Split-type Air-Conditioner

MXZ-2D33VA

MXZ-2D40VA

MXZ-2D53VA(H)

English is original.

Übersetzung des

Originals

Traduction du texte

d’origine

Vertaling van het

origineel

Traducción del

original

Traduzione

dell’originale

Μετάφραση του

αρχικού

Tradução do

original

Oversættelse af

den originale tekst

Översättning från

originalet

Installation Manual

• This manual only describes the installation of outdoor unit.

When installing the indoor unit, refer to the installation manual of indoor unit.

Installationsanleitung

• Diese Installationsanleitung gilt nur für die Installation des Außengerätes.

Zur Installation des Innengeräts siehe die Installationsanleitung für Innengeräte.

Notice d’installation

• Cette notice ne décrit que l’installation de l’appareil extérieur.

Lors de l’installation de l’appareil intérieur, consultez la notice d’installation de cet

appareil.

Installatiehandleiding

• Deze handleiding beschrijft alleen de installatie van de buitenunit.

Raadpleeg de installatiehandleiding van de binnenunit wanneer u deze instal-

leert.

Manual de instalación

• En este manual sólo se describe la instalación de la unidad exterior.

Para instalar la unidad interior, consulte el manual de instalación de dicha uni-

dad.

Manuale per l’installazione

• Questo manuale descrive solo l’installazione dell’unità esterna.

Per l’installazione dell’unità interna, fare riferimento al relativo manuale di instal-

lazione.

Εγχειρίδιο εγκατάστασης

•

Στο παρόν εγχειρίδιο περιγράφεται μόνο η εγκατάσταση της μονάδας εξωτερικού χώρου.

Για την εγκατάσταση της μονάδας εσωτερικού χώρου, ανατρέξτε στο εγχειρίδιο

εγκατάστασης της μονάδας εσωτερικού χώρου.

Manual de Instalação

• Este manual descreve apenas a instalação da unidade exterior.

Quando proceder à instalação da unidade interior, consulte o manual de instalação

da unidade interior.

Installationshåndbog

• Denne håndbog beskriver kun, hvordan udendørsenheden installeres.

Vedrørende installation af indendørsenheden henvises til installationshåndbogen

for indendørsenheden.

Installationsanvisning

• Denna installationsanvisning beskriver endast installation av utomhusenheten.

Se den separata installationsanvisningen för inomhusenheten.

For INSTALLER

Für INSTALLATEUR

Destinée à l’INSTALLATEUR

Voor de INSTALLATEUR

Para el INSTALADOR

Per il TECNICO INSTALLATORE

Για τον ΤΕΧΝΙΚΟ

Para o INSTALADOR

Til INSTALLATØREN

För INSTALLATÖREN

English

Deutsch

Français

Nederlands

Español

Italiano

Ελληνικά

Português

Dansk

Svenska

Orijinalin çevirisi

Перевод

оригинала

Kurulum Kılavuzu

• Bu kılavuzda yalnızca dış ünitenin kurulumu açıklanmaktadır.

İç ünite kurulum işlemini yaparken iç ünite kurulum kılavuzuna bakın.

Руководство по установке

•

В данном руководстве приводится описание установки только наружного прибора.

При установке внутреннего прибора см. руководство по установке внутреннего

прибора.

TESİSATÇI İÇİN

Для МОНТАЖНИКА

Türkçe

Русский

En-1

CONTENTS

1. BEFORE INSTALLATION ............................................................1

2. OUTDOOR UNIT INSTALLATION ...............................................

3. FLARING WORK AND PIPE CONNECTION ...............................

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN .........

ENGLISH

5. RELOCATION AND MAINTENANCE ..........................................

Phillips screwdriver

Level

3

3

4

5

Scale

Utility knife or scissors

Torque wrench

Wrench (or spanner)

4 mm hexagonal wrench

Required Tools for Installation

1. BEFORE INSTALLATION

1-1. THE FOLLOWING SHOULD ALWAYS BE OBSERVED FOR SAFETY

• Be sure to read “THE FOLLOWING SHOULD ALWAYS BE OBSERVED FOR SAFETY” before installing the air conditioner.

• Be sure to observe the warnings and cautions specied here as they include important items related to safety.

• After reading this manual, be sure to keep it together with the OPERATING INSTRUCTIONS for future reference.

WARNING

Do not install the unit by yourself (user).

n

Incomplete installation could cause re or electric shock, injury due to the

unit falling, or leakage of water. Consult the dealer from whom you pur

chased the unit or a qualied installer.

Perform the installation securely referring to the installation manual.

n

Incomplete installation could cause re, electric shock, injury due to the

unit falling, or leakage of water.

