Mitsubishi Electronics MXZ-24UV - E2 User Manual

SPLIT-TYPE, HEAT PUMP AIR CONDITIONER

SERVICE MANUAL

Inverter-controlled multi system

Model

Revision:

• MXZ-24UV - has been added.

• Please void OB287.

E2

No. OB287

REVISED EDITION-A

MXZ-24UV MXZ-24UV -

Model indication

E1

E2

CONTENTS

1. TECHNICAL CHANGES ····································2

2. PART NAMES AND FUNCTIONS······················3

3. INDOOR/OUTDOOR

CORRESPONDENCE TABLE ···························4

4. INDOOR UNITS COMBINATION ·······················5

5. SPECIFICATION·················································7

6. NOISE CRITERIA CURVES······························ 8

7. OUTLINES AND DIMENSIONS························ 9

8. WIRING DIAGRAM ··········································10

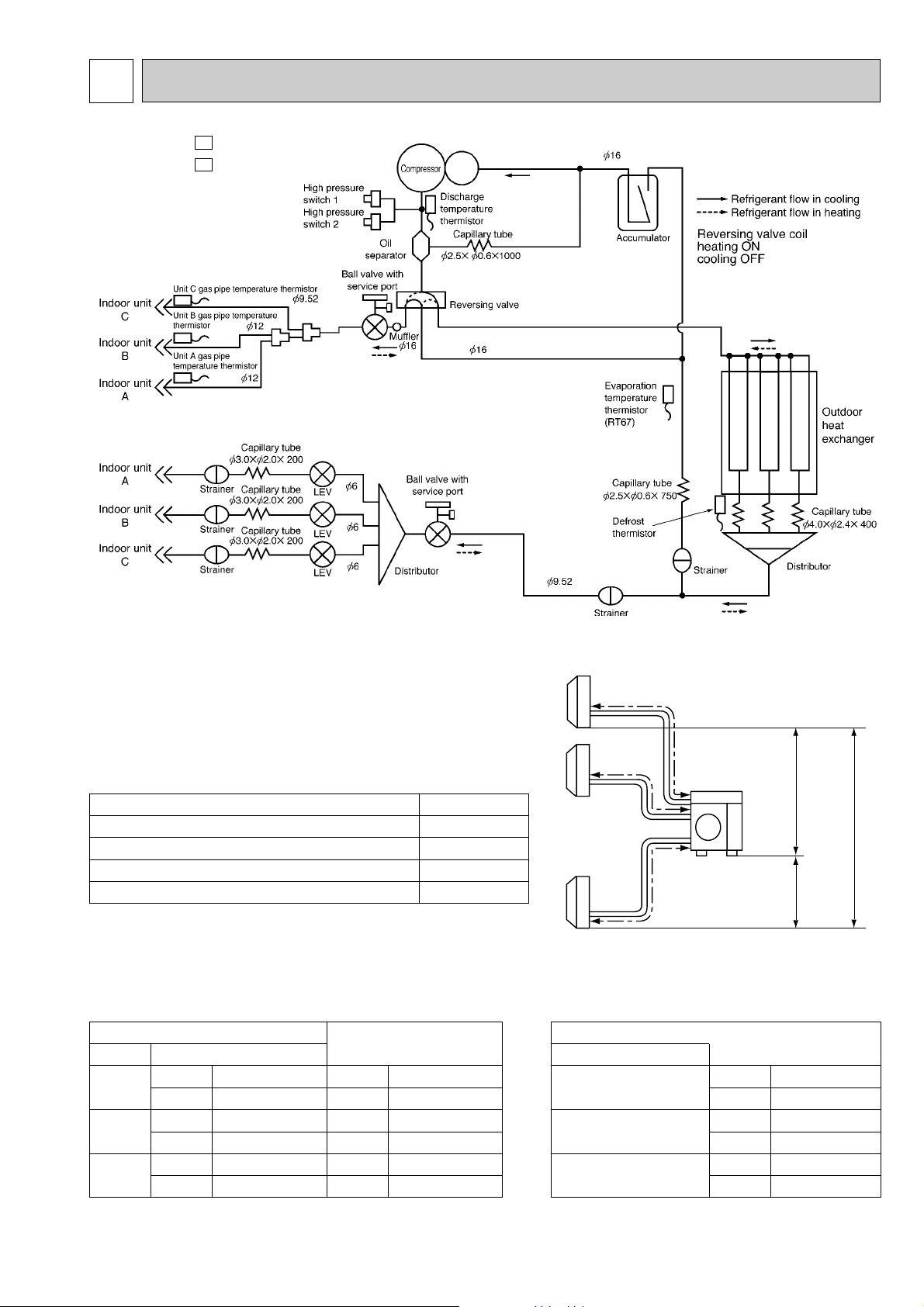

9. REFRIGERANT SYSTEM DIAGRAM··············11

10. PERFORMANCE CURVES······························12

11. MICROPROCESSOR CONTROL·····················18

12. TROUBLESHOOTING ······································24

13. DISASSEMBLY INSTRUCTIONS·····················36

14. PARTS LIST······················································39

15. OPTIONAL PARTS ···········································42

This manual describes technical data of the outdoor unit.

For the indoor unit refer to the service manuals No. OB229, OB227 REVISED EDITION-B, OB252, OB212,

OB239 and OC165 of corresponding models.

1

TECHNICAL CHANGES

MXZ-24UV - ➔ MXZ-24UV -

1. Combinations of the connectable indoor units have increased.

2. Noise filter P.C. board has changed to improve the capacity for protecting the inverter-controlled circuit when the

voltage higher than the rated one is aupplied with the inverter-controlled circuit.

3. Noise filter P.C. board for “E1” and “E2” are not interchangeable.

4. Service parts have been changed as follows according to above change;

•The value of R(resistor)has changed. 10Ω ➔ 20Ω

•TB6(terminal block) has been removed.

E2E1

2

2

PART NAMES AND FUNCTIONS

OUTDOOR UNIT

MXZ-24UVMXZ-24UV-

E1

E2

Air outlet

Air inlet

Model indication

(back and side)

