Mitsubishi Electric MUY-TP-VF, MSY-TP35VF-E1, MSY-TP35VF-ET1, MSY-TP50VF-E1, MSY-TP50VF-ET1 Service Manual

Page 1

CONTENTS

1. TECHNICAL CHANGES ··································· 3

2. PART NAMES AND FUNCTIONS ····················· 4

3. SPECIFICATION ················································ 5

4. NOISE CRITERIA CURVES ······························ 6

5. OUTLINES AND DIMENSIONS ························ 7

6. WIRING DIAGRAM ············································ 8

7. REFRIGERANT SYSTEM DIAGRAM ··············· 9

8. SERVICE FUNCTIONS ··································· 10

9. MICROPROCESSOR CONTROL ····················11

10. TROUBLESHOOTING ····································· 17

11. DISASSEMBLY INSTRUCTIONS ···················· 27

MSY-TP35VF

-

E1

,

ET1

MSY-TP50VF

-

E1, ET1

Outdoor unit service manual

MUY-TP·VF Series (OBH817)

SERVICE MANUAL

No. OBH816

PARTS CATALOG (OBB816)

Models

INDOOR UNIT

Page 2

2

<Preparation before the repair service>

Prepare the proper tools.

Prepare the proper protectors.

Provide adequate ventilation.

After stopping the operation of the air conditioner, turn off the power-supply breaker and remove the power plug.

Discharge the capacitor before the work involving the electric parts.

<Precautions during the repair service>

Do not perform the work involving the electric parts with wet hands.

Do not pour water into the electric parts.

Do not touch the refrigerant.

Do not touch the hot or cold areas in the refrigeration cycle.

When the repair or the inspection of the circuit needs to be done without turning off the power, exercise great caution not to

touch the live parts.

Use the specied refrigerant only

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused by

failure to follow the instructions.

OBH816

Page 3

3

1

TECHNICAL CHANGES

MSY-TP35VF -

E1

,

ET1

MSY-TP50VF -

E1

,

ET1

1. New model

OBH816

Page 4

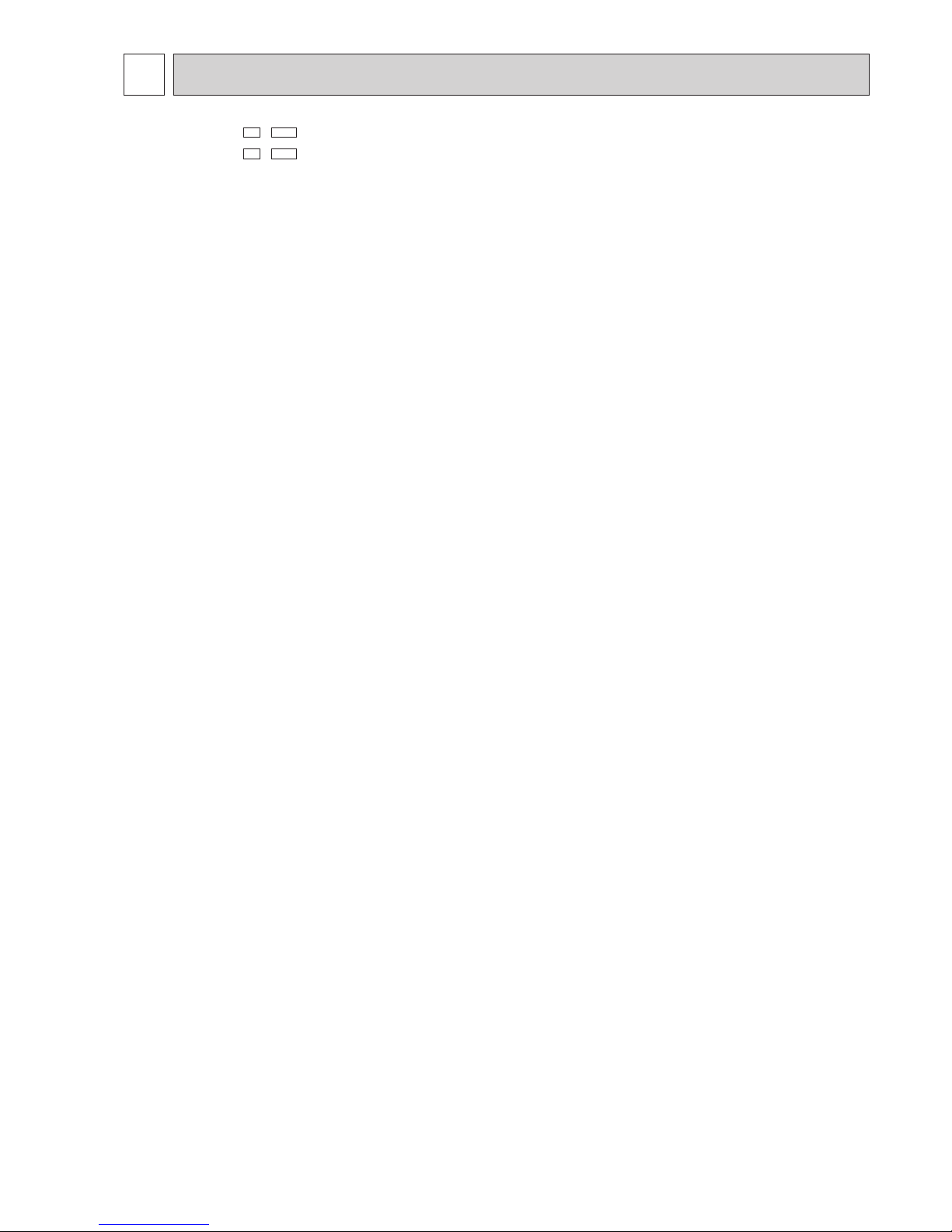

4

Operation indicator lamp

Remote control

receiving section

Horizontal vane

Air inlet

Air filter

Front panel

Air outlet

Heat exchanger

Emergency operation switch

ACCESSORIES

MSY-TP35VF MSY-TP50VF

Installation plate 1

Installation plate xing screw 4 × 25 mm 5

Felt tape (Used for left or left-rear piping) 1

2

PART NAMES AND FUNCTIONS

OBH816

Page 5

5

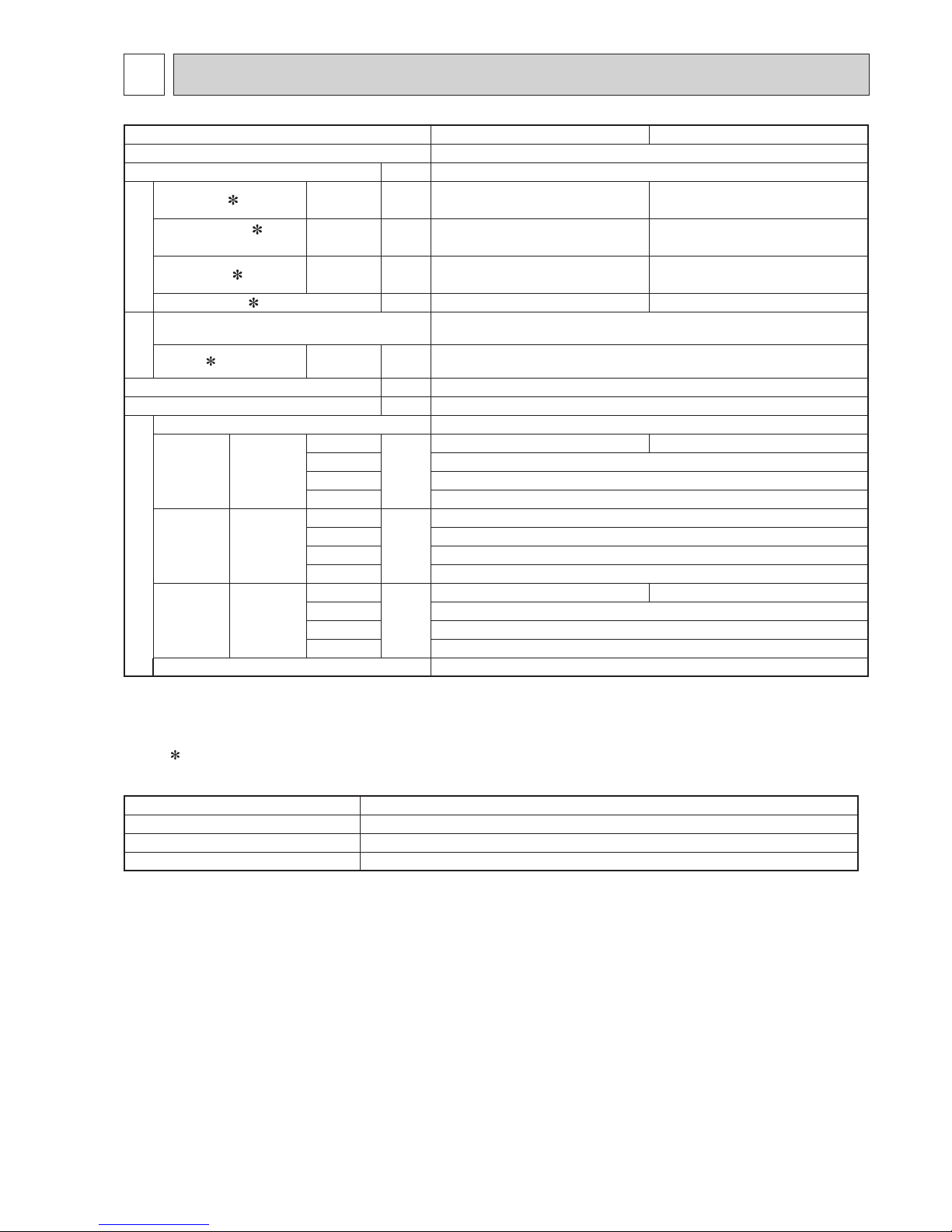

Indoor model MSY-TP35VF MSY-TP50VF

Power supply Single phase 230 V, 50 Hz

Breaker Capacity A

10

Electrical data

Power input 1 (Total) Cooling W 760 1,450

Running current

1

(Total)

