Page 1

REGRINDING MANUAL FOR SOLID CARBIDE DRILL

MWE / MWS

April 30, 2009

type

MITSUBISHI MATERIALS CORPORATION CARBIDE & TOOLS DIVISION

Page 2

Checking conditions of the cutting edge

• Check wear conditions of and damage to the cutting edge.

• If there is serious damage such as fracture on the cutting edge, grind the edge until the damage is all

gone.

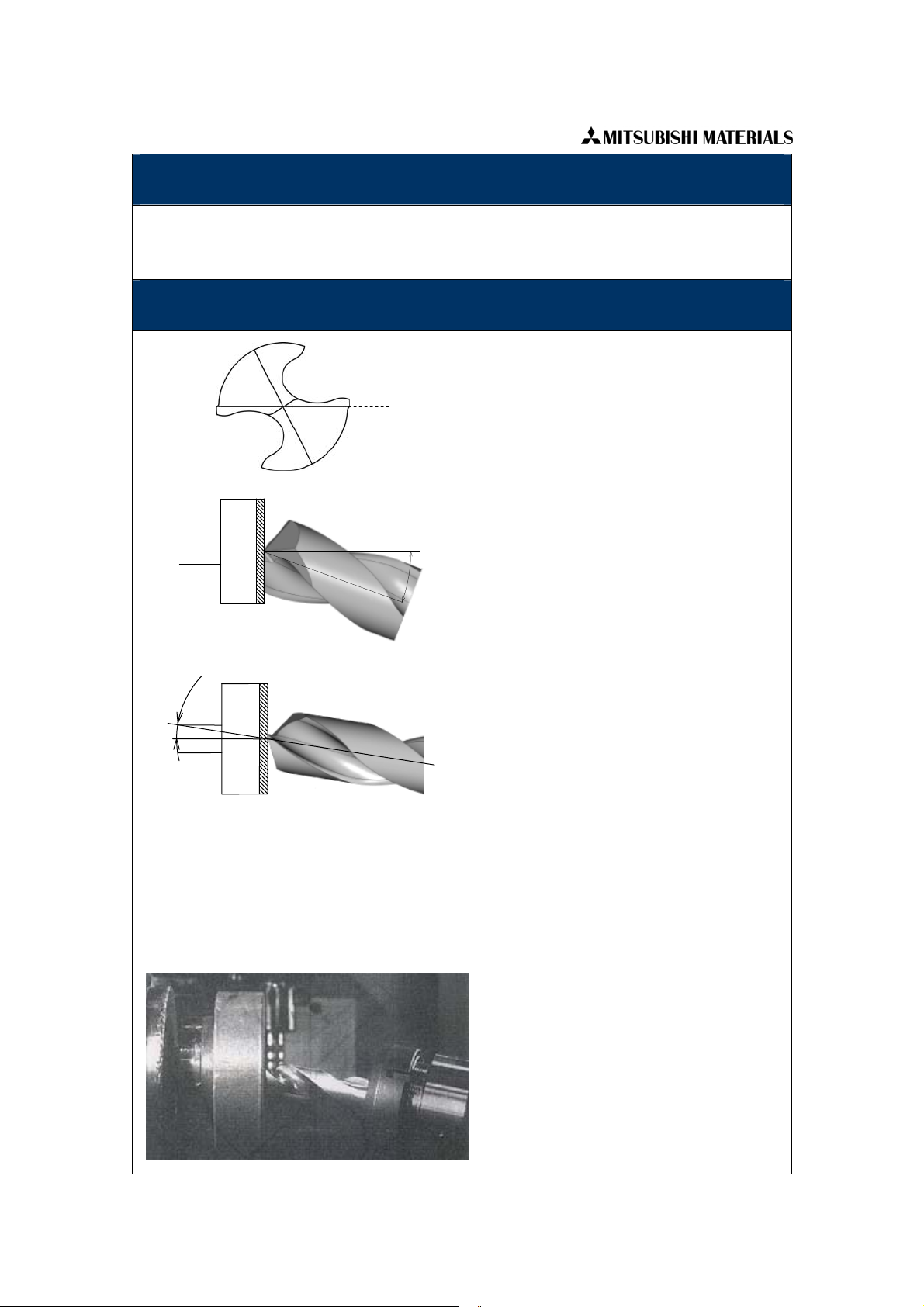

Grinding first relief face

Fig.1

Fig.2

図3

9°~11°

Horizontal

゚

0

2

• Install the drill by using collet chuck. As

shown in fig.1, set the drill phase in order

that the corner of center cutting edge and

the shoulder of outer peripheral edge

become parallel to each other when seen

from the top.

• As shown in fig.2, rotate the drill (work

head) 20°so that the point angle will be

140°.

