Page 1

MOULDED CASE CIRCUIT BREAKERS

TECHNICAL NOTES

ADVANCED AND EVER ADVANCING

00

A

Page 2

We have the pleasure of providing all our customers with the technical information for Mitsubishi

moulded case circuit breakers. This indicates the fundamental data of our circuit breakers

regarding the applicable standards, constructional principles, and operational performances.

Please refer to the catalogue of our circuit breakers for details of specifications.

Also please stand in need of the handling and maintenance manual for maintaning the circuit

breakers in service continuously.

We do hope they are available for all our customers to built more efficient systems.

CONTENTS

1. INTRODUCTION ...............................................2

2. FEATURES .......................................................3

2.1 Arc-Extinguishing Device – ISTAC.................. 3

2.2 Digital ETR ......................................................... 4

3. CONSTRUCTION AND OPERATION............... 6

4. CHARACTERISTICS AND

PERFORMANCE............................................. 11

4.1 Overcurrent-Trip Characteristics ................... 11

4.2 Short-Circuit Trip Characteristics.................. 11

4.3 Effects of Mounting Attitudes ........................ 12

4.4 DC Tripping Characteristics of AC-Rated

MCCBs.............................................................. 12

4.5 Frequency Characteristics ............................. 12

4.6 Switching Characteristics............................... 13

4.7 Dielectric Strength........................................... 13

5. CIRCUIT BREAKERS SELECTION ............... 14

5.1 Circuit Breakers Selection Table ................... 14

6. PROTECTIVE CO-ORDINATION ................... 39

6.1 General ............................................................. 39

6.2 Interrupting Capacity Consideration ............. 40

6.3 Selective-Interruption...................................... 41

6.4 Cascade Back-up Protection.......................... 46

2

t Let-Through Characteristics and Current

6.5 I

Limiting Characteristics.................................. 48

6.6 Protective Coordination with Wiring ............. 49

6.7 Protective Coordination with

Motor Starters .................................................. 52

6.8 Coordination with Devices on the

High-Voltage Circuit ........................................ 54

7. SELECTION .................................................... 57

7.1 For Motor Branch Circuits .............................. 57

7.2 For Lighting and Heating Branch Circuits .... 57

7.3 For Main Circuit ............................................... 58

7.4 For Welding Circuits ....................................... 58

7.5 For Transformer-Primary Use ........................ 60

7.6 For Capacitor Circuits..................................... 61

7.7 For Thyristor Circuits...................................... 62

7.8 Selection of MCCBs in inverter circuit .......... 68

8. ENVIRONMENTAL CHARACTERISTICS ...... 70

8.1 Atmospheric Environment.............................. 70

8.2 Vibration-Withstand Characteristics ............. 71

8.3 Shock-Withstand Characteristics .................. 72

9. SHORT-CIRCUIT CURRENT

CALCULATIONS ............................................ 73

9.1 Purpose ............................................................ 73

9.2 Definitions ........................................................ 73

9.3 Impedances and Equivalent Circuits of

Circuit Components ........................................ 73

9.4 Classification of Short-Circuit Current.......... 76

9.5 Calculation Procedures .................................. 77

1

Page 3

1. INTRODUCTION

Mitsubishi Advancing Technology

Mitsubishi, the leading manufacturer of circuit breakers, has been providing customers with a wide range

of highly reliable and safe moulded case circuit breakers (MCCB) and earth-leakage circuit breakers

(ELCB), corresponding to the needs of the age.

Since production began in 1933 many millions of

Mitsubishi ACBs, MCCBs and MCBs have been sold

throughout many countries.

In 1985 a new design concept for controlling arc energies within MCCBs – vapour jet control (VJC) – was

introduced and significantly improved performance. It

is provided the technological advance for a new ‘super series’ range of MCCBs and is used in all present

ratings from 3 to 1600 amps.

In 1995 Mitsubishi offers the new PSS (Progressive

Super Series) breakers having ratings from 3 to 250

amps that concentrate the most advanced technologies into a compact body. Their four major features

are:

• New circuit-breaking technology ISTAC for a higher

current-limiting performance, upgrading the circuitbreaking capability.

• Electronic circuit breakers with the Digital ETR protecting the circuit accurately.

• One-frame, one-size design allowing efficient panel

design.

• Cassette-type internal accessories that allow installation by the user.

Progressive Super Series, an integration of technology and know-how from this comprehensive electronic

product manufacturer, will create its own fields of application with its excellent performance.

A Brief Chronology

1933 Moulded case circuit breaker production

begins.

1952 Miniature circuit breaker production be-

gins.

1968 Manufacture commences of short-time-

delayed breakers.

1969 Production and sale of first residual cur-

rent circuit breakers.

1970 170kA breaking level ‘permanent power

fuse’ integrated MCCBs is introduced.

1973 Introduction of first short-time delay and

current-limiting selectable breakers go on

sale.

1974 First MELNIC solid-state electronic trip

unit MCCBs are introduced.

1975 ELCBs with solid-state integrated circuit

sensing devices are introduced.

1977-1979 Four new ranges of MCCBs are intro-

duced – economy, standard, current limiting, ultra current limiting and motor rated

designs – a comprehensive coverage of

most application requirements.

1982 Compact ACBs with solid-state trip de-

vices and internally mounted accessories

introduced.

1985-1989 Super series MCCBs with VJC and ETR

are developed and launched – awarded

the prestigious Japanese MInister of Construction Prize.

1990 New 200kA level U-series MCCBs super

current limiting breakers are introduced.

1991 Super-NV ELCBs and Super-AE ACBs

are introduced.

1995 Progressive Super Series 30~250 amps

are introduced.

1997 Progressive Super Series 400~800 amps

are introduced.

2

Page 4

2. FEATURES – Advanced MCCB Design Technol-

ogy & Performance

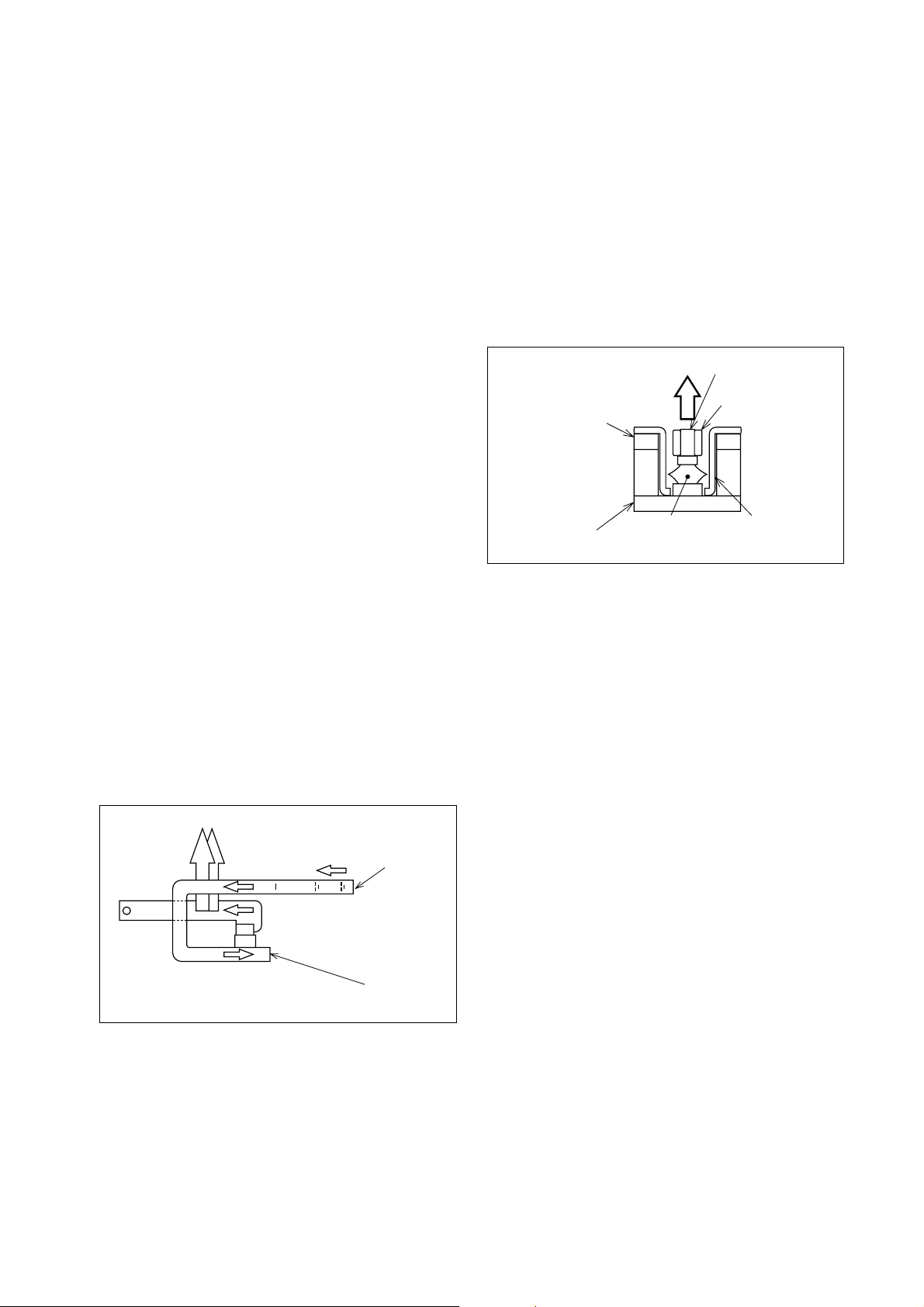

2.1 Arc-Extinguishing Device – ISTAC

Mitsubishi has developed an epoch-making ISTAC

technology to realize an improved current-limiting and

breaking performance within a smaller breaking space.

Introduction of ISTAC technology upgrades the cur-

rent-limiting, selective-breaking, and cascade-breaking performance. The maximum peak let-through cur-

rent Ip decreases to about 80% (compared with

Mitsubishi’s 100AF). The passing energy I2t decreases to about 65% (compared with Mitsubishi’s

100AF). The smaller breaking space has led to an

improved function, a smaller size, and a standardization of the breakers.

Triple forces accelerating

The triple forces generated by a newly designed current pass and the Vapor Jet Control (VJC) insulating materials which makes up a slot-type breaking

construction accelerate the movable conductor, and

separate the contacts faster than ever before in shortbreaking.

Electromagnetic attractive force which works between

a current of the movable conductor and a current of

the fixed upper conductor.

Electromagnetic repulsive force which works between

a current of the movable conductor and a current of

the fixed lower conductor.

Pressure which works on the movable conductor by

gas generated in the slot.

The VJC suppresses the emergence of carbide products in breaking a current and contribute to the recovery of insulation immediately thereafter.

The VJCs on the fixed and movable contacts work

together to forcefully reduce the arc spot and rapidly

contract the total arc being extinguished.

Movable contact

Upper,

fixed-contact

conductor

Lower,

fixed-contact

conductor

Pressure

Arc

3

Movable

contact VJC

Fixed contact

VJC

Vapor jet control (VJC)

Vapor Jet Controllers made of insulating material are

arranged around the contacts where they control the

arc as follows:

1. The arc spot is forcibly reduced by the arrangement of the insulating material.

2. The arc column is contracted.

3. Adiabatic expansion cools the arc.

4. The arc is transferred at the optimum moment to

the arc-extinguishing chamber by the arrangement

of the Vapor Jet Controllers.

Repulsive

force

Movable

contact

2

1

Attractive

force

Current A

Current B

Current C

Current

Upper,

fixed-contact

conductor

Lower,

fixed-contact

conductor

Arc control by slot-breaking

The VJC of the fixed contact incorporates newly developed insulation made of ceramic fiber and metal

hydroxide. The substantially improves the VJC effect.

The arc-extinguishing gas energies to improve the

capability of extinguishing the arc.

