Mitsubishi Electric MSZ09UN, MSZ12UN, MUZ12UN, MUZ09UN Service Manual

L

I

S

T

E

D

CUS

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

Revision A:

●Conditions of operation frequency have been added.

Please void OB297.

SERVICE MANUAL

Wireless type

Models

MSZ09UN (W) · MUZ09UN

MSZ12UN (W) · MUZ12UN

No. OB297

REVISED EDITION-A

MSZ09UN

INDOOR UNIT

MUZ09UN

MUZ12UN

OUTDOOR UNIT

Remote

controller

CONTENTS

1. FEATURES·························································2

2. PART NAMES AND FUNCTIONS······················4

3. SPECIFICATION·················································6

4. DATA···································································8

5. OUTLINES AND DIMENSIONS·······················18

6. WIRING DIAGRAM ··········································20

7. REFRIGERANT SYSTEM DIAGRAM··············22

8. MICROPROCESSOR CONTROL ····················23

9. SERVICE FUNCTIONS ····································39

10. TROUBLESHOOTING ······································41

11. DISASSEMBLY INSTRUCTIONS·····················61

12. PARTS LIST······················································68

13. OPTIONAL PARTS···········································74

The Slim Line.

From Mitsubishi Electric.

TM

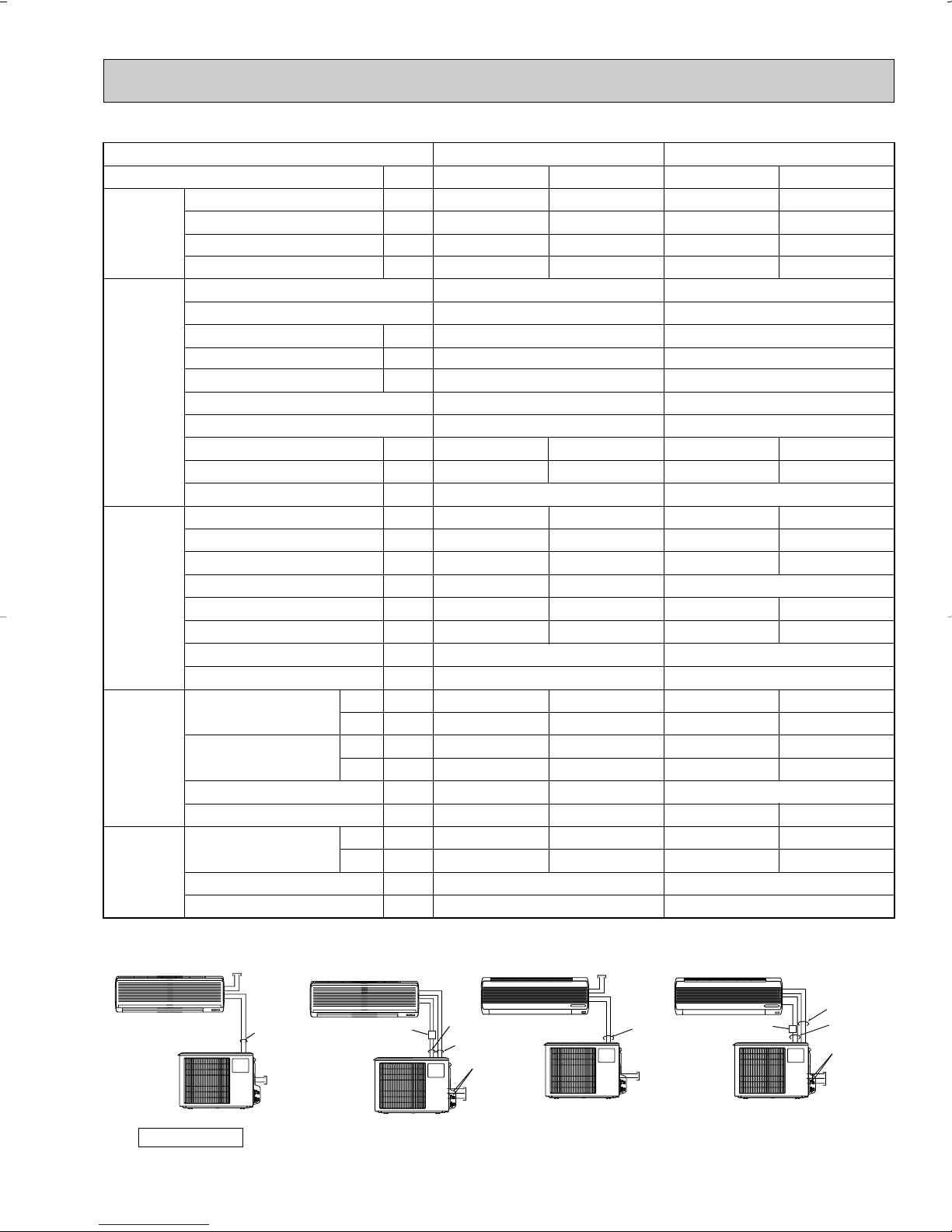

MSZ09UN

MUZ09UN

MUZ12UN

LCD wireless

remote controller

MSZ12UN

Hours

Room T emperature

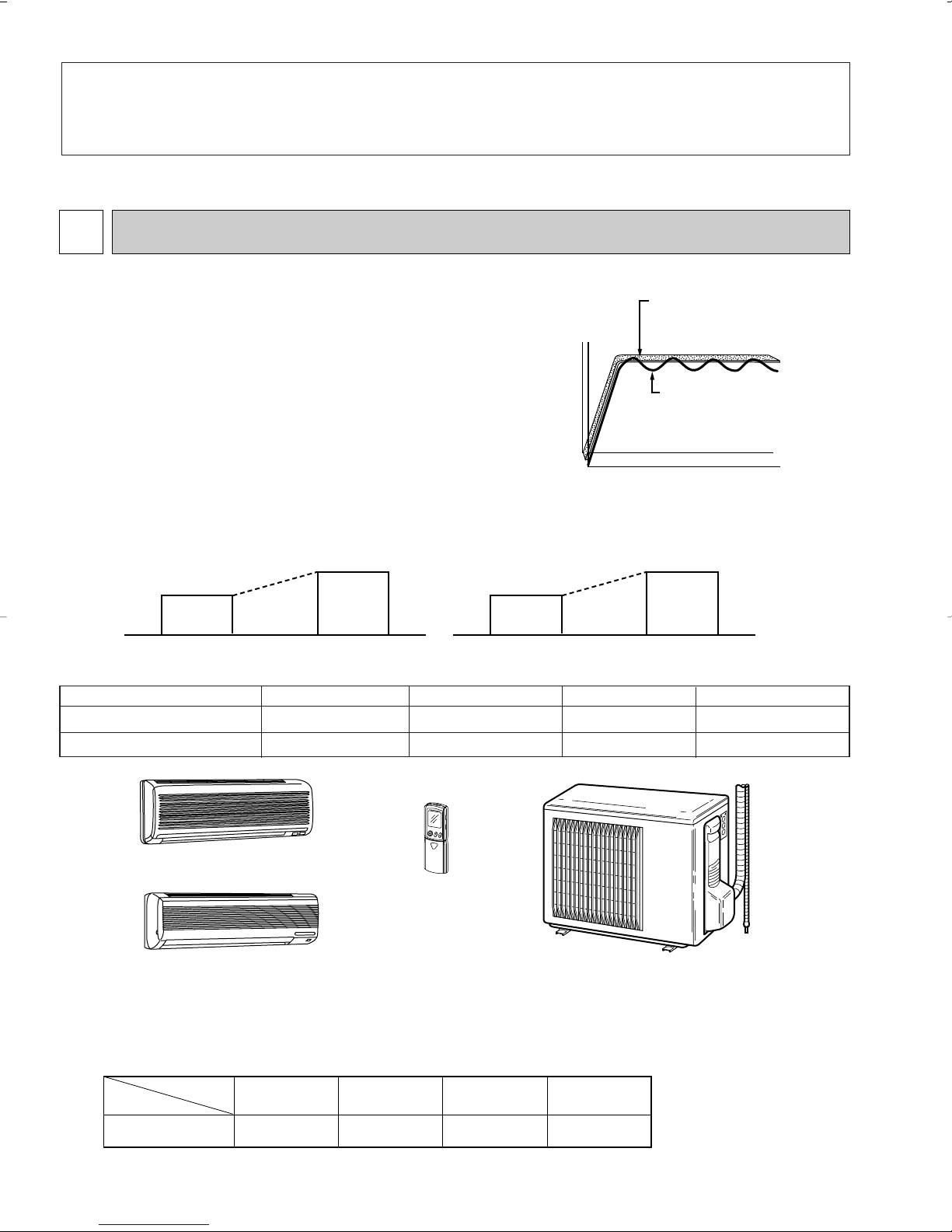

Single speed comppressor Model

Temperature is adjusted by

turning on/ off the compressor.

Inverter Model

Constant temperature is maintained

by compressor speed control.

10

13

Cool

MSH12EN

MSZ12UN

6.8

7.7

Heat

MSH12EN

MSZ12UN

Revision A:

• Conditions of operation frequency have been added.

• SPECIFICATION, DATA, WIRING DIAGRAM and PARTS LIST have been partially modified.

1

FEATURES

Optimum comfort year-round

To ensure that a room is never too cold or too hot, inverter technology

allows the system to detect subtle fluctuations in room temperature and

adjust automatically. Unlike conventional air conditioning units that must start

or stop the compressor repetitively, inverter units offer finely tuned operation

– such as the accurate control of room temperature – for a more comforting

airflow and far less temperature variations.

High–speed cooling & heating

Ideal and comforting performance is assured by controlling compressor

rotation according to the cooling and heat load of a room. Inverter technology promotes maximum compressor efficiency by flexibly changing

the rotation speed of it to accurately match operating requirements.

Extra energy – savings

Inverter technology makes the value of SEER and HSPF better compared to non-inverter model’s value.

Model Cooling capacity Heating capacity SEER HSPF(

MSZ09UN 8,800 Btu/h 12,300 Btu/h 12.0 7.7/6.7

MSZ12UN 11,400 Btu/h 16,000 Btu/h 13.0 7.7/6.7

The sound level of indoor unit has been lowered.

Sound level

Fan speed

High / Low

Model

MSH09EW

43 / 32

MSZ09UN

36 / 22

MSH12EN

48 / 38

2

MSZ12UN

42 / 35

(dBA)

44/55

)

SWING

Single rotary:

Centrifugal force always

produced in one direction,

resulting in excessive vibration.

Twin rotary:

Centrifugal force of one

roller counterbalanced

by that of the other roller

for significantly lower vibration.

MSH09EW

MSH12EN

Model

Size

MSZ09UN

MSZ12UN

14-13/16

10-15/16

12-5/8

14-3/16

(in.)

The height of indoor unit has been shortened.

MUH12EN

Sound level (Cooling/Heating)

MUZ12UN

49 / 49

54 / 54

dB(A)

