General-Purpose AC Servo

Multi-network Interface AC Servo

MODEL

MR-J4-_TM_

SERVO AMPLIFIER

INSTRUCTION MANUAL

(EtherCAT)

E

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until

you have read through this Instruction Manual, Installation guide, and appended documents carefully. Do not

use the equipment until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

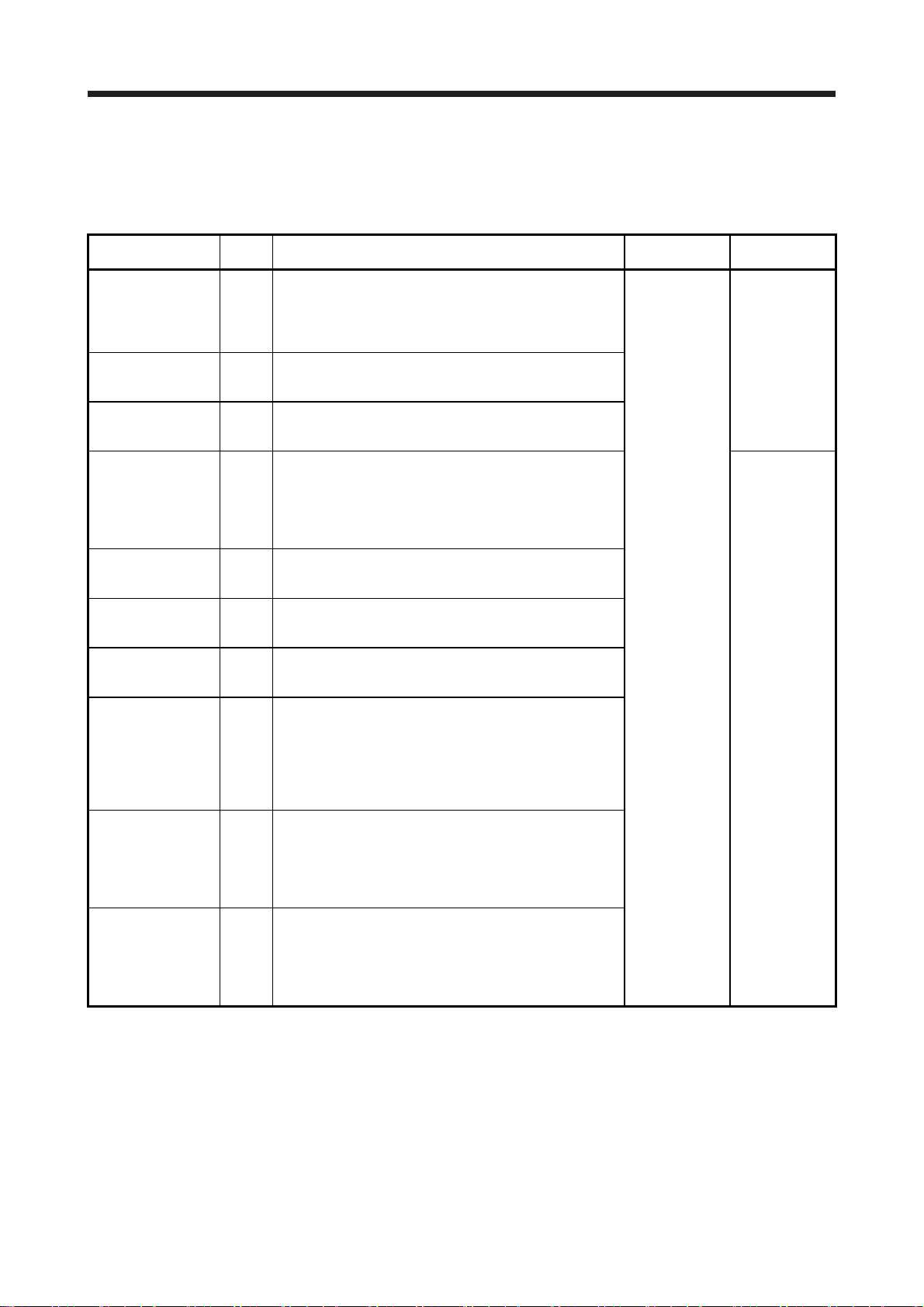

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by

Indicates what must be done. For example, grounding is indicated by

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

.

.

A - 1

1. To prevent electric shock, note the following

WARNING

Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge lamp

turns off. Then, confirm that the voltage between P+ and N- is safe with a voltage tester and others.

Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp is off or

not, always confirm it from the front of the servo amplifier.

Ground the servo amplifier and servo motor securely.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, it

may cause an electric shock.

Do not operate switches with wet hands. Otherwise, it may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

During power-on or operation, do not open the front cover of the servo amplifier. Otherwise, it may cause

an electric shock.

Do not operate the servo amplifier with the front cover removed. High-voltage terminals and charging

area are exposed and you may get an electric shock.

Except for wiring and periodic inspection, do not remove the front cover of the servo amplifier even if the

power is off. The servo amplifier is charged and you may get an electric shock.

To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo

amplifier to the protective earth (PE) of the cabinet.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo amplifier, servo motor, and regenerative resistor on incombustible material. Installing

them directly or close to combustibles will lead to smoke or a fire.

Always connect a magnetic contactor between the power supply and the main circuit power supply (L1,

L2, and L3) of the servo amplifier, in order to configure a circuit that shuts down the power supply on the

side of the servo amplifier’s power supply. If a magnetic contactor is not connected, continuous flow of a

large current may cause smoke or a fire when the servo amplifier malfunctions.

Always connect a molded-case circuit breaker, or a fuse to each servo amplifier between the power

supply and the main circuit power supply (L1, L2, and L3) of the servo amplifier, in order to configure a

circuit that shuts down the power supply on the side of the servo amplifier’s power supply. If a moldedcase circuit breaker or fuse is not connected, continuous flow of a large current may cause smoke or a

fire when the servo amplifier malfunctions.

When using the regenerative resistor, switch power off with the alarm signal. Otherwise, a regenerative

transistor malfunction or the like may overheat the regenerative resistor, causing smoke or a fire.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and servo motor.

A - 2

3. To prevent injury, note the following

CAUTION

Only the power/signal specified in the Instruction Manual should be applied to each terminal. Otherwise,

it may cause an electric shock, fire, injury, etc.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc., may occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc., may occur.

The servo amplifier heat sink, regenerative resistor, servo motor, etc., may be hot while the power is on

and for some time after power-off. Take safety measures such as providing covers to avoid accidentally

touching them by hands and parts such as cables.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury,

electric shock, fire, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of product packages is not allowed.

Do not hold the front cover, cables, or connectors when carrying the servo amplifier. Otherwise, it may

drop.

Install the servo amplifier and the servo motor in a load-bearing place in accordance with the Instruction

Manual.

Do not get on or put heavy load on the product. Otherwise, it may cause injury.

The equipment must be installed in the specified direction.

Maintain specified clearances between the servo amplifier and the inner surfaces of a control cabinet or

other equipment.

Do not install or operate the servo amplifier and servo motor which have been damaged or have any

parts missing.

Do not block the intake and exhaust areas of the servo amplifier. Otherwise, it may cause a malfunction.

Do not drop or apply heavy impact on the servo amplifiers and the servo motors. Otherwise, it may cause

injury, malfunction, etc.

Do not strike the connector. Otherwise, it may cause a connection failure, malfunction, etc.

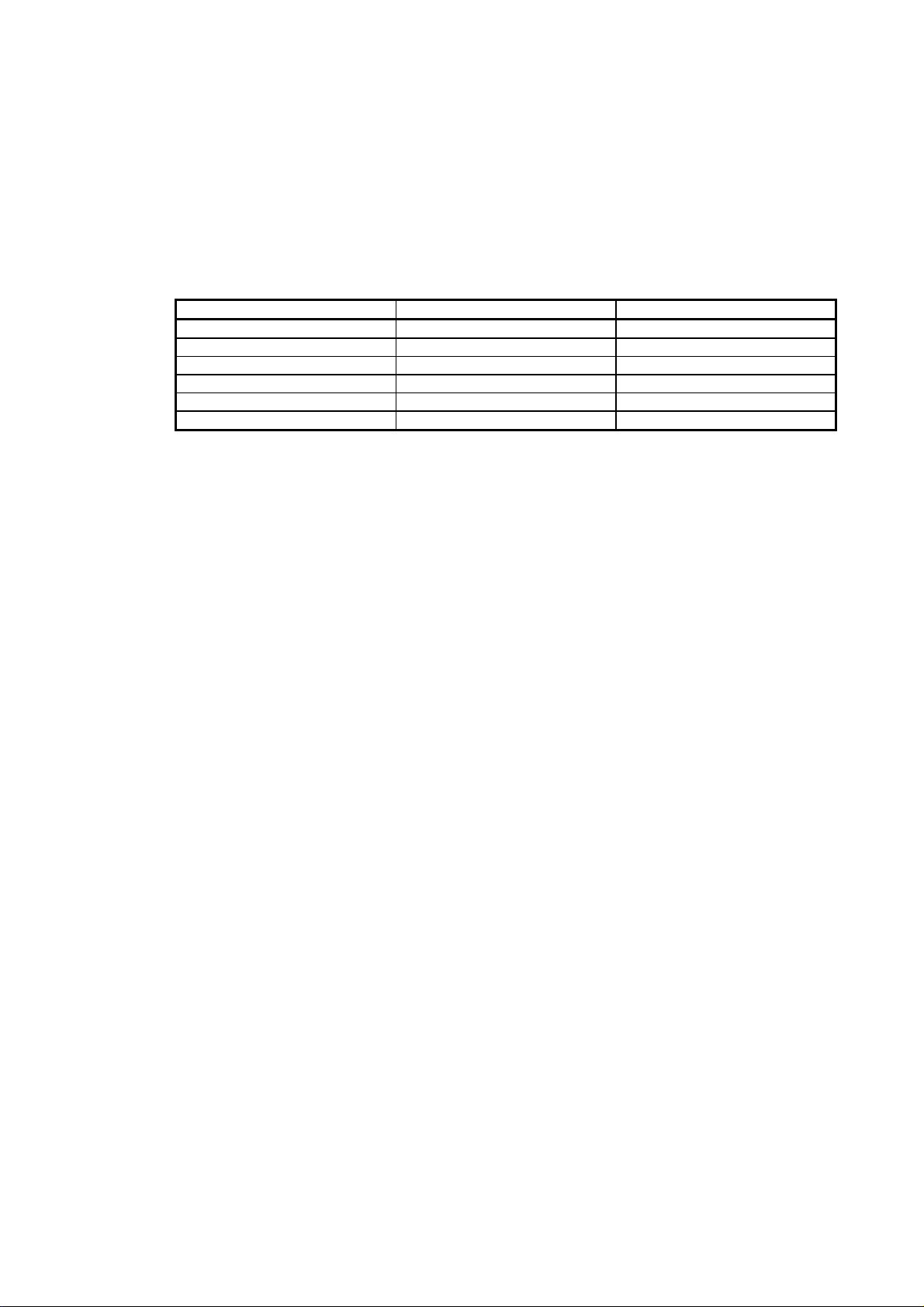

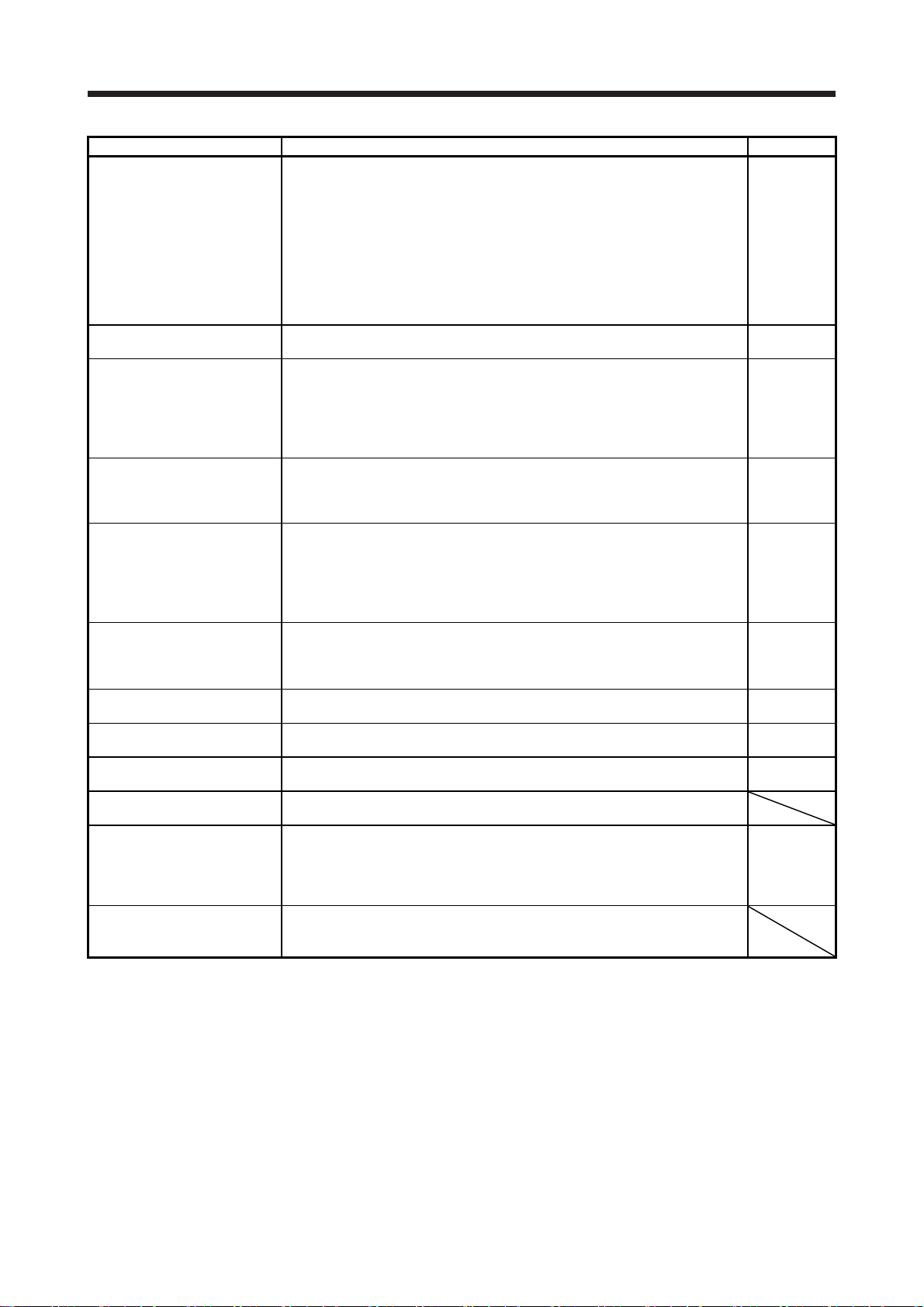

When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient

temperature

Storage -20 °C to 65 °C (non-freezing)

Ambient

humidity

Storage

Ambience Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

Altitude 2000 m or less above sea level (Contact your local sales office for the altitude for options.)