3

Page 5

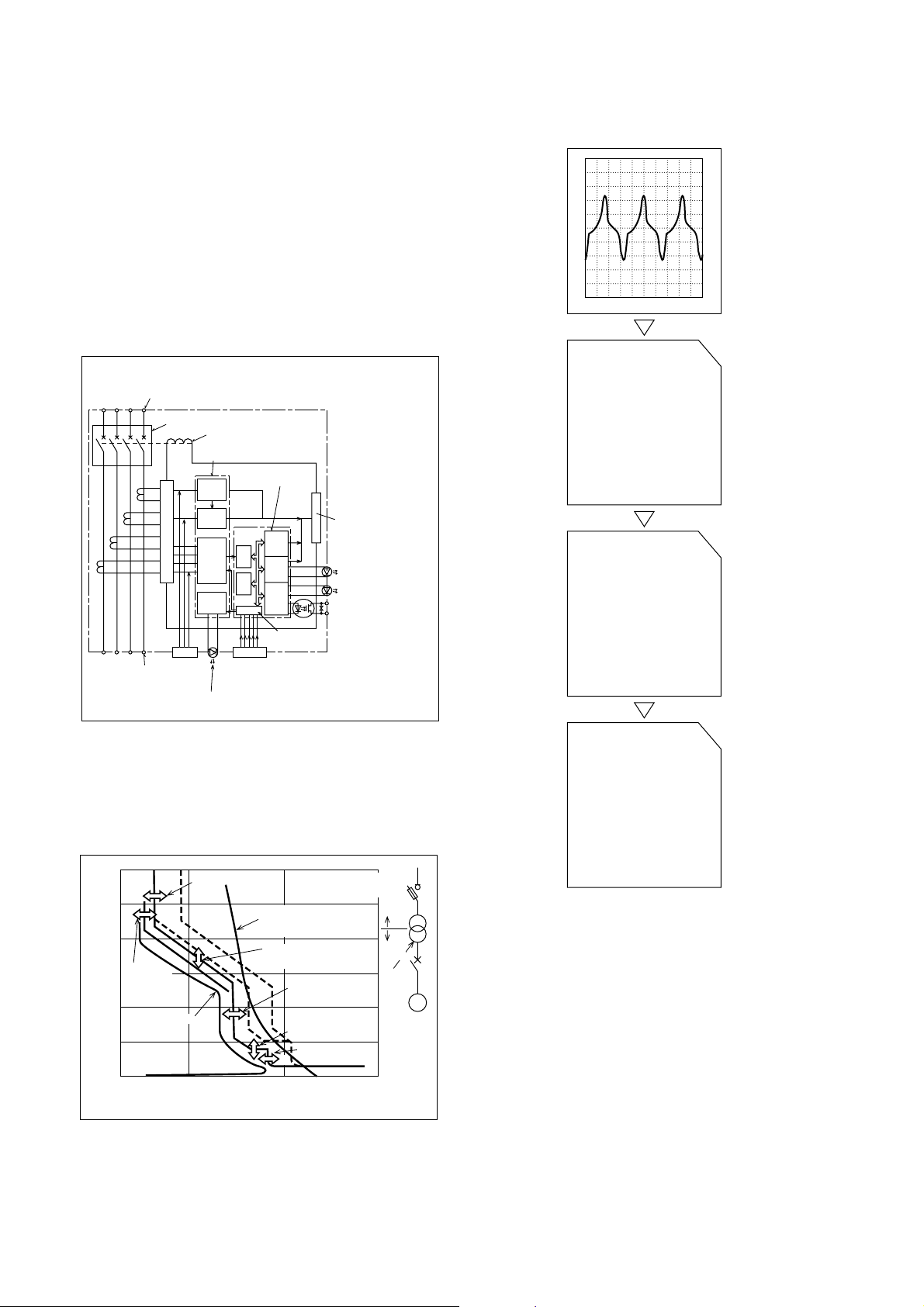

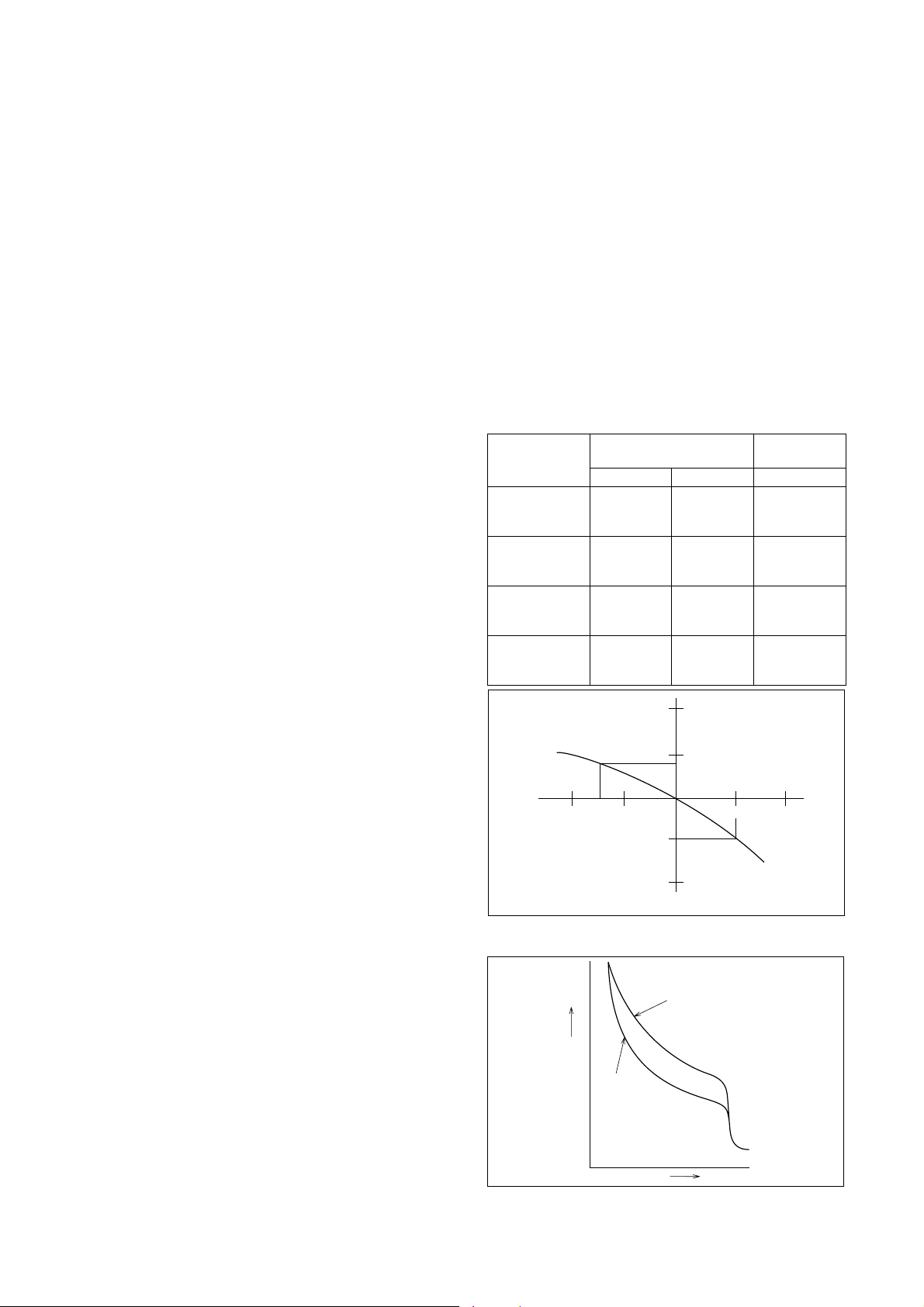

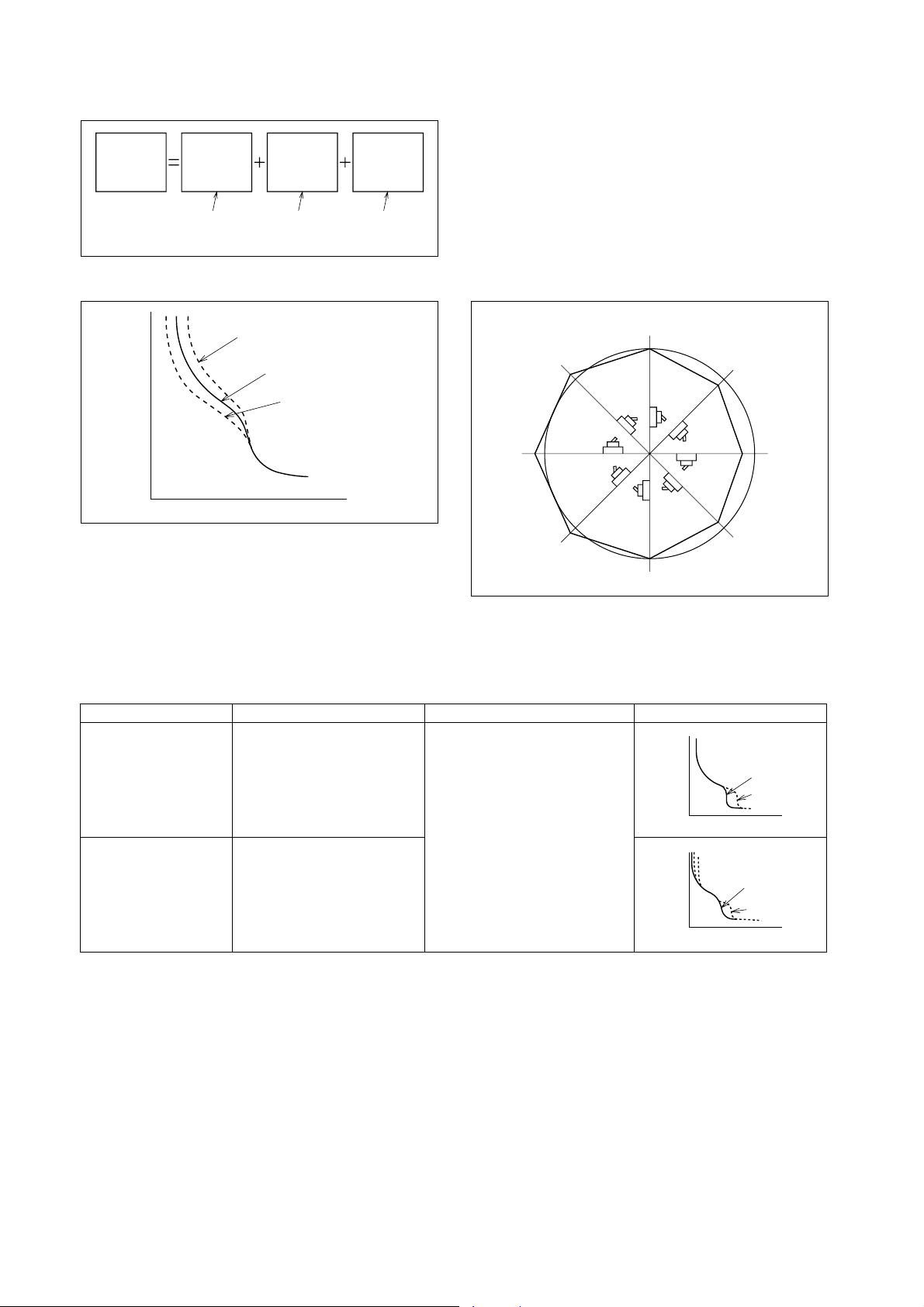

2.2 Digital ETR (Electronic Trip Relay)

Sampling and A/D

conversion

Calculating

the digitally

effective value

Processing

the long time-delay

pre-alarm

characteristics

Mitsubishi’s electronic MCCBs are equipped with a

digital ETR to enable fine protection.

The digital ETR contains Mitsubishi’s original double

IC (8 bit microcomputer and custom-IC).

Digital detection of the effective value

Electronic devices such as an inverter distort the current waveform. Mitsubishi’s PSS electronic breakers

are designed to detect digitally the effective value of

the current to minimize over-current tripping errors.

This enables fine protection for the system.

I : Instantaneous

Power-source side terminal

Breaking mechanism

CT

CT

CT

CT

Load-side

terminal

Load-current indication LED (70%)

PSS

Rectifying circuit

WDT

Test input

Trip coil

Custom IC

Microcomputer

I

CV

A/D

convertor

CPU

Characteristics

setting part

SSW

LSW

PSW

Input and

output

circuit

CV : Constant

voltage

circuit

Phaseselection

sampling

circuit

Short

time-delay

soft ware

Trigger circuit

Over-current

indication LED

Pre-alarm

indication LED

Pre-alarm

output

LSW : Long

time-delay

soft ware

PSW : Pre-alarm

soft ware

WDT : Watch-dog

timer

circuit

Processing of the digital ETR

Standard equipped pre-alarm system

Mitsubishi’s PSS electronic breakers have a pre-alarm

system as a standard. When the load current exceeds

the set pre-alarm current, the breaker lights up an LED

and outputs a pre-alarm signal.

4

1×10

3

1×10

I

P

2

1×10

Pre-alarm

10

current

Time (s)

0.1

0.01

1

Load current

4

I

r

10

Current setting

T

L

I

s

T

s

Current (A)

High-voltage fuseAllowable short-time

characteristics

Long time-delay

operating time

Short time-delay

tripping current

Short time-delay

operating time

Instantaneous

tripping current

I

i

2

10

Current-Converted value

on the high-voltage side

Switch

with fuse

High

voltage

Low

voltage

Transformer

MCCB

(electronic)