• As shown in fig.3, set inclination angle of

the drill (work head) at 9°~11°. This angle

will become first relief angle.

Copyright © 2009 MITSUBISHI MATERIALS CORPORATION. All rights reserved

• Finishing first relief face on one side of

the cutting edge, index the drill 180°and

grind the other side until both sides are at

the same position.

*Depth of cut is 0.02 ~ 0.03mm/path.

• Finally decrease depth of cut to about

0.01mm, and finish both sides at the

position.

• For finishing, repeat oscillation 2 ~ 3

times as slow as possible. This also

serves for the purpose of spark-out.

• Grind until there is no wear or fracture left

on the cutting edge. (Please pay attention

to the damage at the margin, too.)

Page 3

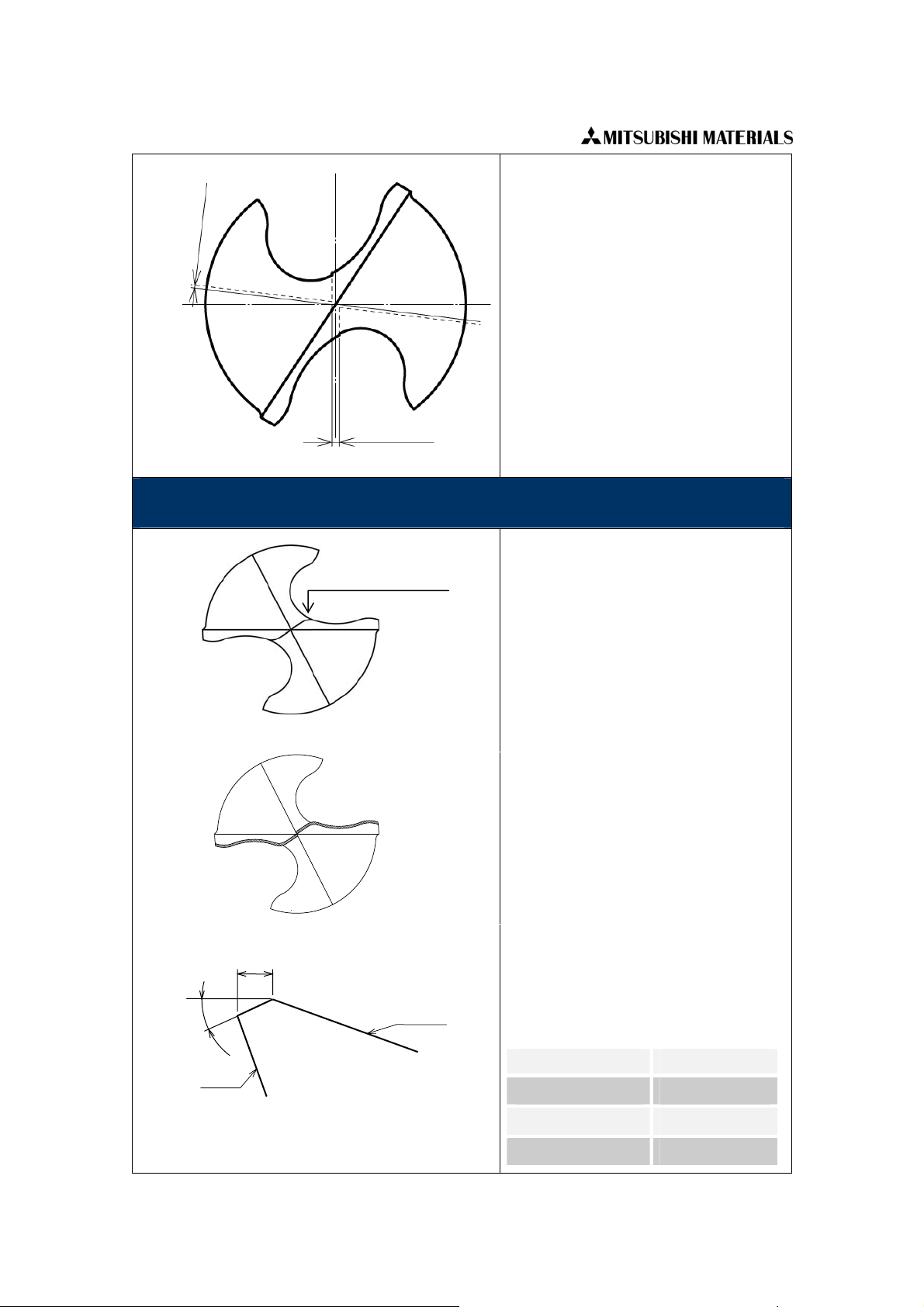

Grinding second relief face

Fig.4

23°~27°

8°~12° 15°

• Grind until lip height difference (axial

runout of front cutting edge) is 0.02mm or

less.

• After grinding first relief face, grind

second relief face.

