Mitsubishi MVZ-A24AA7, MVZ Series, MVZ-A36AA7, MVZ-A30AA7, PVA series Service Manual

...

Air-Conditioners

SERVICE MANUAL

Series MVZ

Model name

Model name

<Indoor unit>

<Indoor unit>

MVZ-A12AA4

MVZ-A12, 18, 24, 30, 36AA7

MVZ-A18AA4

Multi-Position Air Handler

-

M-SERIES

INDOOR UNIT

Contents

1. SAFETY PRECAUTION .....................................................................................................................................................2

1-1. Always observe for safety .........................................................................................................................................2

1-2. Cautions related to new refrigerant ...........................................................................................................................2

2. PART NAMES AND FUNCTIONS ......................................................................................................................................3

3. SPECIFICATION ................................................................................................................................................................4

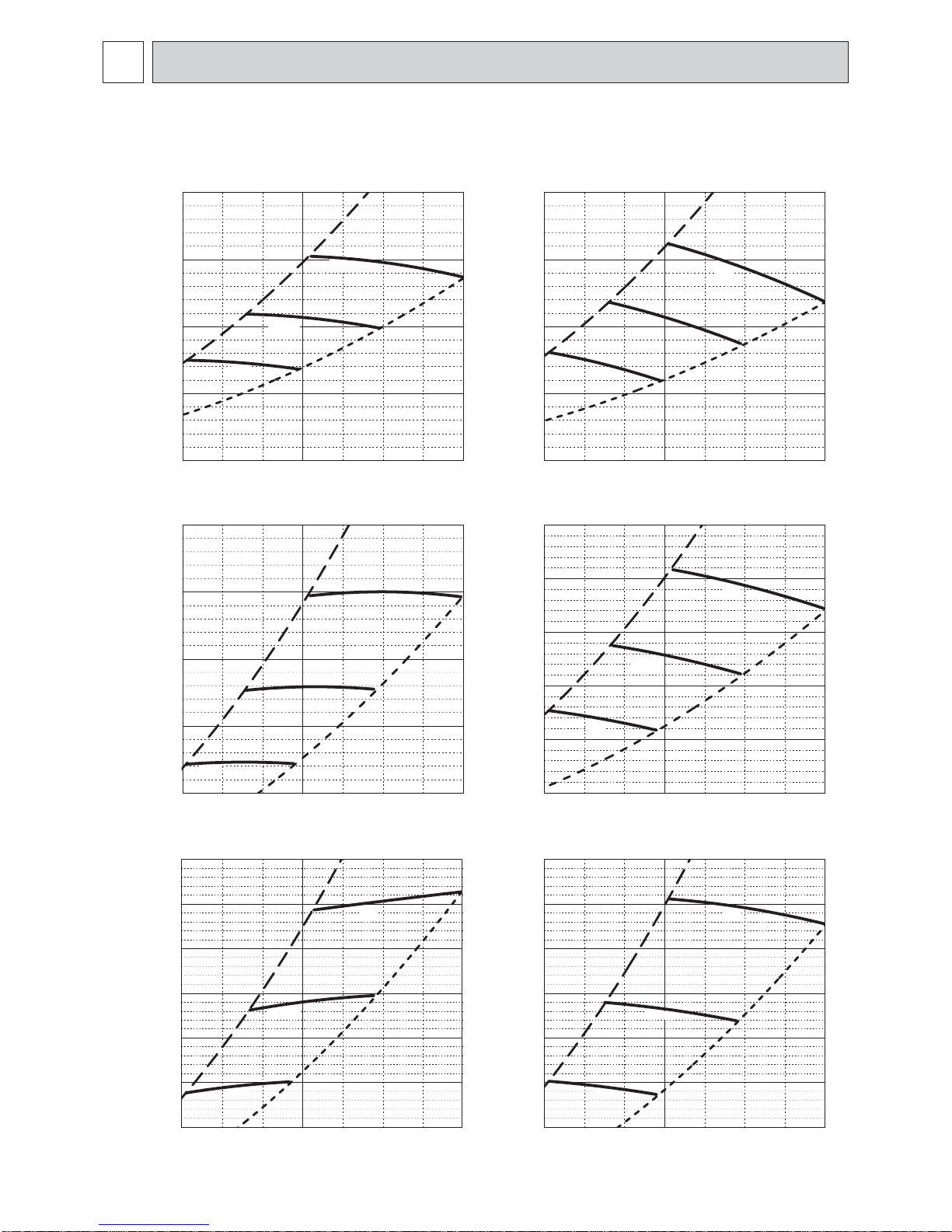

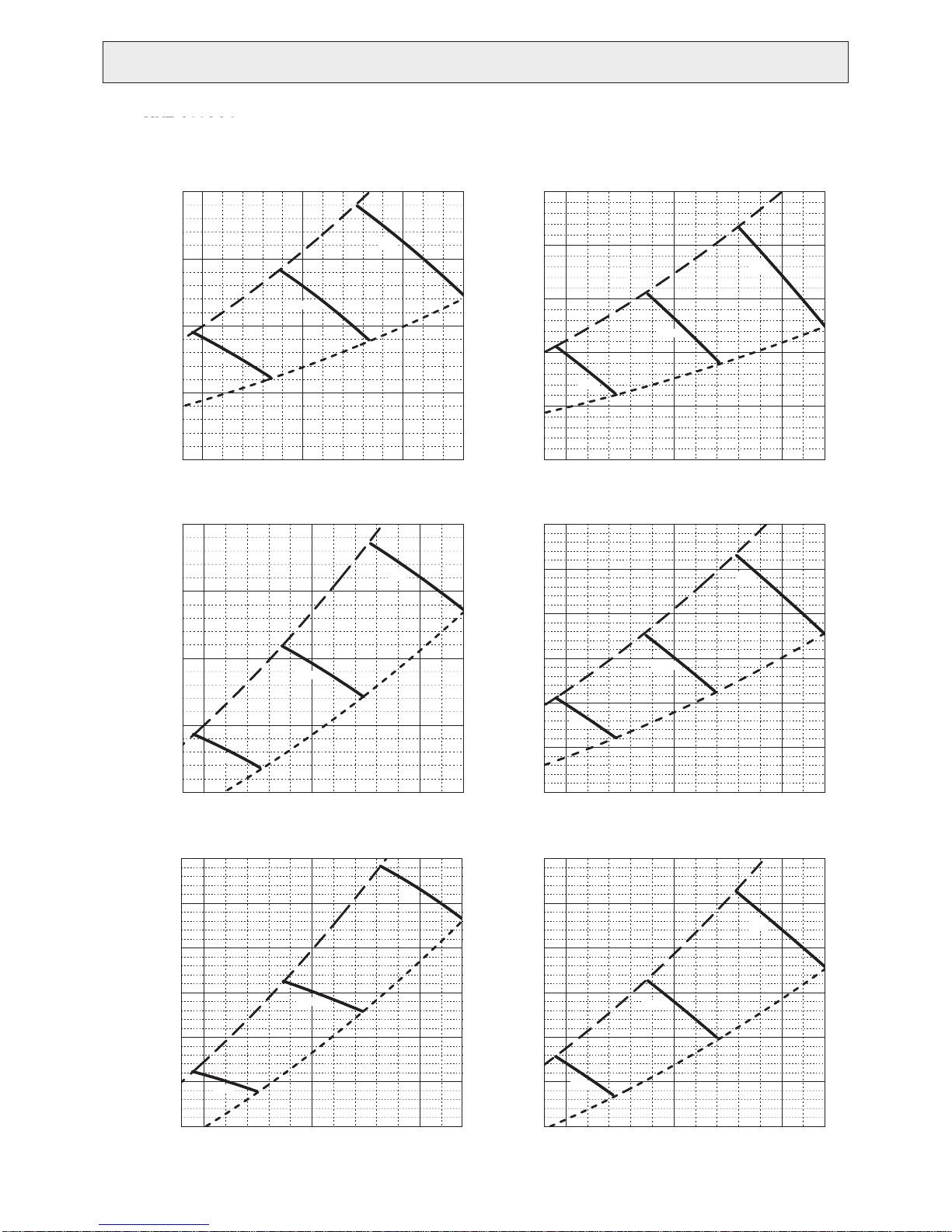

4. FAN PERFORMANCE AND CORRECTED AIR FLOW .....................................................................................................6