Vibration resistance 5.9 m/s2, at 10 Hz to 55 Hz (X, Y, Z axes)

When the product has been stored for an extended period of time, contact your local sales office.

When handling the servo motor, be careful with the sharp edges of the servo motor.

The servo amplifier must be installed in a metal cabinet.

Operation 0 °C to 55 °C (non-freezing)

Operation

5 %RH to 90 %RH (non-condensing)

A - 3

CAUTION

When fumigants that contain halogen materials, such as fluorine, chlorine, bromine, and iodine, are used

for disinfecting and protecting wooden packaging from insects, they cause a malfunction when entering

our products. Please take necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation, such as heat treatment.

Additionally, disinfect and protect wood from insects before packing the products.

To prevent a fire or injury in case of an earthquake or other natural disasters, securely install, mount, and

wire the servo motor in accordance with the Instruction Manual.

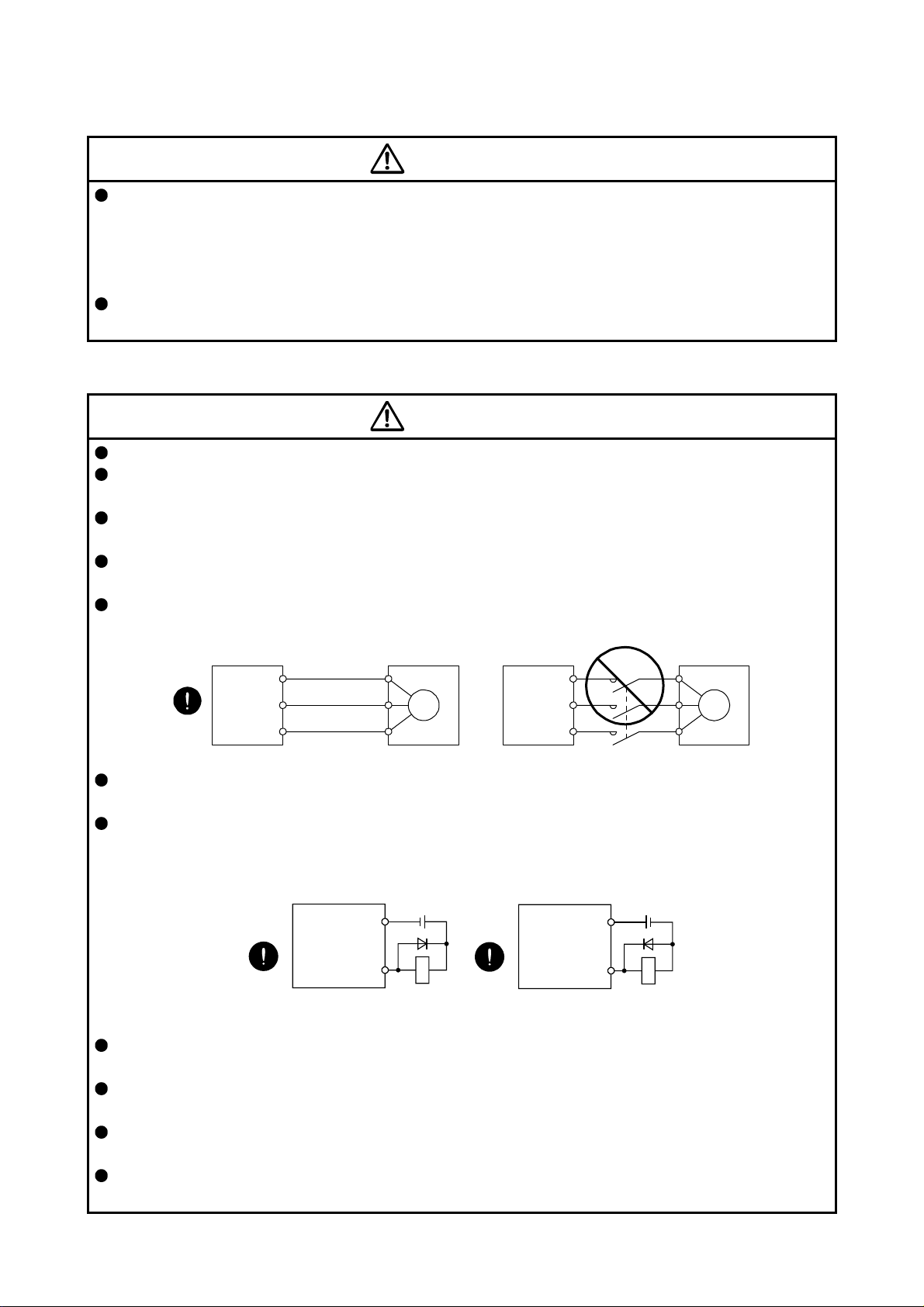

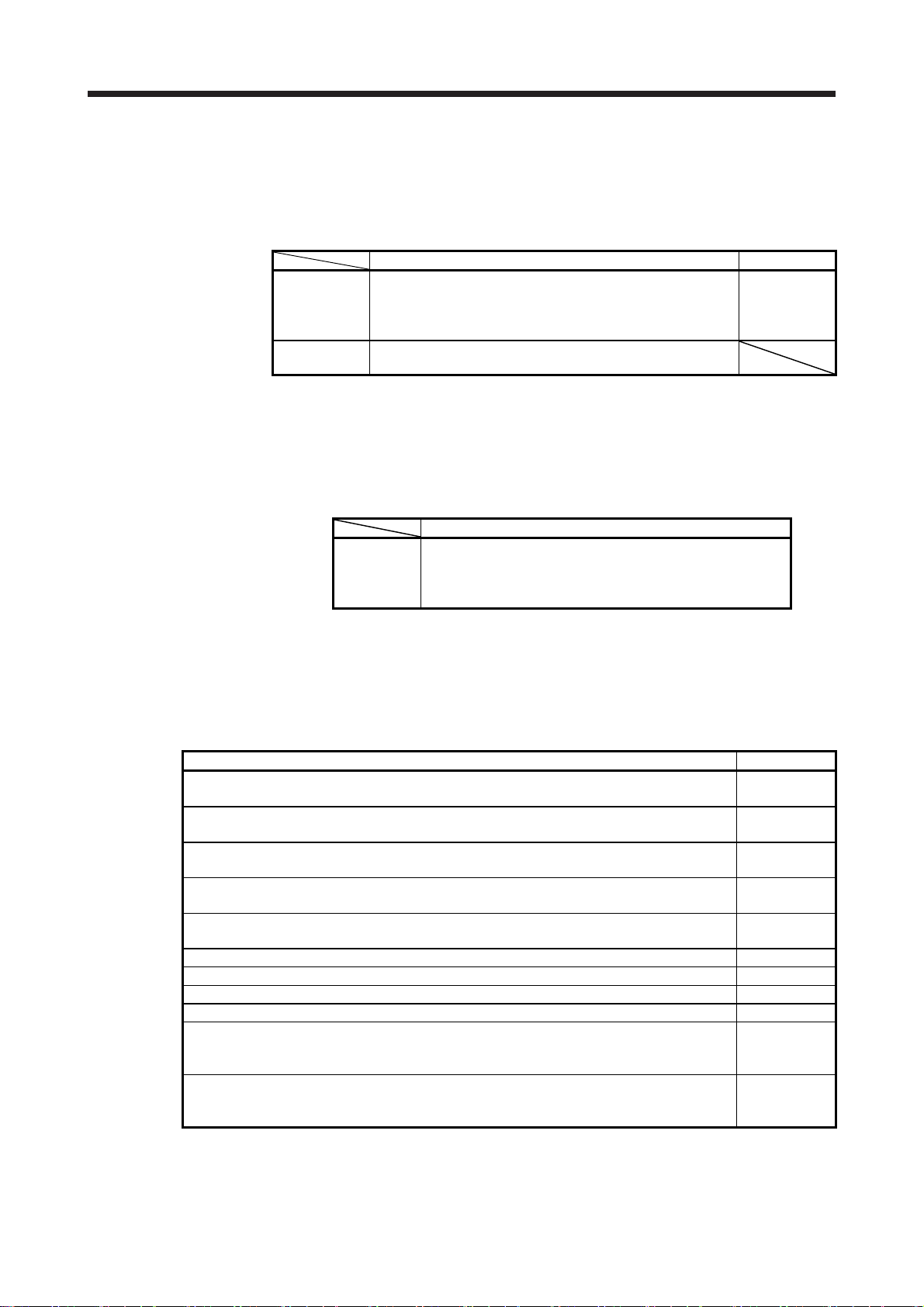

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Make sure to connect the cables and connectors by using the fixing screws and the locking mechanism.

Otherwise, the cables and connectors may be disconnected during operation.

Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF(-H)) on the servo

amplifier output side.

To avoid a malfunction, connect the wires to the correct phase terminals (U/V/W) of the servo amplifier

and servo motor.

Connect the servo amplifier power output (U/V/W) to the servo motor power input (U/V/W) directly. Do

not connect a magnetic contactor and others between them. Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

W

M

The connection diagrams in this Instruction Manual are shown for sink interfaces, unless stated

otherwise.

The surge absorbing diode installed to the DC relay for control output should be fitted in the specified

direction. Otherwise, the converter unit and the drive unit will malfunction and will not output signals,

disabling the emergency stop and other protective circuits.

Servo amplifier

DOCOM

Control output

signal

For sink output interface

24 V DC

RA

Servo amplifier

24 V DC

DOCOM

Control output

signal

For source output interface

RA

When the wires are not tightened enough to the terminal block, the wires or terminal block may generate

heat because of the poor contact. Be sure to tighten the wires with specified torque.

Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo amplifier may cause a

malfunction.

Configure a circuit to turn off EM2 or EM1 when the main circuit power supply is turned off to prevent an

unexpected restart of the servo amplifier.

To prevent malfunction, avoid bundling power lines (input/output) and signal cables together or running

them in parallel to each other. Separate the power lines from the signal cables.

A - 4

(3) Test run and adjustment

CAUTION

When executing a test run, follow the notice and procedures in this instruction manual. Otherwise, it may

cause a malfunction, damage to the machine, or injury.

Before operation, check and adjust the parameter settings. Improper settings may cause some machines

to operate unexpectedly.

Never make a drastic adjustment or change to the parameter values as doing so will make the operation

unstable.

Do not get close to moving parts during the servo-on status.

(4) Usage

CAUTION

Provide an external emergency stop circuit to stop the operation and shut the power off immediately.

For equipment in which the moving part of the machine may collide against the load side, install a limit

switch or stopper to the end of the moving part. The machine may be damaged due to a collision.

Do not disassemble, repair, or modify the product. Otherwise, it may cause an electric shock, fire, injury,

etc. Disassembled, repaired, and/or modified products are not covered under warranty.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off in order to prevent a

sudden restart. Otherwise, it may cause an accident.

Use a noise filter, etc., to minimize the influence of electromagnetic interference. Electromagnetic

interference may affect the electronic equipment used near the servo amplifier.

Do not burn or destroy the servo amplifier. Doing so may generate a toxic gas.

Use the servo amplifier with the specified servo motor.

Wire options and peripheral equipment, etc. correctly in the specified combination. Otherwise, it may

cause an electric shock, fire, injury, etc.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

For such reasons as incorrect wiring, service life, and mechanical structure (e.g. where a ball screw and

the servo motor are coupled via a timing belt), the electromagnetic brake may not hold the motor shaft.

To ensure safety, install a stopper on the machine side.

If the dynamic brake is activated at power-off, alarm occurrence, etc., do not rotate the servo motor by an

external force. Otherwise, it may cause a fire.

A - 5

(5) Corrective actions

CAUTION

Ensure safety by confirming the power off, etc. before performing corrective actions. Otherwise, it may

cause an accident.

If it is assumed that a power failure, machine stoppage, or product malfunction may result in a hazardous

situation, use a servo motor with an electromagnetic brake or provide an external brake system for

holding purpose to prevent such hazard.

Configure an electromagnetic brake circuit which is interlocked with an external emergency stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

Contacts must be opened with

the emergency stop switch.

Servo motor

B

Electromagnetic brake

When an alarm occurs, eliminate its cause, ensure safety, and deactivate the alarm to restart operation.

If the molded-case circuit breaker or fuse is activated, be sure to remove the cause and secure safety

before switching the power on. If necessary, replace the servo amplifier and recheck the wiring.

Otherwise, it may cause smoke, fire, or an electric shock.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

After an earthquake or other natural disasters, ensure safety by checking the conditions of the

installation, mounting, wiring, and equipment before switching the power on to prevent an electric shock,

injury, or fire.

RA

24 V DC

(6) Maintenance, inspection and parts replacement

CAUTION

Make sure that the emergency stop circuit operates properly such that an operation can be stopped

immediately and a power is shut off by the emergency stop switch.

It is recommended that the servo amplifier be replaced every 10 years when it is used in general

environment.

When using the servo amplifier that has not been energized for an extended period of time, contact your

local sales office.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Instruction Manual.

A - 6

DISPOSAL OF WASTE

Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and

regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, the servo amplifier may malfunction when the

EEP-ROM reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes

Write to the EEP-ROM due to point table setting changes

STO function of the servo amplifier

When using the STO function of the servo amplifier, refer to chapter 13 of "MR-J4-_TM_ Servo Amplifier

Instruction Manual".

For the MR-J3-D05 safety logic unit, refer to app. 5 of "MR-J4-_TM_ Servo Amplifier Instruction Manual".