Cooling A 3.6 6.4

Power factor

1 (Total) Cooling % 91 98

Starting current

1 (Total) A 3.6 6.4

Fan motor

Model RC0J30-MD

Current

1 Cooling A 0.32

Dimensions W × H × D mm 923 × 305 × 250

Weight kg 12.5

Special remarks

Air direction 5

Airow

Cooling

Super High

m

3

/h

984 990

High 822

Med. 696

Low 606

Sound

level

Cooling

Super High

dB(A)

45

High 40

Med. 36

Low 31

Fan speed

Cooling

Super High

rpm

1,070 1,080

High 930

Med. 820

Low 740

Fan speed regulator 4

NOTE : Test conditions are based on ISO 5151.

Cooling : Indoor Dry-bulb temperature 27°C Wet-bulb temperature 19°C

Outdoor Dry-bulb temperature 35°C

1 Measured under rated operating frequency.

Specifications and rated conditions of main electric parts

Fuse (F11) T3.15AL250V

Horizontal vane motor (MV) 12 V DC

Varistor

(NR11)

470 V

Terminal block (TB) 5P

3

SPECIFICATION

OBH816

Page 6

6

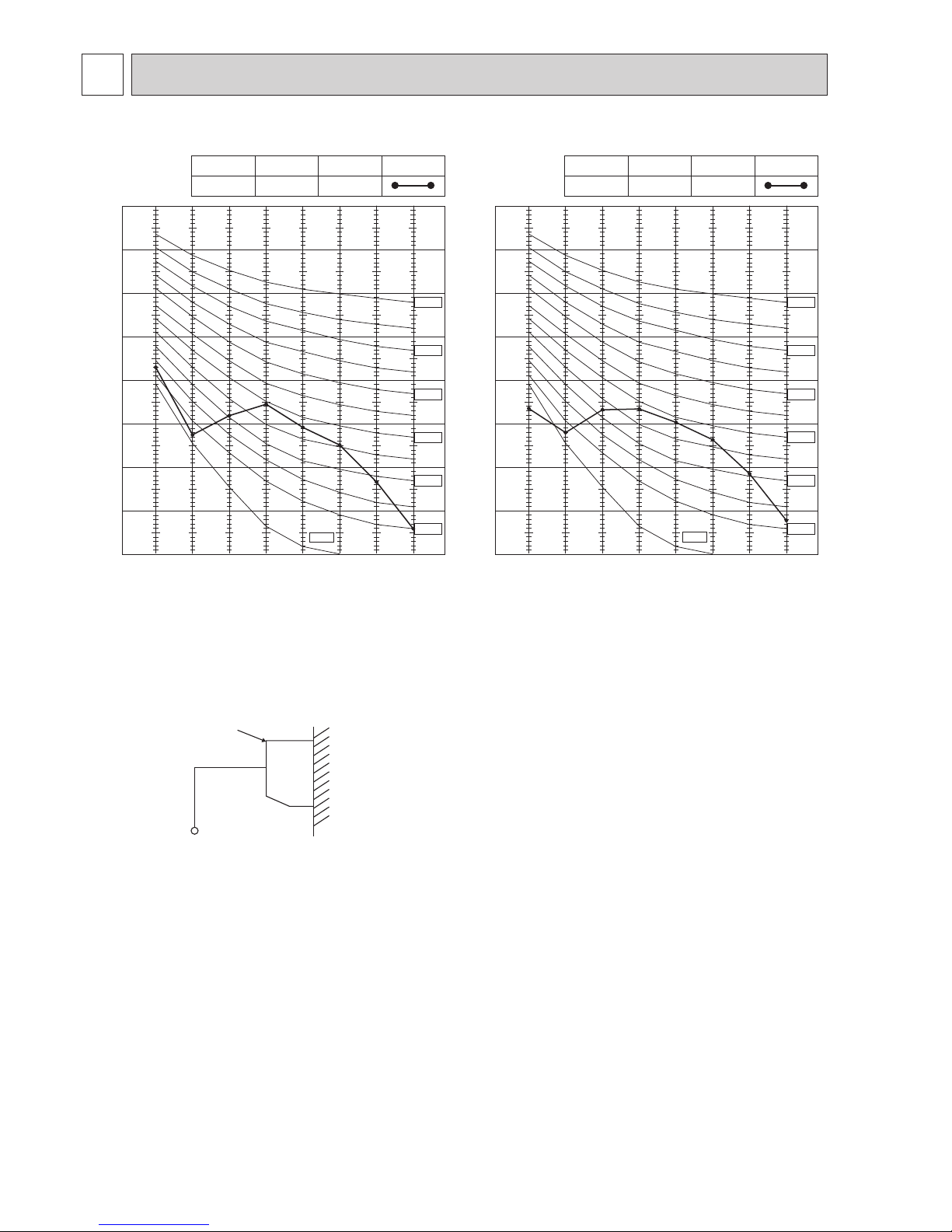

4

NOISE CRITERIA CURVES

MSY-TP35VF MSY-TP50VF

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-10

COOLING

FUNCTION

SPL(dB(A))

LINE

Super High

FAN SPEED

45

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-10

COOLING

FUNCTION

SPL(dB(A))

LINE

Super High

FAN SPEED

45

INDOOR UNIT

WALL

MICROPHONE

0.8m

1m

Test conditions

Cooling : Dry-bulb temperature 27°C Wet-bulb temperature 19°C

OBH816

Page 7

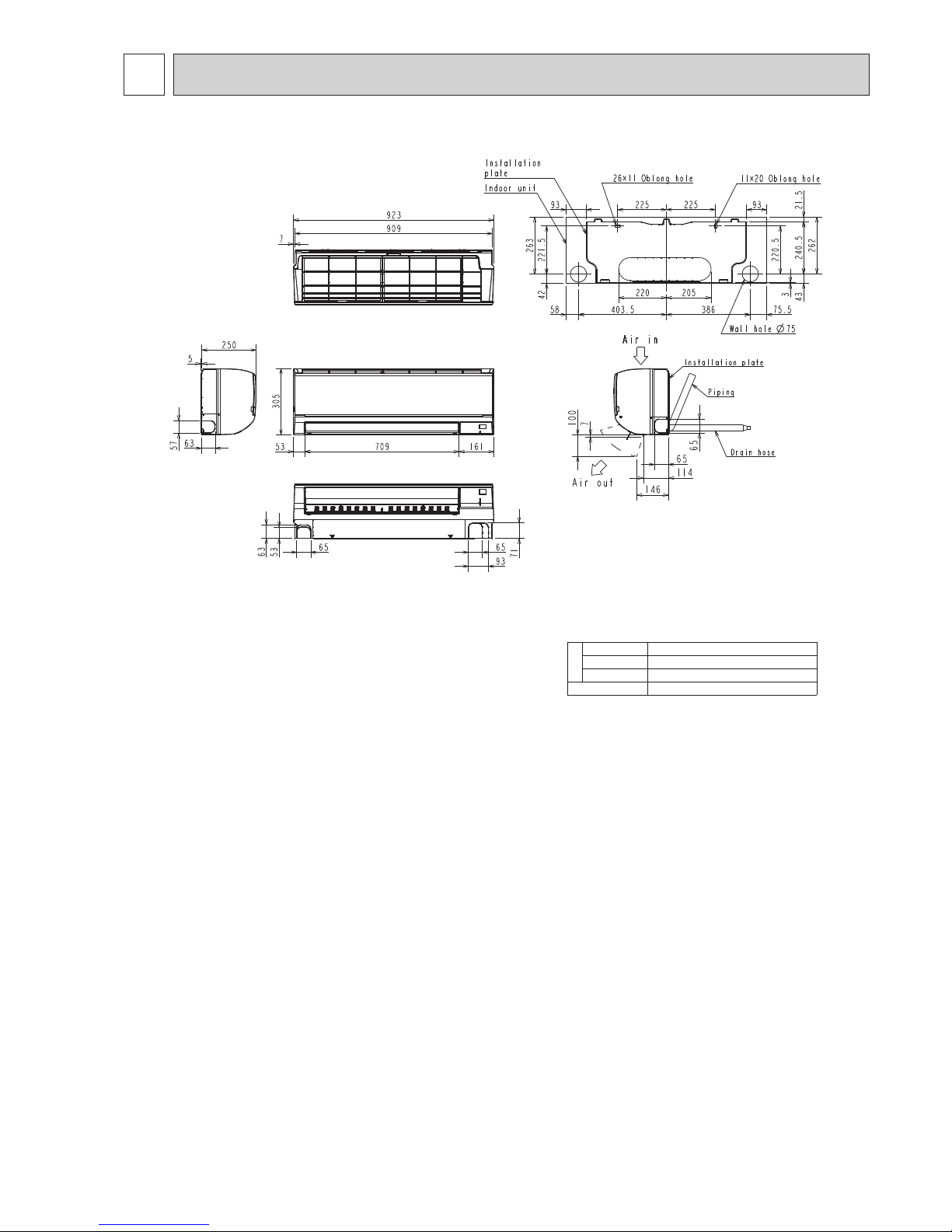

7

Unit: mm

5

OUTLINES AND DIMENSIONS

MSY-TP35VF MSY-TP50VF

Piping

Insulation Ø50 O.D

Liquid line Ø8 - 0.5m (Flared connection Ø6.35)