MVZ-A12AA7 ...................................................................................................................................................................6

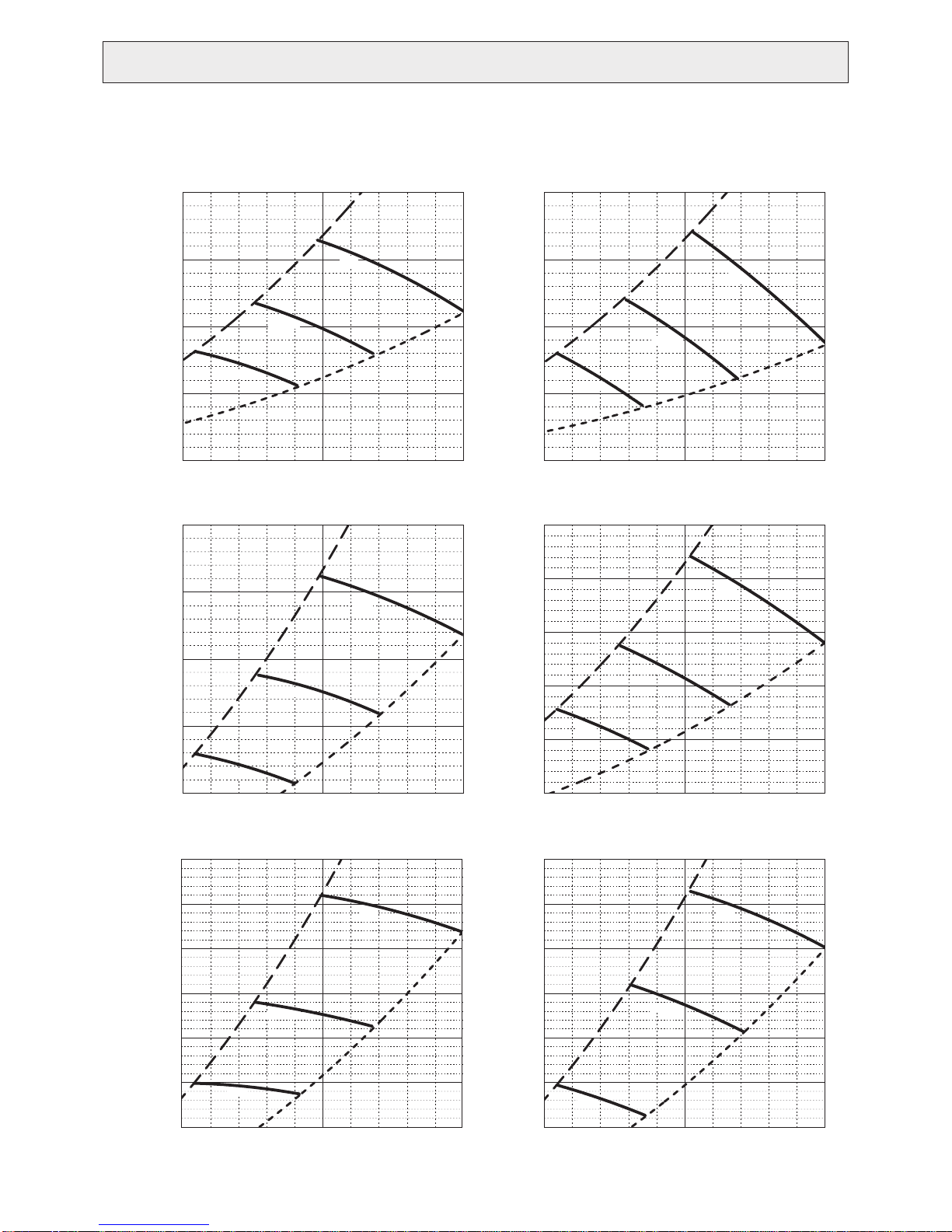

MVZ-A18AA7 ...................................................................................................................................................................7

