Mitsubishi Electric MUZ-JP WA, MSZ-JP12WA, MSZ-JP09WA Service Manual

INDOOR UNIT

INDOOR UNIT

SERVICE MANUAL

Models

U1

MSZ-JP09WA

MSZ-JP12WA

-

U1

-

No. OBH820

MSZ-JP09WA

Outdoor unit service manual

MUZ-JP•WA Series (OBH821)

CONTENTS

1. TECHNICAL CHANGES

2. PART NAMES AND FUNCTIONS ··················3

3. SPECIFICATION ········································4

4. OUTLINES AND DIMENSIONS ·····················6

5. WIRING DIAGRAM ·····································7

6. REFRIGERANT SYSTEM DIAGRAM ·············8

7. SERVICE FUNCTIONS ································9

8. MICROPROCESSOR CONTROL ················ 11

9. TROUBLESHOOTING ·······························15

10. DISASSEMBLY INSTRUCTIONS ·················27

PARTS CATALOG (OBB820)

· ·······························

2

Use the specifi ed refrigerant only

OBH820

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused by

failure to follow the instructions.

1

TECHNICAL CHANGES

MSZ-JP09WA

MSZ-JP12WA

1. New model

U1

-

U1

-

2

2

OBH820

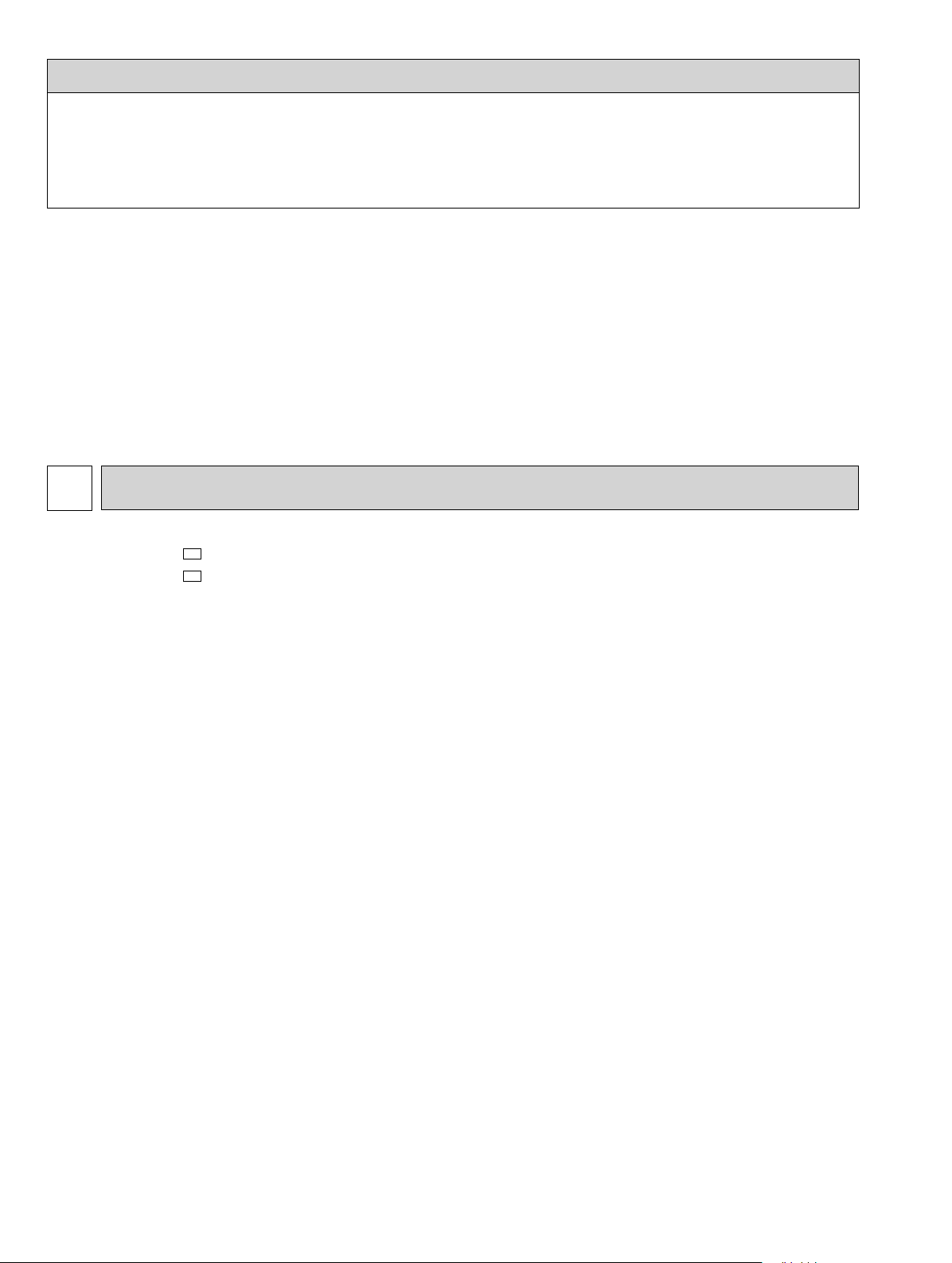

PART NAMES AND FUNCTIONS

MSZ-JP09WA MSZ-JP12WA

Air ¿ lter

Air cleaning ¿ lter

(Anti-Allergy Enzyme

Filter, option)

Air inlet

Air outlet

Horizontal vane

Display section

Front panel

Heat exchanger

Remote controller

Remote control receiving section

ACCESSORIES

Installation plate 1

Attachment screws for the installation plate

4 × 25 mm

Battery (AAA) for remote controller 2

Wireless remote controller 1

Felt tape (For left or left-rear piping) 1

Remote controller holder 1

Screws for the remote controller holder

3.5 × 16 mm (Black)