3

3

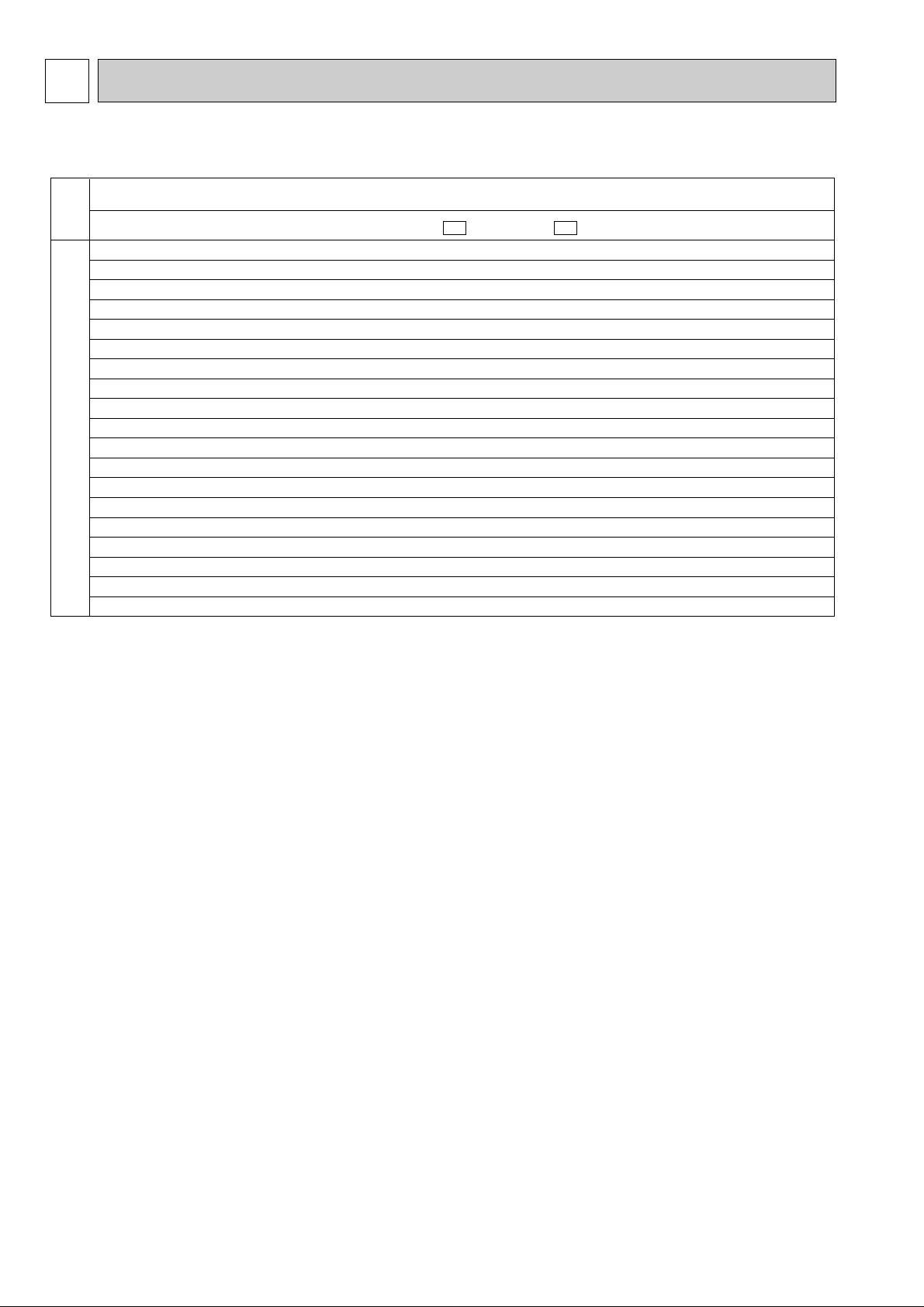

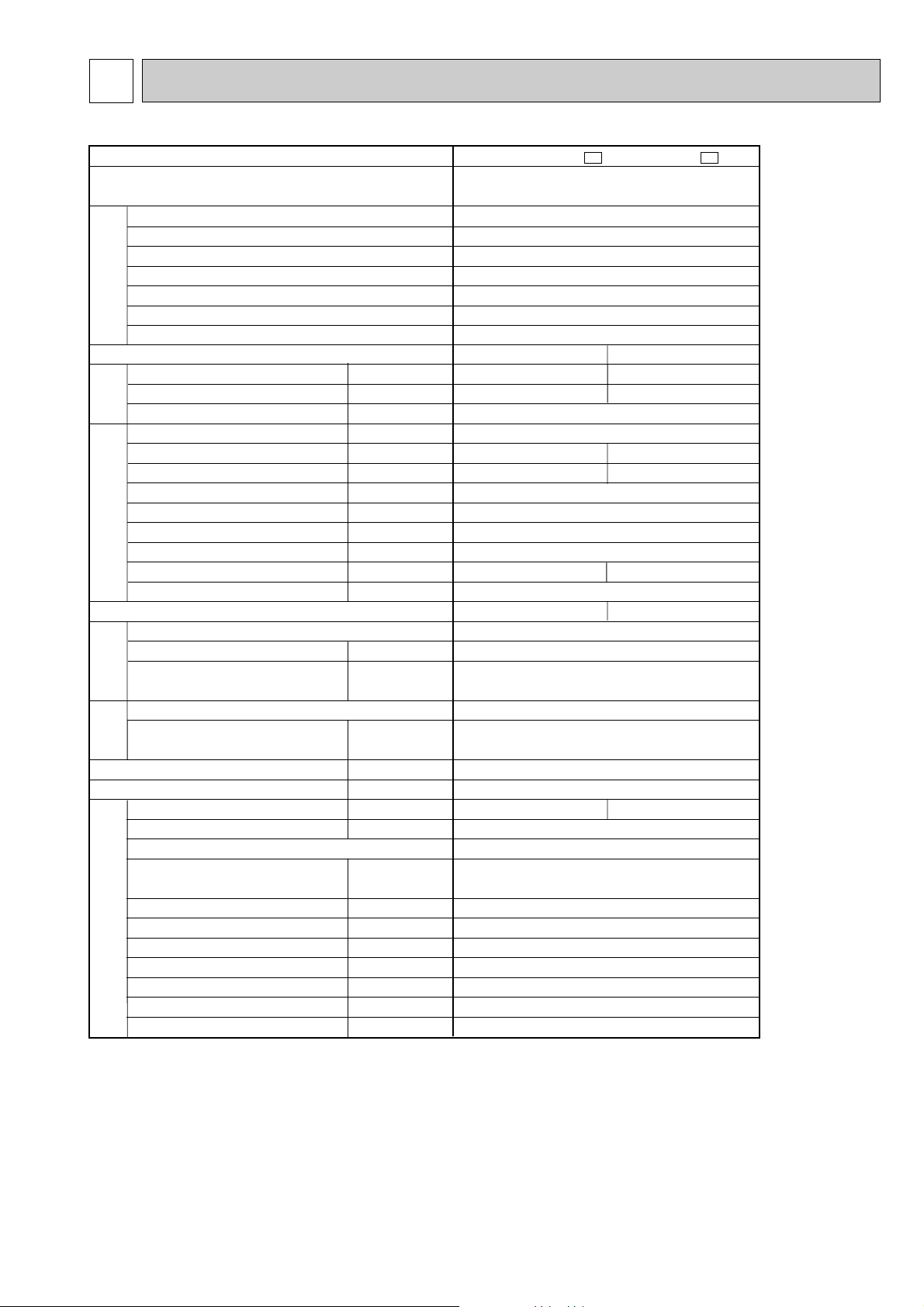

❈There is no combination other than this table.

MXZ-24UV- E1 , MXZ-24UV- E2

OUTDOOR UNIT

Combination of the connectable indoor units

07+07

07+09

07+12

07+18

09+09

09+12

09+18

12+12

12+18

18+18

07+07+07

07+07+09

07+07+12

07+07+18

07+09+09

07+09+12

07+09+18

09+09+09

09+09+12

NOTE: SLH-1AR is equivalent to class 09 (9000BTU).

INDOOR / OUTDOOR CORRESPONDENCE TABLE

MCFH-13NV, SEH-1.6AR, SLH-1.6AR is equivalent to class 12 (12000BTU).

MCFH-18NV, SEH-2AR,SLH-2AR is equivalent to class 18 (18000BTU).

4

07

09

12

18

07+07

07+09

07+12

07+18

09+09

09+12

09+18

12+12

12+18

18+18

07+07+07

07+07+09

07+07+12

07+07+18

07+09+09

07+09+12

07+09+18

09+09+09

09+09+12

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

3.62

4.35

6.96

11.11

7.44

7.83

11.01

14.40

9.18

13.19

14.40

14.40

14.40

14.40

8.94

10.05

10.05

10.05

10.05

10.05

10.05

10.05

10.05

2.2

(0.9-2.7)

2.8

(0.9-3.2)

4.0

(0.9-4.5)

5.0

(0.9-5.4)

4.4

(1.8-5.4)

5.0

(1.8-5.8)

6.2

(1.8-6.7)

7.1

(1.8-7.6)

5.6

(1.8-6.2)

6.8

(1.8-7.4)

7.1

(1.8-7.6)

7.1

(1.8-7.6)

7.1

(1.8-7.6)

7.1

(1.8-7.6)

6.6

(2.4-8.1)

7.1

(2.4-8.5)

7.1

(2.4-8.5)

7.1

(2.4-8.5)

7.1

(2.4-8.5)

7.1

(2.4-8.5)

7.1

(2.4-8.5)

7.1

(2.4-8.5)

7.1

(2.4-8.5)

750

(260-930)

900

(260-1040)

1440

(260-1700)

2300

(260-2980)

1540

(580-1960)

1620

(580-2050)

2280

(580-2540)

2980

(580-3450)

1900

(580-2180)

2730

(580-3230)

2980

(580-3450)

2980

(580-3450)

2980

(580-3450)

2980

(580-3450)

1850

(700-3650)

2080

(700-4070)

2080

(700-4070)

2080

(700-4070)

2080

(700-4070)

2080

(700-4070)

2080

(700-4070)

2080

(700-4070)

2080

(700-4070)

—

—

—

—

—

—

—

—

—

—

—

—

—

—

2.2

2.8

3.4

3.8

2.55

3.15

3.55

2.37

3.0

—

—

—

—

2.2

2.8

4.0

4.95

2.8

4.0

4.55

3.55

3.95

3.55

2.2

2.15

1.85

1.65

2.55

2.2

2.0

2.37

2.05

2.2

2.8

4.0

5.0

2.2

2.2

2.2

2.15

2.8

2.8

2.55

3.55

3.15

3.55

2.2

2.15

1.85

1.65

2.0

1.75

1.55

2.37

2.05

Indoor units

combination

Unit A Unit B Unit C

Cooling capacity (kW)

Total

Outdoor unit

power consumption

(W)

Current

(A)

Power

factor

(%)

NOTE: Electrical data is for outdoor unit only.