Gas line Ø12 - 0.45m (Flared connection Ø9.52)

Drain hose

Insulation Connected part Ø16 O.D

OBH816

Page 8

8

6

WIRING DIAGRAM

MSY-TP35VF -E1 MSY-TP50VF -

E1

MSY-TP35VF -

ET1

MSY-TP50VF -

ET1

Terminal bloğu

Konektör

KANAT MOTORU

(YATAY)

TERMİK SİGORTA

(

102

Ý

4.5A

)

GÜÇ KAYNAĞI

DIŞ ÜNİTEYE

SİGORTA

3.

Sembolleri gösterir

2.

Sadece bakır besleme

kablosu kullanın

NOTLAR

:

1.

Dış ünite elektronik kablolaması için dış ünite

elektronik kablo devre şemasını referans alınız.

İÇ ÜNİTE GÜÇ

KARTI

İÇ ÜNİTE ELEKTRONİK

KONTROL KARTI

REAKTÖR

PARÇA ADI

SİGORTA

(T3.15AL250V)

FAN MOTORU

VARİSTÖR

ODA SICAKLIK

TERMİSTÖRÜ

BORU SICAKLIK

TERMİSTÖRÜ(ANA)

BORU SICAKLIK

TERMİSTÖRÜ(YARDIMCI)

TRAFO

TERMİNAL BLOĞU

KONTAKTÖR

TERMİNAL UCU

OBH816

Page 9

9

MSY-TP35VF MSY-TP50VF

Unit: mm

7

REFRIGERANT SYSTEM DIAGRAM

Indoor

heat

exchanger

Flared connection

Room temperature

thermistor

RT 11

Flared connection

Refrigerant flow in cooling

Refrigerant pipe ø9.52

(with heat insulator)

Refrigerant pipe ø6.35

(with heat insulator)

Indoor coil

thermistor

RT12

Indoor coil

thermistor

RT13

OBH816

Page 10

10

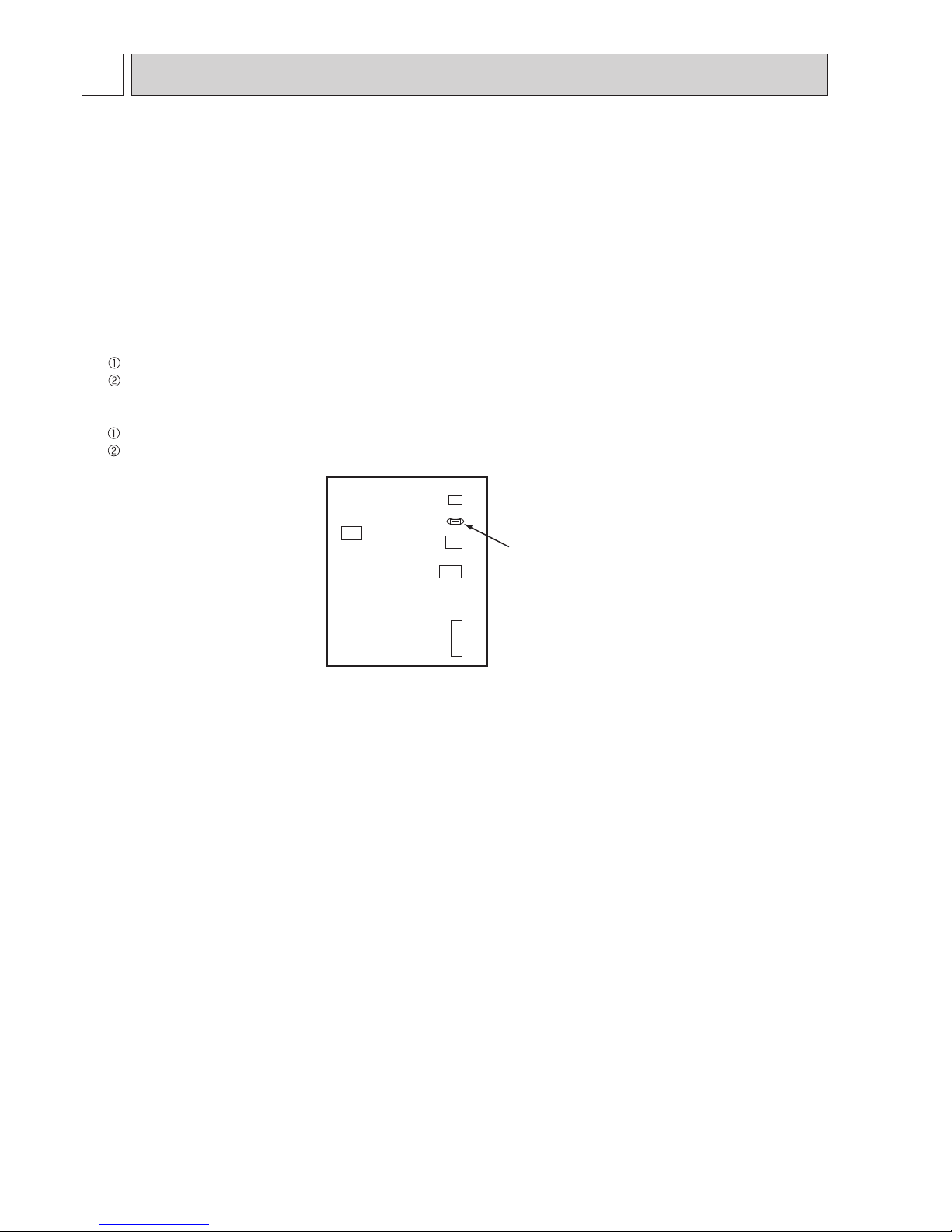

8-1. TIMER SHORT MODE

For service, the following set time can be shortened by bridging the timer short mode point on the electronic control P.C.

board. (Refer to 10-7.)

Set time : 3-minute → 3-second (It takes 3 minutes for the compressor to start operation. However, the starting time is

shortened by bridging the timer short mode point.)

NOTE: While the relay 52C is ON, the compressor starting time cannot be shortened.

MSY-TP35VF MSY-TP50VF

8

SERVICE FUNCTIONS

NOTE:

• The operation settings are memorized when 10 seconds have passed after the indoor unit was operated with the remote

controller.

• If main power is turned OFF or a power failure occurs while AUTO START/STOP timer is active, the timer setting is can-

celled.

• If the unit has been turned OFF with the remote controller before power failure, the auto restart function does not work

as the power button of the remote controller is off.

• To prevent the breaker from tripping OFF due to the rush of starting current, systematize other home appliance not to

turn ON at the same time.

• When some air conditioners are connected to the same supply system, if they are operated before power failure, the

starting current of all the compressors may flow simultaneously at restart.

Therefore, the special counter measures are required to prevent the main voltage-drop or the rush of the starting current

by adding to the system that allows the units to start one by one.

JR77

Indoor electronic

control P.C. board

CN10ACN 111

CN151

CN112

CN110

8-2. AUTO RESTART FUNCTION

When the indoor unit is controlled with the remote controller, the operation mode, the set temperature, and the fan speed

are memorized by the indoor electronic control P.C. board. “AUTO RESTART FUNCTION” automatically starts operation in

the same mode just before the shutoff of the main power.

Operation

If the main power has been cut, the operation settings remain.

After the power is restored, the unit restarts automatically according to the memory.

(However, it takes at least 3 minutes

for the compressor to start running.)

How to disable “AUTO RESTART FUNCTION”

Turn off the main power for the unit.

Cut the Jumper wire to JR77 on the indoor electronic control P.C. board. (Refer to 10-7.)

OBH816

Page 11

11

WIRED REMOTE CONTROLLER (Option : Example) PAR-33MAA

MSY-TP35VF MSY-TP50VF

9

MICROPROCESSOR CONTROL

The main display can be displayed in 2 different modes: "Full" and "Basic."

The initial setting is "Full."

Fri

Mode Temp. Fan

Room

Cool Auto

Set temp.

Fri

Cool

Mode Temp. Fan

AutoSet temp.

1

2

3

4

5

21

20

4

3

191716

15

14

13

12

6

8

10

1

11

7

9

22

5

2

Fan speed setting appears here.

