

0.86

Stainless steel

Plate fin coil

Sirocco (direct) ✕ 2

0.04

17-19 <600-670>

0 (direct blow)

Remote controller & built-in

34-38

26(1)

1,136(44-3/4)

650(25-5/8)

280(11)

41(90)

PU-P3VGAA

1.UK / PU-P3YGAA1.UK

Single-phase, 50Hz, 220-230-240V / 3-phase, 50Hz, 380-400-415V (4wires)

14.02 / 4.78

93 / 47

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE52VNJMT / NE52YDKMT

2.5

Line start

38

Plate fin coil

Propeller (direct) ✕ 1

0.070

50(1,770)

—

49

900(35-7/16)

330+20(13+3/4)

855(33-5/8)

79(174)

R407C

3.3(7.3)

1.3 (Ester) MEL56

9.52(3/8)

15.88(5/8)

Flared

Flared

Max. 50m

Max. 50m

Btu/h

W

kW

kW

A

A

kW

K/min <CFM>

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

A

A

KW

W

kW

K/min <CFM>

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Anti-phase protector, Thermal relay,

HP switch, Discharge thermo

Inner thermostat,

HP switch, Discharge thermo

Capacity

Rating Conditions (ISO T1)

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80°F), W.B. 19:(66°F)

Outdoor : D.B. 35:(95°F), W.B. 24:(75°F)

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit Single phase 230V 50Hz / 3 phase 400V 50Hz

8

Page 9

Rating Conditions (ISO T1)

OUTDOOR UNIT

REFRIGERANT

PIPING

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Operation control & Thermostat

Noise level(Lo-Hi)

Unit drain pipe I.D.

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Crankcase heater

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Indoor side

Outdoor side

Height difference

Piping length

Liquid

Gas

Cooling

W

D

H

Input

Running current

Starting current

Fan(drive))No.

Fan motor output

Airflow(Lo-Hi)

External static pressure

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive))No.

Fan motor output

Airflow

Charge

Compressor oil (Model)

W

D

H

Item

Service Ref.

PCA-P5HA

Function

Total input

Upper limit

Lower limit

Indoor

D.B. 35:, D.B. 22.5:

D.B. 19:, D.B. 15:

Outdoor

D.B. 46:

D.B. -5:

Cooling

INDOOR UNIT

Cooling

44,400

13,000

4.90

PCA-P5HA

Single phase, 50Hz, 220-230-240V

0.26

1.19

2.38

Stainless steel

Plate fin coil

Sirocco (direct) ✕ 4

0.08+0.08

30-38 <1,060-1,350>

0 (direct blow)

Remote controller & built-in

44-50

26(1)

1,520(59-7/8)

650(25-5/8)

280(11)

56(124)

PU-P5YGAA

1.UK

3-phase, 50Hz, 380-400-415V (4wires)

6.85

65.5

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

ZR61KCW-TFD

3.5

Line start

Anti-phase protector, Internal thermostat, HP switch, Thermal relay, Discharge thermo

38

Plate fin coil

Propeller (direct) ✕ 2

0.070+0.070

95(3,360)

—

55

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

112(247)

R407C

4.6(10.1)

1.690 (Ester) 3MAW-POE

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Btu/h

W

kW

kW

A

A

kW

K/min <CFM>

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

A

A

KW

W

kW

K/min <CFM>

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

2. Guaranteed operating range

Capacity

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27:(80°F), W.B. 19:(66°F)

Refrigerant piping length (one way) : 5m(16ft)

3. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit 3 phase 400V 50Hz

Outdoor : D.B. 35:(95°F), W.B. 24:(75°F)

9

Page 10

4 DATA

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

26

26

26

28

28

28

30

30

30

32

32

32

34

34

34

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

CA

7,425

7,950

8,550

7,425

7,950

8,550

7,425

7,950

8,550

7,425

7,950

8,550

7,425

7,950

8,550

7,425

7,950

8,550

7,425

7,950

8,550

7,425

7,950

8,550

SHC(W)

4,604

3,975

3,249

5,198

4,611

3,933

5,792

5,247

4,617

6,386

5,883

5,301

6,980

6,519

5,985

7,425

7,155

6,669

7,425

7,791

7,353

7,425

7,950

8,037

SHF

0.62

0.50

0.38

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.94

0.82

0.70

1.00

0.90

0.78

1.00

0.98

0.86

1.00

1.00

0.94

P.C.

2.69

2.74

2.82

2.69

2.74

2.82

2.69

2.74

2.82

2.69

2.74

2.82

2.69

2.74

2.82

2.69

2.74

2.82

2.69

2.74

2.82

2.69

2.74

2.82

CA

7,200

7,725

8,363

7,200

7,725

8,363

7,200

7,725

8,363

7,200

7,725

8,363

7,200

7,725

8,363

7,200

7,725

8,363

7,200

7,725

8,363

7,200

7,725

8,363

SHC(W)

4,464

3,863

3,178

5,040

4,481

3,847

5,616

5,099

4,516

6,192

5,717

5,185

6,768

6,335

5,854

7,200

6,953

6,523

7,200

7,571

7,192

7,200

7,725

7,861

SHF

0.62

0.50

0.38

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.94

0.82

0.70

1.00

0.90

0.78

1.00

0.98

0.86

1.00

1.00

0.94

P.C.

