Mitsubishi MXZ-18NV, MXZ-32NV SERVICE MANUAL

SPLIT-TYPE,HEAT PUMP AIR CONDITIONERS

SERVICE MANUAL

Inverter-controlled multi system

Models

Revision:

●MXZ-18NV- and MXZ-18NV- have been added.

●Page layout has been changed.

●Performance curves has been modified.

●The graph of the outdoor low pressure in the HEAT

operation of the PERFORMANCE CURVE of MXZ32NV was deleted.

●Please void OB185 REVISED EDITION Aand B.

E2E1

No. OB185

REVISED EDITION C

MXZ-18NV MXZ-32NV MXZ-18NV MXZ-32NV -

MXZ-32NV

Model indication

E1

E1

E2

E2

CONTENTS

1. TECHNICAL CHANGES····································2

2. PART NAMES AND FUNCTIONS······················2

3. INDOOR /OUTDOOR

CORRESPONDENCE TABLE··········3

4. INDOOR UNITS COMBINATION ·······················4

5. SPECIFICATION·················································9

6. OUTLINES AND DIMENSIONS························11

7. WIRING DIAGRAM ··········································13

8. REFRIGERANT SYSTEM DIAGRAM··············15

9. PERFORMANCE CURVES······························20

10. MICROPROCESSOR CONTROL ····················30

11. TROUBLESHOOTING ······································39

12. DISASSEMBLY INSTRUCTIONS·····················53

13. PARTS LIST······················································57

14. OPTIONAL PARTS····································BACK

This manual describes technical data of outdoor unit.

For indoor unit refer to the service manuals No.OB207 and OB196 REVISED EDITION Aof corresponding

models.

1

TECHNICAL CHANGES

MXZ-18LV- →MXZ-18NV-

1. Inverter assembly has changed.

2. Gas pipe thermistors were added.

3. H.P.S. has changed.

MXZ-18NV- →MXZ-18NV-

1. MSH-07NV

2. Outdoor unit electronic control P.C. board has changed.

3. The outdoor fan speed control has changed.(HEAT mode single operation : Lo → Hi)

MXZ-32AV- →MXZ-32NV-

1. The desital display self-diagnosis function has adopted.

2. The desorption method of LEV has changed the screw method to the one touch method.

3. The position of the electronical parts has changed.

4. The chargeless system has adopted.

5. The scroll compressor has adopted.

6. The micro control P.C.board has simplifed.

7. The fan speed level has becomed 3 levels (Hi / Me / Lo).

8. The low pressure switch has adopted .

9. The ditection of connector deviation has becomed easily.

MXZ-32NV- →MXZ-32NV-

1. MCFH-13NV

-

and MSH-12NV

-

and MCFH-18NV

E1E1

E2E1

E2E2

-

has been added to the combination of the connectable indoor units.

E1E2

E2E1

E2E2

-

has been added to the combination of the connectable indoor units.

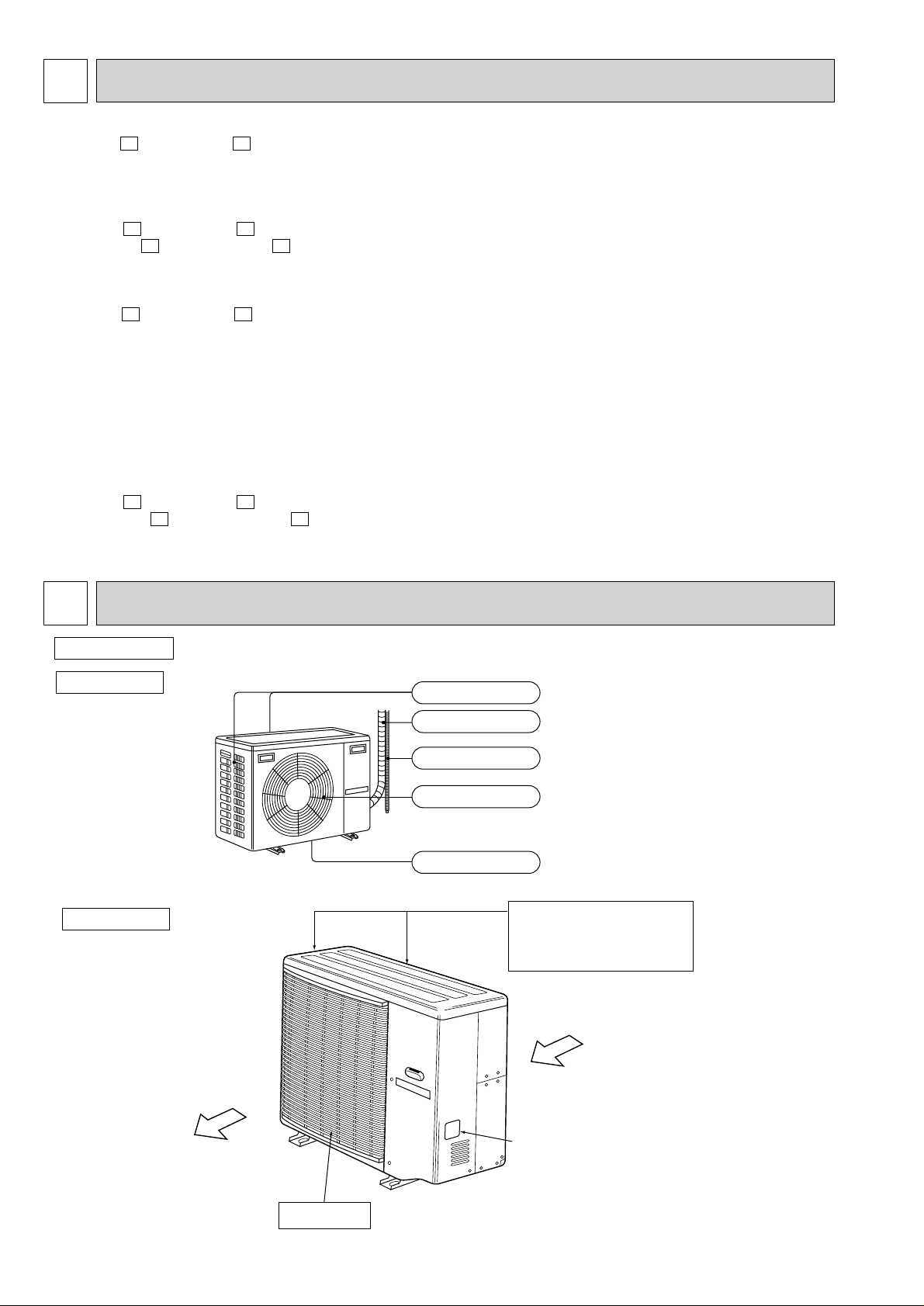

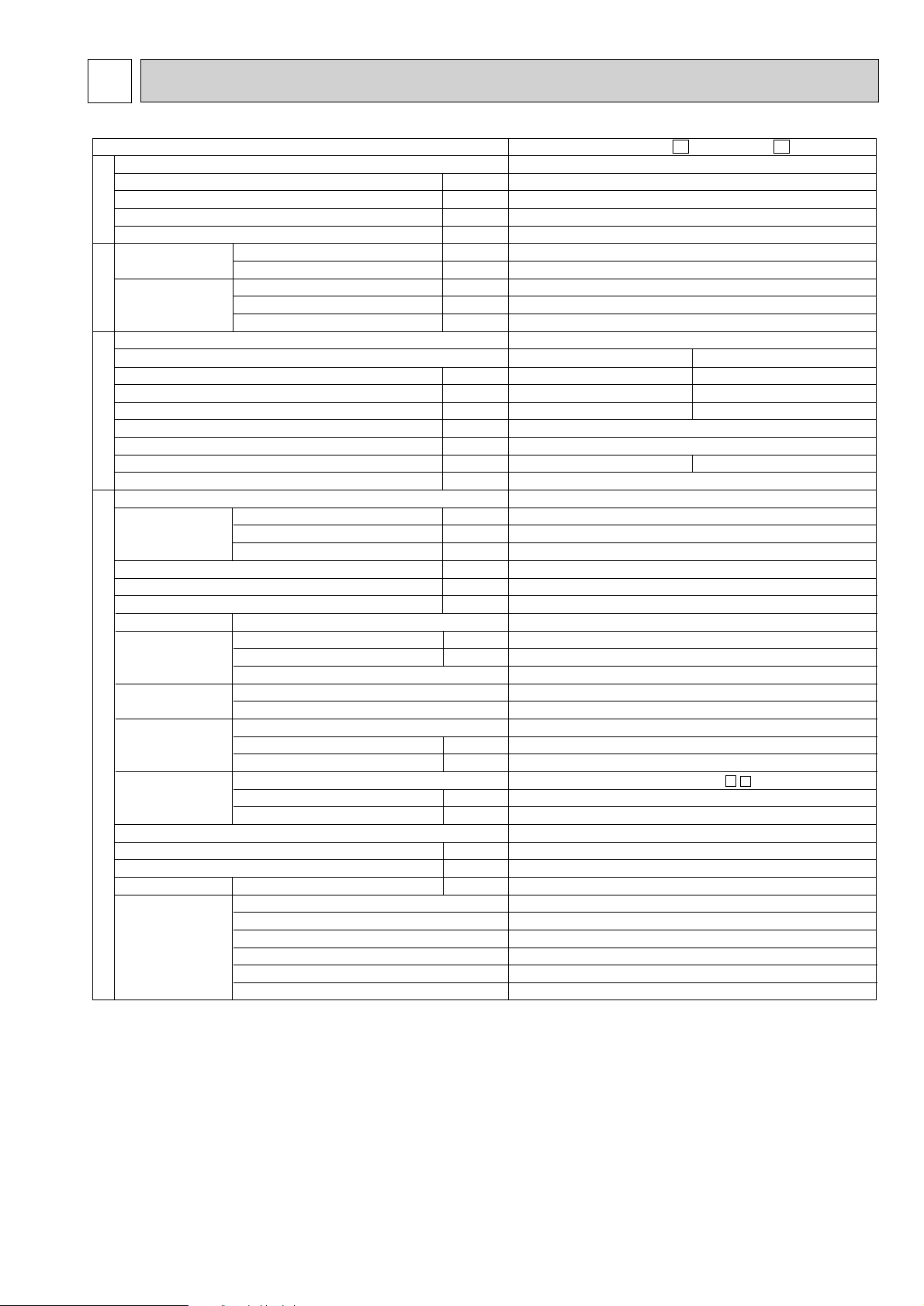

PART NAMES AND FUNCTION2

Outdoor unit

MXZ-18NV

MXZ-32NV

Air inlet

Piping

Drainage hose

Air outlet

Drain outlet

(back and side)

Air intake

Located on the back

and the left side.

