Mitsubishi Electric MUZ-SF25VE-E1, MUZ-SF25VEH-E1, MUZ-SF42VE-E1, MUZ-SF50VE-E1, MUZ-SF35VEH-E1 Service Manual

...

SERVICE MANUAL

CONTENTS

1. TECHNICAL CHANGES ··································· 3

2. PART NAMES AND FUNCTIONS ····················· 4

3. SPECIFICATION ················································ 5

4. NOISE CRITERIA CURVES ······························ 6

5. OUTLINES AND DIMENSIONS ························ 8

6. WIRING DIAGRAM ············································ 9

7. REFRIGERANT SYSTEM DIAGRAM ··············11

8. PERFORMANCE CURVES ····························· 13

9. ACTUATOR CONTROL ··································· 27

10. SERVICE FUNCTIONS ···································· 28

11. TROUBLESHOOTING ····································· 28

12. DISASSEMBLY INSTRUCTIONS ···················· 45

Models

SPLIT-TYPE AIR CONDITIONERS

NOTE:

RoHS compliant products have <G> mark on the spec name plate.

HFC

utilized

R410A

No. OBH629

OUTDOOR UNIT

Indoor unit service manual

MSZ-SF•VE Series (OBH600)

PARTS CATALOG (OBB629)

MUZ-SF25VE MUZ-SF25VEH

MUZ-SF35VE MUZ-SF35VEH

MUZ-SF42VE MUZ-SF42VEH

MUZ-SF25VE

-

E1

MUZ-SF42VE

-

E1

MUZ-SF25VEH

-

E1

MUZ-SF42VEH

-

E1

MUZ-SF35VE

-

E1

MUZ-SF50VE

-

E1

MUZ-SF35VEH

-

E1

MUZ-SF50VEH

-

E1

2

<Preparation before the repair service>

Prepare the proper tools.

Prepare the proper protectors.

Provide adequate ventilation.

After stopping the operation of the air conditioner, turn off the power-supply breaker and remove the power plug.

Discharge the capacitor before the work involving the electric parts.

<Precautions during the repair service>

Do not perform the work involving the electric parts with wet hands.

Do not pour water into the electric parts.

Do not touch the refrigerant.

Do not touch the hot or cold areas in the refrigeration cycle.

When the repair or the inspection of the circuit needs to be done without turning off the power, exercise great caution not to

touch the live parts.

Use the specifi ed refrigerant only

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused by

failure to follow the instructions.

OBH629

3

MUZ-SF25VE -

E1

MUZ-SF25VEH -

E1

MUZ-SF35VE -

E1

MUZ-SF35VEH -

E1

MUZ-SF42VE -

E1

MUZ-SF42VEH -

E1

MUZ-SF50VE -

E1

MUZ-SF50VEH -

E1

1. New model

TECHNICAL CHANGES

1

OBH629

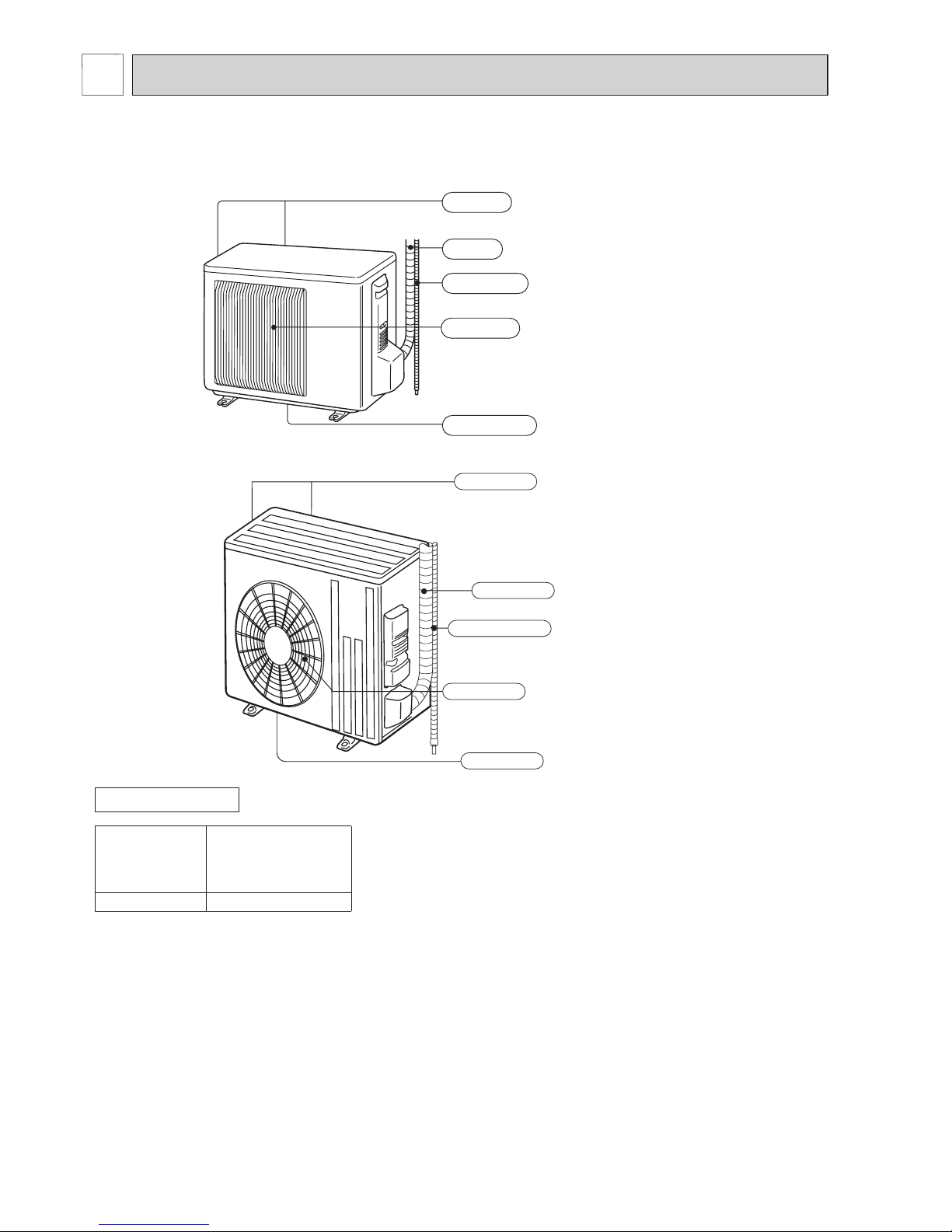

4

Air outlet

Drain outlet

Piping

Drain hose

Air inlet

(back and side)

MUZ-SF25VE MUZ-SF25VEH

MUZ-SF35VE MUZ-SF35VEH

MUZ-SF42VE MUZ-SF42VEH

PART NAMES AND FUNCTIONS

2

ACCESSORIES

MODELS

MUZ-SF25VE

MUZ-SF35VE

MUZ-SF42VE

MUZ-SF50VE

Drain socket 1

MUZ-SF50VE MUZ-SF50VEH

Piping

Air outlet

Drain outlet

Air inlet

(back and side)