3

10

M

Load

Page 6

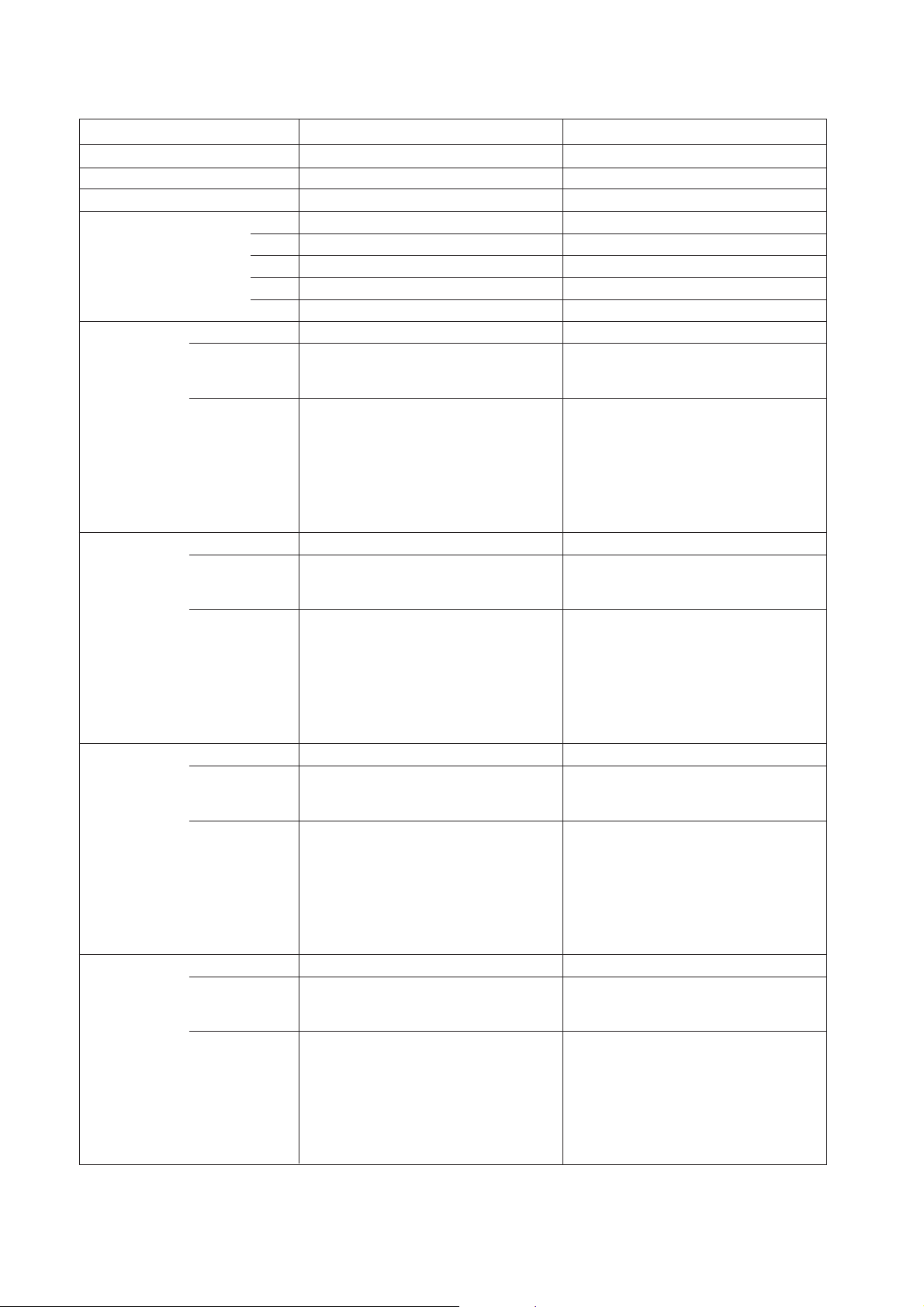

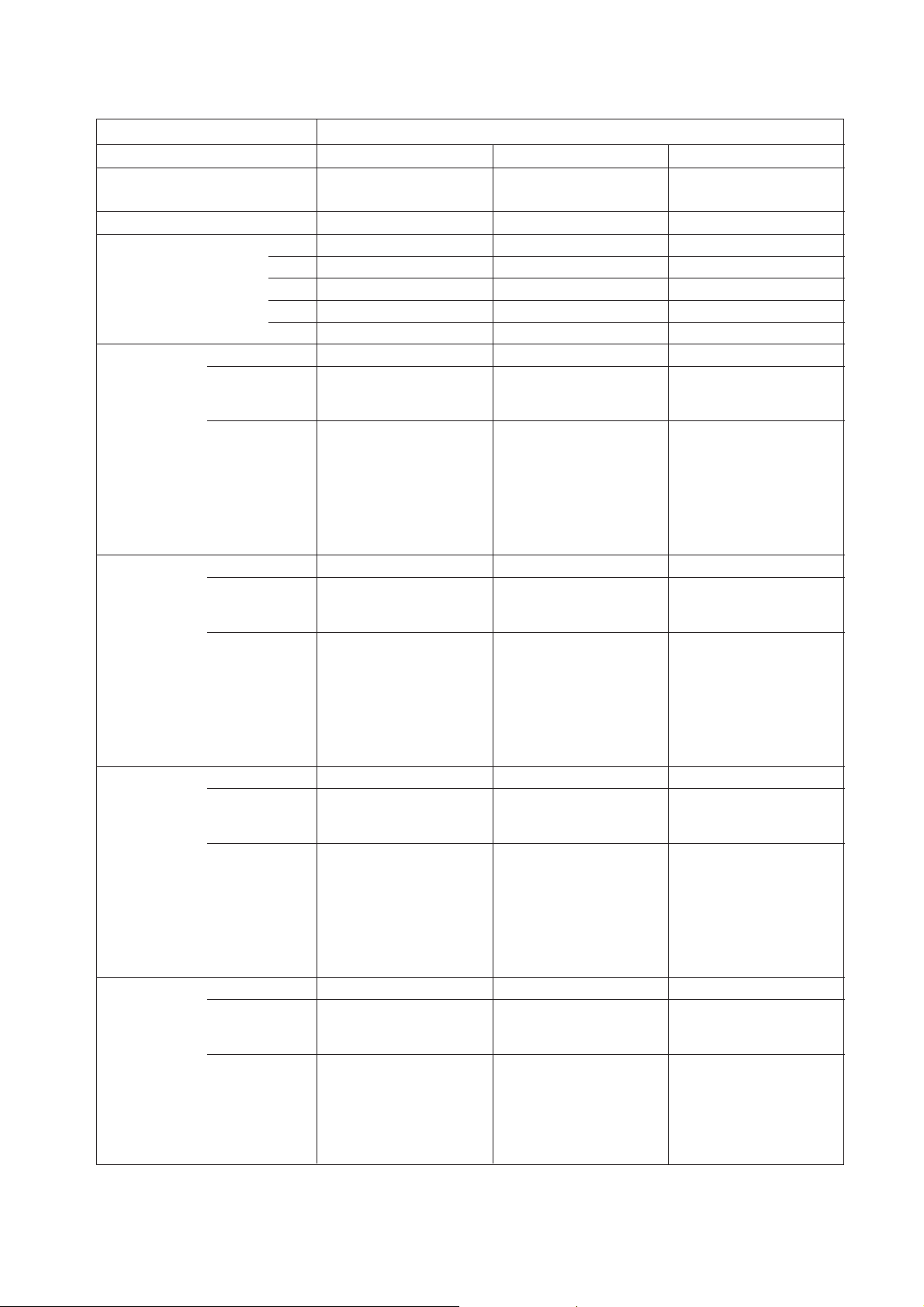

2.3 Equipment of High Technology

Series

NF-S

NF-C

NF-U

Type

NF30-SP

NF50-HP

NF50-HRP

NF60-HP

NF100-SP

NF100-HP

NF100-SEP

NF100-HEP

NF160-SP

NF160-HP

NF250-SP

NF250-HP

NF250-SEP

NF250-HEP

NF400-SP

NF400-SEP

NF400-HEP

NF400-REP

NF630-SP

NF630-SEP

NF630-HEP

NF630-REP

NF800-SEP

NF800-HEP

NF800-REP

NF1000-SS

NF1250-SS

NF1600-SS

NF50-CP

NF60-CP

NF100-CP

NF250-CP

NF400-CP

NF630-CP

NF800-CEP

NF100-RP

NF100-UP

NF225-RP

NF225-UP

NF400-UEP

NF630-UEP

NF800-UEP

NF1250-UR

ISTAC

●

●

●

●

●

●

●

●

●

●

●

●

Advanced Technology

VJC

Digital-ETR

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

Analog-ETR

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

5

Page 7

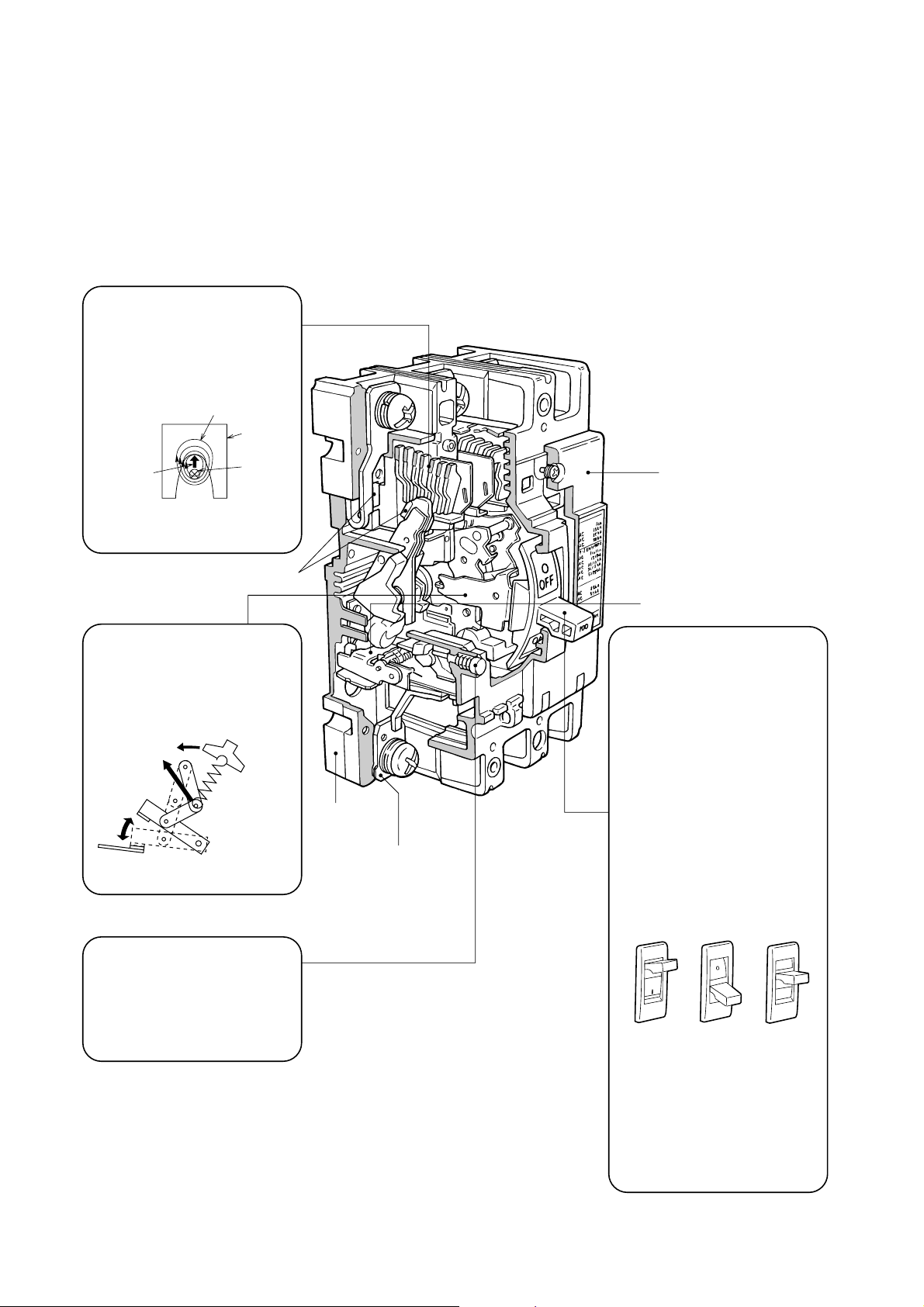

3. CONSTRUCTION AND OPERATION

3.1 General

The primary components are: a switching mechanism,

an automatic tripping device (and manual trip button),

contacts, an arc-extinguishing device, terminals and

a molded case.

Arc-Extinguishing Device

Mitsubishi MCCBs feature excellent arc-extinguishing performance by virtue of the optimum

combination of grid gap, shape,

and material.

Magnetic flux

Grid

Magnetic

force

Arc extinction

Switching Mechanism

The contacts open and close rapidly, regardless of the moving

speed of the handle, minimizing

contact wear and ensuring safety.

Rapid

movement

Arc

Contact

Link-mechanism

operation

Molded case

(Base)

Terminal

Molded case

(Cover)

Automatic tripping device

Handle

1. Trip indication

The automatically tripped condition is indicated by the handle in

the center position between ON

and OFF, the yellow (or white)

line cannot be seen in this position.

2. Resetting

Resetting after tripping is performed by first moving the handle to the OFF position to engage the mechanism, then returning the handle to ON to reclose the circuit.

3. Trip-Free

Even if the handle is held at

ON, the breaker will trip if an

overcurrent flows.

Trip Button (Push to Trip)

Enables tripping mechanically

from outside, for confirming the

operation of the accessory switches and the manual resetting function.

6

Fig. 3.1 Type NF100-SP Construction

ON

ON OFF Trip

4. Contact On Mechanism

Even in the worst case in which

welding occurs owing to an

overcurrent, the breaker will trip

and the handle will maintain to

ON, indicating the energizing

state.

OFF

Handle indication

OFF

ON

Page 8

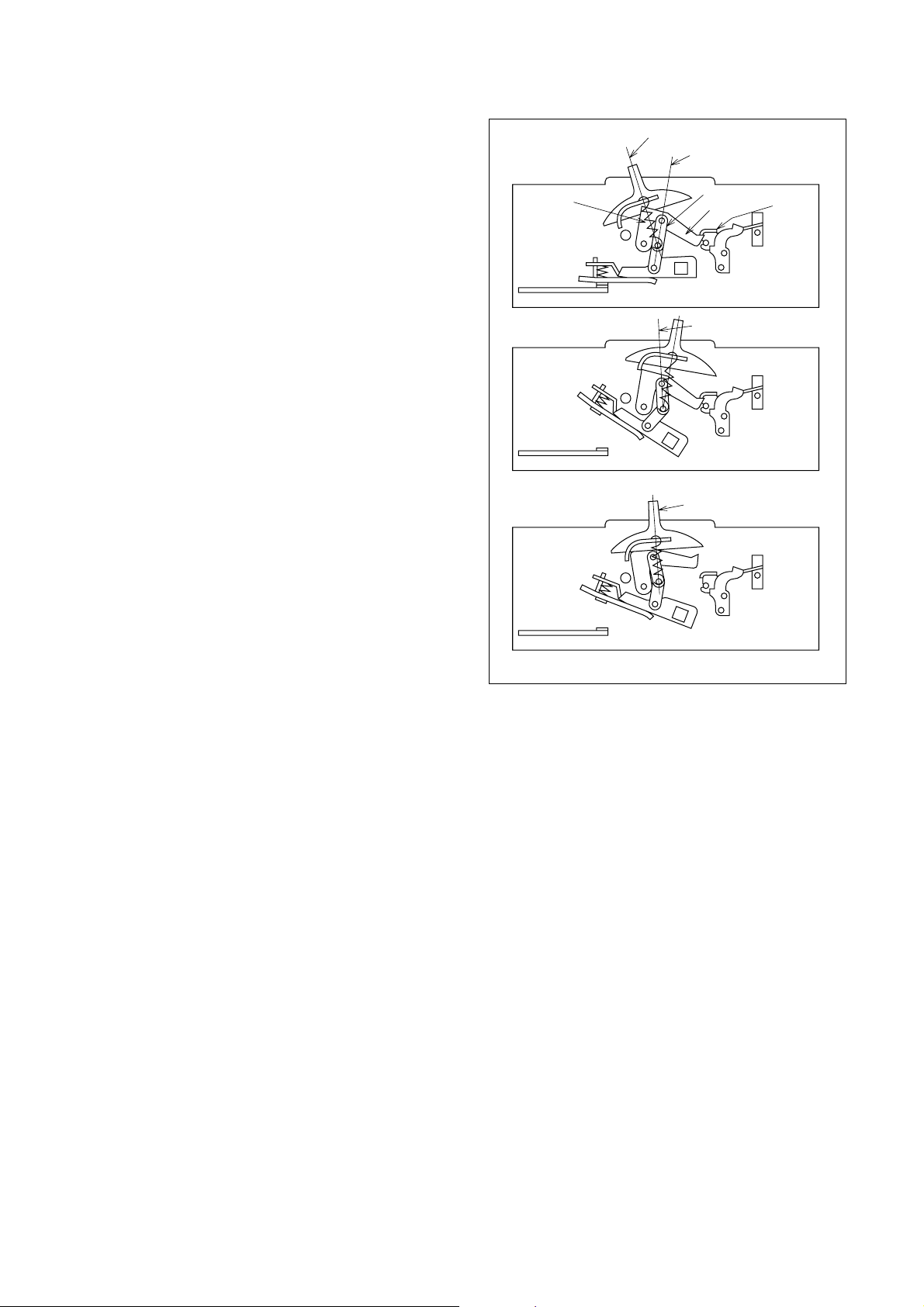

3.2 Switching Mechanism

Spring tension line

Toggle link

Cradle

Bracket

Spring

a) On

b) Off

c) Tripped

ON to OFF dead-point line

OFF to ON dead-point line

Handle centered; indicates

tripped condition

The ON, OFF and TRIPPED conditions are shown in

Fig. 3.2. In passing from ON to OFF, the handle tension spring passes through alignment with the toggle

link (“dead point” condition). In so doing, a positive,

rapid contact-opening action is produced; the OFF to

ON contact closing acts in a similar way (“quick make”

and “quick break” actions). In both cases the action of

the contacts is always rapid and positive, and independent of the human element – i.e., the force or

speed of the handle.

In auto tripping a rotation of the bracket releases

the cradle and operates the toggle link to produce the

contact-opening action described above. In the tripped

condition the handle assumes the center position between on and off, providing a visual indication of the

tripped condition. Also, auto trip is “trip free,” so that

the handle cannot be used to hold the breaker in the

ON condition. The protective contact-opening function cannot be defeated.

