Mitsubishi MR-J4-10GF, MR-J4-100GF, MR-J4-70GF, MR-J4-20GF, MR-J4-200GF Instruction Manual

...

General-Purpose AC Servo

CC-Link IE Field Network Interface

Servo Amplifier Instruction Manual

(Motion Mode)

-MR-J4-_GF_

-MR-J4-_GF_-RJ

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

(Please read the instructions carefully before using the equipment.)

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until you have read

through this Instruction Manual, Installation guide, and appended documents carefully. Do not use the equipment until you

have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so on are classified

into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

1

[To prevent electric shock, note the following]

WARNING

● Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge

lamp turns off. Then, confirm that the voltage between P+ and N- is safe with a voltage tester and

others. Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp

is off or not, always confirm it from the front of the servo amplifier.

● Ground the servo amplifier and servo motor securely.

● Any person who is involved in wiring and inspection should be fully competent to do the work.

● Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, it

may cause an electric shock.

● Do not operate switches with wet hands. Otherwise, it may cause an electric shock.

● The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

● During power-on or operation, do not open the front cover of the servo amplifier. Otherwise, it may

cause an electric shock.

● Do not operate the servo amplifier with the front cover removed. High-voltage terminals and charging

area are exposed and you may get an electric shock.

● Except for wiring and periodic inspection, do not remove the front cover of the servo amplifier even if

the power is off. The servo amplifier is charged and you may get an electric shock.

● To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the

servo amplifier to the protective earth (PE) of the cabinet.

● To avoid an electric shock, insulate the connections of the power supply terminals.

[To prevent fire, note the following]

CAUTION

● Install the servo amplifier, servo motor, and regenerative resistor on incombustible material. Installing

them directly or close to combustibles will lead to smoke or a fire.

● Always connect a magnetic contactor between the power supply and the main circuit power supply

(L1/L2/L3) of the servo amplifier, in order to configure a circuit that shuts down the power supply on

the side of the servo amplifier’s power supply. If a magnetic contactor is not connected, continuous

flow of a large current may cause smoke or a fire when the servo amplifier malfunctions.

● Always connect a molded-case circuit breaker, or a fuse to each servo amplifier between the power

supply and the main circuit power supply (L1/L2/L3) of the servo amplifier, in order to configure a

circuit that shuts down the power supply on the side of the servo amplifier’s power supply. If a moldedcase circuit breaker or fuse is not connected, continuous flow of a large current may cause smoke or

a fire when the servo amplifier malfunctions.

● When using the regenerative resistor, switch power off with the alarm signal. Otherwise, a

regenerative transistor malfunction or the like may overheat the regenerative resistor, causing smoke

or a fire.

● Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and servo motor.

2

[To prevent injury, note the following]

CAUTION

● Only the power/signal specified in the Instruction Manual should be applied to each terminal.

Otherwise, it may cause an electric shock, fire, injury, etc.

● Connect cables to the correct terminals. Otherwise, a burst, damage, etc., may occur.

● Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc., may occur.

● The servo amplifier heat sink, regenerative resistor, servo motor, etc., may be hot while the power is

on and for some time after power-off. Take safety measures such as providing covers to avoid

accidentally touching them by hands and parts such as cables.

3

[Additional instructions]

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury, electric shock, fire,

etc.

[Transportation and installation]

CAUTION

● Transport the products correctly according to their mass.

● Stacking in excess of the specified number of product packages is not allowed.

● Do not hold the front cover, cables, or connectors when carrying the servo amplifier. Otherwise, it may

drop.

● Install the servo amplifier and the servo motor in a load-bearing place in accordance with the

Instruction Manual.

● Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

● The equipment must be installed in the specified direction.

● Maintain specified clearances between the servo amplifier and the inner surfaces of a control cabinet

or other equipment.

● Do not install or operate the servo amplifier and servo motor which have been damaged or have any

parts missing.

● Do not block the intake and exhaust areas of the servo amplifier. Otherwise, it may cause a

malfunction.

● Do not drop or apply heavy impact on the servo amplifiers and the servo motors. Otherwise, it may

cause injury, malfunction, etc.

● Do not strike the connector. Otherwise, it may cause a connection failure, malfunction, etc.