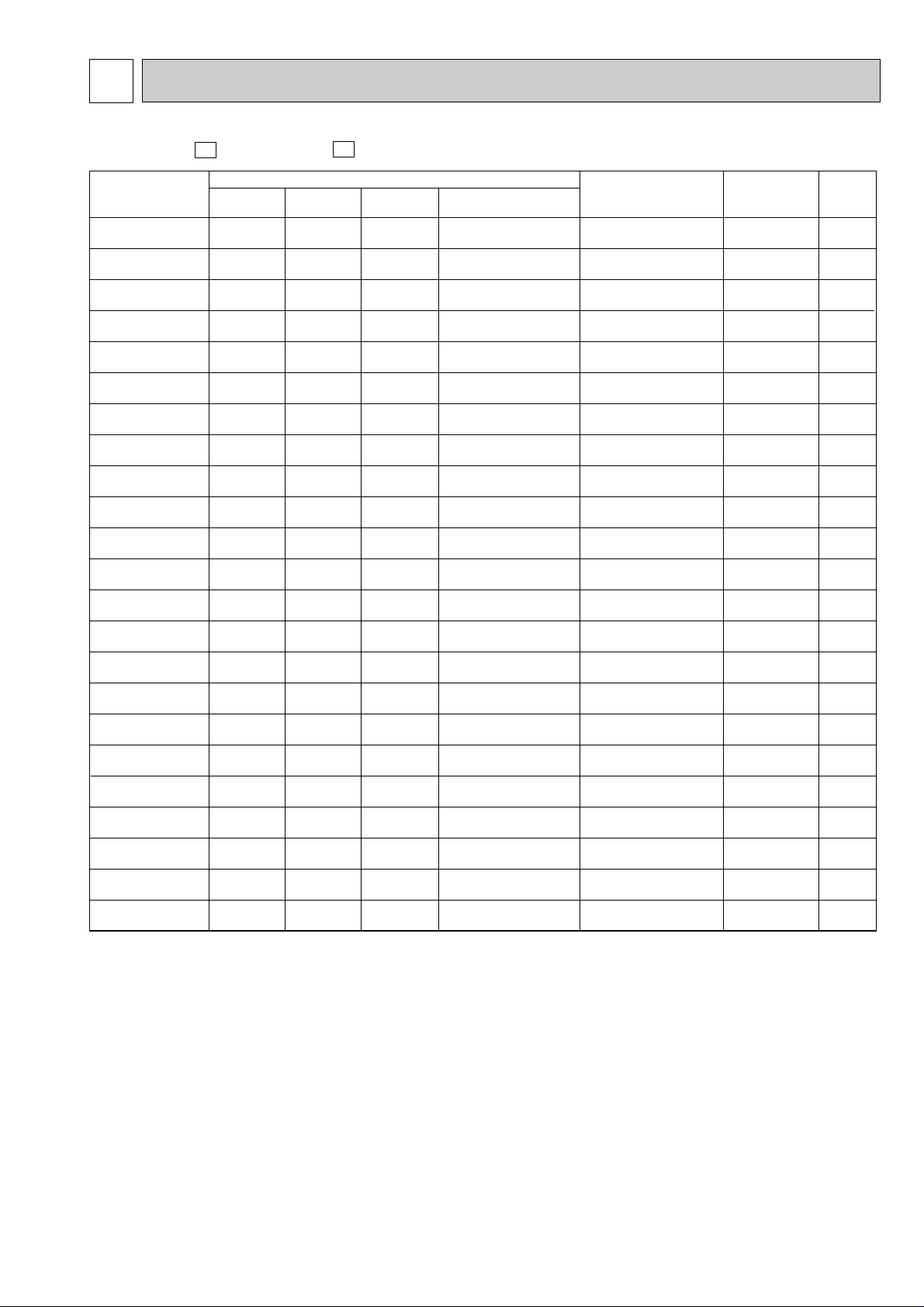

MXZ-24UV -

E1 , MXZ-24UV - E2

4

INDOOR UNITS COMBINATION

NOTE: SLH-1AR is equivalent to class 09 (9000BTU).

MCFH-13NV, SEH-1.6AR, SLH-1.6AR is equivalent to class 12 (12000BTU).

MCFH-18NV, SEH-2AR,SLH-2AR is equivalent to class 18 (18000BTU).

5

NOTE: Electrical data is for outdoor unit only.

07

09

12

18

07+07

07+09

07+12

07+18

09+09

09+12

09+18

12+12

12+18

18+18

07+07+07

07+07+09

07+07+12

07+07+18

07+09+09

07+09+12

07+09+18

09+09+09

09+09+12

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

5.46

6.38

9.23

11.11

9.32

9.90

12.32

13.19

11.35

12.75

13.19

13.19

13.19

13.19

11.69

12.08

12.08

12.08

12.08

12.08

12.08

12.08

12.08

3.2

(0.9-4.1)

4.0

(0.9-4.8)

6.0

(0.9-7.2)

7.1

(0.9-7.8)

6.4

(1.8-7.2)

7.2

(1.8-8.7)

8.6

(1.8-10.6)

9.0

(1.8-10.9)

8.0

(1.8-10.1)

8.8

(1.8-10.8)

9.0

(1.8-10.9)

9.0

(1.8-10.9)

9.0

(1.8-10.9)

9.0

(1.8-10.9)

8.6

(2.1-10.6)

9.0

(2.1-10.9)

9.0

(2.1-10.9)

9.0

(2.1-10.9)

9.0

(2.1-10.9)

9.0

(2.1-10.9)

9.0

(2.1-10.9)

9.0

(2.1-10.9)

9.0

(2.1-10.9)

1130

(270-1600)

1320

(270-1700)

1900

(270-2570)

2300

(270-2830)

1930

(470-2300)

2050

(470-2680)

2550

(470-3800)

2730

(470-3880)

2350

(470-3560)

2640

(470-3850)

2730

(470-3880)

2730

(470-3880)

2730

(470-3880)

2730

(470-3880)

2420

(520-3000)

2500

(520-3180)

2500

(520-3180)

2500

(520-3180)

2500

(520-3180)

2500

(520-3180)

2500

(520-3180)

2500

(520-3180)

2500

(520-3180)

—

—

—

—

—

—

—

—

—

—

—

—

—

—

2.87

3.5

4.4

4.7

3.2

4.1

4.5

3.0

3.9

—

—

—

—

3.2

4.0

5.4

6.2

4.0

5.3

5.75

4.5

4.9

4.5

2.87

2.75

2.3

2.15

3.2

2.7

2.5

3.0

2.55

3.2

4.0

6.0

7.1

3.2

3.2

3.2

2.8

4.0

3.5

3.25

4.5

4.1

4.5

2.87

2.75

2.3

2.15

2.6

2.2

2.0

3.0

2.55

Indoor units

combination

Unit A Unit B Unit C

Heating capacity (kW)

Total

Outdoor unit

power consumption

(W)

Current

(A)

Power

factor

(%)

NOTE: SLH-1AR is equivalent to class 09 (9000BTU).

MCFH-13NV, SEH-1.6AR, SLH-1.6AR is equivalent to class 12 (12000BTU).

MCFH-18NV, SEH-2AR,SLH-2AR is equivalent to class 18 (18000BTU).

