Mitsubishi MT160, MT160-180, MT180 Repair Manual

i

ISO

p

I

I

I I

FRONT

STEERING

AXLE

AND

UN

ISSION

I

ION

I

I

GE

SYSTEM

SYSTEM

SYSTEM

(Sliding gear type)

(Hydrostatic Transmission)

(Position Control)

I

E L

ISO

TABLE

Specifications

Greasing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Periodical

Lubrication

Wiring

An tifreeze

Tigh tening

Serial

Sealants

diagram.

number

..............................................

maintenance

table

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

................................................

torque

location

..................................................

services

..........................................

..........................................

........................................

OF

CONTENTS

................................

..

..

Page

I-I

1-12

1-13

1-14

1-15

1-16

1-17

1-17

1-18

t

1

.:..,

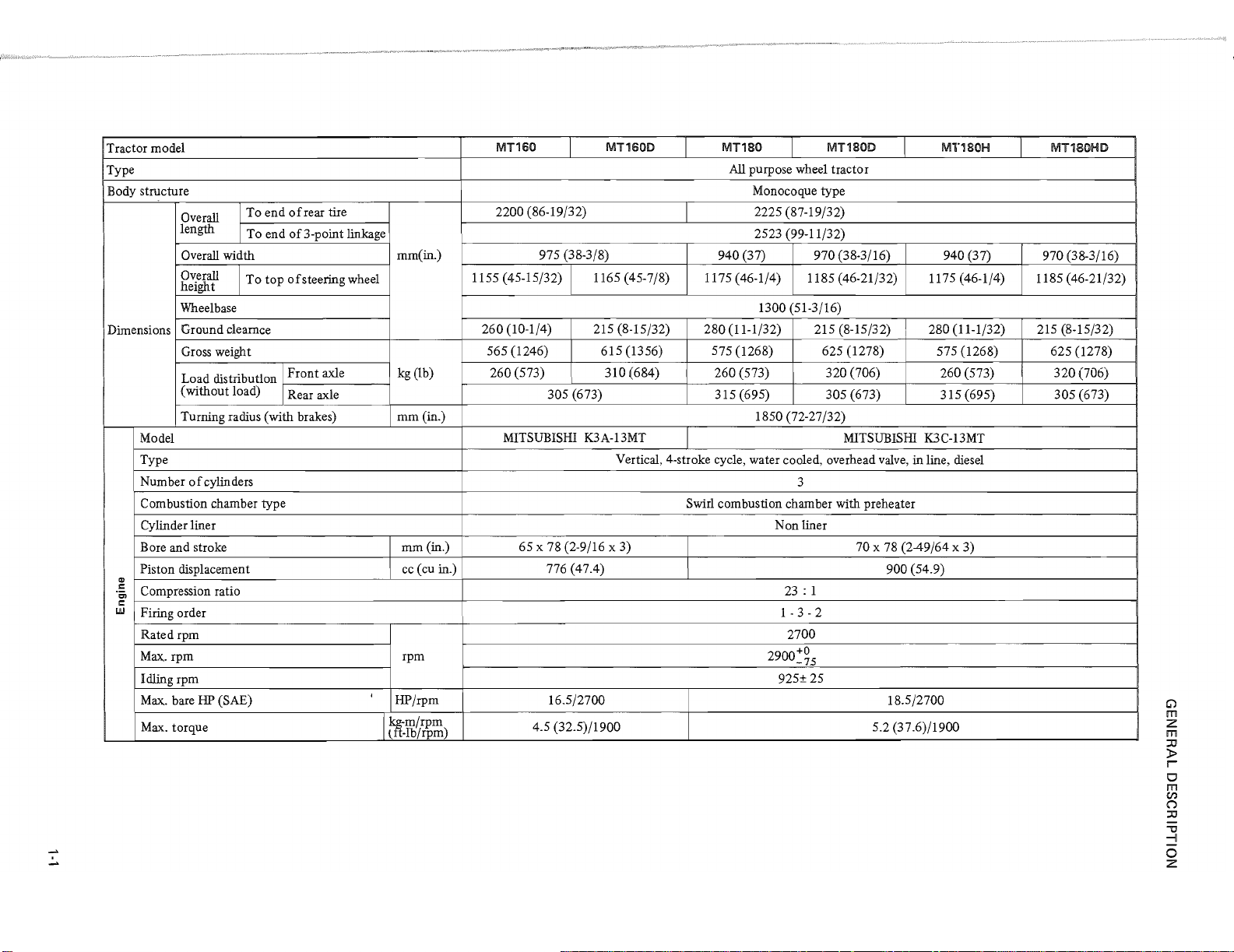

Tractor model

Type

Body structure

Overall

length

Overall width

Overall

height

Wheelbase

Dimensions

CD

c

's,

c

w

Ground clearnce

Gross

Load distribution

(without load)

Turning radius (with brakes) mm (in.)

Model

Type

Number ofcylinders

Combustion chamber type

Cylinder liner

Bore and stroke

Piston displacement

Compression ratio

Firing order

Rated rpm

Max.

rpm

Idling rpm

Max.

bare

HP

Max.

torque

l To end

of

rear tire

I To end of3-point linkage

I To top

weight

of

steering wheel

I Front axle

I Rear axle

(SAE)

-

MT160

2200 (86-19/32)

mm(in.)

1155 (45-15/32) 1165 (45-7/8)

260 (10-1/4) 215 (8-15/32)

565 (1246) 615 (1356) 575 (1268) 625 (1278)

kg

(lb)

mm (in.)

cc

(cu in.)

rpm

,

HP/rpm

Jllli~/rpm

~

t-Ip/rpm)_

260 (573)

MlTSUBISHI K3A-13MT

65 x 78 (2-9/16 x 3)

MT160D

975 (38-3/8)

310 (684) 260 (573)

305 (673)

Vertical, 4-stroke cycle, water cooled, overhead

776 (47.4) 900 (54.9)

16.5/2700

4.5 (32.5)/1900

MT180

All

purpose wheel tractor

Monocoque type

2225 (87-19/32)

2523 (99-11/32)

940 (37)

1175 (46-1/4) 1185 (46-21/32) 1175 (46-1/4)

1300 (51-3/16)

280 (11-1/32) 215 (8-15/32) 280 (11-1/32)

315 (695) 305 (673)

1850 (72-27/32)

Swirl combustion chamber with preheater

Non liner

2900+

925± 25

MT180D

970 (38-3/16) 940 (37)

320 (706) 260 (573)

MITSUBISlll K3C-13MT

valve,

3

70 x 78 (2-49/64 x 3)

23:

1

1 -3 - 2

2700

0

-75

18.5/2700

5.2 (37.6)/1900

MT180H

575 (1268)

315(695)

in line, diesel

MT180HD

970 (38-3/16) I

1185 (46-21/32) I

215 (8-15/32)

625 (1278)

320 (706)

305 (673)

I

I

I

G')

m

Z

m

:0

»

r

o

m

Ul

()

:0

-0

-;

o

z

r:.,

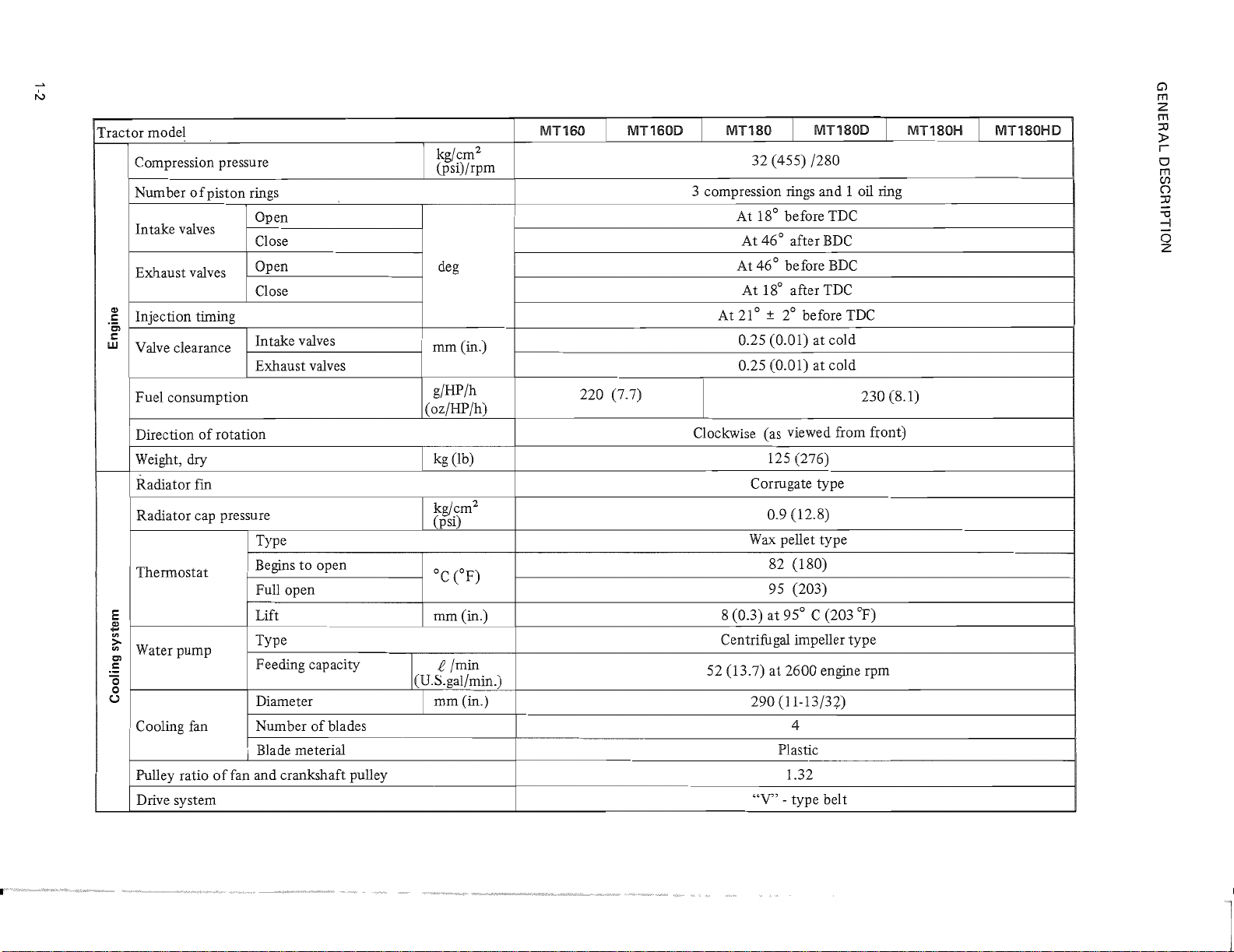

Tractor model

Compression pressure

Number

ofpiston

rings

Open

Intake valves

Exhaust valves

Close

Open

Close

Q)

c

Injection timing

'0,

c

w

Valve clearance

Intake valves

Exhaust valves

Fuel consumption

of

Direction

rotation

Weight, dry

-

Radiator fin

Radiator cap pressure

Type

Begins

to

Thermostat

open

Full open

E

Q)

....

en

>-

en

Water pump

Cl

c Feeding capacity

"0

0

u

Cooling fan Number

Lift

Type

Diameter

of

Blade meterial

Pulley ratio

offan

and crankshaft pulley

Drive system

blades

2

kg/cm

(psi)jrpm

deg

mm(in.)

g/HP/h

(oz/HP/h)

kg

(lb)

2

kg/cm

(psi)

°c

CF)

mm (in.)

\'

g /min

(U.S. gal/min.)

mm (in.)

MT160

MT160D

I

220 (7.7)

1

MT180

I

MT180D

I

32 (455) /280

compression rings and 1 oil ring

3

At

18° before TDC

At

46° after

At 46° before

At

18°

At

21

° ± 2° before TDC

after

BDC

BDC

TDC

0.25 (0.01) at cold

0.25 (0.01) at cold

230 (8.1)

I

Clockwise (as viewed from front)

125 (276)

Corrugate type

0.9 (12.8)

Wax

pellet type

82 (180)

95 (203)

8 (0.3)

at 95° C (203

Centrifugal impeller type

52 (13.7) at 2600 engine rpm

290

(ll-13/Tn

4

Plastic

1.32

"V"

- type belt

OF)

MT180H

MT180HD

I

CJ

m

Z

m

:0

~

r

o

m

til

(')

:0

-0

-l

o

Z

I

r

l

w

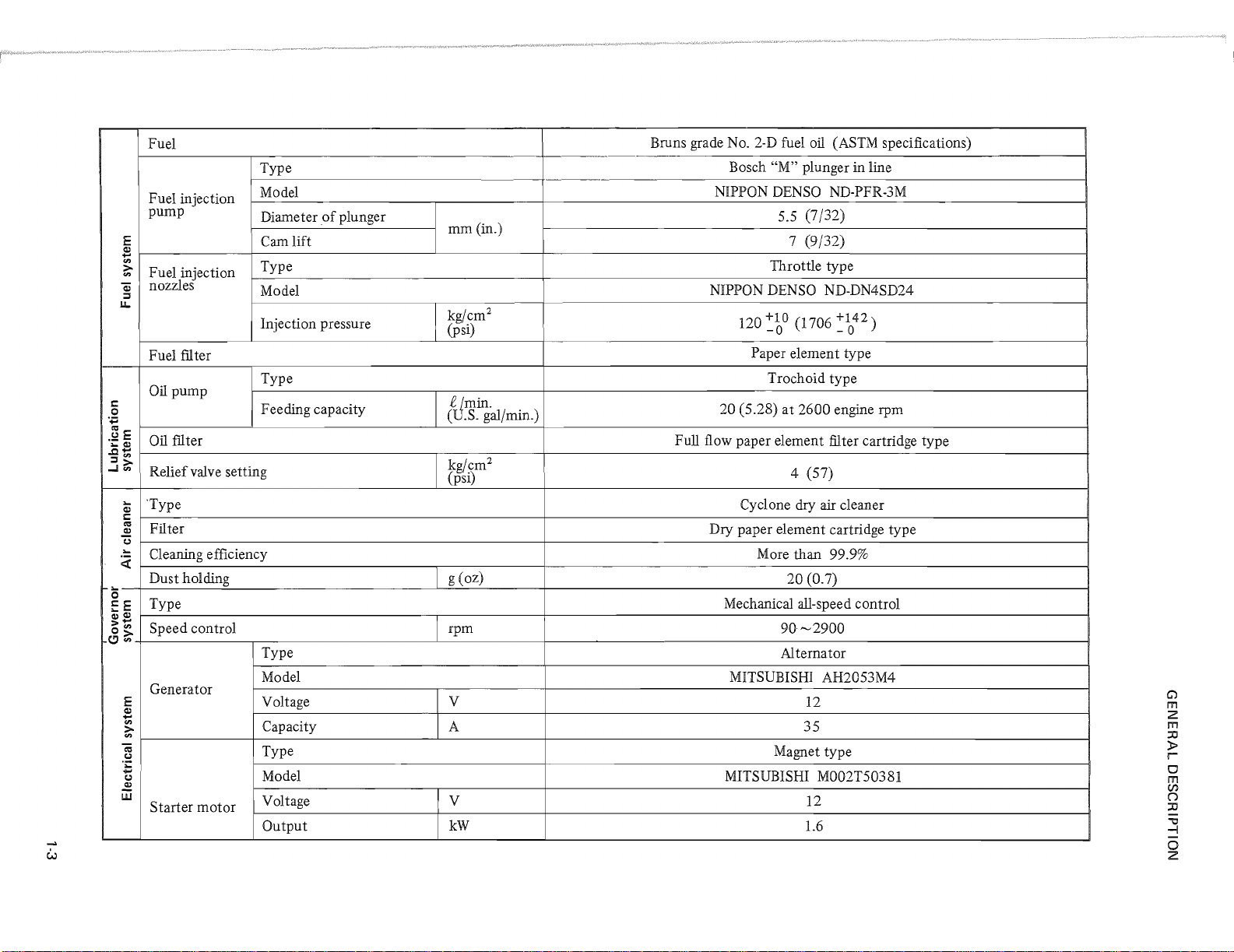

Fuel

Type

Fuel injection

pump

E

al

...