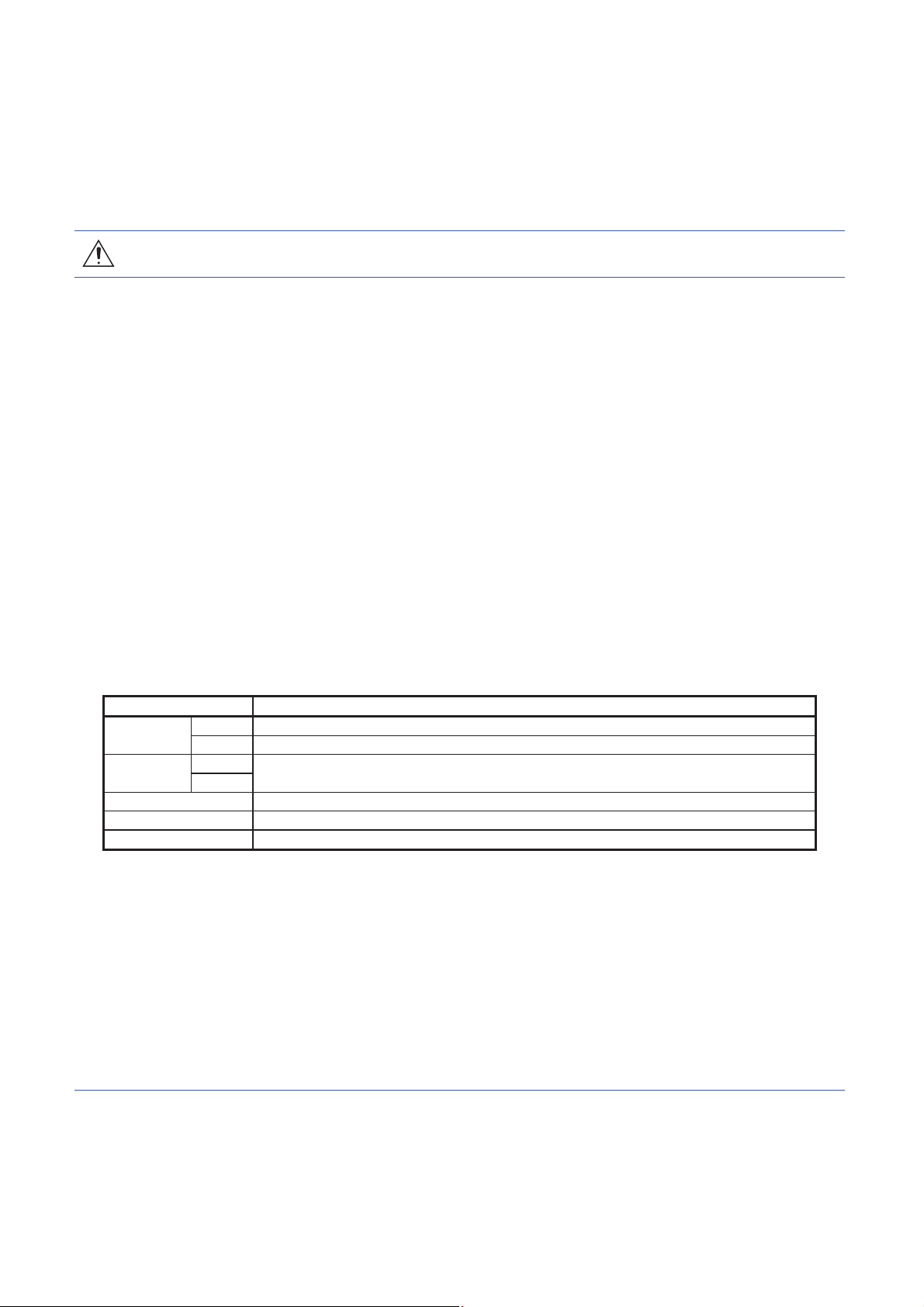

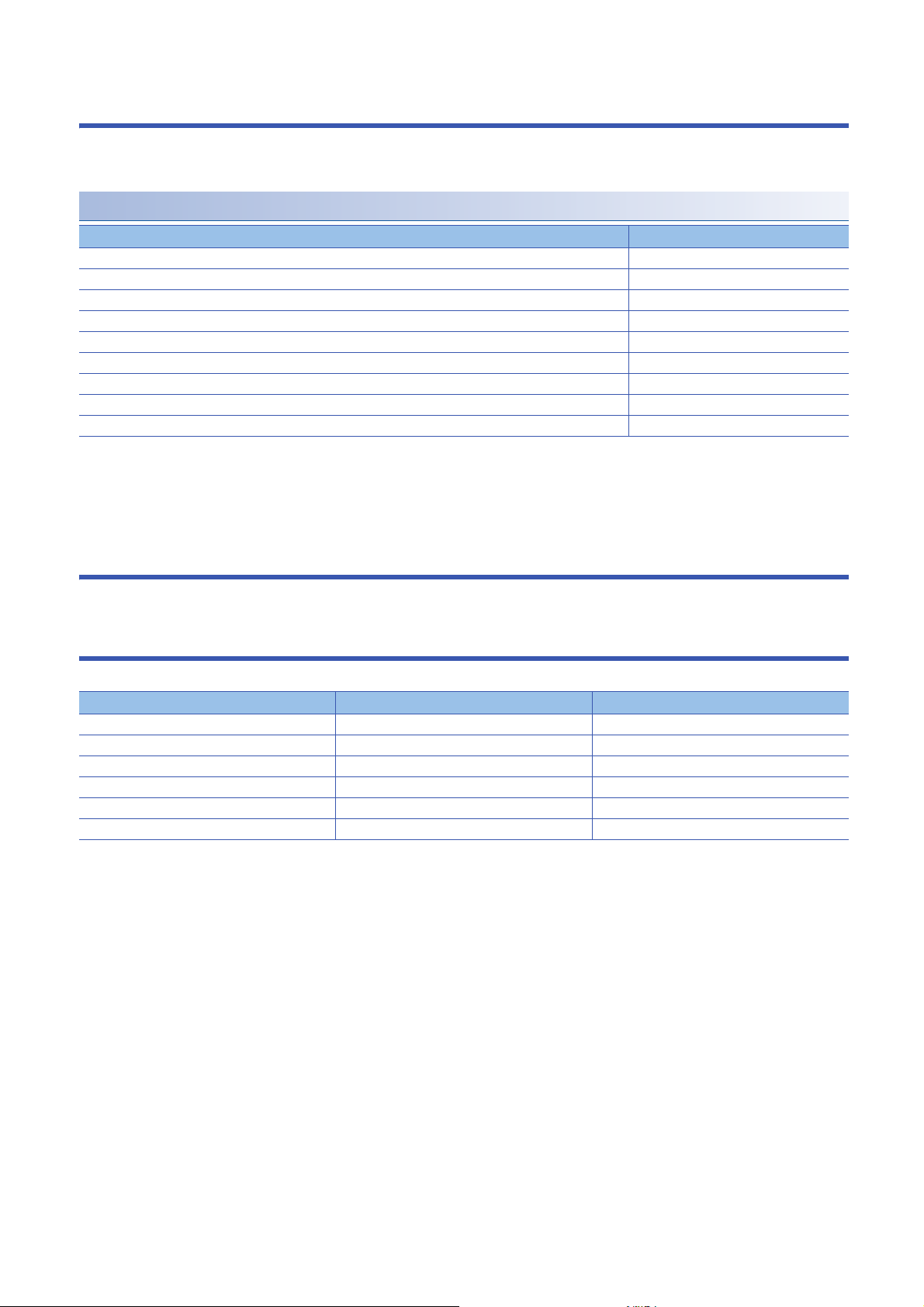

● When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient

temperature

Ambient

humidity

Vibration resistance

Operation

Storage

Operation

Storage

Ambience

Altitude

Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

2000 m or less above sea level (Contact your local sales office for the altitude for options.)

0 °C to 55 °C (non-freezing)

-20 °C to 65 °C (non-freezing)

5 %RH to 90 %RH (non-condensing)

2

, at 10 Hz to 55 Hz (X, Y, Z axes)

5.9 m/s

● When the product has been stored for an extended period of time, contact your local sales office.

● When handling the servo motor, be careful with the sharp edges of the servo motor.

● The servo amplifier must be installed in a metal cabinet.

● When fumigants that contain halogen materials, such as fluorine, chlorine, bromine, and iodine, are

used for disinfecting and protecting wooden packaging from insects, they cause a malfunction when

entering our products. Please take necessary precautions to ensure that remaining materials from

fumigant do not enter our products, or treat packaging with methods other than fumigation, such as

heat treatment. Additionally, disinfect and protect wood from insects before packing the products.

● To prevent a fire or injury in case of an earthquake or other natural disasters, securely install, mount,

and wire the servo motor in accordance with the Instruction Manual.

4

[Wiring]

24 V DC

RA

DOCOM

Control output

signal

Servo amplifier

For sink output interface

24 V DC

RA

DOCOM

Control output

signal

Servo amplifier

For source output interface

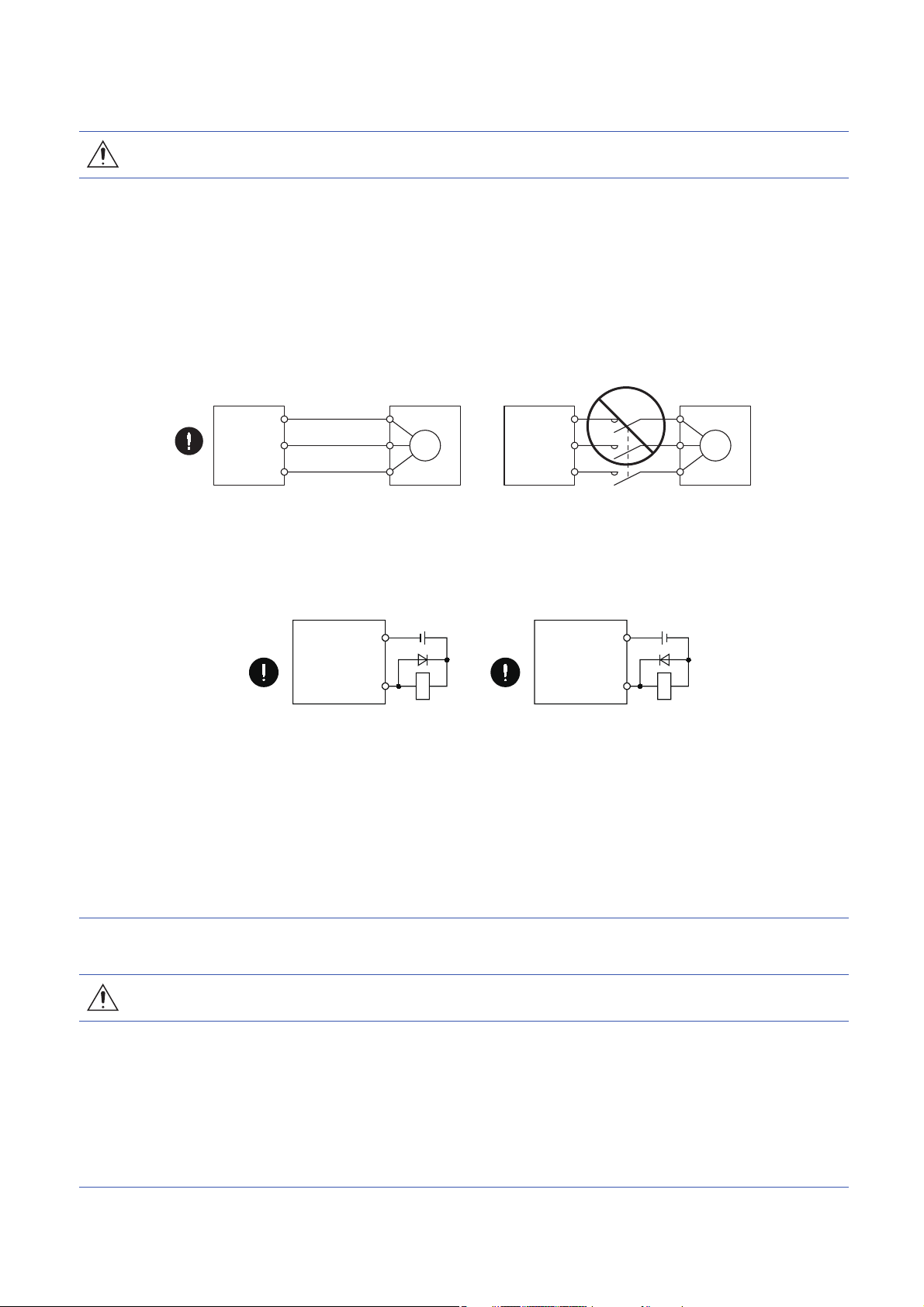

CAUTION

● Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

● Make sure to connect the cables and connectors by using the fixing screws and the locking

mechanism. Otherwise, the cables and connectors may be disconnected during operation.

● Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF(-H)) on the servo

amplifier output side.

● To avoid a malfunction, connect the wires to the correct phase terminals (U/V/W) of the servo amplifier

and servo motor.

● Connect the servo amplifier power output (U/V/W) to the servo motor power input (U/V/W) directly. Do

not connect a magnetic contactor and others between them. Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

● The connection diagrams in this Instruction Manual are shown for sink interfaces, unless stated

otherwise.