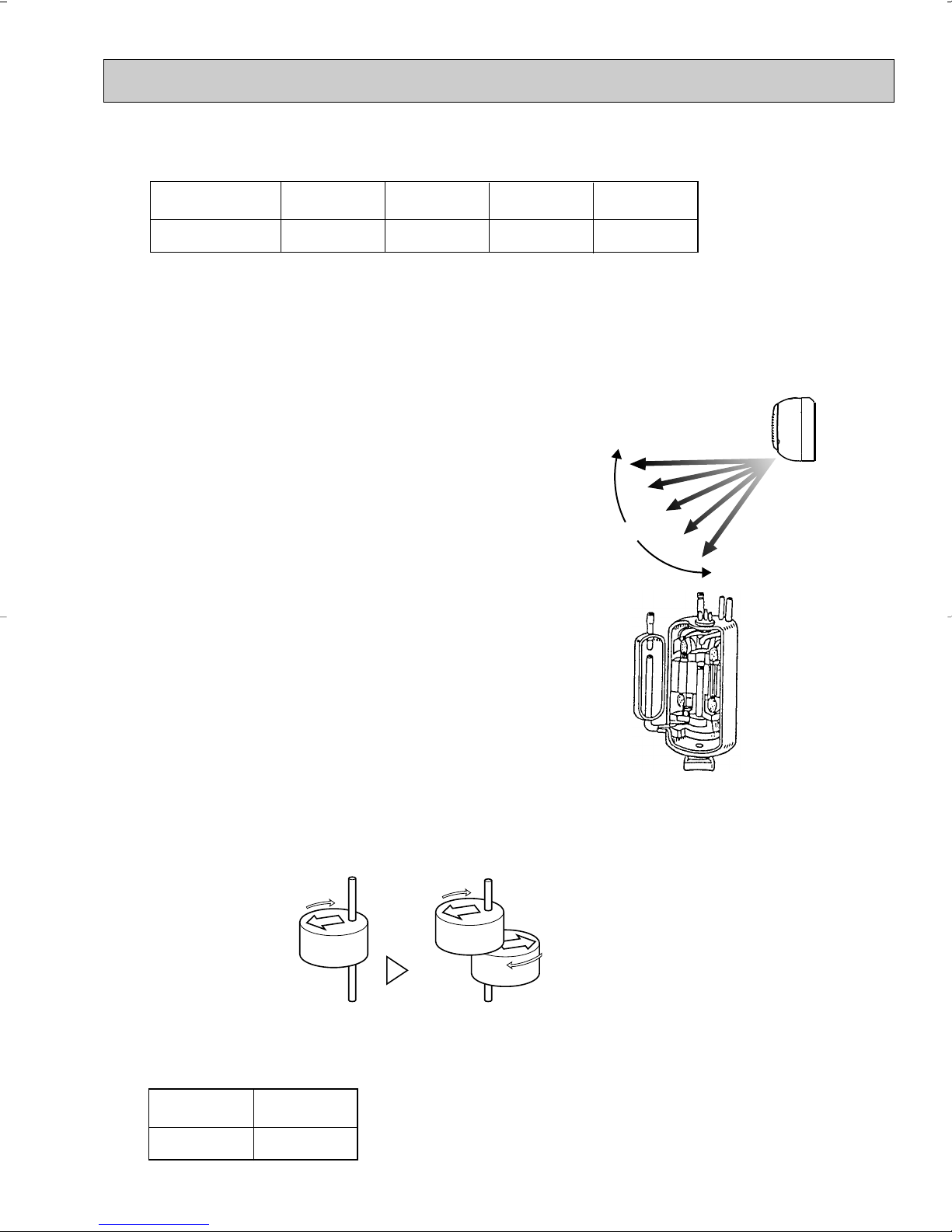

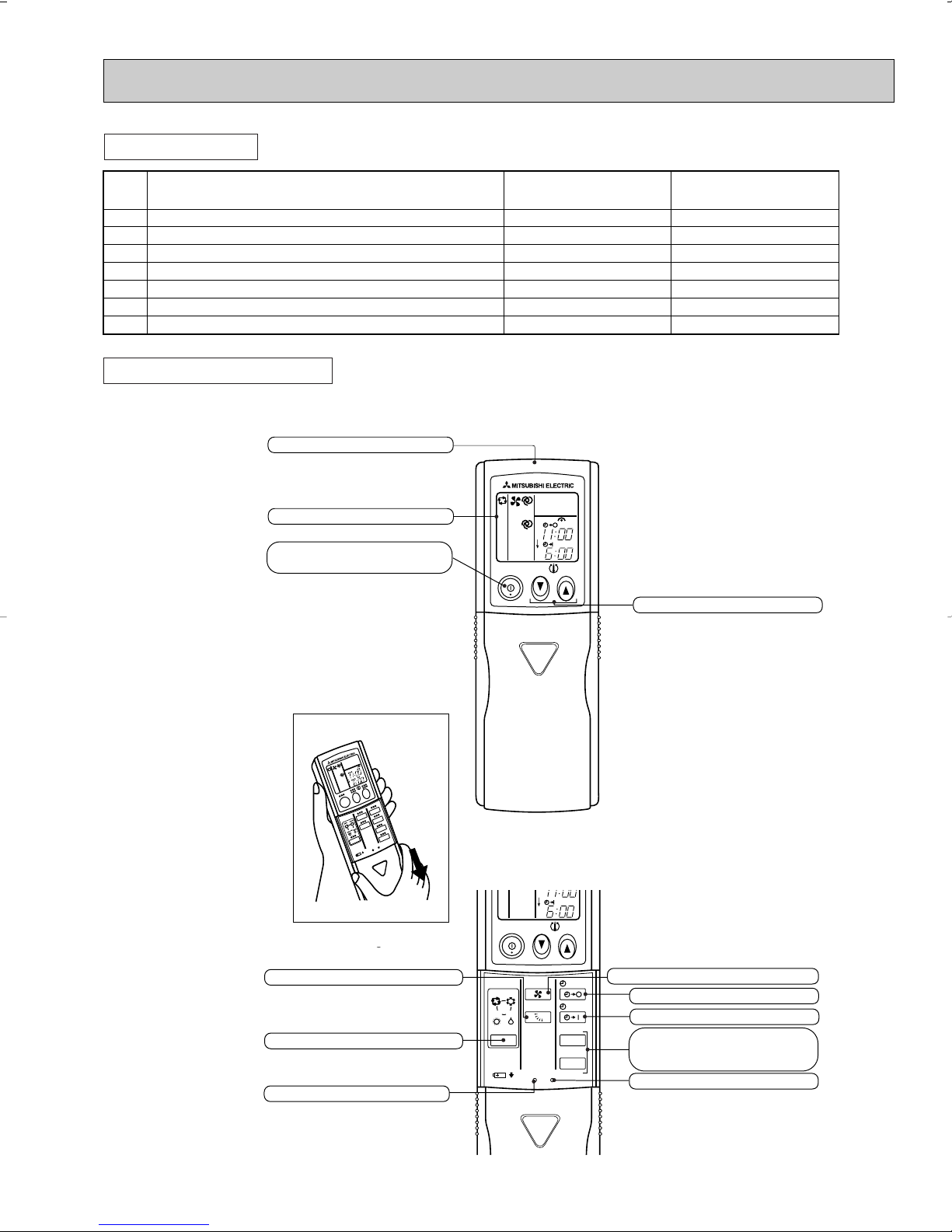

“I FEEL CONTROL” IN OUR LCD WIRELESS REMOTE CONTROLLER WITH ON/OFF PROGRAM TIMER

Mitsubishi Electric’s new wireless remote controller incorporates a number of advanced features that provides even greater

control and ease-to-use. It has a liquid crystal display which indicates such information as mode, fan speed and temperature

selected as well as the programmed ON/OFF timer. It is also equipped with “I Feel Control”, a unique Mitsubishi Electric feature that allows the user to adjust the temperature to exactly the level he or she wants simply by tapping the button that

describes present conditions : “Too Cool” or “Too Warm”. The optimum temperature set this way is that memorized for immediate recall whenever the air conditioner is used again.

Select desired air flow direction.

REMOTE-CONTROL OPERATION MODE

Using the remote controller, you can select from five airflow set-

tings to match room layout and the location of people. Also, you

can set the vane to swing automatically.

AUTO-RESTART FUNCTION

The auto-restart function restarts the equipment when power is

restored following an outage automatically. Operation resumes in

the mode in which the equipment was running immediately before

the outage.

HIGH PERFORMANCE ROTARY COMPRESSOR

The advanced design of Mitsubishi Electric’s powerful and energy

efficient rotary compressor results in lower operating costs and

longer service life.

Outdoor unit: Twin rotary compressor greatly reduces noise

Unlike conventional models equipped with a single rotary, the features a twin-rotary compressor that provides balanced rotation – the centrifugal force of one roller is counterbalanced by the other – for significantly reduced vibration and noise. It’s

exactly this kind of technology that makes Mitsubishi Electric’s outdoor units so quiet.

The sound level of outdoor unit has been lowered.

3

2

Operation section

Emergency operation switch

Horizontal vane

Air filter

Deodorizing filter(option)

(gray sponge type)

Vertical vanes

Air inlet

Grille

Remote control

receiving section

Remote controller

Air cleaning filter(option)

(white bellows type)

Front panel

Emergency operation switch

Operation indicator lamp

Receiving section

Operation indicator lamp

Receiving section

Air inlet (back and side)

Piping

Drainage hose

Service panel

Air outlet

Drain outlet

PART NAMES AND FUNCTIONS

INDOOR UNIT

MSZ09UN

(When the grille is opened)

MSZ09UN

MSZ09UN

MSZ12UN

MSZ12UN

OUTDOOR UNIT

MUZ09UN

MUZ12UN

MSZ12UN

4

Installation plate

Installation plate fixing screw 4 x 25 mm(0.16 x 0.98 in.)

Remote controller mounting hardware

Fixing screw for 3 3.5 x 16 mm(0.14 x 0.63 in.) (Black)

Battery (AAA) for remote controller

Wireless remote controller

Felt tape (Used for left or left-rear piping)

1

5

1

2

2

1

1

1

2

3

4

5

6

7

MSZ09UN

1

6

1

2

2

1

1

MSZ12UN

ACCESSORIES

ON/OFF

TOO

COOL

PM

AM

TOO

WARM

ON/OFF

FAN

TOO

WARM

TOO

COOL

VANE

MODE

STOP

START

HR.

MIN.

I FEEL

COOL

HEAT

DRY

PM

CLOCK

AM

RESET CLOCK

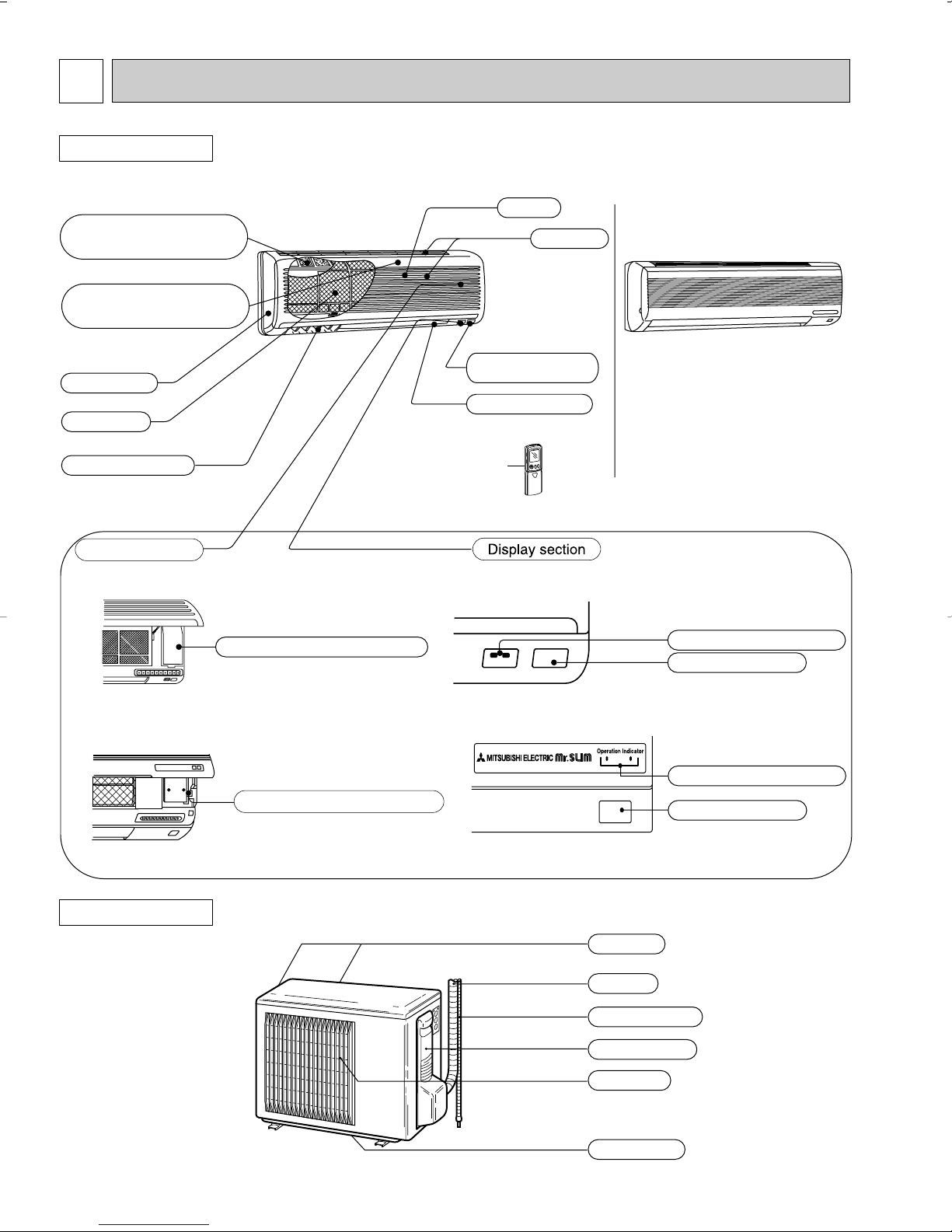

Open the front lid.

Signal transmitting section

Operation display section

OPERATE /STOP

(ON /OFF)button

TEMPERATURE buttons

OPERATION SELECT button

FAN SPEED CONTROL button

OFF-TIMER button

HR. button

MIN. button

(TIME SET button)

ON-TIMER button

RESET button

VANE CONTROL button

CLOCK SET button

REMOTE CONTROLLER

MSZ09UN

MSZ12UN

5

3

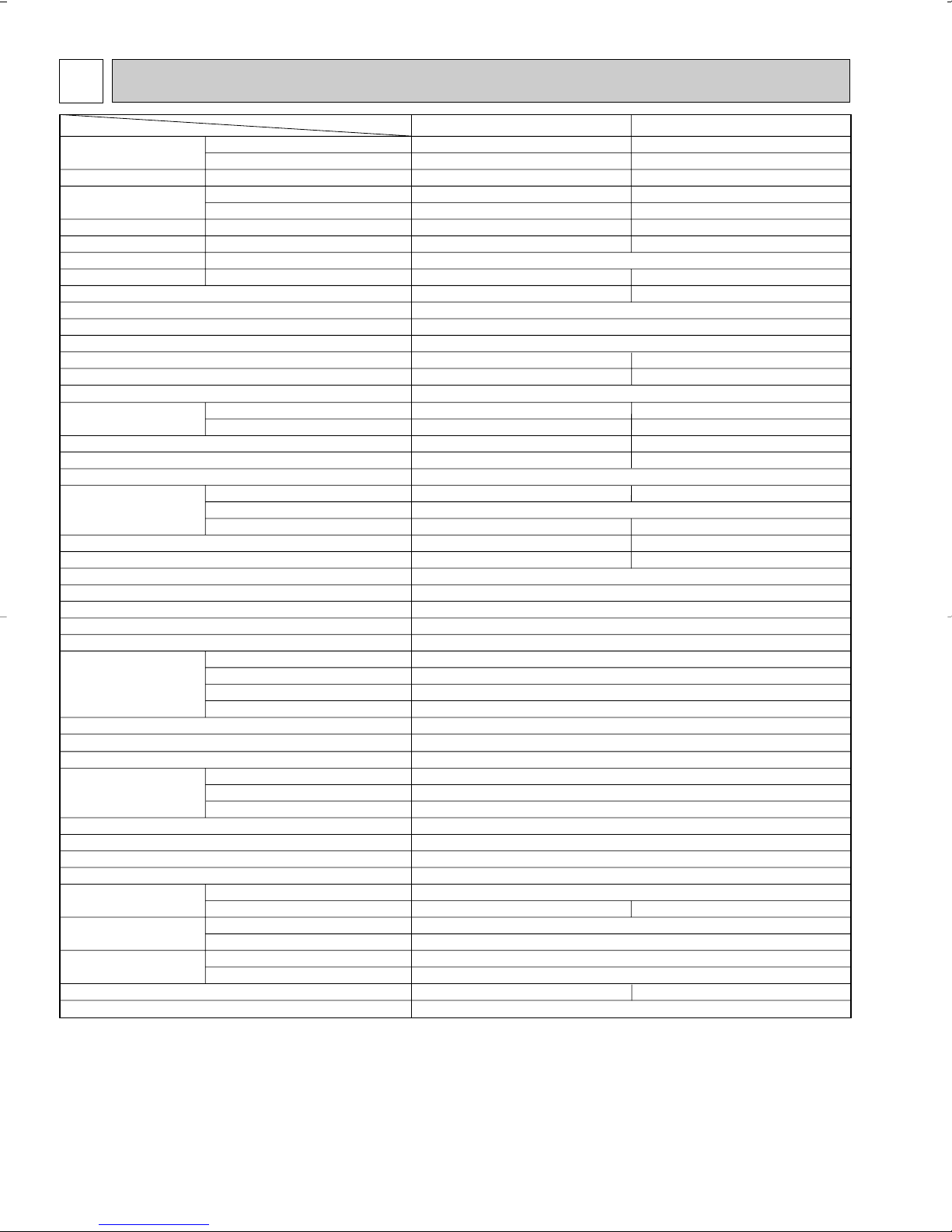

Item

Model

MSZ12UN

Capacity

Rated(Minimum~Maximum)

Capacity Rated

Power consumption

Rated(Minimum~Maximum)

Power consumption Rated

EER [SEER]

HSPF IV(V)

COP

INDOOR UNIT MODEL

External finish

Power supply

Max. fuse size (time delay)/ Disconnect switch

Min. circuit ampacity

Fan motor

Auxiliary heater

Airflow Low—Med.—High

Moisture removal

Sound level Low-Med.-High

Cond. drain connection O.D.

Dimensions

Weight

OUTDOOR UNIT MODEL

External finish

Power supply

Max. fuse size (time delay)

Min. circuit ampacity

Fan motor

Compressor

Refrigerant control

Sound level

Defrost method

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

Refrigerant pipe size

(Min. wall thickness)

Connection method

Between the indoor

& outdoor units

Refrigerant charge (R22)

Refrigerating oil (Model)

Btu/h

Btu/h

Btu/h

W

W

W

V, phase, Hz

A

A

F.L.A

A(kW)

CFM

CFM

pt./h

dB(A)

in.

in.

in.

in.

Ib.

V, phase, Hz

A

A

F.L.A

R.L.A

L.R.A

dB(A)

in.

in.

in.

Ib.

in.

in.

ft.

ft.

oz.

7.7 (6.7)

White

115, 1, 60

15

–

5/8

7-1/2

Munsell 5.6Y 8.0/0.5

208/230, 1, 60

15

14

0.43

SHV-130FEA

U-V 1.05 U-W 1.05 U-W 1.05

9.7

41

Liner expansion valve

49

Reverse cycle

28

10-1/16

21-1/4

75

Wireless type

12V DC

Not supplied (optional parts)

1/4 (0.0265)

Flared

Flared

Max. 25

Max. 49

10.8 (MS56)

11,400(2,900~13,000)

16,000(2,400~19,500)

11,600

1,140(290~1,460)

1,590(280~2,050)

1,760

10.0[13.0]

2.95

MSZ12UN

0.6

0.43

360-395-452

360(311)-395(339)-452(388)

2.8

35-39-42

39-15/16

12-5/8

31

MUZ12UN

1/2 (0.0285)

2 Ib. 14 oz.

8,800(2,600~9,700)

12,300(2,300~15,700)

10,000

980(290~1,250)

1,320(280~1,770)

1,420

9.0 [12.0]

2.73

MSZ09UN

0.5

0.37

184-237-297

148(124)-215(180)-279(233)

2.3

22-29-36

33-1/2

10-15/16

20

3/8 (0.0285)

2 Ib. 7 oz.

❈1 ❈3

❈1

❈1

❈2

❈1

❈1

❈2

Cooling

Heating 47

Heating 17

Cooling

Heating 47

Heating 17

Cooling

Heating

Heating

MSZ09UN

MUZ09UN

HEAT Dry

COOL Dry(Wet)

W

D

H

Model

Winding resistance (at 68˚F) Ω

W

D

H

Liquid

Gas

Indoor

Outdoor

Height difference

Piping length

❈1

❈4

SPECIFICATION

NOTE : Test conditions are based on ARI 210/240.

