Page 1

Air-Conditioners

PCA-A•KA4

INSTALLATION MANUAL

For safe and correct use, read this manual and the outdoor unit installation manual thoroughly before installing

the air-conditioner unit.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil extérieur pour une utilisation sûre et correct.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de

aire acondicionado.

FOR INSTALLER

POUR L’INSTALLATEUR

PARA EL INSTALADOR

English

Français

Español

Page 2

Contents

1. Safety precautions .....................................................................................2

2. Installation location .................................................................................... 3

3. Installing the indoor unit ............................................................................3

4. Installing the refrigerant piping .................................................................. 5

1. Safety precautions

Before installing the unit, make sure you read all the “Safety precau-

►

tions”.

Please report to your supply authority or obtain their consent before

►

connecting this equipment to the power supply system.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

Warning:

• Ask a dealer or an authorized technician to install the unit.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specifically made for use with refrigerant

specified in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to mini

mize the risk of damage from earthquakes, typhoons, or strong winds. An

incorrectly installed unit may fall down and cause damage or injuries.

The unit must be securely installed on a structure that can sustain its weight.

•

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration in the room from exceeding the

safety limit in the event of refrigerant leakage. Should the refrigerant leak

and cause the concentration limit to be exceeded, hazards due to lack of

oxygen in the room may result.

5. Drainage piping work .................................................................................6

6. Electrical work ...........................................................................................6

7. Test run ....................................................................................................10

8. Easy maintenance function (For wired remote controller only) ............... 12

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the

Operation Manual and perform the test run to ensure normal operation. Both the

Installation Manual and Operation Manual must be given to the user for keeping.

These manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affixed to the main unit.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a flame, poisonous gases will be released.

• All electric work must be performed by a qualified technician according to

local regulations and the instructions given in this manual.

• Use only specified cables for wiring.

-

• The terminal block cover panel of the unit must be firmly attached.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or

an authorized technician to install them.

• The user should never attempt to repair the unit or transfer it to another

location.

• After installation has been completed, check for refrigerant leaks. If refrigerant leaks into the room and comes into contact with the flame of a heater

or portable cooking range, poisonous gases will be released.

1.1. Before installation (Environment)

Caution:

• D

o not use the unit in an unusual environment. If the air conditioner is installed in areas exposed to steam, volatile oil (including machine oil), or sulfuric gas, areas exposed to high salt content such as the seaside, the performance can be significantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

flow, or accumulate. If combustible gas accumulates around the unit, fire or

explosion may result.

• Do not keep food, plants, caged pets, artwork, or precision instruments in

the direct airflow of the indoor unit or too close to the unit, as these items

can be damaged by temperature changes or dripping water.

1.2. Before installation or relocation

Caution:

• Be extremely careful when transporting the units. Two or more persons are

needed to handle the unit, as it weighs 20 kg, 44 lbs or more. Do not grasp

the packaging bands. Wear protective gloves as you can injure your hands

on the fins or other parts.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause stabs or other

injuries.

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of sufficient capacity. Otherwise,

a short circuit, overheating, or fire may result.

• When installing the power lines, do not apply tension to the cables.

• When the room humidity exceeds 80% or when the drainpipe is clogged,

water may drip from the indoor unit. Do not install the indoor unit where

such dripping can cause damage.

• When installing the unit in a hospital or communications office, be prepared for noise and electronic interference. Inverters, home appliances,

high-frequency medical equipment, and radio communications equipment

can cause the air conditioner to malfunction or breakdown. The air conditioner may also affect medical equipment, disturbing medical care, and

communications equipment, harming the screen display quality.

• Thermal insulation of the refrigerant pipe is necessary to prevent condensation. If the refrigerant pipe is not properly insulated, condensation will be

formed.

Place thermal insulation on the pipes to prevent condensation. If the drain-

•

pipe is installed incorrectly, water leakage and damage to the ceiling, floor,

furniture, or other possessions may result.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all flare nuts to specification using a torque wrench. If tightened

too much, the flare nut can break after an extended period.

• Be sure to ground the unit. If the unit is not properly grounded, electric

shock may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse),

and molded case circuit breaker) with the specified capacity. If the circuit

breaker capacity is larger than the specified capacity, breakdown or fire

may result.

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation. Starting operation just after turning on the power switch can severely

damage the internal parts.

• Before starting operation, check that all panels, guards and other protective parts are correctly installed. Rotating, hot, or high voltage parts can

cause injuries.

2

Do not operate the air conditioner without the air filter set in place. If the air

•

filter is not installed, dust may accumulate and breakdown may result.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the refrigerant pipes with bare hands during operation.

• After stopping operation, be sure to wait at least five minutes before turn

ing off the main power switch. Otherwise, water leakage or breakdown may

result.

-

Page 3

2. Installation location

Min. 11-13/16

W

Min. 10-5/8

26-3/4

Fig. 2-1

Max. 9-13/16

3. Installing the indoor unit

70+6

Fig. 3-1

A

3-1/812-5/8

26-3/4

9-5/16

Min. 19-11/16

9-5/16

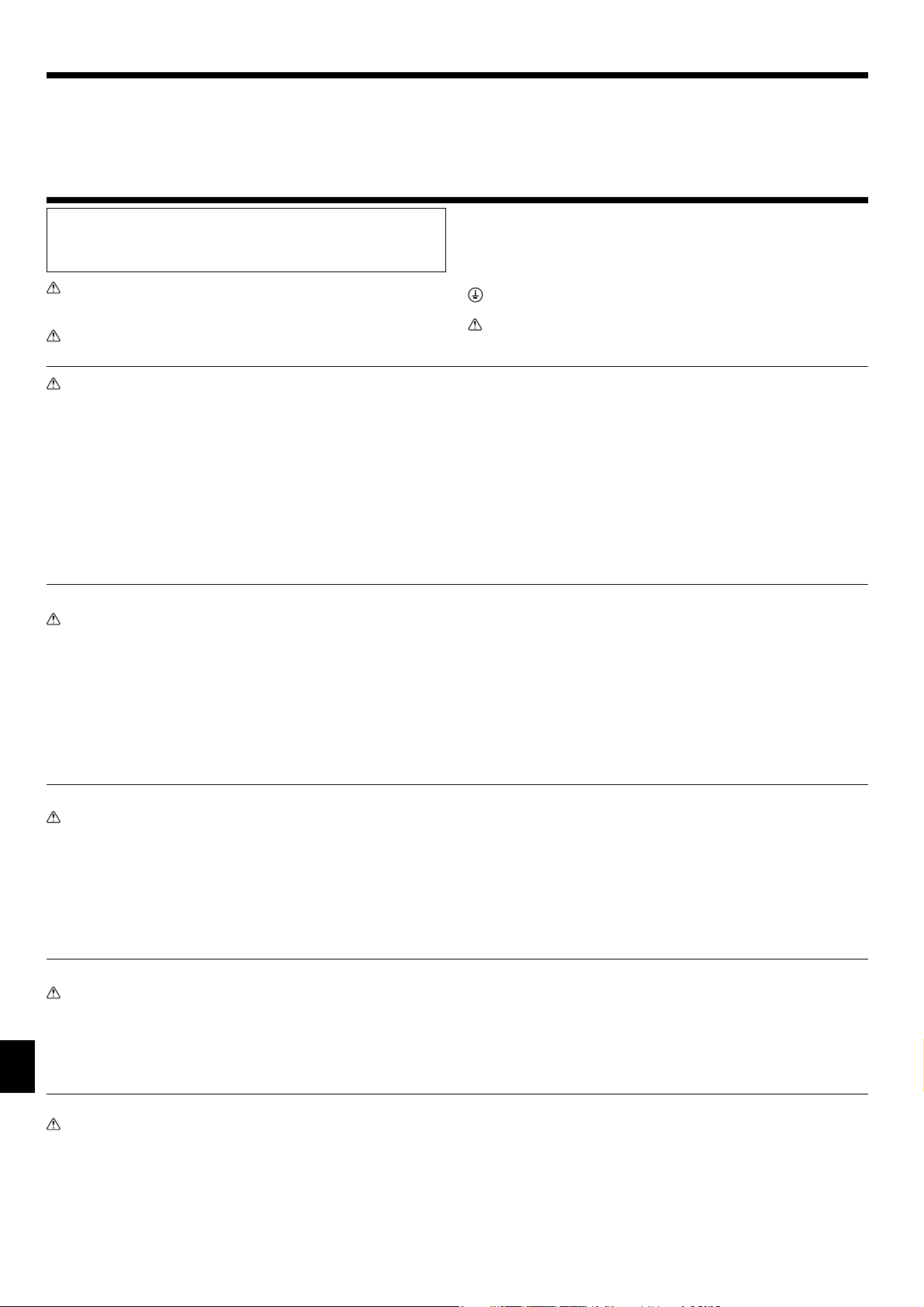

2.1. Outline dimensions (Indoor unit) (Fig. 2-1)

Select a proper position allowing the following clearances for installation and maintenance.

(inch)

Models W

A24, 30 50-3/8

A36, 42 63

Warning:

Mount the indoor unit on a ceiling strong enough to withstand the weight of

the unit.

2.2. Outline dimensions (Outdoor unit)

Refer to the outdoor unit installation manual.

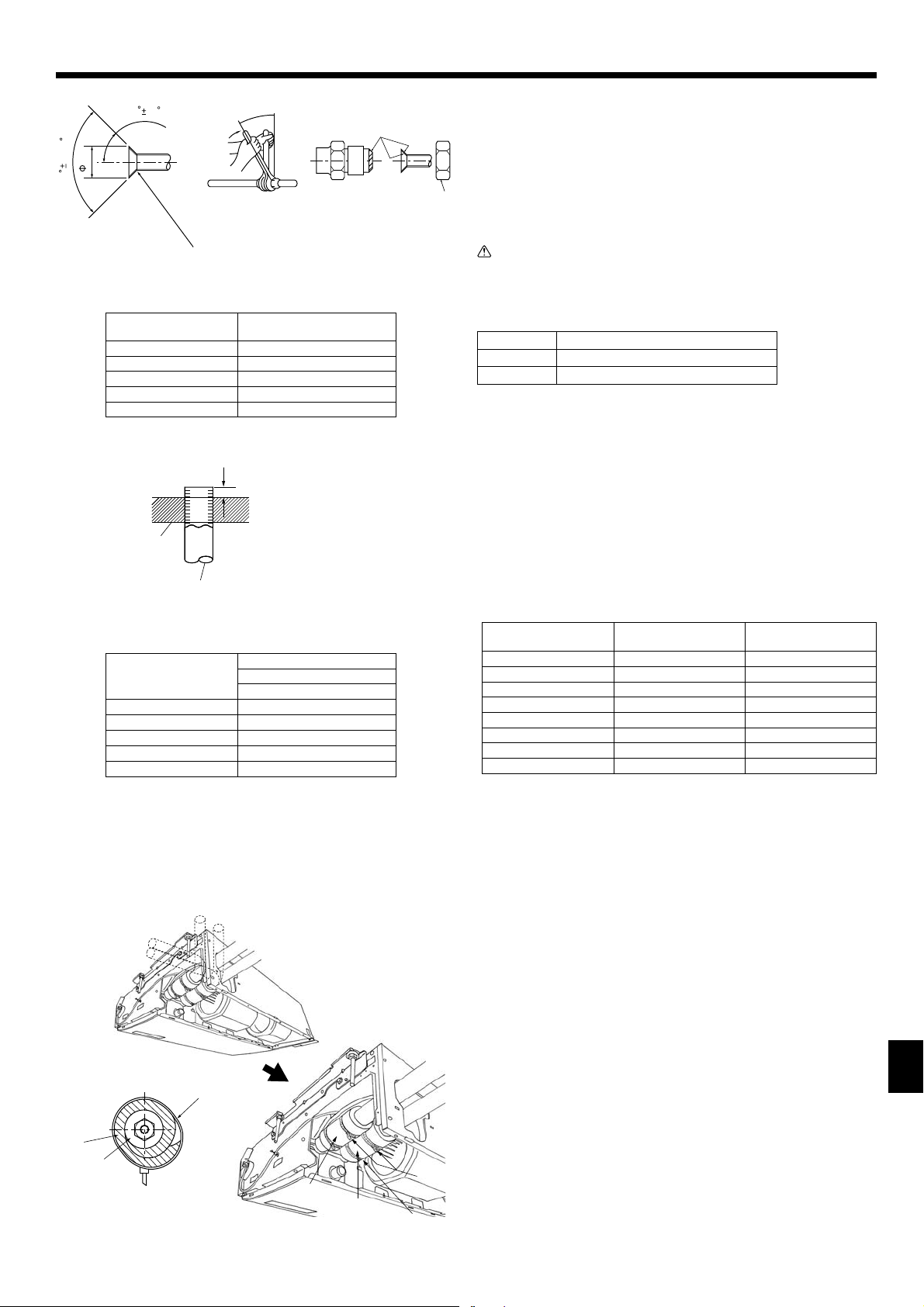

3.1. Check the indoor unit accessories (Fig. 3-1)

The indoor unit should be supplied with the following accessories

(contained in the inside of the intake grille).