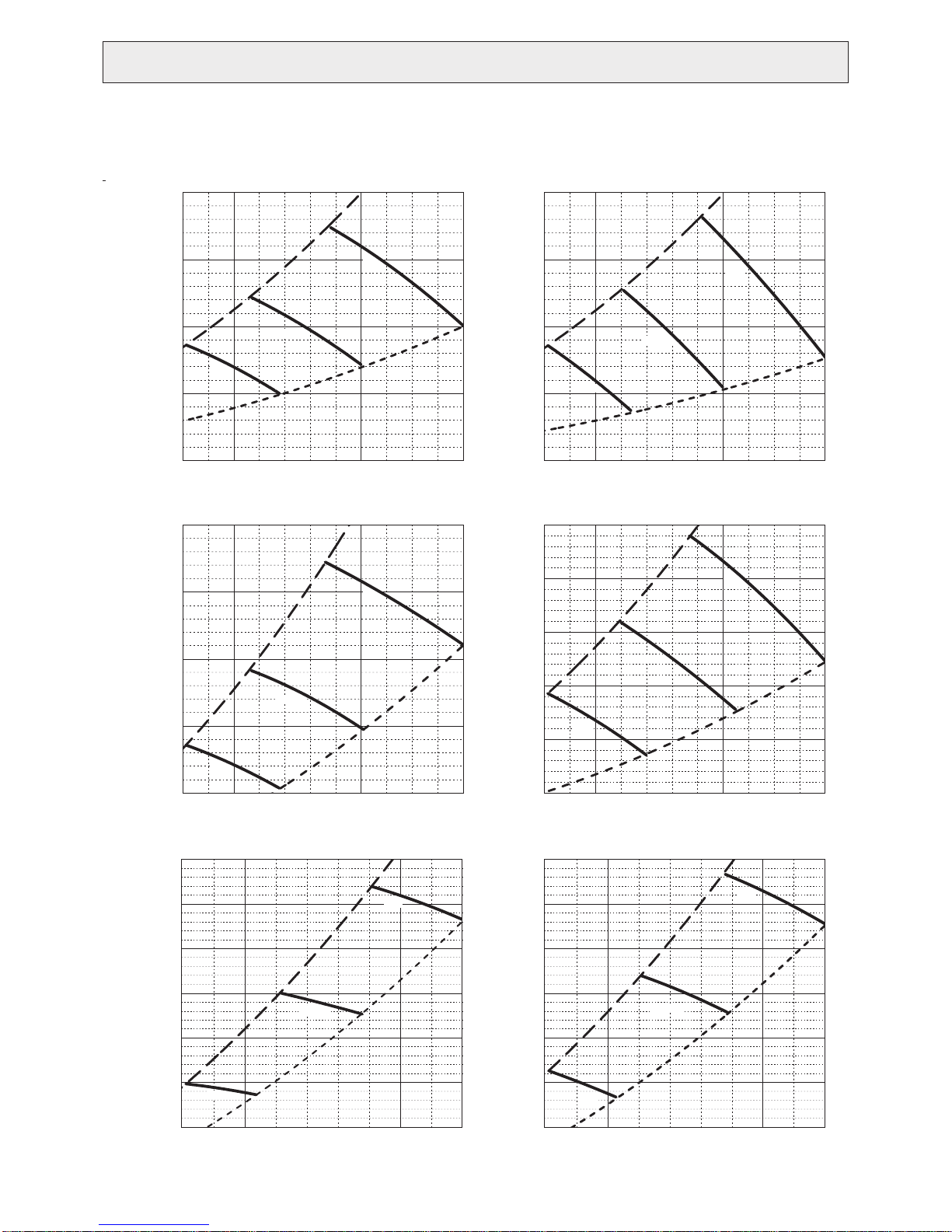

MVZ-A24AA7 ...................................................................................................................................................................8

MVZ-A30AA7 ...................................................................................................................................................................9

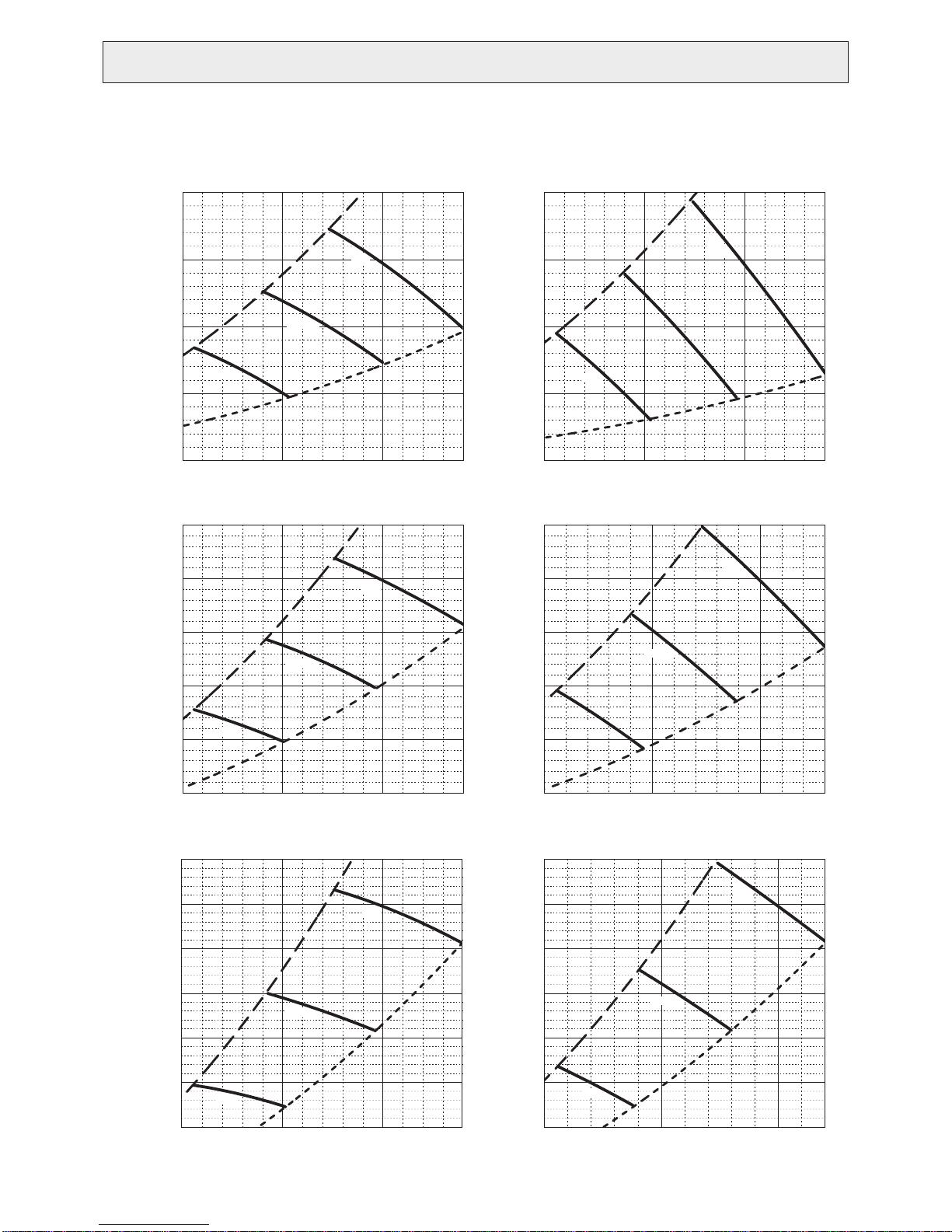

MVZ-A36AA7 .................................................................................................................................................................10

MVZ-A12, 18, 24, 30, 36AA7 .........................................................................................................................................11