In multipole breakers the poles are separated by

integral barriers in the molded case. The moving contacts of the poles are attached to the central toggle

link by a common-trip bar, however, so that tripping,

opening and closing of all poles is always simultaneous. This is the “common trip” feature, by which

single phasing and similar unbalance malfunctions are

effectively prevented.

Fig. 3.2 Switching Mechanism Action

3.3 Automatic Tripping Device

There are three types of device, the thermal-magnetic

type, the hydraulic-magnetic type and the electronic

trip relay type.

7

Page 9

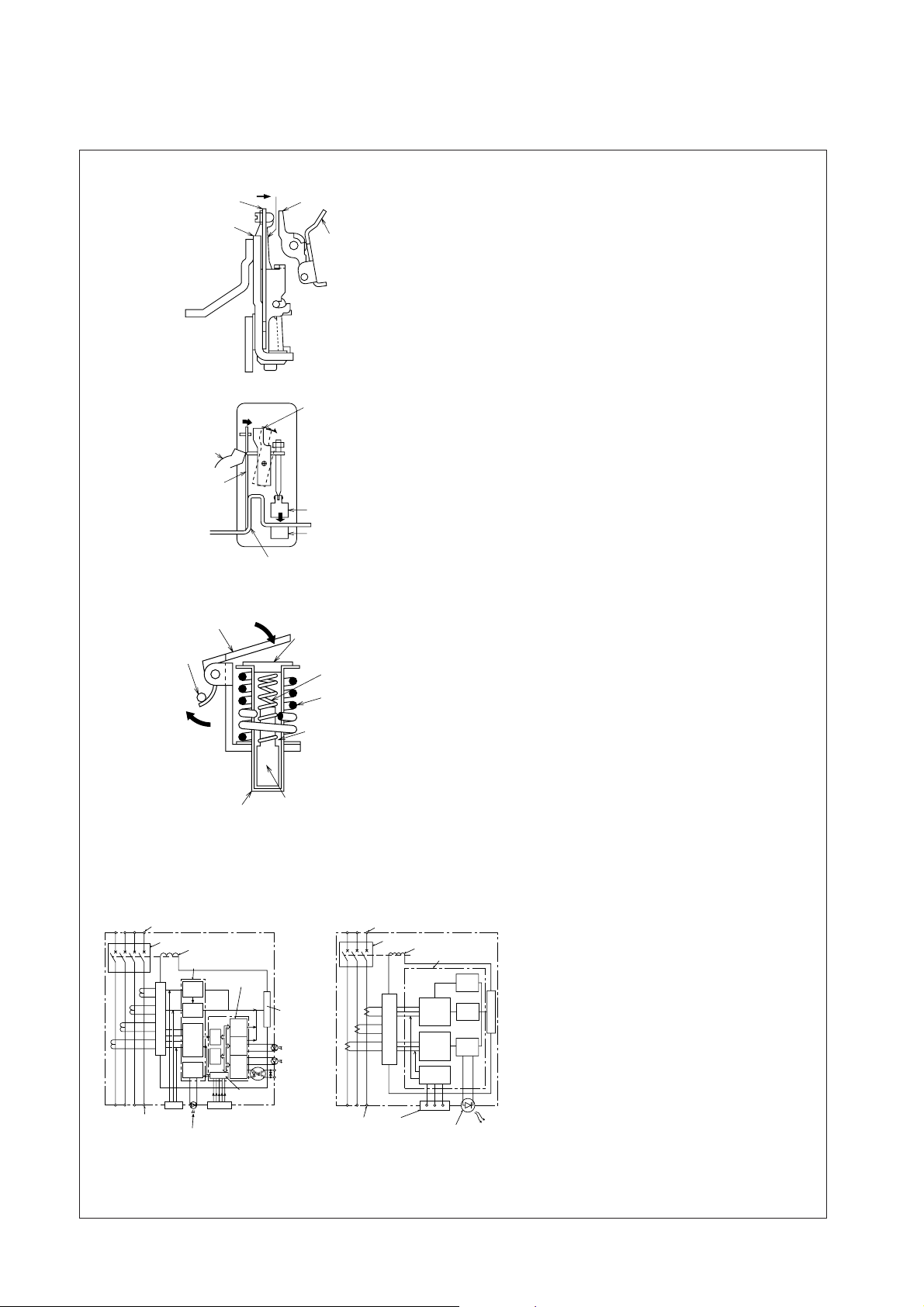

■Automatic Tripping Devices

●Thermal-Magnetic Type (100~630A Frame)

Bimetal

Heater

●Thermal-Magnetic Type (1000~4000A Frame)

Latch

Bimetal

Armature

Heater

Trip bar

Latch

Trip bar

Armature

Stationary core

1. Time-Delay Operation

An overcurrent heats and warps the bimetal to actuate the trip bar.

2. Instantaneous Operation

If the overcurrent is excessive, the

amature is attracted and the trip bar actuated.

Fig. 3.3

1. Time-Delay Operation

An overcurrent heats and warps the bimetal to actuate the trip bar.

2. Instantaneous Operation

If the overcurrent is excessive, magnetization of the stationary core is strong

enough to attract the armature and actuate the trip bar.

Fig. 3.4

●Hydraulic-Magnetic Type (30~60A Frame)

Armature

Trip bar

Pipe

Pole piece

Damping spring

Coil

Silicon oil

Moving core

Fig. 3.5

●Principle of Electronic Trip Relay (ETR) Operation

(100~800A Frame)

Power-source side terminal

Breaking mechanism

Custom IC

CT

CT

CT

Load-side

terminal

CT

CV

PSS

Rectifying circuit

WDT

Test input

Load-current indication LED (70%)

Trip coil

Microcomputer

I

A/D

convertor

CPU

Characteristics

setting part

SSW

LSW

PSW

Input and

output

Trigger circuit

Over-current

indication LED

Pre-alarm

indication LED

Pre-alarm

output

(1000~1600A Frame)

Power-supply side terminal

Switching mechanism

Trip coil

Special IC

Peak

conversion

Rectifier circuit

Test

terminals

and

largest-phase

selection

Effective value

conversion

and

largest-phase

selection

Test-signal

generator

circuit

Overcurrent display

LED

Fig. 3.6

CT

Load-side

terminal

CT

CT

Instantaneous

circuit

Shortdelay

circuit

Longdelay

circuit

1. Time-Delay Operation

At an overcurrent flow, the magnetic

force of the coil overcomes the spring,

the core closes to the pole piece, attracts

the armature, and actuates the trip bar.

The delay is obtained by the viscosity of

silicon oil.

2. Instantaneous Operation

If the overcurrent is excessive, the armature is instantly attracted, without the

influence of the moving core.

1. The current flowing in each phase is

monitored by a current transformer (CT).

2. Each phase of the transformed current

undergoes full-phase rectification in the

rectifier circuit.

3. After rectification, each of the currents

are converted by a peak-conversion and

an effective-value conversion circuit.

4. The largest phase is selected from the

Trigger circuit

converted currents.

5. Each time-delay circuit generates a time

delay corresponding to the largest

phase.

6. The trigger circuit outputs a trigger signal.

7. The trip coil is excited, operating the

switching mechanism.