2.84

2.89

2.96

2.84

2.89

2.96

2.84

2.89

2.96

2.84

2.89

2.96

2.84

2.89

2.96

2.84

2.89

2.96

2.84

2.89

2.96

2.84

2.89

2.96

CA

6,975

7,463

8,138

6,975

7,463

8,138

6,975

7,463

8,138

6,975

7,463

8,138

6,975

7,463

8,138

6,975

7,463

8,138

6,975

7,463

8,138

6,975

7,463

8,138

SHC(W)

4,325

3,731

3,092

4,883

4,328

3,743

5,441

4,925

4,394

5,999

5,522

5,045

6,557

6,119

5,696

6,975

6,716

6,347

6,975

7,313

6,998

6,975

7,463

7,649

SHF

0.62

0.50

0.38

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.94

0.82

0.70

1.00

0.90

0.78

1.00

0.98

0.86

1.00

1.00

0.94

P.C.

3.01

3.09

3.16

3.01

3.09

3.16

3.01

3.09

3.16

3.01

3.09

3.16

3.01

3.09

3.16

3.01

3.09

3.16

3.01

3.09

3.16

3.01

3.09

3.16

1. PERFORMANCE DATA (240V)

1) COOLING CAPACITY<1>

PCA-P3HA

Notes CA : Capacity (W) SHC(W) : Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

10

Page 11

COOLING CAPACITY<2>

PCA-P3HA

Indoor

Intake air

D.B.(°C)

20

20

20

22

22

22

24

24

24

26

26

26

28

28

28

30

30

30

32

32

32

34

34

34

Indoor

Intake air

W.B.(°C)

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

CA

6,675

7,200

7,800

6,675

7,200

7,800

6,675

7,200

7,800

6,675

7,200

7,800

6,675

7,200

7,800

6,675

7,200

7,800

6,675

7,200

7,800

6,675

7,200

7,800

Outdoor intake air D.B.(°C)

35 40 45

SHC(W)

4,139

3,600

2,964

4,673

4,176

3,588

5,207

4,752

4,212

5,741

5,328

4,836

6,275

5,904

5,460

6,675

6,480

6,084

6,675

7,056

6,708

6,675

7,200

7,332

SHF

0.62

0.50

0.38

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.94

0.82

0.70

1.00

0.90

0.78

1.00

0.98

0.86

1.00

1.00

0.94

P.C.

3.23

3.31

3.39

3.23

3.31

3.39

3.23

3.31

3.39

3.23

3.31

3.39

3.23

3.31

3.39

3.23

3.31

3.39

3.23

3.31

3.39

3.23

3.31

3.39

CA

6,375

6,975

7,500

6,375

6,975

7,500

6,375

6,975

7,500

6,375

6,975

7,500

6,375

6,975

7,500

6,375

6,975

7,500

6,375

6,975

7,500

6,375

6,975

7,500

SHC(W)

3,953

3,488

2,850

4,463

4,046

3,450

4,973

4,604

4,050

5,483

5,162

4,650

5,993

5,720

5,250

6,375

6,278

5,850

6,375

6,836

6,450

6,375

6,975

7,050

SHF

0.62

0.50

0.38

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.94

0.82

0.70

1.00

0.90

0.78

1.00

0.98

0.86

1.00

1.00

0.94

P.C.

3.46

3.56

3.63

3.46

3.56

3.63

3.46

3.56

3.63

3.46

3.56

3.63

3.46

3.56

3.63

3.46

3.56

3.63

3.46

3.56

3.63

3.46

3.56

3.63

6,075

6,525

7,050

6,075

6,525

7,050

6,075

6,525

7,050

6,075

6,525

7,050

6,075

6,525

7,050

6,075

6,525

7,050

6,075

6,525

7,050

6,075

6,525

7,050

CA

SHC(W)

3,767

3,263

2,679

4,253

3,785

3,243

4,739

4,307

3,807

5,225

4,829

4,371

5,711

5,351

4,935

6,075

5,873

5,499

6,075

6,395

6,063

6,075

6,525

6,627

SHF

0.62

0.50

0.38

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.94

0.82

0.70

1.00

0.90

0.78

1.00

0.98

0.86

1.00

1.00

0.94

P.C.

3.75

3.83

3.90

3.75

3.83

3.90

3.75

3.83

3.90

3.75

3.83

3.90

3.75

3.83

3.90

3.75

3.83

3.90

3.75

3.83

3.90

3.75

3.83

3.90

Notes CA : Capacity (W) SHC(W) : Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

11

Page 12

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

26

26

26

28

28

28

30

30

30

32

32

32

34

34

34

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

CA

12,870

13,780

14,820

12,870

13,780

14,820

12,870

13,780

14,820

12,870

13,780

14,820

12,870

13,780

14,820

12,870

13,780

14,820

12,870

13,780

14,820

12,870

13,780

14,820

SHC(W)

8,366

7,303

6,076

9,395

8,406

7,262

10,425

9,508

8,447

11,454

10,611

9,633

12,484

11,713

10,819

12,870

12,815

12,004

12,870

13,780

13,190

12,870

13,780

14,375

SHF

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.97

0.85

0.73

1.00

0.93

0.81

1.00

1.00

0.89

1.00

1.00

0.97

P.C.

3.92

3.99

4.12

3.92

3.99

4.12

3.92

3.99

4.12

3.92

3.99

4.12

3.92

3.99

4.12

3.92

3.99

4.12

3.92

3.99

4.12

3.92

3.99

4.12

CA

12,480

13,390

14,495

12,480

13,390

14,495

12,480

13,390

14,495

12,480

13,390

14,495

12,480

13,390

14,495

12,480

13,390

14,495

12,480

13,390

14,495

12,480

13,390

14,495

SHC(W)

8,112

7,097

5,943

9,110

8,168

7,103

10,109

9,239

8,262

11,107

10,310

9,422

12,106

11,382

10,581

12,480

12,453

11,741

12,480

13,390

12,901

12,480

13,390

14,060

SHF

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.97

0.85

0.73

1.00

0.93

0.81

1.00

1.00

0.89

1.00

1.00

0.97

P.C.