● The surge absorbing diode installed to the DC relay for control output should be fitted in the specified

direction. Otherwise, the converter unit and the drive unit will malfunction and will not output signals,

disabling the emergency stop and other protective circuits.

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

M

W

● When the wires are not tightened enough to the terminal block, the wires or terminal block may

generate heat because of the poor contact. Be sure to tighten the wires with specified torque.

● Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo amplifier may cause a

malfunction.

● Configure a circuit to turn off EM2 or EM1 when the main circuit power supply is turned off to prevent

an unexpected restart of the servo amplifier.

● To prevent malfunction, avoid bundling power lines (input/output) and signal cables together or

running them in parallel to each other. Separate the power lines from the signal cables.

[Test run and adjustment]

CAUTION

● When executing a test run, follow the notice and procedures in this instruction manual. Otherwise, it

may cause a malfunction, damage to the machine, or injury.

● Before operation, check and adjust the parameter settings. Improper settings may cause some

machines to operate unexpectedly.

● Never make a drastic adjustment or change to the parameter values as doing so will make the

operation unstable.

● Do not get close to moving parts during the servo-on status.

5

[Usage]

CAUTION

● Provide an external emergency stop circuit to stop the operation and shut the power off immediately.

● For equipment in which the moving part of the machine may collide against the load side, install a limit

switch or stopper to the end of the moving part. The machine may be damaged due to a collision.

● Do not disassemble, repair, or modify the product. Otherwise, it may cause an electric shock, fire,

injury, etc. Disassembled, repaired, and/or modified products are not covered under warranty.

● Before resetting an alarm, make sure that the run signal of the servo amplifier is off in order to prevent

a sudden restart. Otherwise, it may cause an accident.

● Use a noise filter, etc., to minimize the influence of electromagnetic interference. Electromagnetic

interference may affect the electronic equipment used near the servo amplifier.

● Do not burn or destroy the servo amplifier. Doing so may generate a toxic gas.

● Use the servo amplifier with the specified servo motor.

● Wire options and peripheral equipment, etc. correctly in the specified combination. Otherwise, it may

cause an electric shock, fire, injury, etc.

● The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

● For such reasons as incorrect wiring, service life, and mechanical structure (e.g. where a ball screw

and the servo motor are coupled via a timing belt), the electromagnetic brake may not hold the motor

shaft. To ensure safety, install a stopper on the machine side.

● If the dynamic brake is activated at power-off, alarm occurrence, etc., do not rotate the servo motor by

an external force. Otherwise, it may cause a fire.

6

[Corrective actions]

Servo motor

Electromagnetic brake

B

U

RA

Contacts must be opened with

the emergency stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

24 V DC

CAUTION

● Ensure safety by confirming the power off, etc. before performing corrective actions. Otherwise, it may

cause an accident.

● If it is assumed that a power failure, machine stoppage, or product malfunction may result in a

hazardous situation, use a servo motor with an electromagnetic brake or provide an external brake

system for holding purpose to prevent such hazard.

● Configure an electromagnetic brake circuit which is interlocked with an external emergency stop

switch.

● When an alarm occurs, eliminate its cause, ensure safety, and deactivate the alarm to restart

operation.

● If the molded-case circuit breaker or fuse is activated, be sure to remove the cause and secure safety

before switching the power on. If necessary, replace the servo amplifier and recheck the wiring.

Otherwise, it may cause smoke, fire, or an electric shock.

● Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

● After an earthquake or other natural disasters, ensure safety by checking the conditions of the

installation, mounting, wiring, and equipment before switching the power on to prevent an electric

shock, injury, or fire.

[Maintenance, inspection and parts replacement]

CAUTION

● Make sure that the emergency stop circuit operates properly such that an operation can be stopped

immediately and a power is shut off by the emergency stop switch.

● It is recommended that the servo amplifier be replaced every 10 years when it is used in general

environment.

● When using the servo amplifier that has not been energized for an extended period of time, contact

your local sales office.

[General instruction]

● To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards

must be installed as specified. Operation must be performed in accordance with this Instruction

Manual.

7

DISPOSAL OF WASTE

• Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and regulations.

EEP-ROM LIFE

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If the total number of

the following operations exceeds 100,000, the servo amplifier may malfunction when the EEP-ROM reaches the end of its

useful life.

• Write to the EEP-ROM due to parameter setting changes

• Write to the EEP-ROM due to device changes

STO FUNCTION OF THE SERVO AMPLIFIER

When using the STO function of the servo amplifier, refer to the following.

Page 453 USING STO FUNCTION

For the MR-J3-D05 safety logic unit, refer to the following.

Page 586 MR-J3-D05 Safety logic unit

COMPLIANCE WITH GLOBAL STANDARDS

For the compliance with global standards, refer to the following.

Page 572 Compliance with global standards

8

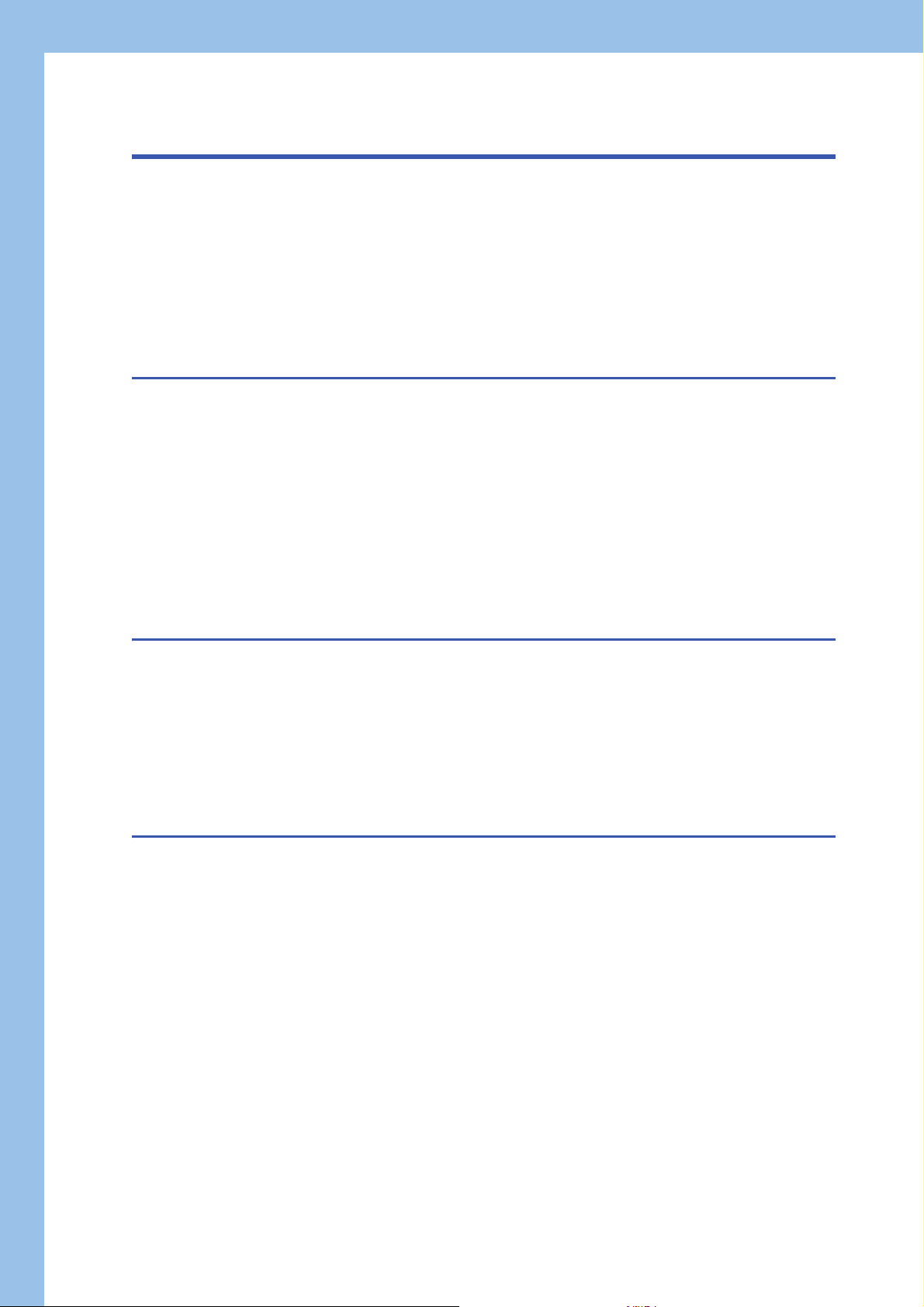

ABOUT THE MANUALS

You must have this Instruction Manual and the following manuals to use this servo. Ensure to prepare them to use the servo

safely.

Relevant manuals

Manual name Manual No.