When installing the unit, use appropriate protective equipment and

n

tools for safety.

Failure to do so could cause injury.

Install the unit securely in a place which can bear the weight of the

n

unit.

If the installation location cannot bear the weight of the unit, the unit

could fall causing injury.

Electrical work should be performed by a qualified, experienced

n

electrician, according to the installation manual. Be sure to use an

exclusive circuit. Do not connect other electrical appliances to the

circuit.

If the capacity of the power circuit is insufcient or there is incomplete

electrical work, it could result in a re or an electric shock.

Do not damage the wires by applying excessive pressure with parts

n

or screws.

Damaged wires could cause re or electric shock.

Be sure to cut off the main power in case of setting up the indoor P.C.

n

board or wiring works.

Failure to do so could cause electric shock.

Use the specied wires to connect the indoor and outdoor units se

n

curely and attach the wires rmly to the terminal block connecting

sections so the stress of the wires is not applied to the sections. Do

not extend the wires, or use intermediate connection.

Incomplete connecting and securing could cause re.

Do not install the unit in a place where inammable gas may leak.

n

If gas leaks and accumulates in the area around the unit, it could cause

an explosion.

Do not use intermediate connection of the power cord or the exten

n

sion cord and do not connect many devices to one AC outlet.

It could cause a re or an electric shock due to defective contact, defec

tive insulation, exceeding the permissible current, etc.

Be sure to use the parts provided or specied parts for the installa-

n

tion work.

The use of defective parts could cause an injury or leakage of water due

to a re, an electric shock, the unit falling, etc.

When plugging the power supply plug into the outlet, make sure

n

that there is no dust, clogging, or loose parts in both the outlet and

the plug. Make sure that the power supply plug is pushed completely into the outlet.

If there is dust, clogging, or loose parts on the power supply plug or the

outlet, it could cause electric shock or re. If loose parts are found on the

power supply plug, replace it.

CAUTION

Install an earth leakage breaker depending on the installation place.

n

If an earth leakage breaker is not installed, it could cause electric shock.

Perform the drainage/piping work securely according to the installa

n

tion manual.

If there is defect in the drainage/piping work, water could drop from the

unit, soaking and damaging household goods.

(Could lead to death, serious injury, etc.)

Attach the electrical cover to the indoor unit and the service panel

n

to the outdoor unit securely.

If the electrical cover of the indoor unit and/or the service panel of the

-

outdoor unit are not attached securely, it could result in a re or an

electric shock due to dust, water, etc.

When installing, relocating, or servicing the unit, make sure that

n

no substance other than the specied refrigerant (R410A) enters

the refrigerant circuit.

Any presence of foreign substance such as air can cause abnormal

pressure rise and may result in explosion or injury. The use of any re

frigerant other than that specied for the system will cause mechanical

failure, system malfunction, or unit breakdown. In the worst case, this

could lead to a serious impediment to securing product safety.

Do not discharge the refrigerant into the atmosphere. If refrigerant

n

leaks during installation, ventilate the room.

If refrigerant comes in contact with a re, harmful gas could be gener

ated.Refrigerant leakage may cause suffocation. Provide ventilation in

accordance with EN378-1.

Check that the refrigerant gas does not leak after installation has

n

been completed.

If refrigerant gas leaks indoors, and comes into contact with the ame

of a fan heater, space heater, stove, etc., harmful substances will be

generated.

Use appropriate tools and piping materials for installation.

n

The pressure of R410A is 1.6 times more than R22. Not using appropri

ate tools or materials and incomplete installation could cause the pipes

to burst or injury.

When pumping down the refrigerant, stop the compressor before

n

disconnecting the refrigerant pipes.

If the refrigerant pipes are disconnected while the compressor is run

ning and the stop valve is open, air could be drawn in and the pressure

in the refrigeration cycle could become abnormally high. This could

cause the pipes to burst or injury.

When installing the unit, securely connect the refrigerant pipes

n

-

before starting the compressor.

If the compressor is started before the refrigerant pipes are connected

and when the stop valve is open, air could be drawn in and the pres

sure in the refrigeration cycle could become abnormally high. This

could cause the pipes to burst or injury.

Fasten a are nut with a torque wrench as specied in this manu-

n

al.

If fastened too tight, a are nut may break after a long period and cause

refrigerant leakage.

The unit shall be installed in accordance with national wiring regu-

n

lations.

Earth the unit correctly.

n

Do not connect the earth to a gas pipe, water pipe, lightning rod or tele

phone earth. Defective earthing could cause electric shock.