Drain hose

OBH629

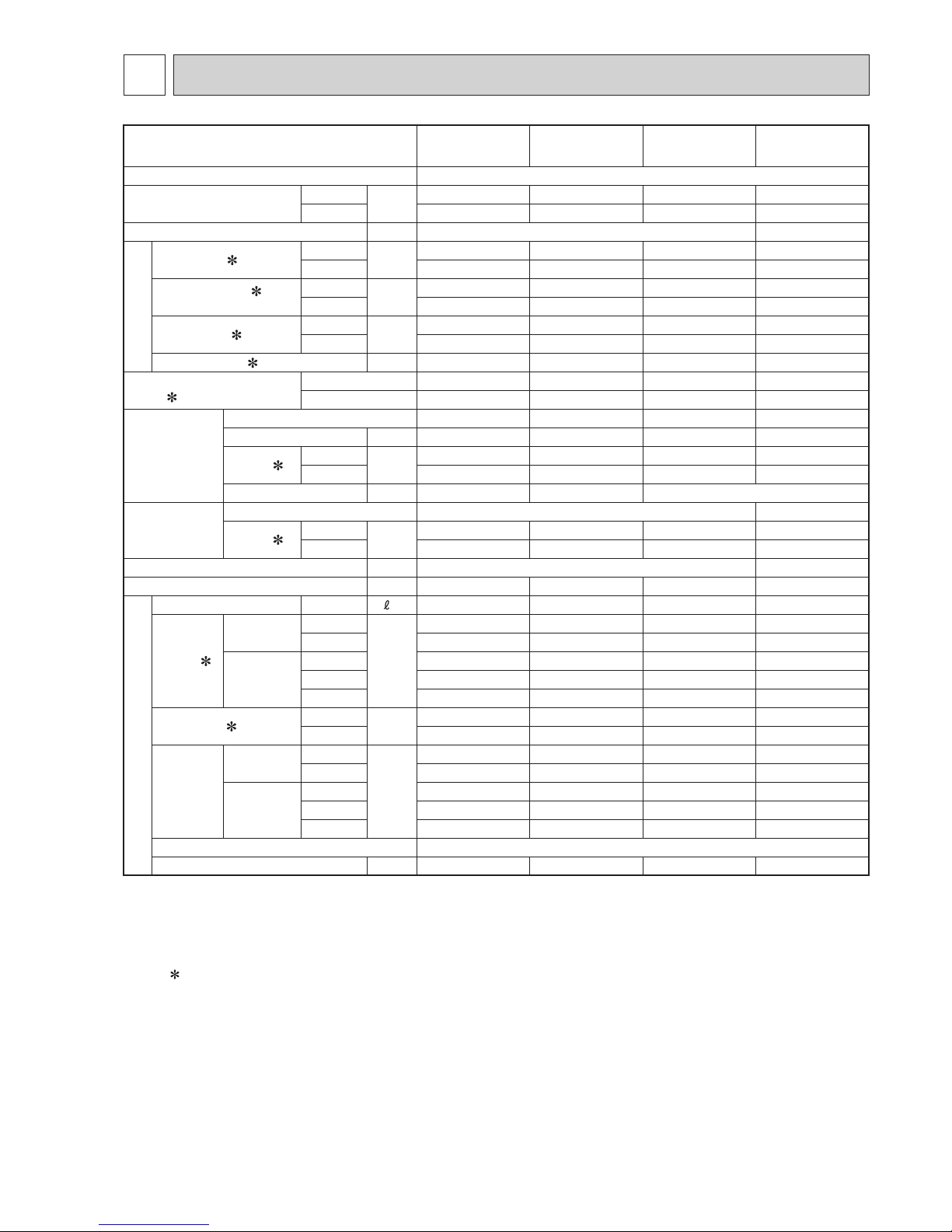

5

Outdoor model

MUZ-SF25VE

MUZ-SF25VEH

MUZ-SF35VE

MUZ-SF35VEH

MUZ-SF42VE

MUZ-SF42VEH

MUZ-SF50VE

MUZ-SF50VEH

Power supply Single phase, 230 V, 50 Hz

Capacity

Rated frequency (Min.-Max.)

Cooling

kW

2.5 (0.9 - 3.4) 3.5 (1.1 - 3.8) 4.2 (0.8 - 4.5) 5.0 (1.4 - 5.4)

Heating 3.2 (1.0 - 4.1) 4.0 (1.3 - 4.6) 5.4 (1.3 - 6.0) 5.8 (1.6 - 7.3)

Breaker Capacity A 10 16

Electrical data

Power input 1 (Total)

Cooling

W

600 1,080 1,340 1,660

Heating 780 1,030 1,580 1,700

Running current

1

(Total)

Cooling

A

3.2 4.9 6.0 7.4

Heating 3.9 4.7 7.0 7.6

Power factor

1 (Total)

Cooling

%

81 95 97 97

Heating 86 95 98 97

Starting current

1 (Total) A 3.9 4.9 7.0 7.6

Coeffi cient of performance

(COP) 1 (Total)

Cooling 4.17 3.24 3.13 3.01

Heating 4.10 3.88 3.42 3.41

Compressor

Model KNB073FKVMC KNB092FNDMC SNB130FGAMT SNB130FGBMT

Output W 550 650 900 900

Current

1

Cooling

A

3.04 4.74 5.84 7.22

Heating 3.70 4.48 6.78 7.33

Refrigeration oil (Model) L 0.32 (FV50S) 0.27 (FV50S) 0.35 (FV50S)

Fan motor

Model RC0J50-FA RC0J60-BD

Current

1

Cooling

A

0.20 0.24 0.30 0.84

Heating 0.29 0.30 0.28 0.93

Dimensions W × H × D mm 800 × 550 × 285 840 × 880 × 330

Weight kg 31 31 35 55

Special remarks

Dehumidifi cation Cooling /h 0.3 1.0 1.7 2.2

Air fl ow 1

Cooling

High

m3/h

1,698 1,956 1,806 2,868

Low 1,698 1,806 1,038 1,602

Heating

High 2,064 2,178 2,016 2,778

Med. 1,698 1,932 1,770 2,778

Low 1,350 1,476 1,326 2,124

Sound level 1

Cooling

dB(A)

47 49 50 52

Heating 48 50 51 52

Fan speed

Cooling

High

rpm

740 800 810 840

Low 740 740 490 480

Heating

High 890 890 900 810

Med. 740 790 770 810

Low 600 610 610 620

Fan speed regulator 3

Refrigerant fi lling capacity (R410A) kg 0.7 0.8 1.15 1.55

NOTE: Test conditions are based on ISO 5151.

Cooling: Indoor Dry-bulb temperature 27°C Wet-bulb temperature 19°C

Outdoor Dry-bulb temperature 35°C

Heating: Indoor Dry-bulb temperature 20°C

Outdoor Dry-bulb temperature 7°C Wet-bulb temperature 6°C

Refrigerant piping length (one way): 5 m

1 Measured under rated operating frequency.

SPECIFICATION

3

OBH629

6

Specifi cations and rated conditions of main electric parts

Model

Item

MUZ-SF25VE MUZ-SF25VEH MUZ-SF35VE MUZ-SF35VEH MUZ-SF42VE MUZ-SF42VEH MUZ-SF50VE MUZ-SF50VEH

Smoothing

capacitor

(C61, C62) 620 μF 420 V

(C63) — 620 μF 420 V

Diode module (DB61) 15 A 600 V 25 A 600 V

Fuse

(F61) T20AL250V

(F701, F801, F901)

T3.15AL250V

Defrost heater (H) —

230 V

130 W

—

230 V

130 W

—

230V

130W

—

230V

130W

Intelligent power

module

(IC700) 15 A 600 V 20 A 600 V

(IC932) 8A600V

Expansion valve

coil

(LEV) 12 V DC

Reactor (L61) 18 mH 23 mH

Power factor

controller

(IC820) 20A 600V

Current-limiting

PTC thermistor

(PTC64, PTC65)