MELSERVO MR-J4-_GF_(-RJ) Servo Amplifier Instruction Manual (I/O Mode) SH(NA)030221ENG

MELSERVO MR-J4-_GF_(-RJ) Servo Amplifier Instruction Manual (CC-Link IE Field Network Basic) SH(NA)030273ENG

MELSERVO-J4 Servo Amplifier Instruction Manual (Troubleshooting) SH(NA)030109ENG

MELSERVO MR-D30 Instruction Manual

MELSERVO Servo Motor Instruction Manual (Vol. 3)

MELSERVO Linear Servo Motor Instruction Manual

MELSERVO Direct Drive Motor Instruction Manual

MELSERVO Linear Encoder Instruction Manual

MELSERVO EMC Installation Guidelines IB(NA)67310ENG

*1 It is necessary for using an MR-D30 functional safety unit.

*2 It is necessary for using a rotary servo motor.

*3 It is necessary for using a linear servo motor.

*4 It is necessary for using a direct drive motor.

*5 It is necessary for using a fully closed loop system.

*1

*2

*3

*4

*3*5

SH(NA)030132ENG

SH(NA)030113ENG

SH(NA)030110ENG

SH(NA)030112ENG

SH(NA)030111ENG

WIRING

Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 .

U.S. CUSTOMARY UNITS

U.S. customary units are not shown in this manual. Convert the values if necessary according to the following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N.m] 141.6 [oz.inch]

-4

Moment of inertia 1 [(× 10

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [] × 9/5 + 32 N []

kg.m2)] 5.4675 [oz.inch2]

9

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

DISPOSAL OF WASTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

EEP-ROM LIFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

STO FUNCTION OF THE SERVO AMPLIFIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

COMPLIANCE WITH GLOBAL STANDARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ABOUT THE MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

U.S. CUSTOMARY UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CHAPTER 1 FUNCTIONS AND CONFIGURATION 18

1.1 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.2 Function block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3 Servo amplifier standard specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.4 Combinations of servo amplifiers and servo motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.5 Function list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.6 Model designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.7 Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Parts identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Removal and reinstallation of the front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.8 Configuration including peripheral equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

CHAPTER 2 INSTALLATION 76

2.1 Installation direction and clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.2 Keeping out of foreign materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.3 Encoder cable stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.4 Inspection items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.5 Parts having service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.6 Restrictions when using the servo amplifiers at altitude exceeding 1000 m and up to 2000 m above sea

level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

CHAPTER 3 SIGNALS AND WIRING 82

3.1 Connection example of power circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

200 V class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

400 V class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

100 V class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.2 I/O signal connection example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

For sink I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

For source I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.3 Explanation of power supply system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Signal explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Power-on sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Wiring CNP1, CNP2, and CNP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.4 Connectors and pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3.5 Signal (device) explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Input device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Output device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10

3.6 Forced stop deceleration function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Forced stop deceleration function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Base circuit shut-off delay time function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Vertical axis freefall prevention function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Residual risks of the forced stop function (EM2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3.7 Alarm occurrence timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

When you use the forced stop deceleration function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

When you do not use the forced stop deceleration function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

3.8 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Internal connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Detailed explanation of interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Source I/O interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.9 Servo motor with an electromagnetic brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Safety precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Timing chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

3.10 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

CHAPTER 4 STARTUP 127

4.1 Switching power on for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Startup procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Wiring check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Surrounding environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Settings of GX Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

4.2 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4.3 Switch setting and display of the servo amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Scrolling display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Status display of a station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

CC-Link IE Field status display LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.4 Test operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.5 Test operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Test operation mode in MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Motor-less operation in controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

4.6 Home position return mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Outline of home position return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

CiA 402-type homing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Operation example of Manufacturer-specific Homing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

CONTENTS

CHAPTER 5 PARAMETERS 168

5.1 Parameter list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Basic setting parameters ([Pr. PA_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Gain/filter setting parameters ([Pr. PB_ _ ]). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Extension setting parameters ([Pr. PC_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

I/O setting parameters ([Pr. PD_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Extension setting 2 parameters ([Pr. PE_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Extension setting 3 parameters ([Pr. PF_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Linear servo motor/DD motor setting parameters ([Pr. PL_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Positioning control parameters ([Pr. PT_ _ ]). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Network setting parameters ([Pr. PN_ _]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

5.2 Detailed list of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

11

Basic setting parameters ([Pr. PA_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Gain/filter setting parameters ([Pr. PB_ _ ]). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Extension setting parameters ([Pr. PC_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

I/O setting parameters ([Pr. PD_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Extension setting 2 parameters ([Pr. PE_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Extension setting 3 parameters ([Pr. PF_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Linear servo motor/DD motor setting parameters ([Pr. PL_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Positioning control parameters ([Pr. PT_ _ ]). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Network setting parameters ([Pr. PN_ _ ]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

5.3 Software limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

CHAPTER 6 NORMAL GAIN ADJUSTMENT 227

6.1 Different adjustment methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Adjustment on a single servo amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Adjustment using MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

6.2 One-touch tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

One-touch tuning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Display transition and operation procedure of one-touch tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Caution for one-touch tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

One-touch tuning via a network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

6.3 Auto tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Auto tuning mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Auto tuning mode basis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Adjustment procedure by auto tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Response level setting in auto tuning mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240

6.4 Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

6.5 2 gain adjustment mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

CHAPTER 7 SPECIAL ADJUSTMENT FUNCTIONS 247

7.1 Filter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Machine resonance suppression filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Adaptive filter II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Shaft resonance suppression filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Low-pass filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Advanced vibration suppression control II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Command notch filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

7.2 Gain switching function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Function block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Gain switching procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

7.3 Tough drive function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Vibration tough drive function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Instantaneous power failure tough drive function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

7.4 Compliance with SEMI-F47 standard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

7.5 Model adaptive control disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

7.6 Lost motion compensation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

7.7 Super trace control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

12

CHAPTER 8 TROUBLESHOOTING 280

8.1 Explanation for the lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

8.2 Alarm list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

8.3 Warning list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

8.4 Troubleshooting at power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

CHAPTER 9 DIMENSIONS 292

9.1 Servo amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

9.2 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

CHAPTER 10 CHARACTERISTICS 311

10.1 Overload protection characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

10.2 Power supply capacity and generated loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

10.3 Dynamic brake characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Dynamic brake operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Permissible load to motor inertia when the dynamic brake is used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .322

10.4 Cable bending life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

10.5 Inrush currents at power-on of main circuit and control circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

CHAPTER 11 OPTIONS AND PERIPHERAL EQUIPMENT 327

11.1 Cable/connector sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Combinations of cable/connector sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

MR-D05UDL3M-B STO cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Battery cable/junction battery cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

11.2 Regenerative options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Combination and regenerative power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Selection of the regenerative option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Parameter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Connection of regenerative option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

11.3 FR-BU2-(H) brake unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Brake unit parameter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Connection example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

11.4 FR-RC-(H) power regeneration converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

11.5 FR-CV-(H) power regeneration common converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Model designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

11.6 Junction terminal block PS7DW-20V14B-F (recommended) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

11.7 MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Precautions for using USB communication function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

11.8 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Selection of battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

MR-BAT6V1SET-A battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

MR-BAT6V1BJ battery for junction battery cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

MR-BT6VCASE battery case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

MR-BAT6V1 battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

CONTENTS

13

11.9 Selection example of wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

11.10 Molded-case circuit breakers, fuses, magnetic contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .404

11.11 Power factor improving DC reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

11.12 Power factor improving AC reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

11.13 Relay (recommended) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

11.14 Noise reduction techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

11.15 Earth-leakage current breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

11.16 EMC filter (recommended) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

11.17 External dynamic brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

11.18 Panel through attachment (MR-J4ACN15K/MR-J3ACN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 442

CHAPTER 12 ABSOLUTE POSITION DETECTION SYSTEM 447

12.1 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Parameter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Confirmation of absolute position detection data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

12.2 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Using MR-BAT6V1SET-A battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Using MR-BAT6V1BJ battery for junction battery cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Using MR-BT6VCASE battery case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

CHAPTER 13 USING STO FUNCTION 453

13.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Terms related to safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Residual risks of the STO function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

13.2 STO I/O signal connector (CN8) and pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

Signal (device) explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

How to pull out the STO cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 457

13.3 Connection example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

Connection example for CN8 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

External I/O signal connection example using an MR-J3-D05 safety logic unit . . . . . . . . . . . . . . . . . . . . . . . . 459

External I/O signal connection example using an external safety relay unit . . . . . . . . . . . . . . . . . . . . . . . . . . .462

13.4 Detailed explanation of interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Sink I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Source I/O interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

CHAPTER 14 USING A LINEAR SERVO MOTOR 465

14

14.1 Functions and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Configuration including peripheral equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