❈1 : Rating conditions (cooling) — Indoor : 80˚FDB, 67˚FWB, Outdoor : 95˚FDB, (75˚FWB) Rated frequency: Hz

❈2 : (heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 17˚FDB, 15˚FWB Maximum frequency: Hz

(heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 47˚FDB, 43˚FWB Rated frequency: Hz

6

Indoor

unit

w Max. Height

difference 25ft.

Outdoor unit

Refrigerant Piping

Max.length

A

w Height difference should be within

25ft. regardless of which unit,

indoor or outdoor position is high.

Outside

diameter

Minimum

Wall

thickness

Outside

diameter

Minimum

Wall

thickness

MSZ09UN

MSZ12UN

MUZ09UN

MUZ12UN

Additional piping

Max. length : ft.

A

49

Gas

Piping size : in. Length of connecting pipe : in.

Liquid

Indoor unit

Outdoor unit

Model

Gas :

Liquid :00

Gas :

Liquid :

16-15/16

19-11/16

[ 3/8

[ 1/2

[ 1/4

0.0285

0.0265

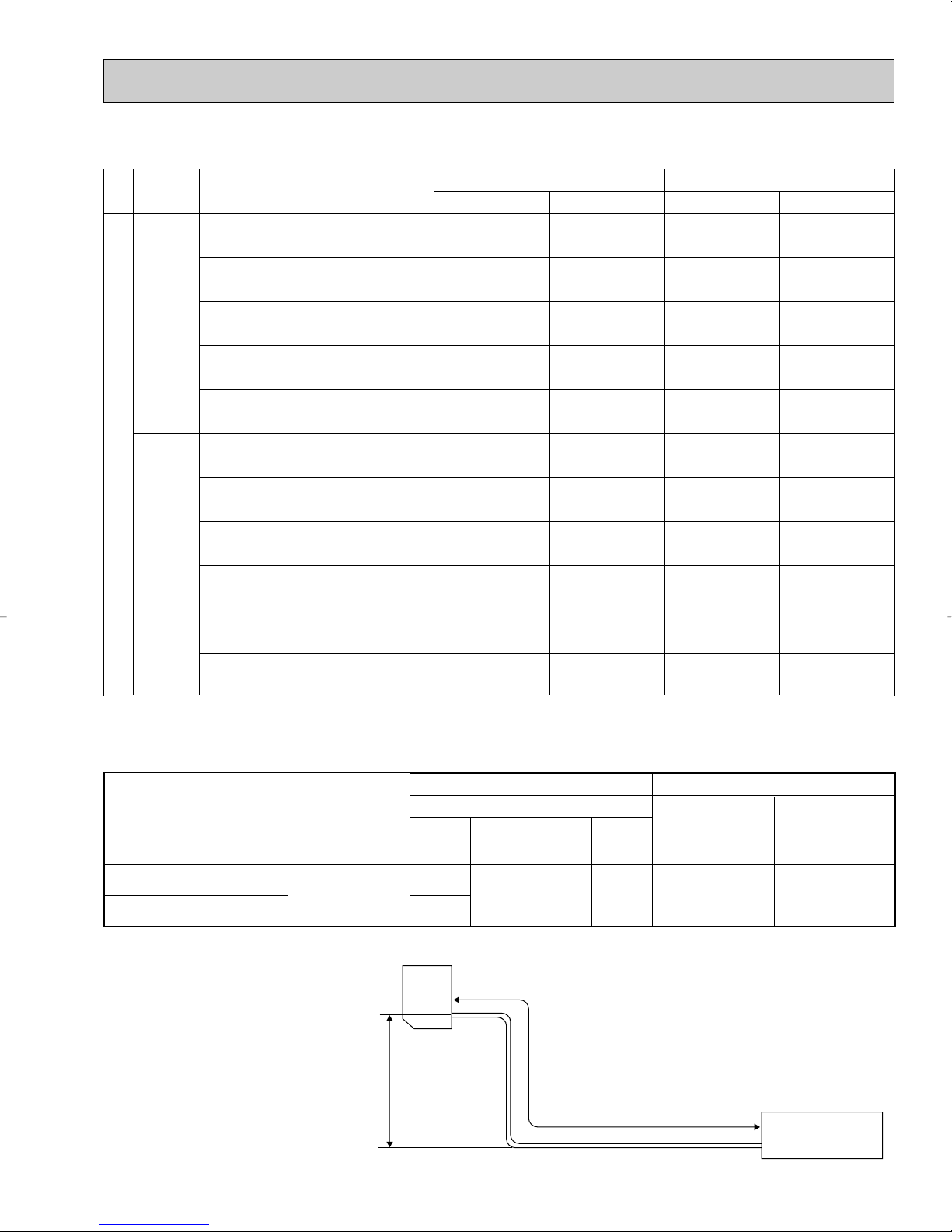

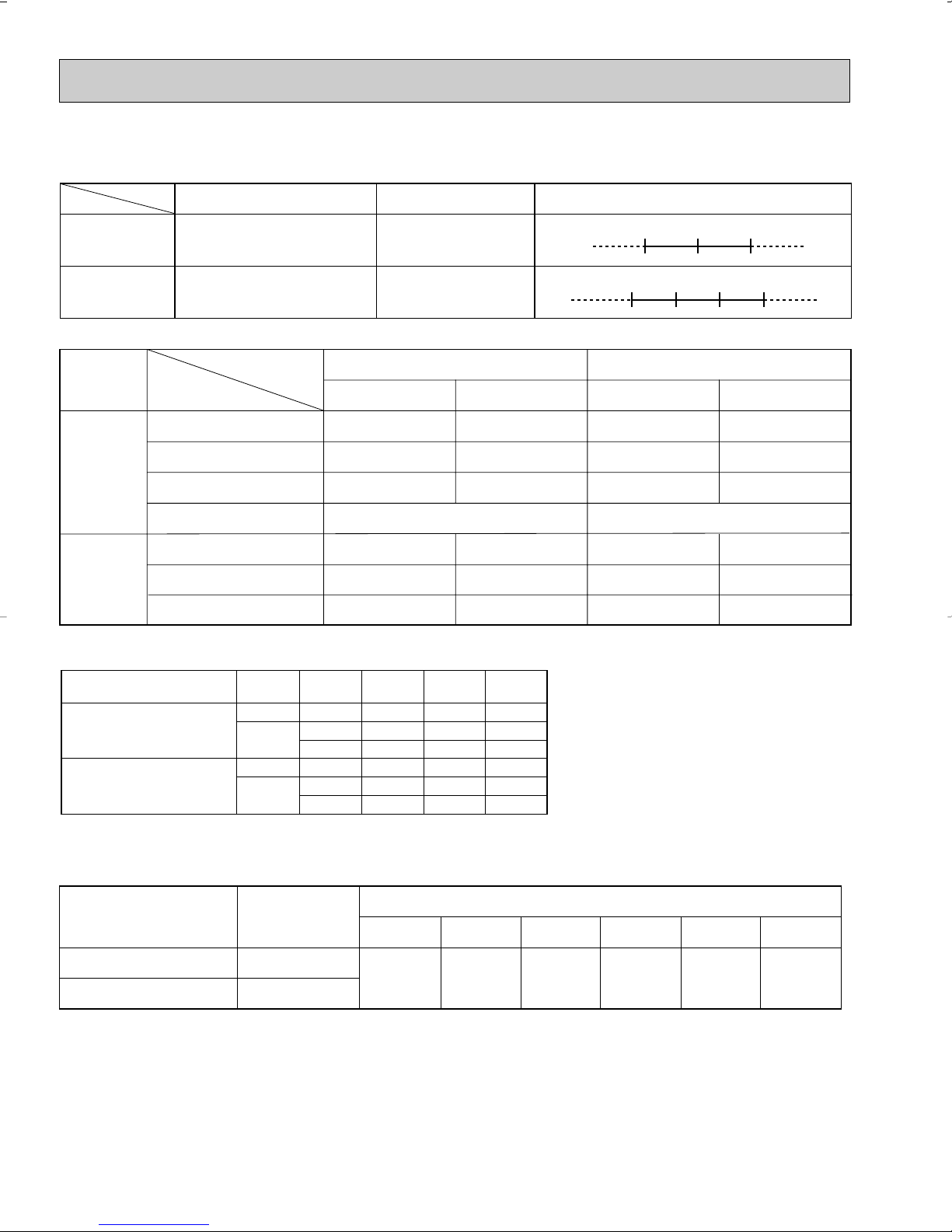

Test condition

SEER

(Cooling)

HSPF

(Heating)

ARI

Mode

"A" Cooling Steady State

at rated compressor Speed

"B-2" Cooling Steady State

at rated compressor Speed

"B-1" Cooling Steady State

at minimum compressor Speed

Low ambient Cooling Steady State

at minimum compressor Speed

Intermediate Cooling Steady State

At Intermediate compressor Speed

❈5

Standard Rating-Heating

at rated compressor Speed

Low temperature Heating

at rated compressor Speed

Max temperature Heating

at minimum compressor Speed

High temperature Heating

at minimum compressor Speed

Frost Accumulation

at rated compressor Speed

Test

Indoor air condition Outdoor air condition

Dry bulb

Wet bulb

Dry bulb

Wet bulb

80

80

80

80

80

70

70

70

70

70

70

67

67

67

67

67

60

60

60

60

60

60

Frost Accumulation

at Intermediate compressor Speed

❈5

95

82

82

67

87

47

17

62

47

35

35

(75)

(65)

(65)

(53.5)

(69)

43

15

56.5

43

33

33

❈5 : At Intermediate compressor Speed

=("Cooling rated compressor speed" - "minimum compressor speed") / 3 + "minimum compressor speed".

(Unit : [˚F])

❈3, ❈4

MAX. REFRIGERANT PIPING LENGTH

MAX. HEIGHT DIFFERENCE

7

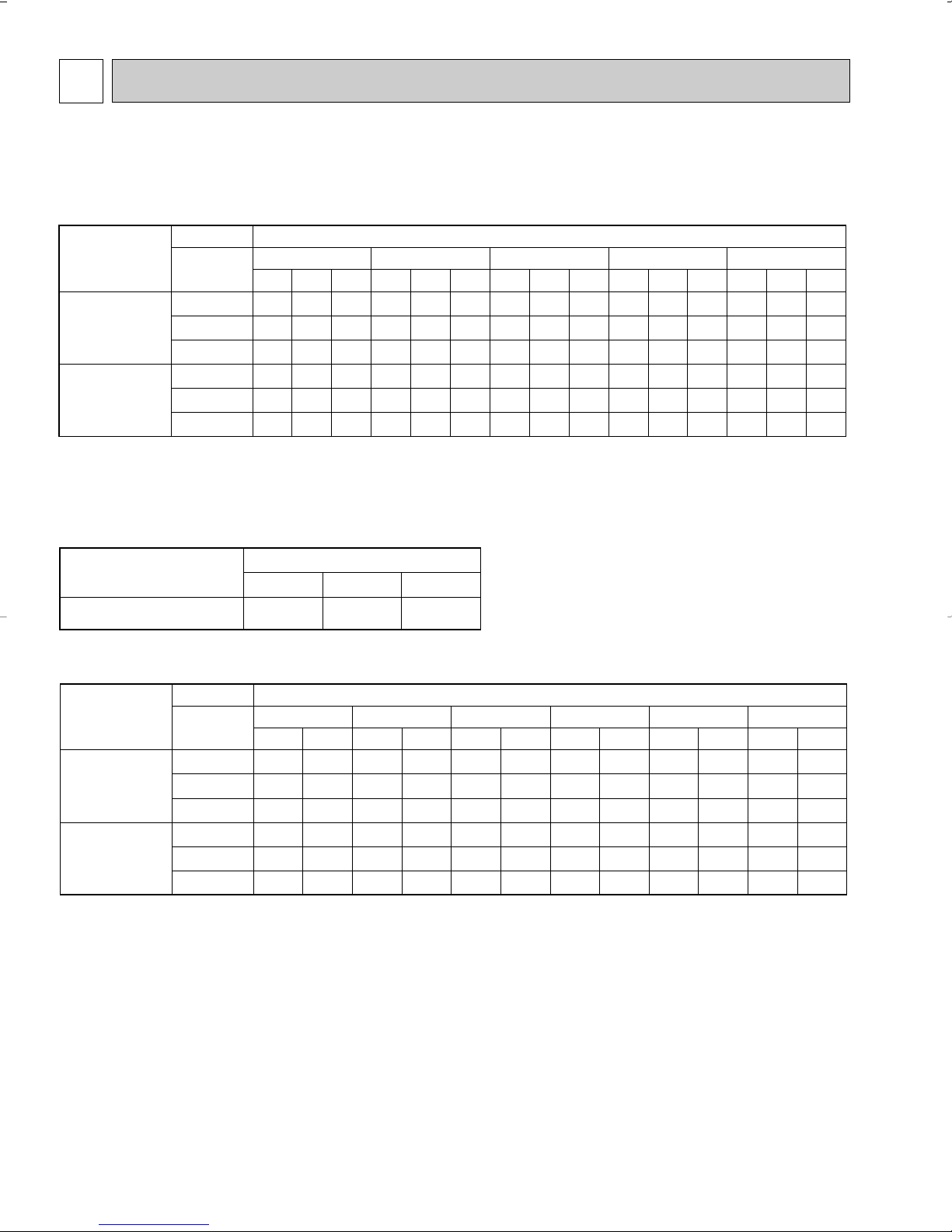

4

Model

Indoor air Outdoor intake air DB temperature(˚F

)

71

67

63

71

67

63

10.8

10.2

9.6

14.0

13.2

12.4

6.1

7.1

8.0

8.3

9.7

10.7

0.87

0.82

0.78

1.01

0.96

0.91

10.1

9.5

8.9

13.1

12.3

11.5

5.7

6.7

7.4

7.8

9.0

9.9

0.96

0.91

0.87

1.11

1.05

1.01

9.5

8.8

8.3

12.3

11.4

10.7

5.4

6.2

6.9

7.3

8.3

9.3

1.03

0.98

0.94

1.20

1.14

1.09

8.8

8.2

7.5

11.4

10.6

9.7

5.0

5.7

6.3

6.8

7.7

8.4

1.08

1.04

1.00

1.26

1.21

1.16

8.1

7.5

6.9

10.5

9.7

8.9

4.6

5.3

5.7

6.3

7.1

7.7

1.13

1.09

1.04

1.31

1.27

1.21

IWB

(˚F)

75 85 95 105 115

MSZ09UN

MSZ12UN

NOTE 1. IWB : Intake air wet-bulb temperature

TC : Total Capacity (x10

3

Btu/h), SHC : Sensible Heat Capacity (x10

3

Btu/h)

TPC : Total Power Consumption (kW)

2. SHC is based on 80˚F of indoor intake air DB temperature.

TC SHC

TPC TC SHC

TPC

TC SHC

TPC

TC SHC TPC

TC SHC

TPC

Model

Refrigerant piping length (one way : ft.)

1.0

25 (std.)