Compliance with global standards

For the compliance with global standards, refer to app. 4 of "MR-J4-_TM_ Servo Amplifier Instruction

Manual".

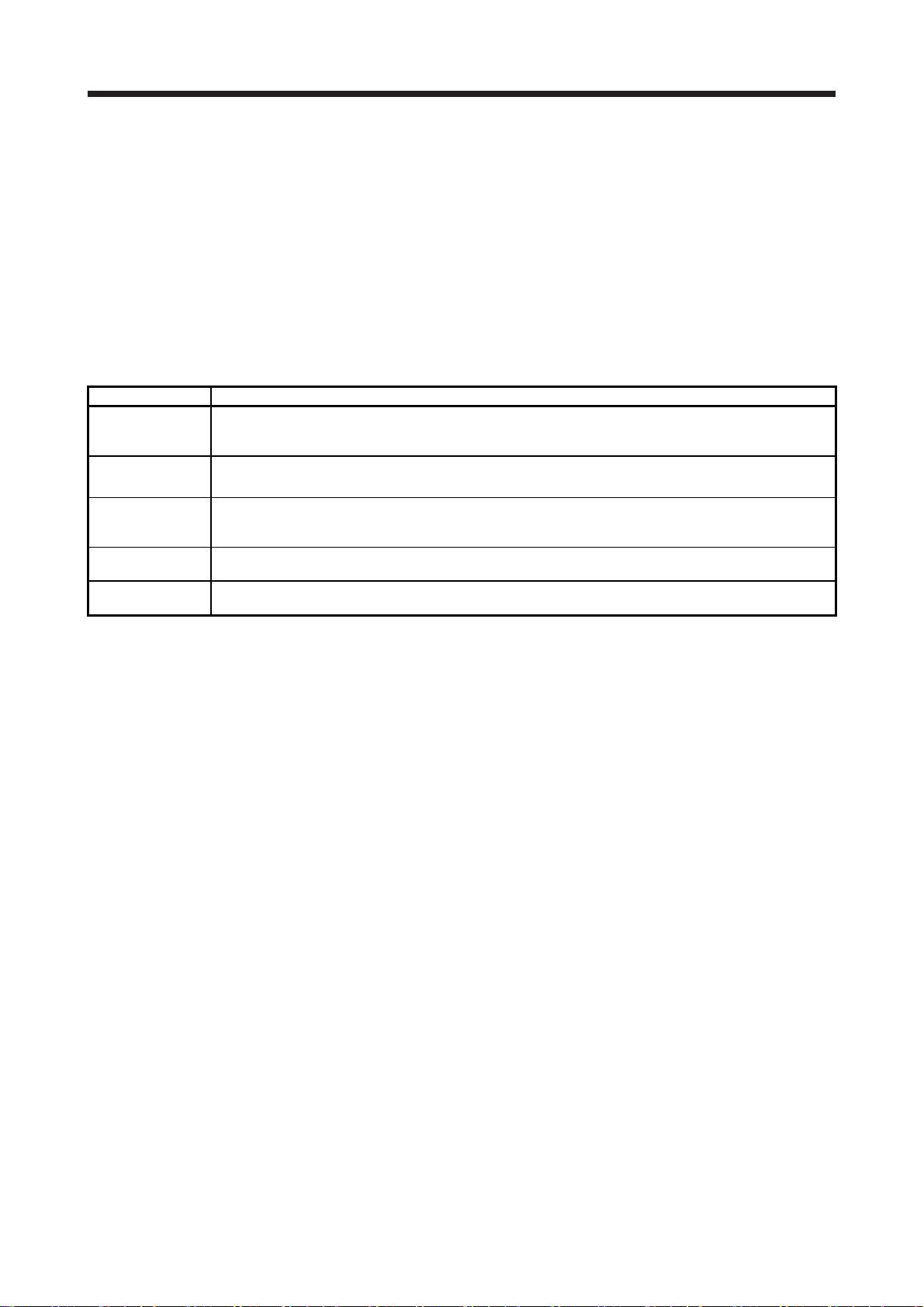

«About the manuals»

You must have this Instruction Manual and the following manuals to use this servo. Ensure to prepare

them to use the servo safely.

Relevant manuals

Manual name Manual No.

MELSERVO MR-J4-_TM_ Servo Amplifier Instruction Manual SH(NA)030193ENG

MELSERVO-J4 Servo Amplifier Instruction Manual (Troubleshooting) SH(NA)030109ENG

MELSERVO MR-D30 Instruction Manual (Note 5) SH(NA)030132ENG

MELSERVO Servo Motor Instruction Manual (Vol. 3) (Note 1) SH(NA)030113ENG

MELSERVO Linear Servo Motor Instruction Manual (Note 2) SH(NA)030110ENG

MELSERVO Direct Drive Motor Instruction Manual (Note 3) SH(NA)030112ENG

MELSERVO Linear Encoder Instruction Manual (Note 2, 4) SH(NA)030111ENG

MELSERVO EMC Installation Guidelines IB(NA)67310ENG

Note 1. It is necessary for using a rotary servo motor.

2. It is necessary for using a linear servo motor.

3. It is necessary for using a direct drive motor.

4. It is necessary for using a fully closed loop system.

5. It is necessary for using an MR-D30 functional safety unit.

A - 7

«Wiring»

Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 °C.

«U.S. customary units»

U.S. customary units are not shown in this manual. Convert the values if necessary according to the

following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

Moment of inertia 1 [(× 10-4 kg•m2)] 5.4675 [oz•inch2]

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

A - 8

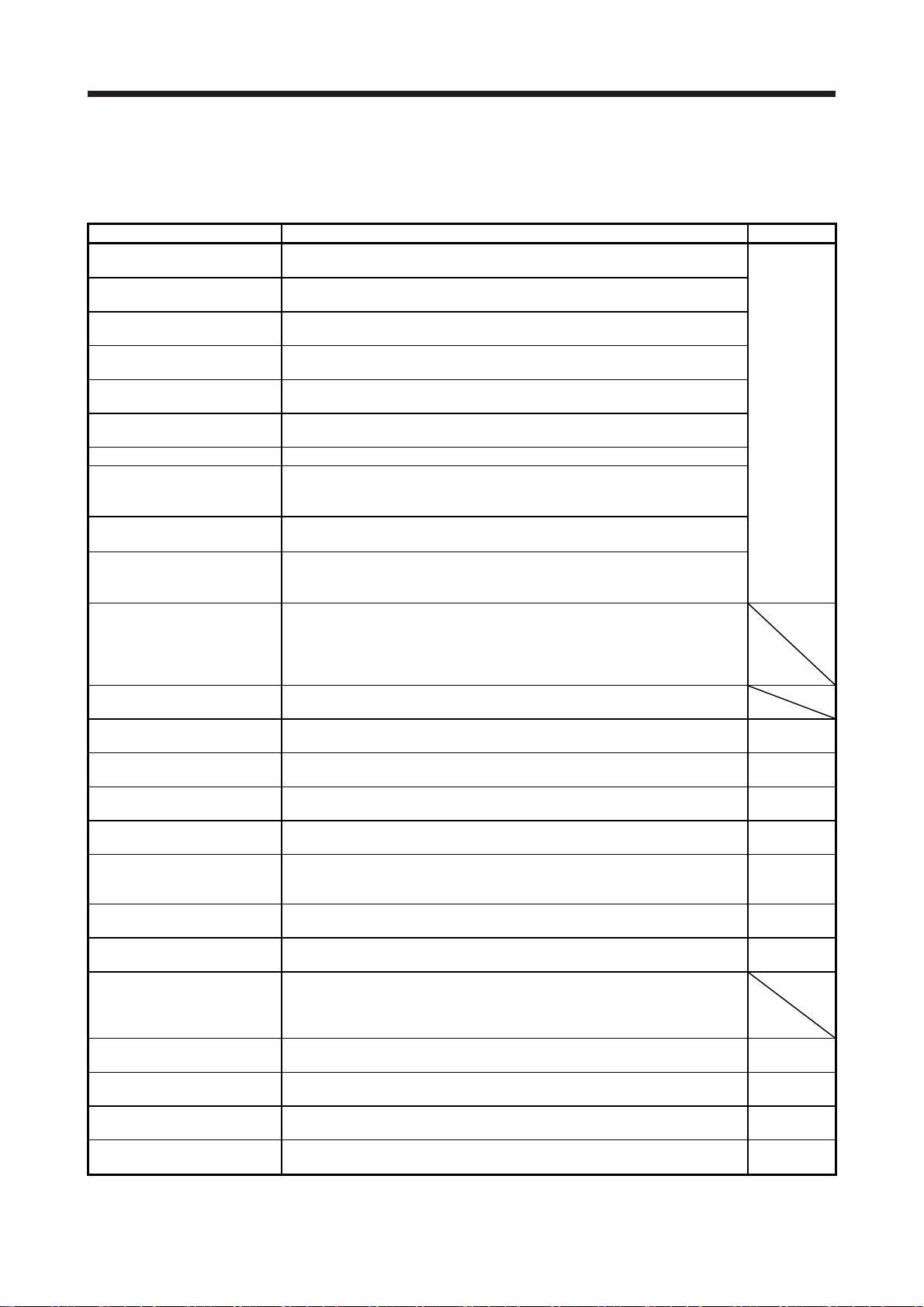

CONTENTS

1. EtherCAT COMMUNICATION 1- 1 to 1-12

1.1 Summary ........................................................................................................................................... 1- 1

1.2 Function list ....................................................................................................................................... 1- 4

1.3 Communication specifications .......................................................................................................... 1- 7

1.4 EtherCAT State Machine (ESM) ....................................................................................................... 1- 8

1.4.1 Communication status ................................................................................................................ 1- 8

1.4.2 EtherCAT state ........................................................................................................................... 1- 9

1.4.3 Startup ....................................................................................................................................... 1-10

1.4.4 Network disconnection procedure ............................................................................................. 1-11

1.5 Summary of object dictionary (OD).................................................................................................. 1-12

1.5.1 Section definition of object dictionary ........................................................................................ 1-12

1.5.2 Saving object dictionary data to EEP-ROM .............................................................................. 1-12

2. EtherCAT NETWORK MODULE (ABCC-M40-ECT) 2- 1 to 2- 4

2.1 Specifications .................................................................................................................................... 2- 1

2.2 Parts identification ............................................................................................................................. 2- 2

2.3 LED indication ................................................................................................................................... 2- 2

2.3.1 LED indication definition ............................................................................................................. 2- 2

2.3.2 LED indication list ....................................................................................................................... 2- 3

2.4 Connecting Ethernet cable ............................................................................................................... 2- 4

3. PDO (PROCESS DATA OBJECT) COMMUNICATION 3- 1 to 3- 6

3.1 PDO communication cycle ................................................................................................................ 3- 1

3.2 PDO setting-related object ................................................................................................................ 3- 1

3.3 PDO default mapping ....................................................................................................................... 3- 2

3.4 PDO variable mapping ...................................................................................................................... 3- 4

3.5 Mapping-necessary objects .............................................................................................................. 3- 5

4. SDO (SERVICE DATA OBJECT) COMMUNICATION 4- 1 to 4- 2

4.1 SDO communication-related service ................................................................................................ 4- 1

4.2 SDO Abort Code ............................................................................................................................... 4- 2

5. CiA 402 DRIVE PROFILE 5- 1 to 5-90

5.1 FSA state .......................................................................................................................................... 5- 1

5.2 Controlword/Control DI ..................................................................................................................... 5- 4

5.2.1 Bit definition of Controlword ....................................................................................................... 5- 4

5.2.2 Bit definition of Control DI .......................................................................................................... 5- 5

5.3 Statusword/Status DO ...................................................................................................................... 5- 7

5.3.1 Bit definition of Statusword ......................................................................................................... 5- 7

5.3.2 Bit definition of Status DO .......................................................................................................... 5- 8

5.4 Control mode ................................................................................................................................... 5-12

5.4.1 Selecting control mode (Modes of operation) ........................................................................... 5-12

5.4.2 Control switching ....................................................................................................................... 5-12

5.4.3 Cyclic synchronous position mode (csp) .................................................................................. 5-13

1

5.4.4 Cyclic synchronous velocity mode (csv) ................................................................................... 5-16

5.4.5 Cyclic synchronous torque mode (cst) ...................................................................................... 5-18

5.4.6 Profile position mode (pp) ......................................................................................................... 5-20

5.4.7 Profile velocity mode (pv) .......................................................................................................... 5-24

5.4.8 Profile torque mode (tq) ............................................................................................................ 5-27

5.4.9 Homing mode (hm) ................................................................................................................... 5-30

5.4.10 Point table mode (pt) ............................................................................................................... 5-59

5.4.11 Jog mode (jg) .......................................................................................................................... 5-64

5.4.12 Indexer mode (idx) .................................................................................................................. 5-71

5.5 Touch probe ..................................................................................................................................... 5-78

5.6 Quick stop ........................................................................................................................................ 5-82

5.7 Halt ................................................................................................................................................... 5-83

5.8 Software position limit ...................................................................................................................... 5-84

5.9 Torque limit ...................................................................................................................................... 5-84

5.10 Polarity ........................................................................................................................................... 5-85

5.11 Degree function ............................................................................................................................. 5-87

5.12 Torque offset .................................................................................................................................. 5-89

6. MANUFACTURER FUNCTIONS 6- 1 to 6-12

6.1 Object for status monitor ................................................................................................................... 6- 1

6.2 Incremental counter .......................................................................................................................... 6- 3

6.3 Stroke end ......................................................................................................................................... 6- 3

6.4 Definition of alarm-related objects .................................................................................................... 6- 4

6.5 Parameter object ............................................................................................................................... 6- 5

6.5.1 Definition of parameter objects .................................................................................................. 6- 5

6.5.2 Enabling parameters .................................................................................................................. 6- 6

6.6 Scale measurement function ............................................................................................................ 6- 7

6.7 One-touch tuning .............................................................................................................................. 6- 8

6.8 Machine diagnosis function ............................................................................................................. 6-10

6.9 Servo amplifier life diagnosis function ............................................................................................. 6-12

7. OBJECT DICTIONARY 7- 1 to 7-82

7.1 Store Parameters .............................................................................................................................. 7- 1

7.2 Supported object dictionary list ......................................................................................................... 7- 2

7.3 Object dictionary ............................................................................................................................... 7- 6

7.3.1 General Objects ......................................................................................................................... 7- 6

7.3.2 PDO Mapping Objects .............................................................................................................. 7-12

7.3.3 Sync Manager Communication Objects .................................................................................... 7-16

7.3.4 Parameter Objects .................................................................................................................... 7-21

7.3.5 Alarm Objects ............................................................................................................................ 7-24

7.3.6 Monitor Objects ......................................................................................................................... 7-27

7.3.7 Manufacturer Specific Control Objects ..................................................................................... 7-40

7.3.8 PDS Control Objects ................................................................................................................. 7-51

7.3.9 Position Control Function Objects ............................................................................................. 7-55

7.3.10 Profile Velocity Mode Objects ................................................................................................. 7-58

7.3.11 Profile Torque Mode Objects .................................................................................................. 7-60

7.3.12 Profile Position Mode Objects ................................................................................................. 7-62

7.3.13 Homing Mode Objects............................................................................................................. 7-66

7.3.14 Factor Group Objects .............................................................................................................. 7-72

2

7.3.15 Touch Probe Function Objects ............................................................................................... 7-75

7.3.16 Optional application FE Objects .............................................................................................. 7-76

7.3.17 Point Table Mode Objects ....................................................................................................... 7-79

7.3.18 Cyclic synchronous position mode Objects ............................................................................ 7-82

3

MEMO

4

1. EtherCAT COMMUNICATION

1. EtherCAT COMMUNICATION

1.1 Summary

EtherCAT is the abbreviation of Ethernet for Control Automation Technology. It is open network

communication between a master and slaves developed by Beckhoff Automation that uses real-time

Ethernet. ETG (EtherCAT Technology Group) owns EtherCAT.