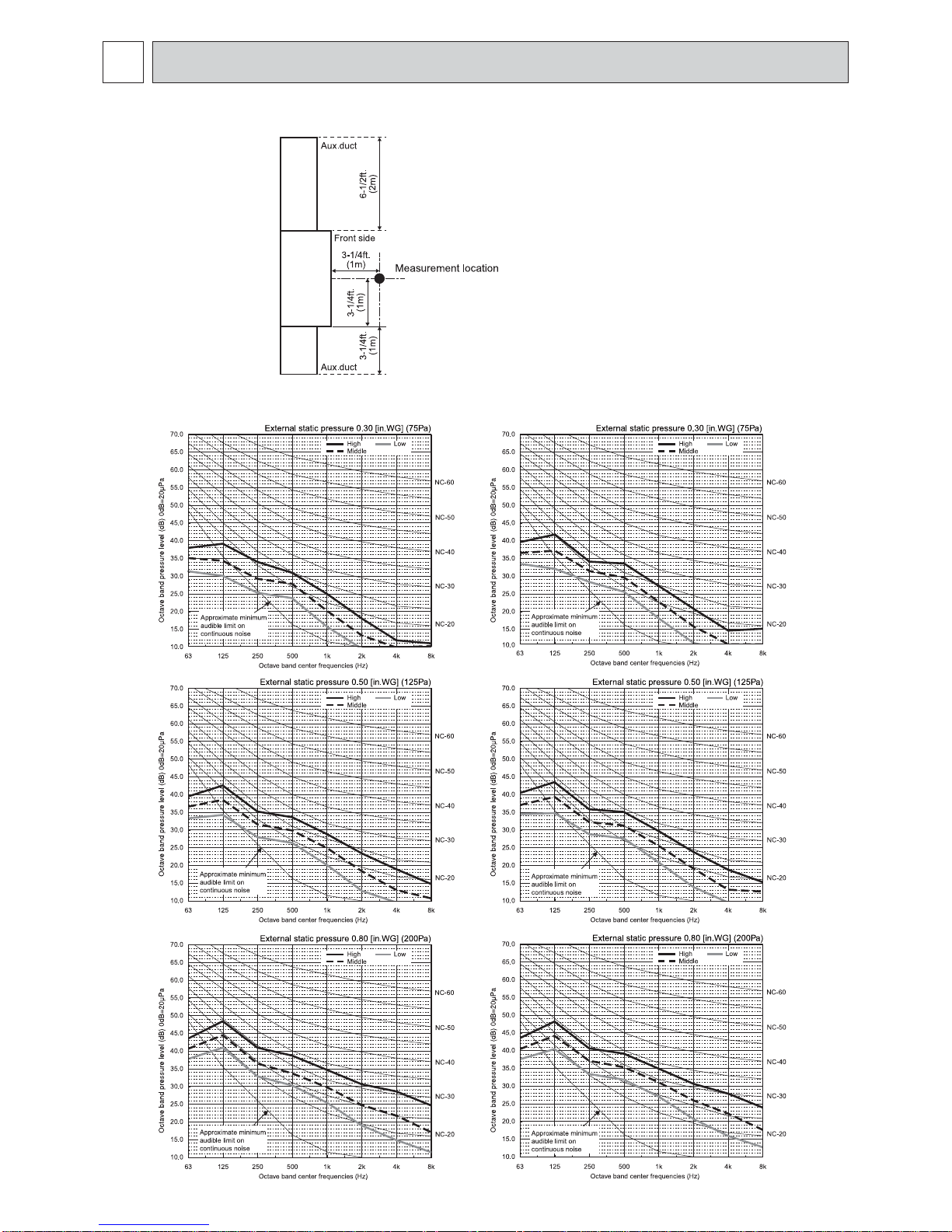

5. SOUND PRESSURE LEVELS .........................................................................................................................................12

5-1. Sound pressure level ..............................................................................................................................................12

5-2. NC curves ...............................................................................................................................................................12

6. OUTLINES & DIMENSIONS ............................................................................................................................................15

7. WIRING DIAGRAM ..........................................................................................................................................................17

8. REFRIGERANT SYSTEM DIAGRAM ..............................................................................................................................18

9. HEATER CONTROL .........................................................................................................................................................19

&RQWURO6SHFL¿FDWLRQV$QG)XQFWLRQ6HWWLQJ ...........................................................................................................19

9-2. Fan control ..............................................................................................................................................................21

9-3. CN24RELAY-KIT-CM3 (Optional Parts) installation ................................................................................................22

10. HUMIDIFIER CONTROL ................................................................................................................................................24

&RQWURO6SHFL¿FDWLRQV ...........................................................................................................................................24

10-2. Installation .............................................................................................................................................................24

11.

ERV (ENERGY RECOVERY VENTILATION) CONTROL .......................................................................................................................25

&RQWURO6SHFL¿FDWLRQV ............................................................................................................................................25

12. TROUBLESHOOTING ...................................................................................................................................................26

12-1. Cautions on troubleshooting .................................................................................................................................26

12-2. Self-check function ................................................................................................................................................27

12-3. Self-diagnosis action table ....................................................................................................................................29

12-4. Troubleshooting by inferior phenomena ...............................................................................................................33

12-5. Test point diagram .................................................................................................................................................34

12-6. Trouble criterion of main parts...............................................................................................................................36

12-7. Thermistor .............................................................................................................................................................36

12-8. DC Fan motor (FAN MOTOR/INDOOR CONTROLLER BOARD) .......................................................................37

12-9. Functions of DIP switch and jumper wire ..............................................................................................................38

13. DISASSEMBLY PROCEDURE ......................................................................................................................................39

13-1. Control box ............................................................................................................................................................39

13-2. Thermistor (Return Air) ..........................................................................................................................................40

13-3. Coil Assembly........................................................................................................................................................41

13-4. Blower/Fan Assembly............................................................................................................................................43

SAFETY PRECAUTION1

1-1. Always observe for safety

Before obtaining access to terminal, all supply

circuits must be disconnected.

1-2. CAUTIONS RELATED TO NEW REFRIGERANT

1-2. Cautions related to new refrigerant

Cautions for units utilising refrigerant R410A

Use new refrigerant pipes.

In case of using the existing pipes for R22, be careful with

the followings.

· For A36 and A42, be sure to perform replacement oper-

ation before test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

Store the piping to be used indoors during

installation and both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Tools for R410A

Gauge manifold

Charge hose

Gas leak detector

Torque wrench

Flare tool

Size adjustment gauge

Vacuum pump adaptor

Electronic refrigerant

charging scale

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil etc.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Ventilate the room if refrigerant leaks during

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

2

Gravimeter

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1 Gauge manifold

2 Charge hose

3 Electronic scale

4 Gas leak detector

5 Adaptor for reverse flow check

6 Refrigerant charge base

7 Refrigerant cylinder

8 Refrigerant recovery equipment

· Only for R410A

· Use the existing fitting specifications. (UNF1/2)

· Use high-tension side pressure of 5.3MPa·G or over.

· Only for R410A

· Use pressure performance of 5.09MPa·G or over.

· Use the detector for R134a, R407C or R410A.

· Attach on vacuum pump.

· Only for R410A · Top of cylinder (Pink)