4.14

4.21

4.31

4.14

4.21

4.31

4.14

4.21

4.31

4.14

4.21

4.31

4.14

4.21

4.31

4.14

4.21

4.31

4.14

4.21

4.31

4.14

4.21

4.31

CA

12,090

12,935

14,105

12,090

12,935

14,105

12,090

12,935

14,105

12,090

12,935

14,105

12,090

12,935

14,105

12,090

12,935

14,105

12,090

12,935

14,105

12,090

12,935

14,105

SHC(W)

7,859

6,856

5,783

8,826

7,890

6,911

9,793

8,925

8,040

10,760

9,960

9,168

11,727

10,995

10,297

12,090

12,030

11,425

12,090

12,935

12,553

12,090

12,935

13,682

SHF

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.97

0.85

0.73

1.00

0.93

0.81

1.00

1.00

0.89

1.00

1.00

0.97

P.C.

4.39

4.51

4.61

4.39

4.51

4.61

4.39

4.51

4.61

4.39

4.51

4.61

4.39

4.51

4.61

4.39

4.51

4.61

4.39

4.51

4.61

4.39

4.51

4.61

COOLING CAPACITY<3>

PCA-P5HA

Notes CA : Capacity (W) SHC(W) : Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

12

Page 13

COOLING CAPACITY<4>

PCA-P5HA

Indoor

Intake air

D.B.(°C)

20

20

20

22

22

22

24

24

24

26

26

26

28

28

28

30

30

30

32

32

32

34

34

34

Indoor

Intake air

W.B.(°C)

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

16

18

20

CA

11,570

12,480

13,520

11,570

12,480

13,520

11,570

12,480

13,520

11,570

12,480

13,520

11,570

12,480

13,520

11,570

12,480

13,520

11,570

12,480

13,520

11,570

12,480

13,520

Outdoor intake air D.B.(°C)

35 40 45

SHC(W)

7,521

6,614

5,543

8,446

7,613

6,625

9,372

8,611

7,706

10,297

9,610

8,788

11,223

10,608

9,870

11,570

11,606

10,951

11,570

12,480

12,033

11,570

12,480

13,114

SHF

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.97

0.85

0.73

1.00

0.93

0.81

1.00

1.00

0.89

1.00

1.00

0.97

P.C.

4.70

4.83

4.95

4.70

4.83

4.95

4.70

4.83

4.95

4.70

4.83

4.95

4.70

4.83

4.95

4.70

4.83

4.95

4.70

4.83

4.95

4.70

4.83

4.95

CA

11,050

12,090

13,000

11,050

12,090

13,000

11,050

12,090

13,000

11,050

12,090

13,000

11,050

12,090

13,000

11,050

12,090

13,000

11,050

12,090

13,000

11,050

12,090

13,000

SHC(W)

7,183

6,408

5,330

8,067

7,375

6,370

8,951

8,342

7,410

9,835

9,309

8,450

10,719

10,277

9,490

11,050

11,244

10,530

11,050

12,090

11,570

11,050

12,090

12,610

SHF

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.97

0.85

0.73

1.00

0.93

0.81

1.00

1.00

0.89

1.00

1.00

0.97

P.C.

5.05

5.19

5.29

5.05

5.19

5.29

5.05

5.19

5.29

5.05

5.19

5.29

5.05

5.19

5.29

5.05

5.19

5.29

5.05

5.19

5.29

5.05

5.19

5.29

10,530

11,310

12,220

10,530

11,310

12,220

10,530

11,310

12,220

10,530

11,310

12,220

10,530

11,310

12,220

10,530

11,310

12,220

10,530

11,310

12,220

10,530

11,310

12,220

CA

SHC(W)

6,845

5,994

5,010

7,687

6,899

5,988

8,529

7,804

6,965

9,372

8,709

7,943

10,214

9,614

8,921

10,530

10,518

9,898

10,530

11,310

10,876

10,530

11,310

11,853

SHF

0.65

0.53

0.41

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.97

0.85

0.73

1.00

0.93

0.81

1.00

1.00

0.89

1.00

1.00

0.97

P.C.

5.46

5.59

5.68

5.46

5.59

5.68

5.46

5.59

5.68

5.46

5.59

5.68

5.46

5.59

5.68

5.46

5.59

5.68

5.46

5.59

5.68

5.46

5.59

5.68

Notes CA : Capacity (W) SHC(W) : Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

13

Page 14

Refrigerant piping length (one way)

Service Ref.

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

PCA-P3HA

PCA-P5HA

1.00

1.00

0.981

0.981

0.968

0.968

0.952

0.952

0.940

0.940

0.925

0.925

0.913

0.913

0.900

0.900

0.886

0.886

0.874

0.874

Cooling capacity correction factors

OUTDOOR D.B.(°C)

TOTAL INPUT (RATIO) CAPACITY (RATIO)

INDOOR W.B.(°C)

INDOOR W.B.(°C)

1.4

1.2

1.0

0.8

10

22

20

18

16

22

20

18

16

20 30 46400-5

1.2

1.0

0.8

0.6

0.4

Cooling

14

Page 15

Refrigerant piping length (one way)

Service Ref.

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

PCA-P3HA

PCA-P5HA

1.00

1.00

0.998

0.998

0.995

0.995

0.993

0.993

0.990

0.990

0.988

0.988

0.985

0.985

0.983

0.983

0.980

0.980

0.978

0.978

2) HEATING CAPACITY

Service Ref.

15

20

25

15

20

25

CA

-10 -5 0 5 10 15

Outdoor intake air W.B.(°C)Indoor

Intake

air

D.B.(°C)

P.C.

