Page 1

Air-Conditioners

PLH18, 24, 30, 36, 42AK

PL12, 18, 24, 30, 36, 42AK

PCH24, 30, 36, 42GK

PC24, 30, 36, 42GK

PKH18, 24, 30, 36FK3

PK12, 18, 24, 30, 36FK3

PKH18, 24, 30, 36FL

PK18, 24, 30, 36FL3

OPERATION MANUAL

For safe and correct use, please read this operation manual thoroughly before operating the air-conditioner unit.

FOR USER

Page 2

2

s Before installing the unit, make sure you read all the “Safety precautions”.

s The “Safety precautions” provide very important points regarding safety.

Make sure you follow them.

s If none of the above apply, turn the main switch off and contact the

dealer from whom you bought the air-conditioner, telling him the model

name and the nature of the problem.

Do not try to fix the unit yourself.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

1. Safety PrecautionsContents

1. Safety Precautions .................................................................................... 2

2. Operation ................................................................................................... 3

2.1. Switching the unit on/off .............................................................. 3

2.2. Mode select ................................................................................. 3

2.3. Selecting a temperature .............................................................. 3

2.4. Selecting a fan speed .................................................................. 3

2.5. Adjusting airflow direction............................................................ 4

2.6. Using the timer ............................................................................ 4

3. Care and cleaning ..................................................................................... 5

3.1. Cleaning the filters and the indoor unit ........................................ 5

3.2. Care and cleaning ....................................................................... 6

4. Troubleshooting ......................................................................................... 6

5. Specifications ............................................................................................ 7

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• The unit should not be installed by the user. Ask the dealer or an authorized

company to install the unit. If the unit is installed improperly, water leakage,

electric shock or fire may result.

• Do not stand on, or place any items on the unit.

• Do not splash water over the unit and do not touch the unit with wet hands.

An electric shock may result.

• Do not spray combustible gas close to the unit. Fire may result.

• Do not place a gas heater or any other open-flame appliance where it will be

exposed to the air discharged from the unit. Incomplete combustion may

result.

Caution:

• Do not use any sharp object to push the buttons, as this may damage the

remote controller.

• Never block or cover the indoor or outdoor unit’s intakes or outlets.

Warning:

• Do not remove the front panel or the fan guard from the outdoor unit when it

is running. You could be injured if you touch rotating, hot or high-voltage

parts.

• Never insert fingers, sticks etc. into the intakes or outlets, otherwise injury

may result, since the fan inside the unit rotates at high speed.

• If you detect odd smells, stop using the unit, turn off the power switch and

consult your dealer.

• This air conditioner is NOT intended for use by children or infirm persons

without supervisions.

• Young children should be supervised to ensure that they do not play with

the air conditioner.

Disposing of the unit

When you need to dispose of the unit, consult your dealer. If pipes are removed

incorrectly, refrigerant (fluorocarbon gas) may blow out and come into contact with

your skin, causing injury. Releasing refrigerant into the atmosphere also damages

the environment.

O

N

/

O

F

F

–

S

T

A

N

D

B

Y

D

E

F

R

O

S

T

D

R

Y

C

O

O

L

A

U

T

O

F

A

N

H

E

A

T

C

E

N

T

R

A

L

L

Y

C

O

N

T

R

O

L

L

E

D

˚

F

S

W

I

N

G

F

A

N

S

P

E

E

D

A

U

T

O

R

E

T

U

R

N

N

O

T

A

V

A

IL

A

B

L

E

˚

F

C

H

E

C

K

M

O

D

E

F

IL

T

E

R

T

I

M

E

R

T

E

S

T

R

U

N

T

I

M

E

R

O

F

F

C

L

O

C

K

A

U

T

O

A

U

T

O

C

H

E

C

K

S

E

T

T

E

M

P

.