(Could lead to serious injury in particular environments when operated incorrectly.)

Do not touch the air inlet or the aluminum ns of the outdoor unit.

n

This could cause injury.

-

Do not install the outdoor unit where small animals may live.

n

If small animals enter and touch the electric parts inside the unit, it

could cause a malfunction, smoke emission, or re. Also, advise user

to keep the area around the unit clean.

Flare tool for R410A

Gauge manifold for R410A

Vacuum pump for R410A

Charge hose for R410A

Pipe cutter with reamer

-

-

-

-

-

-

1-2. SPECIFICATIONS

Power supply *1

Model

MXZ-2D33VA

MXZ-2D40VA

MXZ-2D53VA(H)

*1 Connect to the power switch which has a gap of 3 mm or more when

open to interrupt the source power phase. (When the power switch is shut

off, it must interrupt all phases.)

*2 Use wires in conformity with design 60245 IEC 57. Use the indoor/out

door connecting wire in conformity with the wire specications specied in

the installation manual of the indoor unit.

*3 Never use pipes with thickness less than specied. The pressure resist

ance will be insufcient.

*4 Use a copper pipe or a copper-alloy seamless pipe.

*5 Be careful not to crush or bend the pipe during pipe bending.

Rated

Voltage

230 V 50 Hz

Fre-

quency

Breaker

capacity

10 A 3-core 1.0 mm

15 A 3-core 2.0 mm

Wire specications *2 Pipe length and height difference

Power supply

Indoor/outdoor

connecting wire

2

4-core

2

1.0/1.5 mm

Max. pipe length

per indoor unit /

for multi-system

15 m / 20 m 10 m 15 / 20

2

20 m / 30 m 15 m 20 / 30

*6 Refrigerant pipe bending radius must be 100 mm or more.

*7 Insulation material : Heat resisting foam plastic 0.045 specic gravity

-

-

*8 Be sure to use the insulation of specied thickness. Excessive thickness

may cause incorrect installation of the indoor unit and insufcient thick-

ness may cause dew drippage.

*9 If the outdoor unit is installed higher than the indoor unit, max. height

difference is reduced to 10 m.

*10 If pipe length exceeds 20 m, additional refrigerant (R410A) charge is re-

quired. (No additional charge is required for pipe length less than 20 m.)

Additional refrigerant = A × (pipe length (m) - 20)

Max. height

difference

Max. no. of bends

per indoor unit /

*9

for multi system

*3, *4, *5, *6, *7, *8

Refrigerant adjust

ment A *10

-

20 g/m

En-2

1-3. SELECTING OPTIONAL DIFFERENT-DIAMETER JOINTS

If the diameter of connection pipe does not match the port size of outdoor unit, use optional different-diameter joints according to the following table.

(Unit: mm (inch))

Port size of outdoor unit Optional different-diameter joints (port size of outdoor unit → diameter of connection pipe)

→

MXZ-2D Liquid / Gas

A , B UNIT 6,35 (1/4) / 9,52 (3/8)

6,35 (1/4)

9,52 (3/8)

9,52 (3/8)

12,7 (1/2)

12,7 (1/2)

9,52 (3/8) : PAC-493PI

→

12,7 (1/2) : MAC-A454JP

→

15,88 (5/8) : PAC-SG76RJ

→

9,52 (3/8) : MAC-A455JP

→

15,88 (5/8) : MAC-A456JP

Refer to the installation manual of indoor unit for the diameter of connection pipe of indoor unit.