6

5

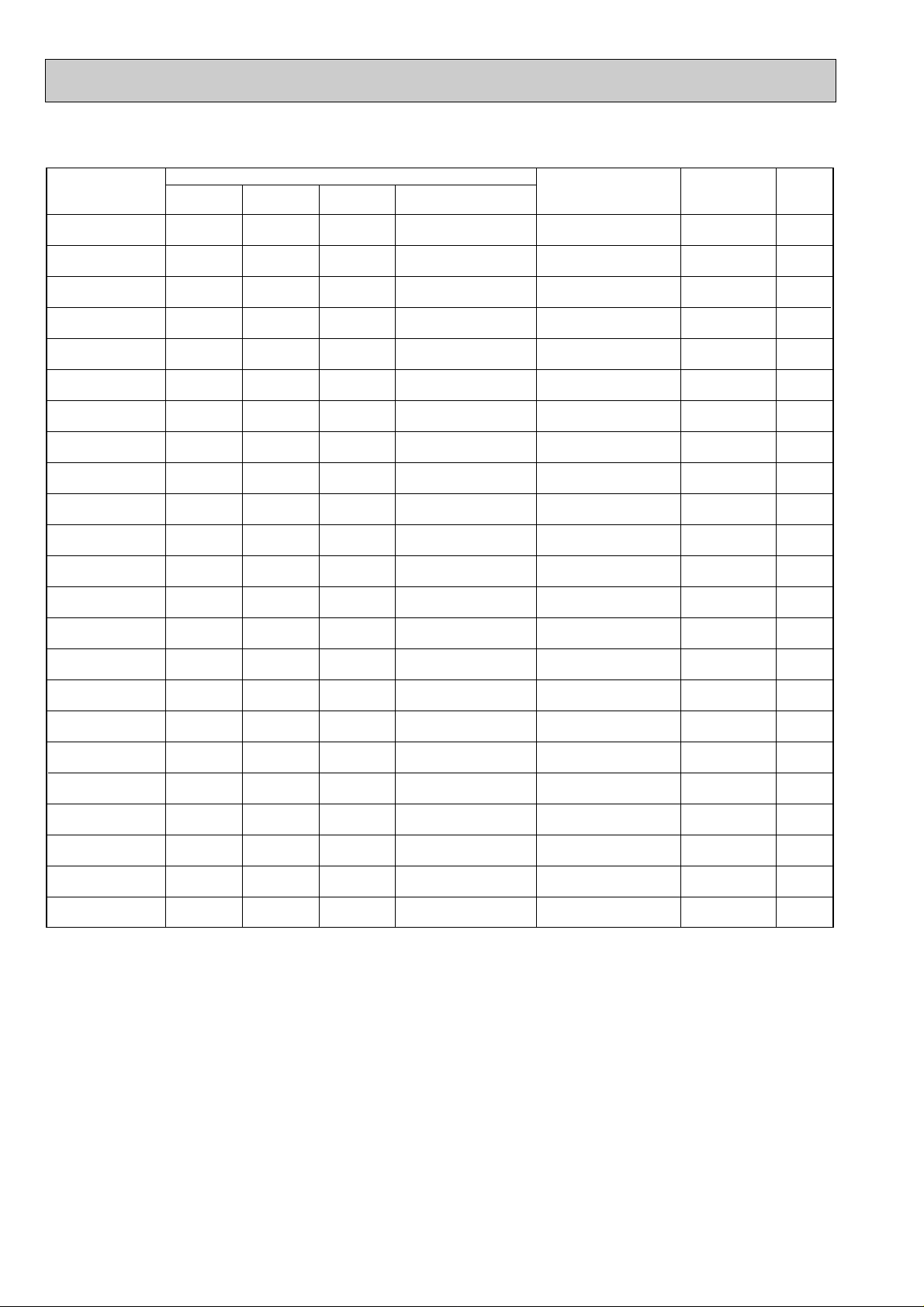

Outdoor model

Indoor units number

Indoor units total capacity (Connectable)

Indoor units total capacity (Simultaneous operation)

Piping total length

Connecting pipe length

Height difference (Indoor ~ Outdoor)

Height difference (Indoor ~ Indoor)

Function

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Crankcase heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at20:)

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Sound level (High)

Fan speed (High)

Fan speed regulator

Refrigerant filling

capacity(R22)

Refrigerating oil (Model)

Thermistor RT61

Thermistor RT62

Thermistor RT63

Thermistor RT65

Thermistor RT66,67

Thermistor RT68

kW

R/h

K /h

A

A

W

A(kW)

W

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

k"

k"

k"

k"

k"

k"

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity System

Coefficient of performance(C.O.P)

Outdoor unit power supply

MXZ-24UV -

E1

, MXZ-24UV -

E2

Single phase

230V,50Hz

2 to 3

✽2 Total model name 34 (3 indoor units) / 36 (2 indoor units)

✽2 Total model name 34 (3 indoor units) / 36 (2 indoor units)

Max. 50

Max. 25

10

10

2520

25

—

—

90.0

12.08

0.6

THV247FBA (ROTARY)

2000

U-V 0.61

V-W 0.61 W-U 0.61

RA6V60-BA

WHT-BLK 78.7 BLK-YLW 26.9

YLW-BLU 11.7 BLU-RED 83.6

900o900o320 (+35)

78

550

3

3.9

870 (MS-56)

13.4 (at 100:)

10.0 (at 25:)

10.0 (at 25:)

17.0 (at 50:)

10.0 (at 25:)

10.0 (at 25:)

Cooling

7.1 (0.9~8.5)

—

10.05

2080 (260~4070)

8.7

2.68

46

Heating

9.0 (0.9~10.9)

—

12.08

2500 (270~3180)

9.1

3.35

47

SPECIFICATION

NOTE: Test conditions are based on ISO5151 (Refrigerant piping length (one way): 5m)

✽1 Electrical data is for only outdoor unit.

✽2 However, please refer to “INDOOR/OUTDOOR CORRESPONDENCE TABLE” of page 3 for the combination.

TEST CONDITIONS COOLING INDOOR DB27.0°C WB19.0°C

HEATING INDOOR DB20.0°C

OUTDOOR DB35.0°C WB24.0°C

OUTDOOR DB 7.0°C WB 6.0°C

7

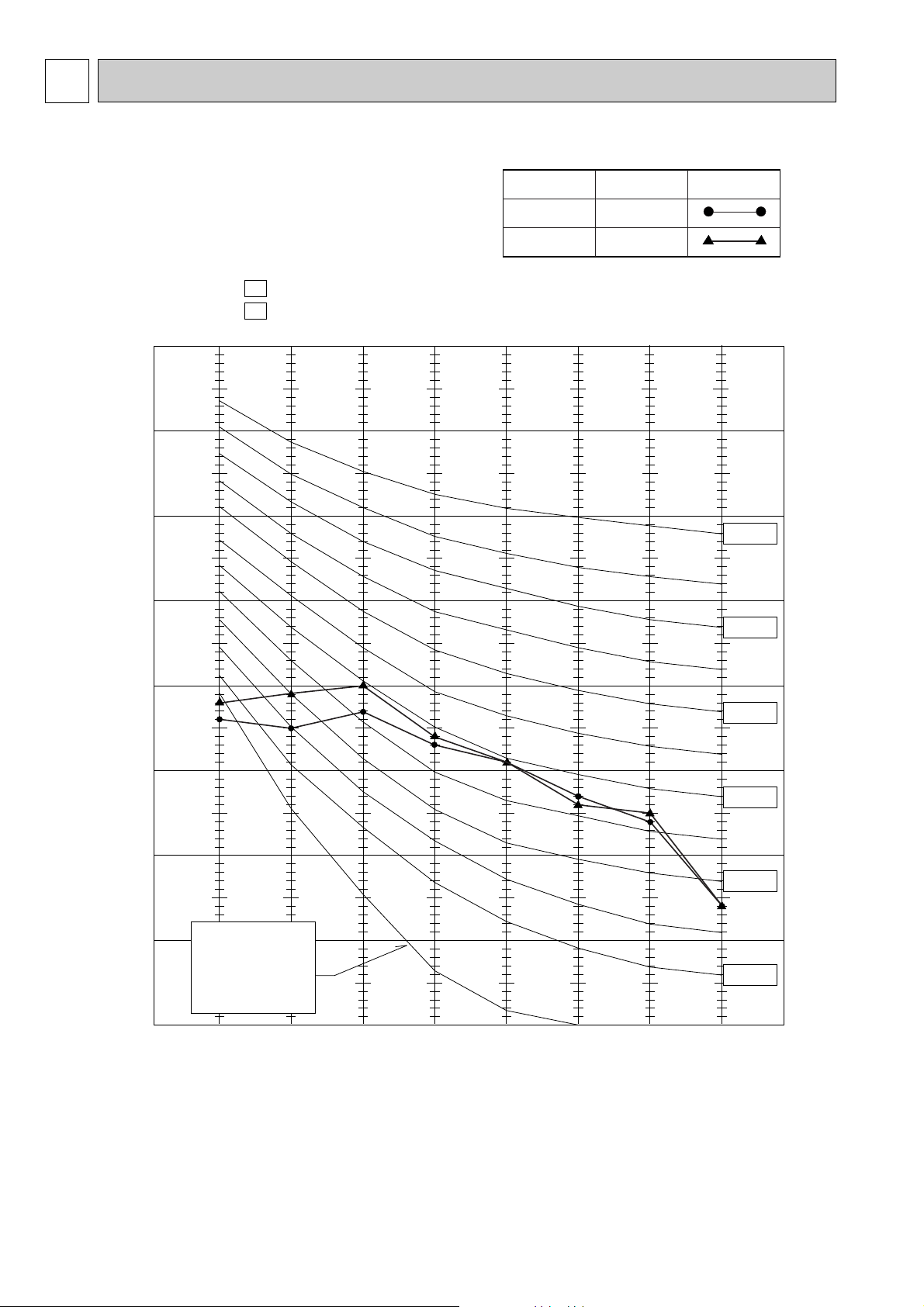

NOISE CRITERIA CURVES6

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB = 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions.