• As shown in fig.2 of the previous section,

keep rotation angle of the drill (work

head) at 20°.

• As shown in fig.4, set inclination angle of

the drill (work head) at 23°~ 27°.

If inclination angle of the drill (work head)

cannot be increased to 23°~27°, get the

wheel inclined 15°as shown in fig.5.

Fig.5

Fig.6

More grinding

necessary

Paralle

Too much

grinding

• Grind second relief face, and the

ridgeline of first and second relief face will

appear.

• As shown in fig.6, it is ideal that the

ridgeline is parallel to the line connecting

the corner of center cutting edge and the

shoulder of outer peripheral edge. Adjust

the drill phase while grinding.

• Grind until ridgelines on both sides

become one line. By this, the center point

at the top will be formed. As such, please

be careful not to grind too much or too

little.

Copyright © 2009 MITSUBISHI MATERIALS CORPORATION. All rights reserved

Page 4

Grinding thinning face

Height gage

Fig.7

Fig.8

65°

• After grinding second relief face, grind

thinning face. Type of the thinning is

X-thinning.

• First, set the work head horizontal so that

the center of the drill will be horizontal.

Drill rotation angle is 0°. Set the direction

of table oscillation parallel with the center

line of the drill.

• As shown in fig.7, set the drill phase so

that the line connecting the shoulder of

both sides will be horizontal by using a

device such as height gage.

• Then, as shown in fig.8, rotate the drill

counter clockwise 65°when seen from the

top.

Fig.9

35°

Cutting direction

Fig.10

θ

Drill

L

L=0.5×φD1×(1-cosθ)+H×tan10°×cosθ

Max. wheel diameter φD1

35°

35°

• Set the vertical position of the wheel so

that the open angle of the thinning from

the drill center will be 35°, as shown in

fig.9.

• As shown in fig.10, set the wheel height

so that the center line of the drill will be

higher than the bottom of the the wheel

edge by “L”. (Please refer to the formula

H

in figure 10.)

• As shown in fig.9, grind the thinning face

by sliding the table to the direction shown

by the arrowhead, pressing the drill

against the wheel. Grind slowly adjusting

the top end of cut by using a device such

as a stopper.

Copyright © 2009 MITSUBISHI MATERIALS CORPORATION. All rights reserved

Page 5

Y

-0.03~0.03

part

Honing

Fig.11

Fig.12

0.1~0.2

X part

R(0.1~0.15)×φD)

• Adjust the wheel position while grinding

so that the measurements of the thinning

(X part, Y part) will be the same as those

of fig.10. (Dotted lines show the final

positions.

• (Grinding tip) To make the task easy,

grind the two cutting edges alternately,

using a mirror to check the configuration

while grinding.

• After grinding thinning face, grind honed

edges. This is the last procedure for

regrinding.

• First, as shown in fig.11, grind the edge

at the cross section of the thinning edge

and major cutting edge with diamond file

until it becomes R-shaped.

• Appropriate R size is approximately (0.1

~ 0.15) x ØD.

• As shown in fig.12, thoroughly grind

honed edges on both sides evenly. First,

use a diamond file with grain size #400

for honing, and finish by using a hand lap

with grain size #1500.

• As shown in fig.13, honing angle is 25°.

W

25°

Relief face

Center line of the drill

Rake face

Fig.13

Copyright © 2009 MITSUBISHI MATERIALS CORPORATION. All rights reserved

• Change honing width inb accordance

with tool diameter (Please refer to table

1).

Table.1

Tool diameter φD Honing width W

φ5 less

φ5 over φ10 less

φ10 over φ20 less

0.025~0.05

0.05~0.1

0.10~0.15

Unit (mm)

Page 6

This is the end of regrinding. Please ascertain that all the following specifications are fulfilled before using

WSTAR drill again.

• Lip height difference (axial runout of front cutting edge) < 0.02mm

• There is no damage left on the cutting edge.

• Appropriate honing is applied to the edge.

• There is no grinding burr.

Grinding tools for first and second relief face

Diamond wheel

R-129936

Φ75~φ100

3~5

Grinding tools for thinning face

Diamond wheel

100°

R-146074

Φ100~φ150

10

5~10

Grain size

Rough grind : #200

Finish grind : #400 over

3~5

Grain size: #400 over

Grinding tools for honing

Diamond file

※ Diamond wheels and diamond files above are available at our divisions and sales offices. To order these products, please

contact one of our sales offices or divisions near from you. (Order numbers are underlined in the right column of the table.)

Copyright © 2009 MITSUBISHI MATERIALS CORPORATION. All rights reserved

Round file: P-56006C

Grain size: #600

Harf round file: P-68852

Grain size: #400

Hand hone: 000064

Grain size: #1500

Loading...

Loading...