8

Page 10

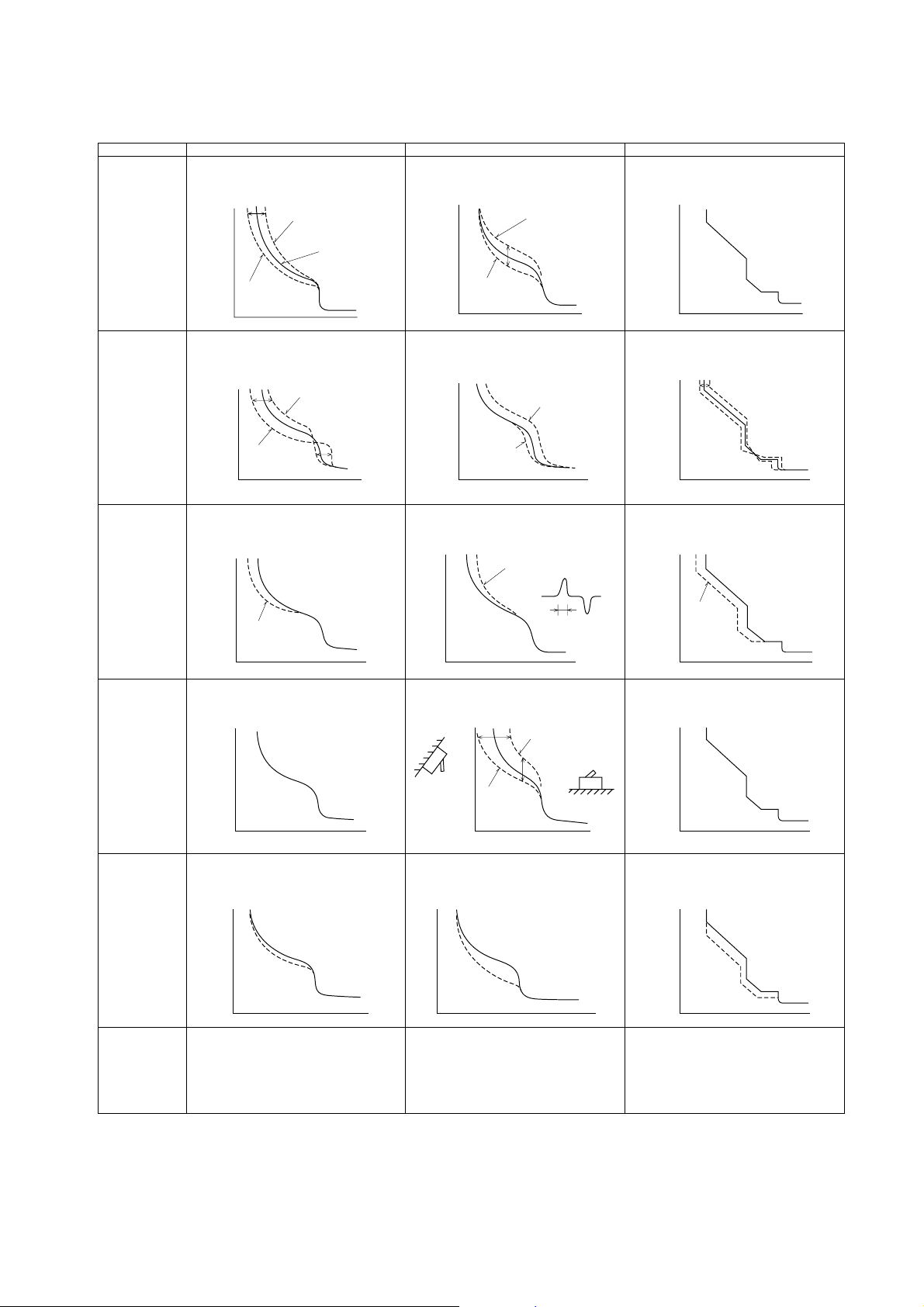

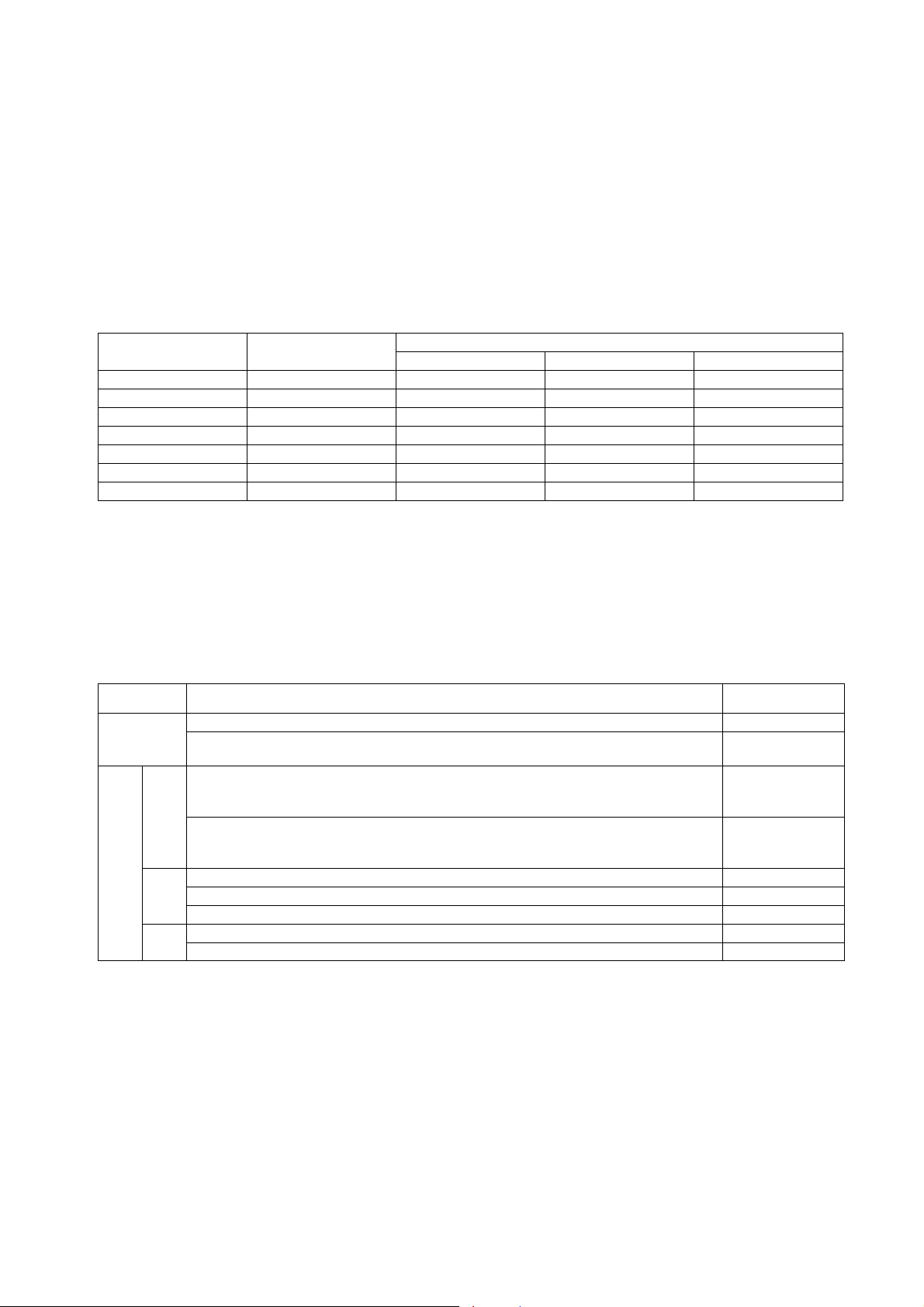

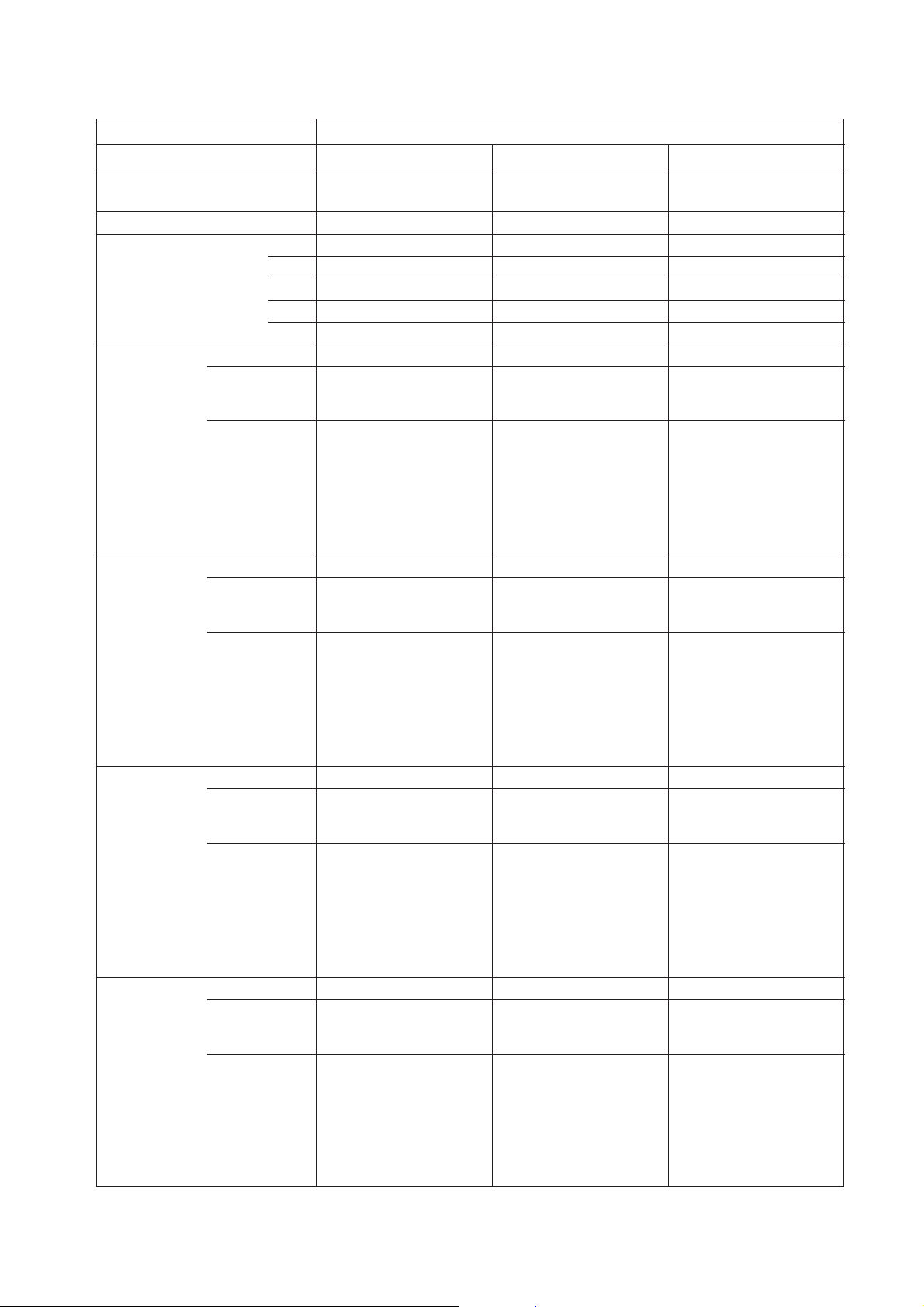

Table 3.1 Comparison of Thermal-Magnetic, Hydraulic-Magnetic and Electronic Types

Item

Operating current is affected by ambient

temperature (bimetal responds to absolute

temperature not temperature rise).

Ambient

temperature

Thermal-magnetic type

Low temperature

Standard temperature

Hydraulic-magnetic type

Affected only to the extent that the damping-oil viscosity is affected.

Low temperature

Negligible effect

Electronic type

Frequency

Distorted

wave

Operating time

High temperature

Current

Negligible effect up to several hundred Hz;

above that the instantaneous trip is affected due to increased iron losses.

Low frequency

High frequency

Operating time

Current

Negligible effect up to 630A;

Above that operating current decreases

due to increase of a fever.

Above 700A

Operating time

Current

Negligible effect.

Operating time

High temperature

Current

Trip current increases with frequency, due

to increased iron losses.

High frequency

Low frequency

Operating time

Current

IF distortion is big, minimum operating current increases.

Small current width

Current width

Operating time

Current

Mounting attitude changes the effective

weight of the magnetic core.

Operating time

Current

Tripping current of some types decrease

due to CT or condition of operating circuit

with high frequency, and others increase.

Operating time

Current

For peak value detection, operating current

drops.

Peak value

detection

Operating time

Current

Negligible effect

Mounting

attitude

Flexibility

of operating

characteristics

Flexibility of

rated current

Operating time

Current

Bimetal must provide adequate deflection

force and desired temperature characteristic. Operating time range is limited.

Operating time

Current

Units for small rated currents are physically

impractical.

Horizontal

ON OFF

Current

OFF

ON

Ceiling

Operating time

Oil viscosity, cylinder, core and spring design, etc., allow a wide choice of operating

times.

Operating time

Current

Coil winding can easily be designed to suit

any ampere rating.

Operating time

Current

Operating time can be easily shortened.

To lengthen operating time is not.

Operating time

Current

Within the range of 50(60)~100% of rated

current, any ampere rating are practical.

Also, to lower the value of short-time delay

or instantaneous trip can be easily done

comparatively.

9

Page 11

3.4 Contacts

A pair of contacts comprises a moving contact and a

fixed contact. The instants of opening and closing

impose the most severe duty. Contact materials must

be selected with consideration to three major criteria:

1. Minimum contact resistance

2. Maximum resistance to wear

3. Maximum resistance to welding

Silver or silver-alloy contacts are low in resistance,

but wear rather easily. Tungsten, or majority-tungsten

alloys are strong against wear due to arcing, but rather

high in contact resistance. Where feasible, 60%+ silver alloy (with tungsten carbide) is used for contacts

primarily intended for current carrying, and 60%+ tungsten alloy (with silver) is used for contacts primarily

intended for arc interruption. Large-capacity MCCBs

employ this arrangement, having multicontact pairs,

with the current-carrying and arc-interruption duties

separated.

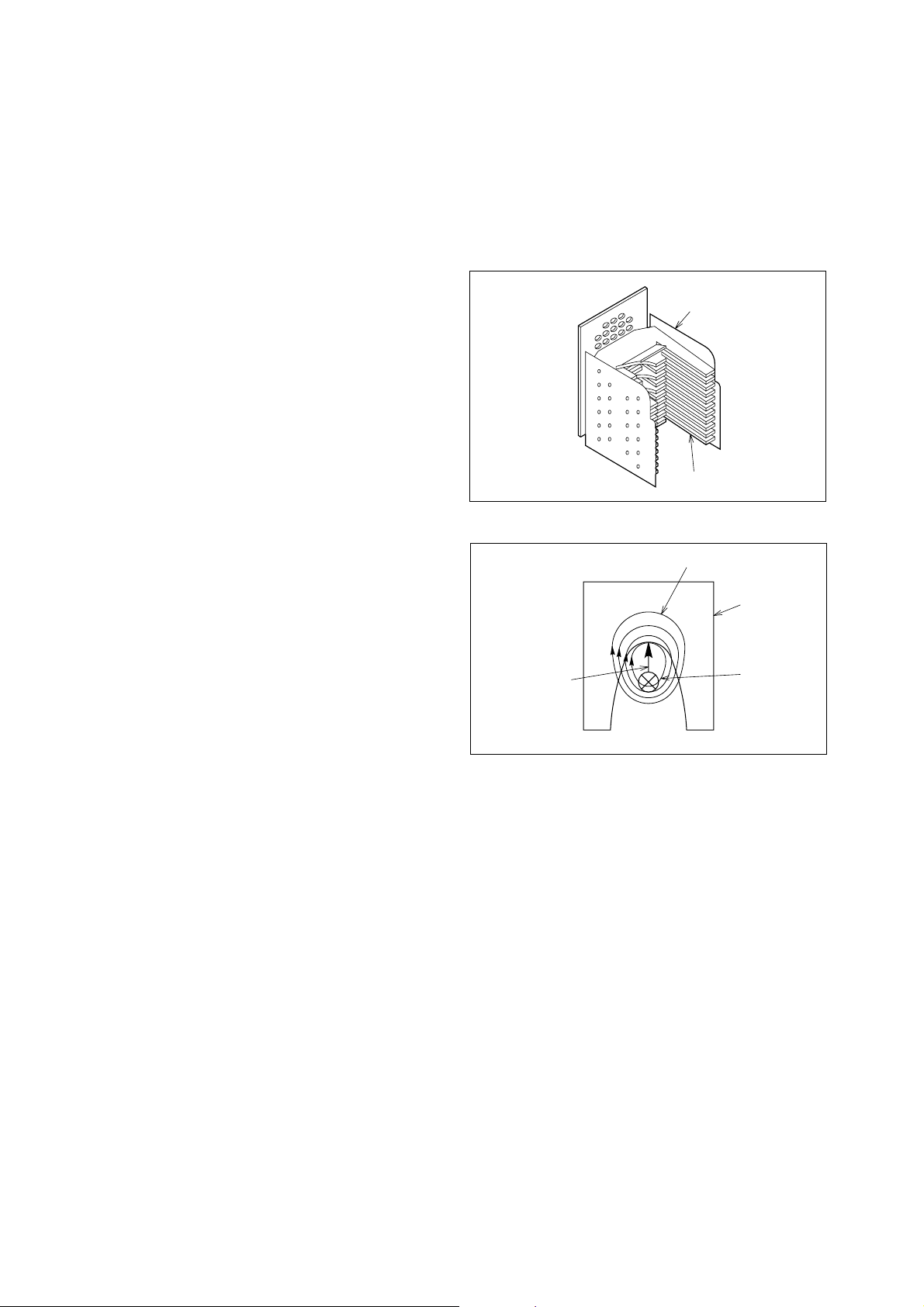

3.5 Arc-Extinguishing Device

Arcing, an inevitable aspect of current interruption,

must be extinguished rapidly and effectively, in normal switching as well as protective tripping, to minimize deterioration of contacts and adjacent insulating materials. In Mitsubishi MCCBs a simple, reliable,

and highly effective “de-ion arc extinguisher,” consisting of shaped magnetic plates (grids) spaced apart in

an insulating supporting frame, is used (Fig. 3.7). The

arc (ionized-path current) induces a flux in the grids

that attracts the arc, which tends to “lie down” on the

grids, breaking up into a series of smaller arcs, and

also being cooled by the grid heat conduction. The

arc (being effectively longer) thus requires far more

voltage to sustain it, and (being cooler) tends to lose

ionization and extinguish. If these two effects do not

extinguish the arc, as in a very large fault, the elevated

temperature of the insulating frame will cause gassing-out of the frame material, to de-ionize the arc.

Ac arcs are generally faster extinguishing due to the

zero-voltage point at each half cycle.

3.8 Trip Button

This is a pushbutton for external, mechanical tripping

of the MCCB locally, without operating the externalaccessory shunt trip or undervoltage trip, etc. It enables easy checking of breaker resetting, control-circuit devices associated with alarm contacts, etc., and

resetting by external handle.

Supporting

frame

Grids

Fig. 3.7 The De-Ion Arc Extinguisher

Induced flux

Grid

Attraction force

Fig. 3.8 The Induced-Flux Effect

Arc

3.6 Molded Case

The integral molded cases used in Mitsubishi MCCBs

are constructed of the polyester resin containing glass

fibers, the phenolic resin or glass reinforced nylon.

They are designed to be suitably arc-, heat- and gasresistant, and to provide the necessary insulating

spacings and barriers, as well as the physical strength

required for the purpose.

3.7 Terminals

These are constructed to assure electrical efficiency

and reliability, with minimized possibility of localized

heating. A wide variety of types are available for ease

of mounting and connection. Compression-bonded

types and bar types are most commonly used.

10

Page 12

Rated current

(A)

30 or less

31~63

64~100

101~250

251~400

401~630

631~800

801~1000

1001~1250

1251~1600

1601~2000

2001~4000

Tripping time

(minutes, max.)

200%

8.5

4

8.5

8

10

12

14

16

18

20

22

24

130%

60

60

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

60

60

120

105%

Non-Tripping time

(minutes, max.)

4. CHARACTERISTICS AND PERFORMANCE

4.1 Overcurrent-Trip Characteristics (Delay

Tripping)

Tripping times for overcurrents of 130 and 200% of

rated current are given in Table 4.1, assuming ambient temperatures of 40°C, a typical condition inside

of panelboards. The figures reflect all poles tested together for 130% tripping, and 105% non-tripping.

Within the range of the long-delay-element (thermal

or hydraulic) operation, tripping times are substantially linear, in inverse relationship to overcurrent magnitude.

The tripping times are established to prevent excessive conductor-temperature rise; although times

may vary among MCCBs of different makers, the lower

limit is restricted by the demands of typical loads: tungsten-lamp inrush, starting motor, mercury-arc lamps,

etc. The tripping characteristics of Mitsubishi MCCBs

are established to best ensure protection against abnormal currents, while avoiding nuisance tripping.

4.1.1 Ambient Temperature and Thermal Tripping

Fig. 4.1 is a typical ambient compensation curve

(curves differ according to types and ratings), showing that an MCCB rated for 40°C ambient use must

be derated to 90% if used in a 50°C environment. In

an overcurrent condition, for the specified tripping time,

tripping would occur at 180% rated current, not 200%.

At 25°C, for the same tripping time, tripping would

occur at 216%, not 200%.

4.1.2 Hot-State Tripping

The tripping characteristics described above reflect

“cold-state tripping” – i.e., overloads increased from

zero – and the MCCB stabilized at rated ambient. This

is a practical parameter for most uses, but in intermittent operations, such as resistance welding, motor

pulsing, etc., the “hot state” tripping characteristic must

be specified, since over-loads are most likely to occur with the MCCB in a heated state, while a certain

load current is already flowing.

Where the MCCB is assumed to be at 50% of rating when the overload occurs, the parameter is called

the 50% hot-state characteristic; if no percentage is

specified, 100% is assumed. Hot-state ratings of 50%

and 75% are common.