· Cylinder with syphon

Unit

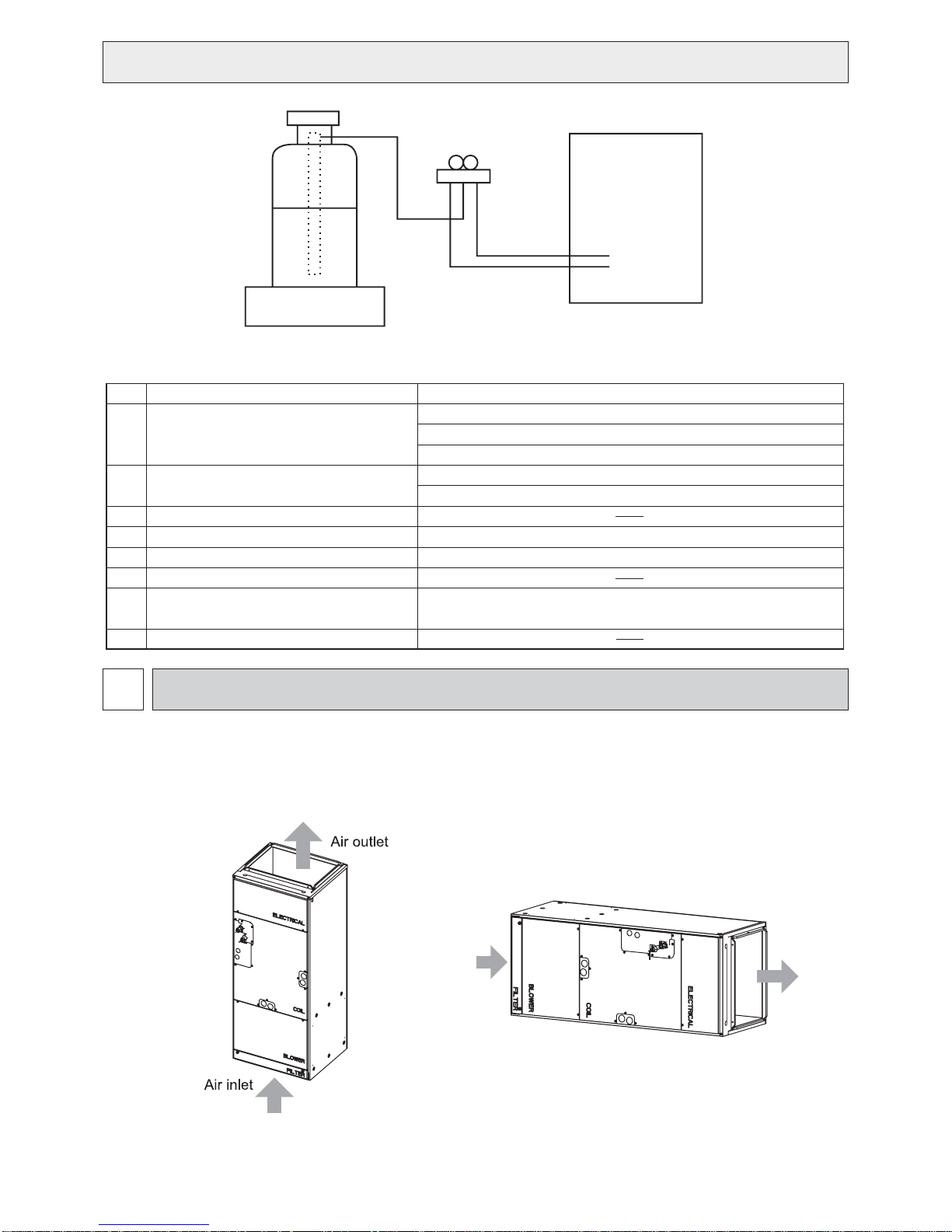

PART NAMES AND FUNCTIONS2

Indoor Unit

•

(1)Vertical

(2)Horizontal Right

Air

inlet

Air

outlet

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

3

(3)Horizontal left

(4)Down flow

Air inlet

Air

outlet

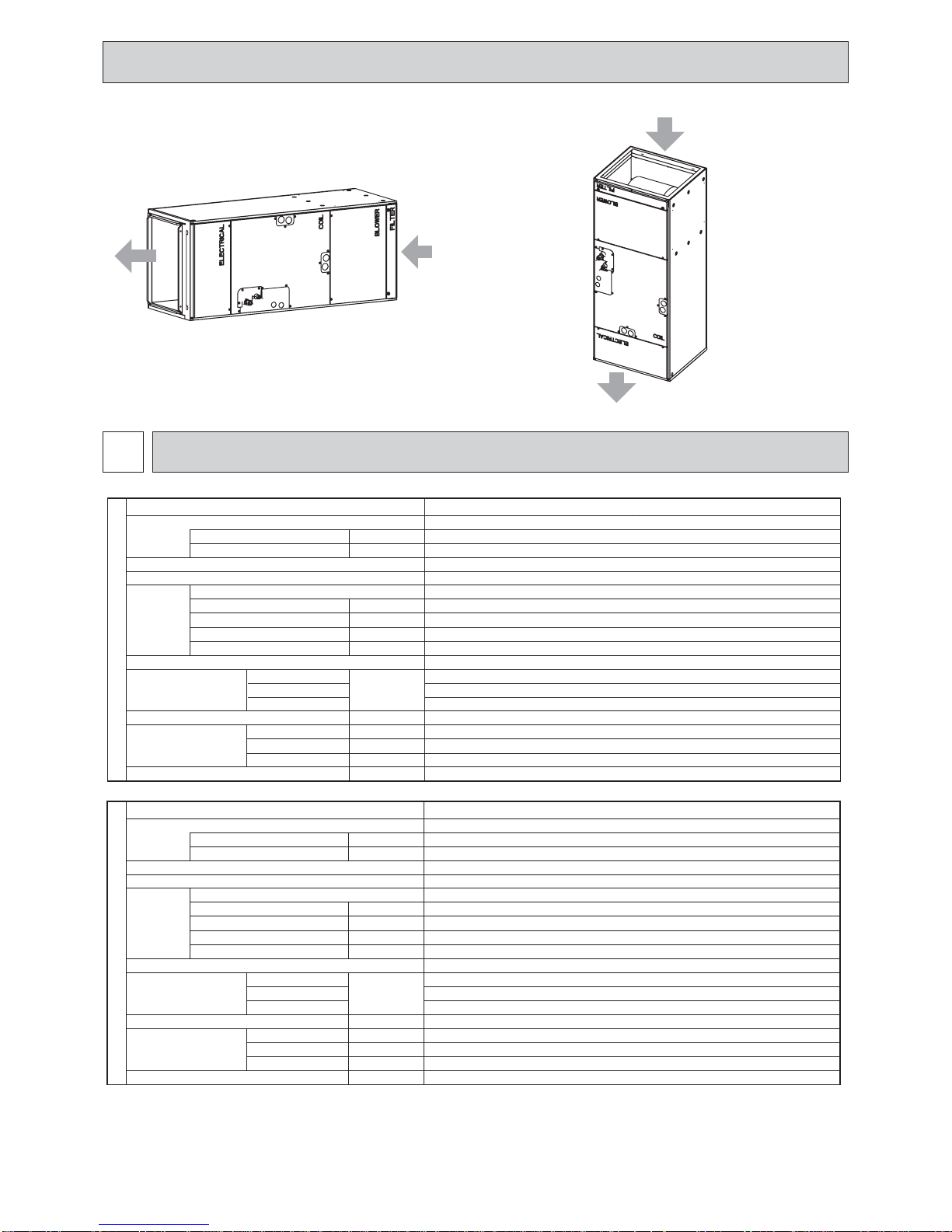

SPECIFICATION3

Servi ce Ref .

Power supply (phase, cycle, voltage)

External finish

Heat exchanger

Fan

Operation control & Thermostat

INDOOR UNIT

Sound pressure level

(Low-Mid-High)

Drain pipe mm (in . )

Dime ns ions W mm (in. )

Weight

Max. Fuse Size

Min. Circuit Ampacity A

Fan (drive) x No.

Fan motor output

Fan mot or

Airflow (Low-Mid-High)

External static pressure

75Pa (0.30 in.WG)

125Pa (0.50 in.WG)

200Pa (0.80 in.WG)

D mm (in. )

H mm (in. )

m

A

kW

F.L.A

3

/mi n (CF M)

Pa (in.WG)

dB ( A )

kg (lbs )

Air

inlet

Air outlet

MVZ-A12AA7

1 pha s e, 60H z, 208/230V

Galvanized steel cabinet - Powder coated Slate Gray

7.9-9.6-11.3 (280-340-400)

75-125-200 (0.30-0.50-0.80)

Remote controller & built-in

15

3.00

Plate n coil

Sirocco fan

19.05 (3/4) FPT

1275 (50-1/4)

x 1

0.121

2.4

24-28-32

27-31-35

32-36-41

432 (17)

548 (21-5/8)

51 (113)

Servi ce Ref .

Power supply (phase, cycle, voltage)

External finish

Heat exchanger

Fan

Operation control & Thermostat

INDOOR UNIT

Sound pressure level

(Low-Mid-High)

Dra in pipe mm (in. )

Dime ns ions W mm (in. )

Weight

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

Max. Fuse Size

Min. Circuit A mpacity A

Fan (drive) x No.