Air in

Air out

Model indication

Air outlet

2

3

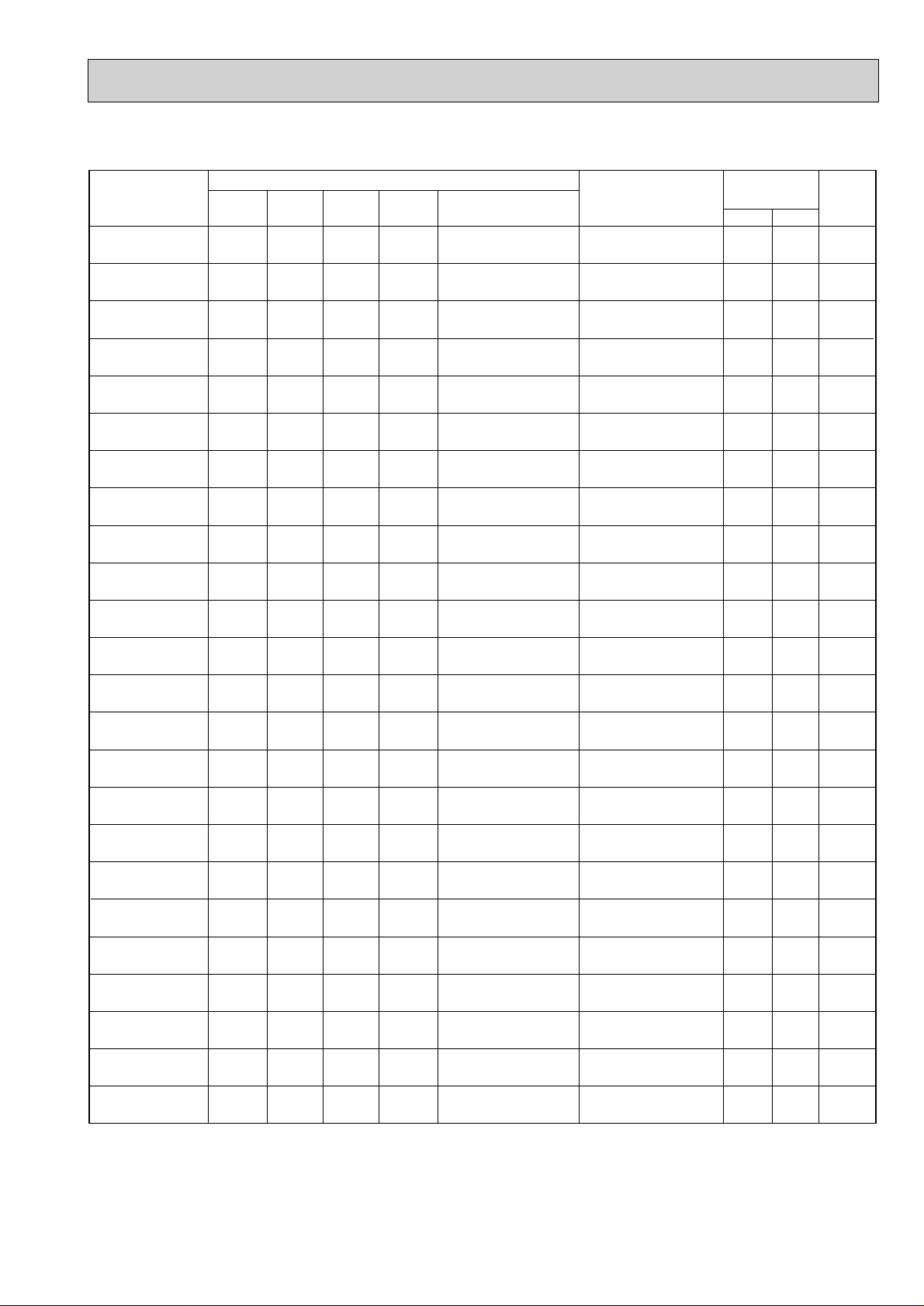

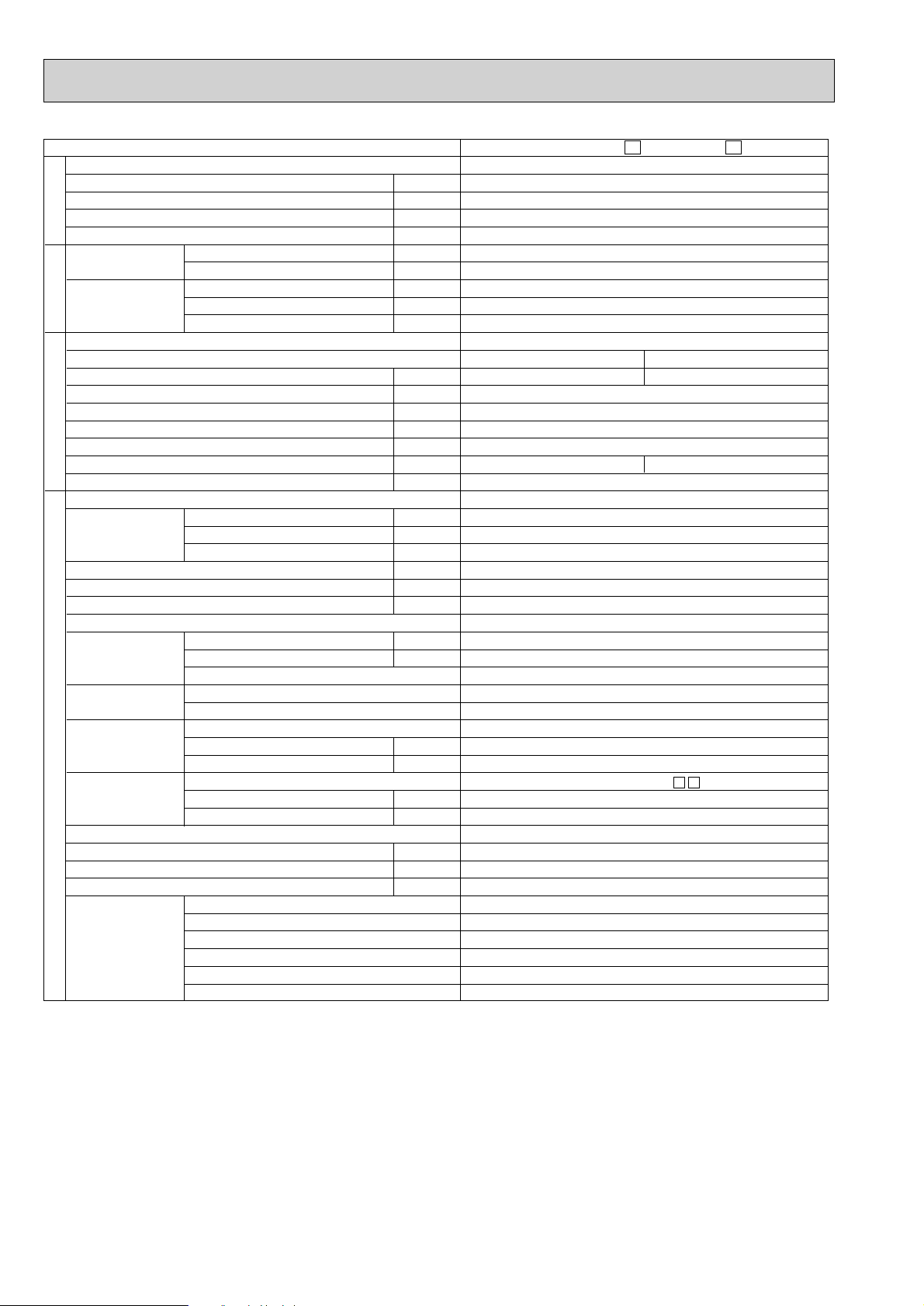

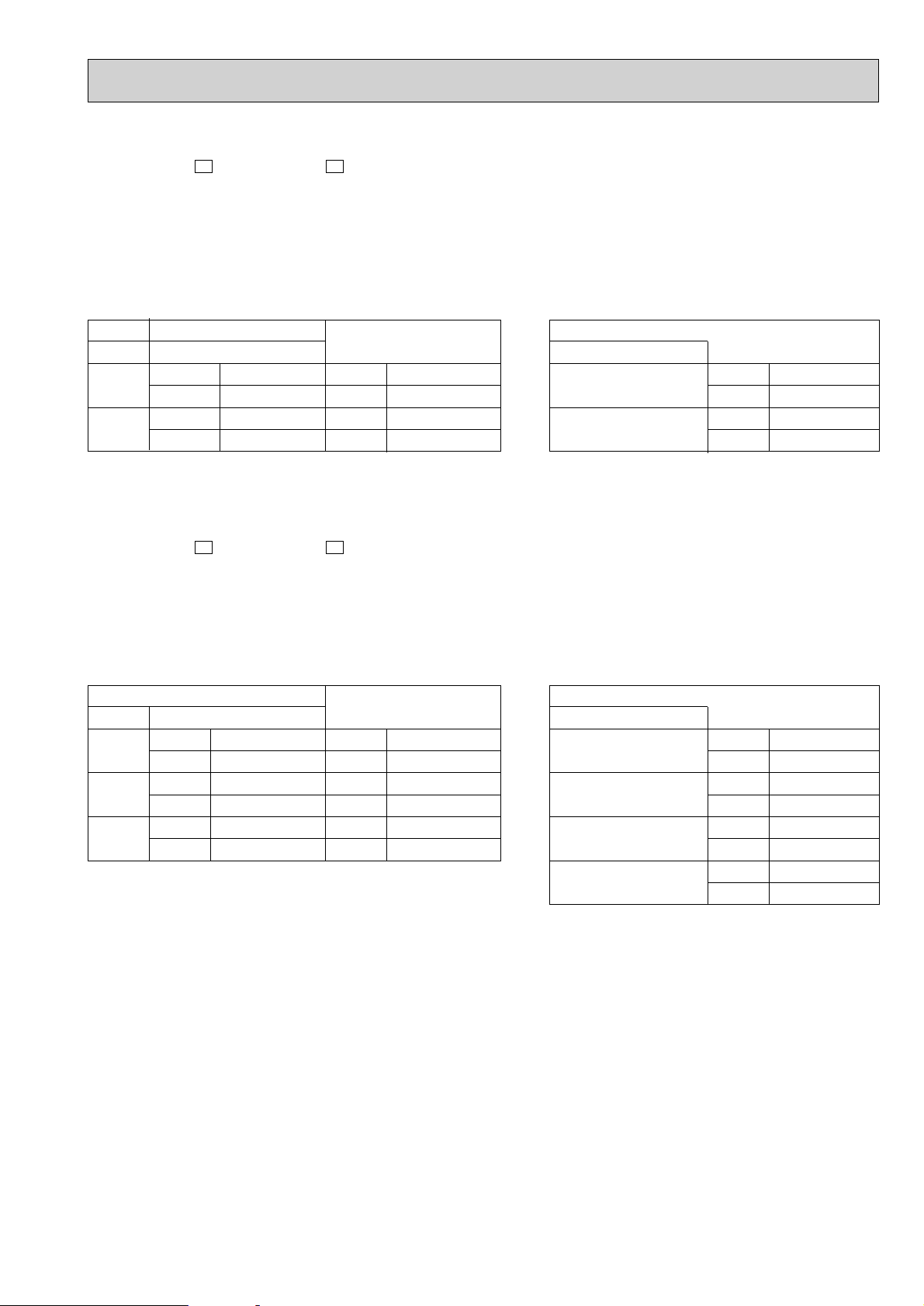

❈There is no combination other than this table.

MXZ-32NV- E2

MXZ-18NV- E2

OUTDOOR UNIT

Combination of the connectable indoor units

07+07+07

07+07+09

07+07+12

07+07+18

07+09+09

07+09+12

07+09+18

07+12+12

07+12+18

07+18+18

09+09+09

09+09+12

09+09+18

09+12+12

09+12+18

09+18+18

12+12+12

12+12+18

07+07+07+07

07+07+07+09

07+07+07+12

07+07+07+18

07+07+09+09

07+07+09+12

07+07+09+18

07+07+12+12

07+07+12+18

07+09+09+09

07+09+09+12

07+09+09+18

07+09+12+12

09+09+09+09

09+09+09+12

09+09+09+18

09+09+12+12

MXZ-32NV-

E1

07+07+07

07+07+09

07+07+(12 or 13)

07+07+18

07+09+09

07+09+(12 or 13)

07+09+18

07+(12 or 13)+(12 or 13)

07+(12 or 13)+18

07+18+18

09+09+09

09+09+(12 or 13)

09+09+18

09+(12 or 13)+(12 or 13)

09+(12 or 13)+18

09+18+18

(12 or 13)+(12 or 13)+(12 or 13)

(12 or 13)+(12 or 13)+18

07+07+07+07

07+07+07+09

07+07+07+(12 or 13)

07+07+07+18

07+07+09+09

07+07+09+(12 or 13)

07+07+09+18

07+07+(12 or 13)+(12 or 13)

07+07+(12 or 13)+18

07+09+09+09

07+09+09+(12 or 13)

07+09+09+18

07+09+(12 or 13)+(12 or 13)

09+09+09+09

09+09+09+(12 or 13)

09+09+09+18

09+09+(12 or 13)+(12 or 13)

OUTDOOR UNIT

09+09

-

MXZ-18NV- E1

09+09

07+12

INDOOR / OUTDOOR CORRESPONDENCE TABLE

MXZ-18NV

MXZ-32NV

3

4

Outdoor unit

power consumption

(kW)

07

09

12

07+12

09+09

Indoor units

combination

Unit B

Unit A

Cooling capacity (kW)

Total

220V 240V

Current

(A)

Power

factor

(%)

2.3

2.5

3.4

2.0

2.25

-

-

-

2.5

2.25

2.3

(1.6 - 2.8)

2.5

(1.7 - 3.0)

3.4

(1.8 - 3.8)

4.5

(2.0 - 4.5)

4.5

(1.9 - 4.5)

1.02

(0.855 - 1.33)

1.05

(0.855 - 1.36)

1.45

(0.855 - 1.63)

2.00

(0.91- 2.00)

2.00

(0.91 - 2.00)

5.20

5.36

7.40

10.21

10.21

89 - 90

89 - 90

89 - 90

89 - 90

89 - 90

4.72

4.86

6.71

9.26

9.26

Outdoor unit

power consumption

(kW)

07

09

12

07+12

09+09

Indoor units

combination

Unit B

Unit A

Heating capacity (kW)

Total

220V 240V

Current

(A)

Power

factor

(%)

3.3

3.6

4.0

2.7

2.9

-

-

-

3.1

2.9

3.3

(2.0 - 4.0)

3.6

(2.0 - 4.5)

4.0

(2.2 - 4.7)

5.8

(2.1 - 5.8)

5.8

(2.0 - 5.8)

1.45

(0.69 - 1.60)

1.47

(0.69 - 1.62)

1.63

(0.69 - 1.69)

1.785

(0.69 - 1.785)

1.785

(0.69 - 1.785)

7.40

7.50

8.32

9.02

9.02

89 - 90

89 - 90

89 - 90

90 - 90

90 - 90

6.71

6.80

7.54

8.26

8.26

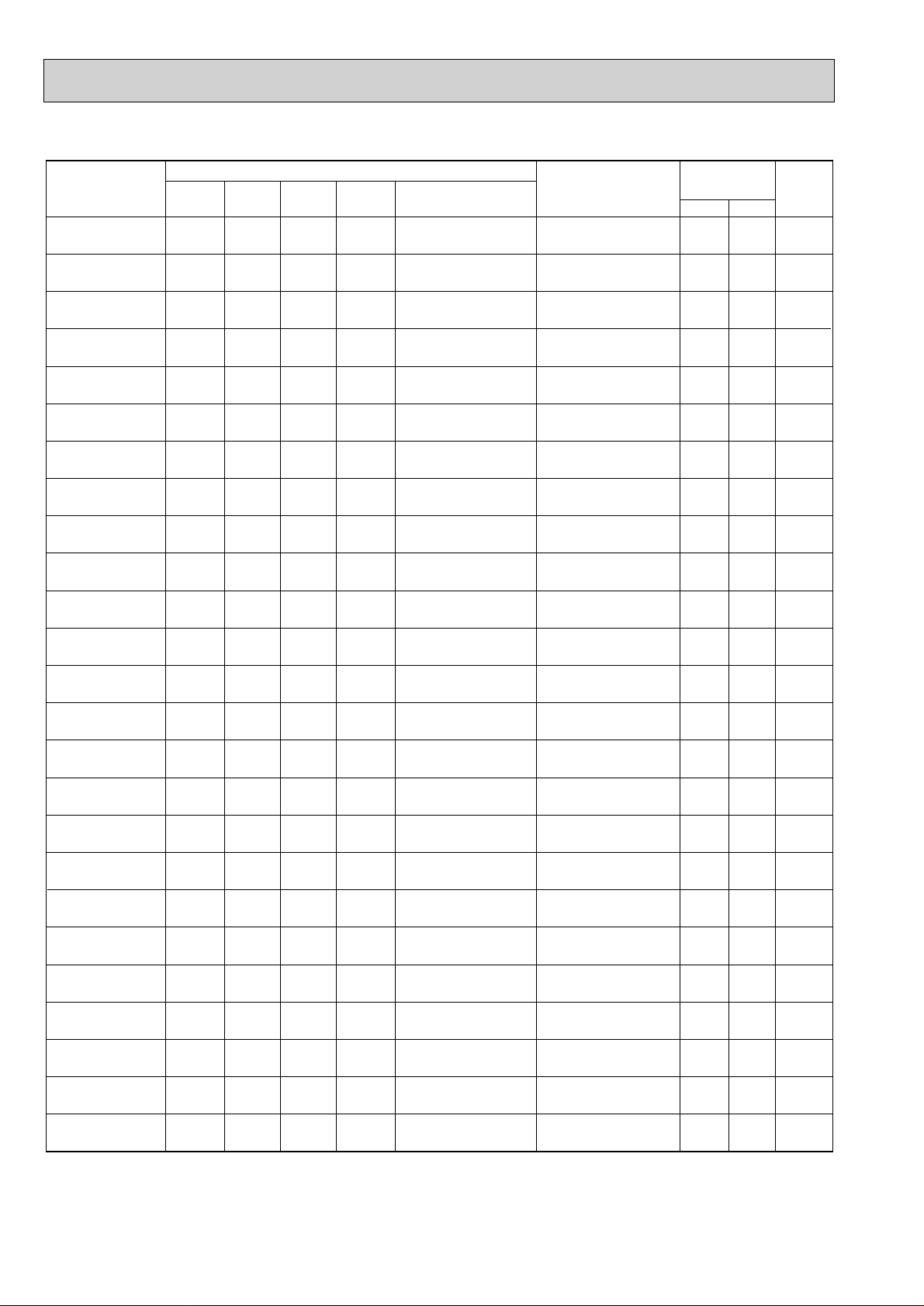

INDOOR UNITS COMBINATION

MXZ-18NV

NOTE:Electrical data is for outdoor unit only.