'"

>-

Fuel injection

'"

nozzles

Cii

::

u.

Model

Diameter

Cam lift

Type

Model

Injection pressure

Fuel filter

Oil pump

s::

0

.

.;:;

.2

E

Oil

"-al

.0

.....

::'"

...I~

"-

al

s::

C<l

al

t;

"-

~

filter

Relief valve setting

Type

Filter

Cleaning efficiency

Type

Feeding capacity

Dust holding

(5

Type

EE

alal

>

....

Speed control

0'"

C!l~

Type

Generator

E Voltage

al

....

'"

>-

'"

C;;

.~

...

<.J

.2

w

Starter motor

Model

Capacity

Type

Model

Voltage

Output

of

plunger

mm (in.)

2

kg/cm

(psi)

CJmin.

( .S. gal/min.)

2

kg/cm

(psi)

g (oz)

rpm

V

A

V

kW

Bruns grade No. 2-D fuel

oil

(ASTM specifications)

Bosch "M" plunger in line

NIPPON

DENSO

ND-PFR-3M

5.5 (7/32)

7 (9/32)

Throttle type

NIPPON DENSO ND-DN4SD24

120

+10

(1706

-0

+142)

- 0

Paper element type

Trochoid type

20 (5.28) at 2600 engine rpm

Full flow paper element filter cartridge type

4 (57)

Cyclone dry air cleaner

Dry paper element cartridge type

More than 99.9%

20 (0.7)

Mechanical all-speed control

90~2900

Alternator

MITSUBISHI AH2053M4

12

35

Magnet type

MITSUBISHI M002T50381

12

1.6

---

...

--

Cl

m

Z

m

:0

»

r

o

m

en

(')

:0

'"tl

---

--

--

-

-I

o

Z

j,.

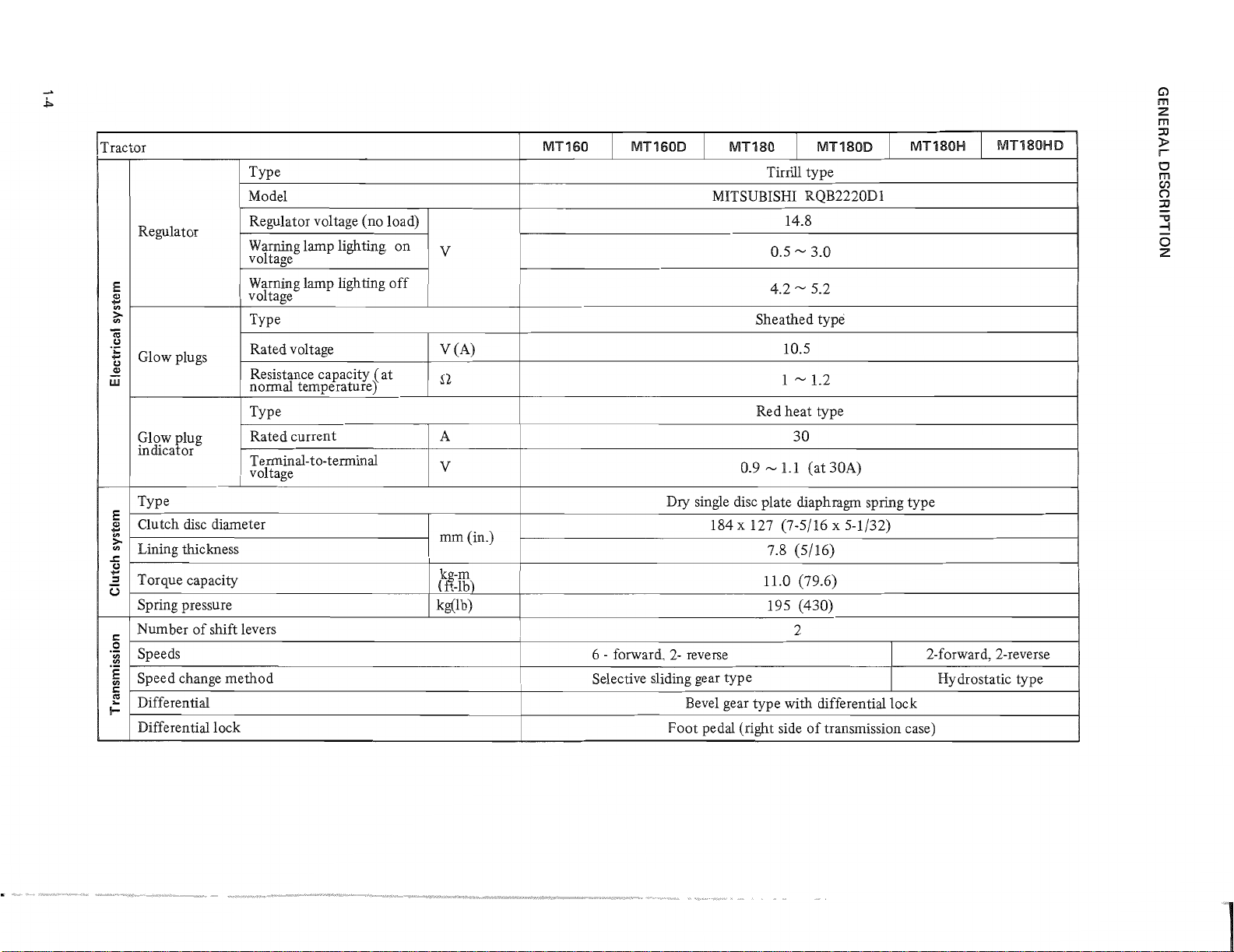

Tractor

Regulator

E

CD

....

'"

>-

'"

iii

.~

....

Glow plugs

t.:I

~

w

Glow

indica or

~lug

Type

Model

Regulator voltage (no load)

Warning lamp lighting. on

voltage

Warning lamp lighting

off

V

voltage

Type

Rated voltage V (A)

Resistance capacity

normal temperature)

(at

n

Type

Rated current

Terminal-to-terminal

voltage

A

V

MT160

MT160D

I

I

MT180

MT180D

I

Tirrill type

MITSUBISHI RQB2220Dl

14.8

0.5

~

3.0

~

5.2

4.2

Sheathed type

10.5

1

~

1.2

Red heat type

30

0.9 ~ 1.1

(at

30A)

MT180H I MT180HD

G)

m

Z

m

:0

»

r

o

m

en

()

:0

-0

~

o

z

Type

E

CD

Clutch disc diameter

....

'"

>-

Lining thickness

'"

J::

t.:I

...

:::I

Torque capacity

U

Spring pressure

Number

s:::

.~

en

Speeds

.~

E

Speed change method

s:::

'"

co

...

Differential

I-

of

shift levers

Differential lock

mm(in.)

~-m

( -lb)

kg(lb)

Dry single disc plate diaphragm spring type

184 x 127 (7-5/16 x 5-1/32)

2-

6 - forward,

reverse

Selective sliding gear type

Bevel gear type with differential lock

Foot

pedal (right side

7.8 (5/16)

11.0 (79.6)

195 (430)

2

of

transmission case)

2-forward, 2-reverse

Hydrostatic type

------

----

--

1

1

cJ,

'"0

'"

cu

cu

Cl..

'"

Q)

;;-

<e

...

E--

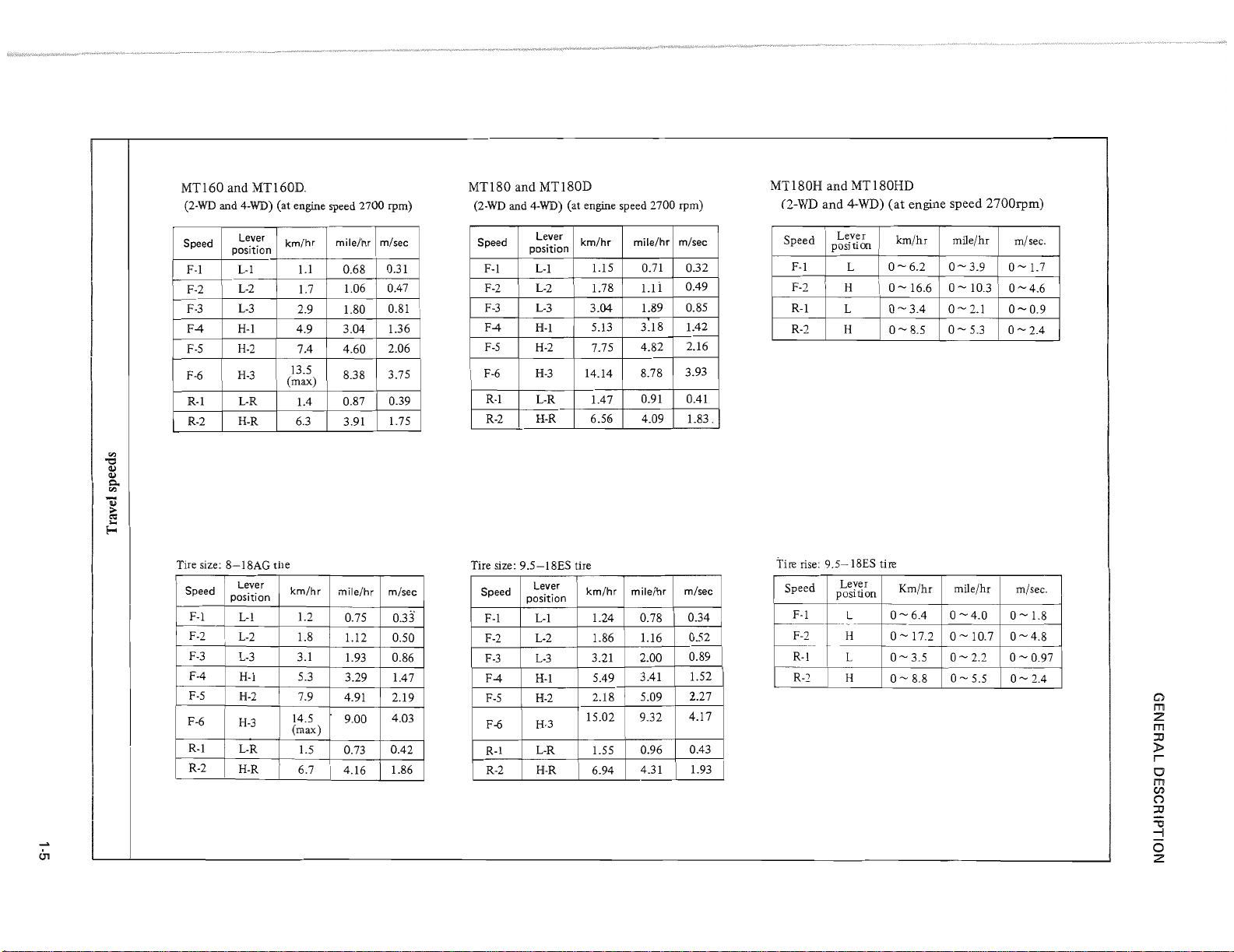

MTl60

(2-WD

and

Speed

F-l L-I

F-2

F-3

F-4 H-I

F-5

F-6

I

R-I

I

R-2

Tire size:

Speed

F-I

F-2

F-3

F-4

F-5

F-6

I

R-J

I L-R

R-2

I

and MTl60D.

4-WD)

(at engine speed 2700 rpm)

Lever

position

km/hr mile/hr m/sec

L-2

L-3

H-2

H-3

13.5

(max)

L-R

H-R

8-18AG

Lever

position

tile

km/hr

L-l

L-2

L-3

H-J

H-2

H-3

14.5

(max)

I

H-R

I

-

1.1

1.7

2.9

4.9 3.04

7.4 4.60

1.4

6.3

0.31

0.68

0.47 F-2

1.06

0.81

1.80

1.36

2.06

3.75

8.38

0.39

0.87

1.75

3.91

mile/hr m/sec Speed

1.2

1.8

3.1

5.3

7.9

1.5

6.7

0.75

1.12 0.50

1.93

3.29

4.91

9.00

0.73

4.16

0.33·

0.86

1.47

2.19

4.03

0.42

1.86

MTl80

and

MTl80D

(2-WD

and

4-WD)

(at engine speed 2700 rpm)

Speed

Lever

position

F-I L-I

L-2

F-3

L-3

F-4 H-I 5.13

F-5

F-6

R-I

R-2

Tire size:

F-I

F-2

F-3

H-2

H-3

L-R

H-R

9.5-18ES

Lever

position

L-l

L-2

L-3

F-4 H-I

F-5

F-6

R-J

R-2

H-2

H-3

L-R 1.55

H-R 6.94

km/hr mile/hr m/sec

1.15

1.78

3.04

0.71 0.32

1.11

1.89 0.85

3.18

4.82 2.16

8.78

0.91 I 0.41

4.09 I 1.83.

14.14

I

I

7.75

1.47 I

6.56 I

tire

km/hr mile/hr m/sec

1.24

0.78

1.86 1.16

3.21 2.00

5.49

2.18

3.41

5.09

15.02 9.32

0.96

4.31

0.49

1.42

3.93

0.34

0.52

0.89

1.52

1..27

4.17

0.43

1.93

MTl80H

and

(2-WD and 4-WD)

F-I

F-2

R-I

R-2

F·l

F-2

R-J

R-2

rise:

Lever

position

L

H

L

H

9.5-18ES

Lever

position

L

f----

H

L

H

Speed

-

Tire

Speed

----

~---

MTl80HD

(at

lan/hr

0~6.2

o

~

0~3.4

O~

tire

Km/hr mile/hr

0~6.4

-

o ~ 17.2

0~3.5

O~

engine speed 2700rpm)

0~3.9

16.6 o

0~2.1

8.5

O~

0~4.0

O~

0~2.2

8.8

o~

mile/hr

~

10.3

5.3

10.7

5.5

m/sec.