4 Fan speed

Appears while the units are operated in the

energy-saving mode.

Appears while the outdoor units are operated in

the silent mode.

Preset temperature appears here.

Appears when the ON/OFF operation is centrally

controlled.

Current time appears here.

Appears when the buttons are locked.

Indoor unit operation mode appears here.

Appears when the operation mode is centrally

controlled.

15

16

2 Preset temperature

6

12

1 Operation mode

7

Appears when the units are operated in the

energy-saving mode with 3D i-see Sensor.

18

Indicates the louver setting.

Indicates the ventilation setting.

Appears when the On/Off timer or Night setback

function is enabled.

20

21

13

Indicates when filter needs maintenance.

Appears when the filter reset function is centrally

controlled.

Appears when the preset temperature is centrally

controlled.

10

9

8

Appears when the Weekly timer is enabled.

14

Appears when the preset temperature range is

restricted.

22

Functions of the corresponding buttons appear

here.

5 Button function guide

Appears when the built-in thermistor on the

remote controller is activated to monitor the

room temperature (a).

appears when the thermistor on the

indoor unit is activated to monitor the room

temperature.

17

3 Clock

(See the Installation Manual.)

Current room temperature appears here.

11 Room temperature

(See the Installation Manual.)

Note: All icons are displayed for explanation.

5

6

1234

Press to turn ON/OFF the indoor unit.

1

This lamp lights up in green while the unit

is in operation. It blinks while the remote

controller is starting up or when there is

an error.

Press to save the setting.

Main display: Press to change the operation

mode.

Main menu: Press to move the cursor down.

Press to return to the previous screen.

Main

display

: Press to decrease temperature.

Main menu: Press to move the cursor up.

Press to bring up the Main menu.

Main

display

: Press to increase temperature.

Main menu: Press to go to the previous page.

Operation settings will appear.

When the backlight is off, pressing any

button turns the backlight on and it

will stay lit for a certain period of time

depending on the screen.

Main

display

: Press to change the fan speed.

Main menu: Press to go to the next page.

6 ON/OFF lamp

2 SELECT button

7 Function button F1

3 RETURN button

8 Function button F2

4 MENU button

9 Function button F3

5 Backlit LCD

10 Function button F4

Fri

Room

Set temp.

Mode Temp. Fan

Cool Auto

Main

Main display:

Cursor Page

Main menu

Vane·Louver·Vent. (Lossnay)

High power

Timer

Weekly timer

OU silent mode

The functions of the function buttons

change depending on the screen. Refer

to the button function guide that appears

at the bottom of the LCD for the functions

they serve on a given screen.

When the system is centrally controlled,

the button function guide that

corresponds to the locked button will not

appear.

Main display Main menu

Function guide

7 8 9 0 7 8 9 10

• When the backlight is off, pressing any button turns the backlight on and

does not perform its function. (except for the OFF/ON button)

• Most settings (except OFF/ON, mode, fan speed, temperature) can be

made from the Menu screen.

Display

Full mode

Basic mode

Controller interface

Function buttons

10987

18

Indicates the vane setting.

19

OFF/ON button

OBH816

Page 12

12

Not all functions are available on all models of indoor units.

Energy-saving

Auto return

Schedule

Night setback

Main menu

Press button.

Move the cursor to the desired item with

and

buttons, and press

button.

Vane · Louver · Vent. (Lossnay)

High power

Weekly timer

Restriction

Maintenance

Initial setting

ON/OFF timer

Auto-OFF timer

Temp. range

Operation lock

Manual vane angle

Main/Sub

Timer

Main display

Contrast

Display details

Auto mode

Administrator password

Language selection

Daylight saving time

Service

Input maintenance info.

Function setting

Check

Self check

Maintenance password

Remote controller check

Test run

Clock

Auto descending panel

Menu structure

Filter information

Error information

3D i-see Sensor

OBH816

Page 13

13

Setting and display items Setting details

Vane · Louver · Vent.

(Lossnay)

Use to set the vane angle.

• Select a desired vane setting from 5 different settings.

Use to turn ON/OFF the louver.

Not available

Use to set the amount of ventilation.

Not available

High power Use to reach the comfortable room temperature quickly.

Not available

Timer ON/OFF timer* Use to set the operation ON/OFF times.

• Time can be set in 5-minute increments.

Auto-Off timer Use to set the Auto-OFF time.

• Time can be set to a value from 30 to 240 in 10-minute increments.

Filter information Use to check the lter status.

Not available

Error information Use to check error information when an error occurs.

• Check code, error source, refrigerant address, unit model, manufacturing number, contact information (dealer's phone

number) can be displayed.

(The unit model, manufacturing number, and contact information need to be registered in advance to be displayed.)

Weekly timer* Use to set the weekly operation ON/OFF times.

• Up to 8 operation patterns can be set for each day.

(Not valid when the ON/OFF timer is enabled.)

Energy saving Auto return Use to get the units to operate at the preset temperature after performing energy-saving operation for a

specied time period.

• Time can be set to a value from 30 and 120 in 10-minute increments.

(This function will not be valid when the preset temperature ranges are restricted.)

Schedule* Set the start/stop times to operate the units in the energy-saving mode for each day of the week, and set the

energy-saving rate.

Not available

Night setback* Use to make Night setback settings.

•

Select "Yes" to enable the setting, and "No" to disable the setting. The temperature range and the start/stop times can be set.

Restriction Temp. range Use to restrict the preset temperature range.

• Different temperature ranges can be set for different operation modes.

Operation lock Use to lock selected functions.

• The locked functions cannot be operated.

Maintenance Auto descending panel Not available

Manual vane angle Not available

3D i-see Sensor Not available

Initial setting Main/Sub When connecting 2 remote controllers, one of them needs to be designated as a sub controller.

Clock Use to set the current time.

Main display Use to switch between "Full" and "Basic" modes for the Main display.

• The initial setting is "Full."

Contrast Use to adjust screen contrast.

Display details Make the settings for the remote controller related items as necessary.

Clock: The initial settings are "Yes" and "24h" format.

Temperature: Set either Celsius (°C) or Fahrenheit (°F).

Room temp. : Set Show or Hide.

Auto mode: Set the Auto mode display or Only Auto display.

Auto mode Whether or not to use the AUTO mode can be selected by using the button.

This setting is valid only when indoor units with the AUTO mode function are connected.

Administrator

pass-

word

The administrator password is required to make the settings for the following items.

• Timer setting • Energy-saving setting • Weekly timer setting

• Restriction setting • Outdoor unit silent mode setting • Night set back

Language selection Use to select the desired language.

Daylight saving time Sets the daylight saving time.

Service Test run Select "Test run" from the Service menu to bring up the Test run menu.

Not available

Input maintenance Select "Input maintenance Info." from the Service menu to bring up the Maintenance information screen.

The following settings can be made from the Maintenance Information screen.

• Model name input • Serial No. input • Dealer information input

Function setting Not available

Check Error history: Display the error history and delete the error history.

Refrigerant leak check: Not available

Smooth maintenance: Not available

Request code

: Not available

Self check Error history of each unit can be checked via the remote controller.

Maintenance password Use to change the maintenance password.

Remote controller

check

When the remote controller does not work properly, use the remote controller checking function to troubleshoot the problem.

* Clock setting is required.

Main menu list

OBH816

Page 14

14

(1) Press

button.

OFF/ON lamp will light up in green and the operation will start.

(2) Select COOL mode with

button.

(3) Press

button to decrease the preset temperature, and button to increase.

The setting range is 16 ~ 31°C.

1. Coil frost prevention

The compressor operational frequency is controlled by

the temperature of the indoor heat exchanger to prevent

the coil from frosting.

When the temperature of indoor heat exchanger

becomes too low, the coil frost prevention mode works.

The indoor fan operates at the set speed and the compressor stops. This mode continues until the temperature of indoor heat exchanger rises.

9-2. DRY ( ) OPERATION

(1) Press button.

OFF/ON lamp will light up in green and the operation

will start.

(2) Select DRY mode with

button.

(3) Press

button to decrease the preset temperature, and button to in crease.

1. Coil frost prevention

Coil frost prevention works the same way as that in COOL mode. (9-1.1.)

Operation status memory

Remote controller setting

Operation mode Operation mode before the power was turned off

Preset temperature Preset temperature before the power was turned off

Fan speed Fan speed before the power was turned off

Settable preset temperature range

Operation mode Preset temperature range

Cool/Dry 16 ~ 31ºC

Fan/Ventilation Not settable

Operation Indicator lamp

The operation indicator at the right side of the indoor unit indicates the operation state.

•The following indication applies regardless of shape of the indication.

Indication Operation state Room temperature

The unit is operating to

reach the set temperature.

About 2°C or more away

from set temperature

The room temperature is

approaching the set temperature.

About 1 to 2°C from set

temperature

Lit

Blinking

Not lit

INDOOR UNIT DISPLAY SECTION

9-1. COOL ( ) OPERATION

Mode selection

Press button to go through the operation

modes in the order of “Cool”, “Dry”, and

“Fan”. Select the desired operation mode.

Cool Dry Fan

F1 F2 F3 F4

Cool

Room

AutoSet temp.