4

MXZ-32NV

Indoor units

combination

07

09

12(13)

18

07+07

07+09

07+12(13)

07+18

09+09

09+12(13)

09+18

12(13)+12(13)

12(13)+18

18+18

07+07+07

07+07+09

07+07+12(13)

07+07+18

07+09+09

07+09+12(13)

07+09+18

07+12(13)+12(13)

07+12(13)+18

07+18+18

Heating capacity (kw)

Unit A Unit B Unit C Unit D

2.2

2.8

4.0

5.0

2.2

2.2

2.2

2.2

2.8

2.8

2.8

4.0

3.5

4.0

2.2

2.2

2.1

1.9

2.2

1.9

1.7

1.8

1.6

1.5

-

-

-

-

2.2

2.8

4.0

5.0

2.8

4.0

5.0

4.0

4.5

4.0

2.2

2.2

2.1

1.9

2.8

2.5

2.3

3.1

2.8

3.25

-

-

-

-

-

-

-

-

-

-

-

-

-

-

2.2

2.8

3.8

4.2

2.8

3.6

4.0

3.1

3.6

3.25

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Total

2.2

(1.8-2.7)

2.8

(1.8-3.2)

4.0

(2.2-4.5)

5.0

(2.2-5.4)

4.4

(3.0-5.4)

5.0

(3.0-6.0)

6.2

(3.0-7.2)

7.2

(3.0-7.6)

5.6

(3.0-6.4)

6.8

(3.0-7.6)

7.8

(3.0-8.6)

8.0

(3.0-8.8)

8.0

(3.0-8.8)

8.0

(3.0-8.8)

6.6

(3.7-8.1)

7.2

(3.7-8.5)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

7.8

(3.7-8.8)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

NOTE: Electrical data is for outdoor unit only.

Outdoor unit

power consumption

(kw)

1.00

(0.96-1.14)

1.77

(0.96-1.36)

1.42

(1.00-1.63)

1.84

(1.00-1.99)

1.63

(1.30-2.03)

1.88

(1.30-2.23)

2.38

(1.30-2.98)

2.74

(1.30-2.98)

2.13

(1.30-2.43)

2.63

(1.30-2.88)

3.29

(1.30-3.60)

3.38

(1.30-3.60)

3.38

(1.30-3.60)

3.38

(1.30-3.60)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

Current

(A)

220V 240V

5.05

5.91

7.17

9.29

8.23

9.49

12.02

13.84

10.76

12.18

16.62

17.07

17.07

17.07

17.07

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

4.63

5.42

6.57

8.52

7.55

8.70

11.09

12.69

9.86

12.18

15.23

15.65

15.65

15.65

15.65

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

Power

factor

(%)

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

5

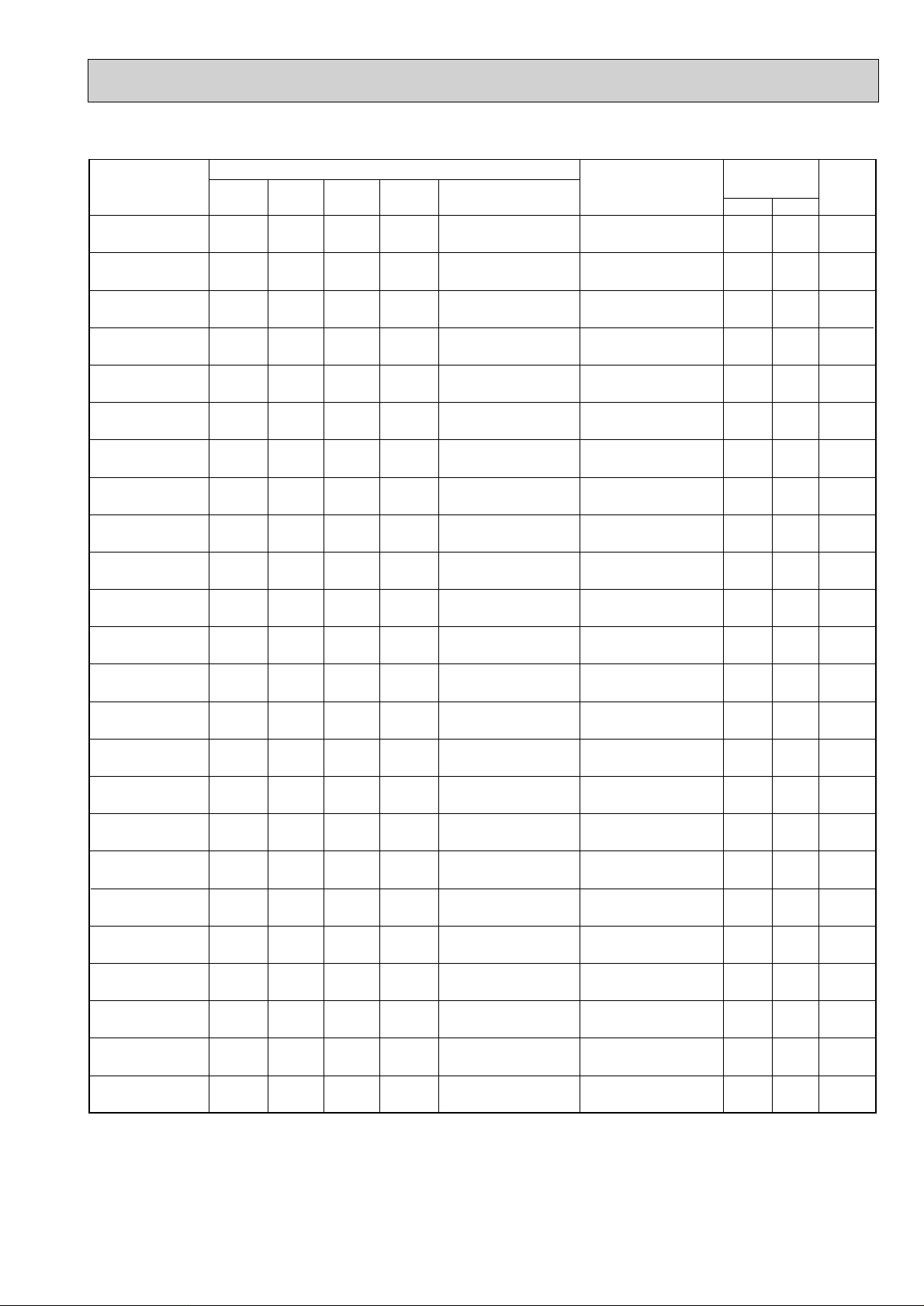

Indoor units

combination

Unit A Unit B Unit C Unit D

Heating capacity (kw)

Total

Outdoor unit

power consumption

(kw)

Current

(A)

Power

factor

(%)

220V 240V

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

14.95

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

16.31

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

8.0

(3.7-9.0)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

3.23

(1.30-3.96)

-

-

-

-

-

-

-

-

2.0

2.4

2.9

3.5

2.2

2.8

3.2

2.6

3.0

2.1

2.7

3.1

2.45

2.0

2.6

3.0

2.35

2.67

3.4

3.8

3.0

3.4

3.1

2.67

3.1

2.0

1.87

1.7

1.5

2.2

2.0

1.8

2.6

2.4

2.1

1.9

1.75

2.45

2.0

1.8

1.67

2.35

2.67

2.3

2.1

2.0

1.9

1.8

2.67

2.45

2.0

1.87

1.7

1.5

1.8

1.6

1.5

1.4

1.3

1.7

1.5

1.4

1.35

2.0

1.8

1.67

1.65

2.67

2.3

2.1

3.0

2.7

3.1

2.67

2.45

2.0

1.87

1.7

1.5

1.8

1.6

1.5

1.4

1.3

2.1

1.9

1.75

1.75

2.0

1.8

1.67

1.65

09+09+09

09+09+12(13)

09+09+18

09+12(13)+12(13)

09+12(13)+18

09+18+18

12(13)+12(13)

+12(13)

12(13)+12(13)+18

07+07+07+07

07+07+07+09

07+07+07+12(13)

07+07+07+18

07+07+09+09

07+07+09+12(13)

07+07+09+18

07+07+12(13)

+12(13)

07+07+12(13)+18

07+09+09+09

07+09+09+12(13)

07+09+09+18

07+09+12(13)

+12(13)

09+09+09+09

09+09+09+12(13)

09+09+09+18

09+09+12(13)

+12(13)

NOTE: Electrical data is for outdoor unit only.

6

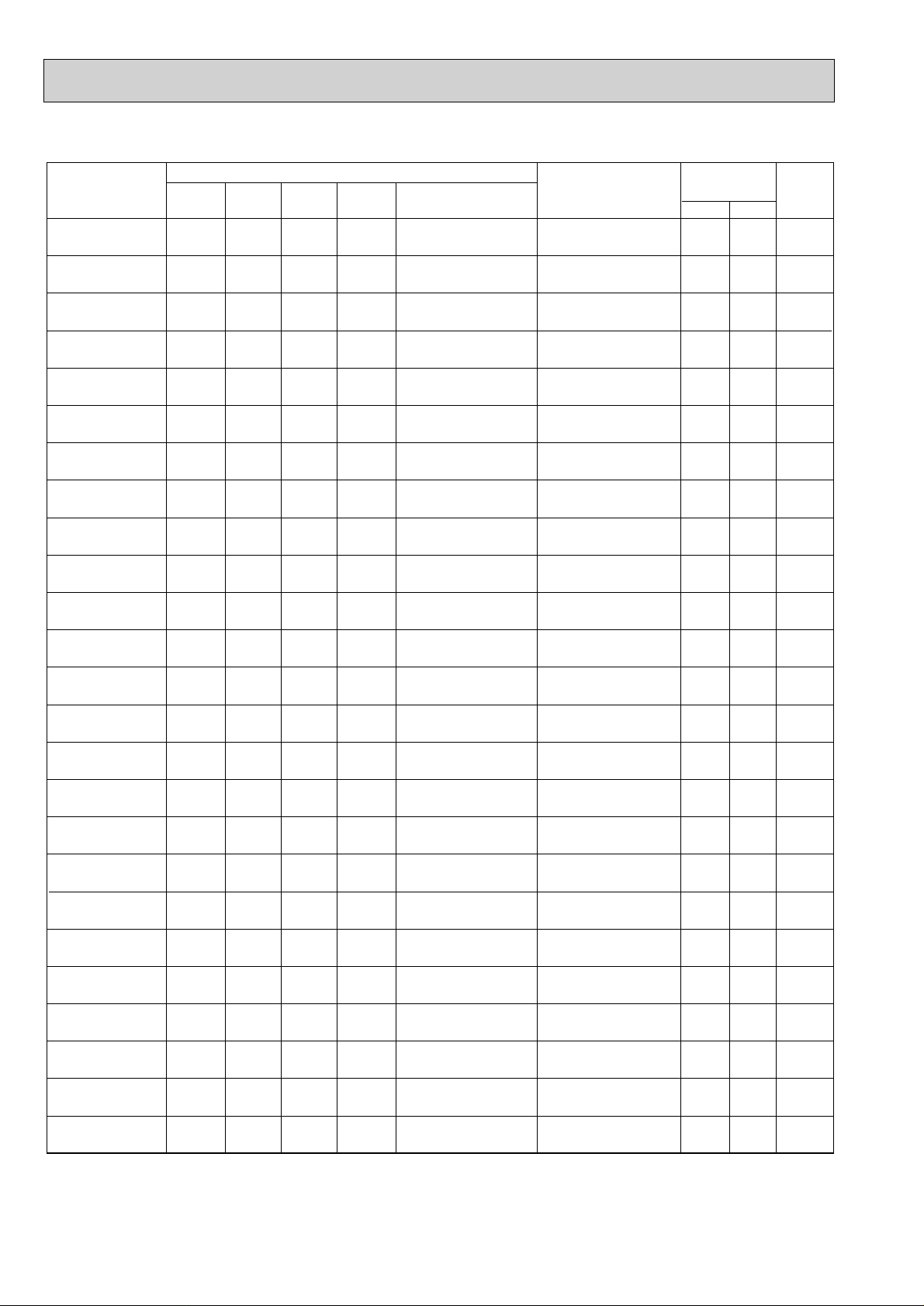

Indoor units

combination

07

09

12(13)

18

07+07

07+09

07+12(13)

07+18

09+09

09+12(13)

09+18

12(13)+12(13)

12(13)+18

18+18

07+07+07

07+07+09

07+07+12(13)

07+07+18

07+09+09

07+09+12(13)

07+09+18

07+12(13)+12(13)

07+12(13)+18

07+18+18

Heating capacity (kw)

Unit A Unit B Unit C Unit D

3.4

4.0

6.0

7.1

3.4

3.4

3.35

2.85

4.0

3.7

3.35

4.65

4.3

4.65

3.1

2.95

2.5

2.3

2.8

2.4

2.2

2.0

1.9

1.9

-

-

-

-

3.4

4.0

5.95

6.45

4.0

5.6

5.95

4.65

5.0

4.65

3.1

2.95

2.5

2.3

3.25

2.8

2.6

3.65

3.4

3.75

-

-

-

-

-

-

-

-

-

-

-

-

-

-

3.1

3.4

4.3

4.7

3.25

4.1

4.5

3.65

4.0

3.75

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Total

3.4

(2.1-3.6)

4.0

(2.1-4.2)

6.0

(2.2-6.3)

7.1

(2.2-7.5)

6.8

(4.1-7.2)

7.4

(4.1-7.8)

9.3

(4.1-9.7)

9.3

(4.1-9.7)

8.0

(4.1-8.4)

9.3

(4.1-9.7)

9.3

(4.1-9.7)

9.3

(4.1-9.7)

9.3

(4.1-9.7)

9.3

(4.1-9.7)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

NOTE: Electrical data is for outdoor unit only.