Accessory name Q’ty

Washer 4 pcs

Pipe cover 1 pc Large size (For gas tubing)

Pipe cover 1 pc Small size (For liquid tubing)

Band 4 pcs

Joint socket 1 pc Marked with “UNIT”

Socket cover 1 pc

Drain tubing cover 1 pc

3.2. Preparation for installation (Fig. 3-2)

3.2.1. Suspension bolt installing spacing

Models A B

A24,30 48-11/16 50-3/8

A36,42 61-5/16 63

(inch)

1/16

7-1/21-13/16

9-3/16

9-11/16

B

1/4

2-15/16

Fig. 3-2

3-1/8 Ø2-9/16 Ø3-15/16

1/16

3-3/8

3-3/8

1/16

4-15/16

7-1/2

5-7/16

6-5/167-1/2

4-15/16

7-1/16

7-7/8

9-3/16

9-11/16

2-3/4

1-13/16

Front side outlet

Left side outlet

Right side outlet

Independent piece (Removable)

Right drain tubing

In case of the rear pipe arrangement, make sure to remove the shaded portions

from the independent piece. Then put the independent piece back in initial

position.

(The heat exchanger might be clogged because of dust)

Left drain tubing

Gas tubing

Liquid tubing

Rubber plug

with Joint socket

3.2.3. Selection of suspension bolts and tubing positions (Fig. 3-3)

Caution:

Install the indoor unit at least 8 ft. (2.4 m) above floor or grade level. For

appliances not accessible to the general public.

Using the pattern paper provided for installation, select proper positions for suspension bolts and tubing and prepare relative holes.

Pattern paper

Suspension bolt hole

Indoor unit width

Secure the suspension bolts or use angle stock braces or square timbers for bolt

installation.

Use inserts of 220-230 lbs. each.

Use suspension bolts of W 3/8 or M10 in size.

3.2.2. Refrigerant and drain tubing location

Fig. 3-3

3

Page 4

3. Installing the indoor unit

A

B

Fig. 3-4

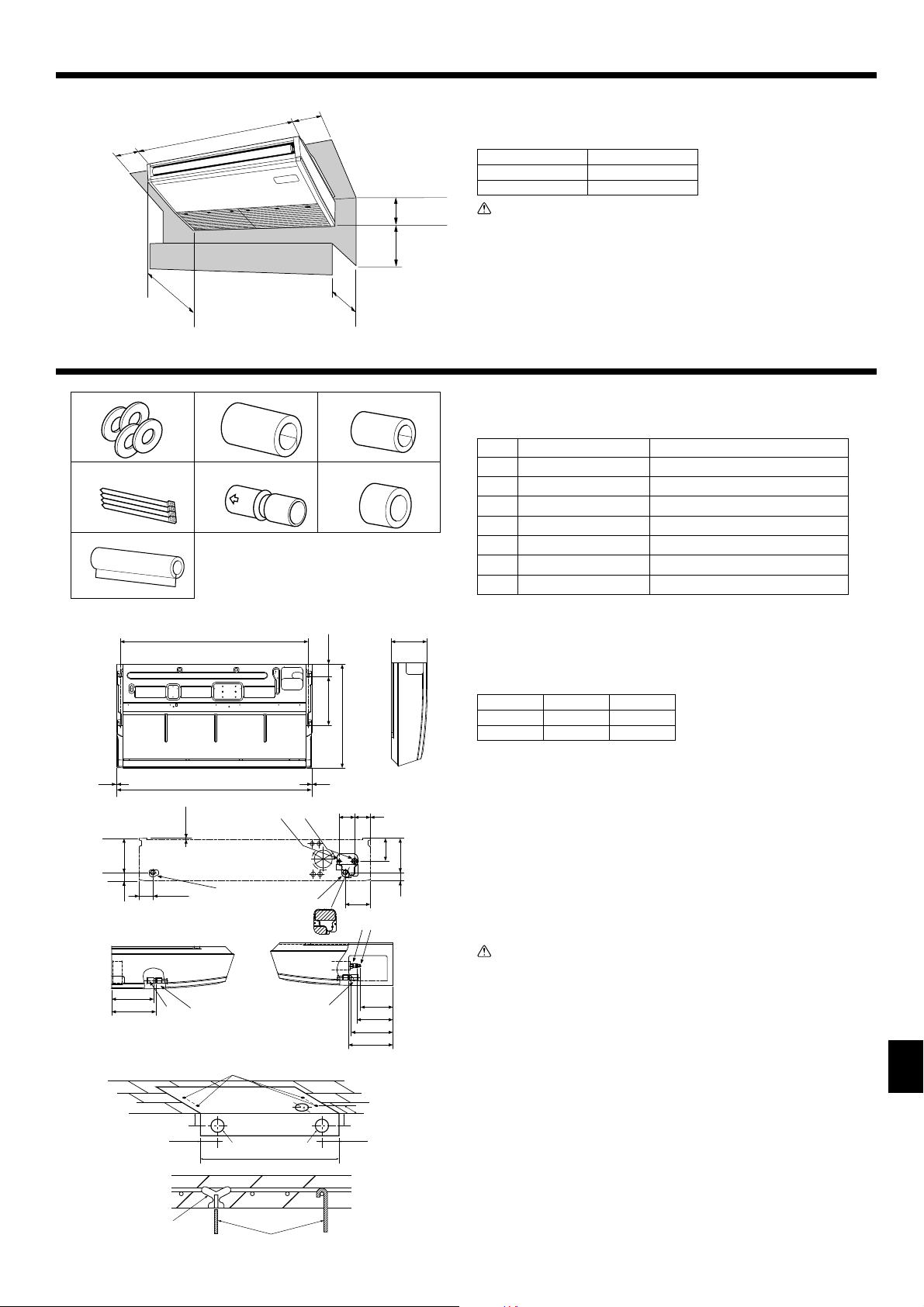

3.2.4. Fresh air intake hole (Fig. 3-4)

At the time of installation, use the duct holes (knock out) located at the positions

shown in following diagram, as and when required.

Indoor unit

Fresh air intake hole (knock out hole)

Filter

in. (mm)

C

ABC

10-3/16

(259.5)

ø 3-15/16

(ø 100)

4-5/16

(109)

3.2.5. Indoor unit preparation (Fig. 3-5)

1. Install the suspending bolts. (Procure the W 3/8 or M10 bolts locally.)

Predetermine the length from the ceiling ( within 3-15/16 in. (100 mm)).

Ceiling surface Suspending bolt Suspending bracket

2. Remove the intake grille.

Slide the intake grille holding knobs (at 2 or 3 locations) backward to open the

intake grille.

3. Remove the side panel.

Remove the side panel holding screws (1 in each side, right and left) then slide

the side panel forward for removal.

Intake grille

Intake grille holding knob

Slide

Hinge

Pushing the hinge, pull out the intake grille.

Forcing open the intake grille or opening it to an angle of more than 120° may

damage the hinges.

Slide the side panel forward.

Side panel

Remove the side panel holding screws.

Remove the protective vinyl of vane.

Fig. 3-5

0

/ 5

2

5

/

3

(inch)

1

25/64-25/32

3

0

22

4

3

5

Fig. 3-6

1/4-15/32

3.3. Installing the indoor unit (Fig. 3-6)

Use a proper suspending method depending on the presence or absence of ceiling

materials as follows.

In the presence of ceiling materials1 Ceiling

In the absence of ceiling materials2 Suspending bolt

Suspending bracket

/

Unit

0

1) Directly suspending the unit

Installing procedures

1. Install the washer (supplied with the unit) and the nuts (to be locally procured).

2. Set (hook) the unit through the suspending bolts.

3. Tighten the nuts.

Check the unit installing condition.

• Check that the unit is horizontal between the right and left sides.

• Check that the front and the rear of suspending brackets are horizontal.

(To keep drainage, the unit is inclined to the suspending brackets. The unit

slopes continuously downward from the front to the rear is the right installation

position.)

2)

Installing the suspending bracket first onto the ceiling (Fig. 3-7)

Installing procedures

1. Remove the suspending brackets and U-shaped washers from the unit.

2. Adjust the suspending bracket holding bolts on the unit.

3. Attach the suspending brackets to the suspending bolts.

4. Check that the suspending brackets are horizontal (front and rear/right and left).

5. Set (hook) the unit to the suspending brackets.

6. Tighten fixed bolts of the suspending brackets.

Be sure to install the U-shaped washers.

+

Suspending bracket holding bolt

Unit

U-shaped washer

Suspending bolt

Washer

Double nuts

Washer

3

Washer (Local procurement)

4

Double nuts

5

A24,30 47 - 5/10

A36,42 59 - 7/8

(inch)

Fig. 3-7

4

Page 5

4. Installing the refrigerant piping

45 2

A

90 0.5

R1/64 to R1/32

Fig. 4-1

Flare cutting dimensions in. (mm)

Copper pipe O.D.

1/4” (ø6.35) 11/32-23/64 (8.7 - 9.1)

3/8" (ø9.52) 1/2-33/64 (12.8 - 13.2)

1/2" (ø12.7) 41/64-21/32 (16.2 - 16.6)

5/8" (ø15.88) 49/64-25/32 (19.3 - 19.7)

3/4" (ø19.05) 29/32-59/64 (22.9 - 23.3)

Flare dimensions

øA dimensions

B

Die

Copper pipe

Fig. 4-2

in. (mm)

Copper pipe O.D.

1/4” (ø6.35) 0-1/64 (0 - 0.5)

3/8" (ø9.52) 0-1/64 (0 - 0.5)

1/2" (ø12.7) 0-1/64 (0 - 0.5)

5/8" (ø15.88) 0-1/64 (0 - 0.5)

3/4" (ø19.05) 0-1/64 (0 - 0.5)

B

Flare tool for R410A

Clutch type

4.1. Precautions

For devices that use R410A refrigerant

• Use ester oil, ether oil or alkylbenzene oil (small amount) as the refrigeration oil applied to the flared sections.

• Use C1220 copper phosphorus for copper and copper alloy seamless

pipes, to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses specified in the table below. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust.

Warning:

When installing or moving the air conditioner, use only the specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. Air enclosed in the lines can

cause pressure peaks resulting in a rupture and other hazards.

in. (mm)

A24, 30, 36, 42

Liquid pipe 3/8" (ø9.52) thickness 1/32" (0.8)

Gas pipe 5/8" (ø15.88) thickness 3/64" (1.0)

• Do not use pipes thinner than those specified above.

4.2. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 212 °F (100 °C)

or more, thickness of 1/2 in. (12 mm) or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam insulation materials (specific gravity of 0.03, thickness of 23/64 in. (9 mm) or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

flare nut.

• Use 2 wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections. Insulate carefully.

Flare nut tightening torque

Copper pipe O.D.

(mm, inch)

ø6.35, 1/4 17, 43/64 14-18, 10-13

ø6.35, 1/4 22, 7/8 34-42, 25-30

ø9.52, 3/8 22, 7/8 34-42, 25-30

ø12.7, 1/2 26, 1-3/64 49-61, 35-44

ø12.7, 1/2 29, 1-9/64 68-82, 49-59

ø15.88, 5/8 29, 1-9/64 68-82, 49-59

ø15.88, 5/8 36, 1-27/64 100-120, 71-86

ø19.05, 3/4 36, 1-27/64 100-120, 71-86

Apply refrigerating machine oil over the entire flare seat surface.

Use correct flare nuts meeting the pipe size of the outdoor unit.

Flare nut O.D.

(mm, inch)

Tightening torque

(N-m, ft.lbs)

Fig. 4-3

4.3. Indoor unit (Fig. 4-3)

Installing procedures

1. Slide the supplied pipe cover over the gas tubing until it is pressed against the

sheet metal inside the unit.

2. Slide the provided pipe cover over the liquid tubing until it is pressed against

the sheet metal inside the unit.

3. Tighten the pipe covers and at the both ends 3/4 in. (20 mm) with the supplied bands .

Gas tubing

Liquid tubing

Band

Pipe cover

Pipe cover

Press the pipe cover against the sheet metal.

Refrigerant tubing heat insulating material

4.4. For twin combination

Refer to the outdoor unit installation manual.