S

T

A

R

T

S

T

O

P

Page 3

3

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

A

1

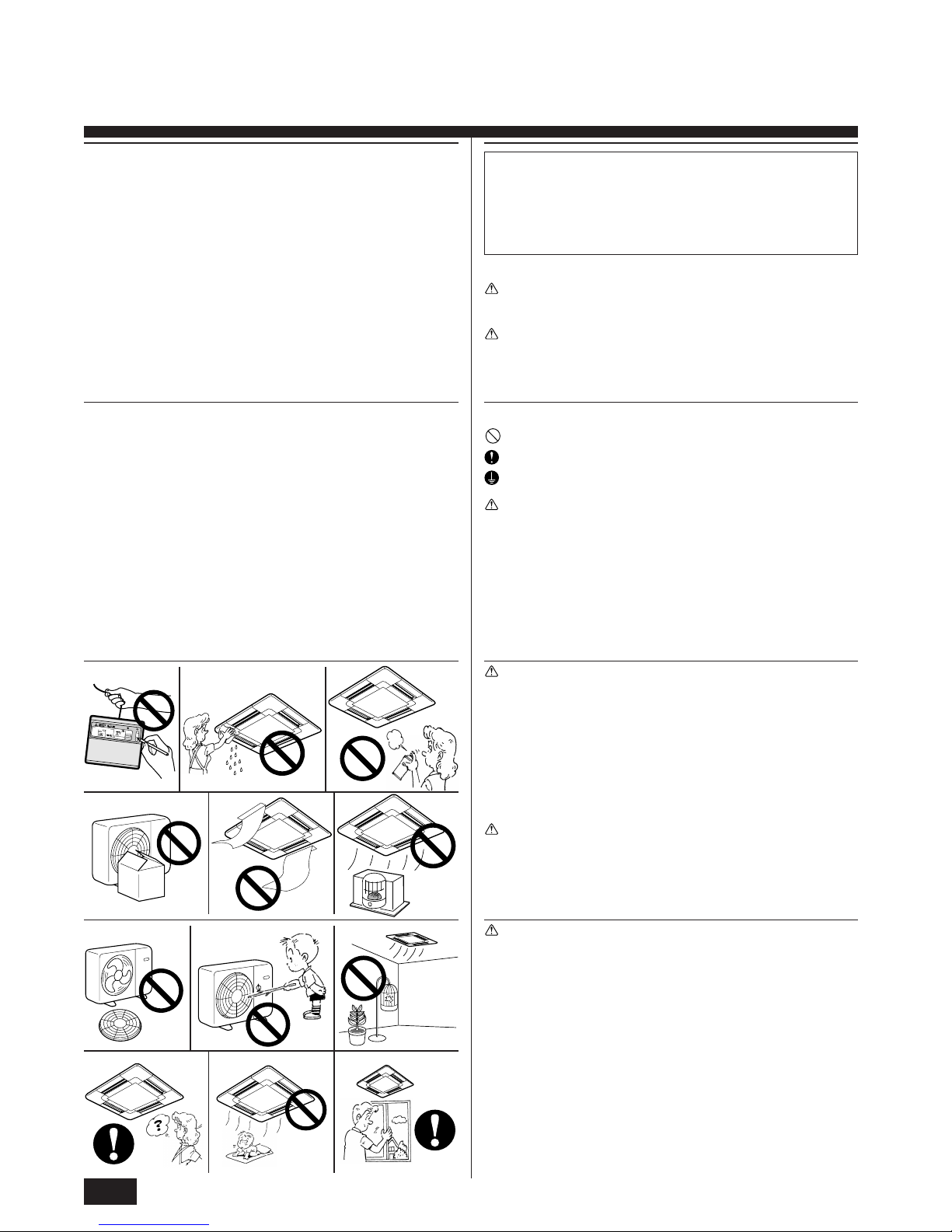

2. Operation

Operating range

Indoor air intake temperature Outdoor air intake temperature

Cooling

Maximum 95 °F DB, 71 °F WB 115 °F DB

Minimum 67 °F DB, 57 °F WB 0 °F DB*

Heating

Maximum 80 °F DB, 67 °F WB 75 °F DB, 65 °F WB

Minimum 70 °F DB, 60 °F WB 17 °F DB, 15 °F WB

* With wind baffle installed. Without wind baffle, the minumum temperature will be

23 °F DB.

2.1. Switching the unit on/off

• The power supply should not be turned off while the air conditioner is in use. This

can cause the unit to break down.

1 Press the ON/OFF button.

A The ON indicator should light up.

• Even if you press the ON/OFF button immediately after shutting down the operation in progress, the air conditioner will not start for about three minutes. This is to

prevent the internal components from being damaged.

• If the operation stops due to a power failure, the unit will not automatically restart

until the power has been restored. Press the ON/OFF button to restart.

2.2. Mode select

1 If the unit is off, press the ON/OFF button to turn it on.

A The ON indicator should light up.

2

Press the operation mode button C and select the operation mode.

B

COOL Cooling mode AUTO Automatic (cooling/heating) mode

(For PLH/PCH/PKH)

DRY Drying mode HEAT Heating mode

(For PLH/PCH/PKH)

FAN Fan mode

(For PL/PC/PK)

Note:

The heating display and the automatic display does not appear in models that

operate exclusively as cooling only air-conditioner.

2.3. Selecting a temperature

ss

ss

s To decrease the room temperature:

1 Press set temperature button to set the desired temperature.

A The selected temperature is displayed.

• Each time you press the button, the temperature value decreases by 2 °F.

ss

ss

s To increase the room temperature:

1 Press set temperature button to set the desired temperature.

A The selected temperature is displayed.

• Each time you press the button, the temperature value increases by 2 °F.

• Available temperature ranges are as follows:

Cooling & Drying: 65 - 87 °F

Heating: 61 - 83 °F

Automatic: 65 - 83 °F

• The display flashes either 47 °F or 97 °F to inform you if the room temperture is

lower or higher than the displayed temperature.

2.4. Selecting a fan speed

1 Press fan speed button to select a desired fan speed.

• Each time you press the button, available options change with the display A on

the remote controller, as shown below.

Wireless type Wired type

Display

FAN

SPEED

FAN

SPEED

Available

Option (Fan Speed Switch)

Low-High Low-High

The display and the fan speed of the unit will differ in the following situations:

• When STAND BY and DEFROST are displayed.

• Just after the heating mode (while waiting to change to another mode).

• When the temperature of the room is higher than the temperature setting of the

unit operating in the heating mode.

• In Dry mode, where the speed is set automatically and cannot be changed. Only

the display on the remote controller changes.