2.01

2.18

2.32

2.94

3.19

3.39

CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

5,842

5,612

5,428

10,160

9,760

9,440

2.22

2.39

2.59

3.24

3.49

3.78

6,348

6,072

5,888

11,040

10,560

10,240

2.56

2.76

3.00

3.74

4.03

4.38

7,084

6,716

6,440

12,320

11,680

11,200

3.07

3.31

3.51

4.48

4.83

5.13

9,292

8,970

8,464

16,160

15,600

14,720

3.41

3.68

3.94

4.98

5.38

5.75

10,488

10,120

9,752

18,240

17,600

16,960

3.68

3.96

4.25

5.38

5.78

6.20

11,684

11,270

10,856

20,320

19,600

18,880

PCA-P3HA

PCA-P5HA

Notes CA : Capacity (W)

P.C. : Power consumption (kW)

Heating capacity correction factors

Heating

Correcting the capacity line influenced by frosting.

Not correcting the capacity line influenced by frosting.

1.4

1.2

15

20

INDOOR D.B. (°C)

25

1.0

0.8

0.6

0.4

1.4

1.2

1.0

0.8

0.6

TOTAL INPUT (RATIO) CAPACITY (RATIO)

0.4

-12 -10 -5 0 5 10 15

OUTDOOR W.B. (°C)

INDOOR D.B. (°C)

25

20

15

15

Page 16

2. ELECTRICAL DATA

Indoor

Outdoor

Input (kW)

Current (A)

Current (A)

Starting current (A)

Mode

Capacity (W)

Total Input (kW) (In + Out)

Service

Ref.

Indoor unit

Outdoor unit

Cooling

7,500

3.36

0.09

0.44

15.31

85

Heating

9,200

3.41

0.09

0.44

15.54

85

Cooling

7,500

3.36

0.09

0.44

5.23

43

Heating

9,200

3.41

0.09

0.44

5.32

43

Cooling

13,000

4.90

0.26

1.24

7.22

65.5

Heating

16,000

4.98

0.26

1.24

7.46

65.5

PUH-P3VGAA1.UK PUH-P3YGAA1.UK PUH-P5YGAA1.UK

PCA-P3HA PCA-P5HA

Cooling

13,000

4.90

0.26

1.19

6.85

65.5

Heating

16,000

4.98

0.26

1.19

7.07

65.5

PUH-P5YGAA1.UK

PCA-P5HA

Cooling

13,000

4.90

0.27

1.14

6.61

65.5

Heating

16,000

4.98

0.27

1.14

6.82

65.5

PUH-P5YGAA1.UK

PCA-P5HA

Indoor

Outdoor

Input (kW)

Current (A)

Current (A)

Starting current (A)

Mode

Capacity (W)

Total Input (kW) (In + Out)

Service

Ref.

Indoor unit

Outdoor unit

Cooling

7,500

3.36

0.09

0.43

14.63

89

Heating

9,200

3.41

0.09

0.43

14.85

89

Cooling

7,500

3.36

0.09

0.43

4.96

45

Heating

9,200

3.41

0.09

0.43

5.04

45

PUH-P3VGAA1.UK PUH-P3YGAA1.UK

PCA-P3HA

Indoor

Outdoor

Input (kW)

Current (A)

Current (A)

Starting current (A)

Mode

Capacity (W)

Total Input (kW) (In + Out)

Service

Ref.

Indoor unit

Outdoor unit

Cooling

7,500

3.36

0.09

0.41

14.02

93

Heating

9,200

3.41

0.09

0.41

14.24

93

Cooling

7,500

3.36

0.09

0.41

4.78

47

Heating

9,200

3.41

0.09

0.41

4.86

47

PUH-P3VGAA1.UK PUH-P3YGAA1.UK

PCA-P3HA

Indoor·······220V 50Hz Single phase

Outdoor····220V 50Hz Singel phase / 380V 50Hz 3 phase

Indoor·······230V 50Hz Single phase

Outdoor····230V 50Hz Singel phase / 400V 50Hz 3 phase

Indoor·······240V 50Hz Single phase

Outdoor····240V 50Hz Singel phase / 415V 50Hz 3 phase

2.1. Heat pump type

Rating Conditions (ISO T1)

16

Page 17

2.2. Cooling only type

Indoor

Outdoor

Input (kW)

Current (A)

Current (A)

Starting current (A)

Mode

Capacity (W)

Total Input (kW) (In + Out)

Service

Ref.

Indoor unit

Outdoor unit

Cooling

7,500

3.36

0.09

0.44

15.31

85

Cooling

7,500

3.36

0.09

0.44

5.23

43

Cooling

13,000

4.90

0.26

1.24

7.22

65.5

PU-P3VGAA1.UK PU-P3YGAA1.UK PU-P5YGAA1.UK

PCA-P3HA PCA-P5HA

Indoor

Outdoor

Input (kW)

Current (A)

Current (A)

Starting current (A)

Mode

Capacity (W)

Total Input (kW) (In + Out)

Service

Ref.

Indoor unit

Outdoor unit

Cooling

7,500

3.36

0.09

0.43

14.63

89

Cooling

7,500

3.36

0.09

0.43

4.96

45

Cooling

13,000

4.90

0.26

1.19

6.85

65.5

PU-P3VGAA1.UK PU-P3YGAA1.UK PU-P5YGAA1.UK

PCA-P3HA PCA-P5HA

Indoor

Outdoor

Input (kW)

Current (A)

Current (A)

Starting current (A)

Mode

Capacity (W)

Total Input (kW) (In + Out)

Service

Ref.