33 Ω

Terminal block (TB) 5 P

Relay

(X63) 3 A 250 V

(X64) 20 A 250 V

(X66) — 3 A 250 V — 3 A 250 V — 3 A 250 V — 3 A 250 V

(X69) 10A 230V

R.V.coil (21S4) 220 - 240 V AC

Heater protector (26H) — Open 45°C — Open 45°C — Open 45°C — Open 45°C

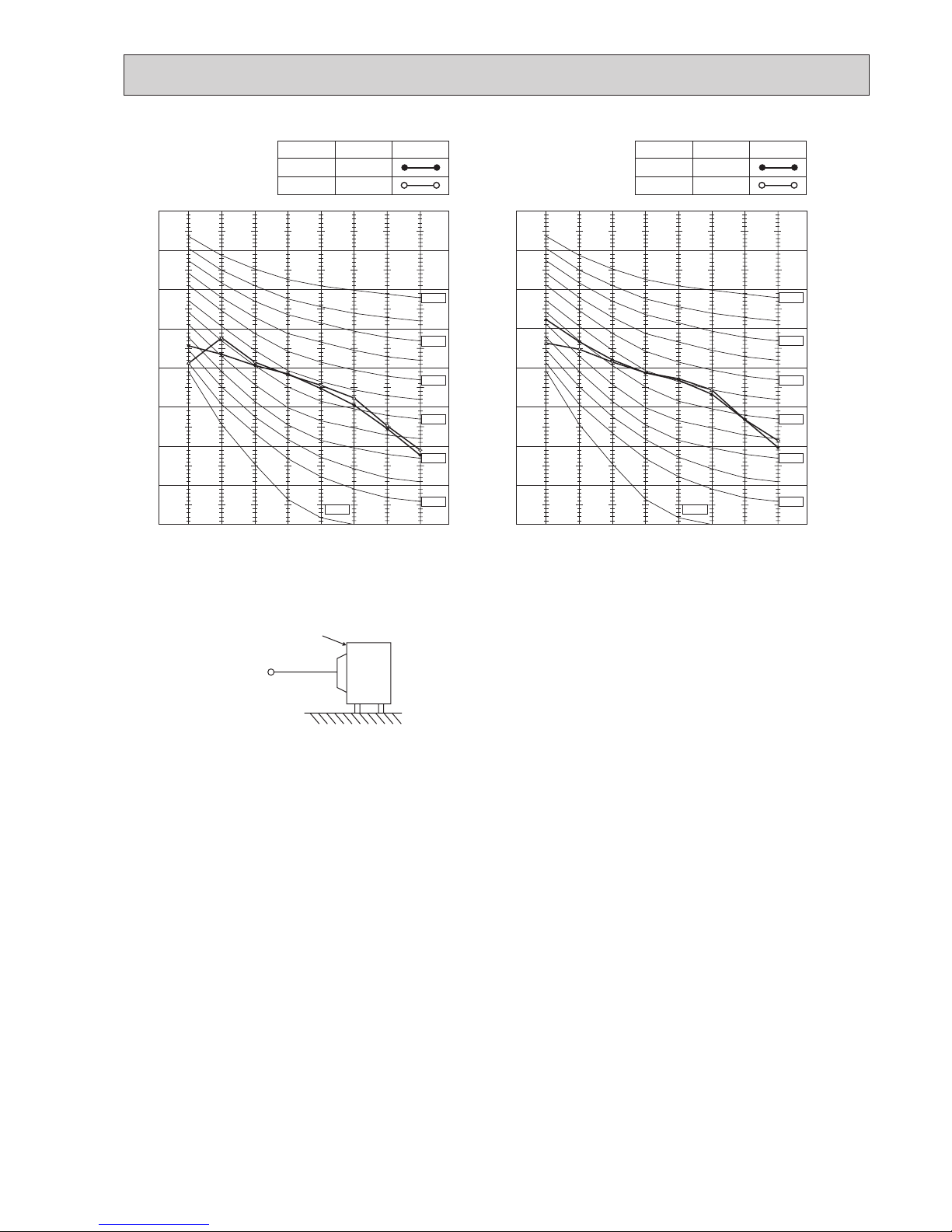

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

COOLING

FUNCTION

SPL(dB(A)) LINE

HEATING

47

48

NC-10

MUZ-SF25VE MUZ-SF25VEH

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

COOLING

FUNCTION

SPL(dB(A))

LINE

HEATING

49

50

NC-10

MUZ-SF35VE MUZ-SF35VEH

NOISE CRITERIA CURVES

4

OBH629

7

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, 0dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

COOLING

FUNCTION

SPL(dB(A)) LINE

HEATING

50

NC-10

51

MUZ-SF42VE MUZ-SF42VEH

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

COOLING

FUNCTION

SPL(dB(A)) LINE

HEATING

52

NC-10

52

MUZ-SF50VE MUZ-SF50VEH

Test conditions

Cooling: Dry-bulb temperature 35°C

Heating: Dry-bulb temperature 7°C Wet-bulb temperature 6°C

OUTDOOR UNIT

MICROPHONE

1 m

OBH629

8

Unit: mm

MUZ-SF25VE MUZ-SF25VEH MUZ-SF35VE MUZ-SF35VEH

MUZ-SF42VE MUZ-SF42VEH

10

69

800

302.5

500 Bolt pitch for installation

150

22.3

Handle

550

280

164.5

99.5

170.5

23

Service panel

Service port

285

344.5

44

400

Air in

Air out

Air in

17.5

Bolt pitch for

installation

304~325

40

Liquid refrigerant pipe joint

Refrigerant pipe (flared) ø6.35

Gas refrigerant pipe joint

Refrigerant pipe (flared) ø9.52

43

35

2 holes 10 X 21

REQUIRED SPACE

100 mm or more

350 mm or more

200 mm or more

100 mm or more

100 mm or more

Drain hole ø42 (MUZ-SF25/35/42VE)

Drain hole ø33 (MUZ-SF25/35/42VEH)