Mode Temp. Fan

Fri

F1

Example display

(Centigrade in 0.5-degree

increments)

Preset temperature will be displayed either in Centigrade in 0.5- or 1-degree•

increments, or in Fahrenheit, depending on the display mode setting on the

remote controller.

Cool

Room

AutoSet temp.

Mode Temp. Fan

Fri

F1 F2 F3 F4

Cool

Room

AutoSet temp.

Mode Temp. Fan

Fri

OBH816

Page 15

15

9-4. AUTO VANE OPERATION

1. Horizontal vane

(1) Vane motor drive

These models are equipped with a stepping motor for the horizontal vane. The rotating direction, speed, and angle of

the motor are controlled by pulse signals (approximately 12 V) transmitted from indoor microprocessor.

(2) How to set the vane angle

Press the button.

Select “Vane·Louver·Vent. (Lossnay)” with or button, and press button.

Press or button to go through the vane setting options: “Auto”, “Step 1”, “Step 2”, “Step 3”, “Step 4”, “Step 5”

and “Swing”, and select the desired setting.

Press button to go back to the Main menu.

(3) Positioning

To confirm the standard position, the vane moves until it touches the vane stopper. Then the vane is set to the selected

angle.

Confirmation of standard position is performed in the following cases:

(a) When the operation starts or finishes (including timer operation).

(b) When the test run starts.

F1 F2 F3 F4

Cool

Room

AutoSet temp.

Mode Temp. Fan

Fri

Press button to go through the fan speeds in the following order.

Auto

Low Med.

Super High High

F1 F2 F3 F4

Main

Main display:

Cursor Page

Main menu

Vane·Louver·Vent. (Lossnay)

High power

Timer

Weekly timer

OU silent mode

F1 F2 F3 F4

Fri

Swing Off Off

LouverVent.Vane

Auto

Auto

Swing

Step 1 Step 2

Step 4Step 3

Swing

Step 5

9-3. FAN( )OPERATION

(1) Press button. OFF/ON lamp will light up in green and the operation will start.

(2) Select FAN mode with button.

(3) Press

button to select the desired fan speed. When AUTO, it becomes Low.

Only indoor fan operates. Outdoor unit does not operate.

OBH816

Page 16

16

(4) VANE AUTO (

) mode

In VANE AUTO mode, the microprocessor automatically determines the vane angle to make the optimum room temperature distribution.

Horizontal

position

In COOL and DRY operation

Vane angle is fixed to Horizontal position.

(5) STOP (operation OFF) and ON TIMER standby

In the following cases, the horizontal vane returns to the closed position.

(a) When

button is pressed (POWER OFF).

(b) When the operation is stopped by the emergency operation.

(c) When ON TIMER is ON standby.

(6) Dew prevention

During COOL or DRY operation with the vane angle at Angle 3 ~ 5 when the compressor cumulative operation time

exceeds 1 hour, the vane angle automatically changes to Angle 2 for dew prevention.

(7) SWING (

) mode

Select “Swing” to move the vanes up and down automatically.

When set to “Step 1” through “Step 5”, the vane will be xed at the selected angle.

9-5. TIMER OPERATION (ON/OFF TIMER)

The unit automatically turns on or off at the preset time.

Select "Timer" from the Main menu, and press

button (Refer to the appropriate operation manual include with

remote controller.).

EMERGENCY OPERATION switch

9-6. EMERGENCY/TEST OPERATION

In the case of test run operation or emergency operation, use EMERGENCY OPERATION switch on the right side of the

indoor unit. Emergency operation is available when the remote controller is missing or has failed, or when the batteries in

the remote controller are running down. The unit will start and OPERATION INDICATOR lamp will light up.

The first 30 minutes of operation is the test run operation. This operation is for servicing. The indoor fan runs at High

speed and the temperature control does not work.

After 30 minutes of test run operation, the system shifts to EMERGENCY COOL MODE with a set temperature of 24°C.

The fan speed shifts to Med.

The coil frost prevention works even in the test run or the emergency operation.

In the test run or emergency operation, the horizontal vane operates in VANE AUTO (

) mode.

Emergency operation continues until EMERGENCY OPERATION switch is pressed once or the unit receives any signal

from the remote controller. In the latter case, normal operation will start.

NOTE: Do not press EMERGENCY OPERATION switch during normal operation.

Operation mode COOL

Set temperature 24°C

Fan speed Med.

Horizontal vane Auto

The operation mode is indicated by the

Operation Indicator lamp as follows:

Operation Indicator lamp

EMERGENCY COOL

↓

STOP

Lit

Not lit

9-7. 3-MINUTE TIME DELAY OPERATION

When the system turns OFF, compressor will not restart for 3 minutes as 3-minute time delay function operates to protect

compressor from overload.

OBH816

Page 17

17

3. Troubleshooting procedure

1) Check if the OPERATION INDICATOR lamp on the indoor unit is blinking ON and OFF to indicate an abnormality.

To make sure, check how many times the OPERATION INDICATOR lamp is blinking ON and OFF before starting ser-

vice work.

2) Before servicing, check that the connector and terminal are connected properly.

3) When the P.C. board seems to be defective, check the copper foil pattern for disconnection and the components for

bursting and discoloration.

4) When troubleshooting, Refer to 10-2, 10-3 and 10-4.

10-1. CAUTIONS ON TROUBLESHOOTING

1. Before troubleshooting, check the following:

1) Check the power supply voltage.

2) Check the indoor/outdoor connecting wire for miswiring.

2. Take care of the following during servicing

1) Before servicing the air conditioner, be sure to turn OFF the main unit first with the remote controller, and then after

confirming the horizontal vane is closed, turn OFF the breaker and/or disconnect the power plug.

2) Be sure to turn OFF the power supply before removing the front panel, the cabinet, the top panel, and the P.C. board.

3) When removing the P.C. board, hold the edge of the board with care NOT to apply stress on the components.

4) When connecting or disconnecting the connectors, hold the connector housing. DO NOT pull the lead wires.

MSY-TP35VF MSY-TP50VF

10

TROUBLESHOOTING

Lead wiring

Connector housing

<Incorrect>

<Correct>

OBH816

Page 18

18

10-2. FAILURE MODE RECALL FUNCTION

Outline of the function

This air conditioner can memorize the abnormal condition which has occurred once.

Even though LED indication listed on the troubleshooting check table (10-4.) disappears, the memorized failure details can

be recalled.

This mode is very useful when the unit needs to be repaired for the abnormality which does not recur.

1. Flow chart of failure mode recall function for

the indoor/outdoor unit

Does upper lamp of OPERATION INDICATOR

lamp on the indoor unit blink at the interval of 0.5

seconds?

Blinks: Either indoor or outdoor unit is abnormal.

Beep is emitted at the same timing as the

blinking of upper lamp of OPERATION

INDICATOR lamp. 2

Indoor unit is normal.

But the outdoor unit might be abnormal because there are some abnormalities that cannot be recalled with this way.

Check if outdoor unit is abnormal according to the detailed outdoor unit

failure mode recall function.

No

Yes

The cause of abnormality cannot be found because the abnormality does not recur.

Turn ON the power supply.

<Preparation of the remote controller>

While pressing both OPERATION SELECT button and TOO COOL button on the

remote controller at the same time, press RESET button.

First, release RESET button.

Hold down the other 2 buttons for another 3 seconds. Make sure that the indicators

on the LCD screen shown in the right gure are all displayed. Then release the buttons.

Before blinking, does upper lamp of

OPERATION INDICATOR lamp stay ON for 3

seconds?

When it stays ON for 3 seconds (without beep):

The outdoor unit is abnormal.

The indoor unit is abnormal.

Check the blinking pattern, and identify the abnormal point by referring to the

indoor unit failure recall mode table. (Refer to 10-2.2)

Make sure to check at least 2 consecutive blinking cycles.

2

Release the failure mode recall function by the following procedures.

Turn OFF the power supply and turn it ON again.

Press RESET button of the remote controller.

The outdoor unit is abnormal.

Check the blinking pattern, and identify the abnormal point by referring to the outdoor unit failure recall mode table. (Refer to outdoor unit

service manual.)

Make sure to check at least 2 consecutive blinking cycles.

3

Repair the failure parts.

Yes

(Blinks)

No

(OFF)

Setting up the failure mode recall function

Judgment of indoor/outdoor abnormality

Releasing the failure mode recall function

Deleting the memorized abnormal condition

Operational procedure

NOTE: 1. Make sure to release the failure mode recall function after it is set up, otherwise the unit cannot operate properly.

2. If the abnormal condition is not deleted from the memory, the last abnormal condition is kept memorized.

2. Blinking pattern when the indoor unit is abnormal:

3.Blinking pattern when the outdoor unit is abnormal:

ON

OFF

Beeps

Repeated cycle Repeated cycle

ON

OFF

No beep Beeps

Repeated cycle

2.5-second OFF

Blinking at 0.5second interval

2.5-second OFF 3-second ON

Blinking at 0.5second interval

Beeps

Repeated cycle

2.5-second OFF

Blinking at 0.5-

second interval

No beep Beeps

Repeated cycle

2.5-second OFF 3-second ON

Blinking at 0.5second interval

Repeated cycle

Beeps

1. Regardless of normal or abnormal condition, a short beep is emitted once the signal

is received.