Outdoor unit

power consumption

(kw)

1.20

(0.91-1.28)

1.43

(0.91-1.51)

1.79

(0.94-1.88)

2.10

(0.94-2.21)

1.98

(1.13-2.18)

2.23

(1.13-2.33)

2.82

(1.13-2.96)

2.82

(1.13-2.96)

2.38

(1.13-2.54)

2.82

(1.13-2.96)

2.82

(1.13-2.96)

2.82

(1.13-2.96)

2.82

(1.13-2.96)

2.82

(1.13-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-3.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-3.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

Current

(A)

220V 240V

6.06

7.22

9.04

10.61

10.00

11.26

14.24

14.24

12.02

14.24

14.24

14.24

14.24

14.24

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

5.55

6.62

8.29

9.72

9.17

10.32

13.05

13.05

11.01

13.05

13.05

13.05

13.05

13.05

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

Power

factor

(%)

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

7

Indoor units

combination

Unit A Unit B Unit C Unit D

Heating capacity (kw)

Total

Outdoor unit

power consumption

(kw)

Current

(A)

Power

factor

(%)

220V 240V

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

90

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

12.87

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

14.04

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

9.3

(5.2-10.6)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

2.78

(1.19-2.96)

-

-

-

-

-

-

-

-

2.32

2.7

3.3

3.6

2.5

3.3

3.7

2.95

3.3

2.4

3.2

3.6

2.9

2.32

3.15

3.45

2.8

3.1

4.0

4.4

3.5

3.8

3.65

3.1

3.58

2.32

2.2

2.0

1.9

2.5

2.2

2.1

2.95

2.8

2.4

2.15

2.0

2.9

2.32

2.05

1.95

2.8

3.1

2.65

2.45

3.5

3.3

3.65

3.1

2.86

2.32

2.2

2.0

1.9

2.15

1.9

1.75

1.7

1.6

2.4

2.15

2.0

1.9

2.32

2.05

1.95

1.85

3.1

2.65

2.45

2.3

2.2

2.0

3.1

2.86

2.32

2.2

2.0

1.9

2.15

1.9

1.75

1.7

1.6

2.1

1.8

1.7

1.6

2.32

2.05

1.95

1.85

09+09+09

09+09+12(13)

09+09+18

09+12(13)+12(13)

09+12(13)+18

09+18+18

12(13)+12(13)

+12(13)

12(13)+12(13)+18

07+07+07+07

07+07+07+09

07+07+07+12(13)

07+07+07+18

07+07+09+09

07+07+09+12(13)

07+07+09+18

07+07+12(13)

+12(13)

07+07+12(13)+18

07+09+09+09

07+09+09+12(13)

07+09+09+18

07+09+12(13)

+12(13)

09+09+09+09

09+09+09+12(13)

09+09+09+18

09+09+12(13)

+12(13)

NOTE: Electrical data is for outdoor unit only.

8

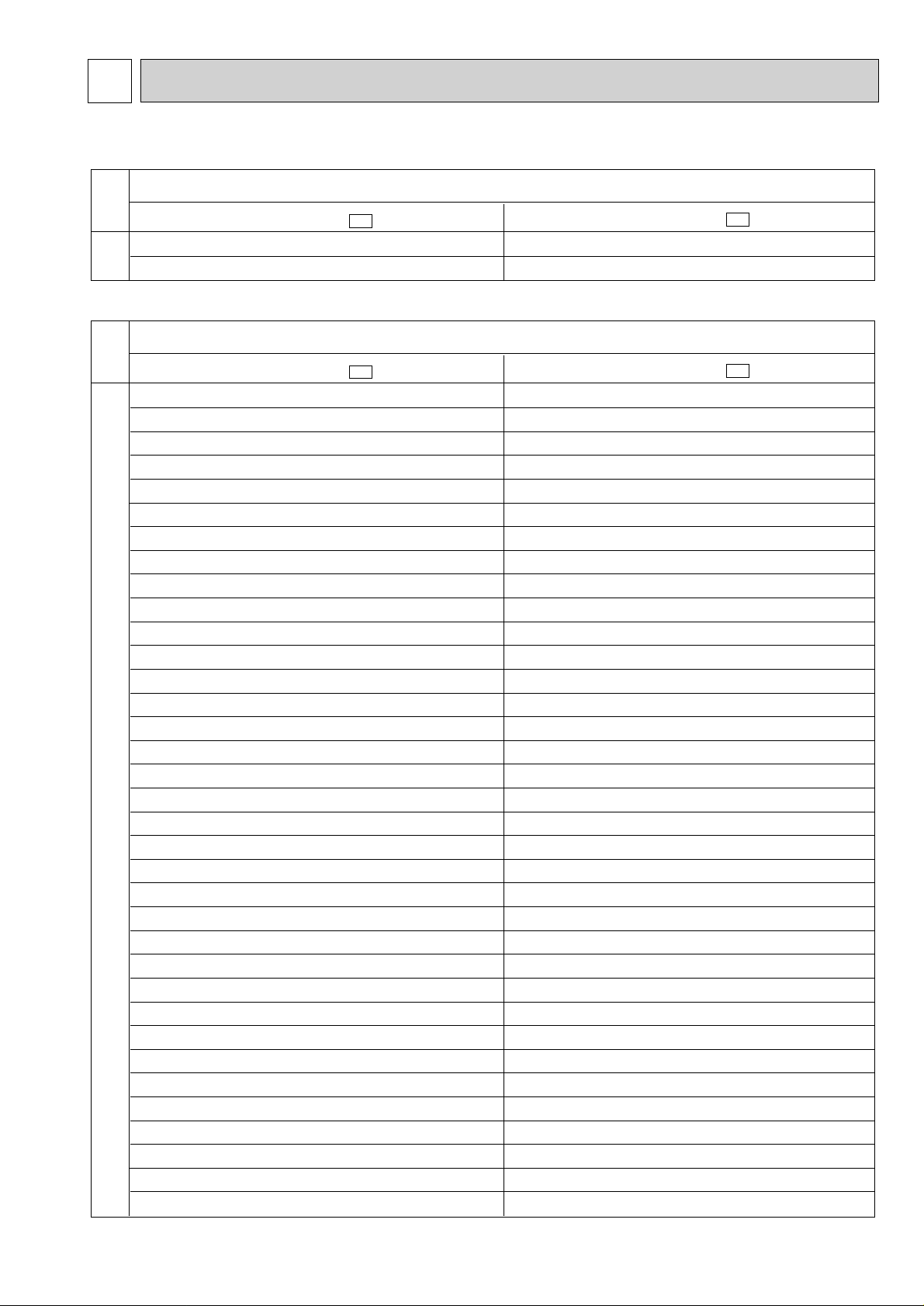

5

Indoor units number

Piping total length

Connecting pipe length

Height difference (indoor ~ outdoor)

Height difference (indoor ~ indoor)

Cooling

Heating

Power supply

Mode

Power consumption

Running current

Power factor

Crankcase heater

Starting current

Compressor motor current

Fan motor current

External finish

Dimensions

Weight

Refrigerant filling capacity (R-22)

Refrigerating oil <Model>

In/Out connecting wire (Each room)

Refrigerant

piping

Protective

device

Compressor

Fan motor

Air flow amount change

Fan speed

Air flow

Power outlet

Thermistor

Model

m

m

m

m

kW

dB

kW

W

dB

W

A

%

W

A

A

A

mm

mm

mm

kg

kg

cc

mm

mm

W

"

W

"

rpm

K/h

A

Capacity

Sound level

Capacity

Booster heater

Sound level

Height

Width

Depth

Liquid pipe

Gas pipe

Connection method

Compressor

Fan motor

Model

Output

Winding resistance (at 20 :)

Model

Output

Winding resistance (at 20 :)

RT61 (at 25:)

RT62 (at 100:)

RT63 (at 70:)

RT64 (at 25:)

RT65 (at 25:)

RT66, 67 (at 25:)

Capacity System

Electrical data ✻ 1

Outdoor unit

2

Max. 30

Max. 20

Max. 7

Max. 7

4.5 (1.7 ~ 4.5)

45

5.8 (2.0 ~ 5.8)

-

46

Single phase, 220-240V, 50Hz

-

10.21

0.4

Munsell 5Y 7/1

650

875

295 (+30)

56

1.3

570cc <MS-56>

2-core, 1pc. [2.0mm

[9.52 (2pcs)

[6.35 (2pcs)

Flared

✻ 2

Inner thermostat

RHV-207FEM (Rotary)

1,100

1.195(U-V, V-W, W-U)

RA6V50 -

50

BLK-WHT 163, BLK-YLW 72, YLW-RED 36

2

630-670

2,460 - 2,580

25

10.0k"

13.4k"

7.9k"

10.0k"

10.0k"

10.0k"

MXZ-18NV-

E1

MXZ-18NV-

E2

Cooling

2,000 (855~2000)

10.21(5.28 - 10.21) - 9.26(4.83 - 9.26)

89 - 90

9.74(4.87 - 9.74) - 8.86(4.43 - 8.86)

Heating

1,785 (690~1785)

9.02(6.38 - 9.02) - 8.26(5.83 - 8.26)

90 - 90

8.62(5.98 - 8.62) - 7.86(5.43 - 7.86)

SPECIFICATION

TEST CONDITIONS COOLING INDOOR DB27.0°C WB19.0°C

HEATING INDOOR DB20.0°C

✽1 Electrical data is for only outdoor unit.

OUTDOOR DB35.0°C WB24.0°C

OUTDOOR DB 7.0°C WB 6.0°C

✽2 Current detection

Discharge temperature detection

High-pressure switch

9

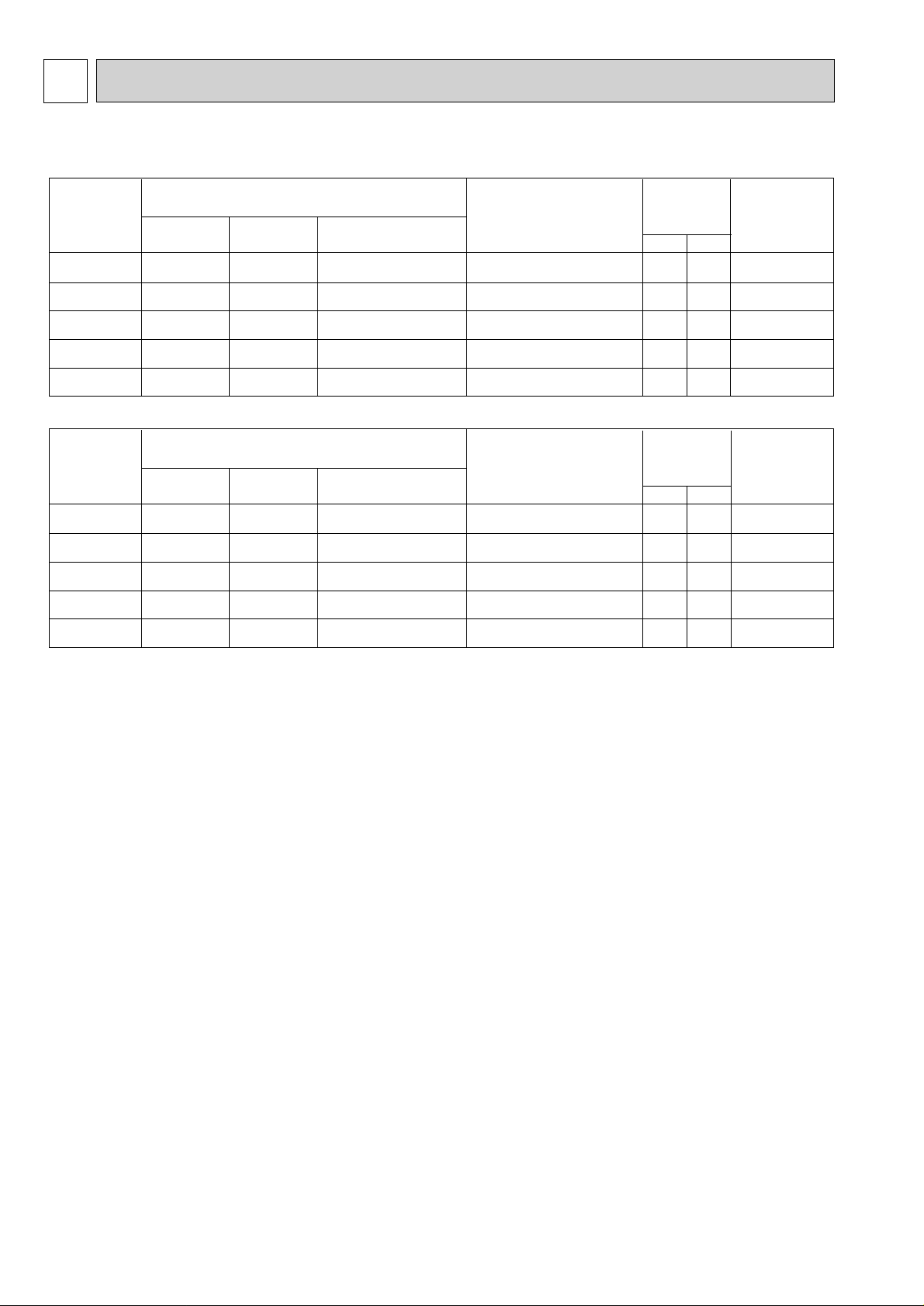

Indoor units number

Piping total length

Connecting pipe length

Height difference (indoor ~ outdoor)