MUZ-SF50VE MUZ-SF50VEH

OUTLINES AND DIMENSIONS

5

417.5

40

42

Drain hole

175

500

330

50

Air in

Air out

2-holes 10 21

360

840

109

81

880

452

Service panel

99.5

164.5

195

35

44

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) Ø 6.35

Gas refrigerant pipe joint

Refrigerant pipe (flared) Ø 12.7

350 mm or more

100 mm or more

REQUIRED SPACE

500 mm or more

100 mm or more

500 mm or more

OBH629

9

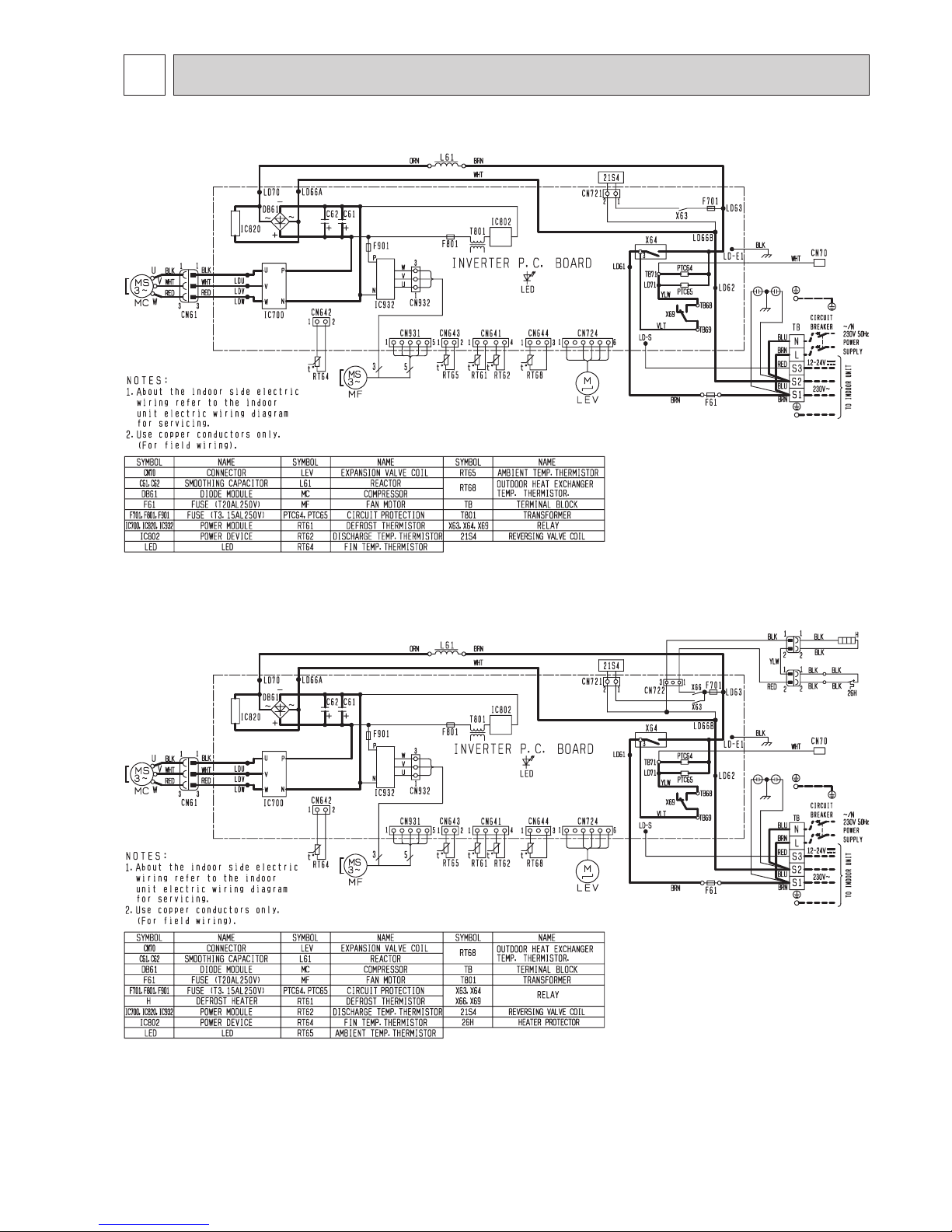

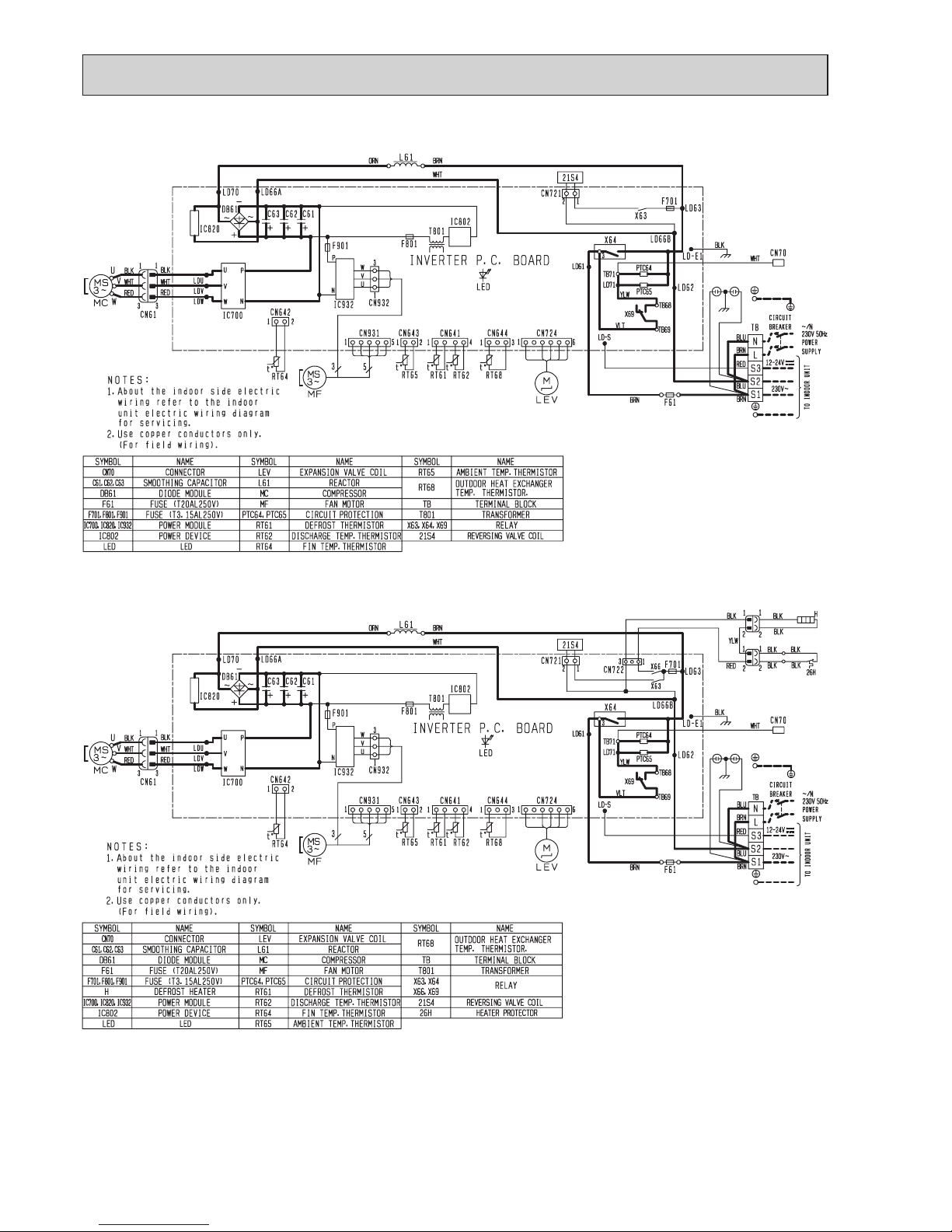

WIRING DIAGRAM

6

MUZ-SF25VEH MUZ-SF35VEH

MUZ-SF25VE MUZ-SF35VE

OBH629

10

MUZ-SF42VE MUZ-SF50VE

MUZ-SF42VEH MUZ-SF50VEH

OBH629

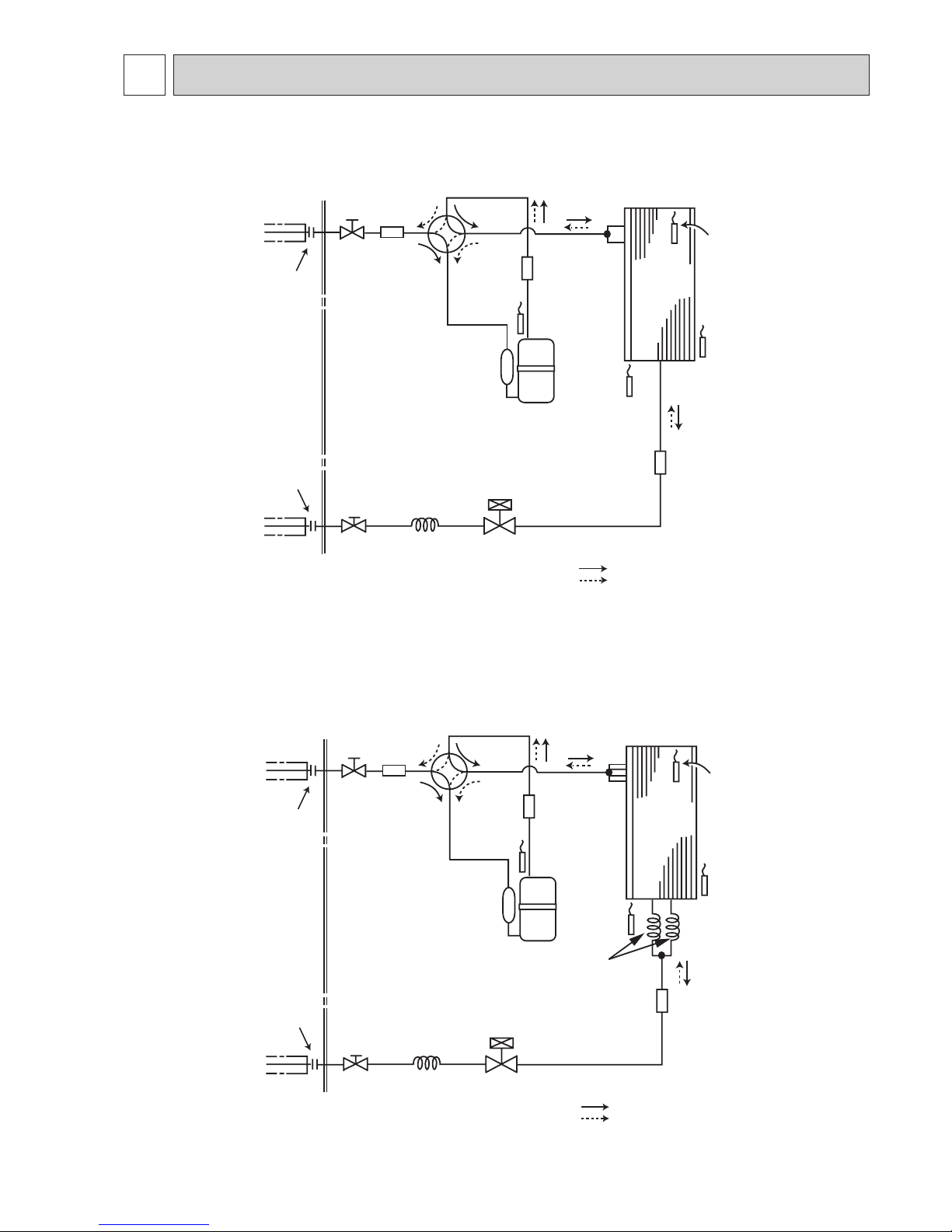

11

Unit: mm

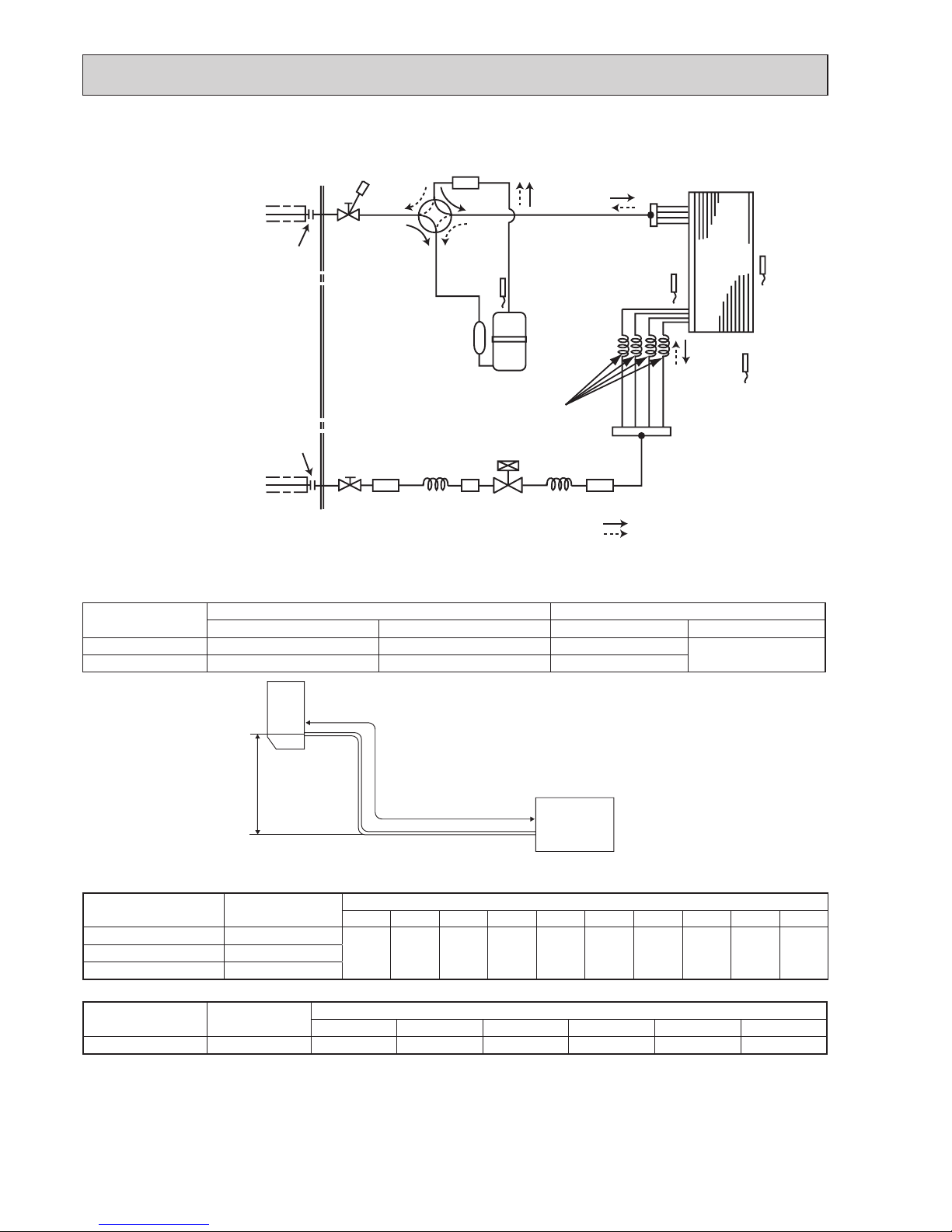

MUZ-SF25VE MUZ-SF25VEH MUZ-SF35VE MUZ-SF35VEH

Outdoor

heat

exchanger

Flared connection

Defrost

thermistor

RT61

Discharge

temperature

thermistor

RT62

Flared connection

Stop valve

(with strainar)

Stop valve

Refrigerant flow in cooling

Compressor

4-way valve

Refrigerant flow in heating

Refrigerant pipe ø9.52

(with heat insulator)

Refrigerant pipe ø6.35

(with heat insulator)

R.V. coil

heating ON

cooling OFF

Strainer

#100

LEV

Ambient

temperature

thermistor

RT65

Muffler

Capillary tube

ø3.0×ø2.0×240

Outdoor heat

exchanger

temperature

thermistor

RT68

Muffler

REFRIGERANT SYSTEM DIAGRAM

7

Unit: mm

MUZ-SF42VE MUZ-SF42VEH

Outdoor

heat

exchanger

Flared connection

Defrost

thermistor

RT61

Discharge

temperature

thermistor

RT62

Flared connection

Stop valve

(with strainar)

Stop valve

Refrigerant flow in cooling

Compressor

4-way valve

Refrigerant flow in heating

Refrigerant pipe ø9.52

(with heat insulator)

Refrigerant pipe ø6.35

(with heat insulator)

R.V. coil