O~

1.7

0~4.6

0~0.9

0~2.4

m/sec.

O~

1.8

0~4.8

o

~

0.97

O~

2.4

G)

m

Z

m

:0

»

r

0

m

en

(")

:0

-0

-l

0

Z

6l

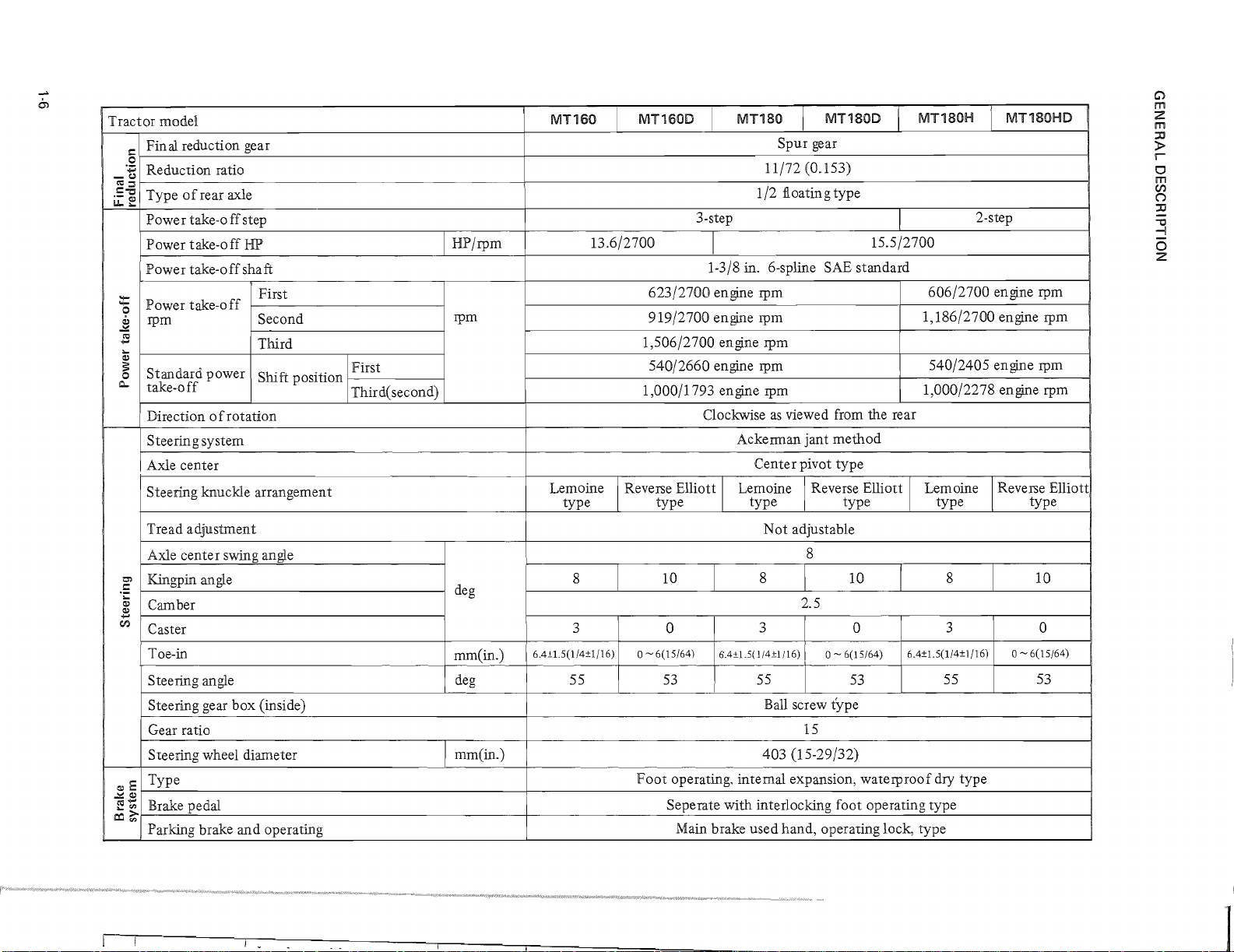

Tractor model

t::

Final reduction gear

0

'';::;

Reduction ratio

_<.l

ce~

t::-c

Type

of

.-

IJ..

'"

...

rear axle

Power take-o ff step

Power take-off

Power take-o

..-

Power take-o

-

0

.;,

rpm

.:.:

ce

...

...

'"

s:

Standard power

0

Q..

take-off

ff

ff

HP

shaft

Direction 0 f rotation

Steering system

Axle center

Steering knuckle arrangement

First

Second

Third

Shift position

First

Third( second)

HP/rpm

rpm

MT160

13.6/2700

Lemoine

type

MT160D

MT180

3-step

1-3/8 in. 6-spline

623/2700 engine rpm

919/2700 engine rpm

1,506/2700 engine rpm

540/2660 engine rpm

1,000/1793 engine rpm

Clockwise

Ackerman

Reverse Elliott

I Lemoine Reverse Elliott I Lemoine

type type

MT180D

Spur gear

11/72 (0.153)

1/2 floating type

SAE

as

viewed from the rear

jant

method

Center pivot type

type type type

15.5/2700

standard

MT180H

MT180HD

2-step

606/2700 engine rpm

1,186/2700 engine rpm

540/2405 engine rpm

1,000/2278 engine rpm

Reverse Elliott

G>

m

Z

m

:Il

»

r

o

m

(J)

(")

:Il

-c

-I

o

Z

I

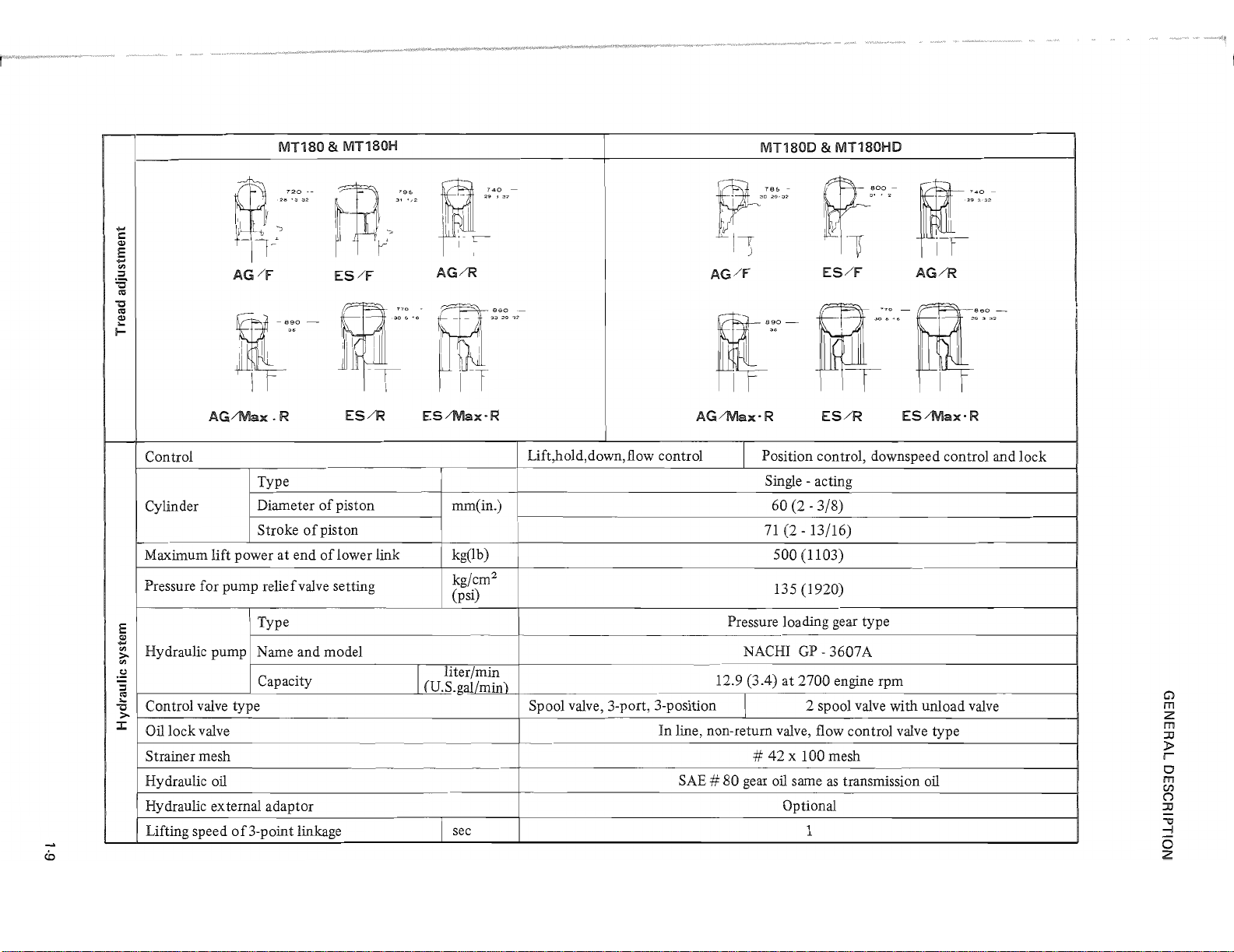

Tread adjustment

Axle center

Cl

Kingpin angle

.§

Camber

'"

...

'"

en

Caster

Swing

Toe-in

Steering angle

Steering gear box (inside)

Gear ratio

Steering wheel diameter

Type

",E

.:.:'"

ttl ....

...

<J>

Brake pedal

oa~

Parking brake and operating

I _

angle

deg

mm(in.)

deg

mm(in.)

8 10

3

6.4±L5(l

/4±1 / 16)

55

Not

adjustable

8

8

10

2.5

0

0-6(15/64)

53

3

6'.4±L5(\/4±1/16)

55

0

0-6(15/64)

53

Ball screw fype

15

403 (15-29/32)

Foot

operating, internal expansion, waterproof dry type

Seperate with interlocking foot operating type

Main brake used hand, operating lock, type

8

3 0

6.4±L5(1/4±1/16)

55

10

0-6(15/64)

53

I

I

~

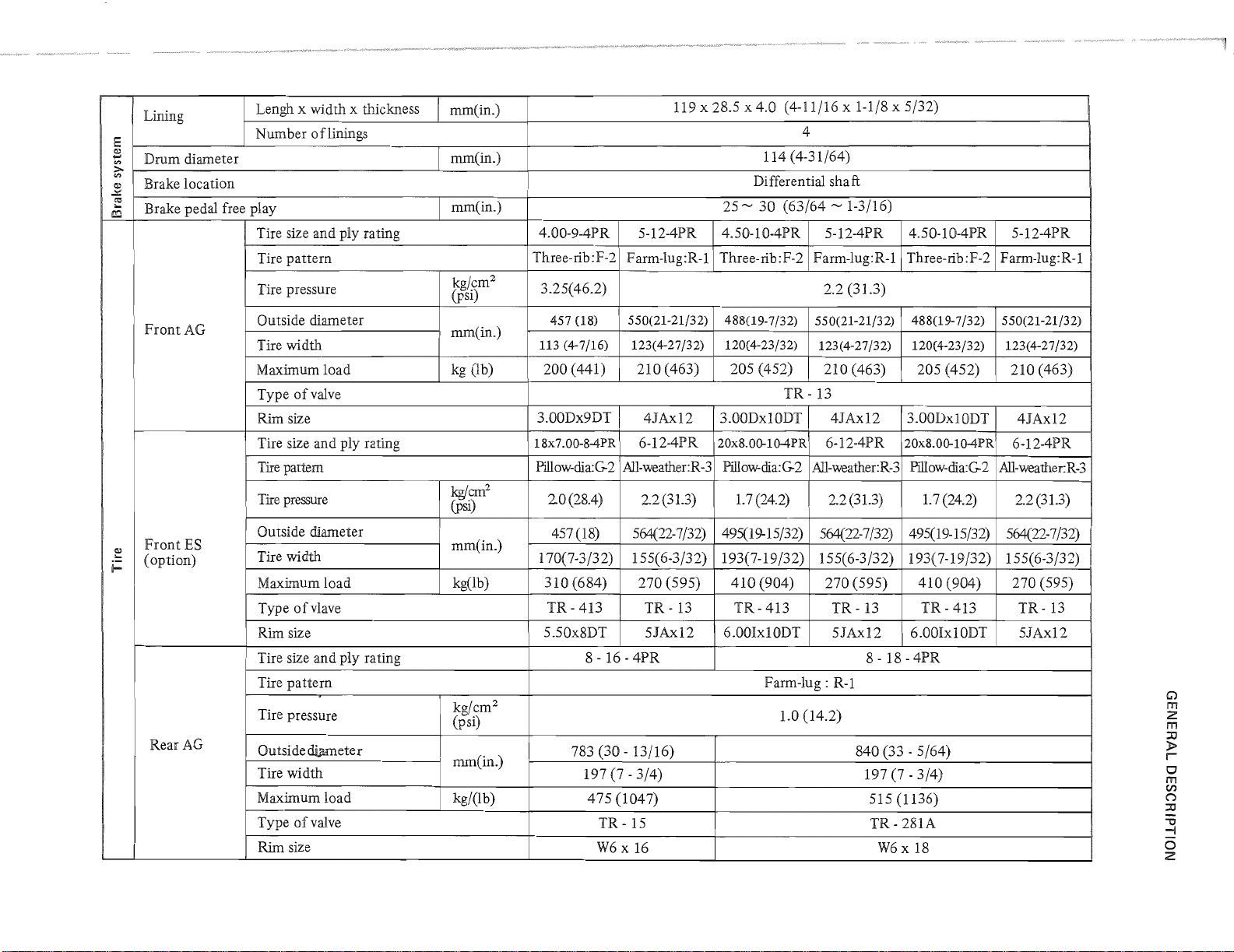

Lining

E

Ol

....

Drum diameter

'"

>-

'"

Ol Brake location

~

::!