Operation indicator lamp

Emergency operation switch

5

2

3

3

OBH820

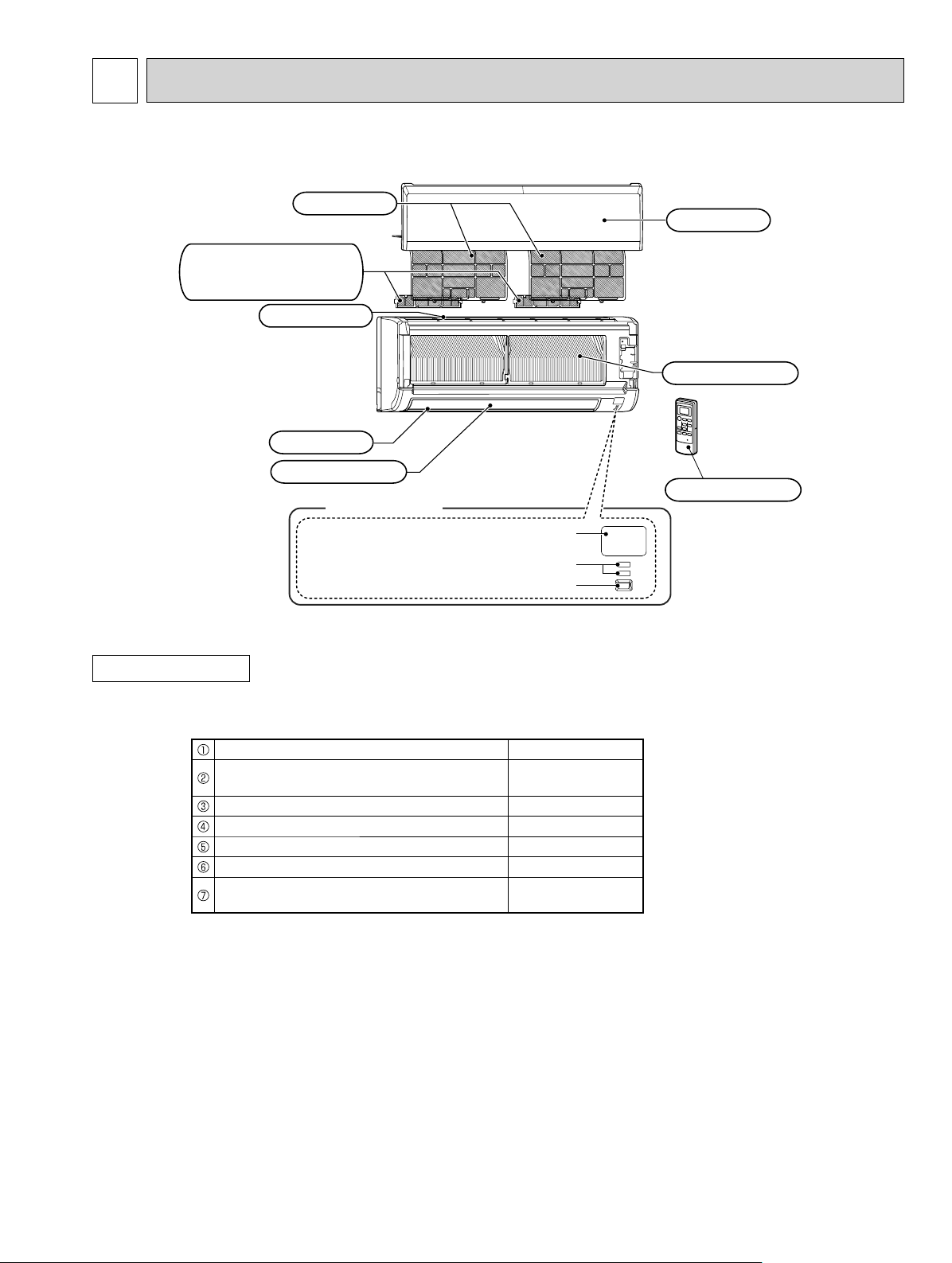

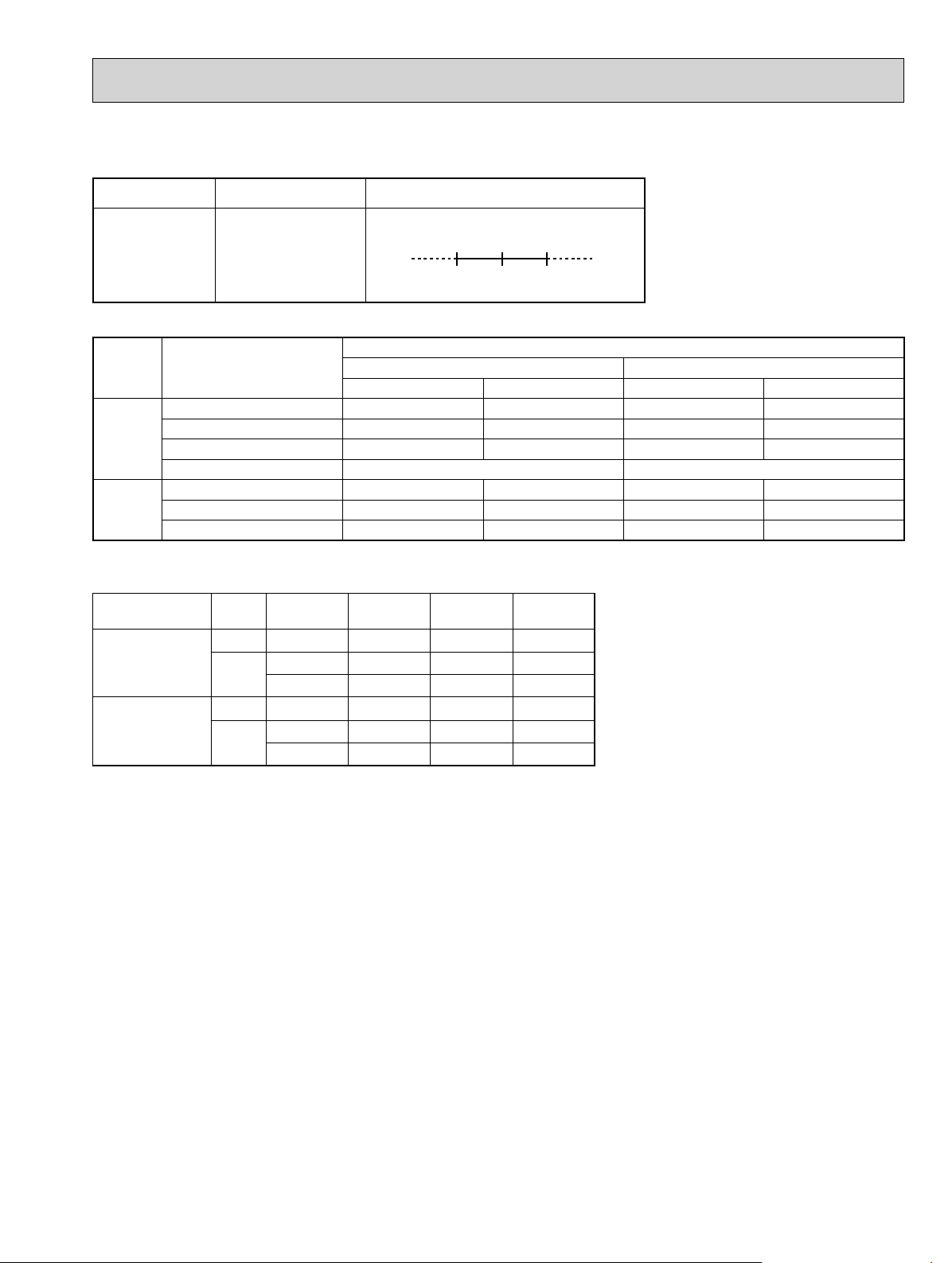

Indoor model MSZ-JP09WA MSZ-JP12WA

Power supply V, phase, Hz 115, 1, 60

Max. fuse size (time delay)/ Disconnect switch

Min. circuit ampacity A 1.4

Fan motor F.L.A 1.07

Airfl ow

Super High - High - Med. Low

Moisture removal pt./h 1.5 2.5

Sound level

Super High - High - Med. Low

Fan speed

Super High - High - Med. Low

Cond. drain connection O.D. in. 5/8

Dimensions

Weight Ib. 22

External fi nish Munsell 1.0Y 9.2/0.2

Control voltage (by built-in transformer) 12 - 24 V DC

NOTE: Test conditions are based on AHRI 210/240.

SPECIFICATION

COOL Dry

(Wet)

HEAT Dry CFM 406 - 321 - 237 - 170

Cooling dB(A) 43 - 37 - 30 - 22 45 - 37 - 30 - 22

Heating dB(A) 43 - 37 - 30 - 22

Cooling rpm 1,020 - 860 - 670 - 530

Heating rpm 1,040 - 860 - 670 - 530

W

D 9-1/8

H 11-5/8

A15 20

CFM

in.

399 - 321 - 237 - 170

(364 - 286 - 201 - 134)