Cooling :DB35: WB24:

Heating :DB 7: WB 6:

COOL

NOTCH

HEAT

46

SPL(dB(A))

47

LINE

MXZ-24UV -

E1

MXZ-24UV -

E2

8

7

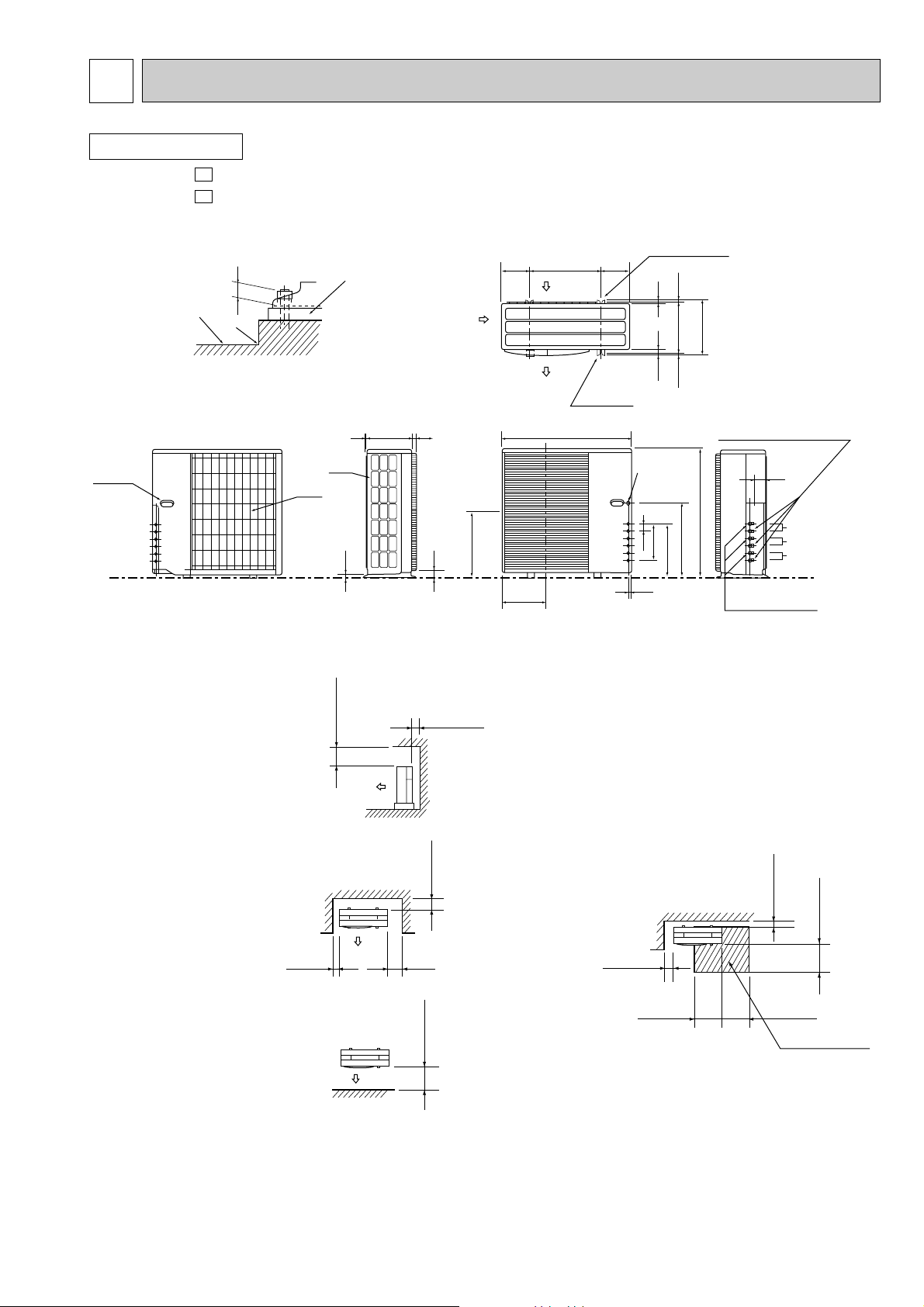

OUTLINES AND DIMENSIONS

OUTDOOR UNIT

MXZ-24UV MXZ-24UV -

Handle for

moving

E1

E2

Less than

25

Veranda

Base bollt length

Base

Rubber cushion

Air in

Air in

10 35320

23

Unit: mm

2-U-shape notched holes

200 200

Air in

460

33

317

500

Air in

Air out

2-12 ✕ 36 Oval hole

(Base bolt M10)

900

(Base bolt M10)

(16) (16)

27 40

355

Indoor and

outdoor

connect wiring

23✕45 hole

531.3

250

50

381.8

23

387

[

9.52 (flared) 3/8 (C unit)

12.7 (flared) 1/2 (A , B unit)

[

88

900

C unit connection

B unit connection

A unit connection

Liquid pipe

[

6.35 (flared) 1/4

1.Installation space

Note : Leave front and both sides

clearance fully.

Note : Leave front and overhead

clearance fully.

Note : Leave front, overhead and

both clearance fully.

More than

100

More than

500

More than

100

More than

200

More than

350

More than

500

Note : Obsacle on front and rear sid only.

The unit can be used by attaching an optional

outdoor outlet guide (MAC-855SG)

(but both sides and the top are opend.)

2.Service space

More than

100

More than

350

More than

100

More than

350

Service space

More than

500

9

8

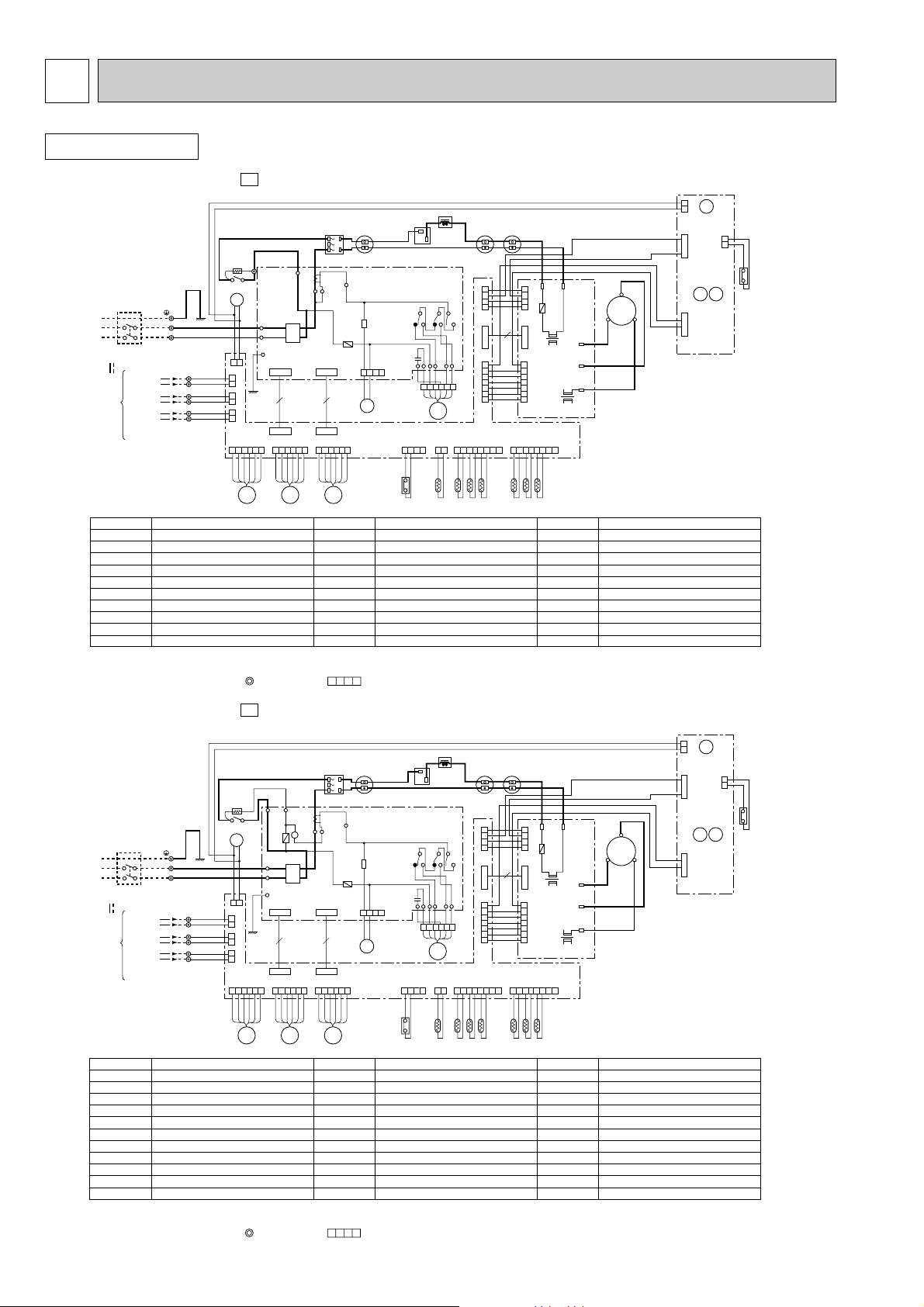

POWER SUPPLY

~/N 230V

50Hz

INDOOR

UNIT (A)