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

A

1

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

1

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

B

C

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

A

1

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

A

1

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

A

1

BC

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

A

1

FAN

FAN

Page 4

4

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

F

1

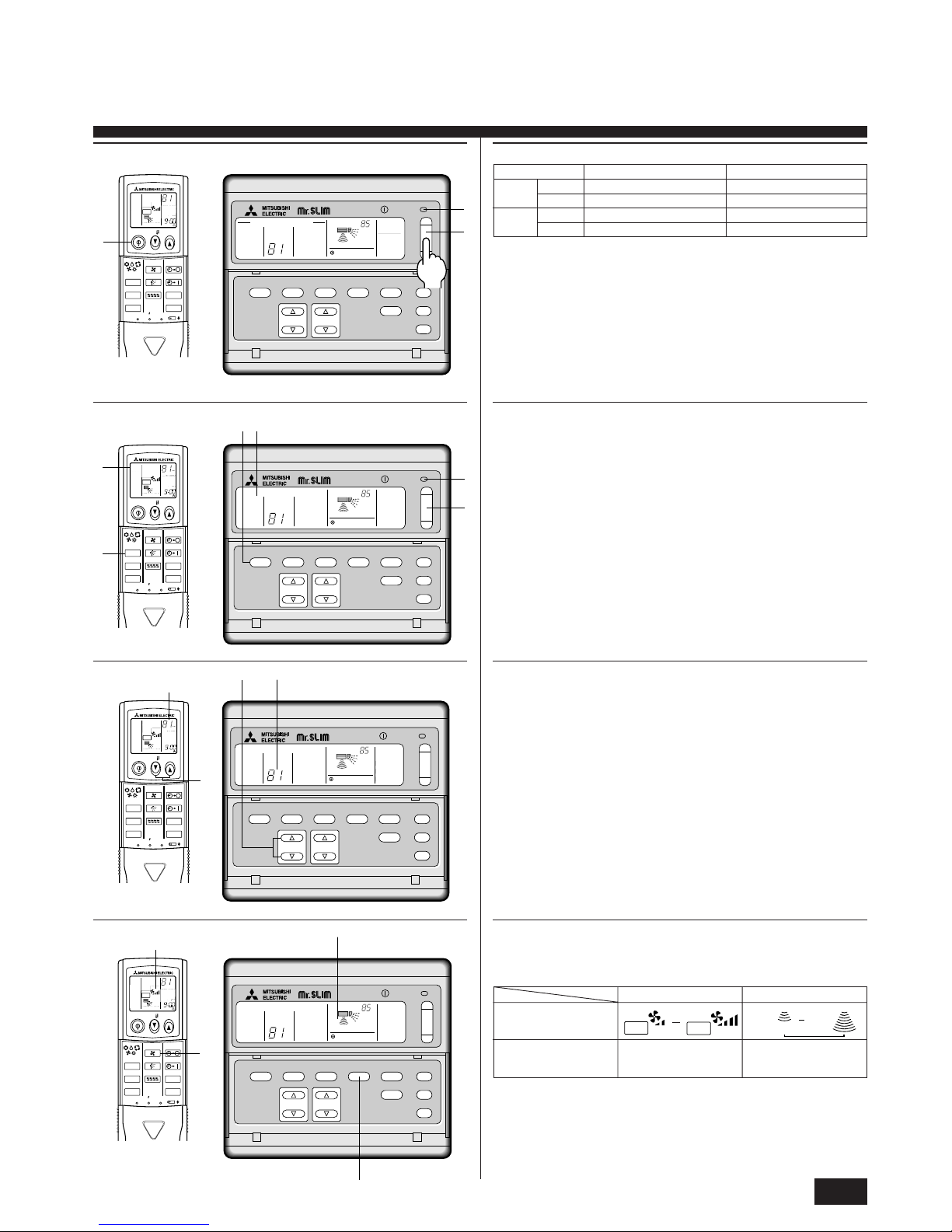

2. Operation

2.5. Adjusting airflow direction

The vertical air vane helps select the vertical direction of the airflow.

1 Press AIR DISCHARGE button to select the vertical airflow direction.

• Each time you press the button, the option changes are displayed on the remote

controller, as shown below.

A (swing) → B → C → D → E → A

• In cooling/drying mode with the fan speed set to LOW, every press on the button

will change the direction in the order of A, B, D, A. (C can not be set)

• If D or E is set, the angle will automatically revert to B after one hour of operation.

(Do not use D and E too often in cooling/drying mode with the fan speed set to

LOW, or condensation or dripping can occur.)

F “AUTO RETURN” should be displayed.

• When the angle setting is C in cooling mode, switching the fan speed from HIGH

to LOW will cause the angle to revert to B automatically.

• The airflow direction can not be set with UP/DOWN while the SWING setting is being used.

• The arrow indicators are alternately displayed when the air sweep is in operation,

however they are not displayed when the air sweep is not in operation.

• The left/right guide vanes of PC(H) series and the guide vane of the PK(H) serises

can be changed manually.

2.6. Using the timer

1) Set the current time

1 Press clock/timer button to display the “CLOCK” B.

Remote

CLOCK

→

AUTO

START

→

AUTO

STOP

→ No Display

controller display A

2 Each time you press

TIMER SET

button, the time increases in increments of one minute.

Each time you press

TIMER SET

button, the time decreases in increments of one minute.

• Press and hold the button to rapidly change the time.

• The time changes in increments of one minute → ten minutes → in units of hour; in

this order.

• Approximately ten seconds after pressing the button, the display on the remote

controller will turn off.

(For Wireless Remote Controller)

1 Press the CLOCK button using a thin stick and blink the time A.

2 Press the h and

min

button to set the current time.

3 Press the CLOCK button using a thin stick.

2) Set the time to start the unit as follows

1 Press clock/timer button to display B

AUTO

START

.

2 Press

TIMER SET

button to set the time that you want the unit to start.

The start time is displayed at A.

(For Wireless Remote Controller)

1 Press the

AUTO START

button.

• Time can be set while the following symbol is blinking.

ON time : B START is blinking.

2 Use the

h

and

min

buttons to set the desired time.

3 To cancel the ON timer, press the

AUTO START

button.

3) Set the time to stop the unit as follows

1 Press clock/timer button to display C

AUTO

STOP

.

2 Press

TIMER SET

button to set the time that you want the unit to stop.

The stop time is displayed at A.

(For Wireless Remote Controller)

1 Press the

AUTO STOP

button.

• Time can be set while the following symbol is blinking.

OFF time : C STOP is blinking.