31-7/16

4

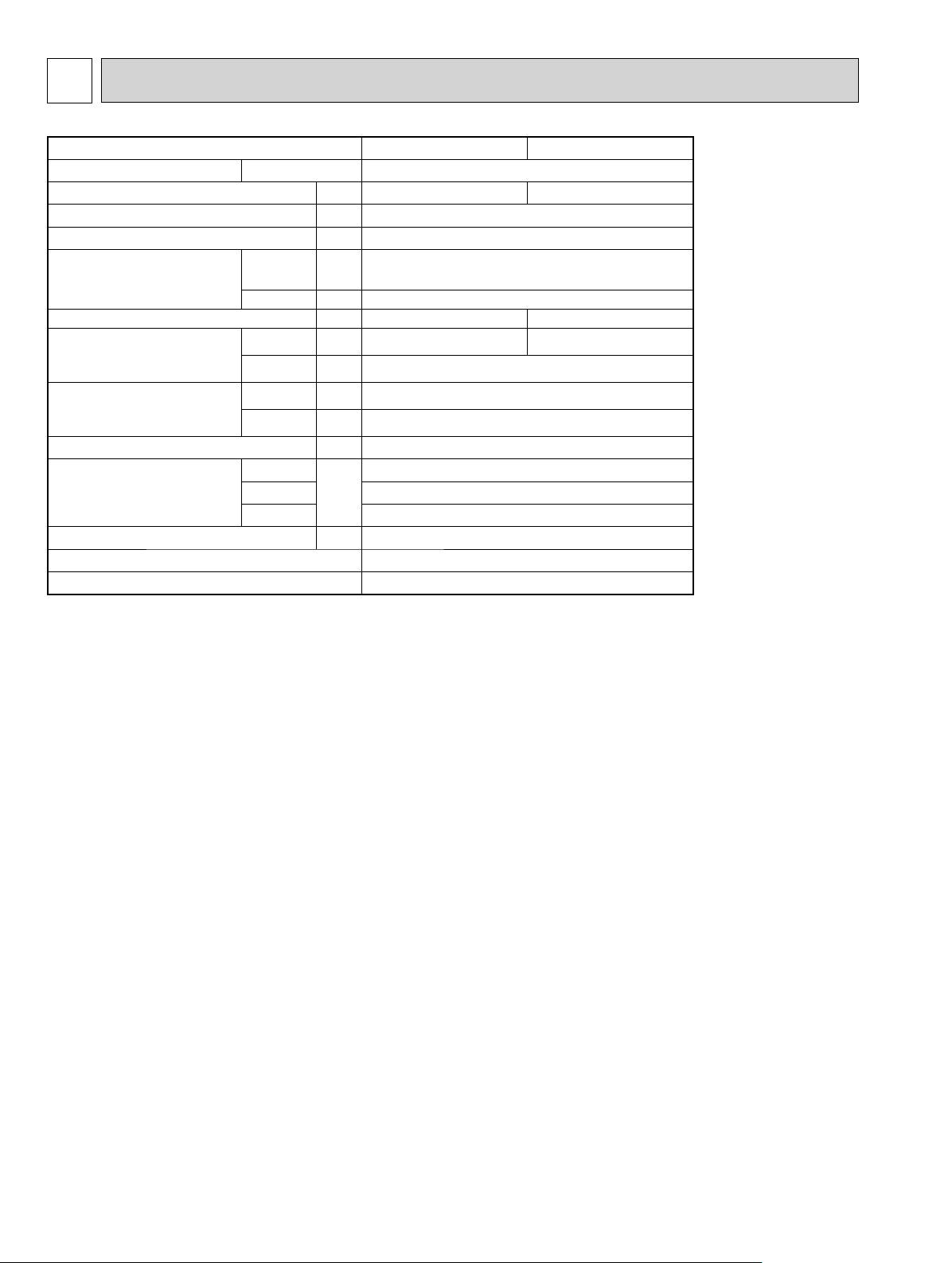

3-1. OPERATING RANGE

OBH820

(1) POWER SUPPLY

Rated voltage Guaranteed voltage (V)

Indoor unit

115 V

1 phase

60 Hz

(2) OPERATION

Mode Condition

Standard temperature 80 67 95 —

Cooling

Heating

Maximum temperature 90 73 115 —

Minimum temperature 67 57 14 —

Maximum humidity 78% —

Standard temperature 70 60 47 43

Maximum temperature 80 67 75 65

Minimum temperature 70 60 -4 -5

3-2. OUTLET AIR SPEED AND COVERAGE

Model Mode Function

HEAT Dry 406 20.6 29.5

MSZ-JP09WA

MSZ-JP12WA

COOL

HEAT Dry 406 20.6 29.5

COOL

Dry 399 20.2 29.0

Wet 364 18.4 26.5

Dry 399 20.2 29.0

Wet 364 18.4 26.5

Airfl ow

(CFM)

Min. 103

Indoor Outdoor

DB WB DB WB

Air speed

(ft./s.)

115

Max. 127

Intake air temperature (°F)

Coverage

(ft.)

● The air coverage is the figure up to the

position where the air speed is 1 ft./s.,

when air is blown out horizontally from

the unit properly at the High speed position.

The coverage should be used only as a

general guideline since it varies according to the size of the room and furniture

arranged inside the room.