Height difference (indoor ~ indoor)

Cooling

Heating

Power supply

Mode

Power consumption

Running current

Power factor

Crankcase heater

Starting current

Compressor motor current

Fan motor current

External finish

Dimensions

Weight

Refrigerant filling capacity (R-22)

Refrigerating oil <Model>

In/Out connecting wire (Each room)

Refrigerant

piping

Protective

device

Compressor

Fan motor

Air flow amount change

Fan speed

Air flow

Power outlet

Thermistor

Model

m

m

m

m

kW

dB

kW

W

dB

W

A

%

W

A

A

A

mm

mm

mm

kg

kg

cc

mm

mm

W

"

W

"

rpm

K/h

A

Capacity

Sound level

Capacity

Booster heater

Sound level

Height

Width

Depth

Liquid pipe

Gas pipe

Connection method

Compressor

Fan motor

Model

Output

Winding resistance (at 20 :)

Model

Output

Winding resistance (at 20 :)

RT61 (at 100:)

RT62 (at 25:)

RT63 (at 50:)

RT64 (at 25:)

RT65 (at 25:)

RT70,66, 67,68,69 (at 25:)

Capacity System

Electrical data ✻ 1

Outdoor unit

3-4

Max. 60

Max. 25

Max. 10

Max. 10

8.0 (1.8 ~ 9.0)

45-47

9.3 (2.1 ~ 10.6)

-

46-48

Single phase, 220-240V, 50Hz

16.31(4.85 - 20.00) - 14.95(4.44 - 18.33)

90

25

16.31 - 14.95

0.4

Munsell 5Y 8/1

900

900

320 (+35)

83.5

4.2

1070cc <MS-32>

2-core, 1pc. [2.0mm

[12.7 (2pcs) [9.52 (2pcs)

[6.35 (4pcs)

Flared

✻ 2

Inner thermostat

CHV253FAA (Scroal)

2,000

0.54(U-V, V-W, W-U)

RA6V60-

60

BLK-WHT 79.0, BLK-YLW 27.0, YLW-BLU 12.0 BLU-RED 84.0

3

630 - 680 / 525 - 570 / 460 - 500

3000 / 2400 / 2100

25

13.4k"

10.0k"

17.0k"

10.0k"

10.0k"

10.0k"

Cooling

3,230 (960~3,960)

15.71(4.25 - 19.40) - 14.35(3.84 - 17.73)

Heating

2,780 (910~2,960)

13.44(4.00 - 14.35) - 12.27(3.62 - 13.10)

MXZ-32NV-

E1

MXZ-32NV-

E2

TEST CONDITIONS COOLING INDOOR DB27.0°C WB19.0°C

✽1 Electrical data is for only outdoor unit.

OUTDOOR DB35.0°C WB24.0°C

HEATING INDOOR DB20.0°C

OUTDOOR DB 7.0°C WB 6.0°C

✽2 Current detection

Discharge temperature detection

High-pressure switch

Crankcase heater

Low-pressure switch

Inner thermostat

10

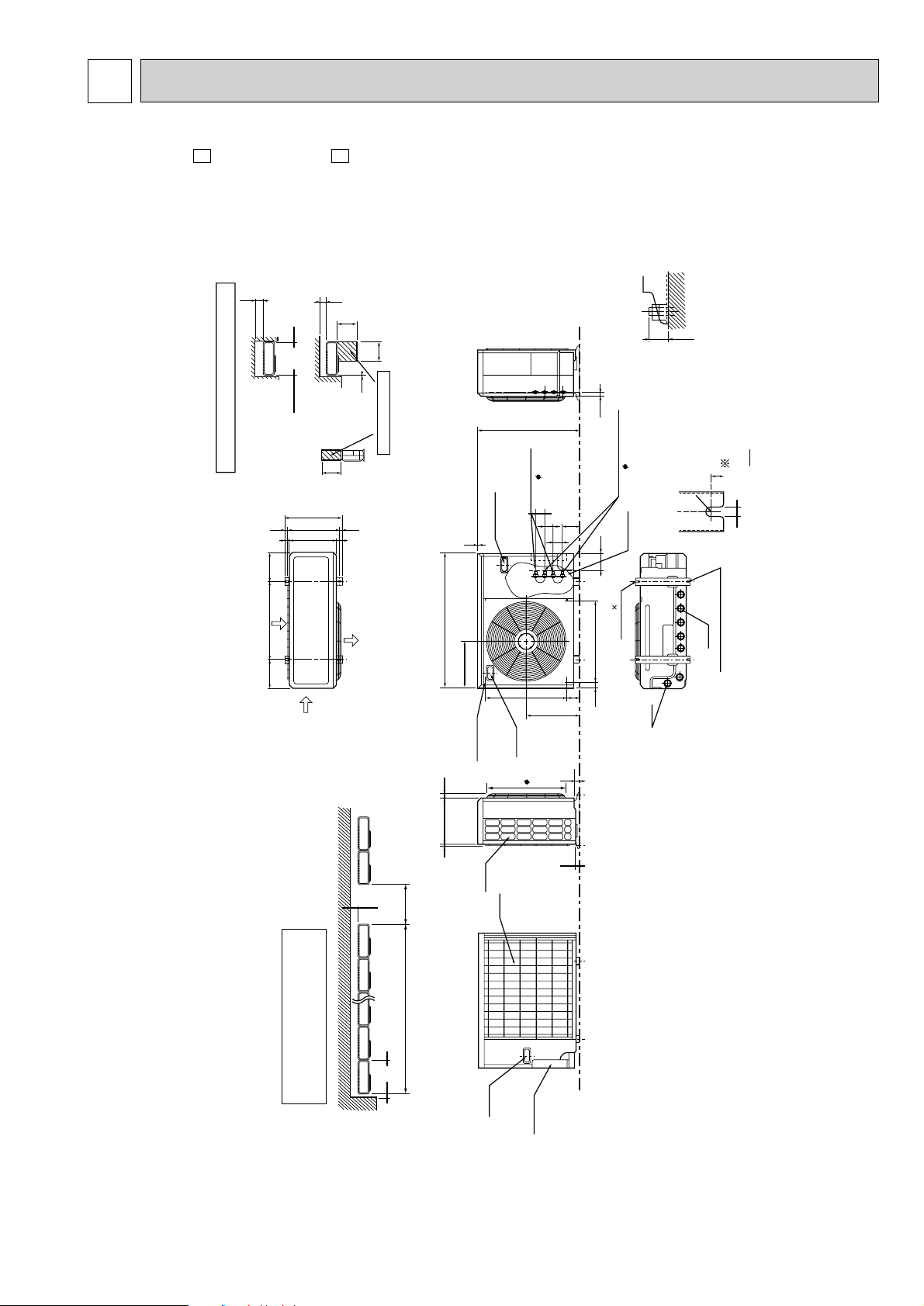

6 OUTLINES AND DIMENSIONS

Necessary surrounding clearance

Necessary surrounding clear-

ance for concentrated installa-

tion.

Leave overhead clearance fully

100

Handle for

monving

200

1000

2957

23

Max. 25

Base bolt length

To drain water in a mass, use

optional drain pan and drain

socket.

Drain pan : PAC-928DP,PAC-SA44DP

Drain socket : PAC-SA46DS

Drain hole

Drain hole

(Base bolt M10)

(Base bolt M10)

2 Oval hols (12 13)

2-U-Shape noched hols

33

524

339

302

524

77

2

25

12

17

R6

40

116

A

B

57

107

57

57

505

30 870

650

10

Max. 10 units

Air in

Air in

Air out

185 185500

362

10

10

500

500

100

500

10

200

330

39.5 27.5

1715

Leave front clearance fully

Space for servicing

Leave overhead

clearance fully

Rear piping

hole

Rear

air-intake

Side

air-intake

Handle for

moving

Handle for moving

Liquid pipe

(flared 6.35)

Ground

terminal

Outlet guide

mounting hole

Gas pipe

(flared 9.52)

MXZ-18NV - MXZ-18NV -

E2E1

Unit:mm

11

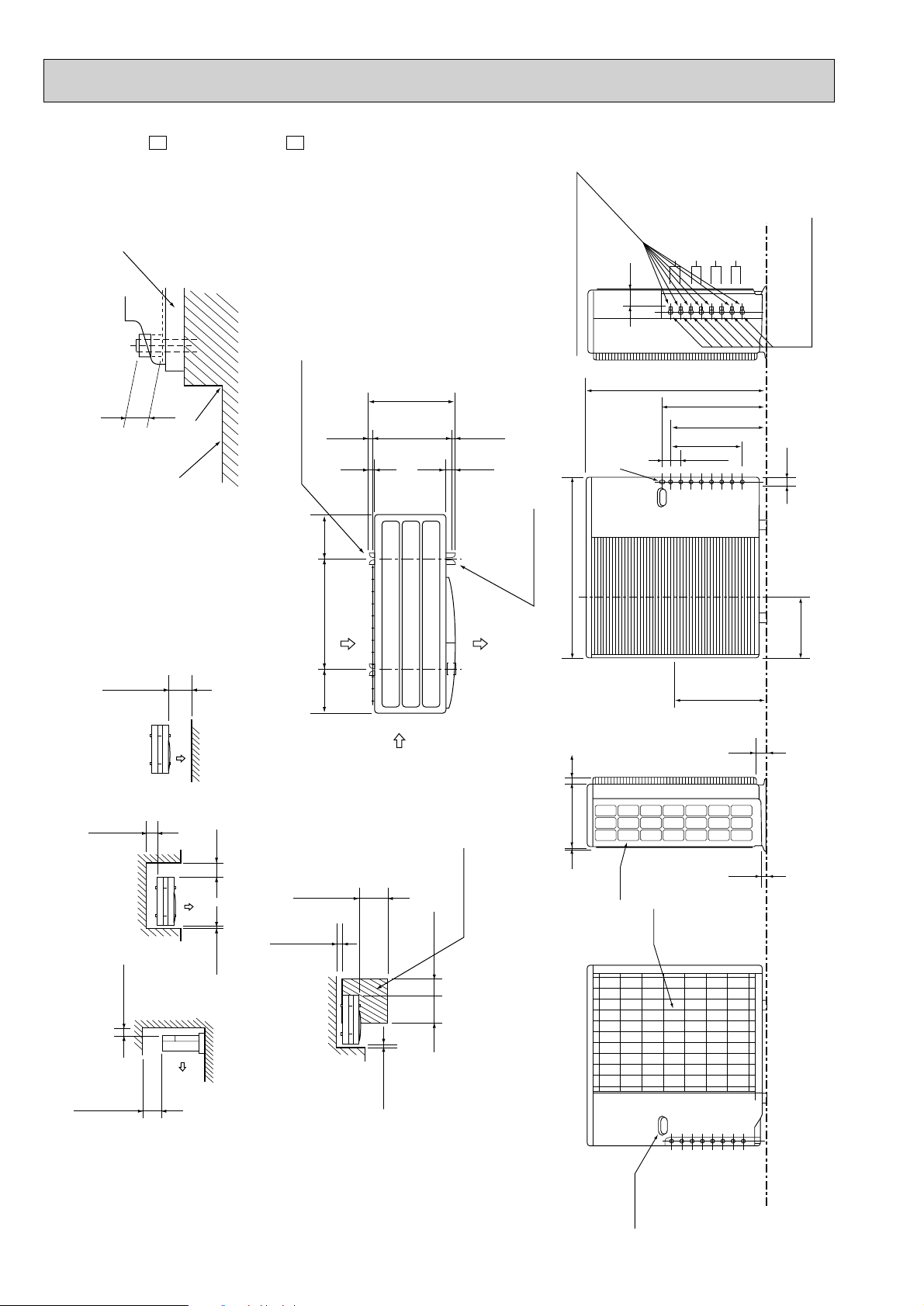

MXZ-32NV - MXZ-32NV -

1.Installation space

2.Service space

More than

100

More than

200

More than

100

More than

500

More than

500

More than

10

More than

10

More than

500

Base bollt length

Less than

25

More than

350

More than

350

Service space

Air in

2-U-shape notched holes

(Base bolt M10)

(Base bolt M10)

Air in

Air out

200 200

387

355

27 40

(16) (16)

500

Veranda

Base

Rubber cushion

More than

500

Note : Leave front and both sides

clearance fully.

Note : Leave front and overhead

clearance fully.

Note : Leave front, overhead and

both clearance fully.