5

Page 6

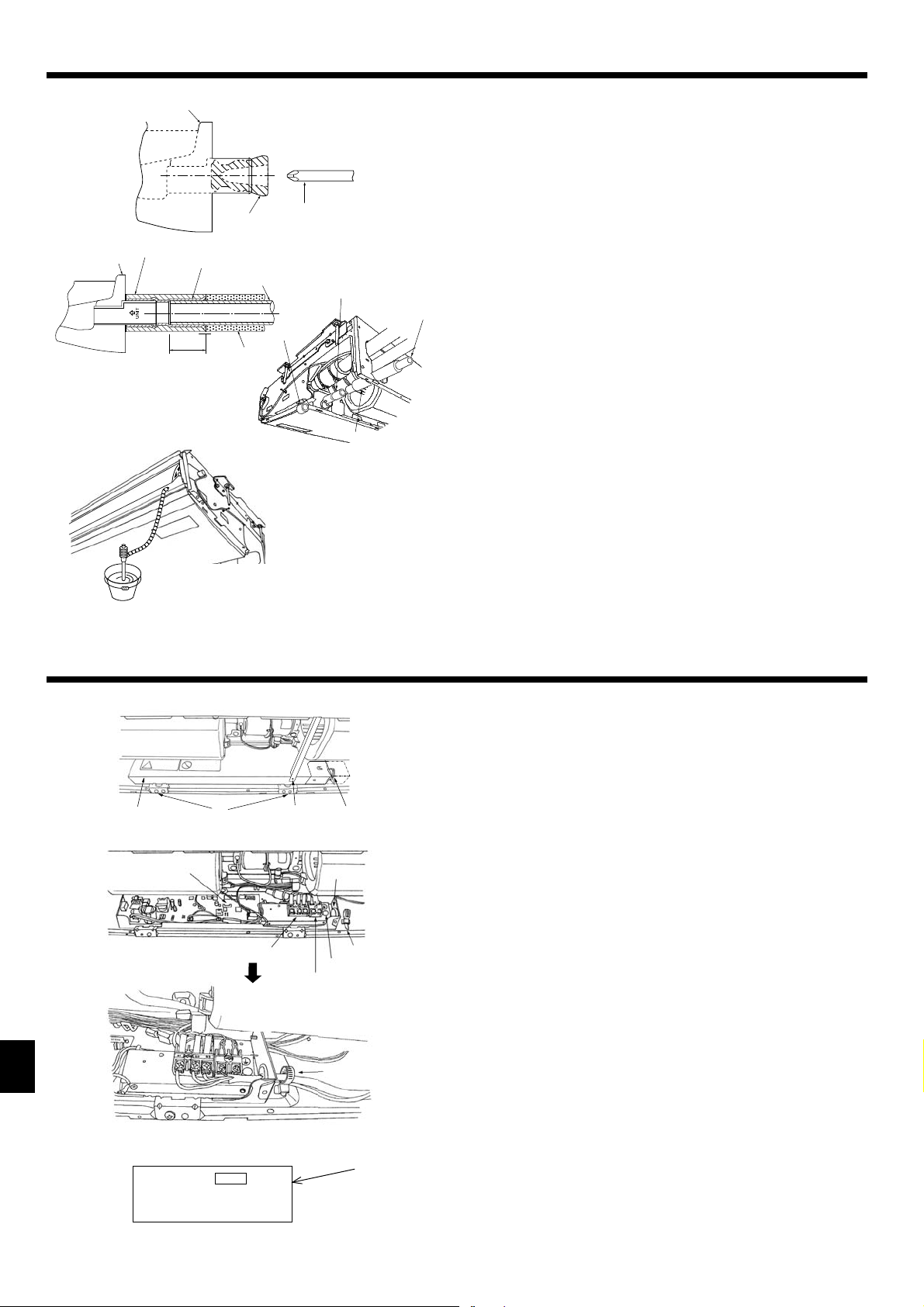

5. Drainage piping work

Fig. 5-2

• For left side tubing, be sure to insert the rubber plug into the right drain port. (Fig.

5-1)

• Use VP-20 (O.D. ø26 (1”) PVC TUBE) for drain piping and provide 1/100 or more

downward slope.

• After completion of work, check that correct drain is available from the outfl ow

port of the drain tubing.

Drain pan

Plug

Insert the driver etc.in the plug deeply.

Fig. 5-1

Installing procedures (Fig. 5-2)

1. Attach the joint socket supplied with the unit to the drain port on the unit with a

vinyl chloride adhesive.

2. Fasten the socket cover supplied with the unit to the joint socket .

3. Attach the fi eld drain tubing (VP-20) to the joint socket with a vinyl chloride

adhesive.

4. Wrap the drain tubing cover supplied with the unit. (Seam taping)

Drain pan

Drain tubing

Socket cover

Joint socket

Drain tubing cover

Insertion length 1-15/32 in. (37mm)

5. Check for correct drainage. (Fig. 5-3)

* Fill the drain pan with water of about 1/4 gal (1 L) from the air outlet.

6. Electrical work

Fig. 5-3

6.1. Electric wiring

Wiring procedures

1. Remove the tapping screw then remove the beam.

2. Remove the (2) tapping screws then remove the electric part cover .

3. For radio frequency interface.

Connect the electric cord of radio frequency interface securely to CN105 (RED)

on indoor controller board.

For wired remote controller

Connect the electric wires securely to the corresponding terminals (Fig. 6-1)

4. Replace the removed parts.

5. Tie the electric wires with the local wiring clamp located in the right side of the

junction box.

Cover

Set screws (2 pcs)

Set screws (Beam)

Wiring clamp

Indoor controller board

Wire service entrance

Terminal block for indoor and outdoor units connection

Grounding cable connector

Terminal block for wired remote controller

Secure with the wiring clamp.

7

7

Fig. 6-1

CN105

(RED)

Fig. 6-2

6

Page 7

6. Electrical work

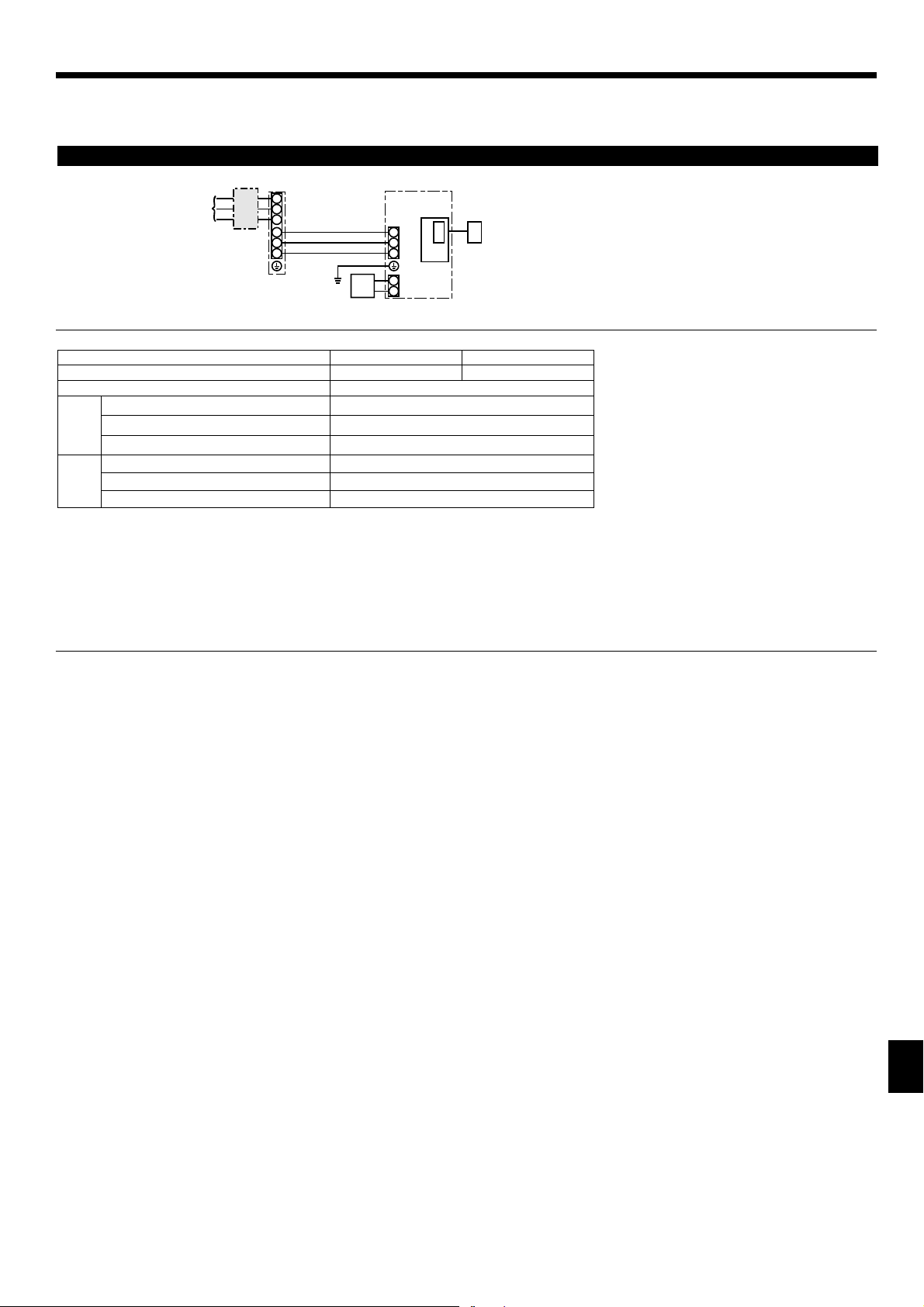

6.1.1. Indoor unit power supplied from outdoor unit

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

1 System

1:1 System

L1

L2

GR

S1

S2

S3

*

Affix a label A that is included with the manuals near each wiring diagram for the indoor and outdoor units.

CN105

(RED)

S1

S2

S3

1

2

Outdoor unit power supply

Wiring circuit breaker or isolating switch

Outdoor unit

Indoor unit/outdoor unit connecting cords

Wired remote controller

Indoor unit

Indoor unit earth

Indoor controller board

Radio frequency interface for RF thermostat

Indoor unit model PCA-A24,30 PCA-A36, 42

Minimum circuit ampacity 1A 2A

Maximum rating of overcurrent protective device 15A

Indoor unit-Outdoor unit *1 3 × AWG16 (polar)

Indoor unit earth 1 × Min. AWG16

× size

Wiring

Wire No.

Wired remote controller-Indoor unit *2 2 × AWG22 (Non-polar, unshielded)

Indoor unit-Outdoor unit S1-S2 *3 AC 208/230 V

Indoor unit-Outdoor unit S2-S3 *3 DC24 V

rating

Circuit

Wired remote controller-Indoor unit *3 DC12 V

*1. Max. 50 m, 165 ft

*2. The 10 m, 30 ft wire is attached in the wired remote controller accessory. Max. 500 m, 1500 ft

*3. The figures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are not electrically insulataed by the transformer or other device.

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Use copper supply wires.

3. Use wires rated 600V or more for the power supply cables and the indoor unit/outdoor unit connecting cables.

4. Install an earth longer than other cables.

6.2. Remote controller

6.2.1. For wired remote controller

1) 2 wired remote controllers setting

If 2 wired remote controllers are connected, set one to “Main” and the other to “Sub”.

For setting procedures, refer to “Function selection of remote controller” in the operation manual for the indoor unit.