Brake pedal free play

m

FrontAG

Front

~

I-

ES

(option)

Rear AG

Lengh x width x thickness

Number oflinings

Tire size and ply rating

Tire pattern

Tire pressure

Outside diameter

Tire width

Maximum load

Type

of

valve

Rim size

Tire size and ply rating

Tire

pattem

Tire

pressure

Outside diameter

Tire width

Maximum load

Type

of

vI

ave

Rim size

Tire size and ply rating

Tire pattern

Tire pressure

Outside <llinneter

Tire width

Maximum load

of

Type

valve

Rim size

mm(in.)

mm(in.)

mm(in.)

kg/cm

(psi)

mm(in.)

kg (lb)

2

kgfcrn

(Psi)

mm(in.)

kg(1b)

kg/cm

(psi)

mm(in.)

kg/(lb)

119 x 28.5 x 4.0 (4-11/16 x 1-1/8 x 5/32)

4

114 (4-31/64)

Differential shaft

25

~

30

(63/64 ~ 1-3/16)

4.00-9-4PR

5-12-4PR 4.50-10-4PR

5-12-4PR

4.50-10-4PR 5-12-4PR

Three-rib:F-2 Farm-lug:R-1 Three-rib:F-2 Farm-lug:R-l Three-rib:F-2 Farm-lug:R-l

2

3.25(46.2)

457

(18) 550(21-21/32)

113 (4-7/16) 123(4-27/32) 120(4-23/32) 123(4-27/32) 120(4-23/32) 123(4-27/32)

200(441)

210

(463)

488(19-7/32) 550(21-21/32) 488(19-7/32) 550(21-21/32)

205

(452)

2.2 (31.3)

210

(463)

205

(452)

TR-13

3.00Dx9DT

18x7.00-8-4PR 6-12-4PR 20x8.00-10-4PR 6-12-4PR 20x8.00-10-4PR 6-12-4PR

Pillow-dia:G 2

20(28.4) 2.2(31.3) 1.7 (24.2) 2.2(31.3)

457 (18)

170(7-3/32) 155(6-3/32) 193(7-19/32) 155(6-3/32)

310

(684)

TR

- 413

5.50x8DT

8 - 16 -

2

4JAx12 3.00DxlODT 4JAx12 3.00DxlODT 4JAx12

All-weather:R-3

Pillow-dia:G 2

All-weather:R-3

Pillow-dia:G2

1.7(24.2) 2.2(31.3)

564(22-7/32) 495(19-15/32) 564(22-7/32)

495(19-15/32) 564(22-7/32)

193(7-19/32)

270

(595)

TR-13

410

TR-

(904)

413

270

TR-13

(595)

410

(904) 270 (595)

TR-

413

5JAx12 6.00IxlODT 5JAx12 6.00IxlODT 5JAx12

4PR

Farm-lug:

R-l

8 - 18 -

4PR

1.0 (14.2)

783 (30 - 13/16)

197

(7 -3/4)

475

(1047) 515 (1136)

TR-15

W6

x 16

-------

840 (33 - 5/64)

197

(7 -3/4)

TR-

281A

W6

x 18

~-~

~-

210

(463)

All-weather:R-3

155(6-3/32)

TR-13

I

Gl

m

2

m

::0

»

r

o

m

en

(')

::0

"'0

-l

o

2

Co

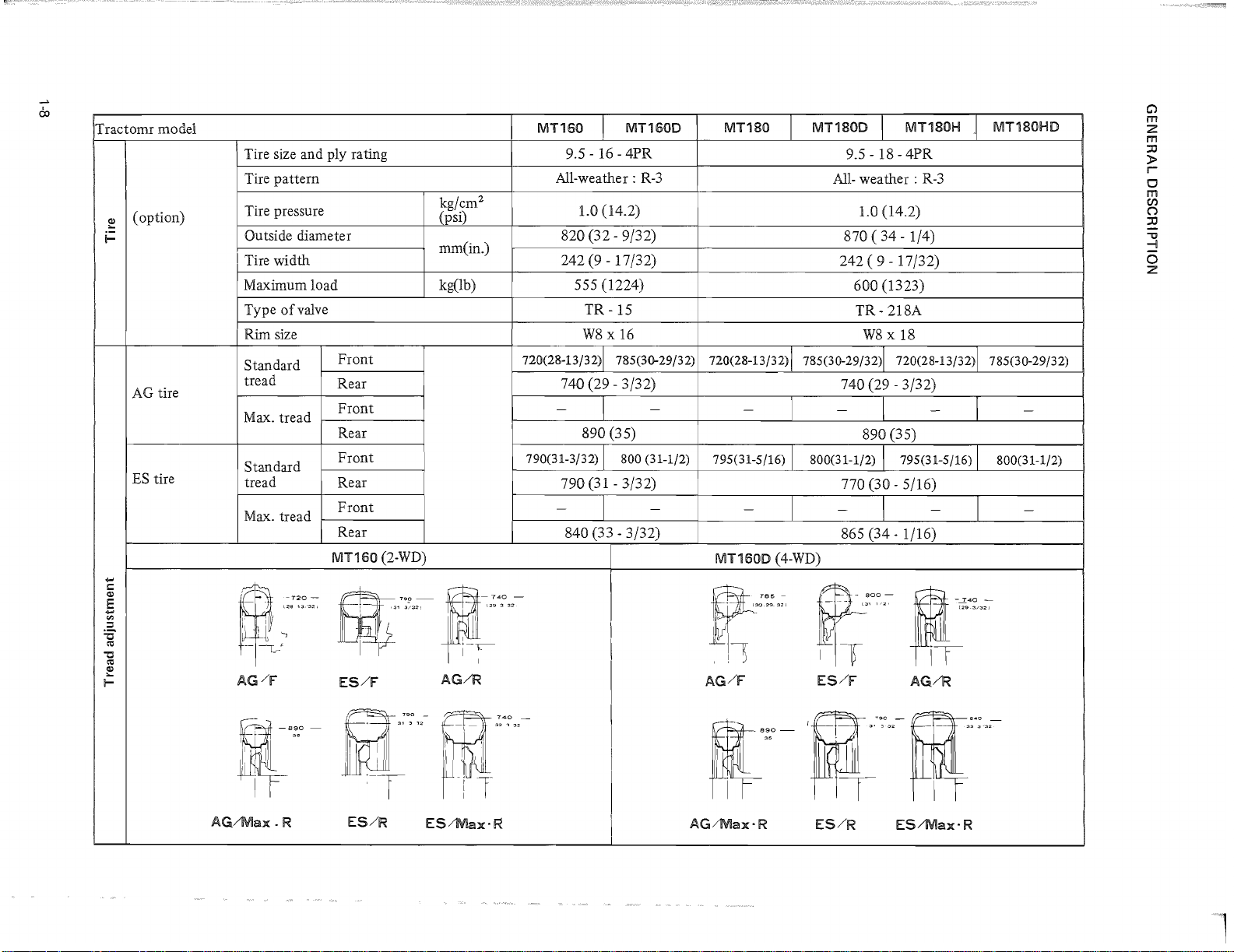

Tractomr model

(option)

CI)

...

I-

AG

tire

ES

tire

....

I:

CI)

E

...

'"

::l

:0

'"

-c

CI)

'"

...

I-

MT160

Tire size and ply rating

Tire pattern

Tire pressure

Outside diameter

I Tire width

Maximum load kg(lb) 555 (1224)

Type

of

valve

Rim size

Standard

tread

Max. tread

Standard

tread

Max.

tread

- -

l<!e.'''L'321

~"O-

I',

I

"

~

~

~-~

AG/F

Front

Rear

Front

Rear

Front

Rear

Front

Rear

MT160

(2-WD)

$/--

11"'"

ES/F

kg/cmz

(psi)

mm(in.)

720(28-13/32)1 785(30-29/32)

790(31-3/32) 1

m-'"o-

:;'"

AG/R

I

9.5 -

16

- 4PR

All-weather:

1.0 (14.2)

820 (32 - 9/32)

242(9-17/32)

TR-15

W8x

16

740 (29 - 3/32)

-

1

890 (35)

800 (31-1/2)

790

(31-

3/32)

-

1

840 (33 - 3/32)

MT160D

R-3

-

-

MT180

720(28-13/32)1 785(30-29/32A 720(28-13/32)1 785(30-29/32)

-

795(31-5/16) 1

-

MT160D

'I""'"

f''''-

I

!~

AG/F

MT180D

I

9.5-18-4PR

All-

870 (

242 ( 9 - 17/32)

600 (1323)

TR-

740 (29 - 3/32)

-

I

800(31-1/2) 1 795(31-5/16) 1 800(31-1/2)

770 (30 - 5/16)

-

I

865 (34 - 1/16)

(4-WD)

w;:--

,,--,'"

ES/F

MT180H

I

weather:

1.0 (14.2)

34

- 1/4)

218A

W8x18

I

890 (35)

1

.n

m'~

AG/R

R-3

~

MT180HD

-

I

-

1

-

-

h---""

Gl

m

Z

m

::tJ

l>

r

o

m

Ul

()

::tJ

"'tI

-I

o

Z

t

i

~.--

Ii

1315)

I I

i

AG/Max.R

S'.,

II

•

I

;--1

ES/R

,"0'

-

~rr'"o

i

II!

.

-iT

ES/Max·R

''''0.

I

l

890-

II

I

,35)

~'.o_~.'"

i

AG/Max·R

~--

- -

ES/R

(3,

_3/3<:)

,

--r-

~-

I

ES/Max·R

(3:l_3/32~

I

I

I

"1

r"

"1

MT180

I r

""

...

s::

Q)

E

...

'"

:::I

:0-

ct!

"C

ct!

~

I-

m

I

-1-~

AG/F

I I

I'

".-

~

I

'"'30>

'>0

'"

'3.

i

AG/Max.R

Control

Type

Cylinder Diameter

Stroke

of

Maximum lift power

Pressure for pump reliefvalve setting

at

end

& MT180H

,

f~

I,

II

ES/F

~

i'.

ES/R

of

piston mm(in.)

piston

oflower

:"~,

-

~",""e.

" I I

'ff

-;""

link

'i-~

' I

AG/R

..

-

~"".-

fi-~"··

ES/Max-R

kg(lb)

kg/cm

(psi)

MT180D & MT180HD

' .

785

,I

, i I

,:

i~1

~Ik

' ! )

AG/F

m~"-

' i

AG/Max'R

Lift,hold,down,flow control

2

~

'30'Om'

(361

II

Position control, downspeed control and lock

I

Single -acting

60 (2 - 3/8)

71

500 (1103)

135 (1920)

~

ES/F

~-·-m"""-

ES/R

(2 - 13/16)

...

I

,,"

III

:

-1

'-r'""

-

~"".-

-

\-1

AG/R

i

",,,"

ES/Max·R

I

cO

E

Q)

...

Hydraulic pump

'"

>

'"

Co)

:::I

ct!

"-

Control valve type

"C

>

J:

Oil lock valve

Strainer mesh

Hydraulic

Hydraulic external adaptor

Lifting speed

oil

on-point

Type

Name and model

Capacity

linkage

I liter/min

(U.S.gai/min )

sec

Spool valve, 3-port, 3-position

In line, non-return valve, flow control valve type

SAE # 80

Pressure loading gear type

GP

NACHI

12.9 (3.4) at 2700 engine rpm

I

# 42 x 100 mesh

gear oil same

- 3607 A

2 spool valve with unload

as

transmission oil

Optional

1

G)

valve

---_

...

--,--

-

m

Z

m

::c

»

r

o

m

CIl

()

::c

-0

-l

o

Z

....

o

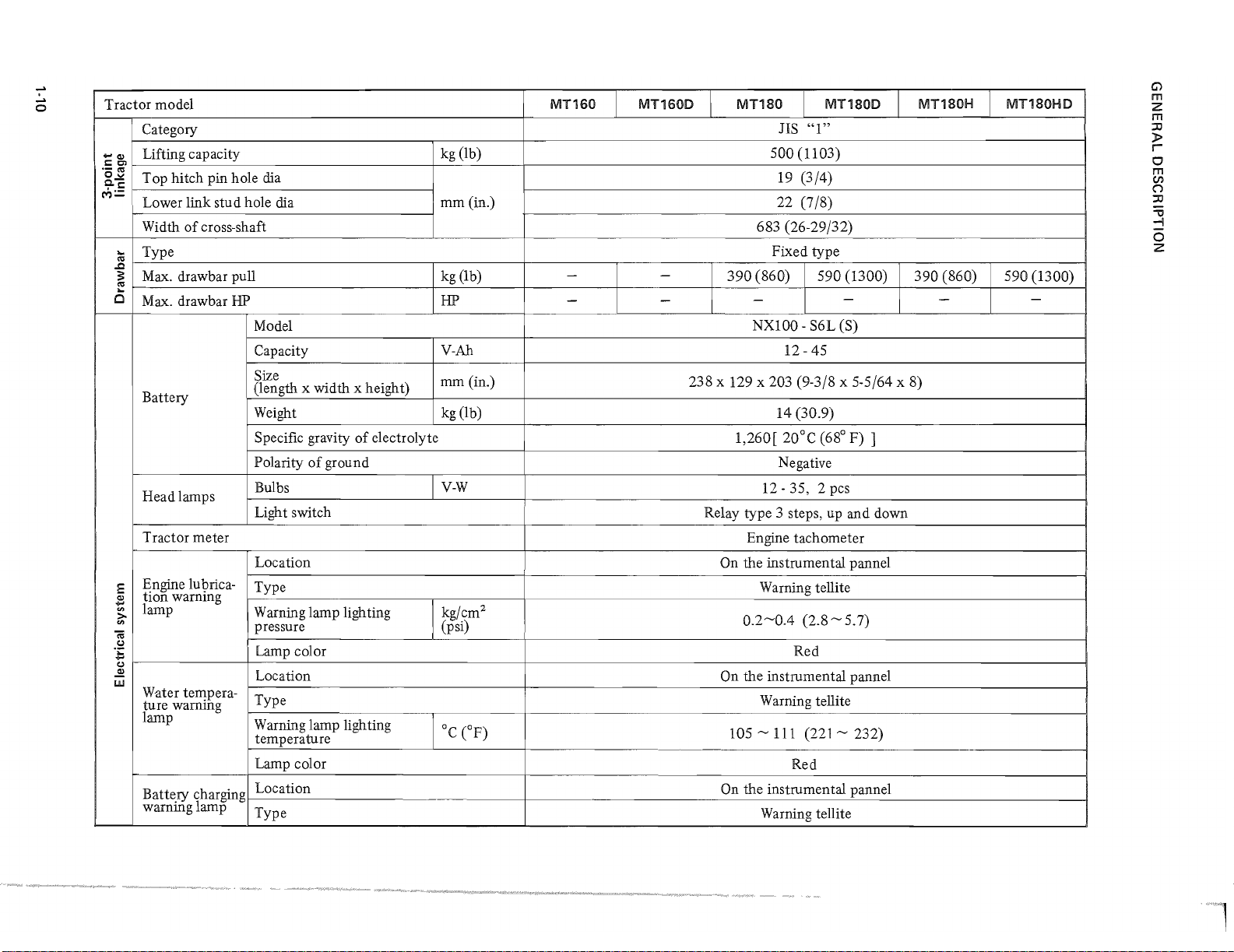

Tractor model

Category

Lifting capacity

~C!l

S:::e>

.-

'"

o~

Top hitch pin hole dia

Cos:::

M=

Lower link stud hole dia

Width

of

cross-shaft

...