2 Use the

h

and

min

buttons to set the desired time.

3 To cancel the OFF timer, press the

AUTO STOP

button.

4) Changing the set times

1 Press clock/timer button to display the time (CURRENT, START, STOP) you want

to change.

2 Press

TIMER SET

button to set the desired time.

• When change is made to either one of a pair, e.g., AUTO START or AUTO STOP,

set the time you need not to change to

. This display is available following

23:50.

(For Wireless Remote Controller)

Press the

AUTO START

or

AUTO STOP

to cancel the timer and repeat from 2) or 3).

↑

ABCDE

ABCDE

PL(H) Swing 30° 45° 55° 70°

PK(H)* Swing 10° 30° 60° 70°

PK12FK3 – 10° 30° 60° 70°

PC(H) Swing

100% Horizontal

20° 40° 60°

* Except PK12FK3

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

1

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

B

1

2

A

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

A

2

13

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

ABC

1

2

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL

SELECT

NOT AVAILABLE

SWING

CHECK

FAN

TEST

RUN

˚F

˚C

AMPMSTOP

START

AMPM

COOL

DRY

AUTO

FAN

HEAT

C

13

A

B

2

Page 5

5

C

B

D

A

ON/OFF

–

STAND BY

DEFROST

DRYCOOL

AUTOFAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCKAUTO AUTO

CHECKSET TEMP. STARTSTOP

B

A

D

C

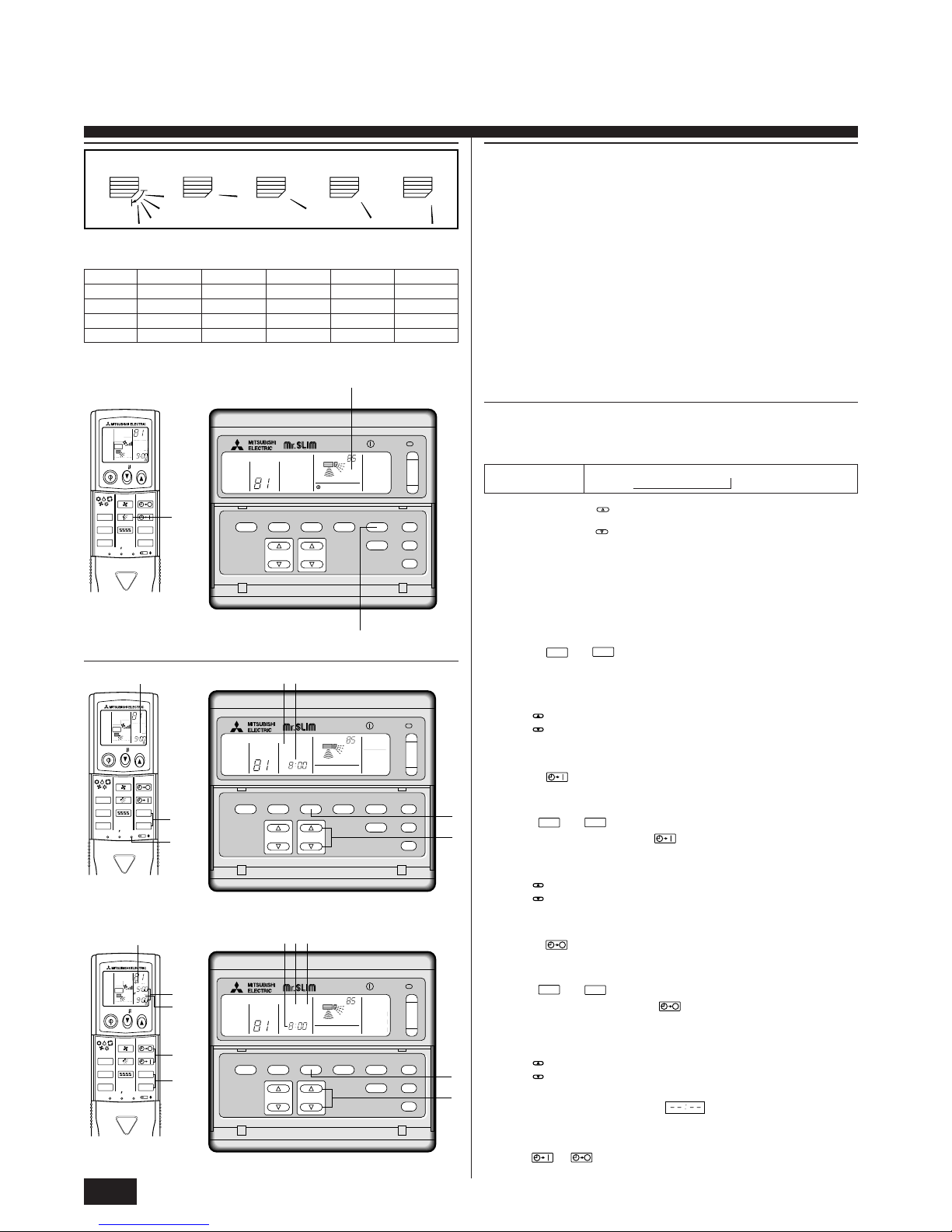

3. Care and cleaning

Caution:

• Always turn off the power, first on the remote controller and then the main

switch, before cleaning or servicing the unit.

• When installing or removing the filter or the intake grille, do not stand on an

unsteady surface. You may fall and injure yourself. Be also careful not to let

dust fall into your eyes.

Dirty or clogged filters block the airflow and reduce efficiency. Very dirty filters can

damage the air-conditioner itself.

■ PLH/PL Series

Intake grille removal

• Pull the knob on the intake grille in the direction indicated by the arrow and it

should open.