The EtherCAT communication is available when the EtherCAT network module (ABCC-M40-ECT

manufactured by HMS Industrial Networks) is connected to the MR-J4-_TM_ servo amplifier. The MR-J4_TM_ servo amplifier to which the EtherCAT network module is connected operates as a slave station

compliant with CAN application protocol over EtherCAT (CoE) standards. The device type is a power drive

system and is compatible with the CiA 402 drive profile.

(1) CiA 402 drive profile compatible

The MR-J4-_TM_ servo amplifier operates as a slave station compliant with CAN application protocol

over EtherCAT (CoE) standards. The device type is a power drive system and is compatible with the CiA

402 drive profile.

1 - 1

1. EtherCAT COMMUNICATION

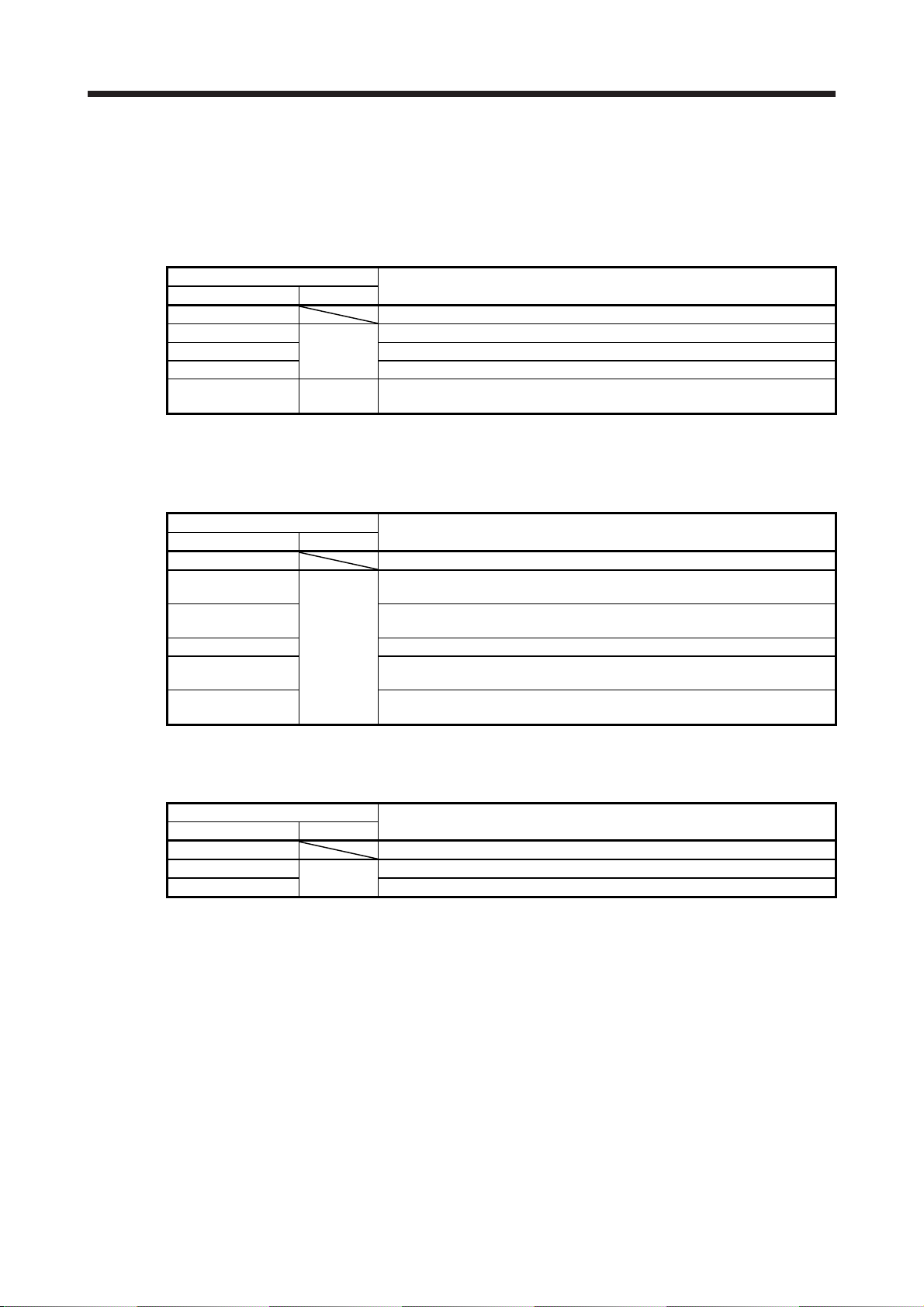

(2) Various control modes supported

The MR-J4-_TM_ servo amplifier supports the following control modes. In the table below, whether the

synchronous mode and asynchronous mode can be used in each control mode. For the synchronous

mode and asynchronous mode, refer to (3) in this section.

Control mode Symbol Description

This is a position mode where a position command is received

Cyclic synchronous

position mode

Cyclic synchronous

velocity mode

Cyclic synchronous

torque mode

Profile position mode pp

Profile velocity mode pv

Profile torque mode tq

Homing mode hm

Point table mode pt

JOG mode jg

Indexer mode idx

at a constant period to drive the servo motor in the

synchronous or asynchronous communication with a

csp

controller.

Use an absolute position address for a command.

This is a speed mode where a speed command is received at

csv

a constant period to drive the servo motor in the synchronous

or asynchronous communication with a controller.

This is a torque mode where a torque command is received at

cst

a constant period to drive the servo motor in the synchronous

or asynchronous communication with a controller.

This is a positioning operation mode where an end position

command is received to drive the servo motor in the

synchronous or asynchronous communication with a

controller.

Use an absolute position address or relative position address

for a command.

This is a mode where a target speed command is received to

drive the servo motor in the synchronous or asynchronous

communication with a controller.

This is a mode where a target torque command is received to

drive the servo motor in the synchronous or asynchronous

communication with a controller.

This is a mode where the servo amplifier performs a home

position return operation using the method directed by the

controller.

In this control mode, the servo motor is driven according to

the travel distance and speed stored in the point table No.

which is specified in the synchronous or asynchronous

communication with a controller. This control mode is specific

to Mitsubishi Electric, not in CiA 402 standard.

This is available with servo amplifiers with software version

B2 or later.

In this control mode, the servo motor is manually driven at a

speed set in the synchronous or asynchronous

communication with a controller. This control mode is not in

CiA 402 standard (Mitsubishi Electric original).

This is available with servo amplifiers with software version

B2 or later.

In this control mode, the servo motor is driven to the station

specified in the synchronous or asynchronous communication

with a controller. This control mode is not in CiA 402 standard

(Mitsubishi Electric original).

This is available with servo amplifiers with software version

B2 or later.

Note 1. Servo amplifiers with software version B3 or earlier cannot be used in the asynchronous mode. When the controller sends an

operation command in the asynchronous mode, the error code that indicates the state transition is not allowed is notified and

the ERROR LED of the network module blinks.

2. Servo amplifiers with software version B4 or later can be used in the asynchronous mode. When it is used in the asynchronous

mode, Cycle time (1C32h: 2) setting is required. For details on Cycle time (1C32h: 2), refer to (4) in this section.

Synchronous

mode

Available

Asynchronous

mode

Available

(Note 1, 2)

Available

1 - 2

1. EtherCAT COMMUNICATION

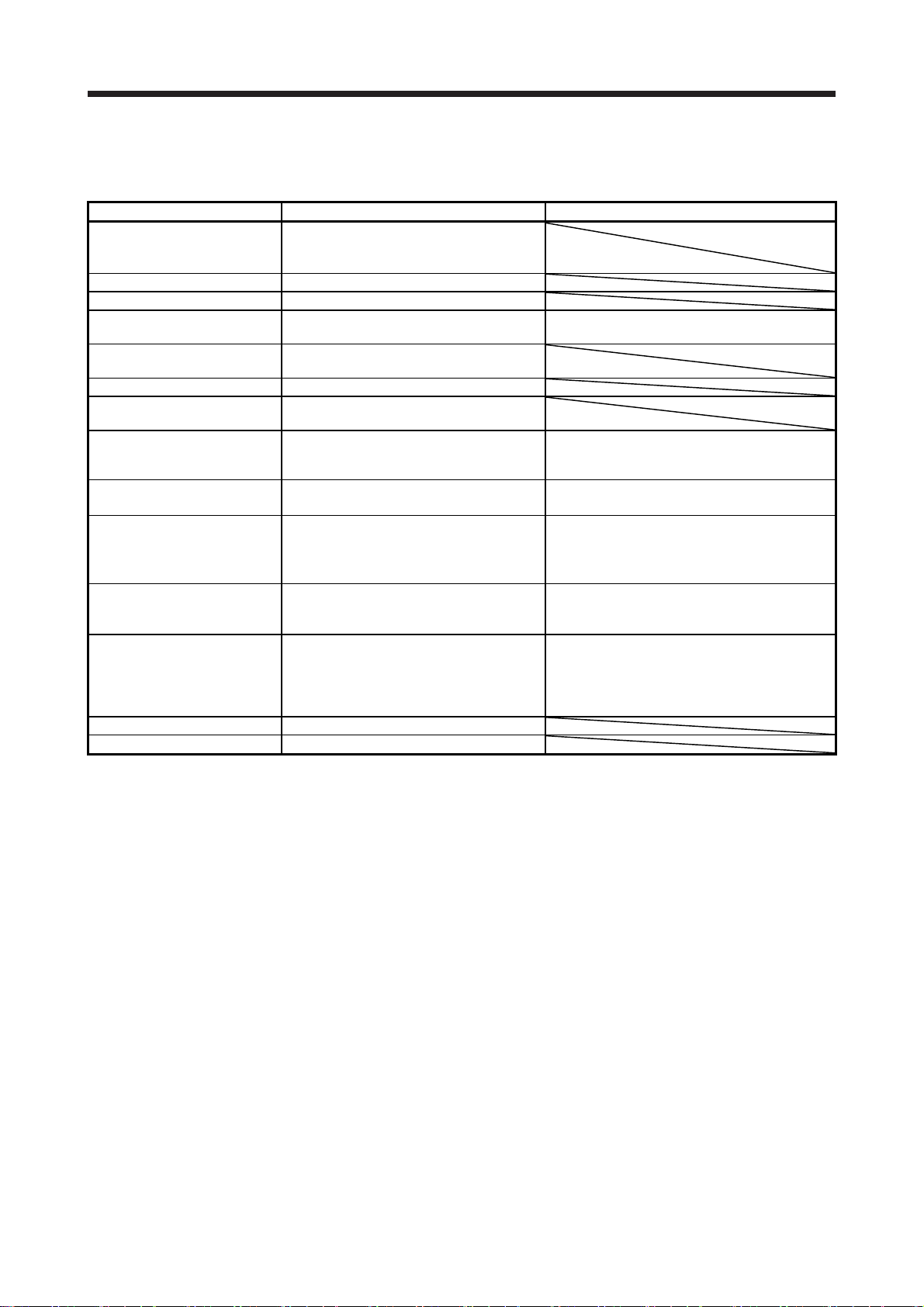

(3) Synchronous mode (DC mode)

In the synchronous mode, it is necessary to keep the synchronous jitter 2 μs or less. When the

synchronous jitter is 2 μs or more, an error may be detected and an alarm may set off.

Synchronous mode setting

Sync0 Sync1

0.25 ms (When the PDO communication cycle is set to 0.25 ms)

Cycle time

(1C32h: 2)

Shift time

(1C32h: 3)

(4) Asynchronous mode (Free-run mode)

In the asynchronous mode, when using the cyclic synchronous position mode, the cyclic synchronous

speed mode, and the cyclic synchronous torque mode, set as shown in the following table. Input the

command value for each communication cycle set in Cycle time (1C32h: 2). If the command is not

inputted on each communication cycle, the previously input command will be maintained.

Note. If the value is not set for Cycle time, the PDO communication cycle is 0.25 ms (initial

(5) Compliance with standards

MR-J4-_TM_ servo amplifiers comply with the following standards. Refer to the following standards for

the description not written in this Instruction Manual.