Press STOP/OPERATE (OFF/ON) button of the remote controller (the set temperature is

displayed) with the remote controller headed towards the indoor unit.

1

After repairing the unit, recall the failure mode again according to "Setting up the failure mode recall function" men-

tioned above.

Press STOP/OPERATE (OFF/ON) button of the remote controller (the set temperature is displayed) with the remote

controller headed towards the indoor unit.

Press EMERGENCY OPERATION switch so that the memorized abnormal condition is deleted.

Release the failure mode recall function according to "Releasing the failure mode recall function" mentioned above.

NOTE: Use the wireless remote controller of MSZ-HJ25VA-E2 (Refer to parts catalog OBB647.) .

The remote controller has the indication of "HEAT" and a button for it, but HEAT mode cannot be used since MSY-

TP series are cooling only model.

The remote controller has the indication of "ECONO COOL" and a button for it, but ECONO COOL mode cannot be

used since it is not available on MSY-TP series.

OBH816

Page 19

19

10-3. INSTRUCTION OF TROUBLESHOOTING

Indoor unit operates.

Outdoor unit

does not operate.

If blinking of OPERATION INDICATOR lamp cannot be checked,

it can be checked with failure

mode recall function.

Indoor unit does

not receive

the signal from

remote controller.

OPERATION INDICATOR

lamp on the indoor unit is

blinking on and off.

Outdoor unit

operates only

in Test Run

operation.

Outdoor unit

does not

operate even

in Test Run

operation.

Indoor unit

operates, when

EMERGENCY

OPERATION

switch is pressed.

Indoor unit does

not operate, when

EMERGENCY

OPERATION

switch is pressed.

Check room

temperature

thermistor.

Refer to 10-7.

"Test point

diagram and

voltage".

Refer to "How

to check

inverter/compressor".

Check the instruction manual

of wired remotecontroller or replace the indoor

electronic

control P.C.

board".

1. Check indoor/outdoor connecting wire.

(Check if the power is

supplied to the indoor

unit.)

2. Refer to 10-6.

"Check of indoor P.C.

board and indoor fan

motor".

Start

"Test Run operation" means

the operation within 30 minutes

after EMERGENCY OPERATION switch is pressed.

Refer to outdoor unit service manual.

Upper lamp

Blink on and

off at 0.5-second intervals

Cause:

Indoor/Outdoor

unit

• Miswiring or

trouble of

serial signal

Upper lamp

2-time blink

Cause:

Indoor unit

• Trouble

of room

temperature

/ indoor coil

thermistor

Upper lamp

3-time blink

Cause:

Indoor unit

• Trouble of

indoor fan

motor

Upper lamp

4-time blink

Cause:

Indoor unit

• Trouble

of indoor

unit control

system

Upper lamp

5-time blink

Cause:

Outdoor unit

• Outdoor

power system abnormality

Upper lamp

6-time blink

Cause:

Outdoor unit

• Trouble of

thermistor in

outdoor unit

Upper lamp

7-time blink

Cause:

Outdoor unit

• Trouble of

outdoor control system

Upper lamp

14-time blink

or more

Cause:

Outdoor unit

• Other abnormality

Refer to

10-6. "How

to check miswiring and

serial signal

error".

Check room

temperature

thermistor

and indoor

coil thermistor. Refer to

10-7."Test

point diagram

and voltage".

Refer to

10-6.

"Check of

indoor fan

motor".

Replace the

indoor electronic control

P.C. board.

Refer to

"How to

check

inverter/compressor".

Refer to

"Check of

outdoor thermistors".

Replace the

inverter P.C.

board or

the outdoor

electronic

control P.C.

board.

Check "Flow

chart of the

detailed

outdoor unit

failure mode

recall function."

OBH816

Page 20

20

10-4. TROUBLESHOOTING CHECK TABLE

Before taking measures, make sure that the symptom reappears for accurate troubleshooting.

When the indoor unit has started operation and detected an abnormality of the following condition (the first detection after

the power ON), the indoor fan motor turns OFF and OPERATION INDICATOR lamp blinks.

No.

Abnormal

point

Operation indicator lamp Symptom Condition Remedy

1

Miswiring

or serial

signal

Upper lamp blinks.

0.5-second ON

0.5-second OFF

Indoor unit and

outdoor unit do

not operate.

The serial signal from the outdoor unit is not

received for 6 minutes.

•

Refer to 10-6.

"How to check

miswiring and serial signal error".

2

Indoor coil

thermistor

Upper lamp blinks.

2-time blink

2.5-second OFF

The indoor coil or the room temperature thermistor is short or open circuit.

•

Refer to the characteristics of

indoor coil thermistor, and the

room temperature thermistor

(10-7.).

Room temperature

thermistor

3

Indoor fan

motor

Upper lamp blinks.

3-time blink

2.5-second OFF

The rotational frequency feedback signal is

not emitted during the indoor fan operation.

•

Refer to 10-6.

"Check of

indoor fan motor".

4

Indoor control system

Upper lamp blinks.

4-time blink

2.5-second OFF

It cannot properly read data in the nonvolatile

memory of the indoor electronic control P.C.

board.

•

Replace the indoor electronic

control P.C. board.

5

Outdoor

power system

Upper lamp blinks.

5-time blink

2.5-second OFF

It consecutively occurs 3 times that the compressor stops for overcurrent protection or

start-up failure protection within 1 minute after

start-up.

•

Refer to "How to check of inverter/compressor".

Refer to outdoor unit service

manual

•

Check the stop valve.

6

Outdoor

thermistors

Upper lamp blinks.

6-time blink

2.5-second OFF

The outdoor thermistors short or open circuit

during the compressor operation.

•

Refer to "Check of outdoor

thermistor".

Refer to outdoor unit service

manual.

7

Outdoor

control system

Upper lamp blinks.

7-time blink

2.5-second OFF

It cannot properly read data in the nonvolatile

memory of the inverter P.C. board or the outdoor electronic control P.C. board.

•

Replace the inverter P.C. board

or the outdoor electronic control P.C. board.

Refer to outdoor unit service

manual.

8

Other abnormality

Upper lamp blinks.

14-time blink or more

2.5-second OFF

An abnormality other than above mentioned

is detected.

•

Check the stop valve.

•

Conrm the abnormality in

detail using the failure mode

recall function for outdoor unit.

9

Outdoor

control system

Upper lamp lights up

Outdoor unit

does not operate

It cannot properly read data in the nonvolatile

memory of the inverter P.C. board or the outdoor electronic control P.C. board.

•

Check the blinking pattern of

the LED on the inverter P.C.

board or the outdoor electronic

control P.C. board.

OPERATION INDICATOR

Lit

Blinking

Not lit

OBH816

Page 21

21

10-5. TROUBLE CRITERION OF MAIN PARTS

MSY-TP35VF MSY-TP50VF

Part name Check method and criterion Figure

Room temperature

thermistor (RT11)

Measure the resistance with a tester.

Refer to 10-7. "Test point diagram and voltage", "2. Indoor electronic control

P.C. board", for the chart of thermistor.

Indoor coil thermistor

(RT12, RT13)

Indoor fan motor (MF)

Check 10-6. .

Vane motor (MV)

Measure the resistance between the terminals with a tester.

(Part temperature 10 ~ 30°C)

Color of the lead wire Normal

RED - BLK 235 ~ 255 Ω

BLK

BLK

RED

BLK

BLK

ROTOR

OBH816

Page 22

22

10-6. TROUBLESHOOTING FLOW

A Check of indoor fan motor

The indoor fan motor error has occurred, and the indoor fan does not operate.

Turn OFF the power supply.

Is there any foreign matter that interferes

the rotation of the line ow fan?

Yes

No

Remove the foreign matter and

adjust the line ow fan.

Pay enough attention to the high voltage on the fan motor connector CN211.

Turn ON the power supply, wait 5 seconds or more, and then press

EMERGENCY OPERATION switch.

Measure the supply voltage as follows within 12 seconds after EMERGENCY OPERATION switch is pressed.

If more than 12 seconds passes, turn OFF the power supply and turn it

ON again, then measure the voltage.

<Indoor power P.C. board>

1. Measure the voltage between CN211

(+) and (–).

2. Measure the voltage between CN211

(+) and (–).

<Indoor electronic control P.C. board>

3. Measure the voltage between CN10A (+) and GND (–).

If more than 12 seconds passes after EMERGENCY OPERATION switch

is pressed, the voltage measured at 2. above goes 0 V DC although the

indoor P.C. board is normal.

Does the voltage between CN211

(+) and (–) on the power P.C. board

rise to the range of 3 to 6 V DC within

12 seconds after EMERGENCY

OPERATION switch is pressed?

Replace the indoor fan motor.

Yes

No

The indoor fan motor error has occurred, and the indoor fan repeats "12-second ON and 30-second OFF" 3 times, and then stops.

Measure the voltage between CN211

(+) and (–) while the fan motor is

rotating.

Replace the indoor power

P.C. board.

Is it unchanged holding 0

or 15 V DC?

No

(Changed)

Yes

(Unchanged)

Measure the voltage CN10A

(+) and GND (–) on the indoor

electronic control P.C board when

the fan motor is rotaring.