Fan motor output

Fan mot or

Airflow (Low-Mid-High)

External static pressure

75Pa (0.30 in.WG)

125Pa (0.50 in.WG)

200Pa (0.80 in.WG)

D mm (in. )

H mm (in. )

kW

F.L.A

3

/mi n (CF M)

m

Pa (in.WG)

dB ( A )

kg (lbs )

MVZ-A18AA7

A

Galvanized Steel Cabinet - Powder coated Slate Gray

1 pha s e, 60H z, 208/230V

11.6-14.1-16.6 (410-497-585)

75-125-200 (0.30-0.50-0.80)

Remote controller & built-in

15

3.00

Plate n coil

Sirocco fan

19.05 (3/4) FPT

1275 (50-1/4)

x 1

0.121

2.4

26-30-34

28-32-36

33-37-41

432 (17)

548 (21-5/8)

51 (113)

4

Servi ce Ref .

Power supply (phase, cycle, voltage)

External finish

Heat exchanger

Fan

Operation control & Thermostat

INDOOR UNIT

Sound pressure level

(Low-Mid-High)

Drain pipe mm (in . )

Dime ns ions W mm (in. )

Weight

Max. Fuse Size

Min. Circuit A mpacity A

Fan (drive) x No.

Fan motor output

Fan mot or

Airflow (Low-Mid-High)

External static pressure

75Pa (0.30 in.WG)

125Pa (0.50 in.WG)

200Pa (0.80 in.WG)

D mm (in. )

H mm (in. )

3

m

/mi n (CF M)

Pa (in.WG)

dB ( A )

kg (lbs )

kW

F.L.A

MVZ-A24AA7

A

Galvanized Steel Cabinet - Powder coated Slate Gray

1 phase, 60Hz, 208/230V

14.6-17.7-20.8 (515-625-735)

75-125-200 (0.30-0.50-0.80)

Remote controller & built-in

15

3.00

Plate n coil

Sirocco fan

19.05 (3/4) FPT

1275 (50-1/4)

x 1

0.121

2.4

28-33-36

30-34-38

34-38-42

432 (17)

548 (21-5/8)

51 (113)

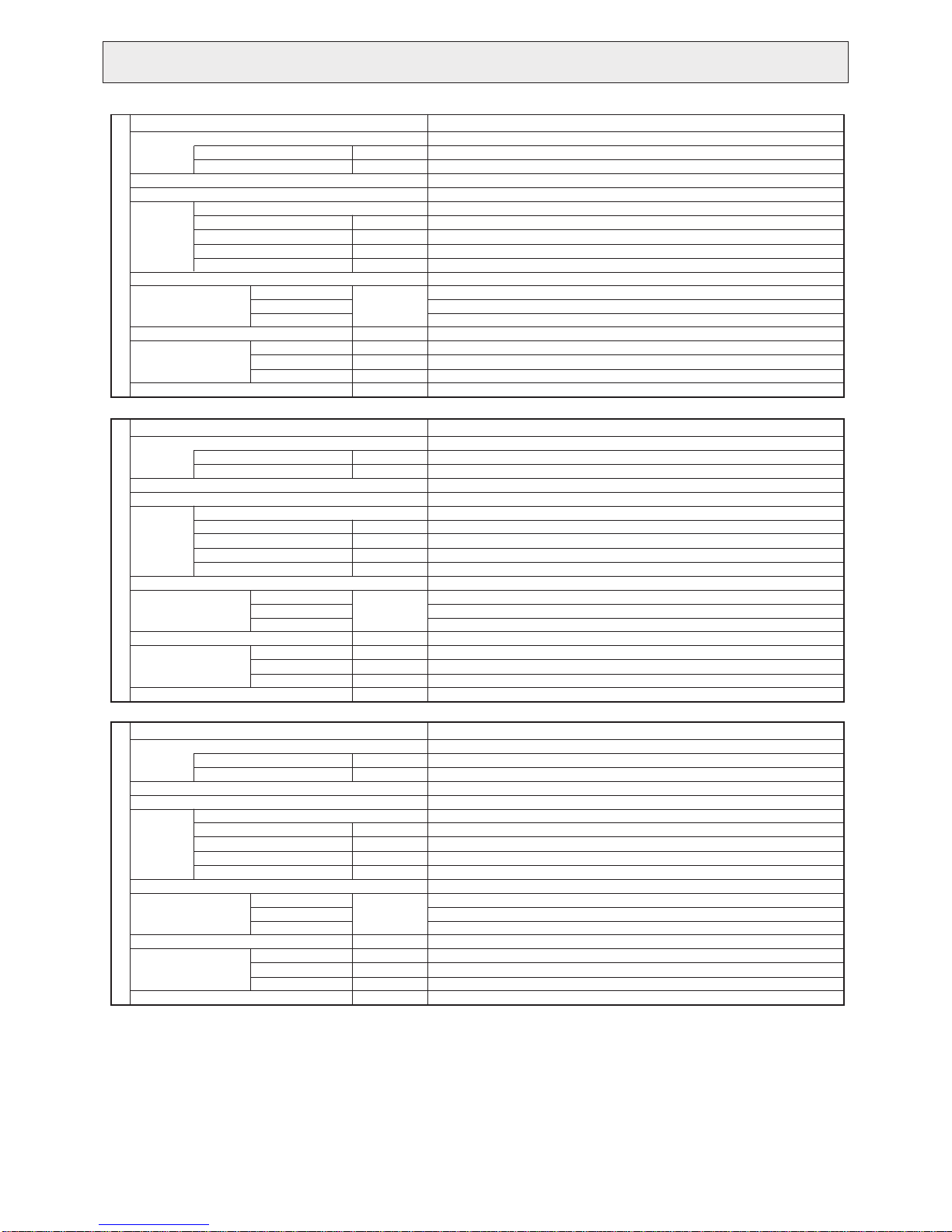

Servi ce Ref .

Power supply (phase, cycle, voltage)

External finish

Heat exchanger

Fan

Operation control & Thermostat

INDOOR UNIT

Sound pressure level

(Low-Mid-High)

Drain pipe mm (in . )

Dime ns ions W mm (in. )

Weight

Servi ce Ref .

Power supply (phase, cycle, voltage)

External finish

Heat exchanger

Fan

Operation control & Thermostat

INDOOR UNIT

Sound pressure level

(Low-Mid-High)

Drain pipe mm (in . )

Dime ns ions W mm (in. )

Weight

Max. Fuse Size

Min. Circuit A mpacity A

Fan (drive) x No.

Fan motor output

Fan mot or

Airflow (Low-Mid-High)

External static pressure

75Pa (0.30 in.WG)

125Pa (0.50 in.WG)

200Pa (0.80 in.WG)

D mm (in. )

H mm (in. )

Max. Fuse Size

Min. Circuit A mpacity A

Fan (drive) x No.