ETG.1000.2 EtherCAT Specification – Part2

Physical Layer service definition and protocol specification

ETG.1000.3 EtherCAT Specification – Part3

Data Link Layer service definition

ETG.1000.4 EtherCAT Specification – Part4

Data Link Layer protocol specification

ETG.1000.5 EtherCAT Specification – Part5

Application Layer service definition

ETG.1000.6 EtherCAT Specification – Part6

Application Layer protocol specification

ETG.1020 EtherCAT Protocol Enhancements V1.1.0

ETG.1300 EtherCAT Indicator and Labeling Specification V1.1.0

ETG.2000 EtherCAT Slave Information (ESI) Specification V1.0.7

ETG.6010 Implementation Directive for CiA 402 Drive Profile V1.1.0

IEC 61800-7-201 Adjustable speed electrical power drive systems –

Part 7-201: Generic interface and use of profiles for power drive systems –

Profile type 1 specification

Adjustable speed electrical power drive systems –

Part 7-301: Generic interface and use of profiles for power drive systems –

Mapping of profile type 1 to network technologies

0.5 ms (When the PDO communication cycle is set to 0.5 ms)

1 ms (When the PDO communication cycle is set to 1 ms)

2 ms (When the PDO communication cycle is set to 2 ms)

0

Local Cycle time

Cycle time

(1C32h: 2)

(Note)

value).

0.25 ms (When the PDO communication cycle is set to 0.25 ms)

0.5 ms (When the PDO communication cycle is set to 0.5 ms)

1 ms (When the PDO communication cycle is set to 1 ms)

2 ms (When the PDO communication cycle is set to 2 ms)

Standards Version

Unused

V1.0.3

V1.0.3

V1.0.3

V1.0.3

V1.0.3

Edition 1.0

Edition 1.0

1 - 3

1. EtherCAT COMMUNICATION

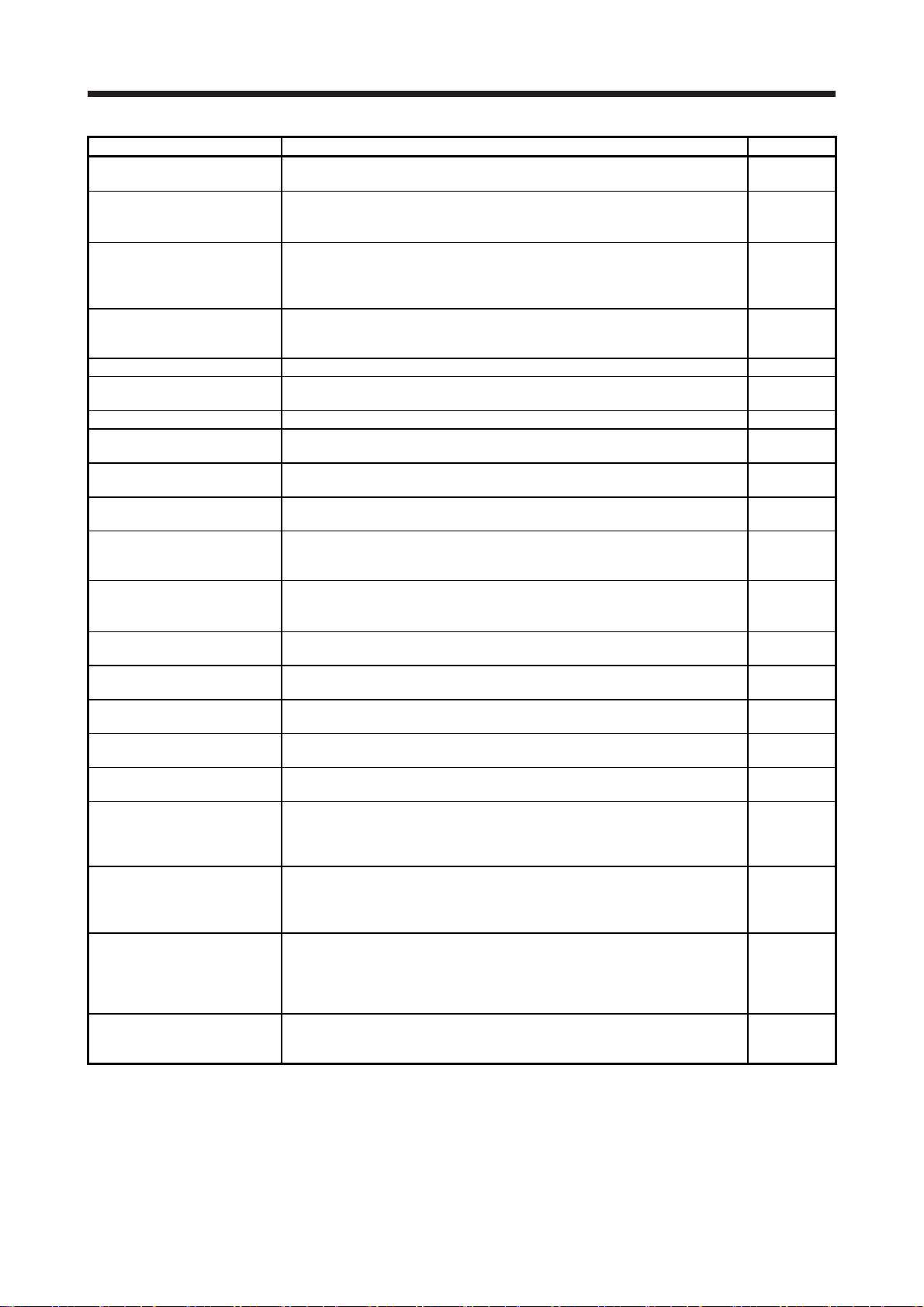

1.2 Function list

The following table lists the functions available with the MR-J4-_TM_ servo amplifier to which the EtherCAT

network module is connected. "MR-J4-_TM_" means "MR-J4-_TM_ Servo Amplifier Instruction Manual".

Cyclic synchronous position

mode (csp)

Cyclic synchronous velocity

mode (csv)

Cyclic synchronous torque mode

(cst)

Profile position mode (pp)

Profile velocity mode (pv)

Profile torque mode (tq)

Homing mode (hm) The home position return operation specified in each network is supported.

Point table mode (pt)

Indexer mode (idx)

JOG mode (jg)

Model adaptive control

High-resolution encoder

Absolute position detection

system

Gain switching function

Advanced vibration suppression

control II

Machine resonance suppression

filter

Shaft resonance suppression

filter

Adaptive filter II

Low-pass filter

Machine analyzer function

Robust filter

Slight vibration suppression

control

Electronic gear

S-pattern acceleration/

deceleration time constant

Function Description Reference

The position control operation performed by a synchronous sequential position

command through network is supported.

The speed control operation performed by a synchronous sequential speed

command through network is supported.

The torque control operation performed by a synchronous sequential torque

command through network is supported.

The positioning operation performed by an asynchronous end position command

through network is supported.

The speed control operation performed by an asynchronous speed command

through network is supported.

The torque control operation performed by an asynchronous torque command

through network is supported.

Select any 1 to 255 point table and perform operation in accordance with the set

values.

This is available with servo amplifiers with software version B2 or later.

Perform operation to the station positions divided into 2 to 255.

This is available with servo amplifiers with software version B2 or later.

This is a control mode where the servo motor speed is set to drive the servo motor

manually.

This is available with servo amplifiers with software version B2 or later.

This function achieves a high response and stable control following the ideal

model. The two-degrees-of-freedom model adaptive control enables you to set a

response to the command and a response to the disturbance separately.

Additionally, this function can be disabled. To disable this function, refer to section

7.5 of "MR-J4-_TM_ Servo Amplifier Instruction Manual".

High-resolution encoder of 4194304 pulses/rev is used for the encoder of the rotary

servo motor compatible with the MELSERVO-J4 series.

Setting a home position once makes home position return unnecessary at every

power-on.

You can switch gains during rotation/stop, and can use input devices to switch

gains during operation.

This function suppresses vibration at an arm end or residual vibration.

This filter function (notch filter) decreases the gain of the specific frequency to

suppress the resonance of the mechanical system.

When a load is mounted to the servo motor shaft, resonance by shaft torsion

during driving may generate a mechanical vibration of high frequency. The shaft

resonance suppression filter suppresses the vibration.

The servo amplifier detects mechanical resonance and sets filter characteristics

automatically to suppress mechanical vibration.

Suppresses high-frequency resonance which occurs as the servo system response

is increased.

This function analyzes the frequency characteristic of the mechanical system by

simply connecting an MR Configurator2-installed personal computer and the servo

amplifier.

MR Configurator2 is necessary for this function.

For roll feed axis, etc. of which a response level cannot be increased because of

the large load to motor inertia ratio, this function improves a disturbance response.

This function suppresses vibration of ±1 pulse generated at a servo motor stop. [Pr. PB24]

Positioning control is performed with the value obtained by multiplying the position

command from the controller by a set electronic gear ratio.

Speed can be increased and decreased smoothly. [Pr. PT51]

Section 5.4

MR-J4-_TM_

Chapter 12

MR-J4-_TM_

Section 7.2

MR-J4-_TM_

Section 7.1.5

MR-J4-_TM_

Section 7.1.1

MR-J4-_TM_

Section 7.1.3

MR-J4-_TM_

Section 7.1.2

MR-J4-_TM_

Section 7.1.4

[Pr. PE41]

[Pr. PA06]

[Pr. PA07]

1 - 4

1. EtherCAT COMMUNICATION

Function Description Reference

Auto tuning

Brake unit

Power regeneration converter

Regenerative option

Alarm history clear This function clears alarm histories. [Pr. PC21]

Torque limit Limits the servo motor torque.

Speed limit This function limits the servo motor speed. [Pr. PT67]

Status display Shows servo status on the 3-digit, 7-segment LED display

Input signal selection (device

settings)

Output signal selection (device

settings)

Output signal (DO) forced output

Test operation mode

Analog monitor output This function outputs servo status with voltage in real time.

MR Configurator2

Linear servo system

Direct drive servo system The direct drive servo system can be configured to drive a direct drive motor.

Fully closed loop system Fully closed loop system can be configured using the load-side encoder.

Latch function

(Touch probe)

One-touch tuning

SEMI-F47 function

Tough drive function

Automatically adjusts the gain to optimum value if load applied to the servo motor

shaft varies.

Use the brake unit when the regenerative option cannot provide sufficient

regenerative capability.

The brake unit can be used for the servo amplifiers of the 5 kW or more.

Use the power regeneration converter when the regenerative option cannot provide

sufficient regenerative capability.

The power regeneration converter can be used for the servo amplifiers of the 5 kW

or more.

Use a regenerative option when the built-in regenerative resistor of the servo

amplifier does not have sufficient regenerative capacity for a large regenerative

power generated.

LSP (Forward rotation stroke end), LSN (Reverse rotation stroke end) and other

input device can be assigned to any pins.

The output devices including ALM (Malfunction) can be assigned to specified pins

of the CN3 connector.

Turns on/off the output signals forcibly independently of the servo status.

Use this function for checking output signal wiring, etc.

Jog operation, positioning operation, motor-less operation, DO forced output, and

program operation

MR Configurator2 is necessary for this function.

Using a personal computer, you can perform the parameter setting, test operation,

monitoring, and others.

Linear servo system can be configured using a linear servo motor and linear

encoder.

This function latches the current position at the rising edge of the external latch

input signal.

Gain adjustment is performed just by one click a certain button on MR

Configurator2.

Also, one-touch tuning can be performed via a network. One-touch tuning via a

network is available with servo amplifiers with software version B0 or later.

This function enables to avoid triggering [AL. 10 Undervoltage] using the electrical

energy charged in the capacitor in case that an instantaneous power failure occurs

during operation. Use a 3-phase for the input power supply of the servo amplifier.

Using a 1-phase 100 V AC/200 V AC for the input power supply will not comply

with SEMI-F47 standard.

This function makes the equipment continue operating even under the condition

that an alarm occurs. The tough drive function includes two types: the vibration

tough drive and the instantaneous power failure tough drive.

MR-J4-_TM_

Section 6.3

MR-J4-_TM_

Section 11.3

MR-J4-_TM_

Section 11.4

MR-J4-_TM_

Section 11.2

[Pr. PA11]

[Pr. PA12]

MR-J4-_TM_

Section 4.3

[Pr. PD03] to

[Pr. PD05]

[Pr. PD07] to

[Pr. PD09]

MR-J4-_TM_

Section 4.5.1

(1) (d)

MR-J4-_TM_

Section 4.5

[Pr. PC09]

[Pr. PC10]

MR-J4-_TM_

Section 11.7

MR-J4-_TM_

Chapter 14

MR-J4-_TM_

Chapter 15

MR-J4-_TM_

Chapter 16

Section 5.5

MR-J4-_TM_

Section 3.5

[Pr. PD37]

Section 6.7

MR-J4-_TM_

Section 6.2

MR-J4-_TM_

Section 7.4

[Pr. PA20]

[Pr. PF25]

MR-J4-_TM_

Section 7.3

1 - 5

1. EtherCAT COMMUNICATION

Function Description Reference

This function continuously monitors the servo status and records the status

transition before and after an alarm for a fixed period of time. You can check the

recorded data on the drive recorder window on MR Configurator2 by clicking the

"Graph" button.

Drive recorder function

STO function

Servo amplifier life diagnosis

function

Power monitoring function

Machine diagnosis function

Scale measurement function

MR-D30 functional safety unit MR-D30 functional safety unit is supported.

Lost motion compensation

function

Super trace control

Limit switch

Software limit

FoE (File Access over

EtherCAT)

However, the drive recorder is not available when:

1. The graph function of MR Configurator2 is being used.

2. The machine analyzer function is being used.

3. [Pr. PF21] is set to "-1".

4. The controller is not connected (except the test operation mode).

5. An alarm related to the controller is occurring.

This amplifier complies with the STO function as functional safety of IEC/EN

61800-5-2. You can create a safety system for the equipment easily.

You can check the cumulative energization time and the number of on/off times of

the inrush relay. This function gives an indication of the replacement time for parts

of the servo amplifier including a capacitor and a relay before they malfunction.

This function is available with MR Configurator2 or via a network.

The servo amplifier life diagnosis function via a network is available with servo

amplifiers with software version B0 or later.

This function calculates the power running energy and the regenerative power from

the data in the servo amplifier such as speed and current. Power consumption and

others are displayed on MR Configurator2. Also, the power monitoring function can

be used via a network.

From the data in the servo amplifier, this function estimates the friction and

vibrational component of the drive system in the equipment and recognizes an

error in the machine parts, including a ball screw and bearing.

This function is available with MR Configurator2 or via a network.

The machine diagnosis function via a network is available with servo amplifiers

with software version B0 or later.

The function transmits position information of a scale measurement encoder to the

controller by connecting the scale measurement encoder in semi closed loop

control.