Type

..c

'"

s:

Max.

...

'"

0

drawbar pull kg (Ib)

Max. drawbar

Battery

Head lamps

Tractor meter

Engine lubrica-

E

tion warning

.lB

lamp

'"

>

'"

cti

Co)

.;:

..

Co)

..:2

w

Water terrwera-

ture warrung

lamp

Battery charging

warning lamp

HP

Model

Capacity

Size

(length x width x height)

Weight

Specific gravity

Polarity

of

ground

of

electrolyte

Bulbs

Light switch

Location

Type

Warning lamp lighting

pressure (psi)

Lamp color

Location

Type

Warning lamp lighting

temperature

Lamp color

Location

Type

--_._-

--

kg (lb)

mm(in.)

HP

V-Ah

mm

(in.)

kg

(lb)

V-W

2

kg/cm

°c

CF)

MT160

-

-

MT160D

-

-

MT180

ns

MT180D

"1"

500 (1103)

19 (3/4)

22 (7/8)

683 (26-29/32)

Fixed type

390

(860) 590 (1300)

-

NXIOO

-

- S6L (S)

12 -45

238 x 129 x 203 (9-3/8 x 5-5/64 x 8)

14 (30.9)

1,260[ 20°C (68° F) ]

Negative

12 - 35, 2 pcs

Relay type 3 steps, up and down

Engine tachometer

On the instrumental pannel

Warning tellite

0.2

~0.4

(2.8 ~ 5.7)

Red

On the instrumental pannel

Warning tellite

105 ~ 111

(221 ~ 232)

Red

On

the instrumental panne1

Warning tellite

MT180H

390

(860)

-

MT180HD

590 (1300)

-

G)

m

Z

m

:0

»

r

o

m

en

()

:0

."

-I

o

Z

'1

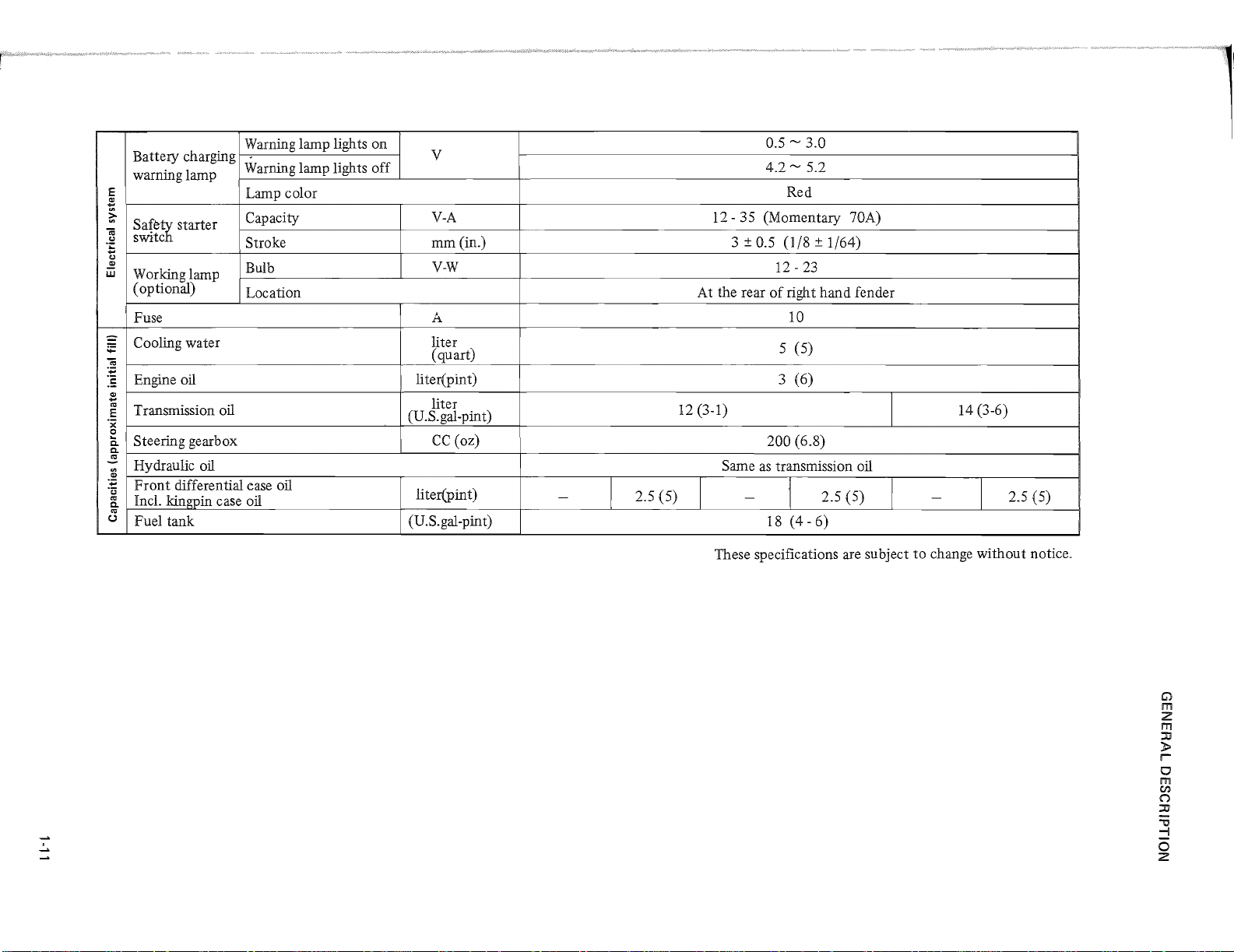

Battery charging

warning lamp

E

.,

....

~

Safe~

co

SWltc

·5

'"

~

w

Working lamp

(optional)

starter

Warning lamp lights on

Warning lamp lights

off

Lamp color

Capacity

Stroke

Bulb

Location

Fuse

Cooling water

;;::

co

.

.;::;

Engine oil

:~

~

'"

Transmission oil

E

·x

0

"-

Steering gearbox

0.

0.

'"

-

Hydraulic oil

'"

-!

Front

.tj

'"

0.

'"

u

differential case oil

Incl. kingpin case oil

Fuel tank (U.S.gal-pint)

liter(pint)

(U.S. gal-pint)

liter(pint)

V

V-A

mm (in.)

V-W

A

liter

(quart)

liter

CC

(oz)

0.5 ~ 3.0

4.2

~

5.2

I

Red

12 - 35 (Momentary 70A)

3 ± 0.5

(l/8

± 1/64)

12 - 23

of

At the rear

righ t hand fender

10

5 (5)

3 (6)

12(3-1)

I

14 (3-6)

200 (6.8)

Same

as

transmission oil

-

2.5 (5)

I

~~

--~--

I

---_._.-

-

18 (4 -6)

l

-

2.5 (5)

These specifications are subject

-

f

to

change without notice.

I

2.5 (5)

..:.,.

G)

m

Z

m

:0

»

r

o

m

en

(")

:0

-0

-l

o

Z

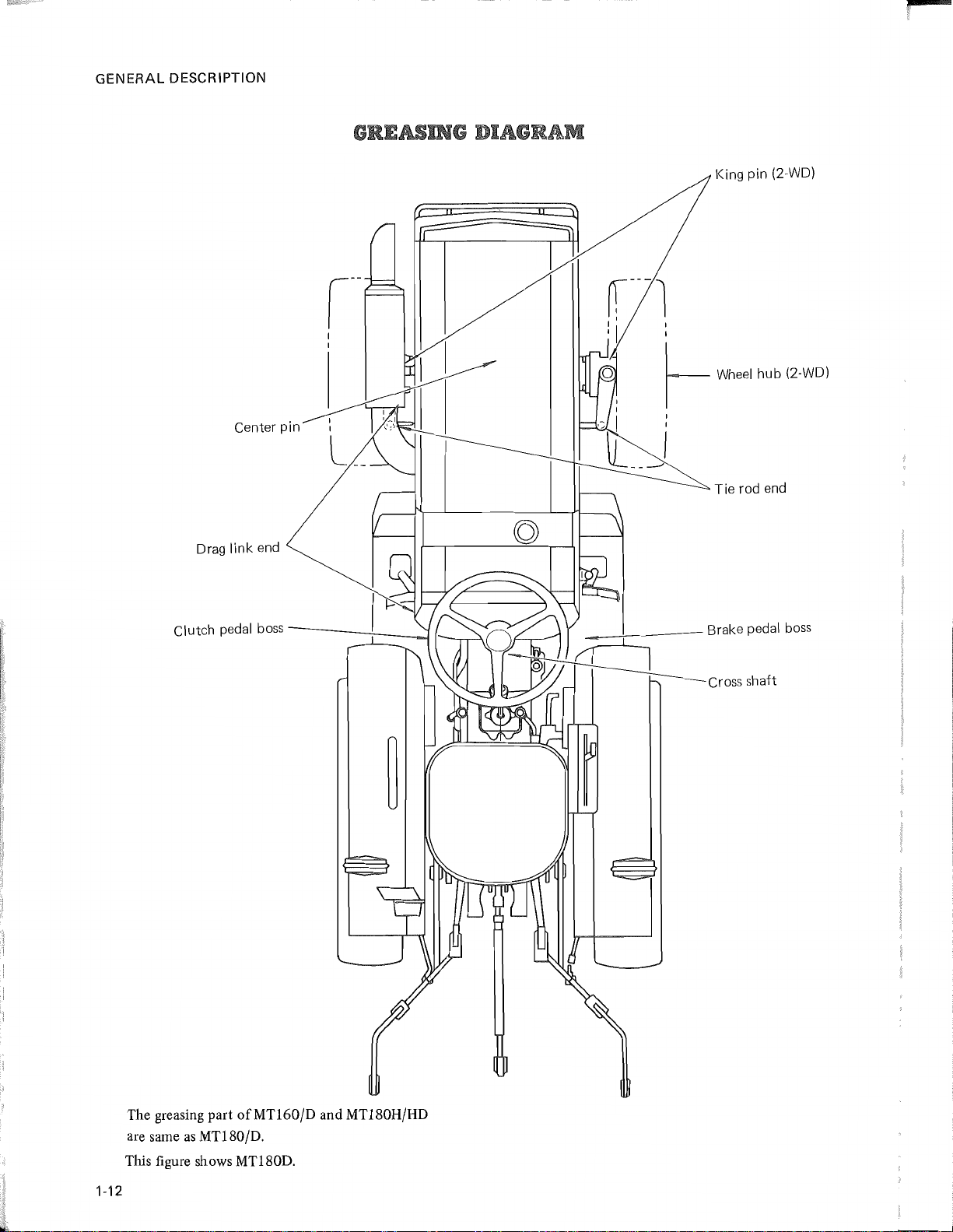

GENERAL

DESCRIPTION

GREASING JlUllJIlA"l"-""'''''''''''''-'''''

Center pin

Drag link end

f---l

I

I'

, I

,

I

,~

I :

lL

,

~

____

I

King pin

Wheel

Tie rod end

(2-WD)

hob

12-WDI

Clutch pedal

boss--

__

~_~

Brake pedal boss

l

Cross shaft

The greasing part

as

are same

This figure shows MTl80D.

1-12

MTl80/D.

ofMTl60/D

and MTl80H/HD

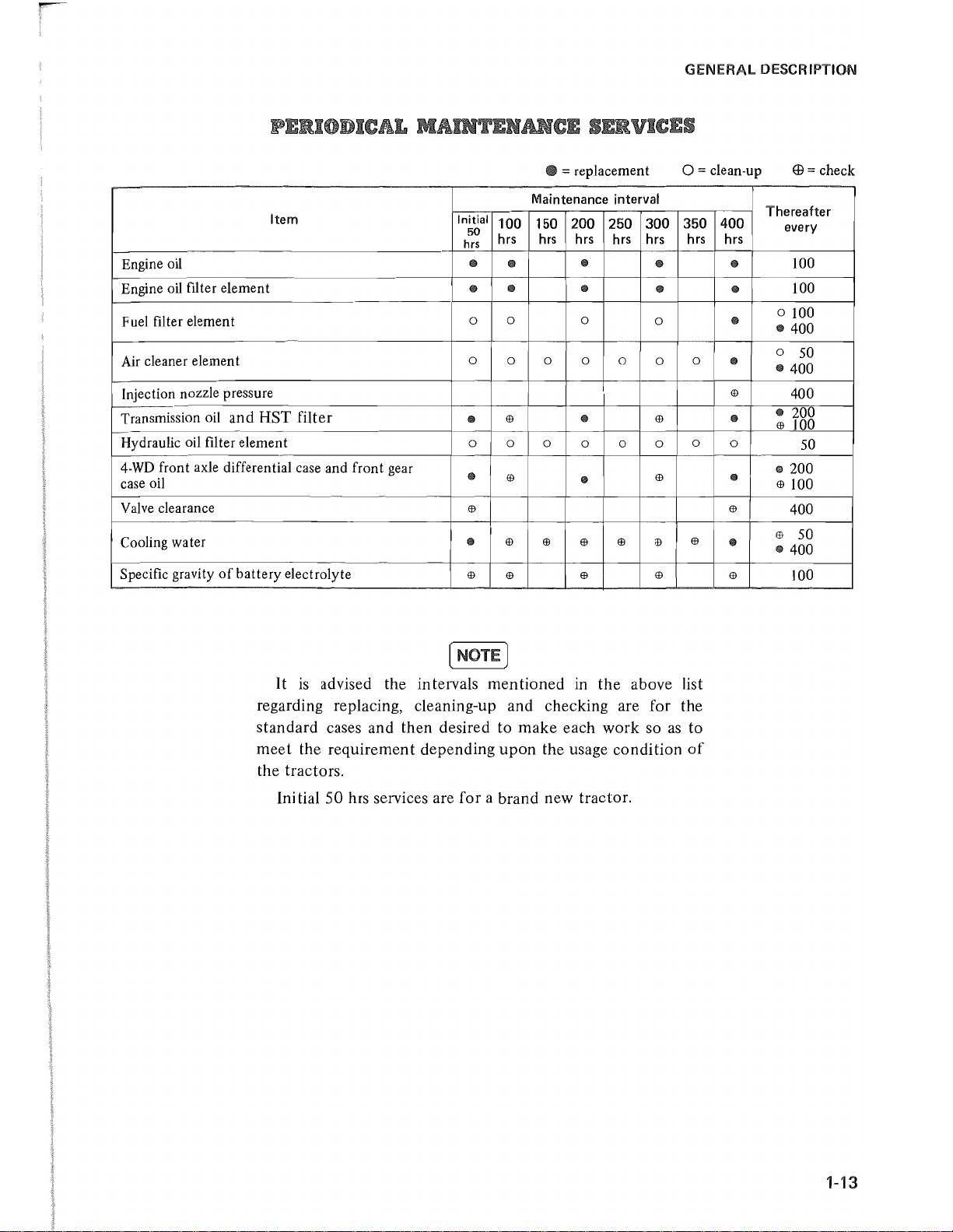

• = replacement

GENERAL DESCRIPTION

0=

clean-up

EB

= check

Item

Engine oil

Engine oil filter

element

Fuel filter element

Air cleaner element

Injection nozzle pressure

Transmission oil

and HST filter

Hydraulic oil filter element

4-WD

front axle differential case and

case oil

Valve clearance

Cooling water

Specific gravity

of

battery

electrolyte

front

gear

Maintenance interval

Initial

100

150

50

hrs hrs hrs hrs hrs hrs

hrs

till

till

till

•

0 0

0

0

0 0

6J

till

0 0 0

till

Ef)

6J

6J

•

6J

6J 6J

200 250

6J

till

till

0

•

0 0 0

till

6J

0

6J

300 350

till

till

0

0 0

6J

0

6J

6J

6J

6J

400

hrs

till

•

till

till

6J

•

0

•

6J

•

6J

Thereafter

every

100

100

o 100

.400

0

50

·400

400

• 200

6J

100

50

.200

6J

100

400

6J

50

·400

100

[NOTE]

It

is

advised the intervals mentioned in the above list

regarding replacing, cleaning-up and checking are for the

standard cases and then desired to make each work so

meet the requirement depending upon the usage condition

the tractors.