Indoor unit

Outdoor unit

Cooling

7,500

3.36

0.09

0.41

14.02

93

Cooling

7,500

3.36

0.09

0.41

4.78

47

Cooling

13,000

4.90

0.26

1.14

6.61

65.5

PU-P3VGAA1.UK PU-P3YGAA1.UK PU-P5YGAA1.UK

PCA-P3HA PCA-P5HA

Indoor·······220V 50Hz Single phase

Outdoor····220V 50Hz Singel phase / 380V 50Hz 3 phase

Indoor·······230V 50Hz Single phase

Outdoor····230V 50Hz Singel phase / 400V 50Hz 3 phase

Indoor·······240V 50Hz Single phase

Outdoor····240V 50Hz Singel phase / 415V 50Hz 3 phase

Rating Conditions (ISO T1)

17

Page 18

3. STANDARD OPERATION DATA

Electrical circuit Total Refrigerant circuitIndoor side

Outdoor

side

Capacity

Input

Indoor unit Service Ref.

Phase, Hz

Volts

Amperes

Outdoor unit Service Ref.

Phase, Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

Mode

Service Ref.

SHF

BF

W

KW

V

A

V

A

°C

°C

°C

m

°C

°C

°C

°C

°C

Cooling

7,500

3.36

0.43

14.63/4.96

84

59

2.9

5

27

19

13

35

24

0.72

0.14

Heating

9,200

3.41

0.43

14.85/5.04

89

62

-0.7

5

20

15

47

7

6

—

—

PCA-P3HA

1, 50

230

PUH-P3VGAA

1.UK

/PUH-P3YGAA

1.UK

1, 50/3, 50

230/400

2.31

(23.5)

0.45

(4.6)

2.43

(24.8)

0.39

(4.0)

MPa

(Of/F)

MPa

(Of/F)

D.B.

W.B.

D.B.

D.B.

W.B.

PCA-P3HA

Cooling

13,000

4.90

1.19

6.85

73

54

4.8

5

27

19

15

35

24

0.72

0.19

Heating

16,000

4.98

1.19

7.07

73

55

-0.3

5

20

15

43

7

6

—

—

PCA-P5HA

1, 50

230

PUH-P5YGAA

1.UK

3, 50

400

2.01

(20.5)

0.46

(4.6)

2.07

(21.1)

0.38

(3.8)

PCA-P5HA

3.1 Heat pump type

Rating Conditions (ISO T1)

The unit of pressure has been changed to Mpa on the international system of unit (SI unit system).

The converted score against the traditional unit system can be gotten according to the formula below.

1(Mpa)=10.2(

OOf/FF

)

18

Page 19

3.2 Cooling only type

Electrical circuit Total Refrigerant circuitIndoor side

Outdoor

side

Capacity

Input

Indoor unit Service Ref.

Phase, Hz

Volts

Amperes

Outdoor unit Service Ref.

Phase, Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

Mode

Service Ref.

SHF

BF

W

KW

V

A

V

A

°C

°C

°C

m

°C

°C

°C

°C

°C

Cooling

7,500

3.36

PCA-P3HA

1, 50

230

0.43

PU-P3VGAA

1.UK

/PU-P3YGAA

1.UK

1, 50/3, 50

230/400

14.63/4.96

84

59

2.9

5

27

19

13

35

24

0.72

0.14

2.31

(23.5)

0.45

(4.6)

MPa

(Of/F)

MPa

(Of/F)

D.B.

W.B.

D.B.

D.B.

W.B.

PCA-P3HA

Cooling

13,000

4.90

PCA-P5HA

1, 50

230

1.19

PU-P5YGAA

1.UK

3, 50

400

6.85

73

54

4.8

5

27

19

15

35

24

0.75

0.19

2.01

(20.5)

0.46

(4.6)

PCA-P5HA

Rating Conditions (ISO T1)

The unit of pressure has been changed to Mpa on the international system of unit (SI unit system).

The converted score against the traditional unit system can be gotten according to the formula below.

1(Mpa)=10.2(OOf/FF)

4. OUTLET AIR SPEED AND COVERAGE RANGE

Air flow

Air speed

Coverage range

m3/min

m/sec

m

PCA-P3HA PCA-P5HA

19

2.9

7.9

13.2

38

4.2

19

Page 20

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

PCA-P3HA

NOTCH

Hi

Lo

SPL(dB)

38

34

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

PCA-P5HA

NOTCH

Hi

Lo

SPL(dB)

50

44

LINE

5. NOISE CRITERION CURVES

1m

1m

unit

about 1.4m

MICROPHONE

ceiling

20

Page 21

5

Ceiling

Less than

Less than

or more

Less than

or more

or more

300

<Suspension bolt pitch>

model:PAC-SG38KF-E (12pcs.)

Filter element for the exchange

1.Use M10 or W3/8 screw for anchor bolt.

NOTES.

Option parts:duct flange( [ 200). model: PAC-SF28OF-E(1 pcs.)

Knock out hole for wiring arrangement : 2- [ 27

(122)

<Filter contour dimension>

16

handle

100

1001136

366

480

176

318

650

<Flexible hose(accessory)>

Terminal block

9

Terminal block(remote controller)

8

Terminal block(indoor/outdoor connecting line)

78

Inspection port

(pipe sensor)

The half bottom of FAN CASING

can be separated.