4.2 Short-Circuit Trip Characteristics (In-

stantaneous Tripping)

For Mitsubishi MCCBs with thermal-magnetic trip units

the instantaneous-trip current can be specified independently of the delay characteristic, and in many

cases this parameter is adjustable offering considerable advantage in coordination with other protection

and control devices. For example, in coordination with

motor starters, it is important to set the MCCB instantaneous-trip element at a lower value than the fusing

(destruction) current of the thermal overload relay

(OLR) of the starter.

For selective tripping, it must be remembered that

even though the branch-MCCB tripping time may be

shorter than the total tripping time of the main MCCB,

in a fault condition the latter may also be tripped because its latching curve overlaps the tripping curve of

the former. The necessary data for establishing the

required compatibility is provided in the Mitsubishi

MCCB sales catalogues.

The total clearing time for the “instantaneous” tripping feature is shown in Fig. 4.3; actual values differ

for each MCCB type.

Table 4.1 Overcurrent Tripping Times

120

110

108

100

20 25

% rating compensation

Fig. 4.1 Typical Temperature-Compensation Curve

Hot state

Operating time

Fig. 4.2 Hot-State-Tripping Curve

40

30

90

80

Ambient temperature (:)

Cold state

Current

50 60

11

Page 13

Total

clearing

time

Fig. 4.3 Instantaneous Tripping Sequence

Latching

(relay)

time

Electromagnet

oparating

time

Floor-mounted

Mechanical

delay

time

Time for

contacts to

open

Arcing

time

Arcextinguishing

time

4.3 Effects of Mounting Attitudes

Instantaneous tripping is negligibly affected by mounting attitude, for all types of MCCB. Delay tripping is

also negligibly affected in the thermal types, but in

the hydraulic-magnetic types the core-weight effect

becomes a factor. Fig. 4.4 shows the effect, for vertical-surface mounting and for two styles of horizontalsurface mounting.

(vertical plane)

100%

Wall-mounted

(horiz. or vert. attitude)

Ceiling-mounted

Tripping time

Overcurrent

Fig. 4.4 Effect of Mounting Attitude on the Hydraulic-

Magnetic MCCB Tripping Curves

Fig. 4.5 Effects of Nonvertical-Plane Mounting on Current

4.4 DC Tripping Characteristics of AC-Rated MCCBs

Table 4.2 DC Tripping Characteristics

Trip unit

Thermal

magnetic

Hydraulic

magnetic

Long delay

No effect below 630A

frame. Above this, AC

types cannot be used

for DC.

DC minimum-trip

values are 110~140%

of AC values.

Instantaneous

DC inst.-trip current is

approx. 130% of AC

value.

107%

107%

Rating

ON

ON

ON

ON

ON

ON

100%

93%

ON

ON

93%

Tripping curve

AC

Tripping time

Tripping time

DC

Overcurrent

AC

DC

Overcurrent

90%110%

4.5 Frequency Characteristics

At commercial frequencies the characteristics of

Mitsubishi MCCBs of below 630A frame size are virtually constant at both 50Hz and 60Hz (except for the

E Line models, the characteristics of MCCBs of 2000A

frame and above vary due to the CT used with the

delay element).

At high frequencies (e.g., 400Hz), both the current

capacity and delay tripping curves will be reduced by

skin effect and increased iron losses.

Performance reduction will differ for different types;

at 400Hz it will become 80% of the rating in breakers

of maximum rated current for the frame size, and 90%

12

of the rating in breakers of half of the maximum rating

for the frame size.

The instantaneous trip current will gradually increase with frequency, due to reverse excitation by

eddy currents. The rise rate is not consistent, but

around 400Hz it becomes about twice the value at

60Hz. Mitsubishi makes available MCCBs especially

designed for 400Hz use. Apart from operating characteristics they are identical to standard MCCBs (S

Line).

Page 14

4.6 Switching Characteristics

Frame size

100 or less

225

400, 630

800

1000~2000

2500, 3000

3200, 4000

Operations per hour

120

120

60

20

20

10

10

Number of operations

Without current

8500

7000

4000

2500

2500

1500

1500

With current

1500

1000

1000

500

500

500

500

Total

10000

8000

5000

3000

3000

2000

2000

The MCCB, specifically designed for protective interruption rather than switching, and requiring high-contact pressure and efficient arc-extinguishing capability, is expected to demonstrate inferior capability to

that of a magnetic switch in terms of the number of

operations per minute and operation life span. The

specifications given in Table 4.3 are applicable where

the MCCB is used as a switch for making and break-

Table 4.3 MCCB Switching Endurance

ing rated current.

Electrical tripping endurance in MCCBs with shunt

or undervoltage tripping devices is specified as 10%

of the mechanical-endurance number of operations

quoted in IEC standards.

Shunt tripping or undervoltage tripping devices are

intended as an emergency trip provision and should

not be used for normal circuit-interruption purposes.

4.7 Dielectric Strength

In addition to the requirements of the various international standards, Mitsubishi MCCBs also have the

impulse-voltage withstand capabilities given below

(Table 4.4). The impulse voltage is defined as sub-

Table 4.4 MCCB Impulse Withstand Voltage (Uimp)

Type

NF

Line

MB

MB30-CS

MB30-SP MB50-CP MB50-SP

MB100-SP MB225-SP

NF30-SP NF50-HP NF60-HP

NF50-HRP NF100-SP NF100-HP NF100-SEP NF100-HEP

NF160-SP NF160-HP NF250-SP NF250-HP NF250-SEP NF250-HEP

S

NF400-SP NF400-SEP NF400-HEP NF400-REP NF630-SP NF630-SEP

NF630-HEP NF630-REP NF800-SEP NF800-HEP NF800-REP

NF800-REP NF1000-SS NF1250-SS NF1600-SS

NF30-CS

NF50-CP NF60-CP NF100-CP NF250-CP

C

NF400-CP NF630-CP NF800-CEP

NF100-RP NF100-UP NF225-RP NF225-UP

U

NF400-UEP NF630-UEP NF800-UEP

stantially square-wave, with a crest length of

0.5~1.5µsec and a tail-length of 32~48µsec. The voltage is applied between line and load terminals (MCCB

off), and between live parts and ground (MCCB on).

Impulse-voltage (kA)