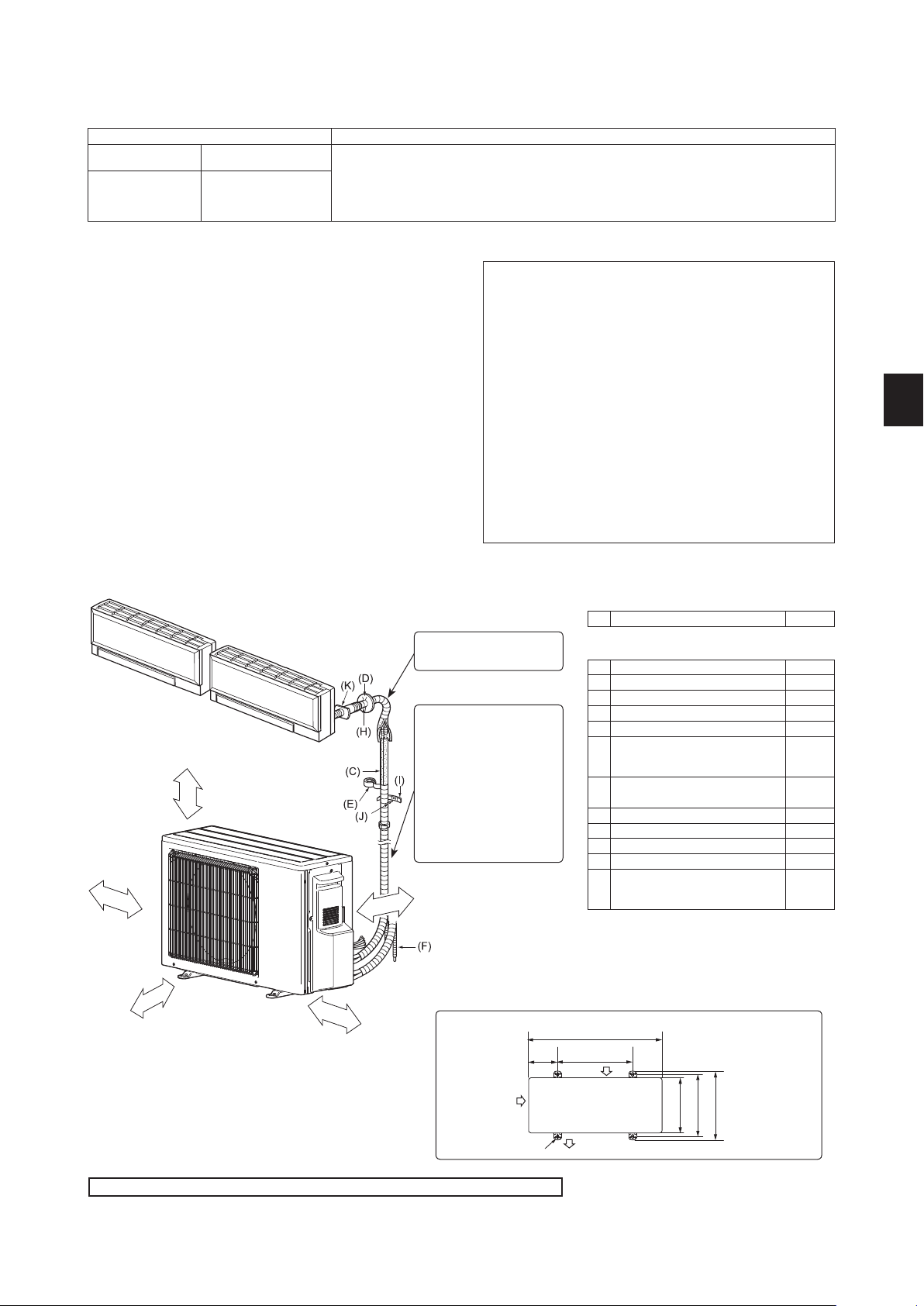

1-4. SELECTING THE INSTALLATION LOCATION

• Where it is not exposed to strong wind.

• Where airow is good and dustless.

• Where rain or direct sunshine can be avoided as much as possible.

• Where neighbours are not annoyed by operation sound or hot air.

• Where rigid wall or support is available to prevent the increase of op

eration sound or vibration.

• Where there is no risk of combustible gas leakage.

• When installing the unit, be sure to secure the unit legs.

• Where it is at least 3 m away from the antenna of TV set or radio. Op

eration of the air conditioner may interfere with radio or TV reception in

areas where reception is weak. An amplier may be required for the affected device.

• Install the unit horizontally.

• Please install it in an area not affected by snowfall or blowing snow.

In areas with heavy snow, please install a canopy, a pedestal and/or

some bafe boards.

Note:

It is advisable to make a piping loop near outdoor unit so as to reduce

vibration transmitted from there.

-

-

Note:

When operating the air conditioner in low outside temperature, be sure

to follow the instructions described below.

• Never install the outdoor unit in a place where its air inlet/outlet side

may be exposed directly to wind.

• To prevent exposure to wind, install the outdoor unit with its air inlet

side facing the wall.

•

To prevent exposure to wind, it is recommended to install a baffle

board on the air outlet side of the outdoor unit.

Avoid the following places for installation where air conditioner trouble

is liable to occur.

• Where ammable gas could leak.

• Where there is much machine oil.

• Where oil is splashed or where the area is lled with oily smoke (such

as cooking areas and factories, in which the properties of plastic

could be changed and damaged).

• Salty places such as the seaside.

• Where sulde gas is generated such as a hot spring.

• Where there is high-frequency or wireless equipment.

• Where there is emission of high levels of VOCs, including phthalate

compounds, formaldehyde, etc., which may cause chemical crack

ing.