Replace the indoor fan motor.

Is there 325 V DC

between CN211 (+)

and (–) ?

Yes

Does the voltage between CN10A

(+) and GND (–) on the indoor

electronic control P.C. board fall to

2 V or less within 12 seconds after

EMERGENCY OPERATION switch is

pressed?

Replace the indoor electronic

control P.C. board.

No

Yes

Replace the indoor power P.C.

board.

Is it unchanged holding 0

or 5 V DC?

No

(Changed)

Yes

(Unchanged)

Replace the indoor

electronic control P.C.

board.

No

OBH816

Page 23

23

B Check of indoor P.C. board and indoor fan motor

Turn OFF the power supply.

Remove indoor fan motor connector CN211

from indoor power P.C. board and vane

motor connector CN151 from the indoor

electronic control P.C. board and turn ON

the power supply.

Does the unit operate with the remote

controller?

Does OPERATION INDICATOR lamp light

up by pressing EMERGENCY OPERATION

switch?

Yes

No

Measure the resistance of indoor fan

motor.

Refer to 10-5.

Short circuit:

Replace the indoor fan motor.

Turn OFF the power supply.

Check both “parts side” and “pattern

side” of the indoor power P.C. board

visually.

Replace the varistor (NR11)

and fuse (F11). 3

Is the varistor (NR11)

burnt and the fuse (F11)

blown?

No

No

Yes

Yes

Be sure to check both the fuse

and the varistor in any case.

Is the fuse (F11) blown

only?

Measure the resistance between

CN211

(+) and (-) of indoor fan

motor connector. 1, 2

Yes

Is the resistance 1MΩ or more?

Replace the fuse (F11) and the

indoor fan motor. 3

No

Replace the fuse (F11).

3

Measure the resistance of reactor (L111)

on the indoor power P.C. board.

No

No

Replace the indoor

power P.C. board, the

indoor terminal P.C.

board and the indoor fan

motor.

Replace the indoor electronic control P.C. board.

Measure the resistance of the vane

motor coil.

Refer to 10-5.

Short circuit:

Replace the vane motor and the indoor

electronic control P.C. board.

1. The fan motor connector's lead wire is red,

whereas is black.

2. Connect "+" of the tester to fan motor

connector's lead wire, and “-” to lead wire,

otherwise the resistance cannot be measured

properly.

3. Please replace the fuse after removing the

indoor power P.C. board from the electrical

box.

Is there approximately 5 V DC between

5 V (+) and GND (-) of the indoor

electronic control P.C. board? Is there

approximately 9 V to 13 V DC between

12 V (+) and GND (-) of the indoor

electronic control P.C. board?

Is the connector CN10A on

the indoor electronic control

P.C. board or lead wires

disconnected?

Yes

Replace the indoor fan motor.

Yes

Connect the connector CN10A or repair

disconnection.

No

Indoor electronic control

P.C. board

GND

CN10A

12 V DC

5 V DC

Indoor power P.C. board

CN211

L111

Is the resistance of reactor (L111)

approximately 4 Ω ?

Yes

With a tester, check the

continuity between the

connector CN201

on the

indoor power P.C. board and

S2 on the terminal block.

Is electricity

conducted? (The

resistance is 0 Ω .)

Yes

No

The thermal fuse connected

to the terminal block has

failed.

Replace the terminal block

assembly.

OBH816

Page 24

24

C How to check miswiring and serial signal error

A

• Reinstall either the unit

or the light

away from

each other.

• Attach a lter

on remote

control

receiving

section of

the indoor

unit.

• Turn OFF inverter-controlled lighting

equipment.

• Turn OFF the power supply and then

turn ON again.

• Press the emergency operation switch.

After the relay

52C is turned on

3 minutes later, is

miswiring or the

serial signal error

indicated?

No

B

Yes

1 Make sure that the wiring is correct. If the pro-

cedure is performed without correcting miswiring, it may lead to damage to the P.C. board.

3

Be sure to release the failure-mode recall function after checking.

Turn OFF the power supply.

Is there rated voltage in the

power supply?

Yes

No

1. Turn ON the power supply.

2. Press the emergency operation switch.

Check the power supply.

Has the relay 52C been turned on 3 minuets later ?

[The relay will be turned on in 3 to 7 seconds by

bridging the timer short mode point (Refer to 11-7.).]

Is there any miswiring, poor

contact, or wire disconnection of the indoor/outdoor

connecting wire?

Correct them.

No

Yes

Aim the remote controller at the indoor unit, and press OPERATE (OFF/ON) button. The relay 52C will be turned on, and the

outdoor unit will be energized.

Is the rated supply voltage applied

between the S1 and S2 on the

outdoor terminal block? (Check of

supply voltage)

No

Is there any problem in the

indoor/outdoor connecting wire,

such as the damage of the wire,

intermediate connection, poor

contact with the terminal block?

Yes

Replace

the indoor/

outdoor connecting wire.

No

Replace the indoor electronic control

P.C. board.

3

Is there approximately 250 V DC – 370

V DC between DB61 (+) and DB61

(–) on the inverter P.C. board in the

outdoor unit? (Voltage check of the

inverter P.C. board in the outdoor unit)

No

Replace the

inverter P.C.

board in the

outdoor unit. 2

Yes

Yes

Does the LED on the inverter P.C.

board in the outdoor unit repeat

"3.6-second-OFF and 0.8-secondON quick blinking" for 3 minutes

after the outdoor unit is energized?

(Check the blinking pattern within 3

minutes after LED is turned on. After 3 minutes, LED will blink 6 times

whether the inverter P.C. board in

the outdoor unit is normal or not.)

No

Replace the

inverter P.C.

board in the

outdoor unit.

2

Yes

A

2

Be careful of 140

V DC – 280 V DC

residual charge in

the capacitor on the

main inverter circuit.

B

Turn OFF the power supply. Make sure again that the

indoor/outdoor connecting wire is correctly connected.

With the indoor/outdoor connecting wire connected, bridge

between S2 and S3 on the outdoor terminal block. 1

<Preparation of the remote controller>

While pressing both OPERATION SELECT button and

TOO COOL button on the remote controller at the same

time, press RESET button.

First, release RESET button.

Hold down the other two buttons for another 3 seconds.

Make sure that the indicators on the LCD screen shown in

the right gure are all displayed. Then release the buttons.

(Setting up the failure mode recall function)

Indication of miswiring

Indication of serial signal error

OPERATION

INDICATOR lamp

Continuous blinks

Initializing the determination of the power

receiving system

The microprocessor may have mistaken the

unit as a model receiving power from the

outdoor unit. Follow the procedure below to

start the determination of the power receiving system all over again.

1. Hold down the emergency operation

switch for 30 seconds. (Do not release the

switch even though a buzzer beeps once

in about 5 seconds. Keep holding down

the switch until a buzzer beeps again for

1 second after 30 seconds. Figure 1)

2. Turn off the power supply.

3. Wait for about 30 seconds.

4. Turn on the power supply.

5. Press the emergency operation switch.

6. The relay 52C will be turned on in 3 minutes.

Has the miswiring or the serial error

been indicated?

Yes

No

ON

OFF

Buzzer

0.5-second 1-second

ON

OFF

Emergency

operation switch

30-second

ON

OFF

5-second

Beeps

BeepsBeeps

Figure 1

Yes

No

NOTE: Use the wireless remote controller of

MSZ-HJ25VA-

E2

(Refer to parts cat-

alog OBB647.).

The remote controller has the indication

of "HEAT" and a button for it, but HEAT

mode cannot be used since MSY-TP

series are cooling only model.

The remote controller has the indication

of "ECONO COOL" and a button for

it, but ECONO COOL mode cannot be

used since it is not available on MSY-

TP series.

OBH816

Page 25

25

D Electromagnetic noise enters into TV sets or radios

Yes

Is the unit earthed?

No

Earth the unit.

Yes

Is the distance between the antennas

and the indoor unit within 3 m, or is the

distance between the antennas and the

outdoor unit within 3 m?

No

Extend the distance between the antennas and

the indoor unit, and/or the antennas and the

outdoor unit.

Is the distance between the TV sets or

radios and the indoor unit within 1 m, or

is the distance between the TV sets or

radios and the outdoor unit within 3 m?

Yes

Extend the distance between the TV sets and/or

radios and the indoor unit, or the TV sets or

radios and the outdoor unit.

Are the antennas damaged?

Is the coaxial cable damaged?

Is there any poor contact in the antenna wiring?

Yes

No

No

Replace or repair the antenna.

Replace or repair the coaxial cable.

Is the indoor/outdoor connecting wire

of the air conditioner and the wiring of

the antennas close?

Yes

Extend the distance between the indoor/outdoor

connecting wire of the air conditioner and the wiring of the antennas.

No

Even if all of the above conditions are fullled, the electromagnetic noise may enter, depending on the electric eld strength

or the installation condition (combination of specic conditions such as antennas or wiring).

Check the following before asking for service.