7

Page 8

6. Electrical work

MODEL SELECT

ON/OFF TEMP

FAN

VANE

MODE

CHECK

LOUVER

TEST RUN

RESETSET CLOCK

Fig. 6-3

AUTO STOP

AUTO START

h

min

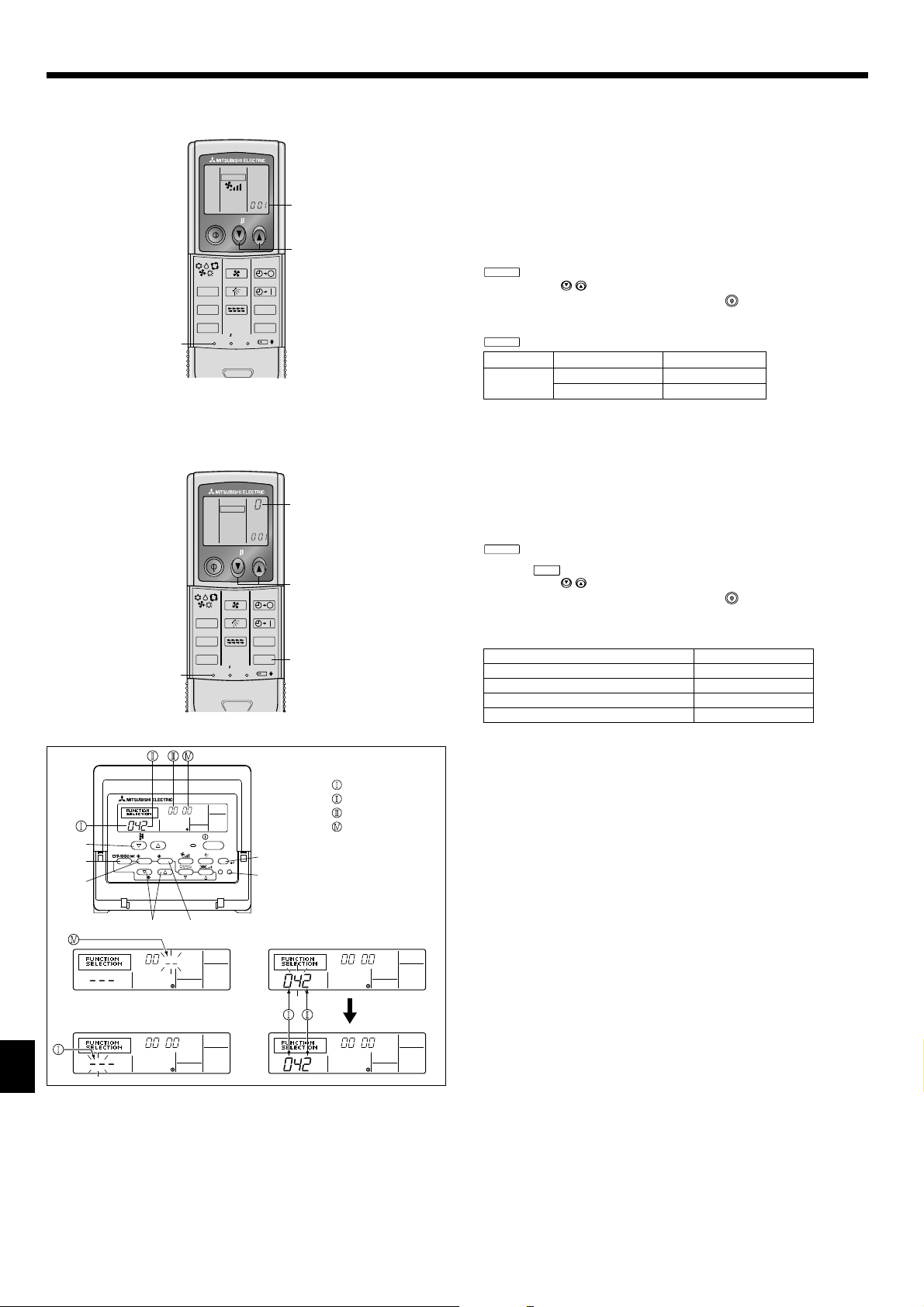

6.2.2. For IR wireless remote controller

1) Installation area

• Area in which the IR wireless remote controller is not exposed to direct sunshine.

• Area in which there is no nearby heating source.

• Area in which the IR wireless remote controller is not exposed to cold (or hot)

winds.

• Area in which the IR wireless remote controller can be operated easily.

• Area in which the IR wireless remote controller is beyond the reach of children.

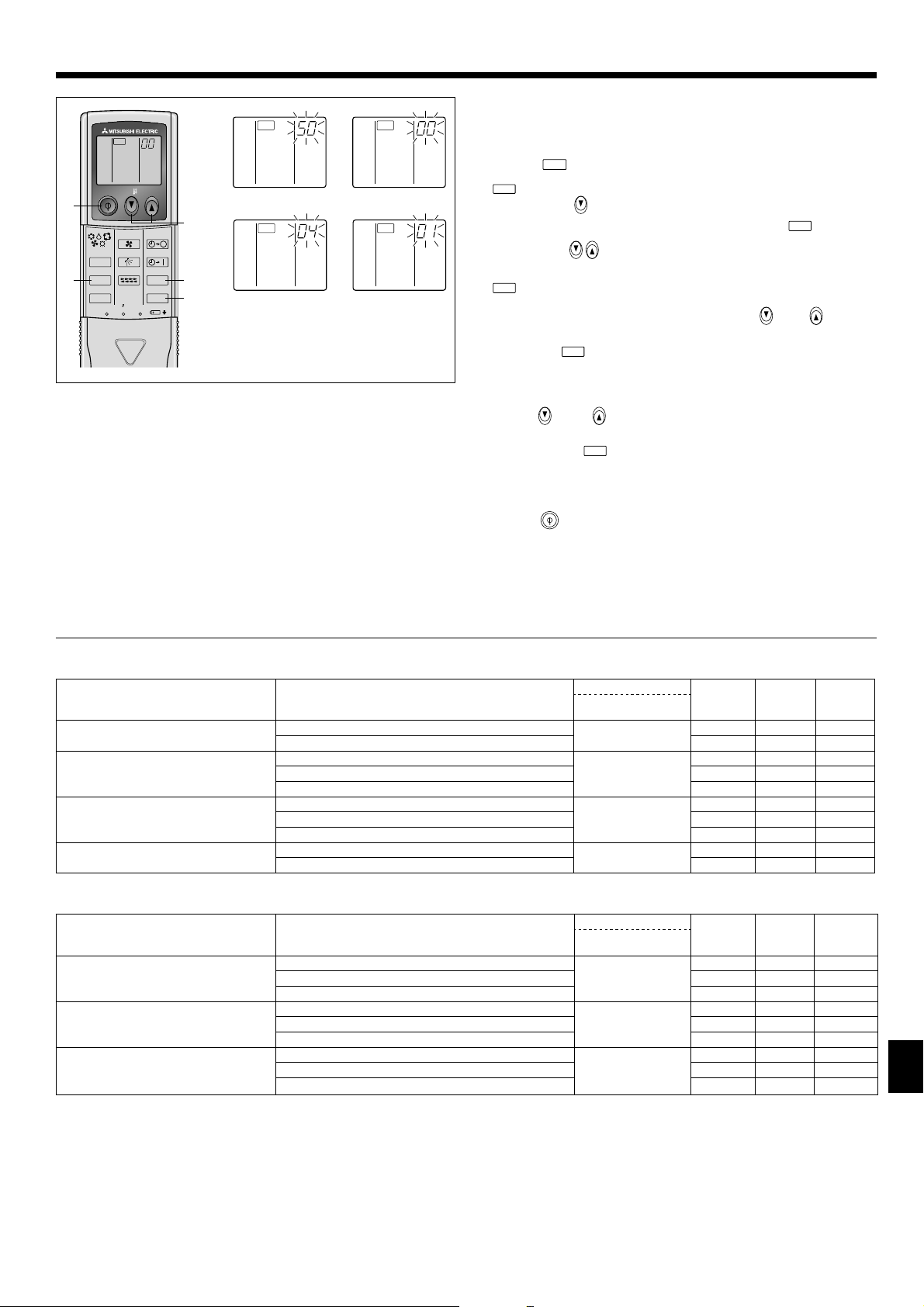

2) Setting (Fig. 6-3)

Insert batteries.

Press the SET button with something sharp at the end.

MODEL SELECT

blinks and Model No. is lighted.

Press the temp

buttons to set the Model No.

If you mistook the operation, press the ON/OFF

button and operate again

from procedure .

Press the SET button with something sharp at the end.

3)

and Model No. are lighted for 3 seconds, then turned off.

MODEL SELECT

Indoor Outdoor

PCA

PUZ 001

PUY 033

Model No.

Assigning a IR wireless remote controller to each unit

Each unit can be operated only by the assigned IR wireless remote controller.

Make sure each pair of an indoor unit PC board and a IR wireless remote controller

is assigned to the same pair No.

MODEL SELECT

Press the SET button with something sharp at the end.

Start this operation from the status of IR wireless remote controller display

turned off.

4) IR wireless remote controller pair number setting operation (Fig. 6-4)

MODEL SELECT

blinks and Model No. is lighted.

min

button twice continuously. Pair No. “0” blinks.

buttons to set the pair number you want to set.

If you mistook the operation, press the ON/OFF

from procedure .

Pair No. of IR wireless remote controller Indoor PC board

0 Initial setting

1 Cut J41

2 Cut J42

3-9 Cut J41, J42

button and operate again

ON/OFF TEMP

FAN

VANE

MODE

LOUVER

CHECK

TEST RUN

RESETSET CLOCK

AUTO STOP

AUTO START

h

min

Press the

Press the temp

Press the SET button with something sharp at the end.

Set pair number is lighted for 3 seconds then turned off.

Fig. 6-4

6.3. Function settings

6.3.1 Function setting on the unit (Selecting the unit functions)

Mode number

Setting number

Refrigerant address

F

E

G

TEMP.

MENU

MONITOR/SET

BACK DAY

PAR-21MAA

ON/OFF

CLOCK

OPERATION

ON/OFF

CHECK

CLEAR

FILTER

A

TEST

B

Unit number

DC

Fig. 6-5

1) For wired remote controller (Fig. 6-5)

Changing the power voltage setting

• Be sure to change the power voltage setting depending on the voltage used.

Go to the function setting mode.

Switch OFF the wired remote controller.

Press the and buttons simultaneously and hold them for at least 2

seconds. FUNCTION will start to flash.

Use the button to set the refrigerant address () to 00.

Press and [--] will start to flash in the unit number () display.

Use the button to set the unit number () to 00.

Press

the MODE button to designate the refrigerant address/unit number. [--]

will flash in the mode number () display momentarily.

Press the buttons to set the mode number () to 04.

Press the button and the current set setting number () will flash.

Use

button to switch the setting number in response to the power supply

the

voltage to be used.

Power supply voltage

230 V : setting number = 1

208 V : setting number = 2

Press the MODE button and mode and the setting number () and () will

change to being on constantly and the contents of the setting can be confirmed.

Press the FILTER and TEST RUN buttons simultaneously for at least two

seconds. The function selection screen will disappear momentarily and the air

conditioner OFF display will appear.

8

Page 9

6. Electrical work

CHECK

ON/OFF TEMP

E

AUTO STOP

AUTO START

h

min

C,D

A

B

FAN

VANE

MODE

LOUVER

CHECK

F

TEST RUN

RESETSET CLOCK

Fig. 6-6

CHECK

2) For IR wireless remote controller (Fig. 6-6)

CHECKCHECK

Changing the power voltage setting

• Be sure to change the power voltage setting depending on the voltage used.

Go to the function select mode

Press the

CHECK

button twice continuously.

(Start this operation from the status of IR wireless remote controller display turned off.)

is lighted and “00” blinks.

CHECK

Press the temp

CHECK

controller toward the receiver of the indoor unit and press the

Setting the unit number

Press the temp

button once to set “50”. Direct the IR wireless remote

h

button .

button and to set the unit number “00”. Direct the IR

wireless remote controller toward the receiver of the indoor unit and press the

min

button .

Selecting a mode

Enter 04 to change the power voltage setting using the

Direct the IR wireless remote controller toward the receiver of the indoor unit

and press the

h

button .

and buttons.

Current setting number: 1 = 1 beep (one second)

2 = 2 beeps (one second each)

3 = 3 beeps (one second each)

Selecting the setting number

Use the

(230 V). Direct the IR wireless remote controller toward the sensor of the indoor

unit and press the

To select multiple functions continuously

and buttons to change the power voltage setting to 01

h

button .

Repeat steps and to change multiple function settings continuously.

Complete function selection

Direct the IR wireless remote controller toward the sensor of the indoor unit and

press the

button .

Note: Whenever changes are made to the function settings after installation

or maintenance, be sure to record the changes with a mark in the

“Setting” column of the Function table.

6.3.2 Function setting on the remote controller

For details on how to operate the remote controller, refer to the appropriate operation manual included with each remote controller.

Function table

Select unit number 00

Mode Settings

Power failure automatic recovery Not available

Indoor temperature detecting Indoor unit operating average

LOSSNAY connectivity Not Supported

Power voltage 230 V

Select unit numbers 01 to 03 or all units (AL [wired remote controller]/07 [wireless remote controller])

Mode Settings

Filter sign 100Hr

Fan speed Silent

Up/down vane setting No vanes

When the power supply returns, the air conditioner will start 3 minutes later.

+

Available

Set by indoor unit’s remote controller 2

Wired remote controller’s internal sensor 3

Supported (indoor unit is not equipped with outdoor-air intake)

Supported (indoor unit is equipped with outdoor-air intake) 3

208 V 2Ο

2500Hr 2Ο

No filter sign indicator 3

Standard 2 Ο

High ceiling 3

Equipped with vanes (vanes angle setup )2Ο

Equipped with vanes (vanes angle setup )

Wired remote controller

(RF thermostat)

+

Wired remote controller

(RF thermostat)

Mode no.

01

(101)

02

(—)

03

(103)

04

(104)

Mode no.

07

(107)

08

(108)

11

(111 )

Setting no.

Initial setting

1

2Ο

1Ο

1Ο

2

1

Setting no.

Initial setting

1

1

1

3

setting

setting

9

Page 10

7. Test run

7.1. Before test run

► After completing installation and the wiring and piping of the indoor and

outdoor units, check for refrigerant leakage, looseness in the power supply or control wiring, wrong polarity, and no disconnection of one phase

in the supply.

Use a 500-volt megohmmeter to check that the resistance between the

►

power supply terminals and ground is at least 1.0 MΩ.

7.2. Test run

Refer to the installation manual that comes with each remote controller for details.

7.3. Self-check

Refer to the installation manual that comes with each remote controller for details.

RF thermostat is not established.