Initial 50 hrs services are for a brand new tractor.

as

to

of

1-13

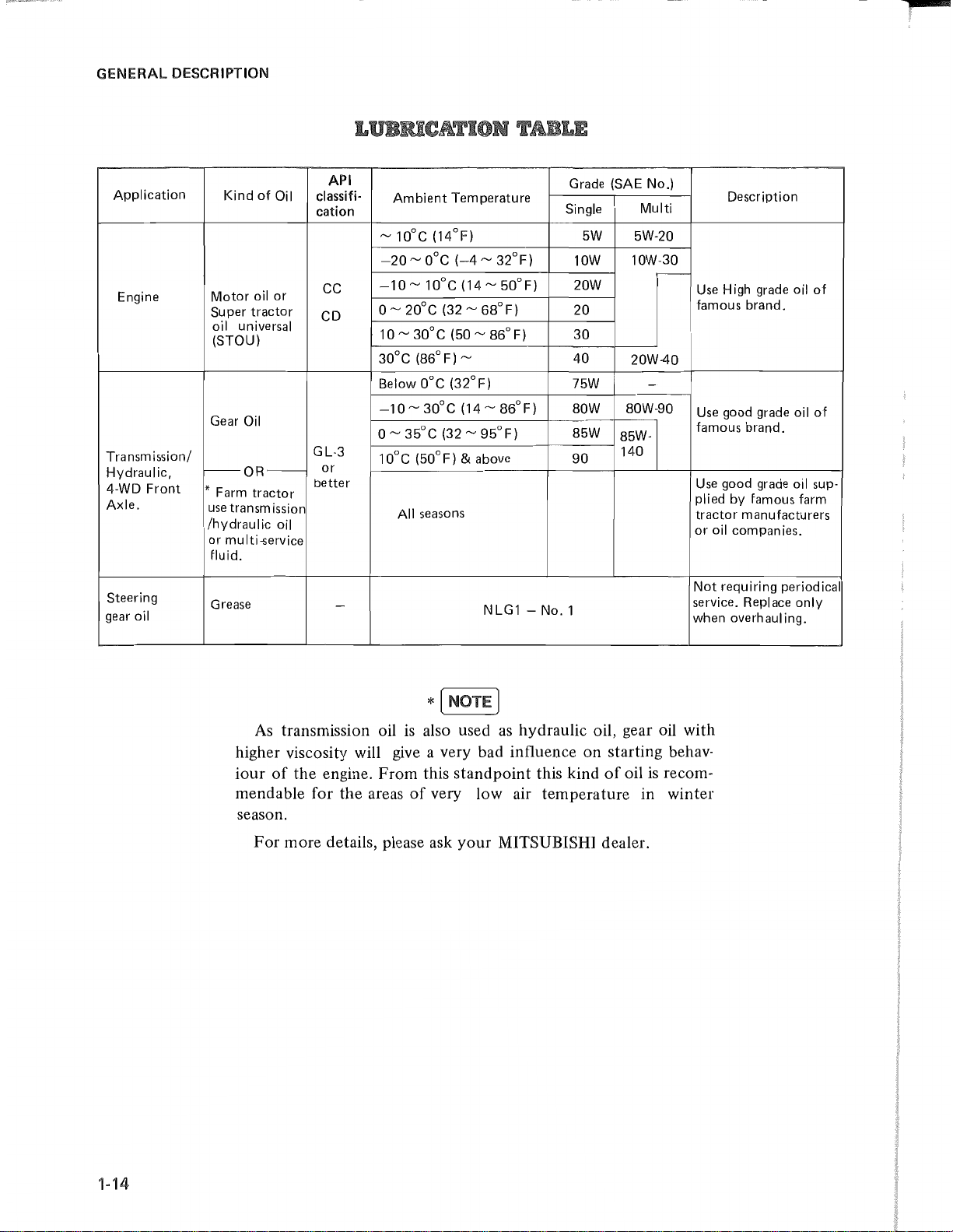

GENERAL

DESCRIPTION

Application

Engine

Transmission/

Hydraulic,

4-WD Front

Axle.

Steering

gear

oil

Kind

of

Motor

oil

Super

tractor

oil universal

(STOU)

Gear

Oil

f--OR-

* Farm

tractor

use

transm

/hydrau I

or

mu

Iti

fluid.

Grease

ic

-service

Oil

or

iss

oil

ion

API

classifi-

cation

ee

eD

GL-3

or

better

-

Ambient

~

100e (14°F)

-20 ~ oOe

-10 ~ 100e (14 ~ 50°F)

o ~ 200e (32 ~ 68°F)

10~30oe

0

30

e (86°F)

Below

-10~30oe

o

~

0

10

e (50°F) &

All

Temperature

(-4 ~ 32°F)

(50~86°F)

~

oOe

(32°F)

(14~86°F)

35°e

(32 ~ 95°F)

seasons

above

NLG1 -

Grade (SAE No.)

Single

5W

10W

20W

20

30

40

75W

80W

85W

90

No.1

Multi

5W-20

10W-30

20W-40

-

80W-90

85W-

140

Description

r---

Use

High

famous brand.

Use

good

famous brand.

Use

good

plied by famous farm

tractor manufacturers

or

oil companies.

Not

requiring periodical

service. Replace only

when overhauling.

grade

grade

grade

oil

of

oil

of

oil sup·

As

transmission oil

higher viscosity will

iour

of

the

engine. From this

give

mendable for the areas

season.

For

more details, please ask

is

also used

as

hydraulic oil, gear oil with

a very bad influence on starting behav-

standpoint

of

very low air temperature in winter

your

this kind

of

oil

MITSUBISHI dealer.

is

recom-

1-14

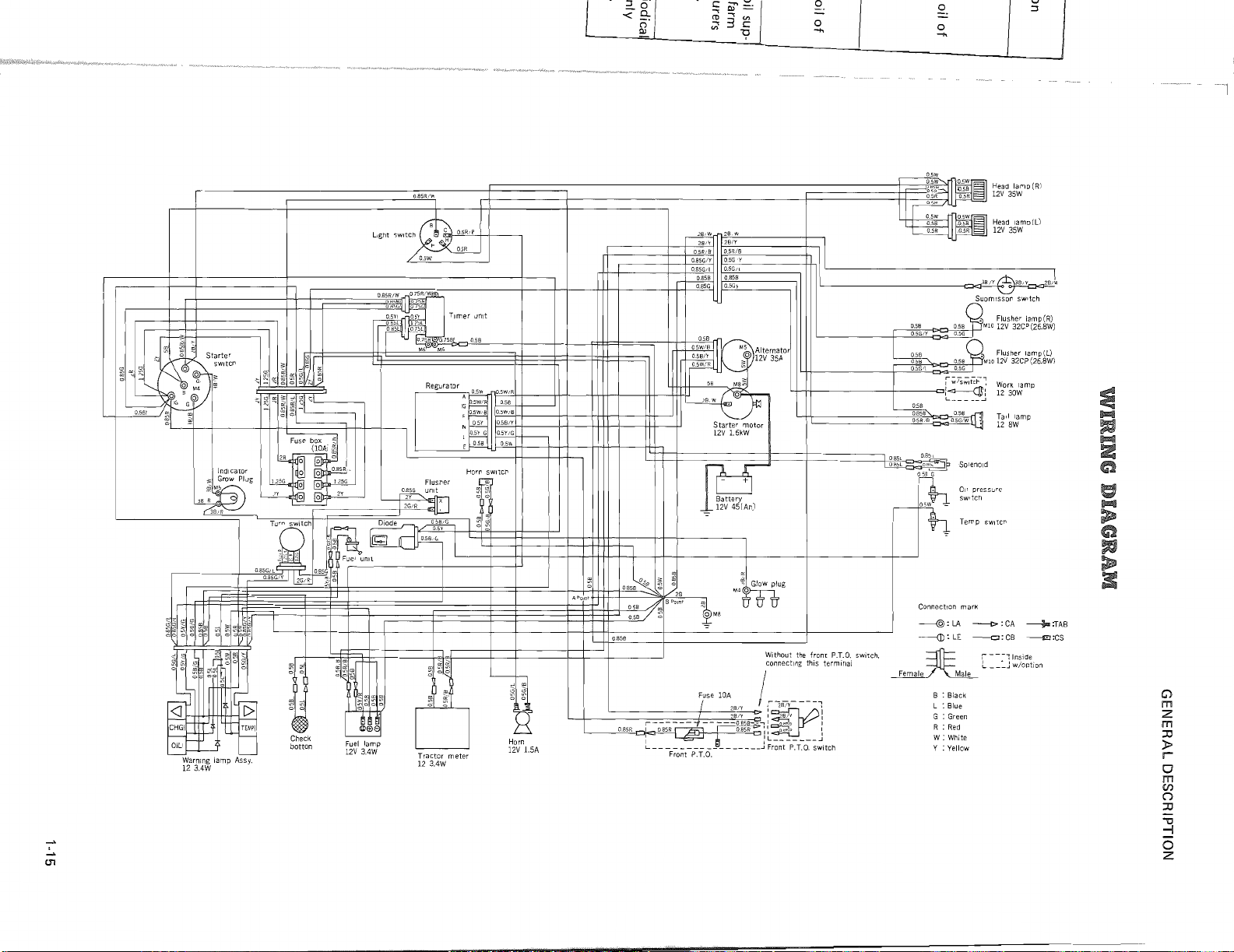

r<"

Light

switch

II

OB5R!W

O.5W.'

"i!l--,0",5R""£.B

+-f--~

05R

Regu

I:~'

F _5W/8 I

L

.5Y/G

'~

E

0.56!

1

~

~I

1\

05W

H:

28/W

28/v

28iY

O.SR/S

05RfB

05G!Y

085G!Y

O.SG/l

085G/L

0858

0858

O.5Gy

O.SSG

I

~ ~

05W

I

!H~;~~'

lO.58

'O-,A

-05R

~

.5W~

DOR

Head

12V

Head

12V

i g I

35W

35W

8/~-.ll/Y_~BJ

OB5L

[TI;SL

SolenOId

Oil pressure

switch

Temp. SWitch

lamp

lamp(L)

(R)

.:..,.

01

'--

Warning lamp Assy.

123.4W

TEMPi

1--

L-

~II

~I

~

Check

botton

'::::::Ef=

~I,

o~

,~~

o

i!>EB6

tI

Fuel

lamp

12V

3.4W

°1?~1

~

~~

~

u

Tractor

123.4W

meter

L----j-

H

Horn

12V

1.5A

0.858

~;:~(

Fuse lOA I

-+

r--

L

___ ~ __

Front P.T.D.

Without the front

connecting this terminal

__

~t

~

",28",1'''---'0>

\ 2B/Y 1

2a~;58

__

-.:~1

______

J

~r~~t

Connection

----@:

LA

----{]):

LE

P.T.C.

switch.

~

______

"

-P~T~O~;~jtCh

~

B : Black

L : Blue

G : Green

R :

W:

Y :

Male

Red

White

Yellow

mark

--!>

:

CA

~

oJ

w/optlOn

----£I

:TAB

:CS

--0:

CB

:--::I",ide

'-

___

G)

m

Z

m

:0

»

r

o

m

en

(")

:0

""C

-I

o

Z

GENERAL

DESCRIPTION

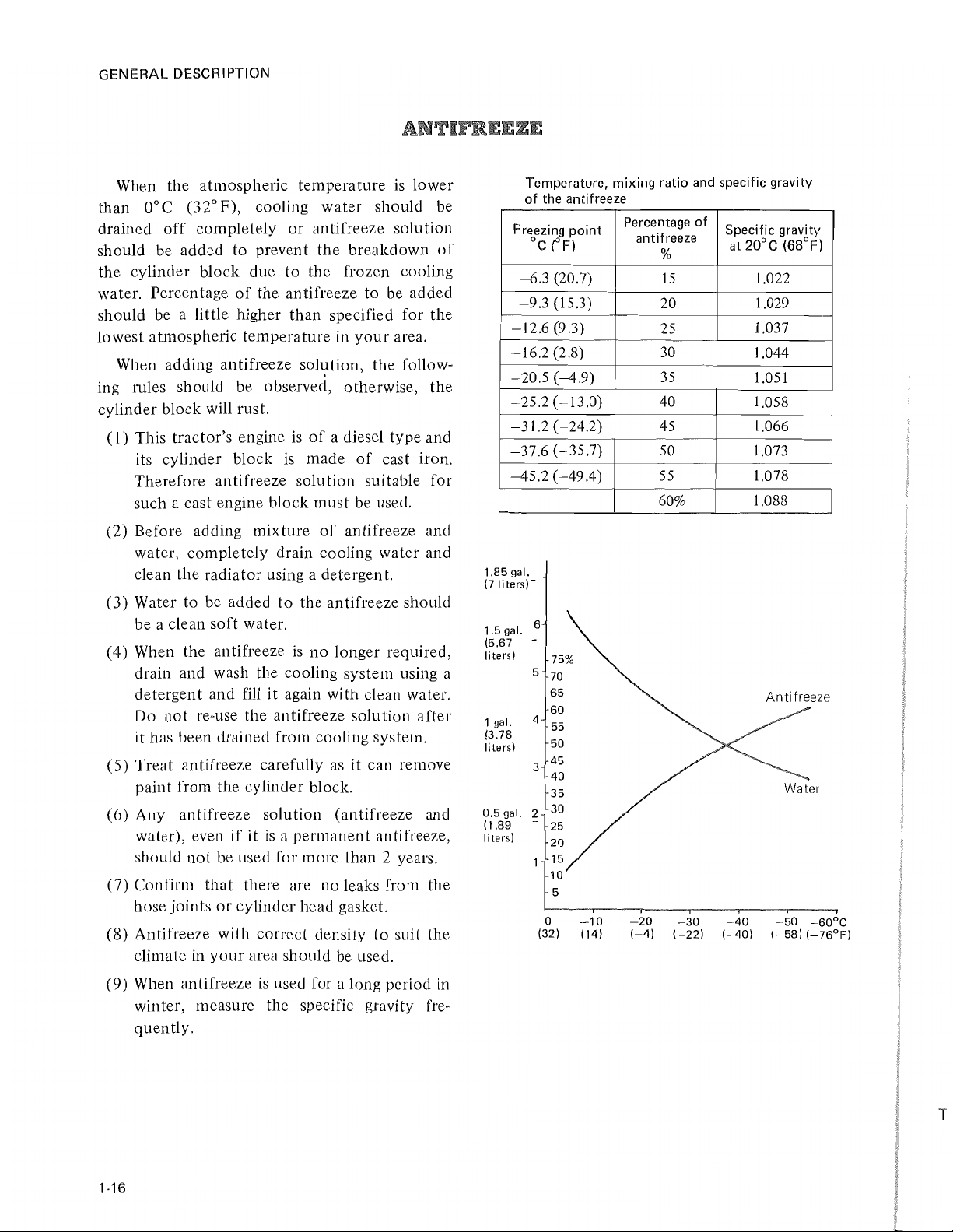

When the atmospheric

than

should be added

drained

O°C

(32°P),

off

completely

to

the cylinder block due

water. Percentage

of

temperature

is

lower

cooling water should be

or

antifreeze solution

prevent

the

breakdown

to

the frozen cooling

of

the antifreeze to be added

should be a little higher than specified for the

lowest atmospheric

temperature

in

your

area.