1. Devices affected by the electromagnetic noise

TV sets, radios (FM/AM broadcast, shortwave)

2. Channel, frequency, broadcast station affected by the electromagnetic noise

3. Channel, frequency, broadcast station unaffected by the electromagnetic noise

4. Layout of ;

indoor/outdoor unit of the air conditioner, indoor/outdoor wiring, earth wire, antennas, wiring from antennas, receiver

5. Electric eld intensity of the broadcast station affected by the electromagnetic noise

6. Presence or absence of amplier such as booster

7. Operation condition of air conditioner when the electromagnetic noise enters in

1) Turn OFF the power supply once, and then turn ON the power supply. In this situation, check for the electromagnetic

noise.

2) Within 3 minutes after turning ON the power supply, press

button on the remote controller for power ON,

and check for the electromagnetic noise.

3) After a short time (3 minutes later after turning ON), the outdoor unit starts running. During operation, check for the

electromagnetic noise.

4) Press button on the remote controller for power OFF, when the outdoor unit stops but the indoor/outdoor

communication still runs on. In this situation, check for the electromagnetic noise.

OBH816

Page 26

26

12V

GND

5V

Room temperature thermistor (RT11)

Indoor coil thermistor (RT12, RT13)

Temperature (°C)

Resistance (kΩ)

Fuse (F11)

T3.15AL250V

Varistor (NR11)

Connector to indoor electronic

control P.C. board (CN20A)

5 V DC

12 V DC

GND

Connector to Indoor fan

motor (CN211)

Reactor (L111 )

Connector to

Terminal block

(CN201)

Indoor terminal block

connecting (TAB1)

(+)3-6 V DC

15 V DC

(-) GND

(High voltage DC)

325 V DC

(+)0 or 15 V DC

Indoor terminal block

connecting (TAB2)

Timer short

mode point

(Refer to

8-1.)

Room temperature thermistor RT11 (CN111)

Connector to

Indoor coil

thermistor

RT12, RT13

(CN112)

Vane motor

(CN151)

Connector to indoor power

P.C. board (CN10A)

12V DC

5V DC

To disable "Auto restart function",cut the

Jumper wire to JR77. (Refer to 8-3.)

Emergency operation

switch (E.O. SW) (SW1)

GND

MSY-TP35VF MSY-TP50VF

1. Indoor power P.C. board

2. Indoor electronic control P.C. board

10-7. TEST POINT DIAGRAM AND VOLTAGE

OBH816

Page 27

OPERATING PROCEDURE PHOTOS/FIGURES

1. Removing the panel

(1) Remove the screw caps on the panel and remove the

screws of the panel.

(2) Pull the panel slightly toward you, and then remove the

panel by pushing it upward.

27

11

DISASSEMBLY INSTRUCTIONS

<Detaching method of the terminal with locking mechanism>

The terminal which has the locking mechanism can be detached as shown below.

There are following 2 types of the terminal with locking mechanism.

The terminal without locking mechanism can be detached by pulling it out.

Check the shape of the terminal before detaching.

(1) Slide the sleeve and check if there is a locking lever or not. (2) The terminal with this connector shown below

has the locking mechanism.

Slide the sleeve.

Pull the terminal while

pushing the locking

lever.

Hold the sleeve, and

pull out the terminal

slowly.

Connector

Sleeve

Locking lever

11-1. MSY-TP35VF MSY-TP50VF

NOTE: Turn OFF the power supply before disassembly.

Photo 1

Screws of the panel

Front panel

: Indicates the visible parts in the photos/figures.

: Indicates the invisible parts in the photos/figures.

OBH816

Page 28

OPERATING PROCEDURE PHOTOS/FIGURES

2. Removing the indoor power P.C. board and the

electrical box

(1) Remove the panel. (Refer to section 1.) Remove the

right corner box.

(2) Disconnect the following connectors:

<Indoor electronic control P.C. board>

CN151 (Vane motor)

CN112 (Indoor coil thermistor)

CN10A (To the indoor power P.C. board)

(3) Unhook the catch on the left side of the control P.C.

board holder. Pull the control P.C. board holder as if

opening the door at 90 degrees. Remove the control P.C.

board holder from the axial rod on the electrical box.

(4) Remove the screw of the V.A. clamp.

(5) Remove the V.A. clamp and the indoor/outdoor con-

necting wire.

(6) Remove the screws of the earth plate. (Photo 2)

(7) Remove the indoor coil thermistor from the water cover.

(8) Disengage the hooks of the water cover and remove

the water cover.

(9) Remove the screw of the electrical cover and remove

the electrical cover.

(10) Disconnect the CN211 (Indoor fan motor) from the

indoor power P.C. board.

(11) Remove the upper catch of the electrical box, and pull

out the electrical box.

To attach the electrical box, pass the wires connecting

the indoor power P.C. board and the indoor electronic

control P.C. board through A. Pass the lead wires of the

fan motor through B as shown in the Photo 3.

(12) Disconnect the following connectors and tabs.

<Indoor power P.C. board>

CN201, TAB1, TAB2 (Terminal block)

CN20A (To the indoor electronic control P.C. board)

28

Photo 2

Screw of the

V.A. clamp

Control P.C. board holder

Screw of the

electrical cover

Water cover

Indoor coil thermistor connector CN112

Indoor coil thermistor

Indoor electronic

control P.C. board

Vane motor

connector (CN151)

Screws of the earth plate

Connector

CN10A

(To indoor power

P.C. board)

Photo 3

TAB1 (Terminal block)TAB2 (Terminal block)

Terminal block

connector CN201

B

A

Connector CN20A

(To indoor electronic P.C. board)

Indoor fan motor

connector CN211

Electrical box

OBH816

Page 29

OPERATING PROCEDURE PHOTOS/FIGURES

3. Removing the indoor electronic control P.C.

board

(1) Remove the panel. (Refer to section 1.) Remove the right

corner box.

(2) Disconnect the following connectors:

<Indoor electronic control P.C. board>

CN151 (Vane motor)

CN112 (Indoor coil thermistor)

CN10A (To the indoor power P.C. board)

(3) Unhook the catch on the left side of the control P.C.

board holder. Pull the control P.C. board holder as if

opening the door at 90 degrees. Remove the control P.C.

board holder from the axial rod on the electrical box.

(4) Remove the room temperature thermistor from the back

side of the control P.C. board holder.

(5) Unhook the catches of the control P.C. board holder, and

open the control P.C. board holder.

(6) Remove the indoor electronic control P.C. board from the

control P.C. board holder.

4. Removing the vane motor

(1) Remove the panel. (Refer to section 1.) Remove the

corner box.

(2) Remove the control P.C. board holder, water cover and

the electrical box. (Refer to section 2.)

(3) Pull out the drain hose from the nozzle assembly and

remove the nozzle assembly.

(4) Remove the screws of the vane motor and remove the

vane motor.

(5) Disconnect the connector from the vane motor.

29

Photo 5

Screws of the vane motor

Photo 4

Room temperature thermistor

Indoor electronic

control P.C. board

Catch

Catch

Control P.C. board holder (Inside)

Control P.C. board holder (Back side)

OBH816

Page 30

OPERATING PROCEDURE PHOTOS/FIGURES

5. Removing the indoor fan motor, the indoor coil

thermistor and the line flow fan

(1) Remove the panel. (Refer to section 1.) Remove the

corner box.

(2) Remove the control P.C. board holder, the water cover,

the electrical box and the nozzle assembly. (Refer to

section 2.)

(3) Remove the screws fixing the motor bed.

(4) Loosen the screw fixing the line flow fan.

(5) Remove the motor bed together with the indoor fan

motor and the motor band.

(6) Disconnect the lead wire of the fan motor from the

motor band.

(7) Disengage the hooks of the motor band and remove

the motor band. Pull out the indoor fan motor.

(8) Remove the indoor coil thermistor from the heat

exchanger.

Install the indoor coil thermistor in its former position

when assembling it.

(9) Remove the screws fixing the left side and upper right

side of the heat exchanger.

(10) Lift the heat exchanger, and pull out the line flow fan

to the lower-left.

When attaching the line flow fan, screw the line flow fan

so 4 mm gap is provided between the right end of the

line flow fan and the right wall of the air passage of the

box (Figure 1).

30

Photo 6

Screw of the line flow fan

Figure 1

4 mm

Screws

of the left

side of

the heat

exchanger

Photo 9

Photo 7

Screws of the

motor bed

Photo 8

Screw of the upper right side of the heat exchanger

OBH816

Page 31

31

Fixing the indoor coil thermistor

There are 2 forms of parts for fixing the indoor coil thermistor.

NOTE:

Take care to avoid loss and accidental falling of the clip-shape part inside the unit.

Mount the clip-shape part on the marked position.

Do not pull the lead wire when removing the indoor coil thermistor.

Holder shapeClip shape

When fixing the indoor coil thermistor

to the clip-shape/holder-shape part, the

lead wire should point down.

1. Set the indoor coil

thermistor in the center of

the clip-shape part.

2. Check the (marked)

mounting position.

3. Mount the

clip-shape part.

Position and procedure for mounting the clip-shape part

About the

same length

OBH816

Page 32

HEAD OFFICE: TOKYO BUILDING, 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

© Copyright 2018 MITSUBISHI ELECTRIC CORPORATION

Published: Oct. 2018. No. OBH816

Made in Japan Specifications are subject to change without notice.

Loading...

Loading...