This is used with servo amplifiers with software version B0 or later.

This function improves the response delay occurred when the machine moving

direction is reversed.

This function sets constant and uniform acceleration/deceleration droop pulses to

almost 0.

Travel intervals can be limited with the limit switch using LSP (Forward rotation

stroke end) and LSN (Reverse rotation stroke end)

Limits travel intervals by address using parameters.

The same function with the limit switch is enabled by setting parameters.

This servo amplifier supports FoE (File Access over EtherCAT). For details,

contact your local sales office.

This is used with servo amplifiers with software version B3 or later.

[Pr. PA23]

MR-J4-_TM_

Chapter 13

Section 6.9

Section 6.1

Section 6.8

Section 6.6

MR-J4-_TM_

Section 17.1

MR-J4-_TM_

Section 17.2

MR-J4-_TM_

Section 7.6

MR-J4-_TM_

Section 7.7

Section 5.8

MR-J4-_TM_

Section 5.3

[Pr. PT15] to

[Pr. PT18]

1 - 6

1. EtherCAT COMMUNICATION

1.3 Communication specifications

The following table shows the communication specifications.

EtherCAT communication

specifications

Physical layer 100BASE-TX (IEEE802.3)

Communication connector RJ45, 2 ports (IN port, OUT port)

Communication cable

Network topology

Variable communication speed 100 Mbps (Full duplex)

Transmission speed between

stations

Number of nodes

SDO (Mailbox) communication

PDO (Process Data)

communication

PDO mapping

Distributed clock (DC)

Explicit Device Identification Supported

LED display RUN, ERROR, LINK/Activity (IN, OUT)

Item Description Remark

IEC 61158 Type121

CAN application protocol over EtherCAT

(CoE), IEC 61800-7 CiA 402 Drive Profile

CAT5e, shielded twisted pair (4 pair) straight

cable

Line, Tree, Star, or a connection topology

where the topologies are used together

Max. 100 m

Max. 65535 The number of connection nodes for actual use

Asynchronous

Sending/Receiving: 1 channel each

Cycle time: Select from 0.25 ms, 0.5 ms, 1

ms, and 2 ms.

Receive (RxPDO): 1 channel

Send (TxPDO): 1 channel

Variable PDO mapping supported Maximum size of RxPDO and TxPDO: 64 bytes

The DC mode and Free-run mode can be

selected.

(In servo amplifiers with software version B3

or earlier, the DC mode is required in the csp,

csv, and cst mode.)

Double-shielded type recommended

varies depending on the specifications of the

master controller used.

Maximum data size in sending/receiving

1486 bytes each

Data size at PDO default mapping

RxPDO: 29 bytes

TxPDO: 41 bytes

each

Maximum number of object mapping: 32 each

Sync0: Set the same cycle as the PDO

communication cycle.

Sync1: Not used

1 - 7

1. EtherCAT COMMUNICATION

1.4 EtherCAT State Machine (ESM)

The communication status of MR-J4-_TM_ servo amplifiers is classified and managed by EtherCAT State

Machine (ESM) that the EtherCAT standard specifies.

1.4.1 Communication status

The following table shows the classification of the communication status. Two communication types are

provided: One is the PDO (process data object) communication where command data and feedback data

are sent and received at a constant period. Another is the SDO (service data object) communication where

object data is sent and received asynchronously. Refer to chapter 3 for details of the PDO communication.

Refer to chapter 4 for details of the SDO communication.

ESM status Description

After the power is on, the communication status is the init state. The SDO communication and PDO

Init

Pre-Operational

Safe-Operational

Operational

Bootstrap

communication cannot be performed. The master accesses the DL-Information register and initializes

communication.

The SDO communication can be performed. The PDO communication cannot be performed. The initial setting

for network and initial transfer of parameters can be performed in this state.

The SDO communication can be performed. Though the PDO communication also can be performed, all

operations (commands) such as servo motor drive are invalid. When the DC mode is selected, synchronization

is established in this state.

Both the SDO communication and PDO communication can be performed. Commands using the PDO

communication are valid and the servo motor can be driven.

The mailbox communication with the FoE protocol can be performed. Firmware can be updated through

EtherCAT in this state. (For manufacturer setting)

1 - 8

1. EtherCAT COMMUNICATION

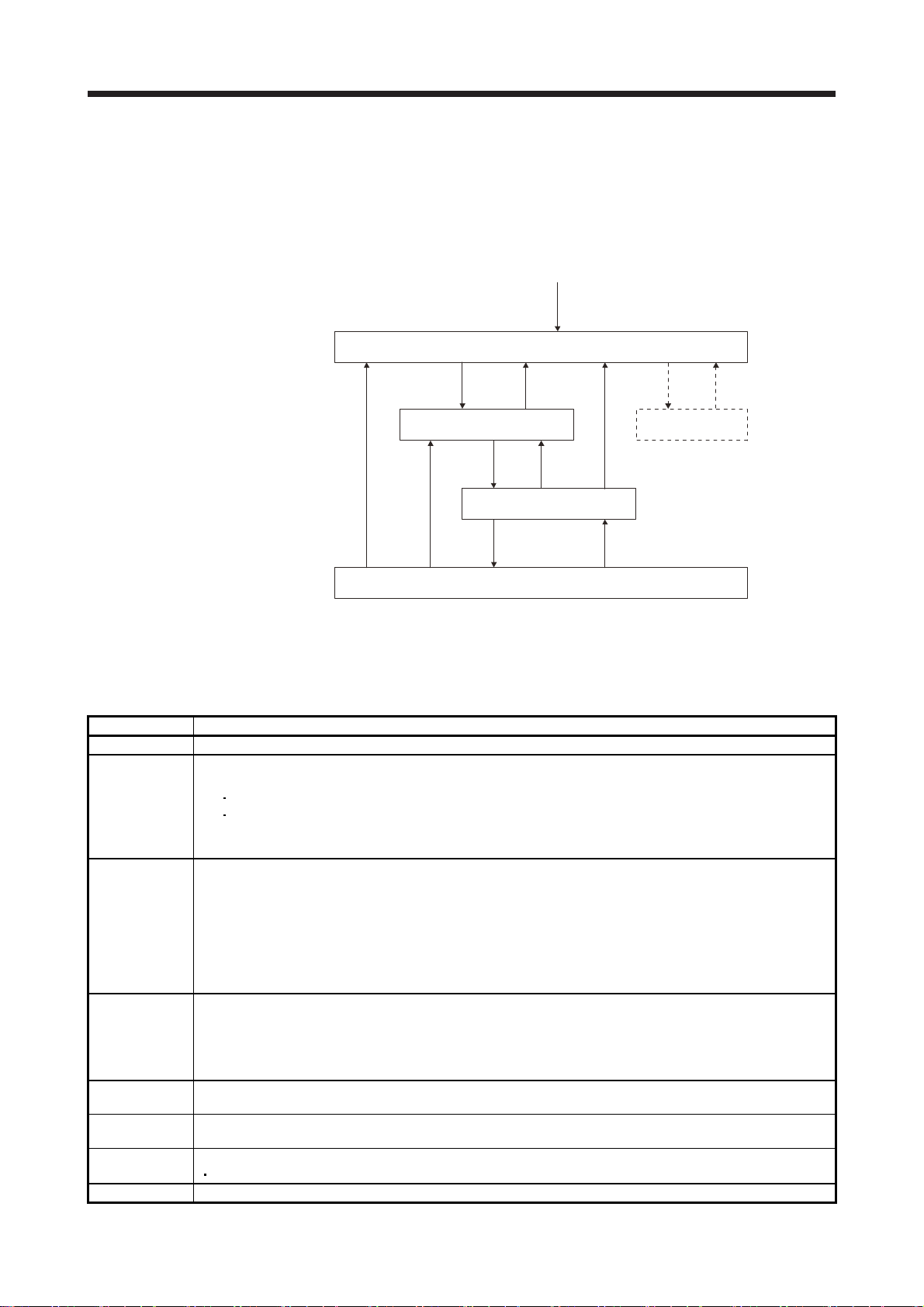

1.4.2 EtherCAT state

EtherCAT states shift under the conditions shown in figure 1.1 and table 1.1.

When the state shifts from the Init state through the Pre-Operational and Safe-Operational state to the

Operational state, the servo amplifier can be operated. When the Operational state shifts to another state,

the servo amplifier executes initialization to clear the internal status.

Power on

(1)

Init

(2)

Pre-Operational

(4)

(12)

Note. This state is for manufacturer setting.

(3)

(5)

Safe-Operational

(7)

Operational

(10)

Bootstrap

(Note)

(6)(9)

(8)

Fig. 1.1

Table. 1.1 EtherCAT state transition

Transition No. Description

(1) Power on

SDO communication configuration

(a) The master sets the registers of the slaves. The following shows the registers to be set.

(2)

(4)

(7)

(5), (12)

(8)

(3), (6), (9), (11)

(10) When the master requests the slave to shift to the Bootstrap state, the state shifts to the Bootstrap state.

DL Address register

Sync Manager channel for SDO communication

(b) The master requests the slaves to shift to the Pre-Operational state.

(c) The state shifts to the Pre-Operational state.

PDO communication configuration

(a) Set the configuration parameter of the master (such as PDO mapping) using the SDO communication.

(b) The master sets the Sync Manager channel and FMMU channel for the PDO communication of the slaves.

FMMU (Fieldbus Memory Management Unit) is a mechanism to manage the relationship between the global

address area and the local address area in the EtherCAT communication. The global address area is used for

the PDO communication. The local address area stores object data for each station.

(c) The master requests the slave to shifts to the Safe-Operational state.

(d) The state shifts to the Safe-Operational state.

Synchronous

(a) The master and slave use Distributed Clocks to synchronize.

(b) The master starts to output a valid command value.

(c) The master requests the slave to shift to the Operational state.

(d) The state shifts to the Operational state.

When the master requests the slave to shifts to the Pre-Operational state, the state shifts to the Pre-Operational

state.

When the master requests the slave to shifts to the Safe-Operational state, the state shifts to the Safe-Operational

state.

In the following case, the state shifts to the init state.

When the master requests the slave to shifts to the Init state.

(11)

1 - 9

1. EtherCAT COMMUNICATION

1.4.3 Startup

The following describes the setting and startup of the EtherCAT communication. Refer to section 4.1 of "MRJ4-_TM_ Servo Amplifier Instruction Manual" for the startup procedure other than the network setting.

(1) Connection with the controller

POINT

Use the latest ESI file when setting up the controller. If the ESI file is old, newly

added objects may not be usable. For ESI files available with the servo

amplifiers you use, contact your local sales office.

Set up the controller following the manual of the controller used. For the setup, the EtherCAT Slave

Information (ESI) file listing the information about the communication setting of devices is available.

Store the ESI file in the controller to use it. The controller configures the setting for the slave connected

to the master according to the contents of the ESI file corresponding to the slave connected.

(2) Parameter setting

Set the control mode with [Pr. PA01 Operation mode]. Refer to section 5.2.1 of "MR-J4-_TM_ Servo

Amplifier Instruction Manual" for the parameter setting.

(3) Node address setting

POINT

The node address of MR-J4-_TM_ servo amplifiers complies with the

specifications of Explicit Device Identification. Configure the setting of Set

Explicit Device Identification for the controller.

Do not connect multiple devices with the same node address setting.

Node address setting via network and Configured Station Alias (0012h) are

available with the combination of servo amplifiers with software version B2 or

later and network modules with software version 2.00.03 or later.

If the value in SII Configured Station Alias is set to other than 0000h when the

node address is set with the axis selection rotary switch (SW2/SW3) or [Pr.

PN01 Node address setting], the ERROR LED of the network module blinks.

Cycling the power resets the set value in SII Configured Station Alias to 0000h

and this enables the servo amplifier to start normally.

Set the node address of EtherCAT with the axis selection rotary switch (SW2/SW3) on the display, [Pr.

PN01 Node address setting] or SII Configured Station Alias as necessary. You can set a node address

as follows. After the node address setting is changed, cycle the power.

Axis selection rotary

switch (SW2/SW3)

00h 0000h 0001h to FFFFh

00h 0001h to FFFFh 0000h (Note) The value of [Pr. PN01] is set as the node address.

01h to FFh 0000h to FFFFh 0000h (Note)

Pr. PN01

SII Configured Station

Alias

Node address setting value

The value set in SII Configured Station Alias via network

is the node address.

The set value of the rotary switch (SW2/SW3) is set as

the node address.

Note. If the value in SII Configured Station Alias is set to other than 0000h, the ERROR LED of the network module blinks. Cycling the

power resets the set value in SII Configured Station Alias to 0000h and this enables the servo amplifier to start normally.

1 - 10

1. EtherCAT COMMUNICATION

(4) Specifying the slave with the node address

The controller can specify the slave with the node address in the following two methods.

(a) Specify with AL Status Code (0134h)

The value of the node address set in the axis selection rotary switch (SW2/SW3) or [Pr. PN01 Node

1.4.4 Network disconnection procedure

To disconnect the network by stopping device operation or other means, follow the procedure shown below.

If the network is disconnected without following the procedure, [AL. 86.1 Network communication error 1]

may occur.

(1) Stop the servo motor.

(2) Set the Shutdown command for Controlword (6040h) to establish the servo-off status.

(3) Shift the state to the Pre-Operational state.

(4) Shut off the power of the servo amplifier and controller.

address setting] can be read.

(b) Specify with Configured Station Alias (0012h)

The value of the node address set in the axis selection rotary switch (SW2/SW3), [Pr. PN01 Node

address setting] or SII Configured Station Alias can be read.

1 - 11

1. EtherCAT COMMUNICATION

1.5 Summary of object dictionary (OD)

POINT

Refer to chapter 7 for details of the object dictionary.

Each data set that CAN application protocol over EtherCAT (CoE) devices have such as control parameters,

command values, and feedback values is handled as an object composed of an Index value, object name,

object type, R/W attribute, and other elements. The object data can be exchanged between the master and

slave devices. The aggregate of these objects is called object dictionary (OD).

1.5.1 Section definition of object dictionary

In the CAN application protocol over EtherCAT (CoE) standard, objects of the object dictionary are

categorized by Index depending on the area type as shown in the following table. Refer to the Reference

column for the chapters and the section where the details of each object are described.