0.954

40

0.927

49

MSZ09UN

MSZ12UN

MUZ09UN

MUZ12UN

Model

Indoor air Outdoor intake air WB temperature(˚F

)

75

70

65

75

70

65

7.1

7.6

7.7

9.3

9.8

10.1

0.98

0.95

0.91

1.18

1.14

1.10

8.9

9.2

9.7

11.6

12.0

12.6

1.16

1.13

1.09

1.39

1.36

1.31

10.6

10.9

11.3

13.8

14.2

14.6

1.29

1.25

1.22

1.55

1.51

1.47

12.0

12.3

12.7

15.6

16.0

16.5

1.35

1.32

1.29

1.63

1.59

1.55

12.4

12.7

13.0

16.1

16.5

17.0

1.37

1.35

1.31

1.65

1.62

1.57

14.0

14.3

14.6

18.2

18.6

19.0

1.43

1.40

1.37

1.72

1.69

1.65

IDB

(˚F)

15 25 35 43 45 55

MSZ09UN

MSZ12UN

NOTE: 1. IDB : Intake air dry-bulb temperature

TC : Total Capacity (x10

3

Btu/h)

TPC : Total Power Consumption (kW)

2. Above data is for heating operation without any frost.

TC TPC TC TPC TC TPC TC TPC TC TPC TC TPC

DATA

MSZ09UN

MSZ12UN

MUZ09UN

MUZ12UN

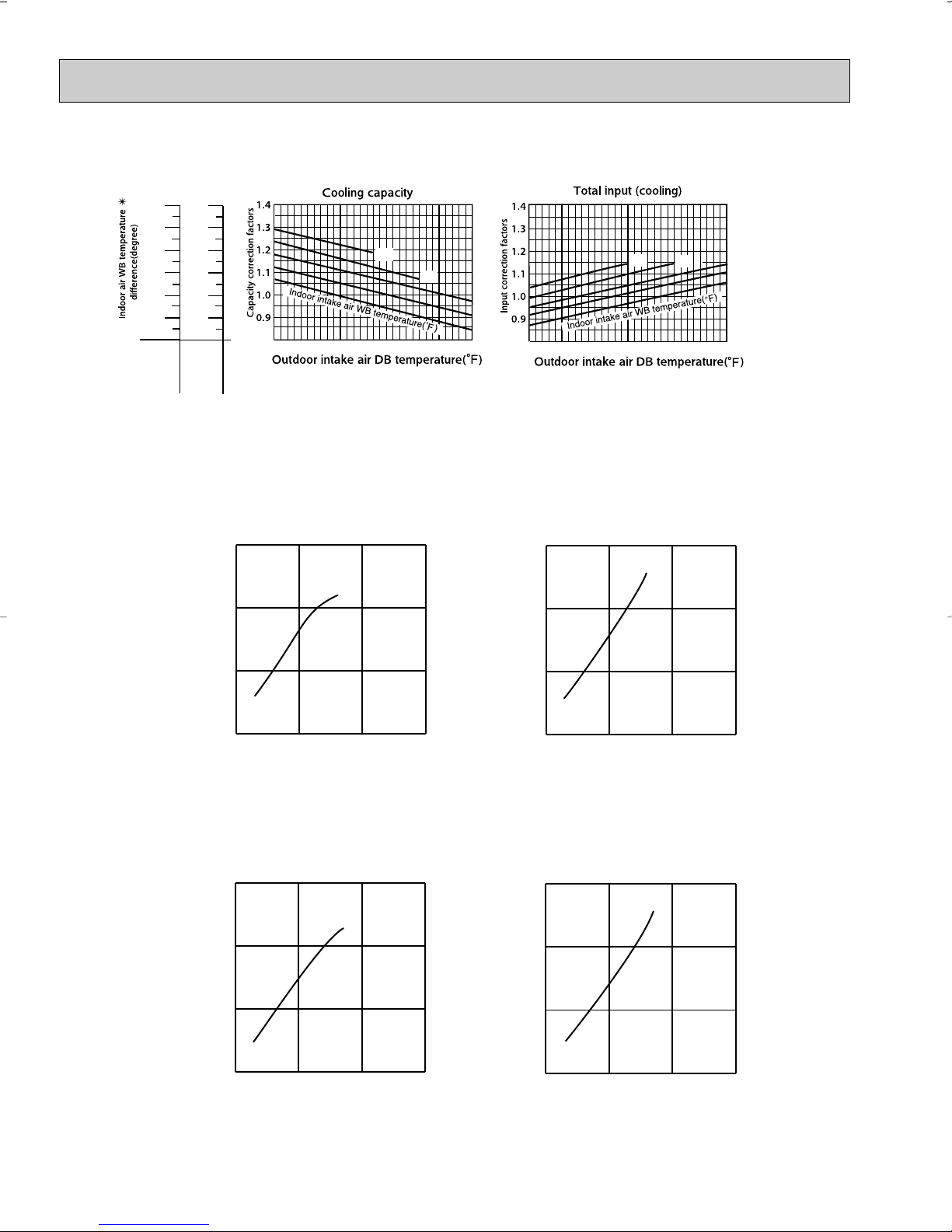

4-1. PERFORMANCE DATA

1) COOLING CAPACITY

2) COOLING CAPACITY CORRECTIONS

3) HEATING CAPACITY

How to operate with fixed operational frequency of the compressor.

1. Press the EMERGENCY OPERATION switch on the front of the indoor unit, and select either EMERGENCY COOL mode

or EMERGENCY HEAT mode before starting to operate the air conditioner.

2. The compressor starts up.

The operational frequency of the compressor is MSZ09UN: 64Hz, MSZ12UN: 70Hz in EMERGENCY COOL mode and

58Hz in EMERGENCY HEAT mode.

3. The fan speed of the indoor unit is High.

4. This operation continues for 30minutes.

5. In order to release this operation, press the EMERGENCY OPERATION switch twice or once, or press any button on the

remote controller.

8

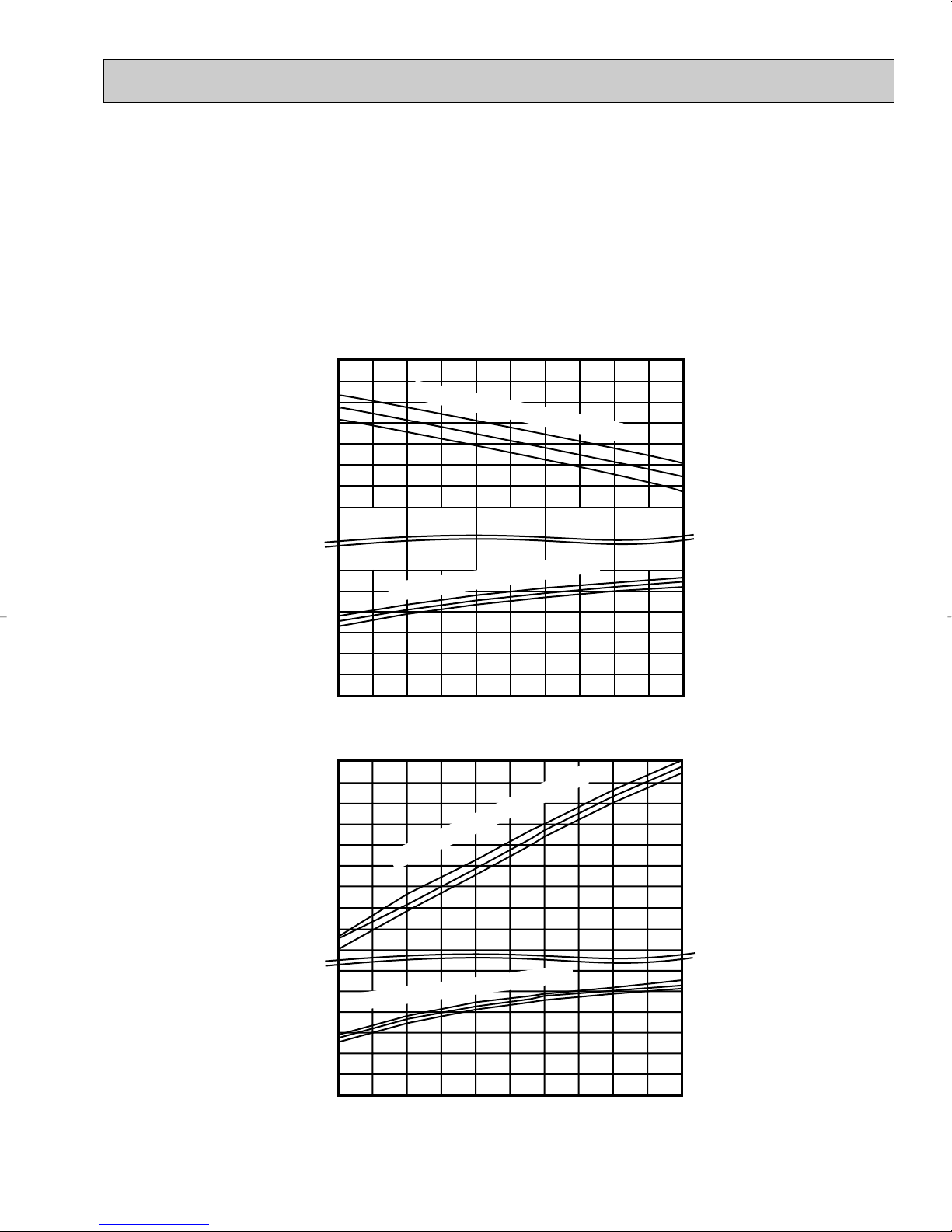

4-2. PERFORMANCE CURVE

71

67

63

71

67

63

65

70

75

75

70

65

Total power consumption (kW) Total capacity (

✕10

3

Btu/h)

Outdoor intake air DB temperature (°F)

SHF at rating condition = 0.70

= 233CFM

= 0.23

Airflow

Bypass Factor

12

10

8

6

1.2

65 75 85 95 105

115

0.8

0.6

Total power consumption (kW) Total capacity ( ✕10

3

Btu/h)

Outdoor intake air WB temperature (°F)

= 297CFM

Airflow

13

15

11

9

7

1.6

1.4

15 25 35 45 55

1.0

0.6

0.8

1.2

1.0

Indoor intake air WB temperature (°F)

Indoor intake air DB temperature (°F)

Indoor intake air DB temperature (°F)

Indoor intake air WB temperature (

°F)

0.4

How to operate with fixed operational frequency of the compressor.

1. Press the EMERGENCY OPERATION switch on the front of the indoor unit, and select either EMERGENCY COOL mode

or EMERGENCY HEAT mode before starting to operate the air conditioner.

2. The compressor starts up.

The operational frequency of the compressor is 64Hz in EMERGENCY COOL mode and 58Hz in EMERGENCY HEAT

mode.

3. The fan speed of the indoor unit is High.

4. This operation continues for 30minutes.

5. In order to release this operation, press the EMERGENCY OPERATION switch twice or once, or press any button on the

remote controller.

MSZ09UN MUZ09UN

(Cooling)

MSZ09UN MUZ09UN

(Heating)

This value of frequency is not the same as the actual frequency in operating. Refer to the page 16, 17 for the relationships

between frequency and capacity.

9

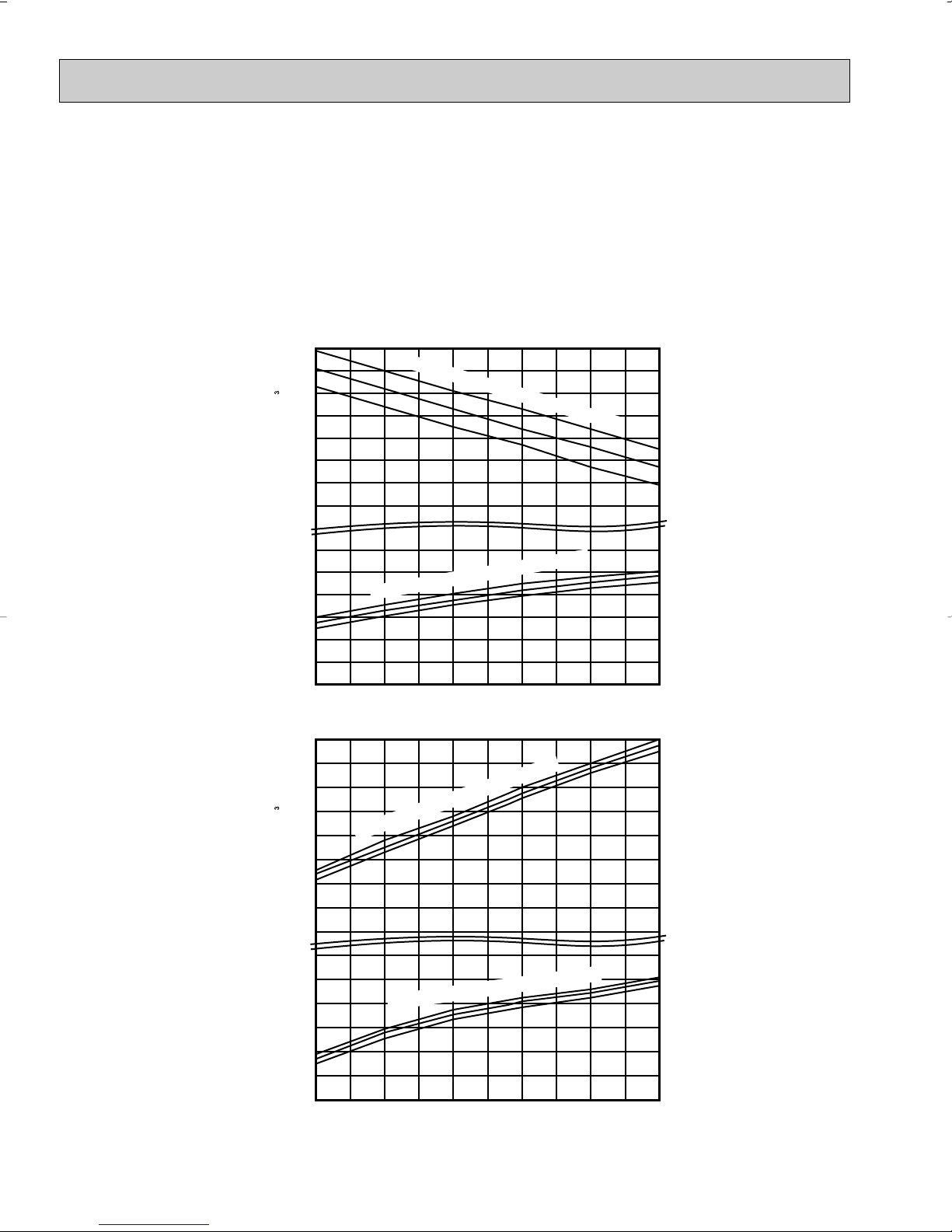

71

67

63

71

67

63

14

12

8

10

1.5

1.3

1.1

0.9

0.7

0.5

Indoor intake air WB temperature (°F)

Indoor intake air WB temperature (°F)

65

70

75

75

70

65

21

17

9

13

2.0

1.0

SHF at rating condition = 0.73

= 388CFM

= 0.19

Airflow

Bypass Factor

65 75 85 95 105 115

Total power consumption (kW) Total capacity ( ✕10 Btu/h)

Outdoor intake air DB temperature (°F)

Indoor intake air DB temperature (

°F)

= 452CFM

Airflow

15 25 35 45 55

Total power consumption (kW) Total capacity ( ✕10 Btu/h)

Outdoor intake air WB temperature (°F)

1.2

1.4

1.6

1.8

Indoor intake air DB temperature (°F)

How to operate with fixed operational frequency of the compressor.

1. Press the EMERGENCY OPERATION switch on the front of the indoor unit, and select either EMERGENCY COOL mode

or EMERGENCY HEAT mode before starting to operate the air conditioner.