• Refer to the following tables for details on the check codes. (IR wireless remote controller)

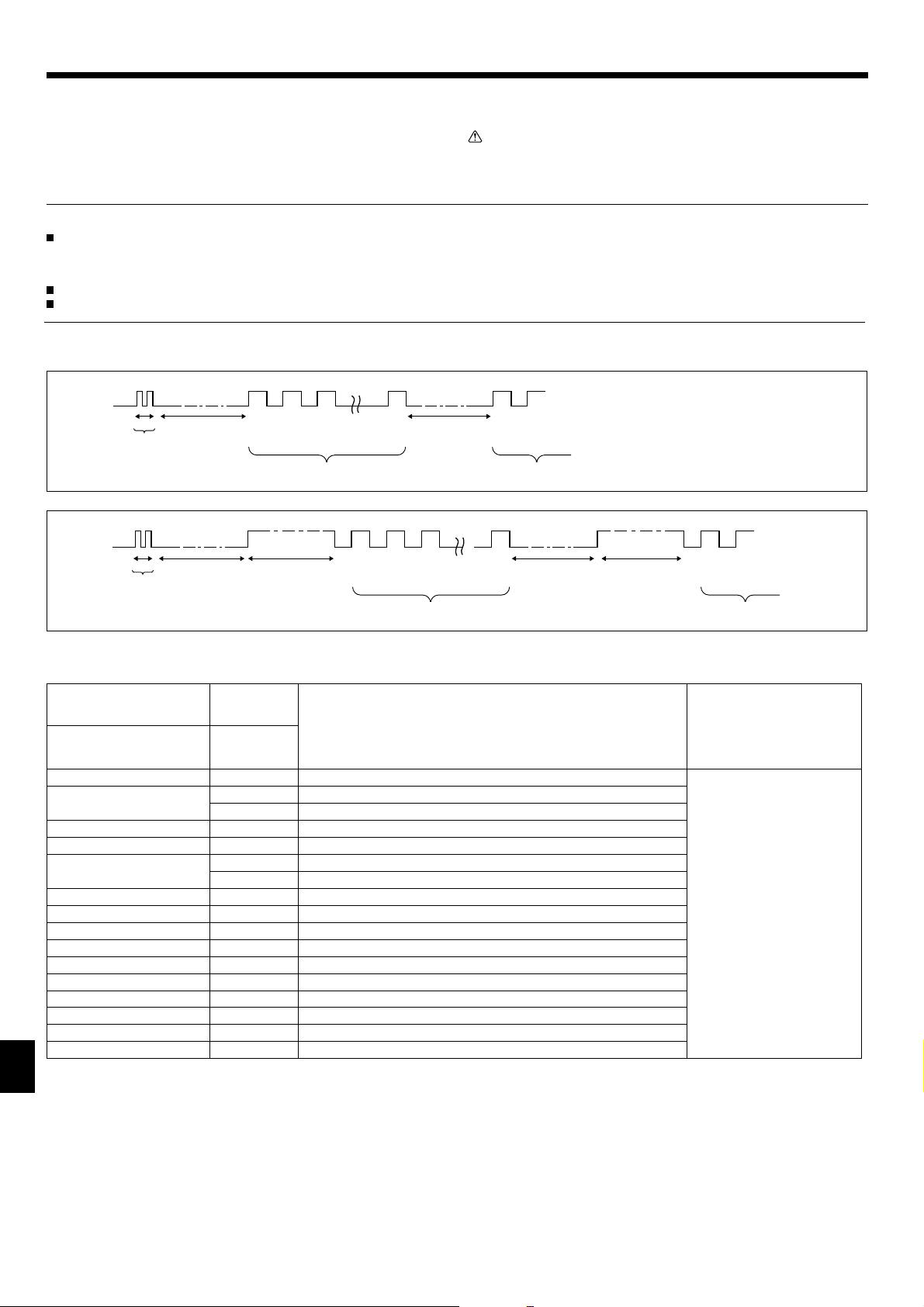

[Output pattern A]

Beeper sounds

OPERATION

INDICATOR

lamp blinking

pattern

[Output pattern B]

Beeper sounds

OPERATION

INDICATOR

lamp blinking

pattern

Beep

Off

Self-check

starts

(Start signal

received)

Self-check

starts

(Start signal

received)

Approx. 2.5 sec.On0.5 sec.On0.5 sec.On0.5 sec.

Beep Beep Beep Beep Beep Beep Beep

Off

Approx. 2.5 sec.OnApprox. 3 sec.On0.5 sec.On0.5 sec.On0.5 sec.

Beep Beep Beep Beep Beep Beep

1st2nd3

Number of blinks/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “P5”)

rd

Number of blinks/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “U2”)

th

n

On

0.5 sec.

1st2nd3

Approx. 2.5 sec.On0.5 sec.On0.5 sec.

► Do not carry out this test on the control wiring (low voltage circuit) termi

Do not use the air conditioner if the insulation resistance is less than 1.0 MΩ.

Off

rd

nals.

Warning:

nd

1st2

Number of blinks/beeps in pattern indicates

the check code in the following table

th

n

On

0.5 sec.

· · · Repeated

Off

Approx. 2.5 sec.OnApprox. 3 sec.On0.5 sec.On0.5 sec.

nd

1st2

Number of blinks/beeps in pattern indicates

the check code in the following table

· · · Repeated

-

[Output pattern A] Errors detected by indoor unit

Wired remote

IR wireless remote controller

controller

RF thermostat

Beeper sounds/OPERATION

INDICATOR lamp blinks

Check code

(Number of times)

1 P1 Intake sensor error

2

P2 Pipe (TH2) sensor error

P9 Pipe (TH5) sensor error

3 E6, E7 Indoor/outdoor unit communication error

4 P4 Drain sensor error / Float switch connector open

5

P5 Drain pump error

PA Forced compressor error

6 P6 Freezing/Overheating protection operation

7 EE Communication error between indoor and outdoor units

8 P8 Pipe temperature error

9 E4 Remote controller signal receiving error

10 — —

11 — —

12 Fb Indoor unit control system error (memory error, etc.)

No sound E0, E3 Remote controller transmission error

No sound E1, E2 Remote controller control board error

No sound – – – – No corresponding

Symptom Remark

10

Page 11

7. Test run

[Output pattern B] Errors detected by unit other than indoor unit (outdoor unit, etc.)

IR wireless remote controller

Beeper sounds/OPERATION

INDICATOR lamp blinks

(Number of times)

1 E9 Indoor/outdoor unit communication error (Transmitting error) (Outdoor unit)

2 UP Compressor overcurrent interruption

3 U3, U4 Open/short of outdoor unit thermistors

4 UF Compressor overcurrent interruption (When compressor locked)

5 U2 Abnormal high discharging temperature/49C worked/insufficient refrigerant

6 U1, Ud Abnormal high pressure (63H worked)/Overheating protection operation

7 U5 Abnormal temperature of heat sink

8 U8 Outdoor unit fan protection stop

9 U6 Compressor overcurrent interruption/Abnormal of power module

10 U7 Abnormality of super heat due to low discharge temperature

11 U9, UH

12 — —

13 — —

14 Others Other errors (Refer to the technical manual for the outdoor unit.)

If the beeper does not sound again after the initial 2 beeps to confirm the self-check start signal was received and the OPERATION INDICATOR lamp does

*1.

not come on, there are no error records.

*2. If the beeper sounds 3 times continuously “beep, beep, beep (0.4 + 0.4 + 0.4 sec.)” after the initial 2 beeps to confirm the self-check start signal was re-

ceived, the specified refrigerant address is incorrect.

• On IR wireless remote controller

The continuous buzzer sounds from receiving section of indoor unit.

Blink of operation lamp

• On wired remote controller

Check code displayed in the LCD.

• If the unit cannot be operated properly after test run, refer to the following table to find the cause.

Wired remote controller LED 1, 2 (PCB in outdoor unit

PLEASE WAIT

PLEASE WAIT → Error code

Display messages do not appear

even when operation switch is

turned ON

(operation lamp does not light up).

On the IR wireless remote controller with condition above, following phenomena take place.

No signals from the remote controller are accepted.

•

• Operation lamp is blinking.

• The buzzer makes a short ping sound.

Note:

Operation is not possible for about 30 seconds after cancellation of function selection. (Correct operation)

For description of each LED (LED1, 2, 3) provided on the indoor controller, refer to the following table.

LED 1 (power for microcomputer) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED 2 (power for remote controller) Indicates whether power is supplied to the remote controller. This LED lights only in the case of

LED 3 (communication between indoor and outdoor units) Indicates state of communication between the indoor and outdoor units. Make sure that this LED

Wired remote

controller

RF thermostat

Check code

Symptom

For about 2 minutes

after power-on

Subsequent to about

2 minutes after

power-on

Symptom Remark

Abnormality such as overvoltage or voltage shortage and abnormal

synchronous signal to main circuit/Current sensor error

After LED 1, 2 are lighted, LED 2 is turned

off, then only LED 1 is lighted. (Correct

operation)

Only LED 1 is lighted. → LED 1, 2 blink.

Only LED 1 is lighted. → LED 1 blinks

twice, LED 2 blinks once.

the indoor unit which is connected to the outdoor unit refrigerant address “0”.

is always blinking.

•For about 2 minutes after power-on, operation of the remote

controller is not possible due to system start-up. (Correct

operation)

•Connector for the outdoor unit’s protection device is not connected.

Reverse or open phase wiring for the outdoor unit’s power

terminal block (L1, L2, GR)

•Incorrect wiring between indoor and outdoor units (incorrect

polarity of S1, S2, S3)

•Remote controller wire short

For details, check the LED

display of the outdoor controller

board.

Cause

11

Page 12

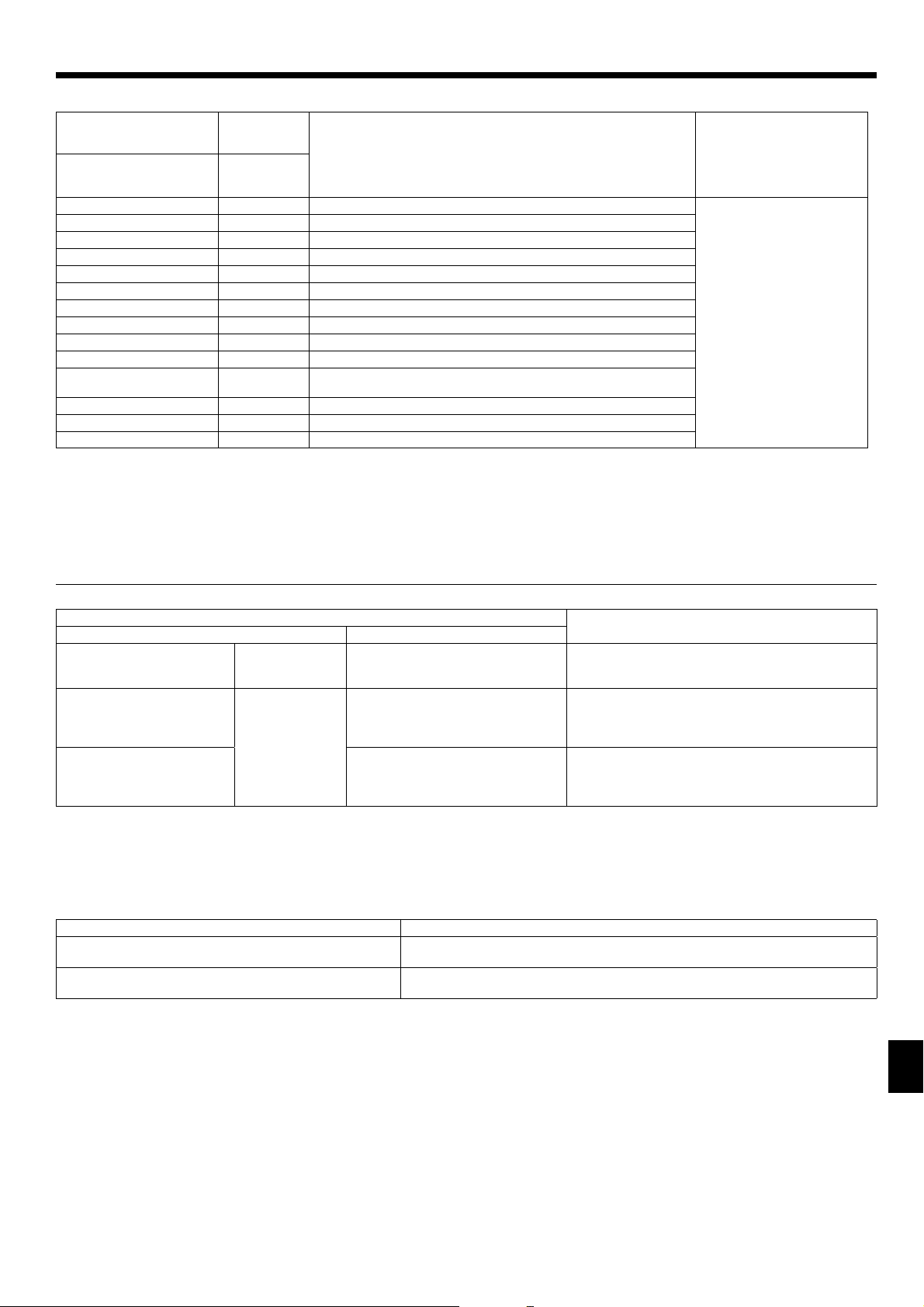

8. Easy maintenance function (For wired remote controller only)

Display example (Comp discharge temperature 147˚F)

D

A

PAR-21MAA

C

B

Maintenance mode operation procedures

(1) Press the

activate the maintenance mode.