When adding an tifreeze solution, the follow-

ing rules should be observed, otherwise, the

cylinder block will rust.

(1)

This tractor's engine

its cylinder block

is

is

of

a diesel type and

made

of

cast iron.

Therefore antifreeze solution suitable for

such a cast engine block

(2) Before adding mixture

must

be used.

of

antifreeze and

water, completely drain cooling water and

clean the radia tor using a de tergen

(3) Water to be added

to

the antifreeze should

t.

be a clean soft water.

(4) When the an tifreeze

is

no

longer required,

drain and wash the cooling system using a

it

detergent and fill

not

Do

it

re-use

has been drained from cooling system.

(5) Treat antifreeze carefully

again with clean water.

the

antifreeze solution after

as

it can remove

paint from the cylinder block.

(6) Any antifreeze solution (antifreeze and

if

it

water), even

should

(7)

Confirm.

hose joints

not

be used for more than 2 years.

that

or

is a permanent

there are no leaks from the

cylinder head gasket.

(8) Antifreeze with correct density

climate in

your

area should be used.

antifreeze,

to

suit the

Temperature, mixing ratio and specific gravity

of the antifreeze

-10

(14)

Percentage of

antifreeze

%

15

20

25

30

35

40

45

50

55

60%

-20

(-4)

I

-30

(-22)

Freezing point

°c

-6.3

-9.3

-12.6

-16.2

-20.5

-25.2

-31.2

-37.6

-45.2

1.85

gal.

(7Iiters)-

1.5

gal.

(5.67

liters)

5

gal.

4

3

2

-

1 gal.

(3.78

liters)

0.5

(1.89

liters)

(OF)

(20.7)

(15.3)

(9.3)

(2.8)

(-4.9)

(-13.0)

(-24.2)

(-35.7)

(-49.4)

6

75%

70

65

60

55

50

45

40

35

30

25

20

1 15

10

5

o

(32)

Specific gravity

at 20°C (68°F)

1.022

1.029

1.037

1.044

1.051

1.058

1.066

1.073

1.078

1.088

Anti freeze

Water

I

-40

(-40)

j ,

-50

(-58)

(-76°F)

-60°C

(9) When antifreeze

is

used for a long period in

winter, measure the specific gravity fre-

quently.

1·16

T

ty

F)

F

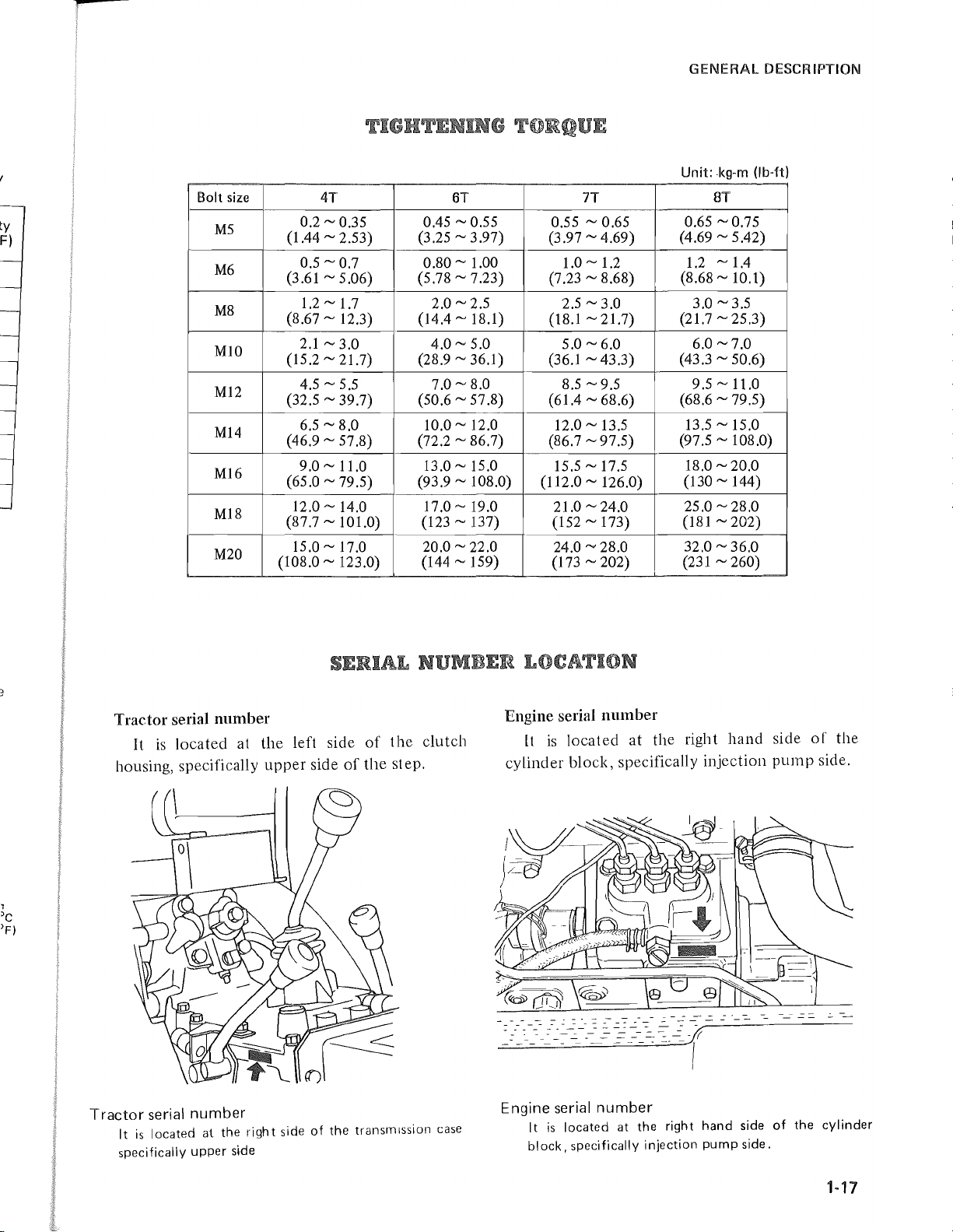

GENERAL DESCRIPTION

Unit·

kg-m

(lb-tt)

."

Bolt

size 4T

M5

M6

M8

MlO

M12

M14

M16

MI8

M20

0.2 ~ 0.35 0.45 ~ 0.55

(1.44

0.5 ~ 0.7

(3.61 ~ 5.06)

1.2

(8.67

2.1

(15.2

4.5

(32.5

6.5 ~ 8.0 10.0 ~ 12.0

(46.9

9.0

(65.0

12.0 ~ 14.0

(87.7

15.0~17.0

(108.0 ~ 123.0)

6T 7T

0.55

(3.25

~

~

2.53)

0.80

(5.78

~ 1.7 2.0 ~ 2.5 2.5 ~ 3.0

~

12.3) (14.4 ~ 18.1)

~

3.0 4.0 ~ 5.0

~

21.7) (28.9 ~ 36.1) (36.1 ~ 43.3)

~ 5.5 7.0 ~ 8.0 8.5 ~ 9.5 9.5 ~ 11.0

~

39.7)

~

57.8) (72.2 ~ 86.7) (86.7 ~ 97.5)

~

11.0

~

79.5) (93.9 ~ 108.0)

(50.6 ~ 57.8)

3.97)

~ 1.00 1.0 ~ 1.2

~

7.23)

~ 15.0

13.0

17.0 - 19.0

~

101.0) (123 ~ 137)

20.0

~22.0

(144

~

159)

~ 0.65

~

~

~

4.69)

8.68)

21.7)

(3.97

(7.23

(18.1

5.0 - 6.0

(61.4 - 68.6)

12.0~13.5

15.5

~ 17.5

(112.0

~

126.0)

21.0 ~ 24.0

(152

~

173)

24.0,....,

(173

28.0 32.0 ~ 36.0

~

202)

8T

~

1.2

0.75

~

5.42)

~1.4

~

10.1)

0.65

(4.69

(8.68

3.0 - 3.5

(21.7

~

25.3)

6.0 ~ 7.0

(43.3

~

50.6)

(68.6 ~ 79.5)

13.5 ~ 15.0

~

~

20.0

108.0)

(97.5

18.0

(130 ~ 144)

25.0

~ 28.0

(181

~202)

(231

~

260)

,

'c

'F)

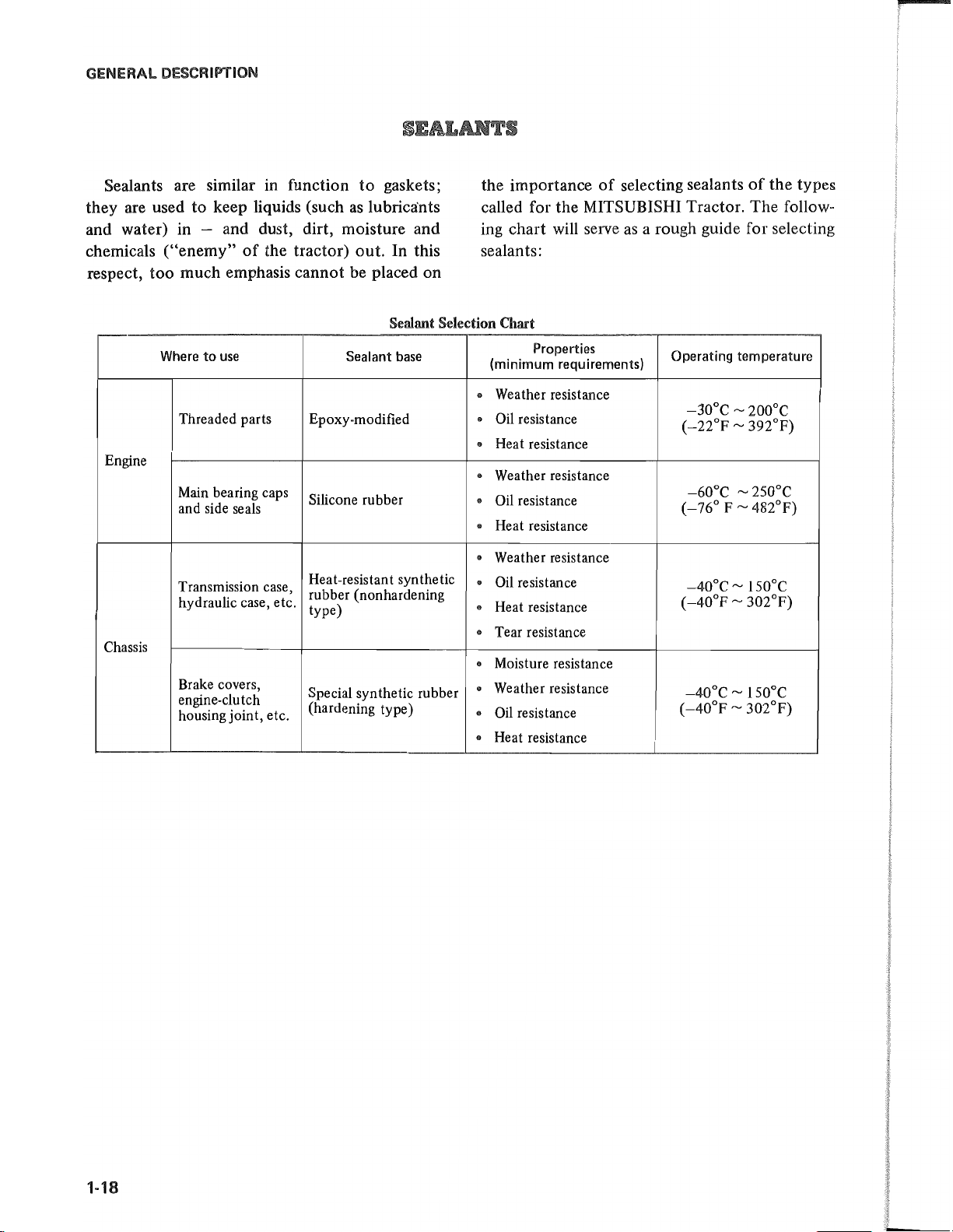

Tractor

It

is

serial

located at

housing, specifically

Tractor

serial

It

is

located

specifically

number

upper

number

at

the

side

the

upper

right

left

side

side

side

of

the

of

the

of

the

step.

transmission

clutch

case

Engine serial

It

is

number

located

at

the right

hand

cylinder block, specifically injection

- - -

-::-:

:---=

-

~

=-

=-=

~~-.:::-

Engine serial

It

is

located

block,

specifically

~

-=

number

::---=-

-=--==-

at

---------

---

- -

=:

~-~1

the

right

injection

-~-----------------

hand

side

pump

side.

side

pump

of

the

of

the

side.