-

1-5. INSTALLATION DIAGRAM

Open as a rule

More than 500 mm

if the front and both

sides are open

More than

100 mm

Open as a rule

More than 500 mm if the back,

both sides and top are open

More than 350 mm

After the leak test, apply insulating material tightly so that there is

no gap.

When the piping is to be attached to a wall containing metals

(tin plated) or metal netting, use

a chemically treated wooden

piece 20 mm or thicker between

the wall and the piping or wrap 7

to 8 turns of insulation vinyl tape

around the piping.

To use existing piping, perform

COOL operation for 30 minutes

and pump down before removing

the old air conditioner. Remake

are according to the dimension

for new refrigerant.

More than 100 mm

More than 200 mm if there are

obstacles to both sides

150

ACCESSORIES

Check the following parts before installation.

(1) Drain socket 1

PARTS TO BE PROVIDED AT YOUR SITE

(A) Power supply cord* 1

(B) Indoor/outdoor unit connecting wire* 1

(C) Extension pipe

(D) Wall hole cover 1

(E) Piping tape 1

Extension drain hose

(F)

(or soft PVC hose, 15 mm inner

diameter or hard PVC pipe VP16)

(G) Refrigeration oil

(H) Putty 1

(I) Pipe xing band 2 to 7

(J) Fixing screw for (I) 2 to 7

(K) Wall hole sleeve 1

Soft PVC hose, 15 mm inner di

(L)

ameter or hard PVC pipe VP16 for

drain socket (1)

* Note:

Place indoor/outdoor unit connecting wire (B) and

power supply cord (A) at least 1 m away from the

TV antenna wire.

The “Q’ty” for (B) to (K) in the above table is quan

tity to be used per indoor unit.

Outdoor unit installation

800

500

Air inlet

1

1

Little

amount

1

-

Air inlet

Units should be installed by licensed contractor according to local code requirements.

4-10 × 21 Oval holes

Air outlet

285

344.5

304~325

(Unit: mm)

En-3

1-6. DRAIN PIPING FOR OUTDOOR UNIT

Please perform the drain piping work only when draining from one place.

1) Provide drain piping before indoor and outdoor piping connection.

2) Connect the soft PVC hose (L) I.D.15 mm as shown in the illustration.

3) Make sure to provide drain piping with a downhill grade for easy drain ow.

Note:

Install the unit horizontally.

Do not use the drain socket (1) in the cold regions. Drain may freeze and it makes

the fan stop.

The outdoor unit produces condensate during the heating operation. Select the in

stallation place to ensure to prevent the outdoor unit and/or the grounds from being

wet by drain water or damaged by frozen drain water.