(2) Press the TEMP. buttons to set the refrigerant address.

(3) Select the data you want to display.

Compressor

information

MENU

Outdoor unit

information

ON/OFF

Indoor unit

information

* The filter operation time displayed is the number of hours the filter has been

used since the filter reset was performed.

(4) Press the

button for 3 seconds to

TEST

Cumulative

operation time

A

Display

Heat exchanger

temperature

A

Display

Indoor room

temperature

Display

A

button.

FILTER

COMP ON

x10 HOURS

OUTDOOR UNIT

H•EXC. TEMP

INDOOR UNIT

INLET TEMP

B

Display

ON/OFF

number

COMP ON

x100 TIMES

Comp discharge

temperature

OUTDOOR UNIT

OUTLET TEMP

Heat exchanger

temperature

INDOOR UNIT

H•EXC. TEMP

Display

MAINTENANCE

A

Operation

current

COMP ON

CURRENT (A)

Outdoor ambient

temperature

OUTDOOR UNIT

OUTDOOR TEMP

Filter operation

time

INDOOR UNIT

FILTER USE H

By using the maintenance mode, you can display many types of maintenance data

on the wired remote controller such as the heat exchanger temperature and compressor current consumption for the indoor and outdoor units.

This function can be used whether the air conditioner is operating or not.

During air conditioner operation, data can be checked during either normal operation or maintenance mode stable operation.

This function cannot be used during the test run.

*

* The availability of this function depends on the connecting outdoor unit. Refer to

the brochures.

Stable operation

Using the maintenance mode, the operation frequency can be fixed and the operation can be stabilized. If the air conditioner is stopped, use the following procedure to start this operation.

Press the

Display

button to select the operation mode.

MODE

Stable cooling

operation

COOL

A

STABLE MODE

Stable heating

operation

HEAT

STABLE MODE

Stable operation

cancellation

STABLE MODE

CANCEL

(5) The data is displayed in .

C

Display

C

Waiting for

response

* Repeat steps (2) to (5) to check another data.

(6) Press the

button for 3 seconds or press the

TEST

deactivate the maintenance mode.

(Airflow temperature display example)

Blinking

Approx.

10 sec.

ON/OFF

147˚F

button to

Press the

Waiting for

stable operation

Display

FILTER

D

button.

Stable

operation

10-20 min.

* You can check the data using steps (3) to (5) of the maintenance mode opera-

tion procedures while waiting for the stable operation.

12

Page 13

Index

1. Consignes de sécurité ............................................................................. 13

2. Emplacement pour l’installation ...............................................................14

3. Installation de l’appareil intérieur ............................................................. 14

4. Installation de la tuyauterie du réfrigérant ............................................... 16

1. Consignes de sécurité

► Avant d’installer le climatiseur, lire attentivement toutes les “Consignes

de sécurité”.

► Veuillez consulter ou obtenir l’autorisation de votre compagnie d’élec-

tricité avant de connecter votre système.

Avertissement:

Précautions à suivre pour éviter tout danger de blessure ou de décès de l’

utilisateur.

Précaution:

Décrit les précautions qui doivent être prises pour éviter d’endommager l’appareil.

Avertissement:

• Contacter un revendeur ou un technicien agréé pour installer l’appareil.

• Pour l’installation, respecter les instructions du manuel d’installation et

utiliser des outils et des composants de tuyau spécialement conçus pour

une utilisation avec le réfrigérant spécifié dans le manuel d’installation de l’

appareil extérieur.

• L’appareil doit être installé conformément aux instructions pour réduire les

risques de dommages liés à des tremblements de terre, des typhons ou

des vents violents. Une installation incorrecte peut entraîner la chute de l’

appareil et provoquer des dommages ou des blessures.

L’appareil doit être solidement installé sur une structure pouvant supporter

•

son poids.

• Si le climatiseur est installé dans une petite pièce, certaines mesures doi-

vent être prises pour éviter que la concentration de réfrigérant ne dépasse

le seuil de sécurité en cas de fuite. En cas de fuite de réfrigérant et de

dépassement

gène dans la pièce peuvent survenir.

1.1. Avant l’installation (Environnement)

Précaution:

• Ne pas utiliser l’appareil dans un environnement inhabituel. Si le climati-

seur est installé dans des endroits exposés à la vapeur, à l’huile volatile

(notamment l’huile de machine), au gaz sulfurique ou à une forte teneur en

sel, par exemple, en bord de mer, les performances peuvent considérablement diminuer et les pièces internes de l’appareil être endommagées.

Ne pas installer l’appareil dans des endroits où des gaz de combustion peu-

•

vent s’échapper, se dégager ou s’accumuler. L’accumulation de gaz de combustion autour de l’appareil peut provoquer un incendie ou une explosion.

• Ne pas placer d’aliments, de plantes, d’animaux en cage, d’objets d’art

ou d’instruments de précision dans la soufflerie d’air direct de l’appareil

intérieur ou à proximité de l’appareil au risque de les endommager par des

variations de température ou des gouttes d’eau.

1.2. Avant l’installation ou le déplacement

Précaution:

• Transporter les appareils avec précaution. L’appareil doit être transporté

par au moins deux personnes, car il pèse 20 kg, 44 lbs minimum. Ne pas le

saisir par les rubans d’emballage. Porter des gants de protection en raison

du risque de se blesser les mains sur les ailettes ou d’autres pièces.

• Veiller à éliminer le matériel d’emballage en toute sécurité. Le matériel d’

emballage (clous et autres pièces en métal ou en bois) peut provoquer des

blessures.

• Isoler le tuyau de réfrigérant pour éviter la condensation. S’il n’est pas cor-

rectement isolé, de la condensation risque de se former.

1.3. Avant l’installation électrique

Précaution:

• Veiller à installer des coupe-circuits. Dans le cas contraire, un choc électri-

que peut se produire.

• Pour les lignes électriques, utiliser des câbles standard de capacité suffi-

sante. Dans le cas contraire, un court-circuit, une surchauffe ou un incendie peut se produire.

Lors de l’installation des lignes électriques, ne pas mettre les câbles sous tension.

•

du seuil de concentration, des risques liés au manque d’oxy-

5. Mise en place du tuyau d’écoulement .....................................................17

6. Installations électriques ...........................................................................17

7. Marche d’essai ........................................................................................21

8. Fonction d’entretien aisé (uniquement pour la télécommande à fil) ........ 23

Une fois l’installation terminée, expliquer les “Consignes de sécurité”, l’utilisation et

l’entretien de l’appareil au client conformément aux informations du mode d’emploi

et effectuer l’essai de fonctionnement en continu pour garantir un fonctionnement

normal. Le manuel d’installation et le mode d’emploi doivent être fournis à l’utilisateur qui doit les conserver. Ces manuels doivent également être transmis aux

nouveaux utilisateurs.

: Indique un élément qui doit être mis à la terre.

Avertissement:

Prendre soin de lire les étiquettes se trouvant sur l’appareil principal.

Aérer la pièce en cas de fuite de réfrigérant lors de l’utilisation. Le contact du

•

réfrigérant avec une flamme peut provoquer des émanations de gaz toxiques.

• Tout tcavail sur les installations électriques doit être effectué par un technicien qualifié conformément aux réglementations locales et aux instructions

fournies dans ce manuel.

• N’utiliser que les câbles spécifiés pour les raccordements.

• Le couvercle du bloc de sortie de l’appareil doit être solidement fixé.

• N’utiliser que les accessoires agréés par Mitsubishi Electric et contacter un

revendeur ou un technicien agréé pour les installer.

• L’utilisateur ne doit jamais essayer de réparer ou de déplacer l’appareil.

• Une fois l’installation terminée, vérifier les éventuelles fuites de réfrigérant.

Si le réfrigérant fuit dans la pièce et entre en contact avec la flamme d’un

chauffage ou d’une cuisinière, des gaz toxiques peuvent se dégager.

• Si l’humidité ambiante dépasse 80% ou si le tuyau d’écoulement est bouché, des gouttes d’eau peuvent tomber de l’appareil intérieur. Ne pas installer l’appareil intérieur dans un endroit où ces gouttes peuvent provoquer

des dommages.

Lors de l’installation de l’appareil dans un hôpital ou un centre de commu-

•

nications, se préparer au bruit et aux interférences électroniques. Les inverseurs, les appareils électroménagers, les équipements médicaux haute

fréquence et de communications radio peuvent provoquer un dysfonctionnement ou une défaillance du climatiseur. Le climatiseur peut également

endommager les équipements médicaux et de communications, perturbant

ainsi les soins et réduisant la qualité d’affichage des écrans.

Placer un isolant thermique sur les tuyaux pour éviter la condensation. L’

•

installation incorrecte du tuyau d’écoulement peut provoquer des fuites d’

eau et endommager le plafond, le sol, les meubles ou d’autres objets.

Ne pas nettoyer le climatiseur à l’eau au risque de provoquer un choc électrique.

•

• Serrer tous les écrous évasés conformément aux spécifications à l’aide d’

une clé dynamométrique. S’ils sont trop serrés, ils peuvent casser après

une période prolongée.

• Veiller à mettre l’appareil à la terre. Une mise à la terre incorrecte de l’appareil peut provoquer un choc électrique.

• Utiliser des coupe-circuits (disjoncteur de fuite à la terre, interrupteur d’isolement (fusible +B) et disjoncteur à boîtier moulé) à la capacité spécifiée. Si

la capacité du coupe-circuit est supérieure à celle spécifiée, une défaillance

ou un incendie peut se produire.

1.4. Avant la marche d’essai

Précaution:

• Activer l’interrupteur principal au moins 12 heures avant la mise en fonctionnement de l’appareil. L’utilisation de l’appareil juste après sa mise sous

tension peut endommager sérieusement les pièces internes.

Avant d’utiliser l’appareil, vérifier que tous les panneaux, toutes les protec-

•

tions et les autres pièces de sécurité sont correctement installés. Les pièces

tournantes, chaudes ou à haute tension peuvent provoquer des blessures.

• Ne pas utiliser le climatiseur si le filtre à air n’est pas installé. Sinon, des

poussières peuvent s’accumuler et endommager l’appareil.

• Ne pas toucher les interrupteurs les mains humides au risque de provoquer

un choc électrique.

• Ne pas toucher les tuyaux de réfrigérant les mains nues lors de l’utilisation.

• A la fin de l’utilisation de l’appareil, attendre au moins cinq minutes avant

de désactiver l’interrupteur principal. Dans le cas contraire, une fuite d’eau

ou une défaillance peut se produire.

13

Page 14

2. Emplacement pour l’installation

A

9-5/16

Min. 11-13/16

W

Min. 10-5/8

26-3/4

Fig. 2-1

Max. 9-13/16

3. Installation de l’appareil intérieur

70+6

Fig. 3-1

9-5/16

Min. 19-11/16

2.1. Dimensions externes (Appareil intérieur) (Fig. 2-1)

Choisir un emplacement approprié en prenant compte des espaces suivants pour l’

installation et l’entretien.

(inch)

Modèles W

A24, 30 50-3/8

A36, 42 63

Avertissement:

Fixer l’appareil intérieur à un plafond suffisamment résistant pour supporter

son poids.

2.2. Dimensions extérieures (Appareil extérieur)

Consulter le manuel d’installation de l’appareil extérieur.

3.1. Vérifier les accessoires qui accompagnent l’appa-

reil intérieur (Fig. 3-1)

L’appareil intérieur devrait être fourni avec les pièces de rechange et accessoires

suivants (se trouvent à l’intérieur de la grille d’aspiration).