Fan motor output

Fan mot or

Airflow (Low-Mid-High)

External static pressure

75Pa (0.30 in.WG)

125Pa (0.50 in.WG)

200Pa (0.80 in.WG)

D mm (in. )

H mm (in. )

3

m

/mi n (CF M)

Pa (in.WG)

dB ( A )

kg (lbs )

3

m

/mi n (CF M)

Pa (in.WG)

dB ( A )

kg (lbs )

kW

F.L.A

kW

F.L.A

MVZ-A30AA7

A

Galvanized Steel Cabinet - Powder coated Slate Gray

1 phase, 60Hz, 208/230V

17.3-21.1-24.8 (613-744-875)

75-125-200 (0.30-0.50-0.80)

Remote controller & built-in

15

4.13

Plate n coil

Sirocco fan

19.05 (3/4) FPT

1378 (54-1/4)

x 1

0.244

3.3

30-34-38

32-36-40

35-39-43

534 (21)

548 (21-5/8)

64 (141)

MVZ-A36AA7

A

Ga lvanized Steel Cabinet - P owder coated S late Gray

1 phase, 60Hz, 208/230V

21.7-26.4-31.0 (767-931-1095)

75-125-200 (0.30-0.50-0.80)

Re m o te co n tr o ll e r & bu il t- i n

15

4.13

Plate fin coil

S irocco fan

0.244

3.3

33-37-41

35-39-43

37-41-45

19.05 (3/4) FP T

534 (21)

548 (21-5/8)

1378 (54-1/4)

64 (141)

1

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

5

FAN PERFORMANCE AND CORRECTED AIR FLOW4

MVZ-A12AA4

MVZ-A12AA7

• Vertical, Horizontal Right, Horizontal Left • Downflow

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.40]

100

[0.40]

100

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.30]

[0.20]

Static pressure (Pa)[in.WG]

[0.10]

[0.60]

[0.50]

[0.40]

Static pressure (Pa)[in.WG]

[0.30]

[0.20]

75

50

Middle

High

Low

25

0

[0]

7

[247]

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

150

125

100

10

[353]

Airflow rate (m

3

/min)[cfm]

High

Middle

75

Low

50

[247]

7

10

[353]

Airflow rate (m

3

/min)[cfm]

[494]

[494]

75

[0.30]

50

[0.20]

Static pressure (Pa)[in.WG]

25

[0.10]

0

[0.60]

[0.50]

[0.40]

[0]

7

[247]

150

125

100

14

Low

10

[353]

Airflow rate (m

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

Middle

3

/min)[cfm]

High

High

[494]

14

Middle

75

[0.30]

Static pressure (Pa)[in.WG]

Low

50

[0.20]

25

[0.10]

14

[247]

7

10

[353]

Airflow rate (m

3

/min)[cfm]

[494]

14

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

[0.90]

200

[0.80]

175

[0.70]

150

[0.60]

Middle

Static pressure (Pa)[in.WG]

125

[0.50]

100

[0.40]

[0.30]

75

7

[247]

Low

10

[353]

Airflow rate (m

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

3

/min)[cfm]

High

[494]

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

[0.90]

200

[0.80]

[0.70]

[0.60]

175

150

High

Middle

Static pressure (Pa)[in.WG]

125

[0.50]

100

[0.40]

75

[0.30]

14

[247]

7

Low

10

[353]

Airflow rate (m

3

/min)[cfm]

[494]

14

6

MVZ-A18AA4

MVZ-A18AA7

• Vertical, Horizontal Right, Horizontal Left • Downflow

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.40]

100

[0.40]

100

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.30]

[0.20]

Static pressure (Pa)[in.WG]

[0.10]

[0.60]

[0.50]

[0.40]

Static pressure (Pa)[in.WG]

75

50

Middle

High

Low

25

0

[0]

10

[353]

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

150

125

100

[530]

Airflow rate (m

15

3

/min)[cfm]

High

Middle

[706]

75

[0.30]

50

[0.20]

Static pressure (Pa)[in.WG]

25

[0.10]

0

[0.60]

[0.50]

[0.40]

[0]

10

[353]

150

125

100

20

Low

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

Middle

[530]

Airflow rate (m

15

3

/min)[cfm]

High

High

[706]

20

Middle

75

[0.30]

Static pressure (Pa)[in.WG]

[0.30]

[0.20]

[0.90]

[0.80]

[0.70]

[0.60]

Static pressure (Pa)[in.WG]

[0.50]

[0.40]

[0.30]

75

Low

50

10

[353]

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

200

175

150

15

[530]

Airflow rate (m3/min)[cfm]

High

Middle

125

100

75

10

[353]

Low

[530]

Airflow rate (m

15

3

/min)[cfm]

[706]

[706]

50

[0.20]

25

20

20

[0.10]

[0.90]

[0.80]

[0.70]

[0.60]

Static pressure (Pa)[in.WG]

[0.50]

[0.40]

[0.30]

225

200

175

150

125

100

75

Low

[353]

10

[530]

Airflow rate (m

15

3

/min)[cfm]

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

High

Middle

Low

[353]

10

[530]

Airflow rate (m

15

3

/min)[cfm]

[706]

[706]

20

20

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

7

MVZ-A24AA4

MVZ-A24AA7

• Vertical, Horizontal Right, Horizontal Left • Downflow

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.40]

100

[0.40]

100

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.30]

[0.20]

Static pressure (Pa)[in.WG]

[0.10]

[0.60]

[0.50]

[0.40]

Static pressure (Pa)[in.WG]

[0.30]

[0.20]

75

50

Middle

High

Low

25

0

[0]

13

[459]

150

125

100

[530]

15

Airflow rate (m

3

/min)[cfm]

[706]

20

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

High

Middle

75

Low

50

[459]

13

[530]

15

Airflow rate (m

3

/min)[cfm]

[706]

20

[847]

[847]

75

[0.30]

50

[0.20]

Static pressure (Pa)[in.WG]

25

[0.10]

0

[0.60]

[0.50]

[0.40]

[0]

150

125

100

24

Low

[459]

13

[530]

15

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

Middle

Airflow rate (m

3

/min)[cfm]

20

[706]

High

High

[847]

24

Middle

75

[0.30]

Static pressure (Pa)[in.WG]

Low

50

[0.20]

25

24

[0.10]

[459]

13

[530]

15

Airflow rate (m

3

/min)[cfm]

20

[706]

[847]

24

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

[0.90]

200

[0.80]

175

[0.70]

150

[0.60]

Static pressure (Pa)[in.WG]

[0.50]

[0.40]

[0.30]

125

100

Low

75

[459]

13

[530]

15

Middle

Airflow rate (m

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

3

/min)[cfm]

High

[706]

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

[0.90]

/min)[cfm]

High

[706]

20

[777]

22

200

[0.80]

175

[0.70]

150

[0.60]

Static pressure (Pa)[in.WG]

125

[0.50]

100

[0.40]

75

20

[777]

22

[0.30]

[459]

Low

13

[530]

15

Middle

Airflow rate (m

3

8

MVZ-A30AA4

MVZ-A30AA7

• Vertical, Horizontal Right, Horizontal Left • Downflow

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.40]

100

[0.40]

100

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.30]

[0.20]

Static pressure (Pa)[in.WG]

[0.10]

[0.60]

[0.50]

[0.40]

[0.30]

Static pressure (Pa)[in.WG]

[0.20]

75

50

Middle

High

Low

25

0

[0]

15

[530]

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

150

125

100

20

[706]

Airflow rate (m

3

/min)[cfm]

[883]

High

Middle

75

50

Low

3

/min)[cfm]

High

High

[883]

25

29

[1024]

75

[0.30]

50

[0.20]

Static pressure (Pa)[in.WG]

25

[0.10]

0

[0.60]

[0.50]

[0.40]

[0]

[530]

150

125

100

25

29

[1024]

Low

15

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

Middle

20

[706]

Airflow rate (m

Middle

75

[0.30]

Static pressure (Pa)[in.WG]

Low

50

[0.20]

25

[0.10]

15

[530]

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

[0.90]

200

[0.80]

175

[0.70]

150

[0.60]

20

[706]

Airflow rate (m

Middle

Static pressure (Pa)[in.WG]

125

[0.50]

100

[0.40]

[0.30]

75

[530]

Low

15

20

[706]

Airflow rate (m

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

3

/min)[cfm]