5

4

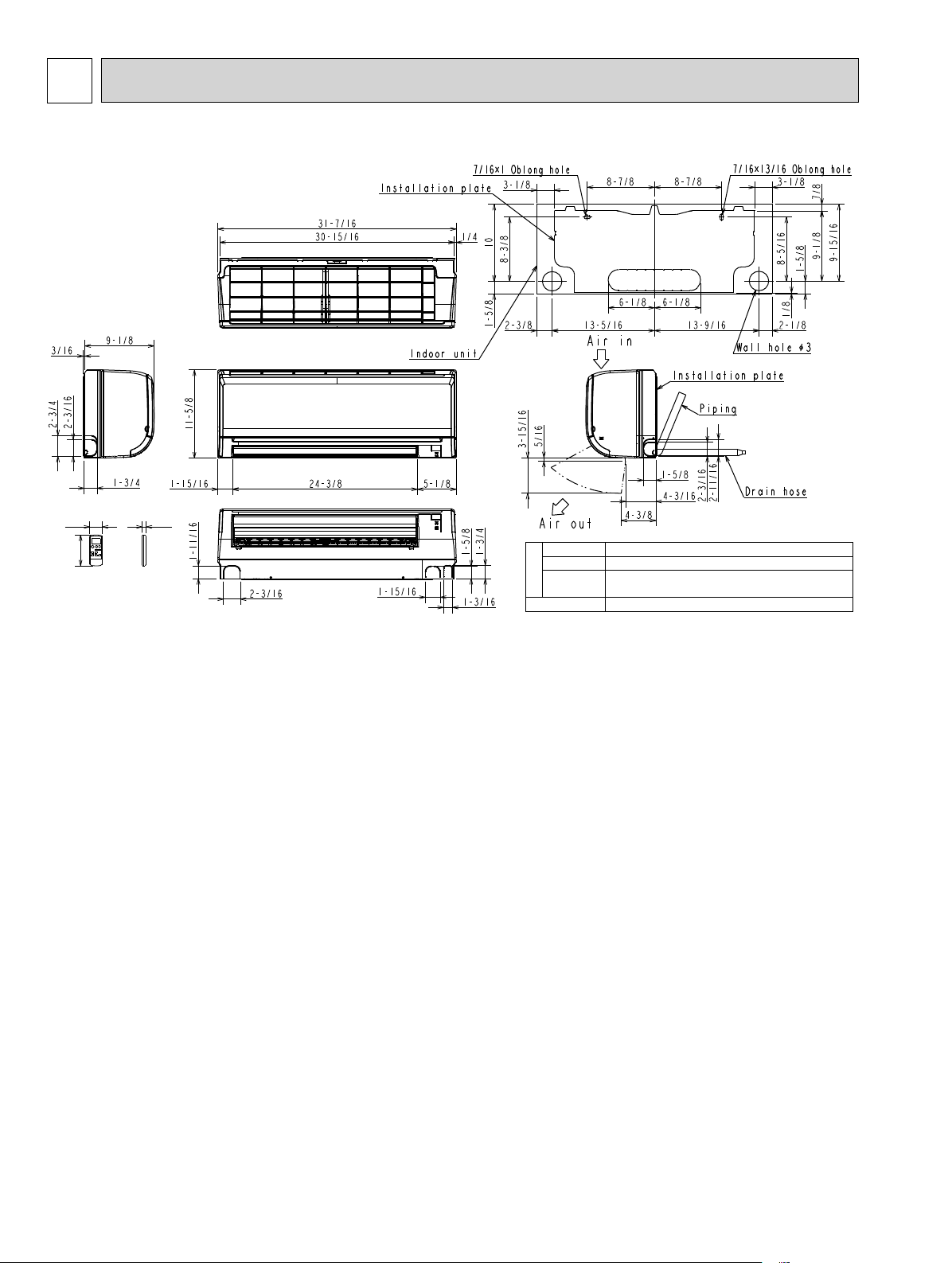

OBH820

OUTLINES AND DIMENSIONS

MSZ-JP09WA MSZ-JP12WA

2-1/4

5-1/2

11/16

Unit: inch

Insulation ø1 - 3/8 O.D

Liquid line ø1/4 19 - 11/16 (Flared connection ø1/4)

Gas line ø3/8 16 - 15/16

Piping

Drain hose Insulation ø1-1/8 O.D Connected part ø5/8 O.D

(Flared connection: ø3/8)