Adjustable part

288

360

<Air outlet>

<Suspension bolt pitch>

<Air outlet>

<Air intake>

<Air intake>

Filter

Terminal block

5

2

1

4

3

Knock out hole for upper Refrigerant-pipe arrangement

6

9

2

1

Flexible hose(accessory)➔Drainage pipe connection(VP-25:pipe outside diameter [ 32)

2

Refrigerant-pipe connection(gas pipe side/flared connection : 5/8F)

38

105

85

90˚

Electrical box

Rear wall

500

250

2 ~ 3

(Gap to ceiling)

Allowing clearances

<gas>

<liquid>

7

Knock out hole (duct for fresh air intake): 2- [ 200

6

5

1

3

4

Knock out hole for left Refrigerant-pipe arrangement

Refrigerant-pipe connection(liquid pipe side/flared connection : 3/8F)

Suspension bolt

130

210

45

165

120

1224

1180

75

1136

986

1098

70

243

254

175

197

110

21

130 15

258 110 102

320 80

90

14018

75

70~90

650

13

289

75

280

495

43

295

[222

[200

OUTLINES AND DIMENSIONS

PCA-P3HA

Unit : mm

21

Page 22

Ceiling

Less than

Less than

Less than

or more

or more

or more

4

3156728

9

Refrigerant-pipe connection(gas pipe side/flared connection : 5/8F)

Knock out hole (duct for fresh air intake) : 2- [ 200

Option parts:duct flange( [ 200). model: PAC-SF28OF-E(1 pcs.)

Flexible hose(accessory)➔Drainage pipe connection(VP-25 : pipe outside diameter [ 32)

Terminal block(indoor/outdoor connecting line)

Terminal block(remote controller)

Refrigerant-pipe connection(liquid pipe side/flared connection : 3/8F)

Knock out hole for left Refrigerant-pipe arrangement

Knock out hole for upper Refrigerant-pipe arrangement

Knock out hole for wiring arrangement : 2- [ 27

Allowing clearances

Rear wall

(Gap to ceiling)

NOTES.

1.Use M10 or W3/8 screw for anchor bolt.

model:PAC-SG38KF-E (12pcs.)

Filter element for the exchange

<Suspension bolt pitch>

(122)246

handle

16

<Flexible hose(accessory)>

Terminal block

78

<Filter contour dimension>

Inspection port

(pipe sensor)

The half bottom of FAN CASING

can be separated.

Adjustable part

288

360

<Air outlet>

<Suspension bolt pitch>

<Air outlet>

<Air intake>

<Air intake>

Filter

Terminal block

5

2

1

4

3

6

9

2

1

176

38 210

105

8545

165

[222

[200

440440298

130

90˚

650

300

1001520100

Electrical box

500

250

2~3

<gas>

<liquid>

Suspension bolt

70

243

254

175

197

110

21

130 15

258

1482

110 102

1370 75

1608

320 801564

1520

90 120

14018

75

70~90

650

13

289

75

280

495

43

295

PCA-P5HA

Unit : mm

22

Page 23

6

J15

Service board

SW1

Manufacture

J14J13J12J11

4

OFF

ON

5321

PCA-P5HA

PCA-P3HA

1234

ON

OFF

Service board

MODELS

SW2

Manufacture

1234

ON

OFF

J24J23J22J21

J24J23J22J21

N

L

LEGEND

NAME

WHT

WHT

BLK

BLK

BLU

Symptom

Check code

Abnormality of room temperature thermistor(TH1).

Abnormality of pipe temperature thermistor/Liquid(TH2).

Freezing /overheating protection is working.

Abnormality of pipe temperature.

Abnormality of pipe temperature thermistor/ Condenser/Evaporator(TH5).

Abnormality of the signal transmission between remote

controller and indoor unit.

Abnormality of the signal transmission between indoor unit and

outdoor unit("EE" indicates abnormality of combination).

Abnormality in outdoor unit. Refer to outdoor unit wiring diagram.

Abnormality in outdoor unit. Refer to outdoor unit wiring diagram.

No trouble generated in the past.

No corresponding unit.

FFFF

----

F✱

U✱

E6—EF

E0—E5

P9

P8

P6

P2

P1

CONNECTING LINE)

SYMBOL

C1,C2

MF1,MF2 FAN MOTOR

CAPACITOR(FAN MOTOR)

CN2

TB6

TRANSMISSION LINE)

TERMINAL BLOCK(REMOTE CONTROLLER

CONNECTOR(PROGRAM TIMER)

REMOTE CONTROLLER BOARDR.B

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

CONDENSER / EVAPORATOR TEMPERATUR THERMISTOR

TH5

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

PIPE TEMPERATUR THERMISTOR/LIQUID

TH2

(0˚C/15kΩ, 25˚C/5.4kΩ DETECT)

ROOM TEMPERATUR THERMISTOR

TH1

TRANSMISSION LINE)

TB5

TERMINAL BLOCK(INDOOR/OUTDOOR

TB4

DEW PREVENTION HEATERH2

TERMINAL BLOCK(REMOTE CONTROLLER

SYMBOL NAME

X1

X4

X5

X6 RELAY(FAN MOTOR)

RELAY(FAN MOTOR)

RELAY(FAN MOTOR)

RELAY(DEW PREVENTION HEATER)

JUMPER WIRE(MODEL SELECTION)

JUMPER WIRE(CAPACITY CODE)

SWITCH(EMERGENCY OPERATION)

SWE

SW2

SW1

POWER SUPPLY(I.B)

POWER SUPPLY(R.B)

TRANSMISSION(INDOOR-OUTDOOR)

LED3

LED2

LED1

CONNECTOR(HA TERMINAL-A)CN41

CONNECTOR(REMOTE SWITCH)

CN32

CONNECTOR(LOSSNAY)CN2L

INDOOR CONTROLLER BOARDI.B

INDOOR POWER BOARD

FUSE(4A)

VARISTORZNR

F1

P.B

[Servicing]

Fasten terminal of the terminal board "TB4" equips lock system.

To remove the fastened terminal,pull it while pressing the protruding

portion(locking lever)of the terminal.The fastened terminal protruding

portion should face upward.