heating ON

cooling OFF

Strainer

#100

Capillary tube

ø3.0×ø1.8×600(×2)

LEV

Ambient

temperature

thermistor

RT65

Muffler

Capillary tube

ø3.0×ø2.0×240

Outdoor heat

exchanger

temperature

thermistor

RT68

Muffler

OBH629

12

MUZ-SF50VE MUZ-SF50VEH

Unit: mm

Outdoor

heat

exchanger

Flared connection

Defrost

thermistor

RT61

Discharge

temperature

thermistor

RT62

Flared connection

Stop valve

Stop valve

(with service port)

Capillary tube

ø

4.0×ø

2.4×100

Capillary tube

ø

4.0×ø

2.4×200

Refrigerant flow in cooling

Compressor

4-way valve

Refrigerant flow in heating

Refrigerant pipe

ø

12.7

(with heat insulator)

Refrigerant pipe ø6.35

(with heat insulator)

LEV

R.V. coil

heating ON

cooling OFF

Muffler

#100

Strainer

#100

Outdoor heat

exchanger

temperature

thermistor

RT68

Am

b

te

m

the

r

RT

6

Strainer

#100

Muffler

Capillary tube

ø3.0×ø2.0×200(×4)

Max. Length

A

Max. Height

difference

B

Indoor

unit

Outdoor unit

MAX. REFRIGERANT PIPING LENGTH and MAX. HEIGHT DIFEFRENCE

Refrigerant piping: m Piping size O.D: mm

Max. Length A Max. Height difference B Gas Liquid

MUZ-SF25/35/42 20 12 9.52

6.35

MUZ-SF50 30 15 12.7

ADDITIONAL REFRIGERANT CHARGE (R410A: g)

Model

Outdoor unit

precharged

7 m 8 m 9 m 10 m 11 m 12 m 13 m 14 m 15 m 20 m

MUZ-SF25 700

0 30 60 90 120 150 180 210 240 390

MUZ-SF35 800

MUZ-SF42 1,150

Calculation: X g = 30 g/m × (Refrigerant piping length (m) - 7)

Model

Outdoor unit

precharged

Refrigerant piping length (one way)

7 m 10 m 15 m 20 m 25 m 30 m

MUZ-SF50 1,550 0 60 160 260 360 460

Calculation: X g = 20 g/m × (Refrigerant piping length (m) – 7)

NOTE: Refrigerant piping exceeding 7 m requires additional refrigerant charge according to the calculation.