6

5

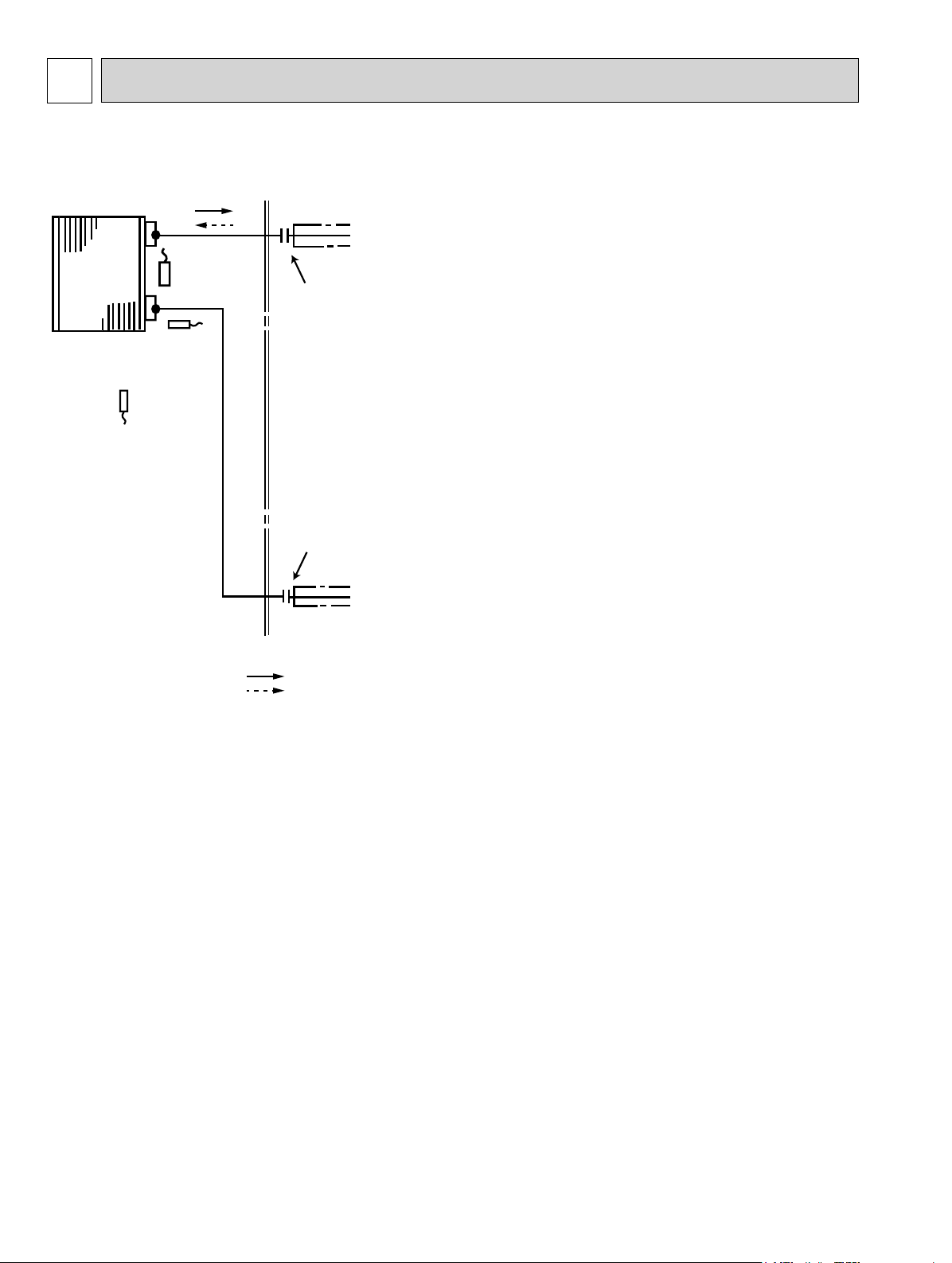

OBH820

MSZ-JP09WA MSZ-JP12WA

WIRING DIAGRAM

7

6

OBH820

REFRIGERANT SYSTEM DIAGRAM

MSZ-JP09WA MSZ-JP12WA

Refrigerant pipe ø3/8 (ø9.52)