2-12 ✕ 36 Oval hole

23

10 35320

900

88

460

50

900

350.0

480.8

531.3

317

23

33

Handle for

moving

Air in

Indoor and outdoor

connect wiring

Air in

23✕45 hole

D unit connection

C unit connection

B unit connection

A unit connection

6.35 (flared) 1/4

Liquid pipe

12.7 (flared) 1/2 (A , B unit)

9.52 (flared) 3/8 (C , D unit)

[[[

E2E1

Unit:mm

12

7

CIRCUIT BREAKER

DC24V

DC24V

TB

TO

INDOOR

UNIT

CONNECTING

DS61

NF61

INDOOR

UNIT (A)

POWER SUPPLY

220-240V

~/N

50Hz

INDOOR

UNIT (B)

TB

NF62

C61

C64

C63

L61

R64

X64

CT61

NR61

AR61

RELAY P.C.BOARD

N

3

N

3

L

N

LDE1

LD62

F62

3

4

1

2

LD77

LD74

LD73LD71

LD72

3

4

2

1

TB62

TB61

LD61

34

LD63

CN941

BRN

GRN/YLW

BLU

RED

BLU

BLU

RED

BLU

BLU

BLU

RED

BLK

WHT

WHT

GRN

BLU

BRN

BLK

YLW

BRN

RED

YLW

YLW

BLU

RED

BRN

RED

T801

C67

LEV A LEV B

1

2

3

4

FUSE1

CN801

CN761

CN601 CN611

TBAC1

TBAC2

BLU

ORN

YLW

WHT

RED

BLK

BLK

WHT

BLU

BLK

ORN

RED

BLK

BLU

BLU

ORN

YLW

WHT

RED

RT64 RT65

SSR61

RT66 RT67 RT61RT62 RT63

6

5

54321543216

321

2

3

4

1

CN682CN771

BLK

BLK

R65

W

V

UP

N

EwN

BwN

EvN

BvN

EuN

BuN

BwPBvPBuP

BLU

RED

RED

WHT

BLK

RED

WHT

BLK

21S4

RED

RED

X67

X60

HPS

CN683

CN63

CN701

CN671CN641CN681CN661

BLK

WHT

ORN

GRY

GRY

GRY

GRY

BLK

BLK

GRY

GRY

GRY

GRY

GRY

GRY

RED

RED

GRN

YLW

RED

BLU

YLW

RED

BRN

RED

ORN

YLW

GRN

BLU

L

MF

MC

V

WU

WHT WHT

C65

ELECTRONIC CONTROL

P.C.BOARD

12 12 2 4321

8

7

6

5

11

FUSE2

TAB91

CN731

CN621

LD64

BLK

+-

~+-

~

DS63

TR

6

123412 12

2

3

4

1

4

3

2

1

2345

1234 1234

3

2

1

CN61

EwPEvPEuP

RED

RED

BLU

GRN

YLW

ORN

RED

BRN

+

~

~

~

-

+

-

❈

❈❈

❈

❈

❈❈

❈

❈

❈

❈❈

❈❈

❈

❈

❈

❈❈❈

❈

❈

❈

❈

❈❈❈

❈

❈

❈

❈

❈

❈

❈

❈

❈

❈

❈❈

❈❈❈

❈

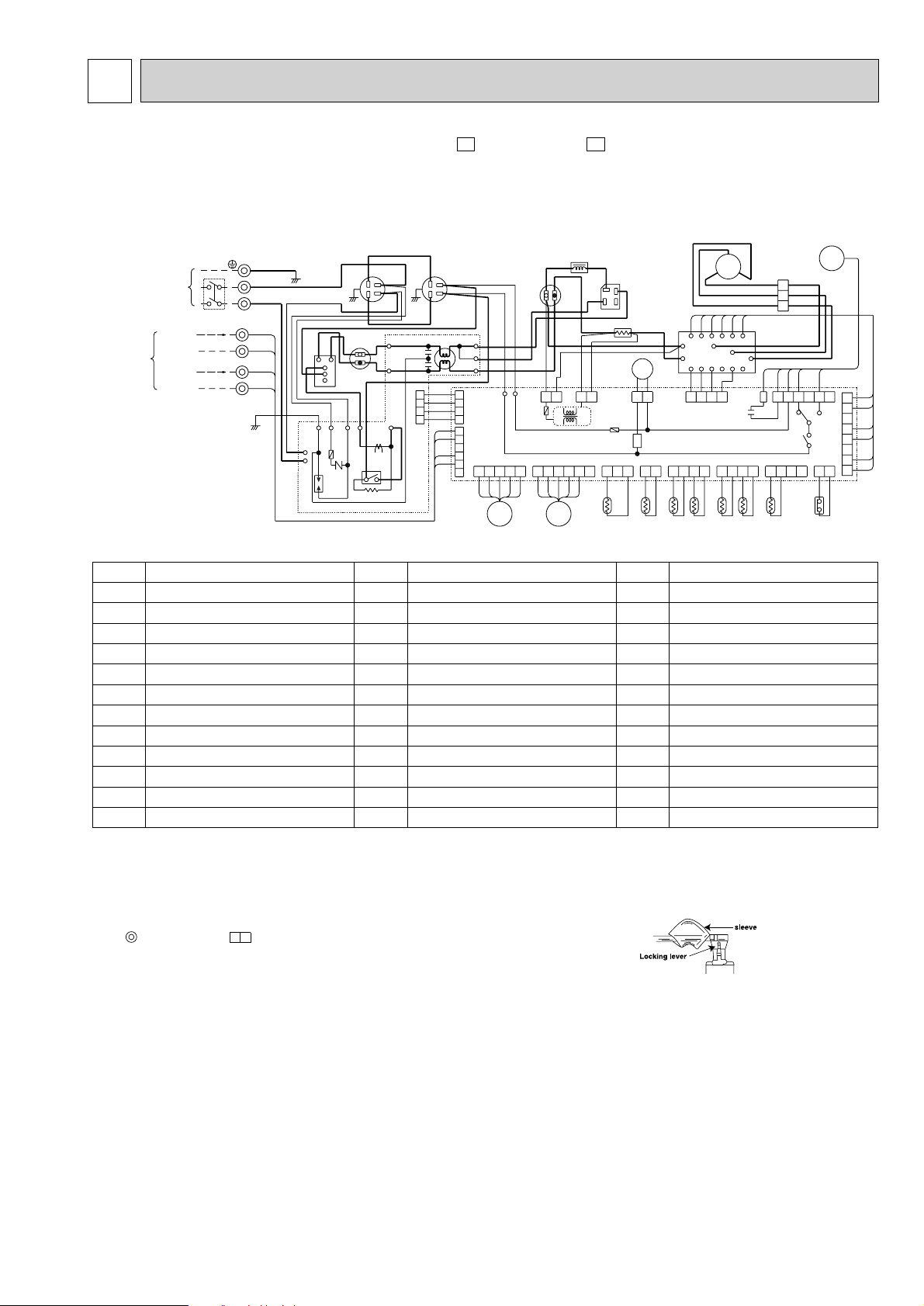

R64

R65

CURRENT-DETECTING RESISTOR

CURRENT-LIMITING RESISTOR

T801 TRANSFORMER

FUSE2

FUSE(3.15A)

FUSE1

FUSE(1A)

F62

FUSE(3.15A)

SYMBOL

NAME

GAS PIPE TEMPERATUREA.THERMISTOR

RT65

GAS PIPE TEMPERATUREB.THERMISTOR

RT64

DEFROST TEMPERATURETHERMISTOR

DISCHARGE TEMPERATURETHERMISTOR

FIN TEMPERATURETHERMISTOR

EVAPORATION TEMPERATURETHERMISTOR

SUCTION TEMPERATURETHERMISTOR

OUTDOOR FAN MOTOR(INNER THERMOSTAT)

RT61

RT62

RT63

RT66

RT67

21S4 R.V.COIL

TB TERMINAL BLOCK

FAN MOTOR RELAY

TR POWER TRANSISTOR MODULE

X60,67

X64 RELAY

SSR61 SOLID STATE RELAY

SYMBOL

SURGE ABSORBER

POWER-FACTOR CAPACITOR

SMOOTHING CAPACITOR

OUTDOOR FAN CAPACITOR

CERAMIC CAPACITOR

CERAMIC CAPACITOR

AR61

C61

C67

C65

C63

C64

NAME

SYMBOL

NAME

MC

MF

NR61

LEV A,B

DS61,63

L

L61

HPS

CT61

COMPRESSOR

CURRENT TRANSFORMER

VARISTOR

REACTOR

DIODE MODULE

HIGH PRESSURE SWITCH

EXPANSION VALVE

CMC COIL

NF61,62 NOISE FILTER

WIRING DIAGRAM

MODELS MXZ-18NV- MXZ-18NV-

E2E1

NOTE:1. For the outdoor electric wining refer to the outdoor unit electric wining diagram for servicing.

2. Use copper conductors only.(For field wining)

3. Symbols below indicate.

: Terminal block, : Connector

4. “ ✻ ”shows the terminals with a lock mechanism,so they cannnot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever (project part) of the terminal with a finger.

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

13

POWER SUPPLY

~/N 220-240V 50Hz

INDOOR

UNIT (A)

12VDC

CIRCUIT BRAKER

TB2

TB3

BLU

RED

TB4

X64

GRN/YLW

GRN/YLW

CN720

CN601

0

4

X64

LD62

CN913

CN791

CN901

64

2

CN902

CN851 CN852

MF61

CH

21S4 21S2

12 12

21

21

12

12

34

123456

12 34567

123456

CN912

C65

LD63

LD64

LDB

LDB

LD61

LDE

L61

F911

SSR61

SSR62

SSR63

X63

X62

X61

1

6

L

N

3

N

INDOOR

UNIT (B)

12VDC

BLU

ORN

CN602

12

3

3

3

N

INDOOR

UNIT (C)

12VDC

BLU

YLW

CN603

12

N

INDOOR

UNIT (D)

12VDC

BLU

BEN

CN604

12

N

BLK

BRN

GRY

BLK

BLK

WHT

YLW

RED

RED

RED

BRN

BLU

ORN

YLW

WHT

ORN

WHT

BLK

BLU

YLW

RED

BLU

BLU

WHT

WHT

ORN

ORN

RED

RED

YLW

YLW

YLW

BLK

BLK

ORN

ORN

BRN

GRY

X65

X66

X67

X67

63H2

X65

X66

CN552

CN553

BLK

RELAY

P.C. BOARD

WHT

WHT

RED

WHT

V

UW

YLW

A

K

L

WHT

NOISE FILTER

P.C.BOARD

RED

DS61

DS62

C61

CT

61

C63 C62

+

+

-

+-+

-

-

BLKREDR

BLU

LEV A

CN792

123456

RED

BRN

BLU

ORN

YLW

WHT

LEV B

CN793

123456

RED

BRN

BLU

ORN

YLW

WHT

LEV C

CN794 CN722 CN663

63H1 RT63

123456

CN662

1234567812 12

123

34

RED

RED

RED

63L

BLK

BLK

BLK

BLK

RT66 RT68

RT67 RT69

GRY

GRY

GRY

GRY

GRY

GRY

GRY

GRY

CN661

CN705

7654321

CN515

1234

4321

CN801

CN501

TAB62

TAB63

T801

CT62

TAB66

TAB65

TAB64

I.P.M P.C. BOARD

F801

(1A)

CN704

CN514

CN554CN551

CN723

12345678

RT62 RT64

RT61 RT65

GRY

GRY

BLK

BLK

GRY

GRY

GRY

GRY

BRN

BLU

ORN

YLW

WHT

LEV D

ELECTRONIC CONTROL P.C. BOARD

MC

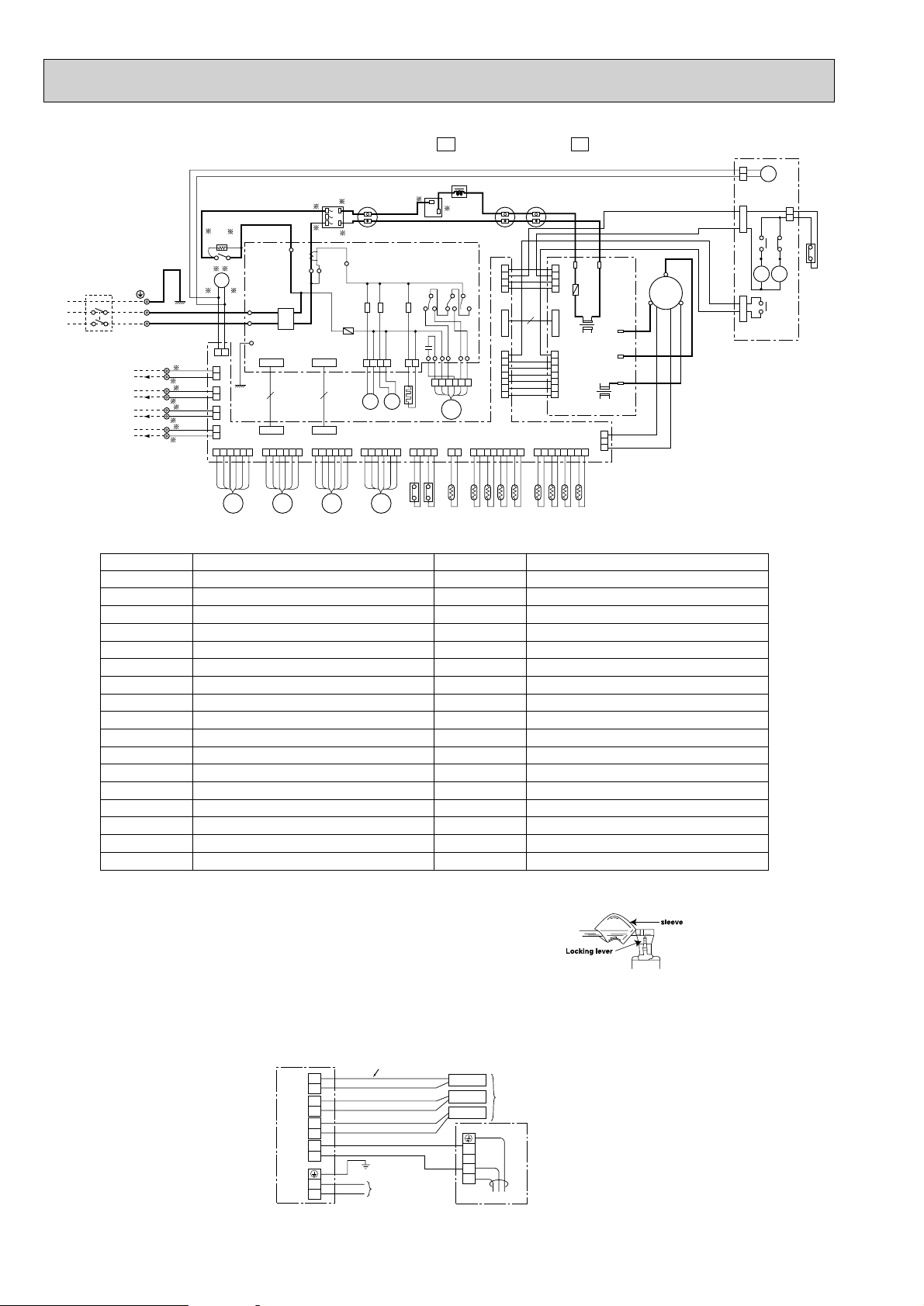

MODELS MXZ-32NV- MXZ-32NV-

OUTDOOR UNIT

GROUND

Power supply cord

Terminal block

POWER SUPPLY

~/N 220-240V 50Hz

Indoor/outdoor connecting wire

Make all connections

as shown below.