• Unhook the hinges to remove the intake grille from the grille.

Filter removal

• Open the intake grille.

• Release the knob on the center edge of the intake grille and pull the filter forward

to remove the filter.

A Knob B Grille C Intake grille D Filter

■ PCH/PC Series

• Open the intake grille.

• Hold the knob on the filter then pull the filter up in the direction of an arrow. To

replace the filter after cleaning, be sure to insert the filter far enough until it fits into

the stopper.

A Filter B Intake Grille C Knob D Stopper

■ PKH/PK Series

• Hold the filter lug (located at the bottom of the intake grill) and pull it out downward.

• To install the filters, push the filter lug upward.

A Filter B Lug

3.1. Cleaning the filters and the indoor unit

Cleaning the filters

• Clean the filters using a vacuum cleaner. If you do not have a vacuum cleaner, tap

the filters against a solid object to knock off dirt and dust.

• If the filters are especially dir ty, wash them in lukewarm water. Take care to rinse

off any detergent thoroughly and allow the filters to dry completely before putting

them back into the unit.

Caution:

• Do not dry the filters in direct sunlight or by using a heat source, such as an

electric heater: this may warp them.

• Do not wash the filters in hot water (above 120°F), as this may warp them.

• Make sure that the air filters are always installed. Operating the unit without

air filters can cause malfunction.

Cleaning the indoor unit

• Wipe the outside of the unit with a clean, dry, soft cloth.

• Clean off any oil stains or finger marks using a neutral household detergent (such

as dishwashing liquid or laundry detergent).

Caution:

Never use gasoline, benzene, thinner, scouring powder or any type of nonneutral detergent, as these substances may damage the unit’s case.

■ PLH/PL Series

■ PCH/PC Series

■ PKH/PK Series

B

A

Page 6

6

4. Troubleshooting

NOTE: After a power cut, the unit will not restart automatically. You will have to restart it by pressing the POWER - ON/OFF button on the remote controller.

Wired remote controllers

In any of the following cases, turn off the main power switch and contact your local dealer for service:

•“CHECK” followed by “P1”, “P2”, “P3”, “P4”, “P5”, “P7” or “CENTRALLY CONTROLLED” is displayed on the control panel.

• The switches do not work properly.

• The circuit breaker trips frequently (or the fuse blows frequently).

• Water has accidentally been splashed into the unit.

• Water leaks from the unit.

• Something is accidentally dropped into the air-conditioner.

• An unusual noise is heard during operation.

Warning:

If the air conditioner operates but does not cool or heat (depending on model) the room, consult your dealer since there may be a refrigerant leak.

Be sure to ask the service representative whether there is refrigerant leakage or not when repairs are carried out.

The refrigerant charged in the air conditioner is safe. Refrigerant normally does not leak, however, if refrigerant gas leaks indoors, and comes into contact with the

fire of a fan heater, space heater, stove, etc., harmful substances will be generated.

Problem

Unit will not start.

Unit discharges air well, but fails to cool

or heat the room well.

Unit does not start immediately.

Unit stops soon after starting.

Cause

Main power switch is turned off.

Main power fuse has blown.

Outdoor unit’s ground fault breaker is open.

A power cut has occurred (see NOTE below).

Improper temperature setting - e.g. you

have selected COOL mode, but the desired

temperature setting is higher than the current room temperature.

Filters are clogged.

Outdoor unit’s intake or outlet is obstructed.

A door or window has been left open.

Unit is waiting three minutes before restarting.

Indoor or outdoor unit’s intake or outlet is

obstructed.

Filters are clogged.

Solution

Turn main power on. Then press the

POWER ON/OFF button to turn the unit

on.

Replace the fuse.

Reset the ground fault breaker.

Wait until power is restored, then press

the POWER ON/OFF button to turn the

unit on.

Check the set temperature on the remote

controller and the actual intake air temperature. Use the COOLER and

WARMER buttons to set the temperature

as described in “Selecting a temperature”

on page 3.

Clean the filter and resume operation.

See “Cleaning the filters and the indoor

unit” on page 5.

Remove the obstruction.

Shut door or window.

Wait until the unit restarts automatically.

The compressor may hesitate resuming

because a three-minute resume prevention circuit is incorporated in the outdoor

unit for protection of the compressor.

Remove obstruction and restart the unit.

Remove the obstruction. Clean the filter

and resume operation.

Display reading

Pilot lamp does not turn on even when the

POWER ON/OFF button is pressed.

Remote controller shows that the unit is

operating.

Remote controller shows that the unit is

operating.

Remote controller check display reads

“CHECK P6” or “CHECK P8”.

4. Troubleshooting

Before you call out a repair man, check the following table to see whether there is a simple solution to your problem.

ON/OFF

–

TIMER SETSET TEMP.

REMOTE CONTROLLER

MODE TIMER ON/OFF CLOCK/TIMER FAN SPEED AIR DISCHARGE FILTER

AIR SWEEP CHECK

TEST RUN

STAND BY

DEFROST

DRY COOL

AUTO FAN

HEAT

CENTRALLY CONTROLLED

˚F

SWING

FAN

SPEED

AUTO

RETURN

NOT AVAILABLE

˚F

CHECK MODE

FILTER

TIMER

TEST RUN

TIMER OFF CLOCK AUTO AUTO

CHECK SET TEMP. START STOP

A

1

3.2. Care and cleaning

Clean the filter

When the A “FILTER” indicator blinks on the remote controller to alert you to the

necessity of cleaning of the filter.

∗ As a guideline for typical office environment, the long-life filter must be cleaned

every 2,500 (PL(H))/100 (PC(H), PK(H)) operating hours.