Nom de l’accessoire Qté

Rondelle 4

Gaine protectrice de tuyau 1 grande taille (pour la tuyauterie à gaz)

Gaine protectrice de tuyau 1 petite taille (pour la tuyauterie à liquide)

Courroie 4

Douille 1 Marquée “UNIT” (APPAREIL)

Gaine de la douille 1

Gaine du tuyau d’évacuation 1

1/16

7-1/21-13/16

9-3/16

9-11/16

B

1/4

2-15/16

Fig. 3-2

3-1/8 Ø2-9/16 Ø3-15/16

3-1/812-5/8

1/16

26-3/4

3-3/8

5-7/16

6-5/167-1/2

4-15/16

3-3/8

1/16

7-1/16

7-7/8

9-3/16

9-11/16

2-3/4

4-15/16

7-1/2

1-13/16

3.2. Préparation à l’installation (Fig. 3-2)

3.2.1. Espacement et installation du boulon de suspension

Modèles A B

A24,30 48-11/16 50-3/8

A36,42 61-5/16 63

3.2.2. Emplacement des tuyaux d’évacuation et du réfrigérant

Sortie de la face avant

Sortie du côté gauche

Sortie du côté droit

Pièce indépendante (peut être enlevé)

Tuyau d’évacuation droit

Dans le cas de la préparation de la conduite arrière, s’assurer de retirer les parties

ombrées de la pièce indépendante

sa position initiale.

(L’échangeur thermique peut-être bouché par de la poussière)

3.2.3. Sélection des boulons de suspension et des emplacements

des tuyaux (Fig. 3-3)

Attention:

Installer l’appareil intérieur à 8 ft. (2,4 m) au moins au-dessus du sol ou sur

un plan surélevé. Pour les appareils qui ne sont pas accessibles au public.

En vous servant du schéma fourni pour l’installation, choisissez les positions correctes pour les boulons de suspension et les tuyaux et préparez les orifices nécessaires.

Schéma

Orifice du boulon de suspension

Largeur de l’appareil intérieur

Fixer les boulons de suspension de la manière décrite ci-dessous ou utiliser des

aisseliers ou des carrés de bois pour l’installation des boulons.

Utiliser des clavettes de 220 à 230 lbs chacune

Utiliser des boulons de suspension de taille W3/8 ou M10.

(inch)

Tuyau d’évacuation gauche

Tuyau à gaz

Tuyau à liquide

Bouchon en caoutchouc

avec douille

. Puis remettre la pièce indépendante dans

14

Fig. 3-3

Page 15

3. Installation de l’appareil intérieur

A

B

Fig. 3-4

3.2.4. Entrée d’air frais (Fig. 3-4)

Au moment de l’installation, utiliser les orifices de conduite (défonçables) situés

aux endroits indiqués dans le diagramme suivant en fonction des nécessités.

Appareil intérieur

Entrée d’air frais (orifice défonçable)

Filtre

in. (mm)

C

ABC

10-3/16

(259,5)

ø 3-15/16

(ø 100)

4-5/16

(109)

3.2.5. Préparation de l’appareil intérieur (Fig. 3-5)

1. Installer les boulons de suspension (les boulons W3/8 ou M10 seront fournis

localement).

Déterminer d’avance la distance du plafond ( à 3-59/64 inch près (100 mm)).

Surface du plafond Boulon de suspension Support de suspension

2. Retirer la grille d’aspiration.

Faire glisser les boutons d’arrêt de la grille d’aspiration (à deux endroits) vers l’

arrière pour ouvrir la grille d’aspiration.

3. Enlever le panneau latéral.

Enlever les vis de fixation du panneau latéral (un de chaque côté, droit et gauche) puis faire glisser le panneau latéral vers l’avant pour l’enlever.

Grille d’aspiration

Bouton d’arrêt de la grille d’aspiration

Les faire glisser

Charnière

Tout en poussant sur la charnière, retirer la grille d’aspiration.

Ne jamais forcer pour ouvrir la grille d’arrivée d’air ni l’ouvrir dans un angle

supérieur à 120° sinon vous risqueriez d’endommager les charnières.

Faire glisser le panneau latéral vers l’avant.

Panneau latéral

Enlever les vis de fixation du panneau latéral.

Retirer la protection en vinyle des volets.

Fig. 3-5

0

/ 5

2

5

/

3

(inch)

1

25/64-25/32

3

0

22

4

3

5

Fig. 3-6

1/4-15/32

Fig. 3-7

3.3. Installation de l’appareil intérieur (Fig. 3-6)

Utiliser la méthode de suspension applicable ci-dessous, selon la présence ou l’

absence de matériaux de plafond.

Si les matériaux de plafond sont présents1 Plafond

S’il n’y a pas de matériaux de plafond

Support de suspension

/

Appareil

0

1) Suspendre l’appareil directement

Méthodes d’installation

1.

Mettre en place la rondelle

localement).

2. Accrocher l’appareil aux boulons de suspension.

3. Serrer les écrous.

Vérifier la condition d’installation de l’appareil

• Vérifier que l’appareil est à l’horizontale entre les côtés droit et gauche.

• Vérifier que les supports de suspension avant et arrière sont à l’horizontale.

(Pour favoriser l’écoulement, l’appareil est incliné sur les supports de suspension.

L’appareil en pente régulière vers le bas de l’avant vers l’arrière correspond à la

position d’installation appropriée.)

2) Installer en premier le support de suspension au plafond (Fig. 3-7)

Méthodes d’installation

1. Retirer les supports de suspension et les rondelles en forme de U de l’appareil.

2. Ajuster les boulons de fixation du support de suspension se trouvant sur l’appareil.

3. Attacher les supports de suspension aux boulons de suspension.

4. Vérifier que les supports de suspension sont à l’horizontale (avant et arrière/

droite et gauche).

5. Accrocher l’appareil aux supports de suspension.

6. Serrez des verrous fixes des supports de la mise en suspension.

Soyez sûr d’avoir mis les rondelles en forme de U en place.

+

Boulon de fixation du support de suspension

Appareil

rondelle en forme de U

boulons de suspension

Rondelle

Ecrous doubles

(fournie avec l’appareil) et les écrous (sera fourni

Boulon de suspension

2

Rondelle

3

Rondelle (

4

Ecrous doubles

5

A24, 30 47 - 5/10

A36, 42 59 - 7/8

sera fourni localement

(inch)

)

15

Page 16

4. Installation de la tuyauterie du réfrigérant

45 2

A

90 0.5

R1/64 to R1/32

Fig. 4-1

Dimension de l’évasement

Diam. ext. Tuyau en cuivre

1/4” (ø6,35) 11/32-23/64 (8,7 - 9,1)

3/8" (ø9,52) 1/2-33/64 (12,8 - 13,2)

1/2" (ø12,7) 41/64-21/32 (16,2 - 16,6)

5/8" (ø15,88) 49/64-25/32 (19,3 - 19,7)

3/4" (ø19,05) 29/32-59/64 (22,9 - 23,3)

in. (mm)

Dimensions évasement Dimen-

sions øA

B

Matrice

Die

Tuyau en cuivre

Copper pipe

Fig. 4-2

in. (mm)

Diam. ext. Tuyau en cuivreBOutil d’évasement pour le R410A

1/4” (ø6,35) 0-1/64 (0 - 0,5)

3/8" (ø9,52) 0-1/64 (0 - 0,5)

1/2" (ø12,7) 0-1/64 (0 - 0,5)

5/8" (ø15,88) 0-1/64 (0 - 0,5)

3/4" (ø19,05) 0-1/64 (0 - 0,5)

Type embrayage

4.1. Consignes

Pour les appareils utilisant le réfrigérant R410A

• Appliquer une petite quantité d’huile ester, éther ou alkylbenzène comme

huile réfrigérante sur les sections évasées.

• Utiliser le cuivre phosphoreux C1220, pour des tuyaux sans soudure en

cuivre et en alliage de cuivre, pour raccorder les tuyaux de réfrigérant. Uti

liser les tuyaux de réfrigérant dont l’épaisseur est spécifiée dans le tableau

ci-dessous. Vérifier que l’intérieur des tuyaux est propre et dépourvu de

tout agent nocif tel que des composés sulfuriques, des oxydants, des dé

bris ou des saletés.

Avertissement:

Lors de l’installation ou du déplacement du climatiseur, n’utiliser que le réfrigérant spécifié (R410A) pour remplir les tuyaux de réfrigérant. Ne pas le

mélanger avec un autre réfrigérant et faire le vide d’air dans les tuyaux. La

présence d’air dans les tuyaux peut provoquer des pointes de pression en

traînant une rupture et d’autres risques.

in. (mm)

A24, 30, 36, 42

Conduit de liquide

Conduit de gaz

•

Ne pas utiliser de tuyaux plus fins que ceux spécifiés ci-dessus.

3/8" (ø9,52) épaisseur 1/32" (0,8)

5/8" (ø15,88) épaisseur 3/64" (1,0)

-

-

-

4.2. Connexion des tuyaux (Fig. 4-1)

• En cas d’utilisation de tuyaux en cuivre disponibles sur le marché, envelopper

les tuyaux de liquide et de gaz avec de la matière isolante vendue dans le commerce sur le marché (résistant à une chaleur de 212°F (100 °C) ou supérieure et

d’une épaisseur de 1/2 in. (12 mm) ou plus).

Les parties intérieures du tuyau d’écoulement doivent également être entourées

•

de matière isolante en mousse de polyéthylène (avec une poids spécifique de 0,03

et de 23/64 in. (9 mm) d’épaisseur ou plus).

• Appliquer un film mince d’huile réfrigérante sur la surface du tuyau et du support

du joint avant de serrer l’écrou évasé.

• Utiliser deux clés pour serrer les connexions des tuyaux.

• Utiliser la matière isolante des tuyaux de réfrigérant fournie afin d’envelopper les

connexions des appareils intérieurs. Effectuer l’isolation avec soin.

Couple de serrage du raccord conique

Diam. ext. Tuyau en

cuivre (mm, inch)

ø6,35, 1/4 17, 43/64 14-18, 10-13

ø6,35, 1/4 22, 7/8 34-42, 25-30

ø9,52, 3/8 22, 7/8 34-42, 25-30

ø12,7, 1/2 26, 1-3/64 49-61, 35-44

ø12,7, 1/2 29, 1-9/64 68-82, 49-59

ø15,88, 5/8 29, 1-9/64 68-82, 49-59

ø15,88, 5/8 36, 1-27/64 100-120, 71-86

ø19,05, 3/4 36, 1-27/64 100-120, 71-86

Appliquer de l’huile réfrigérante sur toute la surface évasée du fond.

Utiliser des écrous évasés corrects correspondant à la taille des tuyaux de l’

appareil extérieur.

Diam.ext. raccord conique

(mm, inch)

Tightening torque

(N-m, ft.lbs)

16

Fig. 4-3

4.3. Appareil intérieur (Fig. 4-3)

Méthodes d’installation

1. Glisser la gaine du tuyau

sée contre la tôle à l’intérieur de l’appareil.

2. Glisser la gaine du tuyau

pressée contre la tôle à l’intérieur de l’appareil.

3. Nouer les courroies fournies

des tuyaux et .

Tuyau à gaz

Tuyau à liquide

Courroie

Gaine de tuyau

autour du tuyau à gaz jusqu’à ce qu’elle soit pres-

autour du tuyau à liquide jusqu’à ce qu’elle soit

aux deux extrémités 3/4 in. (20 mm) des gaines

Gaine de tuyau

Presser la gaine du tuyau contre la tôle.

Matériel isolant du tuyau à réfrigérant

4.4. Pour double/triple combinaison

Consulter le manuel d’installation de l’appareil extérieur.

Page 17

5. Mise en place du tuyau d’écoulement

Fig. 5-2

• Si vous installez le tuyau sur le côté gauche, soyez sûr d’insérer le bouchon en

caoutchouc dans l’orifi ce d’évacuation droit. (Fig. 5-1)

• Utiliser un tuyau VP20 (en PVC, D.E.ø26) pour les tuyaux d’écoulement et prévoir une pente d’1% ou plus.

• Après la fi n des travaux, vérifi er que le correct tuyau d’évacuation sort de l’orifi ce

de débit du tuyau d’évacuation.

Bac d’évacuation

Bouchon

Introduire par exemple un tournevis profondément dans la bouchon.

Fig. 5-1

Méthodes d’installation (Fig. 5-2)

1. Relier la douille fournie avec l’appareil à l’orifi ce d’évacuation de l’appareil

avec un adhésif de chlorure de vinyle.

2. Attacher la gaine (fournie avec l’appareil) au tuyau d’évacuation .

3. Relier le tuyau d’évacuation (VP-20) à la douille avec un adhésif de chlorure

de vinyle.

4. Envelopper la gaine (fournie avec l’appareil) autour du tuyau d’évacuation.

(Bandage de soudure)

Bac d’évacuation

Tuyauterie d’évacuation

Gaine de la douille

Douille

5. Vérifi er que le système d’évacuation est correct. (Fig. 5-3)

* Remplir le bac d’évacuation avec environ 1/4 gal (1 l) d’eau des sorties d’air.

Gaine de la tuyauterie d’évacuation

Longueur d’insertion : 1-15/32 in. (37 mm)

6. Installations électriques

Fig. 5-3

6.1. Installation électrique (Fig. 6-1)

Méthodes pour l’installation électrique

1. Retirer les deux vis à tôle puis retirer la faisceau.

2. Enlever les (2) vis à tôle , puis enlever le couvercle de la partie électrique.

3. Pour l’interface radiofréquence.

Raccorder correctement le câble électrique de l’interface radiofréquence au

connecteur CN105 (RED) du panneau du contrôleur intérieur.