4

6

6

8

4

6

8

6

8

13

Page 15

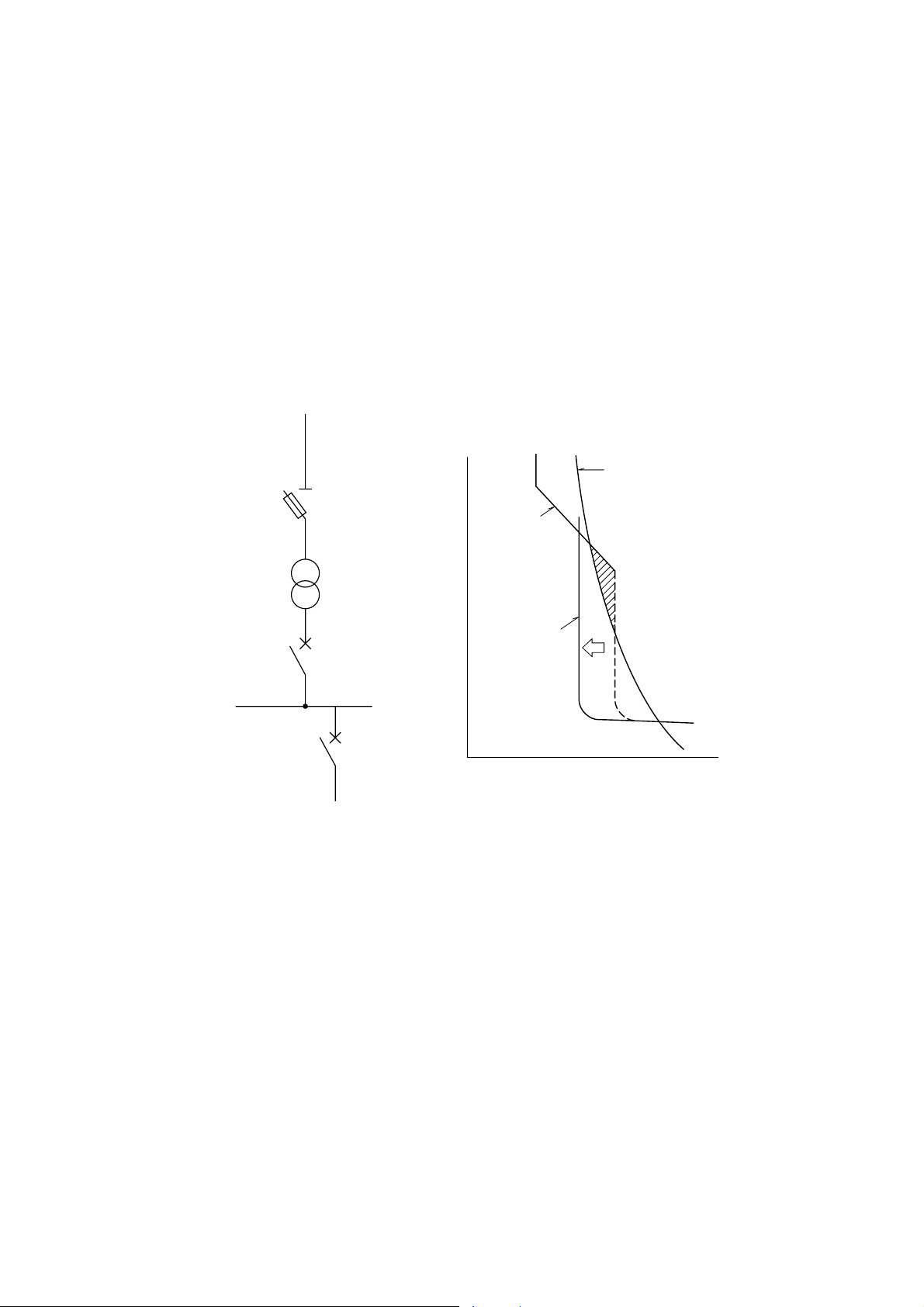

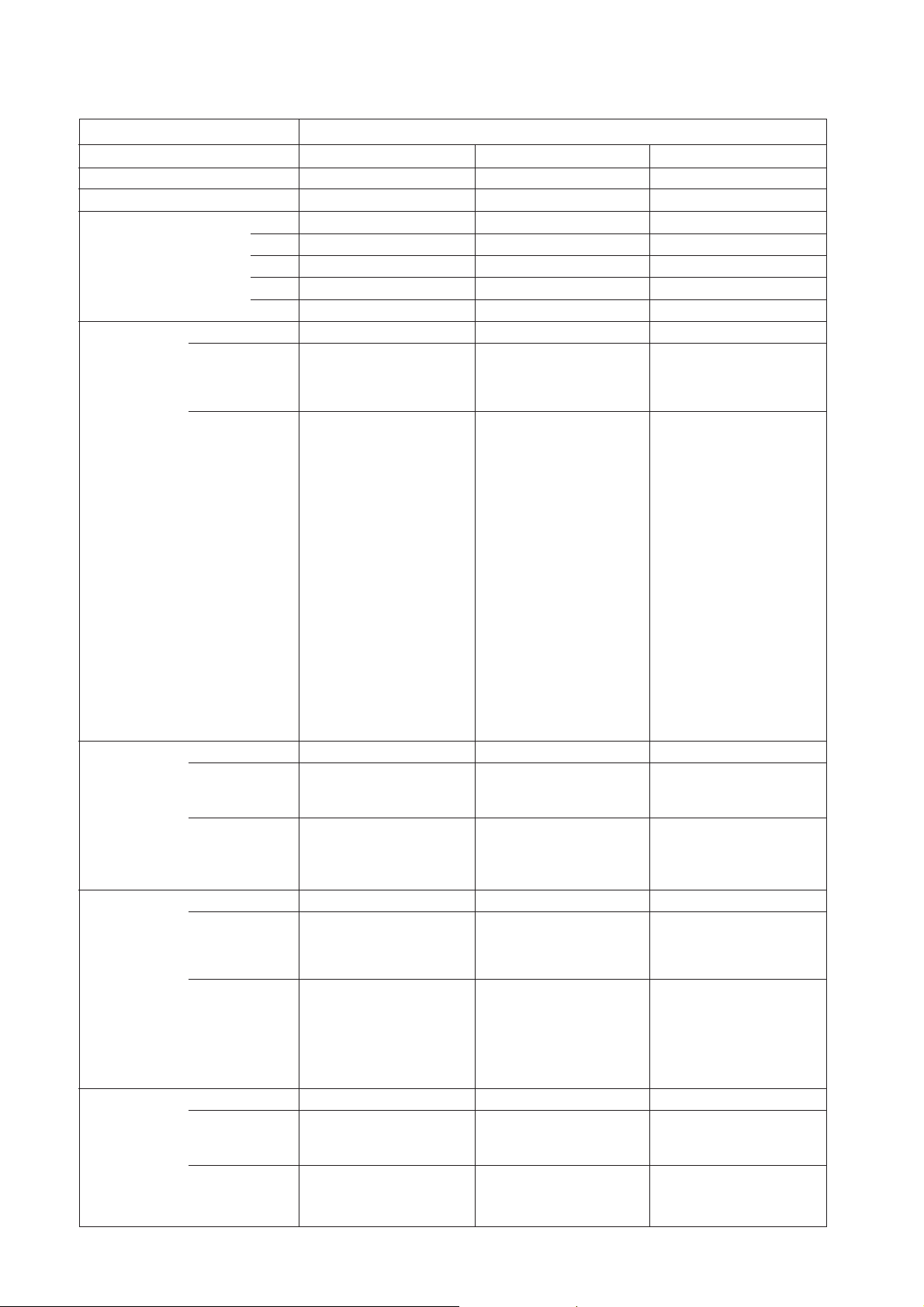

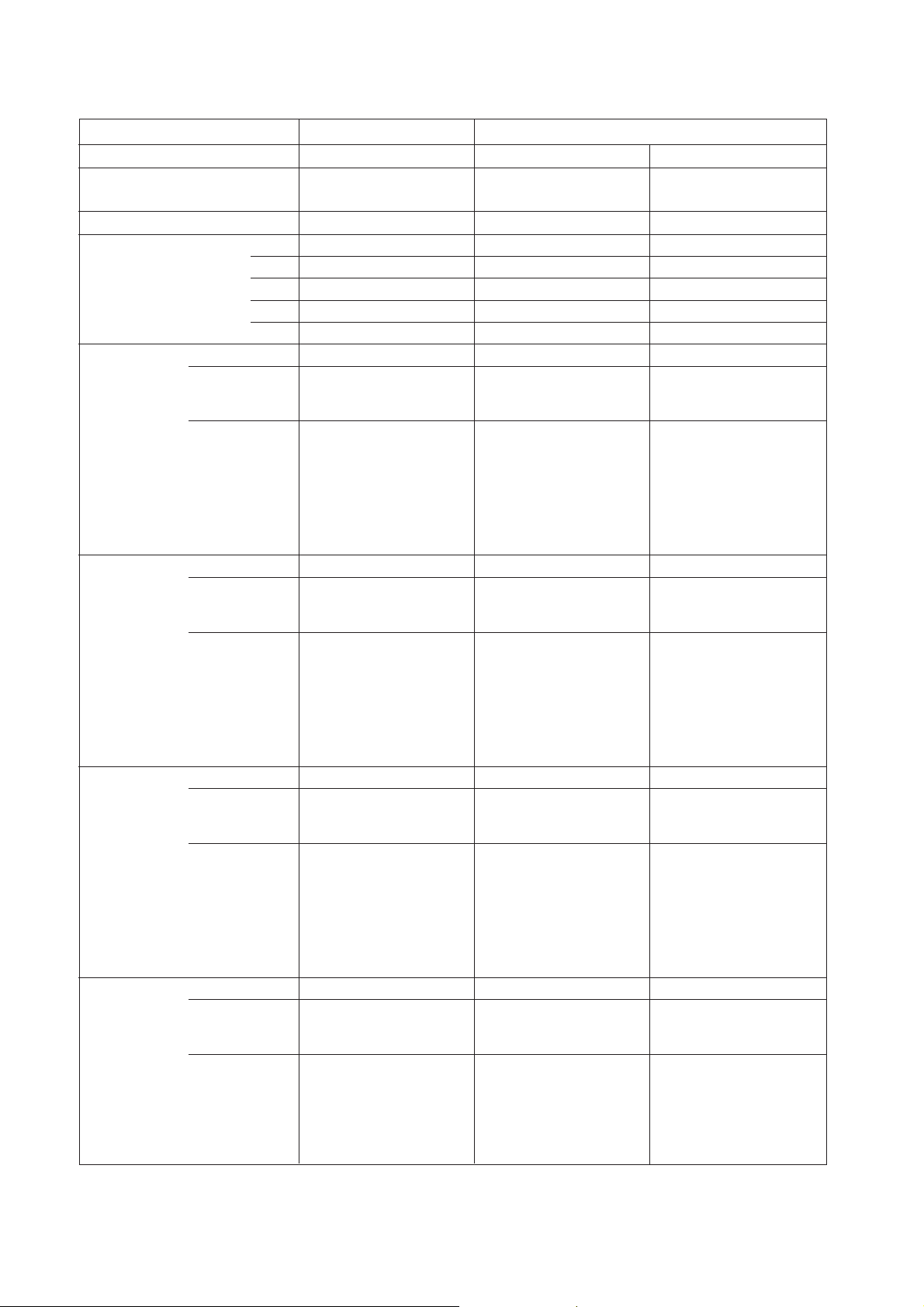

5. CIRCUIT BREAKER SELECTION

5.1 Circuit Breaker Selection Table

Following Table shows various characteristics of each breaker to consider selection and coordination with

upstream devices or loads.

Characteristics

Standard : Standard characteristics MCCBs

Low-inst : Low-inst. MCCBs for Discrimination

When a power fuse (PF) is used as a high-voltage protector, it must be coordinated

with an MCCBs on the secondary side.

PF short-time tolerancs

capacity

Pf.

MCCB

operating

characteristic

curve

Tr.

MCCB1

MCCB2

Generator: Generator-Protection MCCBs

These MCCBs have long-time-delay operation shorter than standard type and low

instantaneous operation.

Mag-Only : Magnetic trip only MCCBs

These are standard MCCBs minus the thermal tripping device. They have no timedelay tripping characteristic, providing protection only against large-magnitude shortcircuit faults.

Low-inst.MCCBs

Time

Current

14

Page 16

CIRCUIT BREAKER SELECTION TABLE

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

Hydraulic-magnetic

Fixed ampere rating and

instantaneous

NF30-CS

3, 5, 10, 15, 20, 30

500

–

–

1.5/1.5 (415V)

1.5/1.5 (380V)

2.5/2 (240V)

23

339± 17

566± 28

10 132 ± 57

15 198 ± 86

20 265 ± 115

30 397 ± 172

30

NF30-SP

3, 5, 10, 15, 20, 30

600

–

2.5/1

2.5/1

5/2

5/2

23

Hydraulic-magnetic

Fixed ampere rating and

instantaneous

333± 10

555± 17

10 110 ± 35

15 165 ± 52

20 220 ± 70

30 330 ± 105

50

NF50-CP

10, 15, 20, 30, 40, 50

600

–

2.5/1

2.5/1

5/2

5/2

23

Hydraulic-magnetic

Fixed ampere rating and

instantaneous

10 110 ± 35

15 165 ± 52

20 220 ± 70

30 330 ± 105

40 440 ± 140

50 550 ± 175

Low-inst

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

–

–

–

–

–

Magnetic

–

–

Fixed ampere rating

instantaneous

330± 6

550± 10

10 100 ± 20

15 150 ± 30

20 200 ± 40

30 300 ± 60

–

–

–

–

–

–

23

Magnetic

Fixed ampere rating

instantaneous

10 100 ± 20

15 150 ± 30

20 200 ± 40

30 300 ± 60

40 400 ± 80

50 500 ± 100

–

–

–

–

–

–

23

15

Page 17

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

50

NF50-HP

10, 15, 20, 30, 40, 50

600

–

7.5/4

10/5

10/5

25/13

234

Hydraulic-magnetic

Fixed ampere rating and

instantaneous

10 110 ± 35

15 165 ± 52

20 220 ± 70

30 330 ± 105

40 440 ± 140

50 550 ± 175

60

NF60-CP

10, 15, 20, 30, 40, 50, 60

600

–

2.5/1

2.5/1

5/2

5/2

23

Hydraulic-magnetic

Fixed ampere rating and

instantaneous

10 110 ± 35

15 165 ± 52

20 220 ± 70

30 330 ± 105

40 440 ± 140

50 550 ± 175

60 660 ± 210

Low-inst

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

–

–

–

–

234

Magnetic

Fixed ampere rating and

instantaneous

10 100 ± 20

15 150 ± 30

20 200 ± 40

30 300 ± 60

40 400 ± 80

50 500 ± 100

–

–

–

–

–

–

23

Magnetic

Fixed ampere rating and

instantaneous

10 100 ± 20

15 150 ± 30

20 200 ± 40

30 300 ± 60

40 400 ± 80

50 500 ± 100

60 600 ± 120

16

Page 18

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Low-inst

Generator

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

690V

500V

440V

400V

230V

Hydraulic-magnetic

Fixed ampere rating and

instantaneous

60

NF60-HP

10, 15, 20, 30, 40, 50, 60

600

–

7.5/4

10/5

10/5

25/13

234

10 110 ± 35

15 165 ± 52

20 220 ± 70

30 330 ± 105

40 440 ± 140

50 550 ± 175

60 660 ± 210

–

–

–

–

–

100

NF100-CP NF100-SP

50, 60, 75, 100

600

–

7.5/4

10/5

10/5

25/13

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

50 750 ± 150

60 900 ± 180

75 1125 ± 225

100 1500 ± 300

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

50 300 ± 60

60 360 ± 72

75 450 ± 90

100 600 ± 120

–

–

15, 20, 30, 40, 50, 60, 75, 100

Thermal, magnetic

Fixed ampere rating and

instantaneous

100 1500 ± 300

Thermal, magnetic

Fixed ampere rating and

instantaneous

100 600 ± 120

690

–

15/8

25/13

30/15

50/25

234

15 225 ± 45

20 300 ± 60

30 450 ± 90

40 600 ± 120

50 750 ± 150

60 900 ± 180

75 1125 ± 225

234

15 90 ± 18

20 120 ± 24

30 180 ± 36

40 240 ± 48

50 300 ± 60

60 360 ± 72

75 450 ± 90

–

–

Mag-Only

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

234 2 3

Magnetic

Fixed ampere rating and

instantaneous

10 100 ± 20

15 150 ± 30

20 200 ± 40

30 300 ± 60

40 400 ± 80

50 500 ± 100

60 600 ± 120

Magnetic

Fixed ampere rating and

instantaneous

100 1000 ± 200

–

50 500 ± 100

60 600 ± 120

75 750 ± 150

–

234

Magnetic

Fixed ampere rating and

instantaneous

15 150 ± 30

20 200 ± 40

30 300 ± 60

40 400 ± 80

50 500 ± 100

60 600 ± 120

75 750 ± 150

100 1000 ± 200

17

Page 19

Frame (A) 100

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

Thermal, magnetic

Adjustable ampere rating

and fixed instantaneous

NF100-CP T/A

15 ~ 20, 20 ~ 25, 25 ~ 40

40 ~ 63, 63 ~ 80, 80 ~ 100

600

–

7.5/4

10/5

10/5

25/13

23

15 ~ 20 225 ± 45

20 ~ 25 300 ± 60

25 ~ 40 375 ± 75

40 ~ 63 600 ± 120

63 ~ 80 945 ± 189

80 ~ 100 1200 ± 240

50

NF50-HRP

15, 20, 30, 40, 50

690

2.5/1

20/10

30/15

30/15

85/43

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

15 225 ± 45

20 300 ± 60

30 450 ± 90

40 600 ± 120

50 750 ± 150

100

NF100-SP T/A

15 ~ 20, 20 ~ 25, 25 ~ 40

40 ~ 63, 63 ~ 80, 80 ~ 100

690

–

15/8

25/13

30/15

50/25

234

Thermal, magnetic

Adjustable ampere rating

and fixed instantaneous

15 ~ 20 225 ± 45

20 ~ 25 300 ± 60

25 ~ 40 375 ± 75

40 ~ 63 600 ± 120

63 ~ 80 945 ± 189

80 ~ 100 1200 ± 240

Low-inst

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

–

–

–

–

–

–

–

Magnetic

Fixed ampere rating and

instantaneous

15 150 ± 30

20 200 ± 40

30 300 ± 60

40 400 ± 80

50 500 ± 100

–

–

–

–

–

–

23

–

–

–

–

–

–

–

–

–

18

Page 20

Frame (A)

Type

Rated current In (A)

15, 20, 30, 40, 50, 60, 75, 100

100

NF100-HP T/ANF100-HP

15 ~ 20, 20 ~ 25, 25 ~ 40

40 ~ 63, 63 ~ 80, 80 ~ 100

NF100-RP

15, 20, 30, 40, 50, 60, 75, 100

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Low-inst

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

690

5/3

30/15

50/25

50/25

100/50

234

Thermal, magnetic

Fixed ampere rating and

instantaneous

15 225 ± 45

20 300 ± 60

30 450 ± 90

40 600 ± 120

50 750 ± 150

60 900 ± 180

75 1125 ± 225

100 1500 ± 300

–

–

690

5/3

30/15

50/25

50/25

100/50

234

Thermal, magnetic

Adjustable ampere rating

and fixed instantaneous

15 ~ 20 225 ± 45

20 ~ 25 300 ± 60

25 ~ 40 375 ± 75

40 ~ 63 600 ± 120

63 ~ 80 945 ± 189

80 ~ 100 1200 ± 240

–

–

690

–

42/42

125/125

125/125

125/125

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

15 225 ± 45

20 300 ± 60

30 450 ± 90

40 600 ± 120

50 750 ± 150

60 900 ± 180

75 1125 ± 225

100 1500 ± 300

–

–

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

–

–

234

Magnetic

Fixed ampere rating and

instantaneous

15 150 ± 30

20 200 ± 40

30 300 ± 60

40 400 ± 80

50 500 ± 100

60 600 ± 120

75 750 ± 150

100 1000 ± 200

–

–

–

–

–

–

–

–

–

–

–

–

–

–

19

Page 21

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Low-inst

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

690V

500V

440V

400V

230V

Thermal, magnetic

Fixed ampere rating and

instantaneous

NF100-UP NF100-SEP

15, 20, 30, 40, 50, 60, 75, 100

690

10/5

200/200

200/200

200/200

200/200

234

15 225 ± 45

20 300 ± 60

30 450 ± 90

40 600 ± 120

50 750 ± 150

60 900 ± 180

75 1125 ± 225

100 1500 ± 300

–

–

15 ~ 20, 30 ~ 50, 60 ~ 100

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Short time delay pick up current

Variation is within ±15% of

setting current

15 30-37.5-45-52.5-60-7520 40-50-60-70-80-100-12030 60-75-90-105-120-15040 80-100-120-140-16050 100-125-150-175-20060 120-150-180-210-24075 150-187.5-225-262.5-300-

100 200-250-300-350-400-

Instantaneous pick up current

Variation is within ±15% of

setting current

30 ~ 50 200 ~ 800

60 ~ 100 400 ~ 1600

100

690

–

15/8

25/13

30/15

50/25

34

2 to 10 Ir

90-105-120-150

140-160-200

180-210-240-300

200-240-280-320-400

250-300-350-400-500

300-360-420-480-600

375-450-525-600-750

500-600-700-800-1000

4 In ~ 16 In

–

–

NF100-HEP

15 ~ 20, 30 ~ 50, 60 ~ 100

690

5/3

30/15

50/25

50/25

100/50

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Short time delay pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

15 30-37.5-45-52.5-60-75-

90-105-120-150

20 40-50-60-70-80-100-120-

140-160-200

30 60-75-90-105-120-150-

180-210-240-300

40 80-100-120-140-160-

200-240-280-320-400

50 100-125-150-175-200-

250-300-350-400-500

60 120-150-180-210-240-

300-360-420-480-600

75 150-187.5-225-262.5-300-

375-450-525-600-750

100 200-250-300-350-400-

500-600-700-800-1000

Instantaneous pick up current

Variation is within ±15% of

setting current

4 In ~ 16 In

30 ~ 50 200 ~ 800

60 ~ 100 400 ~ 1600

–

–

Generator

Mag-Only

20

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

Electronic trip relay

–

–

–

–

–

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Rating: 15 ~ 20A, 30 ~ 50A,

Inst. : Operating characteristics

–

3

60 ~ 100A

must be adjusted as

follows.

STD q 3 (Is setting)

LTD : minimum setting

L = 12sec setting)

(T

–

–

–

–

3

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Rating: 15 ~ 20A, 30 ~ 50A,

60 ~ 100A

Inst. : Operating characteristics

must be adjusted as

follows.