Reset the FILTER indicator

1 Press the FILTER button twice after cleaning.

s When you press the FILTER button twice, the “FILTER” indicator A will be

turned off and reset.

s The FILTER indicator provides you with a guideline for the necessity of

filter cleaning based on total operating hours in typical indoor air conditions. Depending on different operating environments, more or less frequent cleaning may be necessary.

• Not available for wireless remote controller.

3. Care and cleaning

Page 7

7

PLH18AK PLH24AK PLH30AK PLH36AK PLH42AK

18,000 24,000 30,000 35,400 42,000

19,000 [24,500/25,500] 26,000 [31,500/32,500] 33,000 [39,500/41,200] 38,000 [45,900/47,600] 44,300 [52,200/53,900]

11,000 [16,500/17,500] 16,500 [22,000/23,000] 18,500 [25,000/26,700] 23,000 [30,900/32,600] 26,800 [34,700/36,400]

1.75 2.57 3.17 3.63 3.98

1.59 [3.19/3.49] 2.51 [4.11/4.41] 3.04 [4.94/5.44] 3.45 [5.75/6.25] 3.82 [6.12/6.62]

1.32 [2.92/3.22] 2.15 [3.75/4.05] 2.55 [4.45/4.95] 2.93 [5.23/5.73] 3.24 [5.54/6.04]

10.5 10.3 10.4 10.0 10.7

7.2 7.0 6.9 7.1 7.0

PLH18AK PLH24AK PLH30AK PLH36AK PLH42AK

Munsell 0.7Y 8.59/0.97

208/230, 1, 60

20 25

15 17

0.7 1.2 1.4

7.7/8.3 [1.6/1.9] 9.1/10.4 [1.9/2.4] 11.1/12.2 [2.3/2.8]

530-710 710-990 780-1060

490-670 670-950 740-1020

33-1/16

33-1/16

10-3/16 11-3/4

37-3/8

37-3/8

1-3/16

57 71 75

11

PUH18EK PUH24EK PUH30EK PUH36EK PUH42EK7

Munsell 5Y 7/1

208/230, 1, 60

20 30 40

16 20 22 28

0.75 0.65+0.65 0.75+0.75 0.8+0.8

RH247NAB NH33NBD NH41NAD NH47NAD ZR42K3-PFV

12.0 11.5 14.0 17.5 20.4

37 54 73 87 109

0.11/0.17 (23/28) 0.16/0.17 (33/39)

Capillary tube

Reverse cycle

34-1/4 38-3/16

11-5/8 13-9/16

33-1/2 49-9/16

131 202 245 246 246

With grille

Indoor unit-remote controller DC12V, Indoor unit- outdoor unit DC12V

Cooling *1 BTU/h

Capacity Heating *1,*3 BTU/h

Heating *2,*3 BTU/h

Cooling *1 kW

Heating *1,*3 kW

Heating *2,*3 kW

SEER

HSPF

INDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Auxiliary heater A (kW)

Airflow Dry CFM

Lo-Hi Wet CFM

Win

Dimensions D in

Hin

Win

Dimensions

Din

(GRILLE)

Hin

Weight lbs

Weight (GRILLE) lbs

OUTDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Models

Compressor

R. L. A.

L. R. A.

Crankcase heater A (W)

Refrigerant control

Defrost method

Win

Dimensions D in

Hin

Weight lbs

REMOTE CONTROLLER

Control voltage

(by built-in transformer)

Item

Models

Power

consumption

NOTES: *1 Rating conditions (cooling) – indoor: 80°F DB. 67°F WB outdoor: 95°F DB. 75°F WB

(heating) – indoor: 70°F DB. 60°F WB outdoor: 47°F DB. 43°F WB

*2 Rating conditions (heating) – indoor: 70°F DB. 60°F WB outdoor: 17°F DB. 15°F WB

*3 Heating capacity and power consumption in [ ] include auxiliary electric heater operation at 208/230V.

Units should be installed by licensed electric contractor accordingly to local code requirement.

* Specifications subject to change without notice.

5. Specifications

Page 8

8

PL12AK PL18AK PL24AK PL30AK PL36AK PL42AK

12,500 18,400 24,000 31,000 36,500 42,500

1.26 1.85 2.65 3.17 3.64 4.08

10.1 10.2 10.0 10.6 10.5 10.8

PL12AK PL18AK PL24AK PL30AK PL36AK PL42AK

Galvanized sheets with gray heat insulation

Munsell 0.7Y 8.59/0.97

115, 1, 60

15

2.0 3.0

1.2 2.6

420-560 530-710 710-990 780-1060

390-530 490-670 670-950 740-1020

33-1/16

33-1/16

10-3/16 11-3/4

37-3/8

37-3/8

1-3/16

49 53 66 71

11

PU12EK PU18EK PU24EK PU30EK PU36EK PU42EK7

Munsell 5Y 7/1

208/230, 1, 60

15 20 30 40

11 16 20 22 28

0.65 0.75 0.65+0.65 0.75+0.75 0.8+0.8

RH167NAB RH247NAB NH33NBD NH41NAD NH47NAD ZR42K3-PFV

8.9 12.0 11.5 14.0 17.5 20.4

29 37 54 73 87 109

0.11/0.12 (23/28) 0.16/0.17 (33/39)

Capillary tube

34-1/4 38-3/16

11-5/8 13-9/16

25-9/16 33-1/2 49-9/16

105 154 207 220 220

With grille

Indoor unit-remote controller DC12V, Indoor unit- outdoor unit DC12V

Cooling capacity *1 BTU/h

Power consumption *1 kW

SEER

INDOOR UNIT MODELS

External finish

External finish (GRILLE)

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Airflow Dry CFM

Lo-Hi Wet CFM

Win

Dimensions D in

Hin

Win

Dimensions

Din

(GRILLE)

Hin

Weight lbs

Weight (GRILLE) lbs

OUTDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Model

Compressor

R. L. A.

L. R. A.

Crankcase heater A (W)

Refrigerant control

Win

Dimensions D in

Hin

Weight lbs

REMOTE CONTROLLER

Control voltage

(by built-in transformer)

Item

Models

NOTES: *1 Rating conditions (cooling) – indoor: 80°F DB. 67°F WB outdoor: 95°F DB. 75°F WB

Units should be installed by licensed electric contractor accordingly to local code requirement.