2. The compressor starts up.

The operational frequency of the compressor is 70Hz in EMERGENCY COOL mode and 58Hz in EMERGENCY HEAT

mode.

3. The fan speed of the indoor unit is High.

4. This operation continues for 30minutes.

5. In order to release this operation, press the EMERGENCY OPERATION switch twice or once, or press any button on the

remote controller.

MSZ12UN MUZ12UN

(Cooling)

MSZ12UN MUZ12UN

(Heating)

This value of frequency is not the same as the actual frequency in operating. Refer to the page 16, 17 for the relationships

between frequency and capacity.

10

68 70 75 80 85 90 95 100 104

(°F)

40

45

50

55

60

65

70

75

80

85

90

95

100

(PSIG)

Condensing pressure

86

80

75

70

Suction pressure

Outdoor ambient temperature

Indoor DB temperature (

°F)

(PSIG)

86

80

75

70

68 70 75 80 85 90 95 100 104

(°F)

140

160

180

200

220

240

260

280

300

Indoor DB temperature (°F)

Outdoor ambient temperature

75

70

65

(PSIG)

Condensing pressure

Outdoor ambient temperature

5 10152025303540455055606570(°F)

150

160

170

180

190

200

210

220

230

240

250

260

270

280

290

300

310

Indoor DB temperature(

°F)

75

70

65

(PSIG)

Suction pressure

Outdoor ambient temperature

5 10152025303540455055606570(°F)

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

Indoor DB temperature (

°F)

4-3. Condensing pressure

How to operate with fixed operational frequency of the compressor.

1. Press the EMERGENCY OPERATION switch on the front of the indoor unit, and select either EMERGENCY COOL mode

or EMERGENCY HEAT mode before starting to operate the air conditioner.

2. The compressor starts up.

The operational frequency of the compressor is MSZ09UN: 64Hz, MSZ12UN: 70Hz in EMERGENCY COOL mode and

58Hz in EMERGENCY HEAT mode.

3. The fan speed of the indoor unit is High.

4. This operation continues for 30minutes.

5. In order to release this operation, press the EMERGENCY OPERATION switch twice or once, or press any button on the

remote controller.

MSZ09UN

(Cooling)

MSZ09UN

(Heating)

Data is based on the condition of indoor humidity 50%.

Air flow should be set to High speed.

Data is based on the condition of outdoor humidity 75%.

Air flow should be set to High speed.

Data is for heating operation without any frost.

11

MSZ12UN

68 70 75 80 85 90 95 100 104(°F)

50

55

60

65

70

75

80

85

90

95

100

105

110

(PSIG)

Condensing pressure

86

80

75

70

Suction pressure

Outdoor ambient temperature

Indoor DB temperature (

°F)

(PSIG)

86

80

75

70

68 70 75 80 85 90 95 100 104(°F)

140

160

180

200

220

240

260

280

300

Indoor DB temperature (°F)

Outdoor ambient temperature

75

70

65

(PSIG)

Condensing pressure

Outdoor ambient temperature

5 10152025303540455055606570(°F)

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

280

Indoor DB temperature(

°F)

(PSIG)

Outdoor ambient temperature

75

70

65

Suction pressure

5 10152025303540455055606570(°F)

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

Indoor DB temperature (

°F)

(Cooling)

Data is based on the condition of indoor humidity 50%.

Air flow should be set to High speed.

MSZ12UN

(Heating)

Data is based on the condition of outdoor humidity 75%.

Air flow should be set to High speed.

Data is for heating operation without any frost.

12

4-4. STANDARD OPERATION DATA

MSZ09UN

INDOOR UNIT

115V

1phase 60Hz,

2 wires

OUTDOOR UNIT

208/230V

1phase

60Hz,

2 wires

SIGNAL WIRE

2 wires 12V DC

208/230V

1phase

60Hz,

3 wires

115V

INDOOR UNIT

OUTDOOR UNIT

SIGNAL WIRE

2 wires 12V DC

115V

1phase

60Hz,

2 wires

Disconnect

switch

Cooling

8,800

0.70

980

64

0.945

5.34/5.11

237

74

184

112

52

154

80

67

57

56

950

233(Wet)

95

–

Capacity

SHF

Input

Rated frequency

Indoor unit

Power supply (V, phase, Hz)

Input

Fan motor current

Aux. heater current

Outdoor unit

Power supply (V, phase, Hz)

Input

Comp. current

Fan motor current

Condensing pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Comp. shell bottom temp

Ref. pipe length

Refrigerant charge (R22)

Intake air temperature

Discharge air temperature

Fan speed (High)

Airflow (High)

Intake air temperature

Fan speed

Airflow

Unit

Btu / h

—

kW

Hz

kW

A

A

kW

A

A

PSIG

PSIG

˚F

˚F

˚F

˚F

ft.

—

˚F

˚F

˚F

˚F

rpm

CFM

˚F

˚F

rpm

CFM

Cooling

11,400

0.73

1,140

70

1.093

5.84/5.71

256

87

186

54

160

80

67

58

56

388(Wet)

95

–

Heating

16,000

–

1,590

99

1.543

8.24/7.71

265

57

197

34

171

70

60

114

–

452(Dry)

47

43

Heating

12,300

–

1,320

76

1.285

6.84/6.81

276

59

198

122

36

172

70

60

100

–

1,000

297(Dry)

47

43

DB

WB

DB

WB

DB

WB

Item

Model

Total

Electrical

circuit

Refrigerant

circuit

Indoor

unit

Outdoor

unit

MSZ09UN

MSZ09UN

115, 1, 60

0.035

0.34

–

MUZ09UN

208/230, 1, 60

0.36/0.39

25

2 Ib. 7 oz.

650/720

847/953

MSZ12UN

MSZ12UN

115, 1, 60

0.047

0.41

–

MUZ12UN

208/230, 1, 60

0.36/0.39

118

25

2 Ib. 14 oz.

1,200

650/720

847/953

MSZ12UN

INDOOR UNIT

OUTDOOR UNIT

115V

1phase

60Hz,

2wires

208/230V

1phase

60Hz,

2 wires

SIGNAL WIRE

2 wires 12V DC

INDOOR UNIT

OUTDOOR UNIT

208/230V

1phase

60Hz,

3 wires

115V

1phase

60Hz,

2 wires

SIGNAL WIRE

2 wires 12V DC

115V

Disconnect

switch

POWER SUPPLY

✻ Control voltage

Power supply voltage to serial signal circuit is 12V DC.

Voltage between 11- and 33+ on in-out terminal block will be 12V DC peak voltage.

13

4-5. OPERATING RANGE

MSZ09UN

MSZ12UN

MUZ09UN

MUZ12UN

Indoor unit

Outdoor unit

Rated voltage

115V 1phase 60Hz

208/230V 1phase 60Hz

Guaranteed Voltage

Model

Min. 103V

Max. 127V

115V

Min. 198V Max. 253V

208V

230V

Model

MSZ09UN

MSZ12UN

Mode

HEAT

COOL

HEAT

COOL

297

279

233

452

452

388

15.8

14.9

12.4

18.2

18.2

15.6

22.3

21.0

17.6

29.2

29.2

25.2

Air flow

(CFM)

Air speed

(ft./sec.)

Coverage

range (ft.)

Function

Dry

Dry

Wet

Dry

Dry

Wet

MSZ09UN

MSZ12UN

MUZ09UN

MUZ12UN

Outdoor unit

precharged

(up to 25ft.)

2 lb. 7 oz.

2 lb. 14 oz.

25ft.

0

30ft.

1.62

35ft.

3.24

Refrigerant piping length (one way)

40ft.

4.86

45ft.

6.48

49ft.

8.10

Model

78%

—

Function

Cooling

Heating

Standard temperature

Maximum temperature

Minimum temperature

Maximum humidity

Standard temperature

Maximum temperature

Minimum temperature

DB (˚F)

80

95

67

70

80

70

WB (˚F)

67

71

57

60

67

60

Indoor

DB (˚F)

95

115

67

47

75

17

WB (˚F)

—

—

—

43

65

15

Outdoor

Condition

Intake air

temperature

(1) POWER SUPPLY

(2) OPERATION

4-6. OUTLET AIR SPEED AND COVERAGE RANGE

4-7. ADDITIONAL REFRIGERANT CHARGE R22(oz.)

14

● The air coverage range is the figure up

to the position where the air speed is 1

ft./sec., when air is blown out horizontally from the unit properly at the High

speed position.

The coverage range should be used

only as a general guideline since it

varies according to the size of the room

and furniture arranged inside the room.

MSZ09UN

MUZ09UN

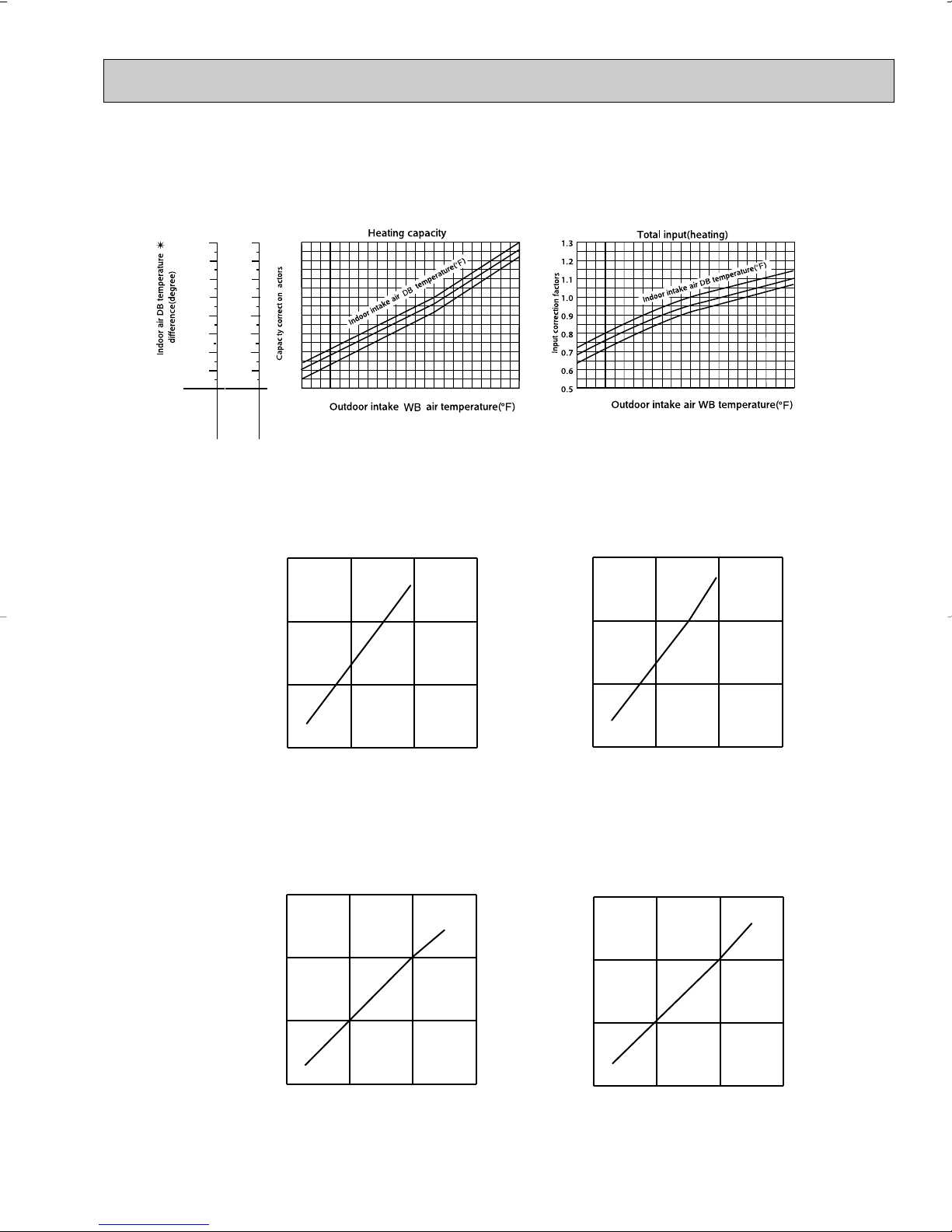

The standard data contained in these specifications apply only to the operation of the system under normal conditions. Since

operating conditions vary according to the areas where these units are installed. The following information has been provided

to clarify the operating characteristics of the system under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

INDOOR UNIT 103 ~ 127V 60Hz

OUTDOOR UNIT 198 ~ 253V 60Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature :°F WB

(2) Indoor outlet air wet-bulb temperature :°F WB

(3) Outdoor intake air dry-bulb temperature :°F DB

(4) Total input :W

(5) Indoor intake air dry-bulb temperature :°F DB

(6) Outdoor intake air wet-bulb temperature :°F WB

(7) Total input :W

Indoor air wet/dry-bulb temperature difference on the left side of the chart on page 16 and 17 shows the difference

between the indoor intake air wet/dry-bulb temperature and the indoor outlet air wet/dry-bulb temperature for your reference at service.

MSZ12UN

MUZ12UN

Cooling

}

Heating

}

How to measure the indoor air wet-bulb/ dry-bulb temperature difference

1. Attach at least 2 sets of wet-and dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet-and dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet-and dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch once (twice) to start the EMERGENCY COOL (HEAT) MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

INDOOR UNIT

OUTDOOR UNIT

15

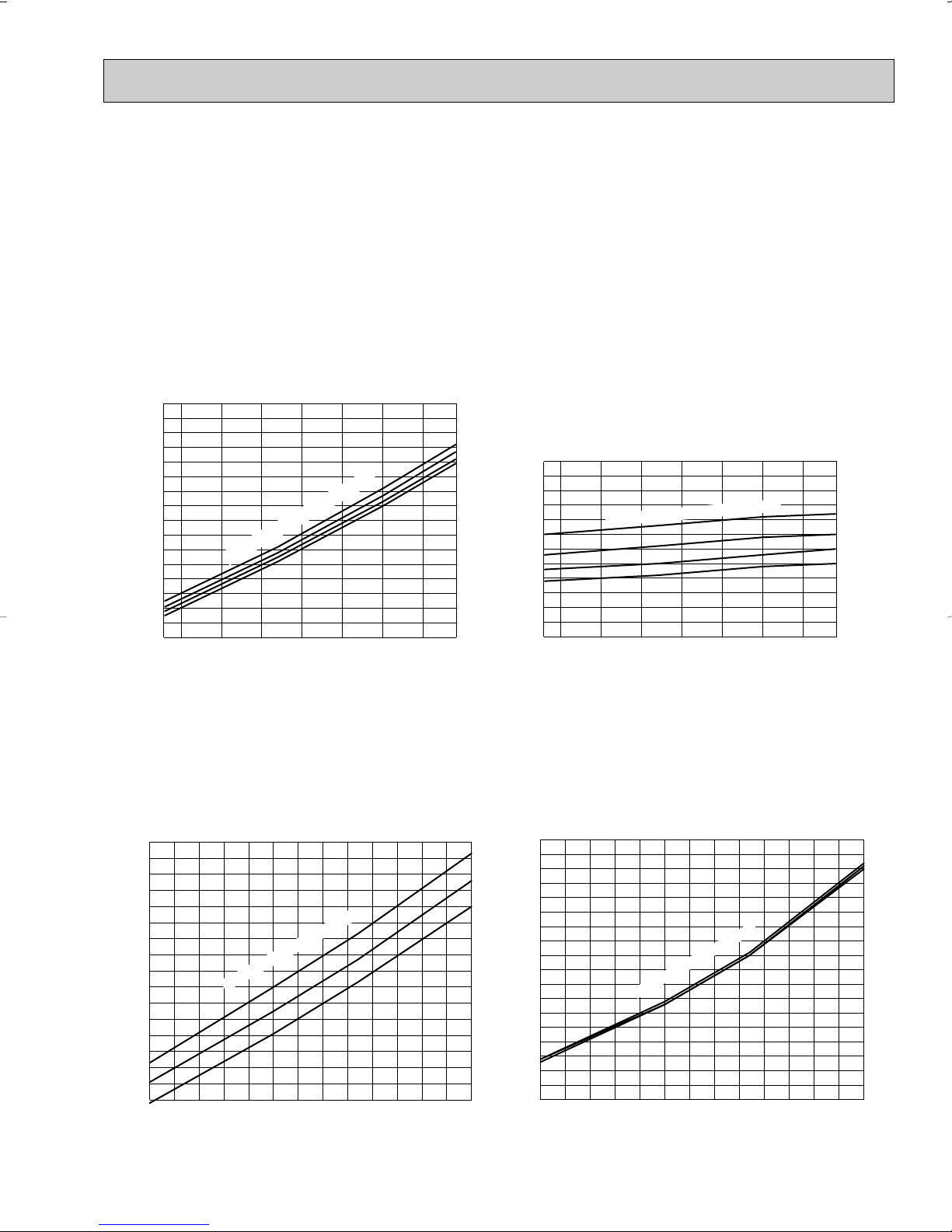

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

Correction of Cooling capacity

Capacity correction factors

The operational frequency of compressor

Correction of total input

Input correction factors

The operational frequency of compressor

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

Correction of Cooling capacity

Capacity correction factors

The operational frequency of compressor

Correction of total input

Input correction factors

The operational frequency of compressor

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

18.7

17.1

15.5

14.0

12.6

11.2

MSZ09UN

MSZ12UN

13.9

12.8

11.7

10.6

9.5

8.5

80 85 90 95 100 105 110

80 85 90 95 100 105 110

79

75

72

68

64

79

75

72

68

64

Cooling capacity

✴ These values are under rated (frequency).