D UNIT

A UNIT

D UNIT

3

C UNIT

C UNIT

3

B UNIT

B UNIT

3

A UNIT

3

N

N

N

N

N

L

3

2

N

L

INDOOR UNIT

INDOOR AND OUTDOOR ELECTRICAL WIRING CONNECTION FIGURE

E2E1

SYMBOL

C61

C62,63

C65

CH

CT61,62

DS61

DS62

F801

F911

L

L61

LEV A~D

R

RT61

RT62

RT63

RT64

NAME

POWER FACTOR CAPACITOR

SMOOTHING CAPACITOR

OUTDOOR FAN CAPACITOR

CRANKCASE HEATER

CURRENT TRANSFORMER

DIODE MODULE

DIODE STACK

FUSE (1A)

FUSE (1A)

REACTOR

COMMON MODE CHOKE COIL

EXPANSION VALVE

RESISTOR

DISCHARGE TEMPERATURE THERMIST OR

DEFROST TEMPERA TURE THERMIST OR

FIN TEMPERATURE THERMIST OR

EVAPORATION TEMPERATURE THERMISTOR

NOTE:1. “- - - - “ denotes the wiring at the site.

2 “❈”show the terminals with a lock mechanism, so they cannot be removed

when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the

terminal with a finger.

14

SYMBOL

RT66,67

RT68,69

SSR61,62

SSR63

TB2,3,4

X61,62,63

X64,65

X66,67

RT65

MC

MF61

T801

21S2

21S4

63H1

63H2

63L

NAME

SUCTION TEMPERATURE THERMIST OR

GUS PIPE TEMPERATURE THERMISTOR

GUS PIPE TEMPERATURE THERMISTOR

COMPRESSOR

OUTDOOR FAN MOTOR (INNER FUSE)

SOLENOID COIL RELAY

CRANKCASE HEATER RELAY

TRANSFORMER

TERMINAL BLOCK

FAN MOTOR RELAY

RELAY

RELAY

SOLENOID COIL

R.V. COIL

HIGH PRESSURE SWITCH

HIGH PRESSURE SWITCH

LOW PRESSURE SWITCH

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

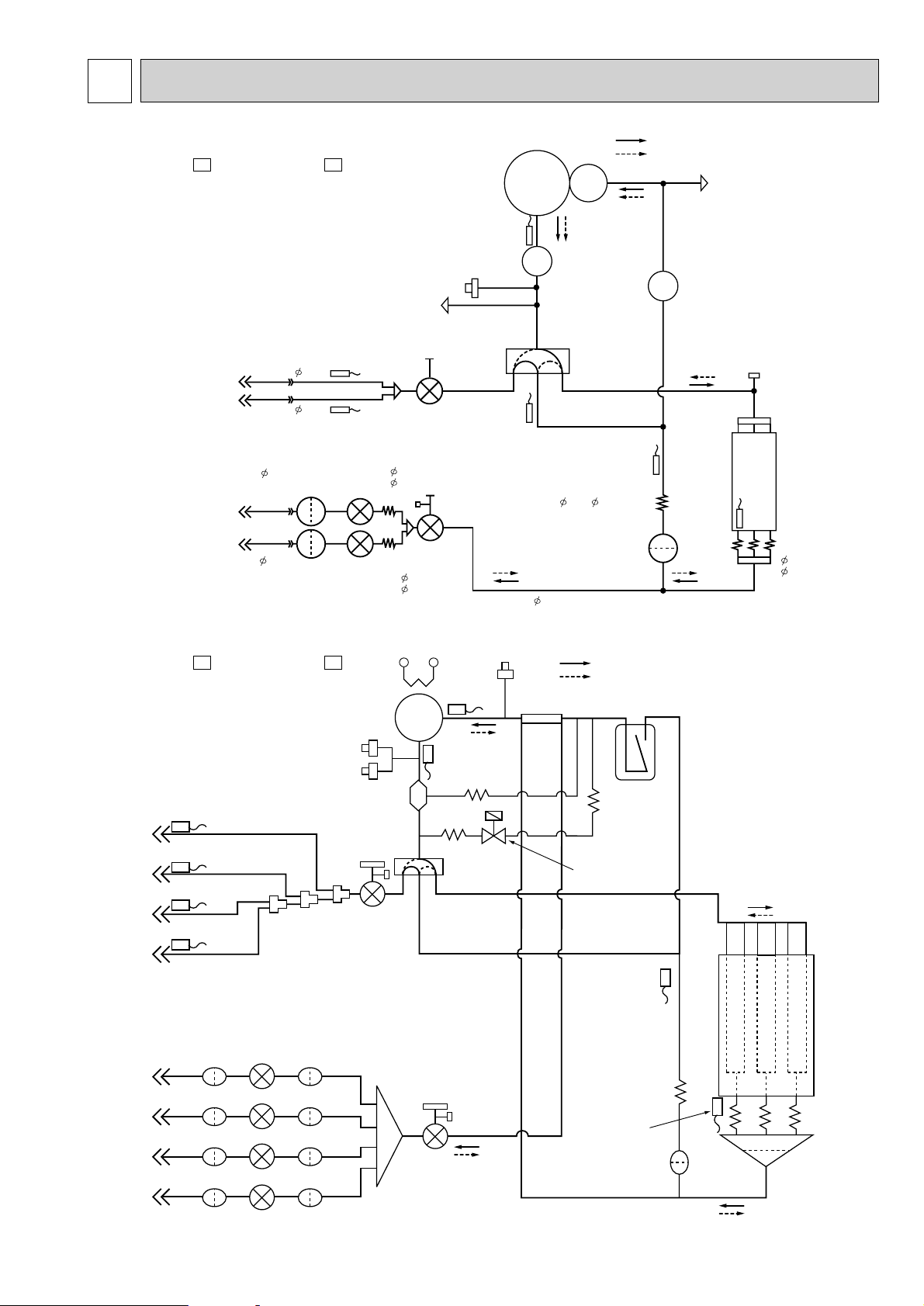

REFRIGERANT SYSTEM DIAGRAM8

9.52

6.35

9.52

9.52

2.0X 0.6X500

Charge port

Capillary

tube

4.0X

2.4X

400

Capillary

tube

4.0X

2.4X

300

Expansion

valve(LEV)

Expansion

valve(LEV)

Strainer

Strainer

Capillary

tube

4.0X

2.4X

300

Ball valve with

service port

Ball valve

Service

port

(high pressure)

Reversing

valve

Suction temperature

thermistor

RT66

Gas pipe

thermistor

Gas pipe

thermistor

Muffler

Compressor

High pressure

switch

Discharge

temperature

thermistor

RT62

Service

port

(Low pressure)

Refrigerant flow in cooling

Refrigerant flow in heating

R.V. coil

heating ON

cooling OFF

Strainer

Capillary

tube

Evaporation

temperature

thermistor

RT67

Defrost

thermistor

RT61

Outdoor

heat

exchanger

6.35

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

8.1 REFRIGERANT SYSTEM DIAGRAM

MXZ-18NV - MXZ-18NV -

E2E1

Unit:mm

MXZ-32NV - MXZ-32NV -

High pressure

switch 1

High pressure

switch 2

Indoor unit

D

Indoor unit

C

Indoor unit

B

Indoor unit

A

Indoor unit

A

Indoor unit

B

Indoor unit

C

Indoor unit

D

Unit D gas pipe temperature thermistor

Unit C gas pipe temperature thermistor

Unit B gas pipe temperature

thermistor

Unit A gas pipe

temperature thermistor

Strainer StrainerLEV

Strainer StrainerLEV

Strainer StrainerLEV

Strainer StrainerLEV

[12

[12

[9.52

[9.52

E2E1

separator

Ball valve with

service port

[6

[6

[6

[6

Compressor

Oil

Capillary tube

[3.0✕[2.0✕500

[16

Ball valve with

service port

Distributor

Low pressure switch

Suction

temperature

thermistor

Discharge

temperature

thermistor

Capillary tube

[2.5✕ [0.6✕1000

Reversing valve

[16

[9.52

Refrigerant flow in cooling

Refrigerant flow in heating

[16

Accumlator

Capillary tube

[3.0✕[2.0✕ 500

2-way-valve

Evaportation

temperature

thermistor

(RT67)

Capillary tube

[2.5✕[0.6✕ 750

Defrost

thermistor

Strainer

R.V. coil

heating ON

cooling OFF

Outdoor

heat

exchanger

Capillary tube

[4.0✕[2.4✕ 400

Distributor

15

a

b

c

d

Outdoor

unit

Indoor

units

H

H

H

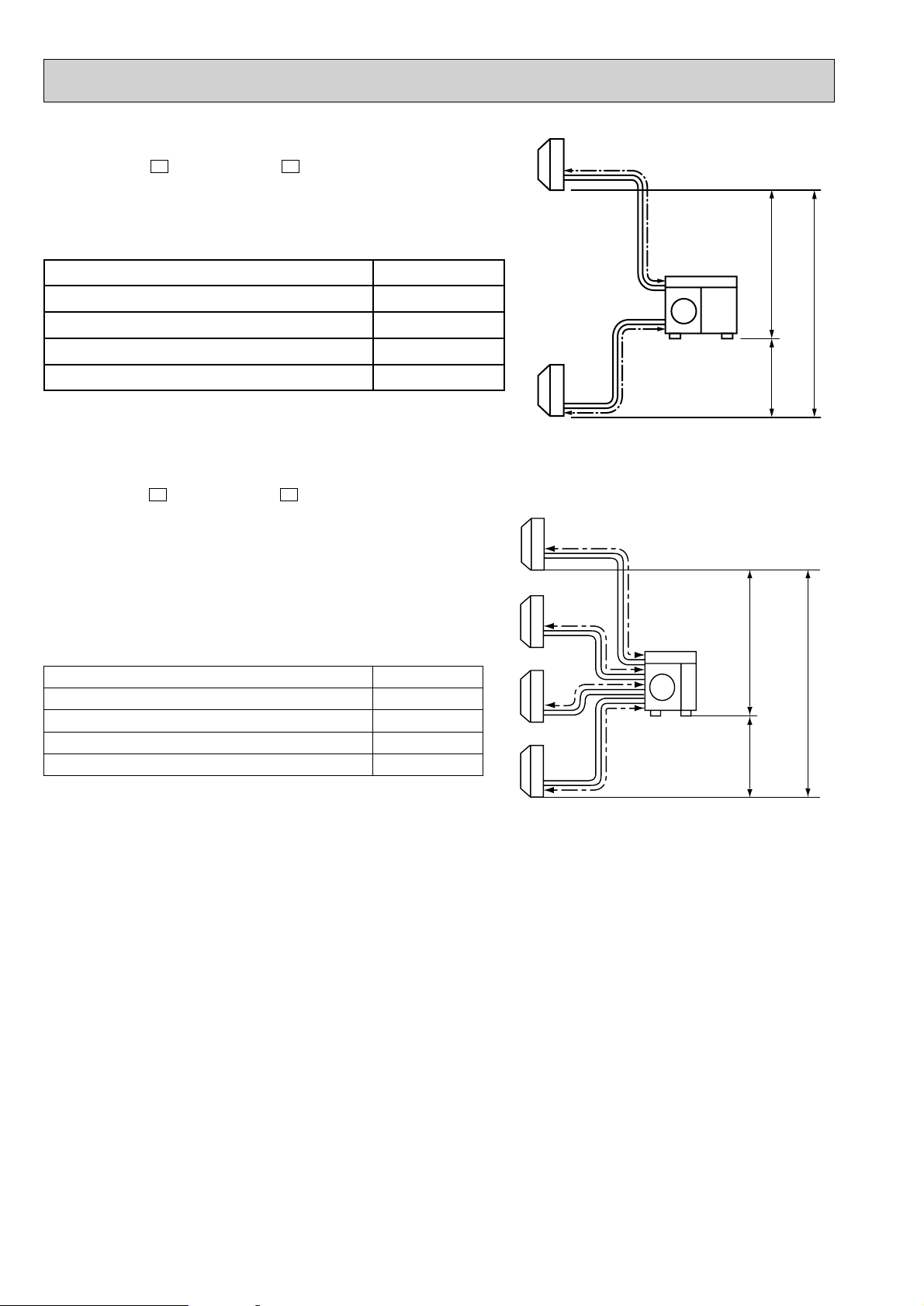

8.2 MAX REFRIGERANT PIPING LENGTH

MXZ-18NV - MXZ-18NV -

Piping length for each indoor unit (a,b) 20m

E2E1

a

Outodoor

unit

H

Total piping length (a+b) 30m

Height difference between units (H) 7m

Bending point for each unit 15

Total bending point 30

❈ It does not matter which unit is higher

MXZ-32NV - MXZ-32NV -

E2E1

Piping length each indoor unit (a, b, c, d) 25m

Total piping length (a+b+c+d) 60m

Height difference between units (H) 10m

Bending point for each unit 15

Total bending point 30

❋It does not matter which unit is higher.