CIRCUIT BRAKER

TB1

TB2

TB3

TB4

BLU

RED

TB5

X64

GRN/YLW

GRN

CN720

CN601

0

4

X64

LD62

CN913

CN791

CN901

64

2

CN902

CN851 CN852

MF61

21S4

12

21

21

12

12

34

123456

12 34567

123456

C65

LD63

LD64

LDB

LDB

LD61

LDE

L61

F911

SSR61

X63

X62

X61

1

6

L

N

3

N

INDOOR

UNIT (B)

BLU

ORN

CN602

12

3

3

N

INDOOR

UNIT (C)

BLU

YLW

CN603

12

N

BLK

BRN

GRY

BLK

BLK

WHT

YLW

RED

RED

RED

BRN

BLU

ORN

YLW

WHT

ORN

WHT

BLK

BLU

YLW

RED

ORN

ORN

RED

RED

YLW

YLW

BLK

BLK

ORN

ORN

BRN

GRY

X65

X66

X67

63H2

CN552

CN553

BLK

RELAY

P.C. BOARD

WHT

WHT

RED

WHT

V

UW

A

K

L

WHT

NOISE FILTER

P.C.BOARD

RED

DS61

DS62

C61

CT

61

C63 C62

+

+

–

+–+

–

-

BLKRED

R

BLU

LEV A

CN792

123456

RED

BRN

BLU

ORN

YLW

WHT

LEV B

CN793

123456

RED

BRN

BLU

ORN

YLW

WHT

LEV C

CN722 CN663

63H1 RT63

CN662

1234567812 1234

RED

RED

BLK

BLK

RT66 RT68

RT67

GRY

GRY

GRY

GRY

GRY

GRY

CN661

CN705

7654321

CN515

1234

4321

CN801

CN501

TAB62

TAB63

T801

CT62

TAB66

TAB65

TAB64

I.P.M P.C. BOARD

F801

(1A)

CN704

CN514

CN554CN551

12345678

RT62

RT61

RT65

GRY

GRY

BLK

BLK

GRY

GRY

ELECTRONIC CONTROL P.C. BOARD

MC

PE

(1A)

TO INDOOR UNIT

CONNECTING 12V

SYMBOL

C61

C62,63

C65

CT61,62

DS61

DS62

F801

F911

L

L61

SYMBOL

LEV A~C

MC

MF61

R

RT61

RT62

RT63

RT65

RT66,67

RT68

NAME

POWER FACTOR CAPACITOR

SMOOTHING CAPACITOR

OUTDOOR FAN CAPACITOR

CURRENT TRANSFORMER

DIODE MODULE

DIODE STACK

FUSE (1A)

FUSE (1A)

REACTOR

COMMON MODE CHOKE COIL

NAME

EXPANSION VALVE

COMPRESSOR

FAN MOTOR (INNER PROTECTOR)

RESISTOR

DISCHARGE TEMPERATURE THERMISTOR

DEFROST TEMPERATURE THERMISTOR

EVAPORATION TEMPERATURE THERMIST OR

FIN TEMPERATURE THERMISTOR

GUS PIPE TEMPERATURE THERMISTOR

GUS PIPE TEMPERATURE THERMISTOR

SYMBOL

SSR61

T801

TB1,2,3,4,5

X61,62,63

X64,65

X66,67

21S4

63H1

63H2

NAME

SOLENOID COIL RELAY

TRANSFORMER

TERMINAL BLOCK

FAN MOTOR RELAY

RELAY

RELAY

R.V. COIL

HIGH PRESSURE SWITCH

HIGH PRESSURE SWITCH

NOTE: 1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

2.Use copper conductors only. (For field wiring)

3.Symboles below indicate. : Terminal block : Connector

POWER SUPPLY

~/N 230V

50Hz

INDOOR

UNIT (A)

CIRCUIT BRAKER

TB1

TB2

TB3

TB4

BLU

RED

X64

GRN/YLW

GRN

CN720

CN601

0

4

X64

LD62

CN913

CN791

CN901

64

2

CN902

CN851 CN852

MF61

21S4

12

21

21

12

12

34

123456

12 34567

123456

C65

LD63

LD64

LDB

LDB

LD61

LDE

L61

F911

SSR61

X63

X62

X61

1

6

L

N

3

N

INDOOR

UNIT (B)

BLU

ORN

CN602

12

3

3

N

INDOOR

UNIT (C)

BLU

YLW

CN603

12

N

BLK

BRN

GRY

BLK

BLK

WHT

YLW

RED

RED

RED

BRN

BLU

ORN

YLW

WHT

ORN

WHT

BLK

BLU

YLW

RED

ORN

ORN

RED

RED

YLW

YLW

BLK

BLK

ORN

ORN

BRN

GRY

X65

X66

X67

63H2

CN552

CN553

BLK

RELAY

P.C. BOARD

WHT

WHT

RED

WHT

V

UW

A

K

L

WHT

NOISE FILTER

P.C.BOARD

RED

DS61

DS62

C61

CT

61

C63 C62

+

+

–

+–+

–

-

BLKRED

R

BLU

LEV A

CN792

123456

RED

BRN

BLU

ORN

YLW

WHT

LEV B

CN793

123456

RED

BRN

BLU

ORN

YLW

WHT

LEV C

CN722 CN663

63H1 RT63

CN662

1234567812 1234

RED

RED

BLK

BLK

RT66 RT68

RT67

GRY

GRY

GRY

GRY

GRY

GRY

CN661

CN705

7654321

CN515

1234

4321

CN801

CN501

TAB62

TAB63

T801

CT62

TAB66

TAB65

TAB64

I.P.M P.C. BOARD

F801

(1A)

CN704

CN514

CN554CN551

12345678

RT62

RT61

RT65

GRY

GRY

BLK

BLK

GRY

GRY

ELECTRONIC CONTROL P.C. BOARD

MC

PE

(1A)

TO INDOOR UNIT

CONNECTING 12V

SYMBOL

C61

C62,63

C65

CT61,62

DS61

DS62

F801

F911

L

L61

LEV A~C

SYMBOL

MC

MF61

R

RT61

RT62

RT63

RT65

RT66,67

RT68

SSR61

T801

NAME

POWER FACTOR CAPACITOR

SMOOTHING CAPACITOR

OUTDOOR FAN CAPACITOR

CURRENT TRANSFORMER

DIODE MODULE

DIODE STACK

FUSE (1A)

FUSE (1A)

REACTOR

COMMON MODE CHOKE COIL

EXPANSION VALVE

NAME

COMPRESSOR

FAN MOTOR (INNER PROTECTOR)

RESISTOR

DISCHARGE TEMPERATURE THERMISTOR

DEFROST TEMPERATURE THERMISTOR

EVAPORATION TEMPERATURE THERMIST OR

FIN TEMPERATURE THERMISTOR

GUS PIPE TEMPERATURE THERMISTOR

GUS PIPE TEMPERATURE THERMISTOR

SOLENOID COIL RELAY

TRANSFORMER

SYMBOL

TB1,2,3,4,5

X61,62,63

X64,65

X66,67

21S4

63H1

63H2

F912

NR63

NAME

TERMINAL BLOCK

FAN MOTOR RELAY

RELAY

RELAY

R.V. COIL

HIGH PRESSURE SWITCH

HIGH PRESSURE SWITCH

FUSE (3.15A)

VARISTOR

NOTE: 1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

2.Use copper conductors only. (For field wiring)

3.Symboles below indicate. : Terminal block : Connector

F912

(3.15A)

N

LD65

NR63

WIRING DIAGRAM

OUTDOOR UNIT

E1

E2

MODELS MXZ-24UV-

MODELS MXZ-24UV-

SG79A845H01

10

SG79Y088H01

9

a

b

c

Outdoor

unit

Indoor

units

H

H

H

REFRIGERANT SYSTEM DIAGRAM

MXZ-24UV MXZ-24UV -

E1

E2

Unit:mm

Piping length each indoor unit (a, b, c) 25m

Total piping length (a+b+c) 50m

Height difference between units (H) 10m

Bending point for each unit 25

Total bending point 50

❋It does not matter which unit is higher.