Please set the voltage using the

remote controller.

For the setting method,please refer to

the indoor unit installation Manual.

S1

S3

S2

TB1

TB1

S1

S2

S3

L1

L2

L3

N

POWER SUPPLY

3N~(3PHASE 4WIRES)

380-400-415V 50Hz

<PU(H)-P3/5YGAA

1.UK>

POWER SUPPLY

~(1PHASE)

220-230-240V 50Hz

<PU(H)-P3VGAA

1.UK>

OUTDOOR UNIT

WHT

BLK

BRN

ORN

YLW

BLU

BLU

YLW

WHT

BLK

BLU

YLW

WHT

YLW

YLW

BLK

RED

ORN

RED

BLK

BLU

YLW

WHT

WHT

YLW

BLU

BLK

RED

ORN

X4

CN32

CN2LCN41

1231X15

TH1

I.B

2

TB5

1

12

TB6

CN2

TH2

1

2

3

2

1

DC14V

CN2S(WHT)

CONT.BOARD

CN02(WHT)

1

2

3

OUTDOOR

CN01(BLU)

F1

TB4

S1

S2

S3

YLW

ORN

BRN

POWER

CN03

(RED)

POWER

CN2D(WHT)

REMOCON

CN22

(BLU)

LIQUID

CN21

(WHT)

INTAKE

CN20

(RED)

12

SW2

SWE

ON

OFF

J23

NOTES:

TRANSMISSION WIRES

DC12V

2121

INDOOR UNIT

R.B

LED1LED2LED3

FAN

(WHT)

1.Since the outdoor side electric wiring may change be sure to

check the outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities,make

wiring matching terminal numbers(S1,S2,S3).

3.Symbols used in wiring diagram above are, :Connector, :Terminal (block).

MF1

ORN

C1

23514

7531

6

X6

X5X6

31

X5 X4

D.HEATER

CNC (RED)

H2

ZNR

P.B

J24

X1

11

MF2

123456

C2

BRN

GRY

For

PCA-P5HA

J22

J21

SW1

J11

J12

J13

J14

J15

TH5

12

PIPE

CN29

(BLK)

12 13

WIRING DIAGRAM

PCA-P3HA

PCA-P5HA

23

Page 24

7 REFRIGERANT SYSTEM DIAGRAM

Indoor unit

Outdoor unit

Thermistor

(TH1)

Strainer

(#50)

Flared

connection

Flexible tube

Service

port

Accumulator

Ball valve

Compressor

Refrigerant pipe

15.88A({5/8")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Distributor

with

strainer

Thermistor

(TH6)

Distributor

with

strainer

Indoor coil

thermistor

(TH2)

Thermistor

(TH5)

Muffler

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Refrigerant flow in heating

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

Indoor unit

Outdoor unit

Thermistor

(TH2)

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L200)✕2pcs

Distributor

with

strainer

Flared

connection

Drier

Liner expansion valve

Bypass

valve

Thermistor

(TH5)

Thermistor

(TH1)

Muffler

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Capillary

tube w1

Refrigerant flow in cooling

Refrigerant flow in heating

w1 : O.D.4.0✕I.D.2.0-L400(PUH-P5YGAA

1.UK)

O.D.4.0✕I.D.3.0-L450(PUH-P6YGAA

1.UK)

Ball valve

(#50)

Strainer

Strainer

(#100)

Strainer

(#100)

Strainer

(#50)

Strainer

(#50)

Indoor unit

Outdoor unit

Thermistor

(TH1)

Flared

connection

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

15.88A({5/8")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Stop valve

(with service port)

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Distributor

with

strainer

Thermistor

(TH6)

Distributor

with

strainer

Indoor coil

thermistor

(TH2)

Thermistor

(TH5)

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

Strainer

(#50)

Indoor unit

Outdoor unit

Thermistor

(TH2)

Flexible tube

Service

port

Accumulator

Compressor

Refrigerant pipe

19.05A({3/4")

(with heat insulator)

Refrigerant pipe

9.52A({3/8")

(with heat insulator)

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L200)✕2pcs

Distributor

with

strainer

Flared

connection

Drier

Thermistor

(TH5)

Thermistor

(TH1)

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Refrigerant flow in cooling

Stop valve

(with service port)

Liner expansion valve

Ball valve

(#50)

Strainer

Strainer

(#100)

Strainer

(#100)

(#50)

Strainer

Strainer

(#50)

PCA-P3HA / PUH-3VGAA1.UK, PUH-3YGAA1.UK

PCA-P5HA / PUH-5YGAA1.UK

Unit : mm

<4-way valve solenoid coil>

Heating : ON

Cooling : OFF

PCA-P3HA / PU-3VGAA1.UK, PU-3YGAA1.UK

PCA-P5HA / PU-5YGAA1.UK

24

Page 25

8

Measure the resistance between the terminals using a tester.

(Winding temperature 20:)

Fan motor

Open or short

Abnormal

White

Orange

Yellow

Blue

Black

Red

Relay

connector

Protector

Protector

OPEN : 135i 5:

CLOSE: 95i 15:

White–Black

Brown–Blue

Blue–Yellow

Yellow–Red

Connector

PCH-P3HA

140.5"

15.4"

28.5"

80.4"

PCH-P5HA

75.6"

36.7"

23.6"

47.8"

Normal

Parts name Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

(Refer to the next pege for a detail.)