MUZ09UN

MUZ12UN

MUZ09UN

MUZ12UN

16

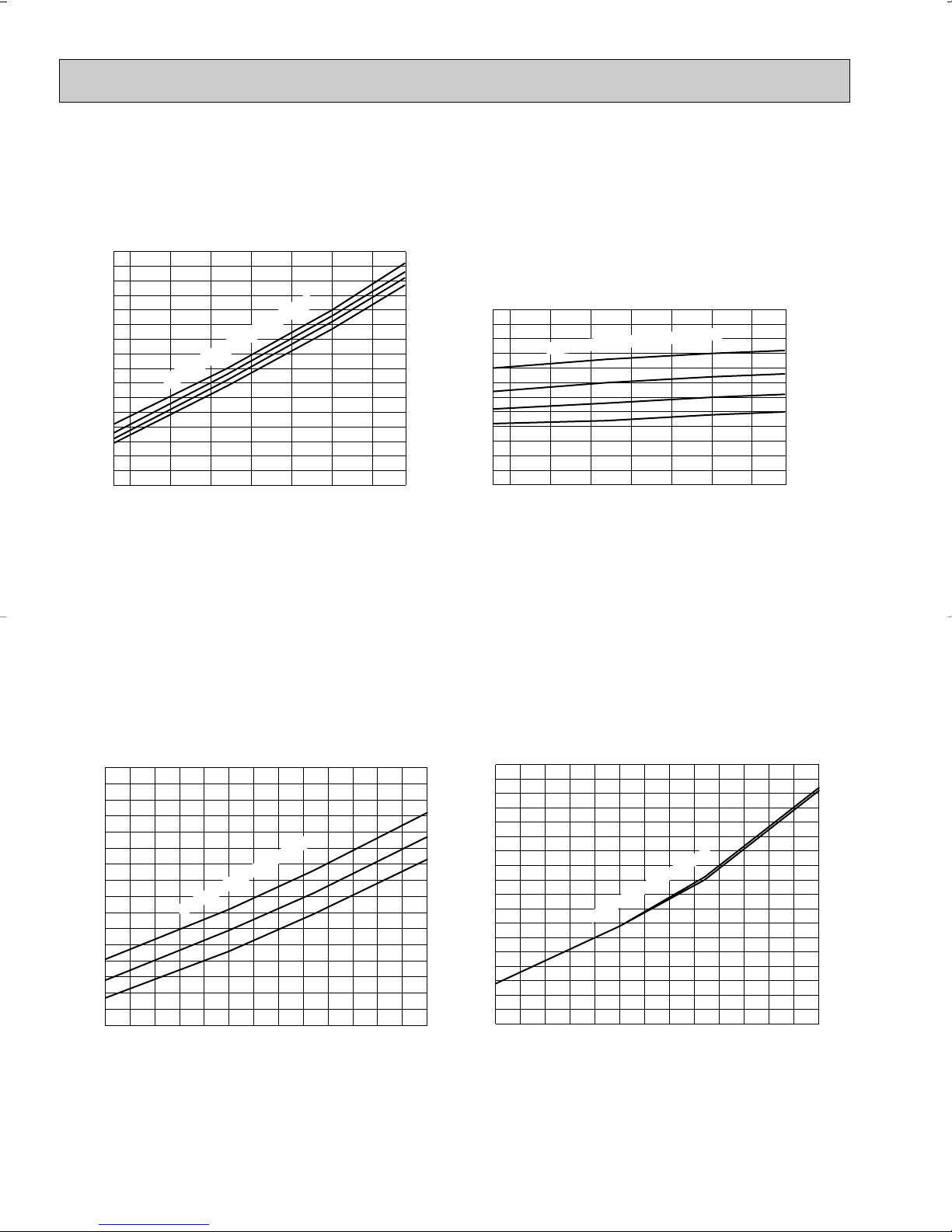

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

Correction of Heating capacity

Capacity correction factors

The operational frequency of compressor

Correction of total input

Input correction factors

The operational frequency of compressor

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

50.4

46.6

42.7

38.9

34.9

31.0

27.2

23.2

MSZ09UN

MSZ12UN

43.2

39.8

36.5

33.1

30.0

26.5

23.2

20.0

14

20

30

40

50

60

59

68

79

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

14

20

30

40

50

59

68

79

60

Heating capacity

NOTE:The following curves are for the heating operation without any frost.

✴ These values are under rated (frequency).

MUZ09UN

Correction of Heating capacity

1.5

1.0

0.5

Capacity correction factors

0.0

0 50 100 150(Hz)

The operational frequency of compressor

MUZ12UN

MUZ09UN

Correction of total input

1.5

1.0

0.5

Input correction factors

0.0

0 50 100 150(Hz)

The operational frequency of compressor

MUZ12UN

17

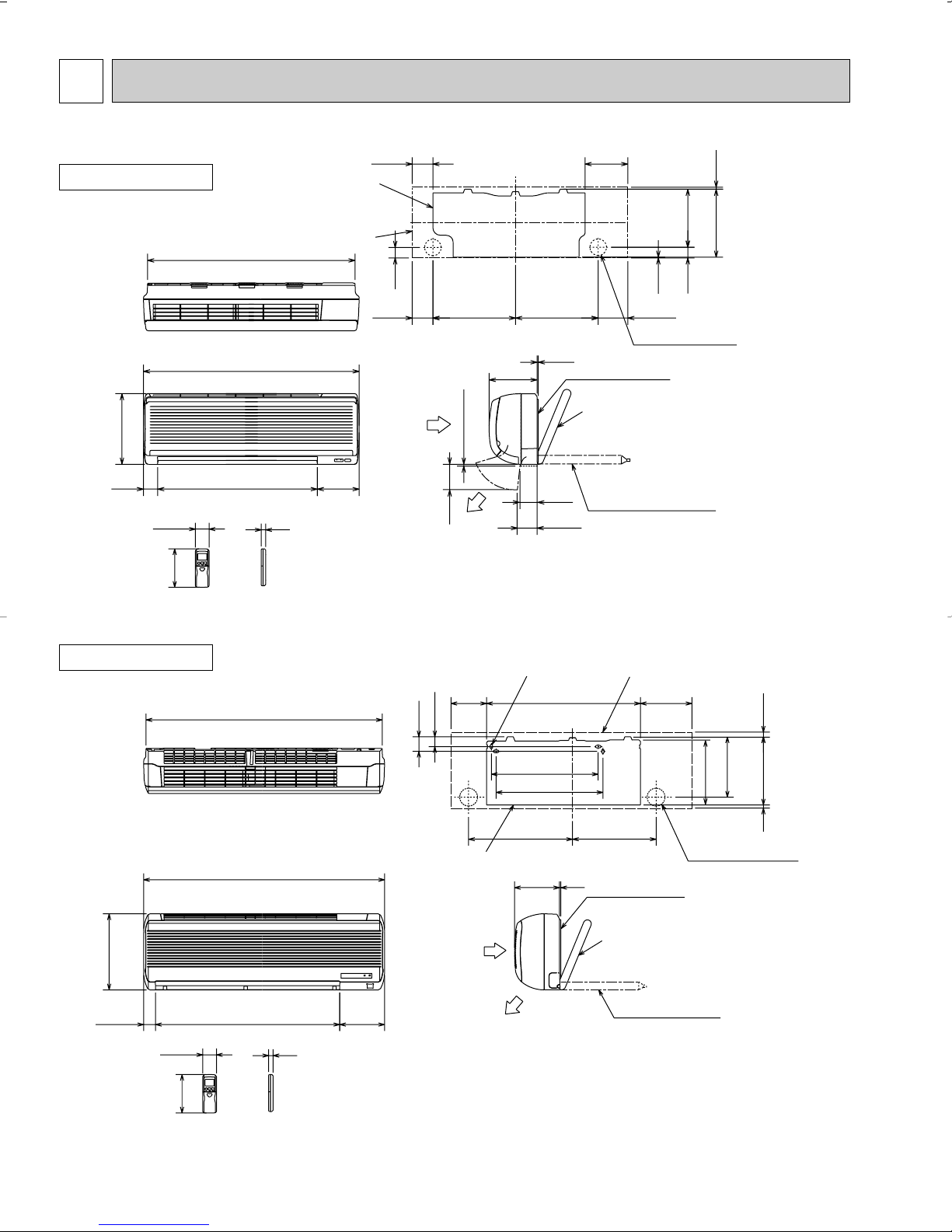

5

6-3/8

3/4

2-5/16

1/8 11-11/16

17-11/16

17-11/16

13-7/817-1/4

10

10-13/16

13/16

2-3/8

1-9/16

5-7/8 25-1/2 8-9/16

3/167-1/2

39-3/16

7-1/230-1/21-15/16

12-5/8

39-15/16

Wireless remote controller

4holes 7/16 O 13/16

Indoor unit

Installation plate

Wall hole [2-15/16

Installation plate

Liquid line [5/16 19-11/16

Gas line [1/2 16-15/16

Insulation [ 1-15/16 O.D

[ 1-1/8 I.D

Insulation [ 1-1/8

Drain hose [

5/8

Air out

{

Air in

OUTLINES AND DIMENSIONS

MSZ09UN

INDOOR UNIT

10-15/16

2-5/16

32-3/16

33-1/2

3/4

6-3/8

Wireless remote controller

3-1/4

Installation plate

Indoor unit

3-1/4

6-1/224-3/42-1/4

1-5/8

Air in

12-13/16 12-13/16

3/16

1/4 or more

3-15/16

Air out

7-7/16

Installation plate

2-5/8

3-1/16

6-5/8

9-1/8

1/8

1-5/8

4-5/8

Wall hole [2-9/16

Liquid line [1/4 19-11/16

Gas line [3/8 16-15/16

{

Insulation [1-7/16 O.D

[13/16 I.D

Drain hose [5/8

(Connected part O.D)

Insulation [1-1/8

Unit: inch

3/16

10-11/16

MSZ12UN

INDOOR UNIT

18

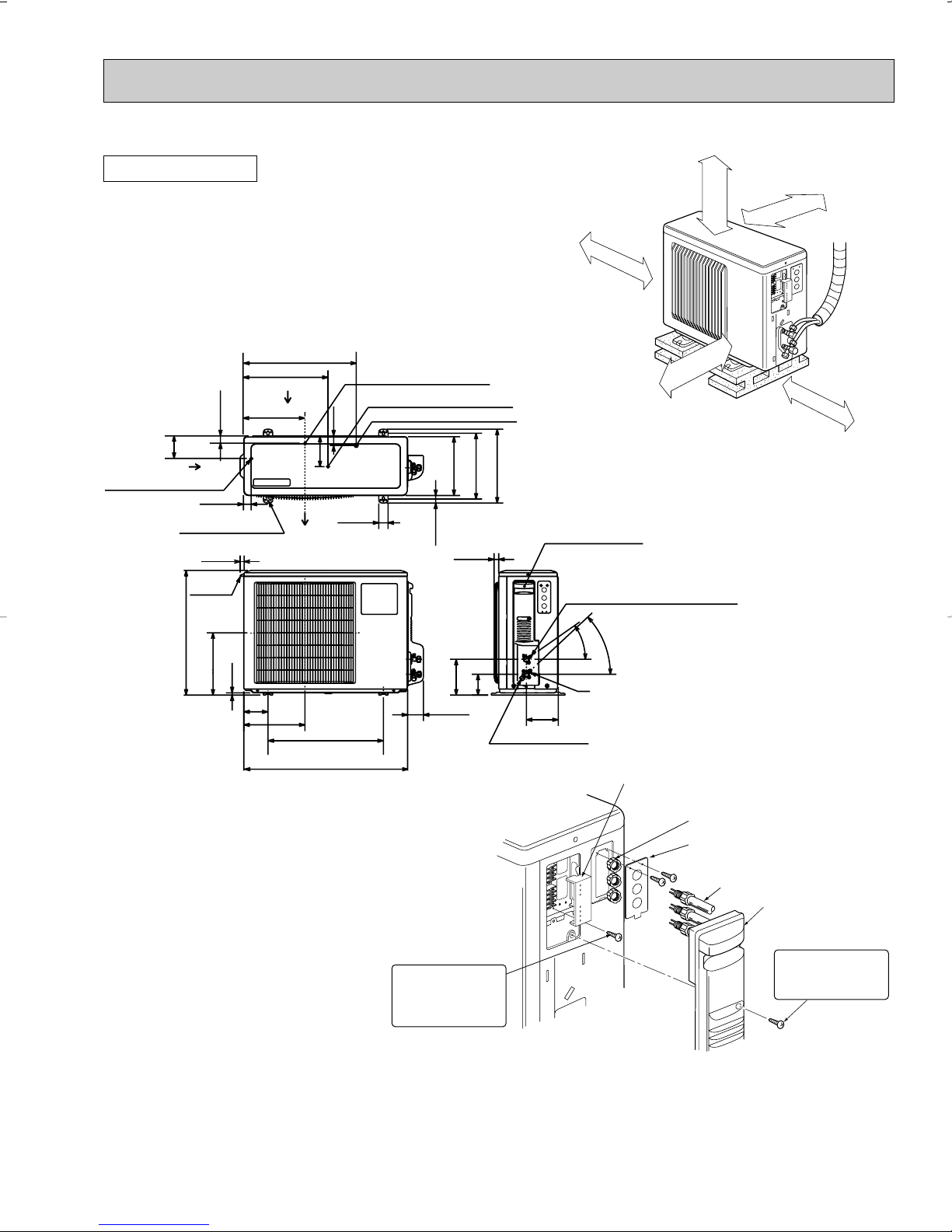

MUZ09UN MUZ12UN

Even if the right/left sides

or back side are vacant, the

top has to be at least 4 in.

unobstructed.

REQUIRED SPACE

Even if the right/left sides or back side

are vacant, the front has to be at least

4 in. unobstructed.

14 in. or more

4 in. or more

4 in. or more

Basically

unobstructed

Basically

unobstructed

WA

WA

WB

WA

WB

In case of poorly-ventilated place, the front or the back

has to be at least 8 in. unobstructed.