● Refrigerant pipe diameter is different according to indoor unit to be connected. When using extension pipes,refer to the

tables below.

● When diameter of refrigerant pipe is different from that of outdoor unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe,see page BACK COVER.

Indoor unit

class Pipe diameter

07/09

12

18

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 9.52(3/8) Gas 9.52(3/8)

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 12.7(1/2) Gas 12.7(1/2)

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 15.88(5/8) Gas 15.88(5/8)

Extension pipe diameter

11

Outdoor unit union diameter

For

Indoor unit A

Indoor unit B

Indoor unit C

Liquid 6.35(1/4)

Gas 12.7(1/2)

Liquid 6.35(1/4)

Gas 12.7(1/2)

Liquid 6.35(1/4)

Gas 9.52(3/8)

Unit : mm (inch)

10

Wet-and dry-bulb

thermometers

Wet-and dry-bulb

thermometers

07 class

7.5

7.0

6.4

5.9

5.3

4.8

8.7

8.1

7.4

6.8

6.2

5.6

10.8

10.1

9.3

8.5

7.7

7.0

6.7

6.2

5.8

5.3

4.8

4.3

18 class

12 class

09 class

32.3

29.8

27.3

24.9

22.4

19.9

17.4

14.9

38.2

35.3

32.4

29.4

26.5

23.5

20.6

17.6

25.9

23.9

21.9

19.9

17.9

15.9

13.9

11.9

27.7

25.6

23.4

21.3

19.2

17.0

14.9

12.8

07 class

09 class

12 class

18 class

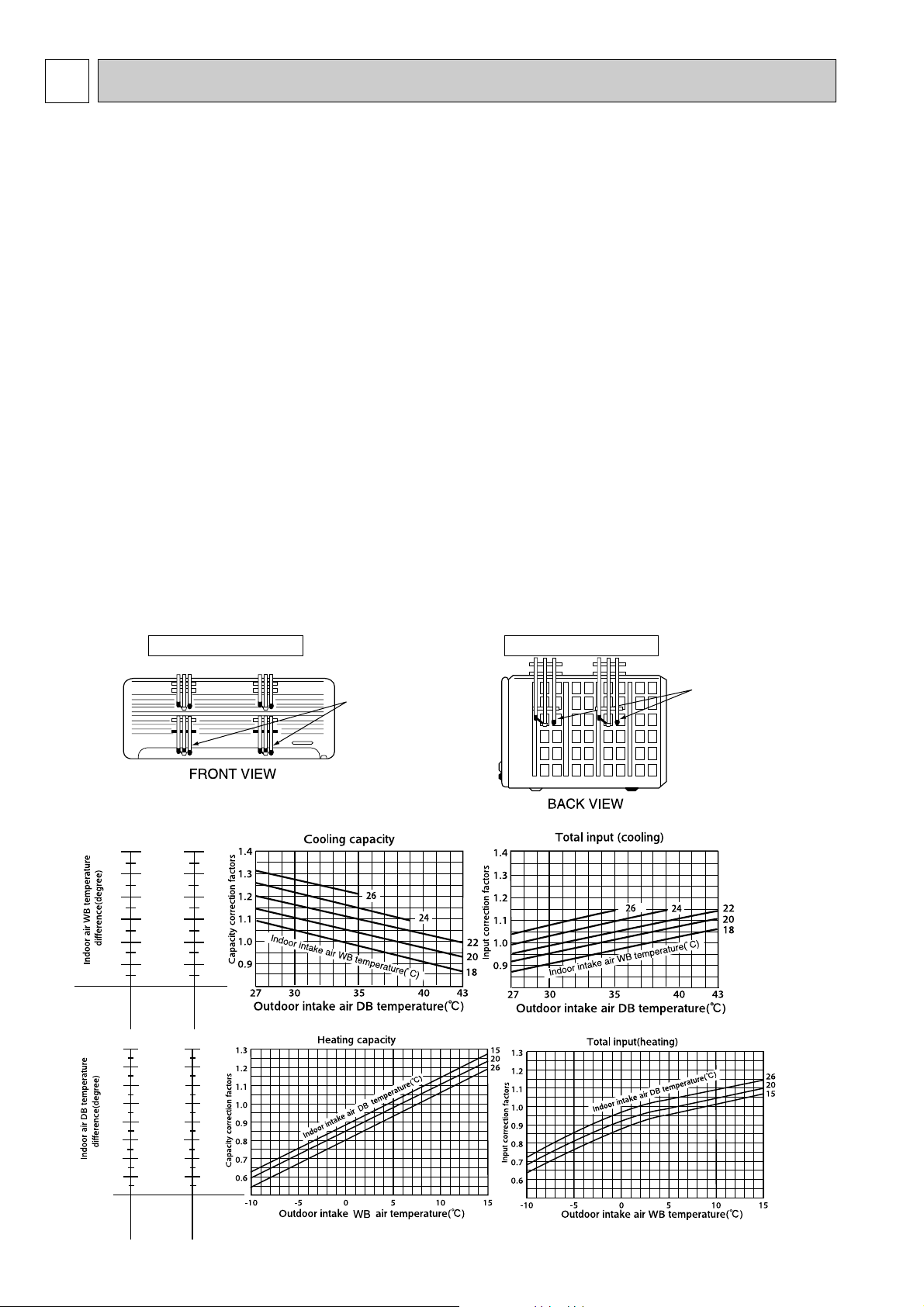

PERFORMANCE CURVES

The standard data contained in these specifications apply only to the operation of the air conditioner under normal conditions,

since operating conditions vary according to the areas where these units are installed. The following information has been provided to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

198 ~ 264V

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature : °CWB

(2) Indoor outlet air wet-bulb temperature : °CWB

(3) Outdoor intake air dry-bulb temperature : °CDB

Cooling

}

(4) Total input: W

(5) Indoor intake air dry-bulb temperature : °CDB

(6) Outdoor intake air wet-bulb temperature : °CWB

(7) Total input : W

}

Heating

Indoor air wet/dry-bulb temperature difference on the left side of the chart on page 14 and 15 shows the difference

between the indoor intake air wet/dry-bulb temperature and the indoor outlet air wet/dry-bulb temperature for your reference at service.

How to measure the indoor air wet-bulb/dry-bulb temperature difference

1. Attach at least 2 sets of wet-and dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet-and dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet-and dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch once(twice) to start the EMERGENCY COOL(HEAT) MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