cylinder

1-17

r

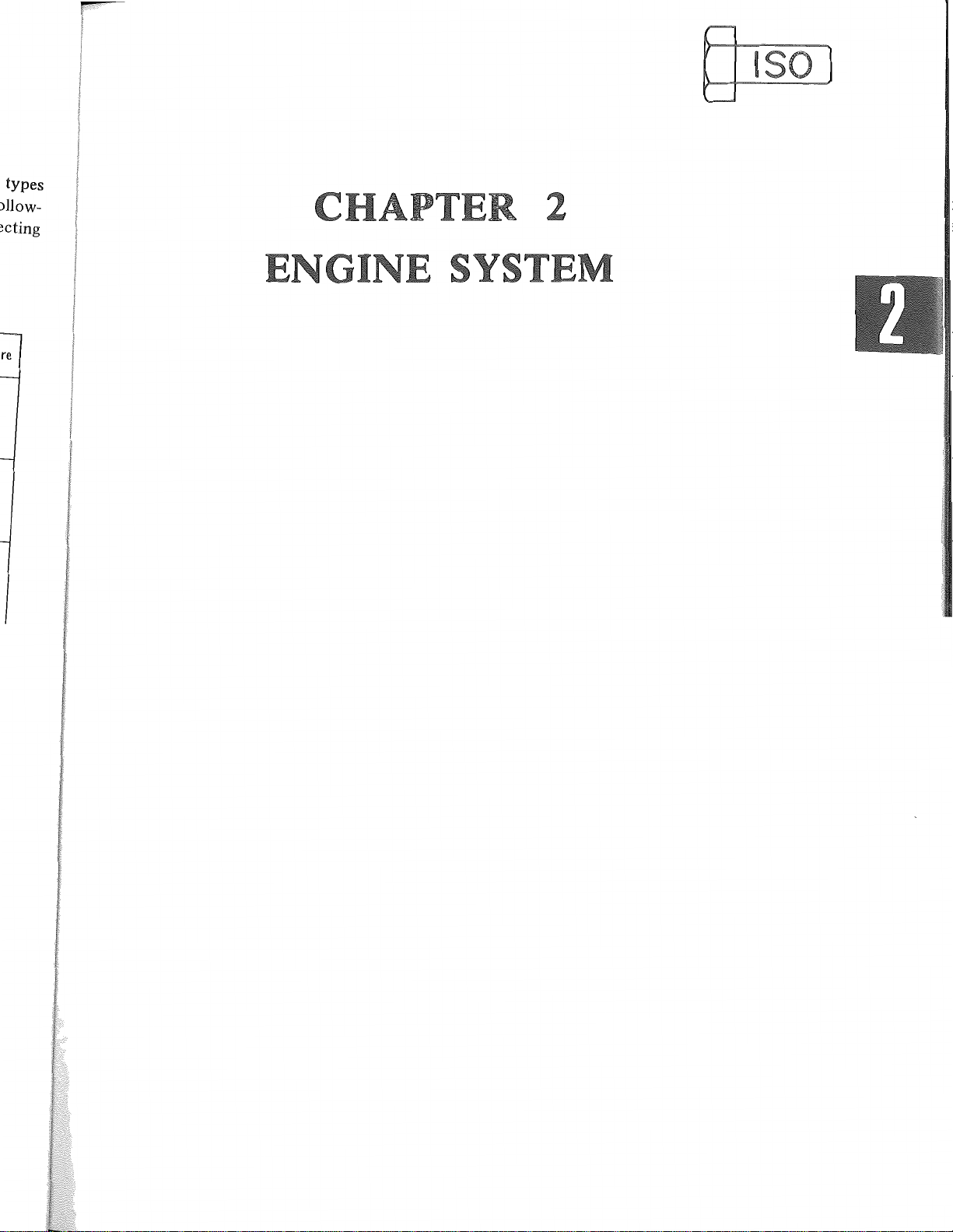

GENERAL DESCRIPTiON

Sealants are similar in function

to

they are used

keep liquids (such

to

gaskets;

as

lubrica'nts

and water) in - and dust, dirt, moisture and

chemicals

respect,

Engine

("enemy"

too

much emphasis cannot be placed on

Where

Threaded parts

Main bearing caps

and side seals

to

of

the tractor) out. In this

use

Epoxy-modified

Silicone rubber

Sealant

Sealant Selection Chart

base

the importance

selecting sealants

of

the types

of

called for the MITSUBISHI Tractor, The follow-

ing chart will serve

as

a rough guide for selecting

sealants:

Properties

(minimum requirements)

..

Weather resistance

Oil resistance

•

..

Heat resistance

Weather resistance

"

..

Oil resistance

Heat resistance

•

Operating

-30°C ~ 200°C

(-22°F ~ 392°F)

-60°C ~ 2S0°C

(_76°

temperature

F ~ 482°F)

Chassis

Transmission case,

hydraulic case, etc,

Brake covers,

engine-clu tch

housing joint, etc,

Heat-resistant synthetic

rubber (nonhardening

type)

Special synthetic rubber

(hardening type)

..

Weather resistance

Oil resistance

•

Heat resistance

"

Tear resistance

"

Moisture resistance

"

Weather resistance

•

..

Oil resistance

Heat resistance

"

-40°C ~ ISO°C

(_40°F ~ 302°F)

-40°C ~ ISO°C

(-40°F ~ 302°F)

1-18

~

types

ol1ow-

ecting

Ire

ISO

f

r

!

TABLE

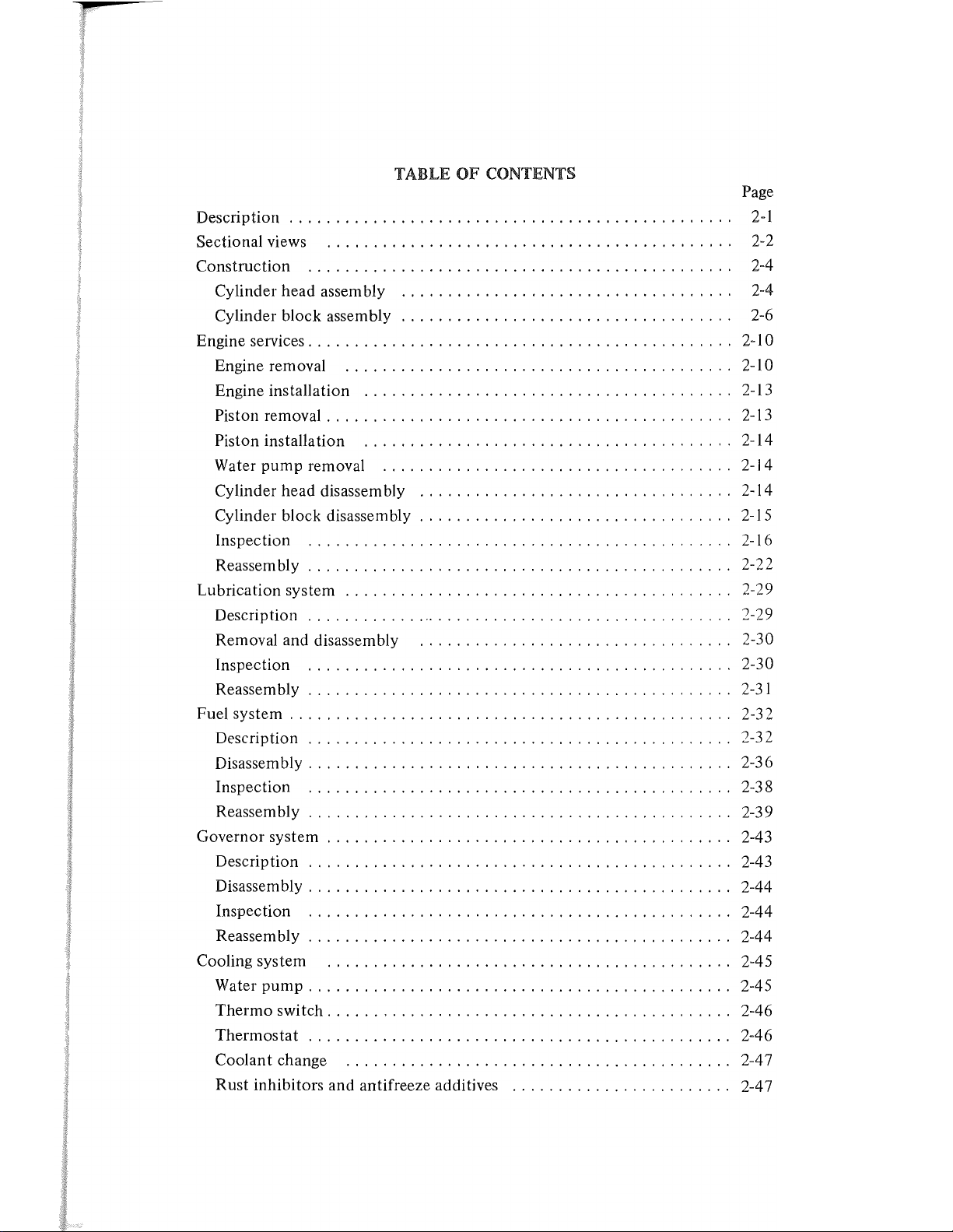

Description

Sectional views

Construction

Cylinder head assembly

Cylinder block assembly

Engine services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine removal

Engine installation

Piston

Piston installation

Water

Cy

linder head disassembly

Cylinder block disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection

Reassembly

Lubrication system

Description

Removal and disassembly

Inspection

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly

Inspection

Reassembly

Governor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description " . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassem bly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection

Reassembly

Cooling system

Water

Thermo

Thermostat

Coolan

Rust

..............................................

....................................

................................

..........................................

........................................

removal.

pump

punlp

switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

removal

..............................................

..............................................

.............

..............................................

..............................................

..............................................

..............................................

..............................................

..................

............................................

............................................

......

..............................................

......................................

..........................................

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

t change 2-47

inhibitors and antifreeze additives

OF

CONTENTS

..................................

"

................................

..................................

:

.........................

........................

. .

Page

"

2-1

2-2

2-4

2-4

..

2-6

..

2-10

2-10

2-13

..

2-13

2-14

2-14

2-14

..

2-15

2-1

2-22

2-29

2-29

2-30

2-30

..

2-31

..

2-32

..

2-32

2-36

2-38

2-39

..

2-43

..

2-43

..

2-44

2-44

" 2-44

2-45

" 2-45

..

2-46

2-46

2-47

6

?

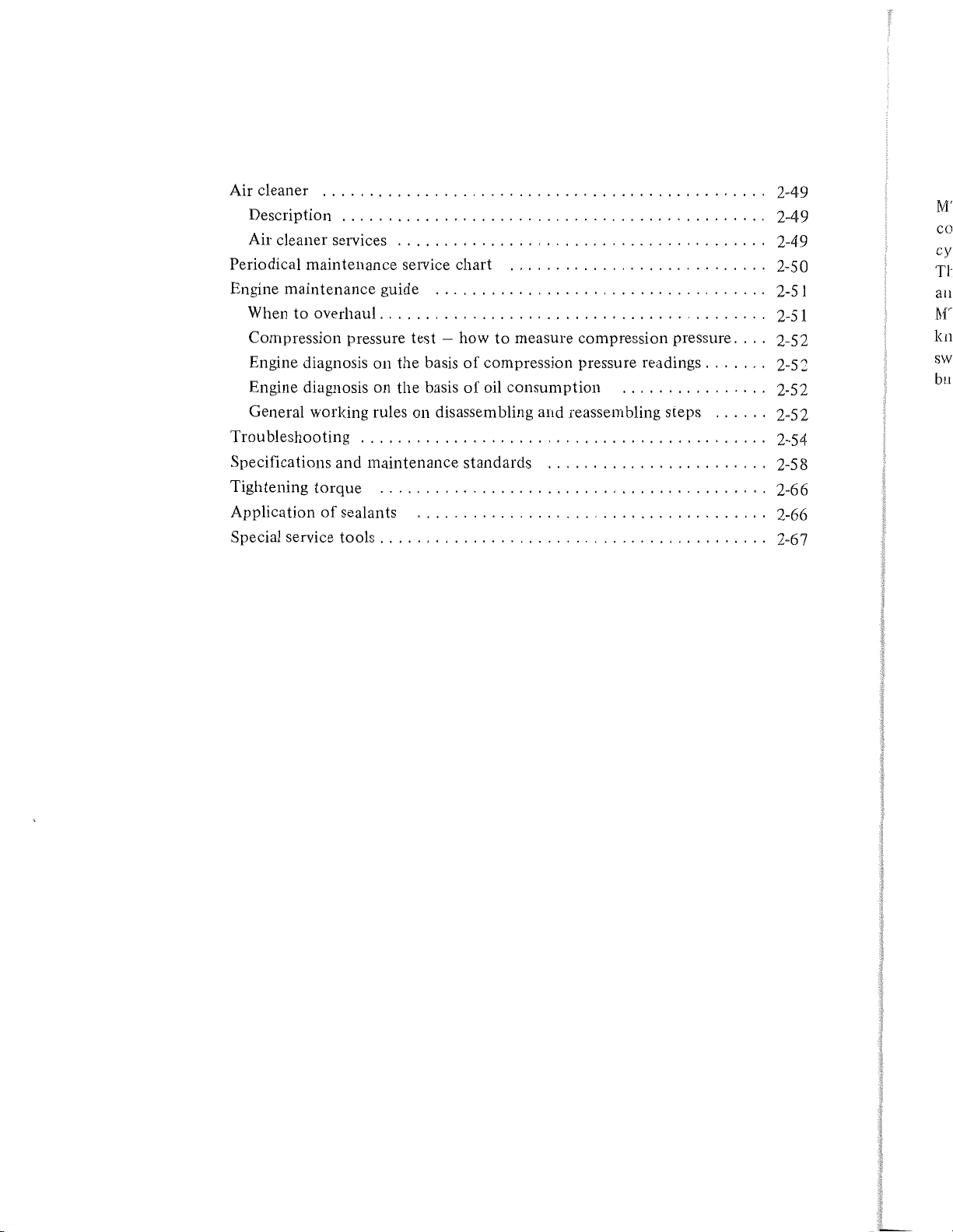

Air cleaner

Description

Air cleaner services

Periodical maintenance service chart

Engine maintenance guide

When

Compression pressure test - how

Engine diagnosis on the basis

Engine diagnosis on the basis

...............................................

.............................................

.......................................

...................................

to

overhaul

.........................................

of

compression pressure readings

of

oil consumption

...........................

to

measure compression pressure

General working rules on disassembling and reassembling steps

Troubleshooting

Specifications and maintenance standards

Tightening

Application

Special service tools

...........................................

torque

of

.........................................

sealants

......................................

.........................................

.......................

......

.....

...

.

.

.

.

.

.

.

.

.

.

.

.

.

2-49

2-49

2-49

2-50

2-51

2-51

2-52

2-52

2-52

2-52

2-54

2-58

2-66

2-66

2-67

Ml

Co(

cyJ

Th

all(

M'l

kw

swi

blli

Loading...

Loading...