OBH629

13

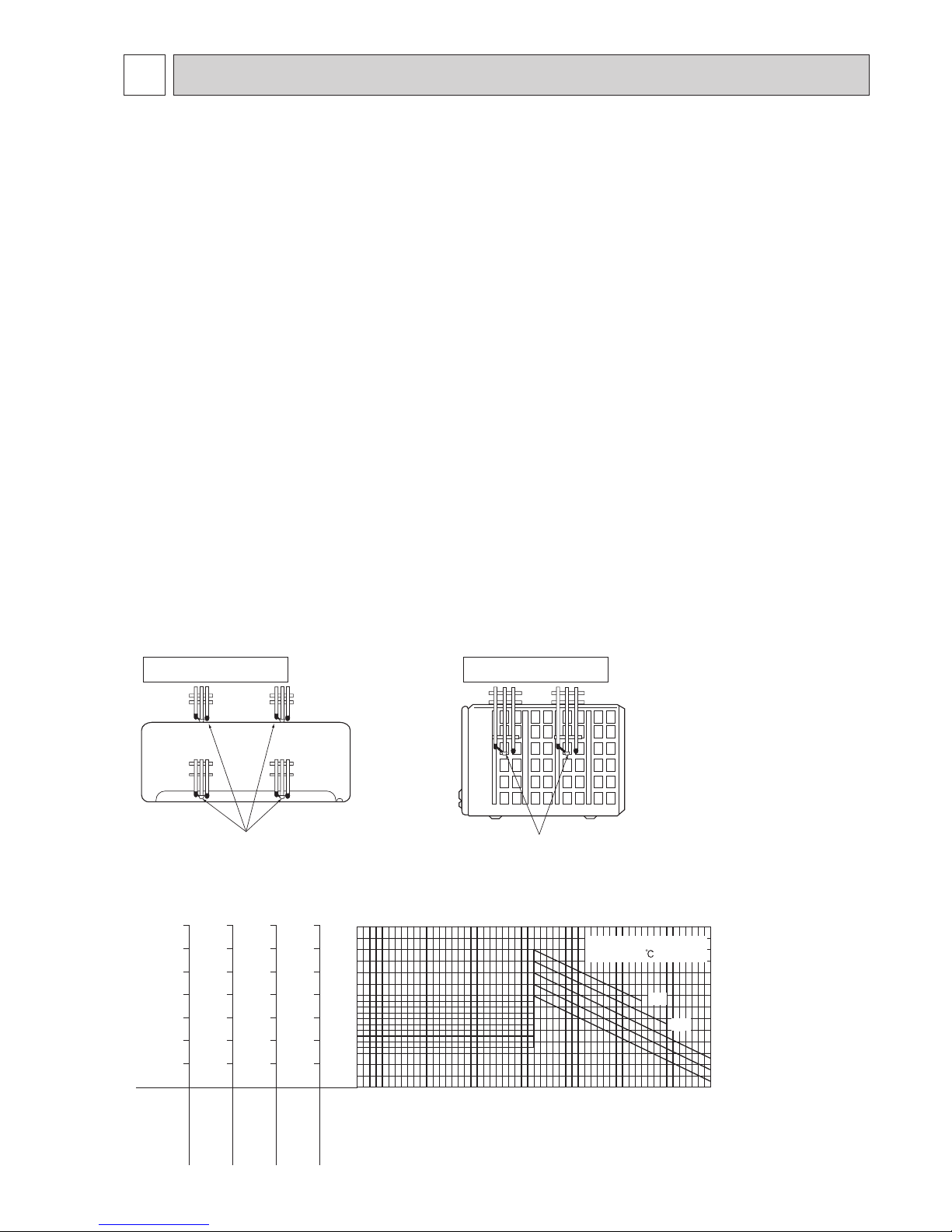

The standard specifications apply only to the operation of the air conditioner under normal conditions. Since operating conditions vary according to the areas where these units are installed, the following information has been provided to clarify the

operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

198 ~ 264 V, 50 Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature: °C [WB]

}

Cooling

(2) Indoor outlet air wet-bulb temperature: °C [WB]

(3) Outdoor intake air dry-bulb temperature: °C [DB]

(4) Total input: W

(5) Indoor intake air dry-bulb temperature: °C [DB]

}

Heating(6) Outdoor intake air wet-bulb temperature: °C [WB]

(7) Total input: W

Indoor air wet and dry bulb temperature difference on the left side of the following chart shows the difference between the

indoor intake air wet and dry bulb temperature and the indoor outlet air wet and dry bulb temperature for your reference at

service.

How to measure the indoor air wet and dry bulb temperature difference

1. Attach at least 2 sets of wet and dry bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet and dry bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet and dry bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch once (twice) to start the EMERGENCY COOL (HEAT) MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

MUZ-SF25VE MUZ-SF25VEH MUZ-SF35VE MUZ-SF35VEH

MUZ-SF42VE MUZ-SF42VEH MUZ-SF50VE MUZ-SF50VEH

INDOOR UNIT OUTDOOR UNIT

Wet and dry bulb

thermometers

FRONT VIEW

Wet and dry bulb

thermometers

BACK VIEW

Cooling capacity (

at Rated frequency)

0.9

1.0

1.1

1.2

1.3

1.4

1.5

-10-5 0 5 1015202530354045

Outdoor intake air Dry-bulb temperature(°C)

Capacity correction factors

26

24

20

18

22

Indoor intake air Wet-bulb

temperature( )

14.2

13.0

11.8

10.7

9.7

8.6

7.6

MUZ-SF50VE

MUZ-SF50VEH

MUZ-SF42VE

MUZ-SF42VEH

MUZ-SF35VE

MUZ-SF35VEH

MUZ-SF25VE

MUZ-SF25VEH

Indoor air Wet-bulb temperature

difference (°C)

7.6

7.0

6.4

5.9

5.3

4.8

4.3

11.3

10.4

9.5

8.6

7.8

7.0

6.2

16.0

14.6

13.3

12.0

10.8

9.6

8.5

8-1. CAPACITY AND INPUT CURVES

PERFORMANCE CURVES8

OBH629

14

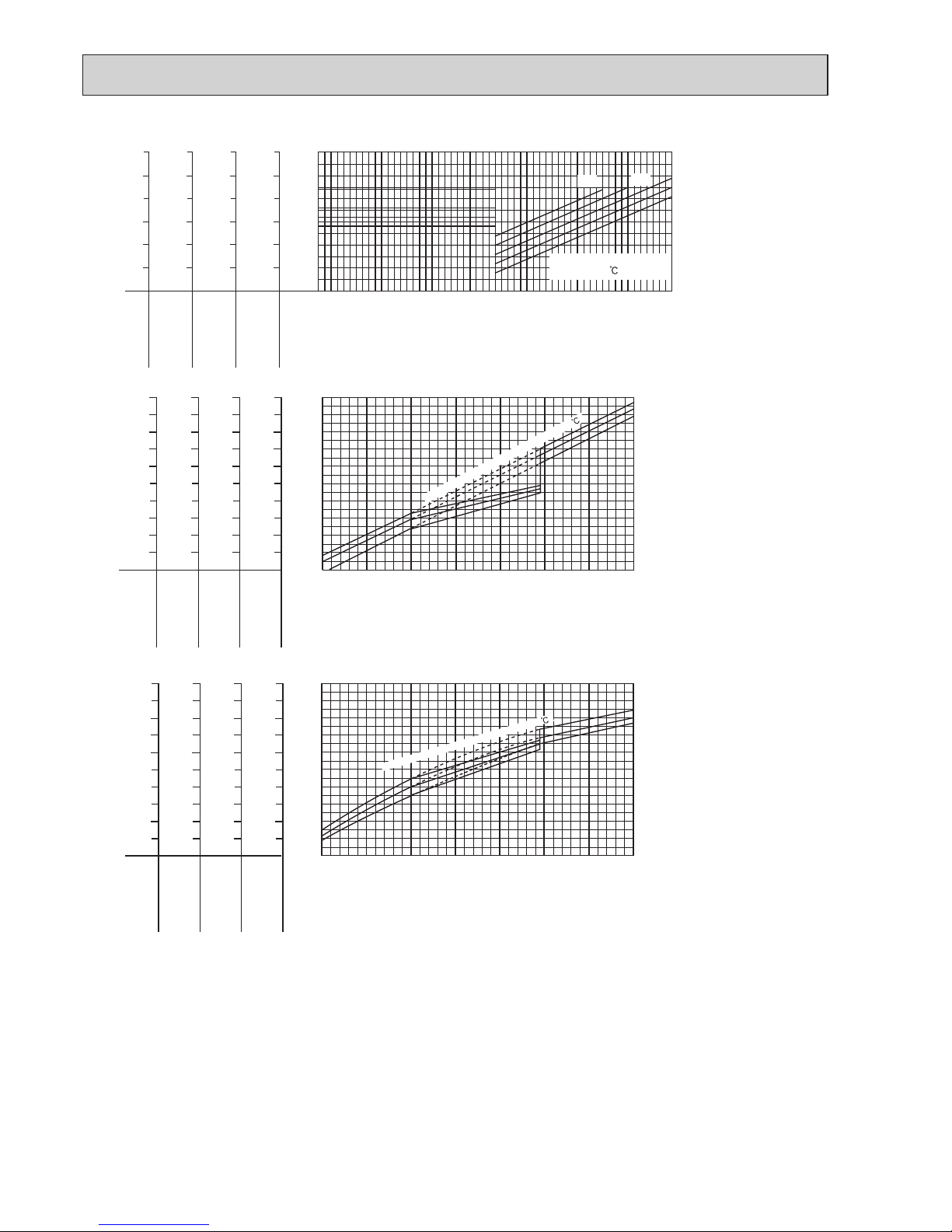

NOTE: The above broken lines are for the heating operation without any frost and defrost operation.