The wall may get dirty in case the air is discharged

toward it.

T.B. cover

Lock nut

Conduit cover

Connector

Service panel

Remove one fixing

screw to open the

service panel

Remove the screw

holding the T.B.

cover, and then

remove the cover

OUTDOOR UNIT

14-7/16

Air in

10-7/16

1-9/32

3-5/8

Air in

Drainage holes [1-3/32

1-5/16

4 holes 3/8o13/16

11/16

Handle

19-1/2

Air out

5

Drainage holes [1-3/32

Drainage holes [1-3/32

Drainage holes [1-3/32

1-3/8

1-9/16

10-1/32

1-9/32

11-7/32

25/32

Unit: inch

12-5/8

Service panel

Liquid refrigerant pipe joint

Refrigerant pipe (flared) [1/4

21-1/4

10-5/8

3/8

4-1/8

10-7/16

19-11/16

Bolt pitch for installation

28

6-3/32

3-17/32

2-11/16

5-7/16

Service port

19

43-

35-

Gas refrigerant pipe joint

Refrigerant pipe (flared)

[3/8 (MUZ09UN

[1/2 (MUZ12UN

)

)

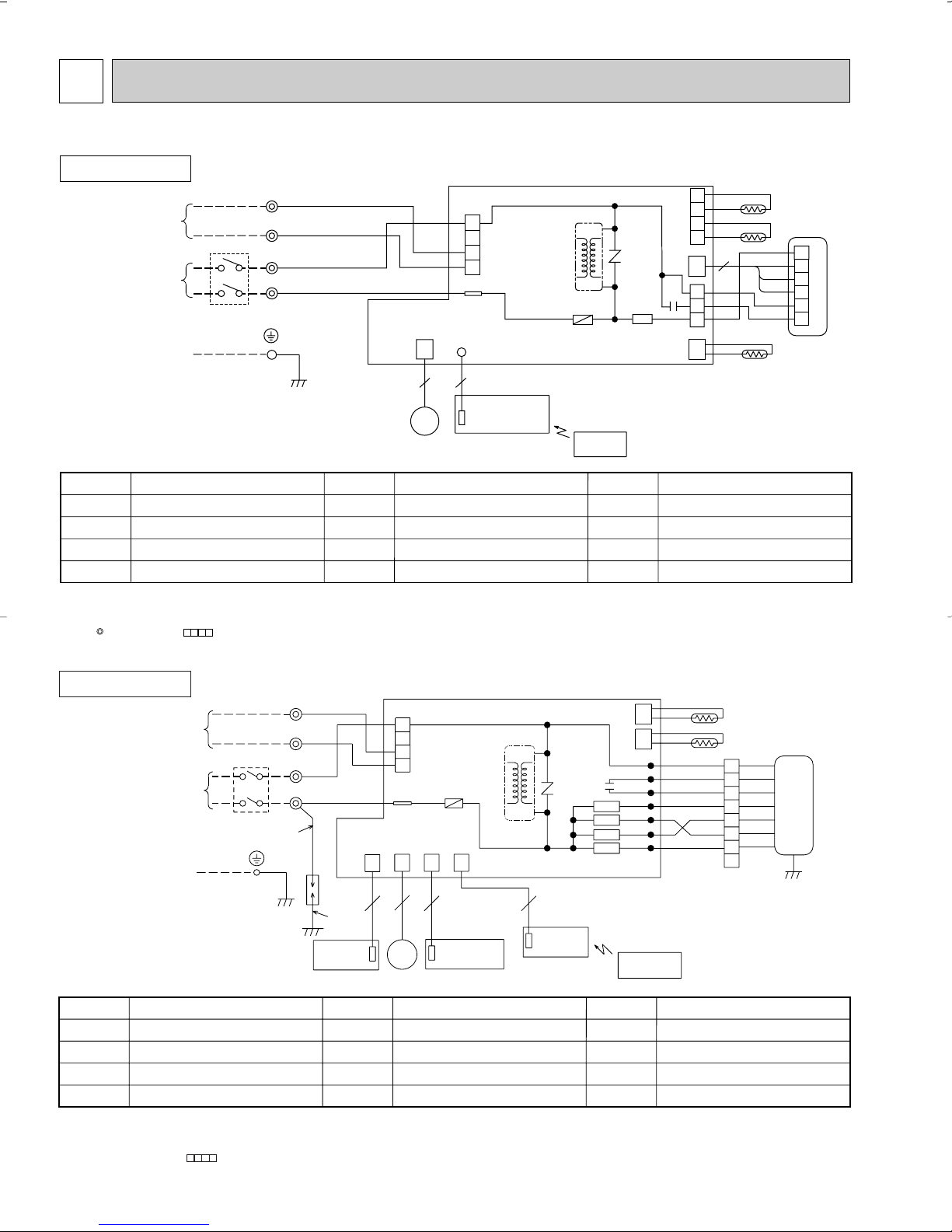

6

HIC1

( )

FROM OUTDOOR

1 phase

60Hz

CONNECTING

WIRE

TO OUTDOOR

UNIT

12V DC

SUPPLY

POWER

WIRES

CONNECTING

UNIT

115V

w A disconnect may be required by local code.

5

TAB12

P.C.BOARD

DISPLAY

MV

RED

GRN/YLW

DSAR

3

L1

RED

BLK

N

3

4

P.C.BOARD

AUTO RESTART

ASSY

CONTROLLER

REMOTE

RECEIVER

ELECTRONIC CONTROL P.C. BOARD

53

F11

TRANS

LDFVL

SR141

NR11

SR142

SR143

SR144

C11

LDFM

LDFL

LDFH

LDC12

LDC11

LDCOM

TO OUTDOOR

CONNECTING

WIRES

UNIT

CN

102CN151CN104CN101

CN

112

CN

111

TB

CN201

ORN

VLT

1-

3+

1

2

BRN

7

BRN

GRN/YLW

8

YLW

BLU

RED

ORN

WHT

BLK

3

BLU

YLW

BLK

5

6

4

ORN

RED

WHT

2

1

MF

RT11

RT12

w

SYMBOL

RT12

SR141~SR144

TB

SYMBOL

MF

MV

NR11

RT11

SYMBOL

C11

DSAR

F11

HIC1

NAME

NAME NAME

INDOOR FAN CAPACITOR

SURGE ABSORVER

FUSE(3A)

DC/DC CONVERTER

INDOOR FAN MOTOR(INNER FUSE)

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMIST OR

INDOOR COIL THERMISTOR

SOLID STATE RELAY

TERMINAL BLOCK

WIRING DIAGRAM

MSZ09UN

MODEL WIRING DIAGRAM

INDOOR UNIT

TB

L1

3+

1-

N

ORN

VLT

BLK

RED

SYMBOL

MV

NR11

RT11

RT12

CN201

1

2

3

4

TAB12

LD101T

CN

151

MV

ELECTRONIC CONTROL P.C. BOARD

5

5

POWER MONITOR,

RECEIVER

P.C.BOARD

NAME NAME

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMIST OR

MAIN INDOOR COIL THERMISTOR

TO OUTDOOR

UNIT

CONNECTING

WIRES

12V DC

FROM OUTDOOR

UNIT

CONNECTING

WIRES

POWER

(

)

SUPPLY

115V

1 phase

60Hz

TO OUTDOOR

UNIT

CONNECTING

WIRE

w

w A disconnect may be required by local code.

SYMBOL

C11

F11

HIC1

NOTE:1. About the outdoor side electric wiring, refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN CAPACITOR

FUSE(3A)

DC/DC CONVERTER

INDOOR FAN MOTOR(INNER FUSE)

MF

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate;

: Terminal block, : Connector

NAME

HIC1

NR11

TRANS

F11

REMOTE

CONTROLLER

SR141

SYMBOL

RT13

SR141

TB

C11

4

3

2

1

CN112

CN

121

1

2

3

CN211

CN

111

3

RT13

RT12

BLK

GRY

YLW

BRN

WHT

RED

RT11

1

2

3

MF

4

5

6

SUB INDOOR COIL THERMISTOR

SOLID STATE RELAY

TERMINAL BLOCK

MSZ12UN

INDOOR UNIT

NOTE:1. About the outdoor side electric wiring, refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate;

/: Terminal block, : Connector

MODEL WIRING DIAGRAM

20

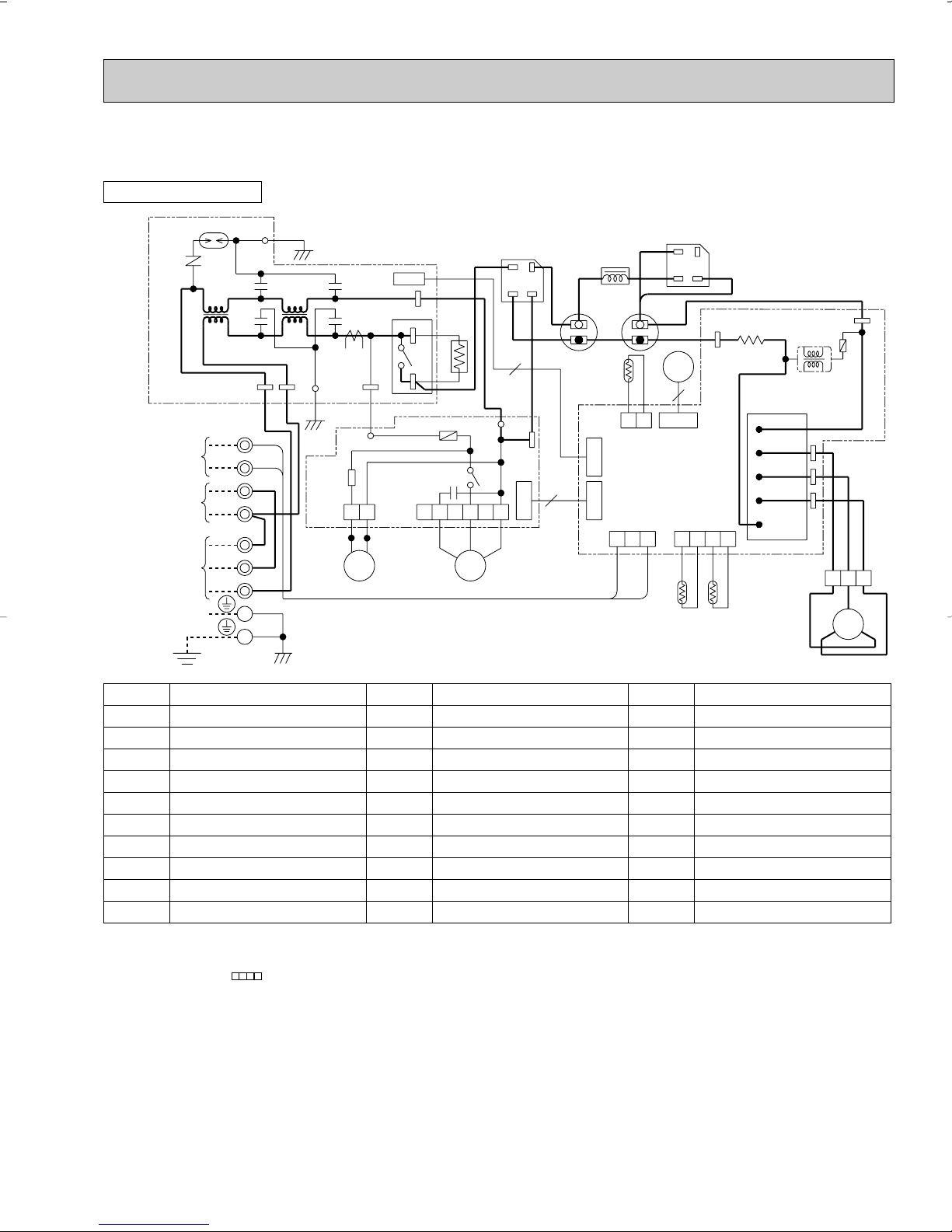

MUZ09UN

MUZ12UN

OUTDOOR UNIT

MODELS WIRING DIAGRAM

DSA61

NR61

NOISE FILTER

P.C. BOARD

FROM INDOOR UNIT

CONNECTING WIRES

12V DC

TO INDOOR UNIT

CONNECTING

115V

1 phase 60Hz

POWER

SUPPLY

208/230V

1 phase 60Hz

INDOOR UNIT

FROM

GROUND

L62

3

1

N

L1

L1

N

L2

LDE2

TAB66

TB2

TB1

CY61

CY62

ORN

VLT

BLK

RED

RED

BLK

BLU

L63

TAB65

GRN

WHT

12

CN725

TAB69

X64

TAB68

RELAY

P.C. BOARD

CN771

CY63

CT61

CY64

LDE1

GRN

LD64

SSR61

CN721

21S4 MF61

R.V. coil

heating ON

cooling OFF

RED

BLU

3

WHT

R64

4

ORN

LD62

F901

C65

53

642

RED

BLK

X61

1

WHT

DS61

(~)

(–) (~)

4

TAB

67

(+)

YLW

BLU

3

CN723

BLK

DS62

RED

(~)

BLK

C63

123

ORN

(–)

YLW

LEV

6

CN724

RT61 RT62

(+)

(~)

TAB

CN641

RED

N

RED

TAB

P

R61

P

U

V

W

4321

T801

TABU

TABV

TABW

N

IPM

BLK

123

WHT

MC

W

BLK

F801

WHT

V

RED

RED

U

L61

BLK

C61

+

–

YLW

CN726

CN722

CN601

VLT

+

–

RT64

21

CN642

ELECTRONIC

CONTROL

P.C. BOARD

SYMBOL

CT61

C61

C63

C65

CY61~64

DSA61

DS61,62

F801

F901

IPM

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

CURRENT TRANSFORMER

POWER-FACTOR CAPACITOR

SMOOTHING CAPACITOR

OUTDOOR FAN CAPACITOR

CAPACITOR

SURGE ABSORBER

DIODE STACK

FUSE (2A)

FUSE (1A)

INTELLIGENT POWER MODULE

2.Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

NAME

SYMBOL

LEV

L61

L62,L63

MC

MF61

NR61

RT61

RT62

RT64

R61

NAME

EXPANSION VALVE COIL

REACTOR

COMMON MODE CHOKE COIL

COMPRESSOR

OUTDOOR FAN MOTOR(INNER PROTECTOR)