3

/min)[cfm]

High

[883]

[883]

25

[0.10]

[0.90]

[0.80]

[0.70]

[0.60]

Static pressure (Pa)[in.WG]

[0.50]

[0.40]

[0.30]

15

[530]

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

200

175

150

125

100

75

[530]

Low

15

25

25

29

[1024]

29

[1024]

20

[706]

Airflow rate (m

Middle

20

[706]

Airflow rate (m

3

/min)[cfm]

3

/min)[cfm]

High

[883]

25

[883]

28

[989]

27

25

[953]

9

MVZ-A36AA4

MVZ-A36AA7

• Vertical, Horizontal Right, Horizontal Left • Downflow

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.40]

100

[0.50]

125

External static pressure 0.30 [in.WG] (75Pa) 208/230V 60Hz

[0.30]

[0.20]

Static pressure (Pa)[in.WG]

[0.10]

[0.60]

[0.50]

[0.40]

Static pressure (Pa)[in.WG]

[0.30]

75

Middle

50

Low

25

0

[0]

19

20

[671]

[706]

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

150

125

100

25

[883]

Airflow rate (m

3

/min)[cfm]

Middle

75

Low

High

High

30

[1059]

33

[1165]

[0.40]

[0.30]

[0.20]

Static pressure (Pa)[in.WG]

[0.10]

[0.70]

[0.60]

[0.50]

[0.40]

Static pressure (Pa)[in.WG]

[0.30]

[0.20]

100

75

Middle

50

Low

25

0

[0]

19

20

[671]

[706]

External static pressure 0.50 [in.WG] (125Pa) 208/230V 60Hz

175

150

125

100

75

25

[883]

Airflow rate (m3/min)[cfm]

Middle

Low

50

High

High

30

[1059]

32

[1130]

50

[0.20]

[0.90]

[0.80]

[0.70]

[0.60]

Static pressure (Pa)[in.WG]

[0.50]

[0.40]

[0.30]

19

20

[671]

[706]

External static pressure 0.80 [in.WG] (200Pa) 208/230V 60Hz

225

200

175

150

125

100

75

[671]

Low

19

20

[706]

25

[883]

Airflow rate (m

Middle

25

[883]

Airflow rate (m

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

3

/min)[cfm]

3

/min)[cfm]

High

30

[1059]

30

[1059]

32

[1130]

32

[1130]

10

[0.10]

[0.80]

[0.70]

[0.60]

[0.50]

Static pressure (Pa)[in.WG]

[0.40]

[0.30]

[0.20]

25

19

20

[671]

[706]

External static pressure 0.60 [in.WG] (150Pa) 208/230V 60Hz

200

175

150

125

25

[883]

Airflow rate (m

3

/min)[cfm]

Middle

100

75

Low

50

[671]

19

20

[706]

25

[883]

Airflow rate (m

3

/min)[cfm]

High

30

[1059]

30

[1059]

32

[1130]

32

[1130]

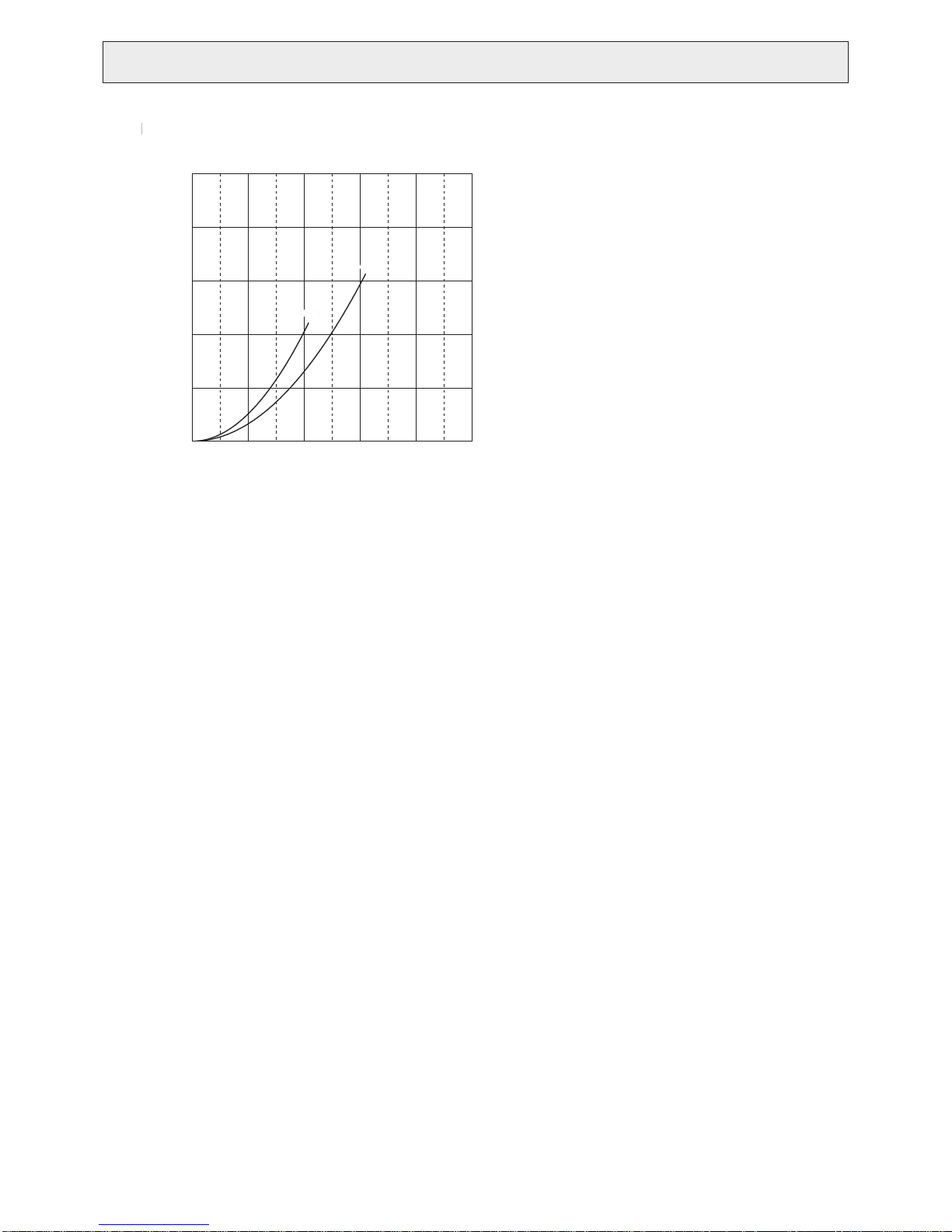

MVZ-A12, 18, 24, 30, 36AA4

A

MVZ-A12, 18, 24, 30, 36AA7

ir filter

Power source:208/230V 60Hz

25

[0.100]

20

[0.080]

15

[0.060]

10

[0.040]

External static pressure (Pa)[in.WG]

5

[0.020]

0

[0]

0

[0]

[353]

10

A12,18,24A12,18,24

20

[706]

Airflow rate (m3/min)[cfm]

[1059]

A30,36

A30,36

30

40

[1412]

50

[1766]

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

11

SOUND PRESSURE LEVELS5

5-1. Sound pressure level

Multi-Position

5-2. NC curves

MVZ-A12AA7 MVZ-A18AA7

6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH © 2016 Mitsubishi Electric US, Inc.

12

Loading...

Loading...