0.8

0.9

1.0

1.1

1.2

1.3

-10-5 0 5 1015202530354045

Outdoor intake air Dry-bulb temperature (°C)

Input correction factors

26

24

22

20

18

Indoor intake air Wet-bulb

temperature( )

Indoor air Wet-bulb temperature

difference (°C)

6.4

5.9

5.3

4.8

4.3

3.8

9.5

8.6

7.8

7.0

6.2

5.4

11.8

10.7

9.7

8.6

7.6

6.7

13.3

12.0

10.8

9.6

8.5

7.4

MUZ-SF50VE

MUZ-SF50VEH

MUZ-SF42VE

MUZ-SF42VEH

MUZ-SF35VE

MUZ-SF35VEH

MUZ-SF25VE

MUZ-SF25VEH

Total input (Cooling :

at Rated frequency

)

Indoor air Dry-bulb temperature

difference (°C)

20.3

18.8

17.2

15.6

14.1

12.5

10.9

9.4

7.8

6.3

32.1

29.6

27.2

24.7

22.2

19.8

17.3

14.8

12.3

9.9

31.6

29.2

26.7

24.3

21.9

19.4

17.0

14.6

12.2

9.7

MUZ-SF50VE

MUZ-SF50VEH

MUZ-SF42VE

MUZ-SF42VEH

MUZ-SF25VEH

MUZ-SF35VE

23.8

21.9

20.1

18.3

16.5

14.6

12.8

11.0

9.1

7.3

MUZ-SF35VEH

MUZ-SF25VE

Outdoor intake air Wet-bulb temperature (°C)

-20 -15 -10 -5 0 5 10 15

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Heating capacity (

at Rated frequency)

Capacity correction factor

15

20

26

Indoor intake air Dry-bulb temperature ( )

Indoor air Dry-bulb temperature

difference (°C)

20.3

18.8

17.2

15.6

14.1

12.5

10.9

9.4

7.8

6.3

MUZ-SF50VE

MUZ-SF50VEH

MUZ-SF42VE

MUZ-SF42VEH

MUZ-SF35VEH

MUZ-SF25VE

23.8

21.9

20.1

18.3

16.5

14.6

12.8

11.0

9.1

7.3

MUZ-SF35VEH

MUZ-SF35VE

32.1

29.6

27.2

24.7

22.2

19.8

17.3

14.8

12.3

9.9

31.6

29.2

26.7

24.3

21.9

19.4

17.0

14.6

12.2

9.7

Outdoor intake air Wet-bulb temperature (°C)

-20 -15 -10 -5 0 5 10 15

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Total input (Heating :

at Rated frequency

)

Input correction factor

15

20

26

Indoor intake air Dry-bulb temperature ( )