STD q 3 (Is setting)

LTD : minimum setting

L = 12sec setting)

(T

–

–

–

Page 22

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

Thermal, magnetic

Fixed ampere rating and

instantaneous

NF160-SP

125, 150, 160

690

–

15/8

25/13

30/15

50/25

234

125 1750 ± 350

150 2100 ± 420

160 2240 ± 448

160

NF160-SP T/A

100 ~ 125, 125 ~ 160

690

–

15/8

25/13

30/15

50/25

234

Thermal, magnetic

Adjustable ampere rating and

fixed instantaneous

100 ~125 1400 ± 280

125 ~ 160 1400 ± 280

NF160-HP

125, 150, 160

690

5/3

30/8

50/13

50/13

100/25

234

Thermal, magnetic

Fixed ampere rating and

instantaneous

125 1750 ± 350

150 2100 ± 420

160 2240 ± 448

Low-inst

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

–

–

–

–

234 234

Magnetic

Fixed ampere rating and

instantaneous

125 1250 ± 250

160 1600 ± 320

–

–

–

–

–

–

–

–

Magnetic

Fixed ampere rating and

instantaneous

125 1250 ± 250

160 1600 ± 320

–

–

–

–

–

–

–

21

Page 23

Frame (A)

Type

Rated current In (A)

160

NF160-HP T/A

125, 150, 175, 200, 225, 250100 ~ 125, 125 ~ 160

NF250-CP

250

NF250-CP T/A

100 ~ 125, 125 ~ 160

150 ~ 200, 200 ~ 250

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Low-inst

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

Thermal, magnetic

Adjustable ampere rating

and fixed instantaneous

690

5/3

30/8

50/13

50/13

100/25

234

100 ~ 125 1400 ± 280

125 ~ 160 1400 ± 280

–

–

–

600

–

10/5

15/8

18/9

30/15

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

125 1750 ± 350

150 2100 ± 420

175 2450 ± 490

200 2800 ± 560

225 3150 ± 630

250 2500 ± 500

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

6 In 4 In

125 750 ± 150 500 ± 100

150 900 ± 180 600 ± 120

175 1050 ± 210 700 ± 140

200 1200 ± 240 800 ± 160

225 1350 ± 270 900 ± 180

250 1500 ± 300 1000 ± 200

600

–

10/5

15/8

18/9

30/15

23

Thermal, magnetic

Adjustable ampere rating

and fixed instantaneous

100 ~ 125 1400 ± 280

125 ~160 1400 ± 280

150 ~200 2100 ± 420

200 ~250 2500 ± 500

–

–

–

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

–

–

Magnetic

–

–

Fixed ampere rating and

instantaneous

125 1250 ± 250

150 1500 ± 300

175 1750 ± 350

200 2000 ± 400

225 2250 ± 450

250 2250 ± 450

–

–

–

23

–

–

–

–

–

–

22

Page 24

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

Thermal, magnetic

Fixed ampere rating and

instantaneous

NF250-SP

125, 150, 175, 200, 225, 250

690

–

15/8

25/13

30/15

50/25

234

125 1750 ± 350

150 2100 ± 420

175 2450 ± 490

200 2800 ± 560

225 3150 ± 630

250 2500 ± 500

250

NF250-SP T/A

100 ~ 125, 125 ~ 160

150 ~ 200, 200 ~ 250

690

–

–

25/20

30/22

50/42

234

Thermal, magnetic

Adjustable ampere rating

and fixed instantaneous

100 ~125 1400 ± 280

125 ~ 160 1400 ± 280

150 ~200 2100 ± 420

200 ~250 2500 ± 500

NF250-HP

125, 150, 175, 200, 225, 250

690

5/3

30/8

50/13

50/13

100/25

234

Thermal, magnetic

Fixed ampere rating and

instantaneous

125 1750 ± 350

150 2100 ± 420

175 2450 ± 490

200 2800 ± 560

225 3150 ± 630

250 2500 ± 500

Low-inst

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

234

Thermal, magnetic

Fixed ampere rating and

instantaneous

6 In4 In

125 750 ± 150 500 ± 100

150 900 ± 180 600 ± 120

175 1050 ± 210 700 ± 140

200 1200 ± 240 800 ± 160

225 1350 ± 270 900 ± 180

250 1500 ± 300 1000 ± 200

–

–

–

234

Magnetic

Fixed ampere rating and

instantaneous

125 1250 ± 250

150 1500 ± 300

175 1750 ± 350

200 2000 ± 400

225 2250 ± 450

250 2250 ± 450

–

–

–

–

–

–

–

Magnetic

–

–

Fixed ampere rating and

instantaneous

125 1250 ± 250

150 1500 ± 300

175 1750 ± 350

200 2000 ± 400

225 2250 ± 450

250 2250 ± 450

–

–

–

–

–

–

234

23

Page 25

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

Thermal, magnetic

Adjustable ampere rating and

fixed instantaneous

250

100 ~ 125, 125 ~ 160

150 ~ 200, 200 ~ 250

690

5/3

30/8

50/13

50/13

100/25

234

100 ~125 1400 ± 280

125 ~160 1400 ± 280

150 ~200 2100 ± 420

200 ~250 2500 ± 500

NF225-RPNF250-HP T/A

125, 150, 175, 200, 225

690

–

42/42

125/125

125/125

125/125

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

125 1750 ± 350

150 2100 ± 420

175 2450 ± 490

200 2800 ± 560

225 3150 ± 630

225

NF225-UP

125, 150, 175, 200, 225

690

10/5

200/200

200/200

200/200

200/200

234

Thermal, magnetic

Fixed ampere rating and

instantaneous

125 1750 ± 350

150 2100 ± 420

175 2450 ± 490

200 2800 ± 560

225 3150 ± 630

Low-inst

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

24

Rating (A) and

Inst. (A)

–

–

–

Page 26

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

690V

500V

440V

400V

230V

NF250-SEP

125-250

690

–

15/8

25/13

30/15

50/25

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Short time delay pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

125 250-312.5-375-437.5-500-

625-750-875-1000-1250

150 300-375-450-525-600-

750-900-1050-1200-1500

175 350-437.5-525-612.5-700-

875-1050-1225-1400-1750

200 400-500-600-700-800-1000-

1200-1400-1600-2000

225 450-562.5-675-787.5-900-

1125-1350-1575-1800-2250

250 500-625-750-875-1000-

1250-1500-1750-2000-2500

Instantaneous pick up current

Variation is within ±15% of

setting current

4 ~ 14 In

125 ~ 250 1000 ~ 3500

250

NF250-HEP

125-250

690

5/3

30/8

50/13

50/13

100/25

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Short time delay pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

125 250-312.5-375-437.5-500-

625-750-875-1000-1250

150 300-375-450-525-600-

750-900-1050-1200-1500

175 350-437.5-525-612.5-700-

875-1050-1225-1400-1750

200 400-500-600-700-800-1000-

1200-1400-1600-2000

225 450-562.5-675-787.5-900-

1125-1350-1575-1800-2250

250 500-625-750-875-1000-

1250-1500-1750-2000-2500

Instantaneous pick up current

Variation is within ±15% of

setting current

4 ~ 14 In

125 ~ 250 1000 ~ 3500

Low-inst

Generator

Mag-Only

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

–

–

–

3

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Rating: 125 ~ 250A

Inst. : Operating characteristics

must be adjusted as

follows.

STD q 3 (Is setting)

LTD : minimum setting

L = 12sec setting)

(T

–

–

–

–

–

–

3

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up, and instantaneous

Rating: 125 ~ 250A

Inst. : Operating characteristics

must be adjusted as

follows.

STD q 3 (Is setting)

LTD : minimum setting

L = 12sec setting)

(T

–

–

–

25

Page 27

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

690V

500V

440V

400V

230V

Thermal, magnetic

Fixed ampere rating and

instantaneous

NF400-CP

250, 300, 350, 400

600

–

15/8

25/13

36/18

50/25

23

400A

NF400-SP

250, 300, 350, 400

690

10/10

30/30

42/42

45/45

85/85

234

Thermal, magnetic

Fixed ampere rating and

instantaneous

NF400-SEP

200 ~ 400

adjustable

690

10/10

30/30

42/42

45/45

85/85

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

Low-inst

Generator

Mag-Only

(Inst trip only)

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

250 2500 ± 500

300 3000 ± 600

350 3500 ± 700

400 4000 ± 800

23

Thermal, magnetic

Fixed ampere rating and

instantaneous

6 In4 In

250 1500±300 1000±200

300 1800±360 1200±240

350 2100±420 1400±280

400 2400±480 1600±320

–

–

–

23

Magnetic

Fixed ampere rating and

instantaneous

250 2500 ± 500

300 3000 ± 600

350 3500 ± 700

400 4000 ± 800

250 3500 ± 700

300 4200 ± 840

350 4900 ± 980

400 5600 ± 1120

–

–

–

–

–

–

234

Magnetic

Fixed ampere rating and

instantaneous

250 2500 ± 500

300 3000 ± 600

350 3500 ± 700

400 4000 ± 800

Short time delay pick up current

Variation is within ±15% of

setting current

200 400-500-600-700-800-

225 450-562.5-675-787.5-

250 500-625-750-875-1000-

300 600-750-900-1050-1200-

350 700-875-1050-1225-

400 800-1000-1200-1400-

Instantaneous pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

1000-1200-1400-16002000

900-1125-1200-15001800-1350-1575-18002250

1250-1500-1750-20002500

1500-1800-2100-24003000

1400-1750-2100-24502800-3500

1600-2000-2400-28003200-4000

4 In ~ 16 I n

1600 ~ 6400

–

–

–

–

–

–

–

–

–

26

Page 28

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

690V

500V

440V

400V

230V

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

400A

NF400-HEP NF400-REP

200 ~ 400

adjustable

690

10/10

50/50

65/65

70/70

100/100

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

200 ~ 400

adjustable

690

15/10

70/35

125/63

125/63

150/75

3

NF400-UEP

200 ~ 400

adjustable

690

35/35

170/170

200/200

200/200

200/200

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

Low-inst

Generator

Mag-Only

(Inst trip only)

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Short time delay pick up current

Variation is within ±15% of

setting current

200 400-500-600-700-800-

225 450-562.5-675-787.5-

250 500-625-750-875-1000-

300 600-750-900-1050-1200-

350 700-875-1050-1225-

400 800-1000-1200-1400-

Instantaneous pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

1000-1200-1400-16002000

900-1125-1200-15001800-1350-1575-18002250

1250-1500-1750-20002500

1500-1800-2100-24003000

1400-1750-2100-24502800-3500

1600-2000-2400-28003200-4000

4 In ~ 16 In

1600 ~ 6400

–

–

–

–

–

–

–

–

–

Short time delay pick up current

Variation is within ±15% of

setting current

200 400-500-600-700-800-

225 450-562.5-675-787.5-

250 500-625-750-875-1000-

300 600-750-900-1050-1200-

350 700-875-1050-1225-

400 800-1000-1200-1400-

Instantaneous pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

1000-1200-1400-16002000

900-1125-1200-15001800-1350-1575-18002250

1250-1500-1750-20002500

1500-1800-2100-24003000

1400-1750-2100-24502800-3500

1600-2000-2400-28003200-4000

4 In ~ 16 I n

1600 ~ 6400

–

–

–

–

–

–

–

–

–

Short time delay pick up current

Variation is within ±15% of

setting current

200 400-500-600-700-800-

225 450-562.5-675-787.5-

250 500-625-750-875-1000-

300 600-750-900-1050-1200-

350 700-875-1050-1225-

400 800-1000-1200-1400-

Instantaneous pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

1000-1200-1400-16002000

900-1125-1200-15001800-1350-1575-18002250

1250-1500-1750-20002500

1500-1800-2100-24003000

1400-1750-2100-24502800-3500

1600-2000-2400-28003200-4000

4 In ~ 16 I n

1600 ~ 6400

–

–

–

–

–

–

–

–

–

27

Page 29

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

690V

500V

440V

400V

230V

Thermal, magnetic

Fixed ampere rating and

instantaneous

630A

NF630-CP NF630-SP

500, 600, 630

600

–

18/9

36/18

36/18

50/25

23

500, 600, 630

690

10/10

30/30

42/42

45/45

85/85

234

Thermal, magnetic

adjustable ampere rating and

fixed instantaneous

NF630-SEP

300 ~ 630

adjustable

690

10/10

30/30

42/42

45/45

85/85

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

Low-inst

Generator

Mag-Only

(Inst trip only)

28

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

500 5000 ± 1000

600 6000 ± 1200

630 6300 ± 1260

–

–

–

–

–

–

23

Magnetic

Fixed ampere rating and

instantaneous

500 5000 ± 1000

600 6000 ± 1200

630 6300 ± 1260

500 Lo 2500 ± 500

2 4000

3 5500

Hi 7000 ± 1400

600 Lo 3000 ± 600

2 4800

3 6600

Hi 8400 ± 1680

630 Lo 3150 ± 630

2 5040

3 6930

Hi 8820 ± 1764

–

–

–

–

–

–

234

Thermal, magnetic

adjustable ampere rating and

fixed instantaneous

500 Lo 2000 ± 400

2 3000

3 4000

Hi 5000 ± 1000

600 Lo 2400 ± 480

2 3600

3 4800

Hi 6000 ± 1200

630 Lo 2520 ± 504

2 3780

3 5040

Hi 6300 ± 1260

Short time delay pick up current

Variation is within ±15% of

setting current

300 600-750-900-1050-1200-

350 700-875-1050-1225-

400 800-1000-1200-1400-

500 1000-1250-1500-1750-

600 1200-1500-1800-2100-

630 1260-1575-1890-2205-

Instantaneous pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

1500-1800-2100-24003000

1400-1750-2100-24502800-3500

1600-2000-2400-28003200-4000

2000-2500-3000-35004000-5000

2400-3000-3600-42004800-6000

2520-3150-3780-44105040-6300

4 In ~ 15 I n

2520 ~ 9450

–

–

–

–

–

–

–

–

–

Page 30

Frame (A)

Type

Rated current In (A)

Rated insulation voltage Ui (V) AC

AC Breaking

capacity (kA rms)

IEC60947-2

Icu/Ics

Standard

Number of poles

Automatic tripping

device

690V

500V

440V

400V

230V

NF630-HEP

300 ~ 630

adjustable

690

15/15

50/50

65/65

70/70

100/100

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

630A

NF630-REP

300 ~ 630

adjustable

690

20/15

70/35

125/63

125/63

150/75

3

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

NF630-UEP

300 ~ 630

adjustable

690

35/35

170/170

200/200

200/200

200/200

34

Electronic trip relay

Adjustable ampere rating

Adjustable long time delay

operating time, short time delay

pick up and instantaneous

Low-inst

Generator

Mag-Only

(Inst trip only)

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Number of poles

Automatic tripping

device

Rating (A) and

Inst. (A)

Short time delay pick up current

Variation is within ±15% of

setting current

300 600-750-900-1050-1200-

350 700-875-1050-1225-

400 800-1000-1200-1400-

500 1000-1250-1500-1750-

600 1200-1500-1800-2100-

630 1260-1575-1890-2205-

Instantaneous pick up current

Variation is within ±15% of

setting current

2 to 10 Ir

1500-1800-2100-24003000