2. OUTDOOR UNIT INSTALLATION

-

(1) Drain socket

(L) Soft PVC hose

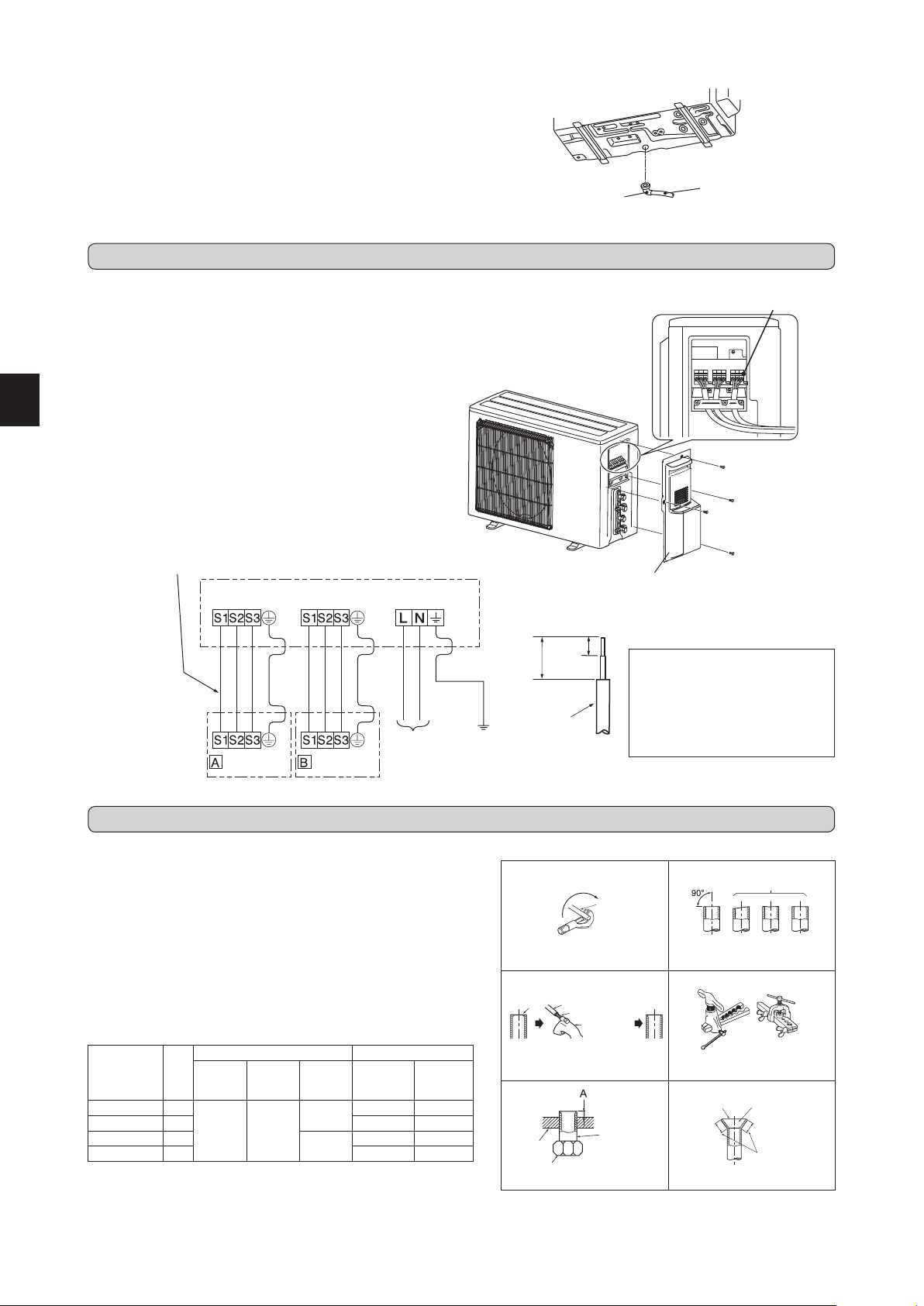

2-1. CONNECTING WIRES FOR OUTDOOR UNIT

1) Remove the service panel.

2) Loosen terminal screw, and connect indoor/outdoor unit connecting

wire (B) from the indoor unit correctly on the terminal block. Be careful

not to make mis-wiring. Fix the wire to the terminal block securely so

that no part of its core is appeared, and no external force is conveyed

to the connecting section of the terminal block.

3) Firmly tighten the terminal screws to prevent them from loosening. Af

ter tightening, pull the wires lightly to conrm that they do not move.

4) Perform 2) and 3) for each indoor unit.

5) Connect power supply cord (A).

6) Fix indoor/outdoor unit connecting wire (B) and power supply cord (A)

with the cable clamps.

7) Close the service panel securely. Make sure that 3-2. PIPE CONNEC

TION is completed.

• After making connections between both power supply cord (A) and

indoor/outdoor unit connecting wire (B), be sure to x both cable and

wire with cable clamps.

Indoor/outdoor unit connecting wire

UNIT

<OUTDOOR UNIT>

Terminal block

<INDOOR UNIT>

UNIT

Terminal block for

power supply

POWER SUPPLY

~/N 230 V 50 Hz

Terminal block for power supply

-

-

Service panel

15 mm

35 mm

• Be sure to attach each screw to its

correspondent terminal when secur

ing th e cord and/or the wire to the

terminal block.

• Make earth wire a little longer than

Lead wire

others. (More than 35 mm)

• For future servicing, give extra length

to the connecting wires.

3. FLARING WORK AND PIPE CONNECTION

3-1. FLARING WORK

1) Cut the copper pipe correctly with pipe cutter. (Fig. 1, 2)

2) Completely remove all burrs from the cut cross section of pipe. (Fig. 3)

• Aim the copper pipe downward while removing burrs to prevent

burrs from dropping in the pipe.

3) Remove are nuts attached to indoor and outdoor units, then put them

on pipe having completed burr removal. (Not possible to put them on

after aring work.)

4) Flaring work (Fig. 4, 5). Firmly hold copper pipe in the dimension

shown in the table. Select A mm from the table according to the tool

selected.

5) Check

• Compare the ared work with Fig. 6.

• If are is noted to be defective, cut off the ared section and do ar

ing work again.