Index Description Reference

0000h to 0FFFh Data type area

1000h to 1FFFh CoE communication area

2000h to 25FFh Parameter area (Vendor-specific) Section 6.5, Chapter 7

2800h to 29FFh Point table area (Vendor-specific) (Note) Chapter 7

2A00h to 2FFFh Servo control command/monitor area (Vendor-specific) Chapter 6, Chapter 7

6000h to 6FFFh CiA 402 Drive profile area

Note. This is available with servo amplifiers with software version B2 or later.

1.5.2 Saving object dictionary data to EEP-ROM

Chapter 1, Chapter 3,

Chapter 4, Chapter 7

Chapter 5, Chapter 7

There are two types of object dictionary data: One is saved to EEP-ROM and another is not saved. Refer to

Section 7.3 for the availability and details of save for each object.

1 - 12

2. EtherCAT NETWORK MODULE (ABCC-M40-ECT)

A

A

2. EtherCAT NETWORK MODULE (ABCC-M40-ECT)

POINT

For EtherCAT Network module, be sure to use ABCC-M40-ECT which is a

dedicated model for Mitsubishi Electric MELSERVO. For purchasing, contact

your local sales office.

Refer to "MR-J4-_TM_ Servo Amplifier Instruction Manual" for how to mount the

EtherCAT Network module (ABCC-M40-ECT) to the MR-J4-_TM_ servo

amplifier.

For the quality assurance on the EtherCAT Network module (ABCC-M40-ECT),

contact HMS Industrial Networks.

The EtherCAT communication with an MR-J4-_TM_ servo amplifier requires the EtherCAT Network module

(ABCC-M40-ECT). The following shows the details.

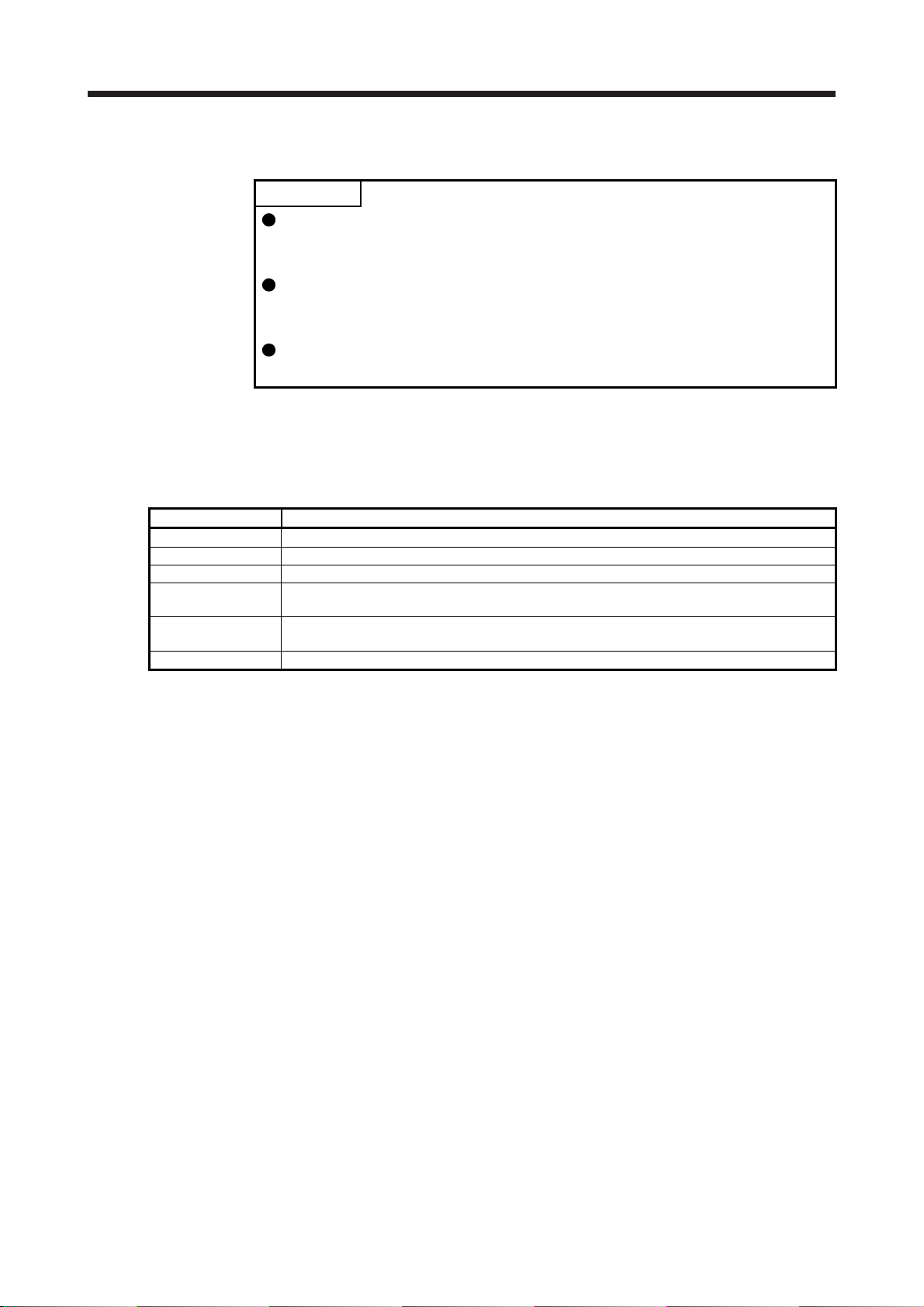

2.1 Specifications

Item Description

Product name ABCC-M40-ECT (Anybus Compact Com M40 ECT)

Model AB6916-C-203 (Note 1, 2, 3, 4)

Manufacturer HMS Industrial Networks

External interface

Dimensions

Mass Approx. 30 g

MR-J4-_TM_ servo amplifier connecting interface: Compact flash connector with standard 50 pins

EtherCAT communication port interface: RJ45 connector

52 (W) × 50 (D) × 20 (H)

(Except the protrusion of the EtherCAT communication port connector)

Note 1. The model name was changed from 6916-C-203 to AB6916-C-203 in November 2018.

2.

3. When using AB6916-B or AB6916-C, Configured Station Alias cannot be used. Refer to section 1.4.3 (3) for details.

4. When using AB6916-B, use EtherCAT Slave Information (ESI). Without ESI, the controller does not recognize the

lthough it is recommended that you use AB6916-C-203 for the servo amplifiers with software version B2 or later,

B6916-B and AB6916-C are also available. Although it is recommended that you use AB6916-C for the servo

amplifiers with software version B1 or earlier, AB6916-B is also available.

711th and later objects because Get OD List can read only object information of 710 sets.

2 - 1

2. EtherCAT NETWORK MODULE (ABCC-M40-ECT)

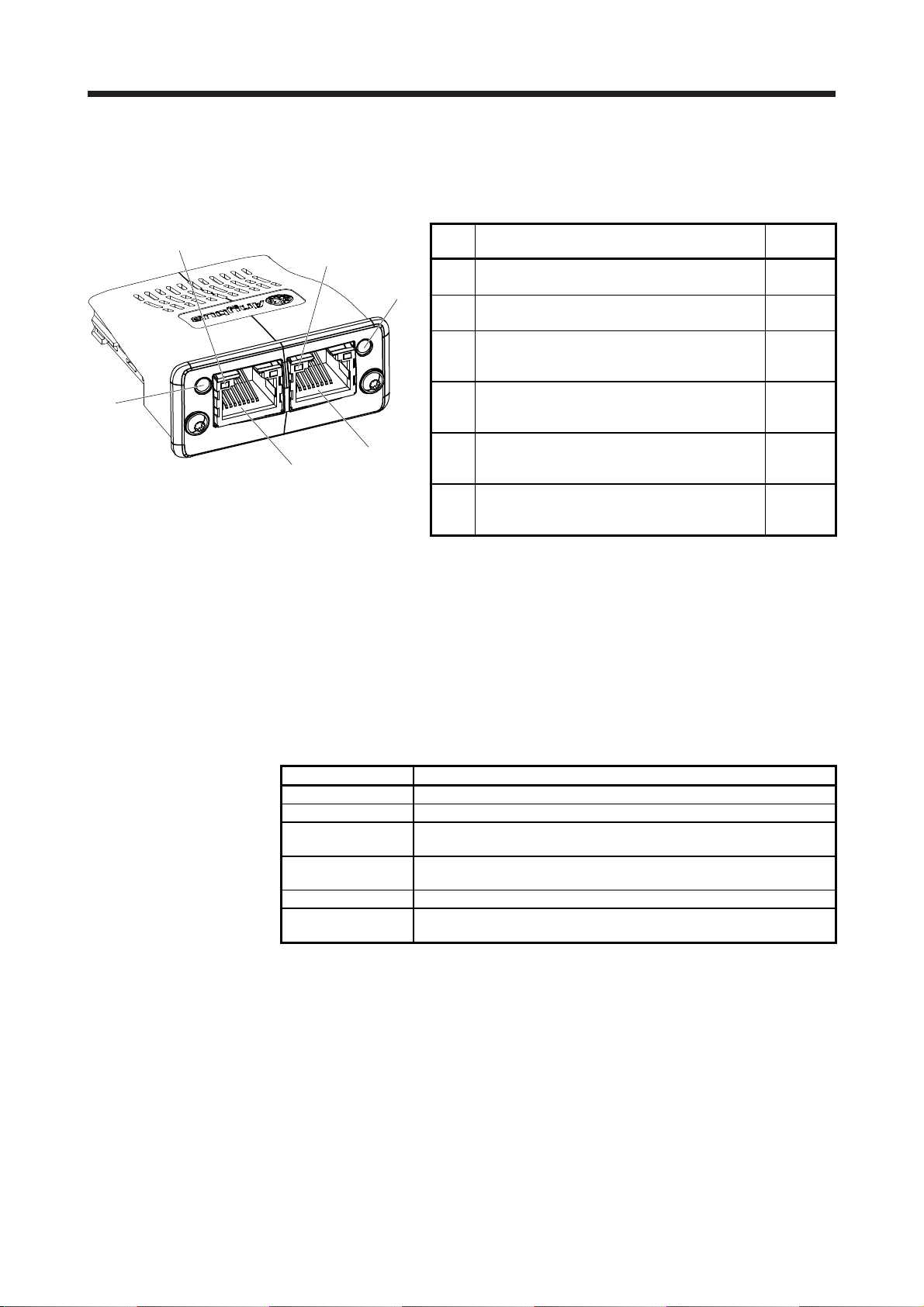

2.2 Parts identification

This section describes the EtherCAT Network module (ABCC-M40-ECT) only. Refer to section 1.7 of "MRJ4-_TM_ Servo Amplifier Instruction Manual" for the MR-J4-_TM_ servo amplifier.

(5)

(6)

2.3 LED indication

(4)

(3)

(2)

(1)

No. Name/Application

ERROR LED

(1)

Indicates an error of the EtherCAT communication.

RJ45 EtherCAT communication port (OUT port)

(2)

Used to connect the next axis servo amplifier.

Link/Activity (OUT port) LED

(3)

Indicates the link status of each EtherCAT

communication port.

RJ45 EtherCAT communication port (IN port)

(4)

Used to connect the EtherCAT master controller or

the previous axis servo amplifier.

Link/Activity (IN port) LED

(5)

Indicates the link status of each EtherCAT

communication port.

RUN LED

(6)

Indicates the EtherCAT communication status

(ESM).

Detailed

explanation

Section

2.3.2 (2)

Section

2.4

Section

2.3.2 (3)

Section

2.4

Section

2.3.2 (3)

Section

2.3.2 (1)

The LEDs of the EtherCAT Network module (ABCC-M40-ECT) function according to the regulations of the

EtherCAT standard (ETG.1300 EtherCAT Indicator and Labeling Specification). Under certain condition,

such as when a fatal error occurs, the EtherCAT Network module (ABCC-M40-ECT) indicates its status by

its own specifications.

2.3.1 LED indication definition

The following shows the LED indication definitions.

LED status Definition

Lit An LED remains lit.

Extinguished An LED remains extinguished.

Flickering An LED is switching between lit and extinguished at 10 Hz cycles (every

50 ms).

Blinking An LED is switching between lit and extinguished at 2.5 Hz cycles (every

200 ms).

Single flash An LED is lit for 200 ms and extinguished 1000 ms repeatedly.

Double flash

An LED is lit for 200 ms, extinguished for 200 ms, lit for 200 ms, and

extinguished for 1000 ms repeatedly.

2 - 2

2. EtherCAT NETWORK MODULE (ABCC-M40-ECT)

2.3.2 LED indication list

(1) RUN LED

The RUN LED indicates the EtherCAT communication status (ESM status). The extinguished RUN LED

may be affected by the LED status of the Link/Activity LEDs. Refer to section 1.4 for the communication

status (ESM status).

Extinguished Indicates that the power supply is shut off or the Init state.

Blinking

Single flash Indicates the Safe-Operational state.

(2) ERROR LED

The ERROR LED indicates an error of the EtherCAT communication. If the servo amplifier indicates an

alarm, follow the remedy of the alarm number.

Extinguished No error

Blinking

Single flash

Double flash Indicates a watchdog error in the Sync manager.

Flickering

(3) Link/Activity LED (OUT port/IN port)

The Link/Activity LEDs indicate the link status of each EtherCAT communication port.

Extinguished Indicates that the power supply is shut off or the link-unestablished state.

Flickering Indicates that the link is established with traffic.

LED

Status Color

Indicates the Pre-Operational state.

Green

Lit Indicates the Operational state.

Lit Red

LED

Status Color

Red

Lit

LED

Status Color

Lit

Green

Indicates that a fatal error has occurred. This indication is specific to the

EtherCAT Network module (ABCC-M40-ECT).

Indicates that the EtherCAT state cannot be changed according to the master

command.

Indicates that the EtherCAT state has been changed autonomously due to an

internal error.

Indicates the EXCEPTION state, which is an error state of the EtherCAT Network

module (ABCC-M40-ECT).

Indicates an error at start-up of the EtherCAT Network module (ABCC-M40ECT).

Indicates that the link is established without traffic.