14.2 Signals and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 470

14.3 Operation and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

Magnetic pole detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 473

Home position return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

Test operation mode in MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

Operation from controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Absolute position detection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

14.4 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 489

Overload protection characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 489

Power supply capacity and generated loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

Dynamic brake characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

Permissible load to motor mass ratio when the dynamic brake is used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 492

CHAPTER 15 USING A DIRECT DRIVE MOTOR 493

15.1 Functions and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 493

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 493

Configuration including peripheral equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 494

15.2 Signals and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 496

15.3 Operation and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

Startup procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

Magnetic pole detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 499

Operation from controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

15.4 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

Overload protection characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

Power supply capacity and generated loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

Dynamic brake characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

CONTENTS

CHAPTER 16 FULLY CLOSED LOOP SYSTEM 513

16.1 Functions and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 513

Function block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 513

Selecting procedure of control mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 514

System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 516

16.2 Load-side encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

Linear encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

Rotary encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

Configuration diagram of encoder cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

MR-J4FCCBL03M branch cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 520

16.3 Operation and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

Home position return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 528

Operation from controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 529

Fully closed loop control error detection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530

Auto tuning function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

Machine analyzer function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

Test operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

Absolute position detection system under fully closed loop system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 532

About MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 533

CHAPTER 17 APPLICATION OF FUNCTIONS 535

17.1 Scale measurement function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535

Functions and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535

15

Scale measurement encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 538

How to use scale measurement function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 541

Controller setting of the scale measurement function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543

17.2 Touch probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

17.3 Backup/restoration function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 548

17.4 Parameter object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 549

Definition of parameter objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 549

Enabling parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

17.5 Machine diagnosis function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

Function summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

How to set the function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

Friction vibration estimation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 554

Failure prediction function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 556

APPENDICES 563

Appendix 1 When using the servo amplifier with the DC power supply input . . . . . . . . . . . . . . . . . . . . . . . . . . . 563

Connection example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 563

Power supply capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

Selection example of wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

Molded-case circuit breakers, fuses, magnetic contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 567

Appendix 2 Handling of AC servo amplifier batteries for the United Nations Recommendations on the Transport

of Dangerous Goods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 569

Appendix 3 Symbol for the new EU Battery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 571

Appendix 4 Compliance with global standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 572

Terms related to safety (IEC 61800-5-2 Stop function) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .572

About safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 572

Installation direction and clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 578

Electrical Installation and configuration diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 578

Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 580

Maintenance and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 581

Transportation and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 582

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

Check list for user documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 585

Appendix 5 MR-J3-D05 Safety logic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 586

Contents of the package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 586

Terms related to safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 586

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 587

Residual risk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 587

Block diagram and timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 588

Maintenance and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 588

Functions and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 589

Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 592

LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 598

Rotary switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 599

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 599

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Combinations of cable/connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Appendix 6 EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 602

Appendix 7 How to replace servo amplifier without magnetic pole detection . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

16

Appendix 8 Two-wire type encoder cable for HG-MR/HG-KR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

Configuration diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

Connector set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

Internal wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 607

Appendix 9 Analog monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

Details of the setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 609

Analog monitor block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 613

Maximum current command (maximum torque) for analog monitor ±8 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 614

Appendix 10Special specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 621

Amplifiers without dynamic brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 621

Without regenerative resistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 622

Special coating-specification product (IEC 60721-3-3 Class 3C2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 623

Appendix 11Driving on/off of main circuit power supply with DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . 625

Connection example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 625

Magnetic contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 626

Appendix 12List of registration objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 627

Servo cyclic transmission function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 627

Servo transient transmission function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 629

Appendix 13Status of general-purpose AC servo products for compliance with the China RoHS directive. . . 632

Appendix 14Encoder output pulse setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 635

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .637

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .641

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .642

CONTENTS

17

1 FUNCTIONS AND CONFIGURATION

1.1 Summary

The Mitsubishi Electric general-purpose AC servo MELSERVO-J4 series have further higher performance and higher

functions compared to the previous MELSERVO-J3 series.

MR-J4-_GF_ servo amplifier can be connected to controllers, such as a simple motion module on CC-Link IE Field Network.

CC-Link IE Field Network is an open network using Ethernet (1000BASE-T), allowing high-speed and large-capacity

communication. A communication speed of 1 Gbps achieves high-speed control of field devices and high-speed

communication between facilities, thus shortening operating cycle.

MELSERVO-J4 series compatible rotary servo motor is equipped with 22-bit (4194304 pulses/rev) high-resolution absolute

encoder. In addition, speed frequency response is increased to 2.5 kHz. Thus, faster and more accurate control is enabled as

compared to MELSERVO-J3 series.

MR-J4-_GF_ servo amplifier operates MELSERVO-J4 series compatible rotary servo motors, linear servo motors, and direct

drive motors as standard.

With one-touch tuning and real-time auto tuning, you can easily adjust the servo gains according to the machine.

The tough drive function and the drive recorder function, which are well-received in the MELSERVO-JN series, have been

improved. The MR-J4 servo amplifier supports the improved functions. Additionally, the preventive maintenance support

function detects an error in the machine parts. This function provides strong support for the machine maintenance and

inspection.

MR-J4-_GF_ servo amplifier supports the Safe Torque Off (STO) function. By combining with optional MR-J3-D05, the servo

amplifier supports Safe stop 1 (SS1) function.

The servo amplifier has a USB communication interface. Therefore, you can connect the servo amplifier to the personal

computer with MR Configurator2 installed to perform the parameter setting, test operation, gain adjustment, and others.

In the MELSERVO-J4 series, servo amplifiers with the CN2L connector are also available as MR-J4-_GF_-RJ.

By using the CN2L connector, an A/B/Z-phase differential output type external encoder can be connected to the servo

amplifier. In a fully closed loop system, a four-wire type external encoder is connectable as well. The following table indicates

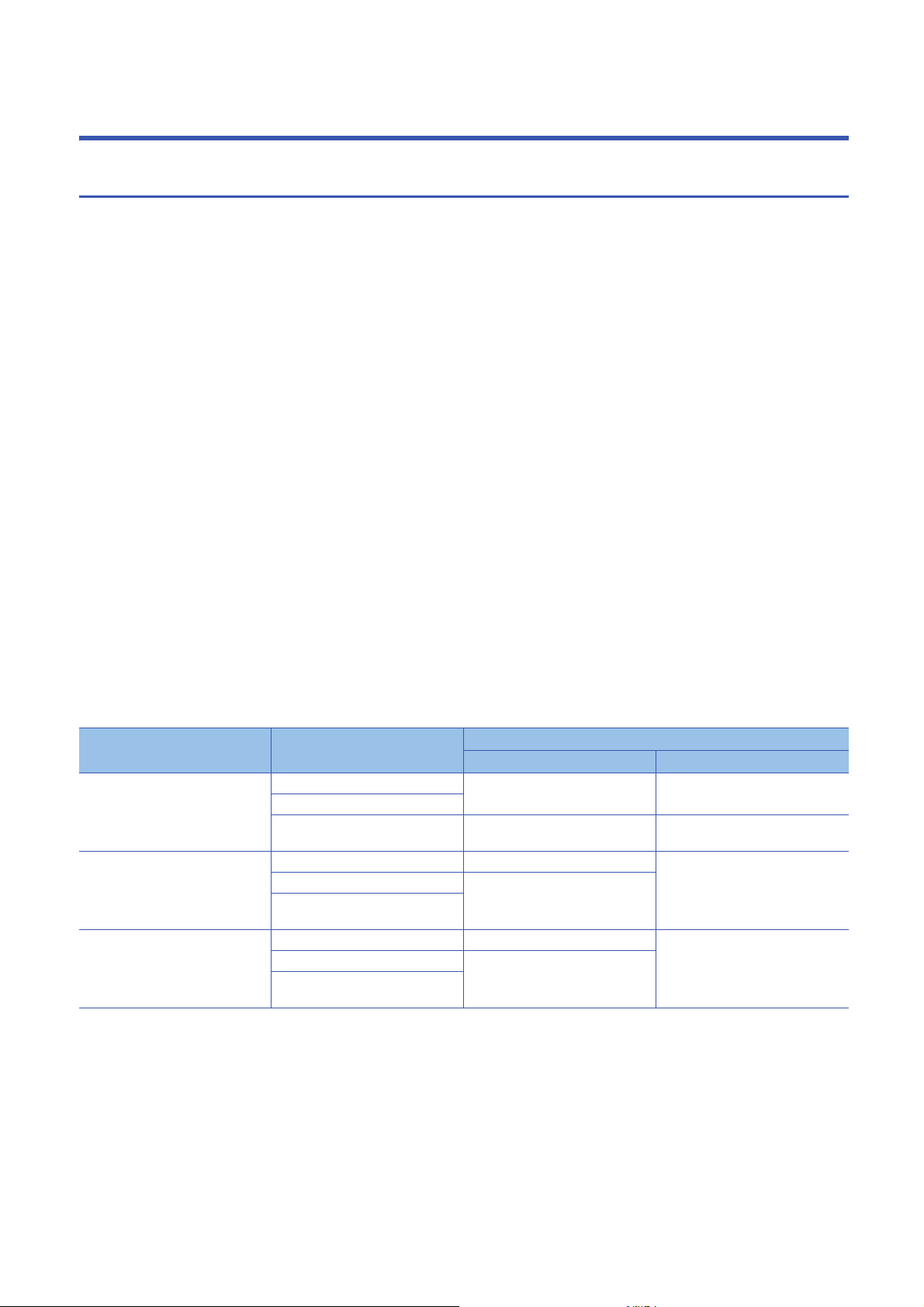

the communication method of the external encoder compatible with MR-J4-_GF_ and MR-J4-_GF_-RJ servo amplifiers.