A (mm) Tightening torque

Pipe diameter

(mm)

ø6.35 (1/4”) 17

ø9.52 (3/8”)

ø12.7 (1/2”)

ø15.88 (5/8”)

Nut

Clutch

(mm)

type tool

for R410A

22 34.3 to 41.2 350 to 420

0 to 0.5 1.0 to 1.5

26

29 73.5 to 78.4 750 to 800

Clutch

type tool

for R22

Wing nut

type tool

for R22

1.5 to 2.0

2.0 to 2.5

N•m kgf•cm

13.7 to 17.7 140 to 180

49.0 to 56.4 500 to 575

-

Burr

Die

Flare nut

Copper pipe

Spare reamer

Pipe cutter

Copper

pipe

Good

No good

Tilted Uneven Burred

Fig. 1 Fig. 2

Flaring tool

Clutch type

Fig. 3 Fig. 4

Smooth all

around

Copper pipe

Fig. 5 Fig. 6

Wing nut type

Inside is shin

ing without any

scratches.

Even length

all around

-

En-4

3-2. PIPE CONNECTION

1) Apply a thin coat of refrigeration oil (G) to the ared ends of the pipes and the pipe connections of the outdoor unit.

2) Align the center of the pipe with that of the pipe connections of the outdoor unit, then hand tighten the are

nut 3 to 4 turns.

3) Tighten the are nut with a torque wrench as specied in the table.

• Over-tightening may cause damage to the are nut, resulting in refrigerant leakage.

• Be sure to wrap insulation around the piping. Direct contact with the bare piping may result in burns or

frostbite.

3-3. INSULATION AND TAPING

1) Cover piping joints with pipe cover.

2) For outdoor unit side, surely insulate every piping including valves.

3) Using piping tape (E), apply taping starting from the entry of outdoor unit.

• Stop the end of piping tape (E) with tape (with adhesive agent attached).

• When piping have to be arranged through above ceiling, closet or where the temperature and humidity

are high, wind additional commercially sold insulation to prevent condensation.