Description

Description

Description

2 - 3

2. EtherCAT NETWORK MODULE (ABCC-M40-ECT)

2.4 Connecting Ethernet cable

POINT

Use a twisted pair cable (double shielded) with Ethernet Category 5e

(100BASE-TX) or higher as the Ethernet cable. The maximum cable length

between nodes is 100 m.

When connecting an Ethernet cable to an EtherCAT network port, ensure that

the connection destination (OUT port (upper side) or IN port (lower side)) is

correct.

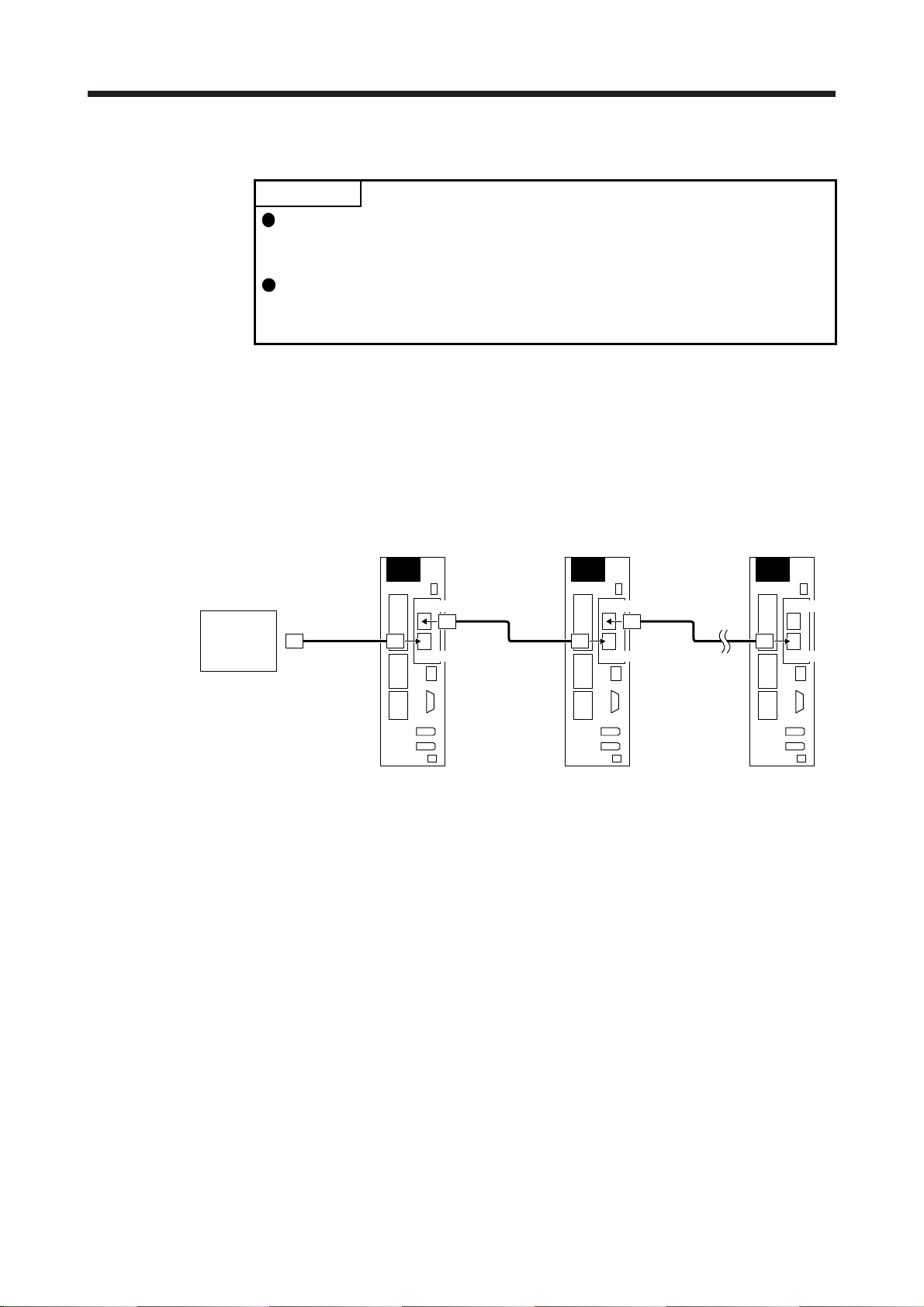

To the RJ45 EtherCAT communication port (IN port), connect the Ethernet cable connected to the controller

or the previous axis servo amplifier. To the RJ45 EtherCAT communication port (OUT port), connect the

Ethernet cable connected to the next axis servo amplifier. When the RJ45 EtherCAT communication port

(OUT port) is not used, leave this port open.

When the node address is not used, an incorrect connection destination sets node addresses that do not

correspond to the actual connection order and may cause a malfunction, such as an unintended axis

operation.

The first axis

servo amplifier

The second axis

servo amplifier

The final axis

servo amplifier

Controller

Ethernet cable

OUT port

IN port

Ethernet cable

OUT port

IN port

Ethernet cable

OUT port

IN port

2 - 4

3. PDO (PROCESS DATA OBJECT) COMMUNICATION

3. PDO (PROCESS DATA OBJECT) COMMUNICATION

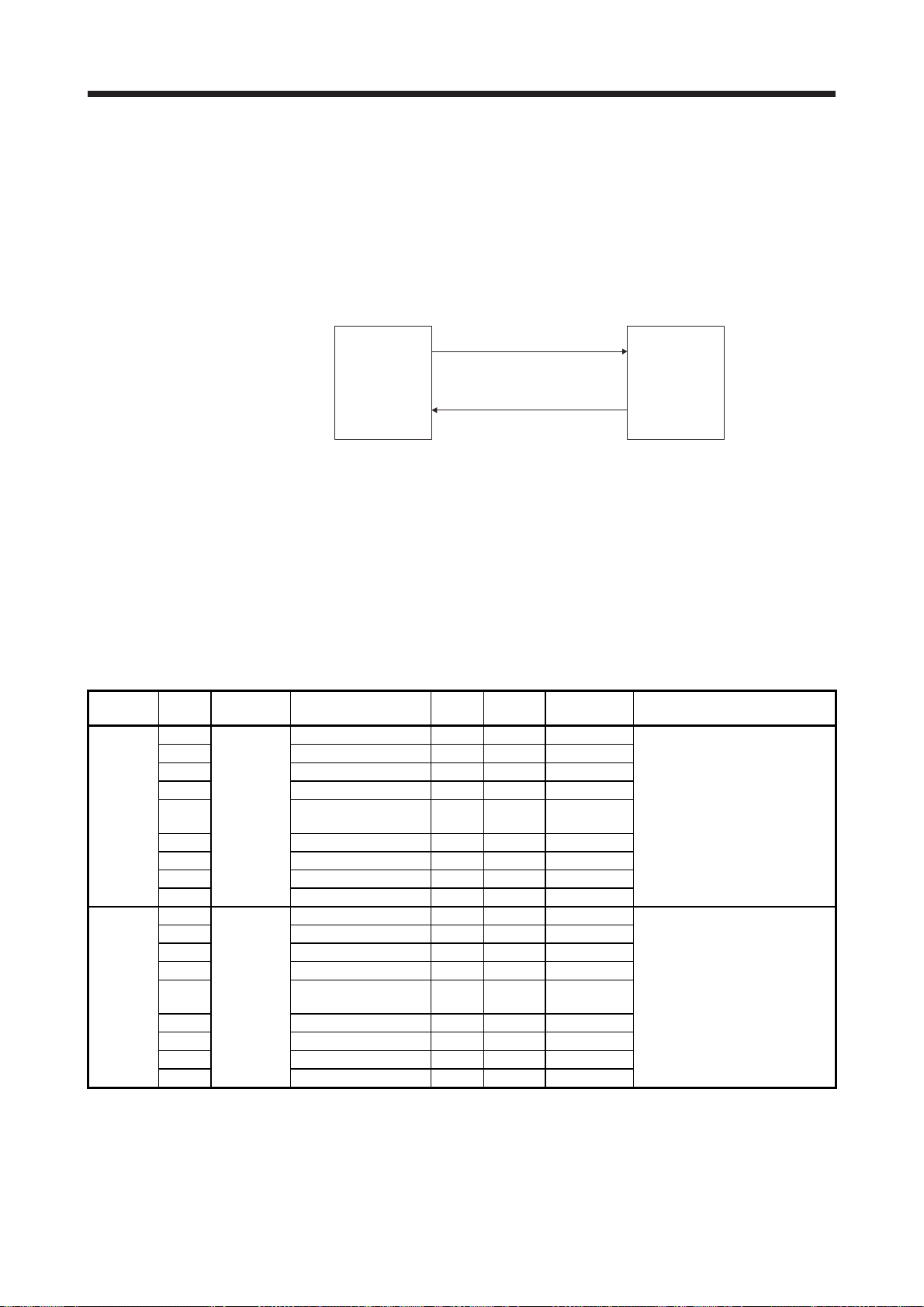

The PDO (process data object) communication can transfer command data and feedback data between a

master (controller) and slaves (servo amplifier) at a constant cycle. PDOs include RxPDOs, which are used

by the slaves to receive data from the controller, and TxPDOs, which are used by the slaves to send data to

the controller.

Master

(controller)

The variable PDO mapping function enables the PDO communication to transfer multiple PDOs in any array.

3.1 PDO communication cycle

Communication at a constant period

Command data (RxPDO)

Status data (TxPDO)

Slave

(servo amplifier)

The same cycle is applied to communication of RxPDOs and TxPDOs of the MR-J4-_TM_ servo amplifier.

The communication cycle can be changed via a network through rewriting the sub object Cycle time (Sub

index = 2) of SM output parameter (1C32h) with SDO download in the Pre Operational state.

3.2 PDO setting-related object

The following table lists the objects related to the PDO setting.

Index Sub Object Name

1C32h

1C33h

0

1 Synchronization type U16 rw 0

2 Cycle time U32 rw 250000

3 Shift time U32 rw (Note) 222222

RECORD

4

5 Minimum cycle time U32 ro 250000

6 Calc and copy time U32 ro 222722

9 Delay time U32 ro 0

12 Cycle time too small U16 ro 0

0

1 Synchronization type U16 rw 0

2 Cycle time U32 ro 250000

3 Shift time U32 rw (Note) 27778

RECORD

4

5 Minimum cycle time U32 ro 250000

6 Calc and copy time U32 ro 306055

9 Delay time U32 ro 0

12 Cycle time too small U16 ro 0

SM output parameter U8 ro 12

Synchronization types

supported

SM input parameter U8 ro 12

Synchronization types

supported

Data

Type

U16 ro 0025h

U16 ro 0025h

Access Default Description

Refer to section 7.3.3 (4).

Refer to section 7.3.3 (5).

Note. No value can be written because Shift time (1C32: 3, 1C33: 3) is set automatically. Writing any value causes SDO Abort Code

(0609 0030h Value range of parameter exceeded).

3 - 1

3. PDO (PROCESS DATA OBJECT) COMMUNICATION

3.3 PDO default mapping

POINT

The MR-J4-_TM_ servo amplifier supports the variable PDO mapping function,

which can select objects transferred in the PDO communication. Refer to section

3.4 for changing the PDO mapping.

(1) RxPDO default mapping

In the default mapping setting, command data is sent from the master (controller) to slaves (servo

amplifier) with RxPDO in the following array. In the MR-J4-_TM_ servo amplifier, the mapping objects of

1600h to 1603h can be used as the RxPDO default mapping table.

Map number Mapping initial setting Expected application of the initial map

1st RxPDO map (1600h) Modes of operation (6060h)

Controlword (6040h)

Control DI 1 (2D01h)

Control DI 2 (2D02h)

Control DI 3 (2D03h)

Target position (607Ah)

Target velocity (60FFh)

Velocity limit value (2D20h) (Note 1)

Target torque (6071h)

Positive torque limit value (60E0h) (Note 2)

Negative torque limit value (60E1h) (Note 2)

Touch probe function (60B8h)

2nd RxPDO map (1601h) Modes of operation (6060h)

Controlword (6040h)

Control DI 1 (2D01h)

Control DI 2 (2D02h)

Control DI 3 (2D03h)

Target position (607Ah)

Target velocity (60FFh)

Velocity limit value (2D20h) (Note 1)

Target torque (6071h)

Profile velocity (6081h)

Profile acceleration (6083h)

Profile deceleration (6084h)

Torque slope (6087h)

Positive torque limit value (60E0h) (Note 2)

Negative torque limit value (60E1h) (Note 2)

Touch probe function (60B8h)

3rd RxPDO map (1602h) Modes of operation (6060h)

Controlword (6040h)

Control DI 1 (2D01h)

Control DI 2 (2D02h)

Control DI 3 (2D03h)

Target point table (2D60h) (Note 3)

Profile velocity (6081h)

Profile acceleration (6083h)

Profile deceleration (6084h)

Touch probe function (60B8h)

4th RxPDO map (1603h) Unassigned

Note 1. The Velocity limit value (2D20h) is a speed limit value for the torque control. Be sure to set a correct value because setting 0

will limit the speed to 0.

2. Positive torque limit value (60E0h)/Negative torque limit value (60E1h) are torque limit values of forward/reverse rotation.

Setting 0 will not generate torque. Be sure to set a correct value.

3. This is available with servo amplifiers with software version B2 or later.

Cyclic synchronous position mode (csp)

Cyclic synchronous velocity mode (csv)

Cyclic synchronous torque mode (cst)

Homing mode (hm)

Mapping for an application in which the modes

above are switched

The following functions can be used together.

Speed limit function (in cst)

Torque limit function

Touch probe function

Map size: 29 bytes

Profile position mode (pp)

Profile velocity mode (pv)

Profile torque mode (tq)

Homing mode (hm)

Mapping for an application in which the modes

above are switched

The following functions can be used together.

Speed limit function (in tq)

Torque limit function

Touch probe function

Map size: 45 bytes

Point table mode (pt) or indexer mode (idx)

Jog mode (jg)

Homing mode (hm)

Mapping for an application in which the modes

above are switched.

Map size: 25 bytes

3 - 2

3. PDO (PROCESS DATA OBJECT) COMMUNICATION

(2) TxPDO default mapping

In the default mapping setting, status data of the MR-J4-_TM_ servo amplifier is sent to the master

(controller) with TxPDO in the following array. In the MR-J4-_TM_ servo amplifier, the mapping objects