(with heat insulator)

Indoor

heat

exchanger

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12 (main)

Indoor coil

thermistor

RT13 (sub)

Flared connection

Flared connection

Unit: inch (mm)

Refrigerant pipe ø1/4 (ø6.35)

(with heat insulator)

Refrigerant flow in cooling

Refrigerant flow in heating

8

7

OBH820

SERVICE FUNCTIONS

MSZ-JP09WA MSZ-JP12WA

7-1. TIMER SHORT MODE

For service, the set time can be shortened by bridging of the timer short point on the indoor electronic control P.C. board.

The time will be shortened as follows. (Refer to 9-7.)

• The set time for the ON/OFF timer can be reduced to 1 second for each minute.

• After the breaker is turned on, the time for starting the compressor, which normally takes 3 minutes, can be reduced to

3 seconds. Restarting the compressor, which takes 3 minutes, cannot be reduced.

7-2. REMOTE CONTROLLER P.C. BOARD MODIFICATION FOR INDIVIDUAL OPERATION

A maximum of 4 indoor units with wireless remote controllers can be used in a room.

In this case, to operate each indoor unit individually by each remote controller, the remote controller P.C. boards must be

modified according to the number of the indoor unit.

How to modify the remote controller P.C. board

Remove batteries before modification.

The board has a print as shown below:

J2

J1

NOTE: For modification, take out the

batteries and press the STOP/

OPERATE (OFF/ON) button 2

or 3 times at first.

After finish modification, put

back the batteries then press

the RESET button.

The remote controller P.C. board has the print “J1” and “J2”. Solder “J1” and “J2” according to the number of indoor unit as

shown in Table 1.

After modification, press the RESET button.

Table 1

1 unit operation 2 units operation 3 units operation 4 units operation

No. 1 unit No modifi cation Same as at left Same as at left Same as at left

No. 2 unit — Solder J1 Same as at left Same as at left

No. 3 unit — — Solder J2 Same as at left

No. 4 unit — — — Solder both J1 and J2

How to set the remote controller exclusively for particular indoor unit

After you turn the breaker ON, the first remote controller that sends the signal to the indoor unit will be regarded as the remote

controller for the indoor unit.

The indoor unit will only accept the signal from the remote controller that has been assigned to the indoor unit once they are

set.

The setting will be cancelled if the breaker is turned OFF, or the power supply is shut down.

Please conduct the above setting once again after the power has been restored.

9

7-3. AUTO RESTART FUNCTION

OBH820

When the indoor unit is controlled with the remote controller, the operation mode, the set temperature, and the fan speed

are memorized by the indoor electronic control P.C. board. “AUTO RESTART FUNCTION” automatically starts operation in

the same mode just before the shut-off of the main power.

Operation

If the main power has been cut, the operation settings remain.

After the power is restored, the unit restarts automatically according to the memory.

(However, it takes at least 3 minutes for the compressor to start running.)

How to disable “AUTO RESTART FUNCTION”

Turn OFF the main power of the unit.

Solder the Jumper wire JR07 on the indoor electronic control P.C. board. (Refer to 9-7.)

JR07

Indoor electronic

control P.C. board

CN111CN112

CN151

CN10A

NOTE:

•

The operation settings are memorized when 10 seconds have passed after the indoor unit was operated with the

remote controller.

• If main power is turned OFF or a power failure occurs while AUTO START/STOP timer is active, the timer setting is

cancelled.

• If the unit has been turned OFF with the remote controller before power failure, the auto restart function does not

work as the power button of the remote controller is OFF.

• To prevent the breaker from tripping OFF due to the rush of starting current, systematize other home appliance not to

turn ON at the same time.

• When some air conditioners are connected to the same supply system, if they are operated before power failure, the

starting current of all the compressors may flow simultaneously at restart.

Therefore, the special counter-measures are required to prevent the main voltage-drop or the rush of the starting

current by adding to the system that allows the units to start one by one.

10

Loading...

Loading...