INDOOR UNIT OUTDOOR UNIT

10-1.CAPACITY AND THE INPUT CURVES

12

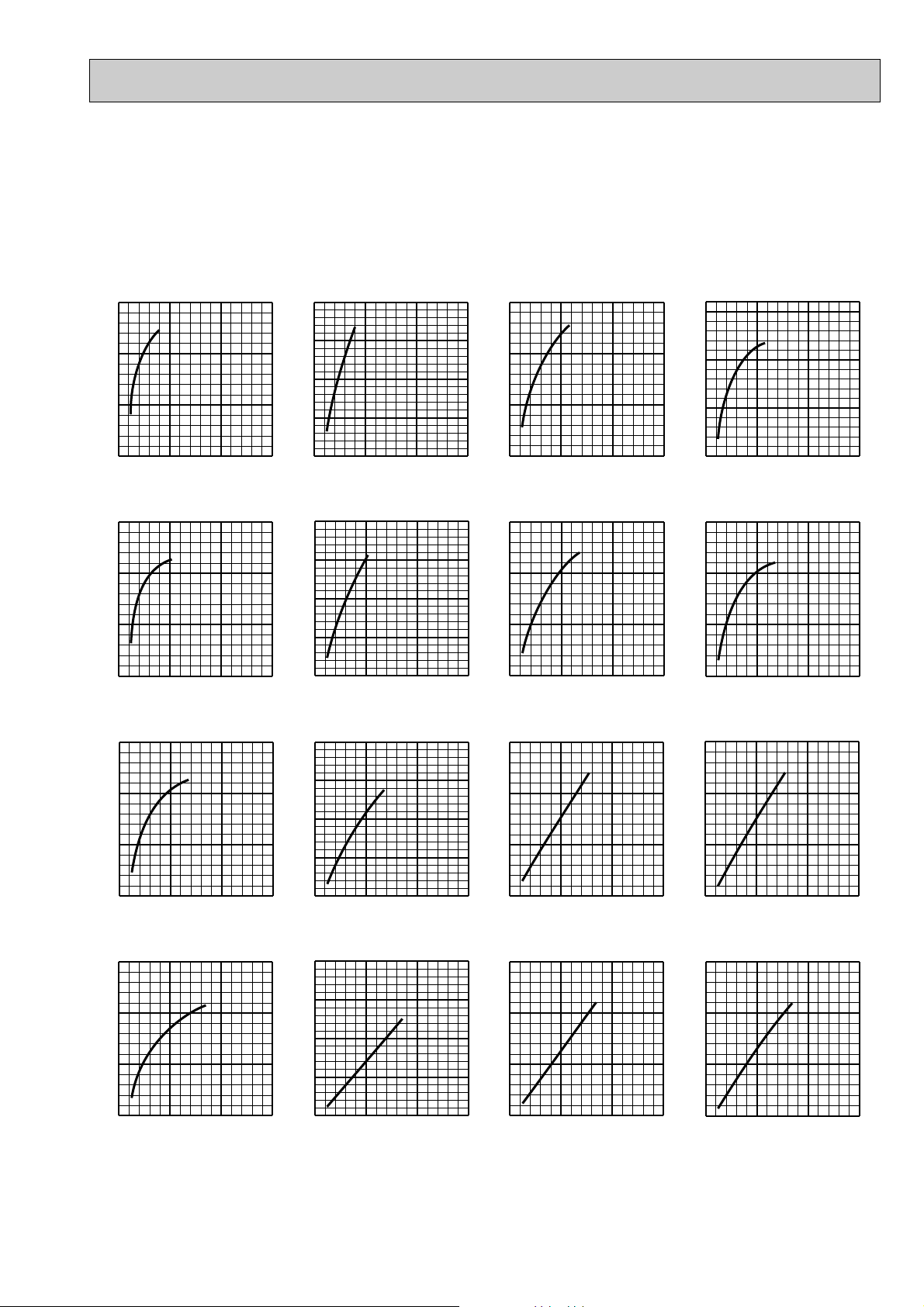

10-2.Capacity and input correction by inverter output frequency

0 50 100 150

0.5

1.0

1.5

<COOL>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

2.0

Frequency

<COOL>Total input

Hz

0 50 100 150

0.5

1.0

1.5

<HEAT>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

Frequency

<HEAT>Total input

Hz

0 50 100 150

0.5

1.0

1.5

<COOL>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

2.0

Frequency

<COOL>Total input

Hz

0 50 100 150

0.5

1.0

1.5

<HEAT>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

Frequency

<HEAT>Total input

Hz

0 50 100 150

0.5

1.0

1.5

<COOL>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

2.0

Frequency

<COOL>Total input

Hz

0 50 100 150

0.5

1.0

1.5

<HEAT>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

Frequency

<HEAT>Total input

Hz

0 50 100 150

0.5

1.0

1.5

<COOL>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

2.0

Frequency

<COOL>Total input

Hz

0 50 100 150

0.5

1.0

1.5

<HEAT>Capacity

Frequency

Hz

0 50 100 150

0.5

1.0

1.5

Frequency

<HEAT>Total input

Hz

1. 07-class unit in single operation

2. 09-class unit in single operation

3. 12-class unit in single operation

4. 18-class unit in single operation

(OUTDOOR UNIT:MXZ-24UV)

NOTE 1 : The dotted line on graphs connects the frequency range in normal operation shown by the full line and the frequency

in test run shown by the point.

13

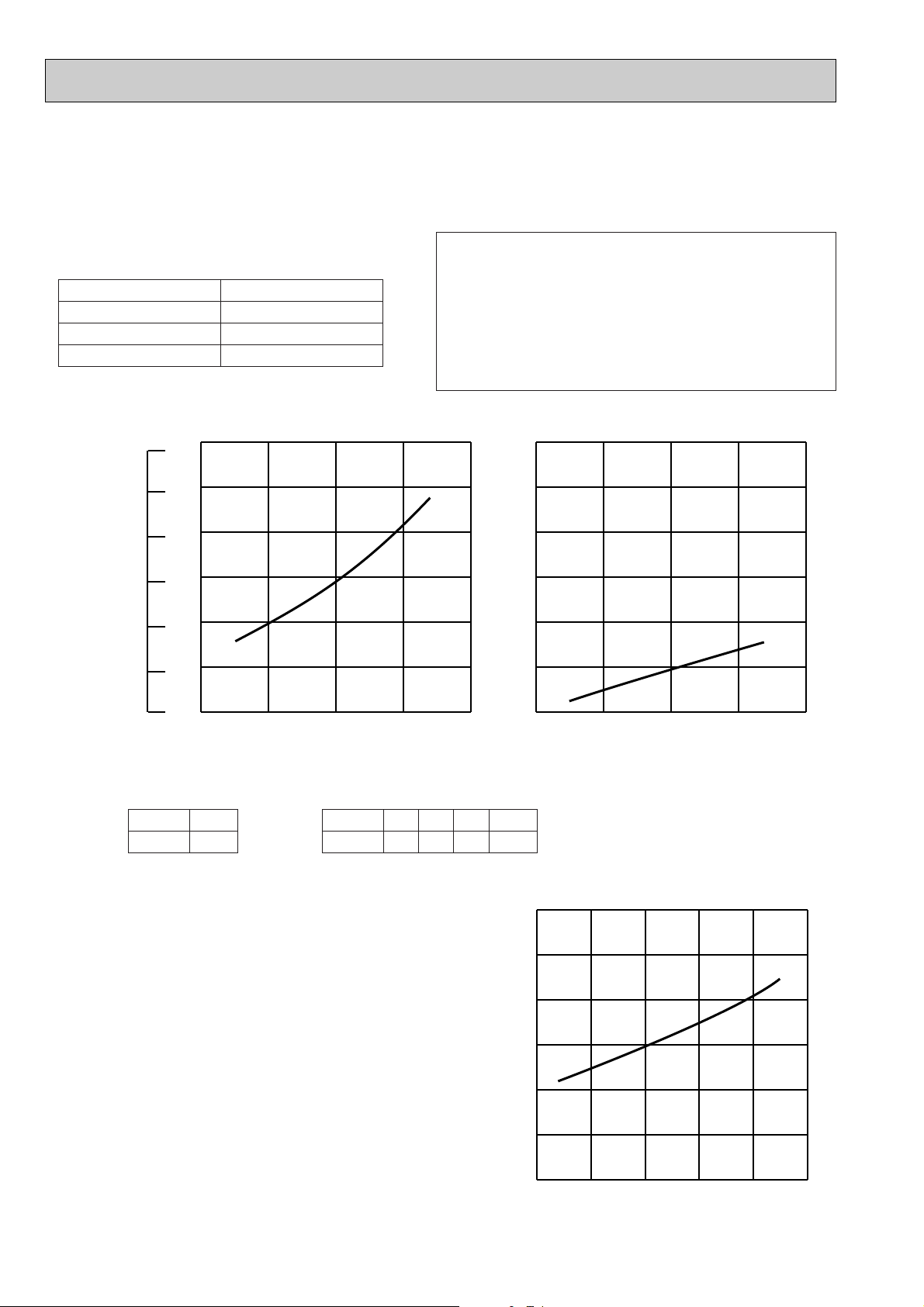

10-3.Outdoor low pressure and outdoor unit current

)

1. 07-class unit in single operation

NOTE:The unit of pressure has been changed to MPa on the international system of units(SI unit system).

The converted score against the traditional unit system can be gotten according to the formula below.

1(MPa • G) =10.2(kgf/ff• G)

(1) COOL operation

1Both indoor and outdoor units are under the same

temperature/humidity condition.

Dry-bulb temperature(°C) Relative humidity(%)

20 50

25 60

30 70

2Air flow speed : HI

3Inverter output frequency : 33Hz

(kgf/F•Gauge)

8

(MPa•Gauge)

0.8

<How to work fixed-frequency operation>

1.Set emergency switch to COOL or HEAT.The switch is located on indoor unit.

2.Press emergency run ON/OFF button.

3.Compressor starts running at rated frequency.

4.Indoor fan runs at HI speed and continues for 30 minutes.

5.To cancel this operation,press emergency run ON/OFF button

or any button on remote controller.

9

0.7

7

0.6

6

0.5

5

0.4

4

Outdoor low pressure

3

0.3

2

0.2

15

Ambient temperature(:)/ Ambient humidity(%)

(2) HEAT operation

①

Indoor Outdoor

➁

Set air flow to Hi speed.

➂

Inverter output frequency is 45Hz.

DB(°C) 20.0

WB(°C) 14.5

20 25

DB(°C) 2 7 15 20.0

WB(°C) 1 6 12 14.5

33Hz

30

35

(;)

(%)

8

7

6

33Hz

5

Outdoor unit current (A)

4

3

15 20 25 30

Ambient temperature(:)/ Ambient humidity(%

35

10

(;)

(%)

14

9

45Hz

8

7

6

Outdoor unit current (A)

5

4

0 5 10 15 20 25

Ambient temperature(:)

Loading...

Loading...