Operation mode External encoder

communication method

Linear servo motor system

Fully closed loop system

Scale measurement function

*5

*5

*5

Two-wire type CN2

Four-wire type

A/B/Z-phase differential output

method

Two-wire type CN2

Four-wire type

A/B/Z-phase differential output

method

Two-wire type CN2

Four-wire type

A/B/Z-phase differential output

method

Connector

MR-J4-_GF_ MR-J4-_GF_-RJ

*1

CN2L

*2*3

*2*3

CN2

CN2L

CN2L

*1

*4

*1 The MR-J4THCBL03M branch cable is necessary.

*2 The MR-J4FCCBL03M branch cable is necessary.

*3 When the communication method of the servo motor encoder is four-wire type, MR-J4-_GF_ cannot be used. Use an MR-J4-_GF_-RJ.

*4 Connect a thermistor to CN2.

*5 This is used with servo amplifiers with software version A1 or later.

18

1 FUNCTIONS AND CONFIGURATION

1.1 Summary

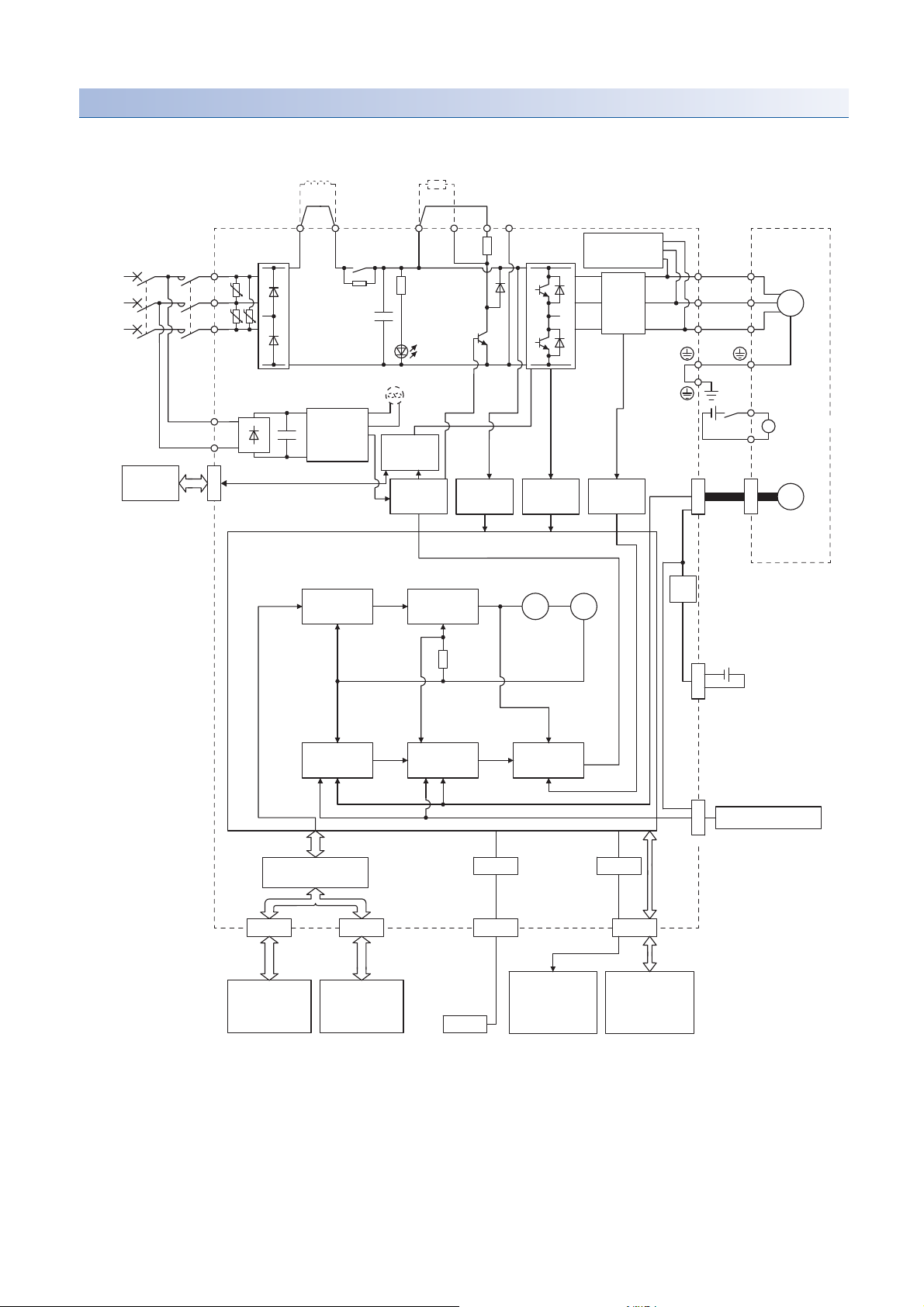

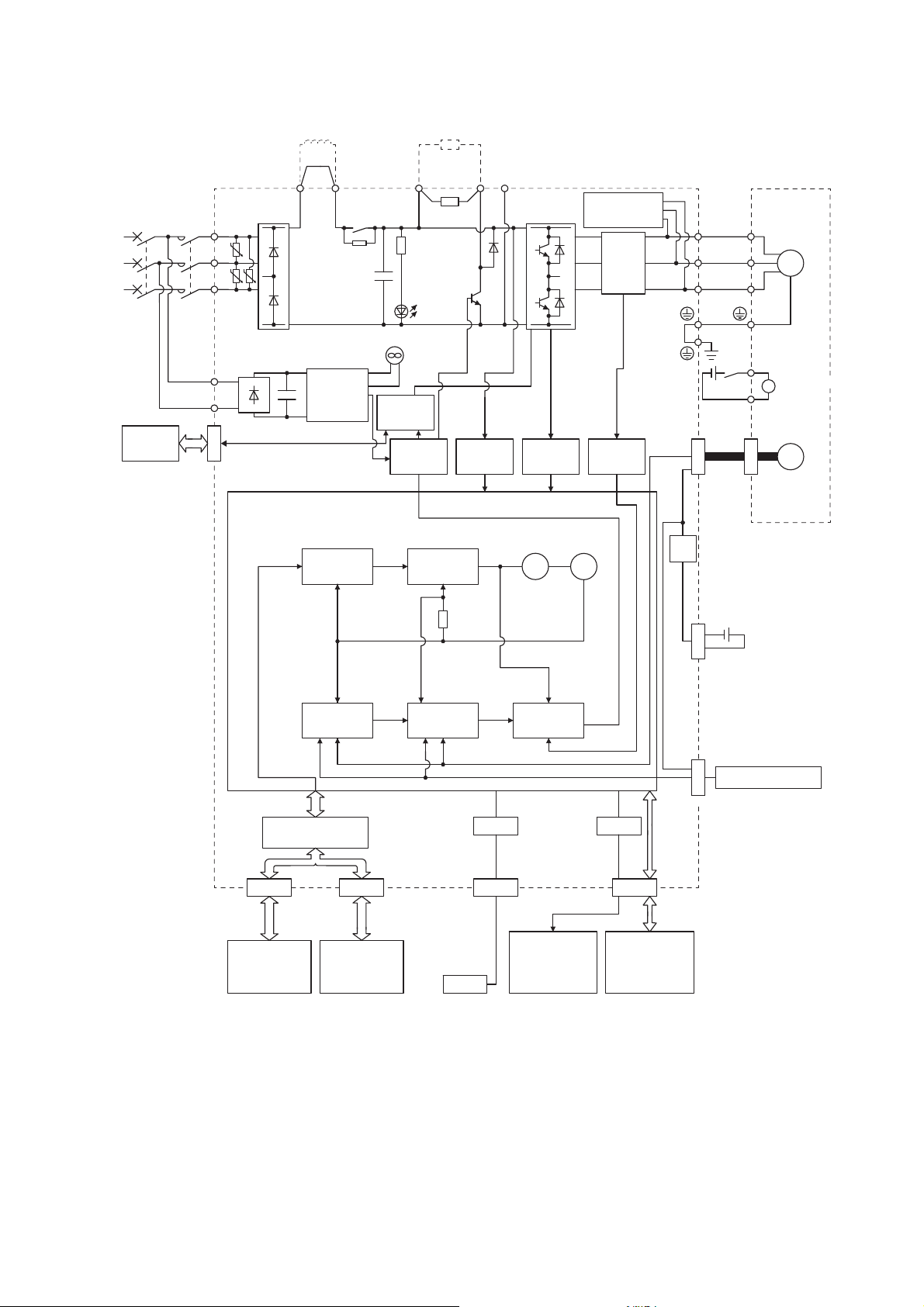

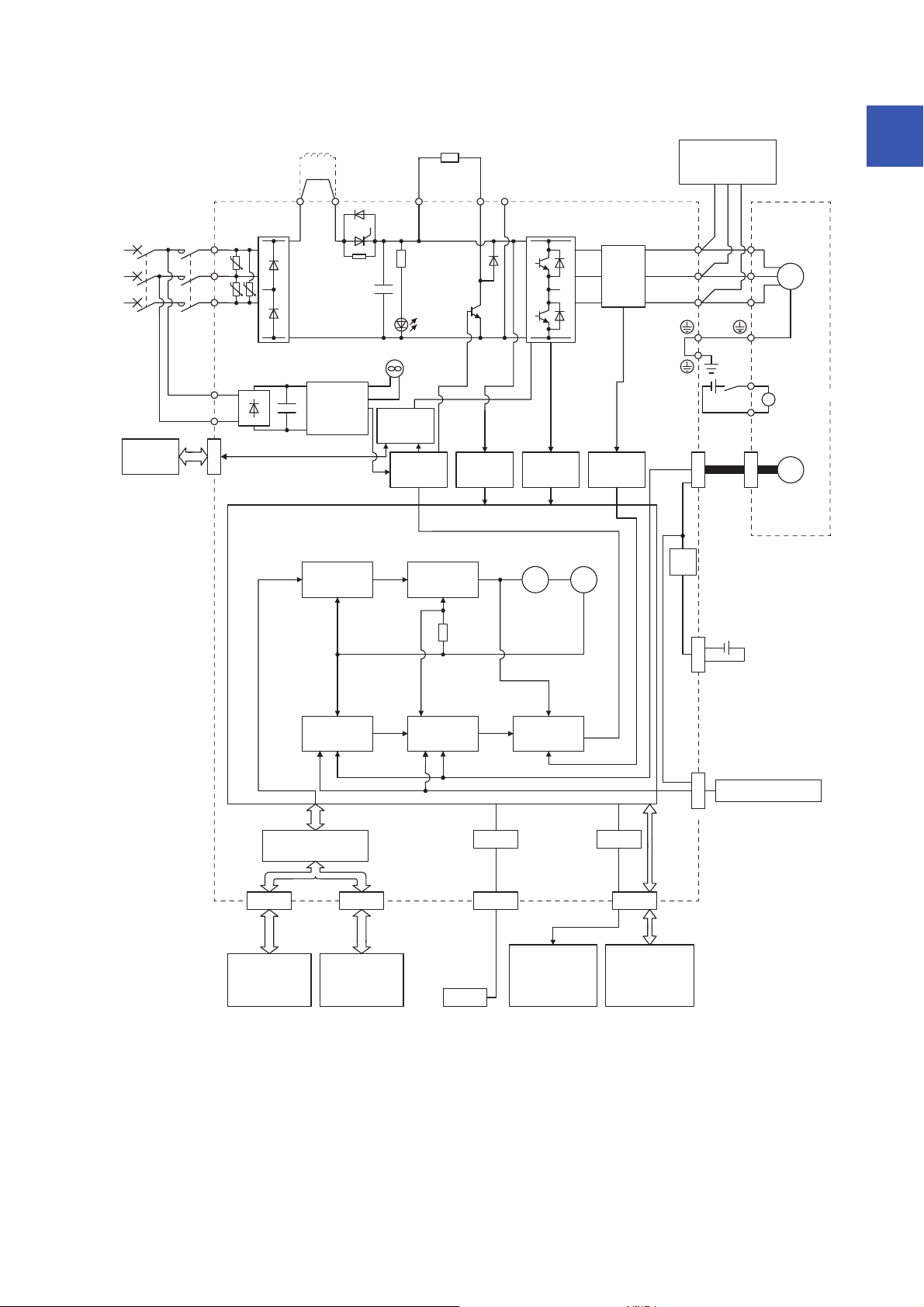

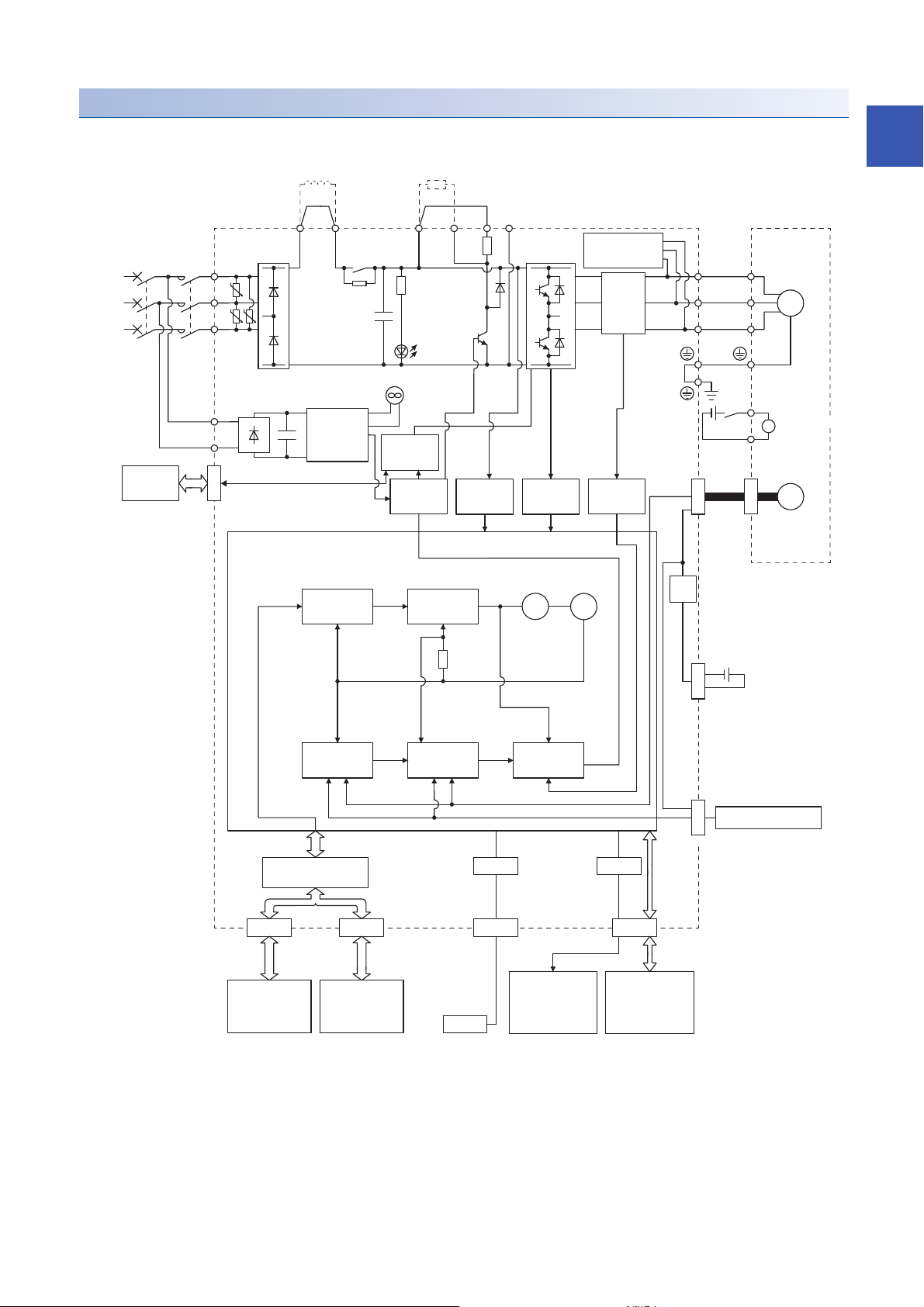

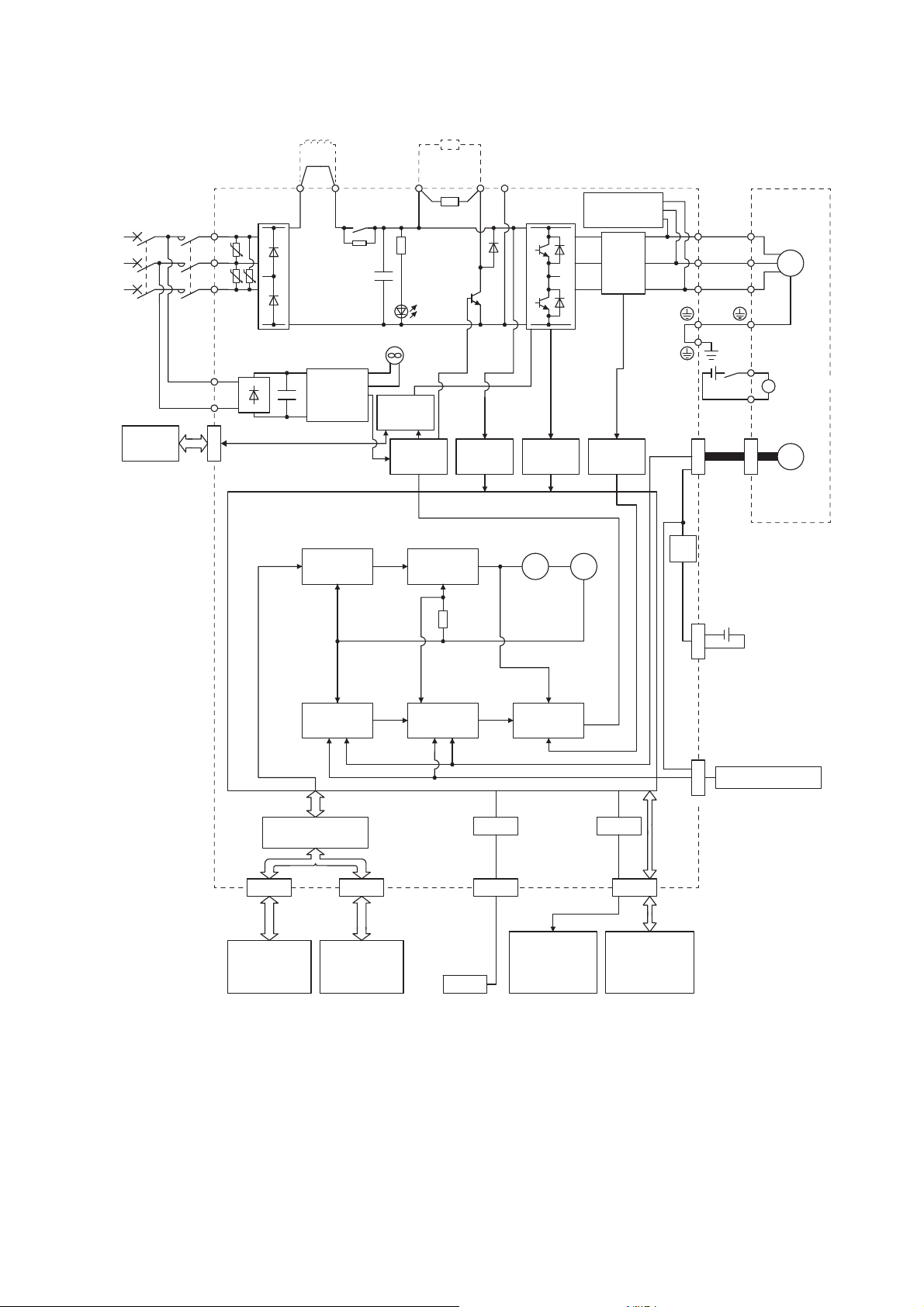

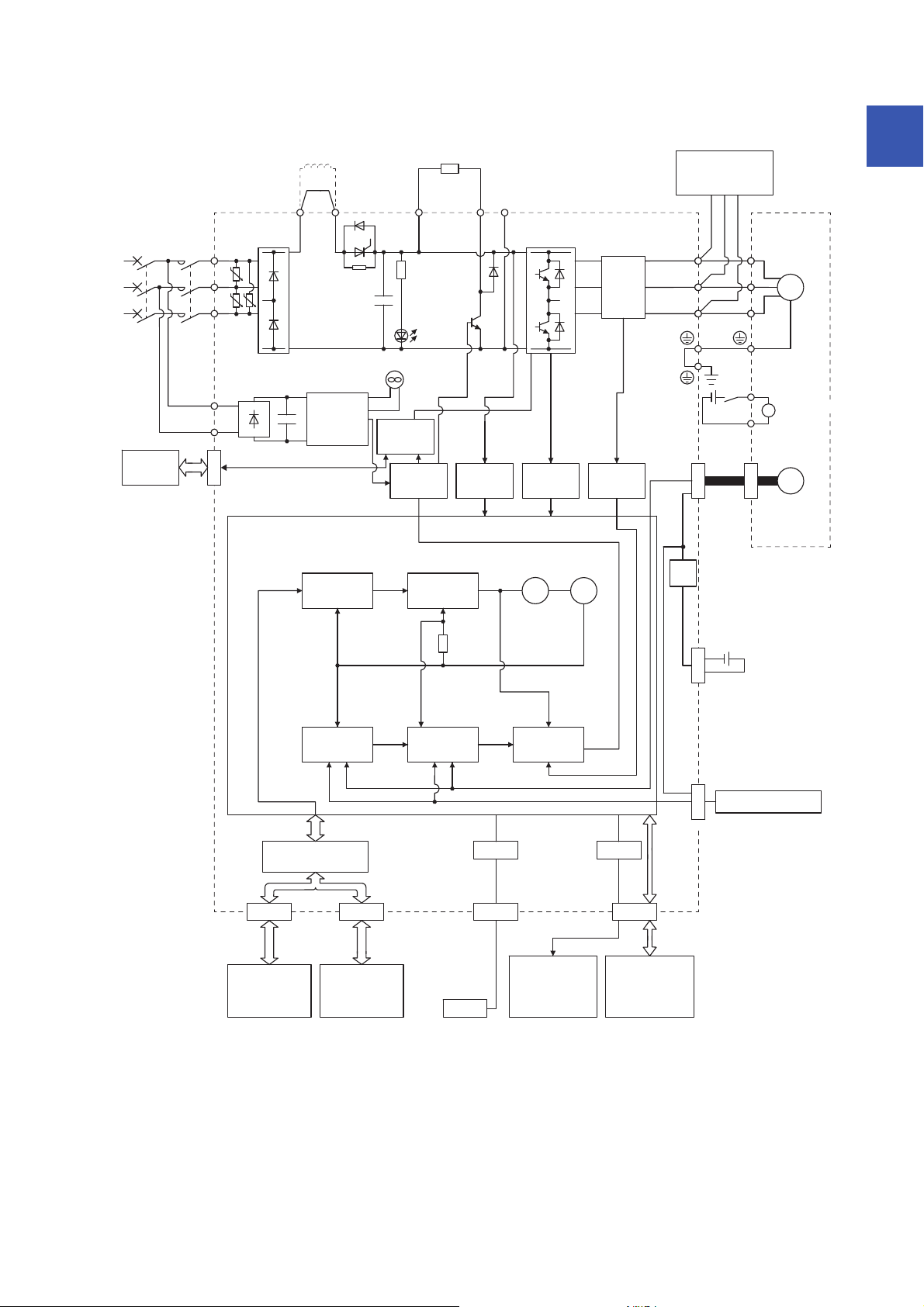

1.2 Function block diagram

The function block diagram of this servo is shown below.

The diagram shows for MR-J4-_GF_-RJ as an example. MR-J4-_GF_ servo amplifier does not have CN2L

connector.

1

1 FUNCTIONS AND CONFIGURATION

1.2 Function block diagram

19

200 V class

Model position

Current

control

Actual

position

control

Actual

speed

control

Virtual

motor

Virtual

encoder

L11

L21

Cooling fan

*3

Encoder

N-CD

L3

L2

L1

Dynamic

brake

circuit

Power factor improving

DC reactor

*6

Current

detection

Overcurrent

protection

Voltage

detection

Power

supply

*2

MCMCCB

Base

amplifier

STO

circuit

CN5

USB

USB

Personal

computer

Controller or

servo amplifier

Controller or

servo amplifier

CN1A

CN1B

D/A

Analog monitor

(2 channels)

Position

command

input

CN3

Servo amplifier

U

V

W

U

V

W

P3

P4

*4

Diode

stack

Relay

P+

+

+

B

RA

24 V DC

B1

B2

Battery

(For absolute position

detection system)

CN4

STO

switch

Model speed Model torque

M

CN2

CN8

Control

circuit

power

supply

Model

position