H

H

b

16

8.3 PIPE SIZE SELECTION

MXZ-18NV - MXZ-18NV -

● Refrigerant pipe diameter is different according to indoor unit to be connected. When using extension pipes, refer to the

table below.

● When diameter of refrigerant pipe is different from that of outdoor unit union, use optional L-joint. For further information on

L-joint, see page 62.

Indoor unit

class Pipe diameter

07/09

12

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 9.52(3/8) Gas 9.52(3/8)

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 12.7(1/2) Gas 12.7(1/2)

E2E1

Extention pipe diameter

Outdoor unit union diameter

For

Indoor unit A

Indoor unit B

Unit : mm (inch)

Liquid 6.35(1/4)

Gas 9.52(3/8)

Liquid 6.35(1/4)

Gas 9.52(3/8)

MXZ-32NV - MXZ-32NV -

●Refrigerant pipe diameter is different according to indoor unit to be connected. When using extention pipes,refer to the tables

below.

●When diameter of refrigerant pipe is different from that of outdoor unit union, use optional Different-diameter pipe. For further

information on Different-diameter pipe,see page 62.

Indoor unit

class Pipe diameter

07/09

12(13)

18

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 9.52(3/8) Gas 9.52(3/8)

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 12.7(1/2) Gas 12.7(1/2)

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 15.88(5/8) Gas 15.88(5/8)

E2E1

Extention pipe diameter

Outdoor unit union diameter

For

Indoor unit A

Indoor unit B

Indoor unit C

Indoor unit D

Unit : mm (inch)

Liquid 6.35(1/4)

Gas 12.7(1/2)

Liquid 6.35(1/4)

Gas 12.7(1/2)

Liquid 6.35(1/4)

Gas 9.52(3/8)

Liquid 6.35(1/4)

Gas 9.52(3/8)

17

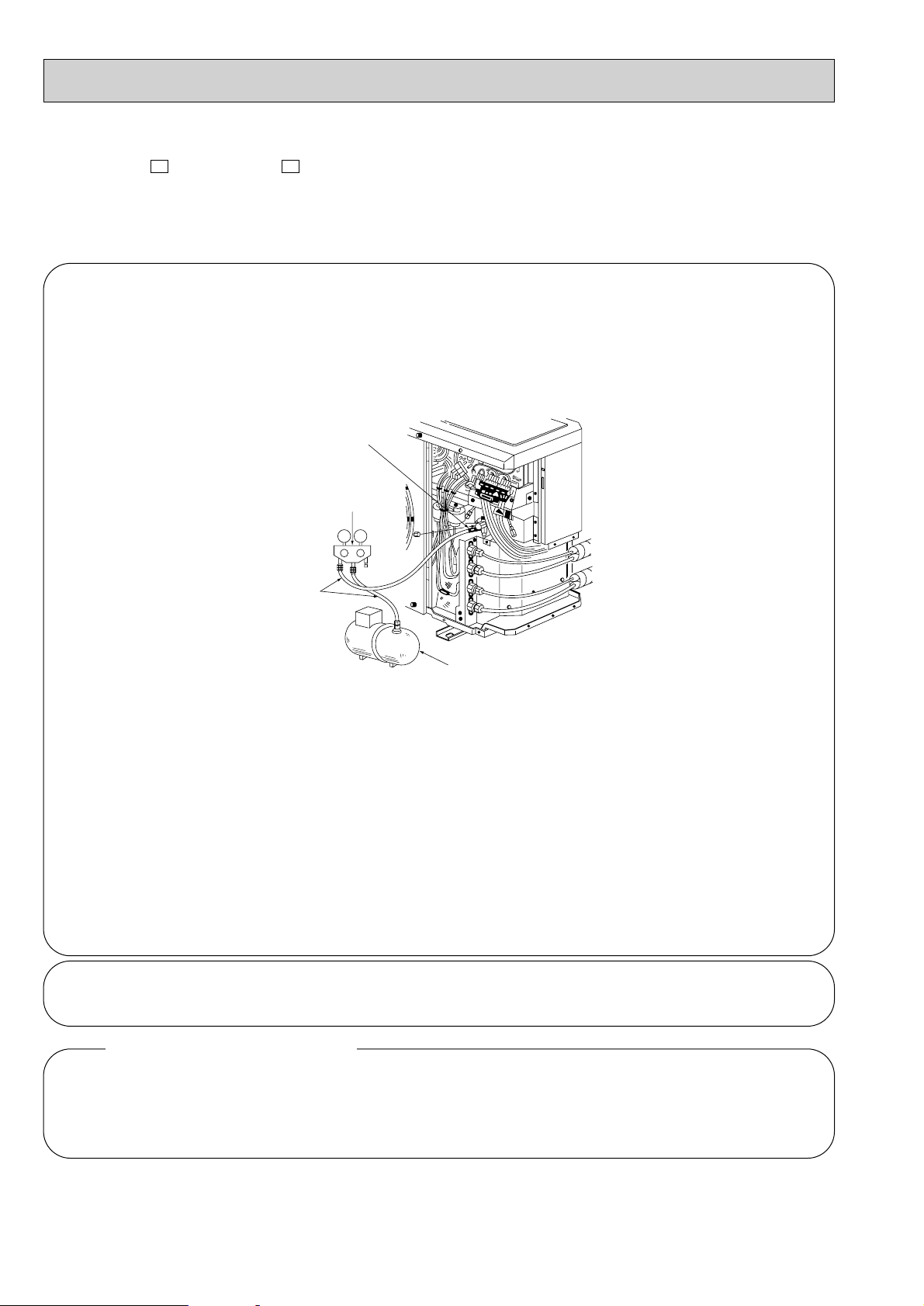

8.4 EVACUATION PROCEDURES

Gauge manifold valve

Connect pipes

Vacuum pump

Service port

MXZ-18NV - MXZ-18NV -

E2E1

CAUTION : If you run this unit with air in its refrigerant pipe before air purge, the compressor will decline in cooling

capacity, which may result in trouble.

❶. Connect the refrigerant pipes (both the liquid and gas pipes) between the indoor and the uotdoor units.

❷. Remove the service port cap of the stop valve on the side of the outdoor unit gas pipe.[ The stop valve

will not work in its initial atate fresh out of the factory (totally closed with cap on).]

❸. Connect the gauge manifold valve and the vacuum pump to the service port of the stop valve on the side

of the outdoor unit gas pipe.

❹. Run the vacuum pump.

❺. Check the vacuum with the gauge manifold valve, then close the gauge manifold valve, and stop the

vacuum pump.

❻. Leave it as is for one or two minutes.Make sure the pointer of the gauge manifold valve remains in the

same position.

❼. Remove the cape from the stop valves of the outdoor unit, liquid pipe, and gas pipe. Pull the handle

towards you with a finger. Turn it one fourth turn counterclockwise, to obtain the full-open position.

❽. Remove the cape manifold valve quickly from the service port of the stop valve.

❾. Tishten the cap to the service port to obtain the initial status.

❿. Thrust the handle of the stop valve into the unit, then retighten the cap.

Leak test

.......

With a gas detector or soap water, check the flared nut connections for any refrigerant leak.

In case of a refrigerant leak

● Retighten the flared nut connections.

● If the leak does not stop even after retightening, repair the leaking point, collect all from inside the unit

through the service port, apply a vacuum to it, then charge a specified amount of gas with a gas cylinder.

18

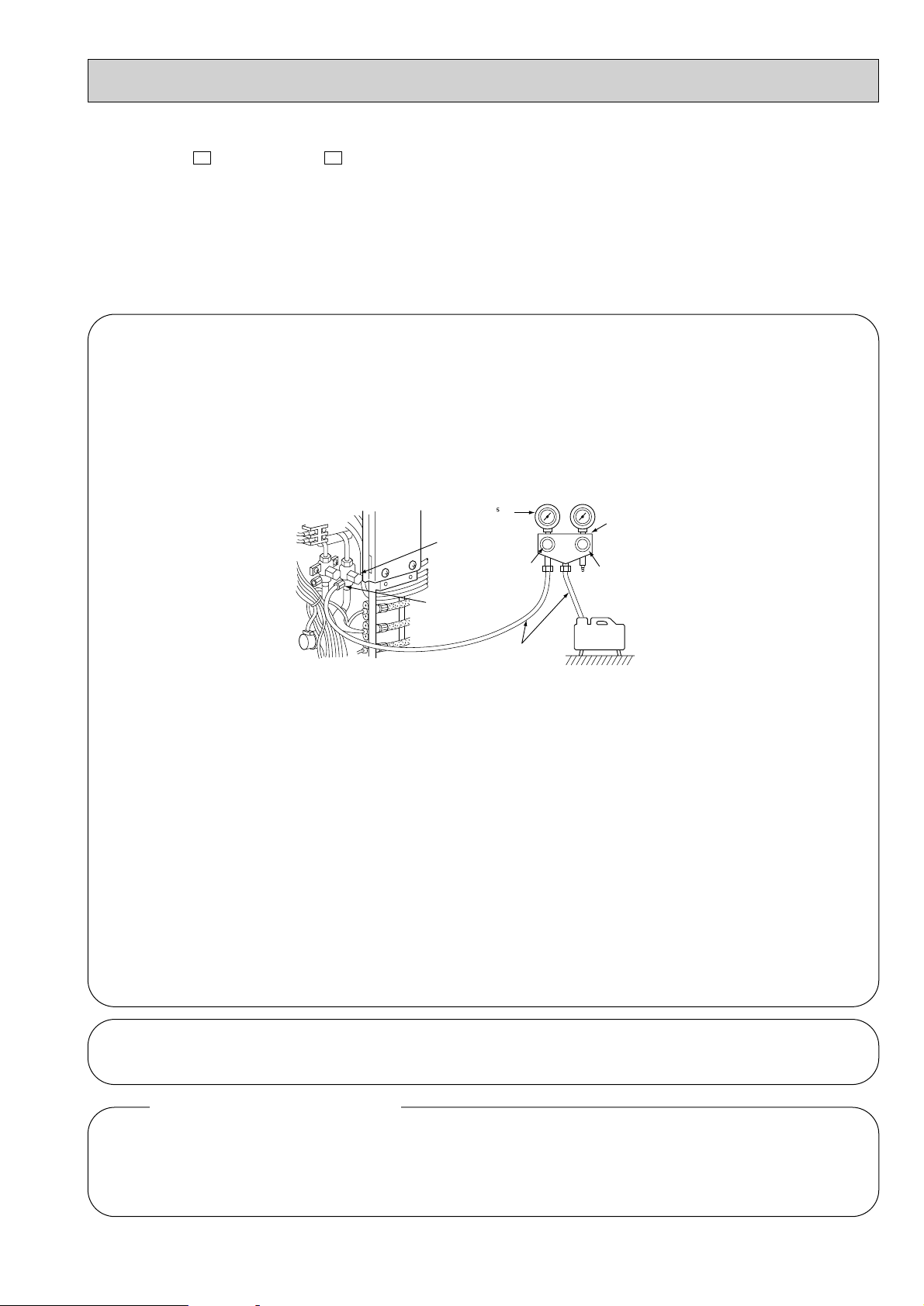

Stop valve

(gas side)

Service port

Valve knob Lo

Valve knob Hi

Charge hose

Vacuum

pump

Gauge

Manifold

Compound gauge Pressure gauge

-1.01✕10 Pa

(-760mmHg)

MXZ-32NV - MXZ-32NV -

E2E1

● For details about how to use manifold valves, see the instruction manual for manifold valves.

● The valve knob Hi below cannot operate during the following work if it is fully closed.

Warning : When installing or moving the unit, do not mix anything other than specified refrigerant (R-22) into the

refrigerating cycle.

If air is mixed, it may cause the refrigerating cycle to get abnormally high temperature, causing a risk of

burst.

❶. Make sure the pipes are connected securely.

❷. Connect the projected side (on which the setting pin is pressed) of the gauge manifold valve´s charge hose to the

stop valve´s service port (gas pipe side).

❸. Make sure the stop valves of gas and liquid pipes are fully closed, and connect the charge house to the vacuum

pump.

❹. Fully open the manifold valve´s valve knob Lo and operate the vacuum pump.

Loosen the stop valve flare nut on the gas pipe side a little bit and make sure that air is entering.

Then tighten the flare nut not to enter the air. After that, make sure that the charge hose is connected firmly to

the service port.

❺. Purge air for more than 15 minutes, and make sure the compound gauge is reading - 1.01 ✕ 10

5

Pa (-760mmHg).

❻. After purging air, fully close the manifold valve´s valve knob Lo and stop operating the vacuum pump.

❼. Leave the situation for about 1 to 2 minutes, make sure the needle of the compound gauge does not return, pull the

stop valve´s knob toward you, and fully open the stop valve by turning it a quarter turn counterclockwise.

❽. Quickly remove the gauge manifold valve´s charge hose from the stop valve´s service port.

❾. Tighten the service port cap 1/12 turn more from where the tightening torque is suddenly increased.

(It is equivalent to a tightening torque of 13.7 to 17.7N-m (140 to 180kgf-cm).)

❿. Tighten the service port cap 1/12 turn more from where the tightening torque is suddenly increased.

(It is equivalent to a tightening torque of 19.6 to 29.4N-m (200 to 300kgf-cm).)

Leak test

● Retighten the flared nut connections.

● If the leak does not stop even after retightening, repair the leaking point, collect all from inside the unit

through the service port, apply a vacuum to it, then charge a specified amount of gas with a gas cylinder.

.......

With a gas detector or soap water, check the flared nut connections for any refrigerant leak.

In case of a refrigerant leak

19

Loading...

Loading...