Pour la télécommande fi laire

Raccorder correctement les fils électriques aux bornes correspondantes

(Fig. 6-1).

4. Remettre en place les pièces enlevées.

5. Attacher les fi ls électriques au serre-fi ls local se trouvant dans le côté droit de la

boîte de jonction.

Couvercle

Vis de serrage (2)

Vis de serrage (Faisceau)

Bride pour câbles

Panneau du contrôleur intérieur

Orifi ce pour l’entretien des câbles

Bloc de sortie pour la connexion des appareils intérieur et extérieur

Connecteur du câble de mise en terre.

Bornier de la télécommande fi laire

Attacher avec la bride des fi ls.

7

Fig. 6-1

CN105

(RED)

Fig. 6-2

7

17

Page 18

6. Installations électriques

6.1.1. Alimentation de l’appareil intérieur provenant de l’appareil extérieur

Les schémas de connexion suivants sont disponibles.

Les schémas d’alimentation de l’appareil extérieur varient selon les modèles.

Système 1:1

L1

L2

GR

S1

S2

S3

*

Apposer une étiquette A fournie avec les manuels près de chaque schéma de câblage des appareils intérieur et extérieur.

CN105

(RED)

S1

S2

S3

1

2

Source d’alimentation de l’appareil extérieur

Coupe-circuit ou interrupteur d’isolement

Appareil extérieur

Cordons de raccordement de l’appareil intérieur/extérieur

Télécommande à fil

Appareil intérieur

Mise à la terre de l’appareil intérieur

Panneau du contrôleur intérieur

Interface radiofréquence pour thermostat radiofréquence

Modèle de l’appareil intérieur PCA-A24,30 PCA-A36, 42

Courant admissible minimum du circuit 1A 2A

Valeur nominale maximum du dispositif de protection contre les surintensités

15A

Appareil intérieur-appareil extérieur *1 3 × AWG16 (polar)

Mise à la terre de l’appareil intérieur 1 × Min. AWG16

taille

Câblage

Télécommande à fil-Appareil intérieur *2 2 × AWG22 (non polarisé, non blindé)

No du câble ×

Appareil intérieur-appareil extérieur S1-S2 *3 AC 208/230 V

Appareil intérieur-appareil extérieur S2-S3 *3 DC24 V

Tension

Télécommande à fil-Appareil intérieur *3 DC12 V

du circuit

*1. 50 m, 165ft max.

*2. Le câble de 10 m (30 pieds) est fixé à la télécommande à fil. 500 m (1500 pieds) maximum

*3. Les chiffres ne s’appliquent PAS toujours à la mise à la terre.

La borne S3 présente une différence de 24 V CC par rapport à la borne S2. Les bornes S3 et S1 ne sont pas isolées électriquement par le transformateur ou tout autre appareil.

Remarques: 1. La taille des fils doit être conforme aux réglementations nationales et locales pertinentes.

2. Utiliser des fils d’alimentation en cuivre.

3. Utiliser des fils d’une intensité nominale de 600V ou plus pour les câbles d’alimentation et les câbles de raccordement de l’appareil intérieur/l’

appareil extérieur.

4. Installer un câble de terre plus long que les autres câbles.

6.2. Télécommande

6.2.1. Pour la télécommande à fil

1) Réglage de 2 télécommandes à fil

Si 2 télécommandes à fil sont connectées, régler la première sur “principal” et la seconde sur “auxiliaire”. Pour prendre connaissance des procédures de configuration,

consultez “Sélection des fonctions” dans le mode d’emploi de l’appareil intérieur.

18

Page 19

6. Installations électriques

MODEL SELECT

ON/OFF TEMP

FAN

AUTO STOP

VANE

LOUVER

RESETSET CLOCK

AUTO START

h

min

MODE

CHECK

TEST RUN

6.2.2. Pour télécommande sans fil infrarouge

1) Lieu d’installation

• À l’abri des rayons directs du soleil.

• À l’écart de toute source de chaleur.

• À l’abri des courants d’air froids (ou chauds).

• Lieu où la télécommande sans fil infrarouge peut être facilement utilisée.

• Hors de la portée des enfants.

2) Programmation (Fig. 6-3)

Introduire les piles.

Appuyer sur le bouton SET

MODEL SELECT

clignote et le numéro du modèle est allumé.

Appuyer sur le bouton temp

Si l’opération est erronée, appuyer sur la touche ON/OFF

partir du point .

Appuyer sur le bouton SET

et le numéro du modèle s’allument pendant trois secondes puis s’éteignent.

MODEL SELECT

Intérieur Extérieur

PCA

à l’aide d’un objet pointu.

pour programmer le numéro du modèle.

à l’aide d’un objet pointu.

No. modèle

PUZ 001

PUY 033

et recommencer à

Fig. 6-3

3) Attribution d’une télécommande sans fil infrarouge à chaque appareil

Seule la télécommande sans fil infrarouge attribuée à un appareil peut commander

cet appareil.

S’assurer qu’un même numéro de paire a été attribué à chaque paire de carte

électronique d’unité extérieure et de télécommande sans fil infrarouge.

4)

Programmation des numéros de paires de la télécommande sans fil infrarouge. (Fig. 6-4)

MODEL SELECT

Appuyer sur le bouton SET à l’aide d’un objet pointu.

Commencer cette opération avec l’affichage de la télécommande sans fil infra-

rouge désactivé.

MODEL SELECT

ON/OFF TEMP

FAN

VANE

MODE

LOUVER

CHECK

TEST RUN

RESETSET CLOCK

Fig. 6-4

AUTO STOP

AUTO START

h

min

Le numéro “0” clignote.

Le numéro de paires attribué s’allume pendant trois secondes puis s’éteint.

clignote et le numéro du modèle s’allume.

Appuyer deux fois sans relâcher sur le bouton

Appuyer sur le bouton temp

choix.

pour attribuer le numéro de paires de votre

min

.

Si l’opération est erronée, appuyer sur la touche ON/OFF

partir du point .

Appuyer sur le bouton SET à l’aide d’un objet pointu.

Numéro de paire de la télécommande sans fil

infrarouge

0 Réglage d’usine

1 Couper J41

2 Couper J42

3-9 Couper J41, J42

Carte à circuit imprimé intérieure

et recommencer à

6.3. Réglage des fonctions

6.3.1.

Mode number

Numéro de mode

Setting number

Numéro de réglage

Refrigerant address

Adresse de réfrigérant

Unit number

TEMP.

MENU

BACK DAY

MONITOR/SET

PAR-21MAA

ON/OFF

CLOCK

OPERATION

ON/OFF

CHECK

CLEAR

FILTER

TEST

Numéro d’appareil

Fig. 6-5

Réglage des fonctions sur l’appareil (sélection des fonctions de l’appareil)

1) Pour la télécommande à fil (Fig. 6-5)

Réglage de la tension d’alimentation

• Toujours veiller à modifier le réglage de tension en fonction de l’alimentation utilisée.

Passer au mode de réglage des fonctions.

Eteindre la télécommande à fil.

Appuyer simultanément sur les touches FILTER et TEST RUN pendant

au moins 2 secondes. FUNCTION commence à clignoter.

Utiliser la touche pour régler l’adresse du réfrigérant () sur 00.

Appuyer sur ; [--] se met à clignoter sur l’affichage du numéro d’appareil ().

Utiliser la touche pour attribuer le numéro 00 à l’appareil ().

Appuyer

Appuyer sur les touches pour régler le numéro de mode () sur 04.

Appuyer sur la touche , le numéro de programmation actuellement sélection-

Utiliser la touche pour changer de numéro de programmation selon la tension

Tension d’alimentation

230 V : numéro de programmation = 1

208 V : numéro de programmation = 2

Appuyer sur la touche MODE , les numéros de programmation et de mode

Appuyer simultanément sur les touches FILTER et TEST RUN pendant

sur la touche (MODE) pour spécifier l’adresse du réfrigérant/numéro

d’appareil; [--] clignote momentanément sur l’affichage du numéro de mode ().

né () clignotera.

d’alimentation à utiliser.

() et () changeront et seront continuellement affichés, et les détails de la

programmation pourront être confirmés.

au moins 2 secondes. L’écran de sélection des fonctions apparaît momentanément, et l’affichage d’arrêt du climatiseur apparaît.

19

Page 20

6. Installations électriques

CHECK

ON/OFF TEMP

AUTO STOP

AUTO START

h

min

FAN

VANE

MODE

LOUVER

CHECK

TEST RUN

RESETSET CLOCK

CHECK

Fig. 6-6

CHECKCHECK

CHECK

2) Pour télécommande sans fil infrarouge. (Fig. 6-6)

Réglage de la tension d’alimentation

• Bien modifier le réglage de la tension en fonction de la tension utilisée.

Accéder au mode de sélection des fonctions

Appuyer sur le bouton

CHECK

deux fois sans le relâcher.

(Commencer cette opération avec l’affichage de la télécommande sans fil infrarouge désactivé.)

CHECK

est allumé est “00” clignote.

Appuyer une fois sur le bouton temp

la télécommande sans fil infrarouge vers le récepteur de l’appareil intérieur, puis

appuyer sur le bouton

Réglage du numéro de l’appareil

Appuyer sur le bouton temp

Pointer la télécommande sans fil infrarouge vers le récepteur de l’appareil intérieur,

puis appuyer sur le bouton

Sélection d’un mode

h

.

min

pour sélectionner le chiffre “50”. Pointer

et pour attribuer le numéro “00” à l’appareil.

.

Entrer 04 pour modifier le réglage de tension d’alimentation à l’aide des touches

temp.

de l’appareil intérieur, puis appuyer sur le bouton

et . Pointer la télécommande sans fil infrarouge vers le récepteur

h

.

Numéro de réglage actuel: 1 = 1 bip (une seconde)

2 = 2 bips (d’une seconde chacun)

3 = 3 bips (d’une seconde chacun)

Sélection du numéro de réglage

Utiliser les touches temp.

et pour régler le réglage de tension d’alimen-

tation sur 01 (230 V). Pointer la télécommande sans fil infrarouge vers le capteur

de l’appareil intérieur, puis appuyer sur le bouton h .

Sélection de plusieurs fonctions de manière continue

Répéter les opérations et pour modifier les réglages de plusieurs fonctions de

manière continue.

Fin de la sélection de fonction

Pointer la télécommande sans fil infrarouge vers le capteur de l’appareil intérieur,

puis appuyer sur le bouton

.

Remarque:

En cas de modification des paramètres des fonctions après installation ou

maintenance, veiller à indiquer les modifications par un repère dans la co

lonne “Réglage” du tableau des fonctions.

-

6.3.2. Réglage des fonctions sur la commande à distance

Consulter le mode d’emploi de l’appareil intérieur.

Tableau des fonctions

Sélectionner l’appareil numéro 00

Mode Paramètre

Restauration automatique après une coupure de courant

Non disponible

Disponible

Détection de la température intérieure Moyenne de fonctionnement de l’appareil intérieur

Réglée par la télécommande de l’appareil intérieur 2

Détecteur interne de la télécommande à fil 3

Connectivité LOSSNAY Non supportée

Supportée (l’appareil intérieur n’est pas équipé d’une prise d’air extérieure)

Supportée (l’appareil intérieur est équipé d’une prise d’air extérieure)

Tension d’alimentation 230 V

208 V 2Ο

Sélectionner les appareils numéro 01 à 03 ou tous les appareils (AL [télécommande avec fil] / 07 [télécommande sans fil])

Mode Paramètre

Signe du filtre 100 heures

2500 heures 2 Ο

Pas d’indicateur de signe du filtre 3

Vitesse du ventilateur Silencieux

Standard 2 Ο

Plafond élevé 3

Réglage haut/bas des volets Pas de volets

Equipé de volets (Réglage de l’angle des ailettes )2Ο

Equipé de volets (Réglage de l’angle des ailettes )

Une fois l’alimentation rétablie, le climatiseur redémarre après 3 minutes.

+

Télécommande

(thermostat RF)

+

Télécommande

(thermostat RF)

No. de mode

à fil

01

(101)

02

(—)

03

(103)

04

(104)

No. de mode

à fil

07

(107)

08

(108)

11

(111 )

No. de réglage

Réglage initial

1

2Ο

1Ο

1Ο

2

3

1

No. de réglage

Réglage initial

1

1

1

3

Réglage

Réglage

20

Page 21

7. Marche d’essai

7.1. Avant la marche d’essai

► Lorsque l’installation, le tuyautage et le câblage des appareils intérieur

et extérieur sont terminés, vérifier l’absence de fuites de réfrigérant, la

fixation des câbles d’alimentation et de commande, l’absence d’erreur de

polarité et contrôler qu’aucune phase de l’alimentation n’est déconnectée.