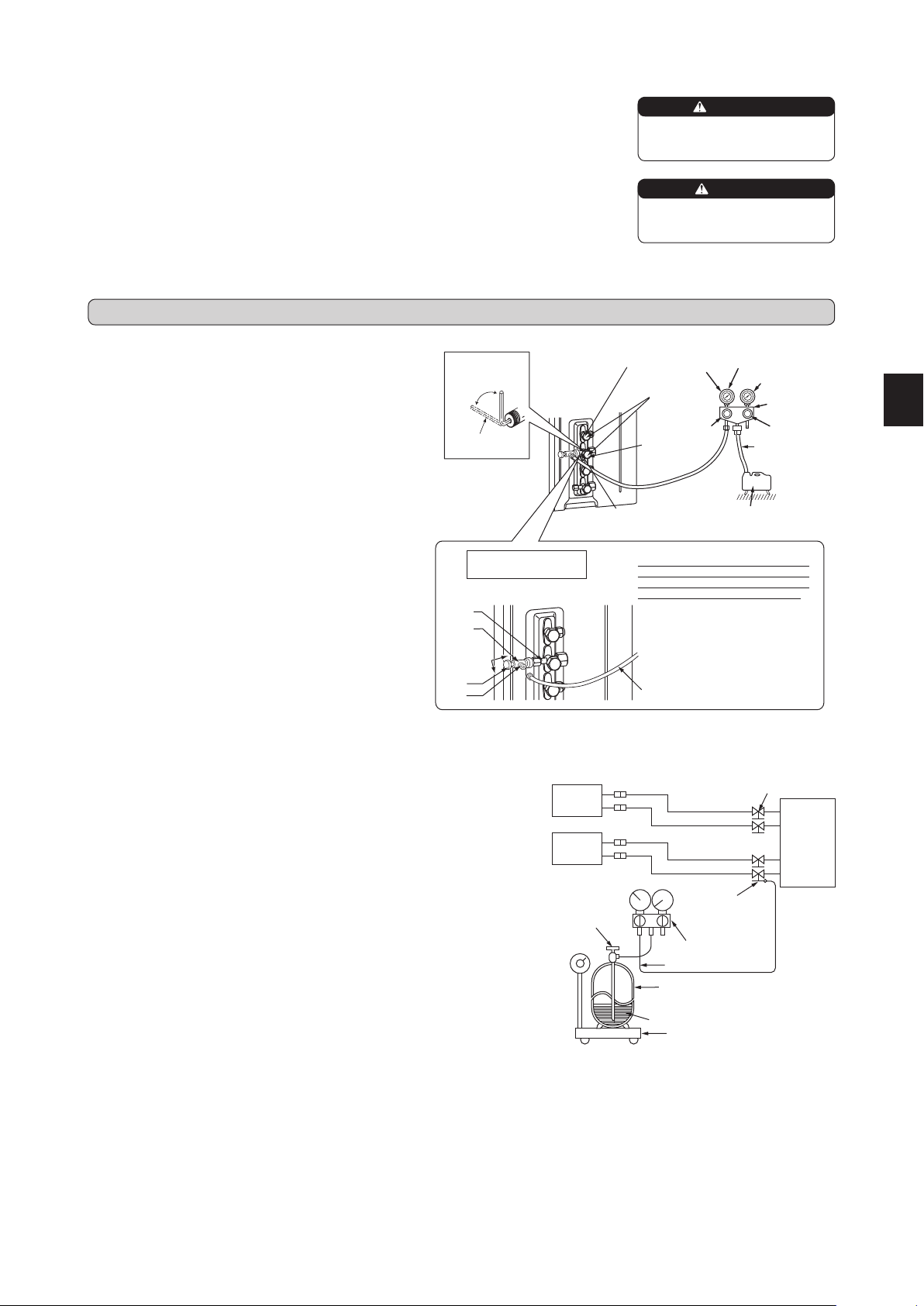

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN

WARNING

When installing the unit, securely

connect the refrigerant pipes before

starting the compressor.

CAUTION

When there are the ports which are

not used, make sure their nuts are

tightened securely.

4-1. PURGING PROCEDURES AND LEAK TEST

1) Remove service port cap of stop valve on the side of the outdoor

unit gas pipe. (The stop valves are fully closed and covered in caps

in their initial state.)

2) Connect gauge manifold valve and vacuum pump to service port of

stop valve on the gas pipe side of the outdoor unit.

3) Run the vacuum pump. (Vacuumize for more than 15 minutes.)

4) Check the vacuum with gauge manifold valve, then close gauge

manifold valve, and stop the vacuum pump.

5) Leave as it is for one or two minutes. Make sure the pointer of

gauge manifold valve remains in the same position. Conrm that

pressure gauge shows -0.101 MPa [Gauge] (-760 mmHg).

6) Remove gauge manifold valve quickly from service port of stop

valve.

7) Fully open all stop valves on the gas pipe and the liquid pipe. Oper

ating without fully opening lowers the performance and this causes

trouble.

8) Refer to 1-2., and charge the prescribed amount of refrigerant if

needed. Be sure to charge slowly with liquid refrigerant. Otherwise,

composition of the refrigerant in the system may be changed and

affect performance of the air conditioner.

9) Tighten cap of service port to obtain the initial status.

10

) Leak test

*Open

Hexagonal wrench

-

Service

port

Control

valve

A

Body

*4 to 5 turns

Open

Close

4-2. GAS CHARGE

Perform gas charge to unit.

1) Connect gas cylinder to the service port of stop valve.

2) Perform air purge of the pipe (or hose) coming from refrigerant gas cylinder.

3) Replenish specied amount of the refrigerant, while operating the air condi

tioner for cooling.

Note:

In case of adding refrigerant, comply with the quantity specied for the refrigerating cycle.

CAUTION:

When charging the refrigerant system with additional refrigerant, be sure to use

liquid refrigerant. Adding gas refrigerant may change the composition of the

refrigerant in the system and affect normal operation of the air conditioner. Also,

charge the liquid refrigerant slowly, otherwise the compressor will be locked.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with

warm water (under 40°C) during cold season. But never use naked re or steam.

*Close

Precautions when using

the control valve

Indoor

-

unit

Indoor

unit

Refrigerant gas

cylinder

operating valve

(for R410A)

Stop valve

for GAS

Stop valve

for LIQUID

Service port cap

(Torque 13.7 to 17.7 N•m,

140 to 180 kgf

When attaching the control valve to

the service port, valve core may de

form or loosen if excess pressure is

applied. This may cause gas leak.

When attaching the control valve to

the service port, make sure that the

valve core is in closed position, and

then tighten part A. Do not tighten

part A or turn the body when valve

core is in open position.

Charge hose

(for R410A)

Union

Union

–0.101 MPa

(–760 mmHg)

Stop valve

cap (Torque

19.6 to 29.4

N•m, 200 to

300 kgf•cm)

•cm)

Charge hose (for R410A)

Refrigerant gas cylinder

for R410A with siphon

Handle

Low

Vacuum pump

(for R410A)

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Service port

Gauge manifold

valve (for R410A)

Compound pressure

gauge (for R410A)

Pressure gauge

(for R410A)

Gauge manifold

valve (for R410A)

Handle High

Charge hose

(for R410A)

-

Stop valve

Outdoor

unit

Refrigerant (liquid)

Electronic scale for

refrigerant charging

Loading...

Loading...