Room temperature

thermistor (TH1)

Pipe temperature

thermistor (TH2)

Condenser/Evaporator

temperature thermistor

(TH5)

Normal

4.3k"~9.6k"

Abnormal

Open or short

TROUBLESHOOTING

HOW TO CHECK THE PARTS

PCA-P3HA

PCA-P5HA

<Thermistor Characteristic graph>

Thermistor for

lower temperature

Room temperature thermistor(TH1)

Pipe temperature thermistor(TH2)

Condenser/evaporator temperature

thermistor(TH5)

Thermistor R0=15kΩ ±3%

Fixed number of B=3480kΩ ±2%

Rt=15exp { 3480( ) }

0: 15kΩ

10: 9.6kΩ

20: 6.3kΩ

25: 5.4kΩ

30: 4.3kΩ

40: 3.0kΩ

1

273+t

1

273

25

< Thermistor for lower temperature >

50

40

30

20

Resistance (K")

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

Page 26

9

Slide

DISASSEMBLY PROCEDURE

PCA-P5HA

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

1. Removing the oil filter

(1) Slide the oil filter towards you to remove. (See figure 1.)

2. Removing the terminal block box cover

(1) Remove the oil filter. (See figure 1.)

(2) Remove a screw for terminal block box cover, and remove

the terminal block box cover. (See photo 1.)

Figure 1

Oil filter

Photo 1

Filter rail Fan guard

Terminal

block box

Screw

Terminal

block box

cover

Clamp for

wiring

3. Removing the control box

(1) Remove the oil filter. (See figure 1.)

(2) Loosen a screw for control box cover to remove the con-

trol box cover. (See photo 2.)

(3) Remove the lead wire from the 2 clips.

(4) Remove the 2 white cord heater relay connectors (1P✕2)

and 2 fan motor relay connectors (6P✕2) in the control

box.

(5) Remove the 2 screws for control box to slide the control

box downward.

Electrical parts in the control box

• Fan motor capacitor

• Indoor controller board

• Power board

Photo 2

Screws for

control box

Screw for

control box

cover

Photo 3

Cord heater

relay

connectors

Power board

Fan motor

relay connectors

Clip for

lead wire

Pipe

temperature

thermistor

connector

(CN21)

Room

temperature

thermistor

connector

(CN20)

26

Fan motor

capacitor

Indoor

controller

board

Page 27

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

4. Removing the fan motor

(1) Remove the oil filter. (See figure 1.)

(2) Remove the control box cover. (See photo 2.)

(3) Remove the room temperature thermistor connector

(CN20) on the indoor controller board. (See photo 3.)

(4) Remove a filter rail that is the nearest to the control box.

(See photo 4.)

(5) Remove the fan guard. (See photo 5.)

(6) Remove the room temperature thermistor together with the

holder at the right side of the casing.

Photo 4

Screws for

filter reil

Photo 5

Control box

cover

Screws for Fan guard

Room

temperature

thermistor

Filter reil

Room

temperature

thermistor

Fan guard

Screws for Fan guard

5. Removing the fan motor and the sirocco fan

(1) Remove the oil filter. (See figure 1.)

(2) Remove the control box cover.

(See photo 2.)

(3) Remove the fan motor relay connectors (6P) in the control

box. (See photo 3.)

(4) Remove the 3 filter rails.

(5) Remove the fan guard.

(6) Remove the lower casing.

(See photo 1, 4.)

(See photo 5.)

(See photo 6.)

(7) Remove the green earth wire from the motor support.

(See photo 7.)

(8) Remove the 2 screws (M5 ✕ 12) for motor support, and

remove the left and right motor supports.

(9) Remove the fan motor together with the sirocco fan.

(10) Remove the 2 set screws (M6) to separate the fan motor

from the sirocco fan.

Photo 6

Screws for casing

Control box

cover

Photo 7

casing

Earth wire

Fan motor

Set screw

Screws for casing

casing

27

Sirocco fan

Screws for

motor support

Motor

support

Sirocco fan

Page 28

OPERATING PROCEDURE PHOTOS

6. Removing the pipe temperature thermistor

(1) Remove the oil filter. (See figure 1.)

(2) Remove the fan guard.

(See photo 1.)

(3) Remove the terminal block box cover.

(4) Remove the white relay connector (2P) in the terminal

block box. (See photo 8.)

(5) Remove the service panel. (See photo 9.)

(6) Remove the pipe temperature thermistor from the holder.

(See photo 10.)

Caution for installation

When installing the pipe temperature

thermistor, slack off its lead wire as

shown in the photo. Otherwise, water

trickled down the lead wire may splash

on the connector and this could cause

a short circuit of the connector.

Photo 8

Photo 9

Photo 10

Relay connector

Terminal block box

Service panel

Screw for

service panel

Inspection port

7. Removing the under panel

(1) Remove the oil filter. (See figure 1.)

(2) Remove the 3 filter rails. (See photo 1, 4.)

(3) Remove the 12 screws (left: 1, right: 1, Bottom: 10) for

under panel, and remove the under panel.

(See photo 11.)

8. Removing the drain pan

(1) Remove the oil filter. (See Figure 1)

(2) Remove the 3 filter rails. (See photo 1, 4.)

(3) Remove the under panel. (See photo 11.)

(4) Pull the blue lead wire for cord heater towards you to

slack off. (See photo 12.)

(5) Remove the 3 screws at the center of the drain pan, and

remove the drain pan.

Photo 11

Screw for

under panel

(left:1)

Photo 12

Pipe temperature

thermistor

Under panel

Slack off

Screw for under panel

(right:1)

Screws for under panel (Bottom:10)

Lead wire for

cord heater

(Note) Remove the drain pan carefully since the drain could

remain in it.

Screws for

drain pan

Drain pan

28

Page 29

OPERATING PROCEDURE PHOTOS

9. Removing the guide vane

(1) Remove the oil filter. (See figure 1.)

(2) Remove the 3 filter rails. (See photo 1, 4.)

(3) Remove the under panel. (See photo 11.)