* Specifications subject to change without notice.

5. Specifications

Page 9

9

PCH24GK PCH30GK PCH36GK PCH42GK

24,000 30,000 35,400 42,000

27,000 [34,000/35,500] 33,000 [40,500/42,500] 38,000 [45,500/47,500] 45,000 [52,500/54,500]

14,800 [21,800/23,300] 20,000 [27,500/29,500] 21,000 [28,500/30,500] 23,800 [31,300/33,200]

2.51 3.23 3.60 4.10

2.46 [4.49/4.94] 3.00 [5.25/5.76] 3.32 [5.57/6.08] 3.76 [6.03/6.52]

1.95 [3.98/4.43] 2.58 [4.83/5.34] 2.63 [4.88/5.39] 3.00 [5.25/5.76]

10.3 10.0 10.3 10.3

6.8 7.0 7.0 7.2

PCH24GK PCH30GK PCH36GK PCH42GK

Munsell 0.7Y 8.59 / 0.97

208 / 230, 1, 60

20 25

15 17

1.1 1.3

9.8/10.8 [2.0/2.5] 10.8/12.0 [2.2/2.8]

710-880 990-1,240

640-810 880-1,130

51-9/16 63-3/4

26-3/4

10-5/8

87 101 106

PUH24EK PUH30EK PUH36EK PUH42EK7

Munsell 5Y 7/1

208/230, 1, 60

20 30 40

16 20 22 28

0.65+0.65 0.75+0.75 0.8+0.8

NH33NBD NH41NAD NH47NAD ZR42K3-PFV

11.5 14.0 17.5 20.4

54 73 87 109

0.16/0.17 (33/39)

Capillary tube

Reverse cycle

34-1/4 38-3/16

11-5/8 13-9/16

49-9/16

202 245 246 246

With indoor unit

Indoor unit-remote controller DC12V, Indoor unit- outdoor unit DC12V

Cooling *1 BTU/h

Capacity Heating *1,*3 BTU/h

Heating *2,*3 BTU/h

Cooling *1 kW

Heating *1,*3 kW

Heating *2,*3 kW

SEER

HSPF

INDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Auxiliary heater A (kW)

Airflow Dry CFM

Lo-Hi Wet CFM

Win

Dimensions D in

Hin

Weight lbs

OUTDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Models

Compressor

R. L. A.

L. R. A.

Crankcase heater A (W)

Refrigerant control

Defrost method

Win

Dimensions D in

Hin

Weight lbs

REMOTE CONTROLLER

Control voltage

(by built-in transformer)

Item

Models

Power

consumption

NOTES: *1 Rating conditions (cooling) – indoor: 80°F DB. 67°F WB outdoor: 95°F DB. 75°F WB

(heating) – indoor: 70°F DB. 60°F WB outdoor: 47°F DB. 43°F WB

*2 Rating conditions (heating) – indoor: 70°F DB. 60°F WB outdoor: 17°F DB. 15°F WB

*3 Heating capacity and power consumption in [ ] include auxiliary electric heater operation at 208/230V.

Units should be installed by licensed electric contractor accordingly to local code requirement.

* Specifications subject to change without notice.

5. Specifications

Page 10

10

PC24GK PC30GK PC36GK PC42GK

25,000 31,000 36,500 42,500

2.61 3.18 3.62 4.10

10.4 10.0 10.3 10.8

PC24GK PC30GK PC36GK PC42GK

Munsell 0.7Y 8.59 / 0.97

115, 1, 60

15

2.0 3.0

1.9 2.4

710-880 990-1,240

640-810 880-1,130

51-9/16 63-3/4

26-3/4

10-5/8

82 95 99

PU24EK PU30EK PU36EK PU42EK7

Munsell 5Y 7/1

208/230, 1, 60

20 30 40

16 20 22 28

0.65+0.65 0.75+0.75 0.8+0.8

NH33NBD NH41NAD NH47NAD ZR42K3-PFV

11.5 14.0 17.5 20.4

54 73 87 109

0.16/0.17 (33/39)

Capillary tube

34-1/4 38-3/16

11-5/8 13-9/16

49-9/16

207 208 220 220

With indoor unit

Indoor unit-remote controller DC12V, Indoor unit- outdoor unit DC12V

Cooling capacity *1 BTU/h

Power consumption *1 kW

SEER

INDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Airflow Dry CFM

Lo-Hi Wet CFM

Win

Dimensions D in

Hin

Weight lbs

OUTDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Model

Compressor

R. L. A.

L. R. A.

Crankcase heater A (W)

Refrigerant control

Win

Dimensions D in

Hin

Weight lbs

REMOTE CONTROLLER

Control voltage

(by built-in transformer)

Item

Models

NOTES: *1 Rating conditions (cooling) – indoor: 80°F DB. 67°F WB outdoor: 95°F DB. 75°F WB

Units should be installed by licensed electric contractor accordingly to local code requirement.

* Specifications subject to change without notice.