Lower limit of guaranteed

oerating range in heating

MUZ-SF25/35/42/50VE: -15°C

MUZ-SF25/35/42/50VEH: -20°C

OBH629

15

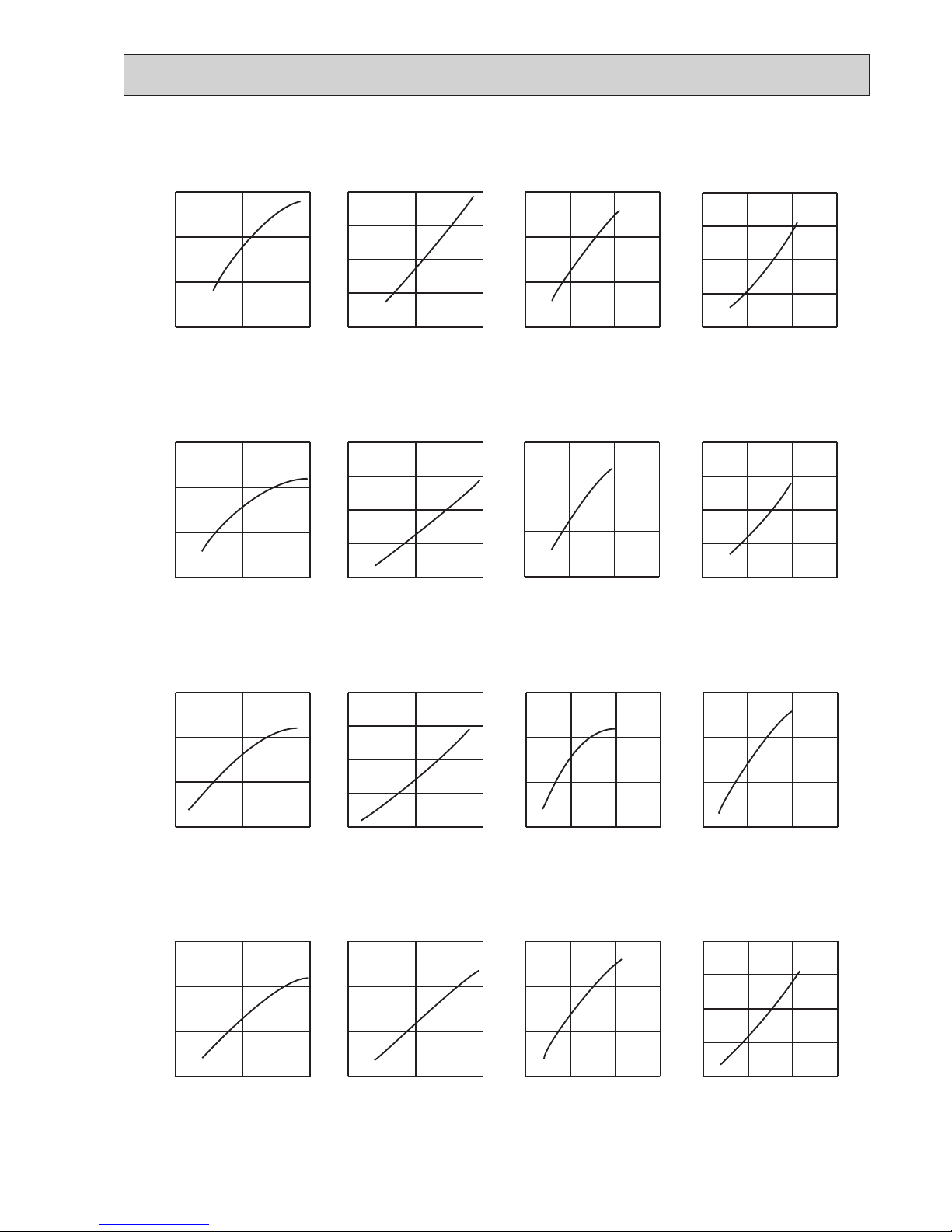

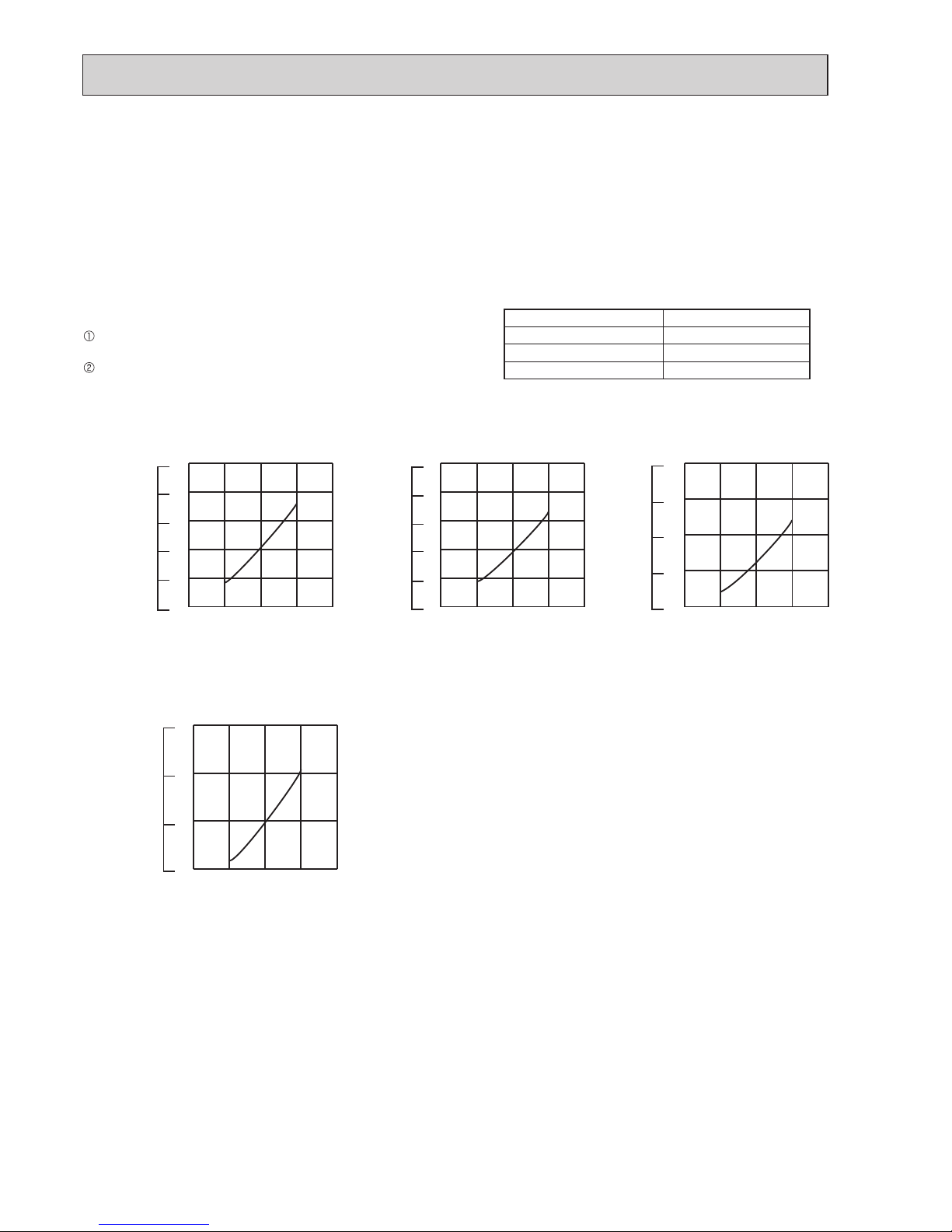

8-2. CAPACITY AND INPUT CORRECTION BY OPERATIONAL FREQUENCY OF COMPRESSOR

0 50 100

0.0

0.5

1.0

1.5

0 50 100

0.0

0.5

1.0

1.5

0 50 100

0.0

0.5

1.0

1.5

0 50 100

0.0

0.5

1.0

1.5

2.0

0 50 100

150

0.0

0.5

1.0

1.5

050100

150

0.0

0.5

1.0

1.5

050100

150

0.0

0.5

1.0

1.5

050100

150

0.0

0.5

1.0

1.5

2.0

0 50 100

0.0

0.5

1.0

1.5

0 50 100

0.0

0.5

1.0

1.5

2.0

0 50 100

0.0

0.5

1.0

1.5

0 50 100

0.0

0.5

1.0

1.5

2.0

050100

150

0.0

0.5

1.0

1.5

0 50 100

150

0.0

0.5

1.0

1.5

2.0

0 50 100

150

0.0

0.5

1.0

1.5

0 50 100

150

0.0

0.5

1.0

1.5

2.0

MUZ-SF25VE MUZ-SF25VEH

MUZ-SF35VE MUZ-SF35VEH

Correction of Cooling capacity

Capacity correction factors

Correction of Cooling input

Input correction factors

Correction of Heating capacity

Capacity correction factors

MUZ-SF42VE MUZ-SF42VEH

Correction of Heating input

Capacity correction factors

Correction of Cooling capacity

Capacity correction factors

Correction of Cooling input

Input correction factors

Correction of Heating capacity

Capacity correction factors

MUZ-SF50VE MUZ-SF50VEH

Correction of Heating input

Capacity correction factors

The o per ational fr equency

of compressor (Hz)

The o per ational fr equency

of compressor (Hz)

The o per ational fr equency

of compressor (Hz)

The o per ational fr equency

of compressor (Hz)

The o per ational fr equency

of compressor (Hz)

The operational frequency

of compressor (Hz)

The operational frequency

of compressor ( Hz)

The operational frequenc y

of compressor ( Hz)

Correction of Cooling capacity

The operational frequency

of compressor (Hz)

Capacity cor rection f actors

Correction of Cooling input

The operational frequenc y

of compressor (Hz )

Input corr ection factors

Correction of Heating capacity

The operational frequenc y

of compressor ( Hz)

Capacity c orr ection factor s

Correction of Heating input

The operational frequency

of compressor ( Hz)

Input corr ection factors

Corr ection of C ooling capacity

The o per ational fr equency

of compressor (Hz)

Capacity cor rection f actors

Corr ection of C ooling input

The operational frequency

of compressor (Hz)

Input correction factors

Correction of Heating capacity

The operational frequency

of compressor ( Hz)

Capacity c orr ection factor s

Correction of Heating input

The operational frequency

of compressor ( Hz)

Input corr ection factors

OBH629

16

15 20 25 30 35

0.4

0.5

0.6

0.7

0.8

0.9

15 20 25 30 35

0.3

0.4

0.5

0.6

15 20 25 30 35

0.3

0.4

0.5

0.6

0.7

0.8

15 20 25 30 35

0.3

0.4

0.5

0.6

0.7

(kgf/cm2[Gauge])(MPa [Gauge])

6

5

4

7

8

9

(kgf/cm2[Gauge])(MPa [Gauge])

4

3

5

6

(kgf/cm2[Gauge])(MPa [Gauge])

3

5

6

4

7

8

(kgf/cm2[Gauge])(MPa [Gaug e])

4

3

5

6

7

50 60 70

Ambient temperature(°C)

Ambient humidity(%)

50 60 70

Ambient temperature(°C)

Ambient humidity(%)

50 60 70

Ambient temperature(°C)

Ambient humidity(%)

50 60 70

Ambient temperature(°C)

Ambient humidity(%)

Outdoor low pressure

MUZ-SF25VE

MUZ-SF25VEH

MUZ-SF35VE

MUZ-SF35VEH

MUZ-SF42VE

MUZ-SF42VEH

MUZ-SF50VE

MUZ-SF50VEH

COOL operation

Both indoor and outdoor unit are under the same temperature/

humidity condition.

Operation: TEST RUN OPERATION (Refer to 8-3.)

8-4. OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

Dry-bulb temperature (°C) Relative humidity (%)

20 50

25 60

30 70

8-3. HOW TO OPERATE FIXED-FREQUENCY OPERATION

<Test run operation>

1. Press EMERGENCY OPERATION switch to start COOL or HEAT mode (COOL: Press once, HEAT: Press twice).

2. Test run operation starts and continues to operate for 30 minutes.

3. Compressor operates at rated frequency in COOL mode or 58 Hz in HEAT mode.

4. Indoor fan operates at High speed.

5.

After 30 minutes, test run operation finishes and EMERGENCY OPERATION starts (operation frequency of compressor varies).

6. To cancel test run operation (EMERGENCY OPERATION), press EMERGENCY OPERATION switch or any button on

remote controller.

NOTE:

The unit of pressure has been changed to MPa on the international system of units (SI unit system)

The conversion factor is: 1 (MPa [Gauge]) = 10.2 (kgf/cm

2

[Gauge])

OBH629

Loading...

Loading...