VARISTOR

DEFROST THERMISTOR

DISCHARGE TEMPERATURE THERMIST OR

FIN TEMPERATURE THERMIST OR

CURRENT-DETECTING RESISTOR

SYMBOL

R64

SSR61

TB1,2

T801

X61

X64

21S4

NAME

CURRENT-LIMITING RESISTOR

SOLID STATE RELAY

TERMINAL BLOCK

TRANSFORMER

FAN MOTOR RELAY

RELAY

R.V. COIL

21

7

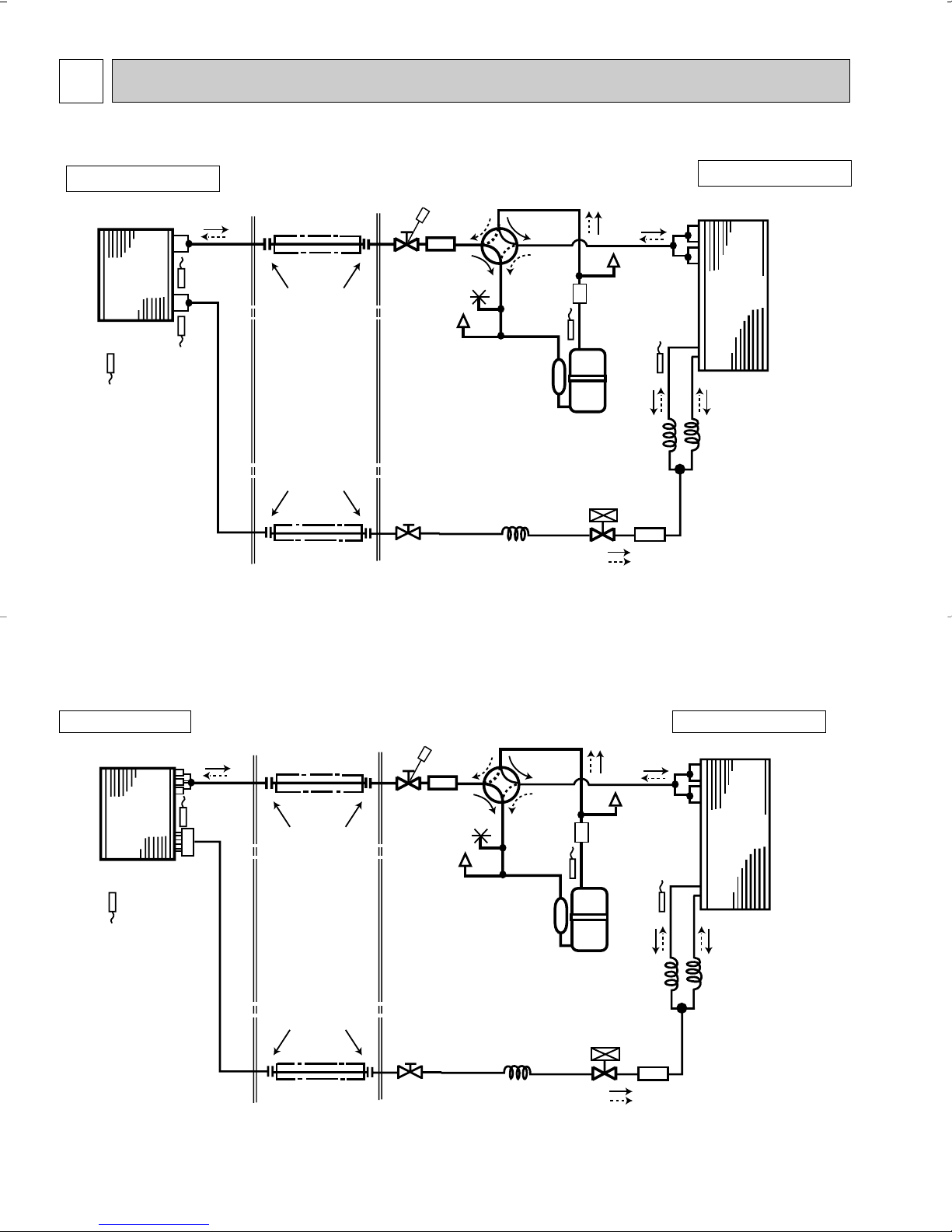

Room

Temperature

thermistor

RT11

Sub

indoor coil

thermistor

RT13

Main

indoor coil

thermistor

RT12

Refrigerant pipe {3/8

(with heat insulator)

Flared connection

Stop valve

(with service port)

Stop valve

(with strainer)

Fusible

plug

Service

port

Service

port

Muffler

Muffler

4-way valve

Compressor

Capillary

tube

Expansion

valve

Capillary tube

O.D.0.12OI.D.0.079O7-7/8

Flow of refrigerant (cooling)

Flow of refrigerant (heating)

Capillary

tube

R.V. coil

heating ON

cooling OFF

O.D.0.12OI.D.0.079O11-13/16 O.D.0.12OI.D.0.079O11-13/16

Discharge

temperature

thermistor

RT62

Flared connection

Refrigerant pipe {1/4

(with heat insulator)

Indoor

heat

exchanger

Outdoor

heat

exchanger

Defrost

thermistor

RT61

Strainer

REFRIGERANT SYSTEM DIAGRAM

MSZ09UN

Unit:inch

MUZ09UN

INDOOR UNIT

OUTDOOR UNIT

Unit:inch

MSZ12UN

MUZ12UN

INDOOR UNIT OUTDOOR UNIT

4-way valve

Discharge

temperature

thermistor

RT62

Service

port

Capillary tube

O.D.0.12OI.D.0.079O7-7/8

O.D.0.12OI.D.0.079O11-13/16 O.D.0.12OI.D.0.079O11-13/16

Service

port

Muffler

Compressor

Defrost

thermistor

RT61

Capillary

tube

Expansion

valve

Strainer

Flow of refrigerant (cooling)

Flow of refrigerant (heating)

Outdoor

heat

exchanger

Capillary

tube

R.V. coil

heating ON

cooling OFF

Indoor

heat

exchanger

Room

Temperature

thermistor

RT11

Main

indoor coil

thermistor

RT12

Refrigerant pipe {1/2

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe {1/4

(with heat insulator)

Stop valve

(with service port)

Stop valve

(with strainer)

Muffler

Fusible

plug

22

8

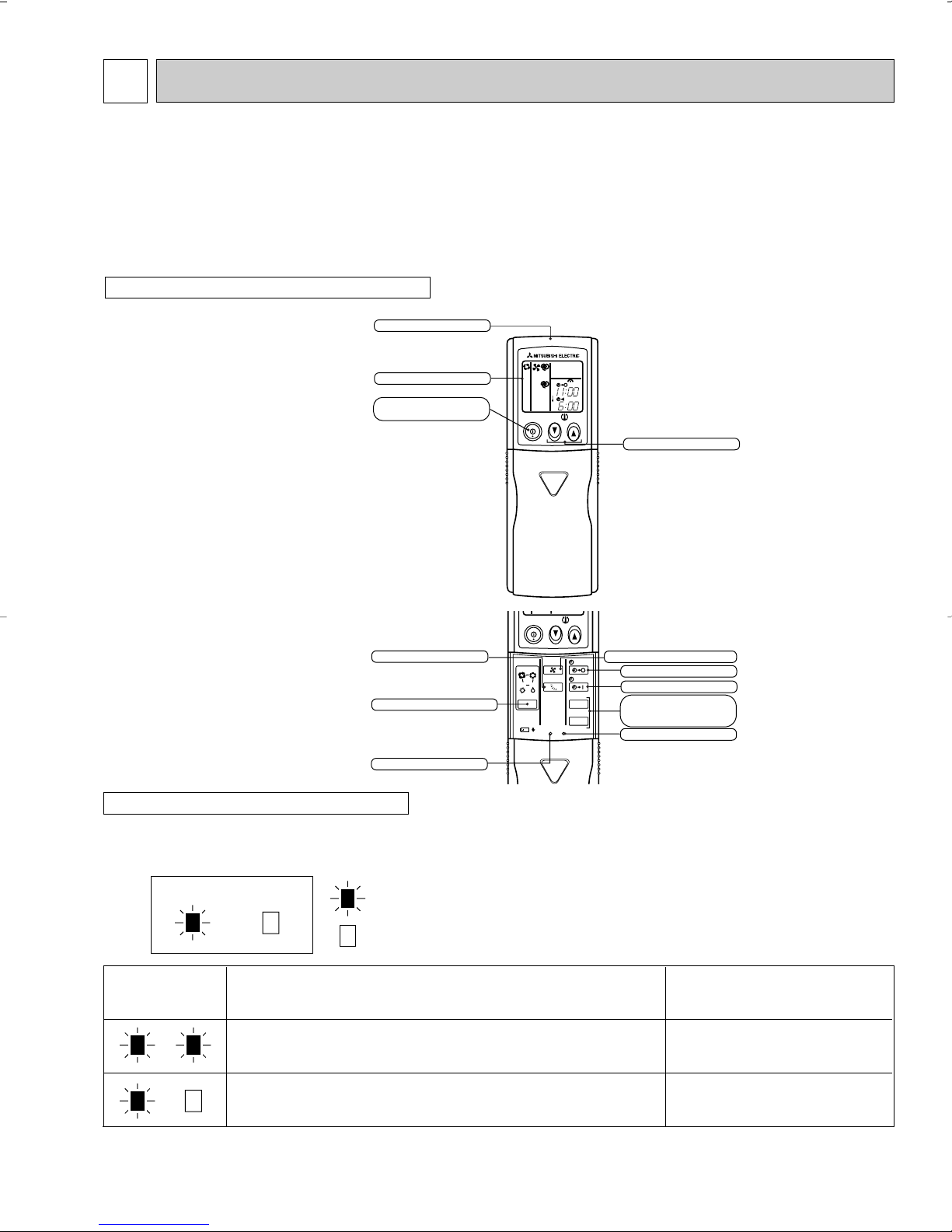

lighted

not lighted

Approx. 4 ˚F or more

Difference between target

temperature and room

temperature

Approx. 4 ˚F or less

This shows that the air conditioner is operating to reach

the target temperature.

Please wait until the target temperature is obtained.

This shows that the room temperature is

approaching the target temperature.

Operation stateIndication

Operation Indicator

Operation Indicator lamp

The operation indicator located at the right side of the indoor unit indicates the operation state.

• The following indication applies regardless of shape of the indicatior.

INDOOR UNIT DISPLAY SECTION

ON/OFF

FAN

TOO

WARM

TOO

COOL

VANE

MODE

STOP

START

HR.

MIN.

I FEEL

COOL

HEAT

DRY

RESET CLOCK

OPERATION SELECT button

FAN SPEED CONTROL button

OFF-TIMER button

HR. button

MIN. button

(TIME SET button)

ON-TIMER button

RESET button

VANE CONTROL button

CLOCK SET button

ON/OFF

TOO

COOL

PM

AM

TOO

WARM

Signal transmitting section

Operation display section

OPERATE /STOP

(ON /OFF)button

TEMPERATURE buttons

MICROPROCESSOR CONTROL

MSZ09UN

MSZ12UN

MUZ09UN

MUZ12UN

Once the operation mode are set, the same operation mode can be repeated by simply turning the OPERATE/STOP(ON/OFF)

button ON.

Indoor unit receives the signal with a beep tone.

When the system turns off, 3-minute time delay will operate to protect system from overload and compressor will not restart for

3 minutes.

WIRELESS REMOTE CONTROLLER

23

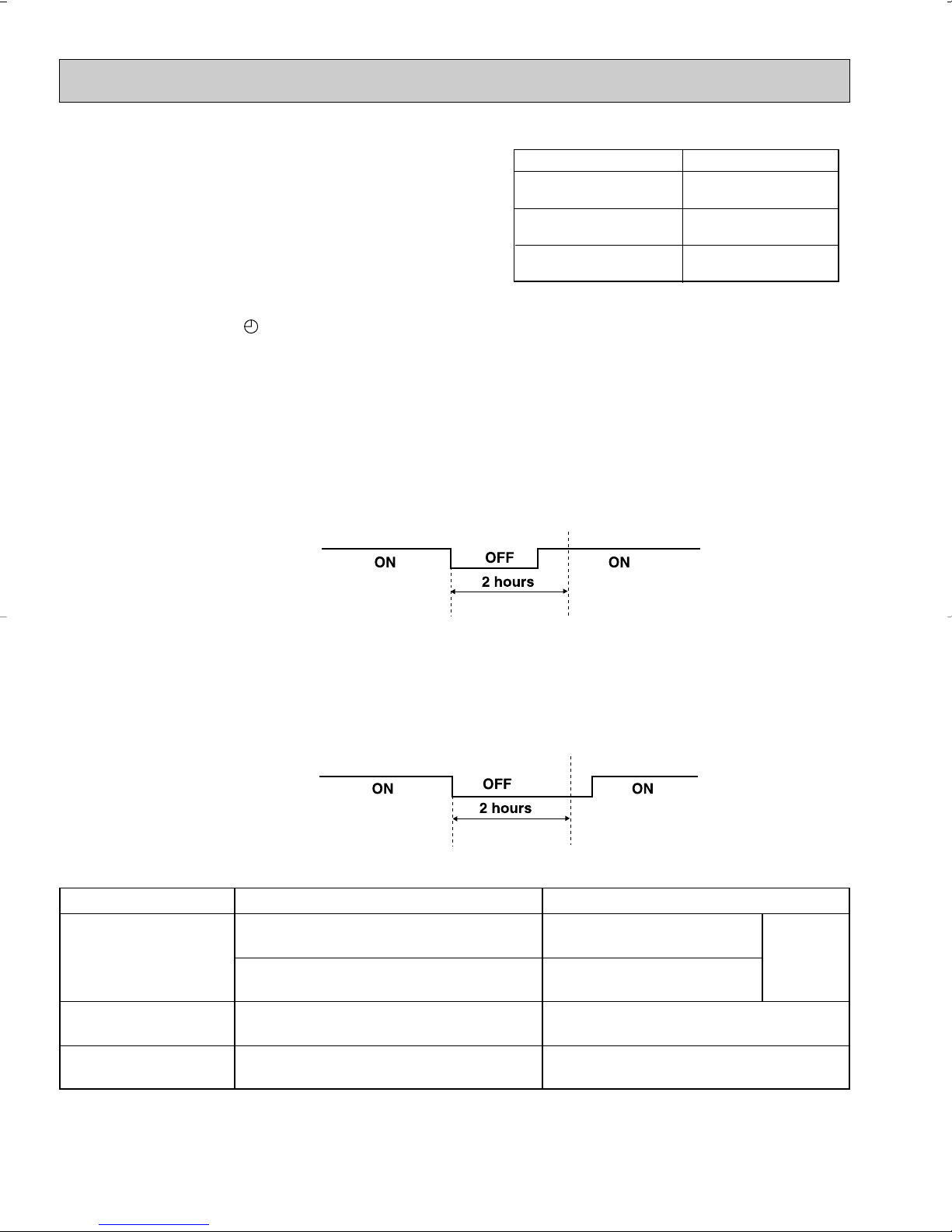

8-1. “I FEEL CONTROL” OPERATION

(1) Press OPERATE/STOP(ON/OFF) button on the remote controller.

OPERATION INDICATOR lamp of the indoor unit turns on with a

beep tone.

(2) Press OPERATION SELECT button to set “I FEEL CONTROL”.

Then a beep tone is heard.

(3) The operation mode is determined by the room temperature at

start-up of the operation.

● Once the mode is fixed, the mode does not change by room temperature afterwards.

● Under the ON-TIMER ( START) operation, mode is determined according to the room temperature as the operation

starts.

● When the system is stopped with the OPERATE/STOP(ON/OFF) button on the remote controller, and restarted within 2

hours in “I FEEL CONTROL” mode, the system operates in previous mode automatically regardless of the room temperature.

Operation time chart

Example

Initial room temperature

77˚F or more

73˚F to 77˚F

less than 73˚F

“I FEEL CONTROL”

“I FEEL CONTROL”

“I FEEL CONTROL”

mode

COOL mode of

DRY mode of

HEAT mode of

Previous operation

COOL mode of

“I FEEL CONTROL”

or COOL mode

When the system is restarted after 2 hours and more, the operation mode is determined by the room temperature at

start-up of the operation.

Operation time chart

Example

Previous operation

COOL mode of

“I FEEL CONTROL” or

COOL mode

(4) The initial set temperature is decided by the initial room temperature.

Restart

COOL mode of

“I FEEL CONTROL”

Restart

COOL or DRY or HEAT

mode of “I FEEL CONTROL” that determined

by room temperature at

start-up of the operation.

Mode Initial room temperature Initial set temperature

COOL mode of

“I FEEL CONTROL”

DRY mode of

“I FEEL CONTROL”

HEAT mode of

“I FEEL CONTROL”

❈1 When the system is restarted with the remote controller, the system operates with the previous set temperature regard-

less of the room temperature at restart.

The set temperature is calculated by the previous set temperature.

79˚F or more

77˚F to 79˚F

73˚F to 77˚F

less than 73˚F

24

75˚F

Initial room temperature

minus 4˚F

Initial room temperature

minus 4˚F

79˚F

❈ 1

Loading...

Loading...