5. Specifications

Page 11

11

5. Specifications

Cooling *1 BTU/h

Capacity Heating *1,*3 BTU/h

Heating *2,*3 BTU/h

Cooling *1 kW

Heating *1,*3 kW

Heating *2,*3 kW

SEER

HSPF

INDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Auxiliary heater A (kW)

Airflow Dry CFM

Lo-Hi Wet CFM

Win

Dimensions D in

Hin

Weight lbs

OUTDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Models

Compressor

R. L. A.

L. R. A.

Crankcase heater A (W)

Refrigerant control

Defrost method

Win

Dimensions D in

Hin

Weight lbs

REMOTE CONTROLLER

Control voltage

(by built-in transformer)

Item

Models

Powe r

consumption

NOTES: *1 Rating conditions (cooling) – indoor: 80°F DB. 67°F WB outdoor: 95°F DB. 75°F WB

(heating) – indoor: 70°F DB. 60°F WB outdoor: 47°F DB. 43°F WB

*2 Rating conditions (heating) – indoor: 70°F DB. 60°F WB outdoor: 17°F DB. 15°F WB

*3 Heating capacity and power consumption in [ ] include auxiliary electric heater operation at 208/230V.

Units should be installed by licensed electric contractor accordingly to local code requirement.

* Specifications subject to change without notice.

PKH18FK3/PKH18FL PKH24FK3/PKH24FL PKH30FK3/PKH30FL PKH36FK3/PKH36FL

18,000 24,000 30,000 34,200

18,600 [24,100/25,100] 25,000 [30,500/31,500] 33,000 [39,100/40,500] 38,000 [44,100/45,500]

10,700 [16,200/17,200] 14,700 [20,200/21,200] 19,000 [25,100/26,500] 19,600 [25,700/27,100]

1.79 2.36 3.12 3.44

1.56 [3.16/3.46] 2.37 [3.97/4.27] 3.02 [4.82/5.22] 3.54 [5.34/5.74]

1.34 [2.94/3.24] 1.92 [3.52/3.82] 2.48 [4.28/4.68] 2.65 [4.45/4.85]

11.1 10.2 10.6 10.5

7.2 6.8 7.1 6.9

PKH18FK3/PKH18FL PKH24FK3/PKH24FL PKH30FK3/PKH30FL PKH36FK3/PKH36FL

Munsell 3.4Y 7.7/0.8

208/230, 1, 60

15

12 13

0.5 0.6

7.6/8.4 [1.6/1.9] 8.7/9.6 [1.8/2.2]

710-530 990-780

640-480 890-700

55-1/8 66-5/32

9-1/4

13-3/8

57 66

PKH18FK3 / PLH18FL PKH24FK3 / PKH24FL PKH30FK3 / PKH30FL PKH36FK3 / PKH36FL

Munsell 5Y 7/1

208/230, 1, 60

20 30

16 20 22

0.75 0.65+0.65 0.75+0.75

RH247NAB NH33NBD NH41NAD NH47NAD

12.0 11.5 14.0 17.5

37 54 73 87

0.11/0.12 (23/28) 0.16/0.17 (33/39)

Capillary tube

Reverse cycle

34-1/4 38-3/16

11-5/8 13-9/16

33-1/2 49-9/16

131 202 245 246

With indoor unit

Indoor unit-remote controller DC12V, Indoor unit- outdoor unit DC12V

Page 12

12

Printed in Japan

BG79P948H04

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

5. Specifications

Cooling capacity *1 BTU/h

Power consumption *1 kW

SEER

INDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Airflow Dry CFM

Lo-Hi Wet CFM

Win

Dimensions D in

Hin

Weight lbs

OUTDOOR UNIT MODELS

External finish

Power supply V, Phase, Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F. L. A.

Model

Compressor

R. L. A.

L. R. A.

Crankcase heater A (W)

Refrigerant control

Win

Dimensions D in

Hin

Weight lbs

REMOTE CONTROLLER

Control voltage

(by built-in transformer)

Item

Models

NOTES: *1 Rating conditions (cooling) – indoor: 80°F DB. 67°F WB outdoor: 95°F DB. 75°F WB

Units should be installed by licensed electric contractor accordingly to local code requirement.

* Specifications subject to change without notice.

PK12FK3 PK18FK3/PK18FL3 PK24FK3/PK24FL3 PK30FK3/PK30FL3 PK36FK3/PK36FL3

12,500 18,500 24,000 30,000 34,200

1.21 1.75 2.34 3.06 3.47

11.5 11.3 10.6 10.7 10.2

PK12FK3 PK18FK3/PK18FL3 PK24FK3/PK24FL3 PK30FK3/PK30FL3 PK36FK3/PK36FL3

Munsell 3.4Y 7.7/0.8

115, 1, 60

15

12

0.7 1.0

490-350 710-530 990-780

440-320 640-480 890-700

49-7/32 55-1/8 66-5/32

7-7/8 9-1/4

11-13/16 13-3/8

37 53 62

PU12EK PU18EK PU24EK PU30EK PU36EK

Munsell 5Y 7/1

208/230, 1, 60

15 20 30

11 16 20 22

0.65 0.75 0.65+0.65 0.75+0.75

RH167NAB RH247NAB NH33NBD NH41NAD NH47NAD

8.9 12.0 11.5 14.0 17.5

29 37 54 73 87

0.11/0.12 (23/28) 0.16/0.17 (33/39)

Capillary tube

34-1/4 38-3/16

11-5/8 13-9/16

25-9/16 33-1/2 49-9/16

105 154 207 208 220

With indoor unit

Indoor unit-remote controller DC12V, Indoor unit- outdoor unit DC12V

Loading...

Loading...